Patents

Literature

323results about "Natural resin purification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Modified protein adhesives and lignocellulosic composites made from the adhesives

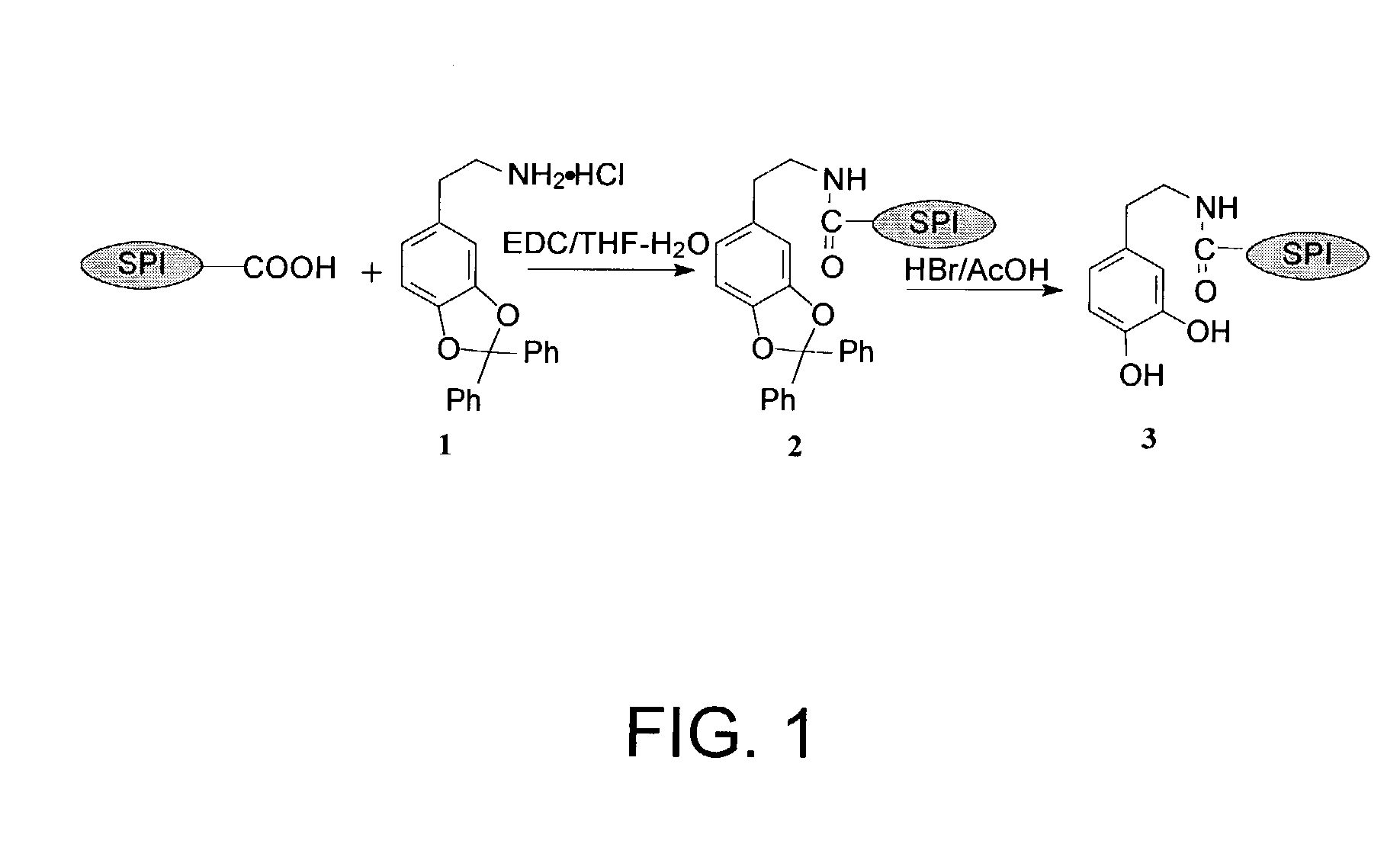

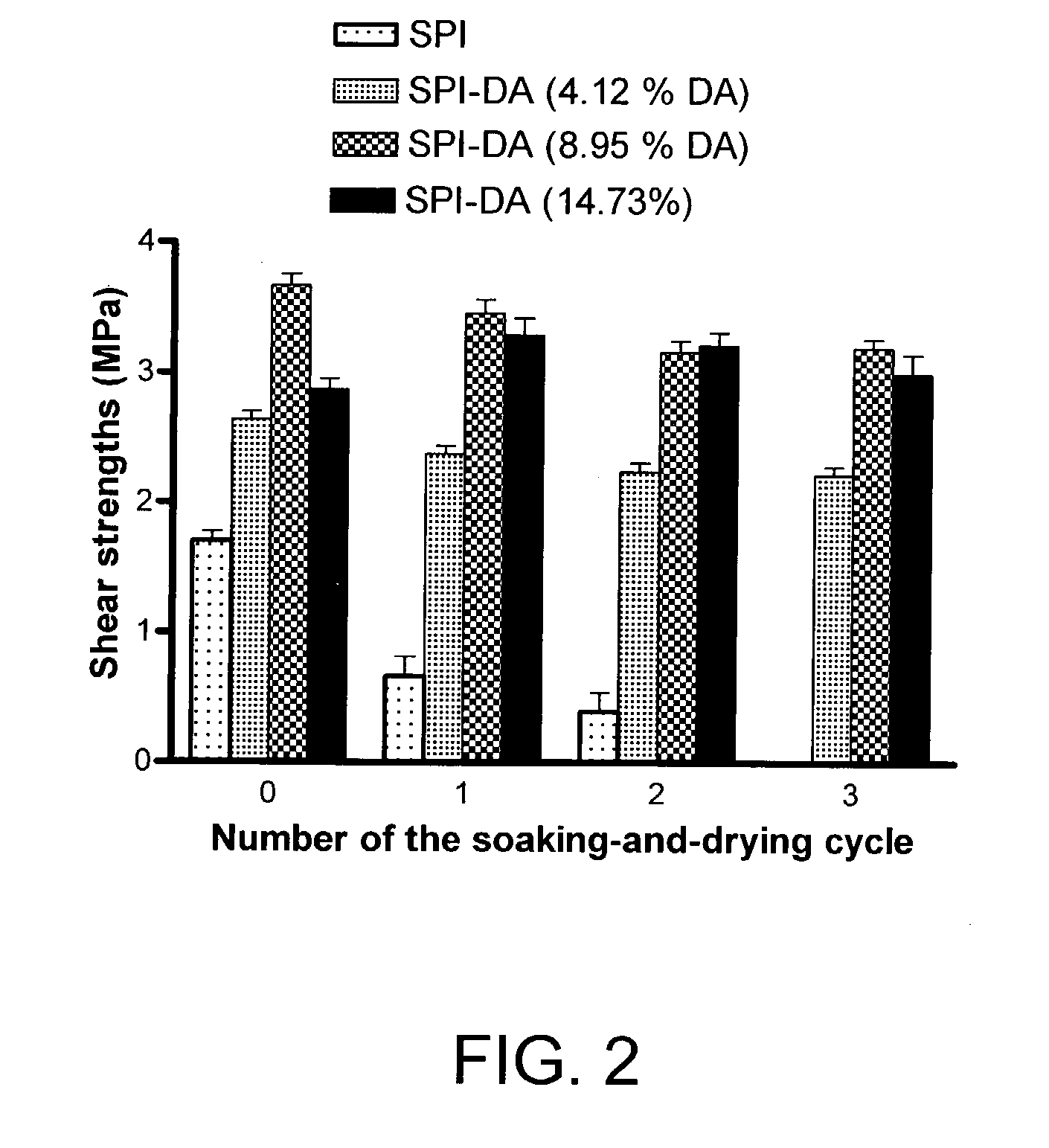

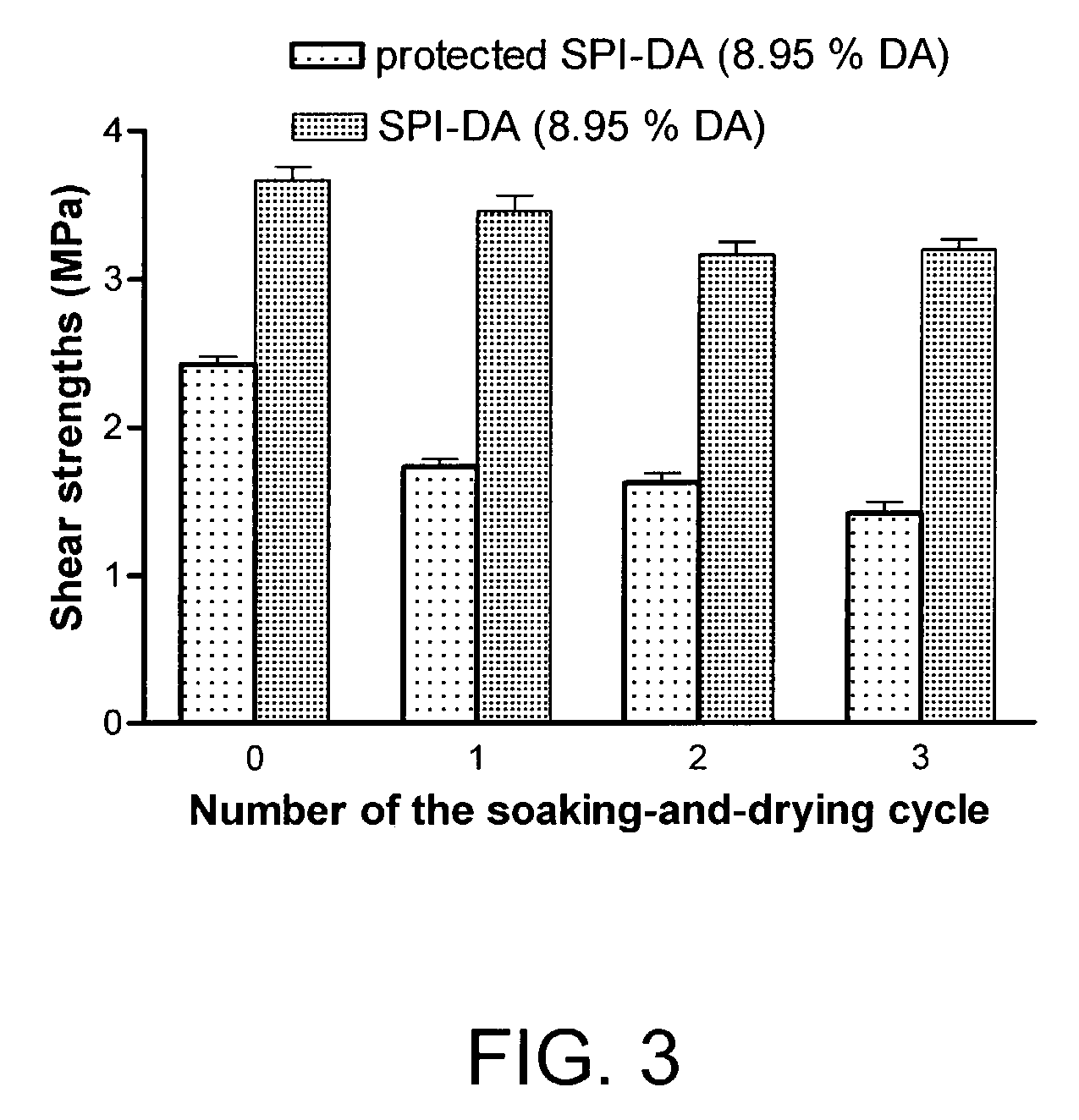

An adhesive composition made by reacting a soy protein with at least one compound under conditions sufficient for introducing additional phenolic hydroxyl functional groups, amine functional groups, and / or thiol functional groups into the soy protein structure.

Owner:THE STATE OF OREGON ACTING BY & THROUGH THE OREGON STATE BOARD OF HIGHER EDUCATION ON BEHALF OF OREGON STATE UNIV

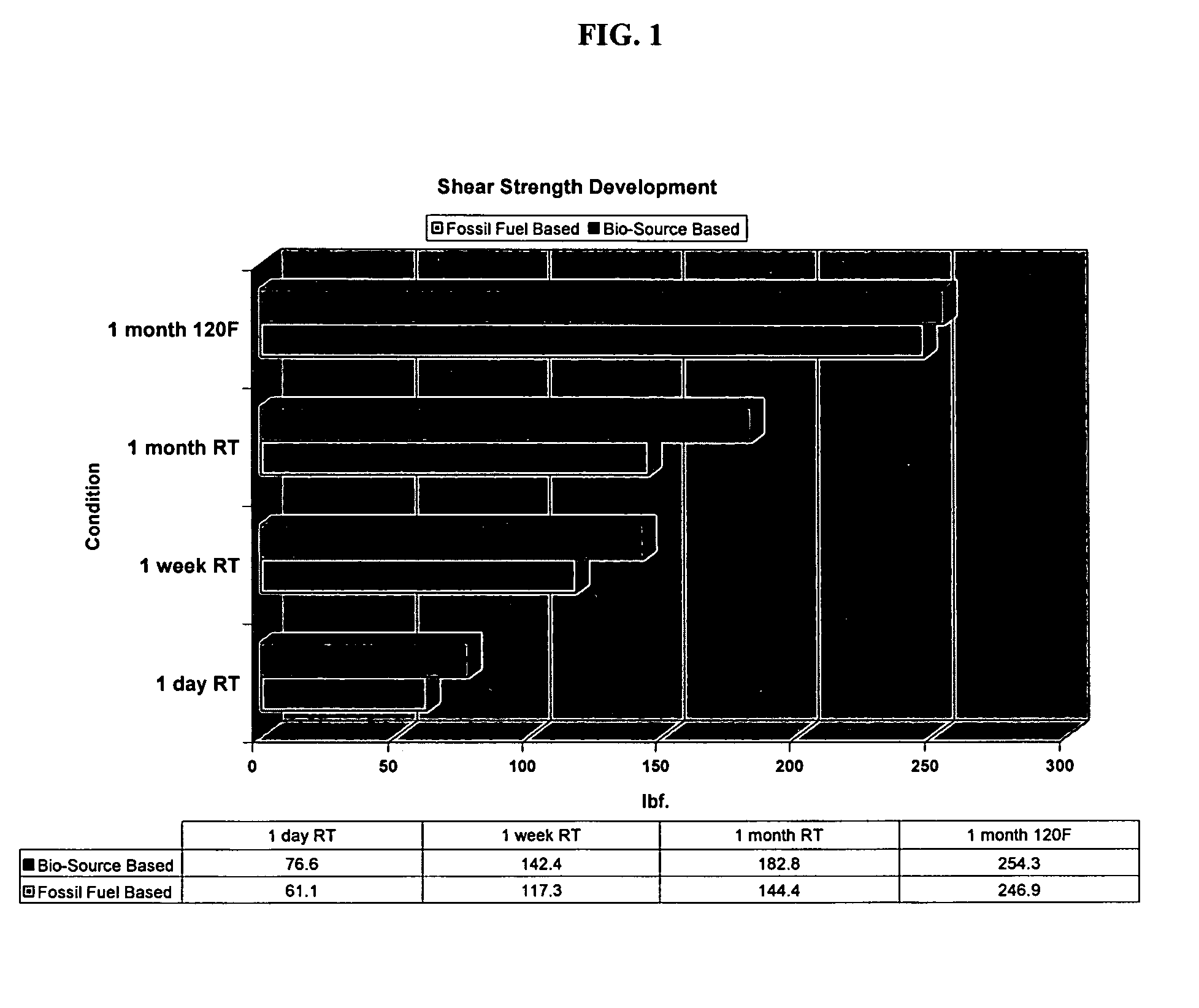

Low VOC bio-source adhesive

ActiveUS20080064852A1High strengthLow and substantially no VOC emissionDrying oil adhesivesProtein adhesivesAdhesiveFatty acid

A one component adhesive composition is provided, which can be formulated from substantially or totally bio-based, renewable raw materials. Such adhesives can be formulated to have high strength and / or low or substantially no VOC emissions. This can be achieved by utilizing polymers that are derived or extracted from renewable plant materials such as soybeans, corn, sunflowers, wheat, etc. Adhesive compositions in accordance with the invention can include oils. The composition preferably contains bio-based oils only, but need not be completely free of fossil fuel or synthetic based oils. It should also include drying oils and / or similarly acting polymers, co-polymers, and fatty acids. Plasticizers, such as hydrogen oxide, derived from renewable sources are utilized to impart performance properties to the formulated adhesive. Metal napthanates can be used to catalyze the drying and / or curing speed when the adhesive composition is applied to a substrate.

Owner:W F TAYLOR

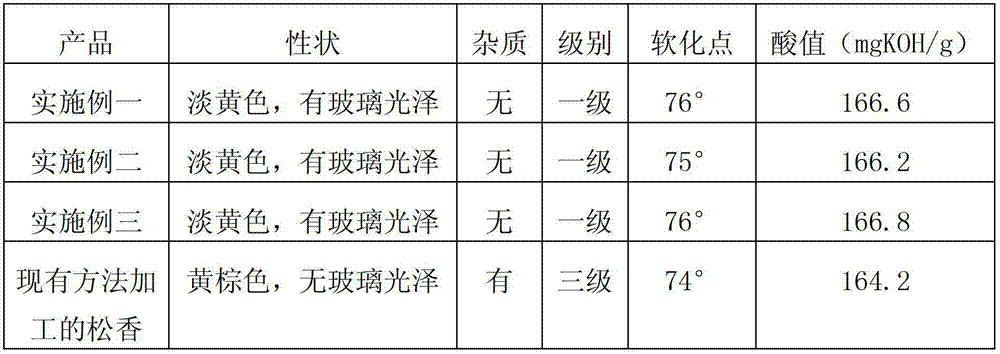

Method for producing pale disproportionated rosin with high content dehydroabietic acid and P-camphogen simultinuously

InactiveCN1616570APrevent browningPrevent oxidationNatural resin purificationNickel catalystDistillation

The process of producing pale disproportionated rosin with high dehydroabietic acid content and paracymene simultaneously includes the following steps: rinsing turpentine to eliminate impurity, dissolving turpentine in turpentine oil to form turpentine solution, catalytic disproportionating turpentine in solution in the presence of Pd / C catalyst, filtering and decompression distillation to obtain pale disproportionated rosin with high dehydroabietic acid content and disproportionated turpentine oil containing paracymene in 20-60 %, and distilling disproportionated turpentine oil to obtain paracymene and pinane. Or, the rinsed turpentine as material may be re-crystallized to purify and catalytically disproportionated to prepare pale disproportionated rosin containing high dehydroabietic acid in 72-82 %. The Pd / C catalyst may be replaced with skeletal nickel catalyst.

Owner:GUANGXI UNIV

Rosin esters for non-woven applications, methods of making and using and products therefrom

InactiveUS20110213120A1Good viscosity stabilityLow color requirementNatural resin chemical modificationNon-woven fabricsNonwoven fabricRosin

Owner:ARIZONA CHEM CO

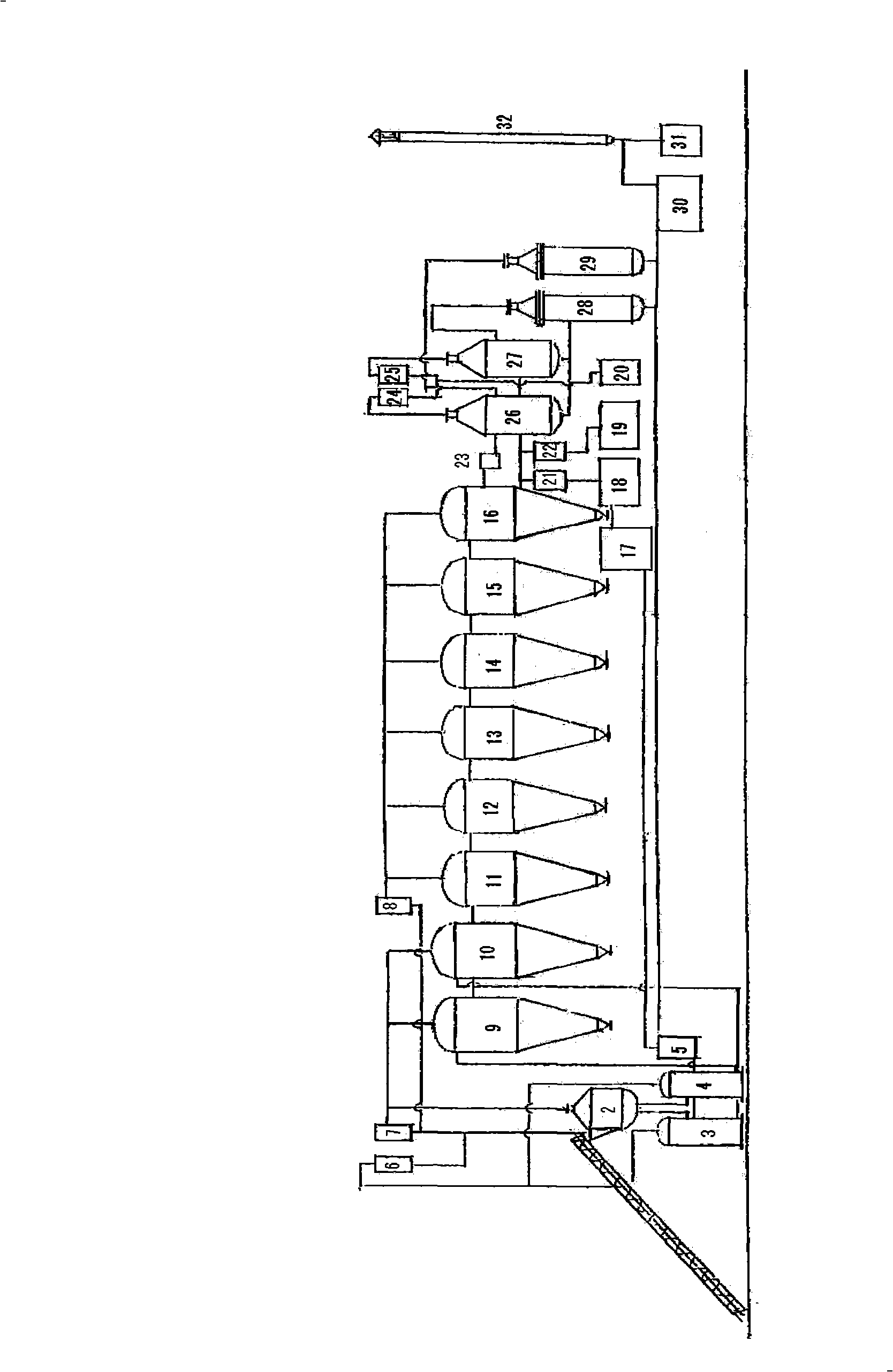

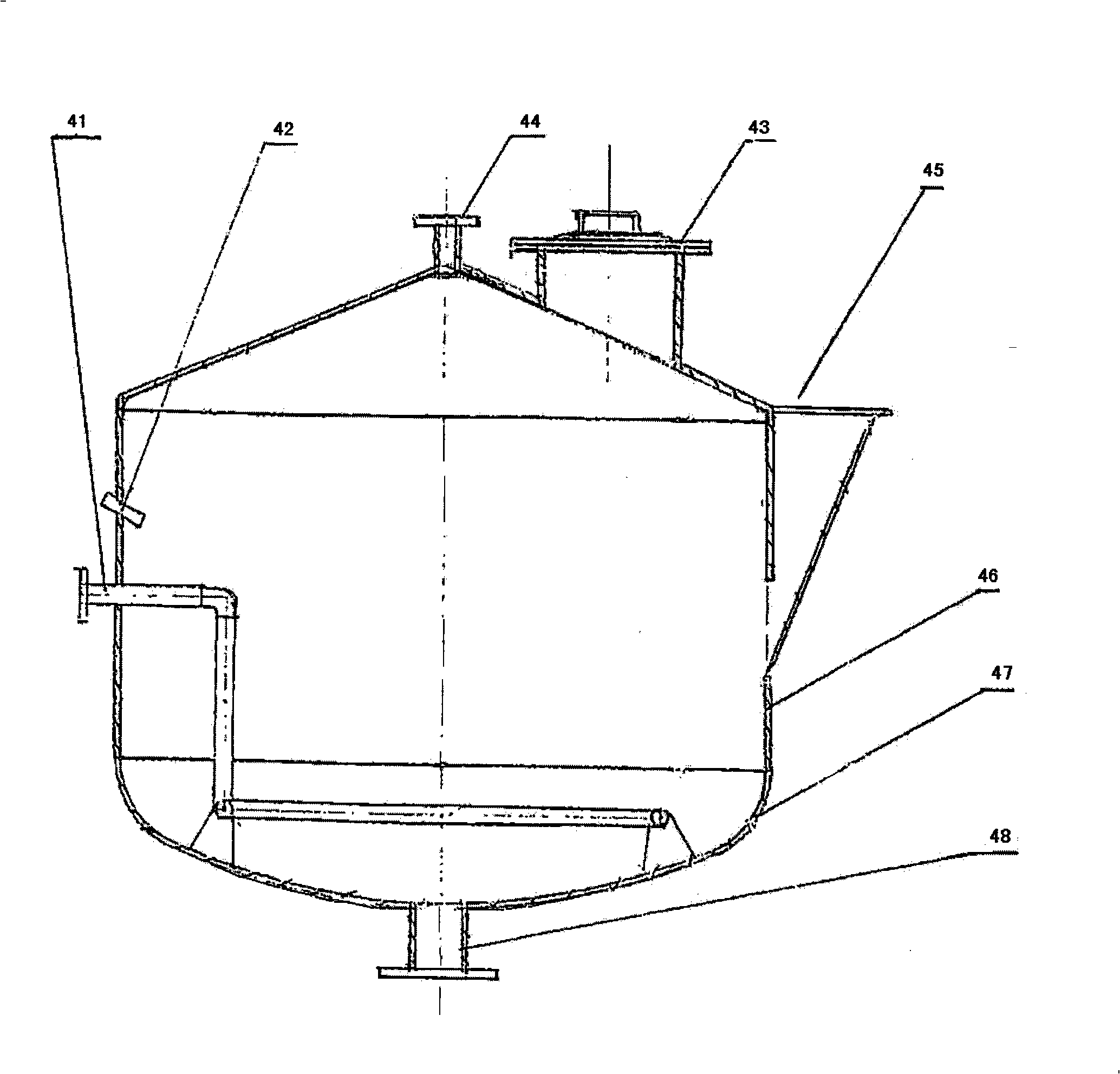

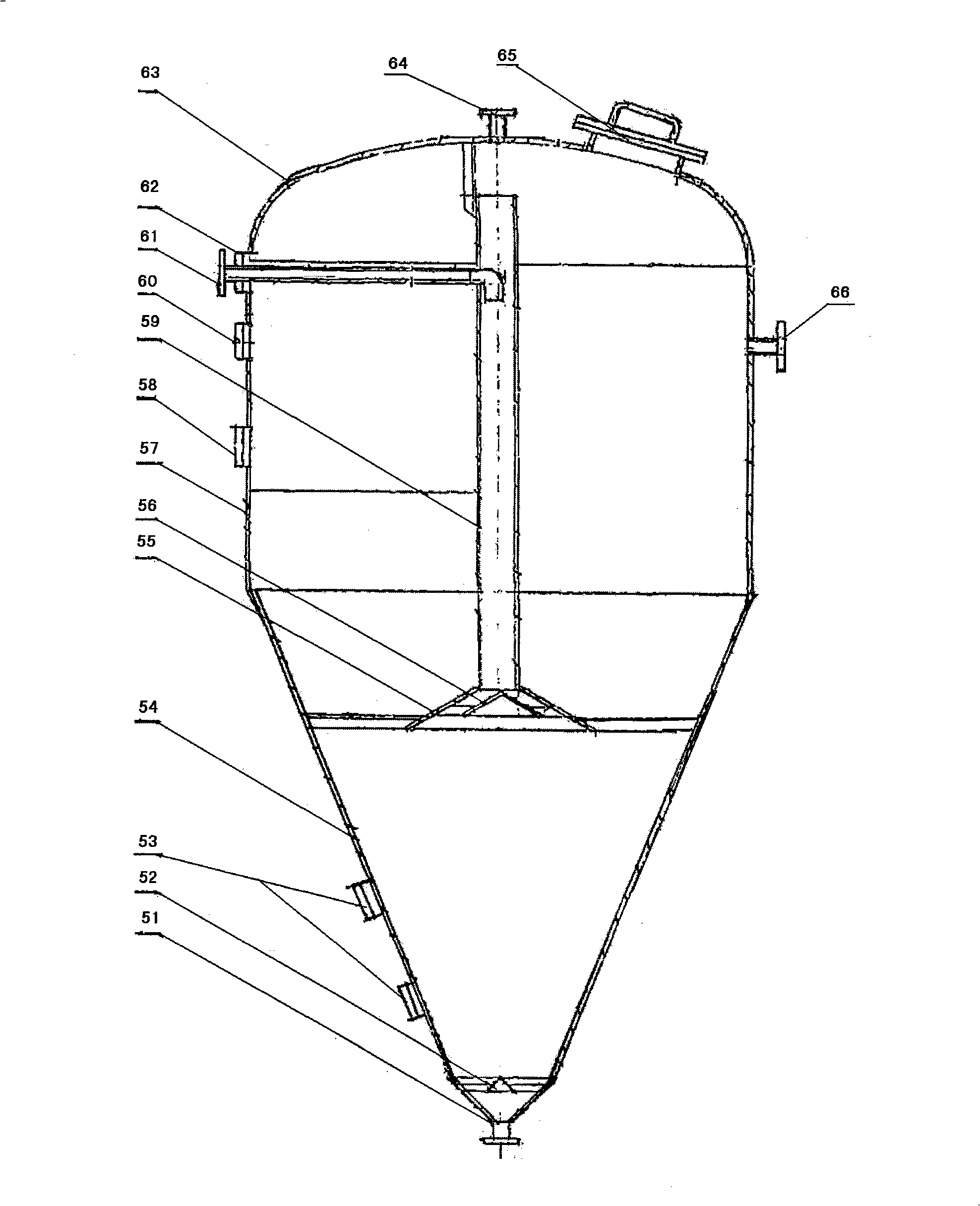

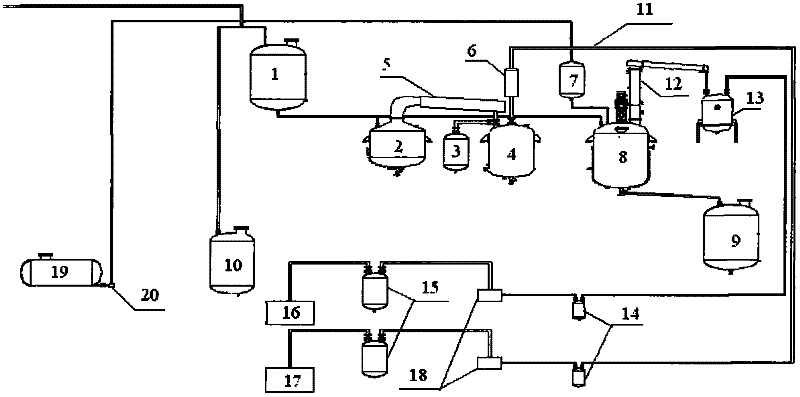

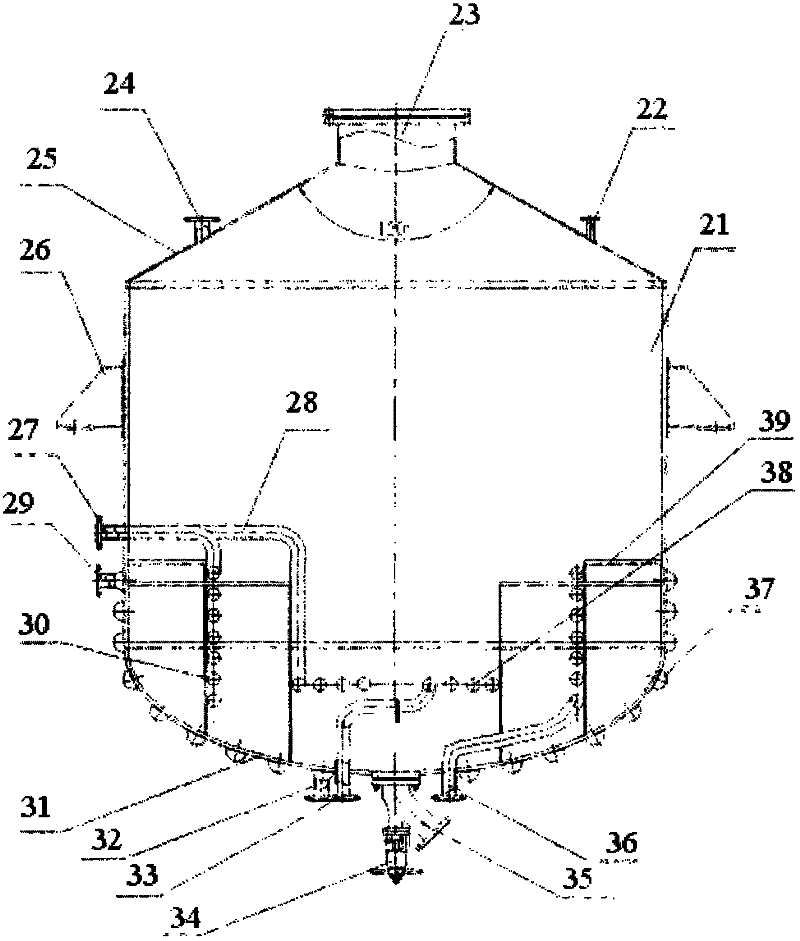

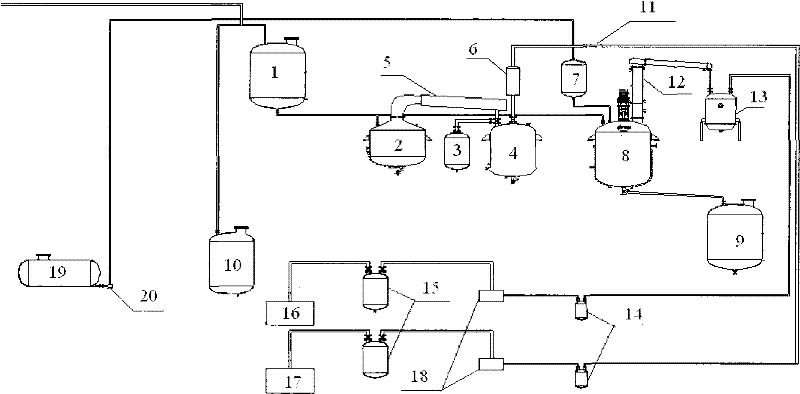

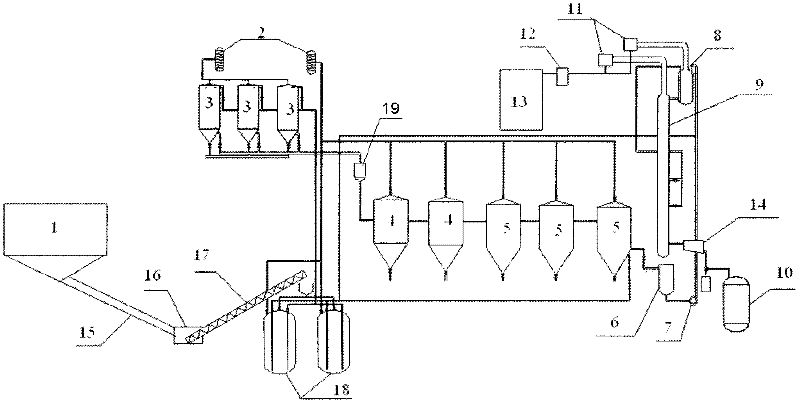

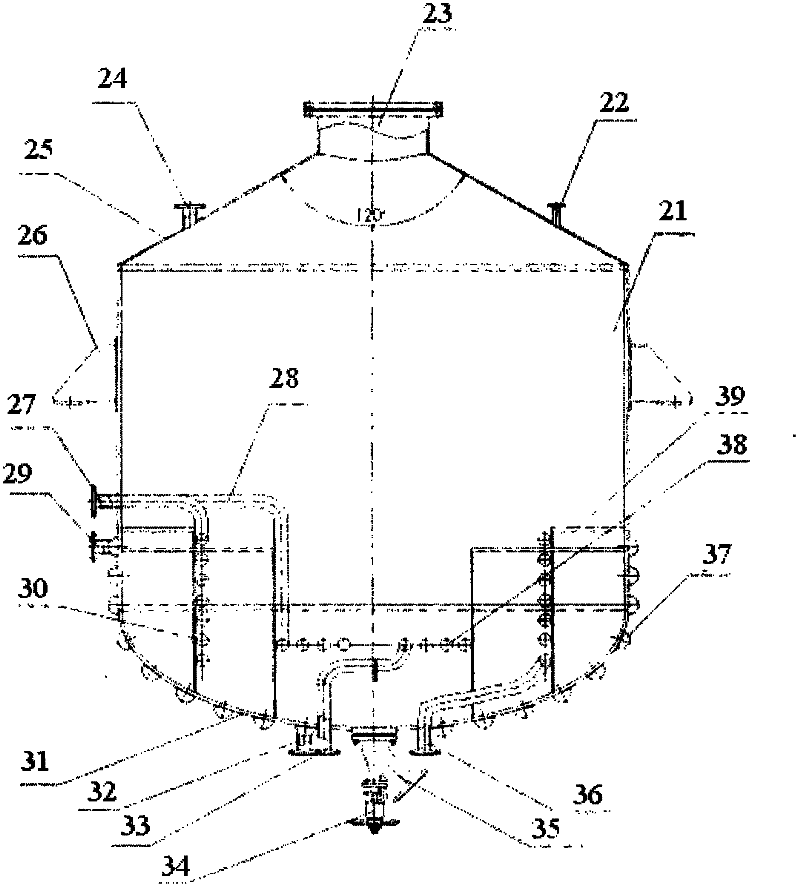

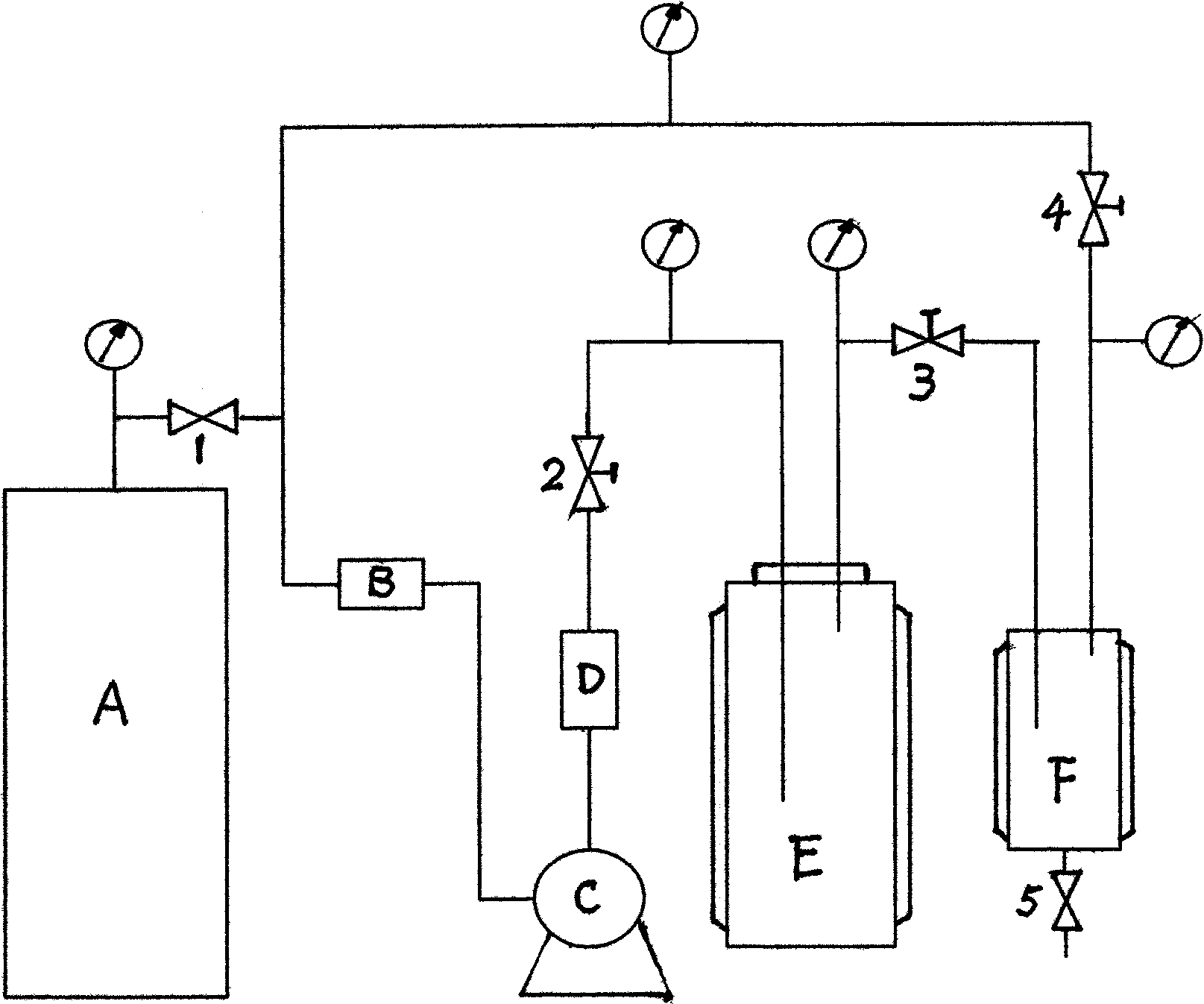

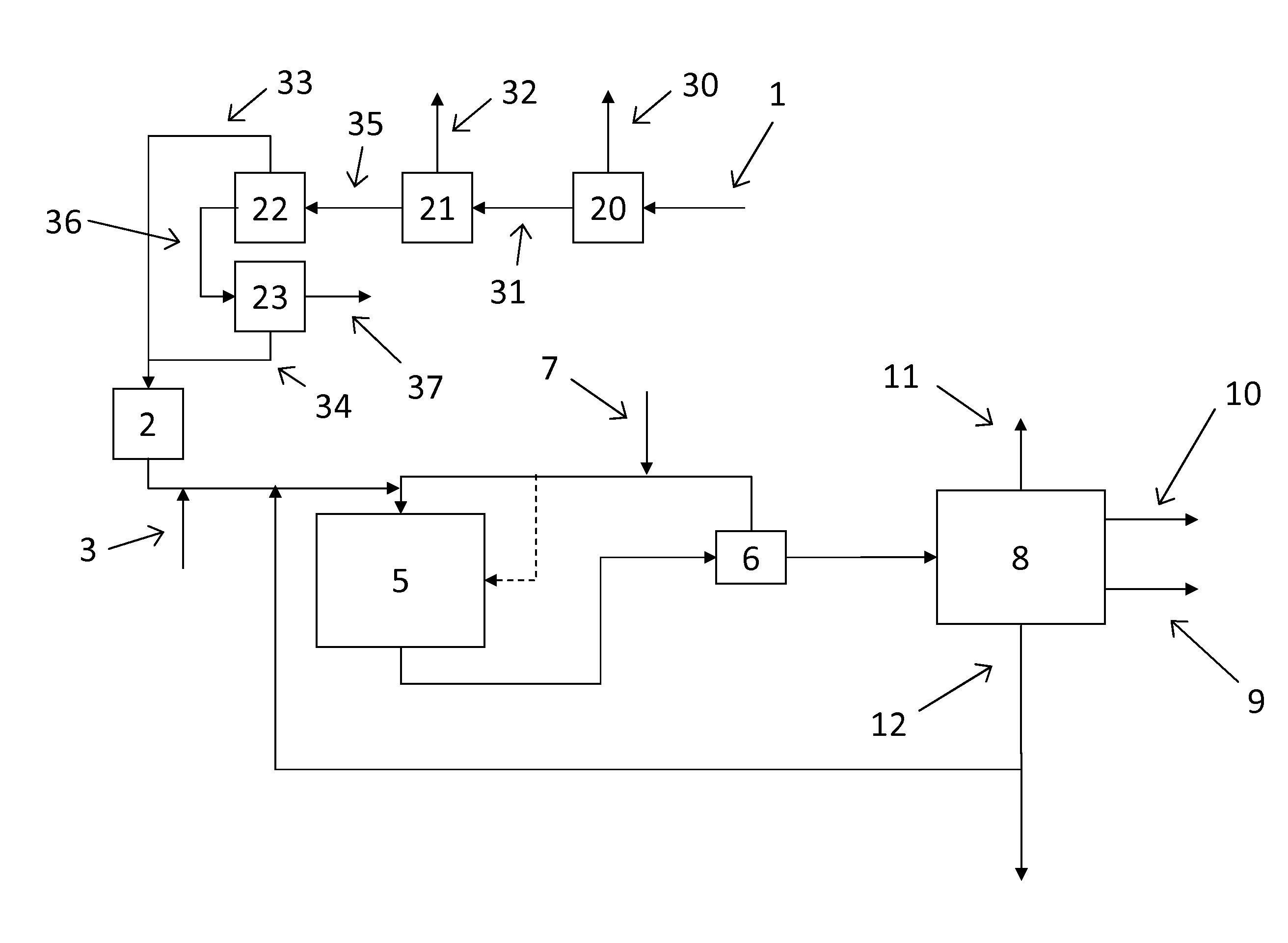

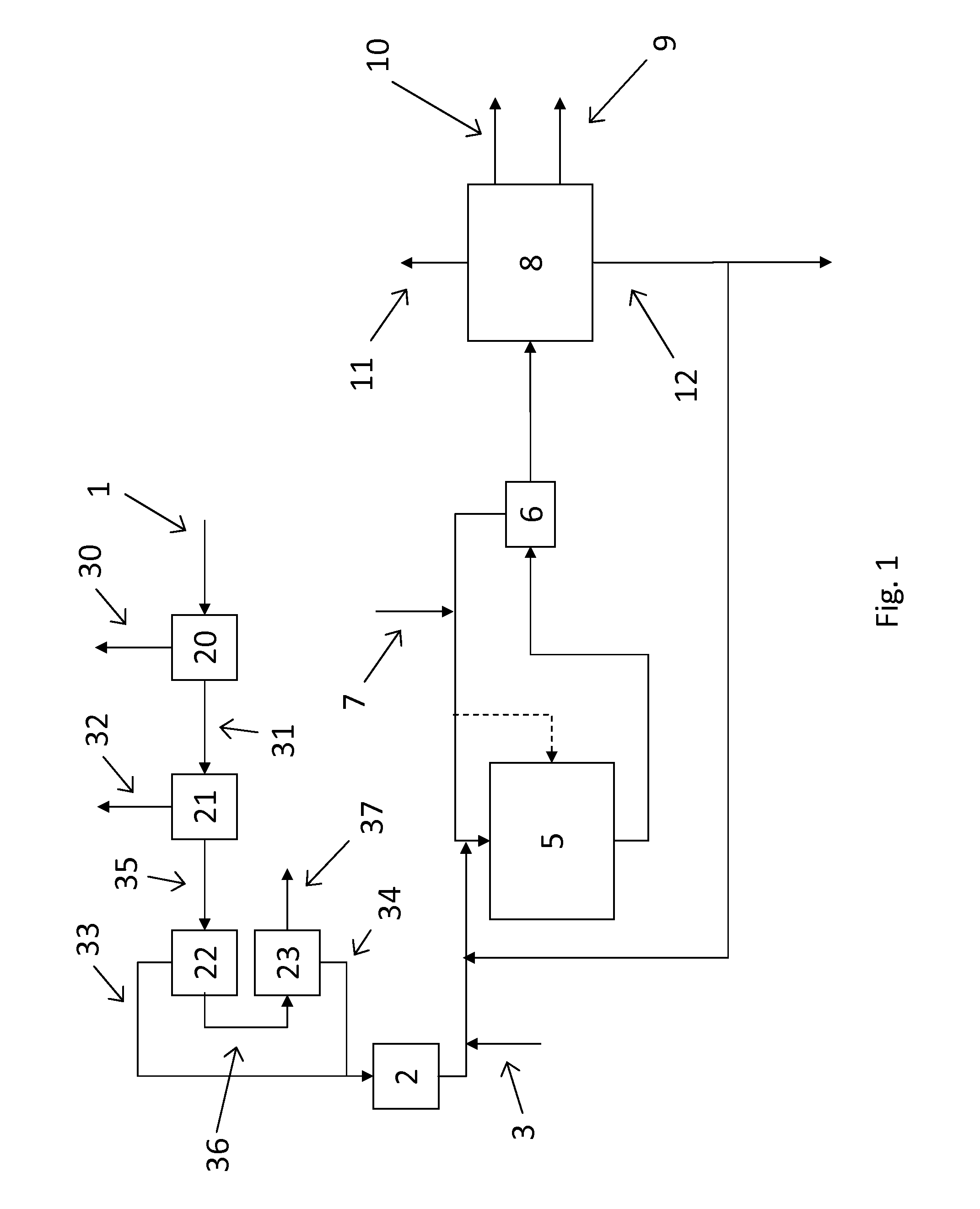

Pine gum processing method and equipment

InactiveCN101343509AIncrease productionRosin quality improvementNatural resin purificationTurpentineRosin

The invention discloses a processing technology of turpentine by a steaming process and the device. The invention adopts the technology that the turpentine is previously preheated and then dissolved, the dissolved turpentine enters into the clearing procedure after adopting the transitional clearing step, the turpentine liquid is preheated after being filtered, then oil gas and colophony are distilled out, turpentine oil is obtained through the condensation of the oil gas, and the distilled high-temperature tail gas and oil gas are recovered to preheat the turpentine and the turpentine liquid; the device adopts that a turpentine preheating pot is arranged in front of a liquating pot; a transitional clarifying kettle is arranged before a clarifying kettle; a distilling and preheating pot is arranged between a turpentine liquid filter and a distillatory kettle. Compared with the prior discontinuous process technology, the processing technology can greatly increase the production, the quality of the colophony is greatly improved, more than 98 percent of the colophony can reach the special grade and the first-grade, the distilling degree of the top grade turpentine reaches 97 percent, half of the standard coal consumed by one ton of colophony is approximately saved, half of the steam and the cooling water are also reduced, and the energy saving and consumption reducing effects are remarkable.

Owner:李国鸿

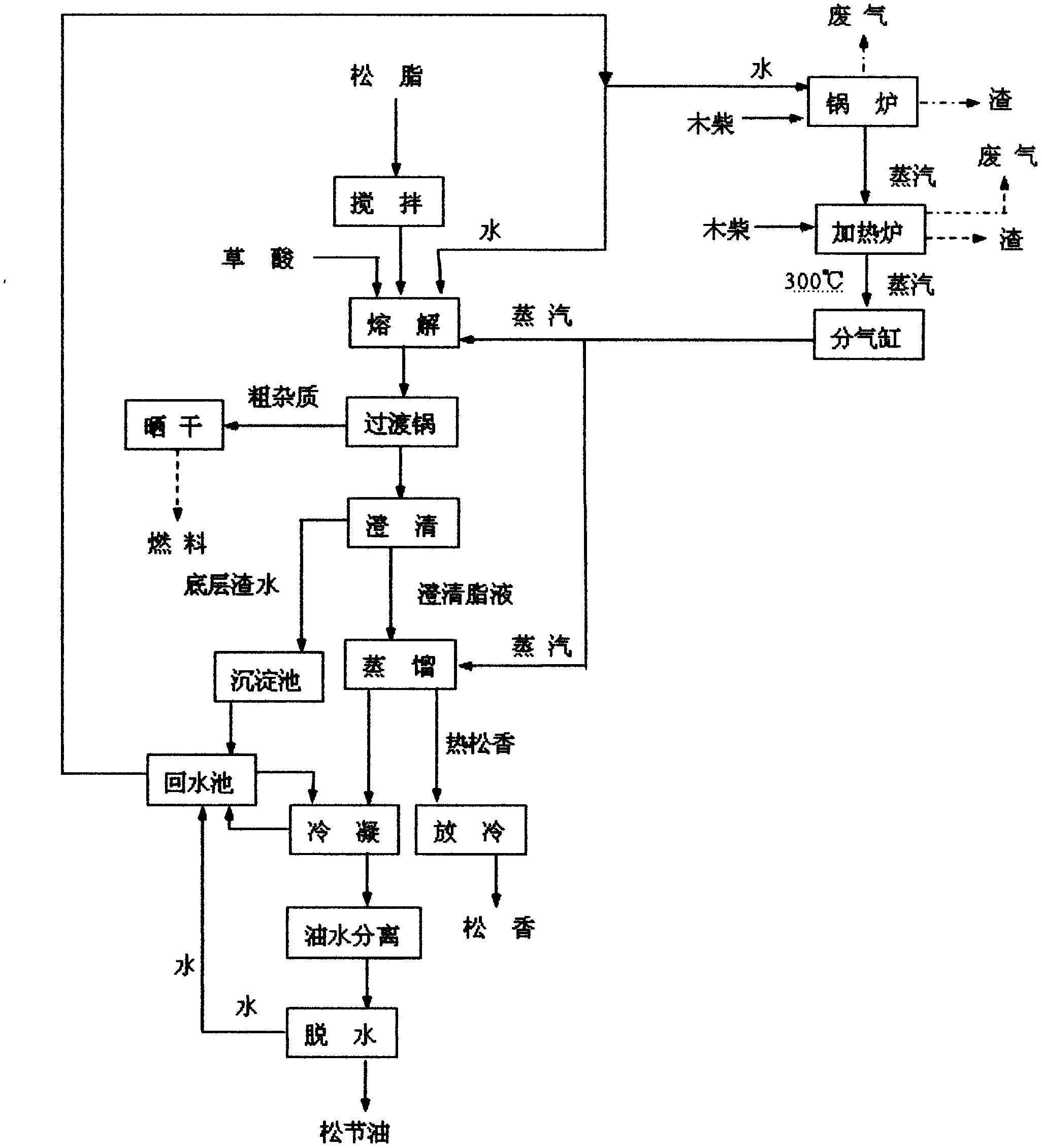

Rosin production technology process

InactiveCN104342034AImprove melting abilityThere will be no meltingChemical industryTurpentine spiritsSteam pressureTurpentine

The invention discloses a rosin production technology process. The process comprises the following steps: conveying turpentine to a melting boiler, adding water, turpentine oil, and oxalic acid, wherein the weight ratio of turpentine to water to turpentine oil is 2-4:1-2:1, and the oxalic acid accounts for 0.1 to 0.3% of the turpentine weight; heating the boiler to melt the mixture in the boiler; transferring the melt mixture to a transition boiler; introducing the melt mixture into a clarifying boiler after precipitation in the transition boiler, then transferring the liquid to a steaming boiler to carry out steaming, wherein during the steaming process, water and turpentine oil are continuously steamed out from the liquid. The provided rosin production technology process has the following advantages: the turpentine is fully stirred before melting so as to grind the turpentine, thus the turpentine melting effect is improved, at the same time the phenomenon that some turpentine is not melted during the melting process is avoided, and thus the yield is increased; moreover, the metling is reduced, the energy consumption is reduced, and the rosin color will not turn darker; the condensed hot water can be directly applied to the boiler so as to reduce the temperature difference between the inlet water and outlet water, the boiler efficiency is improved, the steam pressure is more stable, and more energy is saved.

Owner:琼中森富松香加工厂有限公司

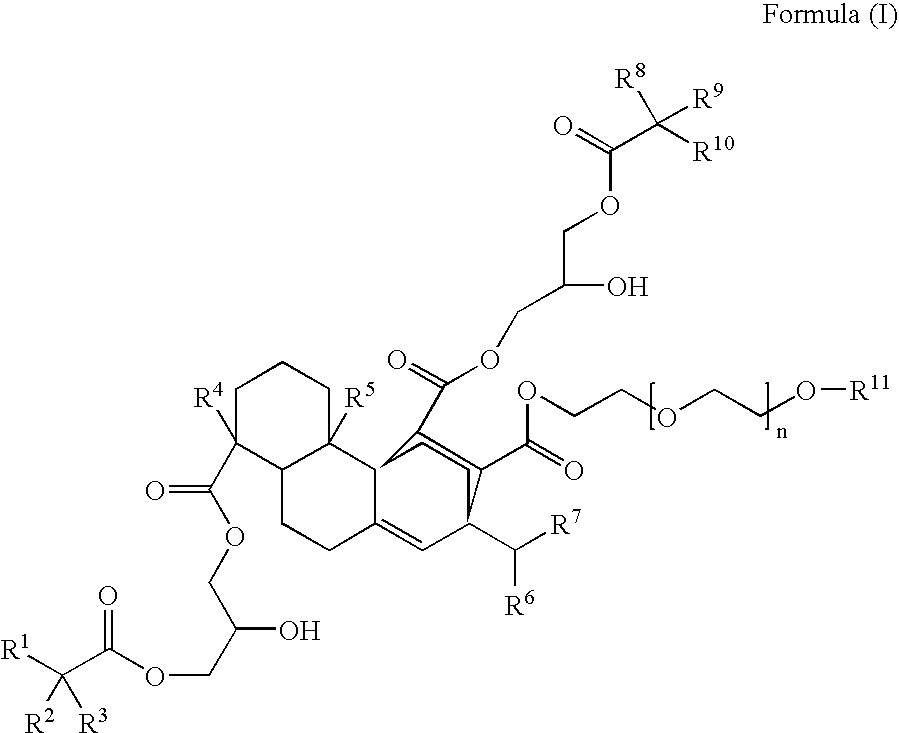

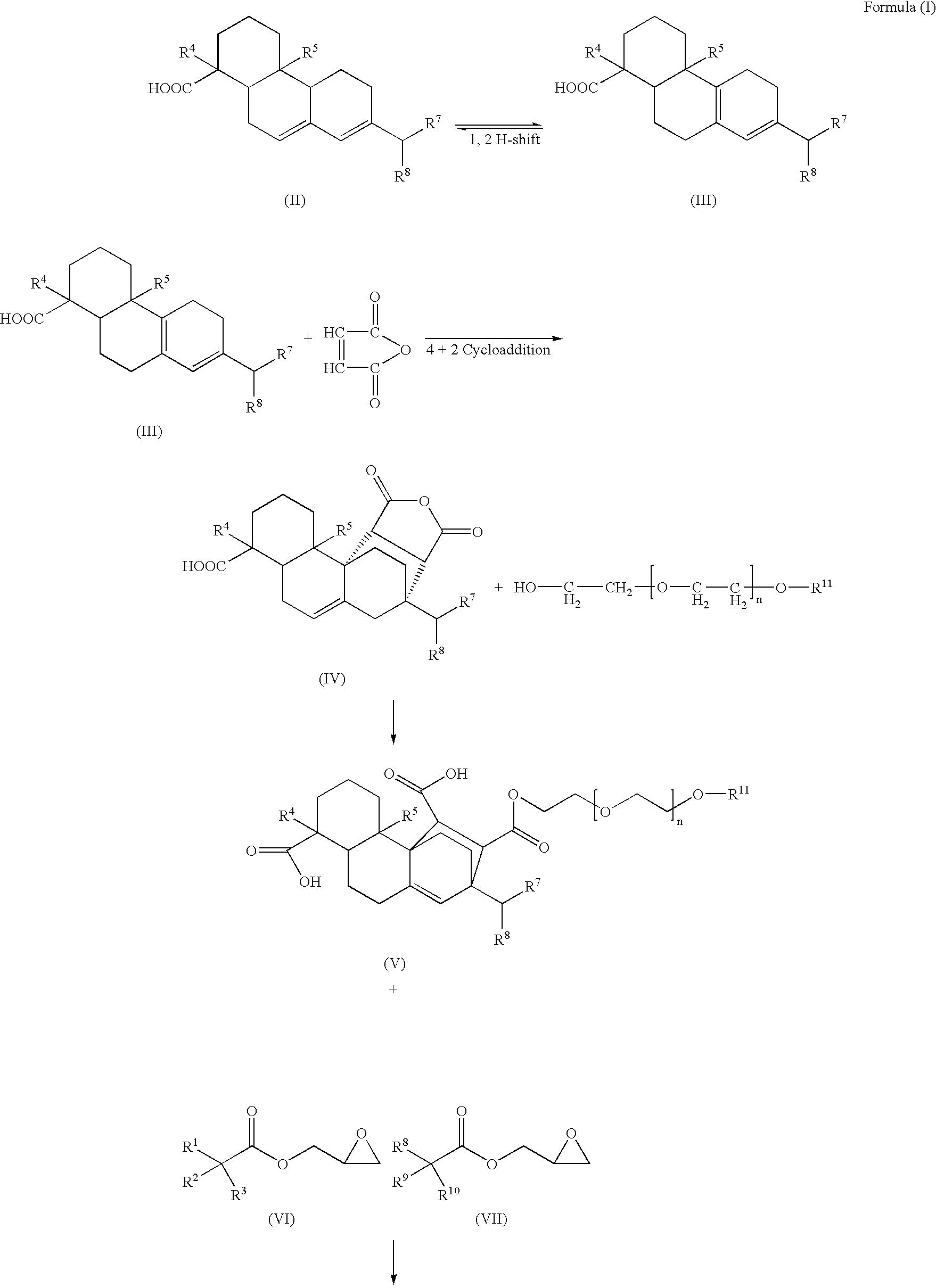

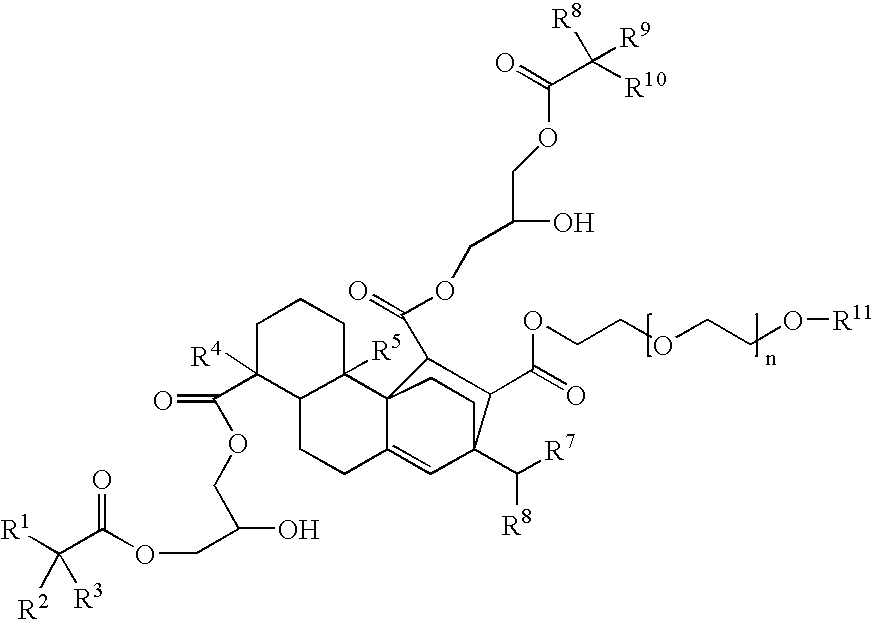

Compounds, rosins, and sizing compositions

The present invention relates to terpene derivative compounds and rosins and sizing compositions comprising such compounds. Compounds of Formula (I) are disclosed in addition to rosins and sizing compositions comprising compounds of Formula (I). Fiber glass strands comprising a plurality of glass fibers at least partially coated with sizing compositions comprising compounds of Formula (I) are also disclosed.

Owner:PPG IND OHIO INC

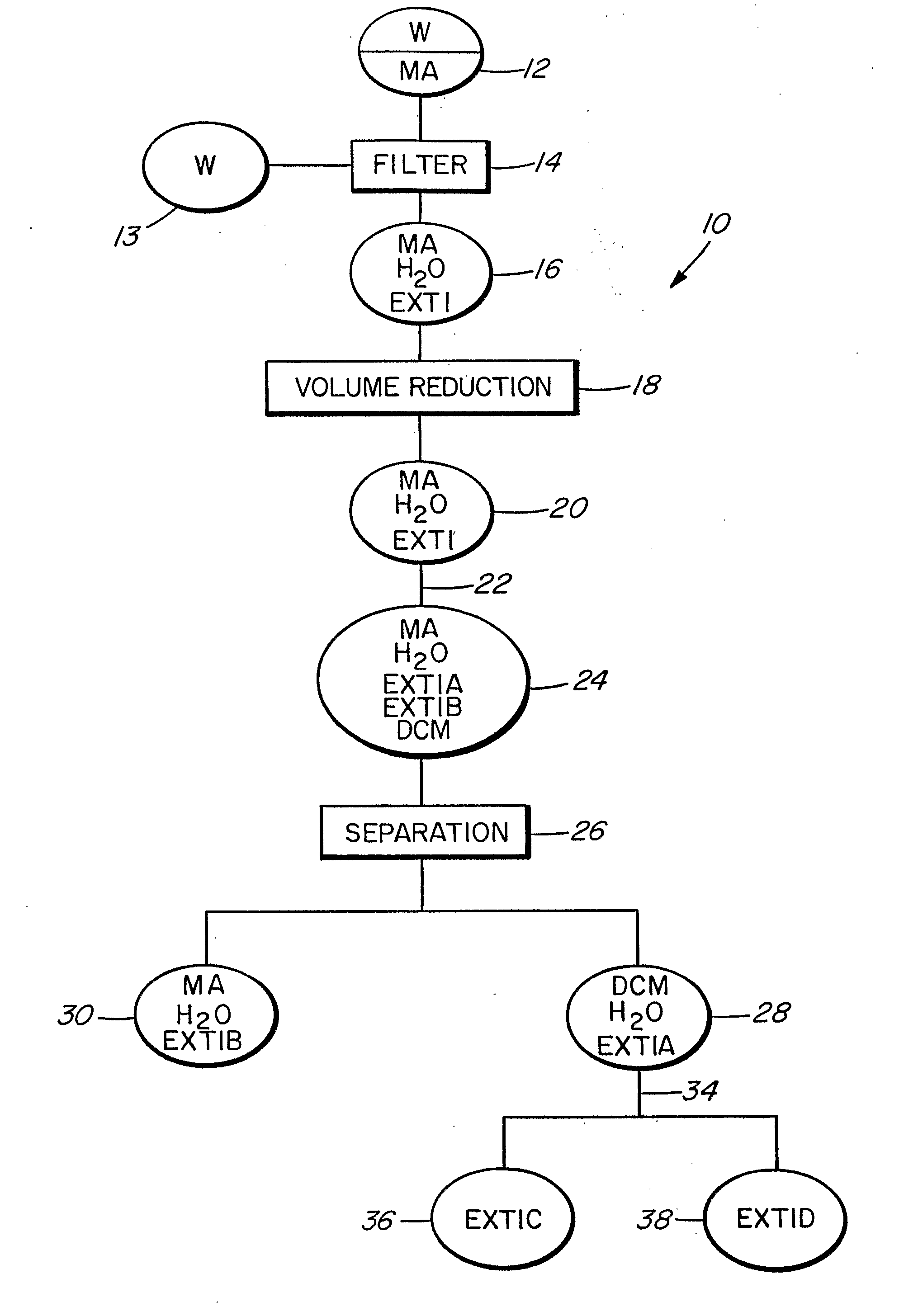

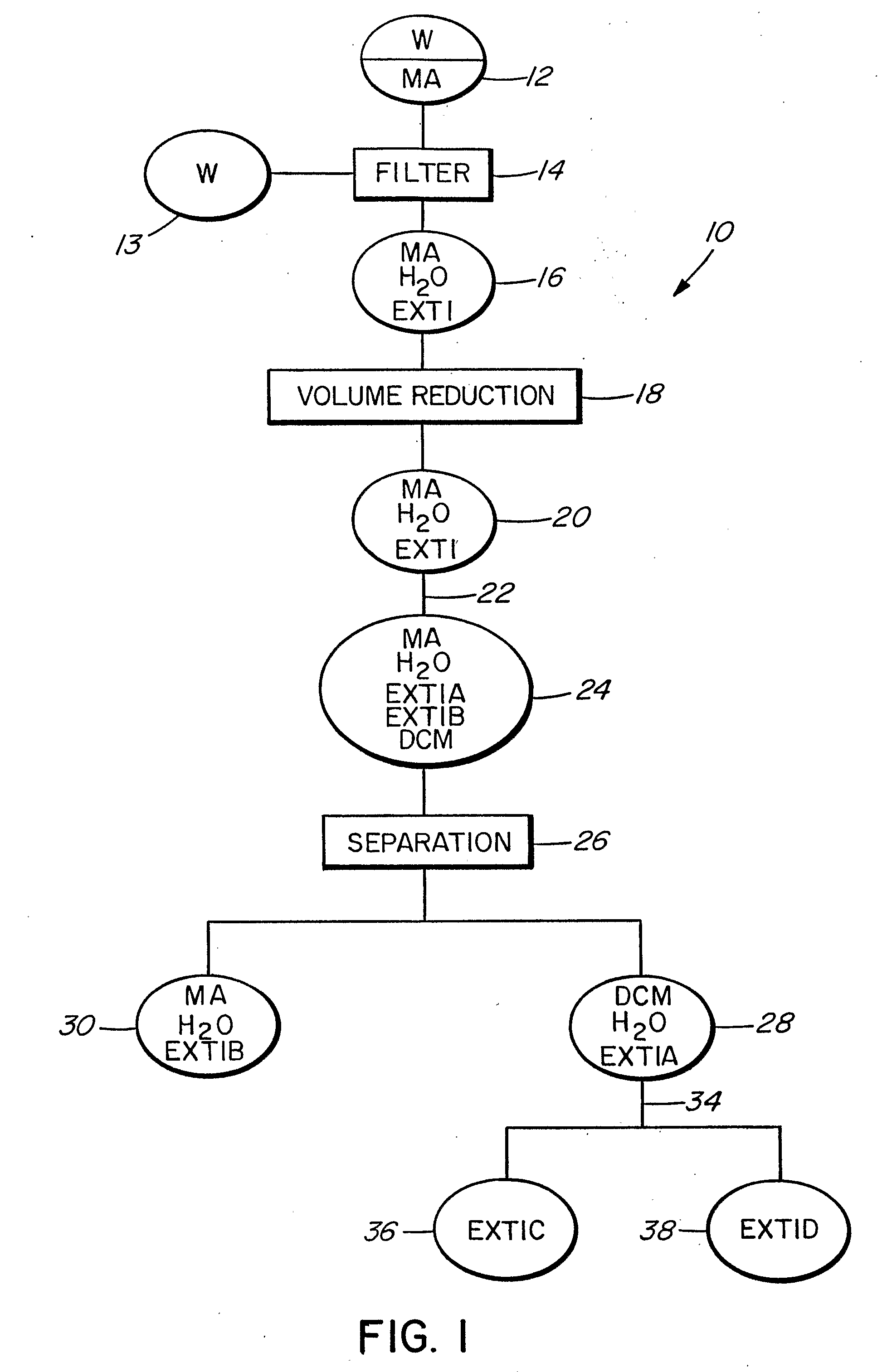

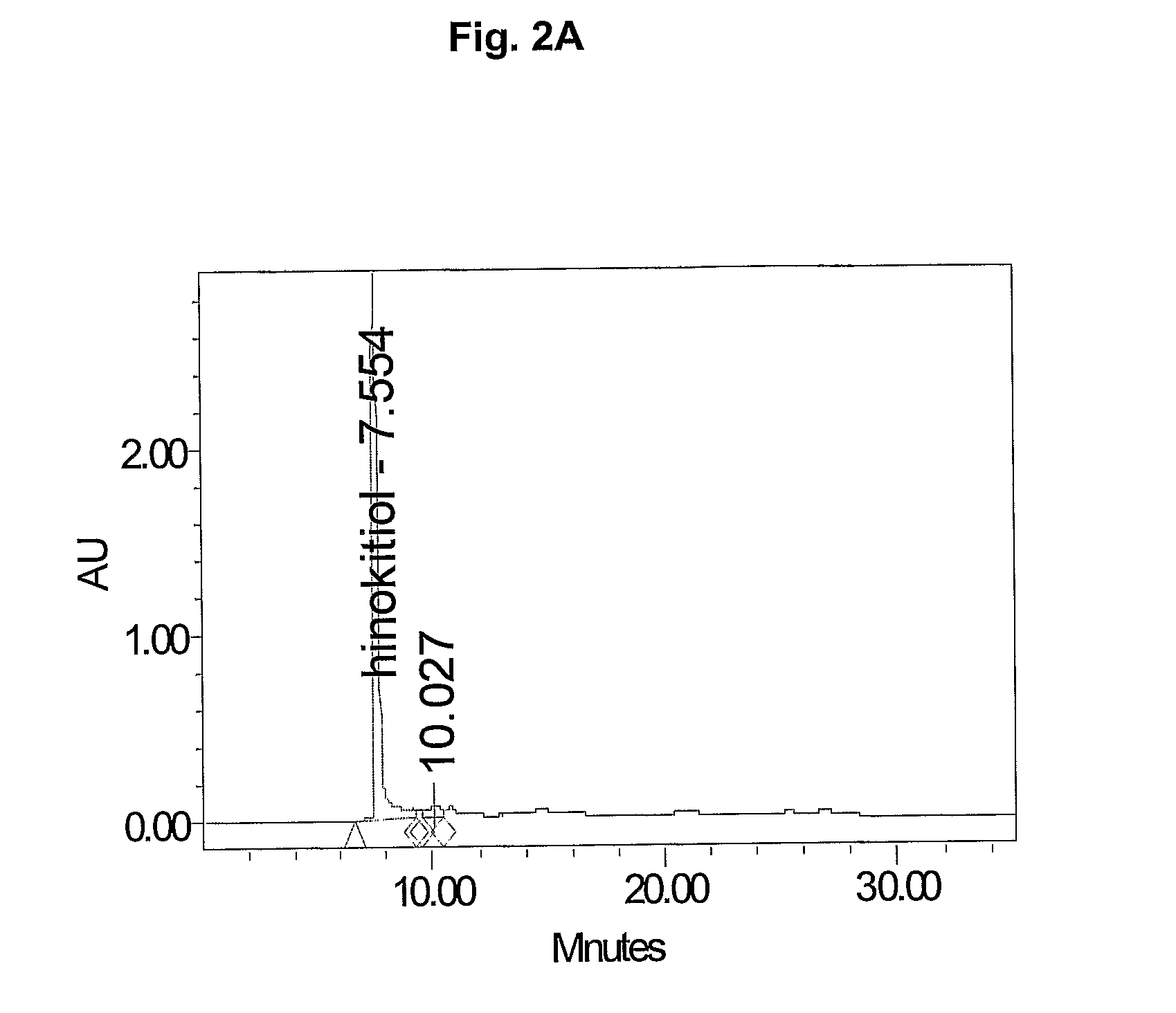

Plant Materials Extraction Method

A process for preparing plant extracts is provided. Plant materials, including tropolones, lignins and polar molecules, are mixed with a liquid polar solvent to form an extraction mixture, which is maintained under extraction conditions effective to extract lignins, polar molecules and at least 50% of the tropolones into the polar solvent to form a pregnant polar solvent liquid phase. The pregnant polar solvent phase is separated from the solid plant materials, and mixed with a substantially immiscible nonpolar solvent under conditions effective to partition the tropolones and lignins substantially into the nonpolar solvent and to partition the polar molecules substantially into the polar solvent to form a partitioned nonpolar solvent phase comprising lignins and tropolones, and a partitioned polar solvent phase comprising the polar molecules, and separating the polar solvent phase from the nonpolar solvent phase to obtain a polar plant extract and a nonpolar plant extract.

Owner:JONES DAVID +1

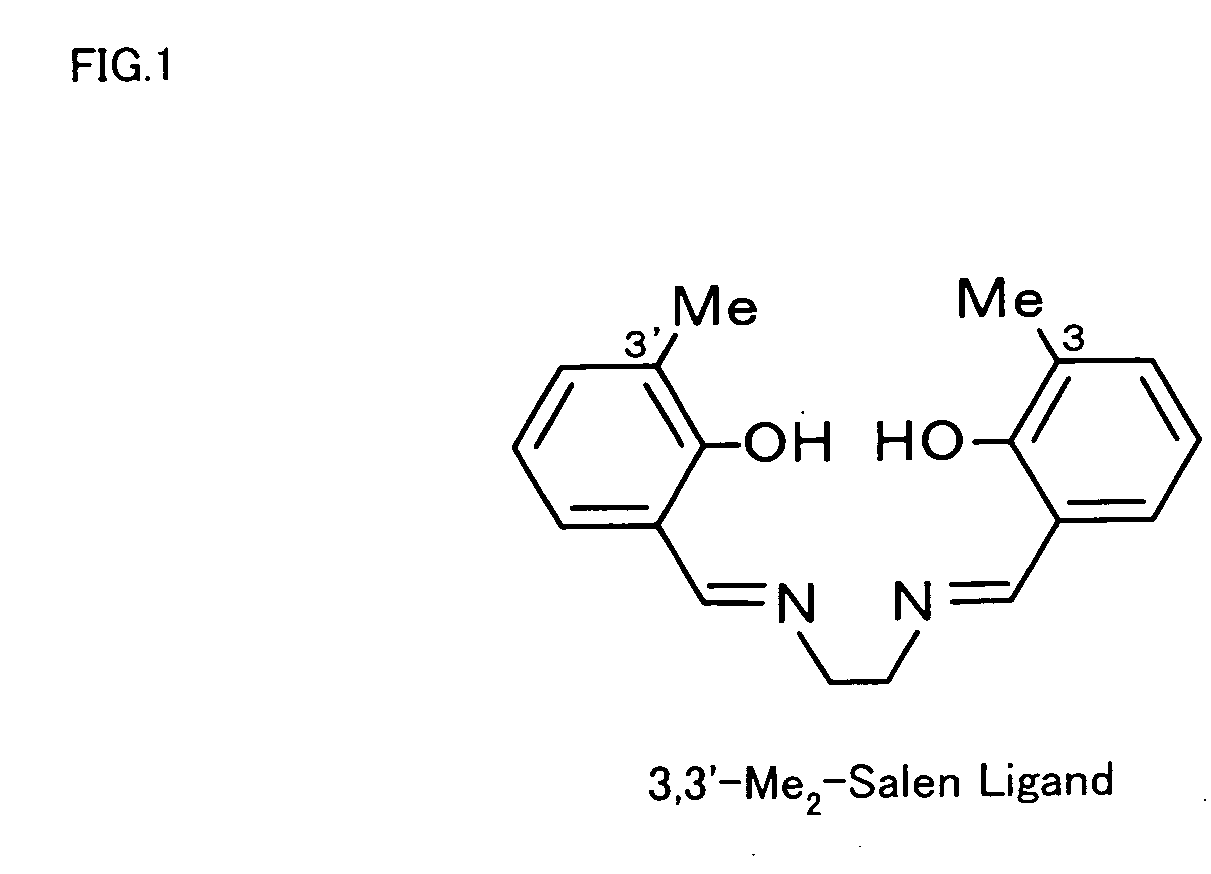

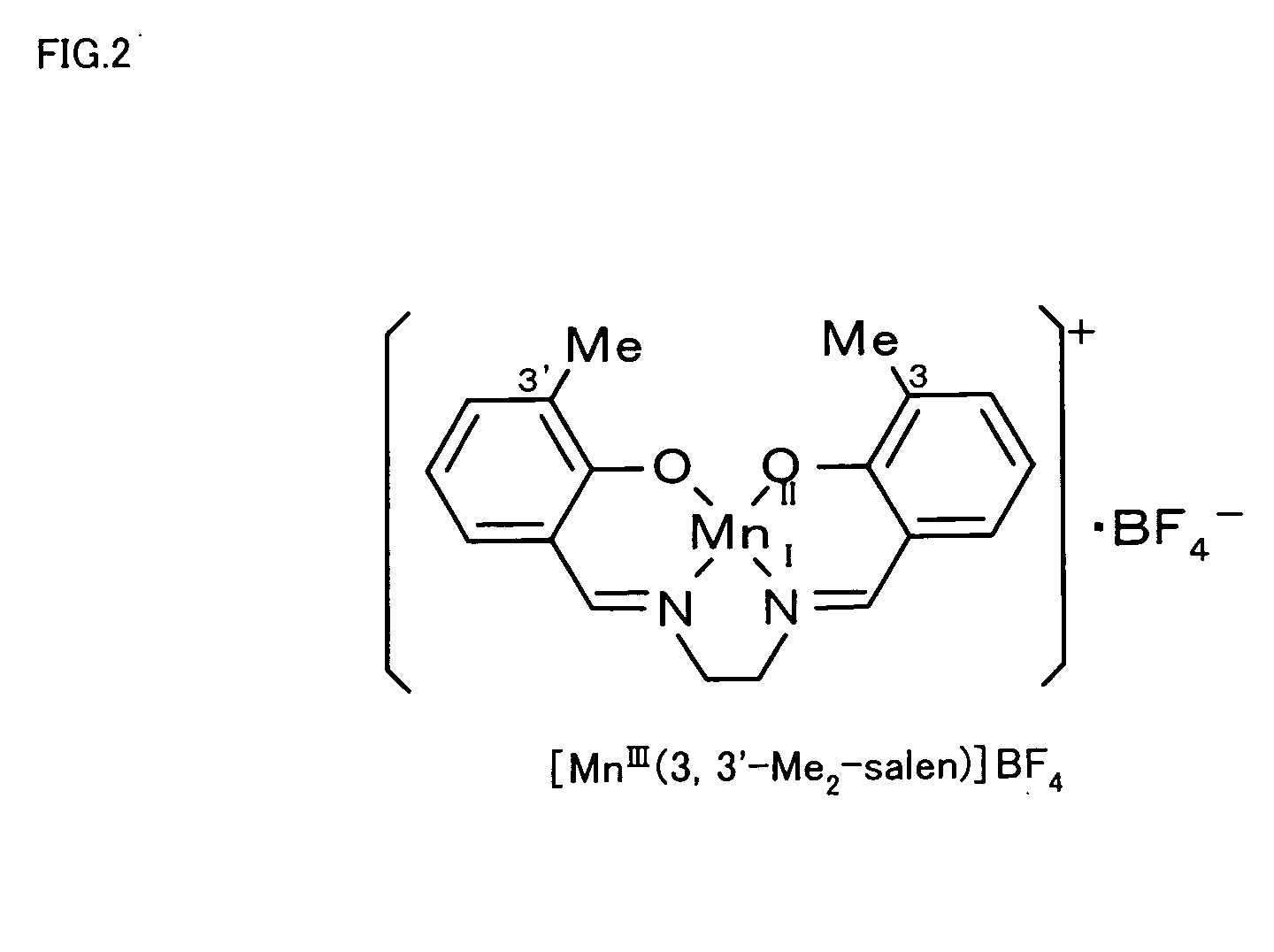

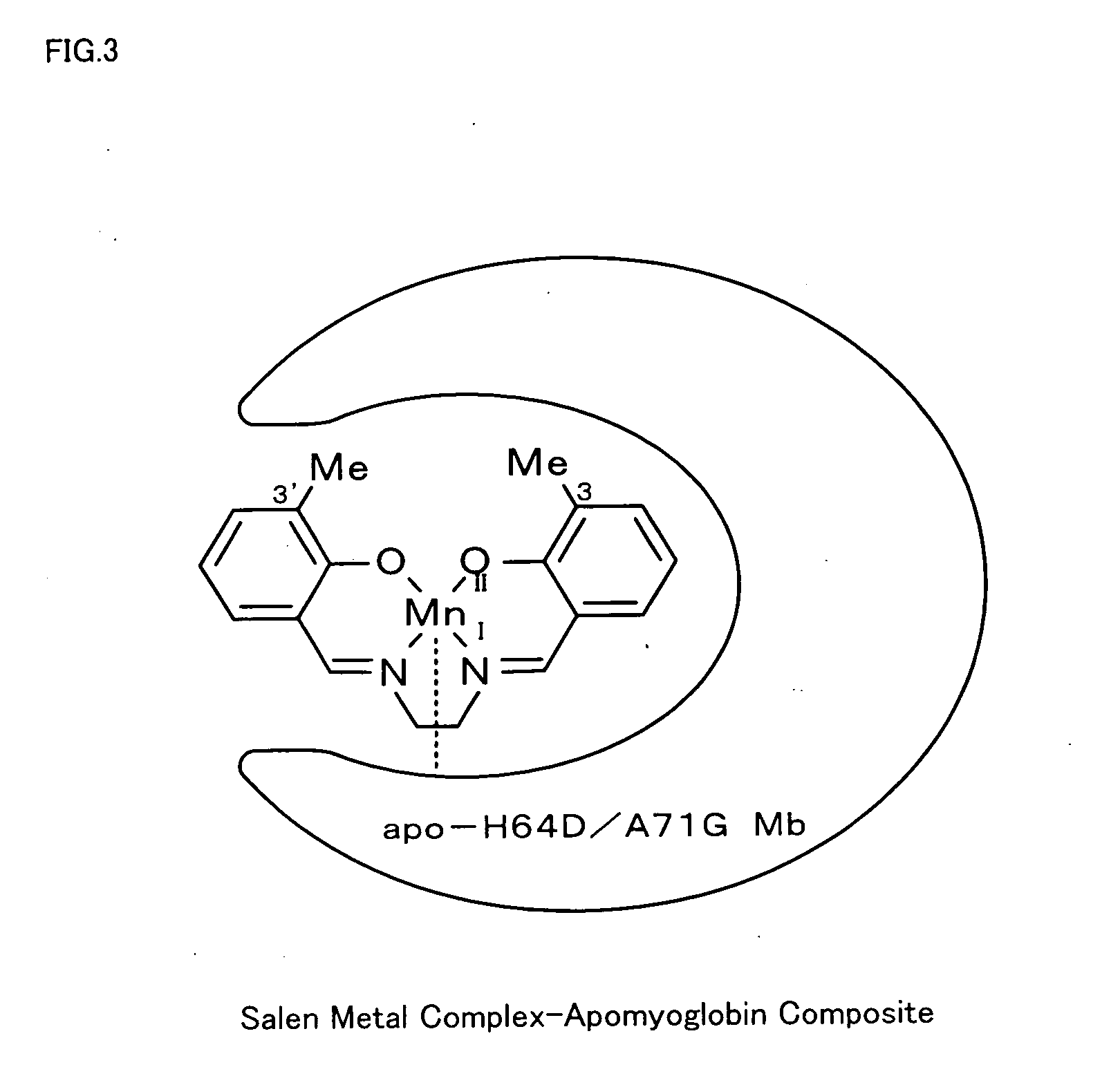

Metal complex-protein composite and oxidation catalyst

InactiveUS20050096260A1Improve responseHigh enantioselectivityPeptide/protein ingredientsOrganic-compounds/hydrides/coordination-complexes catalystsHalogenHydrogen atom

The metal complex-protein composite of the invention has a specific structure that a salen metal complex expressed by Formula (1) given below is received in a cavity of a protein: where M in Formula (1) represents a metal ion, and R1 through R10 independently represent any of hydrogen atom, halogen atoms, alkyl groups containing 1 to 5 carbon atoms, and alkoxy groups containing 1 to 5 carbon atoms.

Owner:NAGOYA INDUSTRIAL SCIENCE RESEARCH INST

Method for refining capsicum oleoresins

InactiveCN102746793AIncrease contentResidue reductionNatural resin purificationAcetic acidPotassium hydroxide

A method for refining capsicum oleoresins uses a capsicum oleoresin with a low capsaicinoid content. The method includes selecting 6% to 9% of potassium hydroxide as a saponifying agent, and subjecting the mixture to saponifying processing at a temperature between 40 DEG C and 55 DEG C for 4 hours to 5 hours; preparing hexyl hydride and 85% to 95% of ethanol into a mixed solvent, subjecting saponifying matter to multiple extraction, concentrating the extracted capsicum oleoresin under the vacuum and warming condition, respectively recycling the hexyl hydride and the ethanol, dissolving the capsicum oleoresin through ethanol, subjecting the capsicum oleoresin to secondary extraction, stirring the extracted capsicum oleoresin evenly, separating a pigment phase and a capsaicin phase, separately heating the concentrated capsaicin phase and the pigment phase, and respectively recycling the ethanol and ethyl acetate. The method for refining capsicum oleoresin increases the content of capsaicin in the capsicum oleoresin, reduces the residual amount of capsochrome in the capsicum oleoresin, enables the color to be light, improves the product quality, expands the applied range, increases the additional value of products and, enhances the market competitiveness.

Owner:云南宏绿辣素有限公司

Production process for rosin resin

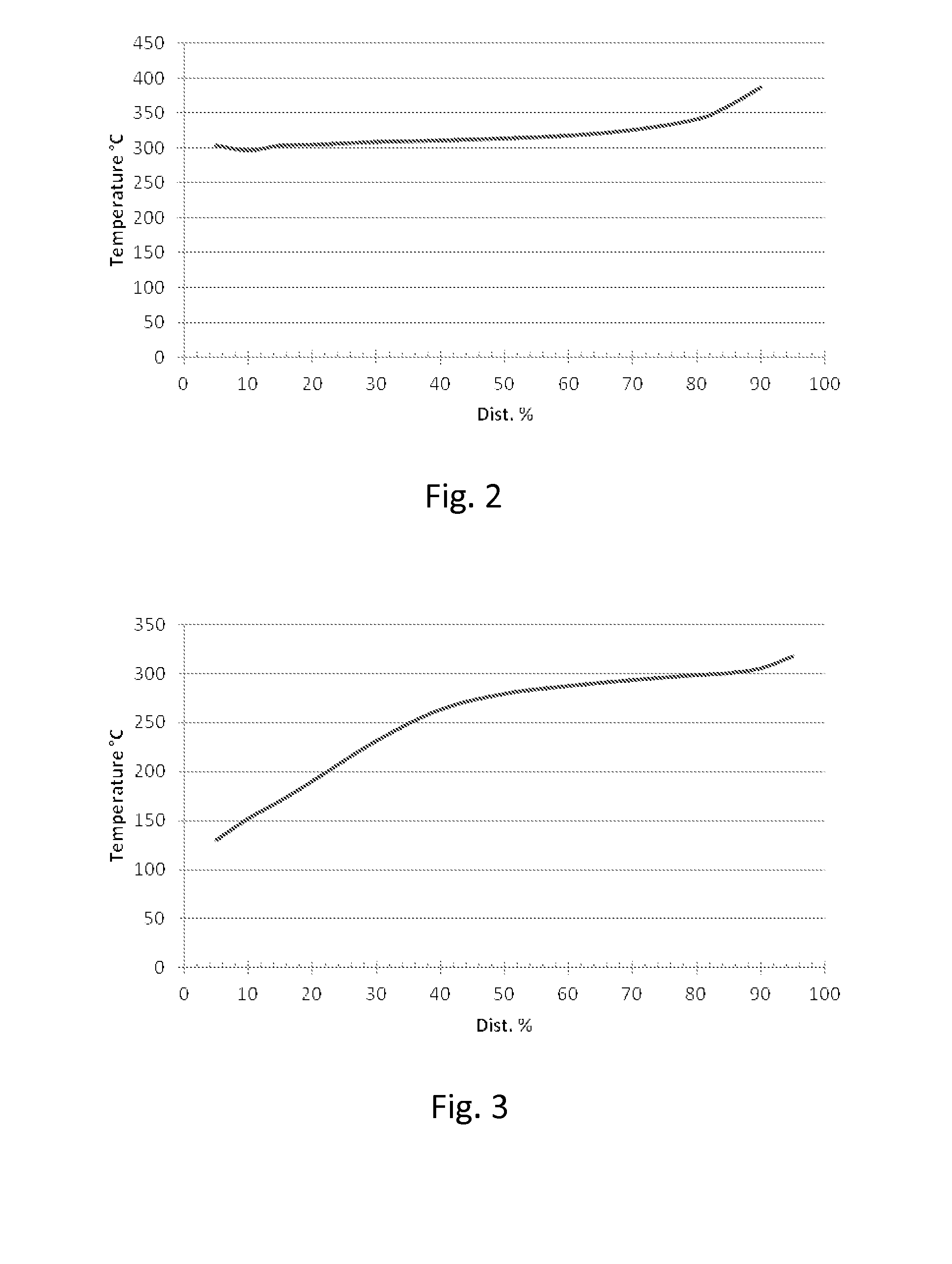

ActiveCN102337078AReduce refluxReduce dead volumeNatural resin chemical modificationNatural resin purificationDistillationRosin

The invention provides a method of preparing rosin ester or modified rosin ester from rosin. The method comprises a preparation step and an esterification step for modified rosin. The invention is characterized by further comprising a refining process for rosin carried out before the esterification step for modified rosin, and the refining process comprises a step of distillation. According to the step of distillation, rosin is placed into a distilling still and heated under vacuum, distilled fractions boiling in a range of 180 to 220 DEG C are collected separately, then main fractions are collected, and refined rosin is obtained after the temperature of rosin reaches 270 DEG C.

Owner:景东力奥林产集团林业化工有限公司

Method for producing rosin

ActiveCN102311705AQuality achievedReduce refluxTurpentine spiritsNatural resin purificationTurpentineRosin

The invention provides a method for producing rosin by turpentine, which comprises the following steps of melting, clarifying and distilling. The melted turpentine liquid is pressed in at least two higher-placed furnaces by vapor pressure in the melting process. The subsequent clarifying process is performed after the melted turpentine liquid is stayed in the higher-placed furnaces. The rosin product obtained by the method of the present invention can reach the grade of national superfine standard.

Owner:景东力奥林产集团林业化工有限公司

Inhibition of rosin crystallization

InactiveUS20040127681A1Prevent spoilagePrevent bacterial growthNatural resin chemical modificationNatural resin purificationCarboxylic acidRosin

The invention relates to the inhibition of crystallization in rosin and rosin-based materials through the use of crystallization inhibitors. More specifically, the crystallization inhibitor is selected from the group consisting of carboxylic acids and the salts of carboxylic acids. The invention also relates to the process of inhibiting crystallization in rosin and rosin-based materials.

Owner:EASTMAN CHEM CO

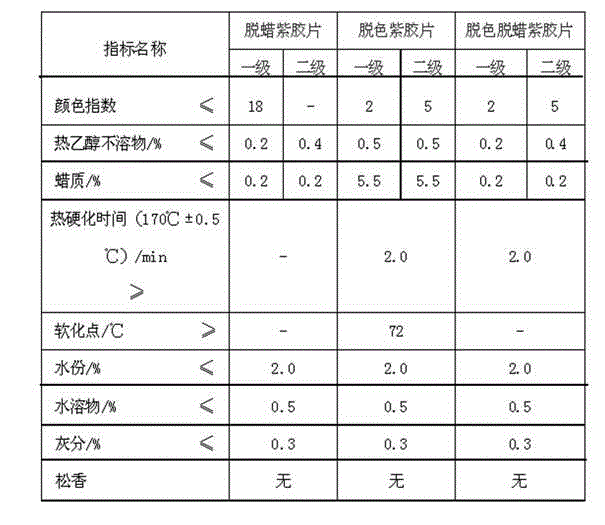

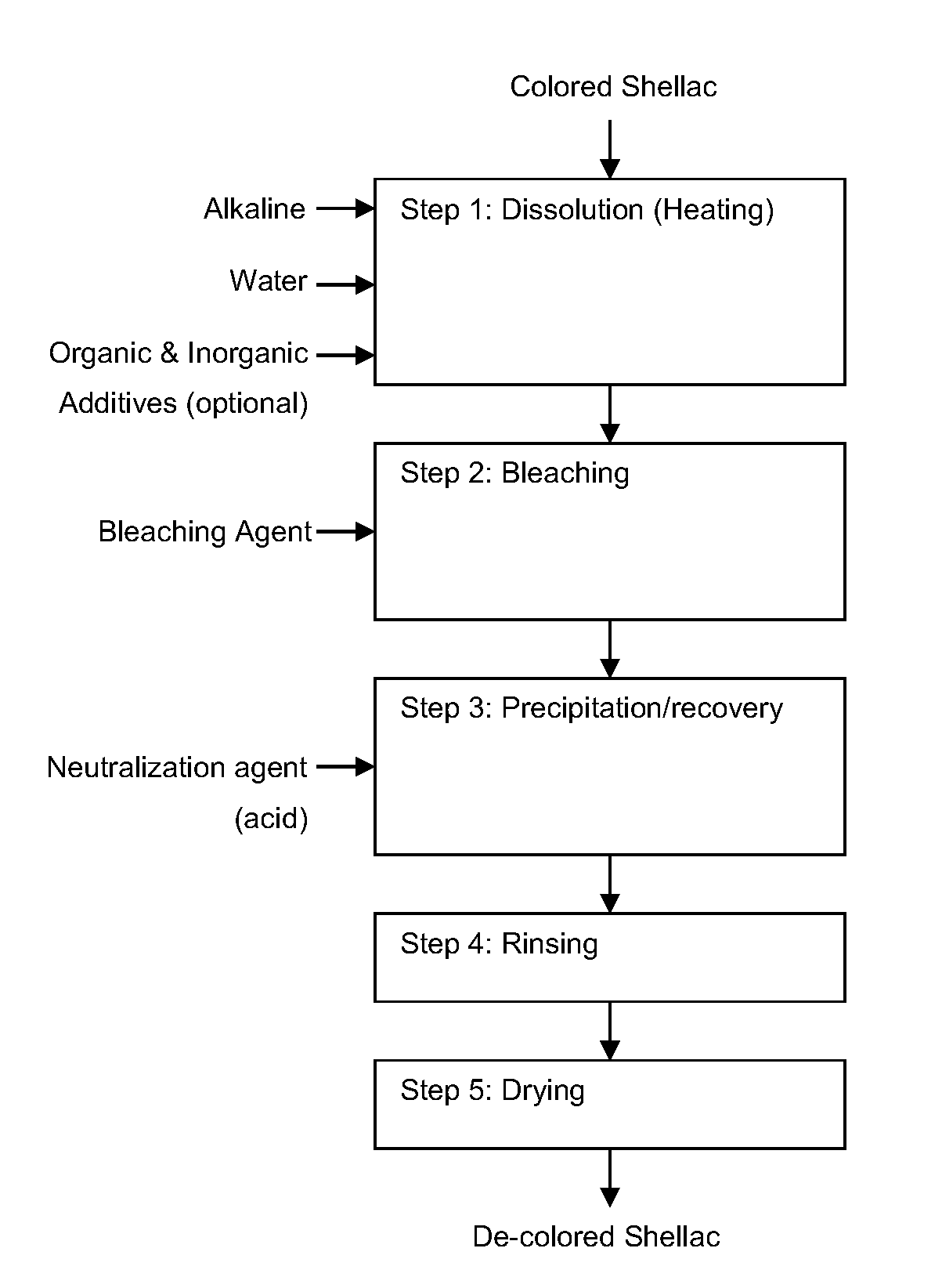

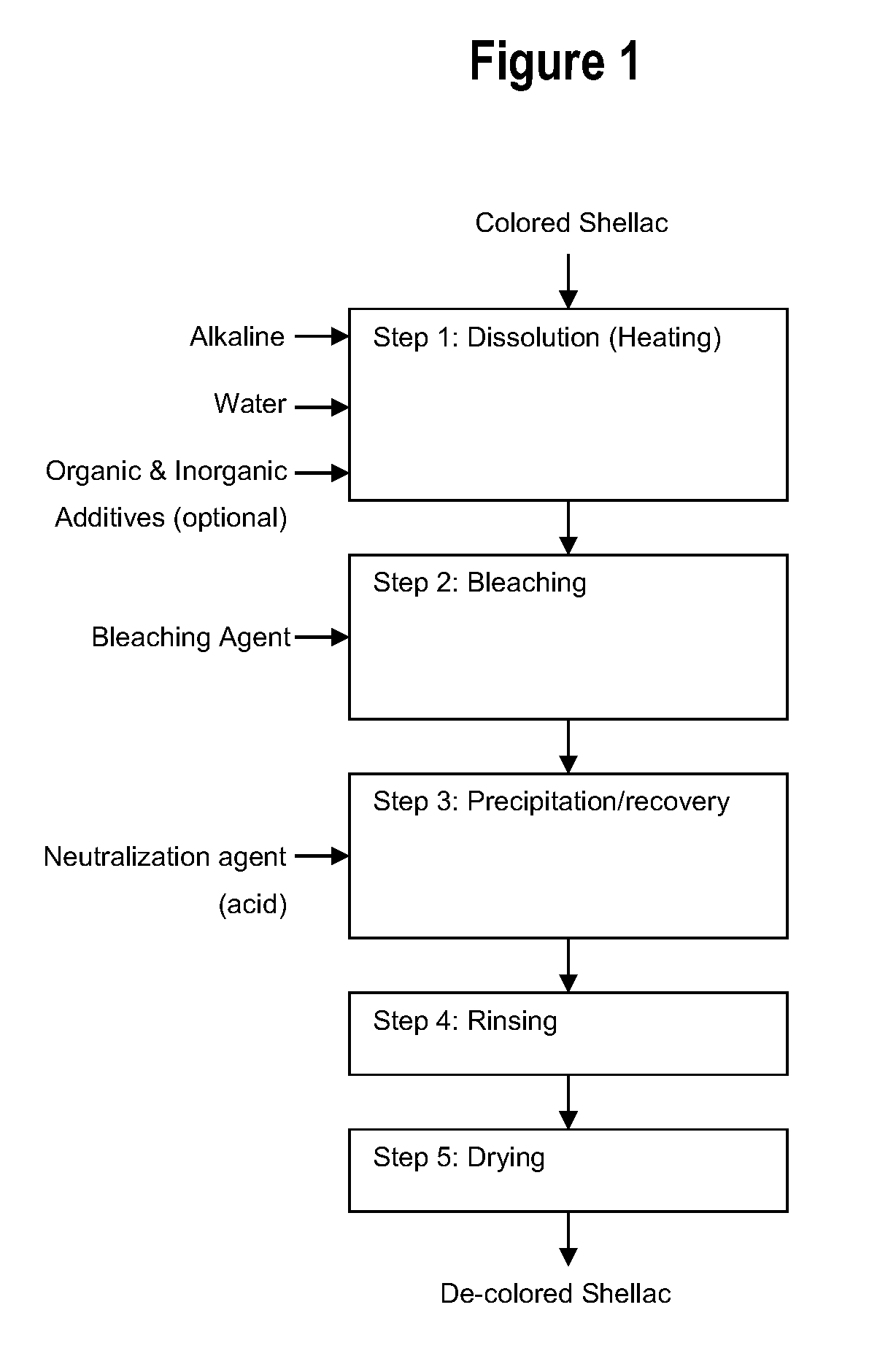

Method for preparing low-chlorine bleach lac

InactiveCN101157828AMeet the requirements of low chlorine bleached shellacNatural resin purificationFood preparationFiltrationBleach

A preparation method of less chlorine bleaching lac: first, lac grains are put into sodium carbonate solution under the temperature of 60 DEG C to 100 DEG C and are completely dissolved. And then the solution is cooled below 70 DEG C and waxiness and insoluble content in the lac are filtrated; the filtrated solution under the temperature of 20 DEG C to 40 DEG C is added with sodium hypochlorite to blanch, then the temperature is increased to 70 DEG C to 100 DEG C. Next, sodium ethoxide is put into the solution to react. After the solution being cooled to room temperature or below 30 DEG C, sodium hypochlorite solution is dropped into the solution to blanch. Then the solution is filtrated with filtration aids such as white mud, diatomite and so on; the filtrated solution is added with dilute sulphuric acid or dilute hydrochloric acid to precipitate. The precipitation is dried by heat air after being washed and solid / liquid separation. In the end, the less chlorine bleaching lac which is white or slight yellow powder can be gotten. The product can satisfy the demand for food industry and pharmacy. The chlorine content in the product is less than 0.3 percent (wt percent). The time for thermal polymerization under the temperature of 170 DEG C plus or minus 1 DEG C amounts to above 5 minutes. The storage period is more than 2 years.

Owner:KUNMING UNIV OF SCI & TECH

Method for manufacturing stabilized polyacetal resin, stabilized polyacetal resin, stabilized polyacetal resin composition, and molded article of stabilized polyacetal resin

The present invention provides an agent to decompose instable terminal group, which is effective in a small adding amount, which sufficiently decreases the quantity of residual instable terminal group, and which generates very little limitation on the treatment method, the apparatus, and the use amount of the agent. Specifically, it provides a method for manufacturing stabilized polyacetal resin having the step of applying heat treatment to a polyacetal resin having an instable terminal group in the presence of an agent to decompose the instable terminal group, which agent is composed of a heterocyclic quaternary ammonium salt, thus decreasing the quantity of the instable terminal group.

Owner:POLYPLASTICS CO LTD

Method for extracting coreopsis tinctoria oil resin by using supercritical or subcritical CO2

InactiveCN102863901AAvoid wastingImprove dissolution rateSenses disorderMetabolism disorderLuteinCoreopsis

The invention discloses a method for extracting coreopsis tinctoria oil resin by using supercritical or subcritical CO2. The method comprises the following steps: coreopsis tinctoria is used as raw material and the coreopsis tinctoria oil resin is extracted by using supercritical or subcritical CO2, wherein the extraction temperature is 20-60 DEG C, the extraction pressure is 15-50MPa, the flow rate of extraction carbon dioxide is 10-30L / h, the extraction time is 2-7 hours, analysis and separation are carried out by second-stage pressure reduction, wherein the first-stage separation pressure is 5-10MPa, the second-stage separation pressure is 4-6MPa, both the separation temperatures of the two stages are 20-60 DEG C, and the analyzed component is the coreopsis tinctoria oil resin with rich lutein and flavones. The coreopsis tinctoria oil resin can be widely applied to medical treatment and health care to exert the functions, and avoids waste of the functional components caused by the use of the coreopsis tinctoria in the traditional tea drinking mode; meanwhile, the residual extracted coreopsis tinctoria slag can be used as raw material for tea bags, and the dissolving-out speed and the dissolving-out amount of plant polyphenol in the coreopsis-tinctoria tea bags are obviously improved compared with those of the unextracted coreopsis tinctoria.

Owner:杨建新

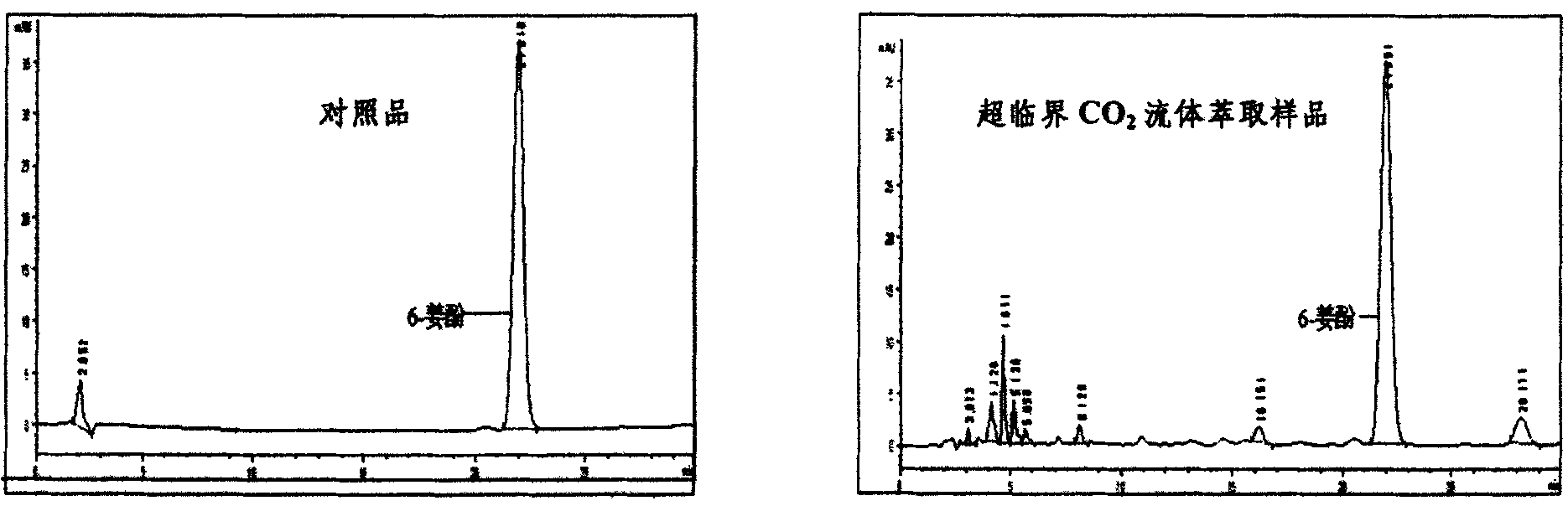

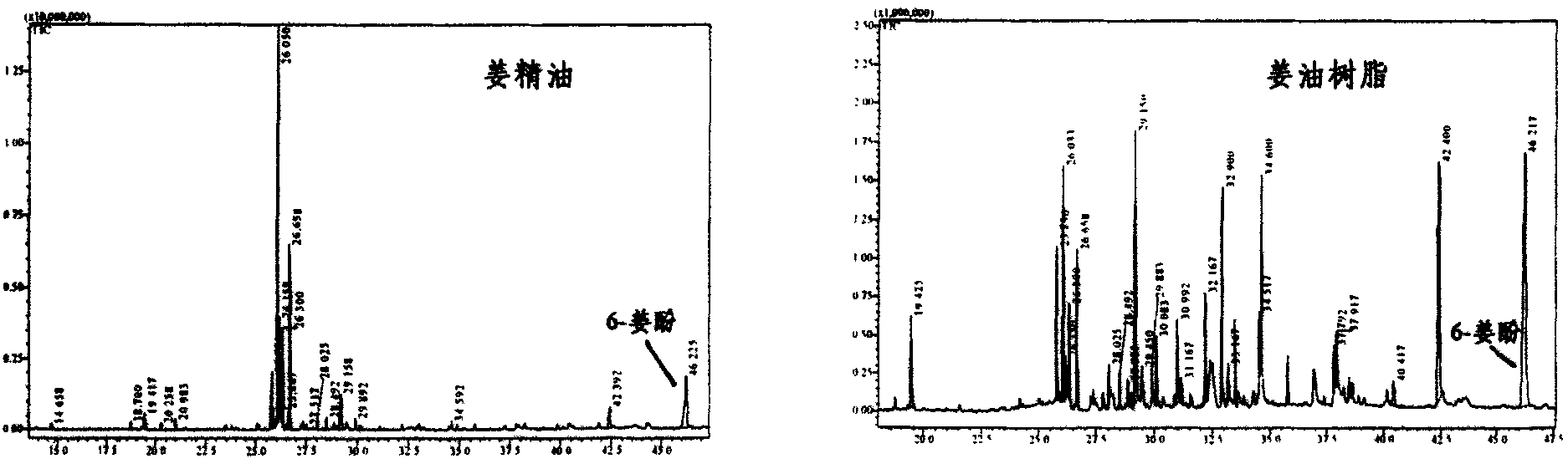

Method for extracting and separating ginger essential oil and ginger oil resin enriched in gingerol

InactiveCN102965197AEfficient use ofReduce occupancyKetone active ingredientsEssential-oils/perfumesGingerolGINGER OIL

The invention relates to a biochemical engineering separating method of natural active products, and especially relates to a method for simultaneously extracting and separating ginger essential oil and ginger oil resin enriched in gingerol in ginger by a supercritical carbon dioxide fluid. The method is characterized in that the pressure and temperature of an extraction kettle is changed, the ginger essential oil containing little 6-gingerol and 6-gingerol-enriched ginger oil resin with large appearance and property difference can be obtained in a separation kettle in different extraction and separation phases. The method uses a separation kettle, the process flow is simple, two important extraction products such as ginger essential oil and ginger oil resin in ginger can be used in the fields of food, cosmetic, medicine and the like and clearly obtained at a time, the investment for equipments and workshops is small, and the large scale production can be carried out.

Owner:GUIZHOU BAILING GRP PARMACEUTIAL CO LTD +1

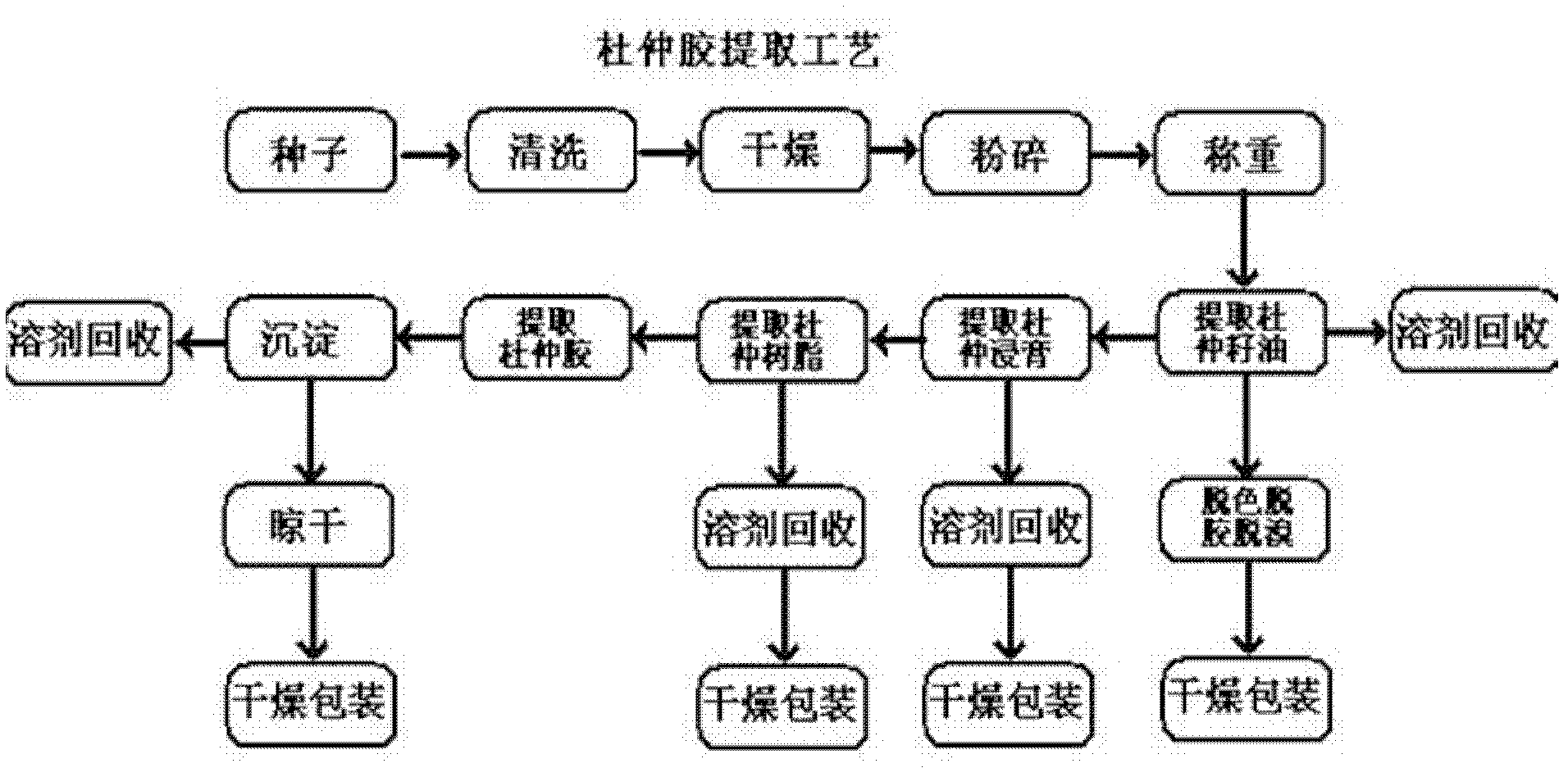

Method for circularly and continuously extracting eucommia gum, eucommia seed oil, eucommia extractum and eucommia resin from eucommia seeds

InactiveCN102807678AImprove resource utilization efficiencyLow energy and material consumptionMetabolism disorderFatty-oils/fats productionSolubilityResource utilization

The invention relates to a method for efficiently, circularly and continuously extracting eucommia gum, eucommia seed oil, eucommia extractum and eucommia resin from eucommia seeds. According to the separation principle of different polarities and different solubility parameters of four substances, the eucommia seed oil, eucommia extractum, eucommia resin and eucommia gum are sequentially extracted by adopting corresponding solvent, the extracts of the four substances are rectified to recover solvents, and the extracts are dried to respectively obtain products, namely the eucommia seed oil, eucommia extractum, eucommia resin and eucommia gum. The method has the characteristics that the shortcoming of resource waste because only one or two components can be extracted from the eucommia seeds in the traditional extraction process is overcome, the maximal resource utilization is realized, the whole process is circular and repeated, the extraction solvent can be circularly utilized, the energy consumption and substance consumption are greatly reduced and the discharge of three wastes does not exist basically.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Processing method of pine resin

InactiveCN103087635AQuality improvementImprove solubilityTurpentine spiritsNatural resin purificationOxalatePine resin

The invention relates to a processing method of pine resin and belongs to the field of rosin production. The processing method of pine resin comprises the following steps of: a, dissolving, namely dissolving the pine resin by adopting a dissolving solution, wherein the dissolving solution comprises the following components in percentage by weight: 55-82% of turpentine oil, 17.5-44.5% of water and 0.1-0.5% of oxalic acid; b, clarifying and colating, namely placing the dissolved pine resin liquid in a transition pot to be clarified and then colating to obtain colature; c, acid washing, namely adding the oxalic acid for washing; d, washing, namely adding hot water for washing; e, clarifying and carrying out refined filtration, namely placing the pine resin liquid into the transition pot to be clarified and then carrying out refined filtration; and f, heating and distilling, namely placing the pine resin liquid in a rectifying tower to be subjected to the heating and distilling, so that rosin and turpentine oil finished products are respectively obtained. The processing method of rosin provided by the invention has the beneficial effect that the qualities of the rosin and turpentine oil obtained by processing pine resin are excellent, so that demand of downstream industries is met.

Owner:云南茶花林化有限公司

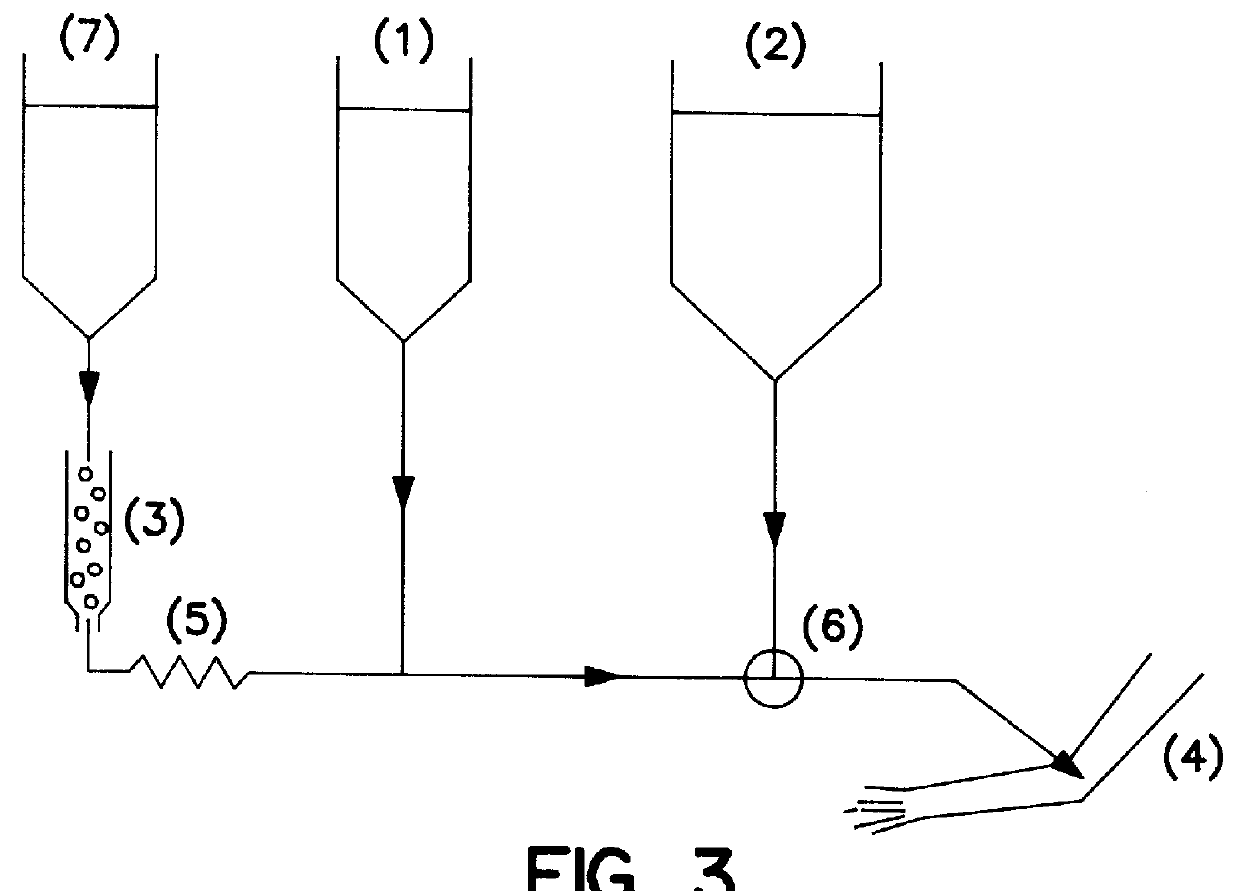

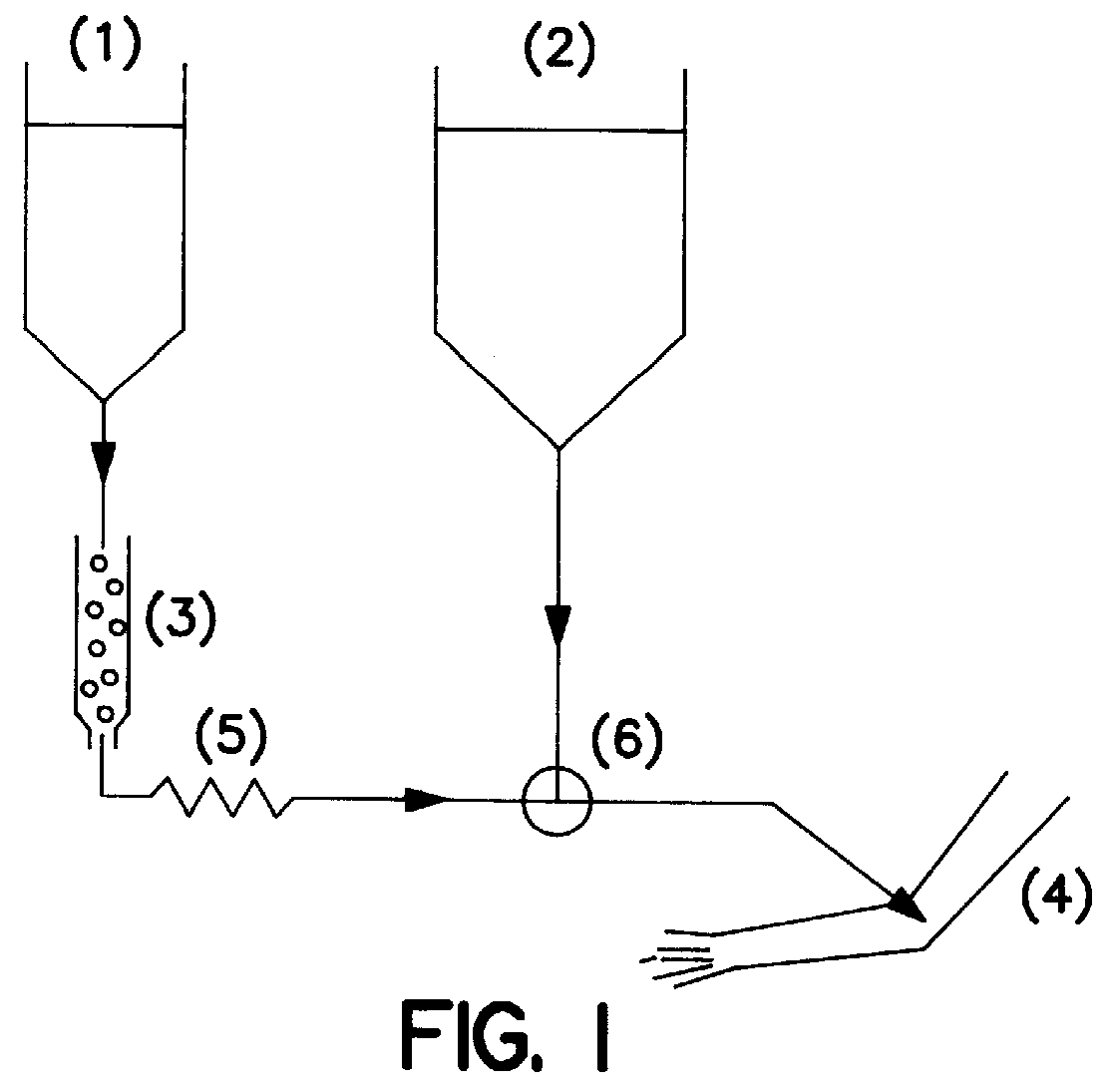

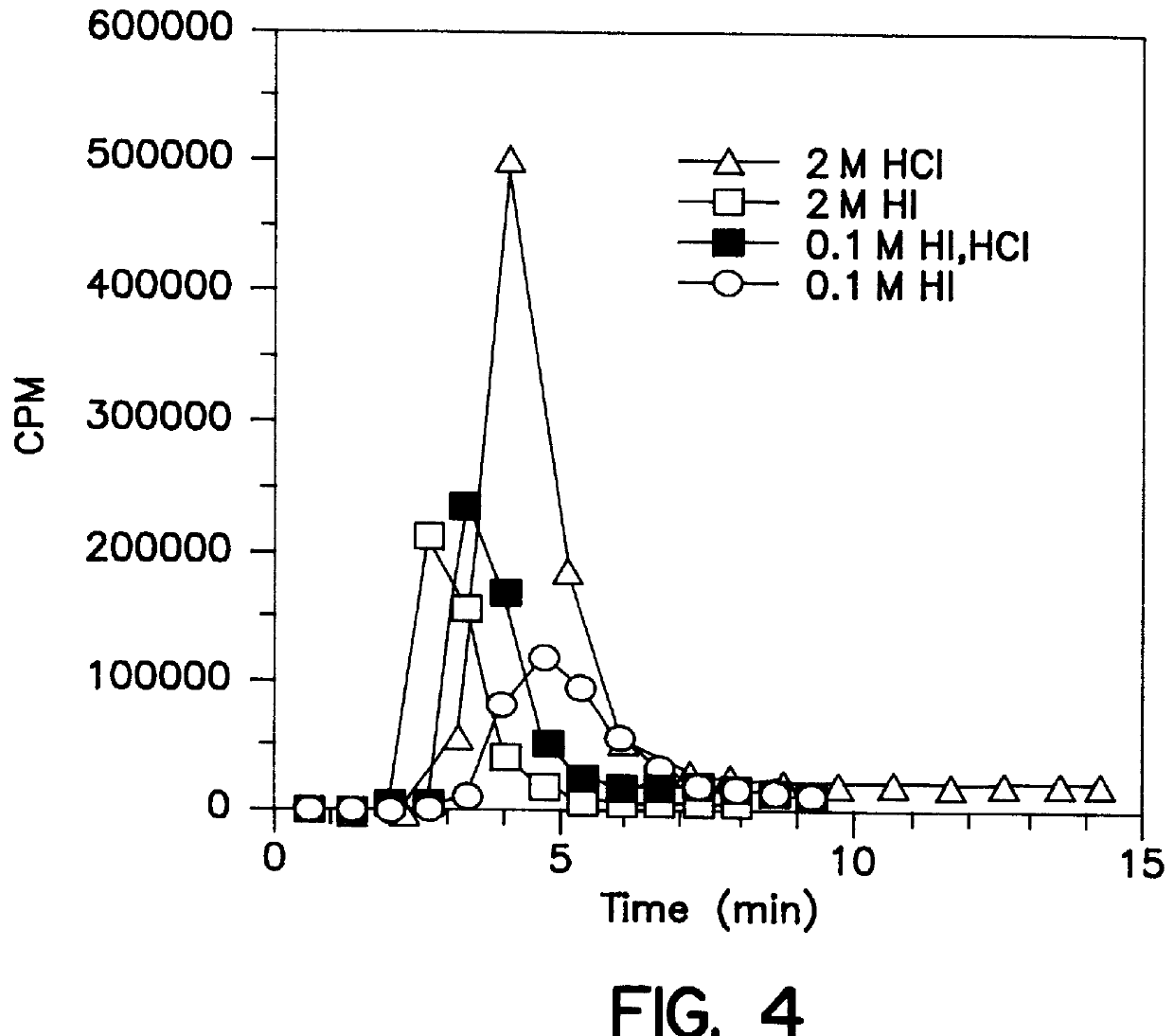

Apparatus for the therapeutic use of .sup.213 Bi

The present invention relates to the field of site directed therapy. More specifically it relates to site directed radio therapy. It provides a method for production of radioimmuno conjugates and an apparatus for radioimmuno therapy. The method, conjugates and apparatus can be practicalized without the need for radioactive shielding and / or airtight facilities. Without these restrictions the invention provides a simple and efficient means of therapy at the bed-side of the patient.

Owner:ACTINIUM PHARMA

Water-white hydrogenating rosin production

InactiveCN1613940AOutstanding FeaturesHighlight significant progressNatural resin purificationReaction temperatureTurpentine

Transparent hydroabietyl is produced by: first rinsing turpentine with sterilized water containing low oxygen to remove the colloid chorophyl, suger and protein; then dissolving turpentine to hydrotrect in the accelerating agent of nicke or Pd / C, at 140-200deg.C and 4.0-15.0MPa, reactingfor 0.5-3.0h, finally, filtrating and vacuum distilling to get the product.

Owner:GUANGXI UNIV

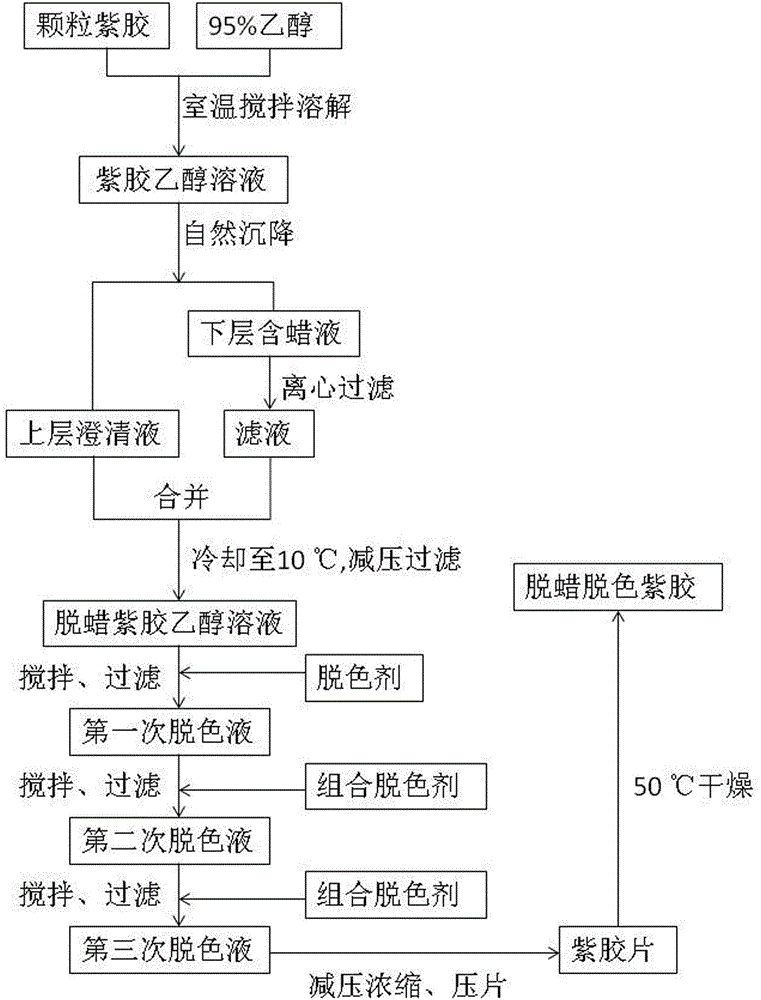

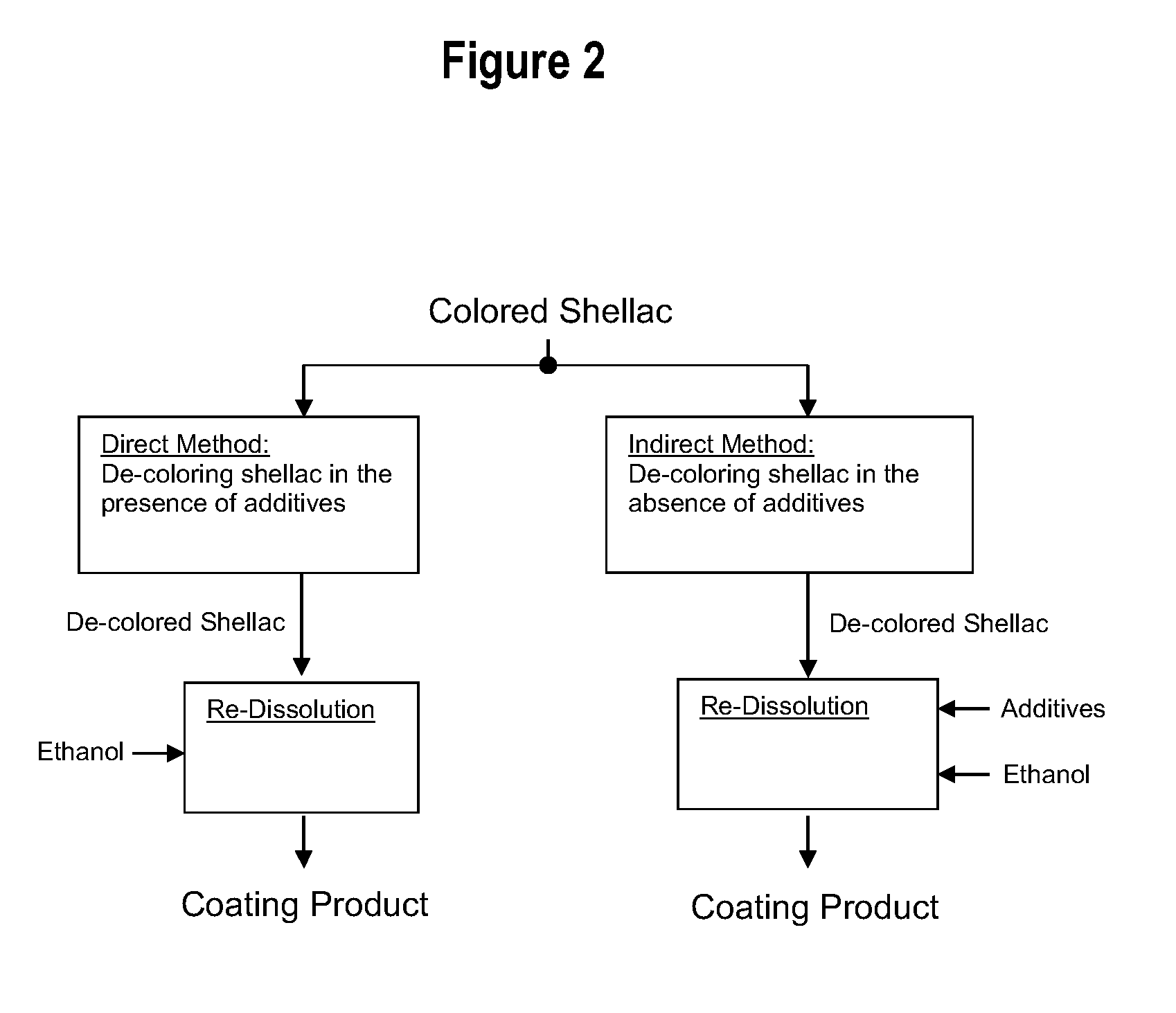

Preparation method of dewaxed and decolorized shellac

The invention relates to a production method of natural resin, and particularly relates to a preparation method of dewaxed and decolorized shellac. The preparation method comprises the following steps: by taking shellac particles as a raw material, adding a 95% ethanol solvent to the shellac particles to obtain a shellac ethanol solution; fully precipitating shellac wax and impurities in the shellac ethanol solution, separating supernatant which accounts for two thirds of the total volume of the solution, performing centrifugal filtration of sediment which accounts for one third of the total volume of the solution to obtain clear liquid, and mixing the clear liquid and the supernatant, wherein the wax content of shellac in the supernatant is less than 0.5%; cooling the shellac ethanol solution obtained by mixing the clear liquid and the supernatant to 10DEG C, performing filtration under reduced pressure to obtain a dewaxed shellac ethanol solution in which the shellac contains less than 0.2% of wax, and performing decolorization of the dewaxed shellac ethanol solution thrice to obtain a dewaxed and decolorized shellac sheet. The method provided by the invention is simple to operate, moderate in decolorization condition and high in product quality and can be used for large-scale production of dewaxed and decolorized shellac.

Owner:MOJIANG SENYUAN TECH

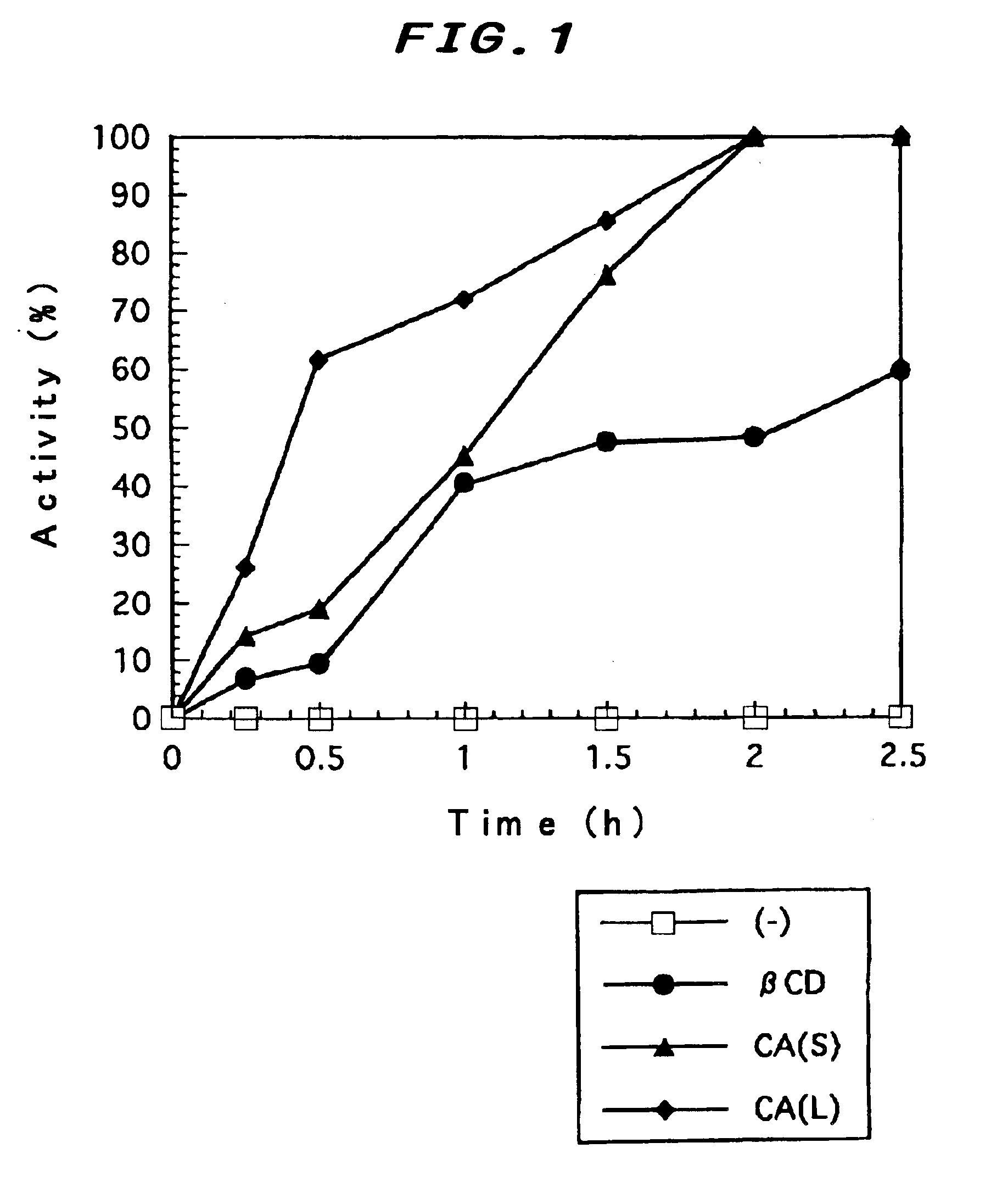

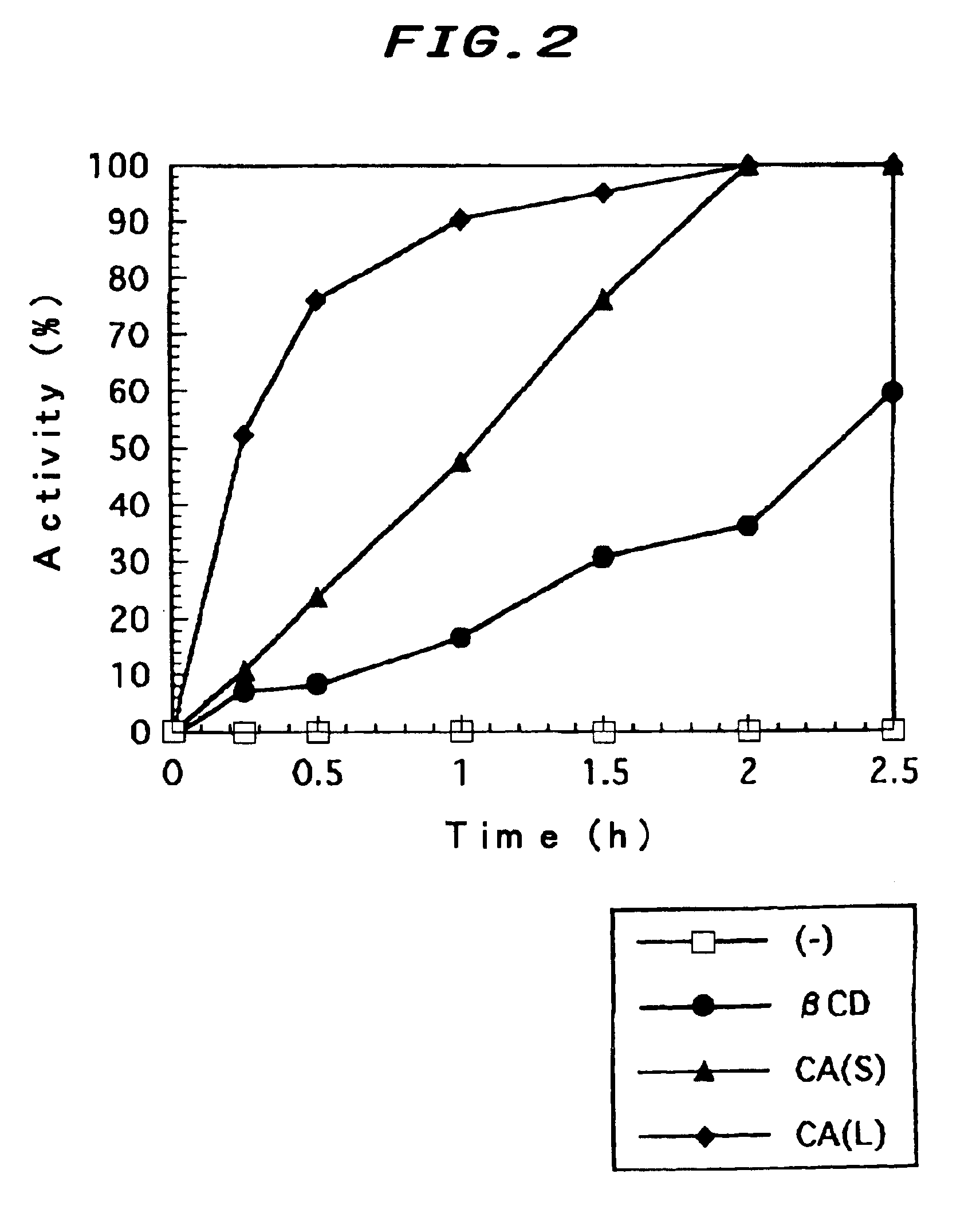

Artificial chaperon kit

The present invention provides an artificial chaperon useful for refolding the proteins having low voluntary folding ability and being difficult or unable to be a native form without a second (or assistant) of a molecular chaperon in a short time, and folding said proteins as an active form. The present invention relates to an artificial chaperon kit characterized in that the kit comprises cyclic saccharide cycloamylose and polyoxyethylenic detergent or cyclic saccharide cycloamylose and ionic detergent. The present invention also relates to a method for diluting the denaturant making the protein a denatured state by adding a specific detergent to a denatured protein, and preventing protein molecules from aggregation, thereafter adding cyclic saccharide cycloamylose, utilizing the inclusion ability thereof to strip detergent, accelerating the proper folding of protein into a correct higher-order structure with activity.

Owner:NAT FOOD RES INST +1

Method for separating tall oil

ActiveCN103897009AImprove product qualityHigh recovery rateFatty acids production/refiningSteroidsDistillationRosin

The invention relates to a method for separating tall oil. The method comprises the steps of thin film distillation, first-stage molecular distillation, second-stage molecular distillation, saponification and esterification, washing and the like. By adopting the method disclosed by the invention, tall oil fatty acid, refined phytosterol and tall oil rosin are obtained by separating the tall oil, wherein the fatty acid content of tall oil fatty acid is more than 90%, and the recovery rate of tall oil fatty acid reaches more than 90%; the phytosterol content of refined phytosterol is more than 90%, and the recovery rate of refined phytosterol reaches more than 80%.

Owner:XIAN HEALTHFUL BIOTECH

Process for purification of biological feed material

ActiveUS20150052807A1High yieldComponent can be very heavyRefining to change hydrocarbon structural skeletonFatty acids production/refiningReactor systemBiofuel

The present invention relates to a process for the purification of biological feed material and to a process for catalytically converting the purified biological feed material into hydrocarbons suitable as biofuel components. The purified feed material is treated in a reactor system including a catalytically active guard bed phase and a catalytically active main reaction phase. At least one of the phases includes a catalyst bed with a combination of hydrodeoxygenating (HDO) and hydrodewaxing (HDW) catalysts. The process provides biofuel with acceptable ignition and cold flow properties.

Owner:UPM-KYMMENE OYJ

Method for de-coloring shellac, de-colored shellac, compositions comprising same, and uses therefor

Owner:D ANTAEUS

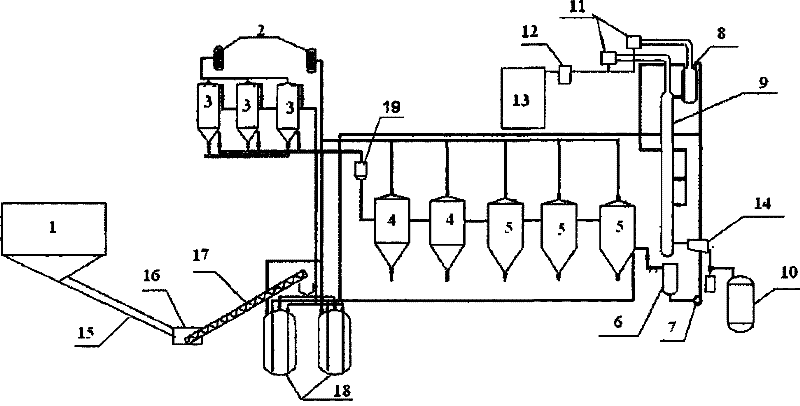

High-efficiency energy-saving low-cost high-quality rosin production process and production line equipment

ActiveCN102643611AShorten production timeIncrease productivityTurpentine spiritsNatural resin purificationProduction lineDistillation

The invention discloses a high-efficiency energy-saving low-cost high-quality rosin production process, which comprises the steps of: firstly carrying out turpentine impurity removal and liquification working procedure: firstly adding a little dissolving oil (5-10%) to turpentine, carrying out pressure filtration with a spiral filter press to remove main mechanical impurities in turpentine, heating refined turpentine at 50-70 DEG C, carrying out pressure filtration with a chamber filter press to further separate the mechanical impurities of turpentine, and inputting the purified turpentine liquid to a turpentine liquid storage tank; and then carrying out turpentine liquid distillation working procedure: inputting the purified turpentine liquid to a distillation tank, separating out rosin and turpentine oil, inputting the turpentine liquid with turpentine oil separated into a reaction kettle, carrying out reduced-pressure distillation to distill heavy turpentine oil, then keeping on heating to gasify the rosin liquid, condensing the rosin vapor into rosin liquid, and inputting to a rosin finished product storage tank. The production line equipment comprises the filter press, the turpentine liquid storage tank, the distillation tank, the reaction kettle, the rosin finished product storage tank, a heavy oil storage tank, a turpentine oil storage tank and a heavy turpentine oil storage tank.

Owner:桂林兴松林化有限责任公司

Degumming process of capsicum extract

InactiveCN102757665AQuality improvementSimple processNatural dyesNatural resin purificationPregnant leach solutionCapsicum extract

The invention provides a degumming process of a capsicum extract, which belongs to the technical field of natural product extraction and separation. The process comprises the following steps of: deseeding, pulverizing and pressing dried capsicums to obtain capsicum particles; mixing and leaching the capsicum particles and a solvent; decompressing and concentrating a leaching liquor to obtain a red capsicum extract; mixing and stirring the red capsicum extract and a composite degumming agent so as to obtain a mixed liquor; and then centrifugally separating the mixed liquor so as to respectively collect a light-phase degummed red capsicum extract and a heavy-phase colloid; and the composite degumming agent is aqueous solution of H3PO4 and NaCl; and the degummed red capsicum extract and low alcohols are mixed, centrifugally extracted from hot and separated so as to obtain a capsicum coat red pigment and a capsicum oleoresin. According to the invention, the obtained capsicum coat red pigment has the advantages of good liquidity, no solidification and caking in low temperature preservation, no layering and no precipitate and contains less than 2% centrifugal precipitate and less than 1% acetone-insoluble material. The hot degree of the obtained sub product capsicum oleoresin is increased by 63% and the color value of the capsicum oleoresin is reduced to less than E10. The degumming process of the capsicum extract, provided by the invention, has the advantages of simplicity, convenience in operation, low cost, safety, environment friendliness and easiness for industrial production.

Owner:JILIN GOLD TOWER IND GRP

Process for Producing Modified Rosin Ester Resin Composition for Use in Lithographic Ink Varnish and Process for Producing Lithographic Ink Varnish

InactiveUS20070221091A1Protect environmentGood printabilityInksNatural resin chemical modificationPolyolVegetable oil

This process for producing a modified rosin ester resin composition for use in a lithographic ink reacts rosin (A), an acid modified rosin (B) which is obtained by denaturating rosin (A) with an α,β-unsaturated dicarboxylic acid and / or anhydride thereof (d), an oil modified rosin (C) which is obtained by denaturating rosin (A) with a vegetable oil (c) having an iodine value of 140 or more, with a polyol (D) of trihydric or more.

Owner:DAINIPPON INK & CHEM INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com