Production process for rosin resin

A technology for rosin and rosin ester, which is applied in the field of rosin preparation of rosin derivatives, can solve the problems that the product quality of rosin ester or modified rosin ester fails to meet the requirements, cannot really realize industrialization, and the preparation process is complicated, and can avoid refining Complete, improve yield and product quality, reduce the effect of dead volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

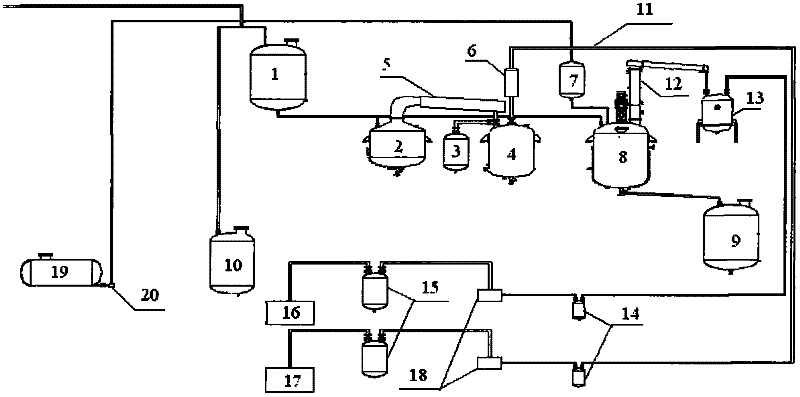

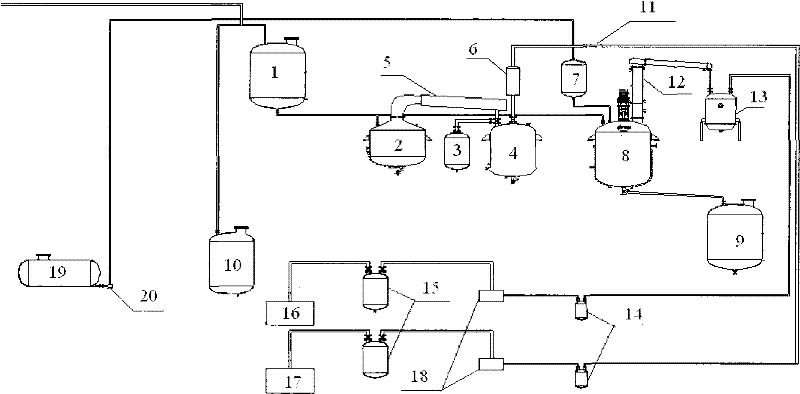

[0070] Embodiment 1: combine below figure 1 A method for preparing fumaric acid-modified rosin glycerides from rosin is described.

[0071] 1. Rosin refining process

[0072] Press the rosin from the rosin dissolving kettle 10 into the rosin measuring tank 1 with nitrogen, transfer it to the distillation kettle 2 after measuring, turn on the hot oil to heat up the material in the distillation kettle, and turn on the vacuum unit, and distill out the part at 180-220 ℃ separately. After collecting in the front distillate storage tank 3, switch the pipeline to the main distillate storage tank 4 to start the main distillate collection, until the material temperature reaches 270 ° C, and when there is no rosin distillation from the sight glass, turn off the hot oil, turn off In the vacuum unit, nitrogen is replaced into the distillation still 2 and the receiving still, and the obtained refined rosin is transferred to the esterification still for further processing.

[0073] After ...

Embodiment 2

[0079] Embodiment 2: combine below figure 1 A method for preparing maleic acid-modified rosin glycerides from rosin is described.

[0080] Refined rosin was obtained using the rosin refining process (step 1) in Example 1.

[0081] Transfer the metered refined rosin into the esterification kettle, add maleic acid for modification at 200°C, add antioxidants and glycerin to carry out esterification at 270°C after modification, and after 6 hours, pass steam and vacuumize. , cool down to 240 ℃, add the auxiliary materials in the later stage, stir evenly, and then transfer to the finished product storage tank.

[0082] The rosin resin in the finished product storage tank is continuously pumped into the granulator with a screw pump, and after being granulated and cooled by the granulator, it becomes a hemispherical granule, which is lifted into the product storage tank by the rosin resin elevator, and then packed into the bag by the packaging tool. Later became product stacking for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com