Patents

Literature

736results about "Natural resin chemical modification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Natural resin formulations

InactiveUS6844420B1Low viscosityImprove liquidityFatty oils/acids recovery from wasteBiofuelsNatural resinDistillation

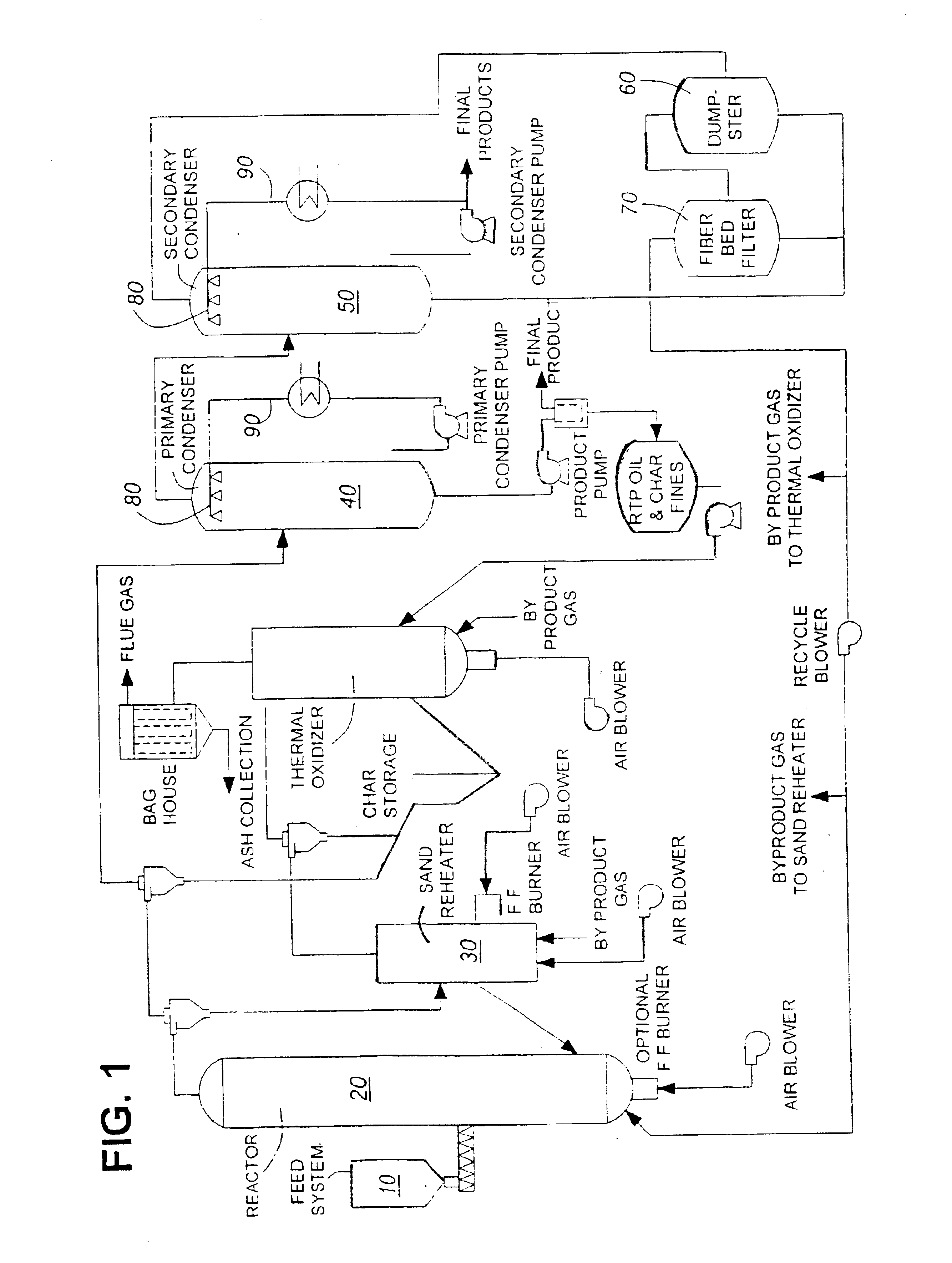

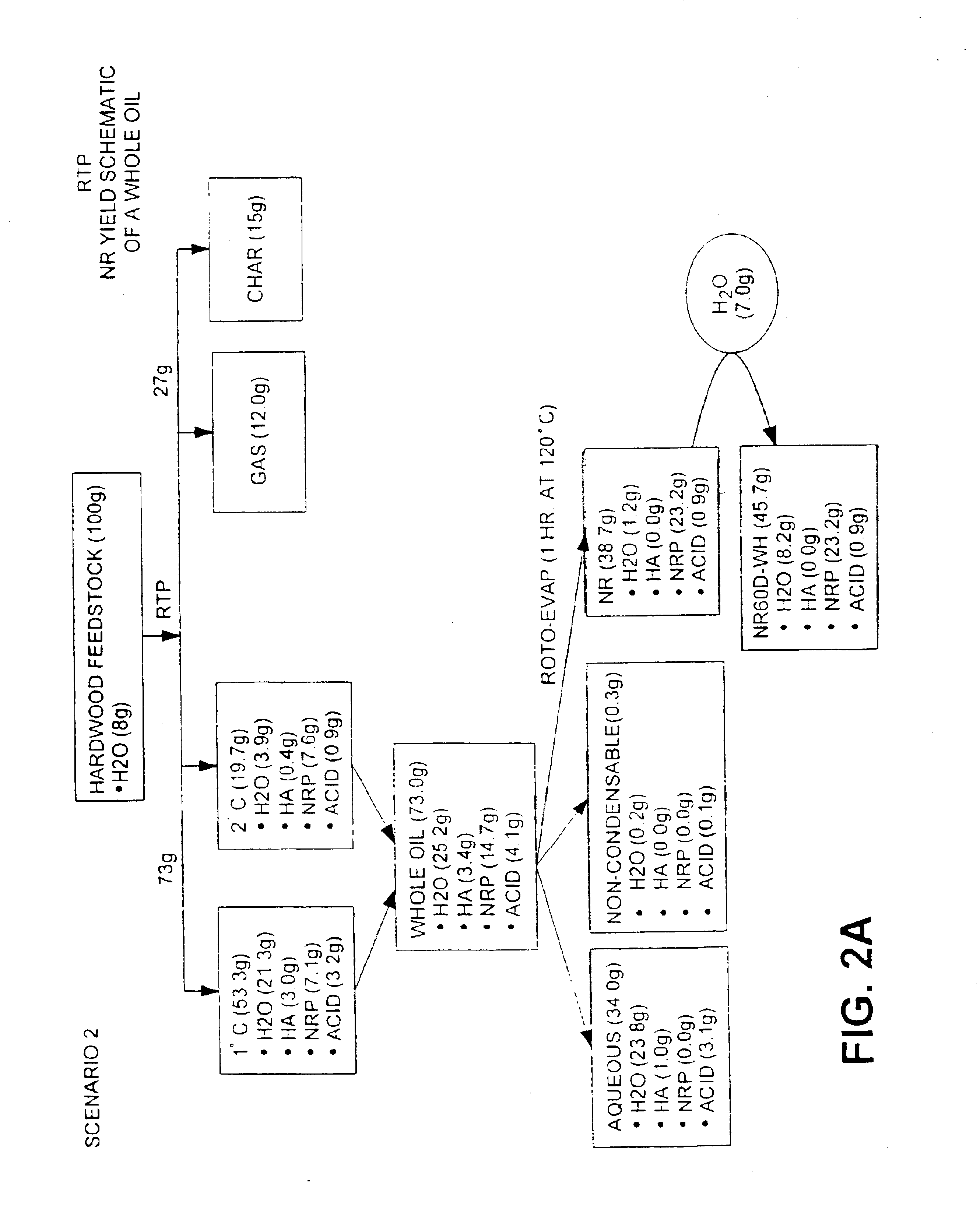

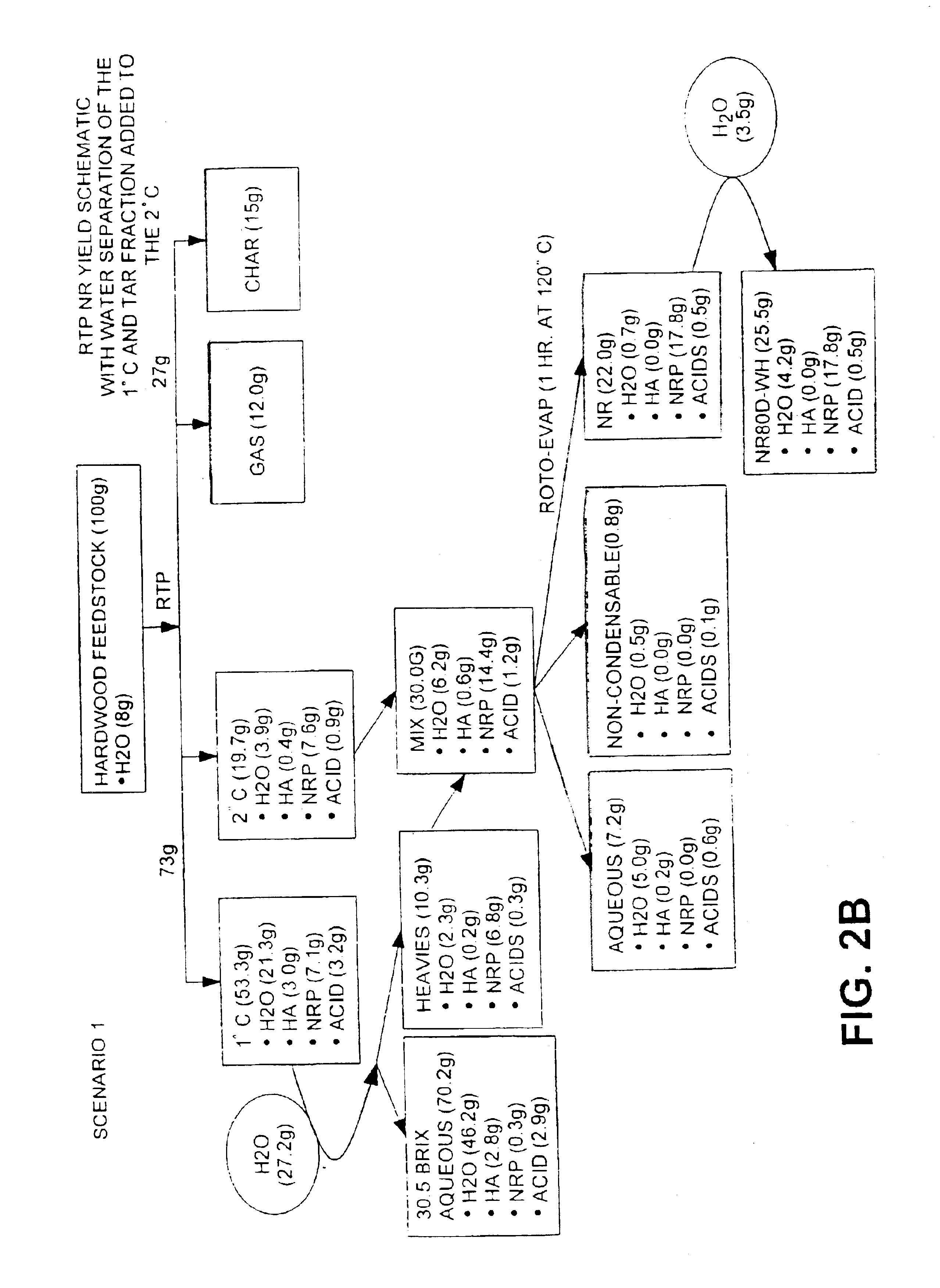

This invention is directed to a method of preparing a natural resin by liquefying wood, bark, forest residues, wood industry residues, or other biomass using rapid destructive distillation (fast pyrolysis). Fast pyrolysis produces both vapors and char from biomass, and following removal of the char from the product vapors, a liquid pitch product is recovered and processed by distillation, evaporation, or a combination thereof, in order to obtain a natural resin which may be in either liquid or solid form. The natural resin comprises a total phenolic content from about 30% to about 80% (w / w), and is a highly-reactive ligninic compound that has been found to be suitable for use within resin formulations without requiring any further extraction or fractionation procedures. Resins comprising up to 60% natural resin have been prepared and tested in board production and found to exhibit similar properties associated with commercially available resins. The natural resin may substitute for phenol, or for both phenol and formaldehyde within phenol-containing resins. Similarly, the natural resin can replace a substantial part of the components within urea-containing resins.

Owner:ENSYN RENEWABLES

Rosin cation asphalt emulgent

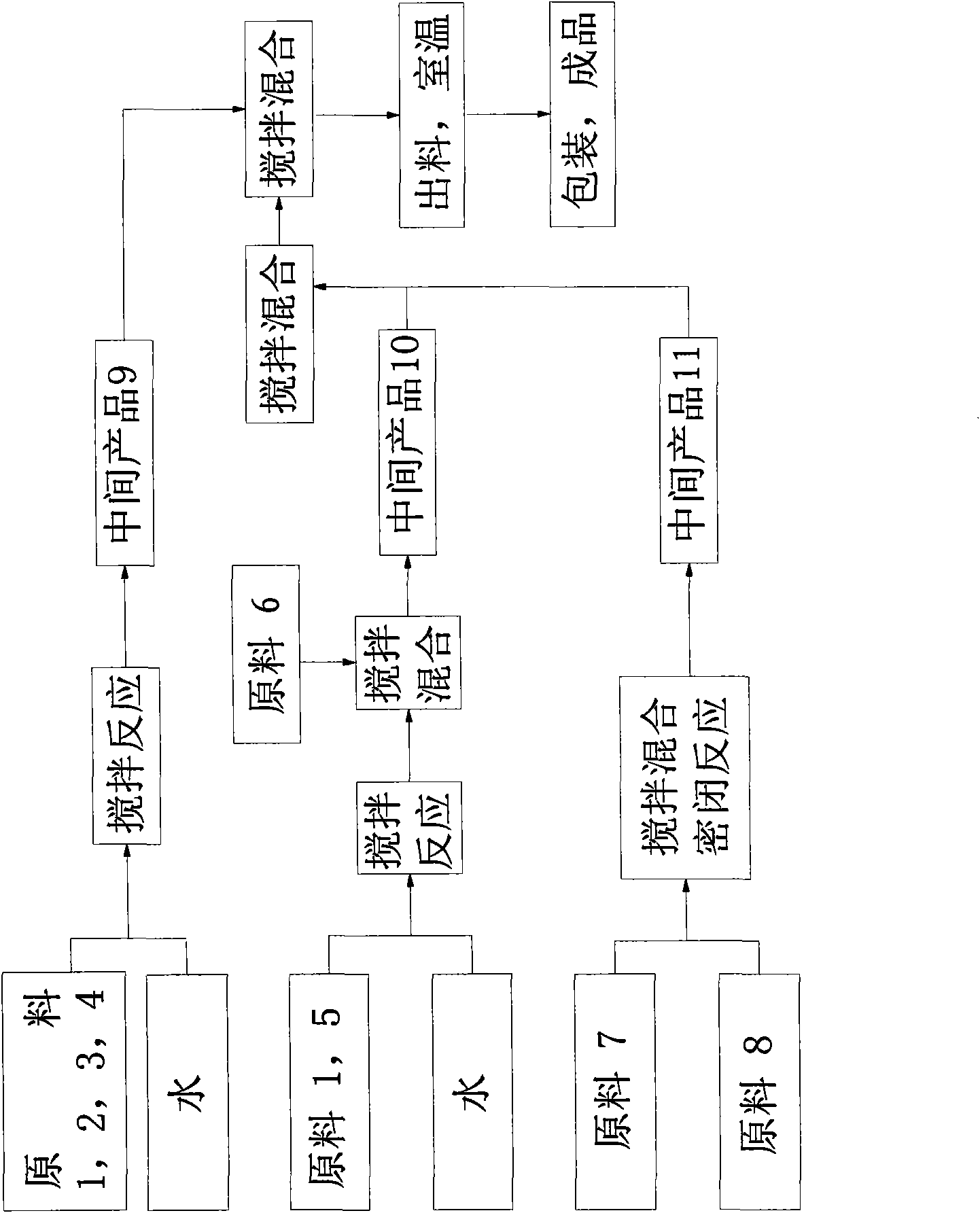

InactiveCN1861721AReduce manufacturing costGood emulsificationTransportation and packagingMixingRosinAsphalt

The invention relates to a rosin cationic bitumen emulsifier. The rosin intermediate is reacted by the rosin and the polyethylene polyamine, then to condensate with the different types of the quaternary ammonium salt to get the emulsifier. The emulsifier can be used to produce the normal cationic emulsifying asphalt or the SBR modified emulsifying asphalt for the road priming oil and the felting oil. The character of the invention is to use the nature resin rosin as the material, so the cost has decreased and it meets the environment need. The emulsifying asphalt can reach the need of the standard of the China ministry of communications and the America ASTMD2397.

Owner:DALIAN UNIV OF TECH

Thermal- and chemical-resistant acid protection coating material and spin-on thermoplastic adhesive

New compositions for use as protective coatings and / or adhesives are provided. The compositions comprise a hydrocarbon resin (e.g., terpene rosin) and a rubber (e.g., EPDM) dispersed or dissolved in a solvent system. The solvent system is preferably a single-solvent system, and the compositions are preferably free of surfactants, dyes, and chromophores. The compositions can be cured or dried to form layers or films that are chemically and thermally resistant, but that can be readily dissolved and removed at the appropriate stage in the fabrication process.

Owner:BREWER SCI

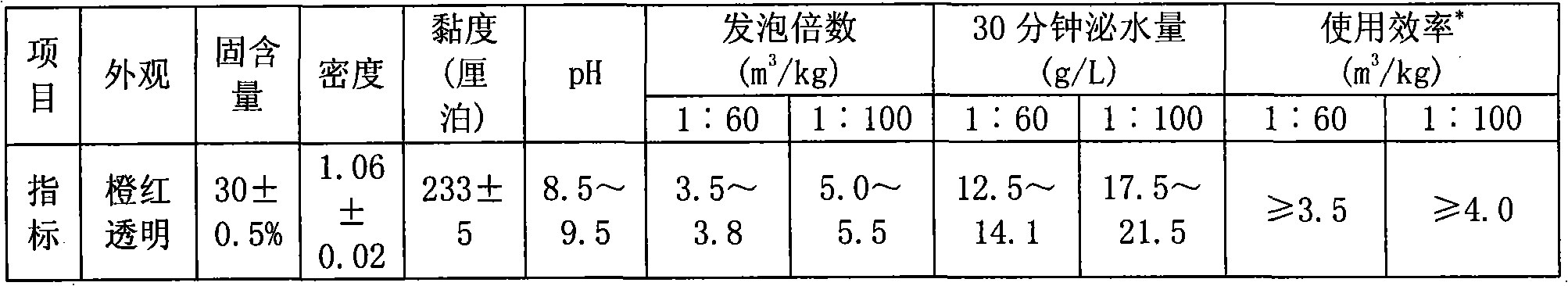

LC-01 type foam concrete foamer

The invention discloses an LC-01 type foam concrete foamer which belongs to a high-efficiency concrete air entraining agent. The invention adopts foaming time of the LC-01 type foam concrete foamer prepared form a double (multi) hydrophilic group surface active agent and a stabilizing agent; if the surface active agent and the stabilizing agent are diluted by the ratio of 1 to 100, 5.0 to 5.6m3 / kgis achieved; cement and powdery coal ash slurry are touched; the deforming rate is less than 12%; and four-stage foam concrete of more than 4m3 / kg can be produced; the cement is touched and defoamingis hardly operated; the four-stage foam concrete (containing 40% of powdery coal ash) which is larger than or equal to 3.5 to 3.8m3 / kg can be produced; and the compressive strength of the four-stagefoam concrete is from 1.2 to 1.5MPa. The invention better solves the contradiction between the foaming time of the foam concrete foamer and the stability when the foam comes into contact with the concrete slurry and enhances the production quantity and the compressive strength of the foam concrete for the foamer of each kilogram severalfold.

Owner:LUOYANG NORMAL UNIV +1

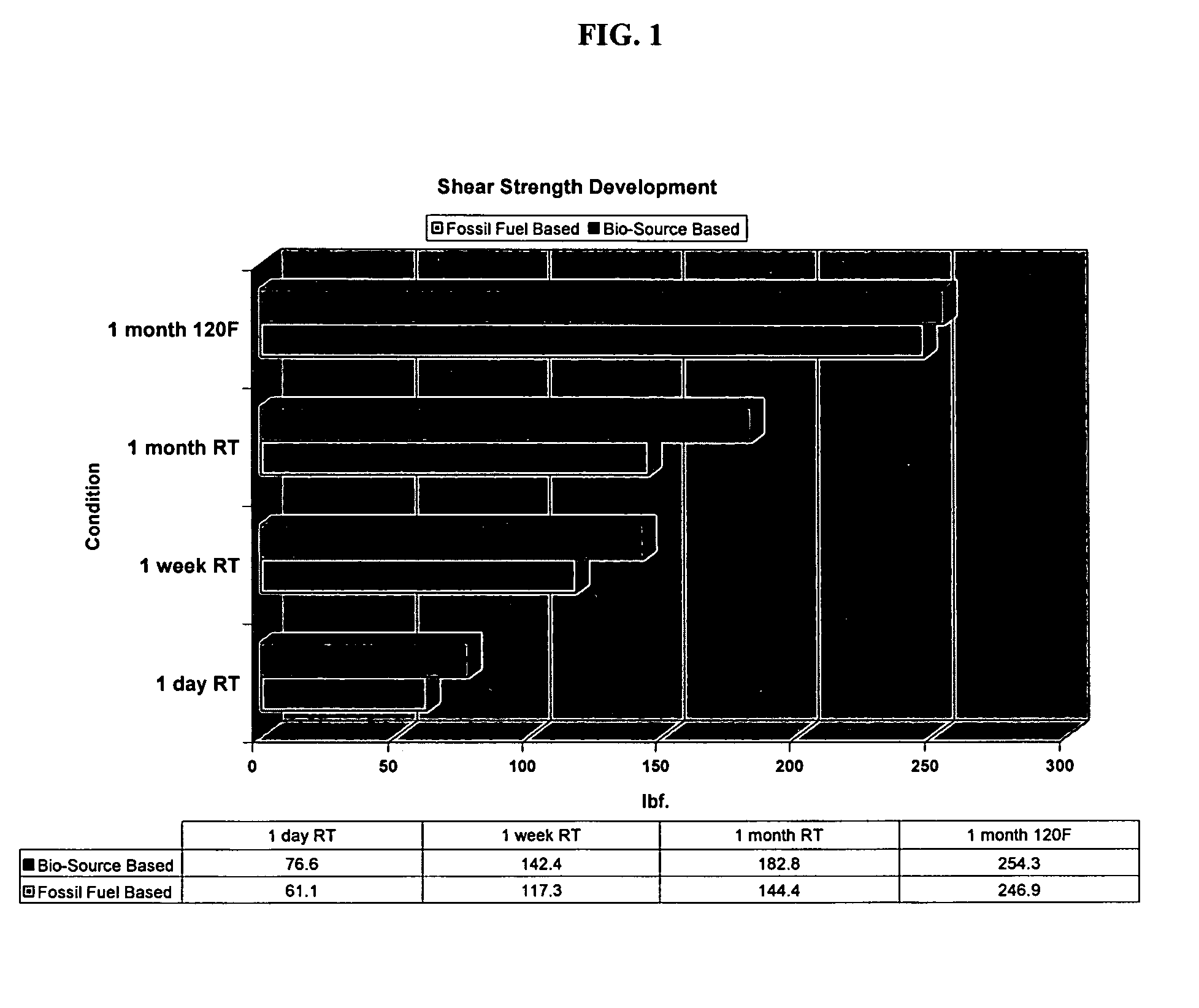

Low VOC bio-source adhesive

ActiveUS20080064852A1High strengthLow and substantially no VOC emissionDrying oil adhesivesProtein adhesivesAdhesiveFatty acid

A one component adhesive composition is provided, which can be formulated from substantially or totally bio-based, renewable raw materials. Such adhesives can be formulated to have high strength and / or low or substantially no VOC emissions. This can be achieved by utilizing polymers that are derived or extracted from renewable plant materials such as soybeans, corn, sunflowers, wheat, etc. Adhesive compositions in accordance with the invention can include oils. The composition preferably contains bio-based oils only, but need not be completely free of fossil fuel or synthetic based oils. It should also include drying oils and / or similarly acting polymers, co-polymers, and fatty acids. Plasticizers, such as hydrogen oxide, derived from renewable sources are utilized to impart performance properties to the formulated adhesive. Metal napthanates can be used to catalyze the drying and / or curing speed when the adhesive composition is applied to a substrate.

Owner:W F TAYLOR

Rosin esters for non-woven applications, methods of making and using and products therefrom

InactiveUS20110213120A1Good viscosity stabilityLow color requirementNatural resin chemical modificationNon-woven fabricsNonwoven fabricRosin

Owner:ARIZONA CHEM CO

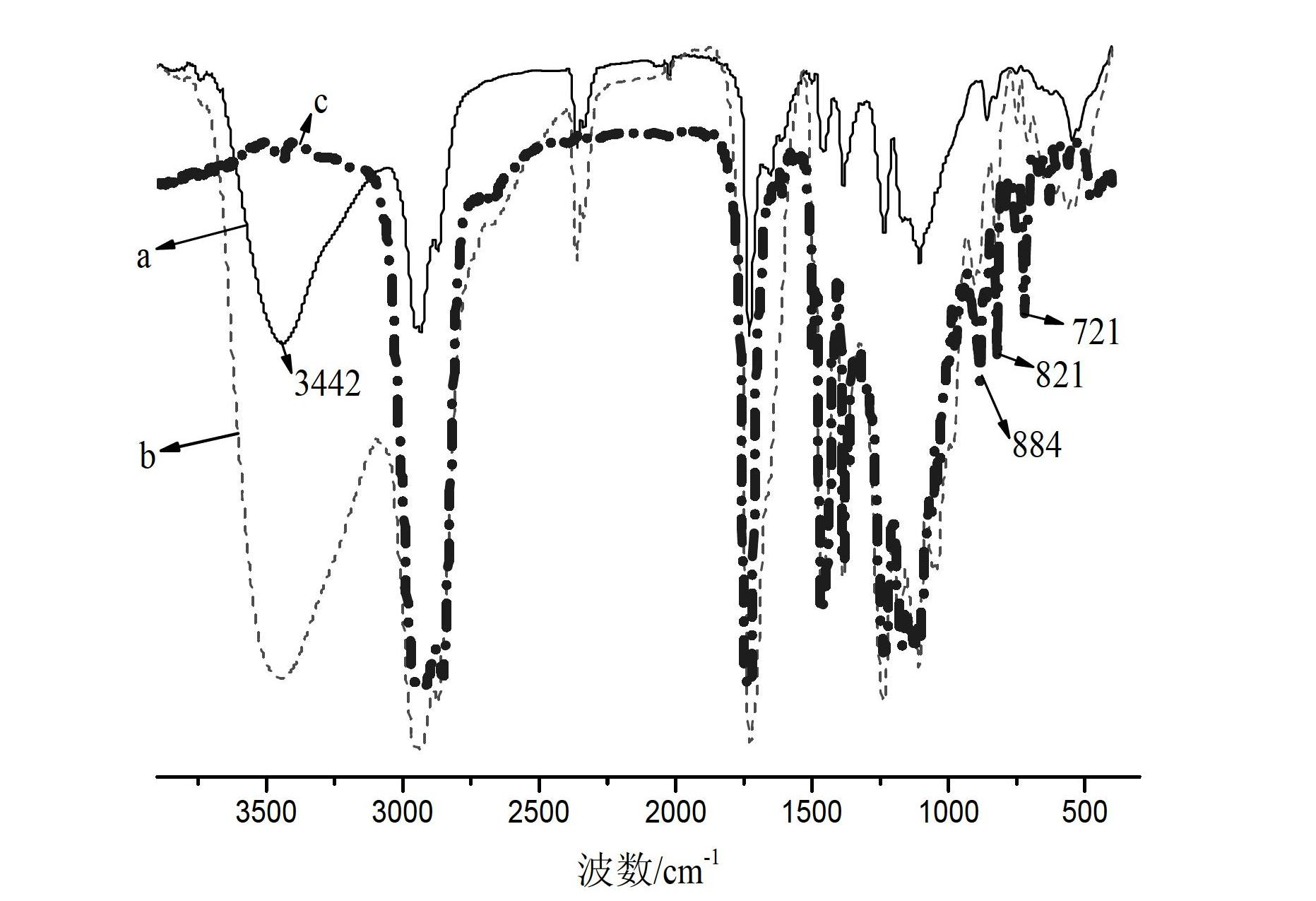

Acrylic acid rosin and epoxy resin prepolymer and preparation method thereof

InactiveCN101544744AImprove brittlenessGood weather resistanceNatural resin chemical modificationNatural productReaction temperature

The invention discloses an acrylic acid rosin and epoxy resin prepolymer and a preparation method thereof. Acrylic acid rosin is molten, diglycidyl ether is added to the molten acrylic acid rosin and reacts with the same under the action of esterification catalyst at the reaction temperature of 120-200 DEG C until the acid number of the reaction system is lower than 10mgKOH / g, the product of reaction is cooled and the acrylic acid rosin and epoxy resin prepolymer is obtained. The acrylic acid rosin and epoxy resin prepolymer is prepared by cheap and available natural products, has excellent mechanical property and uvioresistant property, is especially suitable to manufacture outdoor weather-resisting electric engineering insulating material and can be used as weather-resisting epoxy adhesive, epoxy resin coating, hydrated epoxy coating and the like.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

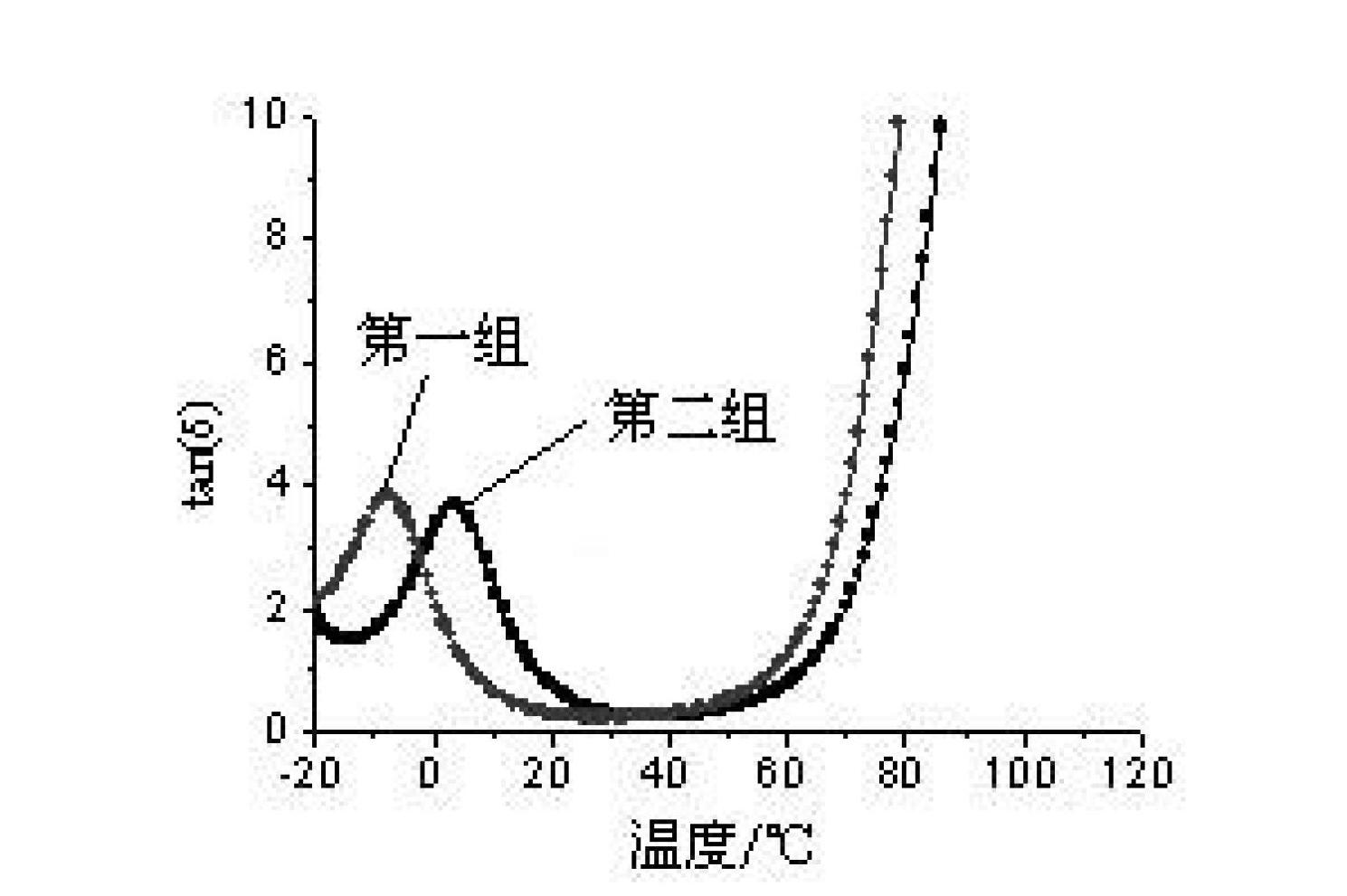

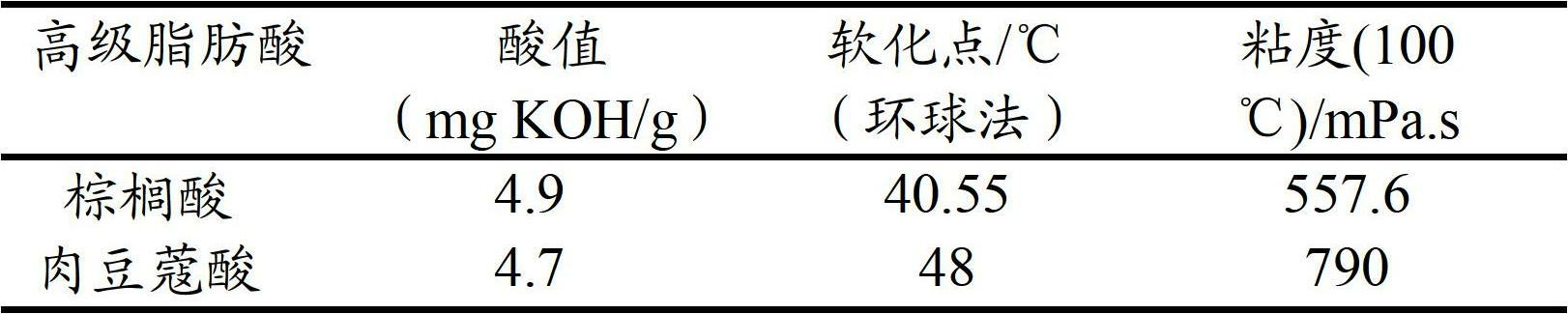

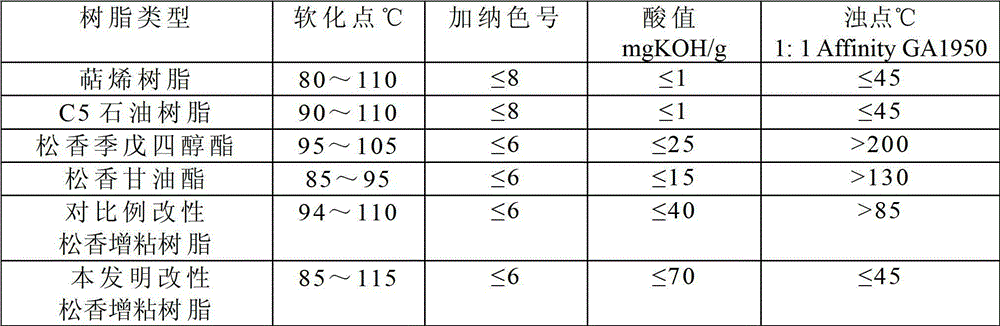

Low-temperature resistant rosin thickening resin, preparation method and usage thereof

ActiveCN102676062ALow softening pointLow viscosityNatural resin chemical modificationRosin adhesivesPolyolHot melt

The invention discloses a preparation method of low-temperature resistant rosin thickening resin, which comprises the following steps of: under the protection of inert gas, melting rosin, and reaction the melted rosin with polyalcohol for 4-24h at the temperature of 200-290 DEG C under the action of catalyst; discharging to obtain polyalcohol modified abietate; and then, under the protection of inert gas, reacting the obtained polyalcohol modified abietate with higher fatty acid at the temperature of 200-290 DEG C for 4-24h, and discharging to obtain the rosin thickening resin; or under the protection of inert gas, melting the rosin, and then adding catalyst, the polyalcohol and the higher fatty acid into the melted rosin, carrying out reaction for 4-24h at the temperature of 200-290 DEG C, and discharging to obtain the rosin thickening resin. The rosin thickening resin prepared by the method is low in softening point and viscosity and higher in cold resistance. Meanwhile, the invention also discloses the low-temperature resistant rosin thickening resin prepared by the method disclosed by the invention, and the usage of the low-temperature resistant rosin thickening resin in preparation of a hot melt pressure sensitive adhesive.

Owner:普洱科茂林化有限公司

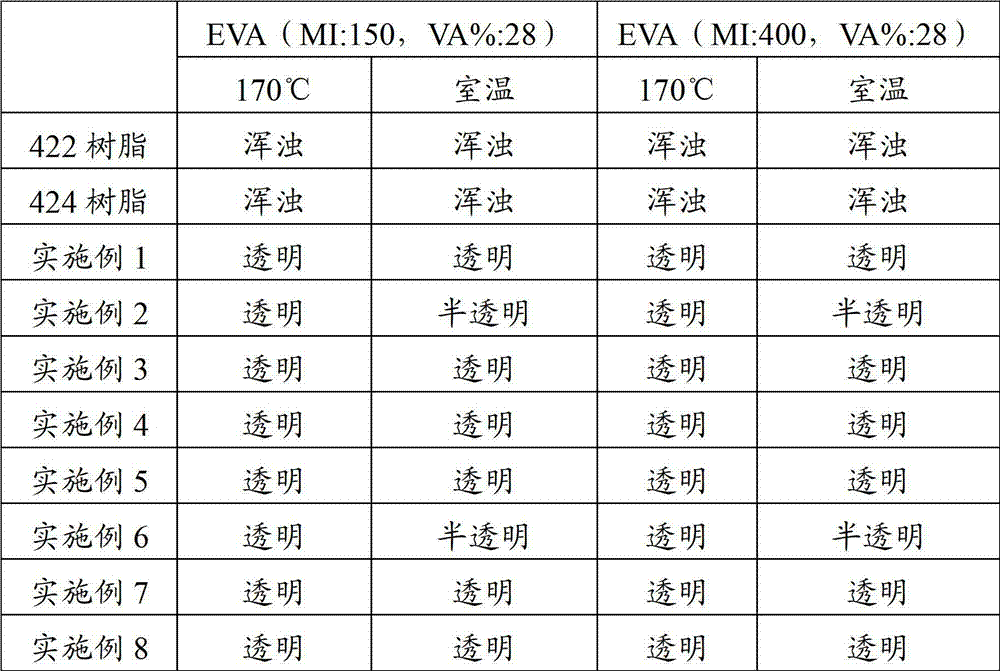

Rosin viscosified resin as well as preparation method and application thereof

ActiveCN102965024AImprove molecular structureHigh softening pointNatural resin chemical modificationRosin adhesivesElastomerDistillation

The invention discloses a preparation method of rosin viscosified resin, and the preparation method comprises the following steps of: (1) adding rosin into a distillation flask, vacuumizing, heating and distilling at the temperature of 240-280 DEG C, so that part of rosin is distilled; and (2) adding the rest rosin in the distillation flask into a reaction flask, adding a catalyst and polyalcohol into the reaction flask under the inert gas protection condition, and reacting for 4-24 hours at the temperature of 240-290 DEG C, so that the rosin viscosified resin is obtained, wherein the rosin contains pinus latteri acid. According to the preparation method disclosed by the invention, the pinus latteri acid contained in the rosin component is utilized, and the pinus latteri acid is rosin binary acid, so that the molecular structure of the resin is increased and the aim of increasing the softening point of the rosin viscosified resin is achieved. Meanwhile, the invention also provides rosin viscosified resin prepared by adopting the preparation method disclosed by the invention, and the rosin viscosified resin has higher softening point and good compatibility with EVA (ethylene vinyl acetate) elastomer and can be better used for preparing hot melt glue.

Owner:普洱科茂林化有限公司

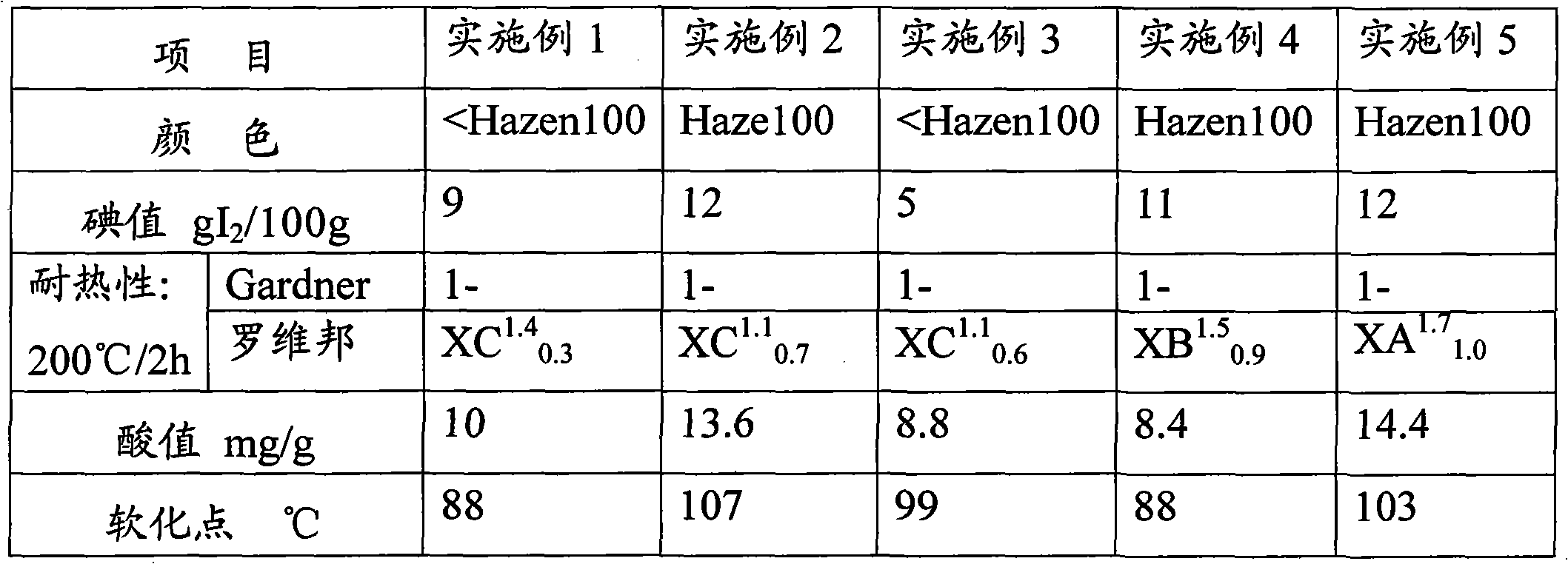

High stability color-less rosin pentaerythrite ester and its prepn

InactiveCN1772829ASimple processEasy to operateNatural resin chemical modificationPentaerythritolBoiling point

The present invention discloses one kind of high stability color-less rosin pentaerythrite ester with Hason color number smaller than 150, color change after being set in a drying tank at 180 deg.c for 8 hr not greater than 1 Ghana color number and color change after being irradiated with ultraviolet lamp for 15 hr not greater than 3 Ghana color number. Its preparation process includes the following steps: distilling rosin to obtain refined rosin; adding pentaerythritol, decolorizing agent, antioxidant and catalyst to refined rosin for esterification until reaching acid value lower than 20 mg / g; decompressing to eliminate low boiling point matter; cooling, adding heat stabilizer and light stabilizer via stirring to obtain the high stability color-less rosin pentaerythrite ester. The present invention has simple technological process and low production cost.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Rosin ester with low color and process for preparing same

A process for producing light color rosins ester resin, preferably based on tall rosin, is described. The process is conducted in the presence of less than 10 weight % of an acid functional organic compound and avoids the need for use of a stoichiometric excess of rosin acid, or a stoichiometric excess of polyol hydroxyl groups. The process allows for the use of lower colored or darker tall oil rosin in the production of low color rosin esters.

Owner:LAWTER

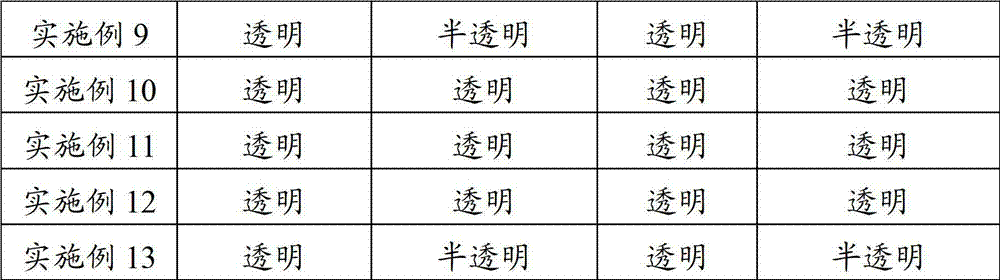

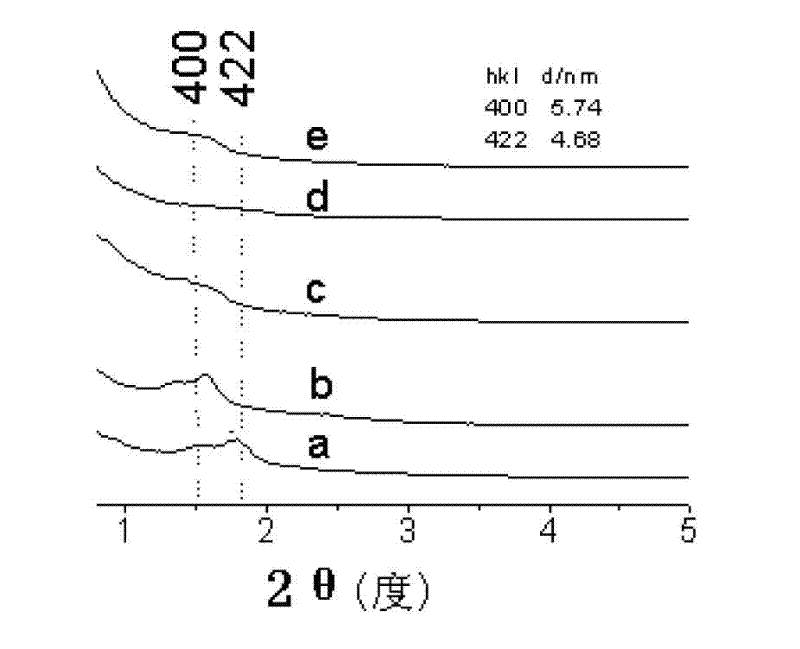

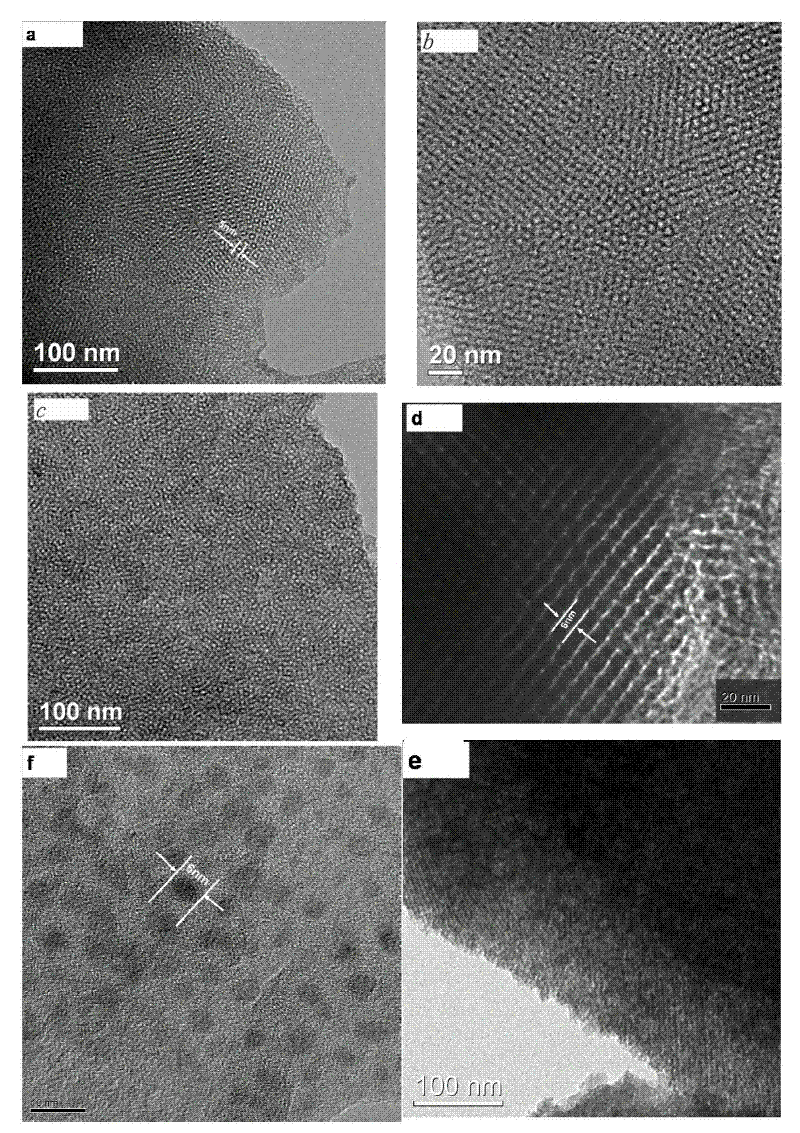

Preparation method of composite ZnO-mesoporous silica nanomaterial

ActiveCN102250610AStable in natureExcellent optical propertiesWater/sewage treatment by irradiationMolecular sieve catalystsPtru catalystOrganosolv

The invention discloses a preparation method of a composite ZnO-mesoporous silica nanomaterial, namely a solvothermal in situ substitution method. The preparation method comprises the following steps of: uniformly mixing silicon-based molecular sieve powder, a ZnO precursor, a doping element and an organic solvent, adding the mixture into a high-pressure reaction kettle, and introducing a shielding gas to the reaction kettle for reaction; filtering the reaction mixture, washing, and drying to obtain dry powder; and heating and calcining the dry powder to obtain the composite ZnO-mesoporous silica nanomaterial. The composite ZnO-mesoporous silica nanomaterial prepared by the preparation method disclosed by the invention has the advantages of uniform ZnO loading, stable properties, excellent optical properties and catalytic properties and strong SHG (second harmonic generation) and TPL (two-photon luminescence) optical properties when used as an excellent catalyst for organic ester synthesis or as a laser nonlinear optical material, and is suitable for being prepared into a purple light-emitting material or a functional polymer additive. The preparation method disclosed by the invention has the advantages of wide and available raw materials, simplicity of operation and advantageous production cost.

Owner:SOUTH CHINA NORMAL UNIVERSITY

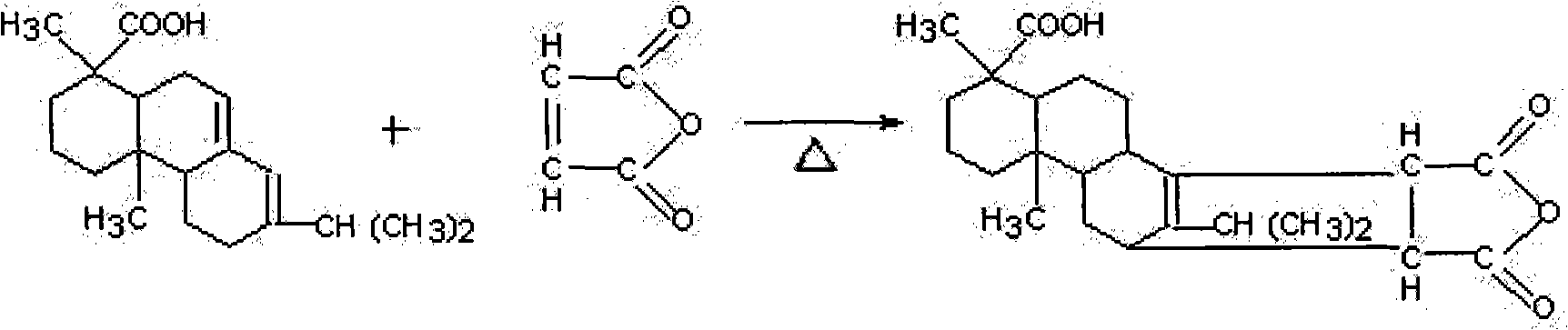

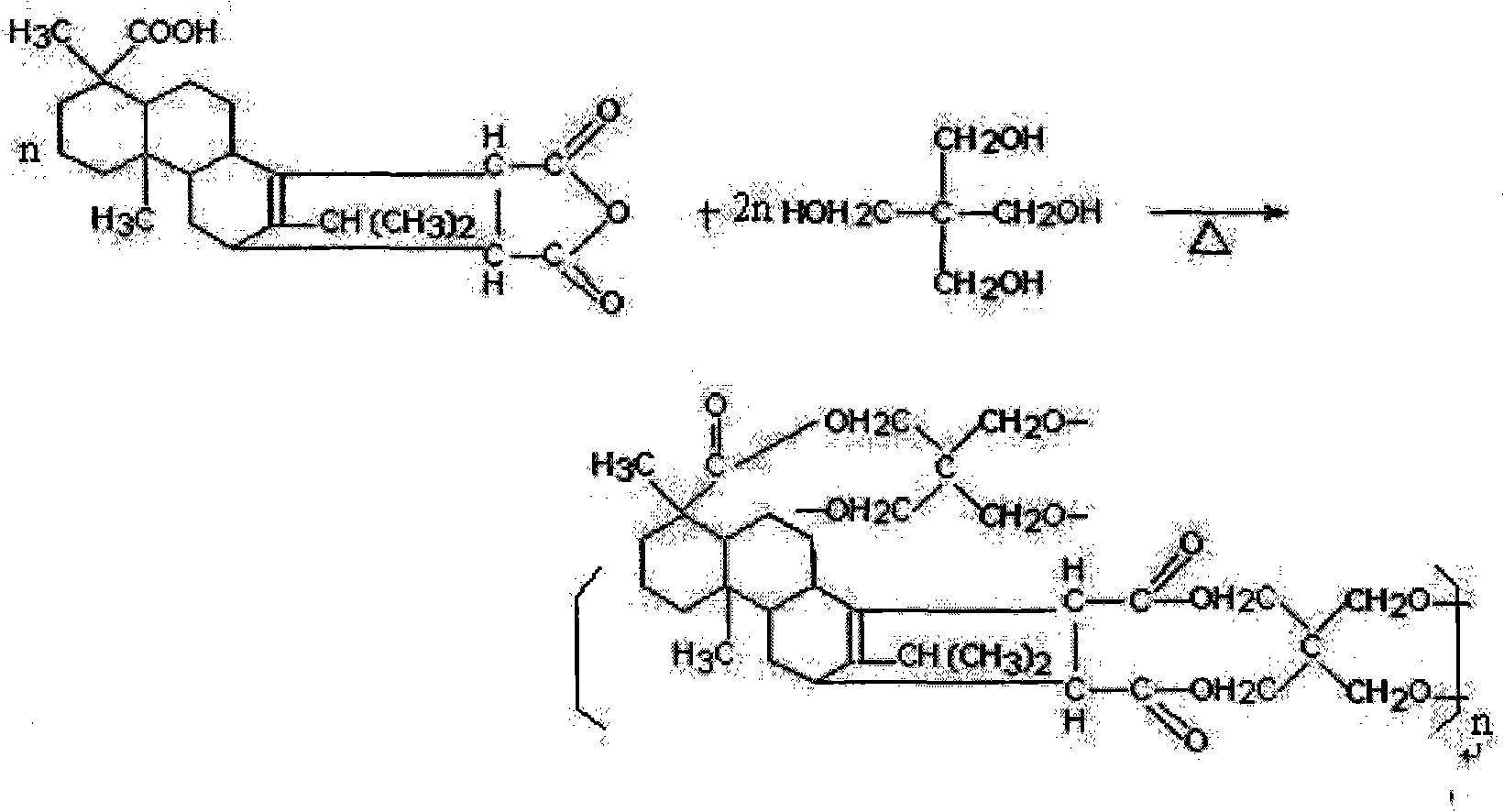

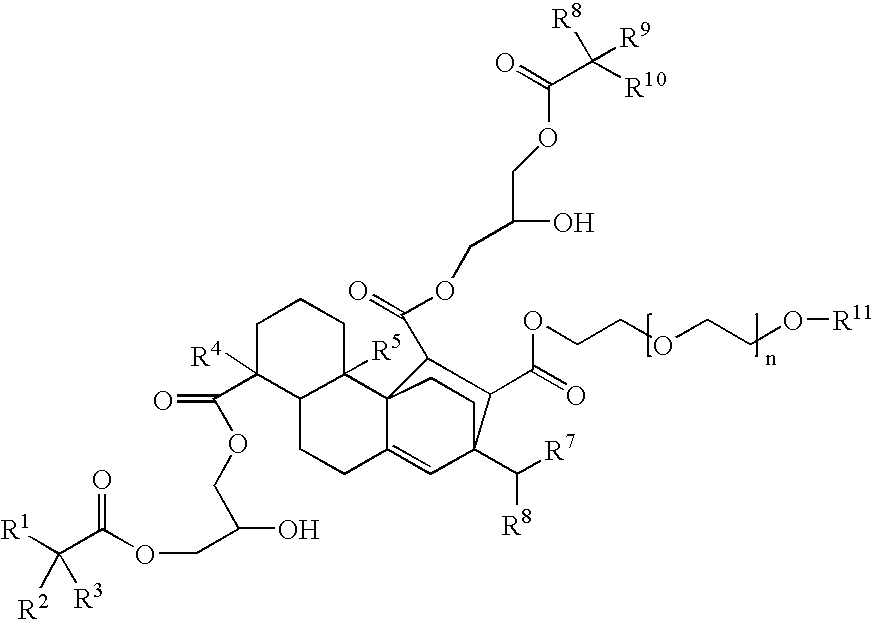

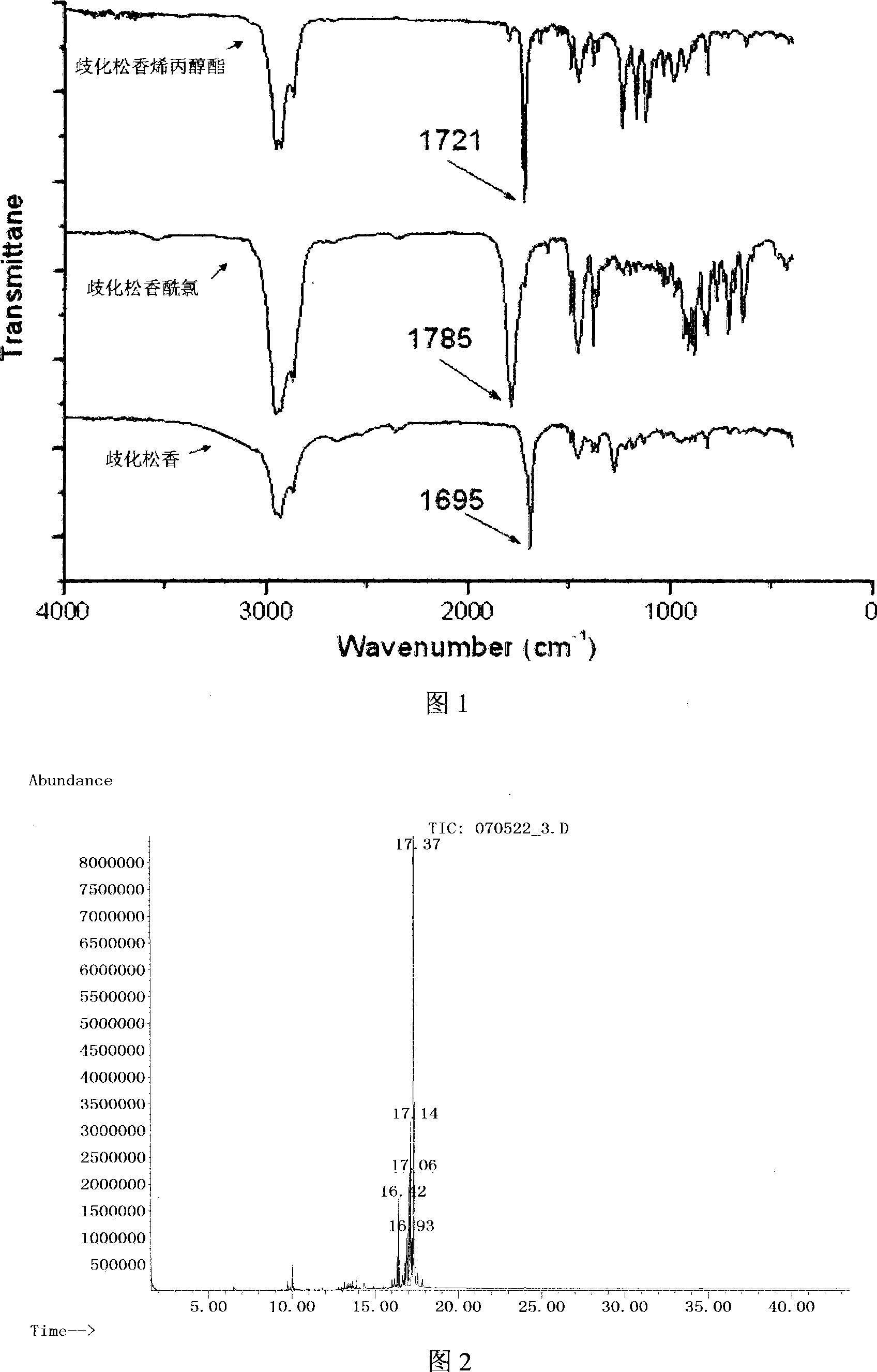

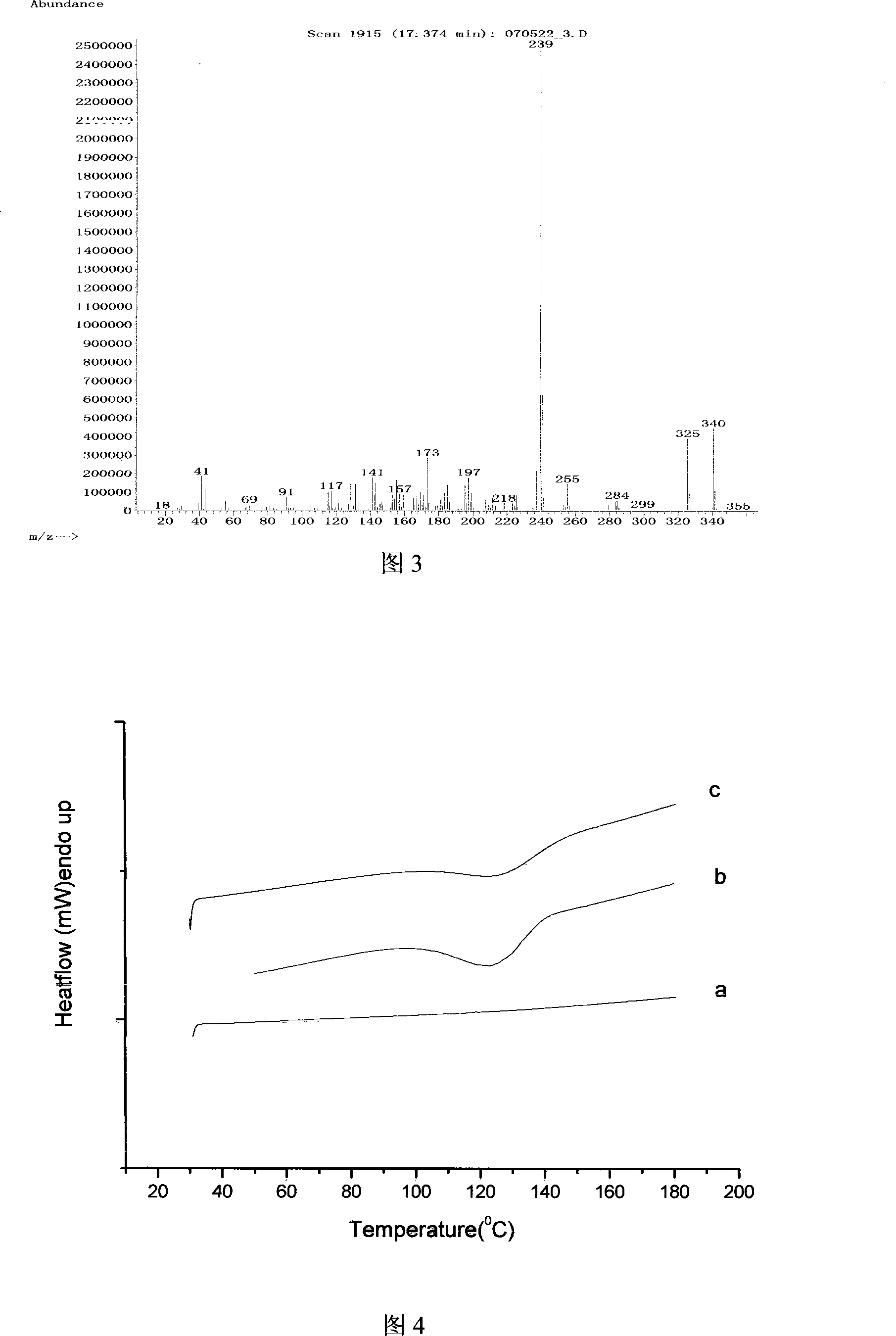

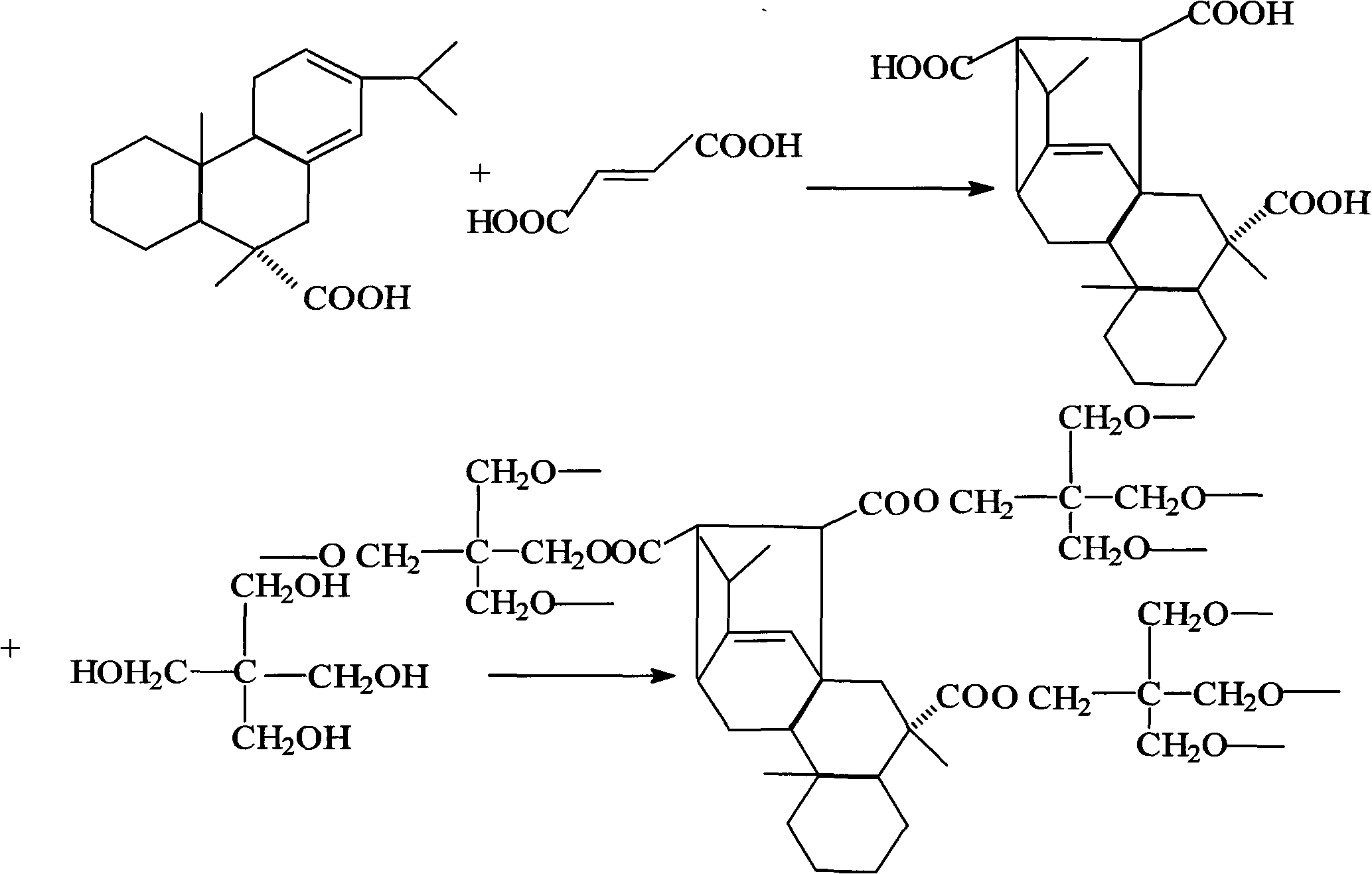

Production method of abietic maleic anhydride resin

InactiveCN102010503AExemption from releaseProtect physical and mental healthInksNatural resin chemical modificationSolubilityReaction temperature

The invention relates to a production method of abietic maleic anhydride resin, comprising the following two reaction steps of: 1, carrying out addition reaction on abietyl and maleic anhydride to generate an abietic maleic anhydride addition product; and 2, carrying out esterification reaction on the abietic maleic anhydride addition product and pentaerythritol to generate the abietic maleic anhydride resin. The production method is easy and convenient to operate, has the advantages of large temperature control range, high operability, small investment and stable product quality and is a method suitable for industrialized production; in the production method, appropriate process conditions including raw material proportion, reaction temperature, reaction time, catalysts, and the like, are adopted, thereby the acid value and the molecular weight range of a resin product can be effectively controlled; in addition, the resin product obtained with the production method has higher acid value of 150-170 mg KOH / g, reasonable softening point at 140-155 DEG C and good water solubility and is suitable for producing water-based ink, and a formed coating film has toughness and better after-tackiness resistance, water resistance and alkali resistance.

Owner:上海华谊精细化工有限公司上海南大化工厂

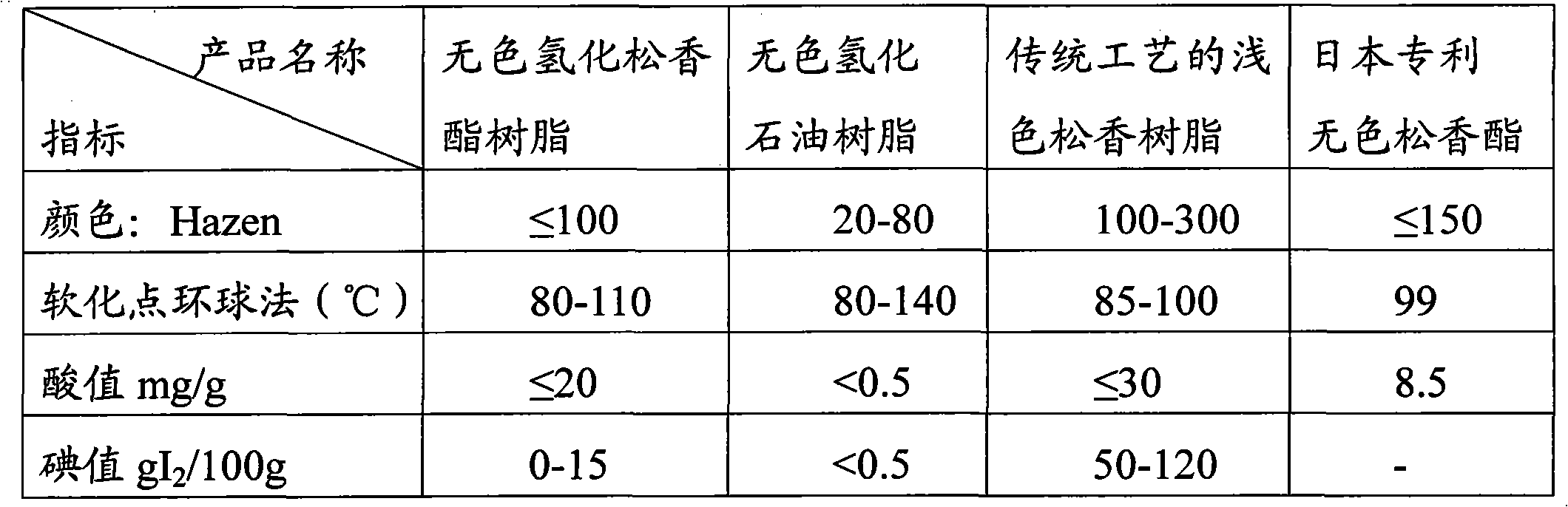

Method for preparing colorless hydrogenated rosin ester resin

ActiveCN102002321AHigh purityReduced chance of poisoningNatural resin chemical modificationAdhesiveDistillation

The invention relates to a method for preparing colorless hydrogenated rosin ester resin. Rosin ester obtained by esterifying rosin purified through distillation is used as a raw material, catalytic hydrogenation is carried out under the action of a solvent and a high activity catalyst, the solvent is separated through distillation, and the colorless hydrogenated rosin ester resin is obtained. The product comprises the following key indexes of: no more than 100 of Hasson color number, no more than 20 mg / g of acid value, 80 to 110 DEG C of softening point and 0 to 15 gI2 / 100g of iodine value. The product can substitute a colorless hydrogenated petroleum resin product to be applied to the high-end adhesive. The method for preparing the colorless hydrogenated rosin ester resin is simple and easy, and the prepared product has the advantages of shadow color, lower iodine value, higher stability and lower preparation cost when being compared with the traditional products.

Owner:广西梧州日成林产化工股份有限公司

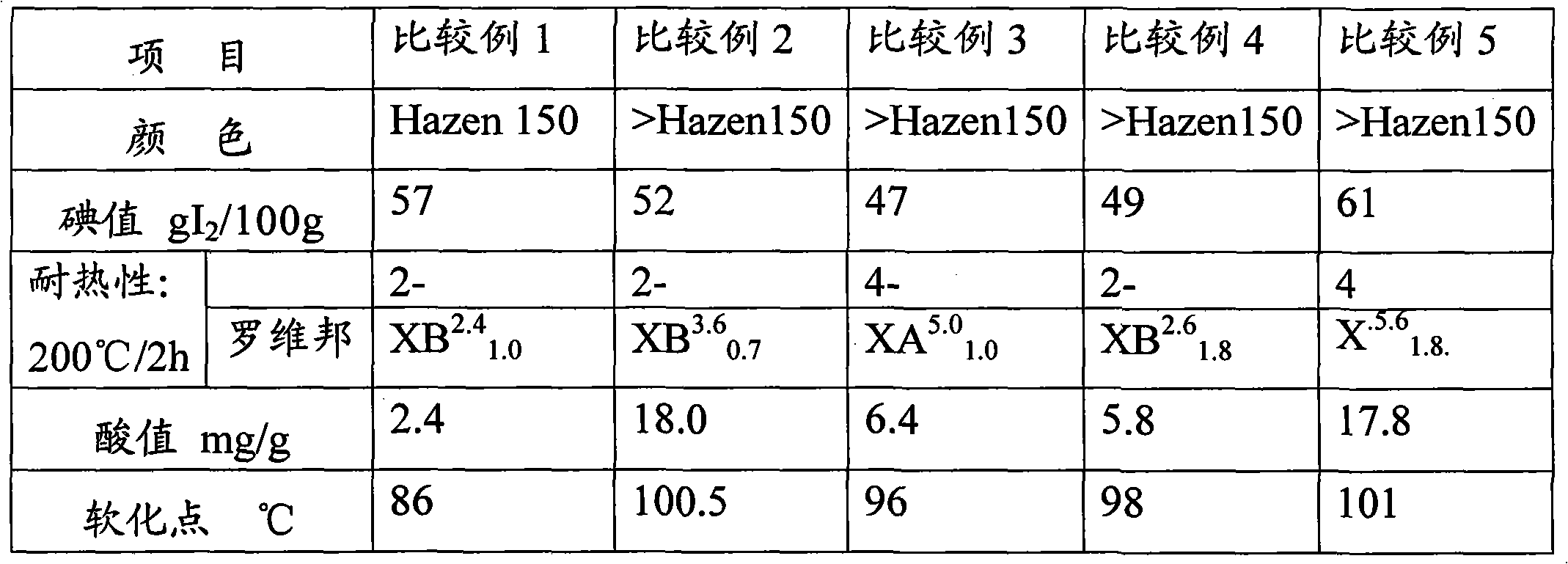

Ph-sensitive sacrificial materials for the microfabrication of structures

ActiveUS20130066045A1High removal rateAltered solubilityShellac coatingsPharmaceutical delivery mechanismSolubilityPorosity

Methods for microfabricating composite materials and composite materials prepared there from are described herein. The sacrificial material can be etched or patterned to create a two-dimensional and / or three-dimensional sacrificial material structure. The resulting sacrificial material structure can be embedded in one or more embedding materials. The sacrificial material(s) are materials whose solubility can be altered by application of a stimulus typically pH, and / or temperature, light, pH, pressure, presence of absence of ions, and combinations thereof. The embedding materials can contain one or more additives that modify one or more properties of the embedding materials, such as degradation properties, porosity, mechanical properties, viscosity, conductive properties, and combinations thereof. The composite materials can be used in tissue engineering, drug screening, toxin detection, drug delivery, filtrations, bioseparations, and as microfluidic devices for fluid mixing and structural repair.

Owner:MASSACHUSETTS INST OF TECH +1

Modified rosin tackifying resin as well as preparation method and application thereof

The invention relates to modified rosin resin and discloses modified rosin tackifying resin as well as a preparation method and application thereof. The preparation method comprises the following steps of: uniformly mixing rosin or rosin derivatives, monoterpene compounds, dicyclopentadiene fractions and catalysts in an autoclave; replacing air in the autoclave by use of nitrogen or carbon dioxide; reacting the mixture at a pressure of 0.2-0.6 Mpa and at 170-290 DEG C for 1 hour to 30 hours; and decompressing after the reaction, and removing low-boiling-point substances, thus obtaining the modified rosin tackifying resin, or adding an antioxidant stabilizer into the mixture at 200-230 DEG C, thus obtaining the modified rosin tackifying resin with higher quality. The softening point of the modified rosin tackifying resin ranges from 80 DEG C to 110 DEG C, the acid value of the tackifying resin is 15-70mg KOH per gram, and the color of the tackifying resin is less than No.6 Ghana color. The modified rosin tackifying resin can be widely applied to the field of tackifiers, coating paint, printing ink and the like, and especially can be applied to the field of metallocene catalysis polyolefin tackifiers.

Owner:广东科茂林产化工股份有限公司

Composite catalyst and its application in preparing light-colored rosin esters

ActiveCN101264454APrevent oxidationPlay a bleaching roleOrganic-compounds/hydrides/coordination-complexes catalystsNatural resin chemical modificationPhosphinic AcidsRosin

The invention provides a compound catalysis used for preparing pale rosin ester, reducing the production cost and simplifying production technique as well as an application thereof. The compound catalysis comprises components of the following mass ratios: 1 to 200 portions of hypophosphorous acid and / or hypophosphite, 1 to 100 portions of sulfur-containing metal salt and 2 to 100 portions of organic disproportionation catalyst. The compound catalysis of the invention can prepare the pale rosin ester using common resin as the raw material to produce the pale rosin ester with solid garner color no larger than 2.

Owner:江西科茂林化科技有限公司

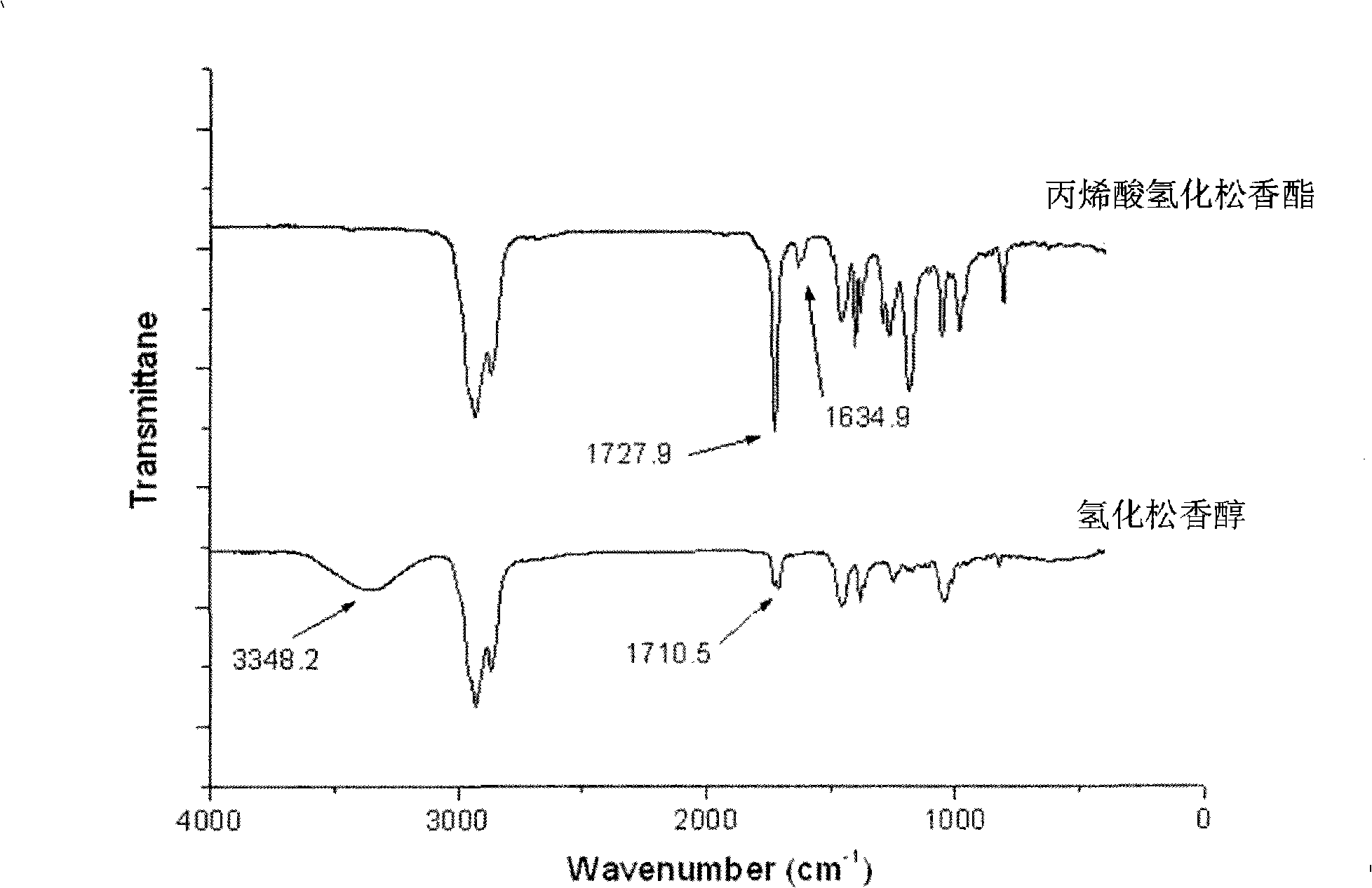

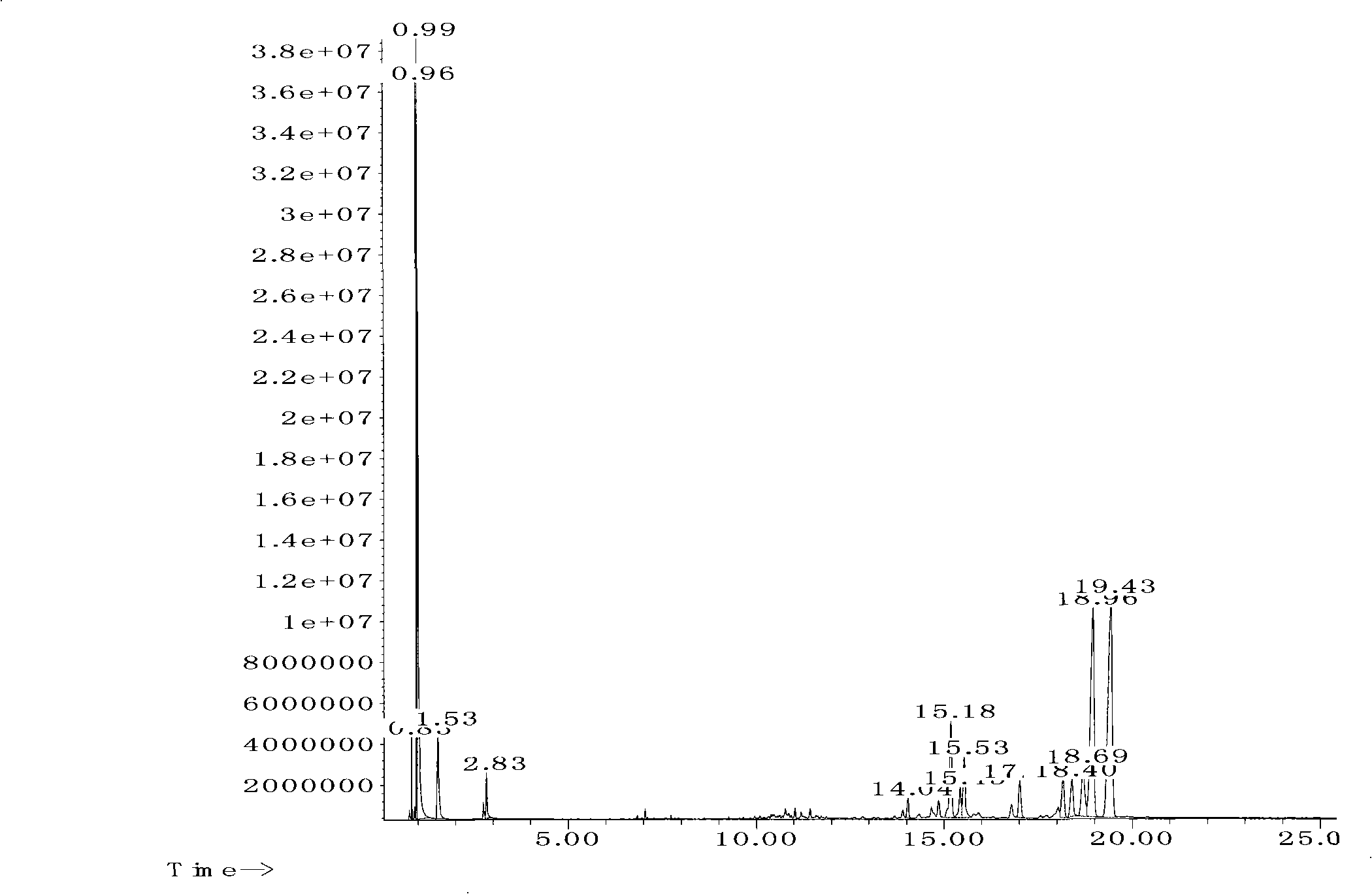

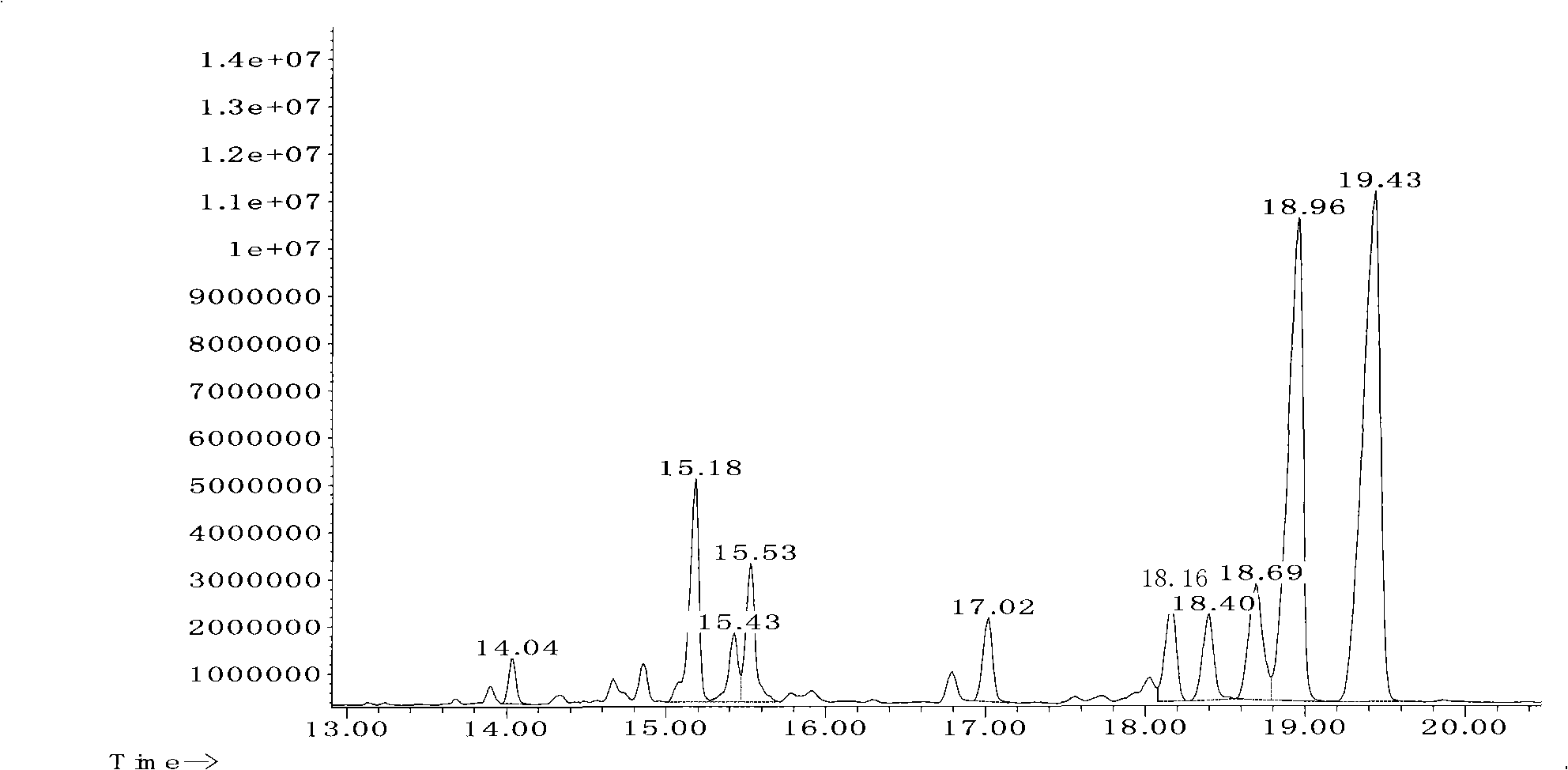

Acrylic acid or methylpropenoic acid rosin derivative ester synthesis method

InactiveCN101492591AHigh reactivityLow reaction temperatureNatural resin chemical modificationPolymer scienceMeth-

The invention discloses a method for synthesizing acrylic acid or methacrylic acid vinsol ester, comprising the following steps: one of vinsols containing hydroxide radical functional groups, acid-binding agent and addition type polymerization inhibitor are dissolved in non-proton transfer solvent, methacrylic chloride or acryloyl chloride is added into the mixed solution, the reaction temperature is 0-85 DEG C, and the reaction time is 0.5-10h; then, the precipitate is filtered, and vacuum extraction is carried out on the obtained filter liquor to remove solvent, so that acrylic acid or methacrylic acid vinsol ester can be obtained; the mass of the non-proton transfer solvent is 100-500% of that of the vinsol; the molal weight of the methacrylic chloride or the acryloyl chloride is 100-500% of that of hydroxide radical of the vinsol containing hydroxide radical functional groups; the dosage of the acid-binding agent is 100-500% of the molal weight of the hydroxide radical of the vinsol containing hydroxide radical functional groups. The synthesized acrylic acid or methacrylic acid vinsol ester can be used for having free radical polymerization reaction, can be applied to the fields such as paint, adhesive, printing ink, paper making, etc. The method has high technical efficiency and good stability of the product.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

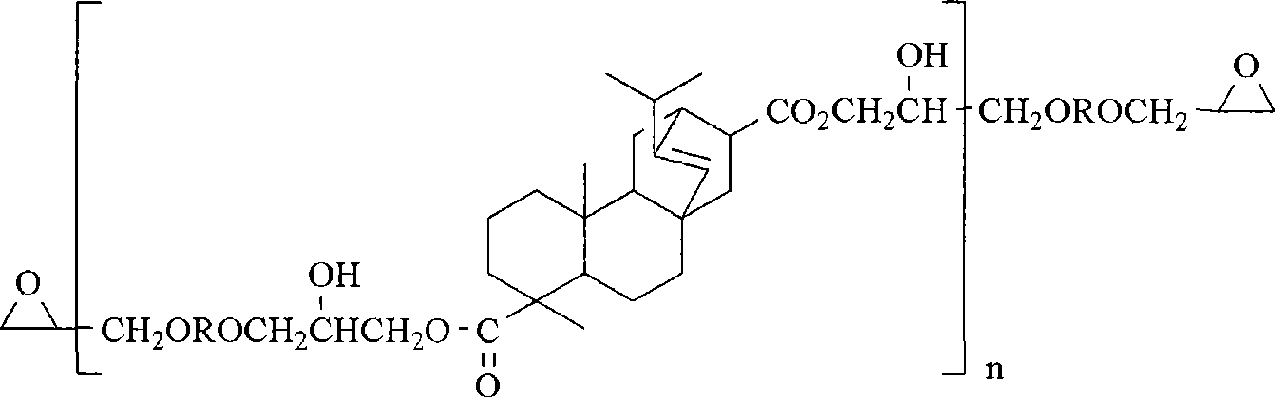

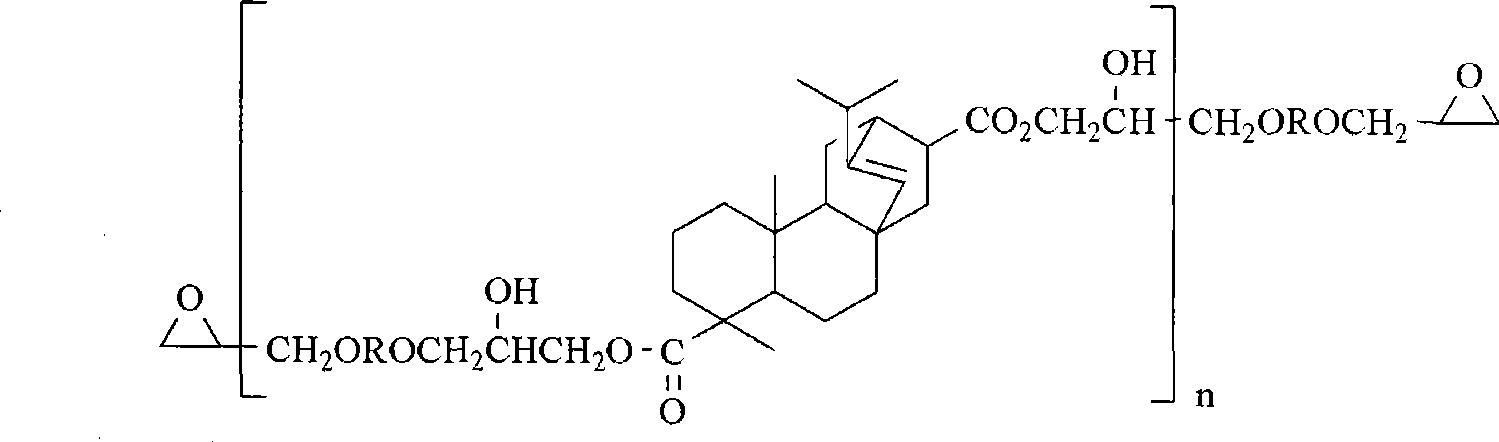

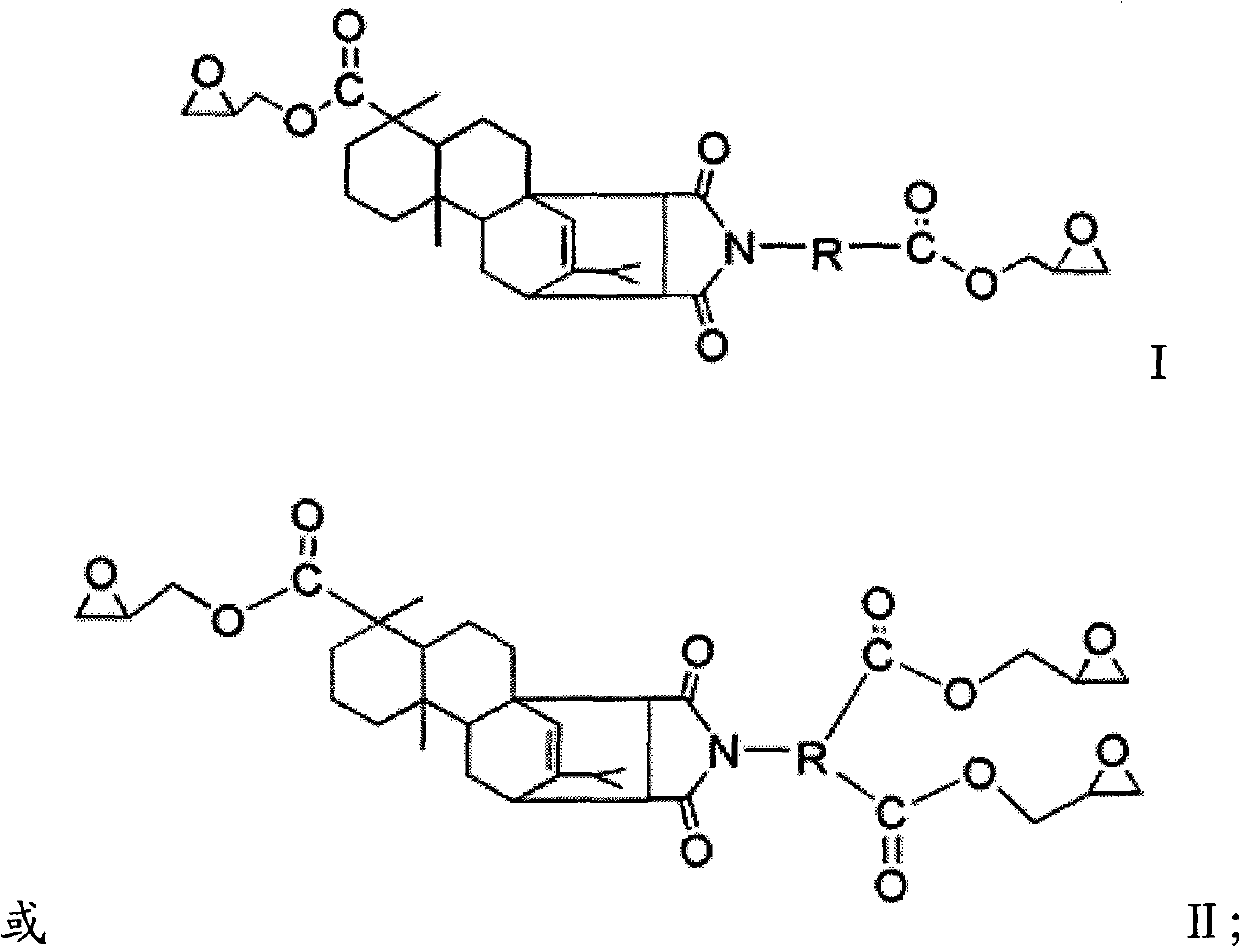

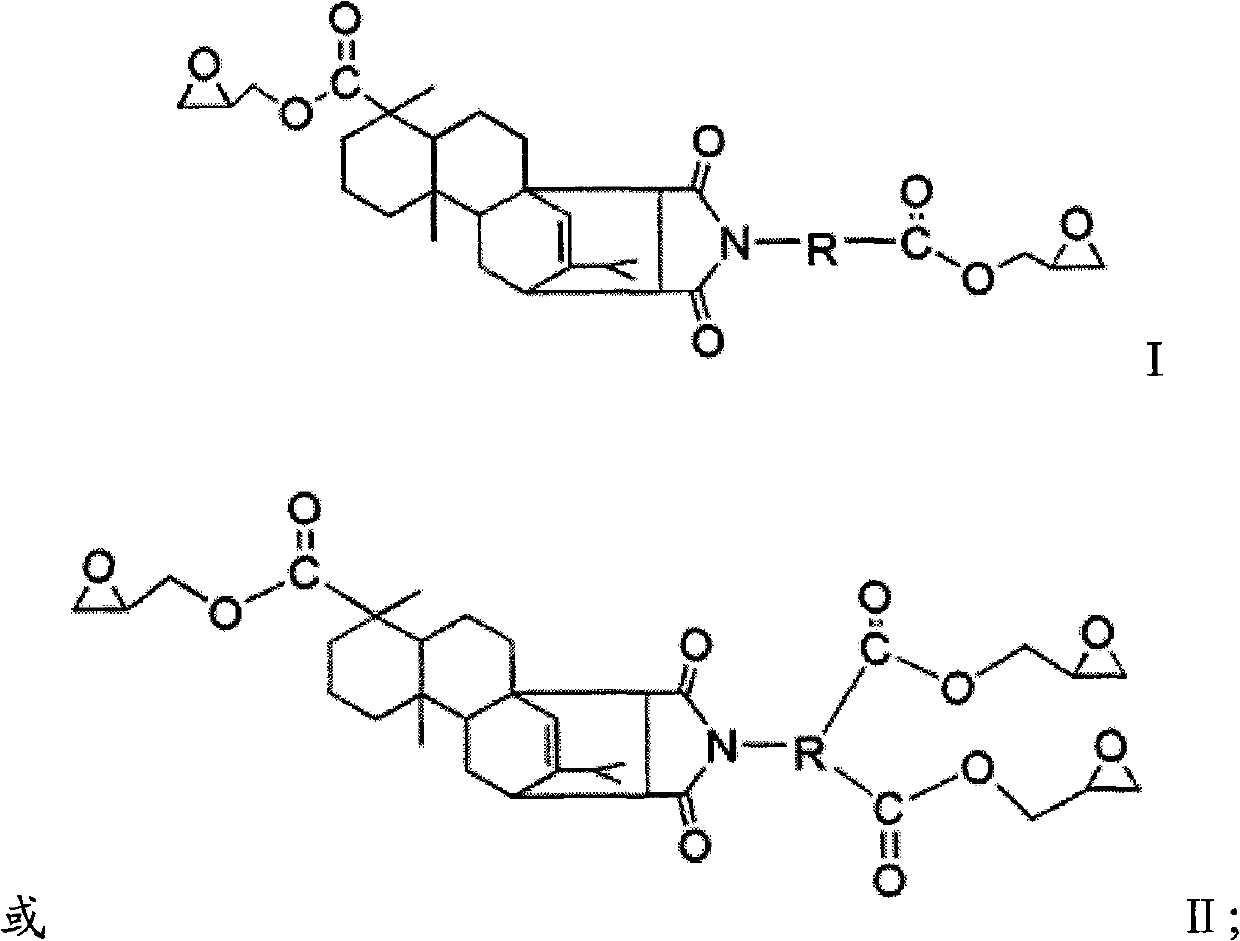

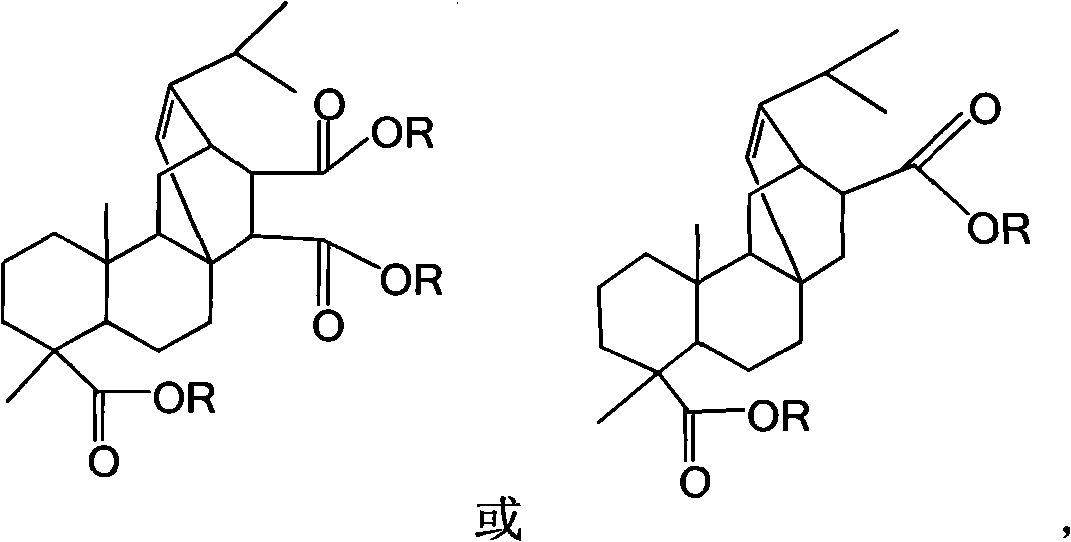

Rosin epoxy resin and preparation method thereof

InactiveCN102329309AGood weather resistanceEasy to makeOrganic chemistryPowdery paintsEpoxyPolyester

The invention discloses a rosin epoxy resin for the solidification of polyester powdery paints. The rosin epoxy resin is a compound with the structure of formula I or formula II. In the formula I or the formula II, R is an aliphatic chain segment or an aromatic chain segment. The invention also discloses a preparation method of the rosin epoxy resin. The preparation method comprises the following steps: 1, treating rosin as a raw material, adding with a catalyst I and maleic anhydride, and carrying out a Diels-Alder reaction to obtain maleopimaric acid anhydride (MPA); 2, reacting a compound containing amino and carboxyl with the MPA to prepare a rosin polyprotic acid; and 3, carrying out a series of chemical reactions on the rosin polyprotic acid, an epoxy alkylogen, a catalyst II, and an alkali to prepare the rosin epoxy resin. The rosin epoxy resin of the invention which has the advantages of environmentally friendly preparation technology, and low manufacture cost is mainly used for solidifying the polyester powdery paints.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

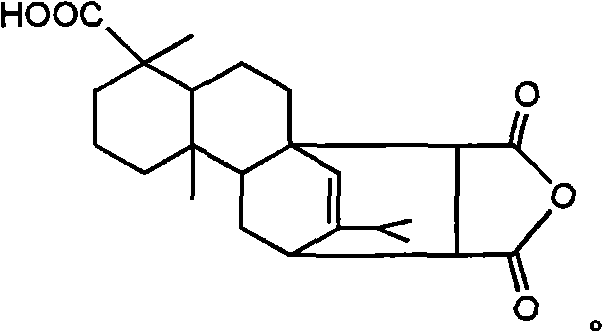

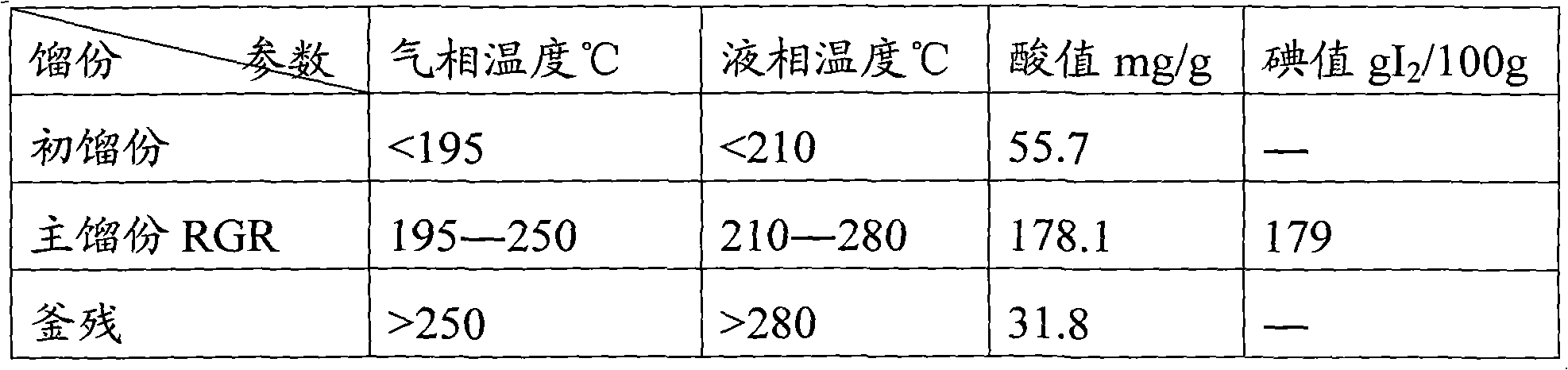

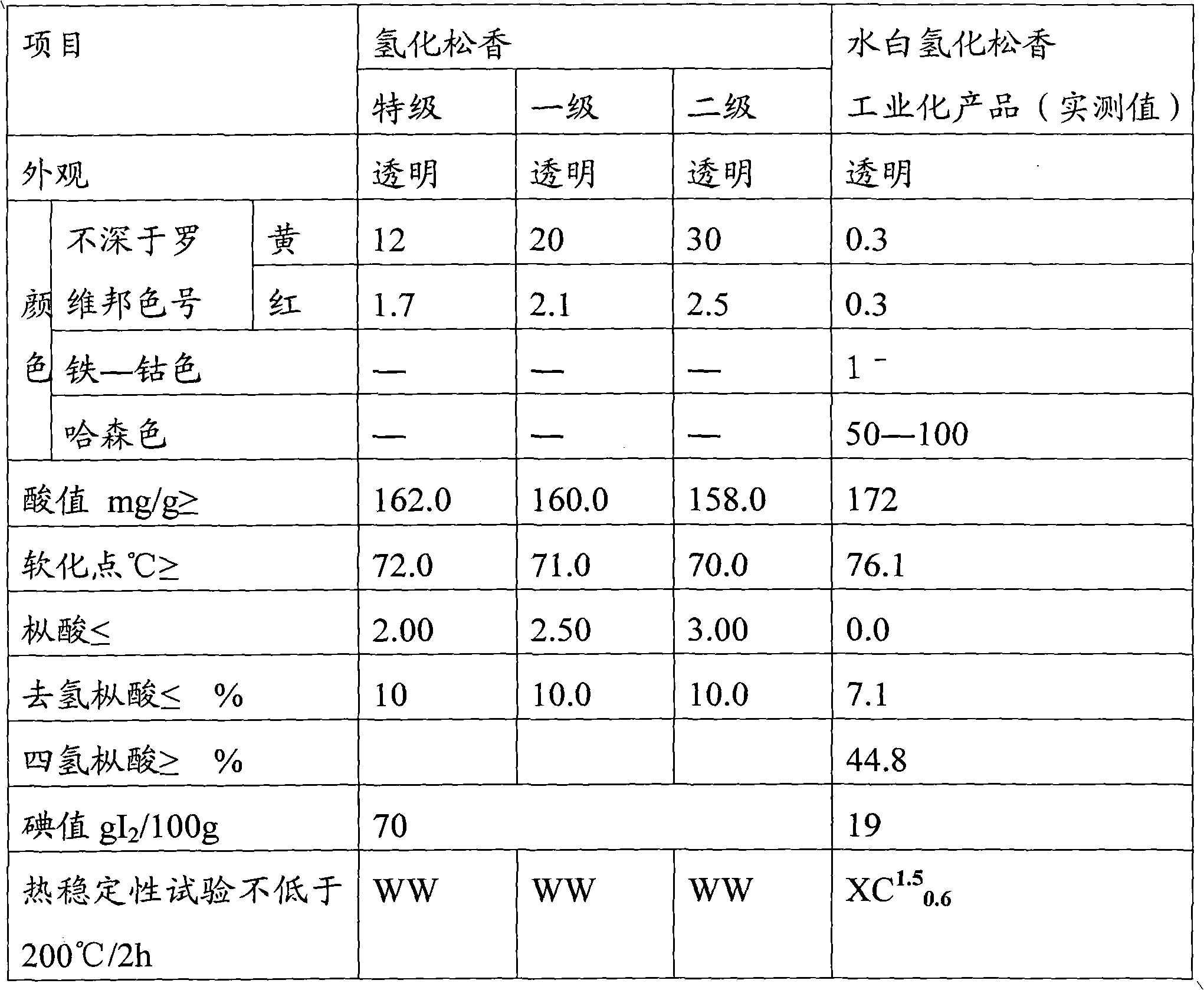

Method for producing water-white hydrogenated rosin

ActiveCN102070988ALow hydrogenation reaction temperatureRelieve pressureNatural resin chemical modificationDistillationSolvent

The invention relates to a method for producing water-white hydrogenated rosin, which comprises the following steps: using light color refined rosin obtained after purifying the rosin as hydrogenation raw materials, using a solvent for preparing solution, carrying out catalytic hydrogenation, then, separating out the solvent through distillation, and obtaining the water-white hydrogenated rosin. When the method provided by the invention is adopted, the water-white hydrogenated rosin with light color (the Lovibond color number of the yellow color is 0.3 to 1.0, and the Lovibond color number of the red color is 0.2 to 0.3), low iodine value and low abietic acid content can be obtained. Compared with the water-white hydrogenated rosin produced by a traditional method, the water-white hydrogenated rosin produced by the method provided by the invention has the advantages of lighter color, higher hydrogenation degree, better stability and lower cost, and the application value of products can be improved when the water-white hydrogenated rosin is applied to aspects such as electronics, paint, bonding agents, dyestuff and the like.

Owner:广西梧州日成林产化工股份有限公司

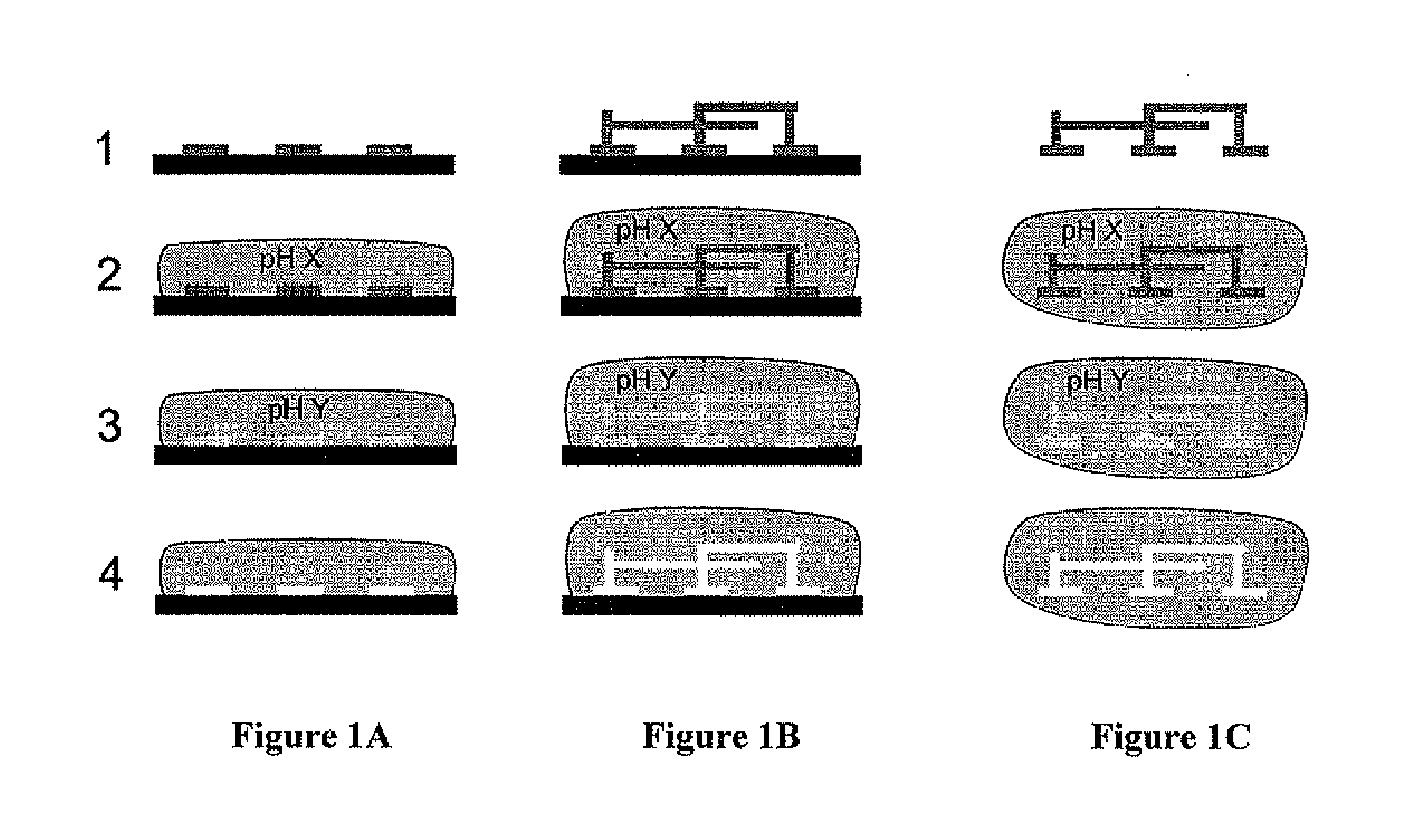

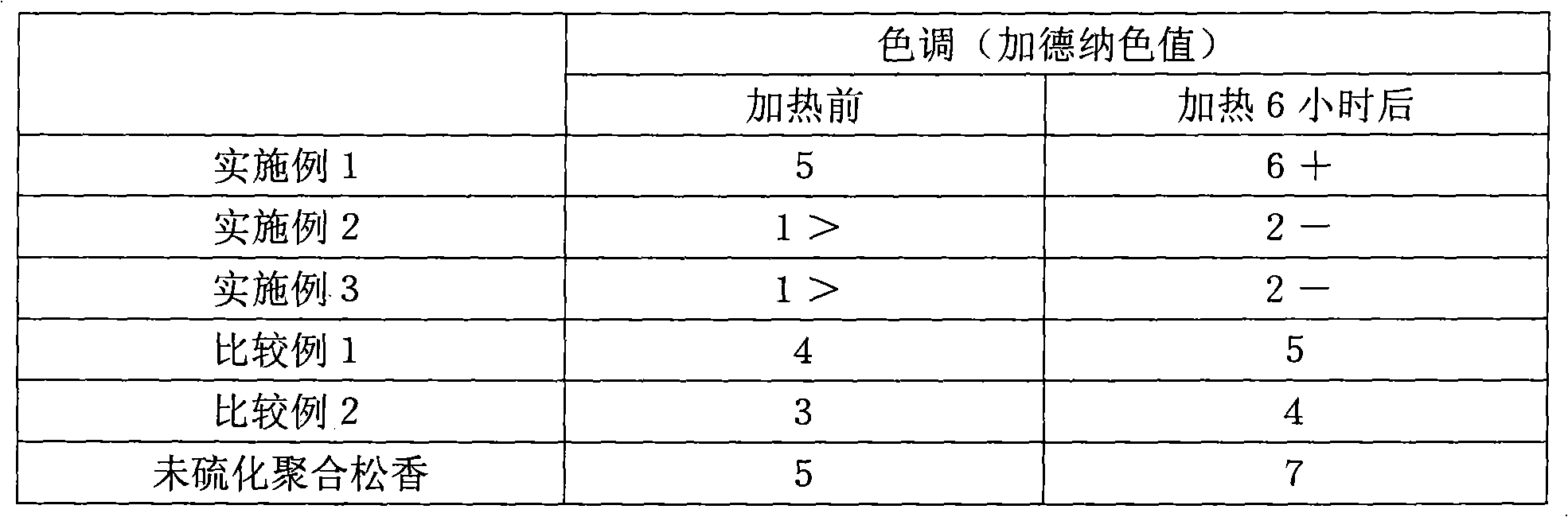

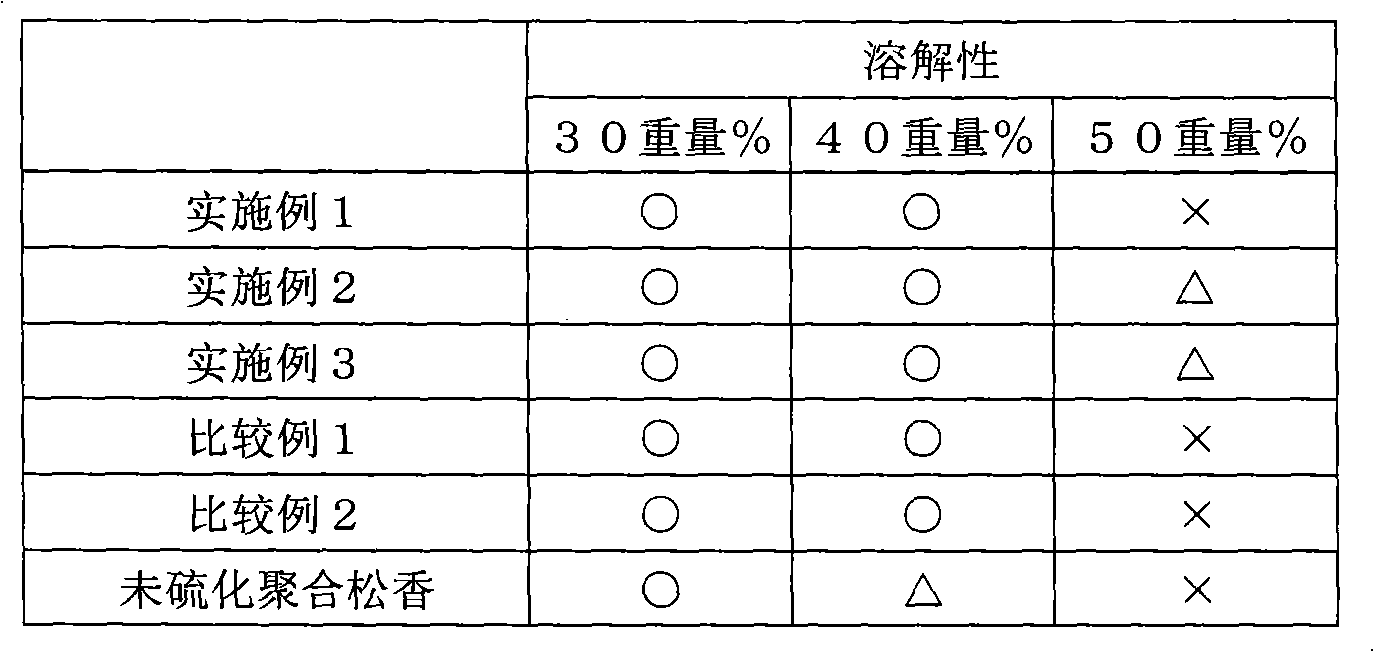

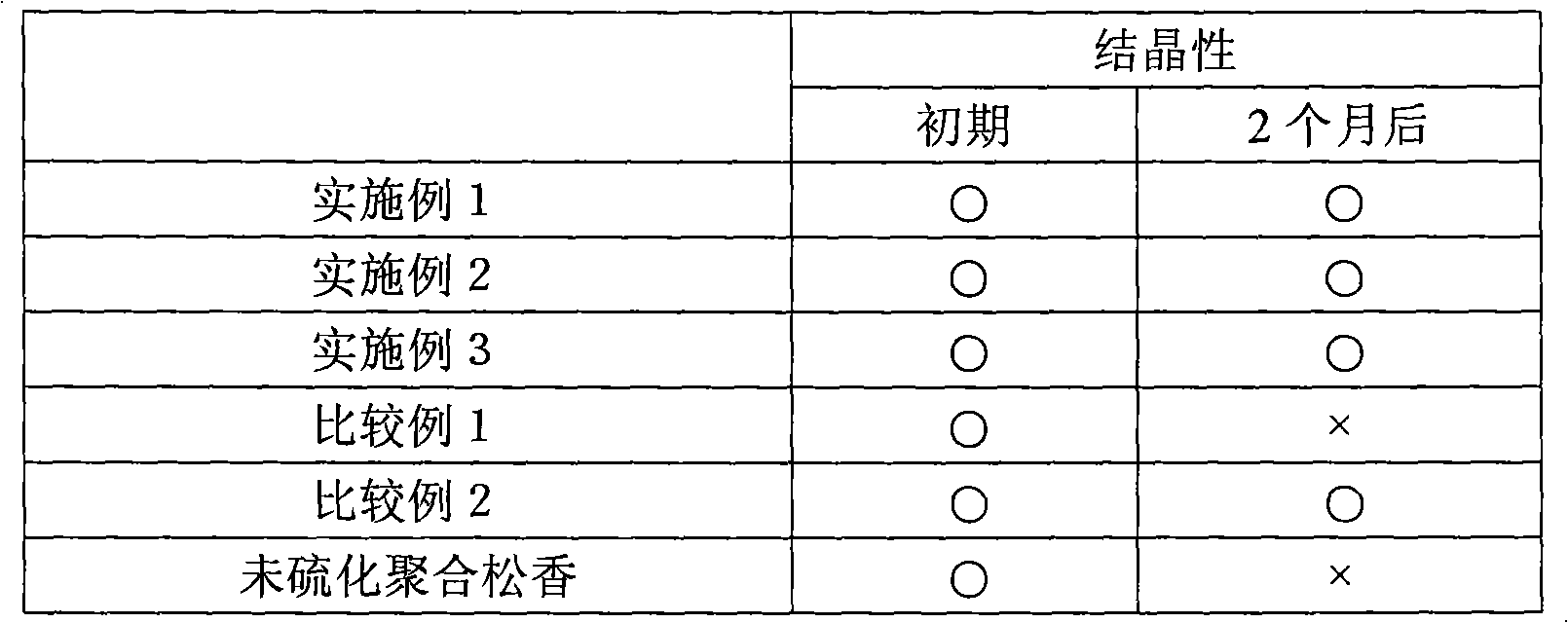

Polymerized rosin derivant, preparing method and uses thereof

InactiveCN101270264AImprove stabilityExcellent toneMacromolecular adhesive additivesWelding/cutting media/materialsAntioxidantSulfur

Besides sulfur component of antioxidant, the invention provides polymerized abietate, hydrogenising polymerized abietate with the sulfur component content below 100 ppm, tackifier comprising the polymerized abietate and hydrogenising polymerized abietate, tackifier resin emulision obtained by emulsifying the tackifier, agglutinant / adhesive composition comprising the tackifier; using the drainage agglutinant / adhesive composition comprising the tackifier liquid is able to obtain the polymerized rosin and polymerized abietate which has excellent hue and storage stability (good thermal stability) under heating so as to execute hydrogenation after storing for a long time and is able to hydrogenate (cause the color intensity) the polymerized rosin and polymerized abietate without problem, and obtain the hydrogenising polymerized rosin and polymerized abietate with excellent hue and storage stability, welding paste for lead-free soldering material with excellent hue, and agglutinant / adhesive composition with excellent hue and storage stability and drainage agglutinant / adhesive composition.

Owner:ARAKAWA CHEM IND LTD

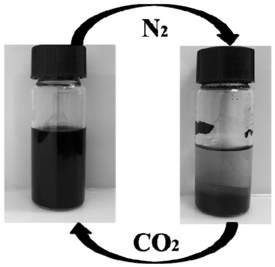

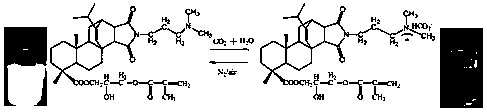

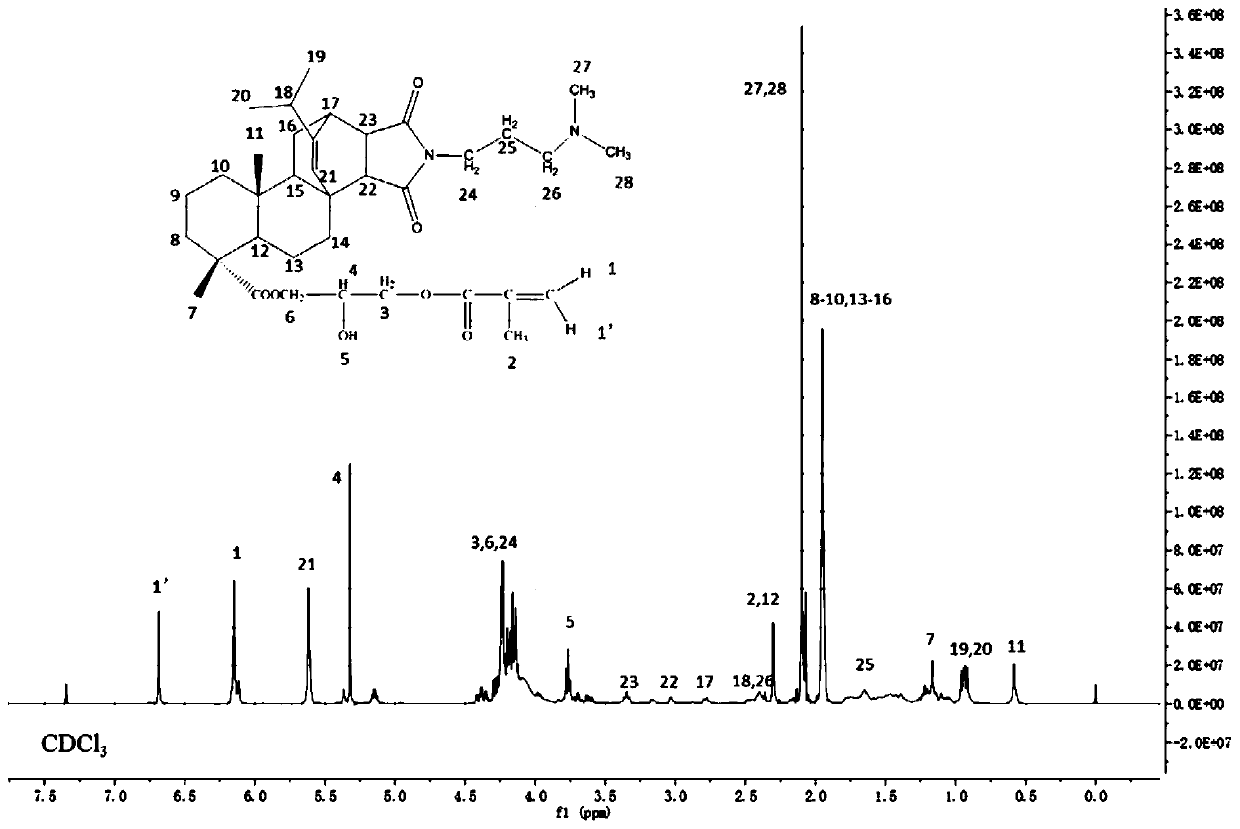

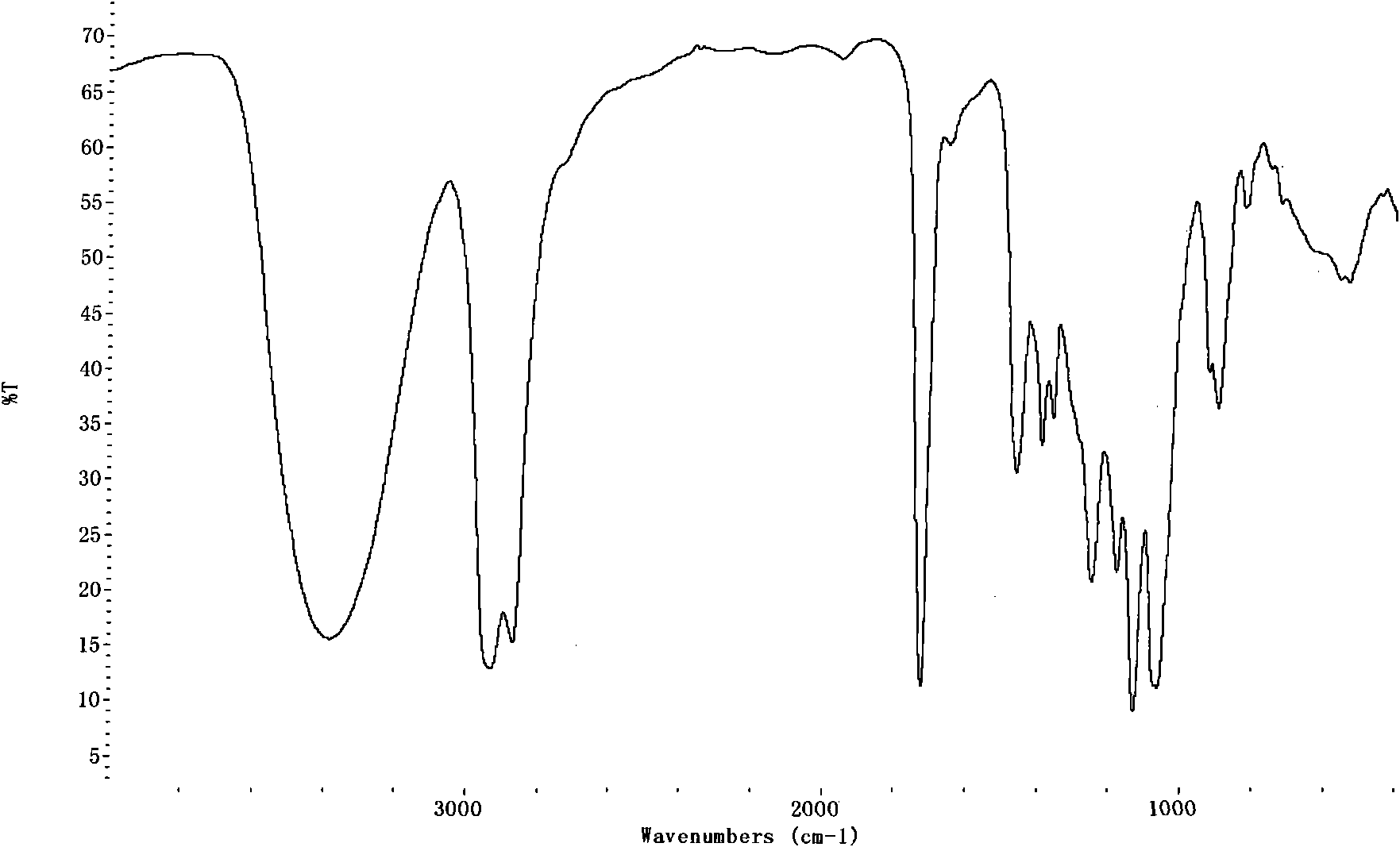

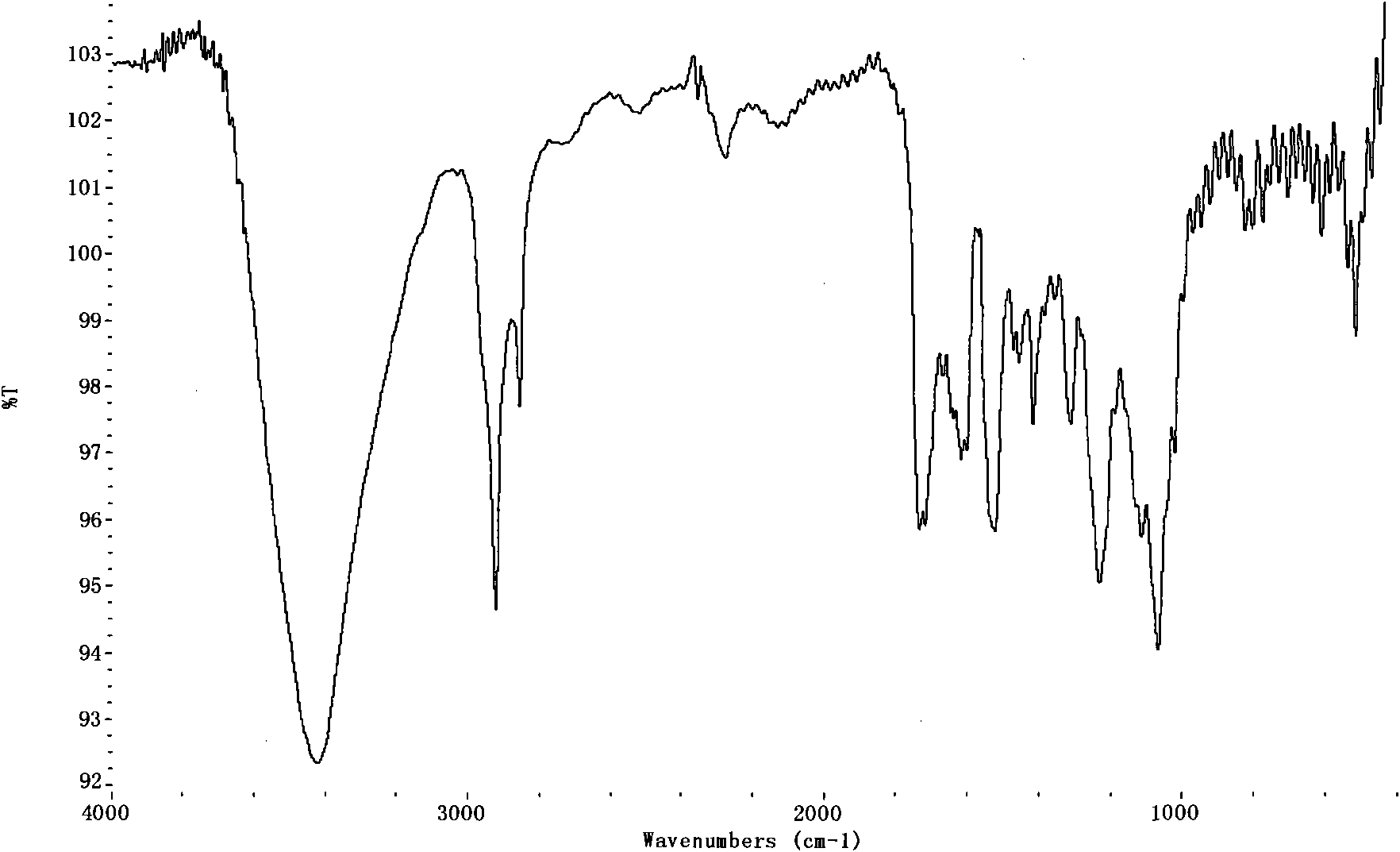

Rosin-based CO2/N2 response type polymerizable surfactant, and preparation method and application thereof

InactiveCN109868066AImprove stabilityGood dispersionTransportation and packagingMixingProtonationGlycidyl methacrylate

The invention discloses a rosin-based CO2 / N2 response type polymerizable surfactant. Maleopimaric acid reacts with glycidyl methacrylate (GMA) for introducing polymerizable monomers, and then an imidization reaction is carried out with N,N-dimethyl-1,3-propane diamine for introducing tertiary amine groups capable of responding to CO2. The surfactant has a response property on CO2 / N2, and after CO2is introduced, a water solution is weakly acidic, so that tertiary amine is protonated to form a tertiary amine salt and then is positively charged to become a form of a water-soluble cation; and after N2 is introduced to drive CO2, the positively charged tertiary amine salt is deprotonated to be recovered to an original state of a water-insoluble tertiary amine, and good response reversibility is achieved. The invention also discloses emulsification performance and dispersion performance of the surfactant, a Pickering emulsion and carbon nano tube dispersion liquid prepared by using the surfactant also have good responsiveness to the CO2 / N2, and end-group double bonds can be used for preparing a high-molecular surfactant by a polymerization reaction.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Rosin polyester polyol for flame-retardant rigid polyurethane foam plastic and preparation method and application thereof

InactiveCN101891883AImprove thermal stabilityImprove flame retardant performanceNatural resin chemical modificationPolyesterPolyol

The invention discloses rosin polyester polyol for flame-retardant rigid polyurethane foam plastic and a preparation method and application thereof. The flame-retardant rosin polyester polyol is prepared by performing esterification reaction on rosin binary acid or rosin ternary acid and small-molecular flame-retardant polyol. The prepared flame-retardant rosin polyester polyol and general polyether glycol and an isocyanate compound are foamed to obtain the flame-retardant rosin-based rigid polyurethane foam plastic in the presence of other auxiliary agents. As the flame-retardant rosin polyester polyol contains a rosin phenanthrene ring rigid structure and a certain amount of flame-retardant nitrogen and phosphorus elements, when the flame-retardant rosin polyester polyol is used in the flame-retardant rigid polyurethane foam plastic, the flame-retardant rigid polyurethane foam plastic has higher thermal stability and flame retardancy and high compressive strength, has an oxygen index of 28 to 31 percent and is applicable to building, heat preservation and special occasions.

Owner:广西鼎弘树脂有限公司

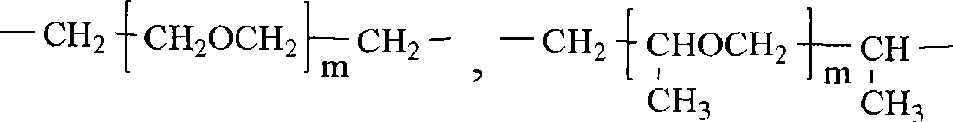

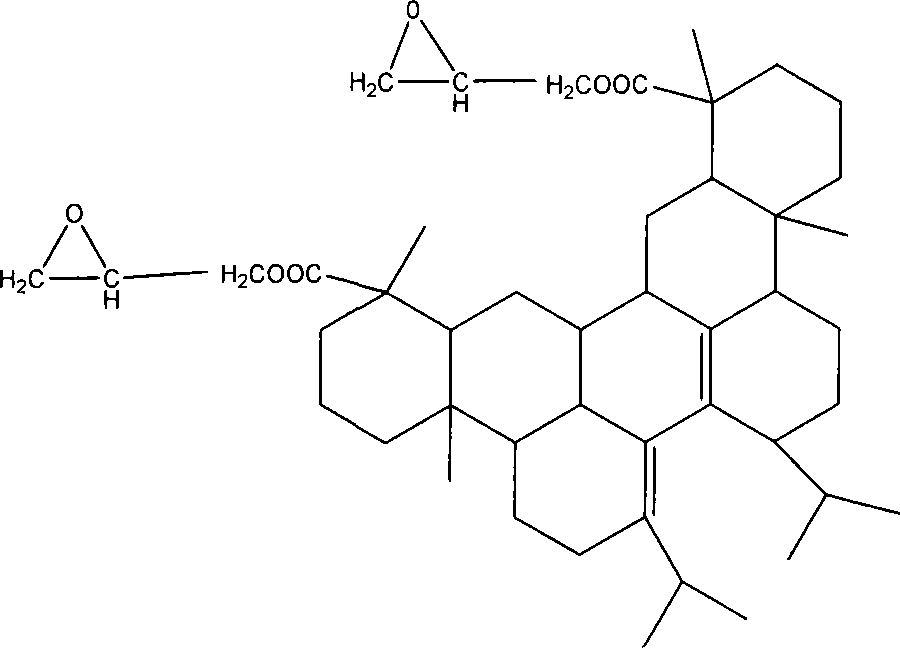

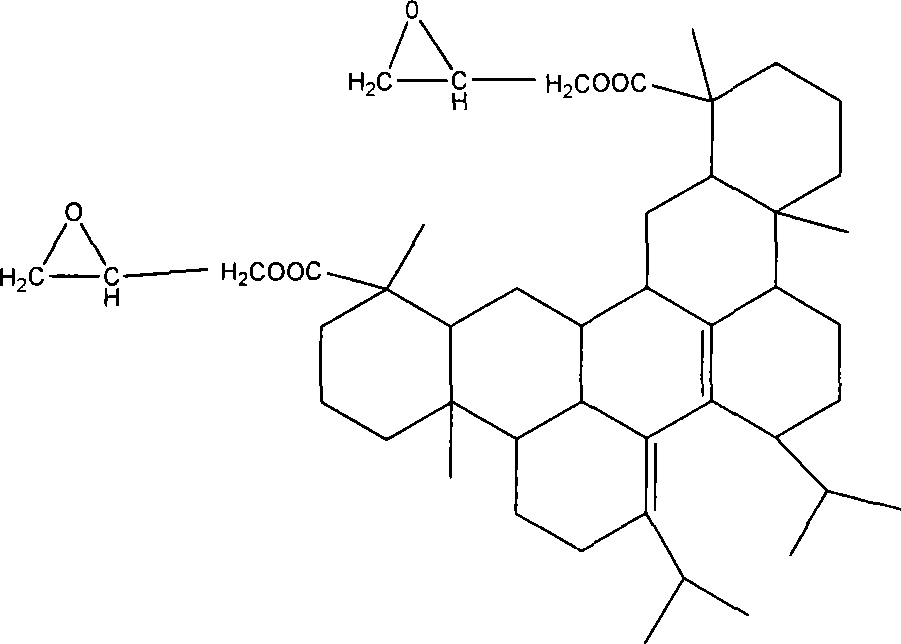

Polymerized resin 2-glycidyl ester epoxy resin and method for producing the same

The invention provides a polymerized colophony diglycidyl epoxy resin and a preparation method thereof. The epoxy resin comes from natural reproducible resource, molecules of the epoxy resin are provided with condensed ring rigid structure, and solidified products of the epoxy resin can be used for replacing present epoxy resin materials and the invention provided with excellent ultraviolet radiation resistance capacity. The preparation method is that the polymerized colophony and epichlorohydrin are stirred and heated and added with a catalyzer for reaction; after the reaction is finished, solvent and sodium hydroxide are added in sequence for reaction, then filtrated; the filtrate is washed until no halogen ion exists and then dried and decompressed to remove the solvent and obtain products. The invention further expands the using range of colophony and exploits a new source and variety of epoxy resin material. The polymerized colophony diglycidyl epoxy resin prepared by the invention has high epoxy value, comparatively fairer color and luster and better heat resistance. The molecule of the polymerized colophony diglycidyl epoxy resin also has a benzene ring structure; therefore, the solidified products thereof are provided with strong ultraviolet radiation resistance capacity, which is the characteristic of cycloaliphatic polymers.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

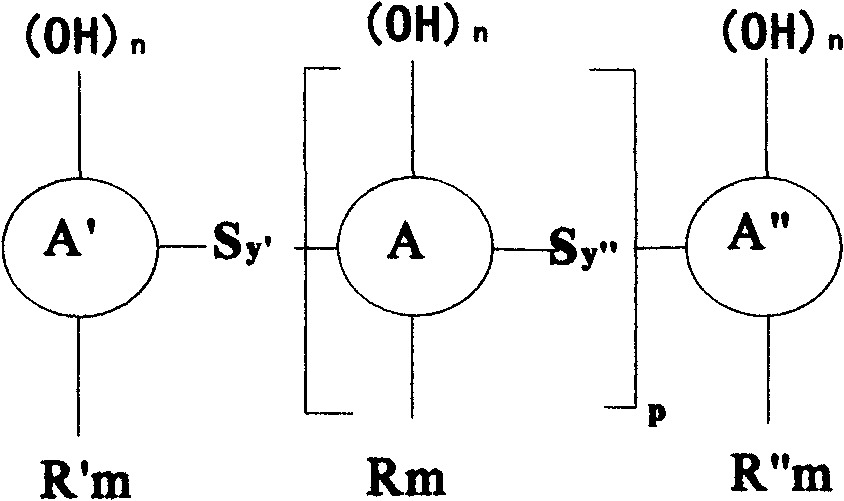

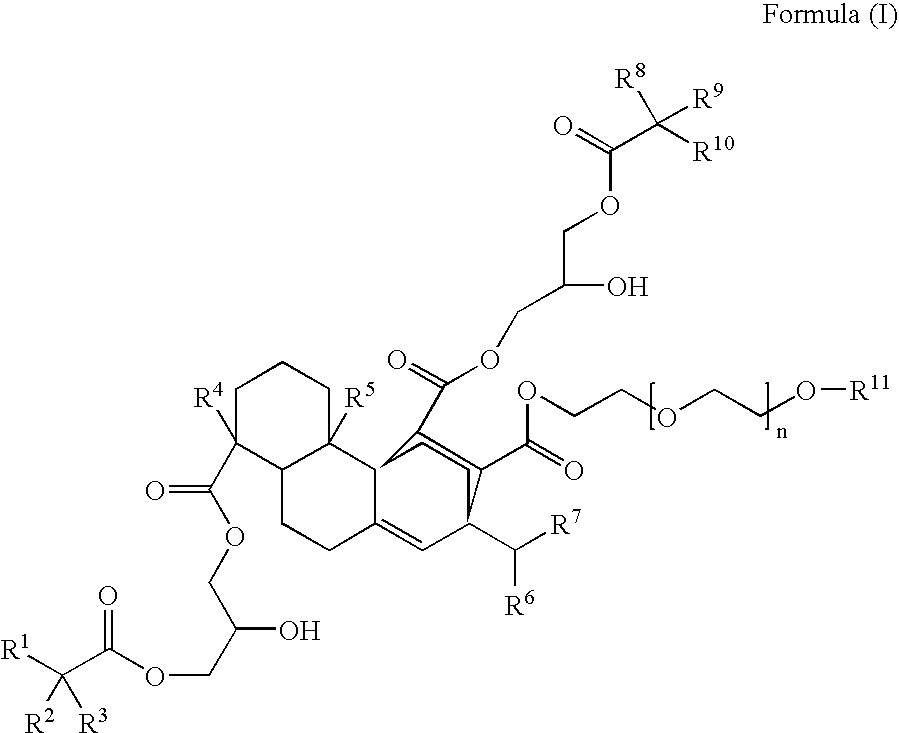

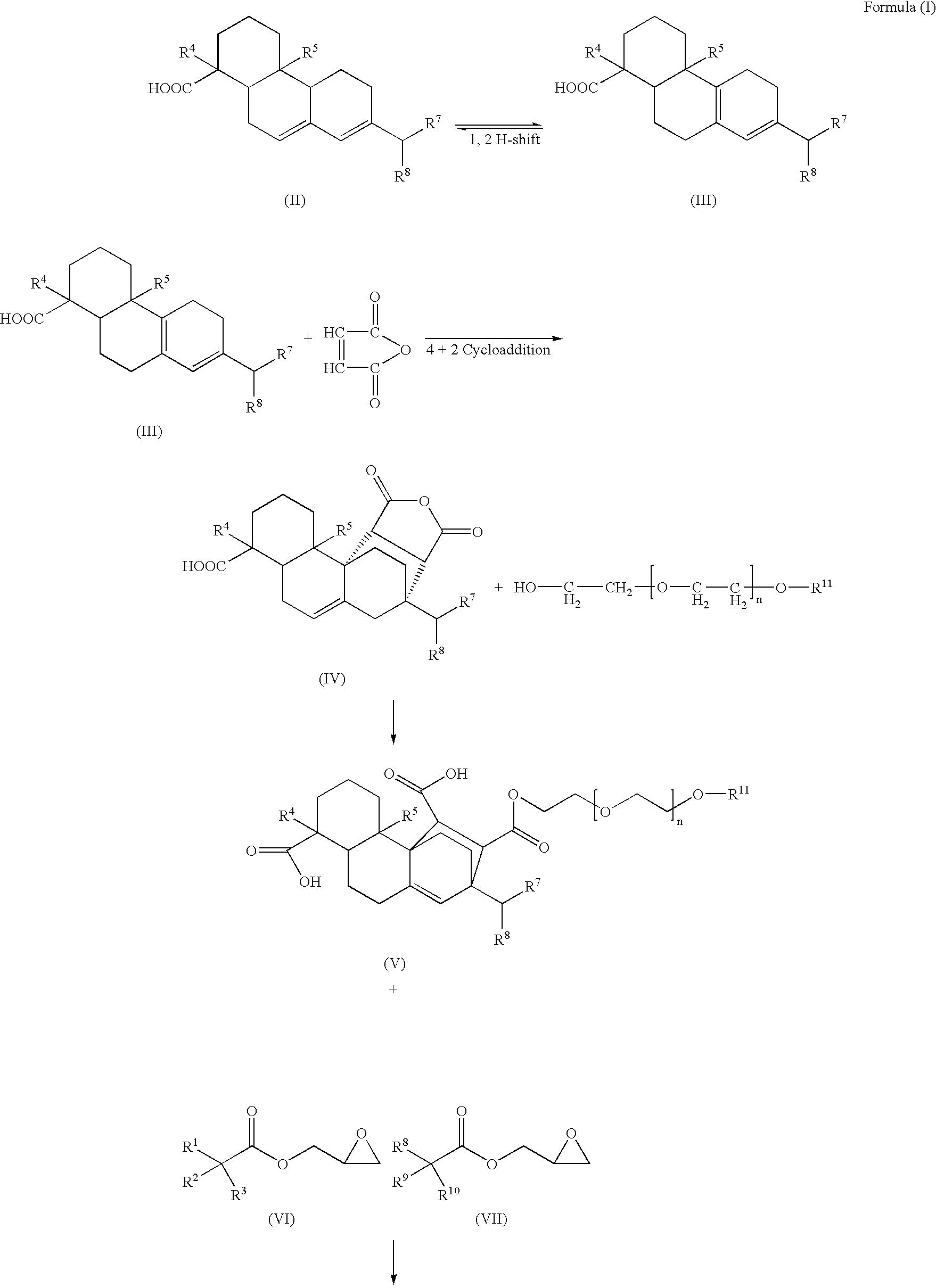

Compounds, rosins, and sizing compositions

The present invention relates to terpene derivative compounds and rosins and sizing compositions comprising such compounds. Compounds of Formula (I) are disclosed in addition to rosins and sizing compositions comprising compounds of Formula (I). Fiber glass strands comprising a plurality of glass fibers at least partially coated with sizing compositions comprising compounds of Formula (I) are also disclosed.

Owner:PPG IND OHIO INC

Method for synthesizing rosin or rosin derivatives allyl ester

InactiveCN101215445AImprove stabilityHigh purityNatural resin chemical modificationReaction temperaturePrinting ink

The invention discloses a method for synthesizing rosin or allyl ester which is rosin derivative, which comprises following steps: dissolving one of the rosin or the rosin derivative in aprotic solvent, adding acylate-chloridized agent, heating to enable reaction temperature to be in 0-85 DEG C, reacting for 0.5-5 hours, acylate-chlorizating carboxy group in the rosin or the rosin derivative, adding acid binding agent, polymerization inhibitor and allyl alcohol into the reaction product of the first step, reacting under 10-80 DEG C for 2-5 hours, removing the aprotic solvent, and obtaining the rosin or the rosin derivative, namely, allyl ester, wherein the using amount of the acid binding agent is 100-150% of the molar weight of carboxy group in the rosin or the rosin derivative and the using amount of the polymerization inhibitor is 1% of the allyl alcohol. Synthetical rosin or rosin derivative, namely, allyl ester, can generate radical polymerization and can be applied in the fields of coating material, cementing compound, printing ink, paper making and the like. The method has high technical efficiency and good product stability.

Owner:JIANGSU QIANGLIN BIO ENERGY

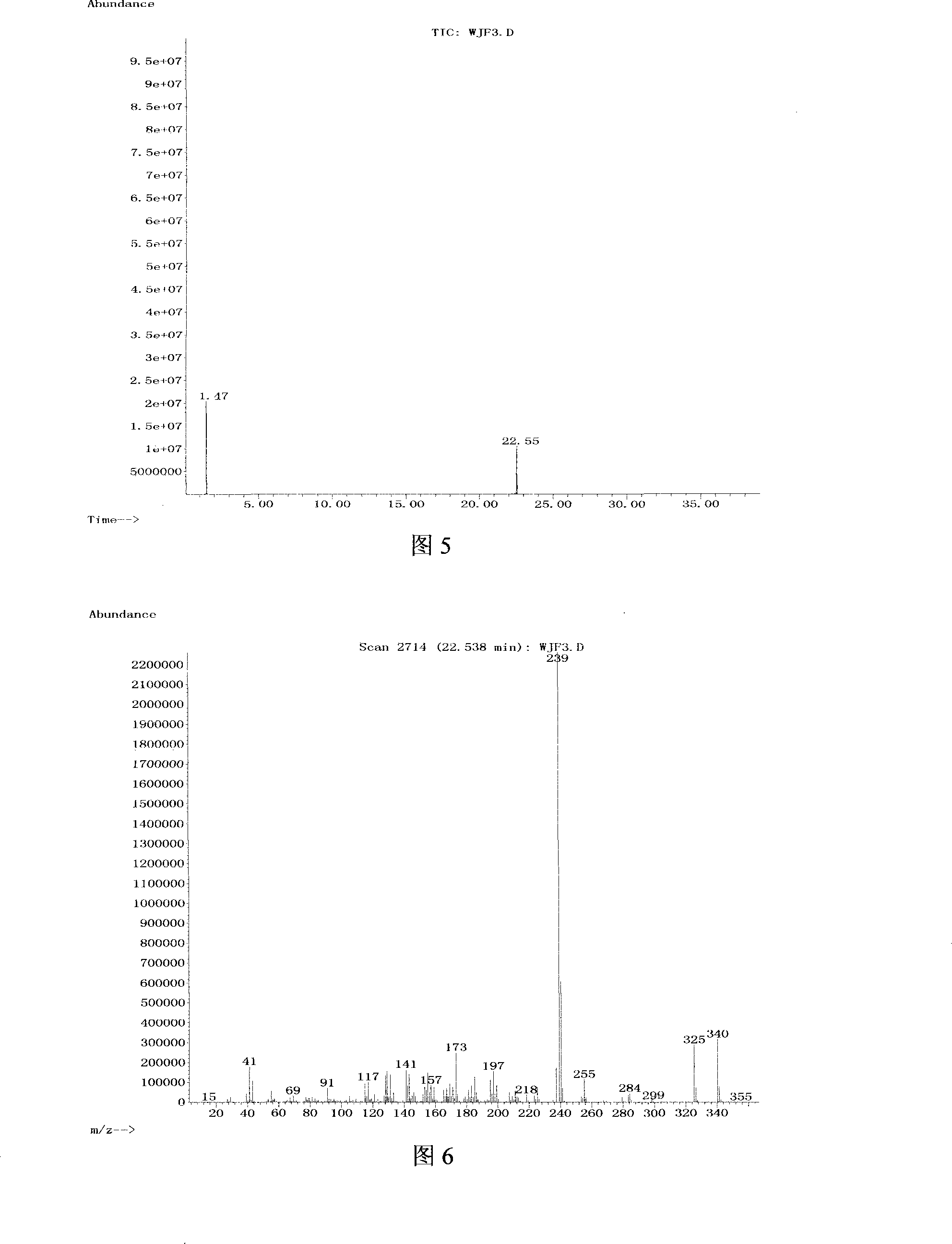

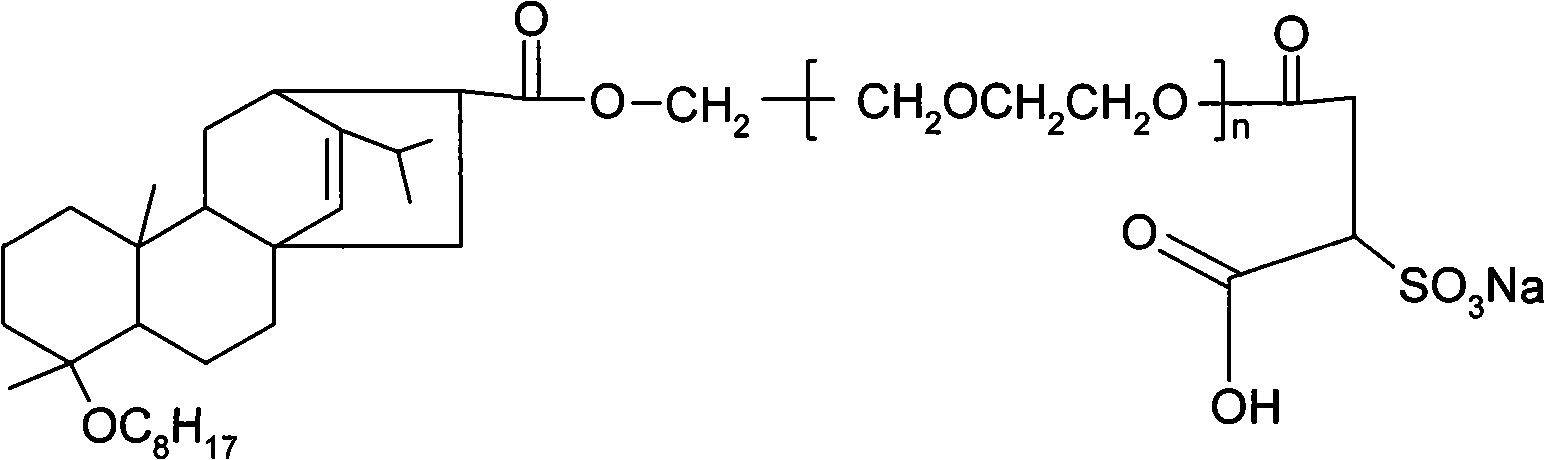

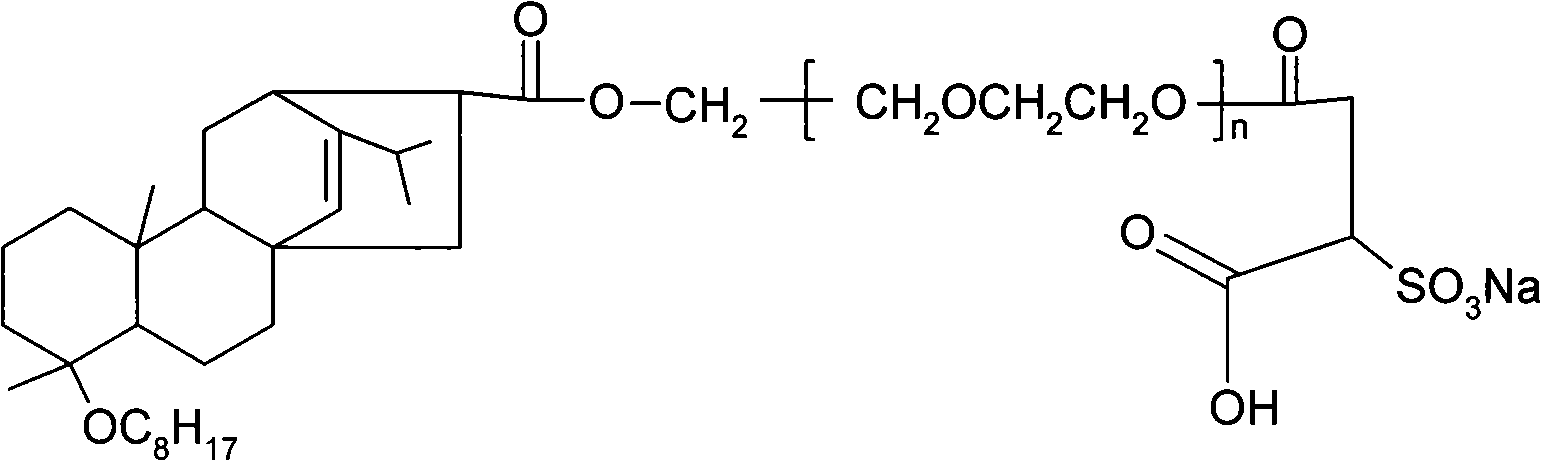

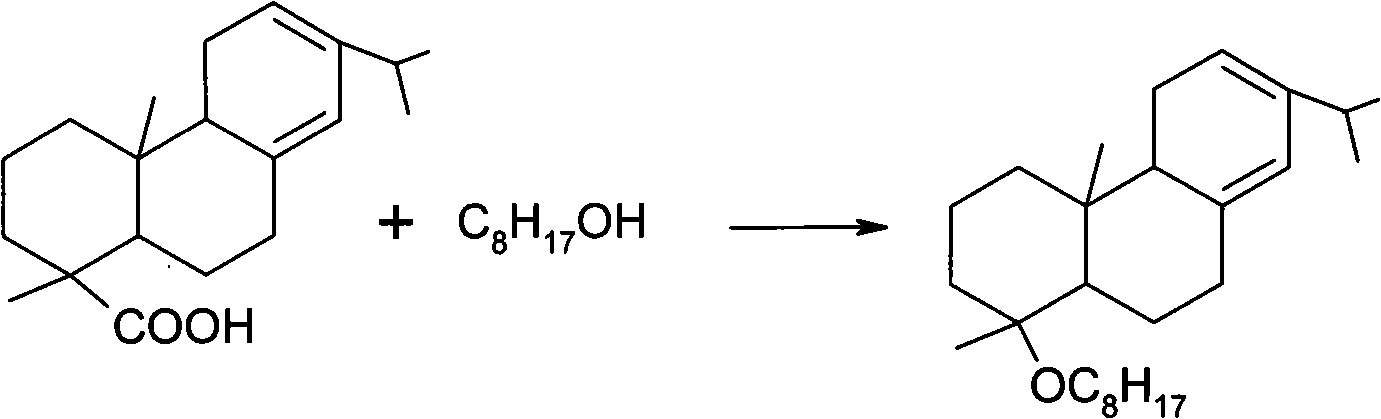

Gum rosin base emulsifier and preparation and use thereof

ActiveCN101298029AEasy to useGood compatibilityTransportation and packagingMixingPolyethylene glycolOctanol

The invention discloses a rosin-based emulsifier and a preparation method and application thereof. The rosin-based emulsifier having the following structural formula is prepared by the steps of reaction between rosin and octanol, addition reaction with acrylic acid, condensation reaction with polyethylene glycol, esterification with maleic anhydride and conjugated reaction with sodium bisulfite. The rosin-based emulsifier prepared by the invention has little effect on the performance of a rosin ester emulsion, can emulsify rosin ester directly without remixing with other surfactants and the rosin ester emulsion prepared has the advantages of small particle size, stable storage and good performance.

Owner:江西金安林产实业有限公司

Preparation method of rosin ester

ActiveCN103627326ALight colorGood weather resistanceNatural resin chemical modificationWeather resistanceAlcohol

The invention discloses a preparation method of a rosin ester, and comprises the following steps: (1) feeding the rosin ester in a reactor, warming to 170-180 DEG C under the protection of inert gas to melt the rosin; (2) adding unsaturated acid which is 0.5-8% of the rosin weight at 130-200 DEG C, and reacting for 0.5-2 hours; (3) adding a homemade composite reduced-color reagent which is 0.01-1% of the rosin weight and alcohol which is 11-18% of the rosin weight at 180-230 DEG C, reacting for 2-8 hours at 180-285 DEG C, adding saturated acid, and then reacting for 2 hours, removing water produced in reaction in a vacuum mode, cooling to 180-240 DEG C, adding a stabilizer which is 0.1-0.6% of the rosin weight to obtain the rosin ester. The preparation method disclosed by the invention is simple in process and low in cost, and the rosin ester with light color, good weather resistance, good yellowing resistance and good temperature tolerance can be prepared.

Owner:湖南科茂林化有限公司

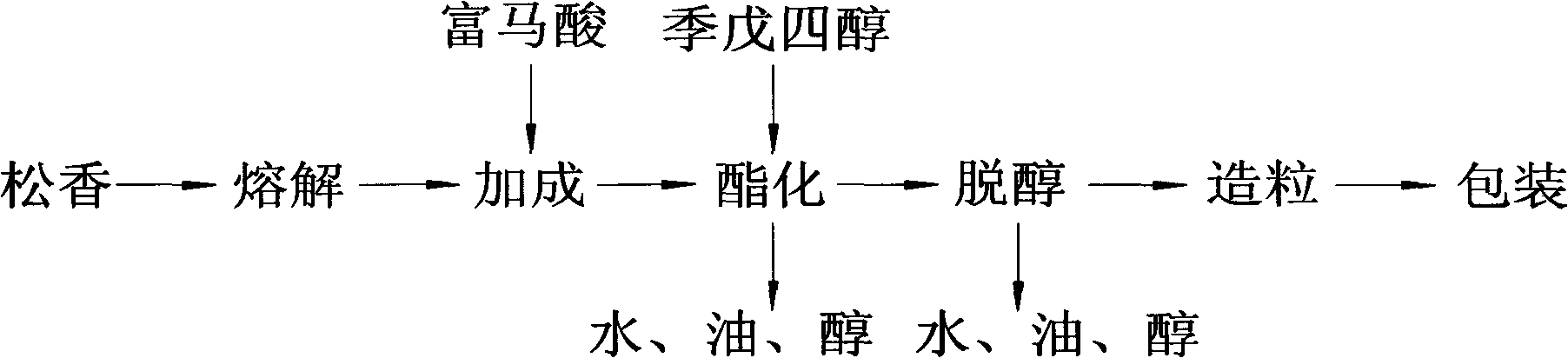

Preparation method of high-viscosity rosin resin

InactiveCN101649161AThe average molecular weight is largeMolecular structure with many branched chainsNatural resin chemical modificationPentaerythritolAdhesive

The invention discloses a preparation method of high-viscosity rosin resin which reaches higher viscosity under the condition of a lower softening point. The high-viscosity rosin resin comprises the following raw materials by weight percent: 85-86 percent of rosin, 2.0-3.0 percent of fumaric acid and 12-13 percent of pentaerythritol. The preparation method comprises the following steps: dissolvingthe rosin and then sucking the rosin into a reaction kettle; cooling to 190 DEG C to 200 DEG C; adding the fumaric acid; reacting in a heat preservation mode; when the softening point reaches 90 DEGC to 95 DEG C, adding the pentaerythritol; heating to 275 DEG C to 280 DEG C; continuing reaction; and when the acid value is smaller than or equal to 16 mg / g and the softening point reaches 110 DEG Cto 115 DEG C, performing dealcoholization and granulation to obtain a finished product. The rosin resin prepared by the preparation method can be conveniently applied to adhesives, coatings, printingink and polyamide resin products.

Owner:张家港市阳光化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com