Composite catalyst and its application in preparing light-colored rosin esters

A composite catalyst and catalyst technology, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve high cost, complex production process, deep color of rosin ester, etc. problem, achieve the effect of preventing oxidation and eliminating conjugated double bonds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

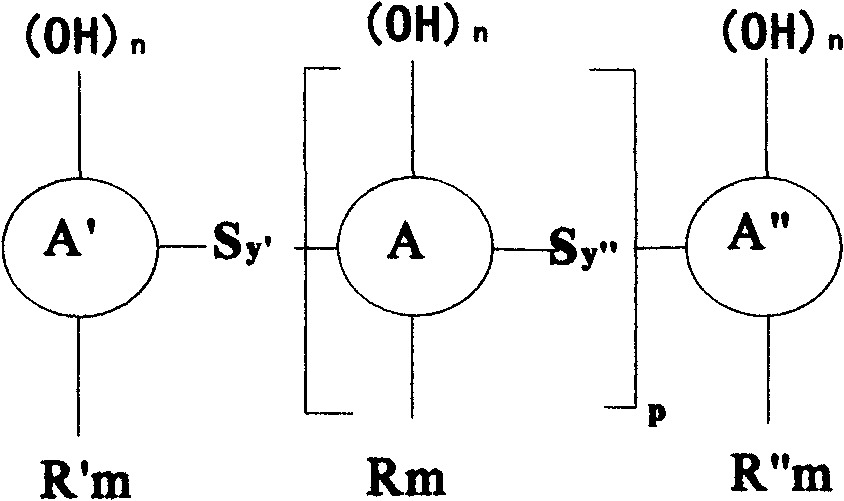

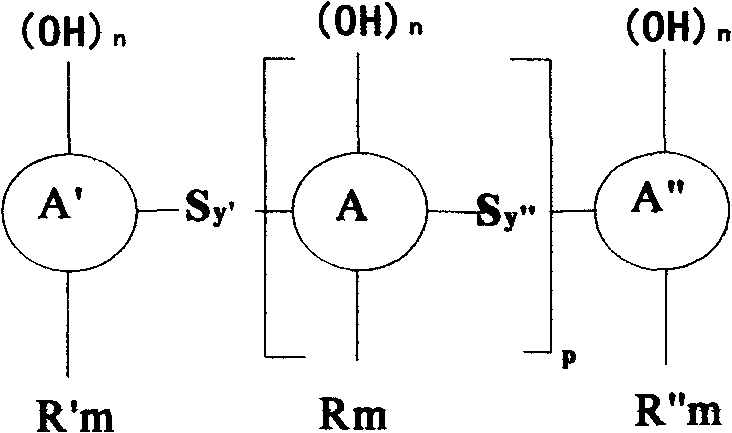

Image

Examples

Embodiment 1

[0034] Add 300 grams of rosin, 0.4 grams of hypophosphorous acid (50% aqueous solution), 0.6 grams of calcium hypophosphite, and 0.15 grams of sodium bisulfite in a reaction vessel equipped with inert gas inlet pipe, return pipe, water separator, thermometer and stirring paddle , 0.51 grams of 2246-S, 0.4 grams of magnesium oxide, 45 grams of 1,6-hexanediol. Slowly raise the temperature to 270°C within 2 hours and react for 10 hours, vacuumize for 45 minutes, naturally cool down to 220°C, add 0.45 grams of tetrakis (β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid) pentaerythritol Ester and 0.3 g of tris(2,4-di-tert-butylphenyl) phosphite, stirred for 10 minutes to release, at room temperature to obtain viscous liquid, acid value: 28.3 (mgKOH / g), color: solid Garner color 1+ .

Embodiment 2

[0036] Add 300 gram rosin, 0.4 gram hypophosphorous acid (50% aqueous solution), 0.6 gram calcium hypophosphite, 0.15 gram thiophene Sodium sulfate, 0.51 grams of 2246-S, 0.4 grams of magnesium oxide, heat and stir, slowly and evenly drop 36 grams of glycerin at 220 ° C, heat up to 270 ° C for 10 hours, vacuum for 60 minutes, naturally cool down to 220 ° C, add 0.45 g tetrakis(β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate) pentaerythritol ester and 0.3 g tris(2,4-di-tert-butylphenyl) phosphite, stirred for 10 minutes release. Acid value: 9.7 (mgKOH / g), softening point: 89°C, color: solid Ghana color 2.

Embodiment 3

[0038] Add 300 grams of rosin, 0.4 grams of hypophosphorous acid (50% aqueous solution), 0.6 grams of calcium hypophosphite, 0.15 grams of sodium bisulfite in the reaction vessel equipped with inert gas inlet pipe, return pipe, water separator, thermometer and stirring blade , 0.51 grams of 2246-S, 0.4 grams of magnesium oxide, and 37 grams of pentaerythritol. Slowly raise the temperature to 270°C within 2 hours and react for 10 hours, vacuumize for 60 minutes, naturally cool down to 220°C, add 0.45 grams of tetrakis (β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid) pentaerythritol Esters and 0.3 g of tris(2,4-di-tert-butylphenyl)phosphite were released after stirring for 10 minutes. Acid value: 17.6 (mgKOH / g); softening point: 103°C; color: solid Garner color 2-.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com