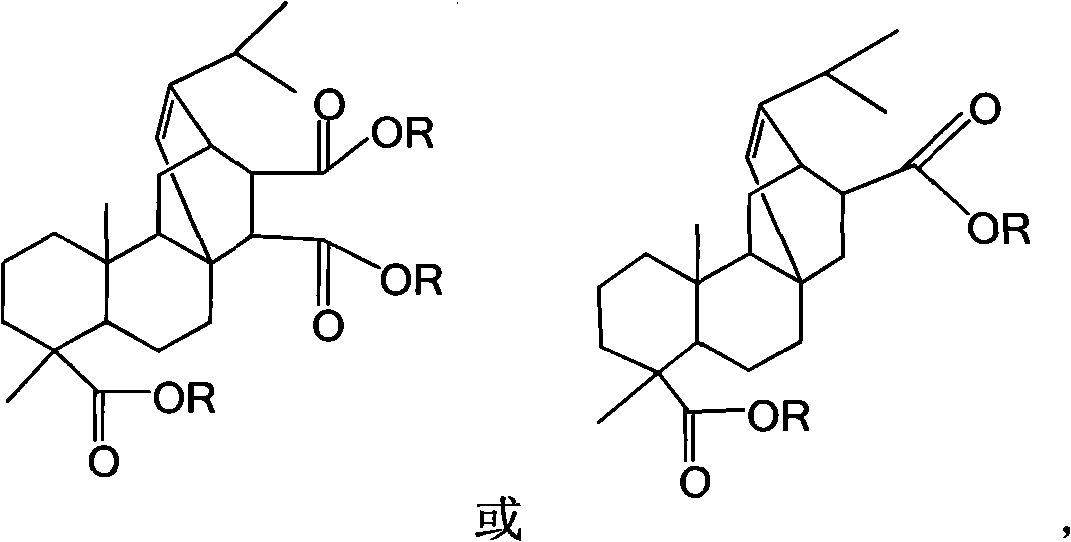

Rosin polyester polyol for flame-retardant rigid polyurethane foam plastic and preparation method and application thereof

A rigid polyurethane and foam technology, applied in the chemical modification of natural resins, etc., can solve the problems of corrosiveness, high price and instability of foaming equipment, and achieve good compressive strength, low cost, high thermal stability and resistance. flammable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The preparation formula and performance test results of flame-retardant rosin-based rigid polyurethane foam are shown in the attached table. Combination polyol and isocyanate are used as main raw materials. When foaming, it is formulated at a ratio of NCO / OH molar ratio of 1.2 to 2.5, and it is produced by conventional methods in combination with common additives. The specific operation is as follows: first stir and disperse the combined polyol evenly at high speed, then mix with isocyanate and stir at high speed for 20-30s at a speed of 3000-3500r / min, pour it into a mold, and cure for 48h.

[0055] The isocyanate can be selected from: toluene diisocyanate, xylene diisocyanate, polymethyl polyphenyl polyisocyanate (PAPI), preferably PAPI, the trade name is: Bayer's Desmodur N, 44V20L, 44V10L, etc.; Huntsman's Superace5005, 2085, etc.; DOW’s PAPI27; BASF’s MR200; Yantai Wanhua’s PM2010, etc. When foaming, the molar ratio of isocyanate and combined polyol is 1.2-2.5 accord...

Embodiment 1

[0058] Combine 40 parts of acrylpimaric acid, 10 parts of polyol (n 1 =1), 0.2 parts by mass of p-toluenesulfonic acid, add a 250mL three-necked flask, heat and increase, control the head temperature not to exceed 102 ℃, continue to increase the temperature to 220 ℃, and then continue to react at 220-240 ℃ for 5-9 hours, when the acid When the value is 10-20mg / g, reduce the temperature to 180℃, vacuum, gradually increase the vacuum degree to 95kPa, vacuumize for about 1-2h, then take a sample to measure the acid value, when the acid value is ≤3mg / g, the temperature is reduced to 100℃, Discharge to obtain flame-retardant rosin polyester polyol. Then, according to the preparation formula of the rigid polyurethane foam in Table 1, the combined polyol was obtained, stirred evenly at high speed, then mixed with isocyanate and stirred at high speed for 20-30s at a rotation speed of 3000-3500r / min, poured into a mold, and cured for 48h.

Embodiment 2

[0060] Combine 40 parts maleepimaric acid and 40 parts polyol (n 1 =3), 0.1 parts by mass of zinc oxide, add a 250mL three-necked flask, heat up, control the head temperature not to exceed 102 ℃, continue to increase the temperature to 220 ℃, and then continue to react at 220-240 ℃ for 5-9h, when the acid value is at At 10-20mg / g, reduce the temperature to 180℃, vacuum, gradually increase the vacuum degree to 95kPa, vacuum for about 1-2h, then take a sample to measure the acid value, when the acid value is less than or equal to 3mg / g, cool to 100℃, discharge The flame-retardant rosin polyester polyol is obtained. Then, according to the preparation formula of the rigid polyurethane foam in Table 1, the combined polyol was obtained, stirred evenly at high speed, then mixed with isocyanate and stirred at high speed for 20-30s at a rotation speed of 3000-3500r / min, poured into a mold, and cured for 48h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com