Preparation method of composite ZnO-mesoporous silica nanomaterial

A technology of mesoporous silica and nanomaterials, applied in the preparation of organic compounds, chemical instruments and methods, luminescent materials, etc., can solve the problems of poor uniformity of nano-zinc oxide, excessive particle size of ZnO, and unstable performance. Achieve the advantages of production cost, uniform ZnO, and stable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A preparation method of composite ZnO mesoporous silicon dioxide nanomaterial, comprising the following steps:

[0033] 1) Solvothermal in-situ substitution: mix silicon-based molecular sieve powder, ZnO precursor, dopant elements, and organic solvent evenly, put them in an autoclave, pass in protective gas, and react at 140-200°C for at least 12 hours; filter the reaction solution , washed and dried to obtain dry powder;

[0034] 2) Calcination and crystallization: heat up the dry powder to 550-700°C, and calcine at a constant temperature for 6-10 hours to obtain a composite ZnO mesoporous silica nanomaterial.

[0035] During solvothermal in-situ substitution, the reaction time can be adjusted according to the actual situation. In order to ensure that the substitution reaction is more complete, the reaction time can be extended appropriately. However, as known to those skilled in the art, if the reaction time is too long, the energy consumed Also more, for the conside...

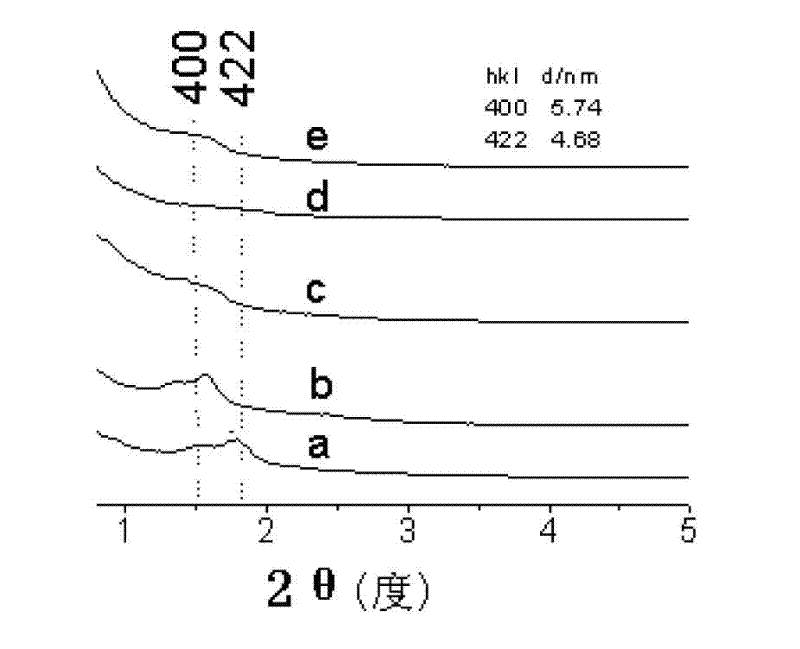

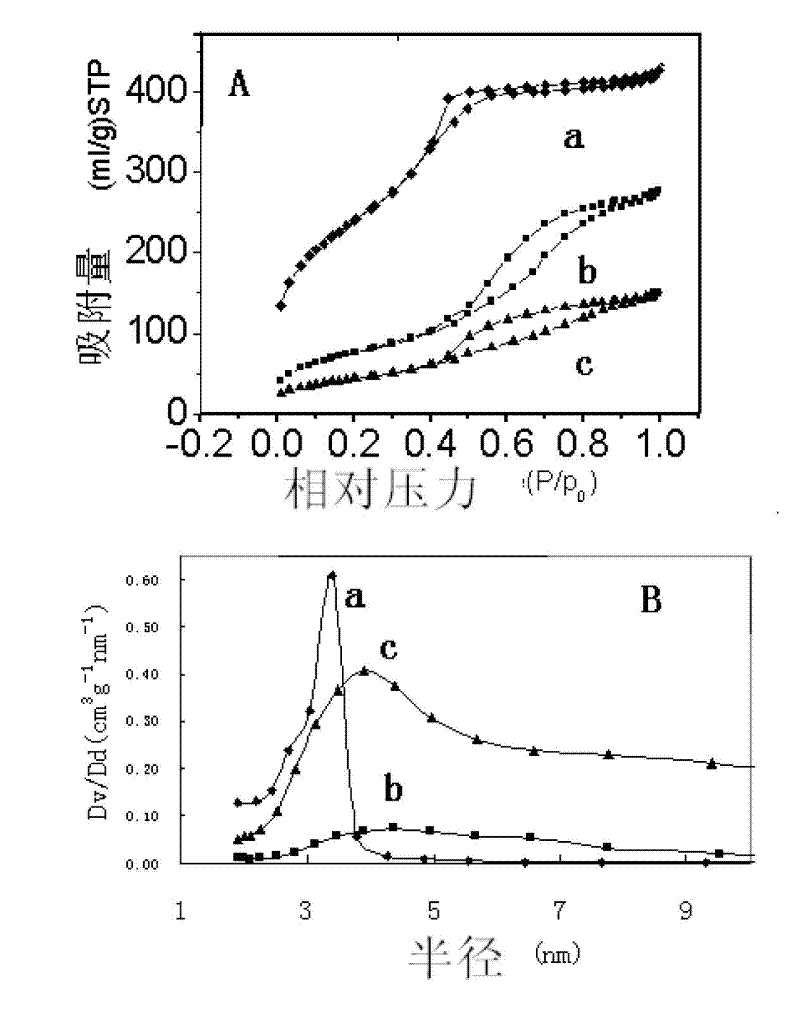

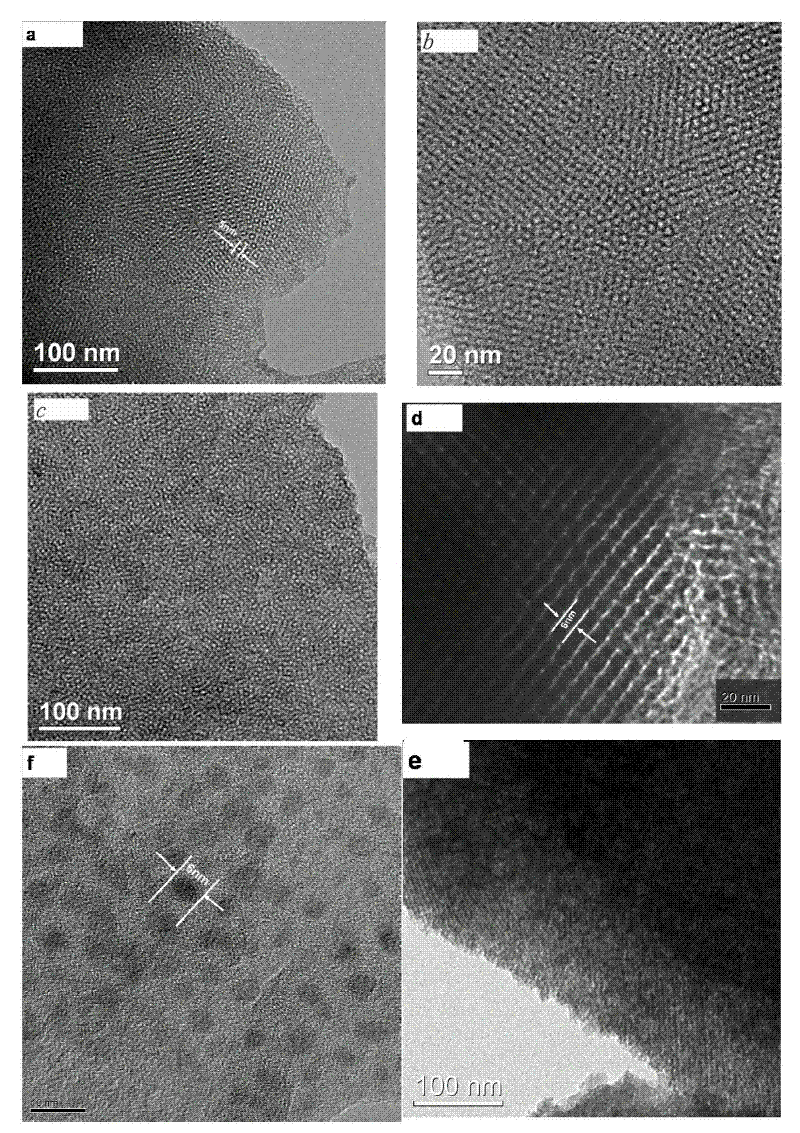

Embodiment 1

[0049] (1) Preparation of the original molecular sieve

[0050] Mix OP1-10 (nonylphenol polyoxyethylene (10) ether), TEOS (tetraethyl silicate), HCl (concentrated hydrochloric acid), H 2 O (water), TBAB (tetrabutylammonium bromide), and petroleum ether are mixed evenly in a molar ratio of 0.2:1:32:200:0.2:2.0, stirred and reacted at room temperature for 3 hours, and left for 24 hours; ultrasonic for 10 minutes Afterwards, it was suction filtered and dried at 90°C for 12 hours to obtain a white original molecular sieve powder.

[0051] (2) Calcination crystallization:

[0052] The temperature of the product obtained in step (1) was raised to 550°C and calcined at a constant temperature for 6 hours to obtain the final product as a white powder nano-mesoporous material SiO 2 .

Embodiment 2

[0054] (1) Preparation of the original molecular sieve

[0055] Mix OP-10 (nonylphenol polyoxyethylene (10) ether), TEOS (tetraethyl silicate), HCl (concentrated hydrochloric acid), H 2 O (water), TBAB (tetrabutylammonium bromide), and petroleum ether are mixed evenly in a molar ratio of 0.4:1:32:200:0.2:2.0, stirred and reacted at room temperature for 3 hours, and left standing for 24 hours; 10 minutes of ultrasound After that, it was suction filtered and dried at 90° C. for 12 hours to obtain a white original molecular sieve powder.

[0056] (2) Solvothermal in situ substitution

[0057] Take 0.5g of the white original molecular sieve powder obtained in step (1) and place it in a 50ml hydrothermal reaction kettle, add 0.1g of zinc acetate doped with 1% aluminum (molar percentage), 10ml of acetone and 10ml of absolute ethanol, and pass nitrogen gas for 3 minutes, React at a constant temperature of 140°C for 24 hours.

[0058] (3) filter and dry

[0059] Suction filter the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com