Acrylic acid or methylpropenoic acid rosin derivative ester synthesis method

A technology of methacrylic acid rosin and rosin derivatives, which is applied in the field of synthesis of rosin derivatives to achieve the effect of maintaining stability, not easy to add reaction, and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The synthesis of acrylic acid or rosin derivative ester of methacrylic acid comprises the following steps,

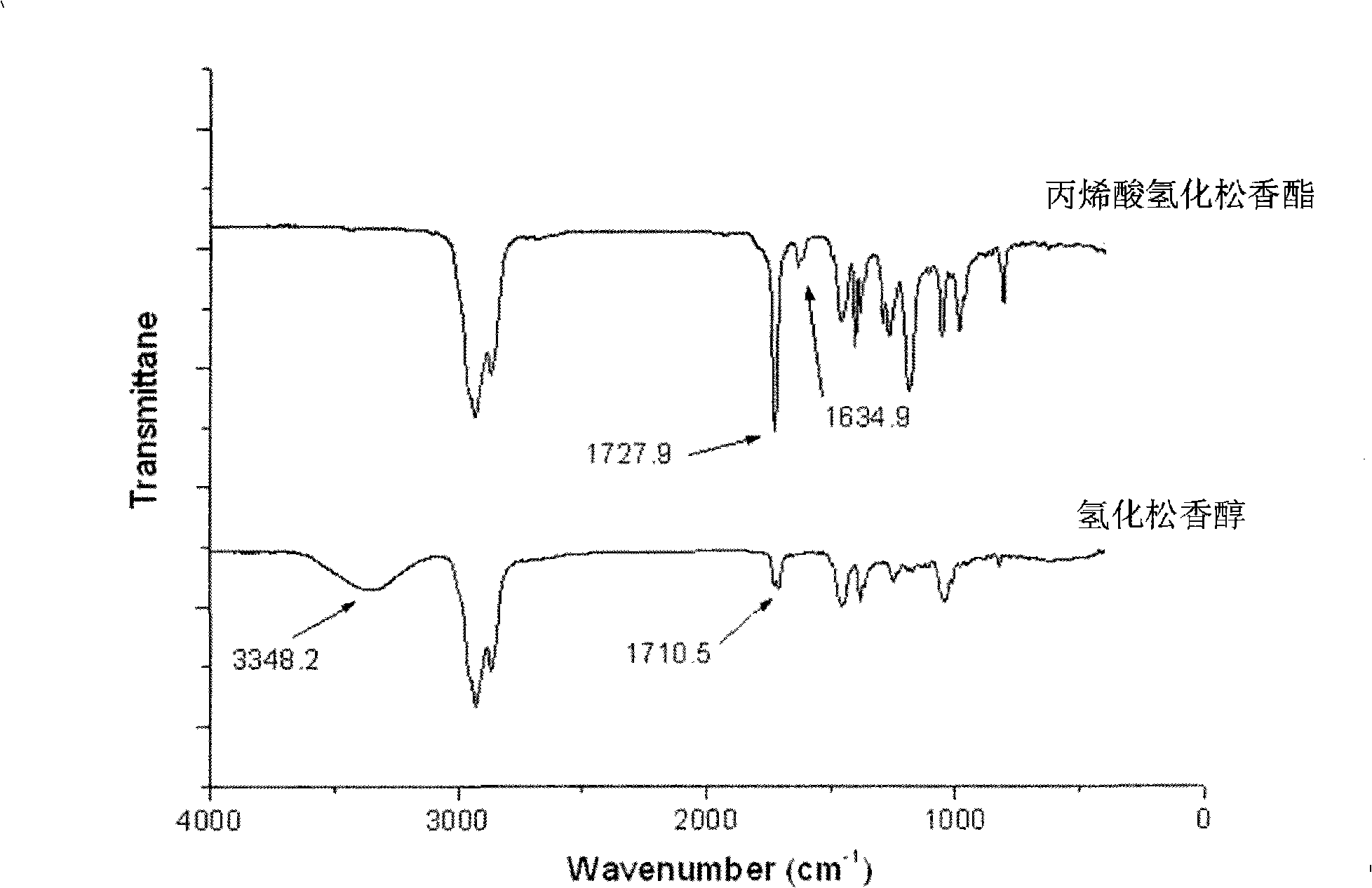

[0051] One of the rosin derivatives containing hydroxyl functional groups, the hydroxyl value is 80-150mgKOH / g, the acid-binding agent and the polymerization inhibitor are dissolved in an aprotic solvent, and the aprotic solvent used is benzene, dichloromethane, One of toluene and tetrahydrofuran, and the water content of the solvent is less than 0.02%, add methacryloyl chloride or acryloyl chloride, heat to make the reaction temperature 0-85°C, for example, the temperature can be selected as: 5°C, 10°C, 15°C ℃, 20℃, 25℃, 30℃, 35℃, 40℃, 45℃, 50℃, 52℃, 55℃, 60℃, 65℃, 70℃, 75℃, 80℃, react for 0.5-10 hours, The time can be selected as: 0.5 hours, 1 hour, 1.5 hours, 2 hours, 2.5 hours, 3 hours, 3.5 hours, 4 hours, 4.5 hours, 4.8 hours, so that the hydroxyl groups in the rosin derivatives are esterified, which can be based on infrared spectroscopy In the process, the...

Embodiment 2

[0054] Synthesis of Hydrogenated Rosin Acrylate:

[0055] Hydrogenated abietyl alcohol (purchased from Eastman Chemical Ltd): Its main components are dehydroabietyl alcohol, dihydroabietyl alcohol and tetrahydroabietyl alcohol, and some unreacted esters.

[0056]

[0057] Dehydroabietyl Alcohol Dihydroabietyl Alcohol Tetrahydroabietyl Alcohol

[0058] The synthetic method of hydrogenated rosin acrylate:

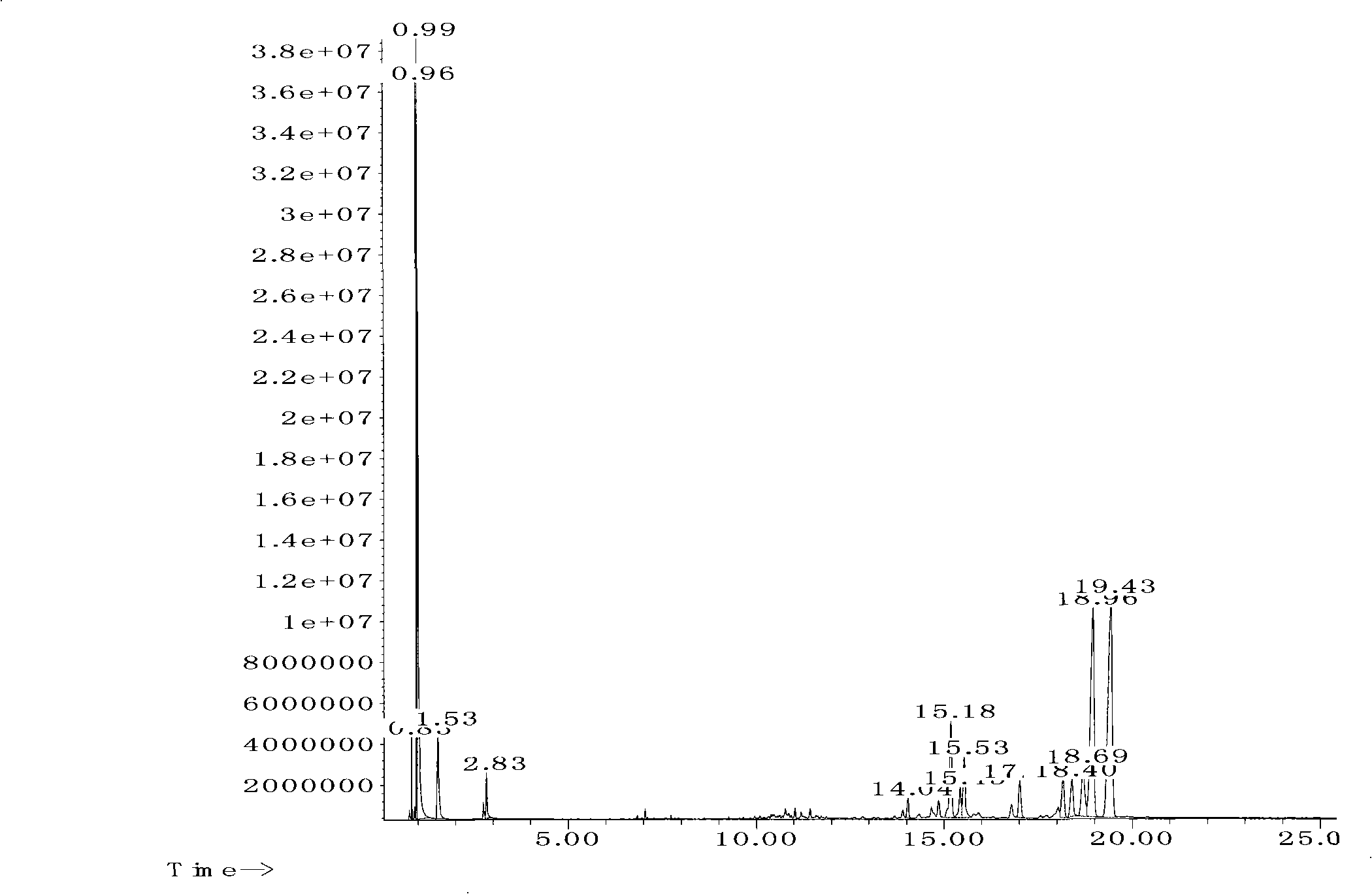

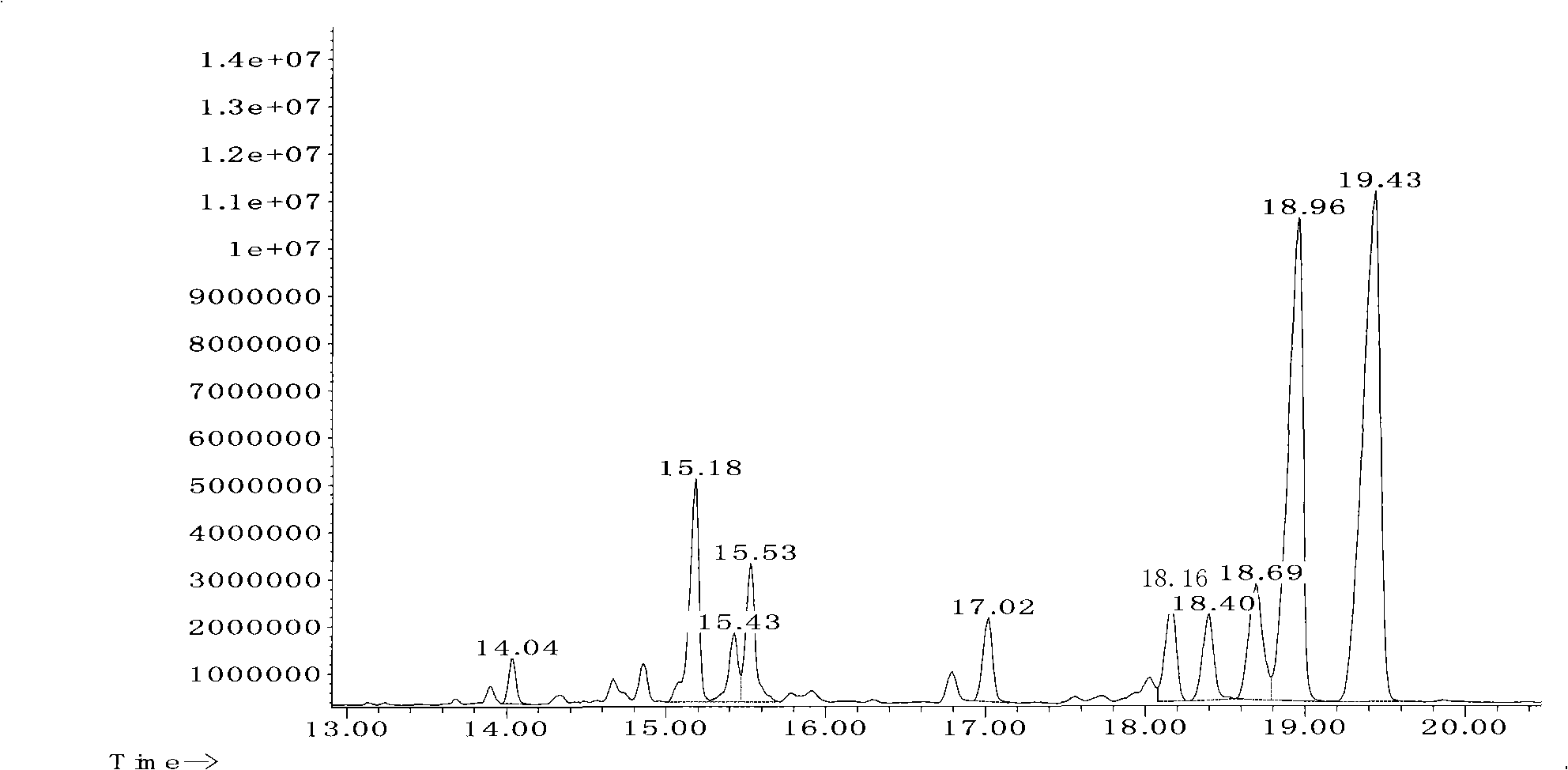

[0059] Dissolve 10g of hydrogenated abietyl alcohol (hydroxyl value, 158mgKOH / g), 3.12g (0.03mol) of acid-binding agent triethylamine and 0.0027g of polymerization inhibitor p-hydroxyanisole in 20g of aprotic solvent tetrahydrofuran, and add acryloyl chloride 2.79g (0.03mol), the reaction is carried out in a four-necked flask equipped with a stirrer, a reflux tube, and a thermometer, heated so that the reaction temperature is at 40°C, and the stirring speed is 150rpm, reacted for 5 hours, filtered out the precipitate, and the resulting filtrate was passed through The sol...

Embodiment 3

[0066] Synthesis of Hydrogenated Rosin Methacrylate

[0067] The synthesis of hydrogenated rosin methacrylate comprises the following steps:

[0068] Hydrogenated abietyl alcohol 10g (hydroxyl value, 158mgKOH / g), acid-binding agent 4-N, N-dimethylaminopyridine 3.67g (0.03mol) and polymerization inhibitor hydroquinone 0.0027g were dissolved in 20g aprotic Add 3.14g (0.03mol) of methacrylic acid chloride to the solvent dichloromethane, heat to make the reaction temperature at 40°C, react for 5 hours, filter off the precipitate, and remove the solvent from the obtained filtrate by vacuum extraction to obtain methacrylic acid hydrogenated rosin Esters (hydroxyl value, 18 mgKOH / g).

[0069]

[0070] Dehydroabietyl Methacrylate Dihydroabietyl Methacrylate Tetrahydroabietyl Methacrylate

[0071] Infrared, gas and mass analysis of products such as Figure 8-12 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com