Patents

Literature

73 results about "Pimaric acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

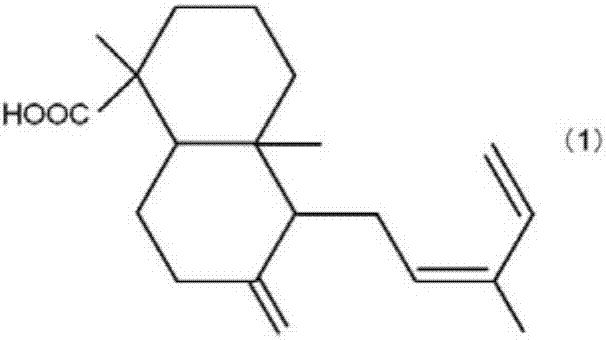

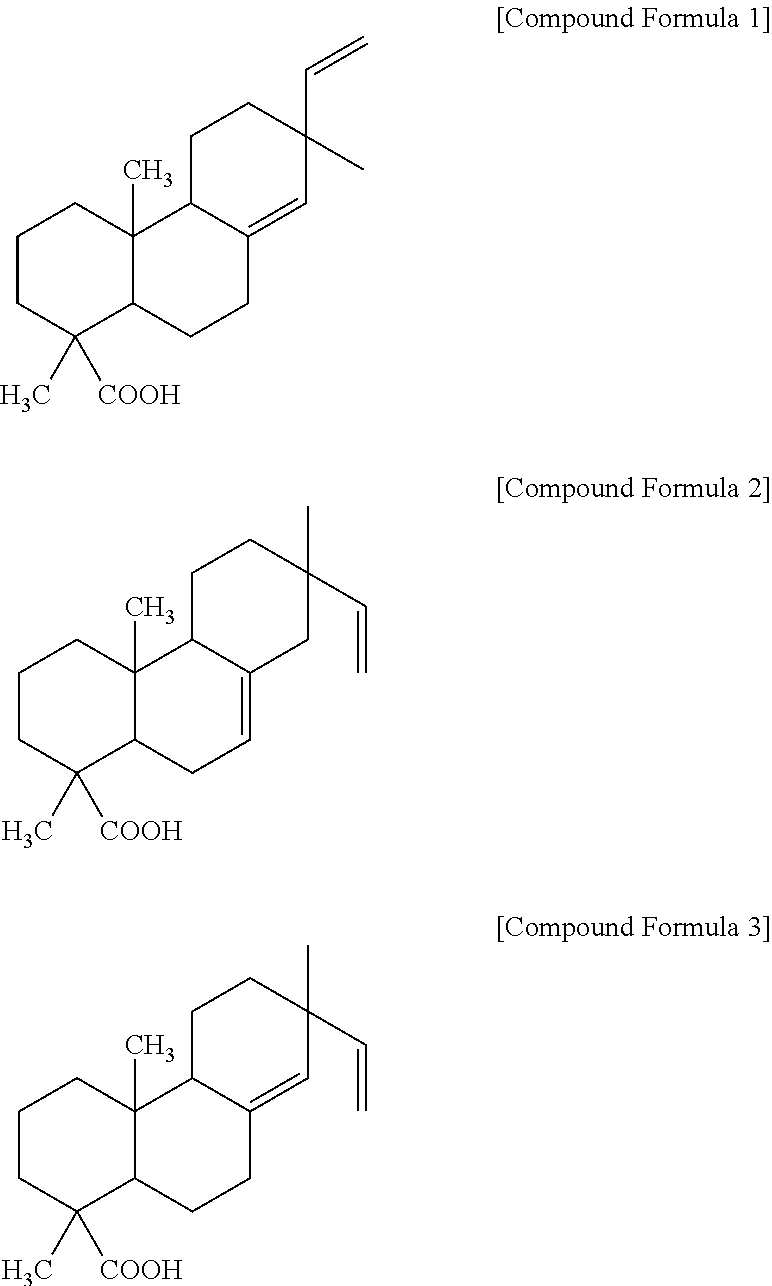

Pimaric acid is a carboxylic acid from the resin acid group, often found in the oleoresins of pine trees. It can be prepared by dehydration of abietic acid, which it usually accompanies in mixtures like rosin. It is soluble in alcohols, acetone, and ethers.

Pimaric type resin acid product, and method of preparing the same

InactiveUS20140148572A1Increase medium temperatureLengthening reaction durationNatural resin processFunctional group formation/introductionBottleSolvent

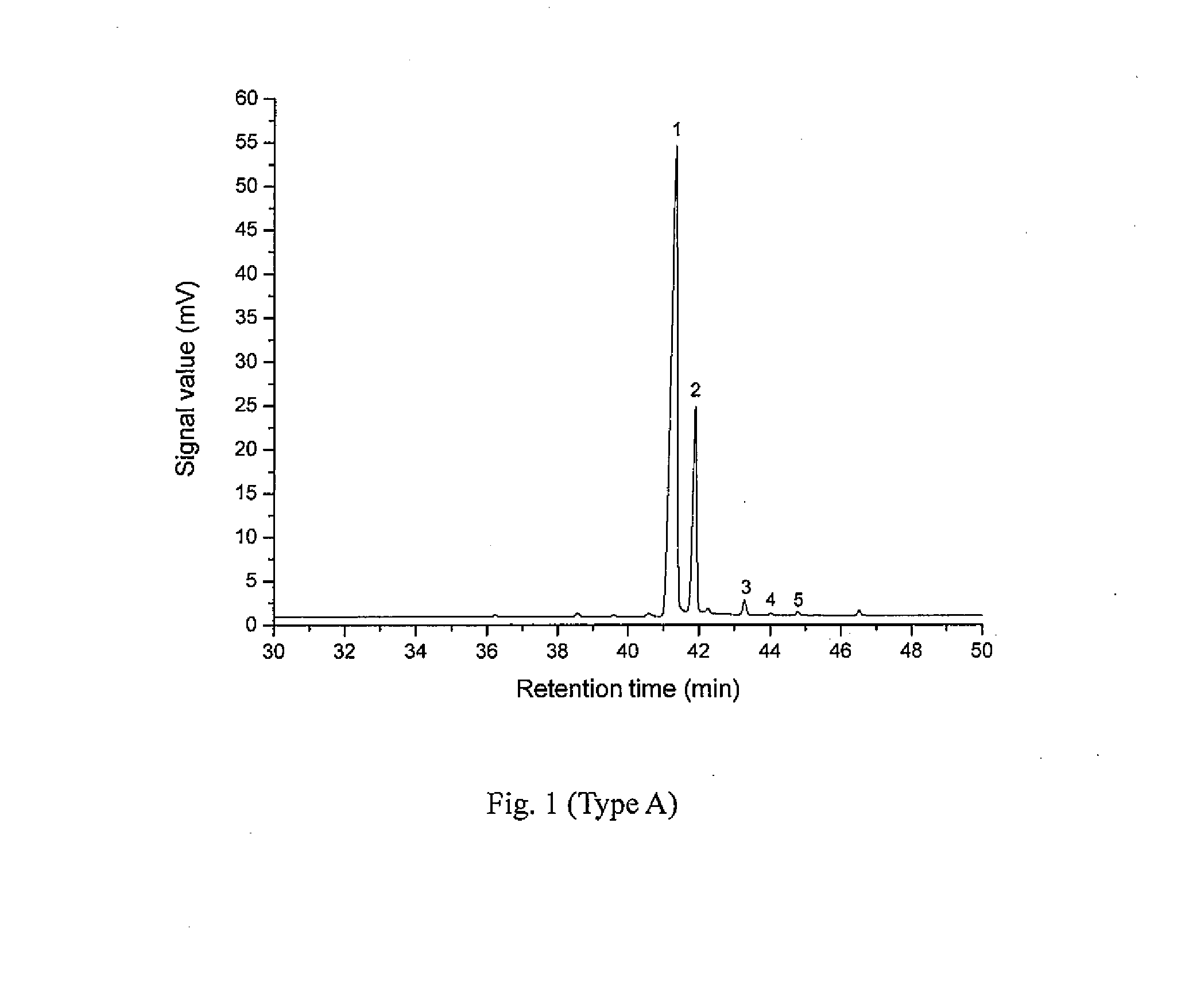

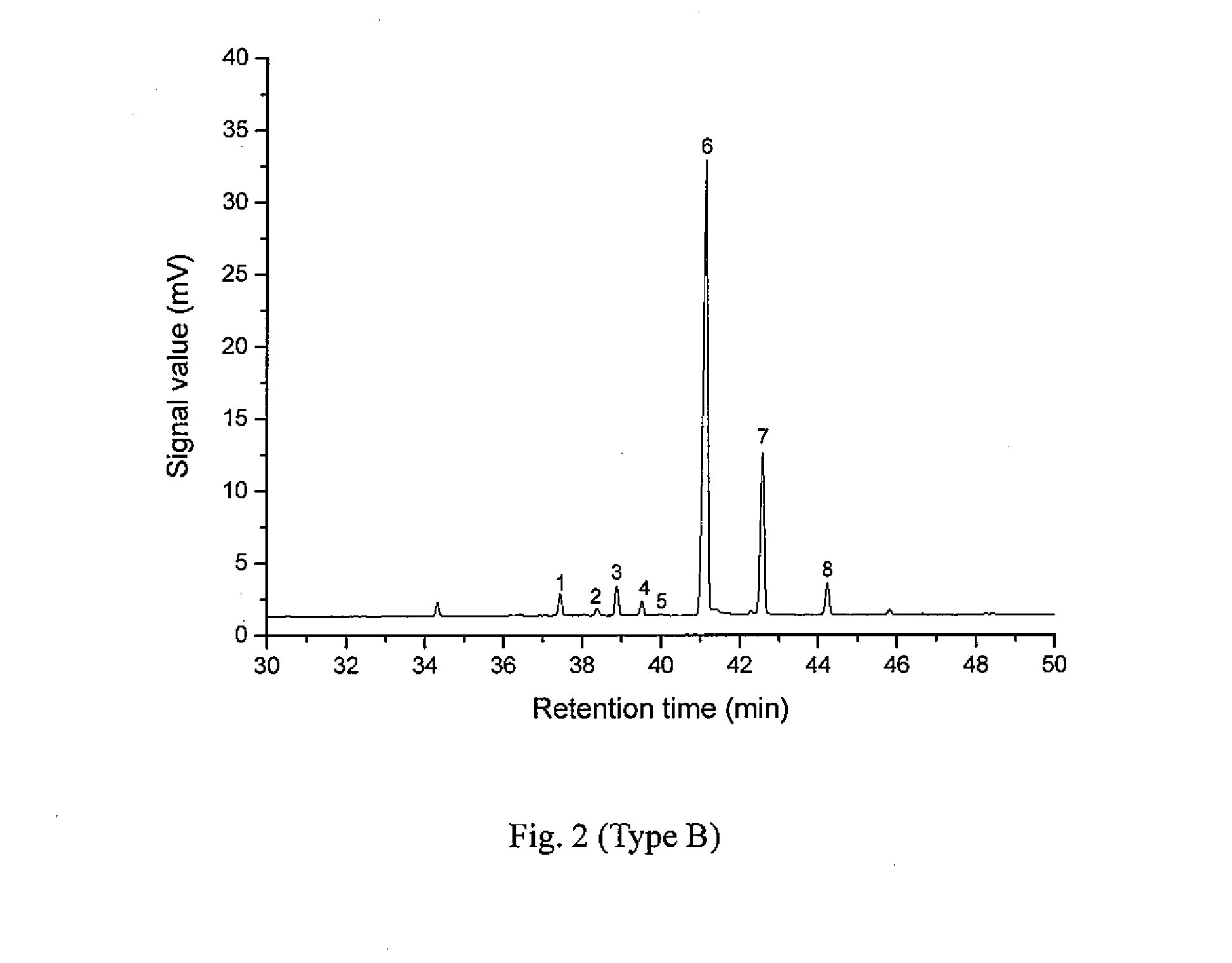

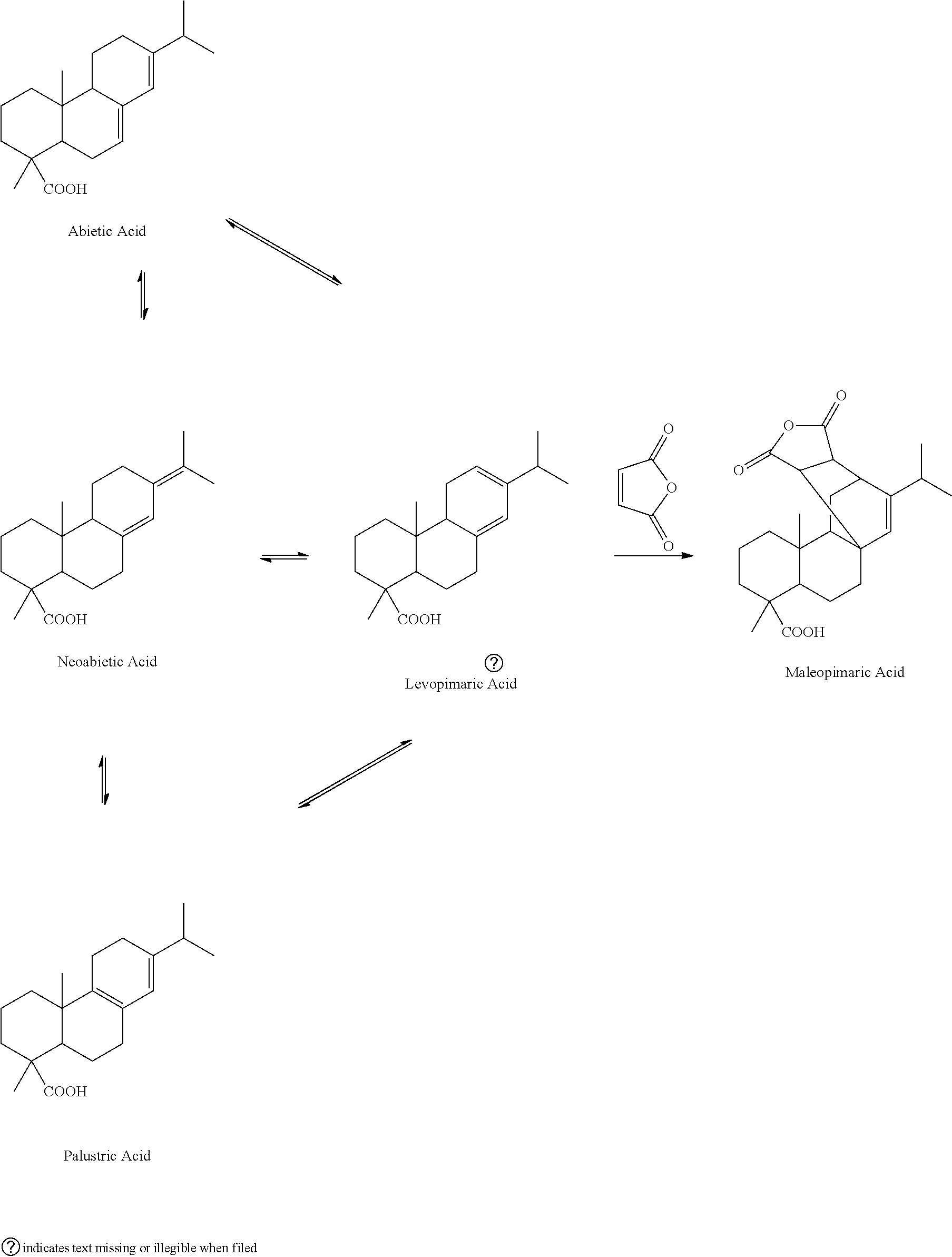

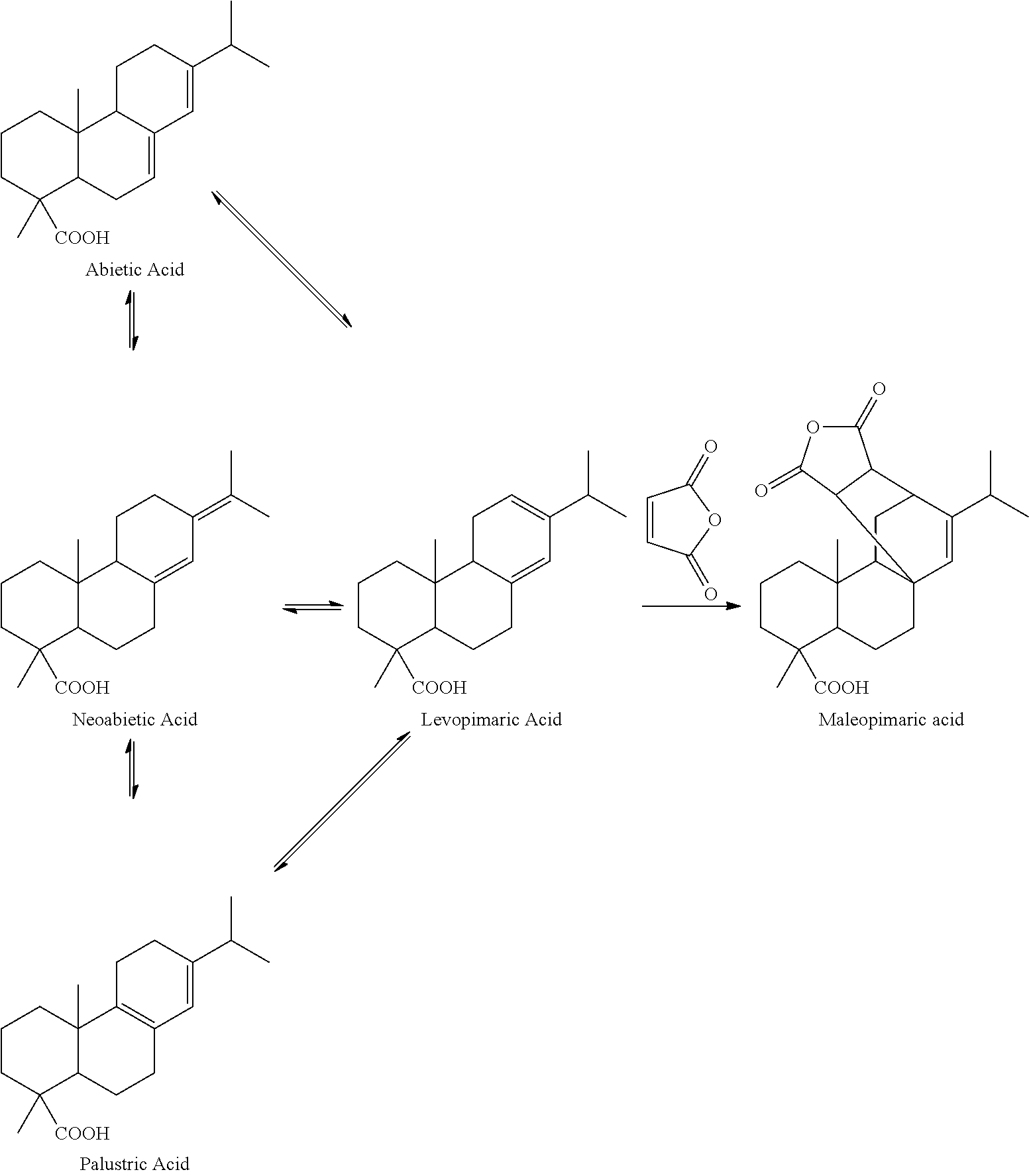

A method for preparing pimaric acid type resin acids includes: step (1) adding refined resin acid, turpentine, or rosin along with maleic anhydride at a mass ratio of 1:0.3-1.5 into a reaction bottle, dissolving the ingredients into a C1-C10 lower fatty acid solvent, the mass ratio of the C1-C10 low fatty acid to refined resin acid is 0.05-30:1, then carrying out additional reaction by heating directly or with assistance of a microwave, subsequently cooling, crystallizing, filtering, and washing; and step (2) combining the filtrates collected in step (1), stripping the solvent by vacuum distillation to obtain pimaric acid type resin acid coarse product, dissolving the resulting coarse product in NaOH aqueous solution to prepare aqueous solution of pimaric acid type resin acid salt, adjusting the pH to 6-14 with a mineral acid or an organic acid, and either directly purifying or acidifying followed by purifying to obtain the final product.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Antifouling coating composition, antifouling coating film formed using the composition, coated article having the coating film on the surface, and antifouling treatment method to form the coating film

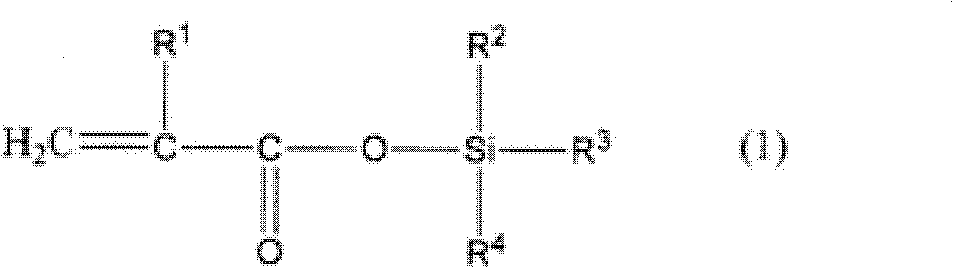

ActiveUS20110172325A1Prevents and inhibits attachmentImprove waterproof performanceFireproof paintsAntifouling/underwater paintsMethacrylateMeth-

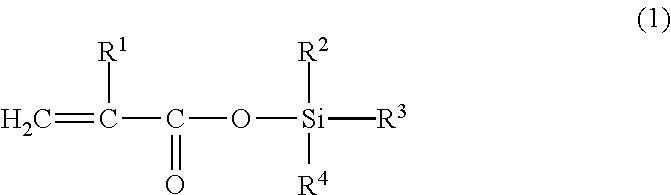

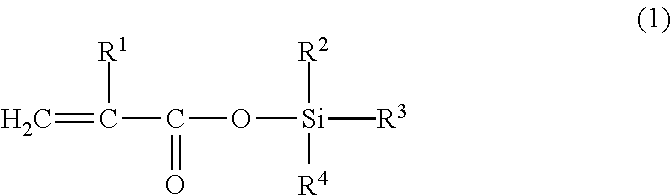

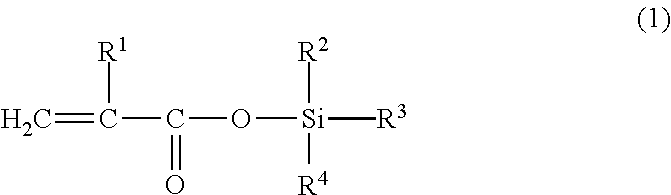

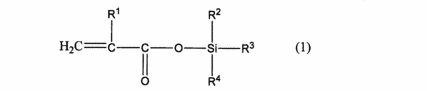

An object of the present invention is to provide a composition for forming an environment friendly antifouling coating film that is unlikely to cause a hairline crack and like coating film defects even when immersed in seawater for a long time, and that prevents or inhibits attachment of slime. An antifouling coating composition of the invention comprises: (A) a triorganosilyl ester-containing copolymer obtained by a mixture of (a) a triorganosilyl (meth)acrylate monomer represented by a general formula (1): R1 is a hydrogen atom or a methyl, and R2, R3, and R4 are equal or different each other, and each represent an alkyl group having 3 to 6 carbons and branched on α-position or a phenyl group, and (b) an ethylenically unsaturated monomer copolymerizable with the triorganosilyl (meth)acrylate monomer, (B) a modified rosin salt which is a salt of a modified rosin and zinc and / or copper, the modified rosin containing, in an amount of 80 weight % or more, two or more members selected from the group consisting of dihydroabietic acid, tetrahydroabietic acid, dehydroabietic acid, pimaric acid, isopimaric acid, and dihydropimaric acid.

Owner:NITTO KASEI CO LTD

Polishing composition, polishing method, and method for forming copper wiring for semiconductor integrated circuit

InactiveUS20080261400A1Little dishingLittle erosionSemiconductor/solid-state device manufacturingSurface treatment compositionsResin acidCarboxylic acid

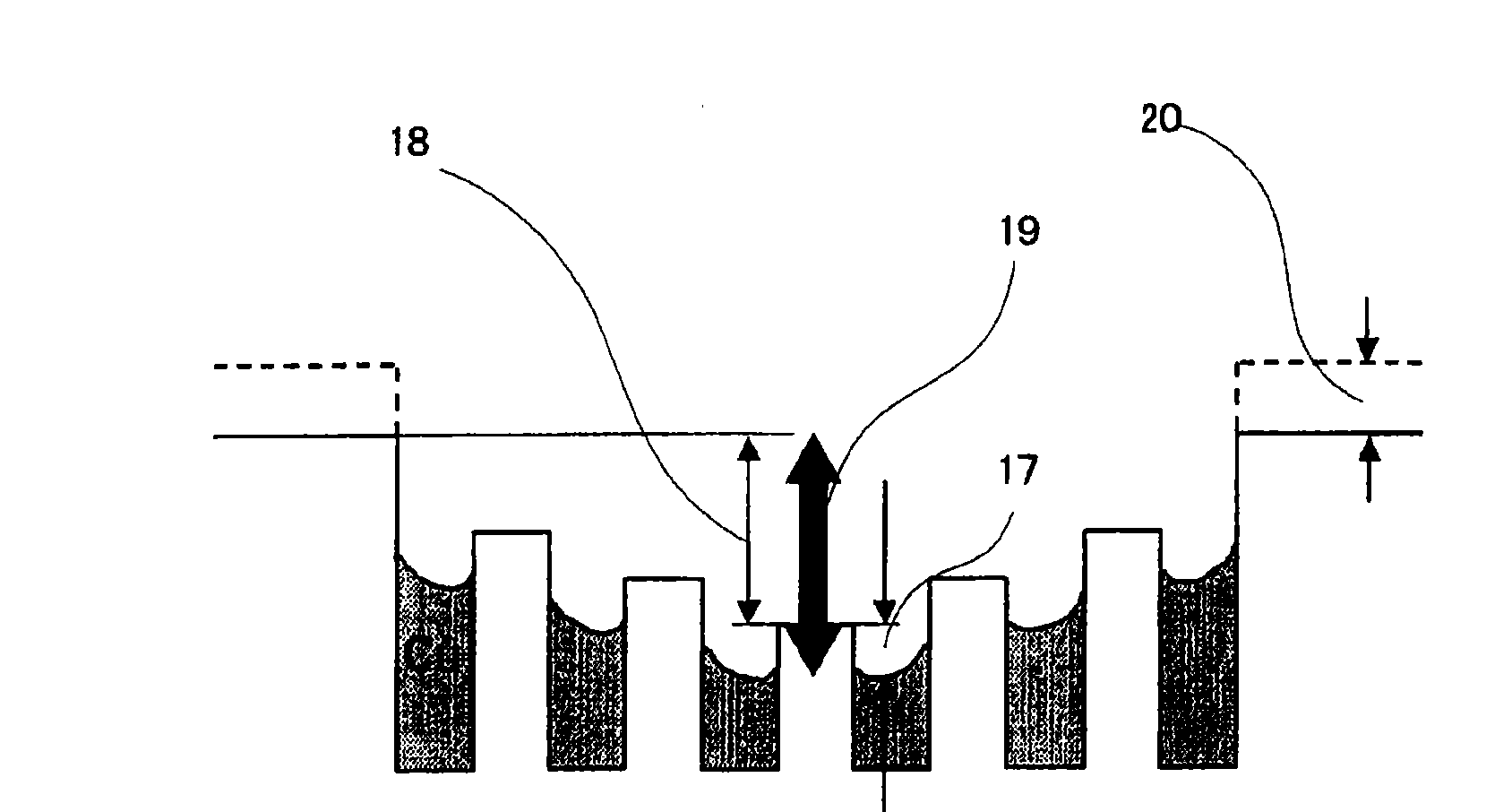

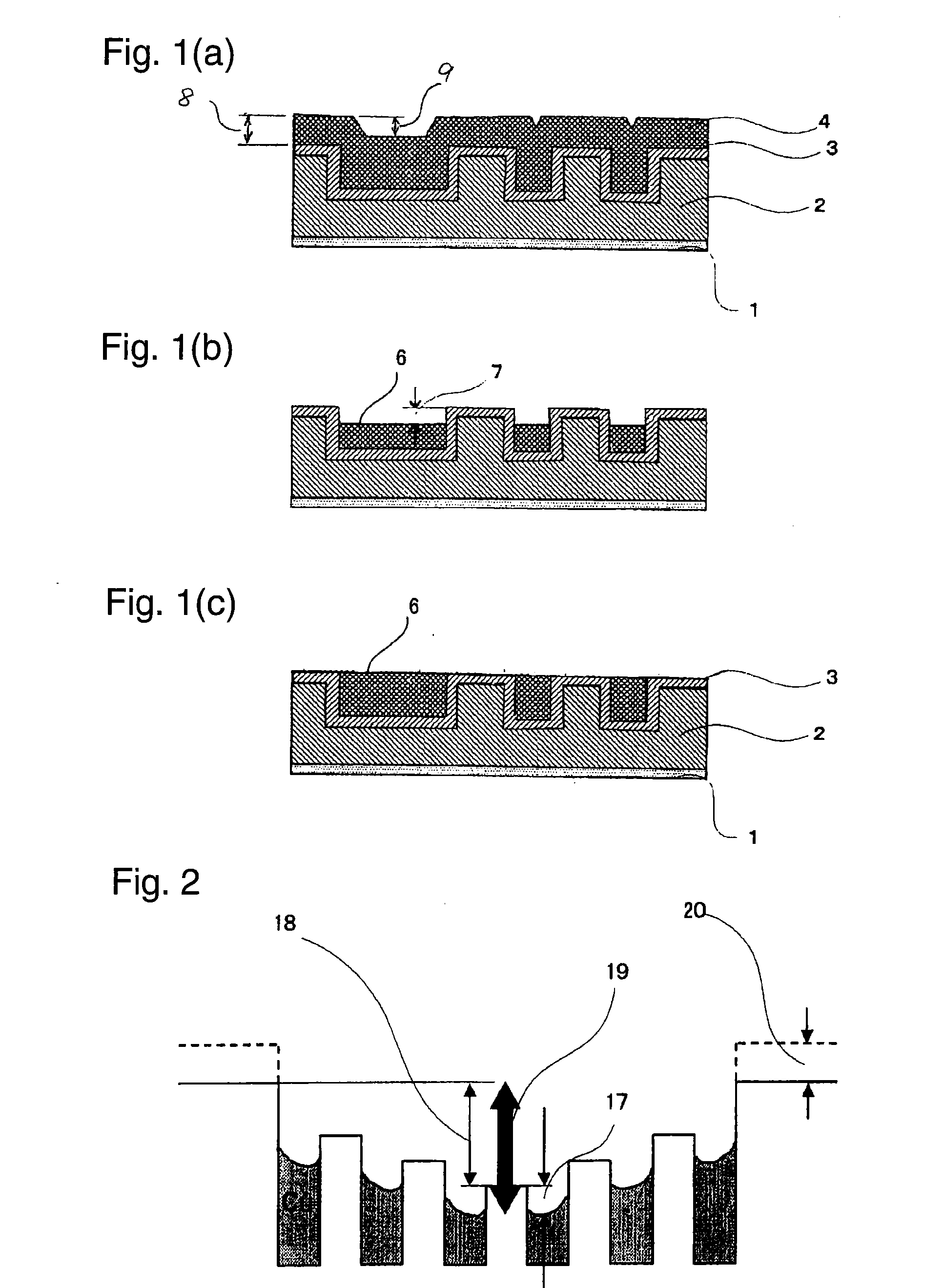

The present invention provides a technique for realizing highly flat surface of a semiconductor integrated circuit employing copper as a wiring metal.The present invention provides a polishing composition containing a neutralized carboxylic acid, an oxidizer and water, wherein a part of the carboxylic acid is an alicyclic resin acid (A) and the pH value is within a range of from 7.5 to 12. The alicyclic resin acid is preferably at least one type selected from the group consisting of abietic acid, an isomer of abietic acid, pimaric acid, an isomer of pimaric acid and derivatives of these, or a rosin. Further, the present invention provides a polishing method of semiconductor integrated circuit surface in which a copper film formed on a surface having a groove for wiring, by using the polishing composition, and the present invention provides a copper wiring for semiconductor integrated circuit formed by this polishing method.

Owner:ASAHI GLASS CO LTD

Preparation method of pimaric acid type resin acid

InactiveUS20120004390A1Increase temperatureYield andOrganic compound preparationNatural resin chemical modificationBottleSolvent

A method for preparing pimaric acid type resin acids includes the following steps: step (1) adding refined resin acid, turpentine, or rosin along with maleic anhydride at a mass ratio of 1:0.3-1.5 into a reaction bottle, dissolving the ingredients into a C1-C10 lower fatty acid solvent, the mass ratio of the C1-C10 low fatty acid to refined resin acid is 0.05-30:1, then carrying out additional reaction by heating directly or with assistance of a microwave, subsequently cooling, crystallizing, filtering, and washing; and step (2) combining the filtrates collected in step (1), stripping the solvent by vacuum distillation to obtain pimaric acid type resin acid coarse product, dissolving the resulting coarse product in NaOH aqueous solution to prepare aqueous solution of pimaric acid type resin acid salt, adjusting the pH level to 6-14 with a mineral acid or an organic acid while stirring, and either directly purifying or acidifying followed by purifying, the resulting precipitation to obtain the final product. The method has the characteristics of high yield, high product content, low cost, and low environmental pollution.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

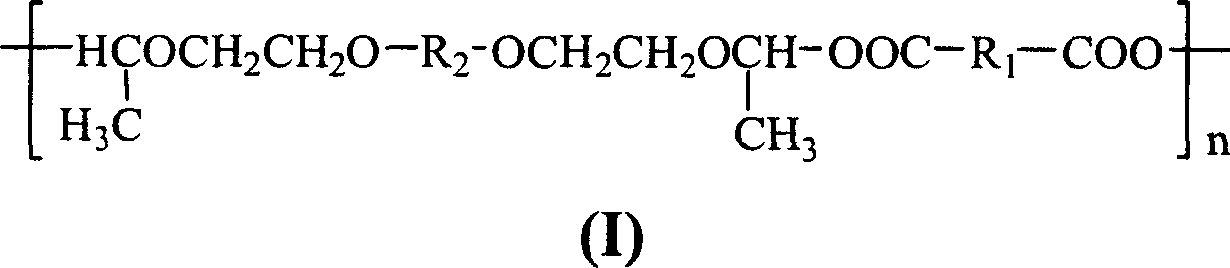

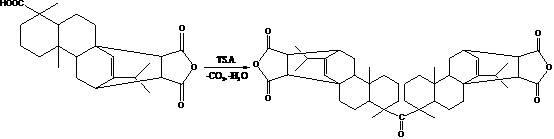

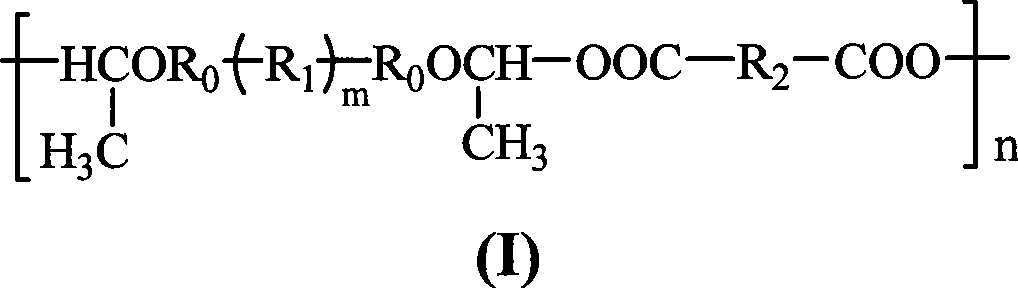

Colophony diacid ester aldehyde acetal polyalcohol, synthesis method and uses of the same

The invention discloses a colophonic diacid ester acetal polymer and synthesizing method, wherein the colophonic diacid consists of propylene pimaric acid and abietic acid dimer, which are heat with each kind of aether vinylicus to produce new-typed ester acetal polymer in the organic solvent; the polymer can do acid decomposition reaction, which forms the new-typed positive photoproduced resist material with photogeneration acid.

Owner:BEIJING NORMAL UNIVERSITY

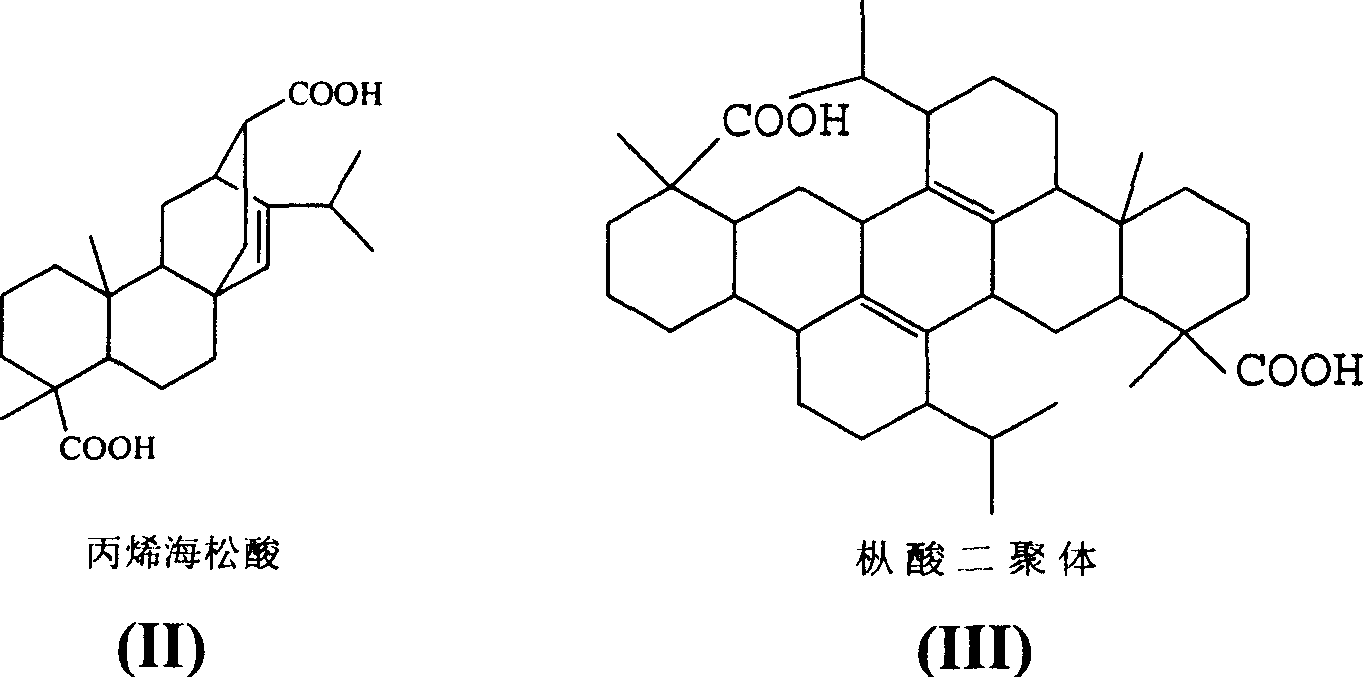

Rosin-based flux for soldering and solder paste

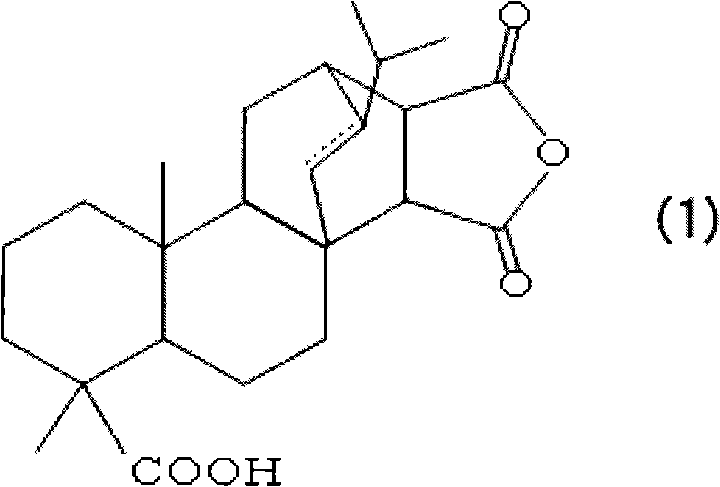

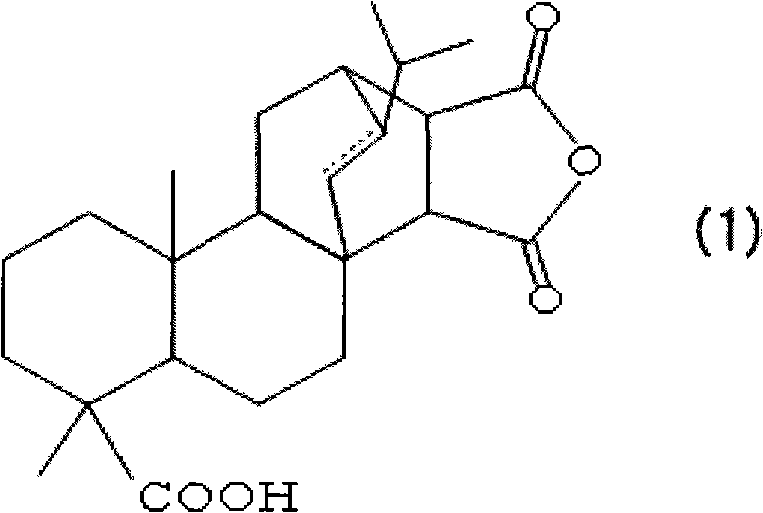

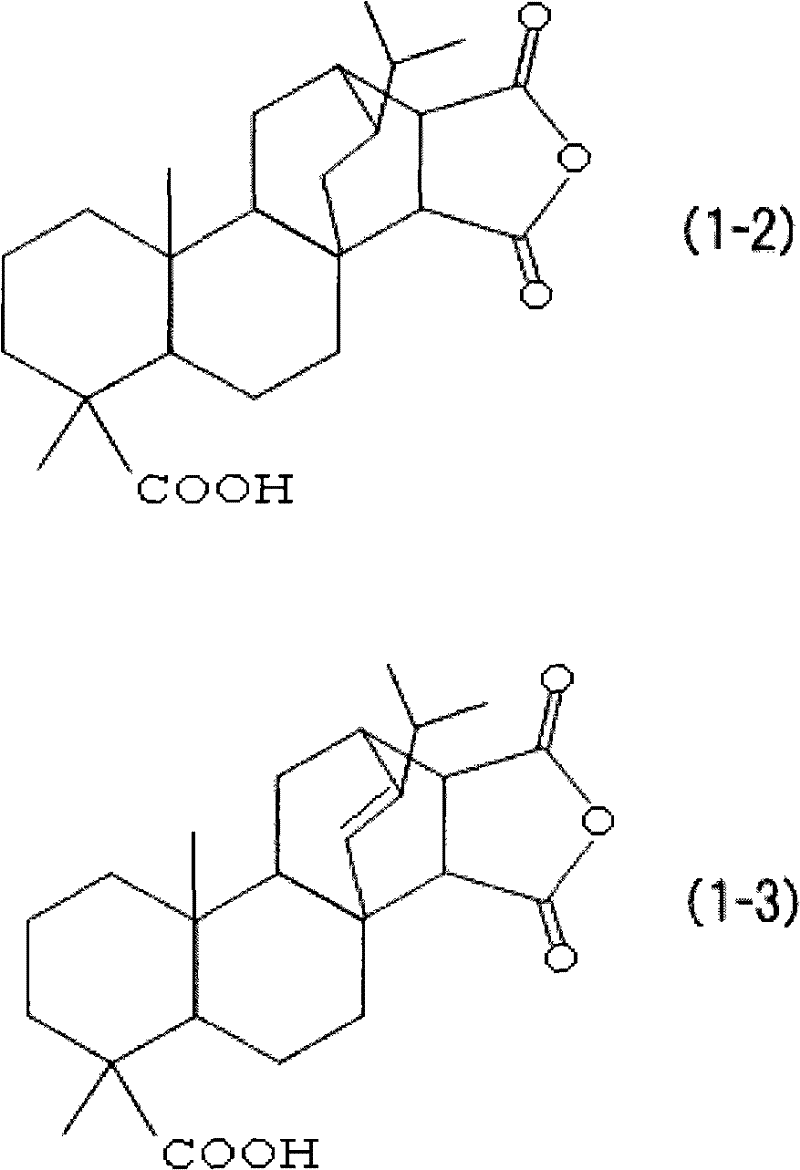

This invention is to provide a rosin-based flux used for soldering, which virtually does not cause scattering during soldering and can inhibit heat slump of the solder paste. This invention adopts the rosin derivative hydride (A) as a base material, which contains maleo pimaric acid anhydride (a-1) represented by the following structure formula (I) and has a melt viscosity of 100 to 1000 mPa.S / 180 DEG C.

Owner:ARAKAWA CHEM IND LTD

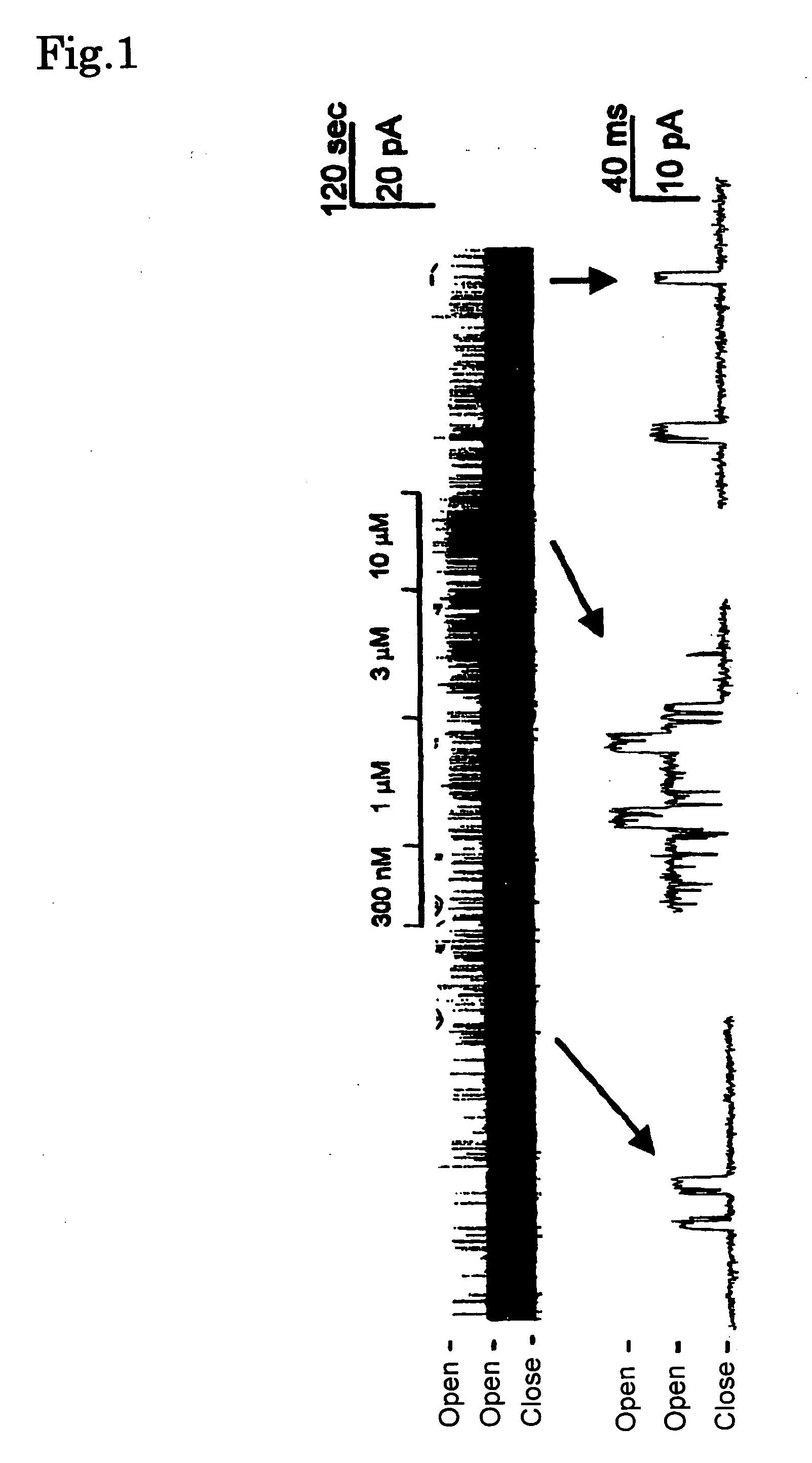

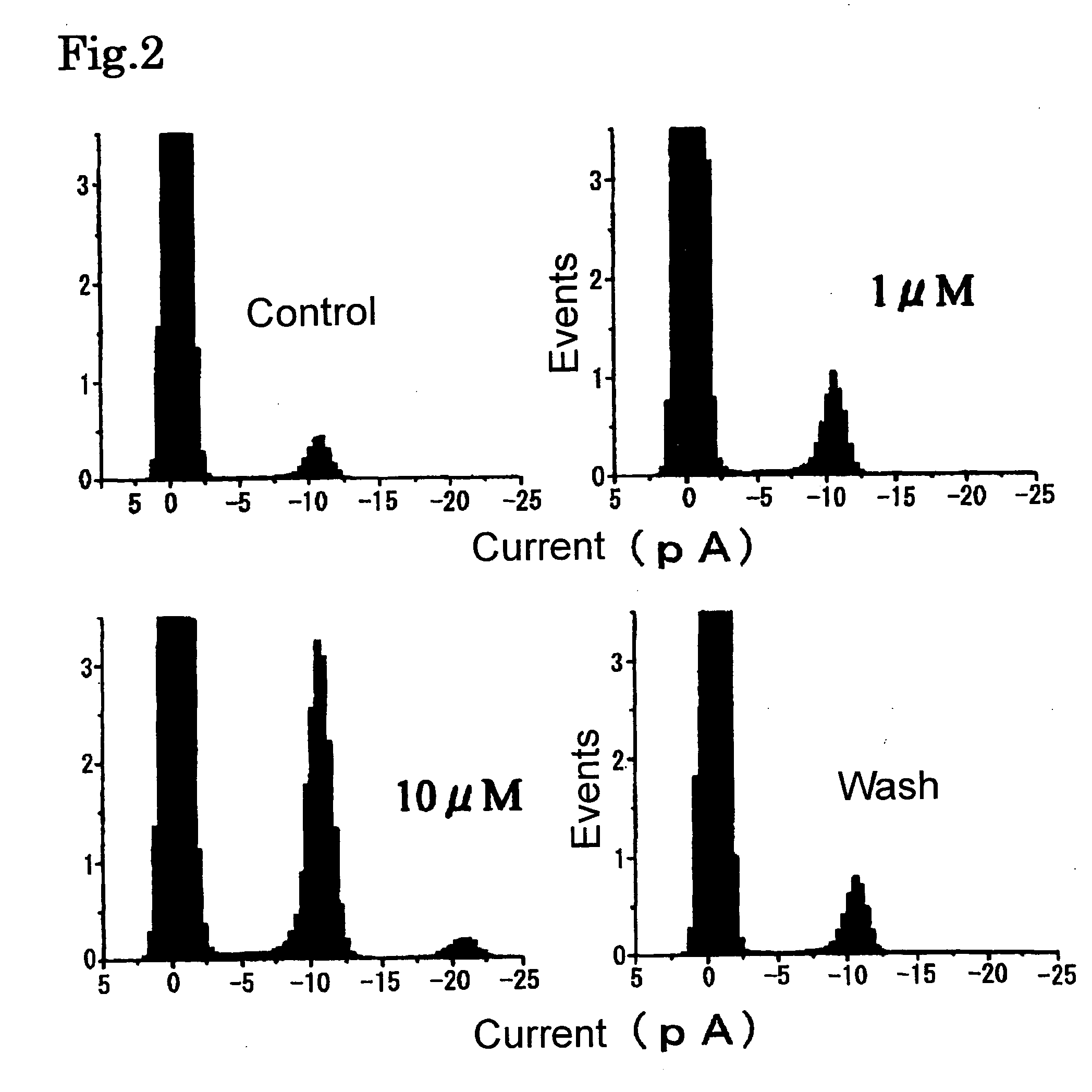

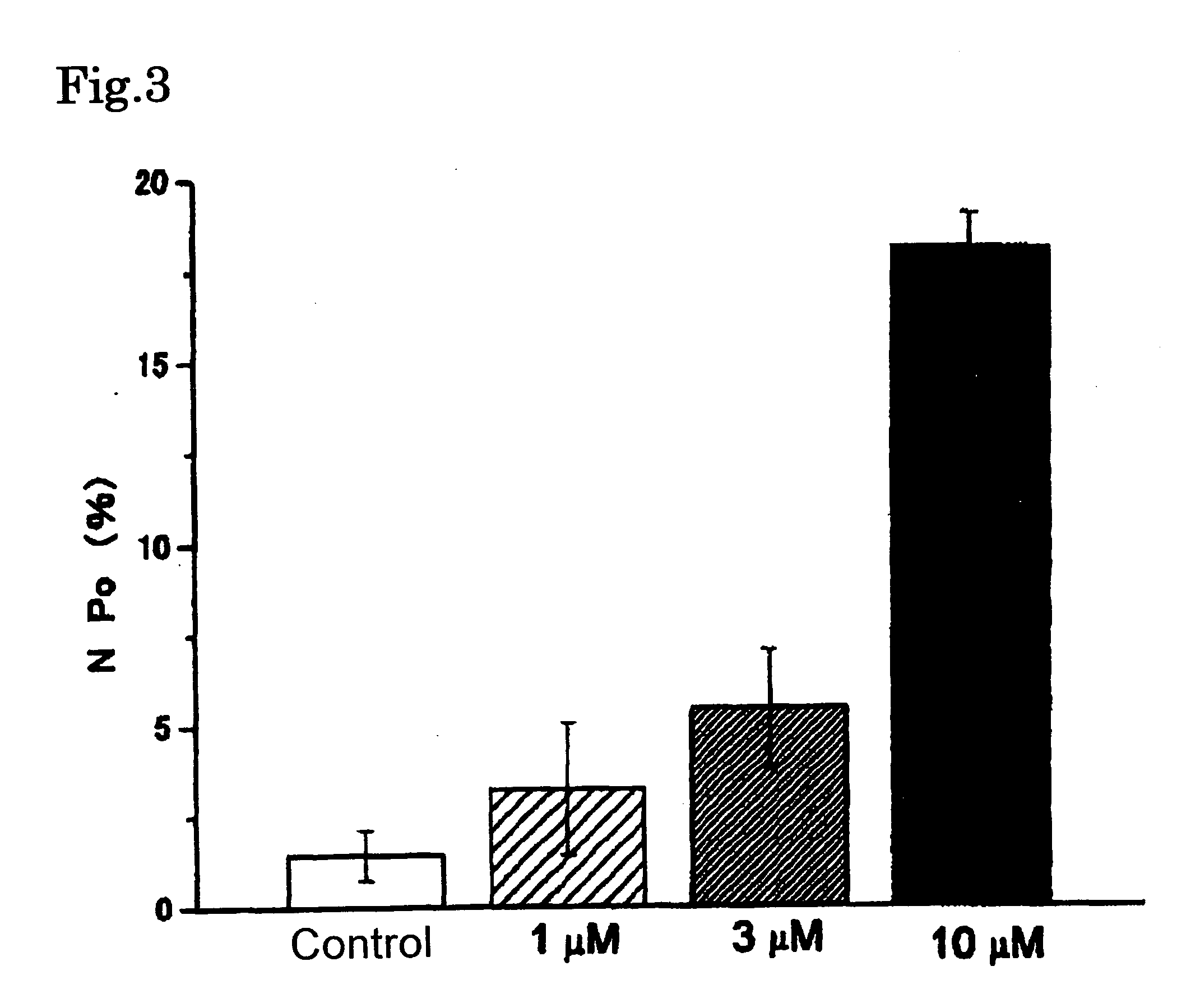

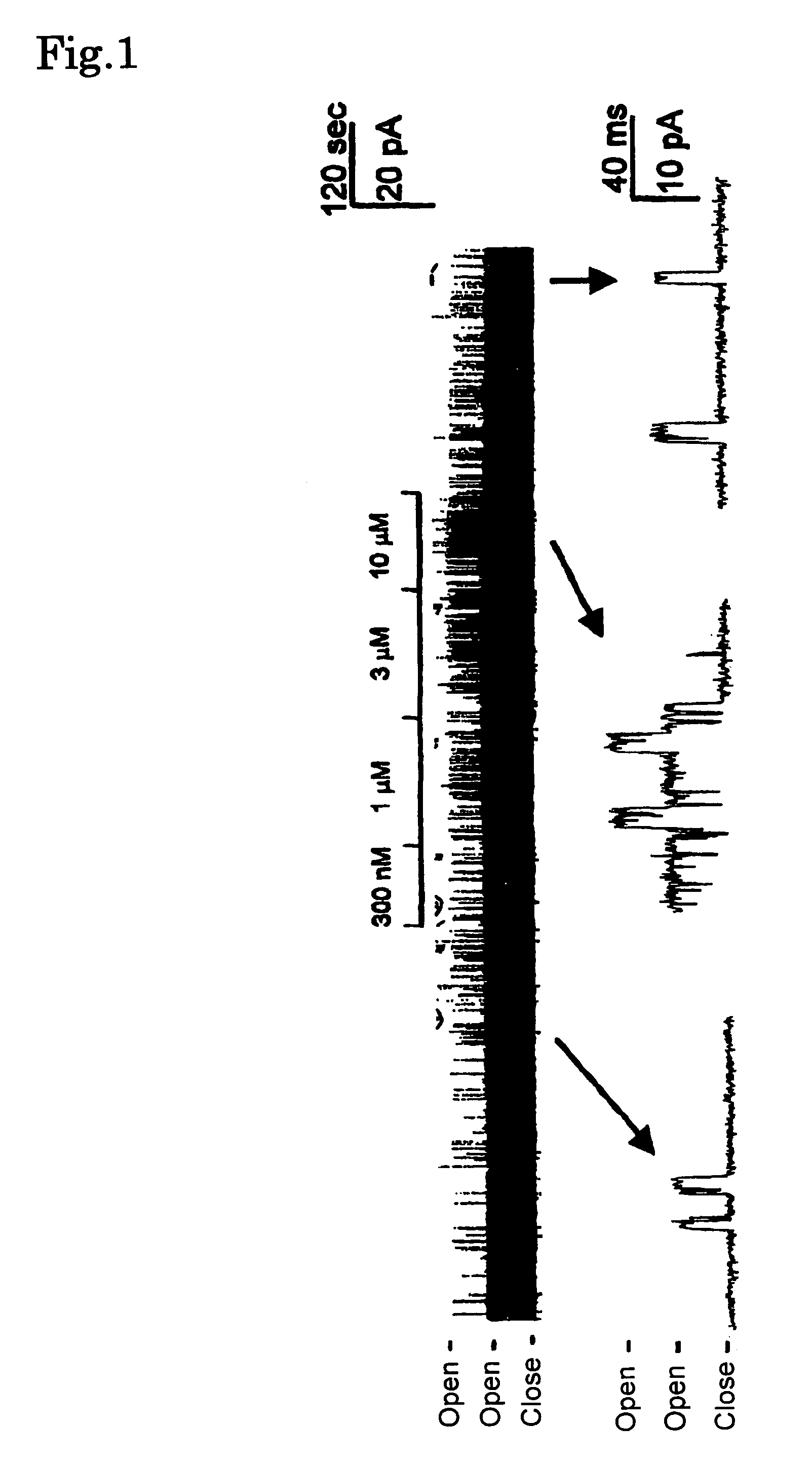

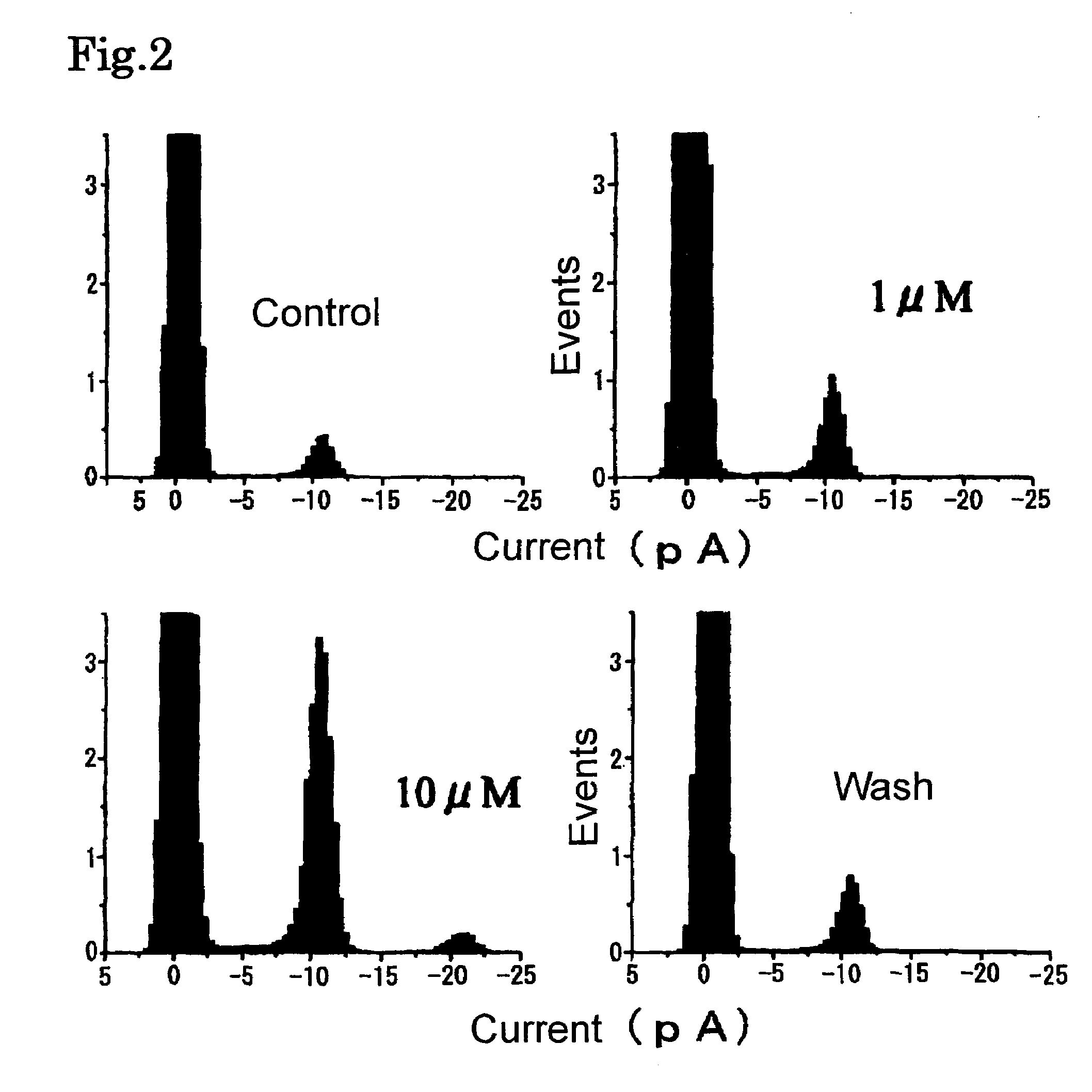

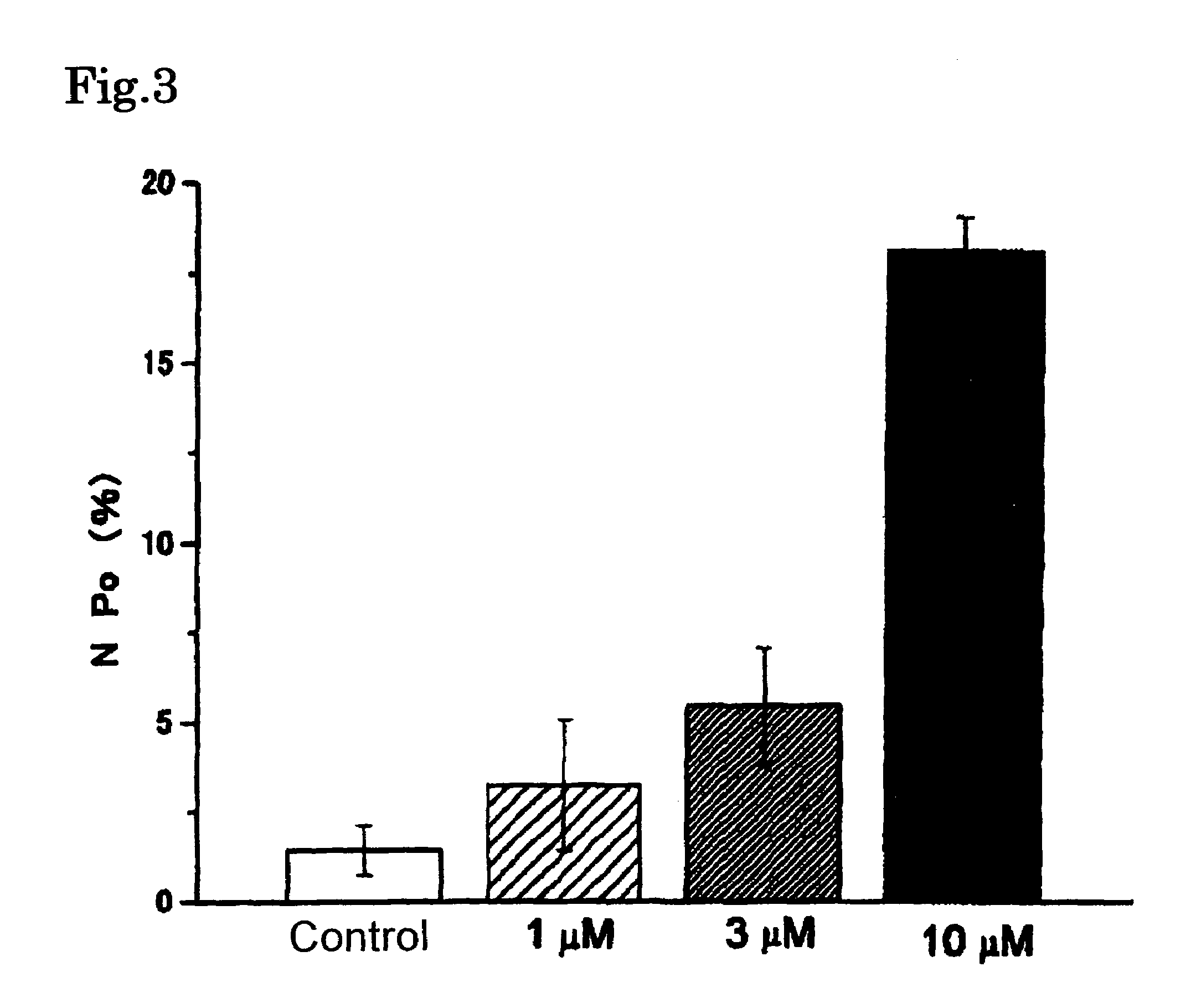

Potassium channel opener

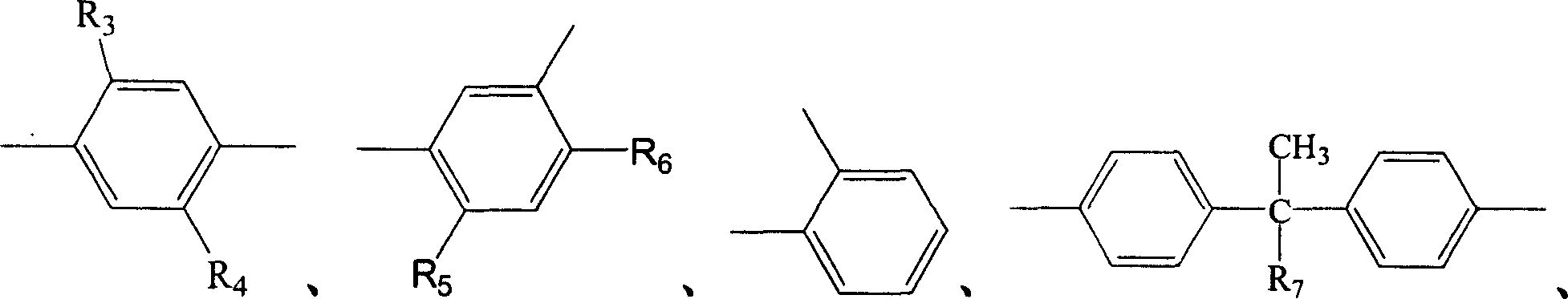

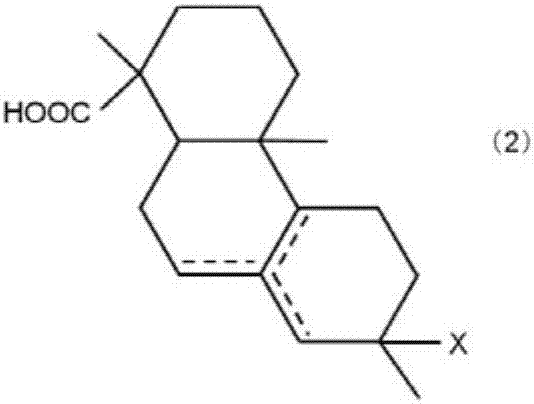

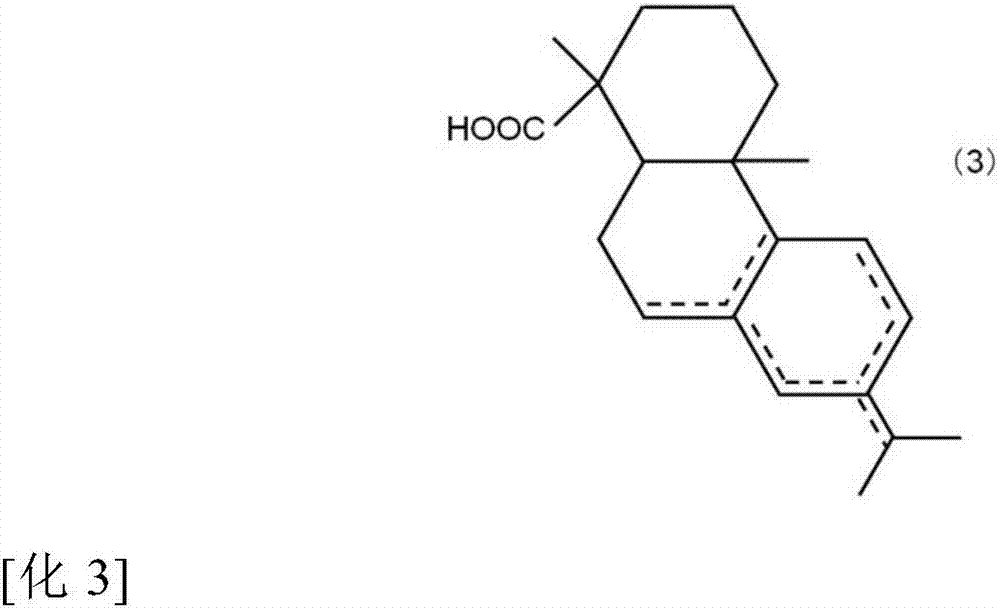

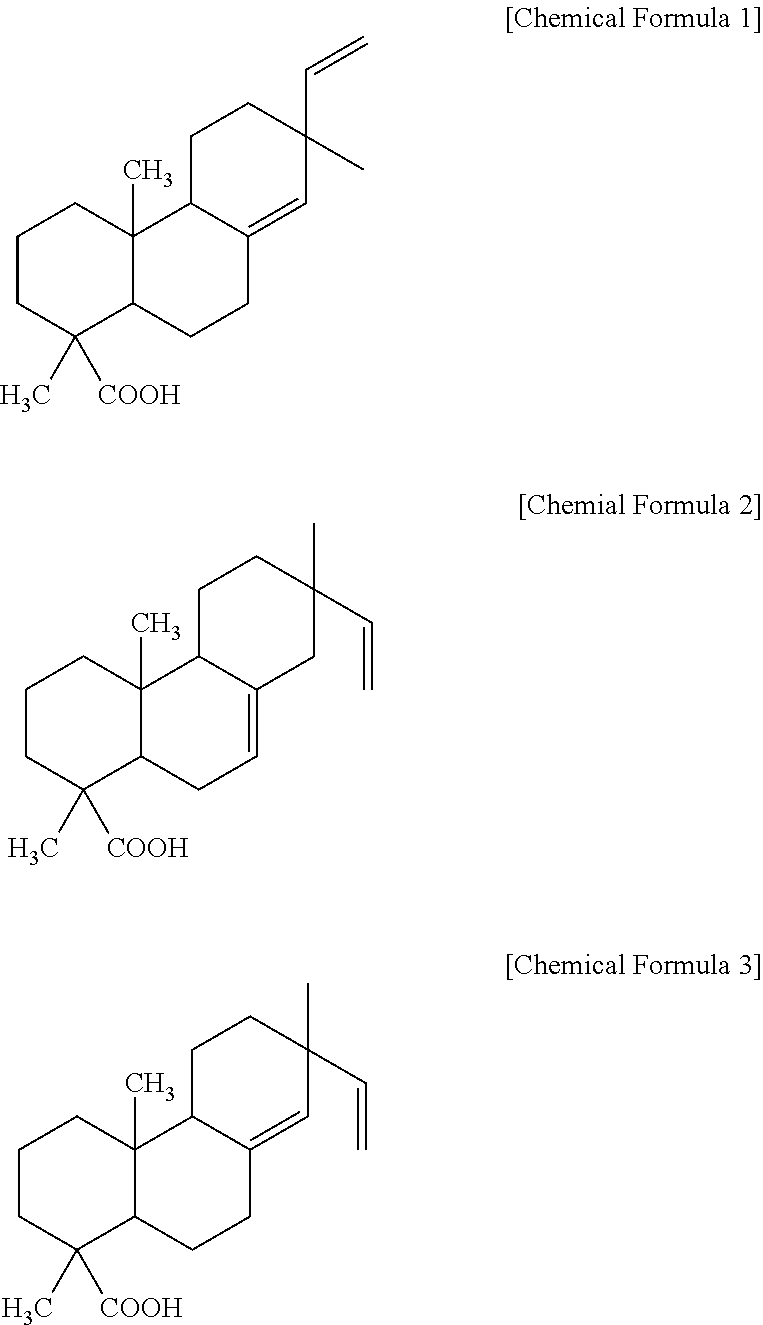

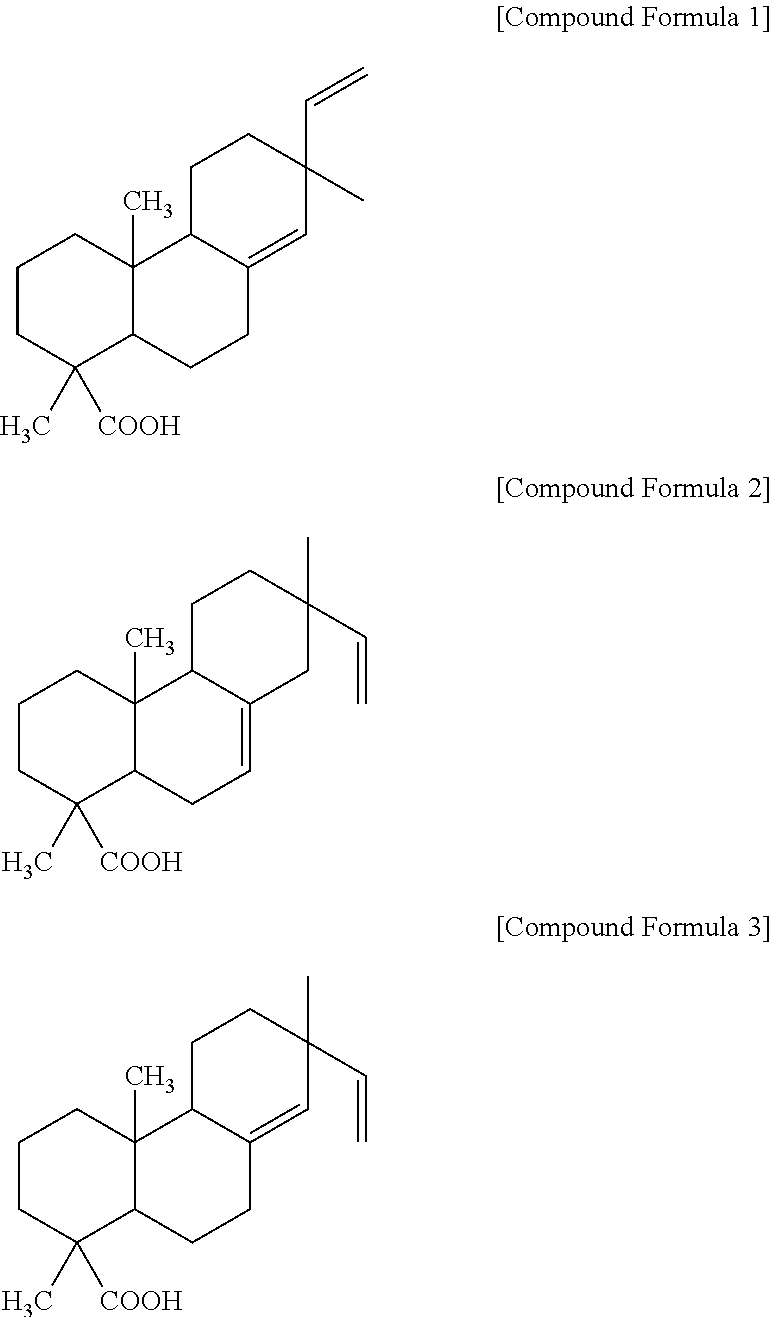

A potassium channel opener including a compound (e.g., pimaric acid) represented by the formula [I]: wherein R1, R2, R3, R4, R5, R6 and R7 are each independently hydrogen, alkyl, alkenyl, halogen, hydroxy, halogenated alkyl, hydroxyalkyl, aminoalkyl, alkoxy, aryl, heteroaryl, acyl, carboxyl, alkoxycarbonyl, hydroxamate, sulfo, carbamoyl, sulfonamide, aldehyde, or nitrile; or R4 and R5 may be bonded to each other to form a ring; or R6 and R7 may be bonded to each other to form a ring; and all of three bonds represented by are single bonds, or one of the three bonds is double bond and the other bonds are single bonds, or a physiologically acceptable salt thereof as an effective ingredient.

Owner:MITSUBISHI TANABE PHARMA CORP

Antifouling coating composition, antifouling coating film formed using the composition, coated article having the coating film on the surface, and antifouling treatment method to form the coating film

ActiveCN102171294APrevent or inhibit adhesionImprove environmental safetyAntifouling/underwater paintsRosin coatingsPhenyl groupMethyl group

Provided is a composition for forming an antifouling coating film having high environmental safety with which hairline cracks or other coating film abnormalities will not easily occur and whereby adhesion of slime is also prevented or limited, even with immersion in seawater over a long time. The antifouling coating composition comprises (A) a triorganosilyl ester-containing copolymer obtained from a mixture of (a) a methacrylic acid triorganosilyl ester monomer represented by general formula (1): (in the formula, R1 represents a hydrogen atom or a methyl group, R2, R3 and R4 may be the same or different and represent a C3-6 alfa-branched alkyl group or phenyl group) and (b) an ethylenic unsaturated monomer that is copolymerizable with the methacrylic acid triorganosilyl ester monomer, and (B) a modified rosin salt that is a salt of zinc and / or copper and a modified rosin containing at least 80 wt% of two or more types selected from dihydroabietic acid, tetrahydroabietic acid, dehydroabietic acid, pimaric acid, isopimaric acid and dihydropimaric acid.

Owner:NITTO KASEI CO LTD

Preparation method of rosin acid

ActiveCN104211597AOrganic compound preparationCarboxylic compound separation/purificationDistillationTurpentine

The invention discloses a preparation method of rosin acid, and belongs to the technical field of deep processing of rosin. The method comprises the following steps: putting turpentine in a melting kettle, adding xylene, turpentine oil, oxalic acid and water, carrying out stirring melting, filtering to remove filter residues, clarifying, separating, distilling in a distillation kettle, rectifying, putting the above obtained rectified material in an esterification kettle, adding maleic acid, glycerin and pimaric acid, carrying out an esterification reaction, cooling, crystallizing, filtering, and washing to prepare the rosin acid. The content of pimaric acid in the rosin acid prepared in the invention reaches above 95%.

Owner:GUANGXI ZHONGCHANG RESIN

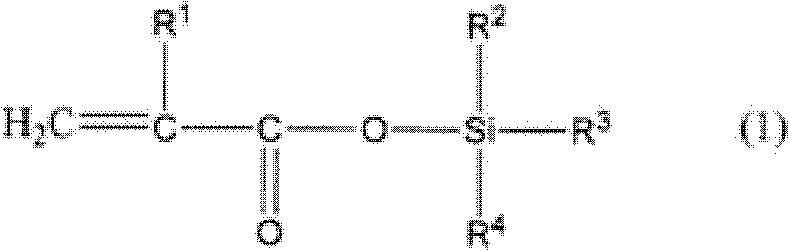

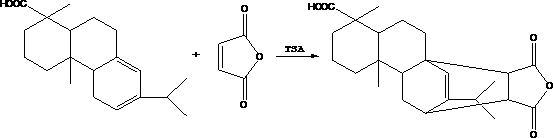

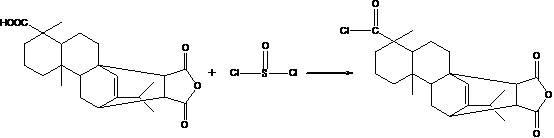

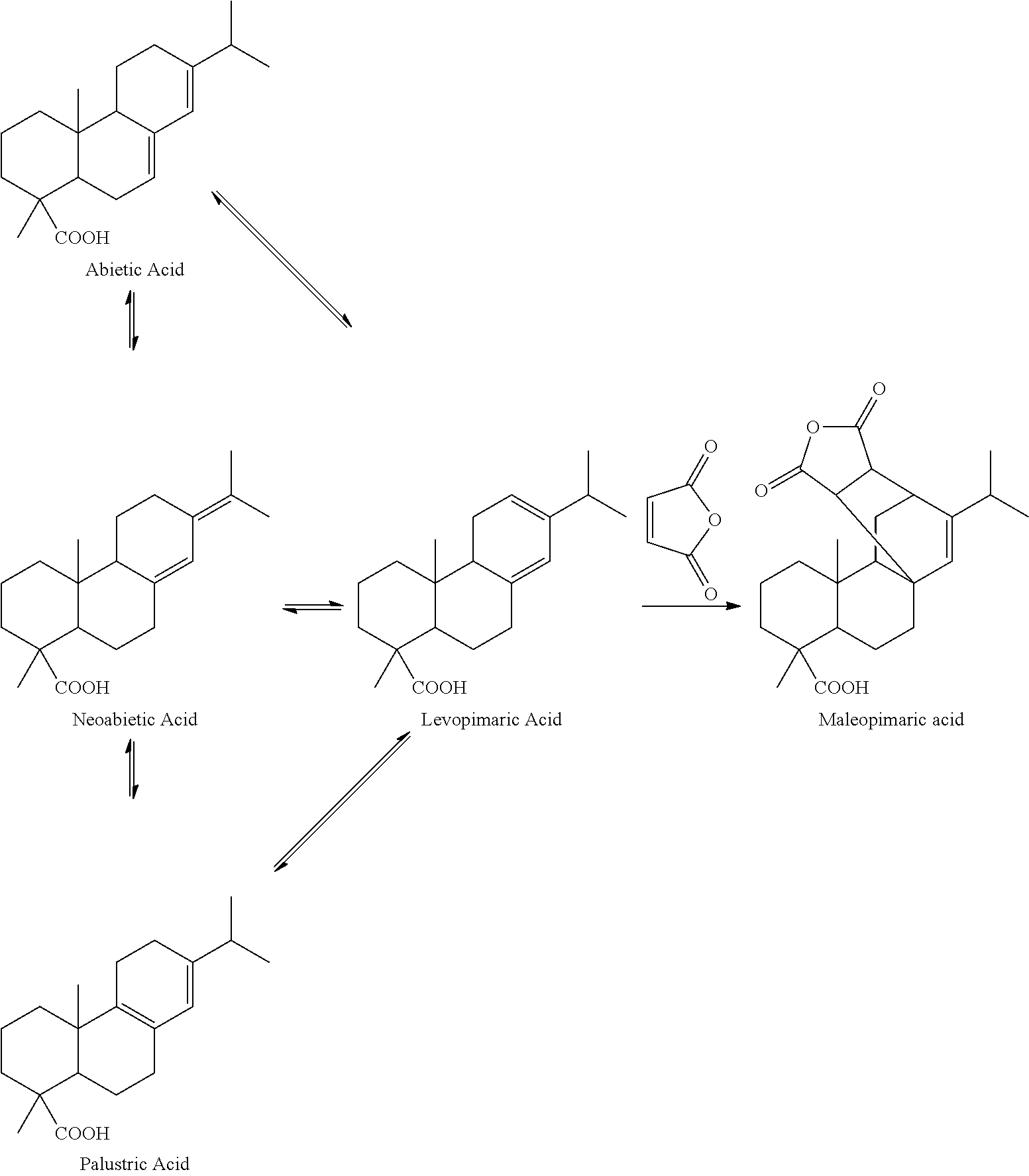

Synthesis method of gum rosin derivative maleopimaric acid dianhydride

The invention discloses a synthetic method of a gum rosin derivative maleopimaric acid dianhydride. Gum rosin is taken as a raw material for synthesizing the gum rosin derivative maleopimaric acid dianhydride. The synthetic method comprises the following steps of: firstly purifying abietic acid from gum rosin, then isomerising the abietic acid at high temperature to obtain pimaric acid, carrying out a reaction of the pimaric acid and maleic anhydride in the presence of p-methylbenzene sulfonic acid to obtain maleopimaric acid anhydride, and then synthesizing 1mol of maleopimaric acid dianhydride with 2mol of maleopimaric acid anhydride, and the maleopimaric acid dianhydride can be used for preparing polyimide by carrying out polymerization with a diamine monomer, or can be used for preparing polyamide imide by carrying out polymerization with a diamine monomer and a diacid monomer and or can be used for preparing polyamide imide by carrying out polymerization with a diamine monomer and an amino acid monomer. By adopting the synthetic method, yield is high, and product purity is high.

Owner:广东中塑新材料股份有限公司

Synthesis method of gum rosin derivatives

The invention discloses a synthesis method of gum rosin derivatives, and particularly relates to a method for preparing the gum rosin derivatives comprising maleopimaric acid acyl chloride. The synthesis method comprises the steps that abietic acid is firstly obtained through purifying the gum rosin; and then after the abietic acid is isomerized through high temperature to obtain pimaric acid, the pimaric acid reacts with maleic anhydride under the condition that p-toluene sulfonic acid exists, so as to obtain the maleopimaric acid acyl chloride. The method disclosed by the invention has the advantages of high process efficiency and good product purity.

Owner:广东中塑新材料股份有限公司

Rosin diacid ester acetal polymer without aryl , process for synthesizing the same and use thereof

The invention relates to a rosin diacid ester acetal polymer containing no aryl, and a synthesis method thereof. Rosin diacid comprises propylene pimaric acid and abietic acid dimer, wherein the two acids and various fatty diol divinyl ether compounds are heated and react in the presence of organic solvent so as to obtain a novel ester acetal polymer. As the polymer is easy to undergo acid-caused decomposition reaction, the acetal polymer together with an optical acid production agent can form a novel chemically-amplified positive photoresist material.

Owner:BEIJING NORMAL UNIVERSITY

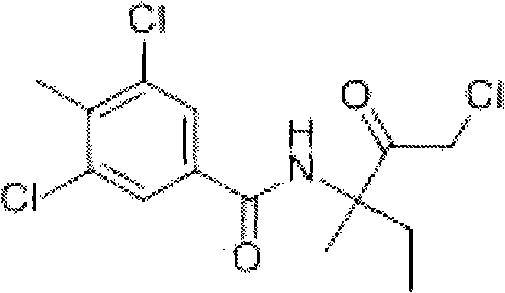

Sterilization composition containing zoxamide and copper pimaric acid

Owner:QINGDAO AUDIS BIO TECH CO LTD

Rosin-type emulsion sizing agent and paper obtained using the sizing agent

ActiveCN106868938AGood storage stabilityImprove mechanical stabilityWater-repelling agents additionRosin additionPolymer sciencePolyol

The present invention provides a rosin-type emulsion sizing agent having good storage stability and mechanical stability, and a paper having a good sizing effect obtained by using the sizing agent. The present invention relates to a rosin-type emulsion sizing agent and a paper obtained by using the sizing agent, wherein the rosin-type emulsion sizing agent is emulsified by the emulsion (B) in the presence of the polymer dispersant (A) (B) is at least one selected from the group consisting of a rosin (B1) and a rosin ester (B2), wherein the rosin (B1) is a rosin (b1) And the alpha, beta-unsaturated carboxylic acid (b2), said rosin (b1) containing 0.1 to 8% by weight of tropisol, 15 to 34.9% by weight of pimaric acid, and rosin (84) is a reaction product of the rosin (b1) and the polyol (b3).

Owner:ARAKAWA CHEM IND LTD

Self-extinction resin emulsion and preparation method thereof, and application of self-extinction resin emulsion in water-based matte ink

The invention discloses a self-extinction resin emulsion. The self-extinction resin emulsion comprises the following components in parts by mass: 5 to 10 parts of polycarbonate polyol, 20 to 30 partsof diisocyanate, 5 to 15 parts of pimaric acid modified polyol, 20 to 25 parts of a carboxylic acid type chain extender, 3 to 6 parts of a neutralizer, 40 to 60 parts of deionized water and 1.0 to 2.0parts of an auxiliary agent. The invention further discloses a preparation method of the self-extinction resin emulsion and application of the self-extinction resin emulsion in water-based matte ink.The obtained self-extinction resin emulsion is good in stability and low in viscosity and is applied to water-based matte ink; an obtained water-based matte ink layer has scratch resistance of largerthan 200 g, alcohol resistance of larger than 300 times and surface energy of larger than or equal to 56 mN / m, presents excellent reprinting performance and is quite suitable for being applied to thefield of packaging of 3C products.

Owner:SUZHOU SHIHUA NEW MATERIAL TECH

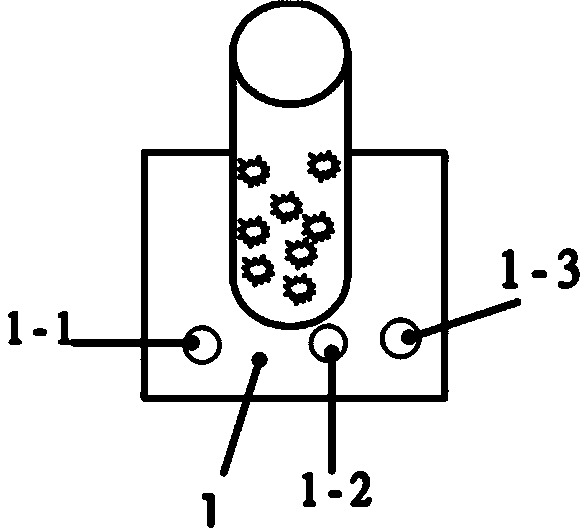

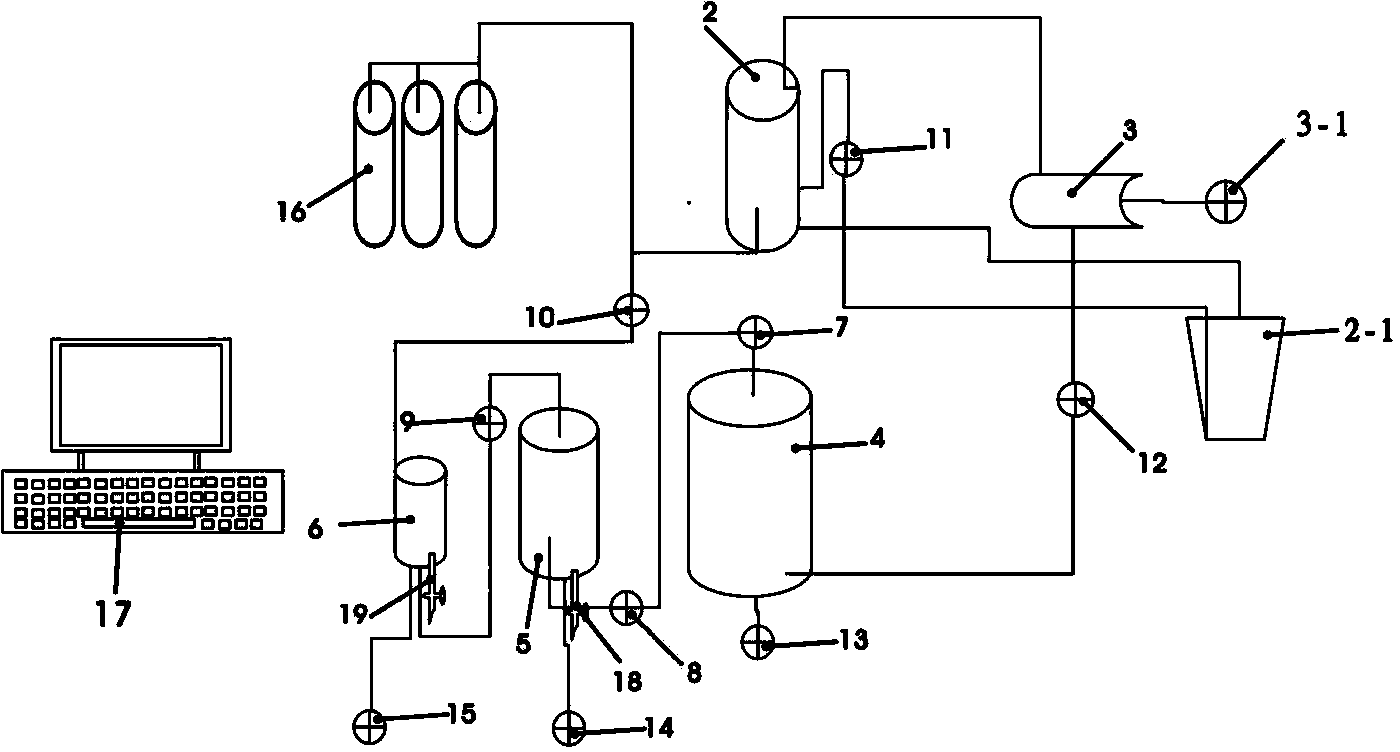

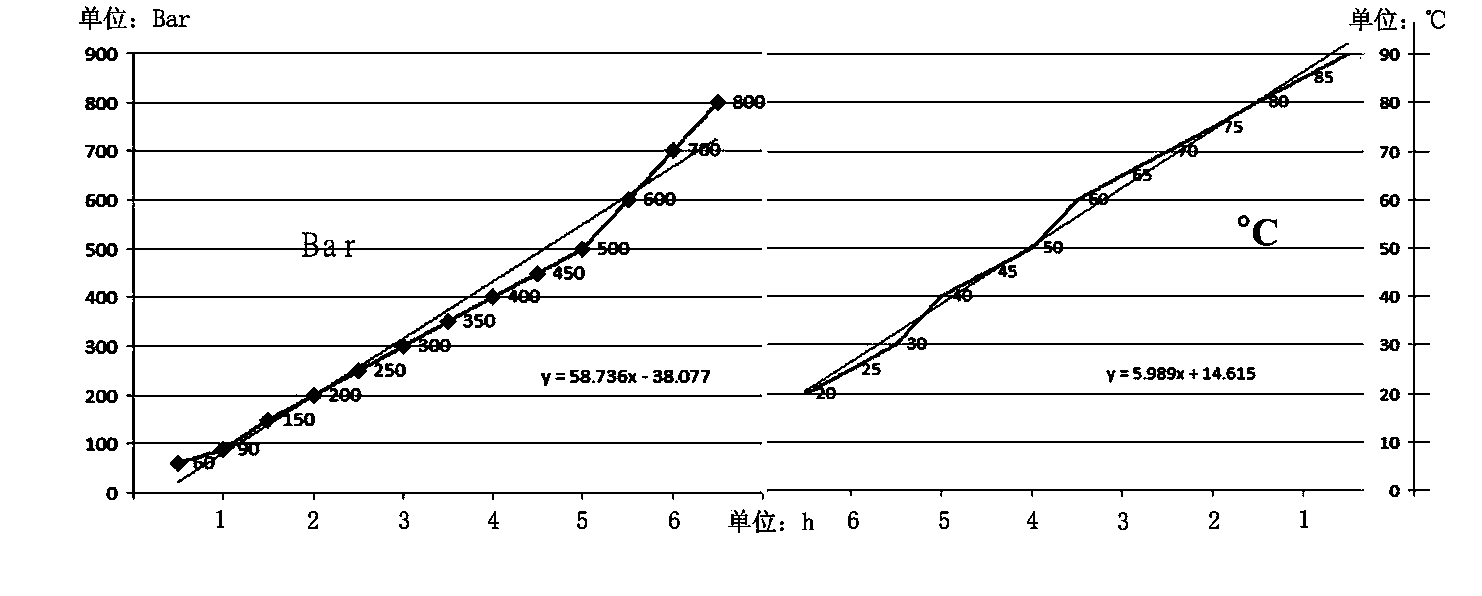

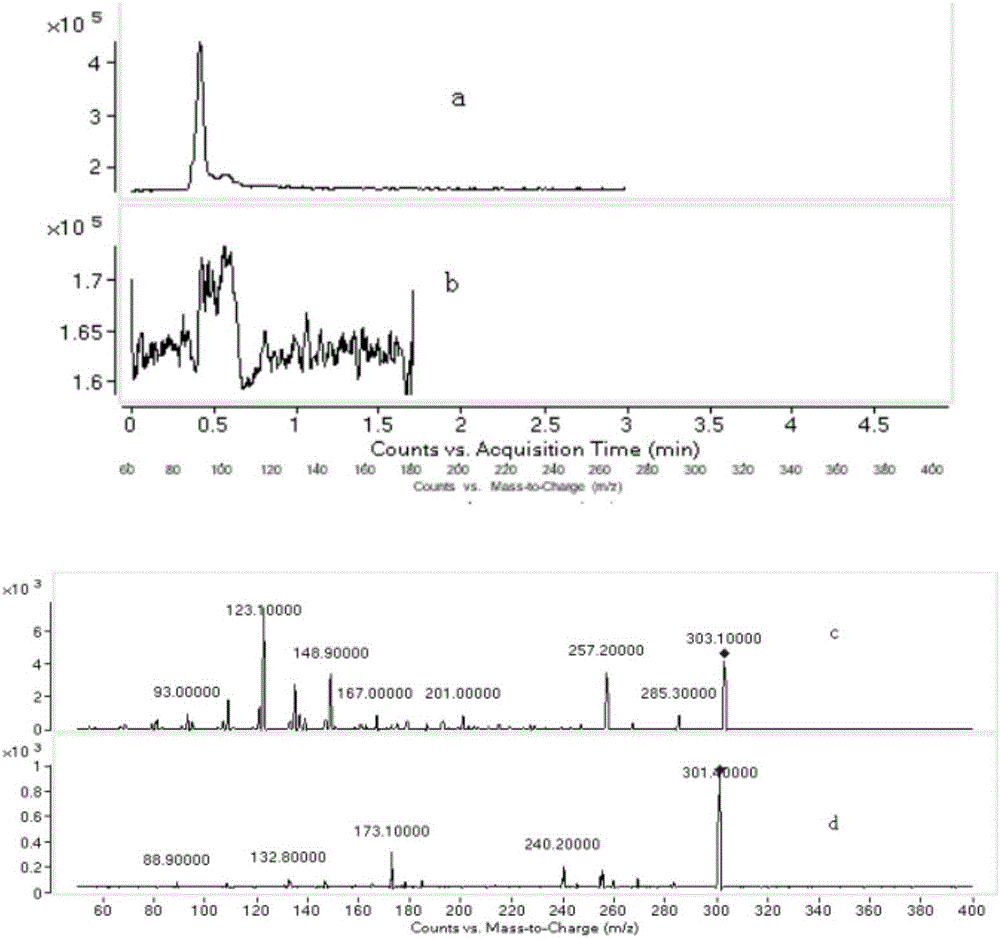

Method for extracting effective ingredients in amber through ultrasonic-assisted extraction and supercritical CO2 gradient elution

ActiveCN103961897AReduce extraction timeReduce energy consumptionInanimate material medical ingredientsSolid solvent extractionAdditive ingredientHigh energy

The invention provides a method for extracting effective ingredients in amber through ultrasonic-assisted extraction and supercritical CO2 gradient elution, and belongs to an extraction technology adopting a high-strength and high-energy ultrasonic-assisted extraction and supercritical CO2 fluid gradient elution. The method comprises the steps as follows: the amber and inactive substances are mixed and added in a pulverizer and pulverized into a mixture; the mixture is added into an ultrasonic-assisted extraction device, ethyl alcohol is injected into the ultrasonic-assisted extraction device, the extraction temperature, time and energy frequency of the ultrasonic-assisted extraction device are set, an ethyl alcohol extract liquor is obtained and taken out, ethyl alcohol is recovered, and an extract is obtained; and the extract is added into a supercritical CO2 extraction device, pressure and temperature gradient change of the supercritical CO2 extraction device is set, and amber acid, abietic acid, d-pimaric acid and essential oil are extracted. Compared with the prior art, the method is simple to operate, safe, reliable, low in cost, energy-saving and environment-friendly, and meanwhile, the obtained amber product is high in purity, good in quality and applicable to preparation of drugs, food and drinks.

Owner:MISAKI BIOTECH

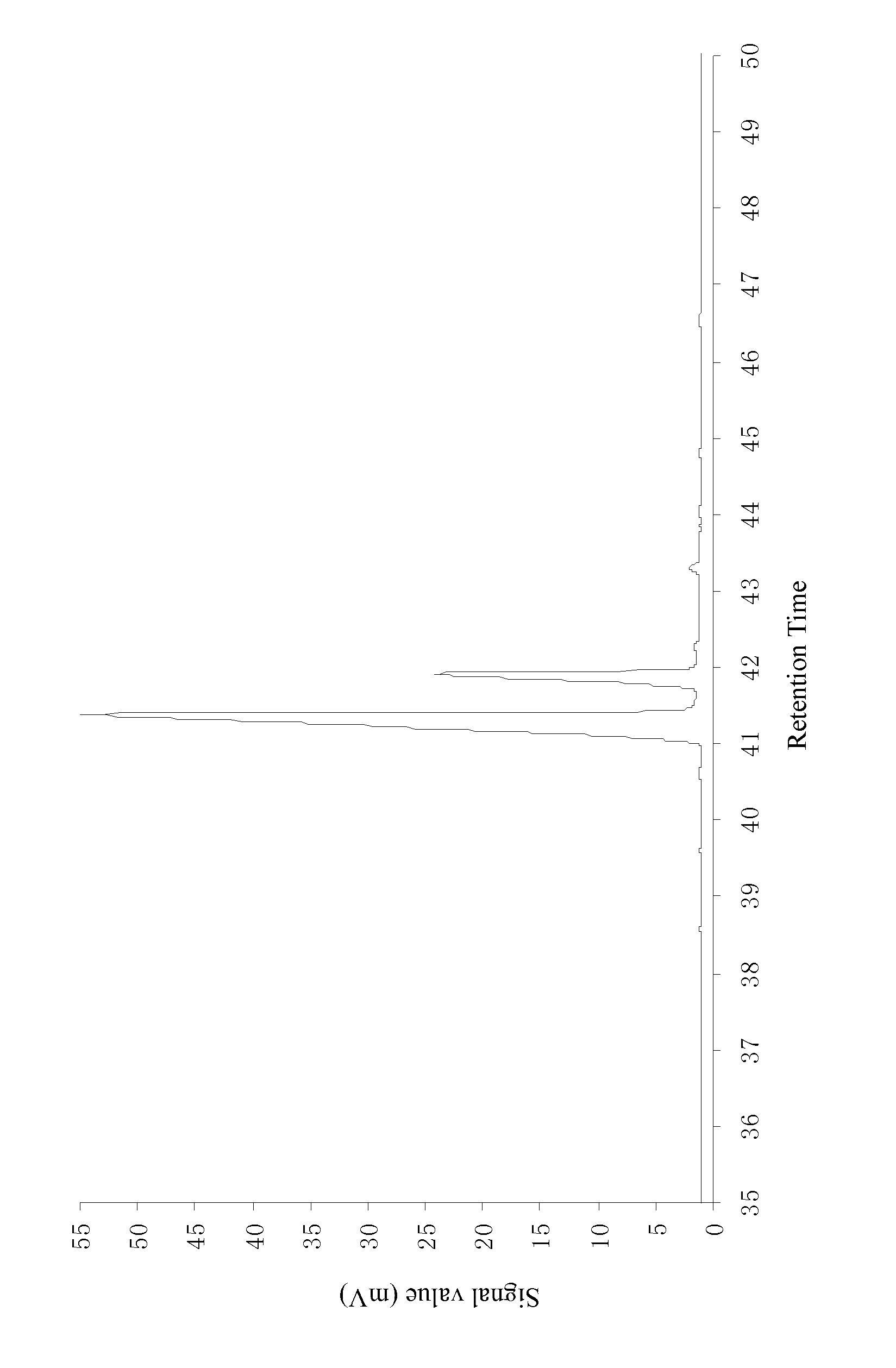

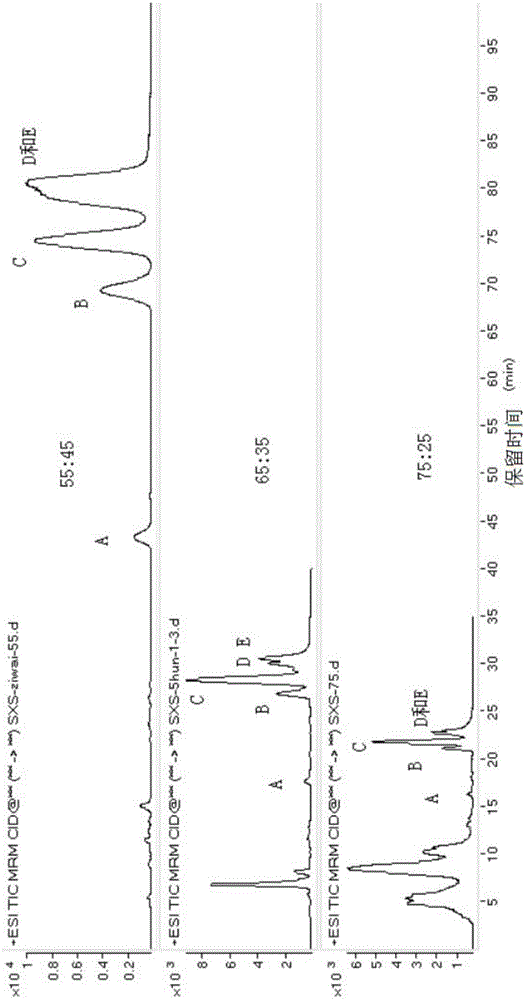

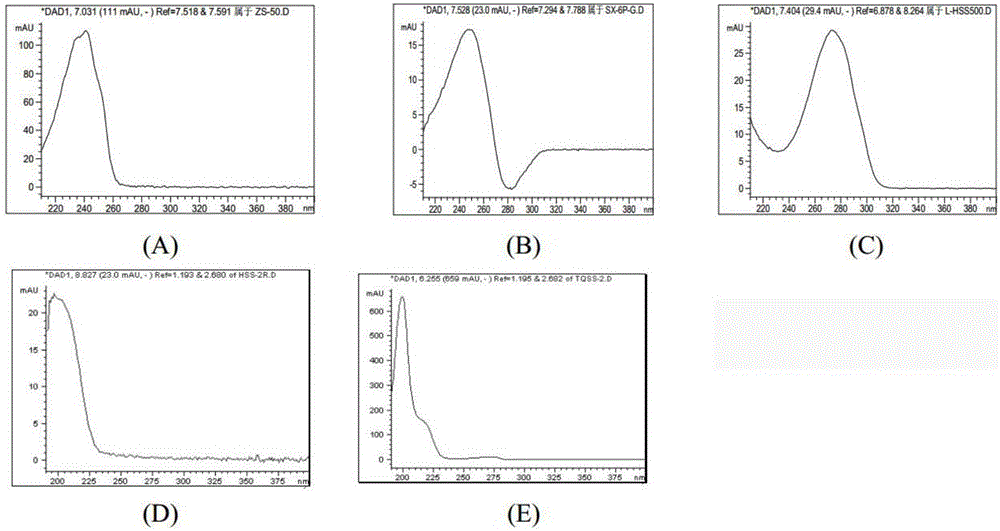

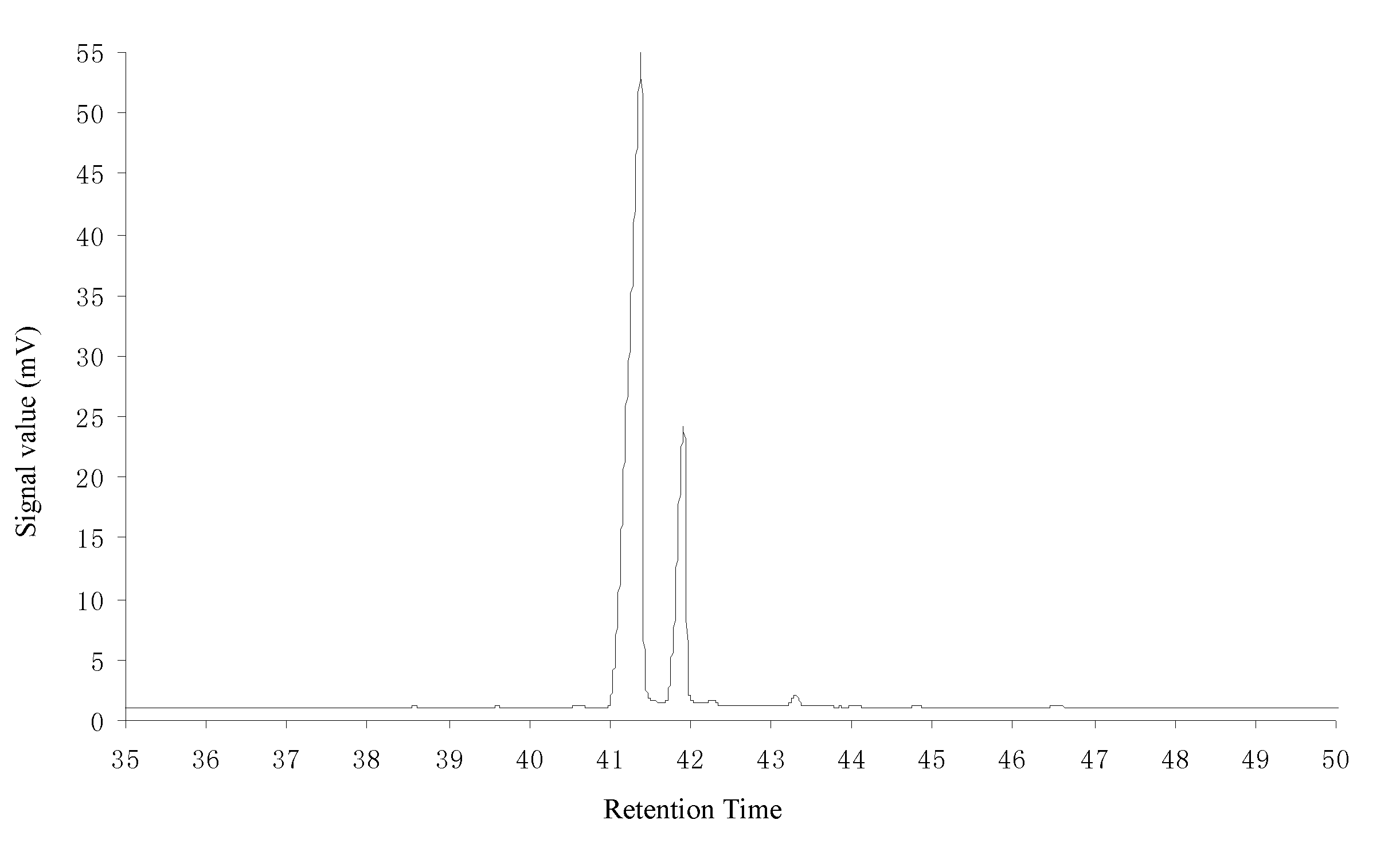

Method for analyzing five colopholic acids in product by virtue of high performance liquid chromatography-tandem mass spectrometry

The invention provides a method for analyzing five colopholic acids in a product by virtue of a high performance liquid chromatography-tandem mass spectrometry, relating to a detection and analysis method for four products including adhesives, paper, rosin soap and printing ink as well as five colopholic acids including abietic acid, neoabietic acid, levopimaric acid, pimaric acid and dehydroabietic acid for shoe materials. The method comprises the steps of after a sample is preprocessed, adding an extraction solvent, carrying out ultrasonic extraction, filtering to obtain an extraction solution, concentrating the extraction solution to a definite volume, and carrying out detection and analysis by virtue of the high performance liquid chromatography-tandem mass spectrometry. The method provided by the invention is simple and convenient, the steps are few, a test result is accurate, and the detection effects of the five colopholic acids are good.

Owner:COMPREHENSIVE TECH SERVICE CENT OF QUANZHOU ENTRY EXIT INSPECTION & QUARANTINE BUREAU OF P R C

Deep-ultraviolet chemically-amplified positive photoresist

ActiveUS9023590B2High transparencyHigh sensitivityOrganic chemistryOrganic compound preparationResistOrganic solvent

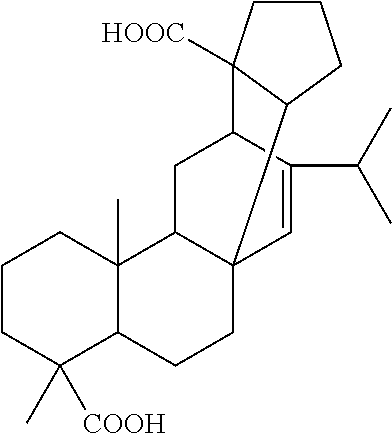

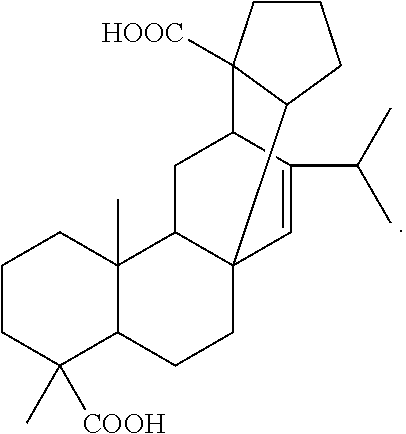

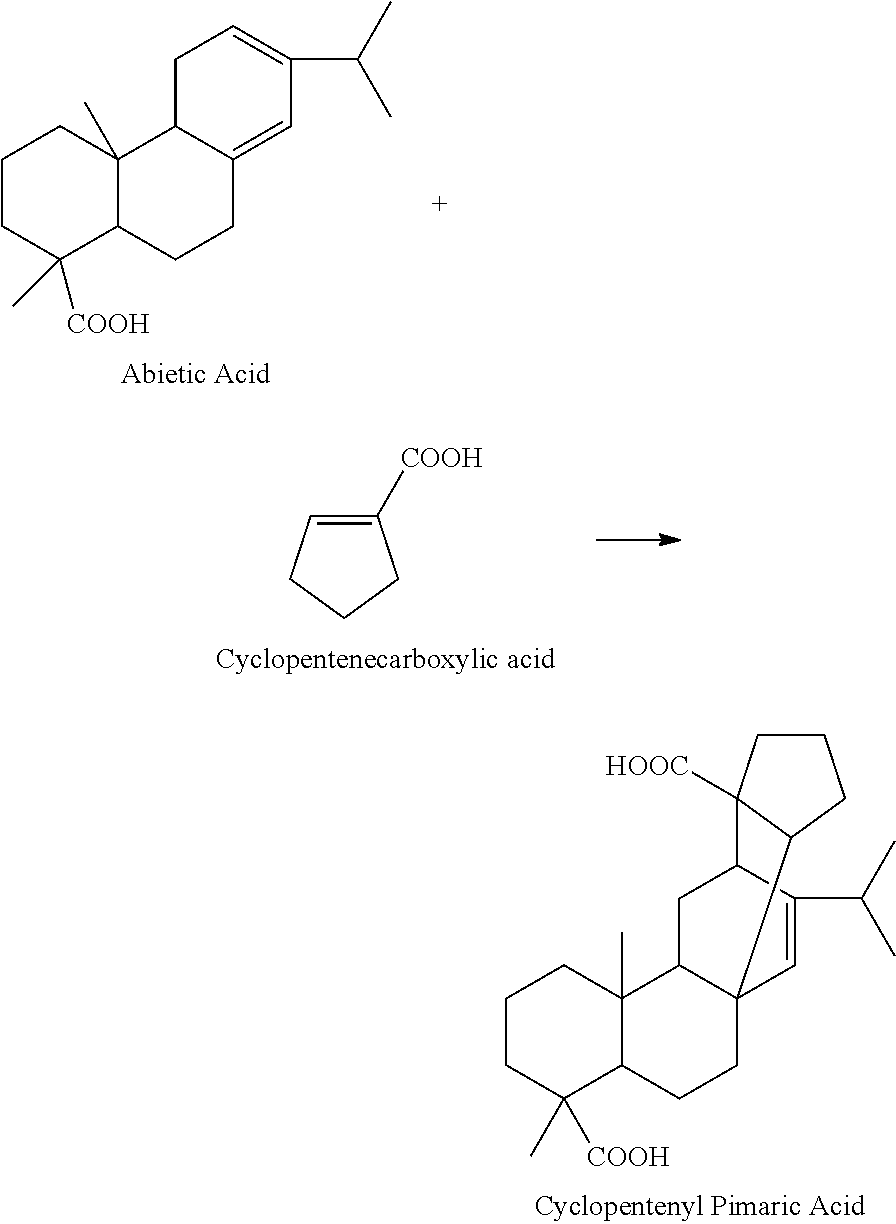

The invention discloses a deep-ultraviolet chemically-amplified positive photoresist. The deep-ultraviolet chemically-amplified positive photoresist according to one embodiment of the invention includes a cyclopentenyl pimaric acid, a divinyl ether, a photoacid generator and an organic solvent. The deep-ultraviolet chemically-amplified positive photoresist according to the invention has a good sensitivity and a good transparency.

Owner:BOE TECH GRP CO LTD

Potassium channel opener

A potassium channel opener including a compound (e.g., pimaric acid) represented by the formula [I]:wherein R1, R2, R3, R4, R5, R6 and R7 are each independently hydrogen, alkyl, alkenyl, halogen, hydroxy, halogenated alkyl, hydroxyalkyl, aminoalkyl, alkoxy, aryl, heteroaryl, acyl, carboxyl, alkoxycarbonyl, hydroxamate, sulfo, carbamoyl, sulfonamide, aldehyde, or nitrile; or R4 and R5 may be bonded to each other to form a ring; or R6 and R7 may be bonded to each other to form a ring; and all of three bonds represented by are single bonds, or one of the three bonds is double bond and the other bonds are single bonds, or a physiologically acceptable salt thereof as an effective ingredient.

Owner:MITSUBISHI TANABE PHARMA CORP

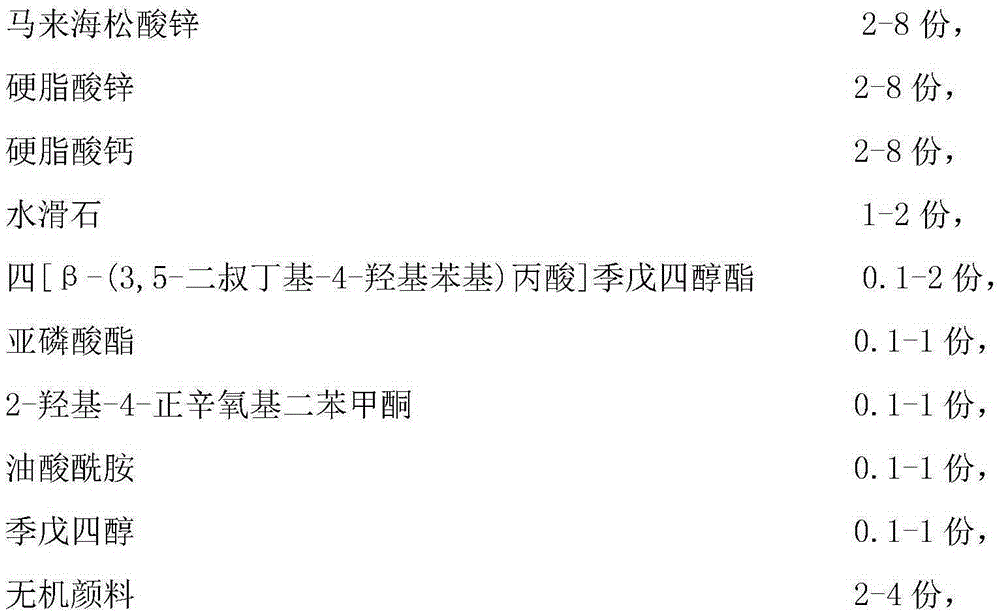

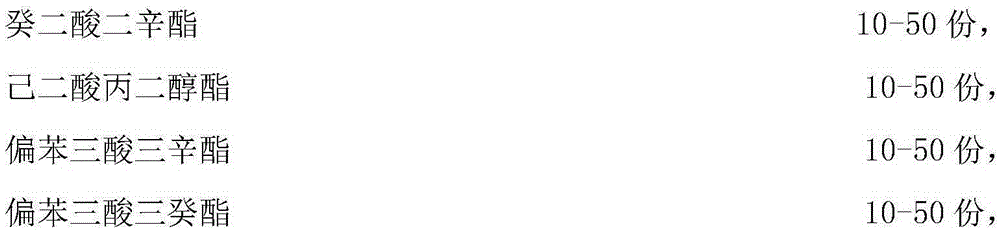

Slush-molded PVC material for automotive trim skin and preparation method of slush-molded PVC material

The invention provides a slush-molded PVC material for automotive trim skin. The slush-molded PVC material is prepared from suspension method type PVC resin, polymer resin, diacetyl epoxy plant triolein, Malay pimaric acid zinc, zinc stearate, calcium stearate, hydrotalcite, tetra[beta-(3,5-di-tert-4-hydroxyphenyl)propionic acid] pentaerythritol ester, phosphite ester, 2-hydroxy-4-n-octyl epoxide benzophenone, oleamide, pentaerythritol, inorganic pigments and an assistant. The invention further provides a preparation method of the slush-molded PVC material for the automotive trim skin. Suspension method PVC is adopted, powder completely and thoroughly absorbs polymer liquid resin oil, and the flowing state of the powder is kept. According to the method, dioctyl sebacate, adipic acid trimethylene glycol ester, trioctyl trimellitate and tridecyl trimellitate are adopted, no orthophthalic resin is adopted, the slush-molded PVC material is environmentally friendly, healthy and safe, and the international environmental health requirement is met.

Owner:苏州聚威共混材料有限公司

Anti-adhesion membrane having effects of diminishing inflammation and resisting bacteria

InactiveCN106075611AHas anti-inflammatory and antibacterial propertiesGood biocompatibilitySurgeryIrritationGlycerol

The invention discloses an anti-adhesion membrane having effects of diminishing inflammation and resisting bacteria. The anti-adhesion membrane comprises the following components in parts by weight: 40-50 parts of polyhydroxyalkanoate, 3-10 parts of lemon peel pectin, 3-8 parts of metronidazole, 5-15 parts of glycerol, 5-11 parts of mupirocin, 1-3 parts of pimaric acid, 2-8 parts of divinylsulfone, 3-8 parts of succinic acid, 2-5 parts of glutamic acid, 11-14 parts of radix sanguisorbae powder, 3-7 parts of aloin, and 10-20 parts of wrinkled gianthyssop herb powder. The anti-adhesion membrane having effects of diminishing inflammation and resisting bacteria disclosed by the invention has the effects of diminishing inflammation and resisting bacteria, and good biocompatibility, and is degradable, convenient to use, good in biodegradability, free of irritation to tissues, and non-toxic and harmless to the human body, and can be widely applied to the medical field.

Owner:HUZHOU GUOXIN MATERIALS

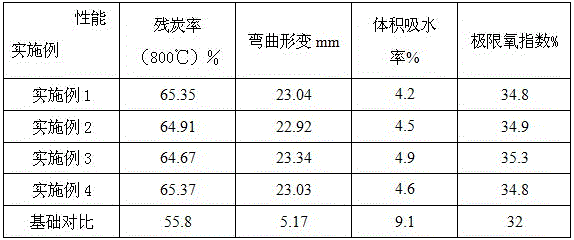

Pimaric acid modified phenolic aldehyde foaming resin

The invention discloses a pimaric acid modified phenolic aldehyde foaming resin, and relates to a foaming resin; the foaming resin is prepared from, by weight, 100 parts of phenolic resin, 80-95 parts of pimaric acid, 3-5 parts of catalyst, 2-6 parts of surface active agent, 8-10 parts of foaming agent, and 12-15 parts of curing agent. The pimaric acid is selected to modify phenolic resin; the used pimaric acid is innoxious substance directly extracted from a plant, and directly added in the phenolic resin, thus the ratio of harmful substance in the resin is reduced, and the product is more environment-friendly. The novel resin is high in mechanical strength and low in water absorbing property; the carbon yield is improved, and the product comprehensive performance is also promoted; the foaming resin has extensive development and application prospect.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Preparation method of pimaric acid type resin acid

InactiveUS8680232B2Increase temperatureYield andOrganic compound preparationNatural resin chemical modificationBottleSolvent

A method for preparing pimaric acid type resin acids includes the following steps: step (1) adding refined resin acid, turpentine, or rosin along with maleic anhydride at a mass ratio of 1:0.3-1.5 into a reaction bottle, dissolving the ingredients into a C1-C10 lower fatty acid solvent, the mass ratio of the C1-C10 low fatty acid to refined resin acid is 0.05-30:1, then carrying out additional reaction by heating directly or with assistance of a microwave, subsequently cooling, crystallizing, filtering, and washing; and step (2) combining the filtrates collected in step (1), stripping the solvent by vacuum distillation to obtain pimaric acid type resin acid coarse product, dissolving the resulting coarse product in NaOH aqueous solution to prepare aqueous solution of pimaric acid type resin acid salt, adjusting the pH level to 6-14 with a mineral acid or an organic acid while stirring, and either directly purifying or acidifying followed by purifying, the resulting precipitation to obtain the final product. The method has the characteristics of high yield, high product content, low cost, and low environmental pollution.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

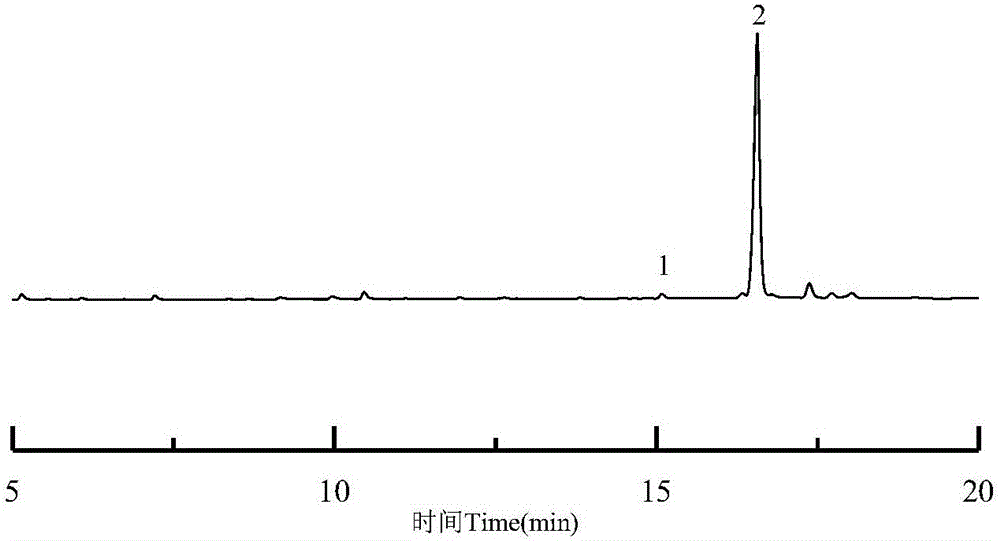

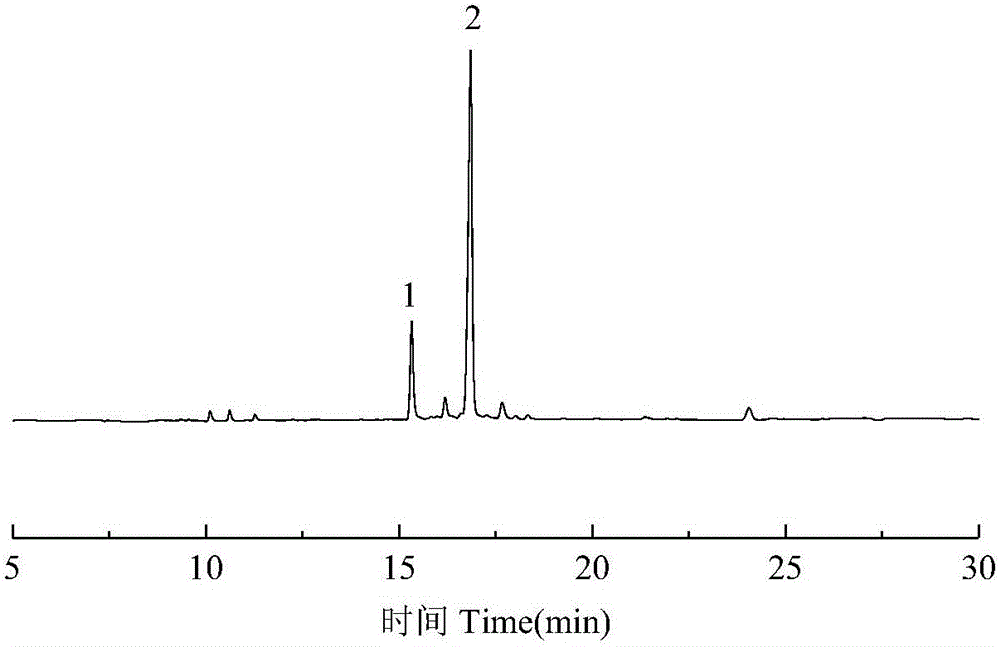

Preparation and separation method of high-purity p-acrylic pimaric acid

ActiveCN105801401AIncrease contentGood repeatabilityOrganic compound preparationCarboxylic compound separation/purificationCyclodextrinSilica gel

The invention relates to a preparation and separation method of high-purity p-acrylic pimaric acid and discloses a preparation and separation method of p-acrylic pimaric acid. The preparation and separation method comprises steps as follows: 1) rosin and acrylic acid are taken as raw materials and subjected to a Diels-Alder reaction under the microwave-assisted condition, and acrylic acid modified rosin is obtained; 2) acrylic pimaric acid is obtained through purification; 3) a p-acrylic pimaric acid product is prepared from the acrylic acid modified rosin or acrylic pimaric acid serving as a raw material through cyclodextrin modified silica gel column chromatography with benzene and ethyl acetate in different volume ratios as developing solvents and has the purity higher than 95%. The method is simple, convenient, efficient and high in repeatability, the obtained p-acrylic pimaric acid has high purity and can be used as a high-purity chemical material or an intermediate, and additional utilization values of rosin can be effectively increased.

Owner:南昌市龙然实业有限公司

Improved concrete anti-cracking modifier

The invention discloses an improved concrete anti-cracking modifier, which is made by the following raw materials in parts by weight: 2.5-4.5 parts of polypropylene fiber, 1.5-2.3 parts of sodium abietate, 2.5-3.3 parts of sodium dodecyl sulfate, 3-7 parts of quartz sand, 7-12 parts of glycerol, 0.5-1.3 parts of citric acid, 1.2-2.7 parts of dodecyl dimethyl benzyl ammonium chloride and 3.2-4.7 parts of pimaric acid soap. Compared with the existing modifier, the dodecyl dimethyl benzyl ammonium chloride can improve the mechanical properties of the concrete such as compression resistance, breaking resistance and adhesivity of concrete under the co-existing of the glycerol, the polypropylene fiber and the citric acid, and increase the compactness, chemical stability, wear resistance and freeze resistance of products, so that the improved concrete modifier can be widely applied to floor materials, paving materials, water-proof materials, adhesive materials, joint and repair materials, antiseptic and liner materials and surface covering materials.

Owner:QINGDAO HIBOUND CHENGYUAN PLASTIC

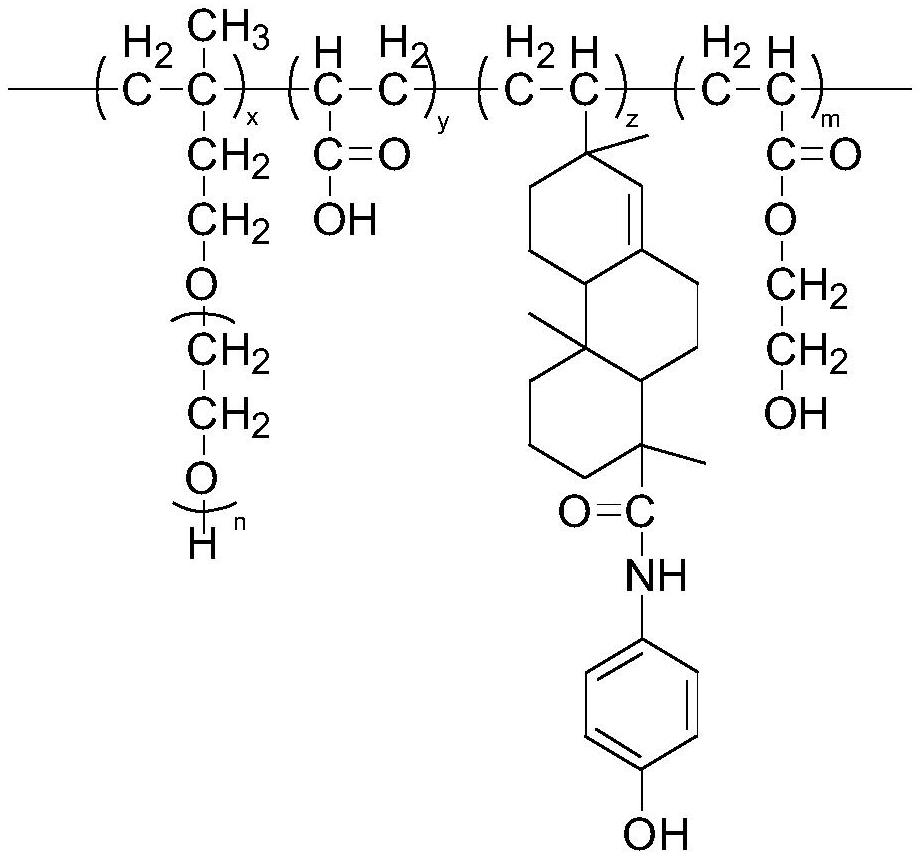

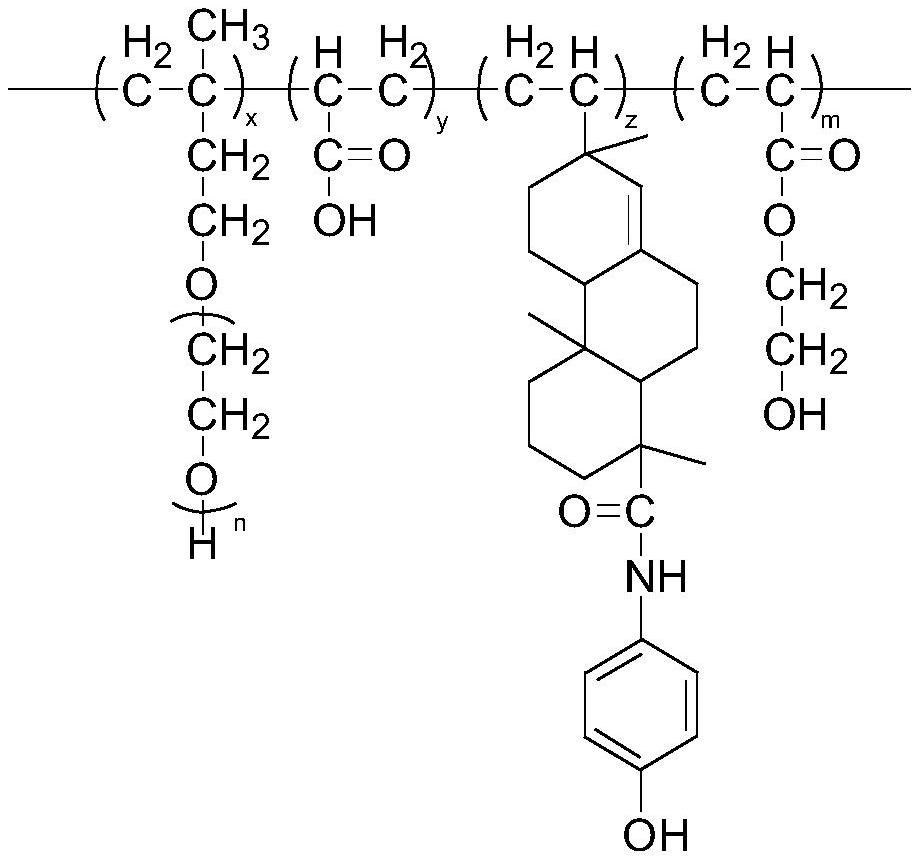

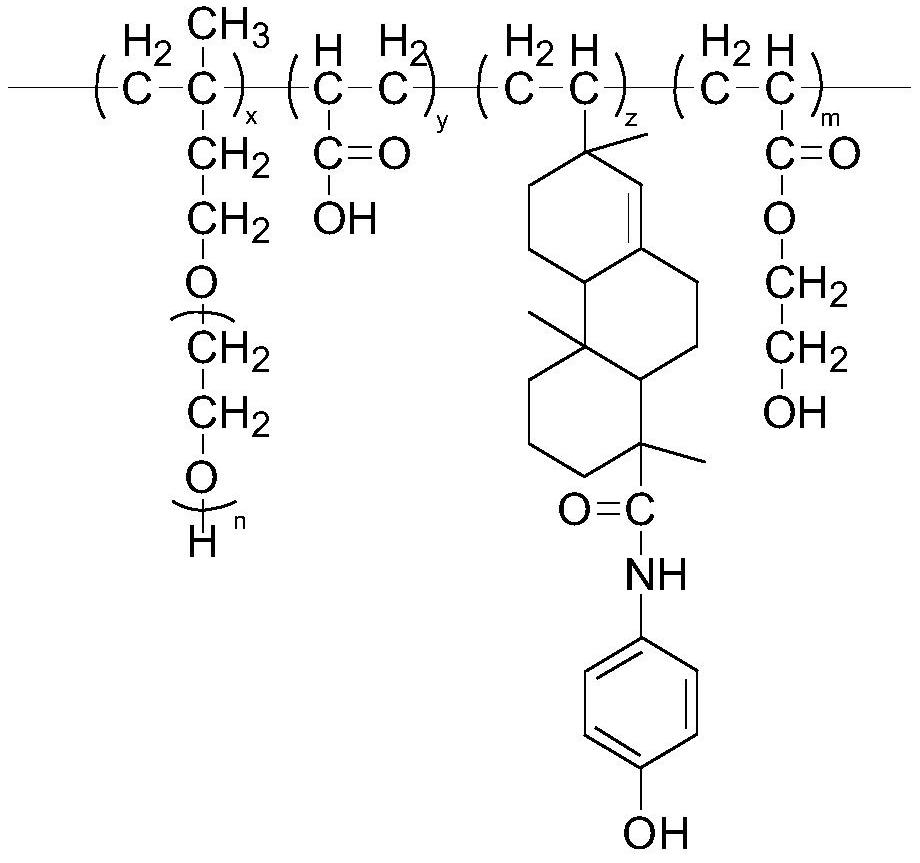

Alkali-soluble polymer compound and photosensitive resin composition using the same

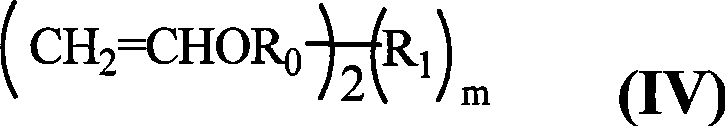

ActiveUS20110269867A1Improving alkali development characteristicPhotopolymerization reactionLavatory sanitoryMicrowave heatingResin acidPolyresin

A novel alkali-soluble polymer compound including a dehydrogenated pimaric acid and / or its isomer as a repeating unit, and a photosensitive resin composition including the alkali-soluble polymer compound as an effective binder matrix are provided. A photosensitive resin composition using the alkali-soluble polymer compound including a dehydrogenated resin acid has excellent photosensitivity and developing characteristics cause a less deformation in a firing process, has excellent elasticity. Thus, the photosensitive resin composition is advantageous for curing various transparent photosensitive materials, in particular, materials of column spacers, an overcoat, a passivation layer, or the like, used for fabricating color filters of an LCD.

Owner:LG CHEM LTD

Planting method of organic vegetable dried ballonflowers

InactiveCN107646348AImprove securityEnsure safetyFertilising methodsPlant protectionInsect pestHigh stress

The invention discloses a planting method of organic vegetable dried ballonflowers. The planting method comprises the following steps of seed germination, seed coating, seedling bed preparation, sowing and seedling raising, seedling management, plant disease and insect pest prevention and control and harvest. The planting method of the organic vegetable dried ballonflowers does not use chemical pesticide in the planting process and is high in safety. In the planting process of the dried ballonflowers, the green pesticide free of pollution is used for preventing and controlling plant diseases and insect pests. For an example, S-S rosin pesticide of which the main component is sodium pimaric acid is used for preventing and controlling aphids, and therefore not only can the plant diseases andthe insect pests be prevented and controlled, but also the safety of the dried ballonflowers can be guaranteed. Used components are free of pollutants and residues and are compatible to the environment. Seeds are coated, and therefore the seed survival rate is increased. After the seed germination is carried out, the seeds are coated, so that the vigor of the seeds are improved in the germinationprocess, the seed germination rate is increased, the growth of seedlings in the seedling culture stage is promoted, and the ballonflowers have high stress resistance.

Owner:巫溪县利安农业发展有限公司

Polycarboxylate superplasticizer and preparation method thereof

ActiveCN112679675AExcellent air-bleed functionEnhanced bleed air functionPolymer scienceFunctional monomer

The invention discloses a polycarboxylate superplasticizer and a preparation method thereof. The polycarboxylate superplasticizer is characterized by being prepared from, by weight, 200 parts of isopentenyl polyoxyethylene ether, 20-80 parts of an unsaturated air-entraining type functional monomer, 12-50 parts of an unsaturated monomer, 0.5-3.0 parts of an initiator, 0.5-2.0 parts of a chain transfer agent, 0.1-1.0 part of a reducing agent; and 300-400 parts of water; wherein the unsaturated air-entraining type functional monomer comprises pimaric acid type resin acid, p-aminophenol, ethanol and a catalyst in a mass ratio of 100: (30-50): 200: (0.1-0.5). The polycarboxylate superplasticizer disclosed by the invention is obtained by free radical copolymerization of the components, and the unsaturated air-entraining functional monomer is introduced into the polycarboxylate superplasticizer, so that the air-entraining function of the polycarboxylate superplasticizer can be effectively improved, the workability of concrete is good, tiny, uniform and stable bubbles are introduced into the concrete, and thus, the permeability resistance and the cracking resistance of the concrete doped with the polycarboxylate superplasticizer are improved.

Owner:ZHEJIANG KZJ NEW MATERIALS CO LTD

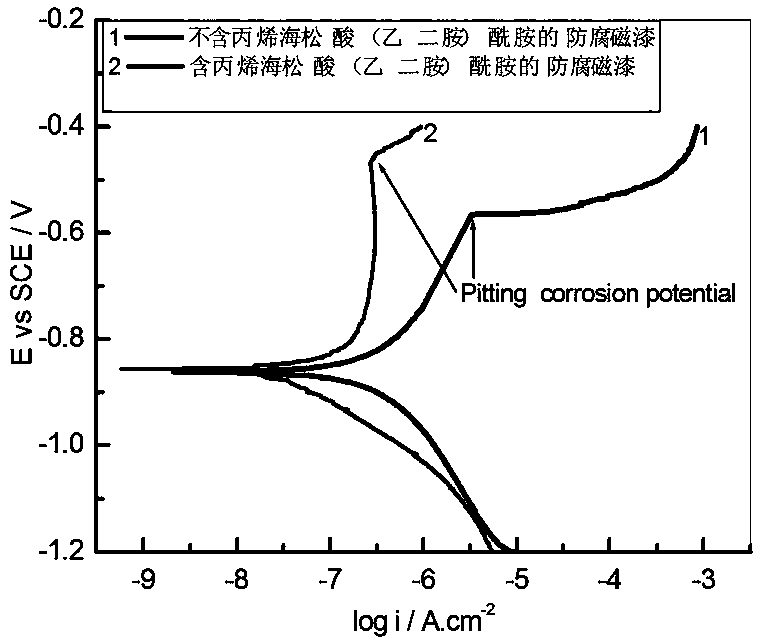

Preparation method of rosin-based long oil alkyd resin anticorrosive enamel with high pitting potential

InactiveCN110256944AImprove pitting resistanceImprove anti-corrosion performanceAnti-corrosive paintsPolyester coatingsEthylenediamineIsobutanol

Owner:GUANGXI UNIV FOR NATITIES

Medical bacteria restraining and sterilizing plastic preparation method

The invention discloses a medical bacteria restraining and sterilizing plastic preparation method. The medical bacteria restraining and sterilizing plastic is prepared from the raw materials of ABS, potassium pyrrolidone carboxylate, pimaric acid, dibutyl mercaptide, phenolsulfonic acid, monoglyceride stearate, diisooctyl phenyl phosphite, dibutyl sebacate, polyethylene glycol oleate, an antioxidant CA, a carbon nano tube, maleic anhydride, sodium hexametaphosphate, calcium hypochlorite, calcite and an ultraviolet light absorber; longitudinal tensile strength of a product is 50 to 70 MPa, andhorizontal tensile strength of the product is 30 to 40 MPa; an escherichia coli antibacterial rate is 99.4 to 99.8%, a staphylococcus aureus antibacterial rate is 98.8 to 99.2%, a pseudomonas aeruginosa antibacterial rate is 98.5 to 99.5%, a salmonella typhimurium antibacterial rate is 93 to 97%, a klebsiella pneumoniae antibacterial rate is 94 to 98%, a bacillus subtilis sterilization rate is 97to 99%, and a sarcina sterilization rate is 93 to 95%; bending strength is 150 to 200 MPa.

Owner:SUZHOU JONATHAN NEW MATERIALS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com