Synthesis method of gum rosin derivatives

A technology of gum rosin and rosin acid acyl, which is applied in the synthesis field of gum rosin derivatives, can solve problems such as unspecified yield, and achieve the effects of high yield and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

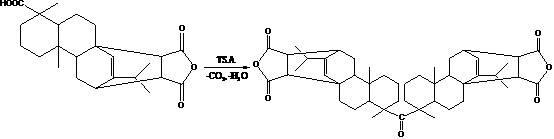

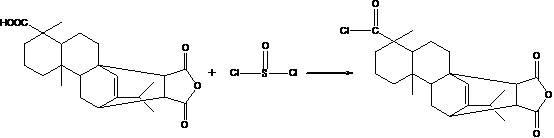

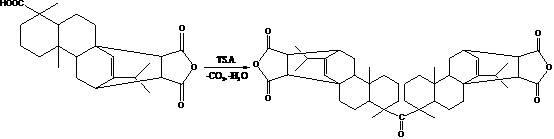

Image

Examples

Embodiment

[0030] Embodiment Its preparation method of maleopimaric anhydride, maleopimaric acid chloride and maleopimaric acid dianhydride is carried out as follows:

[0031] (1) gum rosin purifies abietic acid:

[0032] Add 210g of gasoline (boiling range: 90-100°C) and 100g of gum rosin into a 1L four-neck flask equipped with mechanical stirring, condenser and thermometer, start the stirrer at a stirring speed of 50r / min, and heat slightly to 40°C , so that the gum rosin is dissolved and clarified. Slowly add a solution of 30g cyclohexylamine dissolved in 35g gasoline (the specification is the same as above) to form a large amount of white precipitate. After the reaction at 40°C for 1 hour, cool down to below 5°C with an ice-water bath and keep it for 30min. The precipitate was washed 3 times with gasoline cooled in an ice-water bath. After drying in a vacuum oven at 40°C, grind it into a powder and place it in a 500mL three-necked flask equipped with a mechanical stirrer, a condens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com