Patents

Literature

180 results about "Maleopimaric acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

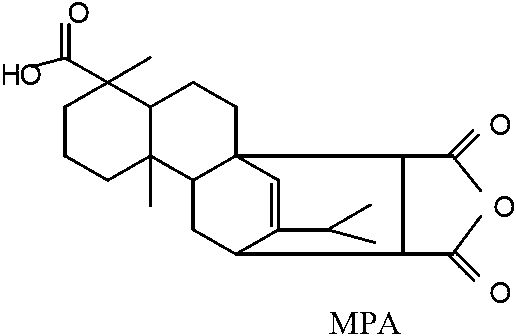

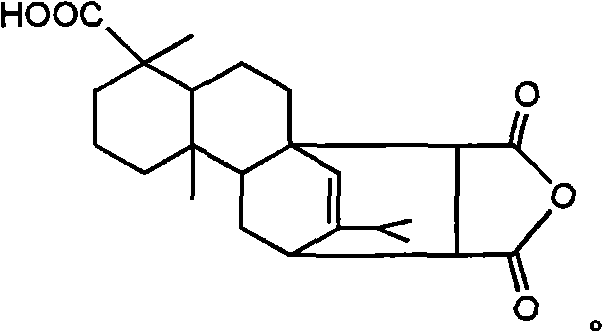

Maleopimaric acid, sodium salt; from MeSH. Depositor-Supplied Synonyms. Chemical names and identifiers provided by individual data contributors and associated to PubChem Substance records. Synonyms of Substances corresponding to a PubChem Compound record are combined.

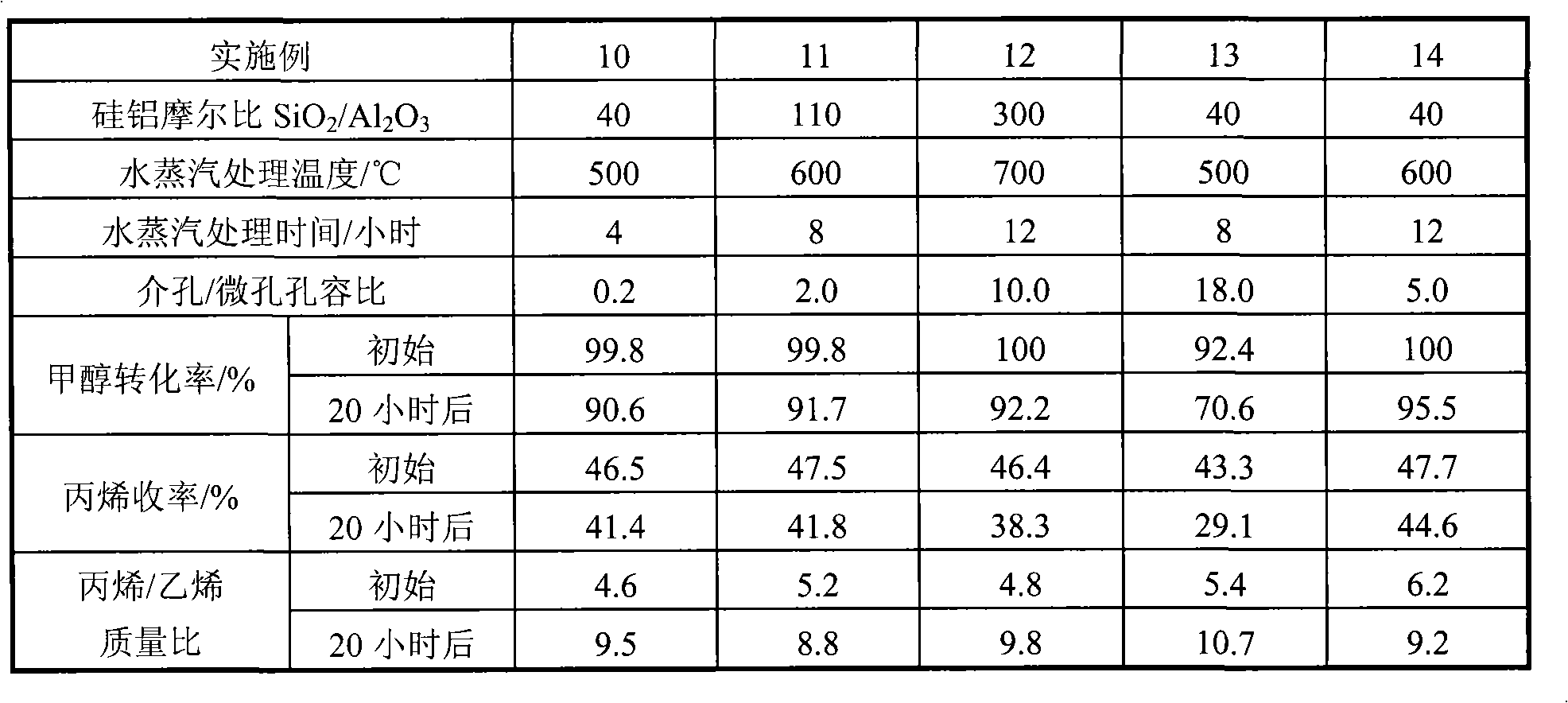

ZSM-5 mesoporous molecular sieve catalyst for preparing propylene from methanol and preparation thereof

ActiveCN101279282AMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMaleopimaric acidAmmonium nitrate

The present invention relates to a ZSM-5 mesoporous molecular sieve catalyst used for manufacturing propylene by methanol and a preparation method thereof, which mainly solves the problems of low propylene selectivity, low propylene / ethylene mass ratio as well as poor thermal stability of molecular sieve and poor water thermal stability in the prior art. The present invention adopts the technical proposal of adopting ZSM-5 mesoporous molecular sieve raw powder with a silicon-aluminum mol ratio SiO2Al2O3 of 20 to 1000 and a weight percentage of 20 to 100 percent as well as at least one caking agent selected from SiO2, clay and Al2O3 to extrude, tablet or spray into shape; then treating for 1 to 8 hours by 0.1 to 3 mol / l of at least one ammonium liquor from ammonium nitrate, ammonium chloride or ammonium sulphate or 0.1 to 8.5 mol / l of at least one acid liquor from muriatic acid, nitric acid, vitriol or acetic acid under a temperature of 20 to 90 DEG C; then using steam to treat for 2 to 15 hours under the temperature condition of 400 to 700 DEG C; using a liquor of 0.1 to 3mol / l selected from at least one of oxalic acid, citric acid or maleic acid under a temperature condition of 20 to 90 DEG C to dip for 2 to 5 hours to obtain the modified molecular sieve catalyst, thus better solving the problems. The present invention can be used in the industrial production of propylene by being converted from methanol.

Owner:CHINA PETROLEUM & CHEM CORP +1

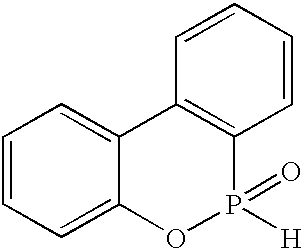

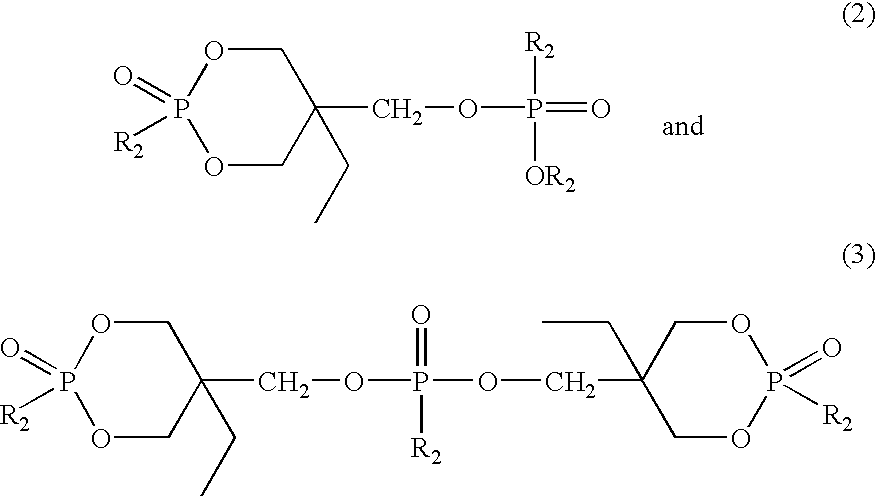

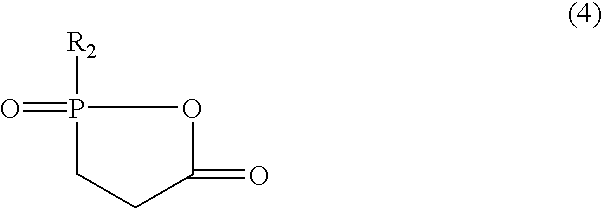

Halogen-free phosphorous-containing flame-resistant epoxy resin compositions

Curable flame-resistant substantially halogen free epoxy resin compositions, comprising:(a) one or more bifunctional or polyfunctional epoxy resin;(b) a specific phosphorous-containing compound;(c) a curing agent consisting of oligomers of styrene and maleic acid and / or maleic anhydride and / or salts or esters of maleic acid;(d) a curing catalyst; and optionally;(e) additives;prepregs derived from said compositions and laminates derived from said prepregs.

Owner:RESOLUTION PERFORMANCE PRODS

Acid soaping agent

ActiveCN101781613AImprove washing fastnessGood anti-staining effectSurface-active detergent compositionsHydrophilic monomerMaleopimaric acid

The invention discloses an addition agent acid soaping agent for dyeing. Although the conventional soaping agent composite has good soaping function, but cannot neutralize the alkaline substances which are remained on the cloth, and the cloth is washed by water for multiple times until the pH value of the cloth is close to neutral, the cloth can be used, so a great amount of water resource is wasted. Fatty alcohol polyethenoxy ether is firstly reacted with acrylic acid or maleic acid to generate a polymerization monomer with surface activity, then under the existence of the evocating agent, the polymerization monomer is polymerized with hydrophilic monomer to generate a macromolecular polymer having dispersion chelation performance, and the macromolecular polymer is compounded with the surface active agent to obtain the acid soaping agent. The prepared acid soaping agent integrates the neutralization process and the soaping process after the dyeing of the active dye, so the process flow is greatly shortened, the water is saved, the energy is saved, the emulsion dispersion chelation performance is excellent, the loose color on the texture can be easy to wash, and the staining prevention performance is excellent.

Owner:HANGZHOU TRANSFAR FINE CHEM CO LTD +2

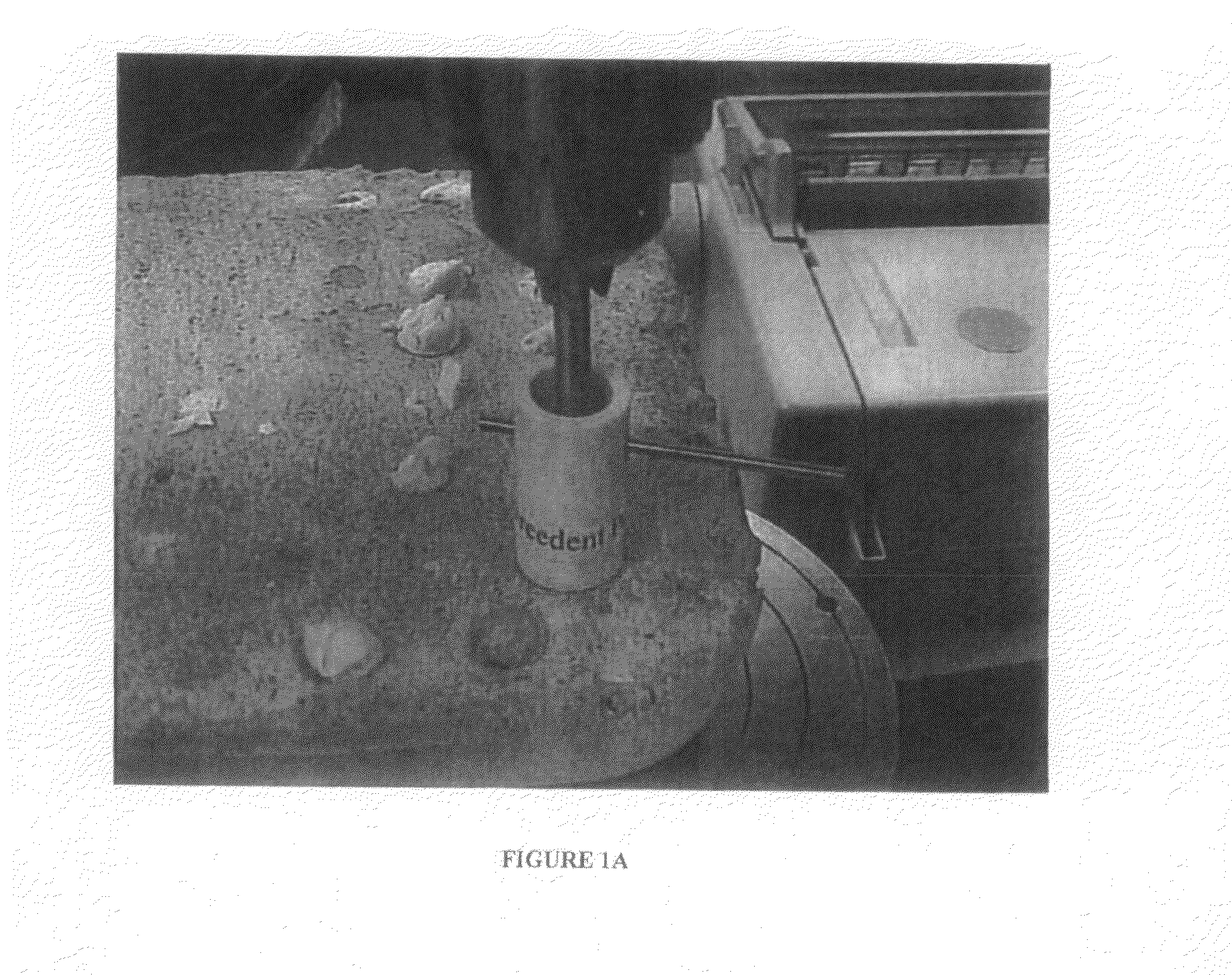

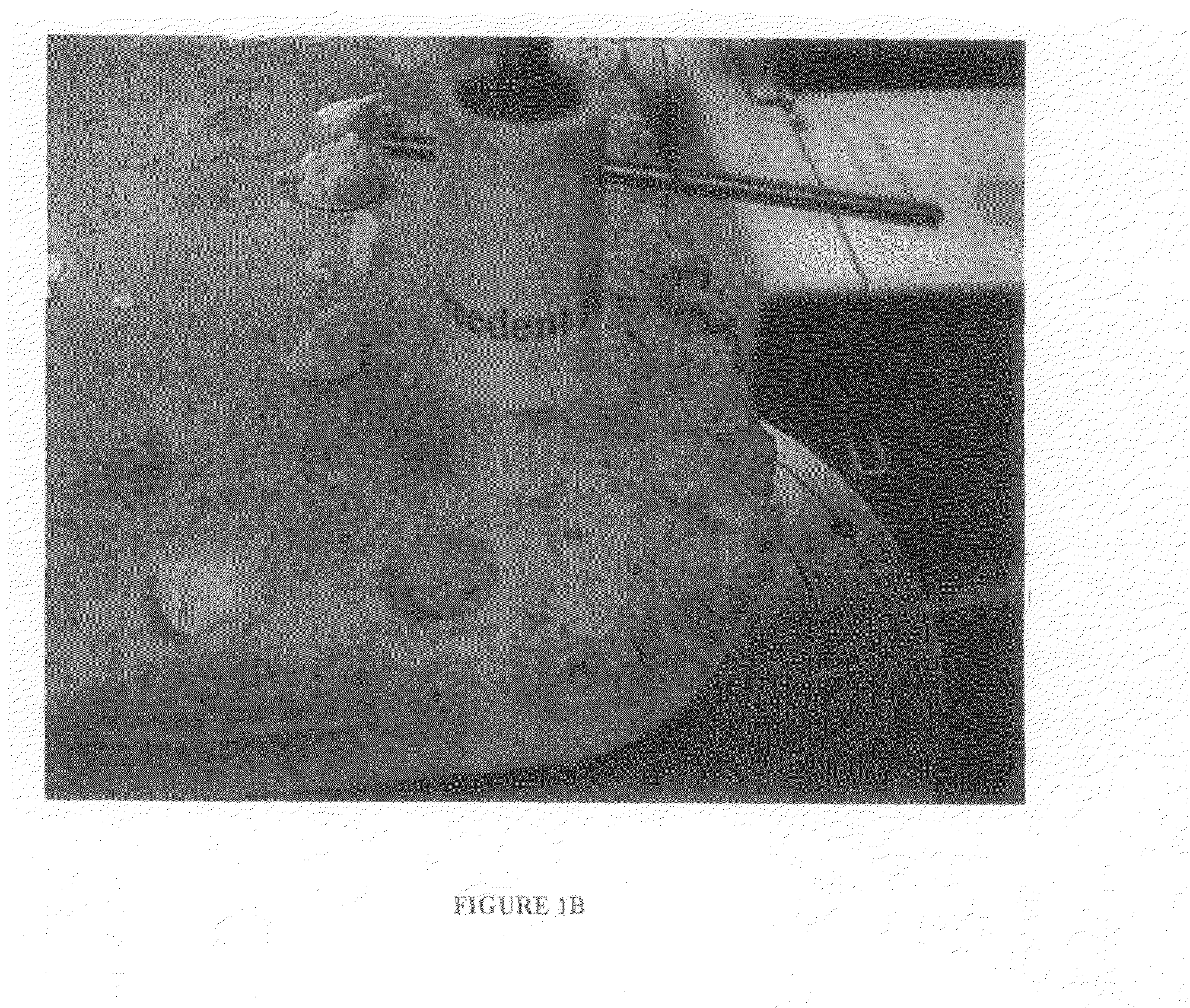

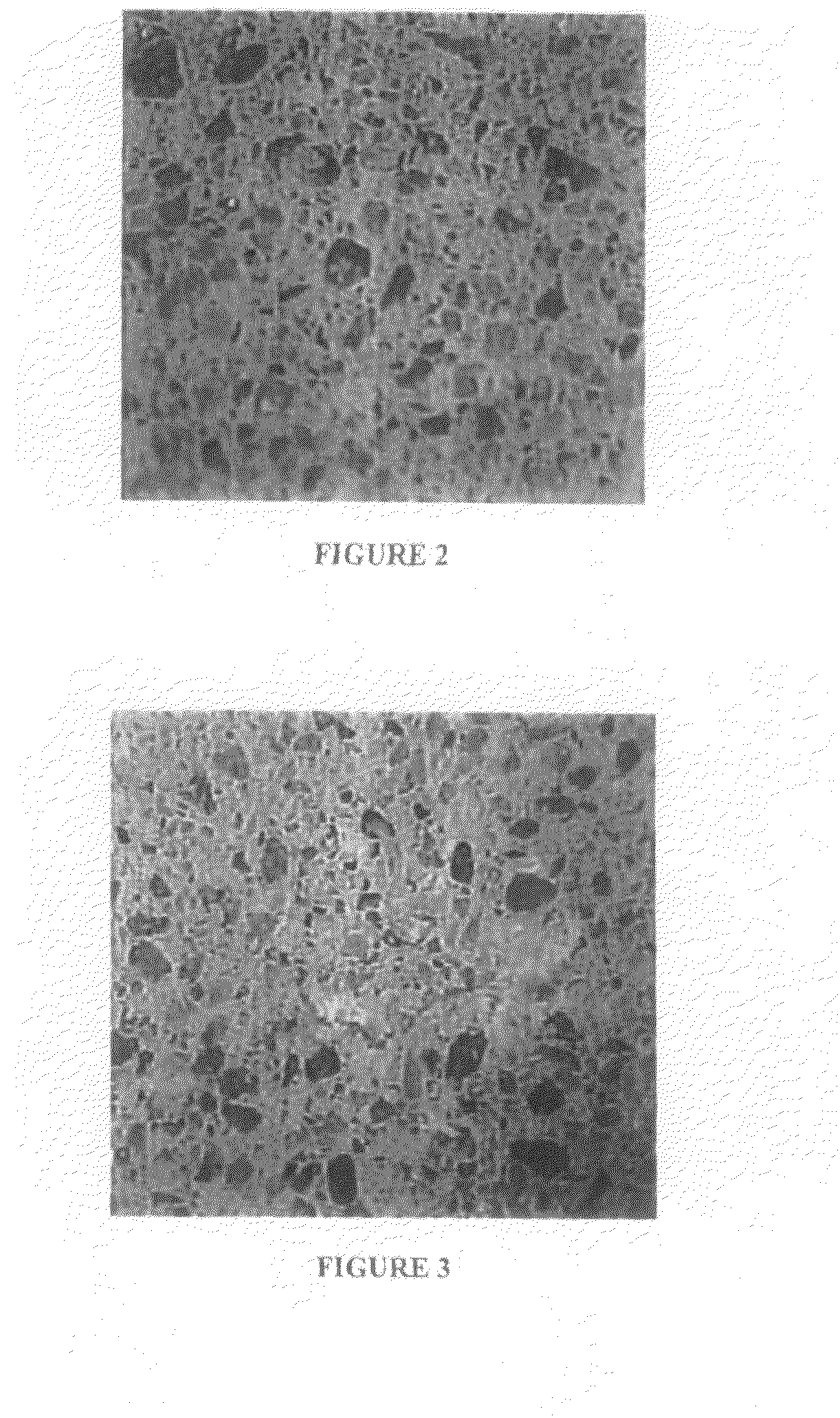

Degradable chewing gum

ActiveUS20080233233A1Reduce viscosityPromote degradationContainers for annular articlesChewing gumMaleopimaric acidEther

The present invention provides gum base compositions and chewing gum compositions having non stick or reduced-stick properties and / or increased degradability. The compositions include a terpolymer of methylvinyl ether, maleic anhydride and maleic acid, which provide increased degradability. Methods of preparing the gum base and chewing gum compositions, as well as methods of use, are provided.

Owner:INTERCONTINENTAL GREAT BRANDS

Maleic acid and ethylene urea containing formulation for removing residue from semiconductor substrate and method for cleaning wafer

InactiveUS6946396B2Efficient removalProvide performanceNon-ionic surface-active compoundsOrganic detergent compounding agentsResistMaleopimaric acid

Owner:NISSAN CHEM IND LTD

Method for preparing ultraviolet (UV)-curable polyisocyanate modified superbranched epoxy acrylate

ActiveCN102234268ALow viscosityGood alkali resistanceOrganic chemistryCoatingsEpoxyMaleopimaric acid

The invention relates to a method for preparing an ultraviolet(UV)-curable polyisocyanate modified superbranched epoxy acrylate, which comprises the following steps of: heating maleopimaric acid tri glycidyl ester, maleopimaric acid and a catalyst for esterification reaction to obtain rosin-based superbranched resin; cooling, and adding epoxy chloropropane, water and a catalyst for reaction to obtain superbranched epoxy resin; adding crylic acid, a catalyst and a polymerization inhibitor for reaction to obtain superbranched epoxy acrylic resin; and reacting the superbranched epoxy acrylic resin with ethylene glycol methacrylate terminated para toluene diisocyanate, a catalyst and a polymerization inhibitor to obtain the final product. Compared with the prior art, the method has the advantages that: rosinyl is introduced into superbranched polyester, and the hardness, strength and other special properties of the resin are improved and the curing speed is improved by utilizing the special rigid condensed ring structure of the rosin. The cured product has higher ultraviolet resistance; and by adjusting the using amount of raw materials, superbranched polyester for ultraviolet-curable coatings meeting different coating requirements can be prepared.

Owner:江苏金隆新材料有限公司

Demetallization agent for hy drocarbon oil and its operation method

InactiveCN1431277ASuitable for decalcificationLow costRefining with acid-containing liquidsPropanoic acidButanedioic acid

A demetalating agent for hydrocarbon oil contains one mor mixture of more than two of formic acid, acetic acid, propionic acid and butanoic acid, one or mixture of butanedioic acid and fumaric acid or maleic acid, polyacrylamide, one or mixture of more than two of S-carboxyethyl thiosuccinic acid, 2-mercaptobenzothiazole, hydroxyethylidene biphosphonic acid and 2-hydroxyphosphion acetic acid, andwater.

Owner:CHINA PETROLEUM & CHEM CORP +1

Vegetable fiber-reinforced biomass resin-based foam plate and preparation method thereof

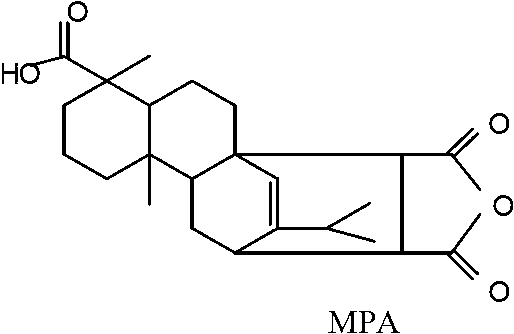

ActiveCN102838844AGive full play to the mechanical propertiesMake full use of the acoustic characteristicsWater basedEpoxy

The invention belongs to the design and manufacturing technology of environment-friendly composite material foaming plate, referring to a vegetable fiber-reinforced biomass resin-based foam plate and a preparation method of the foam plate. A light and high-performance composite material foam plate is manufactured by using vegetable fibers such as ramee, flax, hemp and jute as reinforced body, and loading expansion biomass resin and biomass epoxy resin. The preparation method comprises the steps of manufacturing a fiber felt with a certain thickness by needling or by using adhesive; and carrying out fire retarding or / coupling treatment on the chopped fiber felt; preparing epoxy resin by a MPA (maleopimaric acid anhydride) rosin-based epoxy resin curing agent; preparing epoxy resin into water-based suspension; adding 5-15% (mass percentage) of a microcapsule foaming agent to the suspension; fully immersing the treated fiber felt in the resin suspension, and removing the excess resin; finally, heating the chopped fiber felt immersed by resin for 10-15min in an oven at a certain temperature; after the resin cures, obtaining the vegetable fiber-reinforced biomass resin-based foam plate.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

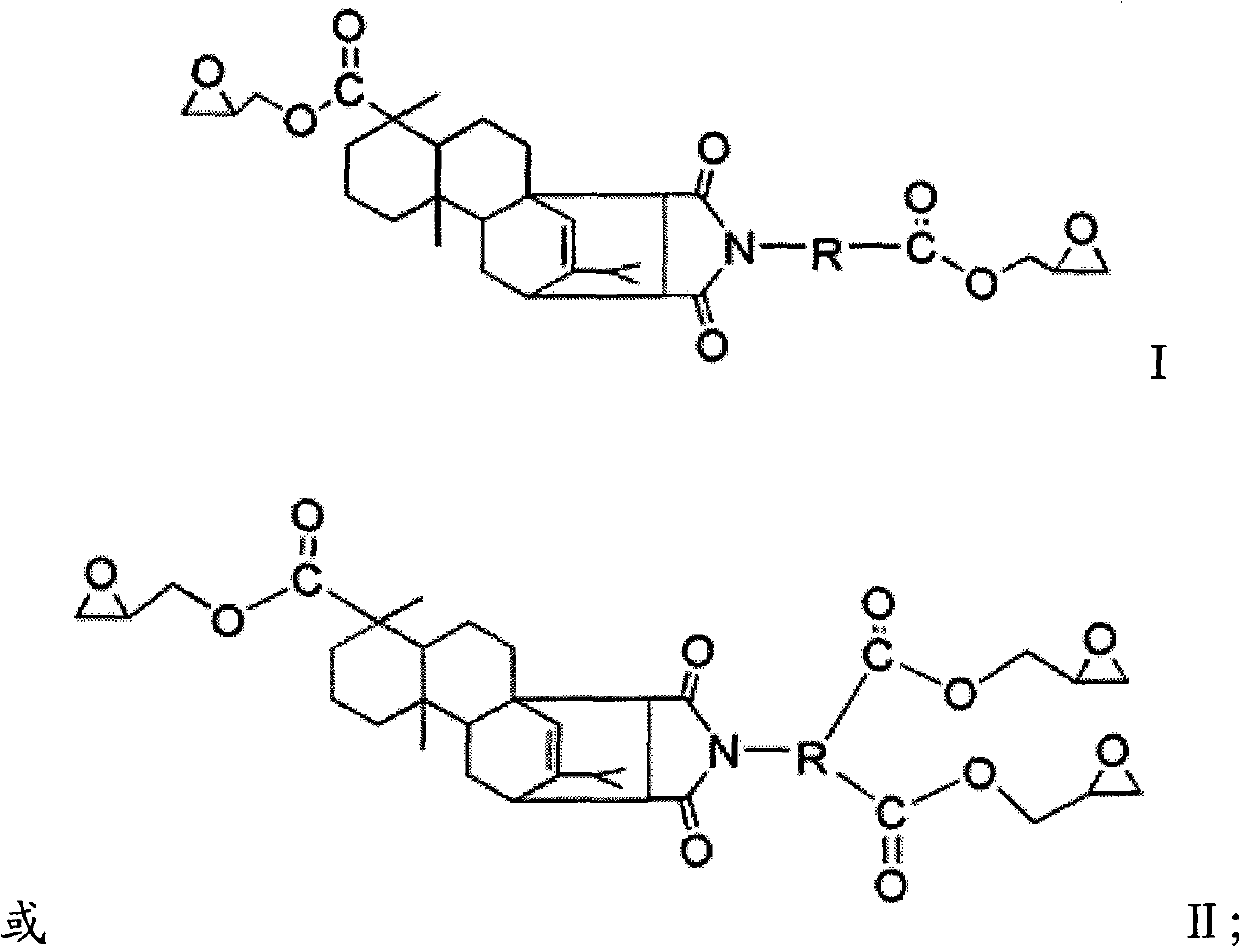

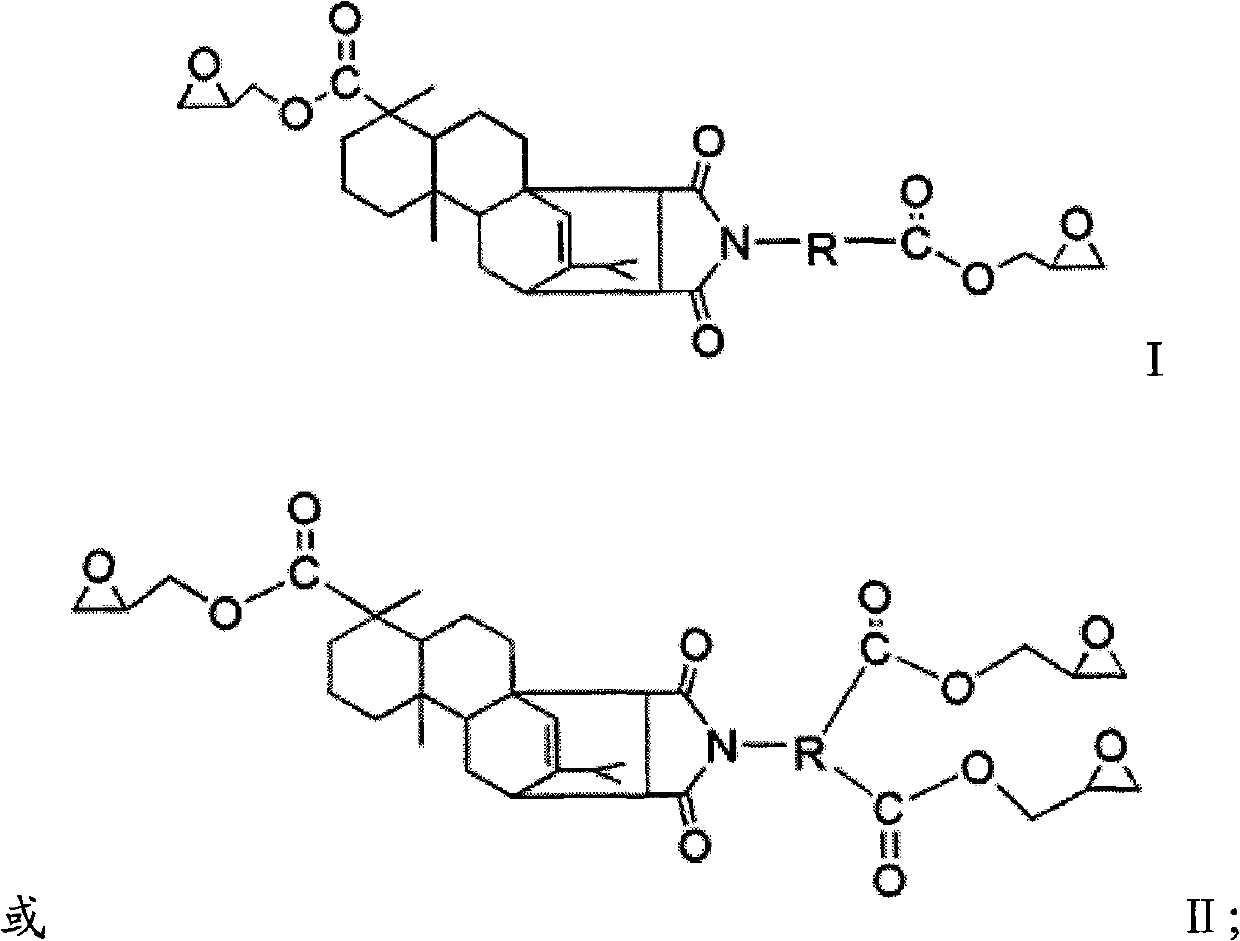

Rosin epoxy resin and preparation method thereof

InactiveCN102329309AGood weather resistanceEasy to makeOrganic chemistryPowdery paintsEpoxyPolyester

The invention discloses a rosin epoxy resin for the solidification of polyester powdery paints. The rosin epoxy resin is a compound with the structure of formula I or formula II. In the formula I or the formula II, R is an aliphatic chain segment or an aromatic chain segment. The invention also discloses a preparation method of the rosin epoxy resin. The preparation method comprises the following steps: 1, treating rosin as a raw material, adding with a catalyst I and maleic anhydride, and carrying out a Diels-Alder reaction to obtain maleopimaric acid anhydride (MPA); 2, reacting a compound containing amino and carboxyl with the MPA to prepare a rosin polyprotic acid; and 3, carrying out a series of chemical reactions on the rosin polyprotic acid, an epoxy alkylogen, a catalyst II, and an alkali to prepare the rosin epoxy resin. The rosin epoxy resin of the invention which has the advantages of environmentally friendly preparation technology, and low manufacture cost is mainly used for solidifying the polyester powdery paints.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

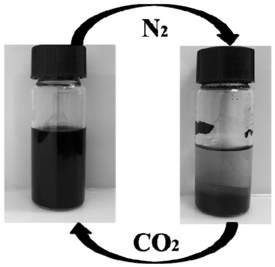

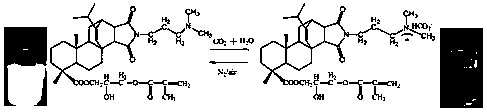

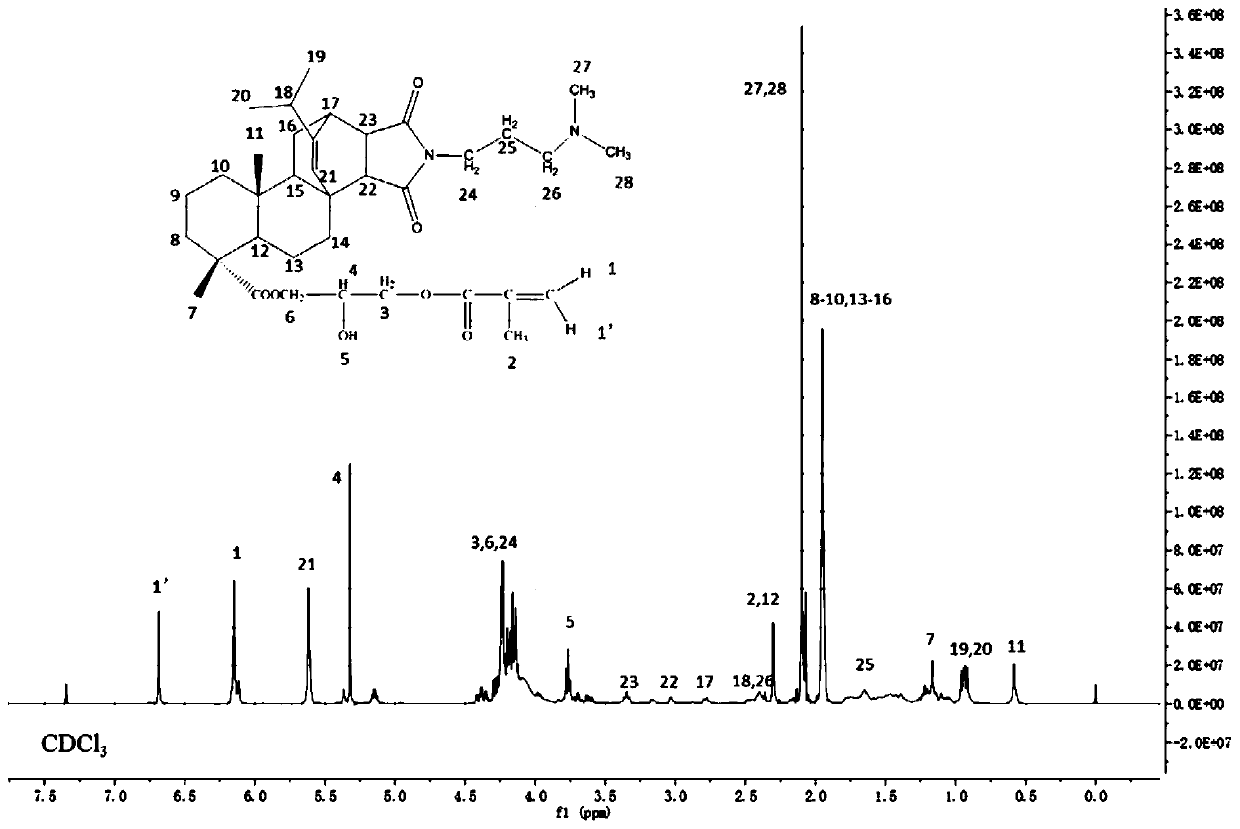

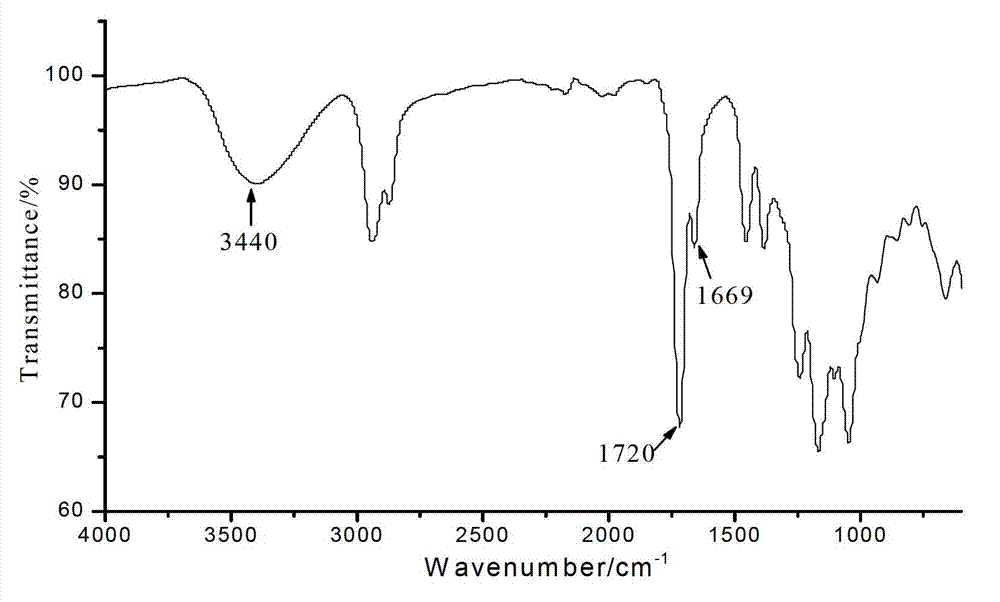

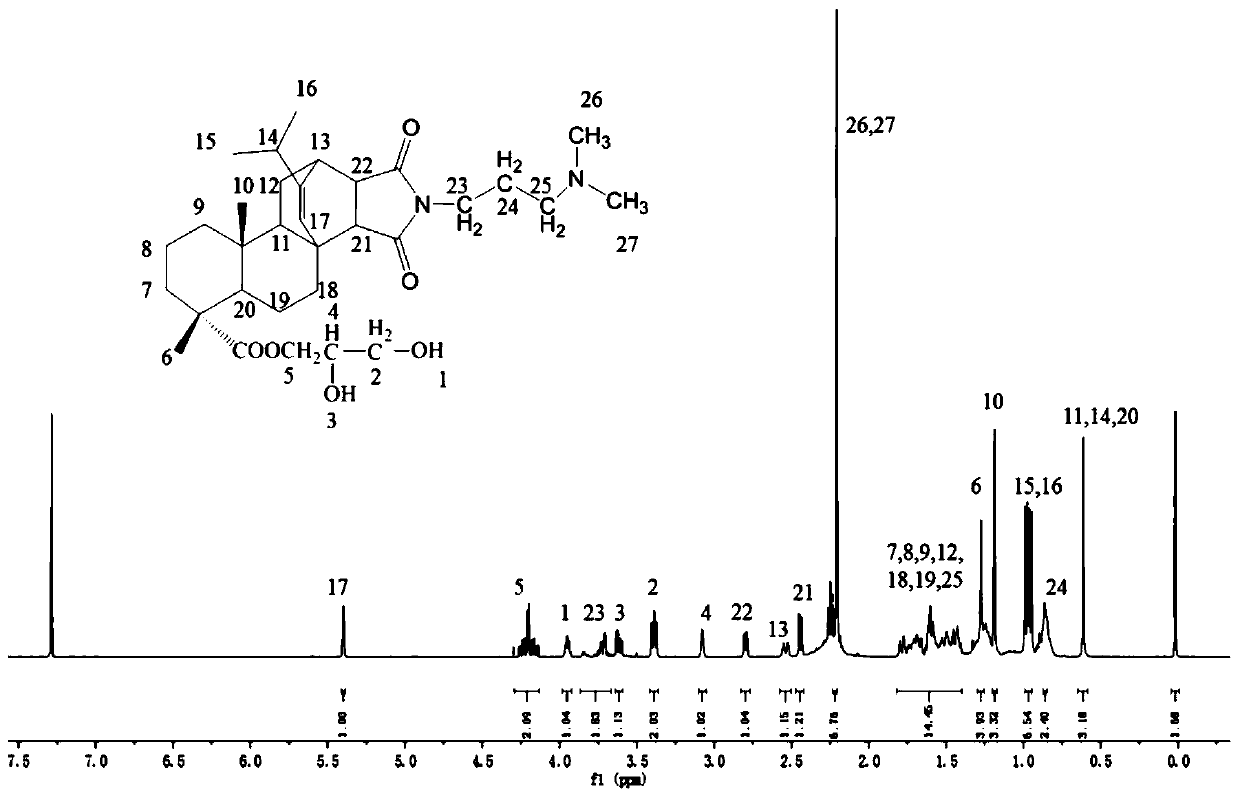

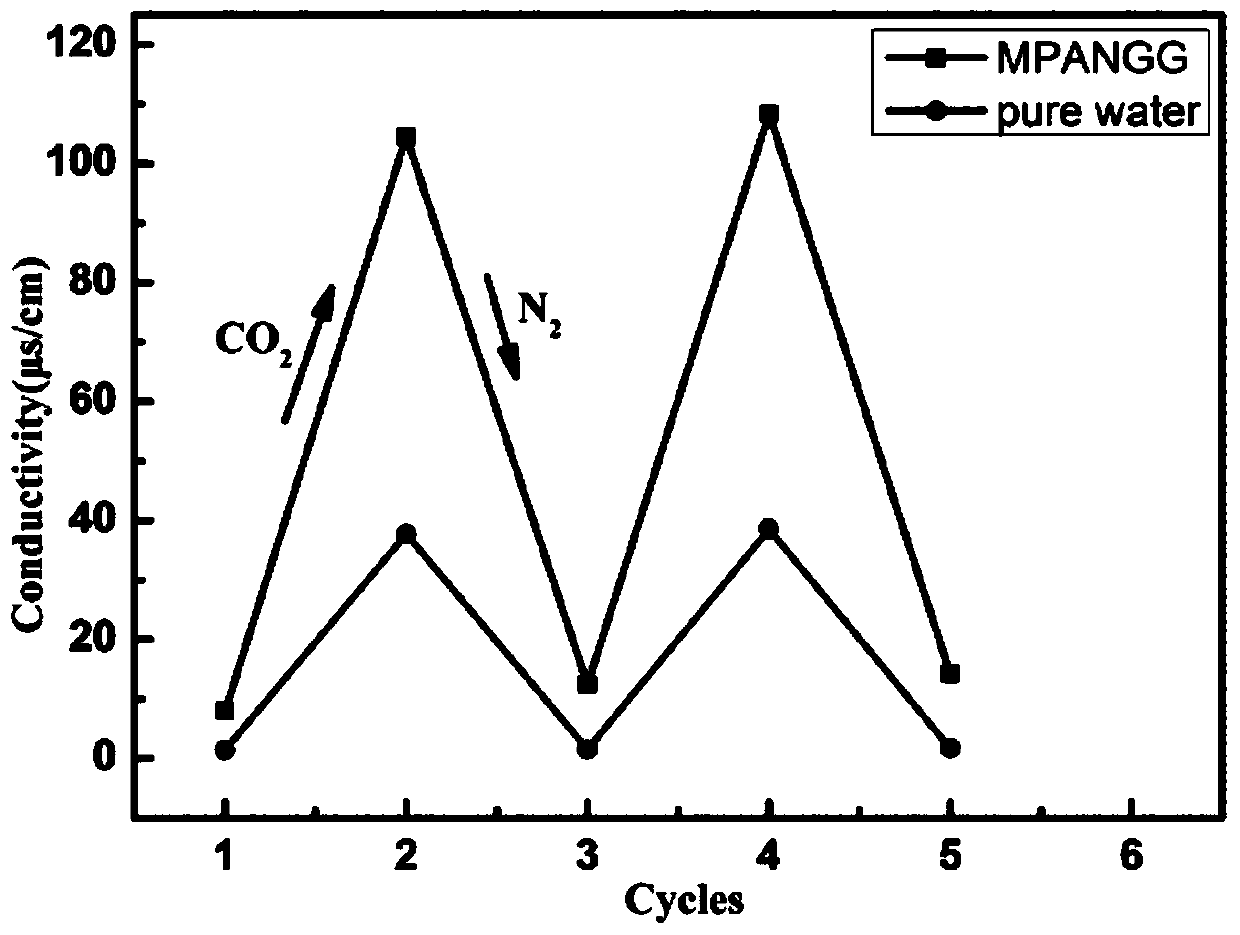

Rosin-based CO2/N2 response type polymerizable surfactant, and preparation method and application thereof

InactiveCN109868066AImprove stabilityGood dispersionTransportation and packagingMixingProtonationGlycidyl methacrylate

The invention discloses a rosin-based CO2 / N2 response type polymerizable surfactant. Maleopimaric acid reacts with glycidyl methacrylate (GMA) for introducing polymerizable monomers, and then an imidization reaction is carried out with N,N-dimethyl-1,3-propane diamine for introducing tertiary amine groups capable of responding to CO2. The surfactant has a response property on CO2 / N2, and after CO2is introduced, a water solution is weakly acidic, so that tertiary amine is protonated to form a tertiary amine salt and then is positively charged to become a form of a water-soluble cation; and after N2 is introduced to drive CO2, the positively charged tertiary amine salt is deprotonated to be recovered to an original state of a water-insoluble tertiary amine, and good response reversibility is achieved. The invention also discloses emulsification performance and dispersion performance of the surfactant, a Pickering emulsion and carbon nano tube dispersion liquid prepared by using the surfactant also have good responsiveness to the CO2 / N2, and end-group double bonds can be used for preparing a high-molecular surfactant by a polymerization reaction.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

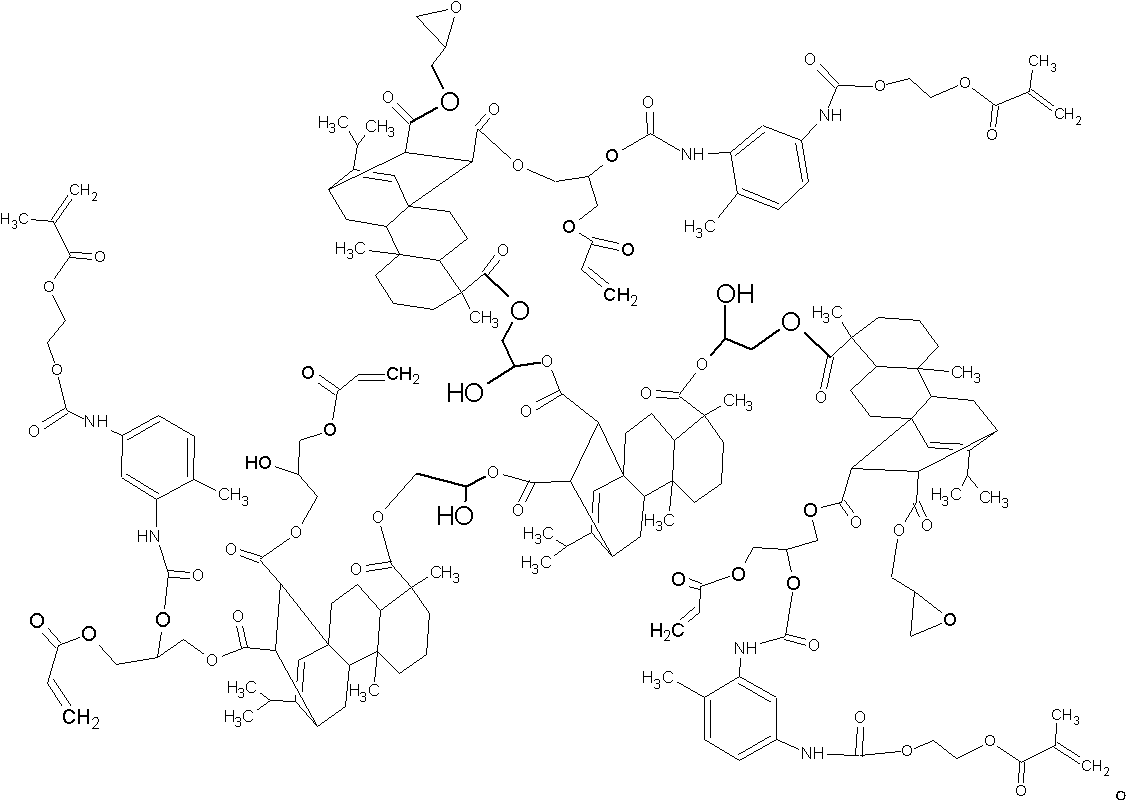

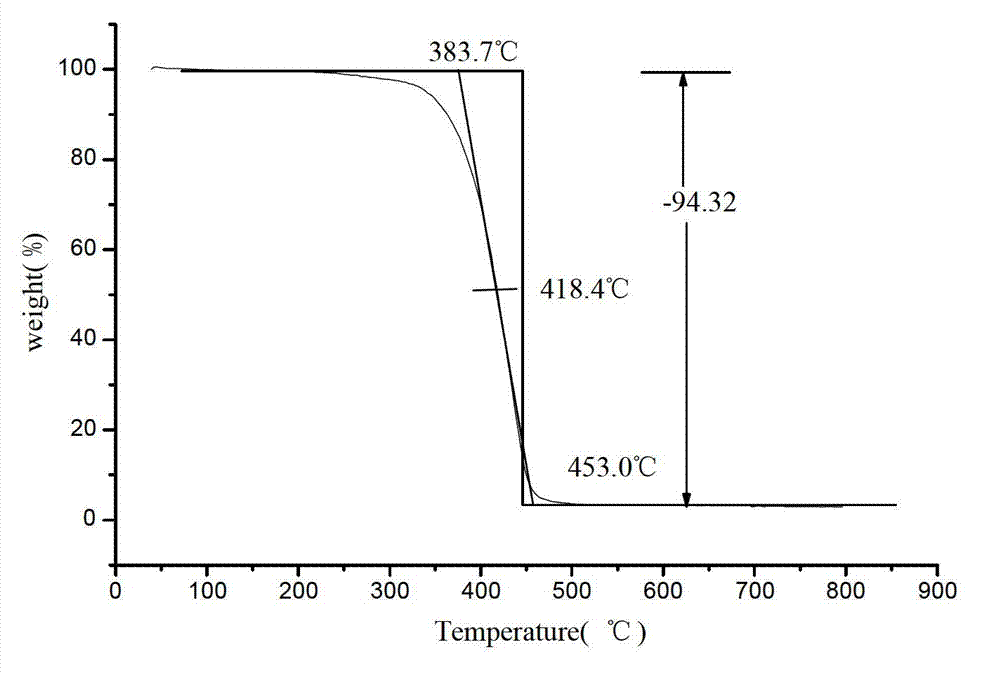

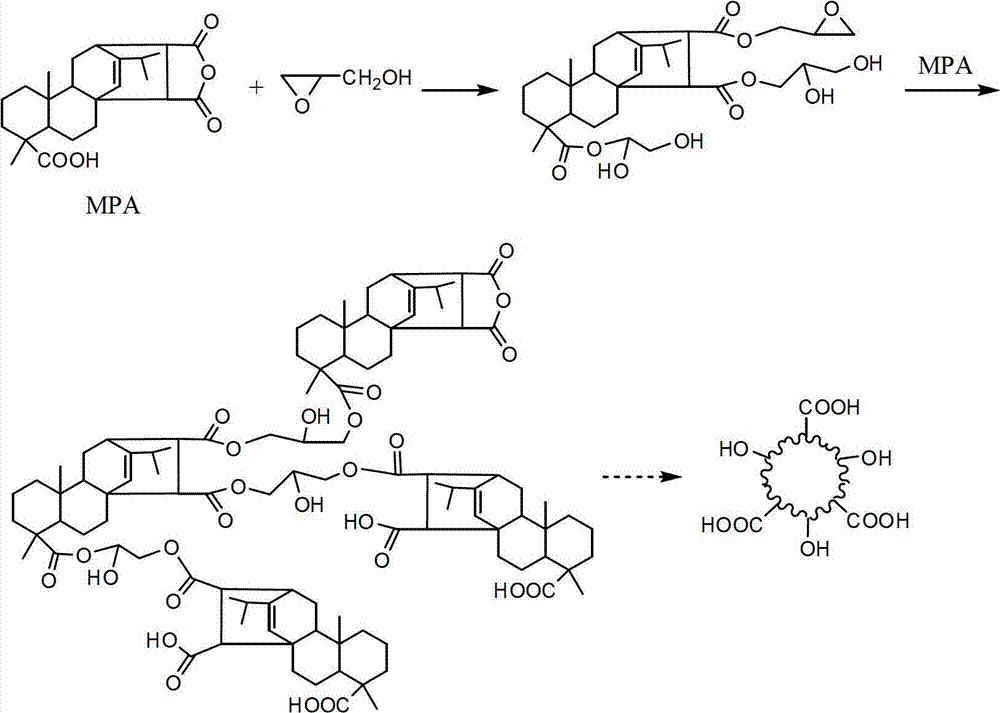

Preparation method for rosin-based hyperbranched polyester and application of rosin-based hyperbranched polyester to epoxy resin

The invention discloses a preparation method for rosin-based hyperbranched polyester and application of the rosin-based hyperbranched polyester to epoxy resin. The method comprises the following steps of: under the protection of nitrogen, reacting maleopimaric acid with a glycidol monomer in a molar ratio of (0.05-10):1 in an aprotic solvent at the temperature of 50 to 150 DEG C for 0.5 to 24 hours; adding a strong acid catalyst into the aprotic solvent, tracking and checking until an acid value is less than or equal to 10mg / g, reducing pressure at the vacuum degree of 0.1 to 100kPa, and continuously reacting for 0.5 to 5 hours to obtain an initial product; and precipitating, filtering, separating, and performing vacuum drying to obtain the rosin-based hyperbranched polyester. The method is simple, expensive equipment and complicated operation are not needed, and the obtained polymer contains a large number of end groups, can be dissolved in various organic solvents, and can be directly applied to the epoxy resin.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

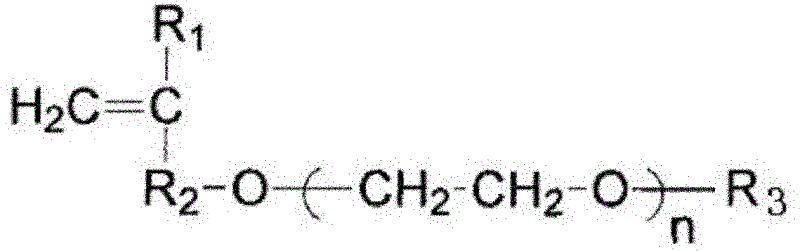

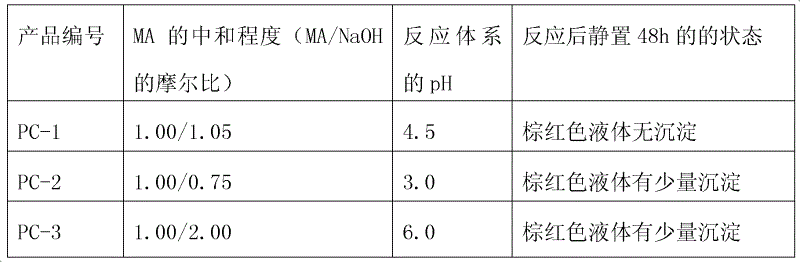

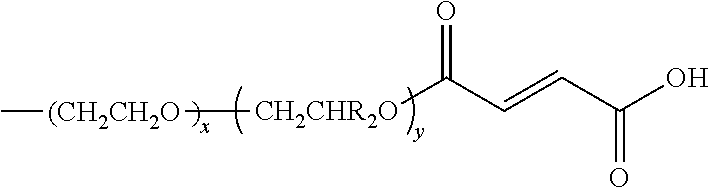

Allyl polyglycol ether polycarboxylic acid water reducer and synthetic method thereof

InactiveCN102617063AHigh polymerization activitySolve the problem of low contentMaleopimaric acidPolymer science

The invention discloses a synthetic method of an allyl polyglycol ether polycarboxylic acid water reducer. According to the method, allyl ether polyethylene glycol macromers, maleic anhydride (MA), acrylic acid, 2-acrylamide-2-methylpropanesulfonic acid (AMPS) and the like are used as main raw materials, a water-soluble hydroperoxide is used as an initiator, a transition metal salt is used as a catalyst, and polymerization is initiated in a specific pH range (2.5-6.0). The method makes the content of maleic acid in a polymer be greatly improved, the water reduction effect be good, and the product cost be greatly reduced and the product applicability be extensive especially replacing parts of acrylic acid by maleic acid, so the method is convenient for industrialized production and popularization.

Owner:CHANGZHOU INST OF CHEM

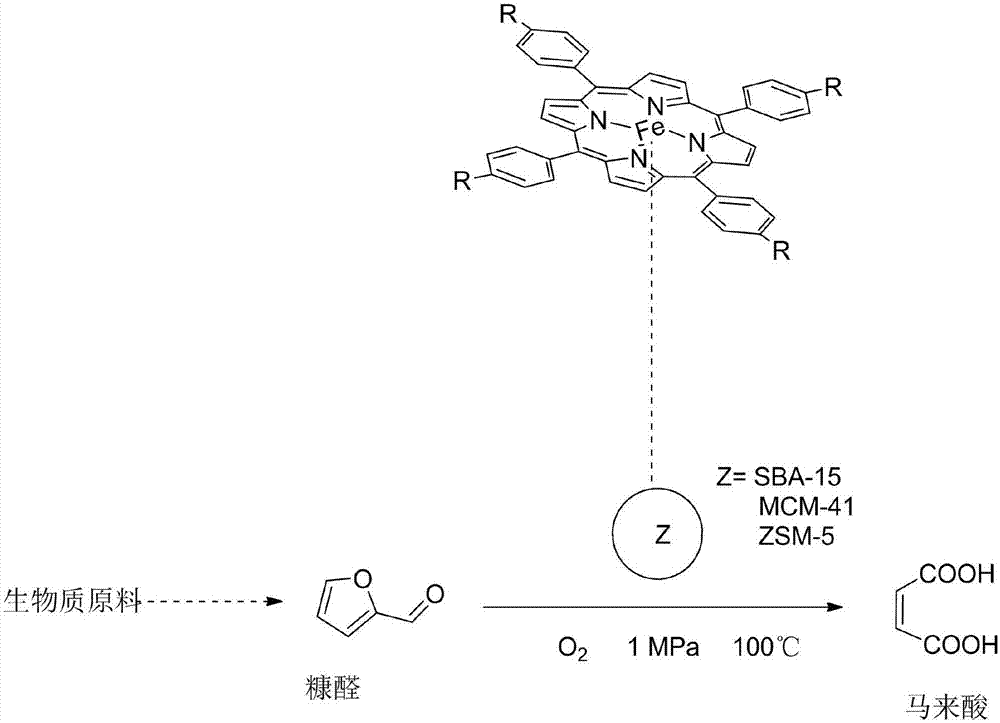

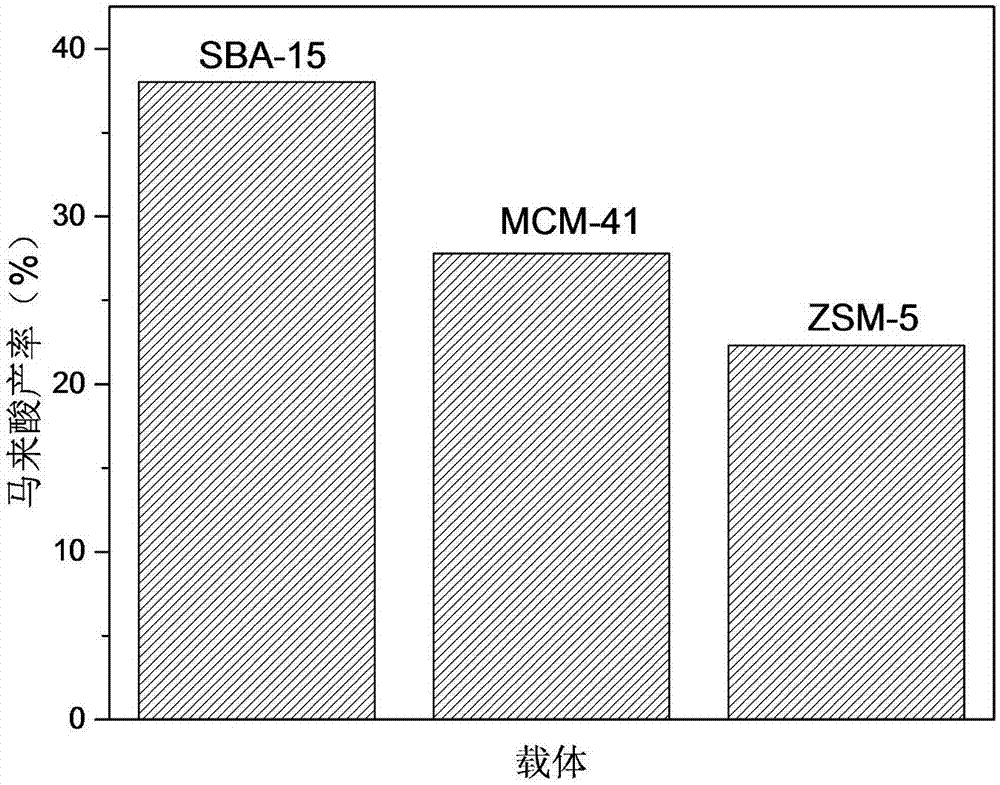

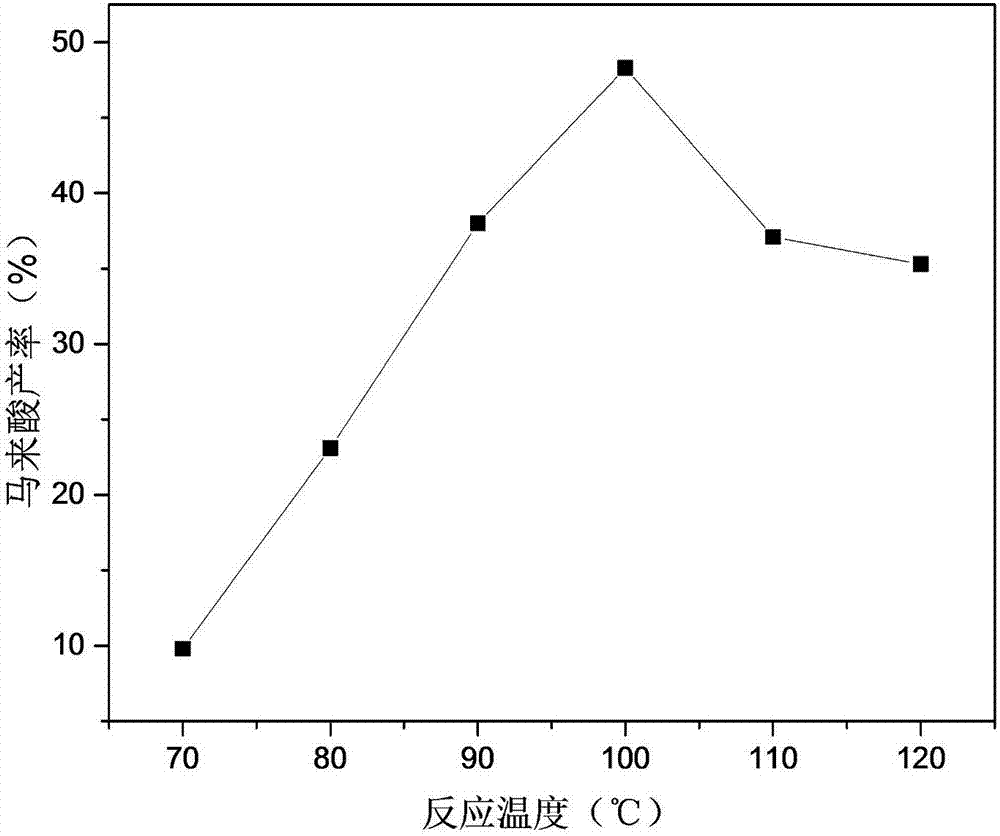

Solid-supported metalloporphyrin catalyst and application thereof in preparation of maleic acid

ActiveCN106925349AGood catalyticMild reaction conditionsMolecular sieve catalystsOrganic compound preparationMaleopimaric acidPorphyrin

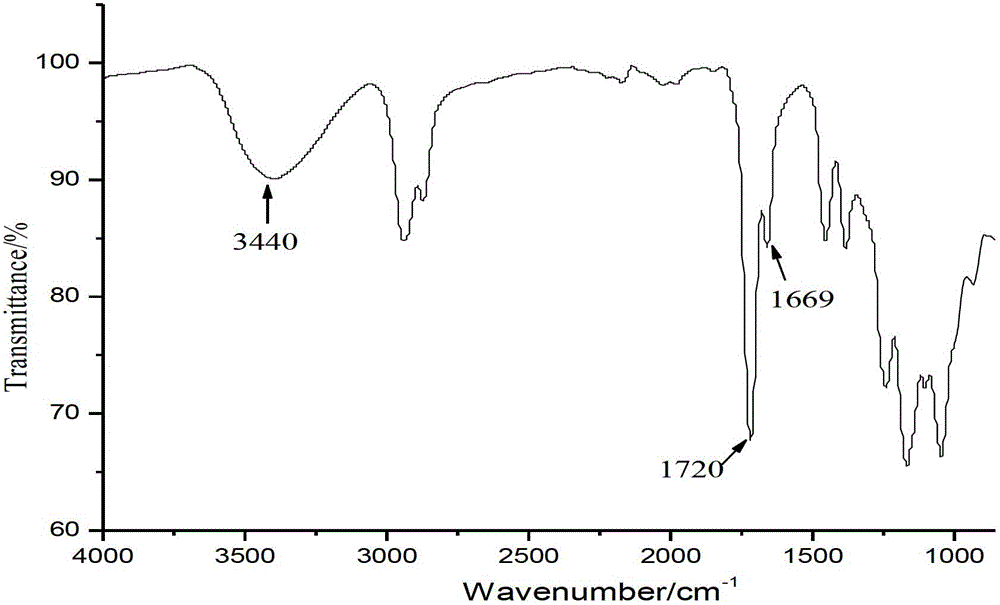

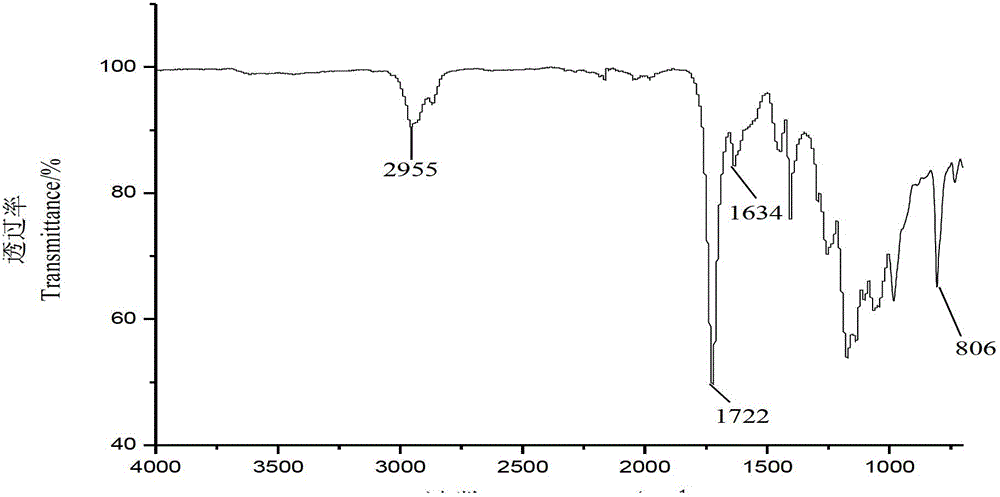

The invention discloses a solid-supported metalloporphyrin catalyst and application thereof in preparation of maleic acid, belonging to the technical field of catalytic application of metalloporphyrin. The solid-supported metalloporphyrin catalyst is used for preparing maleic acid by catalyzing furfural and has a good catalytic effect, and reaction conditions are mild, so that the energy consumption required in the prior art is greatly reduced. By utilizing the catalyst disclosed by the invention, a good microenvironment can be provided for reaction, so that the yield and selectivity of maleic acid are increased; by utilizing a method disclosed by the invention, the conversion rate of furfural is 20.4%-95.6%, the yield of maleic acid is 10%-56.1%, the selectivity of maleic acid is 43.6%-76.1%; and meanwhile, the catalyst is easy to separate, can be repeatedly and circularly utilized and is environment-friendly.

Owner:JIANGNAN UNIV

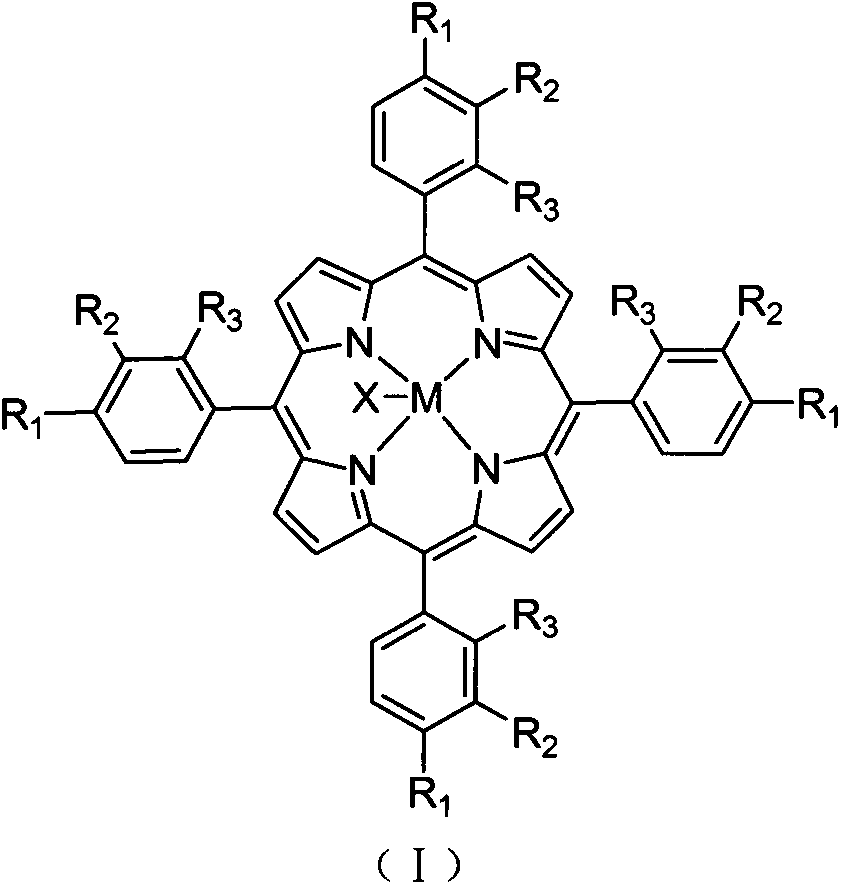

Method for preparing fumaric acid through cis-trans isomerization of maleic acid

InactiveCN103204773AReduce dosageHigh catalytic efficiencyOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsFumaropimaric acidN dimethylformamide

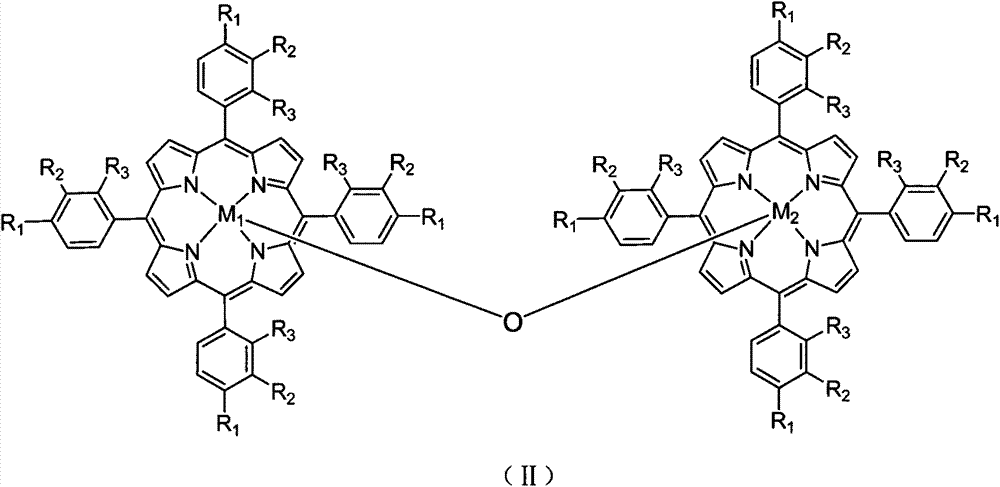

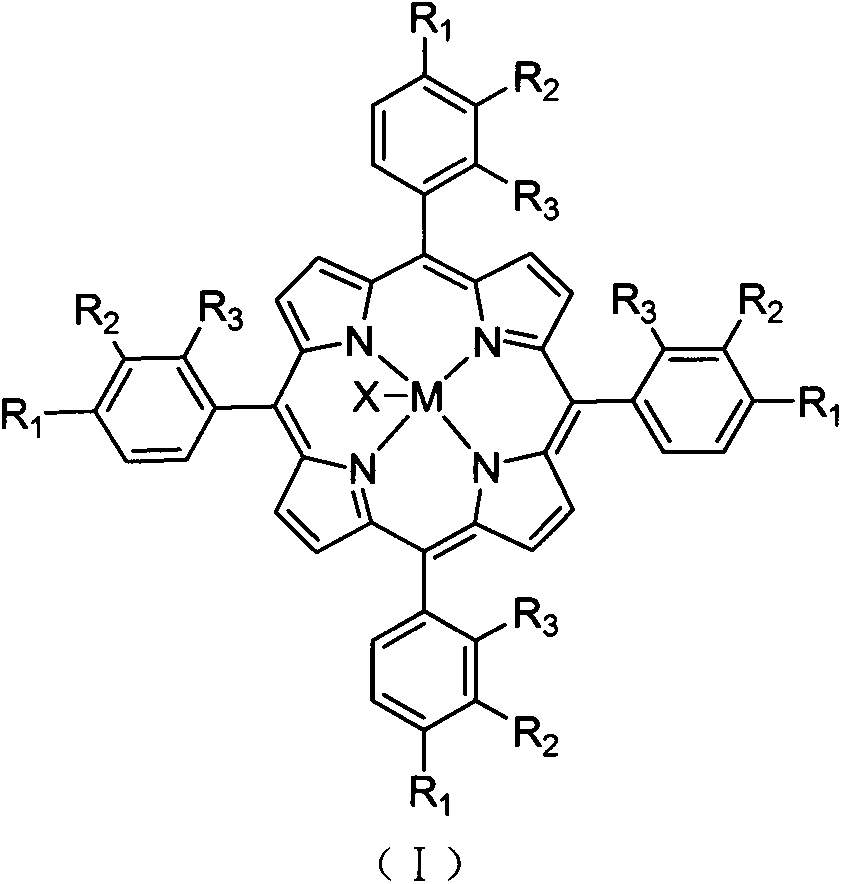

The invention discloses a method for preparing fumaric acid through the cis-trans isomerization of maleic acid. The method comprises the following steps of: taking maleic acid as a raw material in the presence of air or oxygen according to the mass ratio of raw material to the solvent being 1:1-1:80, wherein the solvent contains N,N-dimethylformamide (DMF), dimethyl sulfoxide (DMSO), ethyl acetate, benzene, methylbenzene or nitrobenzene; controlling conditions that the reaction pressure is under 0.1-1.2Mpa and the temperature is 50-150 DEG C, reacting for 1-12 hours by taking monometallic porphyrin in formula (I) or mu-oxo bimetal porphyrin in formula (II) or immobilized metal porphyrin formed as catalysts, wherein the concentration of the catalysts is 5-160PPM; and performing isomerization of maleic acid to obtain the product fumaric acid. The method has the following technical effects of being small in catalyst usage amount, high in catalytic efficiency, free from corrosion action to the equipment, high in conversion rate, high in product yield, and low in production cost.

Owner:XIANGTAN UNIV

Liquid detergent builder and liquid detergent containing the same

ActiveUS7390776B2Improve compatibilityHigh transparencyOrganic detergent compounding agentsOrganic chemistryMaleopimaric acidLotion

A liquid detergent builder which is highly compatible with a surfactant and gives transparent liquid detergents having extremely excellent detergency, a liquid detergent containing the builder, and a liquid detergent containing an acrylic acid-based polymer (salt) having excellent clay dispersibility and good compatibility with a surfactant. The liquid detergent builder comprises an acrylic acid / maleic acid-based copolymer (salt), wherein the acrylic acid / maleic acid-based copolymer (salt) contains maleic acid (salt) in an amount of 5-90 mol % per mole of the sum of acrylic acid (salt) and maleic acid (salt), and a product (MA×Mw) of a weight average molecular weight (Mw) of the copolymer (salt) and a proportion (MA (mol %)) of the maleic acid (salt) in the copolymer (salt) is 450,000 or less.

Owner:NIPPON SHOKUBAI CO LTD

Quick drying polymeric fertilizer additive

InactiveUS20100175443A1Promote plant growthEnhance plant growth and yield characteristicFibre treatmentAmmonium nitrate fertilisersAdjuvantAlcohol

Improved fertilizer compositions are provided, including a solid nitrogenous fertilizer (e.g., urea) together with a polycarboxylated polymeric adjuvant or additive material selected from the group consisting of a salts of copolymers containing individual quantities of maleic and itaconic moieties. The polymer-containing composition also includes from about 10-60% by weight of an organic compound drying agent such as a lower alcohol which facilitates drying and easy field application of the complete fertilizer composition.

Owner:SPECIALTY FERTILIZER PROD LLC

Modified rosin-based hyperbranched polyester and preparation method and application thereof

ActiveCN102977379ANarrow molecular distributionEnd group controllableMaleopimaric acidHyperbranched polyester

The invention discloses a modified rosin-based hyperbranched polyester and a preparation method and application thereof. The preparation method comprises the following steps of: taking maleopimaric acid and glycidol as a monomer, reacting for a certain period of time to obtain an initial product under catalysis condtions, reprecipitating, filtering, separating and drying to obtain the hyperbranched polyester; and taking acrylic acid, acryloyl chloride and the like as modifiers, and carrying out a modification reaction in solvents of toluene, dichloromethane and the like so as to prepare the modified rosin-based hyperbranched polyester. The method is simple, expensive equipment and complex operation are not required, and the polymer contains lots of end vinyl groups, has high photocuring reactivity, is suitable for serving as a curing agent and a prepolymer of other photocuring function materials and is wide in prospect.

Owner:南昌市龙然实业有限公司

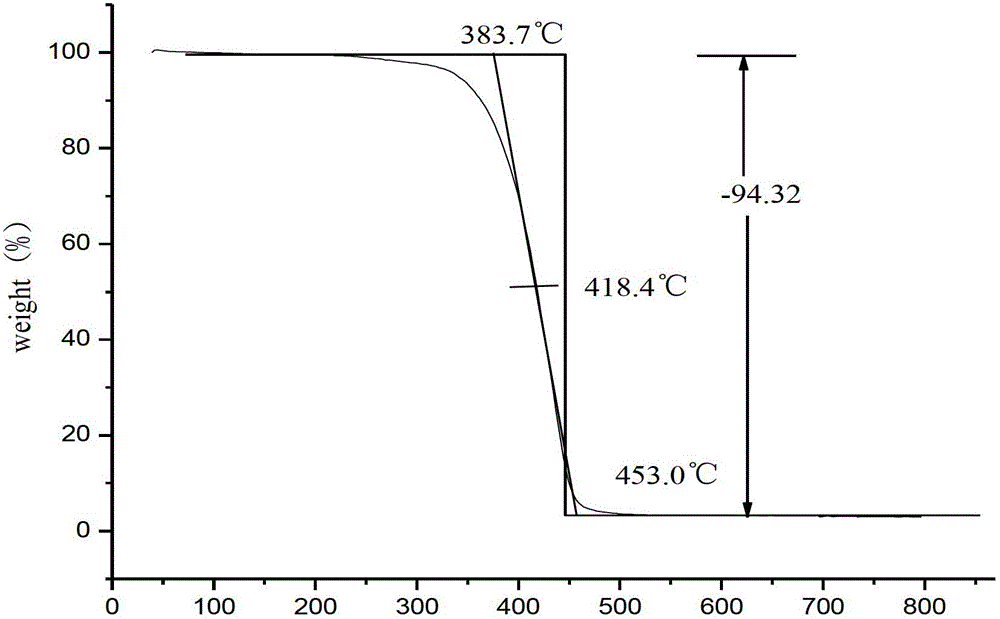

Laundering-durable flame-retarding finishing agent for fabrics

The invention belongs to the field of fabric modification and in particular relates to a finishing agent for flame-retarding modification of fabrics. The flame-retarding finishing agent is prepared from the following components: flame-retarding polyether, sorbitan mo-nooleate, hydroxymethyl cellulose, triisopropyl (2,3-dibromo) propyl ester, ammonium dihydrogen phosphate, guar gum, maleopimaric acid and deionized water; the components are mixed uniformly to obtain the laundering-durable flame-retarding finishing agent for fabrics. The flame-retarding finishing agent is simple and convenient in preparation method and has no sediment and layering phenomenon after preparation, and after the flame-retarding finishing agent is used for flame-retarding finishing to the fabric, the flame retardant property of the fabric cannot be remarkably reduced after multiple times of washing.

Owner:CHANGZHOU MYSUN BIOLOGICAL MATERIALS

Preparation method of polymaleic acid

The invention discloses a preparation method of polymaleic acid, belonging to the field of chemical technology and aiming at providing a preparation method of polymaleic acid with high product yield, low bromine number and stable quality, and meanwhile, the polymaleic acid average molecular weight of which is more than 5500 is suitable for commercial process. The preparation method has the technical key points that 1 part by weight of maleic anhydride, 1.2 to 1.4 parts by weight of distilled water and 0.015 to 0.02 parts by weight of mixture of transition metal ion M compound and ammonium salt are put into a reaction kettle once to be heated from 40 to 60 DEG C to be totally dissolved; then perhydrol is slowly added to polymerize under the condition of continuous stirring, polymerization reaction temperature is controlled to be 90 to 100 DEG C, and heat preservation reaction time is 1 to 2 hours, so that the polymaleic acid whose average molecular weight is bigger than 5500 can be obtained. The yield can be more than 99.0% (counted by maleic anhydride), bromine number is smaller than 30mg / g, and products have stable quality. The preparation method for polymaleic acid has environmentally-friendly and clean technology, produces no three wastes and has the advantages of convenient operation and low production cost, thus the preparation method of polymaleic acid is suitable for large-scale industrial production.

Owner:安徽海瀚水处理科技有限公司

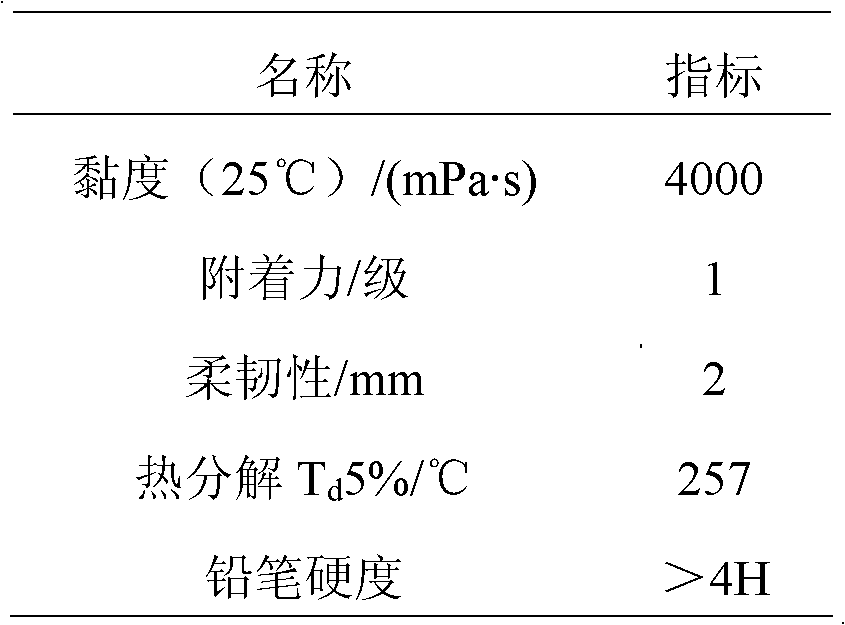

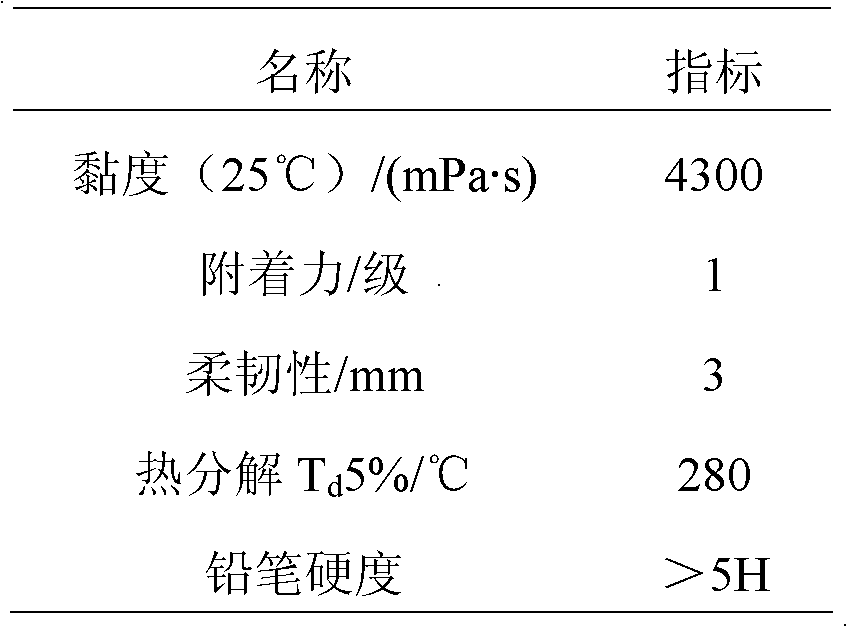

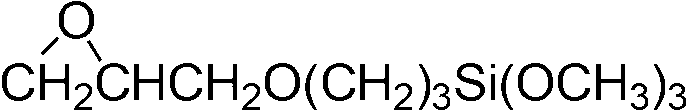

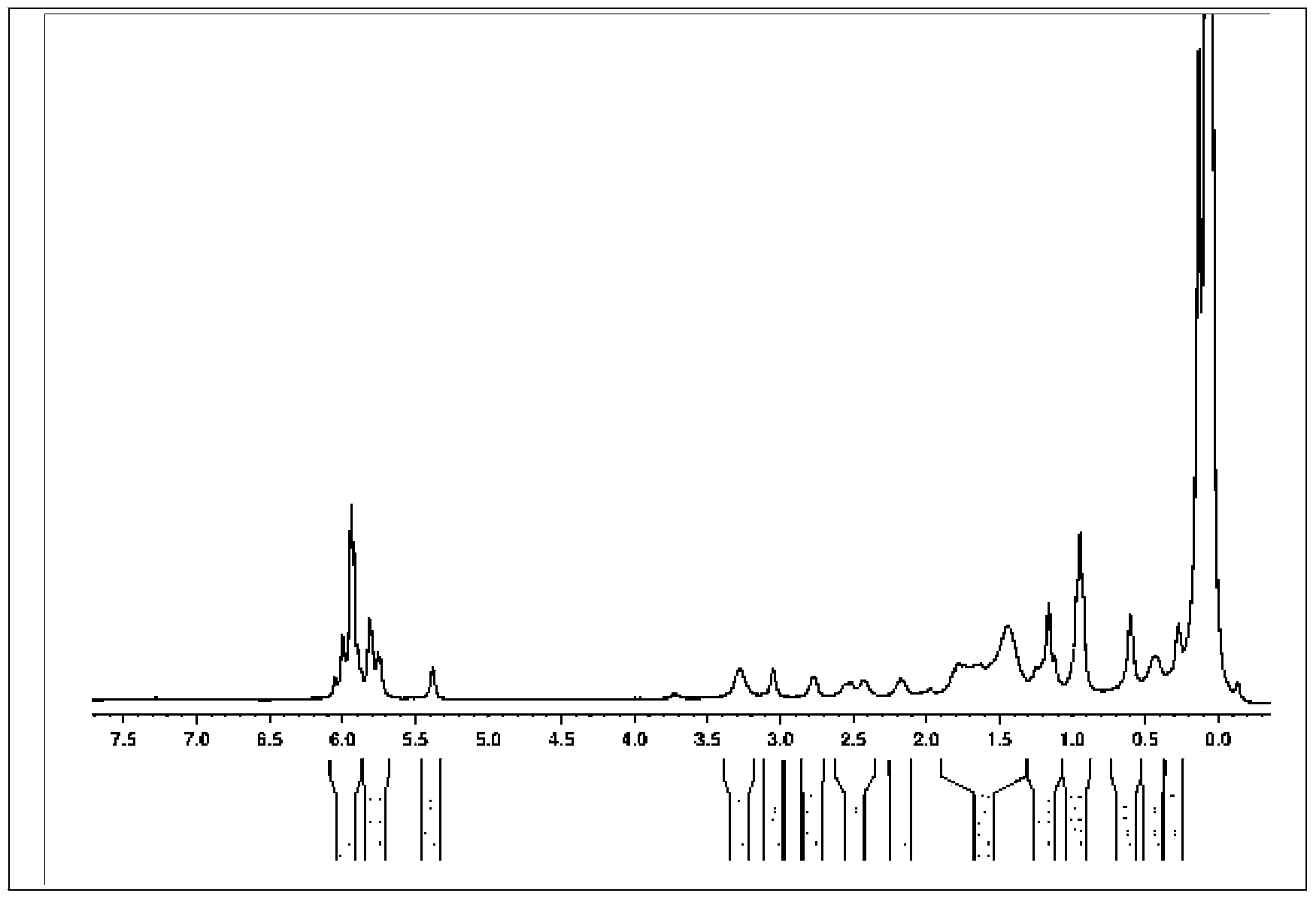

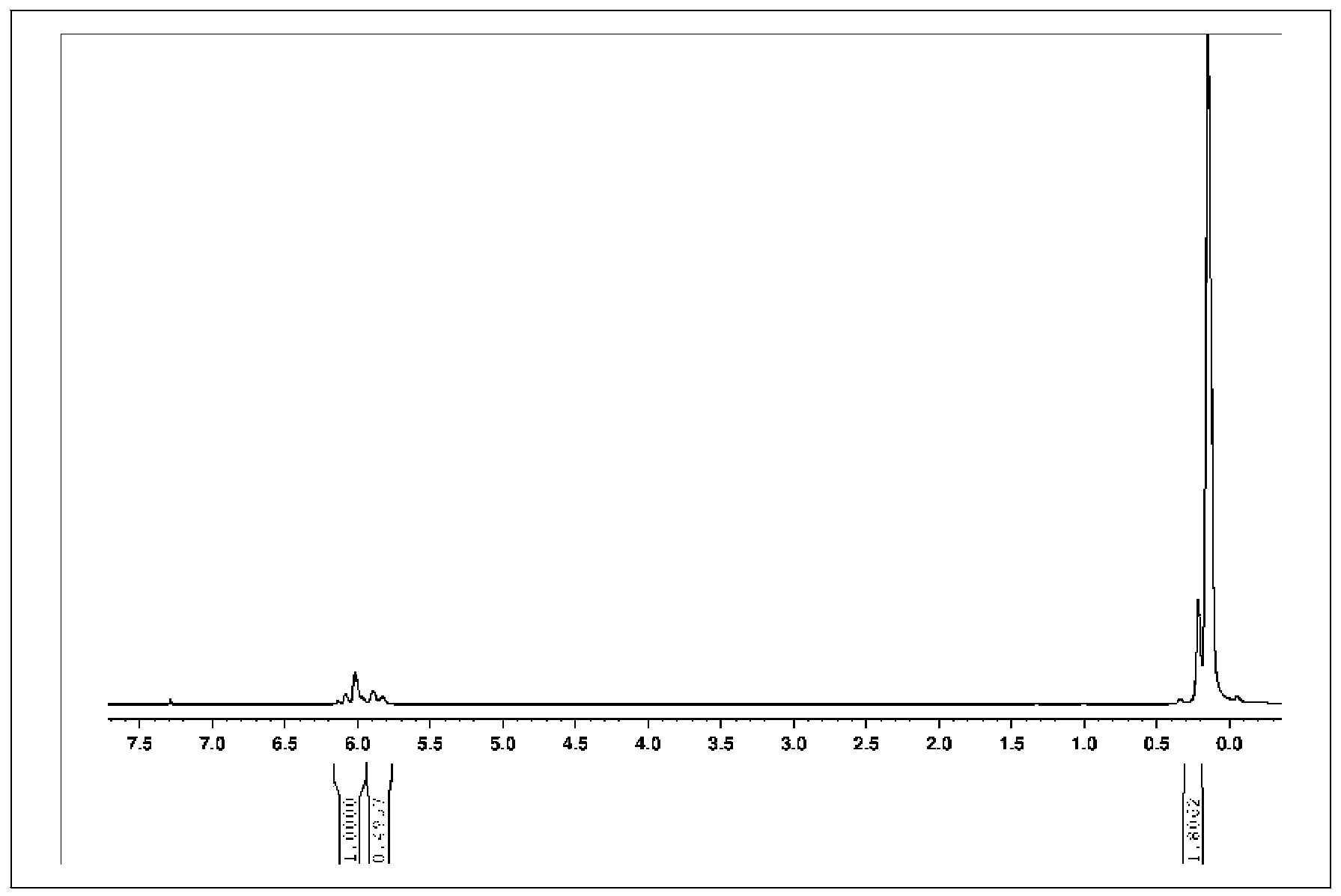

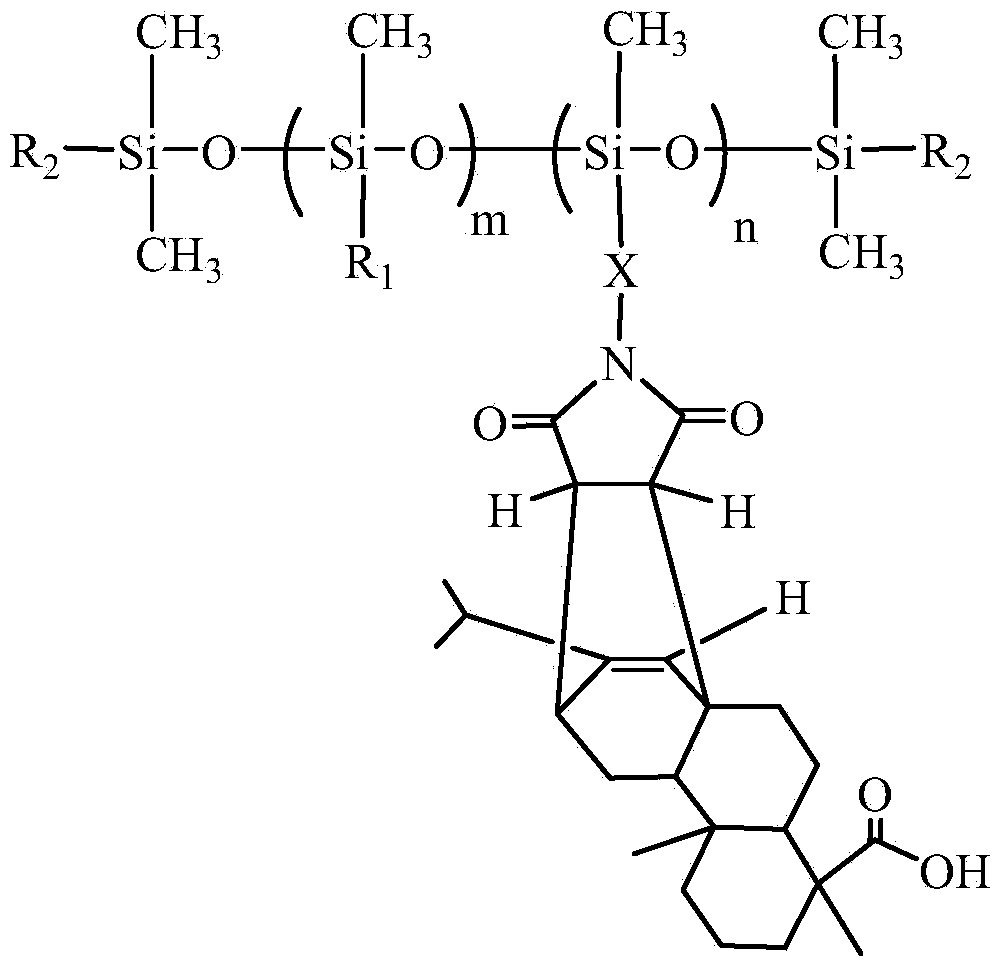

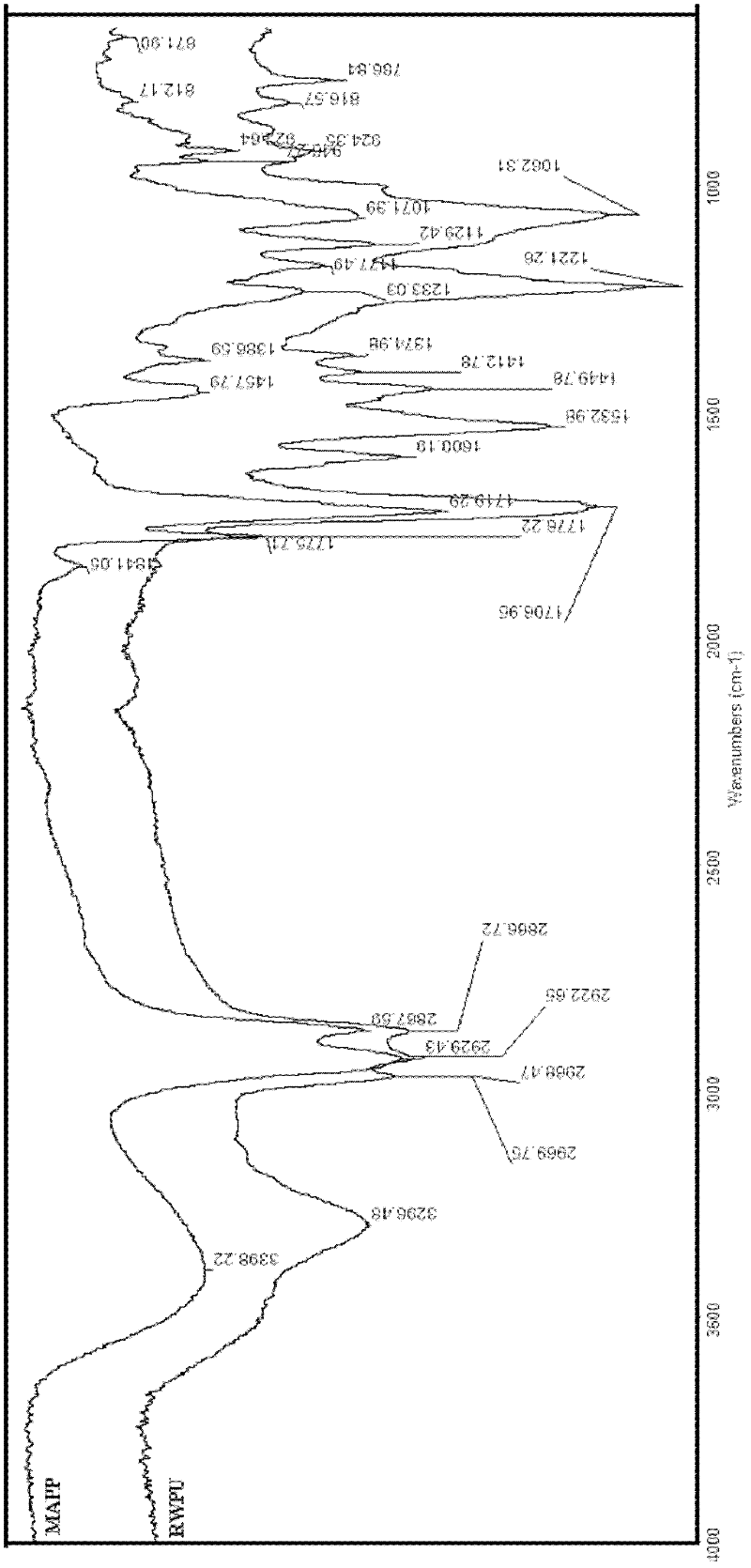

Maleopimaric acid modified polysiloxane resin and preparation method thereof

The invention discloses maleopimaric acid modified polysiloxane resin and a preparation method thereof. The maleopimaric acid modified polysiloxane resin is characterized by having a structure represented by a formula shown in descriptions, wherein R1 is C2-8 straight-chain or branched-chain alkyl, R2 is C2-3 straight-chain alkyl, X is a sub organic group, m and n are natural numbers between 1 and 200, and the ratio of n and m meets the condition that n / m is not smaller than 0.01 and not greater than 10. According to the maleopimaric acid modified polysiloxane resin disclosed by the invention, a ternary phenanthrene ring and an imide heteroatomic ring which have certain rigidity and polarity are introduced into organosilicon resin, so that the rigidity and polarity of a molecular chain are improved, and meanwhile, the properties, such as water resistance, high-temperature resistance, electric insulation, adhesive power and the like, of the resin are improved; the prepared maleopimaric acid modified polysiloxane resin has excellent intermiscibility with organosilicon materials, and mechanical properties, such as hardness, tear strength, resilience and the like, of the organosilicon rubber can be remarkably improved.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Method for synthesizing succinic acid from maleic acid

ActiveCN102417445ALow reaction temperatureLess side effectsCarboxylic preparation by ozone oxidationButanedioic acidMaleopimaric acid

The invention discloses a method for synthesizing succinic acid from maleic acid. The method for synthesizing succinic acid from maleic acid comprises the following steps that 1, a catalyst is added into a fixed bed reactor; 2, hydrogen is fed into the fixed bed reactor so that the pressure is stabilized in a range of 5 to 35atm; the reaction system is heated to a temperature of 50 to 150 DEG C; and a maleic acid or maleate aqueous solution having a mass fraction of 1.0 to 25.0% passes through a catalyst bed layer at an airspeed of 0.01 to 5.00h<-1> and then enters into a liquid gathering tank, wherein in reaction, a feeding rate molar ratio of the hydrogen to the maleic acid or maleate aqueous solution is (3.0 to 15.0): 1; 3, reaction liquid obtained by the step 2 is cooled and filtered to form succinic acid or succinate and filtrate; 4, the obtained succinate is acidized and separated to produce succinic acid; and 5, the filtrate obtained by the step 3 is mixed with maleic acid and the excess hydrogen is recovered and recycled. The method for synthesizing succinic acid from maleic acid has the advantages of mild conditions, low cost and high product purity.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Modified polyvinyl chloride cable material with high cold resistance

InactiveCN104403228AImprove heat resistanceImprove toughnessRubber insulatorsPlastic/resin/waxes insulatorsFiberEpoxy

The invention discloses a modified polyvinyl chloride cable material with high cold resistance. The modified polyvinyl chloride cable material is prepared from the following raw materials: polyvinyl chloride, nitrile rubber, maleic anhydride-grafted polypropylene, ethylene-vinyl acetate-carbon monoxide terpolymer, bamboo fiber, modified kaolin, ultra-fine silica dioxide powder, triethyl citrate, acetyl-tri-n-butyl citrate, epoxy sunflower oil, eicosyl dehydroabietate, modified zinc borate, red phosphorus, nanometer aluminum hydroxide, maleopimaric acid lanthanum, methyl tin mercaptide, barium stearate, an antioxidant, and a lubricant. The modified polyvinyl chloride cable material with the high cold resistance disclosed by the invention is high in cold resistance, good in elasticity, good in impact resistance, and excellent in mechanical property; the cable prepared by the modified polyvinyl chloride cable material is long in service life in the cold environment.

Owner:ANHUI DUJIANG CABLE GROUP

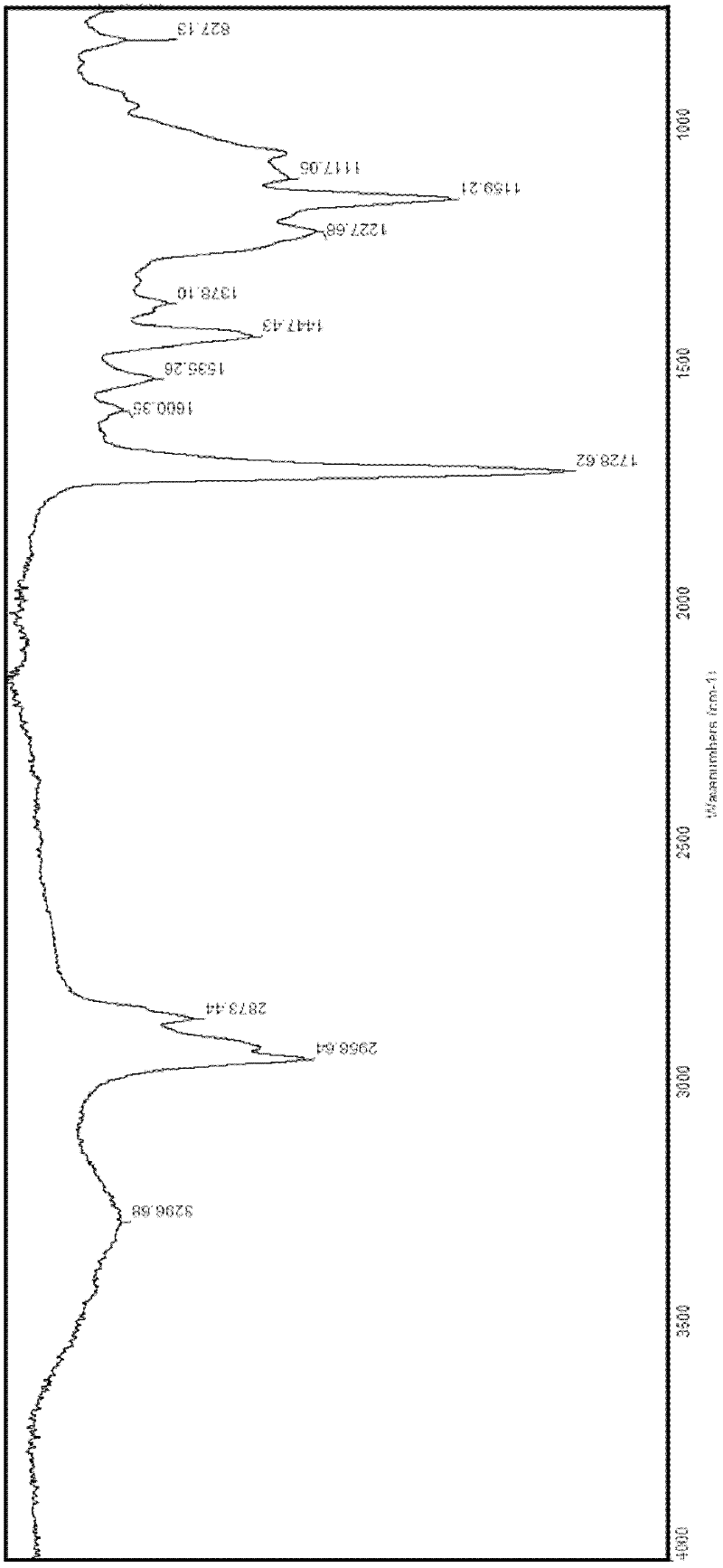

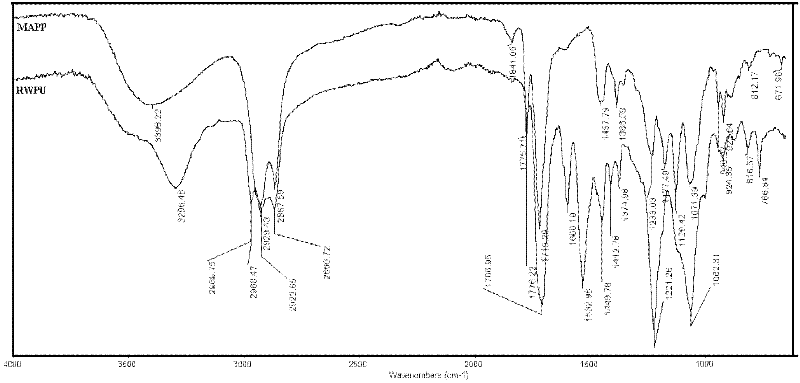

Acrylate modified maleopimaric acid aqueous polyurethane emulsion and preparation method thereof

ActiveCN102408525AHas a fused polycyclic rigid structureImprove mechanical propertiesMaleopimaric acidEmulsion

The invention discloses an acrylate modified maleopimaric acid aqueous polyurethane emulsion and preparation method thereof. The maleopimaric acid aqueous polyurethane emulsion is heated to 40-90 DEG C and acrylate with a mass of 1-50 percent of the maleopimaric acid aqueous polyurethane emulsion is respectively added under a stirring condition; after the maleopimaric acid aqueous polyurethane emulsion and the maleopimaric acid aqueous polyurethane emulsion are stirred uniformly, a persulfate initiator is dropped completely in 2-4h; after the persulfate initiator is dropped, heat preservationreaction is carried out for 1-3h and then the acrylate modified maleopimaric acid aqueous polyurethane emulsion is prepared. The dosage of the persulfate initiator is 0.01-1.5 percent of the mass of the monomer acrylate, the reaction temperature is controlled at 40-90 DEG C and the solid content of the maleopimaric acid aqueous polyurethane emulsion is 20-35wt percent. The prepared product has the characteristics of excellent mechanical property, good water and heat resistance, excellent chemical agent resistance, etc.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Dry mixing extinction type powder coating material with good low-temperature curing property, and preparation method thereof

ActiveCN106243937AReduce consumptionReduce wastePowdery paintsPolyester coatingsMaleopimaric acidExtinction

The present invention relates to a two-component polyester resin for a low-temperature curing dry-mixing extinction powder coating material, and a power composition thereof. According to the present invention, mainly the high acid value component of the dry-mixing extinction polyester resin increases the types and the amounts of triols having high grafting degree; the final acid value of the polyester resin is increased to 65-75 mg KOH / g so as to improve the activity; the low acid value component of the dry-mixing extinction polyester resin mainly selects a lot of flexible raw materials to adjust the melting viscosity of the polyester while high-activity polybasic acid such as maleopimaric acid and benzenetetracarboxylic acid are introduced to perform the end capping so as to increase the acid value to 28-35 mg KOH / g, such that the low-temperature curing performance is ensured; and the dry mixing powder coating material prepared from the high-low acid value component polyester resin can be cured at the low temperature of 140-160 DEG C, and can achieve the extinction effect of the gloss of 20-40%.

Owner:黄山市向荣新材料有限公司

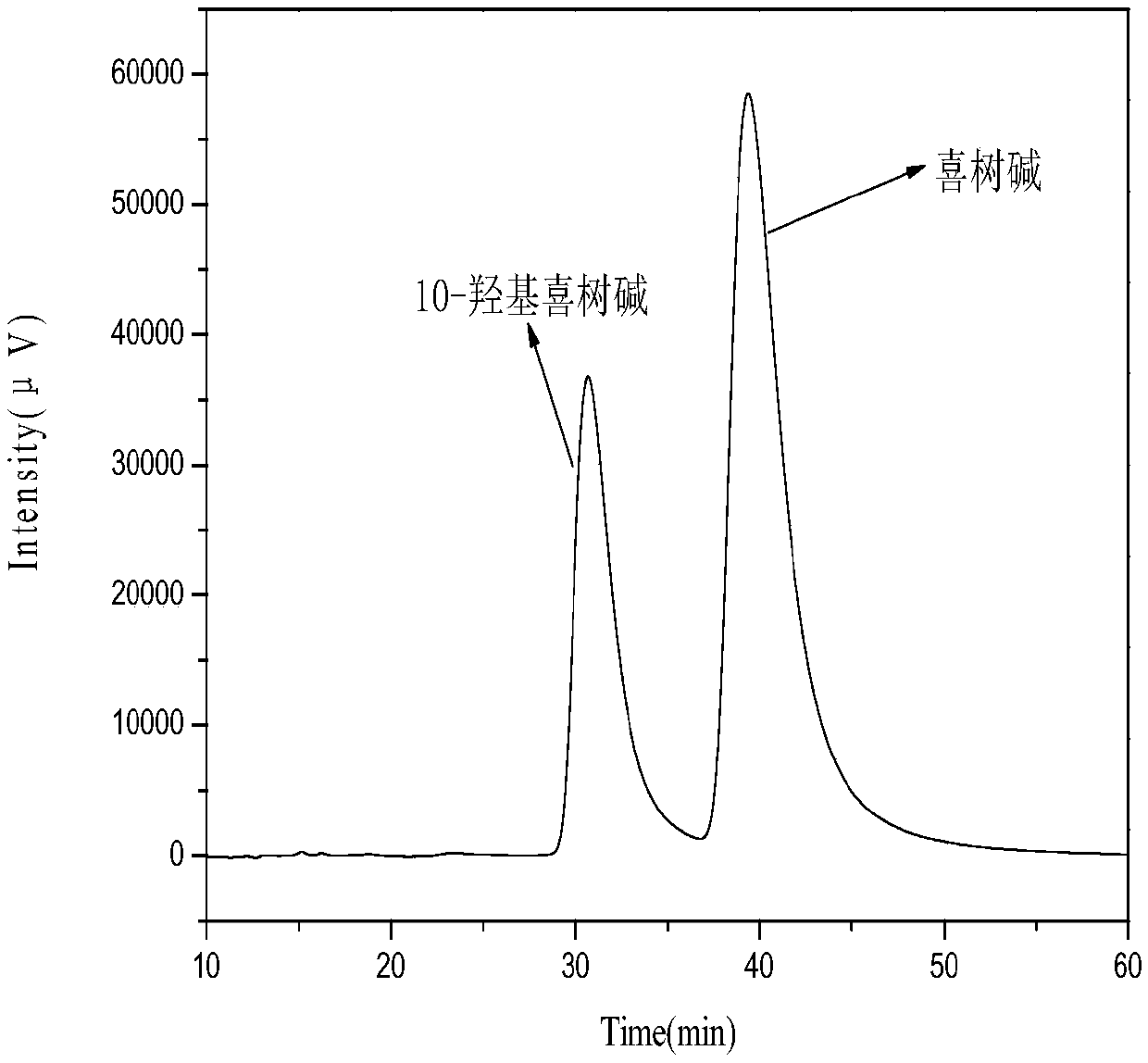

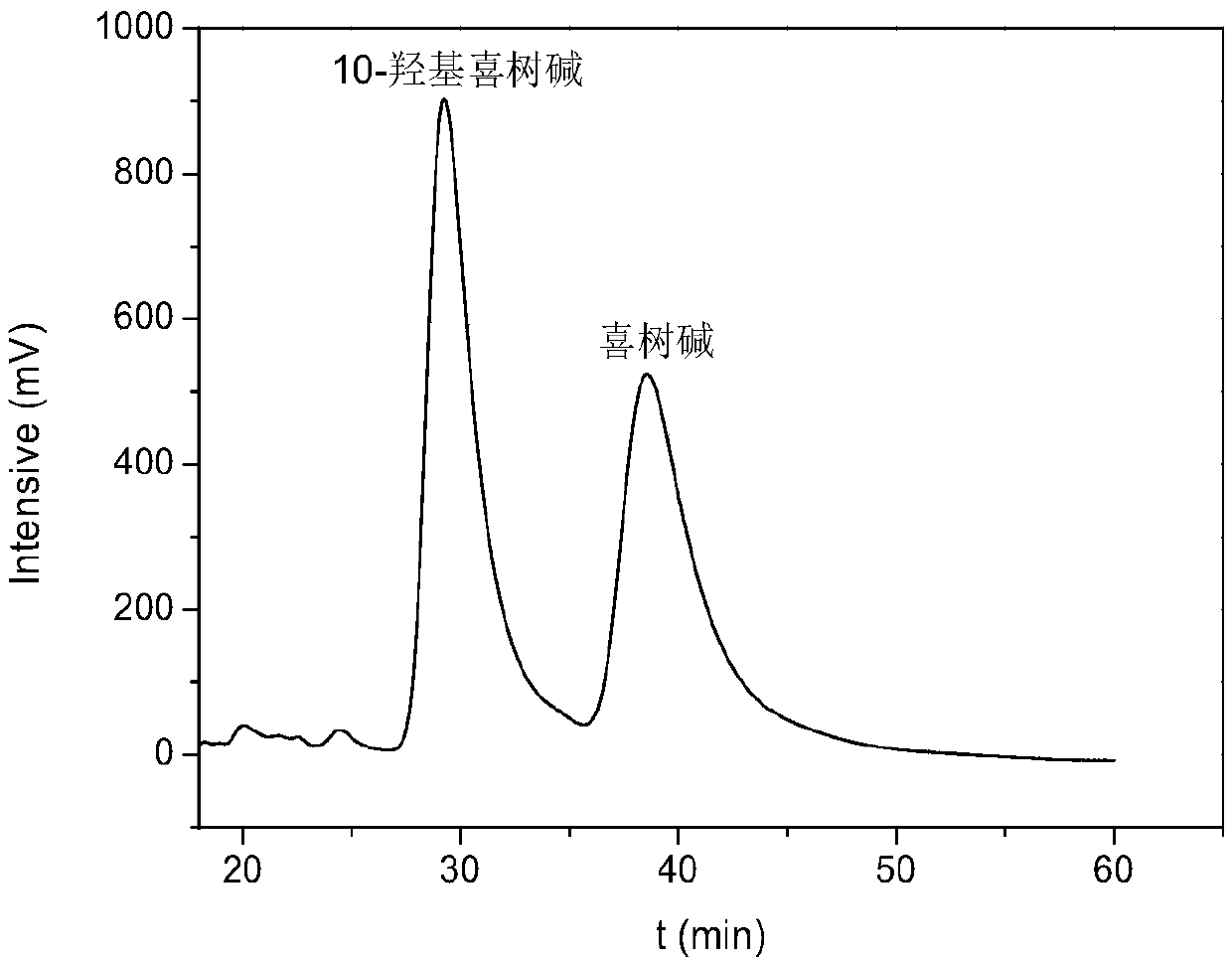

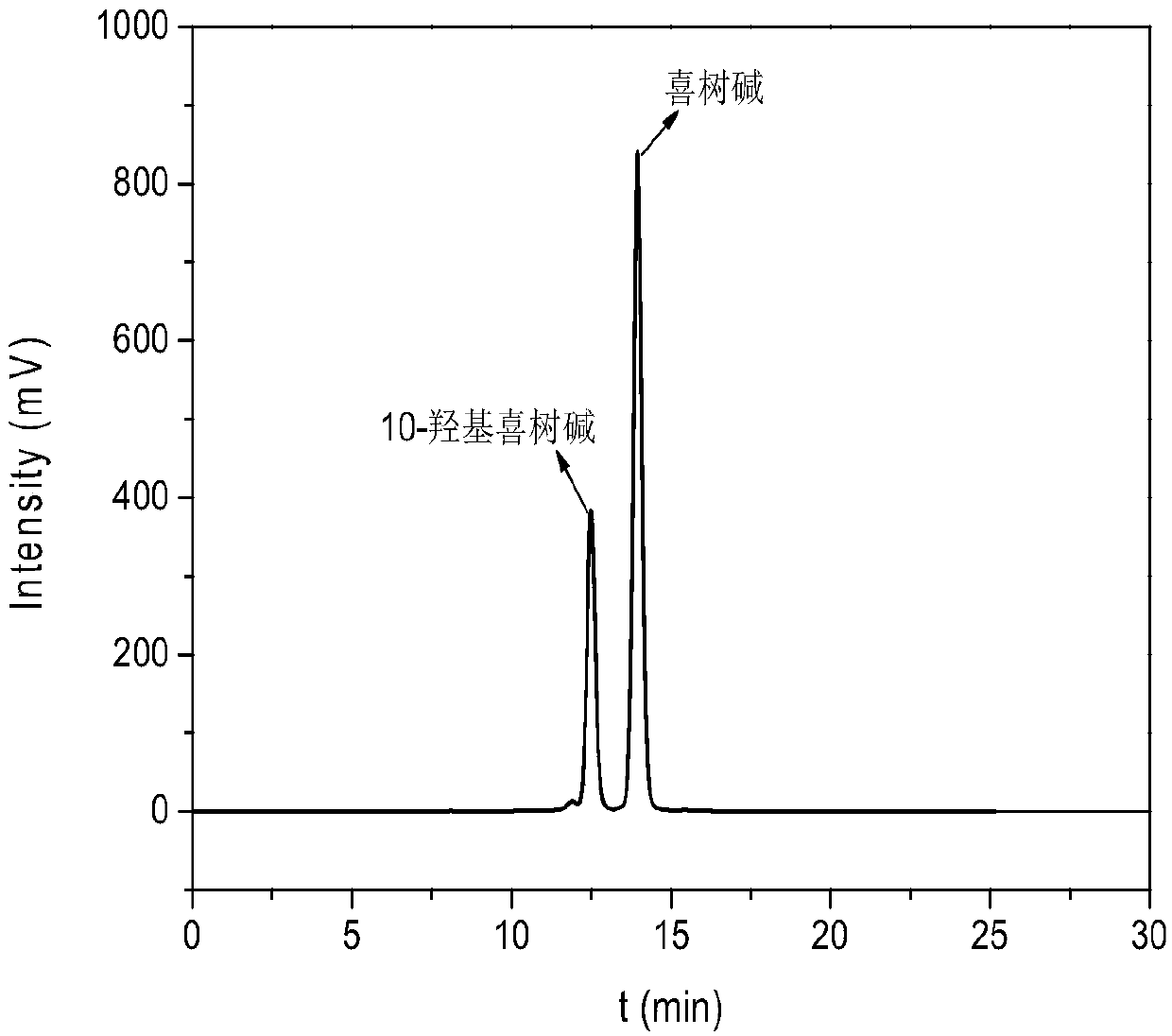

Method for efficient separation of camptothecin and 10-hydroxycamptothecin by core-shell SiO2@rosin-based polymer chromatographic column

The invention discloses a method for efficient separation of camptothecin and 10-hydroxycamptothecin by a core-shell SiO2@rosin-based polymer chromatographic column. The method includes: taking methacrylic acid or methyl methacrylate as the monomer, adopting maleopimaric acid ethylene glycol acrylate or acrylpimaric acid ethylene glycol acrylate as the cross-linking agent, fully mixing the substances with a free radical initiator, then coating a silica gel surface with the mixture, and then carrying out free radical polymerization reaction to obtain core-shell SiO2@rosin-based polymer microspheres, which have a particle size distribution of 2-50microm, a pore size distribution of 0.5-15nm and a specific surface area of 150-350m<2> / g; subjecting the core-shell SiO2@rosin-based polymer microspheres to wet packing to prepare a chromatographic column, using the prepared chromatographic column for HPLC separation on camptothecin and 10-hydroxycamptothecin, and setting the detection wavelength at 254nm, the temperature at 30+ / -10DEG C and the flow rate at 0.3-1.0mL / min, thus achieving a camptothecin and 10-hydroxycamptothecin separation degree of 2.45-3.47. The method provided by the invention has high separation degree and selectivity on camptothecin and 10-hydroxycamptothecin, and also has the advantages of high sensitivity, simple operation, high speed and efficiency, and environmental friendliness.

Owner:GUANGXI UNIV FOR NATITIES +1

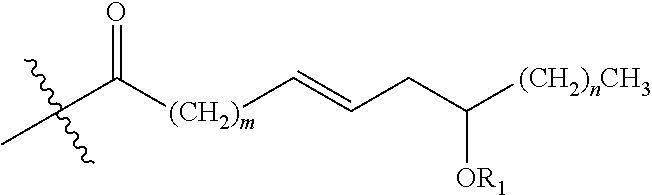

High performance, water-dilutable lubricity additive for multi-metal metalworking applications

ActiveUS20150225666A1Good processing characteristicsMaintain transparencyOrganic chemistryFatty acid chemical modificationMaleopimaric acidMetalworking

The invention provides lubricating composition comprising: (1) a reaction product selected from the group consisting of: (a) a polyalkanoic or polyalkenoic acid derived from hydroxyfatty acids and a block copolymer selected from the group consisting of polyoxyethylene-polyoxypropylene and a reverse block copolymer of polyoxypropylene-polyoxyethylene-polyoxypropylene; (b) the reaction product of (a) with a maleic acid or anhydride; and (c) the reaction product of (a) with maleated soybean oil; and (2) at least one base oil selected from the group consisting of alkyl benzene, normal paraffin, isoparaffin, mineral oil and α-olefin.

Owner:ETHOX CHEM LLC

Method for synthesizing succinic acid from maleic acid

ActiveCN102417445BLow reaction temperatureLess side effectsCarboxylic preparation by ozone oxidationButanedioic acidMaleopimaric acid

The invention discloses a method for synthesizing succinic acid from maleic acid. The method for synthesizing succinic acid from maleic acid comprises the following steps that 1, a catalyst is added into a fixed bed reactor; 2, hydrogen is fed into the fixed bed reactor so that the pressure is stabilized in a range of 5 to 35atm; the reaction system is heated to a temperature of 50 to 150 DEG C; and a maleic acid or maleate aqueous solution having a mass fraction of 1.0 to 25.0% passes through a catalyst bed layer at an airspeed of 0.01 to 5.00h<-1> and then enters into a liquid gathering tank, wherein in reaction, a feeding rate molar ratio of the hydrogen to the maleic acid or maleate aqueous solution is (3.0 to 15.0): 1; 3, reaction liquid obtained by the step 2 is cooled and filtered to form succinic acid or succinate and filtrate; 4, the obtained succinate is acidized and separated to produce succinic acid; and 5, the filtrate obtained by the step 3 is mixed with maleic acid and the excess hydrogen is recovered and recycled. The method for synthesizing succinic acid from maleic acid has the advantages of mild conditions, low cost and high product purity.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Rosin-based CO2/N2 response type surfactant, and preparation method and application thereof

ActiveCN110577486AIn line with the concept of green sustainable developmentGood emulsificationOrganic chemistryTransportation and packagingMaleopimaric acidEmulsion

The invention discloses a rosin-based CO2 / N2 response type surfactant. Maleopimaric acid and N,N-dimethyl-1,3-propane diamine are subjected to an imidization reaction to introduce a tertiary amine group capable of responding to CO2, then the product and epoxypropanol are subjected to an esterification reaction to introduce a hydrophilic group, and the prepared MPANG has good surface activity. After MPANG is dissolved in water, CO2 is introduced into the water, and the aqueous solution is weakly acidic, so that tertiary amine is protonated to form tertiary amine salt and is positively charged to become a cationic surfactant MPANGH<+>; and after N2 is introduced to expel CO2, the tertiary amine salt with positive charges is deprotonated to recover to the initial tertiary amine state. The invention also discloses the emulsifying property of the surfactant, the emulsifying property becomes better after CO2 is introduced into the surfactant and the surfactant becomes a cationic surfactant,and the obtained emulsion also has good responsiveness to CO2 / N2. Furthermore, no matter whether the emulsion is stabilized by a nonionic surfactant or a cationic surfactant, the dosage of the surfactant can be greatly reduced as long as charged particles exist.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Liquid detergent builder and liquid detergent containing the same

ActiveUS20050003993A1Improve compatibilityHigh transparencyOrganic detergent compounding agentsOrganic chemistryMaleopimaric acidLotion

A liquid detergent builder which is highly compatible with a surfactant and gives transparent liquid detergents having extremely excellent detergency, a liquid detergent containing the builder, and a liquid detergent containing an acrylic acid-based polymer (salt) having excellent clay dispersibility and good compatibility with a surfactant. The liquid detergent builder comprises an acrylic acid / maleic acid-based copolymer (salt), wherein the acrylic acid / maleic acid-based copolymer (salt) contains maleic acid (salt) in an amount of 5-90 mol % per mole of the sum of acrylic acid (salt) and maleic acid (salt), and a product (MA×Mw) of a weight average molecular weight (Mw) of the copolymer (salt) and a proportion (MA (mol %)) of the maleic acid (salt) in the copolymer (salt) is 450,000 or less.

Owner:NIPPON SHOKUBAI CO LTD

Rosin graft copolymer dispersant and preparation technique and use thereof

InactiveCN101391195AGood dispersionImprove thermal stabilityTransportation and packagingMixingSolubilityDispersion stability

The invention discloses a rosin graft polymer dispersing agent with high dispersion and stability, low preparation cost and environmental protection as well as a preparation process and applications thereof. The rosin graft polymer dispersing agent is prepared through free radical polymerization of acrylic acid, sodium styrene sulfonate and rosin derivative, the number average relative molecular weight of the rosin graft polymer is between 12000 and 14000, wherein, the rosin derivative is a composition of maleopimaric acid acyl chloride and 2-hydroxyethyl methacrylate. The dispersing agent has advantages of high thermal stability, good water solubility, excellent adaptability to alkali and good dispersion stability, and also has good dispersion effects to pesticide Aatrex water dispersible granules, and can be widely used in the pesticide, paint and other industries. In addition, the preparation process has the advantages of simple operation, short cycle, environmental protection and low cost, and is suitable for the industrial scale production.

Owner:SHANGHAI NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com