Rosin graft copolymer dispersant and preparation technique and use thereof

The technology of a graft polymer and preparation process is applied to a rosin graft polymer dispersant and its preparation process and application field, which can solve the problems of unsatisfactory dispersion effect, poor dispersion stability and high preparation cost, and achieve good dispersion effect, The effect of high thermal stability and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

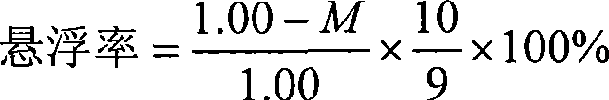

Image

Examples

Embodiment 1

[0025] 1) Preparation of rosin derivative monomer

[0026] In the there-necked flask, add 16.7 mass parts of maleopimaric acid chloride, 5.4 mass parts of hydroxyethyl methacrylate (HEMA), 3.2 mass parts of pyridine, 70 mass parts of toluene and a small amount of hydroquinone, pass N 2 Protect, heat to 100°C, and keep warm for 48 hours; after the reaction, wash with water for 3 times, then evaporate toluene under reduced pressure to obtain rosin derivative monomer (MPAHEMA).

[0027] 2) Preparation of dispersant

[0028] 200 parts of deionized water, 1 part of chain transfer agent sodium bisulfite, and 15 parts of rosin derivatives (MPAHEMA) were added to the four-necked flask, and heated while stirring; when the temperature in the four-necked flask rose to 70 ° C, Add 21.6 parts of acrylic acid, 20 parts of sodium styrene sulfonate and 2.1 parts of initiator ammonium persulfate, and keep it warm for 3 hours; naturally cool to room temperature, and adjust the pH value to 7-8 ...

Embodiment 2

[0035] 1) Preparation of rosin derivative monomer

[0036] As described in Example 1.

[0037] 2) Preparation of dispersant

[0038] 200 parts of deionized water, 2.3 parts of chain transfer agent sodium bisulfite, and 10 parts of rosin derivatives (MPAHEMA) were added to the four-necked flask, and heated while stirring; when the temperature in the four-necked flask rose to 90 ° C, Add 21.6 parts of acrylic acid, 20 parts of sodium styrene sulfonate and 4.6 parts of initiator ammonium persulfate, and keep the reaction for 3 hours; naturally cool to room temperature, and adjust the pH value to 7-8 with aqueous sodium hydroxide solution; put the prepared liquid into Dry in a vacuum oven at 70°C to obtain the target dispersant.

[0039] Using aqueous gel permeation chromatography (GPC), using water as mobile phase and sodium polyacrylate as standard, the number average relative molecular weight of the prepared rosin grafted polymer dispersant is measured to be 12000-14000.

[...

Embodiment 3

[0043] 1) Preparation of rosin derivative monomer

[0044] As described in Example 1.

[0045] 2) Preparation of dispersant

[0046] 200 parts of deionized water, 2.9 parts of chain transfer agent sodium bisulfite, and 5 parts of rosin derivatives (MPAHEMA) were added to the four-necked flask, and heated while stirring; when the temperature in the four-necked flask rose to 80 ° C, Add 21.6 parts of acrylic acid, 20 parts of sodium styrene sulfonate and 5.8 parts of initiator ammonium persulfate, and keep the reaction for 3 hours; naturally cool to room temperature, and adjust the pH value to 7-8 with aqueous sodium hydroxide solution; put the prepared liquid into Dry in a vacuum oven at 70°C to obtain the target dispersant.

[0047] Using aqueous gel permeation chromatography (GPC), using water as mobile phase and sodium polyacrylate as standard, the number average relative molecular weight of the prepared rosin grafted polymer dispersant is measured to be 12000-14000.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com