Patents

Literature

1137results about How to "Suitable for industrial scale production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing polymer microporous foaming material by supercritical mould foaming

The invention provides a method for preparing a polymer microporous foaming material by supercritical mould foaming. The method comprises the following steps of: heating a foaming mould on a mould press to the foaming temperature; placing a polymer into the mould; closing the mould by using the mould press; sealing the mould; introducing supercritical fluid, which swells and diffuses to the polymer, into the mould; and opening the mould by using the mould press to release pressure and foam to obtain the polymer microporous foaming material. Compared with the prior art, the method has the advantages that: the high-temperature and high-pressure supercritical fluid is used for swelling the polymer, so the moulding cycle is greatly shortened; the limit that only microporous foaming sheet material with lesser thickness can be manufactured in the prior art is broken through, so a polymer microporous foaming plate with greater thickness can be manufactured; when the mould is opened, the pressure-releasing speed is high and the foaming pore core-forming speed is high, so the formed microporous foaming material has smaller foaming pores, higher pore density and more excellent performance; and multiple layers of moulds can be placed on one mould press, so the method is suitable for industrialized scale production.

Owner:常州福源科技新材料有限公司

Polypropylene foaming material and production method thereof

The invention discloses a polypropylene foaming material. The polypropylene foaming material comprises the following components according to proportioning by weight: 60-99 parts of polypropylene resin; 0.1-10 parts of nucleating agent; 0.1-5 parts of antioxidant; 0-5 parts of colorant; 0-5 parts of lubricant; and 0-20 parts of filling material; and the melt index of the polypropylene resin is 0.1-20 g / 10 min, and the foaming process adopts supercritical fluid as the foaming agent, i.e. 0.1-20 parts of supercritical fluid (proportioning by weight). The invention also discloses a production method of the foaming material. Compared with the prior art, the invention has the advantages that the universal polypropylene can be adopted as a base material, no polymer is provided, the cross-linking reaction does not occur, the foaming process is free from environmental pollution, and the production method is safe; the quality of the obtained foaming material is stable, the foaming percentage and the cell density are high, the distribution is uniform, and the invention is suitable for the industrial production at a large scale; and meanwhile, the overall production method is simple, the operation is easy, and the production cost is relatively lower.

Owner:合肥朗润中科材料有限公司

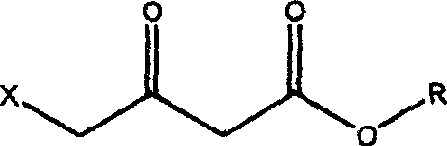

High-performance polycarboxylate water reducing agent and preparation method thereof

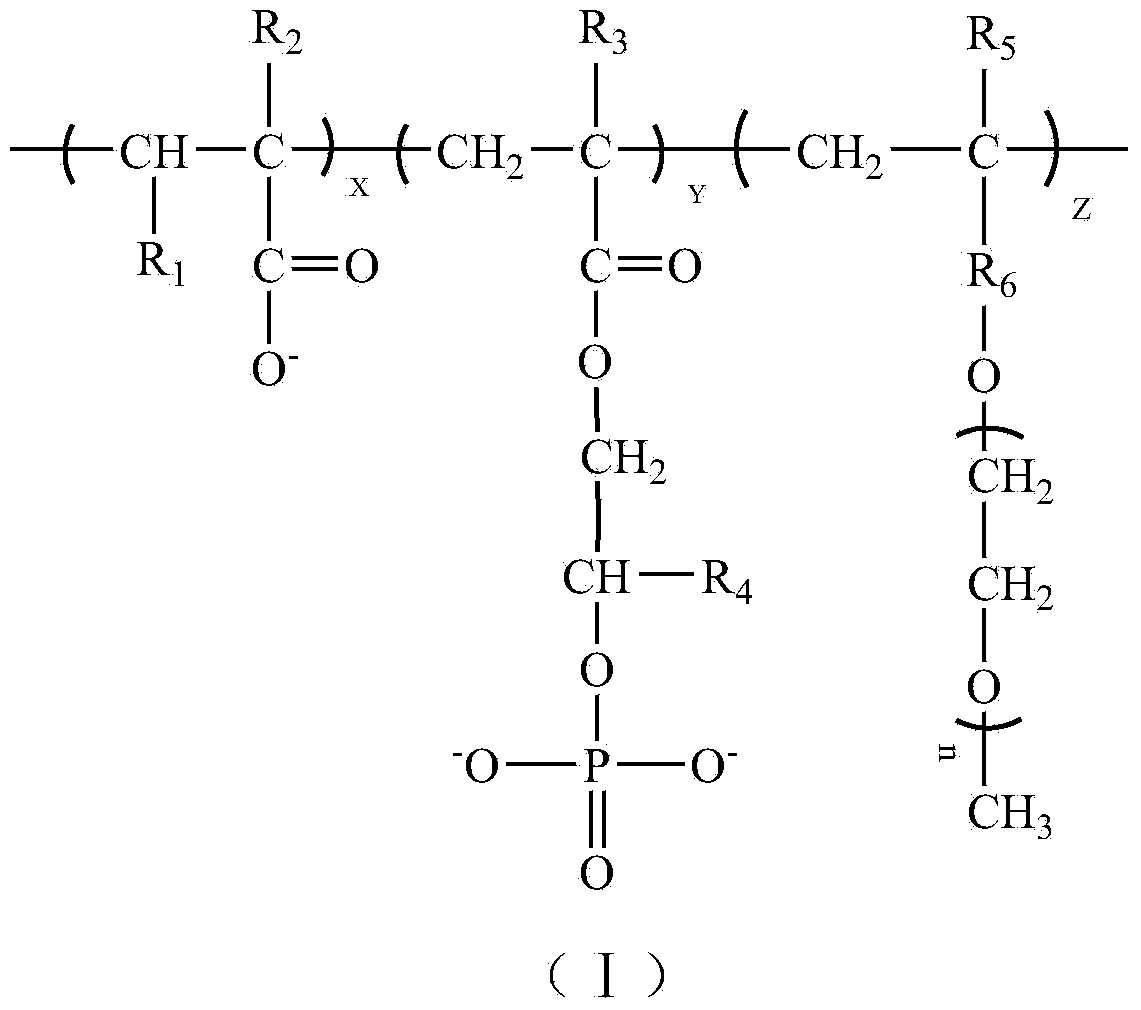

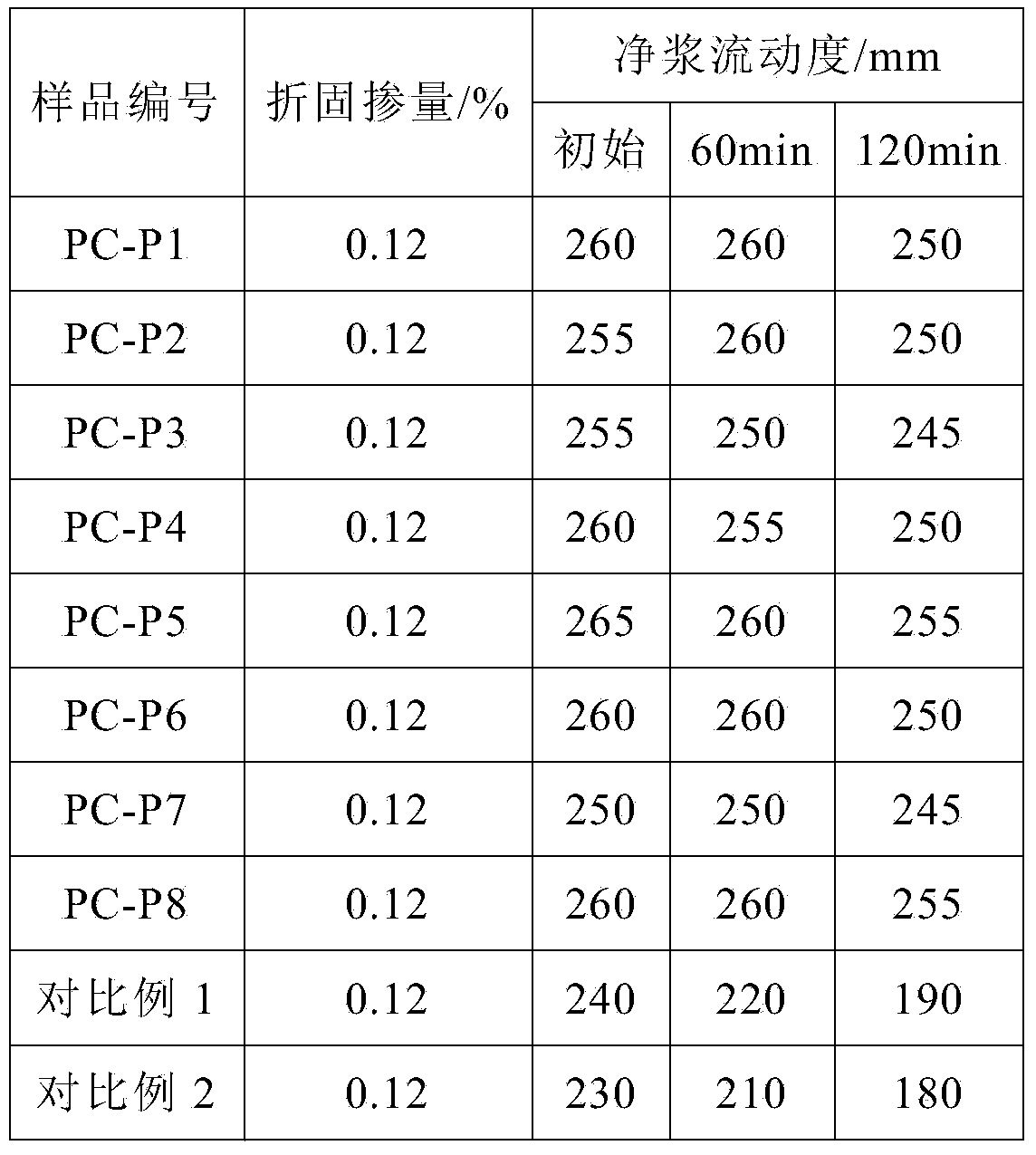

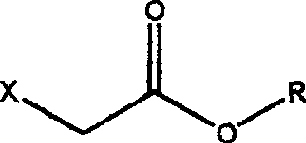

The invention discloses a high-performance polycarboxylate water reducing agent. The polycarboxylate water reducing agent has a structural general formula shown as a structural formula (I). The invention further provides a preparation method of the high-performance polycarboxylate water reducing agent. Apart from a polyether macromonomer and an unsaturated carboxylic acid monomer, an unsaturated phosphate monomer is added to obtain a product, namely, the high-performance polycarboxylate water reducing agent having a phosphate structure. The polycarboxylate water reducing agent disclosed by the invention is safe and simple in preparation process, environmentally friendly, low in energy consumption, low in cost, and suitable for industrial large-scale production. In the structural formula (I), R1 is -H, -COO- or -CH2COO-; R2 is -H or -CH3; R3 is -H or -CH3; R4 is -H or -CH3; R5 is -H or -CH3; R6 is -CH2- or -CH2CH2-; X, Y, Z and n are integers; X=1-100; Y=1-100; Z=1-100; and n=22-53.

Owner:CCCC SHEC WUHAN PORT NEW MATERIALS

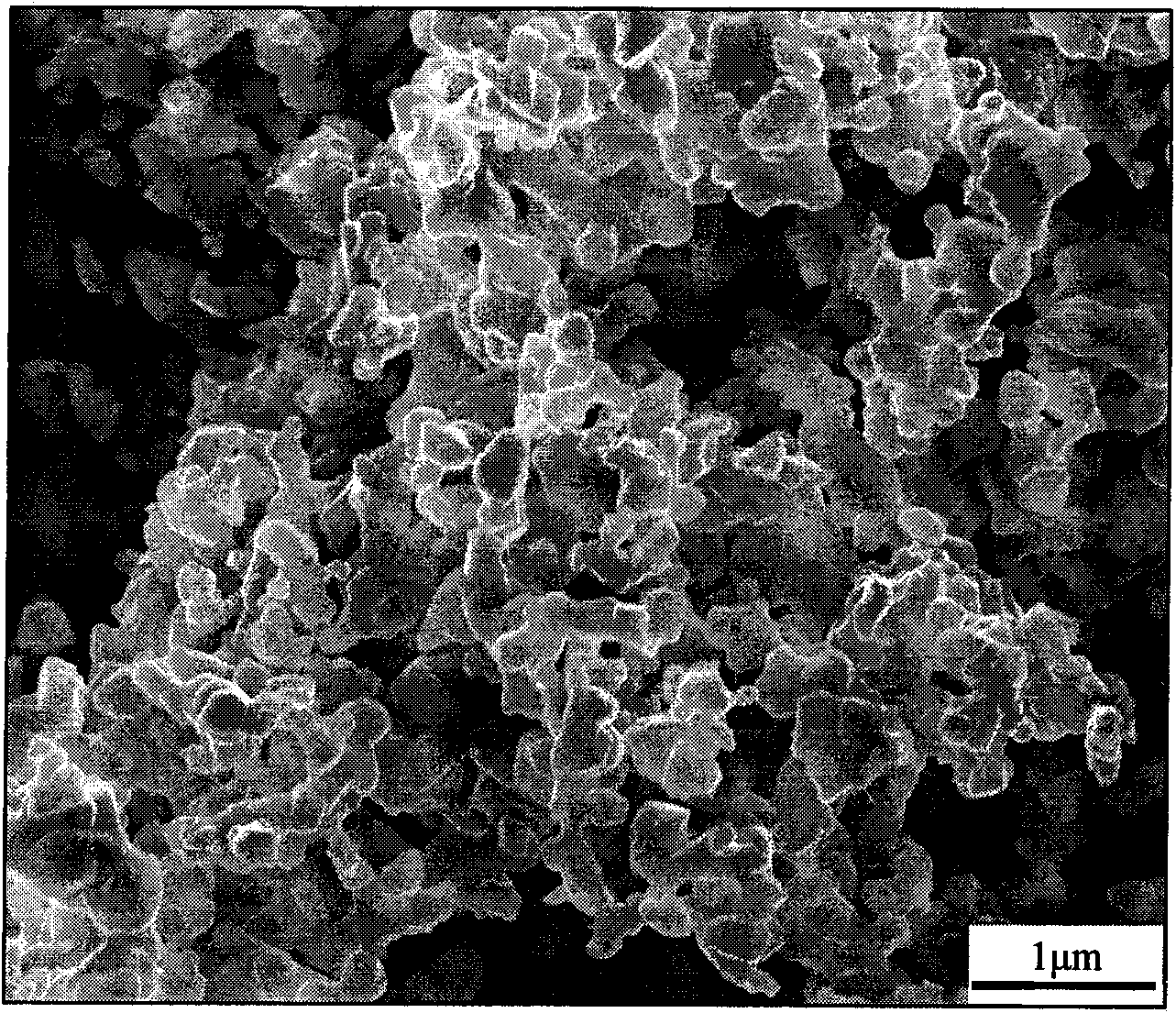

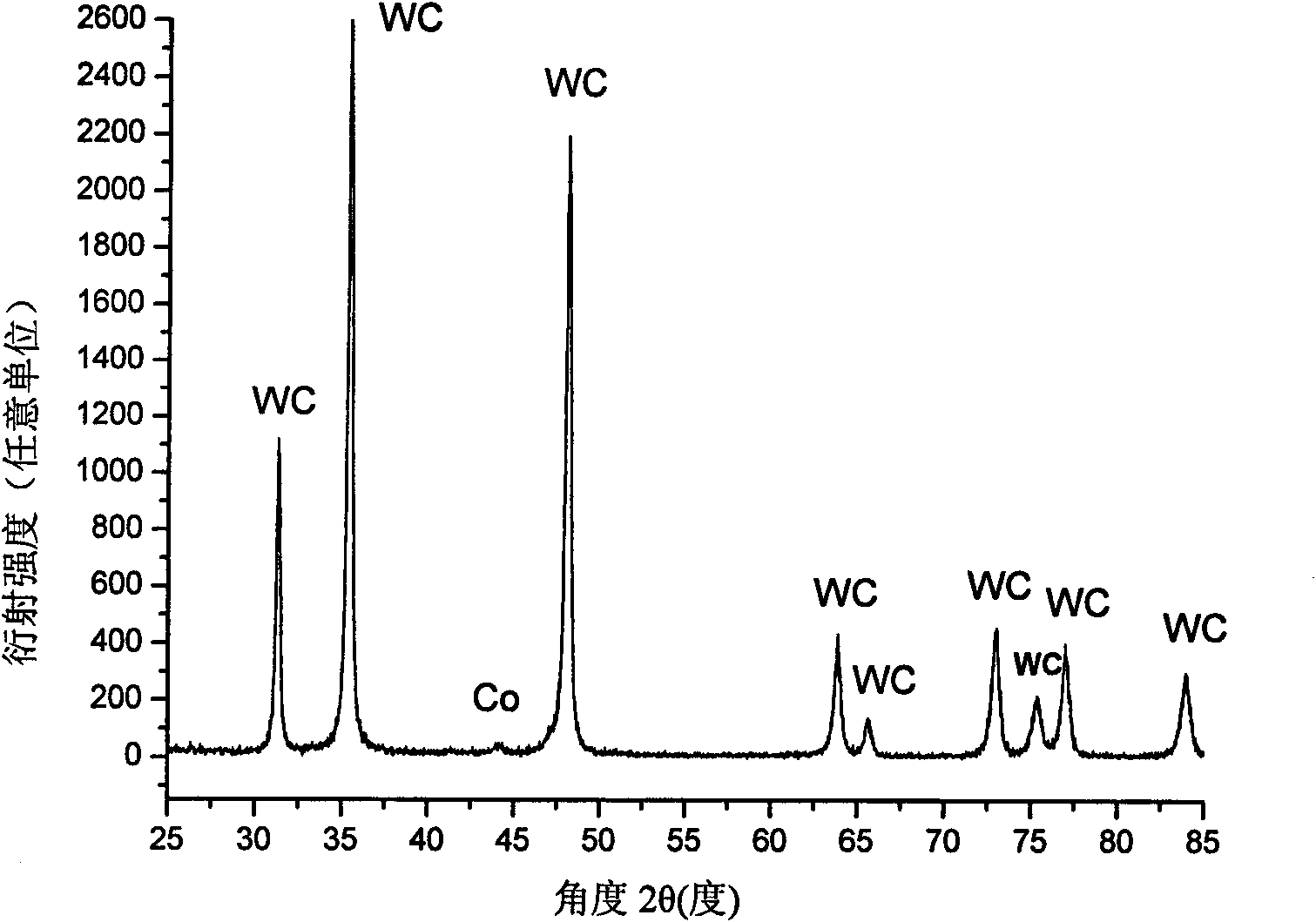

Industrialized preparation method of WC-Co hard alloy with low cost and high performance

ActiveCN101624673ASolve the problem that it is difficult to mix evenlyReduce energy consumptionPolyethylene glycolPrice ratio

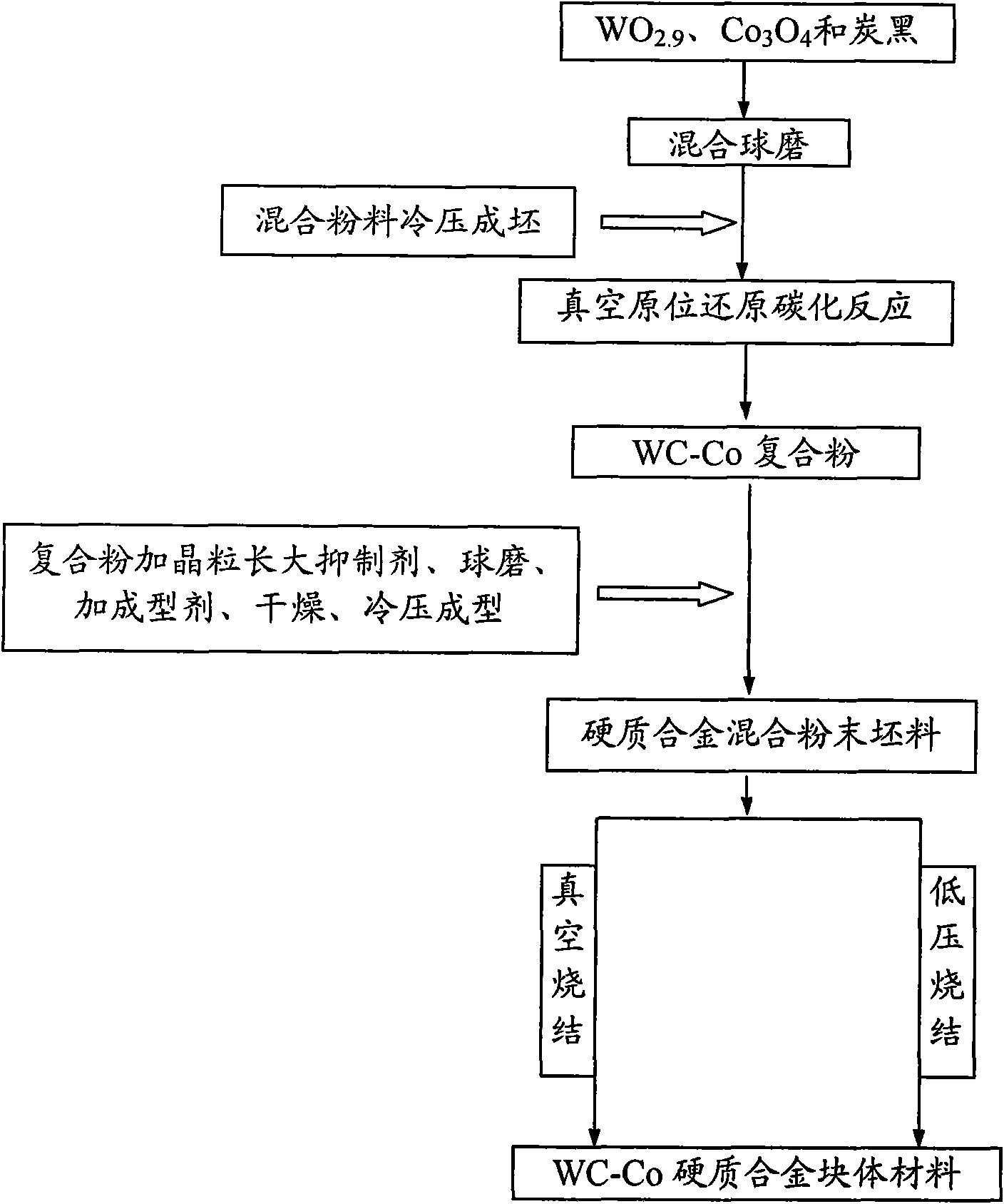

The invention relates to an industrialized preparation method of a WC-Co hard alloy with low cost and high performance, which belongs to the technical field of hard alloys and powder metallurgy. The method comprises the following steps: taking WO2.9, Co3O4 and carbon soot as raw materials, and computing the usage ratio of the three materials according to the requirement of the Co content in a final hard alloy block material; adding 0-1.0 percent by weight of grain growth inhibitor into the prepared WC-Co composite powder, and adding polyethylene glycol as a forming agent into a ball milling tank 4-8 hours before ball milling is finished, wherein 30-80ml of polyethylene glycol is added into the powder material per kilogram; acquiring WC-Co mixed powder with a nanocrystal structure after ball milling, and putting the mixed powder into a mould for press forming after vacuum drying; and sintering the mixed powder stock after press forming in a mode of vacuum sintering or low-pressure sintering. The industrialized preparation method markedly shortens a production period, the provided integrated preparation course markedly reduces the production cost while ensuring the high performance of the hard alloy and has a high performance-price ratio, and the preparation method is suitable for industrialized scale production.

Owner:北硬科技香河有限公司

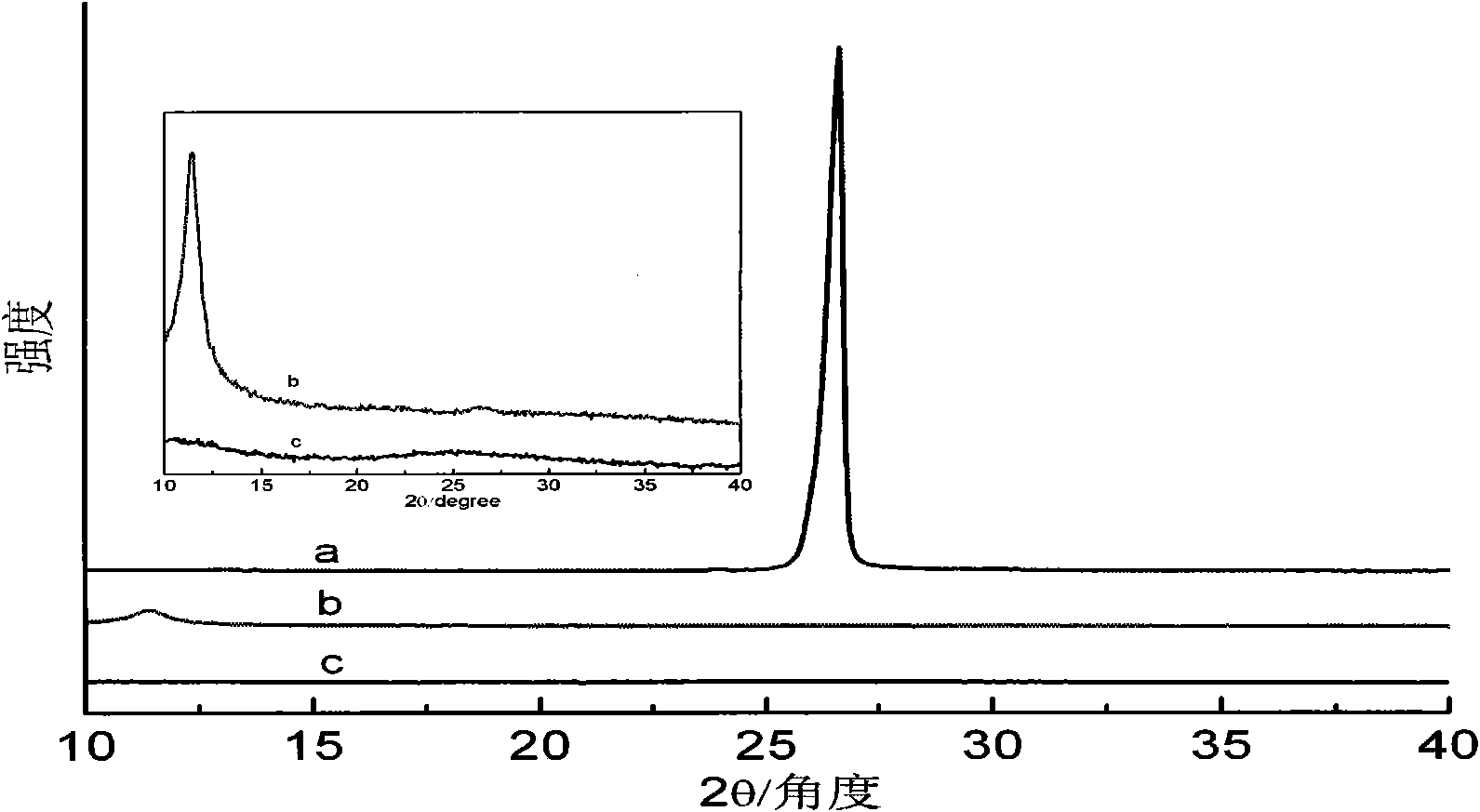

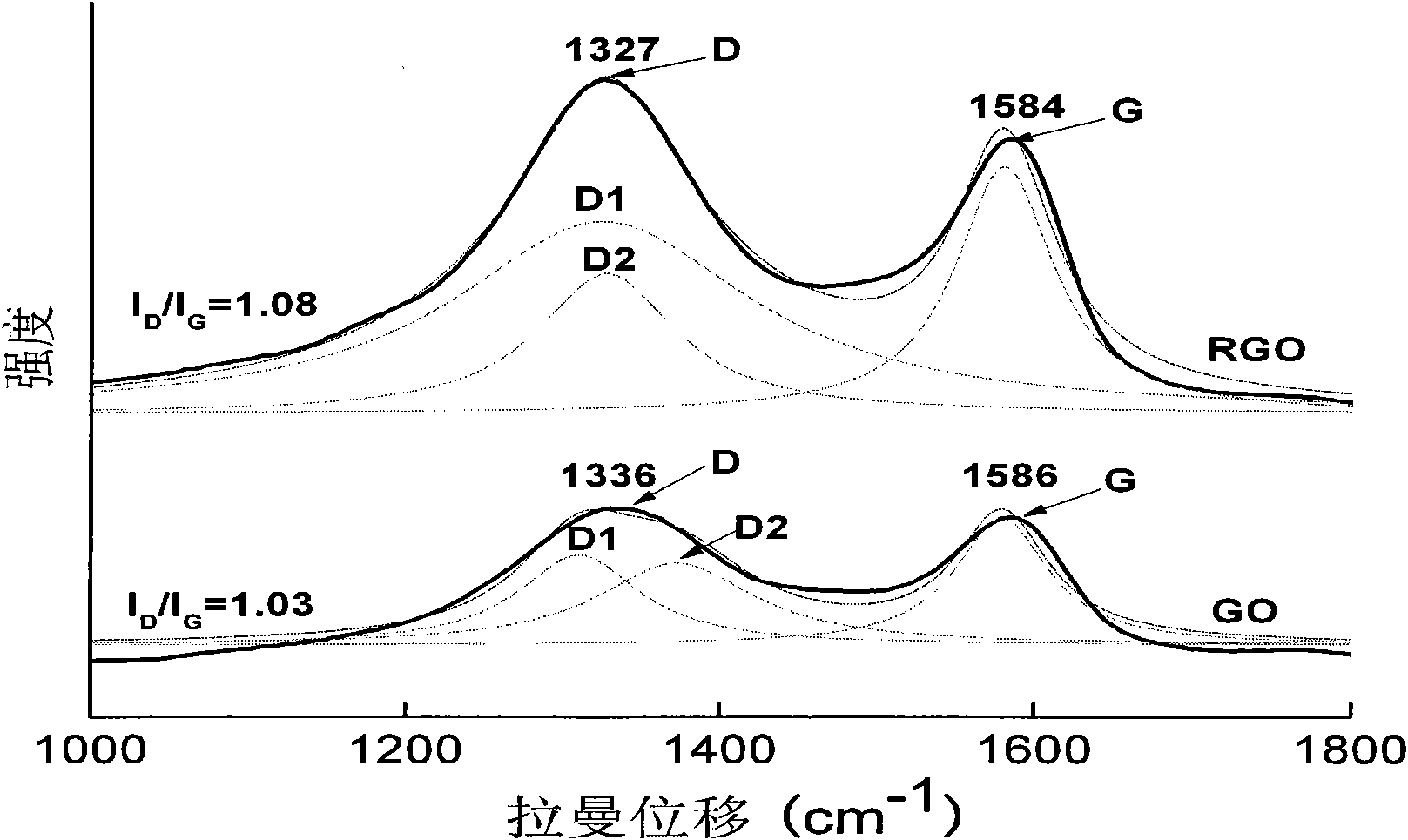

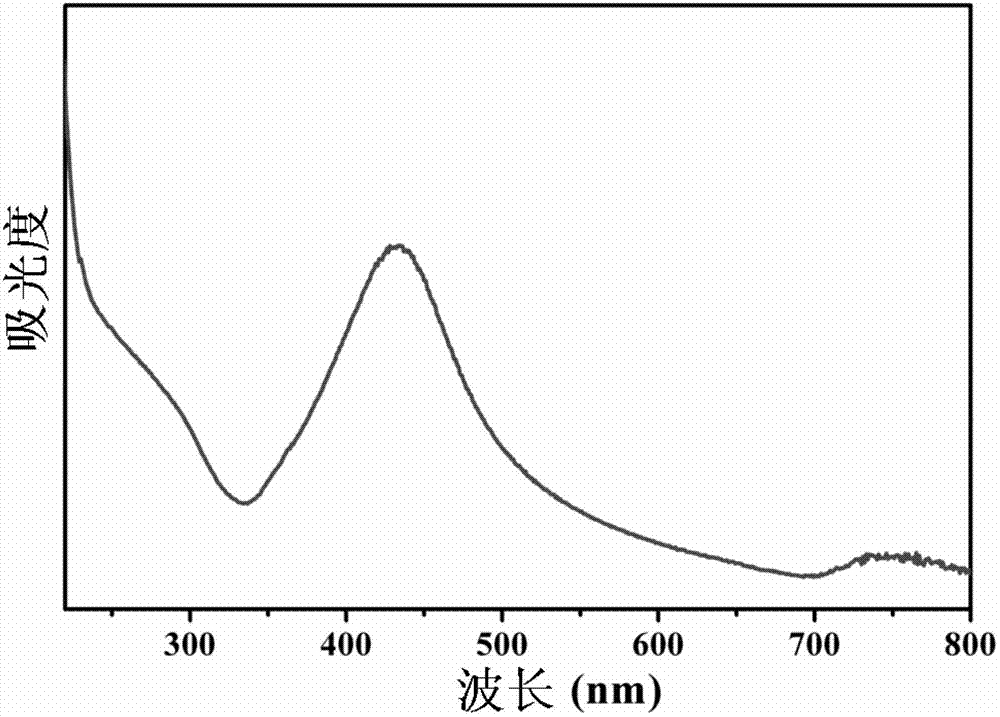

Method of adopting laser radiation for preparing reduction-oxidation graphene

The invention belongs to a method for reducing graphite oxide, and relates to a method of adopting laser radiation for preparing reduction-oxidation graphene. No method in the existing technology can be used to produce a great deal of graphene, thus the material with important value can not be applied. The method comprises the following steps: pouring polar solvent in a quartz container, dissolving graphite oxide in polar solvent to prepare 0.01mg / ml-10mg / ml of polar graphite oxide solution; adjusting the pH value of the polar graphite oxide solution to 9-10, performing supersonic vibration for 1-2 hours; and using excimer laser with more than 1Hz of frequency, 157-353nm of wavelength and more than 40mJ / cm2 of energy density to irradiate the prepared graphite oxide solution to obtain the reduction-oxidation graphene. The method has the advantages that the preparation technology is simple, the preparation time is short; the preparation process can not cause environmental pollution; the prepared graphene product has high reductivity and good product quality; and the equipment is simple, and the method is suitable for industrial production.

Owner:SHANGHAI NORMAL UNIVERSITY

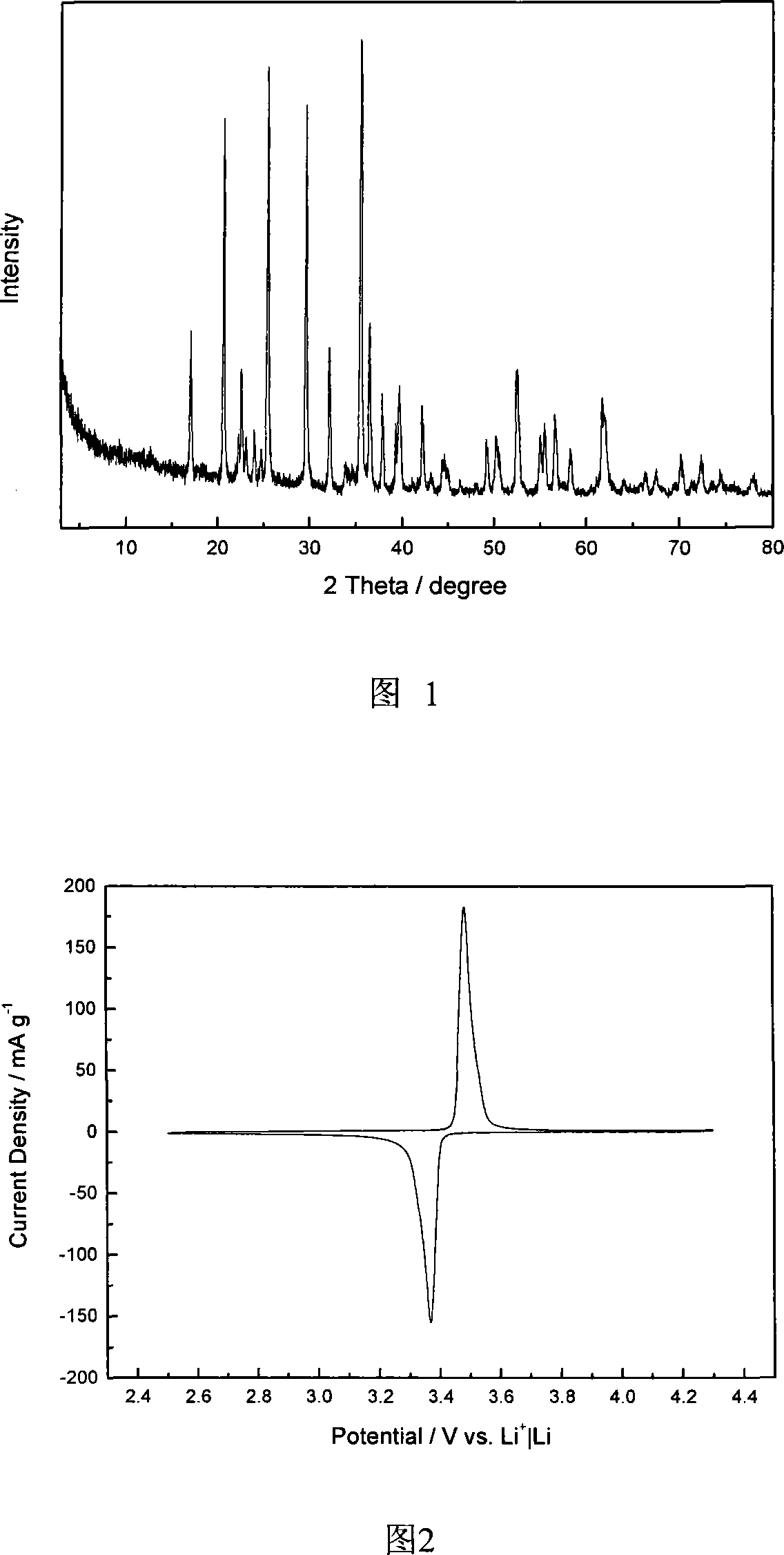

Novel conductive agent doping/coating lithium iron phosphate material and its production method

InactiveCN101222044AHigh specific capacityImprove cycle stabilityElectrode manufacturing processesPhosphorus compoundsHigh rateLithium iron phosphate

The invention discloses a novel lithium iron phosphate material which is adulterated / covered with conductive agents and a preparation method thereof. The lithium iron phosphate material of the invention comprises lithium source compounds, iron source compounds, phosphate radical source compounds and the conductive agents of lithium iron phosphates. The technology of the invention is simple; the material is clean and pollution-free; the cost of the material is low. The invention is suitable for industrialized mass production. Specific capacity of the obtained lithium iron phosphate material is high (more than 140 mAh / g); cyclical stability is good (more than 300 times); high rate charging and discharging performance of the lithium iron phosphate material is particularly prominent (5C capacity can still reach 80 mAh / g); conductivity and stacking density are high; diffusivity of protons is improved; contact between active materials and an electrode is increased; internal resistance of the electrode and a battery is reduced; discharging and cyclical stabilities of the electrode are obviously improved. The invention is widely applied to novel high performance lithium ion batteries.

Owner:NANKAI UNIV

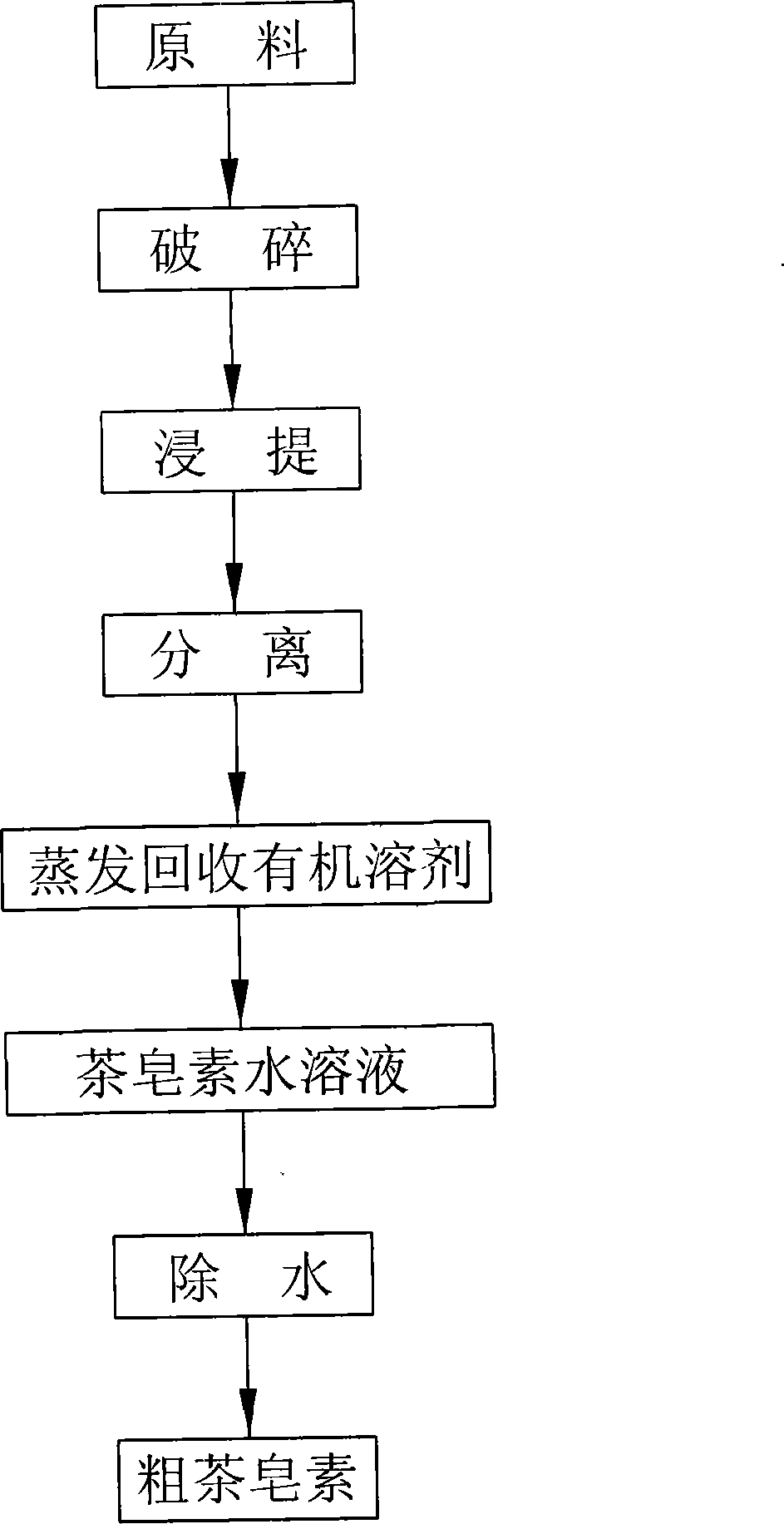

Ultrasonic process of preparing theasaponin

The present invention is ultrasonic process of preparing theasaponin and belongs to the field of agricultural side product processing technology. The technological scheme is that tea seed cake residue after extracting oil is processed through crushing, mixing with organic solvent, ultrasonic leaching, separating, recovering solvent, ultrafiltering to purify and to obtain theasaponin concentrate, decolorizing and drying to obtain theasaponin product. The present invention has the beneficial effects of physical extraction process caused high theasaponin extracting rate, high product purity and quality, simple technological process with low power consumption and low production cost, less pollution, etc.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

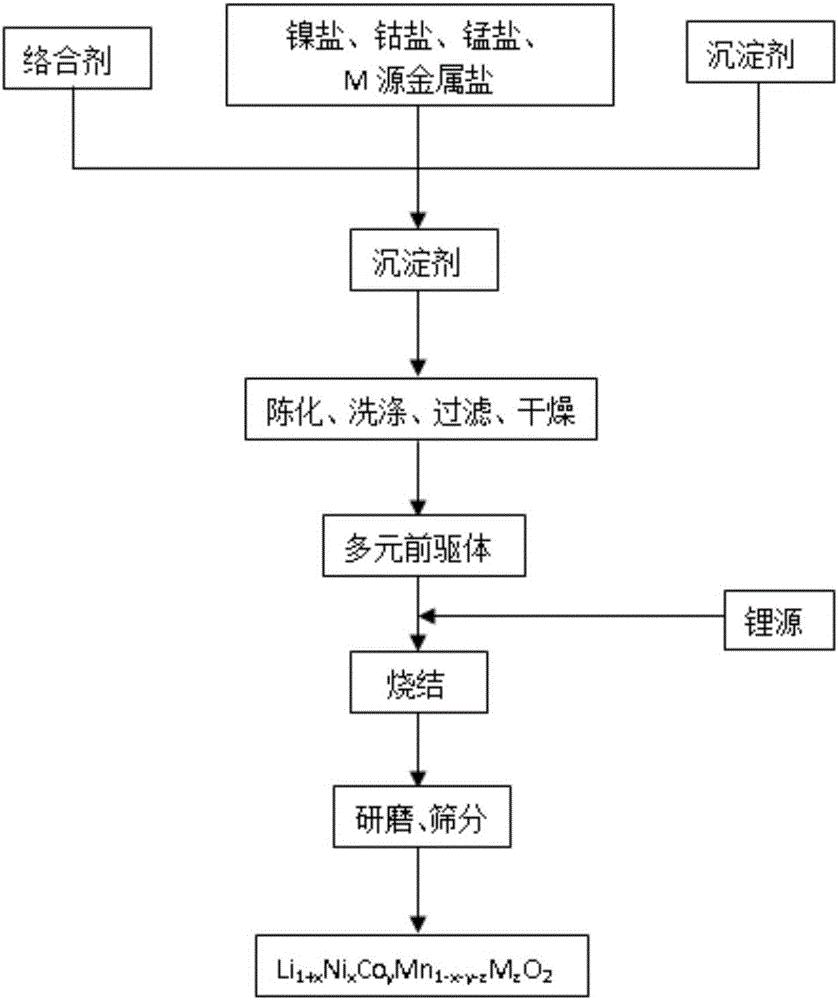

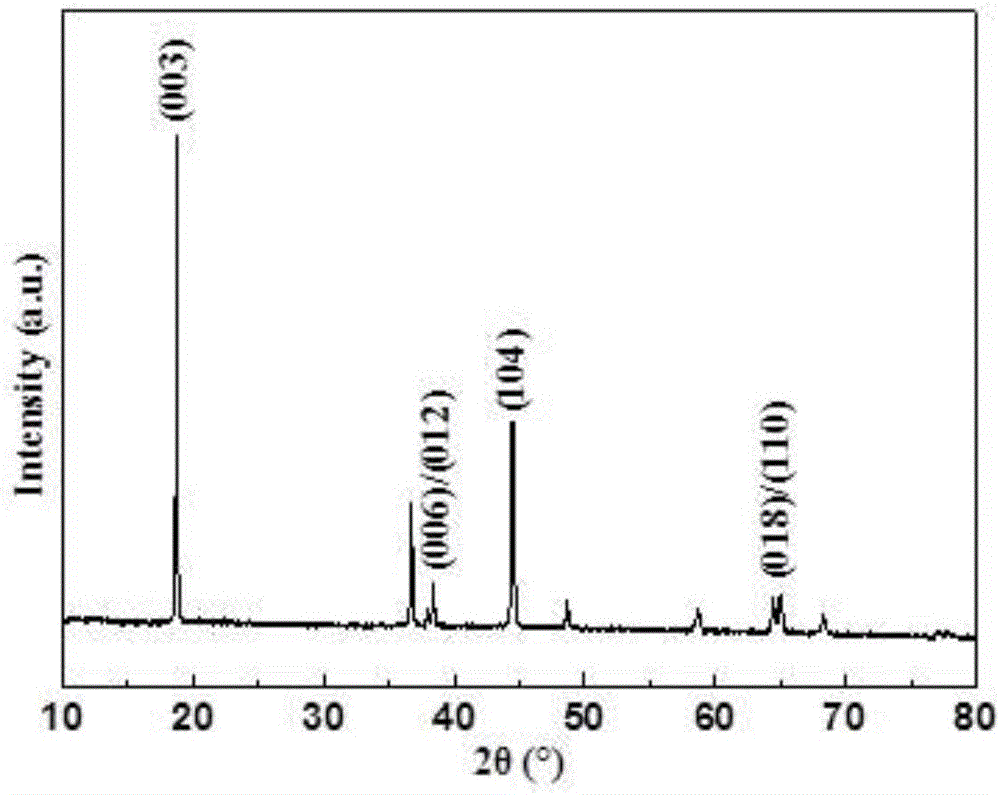

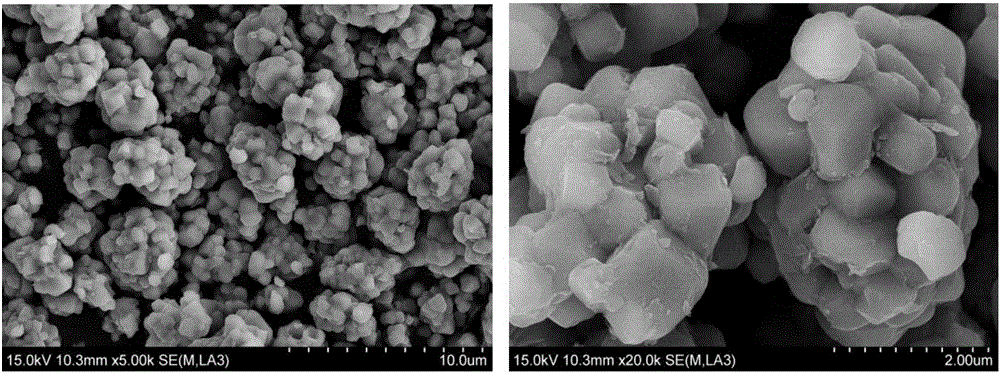

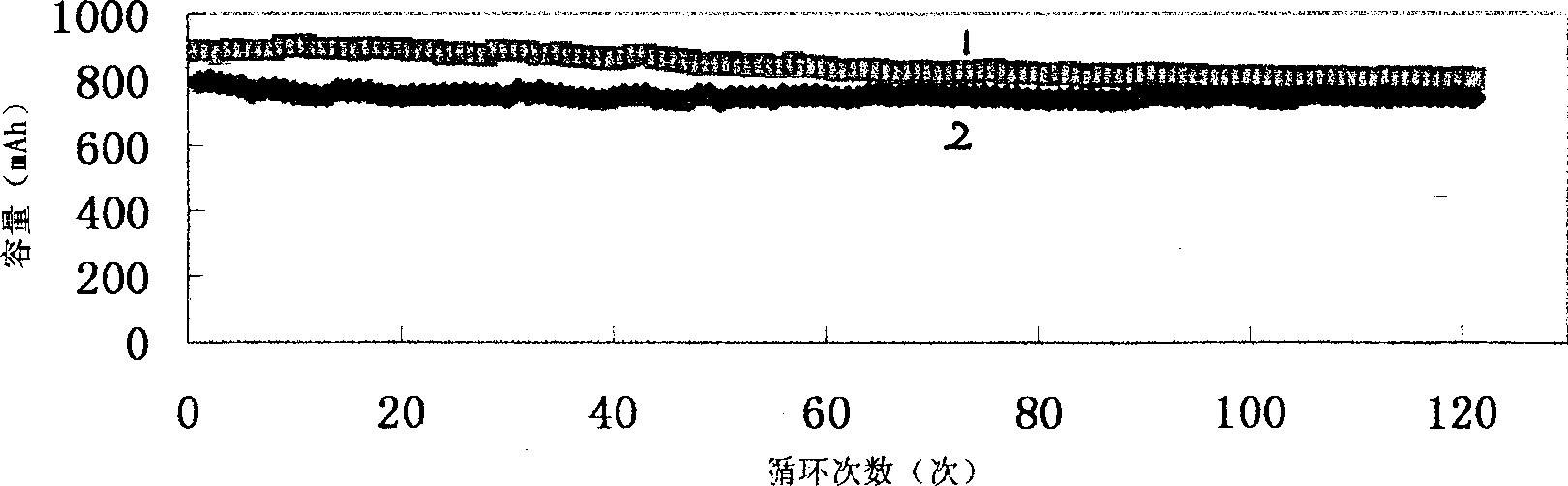

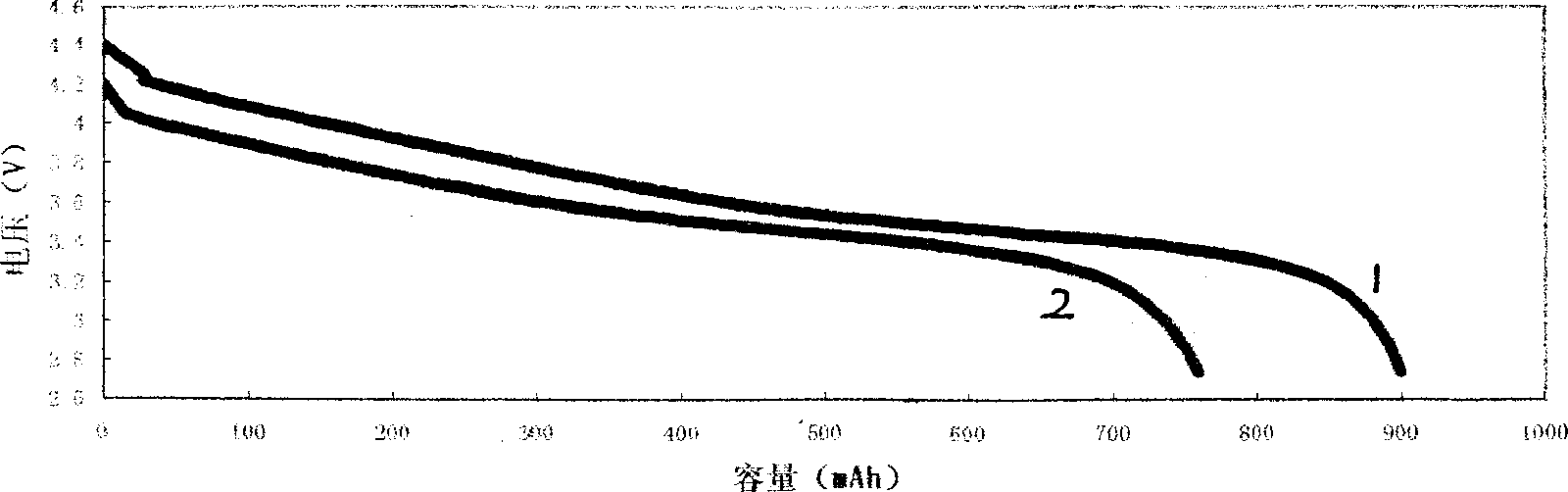

Doped monocrystal multi-component material for lithium ion batteries and preparation method of such doped monocrystal multi-component material

InactiveCN106784686AIncrease energy densityHigh tap densityHybrid capacitor electrodesCell electrodesManganeseCharge discharge

The invention belongs to the technical field of anode materials for lithium ion batteries and particularly discloses a doped monocrystal multi-component material for lithium ion batteries and a preparation method of such doped monocrystal multi-component material. The doped monocrystal multi-component material and the preparation method thereof have the advantages that nickel-cobalt-manganese ternary materials are modified, and M-source metals are doped when a precursor is prepared to decrease the material sintering temperature and improve material tapping density, so that the mixed arrangement degree of Ni<2+> in a Li<+> layer is weakened obviously; through high-temperature sintering and tempering processes, the precursor of the multi-composite material, prepared through a coprecipitation method, is more stable in crystal structure, metal ions in the material are inhibited from dissolving through surface coating, side reaction between the metal ions and electrolyte is inhibited, and stability and electrochemical performance of an active material are further enhanced; a doped monocrystal multi-component material finished product is stable in crystal structure, high in safety and compaction density and excellent in rate capability and cycle performance, so that specific capacity and charge-discharge voltage of the material are further enhanced; the preparation method is small in doping quantity, simple to operate, easy to control, widely applicable and suitable for large-scale production.

Owner:烟台卓能锂电池有限公司

Multi-enzyme and multi-steps type method for producing diet cellulose flour from wheat bran

ActiveCN1718107ACompletely hydrolyzedReduce lossesVegetable proteins working-upFood preparationPhytaseCELLULOSE FLOUR

A process for preparing the edible fibre powder from wheat bran by multi-enzyme step treating method includes such steps as treating wheat bran sequentially by endogenous phytase, amylase, proteinase and lipase to obtain high-purity edible fibres, decoloring by sodium hypochlorite and hydrogen peroxide, squeezing, laying aside and superfine pulverizing.

Owner:江苏江南上一道科技股份有限公司

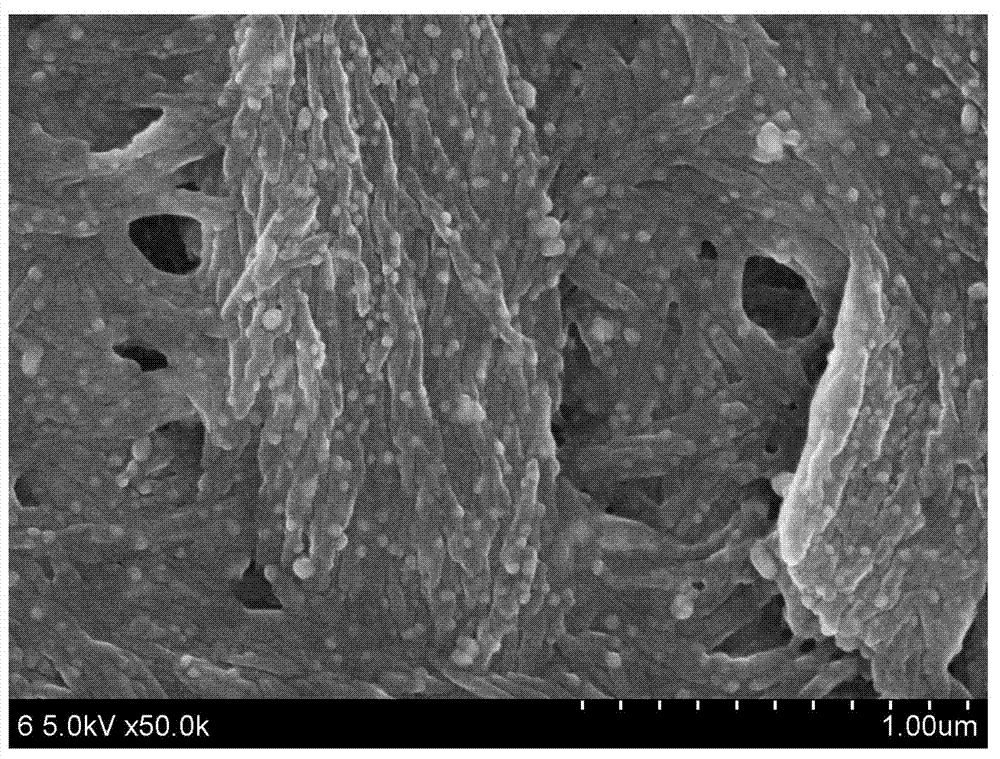

Preparation method for nano-sliver/cellulose nanocrystalline composite particle

InactiveCN102775643AIncrease loadDoes not destroy the glycosidic ring structureNanotechnologyCelluloseFree cooling

The invention relates to a preparation method for a nano-sliver / cellulose nanocrystalline composite particle. The preparation method comprises the following steps of: (1) adding a cellulose raw material into an acid-mixed solution and reacting at the temperature of 50-90DEG C for 1-20 hours; after the reaction is ended, washing a reaction product with deionized water to neutral and obtaining aldehyde cellulose nanocrystalline; and (2) adding the aldehyde cellulose nanocrystalline into a silver nitrate solution; reacting at the temperature of 60-105DEG C for 10-60 minutes; and after naturally cooling, diluting a reaction product with the deionized water, centrifuging and then carrying out free drying or vacuum drying to obtain a nano-silver / CNC (Cellulose Nanocrystalline) composite material. The preparation method disclosed by the invention is simple and convenient in process, easy in operation and environment friendly and can be used for shortening the preparation period; the prepared CNC / nano-silver has the advantages of small size, easy adjustment, large specific area, firmness in combination of the CNC and the nano-silver, durable antibacterial effect, antibacterial and enhancing functions and broad application prospect.

Owner:DONGHUA UNIV

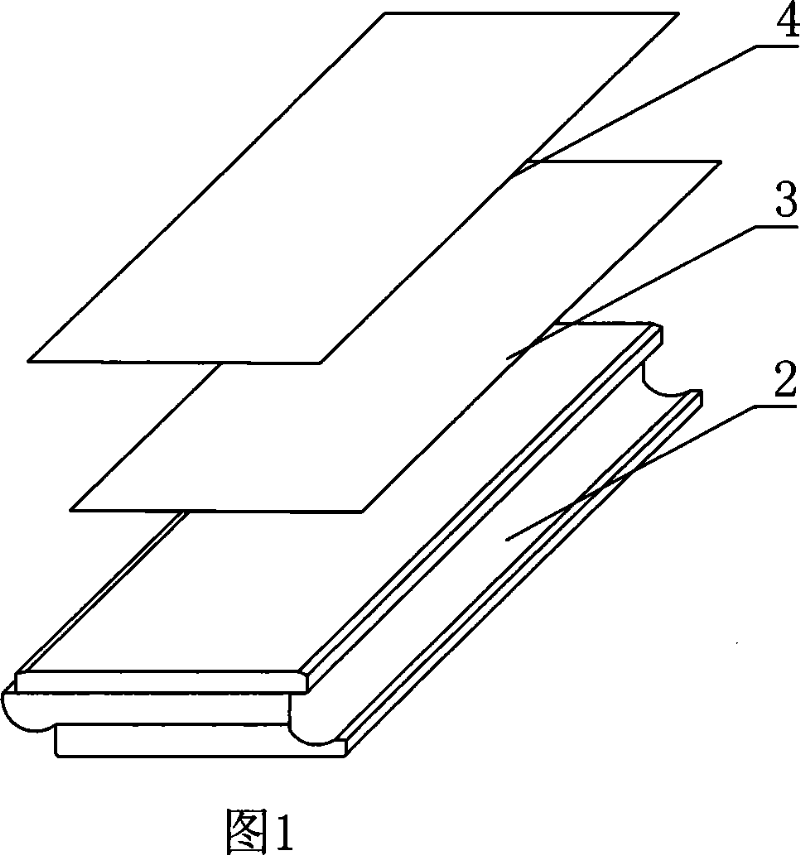

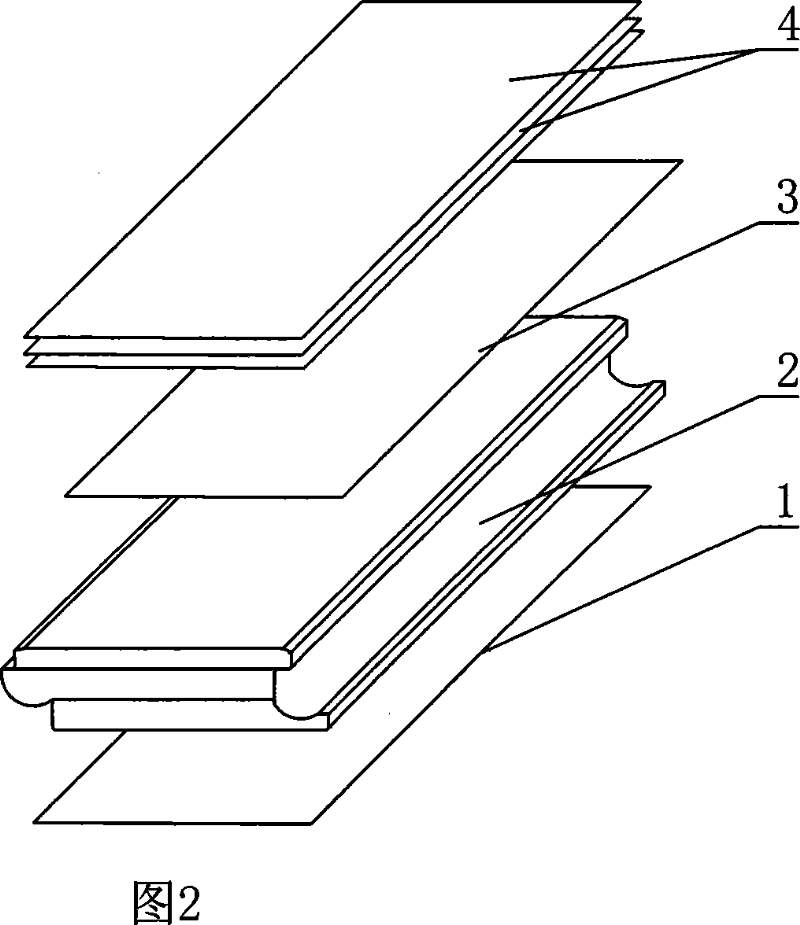

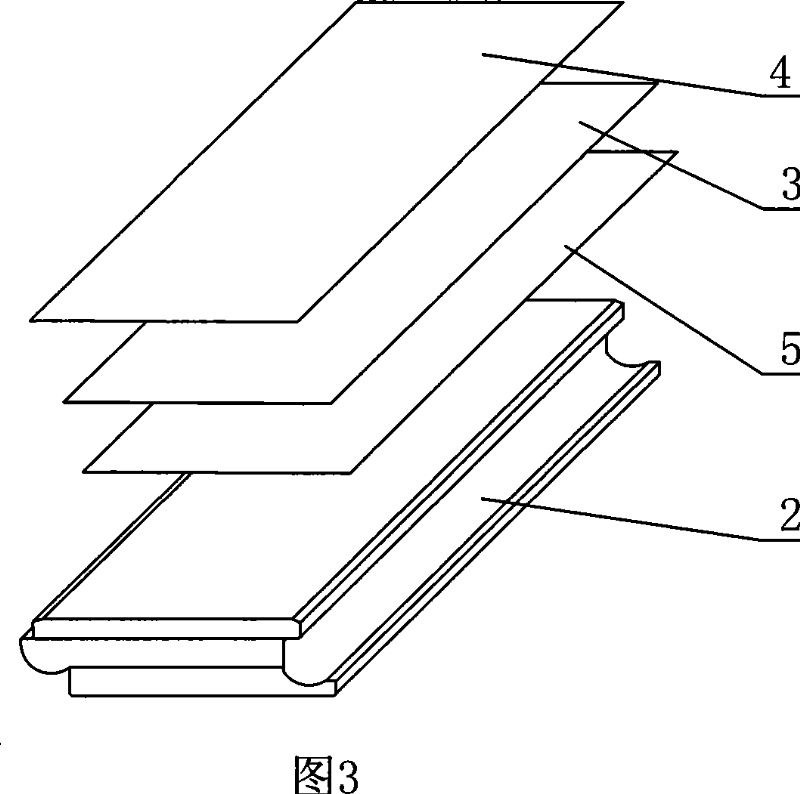

Method for making water-proof floor

A water proof floor is made by dipping 1-3 pieces of anti wearing paper and decorative paper into melamine and dried, applying 2MPa-10MPa pressure with the heating press with these two kinds of paper stacked, in the temperature of 185deg.C-230deg.C, keeping the pressure for 25-60s and cooling naturally to form into the panel, roughening the upper surface of the wood slab or free wax fiber slab to form into uneven surface, applying adhesive agent on the upper surface of the slab, one side of the decorative paper of the panel attached on the up surface of the slab, applying 15MPa-45MPa pressure in normal temperature for 15-60 minutes, sticking the panel to the slab to make a big plate, cutting the big plate to the required strip, having key way vertically and horizontally to make the final product. The floor is not only anti wearing, and water proof, it is also being anti shock, fire resistant, anti erosion, and environment protective in nature.

Owner:高建忠

Method for directly extracting tea saponin from tea seeds

The invention relates to a method for extracting tea saponin directly from tea seeds. The method comprises the following steps: firstly, the oil-tea camellia seeds are hulled, tea kernels are crushed into 200-300 meshes of particles; then, the leaching is carried out, the PH value of the leaching solution is controlled between 5 and 9, the leaching solution is added with organic solution, the amount of the organic solution is determined according to the weight-to-volume ratio (3-8 times) between the oil-tea camellia seeds and the organic solution, the temperature is controlled between 60-80 DEG C, the extraction time is 1-4 hours, and the lixiviation is repeatedly performed for 1-2 times; then, the separation and the solvent recovery are carried out, the filtering or the centrifugal separation is performed to the leaching solution, and meanwhile, the reduced pressure evaporation and the recovery are performed to the organic solvent in the leaching solution to obtain aqueous solution of the tea saponin; and finally, the water is removed from the liquid tea saponin to obtain the crude tea saponin product. The invention has the advantages that the oil-tea camellia seeds are directly taken as the raw materials for extracting the tea saponin, the extract of the obtained tea saponin has high purity and good quality, and the method is suitable for the industrial large-scale production.

Owner:SHAOGUAN COLLEGE

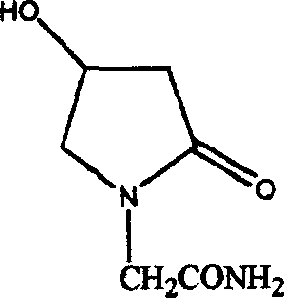

Method of preparing 4-hydroxy pyrrolidone-2-acetamine

InactiveCN1513836ARaw materials are cheap and easy to getLow costOrganic chemistryAcetic acidAlkaline earth metal

A process for preparing 4-hydroxypyrrolidone-2-acetylamine used as brain function improver includes reacting between 4-haloacetoacetic acid derivative and the azide of alkali metal or alkali-earth metal to obtain 4-azoacetoacetic acid derivative, hydrogenating, cyclizing, and ammoniating. Its advantages are high quality and output rate of product, and low cost.

Owner:SUZHOU HOPE TECH

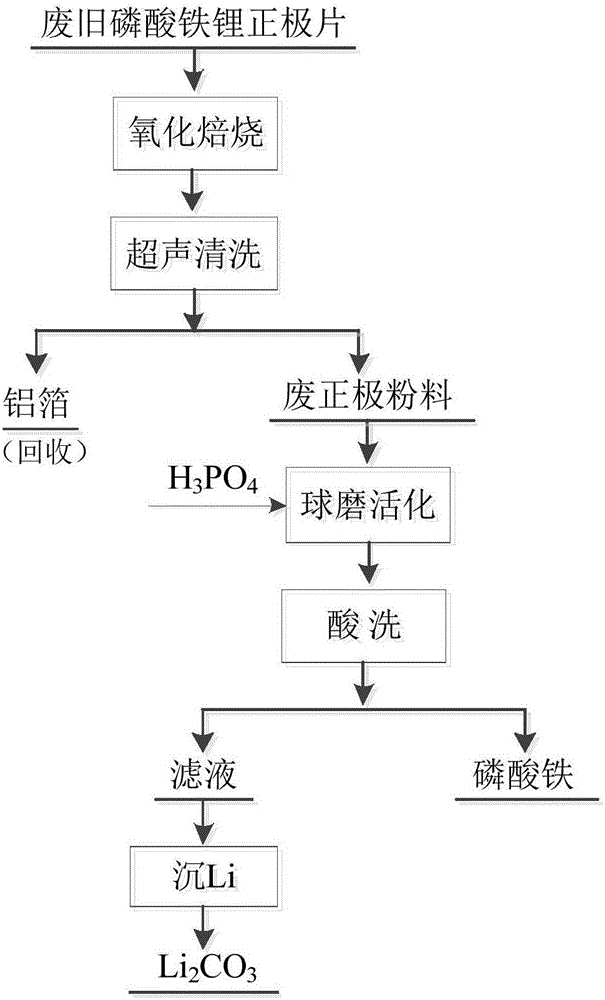

Method for recycling iron phosphate and lithium carbonate from lithium iron phosphate waste

ActiveCN106450547AAdaptableNothing producedWaste accumulators reclaimingBattery recyclingPhosphoric acidIndustrial scale

The invention discloses a method for recycling iron phosphate and lithium carbonate from lithium iron phosphate waste. The method comprises the following specific steps: (I) oxidizing roasting; (II) carrying out pole piece cleaning; (III) adding phosphoric acid and performing ball-milling activation; (IV) performing acid pickling to separate FePO4; and (V) precipitating lithium of the filtrate to obtain a target object Li2CO3. The method disclosed by the invention has the following advantages: the P, Fe and Li resources in the lithium iron phosphate waste can be fully utilized to prepare iron phosphate and lithium carbonate products with high added value, no waste of Fe is generated, the resource recycling rate is high, the technological process is short, the reaction system is simple, a few raw materials are consumed, the cost is low, the product value is high, and the method is very suitable for industrial scale production.

Owner:JINGMEN GEM NEW MATERIAL

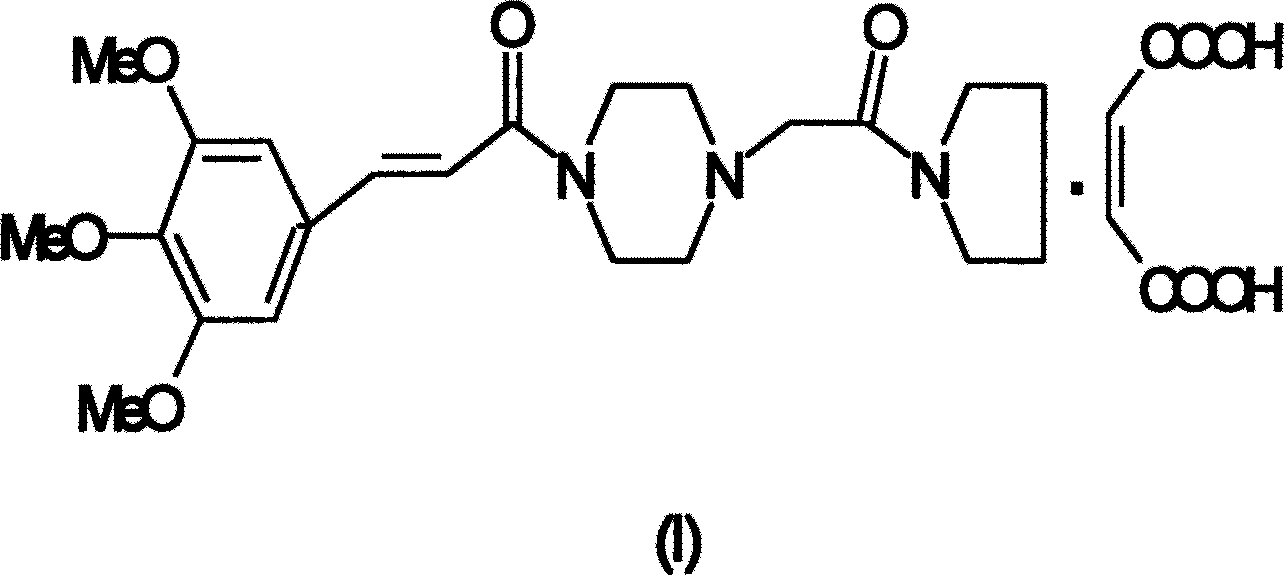

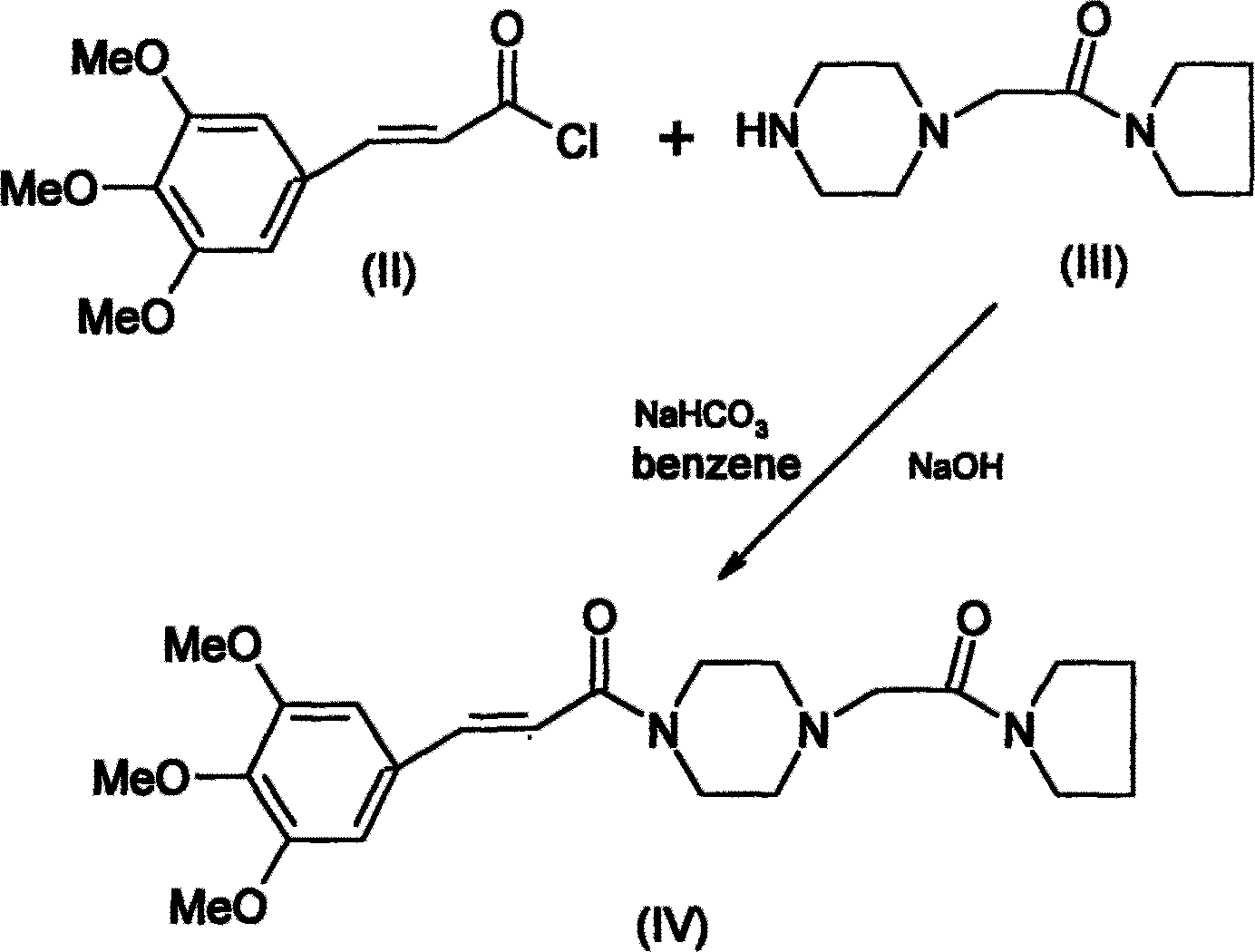

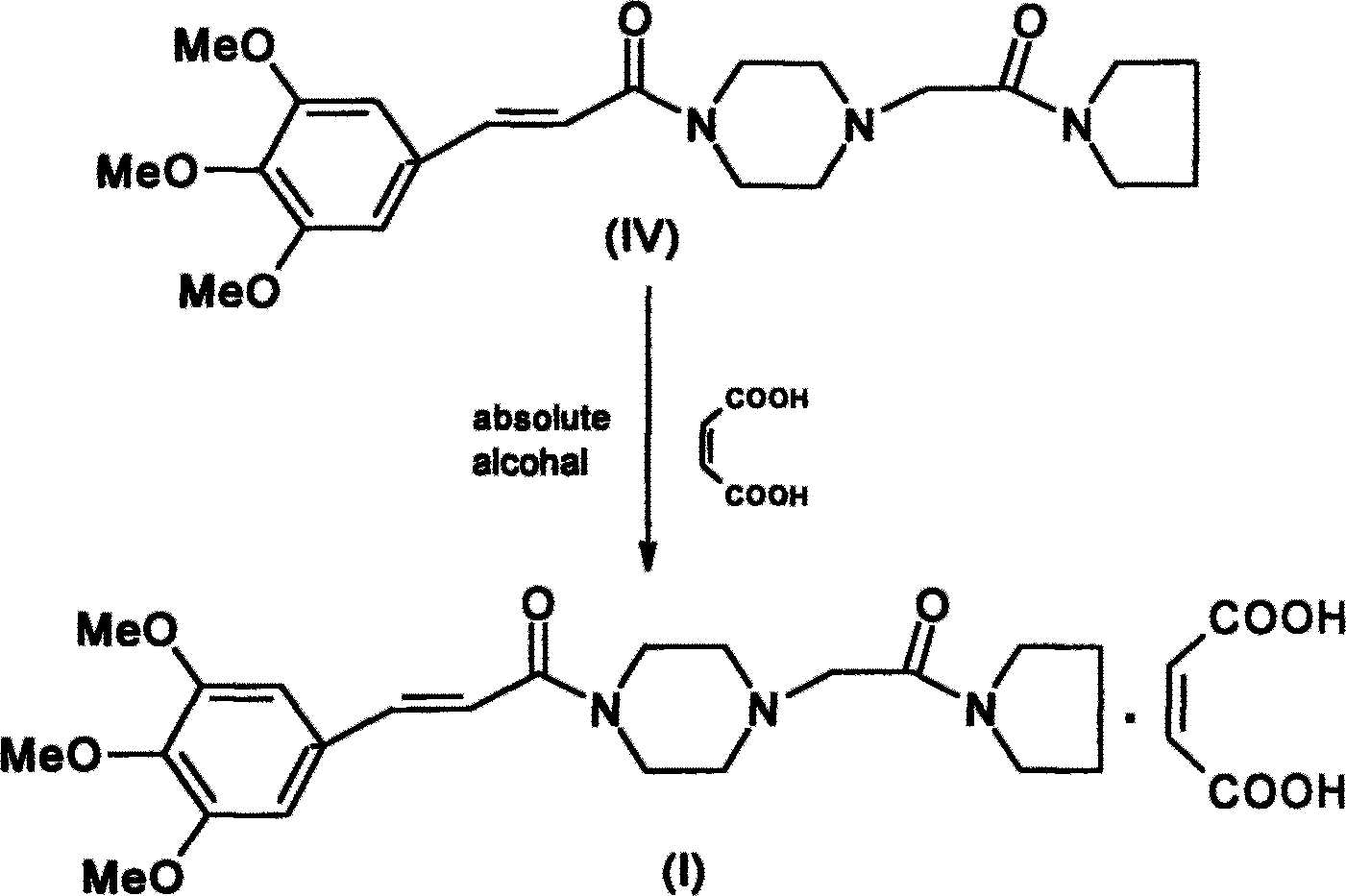

Improved cinepazide maleate preparation method

ActiveCN1876646AHigh melting pointCrystal stableOrganic active ingredientsOrganic chemistrySolventPyrrolidine

The invention relates the preparing method of maleic acid cinprazole. The method comprises the following steps: preparing chloracetyl pyrrolyl; preparing 1- [(1- pyrrolidine carbonyl) methyl] ethyleneamine; preparing 3, 4, 5- trimethoxyl cinnamomum cassia acyl; preparing 1- [(1- pyrrolidine carbonyl) methyl]-4- 3, 4, 5- trimethoxyl cinnamomum cassia acyl) ethyleneamine; preparing 1-[(1- pyrrolidine carbonyl) methyl]-4- 3, 4, 5- trimethoxyl cinnamomum cassia acyl) ethyleneamine maleate; preparing the purification of maleic acid cinprazole. The invention has the character that the solvent is one of chloroform and acetone. The fusing point of the product is 170-175Deg.C. The product has the advantages of high fusing point and stable crystal shape.

Owner:BEIJING SIHUAN PHARMA

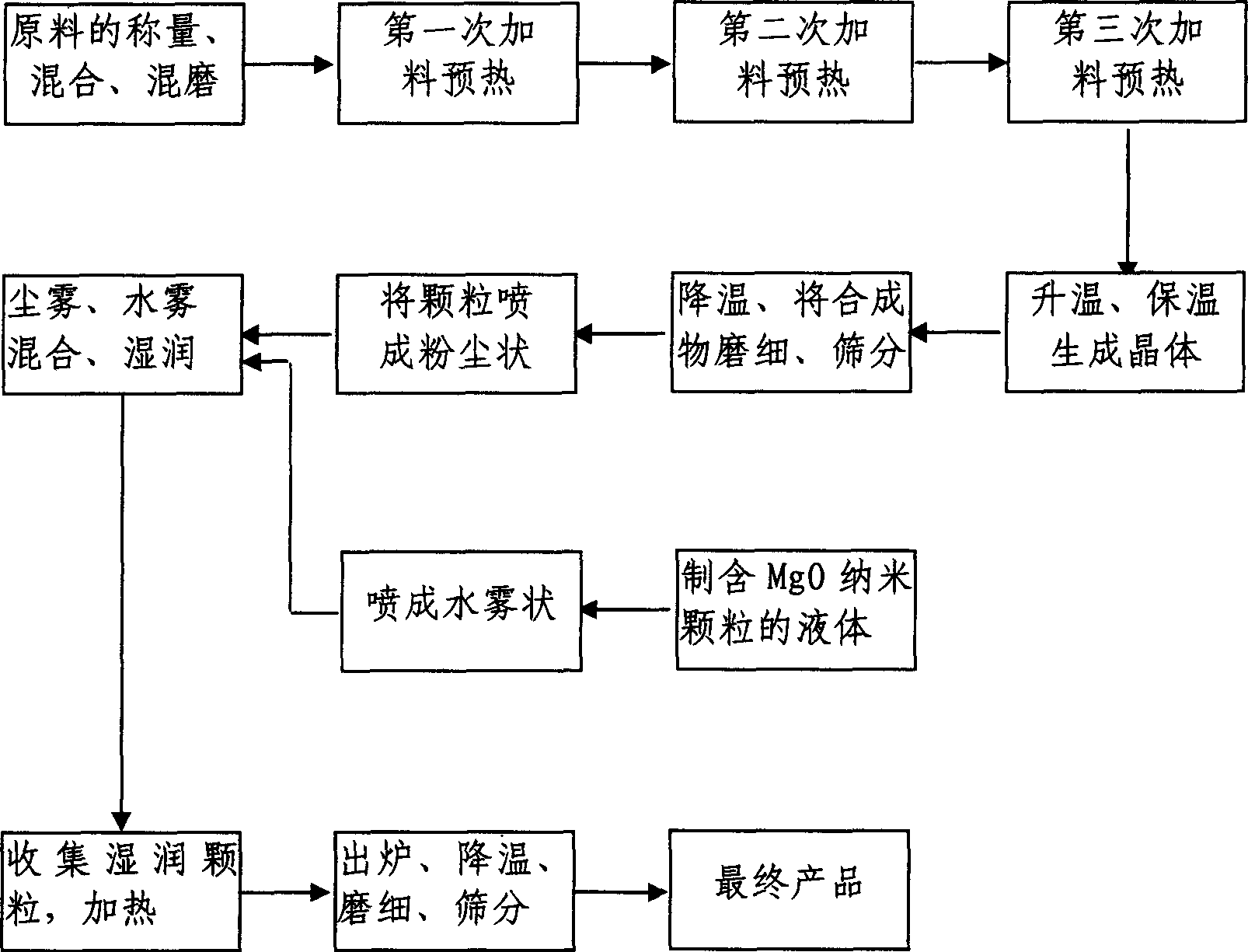

Doping and surface coating lithium nickel cobalt dioxide and its preparing method

This invention relates to lithium ion battery positive electrode mixture and surface nickel-to-cobalt acid lithium and its process method, which is characterized by the following: materials particle inner crystal core is LiNixCoyMgzO2 or LiNixCoyMnzO2; mixing Mg, Mn, or rare earth; outside surface layer is of nanometer MgO. The process method adopts three times adding and heating under 800 degrees temperature. The advantages of this invention embodies in crystal, structure, particle shape, large intensity and good flow and large capacity.

Owner:黎彦希

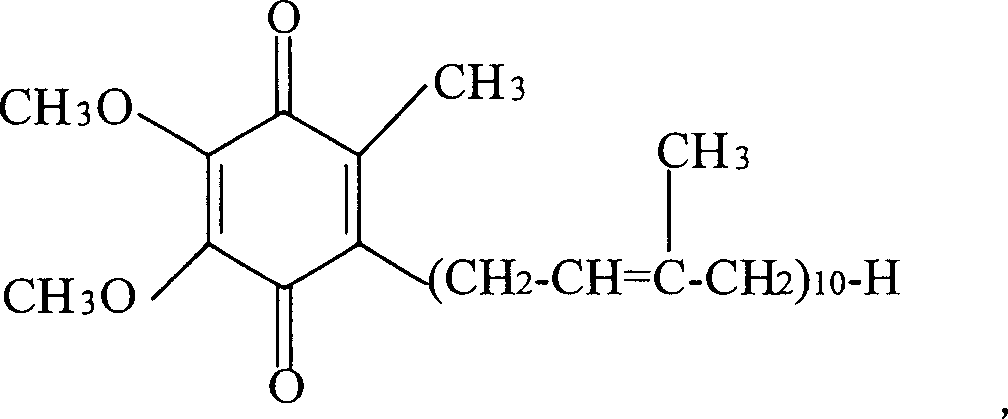

Dry powder composition containing CoQ10 and preparation process thereof

InactiveCN1969833ATransport stableImprove bioavailabilityOrganic active ingredientsPowder deliveryAntioxidantExcipient

The invention discloses a dry powder composition with coenzyme Q10 and preparing method, which comprises the following parts: 1%-60% active coenzyme Q10, 10%-70% excipient, 10%-80% clad wall material, 1%-15% antioxidant and water.

Owner:ZHEJIANG MEDICINE CO LTD XINCHANG PHAMACEUTICAL FACTORY

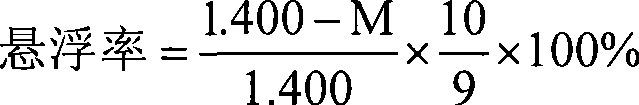

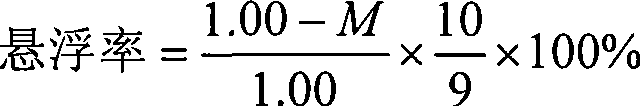

Terpolymer dispersants and preparation technique and use thereof

InactiveCN101391194AGood dispersionImprove thermal stabilityTransportation and packagingMixingSolubilityDispersion stability

The invention discloses a terpolymer dispersing agent with high dispersion and stability, low preparation cost and environmental protection as well as a preparation process and applications thereof. The terpolymer dispersing agent is prepared through free radical copolymerization of acrylic acid, sodium styrene sulfonate, hydroxypropyl acrylate or 2-hydroxyethyl methacrylate, the number average relative molecular weight of the terpolymer is between 2000 and 40000, and the dispersing agent has advantages of high thermal stability, good water solubility, excellent adaptability to acid and alkali and good dispersion stability, and also has good dispersion effects to calcium carbonate, zinc oxide, barium sulfate, titanium dioxide and pesticide Atrazine water dispersible granules and fipronil water dispersible granule, and can be widely used in the pesticide, pigment, dyestuff, coal water slurry and other industries. In addition, the preparation process has the advantages of simple operation, short cycle, environmental protection and low cost, and is suitable for the industrial scale production.

Owner:SHANGHAI NORMAL UNIVERSITY

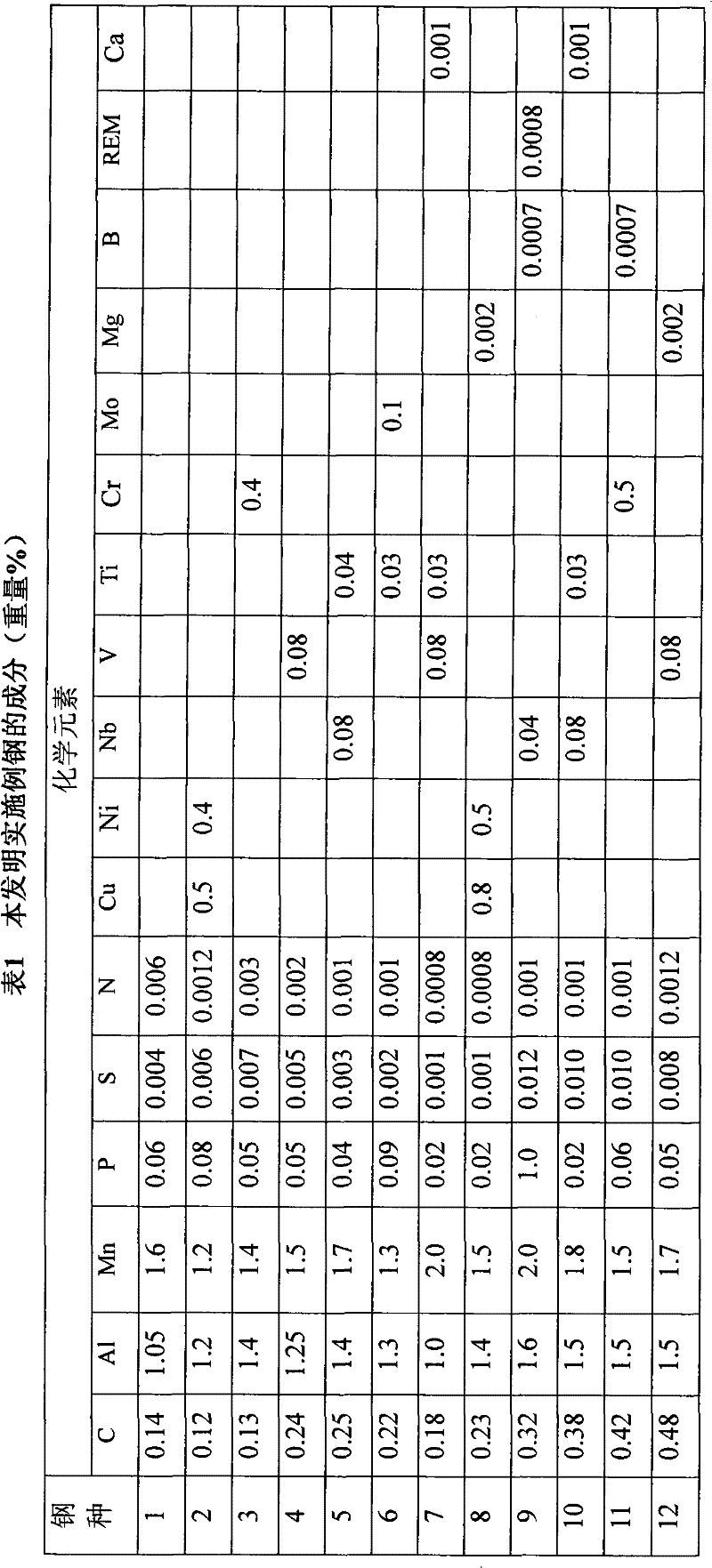

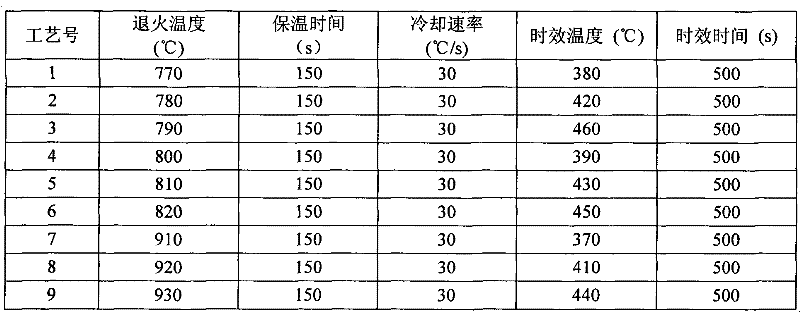

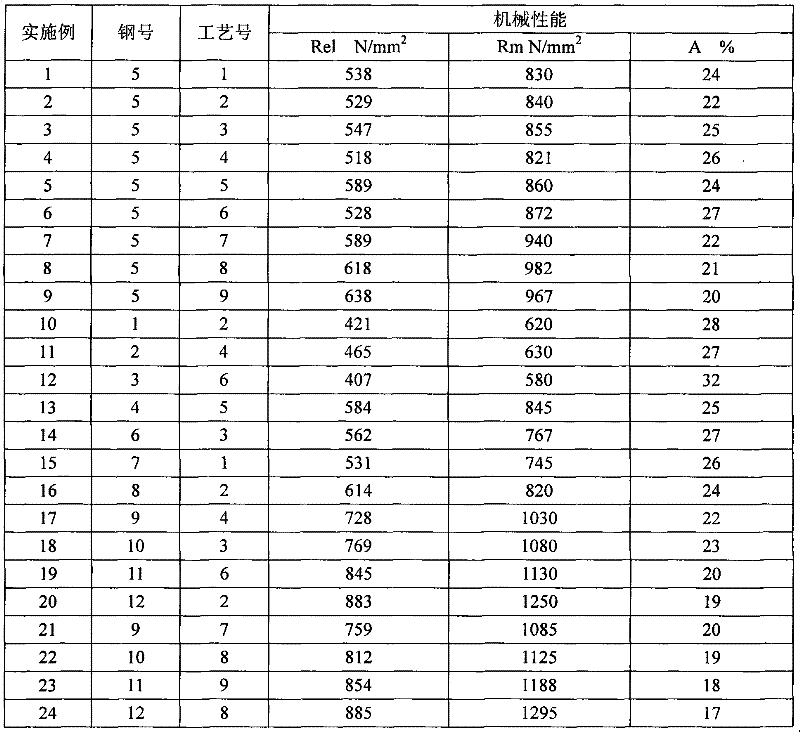

Continuously annealed or hot galvanized cold rolled transformation induced plasticity steel plate and preparation method thereof

ActiveCN102409222AGood strengthHigh strengthTemperature control deviceFurnace typesSteel platesLiquid temperature

The invention provides a continuously annealed or hot galvanized cold rolled transformation induced plasticity steel plate and a preparation method thereof. The steel plate comprises the following components: 0.1-0.5% of C, 0.2-2.0% of Al, 0.5-2.5% of Mn, 0.02-0.12% of P, not more than 0.02% of S, not more than 0.01% of N and the balance of Fe. The method comprises smelting, rolling and continuous annealing or hot galvanizing and is characterized in that the hot rolling heating temperature is 1100-1250 DEG C; the heat is preserved for 1-4 hours; the initial rolling temperature is 1100 DEG C; the finish rolling temperature is 750-900 DEG C; the coiling temperature is less than 700 DEG C; accumulated cold rolled reduction is 40-80%; the continuous annealing temperature is 700-(Ac3+50) DEG C; the heat is preserved for 30-360 seconds; the cooling rate is 10-150 DEG C / s; the aging temperature is 250-600 DEG C; the aging time is 30-1200 seconds; the steel plate is cooled to the room temperature at a rate of 5-100 DEG C / s; the hot galvanizing and annealing temperature is 700-(Ac3+50) DEG C; the heat is preserved for 30-360 seconds; the cooling rate is 10-150 DEG C / s; the steel plate is cooled to 400-500 DEG C and enters into a zinc pot after the heat is preserved for 10-300 seconds; the zinc pot temperature is 450-500 DEG C; the impregnation time is 1-10 seconds; the steel plate is cooled to the zinc liquid temperature to be galvanized; the impregnation temperature is 450-500 DEG C; and the impregnation time is 1-10 seconds. The steel plate has good strength, plasticity, forming property, welding property and galvanizing property and is suitable for industrial production.

Owner:ANGANG STEEL CO LTD

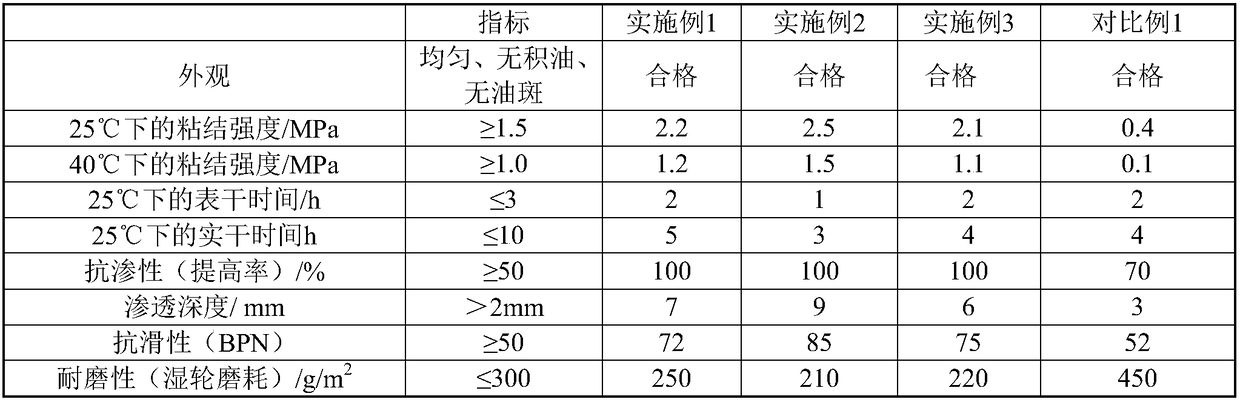

Epoxy modified emulsified asphalt sand-fog-containing sealing layer material and preparation method and application thereof

InactiveCN108070269AGood compatibilityNo premature demulsification and agglomerationIn situ pavingsBuilding insulationsEpoxyBituminous materials

The invention belongs to the technical field of compositions of asphalt materials, and particularly relates to an epoxy modified emulsified asphalt sand-fog-containing sealing layer material. The sand-fog-containing sealing layer material comprises the following main components: emulsified asphalt, epoxy resin and a water-soluble curing agent. The material is good in compatibility, a prepared sand-fog-containing sealing layer is uniform, and does not have accumulated oil or oil spots; the strength of the material is high; the anti-penetrability performance is good; the skid resistance is good;and the wear resistance is also good. The sand-fog-containing sealing layer prepared from the material has good inlaying effect on the original pavement. The preparation method is simple and speedy,convenient to operate and suitable for industrialized large-scale production.

Owner:重庆市智翔铺道技术工程有限公司

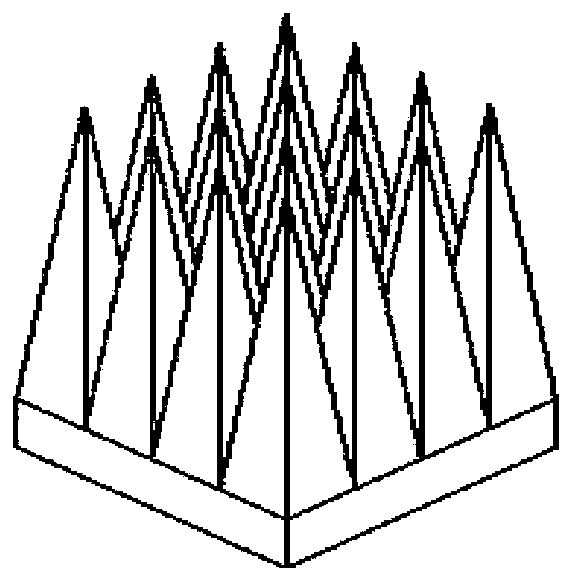

Fire-retardant type wide-frequency-band high-power compound wave-absorbing material and preparing method thereof

ActiveCN103347379AImprove flame retardant performanceImprove power enduranceMagnetic/electric field screeningFibre treatmentPentaerythritolEngineering

The invention relates to a fire-retardant type wide-frequency-band high-power compound wave-absorbing material and a preparing method thereof. The material comprises an outer shell, an inner core and a base, wherein the outer shell is a polyhedron formed by a set of pyramids arranged side by side, the wedges of the pyramids are towards the same side, the inner core is located inside the outer shell, the base is located at the bottom of the outer shell, the outer shell is made of non-woven cloths, the inner core and the base are made of polyurethane foams, the inner surface and the outer surface of the outer shell are respectively provided with a first fire-retardant wave-absorbing agent layer in a coating mode, and the inner core and the base are immersed in second fire-retardant wave-absorbing agents. Both the first fire-retardant wave-absorbing agents and the second fire-retardant wave-absorbing agents comprise acetylene black, alpha-SiC, aluminum hydroxide, kaolin, pentaerythritol, and App-3. The corresponding preparing method comprises the steps of preparing the outer shell, preparing the inner core and the base, and inserting the inner core into the outer shell, and therefore the wave-absorbing material is obtained. The wave-absorbing material has good wave absorbing performance and fire retardance, and the preparing method is simple and easy to implement.

Owner:NANJING LUOPU TECH CO LTD

Preparation method for cellulose crystal susceptible to re-dispersion after drying

InactiveCN103275336AReduce drying energy consumptionInhibition of agglomerationFluidized bed dryingActive agent

The invention discloses a preparation method for a cellulose crystal susceptible to re-dispersion after drying, which comprises selection and using for cellulose crystal materials and non-ionic surface active agents; and a preparing and drying processing method for cellulose crystal suspending liquid materials, wherein the cellulose crystal materials comprise different types of cellulose crystals obtained by different cellulose sources and different processing methods; and the non-ionic surface active agents are APG, poly ethylene glycol, and polypropylene glycol. The preparation method comprises the following steps: mixing and stirring one of the non-ionic surface active agents and one of cellulose crystal suspending liquid to obtain the cellulose crystal suspending liquid materials; the cellulose crystal suspending liquid materials are subjected to drying processing by a fluid bed dryer or a spray dryer to obtain granulated, particulate, or powdered cellulose crystals which can disperse in an aqueous phase system quickly; and obtaining a particle size distribution, which can maintain original properties of the cellulose crystals, is similar to that of the original cellulose crystals after re-dispersing. Therefore, the cellulose crystals capable of re-dispersion provide convenience for the storage, the transportation, and the follow-up application.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Enhanced type composite filler and method for preparing fiber-reinforced plastic product by using same

The invention provides an enhanced composite filler capable of improving the strength, the stiffness and the dimensional stability of a fiber-reinforced plastic product and a method for preparing the fiber-reinforced plastic product by using the enhanced composite filler. The enhanced composite filler specifically consists of three kinds of modified powder, i.e. modified rod-shaped powder, modified flake-shaped powder and modified granular powder, and the modified powder comprises powder and modifiers coated on the surface of the powder, wherein the weight of the modifiers is 0.5-10% of the weight of the modified powder, and the modified rod-shaped powder accounts for 10-90 parts by weight, the modified flake-shaped powder accounts for 5-60 parts by weight, and the modified granular powder accounts for 0.5-40 parts by weight. The method provided by the invention has the advantages that: the prepared product is excellent in strength, stiffness and toughness, the raw materials are easily obtained, and the operating process is simple, so that the method is applicable for industrial scale production.

Owner:秦皇岛耀华装备集团股份有限公司

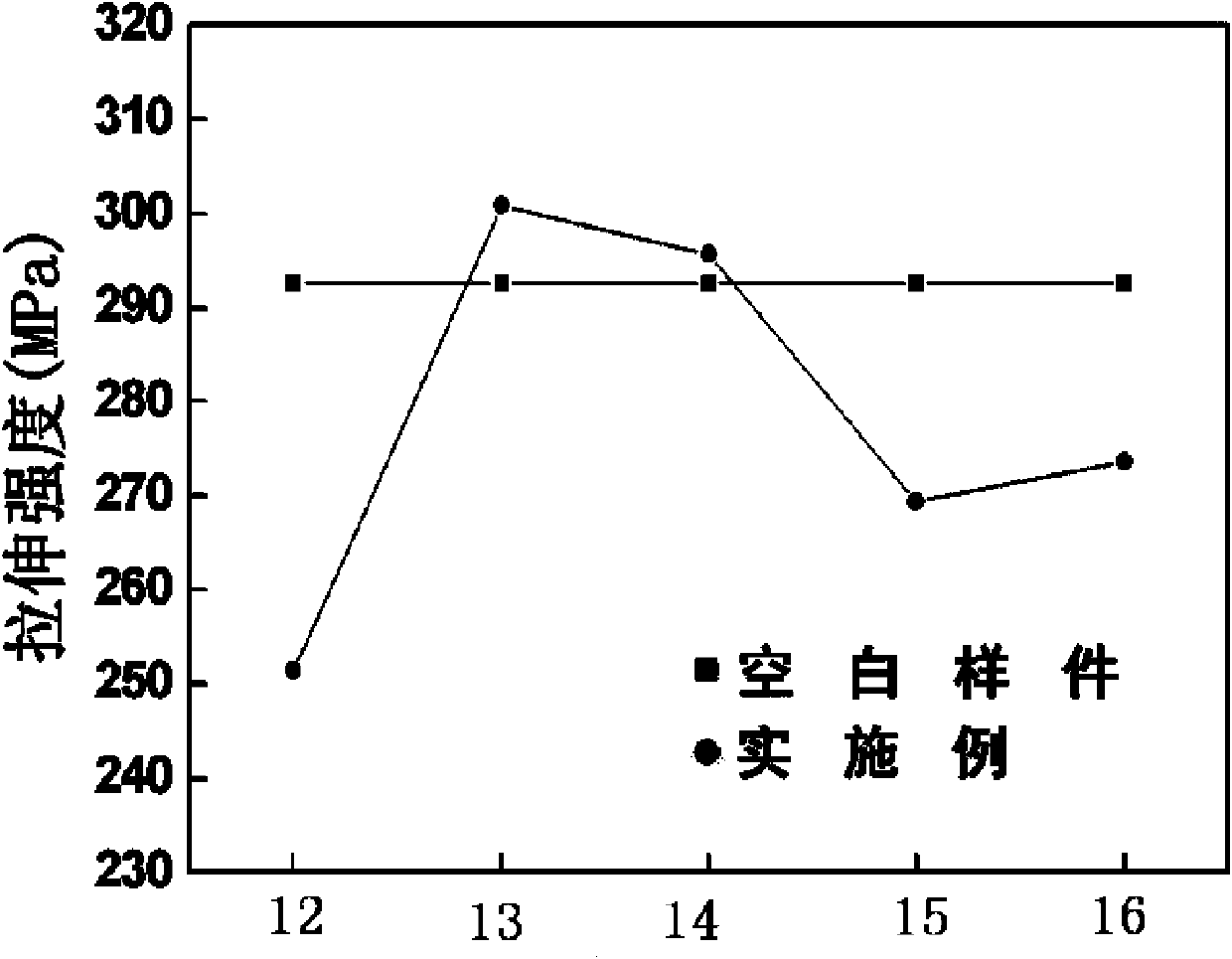

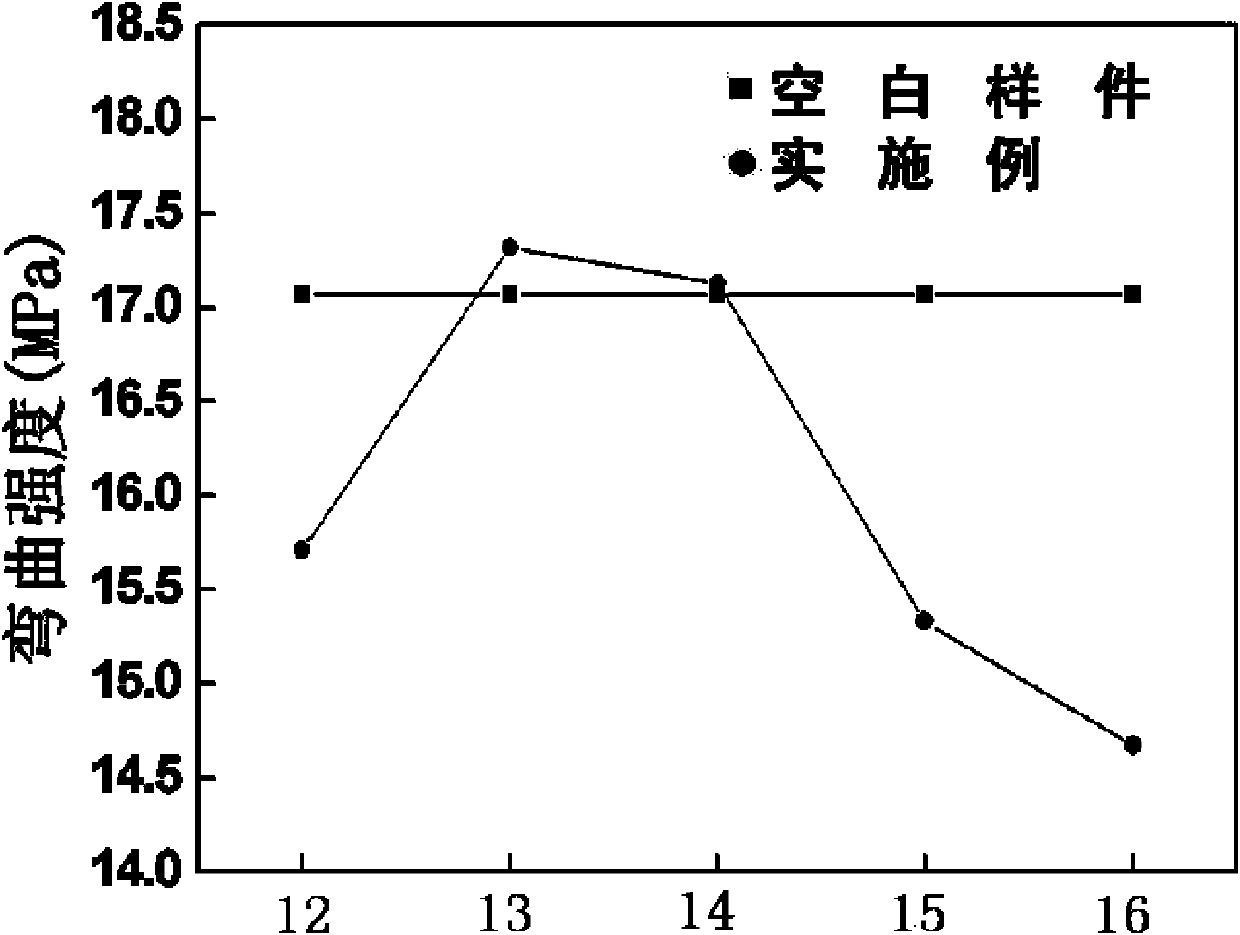

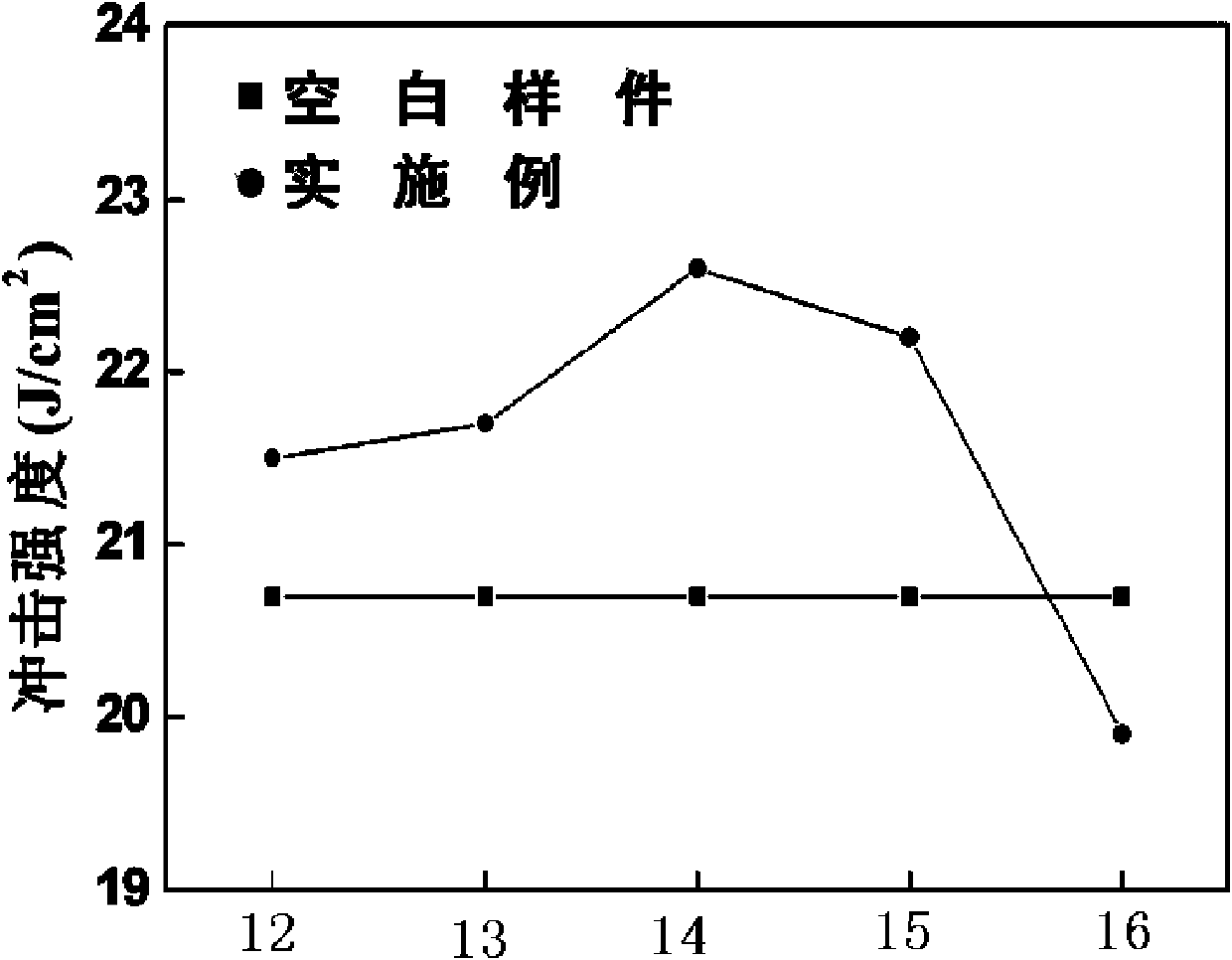

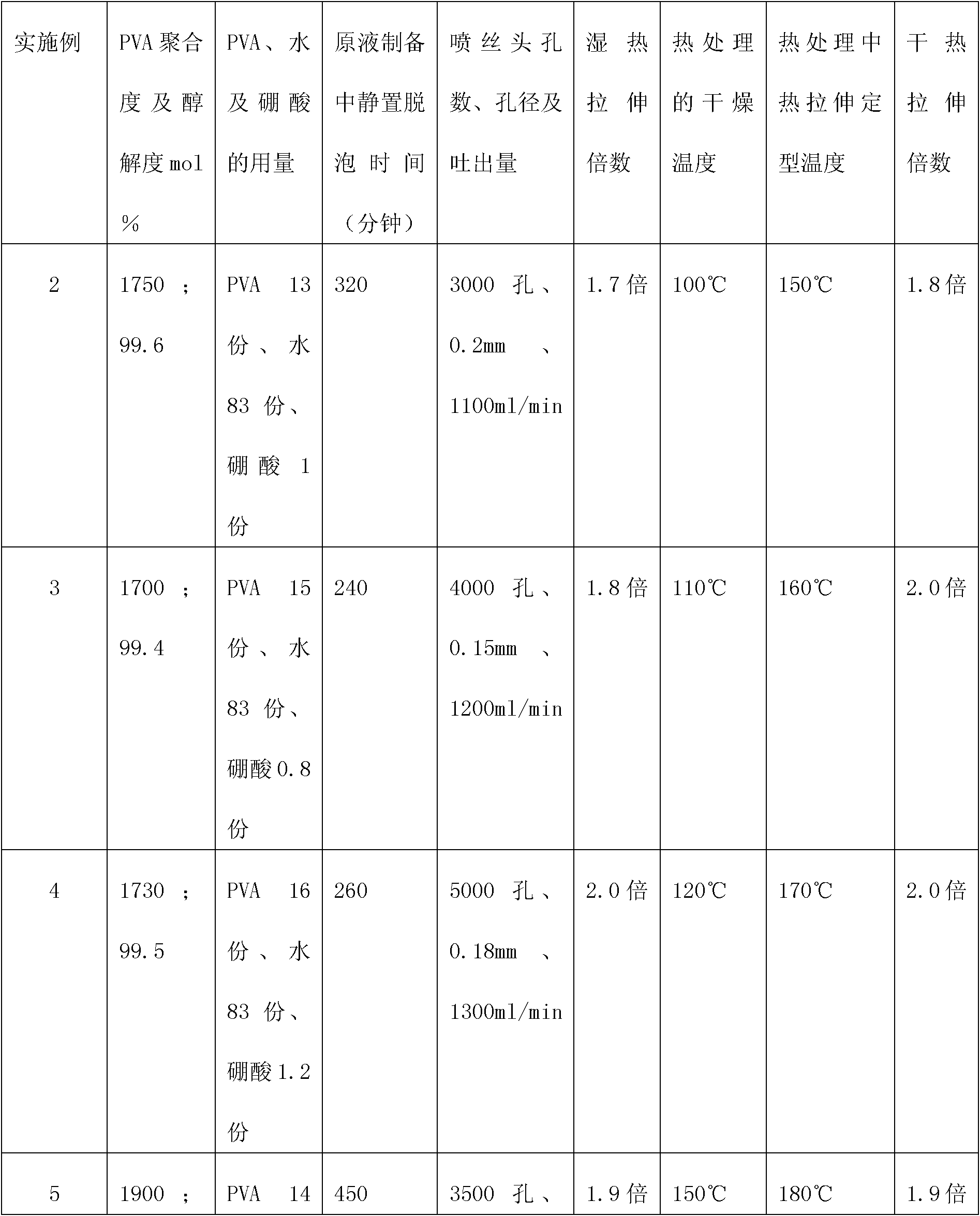

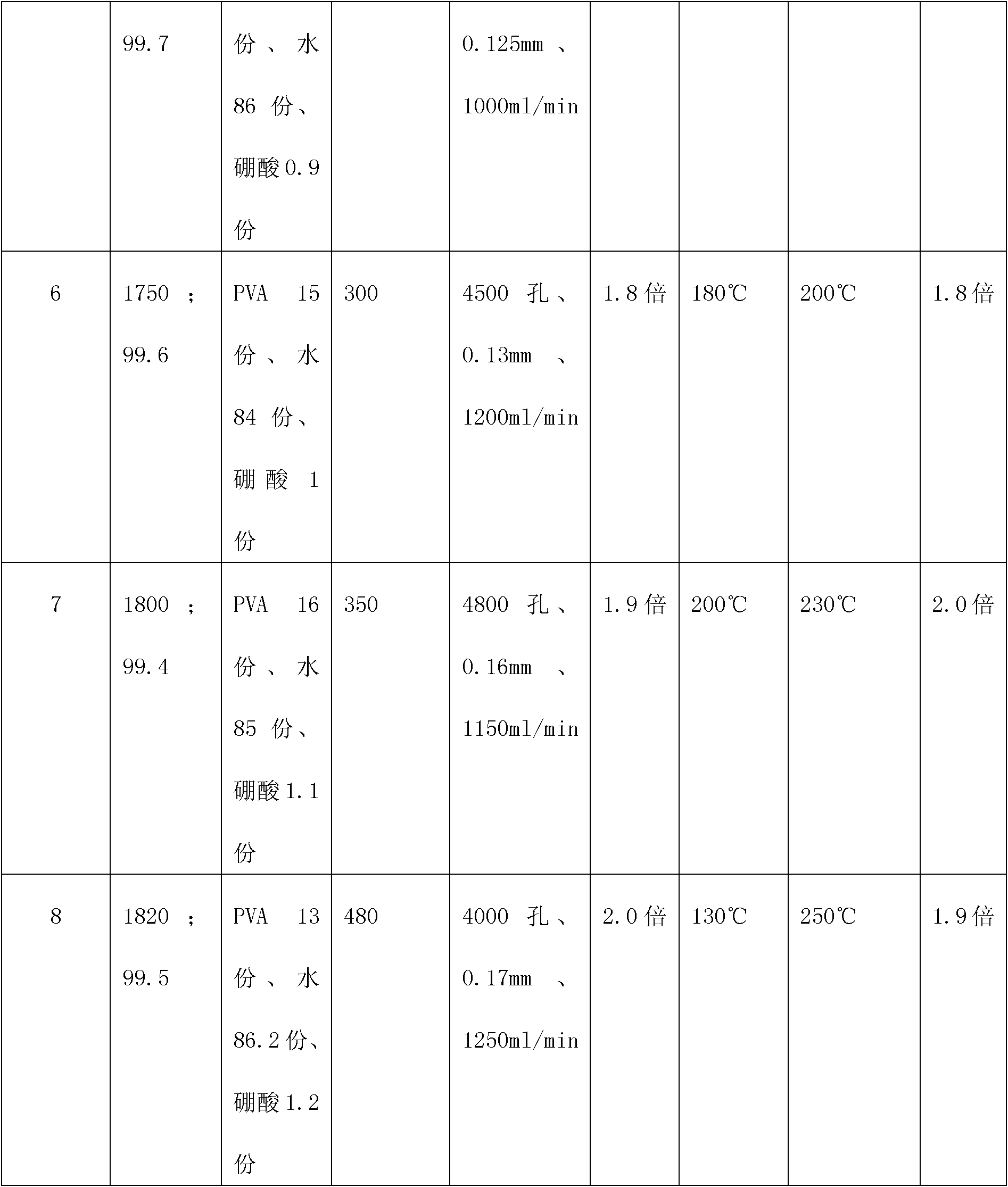

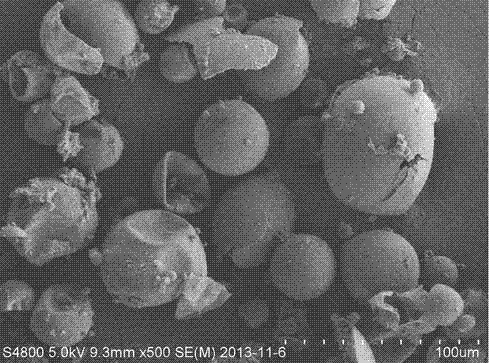

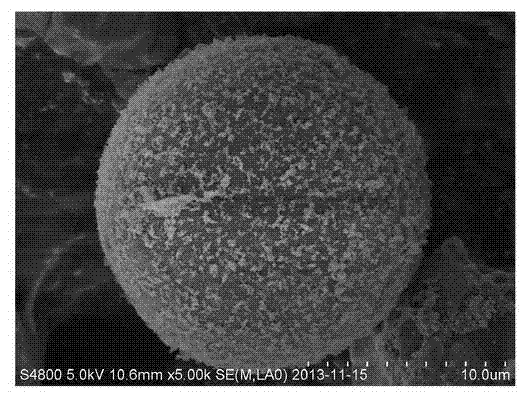

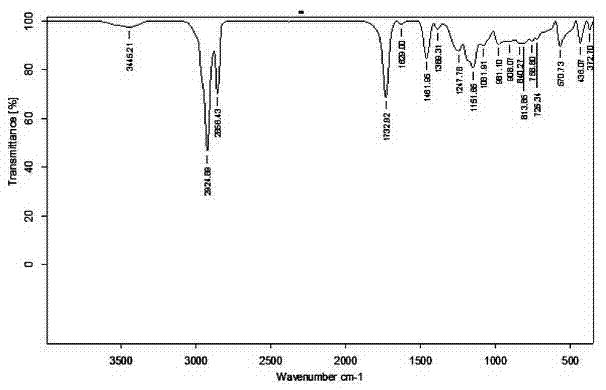

Polyvinyl alcohol fiber and preparation method as well as application thereof

ActiveCN103031611AImprove uniformityImprove stabilitySpinnerette packsArtificial filament heat treatmentFiberPolyvinyl alcohol

The invention discloses a polyvinyl alcohol fiber, which is manufactured by the steps of raw liquid preparation, wet spinning and heat treatment. The polyvinyl alcohol fiber is characterized in that during the step of wet spinning, the specification of the spinneret of a spinneret plate is that meshes are less than or equal to 5000 (preferentially, the meshes are 3000-500), a mesh diameter is 0.125-0.2mm, and an output amount is 1000-1300ml / min; and the thread density of the polyvinyl fiber is 6.0-10.0dtex. According to the PVA (polyvinyl alcohol) fiber, the thread density is 6.0-10.0dtex, the strength is 11.0-14.0cN / dtex, the modulus is 270-320cN / dtex, and the elongation is 7.0-9.0 percent; and the PVA fiber is extremely suitable for application of the construction field of bridges and tunnels. The preparation method of the PVA fiber has a simple process and a mild reaction condition, and is suitable for industrial and scaled production. The prepared PVA fiber has the advantages of good uniformity and excellent stability.

Owner:CHINA PETROCHEMICAL CORP +1

Silicon nitride-modified phase-change and energy-storage microcapsule and preparation method thereof

ActiveCN103805142AGood wear resistanceHigh thermal conductivityHeat-exchange elementsMicroballoon preparationThermal conductivitySilicon nitride

The invention discloses a silicon nitride-modified phase-change and energy-storage microcapsule, comprising a shell material and a cladded core material, wherein the shell material comprises the following raw materials in parts by weight: 50-100 parts of high-molecular polymers and 1-20 parts of silicon nitride powder which is evenly dispersed into the high-molecular polymers; the core material comprises 50-100 parts of organic phase-change and energy-storage materials and 1-20 parts of silicon nitride powder which is evenly dispersed into the organic phase-change and energy-storage materials. The invention also provides a preparation method of the phase-change energy-storage microcapsule. The thermal conductivity of the phase-change and energy-storage material is improved, overheat and overcold degrees in the phase-change process are inhibited, and meanwhile, the thermal endurance and the abrasive resistance, the thermal shock resistance, the fatigue resistance and the like also are improved. The silicon nitride-modified phase-change and energy-storage microcapsule is relatively simple in preparation technology, available in raw materials, strong in controllability, and applicable to the industrial large-scale production, an existing industrial processing technology can be fully utilized, and the performance of the phase-change and energy-storage microcapsule is improved.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

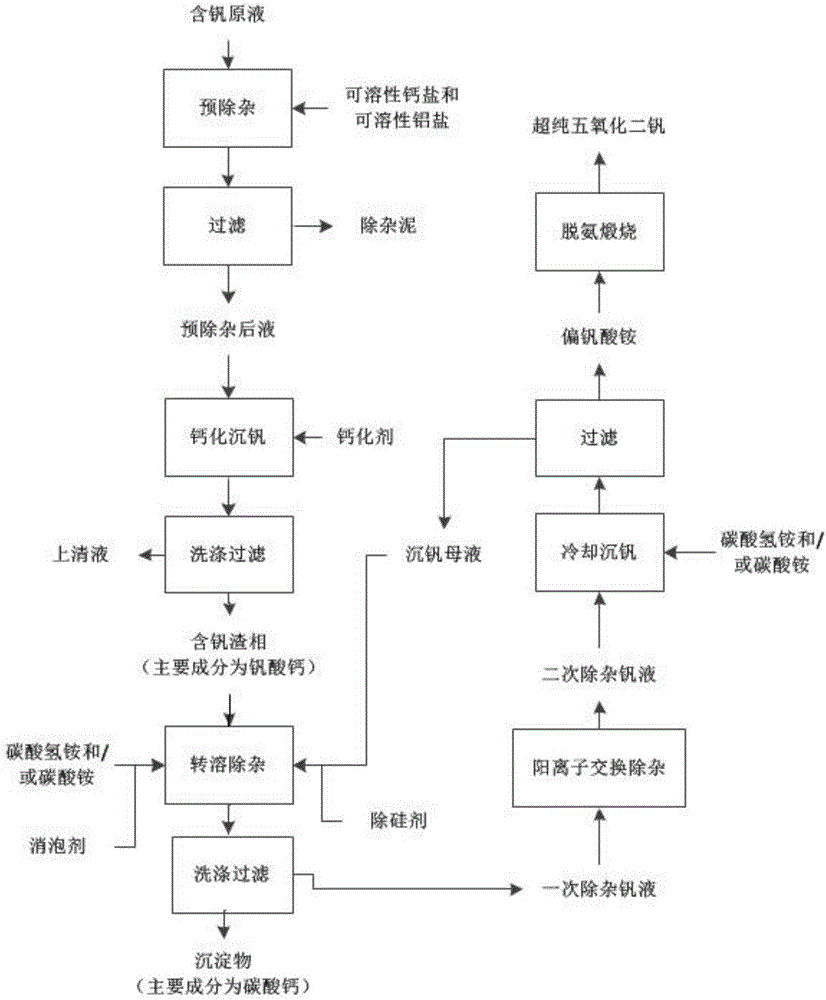

Preparation method of ultra-pure vanadium pentoxide

The invention discloses a preparation method of ultra-pure vanadium pentoxide. The preparation method comprises the following steps of: removing impurities in advance; transferring phosphorus and silicon in a vanadium-containing solution into a solid phase for removal; performing calcification and vanadium precipitation; transferring vanadium in a liquid phase into a calcium vanadate phase; leaving the impurities such as chromium, manganese, potassium and sodium in the liquid phase for removal; performing solubilization reaction of vanadium in the calcium vanadate into the liquid phase through ammonium bicarbonate and / or ammonium carbonate; leaving the calcium, phosphorus, silicon, iron and magnesium in the solid phase for removal; replacing residual trace cations of the liquid phase with ammonium ions by an ammonium type cation exchange system to realize deep purification; and performing cooling vanadium precipitation and deamination calcination to obtain vanadium pentoxide. In the invention, the process route is simple, the drug consumption is low, the vanadium pentoxide with purity of over 99.95% can be stably obtained, and the content of main impurities such as iron, chromium, manganese, silicon, phosphorus, calcium, sodium, magnesium, potassium and aluminum is all lower than 0.002%.

Owner:HEBEI IRON AND STEEL

Prepn process of nanometer tin oxide material with surface decorating silver

The present invention relates to the preparation process of nanometer tin oxide material with surface decorating silver, and belongs to the field of electric contact material preparing technology. The preparation process includes the following steps: adding tin oxide powder of 20-30 nm size into anhydrous ethanol and adding polyglycol as dispersant; ultrasonic stirring at room temperature and stoving; adding the treated nanometer tin oxide powder into 10-30 % concentration silver nitrate solution via electromagnetic and ultrasonic stirring for homogeneous dispersion; adding reductant hydrazine hydrate to reduce silver ion and obtain silver coated nanometer tin oxide powder and stoving at 80-120 deg.c. The present invention has the advantages of simple technological process and being suitable for industrial production, and the surface decorated nanometer tin oxide may be used in producing electric contact with excellent mechanical performance and high conductivity.

Owner:TIANJIN UNIV

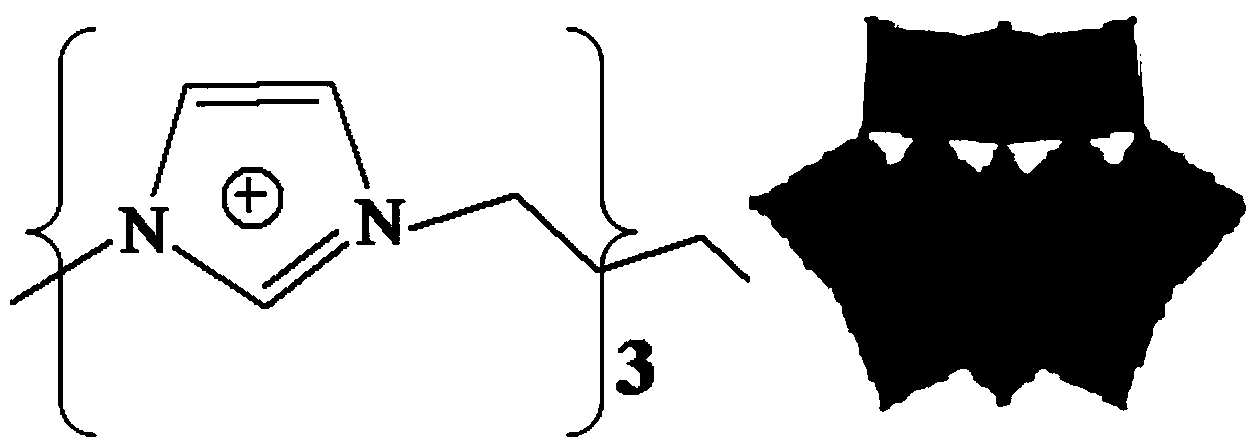

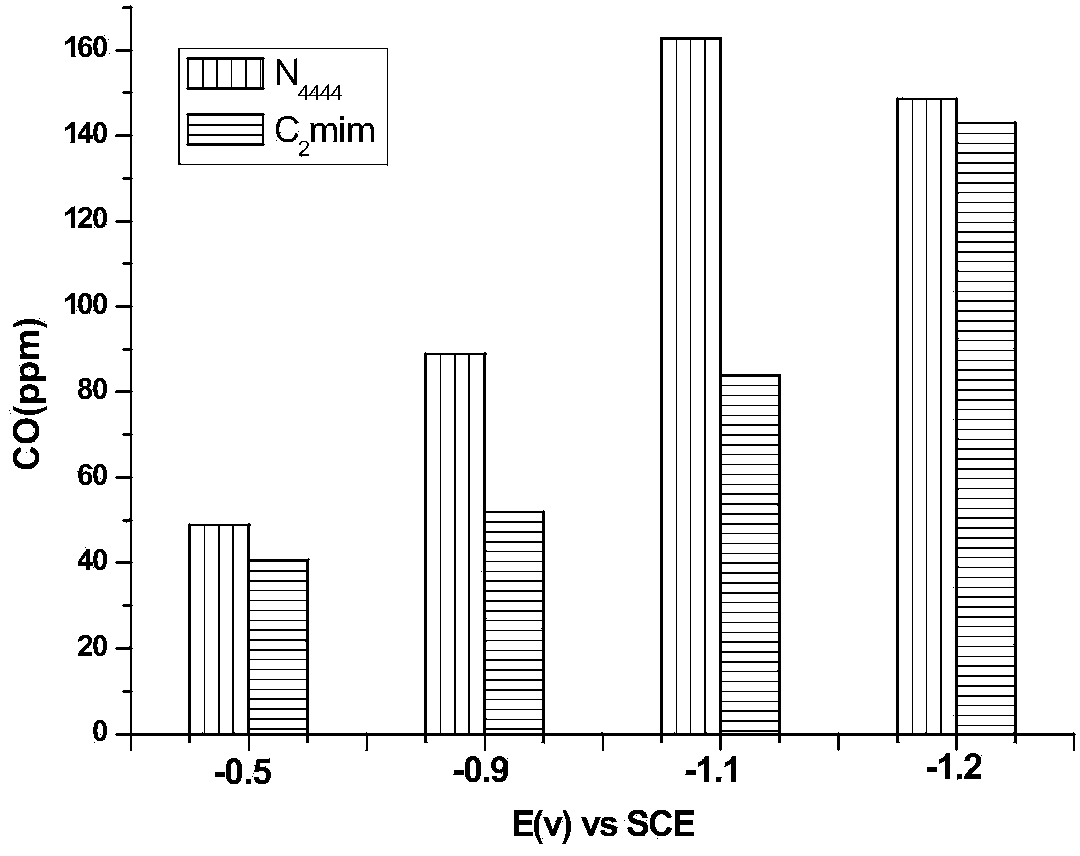

Method for electrocatalytic reduction of carbon dioxide using multi-metal oxygen cluster ionic liquid as electrocatalyst

ActiveCN104032324AEasy to synthesizeRaw materials are easy to getElectrolysis componentsOrganic-compounds/hydrides/coordination-complexes catalystsPhosphomolybdic acidResource utilization

The invention relates to a method for electrocatalytic reduction of CO2 using multi-metal oxygen cluster ionic liquid as electrocatalyst. The method is characterized in that positive ions of the multi-metal oxygen cluster ionic liquid are imidazoles [Cnmim]+(n=2, 4, 6, 8), pyridines [Cnpyr]+(n=2, 4) and quaternary ammonium salts [N4444]+, and negative ions of the multi-metal oxygen cluster ionic liquid are phosphotungstic acid negative ions (PW12O403-) and phosphomolybdic acid negative ions (PMo12O403-); and the electrocatalytic reduction reaction is a three-electrode system, wherein a glassy carbon electrode is a working electrode, a platinum sheet electrode is a counter electrode, and a saturated calomel electrode is a reference electrode. The method is simple in process and convenient in operation, performs the electrocatalytic reduction for the CO2 to form such fuels as methane and carbon monoxide, realizes the resource utilization of the CO2, reduces the atmospheric pollution, and has important significance on the environmental protection.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Environmental protection fire retardation type textile printing coating material and preparation method thereof

ActiveCN103225215AImprove flame retardant performanceFeel goodDyeing processTextile printerEngineering

The present invention discloses an environmental protection fire retardation type textile printing coating material and a preparation method thereof. According to the present invention, a fire retardation type acrylate is adopted as a main base material to prepare a fire retardation type coating material for textile printing, wherein the prepared fire retardation type coating material self-extinguishes within 5 seconds after leaving fire, and has characteristics of good fire retardation effect, good elasticity, low cost, excellent washing fastness resistance, and excellent color fastness; during a production process and a use process of the product, no formaldehyde is released, an environmental protection characteristic is provided, and the product does not contain heavy metals and alkyl phenol substances, and is an environmentally friendly and green product; and the preparation method has characteristics of easy production process control, high production efficiency and stable system, and is suitable for industrial scale production.

Owner:连云港百利合新材料发展有限公司

Environmental-friendly method for large-scale preparation of graphene

The invention provides an environmental-friendly method for large-scale preparation of graphene. A water-soluble organic matter melt is used for assisting in three-roller stripping to prepare the grapheme. The environmental-friendly method specifically comprises the following steps: (1) weighing a water-soluble organic matter and graphite in the mass ratio of (5: 1)-(500:1); (2) putting the water-soluble organic matter on rollers of a three-roller grinding machine, heating the rollers till a softening point of the water-soluble organic matter is reached to prepare an adhesive, operating the three-roller grinding machine, spreading the adhesive on the rollers of the three-roller grinding machine, further slowly adding the graphite, and performing grinding and stripping on the added graphite; and (3) immersing a product obtained in the step (2) into distilled water and washing to remove the water-soluble organic matter so as to obtain the graphene. According to the green method provided by the invention, a physical method is adopted for preparing the graphene, and the preparation process is environmental friendly, non-toxic and harmless, and can be applied to first-layer safety in the biomedical field; and furthermore, the method has the advantages of no special requirements on equipment, low cost, high efficiency, large-scale production and the like, and is simple and easy to operate.

Owner:HUAQIAO UNIVERSITY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com