Patents

Literature

85 results about "POWDERED CELLULOSE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Powdered cellulose: minuscule pieces of wood pulp or other plant fibers that coat the cheese and keep it from clumping by blocking out moisture. Cellulose can improve the texture of packaged food products, including bottled chocolate milk shakes.

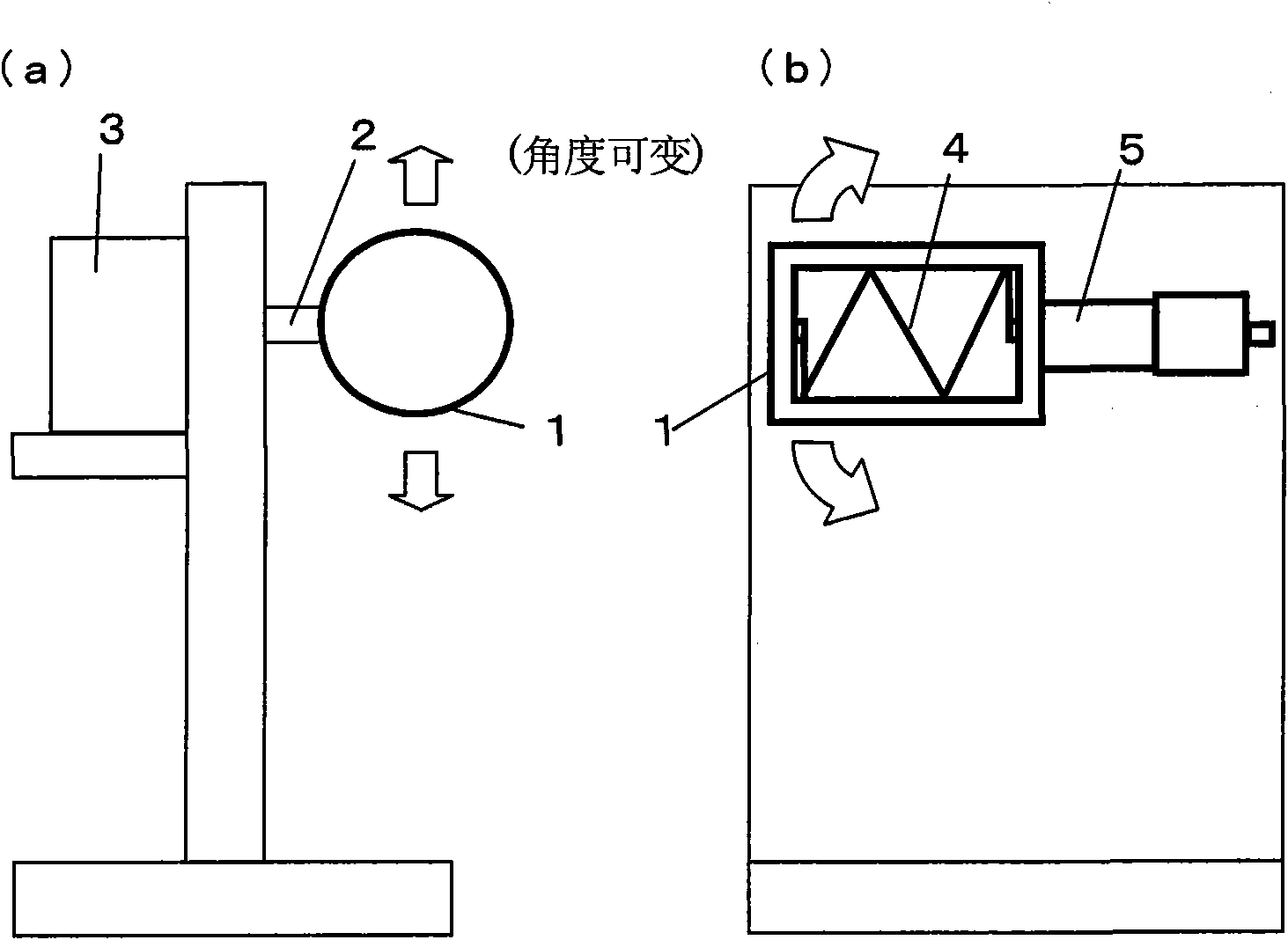

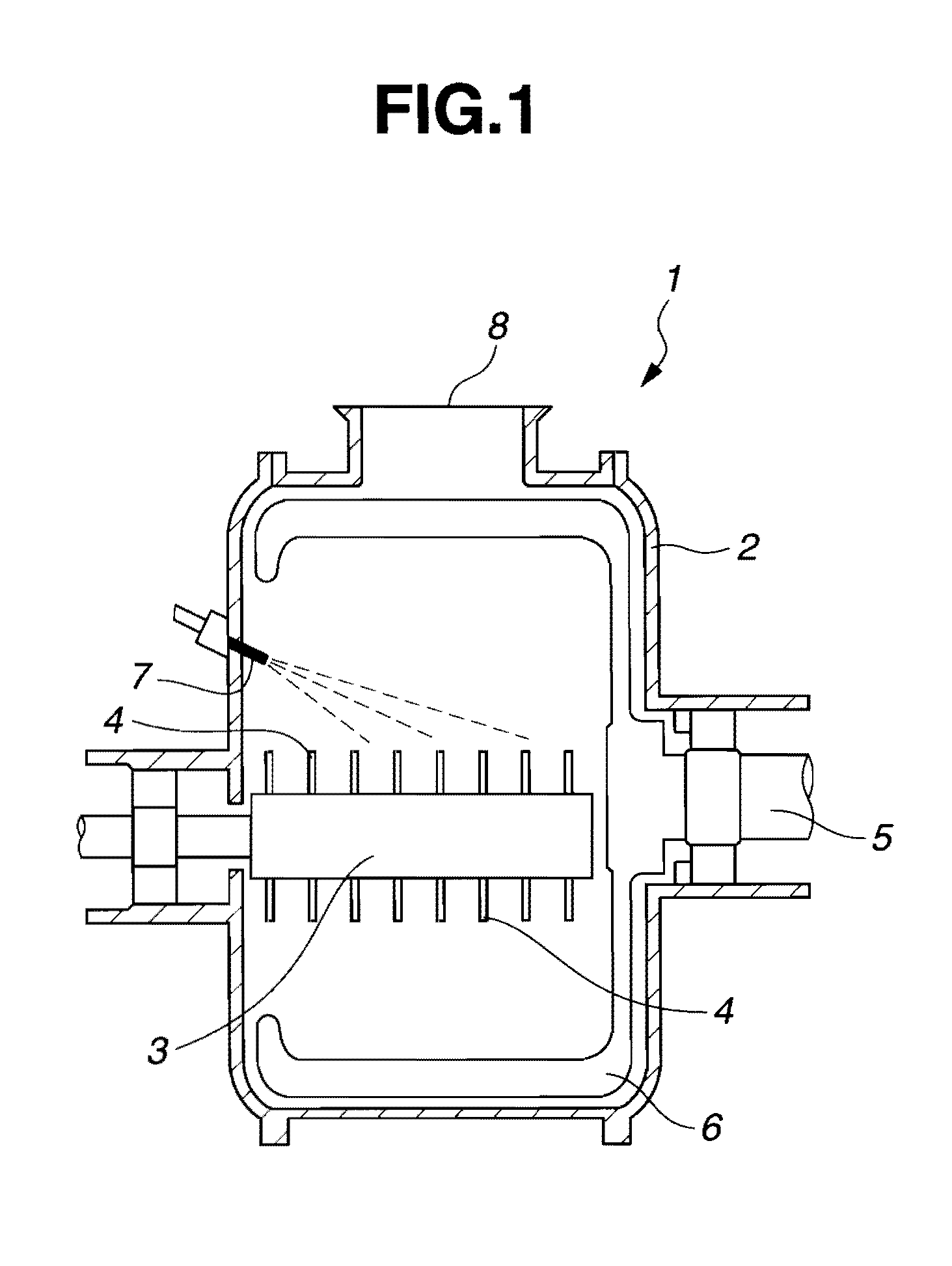

Spherical Particle and Method for Producing the Same

InactiveUS20100247665A1Improve versatilityImprove wear resistancePretreated surfacesPharmaceutical non-active ingredientsMass ratioAlcohol sugars

A spherical particle of the present invention contains a sugar alcohol and a crystalline cellulose and / or powdered cellulose, wherein the mass ratio between the sugar alcohol and the crystalline cellulose and / or powdered cellulose is within a range from 50:50 to 90:10, the particle size is within a range from 75 to 250 μm, the sphericity is not less than 0.8, and the bulk density is not less than 0.6 g / ml. Further, a method for producing the spherical particle of the present invention includes a granulation step of rolling a sugar alcohol having an average particle size of not more than 40 μm and a crystalline cellulose and / or powdered cellulose having an average particle size of not more than 50 μm while spraying a liquid thereon.

Owner:FREUNT IND

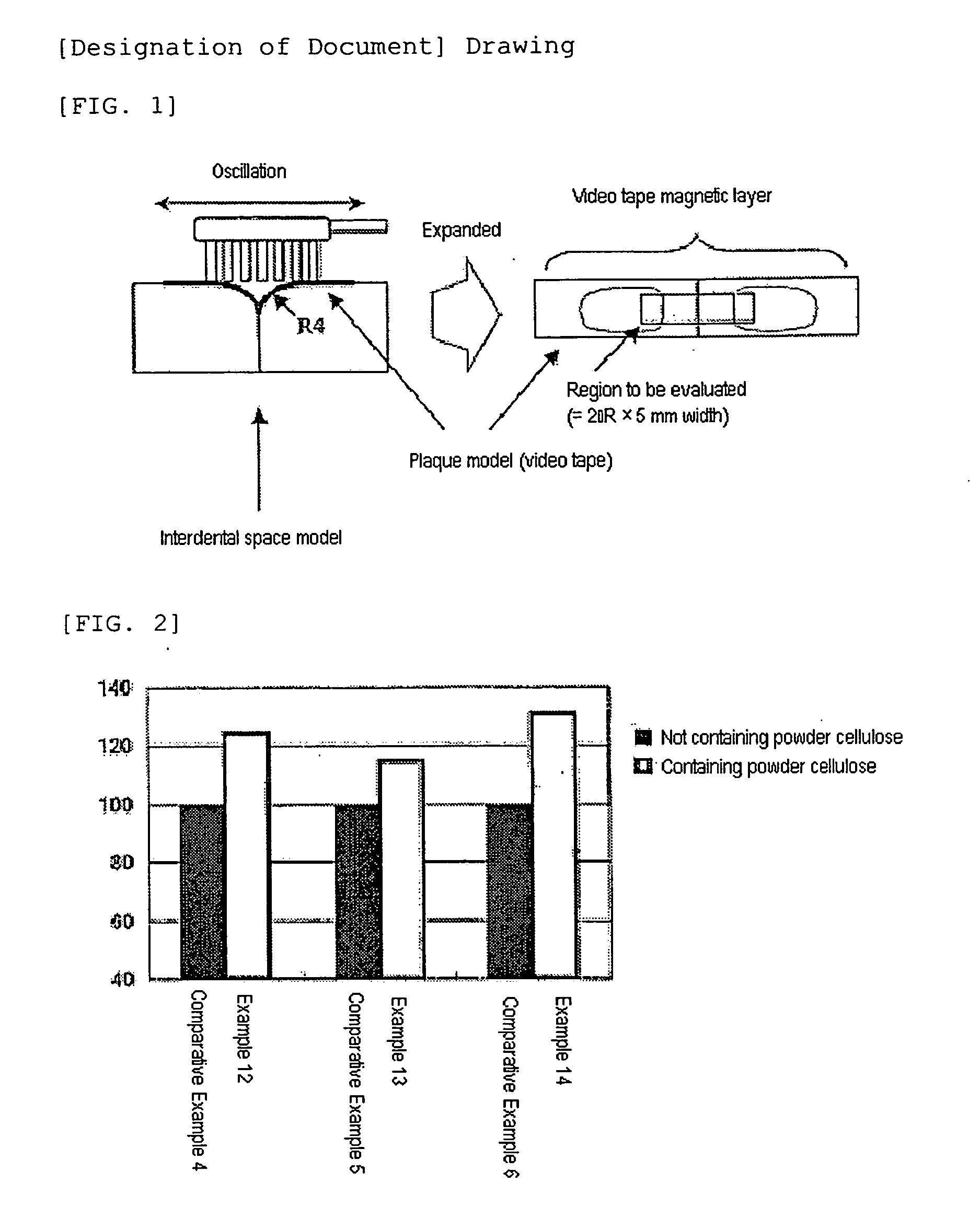

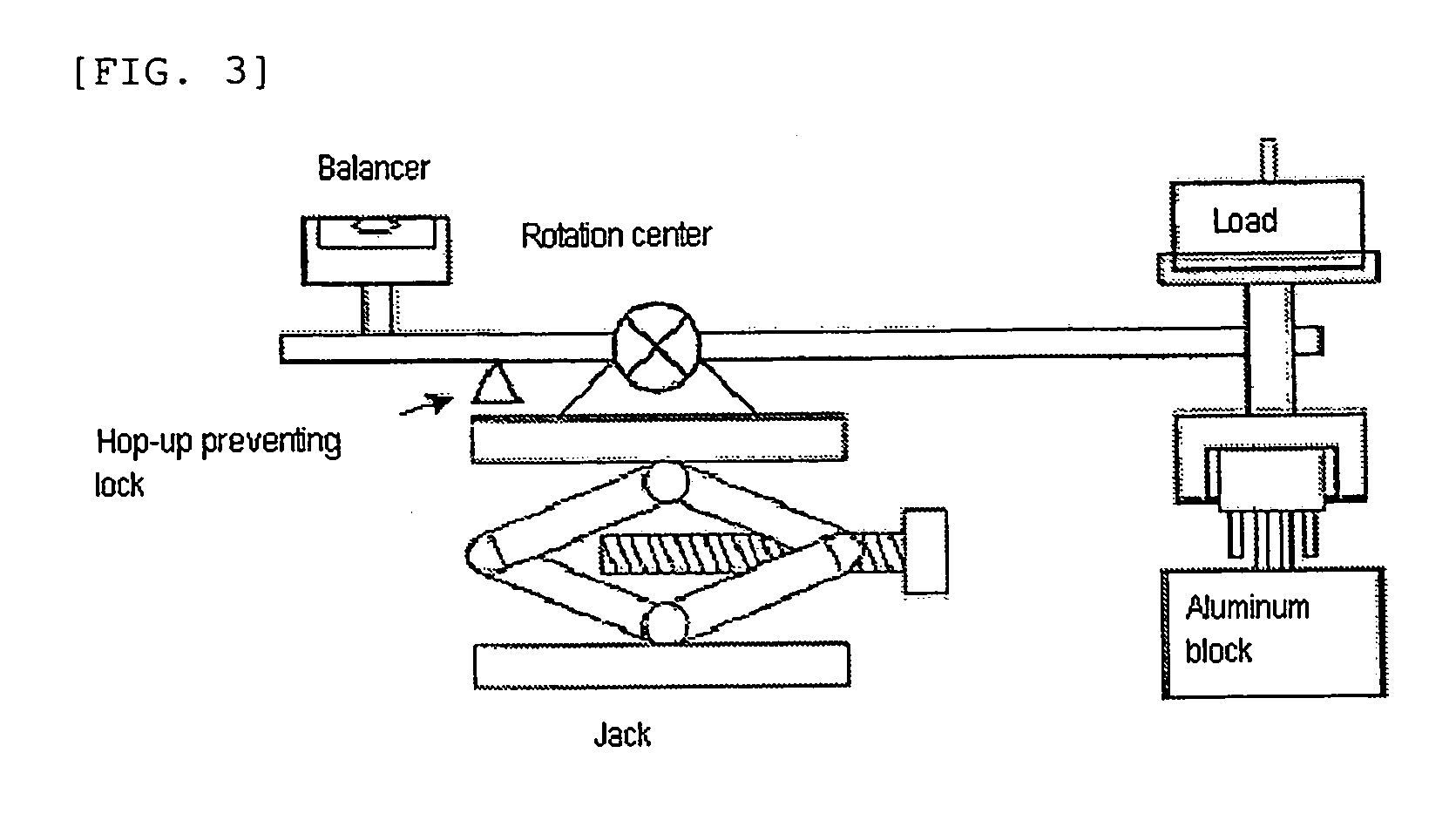

Composition for toothbrushing

Provided is a dentifrice composition excellent in plaque and stain removing effect and feeling upon use. The dentifrice composition has the following components (A), (B) and (C): (A) from 0.2 to 3 weight % of powder cellulose; (B) a surfactant; and (C) from 10 to 30 weight % of an abrasive.

Owner:KAO CORP

Filter media containing powered cellulose and immobilized lipase for swimming pool and spa water filteration

A composition is provided containing powdered cellulose and at least one water insoluble, immobilized water treatment additive. Preferably, a filter media composition is provided containing powdered cellulose and at least one water insoluble, immobilized enzyme such as lipase for filtration of swimming pool and spa water. The lipase may be recombinantly produced, and lipases having 1,3 positional or non-positional specificity are used. The immobilized lipase may be in the form of bead-shaped particles, and immobilization can be on a macroporous acrylic resin. Moisture may be added to the composition to provide a pre-moistened composition that is dustless and provides for improved dispersement and even filter grid coating. In a filtering system, the filter media absorbs oils contained in pool or spa water, and the lipase hydrolyzes the oils.

Owner:PURIFIBER LLC +1

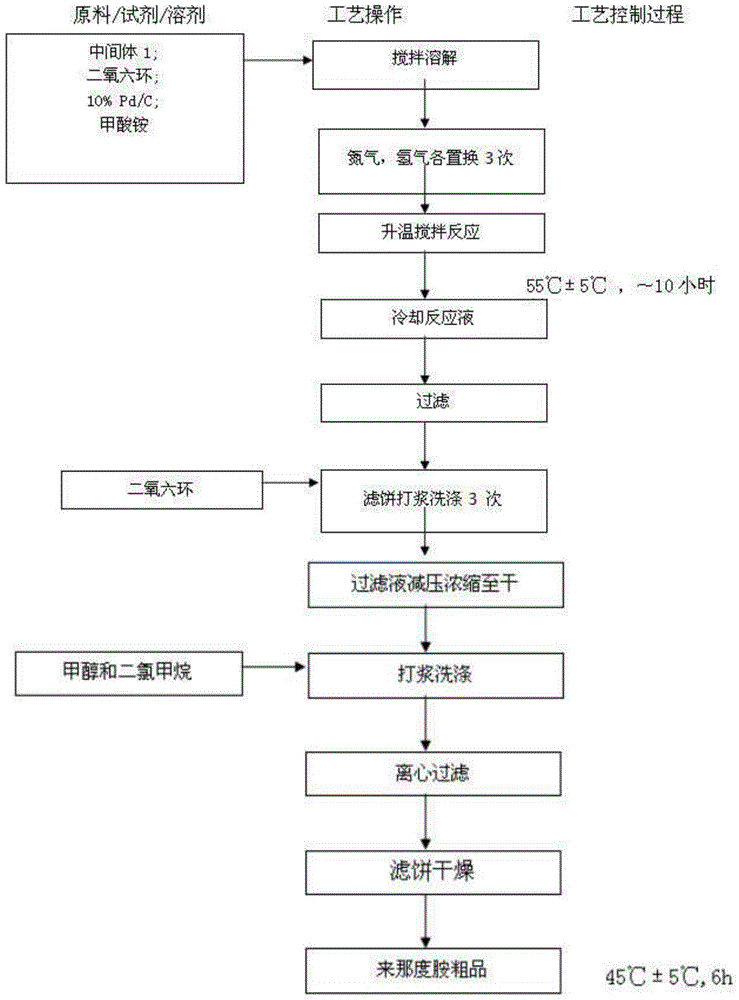

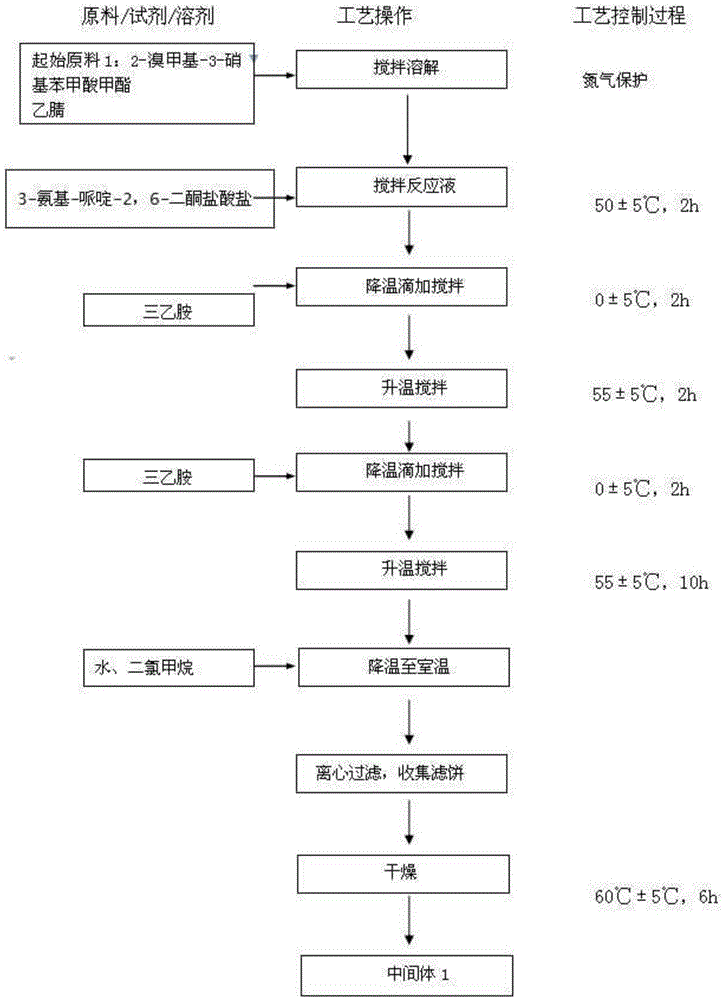

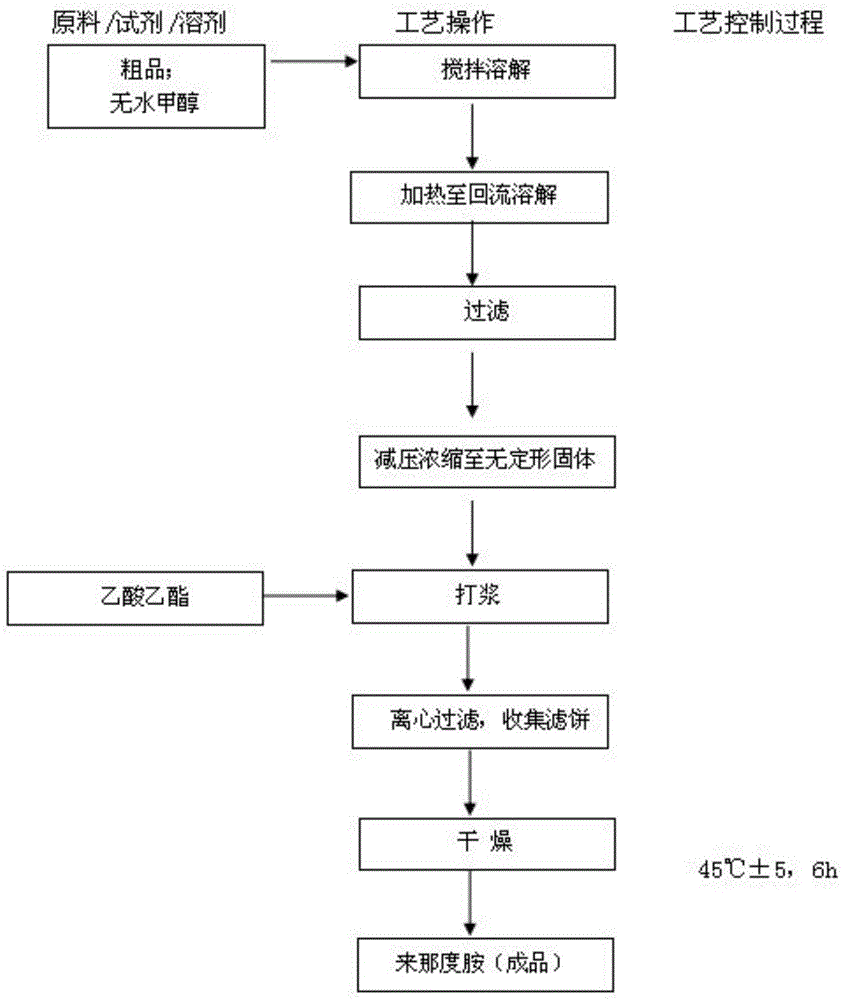

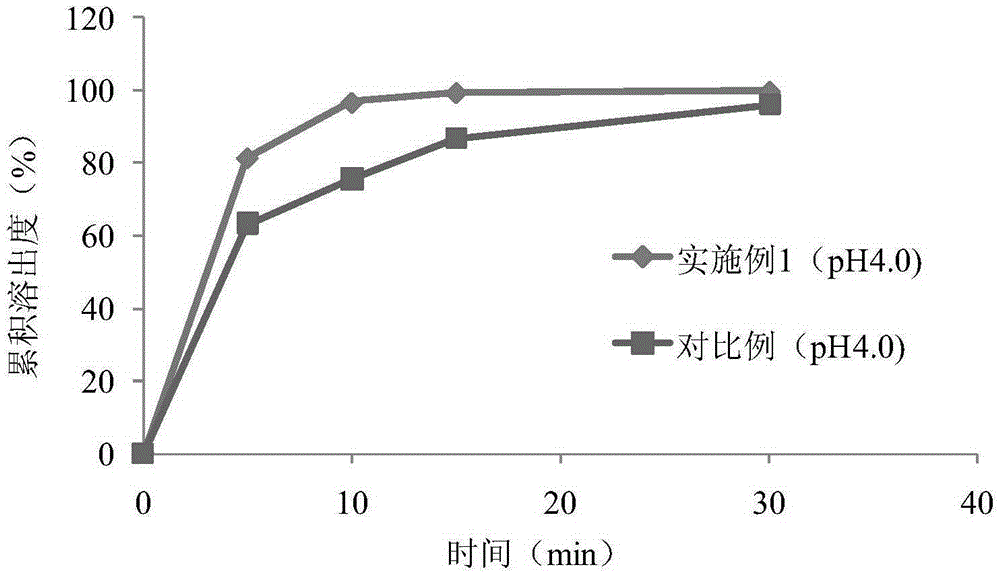

Lenalidomide composition tablets and preparation method thereof

ActiveCN105534981AThe preparation process is stableStable manufacturing processOrganic active ingredientsOrganic chemistryBeta-CyclodextrinsSodium stearyl fumarate

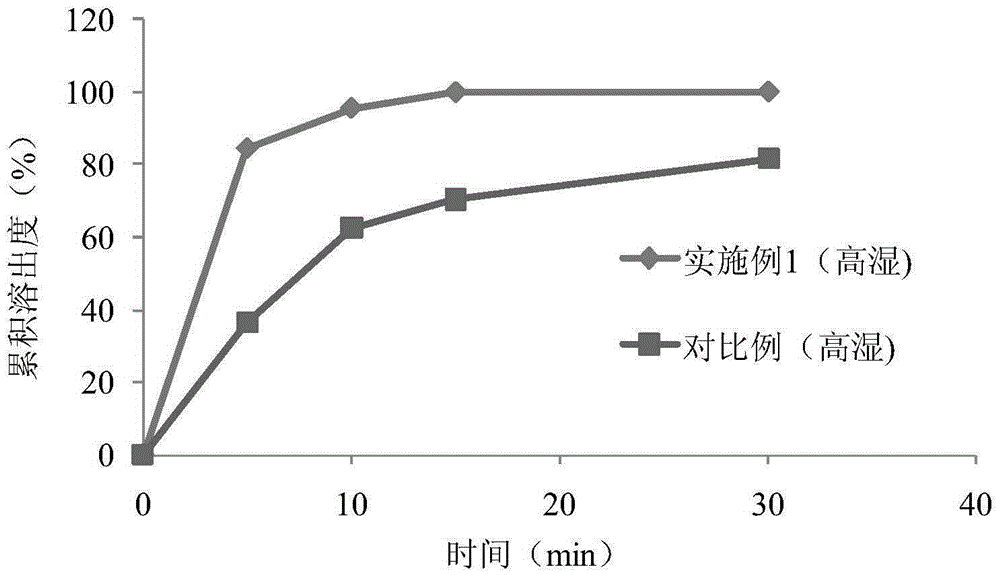

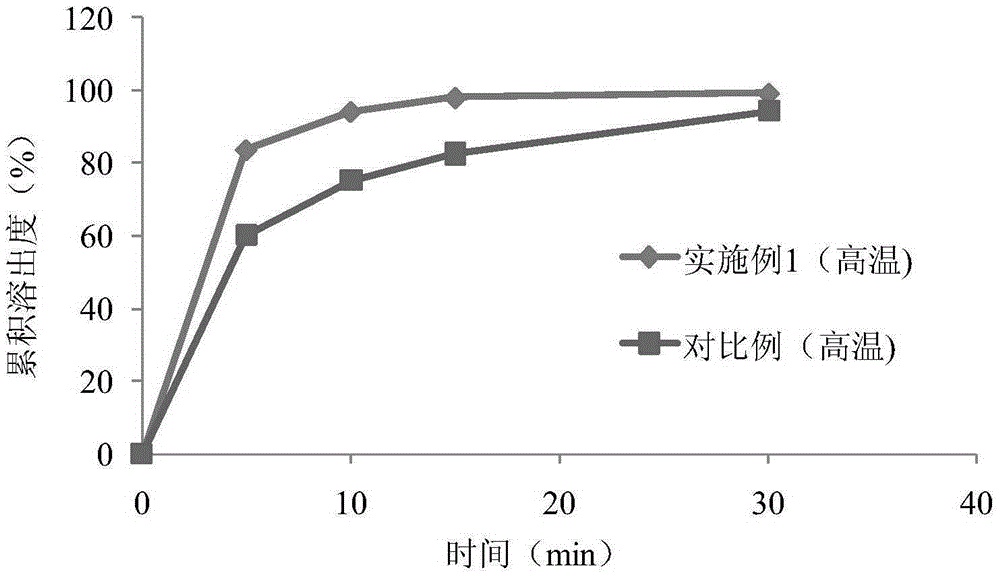

The invention discloses lenalidomide composition tablets and a preparation method thereof. The tablets comprise components in percentage by weight as follows: 10%-18% of lenalidomide crystals, 28%-40% of lactose, 28%-40% of microcrystalline cellulose, 1%-5% of konjac glucomannan, 10%-15% of beta-cyclodextrin, 5%-10% of sodium carboxymethyl starch, 0.5%-1.5% of sodium stearyl fumarate and 0.5%-1.5% of powdered cellulose. The preparation technology of the lenalidomide composition tablets is stable, simple and easy to operate, technological parameters are reliable, and the production cycle is shorter; experimental research shows that the lenalidomide raw material is stable in crystal form, higher in purity and capable of meeting the quality requirement of final products; the synthesis technology is concise, stable, feasible and applicable to mass production; the quality is controllable, the stability is better, and the lenalidomide raw material is unchanged under conditions of affecting factors such as the high temperature, high humidity and 10 days of illumination and is stable after being stored for 6 months under the acceleration condition.

Owner:DEYANG HUAKANG PHARMA

Bleach composition and bleaching detergent composition

InactiveUS20060293204A1High bleaching powerDamage and discoloration of clothes can be suppressedOrganic detergent compounding agentsNon-surface-active detergent compositionsWater insolubleWater soluble

A bleach composition containing (a) a peroxide generating hydrogen peroxide by being dissolved in water, (b) a water-insoluble or poorly water-soluble textile powder selected from powder cellulose, silk powder, wool powder, nylon powder and polyurethane powder, and (c) (c-1) a bleaching activating catalyst and / or (c-2) a bleaching activator. A bleaching detergent composition containing (a) a peroxide generating hydrogen peroxide by being dissolved in water, (b) a water-insoluble or poorly water-soluble textile powder selected from powder cellulose, silk powder, wool powder, nylon powder and polyurethane powder, and (c) (c-1) a bleaching activating catalyst or (c-1) a bleaching activating catalyst and (c-2) a bleaching activator, and (d) a surfactant.

Owner:CIBA SPECIALTY CHEM CORP

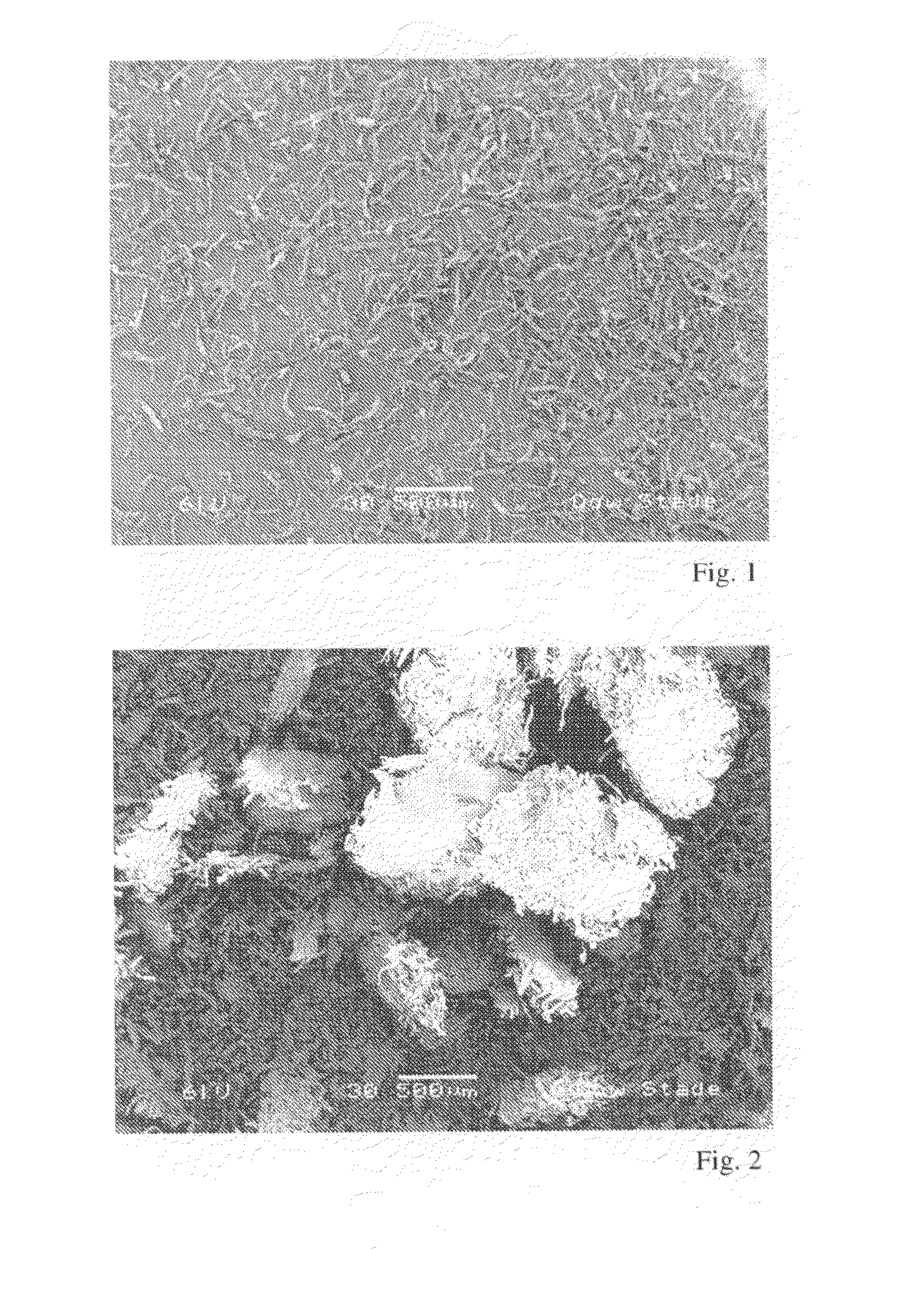

Preparation method for cellulose crystal susceptible to re-dispersion after drying

InactiveCN103275336AReduce drying energy consumptionInhibition of agglomerationFluidized bed dryingActive agent

The invention discloses a preparation method for a cellulose crystal susceptible to re-dispersion after drying, which comprises selection and using for cellulose crystal materials and non-ionic surface active agents; and a preparing and drying processing method for cellulose crystal suspending liquid materials, wherein the cellulose crystal materials comprise different types of cellulose crystals obtained by different cellulose sources and different processing methods; and the non-ionic surface active agents are APG, poly ethylene glycol, and polypropylene glycol. The preparation method comprises the following steps: mixing and stirring one of the non-ionic surface active agents and one of cellulose crystal suspending liquid to obtain the cellulose crystal suspending liquid materials; the cellulose crystal suspending liquid materials are subjected to drying processing by a fluid bed dryer or a spray dryer to obtain granulated, particulate, or powdered cellulose crystals which can disperse in an aqueous phase system quickly; and obtaining a particle size distribution, which can maintain original properties of the cellulose crystals, is similar to that of the original cellulose crystals after re-dispersing. Therefore, the cellulose crystals capable of re-dispersion provide convenience for the storage, the transportation, and the follow-up application.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

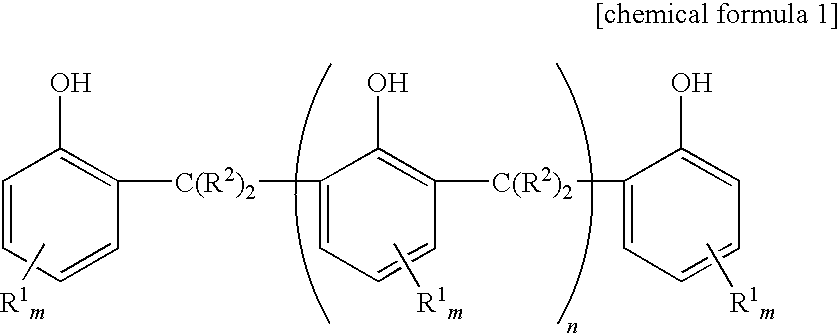

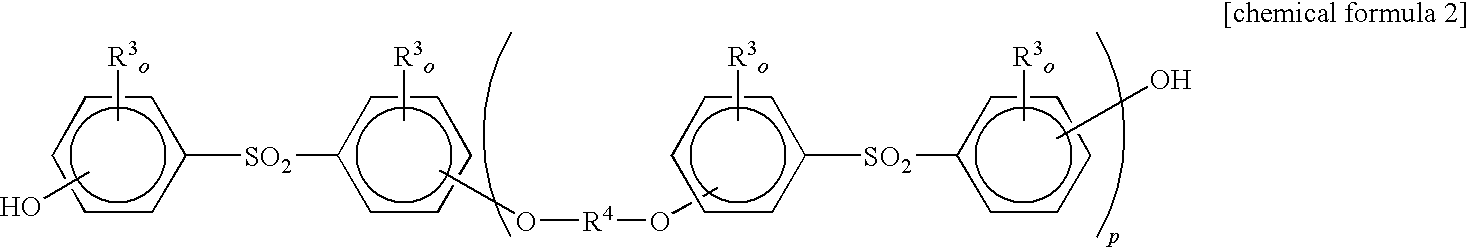

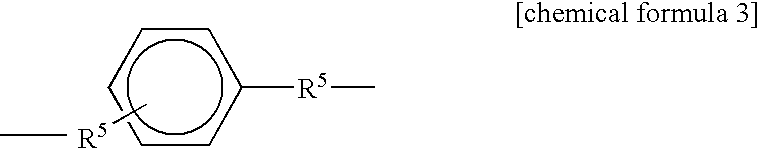

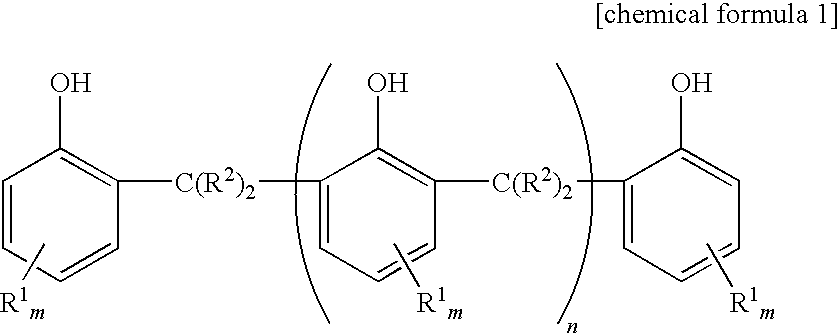

Thermosensitive recording medium

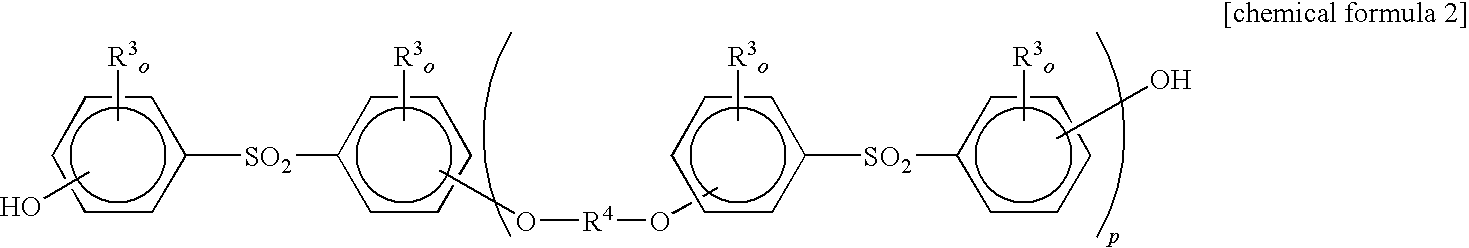

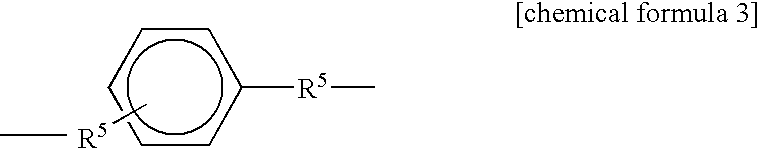

The present invention provides a thermosensitive recording medium, which is excellent in stamping ability, anti-scratching ability, and water and plasticizer resistance of image area as well as in recording sensitivity, image quality and storage stability. The present invention is a thermosensitive recording medium having a thermosensitive recording layer containing at least a colorless or pale colored basic leuco dye and an electron accepting developing agent as a coating layer on a substrate, wherein at least an outermost layer among the thermosensitive recording layer and other optionally prepared coated layers contains powdered cellulose, wherein the powdered cellulose is prepared by a dry grinding process at ambient temperature. The thermosensitive recording medium preferably contains a condensate composition comprising 2,2′-methylenebis(4-t-butylphenol) as an electron accepting developing agent, and a cross-linked diphenylsulfone compound such as 2,2′-bis[4-(4-hydroxyphenylsulfone) phenoxy]diphenylether as a stabilizer.

Owner:NIPPON PAPER IND CO LTD

Extraction of dietary fiber of bitter melon and method for preparing health-caring food by utilizing dietary fiber of bitter melon

The extraction of balsam pear diet fiber and method for preparing a health food by the fiber, whose processes are: clean balsam pears and compress to get extract; dry the remainder balsam pear dregs and comminute it to 80 order to get balsam pear powder; after wash and filter the powder with clean water, add 4 times mass amount water relatives to the powder, then add complex enzyme to enzymolysis; filter it and rinse with clean water; dry to get the balsam pear diet fiber powder and its fiber content beyond 95 percent. The balsam pear diet fiber powder could be processed to ripe balsam pear diet fiber cellulose powder or suppressed to quid tablets; while the balsam pear extract could be adopted to produce antihypelipidemic health food. For the first time, this invention extract balsam pear diet fiber cellulose from balsam pears, whose diet fiber content beyond 95 percent, and it produces a food that has evidence antihypelipidemic effect.

Owner:王美岭 +1

Thermosensitive Recording Medium

The present invention provides a thermosensitive recording medium, which is excellent in stamping ability, anti-scratching ability, and water and plasticizer resistance of image area as well as in recording sensitivity, image quality and storage stability. The present invention is a thermosensitive recording medium having a thermosensitive recording layer containing at least a colorless or pale colored basic leuco dye and an electron accepting developing agent as a coating layer on a substrate, wherein at least an outermost layer among the thermosensitive recording layer and other optionally prepared coated layers contains powdered cellulose, wherein the powdered cellulose is prepared by a dry grinding process at ambient temperature. The thermosensitive recording medium preferably contains a condensate composition comprising 2,2′-methylenebis(4-t-butylphenol) as an electron accepting developing agent, and a cross-linked diphenylsulfone compound such as 2,2′-bis[4-(4-hydroxyphenylsulfone) phenoxy]diphenylether as a stabilizer.

Owner:NIPPON PAPER IND CO LTD

Preparation method of nano micro cellulose fiber non-woven fabric

InactiveCN102619026AStable productionOvercoming the disadvantages of processing high melt fluidity raw materialsNon-woven fabricsSpinning solutions preparationPolymer scienceSpinning

The invention discloses a preparation method of nano micro cellulose fiber non-woven fabric. The preparation method adopts the following process steps: 1. premixing cellulose and a solvent: smashing the cellulose into powder, then preparing the cellulose and the solvent into uniform mixture according to the mass ratio being (1-3):(9-7); 2. preparing cellulose solution feeding the mixture into a double-screw extruder to prepare spinning solution, enabling the spinning solution to pass through a metering pump, then feeding the spinning solution into a spinning die head, extruding the die spinning solution from a spinneret orifice of the die head to form a fine spinning solution flow; 3. stretching air flow: forming high-pressure hot air to high-speed air flow through an air cavity slit of the spinning die head, flowing the high-speed air flow to the fine spinning solution flow to realize the stretching and thinning of the solution; and 4. forming and conducting postprocessing on non-woven fabric to obtain the nano micro cellulose fiber non-woven fabric. In the steps, the solvent is ionic liquid formed by positive ions and negative ions.

Owner:TIANJIN POLYTECHNIC UNIV

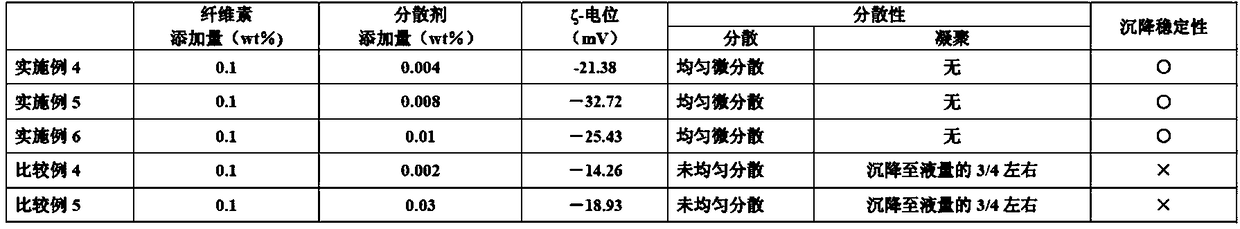

Nanofiber dispersion, method for producing nanofiber dispersion, powdery nanofibers obtained from dispersion, resin composition including said powdery nanofibers, and molding material for 3D printer in which said resin composition is used

ActiveCN108779256AGood dispersionImprove uniformityMaterial nanotechnologyAdditive manufacturing apparatusFiberHeat resistance

The invention aims to obtain a dispersion in which cellulose nanofibers are dispersed well, powdery cellulose nanofibers obtained by powdering the dispersion, a resin composition in which the powderycellulose nanofibers are blended into a resin, and a molding material for 3D printers in which the resin composition is used. A cellulose nanofiber stable dispersion is obtained by treating a mixture,which includes unmodified cellulose nanofibers and a dispersant, together with water by a high-speed stirring-type medialess disperser, and a composition in which cellulose nanofibers are finely anduniformly dispersed is obtained by powdering the dispersion and blending the same with a resin and a rubber component. In addition, a resin composition having improved mechanical properties and heat resistance, the resin composition being obtained by blending the powdered cellulose nanofibers with a thermoplastic resin or thermosetting resin, is also useful as a molding material for 3D printers.

Owner:日本星光工业株式会社

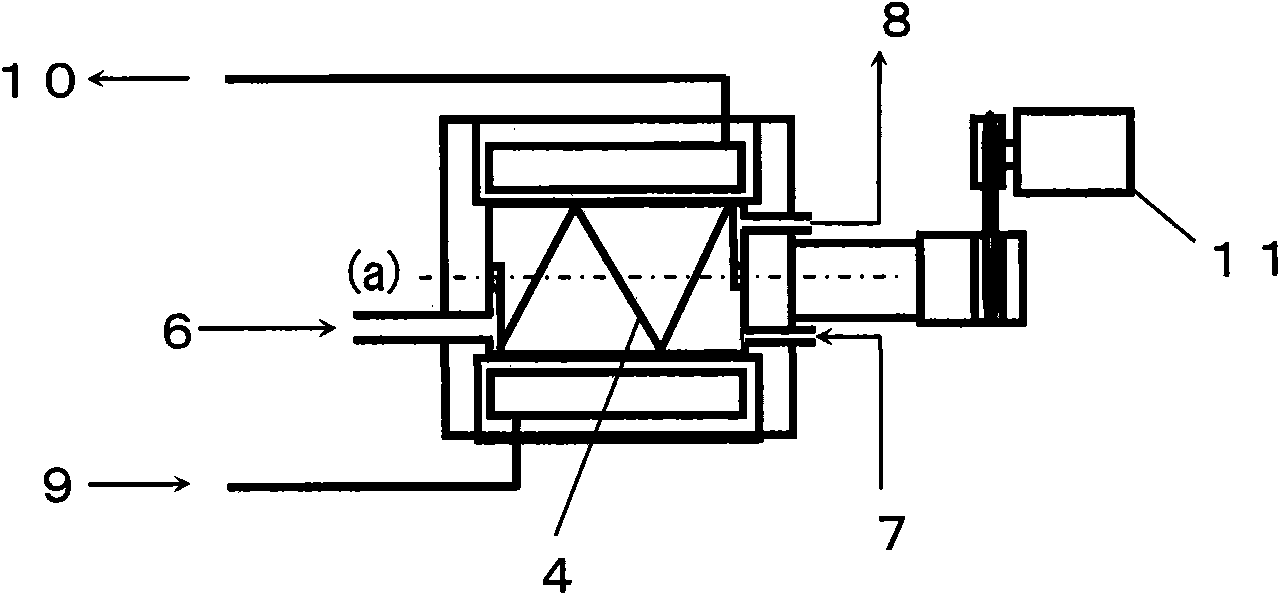

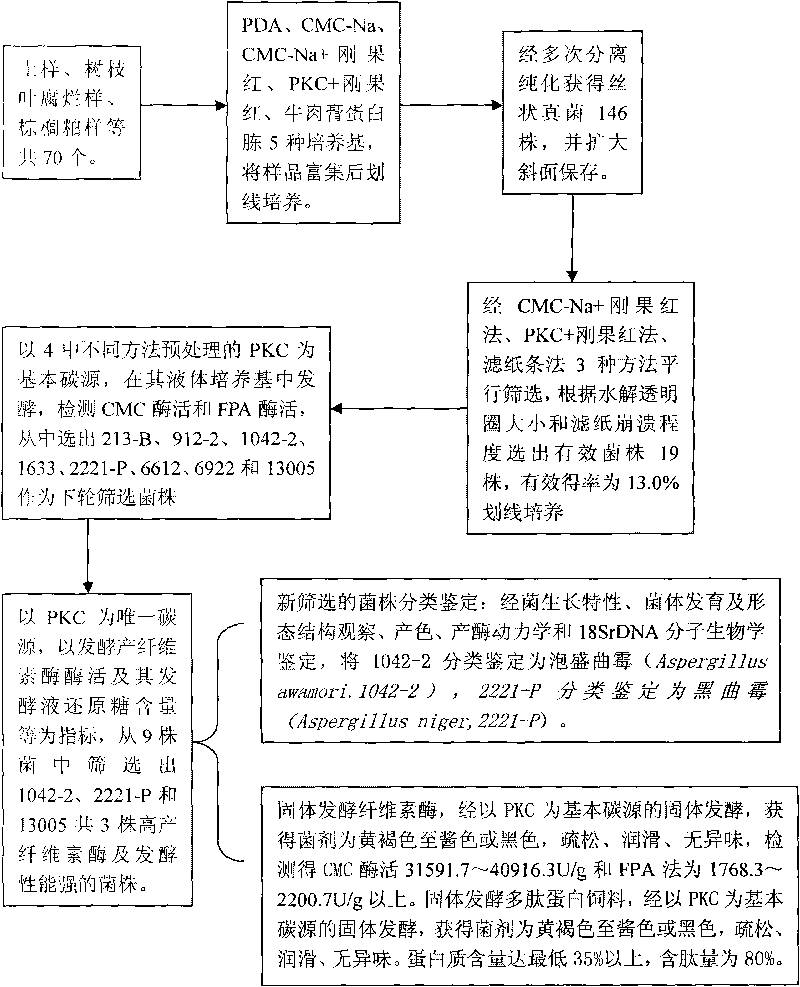

Method for producing cellulose and polypeptide protein feed by fermenting with Aspergillus awamori

InactiveCN101701194AImprove performanceSimple processFungiMicroorganism based processesChemical industryBiofuel

The invention discloses a method for producing cellulose and polypeptide protein feed by fermenting with Aspergillus awamori 1042-2 which belongs to the Aspergillus and has the collection registration number of M209142 in the China Center for Type Culture Collection (CCTCC). The method for producing the cellulose and the polypeptide protein feed comprises the following steps: A, selecting the Aspergillus awamori 1042-2; B, authenticating the Aspergillus awamori 1042-2, C, culturing the Aspergillus awamori 1042-2 liquid; D, fermenting the solid material; and F, postprocessing. The solid culture which is obtained by inoculating the Aspergillus awamori 1042-2 onto the solid culture medium and fermenting the Aspergillus awamori 1042-2 and the solid culture medium is baked to dry, ground, sieved and subjected to the detection of the enzyme activity and the polypeptide protein content. The method for producing the cellulose and the polypeptide protein feed is feasible and easy, the produced powdered cellulose has the CMC enzyme activity of 31397.1-41826.7 U / g and the FPA enzyme activity of 1779.3-2212.1 U / g, has good stability and can be produced on a large scale, and the produced polypeptide protein feed contains more than 35 percent of protein. The Aspergillus awamori 1042-2 can be used for fermenting the palm kernel dregs, other dregs and the vegetable fiber and producing the biological feed, the biological fertilizer, the biological fuel and can be also used in the food industry, chemical industry and the pharmaceutical industry. The polypeptide protein feed produced by fermenting with the Aspergillus awamori 1042-2 can be used as the additive of the protein of various feed.

Owner:武汉博普奥多肽生产技术有限公司

Nutrition liquid for chronic nephropathy and preparation method thereof

InactiveCN1840171AFood safetyReasonable configurationHeavy metal active ingredientsPeptide/protein ingredientsNutritional statusVitamin C

Disclosed is a nutrient solution for treating chronic kidney diseases and its preparing process, wherein each 500ml of the nutrient solution contains carbohydrate compound 55-65g, saturated fatty acid 10-12g, mono-saturated fatty acids 20-24g, protein 6-10g, zinc 5-10mg, ferrum 10-15mg, calcium 0.2-0.5g, cellulose 3-3.5g, complex vitamin B 10-30mg, active vitamin D 0.5-0.8ug, folic acid 1-2mg, vitamin C 50-100mg, pantothenic acid 3-5mg, yeast 10-15g, and probiotic 210-250mg.

Owner:SUZHOU UNIV

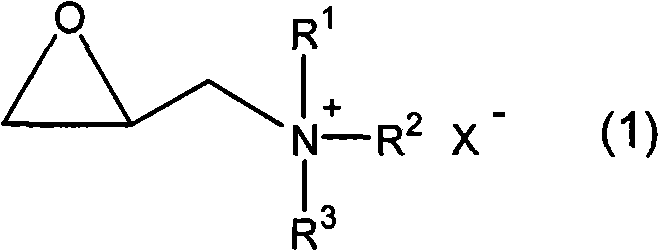

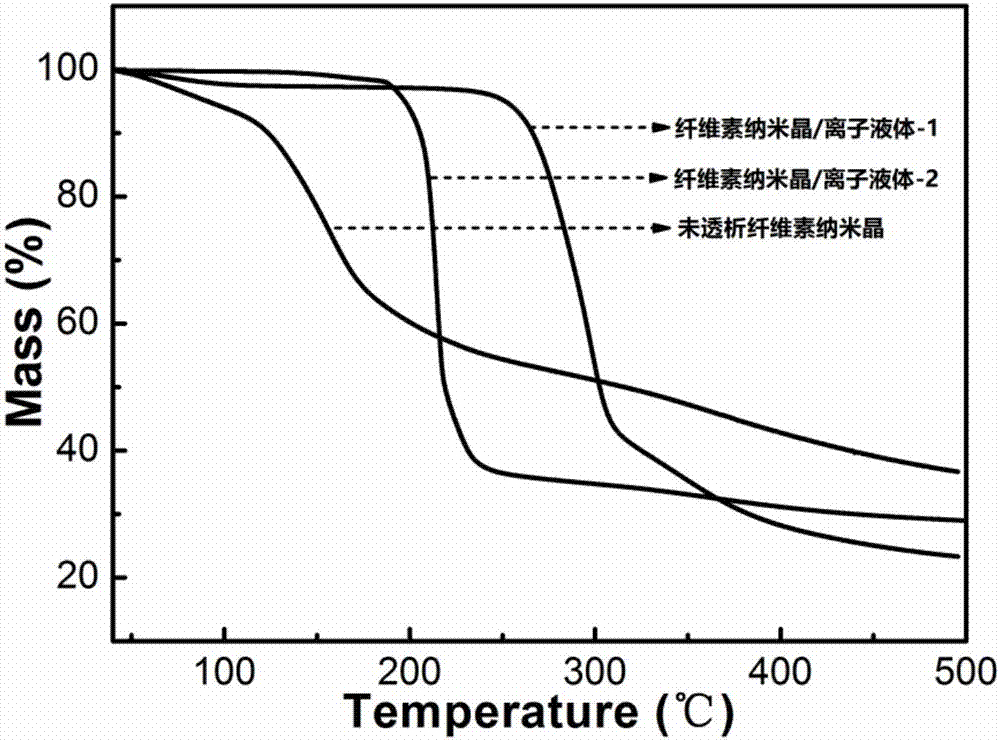

Highly-heat-resistant redispersible powder cellulose nano-crystal and preparation method thereof

The present invention provides a highly-heat-resistant redispersible powder cellulose nano-crystal and a preparation method thereof. According to the method, cellulose is subjected to acidolysis with sulfuric acid, an ionic liquid is added to the obtained cellulose nano-crystal suspension to form the ionic bond between the ionic liquid and the cellulose nano-crystal, and the reaction liquid is dried to obtain the powder cellulose nano-crystal. According to the present invention, with the preparation method, the heat resistance and the re-dispersion in the water of the cellulose nano-crystals are effectively improved, the problem of the heat degradation during the processing of the acidic cellulose nano-crystals adopted as the nanometer filler and the matrix can be effectively solved, the production process is simplified, and the method is suitable for industrial production.

Owner:QINGDAO UNIV OF SCI & TECH

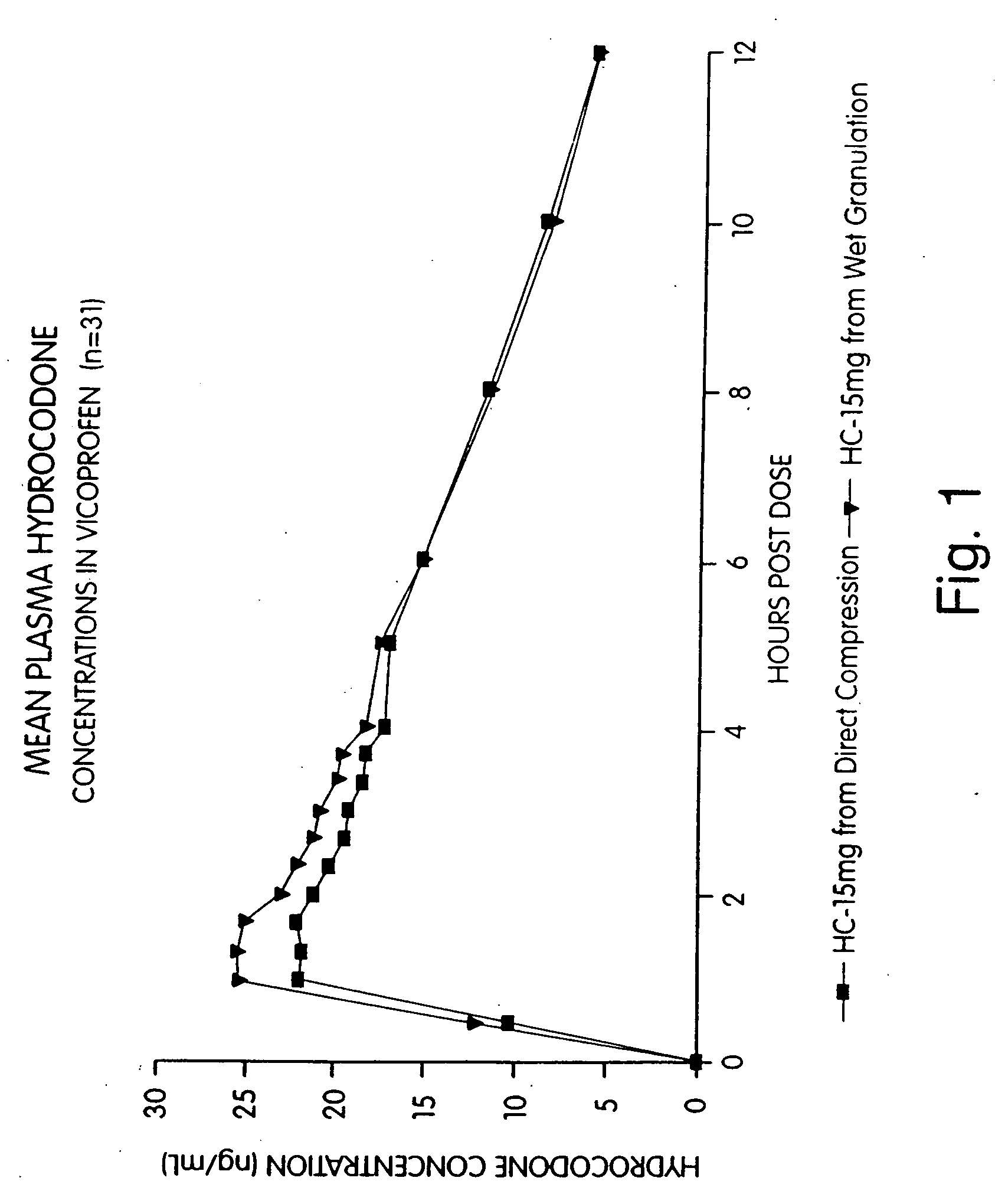

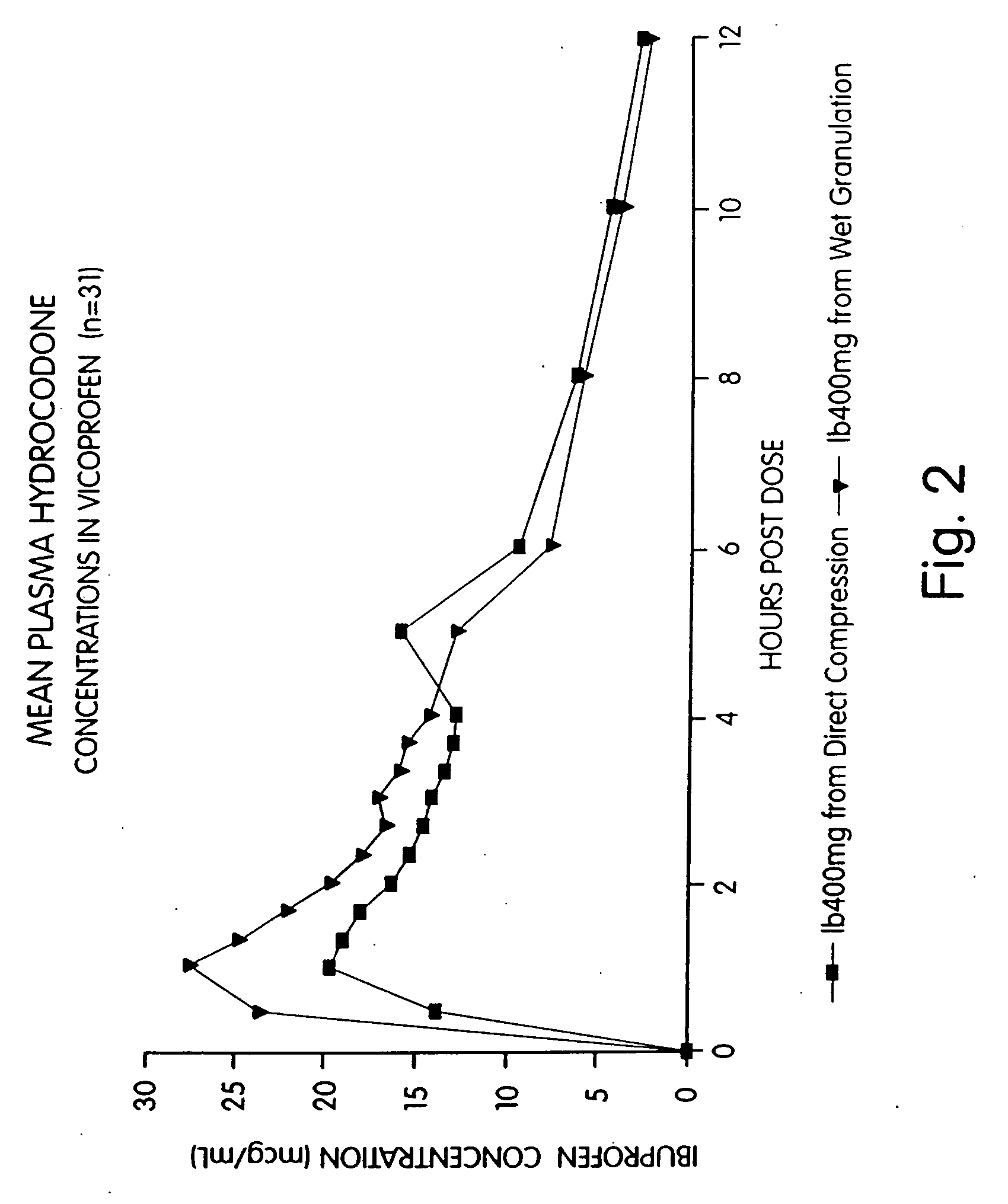

Ibuprofen and narcotic analgesic compositions

Provided herein are compositions and methods of making compositions of ibuprofen in combination with a narcotic analgesic. Specifically provided is a pharmaceutical tablet composition comprising ibuprofen; a narcotic analgesic; colloidal silicon dioxide; a filler selected from the group consisting of microcrystalline cellulose and powdered cellulose; a disintegrant selected from the group consisting of croscarmellose sodium, crospovidone, and sodium starch glycolate; a binder consisting of an akylhydroxy methylcellulose; a starch; and a lubricant. Also provided herein is a method of preparing a pharmaceutical tablet composition comprising: (a) Granulating ibuprofen, a narcotic analgesic, a first glidant, a first disintegrant, a binder, and starch to form granules wherein said granulating step comprises a wet granulation process; (b) blending the granules with extra-granular material comprised of a second glidant, a second disintegrant, a filler and starch to form a blend of granules and extra-granular material; and (c) compressing the blend into a tablet.

Owner:ABBVIE DEUTSHLAND GMBH & CO KG

Medicine composition with norfloxacin and method for preparing medicine composition

ActiveCN105343028AEvenly dispersedUniform contentAntibacterial agentsOrganic active ingredientsNorfloxacinTraditional medicine

The invention relates to a medicine composition with norfloxacin and a method for preparing the medicine composition. The medicine composition comprises an effective quantity of the norfloxacin and pharmaceutical excipients. Proportions of main medicines are 50-80%; the ball forming excipients are selectively one type of microcrystalline cellulose, powdered cellulose, low-substituted hydroxypropyl cellulose and corn starch or combinations of the microcrystalline cellulose, the powdered cellulose, the low-substituted hydroxypropyl cellulose and the corn starch. The medicine composition with the norfloxacin and the method have the advantages that on the one hand, the dissolving-out speeds of oral preparations can be controlled, and on the other hand, the stability of the preparations can be improved.

Owner:ZHEJIANG WANBANG PHARMA

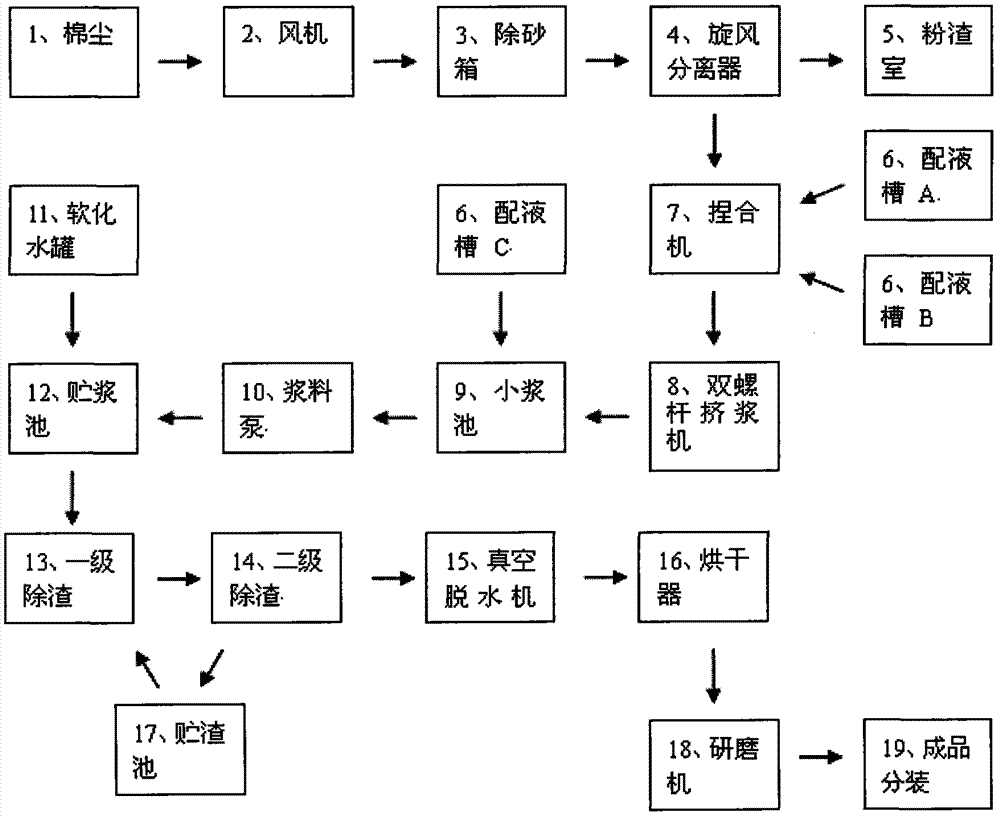

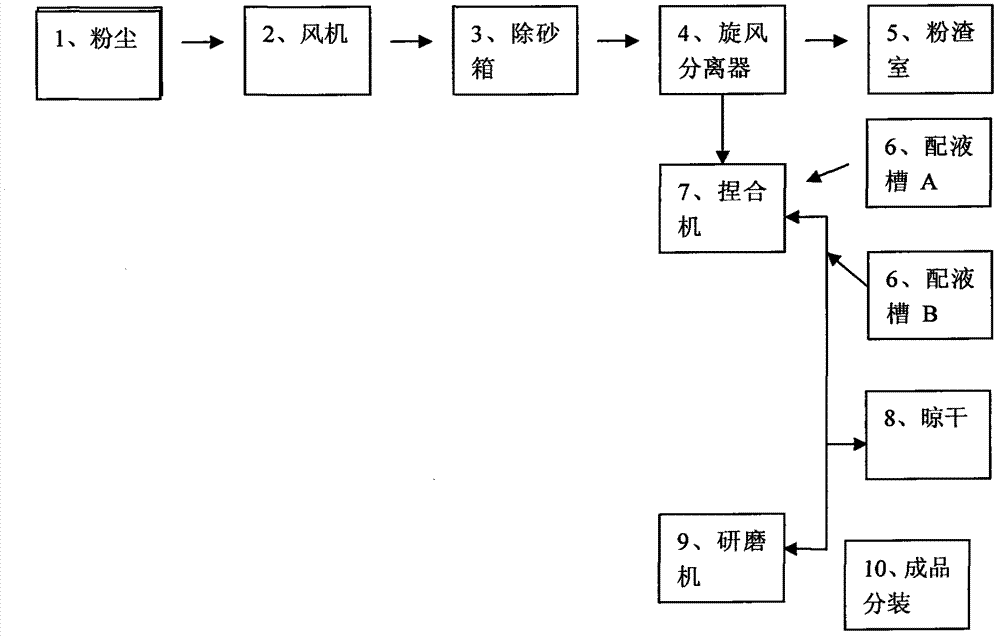

Micro-powder cellulose preparation method

The invention discloses a micro-powder cellulose preparation method, which is characterized in that cotton dust is adopted as a raw material, purity-increase impurity-removing and decoloration degradation are performed, and one of an improved twin-screw slurry extruder, a ball mill, a rod mill and a vibration mill is adopted to carry out a high shear oxidation depolymerization treatment to obtain the micro-powder cellulose, wherein cotton dust can not be used by textile industry. According to the present invention, the characteristic of low polymerization degree of the cotton dust fine fiber is utilized, and the resource is complete, such that large-scale industrial production can be performed, and product stability and purity are high.

Owner:SHANGHAI TONNOR MATERIAL SCI

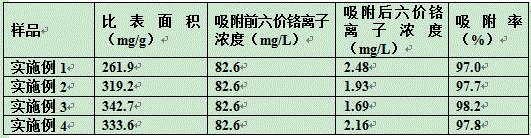

Preparation method of chromium ion removing adsorbent

InactiveCN106111084AWide variety of sourcesLow costOther chemical processesWater contaminantsSorbentThiourea

The invention discloses a preparation method of an adsorbent for removing chromium ions, which comprises crushing banana stalks, adding sodium hydroxide solution to soak them, washing the banana stalk powder with water to neutrality, and adding maleic dihydrogen to the banana stalk powder cellulose. acid, add water and dry at a temperature of 80-100°C for 1-2 hours to obtain modified banana stalk powder; take water hyacinth powder and thiourea and add them to an ultrasonic stirrer, then add an appropriate amount of water for ultrasonic reaction, and place the reacted paste in Heat and dry in an oven at 60-80°C for 2-3 hours to obtain modified water hyacinth powder; add the above-mentioned modified banana stalk powder residue and modified water hyacinth powder to the mixer, add cerium ammonium nitrate and chitosan, and then add water Make it into a paste, put it into microwave heating equipment, microwave at a temperature of 120-140°C for 30-60min, cool to room temperature, and grind to obtain the chromium ion adsorbent. The adsorbent of the invention has the advantages of wide source of raw materials, low cost, large specific surface area, large adsorption capacity, high adsorption efficiency, simple preparation process, etc., and has good adsorption performance for hexavalent chromium ions.

Owner:广西南宁桂尔创环保科技有限公司

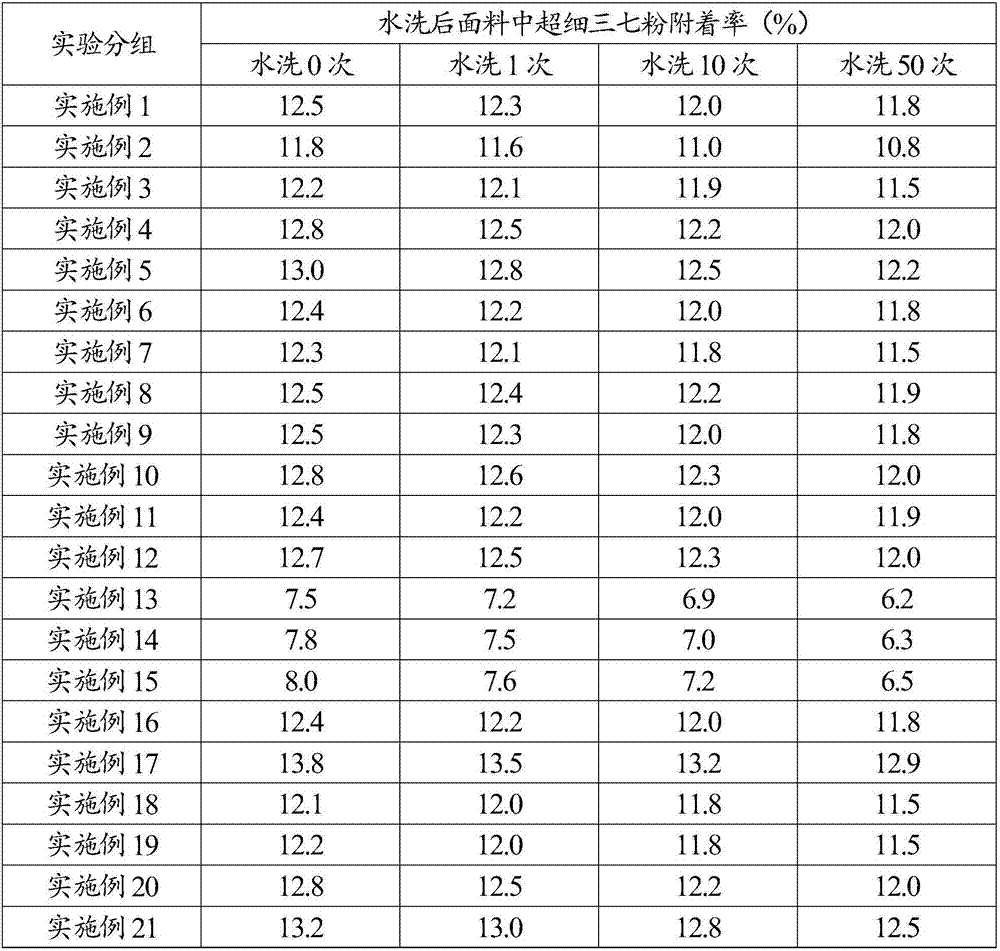

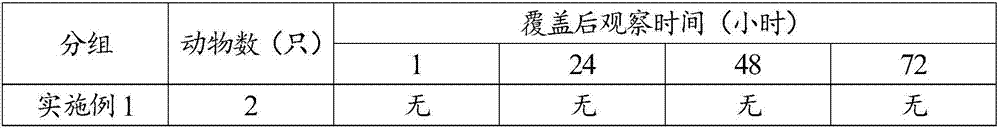

Superfine panax pseudoginseng powder cellulose fiber, and preparation method and application of cellulose fiber

ActiveCN107142541AImprove microcirculationRegulate metabolismCosmetic preparationsToilet preparationsPolymer scienceCutaneous microcirculation

The invention discloses a superfine panax pseudoginseng powder cellulose fiber, and a preparation method and an application of the cellulose fiber. The preparation method comprises the steps of (1) taking 5-40% by weight percentage of panax pseudoginseng powder, adding 2-20% by weight percentage of dispersant, adding 100% by weight percentage of deionized water, performing uniform mixing, and grinding and stirring a mixed system to obtain a panax pseudoginseng powder dispersion liquid, and (2) injecting viscose glue into the panax pseudoginseng powder dispersion liquid by injection prior to spinning, performing sufficient mixing by a static mixer, and then performing wet method spinning and aftertreatment to obtain the superfine panax pseudoginseng powder cellulose fiber finished product, wherein the particle size of the panax pseudoginseng powder is more than 800 meshes; and the volume percentage of the panax pseudoginseng powder dispersion liquid to the viscose glue is 0.5-20%. An adhesion rate of the superfine panax pseudoginseng powder in the fiber is higher; reduction of the adhesion rate after water washing for many times is slow; adhesion is firm; and when shell fabric prepared by the fiber directly contacts skin, the superfine panax pseudoginseng powder can partially enter skin microcirculation, can dilate a blood vessel, can improve human microcirculation, and has a good health-care effect.

Owner:YIBIN PINGSHAN HUIRUI OIL CO LTD

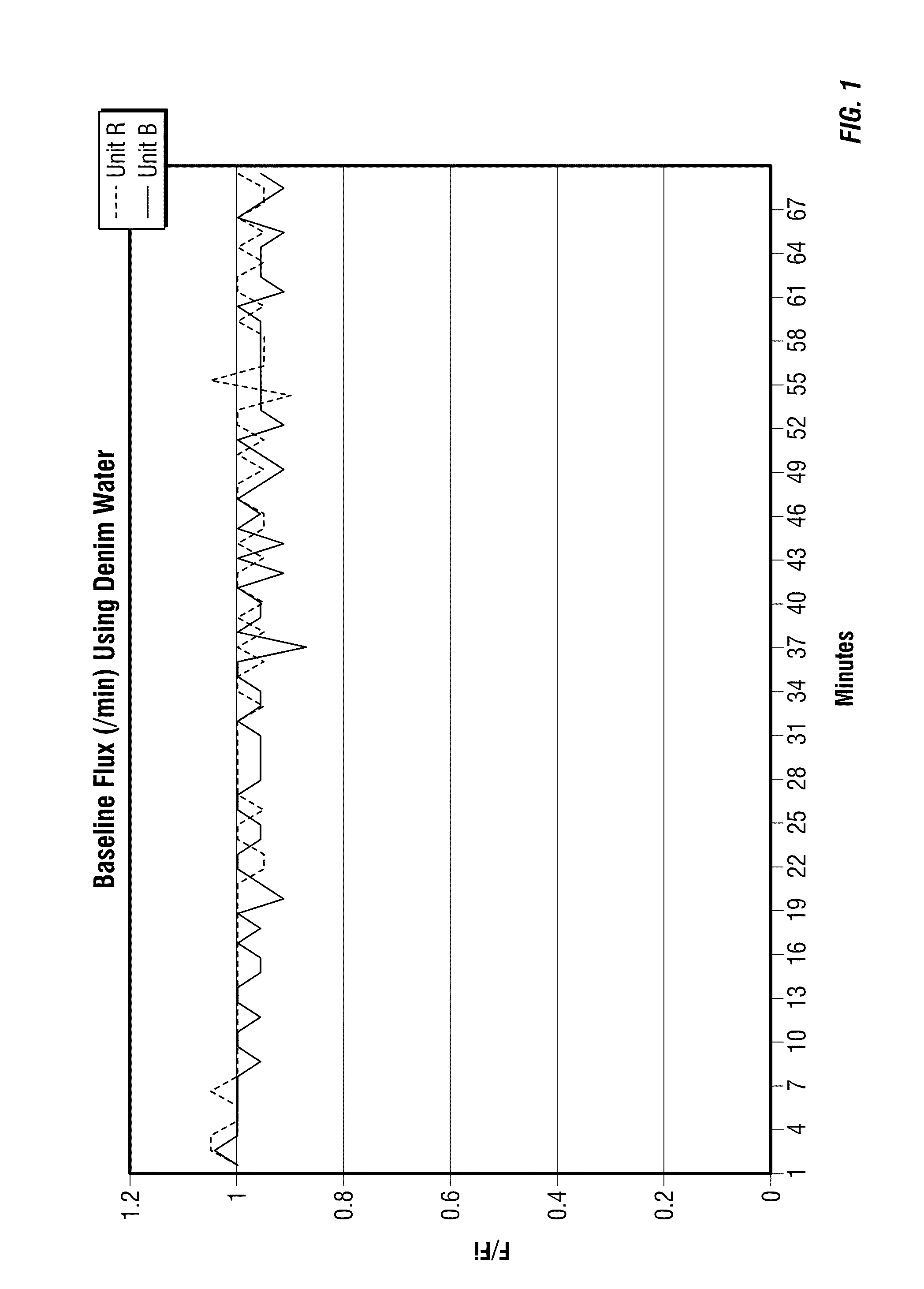

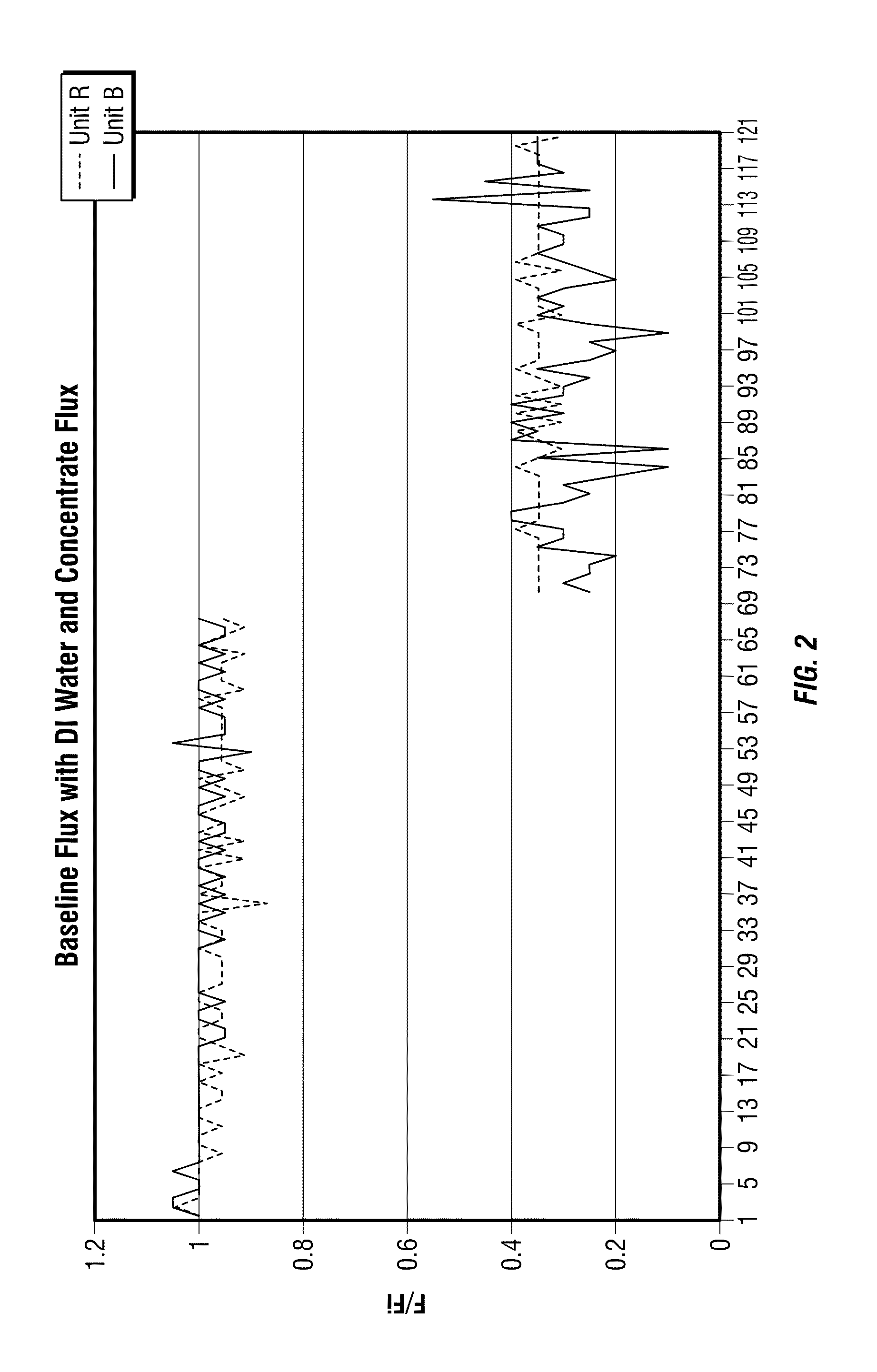

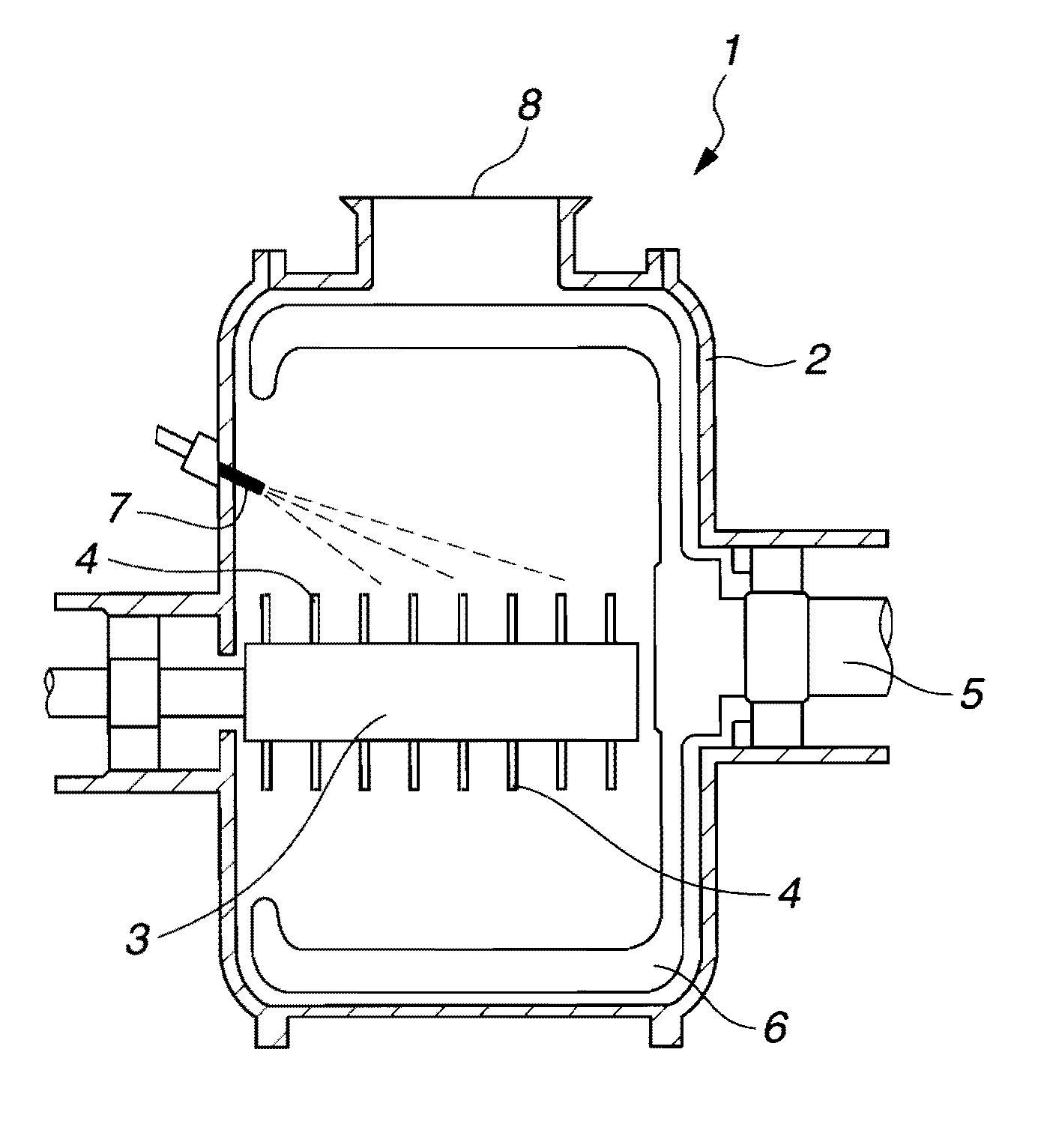

Method for cleaning filter separation systems

InactiveUS20110266217A1Improve filtering effectSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisWastewaterColloid

High shear separations of suspensions and colloid suspensions may be preformed using a fouling reduction agent to optimize the separations. The fouling reduction agents are solids. Exemplary of such solids are powdered cellulose, clays, diatomaceous earth and the like. Process streams which may treated include refinery process waste water, chemical process waste water, food processing waste water, power generation waste water, chemical product streams, and chemical intermediate streams.

Owner:BAKER HUGHES INC

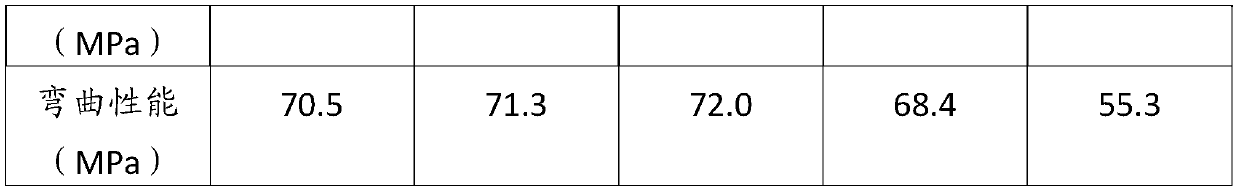

High-density bamboo powder modified polylactic acid biodegradable plastic and preparation method thereof

The invention provides high-density bamboo powder modified polylactic acid biodegradable plastic and a preparation method thereof. The high-density bamboo powder modified polylactic acid biodegradableplastic provided by the invention comprises the following components in parts by mass: 35-60 parts of polylactic acid, 25-40 parts of modified bamboo powder, 10-15 parts of starch, 1.5-2.5 parts of silicate, 3-5 parts of glycerol and 0.5-2 parts of a coupling agent. According to the technical scheme, the bamboo powder cellulose is subjected to graft modification treatment, wherein the N, N-dimethylformamide / aluminum chloride mixed system is an initiator for graft copolymerization reaction of bamboo powder cellulose and caprolactone; hydrophilic, oleophylic and incompatible two chain segmentsare bonded together by adopting a graft copolymerization method, and the modified bamboo powder is easily crosslinked with polylactic acid under the action of a coupling agent to form a blend, so thatthe mechanical property of the bamboo-plastic composite material is improved, the use amount of polylactic acid is further reduced along with the increase of the addition amount of the bamboo powder,and the cost is saved.

Owner:广东亿发新材料科技有限公司

Preparing process of cellulose-acrylate composite microsphere

The preparation process of cellulose-acrylate composite microsphere includes the following steps: dispersing powdered cellulose and emulsifier in water to form water phase, dispersing acrylate in organic solvent to form oil phase, adding the oil phase into the water phase through stirring and heating before adding persulphate as initiator, further heating to 65-90 deg.c and reacting for 0.5-6 hr, cooling to room temperature, filtering to eliminate liquid phase, washing with water and stoving at 20-120 deg.c to obtain the cellulose-acrylate composite microsphere. The process is environment friendly, simple and feasible.

Owner:JIANGSU QIANGLIN BIO ENERGY

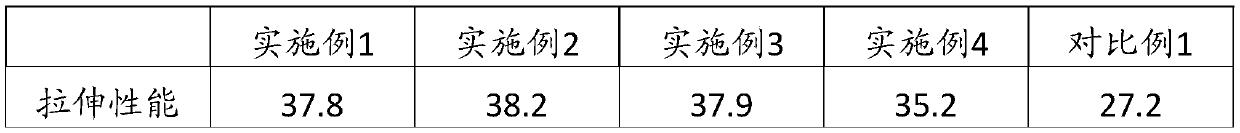

Production process of high-strength corrugated paper

The invention relates to a production process of high-strength corrugated paper. The production process comprises the following steps of: (1) obtaining waste paper pulp from waste paper; (2) obtainingbamboo pulp from bamboo stalks; (3) mixing the waste paper pulp with the bamboo pulp, and adding cationic starch and cellulose powder to obtain papermaking primary pulp; (4) adding a reinforcing agent and an auxiliary agent into the papermaking primary pulp, and uniformly stirring to obtain papermaking pulp; and (5) sequentially carrying out papermaking forming, dehydration, drying, surface sizing and secondary drying on the papermaking pulp to obtain a corrugated paper finished product. According to the invention, dual pulping is carried out on the bamboo stalks; the bamboo fibers can be separated to the greatest extent; the utilization rate of bamboo stalk raw materials is improved; the corrugated paper is more energy-saving and environment-friendly, the gram weight of the corrugated paper can be reduced and the strength of the corrugated paper can be ensured by adding the reinforcing fiber powder into the mixed pulp, and the electrostatic interaction between the pulp can be enhanced by adding the reinforcing agent formed by polymerizing cationic polyacrylamide, hydroxypropyl chitosan and epoxy chloropropane resin, so that the strength of the corrugated paper is further improved.

Owner:东莞顺裕纸业有限公司

Capsule comprising artemisia capillaries and rhizoma imperatae for treating hepatitis

ActiveCN1923264AControl Quality CharacteristicsAccuracyDigestive systemAntiviralsRotary evaporatorMedicine

The invention discloses a capsule preparation and method for controlling quality, wherein the preparation is prepared from oriental wormwood, eupatene, talcum, cogongrass rhizome, dandelion and licorice root through steps of watering, immersing, grilling, coarse straining, centrifuging, filtering by suction, decompression concentrating into thick extract, vacuum drying at 85 deg C, charging right amount of crystalline cellulose and disintegrating into fines, mixing homogenously and split charging.

Owner:FUJIAN COSUNTER PHARMA

Environment-friendly floor cleaning powder and production method thereof

InactiveCN105925401ANo pollution in the processNo corrosionSoap detergents with organic compounding agentsSoap detergents with inorganic compounding agentsSolventSOAP

The invention discloses an environment-friendly floor cleaning powder and a production method thereof, and belongs to the technical field of floor cleaning agents. According to the technical scheme, the environment-friendly floor cleaning powder is prepared from, by weight, 100 parts of solvent water, 10-20 parts of quartz powder with the mesh number of hard friction powder being 10-200, 10-20 parts of expanded perlite with the puffing ratio of light friction powder being 15-20, 1-3 parts of brightening powder, 1-3 parts of emulsifying powder 6501, 1-2 parts of suspension powder cellulose, 1-5 parts of inorganic washing powder sodium citrate, 1-5 parts of organic washing powder natural soap powder and 0.1-1 part of chelated dispersing powder. The invention further discloses the production method of the environment-friendly floor cleaning powder. The environment-friendly floor cleaning powder is better in stain removing effect and more convenient and faster to use.

Owner:ZHEJIANG NORMAL UNIVERSITY

Full-vegetarian dog food formula and preparation methods

ActiveCN108157640ASolve many problems with technical deficienciesSolve the many problems of insufficient technologyAnimal feeding stuffAccessory food factorsPotato starchGlycerol

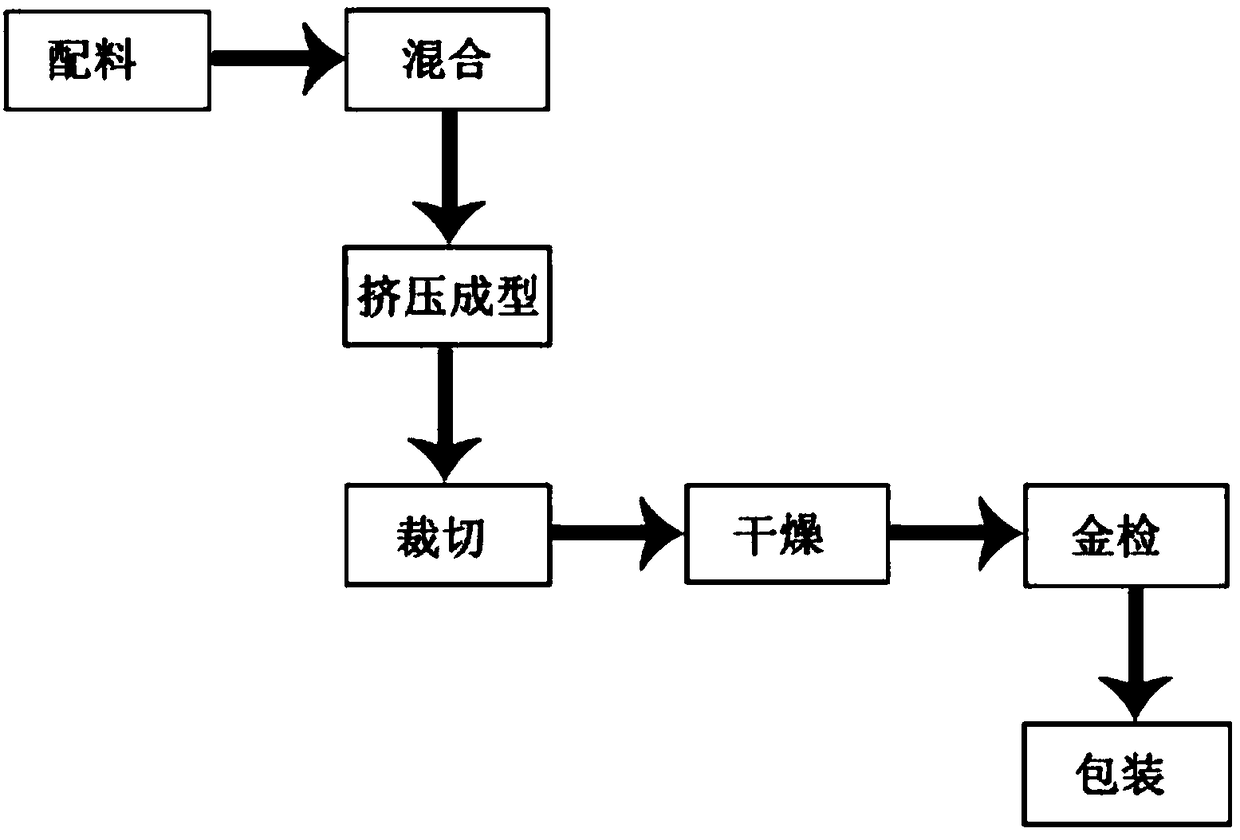

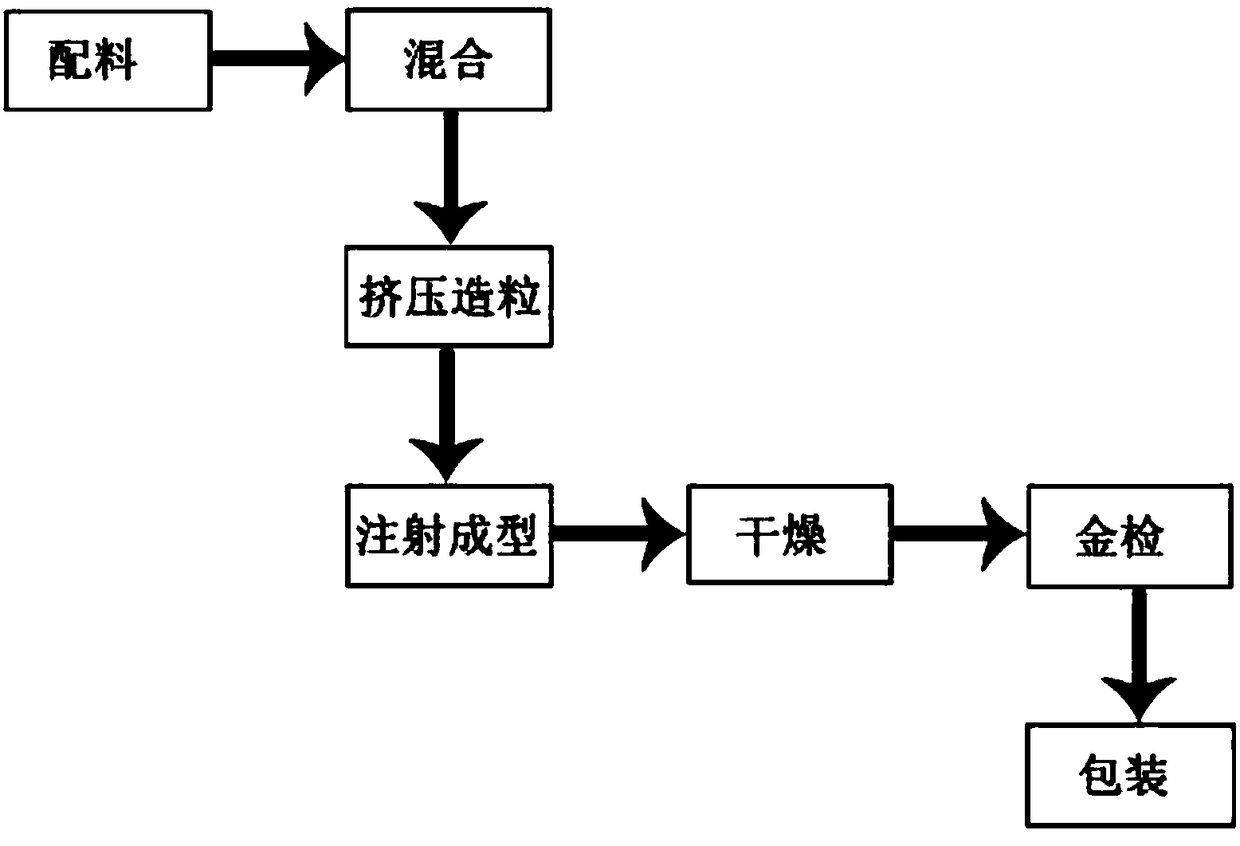

The invention discloses a full-vegetarian dog food formula and preparation methods. The full-vegetarian dog food is characterized by being mainly prepared from potato starch, powdered cellulose, cortex magnolia officinalis extract, yellow pea powder, xylooligosaccharide, yeast cell wall polysaccharides (prebiotics), schizochytrium limacinum powder, rosemary herb extract, sodium hexametaphosphate and glycerin, wherein the powdered cellulose is obtained through fermentation. Two preparation methods are provided; one preparation method includes the steps of material preparing, mixing, extrusion molding, cutting, drying, metal detecting and packaging; the other preparation method includes the steps of material preparing, mixing, extrusion granulating, injection molding, drying, metal detectingand packaging. The full-vegetarian dog food formula and the preparation methods aim at solving various technical problems in the background art.

Owner:佛山市风来客宠物用品有限公司

Preparation of cellulose ether powder

ActiveUS20140109798A1Easily dissolvableCosmetic preparationsNon-macromolecular adhesive additivesEtherWater soluble

Cellulose ether powder is prepared in a safe and easy way by first adding a surfactant solution to surfaces of water-soluble cellulose ether particles, and then adding a tannin solution thereto. The powder thus prepared is free of bitterness and readily dissolvable in cold water without forming clumps.

Owner:SHIN ETSU CHEM IND CO LTD

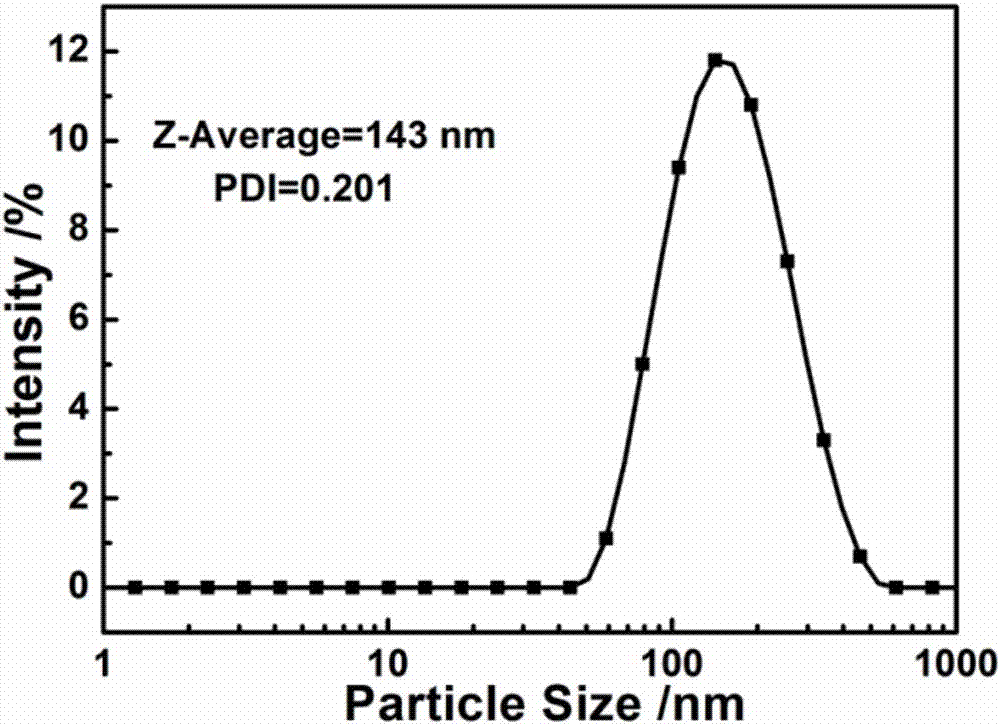

Elemene inclusion complex, preparation and preparation process thereof

InactiveCN100560134CImprove bioavailabilityEasy to useOrganic active ingredientsSuppositories deliveryCross-linkMethyl cellulose

Owner:刘玉辉

Method of preparing alkali cellulose or a cellulose derivative

The throughput of a reactor for producing alkali cellulose and / or a cellulose derivative can be increased by using a granulated cellulose-based material for the preparation of alkali cellulose and / or a cellulose derivative. Cellulose derivatives of essentially the same quality can be produced as in known processes wherein powdered cellulose-based material is used for alkalization and derivatization.

Owner:MERZ GUNNAR R +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com