High-density bamboo powder modified polylactic acid biodegradable plastic and preparation method thereof

A technology of biodegradable plastics and polylactic acid, which is applied in the field of high-density bamboo powder modified polylactic acid biodegradable plastics and its preparation, can solve the problems of poor interfacial compatibility between fibers and polylactic acid, high addition of bamboo powder, and mechanical properties of composite materials. Reduce and other problems, achieve the effect of improving mechanical properties and stability, saving costs, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

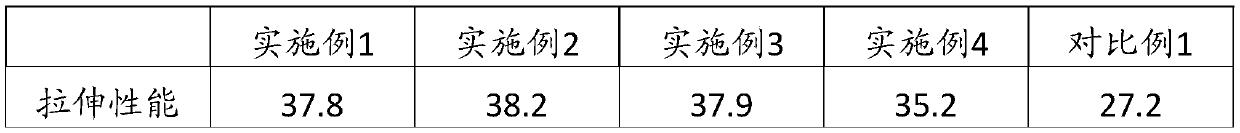

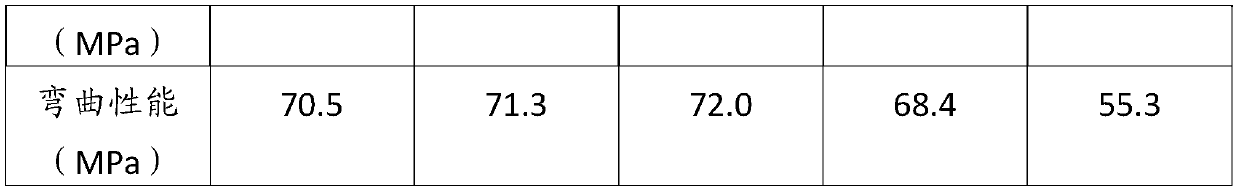

Examples

Embodiment 1

[0028] The preparation method of modified bamboo powder:

[0029] Prepare 1kg of aluminum chloride and 15kg of N,N-dimethylamide to form a mixed solution of N,N-dimethylamide / aluminum chloride; soak 5kg of bamboo powder in acetone solution for 15-24 hours, filter and freeze-dry; Soak the freeze-dried bamboo powder in dimethylacetamide solution for 3-8 hours, filter and freeze-dry; mix the freeze-dried bamboo powder with N,N-dimethylamide / aluminum chloride mixed solution evenly , the temperature of the mixed system was raised to 150° C. under nitrogen atmosphere; 2.5 kg of caprolactone was added to the mixed system, and the stirring reaction was continued for 12 hours. After the reaction was completed, centrifuged, washed and dried to obtain the modified bamboo powder.

[0030] The preparation method of bamboo powder modified polylactic acid biodegradable plastics:

[0031] Put 4.0kg polylactic acid, 3.0kg modified bamboo powder, 1.2kg starch, 0.15kg silicate, 0.35kg glycerin ...

Embodiment 2

[0033] The preparation method of modified bamboo powder:

[0034] Prepare 1kg of aluminum chloride and 17kg of N,N-dimethylamide to form a mixed solution of N,N-dimethylamide / aluminum chloride; soak 5kg of bamboo powder in acetone solution for 15-24 hours, filter and freeze-dry; Soak the freeze-dried bamboo powder in dimethylacetamide solution for 3-8 hours, filter and freeze-dry; mix the freeze-dried bamboo powder with N,N-dimethylamide / aluminum chloride mixed solution evenly , the mixed system was heated to 150° C. under a nitrogen atmosphere; 2.7 kg of caprolactone was added to the mixed system, and the stirring reaction was continued for 12 hours. After the reaction was completed, centrifuged, washed and dried to obtain the modified bamboo powder.

[0035] The preparation method of bamboo powder modified polylactic acid biodegradable plastics:

[0036] Put 4.0kg polylactic acid, 3.0kg modified bamboo powder, 1.2kg starch, 0.15kg silicate, 0.35kg glycerin and 0.1kg couplin...

Embodiment 3

[0038] The preparation method of modified bamboo powder:

[0039] Prepare 1kg of aluminum chloride and 20kg of N,N-dimethylamide to form a mixed solution of N,N-dimethylamide / aluminum chloride; soak 5kg of bamboo powder in acetone solution for 15-24 hours, filter and freeze-dry; Soak the freeze-dried bamboo powder in dimethylacetamide solution for 3-8 hours, filter and freeze-dry; mix the freeze-dried bamboo powder with N,N-dimethylamide / aluminum chloride mixed solution evenly , the mixed system was heated to 150° C. under a nitrogen atmosphere; 3.1 kg of caprolactone was added to the mixed system, and the stirring reaction was continued for 12 hours. After the reaction was completed, centrifuged, washed and dried to obtain the modified bamboo powder.

[0040] The preparation method of bamboo powder modified polylactic acid biodegradable plastics:

[0041] Put 4.0kg polylactic acid, 3.0kg modified bamboo powder, 1.2kg starch, 0.15kg silicate, 0.35kg glycerin and 0.1kg couplin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com