Patents

Literature

3234 results about "Aluminium chloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

This medication is used to help control excessive sweating..

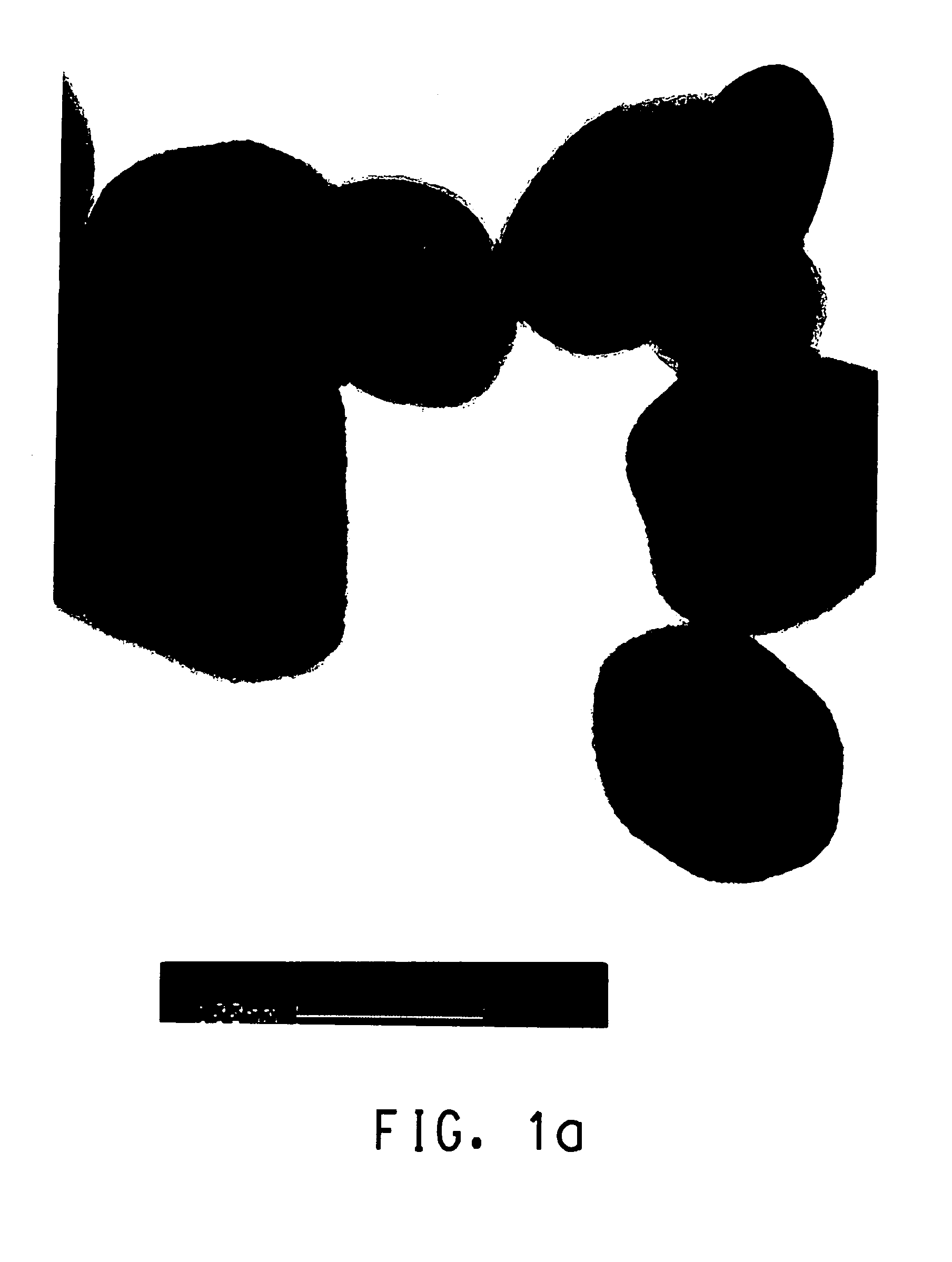

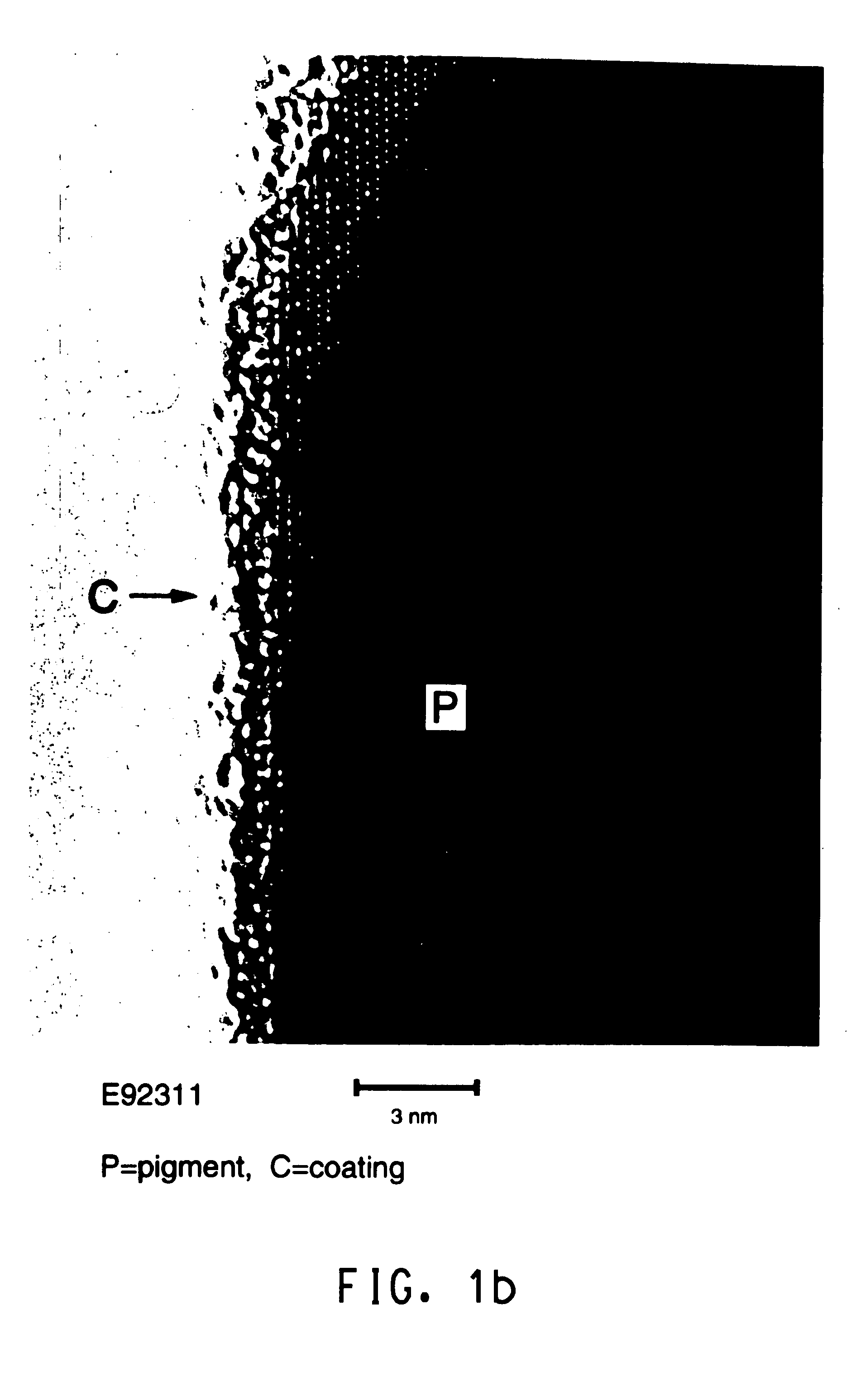

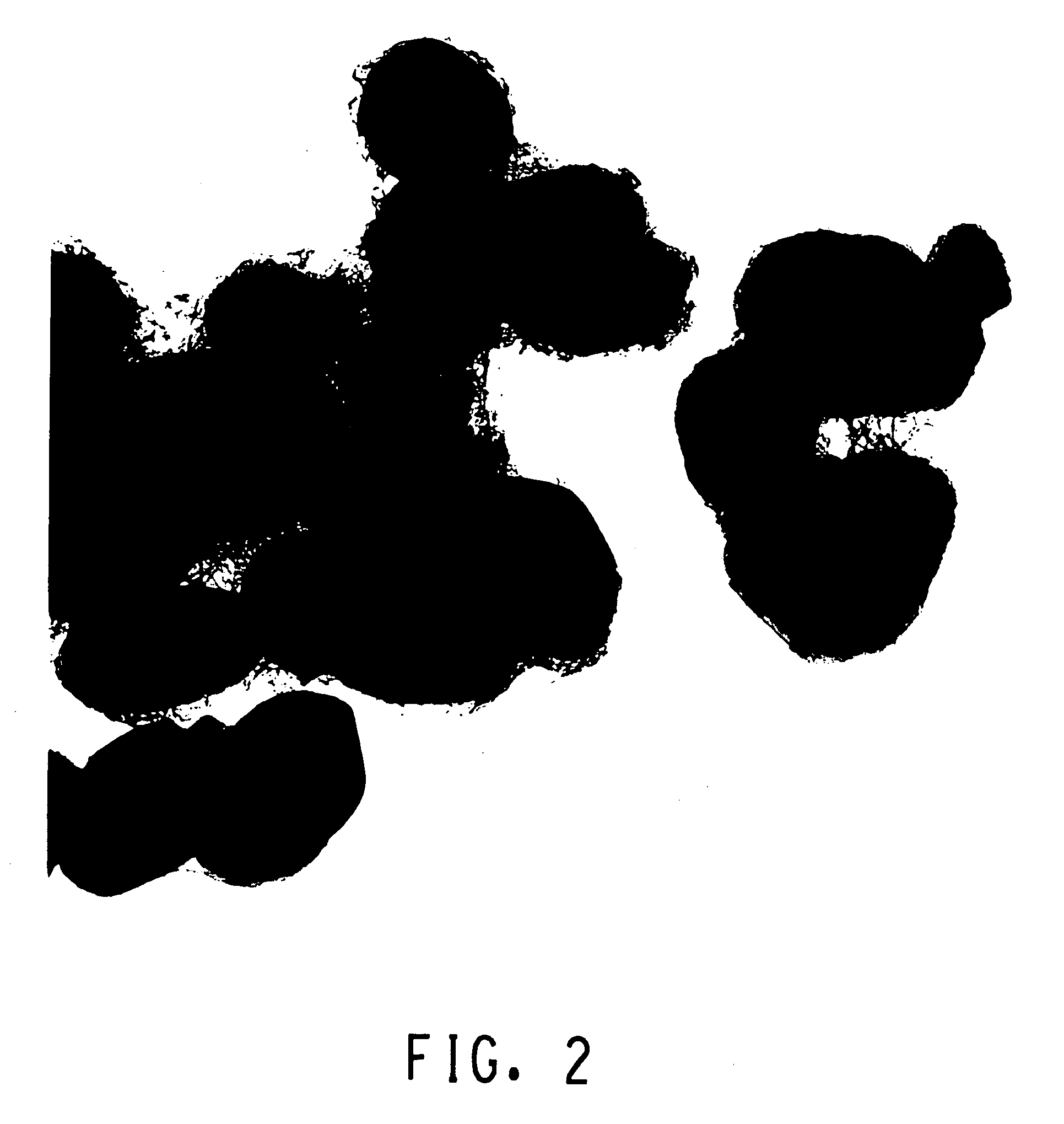

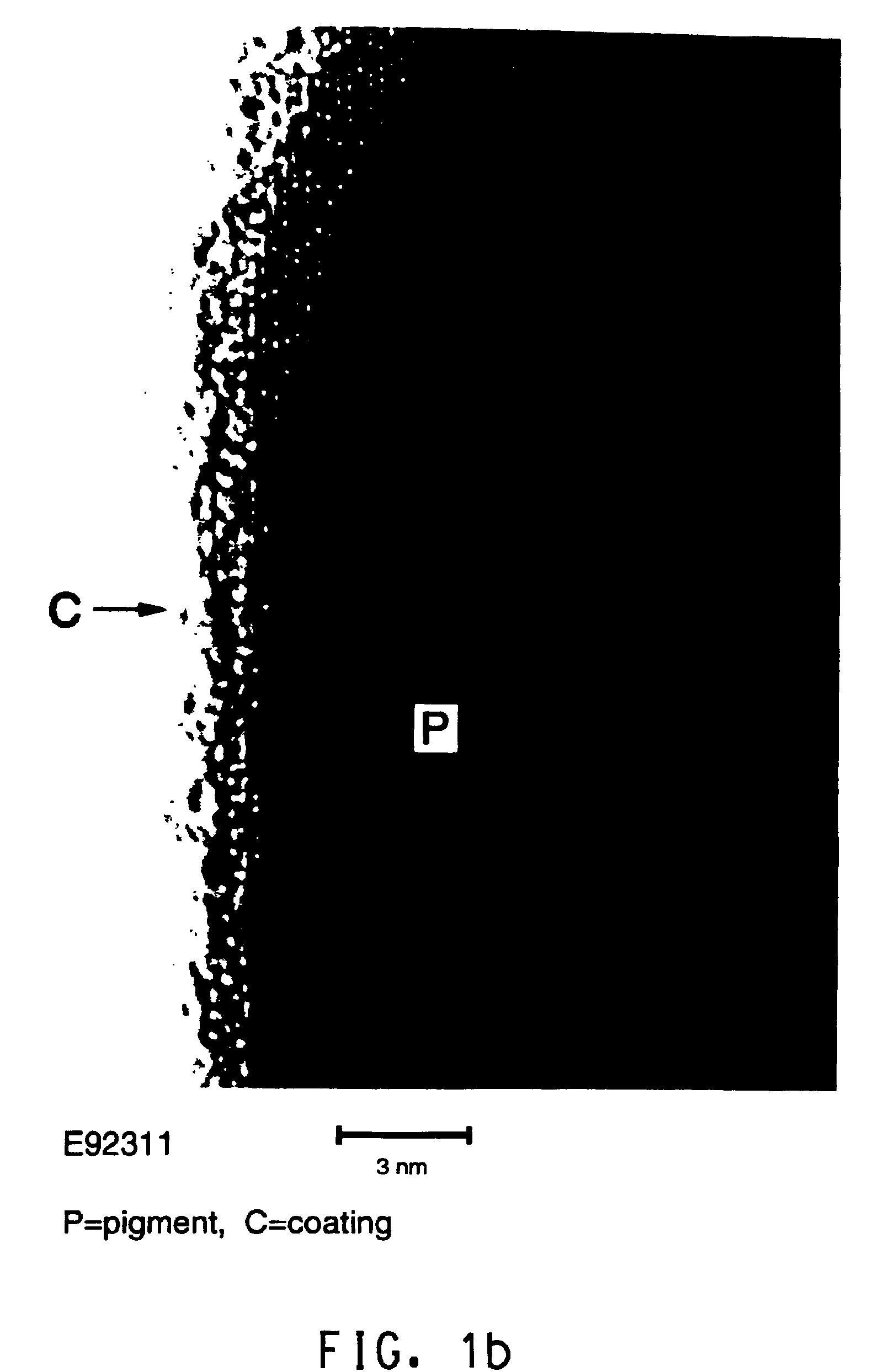

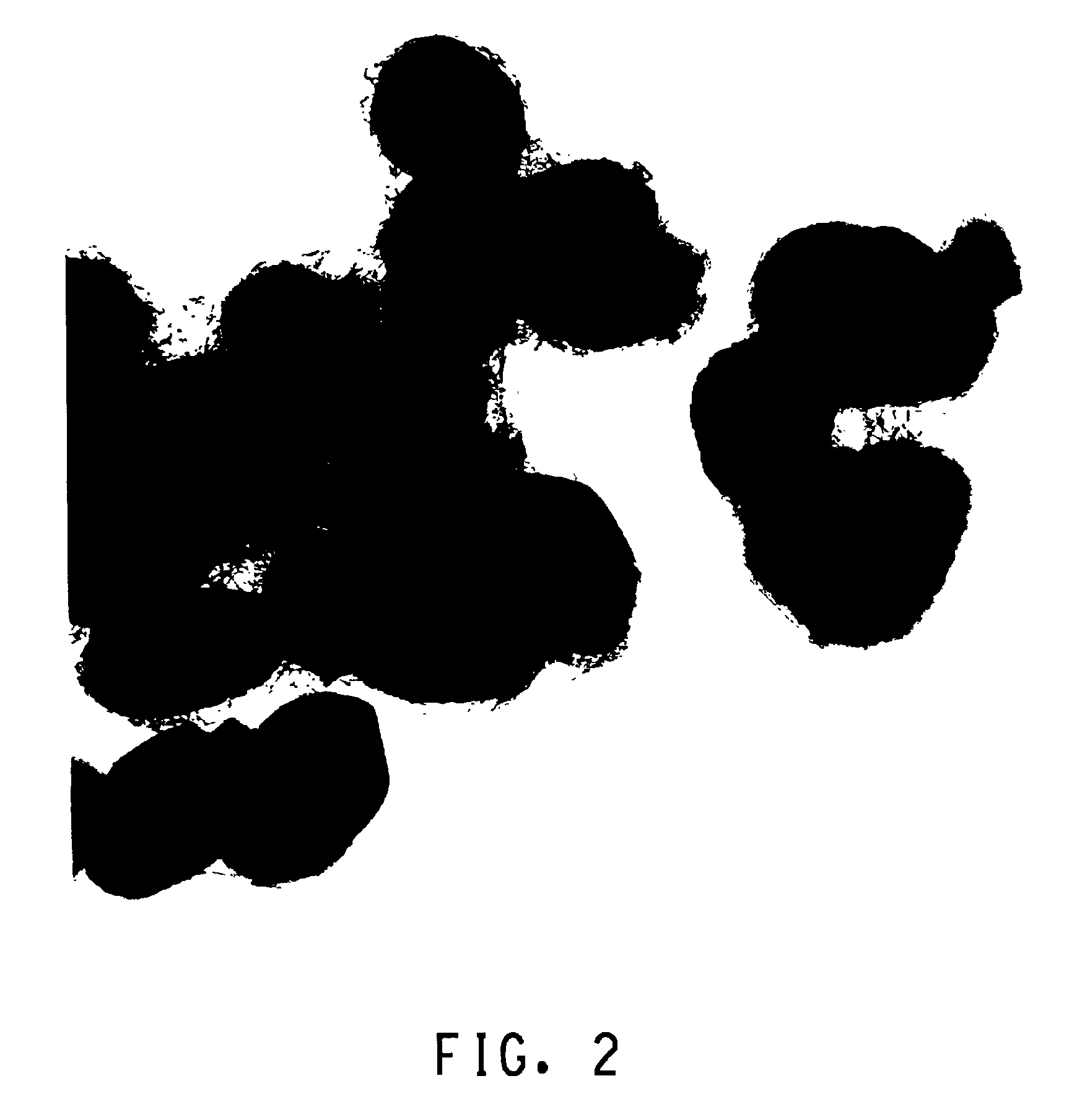

Process for making durable rutile titanium dioxide pigment by vapor phase deposition of surface treatment

The present invention relates to a process for making durable titanium dioxide pigment by vapor phase deposition of surface treatments on the titanium dioxide particle surface by reacting titanium tetrachloride vapor, an oxygen containing gas and aluminum chloride in a plug flow reactor to form a product stream containing titanium dioxide particles; and introducing silicon tetrachloride into the reactor at a point down stream of the point where the titanium tetrachloride and oxygen were contacted and where at least 97% of the titanium tetrachloride has been converted to titanium dioxide or where the reaction temperature is no greater than about 1200° C., and preferably not more than about 1100° C.

Owner:THE CHEMOURS CO FC LLC

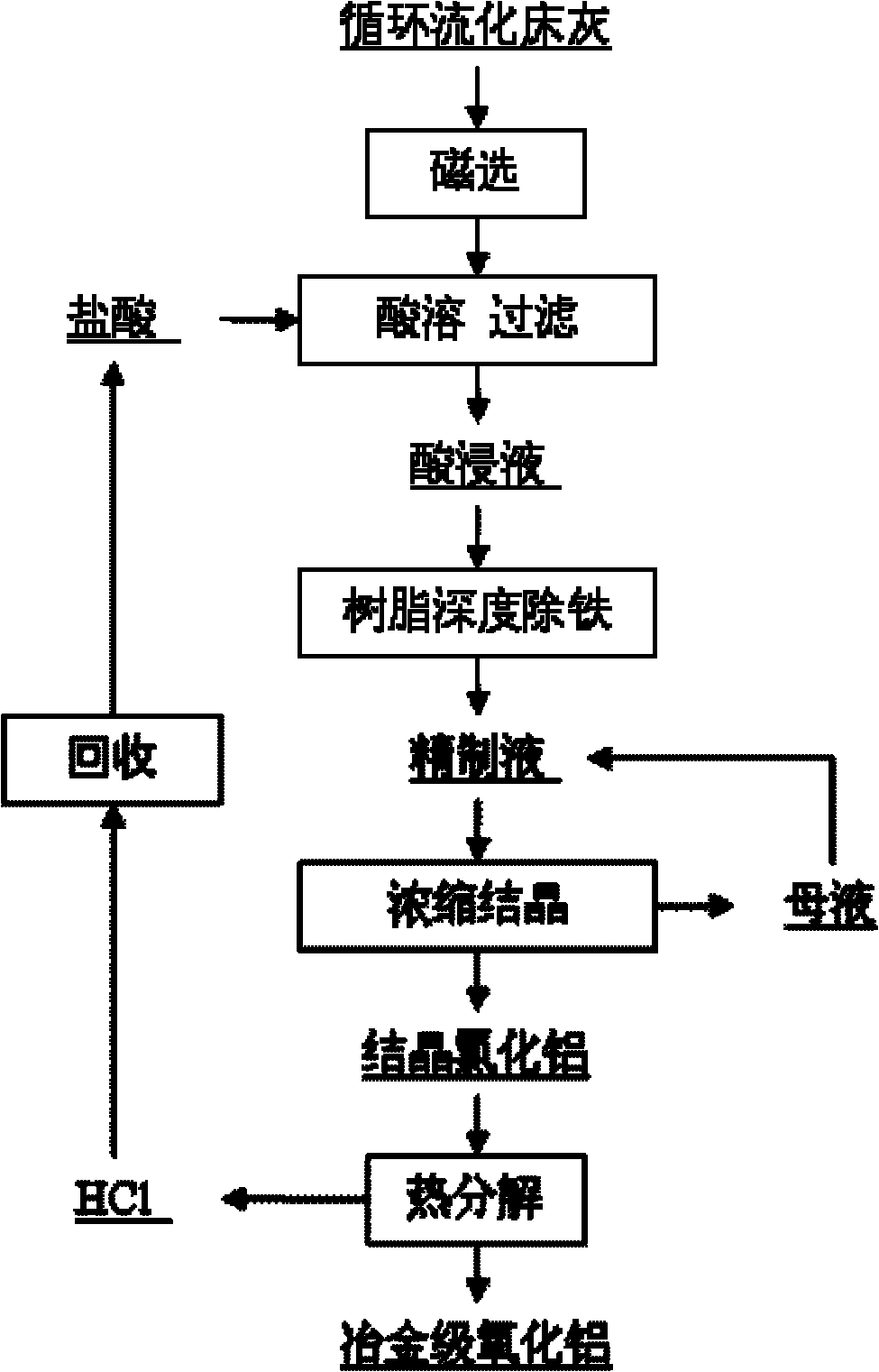

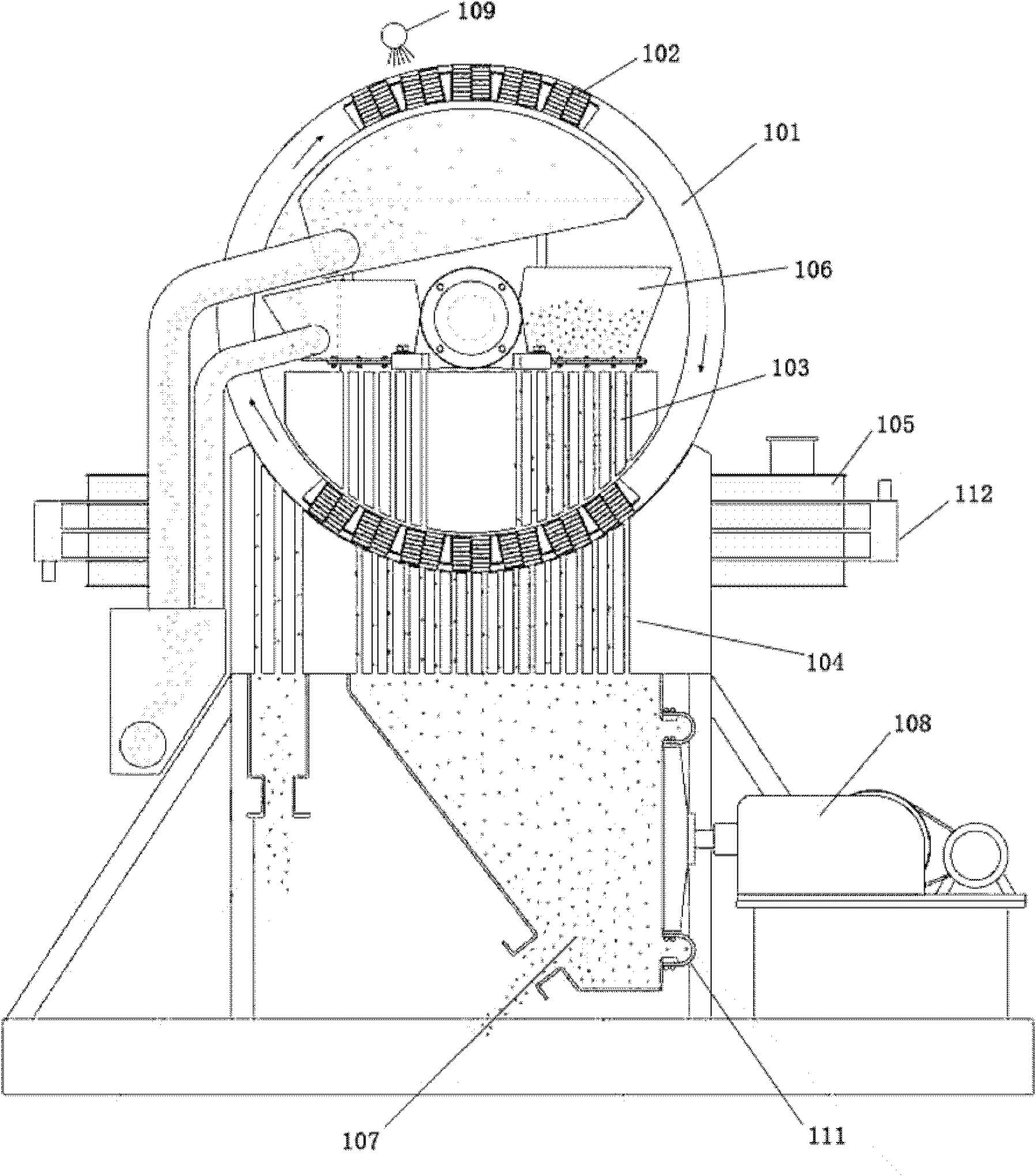

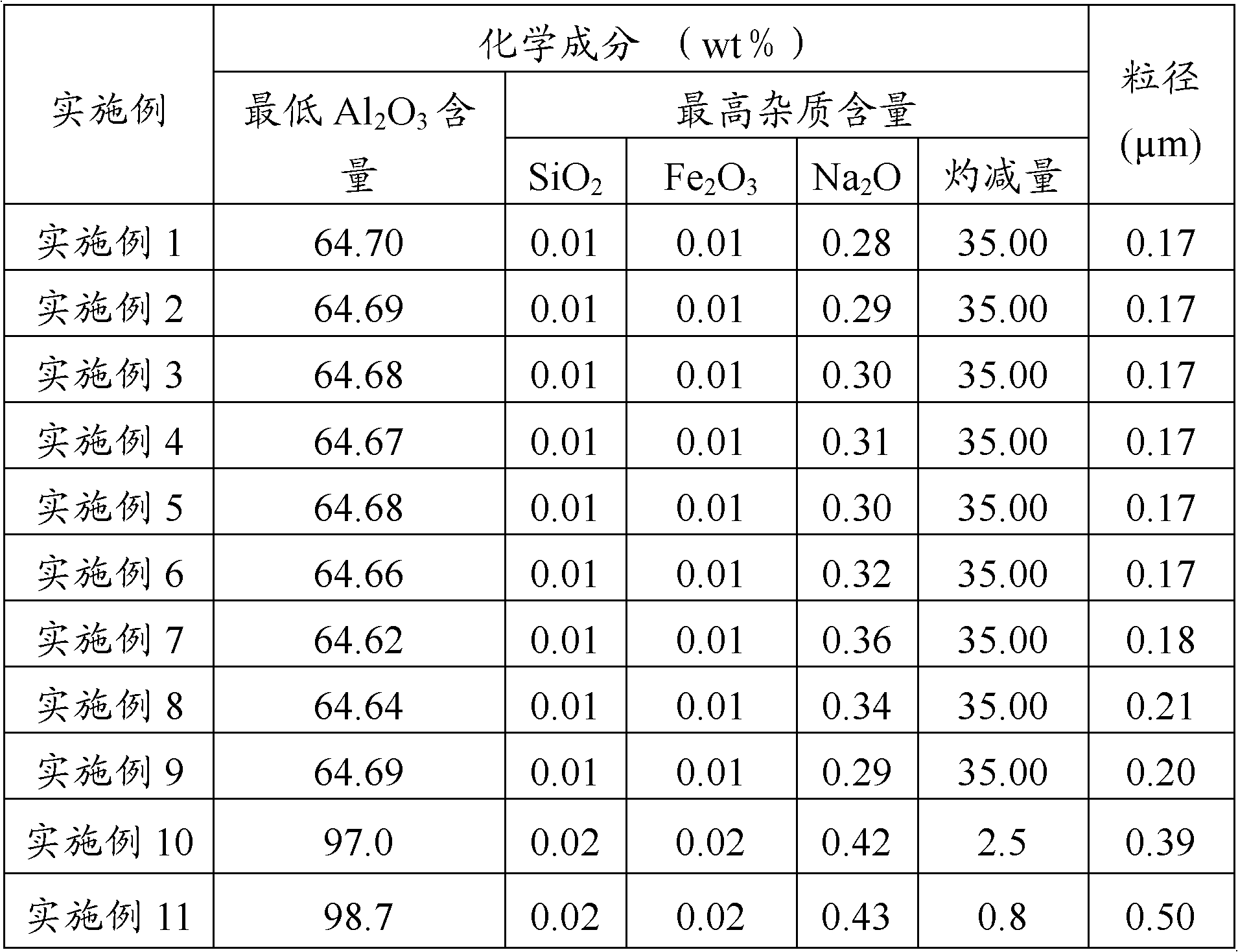

Method for preparing metallurgy-level aluminum oxide by using fluidized bed pulverized fuel ash

ActiveCN102145905AHigh extraction rateReduce manufacturing costSolid waste disposalTransportation and packagingAluminium chloridePulverized fuel ash

The invention discloses a method for preparing metallurgy-level aluminum oxide by using fluidized bed pulverized fuel ash as a raw material. The method comprises the following steps of: a) grinding the pulverized fuel ash, and removing iron by a wet magnetic separation method; b) reacting the pulverized fuel ash subjected to magnetic separation with hydrochloric acid to obtain hydrochloric acid immersion liquid; c) allowing the hydrochloric acid immersion liquid to pass through a large pore type cation resin column for further iron removal to obtain refined aluminum chloride solution; d) concentrating the refined aluminum chloride solution, and crystallizing to obtain an aluminum chloride crystal; and e) calcining the aluminum chloride crystal and decomposing to obtain the metallurgy-level aluminum oxide. The method has a simple process and an easily-controlled production process, and is high in aluminum oxide extraction efficiency, low in production cost and stable in product quality.

Owner:CHINA SHENHUA ENERGY CO LTD

Betaine with Calcium and/or Strontium Antiperspirants

InactiveUS20070020211A1Good curative effectImprove skinCosmetic preparationsToilet preparationsAntiperspirantsBetaine

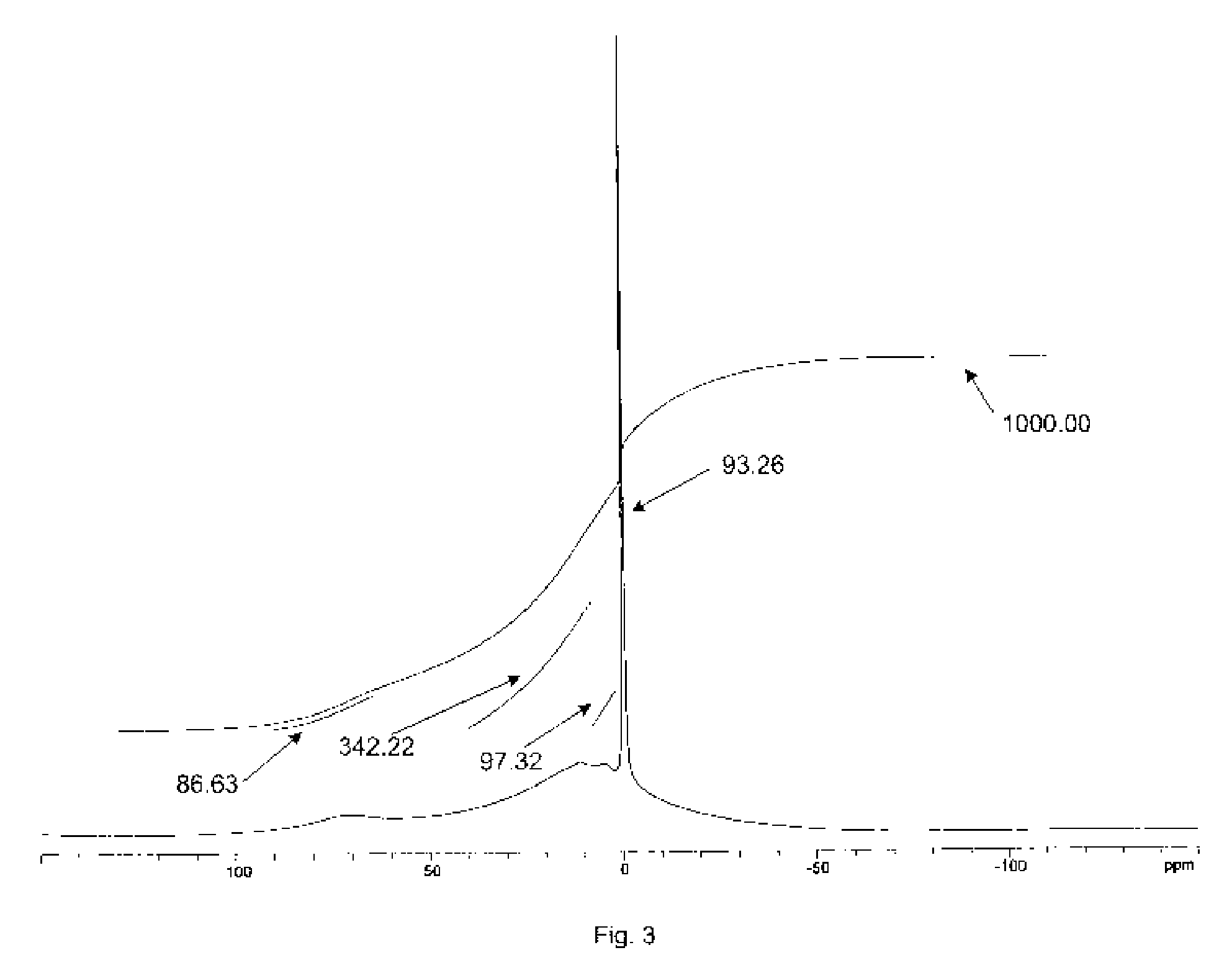

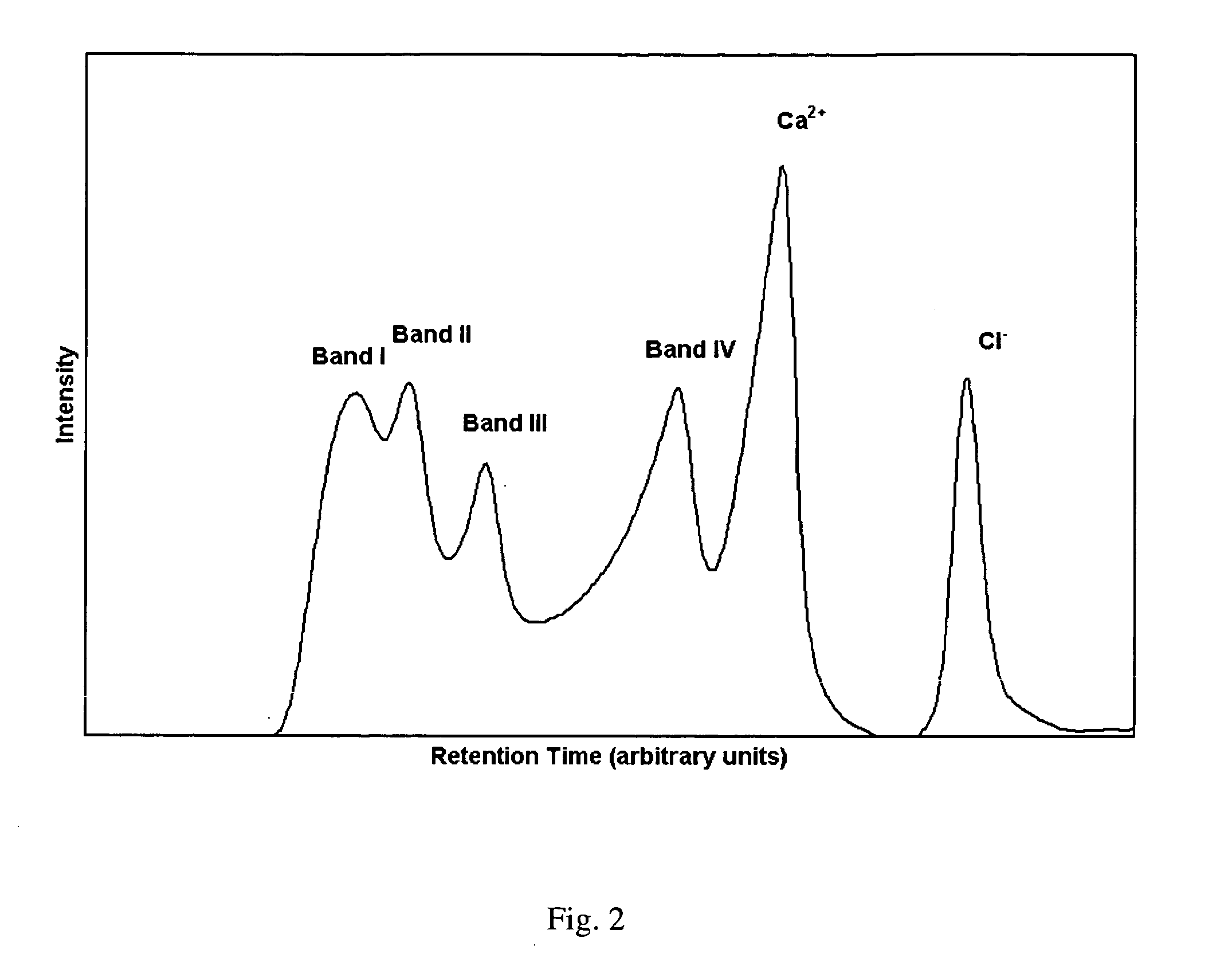

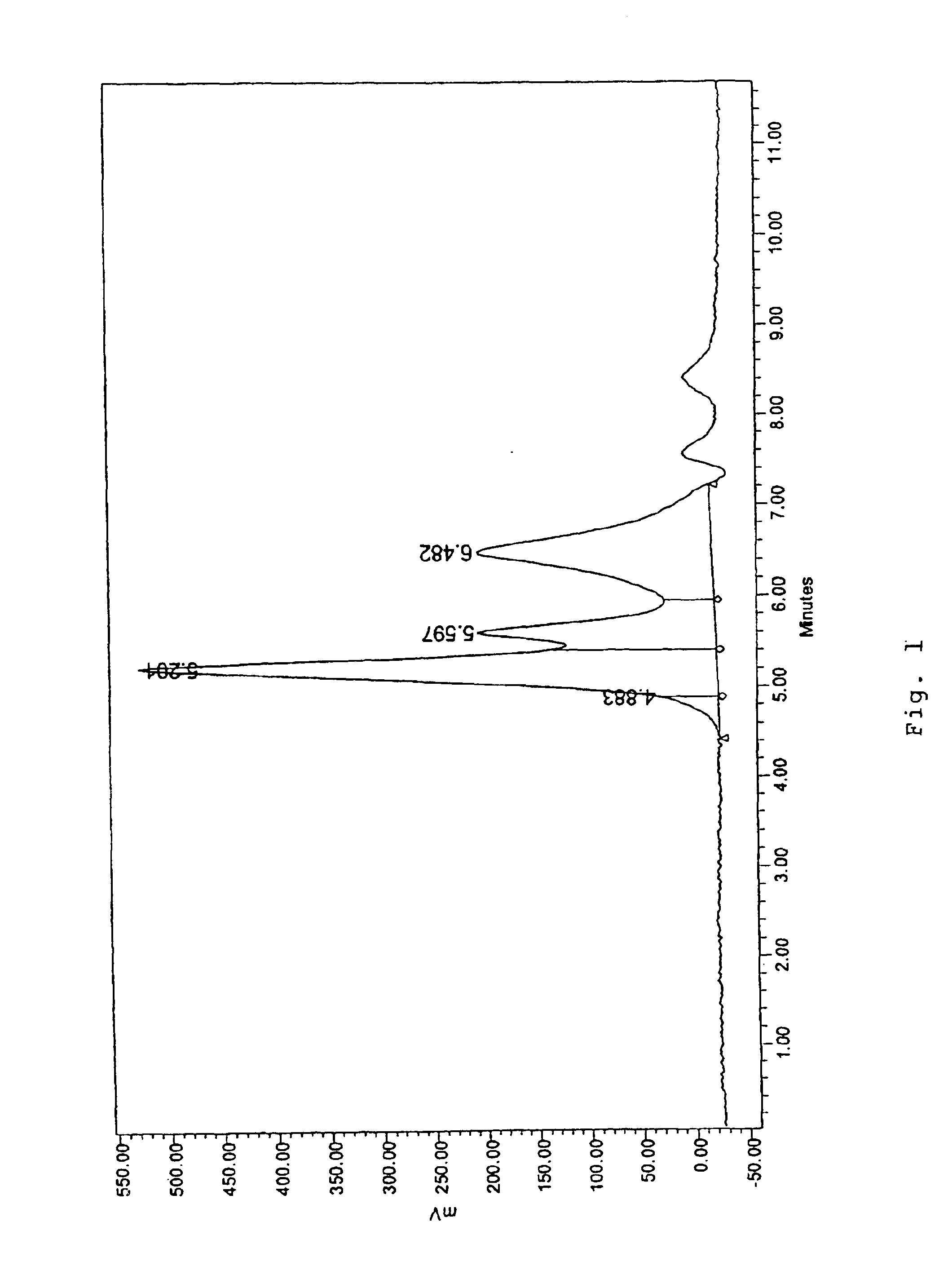

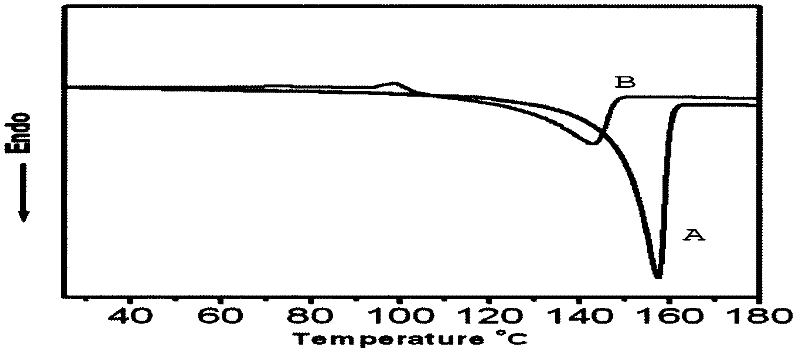

Aluminum and aluminum-zirconium antiperspirant compositions comprising basic aluminum chlorides that have a particular molecular size distribution defined by having an SEC-HPLC Band III / II ratio of at least 0.5, having SEC-HPLC Band III plus Band II area of at least 70% of the total area and having SEC-HPLC Band I content no more than 5% and containing betaine (trimethylglycine), calcium and / or strontium are disclosed. Also disclosed are the methods of making these compositions and the use thereof in consumer acceptable antiperspirant vehicles such as aerosols, gels, roll-on, sticks and soft solids.

Owner:SUMMIT RES LAB

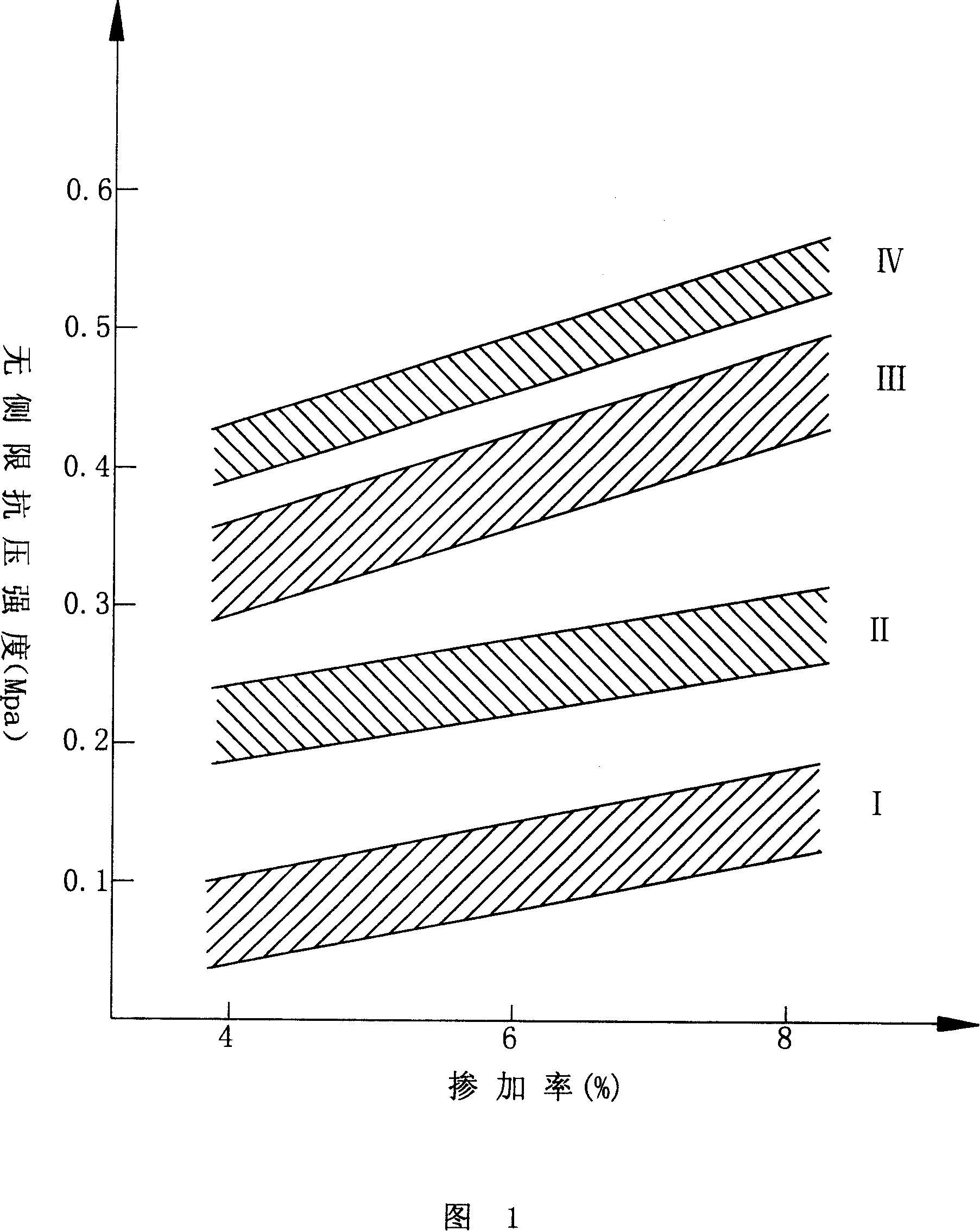

Sludge curing agent and application thereof

ActiveCN101081718AGood boardIncreased durabilitySludge treatment by de-watering/drying/thickeningSolid waste managementSludgeSlag

The present invention is sludge curing agent and its application, and belongs to the field of soil treating chemicals technology. The sludge curing agent includes powdered components and liquid components, the powdered components include cement clinker 30-60 weight portions, slag 30-60 weight portions, lime 3-8 weight portions, gypsum 1-7 weight portions and other sulfates 1-7 weight portions; and the liquid components include polyacrylamide 5-30 weight portions, polyaluminum chloride 0-20 weight portions, mannitol 0-30 weight portions, lignosulfonate 20-80 weight portions, lignosulfonate-iron or chromium ion complex 0-30 weight portions, alkylphenol ethoxylate 0.2-2 weight portions, tannin 0-10 weight portions, humate 0-10 weight portions, and alpa-olefin sulfonate 0.2-2.5 weight portions. The sludge curing agent has low cost, small consumption, high cumulate strength and high cumulate water tolerance, and may be applied widely.

Owner:BEIJING ZHONGYONGJI FIRMING AGENT TECH DEV

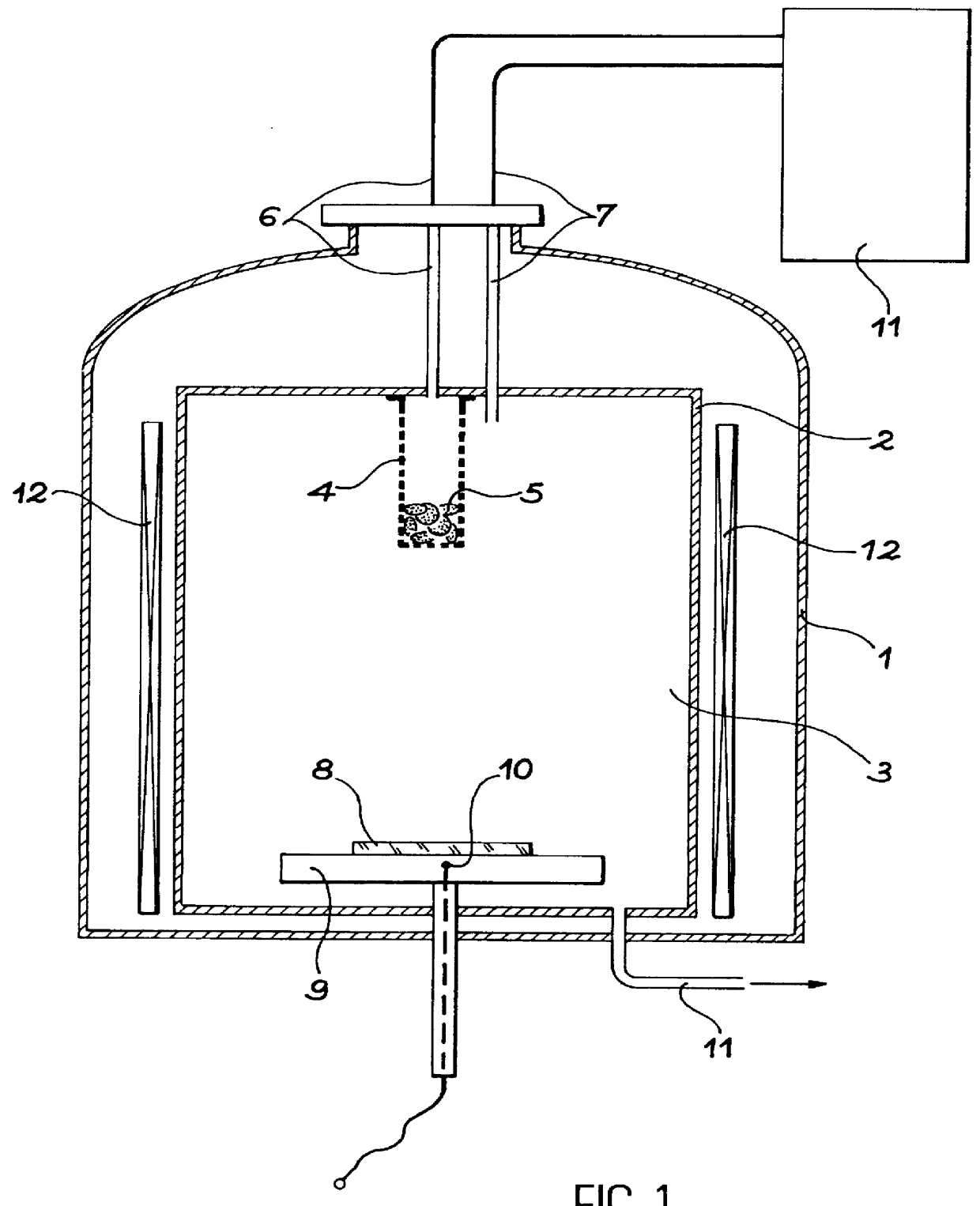

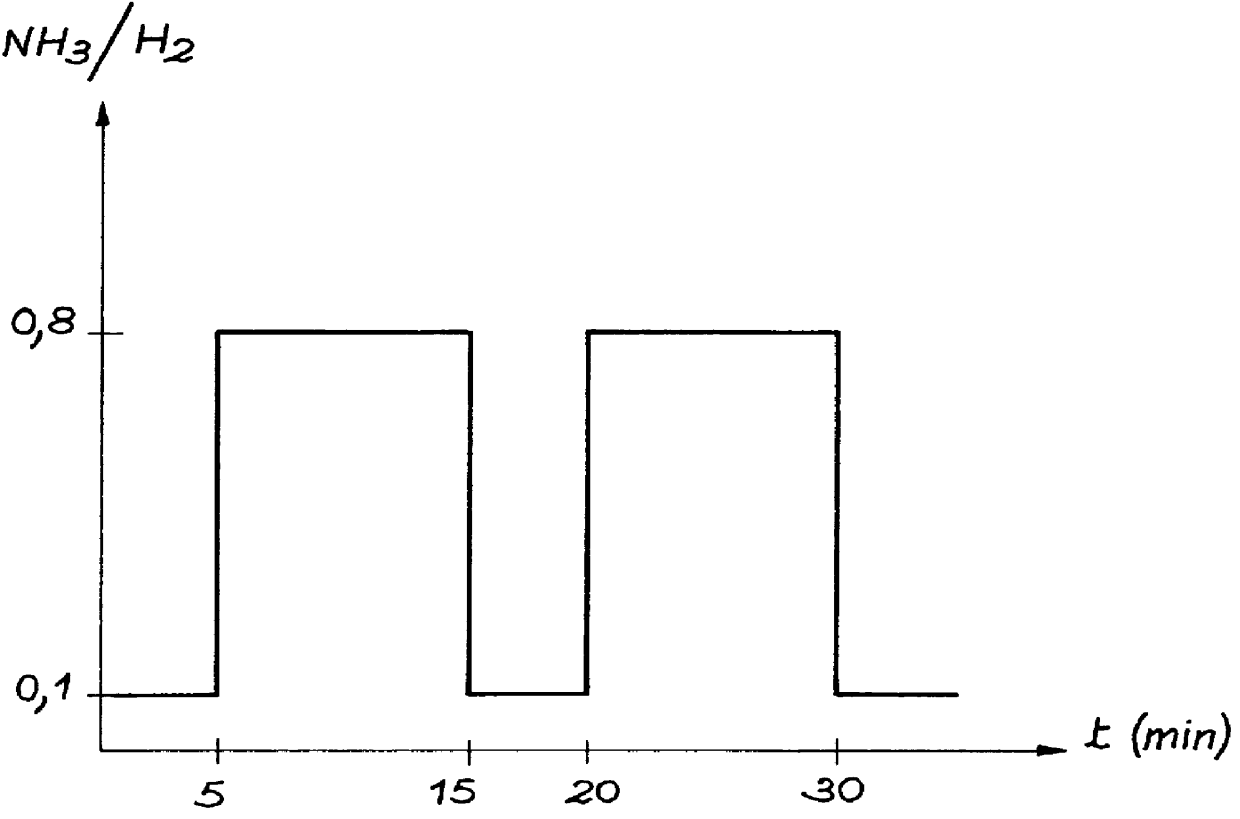

Process for the preparation by chemical vapor deposition (CVD) of a Ti-A1-N based multilayer coating

InactiveUS6040012AConsiderable flexibilityEasy to implementChemical vapor deposition coatingAluminium chlorideWear resistant

The invention relates to a process for the preparation of a multilayer coating, comprising a stack, on a substrate, of several layers chosen from among layers constituting by TiN and layers constituted by (Ti,Al)N, also known as Ti1-xAlxN, the entire coating being produced in a single, continuous operation by thermal chemical vapour deposition (CVD) from a gaseous mixture comprising a reducing gas, such as ammonia or nitrogen, hydrogen and titanium and optionally aluminium chlorides, the nature and / or composition of each deposited layer being instantaneously adjusted by modifying the reducing gas to hydrogen molar ratio in the gaseous mixture. The invention also relates to multilayer coatings comprising (Ti,Al)N layers of variable compositions and in particular with composition gradient. Application to wear-resistant or abrasion-proof coatings having a resistance to oxidation and corrosion, particularly at high temperatures.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

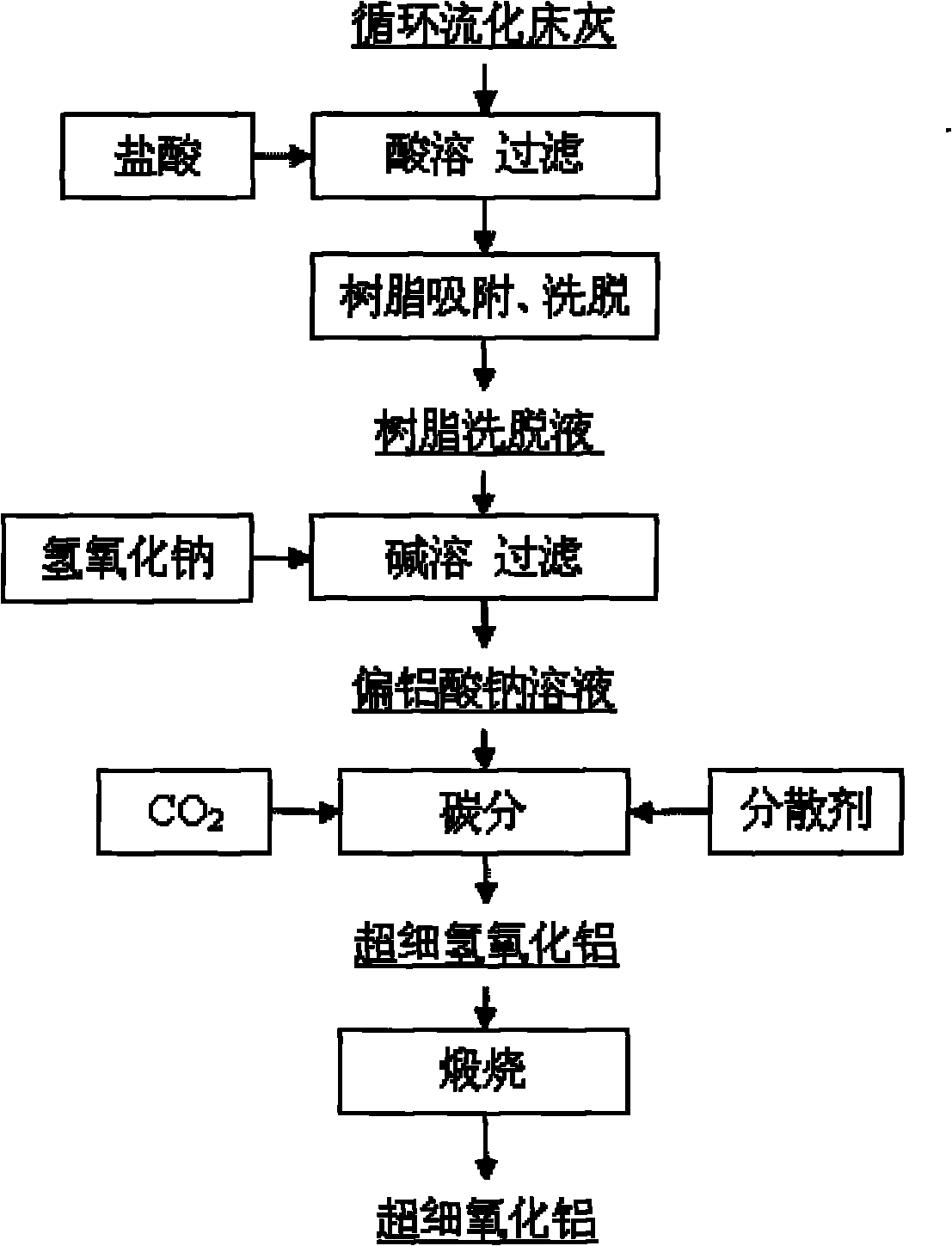

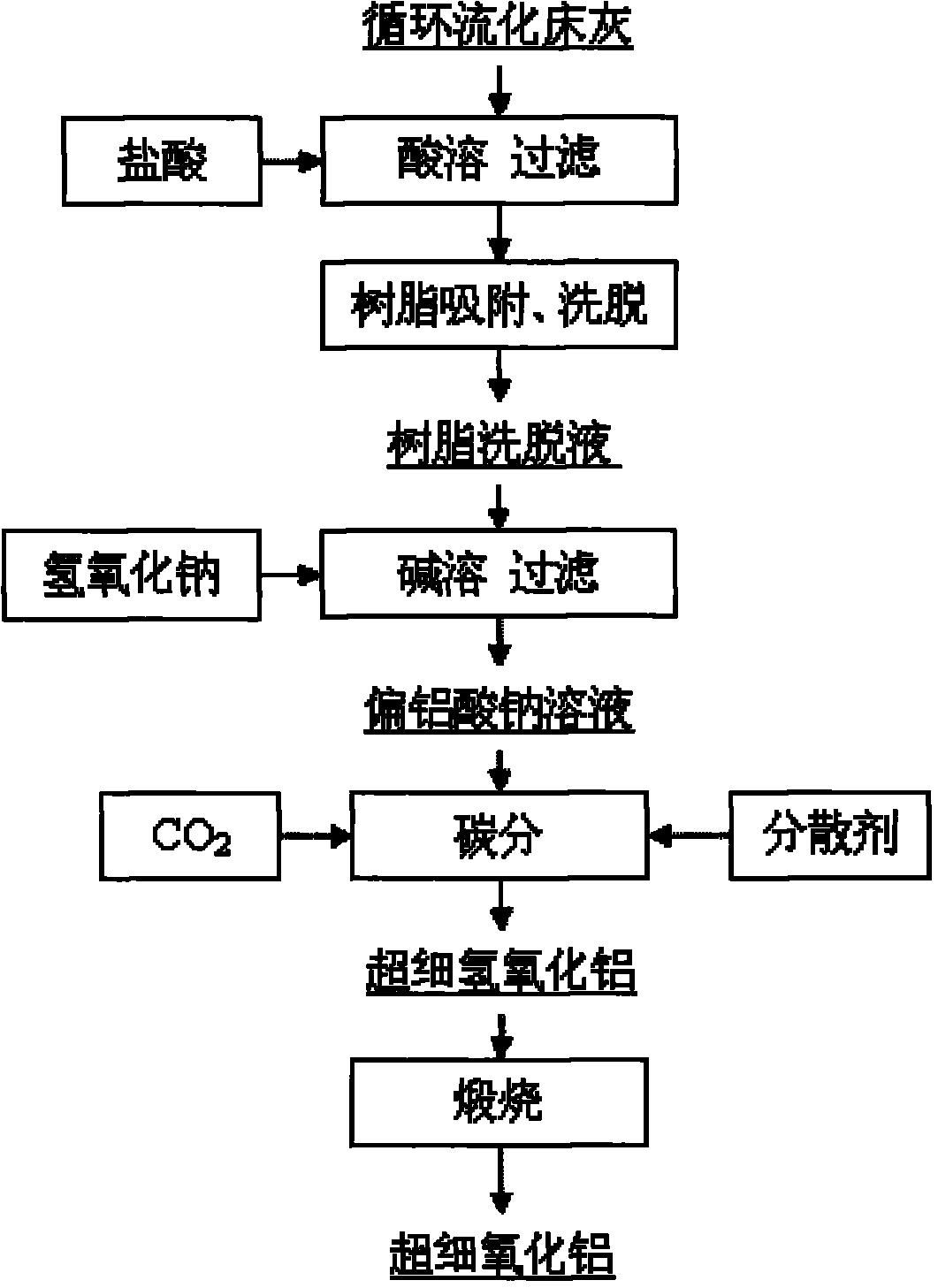

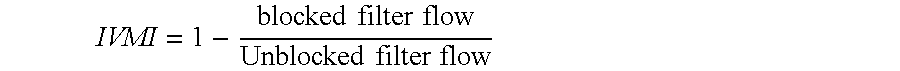

Method for producing superfine aluminium hydroxide and aluminium oxide by using flyash

InactiveCN101870489AHigh purityEliminate high temperature calcination activation stepsProductsReagentsAluminium chlorideDecomposition

The invention discloses a method for producing superfine aluminium hydroxide and aluminium oxide by taking flyash of a recirculating fluidized bed as a raw material. The method comprises the following steps of: a) grinding the flyash, performing wet magnetic separation and deironization, and reacting with hydrochloric acid to obtain hydrochloric acid extract; b) introducing the hydrochloric acid extract into a macroporous cationic resin column for adsorption, after adsorptive saturation of the resin, eluting by using an eluant to obtain eluent containing aluminium chloride and iron chloride; c) removing iron from the eluent by using alkaline solution to obtain solution of sodium metaaluminate; d) adding a dispersing agent into the solution of sodium metaaluminate, and mixing uniformly to obtain dispersion; and e) performing carbon decomposition on the dispersion to obtain the superfine aluminium hydroxide. The superfine aluminium hydroxide is calcined at different temperatures to form gamma-aluminium oxide and alpha-aluminium oxide respectively. Compared with other methods, the method has the advantages of wide sources of raw materials, simple production process and high purity of the products.

Owner:CHINA SHENHUA ENERGY CO LTD +1

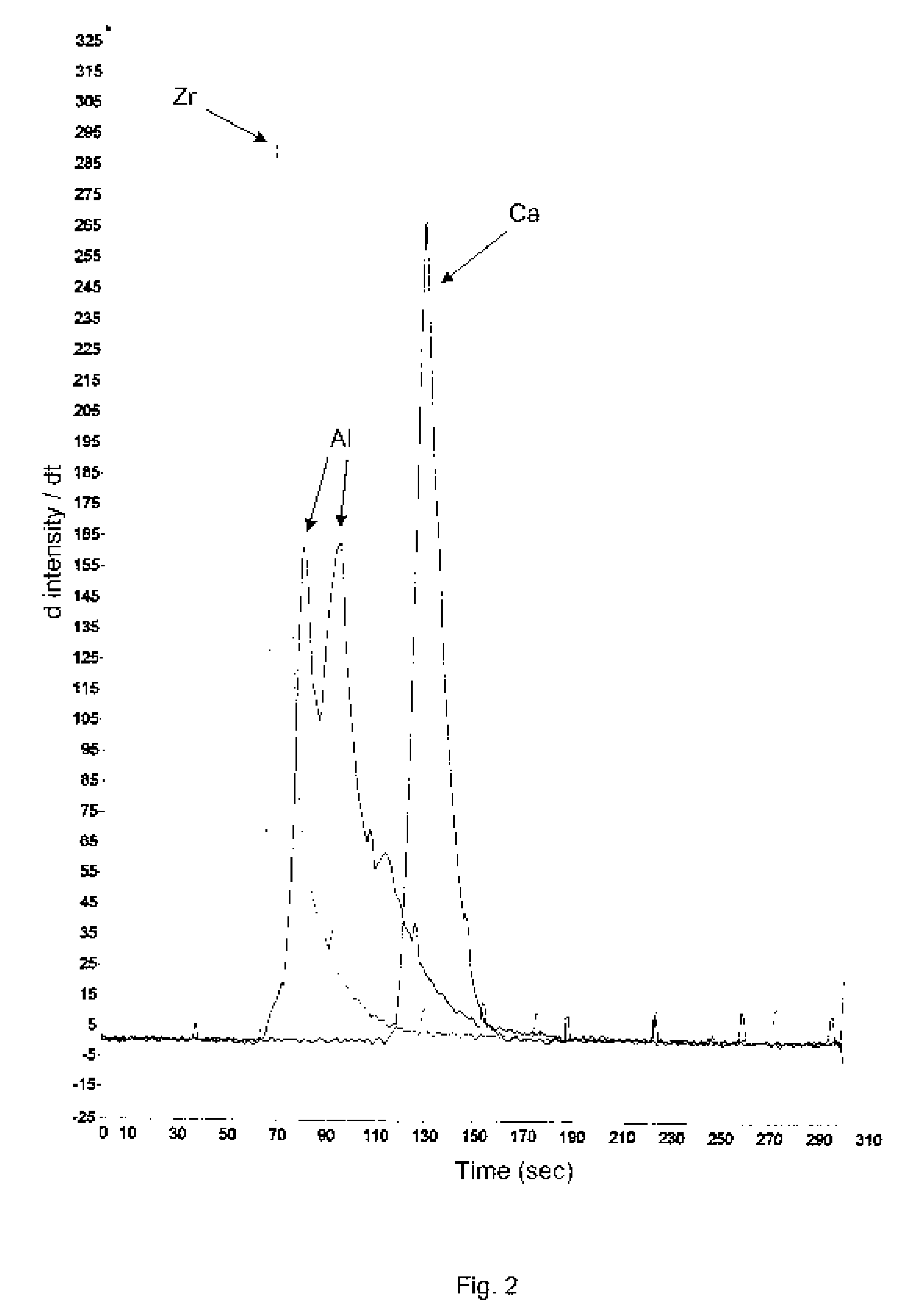

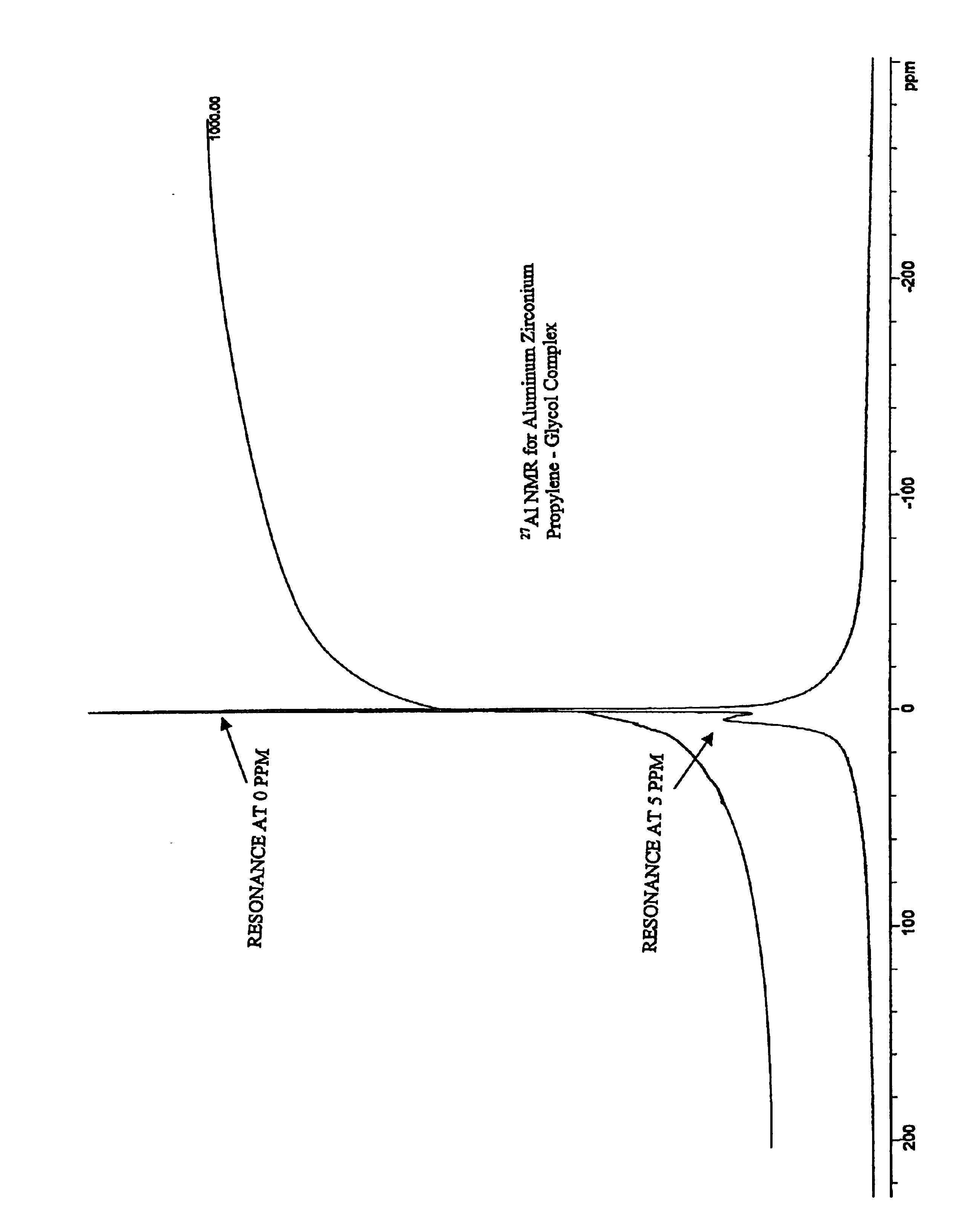

Amino acid free stable aluminum/zirconium antiperspirant solution

InactiveUS6960338B2Improve efficacyHigh proportionCosmetic preparationsToilet preparationsAluminium chloridePolyol

An amino acid free stable aluminum zirconium polyhydric alcohol aqueous solution having a high anhydrous antiperspirant solid concentration and a high percentage of low molecular weight aluminum species, i.e., containing 60% or more of band IV peak area based on high pressure liquid chromatography, is prepared by adding a zirconium salt to an aqueous polyhydric alcohol solution of a basic aluminum chloride.

Owner:GENERAL CHEM CORP +1

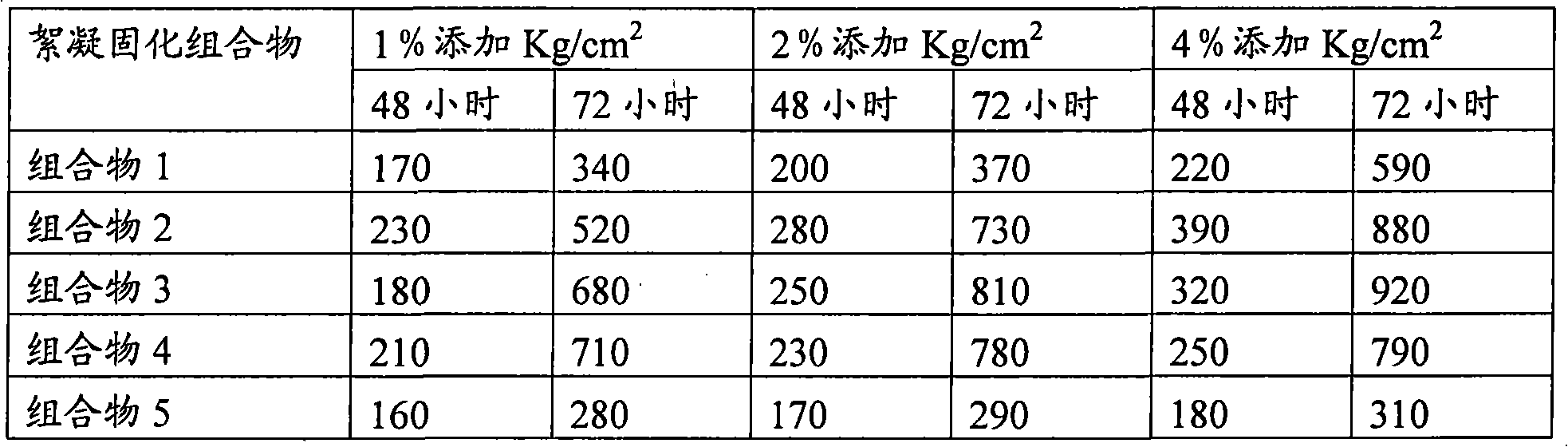

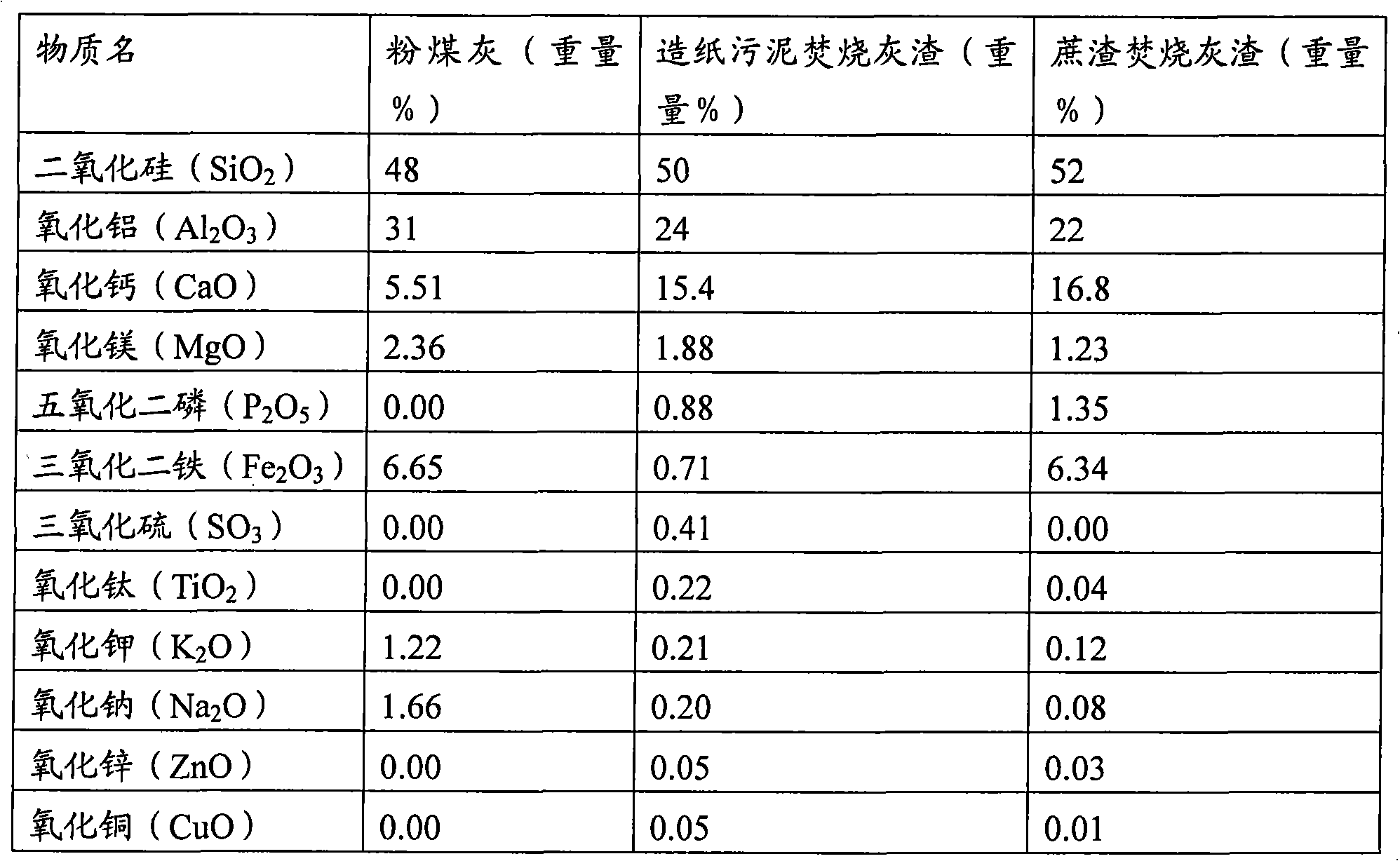

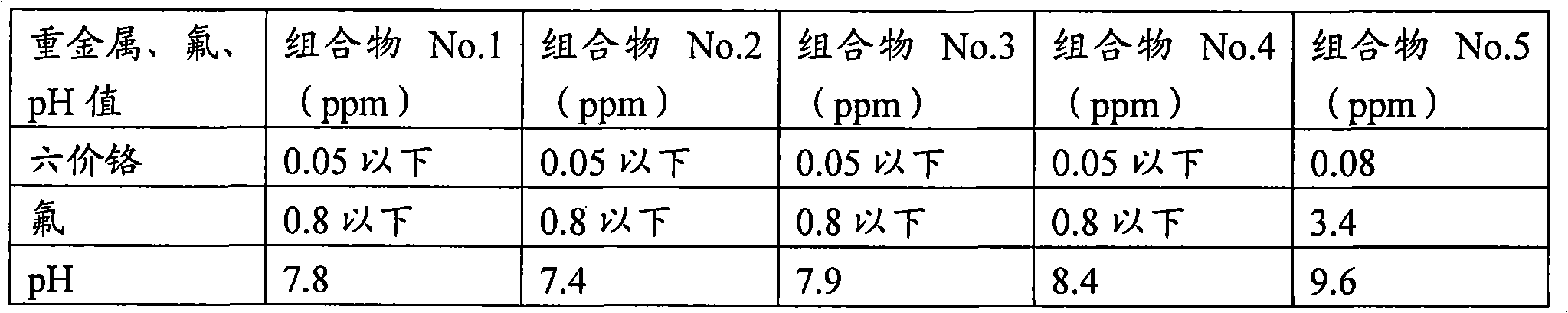

Flocculation curing agent, composition thereof and stabilization improvement method of silt type soil

Owner:株式会社安农津技研 +3

Process for making durable rutile titanium dioxide pigment by vapor phase deposition of surface treatments

The present invention relates to a process for making durable titanium dioxide pigment by vapor phase deposition of surface treatments on the titanium dioxide particle surface by reacting titanium tetrachloride vapor, an oxygen containing gas and aluminum chloride in a plug flow reactor to form a product stream containing titanium dioxide particles; and introducing silicon tetrachloride into the reactor at a point down stream of the point where the titanium tetrachloride and oxygen were contacted and where at least 97% of the titanium tetrachloride has been converted to titanium dioxide or where the reaction temperature is no greater than about 1200° C., and preferably not more than about 1100° C.

Owner:THE CHEMOURS CO FC LLC

Polyaluminum calcium hydroxychlorides and methods of making the same

InactiveUS20080131354A1Improve efficiencyReduce sludge generationCosmetic preparationsChloride preparationAluminum hydrateHigh pressure

A process is provided for the preparation of a novel polyaluminum calcium hydroxychloride composition of enhanced efficiency for water treatment, paper sizing, and antiperspirant applications. The polyaluminum calcium hydroxychloride compositions are prepared via the acidification of higher basicity reaction products to form mid-to-high basicity final products. Two methods are provided for the preparation of higher basicity products, contemplated in the first, and an aqueous acid solution, such as hydrochloric acid, aluminum chloride, or a mixture thereof, is mixed with a strong alkaline calcium salt such as calcium oxide or calcium carbonate and aluminum powder at temperatures greater than 60° C. In a second method, bauxite, aluminum hydrate, or aluminum metal, and calcium aluminate are mixed with hydrochloric acid and are reacted at high temperatures and / or elevated pressures for a certain period of time whereby, when the reaction is complete, the mixtures are filtered to obtain clear solutions. The final PAC-Ca solutions may be dried to powder to have a wide range of basicities from about 40% to about 80%. At lower basicities, the polyaluminum calcium hydroxychloride sales are used preferably as antiperspirants, while at higher basicities, the solutions are used preferably as water treatment chemicals.

Owner:GENERAL CHEM LLC

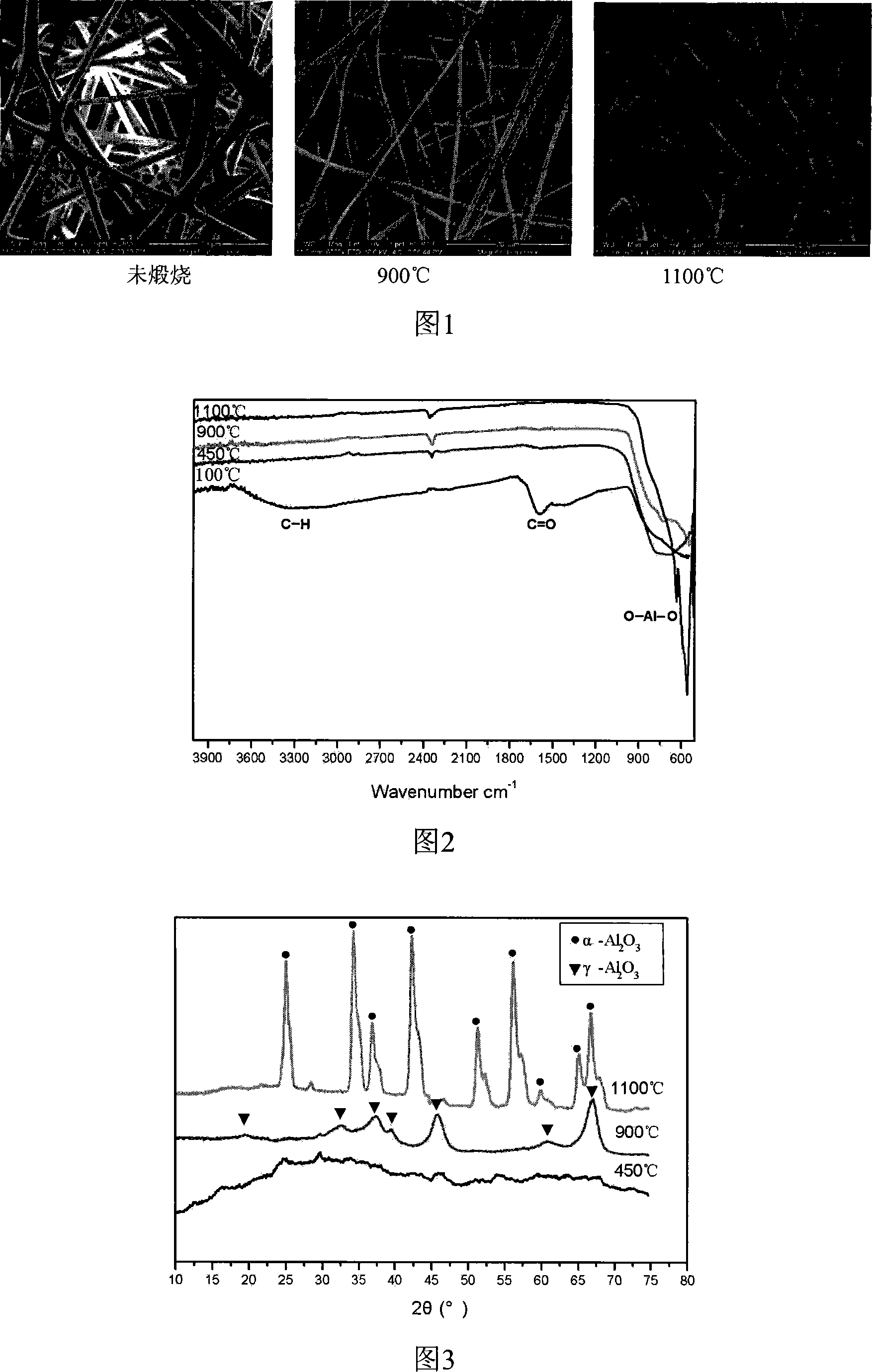

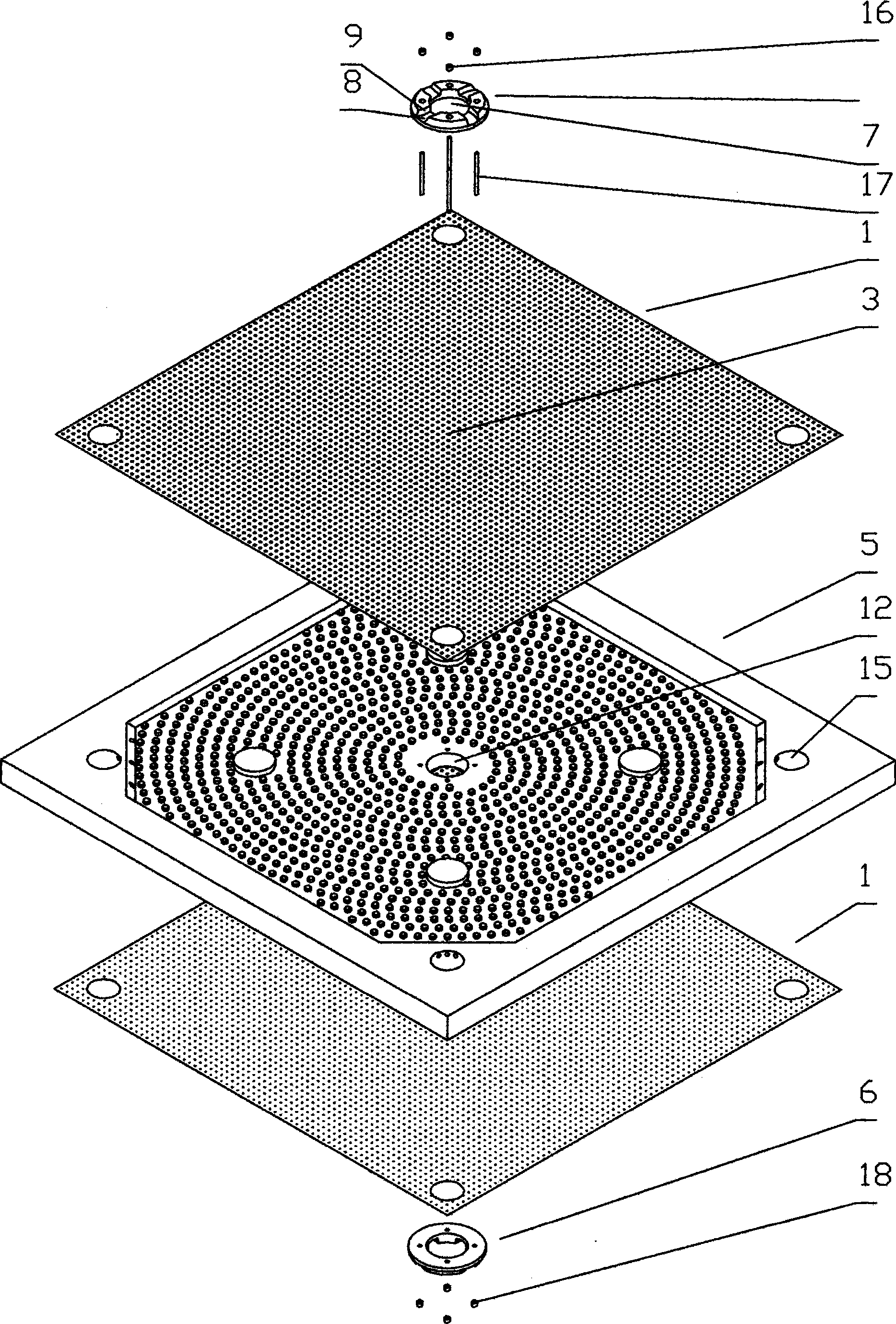

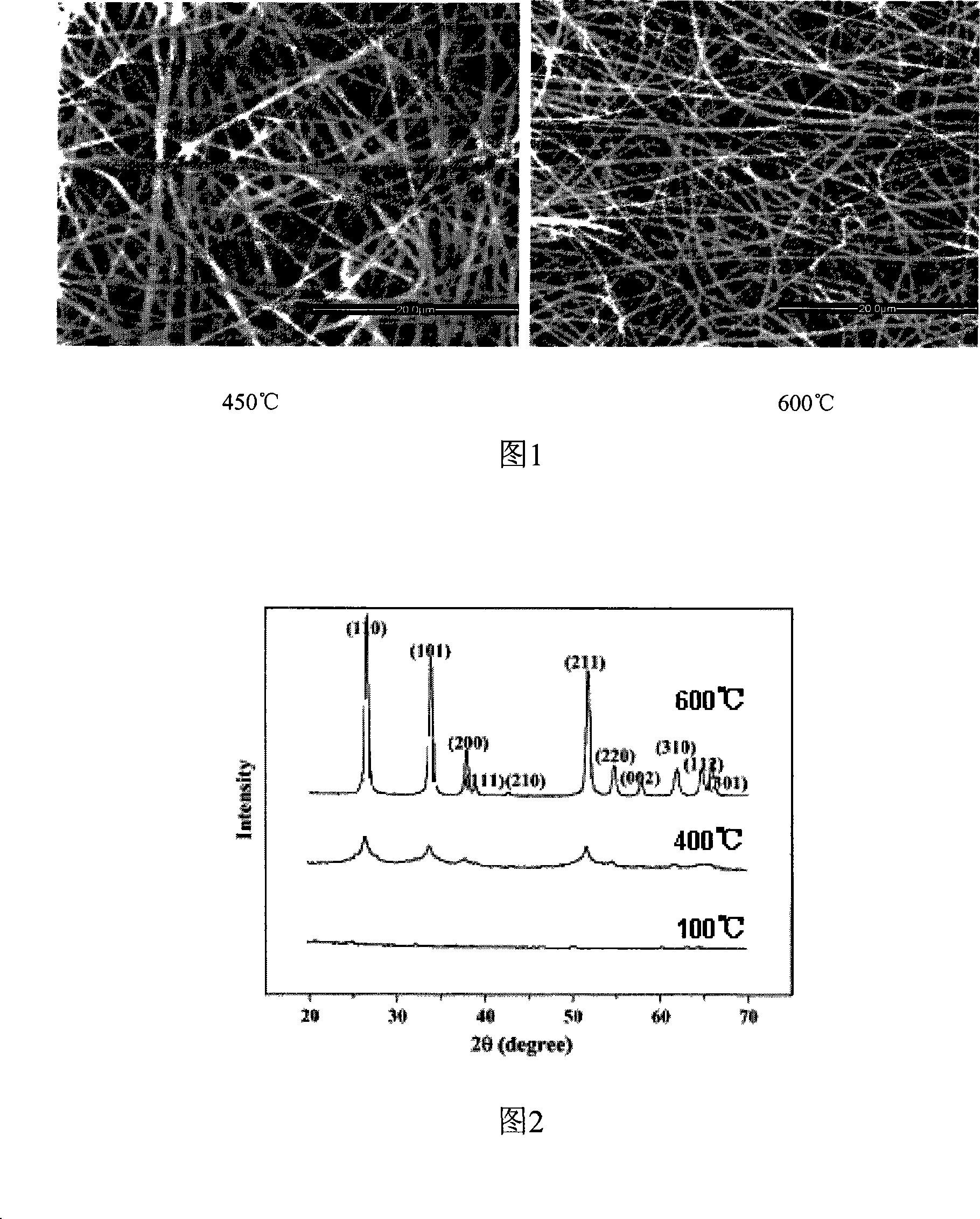

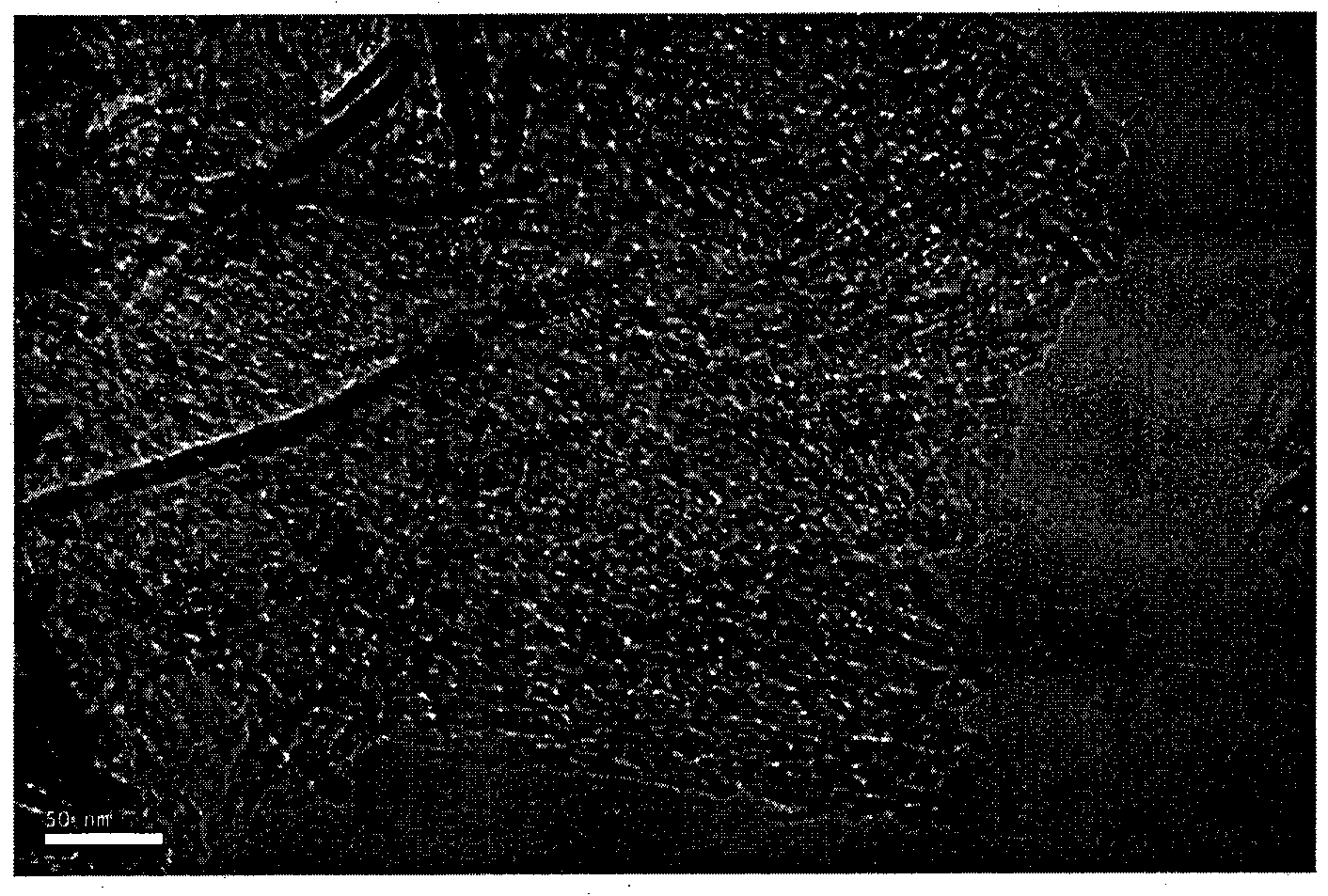

Method for preparing nano alumina fiber film material

The invention relates to a technology of preparing nano alumina fiber membrane material by electrostatic spinning, comprising: 1. the configuration of sol gel electrostatic spinning liquid. Pouring polyvinyl pyrrolidone into ethanol solvent and stirring thereof with high speed until completely dissolved; getting the polyvinyl pyrrolidone ethanol solution with the concentration of 5-8wt%, then, mixing the solution with the aluminum chloride solution with the concentration of 10-30wt%, wherein, the weight ratio between the polyvinyl pyrrolidone and the aluminum chloride is 3:1-1:1, stirring for one hour. 2. Electrostatic spinning. The prepared sol gel spinning liquid is injected into the electrostatic spinning device and electrostaticly spinning thereof is injected into aluminum chloride / polyvinyl pyrrolidone nano fiber membrane under the voltage of 25-35kv, the extrusion speed of 1-10ml / min and the reception distance of 10-20cm. 3. calcining. At last putting the prepared aluminum chloride / polyvinyl pyrrolidone nano fiber membrane into a muffle furnace and raising the temperature to 450-1100 DEG C with the speed of 50 DEG C / h, calcining for five hours and getting amorphous, Gamma type or Alpha type aluminum oxide fiber membrane. The nano aluminum oxide fiber membrane made by the invention is a catalyst and the carrier material of the catalyst and high temperature resistance filtration material with high specific surface area, good thermal stability and excellent mechanical properties. Furthermore, the material can be widely applied in fields such as the insulating materials and reinforced composites of space shuttle and high temperature boiler.

Owner:TIANJIN POLYTECHNIC UNIV

Titania-alumina mixed oxide hydrodesulfurization catalyst and preparing process thereof

ActiveCN101199935AGuaranteed qualityAssurance controlMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsAluminium chlorideHydrodesulfurization

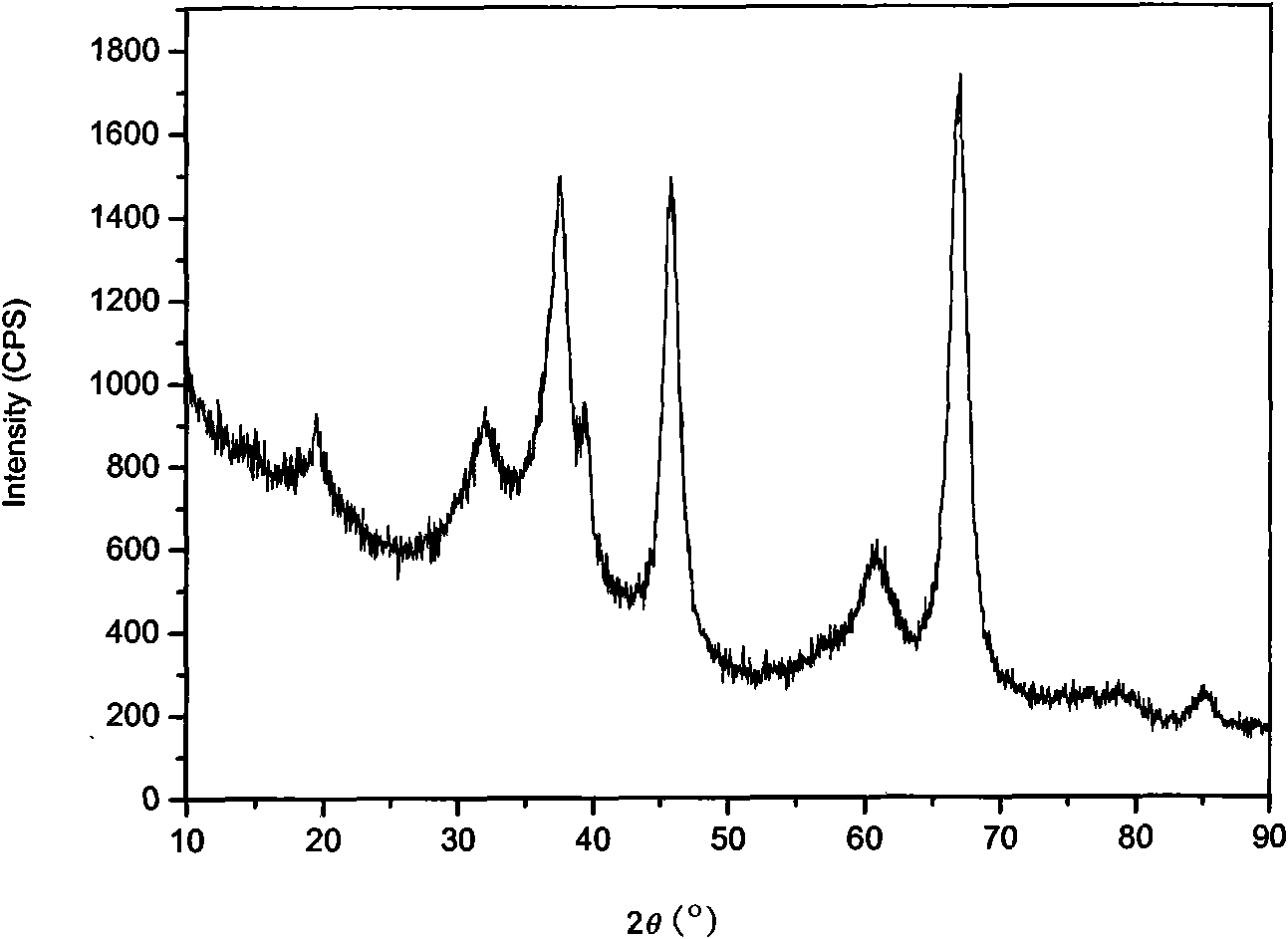

The utility model relates to a synthesis of a titania-alumina mixed oxide material and a catalyst carrier of a supported deep hydrodesulfurization catalyst by taking the compound as the carrier. 1)take the tetrabutyl titanate and the aluminum chloride or the pseudo-boehmite as the raw material, prepare the mesoporous mixed oxide material of TiO2-Al2O3 with the sol-gel method, and use the material as the carrier of the diesel oil deep hydrodesulfurization catalyst; 2)use the dipping method by modifying the active metal variety and the dipping method to get highly dispersed supported mesoporous hydrodesulfurization catalyst of TiO2-Al2O3 compound material after baking; in the diesel oil hydrogenation deep desulfurization reaction, the desulfurization capability is good, and the desulfurization rate can reach 99 percent; if the reaction can be operated under a relative relaxative condition, the sulfur in the diesel oil can be desorbed from 1300ppm to below 15 ppm, or from the 430ppm to below 1ppm; the sulfur content in the product can meet the standard of Europe IV.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Flocculating agent for sludge dewatering and sludge dewatering method

InactiveCN101367597AImprove rigidityImprove toughnessSludge treatment by de-watering/drying/thickeningAluminium chlorohydrateSewage

is the invention discloses a flocculating agent for filthy mud dehydration, which is composed of polyaluminium chloride and polyacrylamide. The flocculating agent addition is 4.92 percent to 10.18 percent by weight of the solid content of the filthy mud; and the polyaluminium is 4.38 percent to 5.33 percent by weight of the flocculating agent. The flocculating agent has the advantages of low specific impedance value of the filthy mud and high solid content of filter mass after dehydration. The method of filthy mud dehydration and the method of flocculating agent adding are as follows: polyaluminium chloride is added first, then is fast stirred at the speed of 32.0 r / m for two minutes and slowly stirred at the speed of 10.0 r / m for three minutes, and the pH value of sewage mud is regulated to 6 to 8; and the polyacrylamide is added, is fast stirred at the speed of 32.0 r / m for three minutes and then is slowly stirred at the speed of 10.0 r / m for seven minutes. The methods have the advantages that the flocculating agent can fully contact solid grains to facilitate the flocculating agent to trap colloid grains, so that the concentration distribution of the flocculating agent is uniform; large grains can not be stirred into small grains, precipitated grains can not be stirred into non-precipitated grains, so that the flocculation effect is improved.

Owner:广州中滔绿由环保科技有限公司

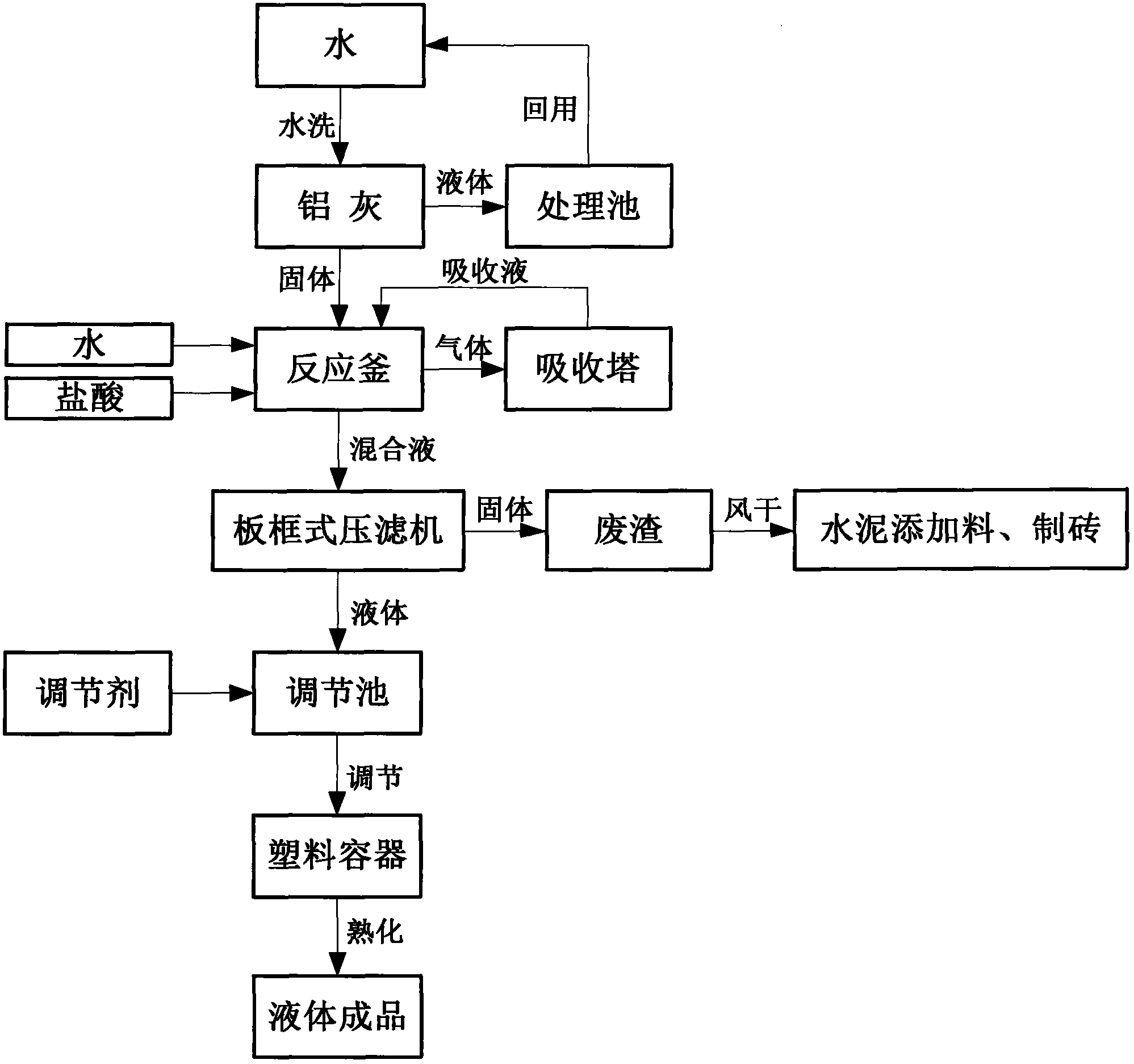

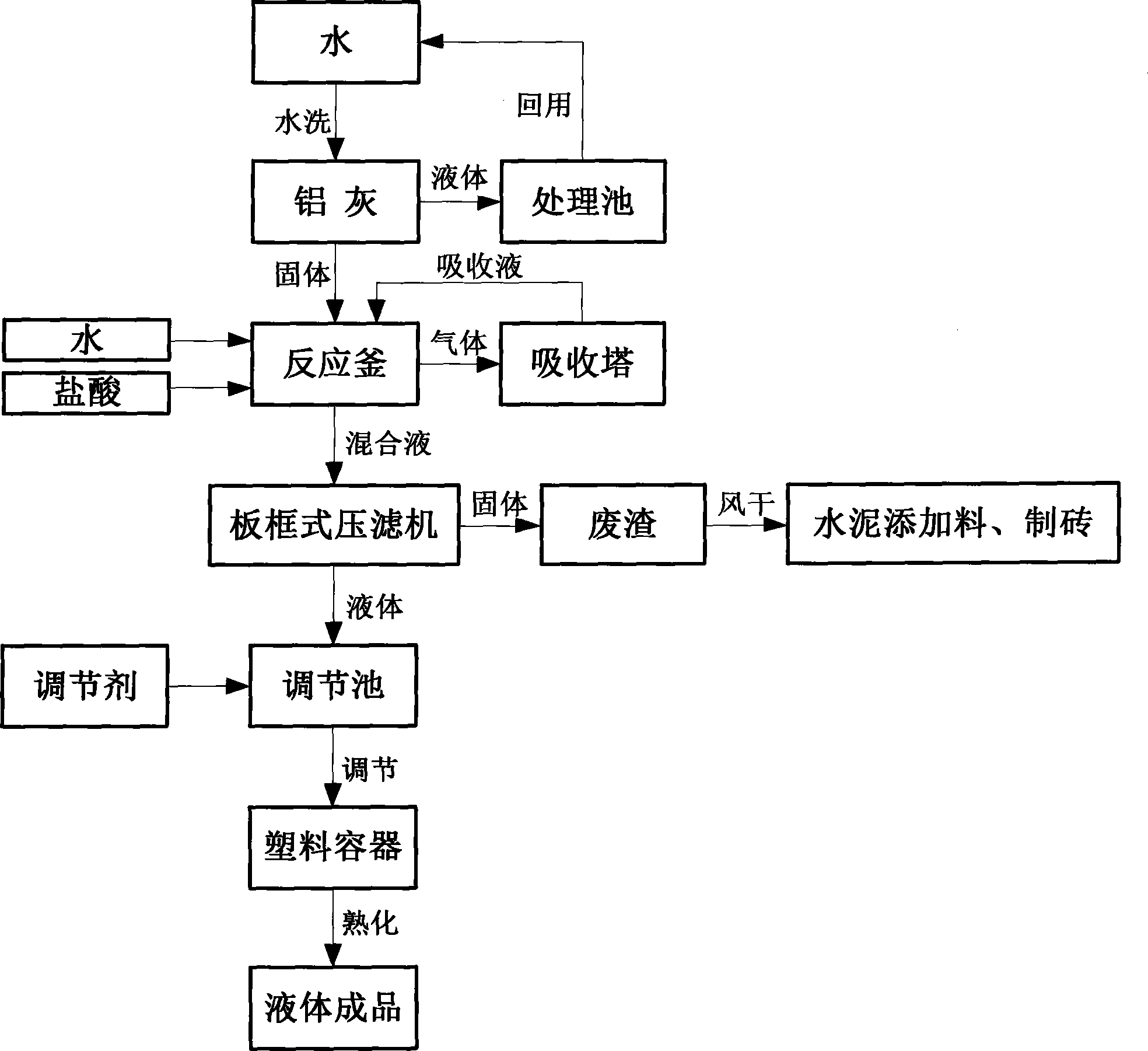

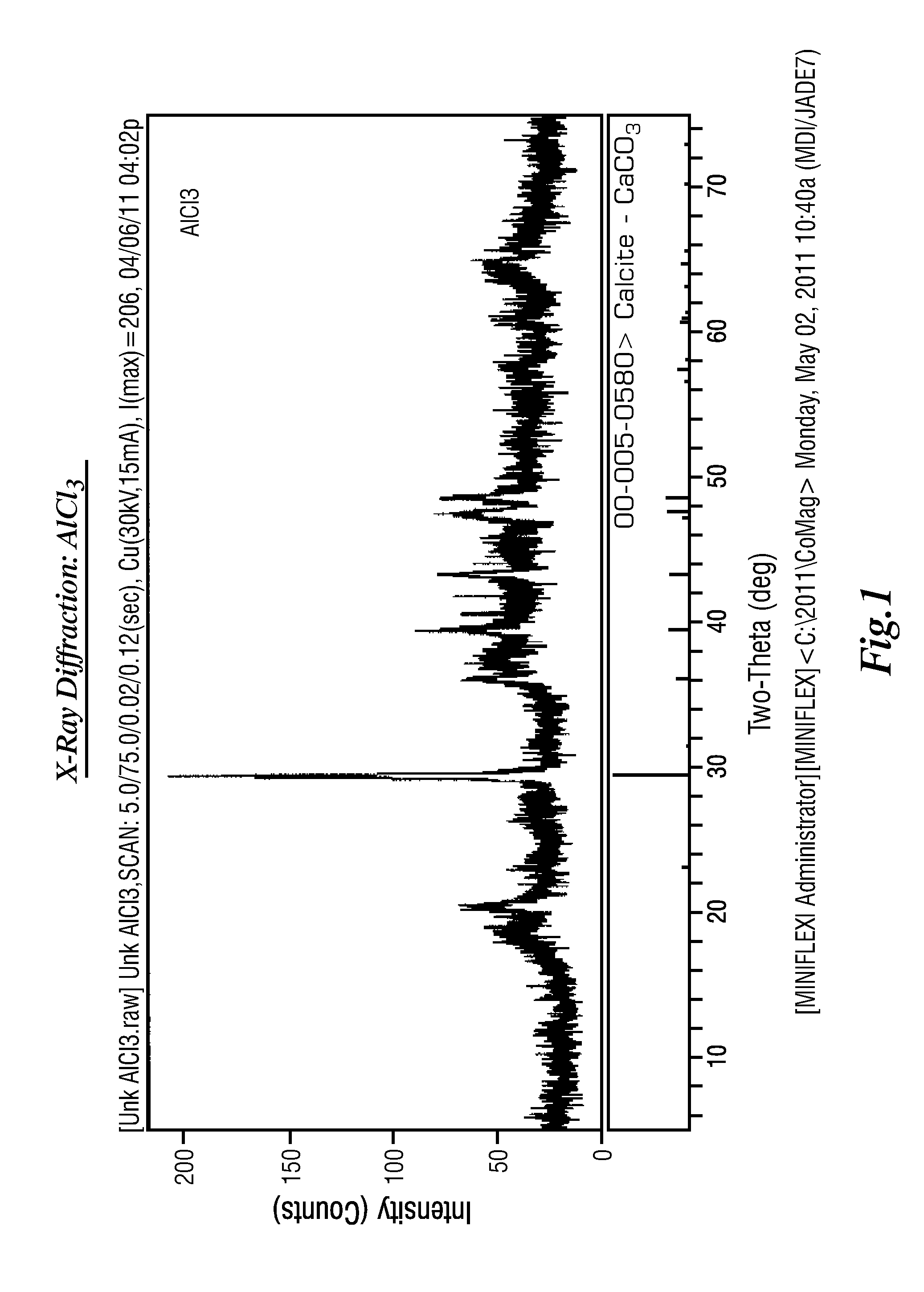

Method for preparing flocculant liquid polyaluminum chloride from aluminum ash

InactiveCN102674422ANo secondary pollutionAvoid secondary pollutionAluminium chloridesWater/sewage treatment by flocculation/precipitationAluminium chlorideAluminate

The invention discloses a method for preparing flocculant liquid polyaluminum chloride from aluminum ash, belonging to the technical field of solid waste treatment environment protection. The method comprises the following steps: uniformly mixing and stirring aluminum ash and water in a volume ratio of 1:(3-5), and soaking for 5-8 hours; pumping the solution into a reaction kettle, adding hydrochloric acid and water in an aluminum ash / hydrochloric acid / water volume ratio of 1:(2.5-3.0):(3.0-4.0), and reacting at 85-100 DEG C for 2-3 hours; carrying out solid-liquid separation with a plate and frame type filter-press, and adding a regulator to regulate the aluminum oxide content and basicity of the liquid, wherein if quicklime is used as the regulator, the volume ratio of the liquid to the quicklime is 1:(0.054-0.086), if aluminum dust is used as the regulator, the volume ratio of the liquid to the aluminum dust is 1:(0.023-0.04), and if solid calcium aluminate is used as the regulator, the volume ratio of the liquid to the solid calcium aluminate is 1:(0.042-0.063); and standing and aging for 48-72 while controlling the temperature at 50-60 DEG C, thereby obtaining the liquid polyaluminum chloride finished product. The invention has the advantages of simple technique, low cost and no secondary pollution, and is a good method for recycling aluminum ash.

Owner:李松 +2

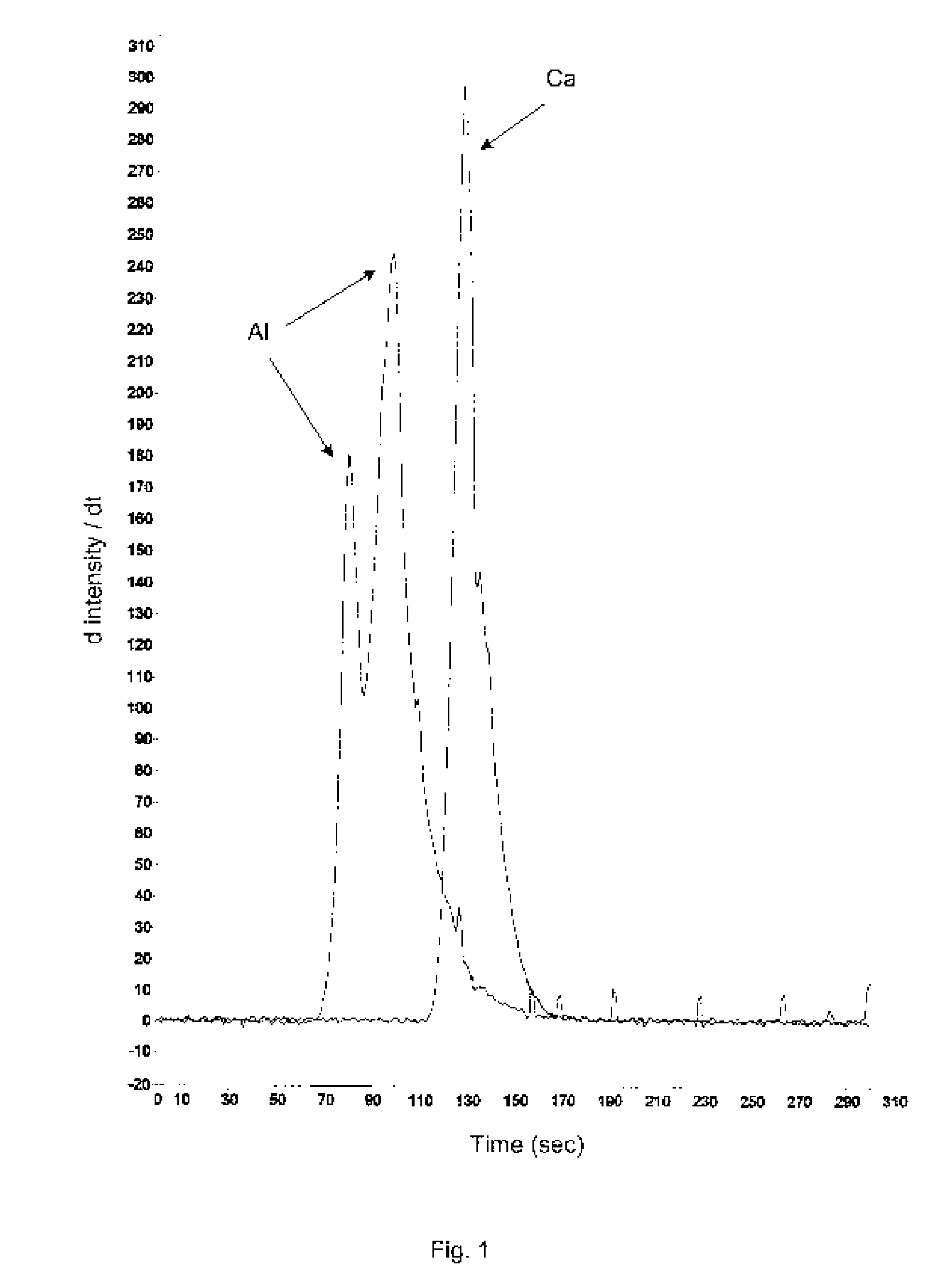

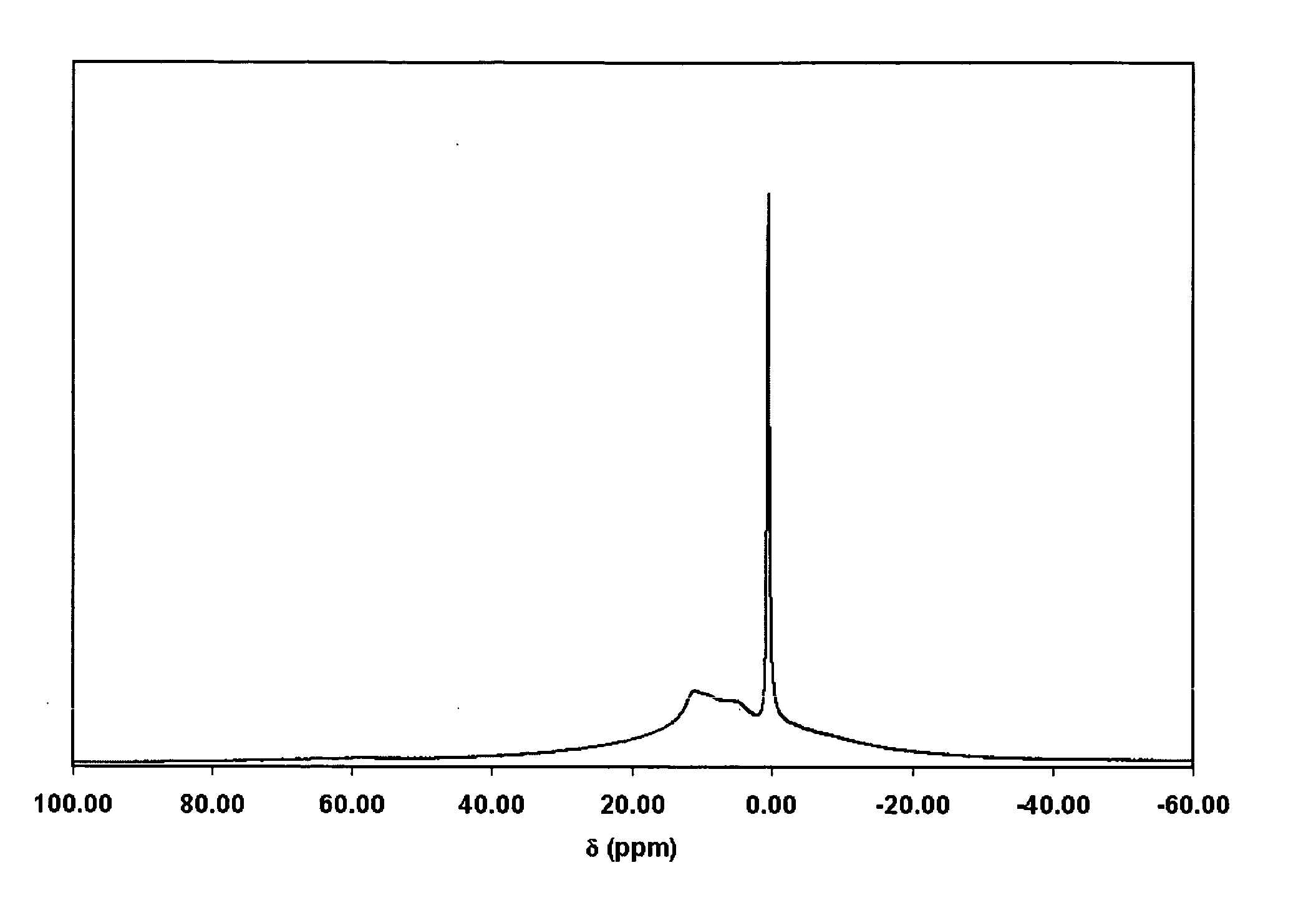

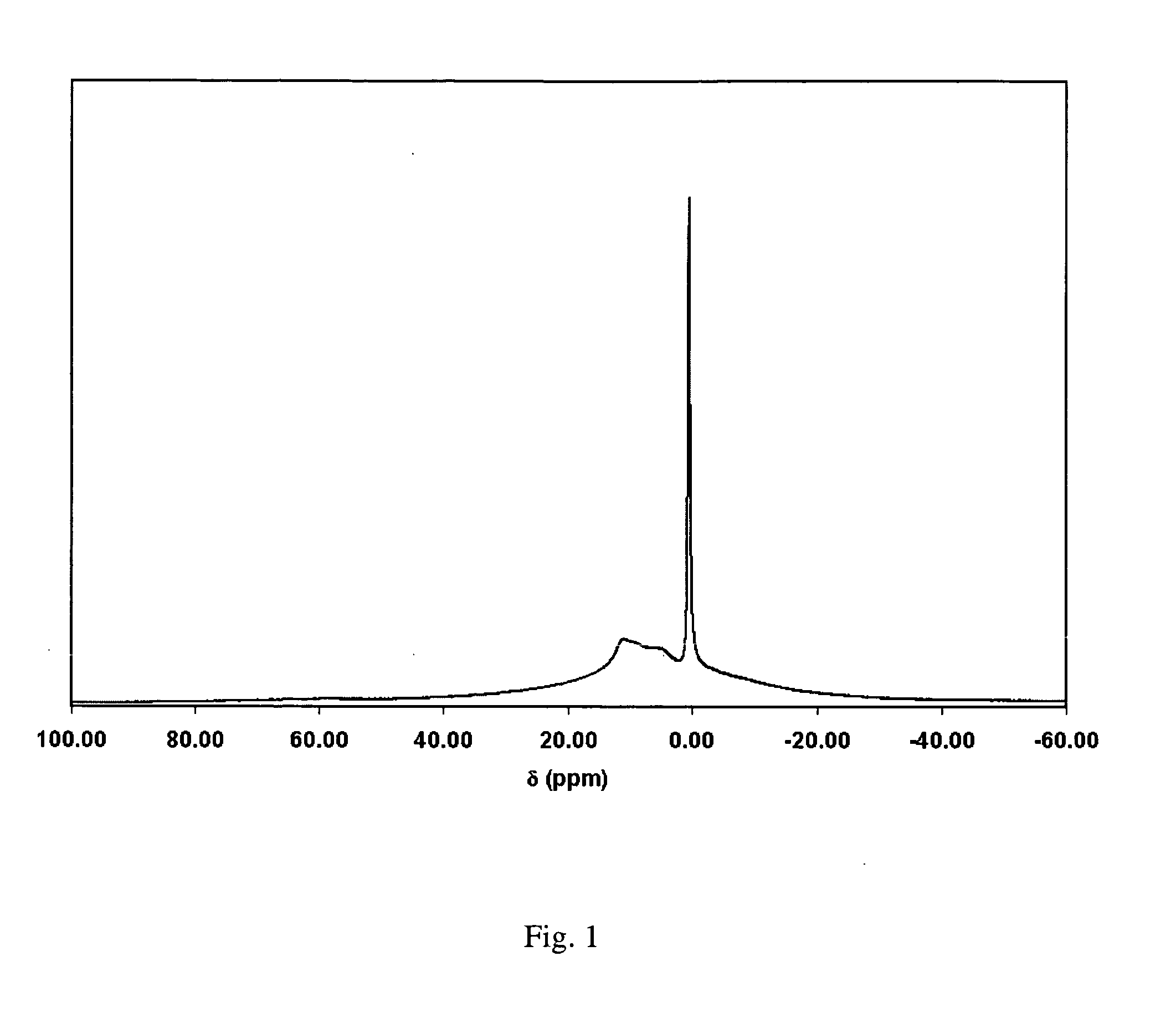

Enhanced efficacy basic aluminum halides, antiperspirant active compositions and methods for making

InactiveUS6902724B1Good curative effectImprove skinCosmetic preparationsToilet preparationsAluminium chloridePharmacology

Disclosed are basic aluminum halides having enhanced antiperspirant efficacy; methods of making such materials and antiperspirant compositions containing such basic aluminum halides, and optionally an amino acid, salts of amino acids, antimicrobial agents, or an organic solvent having at least two carbon atoms and at least one hydroxy group and mixture thereof and methods of making such mixtures. Basic aluminum halides having enhanced antiperspirant efficacy are produced by reacting (a) aluminum powder; (b) an aluminum halide; and (c) water at a temperature greater than about 85° C. This reaction is maintained until reaction products having an Al:halide ratio of about 1.2:1 to 1.5:1 and preferably 1.3 to 1.4:1; and a solution solids concentration of about 30-40 weight percent on an anhydrous basis are obtained. The products are characterized as having a Size Exclusion Chromatography (HPLC) Test Band I of less than 5%, preferably less than 1%, Band II percent aluminum value of 20-60% preferably about 35 to 55%, Band III percent aluminum value of 10 to 35% preferably 15-30% and Band IV value of 15 to 50% and preferably 25 to 35% and sum of peak 3 and 4 areas of at least 45% and no more than 70% and preferably 65%. The enhanced efficacy basic aluminum chloride salts of this invention are more economical to produce, show enhanced efficacy and are more stable compared to the conventional enhanced efficacy aluminum salts which show rapid degradation of Band III to Band II peak areas ratio are less irritant and more skin friendly.

Owner:SUMMIT RES LAB

Method for preparing super-fine aluminum hydroxide and alumina from fly ash

ActiveCN102153117AHigh purityEliminate high temperature calcination activation stepsProductsReagentsAluminium chlorideAluminate

The invention discloses a method for preparing super-fine aluminum hydroxide and super-fine alumina by using fly ash of a circulating fluidized bed as a raw material. The method comprises the following steps of: 1, after grinding the fly ash, carrying out wet magnetic separation on the ground fly ash to remove iron and then performing a reaction of the obtained product and hydrochloric acid to obtain immersion liquid of hydrochloric acid; 2, adsorbing the immersion liquid of hydrochloric acid by filling a macroreticular cation resin column and after a resin is adsorbed and saturated, the resin is eluted by eluent to obtain the eluent containing aluminium chloride and ferric chloride; 3, carrying out alkali dissolution iron removal on the eluent to obtain sodium meta-aluminate solution; 4, adding a dispersant into the sodium meta-aluminate solution and uniformly mixing the mixture to obtain dispersion liquid; and 5, carrying out carbon dioxide decomposition on the dispersion liquid to obtain the super-fine aluminum hydroxide. Gamma-alumina and alpha-alumina can be respectively obtained by calcining the super-fine aluminum hydroxide at different temperatures. Compared with other methods, the method has the advantages of wide raw material sources, simple production process and high product purity.

Owner:CHINA SHENHUA ENERGY CO LTD

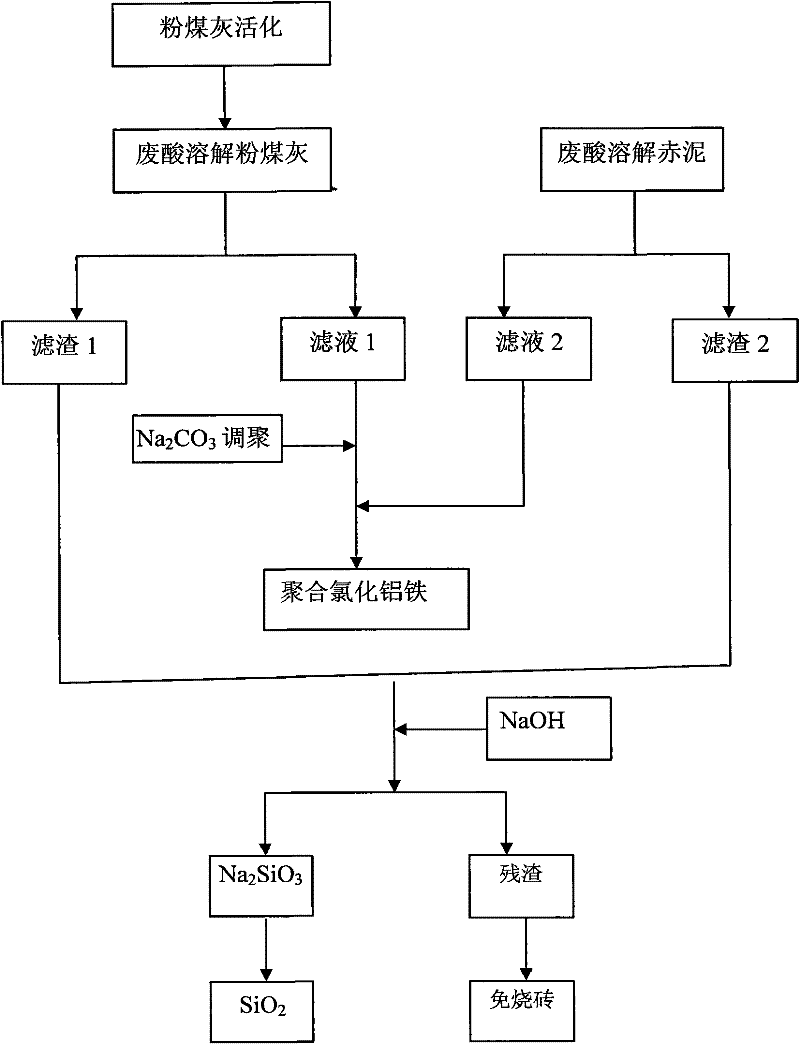

New method for resource comprehensive utilization of red mud and fly ash

InactiveCN102344171AAchieve recyclingAchieve near-zero emissionsSilicaSolid waste disposalAluminium chlorideRed mud

The invention discloses a new method for resource comprehensive utilization of red mud and fly ash, and relates to a comprehensive utilization of industrial waste, specifically to a preparation method for a flocculating agent of aluminum ferric chloride and white carbon black. The method comprises the following steps: (1) acid leaching: the red mud and the activated fly ash are adopted as raw materials, and react with HCl, wherein the leaching temperature is 70-90 DEG C, a solid-liquid ratio is 10:1-10:3, the HCl concentration is 3-6 mol.L<-1>, the leaching time is 4-10 hours; (2) polymerization: Na2CO3 is added to a dissolution solution 1 to carry out telomerization, a dissolution solution 2 is added to the dissolution solution 1 until the dissolution solution 1 is stable, then the polymerization reaction is performed to obtain the polyaluminum ferric chloride, wherein the temperature is 60-70 DEG C, the pH value is 2.5-3.0, the aging time is 12-24 hours; (3) white carbon black preparing: a NaOH solution is adopted to carry out alkali dissolution to dissolve the filter residue, then treatments of acidification and calcination are performed to obtain the powder SiO2, wherein the alkali dissolution temperature is 80-100 DEG C, the time is 4-8 hours.

Owner:孙建之

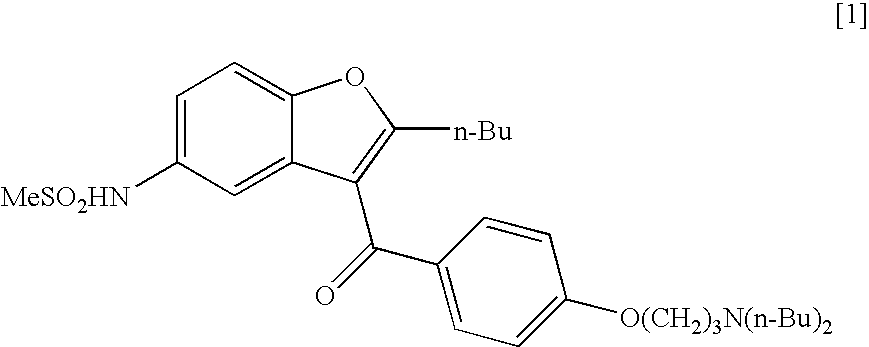

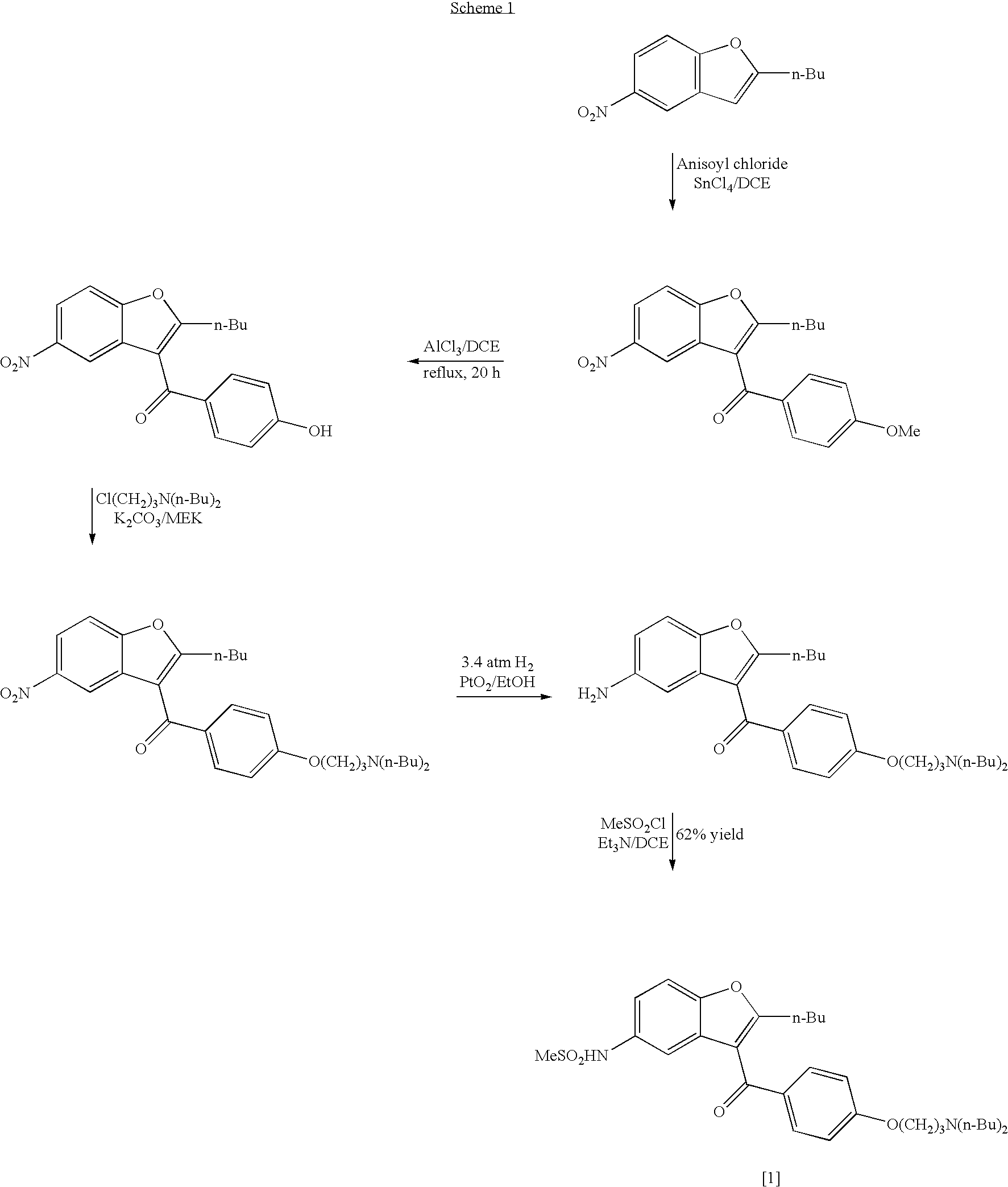

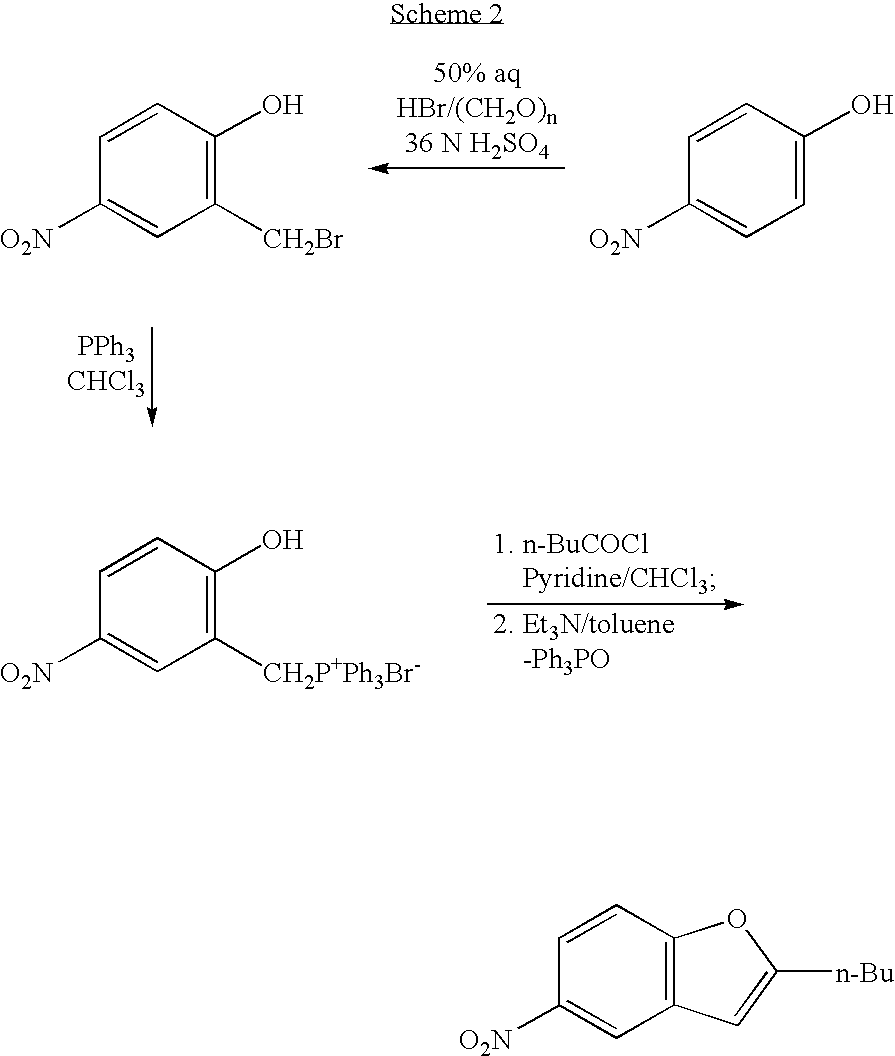

Process for the preparation of dronedarone

InactiveUS20050049302A1High yieldLow costBiocideCarbamic acid derivatives preparationAluminium chlorideDronedarone

The present invention provides, according to an aspect thereof, a novel process for the preparation of dronedarone [1] and pharmaceutically acceptable salts thereof. According to a preferred embodiment, the process comprises N-acetylating of p-anisidine or p-phenetidine with acetic anhydride, reacting of the obtained N-(4-alkoxyphenyl)acetamide with 2-bromohexanoyl chloride or bromide in the presence of aluminum chloride or bromide to obtain N-[3-(2-bromohexanoyl)-4-hydroxyphenyl]acetamide [6a], converting the compound [6a] into 2-butyl-5-benzofuranamine hydrochloride [12a] and subsequently converting [12a] into [1] or pharmaceutically acceptable salts thereof. In accordance with another aspect of this invention, there are provided novel intermediates, inter alia the novel compounds [6a] and [12a]. The novel intermediates of the present invention are stable, solid compounds, obtainable in high yields, which can be easily purified by crystallization and stored for long periods of time.

Owner:ISP INVESTMENTS LLC

Technique for preparing aluminium sol

InactiveCN1445167AReduce manufacturing costGood adhesionAluminium chloridesAluminium oxides/hydroxidesAluminium chlorideAluminium hydroxide

A process for preparing aluminium sol includes such steps as proportionally mixing alumina and / or aluminium hydroxide and / or another aluminium source with sulfuric acid, reaction at 80-150 deg.C for 2-18 hr while stirring, adding water, aqueous solution of hydrochloric acid, or the aqueous solution containing aluminium chloride, adding aluminium, and reaction at 80-150 deg.c and 1-5 atmos for 3-40 hr. Its advantages are low cost, and ihgh viscosity.

Owner:LINZIZHENGHUA ACCESSORY INGREDIENT ZIBO

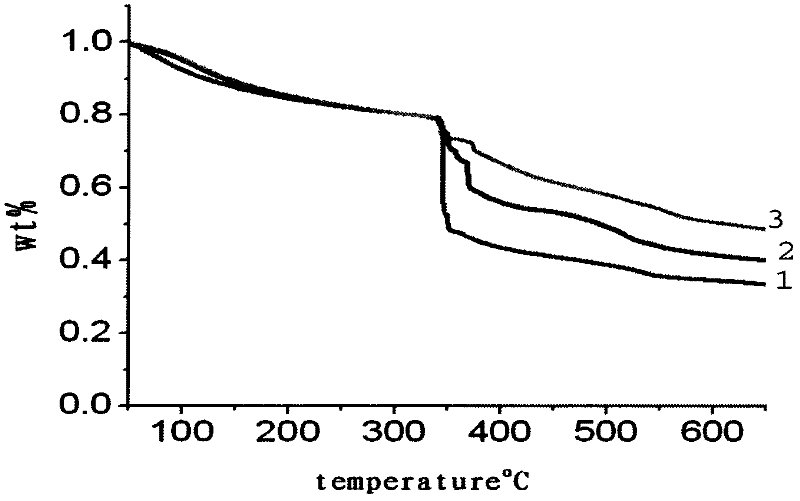

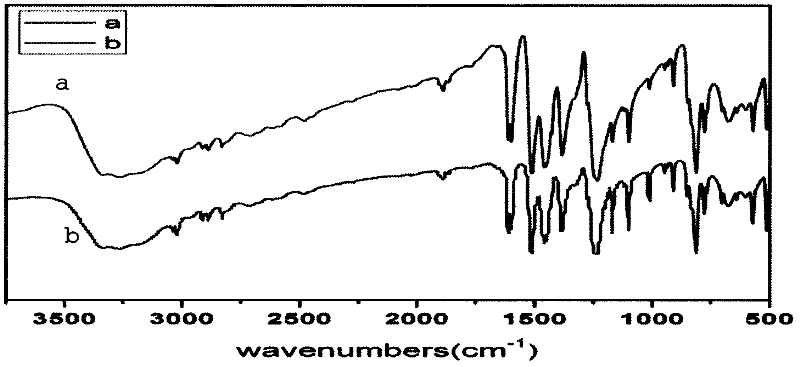

Preparation method of nanometer tin oxide fibre air-sensitive film

The present invention relates to a preparation technique for preparing nanometer tin anhydride fiber gas sensor film material by using an electrostatic spinning method. The present invention comprises: 1, collosol gel static filature liquid allocation: polyethylene ketopyrrolidine is poured into dissolvent containing N, N-dimethyfomamide (DMF); the dissolvent is mixed at high speed to be completely dissolved; the polyethylene ketopyrrolidine / DMF dissolvent with the concentration of 5 wt percent to 8 wt percent is produced; and then, the dissolvent is mixed with qua-water stannic chloride water solution with the concentration of 10 wt percent to 40 wt percent; wherein, the weight ratio of the polyethylene ketopyrrolidine and the stannic chloride is between 3 to 1 and 3 to 4; the product is made after being mixed for 3 hours. 2. electrostatic spinning: The prepared collosol gel static filature liquid is injected into a electrostatic spinning device and transformed into aluminum chloride / polyethylene ketopyrrolidine nanometer fibrous coat on the conditions that the voltage is between 25 Kv and 35 Kv; the extrusion speed is between 1 ml / min and 10 ml / min and the receive distance is between 10 cm and 20 cm through the electrostatic spinning. 3. calcination: finally, the prepared aluminum chloride / polyethylene ketopyrrolidine nanometer fibrous coat is placed in a muffle furnace; the temperature is raised to 450 DEG C to 600 DEG C at the speed of 50 DEG C per hour; nanometer tin anhydride fibrous coat is gained after being calcined for 5 hours. The nanometer tin anhydride fibrous coat produced by the present invention is gas sensing material with high specific area and high sensitivity; in addition, the material can be widely applied to the field of catalyst, laser target material and so on.

Owner:TIANJIN POLYTECHNIC UNIV

Preparation method for bisphenol F

ActiveCN102491879AEasy to separate and recycleThe synthesis process is simpleOrganic chemistryOrganic compound preparationAluminium chlorideSynthesis methods

The invention discloses a synthesis method for bisphenol F, in which aluminium chloride, titanium tetrachloride and modified cation exchange resin are adopted as catalysts, and phenyl hydroxide and formaldehyde are adopted as raw materials. The invention has the technical effects as follows: the aluminium chloride, the titanium tetrachloride and the modified cation exchange resin are adopted for catalysis to synthesize the bisphenol F, and the resin catalyst is easy to separate and recover and can be used repeatedly; 2, a recrystallization and reduced pressure distillation combined separation technology is adopted for coproduction of high-purity bisphenol F and common bisphenol F products, the maximum yield of the bisphenol F reaches 90 percent, the content of 4, 4'-bisphenol F in a dimethyl benzene recrystallization product reaches 93.5 percent, reduced pressure distillation after-products are mainly other two isomers, and the separation of the 4, 4'-bisphenol F is realized effectively; 3, the requirement for the concentration of the formaldehyde raw material is not strict while the traditional one stage process require that the concentration of formaldehyde is above 40 percent; and 4, the synthesis technology is simple, the operation is convenient, and the realization of industrial production is easy.

Owner:湖南嘉盛德材料科技股份有限公司

Stabilized antiperspirant compositions containing soy products

InactiveUS20070009459A1Reducing and stopping perspirationDeodorizing skinCosmetic preparationsHair removalAluminium chlorohydrateSoy product

This invention relates to antiperspirant compositions comprising soy products, one ore more antiperspirant agents such as aluminium chlorohydrate and a stabilizing system, which additionally influence hair growth.

Owner:JOHNSON & JOHNSON CONSUMER FRANCE SAS

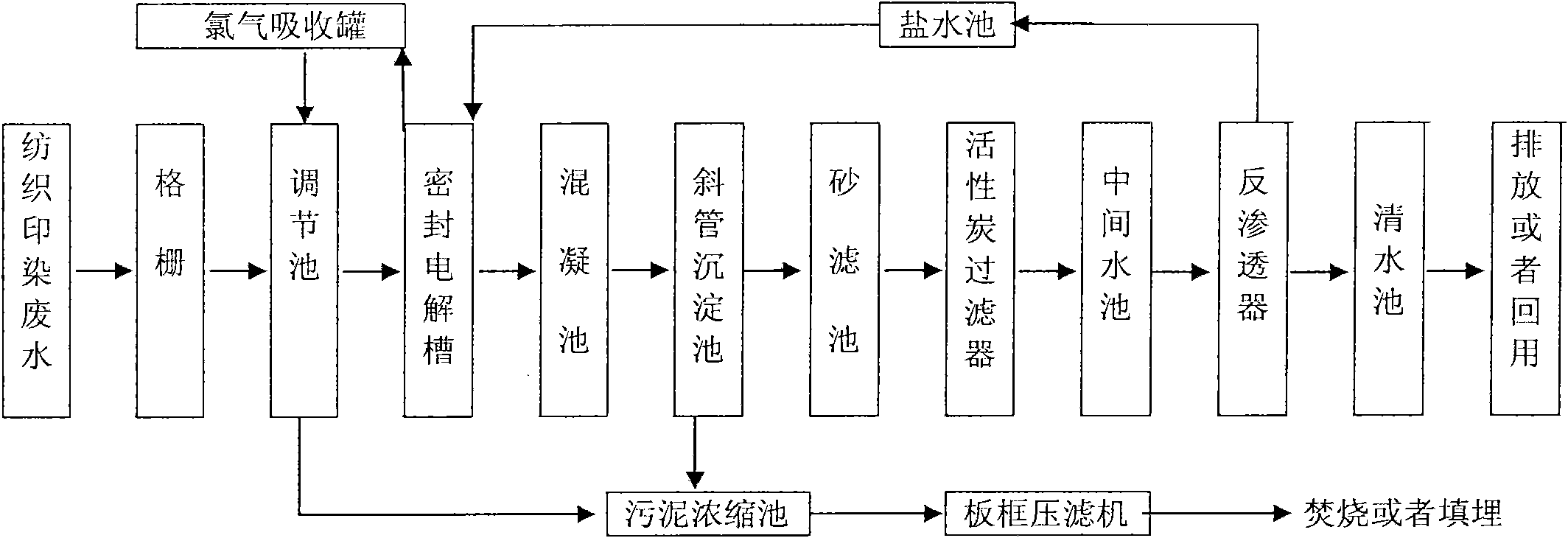

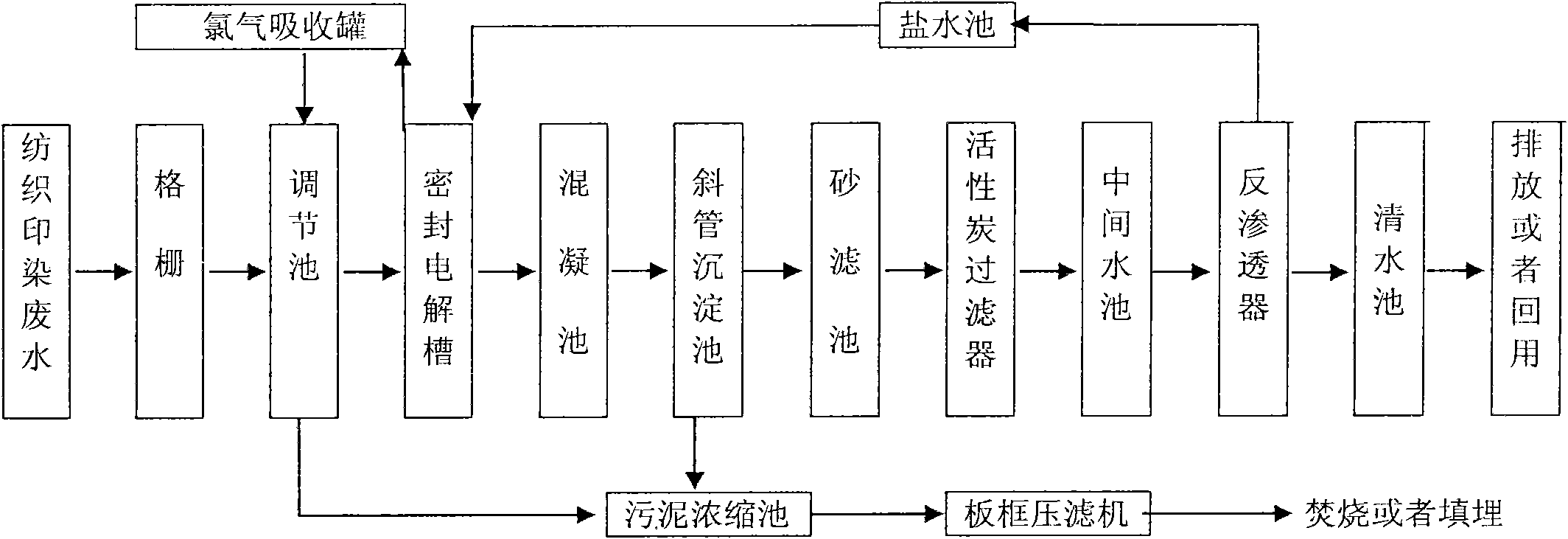

Spinning printing and dyeing waste water reclamation method, device and application thereof

InactiveCN101857328AEfficient removalReduce work stressWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentAluminium chlorideActivated carbon filtration

The invention discloses a spinning printing and dyeing waste water reclamation method, a device and the application thereof. The method comprises the steps of: filtering spinning printing and dyeing waste water; sequentially carrying out homogenizing, equalizing quantity and primary sedimentation on filtrate; adding sodium chloride into waste water supernate, and evenly mixing for indirect electro-catalysis oxidation; sequentially evenly mixing the waste water treated by indirect electro-catalysis oxidation with basic aluminium chloride and polyacrylamide; removing the precipitated supernate, and sequentially treating by activated carbon adsorption and reverse osmosis; removing trace organic chloride generated in the electrolytic process and the rest COD and color; and obtaining recyclable water resource. The device for realizing the method comprises a grate, a regulating reservoir, a sealed electrolytic cell, a flocculation tank, an inclined tube sedimentation tank, a sand filter tank, an active carbon filter, an intermediate water tank, a reverse osmosis unit, a clear water reservoir, a brine tank, a chlorine absorbing tank, a sludge concentration tank and a plate-and-frame filter press. The invention can effectively treat spinning printing and dyeing waste water, and has the advantages of high treatment efficiency, stable effluent quality, simple technological process and the like.

Owner:DONGGUAN HONGJIE ENVIRONMENTAL PROTECTION TECH +1

Active agent for laser welding and method for laser welding by utilizing same

InactiveCN102179645AStrong penetrating powerIncrease profitWelding/cutting media/materialsSoldering mediaAluminium chlorideLithium chloride

The invention discloses an active agent and a method for carrying out surface treatment on materials to be welded of aluminium and aluminium alloys so as to improve the energy utilization rate of the aluminium and the aluminium alloys, deepen the fusion depth of welding seams and further obtain higher welding quality. The active agent for laser welding consists of a chloride and a fluoride, wherein the mass ratio of the chloride to the fluoride is (1-2): (1-4); the chloride is at least one of lithium chloride, sodium chloride, potassium chloride, zinc chloride, magnesium chloride, aluminium chloride, calcium chloride or tin chloride; and the fluoride is at least one of lithium fluoride, sodium fluoride, magnesium fluoride or calcium fluoride. When the surface treatment is carried out, firstly the fluoride and the chloride are mixed fully and uniformly, water is added to form a supersaturated solution, then the supersaturated solution is coated on the surface of a welded test piece as a coating agent, then drying is carried out, and finally laser welding is carried out under the condition of gas protection.

Owner:TIANJIN UNIV

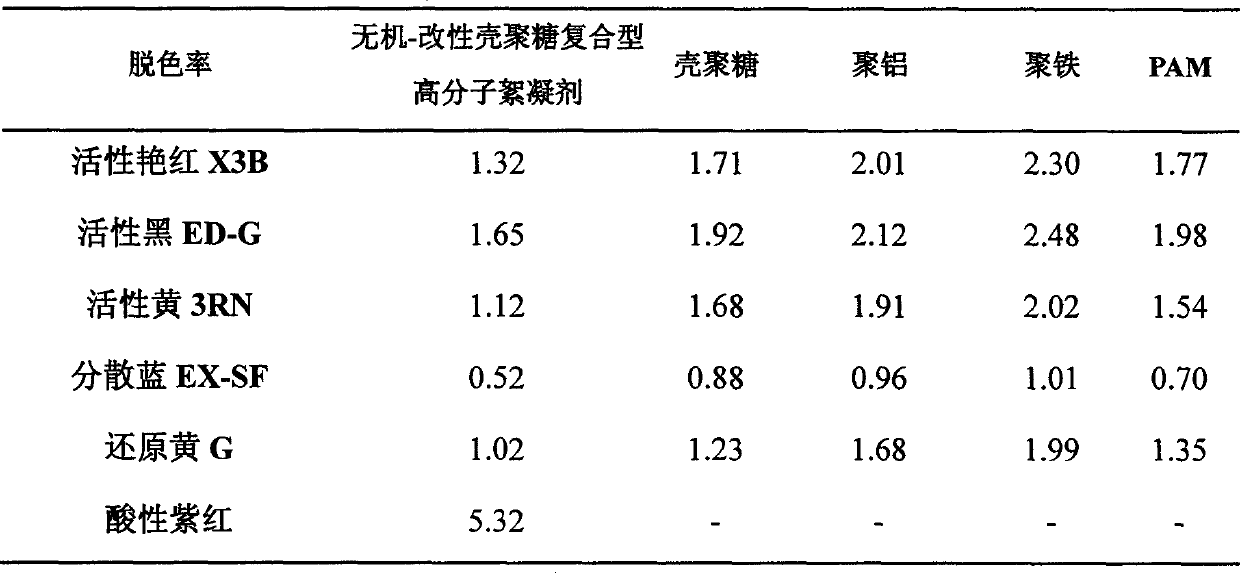

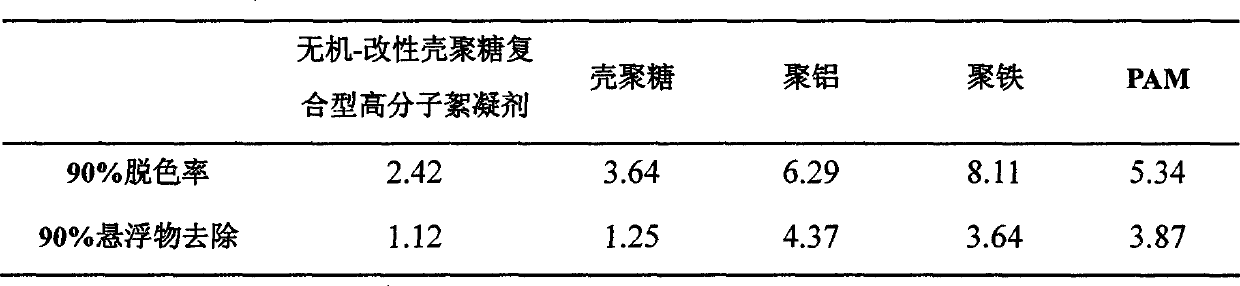

Inorganic-modified chitosan composite type polymeric flocculant

InactiveCN103121742ASimple structureRich sourcesWater/sewage treatment by flocculation/precipitationAluminium chlorideMeth-

The invention relates to an inorganic-modified chitosan composite type polymeric flocculant. The inorganic-modified chitosan composite type polymeric flocculant is characterized in that a method for preparing the composite type polymeric flocculant comprises the following steps of: taking polyacrylamide-modified chitosan as a raw material and methacryloyloxyethyl trimethyl ammonium chloride, maleic acid and ceric ammonium nitrate as initiators, synthesizing a modified chitosan copolymer under a faintly acidic condition and blending the modified chitosan copolymer with polymerized ferric chloride and polymerized aluminium chloride to obtain the inorganic-modified chitosan composite type polymeric flocculant. According to the steps, the mass ratio of modified starch to the chitosan is (1-2): 1, the reaction temperature is 50-60 DEG C, the reaction time is 2-3 hours, and the use amount of the initiators accounts for 0.02 part of the total mass of the system. The inorganic-modified chitosan composite type polymeric flocculant prepared by using the method has the characteristics of high efficiency, low cost and low secondary pollution to environment; and aiming at different sludges, compared with a conventional flocculant, the inorganic-modified chitosan composite type polymeric flocculant disclosed by the invention has the advantages that the wastewater decoloring rate and the wastewater deturbidity rate can reach more than 99 percent under the condition of low use amount.

Owner:WUHAN SLOAN ELECTRIC

Method for producing aluminium and aluminium alloy by low temperature electrolysis

InactiveCN1664170ALight in massNon-volatilePhotography auxillary processesProcess efficiency improvementMetallic materialsIonic liquid

The invention relates to a method of making aluminum and aluminum alloy through electrolyzing in low temperature, which belongs to the metal material field, characterized in that it uses the alumina or silicate mineral containing aluminum as raw materials, and gets anhydrous aluminum chloride after chloridization, then prepares AlCl3 ionic liquid with anhydrous aluminum chloride, and uses the AlCl3 ionic liquid as ionogen, the aluminum will be produced in the cathode while the chlorine will be discharged from the anode. When producing the aluminum alloy, preparing the alloy elements chloridate-AlCl3 ionic liquid through adding alloy elements chloridate MeCln to the AlCl3 ionic liquid, Using the direct current to electrolyzing, wherein the voltage is above the higher decomposition voltage of the aluminium chloride and chloridate and below the electrochemistry window of the ionic liquid, and the aluminum will be produced in the cathode while the chlorine will be discharged from the anode.

Owner:UNIV OF SCI & TECH BEIJING

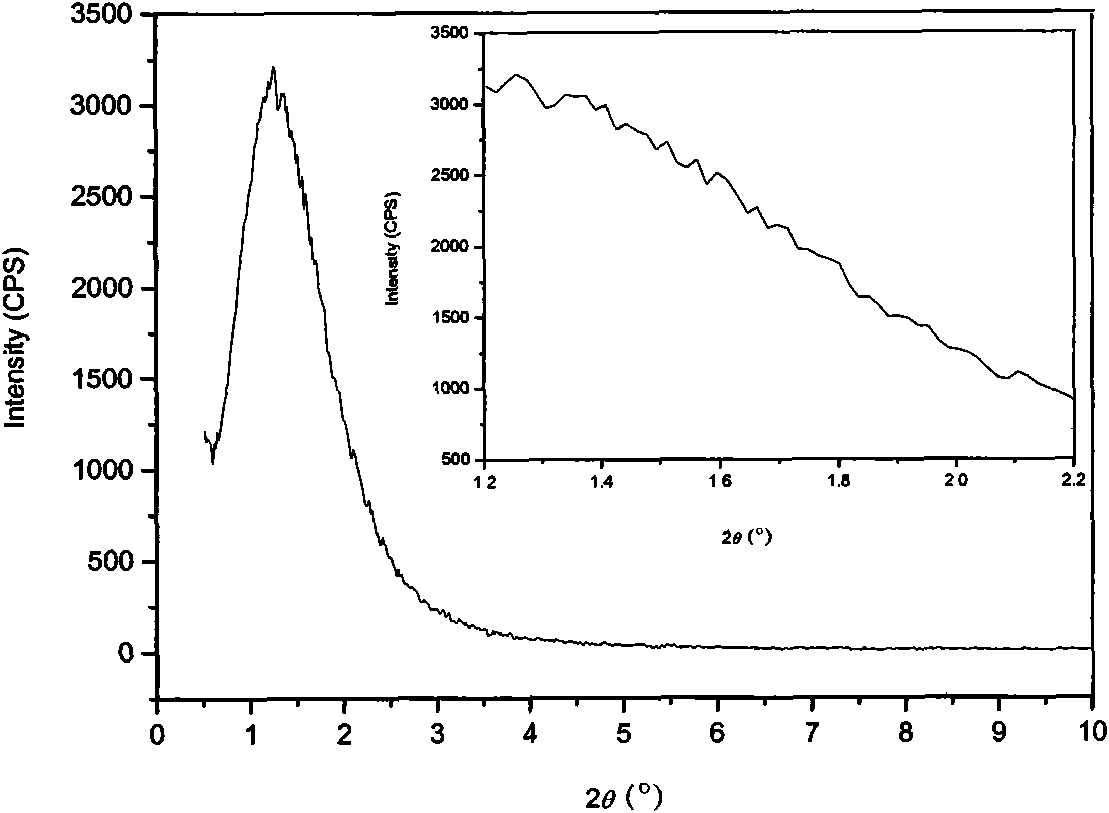

Method for inorganically synthesizing organized mesoporous alumina

InactiveCN101993102ALow costLarge specific surface areaOther chemical processesCatalyst activation/preparationAluminium chlorideNano structuring

The invention belongs to the field of inorganic nano structure materials, in particular to a method for inorganically synthesizing organized mesoporous alumina, which is characterized in that inorganic matters of sodium aluminate and aluminum chloride are in acid-base pairing to prepare mesoporous alumina which has large specific surface area, narrow pore-size distribution, organized pore channel and high hydrothermal stability; and methyl cellulose which is used as a template agent in a synthesizing process has thermosensitivity and is beneficial to recycle. The method for inorganically synthesizing organized mesoporous alumina has the characteristics that raw materials have low cost, the template agent can be recycled, the technology is simple and easy to control, and the like. The method for inorganically synthesizing organized mesoporous alumina is easy to realize industrial production, and the obtained organized mesoporous alumina has wide application prospect in the fields of catalytic reaction, adsorption, separation, and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Extraction of Sulfate from Water

InactiveUS20120031850A1Reduce metal contentLess soluble in waterSedimentation separationRadioactive contaminantsAluminium chlorideAluminite

Sulfate anions and divalent metal ions, such as magnesium, strontium and barium, in water are removed by treating the water with polyaluminum chloride, usually together with lime, to form ettringite and similar crystalline species which are readily removable by settling, filtration and the like. Iron is also removed by oxidation in a variation of the process. The process is particularly useful for treating aqueous solutions used in well treatment, where flowback fluids can provide some of the divalent metal ions necessary to form the ettringite-like materials, thus reducing the amount of lime otherwise necessary and further facilitating recycling of the fluid.

Owner:SMART CHEM SERVICES LP

Compound dust suppression agent for coal mine and preparation method of compound dust suppression agent

InactiveCN102465711AGood dust suppression effectWide range of raw materialsDust removalFire preventionAluminium chlorohydrateRespirable dust

The invention discloses a compound dust suppression agent for a coal mine and a preparation method of the compound dust suppression agent. The compound dust suppression agent comprises the following components in percent by mass: 0.05-1.00 percent of fatty alcohol-polyoxyethylene ether (JFC), 0.05-1.00 percent of sodium dodecyl benzene sulfonate (SDBS), 0.01-0.50 percent of polyacrylamide (PAM), 0.02-0.50 percent of polymeric aluminium (PAC) and the balance of water. The compound dust suppression agent disclosed by the invention has the advantages that the components are water-soluble materials, can be directly sprayed by using the original water spraying system of the mine, have wide sources, do not generate any harmful gases, and are non-toxic and tasteless; and the compound dust suppression agent is convenient for construction, and has better dust suppression effect of respirable dust in comparison that of the prior art.

Owner:SHANDONG UNIV OF SCI & TECH

Synthetic asphalt recycled tire rubber emulsions and processes for making them

Synthetic asphalt and petroleum asphalt modified synthetic asphalt emulsions which contain recycled tire rubber and processes for making the emulsions at temperatures above ambient or room temperature. These emulsions may contain significant quantities of recycled tire rubber and recycled and reclaimed motor oils and fluxes. In addition, aluminum chloride and ferric chloride may be used in clay-in-water solutions to form emulsifying agents for the synthetic asphalt and modified synthetic asphalt mixtures.

Owner:PARTANEN JOHN ERIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com