New method for resource comprehensive utilization of red mud and fly ash

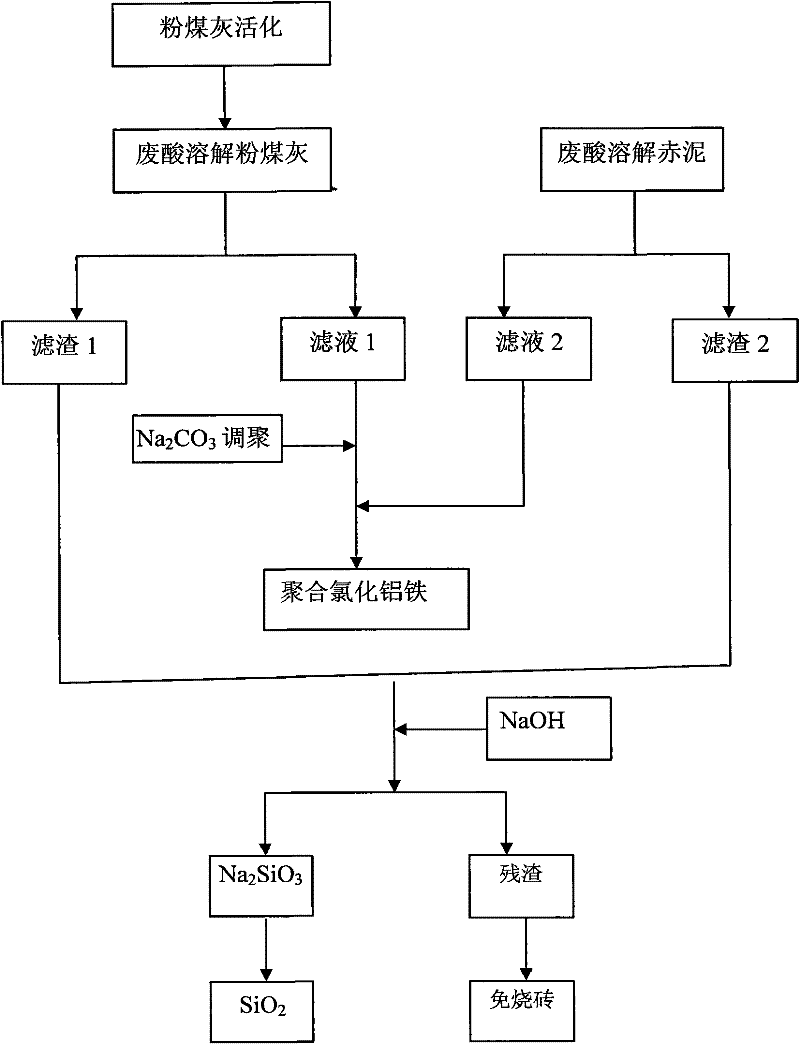

A technology of fly ash and resource utilization is applied in the field of comprehensive utilization of polyaluminum ferric chloride and silicon dioxide, industrial waste red mud and fly ash, and achieves simple operation, reduced manufacturing process difficulty and high separation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Main component content of red mud (mass fraction): Fe 2 O 3 : 26.0%; Al 2 O 3 :18.0%; SiO 2 :17.0%; main component content of fly ash (mass fraction): Fe 2 O 3 : 5.0%; Al 2 O 3 : 20.0%; SiO 2 : 50.0%.

[0029] Weigh 100g fly ash and 7g Na 2 CO 3 Mix, activate at 800°C for 1.0h, and pulverize to 0.1-1.0μm after cooling. Put the activated fly ash into a glass container, add 500mL 6mol·L -1 , React for 8 hours at 80°C and stirring speed 400 rpm (revolutions per minute), and filter to obtain 450 mL of dissolving liquid 1 and 70 g of filter residue 1. Put 20g of red mud into a glass container, add 100mL 6mol·L -1 , React for 6 hours at 80°C and stirring rate 400 rpm (revolutions per minute), and filter to obtain 80 mL of eluate 2 and 12 g of filter residue 2. Transfer 400 mL of dissolution solution 1 to another glass container, and slowly add Na at 65°C 2 CO 3 The solution, until the pH value of the solution is 2.5, and then keep it for 1 hour; add the dissolving liquid 2 to th...

Embodiment 2

[0032] The main component content of red mud (mass fraction): Fe 2 O 3 : 26.0%; Al 2 O 3 :18.0%; SiO 2 :17.0%; main component content of fly ash (mass fraction): Fe 2 O 3 : 5.0%; Al 2 O 3 : 20.0%; SiO 2 : 50.0%.

[0033] Weigh 100g fly ash and 7g Na 2 CO 3 Mix, activate at 800°C for 1.0h, and pulverize to 0.1-1.0μm after cooling. Put the activated fly ash into a glass container, add 500mL 6mol·L -1 , React for 6 hours at 780°C and stirring speed 400 rpm (revolutions per minute), and filter to obtain 460 mL dissolving liquid 1 and 75 g filter residue 1. Put 20g of red mud into a glass container, add 100mL 6mol·L -1 , Reacting for 6 hours at 70°C and stirring rate of 400 rpm (revolutions per minute), and filtering to obtain 80 mL of eluate 2 and 13 g of filter residue 2. Transfer 400mL dissolution solution 1 to another glass container, and slowly add Na at 70°C 2 CO 3 The solution, until the pH value of the solution is 3.0, and then keep it for 1 hour; add the dissolving liquid 2 t...

Embodiment 3

[0036] The main component content of red mud (mass fraction): Fe 2 O 3 : 25.0%; Al 2 O 3 :17.0%; SiO 2 :16.0%; main component content of fly ash (mass fraction): Fe 2 O 3 : 4.0%; Al 2 O 3 : 21.0%; SiO 2 : 50.0%.

[0037] Weigh 100g fly ash and 7g Na 2 CO 3 Mix, activate at 850°C for 1.0h, and pulverize to 0.1-1.0μm after cooling. Put the activated fly ash into a glass container, add 500mL 6mol·L -1 , React for 6 hours at 750°C and a stirring rate of 500 rpm (revolutions per minute), and filter to obtain 450 mL of eluate 1 and 70 g of filter residue 1. Put 15g of red mud into a glass container, add 75mL 6mol·L -1 , React for 6 hours at 80°C and stirring speed 400 rpm (revolutions per minute), and filter to obtain 60 mL of dissolution liquid 2 and 9 g of filter residue 2. Transfer 400 mL of dissolution solution 1 to another glass container, and slowly add Na at 65°C 2 CO 3 The solution, until the pH value of the solution is 2.5, and then keep it for 1 hour; add the dissolving liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com