Patents

Literature

109results about How to "Achieve near-zero emissions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

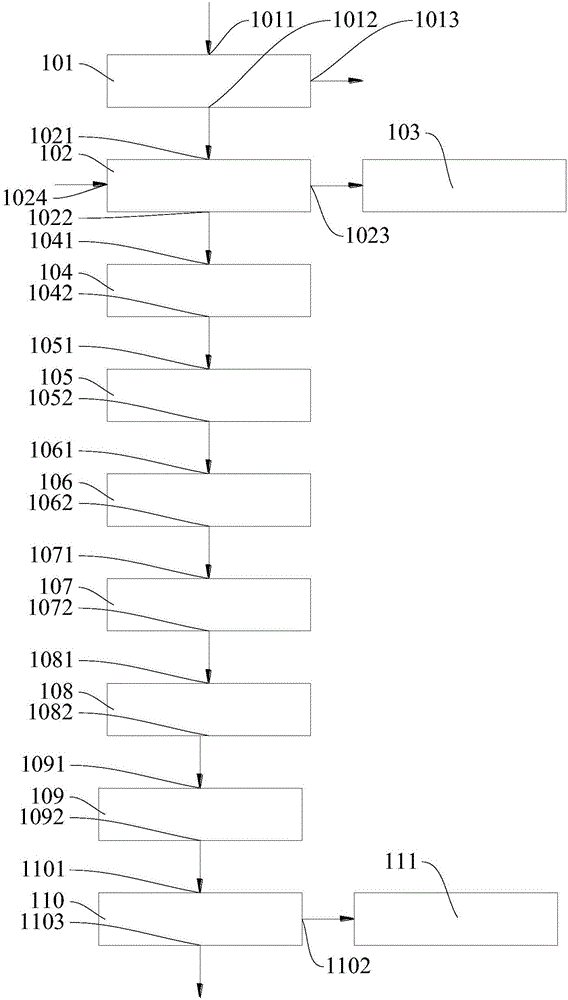

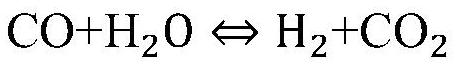

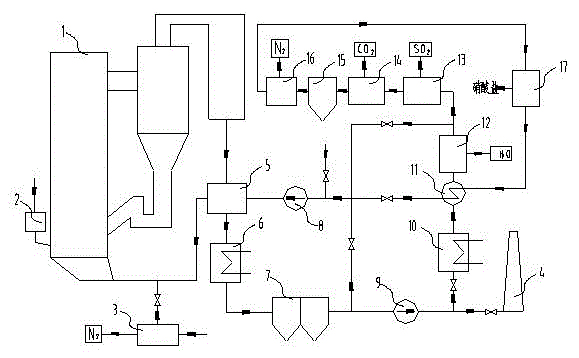

Solid fuel chemical-looping gasification hydrogen production system and method

ActiveCN103113917AEfficient separationAchieve near-zero emissionsHydrogen separation using solid contactCombustible gas productionSolid fuelProcess engineering

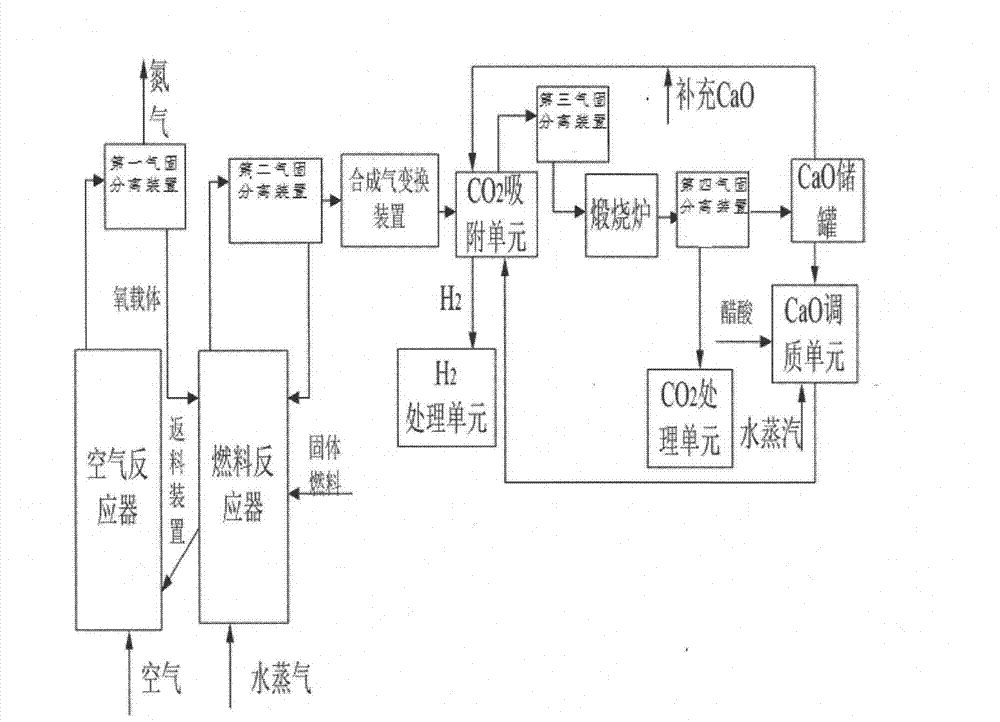

The invention provides a solid fuel chemical-looping gasification hydrogen production system and method. The solid fuel chemical-looping gasification hydrogen production system is characterized by comprising an air reactor, wherein the air reactor is connected with a first gas-solid separation device; the first gas-solid separation device is connected with a fuel reactor; the fuel reactor is connected with a second gas-solid separation device; a gas outlet of the second gas-solid separation device is connected with a synthetic gas converter; the synthetic gas converter is connected with a CO2 adsorption unit; a discharge port of the CO2 adsorption unit is connected with an H2 processing unit; an outlet of the CO2 adsorption unit is connected with a third gas-solid separation device; a CaCO3 solid outlet of the third gas-solid separation device is connected with a calcining furnace; the calcining furnace is connected with a fourth gas-solid separation device; a gas outlet of the fourth gas-solid separation device is connected with a CO2 processing unit; a solid outlet of the fourth gas-solid separation device is connected with a CaO storage tank; and the CaO storage tank is connected with the CO2 adsorption unit. The system can implement near zero discharge of CO2 in the hydrogen production process, and thus, reduces the influence of greenhouse gas on the environment.

Owner:SHANGHAI BOILER WORKS

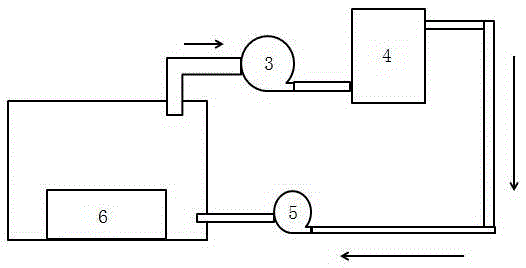

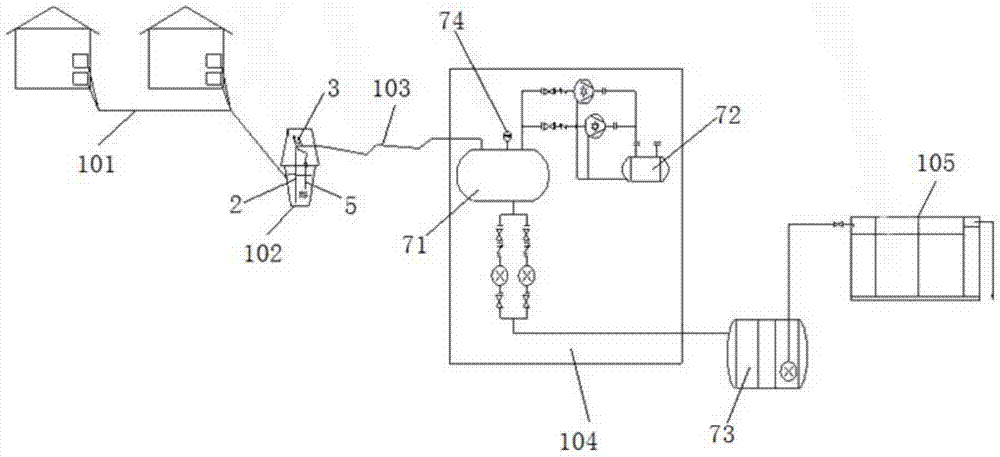

Vacuum sewage collecting and treating system

ActiveCN105507410AChange the singularityImprove securityCesspoolsFatty/oily/floating substances removal devicesSites treatmentSewage

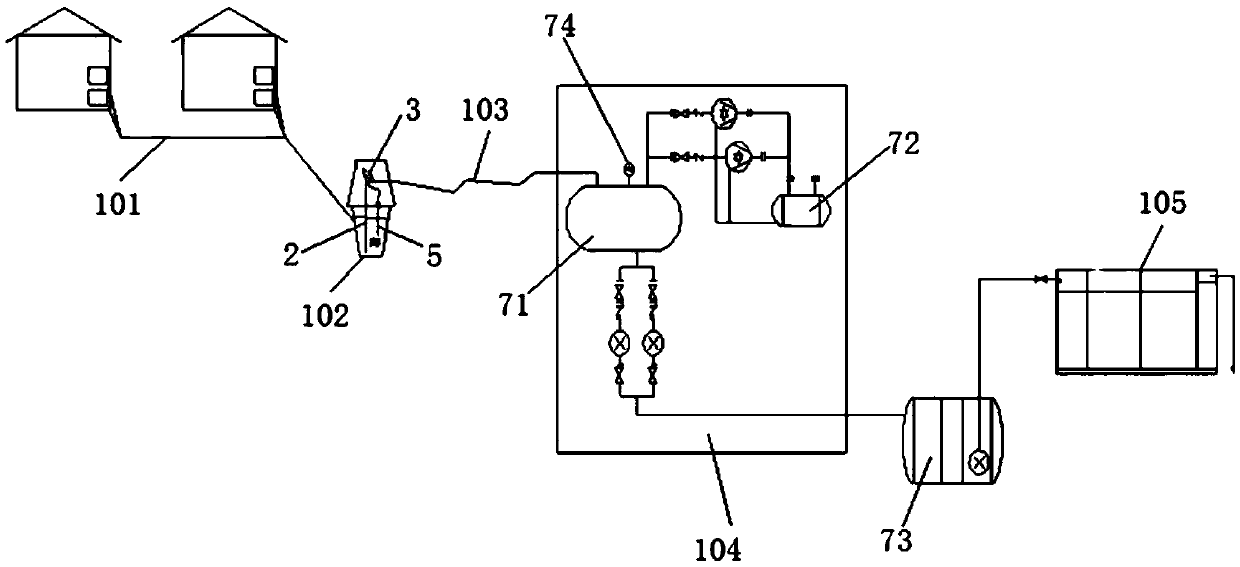

The invention discloses a vacuum sewage collecting and treating system. The vacuum sewage collecting and treating system comprises a sewage gathering pipeline, a vacuum collection well, a vacuum conveying pipeline, a vacuum pump station and a sewage treating device, wherein the sewage enters the vacuum collection well through the sewage gathering pipeline; when the sewage collected in the well reaches a certain amount, the sewage enters the vacuum pump station along the vacuum conveying pipeline; when the liquid level of the sewage in a vacuum sewage storage tank reaches a predetermined liquid level, the sewage conveying pump is started and is used for conveying the sewage to the sewage treating device to purify the sewage. Through the vacuum sewage collecting and treating system, the domestic sewage collection method is changed from the conventional gravity collection into vacuum collection; the sewage treatment is charged from a manner of discharging the sewage into a sewage pipe net and carrying out centralized treatment on the sewage to a process of carrying out on-site treatment by using a small integrated membrane treatment device; collection and treatment are integrated to a complete set of system; the system is not limited by basic supporting facilities and is not required to relay on urban drainage facilities; the system is integrated with the ecological environmental protection technology with efficient collection and efficient treatment functions and is especially suitable for regions such as small towns and countries and the like in which sewage treatment plants are unsuitably built.

Owner:清环拓达(苏州)环境科技有限公司

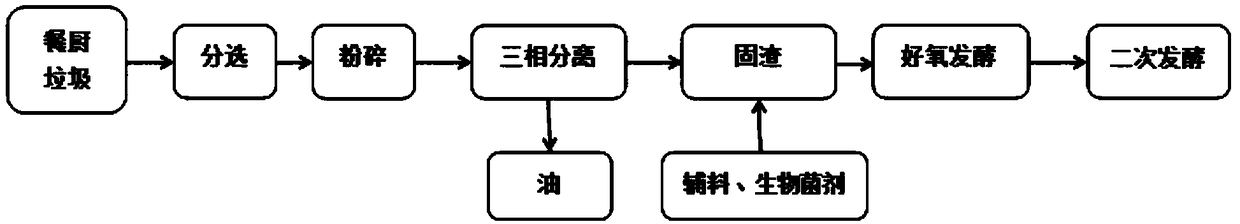

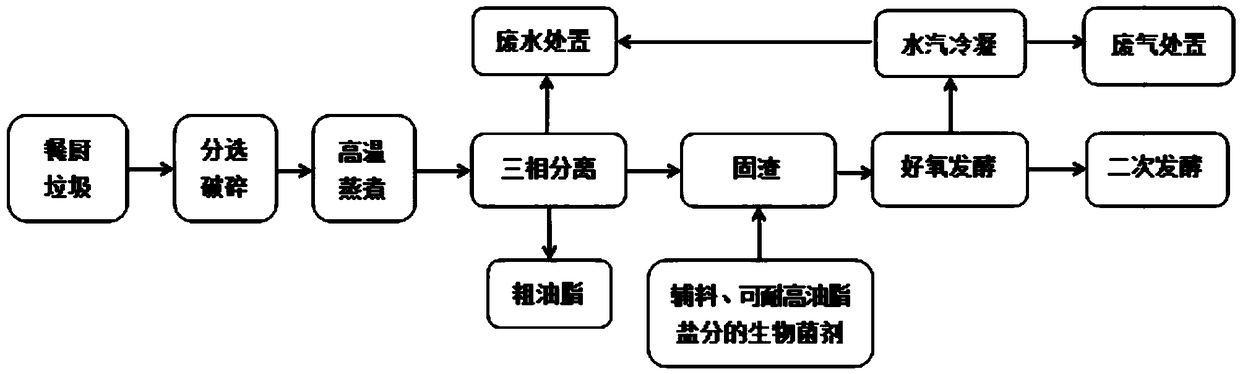

Kitchen waste resourceful treatment process

InactiveCN109467266AAccelerated precipitationImprove resource efficiencyGas treatmentTransportation and packagingOil and greaseSlag

The invention discloses a kitchen waste resourceful treatment process. The kitchen waste resourceful treatment process comprises the steps of carrying out pretreatment on collected kitchen wastes at first, wherein the pretreatment comprises sorting, crushing and cooking kitchen wastes at a high temperature; then carrying out three-phase separation on the pretreated kitchen wastes to separate out crude fat, wastewater and solid slag, and collecting the crude fat in a unified manner; adding a biological agent in the solid slag after three-phase separation, carrying out aerobic fermentation and secondary fermentation, after separating water vapor generated by fermentation, carrying out wastewater disposition and emission on a water portion and the wastewater obtained from three-phase separation, and carrying out waste gas disposition and emission on a waste gas portion. The invention provides the improved kitchen waste resourceful treatment process, the yield of the crude fat of the kitchen wastes is greatly improved, high resourceful earnings can be gained, meanwhile, an aerobic fermentation period can be shortened, the quality of compost is improved, and near zero emission of odor and wastewater is realized.

Owner:长沙工研院环保有限公司

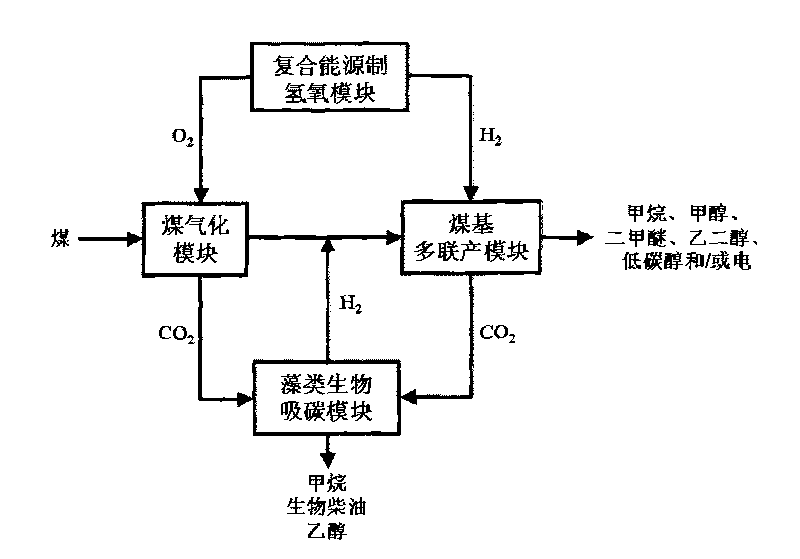

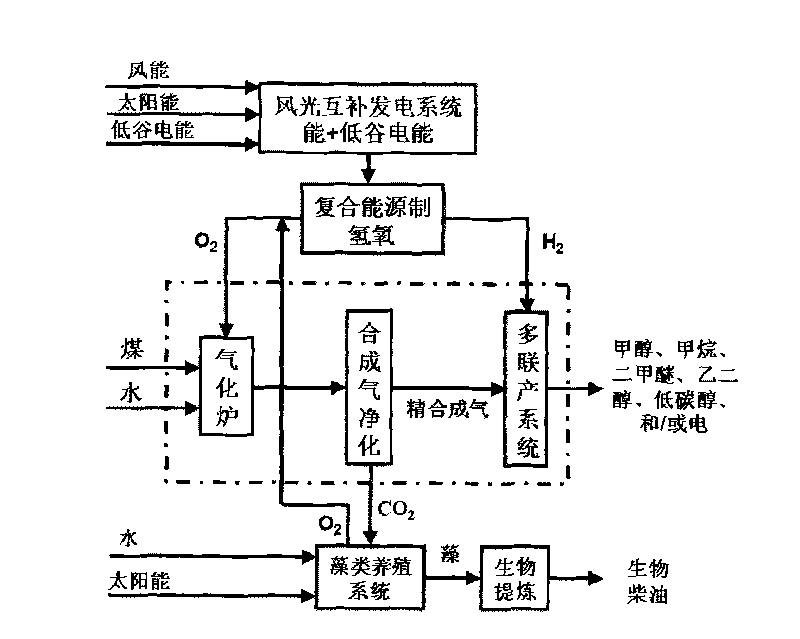

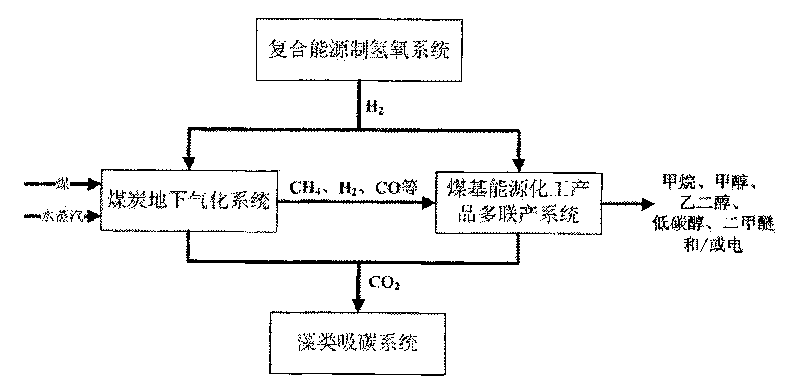

Coal-based energy chemical product poly-generation system and method

ActiveCN101760248ASimple processSimple production processInternal combustion piston enginesEnergy inputWastewaterProcess engineering

The invention provides a coal-based energy chemical product poly-generation system and a coal-based energy chemical product poly-generation method. Renewable energy sources and renewable resources are introduced into the process of producing coal-based energy chemical products, and coal is converted into clean coal-based energy chemical products and / or clean electric power so as to realize comprehensive utilization of wastewater, waste gas and solid waste and near-zero emission of carbon dioxide.

Owner:ENN SCI & TECH DEV

Denitration catalyst activity mother liquor preparation method and application of denitration catalyst activity mother liquor

InactiveCN104841420AWear-resistantCorrosion resistanceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsOxalateAmmonium metatungstate

The invention discloses a denitration catalyst activity mother liquor preparation method, which comprises the following steps: dissolving ammonium metatungstate and ammonium metavanadate into oxalic acid solutions respectively; adding active TiO2 and SiO2 mixed powder into the oxalic acid solution which contains the ammonium metatungstate, mixing, then drying and calcining; adding obtained TiO2-SiO2 / WO3 mixed powder into the oxalic acid solution which contains the ammonium metavanadate, and mixing; finally adding binder to obtain denitration catalyst activity mother liquor. The invention further discloses an application of the denitration catalyst activity mother liquor. The denitration catalyst activity mother liquor is sprayed onto the inner side of a dedusting element; after drying and calcining are carried out, a dedusting unit provided with a denitration catalyst coating which contains TiO2-SiO2 / WO3 / V2O5 active matters is formed. By applying the preparation method disclosed by the invention, the stability of the active denitration catalyst mother liquor is high, the combinability of the active denitration catalyst on the dedusting element is high, and the active denitration catalyst can be widely applied to porous ceramic tube carriers for dedusting.

Owner:GUANGZHOU DEVOTION THERMAL TECH

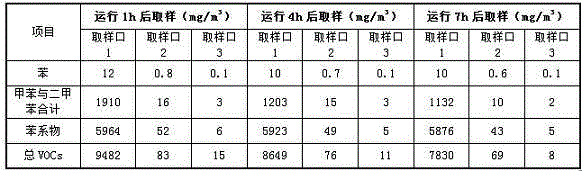

Industrial plant heating and dustless and volatile organic chemicals (VOCs) near zero emission process

ActiveCN105289211ATotal emission reductionReduce production and operation costsUsing liquid separation agentAir quality improvementOrganic chemicalsZero emission

The invention discloses an industrial plant heating and dustless and volatile organic chemicals (VOCs) near zero emission process, which substantially comprises steps: (1) VOCs in industrial plants is collected by utilizing a gas collecting system, and waste gas is collected; (2) the waste gas which is collected in the step (1) is conveyed to a waste gas treatment device, and the VOCs is treated; and (3) gas which is treated in the step (2) is conveyed to plants through a gas send-back system, and is recycled. The industrial plant heating and dustless and volatile organic chemicals (VOCs) near zero emission process enables plants not to have dust and heating, and enables VOCs to be discharged near zero or at zero.

Owner:NANJING GW ENVIRONMENT ENG

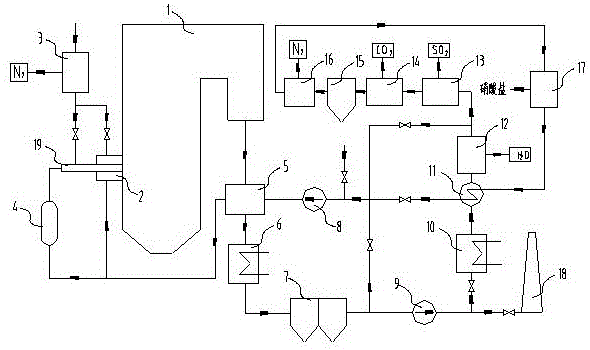

Rare-earth organic extractant and back-extraction process thereof

InactiveCN103602812AAchieve near-zero emissionsReduce pollutionProcess efficiency improvementKeroseneRare earth

The invention discloses a rare-earth organic extractant and a back-extraction process thereof. The organic extractant contains the ingredients in percentage by volume: 20-35% of cyclohexane, 15-45% of liquid ammonia saponification extractant, 15-35% of N235 and 20-40% of sulfonated kerosene, wherein the liquid ammonia saponification extractant is either P507 or P204. The back-extraction process comprises the steps of preparing loading organic phases containing different rare earth concentrations through extraction, back-extracting and precipitating, thereby obtaining rare-earth oxalate with large grain diameter. A non-saponification extraction system is provided by the invention, and near-zero emission of ammonia nitrogen is realized; the back-extraction process disclosed by the invention has the advantages of high phase separation speed, obvious two-phase boundary and high back-extraction ratio; and a crystal is not deposited on a bottom plate of a back-extraction tank and does not scar on the periphery.

Owner:JIANGXI UNIV OF SCI & TECH

Reverse osmosis concentrated water oxidizing and desalting method and system of organic wastewater

PendingCN106746131AEasy to handleDoes not increase the operating load of the secondary reverse osmosisGeneral water supply conservationWater treatment compoundsFiltrationReverse osmosis

The invention provides a reverse osmosis concentrated water oxidizing and desalting method and system of organic wastewater. The method comprises the following steps: S1, performing primary reverse osmosis treatment on the organic wastewater to obtain primary reverse osmosis wastewater; S2, performing an oxidizing reaction on the primary reverse osmosis wastewater under the action of an oxidant to obtain oxidized wastewater; S3, softening the oxidized wastewater under the action of a softener to obtain softened wastewater; S4, coagulating the softened wastewater under the action of a coagulant and a coagulant aid; S5, precipitating a product in the S4 to obtain supernatant wastewater; S6, performing a neutralizing reaction on the supernatant wastewater; S7, performing multimedia filtration on the wastewater neutralized in the S6 to obtain primary filtered wastewater; S8, ultra-filtering the primary filtered wastewater to obtain secondary filtered wastewater; and S9, performing secondary reverse osmosis on the secondary filtered wastewater to obtain secondary concentrated water and reclaimed water.

Owner:上海中耀环保实业有限公司

Fuel and gas-fired boiler oxygen-enriched combustion smoke nearly-zero-emission power generation system

InactiveCN105042575ASave waterGood commercial valueDirect carbon-dioxide mitigationIndirect carbon-dioxide mitigationBurning outZero emission

The invention provides a fuel and gas-fired boiler oxygen-enriched combustion smoke nearly-zero-emission power generation system. The fuel and gas-fired boiler oxygen-enriched combustion smoke nearly-zero-emission power generation system is composed of a boiler, an air bellow, an air separation device, a burner, a multi-stage heat exchanger, a recirculating fan, an induced draft fan, a dehydration device, an SO2 separation device, a CO2 capturing device, a N2 separator, a NOx reaction device and the like. The concentration of oxygen of secondary air is changed so as to ensure that fuel and gas catch fire in time, burn stably and burn out, the boiler efficiency is improved, and adaptability of the boiler to loads is enhanced. By recycling water steam, SO2, NOx, CO2 and the like brought by burning smoke of fuel and gas, integrated desorption of harmful gas and trace elements in smoke is achieved; meanwhile, the temperature of exhausted smoke is reduced to approach the atmosphere temperature, nearly-zero emission of burning smoke is achieved, the environment is protected, and maximum utilization of resources is also achieved.

Owner:SICHUAN CHUANGUO BOILER

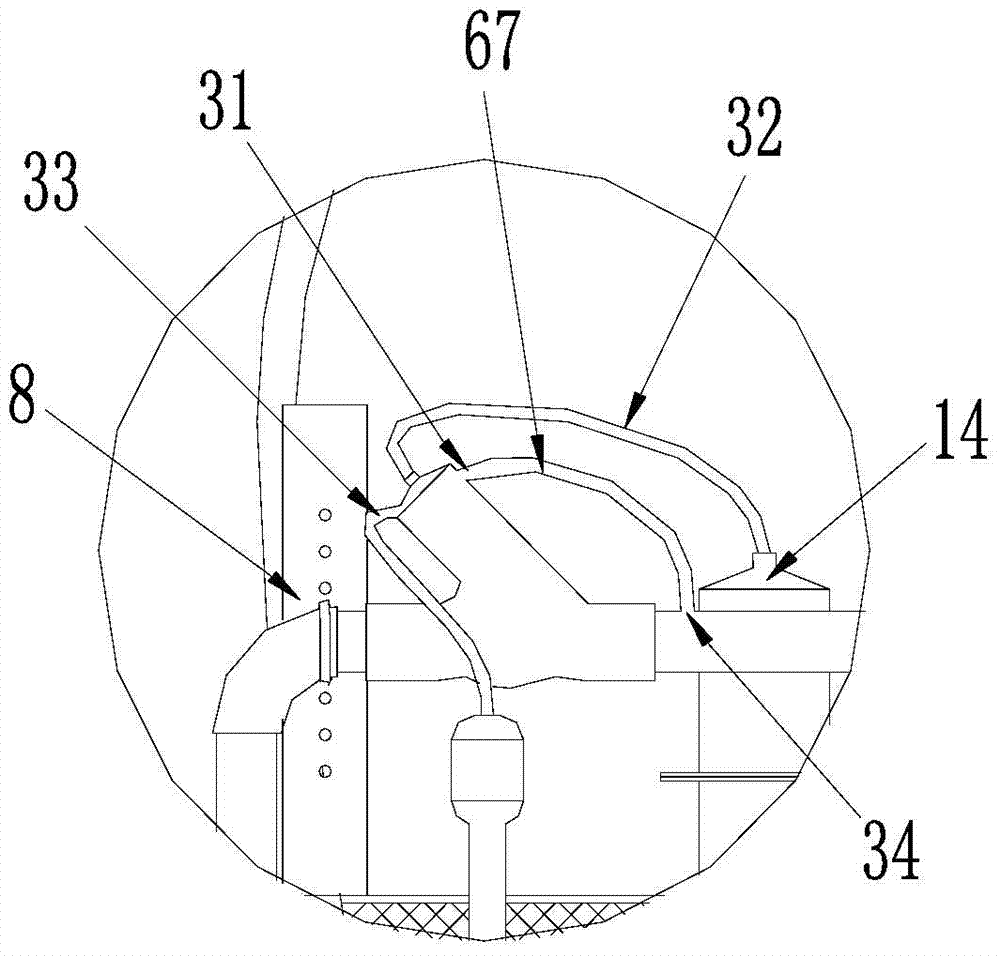

Gradient utilization system and method for waste heat generated during treatment of supercritical water oxidation (SCWO) sludge

ActiveCN109399893AIncrease heatRapid thermal hydrolysis reactionSludge treatment by thermal conditioningSludge treatment by oxidationChemical industryReboiler

The invention discloses a gradient utilization system and method for waste heat generated during treatment of supercritical water oxidation (SCWO) sludge, and belongs to the technical fields of chemical industry and environment protection. The method comprises the following steps: heating sludge for thermal hydrolysis through a thermal hydrolysis reactor; performing first-stage preheating on the sludge through a sludge preheating tank; making the sludge release heat in an SCWO reaction by taking an SCWO technology as a core to become high-temperature thermal fluid; performing high-temperaturesegment preheating on the material to a supercritical condition through a high-temperature preheater, a reboiler, the thermal hydrolysis reactor and the sludge preheating tank in sequence; re-boilingthe deaminized fluid through the reboiler to generate steam for subsequent ammonia stilling; recycling the waste heat of the high-pressure fluid with a waste heat refrigerating-heating unit; introducing the fluid into a deaminizing unit for further performing ammonia nitrogen treatment after the fluid flows through a depressurizing-separating unit; finally recycling the waste heat of the low-pressure fluid through a waste heat heating unit to realize harmless treatment of the sludge and efficient utilization of system energy. By adopting the gradient utilization system and method, the runningcost is lowered effectively, and the economic performance of the system is improved.

Owner:XI AN JIAOTONG UNIV

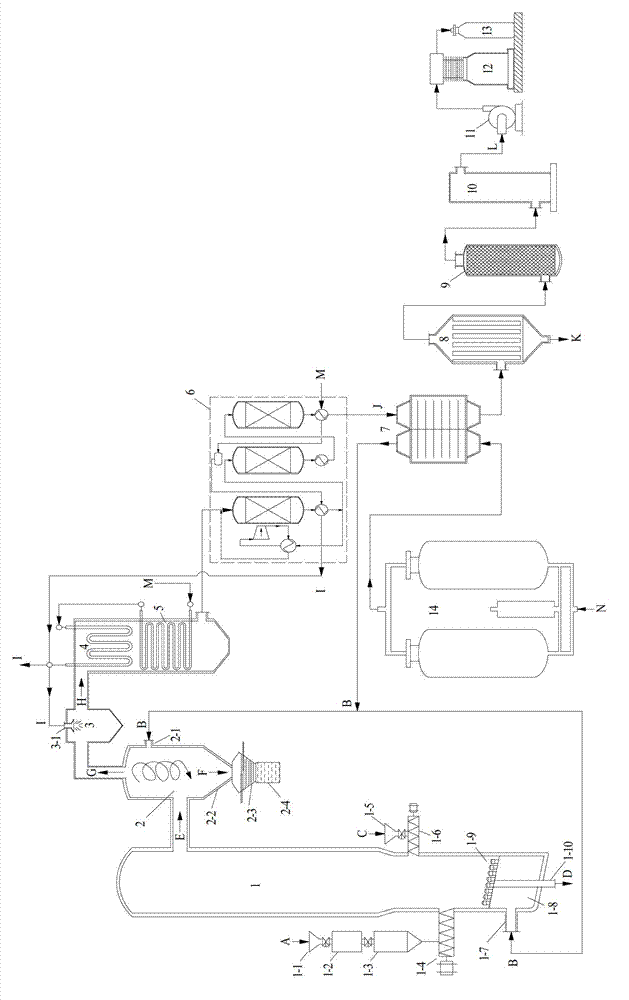

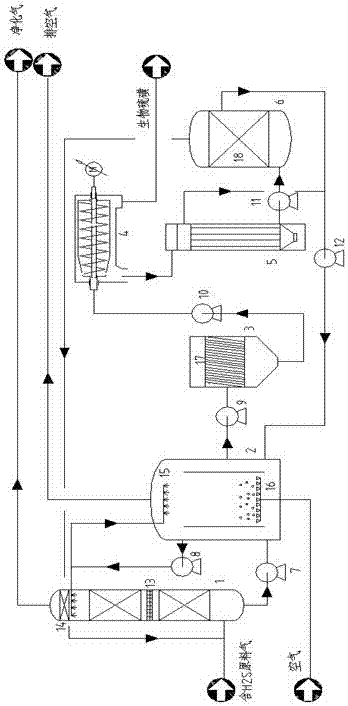

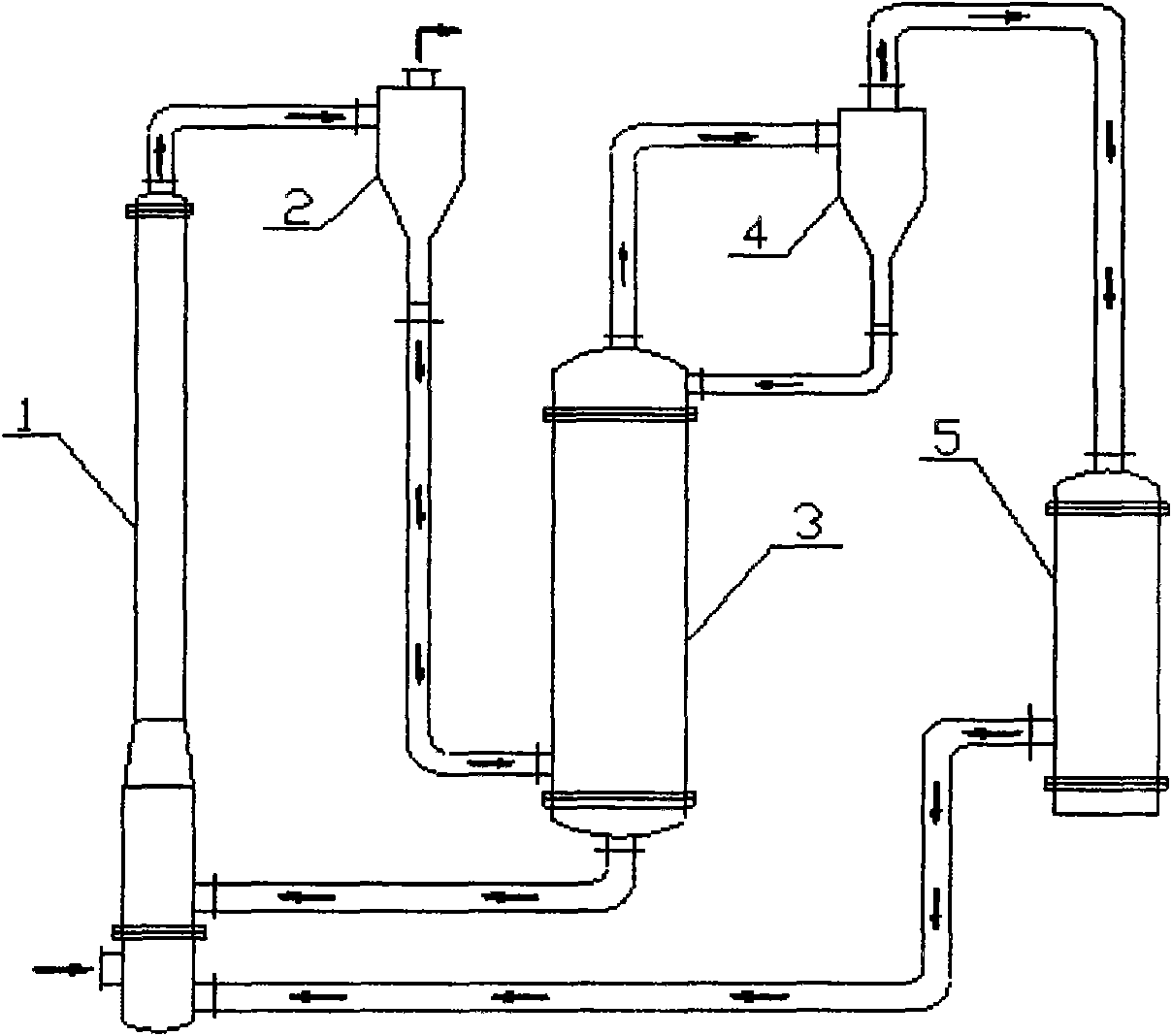

Method for preparing hydrocarbon-rich combustible gas through gasification of combustible solid waste

InactiveCN102816606AReduced risk of clogged equipmentAvoid the risk of clogging equipmentChemical industryGranular/pulverulent flues gasificationSteam reformingWater vapor

The invention relates to a method for preparing hydrocarbon-rich combustible gas through the gasification of combustible solid waste. The method can be used for preparing hydrocarbon-rich high-quality combustible gas. The system is composed of a fluidized bed gasification reactor, a cyclone melting furnace, a water vapor reforming reactor, a super-heater, an economizer, a hydrocarbon synthesis reactor, a heat pipe heat exchanger, a bag filter, a gas scrubbing tower, a dehydration tower, an induced draft fan, a compression device, a gas storage tank, an air separation device, and the like. The method adopts a heat conversion technology especially aiming at high-efficiency and clean utilization of combustible solid waste as an energy. With the method, combustible gas rich in hydrocarbon gas can be prepared, contents of tar and carbon particles in combustible gas can be effectively reduced, metal resources in combustible solid waste can be recovered, and near-zero discharging of pollutants such as dioxin can be realized. With the system, gas preparing cost is reduced with a maximal extent, such that effective recovering and utilization of resources are realized. An overall thermal efficiency is high, and environment pollution is low. The method is highly economic, safe, and reliable.

Owner:SOUTHEAST UNIV

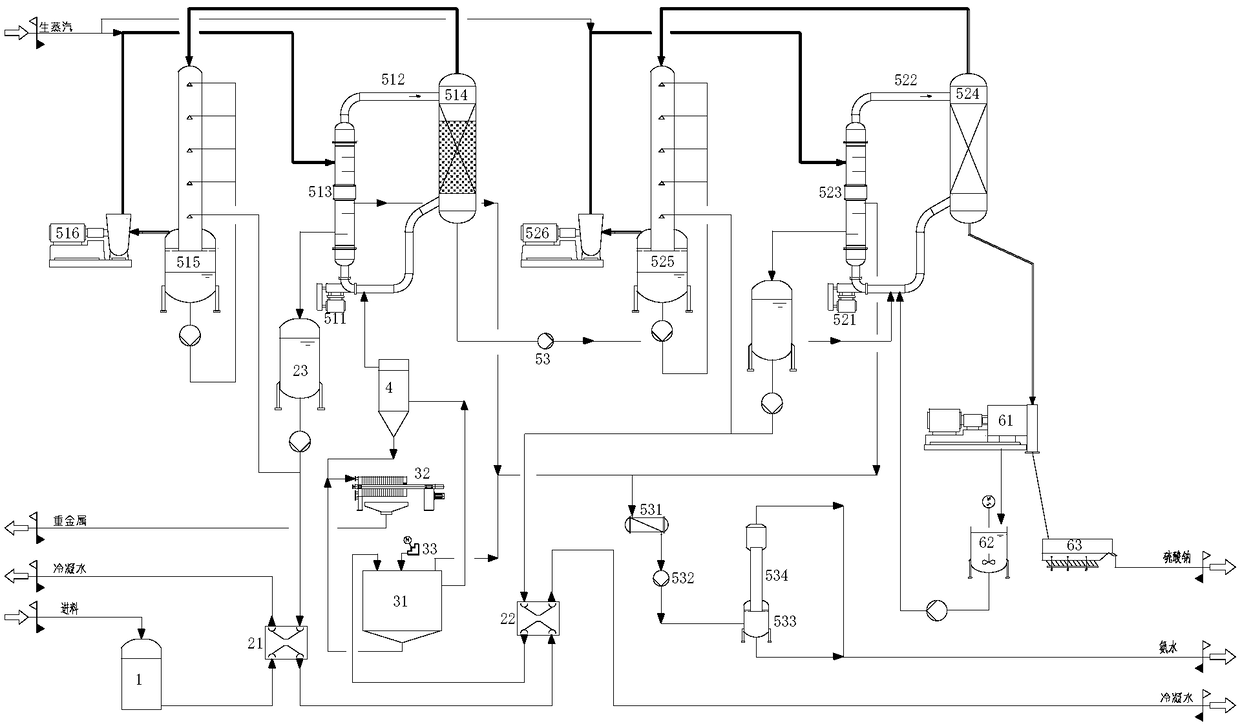

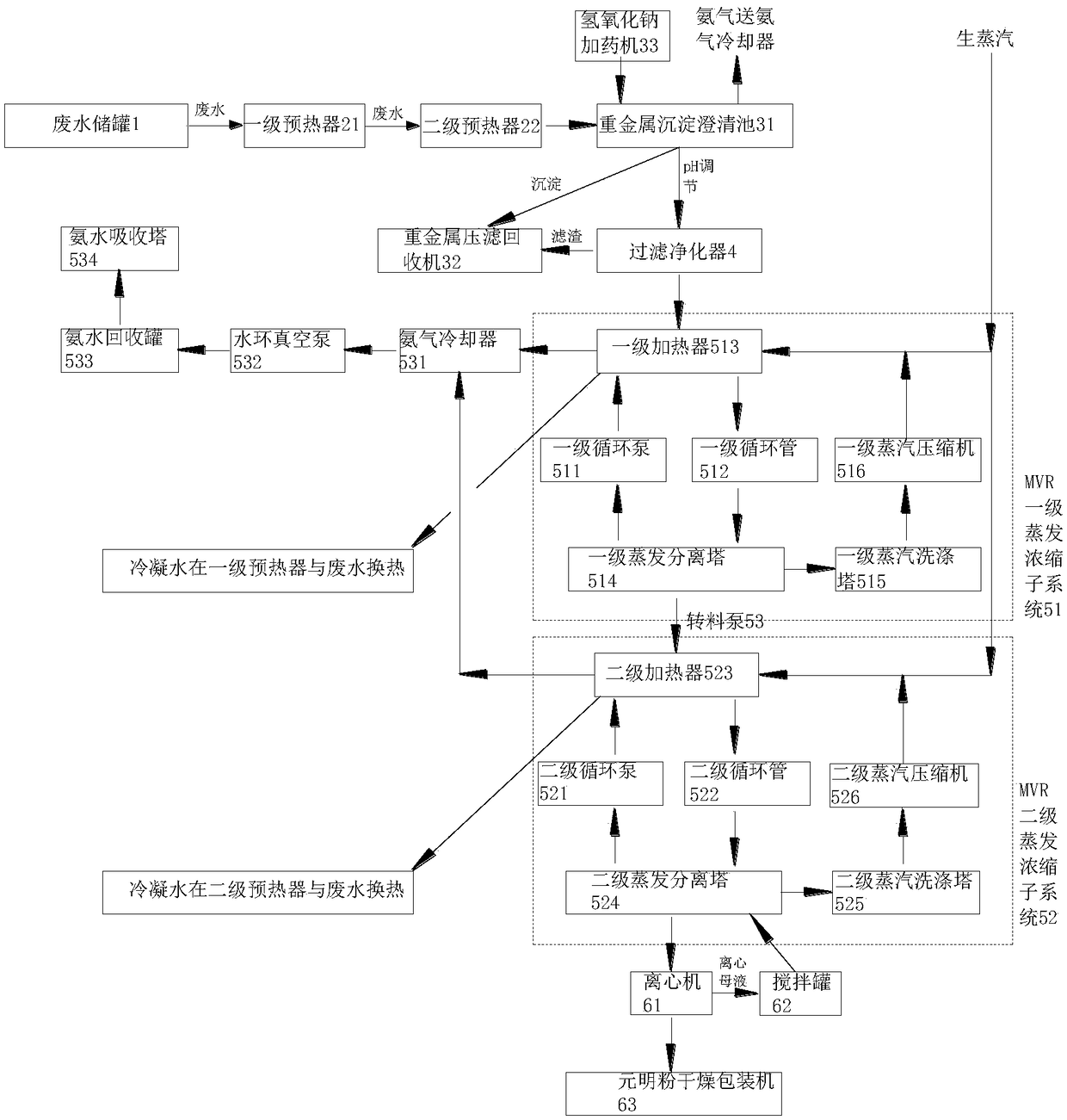

Near-zero-emission treatment system and technology for ternary precursor material production wastewater

ActiveCN109319998AImprove qualityAchieve near-zero emissionsWater contaminantsAlkali metal sulfite/sulfate purificationHigh energyWater vapor

The invention discloses a near-zero-emission treatment system and technology for ternary precursor material production wastewater. Heavy metal is recycled through adopting a precipitation method; water, ammonia gas and sodium sulfate in the wastewater are recycled through adopting a two-grade method MVR (Mechanical Vapor Recompression) technology. The ammonia gas which is volatilized and escaped in wastewater temperature rising, and heavy metal sedimentation and clarification procedures is recycled for production; water steam and ammonia gas are produced in an MVR first-grade evaporation, concentration and separation process; when condensed water is recycled, the ammonia gas is recycled and is used for producing the ammonia gas; an integrated technology for recycling the water and the ammonia gas at the same time is used for replacing an existing single-procedure high-energy-consumption steam stripping process recycling technology of the steam, so that treatment procedures are reducedand the operation cost is reduced; a two-grade MVR evaporation and crystallization technology is used for recycling anhydrous sodium sulfate and the condensed water. The near-zero-emission treatment system and technology have the advantages of protecting the environment, reducing the emission of high-salt-content wastewater, reducing the recycling treatment cost of the wastewater, changing wastesinto valuable things, generating economic benefits and realizing near-zero-emission treatment of the wastewater.

Owner:广州新普利节能环保科技有限公司

Salt-free high-chrome-absorption chrome tanning method for animal skin and application of salt-free high-chrome-absorption chrome tanning method

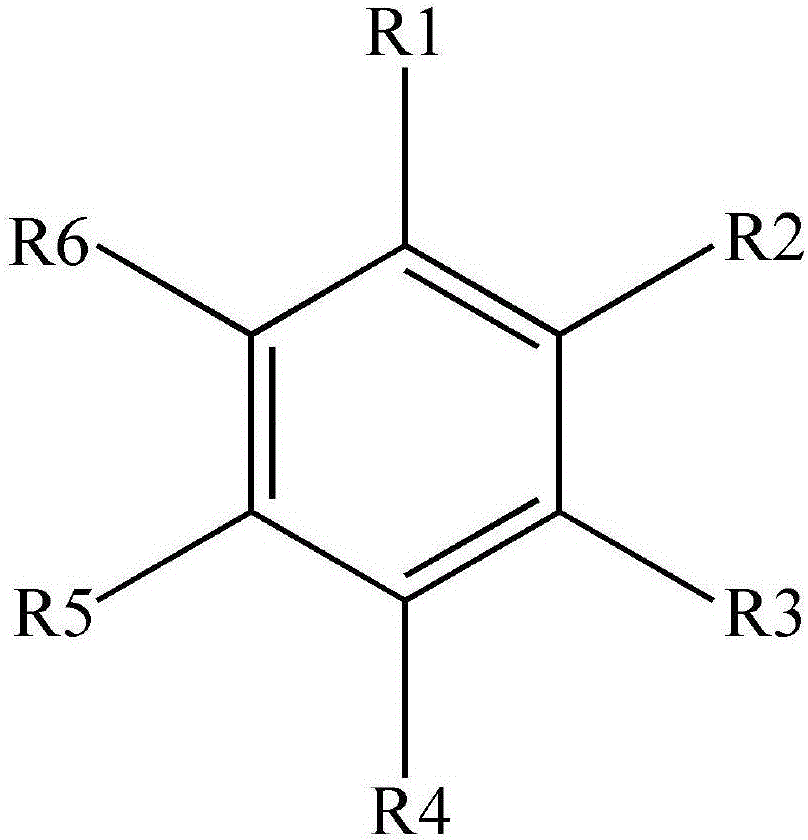

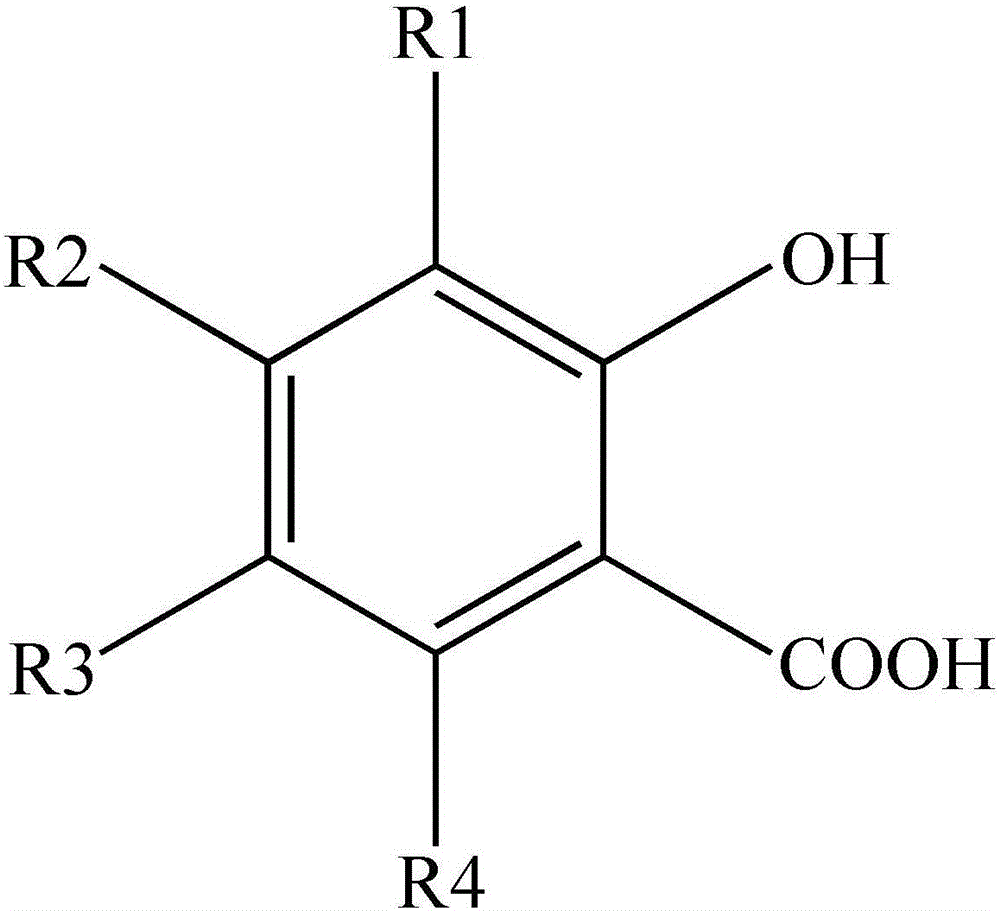

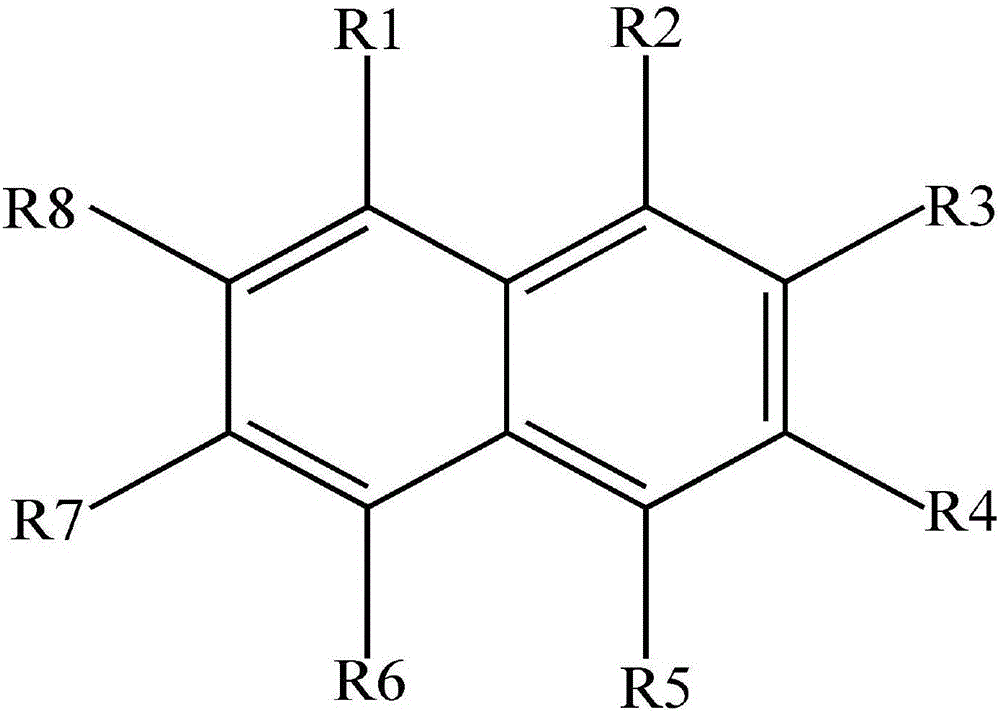

InactiveCN105063253AImprove overall performanceSimplify alkali extraction operationTanning treatmentPre-tanning chemical treatmentAbsorption rateChemistry

The invention discloses a salt-free high-chrome-absorption chrome tanning method for animal skin and application of the salt-free high-chrome-absorption chrome tanning method. The salt-free high-chrome-absorption chrome tanning method is characterized by comprising the following steps of treating pretreated animal skin by using aromatic sulfonic acid or a low-molecular polycondensate thereof; regulating the pH value of the animal skin to 4.0-6.5 under the condition that no neutral salts such as sodium chloride and sodium sulfate are used; and carrying out chrome tanning under a relatively high initial pH value condition to realize salt-free high-chrome-absorption tanning. By using the salt-free high-chrome-absorption chrome tanning method, the problem that the quality and performances of leather or fur are influenced because the skin possibly has the acid expansion phenomenon under salt-free and acidic tanning conditions, the combination of chrome and the surface of the skin are excessively fast during the tanning, and the chrome cannot permeate the skin easily under the relatively high initial pH value condition is solved; and compared with the conventional chrome tanning method, the chrome tanning method disclosed by the invention is advantaged in that the chrome tanning efficiency is remarkably increased, the consumption of chrome can be reduced by more than 30%, the absorption rate of chrome is up to more than 98%, the concentration of chrome in chrome tanning effluent is reduced to be less than 50mg / L, chrome in wet blue leather is more uniformly distributed, and the chrome tanning effluent can be recycled many times. By using the salt-free high-chrome-absorption chrome tanning method, the chlorine and chrome pollution generated in the leather and fur preparation processes is remarkably reduced.

Owner:SICHUAN UNIV

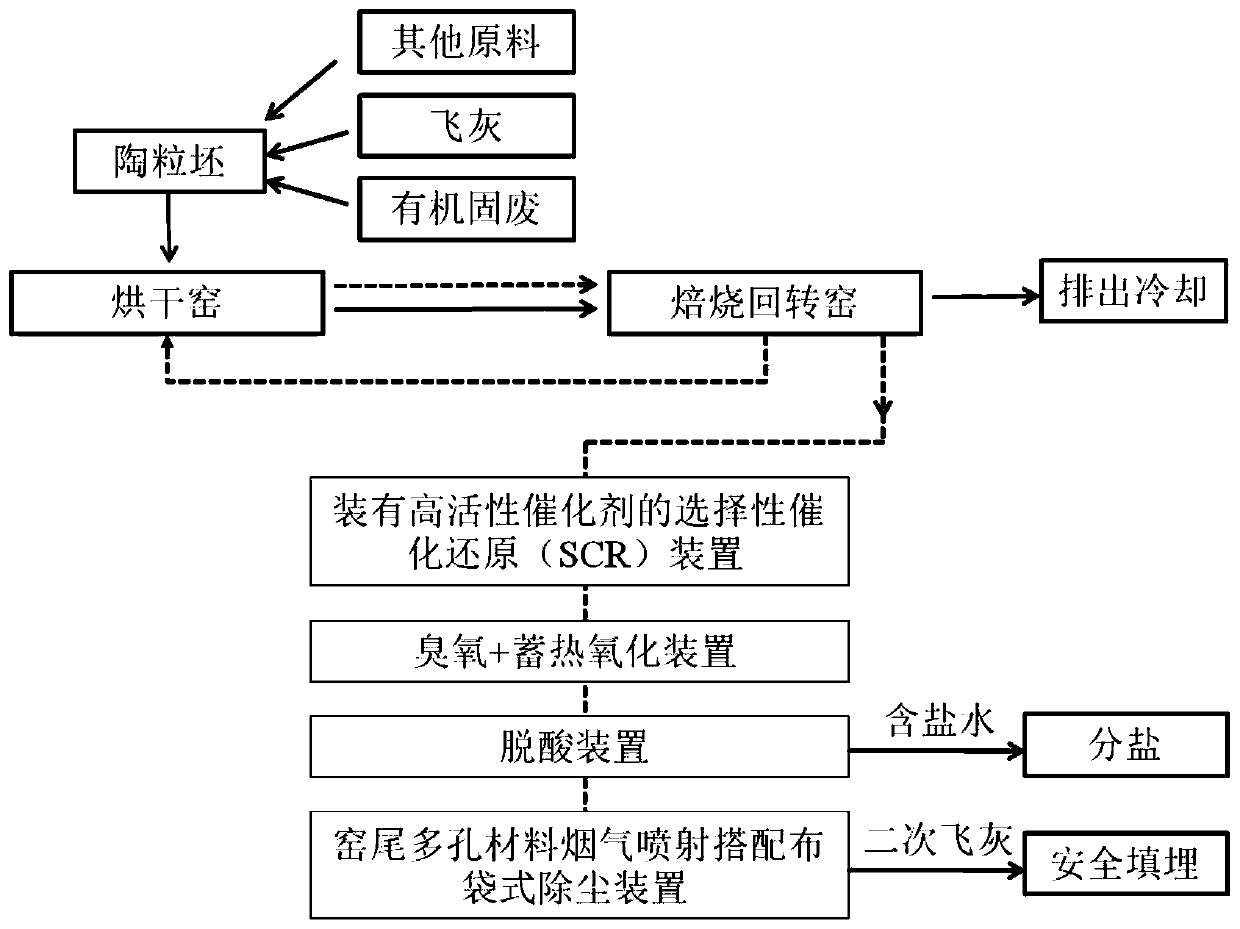

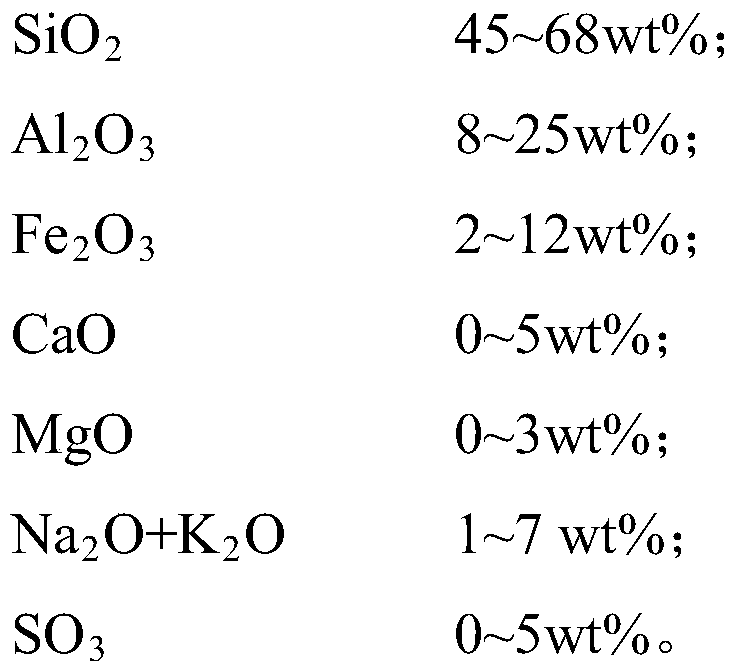

Method for disposal of solid waste by ceramsite kiln and ceramsite kiln for disposal of solid waste

InactiveCN110357578AExpand the usable rangePromote the development of circular economyDispersed particle filtrationDrying gas arrangementsSludgeExpanded clay aggregate

The invention provides a method for disposal of solid waste by a ceramsite kiln and a ceramsite kiln for disposal of solid waste. The ceramsite kiln includes a drying kiln and a calcination rotary kiln. The method includes: preparing ceramsite raw materials, which include solid waste; drying and calcining ceramsite, and enabling circulation flow of the generated flue gas along the drying kiln-calcination rotary kiln-drying kiln; cooling and discharging ceramsite; and disposing flue gas and tail gas. Specifically, the solid waste includes at least one of fly ash or organic solid waste; fly ashis selected from the incineration ash of at least one of domestic garbage, industrial waste or medical waste; the organic solid waste is selected from at least one of polluted soil, oily sludge, sludge obtained by chemical plant sewage treatment, medical solid waste or industrial waste residue. The method adopts fly ash and organic solid waste as the ceramsite raw materials, consumes fly ash and organic solid waste in the ceramsite manufacturing process, not only solves the hidden trouble of pollution caused by fly ash and organic solid waste, but also solves the cost problem caused by the limitation of ceramsite raw materials.

Owner:CHINA BUILDING MATERIALS ACAD

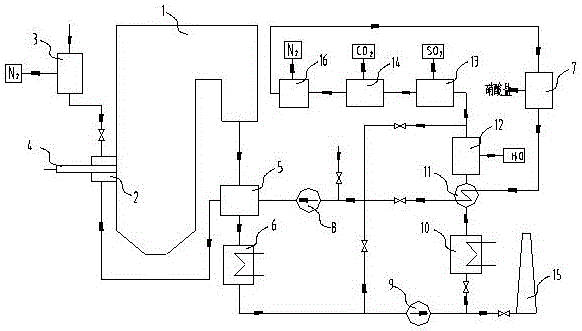

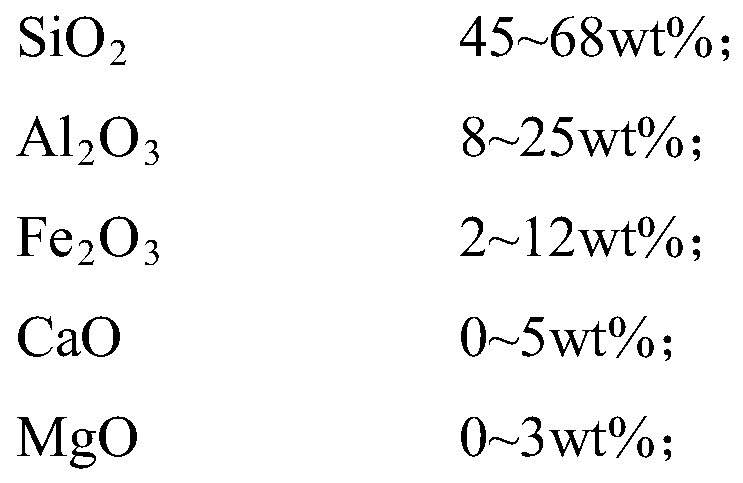

Coal-powder boiler oxygen-enriched combustion smoke near-zero emission and power generation system

InactiveCN105066113AAchieve integrated removalLow running costIndirect carbon-dioxide mitigationNon-combustible gases/liquids supplyBurn outPower generation system

The invention provides a coal-powder boiler oxygen-enriched combustion smoke near-zero emission and power generation system. The system is composed of a boiler, a burner, an air separation device, a powder production system, a multi-stage heat exchanger, a multi-stage deduster, a recirculation draught fan, an induced fan, a dewatering device, an SO2 separation device, a CO2 capture device, an N2 separator, an NOx reaction device and the like. It is ensured that coal powder of different coal types is ignited in time, burns stably and burns out by changing the oxygen concentration of primary air and secondary air and the total oxygen amount, the efficiency of the boiler is improved, and the adaptability of the boiler to loads and coal types is enhanced. Dust, vapor, SO2, NOx, CO2 and the like caused by combustion smoke of coal powder are recycled through all the devices, so that harmful gas, fine particles and microelements in smoke are integrally removed. Meanwhile, the smoke exhaust temperature is reduced to be close to the atmospheric temperature, so that near-zero emission of smoke is achieved, environment protection is achieved, and resource utilization is maximized.

Owner:SICHUAN CHUANGUO BOILER

Totally enclosed less-chrome tanning circulation technique based on zirconium-aluminum-titanium cooperation tanning agent

InactiveCN102978298AReduce the amount requiredLow in chromiumTanning treatmentPre-tanning chemical treatmentProcess engineeringNew materials

The invention discloses a totally enclosed less-chrome tanning circulation technique based on a zirconium-aluminum-titanium cooperation tanning agent, characterized in that the tanning system is formed into a totally enclosed circulation system so as to realize recycling of waste tanning liquid and thoroughly eliminate pollution caused by heavy metal chrome while greatly reducing the dosage of the chrome tanning agent. The technique has the advantages that no new material is added, the tanning liquid has stable components, no secondary pollution is caused, the investment is low and the operation is simple; the dosage of the zirconium-aluminum-titanium cooperation tanning agent and the dosage of the chrome agent are low, and the total dosage of two tanning agents is lower than 9%; the material cost is low and the utilization rate of the chrome salt is higher than 99%; the industrially produced crust leather has the shrinkage temperature of higher than 90 DEG C, and thus can be stored for a long time without deannage, and is excellent in water washing resistance; the grain side of the crust leather is fine, full and elastic and not easy to become loose; the leather body is light in color and excellent in dyeing property, and can be fabricated into different types of leather; and the solid waste is less in chrome content, thereby being convenient for recycling.

Owner:SICHUAN UNIV

Method for closed-circuit microorganism desulfurization and elemental sulfur recovery

ActiveCN107537293AInhibit excessive oxidationReduce secondary processing stepsMethane captureDispersed particle separationEnvironmental resistanceSulfur containing

The invention belongs to the environmental protection industry and the field of three-waste environmental protection purification, and relates to a method for closed-circuit microorganism desulfurization and elemental sulfur recovery, particularly to a process for biological desulfurization treatment of sulfur-containing industrial gases (such as biogas, natural gas, coal chemical industry processgas, refinery gas, sulfur-containing industrial waste gas, and the like, wherein the purposes of closed-circuit biological desulfurization, maximized recovery of elemental sulfur, standard emission of waste gas and near-zero emission of waste liquids can be achieved through chemical absorption, biological oxidation, elemental sulfur recovery, membrane separation, anaerobic reduction and other processes. According to the present invention, the treatment method can meet the biological desulfurization requirements, can solve the difficult problem of elemental sulfur production through sulfide oxidation and enhanced separation, and can be used for biogas, natural gas, coal-to-gas, refinery gas, sulfur-containing industrial waste gas and other industrial large-scale engineering.

Owner:CHINA PETROLEUM & CHEM CORP +1

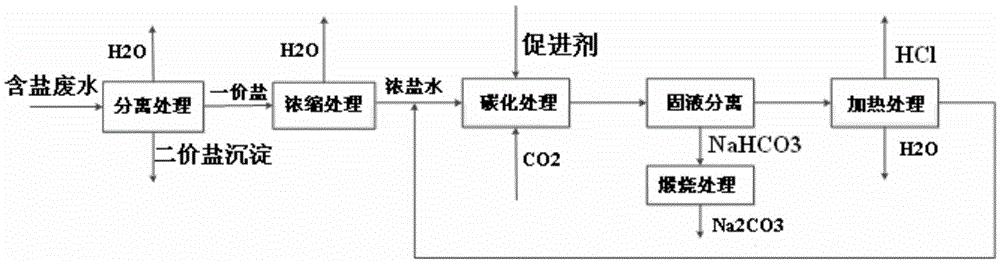

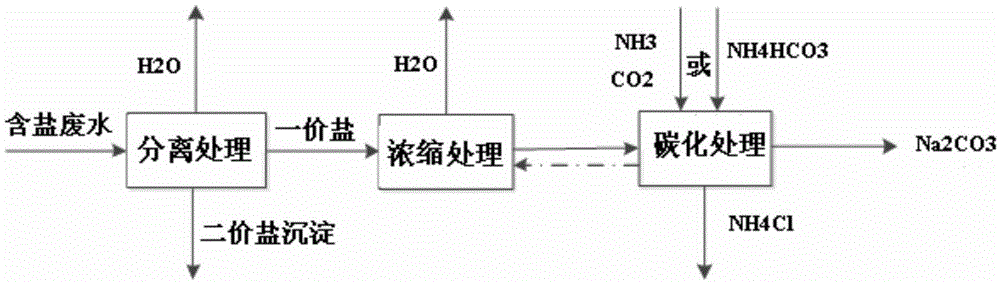

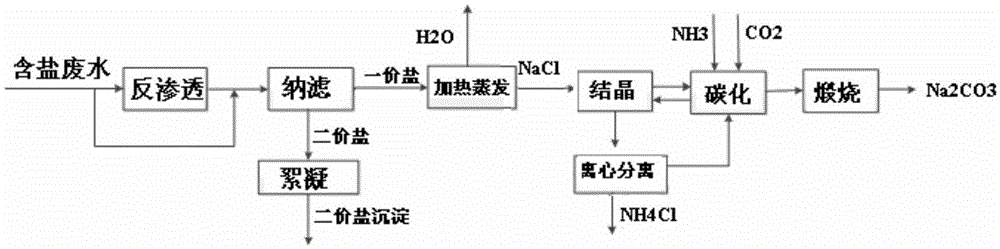

Method for producing sodium carbonate with salt-containing wastewater and CO2

InactiveCN106673019AAddress carbon reduction pressureImprove economyProductsReagentsSodium carbonateChemistry

The invention relates to the field of coal chemical engineering wastewater treatment, and discloses a method for producing sodium carbonate with salt-containing wastewater and CO2. The method comprises the following steps: (1) performing separation treatment on the salt-containing wastewater so as to remove divalent salts in the salt-containing wastewater and obtain mono-valent salt enriched salt-containing water; (2) in the presence of an accelerant and CO2, performing carbonization treatment on the mono-valent salt enriched salt-containing water so as to obtain a sodium bicarbonate precipitate and carbonization mother liquor; (3) performing calcining treatment on the sodium bicarbonate precipitate, thereby obtaining sodium carbonate. By adopting the method disclosed by the invention, CO2 discharged from coal chemical industry production can be successfully used in the salt-containing wastewater treatment process, and besides the difficulty in treating NaCl with a low additional value in the salt-containing wastewater, and great carbon emission reduction burden can be effectively solved, certain economic benefits can be made, and effective technical methods for achieving the purpose of zero emission of the salt-containing wastewater can be provided for enterprises of coal chemical industry and the like.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

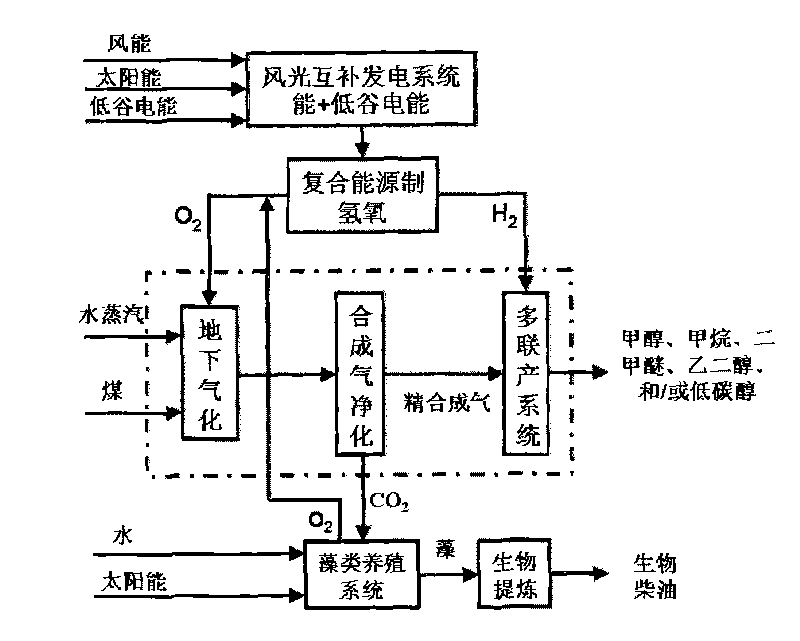

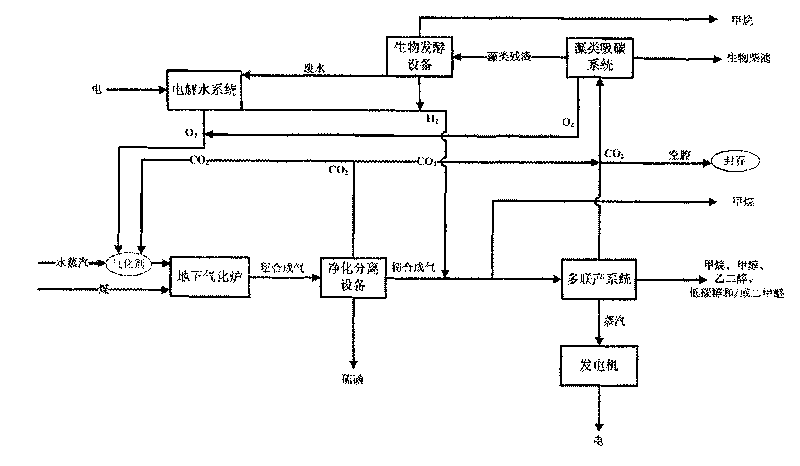

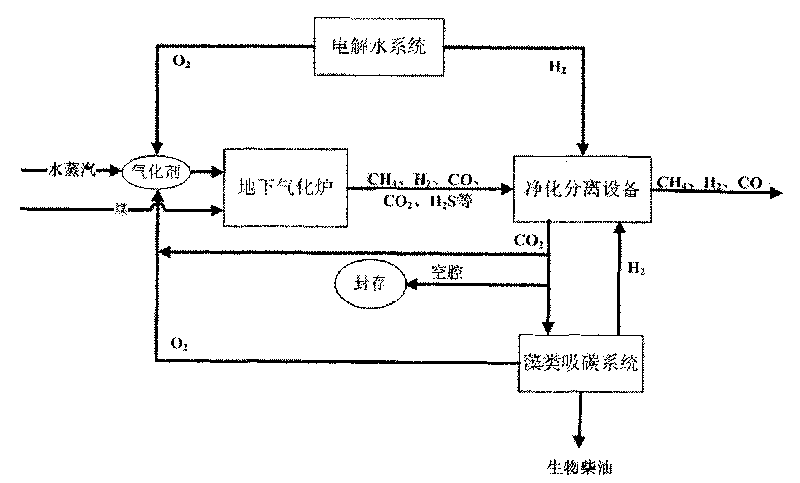

Underground gasification coal derived energy chemical product poly-generation system and method

ActiveCN101760249ALow costSimple processInternal combustion piston enginesBiofuelsCarbon dioxideZero emission

The invention relates to an underground gasification coal derived energy chemical product poly-generation system and a method; by coupling the underground gasification coal and the traditional coal derived energy chemical product poly-generation system, the coal is converted into clean energy chemical product and / or clean electricity such as methane, and the renewable energy and renewable resources are led in the production process of the coal derived energy chemical products, the comprehensive utilization of waste water, waste gas and solid waste and near-zero emission of carbon dioxide are realized.

Owner:ENN SCI & TECH DEV

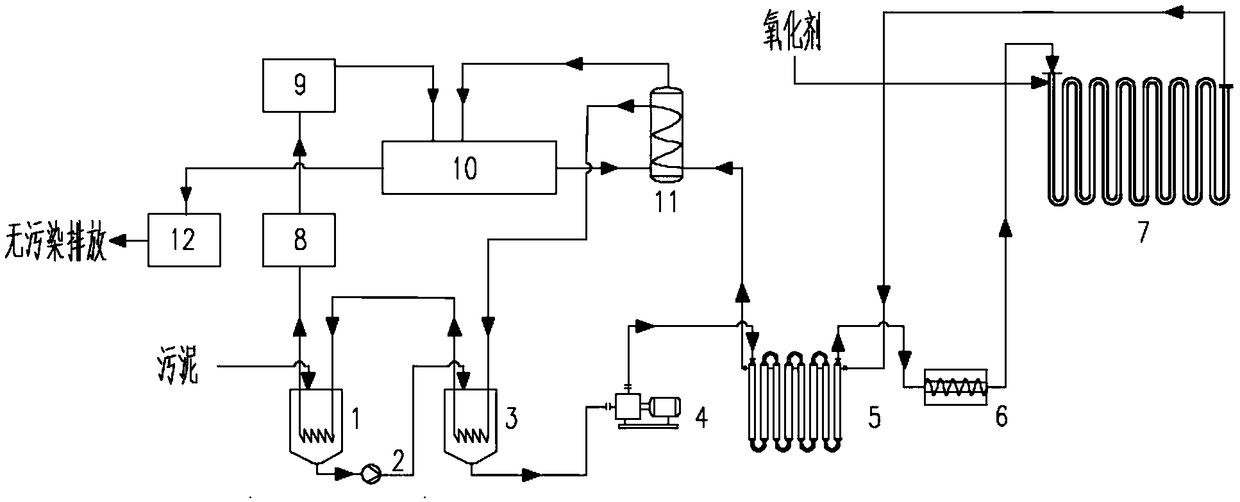

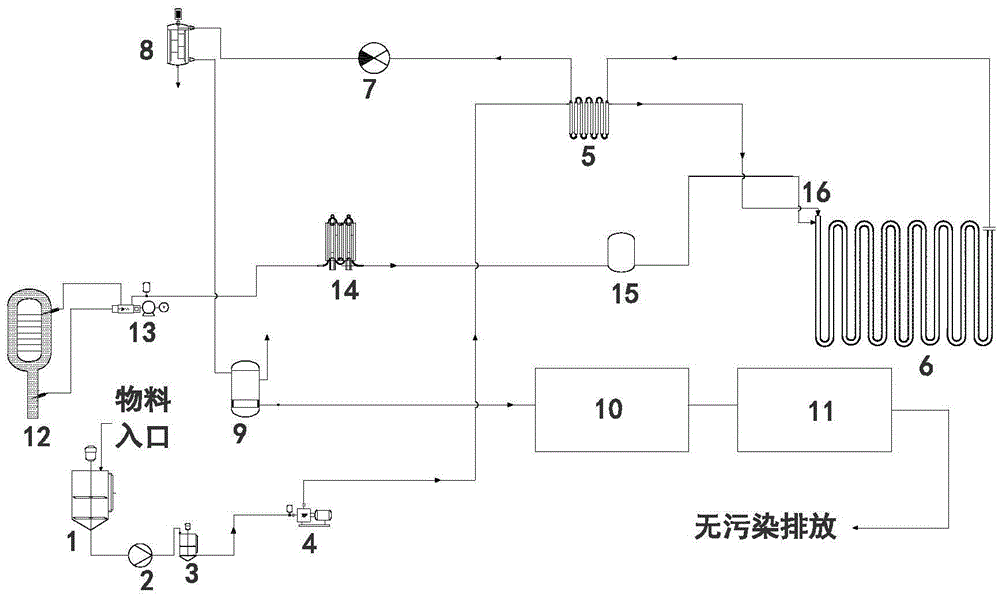

Near zero emission treatment system and method for high-concentration organic wastewater and sludge

ActiveCN105601017AEfficient separationStabilized landfillTreatment involving filtrationMultistage water/sewage treatmentHigh concentrationSludge

The invention discloses a near zero emission treatment system and method for high-concentration organic wastewater and sludge, and belongs to the technical field of chemical engineering and environment protection. The supercritical water oxidation technology is used as the core, waste water and sludge are ground through a sludge homogeneity pump first and are then pressurized through a high-pressure plunger pump and conveyed to a subsequent pipeline to be preheated and mixed with oxygen, and supercritical water oxidation reaction is conducted in a reactor. Fluid obtained after reaction sequentially passes through a self-washing filter and a gas-liquid separator after being subjected to pressure reduction of a pressure reduction device so that insoluble solid and gas can be separated, the fluid then crystallizes through the mechanical vapor recompression (MVR) technology, soluble salt crystallization is conducted, and near zero emission of fed materials is achieved. Meanwhile, the conventional water treatment technologies (such as coagulating sedimentation, the membrane biology technology and the membrane technology) are used for assisting the SCWO technology, running parameters of the SCWO reactor are appropriately decreased, a part of residual COD is processed through the conventional water treatment technology, and the running cost is effectively reduced.

Owner:XI AN JIAOTONG UNIV +1

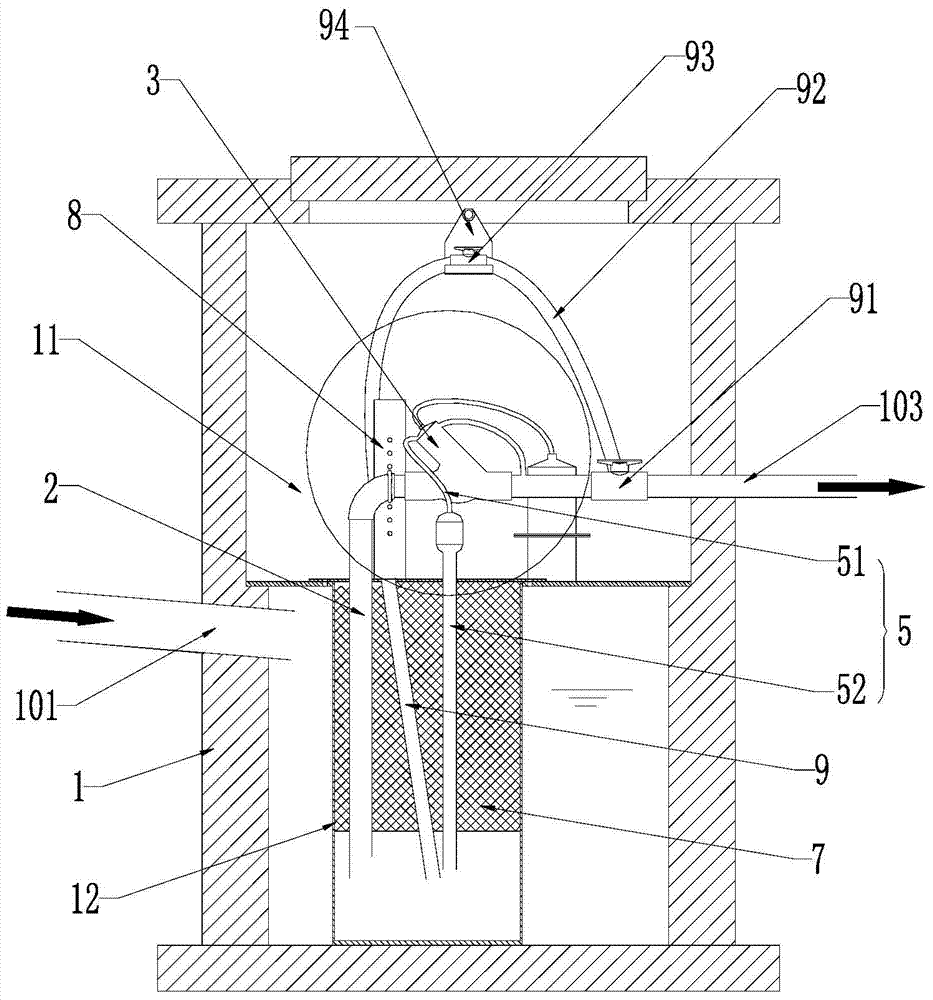

Organic solid rubbish combustion integration device and method

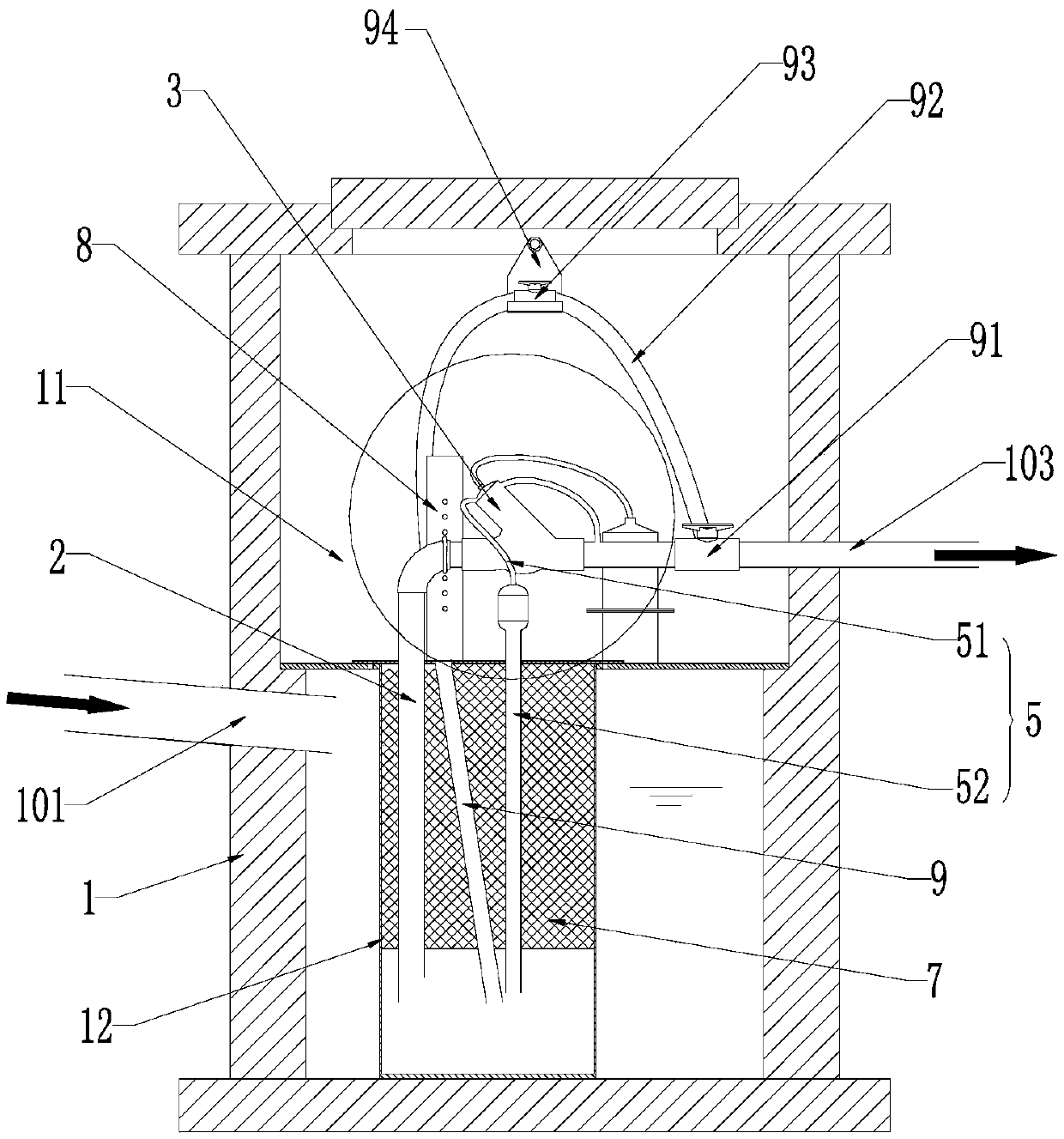

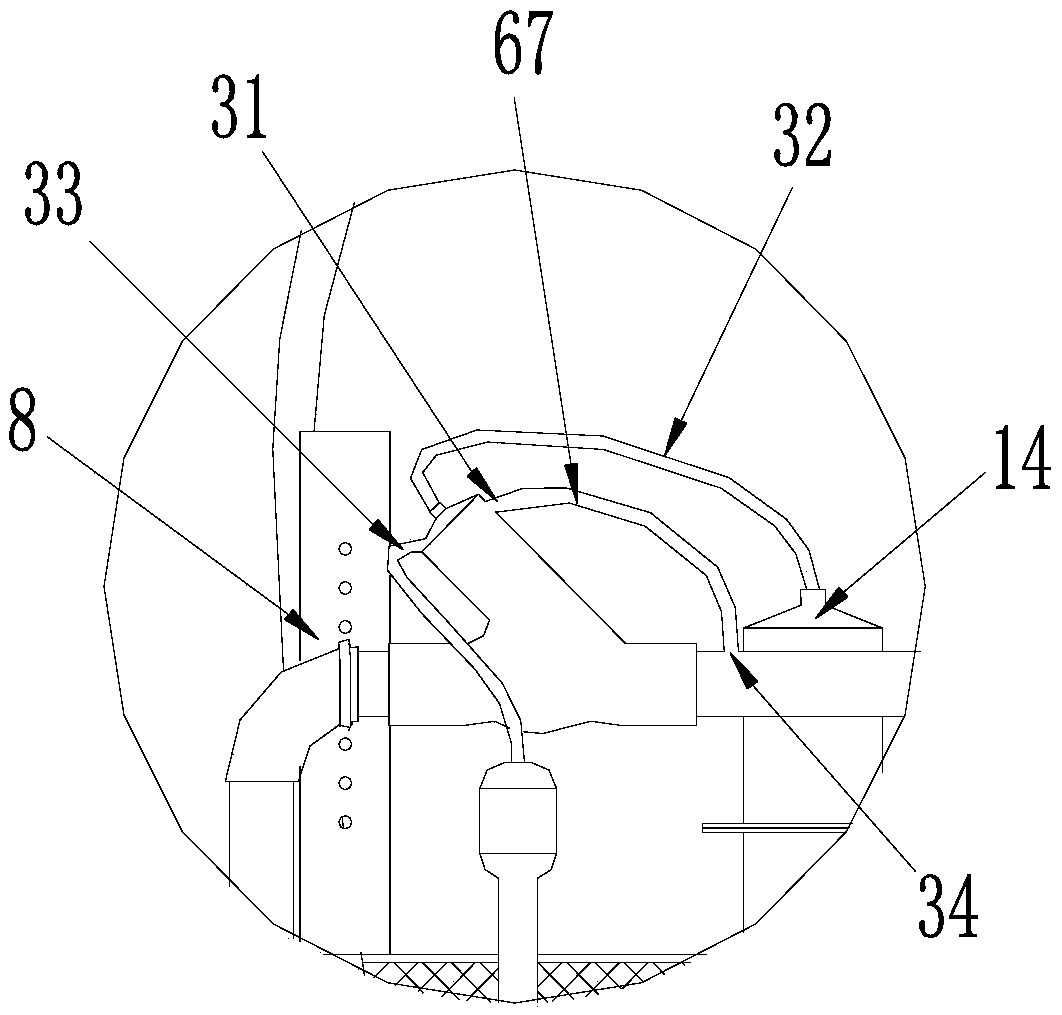

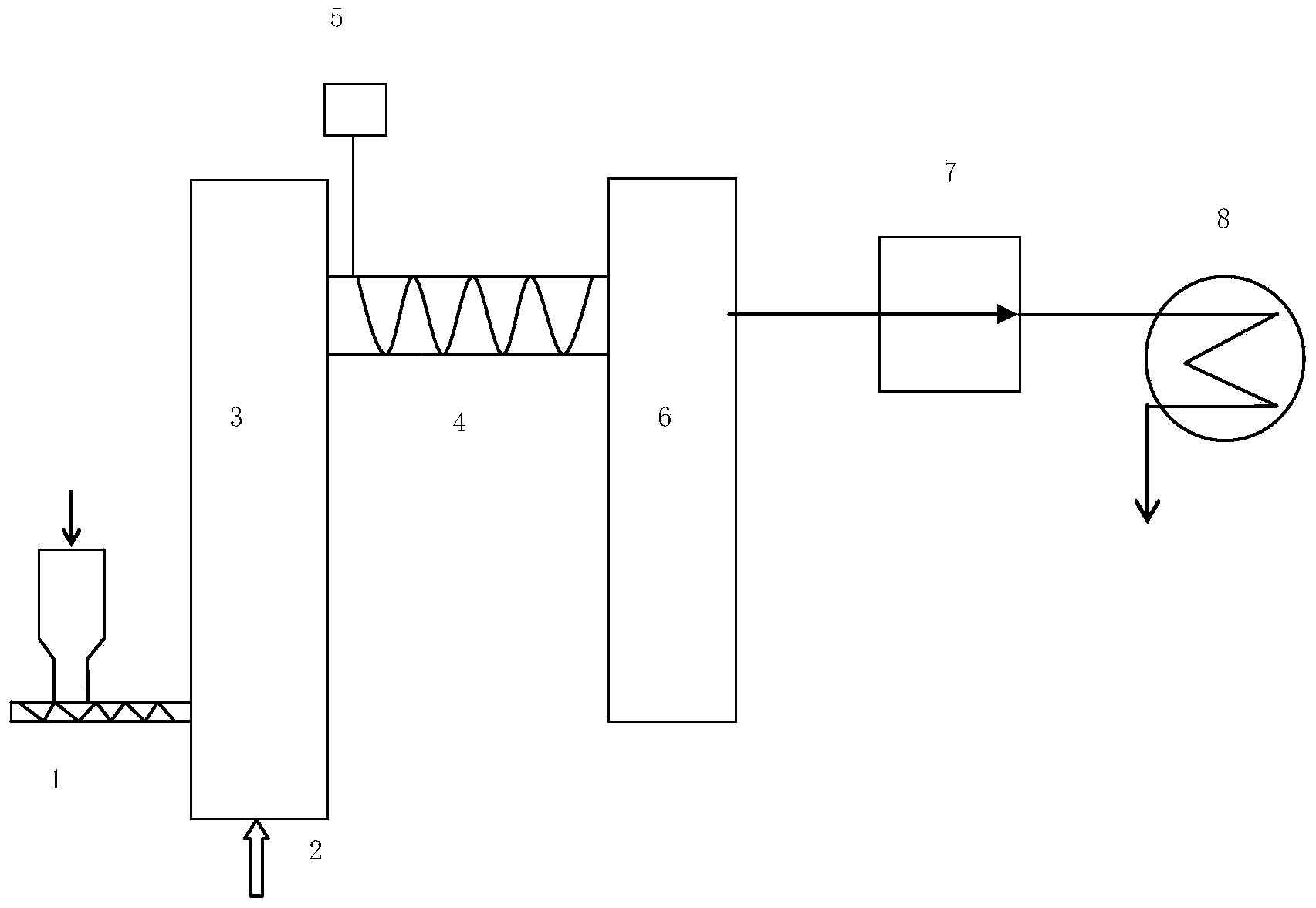

ActiveCN104266195AAchieve near-zero emissionsReasonable structureMachines/enginesIncinerator apparatusCombustionFlue gas

The invention relates to an organic solid rubbish combustion integration device and an organic solid rubbish combustion integration method. The organic solid rubbish combustion integration device is mainly composed of a combustion device, a variable heat exchanger, an area adjuster, a high temperature dust extraction device, a waste heat boiler and a power generation device. The organic solid rubbish combustion integration method includes the steps that organic solid rubbish is fed into the combustion device through a feeder, and simultaneously combustion agents are input into the bottom of the combustion device, high temperature flue gas generated after the rubbish fully burns is exhausted out from an outlet at the upper end of the combustion device, and then enters the variable heat exchanger, the variable heat exchanger is controlled through the area adjuster and used to adjust the heat exchange area between the high temperature flue gas and the variable heat exchanger, and then controls temperature of the high temperature flue gas which enters the high temperature dust extraction device, the high temperature flue gas enters the high temperature dust extraction device for purification treatment after the high temperature flue gas passes through the variable heat exchanger, and finally gas obtained after the high temperature flue gas is purified enters the waste heat boiler and used by the power generation device to generate power.

Owner:DALIAN UNIV OF TECH

Method and device for removing CO2 in fire coal fume based on CO2 circulating carried gas

InactiveCN101607165AAchieve near-zero emissionsSimple processCombination devicesPotassiumProduct gas

The invention relates to a method and a device for removing CO2 in fire coal fume based on CO2 circulating carried gas, being characterized in that: when fume is purified, partial CO2 gas stored in a gas storage tank is taken as the fluidization gas of a first fluidized bed reactor, then a potassium radical absorber is used for removing the CO2 in fire coal fume and the CO2 as the fluidization gas of the first fluidized bed reactor out to be stored in the gas storage tank for recycling; the potassium radical absorber is used for removing the CO2 in the first fluidized bed reactor, and the potassium radical absorber can be regenerated and recycled. The removing method of the invention is simple in process, can realize near zero emission of CO2, thus greatly reducing the running cost of the system and having obvious environment benefit.

Owner:DONGHUA UNIV

Method for recycling and treating reclaimed wastewater of makeup water treatment system of power plant

InactiveCN105502758AAchieve near-zero emissionsReliable recyclingGeneral water supply conservationTreatment involving filtrationWater treatment systemElectrolysis

The invention discloses a method for recycling and treating reclaimed wastewater of a makeup water treatment system of a power plant, which includes the steps of regulation of the pH value of mixed reclaimed wastewater, filtration, reverse osmosis desalination, electrolysis and the like. By means of simple process combination, the method realizes the nearly zero emission of the reclaimed wastewater of the makeup water treatment system of the power plant, i.e., most of the reclaimed wastewater is recovered, only a small amount of filter backwashing water is discharged out, moreover, an industrial salt component in the reclaimed wastewater is completely recycled, and thereby the high-efficiency and reliable recycling of the reclaimed wastewater of the makeup water treatment system of the power plant is realized.

Owner:STATE GRID HEBEI ENERGY TECH SERVICE CO LTD

Method for treating waste water by utilizing dust-containing smoke gas of coal-fired boiler

ActiveCN103214118AReduce upfront investmentAchieve near-zero emissionsUsing liquid separation agentWater/sewage treatmentWater treatment systemWater discharge

The invention discloses a method for treating waste water by utilizing dust-containing smoke gas of a coal-fired boiler. The method comprises the following steps of: filtering waste water; atomizing the filtered waste water into small liquid particles with particle size being less than or equal to 100 microns; and mixing with the dust-containing smoke gas of the coal-fired boiler, wherein the mass flow ratio of the waste water to the dust-containing smoke gas of the coal-fired boiler is less than or equal to 1 / 100, the temperature of the dust-containing smoke gas of the coal-fired boiler is 130 to 180 DEG C, and the smoke dust content of the dust-containing smoke gas is 10 g / Nm<3> to 50 g / Nm<3>. The method is simple; equipment is convenient; the earlier-stage investment of a waste water treatment system is reduced; the operating cost of the traditional treatment method is reduced; the problem of differential treatment caused by difference and instability of waste water discharge is overcome; near zero emission of the waste water is realized; the afterheat of the smoke gas is utilized; and the actual requirements of energy conservation and environmental protection are met.

Owner:STATE GRID CORP OF CHINA +2

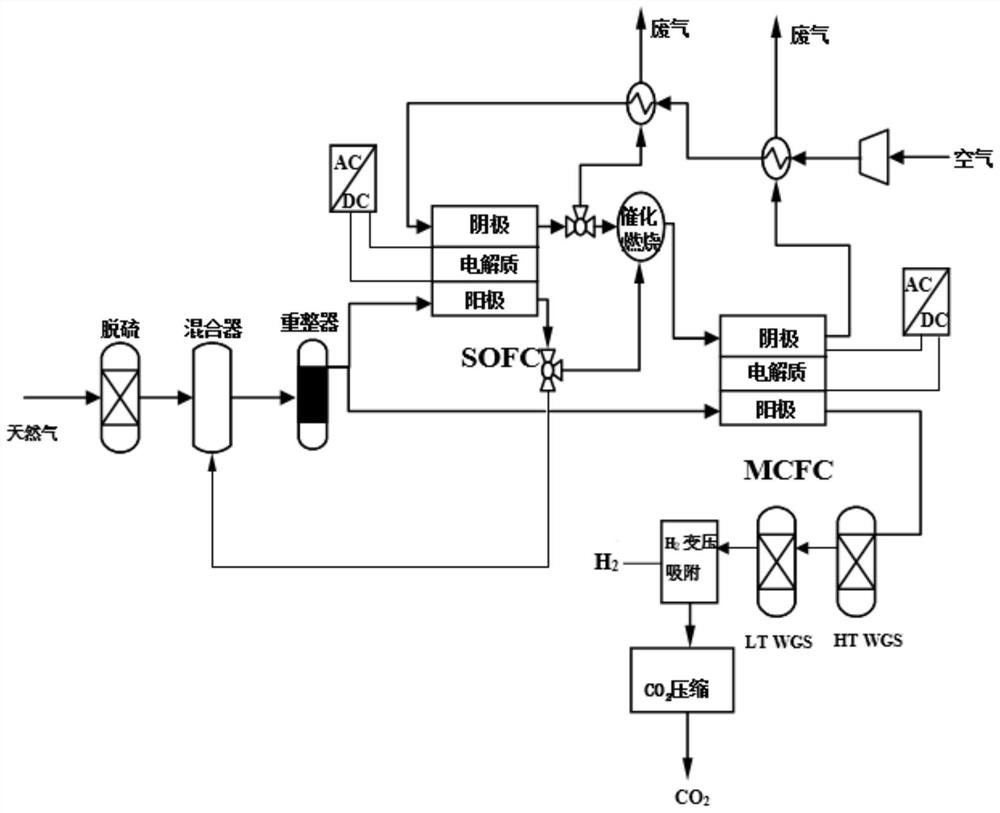

Carbon dioxide near-zero emission composite fuel cell power generation system and power generation method thereof

PendingCN111613819AEmission reductionCapture implementationReactant parameters controlCell electrodesFuel cellsElectrical battery

The invention discloses a carbon dioxide near-zero emission composite fuel cell power generation system and a power generation method thereof. The system comprises a solid oxide fuel cell, a molten carbonate fuel cell, a water gas reaction unit and a carbon dioxide compression unit, wherein a cathode gas outlet of the solid oxide fuel cell is connected with a cathode gas inlet of the molten carbonate fuel cell; a cathode tail gas outlet of the molten carbonate fuel cell is connected with a gas inlet of the water gas reaction unit, the water gas reaction unit is connected with the carbon dioxide compression unit, and the carbon dioxide compression unit is used for compressing carbon dioxide to realize storage of the carbon dioxide; by adopting the composite fuel cell, the performance and the power generation efficiency of the cell stack are improved, and near-zero emission of carbon dioxide is realized.

Owner:HUANENG CLEAN ENERGY RES INST

CFB oxygen-enriched combustion smoke near zero emission power generation system

InactiveCN105042610AAchieve integrated removalLow running costCombustion processDirect carbon-dioxide mitigationWater vaporBurn out

The invention provides a CFB oxygen-enriched combustion smoke near zero emission power generation system which is composed of a boiler, a powder feeding system, an air separating device, a chimney, multiple stages of heat exchangers, multiple stages of dust removers, a recirculating fan, an induced draft fan, a dewatering device, an SO2 separating device, a CO2 catching device, an N2 separator, an NOx reaction device and the like. By changing the concentration of oxygen in secondary gas, it is ensured that coal of different types is stably combusted and burnt out, boiler efficiency is improved, and the adaptability of the boiler to loads and coal types is enhanced. Through all the devices, dust, vapor, SO2, NOx, CO2 and the like brought by coal powder combustion smoke are recycled, harmful gas, fine particles and trace elements in the smoke are integrally removed, the smoke exhaust temperature is lowered to be close to the atmosphere temperature, the near zero emission of the combustion smoke is achieved, the environment is protected, and the maximization of resource utilization is achieved.

Owner:SICHUAN CHUANGUO BOILER

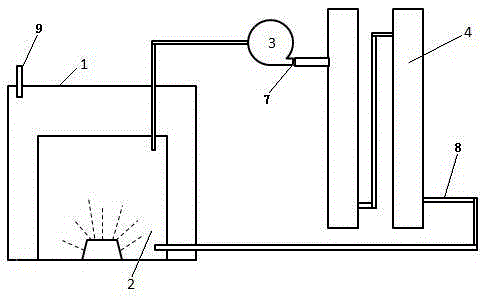

Sewage vacuum collection and treatment system

ActiveCN105507410BChange the singularityImprove securityCesspoolsFatty/oily/floating substances removal devicesSites treatmentSewage

The invention discloses a vacuum sewage collecting and treating system. The vacuum sewage collecting and treating system comprises a sewage gathering pipeline, a vacuum collection well, a vacuum conveying pipeline, a vacuum pump station and a sewage treating device, wherein the sewage enters the vacuum collection well through the sewage gathering pipeline; when the sewage collected in the well reaches a certain amount, the sewage enters the vacuum pump station along the vacuum conveying pipeline; when the liquid level of the sewage in a vacuum sewage storage tank reaches a predetermined liquid level, the sewage conveying pump is started and is used for conveying the sewage to the sewage treating device to purify the sewage. Through the vacuum sewage collecting and treating system, the domestic sewage collection method is changed from the conventional gravity collection into vacuum collection; the sewage treatment is charged from a manner of discharging the sewage into a sewage pipe net and carrying out centralized treatment on the sewage to a process of carrying out on-site treatment by using a small integrated membrane treatment device; collection and treatment are integrated to a complete set of system; the system is not limited by basic supporting facilities and is not required to relay on urban drainage facilities; the system is integrated with the ecological environmental protection technology with efficient collection and efficient treatment functions and is especially suitable for regions such as small towns and countries and the like in which sewage treatment plants are unsuitably built.

Owner:QINGHUAN TUODA (SUZHOU) ENVIRONMENTAL TECH CO LTD

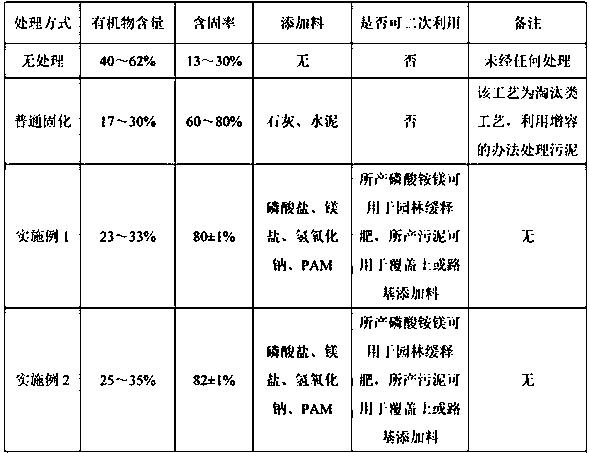

Sludge treatment method

ActiveCN110902981ARealize resourcesAchieve stabilizationWater treatment parameter controlSludge treatment by de-watering/drying/thickeningAmmoniacal nitrogenMagnesium salt

The invention discloses a sludge treatment method, which comprises the following steps: (1) preheating and diluting raw material sludge, and carrying out hydrothermal treatment; (2) carrying out heatexchange on the mud-water mixture subjected to hydrothermal treatment; (3) carrying out solid-liquid separation on the sludge-water mixture subjected to heat exchange to obtain sewage and thickened sludge, and carrying out low-temperature drying on the thickened sludge to obtain dried sludge and condensate; (4) carrying out anaerobic digestion on the sewage, filtering, and carrying out first quality conditioning; (5) evaporating and concentrating the sewage to obtain a sewage concentrated solution and ammonia nitrogen water obtained by condensation; and (6) performing second quality conditioning on the obtained ammonia nitrogen water by adopting phosphate and a magnesium salt, and performing solid-liquid separation to obtain a magnesium ammonium phosphate solid and filtrate. The method islow in comprehensive energy consumption, low in cost, easy in process implementation, short in treatment time, good in harmless effect, high in resource recovery rate, high in stability and high in energy utilization rate.

Owner:HUNAN JUNXIN ENVIRONMENTAL PROTECTION CO LTD

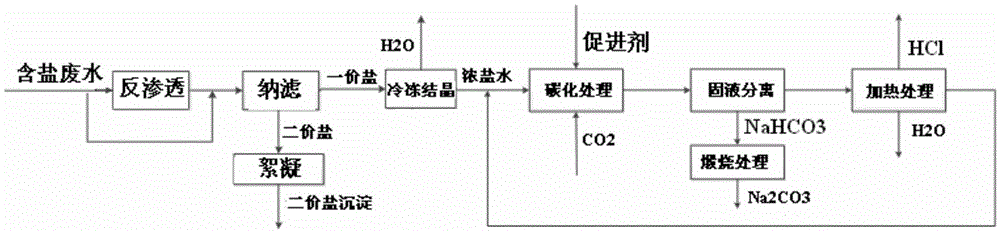

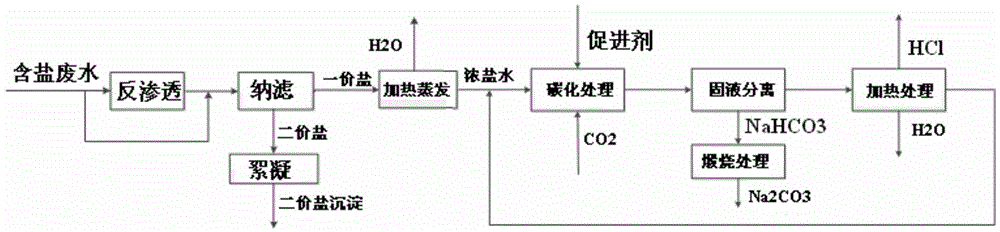

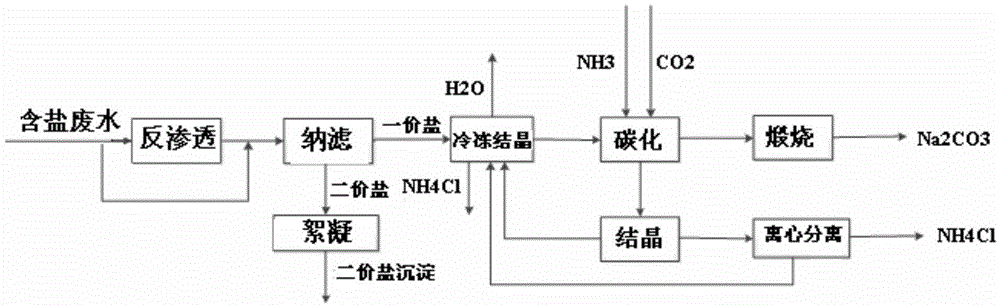

Method for co-producing sodium carbonate and ammonium chloride by utilizing salt-containing wastewater

InactiveCN106673020ASolving Disposal ProblemsHuge pressure to reduce carbon emissionsCarbonate preparationAmmonium chlorideSodium bicarbonateCarbonization

The invention relates to the field of coal chemical industrial wastewater, and discloses a method for co-producing sodium carbonate and ammonium chloride by utilizing salt-containing wastewater. The method comprises: (1) separating the salt-containing wastewater, and removing divalent salt in the salt-containing wastewater to obtain saline water rich in univalent salt; (2) performing carbonization treatment on the saline water rich in the univalent salt to obtain sodium bicarbonate precipitates and carbonized mother liquor; (3) performing calcination treatment on the sodium bicarbonate precipitates obtained in the step (2) to obtain sodium carbonate; (4) performing crystal separation treatment on the carbonized mother liquor obtained in the step (2) to obtain ammonium chloride. The method of the invention not only can effectively solve the problem of disposal of low-additional-value NaCl in the salt-containing wastewater, but also can generate a certain economic benefit, an effective technical means is provided for enterprises such as coal chemical industries to achieve the aim of zero release of the salt-containing wastewater, and the problem of disposal of the low-additional-value NaCl in the salt-containing wastewater and the great carbon emission reduction pressure can be solved.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Combined desulfurization and denitration method for novel dry-process cement production line

InactiveCN110981239ARealization of desulfurization and denitrificationLow costGas treatmentDispersed particle separationPtru catalystProcess engineering

A combined desulfurization and denitration method for a novel dry-process cement production line is disclosed. The method includes adding a raw material modifier and a liquid desulfurization and denitration agent which are two parts into the cement production line. The raw material modifier is added at a raw material elevator, and the liquid desulfurization and denitration agent is added at a windpipe among cyclone preheaters C1-C3. The raw material modifier includes 10-98% of a SO2 absorbent, 0.01-30% of an active component promoting SO2 absorption, 0.01-30% of an active component promotinglimestone decomposition, and 0.01-30% of a denitration catalyst adopting clay as a carrier. The liquid desulfurization and denitration agent includes 0.1-25% of ammonia water, 0.1-40% of a urea solution, or a solution mixture of both. The method has technical advantages of good desulfurization and denitration effects, low cost and no secondary pollution.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com