Method and device for removing CO2 in fire coal fume based on CO2 circulating carried gas

A technology of coal-fired flue gas and circulating carrier gas, which is applied in the direction of combined devices, separation methods, chemical instruments and methods, etc., can solve the problems of high operating cost of carbon dioxide, reduced power generation efficiency of power plants, low carbon dioxide removal rate, etc., and achieve environmental protection Significant benefits, reduced system operating costs, simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

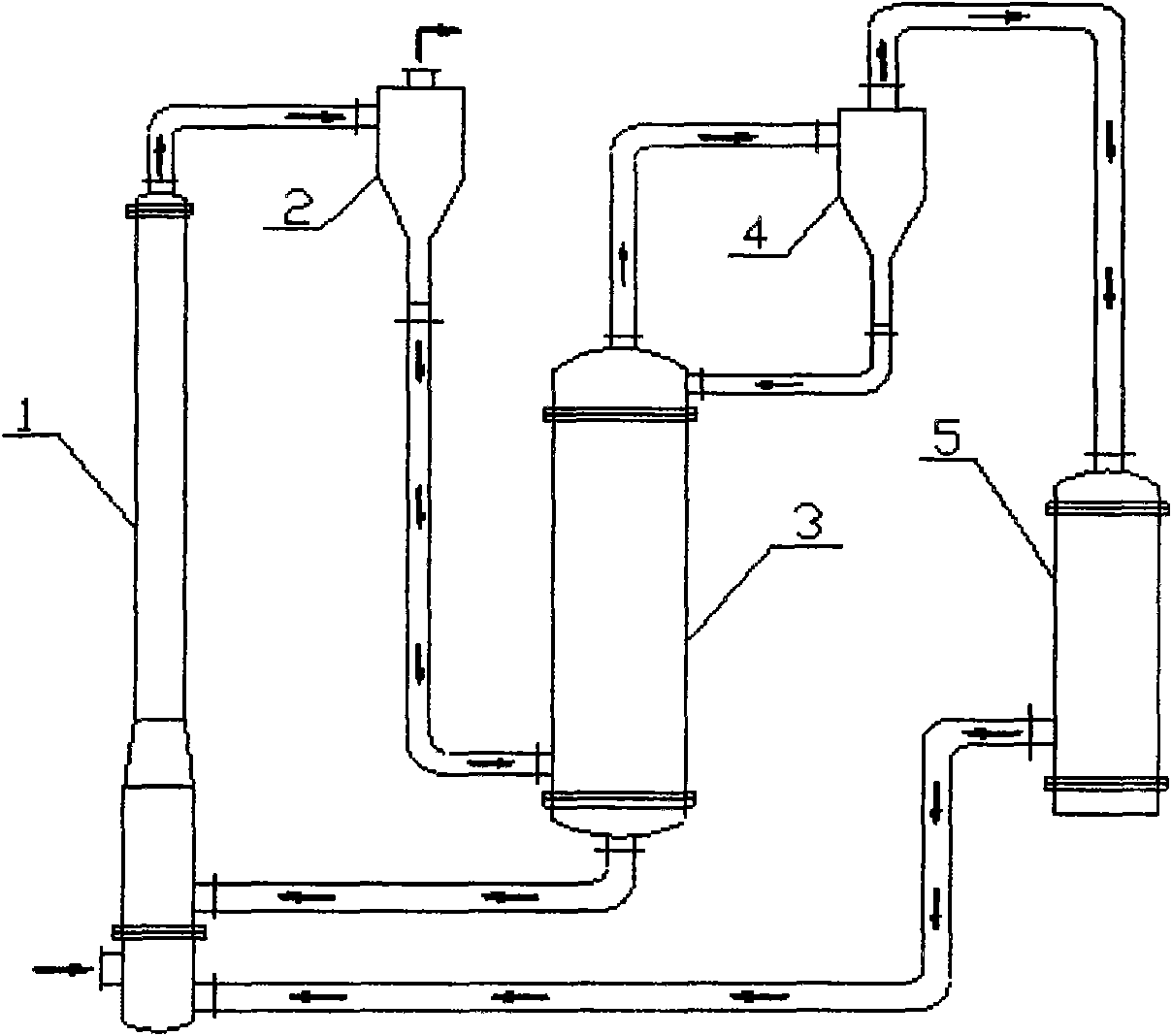

[0023] Such as figure 1 As shown, the present invention is implemented based on a CO 2 Removal of CO from coal-fired flue gas by circulating carrier gas 2 The device of method is made up of first stage fluidized bed reactor (1), second stage fluidized bed reactor (3), first stage cyclone separator (2) and second stage cyclone separator (4) and carbon dioxide storage Gas tank (5) is formed.

[0024] (1) When the inventive method is purifying the flue gas, the coal-fired flue gas enters the first-stage fluidized-bed reactor (1) through the bottom flue gas inlet of the flue gas first-stage fluidized-bed reactor (1); At the same time, part of the carbon dioxide gas collected in the gas storage tank (5) is used as the fluidizing gas of the first-stage fluidized bed reactor (1), and the fluidized gas at the bottom of the first-stage fluidized bed reactor (1) is The inlet enters the first stage fluidized bed reactor (1);

[0025] (2) The potassium-based absorbent in the first-sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com