Patents

Literature

30results about How to "Achieve integrated removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

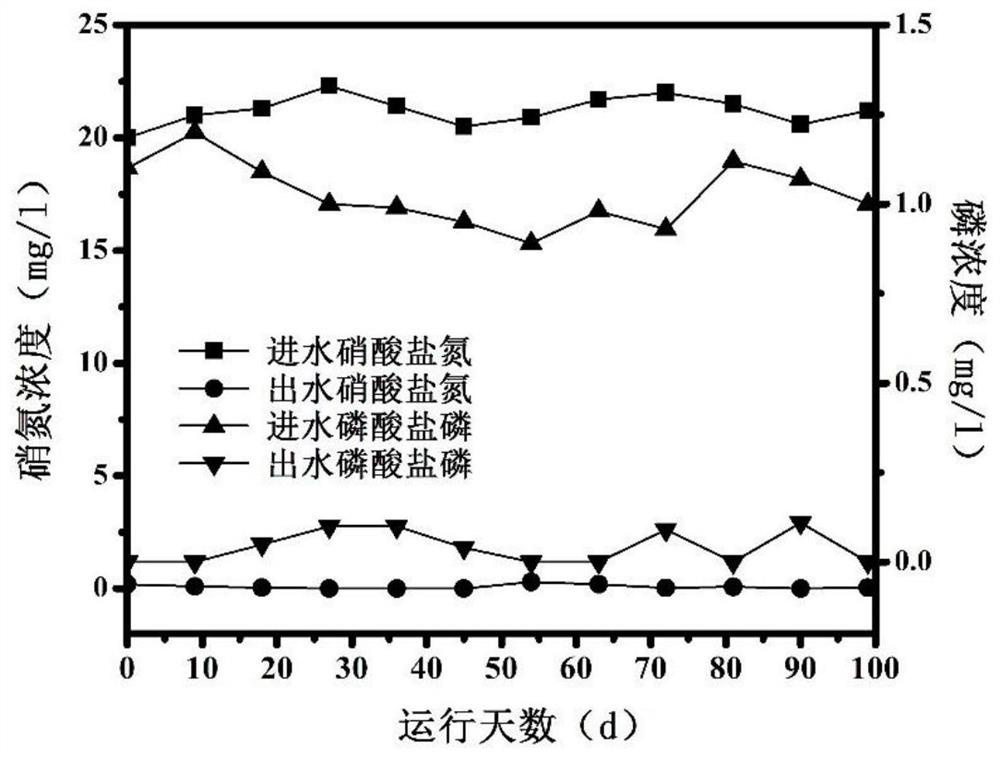

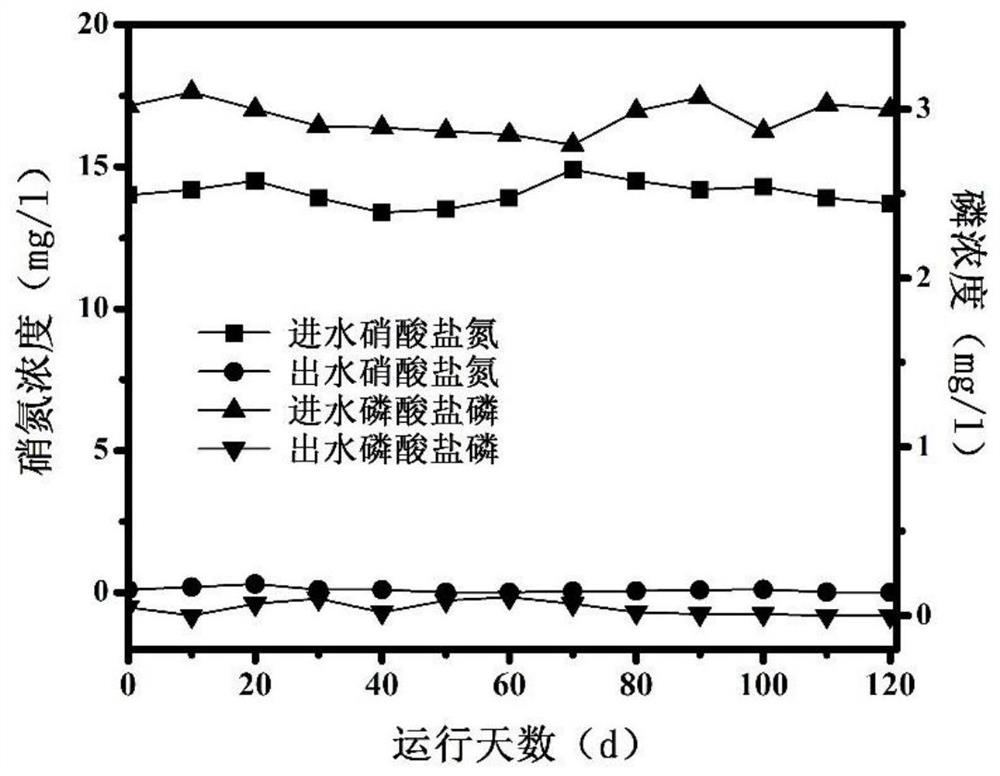

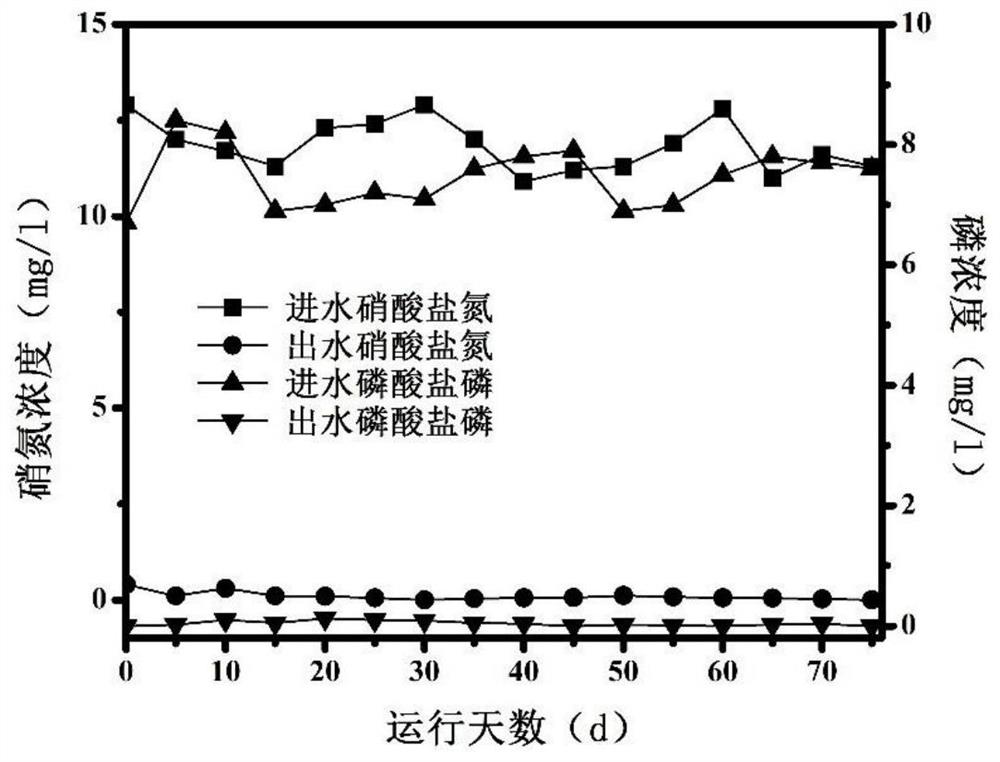

Coupling filler autotrophic denitrification biofilter and application

ActiveCN109052641ADifficult to dissolveIncrease speedWater treatment compoundsTreatment with anaerobic digestion processesBiofilmSewage

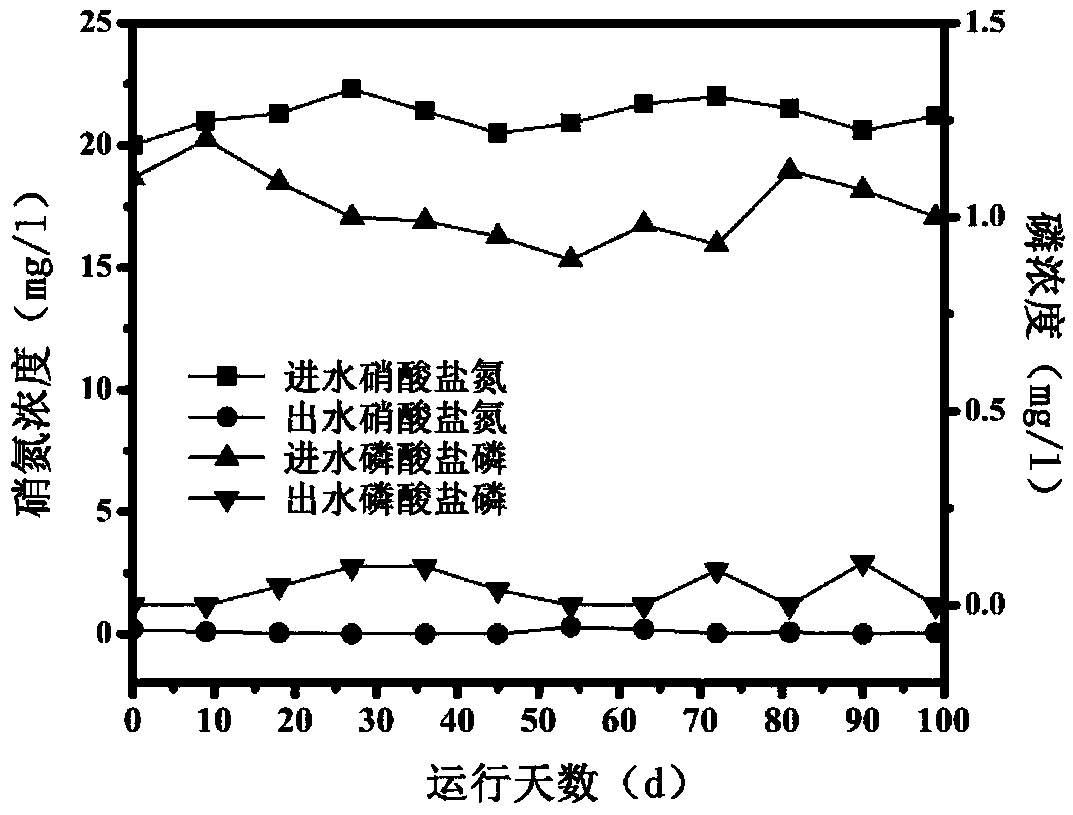

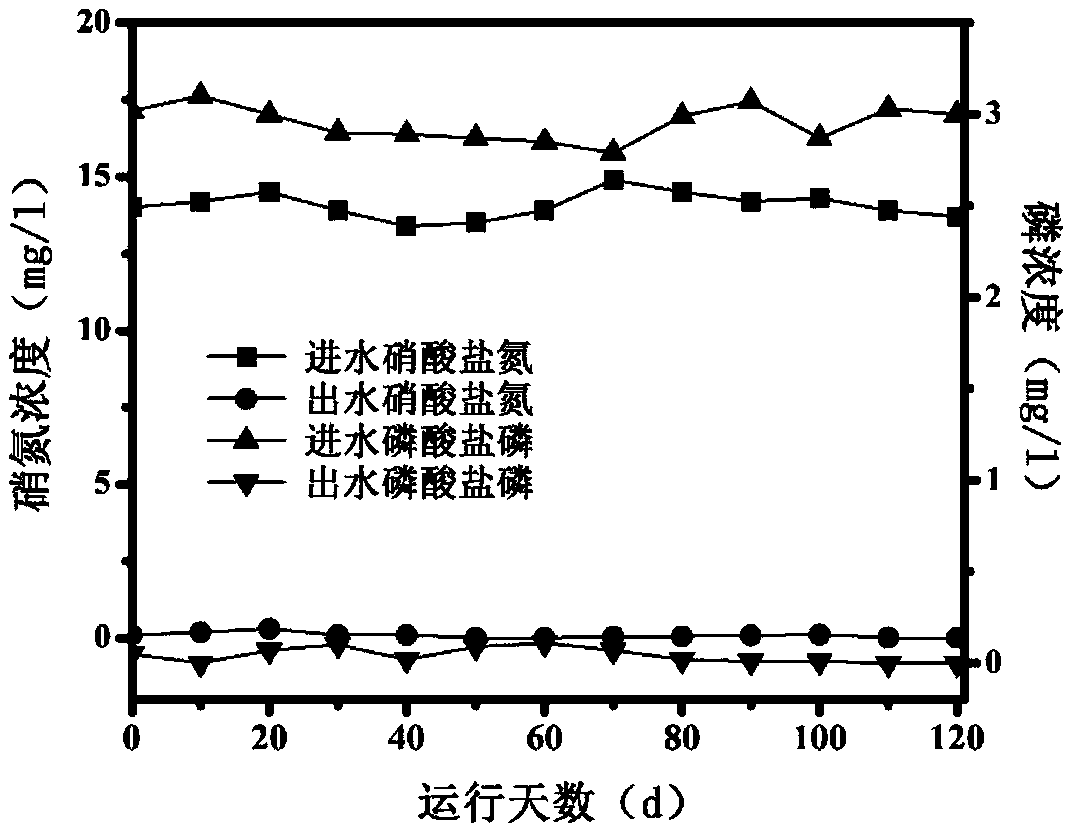

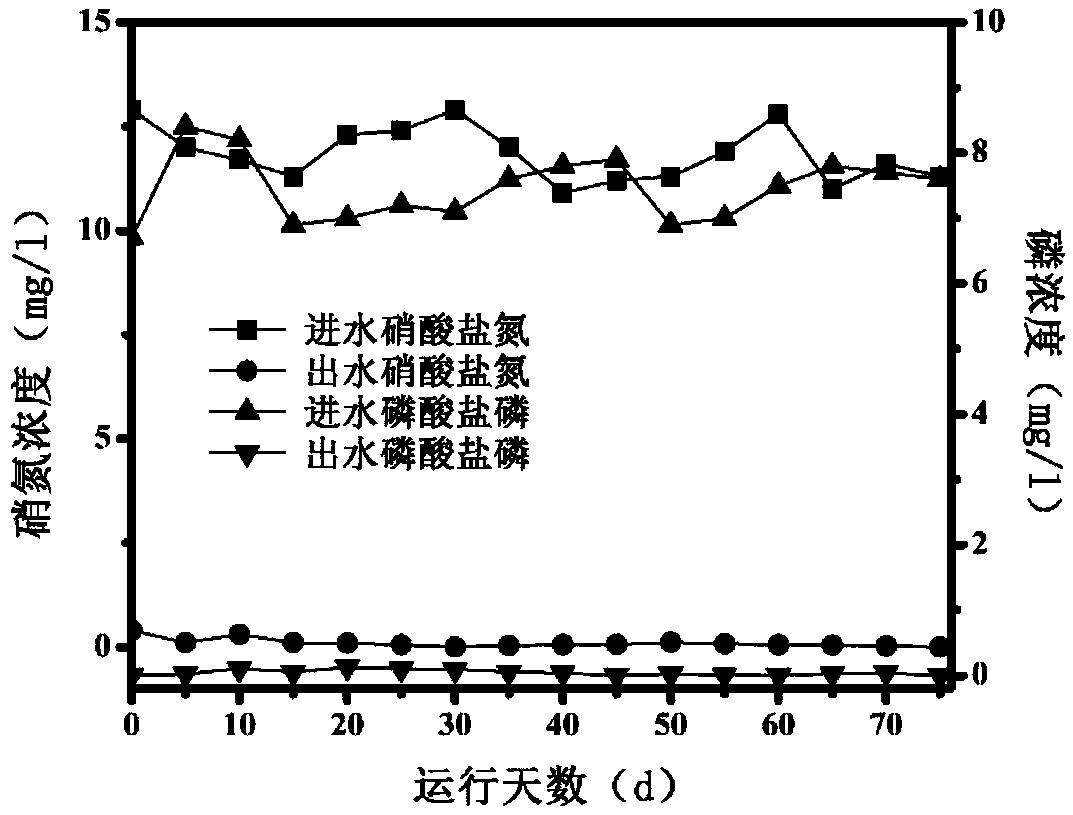

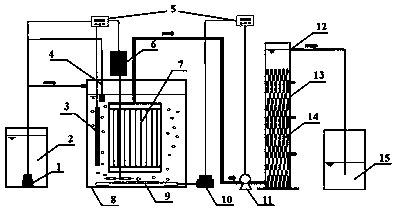

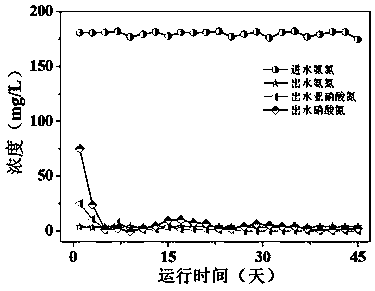

The invention discloses a coupling filler autotrophic denitrification biofilter and application and belongs to the technical field of sewage treatment. Pyrrhotite, sulfur and a carbon source are utilized to be mixed and coupled according to certain proportion; then the materials are put into a reactor, and the autotrophic denitrification biofilter can be formed after inoculating biofilm formation;sewage flows through the biofilter, and nitrogen and phosphorus in the water are removed. The biofilter disclosed by the invention has the advantages of simpleness, easiness, practicability and shortbiofilm formation time; when the biofilter is utilized to treat nitrogen and phosphorus containing sewage, hydraulic retention time is only 0.5 to 3 h, and yielding water can meet a requirement; furthermore, the biofilter has the advantages of excellent nitrogen and phosphorus removal effect, low cost and suitability for engineering application.

Owner:NANJING UNIV

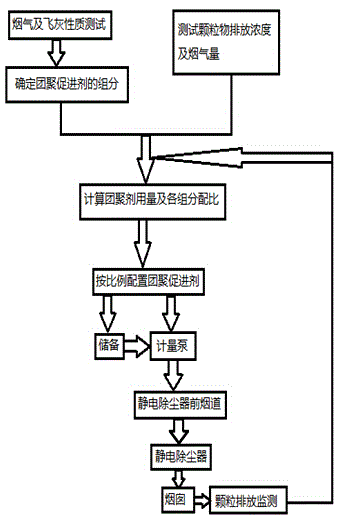

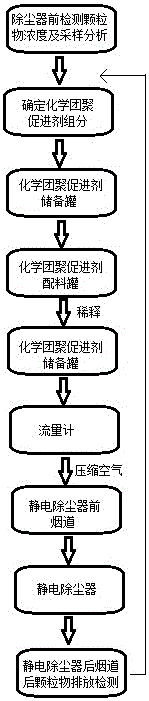

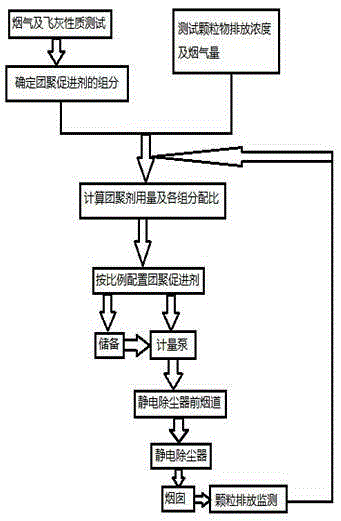

Chemical agglomeration promoter for removing fire coal fine particulate matters and application method of chemical agglomeration promoter

ActiveCN104474830APromote agglomeration and flocculationAgglomeration and flocculation are beneficialAuxillary pretreatmentElectrostatic separationFlue gasFine particulate

The invention discloses a chemical agglomeration promoter for removing fire coal fine particulate matters. The chemical agglomeration promoter is prepared from poly-dimethyl-diallyl-ammonium chloride, sorbitan fatty acid ester and water, wherein the mass percent of poly-dimethyl-diallyl-ammonium chloride is 0.001%-0.01%; and the mass percentage of the sorbitan fatty acid ester is 0.001%-0.1%. The invention also discloses an application method of the chemical agglomeration promoter. The chemical agglomeration promoter is capable of effectively promoting fine particles in a gas flue to agglomerate and flocculate to form large particles, and carrying out integral removal on heavy metals in a flue gas; the efficiency of a dust remover for removing fine particulate matters is improved; and the environment problem is effectively relieved.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

Chemical agglomeration promoter

ActiveCN105771531APromote agglomeration and flocculationReduce surface tensionAuxillary pretreatmentDifferential sedimentationChemical compositionCompound (substance)

The invention provides a chemical agglomeration promoter.The chemical agglomeration promoter is prepared from, by mass, 0.001%-0.01% of polyethyleneimine, 0.001%-0.1% of tween-80 and the balance water.The chemical agglomeration promoter is wide in raw material source, low in price, environmentally friendly, simple in chemical composition, simple and fast in synthesis process and free of harm to the environment; the agglomeration effect on fine particulate matter is significant, and the fine particulate matter emission of a coal-fired power plant can be reduced by 60% or above; besides, the chemical agglomeration promoter does not contain acid matter, and thus corrosion to flue equipment can be avoided; moreover, as most toxic heavy metals are gathered on fine particulate matter, heavy metals can be integrally removed with the chemical agglomeration promoter.

Owner:武汉天空蓝环保科技有限公司

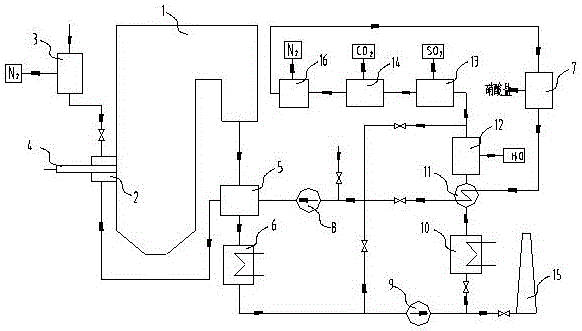

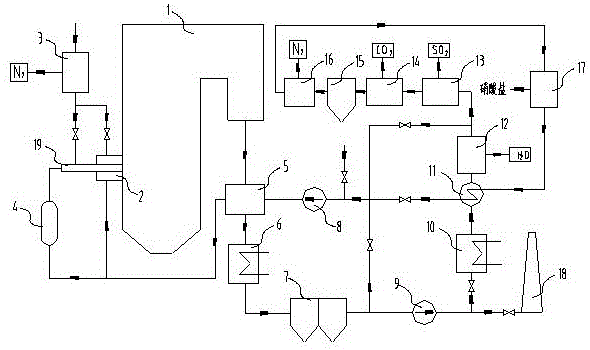

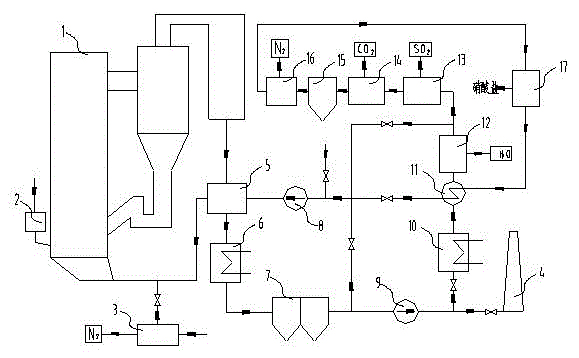

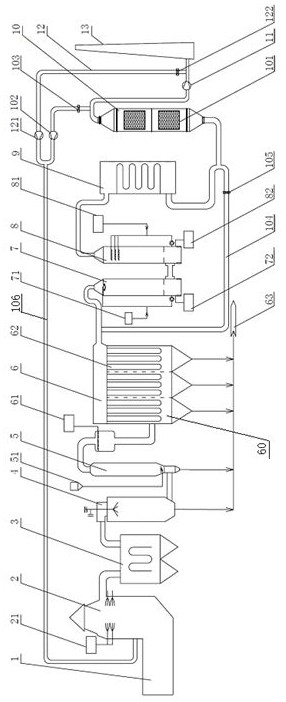

Fuel and gas-fired boiler oxygen-enriched combustion smoke nearly-zero-emission power generation system

InactiveCN105042575ASave waterGood commercial valueDirect carbon-dioxide mitigationIndirect carbon-dioxide mitigationBurning outZero emission

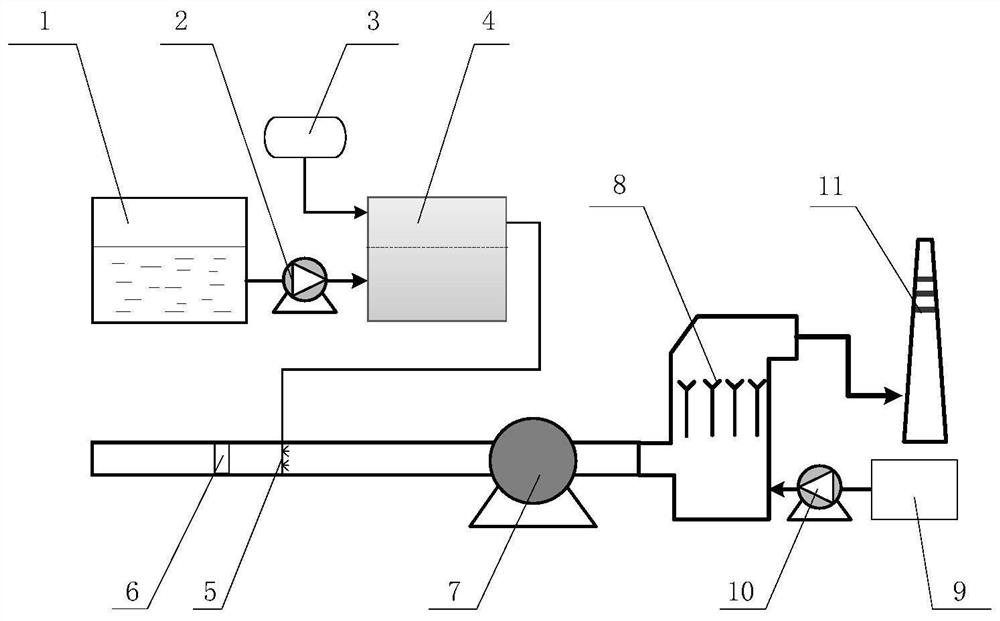

The invention provides a fuel and gas-fired boiler oxygen-enriched combustion smoke nearly-zero-emission power generation system. The fuel and gas-fired boiler oxygen-enriched combustion smoke nearly-zero-emission power generation system is composed of a boiler, an air bellow, an air separation device, a burner, a multi-stage heat exchanger, a recirculating fan, an induced draft fan, a dehydration device, an SO2 separation device, a CO2 capturing device, a N2 separator, a NOx reaction device and the like. The concentration of oxygen of secondary air is changed so as to ensure that fuel and gas catch fire in time, burn stably and burn out, the boiler efficiency is improved, and adaptability of the boiler to loads is enhanced. By recycling water steam, SO2, NOx, CO2 and the like brought by burning smoke of fuel and gas, integrated desorption of harmful gas and trace elements in smoke is achieved; meanwhile, the temperature of exhausted smoke is reduced to approach the atmosphere temperature, nearly-zero emission of burning smoke is achieved, the environment is protected, and maximum utilization of resources is also achieved.

Owner:SICHUAN CHUANGUO BOILER

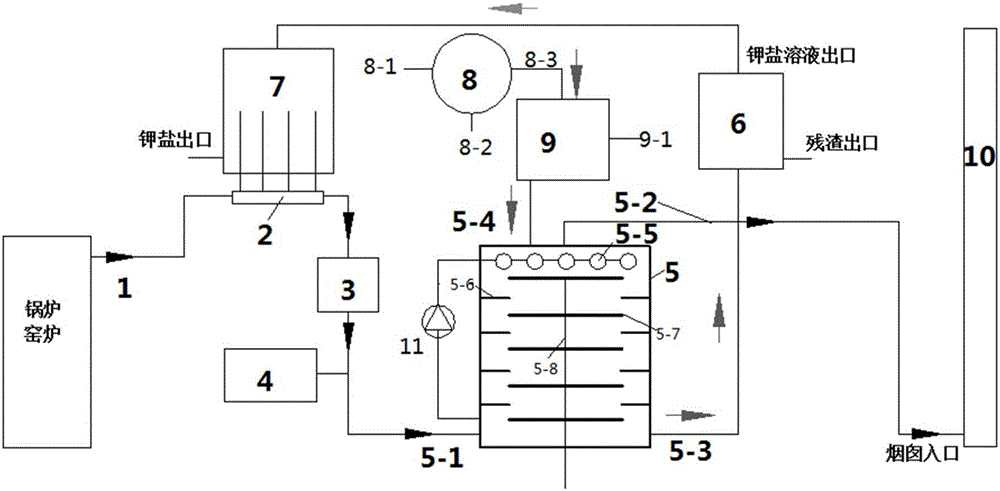

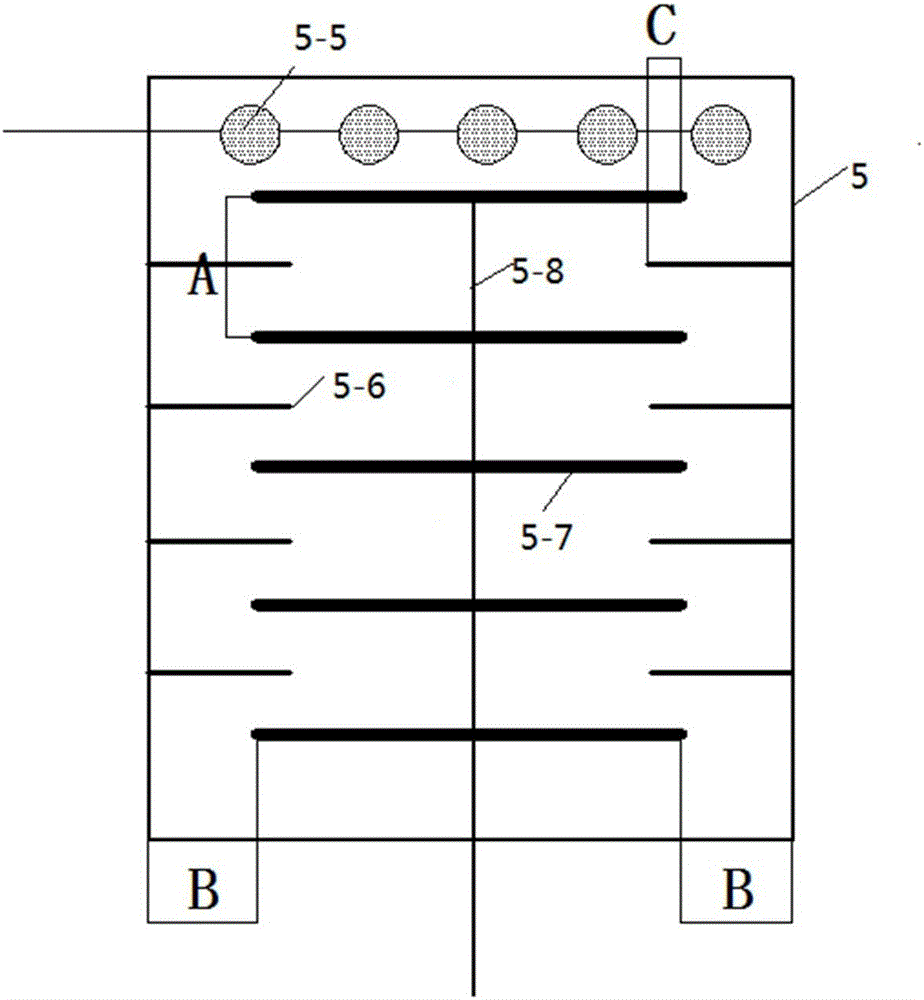

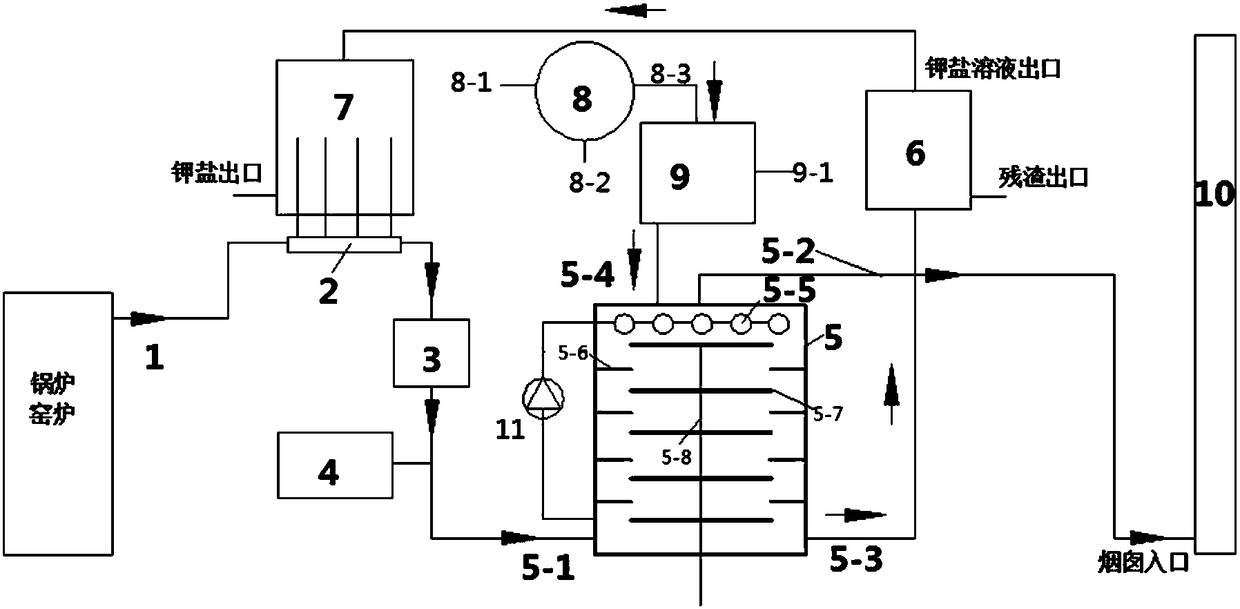

Method and device for integrally removing multiple pollutants in tail gas through plant ash seriflux

ActiveCN105771600AWell mixedAvoid secondary pollutionGas treatmentDispersed particle separationCombustionResource utilization

The invention relates to a method and device for integrally removing multiple pollutants in tail gas through plant ash seriflux. The method comprises the steps that plant ash seriflux is adopted for independently or jointly oxidize and remove SO2, NOx, Hg, H2S, HCl and HF in tail gas of a combustion or chemical device; tail gas containing SO2, NOx, Hg, H2S, HCl and HF from a boiler or kiln or chemical device is cooled and enters a rotary absorption reactor; soluble or acid gas SO2, NO2, Hg2+, H2S, HCl and HF can be directly washed and absorbed by a solution, and indissolvable gas NO and Hg0 can be absorbed by a solution after being pre-oxidized or oxidized by an additive into NO2, HNO2, HNO3 and Hg2+. According to the method, resource utilization can be achieved for solid waste produced by biomass burning, multiple pollutants can be integrally removed, the purpose of dealing with waste by waste is achieved, secondary pollution is avoided in the whole removal process, and the market development and application prospect is wide.

Owner:刘杨先

Coal-powder boiler oxygen-enriched combustion smoke near-zero emission and power generation system

InactiveCN105066113AAchieve integrated removalLow running costIndirect carbon-dioxide mitigationNon-combustible gases/liquids supplyBurn outPower generation system

The invention provides a coal-powder boiler oxygen-enriched combustion smoke near-zero emission and power generation system. The system is composed of a boiler, a burner, an air separation device, a powder production system, a multi-stage heat exchanger, a multi-stage deduster, a recirculation draught fan, an induced fan, a dewatering device, an SO2 separation device, a CO2 capture device, an N2 separator, an NOx reaction device and the like. It is ensured that coal powder of different coal types is ignited in time, burns stably and burns out by changing the oxygen concentration of primary air and secondary air and the total oxygen amount, the efficiency of the boiler is improved, and the adaptability of the boiler to loads and coal types is enhanced. Dust, vapor, SO2, NOx, CO2 and the like caused by combustion smoke of coal powder are recycled through all the devices, so that harmful gas, fine particles and microelements in smoke are integrally removed. Meanwhile, the smoke exhaust temperature is reduced to be close to the atmospheric temperature, so that near-zero emission of smoke is achieved, environment protection is achieved, and resource utilization is maximized.

Owner:SICHUAN CHUANGUO BOILER

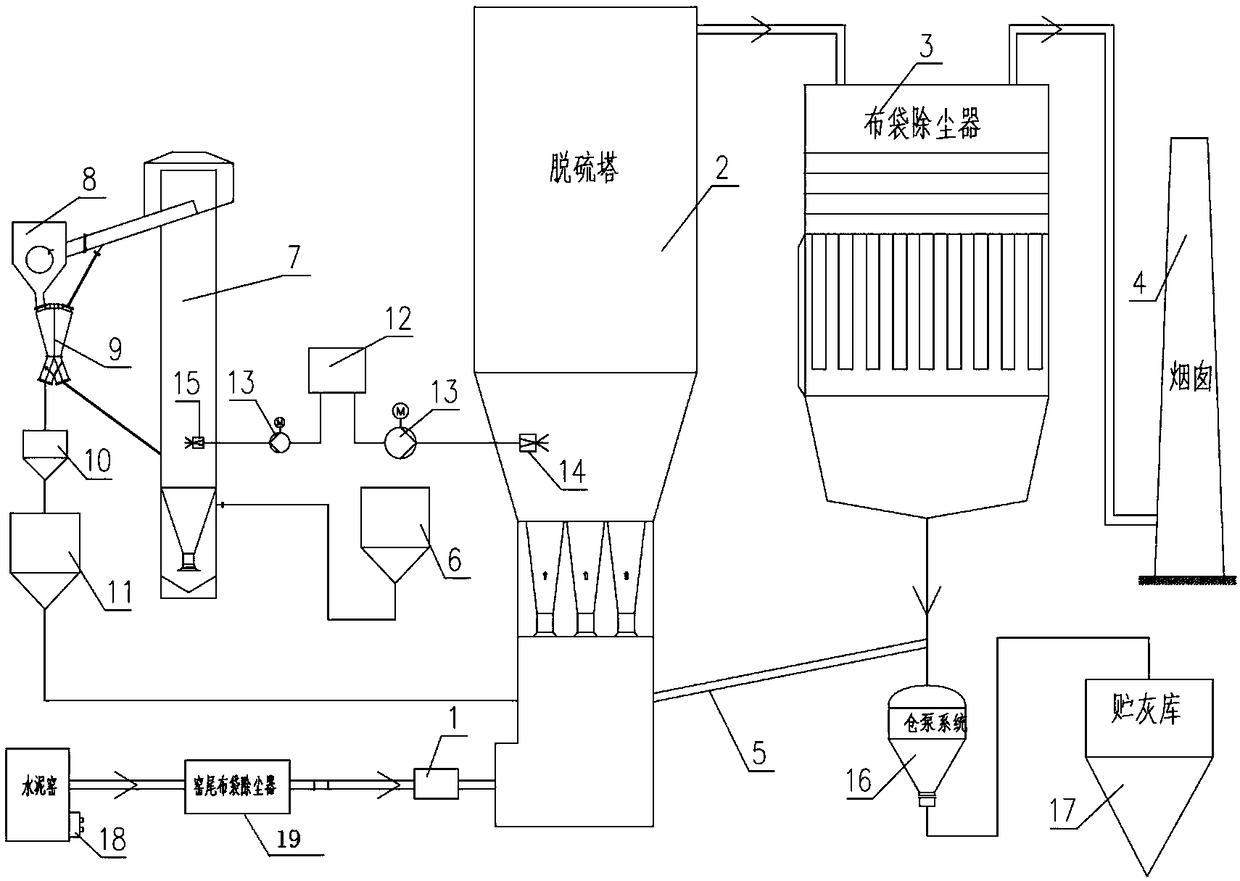

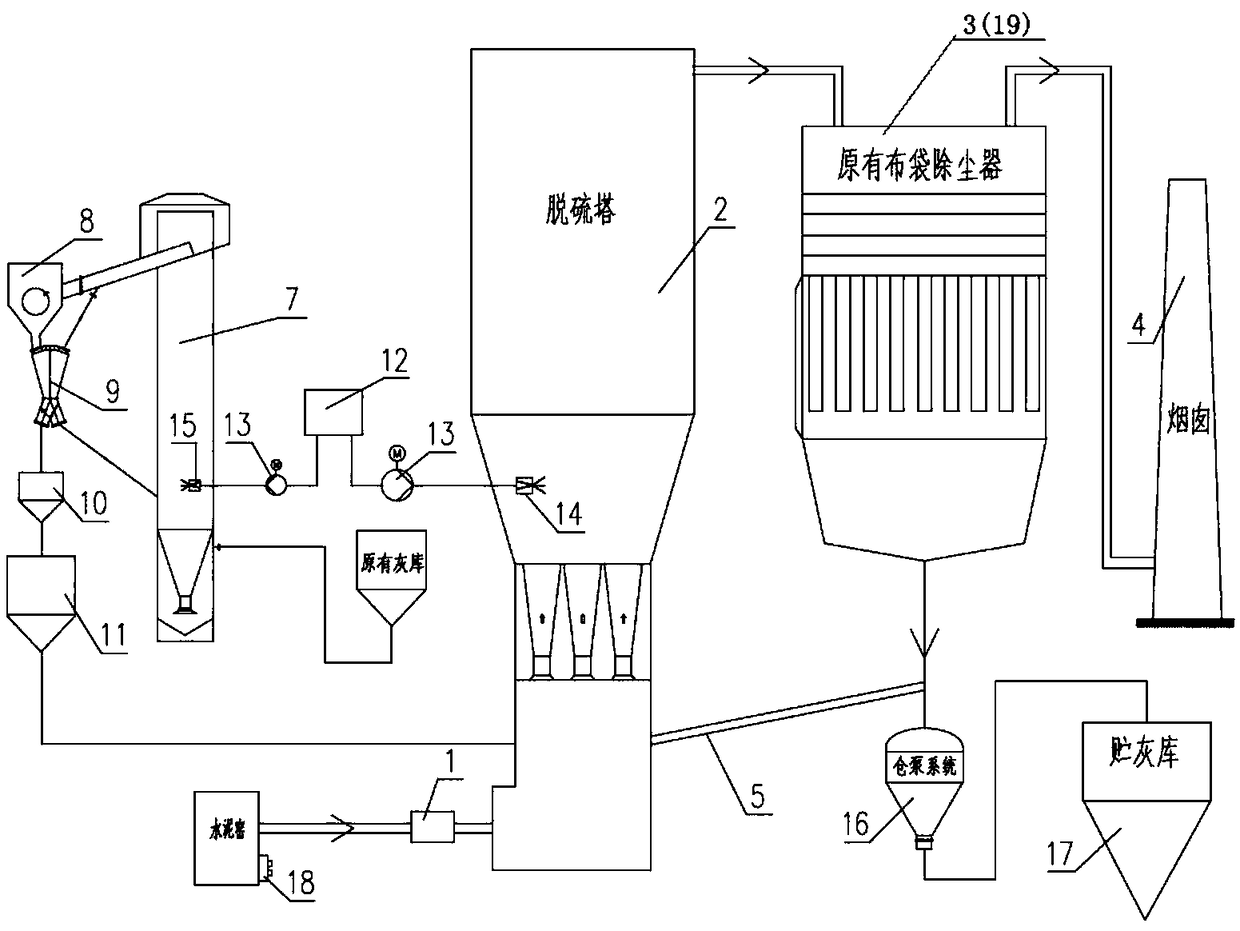

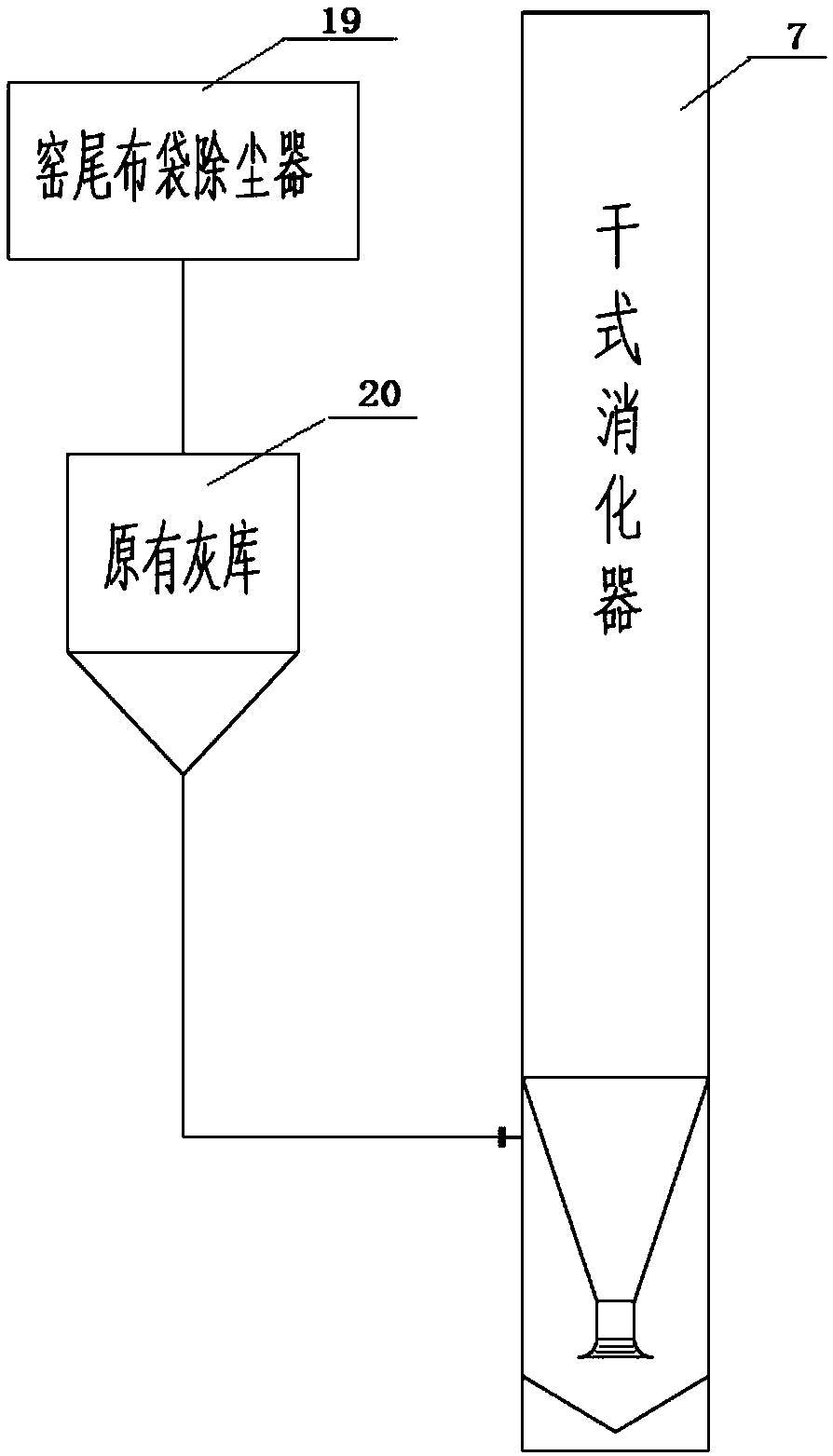

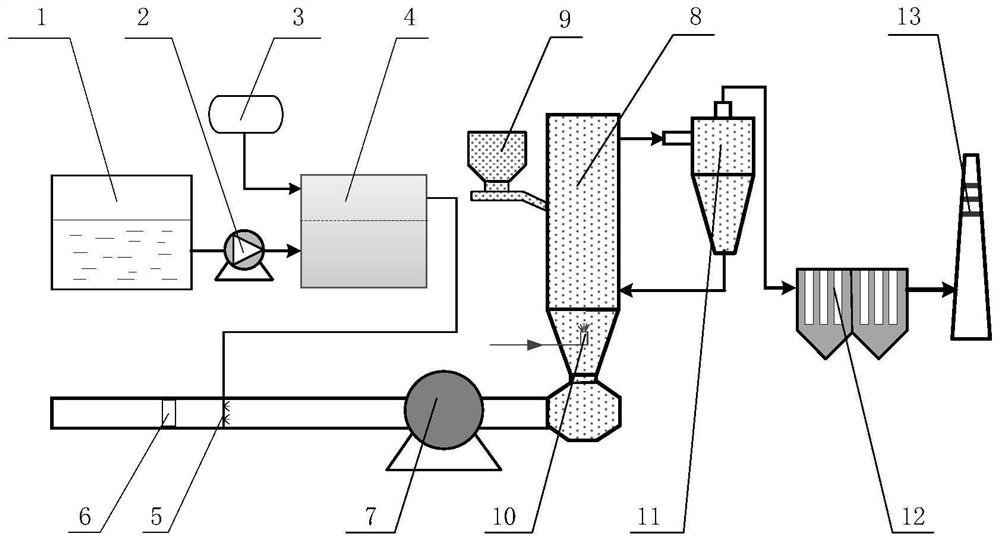

Flue gas system for ultra-clean treatment of cement kiln exhaust gas

PendingCN109364711ALow running costSmall footprintGas treatmentDispersed particle filtrationEngineeringCement kiln

The invention provides a flue gas system for ultra-clean treatment of cement kiln exhaust gas. The flue gas system includes an oxidative denitration reactor, a CFB absorption tower, a bag filter, a process water system, an absorbent preparation and supply system, a desulfurization ash circulation and conveying system and a chimney. The process water system includes a process water tank, a water pump, a desulfurization spray gun and a digestion spray gun. An absorbent preparation system includes a quick lime bin, a dry digester, a cyclone separator, a buffer bin and a slaked lime bin. The desulfurization ash circulation and conveying system includes an air chute and a bin pump. A dry type coupling desulfurization and denitrification technology is adopted, nitrogen oxides and sulfur oxides in flue gas can be effectively removed, to meet national regulations on ultra-low emission of flue gas pollutants, the flue gas system is free of waste water or secondary pollution, and a by-product can be utilized.

Owner:NANJING CEEP TECH

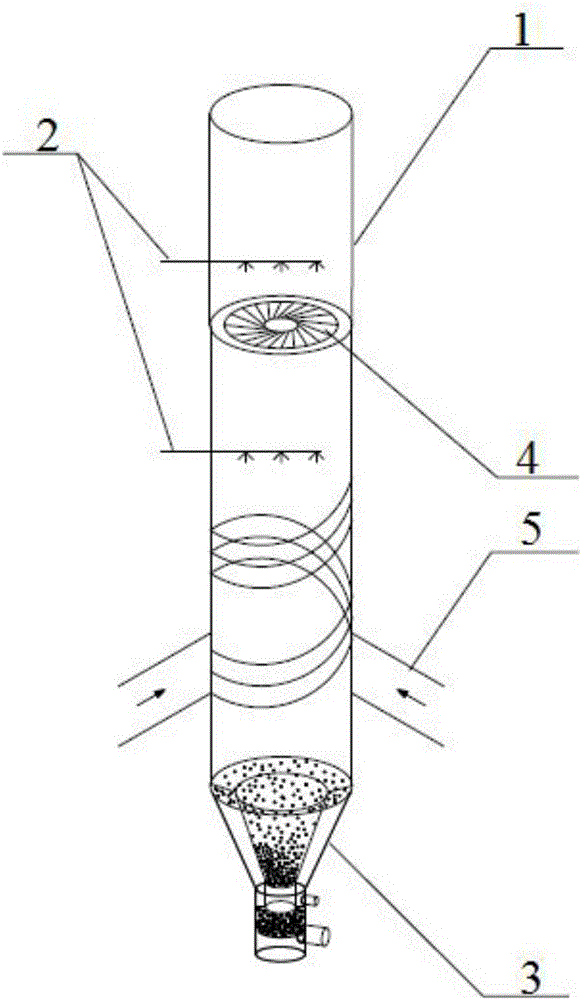

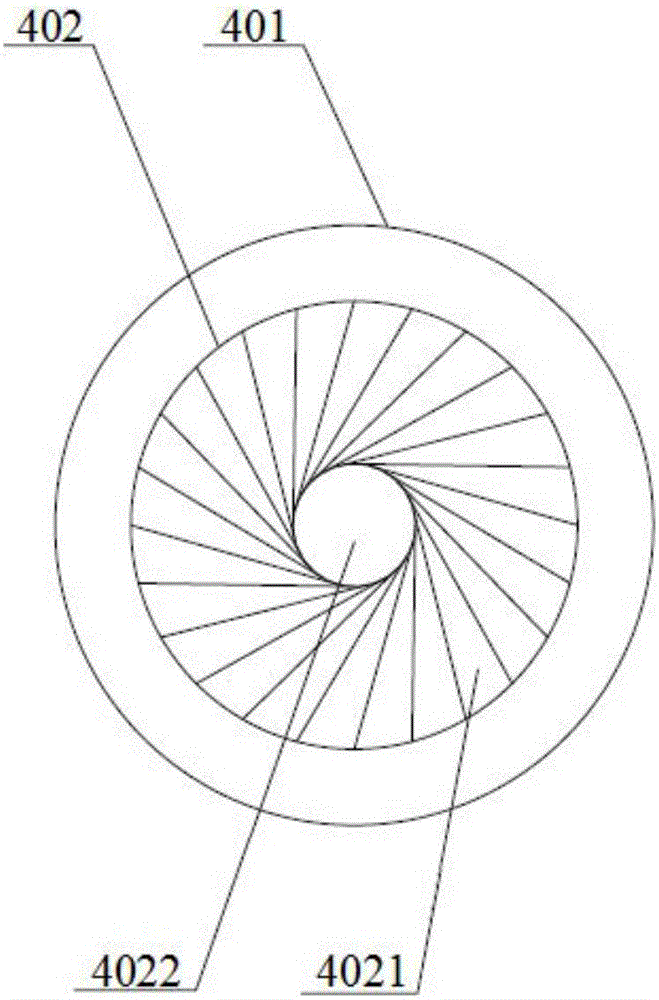

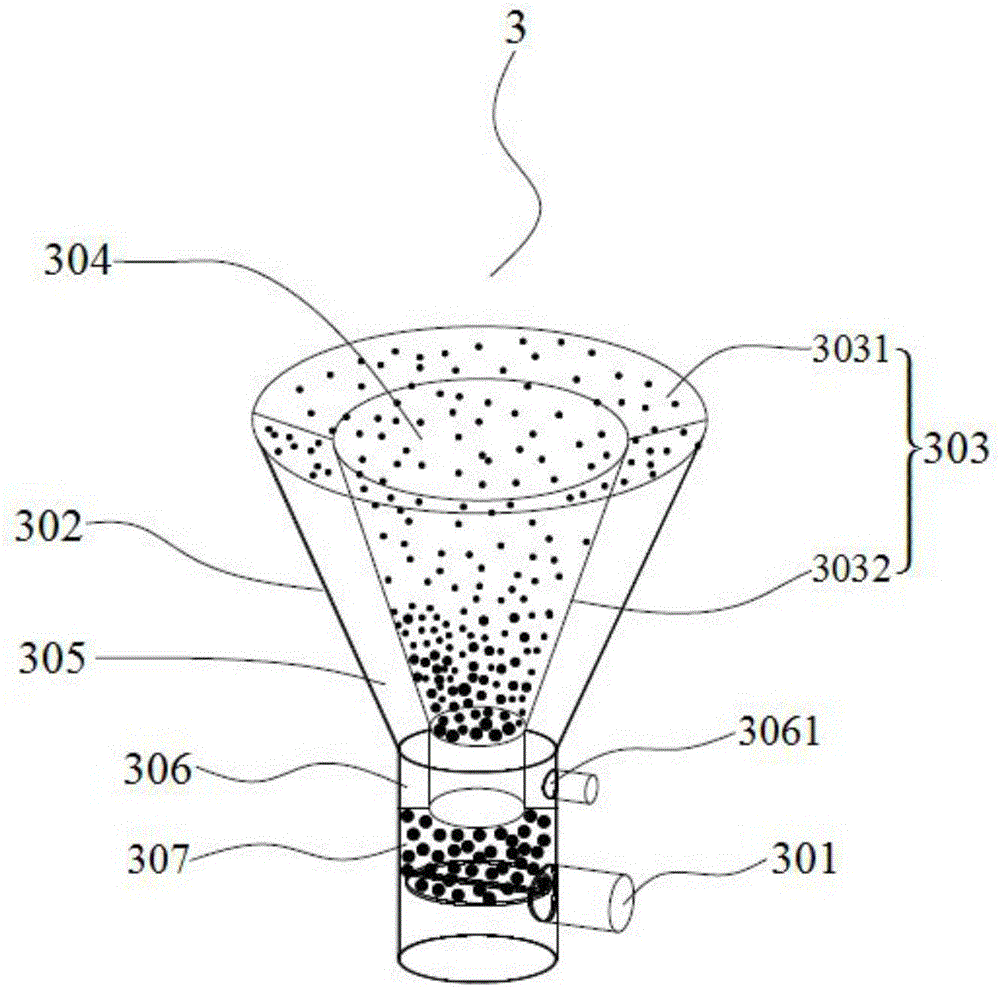

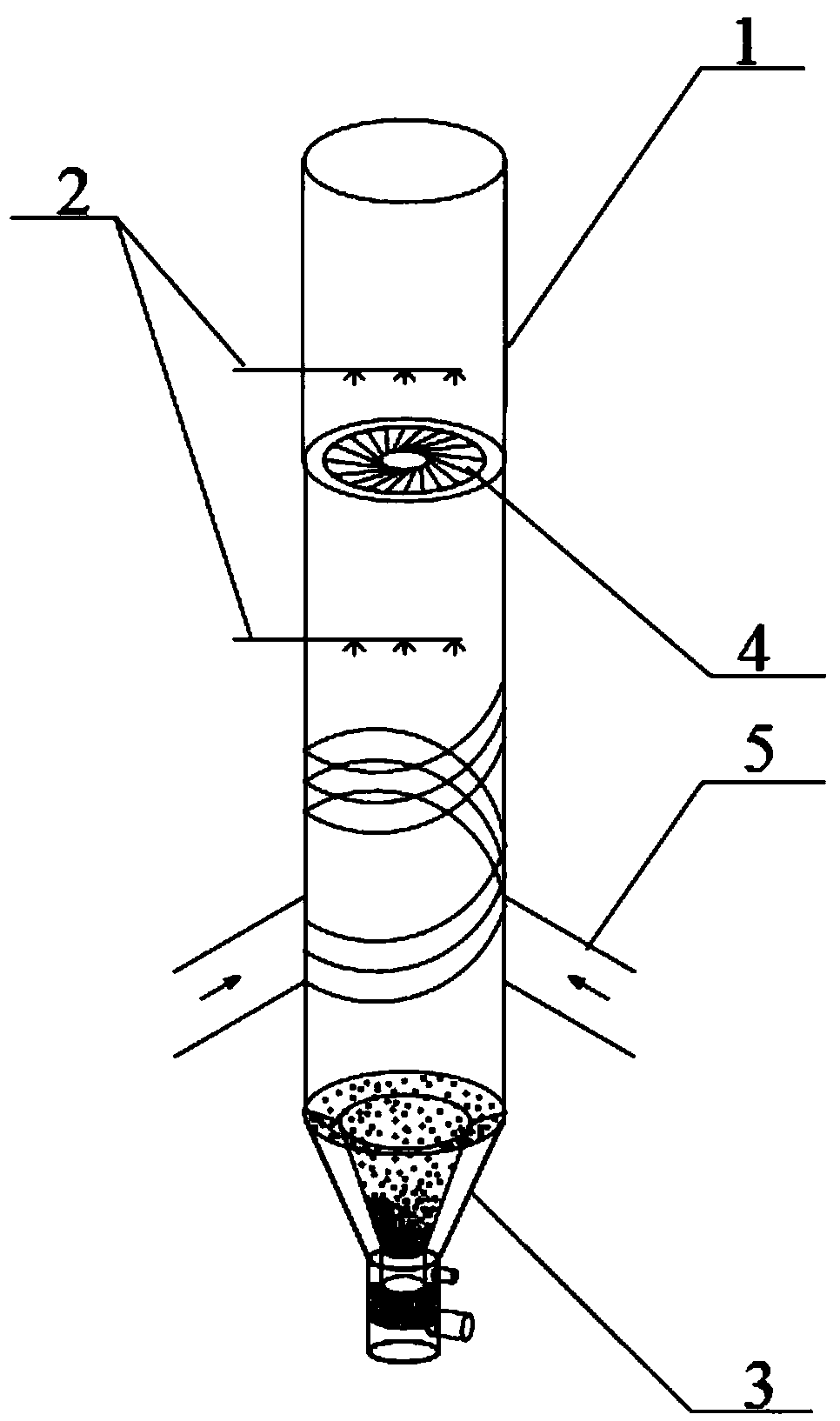

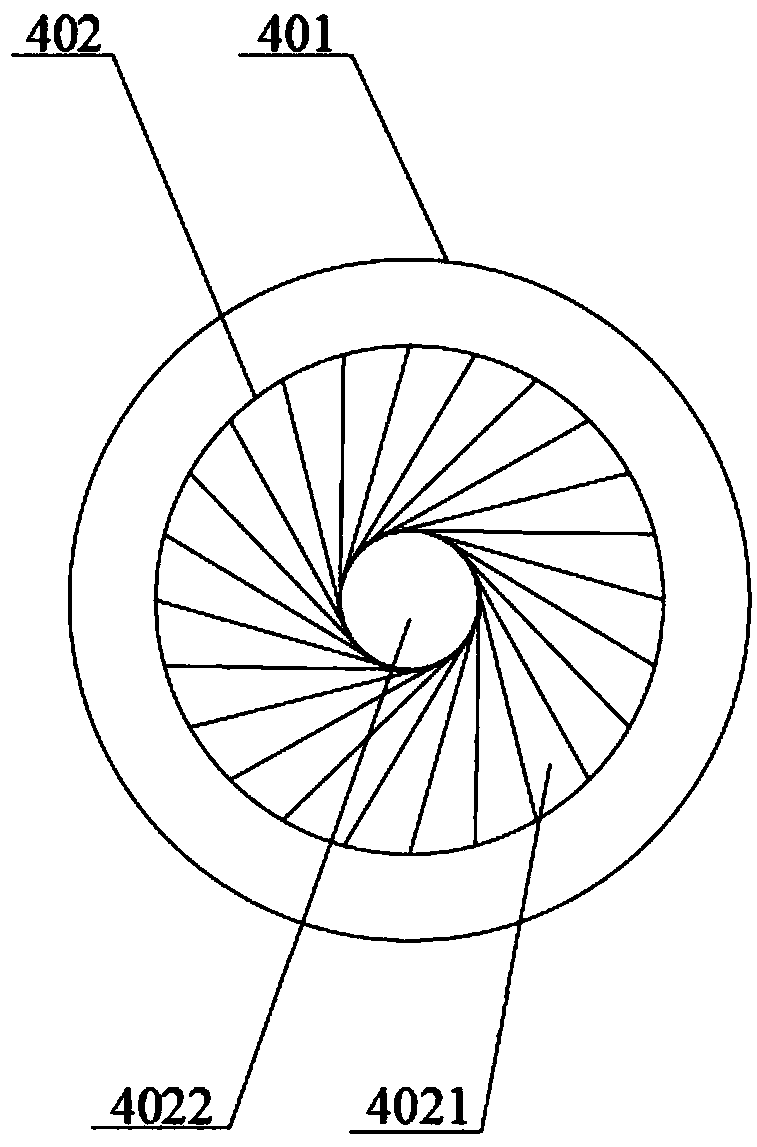

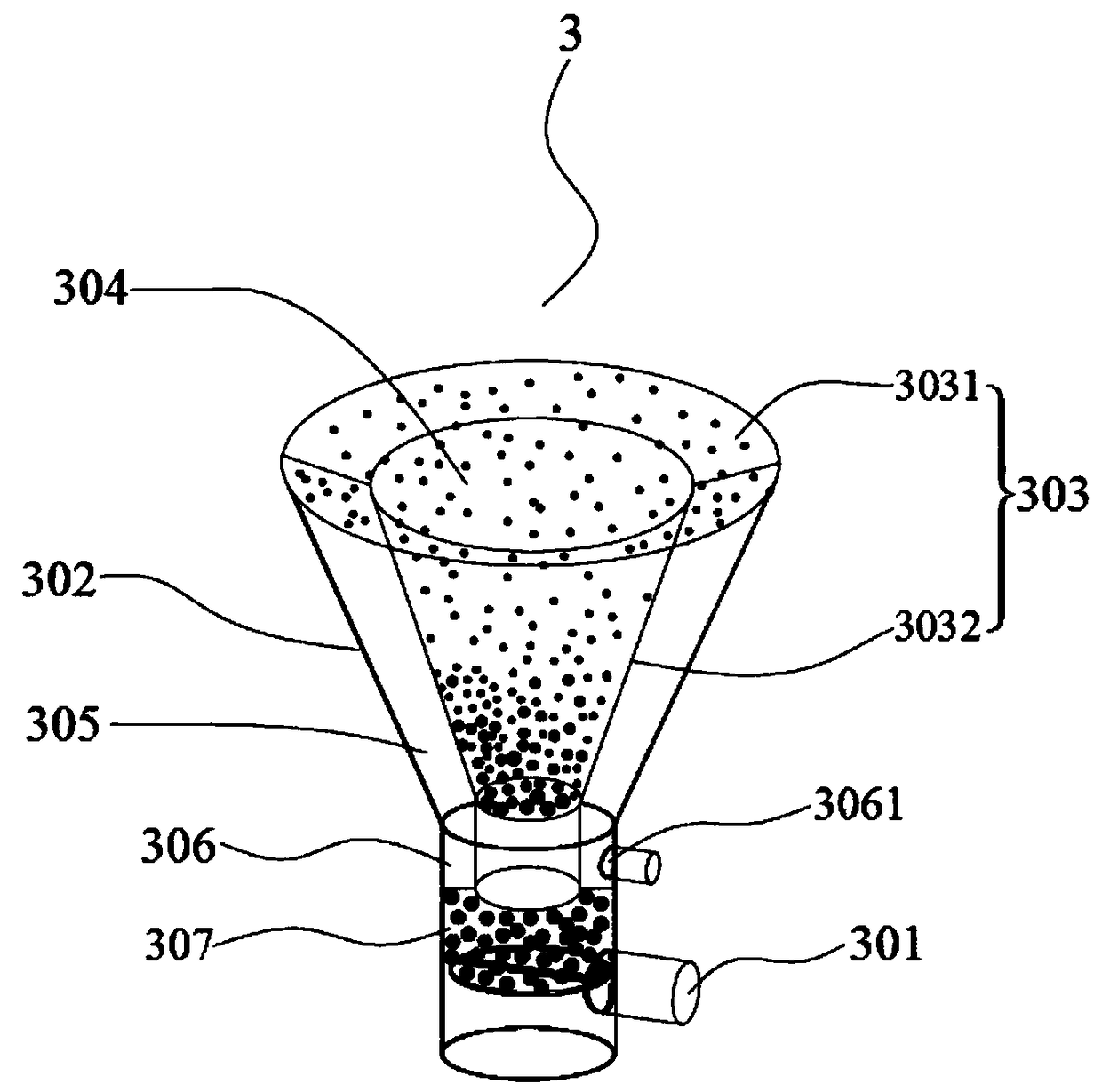

Rotation, confluence and agglomeration tower and method for agglomeration dedusting

The invention relates to a rotation, confluence and agglomeration tower and a method for agglomeration dedusting by adopting the rotation, confluence and agglomeration tower. The rotation, confluence and agglomeration tower comprises a cylindrical tower body, at least one flow guide pipe used for leading in flue gas is arranged on the lower portion of the tower body, each flow guide pipe is connected with the tower body in a tangent manner, and a flue gas outlet is arranged at the top of the tower body; multiple spray layers used for blowing and jetting agglomeration liquid are arranged in the tower body from bottom to top in sequence, and a rotational flow device used for enabling flue gas to form a turbulence state after passing is arranged at least between the two bottommost spray layers. Good agglomeration and dedusting effect can be achieved, subsequent dedusting burden is alleviated effectively, the subsequent dedusting process can even be cancelled, the national flue gas emission standard is met, and meanwhile equipment investment and running cost are lowered.

Owner:武汉天空蓝环保科技有限公司

CFB oxygen-enriched combustion smoke near zero emission power generation system

InactiveCN105042610AAchieve integrated removalLow running costCombustion processDirect carbon-dioxide mitigationWater vaporBurn out

The invention provides a CFB oxygen-enriched combustion smoke near zero emission power generation system which is composed of a boiler, a powder feeding system, an air separating device, a chimney, multiple stages of heat exchangers, multiple stages of dust removers, a recirculating fan, an induced draft fan, a dewatering device, an SO2 separating device, a CO2 catching device, an N2 separator, an NOx reaction device and the like. By changing the concentration of oxygen in secondary gas, it is ensured that coal of different types is stably combusted and burnt out, boiler efficiency is improved, and the adaptability of the boiler to loads and coal types is enhanced. Through all the devices, dust, vapor, SO2, NOx, CO2 and the like brought by coal powder combustion smoke are recycled, harmful gas, fine particles and trace elements in the smoke are integrally removed, the smoke exhaust temperature is lowered to be close to the atmosphere temperature, the near zero emission of the combustion smoke is achieved, the environment is protected, and the maximization of resource utilization is achieved.

Owner:SICHUAN CHUANGUO BOILER

Desulphurization catalyst, and preparation method and applications thereof

ActiveCN110152679ASimple processEnvironmental protection is goodOrganic compound preparationHeterogenous catalyst chemical elementsSulfideGreen environment

The invention provides a desulphurization catalyst, and a preparation method and applications thereof. The desulphurization catalyst is charcoal loaded with active substances, and the active substances comprise iron, cobalt, and molybdenum. According to the preparation method, charcoal is taken as a base material of the desulphurization catalyst, the desulphurization catalyst is invented based ona plurality of sulfides to be removed in gas source, and integrated removing of carbonyl sulfur, mercaptan, and hydrogen sulfide in gas source can be realized under the same technology condition. In desulphurization process using the desulphurization catalyst, hydrolysis is not needed, pre-refining hydrogen sulfide removing is not needed, carbonyl sulfur and hydrogen sulfide are converted into elemental sulfur through one-step catalytic oxidation, mercaptan is oxidized into polysulfides, and the desulphurization catalyst is a green environment-friendly industrial desulphurization catalyst.

Owner:鄂尔多斯市瀚博科技有限公司

A coupling packing autotrophic denitrification biological filter and its application

ActiveCN109052641BDifficult to dissolveIncrease speedWater treatment compoundsTreatment with anaerobic digestion processesBiological filterPyritic sulfur

The invention discloses a coupling filler autotrophic denitrification biofilter and application and belongs to the technical field of sewage treatment. Pyrrhotite, sulfur and a carbon source are utilized to be mixed and coupled according to certain proportion; then the materials are put into a reactor, and the autotrophic denitrification biofilter can be formed after inoculating biofilm formation;sewage flows through the biofilter, and nitrogen and phosphorus in the water are removed. The biofilter disclosed by the invention has the advantages of simpleness, easiness, practicability and shortbiofilm formation time; when the biofilter is utilized to treat nitrogen and phosphorus containing sewage, hydraulic retention time is only 0.5 to 3 h, and yielding water can meet a requirement; furthermore, the biofilter has the advantages of excellent nitrogen and phosphorus removal effect, low cost and suitability for engineering application.

Owner:NANJING UNIV

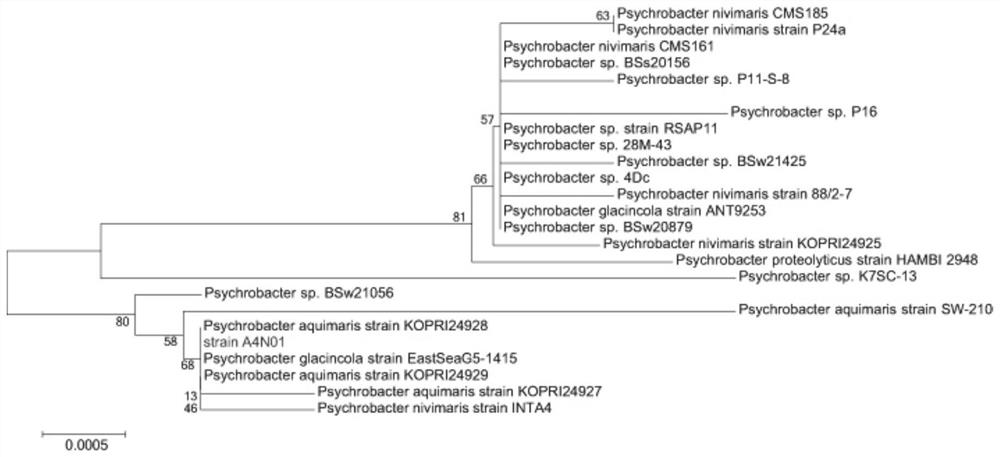

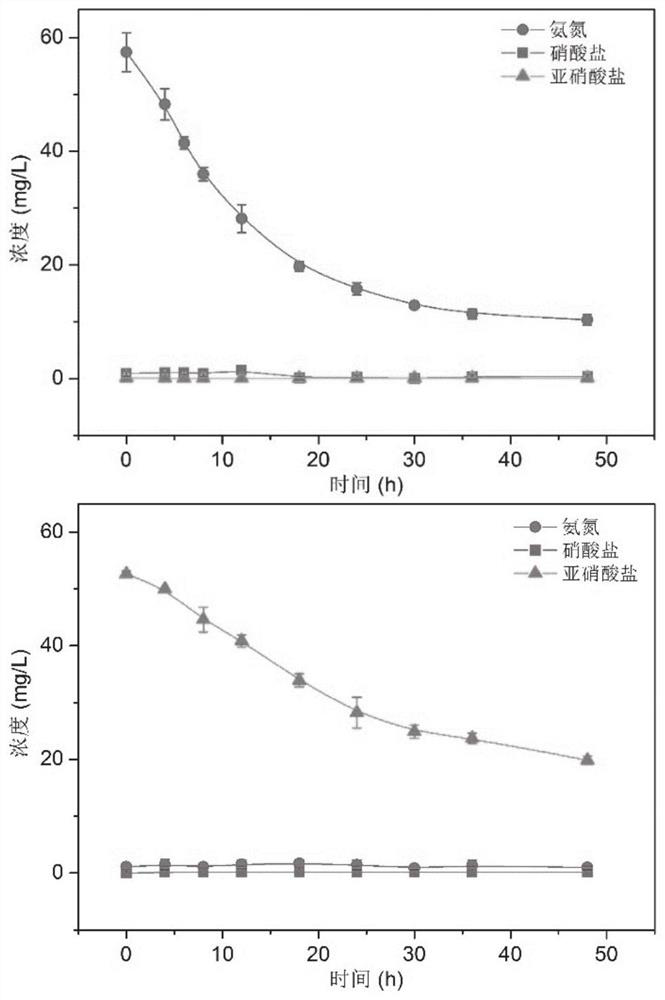

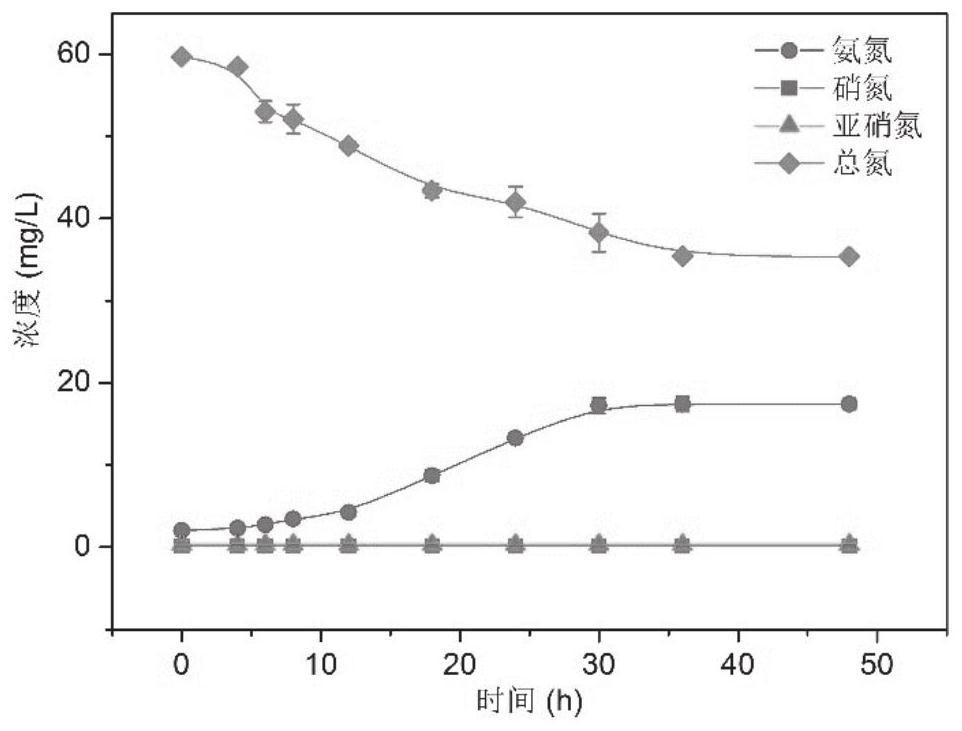

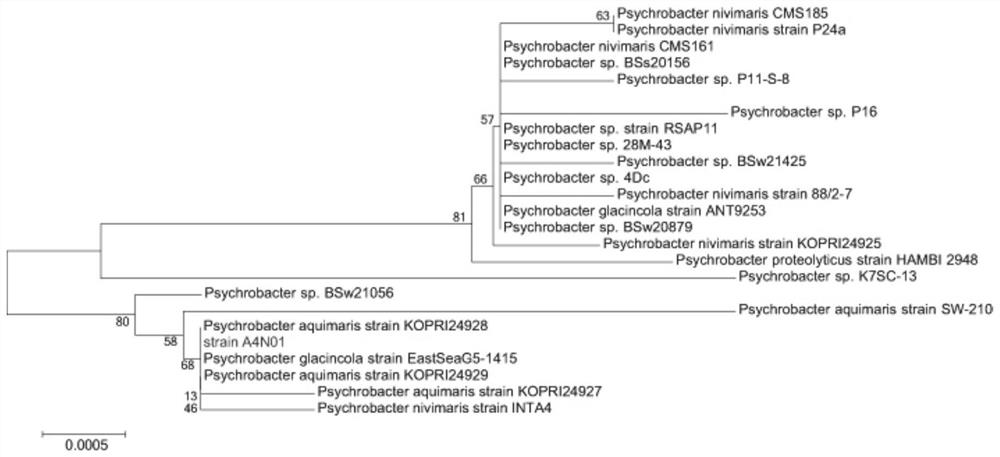

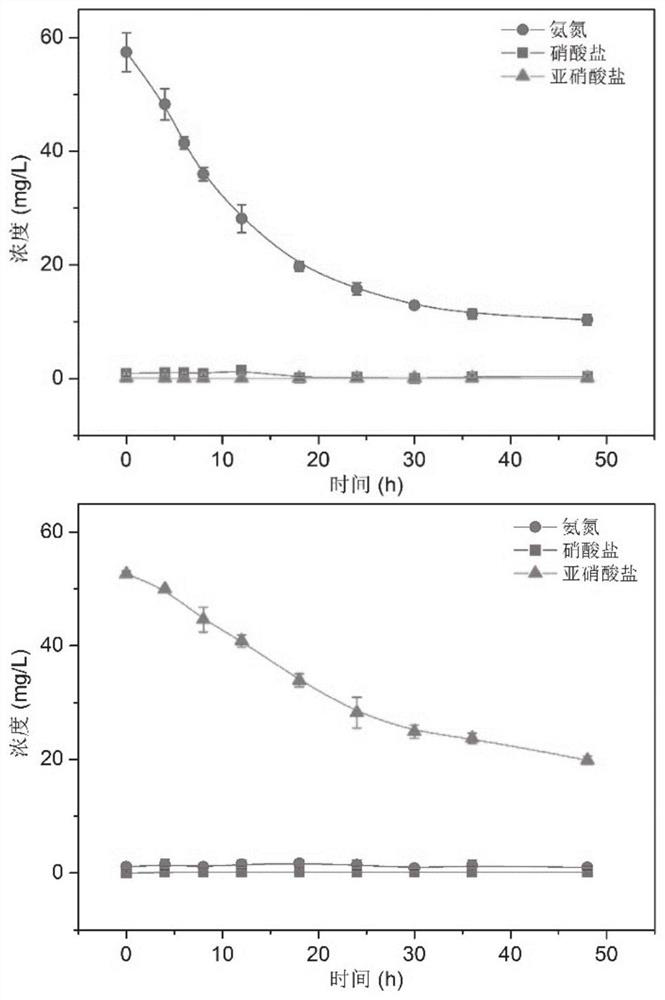

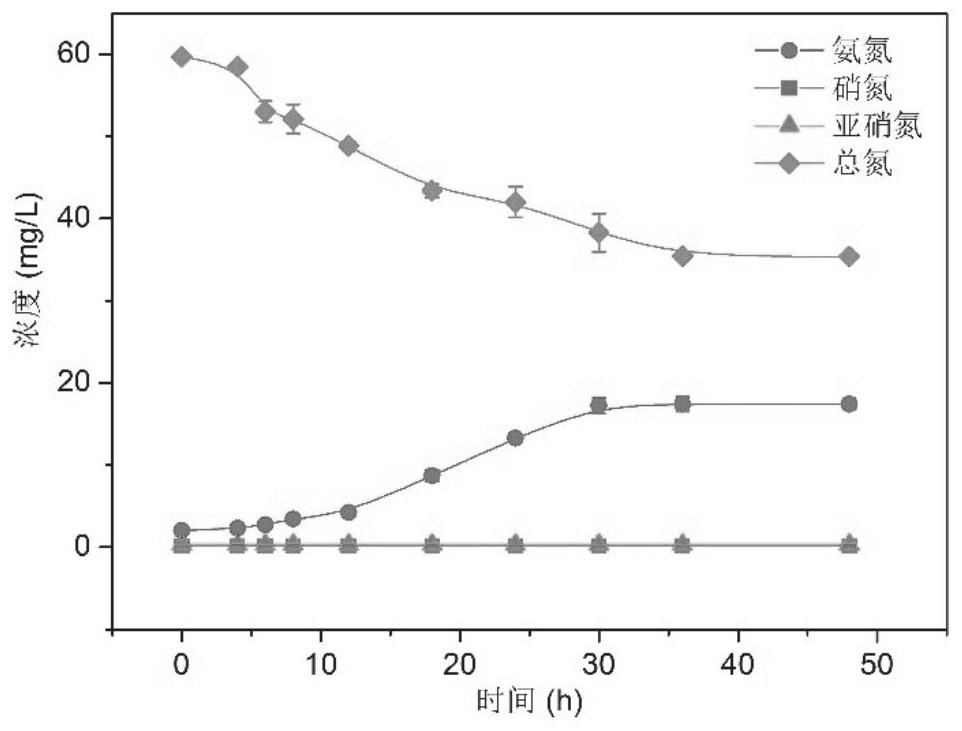

Marine self-flocculating bacterium, halophilic nitrogen assimilation microbiome driven and developed by marine self-flocculating bacterium, and construction method and application of halophilic nitrogen assimilation microbiome

ActiveCN113403234AWide range of toleranceAchieve integrated removalBacteriaSeawater treatmentAlkali soilMicrobiome

The invention provides a marine self-flocculating bacterium, a halophilic nitrogen assimilation microbiome driven and developed by the marine self-flocculating bacterium, and a construction method and application of the halophilic nitrogen assimilation microbiome, and belongs to the technical field of microorganisms and environmental governance and repair. The Psychrobacter aquimaris A4N01 is screened from marine sediments, ammonia nitrogen can be assimilated to synthesize organic nitrogen, organic matter and phosphorus can be synchronously converted, the halophilic nitrogen assimilation microbiome developed by the Psychrobacter aquimaris A4N01 has good nutrient substance conversion and removal capacity and settling performance, and the salinity tolerance is wide; and the halophilic nitrogen assimilation microbiome can be used in the directions of high-salt sewage treatment, saline-alkali soil fertility improvement and the like, realizes recovery of nutrient elements such as nitrogen and phosphorus in a high-salt environment, is simple to operate, low in price and environment-friendly, and thus, has a good practical application value.

Owner:SHANDONG UNIV

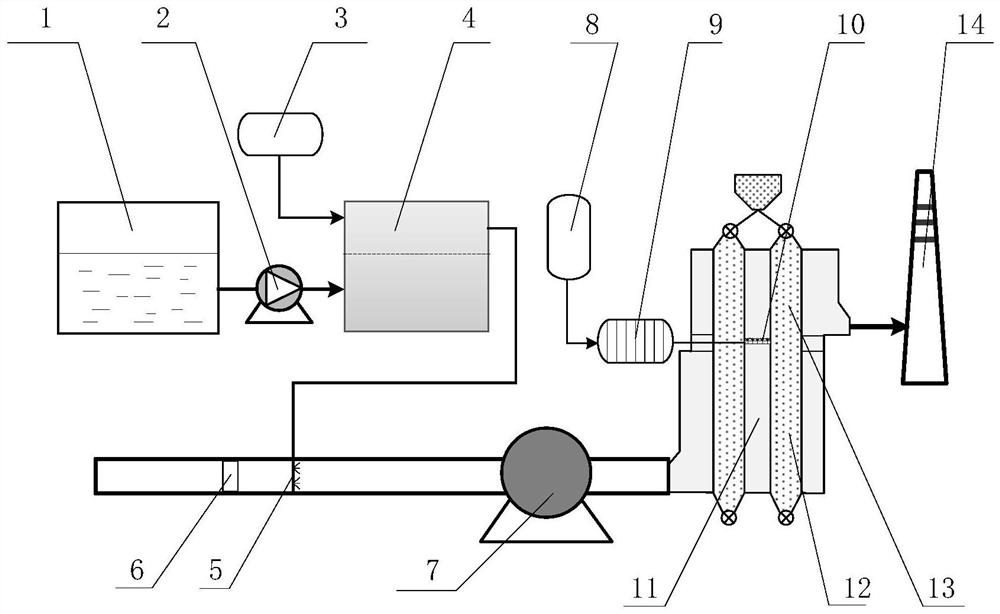

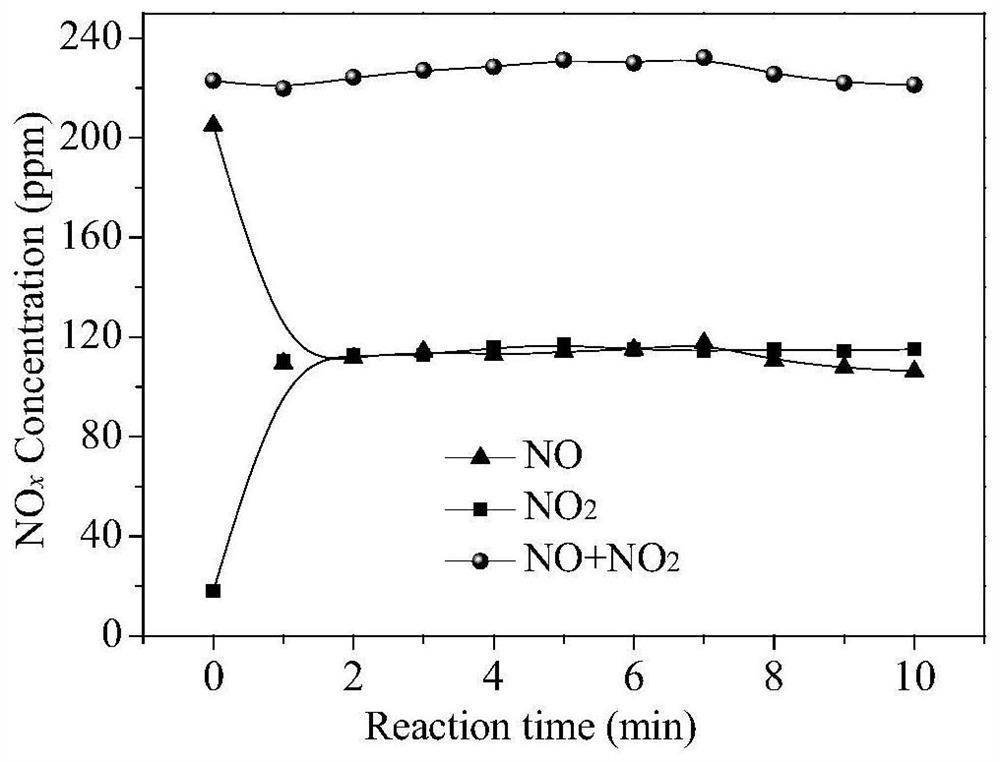

Coal-fired flue gas semi-dry method combined desulfurization and denitrification system and method

PendingCN111905543AMolecular atomization particle size is smallAvoid invalid decompositionGas treatmentDispersed particle separationFlue gasFluidized bed

The invention provides a coal-fired flue gas semi-dry combined desulfurization and denitrification system and method. The coal-fired flue gas semi-dry combined desulfurization and denitrification system comprises a front oxidation system arranged on a flue, an absorption system arranged at an outlet of the flue, and a dust removal system and a chimney which are sequentially connected with the absorption system, wherein the front oxidation system comprises an H2O2 storage tank and an ultrasonic atomizer which are connected in sequence, and a compressed gas tank connected with an inlet of the ultrasonic atomizer; an outlet of the ultrasonic atomizer is connected into the flue; the absorption system comprises an absorption tower; the absorption tower adopts a circulating fluidized bed absorption tower, the top is provided with an absorbent supplementing bin, and the bottom is provided with a water-spraying humidifying device; the flue gas inlet of the absorption tower is connected with the flue outlet, the flue gas outlet of the absorption tower is sequentially connected with the dust removal system and the chimney, the system can effectively meet the requirement for integrated removal of pollutants, integrated removal of SO2 and NOx is achieved, meanwhile, the desulfurization and denitrification efficiency is high, the process is simple, and the investment and operation cost is low.

Owner:XIAN THERMAL POWER RES INST CO LTD

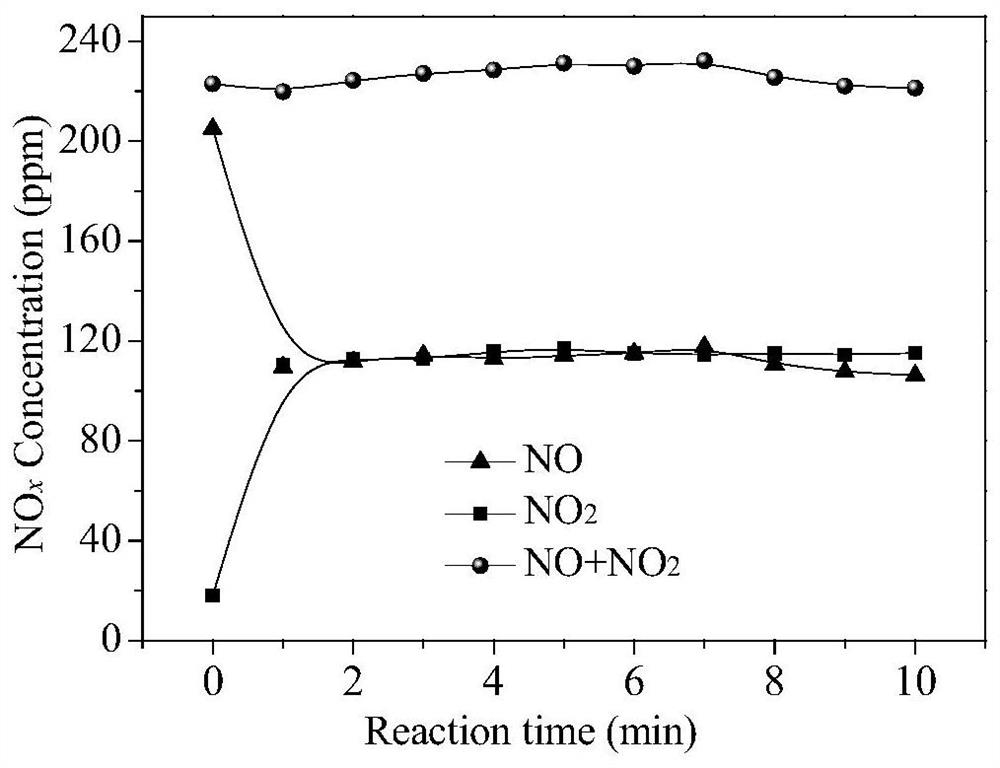

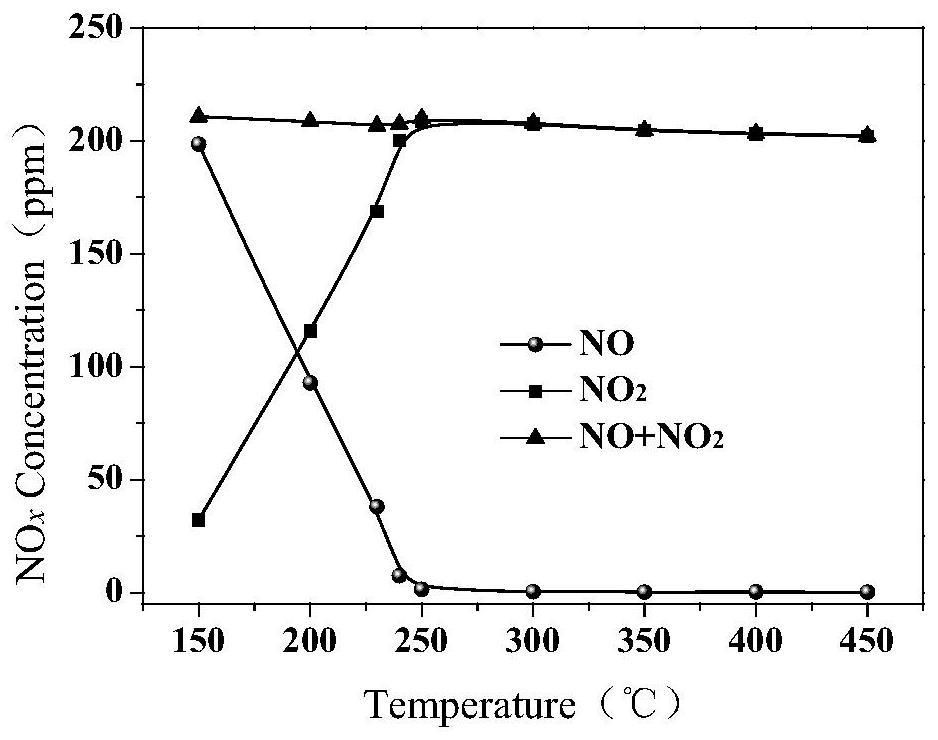

Method and device for removing multi-component pollutants in flue gas based on supergravity technology

PendingCN114768509AEnhanced mass transfer processImprove removal efficiencyGas treatmentDispersed particle separationMultiple componentPollutant

The invention discloses a method and a device for removing multi-component pollutants in flue gas based on a supergravity technology, and the method is characterized in that NOx, SO2 and Hg < 0 > pollutants in the flue gas are synchronously removed by using a multi-component absorption liquid under the condition of a supergravity rotating packed bed; and the absorption liquid and the flue gas are in cross-flow contact in a high gravity field, so that the aim of synchronously removing multi-component pollutants in the flue gas is fulfilled. The supergravity rotating packed bed is composed of a shell, a filler for strengthening gas-liquid mass transfer, a filler base and a motor, the filler for strengthening gas-liquid mass transfer is composed of metal wires, the metal wires are arranged in a crossed mode to form a rhombic hole-shaped net, and the area of rhombic holes is 0.6-0.8 cm < 2 >; in the radial direction, the metal wires arranged in the crossed mode are in a corrugated shape. The supergravity rotating packed bed is used as a gas-liquid reaction place, so that the mass transfer process can be enhanced, and the removal efficiency of pollutants is greatly improved; the method has the advantages of being low in cost, good in economic performance, small in occupied area, capable of achieving resource recycling and the like.

Owner:ZHONGBEI UNIV

Active coke combined desulfurization and denitrification system and method based on pre-oxidation

PendingCN111905541AMolecular atomization particle size is smallAvoid invalid decompositionGas treatmentDispersed particle separationSorbentFlue gas

The invention provides an active coke combined desulfurization and denitrification system and method based on pre-oxidation. The system comprises a pre-oxidation system arranged on a flue, an absorption system and a chimney, wherein the absorption system and the chimney are sequentially arranged at an outlet of the flue; wherein the pre-oxidation system comprises an H2O2 storage tank and an ultrasonic atomizer which are connected in sequence, and a compressed gas tank connected with an inlet of the ultrasonic atomizer, and an outlet of the ultrasonic atomizer is connected into the flue; the absorption system comprises an absorption tower; wherein the absorption tower adopts a sectional cross-flow flue gas purification adsorption tower, and comprises a gas outlet chamber and a gas inlet chamber which are isolated up and down, and a middle gas chamber communicating with the gas outlet chamber and the gas inlet chamber from the middle; active coke is arranged in the adsorbent layer forming the middle gas chamber, the lower section corresponding to the gas inlet chamber is a desulfurization section, the upper section corresponding to the gas outlet chamber is a denitration section, andan ammonia spraying device is arranged in the middle gas chamber; a gas inlet chamber of the absorption tower is connected with a flue outlet and the gas outlet chamber of the absorption tower is connected with the chimney.

Owner:XIAN THERMAL POWER RES INST CO LTD

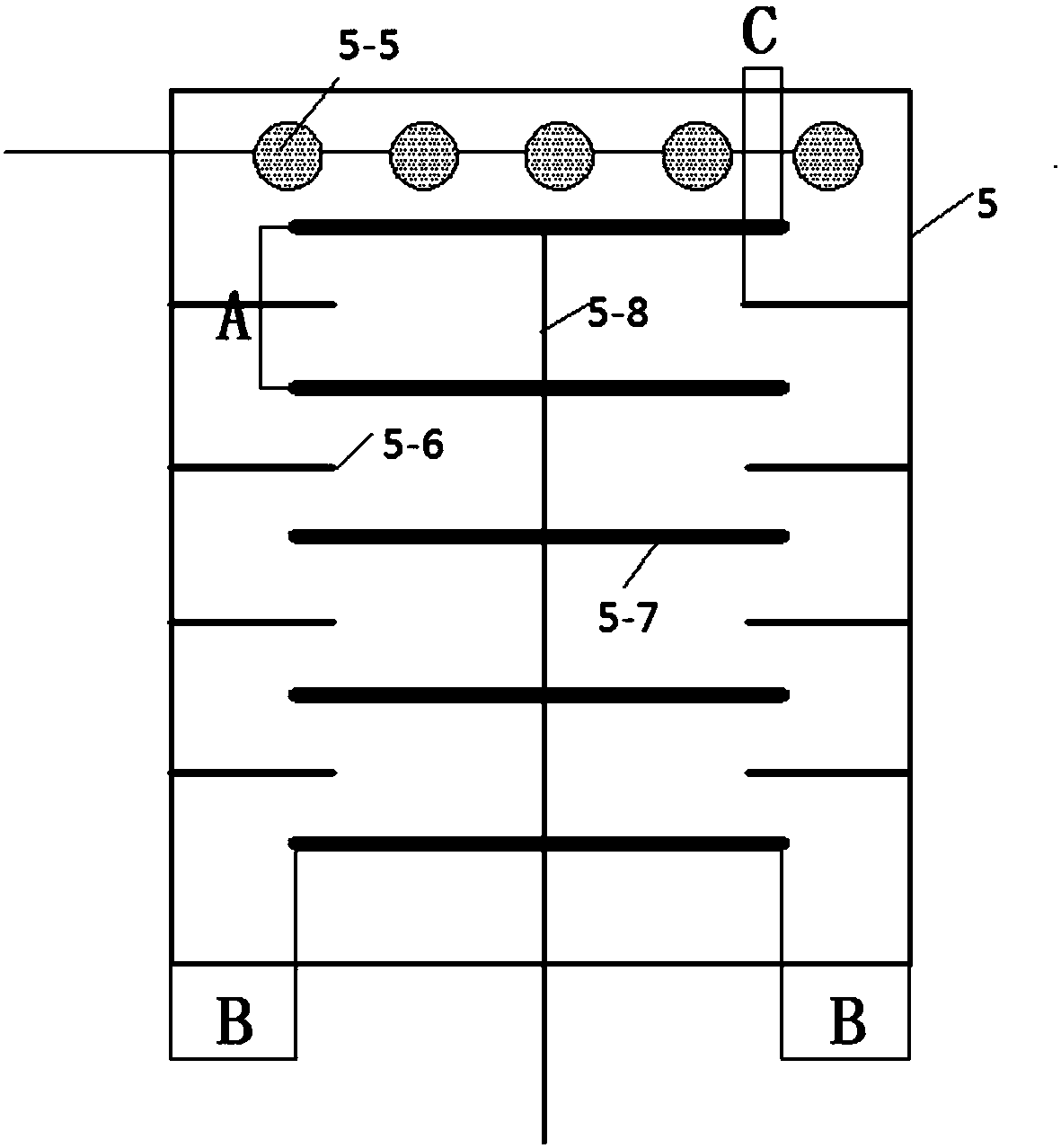

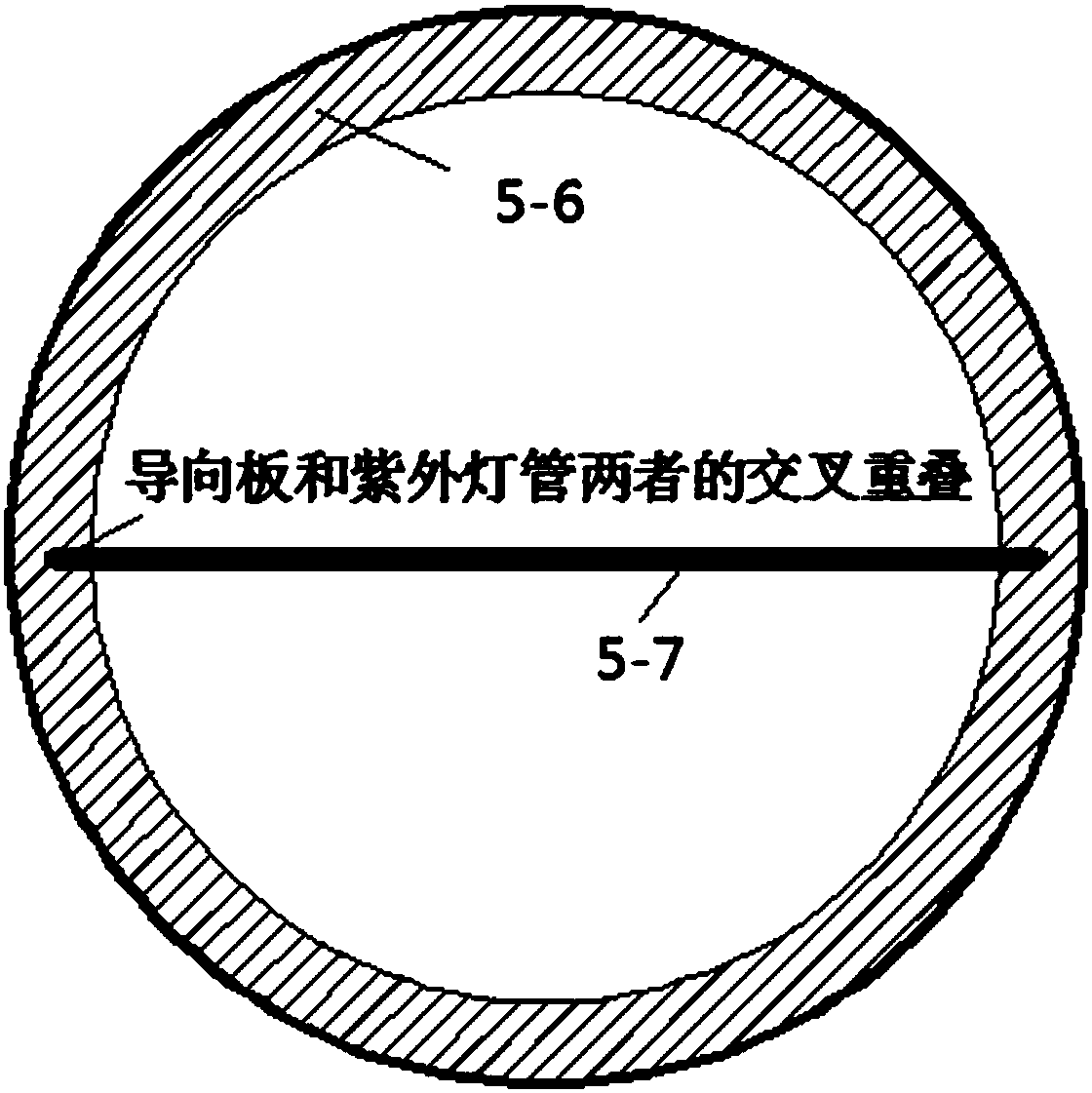

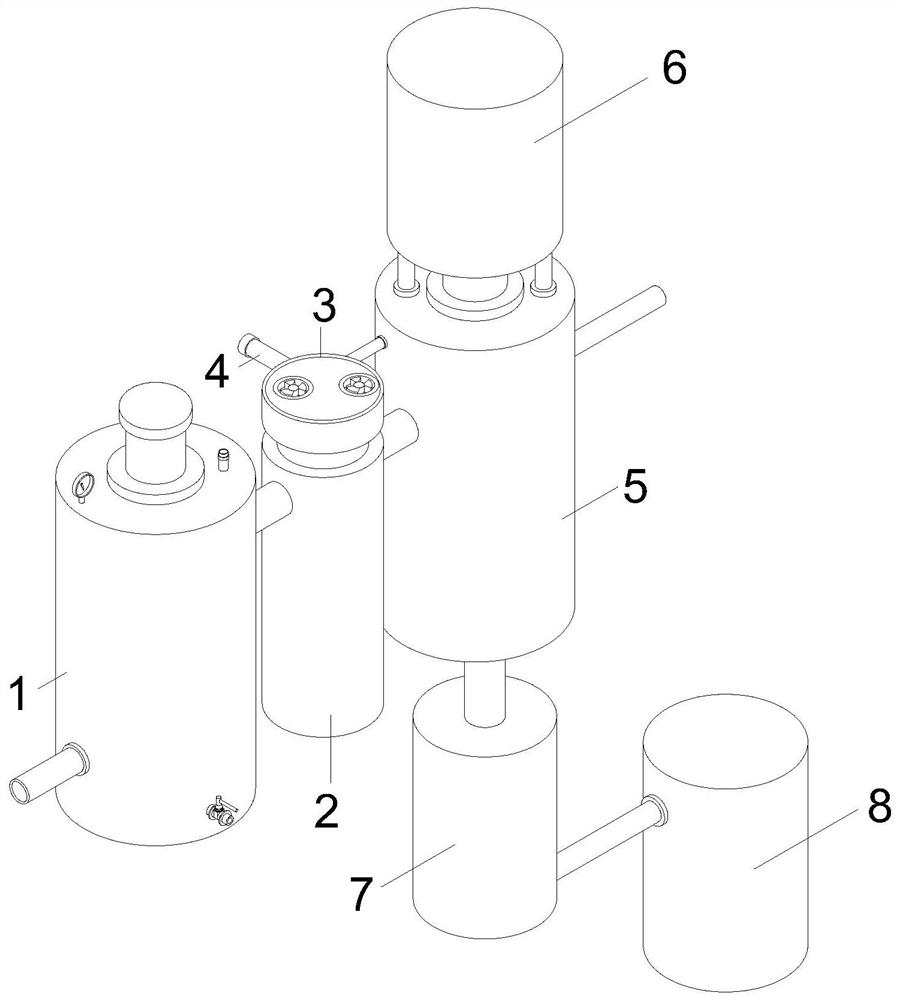

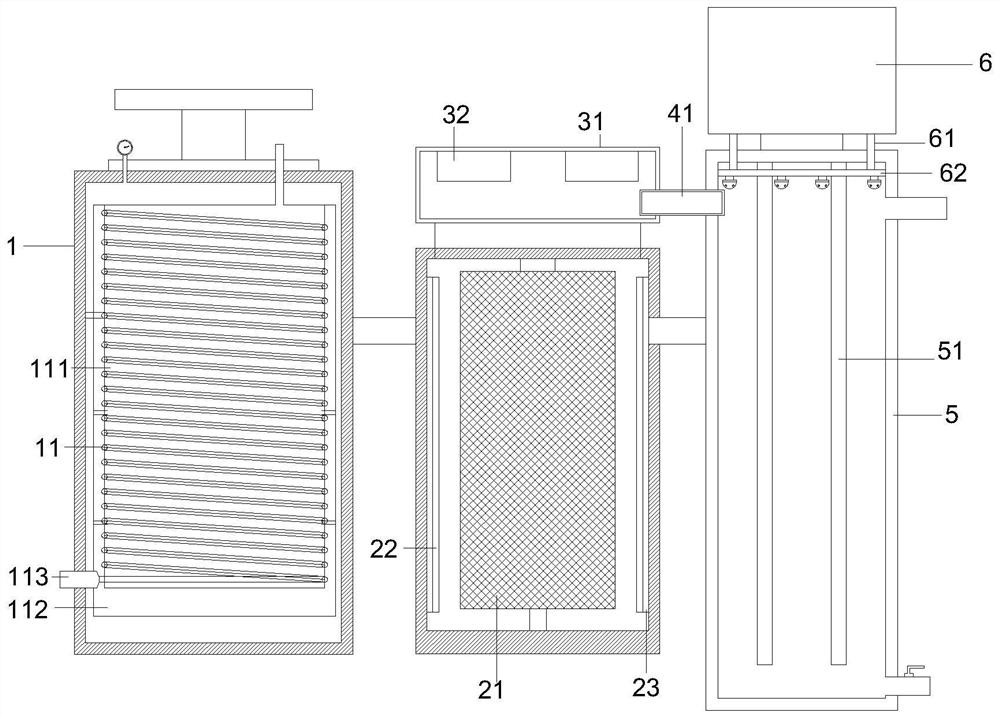

Multi-pollutant collaborative advanced treatment system for hazardous waste incineration flue gas

PendingCN114191958ARealize collaborative purification treatmentAchieve in situ regenerationCombination devicesIncinerator apparatusFiberPtru catalyst

The invention discloses a multi-pollutant collaborative advanced treatment system for hazardous waste incineration flue gas. The multi-pollutant collaborative advanced treatment system comprises a secondary combustion chamber (2), a waste heat boiler (3), a quench tower (4), a dry deacidification tower (5), a ceramic fiber filter tube integrated device (6), a washing tower assembly and a fixed bed activated carbon device (10) which are sequentially connected between a rotary kiln (1) and a discharge assembly. A plurality of ceramic fiber filter tubes (62) loaded with denitration catalysts are arranged in the ceramic fiber filter tube integrated device, flue gas is subjected to preliminary deacidification through the dry deacidification tower, is subjected to integrated deacidification, denitration and dust removal through the ceramic fiber filter tube integrated device, is washed and purified through the washing tower assembly, and is discharged after dioxin and heavy metal are deeply removed through the fixed bed activated carbon device. Integrated removal of dust removal, sulfur nitrate and dioxin is achieved based on the ceramic fiber filter tube, secondary deep removal is conducted on heavy metal and dioxin through fixed bed activated carbon, and collaborative deep removal of multiple pollutants in hazardous waste incineration flue gas is achieved.

Owner:SHANGHAI ELECTROMECHANICAL DESIGN & RES INST CO LTD

Spin confluence agglomeration tower and its agglomeration and dedusting method

ActiveCN105771515BCoagulation time is shortImprove the coagulation effectCombination devicesCycloneFlue gas

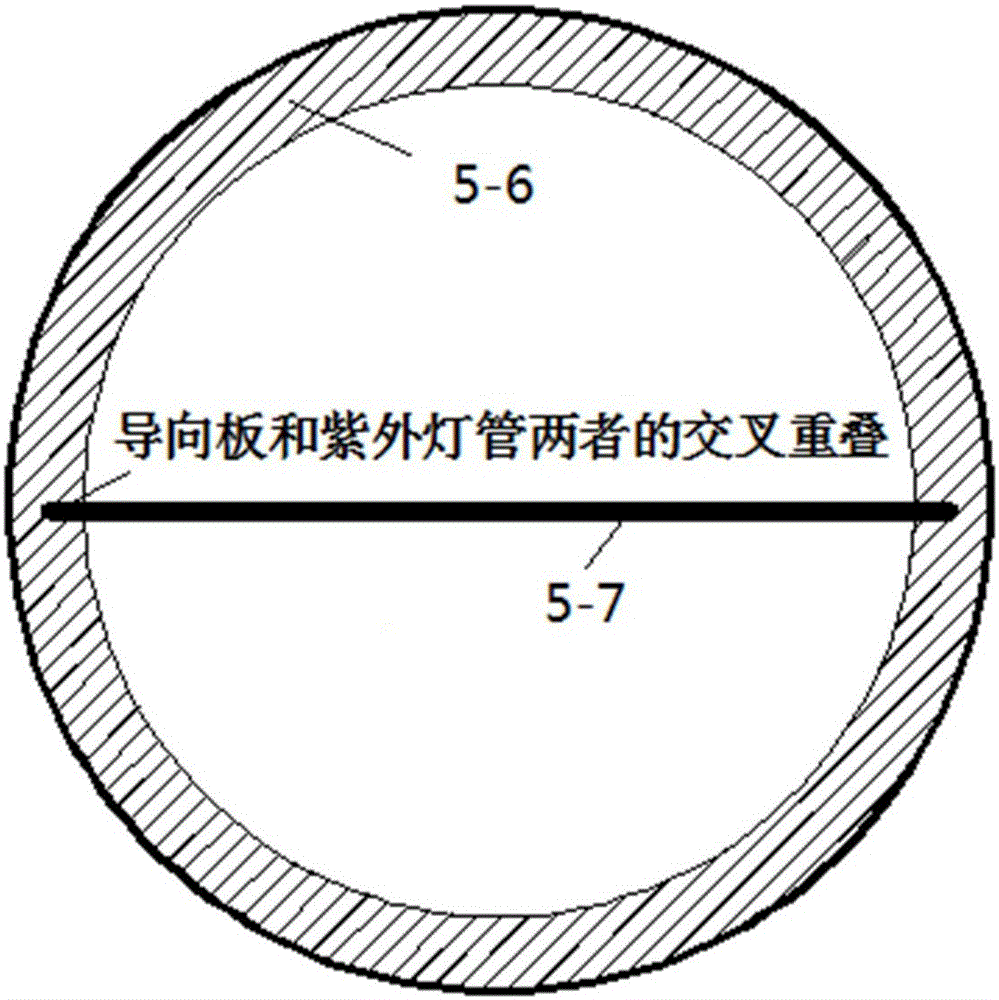

The invention relates to a swirl-convergence agglomeration tower and a method for agglomeration and dust removal using the swirl-convergence agglomeration tower. The swirl-convergence agglomeration tower includes a cylindrical tower body, and at least one guide pipe for introducing flue gas is provided at the lower part of the tower body. The diversion pipe is connected tangentially to the tower body, and the top of the tower body is provided with a flue gas outlet; the tower body is provided with multiple spray layers for spraying the agglomeration liquid in sequence from bottom to top, at least two spray layers at the bottom A swirl device is provided between them to form a turbulent state after the flue gas passes through. The invention can achieve better agglomeration effect and dust removal effect, effectively reduce the subsequent dust removal burden, and even cancel the subsequent dust removal process, and reduce equipment investment and operation cost while meeting the national flue gas emission standard.

Owner:武汉天空蓝环保科技有限公司

Chemical agglomeration accelerator for removing coal-burning fine particles and its application method

ActiveCN104474830BSignificant agglomerationEmission reductionAuxillary pretreatmentElectrostatic separationFlue gasFine particulate

The invention discloses a chemical agglomeration accelerator for removing coal-burning fine particles, which is composed of polydimethyldiallylammonium chloride, sorbitan fatty acid ester and water, wherein the agglomeration accelerator Among them, the mass percentage of the polydimethyldiallylammonium chloride is 0.001%-0.01%, and the mass percentage of the sorbitan fatty acid ester is 0.001%-0.1%. The invention also discloses the use method of the chemical aggregation accelerator. The chemical agglomeration accelerator can not only effectively promote the agglomeration and flocculation of fine particles in the flue gas channel to form large particles, but also perform integrated removal of heavy metals in the flue gas, improve the efficiency of fine particle removal by the dust collector, and effectively alleviate environmental problems.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

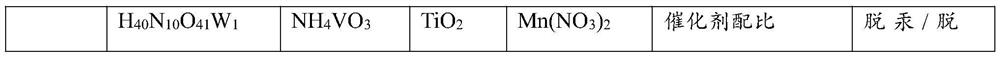

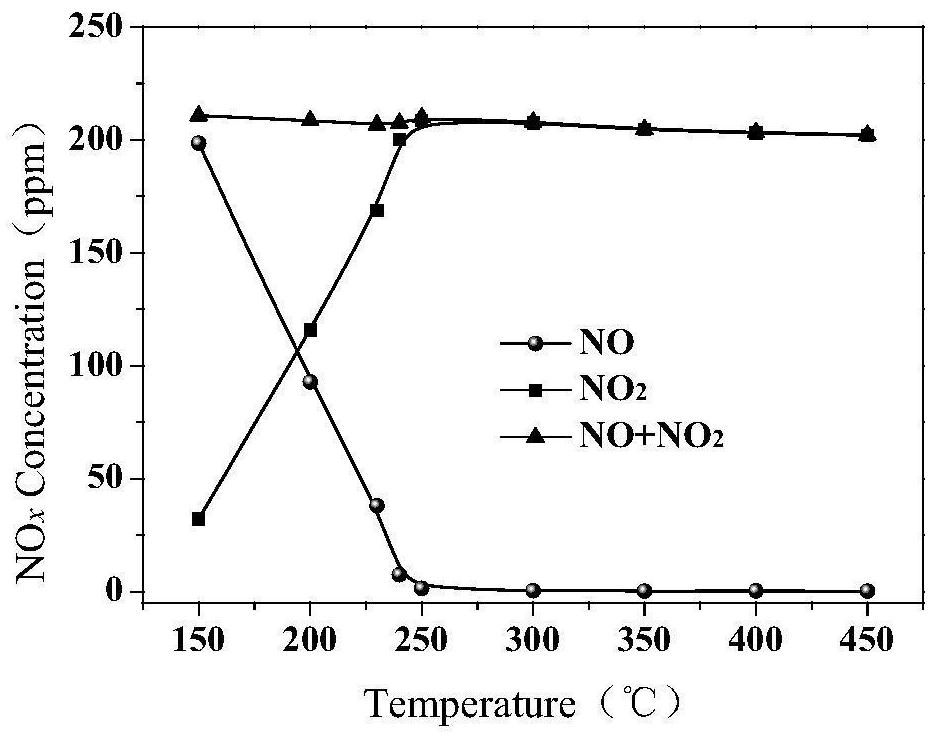

Preparation method of denitration and demercuration catalyst and catalyst prepared thereby

PendingCN112619639AGuaranteed service lifeAchieve integrated removalGas treatmentHeterogenous catalyst chemical elementsPtru catalystPhysical chemistry

The invention relates to the field of air pollution control, in particular to a preparation method of a denitration and demercuration catalyst, and a catalyst prepared by the method. The preparation method of the denitration and demercuration catalyst comprises the following steps of: putting H40N10O41W12 and NH4VO3 into a solvent, performing stirring and dissolving, then adding TiO2 and Mn(NO3)2 into the obtained mixed solution, and continuously performing stirring to obtain viscous liquid; and sequentially drying, calcining and grinding the viscous liquid to obtain the denitration and demercuration catalyst, wherein the mass ratio of H40N10O41W12 to NH4VO3 to TiO2 is (6-20):(1-18):158, and the mass ratio of Mn(NO3)2 to NH4VO3 is (6-48):1. The problem that the denitration and demercuration efficiency is low due to the fact that the activity temperature window of a traditional commercial vanadium-tungsten-titanium catalyst is too high and seriously deviates from the oxidation conversion temperature and denitration temperature window of Hg<0> is solved.

Owner:DATANG ENVIRONMENT IND GRP +1

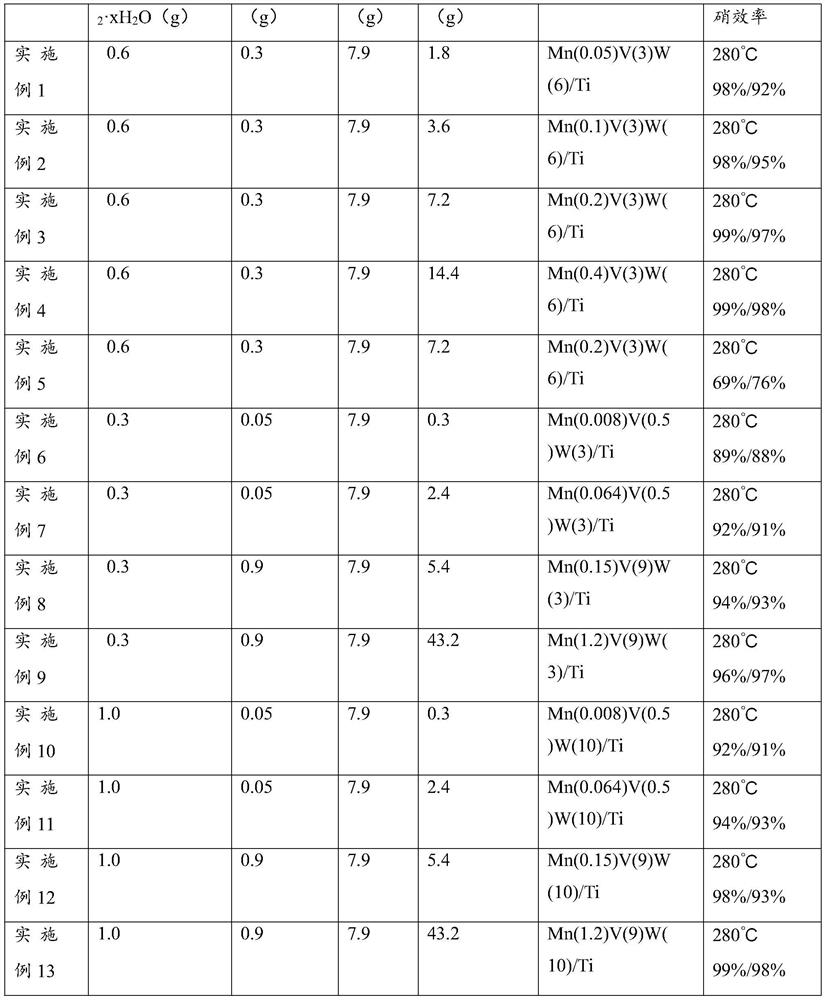

Pulse charge intensification-filtration catalysis integrated flue gas purification device and method

PendingCN112870968AReduce one-time investment and operating costsImprove removal efficiencyCombination devicesGas treatmentFlueNOx

The invention relates to a pulse charge intensification-filtration catalysis integrated flue gas purification device and a method.The device comprises a gas inlet flue, a flue pulse discharger, a catalysis and filtration integrated reactor and a gas outlet flue; the gas inlet flue is arranged on the lower middle portion of the catalysis and filtration integrated reactor, the flue pulse discharger is arranged in the gas inlet flue, and an ash hopper, a flue gas turbulence device, a catalytic filter pipe, a blowback air pipe and a top catalytic reaction layer are respectively arranged in the catalysis and filtration integrated reactor from bottom to top. The invention further provides a flue gas purification method using the device, and the flue gas purification method comprises the steps of (1) pulse charging, (2) coagulation, (3) filtration catalysis and (4) NH3 decomposition. The flue gas purification device has the advantages that PM2.5, NOx, VOCs, heavy metal mercury and other pollutants can be removed at the same time, filtration resistance is reduced, membrane holes are prevented from being blocked, NH3 escape is effectively controlled, and the ultra-low emission and environment-friendly emission requirements are met.

Owner:江苏省环境工程技术有限公司

A marine self-flocculating bacterium and its development-driven salt-adapted nitrogen assimilation microbiome and its construction method and application

ActiveCN113403234BWide range of toleranceAchieve integrated removalBacteriaSeawater treatmentAlkali soilNutrition

The invention provides a marine self-flocculating bacteria and a salt-adapted nitrogen assimilation microbiome, a construction method and application thereof, which belong to the technical field of microorganism and environmental treatment and restoration. In the present invention, a seawater psychrophilic bacillus (Psychrobacter aquimaris) A4N01 is screened from marine sediments, which can assimilate ammonia nitrogen to synthesize organic nitrogen, and simultaneously transform organic matter and phosphorus, and the salt-adapted nitrogen assimilation microbial group developed by it has good nutrition Substance conversion removal ability and sedimentation performance, wide tolerance to salinity, can be used in high-salt sewage treatment, saline-alkali soil fertilization and other directions, to achieve the recovery of nitrogen, phosphorus and other nutrients in high-salt environment, simple operation, low price, Environmentally friendly, so it has good practical application value.

Owner:SHANDONG UNIV

Method and device for integrated removal of multi-pollutants in tail gas by plant ash slurry

ActiveCN105771600BAvoid secondary pollutionAchieve recyclingGas treatmentDispersed particle separationCombustionResource utilization

The invention relates to a method and device for integrally removing multiple pollutants in tail gas through plant ash seriflux. The method comprises the steps that plant ash seriflux is adopted for independently or jointly oxidize and remove SO2, NOx, Hg, H2S, HCl and HF in tail gas of a combustion or chemical device; tail gas containing SO2, NOx, Hg, H2S, HCl and HF from a boiler or kiln or chemical device is cooled and enters a rotary absorption reactor; soluble or acid gas SO2, NO2, Hg2+, H2S, HCl and HF can be directly washed and absorbed by a solution, and indissolvable gas NO and Hg0 can be absorbed by a solution after being pre-oxidized or oxidized by an additive into NO2, HNO2, HNO3 and Hg2+. According to the method, resource utilization can be achieved for solid waste produced by biomass burning, multiple pollutants can be integrally removed, the purpose of dealing with waste by waste is achieved, secondary pollution is avoided in the whole removal process, and the market development and application prospect is wide.

Owner:刘杨先

Flue gas treatment system

InactiveCN113385021AHeating fastFully absorbedGas treatmentDispersed particle separationFlue gasChemical adsorption

The invention discloses a flue gas treatment system which comprises a reaction device and a pressurizing device; the reaction device is arranged at the top end of the pressurizing device through a pipeline, the front end of the reaction device is communicated with a heat exchange device, one end of the pressurizing device is communicated with a washing tank, the top end of the washing tank is communicated with an ammonia water tank, and the bottom end of the washing tank is communicated with a compression device; one end of the compression device is communicated with a crystallizing tank; a structural carbon plate is arranged in the reaction device, the structural carbon plate is fixed in the reaction device through a mounting frame structure; heated liquid can be discharged through an inner cylinder for use for other purposes, and gas after heat exchange enters the reaction device for next operation, so that simpleness and convenience are achieved; the heat in the gas can be fully absorbed, energy waste is avoided, and oxidizing gas entering branch pipes reacts with sulfur-containing compounds in flue gas; and meanwhile, chemical adsorption is generated between the structural carbon plate and SO2, oxidation products of NO and HgO are adsorbed at the same time, and the purpose of removing pollutants is achieved.

Owner:杭州同景科技有限公司

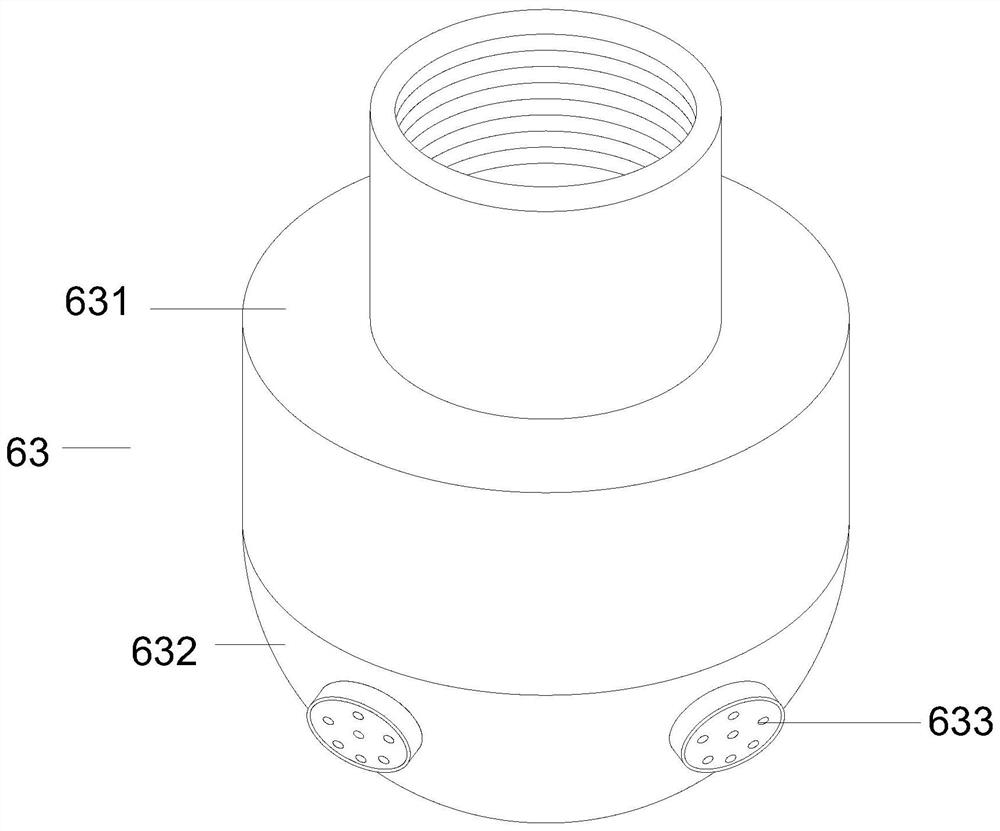

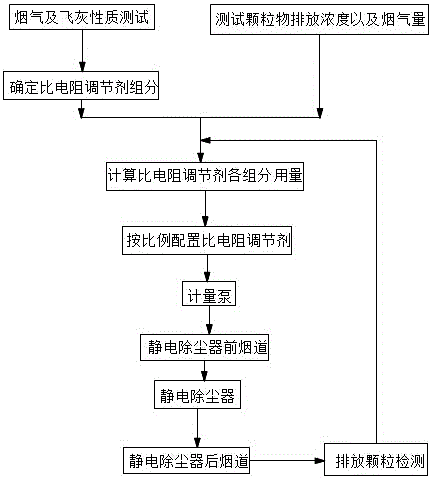

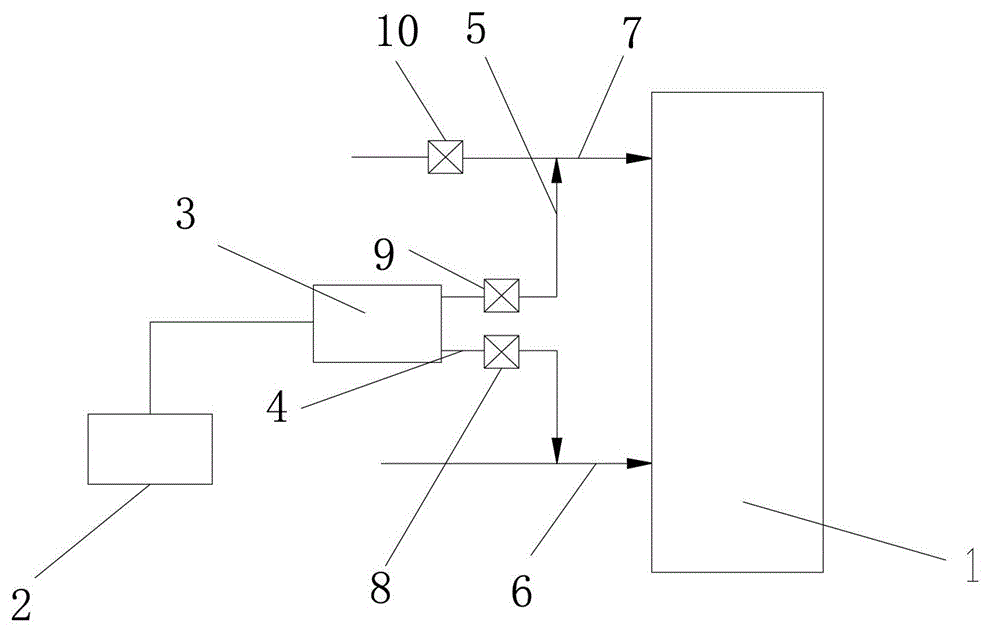

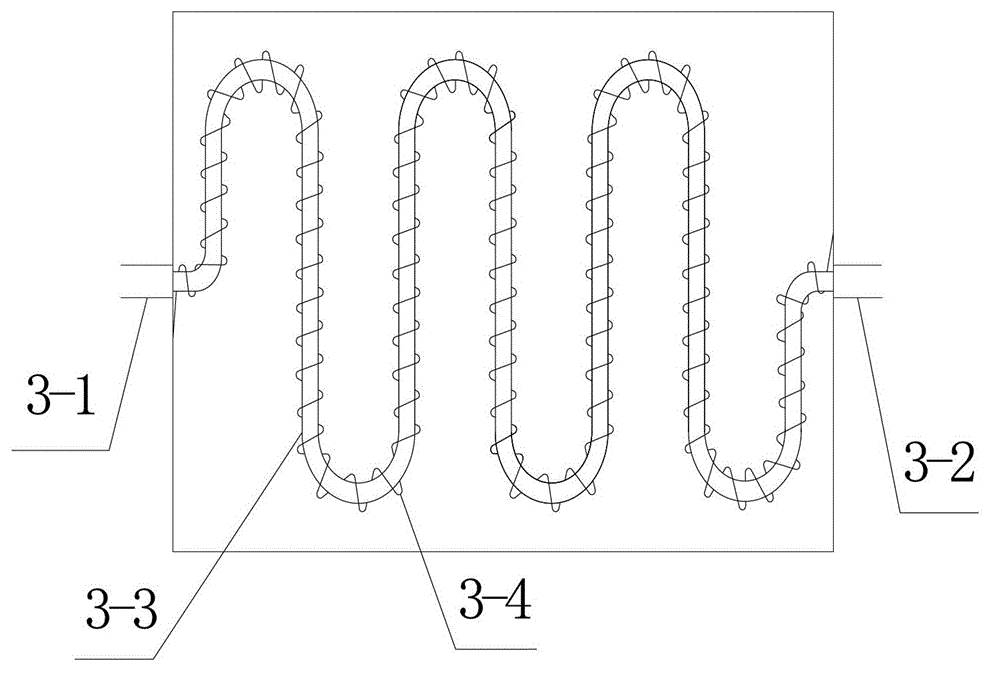

Specific resistance conditioning agent used for lowering fly ash resistivity and application of specific resistance conditioning agent

InactiveCN105107629ALower specific resistanceImprove removal efficiencyExternal electric electrostatic seperatorElectrostatic separation detailsSodium acetateDipotassium phosphate

The invention discloses a specific resistance conditioning agent used for lowering fly ash resistivity. The specific resistance conditioning agent is an aqueous solution containing alkali metal salt; the alkali metal salt comprises sodium acetate and dipotassium phosphate. The invention discloses the application and a using method of the specific resistance conditioning agent. By means of the specific resistance conditioning agent, the specific resistance of fly ash can be effectively reduced, and the removal efficiency over the fly ash of an electrostatic dust collector is improved.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

Superheated steam pulverized coal combustion device

InactiveCN103047672BHigh thermal radiation coefficientReduce CO contentFuel supply regulationIndirect carbon-dioxide mitigationCombustion chamberHigh energy

The invention discloses a superheated steam pulverized coal combustion device, belongs to boiler pulverized coal combustion devices in electric power industry, and solves the problems of complicated equipment, high energy consumption and low energy utilization efficiency of an existing oxygen-enriched pulverized coal combustion device. The superheated steam pulverized coal combustion device comprises a pulverized coal boiler, a steam generator and a heater, a steam outlet of the steam generator is connected with a steam inlet of the heater through a pipeline, a steam outlet of the heater is respectively connected with a primary air pipeline and a secondary air pipeline of the pulverized coal boiler through a distribution pipeline and an air distribution pipeline, and a first flow meter and a second flow meter are mounted in the distribution pipeline and the air distribution pipeline respectively and used for controlling the superheated steam flow ratio of the distribution pipeline and the air distribution pipeline. The internal heat exchange efficiency of a combustion chamber is effectively improved, the device is simplified, investment cost is saved, NOx emission load is reduced, pollutants can be integrally removed, and the superheated steam pulverized coal combustion device is not only applicable to solid fuels, but also applicable to gas and liquid fuels.

Owner:HUAZHONG UNIV OF SCI & TECH

Device for treating high ammonia-nitrogen wastewater integrated with solid-phase denitrifying coupled membrane bioreactor and method

InactiveCN109052623ASmall footprintImprove processing efficiencyTreatment using aerobic processesWater contaminantsFiltration membraneAeration rate

The invention discloses a device for treating high ammonia-nitrogen wastewater integrated with a solid-phase denitrifying coupled membrane bioreactor and a method. The device mainly comprises a membrane bioreactor, a solid-phase denitrifying bio-membrane reactor, a water feeding system, a stirring system, an aerating system, a temperature control system and a water draining system; a micro-filtration membrane component is adopted by the membrane bioreactor; poly(butylene succinate) grains are filled in a solid-phase denitrifying device, wherein the adding volume is 60-80%. The method disclosedby the invention comprises the following steps: quickly realizing the membrane forming of a solid-phase denitrifying reactor in the starting stage and setting aeration rate as 2.8-3.2L / min; setting hydraulic retention time as 24h for the 1st to 10th days, 18h for the 11th-15th days and 12h for the 16th-20th days; setting the aeration rate as 1.8-2.2L / min in the stable stage; setting the hydraulicretention time as 12h. The device disclosed by the invention can solve the problem of ultrahigh organic content of effluent caused by insufficient carbon source and liquid carbon source in the denitrifying stage. The device has the advantages of small floor space, high anti-shock loading capability, no sludge bulking problem, capability of saving energy and reducing consumption, low cost, and thelike.

Owner:UNIV OF JINAN

Pre-oxidation and wet catalysis combined desulfurization and denitrification system and method

PendingCN111905542AAvoid invalid decompositionReduce oxygenGas treatmentDispersed particle separationPtru catalystFlue gas

The invention provides a pre-oxidation and wet catalysis combined desulfurization and denitrification system and method. The pre-oxidation and wet catalysis combined desulfurization and denitrification system comprises a pre-oxidation system arranged on a flue, an absorption system arranged at an outlet of the flue, and a catalyst feeding system and a chimney which are connected with the absorption system respectively, wherein the front oxidation system comprises an H2O2 storage tank and an ultrasonic atomizer which are connected in sequence, and a compressed gas tank connected with an inlet of the ultrasonic atomizer; an outlet of the ultrasonic atomizer is connected into the flue; the absorption system comprises an absorption tower; the absorption tower adopts a wet spraying tower, and aslurry pool for containing alkaline absorption liquid is arranged at the bottom of the absorption tower; a flue gas inlet of the absorption tower is connected with a flue outlet which is connected with a chimney; the catalyst feeding system comprises a catalyst storage tank and a catalyst conveying pump; the catalyst storage tank is connected with the slurry pool through a catalyst conveying pump; and a catalyst for realizing synergistic removal of SO2 and NO2 in the alkaline absorption liquid is contained in the catalyst storage tank.

Owner:XIAN THERMAL POWER RES INST CO LTD

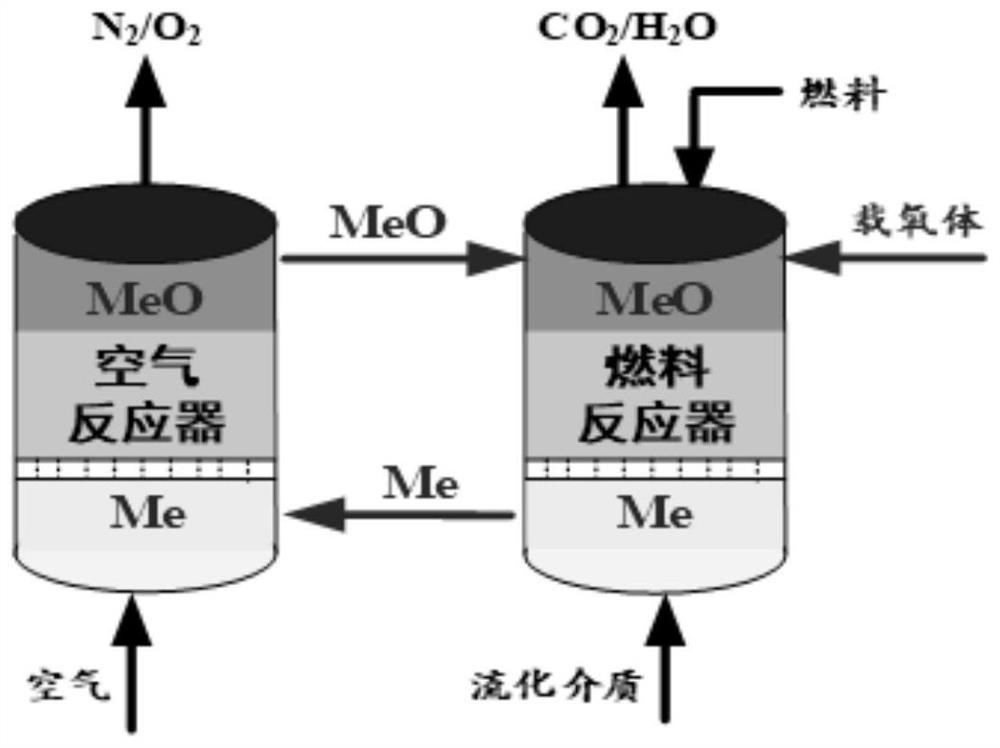

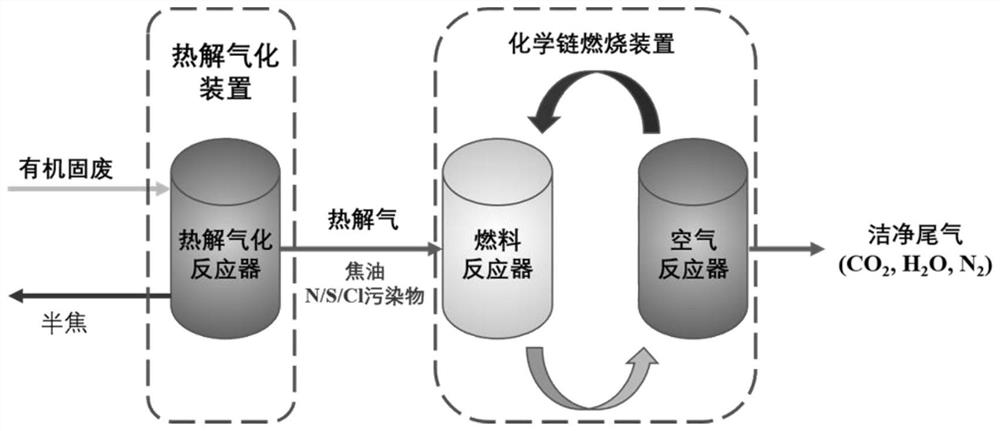

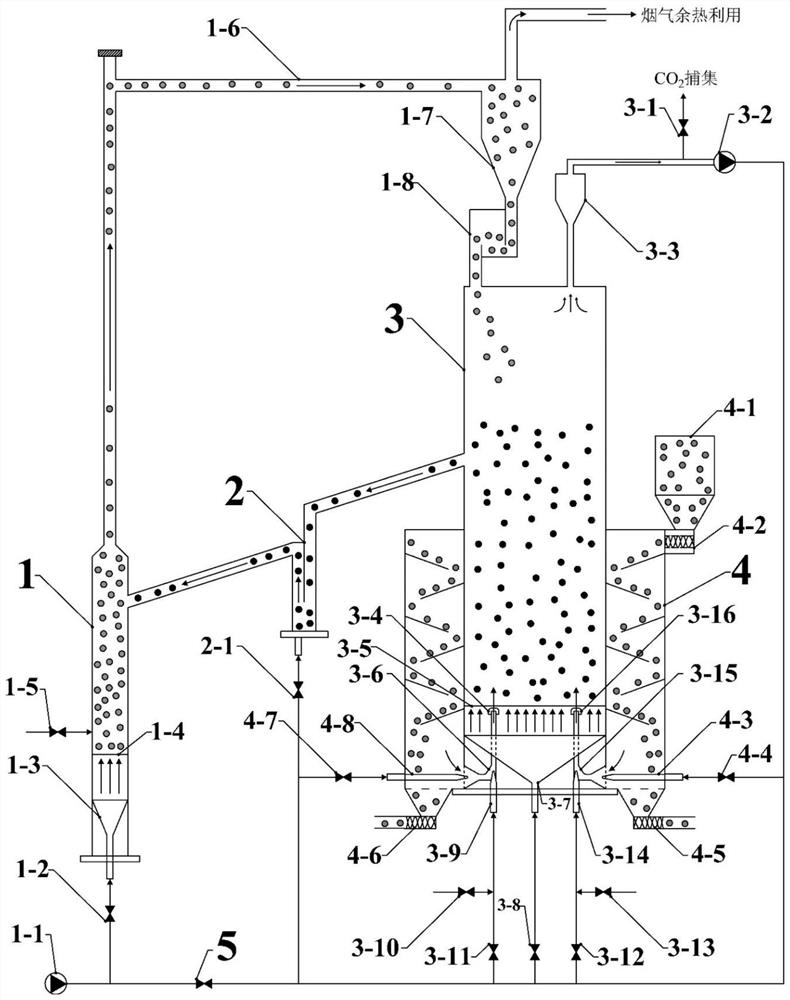

A method and device for removing pollutants by thermally decoupled chemical chain combustion of organic solid waste

ActiveCN113188129BAvoid contactExtended service lifeIndirect carbon-dioxide mitigationIncinerator apparatusProcess engineeringEnvironmental engineering

The invention discloses a method and a device for removing pollutants by thermally decoupling and coupling chemical chain combustion of organic solid waste. The device includes an air reactor, a fuel reactor and a pyrolysis gasifier, the pyrolysis gasifier is sleeved outside the fuel reactor, the air reactor and the fuel reactor are connected through a U-shaped return material, and the air reactor The top end is communicated with one end of the top conveying pipe, the other end of the top conveying pipe is communicated with the top end of the first cyclone separator, and the bottom end of the first cyclone separator is connected with the oxygen carrier return material arranged at the top of the fuel reactor, and the air reacts An air inlet is arranged at the bottom of the reactor, and a fluidizing gas nozzle and several jets are arranged at the lower part of the fuel reactor. Compared with the chemical chain combustion device, the device proposed by the present invention forms a pyrolysis + chemical chain combustion two-stage reaction unit by decoupling the pyrolysis process in the chemical chain combustion, avoiding the complex ash of organic solid waste and the oxygen carrier. Contact, improve the service life of the oxygen carrier.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

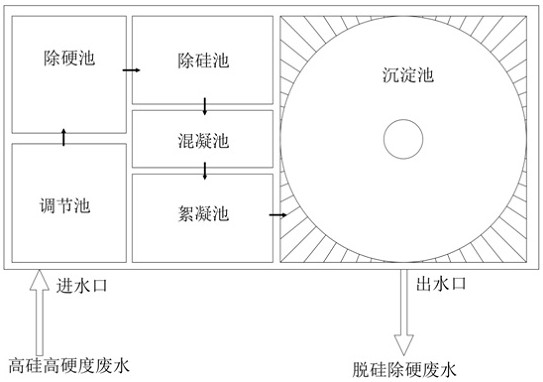

Desiliconization and hardness removal integrated device and method

PendingCN114702158AAchieve integrated removalHigh process integrationWater treatment parameter controlSpecific water treatment objectivesSludgePhysical chemistry

The invention provides a desilicication and hardness removal integrated device and method, and relates to the technical field of wastewater treatment. According to the device disclosed by the invention, the regulating tank, the hardness removal tank, the silicon removal tank, the coagulation tank, the flocculation tank and the sedimentation tank are integrated, so that high-silicon and high-hardness wastewater is subjected to mud-water separation in the same sedimentation tank after hardness removal and desilicication. The method comprises the following steps: sequentially adding sodium hydroxide, sodium carbonate, a desiliconization agent, a coagulant and a flocculant into an adjusting tank, a hardness removal tank, a silicon removal tank, a coagulation tank and a flocculation tank, staying in each tank for a period of time and then entering a sedimentation tank, obtaining clarified desiliconized hardness-removed wastewater at an outlet at the upper part of the sedimentation tank, and obtaining sludge containing a hardness-removed product and a desiliconized product at the bottom of the sedimentation tank. According to the invention, the integration degree is high, the number of coagulation tanks, flocculation tanks and sedimentation tanks is reduced, the process flow is simplified, the removal rates of hardness and silicon in the high-silicon and high-hardness wastewater respectively reach 95% and 90%, the requirements of downstream inflow water quality are met, and the method is a rapid and efficient desilicication and hardness removal method and is suitable for industrial application.

Owner:新疆天业汇合新材料有限公司 +2

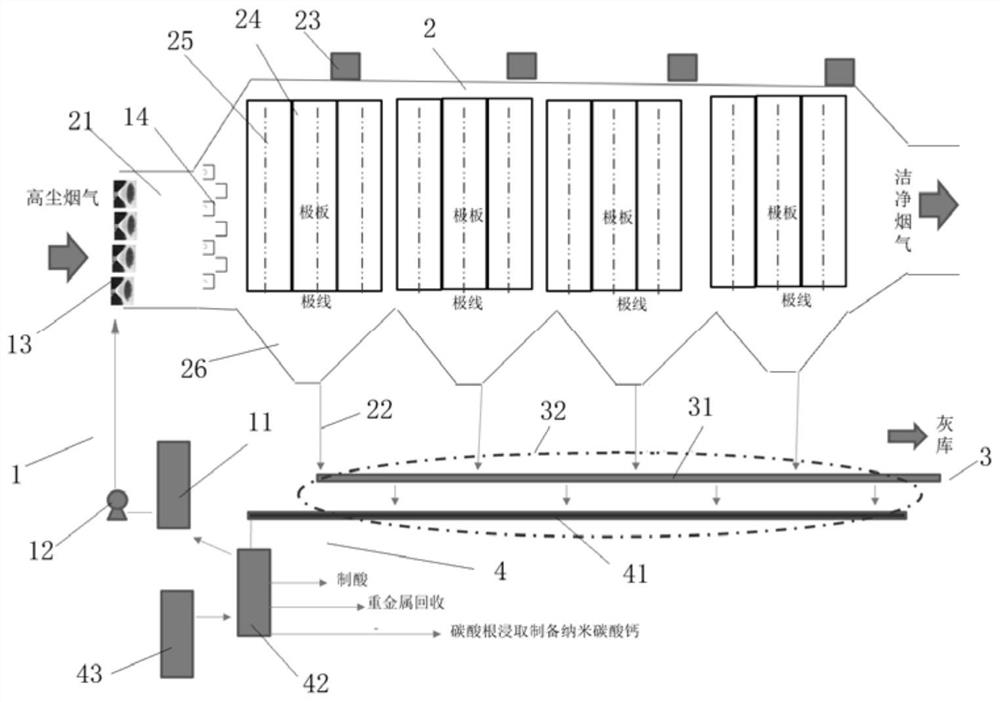

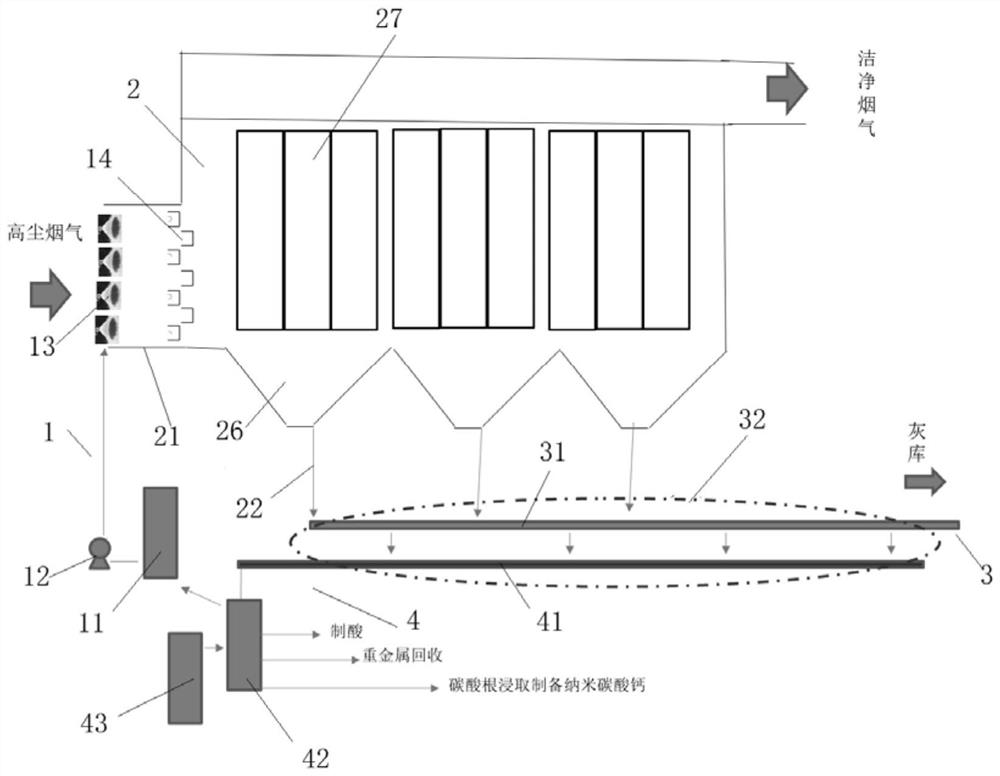

Mercury, sulfur and carbon synergistic and integrated removal dust removal system

PendingCN114768471ARealize synergistic integrationAchieve integrated removalCalcium/strontium/barium carbonatesCombination devicesSorbentEnvironmental engineering

The invention discloses a mercury-sulfur-carbon synergetic integrated removal dust removal system, which comprises an absorbent injection system, a dust removal system, an ash conveying system and a magnetic adsorbent recovery and reuse system, a plurality of dry powder spray guns are arranged on the absorbent injection system, the dry powder spray guns are arranged in an inlet flue of the dust removal system, and the magnetic adsorbent recovery and reuse system is arranged on the dust removal system. The ash conveying system comprises an ash conveying mechanism and a magnetic separation device, an ash discharge port of the dust removal system is connected with an inlet of the ash conveying mechanism, the magnetic separation device is used for magnetically separating out a magnetic adsorbent in fly ash conveyed by the ash conveying mechanism, and an outlet of the magnetic separation device is connected with an inlet of the magnetic adsorbent recycling system. And an outlet of the magnetic adsorbent recycling system is connected to the absorbent injection system. The system can realize integrated removal of dust, sulfur, mercury and carbon, and is small in occupied area, low in cost and more suitable for large-scale engineering popularization.

Owner:浙江菲达环保科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com