Rotation, confluence and agglomeration tower and method for agglomeration dedusting

A technology of agglomeration liquid and tower body, which is applied in the field of agglomeration dust removal and rotary agglomeration agglomeration tower, can solve the problems of poor agglomeration effect and low mixing degree of agglomeration liquid and flue gas, achieve good dust removal effect, reduce subsequent dust removal burden, reduce The effect of equipment investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

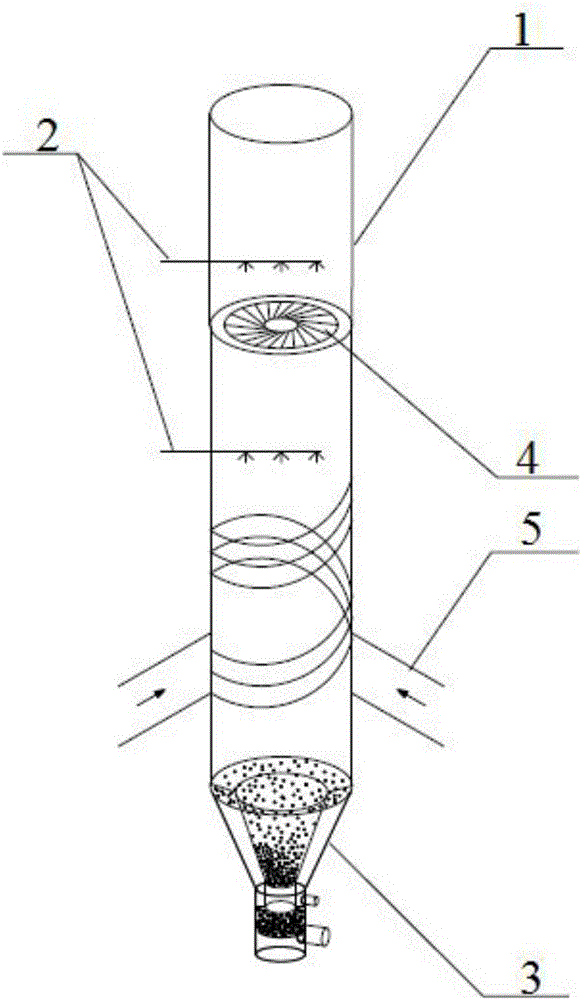

[0025] Such as figure 1 , the embodiment of the present invention provides a swirl confluence agglomeration tower for flue gas dedusting, comprising a cylindrical tower body 1, the lower part of the tower body 1 is provided with at least one guide pipe 5 for introducing flue gas, the guide pipe The flow pipe 5 is connected tangentially to the tower body 1, and the top of the tower body 1 is provided with a flue gas outlet. The tower body 1 is provided with multiple layers of spray layers 2 for spraying the agglomeration liquid sequentially from bottom to top, and at least between the bottom two layers of spray layers 2 is provided with a turbulent state after the flue gas passes through. Cyclone device 4. In this embodiment, two guide tubes 5 are used, and the two guide tubes 5 are symmetrically arranged along the central axis of the tower body 1. After the flue gas is tangentially introduced into the tower body 1 through the two guide tubes 5, it rotates in the tower body 1 ...

Embodiment 2

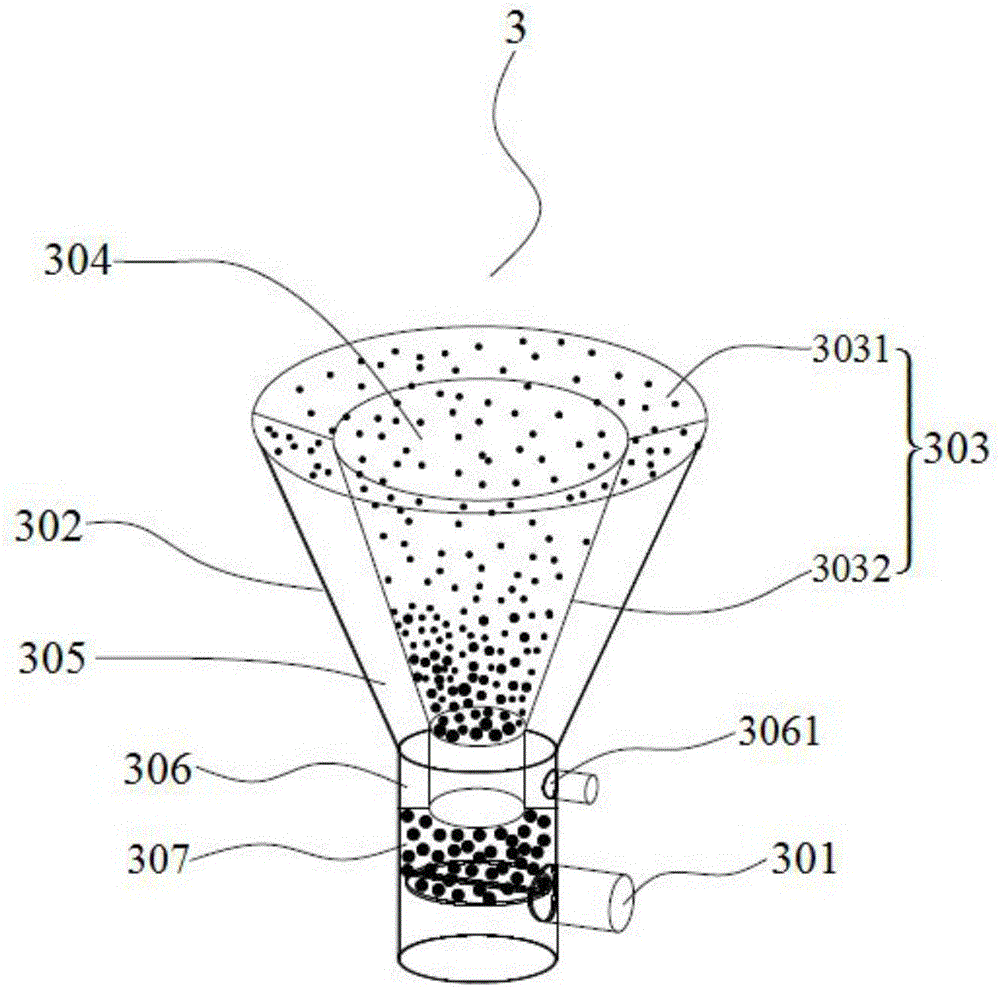

[0034] This embodiment provides an ash hopper 3 that can be used in the first embodiment above as the ash hopper 3 installed at the bottom of the tower body 1 . Such as image 3 , the ash hopper 3 is funnel-shaped, including a cone section and a straight section, the cone section is wide at the top and narrow at the bottom, and is used to form a dust collection chamber, and the straight section is connected to the lower end of the cone section to accommodate the collected dust. There is a dust discharge valve on the section, which can clean the collected dust regularly or irregularly.

[0035] Such as image 3 , the above-mentioned conical section includes an outer conical shell 302 and an inner filter layer 303, wherein the outer conical shell 302 is connected to the bottom of the tower body 1, and the conical shell 302 can be a cone or a pyramid, up and down Both ends are open, and the upper end matches the inner diameter of the tower body 1 for smooth docking; the inner f...

Embodiment 3

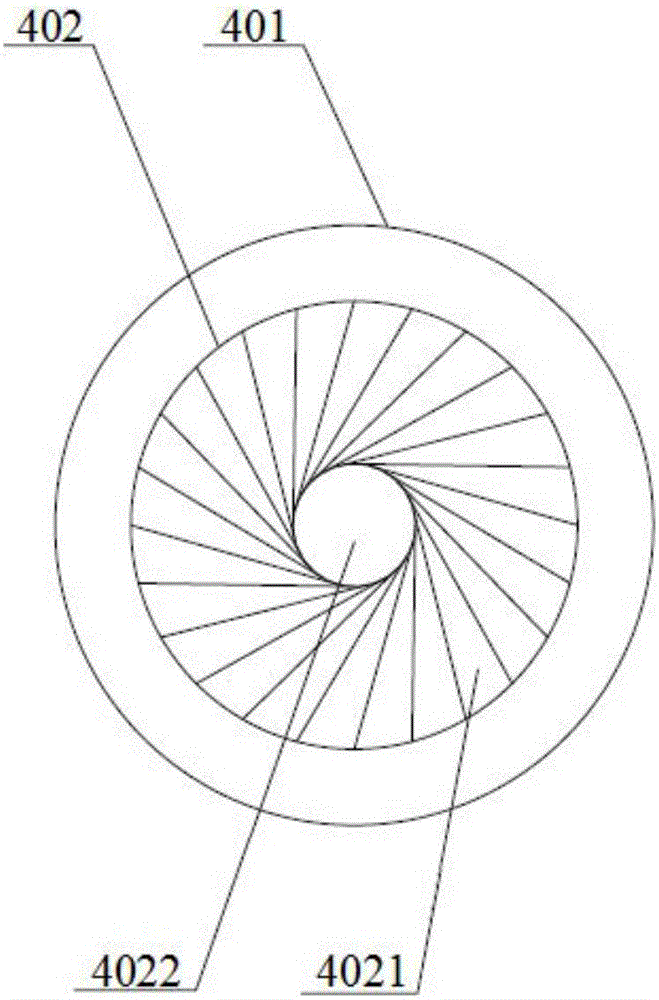

[0038] In Embodiment 1, the spray layer 2 can be provided with a plurality of spray guns in the inner ring of the tower body 1 to completely cover the spray area along the cross section of the tower body 1 . In this embodiment, a spray device is provided, which can be used as the spray layer 2 in the first embodiment.

[0039] Such as Figure 4-Figure 5 , the spraying device includes a plurality of spraying pipes 202, a plurality of spraying pipes 202 are interwoven to form a network frame for erecting in the tower body 1 along the cross section of the tower body 1, each spraying pipe 202 is provided with There is at least one spray head 203 , and the spray areas of each spray head 203 are combined to form a spray surface that can at least cover the cross section of the tower body 1 . Wherein, each spray pipe 202 can separately enter liquid respectively, also can adopt following preferred structure: each node place of described reticular frame is provided with a multi-way con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inclination | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com