Patents

Literature

37 results about "Convective mixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In fluid dynamics, convective mixing is the vertical transport of a fluid and its properties. In many important ocean and atmospheric phenomena, convection is driven by density differences in the fluid, e.g. the sinking of cold, dense water in polar regions of the world's oceans; and the rising of warm, less-dense air during the formation of cumulonimbus clouds and hurricanes.

Microfluidic free interface diffusion techniques

InactiveUS20080182273A1Reduce concentrationFrom normal temperature solutionsFlow mixersFree interfaceCompetitive binding

Owner:CALIFORNIA INST OF TECH +1

Microfluidic free interface diffusion techniques

InactiveUS7306672B2Reduce concentrationFrom normal temperature solutionsFlow mixersDiffusionFree interface

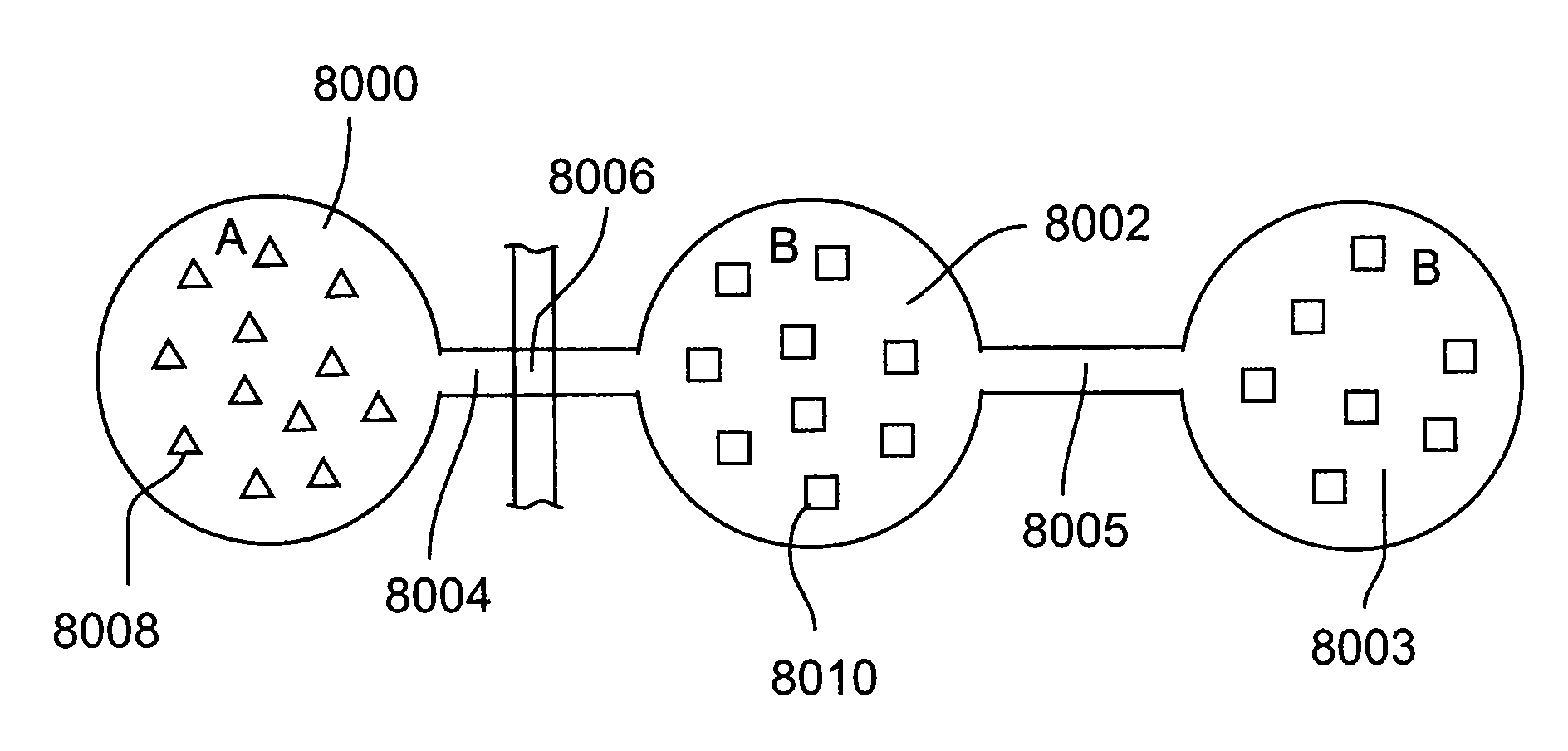

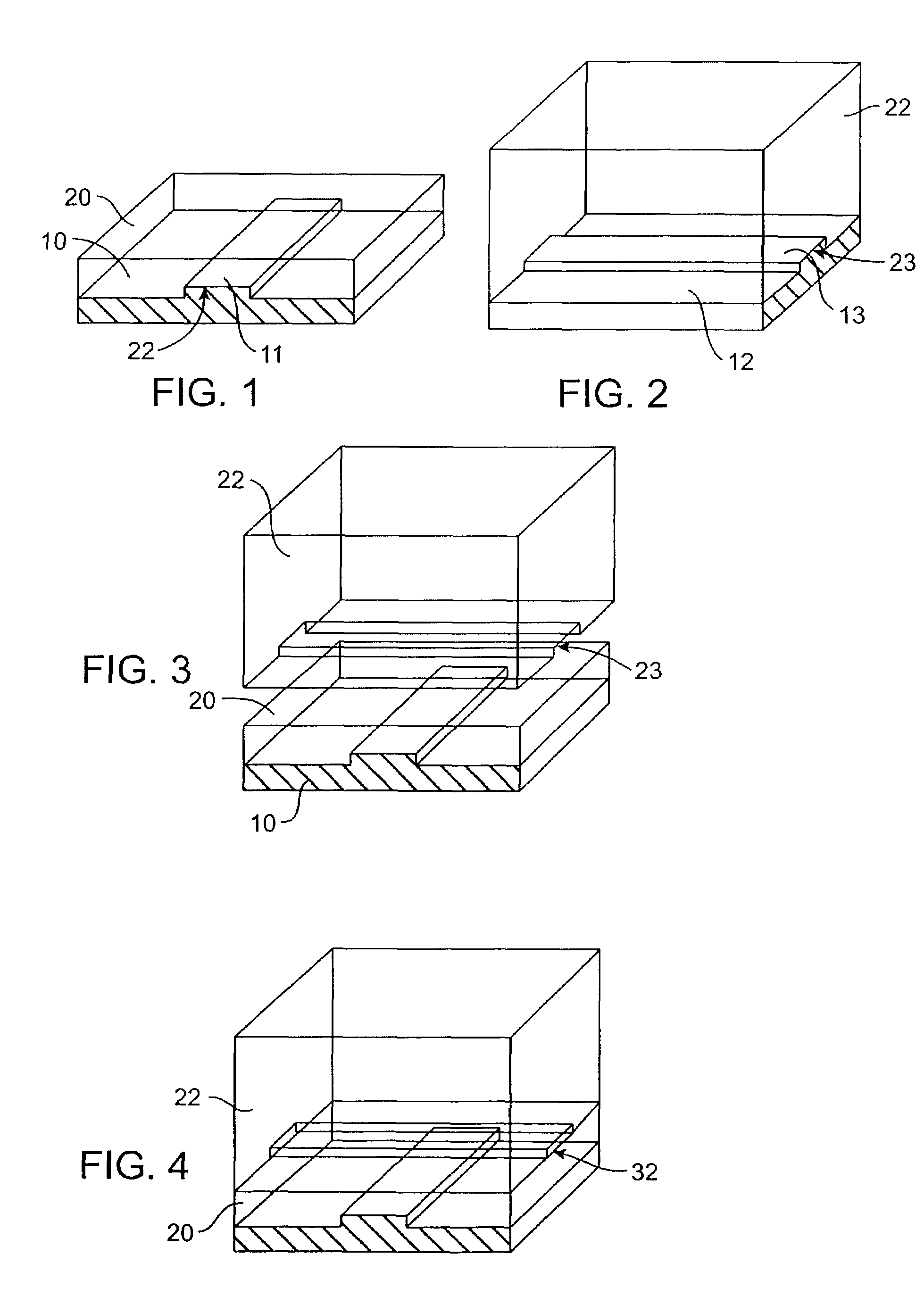

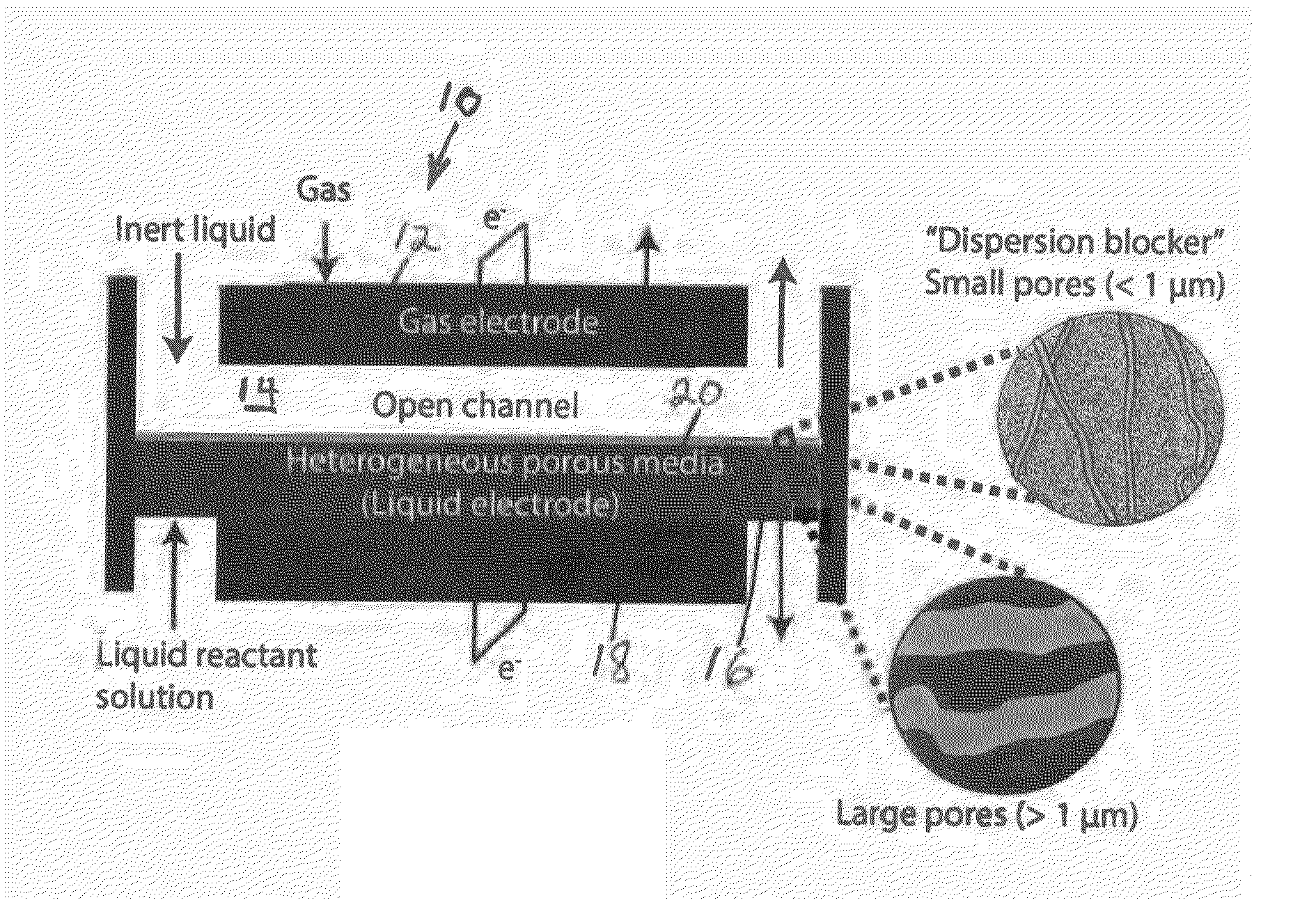

A static fluid and a second fluid are placed into contact along a microfluidic free interface and allowed to mix by diffusion without convective flow across the interface. In accordance with one embodiment of the present invention, the fluids are static and initially positioned on either side of a closed valve structure in a microfluidic channel having a width that is tightly constrained in at least one dimension. The valve is then opened, and no-slip layers at the sides of the microfluidic channel suppress convective mixing between the two fluids along the resulting interface. Applications for microfluidic free interfaces in accordance with embodiments of the present invention include, but are not limited to, protein crystallization studies, protein solubility studies, determination of properties of fluidics systems, and a variety of biological assays such as diffusive immunoassays, substrate turnover assays, and competitive binding assays.

Owner:RGT UNIV OF CALIFORNIA +1

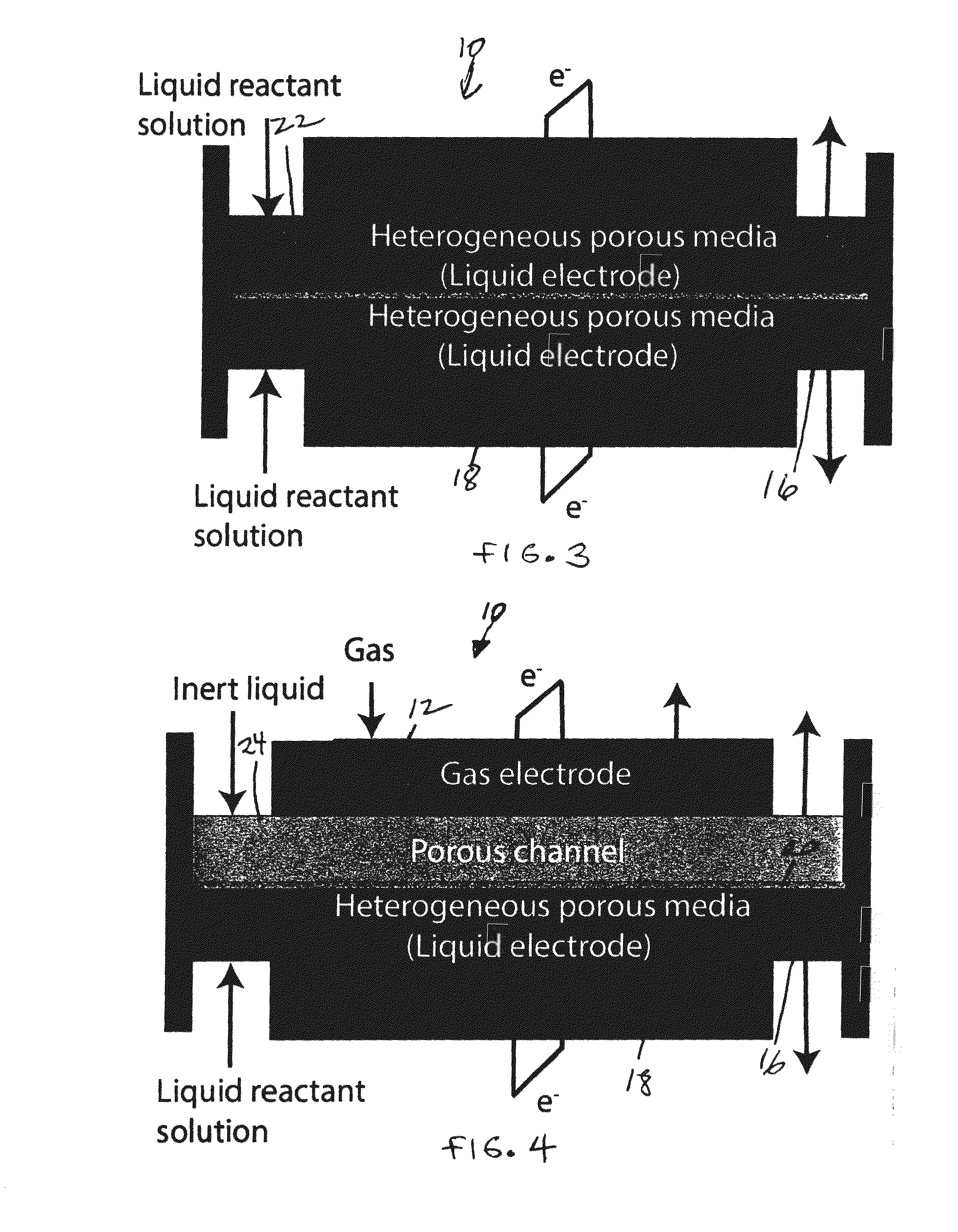

Battery with Heterogeneous Flow-Through Porous Electrodes

ActiveUS20150099199A1Maximizes pressure dropCell electrodesRegenerative fuel cellsStructure propertyElectrochemical energy conversion

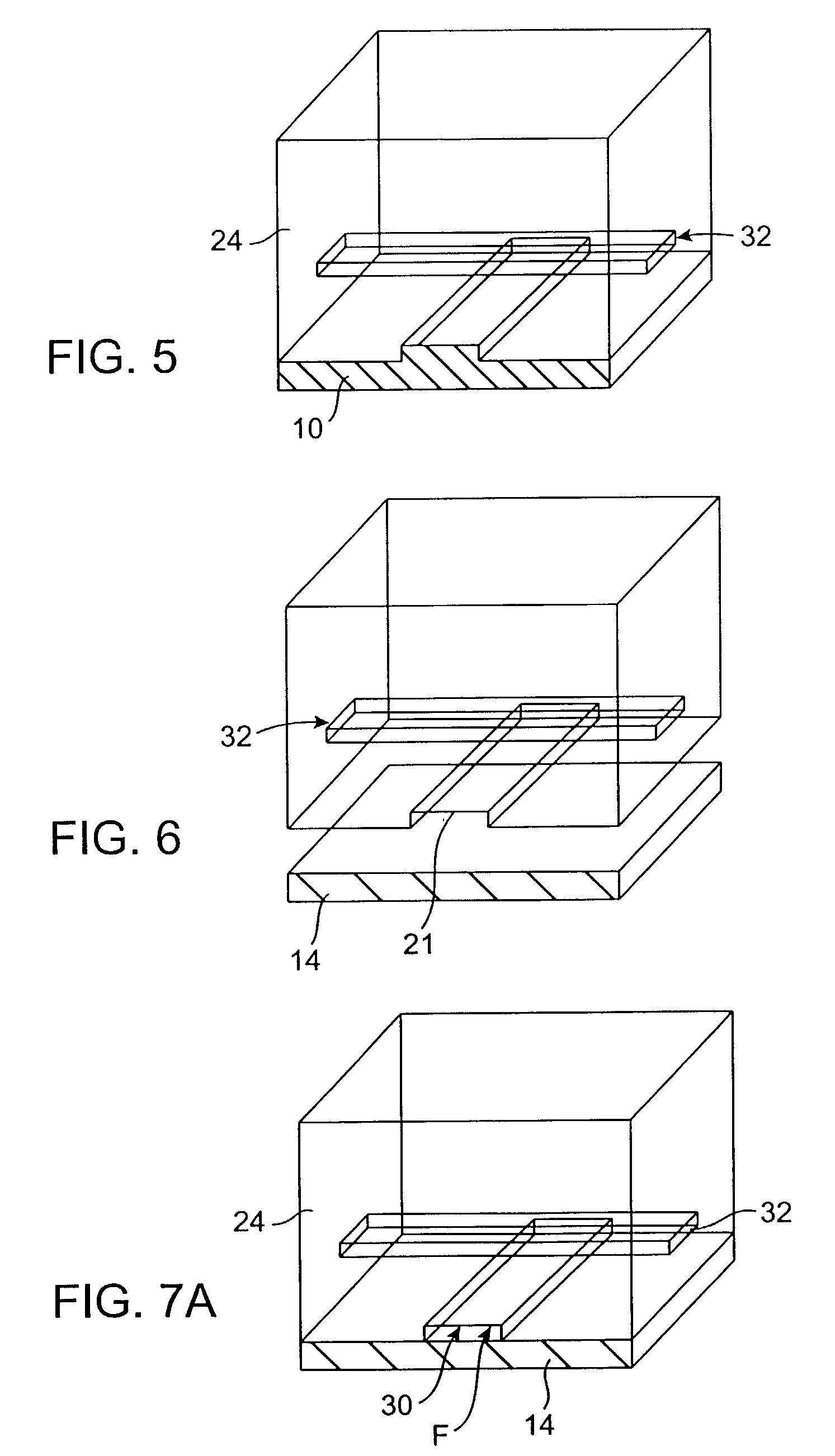

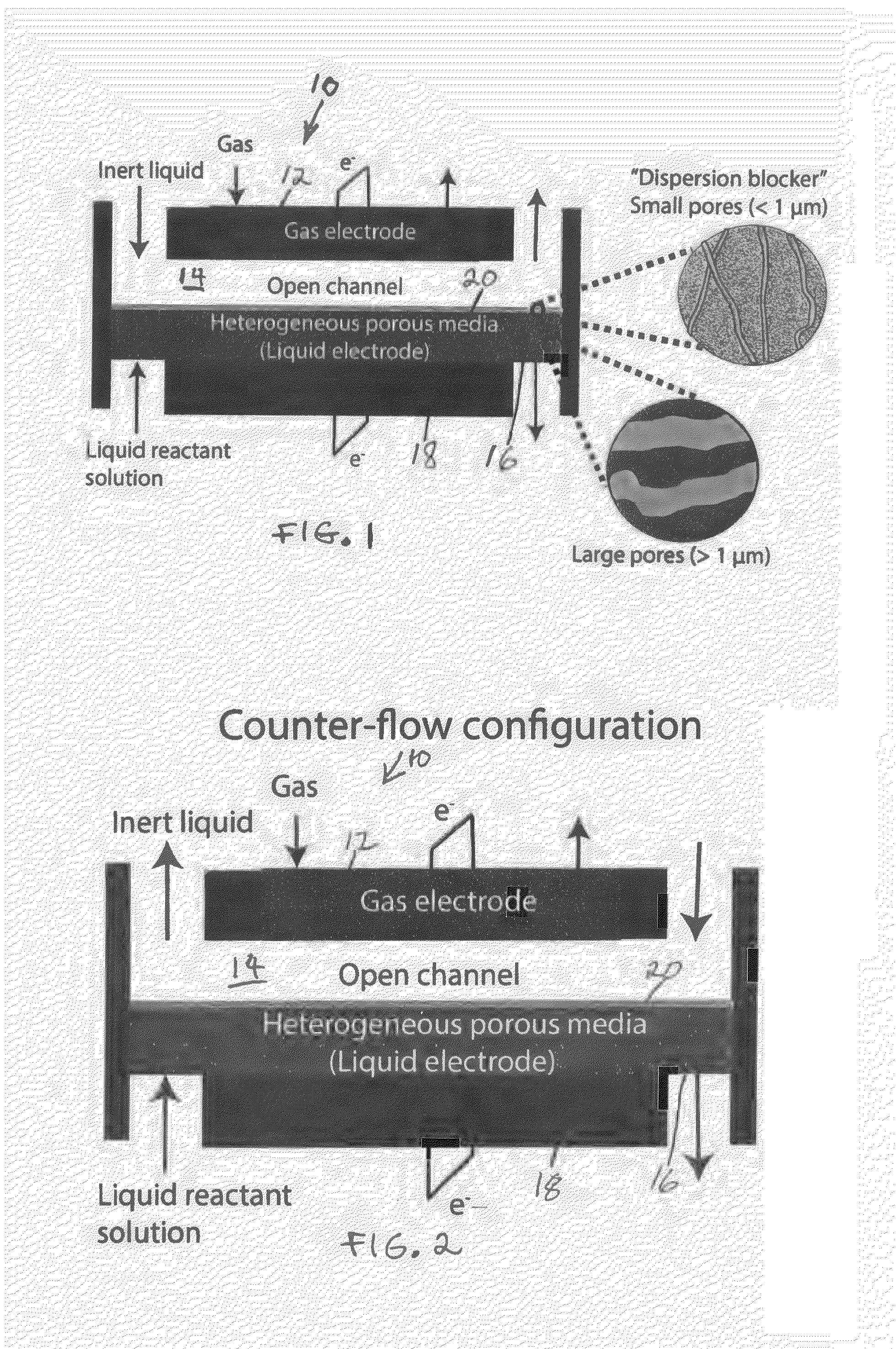

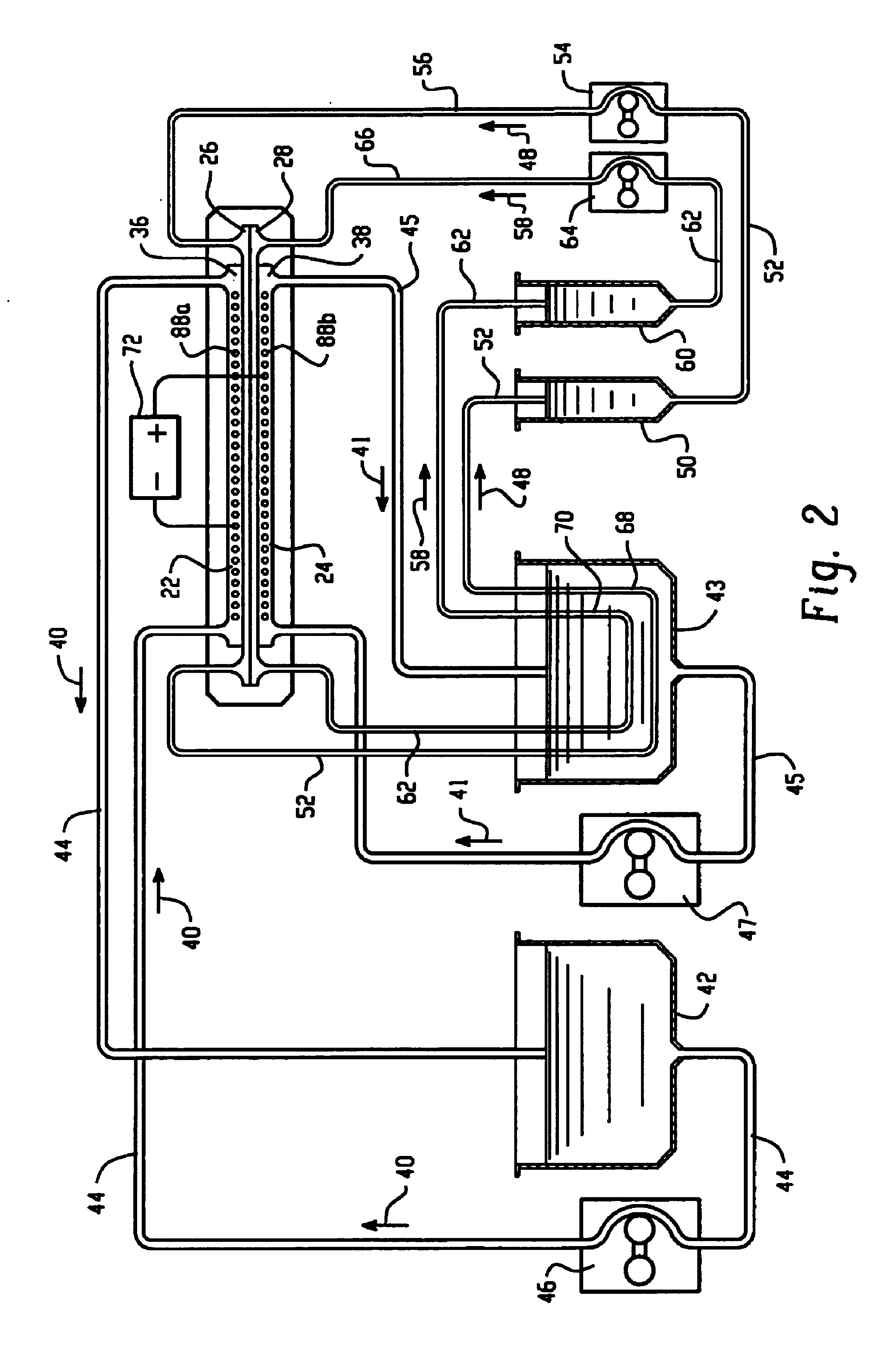

The invention discloses general apparatus and methods for electrochemical energy conversion and storage via a membraneless laminar flow battery. In a preferred embodiment, the battery includes a flow-through porous anode for receiving a fuel and a porous electrolyte channel for transporting an electrolyte adjacent to the porous anode; a flow-through porous cathode is provided for transporting an oxidant; and a porous dispersion blocker is disposed between the electrolyte channel and the porous cathode, which inhibits convective mixing while allowing molecular diffusion and mean flow. Pore structure properties are selected for tuning convective dispersion, conductivity or other macroscopic properties. Specific materials, reactants, fabrication methods, and operation methods are disclosed to achieve stable charge / discharge cycles and to optimize power density and energy density.

Owner:MASSACHUSETTS INST OF TECH

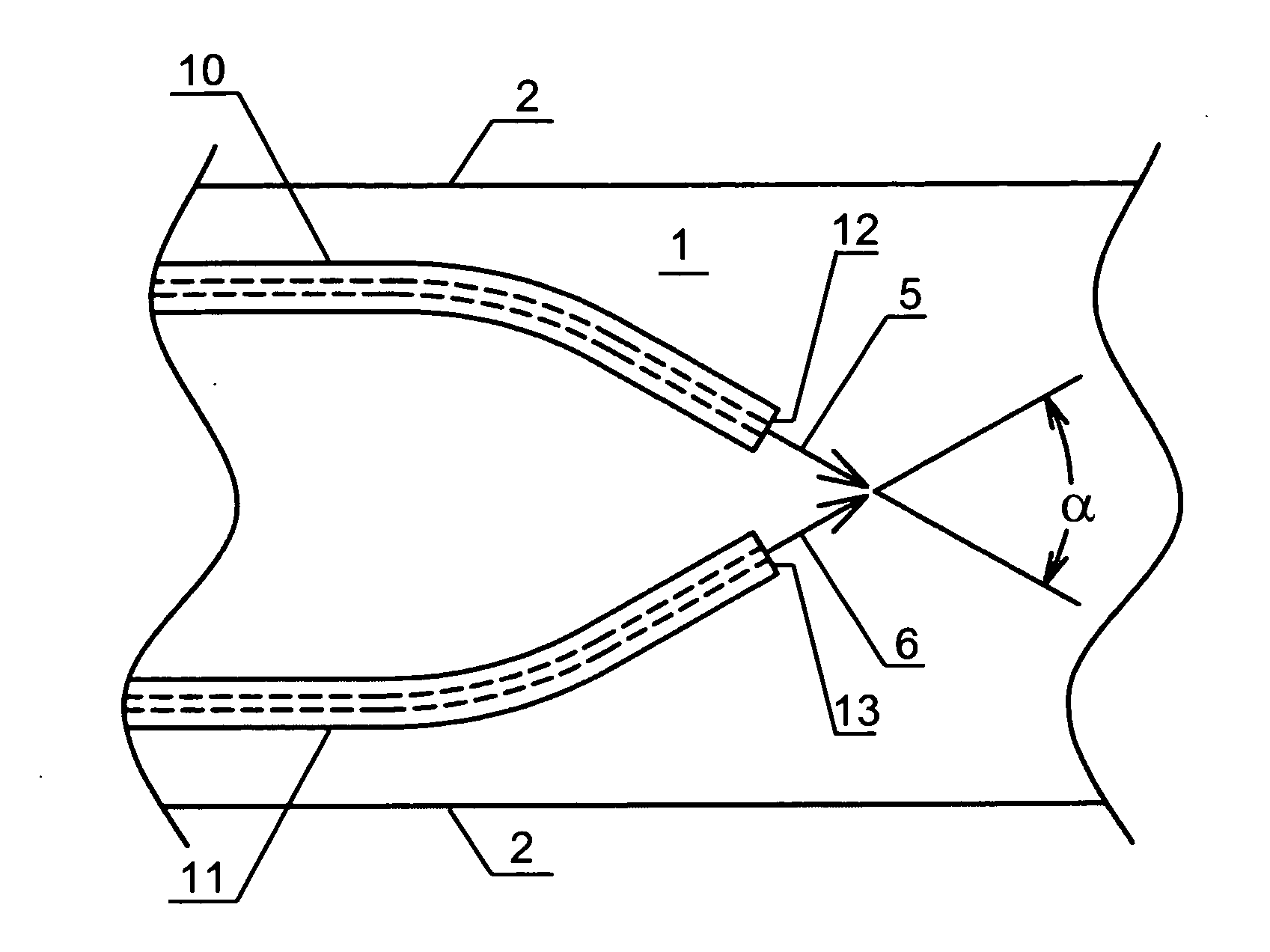

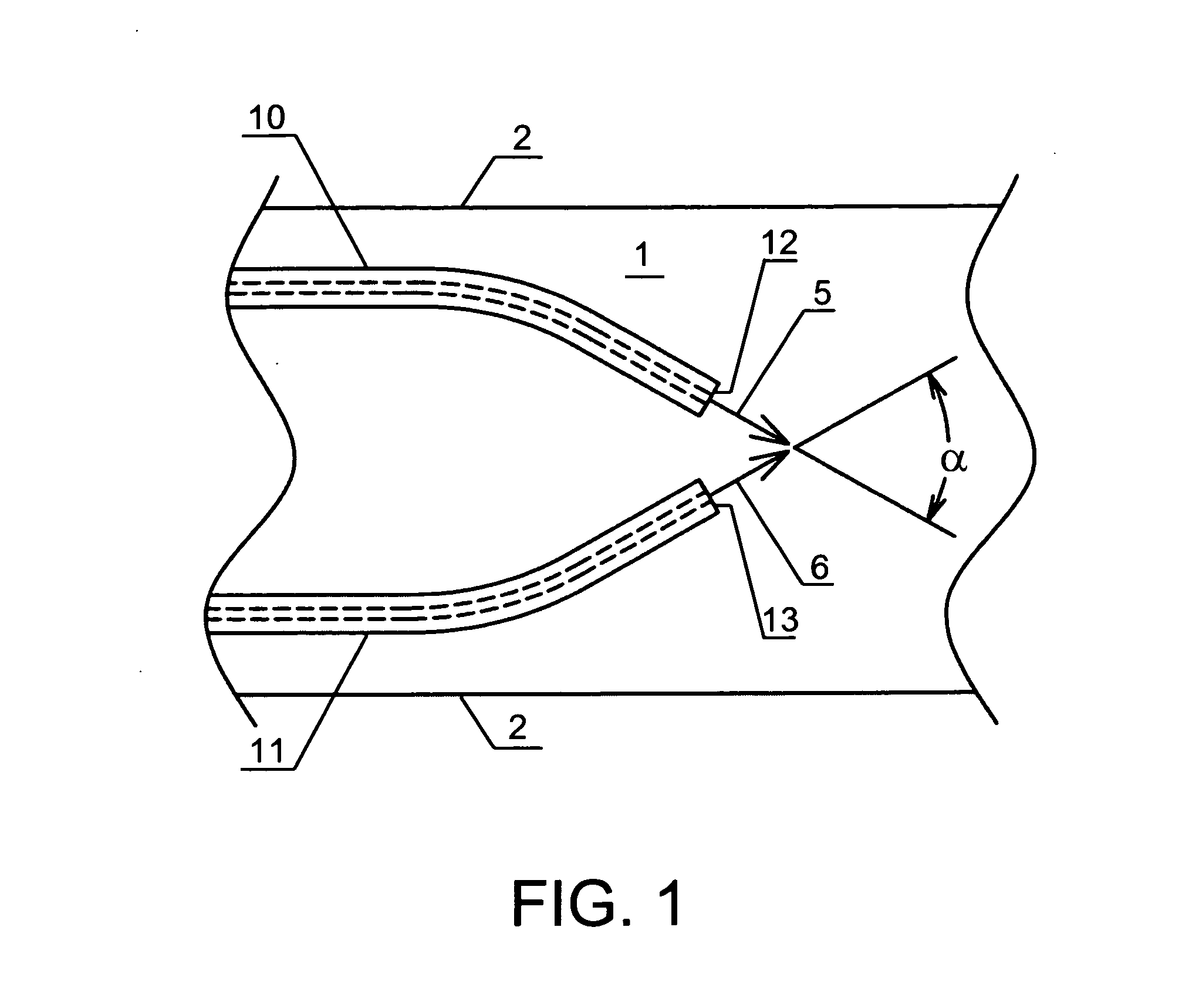

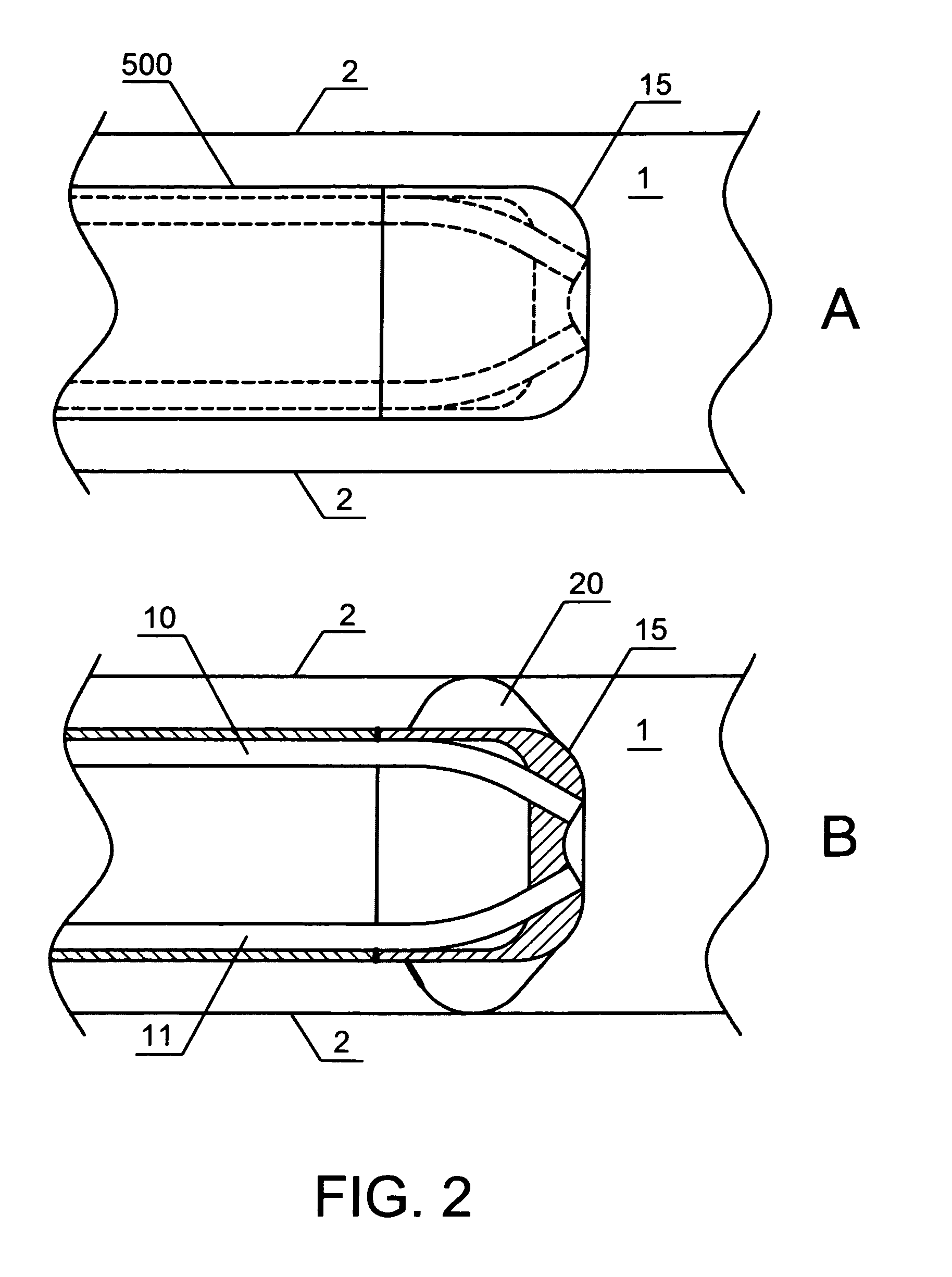

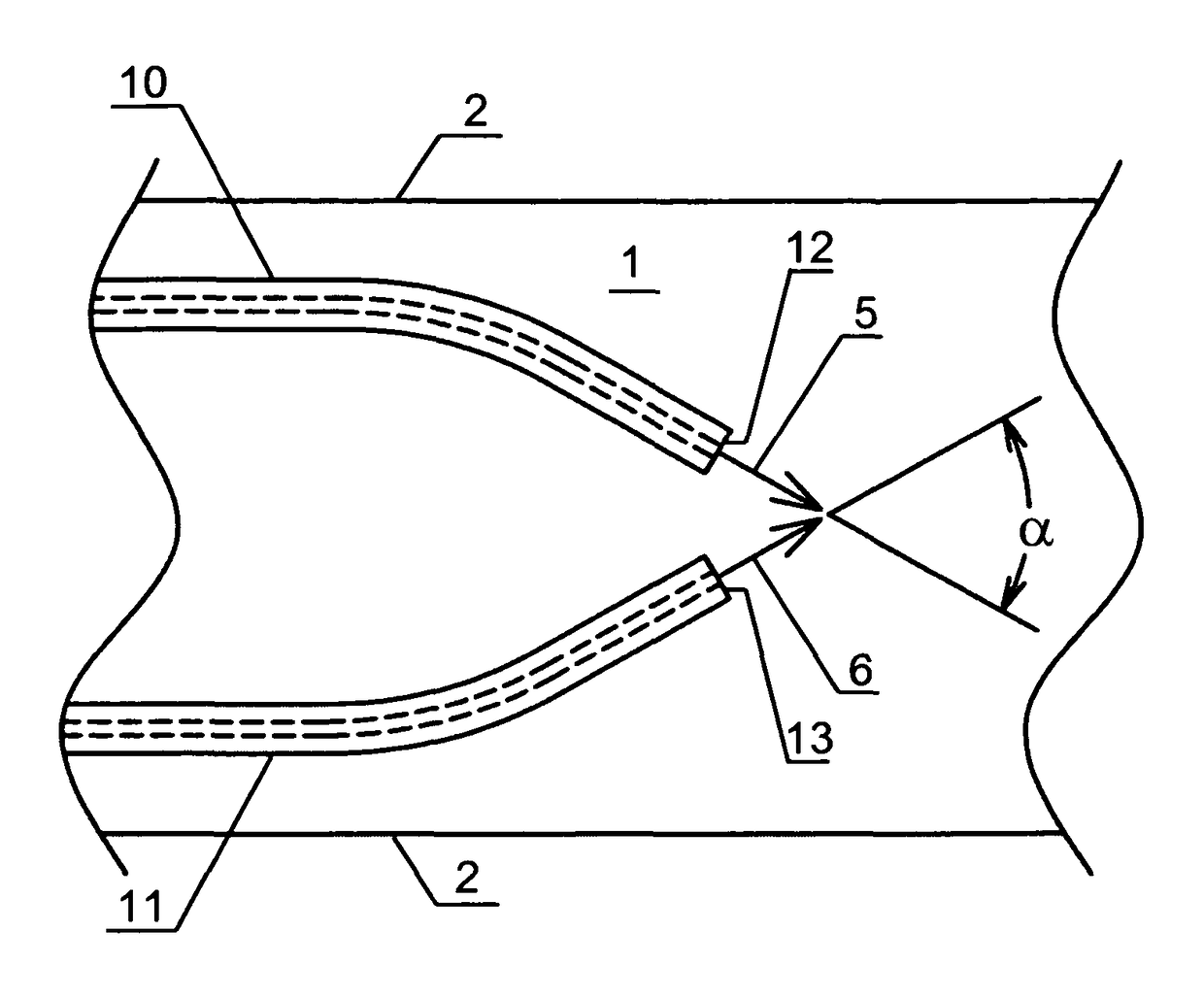

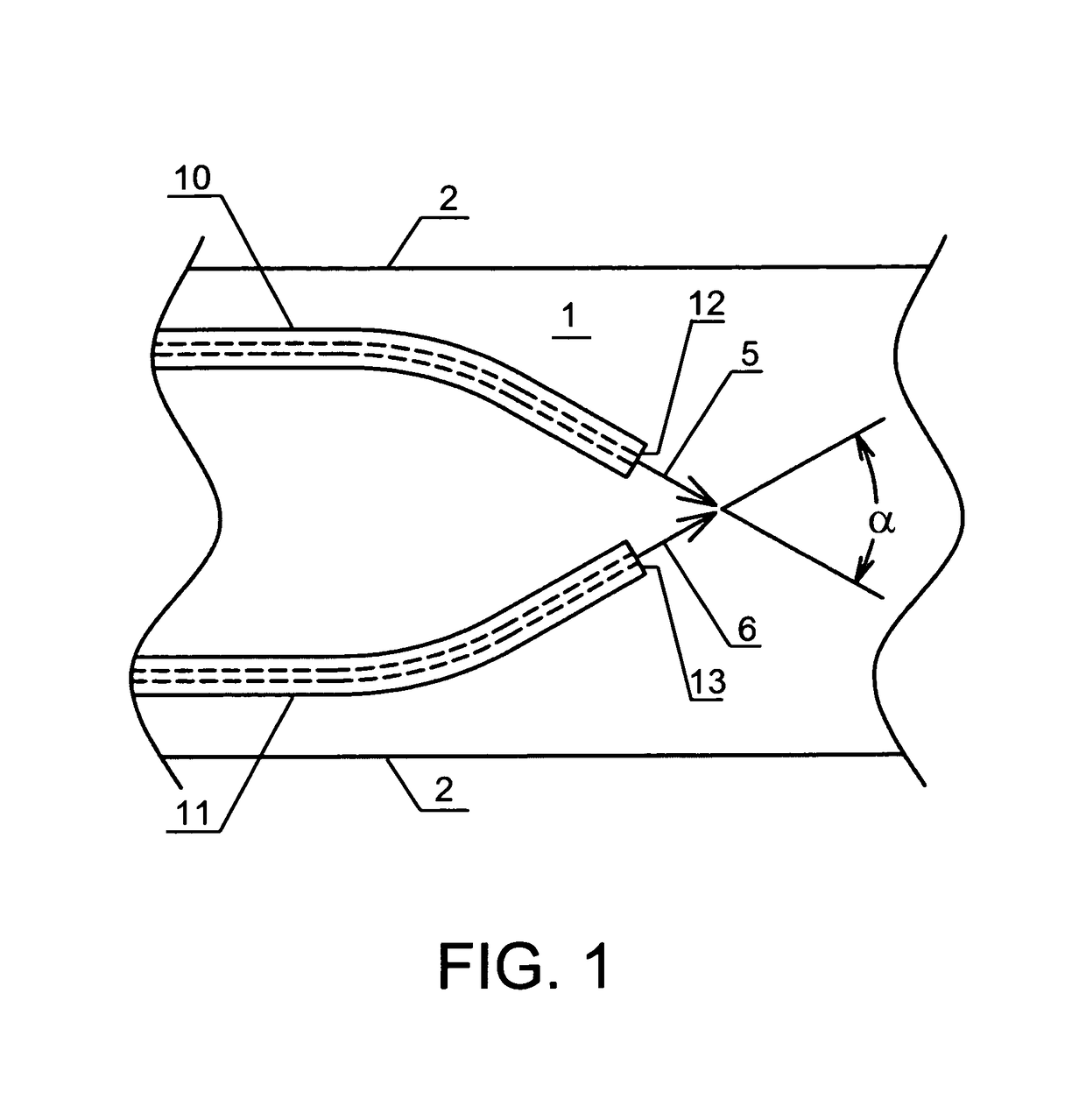

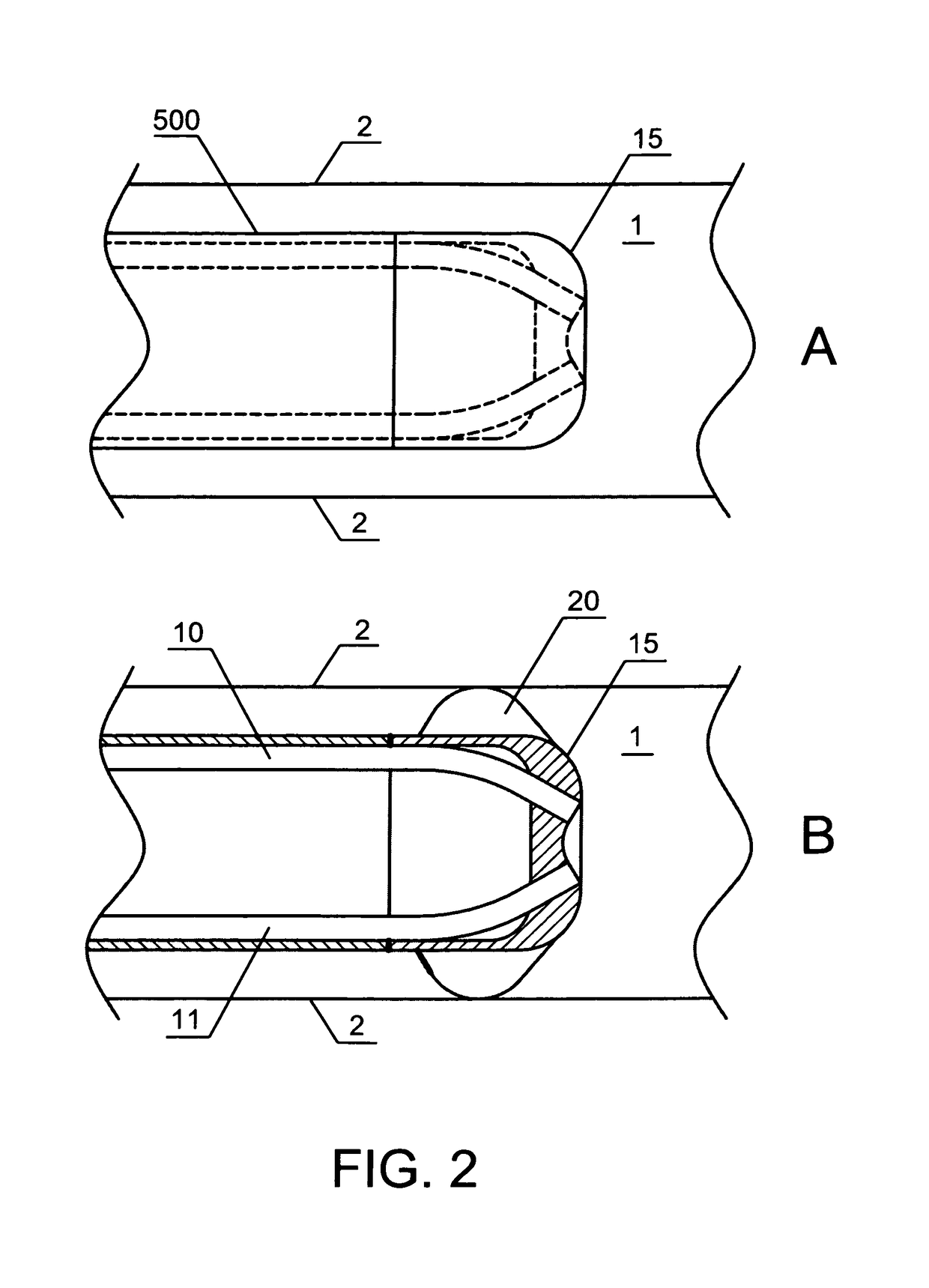

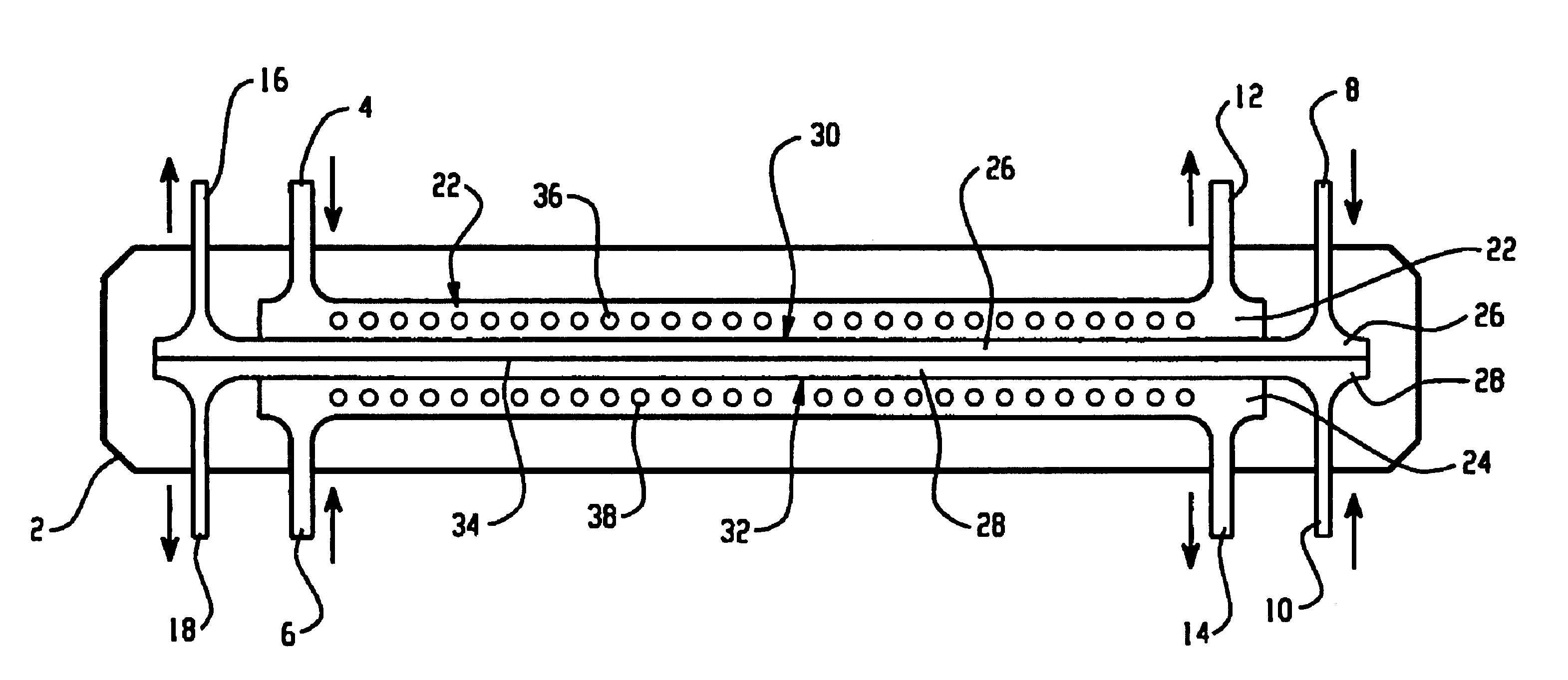

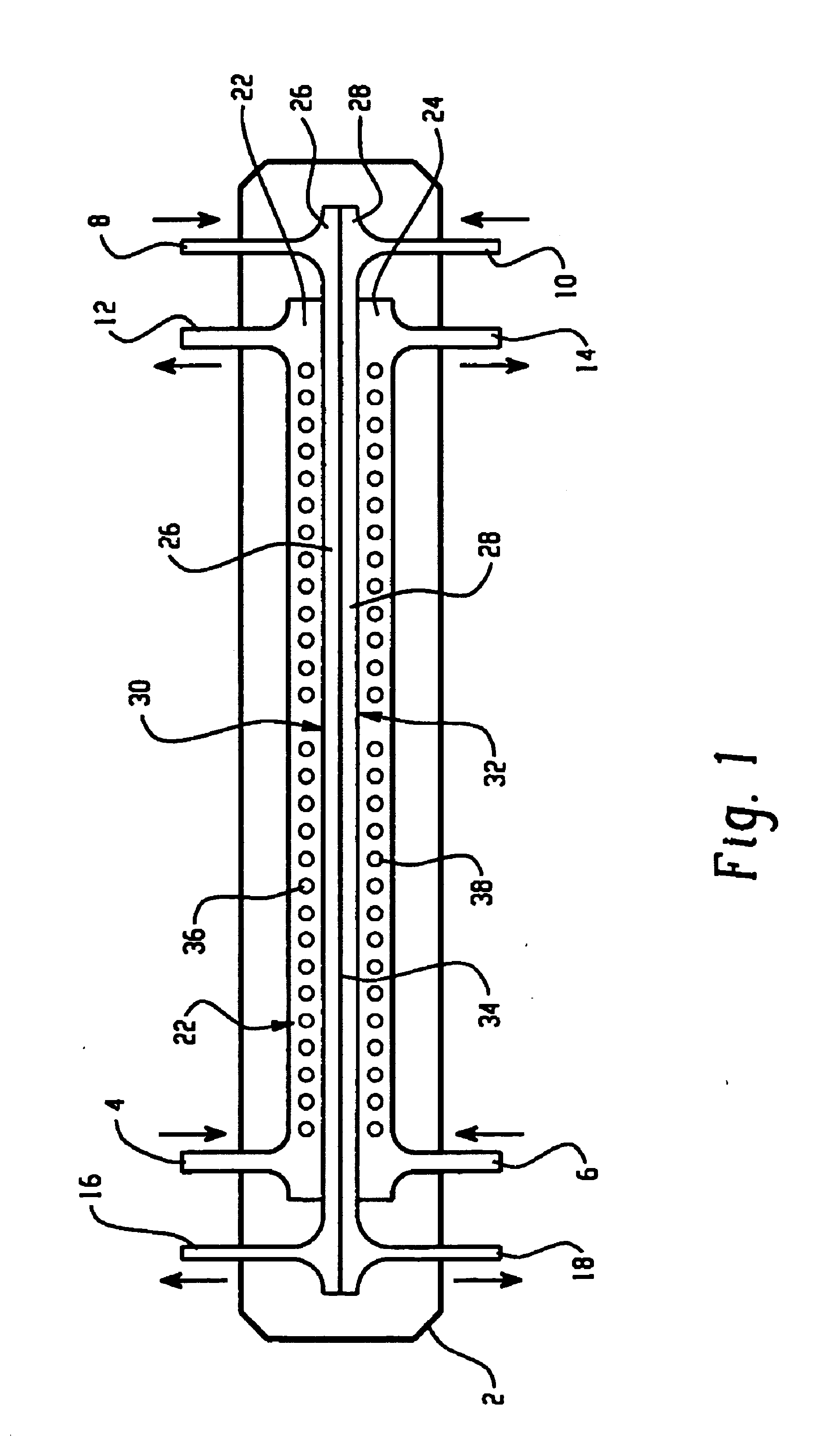

System and method for bubble-free gas-enrichment of a flowing liquid within a conduit

ActiveUS20130294189A1Disperse fastSimplifies cartridgeFlow mixersSpace heating and ventilationCapillary TubingEngineering

The present invention provides a system for enriching a flowing liquid with a dissolved gas inside a conduit. The system comprises two or more capillaries, each capillary delivering a stream of a gas-enriched liquid to the flowing liquid. The first ends of the capillaries are positioned to form an intersecting angle with respect to the effluent streams such that these streams of gas-enriched liquid collide with each other upon exit from the first ends of the capillaries, effecting localized convective mixing within the larger liquid conduit before these gas-enriched streams are able to come into close contact with the boundary surfaces of the conduit, whereby the gas-enriched liquid mixes with the flowing liquid to form a gas-enriched flowing liquid. In the preferred embodiment, no observable bubbles are formed in the gas-enriched flowing liquid. Methods of making and using such system are also provided.

Owner:THEROX

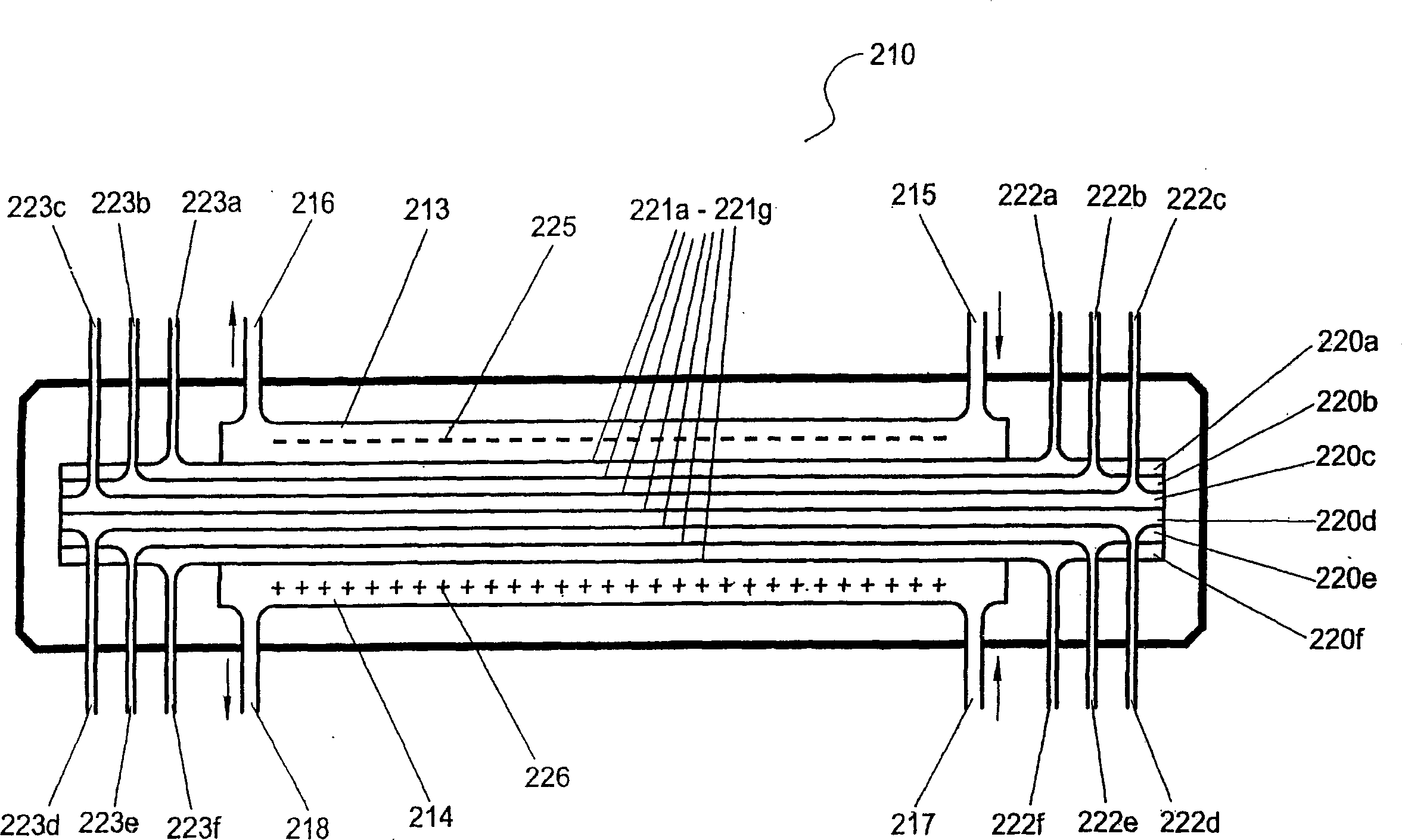

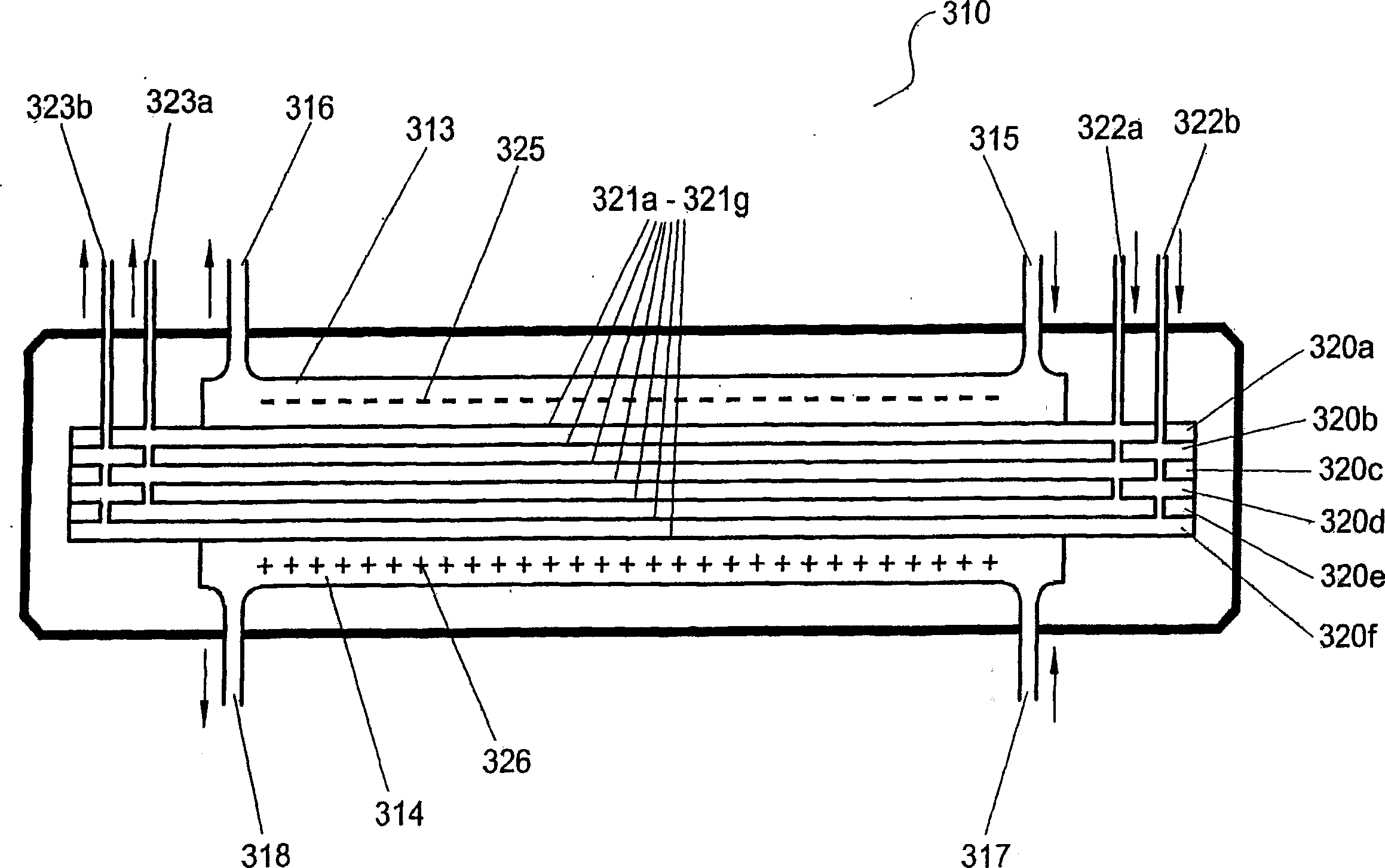

Electrophoresis Apparatus

An electrophoresis apparatus for measuring, characterizing and / or altering a composition of a sample. The apparatus comprises an anode compartment having an anode and a cathode compartment having a cathode. The anode and cathode are spaced at a distance from one another to define an electric field having a direction along a longitudinal axis, and between the anode and cathode compartments can be at least one separation compartment. Each compartment includes means for adding or removing a solution, a first dimension orthogonal to the direction of the electric field, a second dimension orthogonal to the electric field and the first dimension, and a third dimension parallel to the electric field and orthogonal to the first and second dimensions. A ratio of the first and second dimensions define an aspect ratio, at least one aspect ratio being less than one. An ion-permeable barrier is positioned between each compartment to prevent convective mixing therebetween. At least one of the compartments can be made of an electrically insulating material having a thermal conductivity greater than about 1 W / mK and a specific heat greater than about 100 J / kgK.

Owner:TEXAS A&M UNIVERSITY

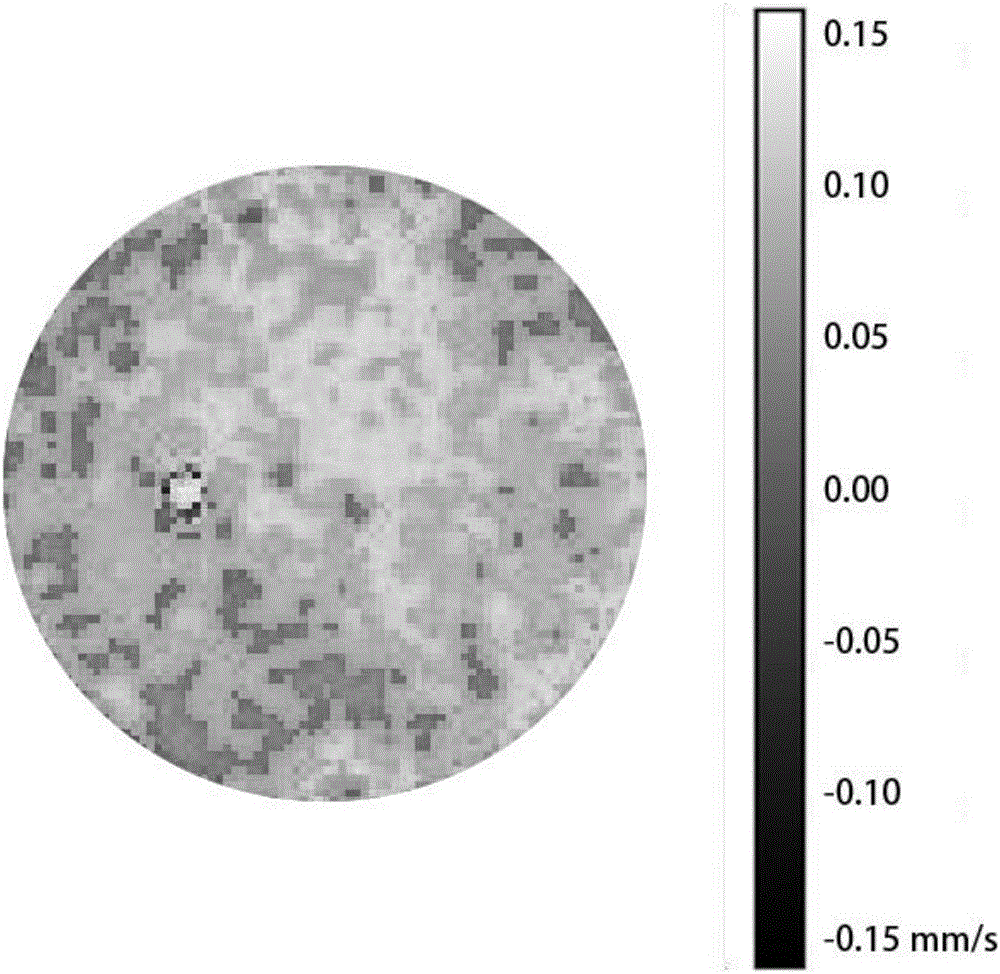

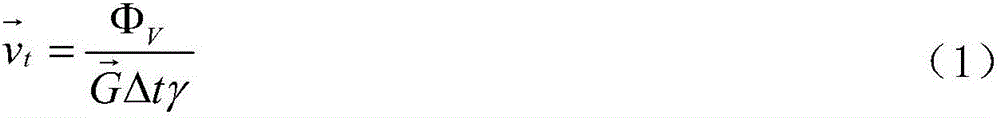

Method for measuring convective mixing process velocity field in porous medium based on nuclear magnetic resonance imaging

InactiveCN106124798AWon't disturbHydrodynamic testingFull-field flow measurementPorous mediumStationary state

The invention relates to a method for measuring a convective mixing process velocity field in a porous medium based on nuclear magnetic resonance imaging, and the method belongs to the technical field of convective mixing process velocity field measurement. The method comprises the steps of carrying out upper-lower layered saturation on two kinds of solutions with different densities in the porous medium at first, placing a sand-filled pipe saturating the two kinds of solutions with different densities in an inverted manner and then placing the sand-filled pipe into a nuclear magnetic probe quickly, adopting a spin echo sequence method added with phase encoding gradient pulses to obtain a proton density image of a fluid and converting the proton density image into a phase image, making difference between the phase image and a stationary state phase image under the same pulsed gradient to obtain a phase shifting image, and measuring to obtain a porous medium convective mixing process velocity field by adopting a phase method. The method realizes the unconventional fluid distribution situation required by convective mixing, is applied to the nuclear magnetic resonance imaging technology, carries out visual observation on the convective mixing process velocity field by non-contact and non-interference means, and does not disturb flow of the fluid.

Owner:DALIAN UNIV OF TECH

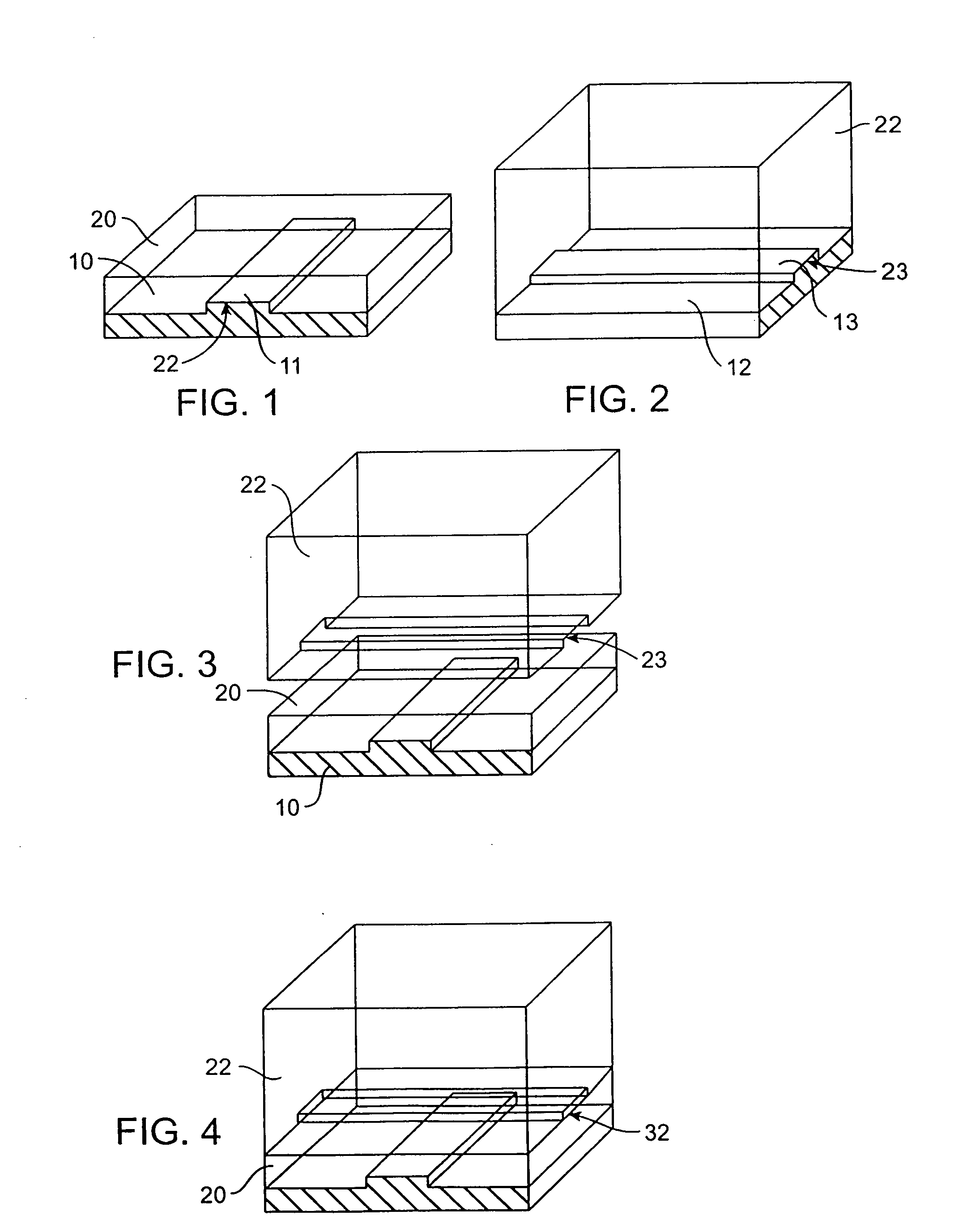

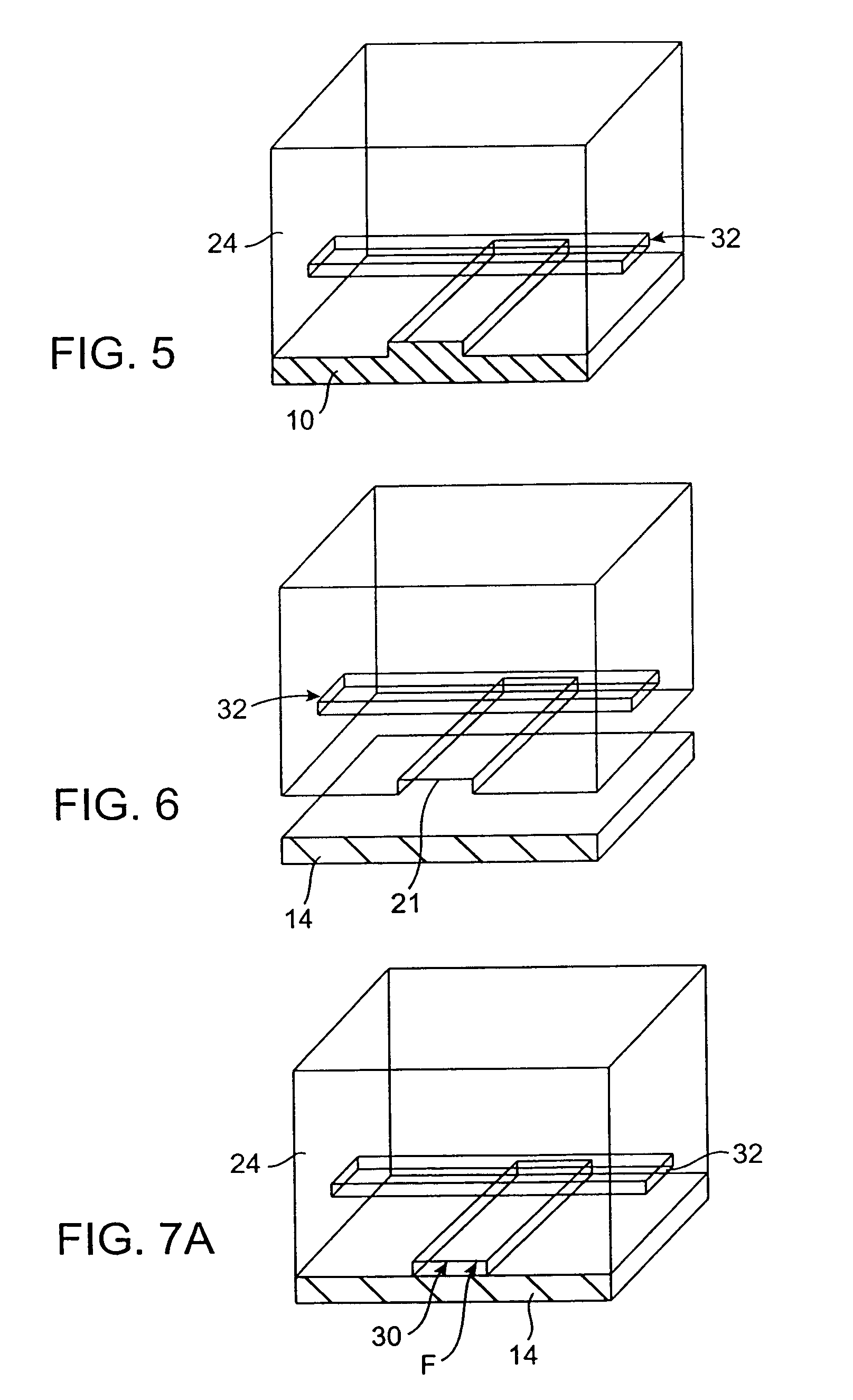

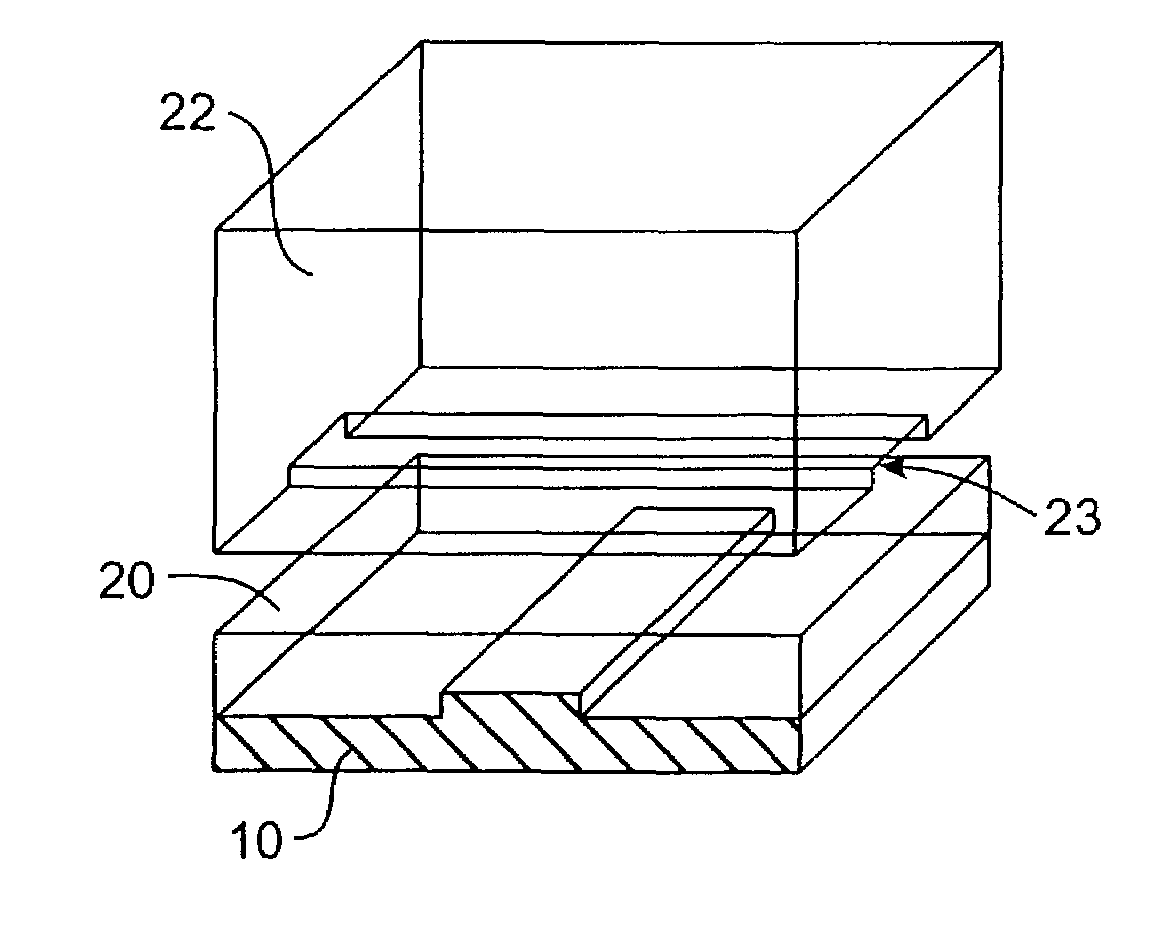

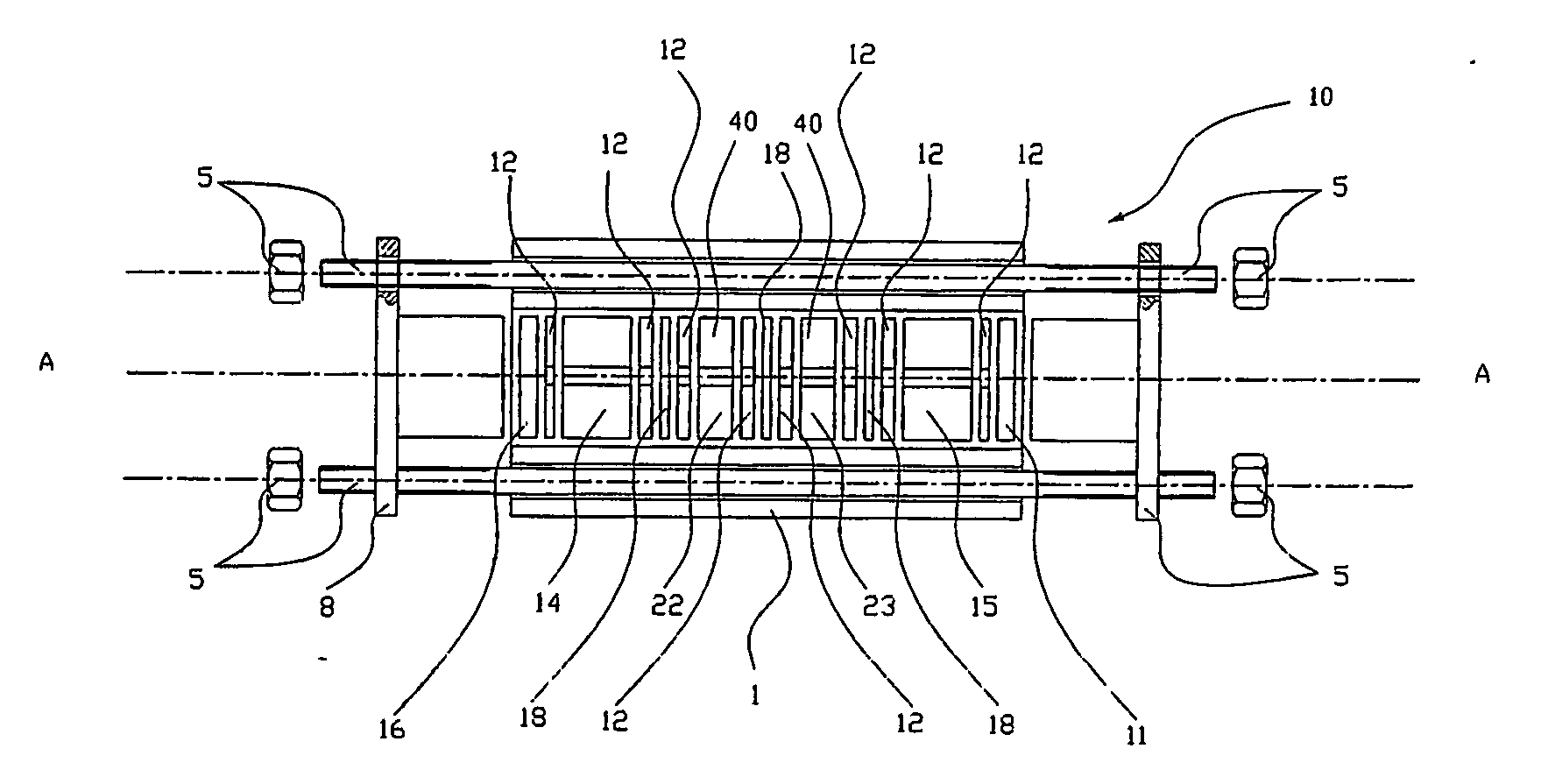

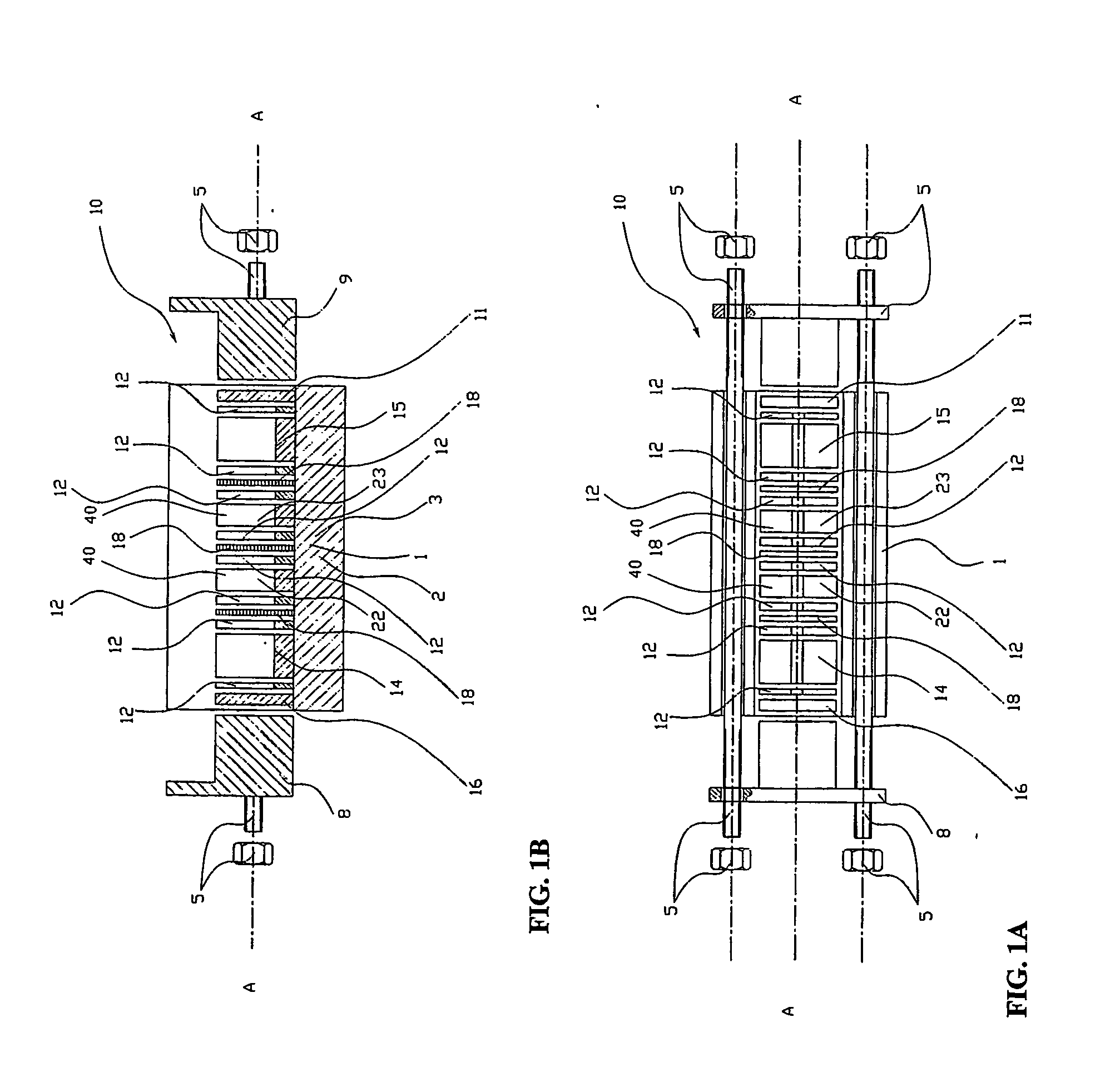

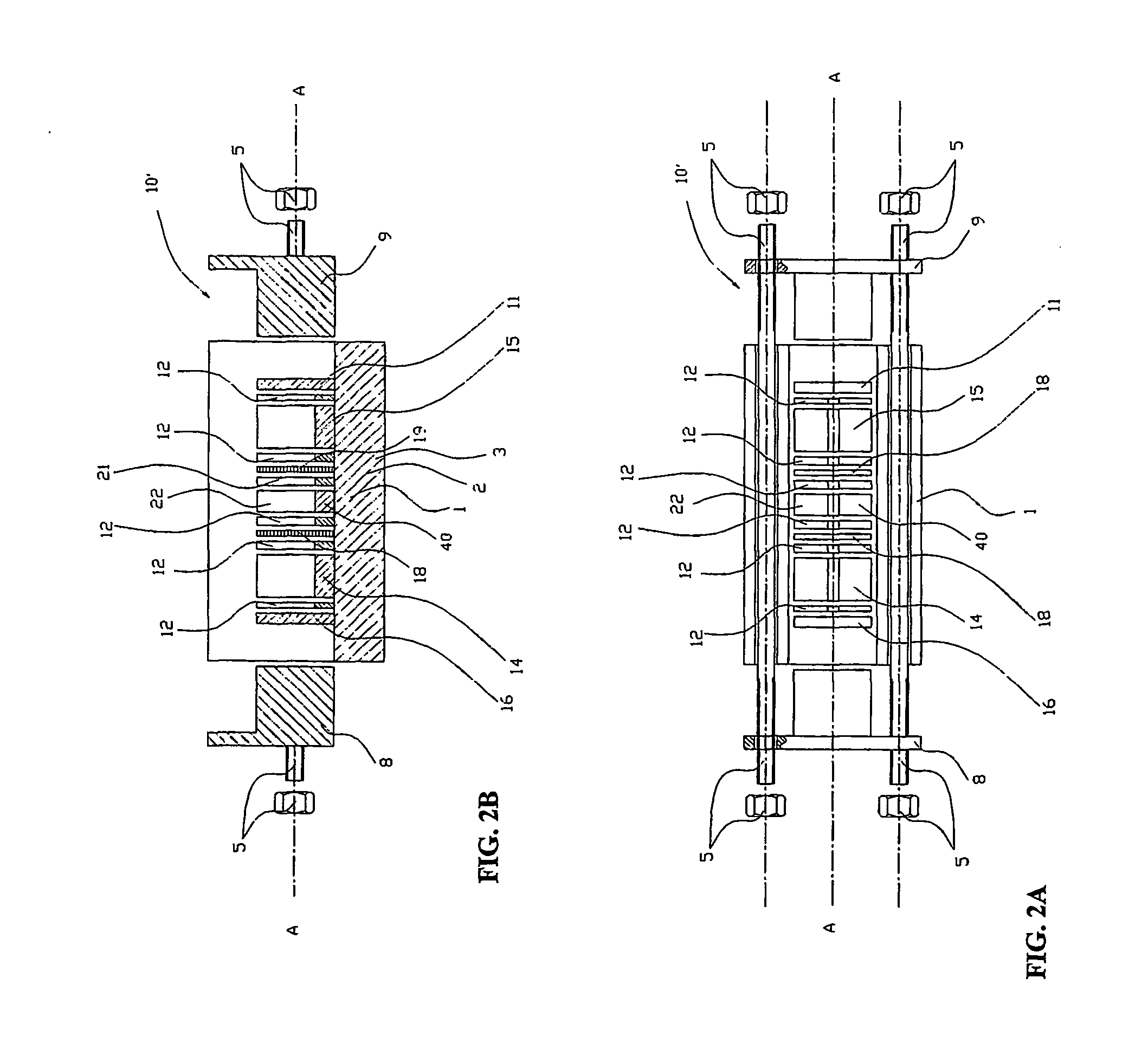

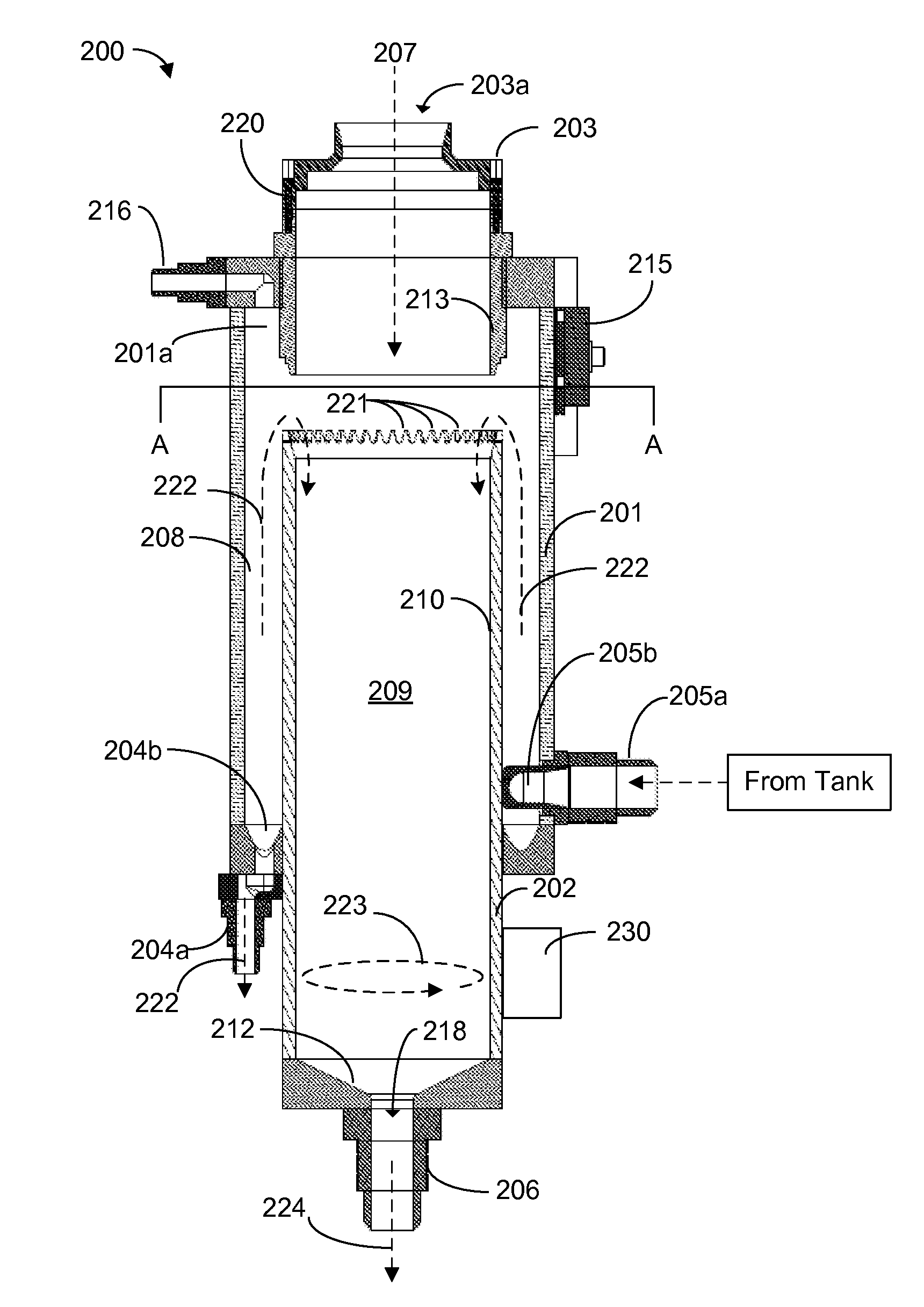

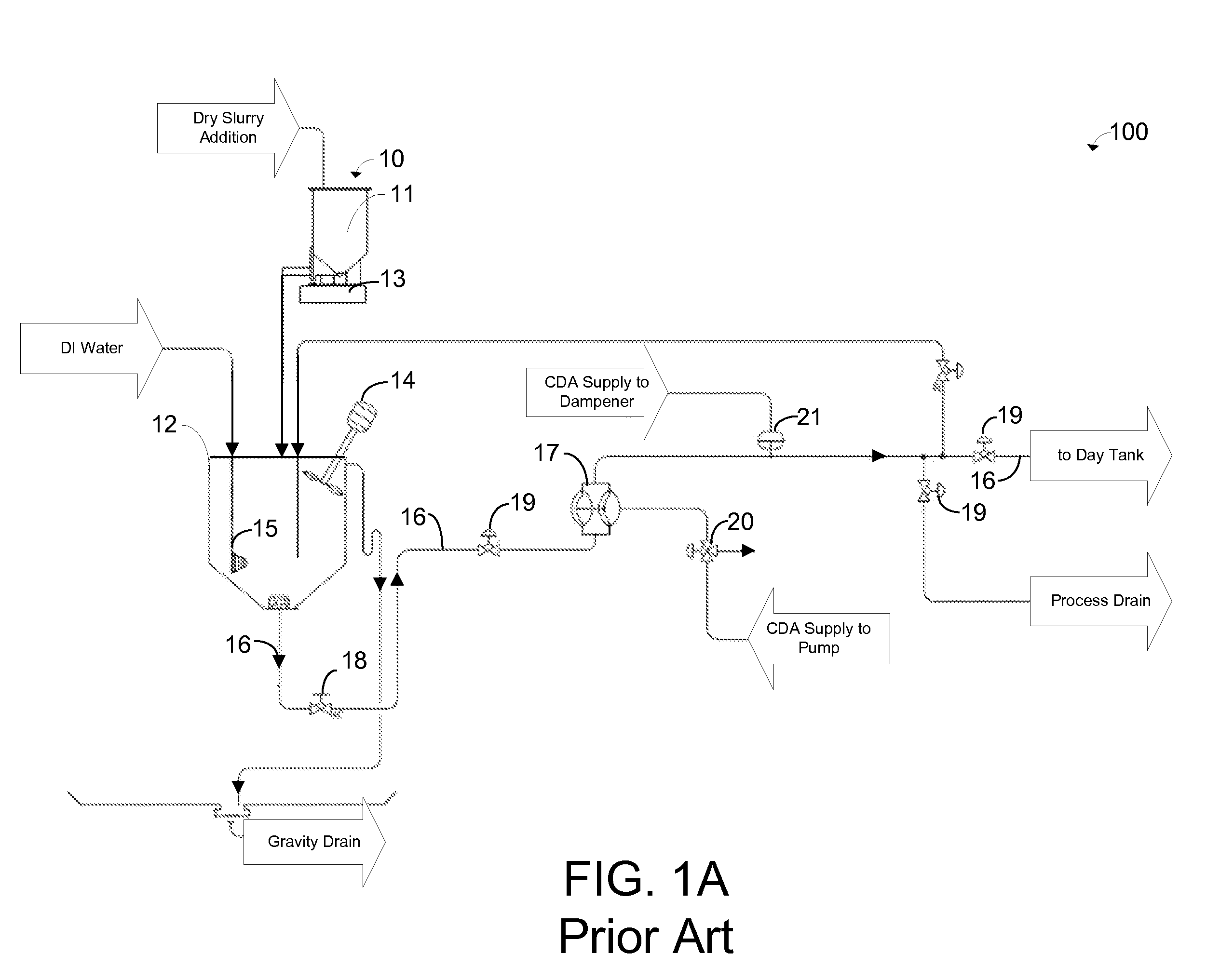

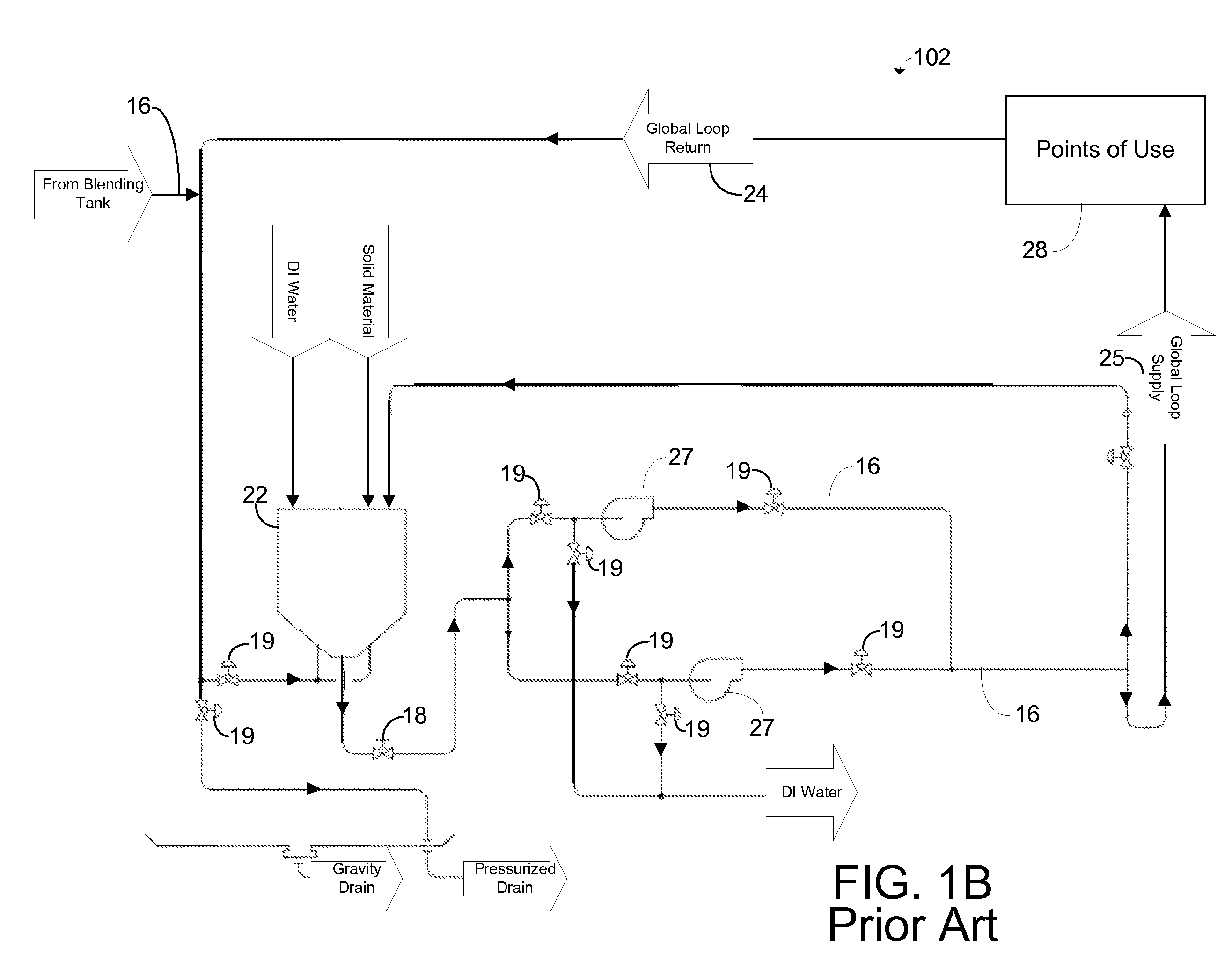

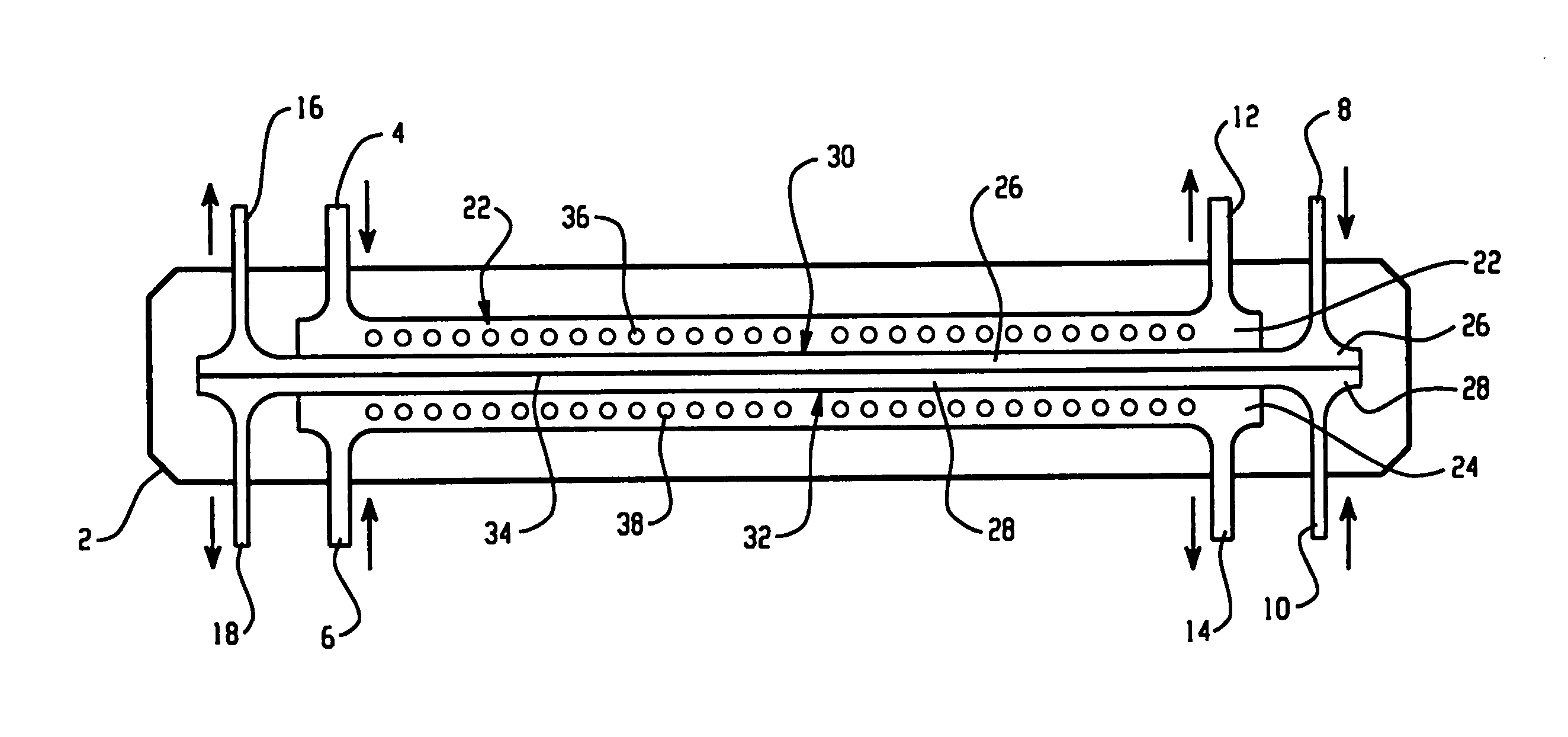

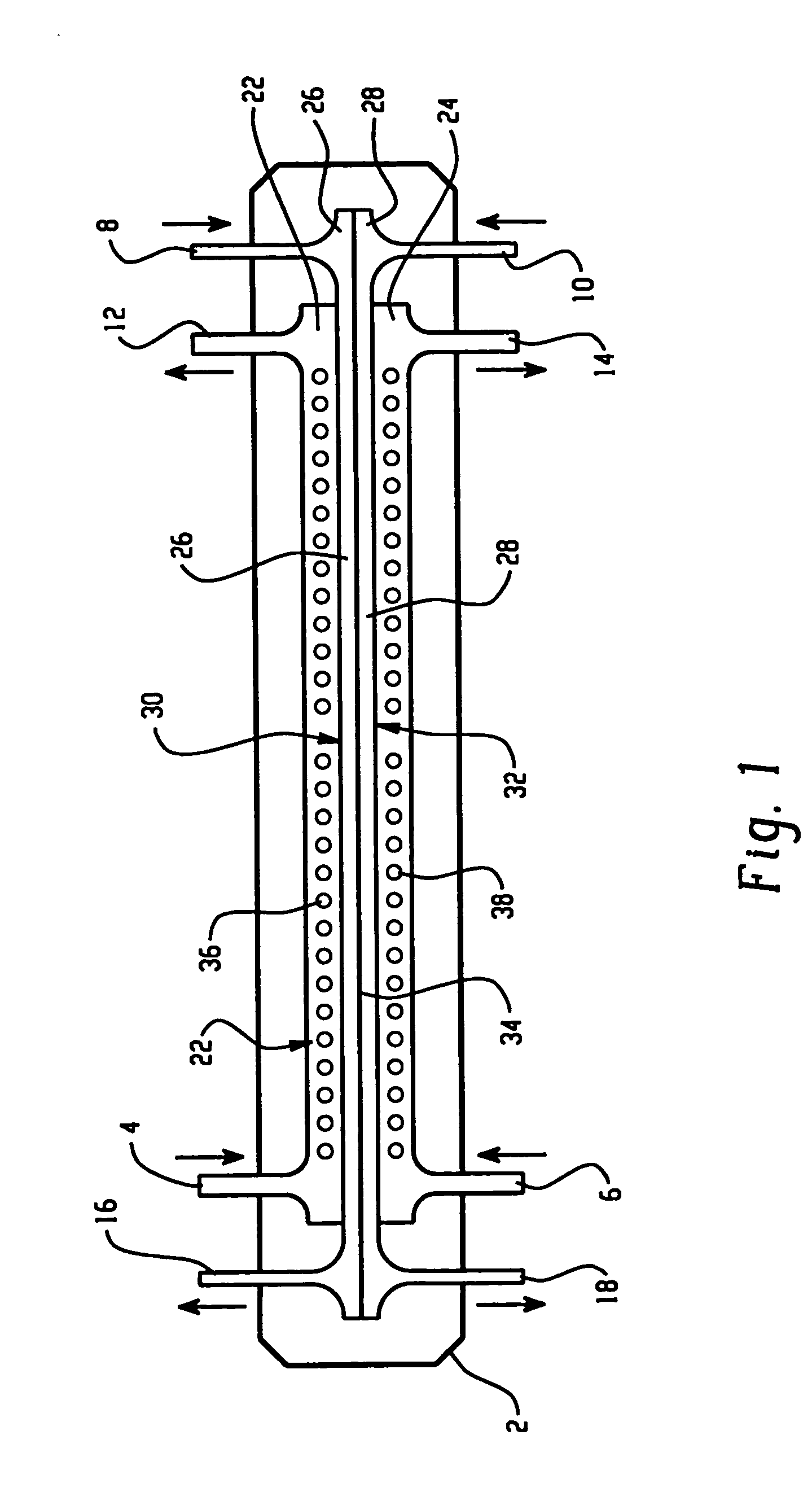

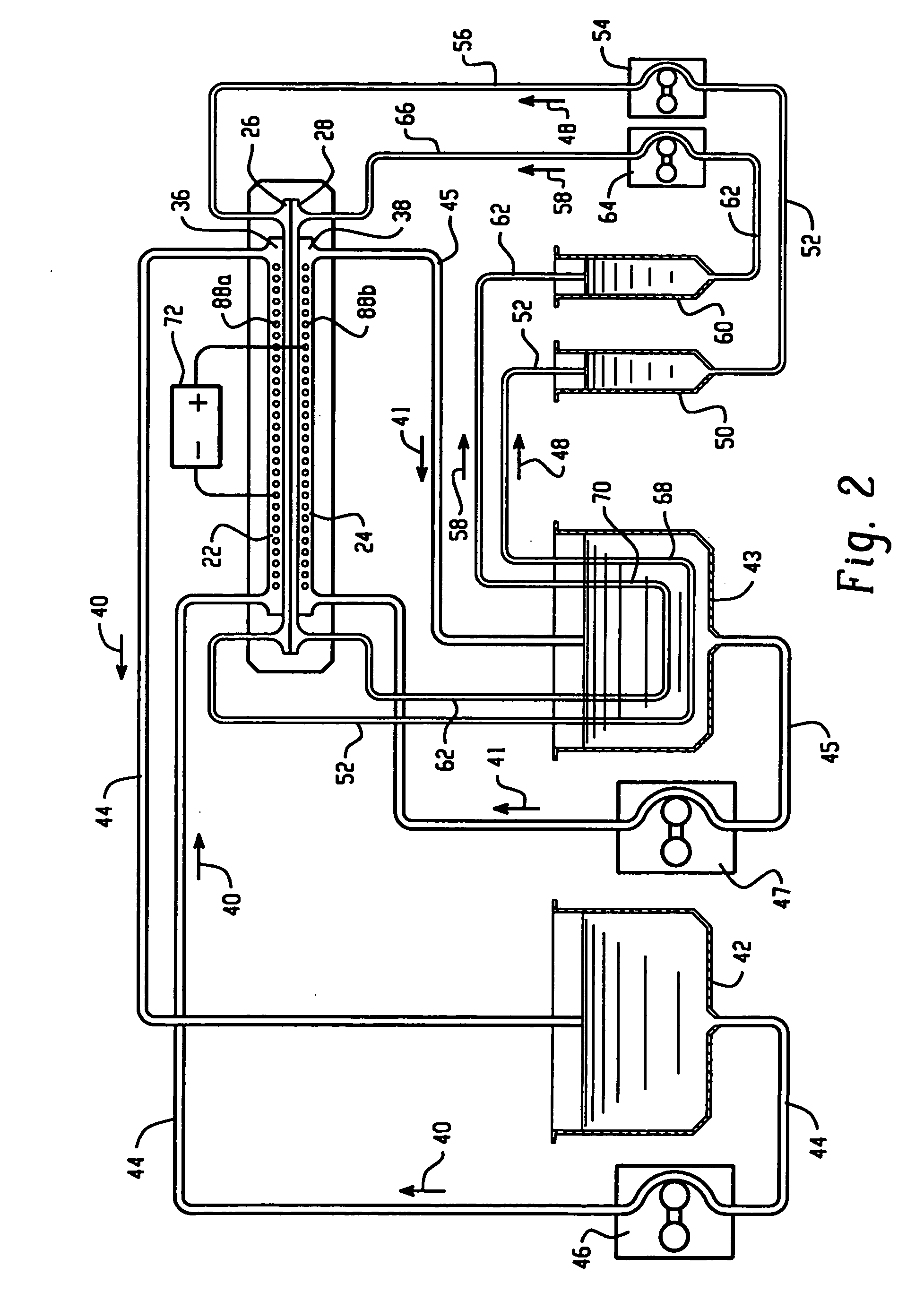

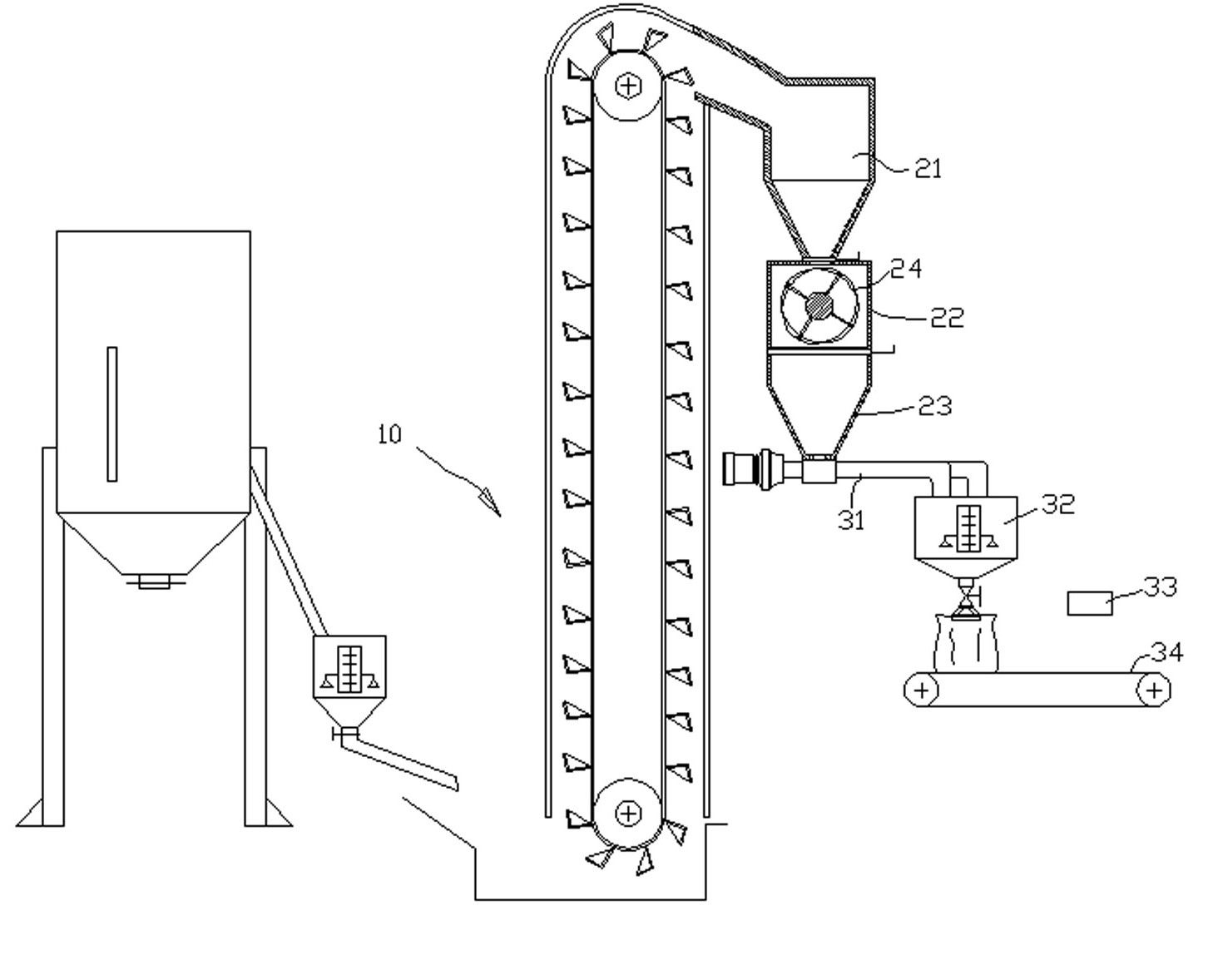

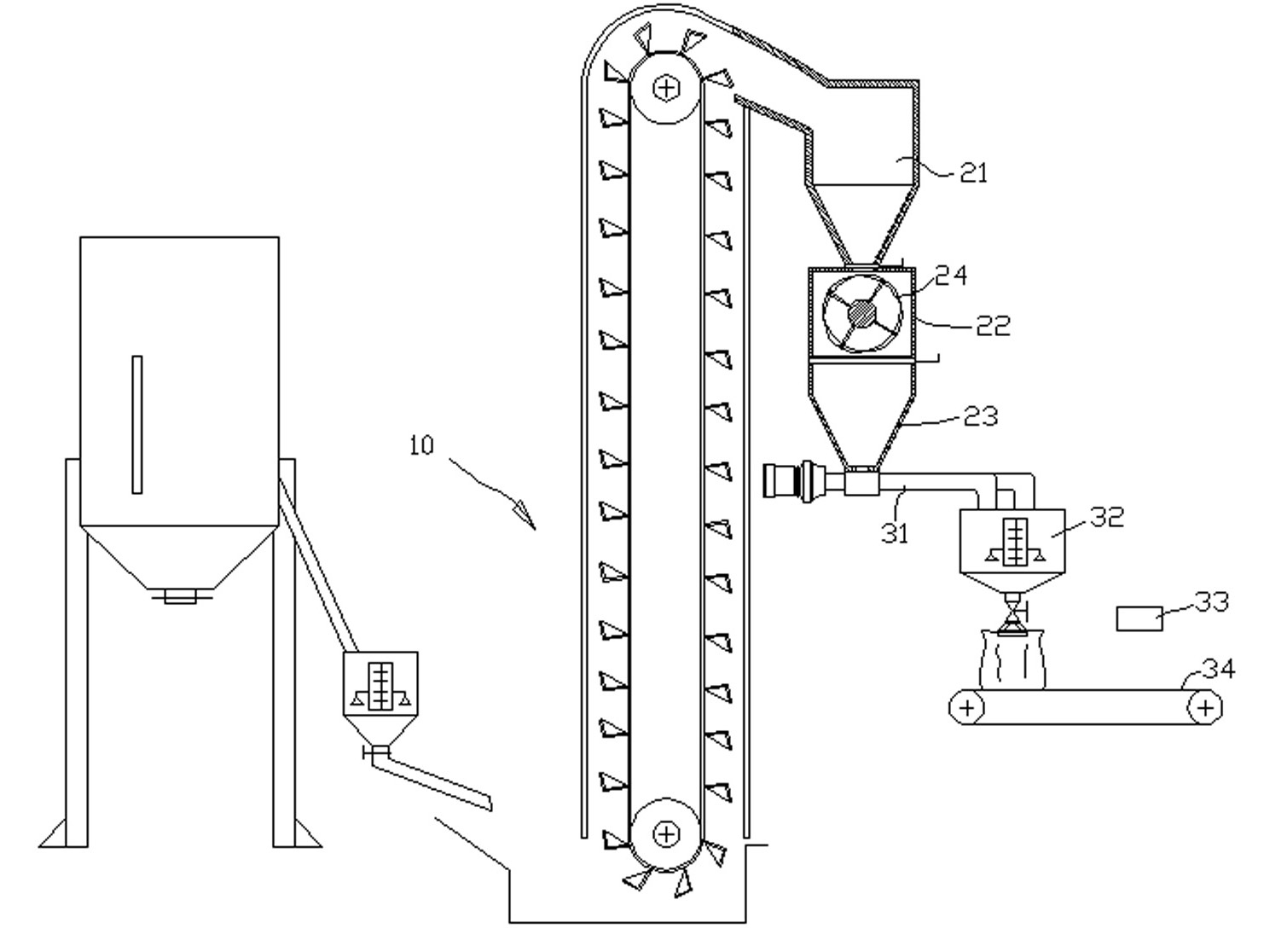

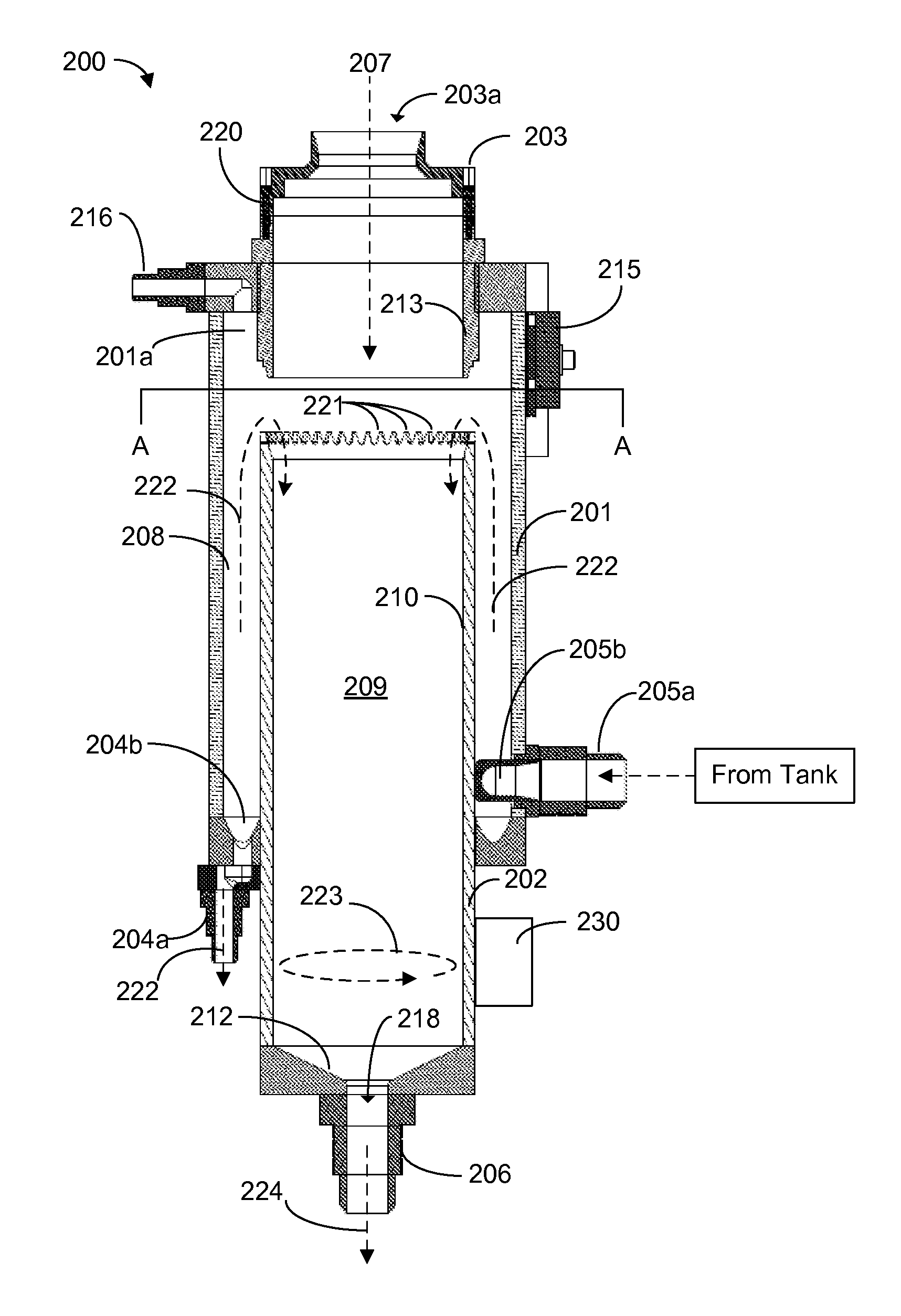

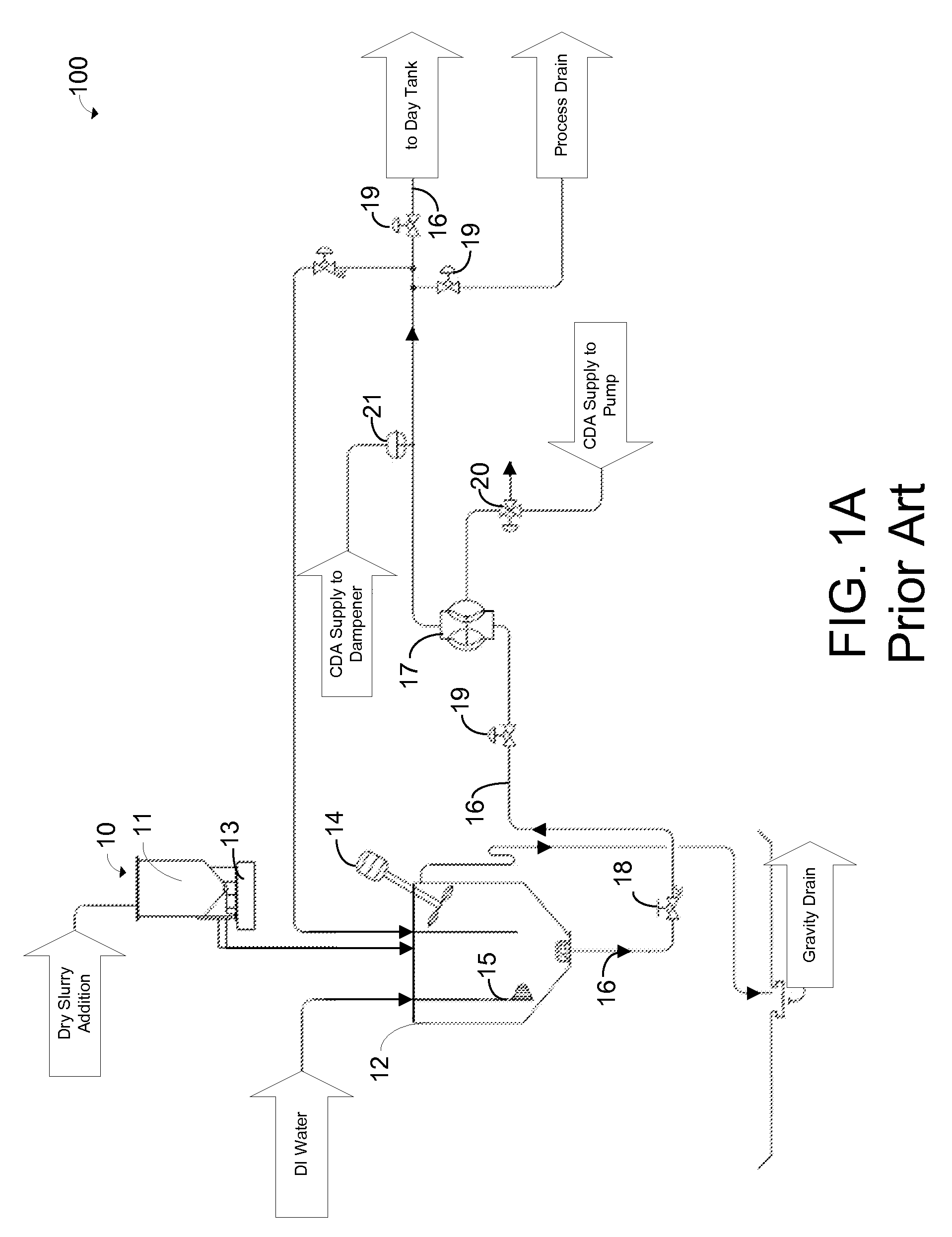

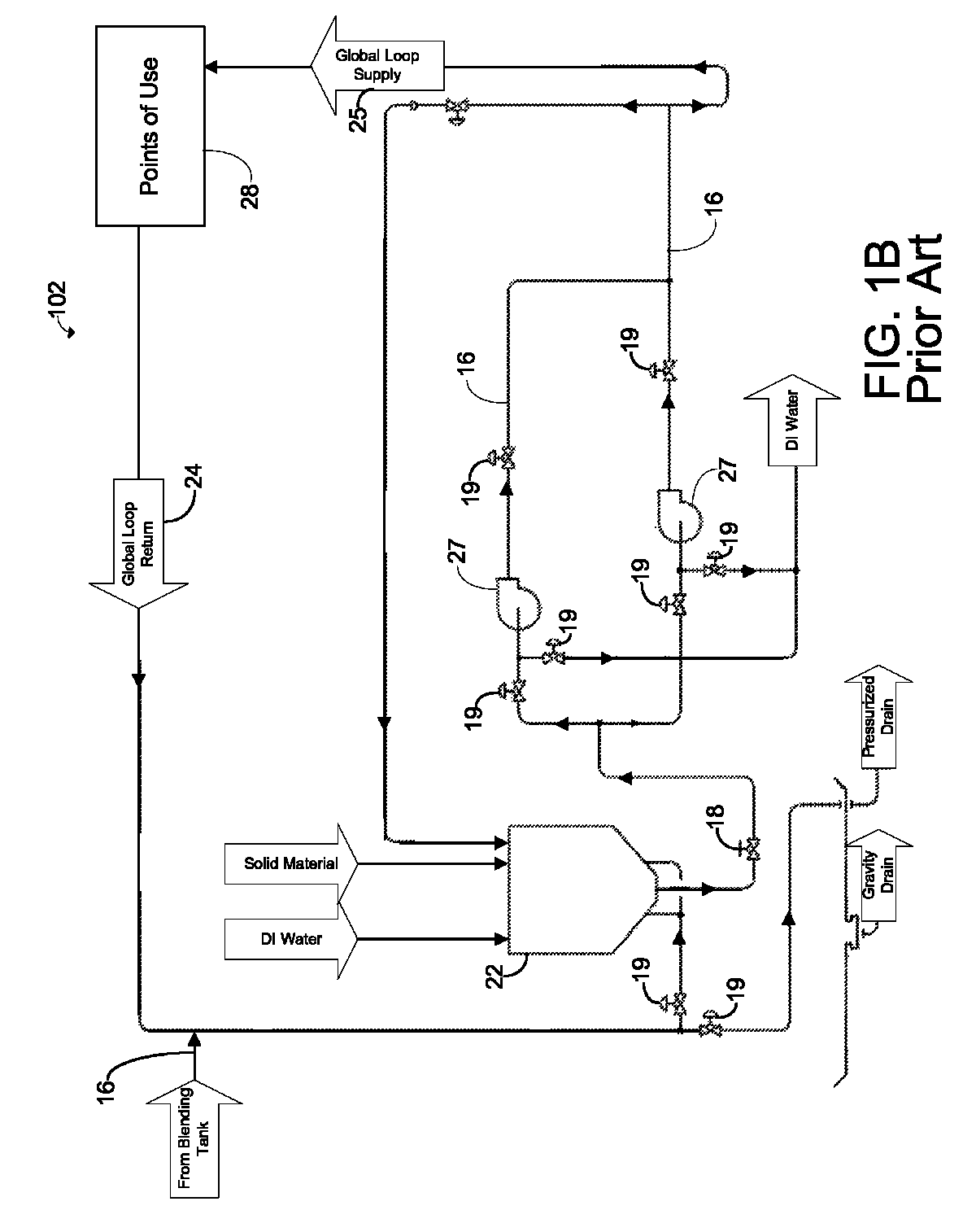

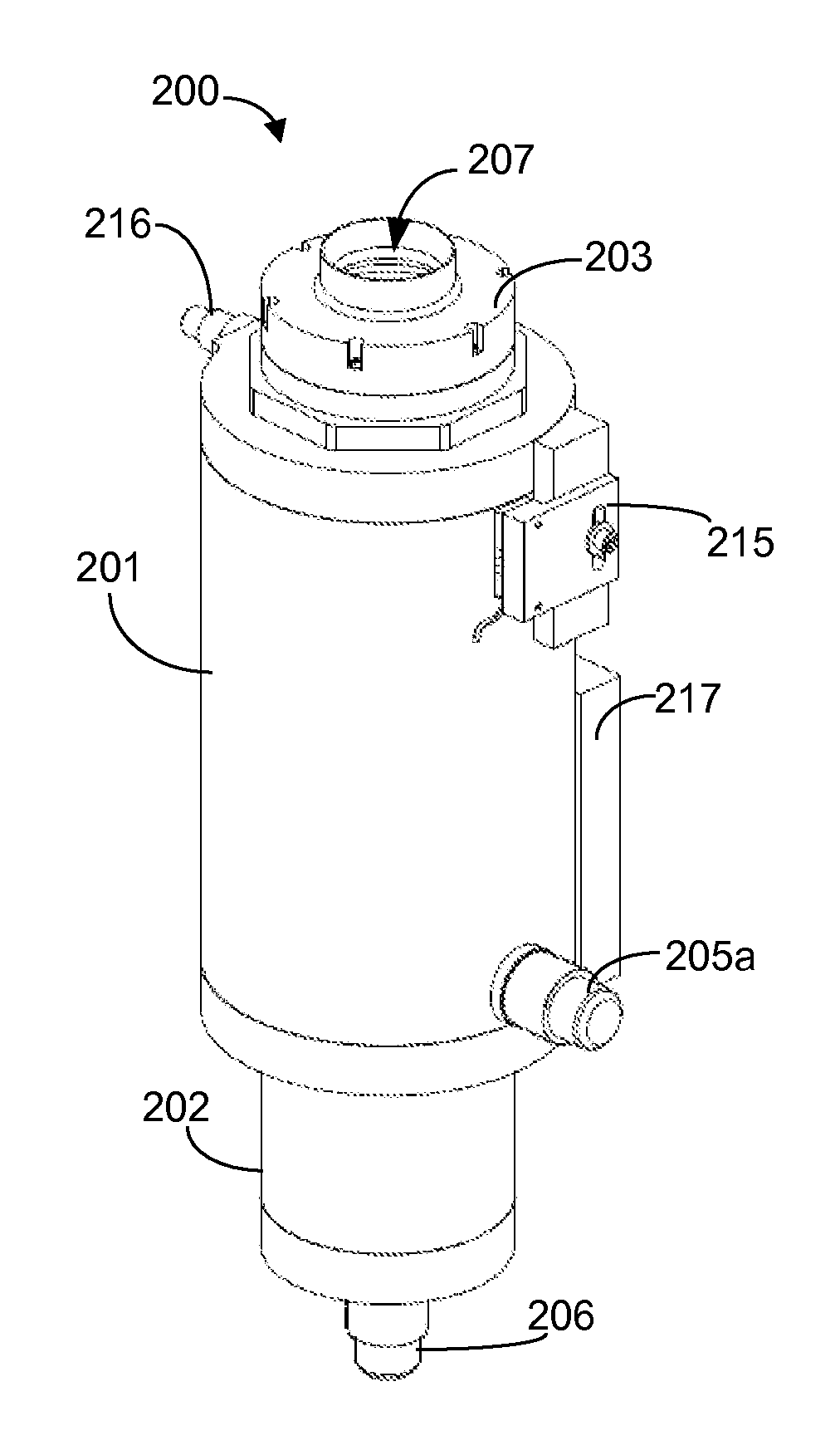

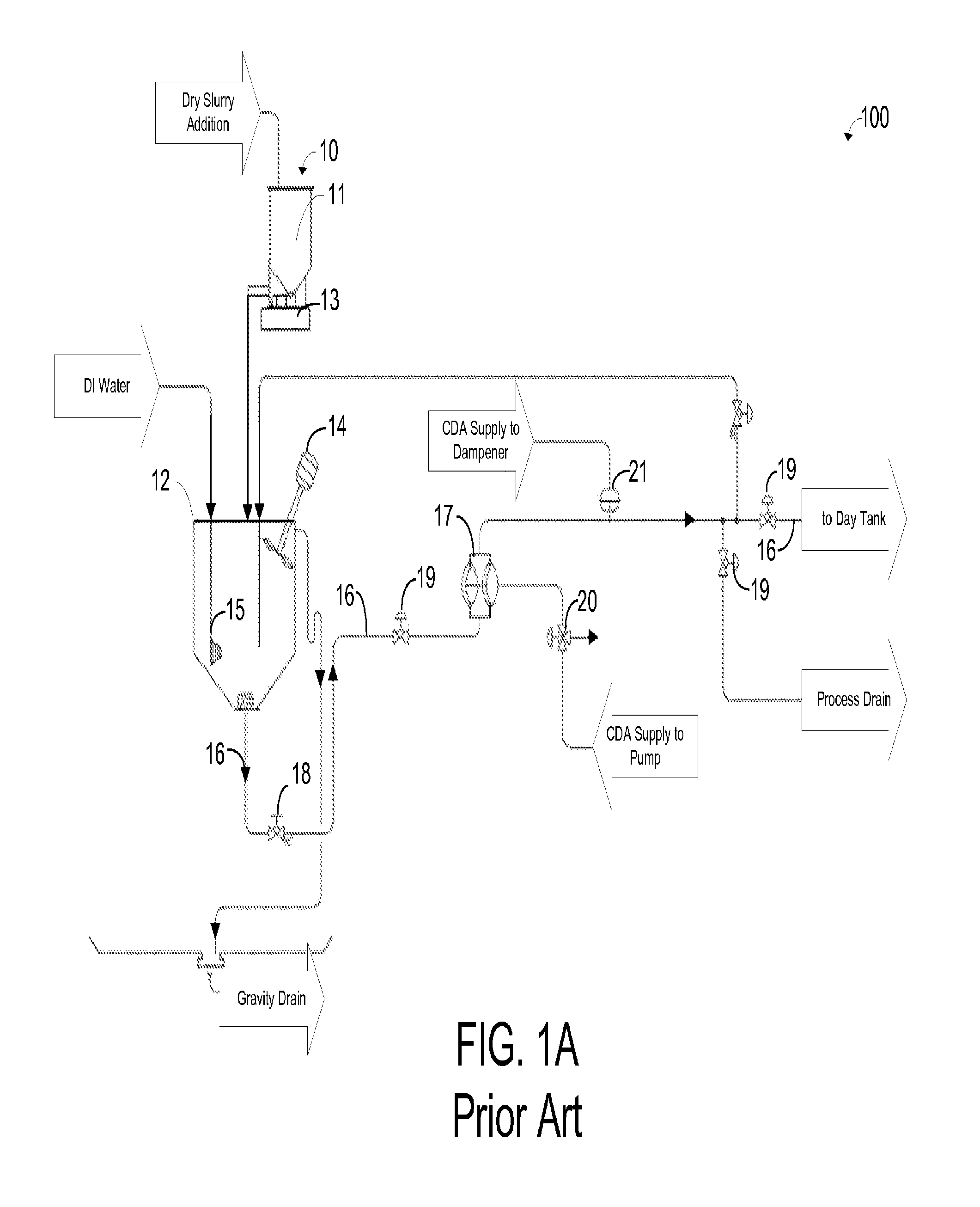

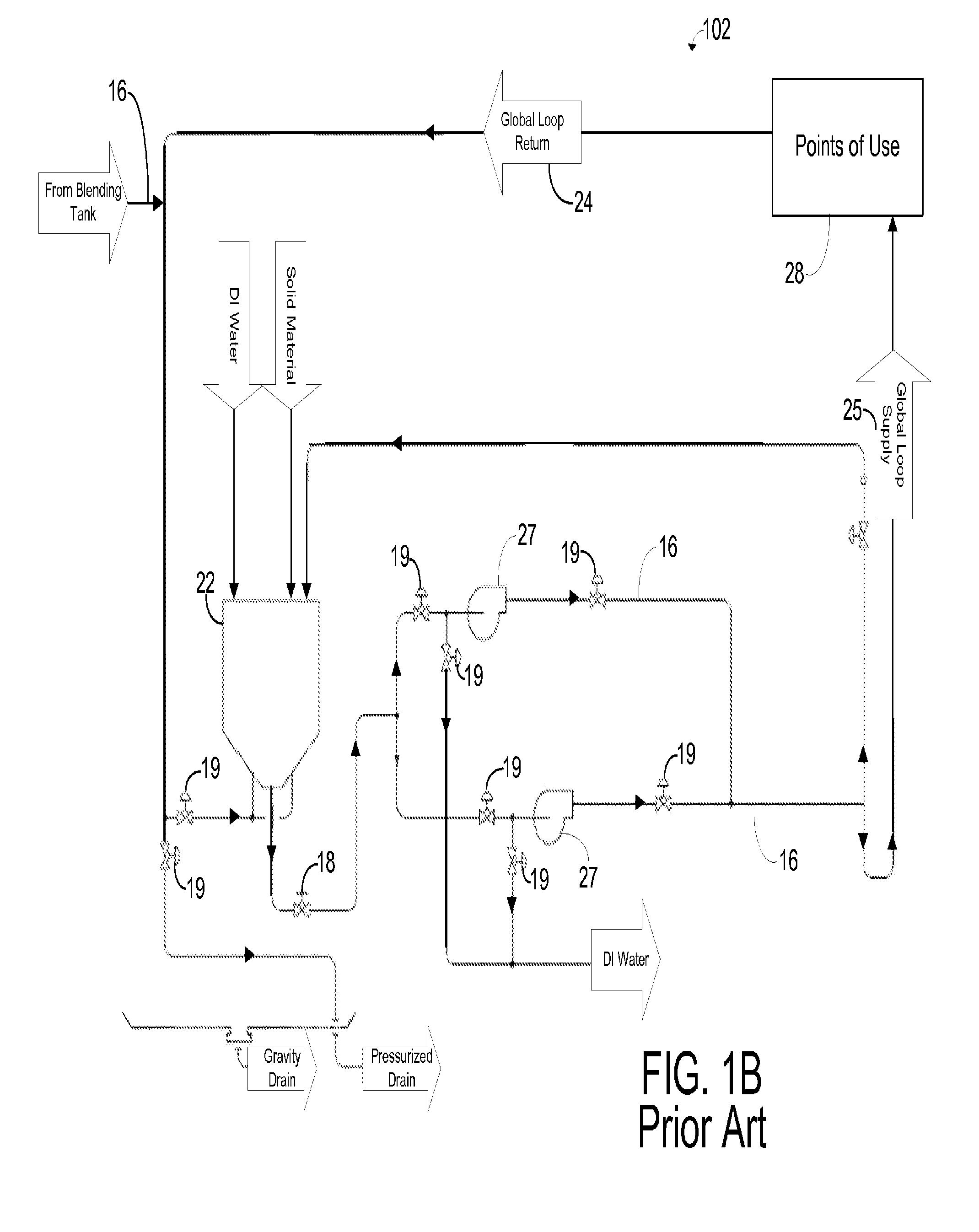

Method and apparatus for blending process materials

ActiveUS20100265788A1Improve mixing efficiencyReduce system costFlow mixersTransportation and packagingProcess engineeringImproved method

An improved method and apparatus for blending process materials. Preferred embodiments of the present invention are directed to a process material contacting system to increase wetted surface area for liquid contact as well as increase forced convective mixing efficiency of the liquid mixture. Use of a novel process material contacting apparatus allows one solid feeding element to serve multiple process material tanks, thus reducing overall system costs and decreasing set-up time / process variability while increasing operational efficiency. According to a preferred embodiment of the present invention, rather than adding a process material to a volume of liquid held in a blending tank, the added process material is remotely blended with the liquid outside the process material tank.

Owner:MEGA FLUID SYST

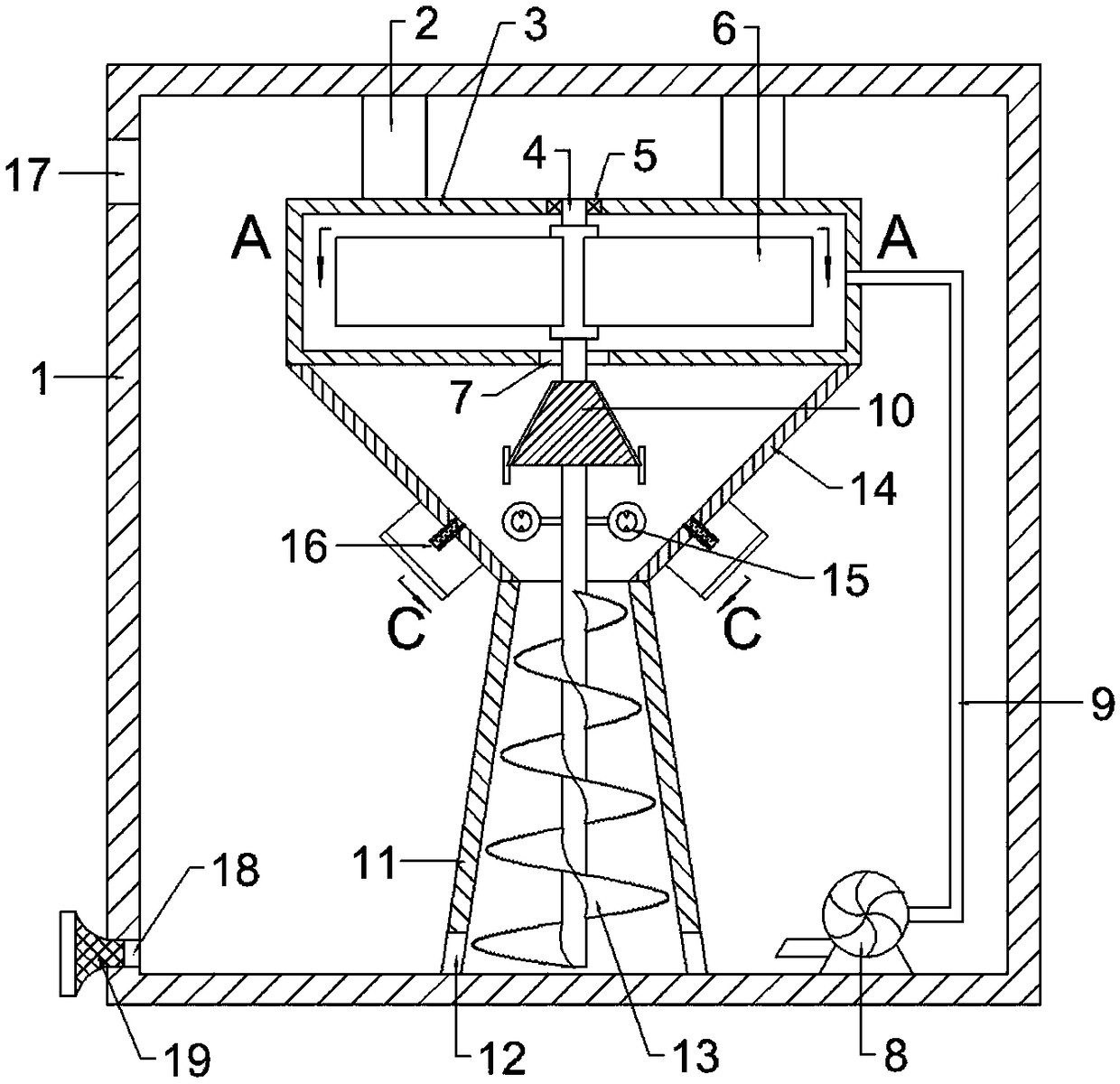

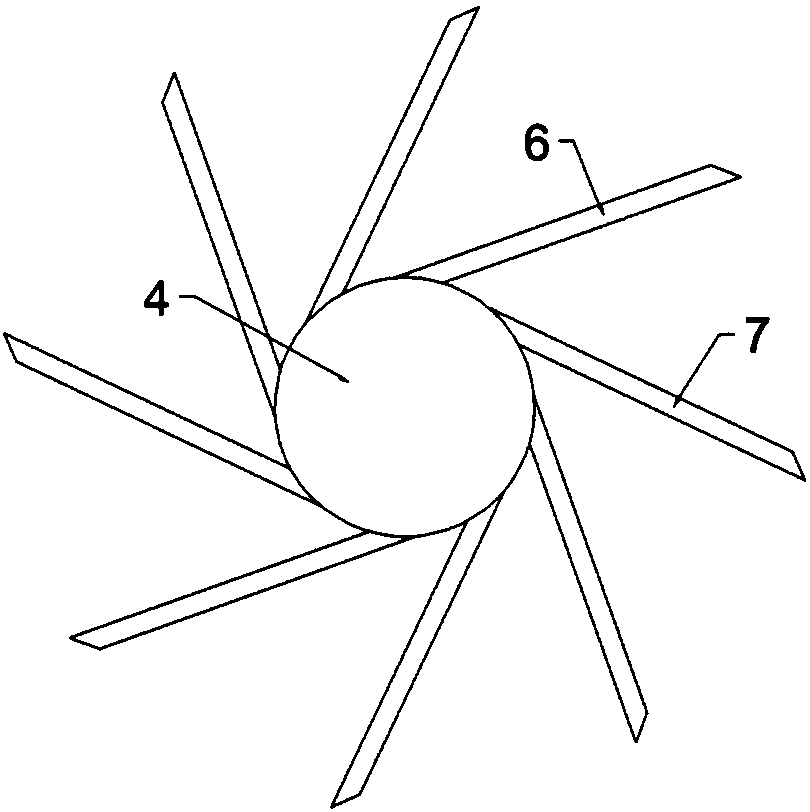

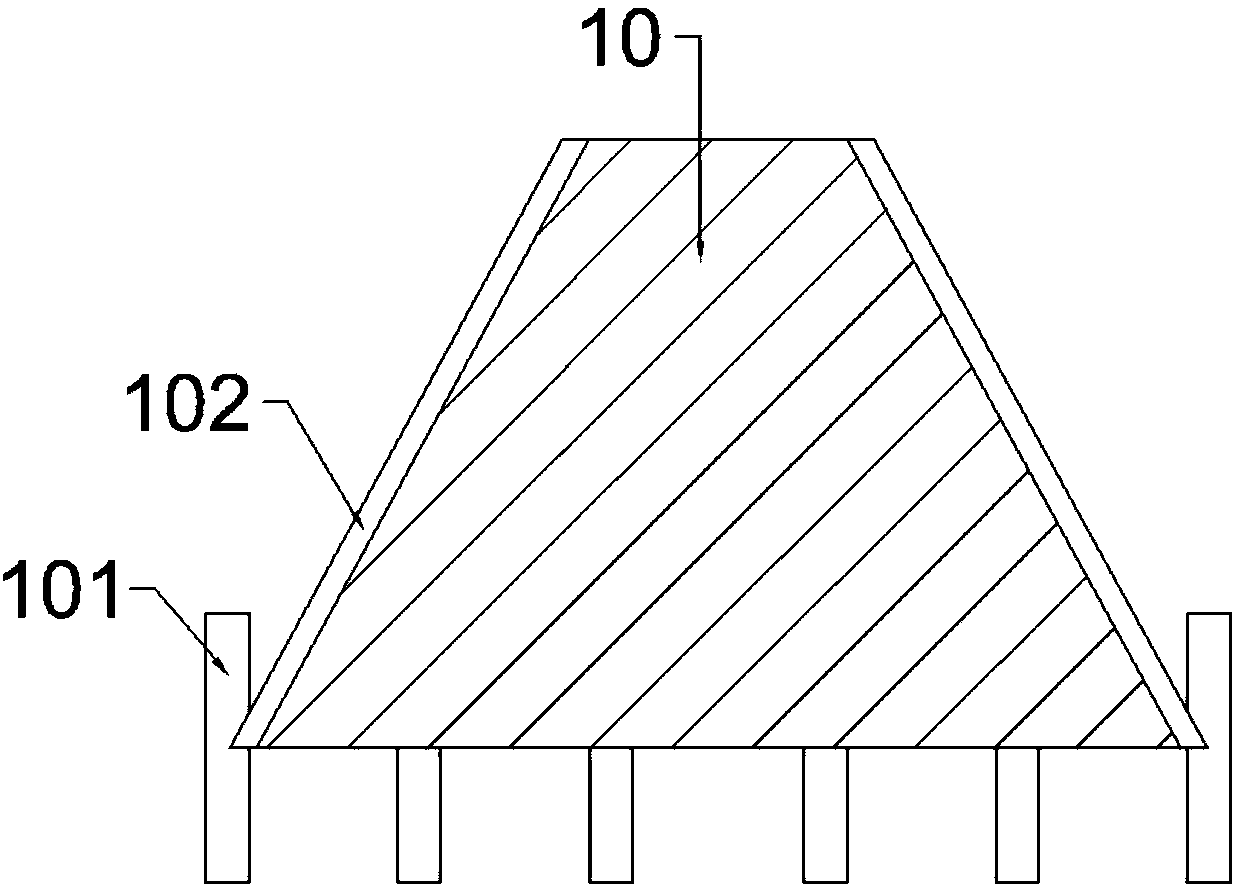

Multiple convective mixing principle based material mixing device for industrial production

ActiveCN108339430ASmall diameterIncrease flow rateRotary stirring mixersTransportation and packagingCircular discEngineering

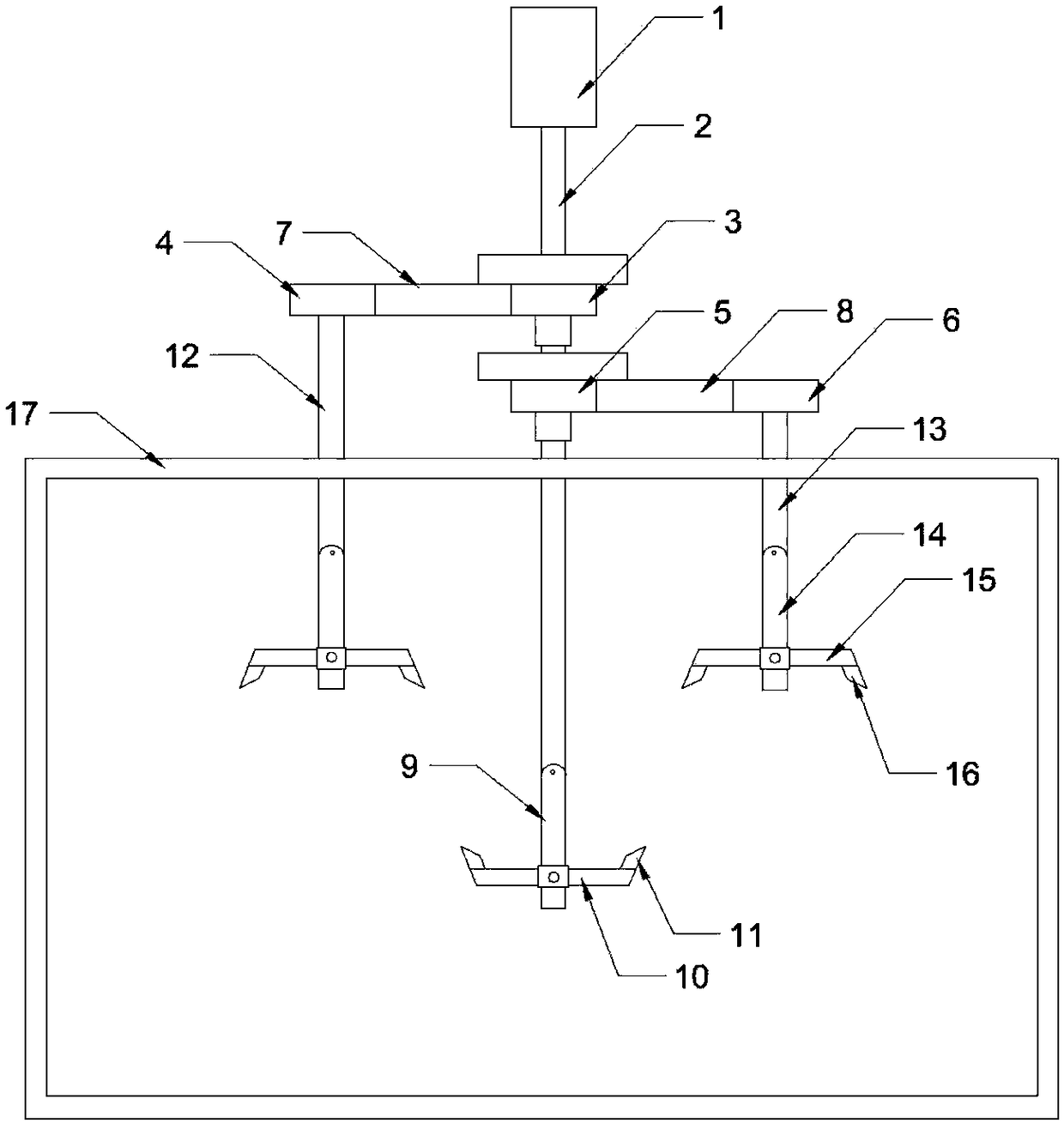

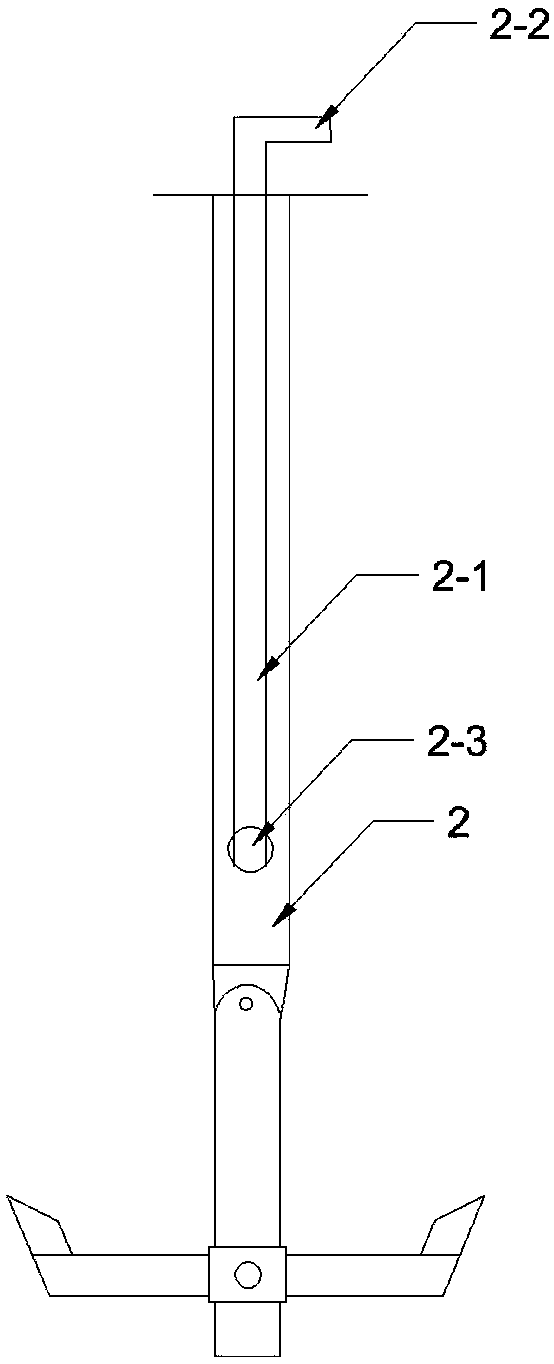

The invention provides a multiple convective mixing principle based material mixing device for industrial production. The material mixing device comprises a mixing shell, wherein the interior of the mixing shell is provided with a circular disc; the top of the circular disc is fixedly connected with the inner top of the mixing shell through four fixing rods; the middle of the circular disc is provided with a rotating shaft; the top end of the rotating shaft is rotationally connected with the upper part of the circular disc; the position, which is in contact with the lower part of the circulardisc, of the rotating shaft is provided with a material dropping through hole; further, the bottom of the rotating shaft passes through the circular disc to downwards extend; the section of the part,which is located in the circular disc, of the rotating shaft is fixedly connected with a plurality of propelling blades; the inner bottom of the mixing shell is provided with a high pressure pump. Thematerial mixing device has the following beneficial effects that a liquid material entering from a material inlet through hole is lifted to be above a supporting sleeve by a spiral auger; as the diameter of the supporting sleeve is gradually reduced, the flow velocity of the material ejected from the supporting sleeve is gradually increased; the first-time impact convection work is carried out with the material dropping from the material dropping through hole, and the certain mixing is realized between the materials.

Owner:台州路桥朝槿自动化科技有限公司

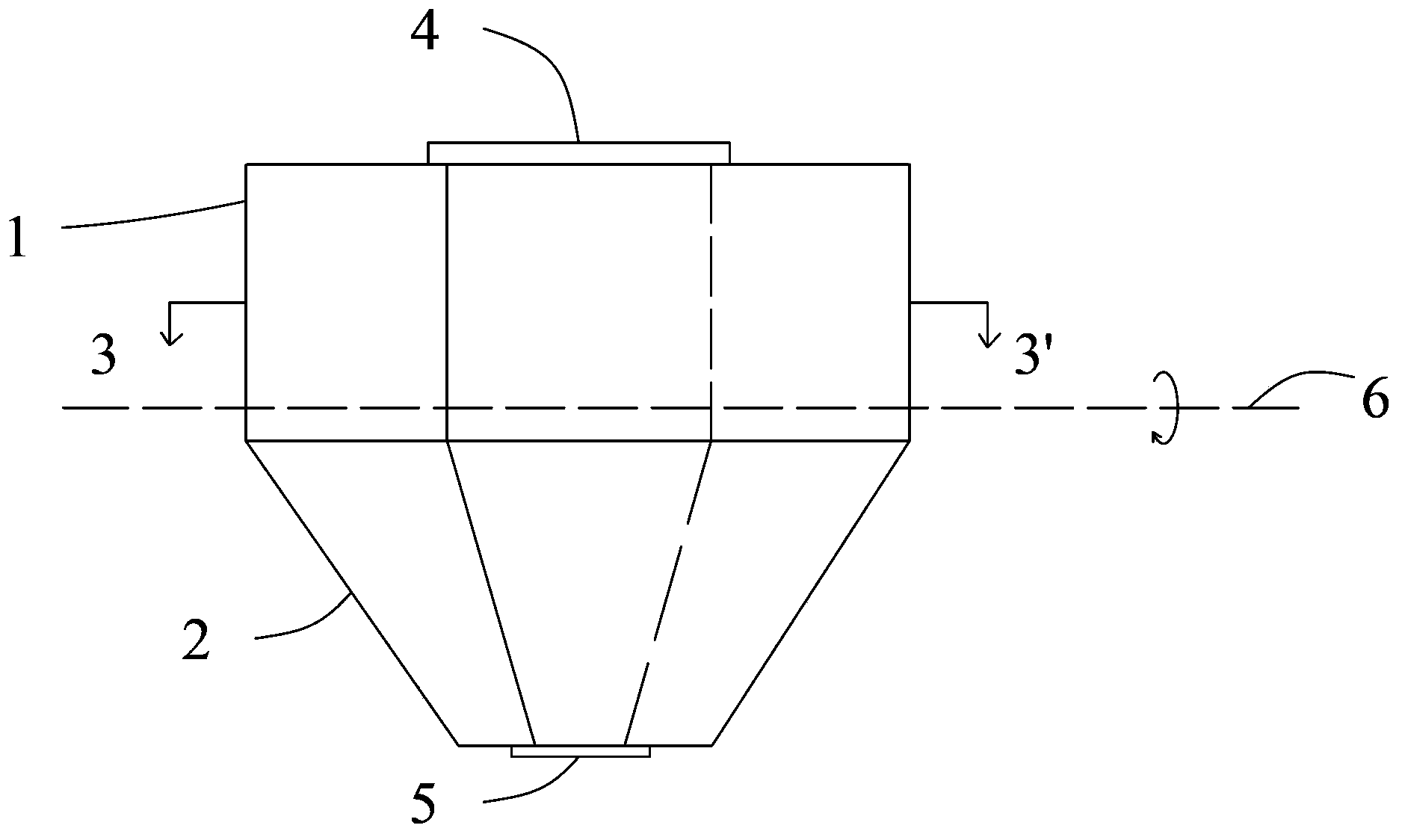

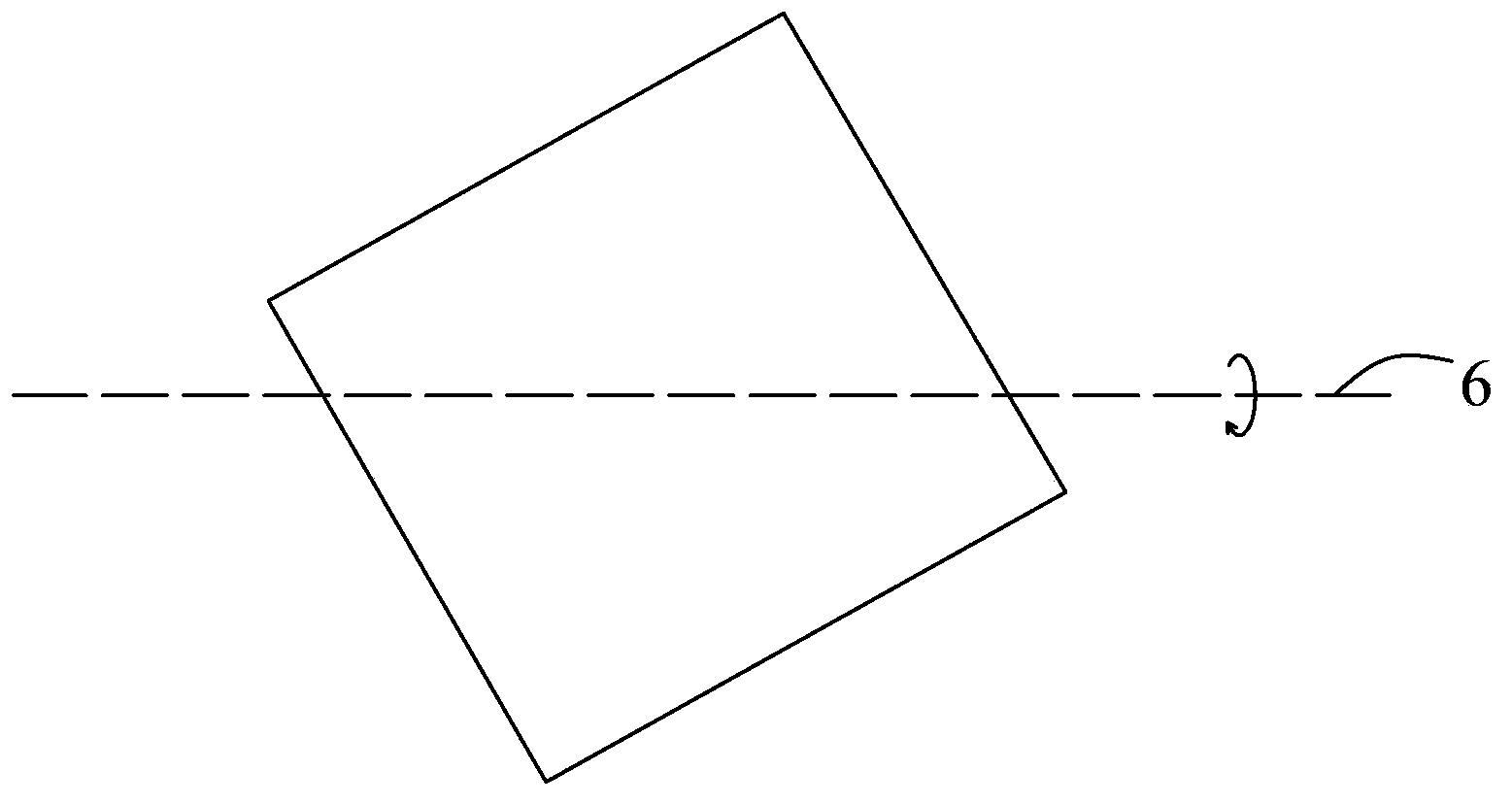

Square-tapered rotary mixer

ActiveCN104275112AOvercome the disadvantage of weak axial mixingFacilitates axial convective mixingRotating receptacle mixersTransportation and packagingEngineeringMixing effect

The invention relates to a square-tapered rotary mixer. The mixer comprises a mixer main body composed of an upper cube and a lower truncated pyramid, and comprises a rotating shaft for providing the mixer rotation power; the mixer also comprises a baffle internal component fixed in the internal cavity of the cube; the baffle internal component comprises a supporting shaft and at least two baffles fixed on the supporting shaft; the supporting shaft is parallel to the rotating shaft of the mixer; gaps exist between the baffles and the axial side wall of the mixer rotating shaft. The corresponding internal component is designed based on the square-tapered mixer, the axial convective mixing of particles is effectively promoted, and thus the particle mixer having the advantages of simple structure operation, low energy consumption and cost and better mixing effect is provided.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

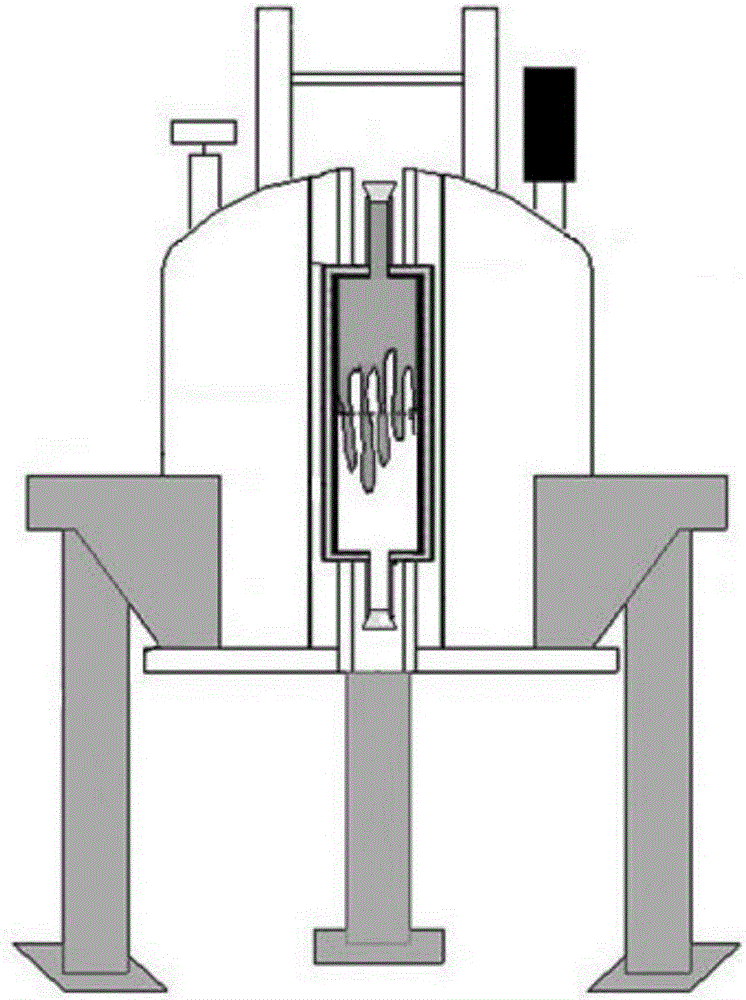

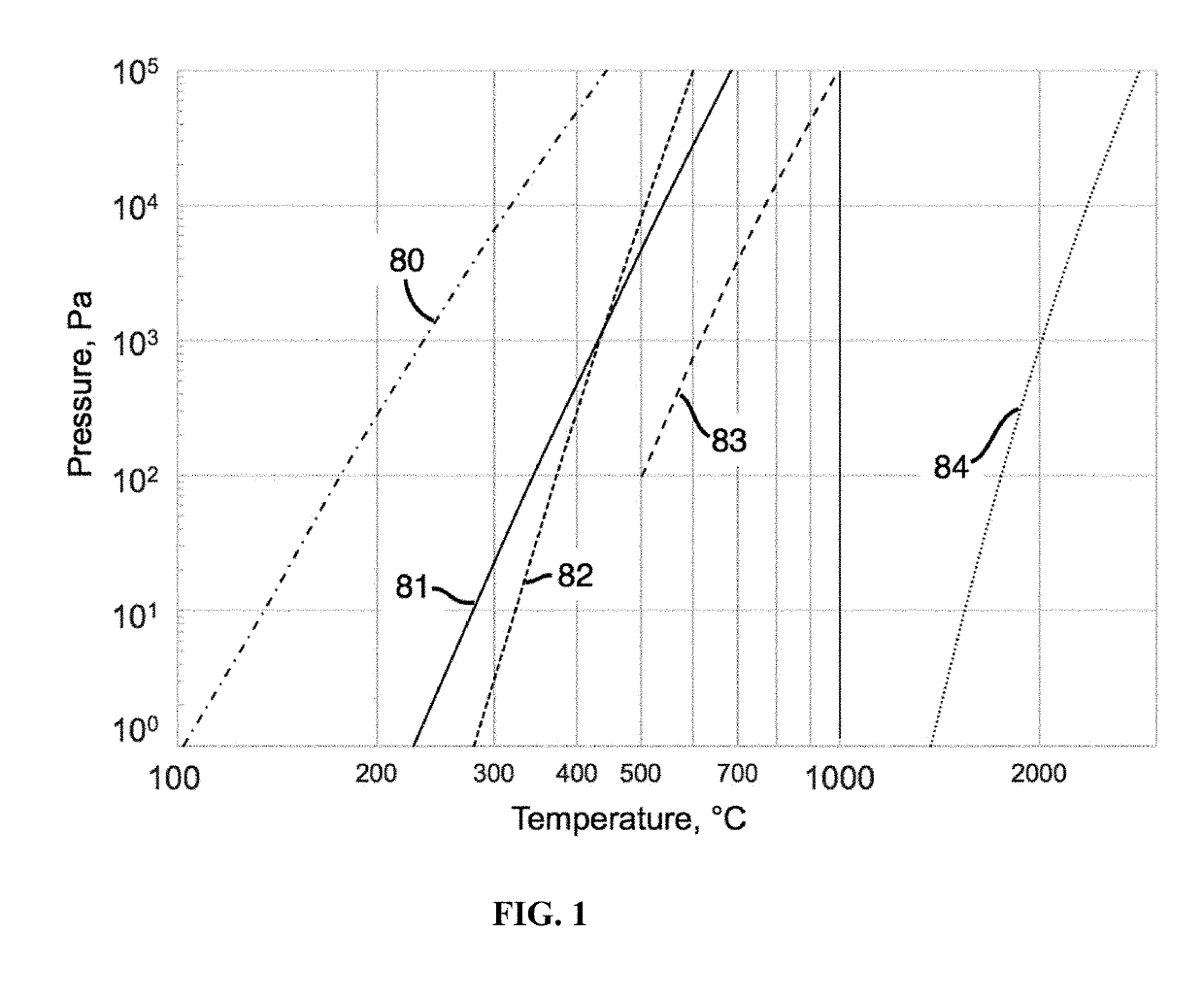

Manufacturing process for striae-free multicomponent chalcogenide glasses via convection mixing

ActiveUS20190194052A1Shorten cycle timeImprove clarityPot furnacesGlass furnace apparatusViscous liquidFurnace temperature

A method for making high optical quality multicomponent chalcogenide glasses without refractive index perturbations due to striae, phase separation or crystal formation using a sealed ampoule with chemical components enclosed inside, a two-zone furnace, a convection heating / mixing step, and multiple fining steps. Initially, the sealed ampoule is oriented vertically within the two-zone furnace and heated to melt the chemical components contained within, and a temperature gradient is created between the top zone and the bottom zone such that the bottom zone has a higher temperature. This temperature gradient causes convection currents within the viscous liquid until it is sufficiently mixed due to the convective flow. Then the temperature gradient is reversed such that the top zone now has a higher temperature and the convective flow ceases. The furnace temperatures are then reduced over a period of time, with holds at multiple temperatures for fining and cooling to form a solid glass.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

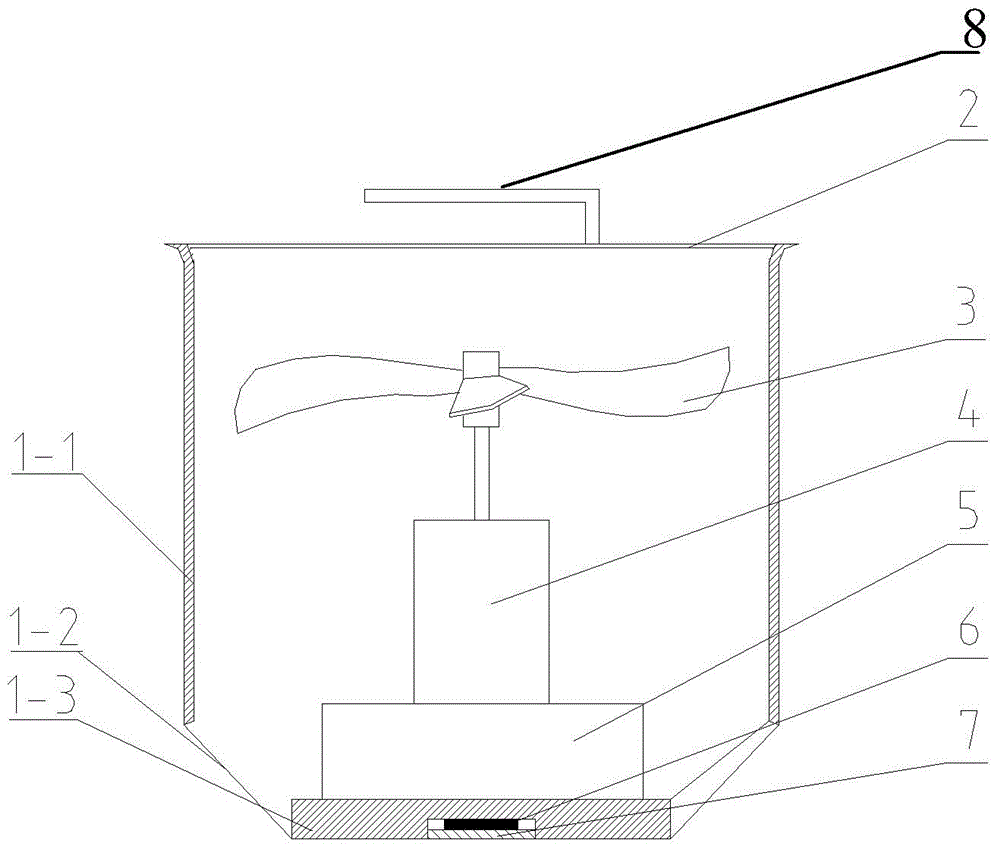

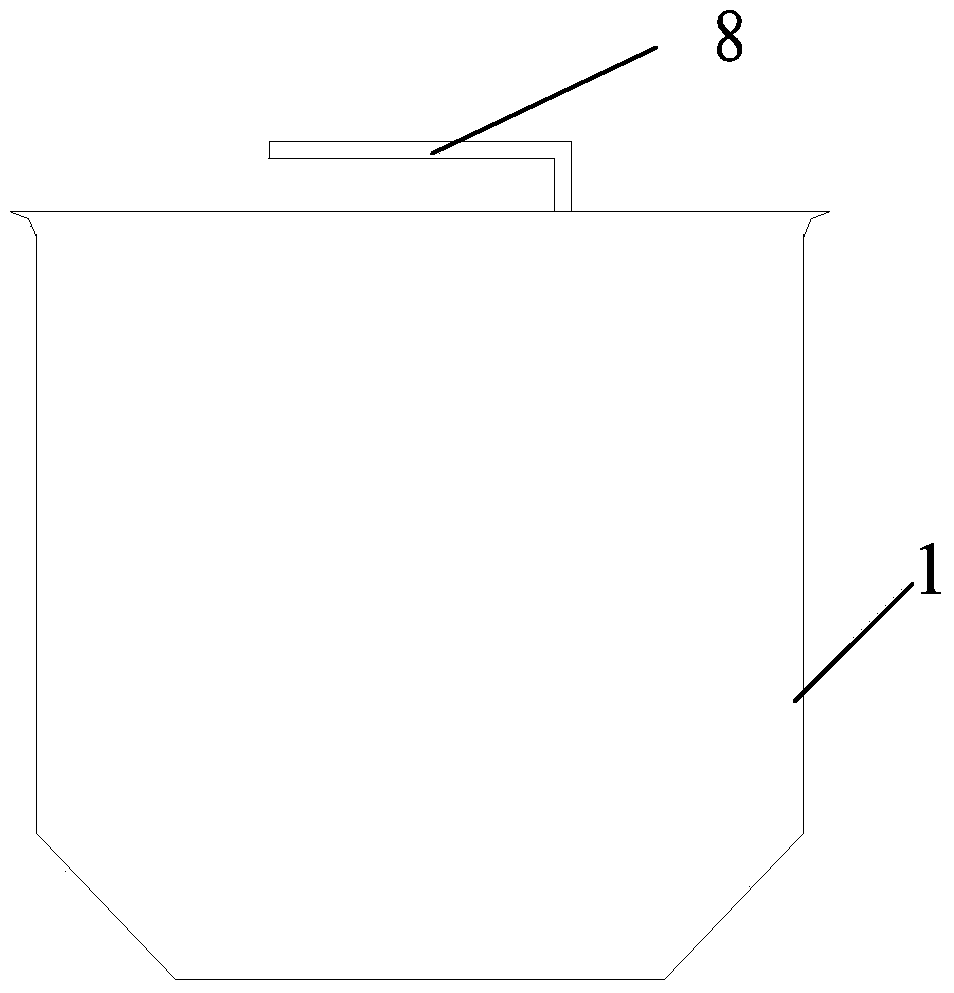

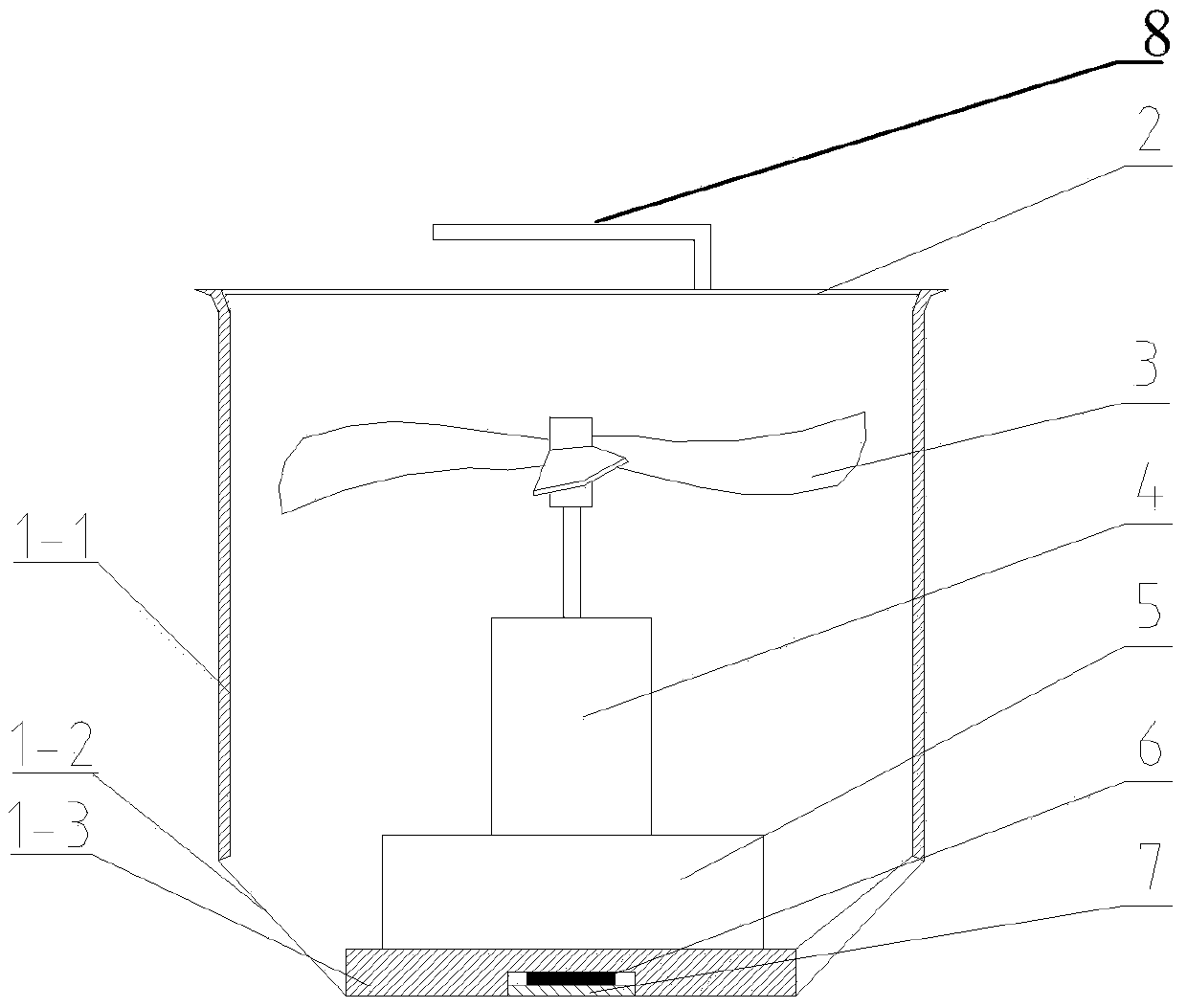

a thermoelectric fan

ActiveCN103629126BLower cold junction temperatureGuaranteed to workAir heatersPump installationsElectric machineryEngineering

The invention discloses a heat electric fan which comprises a flow guiding outer shell with an opening at the upper end. The bottom of the flow guiding outer shell is fixedly provided with a mounting base. A motor which is used for driving a vane to rotate is arranged on the mounting base. A counter bore is formed in the lower end face of the flow guiding outer shell. A thermoelectricity module is arranged in the counter bore. A hot end heat transfer plate which presses the thermoelectricity module tight is arranged at the opening of the counter bore. When the heat electric fan is used in cooperation with a heating stove, by arranging the thermoelectricity module and adopting the thermoelectric conversion technology, heat of a heating furnace is used for electricity generation, accordingly, the fan operates, upper-lower-layer cold-hot air in a camping tent in a heating state is subject to full convective mixing, accordingly, the air temperature gradient in the tent is lowered, the living comfort degree during heating of the tent is improved, the problem of insufficient effective heat is solved, and important effect on improving outdoor camping heating guaranteeing capacity in winter is achieved.

Owner:中国人民解放军32181部队

Anti-rusting high-magnesium aluminum alloy round ingot and manufacturing method thereof

InactiveCN108441723ASolve the problem of adequate alloyingEliminate reductionHigh magnesiumCrack resistance

The invention discloses an anti-rusting high-magnesium aluminum alloy round ingot and a manufacturing method thereof and relates to an aluminum alloy round ingot and a manufacturing method thereof. The invention aims to solve the problem that the anti-rusting high-magnesium aluminum alloy round ingot is low in yield. The ingot mainly comprises the following elements: 0.40-0.8% of Mn, 8.3-9.6% of Mg, 0.004-0.05% of Sb and 0.05-0.15% of Ti. The preparation method comprises the following steps: weighing raw materials, charging and smelting according to a sequence, performing convective mixing, introducing into a holding furnace of a resistance reflection furnace, refining argon-chlorine mixed gases, standing, degassing, and finally casting the ingot. The yield of the ingot disclosed by the invention exceeds 85%, and the problem that an ingot prepared by the conventional method is low in yield is solved. The corrosion resistance and thermal crack resistance of the alloy are improved, and crack tendency is reduced. The preparation method in the invention is applicable to preparation of the anti-rusting high-magnesium aluminum alloy round ingot.

Owner:NORTHEAST LIGHT ALLOY CO LTD

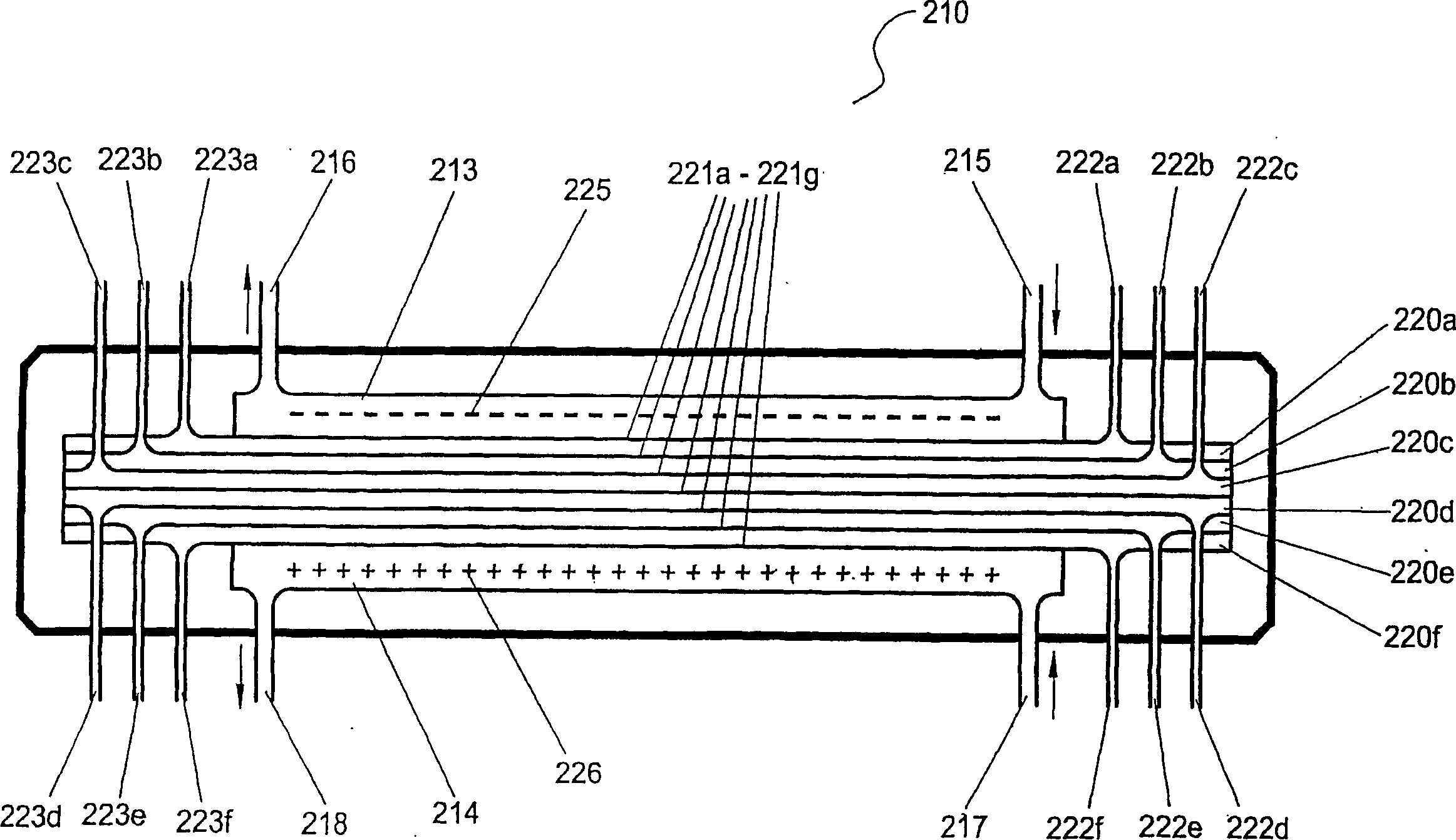

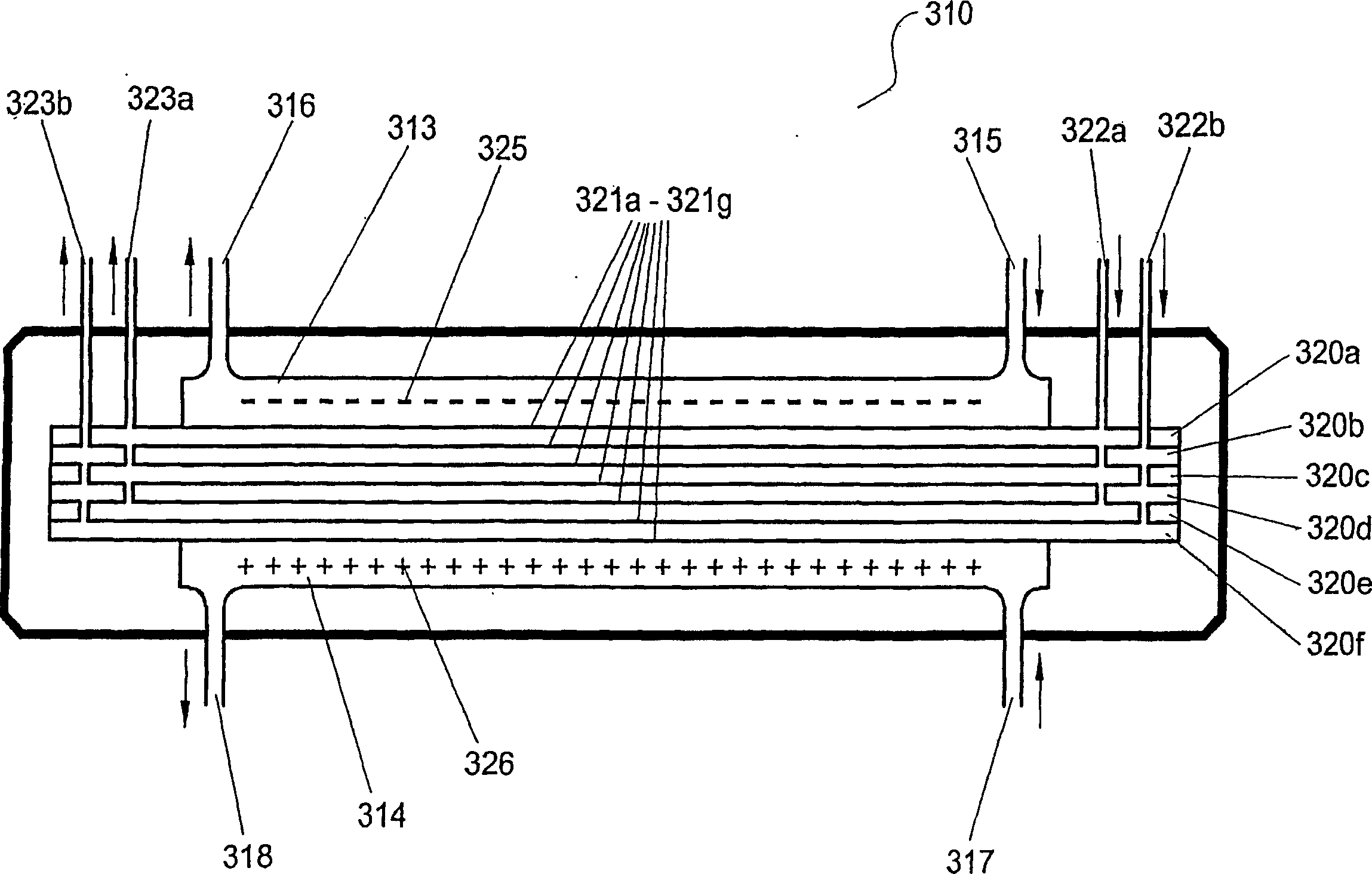

Electrophoresis apparatus and method

InactiveUS20050167270A1Increase separation speedReduce operating costsSludge treatmentElectrostatic separationElectrolysisElectrophoresis

An electrophoretic apparatus comprising: a first electrolyte chamber containing a first electrode; a second electrolyte chamber containing a second electrode; a first sample chamber disposed between the first and second electrolyte chambers and proximate to the first electrolyte chamber; a second sample chamber disposed between the first sample chamber and the second electrolyte; three ion-permeable barriers separating the first electrolyte chamber, the first sample chamber, the second sample chamber, and the second electrolyte chamber, respectively, wherein the ion-permeable barriers impede convective mixing of the contents in each of the respective chambers; a first electrolyte reservoir and a second electrolyte reservoir in fluid communication with the first and second electrolyte chambers, respectively; a first sample reservoir and a second sample reservoir in fluid communication with the first and second sample chambers, respectively; means adapted for communicating a first electrolyte and a second electrolyte between the respective electrolyte chambers and reservoirs; means adapted for communicating a first fluid and a second fluid between the respective sample chambers and reservoirs, wherein at least one of the first and second fluid contains at least a sample, wherein application of an electric potential causes migration of at least one component through at least one of the ion-permeable barriers.

Owner:GRADIPORE +1

Dry-mixed mortar with heat insulation function and preparation process thereof

InactiveCN101928128AStable structureEnergy savingSolid waste managementCement mixing apparatusBuilding energyEconomic benefits

The invention relates to the technical field of building materials, in particular to dry-mixed mortar with a heat insulation function and a preparation process thereof. The dry-mixed mortar comprises the following components: expanded and vitrified small balls, cement and addictive, wherein the proportion ratio of the components is as follows by finished products / m<3>: 100-120kg of expanded and vitrified small balls, 140-160kg of cement and 10-20kg of addictive. The preparation method comprises the following steps: weighting raw materials; subsequently, mixing in a mixing device by two steps: firstly, mixing the raw materials except the expanded and vitrified small balls, and then adding the expanded and vitrified small balls to continuously mix in a closed material convective mixing region; and finally, measuring and packaging. The process of the invention is simple and can obtain the dry-mixed mortar having obvious heat insulation effect, stable structure and light quality, and the materials are evenly mixed; and the product has small coefficient of heat conductivity, superior combination property and extremely high economic benefit and society benefit, meets the new development requirements of building energy conversation, and is suitable for industrial popularization and application.

Owner:DONGGUAN JINGRUN ENVIRONMENTAL TECH

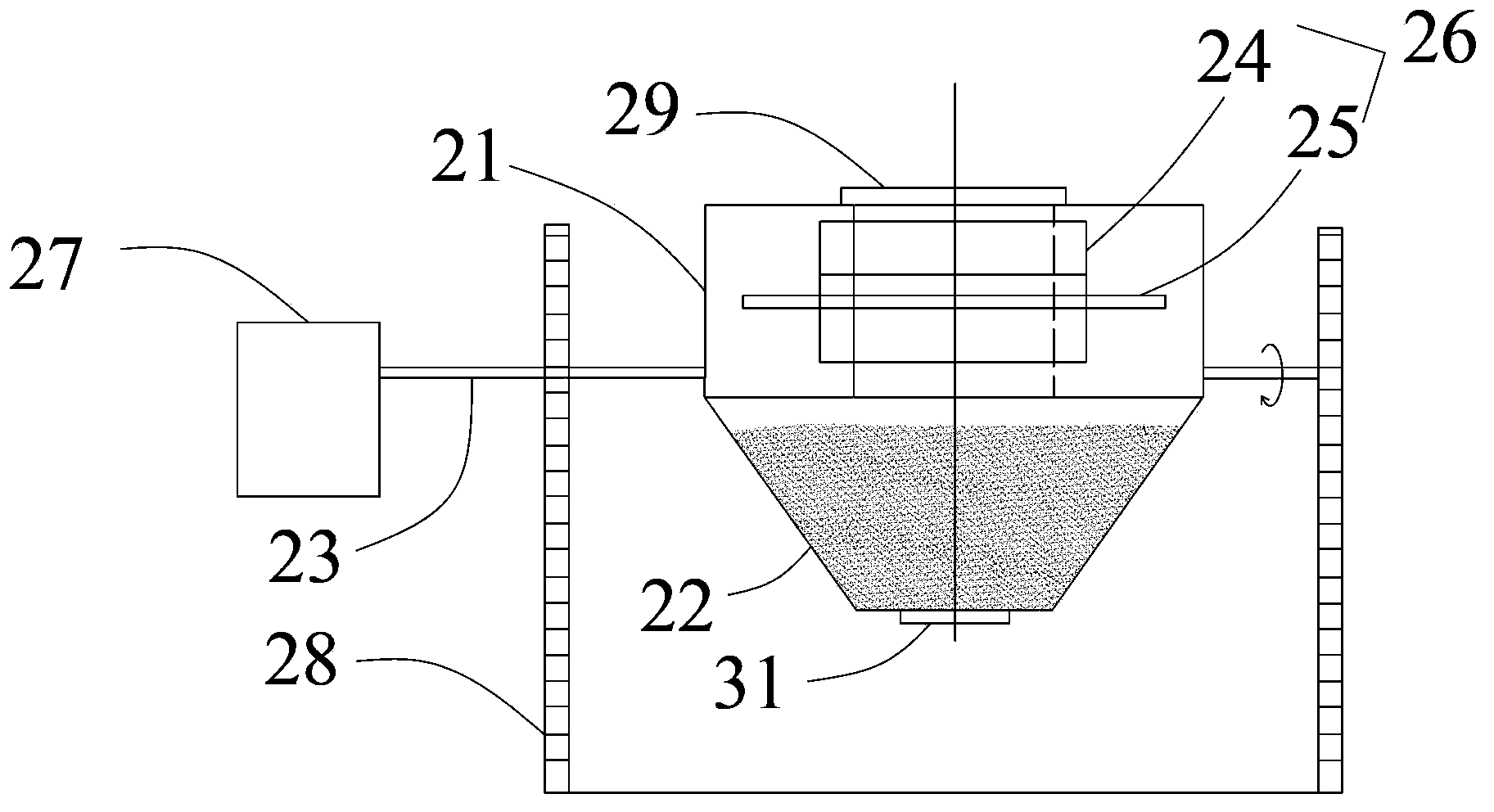

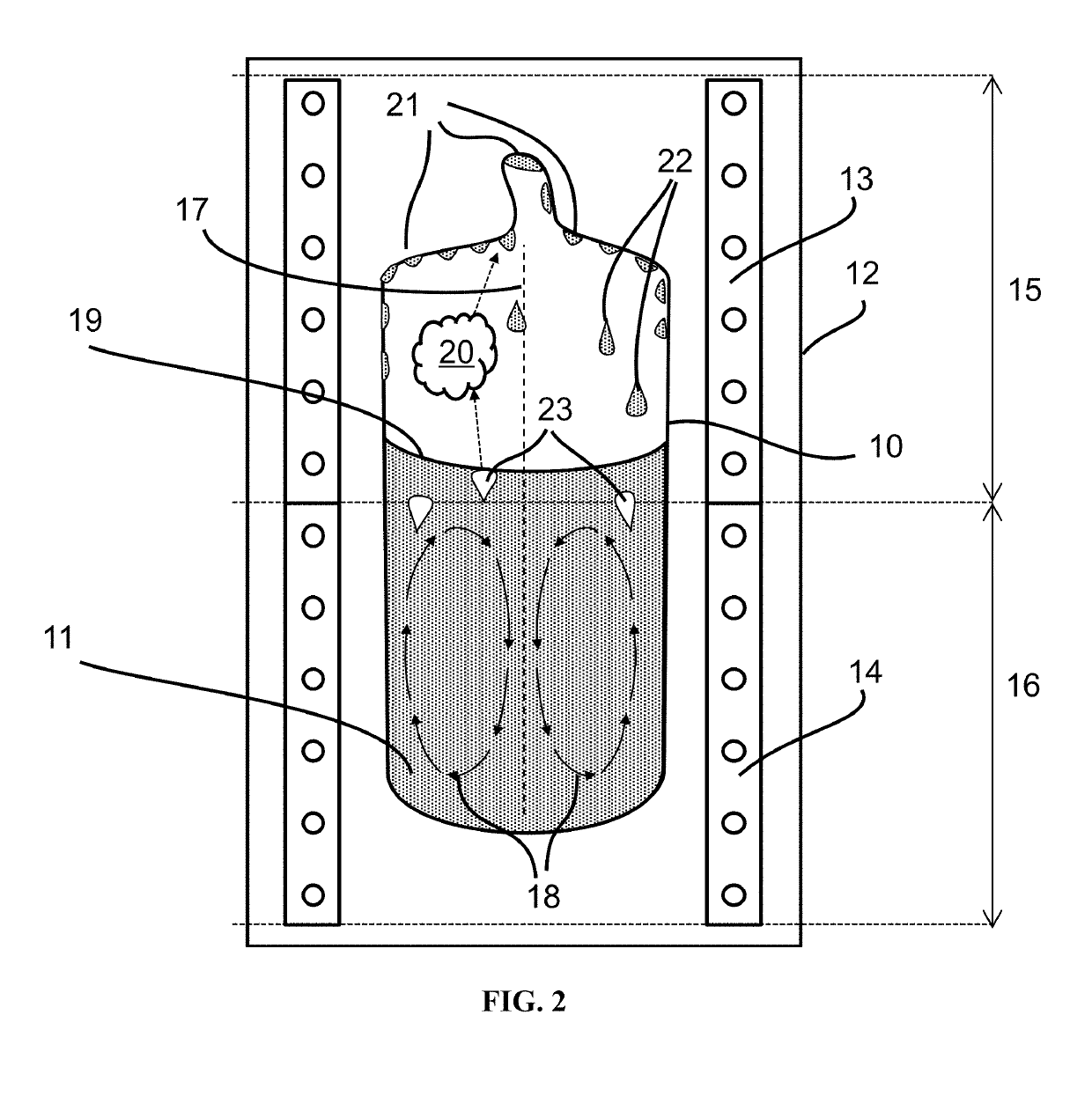

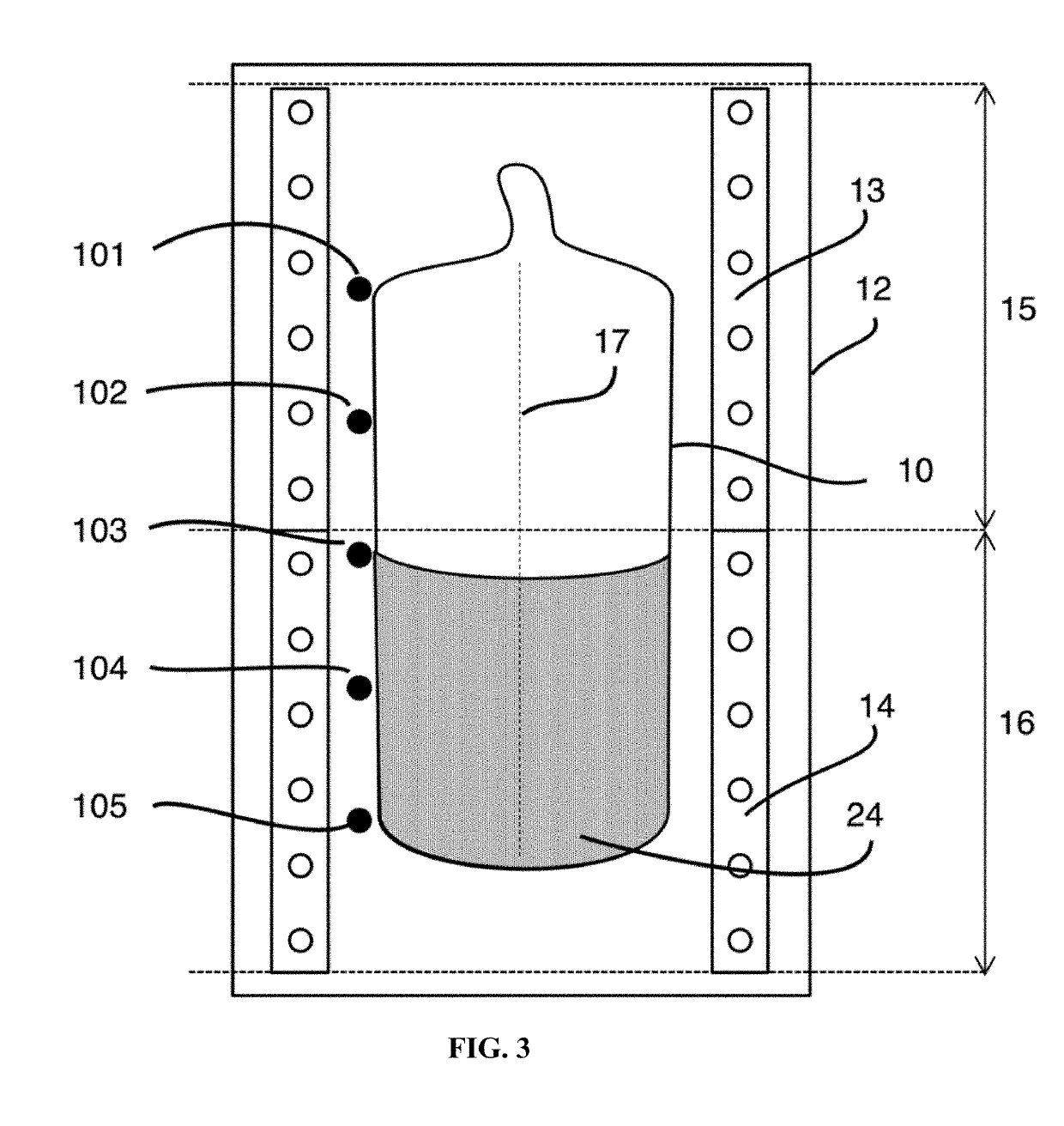

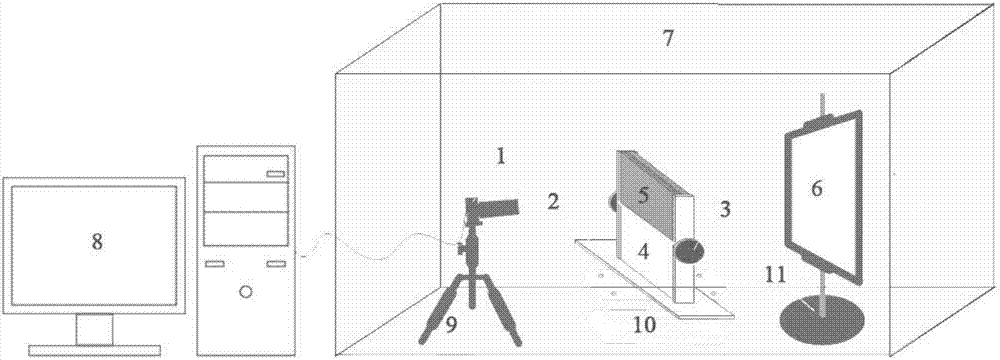

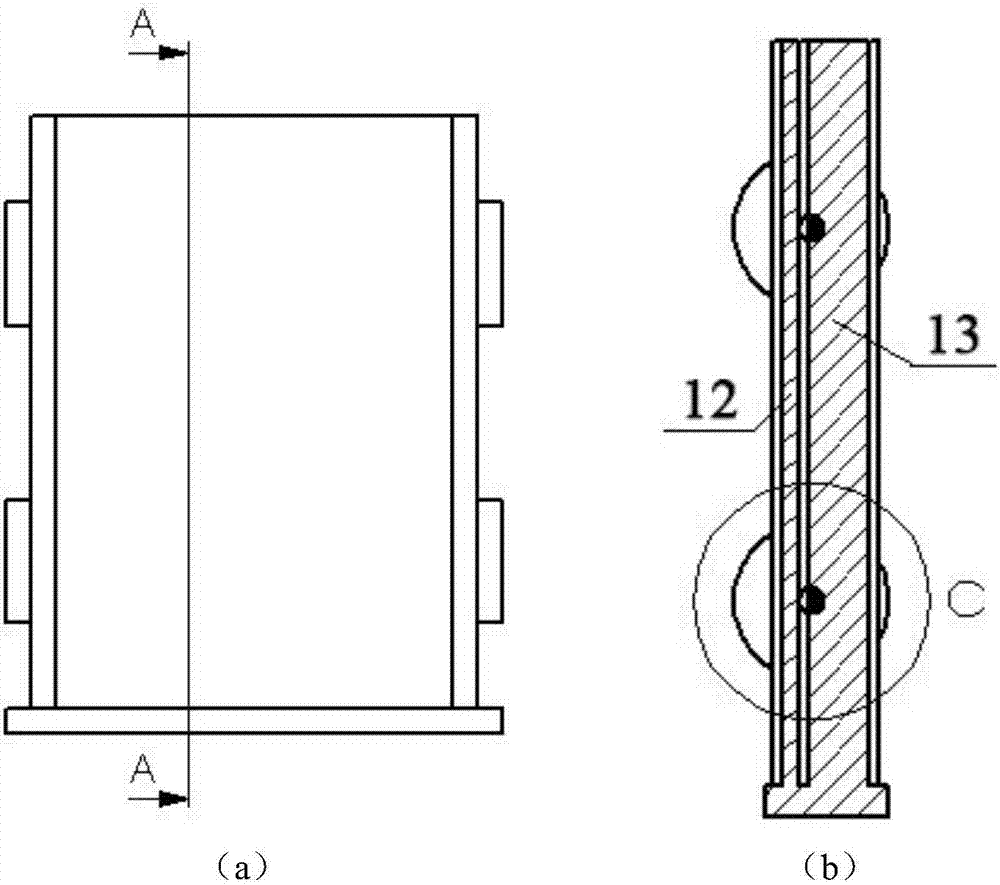

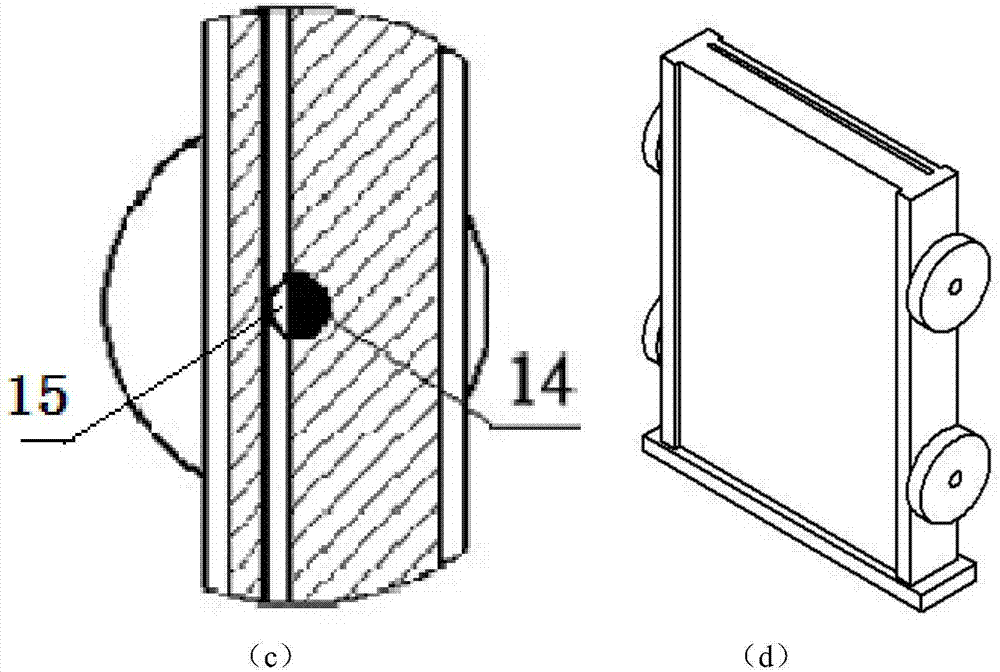

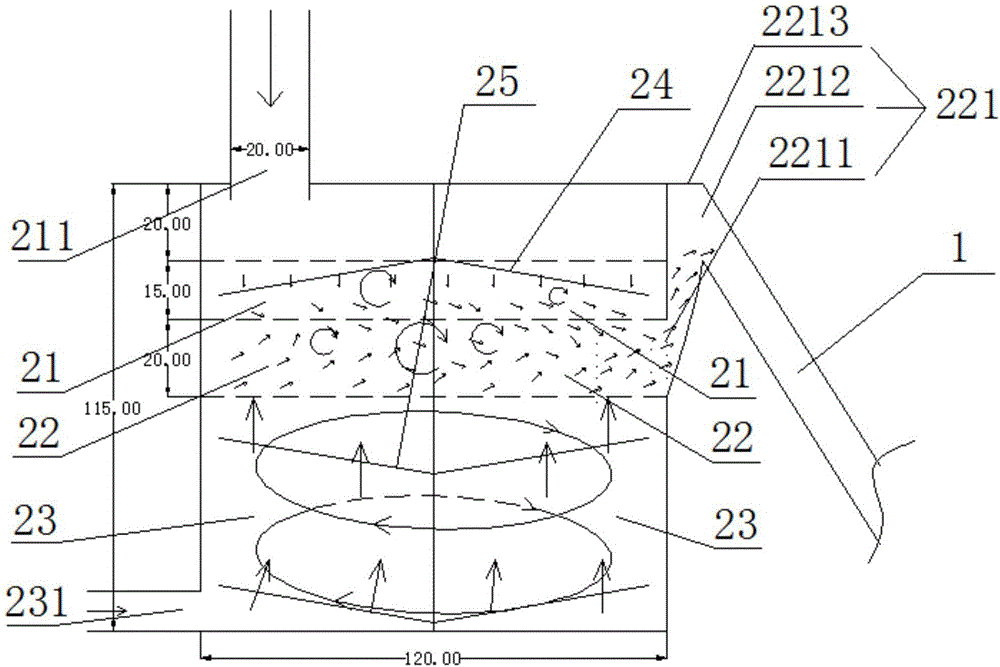

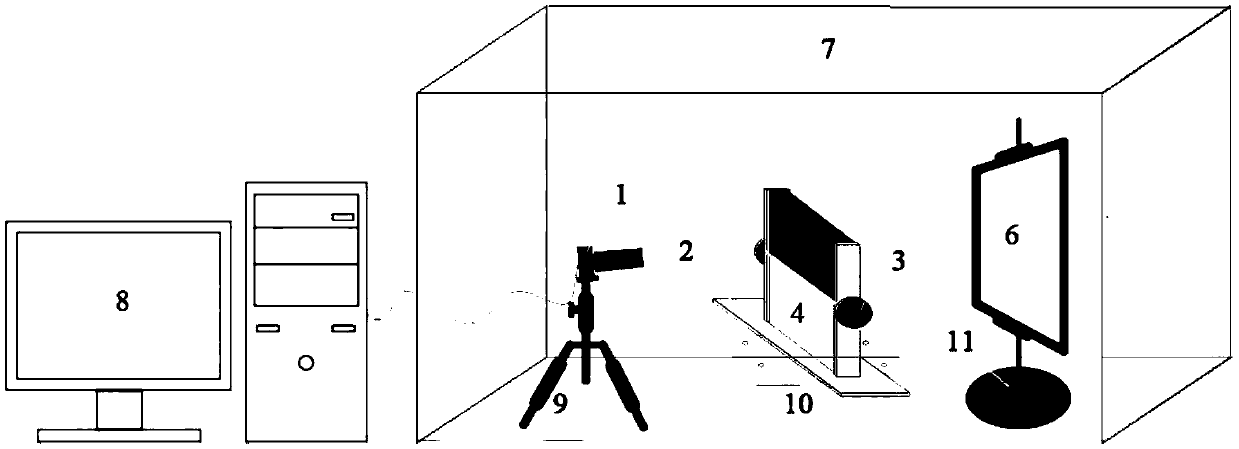

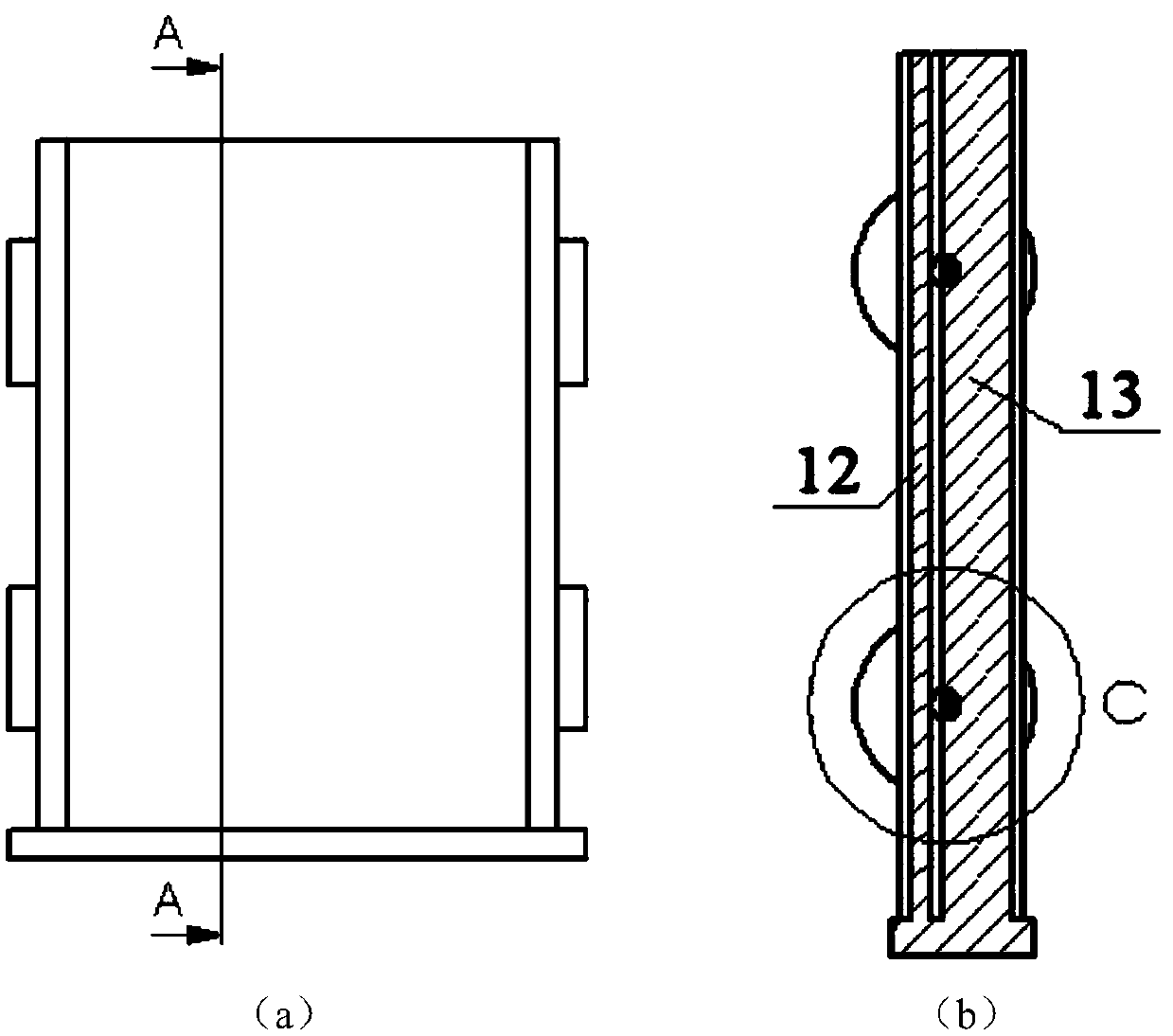

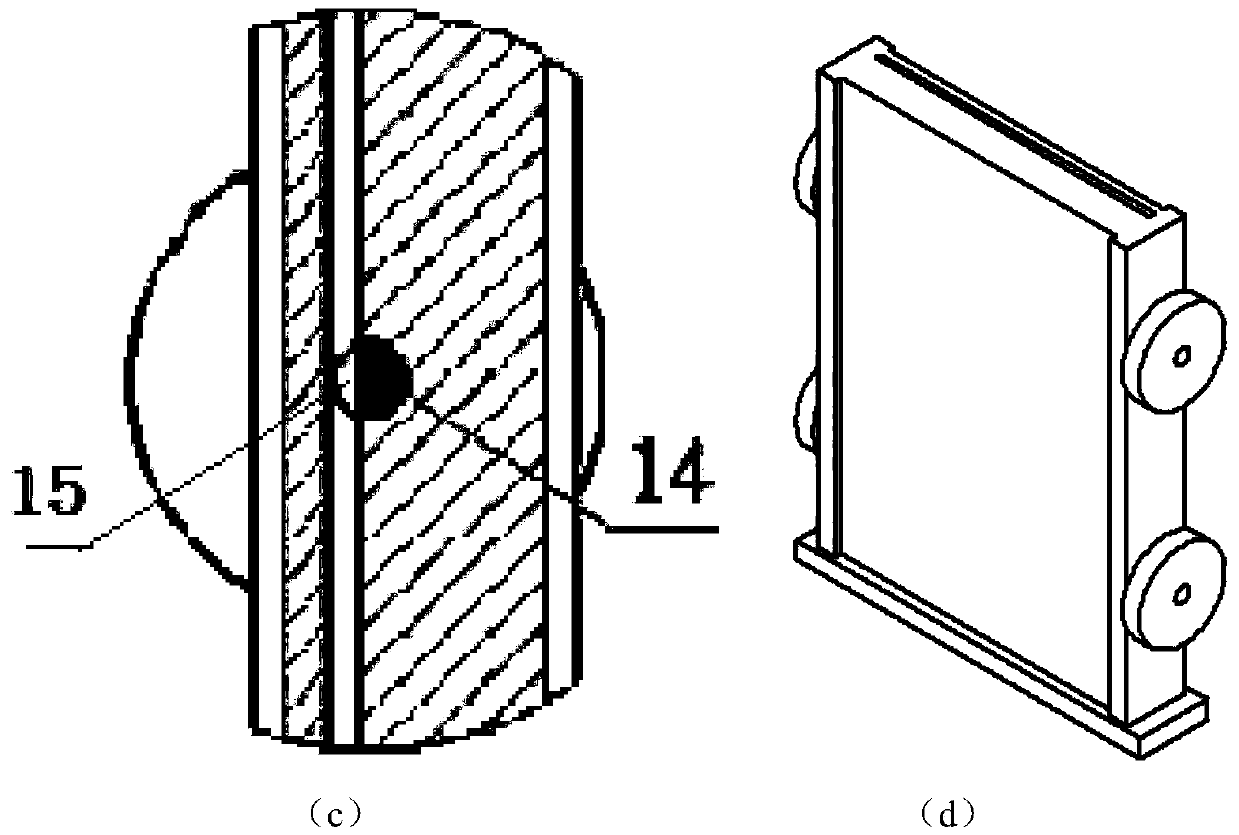

Improved Hele-Shaw box and two-phase fluid density difference convective mixing experimental system formed by improved Hele-Shaw box

ActiveCN106996857AThe experimental system is simpleFacilitate subsequent calculation and analysisHydrodynamic testingTransportation and packagingBoundary changeRotary switch

The invention discloses an improved Hele-Shaw box and a two-phase fluid density difference convective mixing experimental system formed by the improved Hele-Shaw box. The experimental system comprises a CCD camera, the improved vertical type Hele-Shaw box, and an area light source. By adopting the improved vertical type Hele-Shaw box, a lower layer fluid space sealed by a rotary switch is filled with small density fluid, and an upper layer fluid space is filled with large density fluid. The CCD camera, the improved vertical type Hele-Shaw box, and the area light source are disposed in a camera bellows. The rotary switch is used to rotate a rotating shaft arc surface to a gap between two layers of parallel light-transmitting materials to seal lower layer fluid. The large density fluid is disposed in the upper part of the Hele-Shaw box in a filled manner. The switch is opened, and the upper layer fluid and the lower layer fluid are contacted with each other, and a convective mixing experiment caused by a fluid-fluid two-phase fluid density difference is started, and at the same time, the CCD camera starts to shoot the images of the two-phase liquid convective mixing process. The experimental system has advantages of simple structure, convenient operation, accurate timing, and applicability in subsequent researching of interphase boundary changing, fingering generation development time, fingering numbers and other characteristic parameters during convective mixing process.

Owner:DALIAN UNIV OF TECH

Heat electric fan

ActiveCN103629126ALower cold junction temperatureGuaranteed to workAir heatersPump installationsEngineeringHeating furnace

The invention discloses a heat electric fan which comprises a flow guiding outer shell with an opening at the upper end. The bottom of the flow guiding outer shell is fixedly provided with a mounting base. A motor which is used for driving a vane to rotate is arranged on the mounting base. A counter bore is formed in the lower end face of the flow guiding outer shell. A thermoelectricity module is arranged in the counter bore. A hot end heat transfer plate which presses the thermoelectricity module tight is arranged at the opening of the counter bore. When the heat electric fan is used in cooperation with a heating stove, by arranging the thermoelectricity module and adopting the thermoelectric conversion technology, heat of a heating furnace is used for electricity generation, accordingly, the fan operates, upper-lower-layer cold-hot air in a camping tent in a heating state is subject to full convective mixing, accordingly, the air temperature gradient in the tent is lowered, the living comfort degree during heating of the tent is improved, the problem of insufficient effective heat is solved, and important effect on improving outdoor camping heating guaranteeing capacity in winter is achieved.

Owner:中国人民解放军32181部队

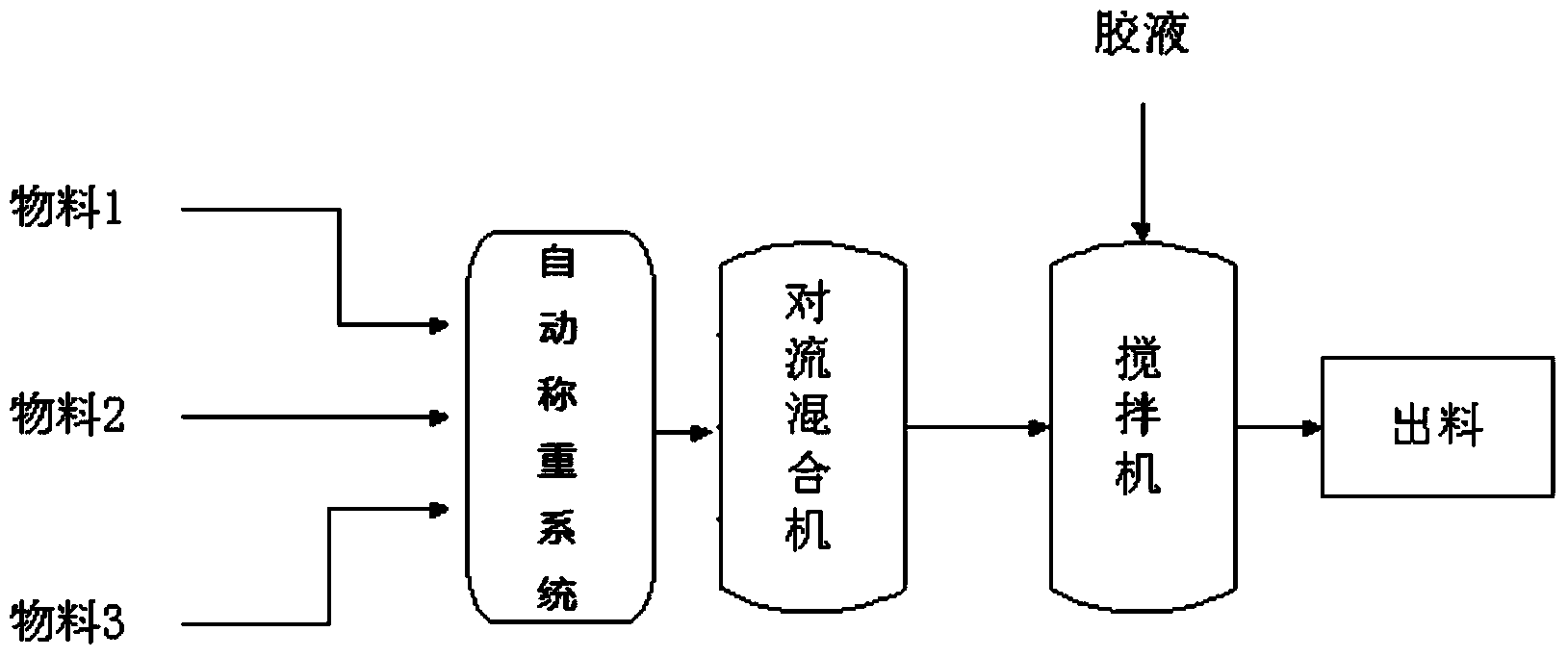

Powder mixing technology

InactiveCN103721586AMix well and evenlyShorten mixing timeTransportation and packagingMixing methodsHigh volume manufacturingMetallurgy

The invention discloses a powder mixing technology. The powder is firstly premixed by virtue of a convective mixing machine before being mixed. The powder mixing technology comprises the following specific steps: weighing different materials by virtue of an automatic weighing system firstly, carrying out convective circulation on a main material in the material in the convective mixing machine firstly, respectively adding other different materials according to requirements, carrying out convective mixing in the convective mixing machine, adding a colloid in the mixed material discharged from the mixing machine to stir in a stirrer, and finishing mixing and discharging. The powder mixing technology provided by the invention has the advantages that stirring time of a sizing agent is shortened, and the powder mixing technology is suitable for volume production.

Owner:HEFEI HENGNENG NEW ENERGY TECH

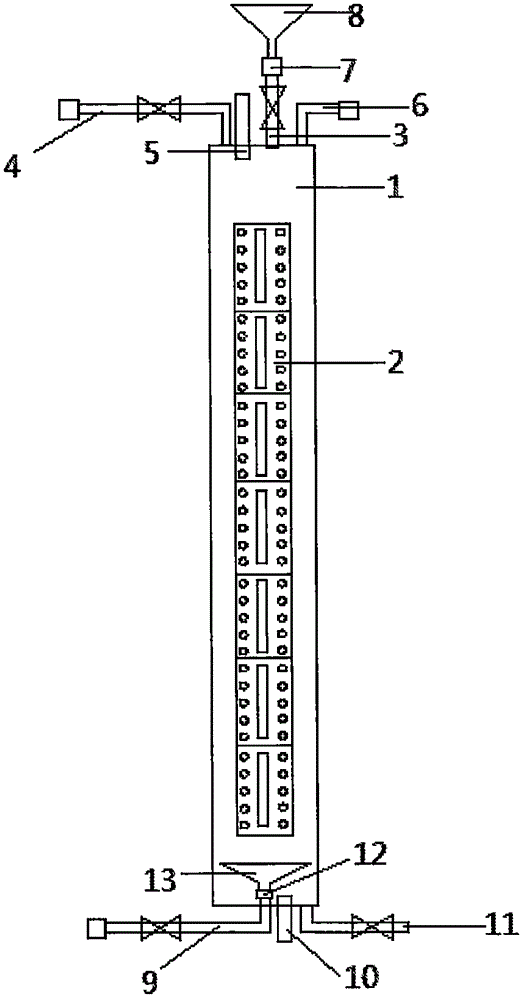

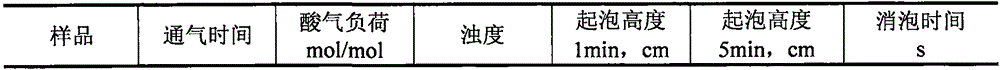

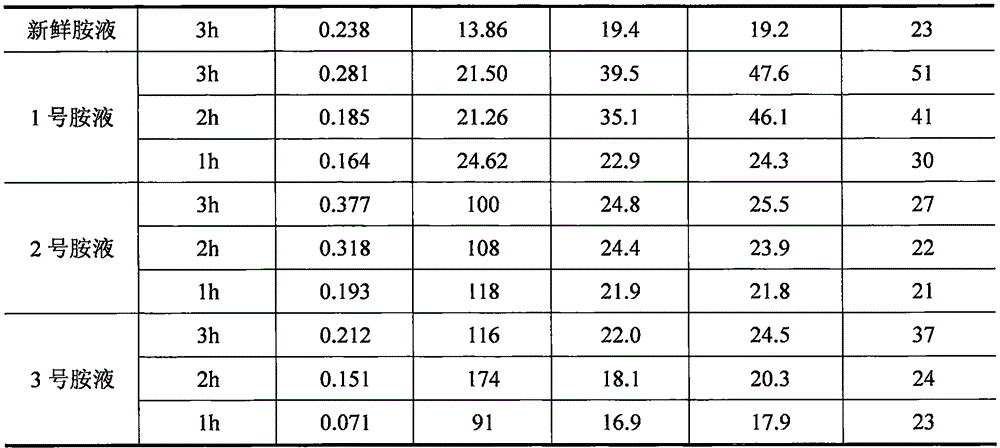

Amine liquid foaming device

InactiveCN106000141ARealize regulationAchieve convective mixingTransportation and packagingMixing methodsWorking pressureEngineering

The invention discloses an amine liquid foaming device, which comprises a cylinder, wherein a foaming cavity is arranged in the cylinder; the upper end of the cylinder is connected with the output end of an amine liquid pipeline, an air discharge pipeline, a first temperature probe and a pressure measuring pipeline; the input end of the amine liquid pipeline is connected with an amine liquid adding container through a nut; the lower end of the cylinder is connected with the output end of an air inlet pipeline, a second temperature probe and a liquid discharging pipeline, wherein the output end of the air inlet pipeline is connected with an air distribution head through a nut. According to the amine liquid foaming device, the real-time detection of pressure and temperature in the cylinder and temperature regulation and control are realized, the regulation of the flow velocity and the flow of air is controlled to realize the regulation of the size and speed of generated foam; the convective mixing of liquid and air in the foaming cavity is realized, and the air is introduced into the foaming cavity through the air distribution head, so that the contact area of the air and the liquid in the foaming cavity can be enlarged. The working pressure of the device is as high as 6.0MPa, the device is simple and reasonable in design, and the field working pressure can be truly simulated so as to research factors which affect amine liquid foaming.

Owner:XI'AN PETROLEUM UNIVERSITY

System and method for bubble-free gas-enrichment of a flowing liquid within a conduit

ActiveUS9919276B2Prevents and minimizes bubble formationSimplifies cartridgeFlow mixersTransportation and packagingEngineeringProduct gas

The present invention provides a system for enriching a flowing liquid with a dissolved gas inside a conduit. The system comprises two or more capillaries, each capillary delivering a stream of a gas-enriched liquid to the flowing liquid. The first ends of the capillaries are positioned to form an intersecting angle with respect to the effluent streams such that these streams of gas-enriched liquid collide with each other upon exit from the first ends of the capillaries, effecting localized convective mixing within the larger liquid conduit before these gas-enriched streams are able to come into close contact with the boundary surfaces of the conduit, whereby the gas-enriched liquid mixes with the flowing liquid to form a gas-enriched flowing liquid. In the preferred embodiment, no observable bubbles are formed in the gas-enriched flowing liquid. Methods of making and using such system are also provided.

Owner:THEROX

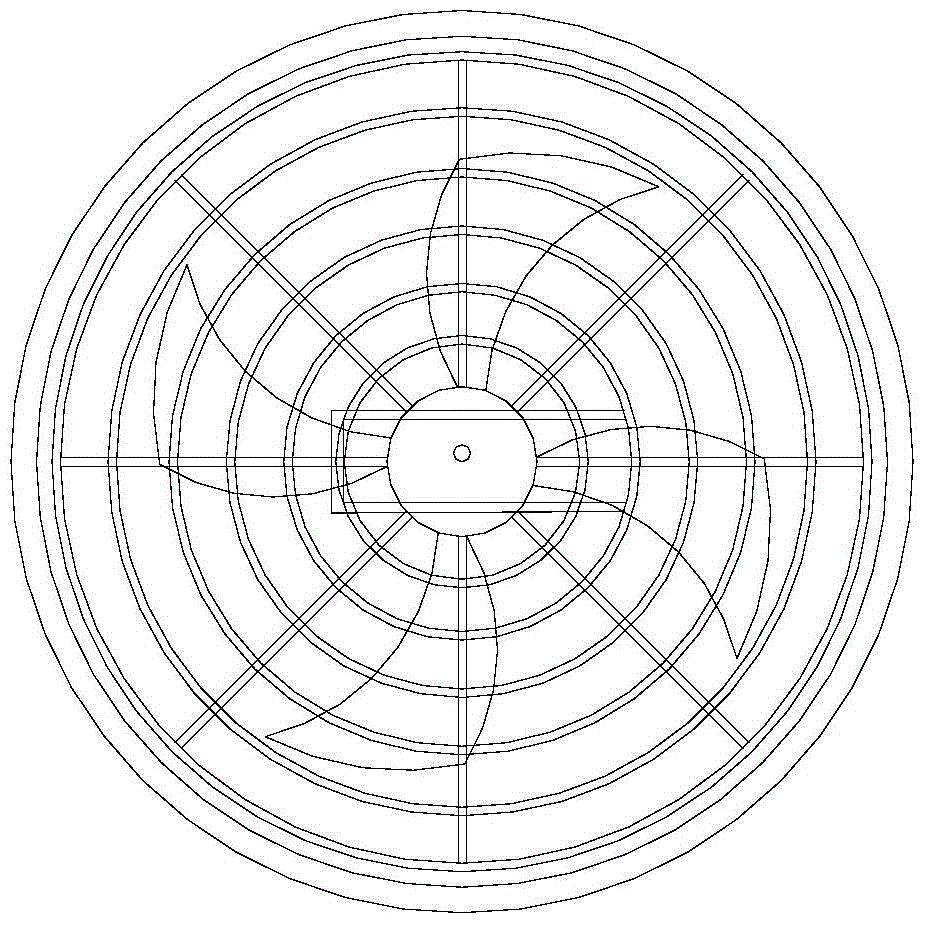

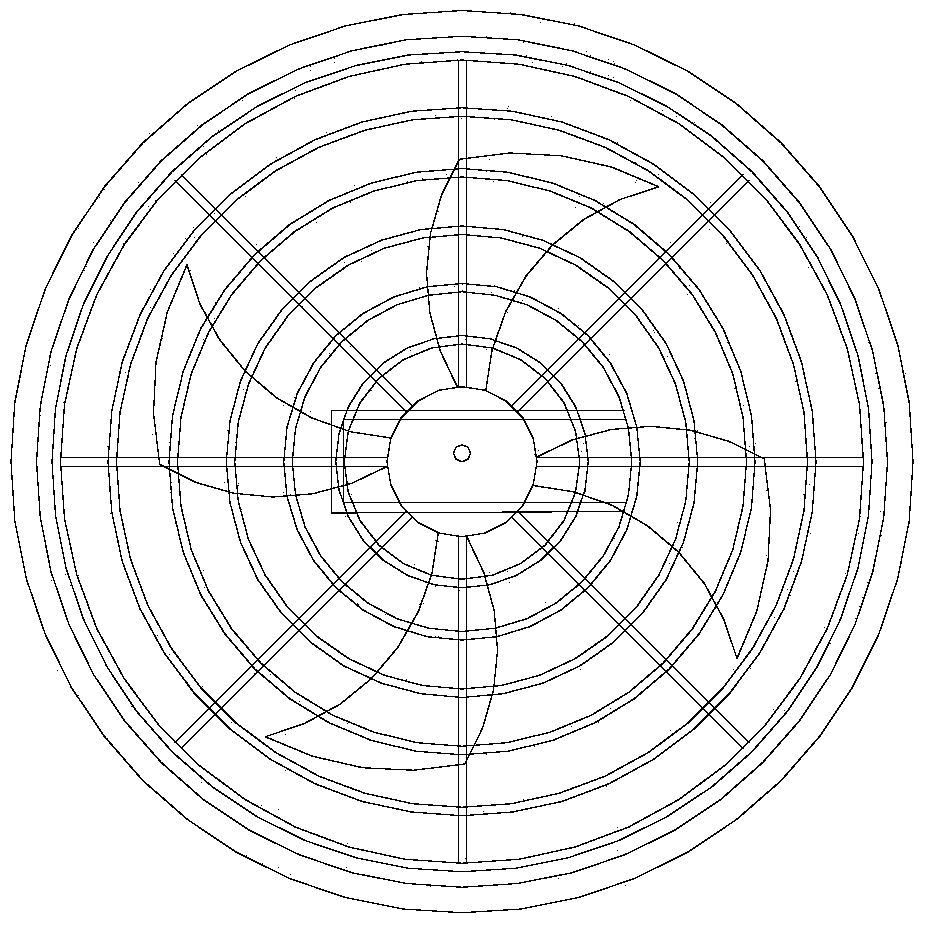

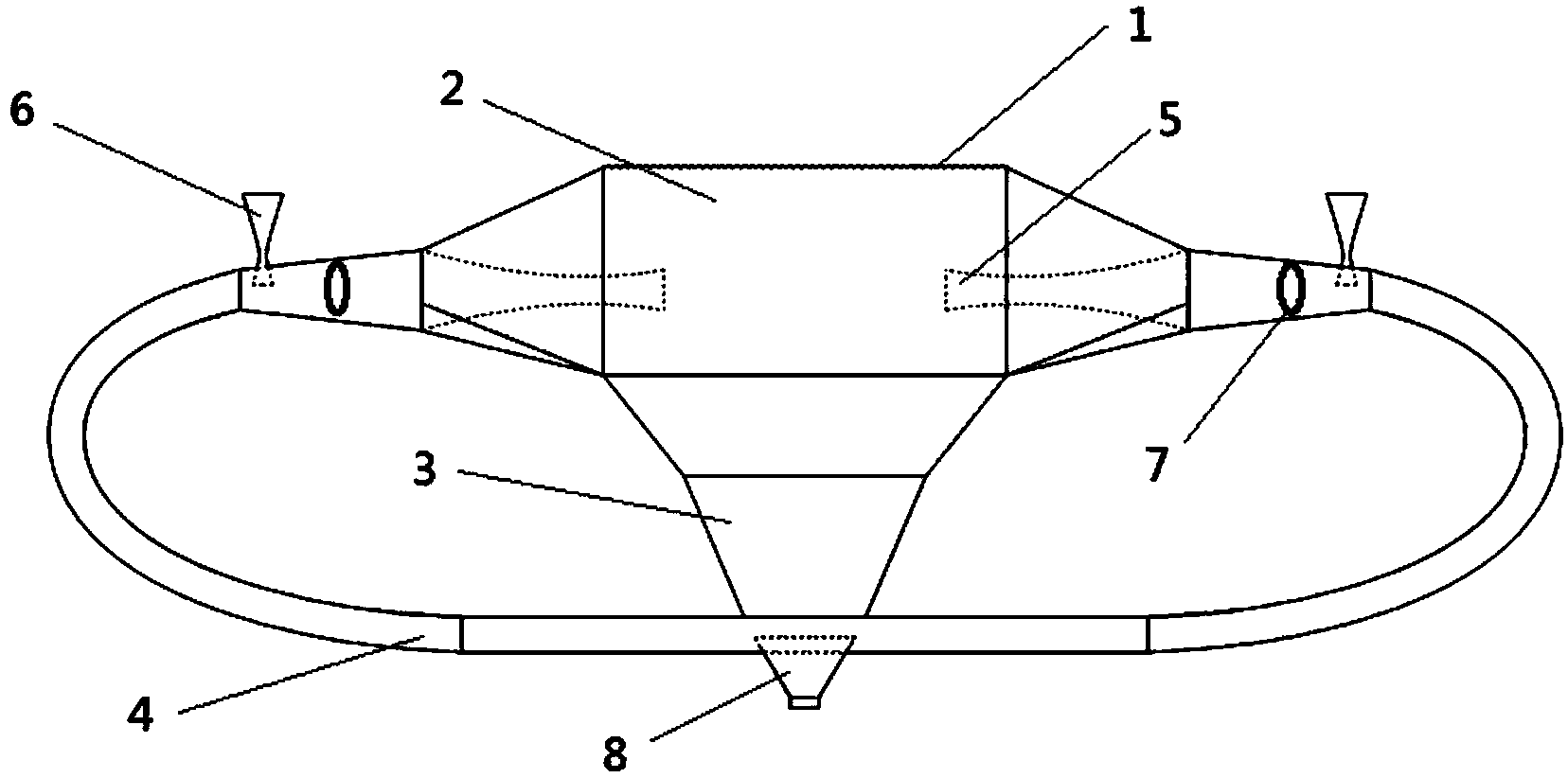

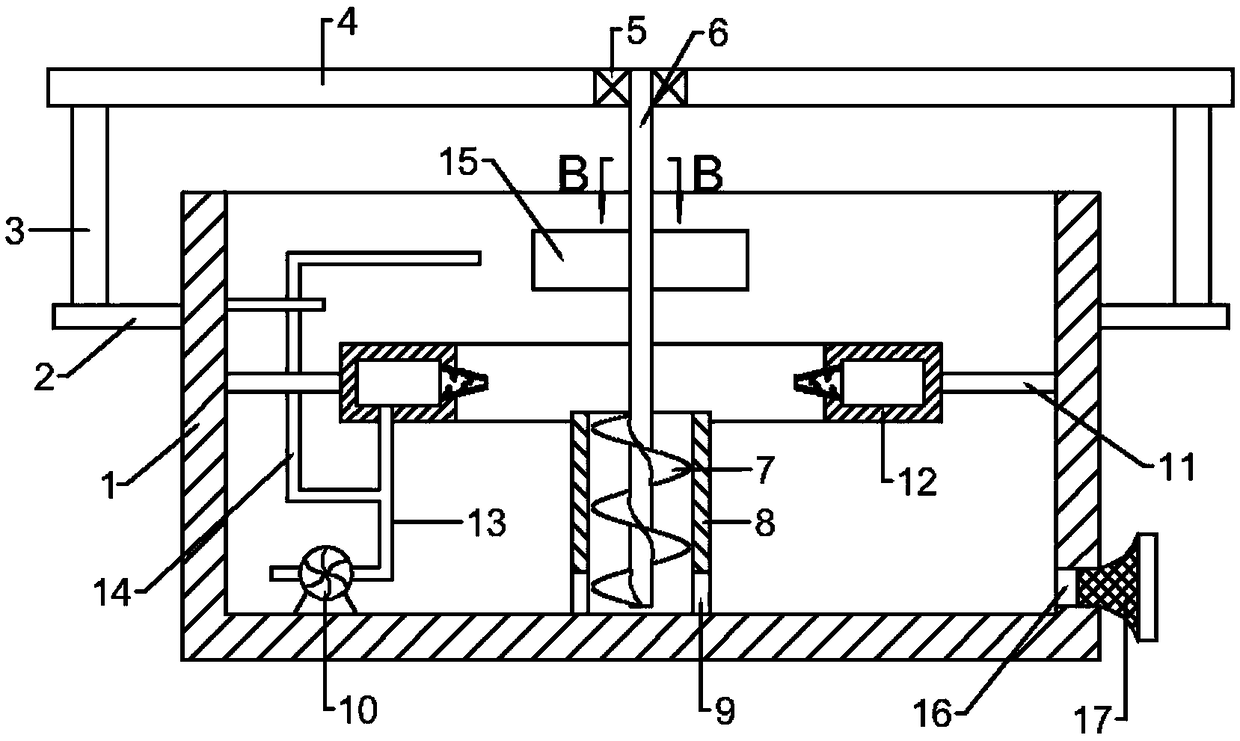

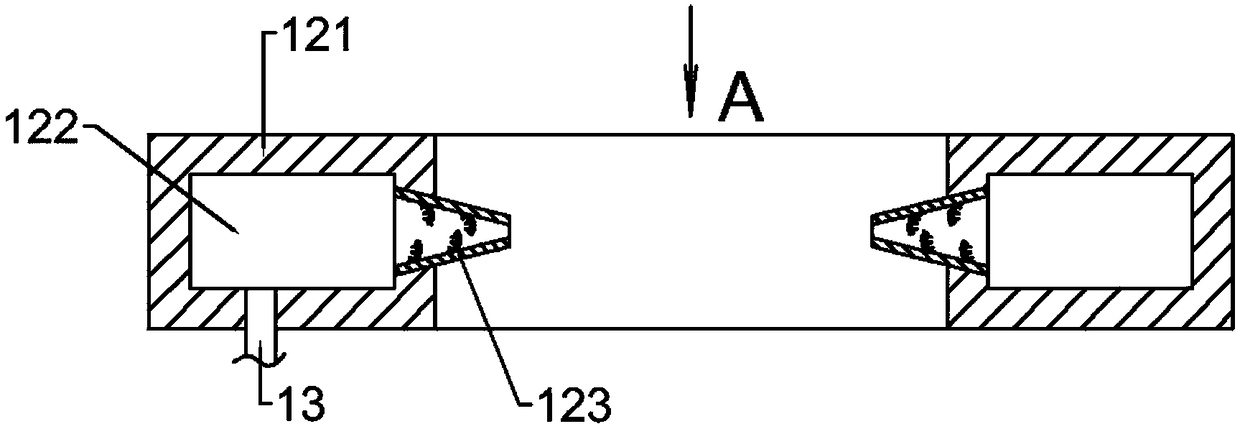

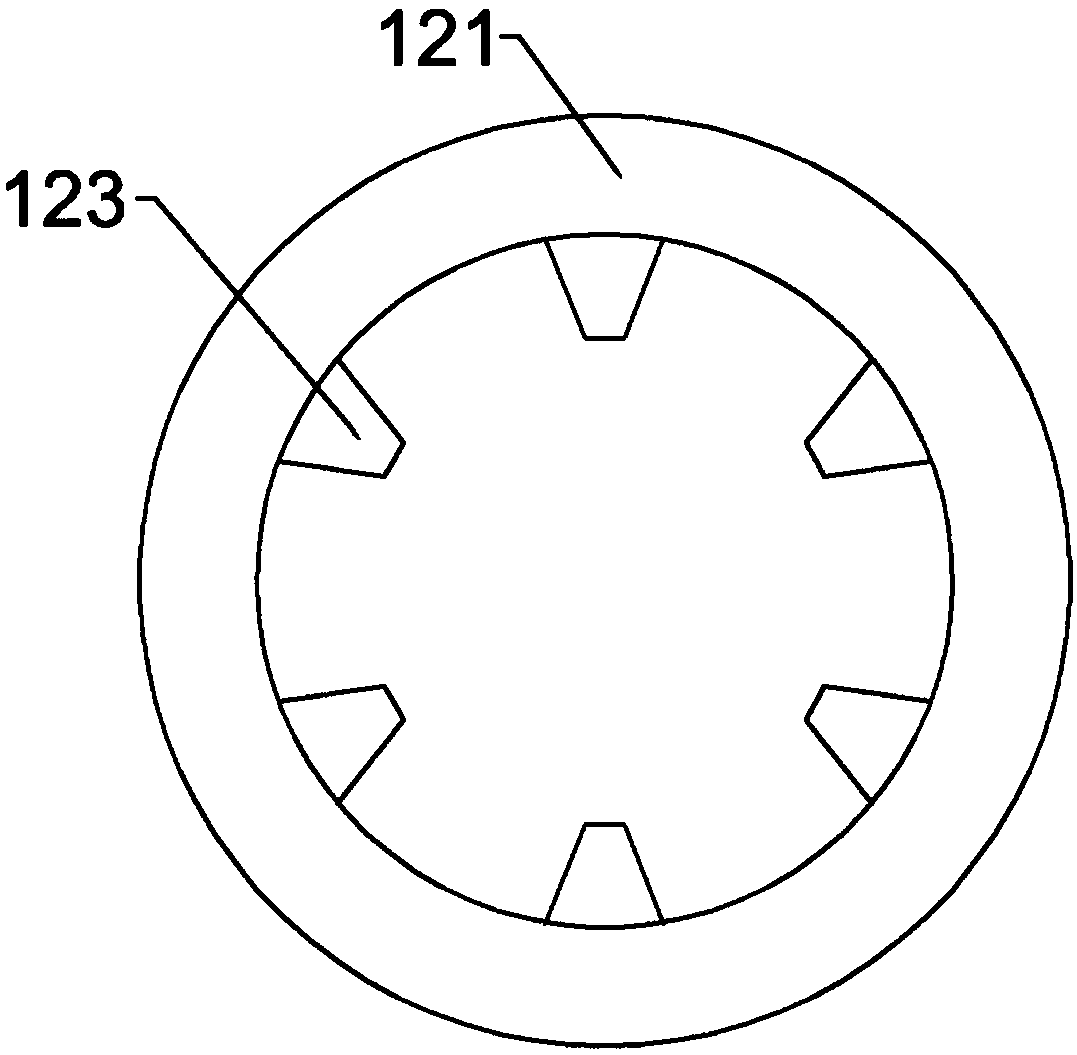

Circular convective mixing principle-based sewage treatment equipment

InactiveCN109160587AEvenly arrangedGood flocculation effectWater/sewage treatment by flocculation/precipitationWater/sewage treatment apparatusFlocculationEngineering

The invention relates to the technical field of sewage treatment, in particular to circular convective mixing principle-based sewage treatment equipment. The equipment comprises a pool body; two mounting seats are symmetrically and fixedly connected with the outer side wall of the pool body; support columns are fixedly connected with the upper sides of the mounting seats; the top ends of the two support columns are fixedly connected with a support plate; a bearing is embedded in the middle of the support plate; the inner ring of the bearing is fixedly connected with a rotation shaft; the rotation shaft extends into the pool body; a spiral auger is arranged at the lower part of the rotation shaft; the spiral auger is sleeved by a sleeve; the bottom end of the sleeve is fixedly connected with the inner bottom of the pool body; a plurality of through holes are uniformly formed in the bottom of the sleeve. The equipment has the beneficial effects that a high-pressure pump pumps sewage intoa circular cavity through a first pipeline, and the sewage is uniformly sprayed out through a water outlet device and carries out convection in the middle of a convective device to ensure that the sewage and a flocculating agent form effective convective mixing treatment, so that the sewage flocculation effect is improved.

Owner:霸州市辉月网络技术有限公司

Multi-port separation apparatus and method

InactiveCN1468138AImprove abilitiesFast separationElectrostatic separationDispersed particle separationElectrophoresisEngineering

Multi-port electrophoresis apparatus comprising: (a) cathode chamber with inlet and outlet means defining an anolyte flow path; (b) anode chamber with inlet and outlet means defining an anolyte flow path, to generate an electric field; (c) at least one electrolyte reservoir in fluid communication with the cathode and anode chambers; (d) means adapted for communicating electrolyte between the lectrolyte reservoir and the cathode and the anode chambers; (e) at least three separation chambers adjacently disposed between the cathode and the anode chambers, the separation chambers formed by a plurality of ion-permeable barriers, adapted to impede convective mixing of contents of adjacent chambers; (f) inlet and outlet means for communicating liquid into and out of the separation chambers; (g) at least one sample reservoir, wherein each sample reservoir is connected with at least one separation chamber; and (h) means for communicating fluids between a sample reservoir and at least one separation chamber.

Owner:GRADIPORE +1

Electrophoresis apparatus and method

InactiveUS6923896B2Increase separation speedImprove abilitiesSludge treatmentElectrostatic separationElectrolysisElectrophoresis

An electrophoretic apparatus comprising: a first electrolyte chamber containing a first electrode; a second electrolyte chamber containing a second electrode; a first sample chamber disposed between the first and second electrolyte chambers and proximate to the first electrolyte chamber; a second sample chamber disposed between the first sample chamber and the second electrolyte; three ion-permeable barriers separating the first electrolyte chamber, the first sample chamber, the second sample chamber, and the second electrolyte chamber, respectively, wherein the ion-permeable barriers impede convective mixing of the contents in each of the respective chambers; a first electrolyte reservoir and a second electrolyte reservoir in fluid communication with the first and second electrolyte chambers, respectively; a first sample reservoir and a second sample reservoir in fluid communication with the first and second sample chambers, respectively; means adapted for communicating a first electrolyte and a second electrolyte between the respective electrolyte chambers and reservoirs; means adapted for communicating a first fluid and a second fluid between the respective sample chambers and reservoirs, wherein at least one of the first and second fluid contains at least a sample, wherein application of an electric potential causes migration of at least one component through at least one of the ion-permeable barriers.

Owner:GRADIPORE +1

Mixing stirring system used for cold salt tanks

PendingCN109420447AFull convective mixingImprove job stabilityRotary stirring mixersTransportation and packagingDrive wheelGear wheel

The invention discloses a mixing stirring system used for cold salt tanks. The mixing stirring system used for cold salt tanks comprises a motor, a main driving rod, a first driving wheel, a second driving wheel, a first driven wheel, a second driven wheel, a first driving belt, a second driving belt, a main stirring paddle, a first auxiliary driving rod, a second auxiliary driving rod, and an auxiliary stirring paddle. The mixing stirring system is invented based on improvement of a conventional stirrer; the single motor is used for driving the stirring paddles arranged at different parts ina tank body to stir; the connecting mode of the stirring paddles with the driving rods is capable of providing molten salt in the tank body with a plurality of stirring modes; the three grade gear design of the first driving wheel and the second driving wheel is adopted, so that the motor is capable of realizing stirring at different rotating speed; upward inclined stirring paddles and downward inclined stirring paddles are adopted, so that full convective mixing of molten salt at the upper layer and the lower layer is realized, full uniform mixing of the molten salt at the upper layer and thelower layer in the tank body is realized, molten salt temperature is ensured to be uniform, and it is beneficial for working stability of power generation devices.

Owner:甘肃光热发电有限公司

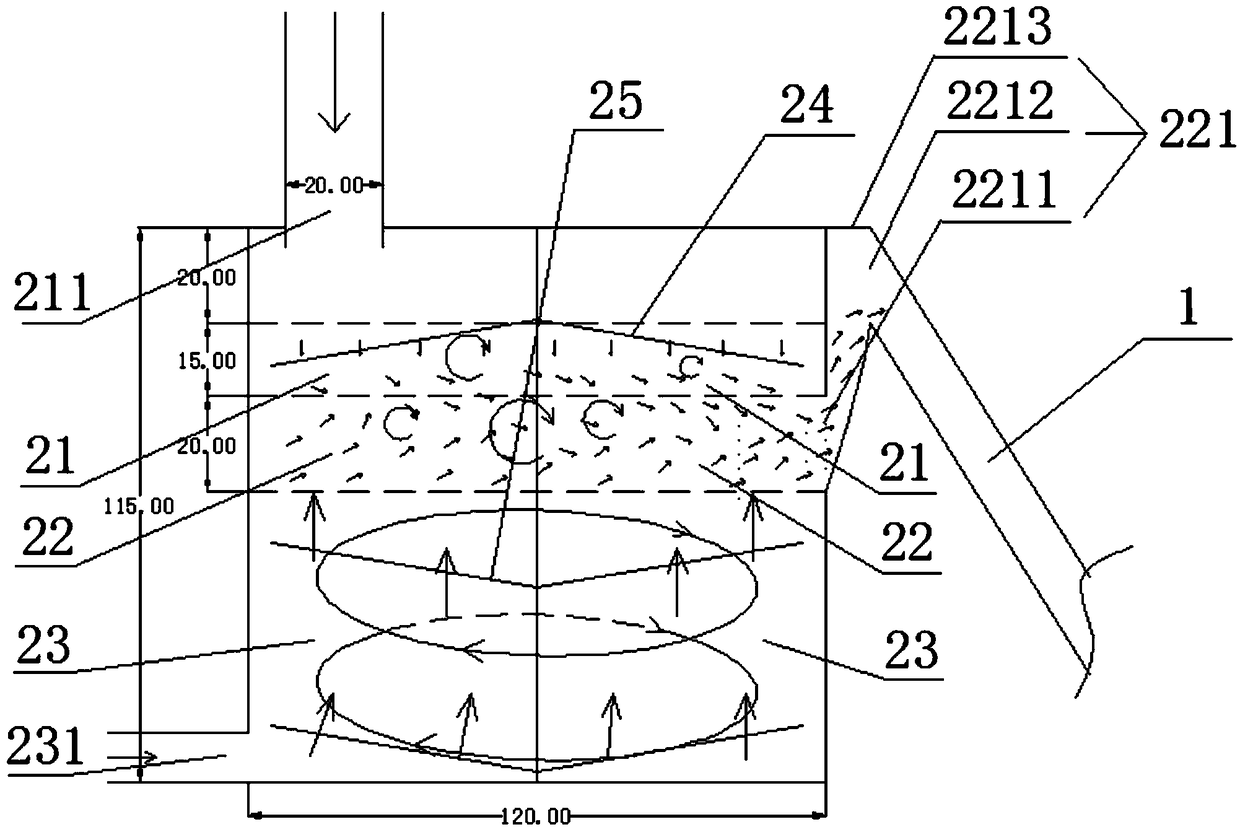

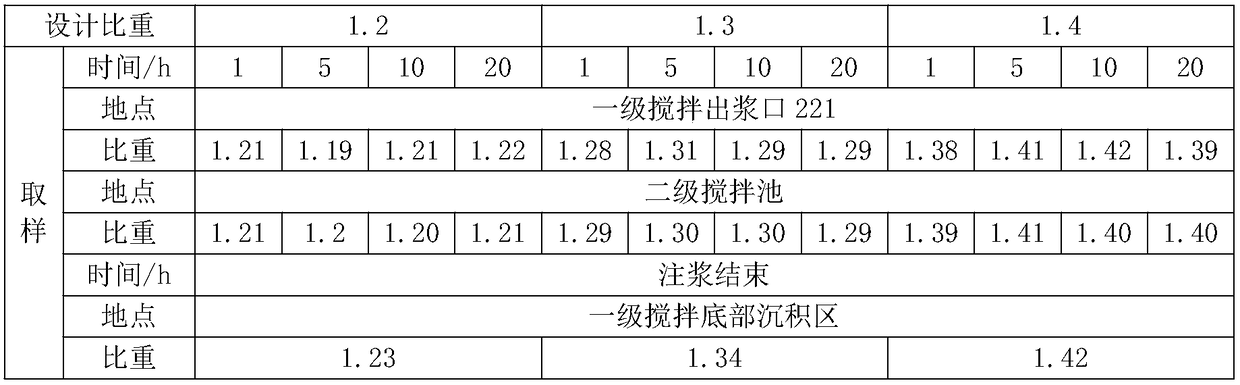

Stirring system

ActiveCN106079070AExquisite structureImprove work efficiencyCement mixing apparatusSlurryEngineering

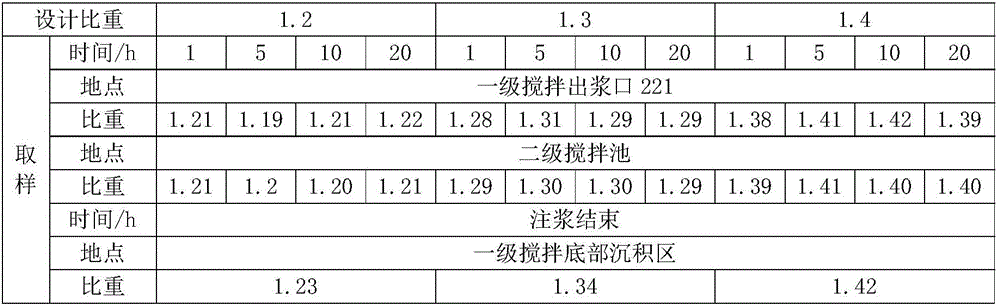

The invention provides a stirring system which comprises a primary stirring device, wherein the primary stirring device comprises a stirring barrel; the stirring barrel is divided into a cement feeding region, a convective mixing region and a water supply region from top to bottom in sequence in a height direction; a cement feeding opening is formed in the top of the cement feeding region; a slurry outlet is formed in the convective mixing region; a water inlet is formed in the water supply region; the water inlet is located on the side wall of the lower end of the stirring barrel; a plurality of groups of stirring fins are arranged in the stirring barrel; rotating shafts of the groups of stirring fins are coaxial; the uppermost group of stirring fins are right-handed spiral fins; the other groups of stirring fins are left-handed spiral fins; the right-handed spiral fins are located in the cement feeding region; and the left-handed spiral fins are located in the water supply region. Compared with the prior art, through the design of the right-handed spiral fins and the left-handed spiral fins in the stirring barrel, the convective mixing region is formed between the right-handed spiral fins and the left-handed spiral fins, and during a rotating process, the right-handed spiral fins accelerate sinking of cement, and the left-handed spiral fins accelerate rising of water, so that deposition of large particles is reduced and a strong convective mixing region is formed near the slurry outlet.

Owner:HUAINAN MINING IND GRP

A Hershaw box and its convective mixing experimental system

ActiveCN106996857BThe experimental system is simpleFacilitate subsequent calculation and analysisHydrodynamic testingTransportation and packagingRotary switchVolumetric Mass Density

The invention develops a Hershaw box and a convection mixing experimental system composed of it. The experiment system includes a CCD camera, a vertical Hershaw box, a surface light source and the like. Vertical Hershaw box, through the rotary switch, the lower fluid space is sealed and filled with low-density fluid, and the upper fluid space is filled with high-density fluid. A CCD camera, a vertical Hershaw box, and a surface light source were placed in a dark box. The rotary switch makes the arc surface of the rotating shaft rotate to the gap between two layers of parallel light-transmitting materials to seal the fluid in the lower layer. Fill the upper part of the Hershaw box with dense fluid. When the switch is turned on, the upper and lower fluids are in contact, and the density difference of the liquid-liquid two-phase fluid causes the convective mixing experiment to start, and at the same time, the CCD camera starts to shoot and record the images of the two-phase liquid convective mixing process. The experimental system is simple, easy to operate, and accurate in timing. It is suitable for follow-up research on characteristic parameters such as phase interface changes, fingering occurrence and development time, and number of fingerings in the convective mixing process.

Owner:DALIAN UNIV OF TECH

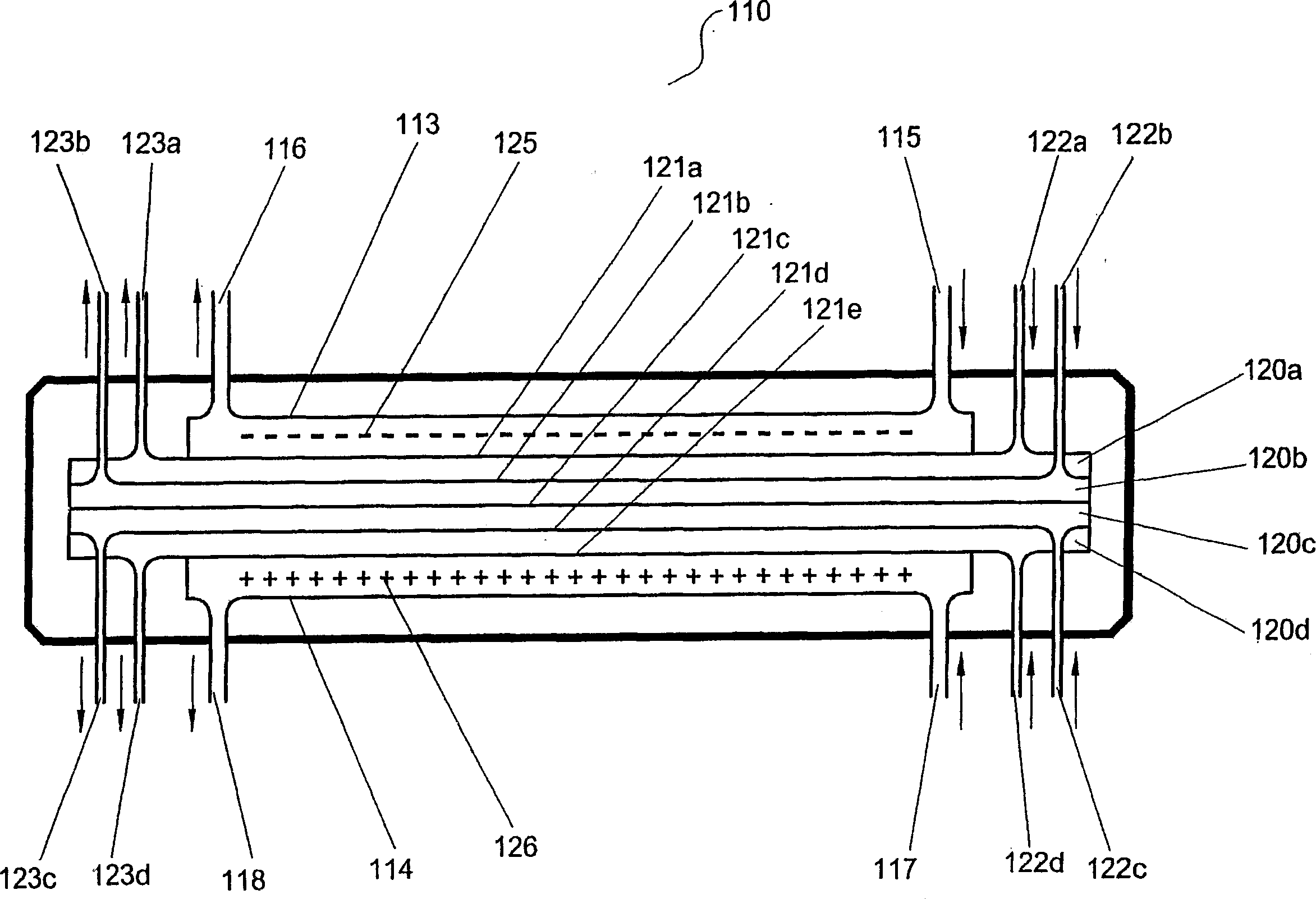

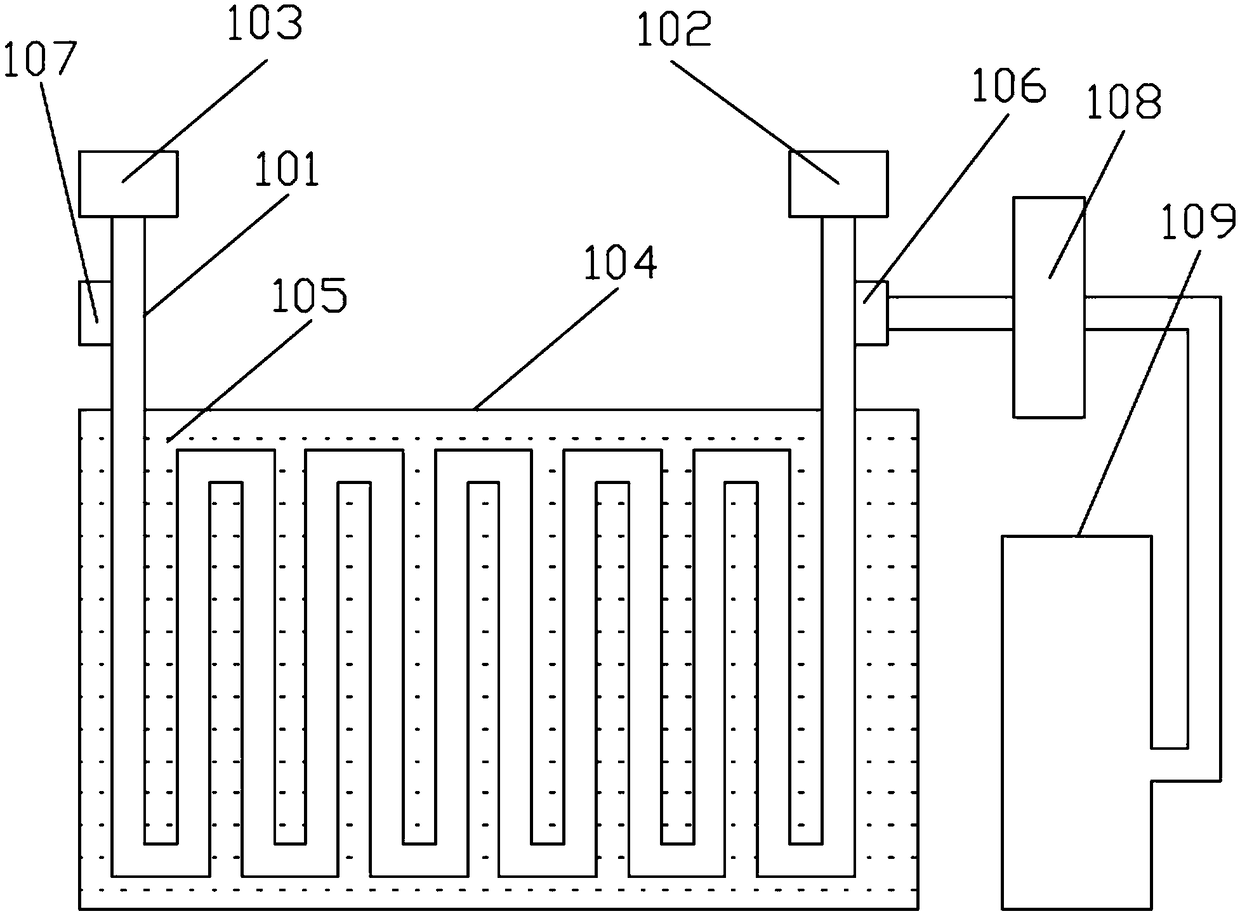

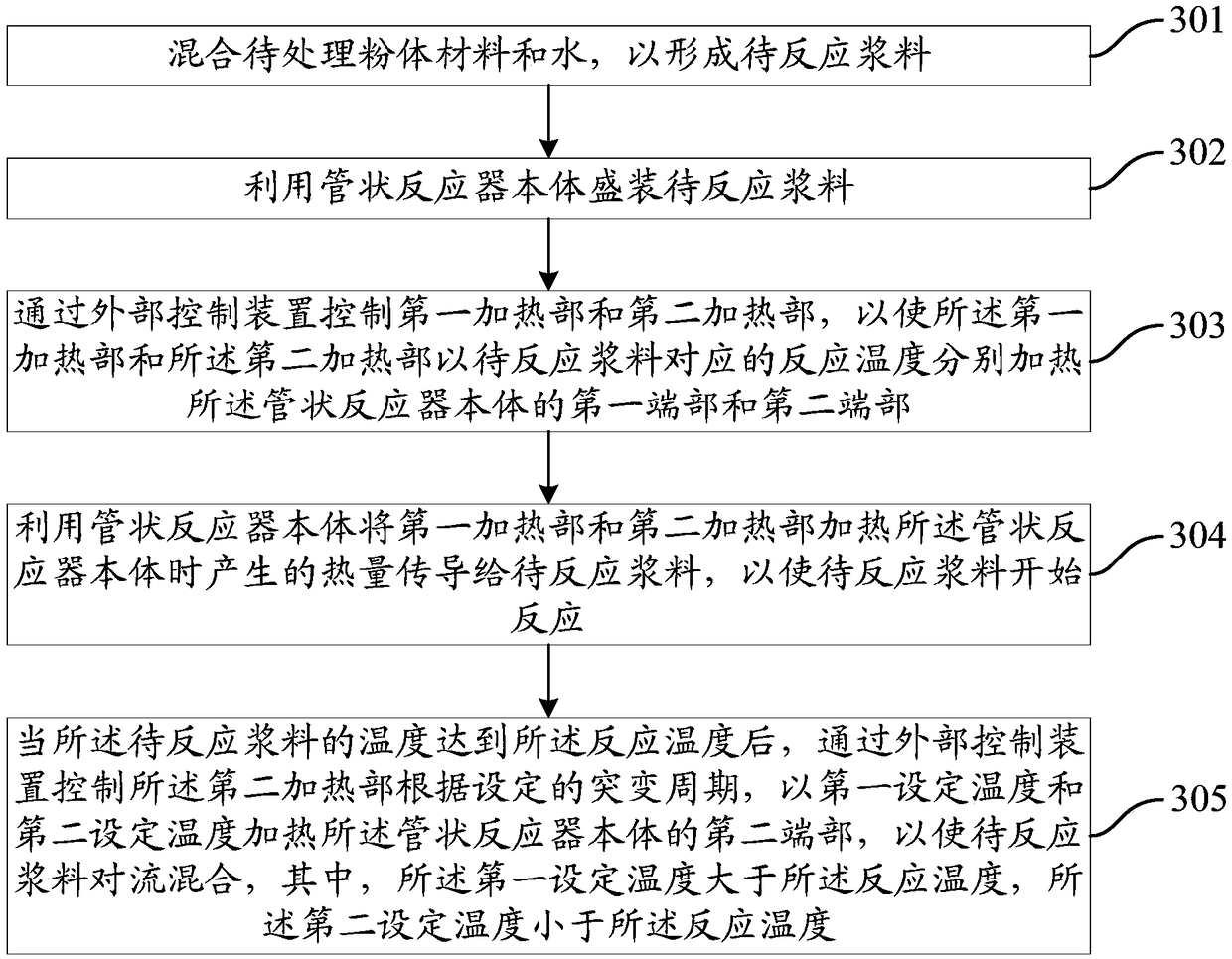

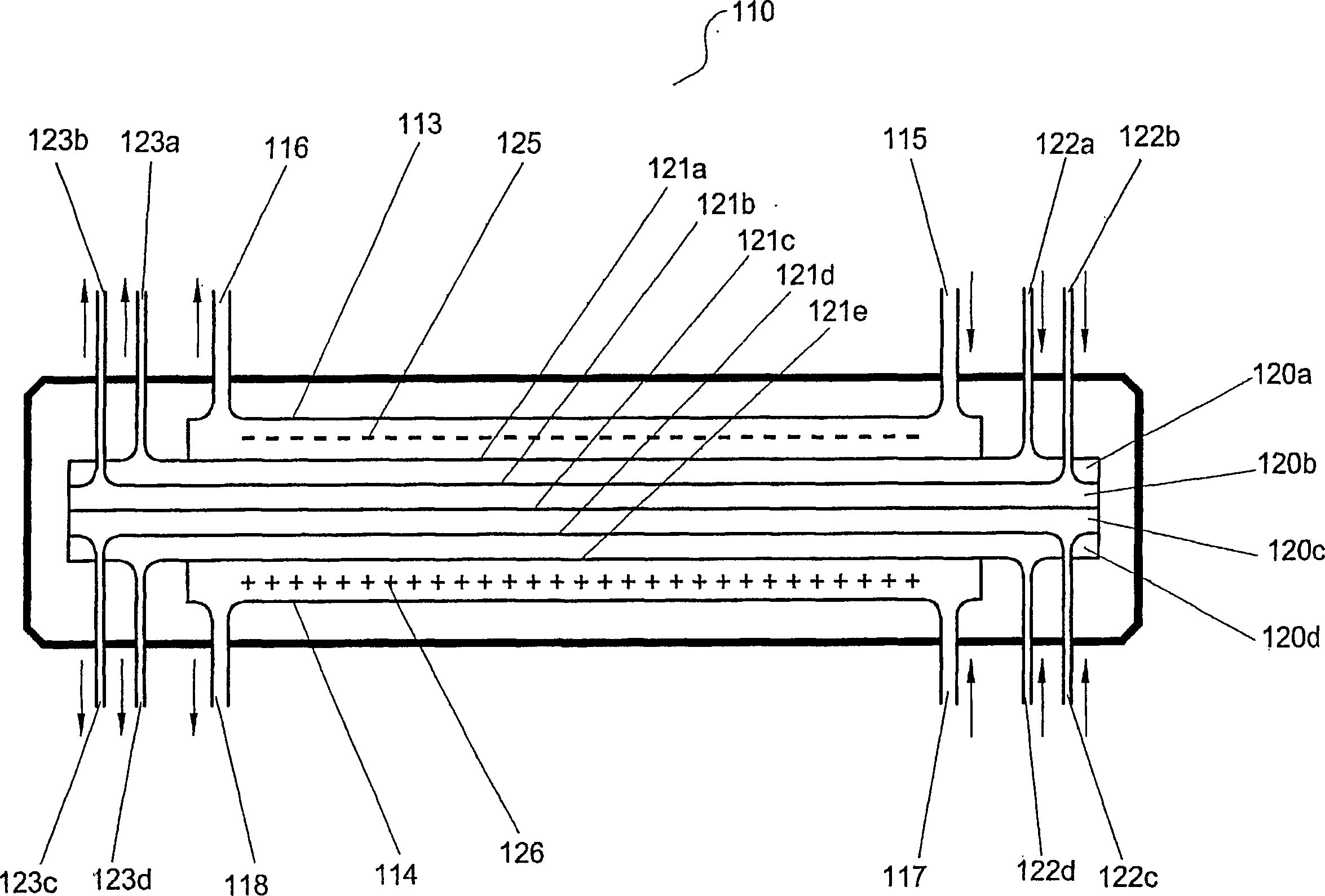

A hydrothermal reaction device and its method and system for processing powder materials

ActiveCN106732310BWell mixedImprove heat transfer performanceChemical/physical/physico-chemical stationary reactorsHeating timeReaction temperature

The invention provides a hydrothermal reaction device as well as a method and a system of treating a powder material thereby. The device comprises a tubular reactor body, a first heating portion and a second heating portion; the first heating portion is controlled by an external control device to heat the first end portion of the tubular reactor body at a reaction temperature corresponding to to-be-reacted slurry; the second heating portion controlled by the control device heats the second end portion of the tubular reactor body at a reaction temperature, and after the to-be-reacted slurry reaches the reaction temperature, the second end port of the tubular reactor body is heated at a first set temperature and a second set temperature according to a set mutant period; and the tubular reactor body conducts heat generated by the heating portions to the inside to-be-reacted slurry thereof so as to enable convective mixing and reacting of the to-be-reacted slurry, wherein the first set temperature is greater than the reaction temperature and the second set temperature is smaller than the reaction temperature. When the hydrothermal reaction device provided by the invention treats the powder material, the heating time can be shortened.

Owner:中清新能源科技发展(海南)有限公司

Multi-port separation apparatus and method

InactiveCN1235667CImprove abilitiesFast separationElectrostatic separationDispersed particle separationElectrophoresisEngineering

Multi-port electrophoresis apparatus comprising: (a) cathode chamber with inlet and outlet means defining an anolyte flow path; (b) anode chamber with inlet and outlet means defining an anolyte flow path, to generate an electric field; (c) at least one electrolyte reservoir in fluid communication with the cathode and anode chambers; (d) means adapted for communicating electrolyte between the lectrolyte reservoir and the cathode and the anode chambers; (e) at least three separation chambers adjacently disposed between the cathode and the anode chambers, the separation chambers formed by a plurality of ion-permeable barriers, adapted to impede convective mixing of contents of adjacent chambers; (f) inlet and outlet means for communicating liquid into and out of the separation chambers; (g) at least one sample reservoir, wherein each sample reservoir is connected with at least one separation chamber; and (h) means for communicating fluids between a sample reservoir and at least one separation chamber.

Owner:GRADIPORE +1

a mixing system

The invention provides a stirring system which comprises a primary stirring device, wherein the primary stirring device comprises a stirring barrel; the stirring barrel is divided into a cement feeding region, a convective mixing region and a water supply region from top to bottom in sequence in a height direction; a cement feeding opening is formed in the top of the cement feeding region; a slurry outlet is formed in the convective mixing region; a water inlet is formed in the water supply region; the water inlet is located on the side wall of the lower end of the stirring barrel; a plurality of groups of stirring fins are arranged in the stirring barrel; rotating shafts of the groups of stirring fins are coaxial; the uppermost group of stirring fins are right-handed spiral fins; the other groups of stirring fins are left-handed spiral fins; the right-handed spiral fins are located in the cement feeding region; and the left-handed spiral fins are located in the water supply region. Compared with the prior art, through the design of the right-handed spiral fins and the left-handed spiral fins in the stirring barrel, the convective mixing region is formed between the right-handed spiral fins and the left-handed spiral fins, and during a rotating process, the right-handed spiral fins accelerate sinking of cement, and the left-handed spiral fins accelerate rising of water, so that deposition of large particles is reduced and a strong convective mixing region is formed near the slurry outlet.

Owner:HUAINAN MINING IND GRP

Method and apparatus for blending process materials

ActiveUS8746960B2Improve mixing efficiencyReduce system costFlow mixersTransportation and packagingEngineeringImproved method

An improved method and apparatus for blending process materials. Preferred embodiments of the present invention are directed to a process material contacting system to increase wetted surface area for liquid contact as well as increase forced convective mixing efficiency of the liquid mixture. Use of a novel process material contacting apparatus allows one solid feeding element to serve multiple process material tanks, thus reducing overall system costs and decreasing set-up time / process variability while increasing operational efficiency. According to a preferred embodiment of the present invention, rather than adding a process material to a volume of liquid held in a blending tank, the added process material is remotely blended with the liquid outside the process material tank.

Owner:MEGA FLUID SYST

Method and apparatus for blending process materials

ActiveUS20140098628A1Improve mixing efficiencyReduce system costFlow mixersTransportation and packagingProcess engineeringEngineering

An improved method and apparatus for blending process materials. Preferred embodiments of the present invention are directed to a process material contacting system to increase wetted surface area for liquid contact as well as increase forced convective mixing efficiency of the liquid mixture. Use of a novel process material contacting apparatus allows one solid feeding element to serve multiple process material tanks, thus reducing overall system costs and decreasing set-up time / process variability while increasing operational efficiency. According to a preferred embodiment of the present invention, rather than adding a process material to a volume of liquid held in a blending tank, the added process material is remotely blended with the liquid outside the process material tank.

Owner:MEGA FLUID SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com