Improved Hele-Shaw box and two-phase fluid density difference convective mixing experimental system formed by improved Hele-Shaw box

A Hershaw box and experimental system technology, which is applied in the field of two-phase fluid density difference convection mixing experimental system, can solve difficult measurement problems, and achieve the effects of convenient operation, simple experimental system, and convenient visual observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] Choose 0.5mol / L NaCl solution as the high-density solution, and deionized water as the low-density solution. Because the two fluids belong to the same color, bromocresol green is selected as the dyeing agent, and 0.001g of bromocresol green is added to the NaCl solution for dyeing to distinguish the two-phase fluid. Carry out the experiment of convective mixing caused by density difference of liquid-liquid two-phase fluid.

[0025] The above liquid-liquid two-phase fluid density difference causes convective mixing method comprising the following steps:

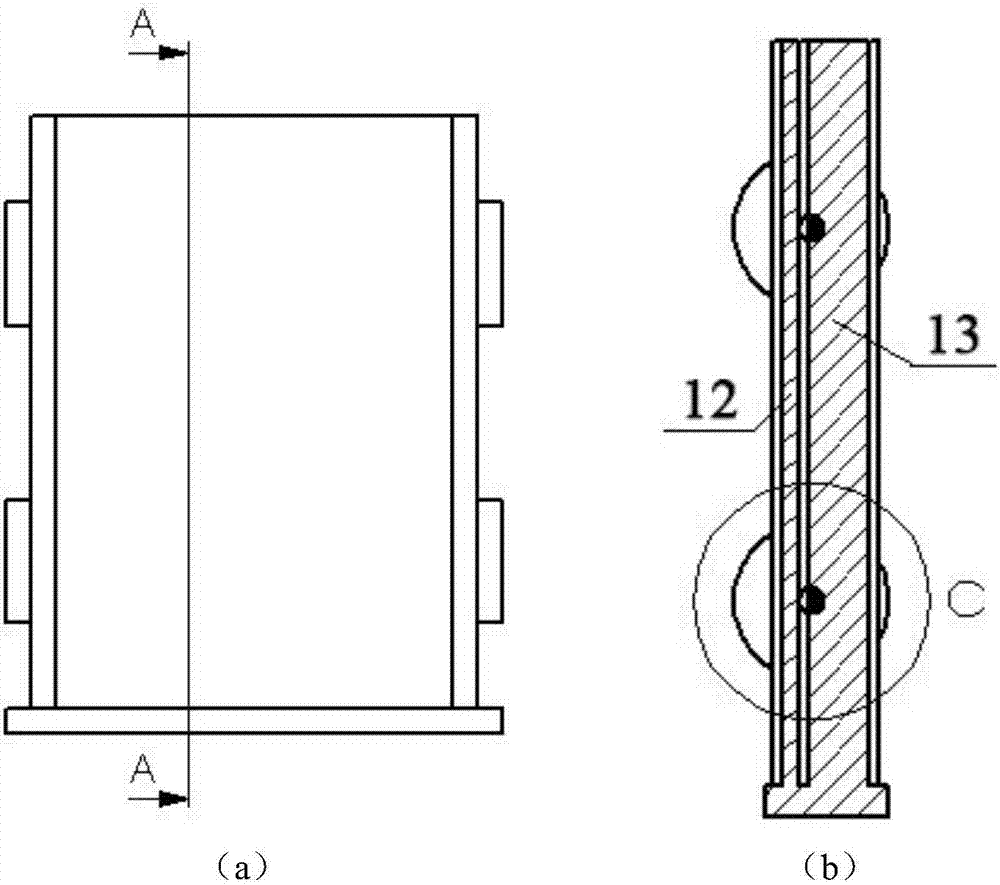

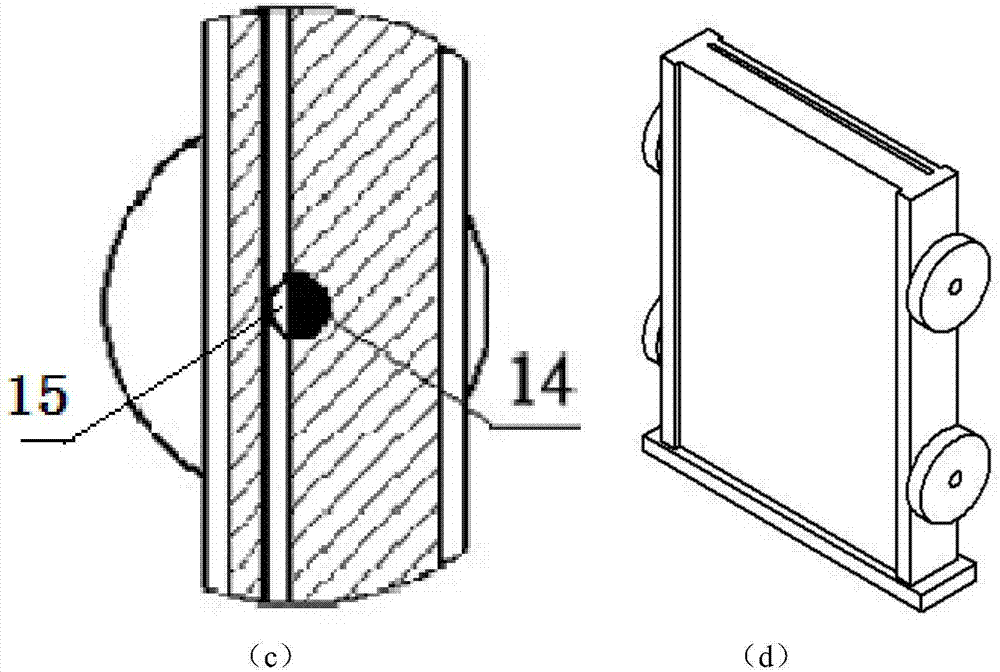

[0026] (1) Fill the lower part of the Hershaw box with deionized water, and turn the switch so that the arc surface of the shaft rotates to the gap between two layers of parallel light-transmitting materials to seal the fluid in the lower layer. Fill the upper part of the Hershaw box with the NaCl solution plus the dye.

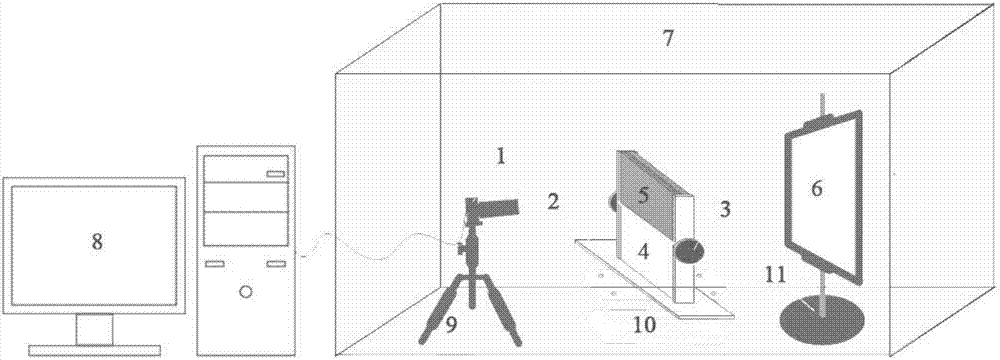

[0027] (2) Place the CCD camera, the Hershaw box filled with upper and lower layers of fluid, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com