Simulator for measuring lubricating oil film thickness of cylinder of internal combustion engine by TDLAS technology

A technology for internal combustion engine cylinders and lubricating oil films, applied to measuring devices, optical devices, instruments, etc., can solve problems such as difficulty in ensuring the accuracy of measurement results, improve the limited pressure rise in cylinders, reduce costs and processing difficulties, and simplify The effect of the experimental system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

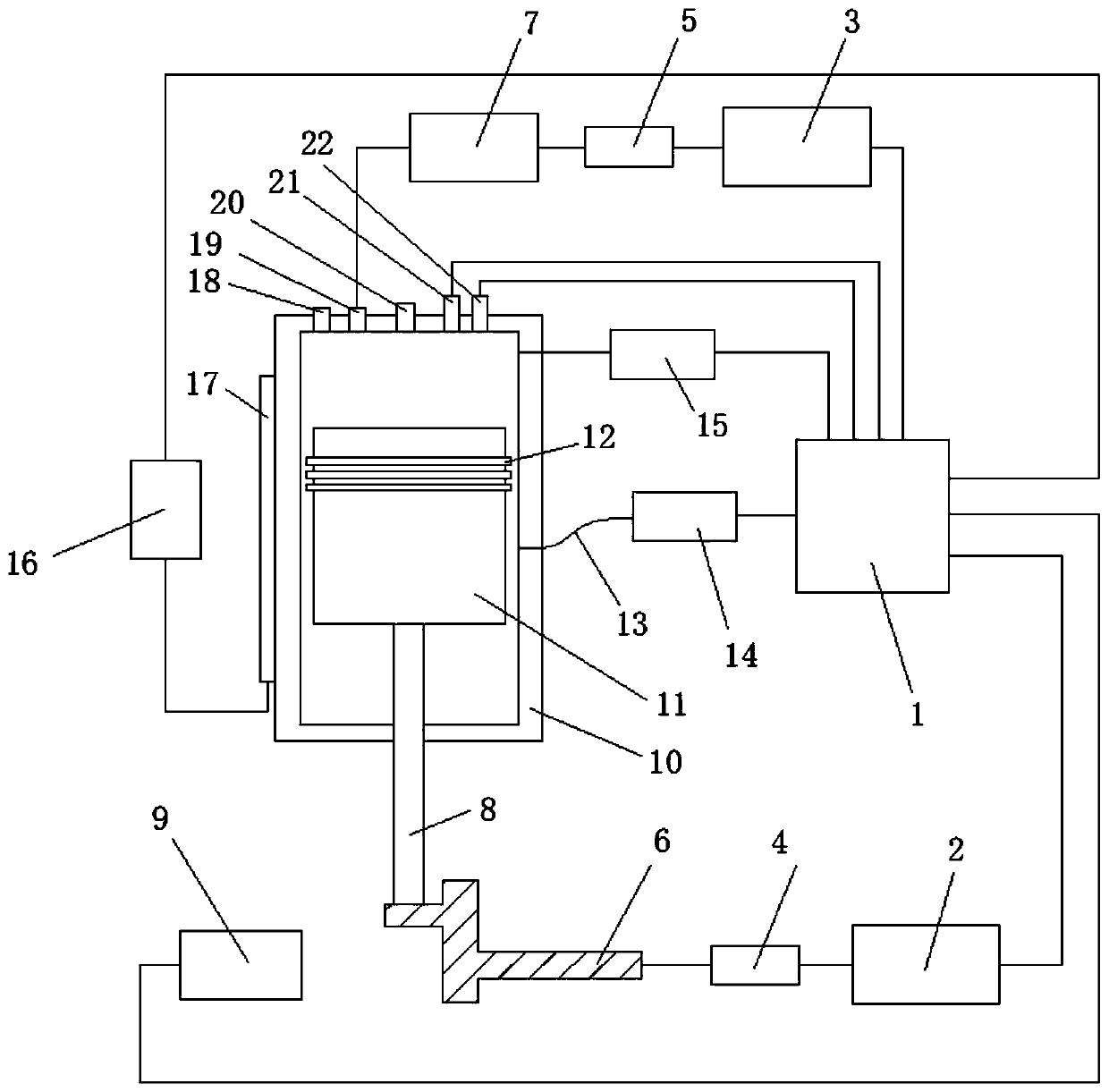

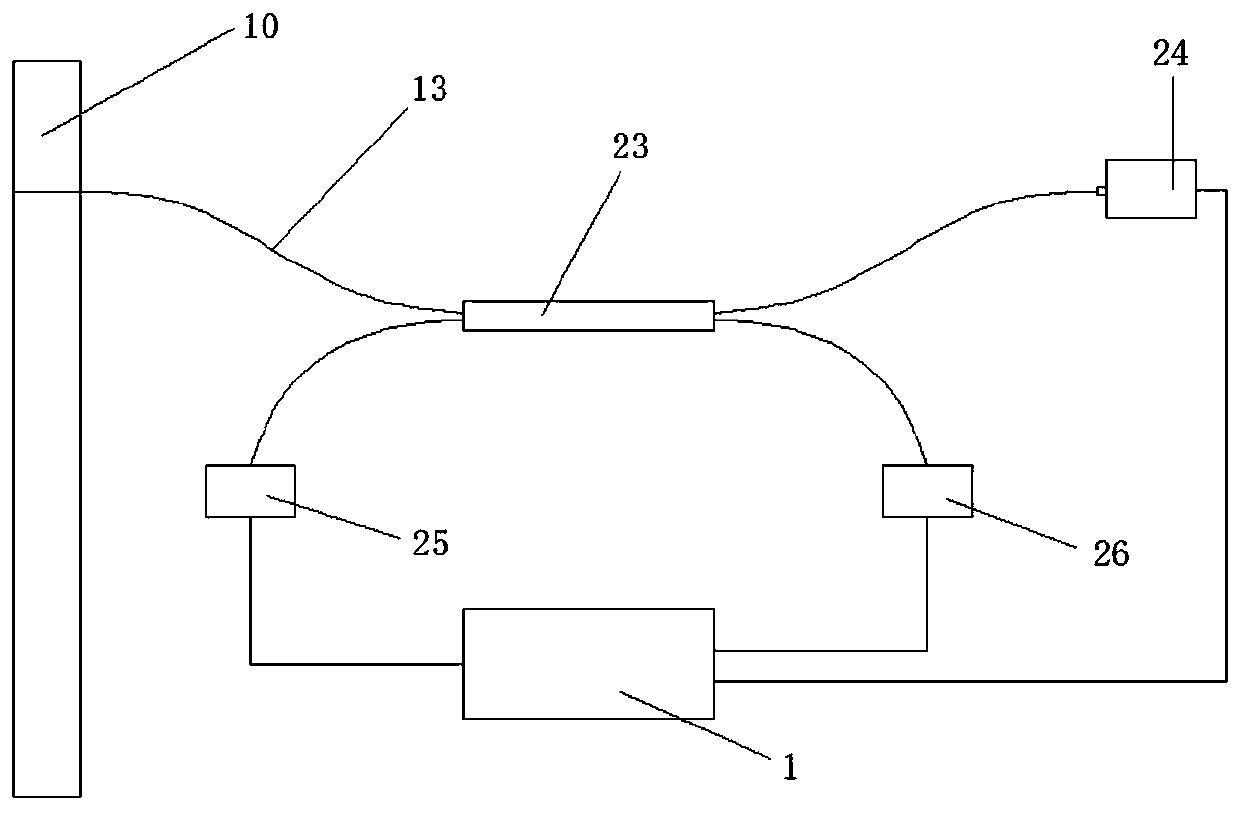

[0026] Specific implementation mode one: combine figure 1 To illustrate this embodiment, the TDLAS technology described in this embodiment measures the internal combustion engine cylinder lubricating oil film thickness simulation device including an internal combustion engine cylinder, a tunable laser 24, a fiber coupler 23, a first laser detector 25, a second laser detector 26 and a computer System 1;

[0027] Described fiber coupler 23 comprises four ports, and the laser light that tunable laser 24 produces enters fiber coupler 23 through No. 1 port, is divided into two identical laser beams through fiber coupler 23, and one of them is emitted through No. 2 end, and From the second laser detector 26, another beam is emitted through the No. 3 port. The No. 3 port is embedded in the cylinder wall of the internal combustion engine cylinder, and the laser emitted from the No. 3 port is irradiated on the lubricating oil film in the internal combustion engine cylinder. The oil fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com