Patents

Literature

187 results about "Variable-geometry turbocharger" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Variable-geometry turbochargers (VGTs), (also known as variable nozzle turbines/VNTs), are a family of turbochargers, usually designed to allow the effective aspect ratio (A:R) of the turbo to be altered as conditions change. This is done because optimum aspect ratio at low engine speeds is very different from that at high engine speeds. If the aspect ratio is too large, the turbo will fail to create boost at low speeds; if the aspect ratio is too small, the turbo will choke the engine at high speeds, leading to high exhaust manifold pressures, high pumping losses, and ultimately lower power output. By altering the geometry of the turbine housing as the engine accelerates, the turbo's aspect ratio can be maintained at its optimum. Because of this, VGTs have a minimal amount of lag, have a low boost threshold, and are very efficient at higher engine speeds. VGTs do not require a wastegate.

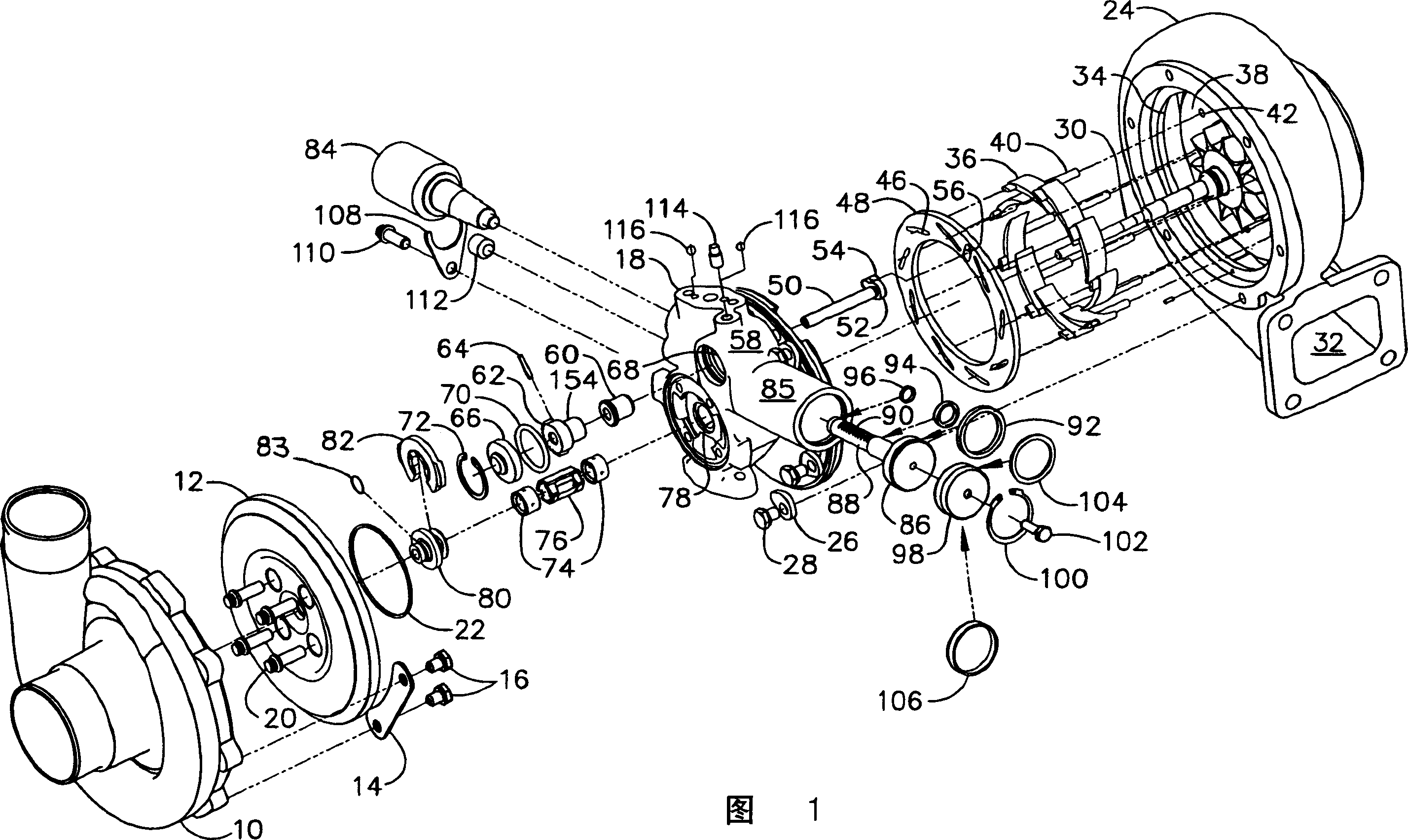

Variable geometry turbocharger

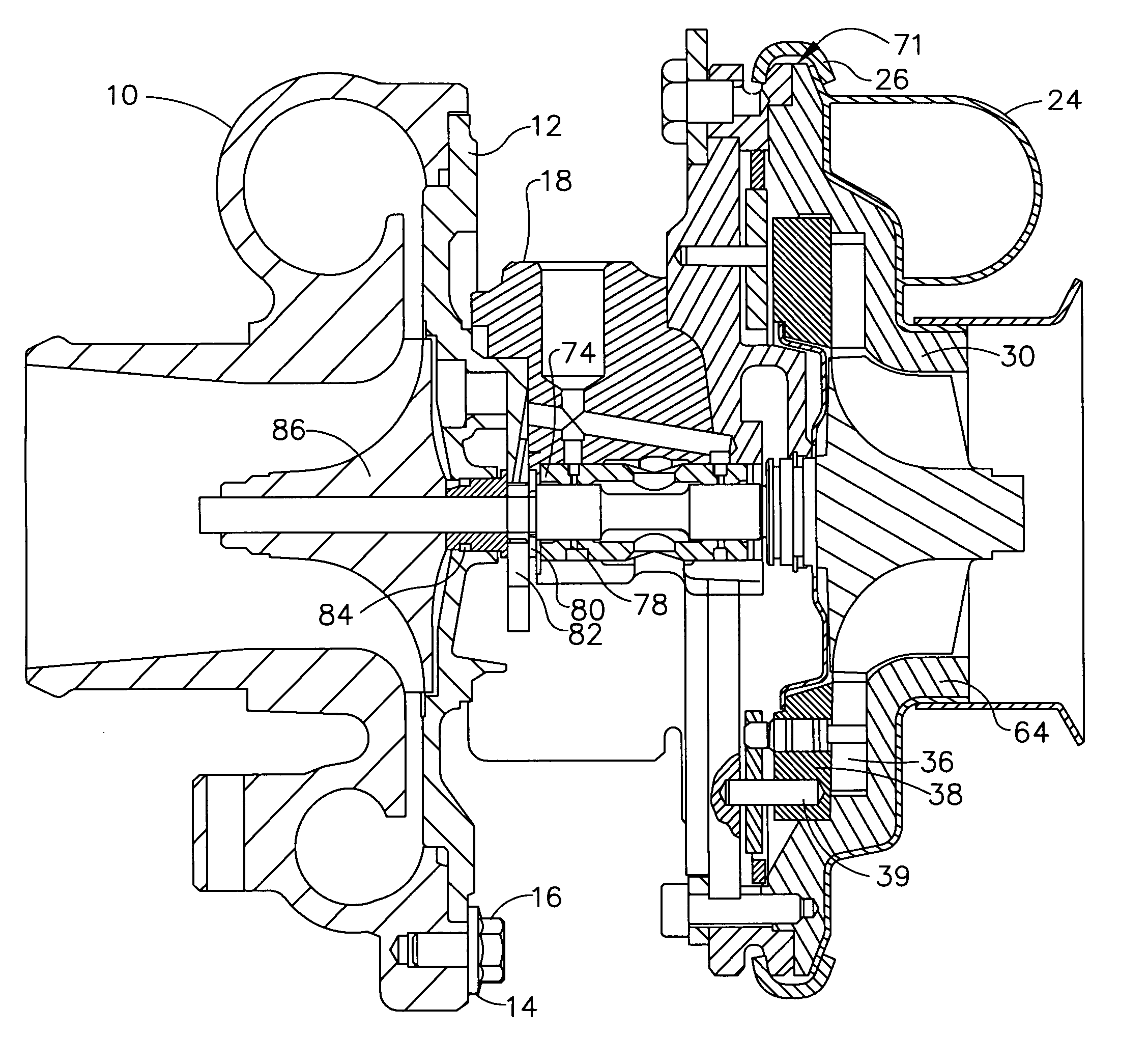

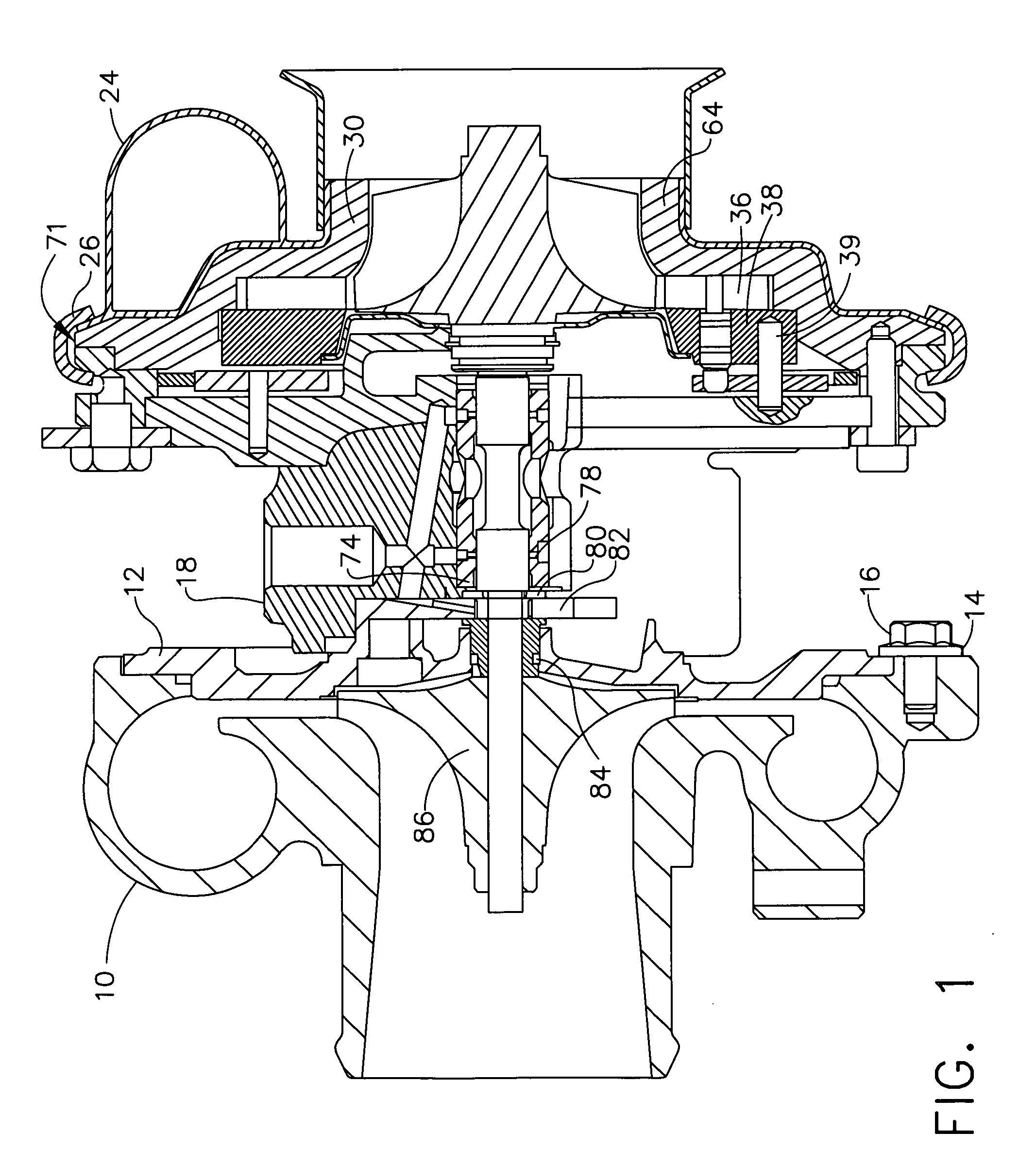

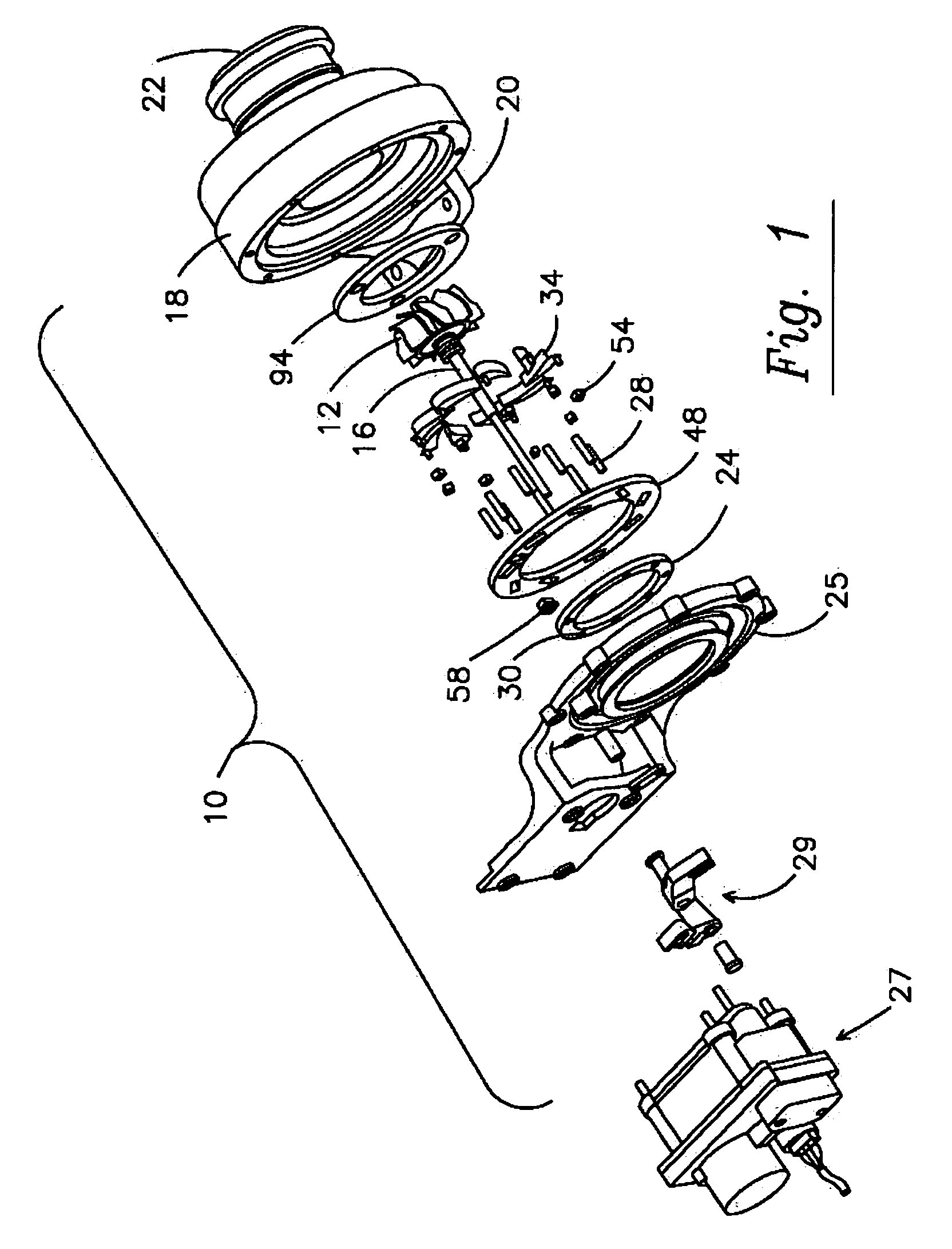

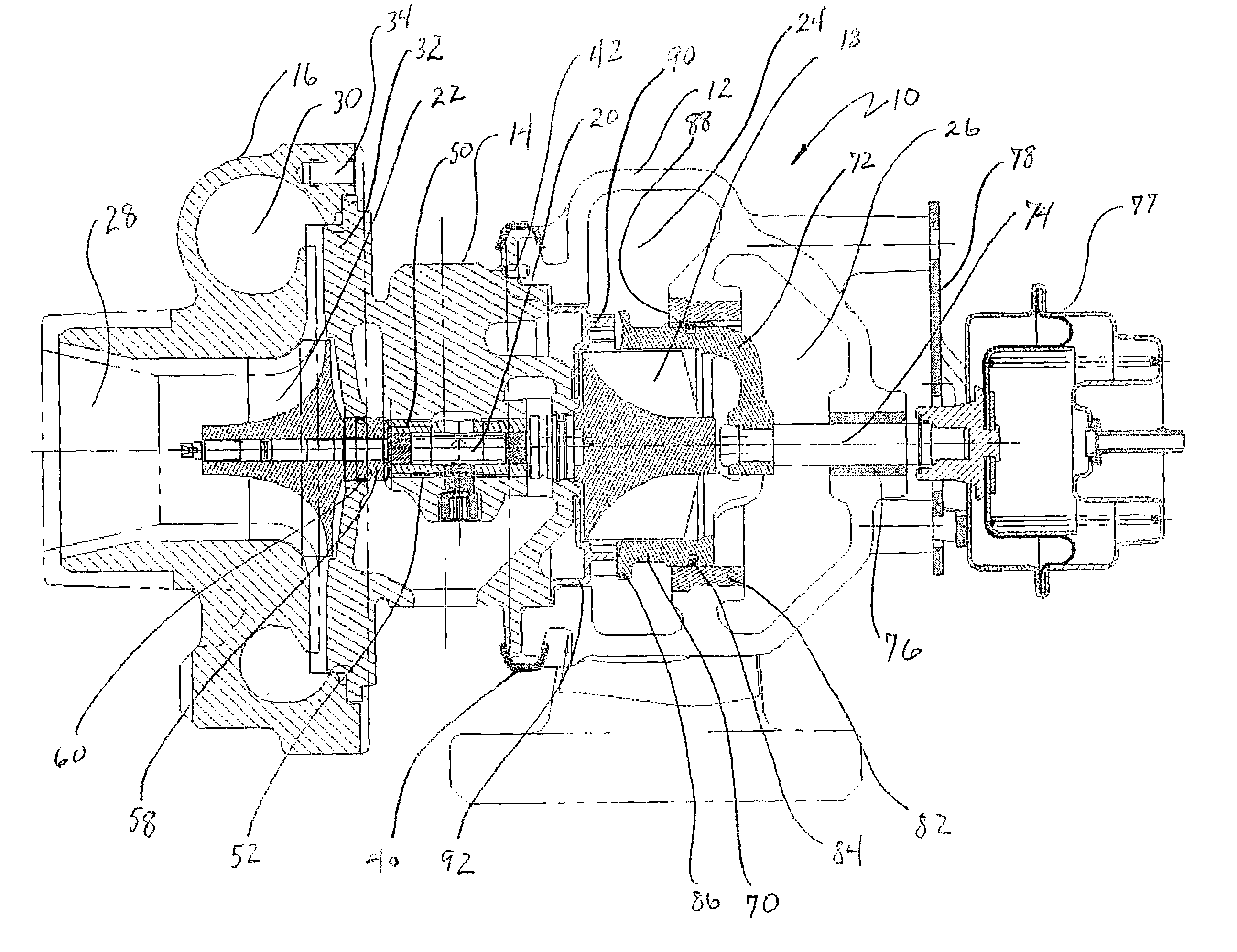

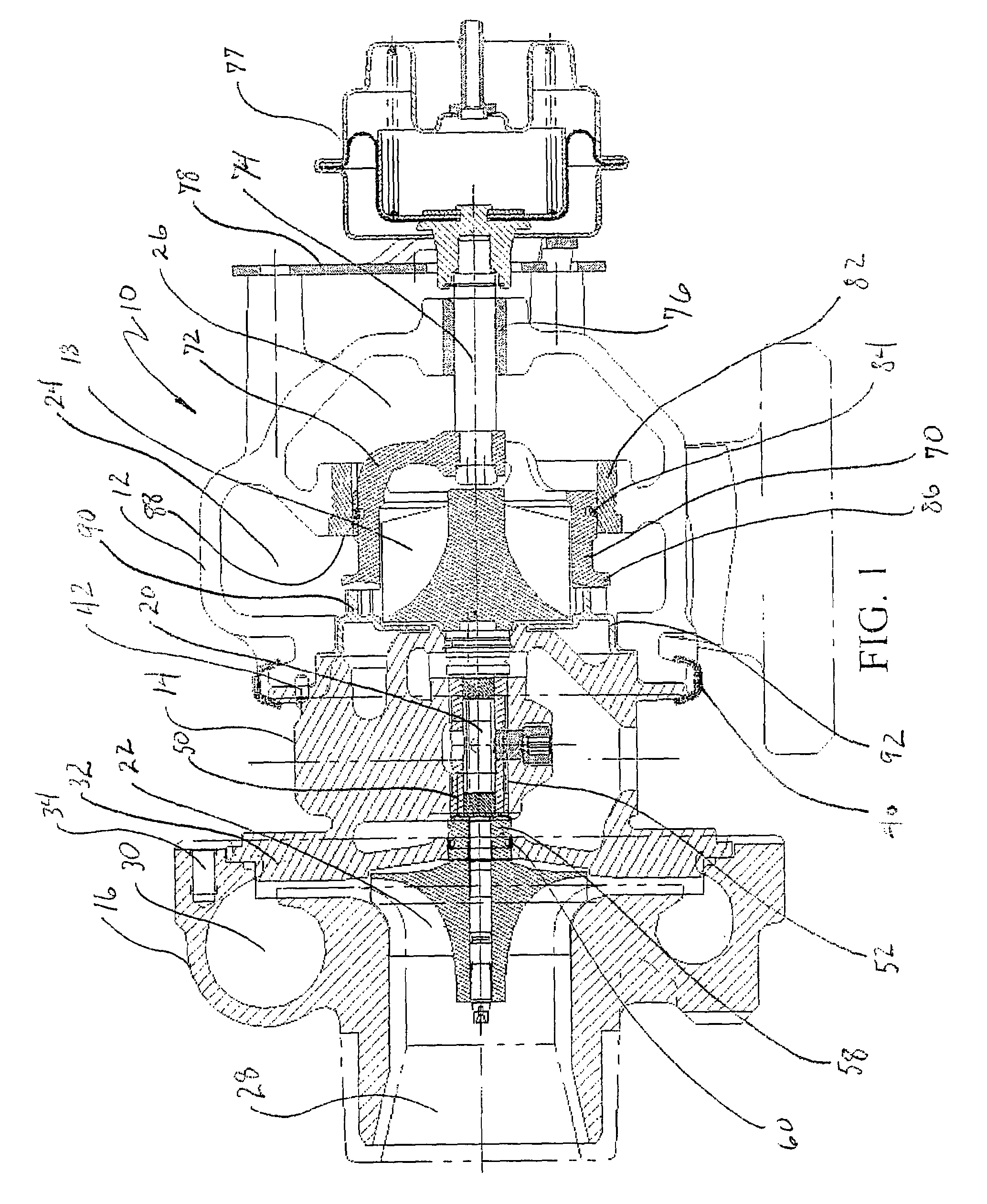

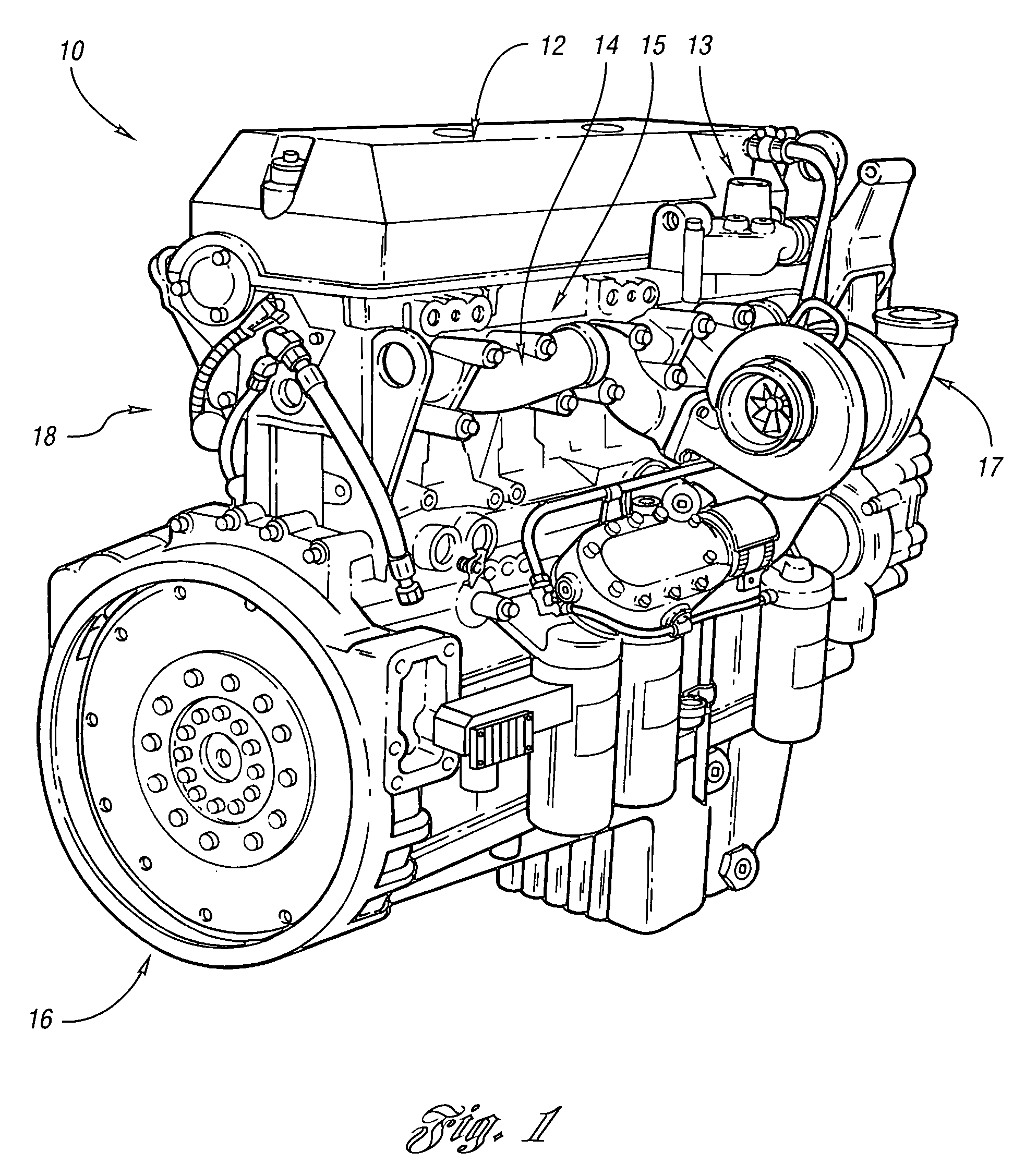

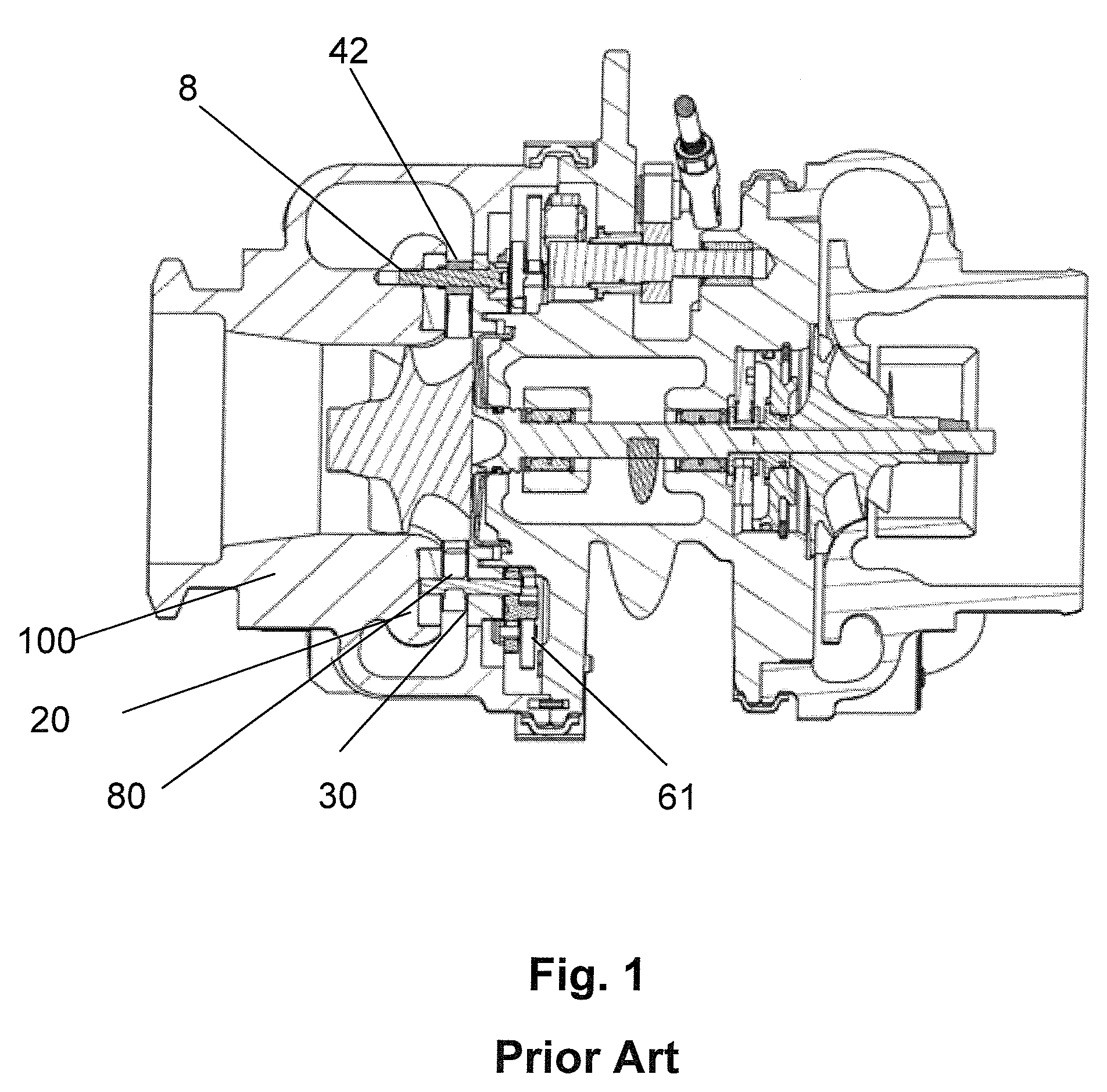

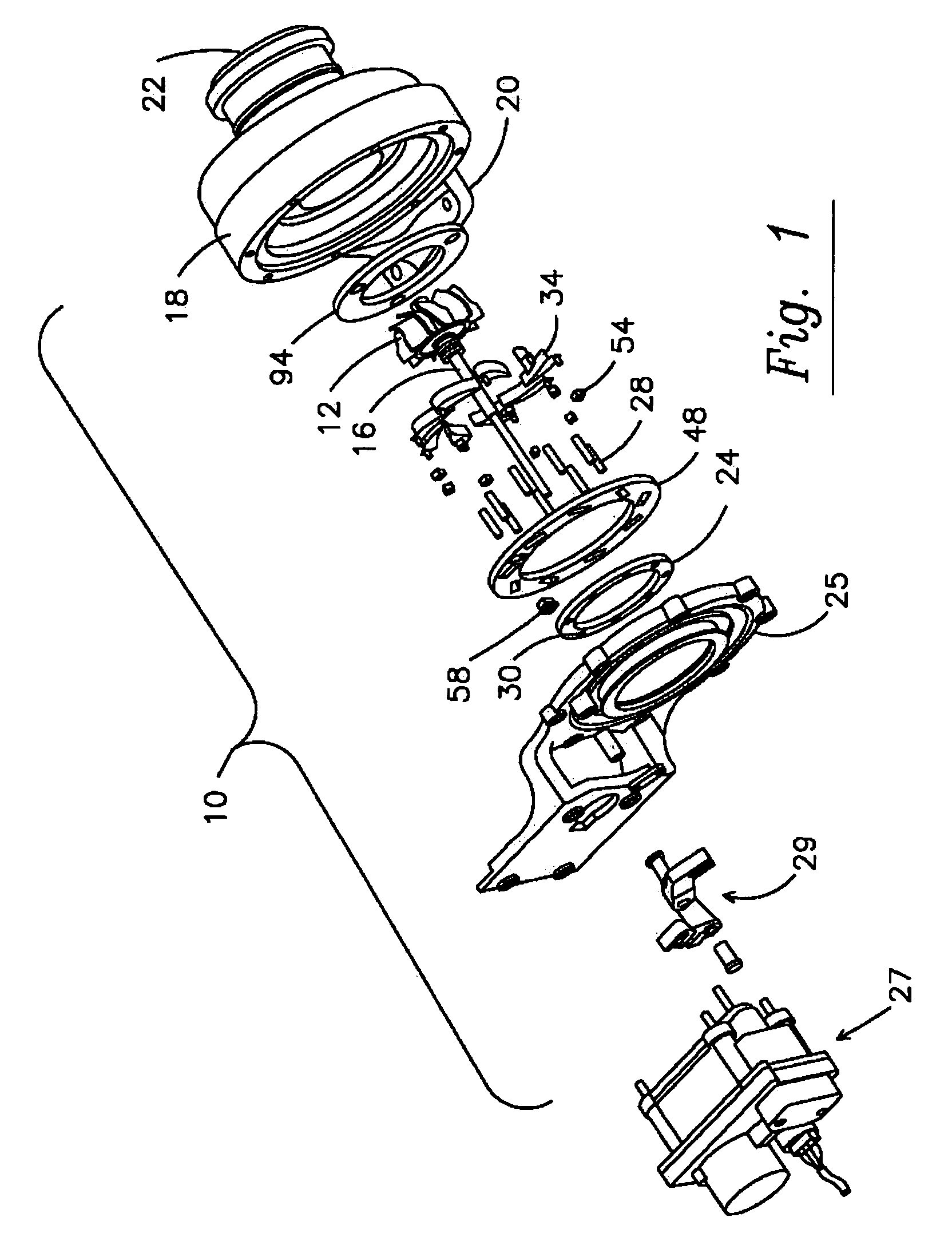

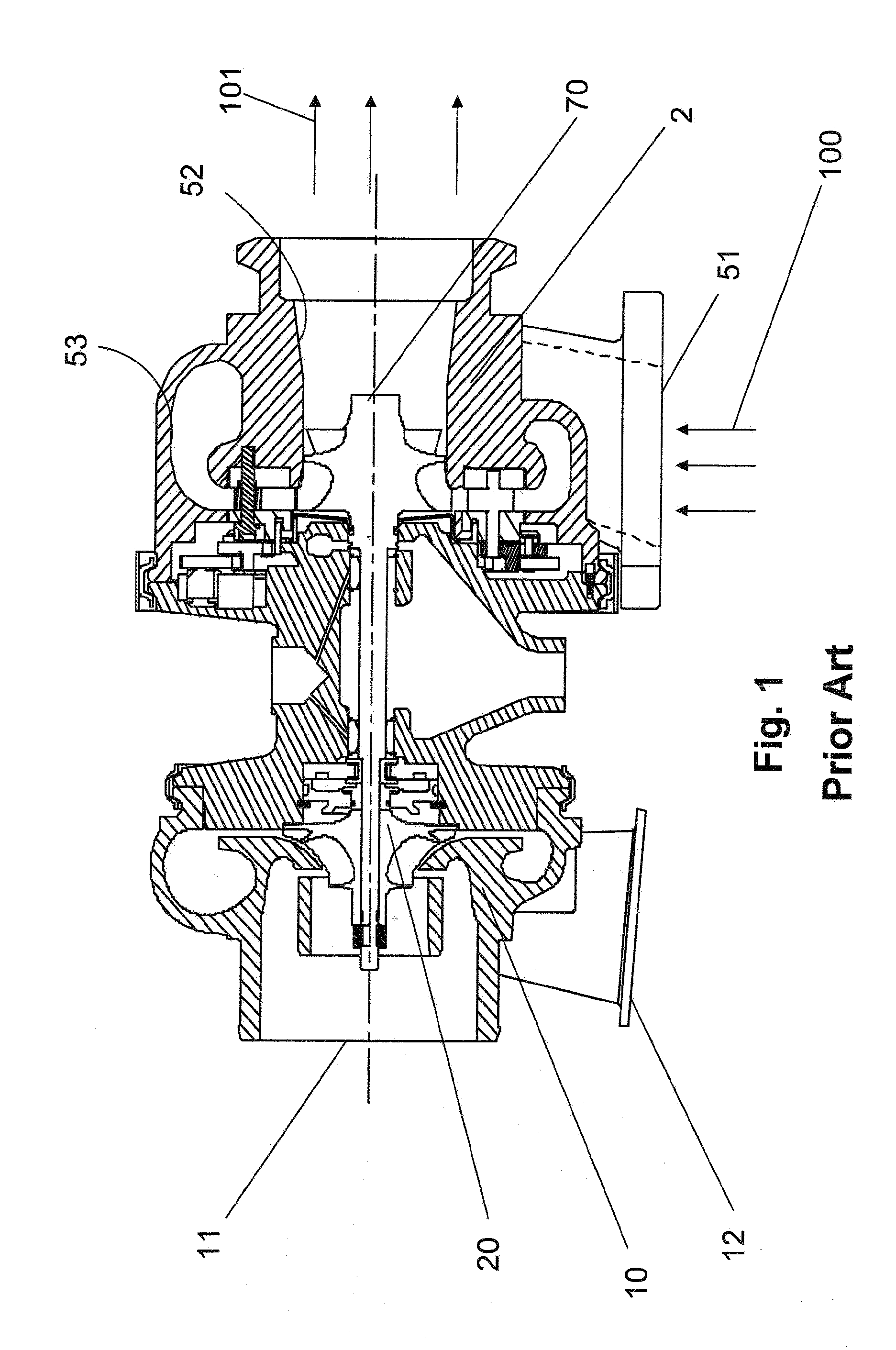

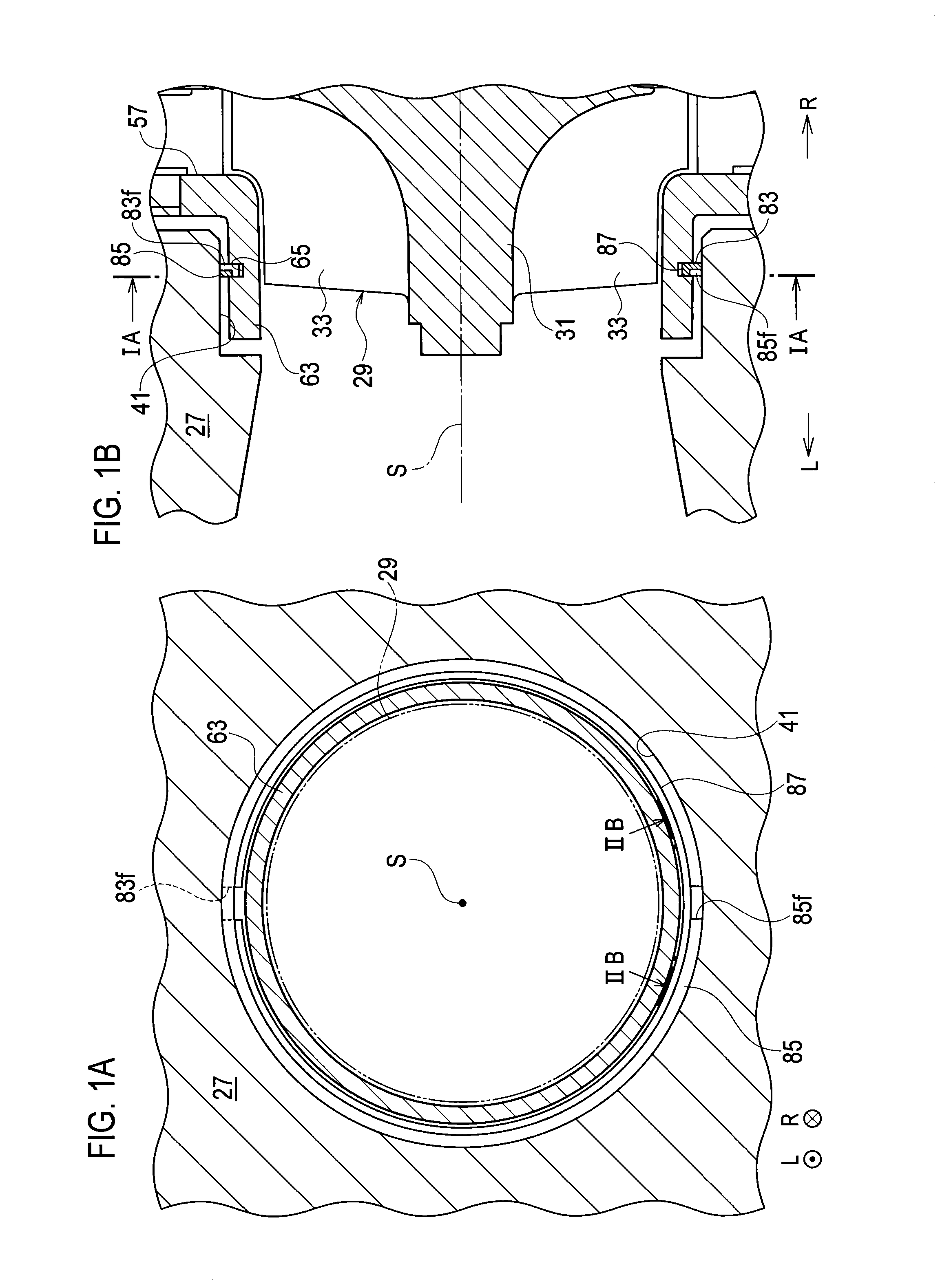

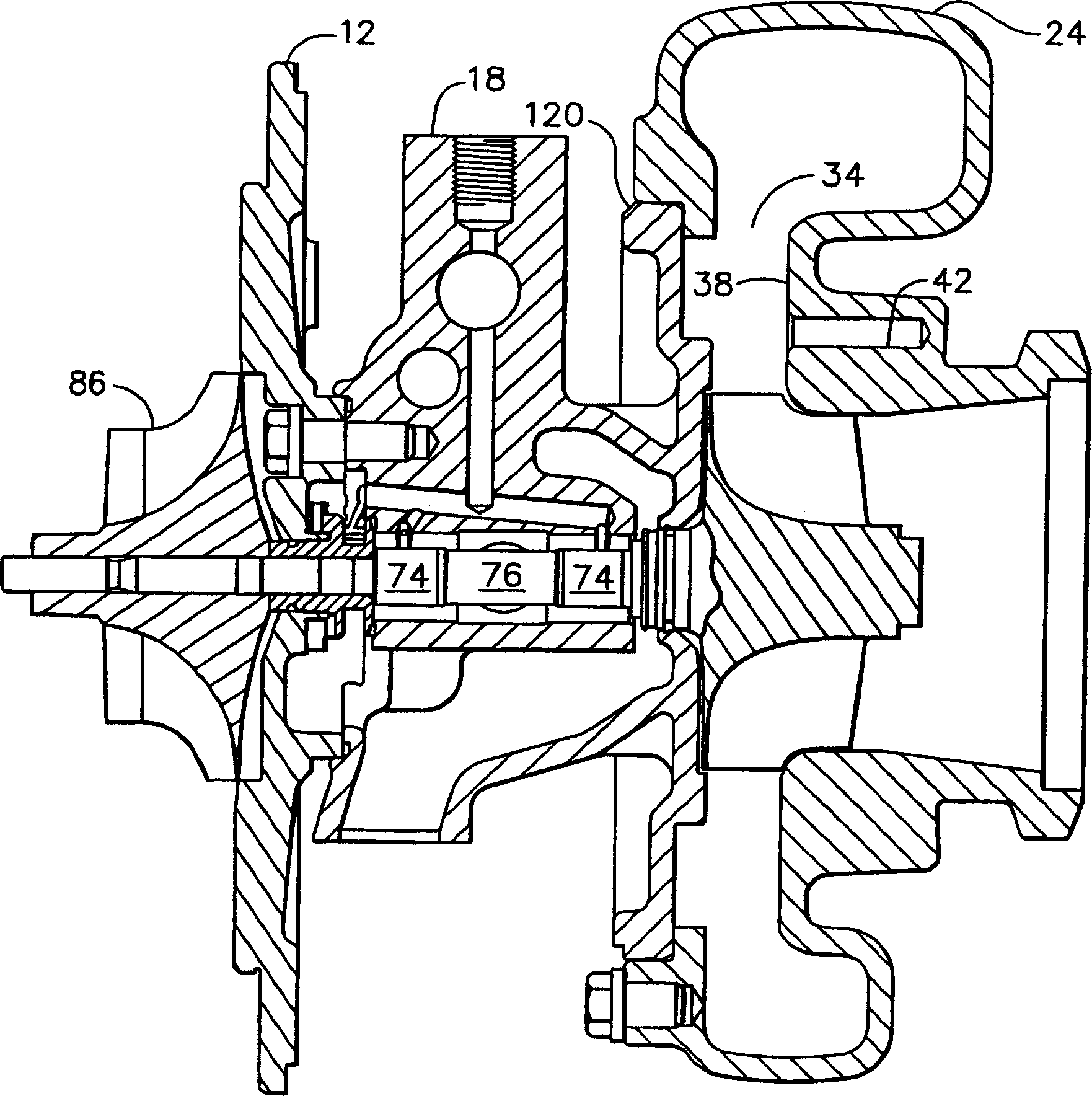

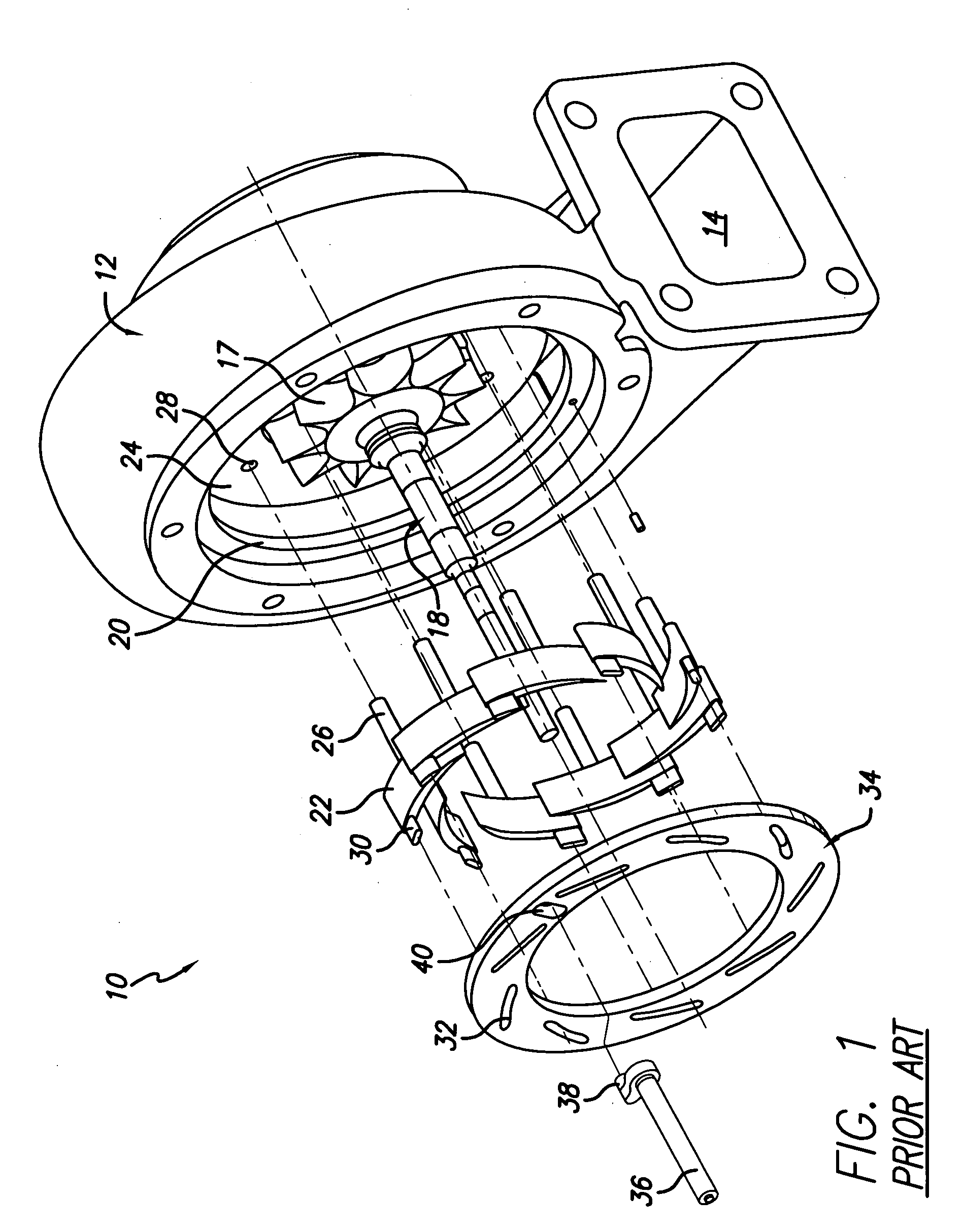

A cartridge is formed by an insert fixed to a base to form turbine intake nozzles in which vanes are rotatably mounted, and the base is fixed to a center housing. A separate exhaust housing which is formed from sheet metal is fixed to the cartridge outside of the insert in order to provide an intake and an outlet for exhaust gases driving a turbine wheel on a shaft journaled in the center housing.

Owner:GARRETT TRANSPORATION I INC

Adaptive variable geometry turbocharger strategy

ActiveUS20090123272A1Provide goodEfficient and reliableElectrical controlInternal combustion piston enginesVariable geometry turbineActuator

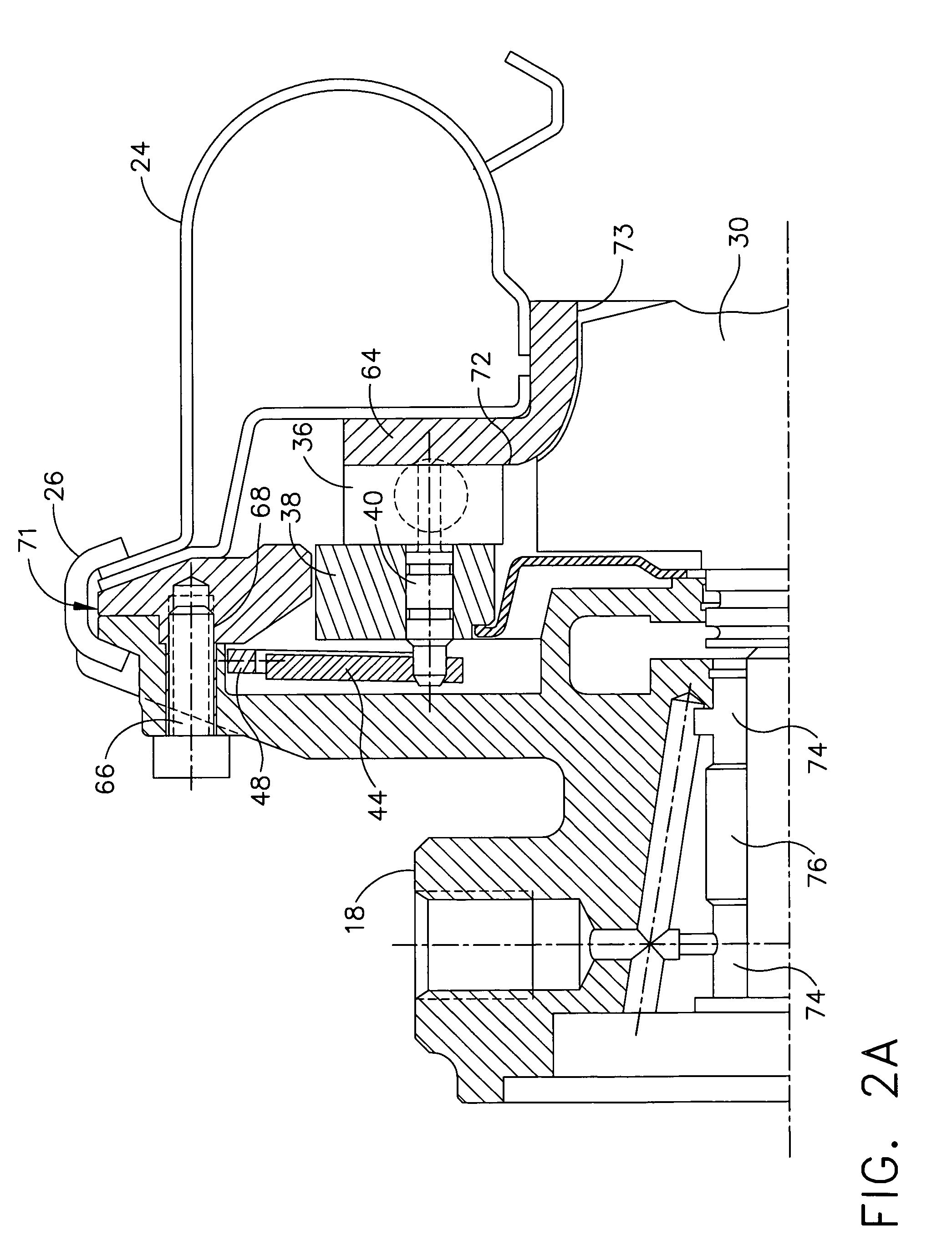

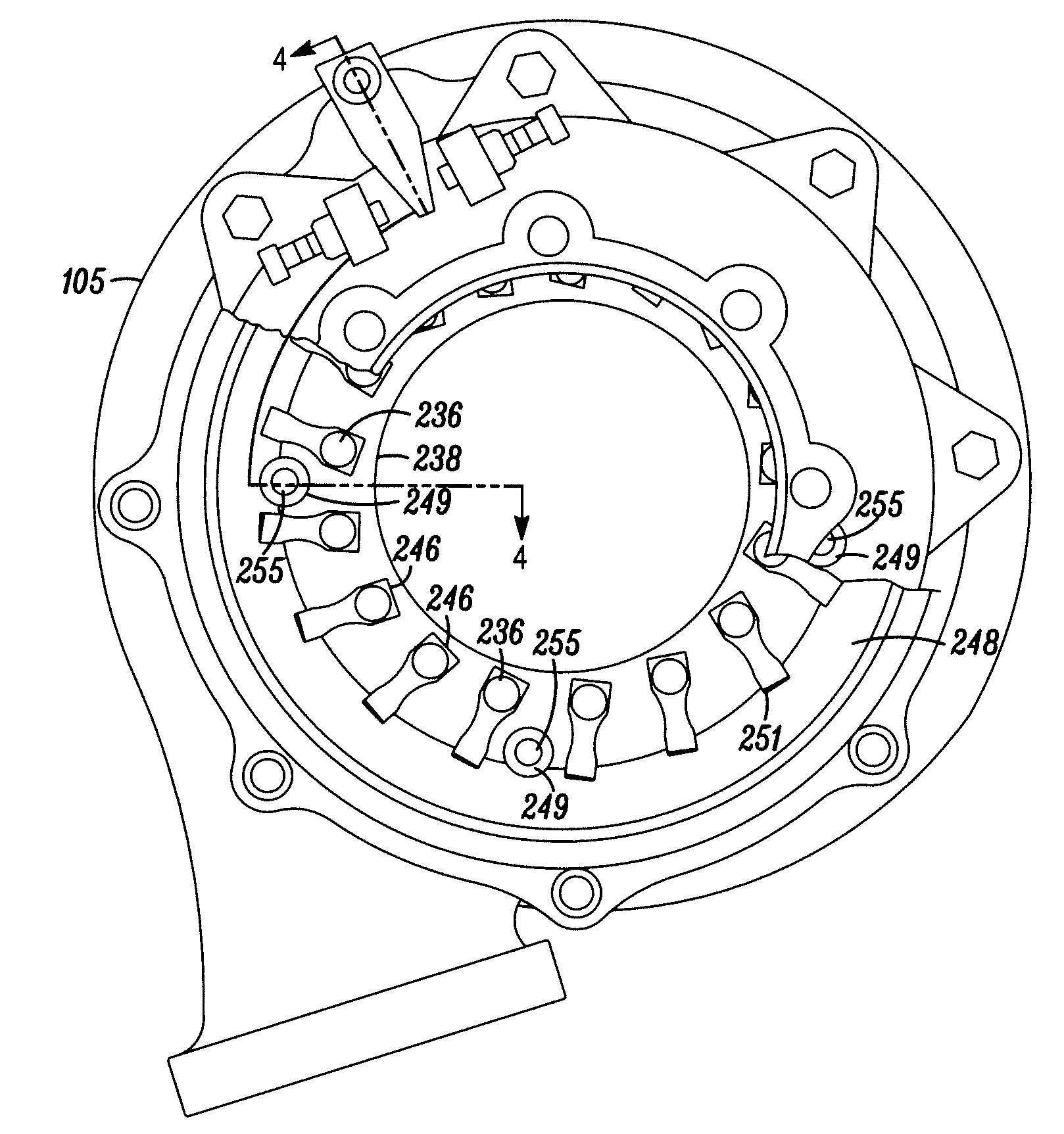

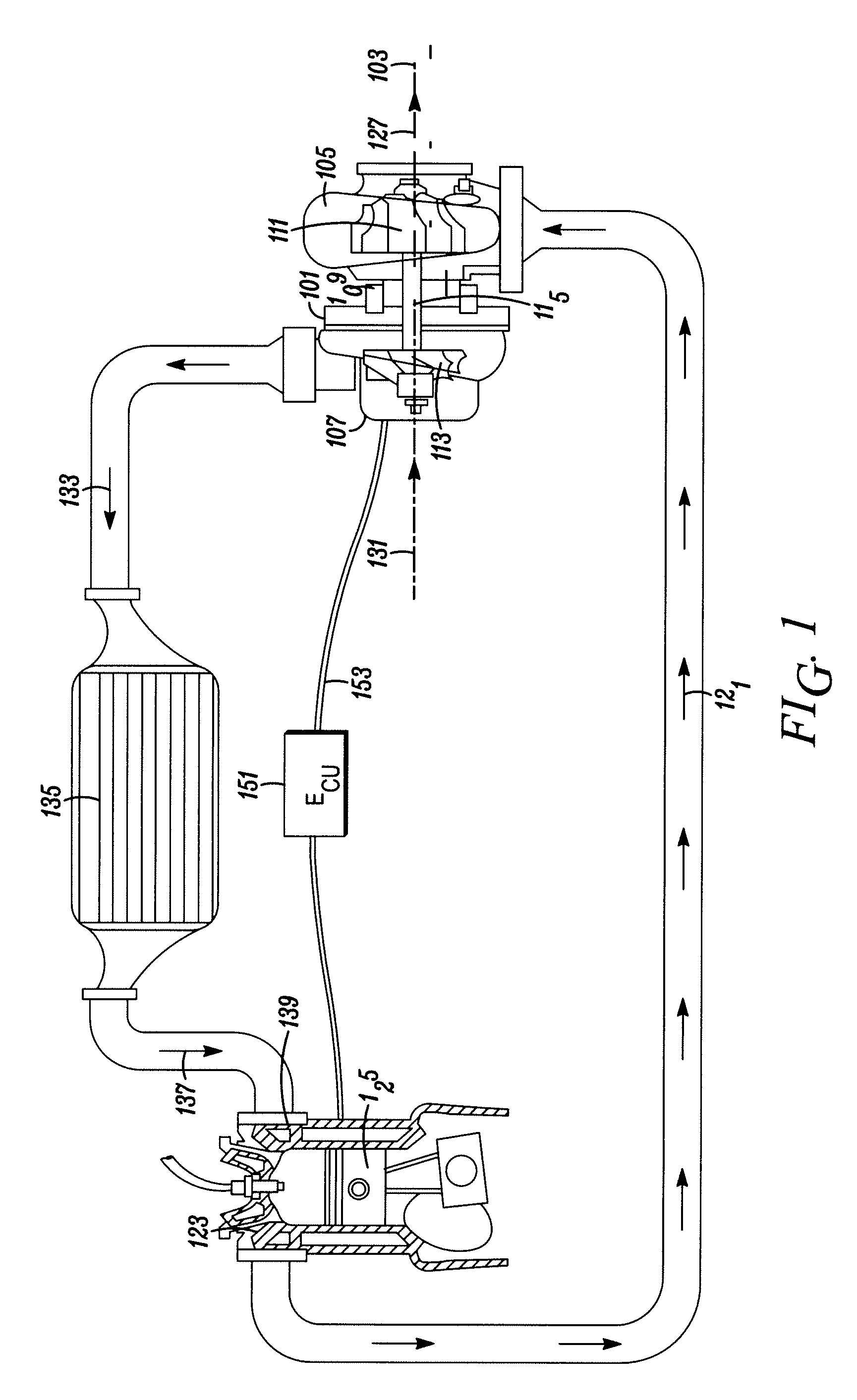

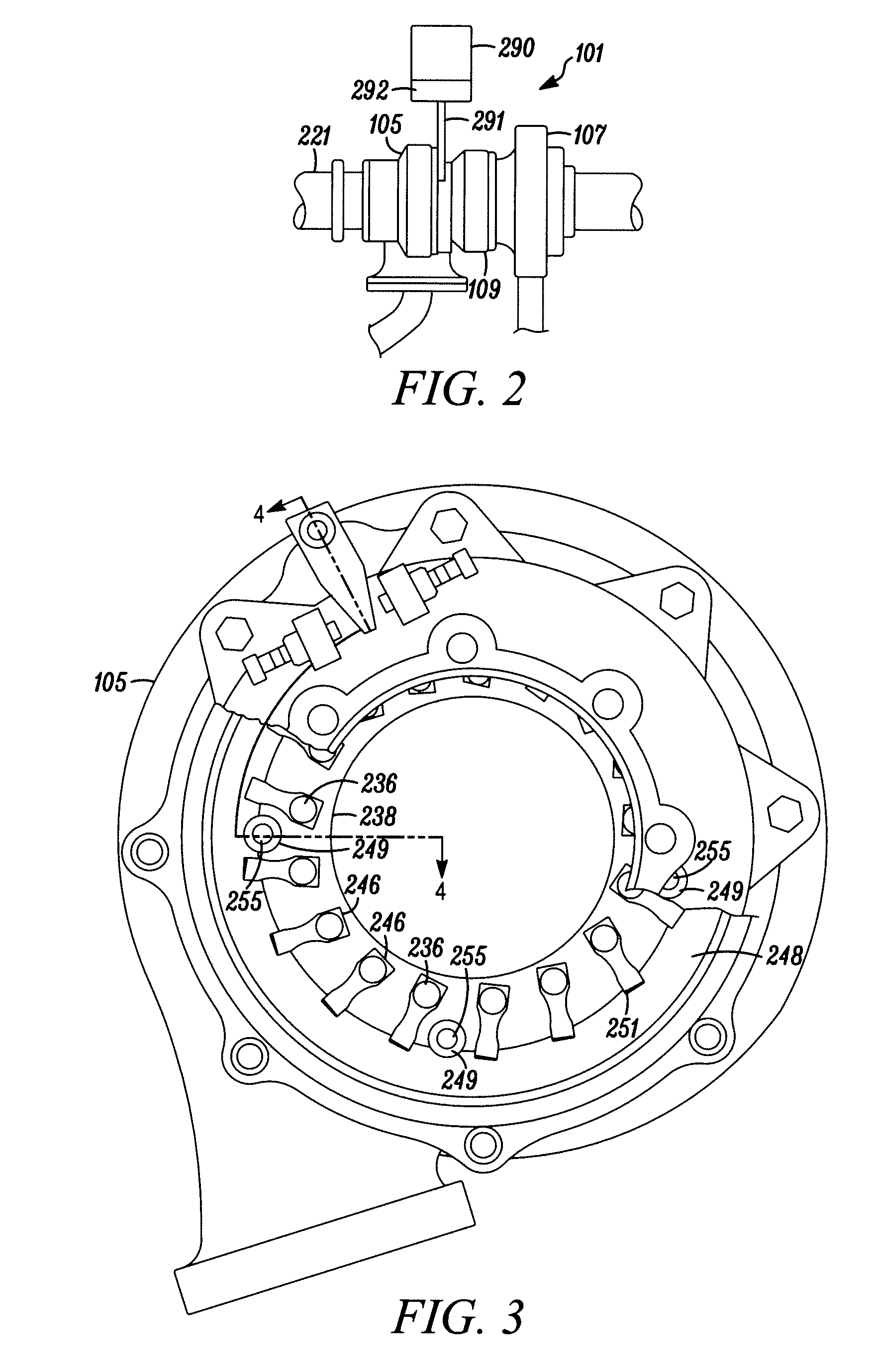

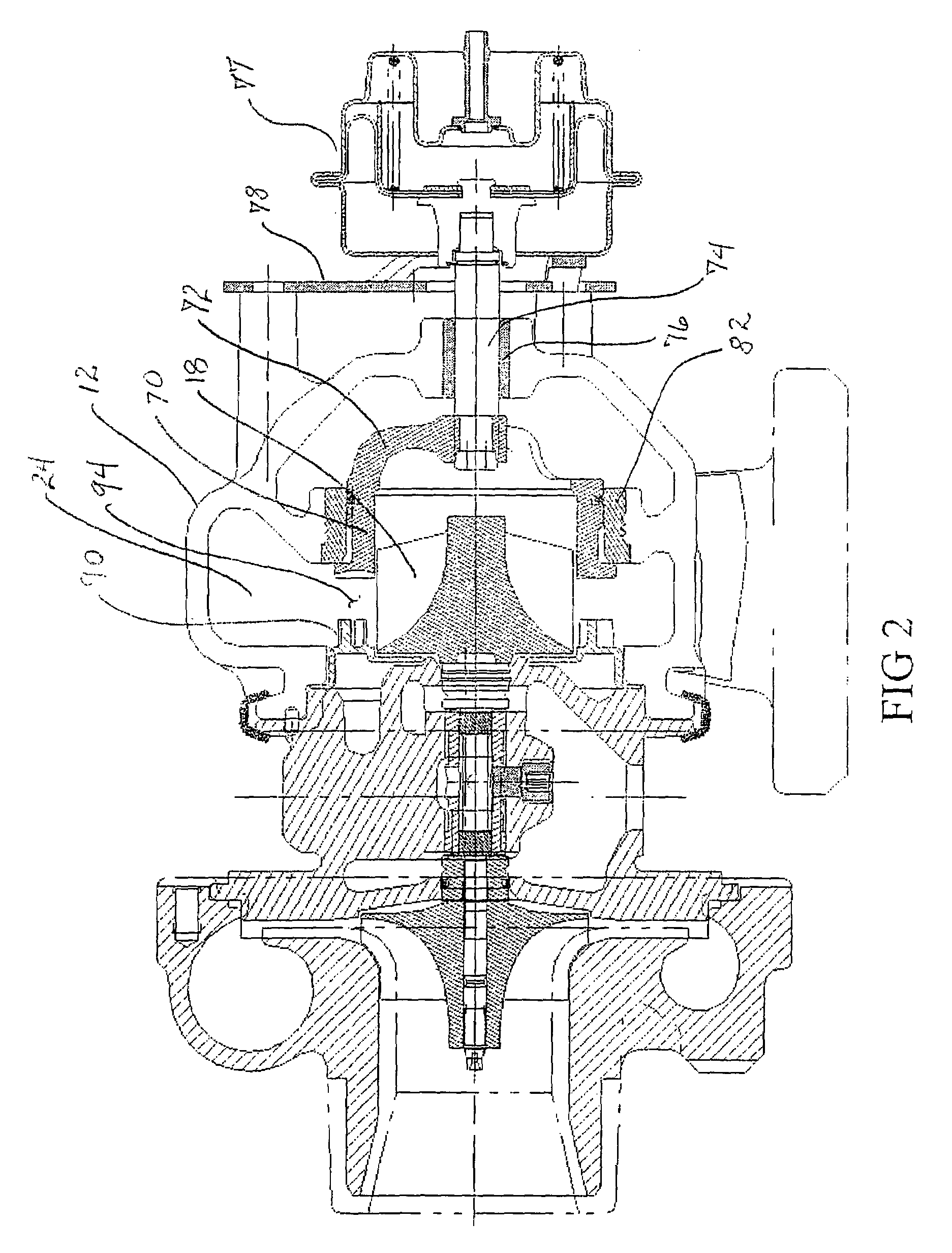

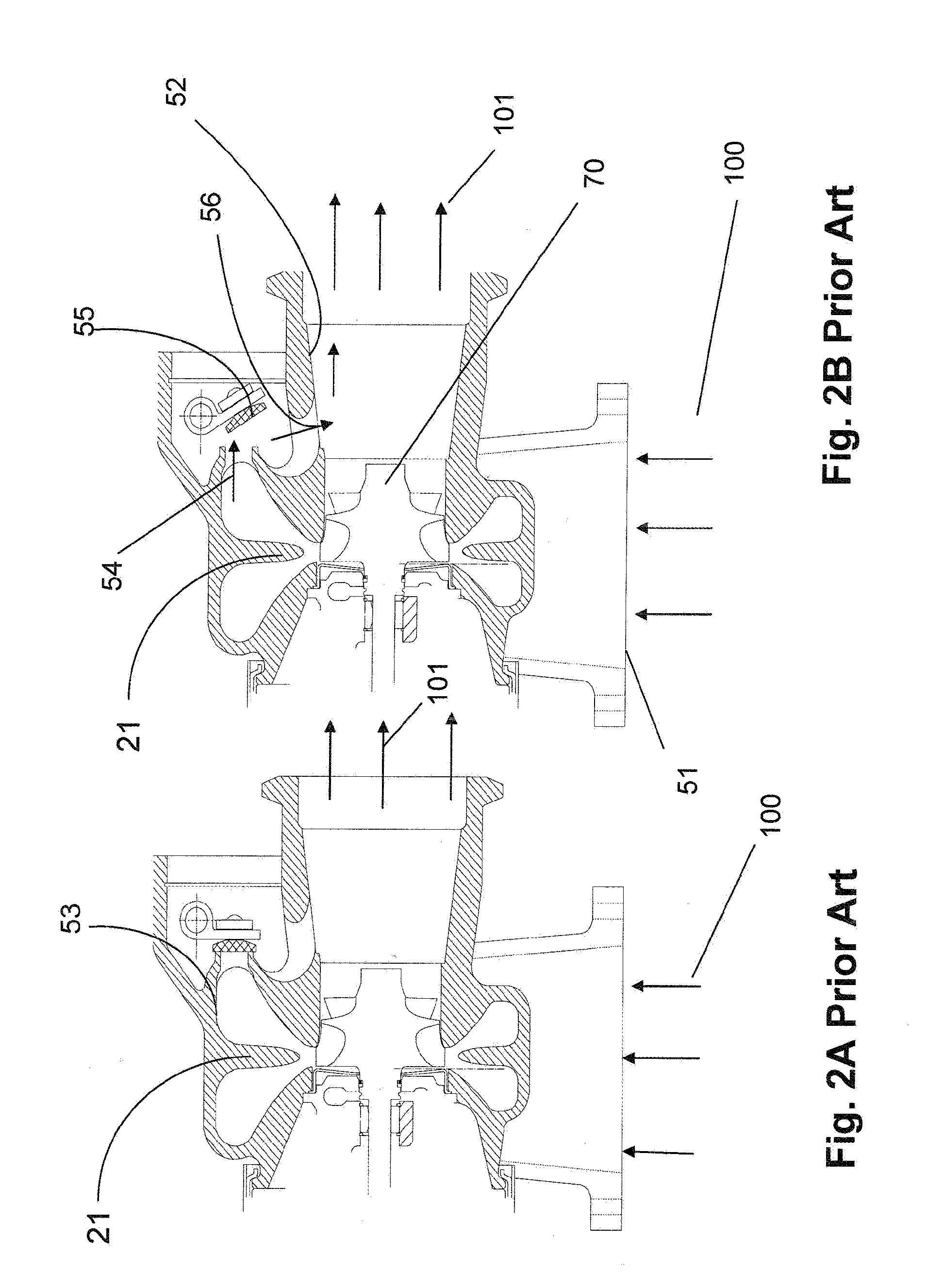

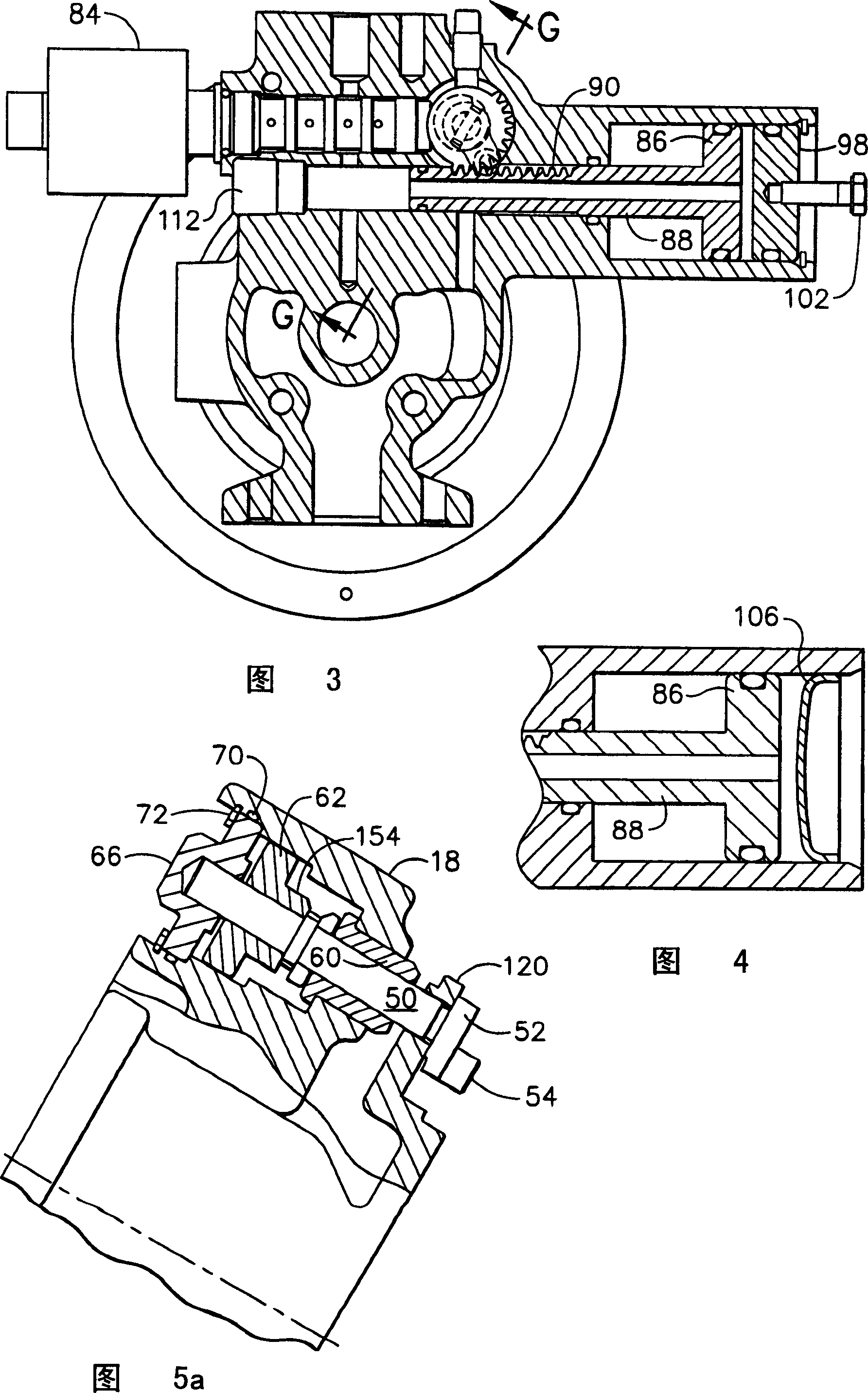

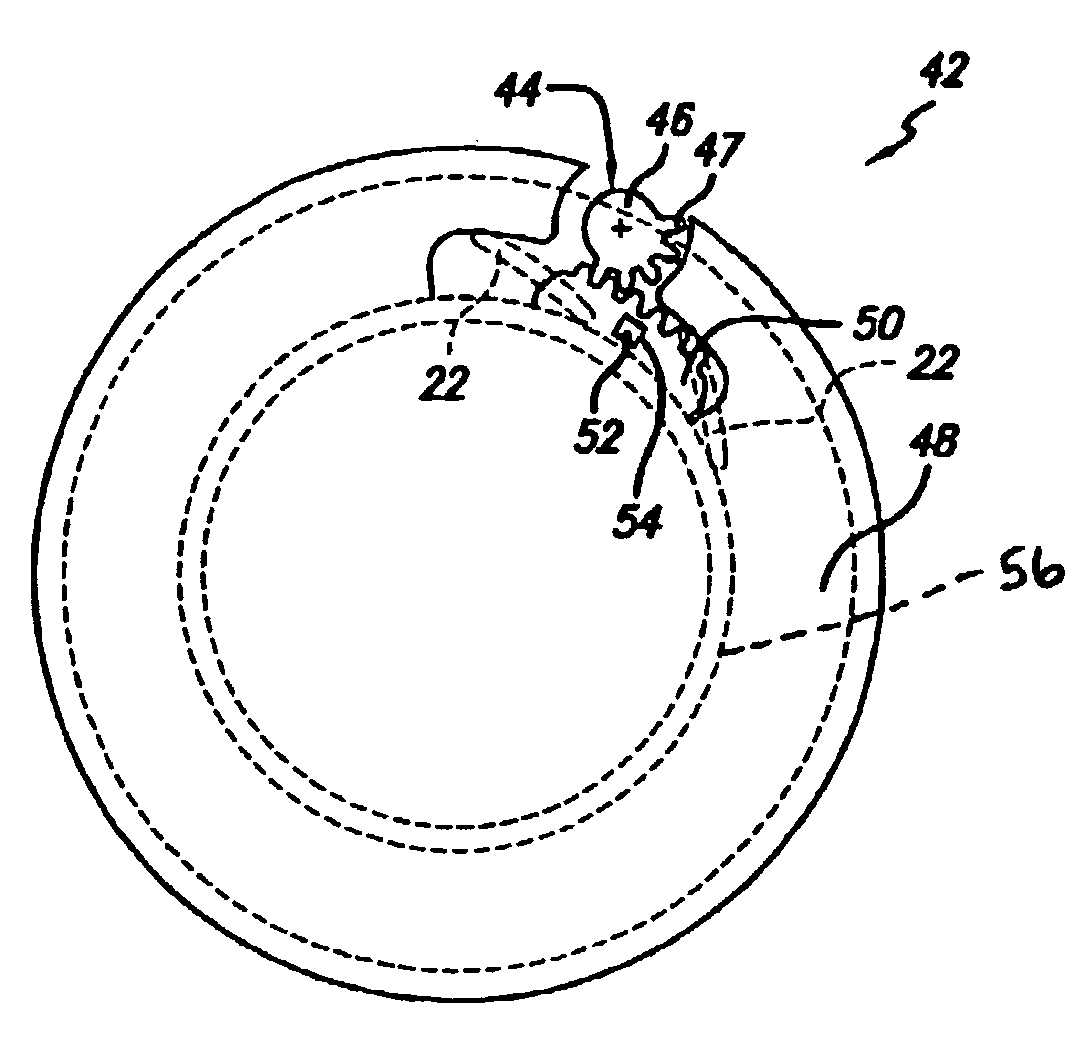

A variable geometry turbocharger employs multiple vanes in the turbine inlet with a unison ring and integral cast wall in the turbine housing forming the nozzle walls. An actuator rotates the unison ring through a rack and pinion driven crank shaft to move the vanes through a range of vane positions that extends between a hard-stop closed position and a hard-stop open position, and that includes a reference position corresponding to a desired flow condition. A variable geometry turbine controller uses a sensor indicating the actuation position of the actuator to guide the operation of the vanes to the reference position. The controller intermittently directs the actuator to force the vanes to the hard-stop closed and hard-stop open positions, and uses sensor information from those positions to reestablish the reference-position information that the actuator uses to guide the actuation of the vanes.

Owner:GARRETT TRANSPORATION I INC

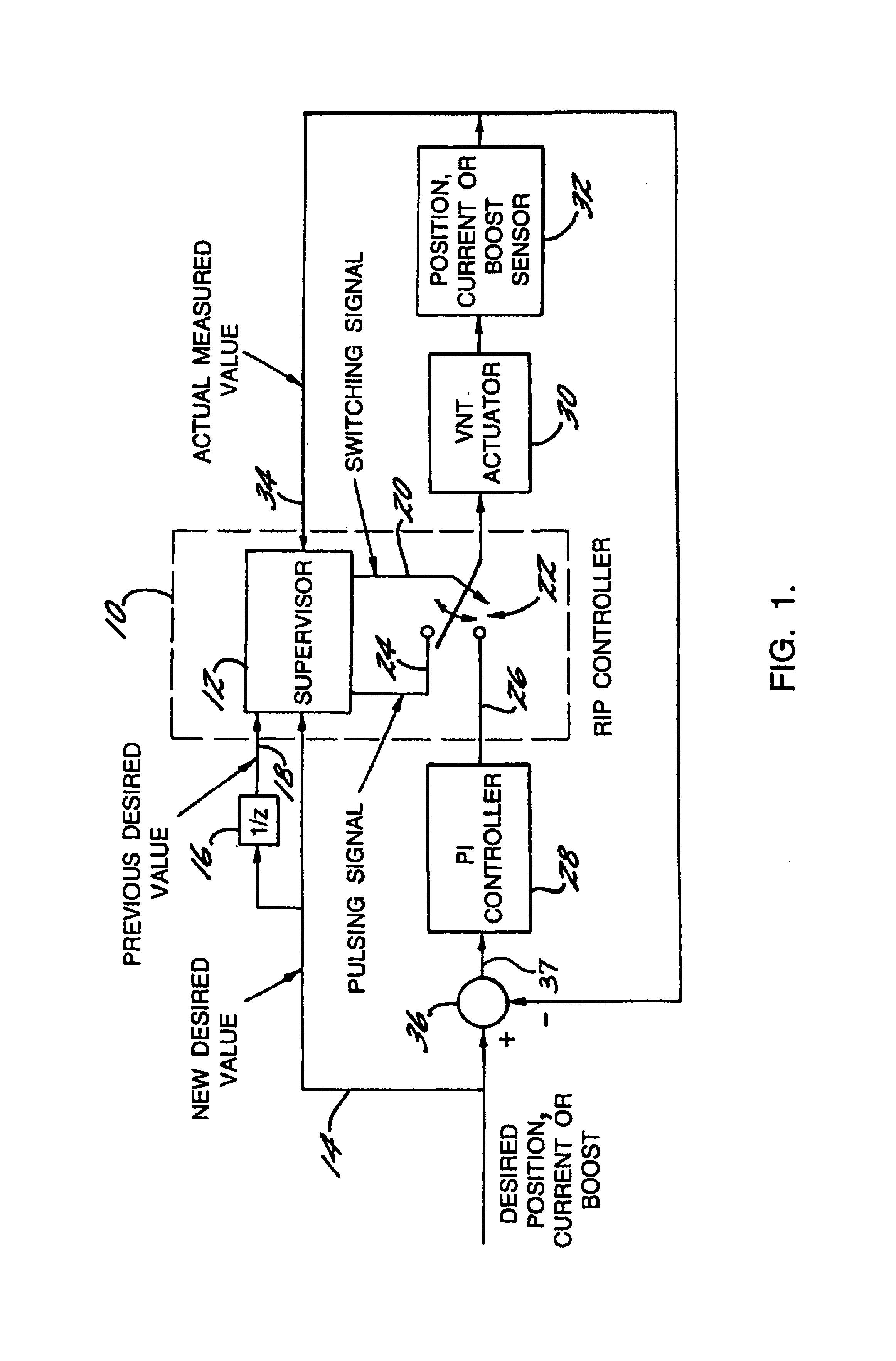

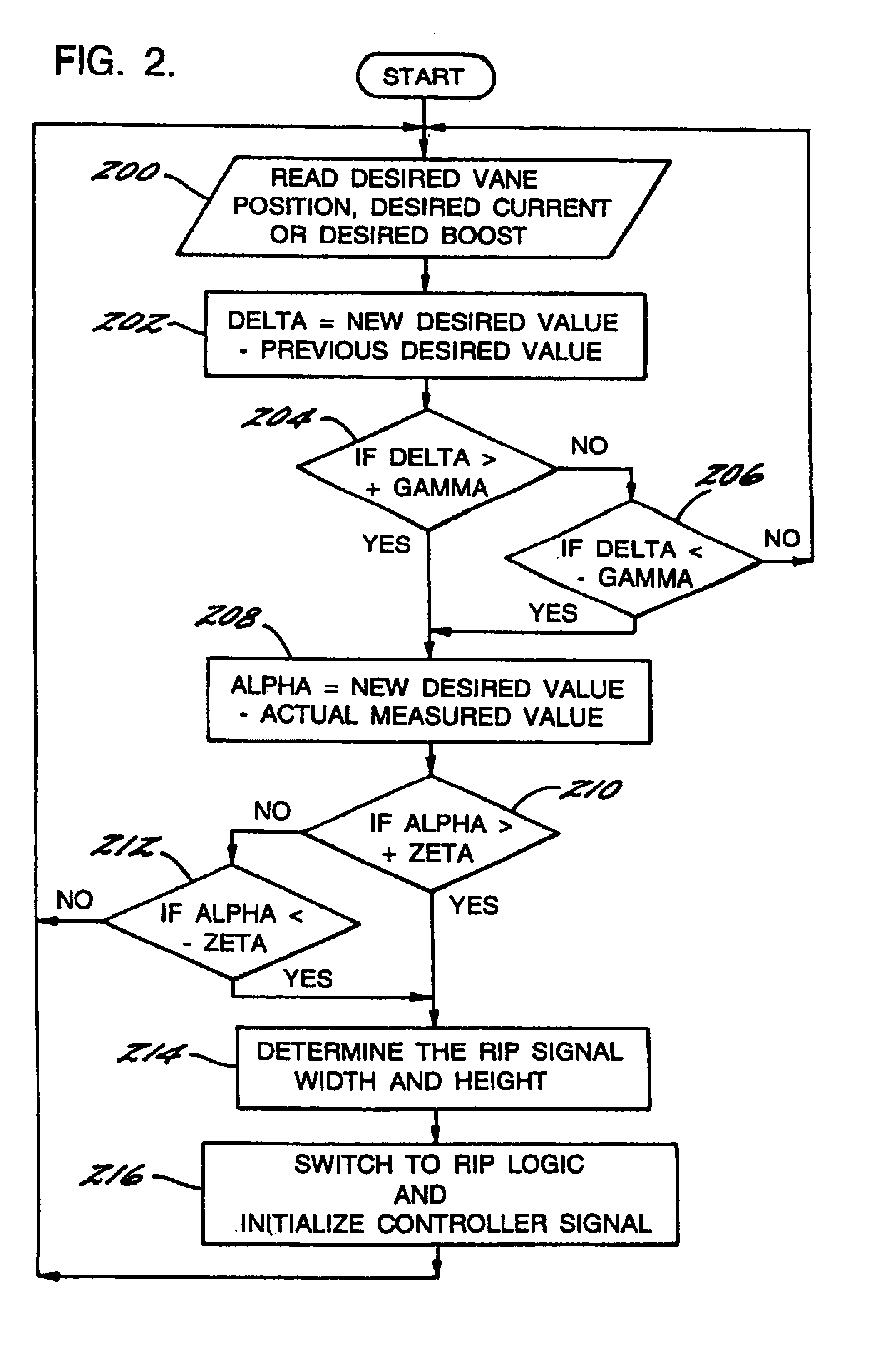

Control system for improved transient response in a variable-geometry turbocharger

A control system for a variable-geometry turbocharger includes a supervisor logic (12) selecting a pulse control output (24) for large variation of desired and previous control signal inputs exceeding a threshold differential and a normal control signal (26) for small control signal input changes. The control system calculates an amplitude and duration for the pulse control output based on input control signal variation or the actual versus desired position of the variable-geometry system in the turbocharger.

Owner:GARRETT TRANSPORATION I INC

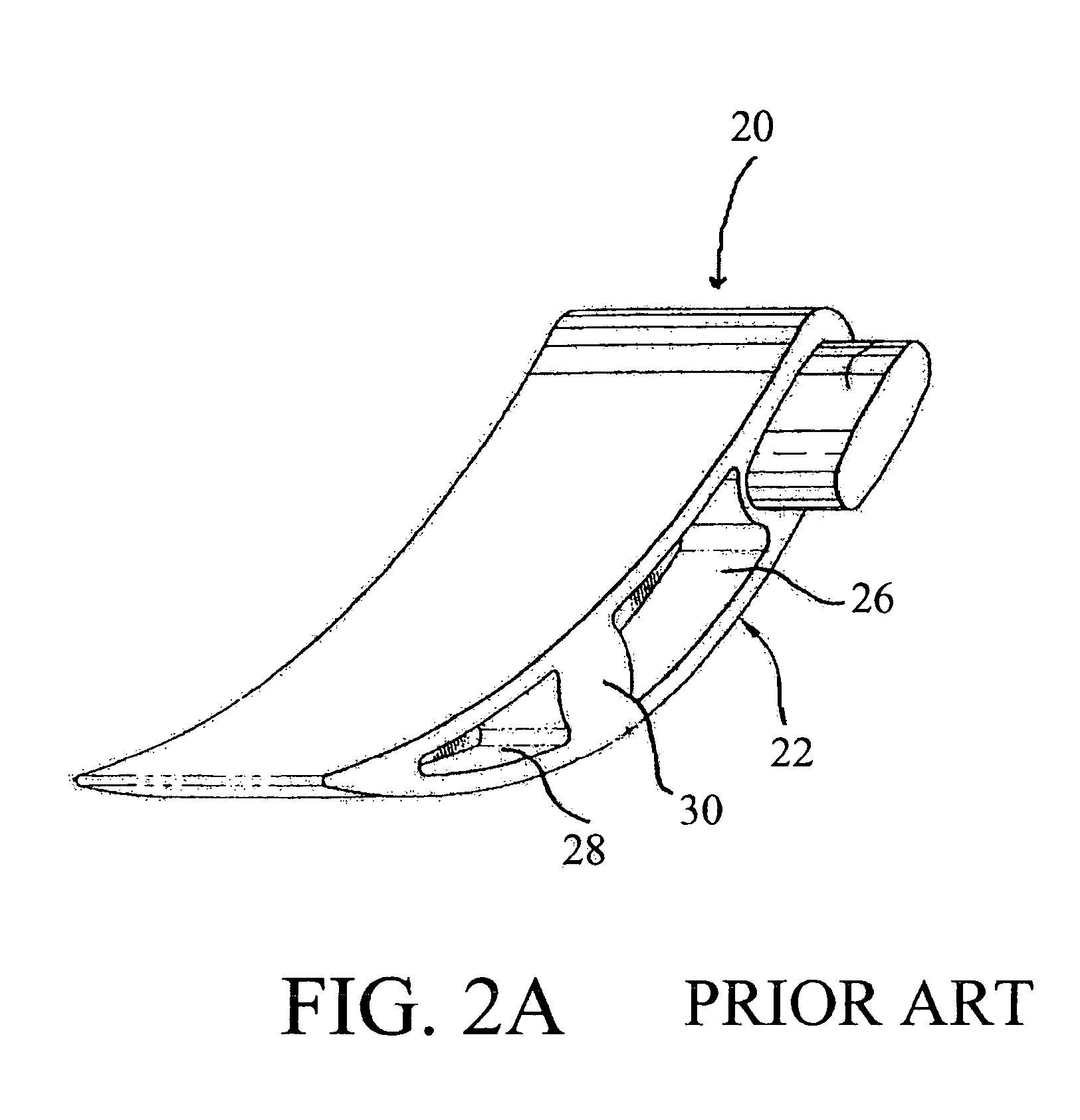

Turbocharger vane

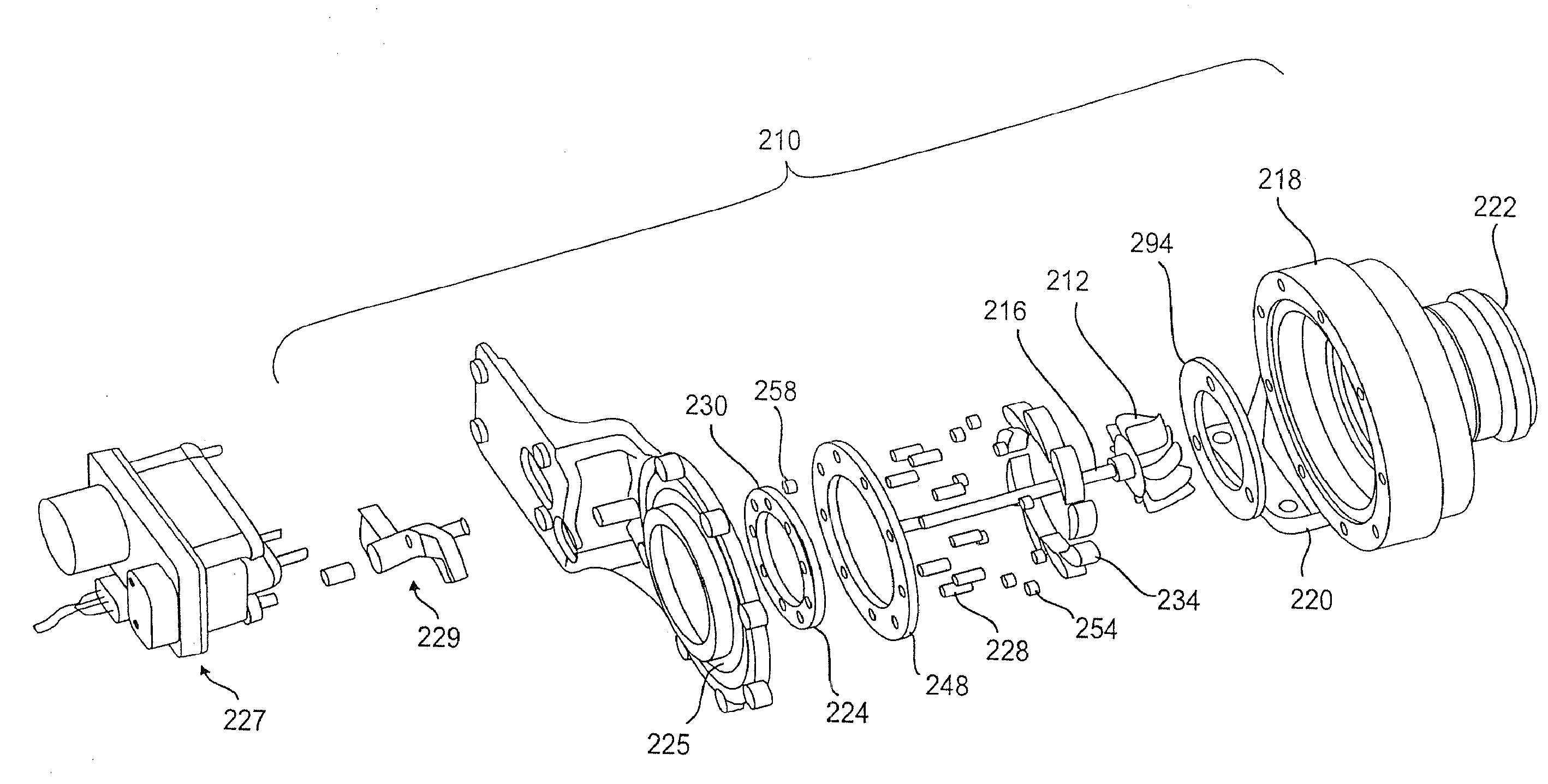

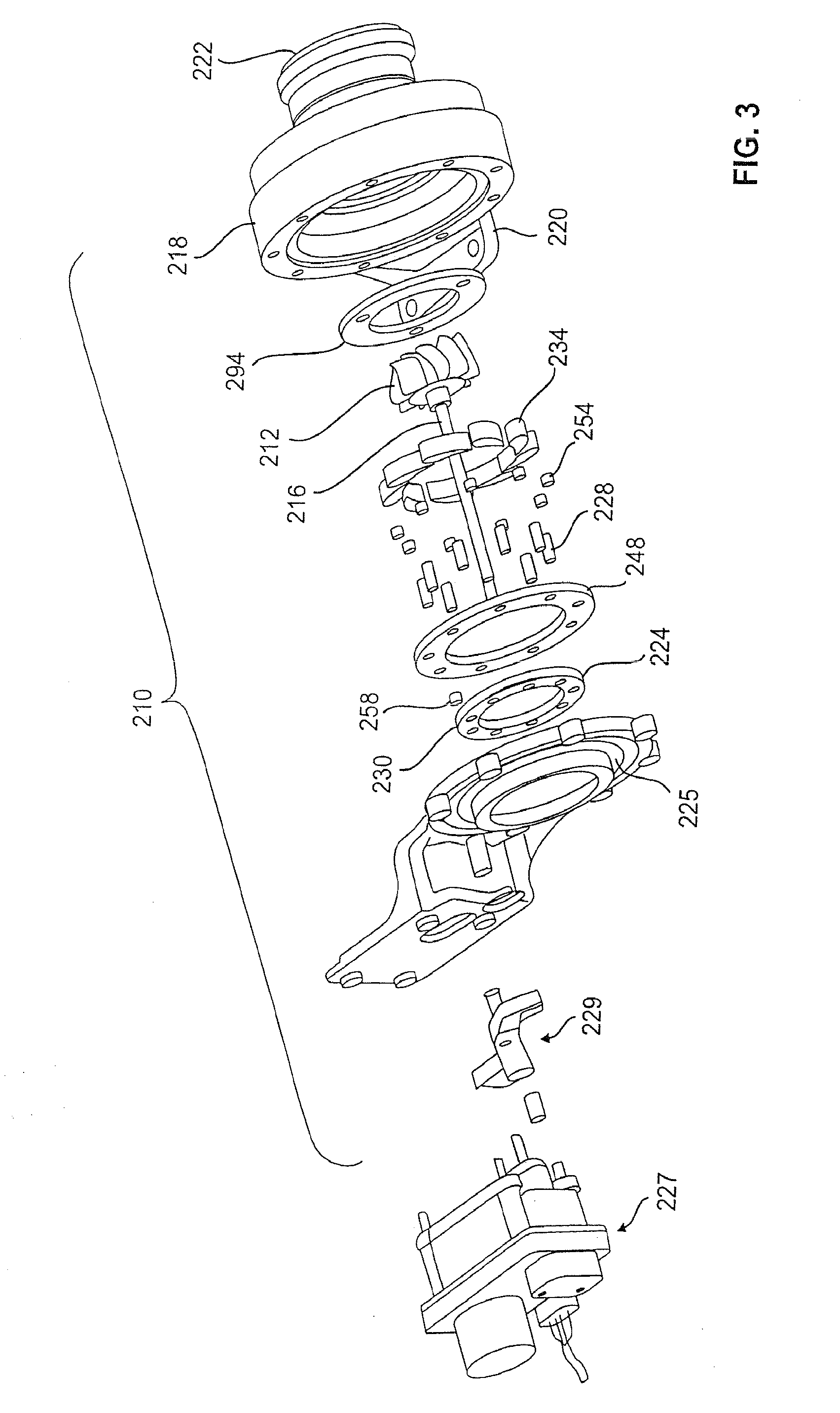

ActiveUS20100098529A1Efficient and cost-effective structureReduce leakageWind motor controlPump componentsHigh pressureBearing surface

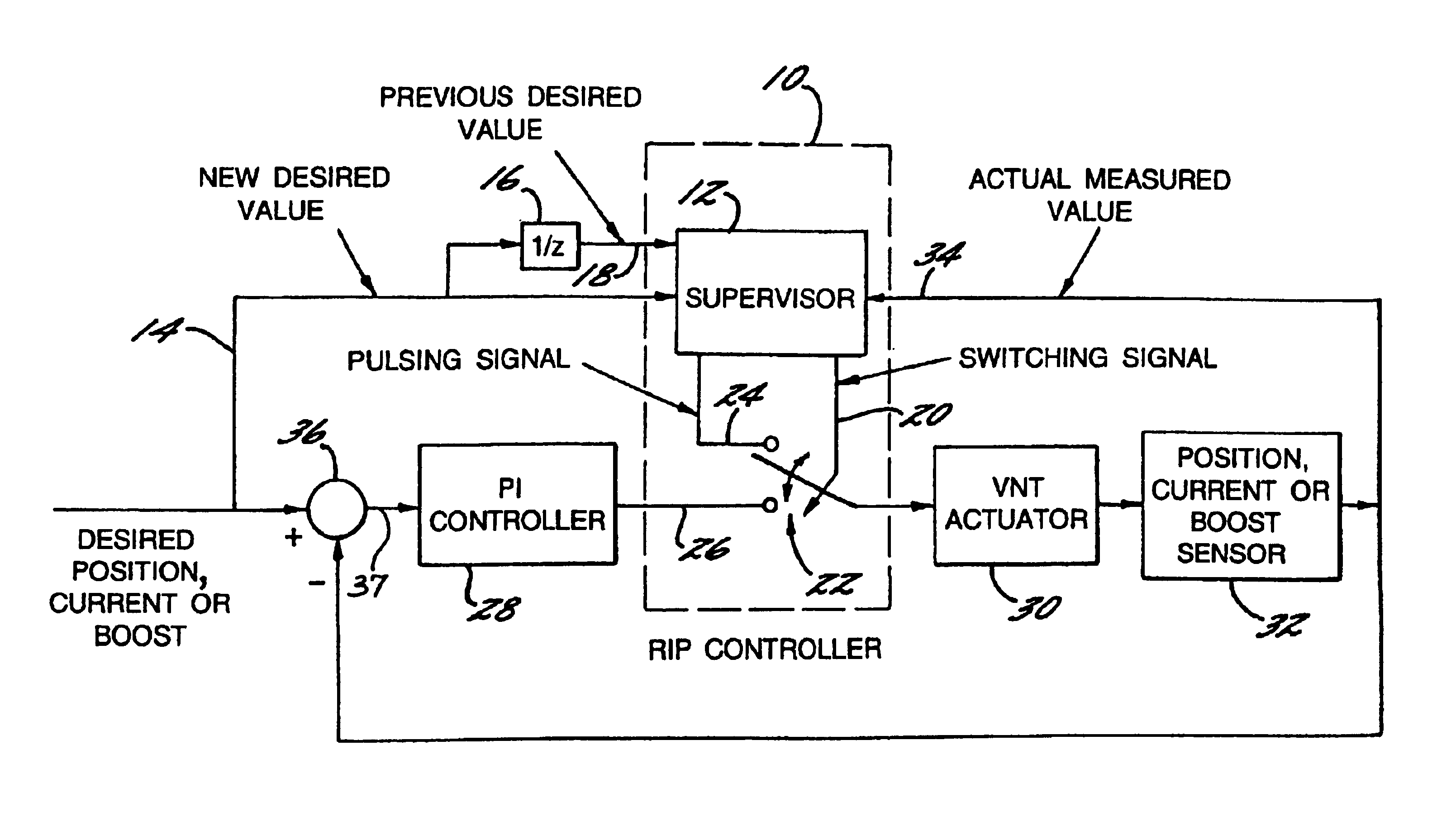

A vane (234) is provided which reduces leakage of gas in a variable geometry turbocharger (210) from the high pressure side of the vane (234) to the low pressure side of the vane (234). The vane (234) can have a channel (330, 430) along a gas bearing surface (325, 425) for reducing the leakage. The channel (330, 430) can be defined at least in part by sideplates (300, 350). The sideplates (300, 350) can be integrally cast with the rest of the vane (234). At least one of the sideplates (300, 350) can have a hole therein for a vane shaft (228) which allows movement of the vane (234) for gas flow control. The 340 sideplates (300, 350) can have edges (301, 351) that conform to the shape of the gas bearing surface (325, 425).

Owner:BORGWARNER INC

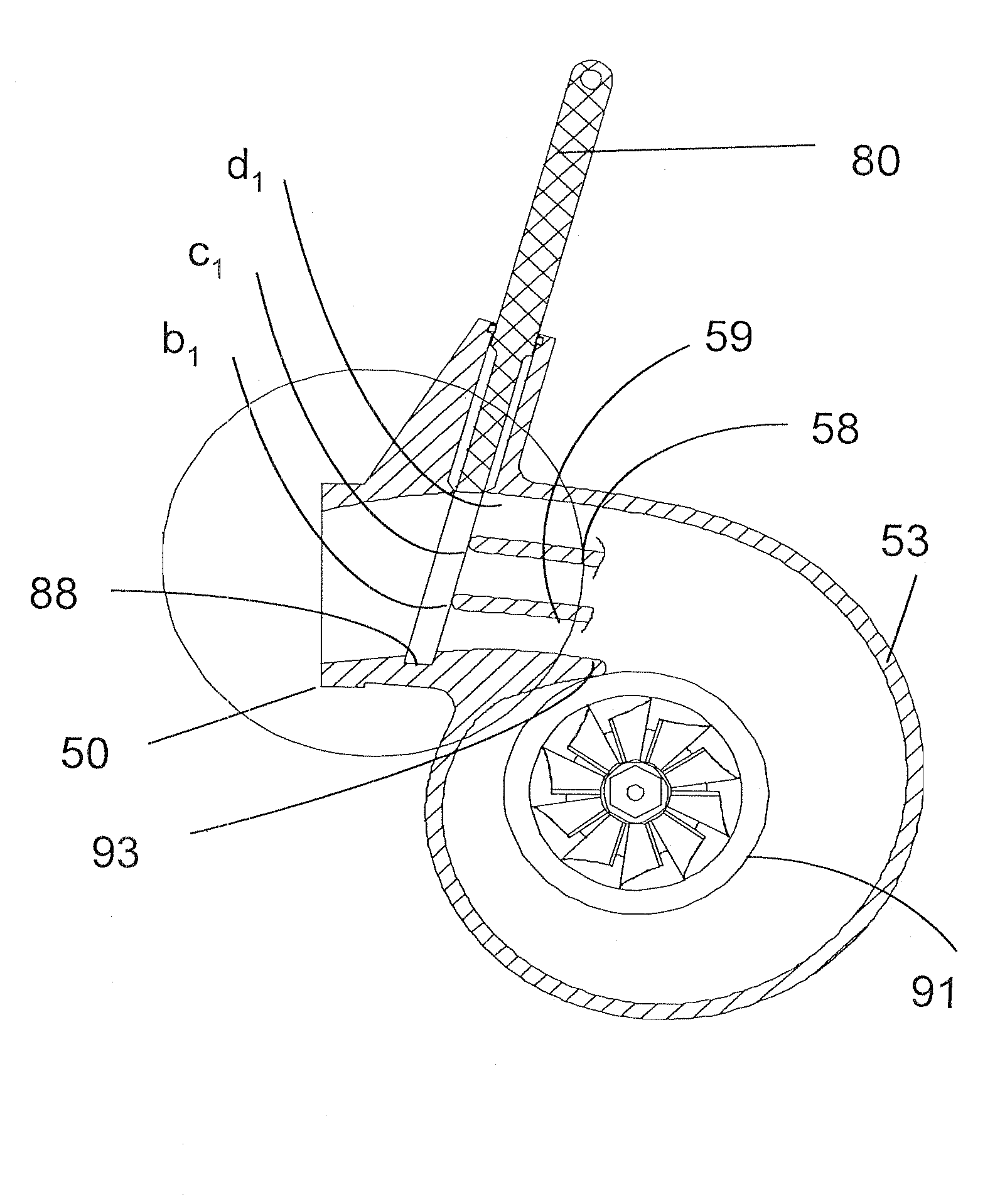

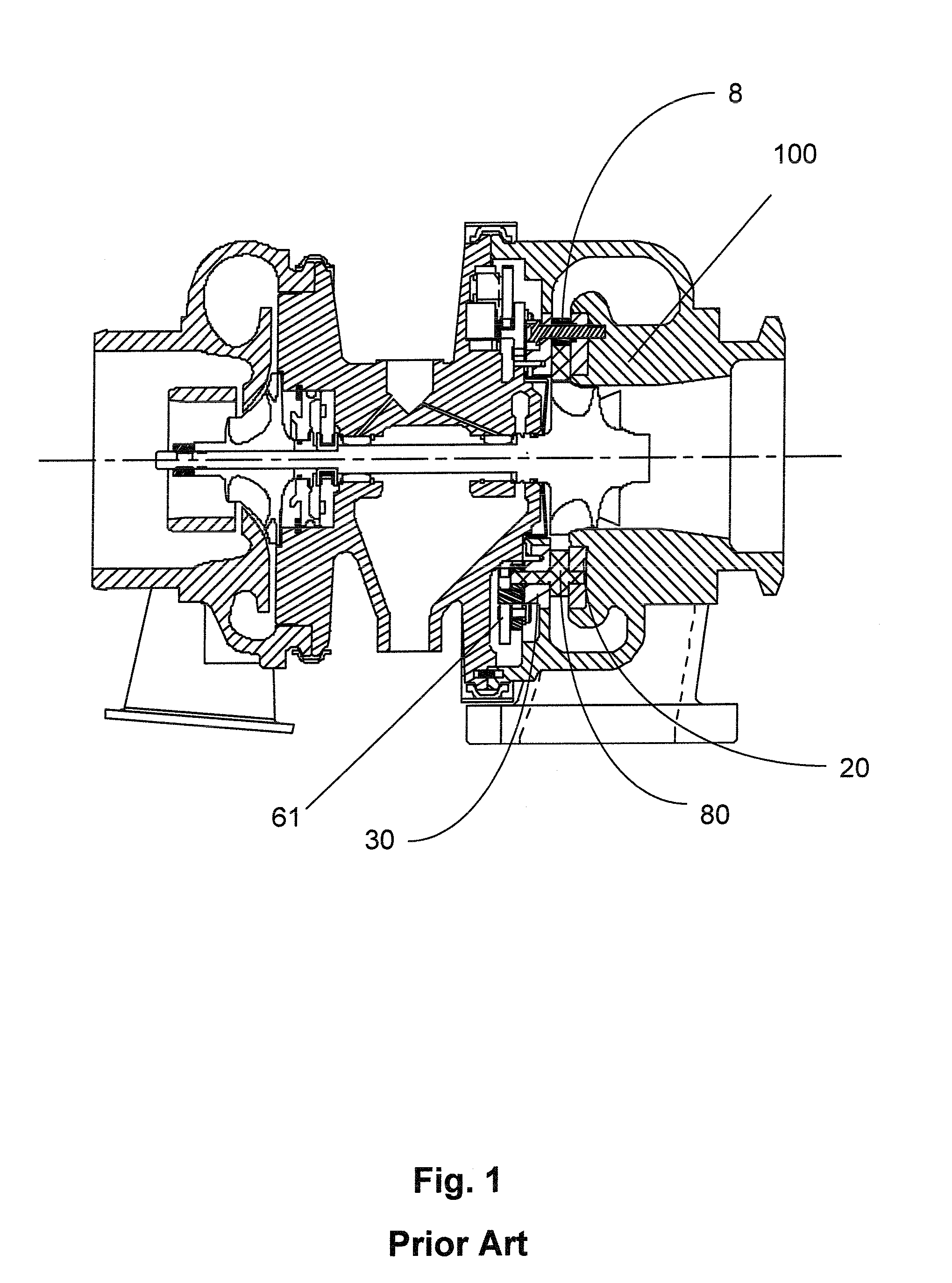

Simplified variable geometry turbocharger with sliding gate and multiple volutes

A simplified, low cost, turbine flow controlling device, using a sliding gate, with an actuator to control exhaust flow to multiple volutes, which volutes have perforated transverse divider walls. By moving the sliding gate (80) from a closed position (88) through a displacement of “a” to the next position b1; and then from position b1 through a displacement of “b” to the next position c1, each a discreet movement, by a simple actuator, an increasing number of volutes are opened for flow from the exhaust manifold, via the volutes with perforated transverse divider walls, to the turbine wheel, without the attenuation of pulse energy usually seen in VTGs, at a cost lower than that of a VTG.

Owner:BORGWARNER INC

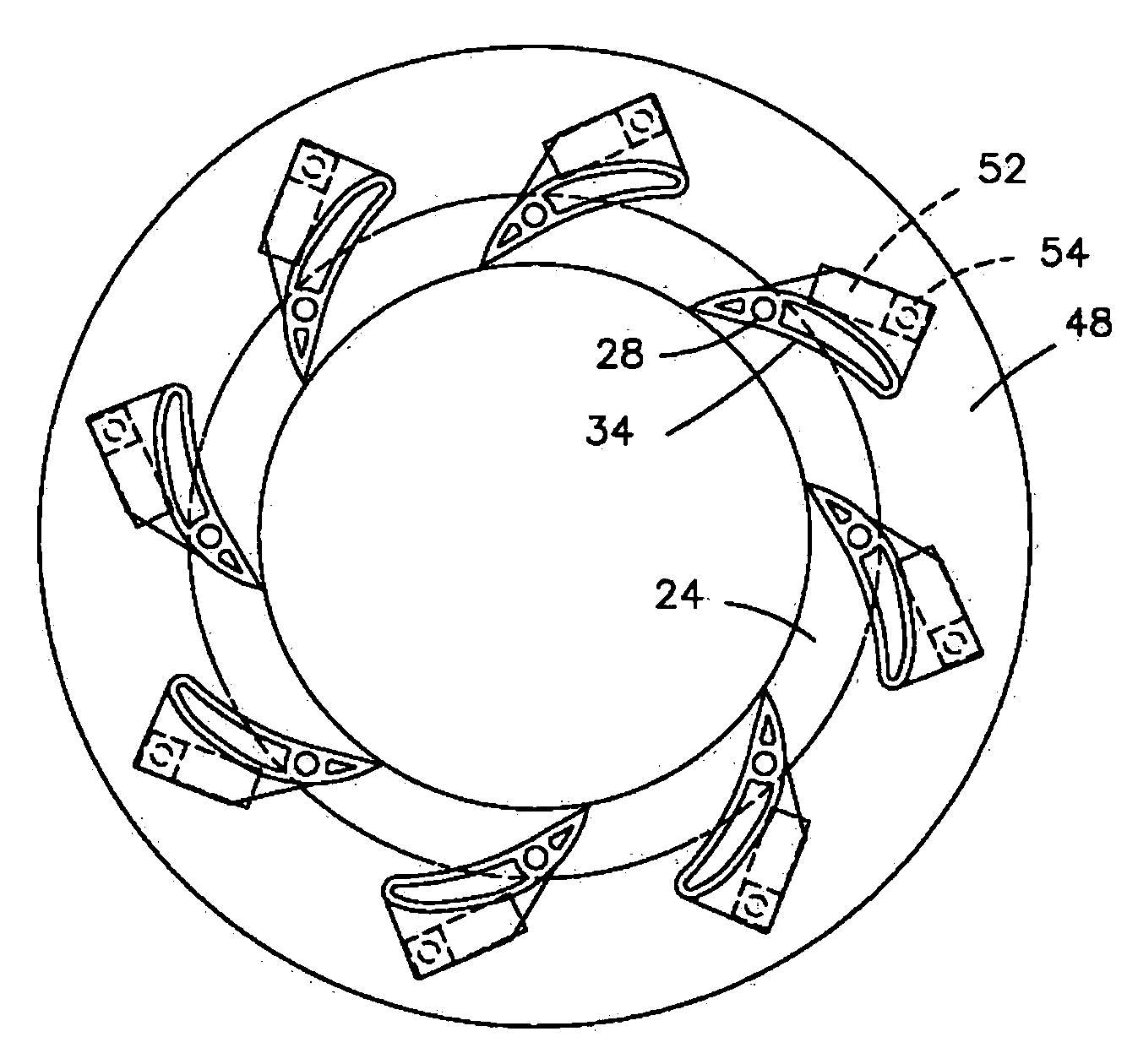

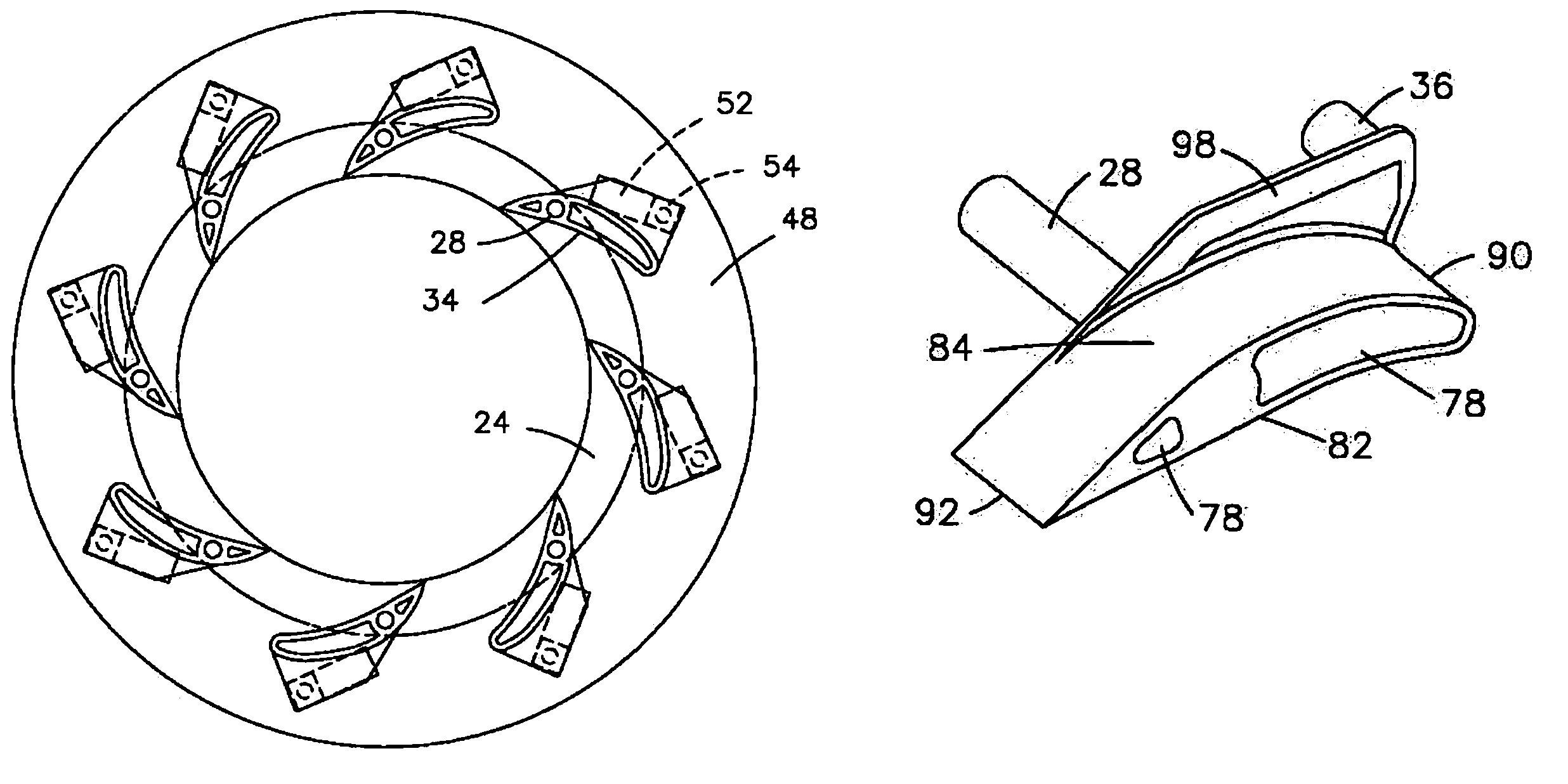

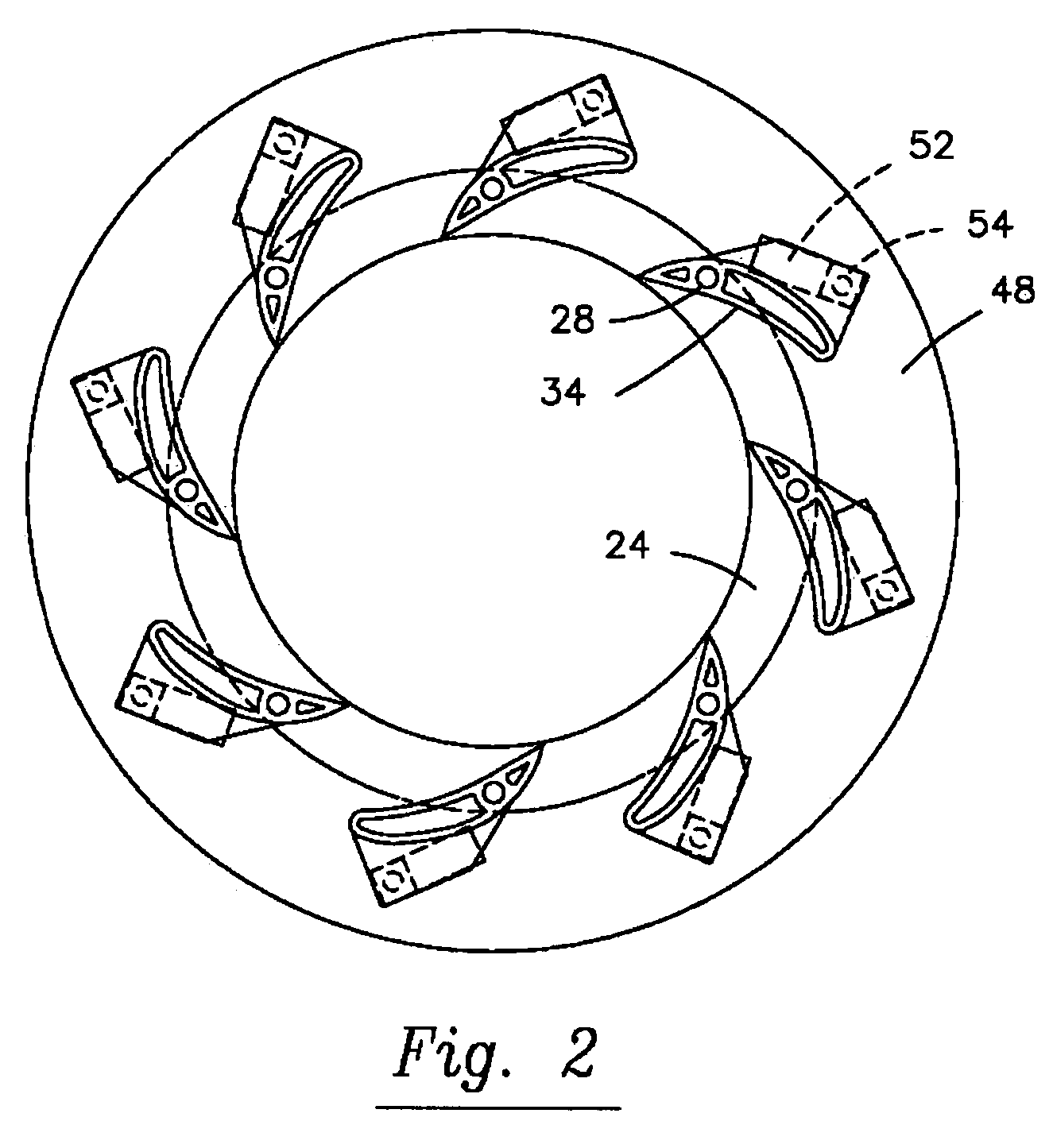

Variable turbine geometry turbocharger

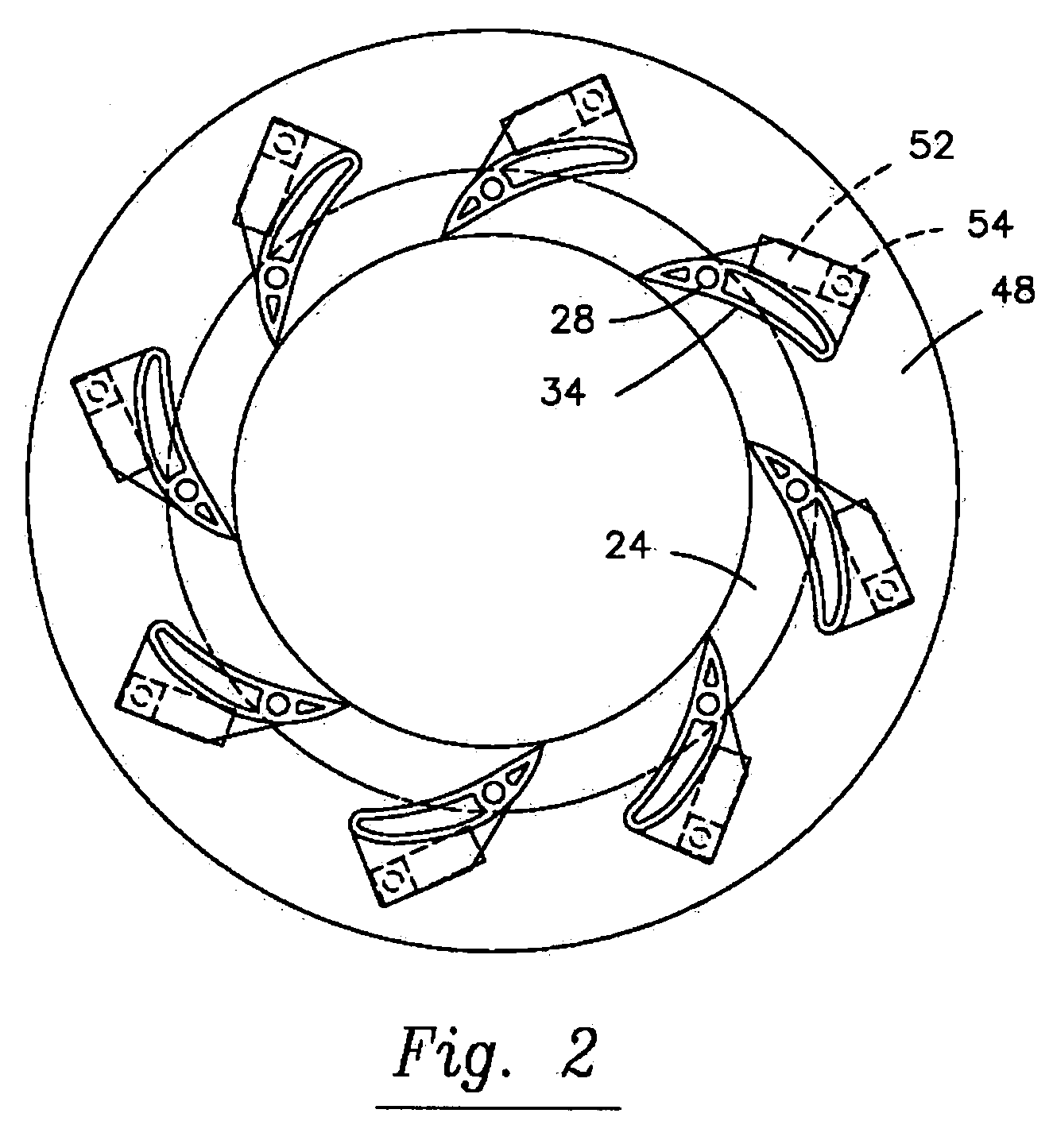

A turbocharger arrangement for a variable geometry turbocharger including pivotable vanes (34) with each vane (34) having a respective vane bore (38) for receiving a vane post (28) into a vane first planar surface (80) and a respective actuation post (36) projecting outwardly from the first planar surface (80).

Owner:BORGWARNER INC

Three-dimensional nozzle ring vane of variable geometry turbocharger and design method thereof

ActiveCN101915130AWide flow rangeImprove turbine efficiencyGas turbine plantsEngine componentsLeading edgeMixed flow

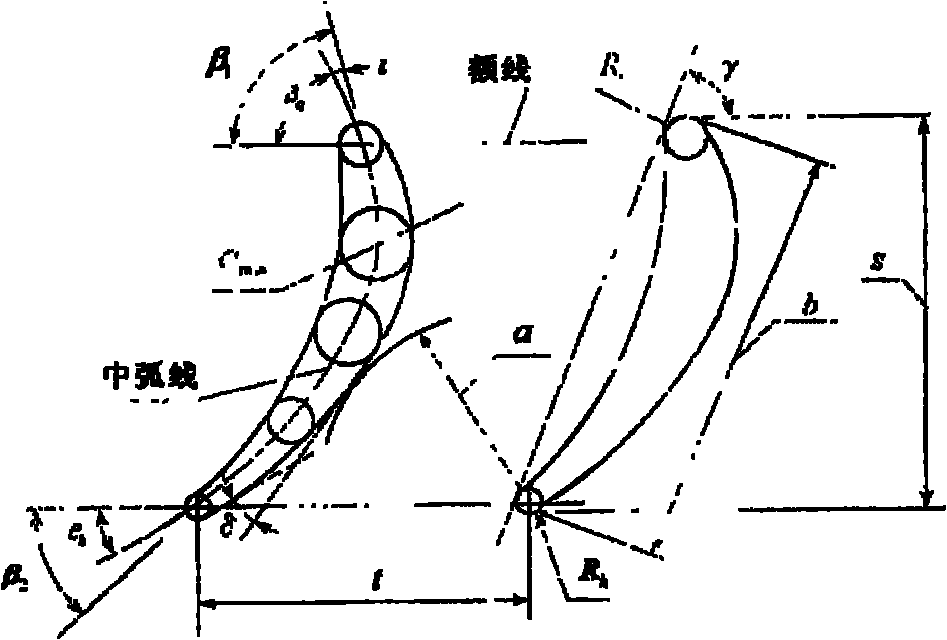

The invention relates to a three-dimensional nozzle ring vane of a variable geometry turbocharger (VGT), comprising a pressure side, a suction side, a vane leading edge and a vane trailing edge, wherein the pressure side corresponds to the concave side of the vane profile; the suction side corresponds to the convex side of the vane profile; the molding lines of the pressure side and the suction side are quadratic curves or biquadratic curves and are not the same; the leading edges of the pressure side and the suction side form the leading edge of the vane; the molding line of the leading edgeof the vane is a quadratic curve and forms the three-dimensional curve leading edge; the trailing edges of the pressure side and the suction side form the trailing edge of the vane; the molding line of the trailing edge of the vane is a quadratic curve, and the height molding line of the trailing edge is identical with the inlet molding line of the turbine vane and the molding line of the trailing edge forms the three-dimensional spatial curve sharp trail. The nozzle ring vane ensures the radial-flow turbine of the VGT to develop into the mixed flow turbine, thus improving the turbine efficiency. The invention also provides a design method of the three-dimensional nozzle ring vane, and the nozzle ring vane designed by the method has higher success rate and lower cost.

Owner:PINGXIANG HUICHENG PRECISION MACHINERY & ELECTRONICS

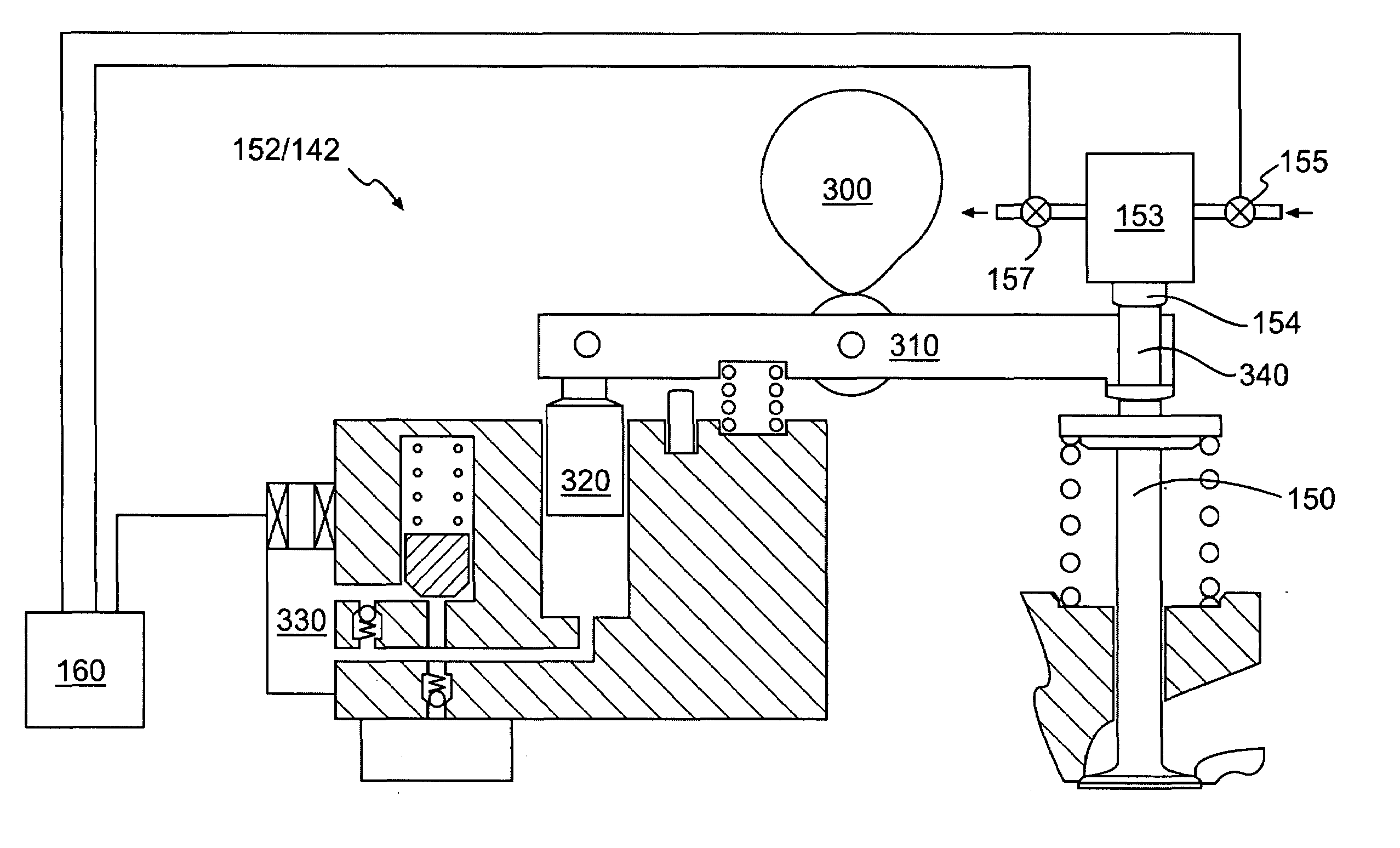

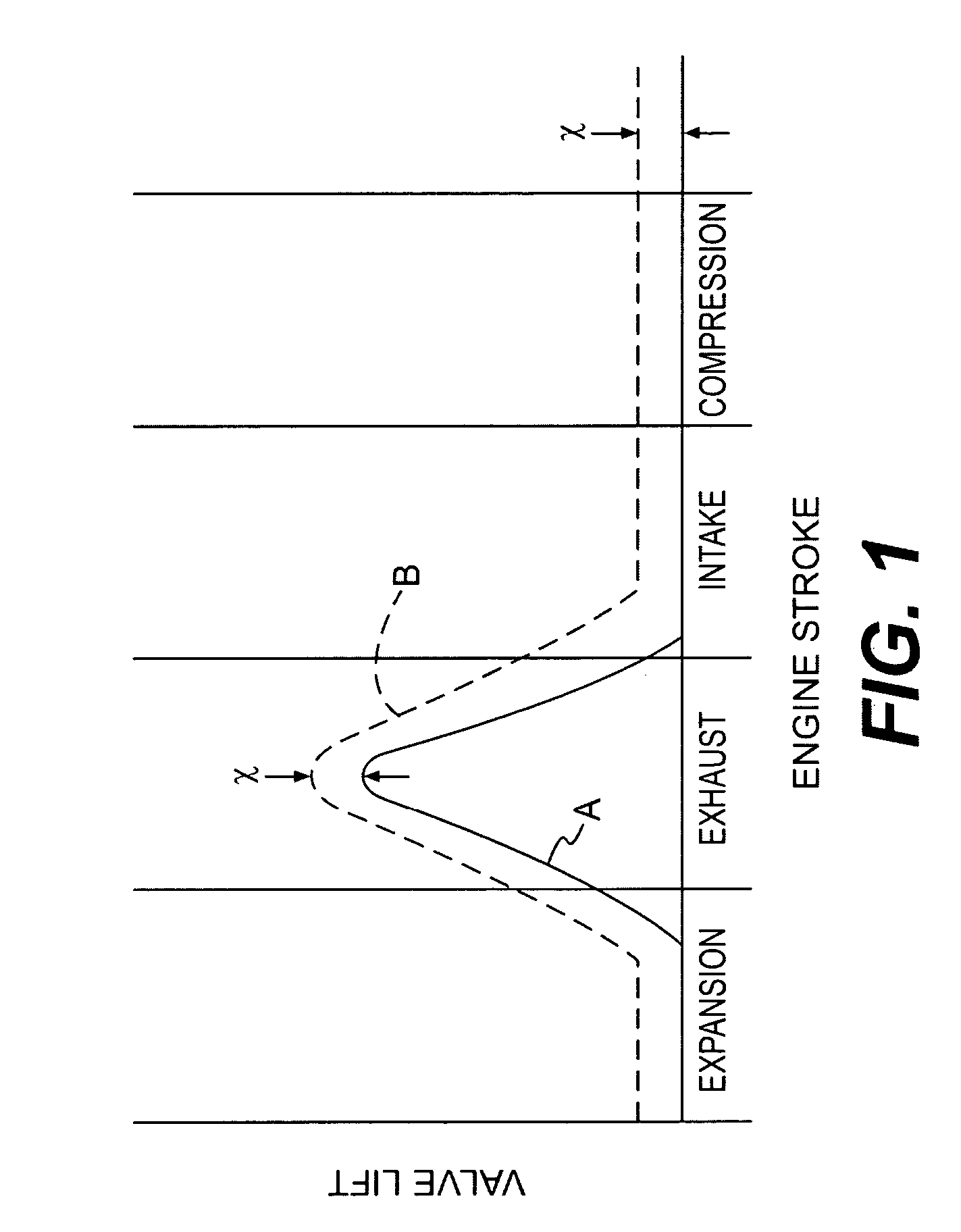

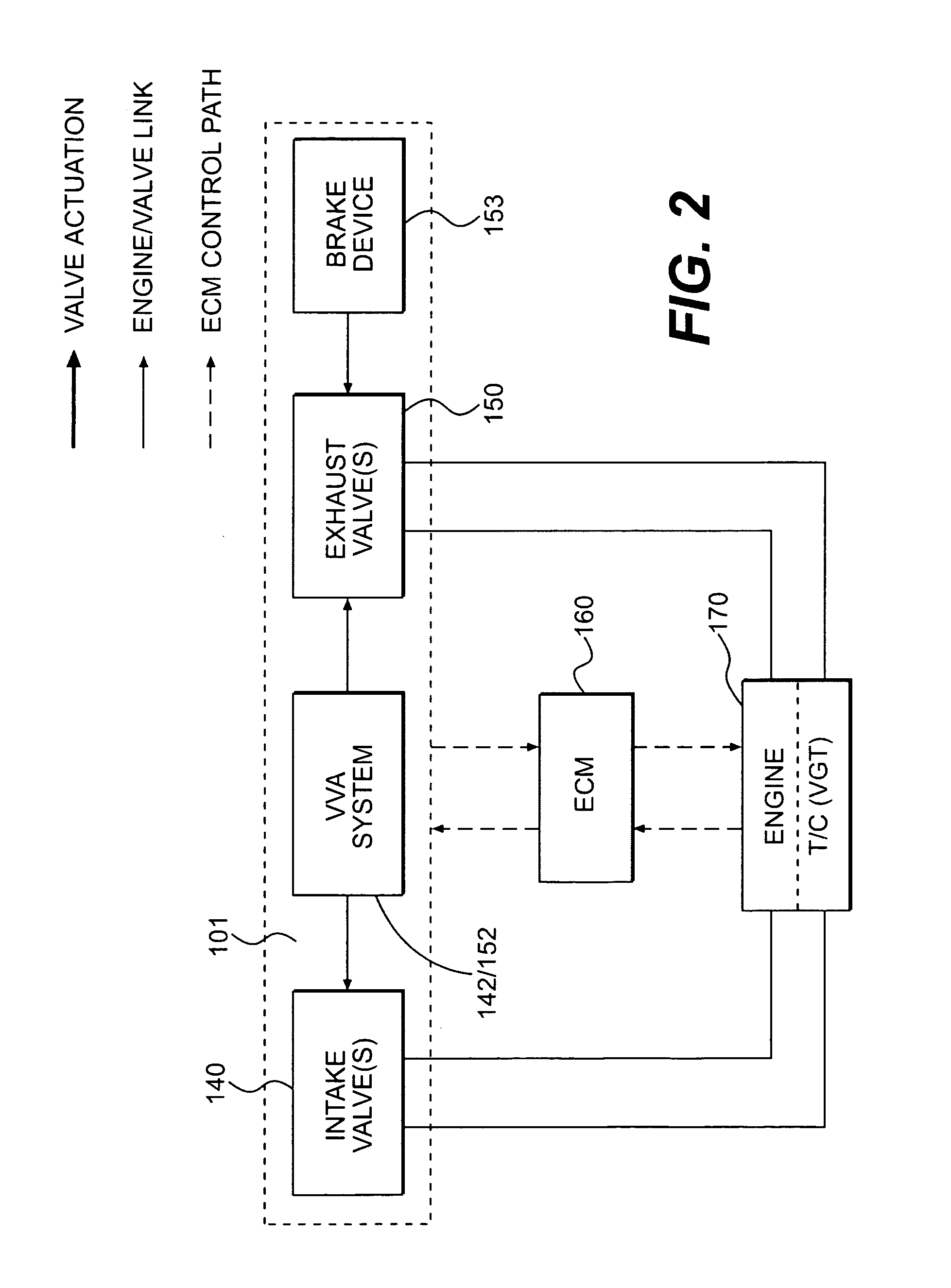

Engine braking methods and apparatus

ActiveUS7162996B2Constant liftNon-fuel substance addition to fuelInternal combustion piston enginesExhaust brakeVariable-geometry turbocharger

Methods and apparatus for providing bleeder-type and compression-release engine braking in an internal combustion engine are disclosed. For bleeder-type engine braking, the exhaust valve is maintained at a small and relatively constant lift throughout all or much of the engine cycle. The engine braking may be combined with exhaust gas recirculation, variable exhaust brake, and / or operation of a variable geometry turbocharger.

Owner:JACOBS VEHICLE SYST

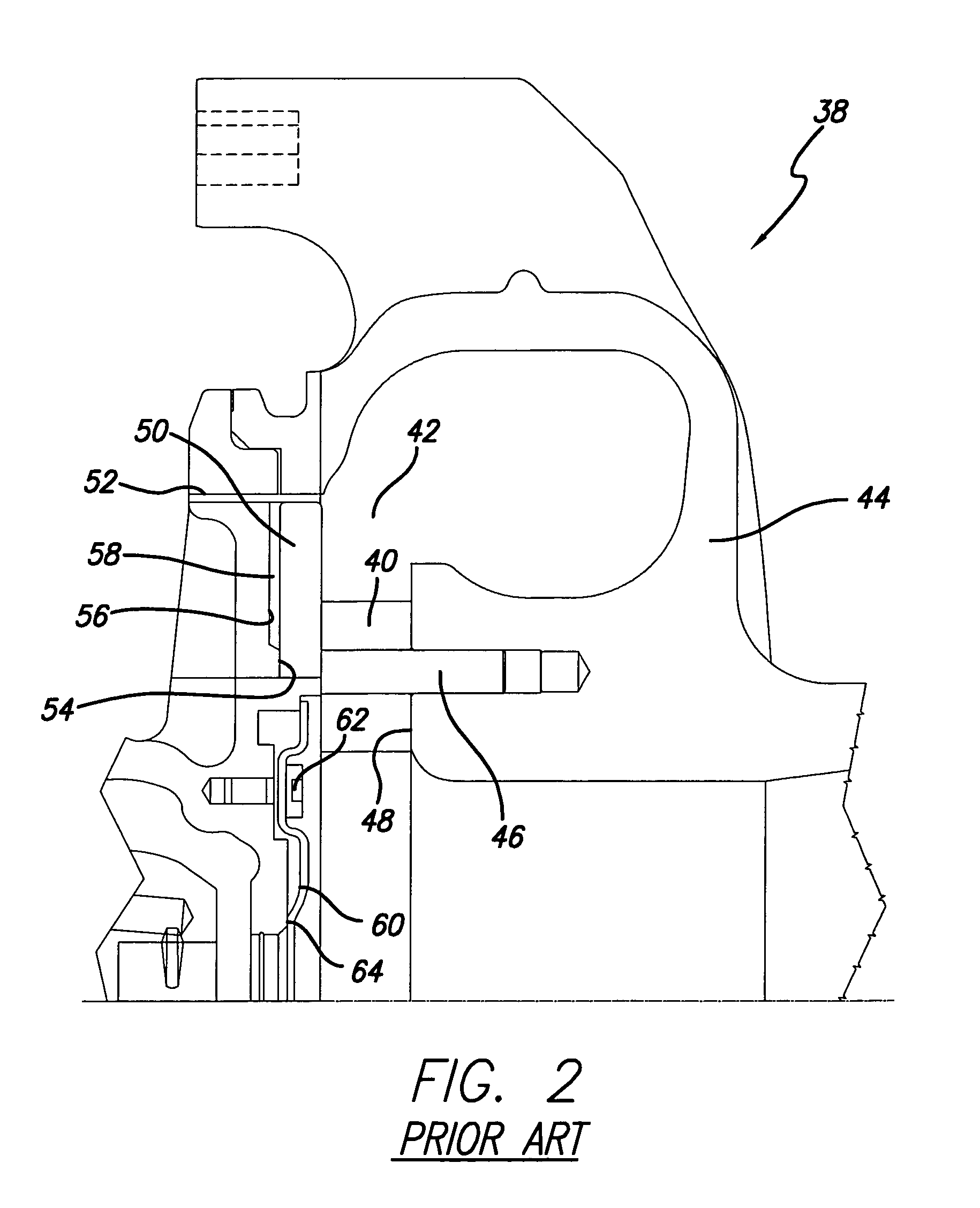

Variable geometry turbocharger with sliding piston

A turbocharger having a variable geometry turbine inlet incorporates a piston movable to vary the area of the inlet nozzle into the turbine. Vanes extending from the heat shield for flow control in the nozzle are engaged by the piston in a first closed position. In a second open position, the piston is spaced from the vanes increasing the inlet nozzle area.

Owner:HONEYWELL GARRETT

System and method for backpressure compensation for controlling exhaust gas particulate emissions

InactiveUS7437874B2Avoiding unnecessary over closureIncreased backpressureAnalogue computers for vehiclesElectrical controlParticulatesExhaust fumes

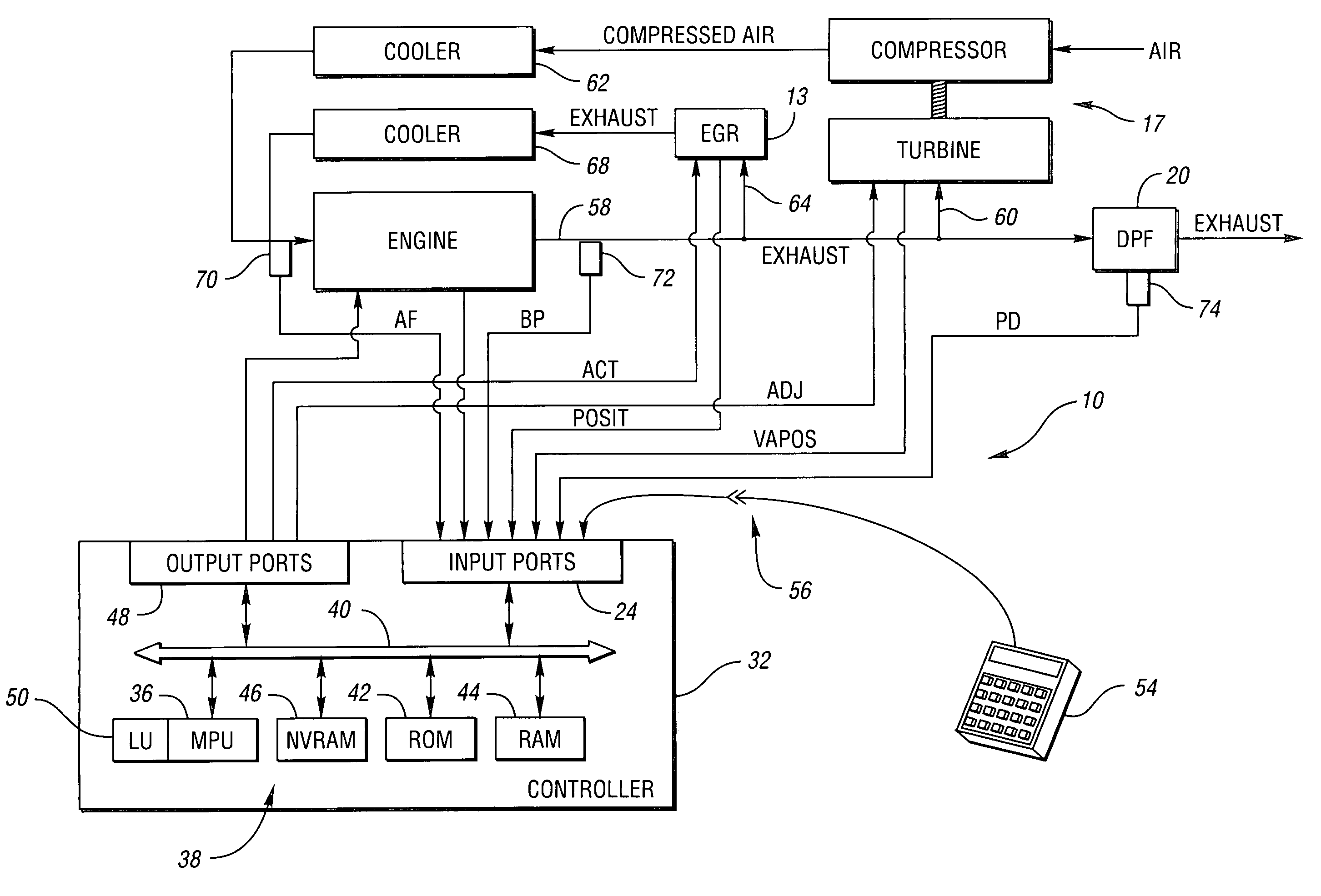

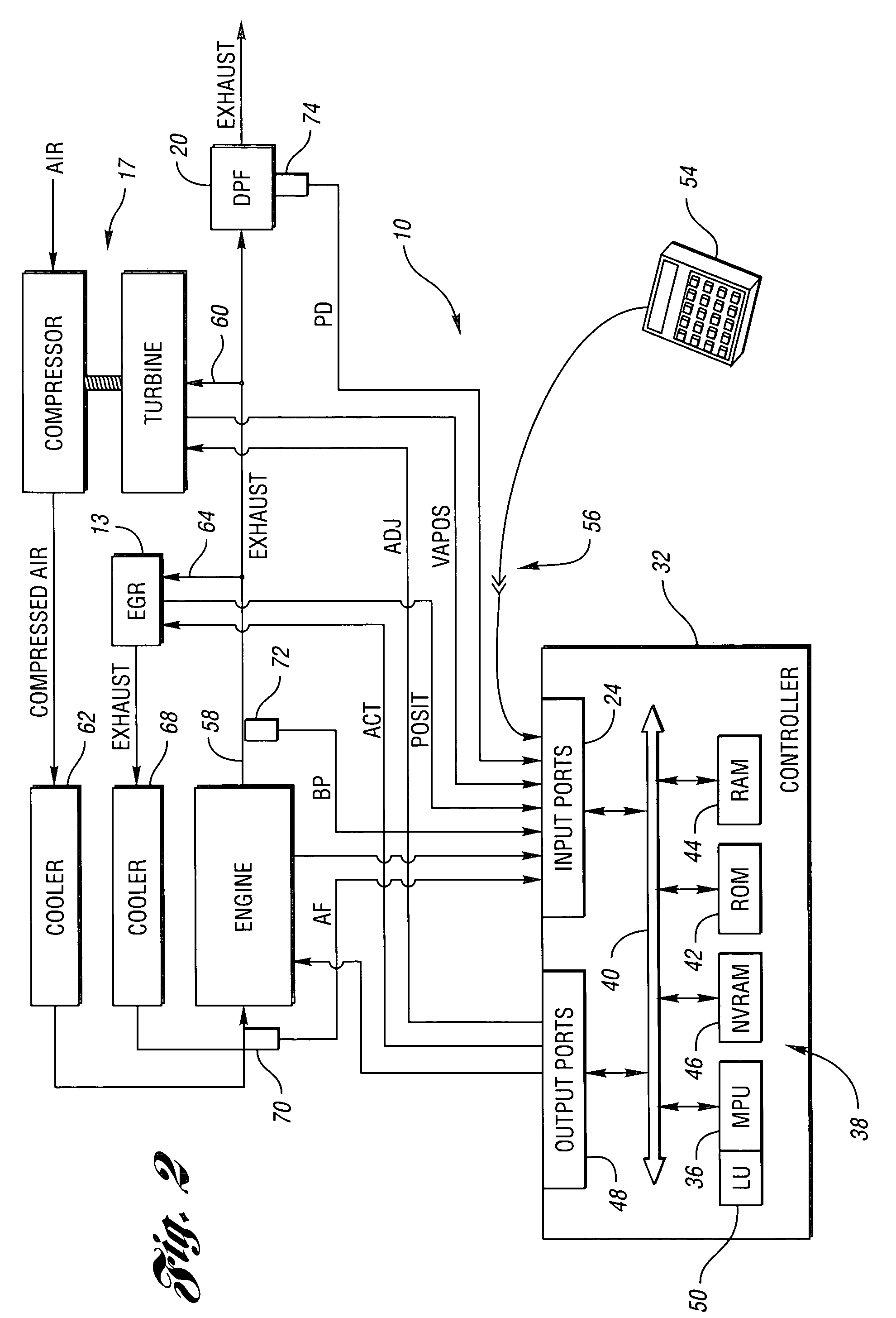

A method for controlling exhaust gas particulate emissions from a compression ignition internal combustion engine having a variable geometry turbocharger (VGT) includes the steps of determining backpressure across the engine and air mass flow into the engine, closing vanes of the VGT to provide air mass flow increase when backpressure is increasing, and stopping the step of closing the vanes of the VGT when a decrease in rate of change of air mass flow is determined.

Owner:DETROIT DIESEL CORP

Simplified variable geometry turbocharger with increased flow range

InactiveUS20130219885A1Low costExpand flow rangeInternal combustion piston enginesPump componentsImpellerTurbine wheel

A variable geometry turbocharger is simplified yet able to maintain pulse energy. In a first embodiment, a turbine housing is provided with a pivoting flow control valve which pivots about a point near the entry to the turbine housing. By moving the valve about the pivot point, the effective volume of the turbine housing volute is varied, thus effectively reducing the volume of exhaust gas in the volute, allowing control of exhaust gas flowing to the turbine wheel. In the second embodiment of the invention, a rotating wedge segment within the volute is rotated from a first position to a second position, changing the effective volume of the volute and allowing control of exhaust gas flowing to the turbine wheel.

Owner:BORGWARNER INC

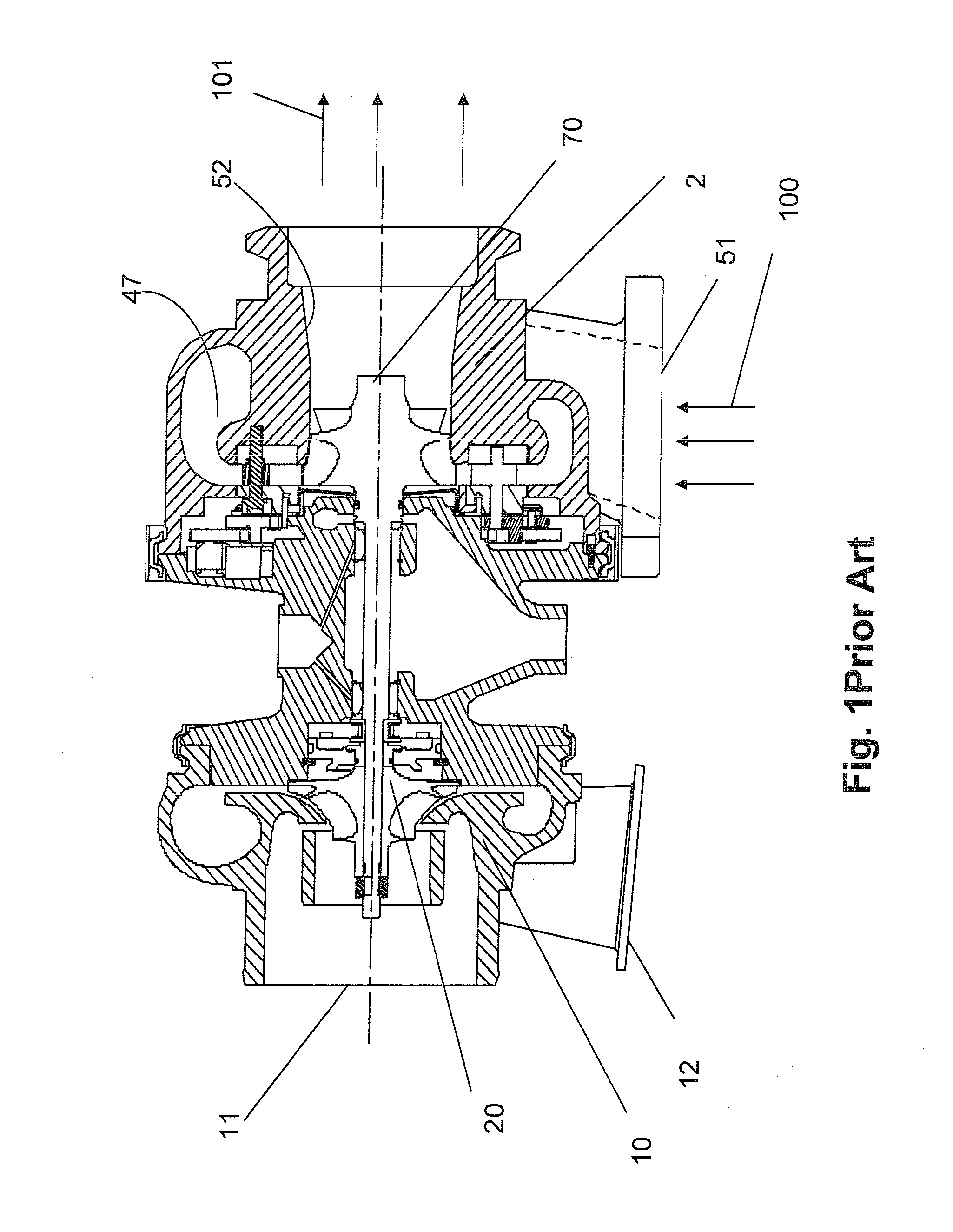

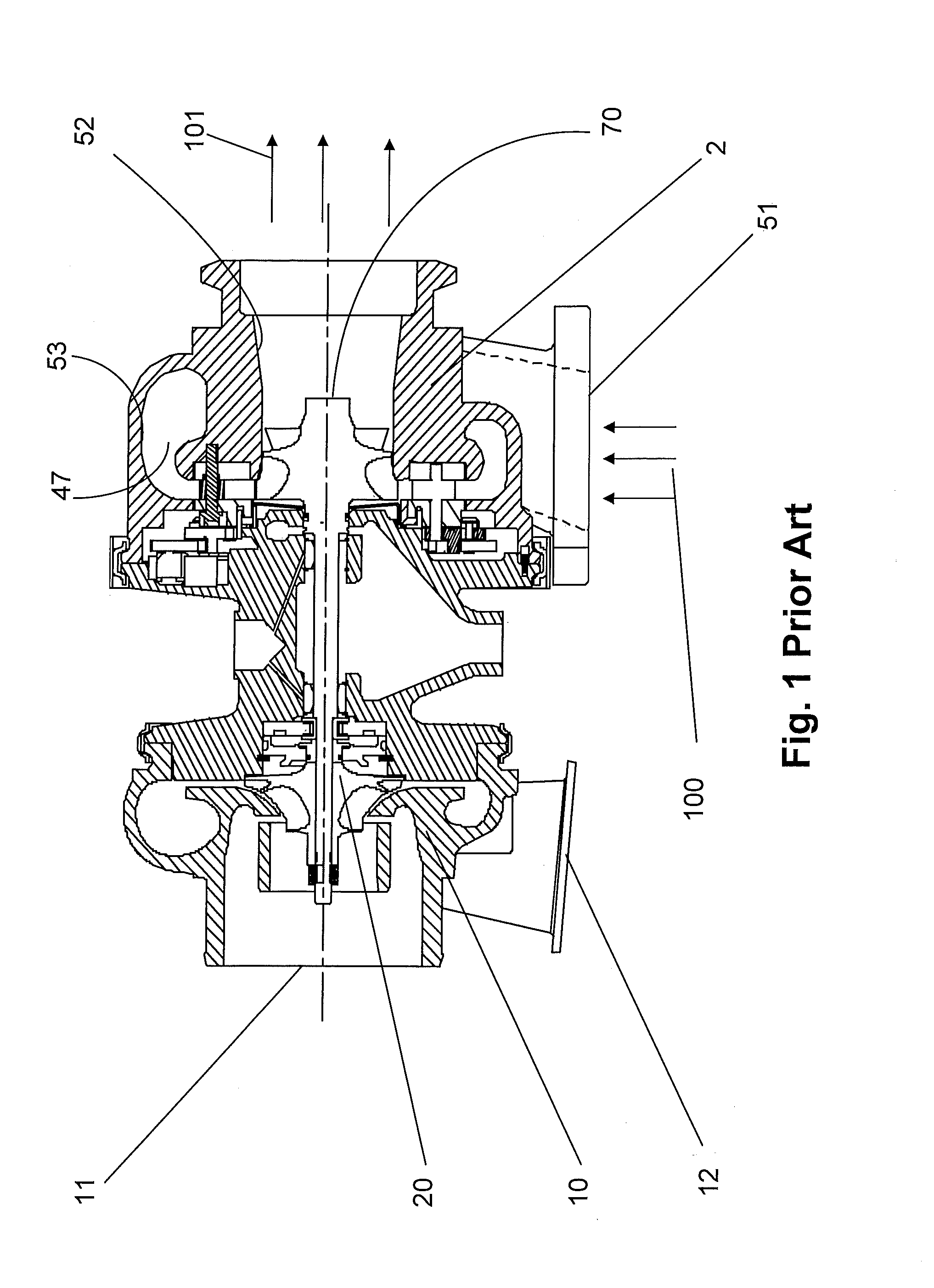

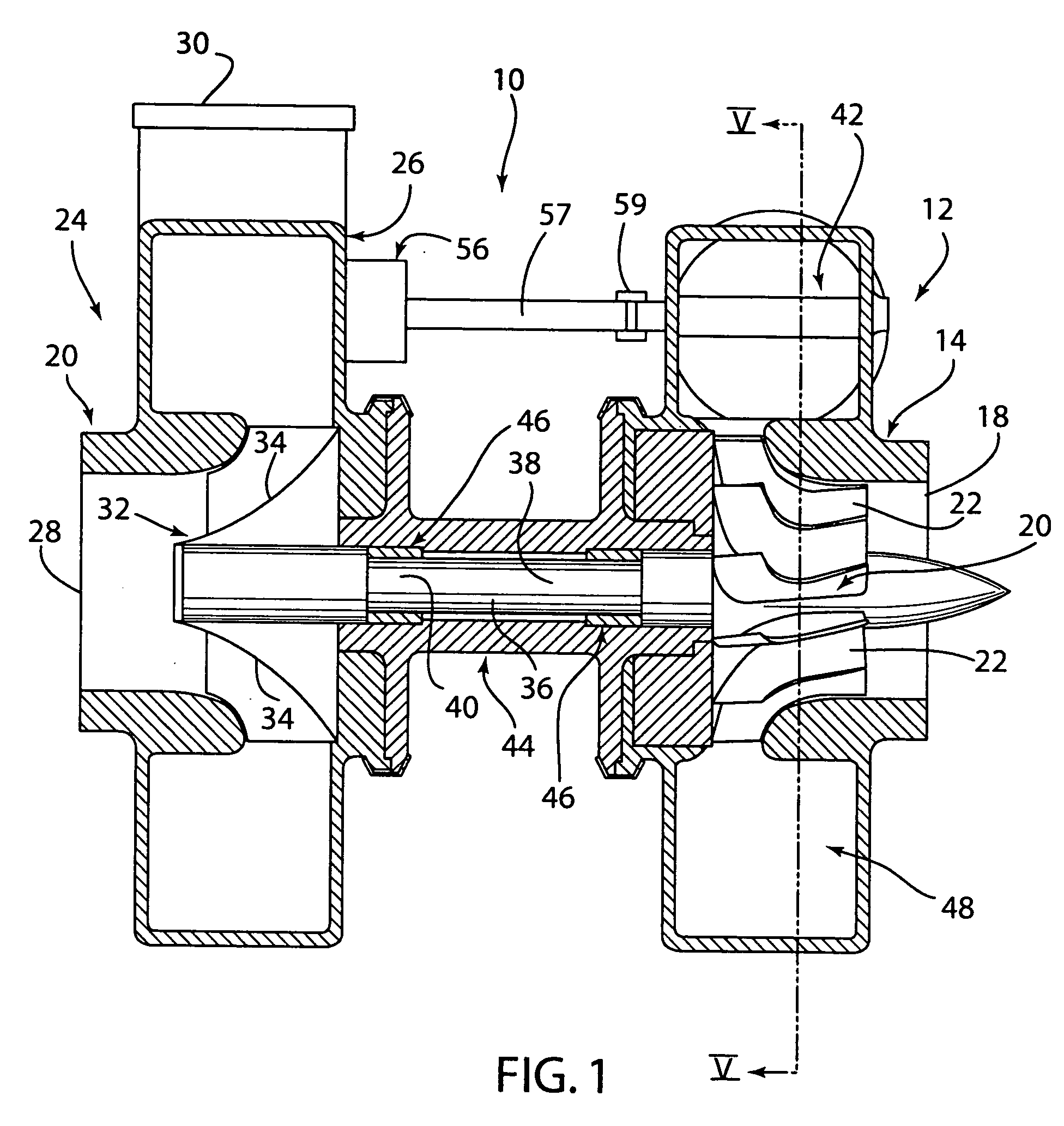

Variable geometry assembly for turbochargers

InactiveUS6925806B1Minimizing and eliminating potentialPrevent unwanted differential thermal expansion effectWind motor controlPump componentsVariable-geometry turbochargerEngineering

A variable geometry turbocharger assembly employing the present invention includes a center housing, a compressor housing attached to one side of the center housing, and a turbine housing attached to another side of the center housing. A plurality of movable vanes is disposed within the turbine housing, and a unison ring is rotatably disposed within the turbine housing to move the vanes in unison. The turbocharger includes a unison ring assembly of this invention that includes an insert that is separate from and attached to the center housing. The support has one or more surfaces to carry the unison ring, and the unison ring is rotatably positioned on the support. The support further provides a space that isolates the unison ring from making contact with contacting the center housing. A heat shroud optionally extends radially inwardly along the center housing and is retained into position by the support.

Owner:HONEYWELL INT INC

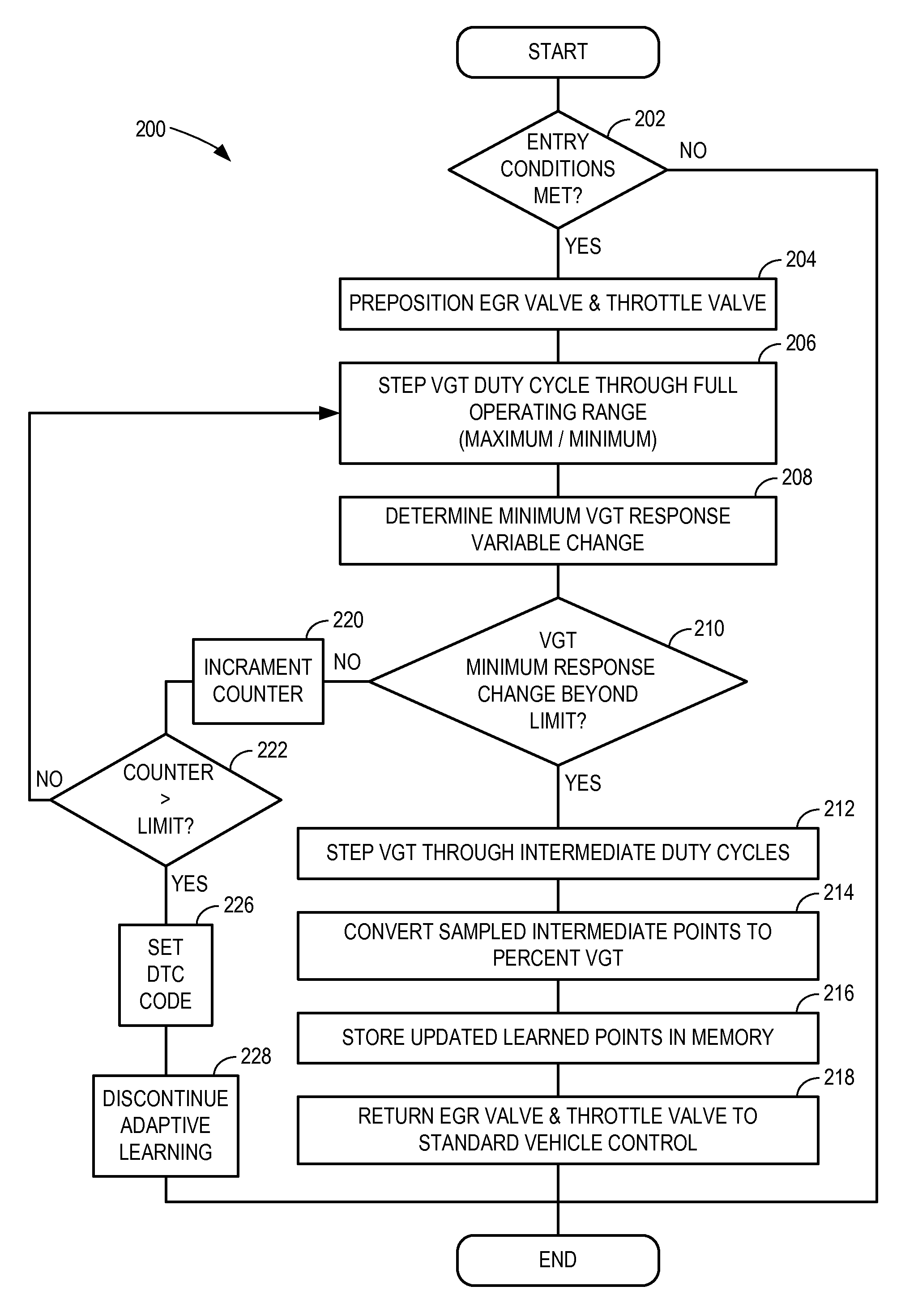

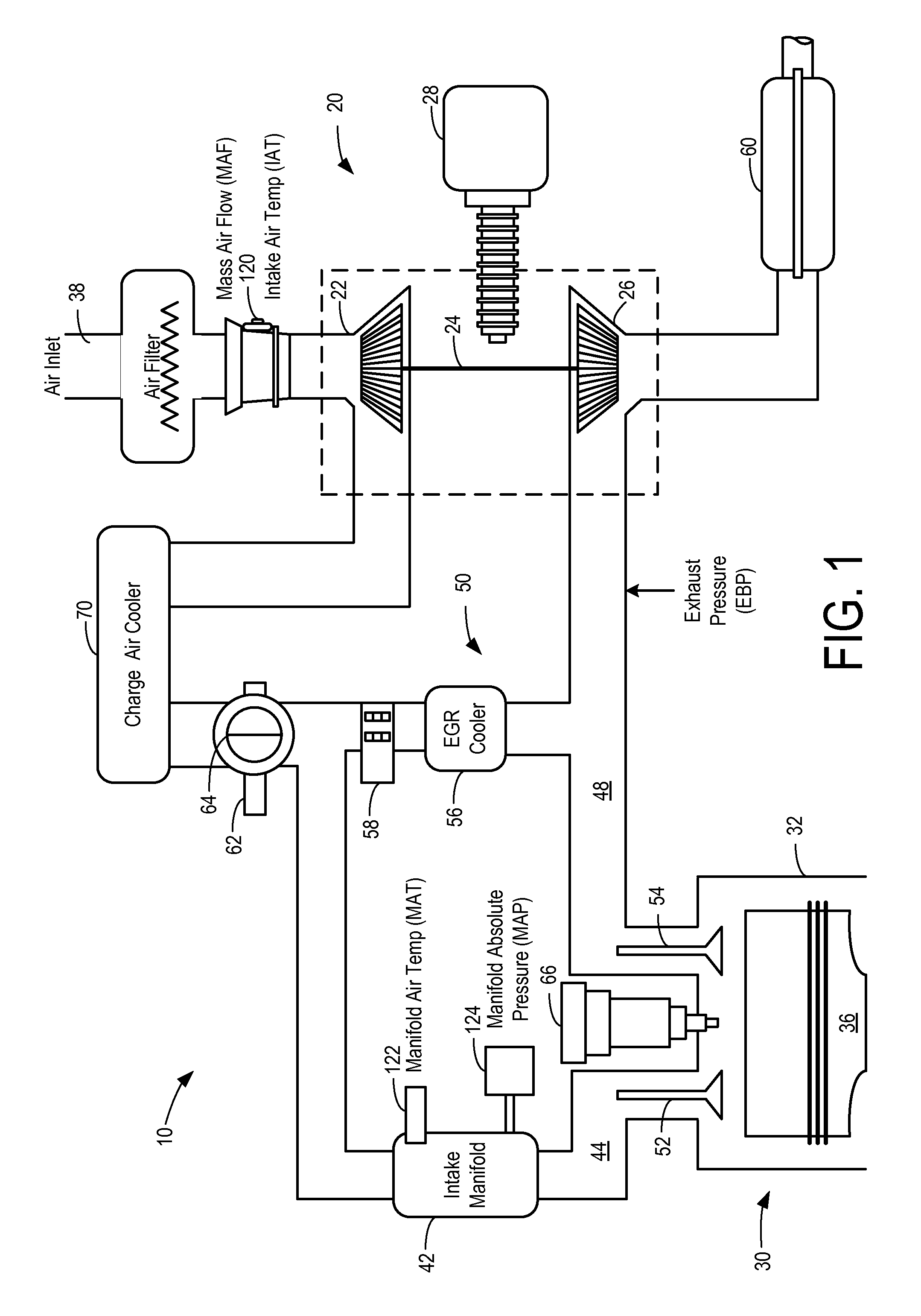

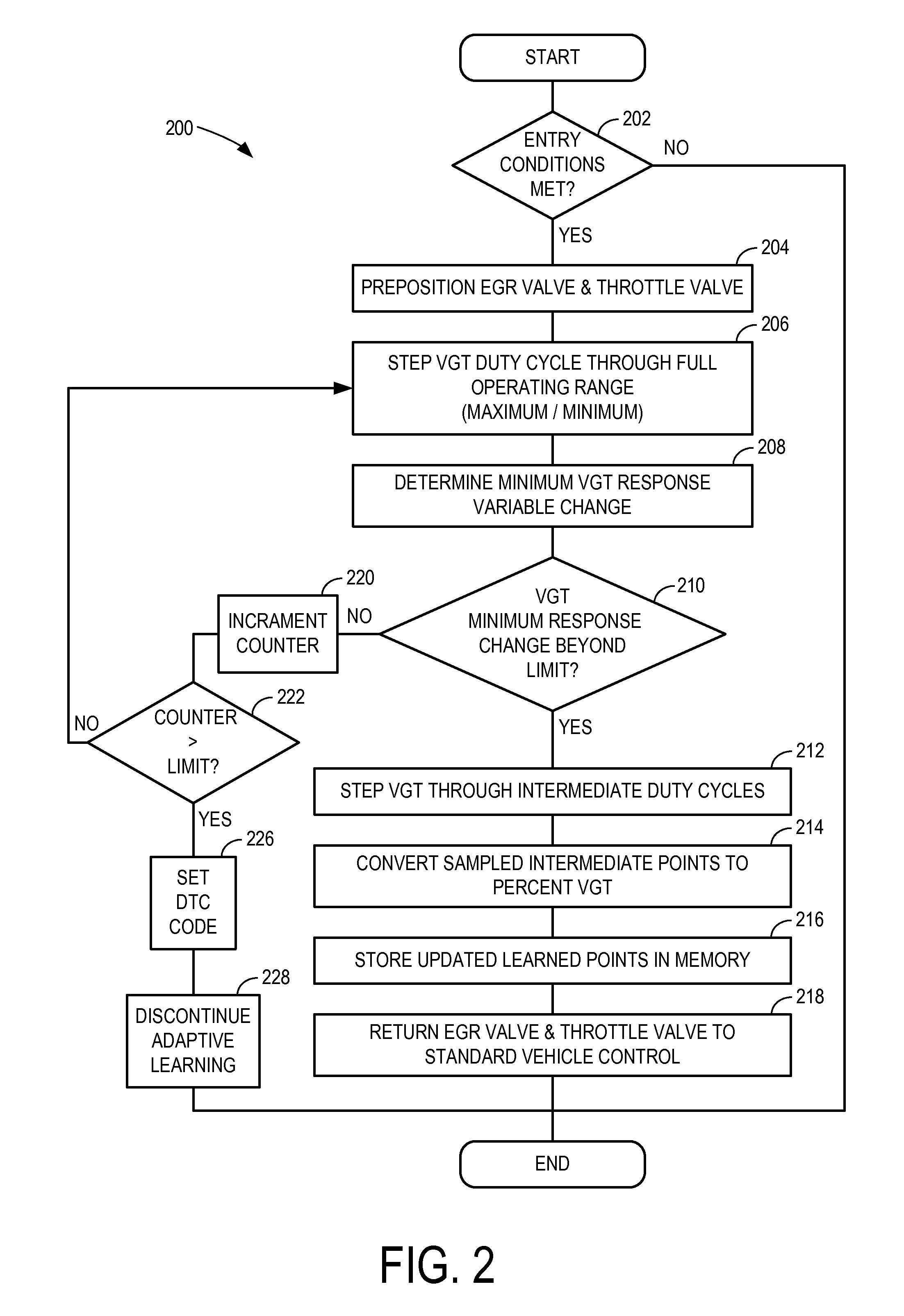

Adaptive learning system and method of vane position for a variable geometry turbocharger

ActiveUS8151567B2Improve performanceImprove efficiencyElectrical controlInternal combustion piston enginesAdaptive learningEngineering

A method of operation for an engine system having a variable geometry turbocharger with a vane is disclosed. In one example, an EGR valve is closed while vane position is adjusted. The method can reduce vane positioning errors during engine operation.

Owner:FORD GLOBAL TECH LLC

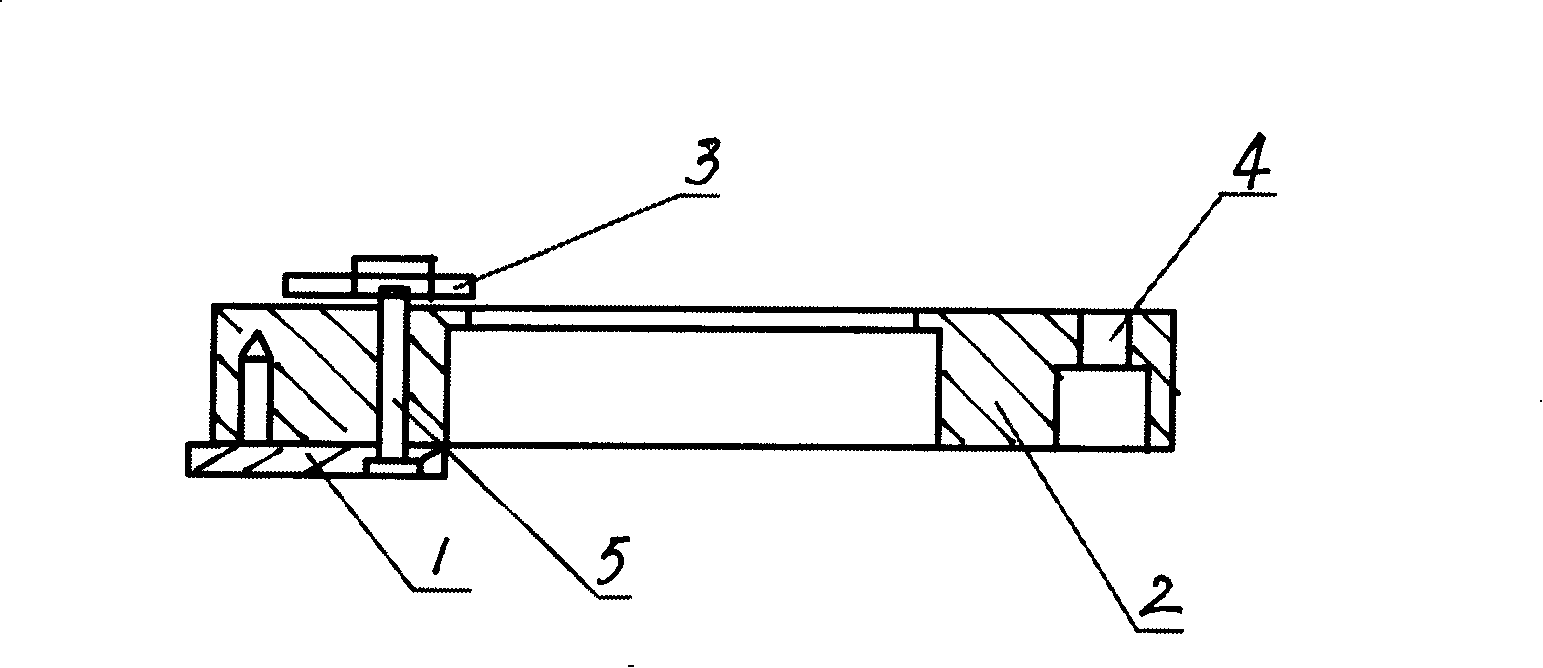

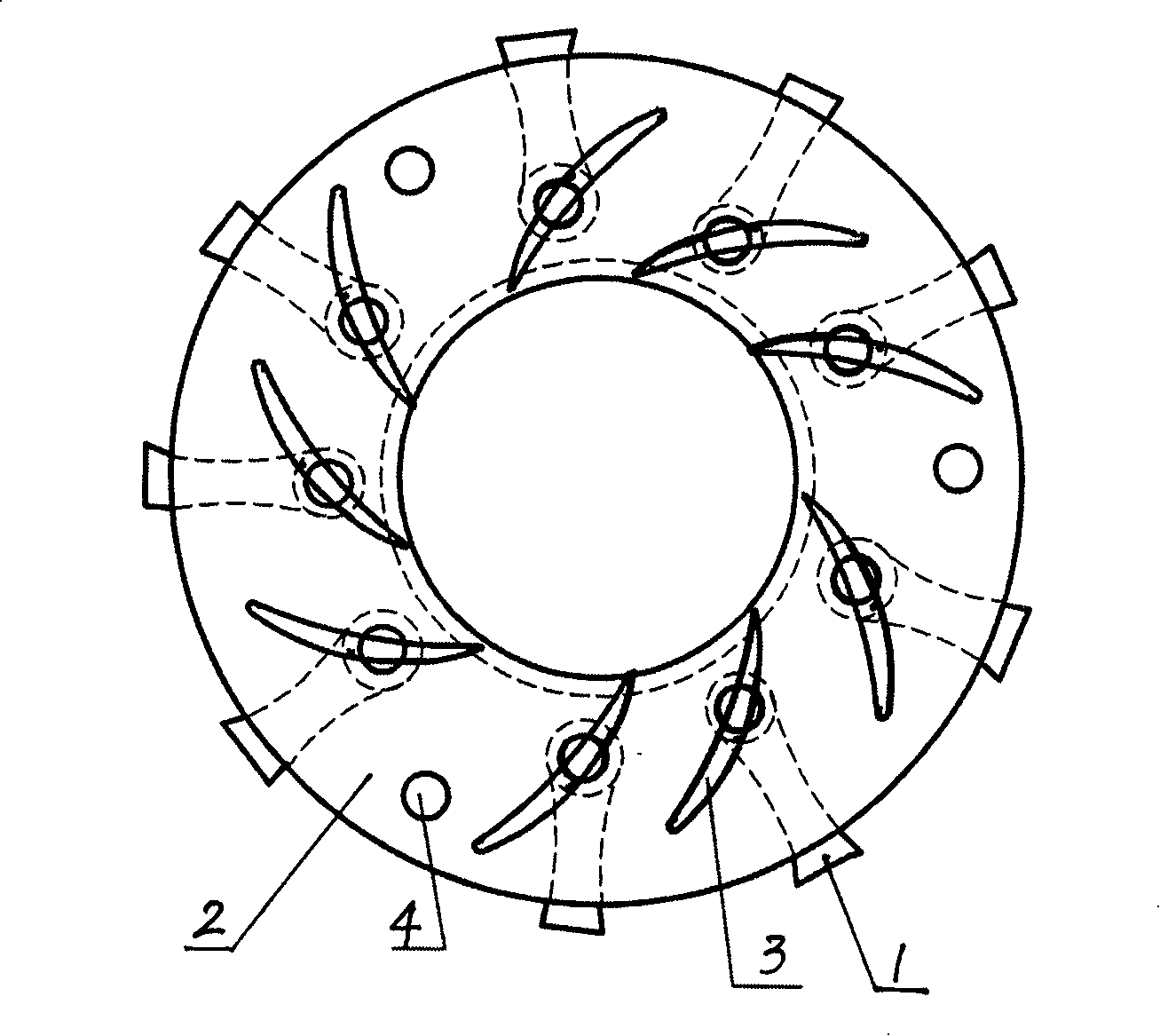

Internal combustion engine variable geometry turbine supercharger nozzle ring components

ActiveCN101191425AExtended service lifeIncrease output powerInternal combustion piston enginesEngine componentsVariable geometry turbineEmission standard

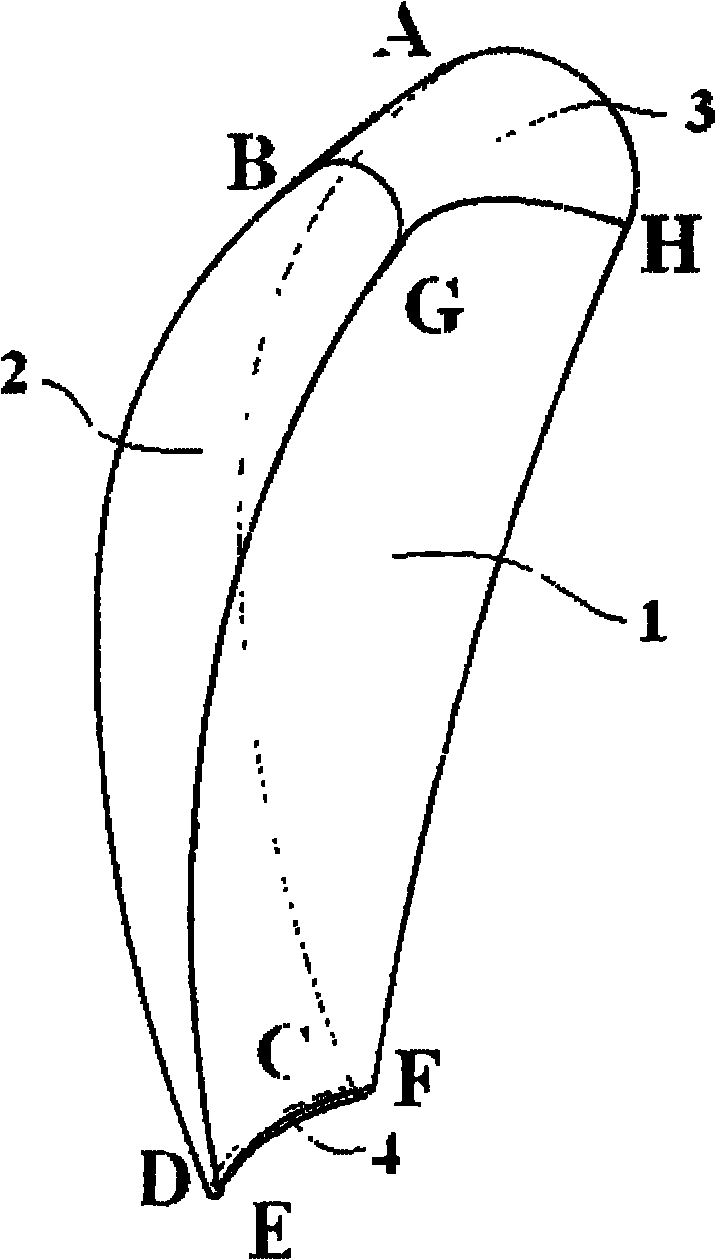

The invention discloses an internal-combustion engine variable geometry turbocharger nozzle ring component, comprising forks(1), a mounting plate(2) and a blade(3), wherein the side surface of the mounting plate(2) is provided with a plurality of groups of blades(3) which are evenly spaced and arranged on the same circumference and are in the same direction, each group of blades which consists of at least three blades(3) and can be mutually opened and folded simultaneously; the other side of the mounting plate is provided with forks(1) which are connected with corresponding blades; because the blades are the three dimensional curved surface, air inlet passages for blades are continuously changed, the air input of the turbocharger is also continuously changed according to the working condition of the engine, thereby the engine can get proper amount of pressurized air under all conditions, which makes that the engine always runs under a reasonable condition, thereby realizing that the turbocharger increases the output power of the engine by 30 to 100 percent, reducing the emission of harmful gas by more than 10 percent, realizing that the fume emission reaches the emission standard of the European IV, lowering oil consumption by 5 to 10 percent and improving the economical efficiency of the automobile.

Owner:PINGXIANG DEBO TECH CO LTD

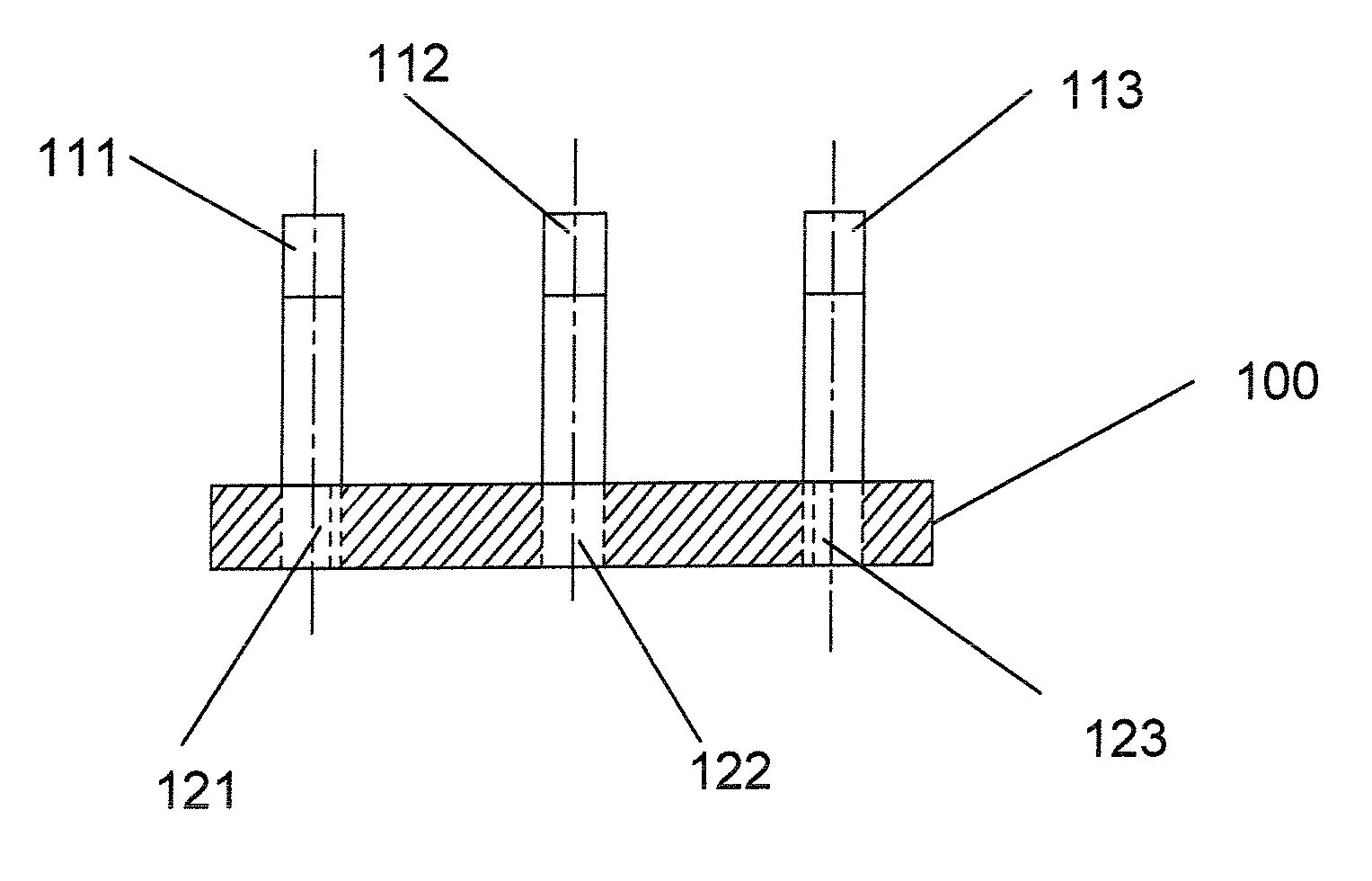

Variable geometry turbocharger lower vane ring retaining system

ActiveUS20100008774A1Minimizes effect of thermalEffective maintenancePump componentsEngine fuctionsThermal expansionTurbine

A vane ring assembly which includes a lower vane ring (22), an upper vane ring (30), one or more guide vanes (80) positioned at least partially between the vane rings, and a plurality of spacers (42, or 50) positioned between the lower and upper vane rings for maintaining a distance between the lower and upper vane rings. By using a first set of fasteners (190) to fasten the lower vane ring to the turbine housing, and a second set of fasteners (191) to fasten the lower vane ring to the upper vane ring, the vane ring assembly is effectively decoupled from the turbine housing with regard to differential thermal expansion, and the co-planerism of the vane rings is easier to maintain.

Owner:BORGWARNER INC

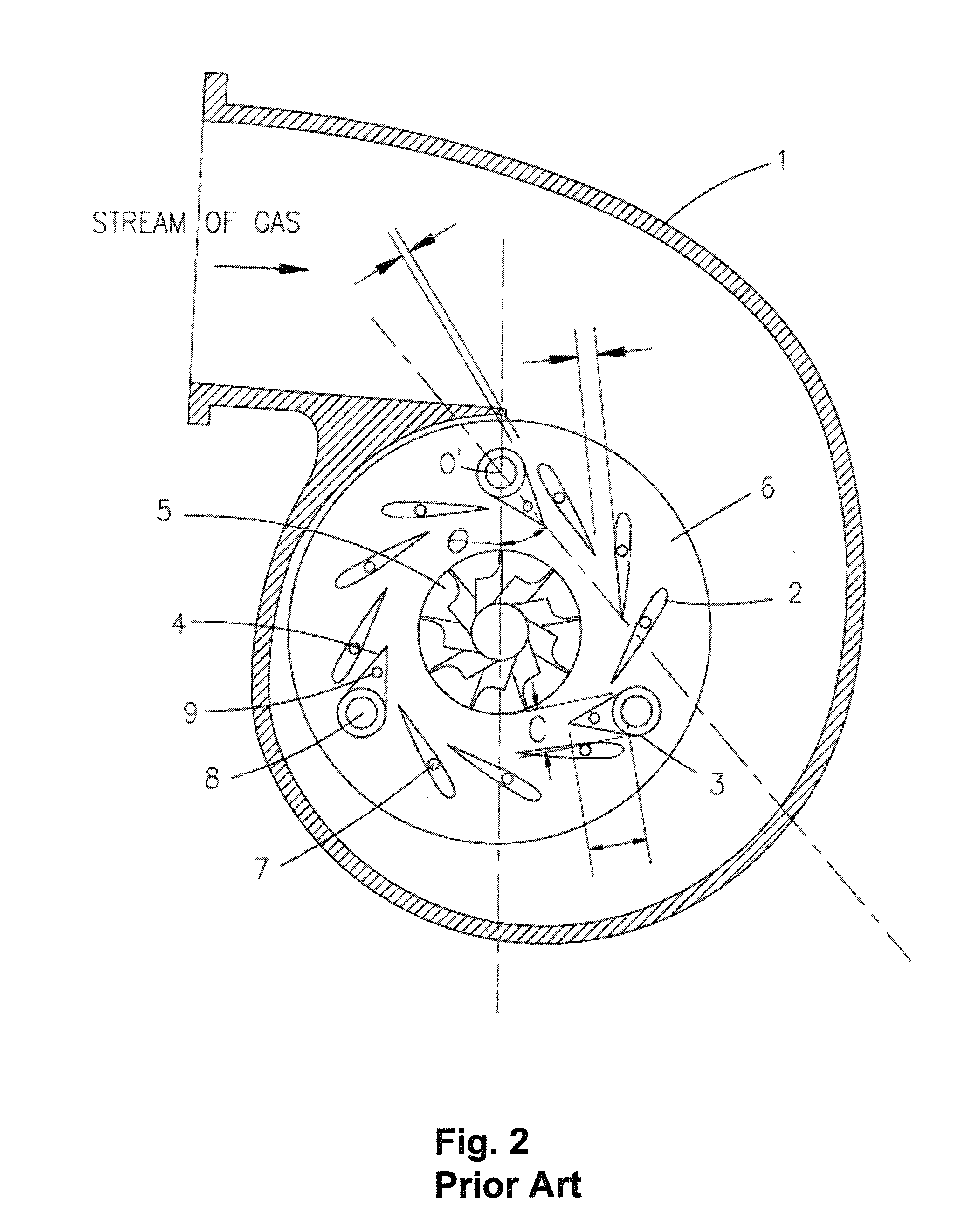

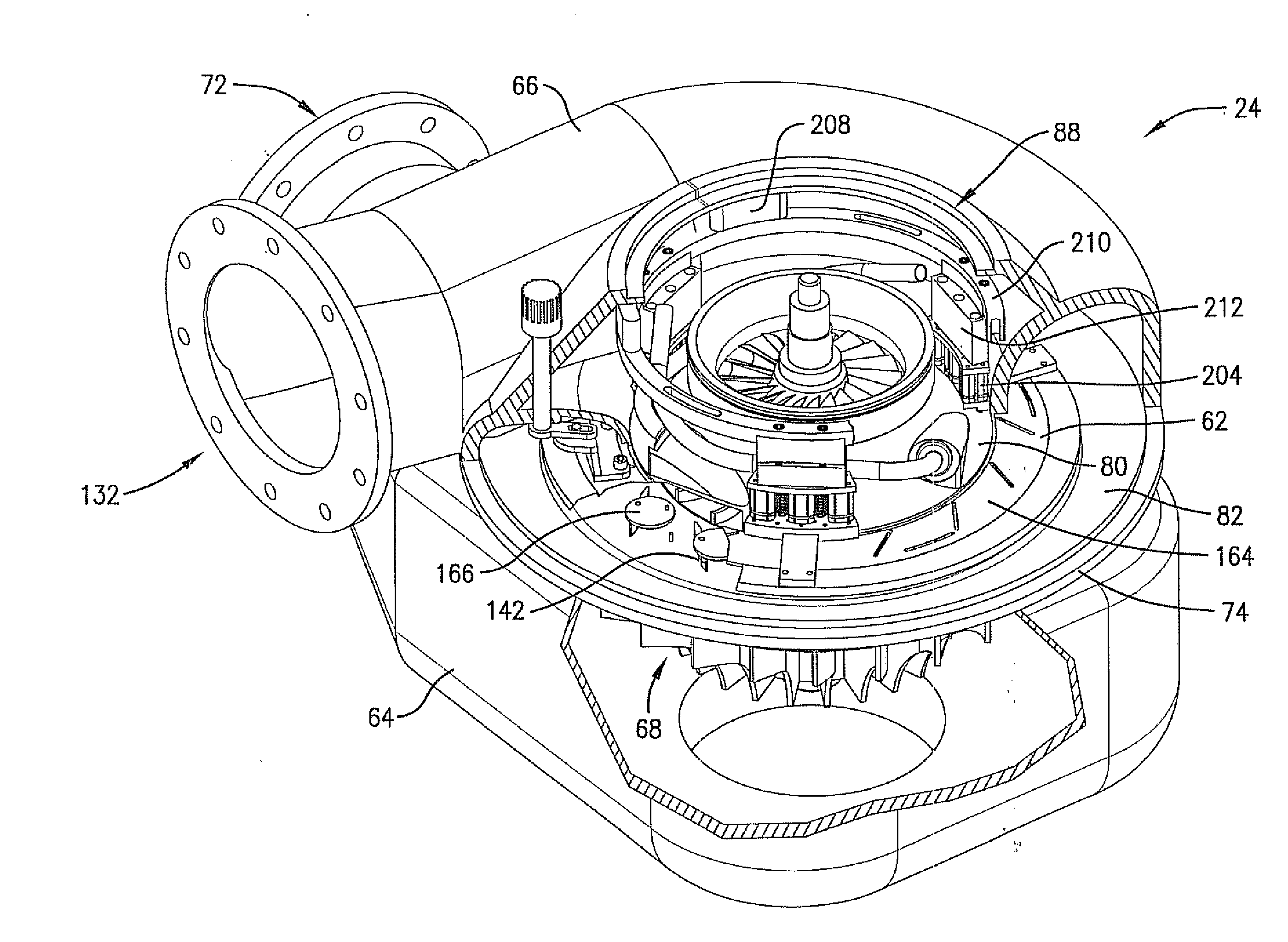

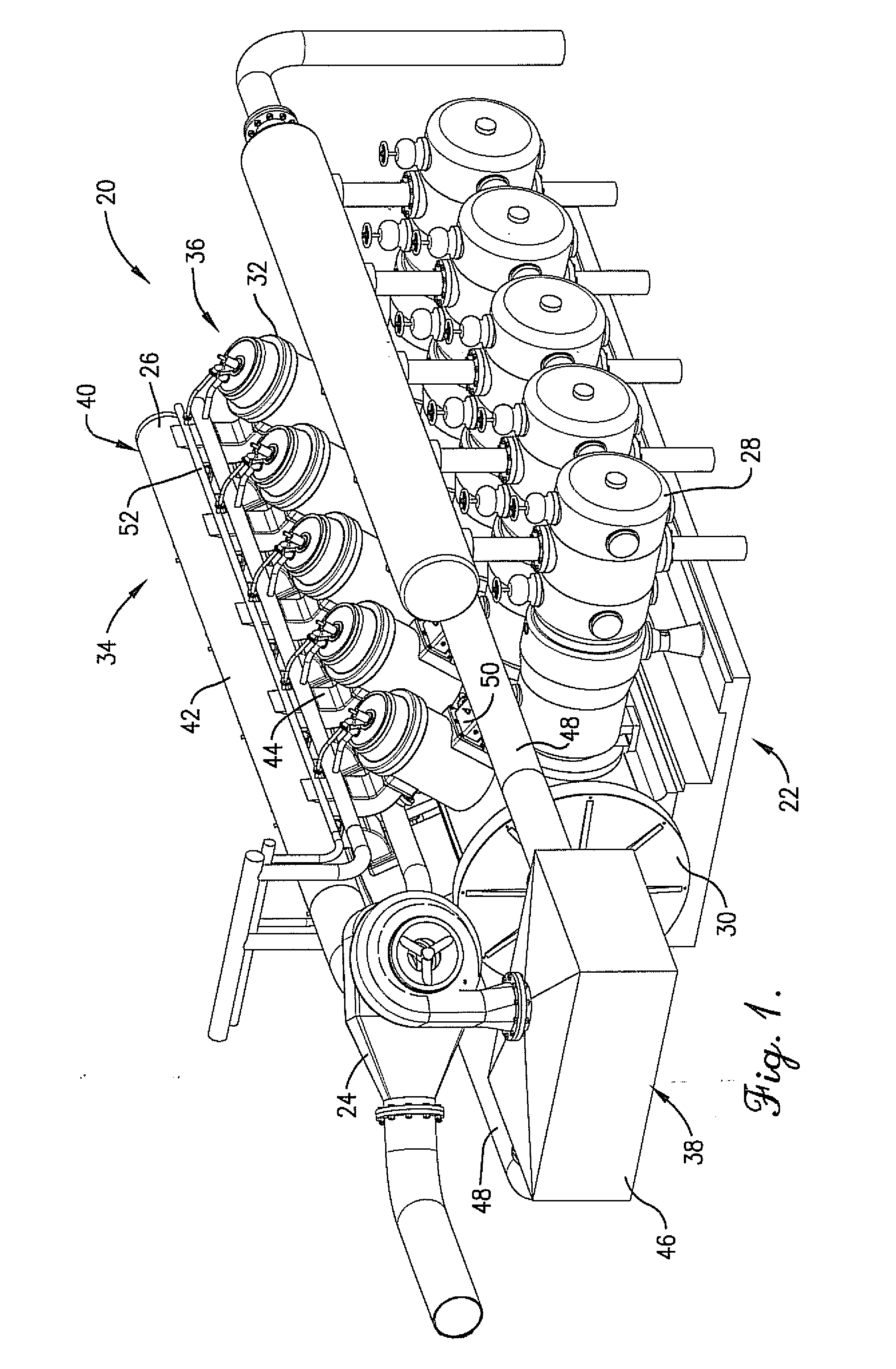

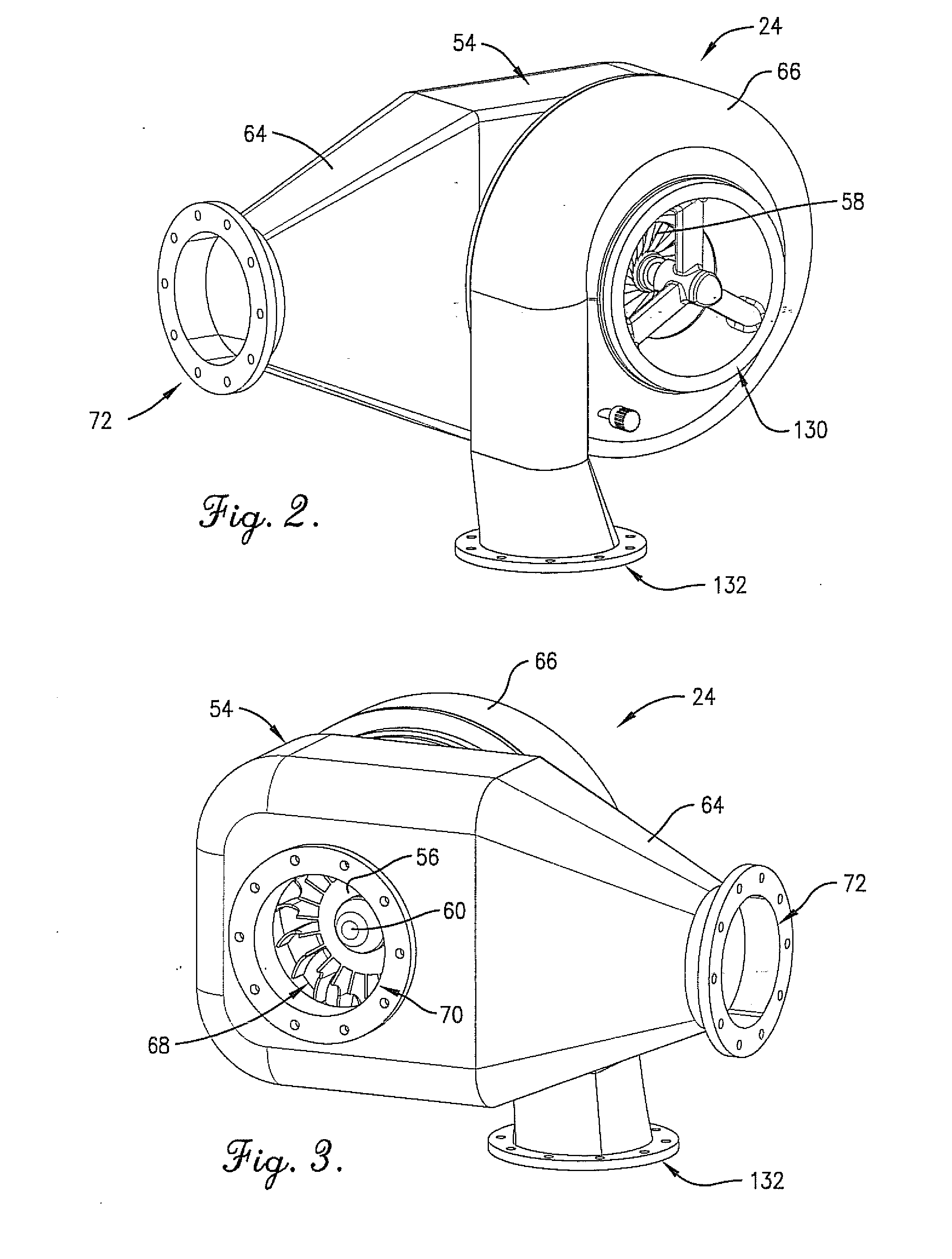

Variable geometry turbocharger

A turbocharged engine includes an internal combustion engine and a variable geometry turbocharger. The turbocharger is adjustable to operate efficiently under various engine operating and environmental conditions. The turbocharger includes a turbine and compressor, with the compressor including a compressor housing, an impeller rotatably mounted in the housing, and an adjustable diffuser vane assembly. The diffuser vane assembly includes a plurality of pivotal diffuser vanes spaced about the impeller and a vane rotation drive that interconnects the vanes and permits simultaneous adjustment of the diffuser vanes to improve the efficiency and operating range of the turbocharger. The diffuser vane assembly also includes a vane locking drive operable to engage the pivotal vanes and prevent vane movement during turbocharger operation.

Owner:KANSAS STATE UNIV RES FOUND

Variable geometry turbocharger, vane ring assembly with retaining member

ActiveUS8061976B2Effective maintenanceCost effectiveWind motor controlPump componentsEngineeringTurbine

A vane ring assembly which includes a lower vane ring (23), an upper vane ring (31), one or more guide vanes (80) positioned at least partially between the vane rings, and a plurality of spacers (49, 50 or 59) positioned between the lower and upper vane rings (23, 31) for maintaining a distance between the lower and upper vane rings, the vane ring assembly being retained in a turbine housing (102) by a retaining ring (400) which is located in a groove (510) in the turbine housing.

Owner:BORGWARNER INC

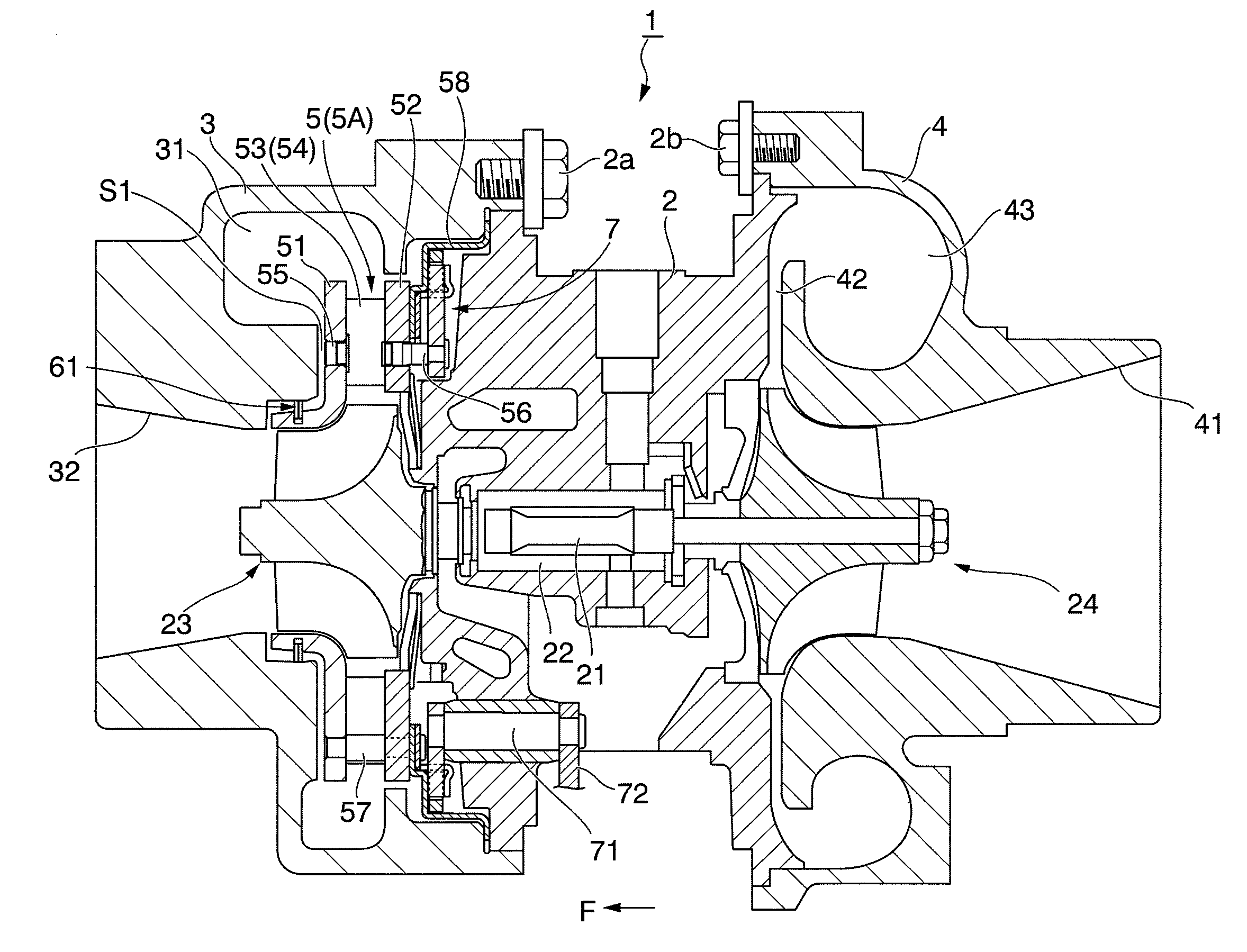

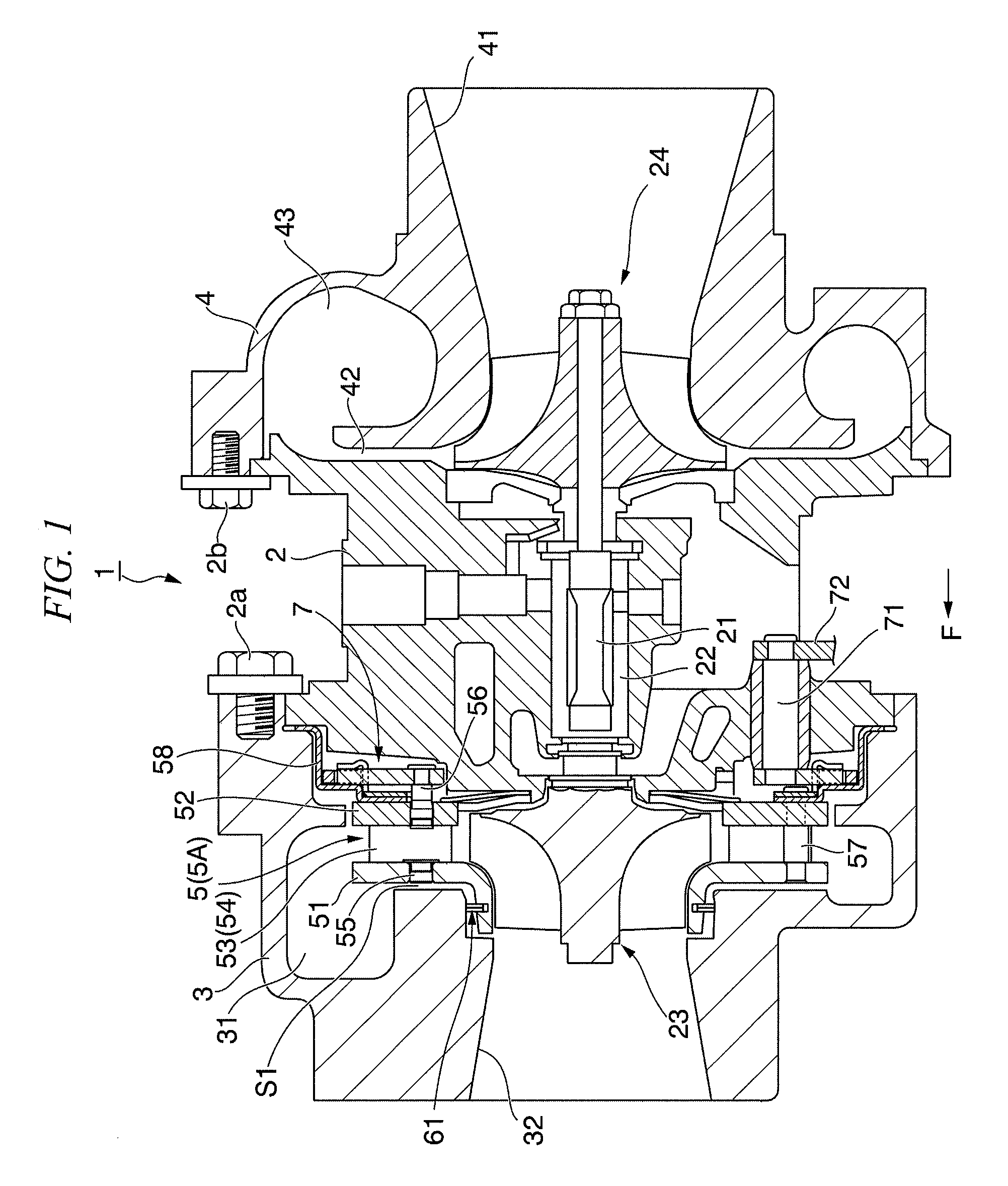

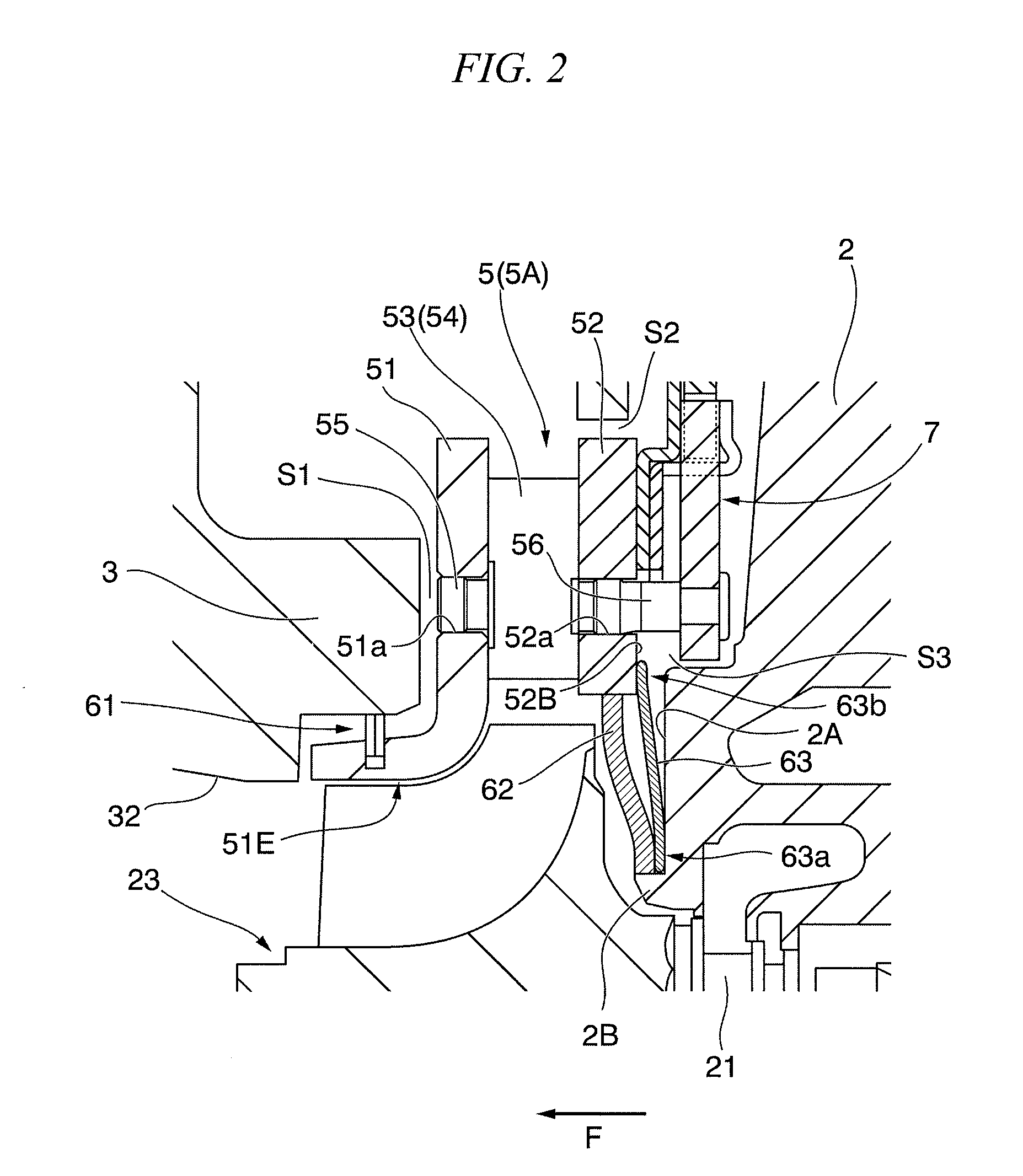

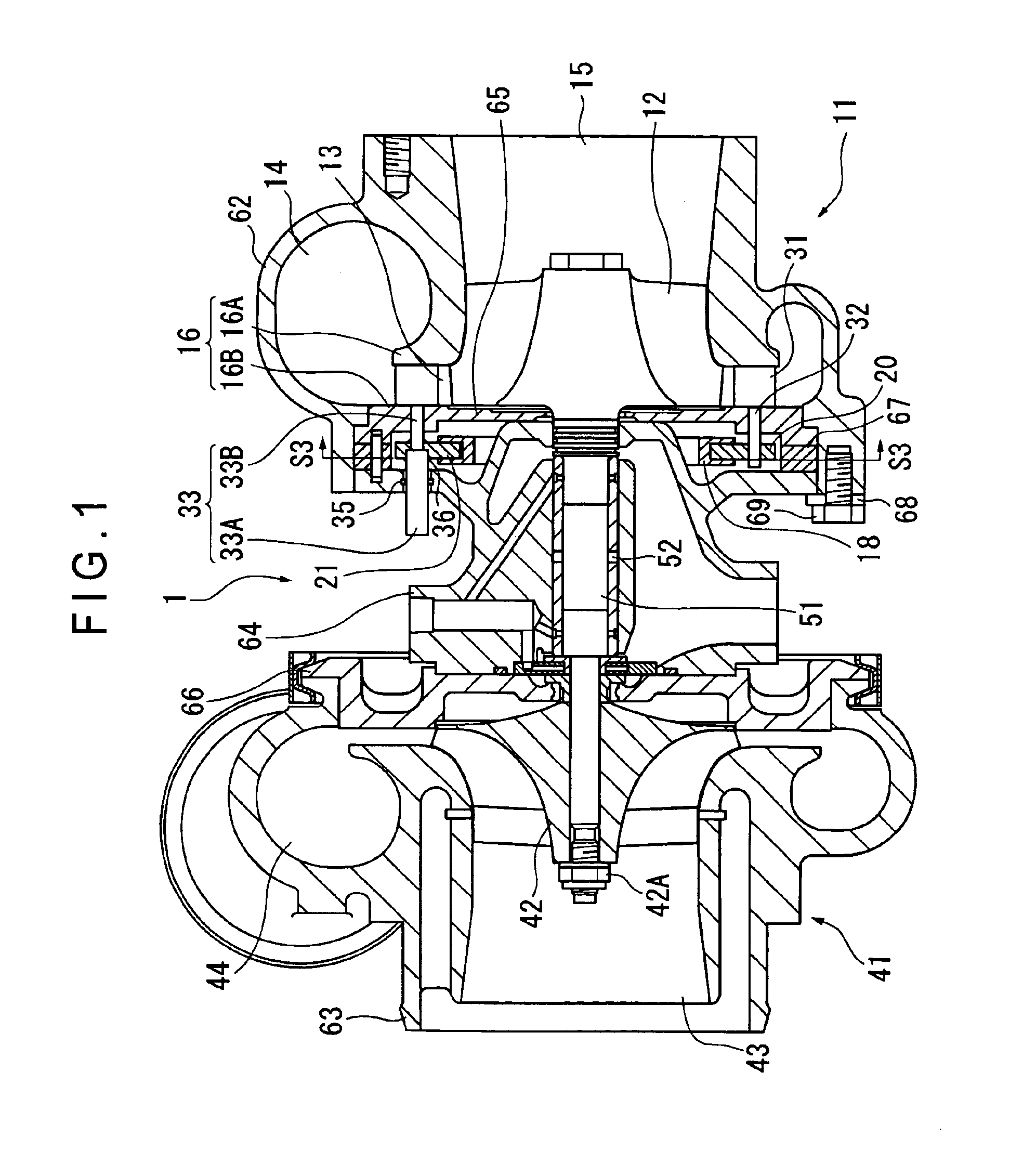

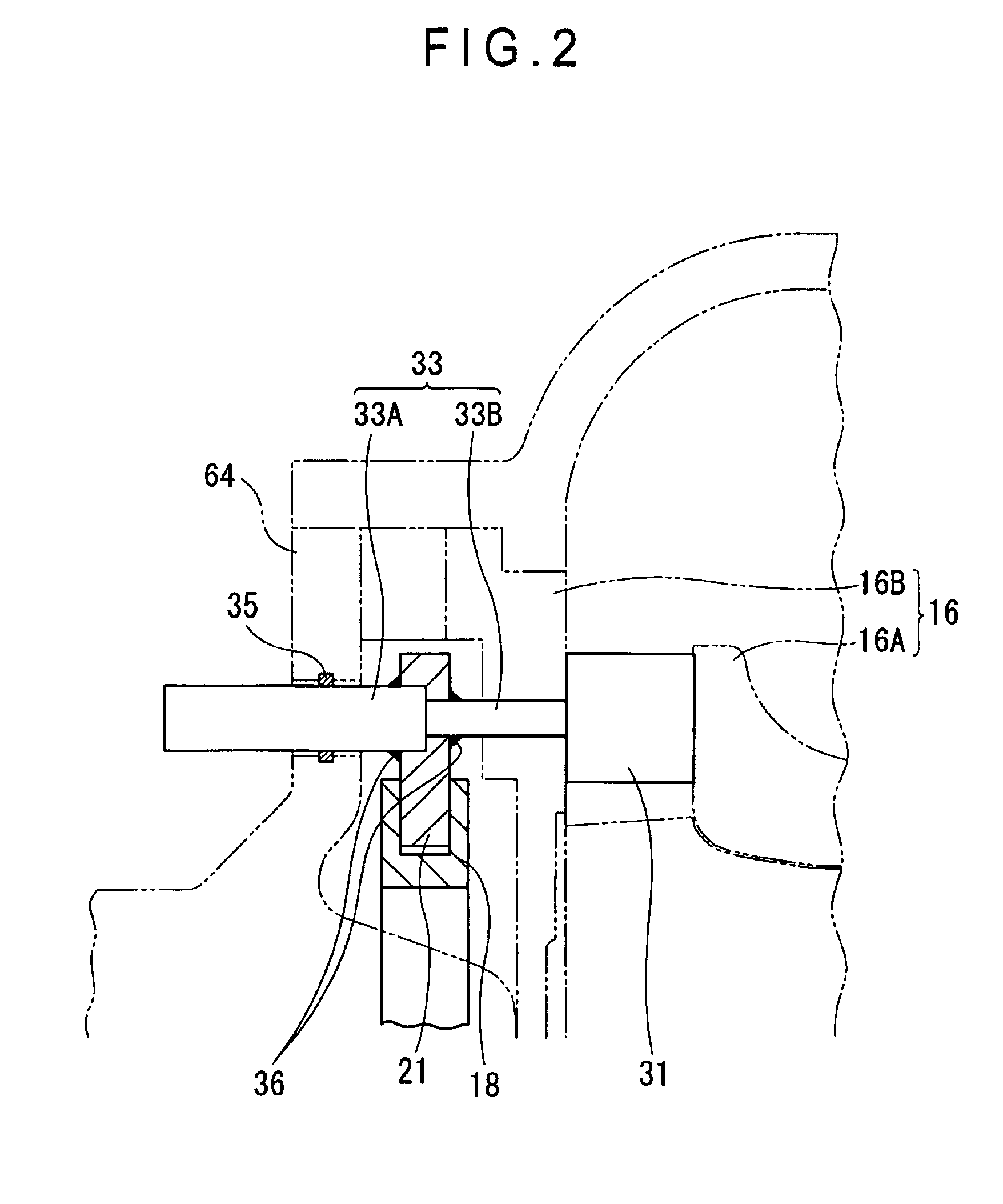

Turbocharger

ActiveUS20120237343A1Increasing efficiency of turbochargerPrevent leakageInternal combustion piston enginesPump componentsImpellerTurbine wheel

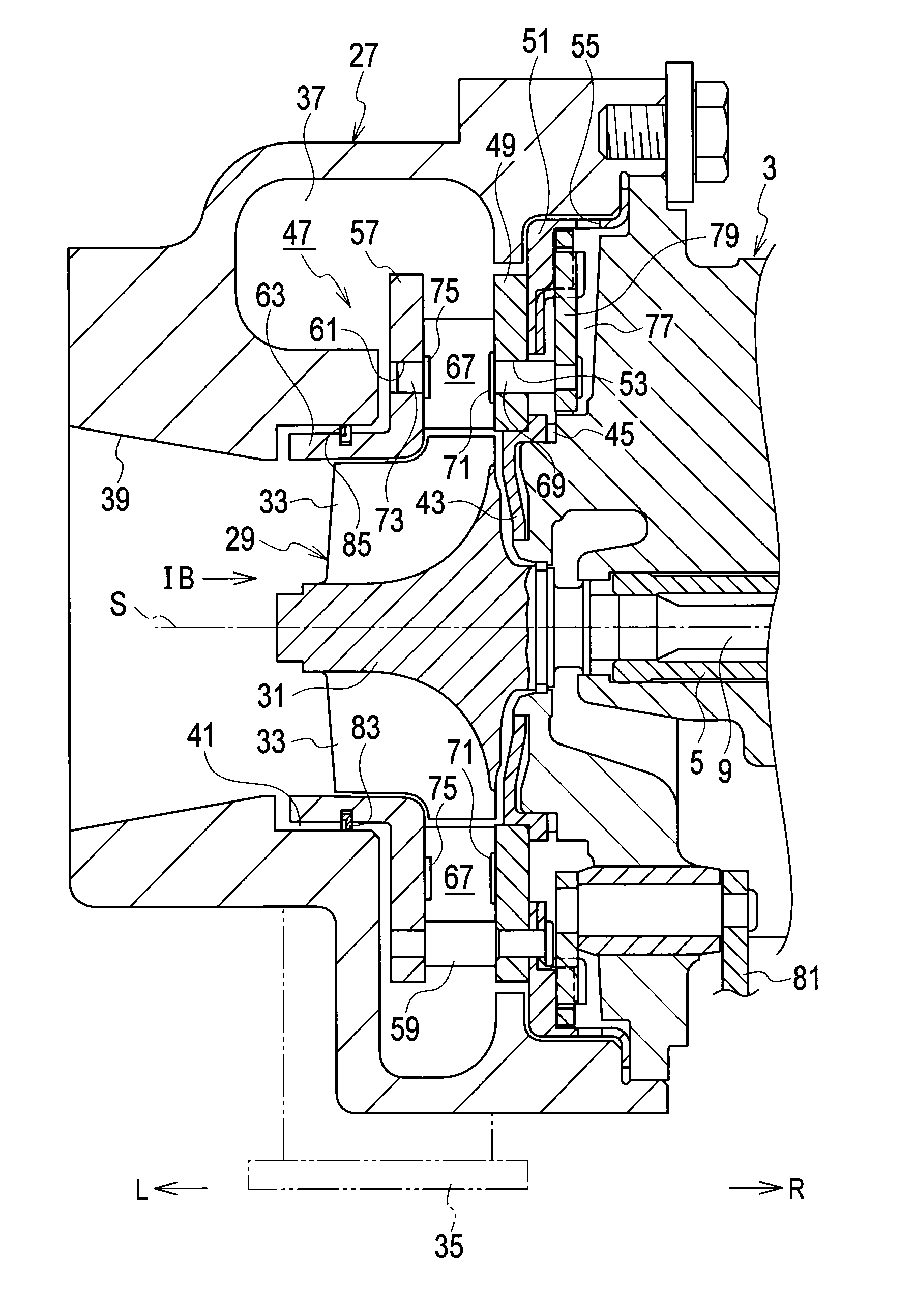

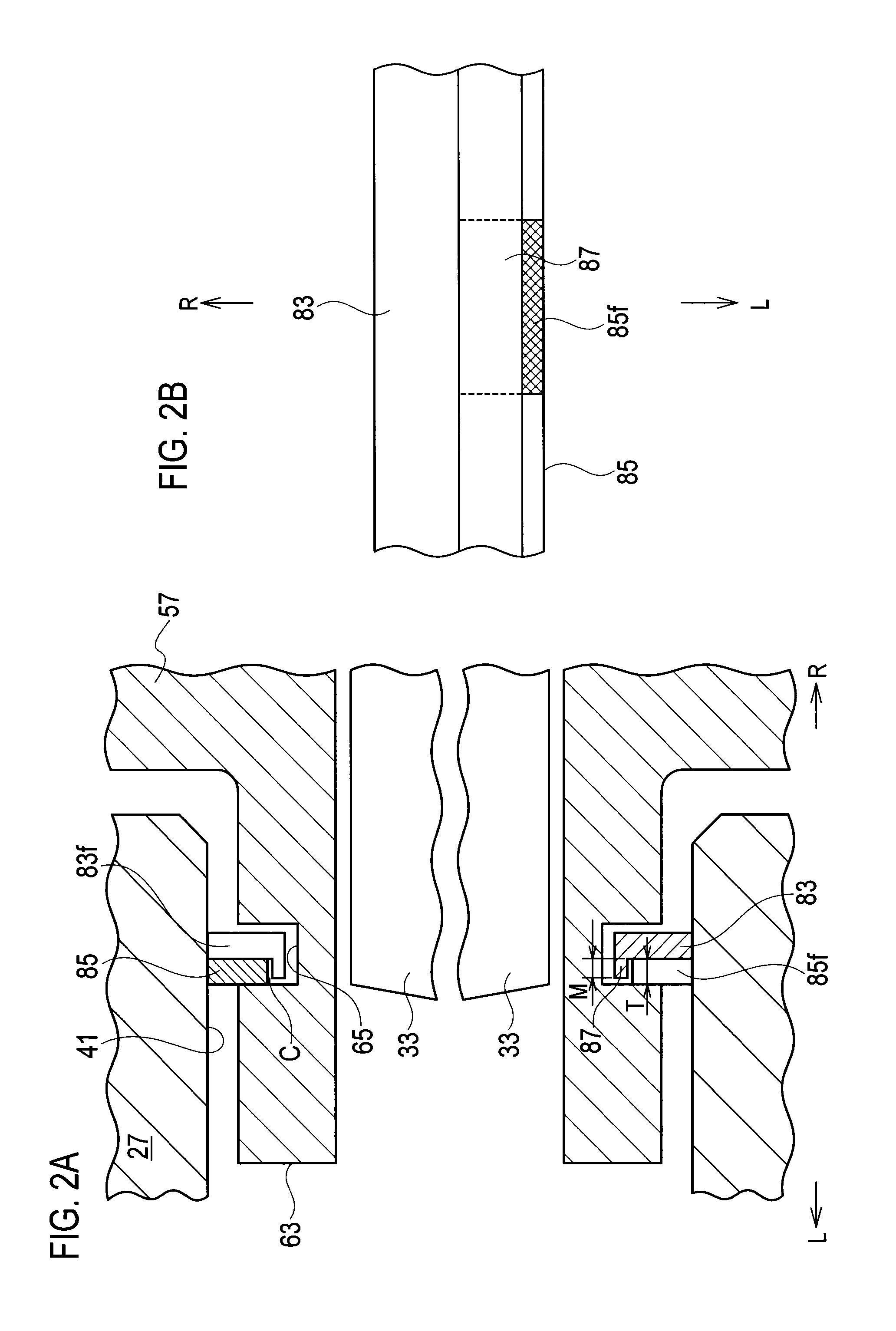

A variable geometry turbocharger includes a bearing housing rotatably supporting a turbine impeller; and an exhaust nozzle changing the flow rate of an exhaust gas supplied to the turbine impeller, wherein the exhaust nozzle has an exhaust inlet wall disposed at the bearing housing side, the turbocharger has a seal member exhibiting a ring shape and sealing a gap formed between the bearing housing and the exhaust inlet wall, and an inner circumferential edge of the seal member firmly contacts the bearing housing and an outer circumferential edge of the seal member firmly contacts the exhaust inlet wall.

Owner:IHI CORP

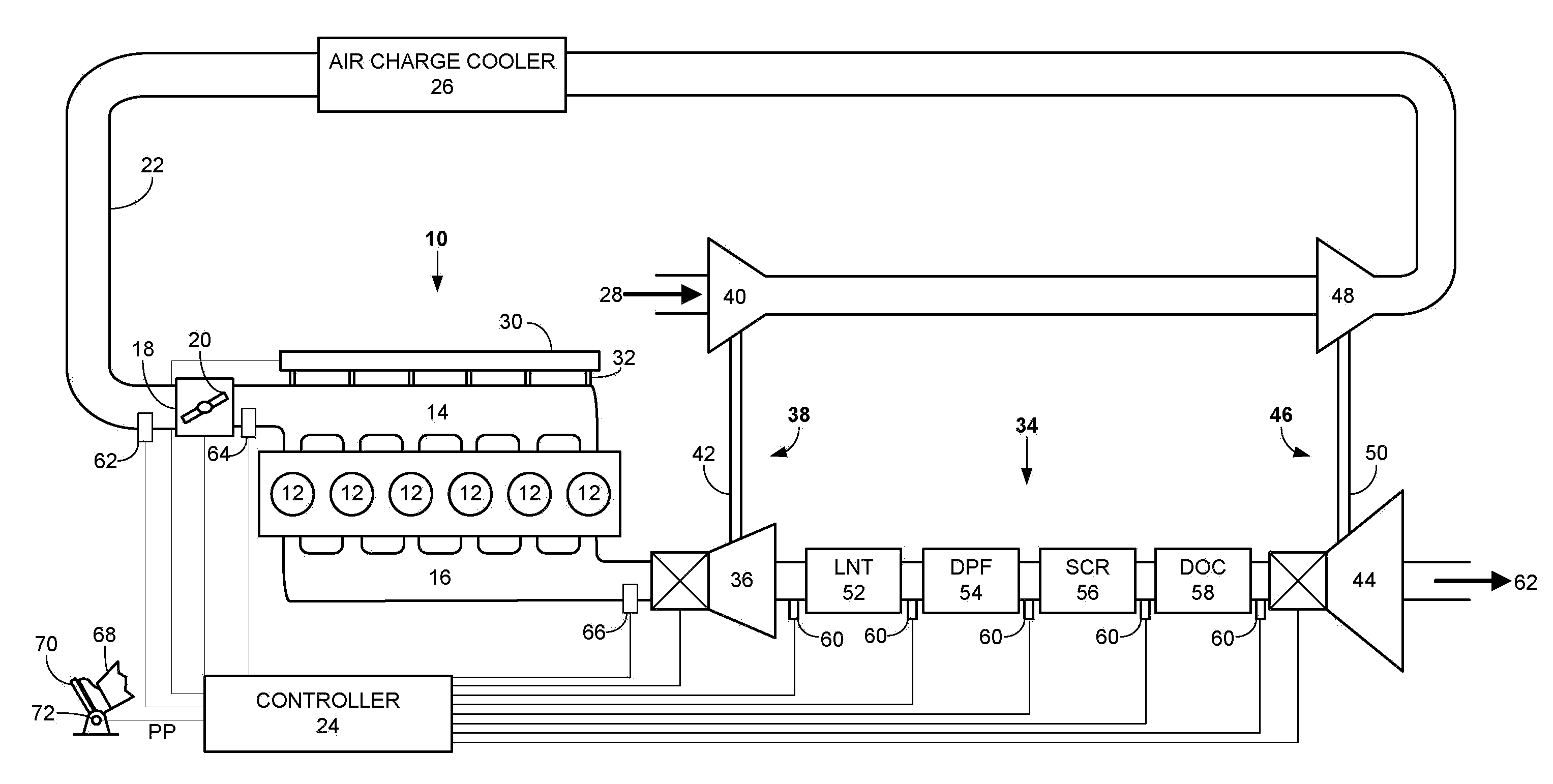

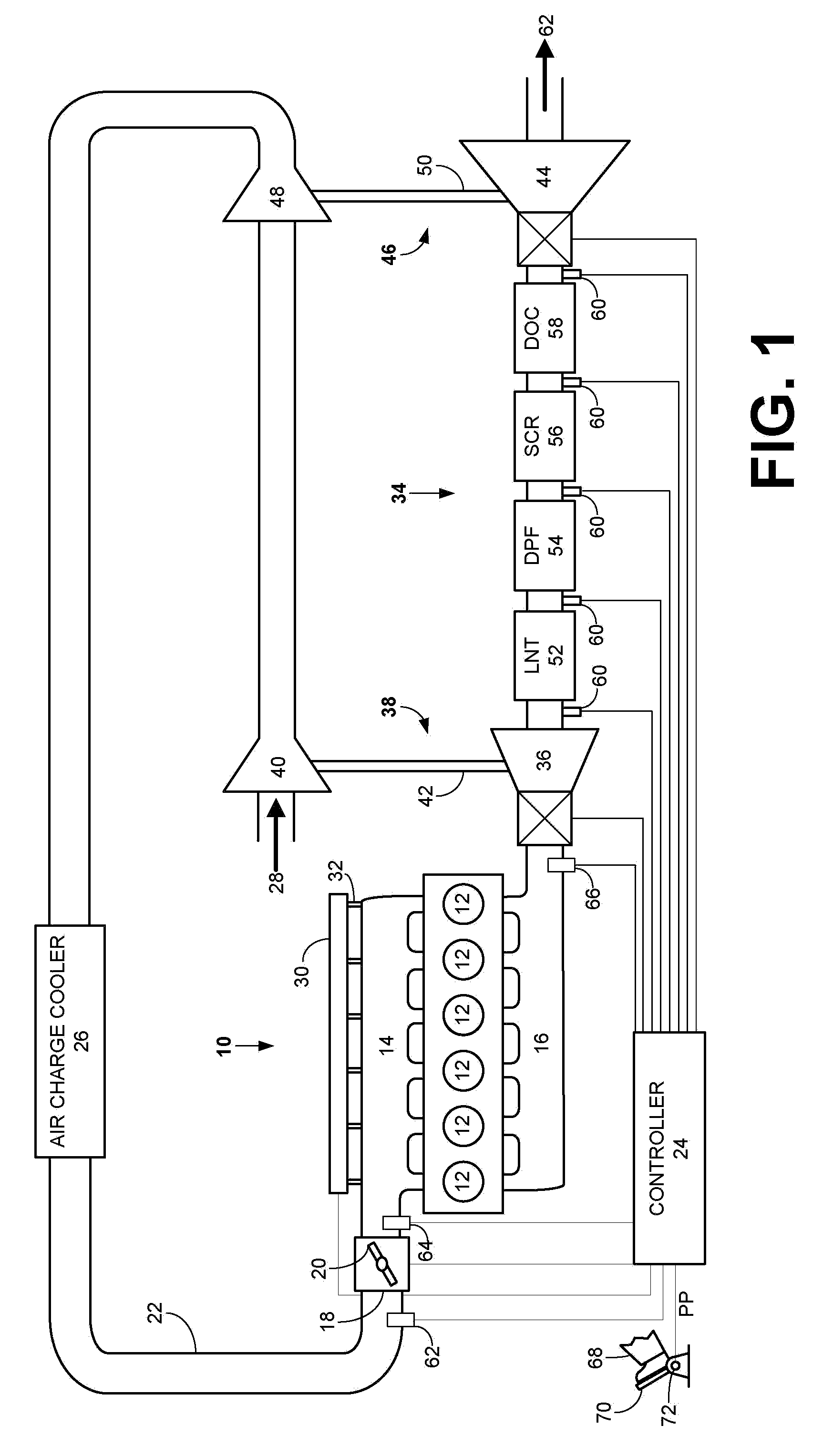

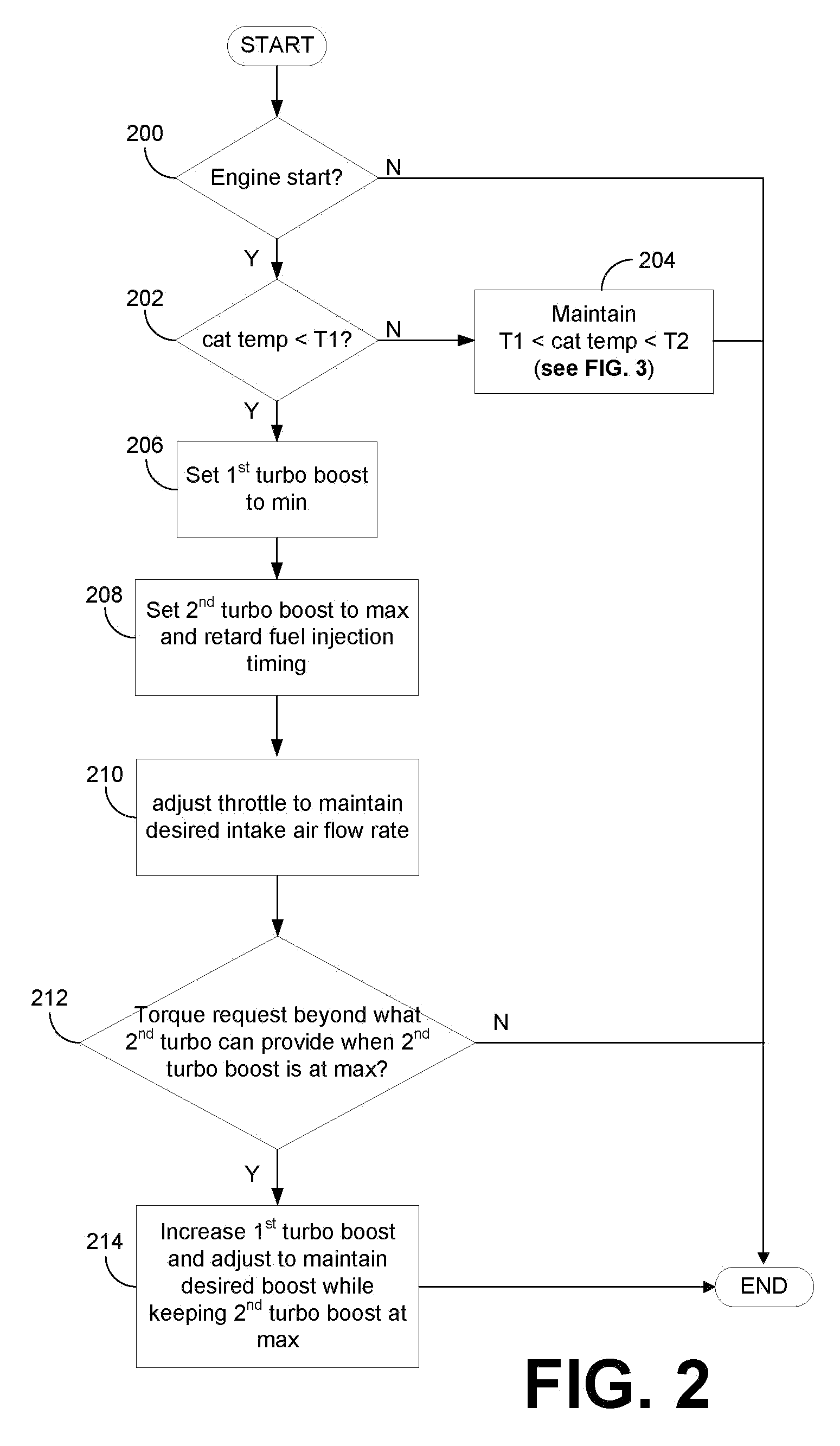

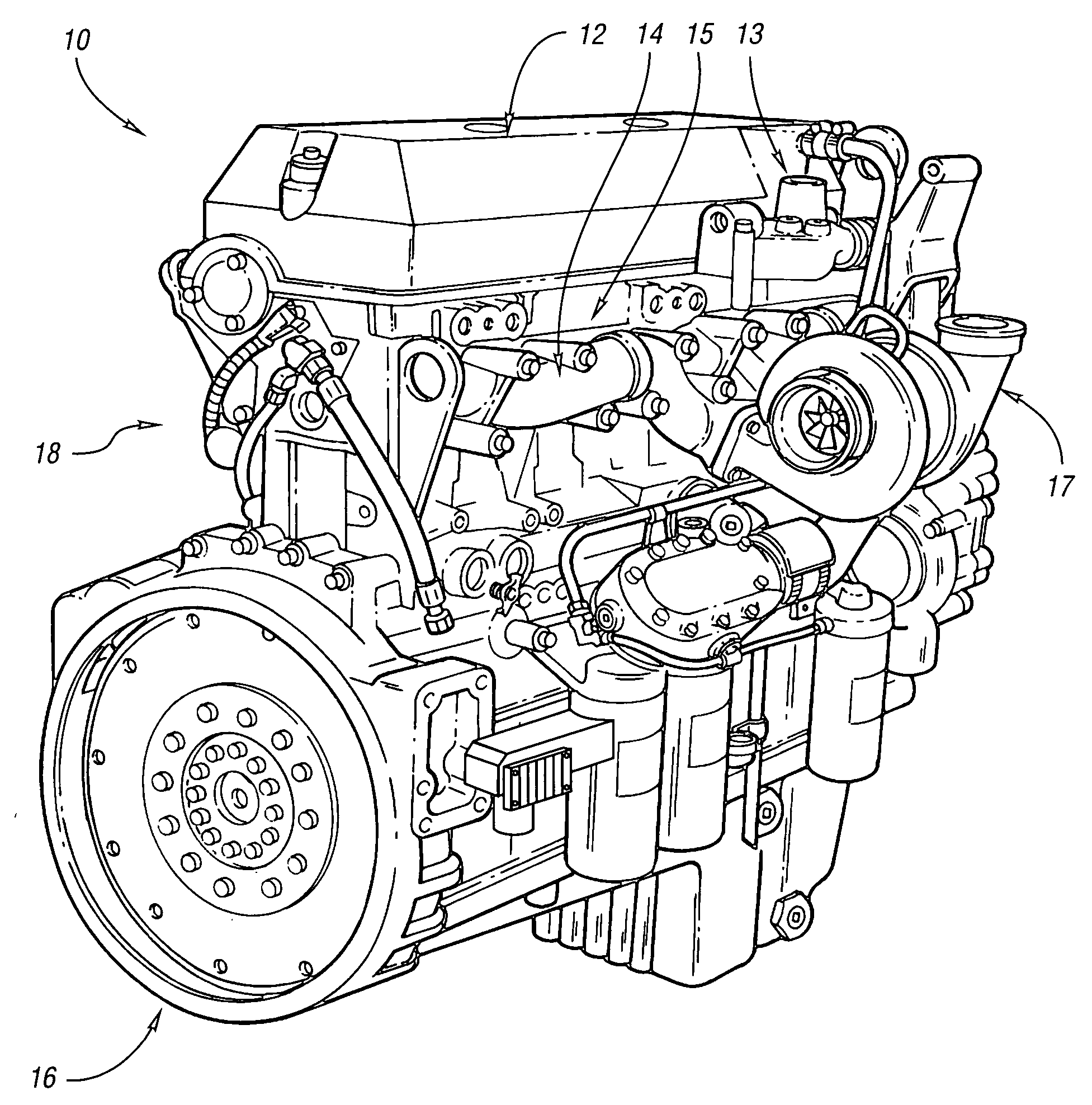

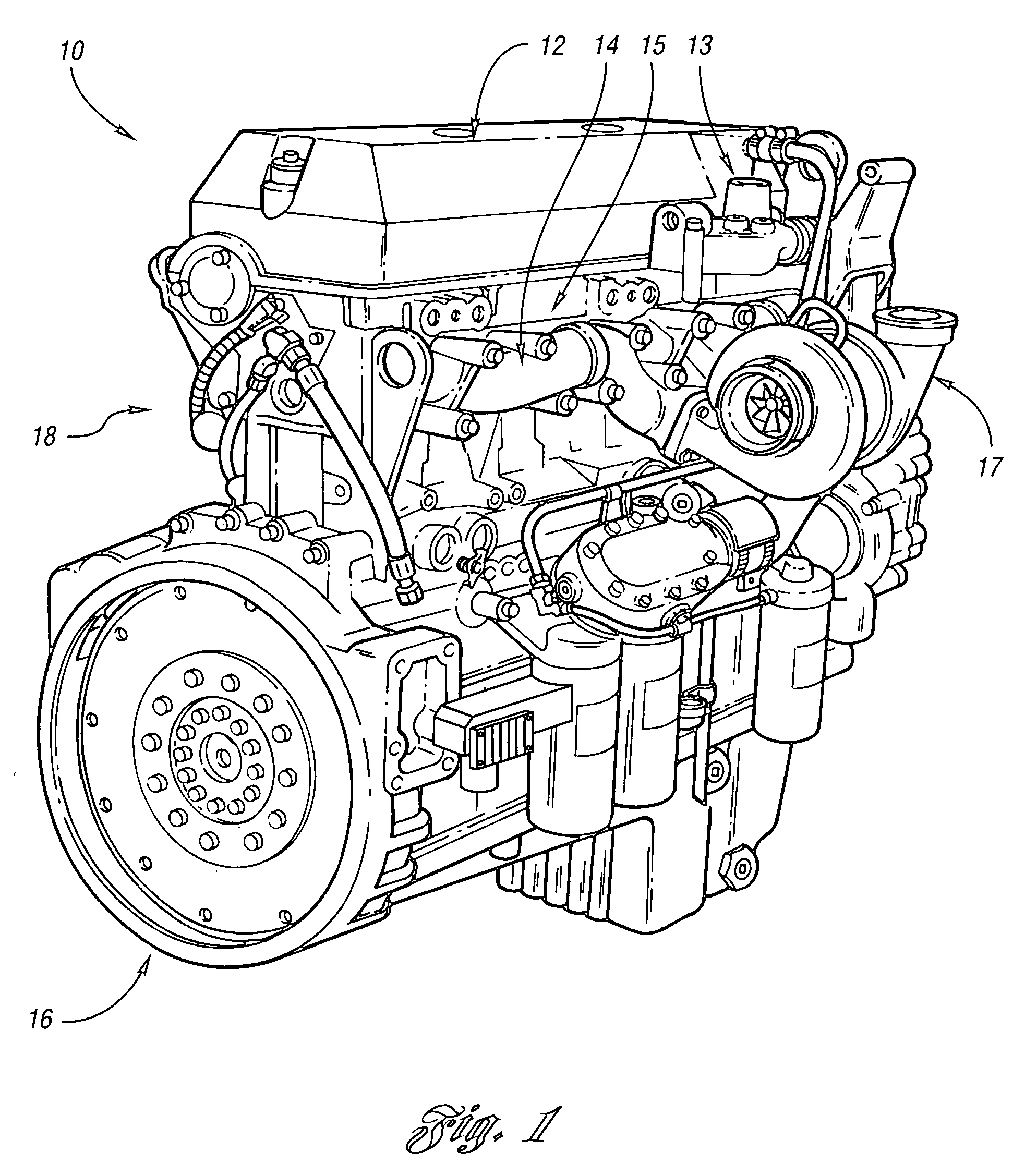

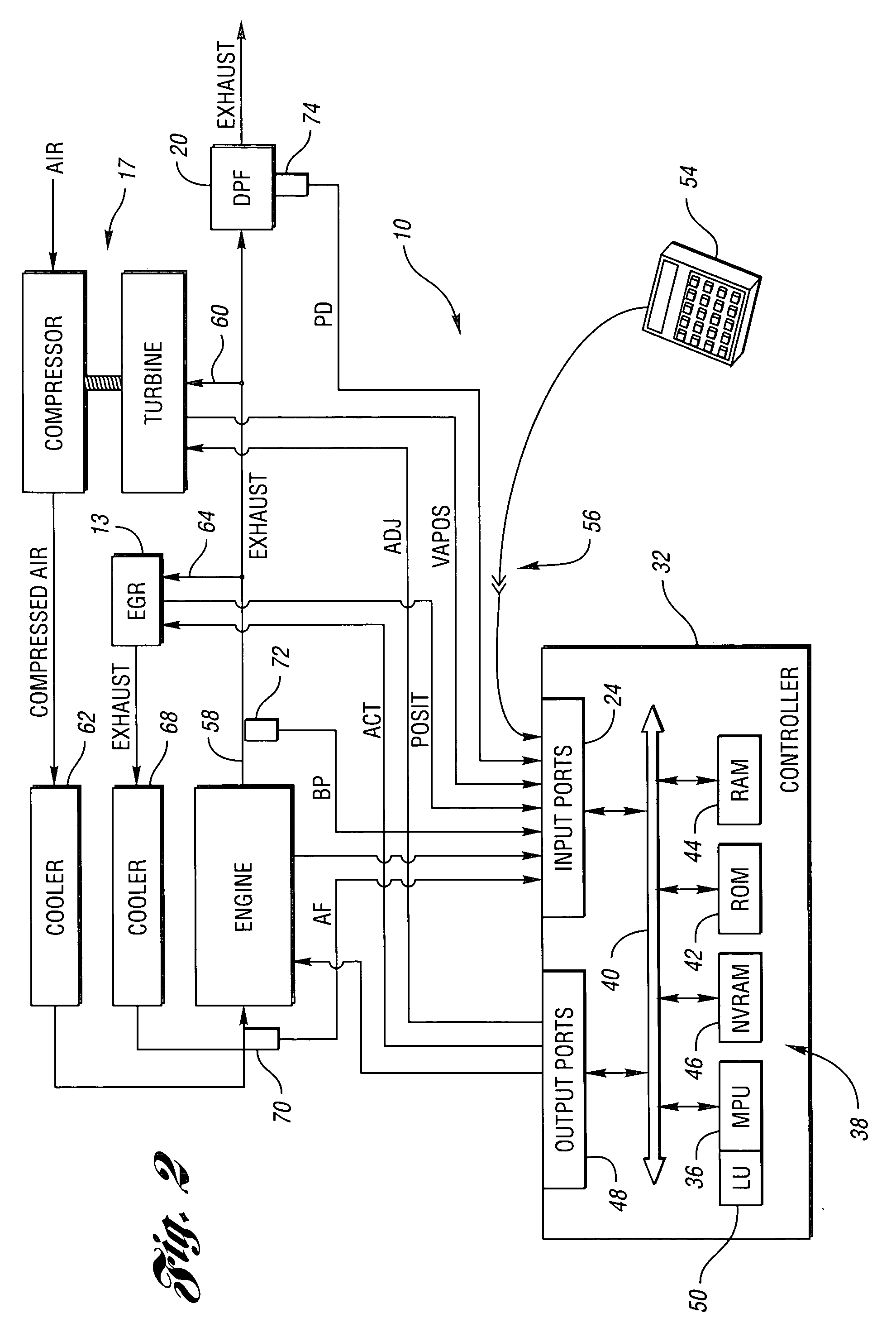

Twin turbo diesel aftertreatment system

ActiveUS20110023480A1Improve NOx conversion efficiencyImprove fuel economyElectrical controlInternal combustion piston enginesCombustionInternal combustion engine

Exhaust temperatures in emission control devices may be directly controlled by an intake air throttle, fuel injection timing, and exhaust pressure when an emission control device is placed between two variable geometry turbocharger exhaust turbines and coupled to a combustion engine. Such an approach may substantially raise the temperature of the exhaust aftertreatment devices in an emission control device during non-warmed exhaust conditions, leading to faster catalytic light-off.

Owner:FORD GLOBAL TECH LLC

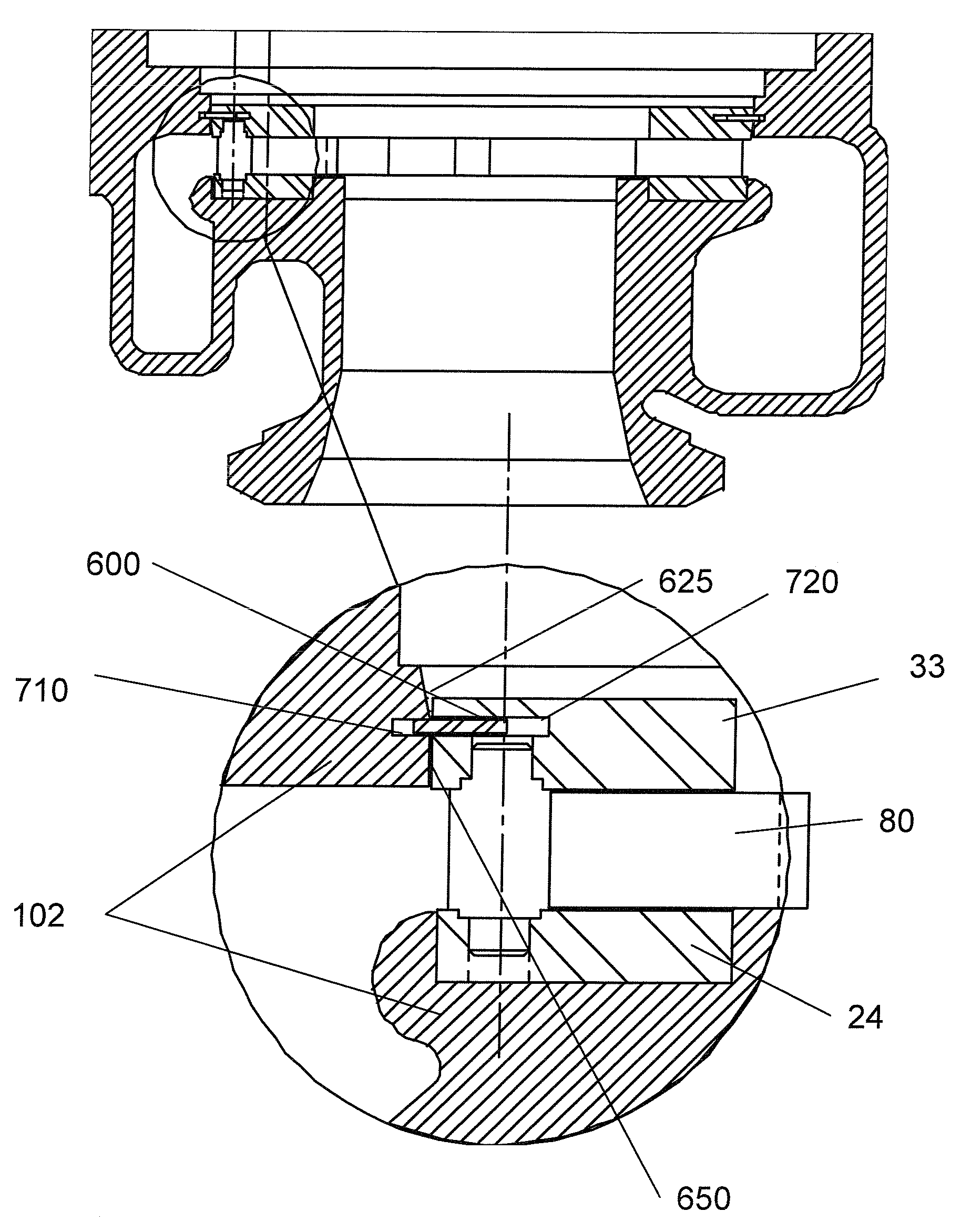

Variable turbine geometry turbocharger

ActiveUS7137778B2Hysteresis assistWind motor controlPump componentsEngineeringVariable-geometry turbocharger

A turbocharger arrangement for a variable geometry turbocharger including pivotable vanes (34) with each vane (34) having a respective vane bore (38) for receiving a vane post (28) into a vane first planar surface (80) and a respective actuation post (36) projecting outwardly from the first planar surface (80).

Owner:BORGWARNER INC

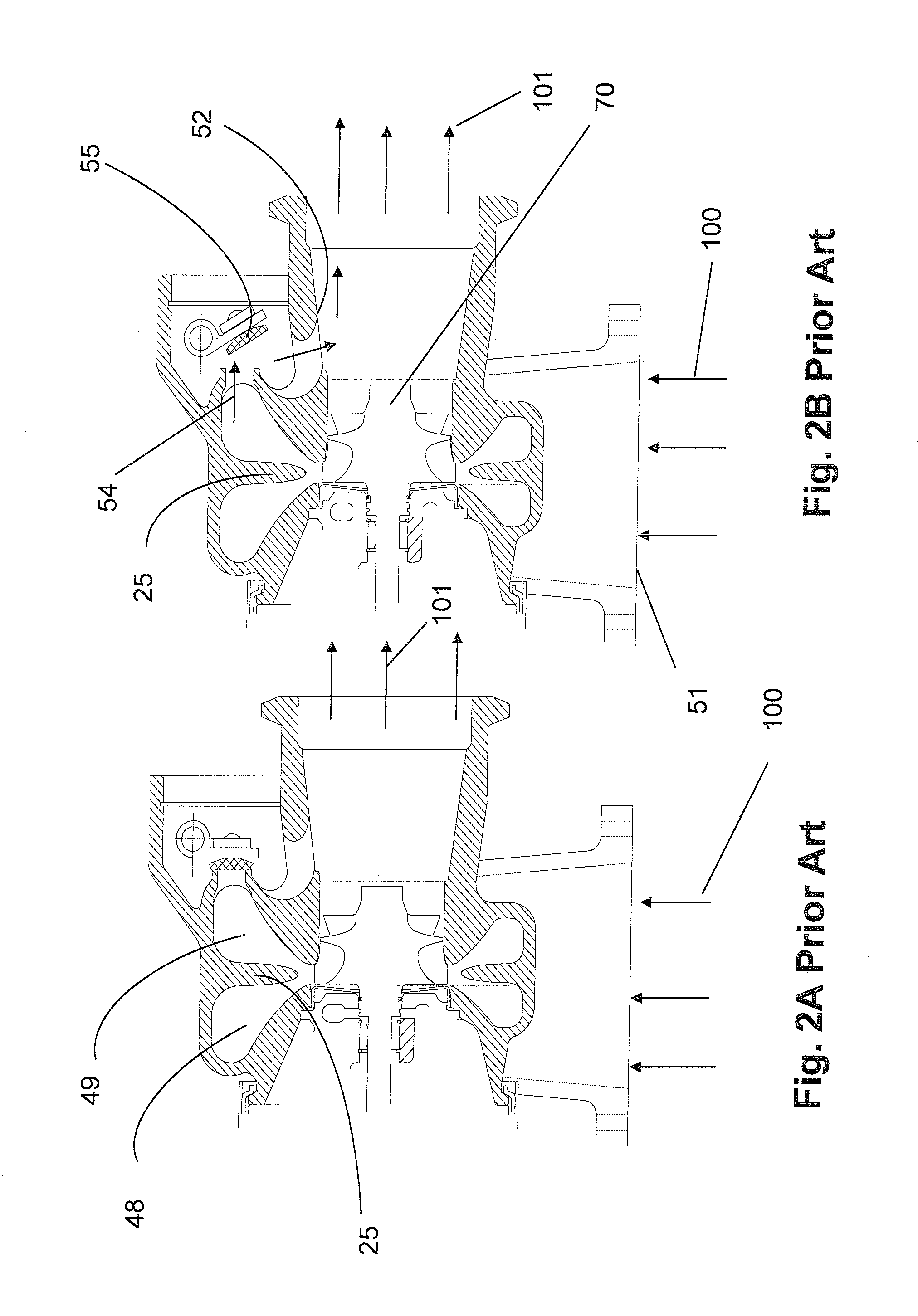

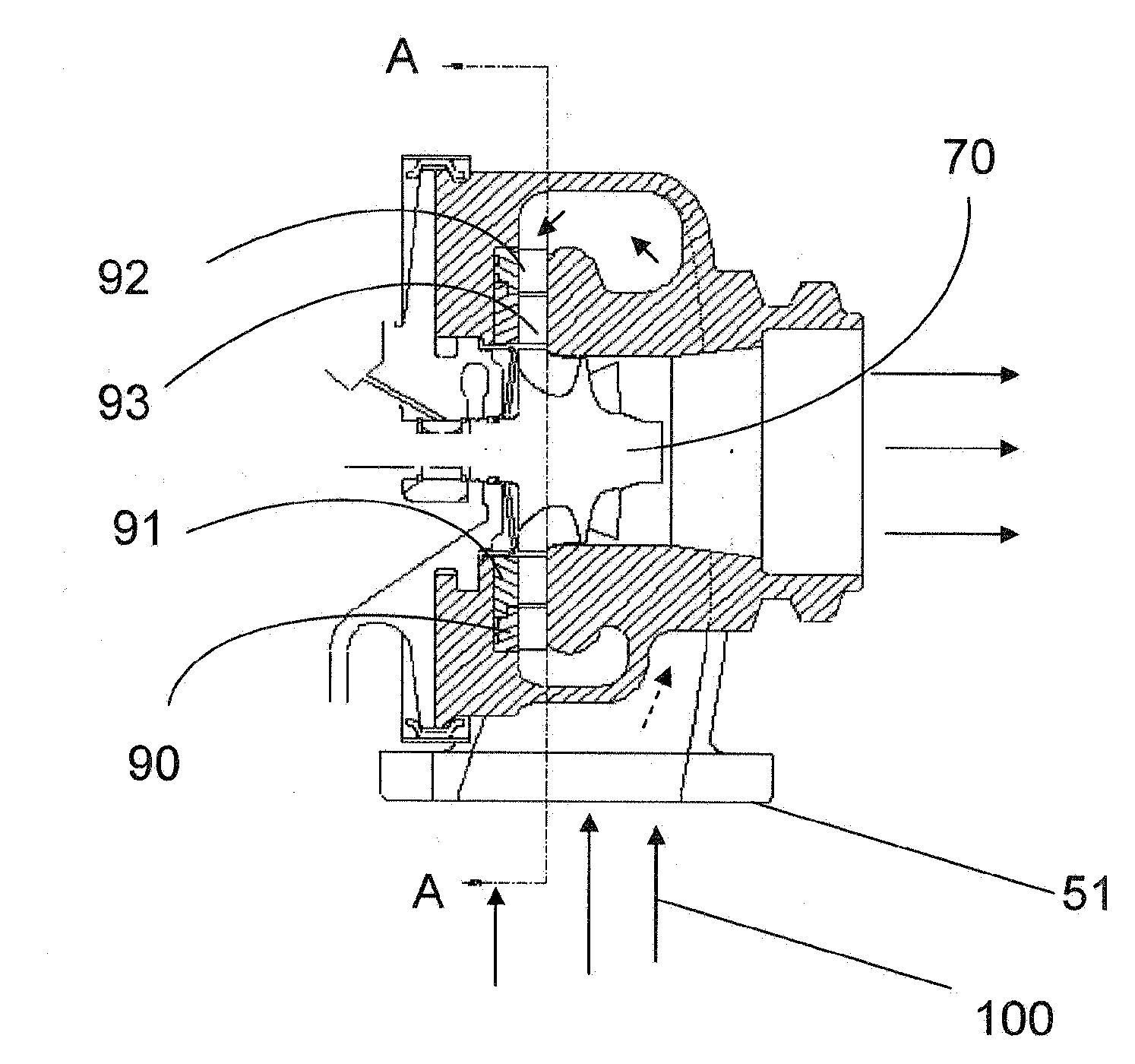

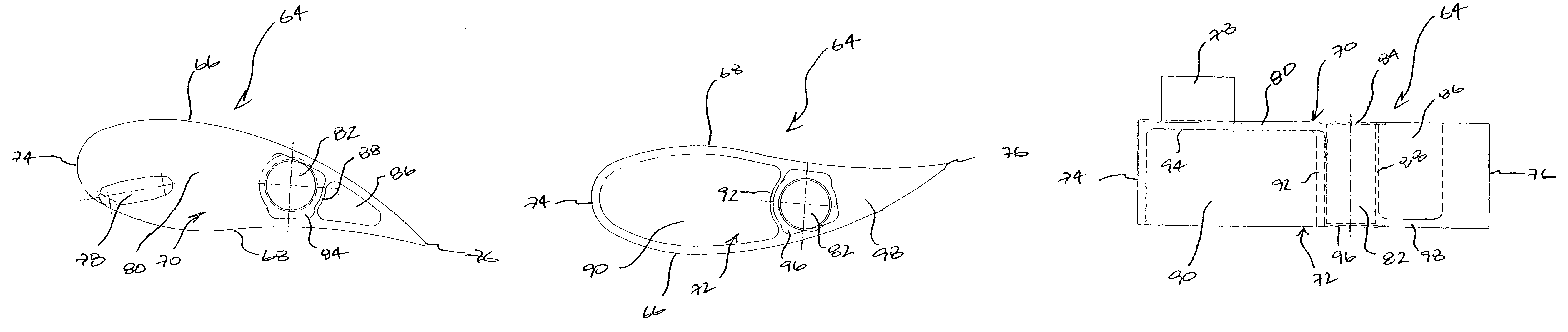

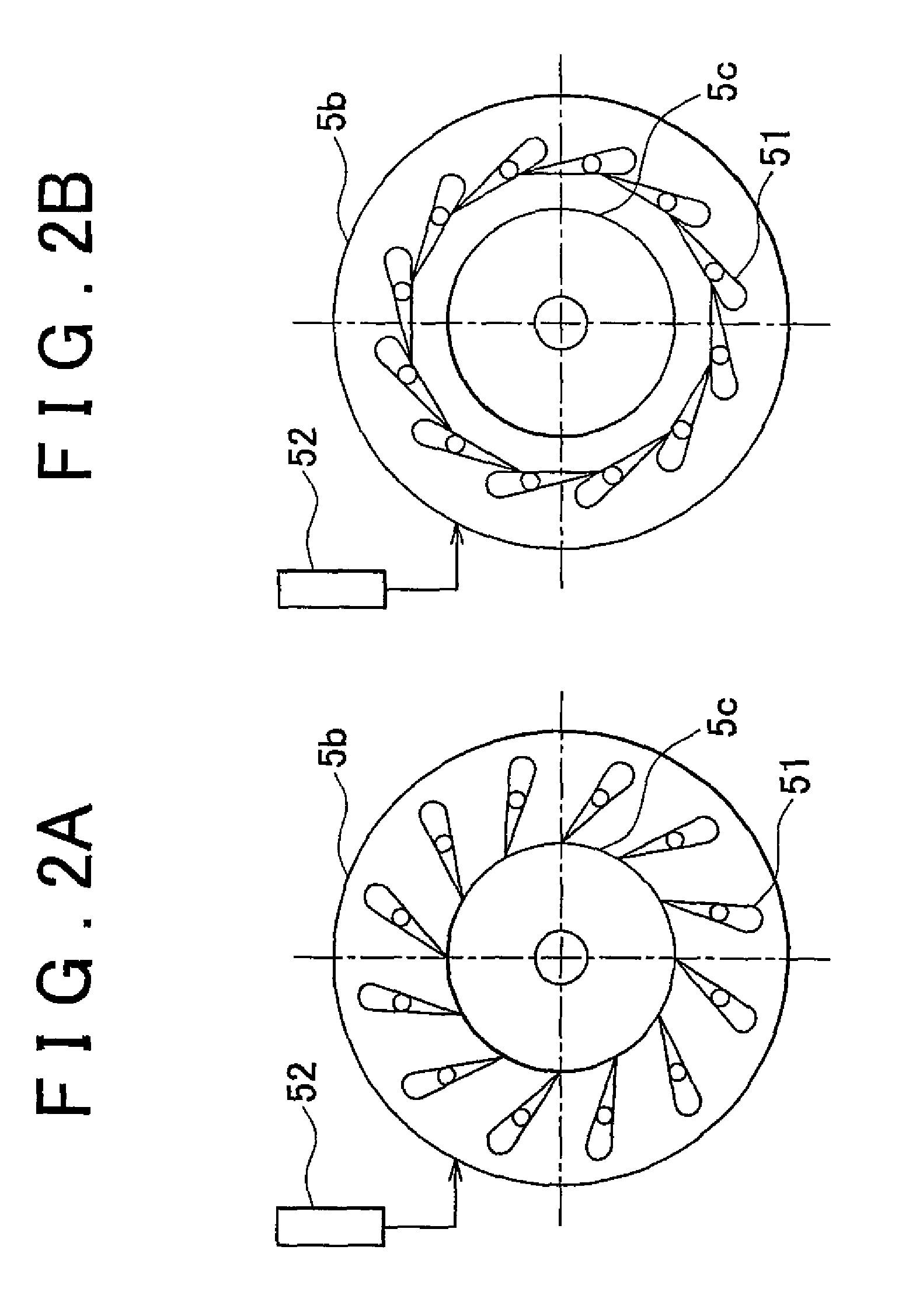

Simplified variable geometry turbocharger with vane rings

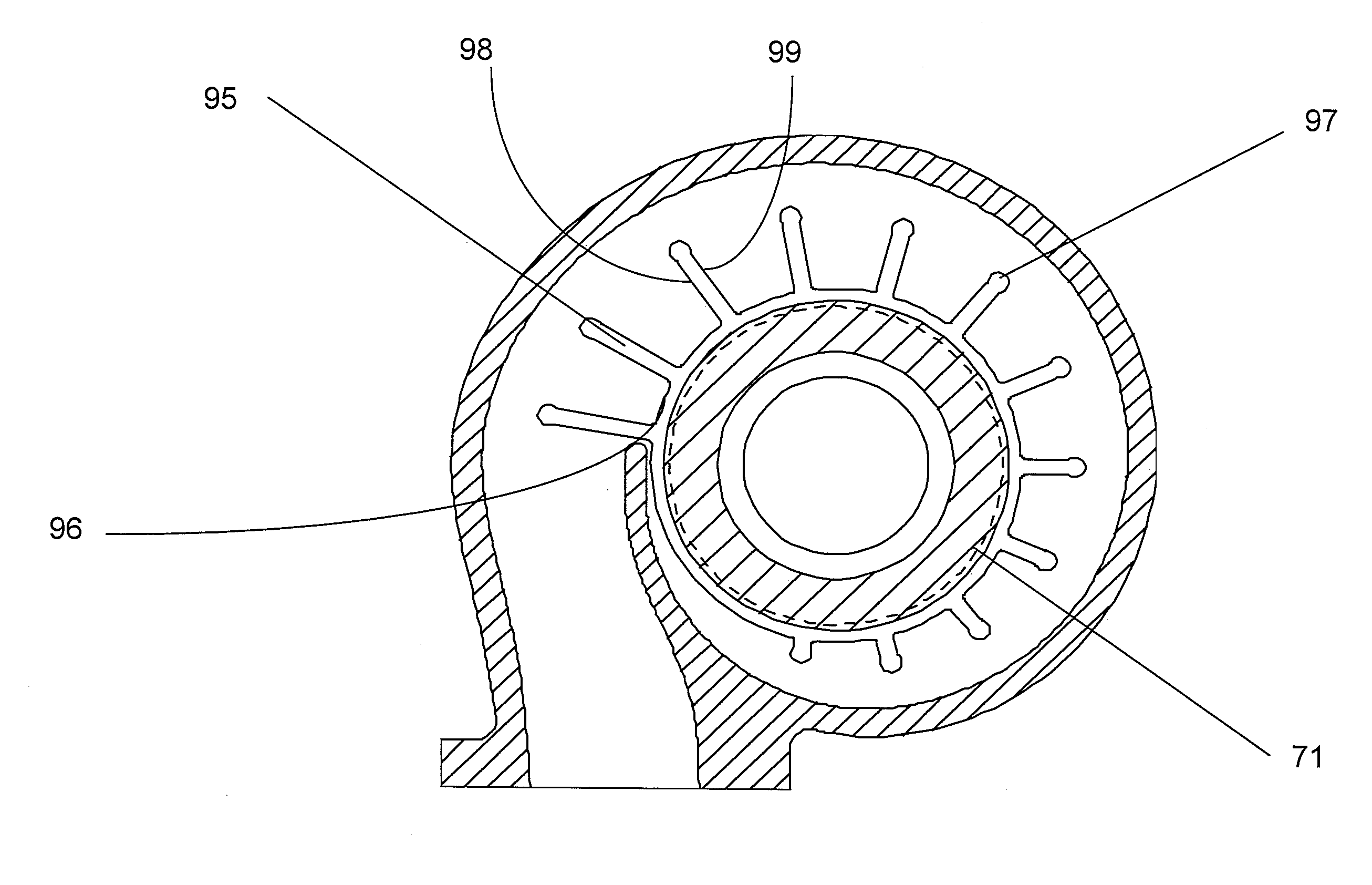

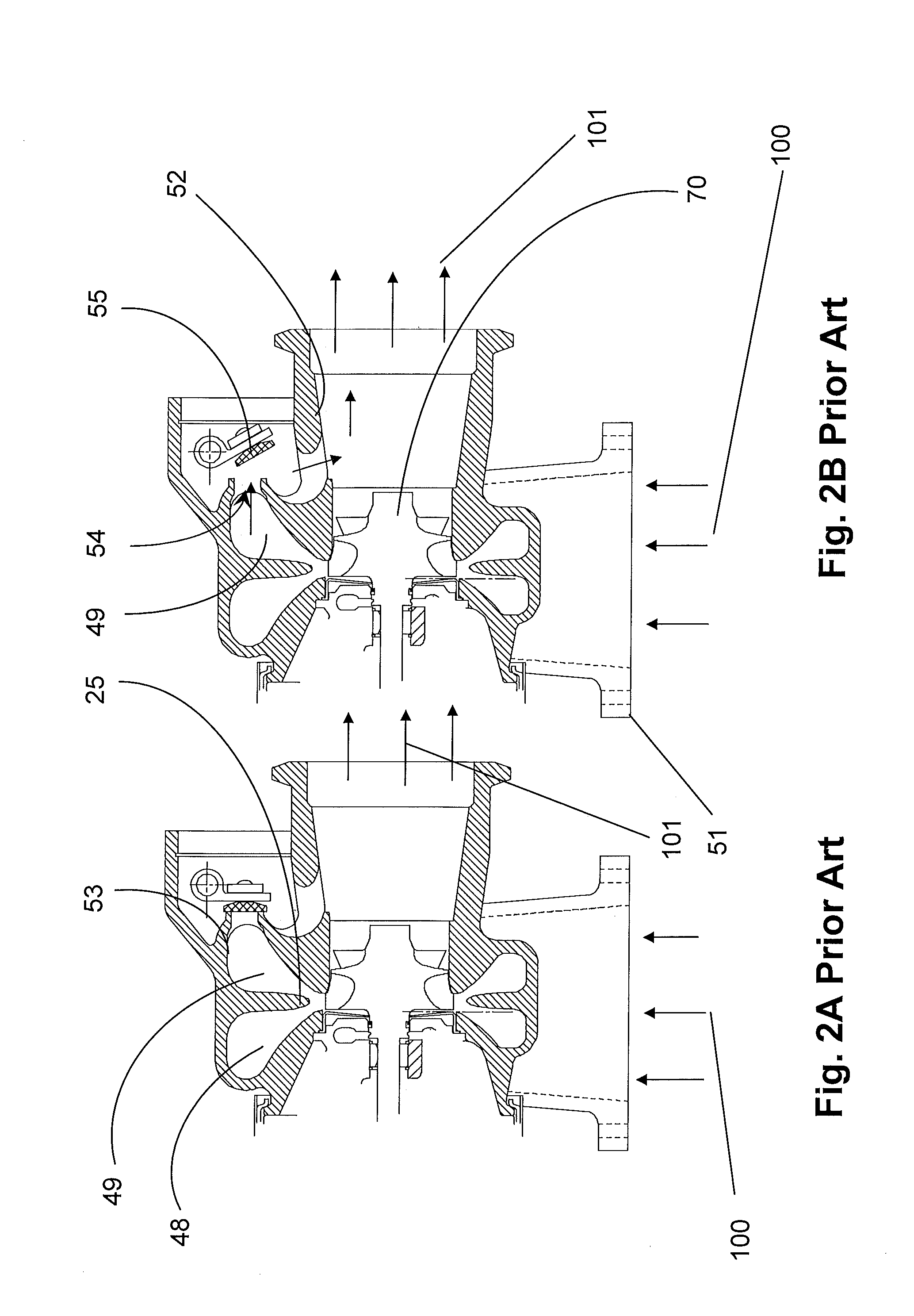

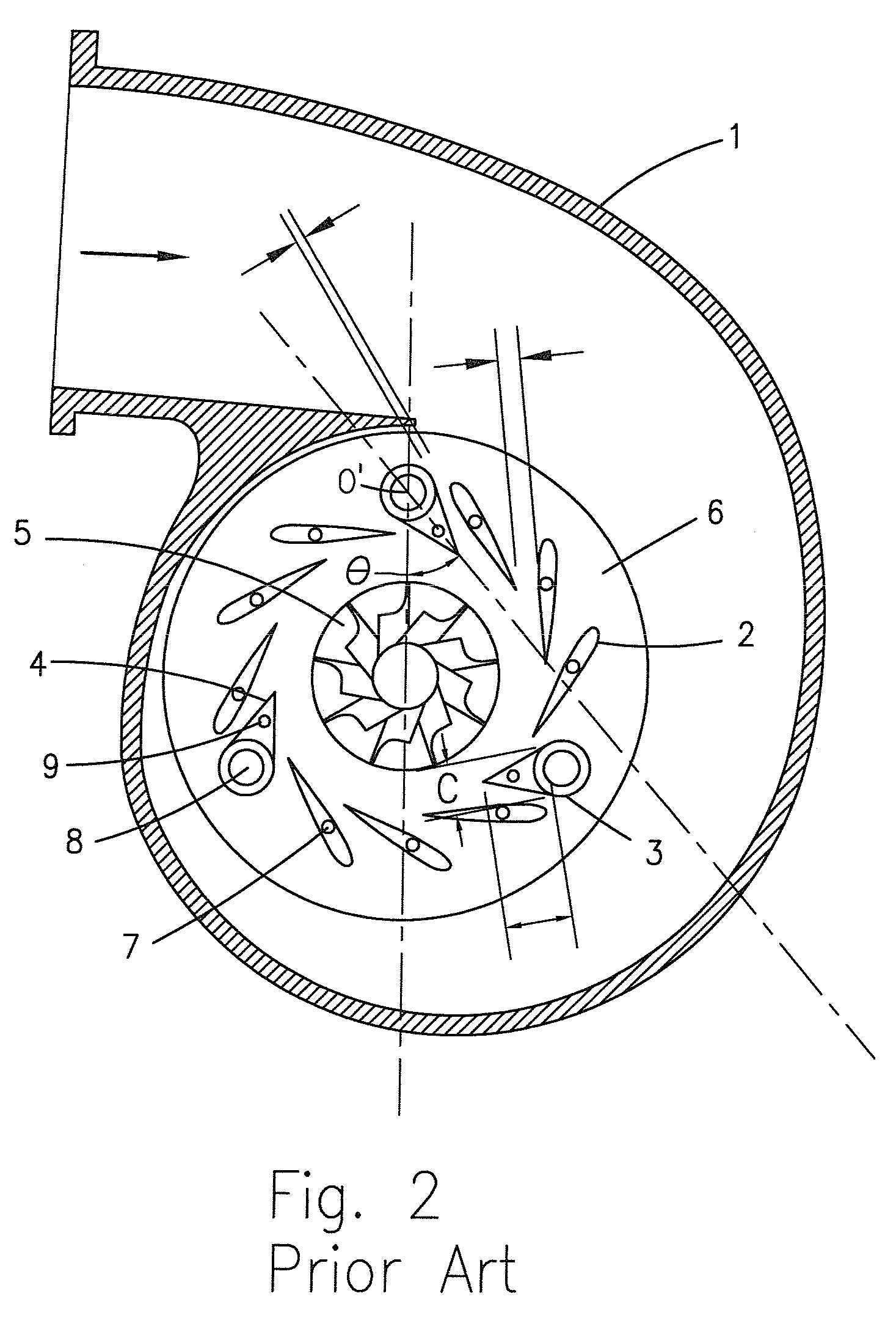

InactiveUS20110243721A1Low costBoost pressure can be modulatedPump componentsCombustion enginesRelative displacementImpeller

The flow path of exhaust gas to the turbine wheel (70) of a turbocharger is influenced by relative motion between two rings of vanes, at least one of which being provided on a vane ring. The outer ring of vanes contains a plurality of vanes (92, 122), the inner ring of vanes contains a plurality of vanes (93, 121), and the inner and outer vanes in registry forming a single generic vane shape. The aerodynamic effect of relative displacement of the outer ring of vanes to the inner ring of vanes produces a modulate-able control of exhaust flow to the turbine wheel.

Owner:BORGWARNER INC

System and method for backpressure compensation for controlling exhaust gas particulate emissions

InactiveUS20060288701A1Avoiding unnecessary over closureIncreased backpressureAnalogue computers for vehiclesElectrical controlParticulatesExhaust fumes

A method for controlling exhaust gas particulate emissions from a compression ignition internal combustion engine having a variable geometry turbocharger (VGT) includes the steps of determining backpressure across the engine and air mass flow into the engine, closing vanes of the VGT to provide air mass flow increase when backpressure is increasing, and stopping the step of closing the vanes of the VGT when a decrease in rate of change of air mass flow is determined.

Owner:DETROIT DIESEL CORP

Variable geometry turbocharger

A turbine comprising a housing, a turbine wheel and at least one movable member. The housing has an interior, an inlet for allowing fluid to enter the interior and an outlet for allowing the fluid to exit the housing. The turbine wheel has turbine blades located in the housing. The at least one movable member is located within the housing and is positioned in a fluid path between the inlet and the turbine blades for selectively controlling a flow of fluid to the turbine blades in the housing.

Owner:SEMRAU H ALBERT

Method for responding to sensor failures on egr/vgt engines

InactiveUS20050066658A1Efficient emissionsEfficient engine operationElectrical controlInternal combustion piston enginesControl logicVariable-geometry turbocharger

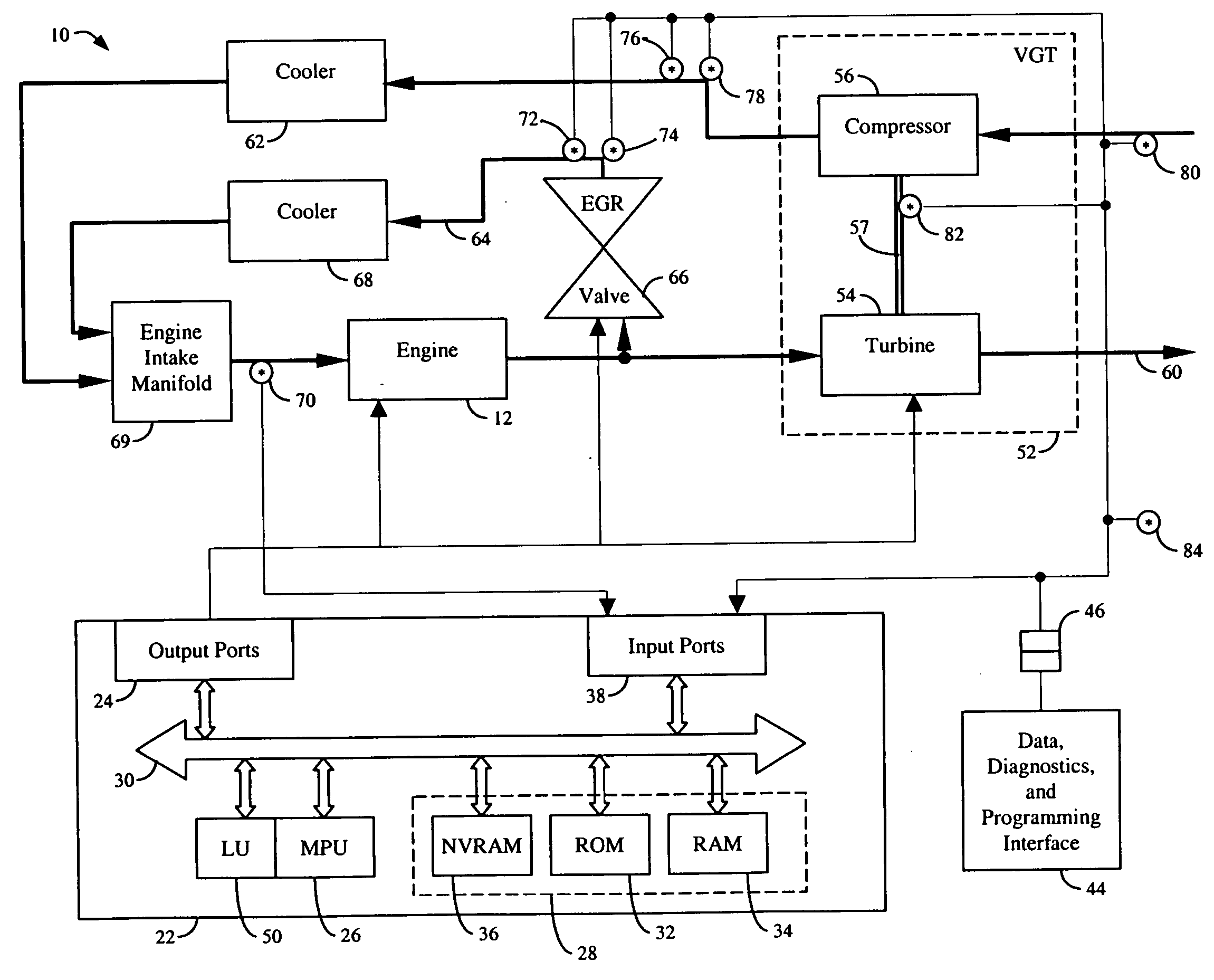

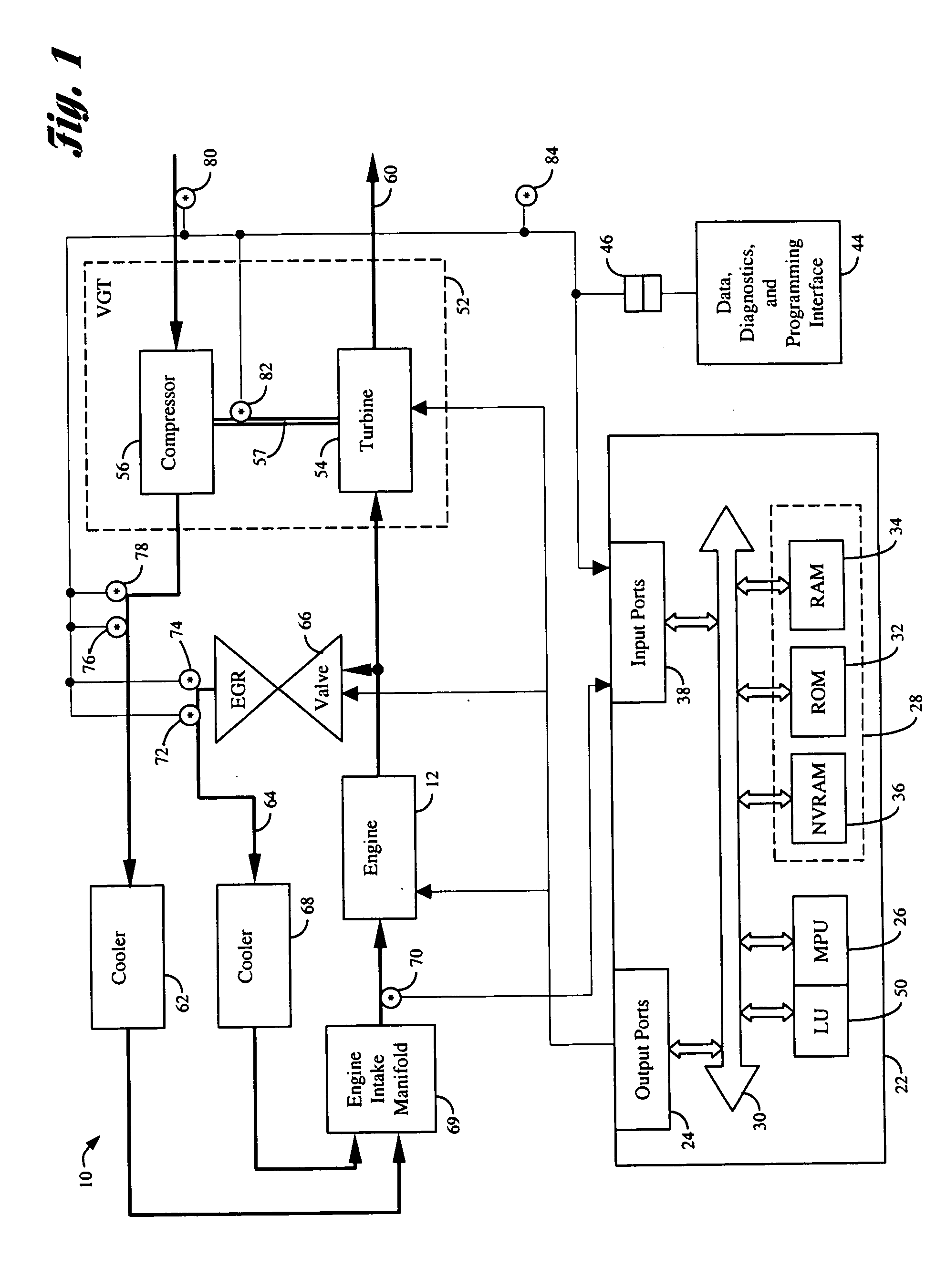

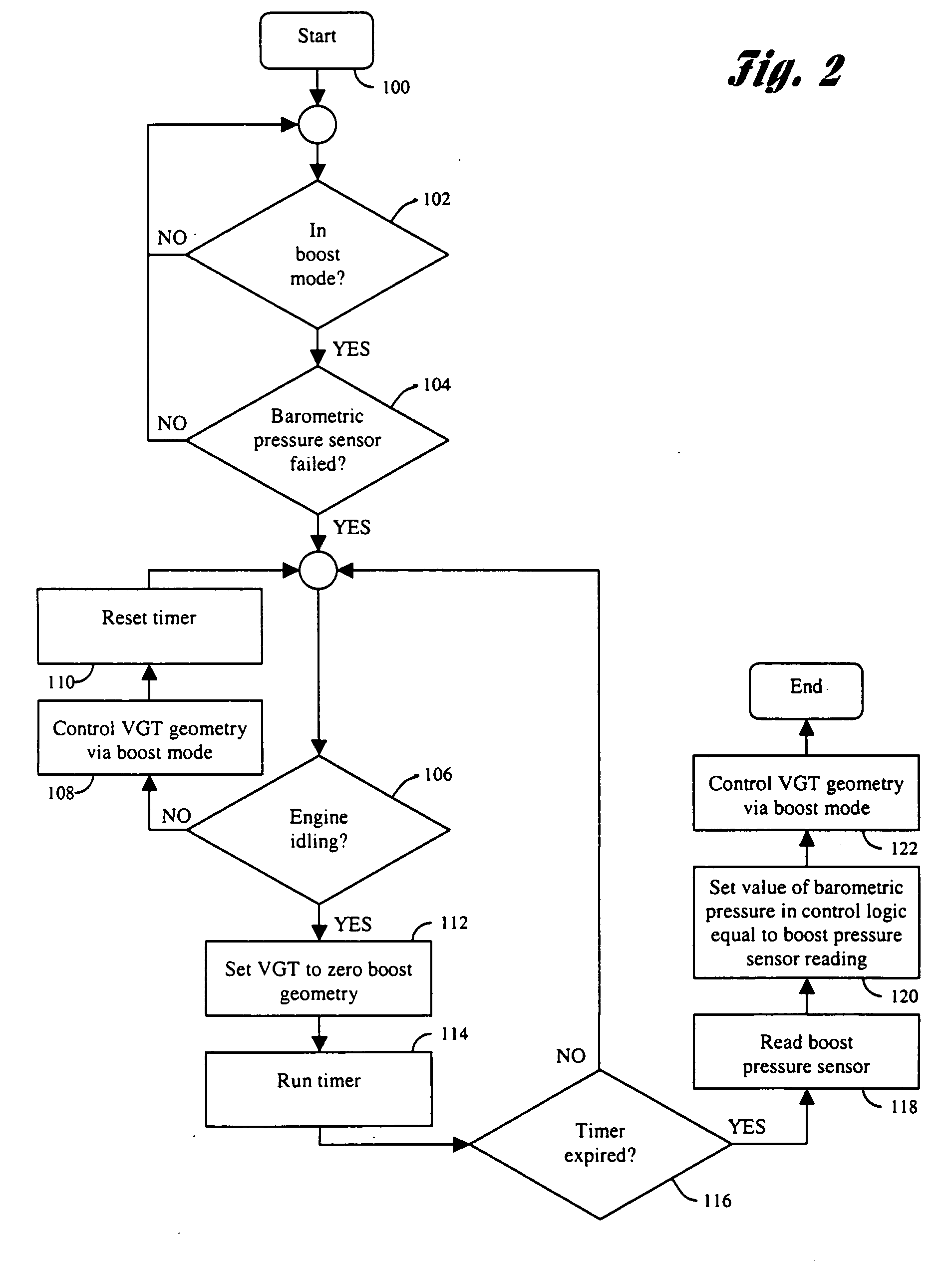

A method for controlling an internal combustion engine having a variable geometry turbocharger (VGT) and an exhaust gas recirculation (EGR) system in the face of sensor failures and mechanical faults includes generating accurate substitute values for use by the engine control logic when EGR and VGT system-related sensors are diagnosed as having failed during operation, and maintaining controlled performance of the VGT system in the face of sensor failures or mechanical faults associated with the EGR or VGT system.

Owner:DETROIT DIESEL CORP

Variable nozzle unit and variable-geometry turbocharger

ActiveUS20150056067A1Improve turbine efficiencyReduce gapEngine manufactureWind motor controlEngineeringFlange

An annular seal flange is formed at an inner peripheral edge portion of an upstream-side seal ring. The seal flange projects in a downstream direction. When seal rings are viewed from radially inside, the seal flange of the upstream-side seal ring is designed to at least partially occlude an end gap of the downstream-side (the most downstream-side) seal ring.

Owner:IHI CORP

Variable geometry turbocharger

ActiveUS7059129B2Easy to operateEngine manufactureWind motor controlComposite constructionLeading edge

A variable geometry turbocharger includes vanes disposed therein having an inner airfoil surface oriented adjacent a turbine wheel, and an outer airfoil surface oriented opposite and parallel to the inner airfoil surface. The vane includes first and second axial surfaces that are each positioned perpendicular to and interposed between the inner and outer airfoil surfaces. A vane leading edge is positioned along a first inner and outer airfoil surface junction, and a trailing edge is positioned along a second inner and outer airfoil surface junction. One or more of the first and second axial surfaces have a composite construction comprising a solid section that extends a distance from the leading edge towards the trailing edge, and a cored-out section that extends a distance from the trailing edge towards the leading edge.

Owner:GARRETT TRANSPORATION I INC

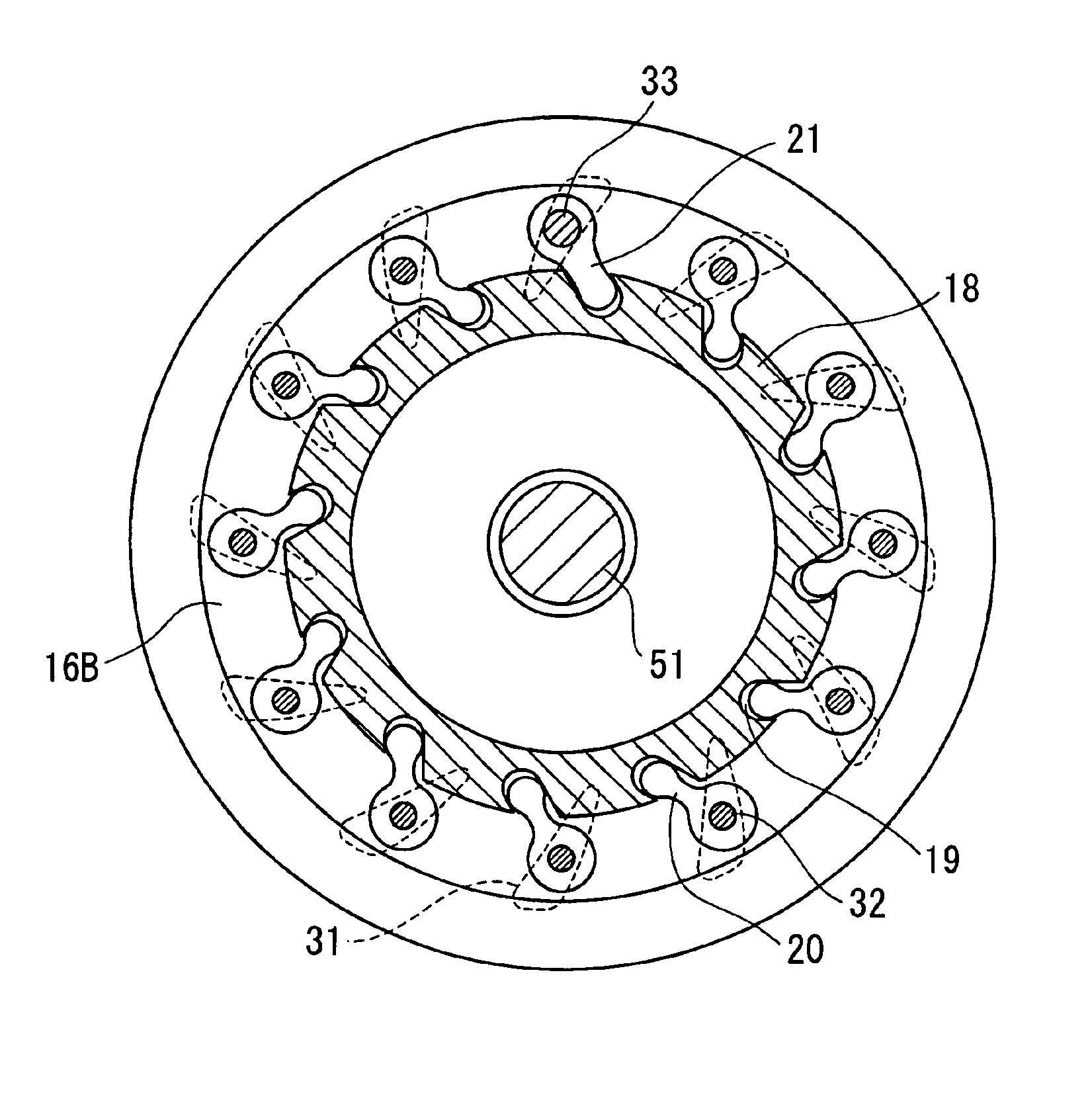

Variable turbocharger

InactiveUS6907733B2Simple structureImprove sealingInternal combustion piston enginesPump componentsCouplingDrive shaft

One of the swing shafts 32 of the nozzle vanes 31 is selected so as to operate as swing drive shaft 33 that projects to the outside. As the swing drive shaft 33 is driven to revolve, all the nozzle vanes 31 are driven to turn by a same angle by way of the driving lever 21 and the coupling ring 18 linked to it. Therefore, it is only the swing drive shaft 33 that projects to the outside, the projecting part can be sealed in a simple and reliable manner to improve the sealing effect and the durability of the variable geometry turbocharger. Additionally, since the rotary motion of the swing drive shaft 33 is directly used to driven the nozzle vanes 31 to swing, the mechanism for transmitting the driving force is simplified.

Owner:KOMATSU LTD

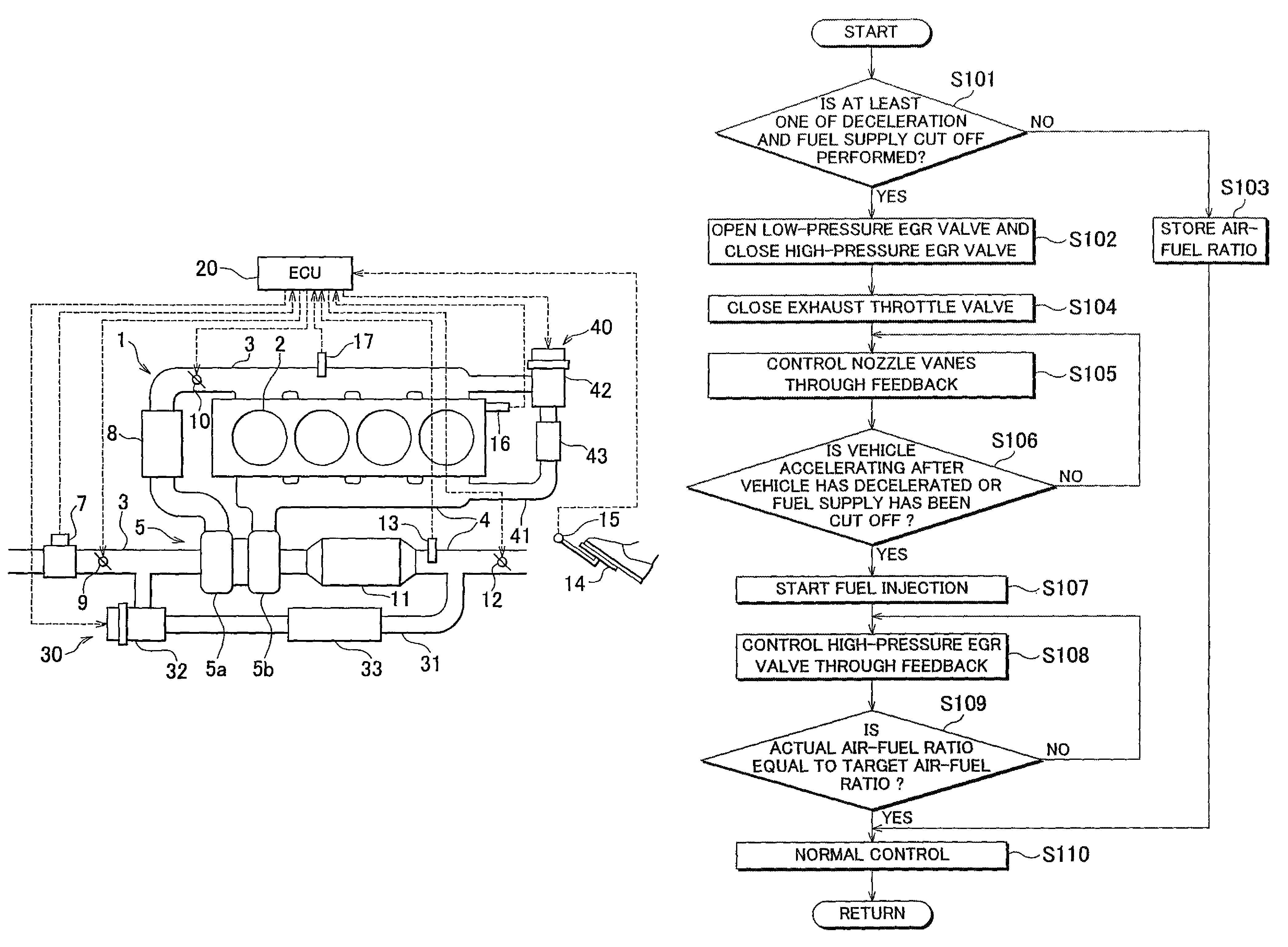

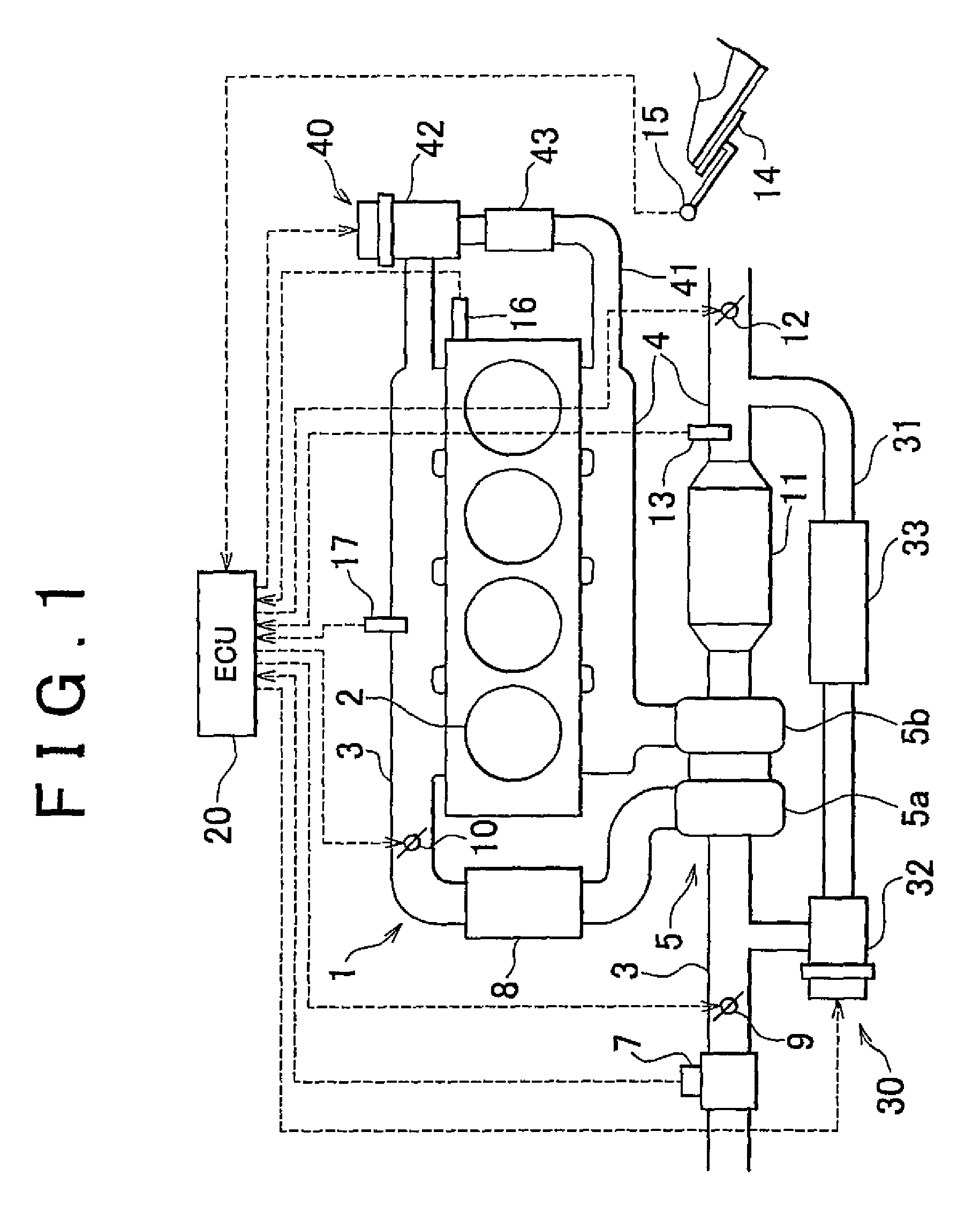

Exhaust gas recirculation apparatus for internal combustion engine and method of controlling exhaust gas recirculation apparatus

InactiveUS8006494B2Fast accelerationElectrical controlInternal combustion piston enginesFuel supplyInternal combustion engine cooling

A variable-geometry turbocharger and a low-pressure EGR passage are provided. The variable-geometry turbocharger includes a turbine provided in an exhaust passage, and a compressor provided in an intake passage. In the variable-geometry turbocharger, the cross sectional area of a path through which exhaust gas passes is adjusted by adjusting the opening degree of a nozzle vane. The low-pressure EGR passage connects the area of the exhaust passage downstream of the turbine to the area of the intake passage upstream of the compressor. The EGR gas is recirculated to the intake passage through the low-pressure EGR passage. The EGR gas is directed to flow through the low-pressure EGR passage when a vehicle is decelerating or when fuel supply to the internal combustion engine is cut off. The pressure in the intake passage is adjusted toward a target pressure by adjusting the opening degree of the nozzle vane when the EGR gas flows through the low-pressure EGR passage.

Owner:TOYOTA JIDOSHA KK

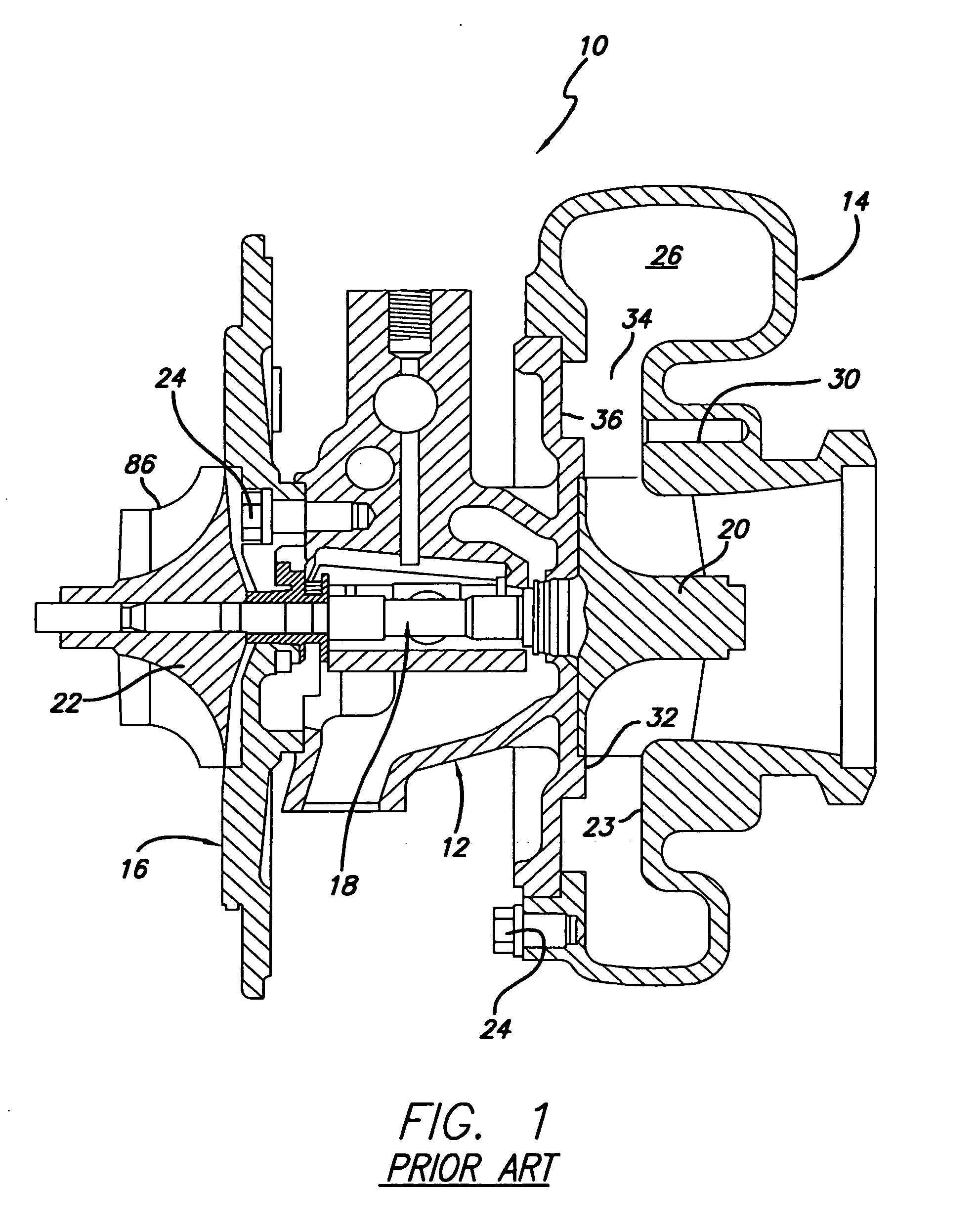

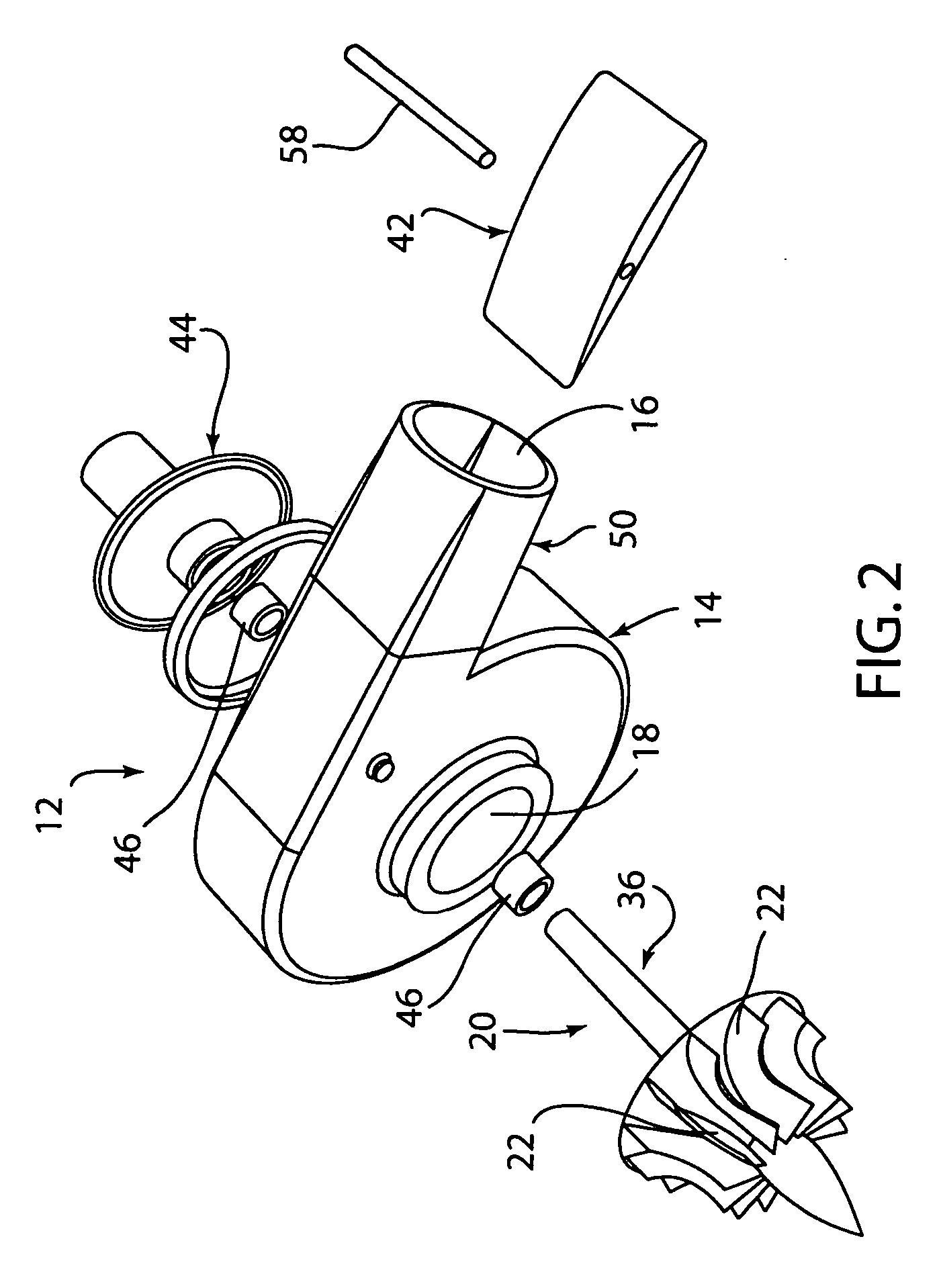

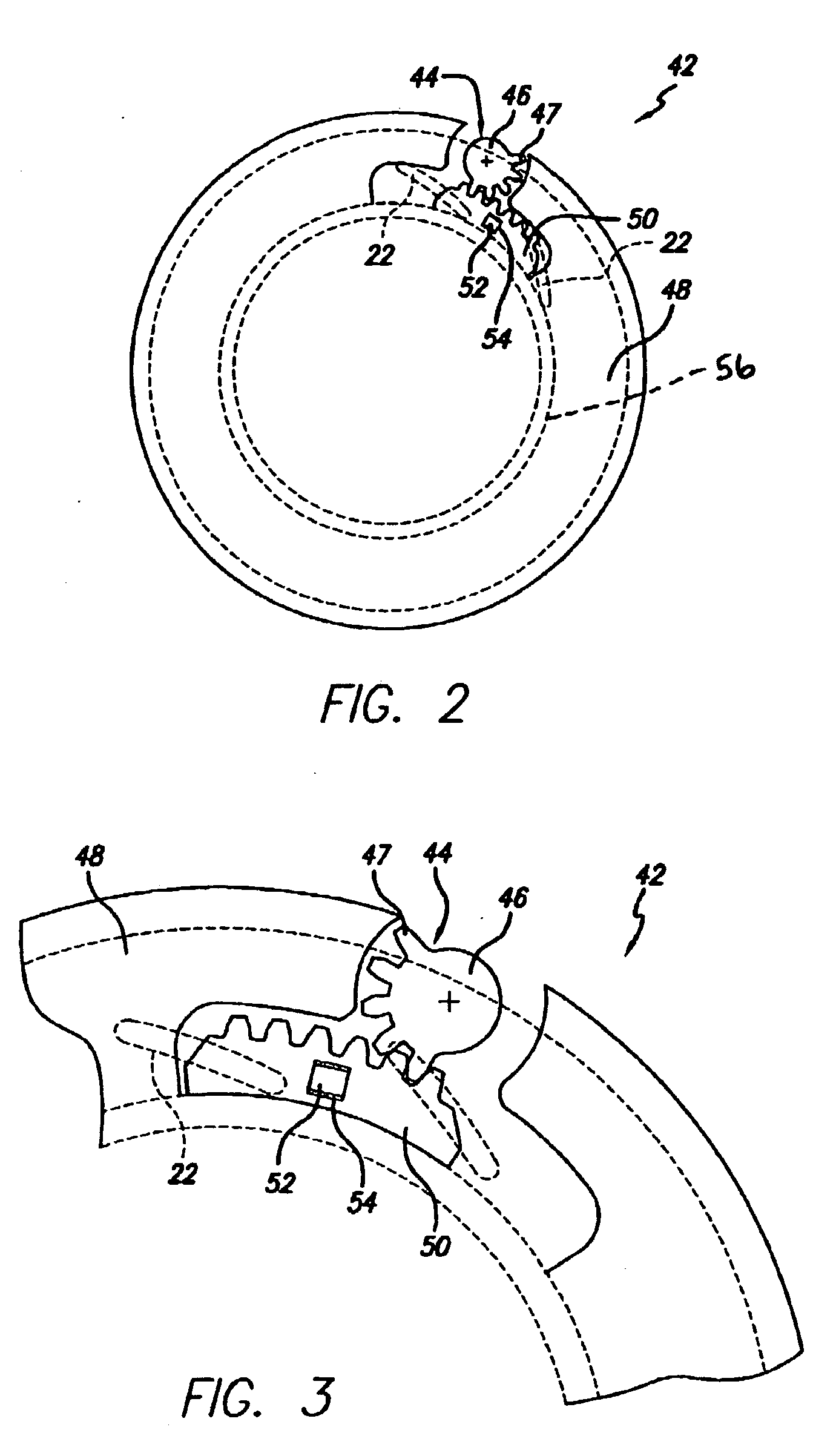

Variable geometry Turbocharger

A variable geometry turbocharger employs multiple vanes (36) in the turbine inlet with a unison ring (48) and integral cast wall in the turbine housing forming the nozzle walls. The unison ring incorporates actuation slots (46) receiving tabs (44) on the vanes (36) for opening the closing the nozzle area upon rotation of the unison ring (48). An integral electrohydraulic actuator rotates the unison ring (48) through a rack and pinion driven crank shaft with direct position feedback to the spring biased variable current solenoid via a cam on the crank shaft.

Owner:GARRETT TRANSPORATION I INC

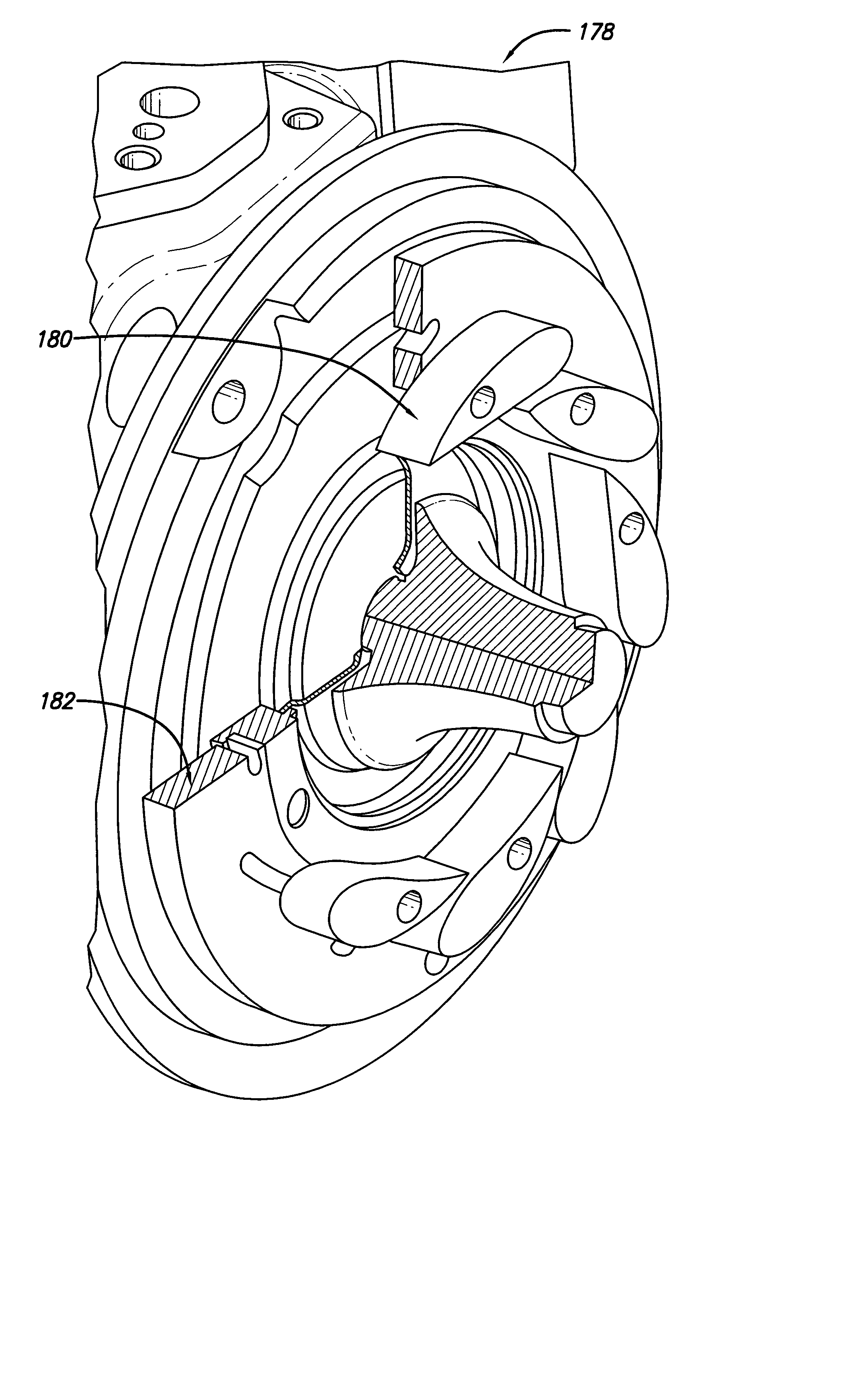

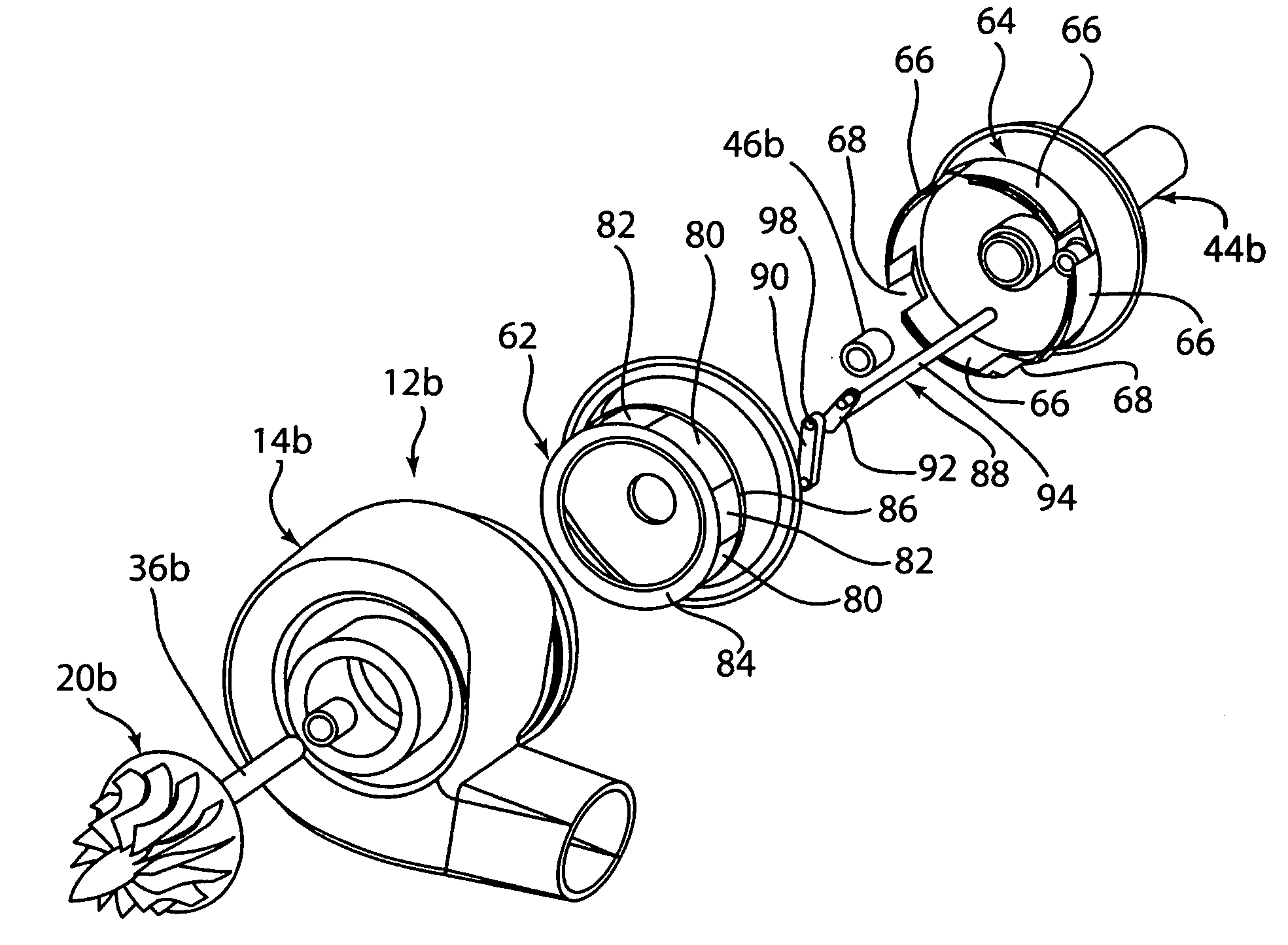

Actuation assembly for variable geometry turbochargers

ActiveUS20050160731A1Minimize and eliminate impairmentInternal combustion piston enginesEngine manufactureEngineeringActuator

Improved actuation assemblies are used with variable geometry turbochargers comprising a plurality of movable aerodynamic vanes attached to a movable unison ring that is coupled to an actuator. The actuation assembly includes a crank arm that is attached at a first end to the actuator, and at a second end to the unison ring. A first gear member is attached to the crank arm second end and includes teeth. The unison ring includes a second gear member attached thereto that also comprises teeth. The teeth of the first and second gear-members are cooperatively engaged with one another. The second gear member is movably attached to the unison ring to maintain predetermined distance between the first and second gear members during operation of the turbocharger and related thermal movement of the unison ring.

Owner:GARRETT TRANSPORATION I INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com