Internal combustion engine variable geometry turbine supercharger nozzle ring components

A technology of turbocharger and internal combustion engine, applied in the direction of internal combustion piston engine, engine components, combustion engine, etc., can solve the problem of low boost regulation performance, blade material performance can not better meet the use requirements, small changes in intake passages, etc. problems, to achieve the effect of reducing fuel consumption, improving economical use, and reducing various losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

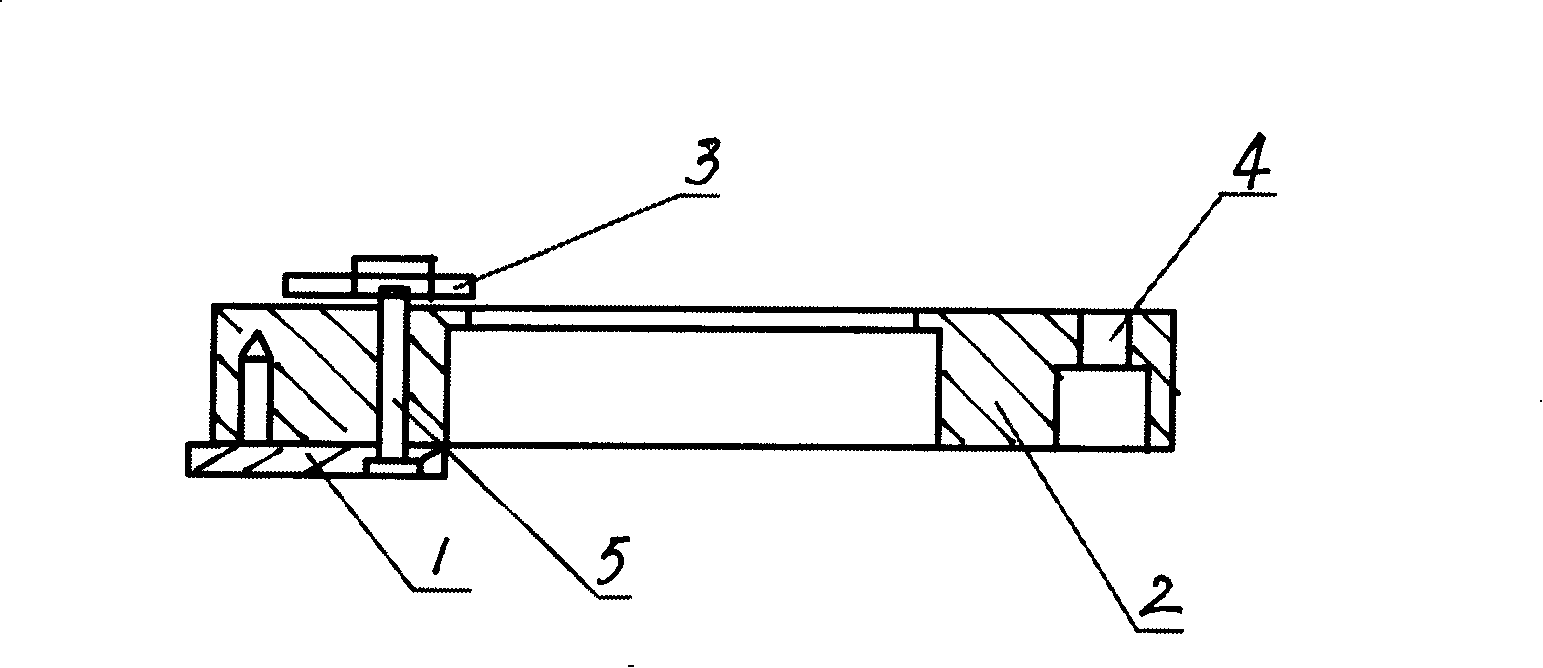

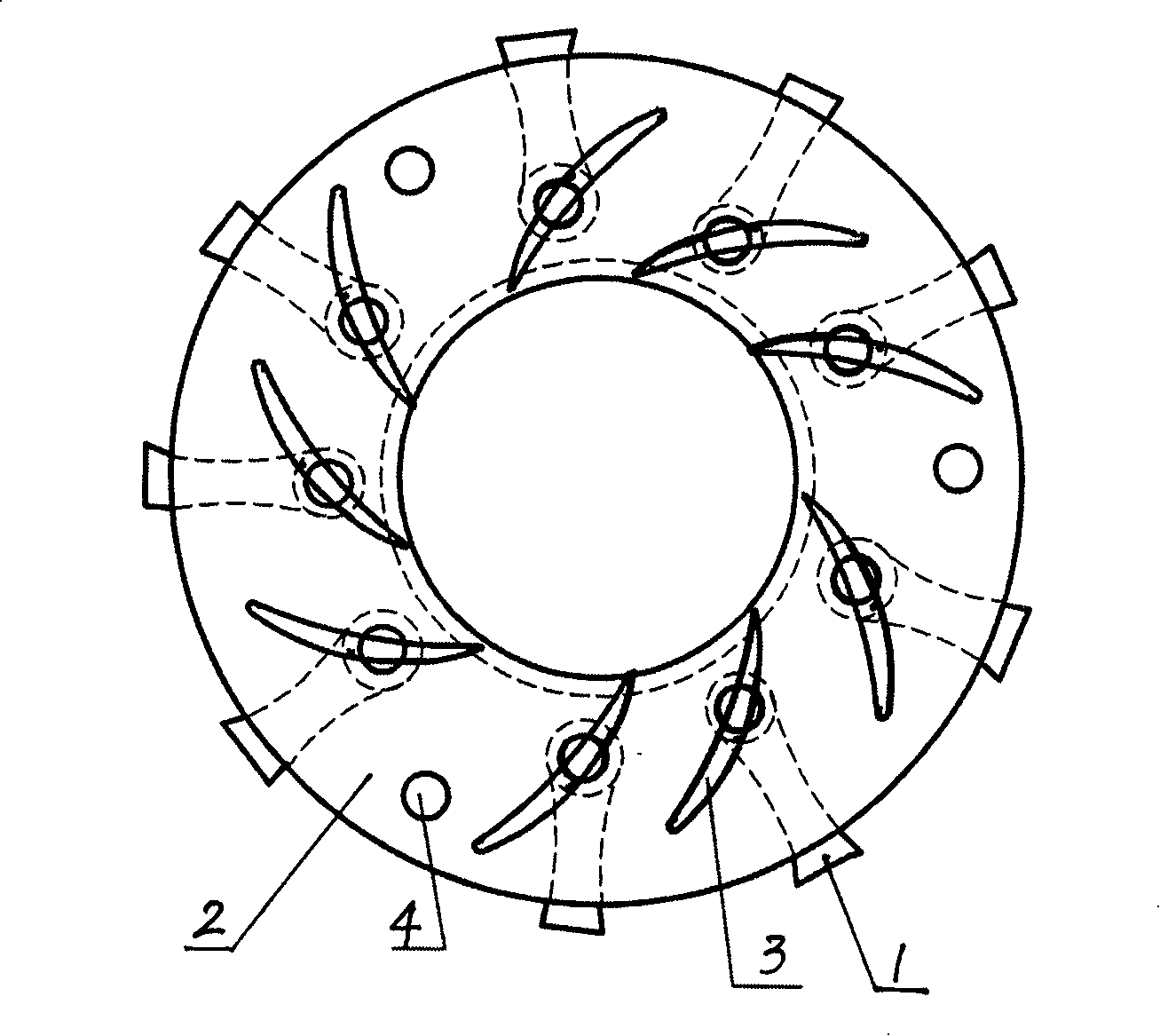

[0020] exist figure 1 and figure 2 middle,

[0021] The nozzle ring assembly of the present invention is a series of products, suitable for turbochargers with a turbine diameter of 30-150mm, and suitable for use with an engine power of 50-1000KW. It includes a fork 1, a mounting plate 2 and blades 3. The mounting plate 2 is in the shape of a ring, and three groups of blades 3 are evenly spaced and arranged in the same direction on the same circumference of the side of the mounting plate 2, and each group is composed of three blades 3. Each group of blades is separated from each other. According to the size of the turbocharger, it can also be grouped into four or five groups. According to the size of the turbocharger, each group can also be composed of four or five pieces. Each group of blades 3 can be opened and stacked with each other at the same time. On the mounting plate 2, there are three connection holes 4 between the positions of each group of blades. On the other s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com