Variable geometry Turbocharger

A turbocharger, geometric size technology, applied in gas turbine installations, machines/engines, combustion engines, etc., can solve problems such as increased manufacturing cost and structural complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

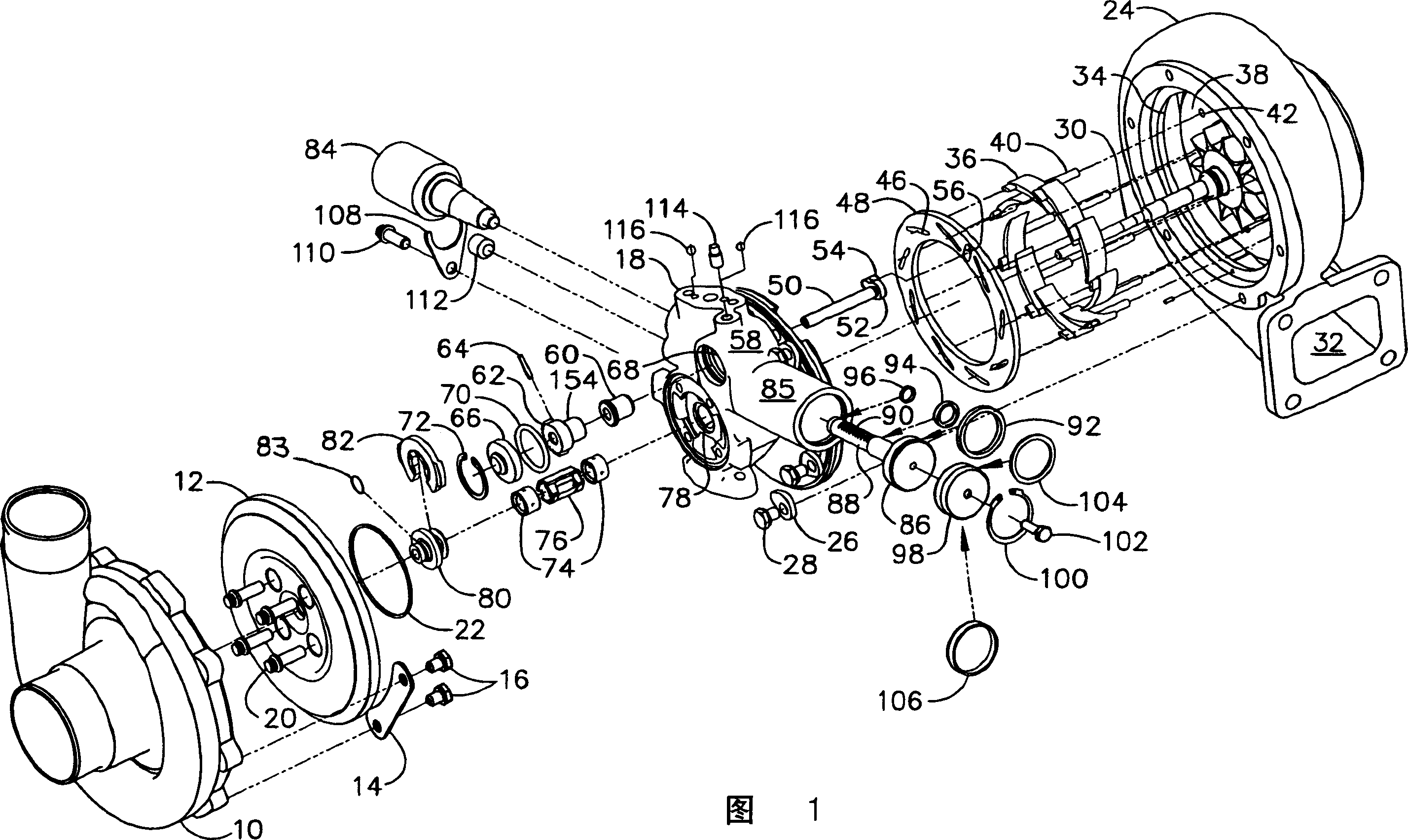

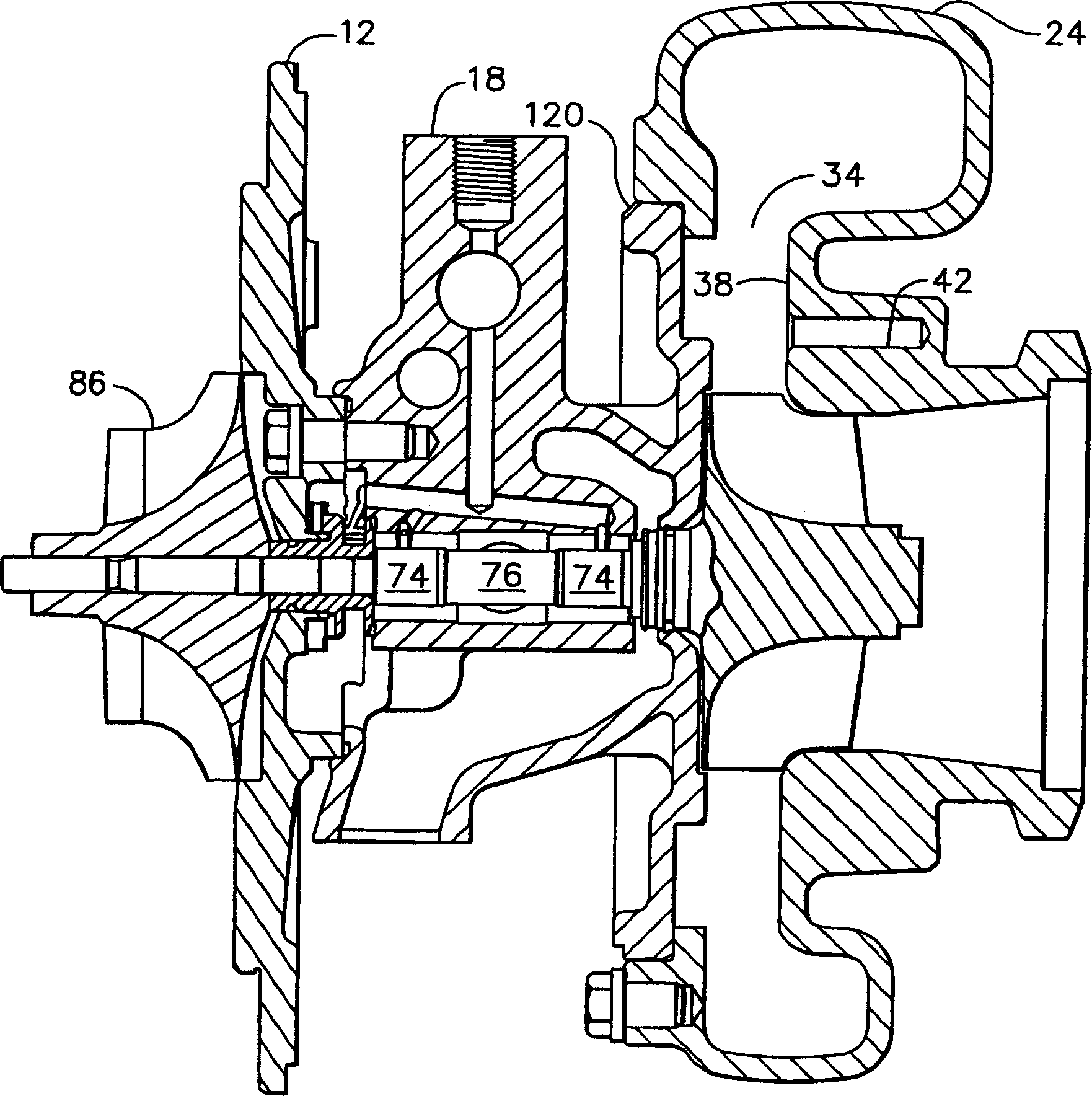

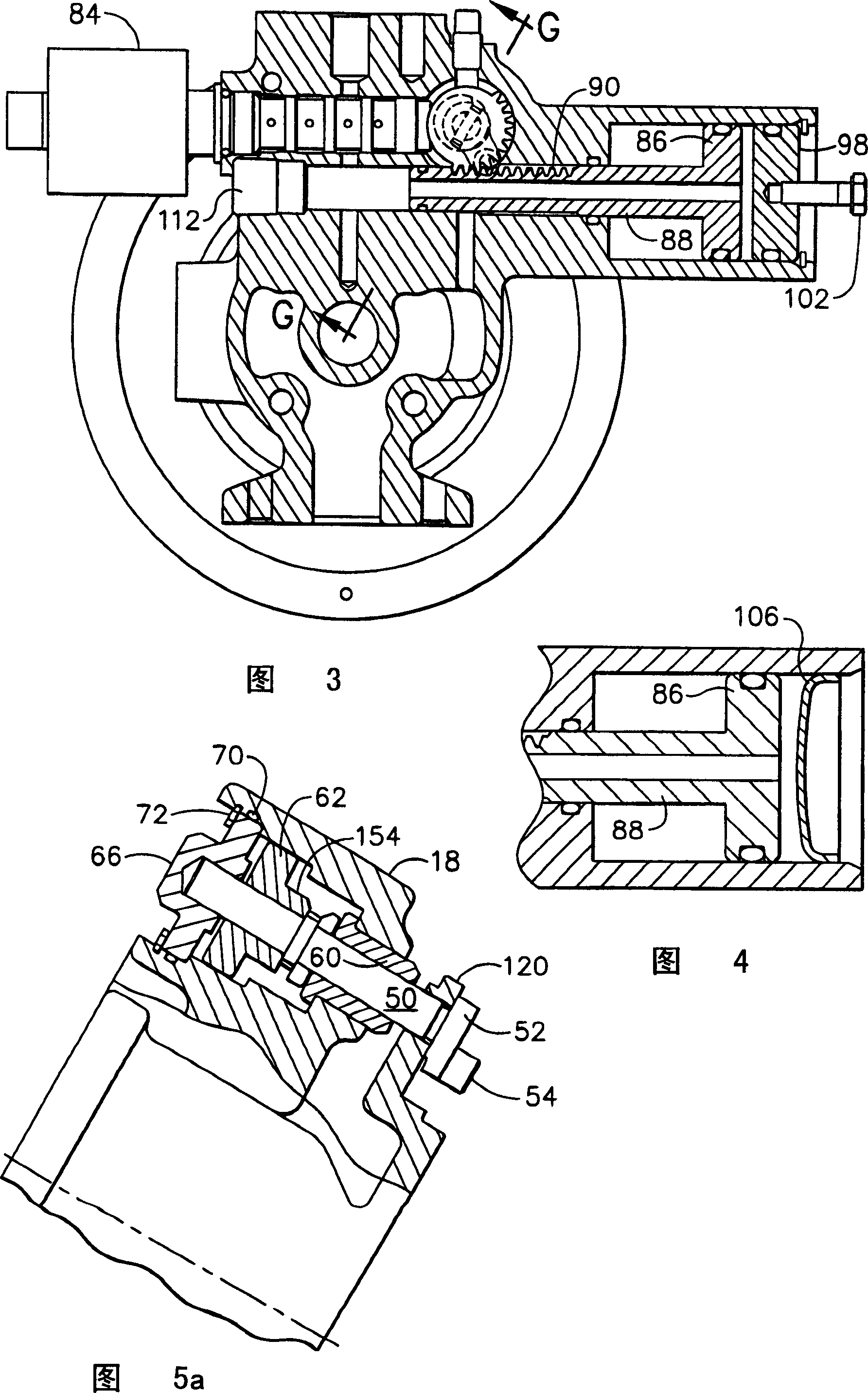

[0021] Referring to the drawings, the embodiment of the invention shown in FIG. 1 includes a compressor housing 10 attached to a back plate 12 using two or more clamps 14 secured by bolts 16. . The backplate is attached to a center housing 18 with bolts 20 and a seal ring 22 . The turbine housing 24 is connected to the center housing with a plurality of clamps 26 secured by bolts 28 . A turbine wheel and shaft assembly 30 is mounted within the turbine housing. Exhaust gases or other high energy gases supplied to the turbocharger enter the turbine housing through an inlet 32 and are distributed through a volute within the turbine housing for substantially radial entry into the turbine through a circumferential nozzle inlet 34 impeller.

[0022] A plurality of vanes 36 are mounted to a nozzle wall 38 machined in the turbine housing with struts 40 extending from the vanes for rotational engagement with holes 42 in the nozzle wall. Actuation tabs 44 extend from the vanes to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com