Patents

Literature

110results about How to "Wide flow range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

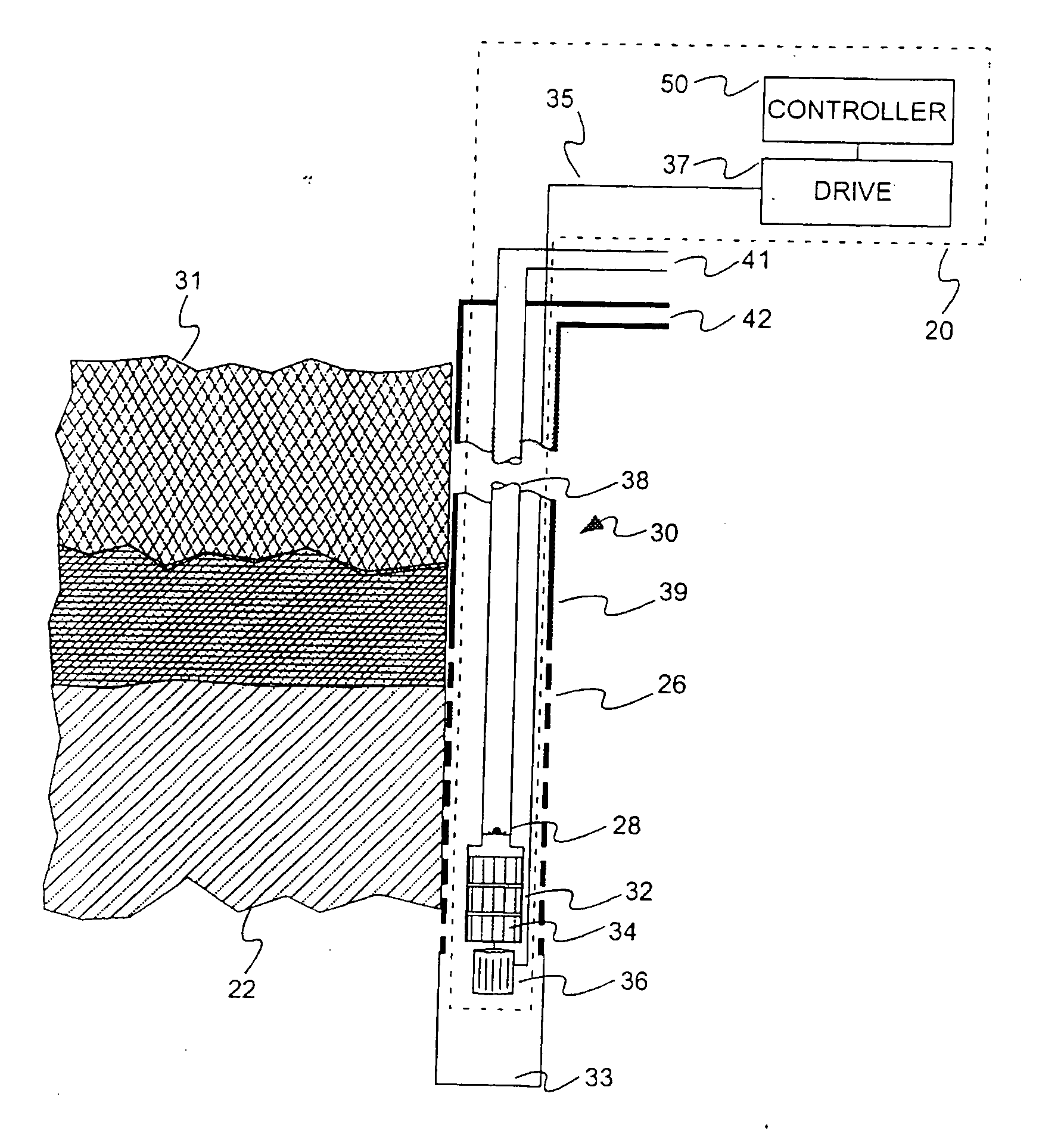

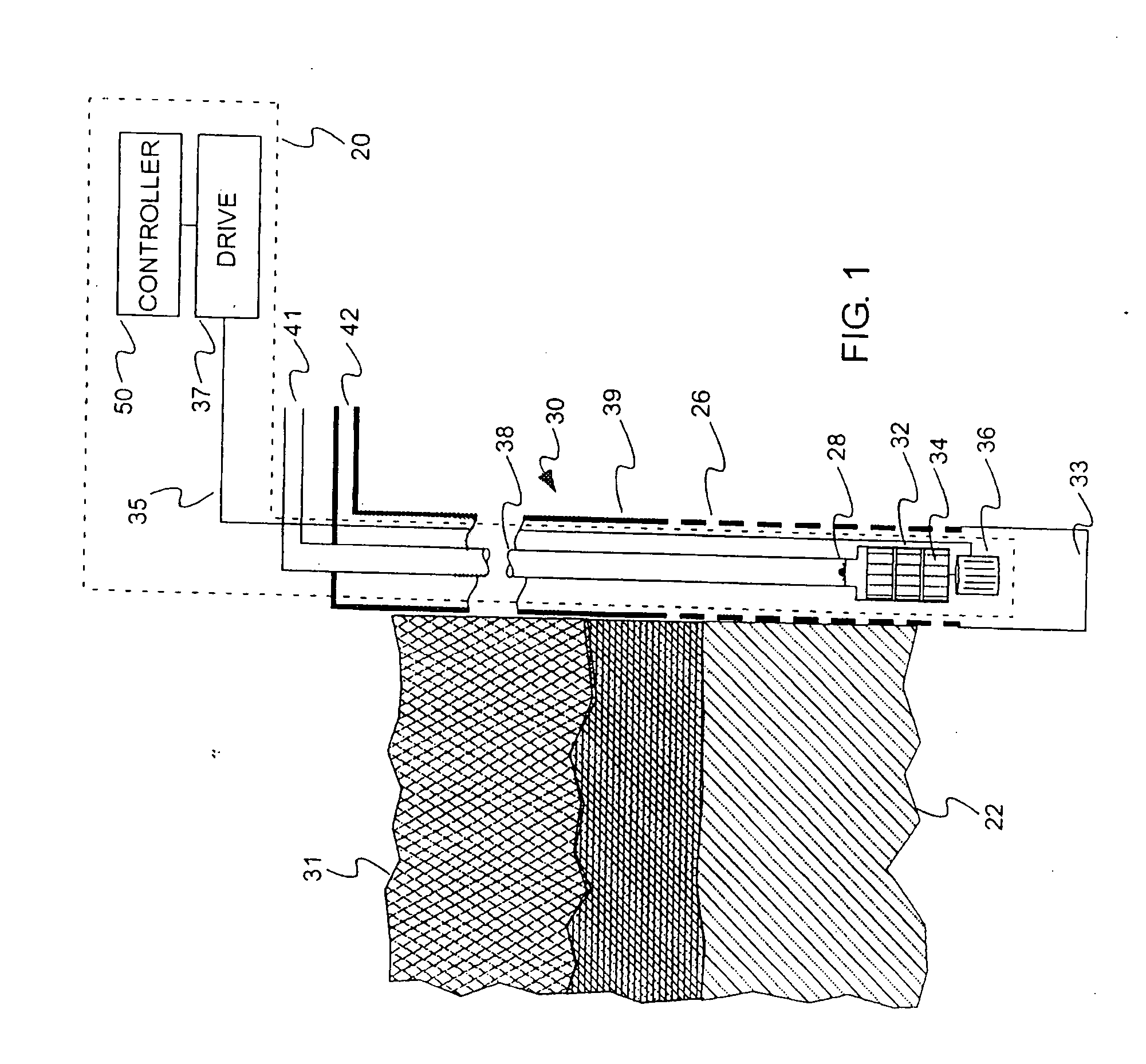

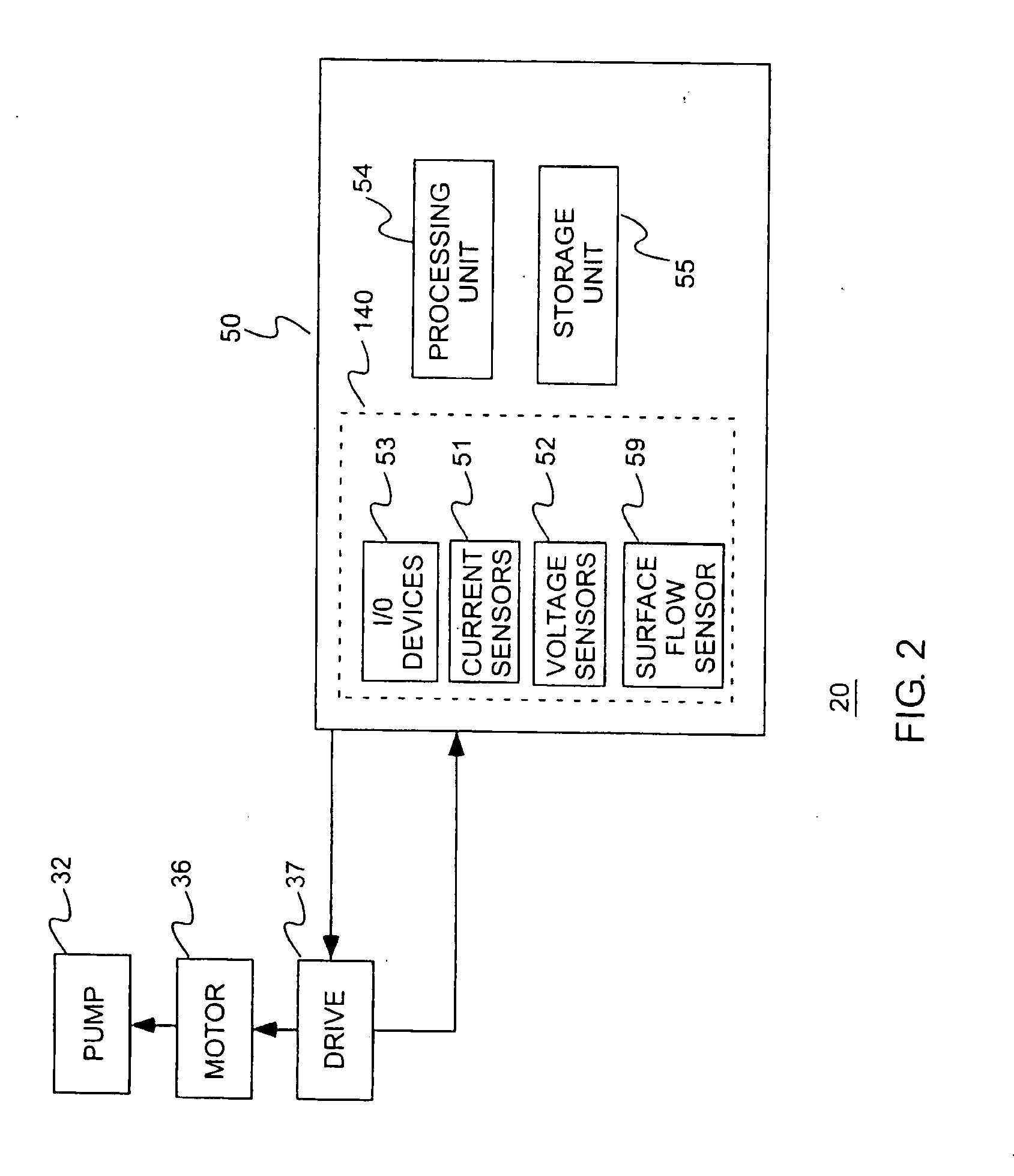

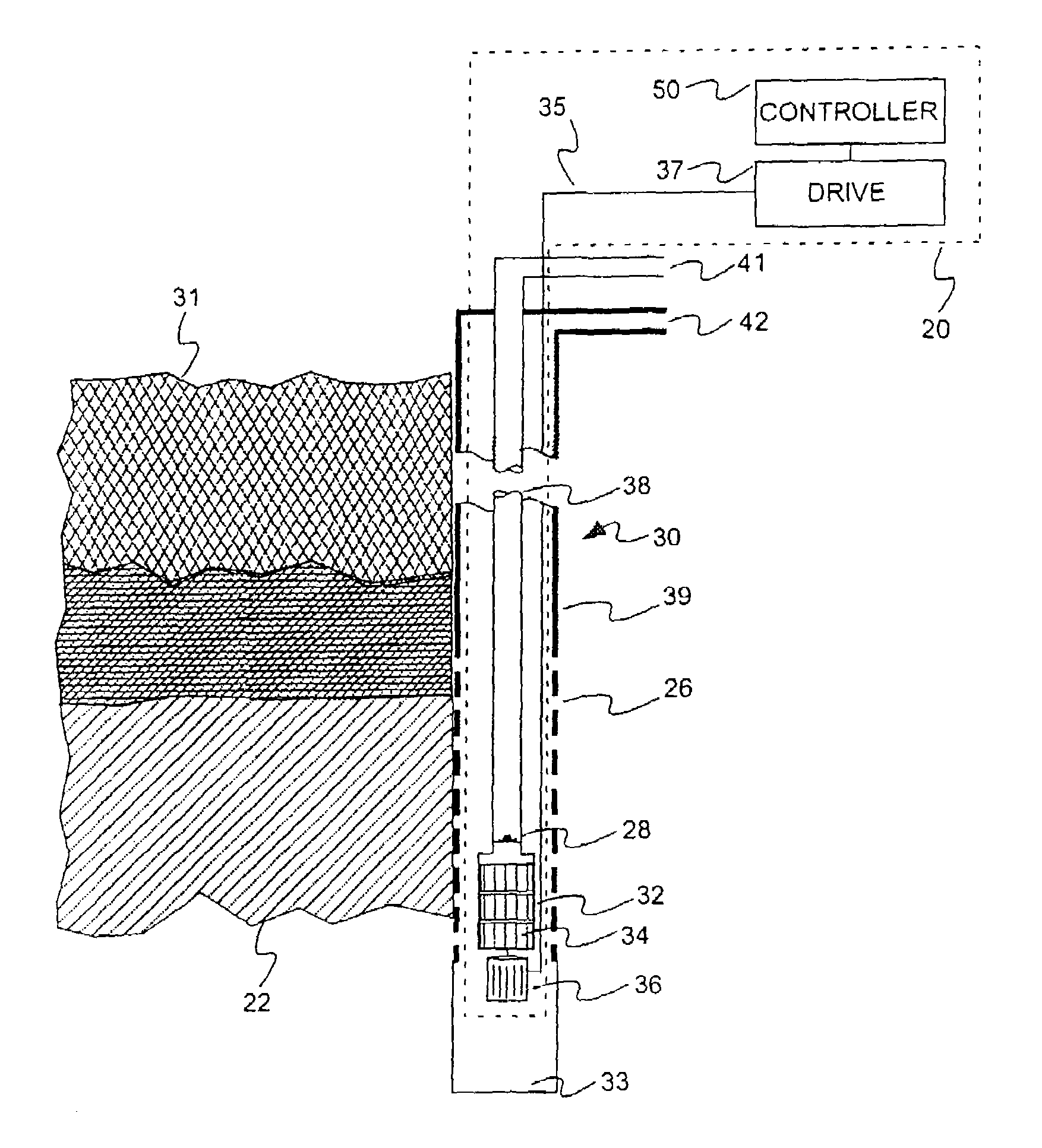

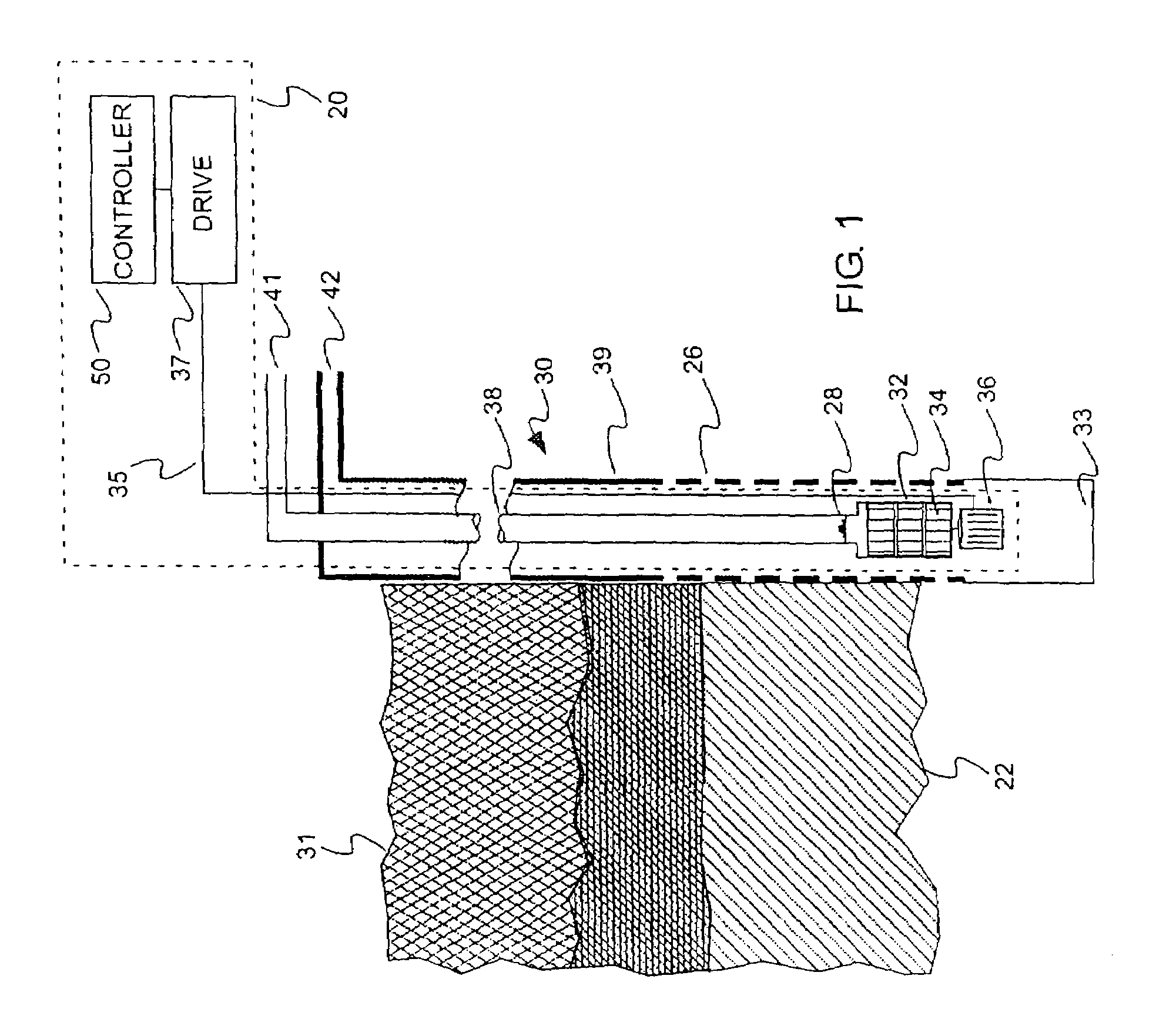

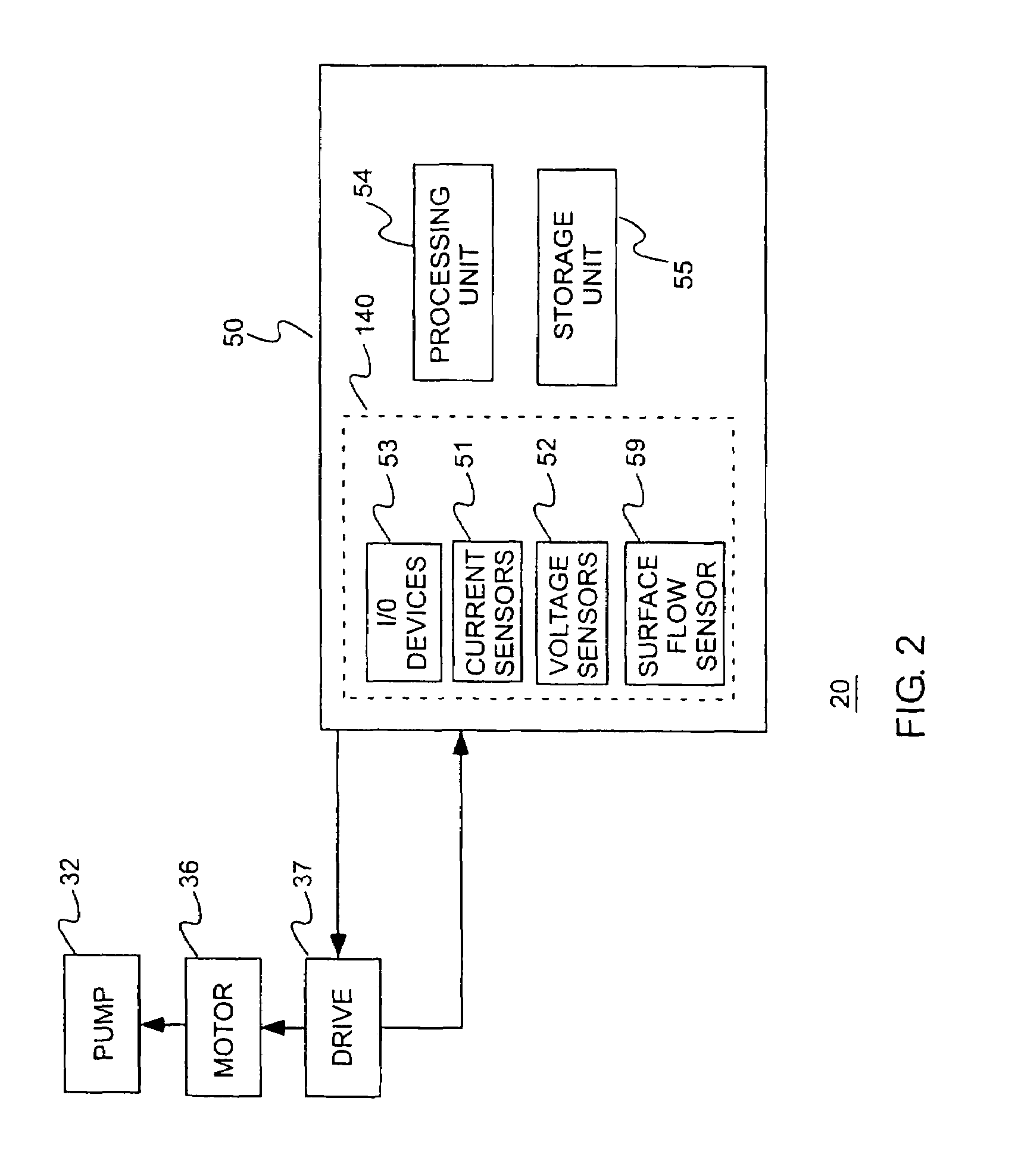

Determination And Control Of Wellbore Fluid Level, Output Flow, And Desired Pump Operating Speed, Using A Control System For A Centrifugal Pump Disposed Within The Wellbore

ActiveUS20080067116A1Enhance market appealBroad possible marketLevel controlWind motor controlEngineeringSystem parameters

A method and apparatus for determining a fluid level and / or output flow during operation of a centrifugal pump, are provided, which may be used for production of gas and / or oil from a well, and include a vector feedback model to derive values of torque and speed from signals indicative of instantaneous current and voltage drawn by the pump motor, a pump model which derives values of the fluid flow rate and the head pressure for the pump from torque and speed inputs, a pumping system model that derives, from the estimated values of the pump operating parameters, an estimated value of fluid level and other pumping system parameters. Controllers responsive to the estimated values of the pumping system parameters control the pump to maintain fluid level at the pump input, near an optimum level, or within a safe operating range and / or output flow from the pump.

Owner:UNICO LLC

Determination and control of wellbore fluid level, output flow, and desired pump operating speed, using a control system for a centrifugal pump disposed within the wellbore

InactiveUS7668694B2Reduce lossesTotal current dropLevel controlWind motor controlStreamflowOperating speed

A method and apparatus for determining a fluid level and / or output flow during operation of a centrifugal pump, are provided, which may be used for production of gas and / or oil from a well, and include a vector feedback model to derive values of torque and speed from signals indicative of instantaneous current and voltage drawn by the pump motor, a pump model which derives values of the fluid flow rate and the head pressure for the pump from torque and speed inputs, a pumping system model that derives, from the estimated values of the pump operating parameters, an estimated value of fluid level and other pumping system parameters. Controllers responsive to the estimated values of the pumping system parameters control the pump to maintain fluid level at the pump input, near an optimum level, or within a safe operating range and / or output flow from the pump.

Owner:UNICO LLC

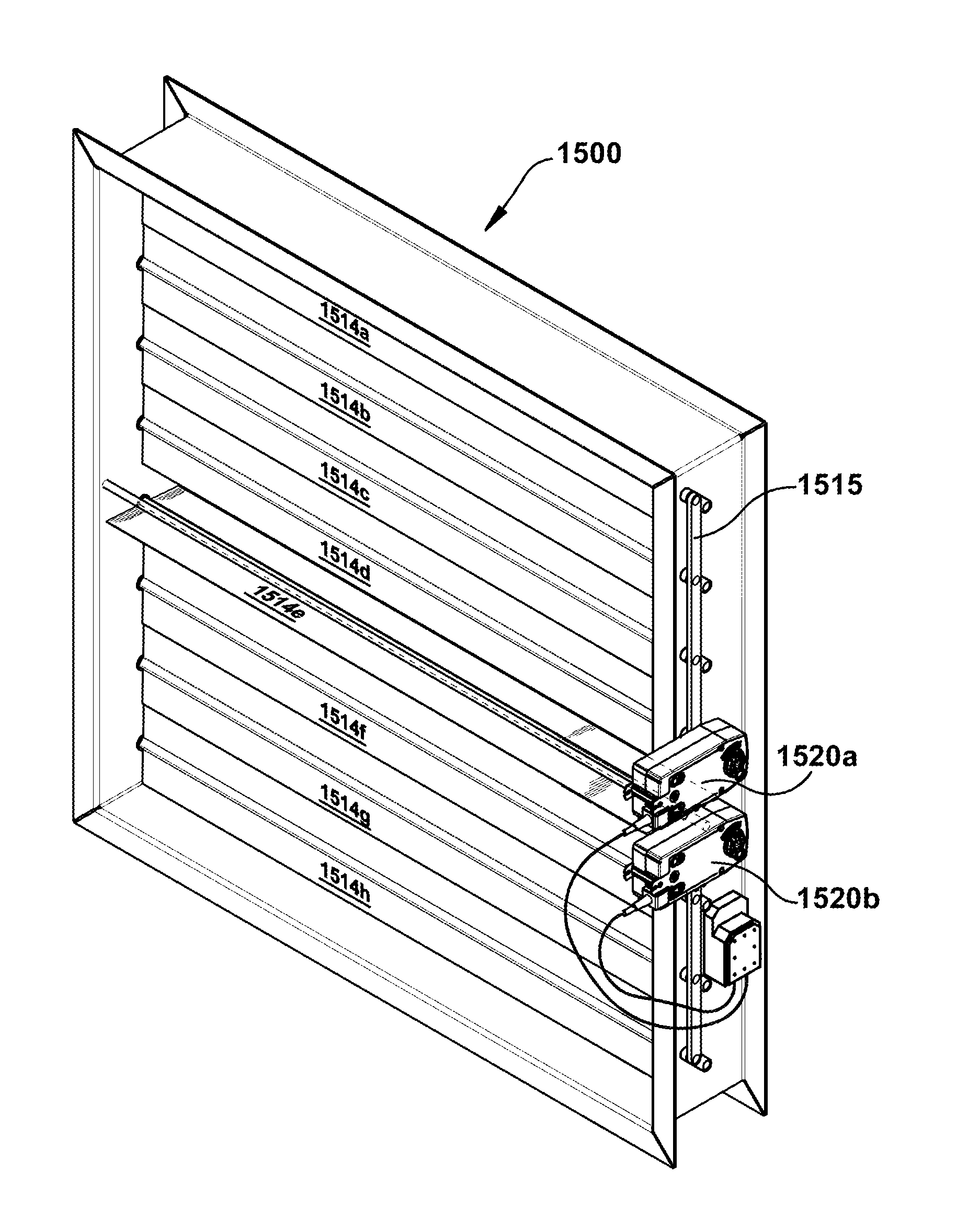

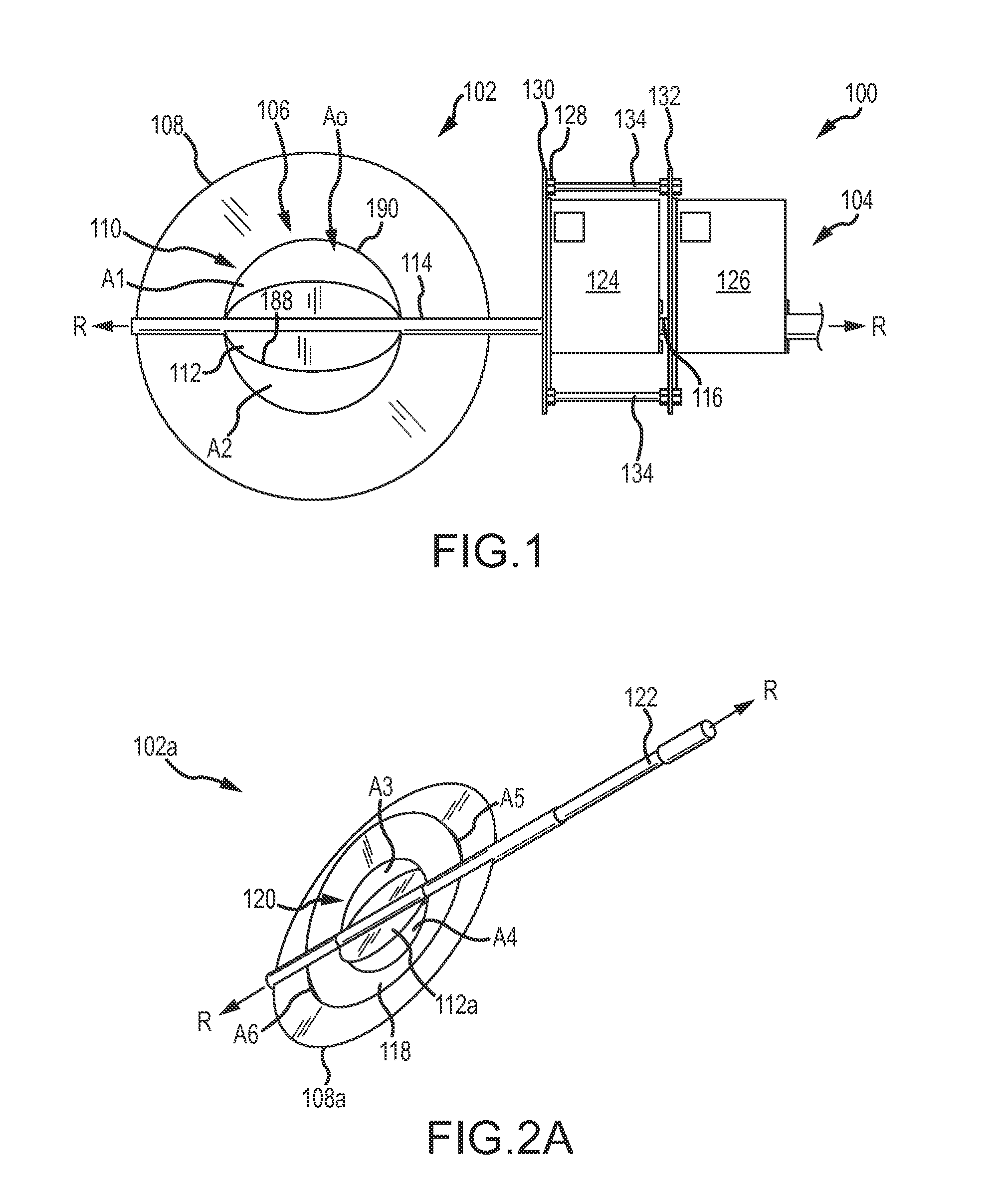

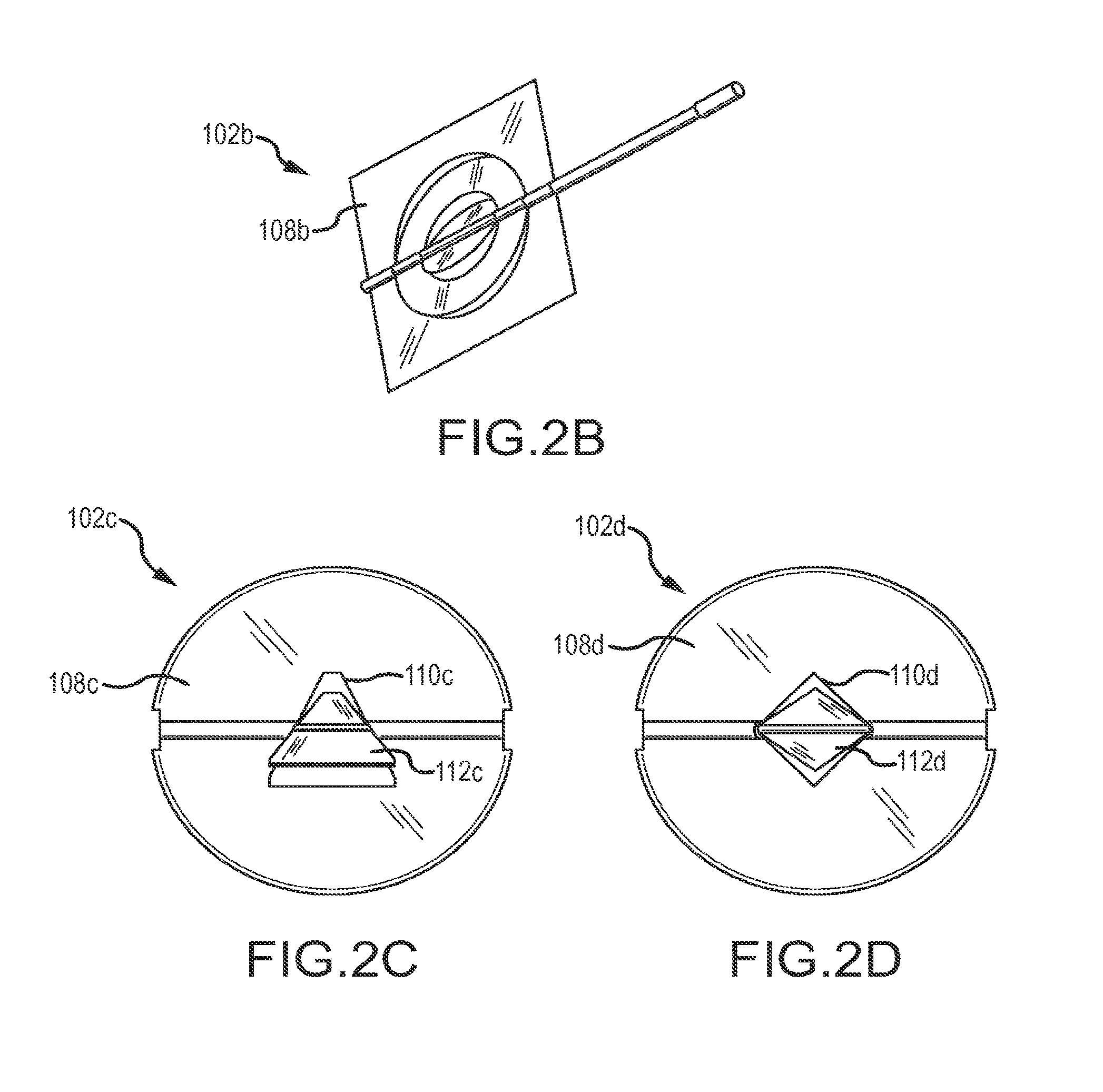

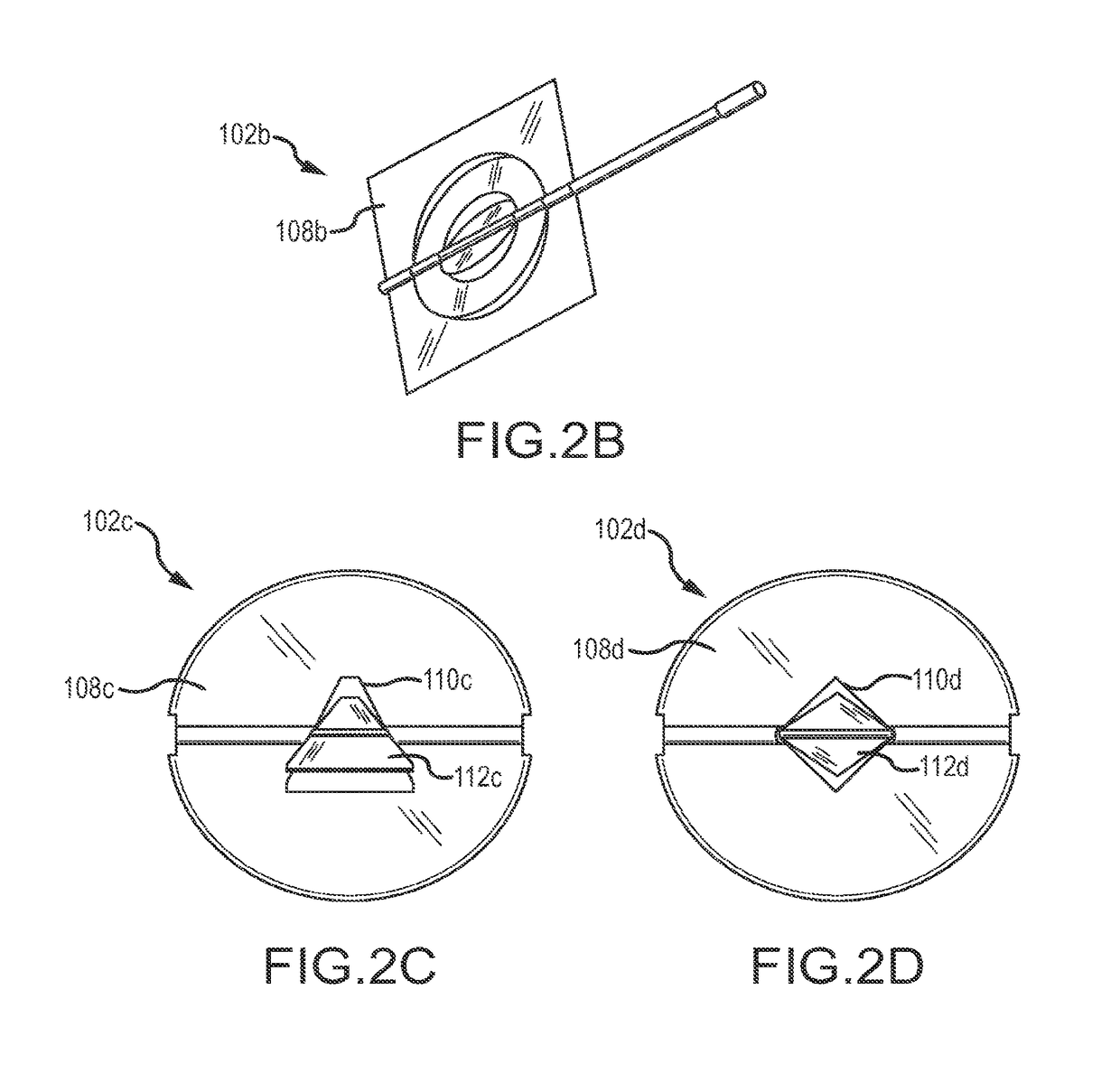

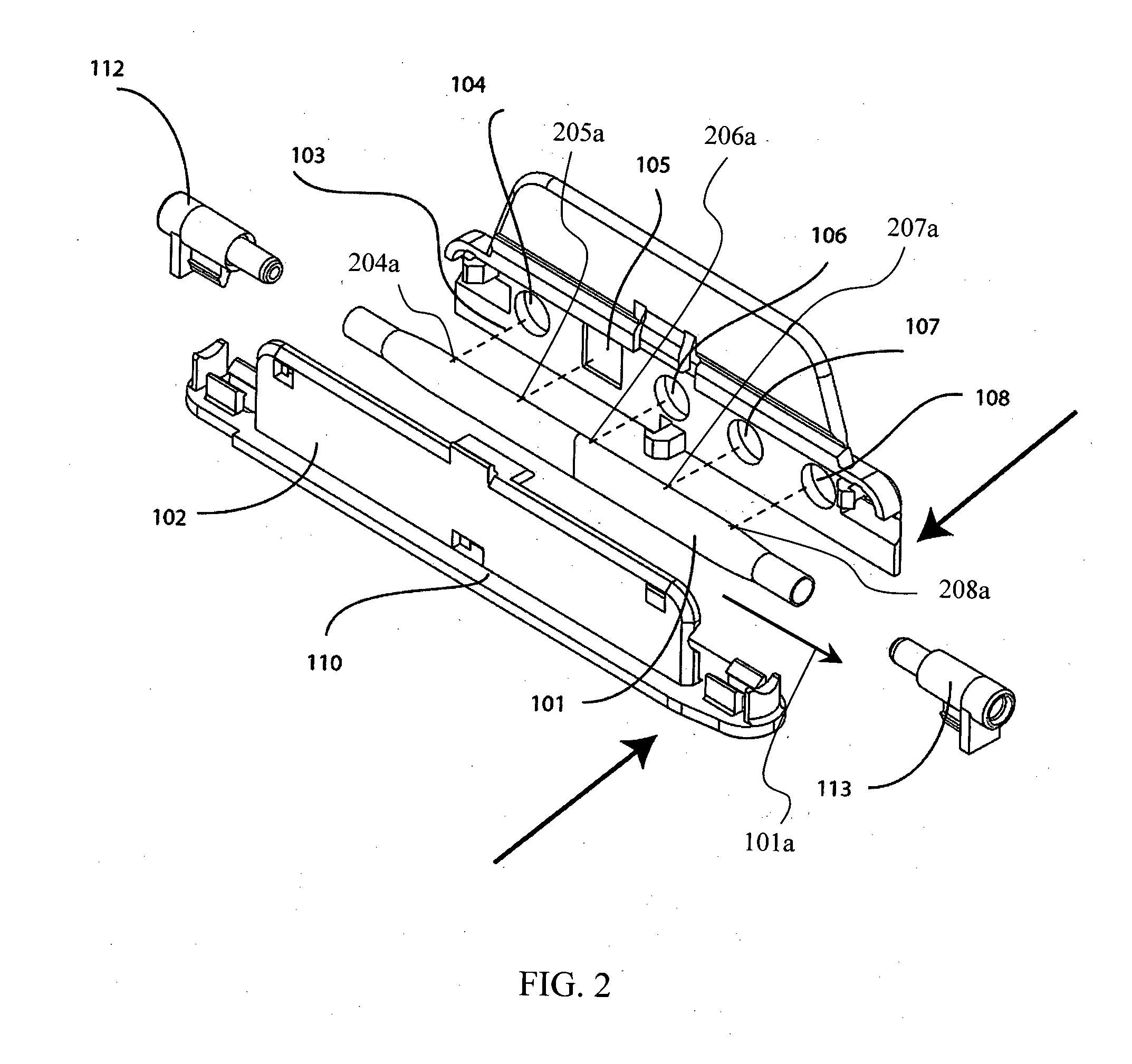

Low flow fluid controller apparatus and system

ActiveUS20170045255A1Improve energy consumptionReduce lossesProgramme controlMechanical apparatusSoftware systemControl system

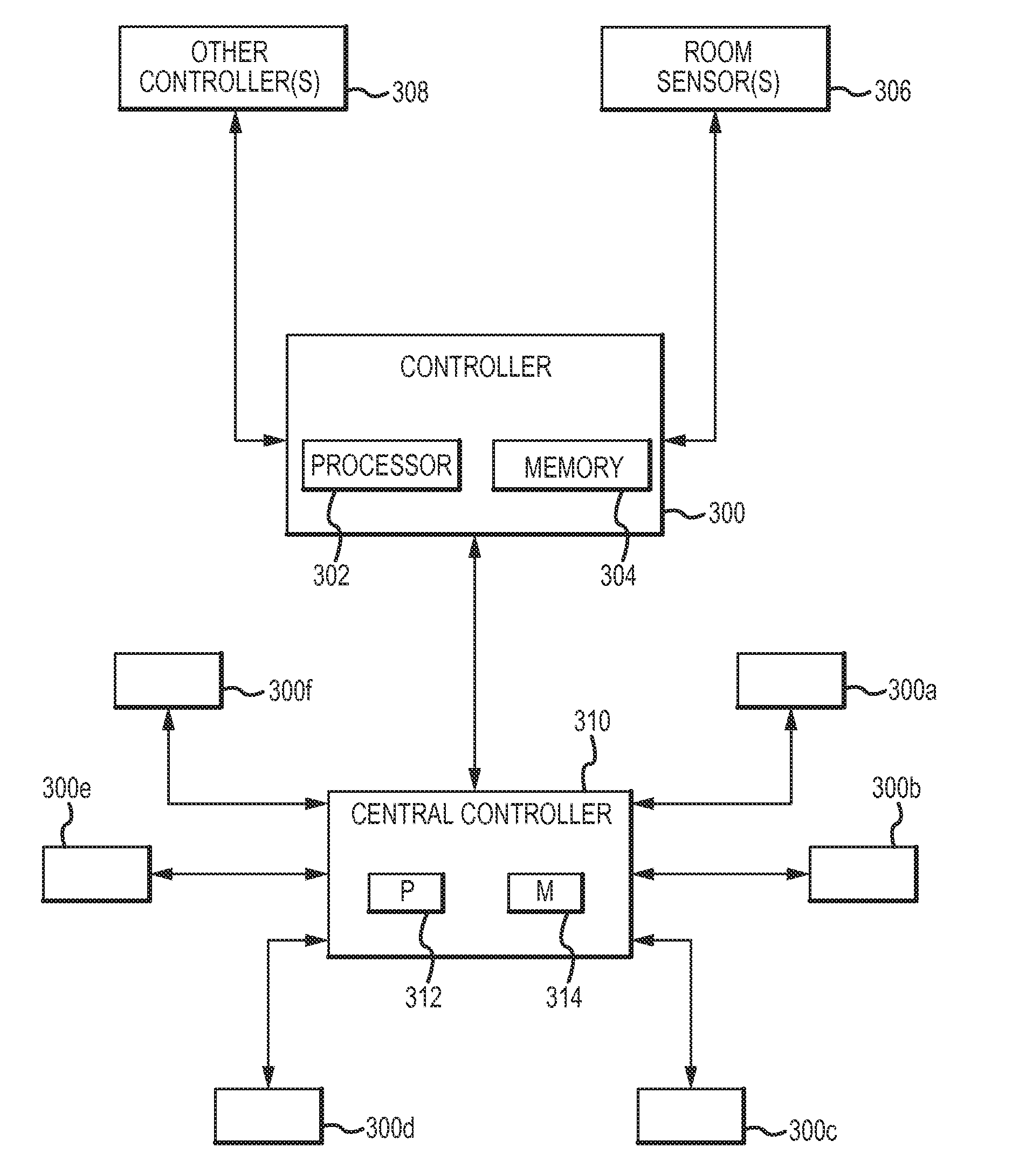

An air distribution apparatus that serves as a single sensing device for both lighting, LiFi, and HVAC functions that are operable on a single platform by building automation systems. The building automation system may be controllable by a single software system or network accessible locally on site or remotely off site. The air distribution apparatus can operate in a single zone or coupled with multiple like apparatuses for multi-zone operation. It is a high turndown, self-balancing system which allows for continuous commissioning with built-in fault diagnostic systems and that may be used as a supply, return, or exhaust system, or a combination thereof. The air distribution apparatus includes multi-stage airflow control systems that operate progressively based on unique actuation mechanisms and / or algorithms that allow for precise flow control and feedback to self-balance and commission the system.

Owner:BEST TECH

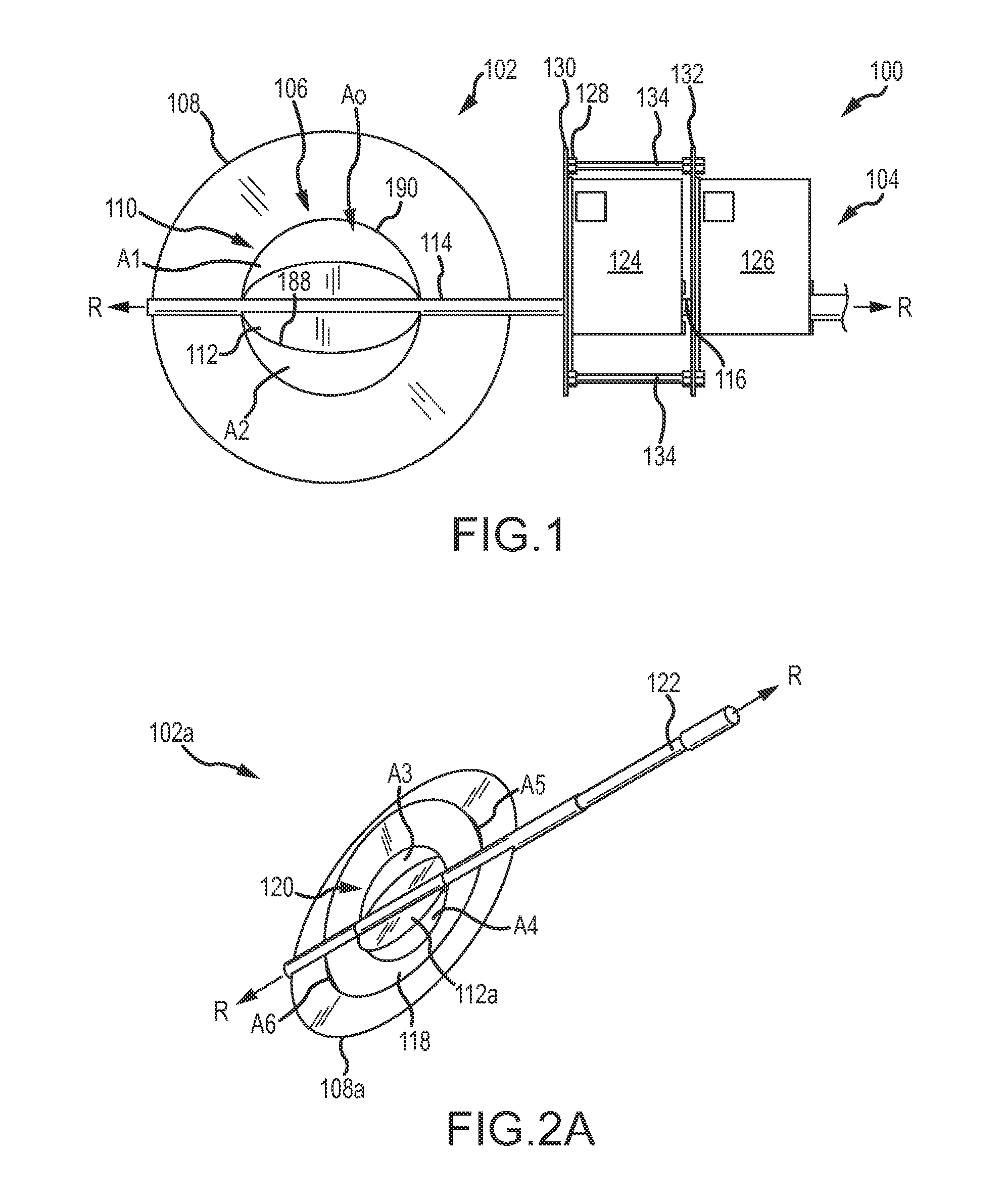

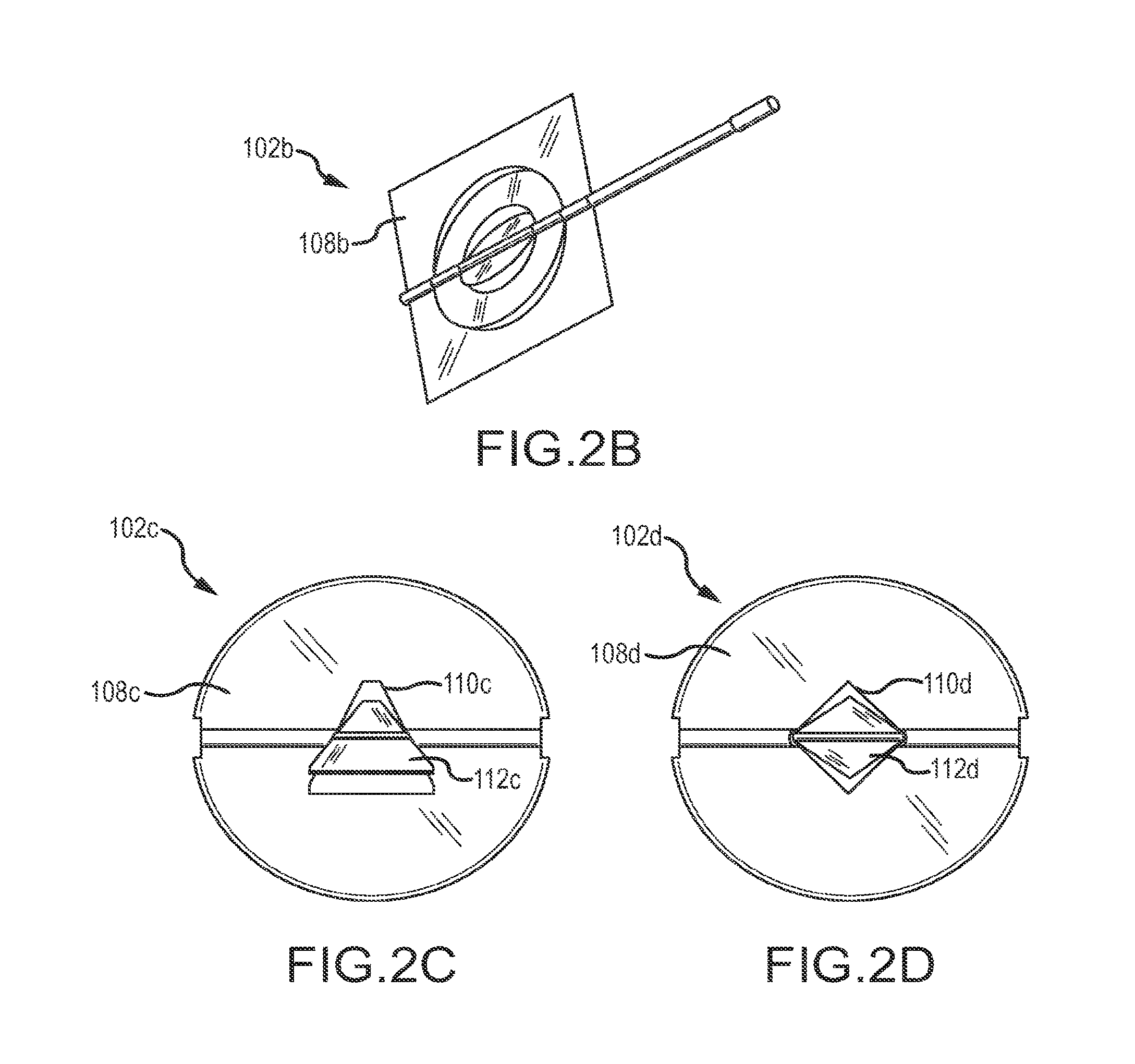

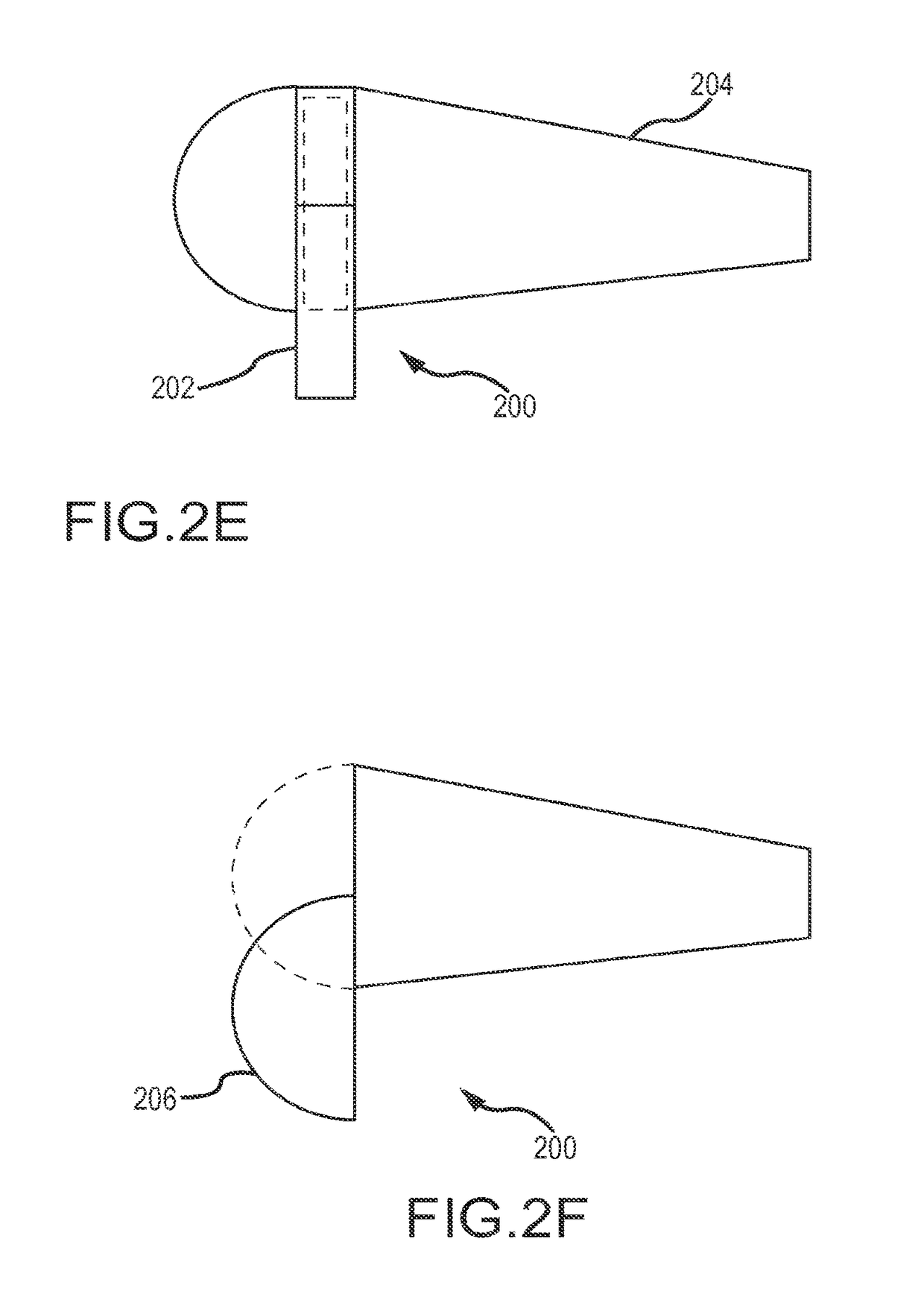

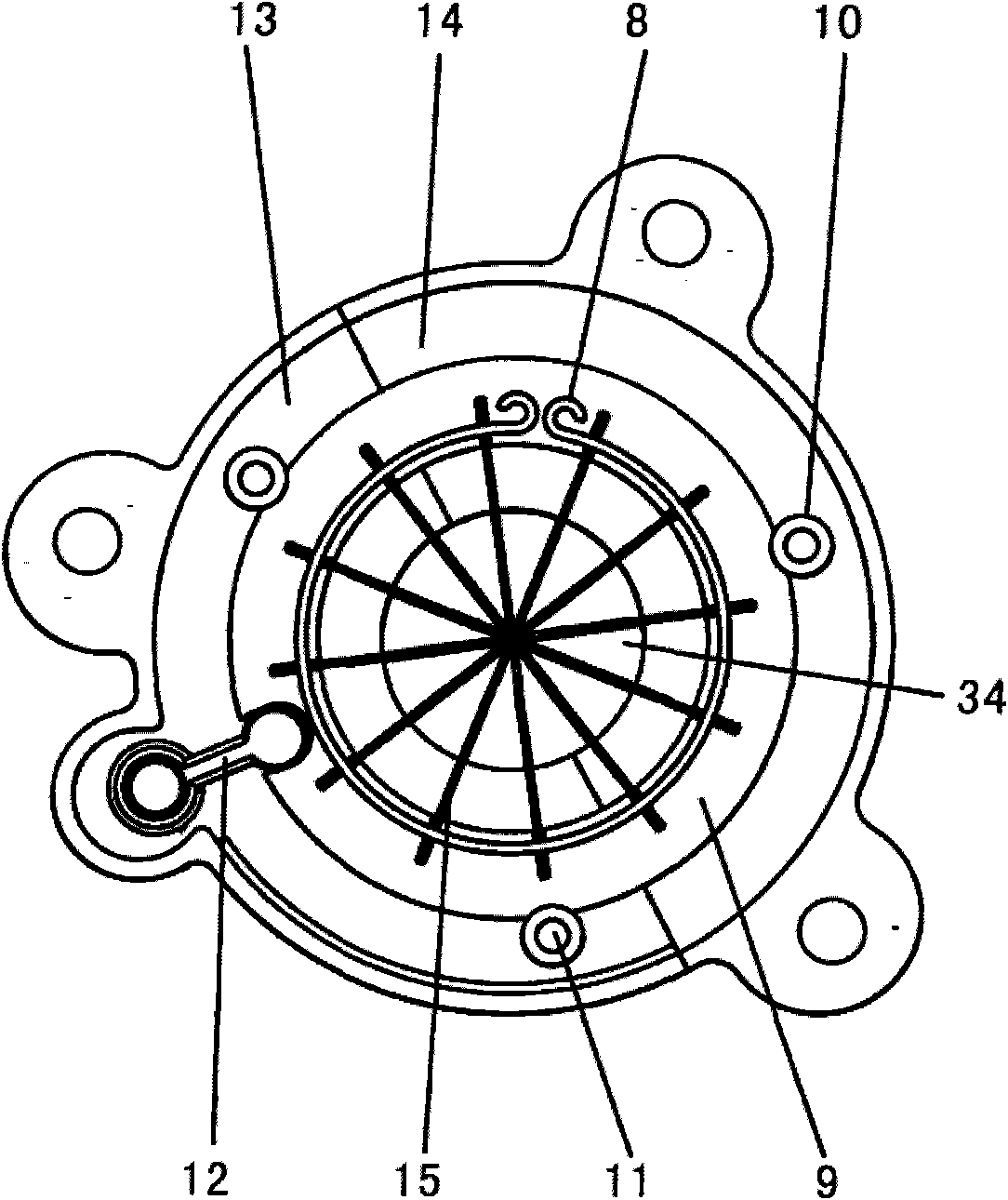

Fluid control measuring device

ActiveUS20150019022A1Precise flow rate QEasy to readMechanical apparatusLighting and heating apparatusNoise generationFluid control

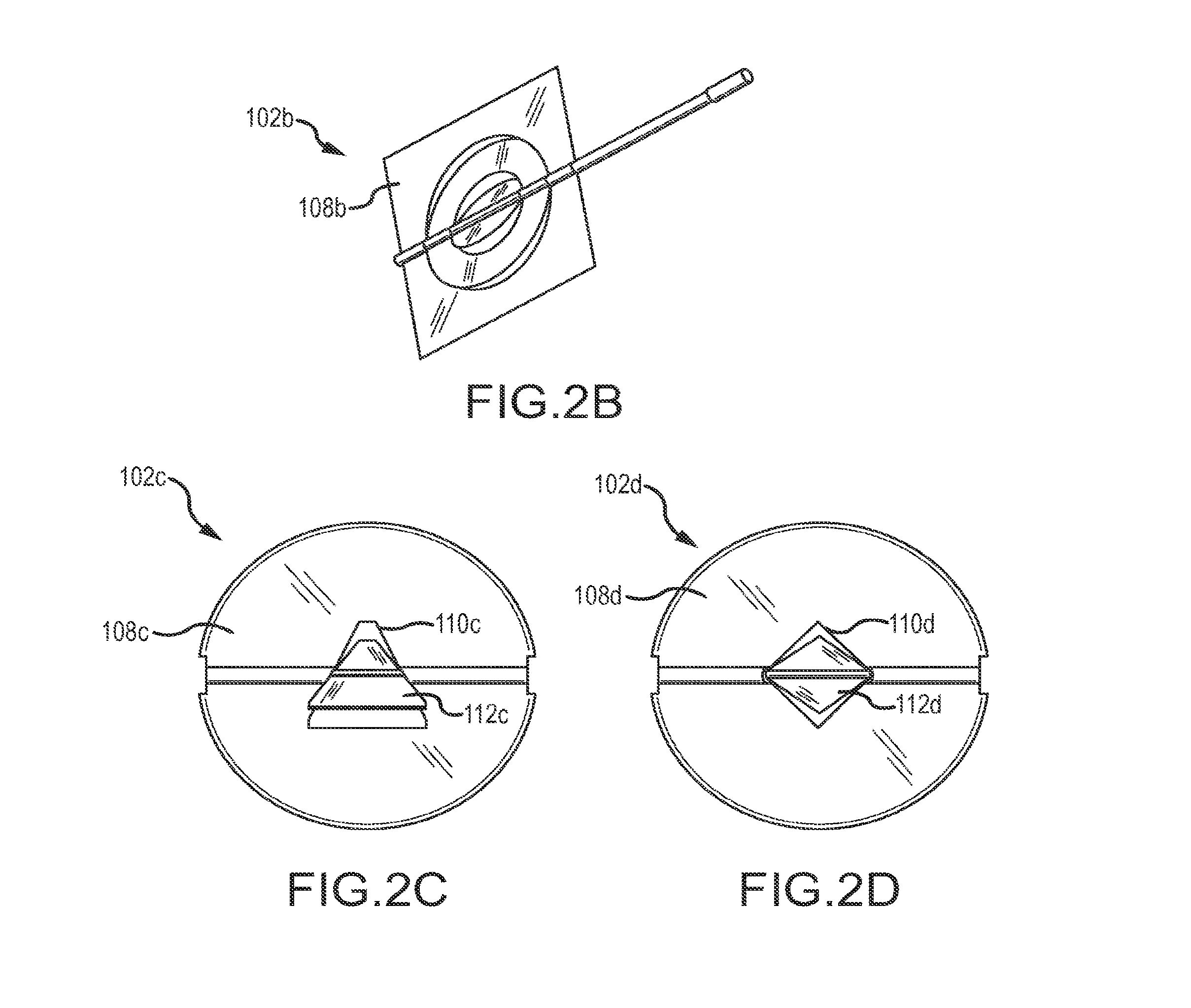

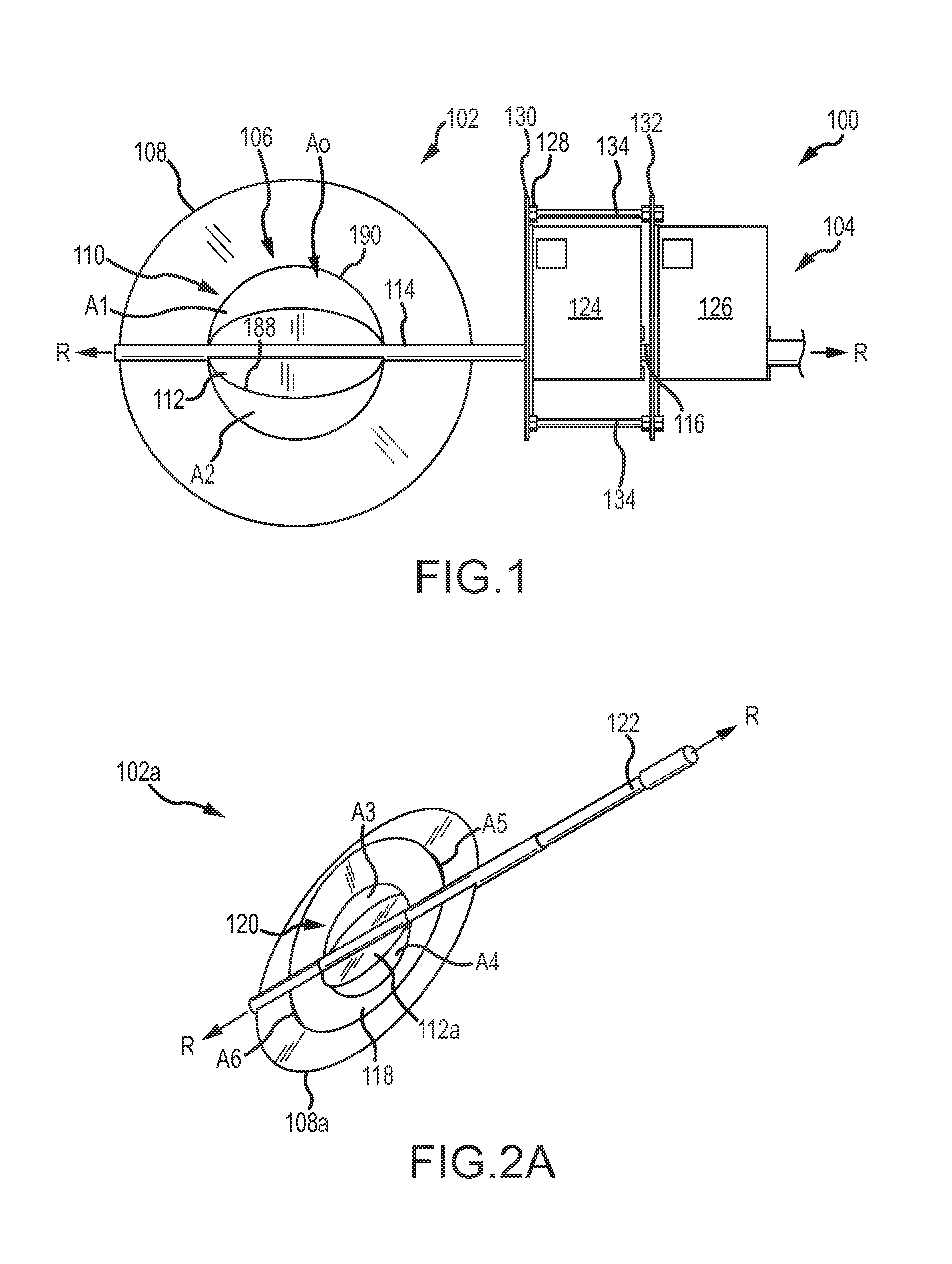

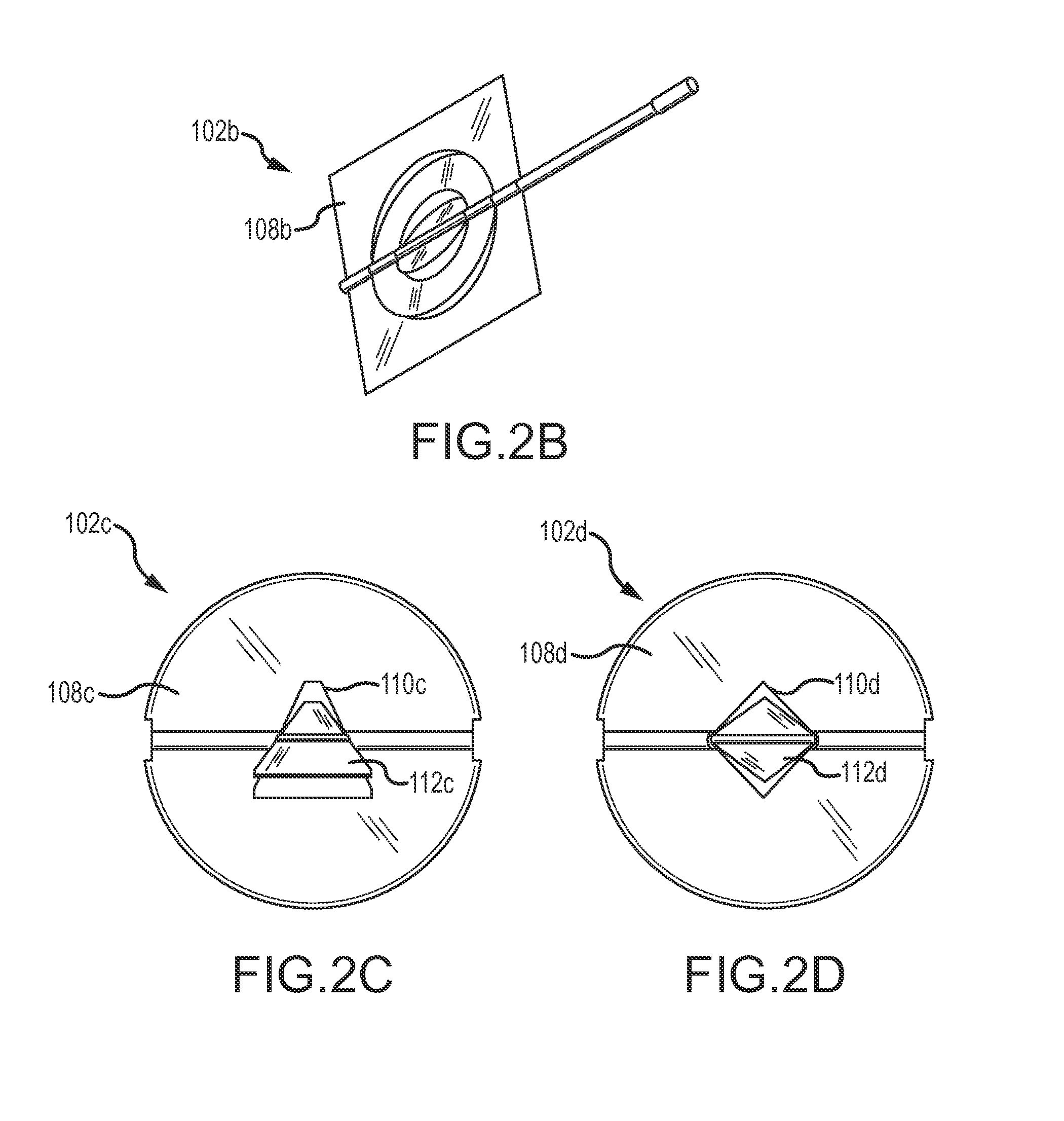

Systems and methods for measuring and controlling fluid flow include an orifice plate defining a variable opening. The orifice plate includes an outer assembly comprising a central opening and an inner assembly extending through the central opening. The flow device regulates high and very low volumes of fluid with precision, inexpensively, with superior acoustics, reduced energy, and simpler design. The high turndown device permits use at lower velocities, thereby reducing noise generation and eliminating need for sound-attenuating liners. The high rangeability device combines several part numbers into fewer parts, thereby streamlining product portfolios. In some cases, cost benefits associated with the flow device allow equipment to be scaled back 100:1 rather than 10:1, providing energy savings, fewer product variations, simple and more robust applications. The device meets new and old building fresh air, comfort and energy codes. The flow device can be engineered, selected, and sized without sophisticated software programs.

Owner:KARAMANOS JOHN C

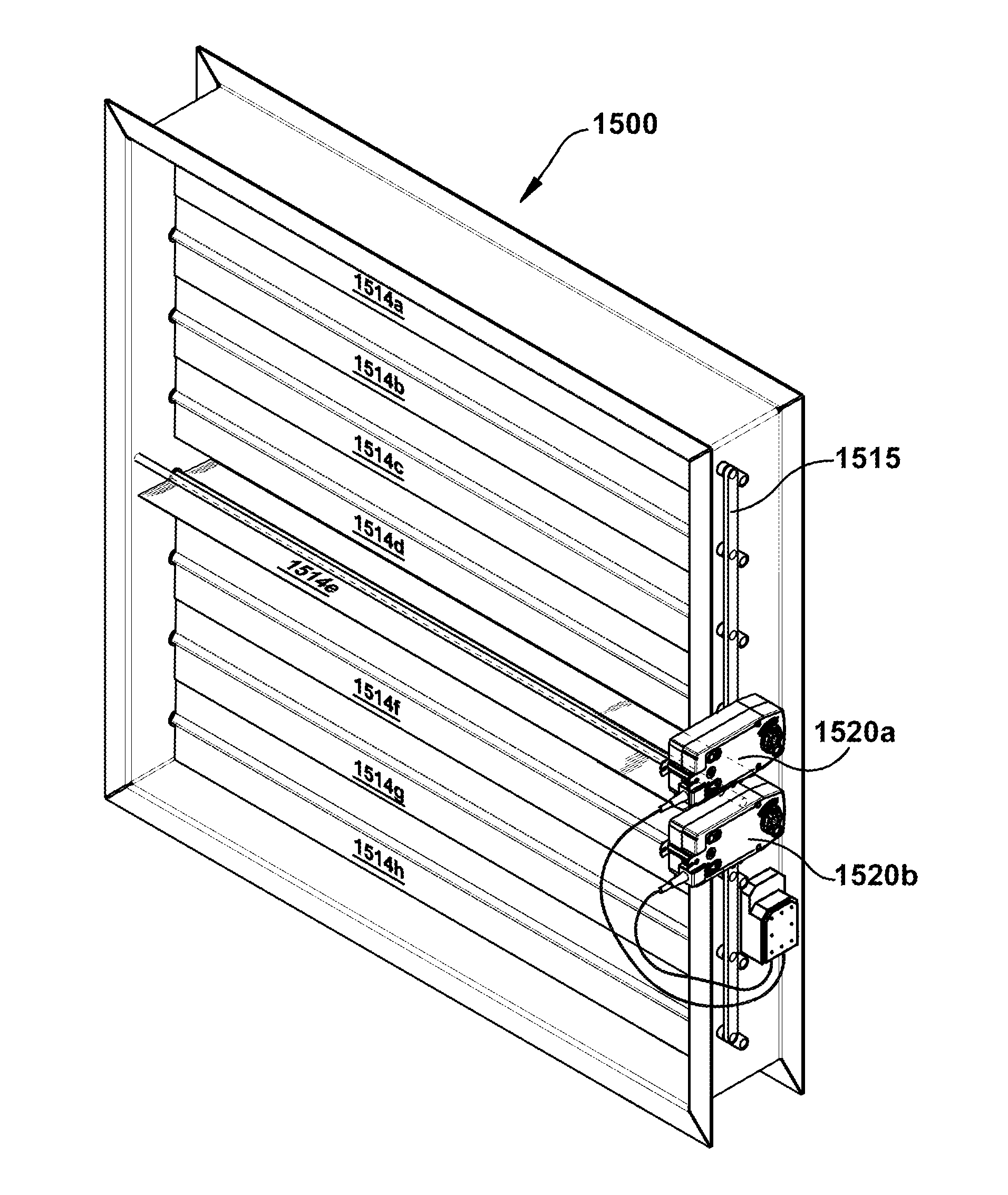

Fluid control measuring and controlling device

ActiveUS20160245541A1Improve energy consumptionReduce lossesProgramme controlMechanical apparatusNoise generationFluid control

Systems and methods for measuring and controlling fluid flow comprises an orifice plate defining a variable opening, wherein the orifice plate includes an outer assembly comprising a central opening and an inner assembly extending through the central opening. Another embodiment comprises a plurality of blades disposed parallel to each other, wherein the blades are pivotable along its longitudinal axis and include at least one low-flow blade or partial blade and a plurality of high-flow blades The flow device regulates high and very low volumes of fluid with precision, inexpensively, with superior acoustics, reduced energy, a simpler design, and prevents building infiltration. The high turndown device permits use at lower velocities, thereby reducing noise generation and eliminating need for sound-attenuating liners. The high rangeability device combines several part numbers into fewer parts, thereby streamlining product portfolios. Cost benefits associated with the flow device allow equipment to be scaled back 100:1 rather than legacy 4:1, providing energy savings, fewer product variations, simple and more robust applications. The device meets new and old building fresh air, comfort and energy codes. The flow device can be engineered, selected, and sized without sophisticated software programs.

Owner:BEST TECH

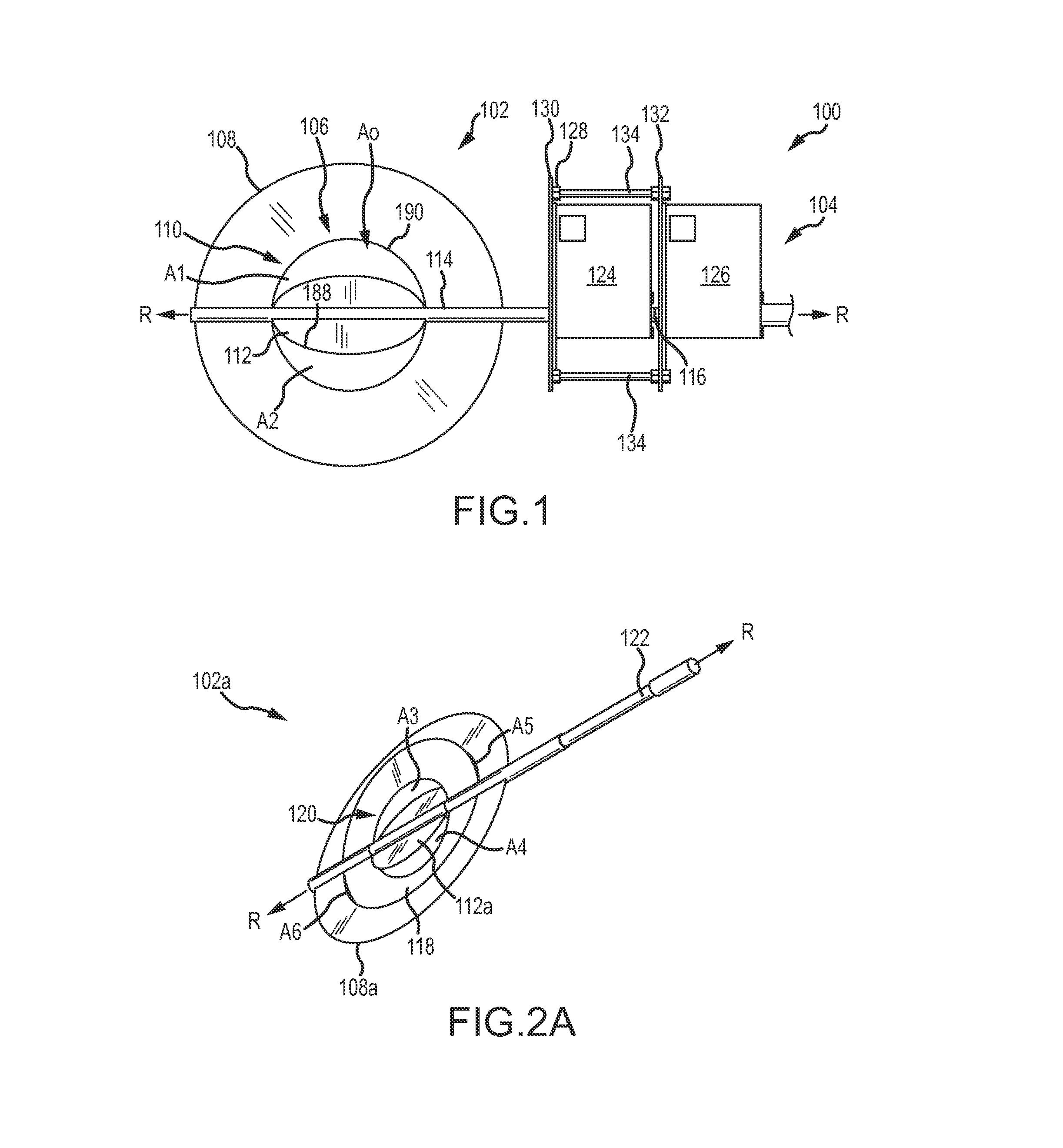

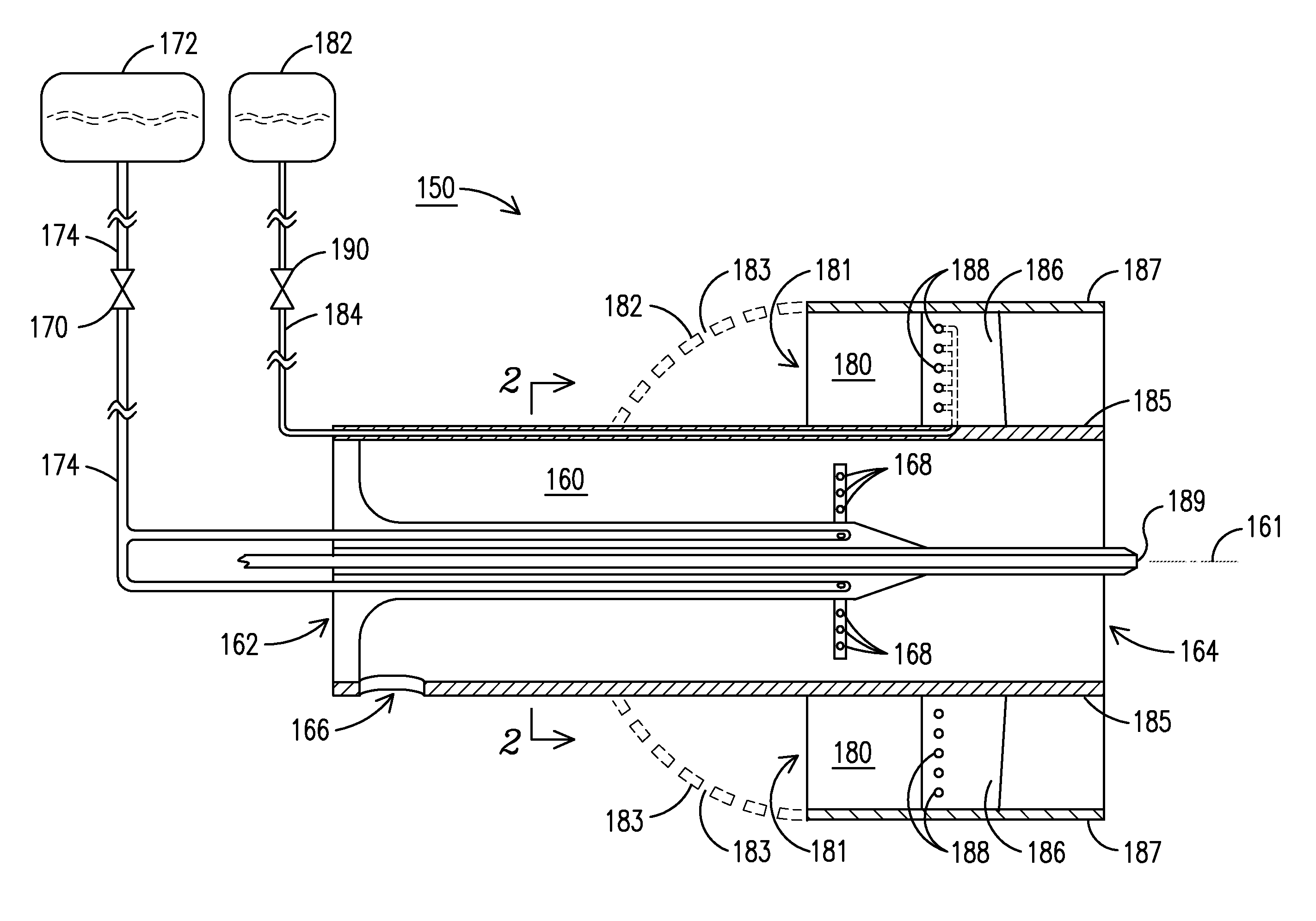

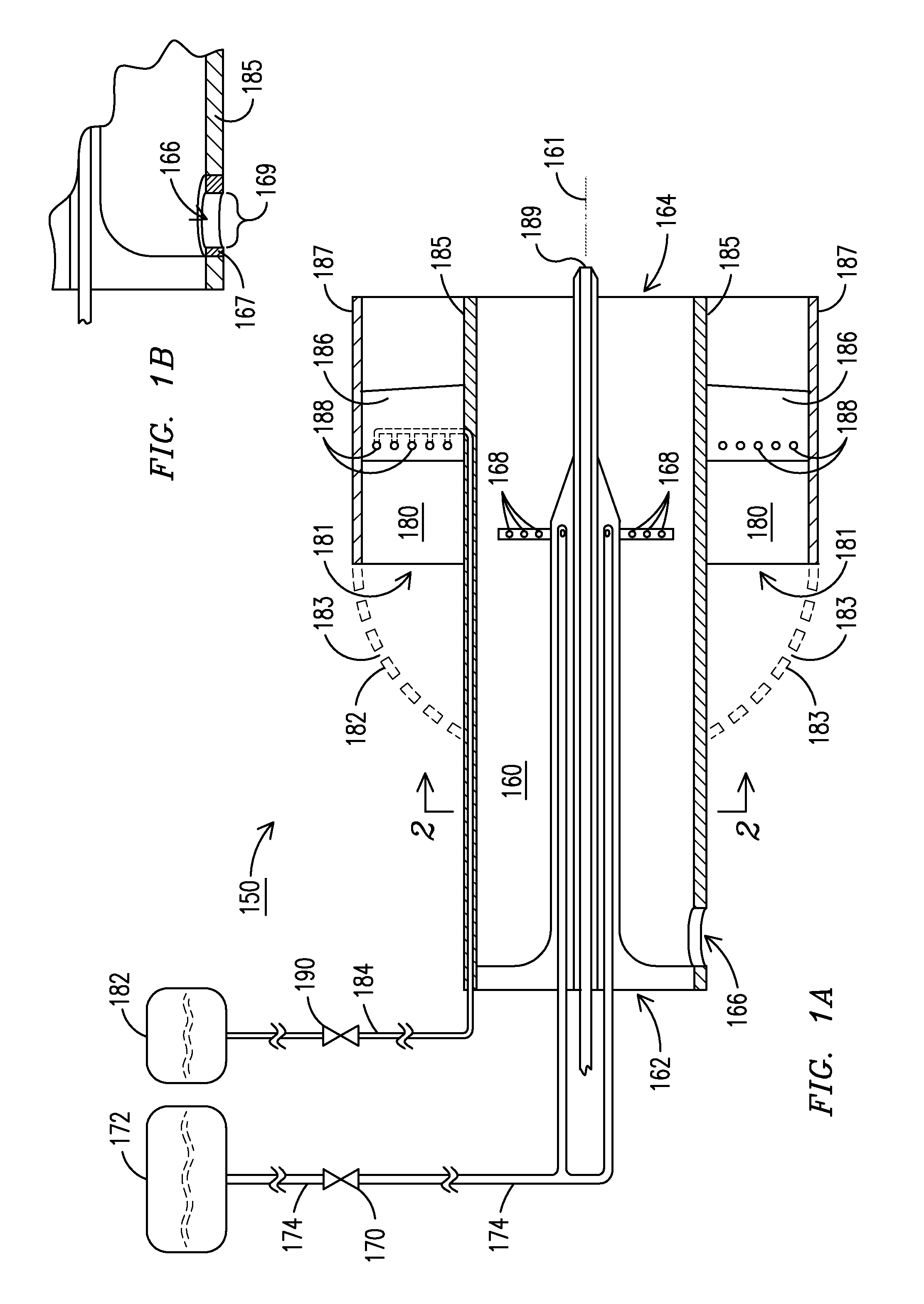

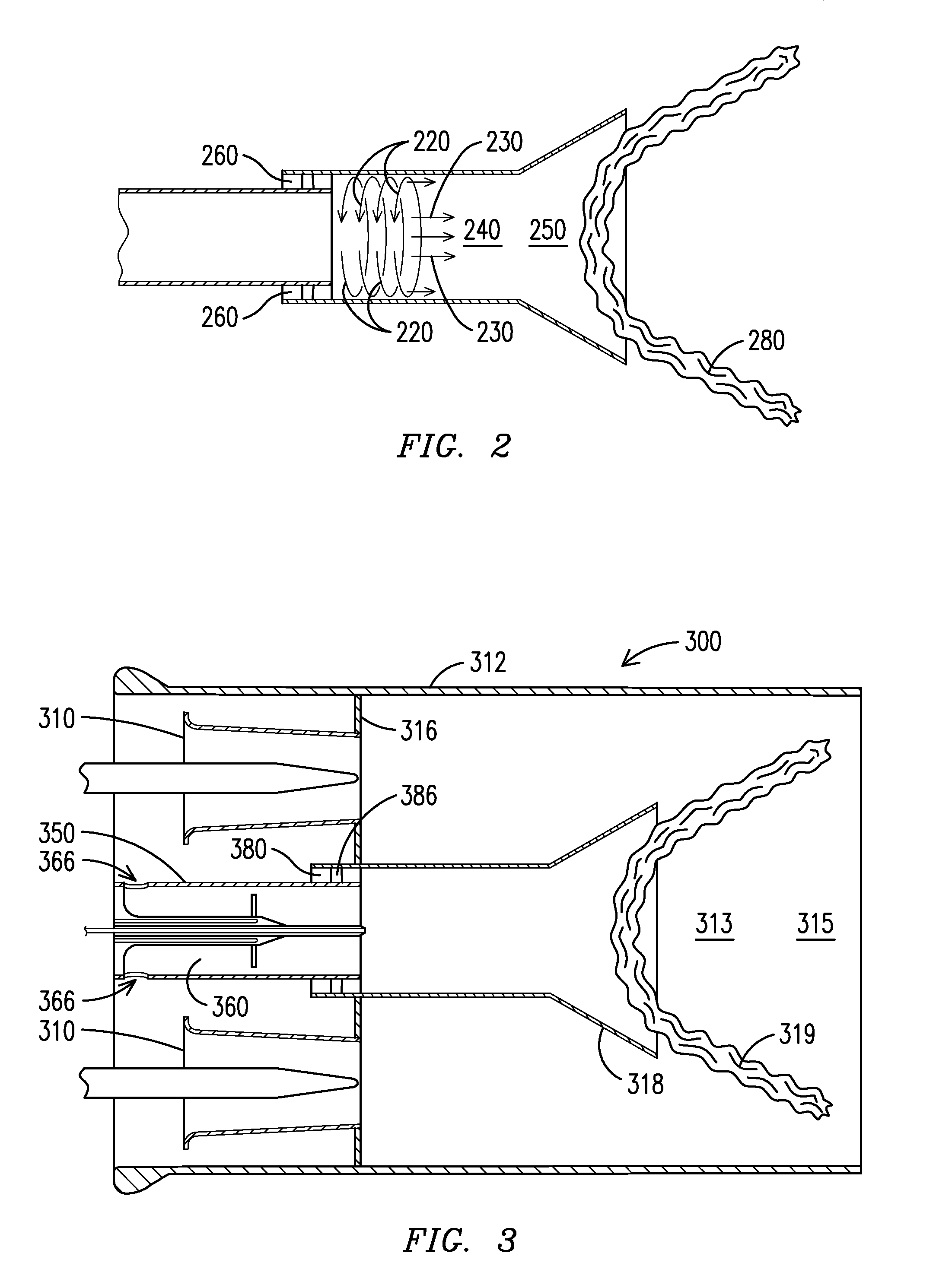

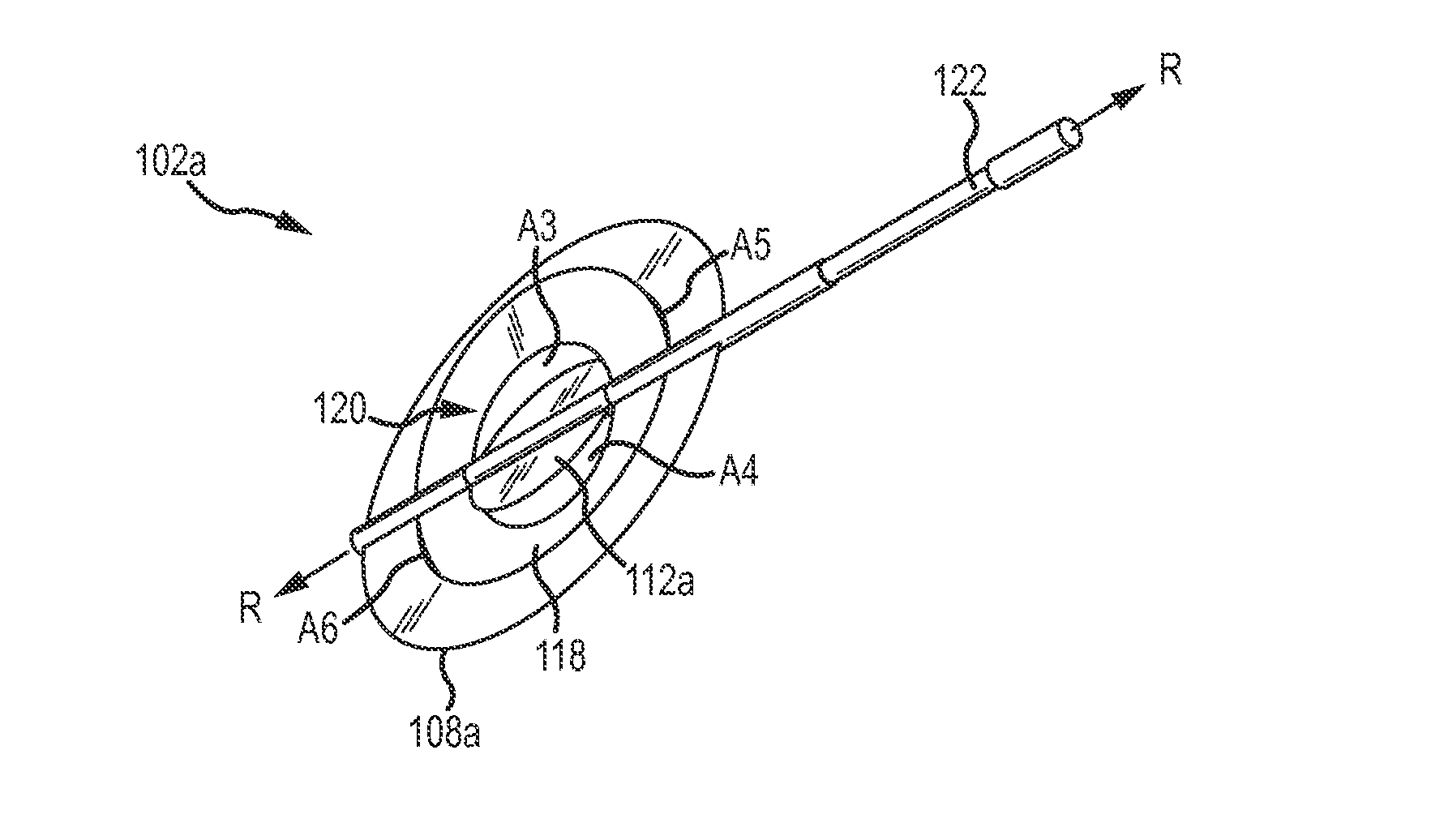

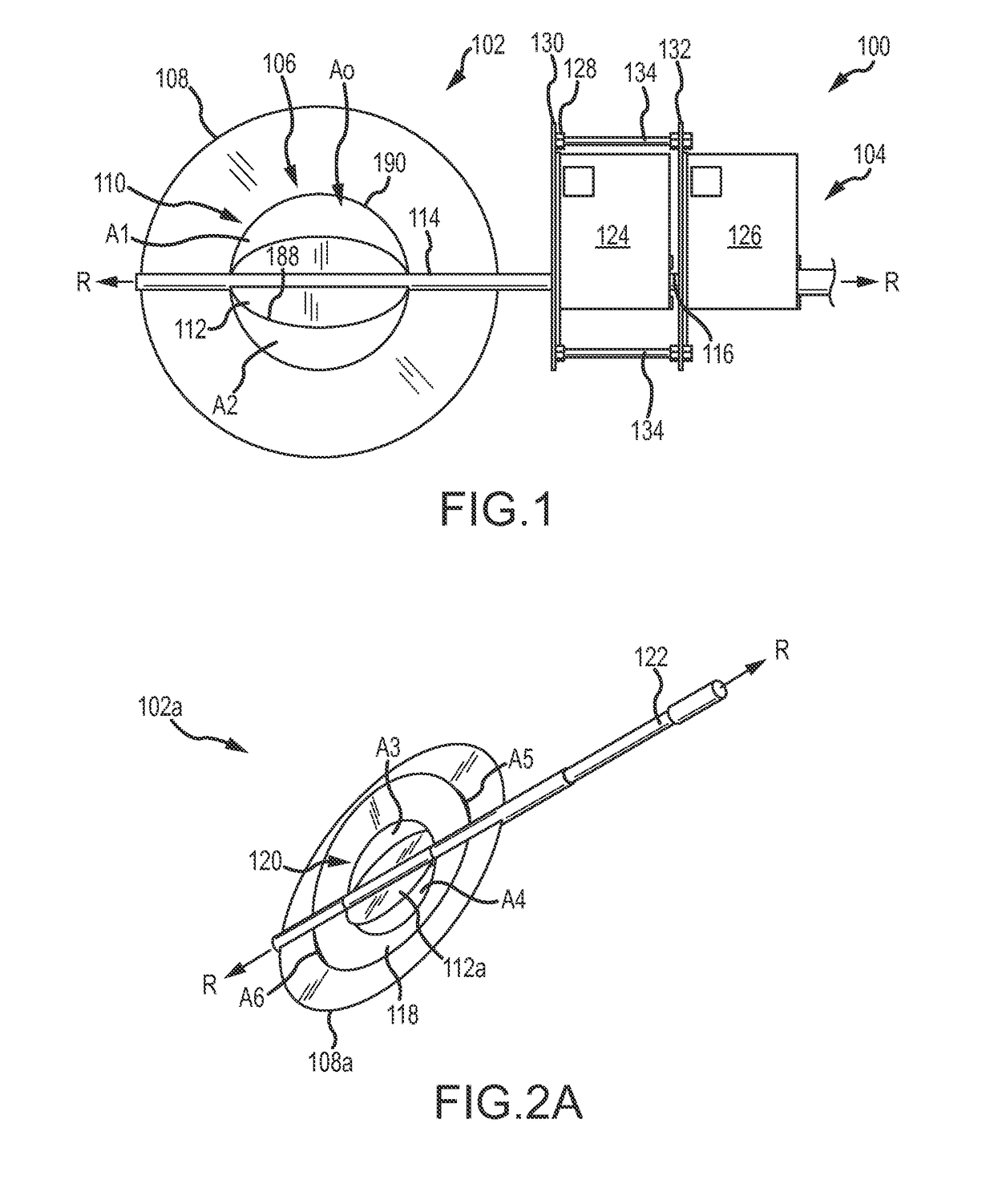

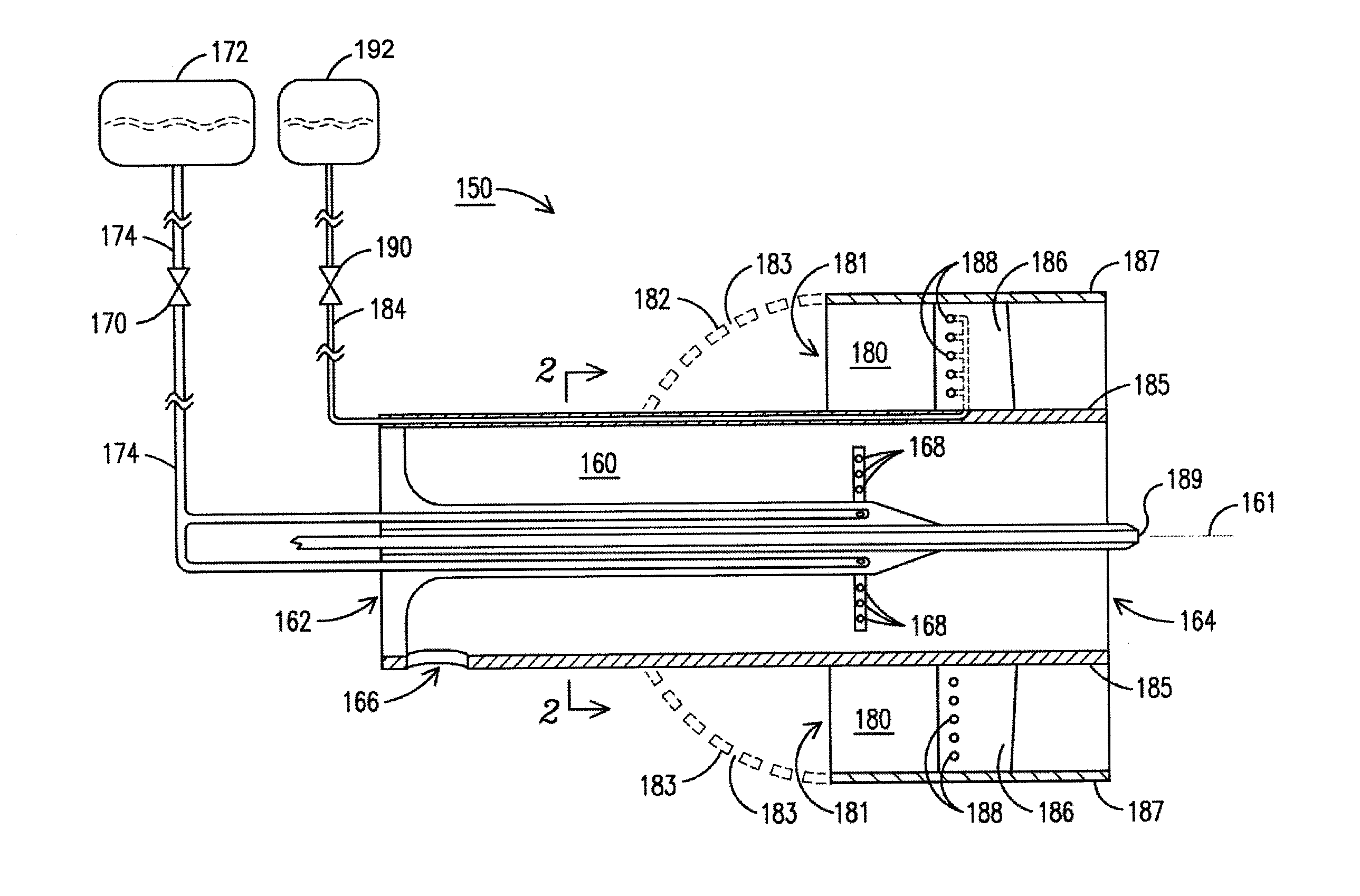

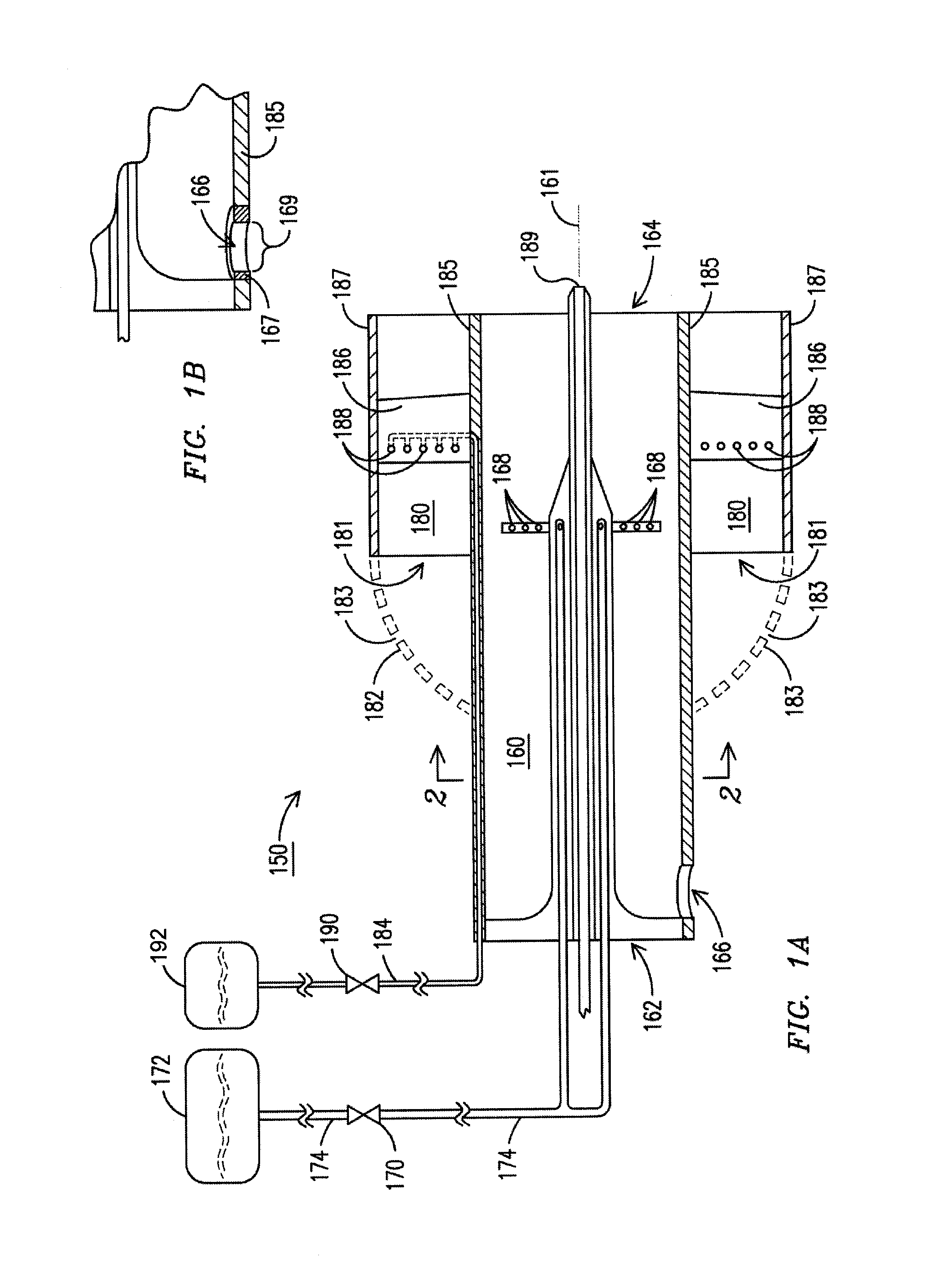

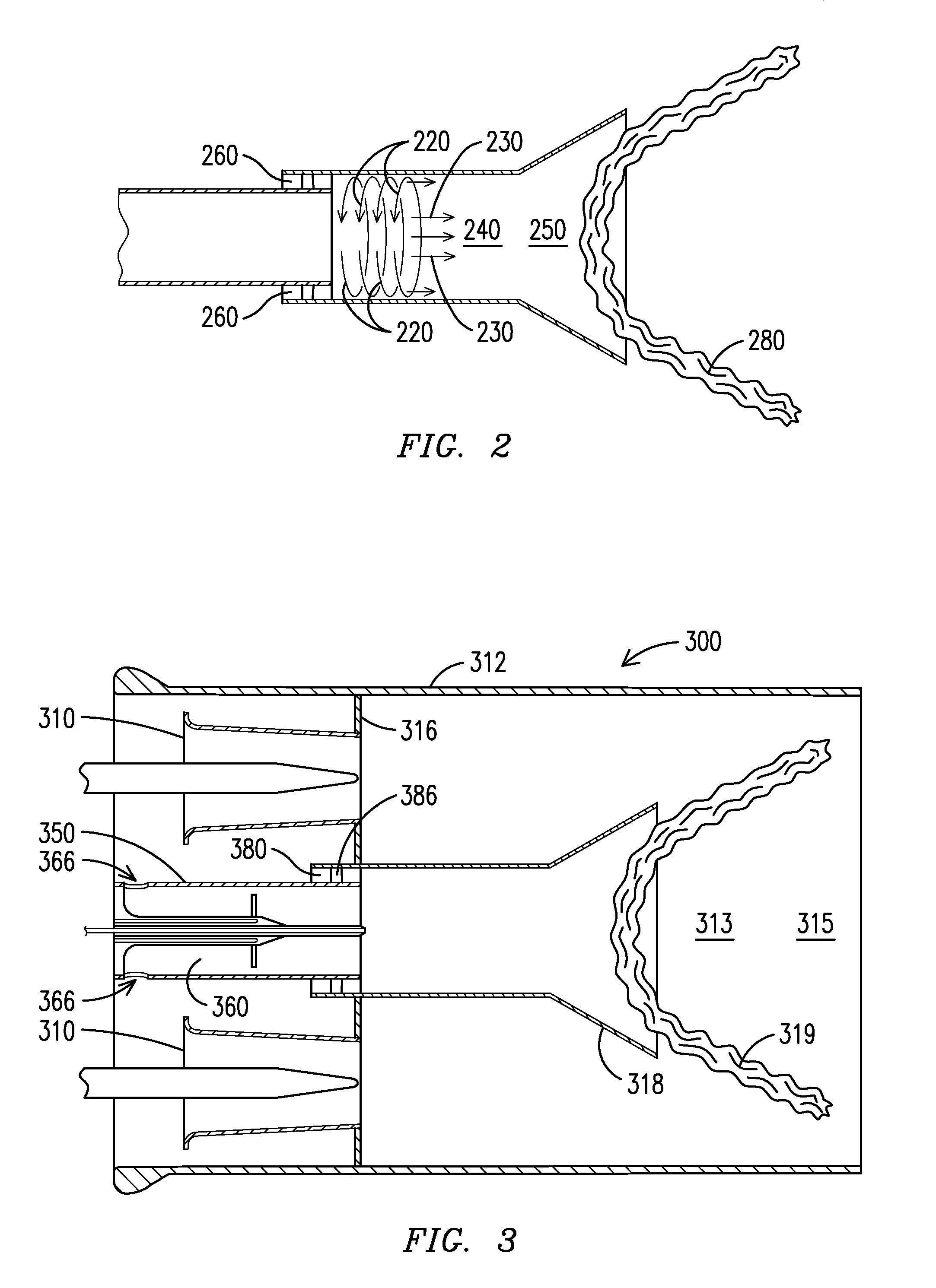

Pilot Burner for Gas Turbine Engine

InactiveUS20100071373A1Fuel/oxidant ratioSuperiorly controllableBurnersContinuous combustion chamberCombustorGas turbines

A pilot burner (150, 350) for a gas turbine engine delivers an inner non-swirling fuel-oxidant mixture surrounded by an outer swirling fuel-oxidant mixture, thereby providing enhanced mixing with no recirculation zone. At least one fluid-restricting inlet port (166, 366) provides an oxidant to an inner mixing passage (160, 360). The inner mixing passage (160, 360) includes a plurality of fuel outlets (168). An outer annular mixing passage (180) receives oxidant from an upstream port (181) surrounding the inner mixing passage and includes at least one swirler element (186, 386) and fuel outlets (188).

Owner:SIEMENS ENERGY INC

Self balancing air fixture

ActiveUS20160341439A1Improve energy consumptionReduce lossesProgramme controlMechanical apparatusSoftware systemEngineering

An air distribution apparatus that serves as a single sensing device for both lighting, LiFi, and HVAC functions that are operable on a single platform by building automation systems. The building automation system may be controllable by a single software system or network accessible locally on site or remotely off site. The air distribution apparatus can operate in a single zone or coupled with multiple like apparatuses for multi-zone operation. It is a high turndown, self-balancing system which allows for continuous commissioning with built-in fault diagnostic systems and that may be used as a supply, return, or exhaust system, or a combination thereof.

Owner:BEST TECH

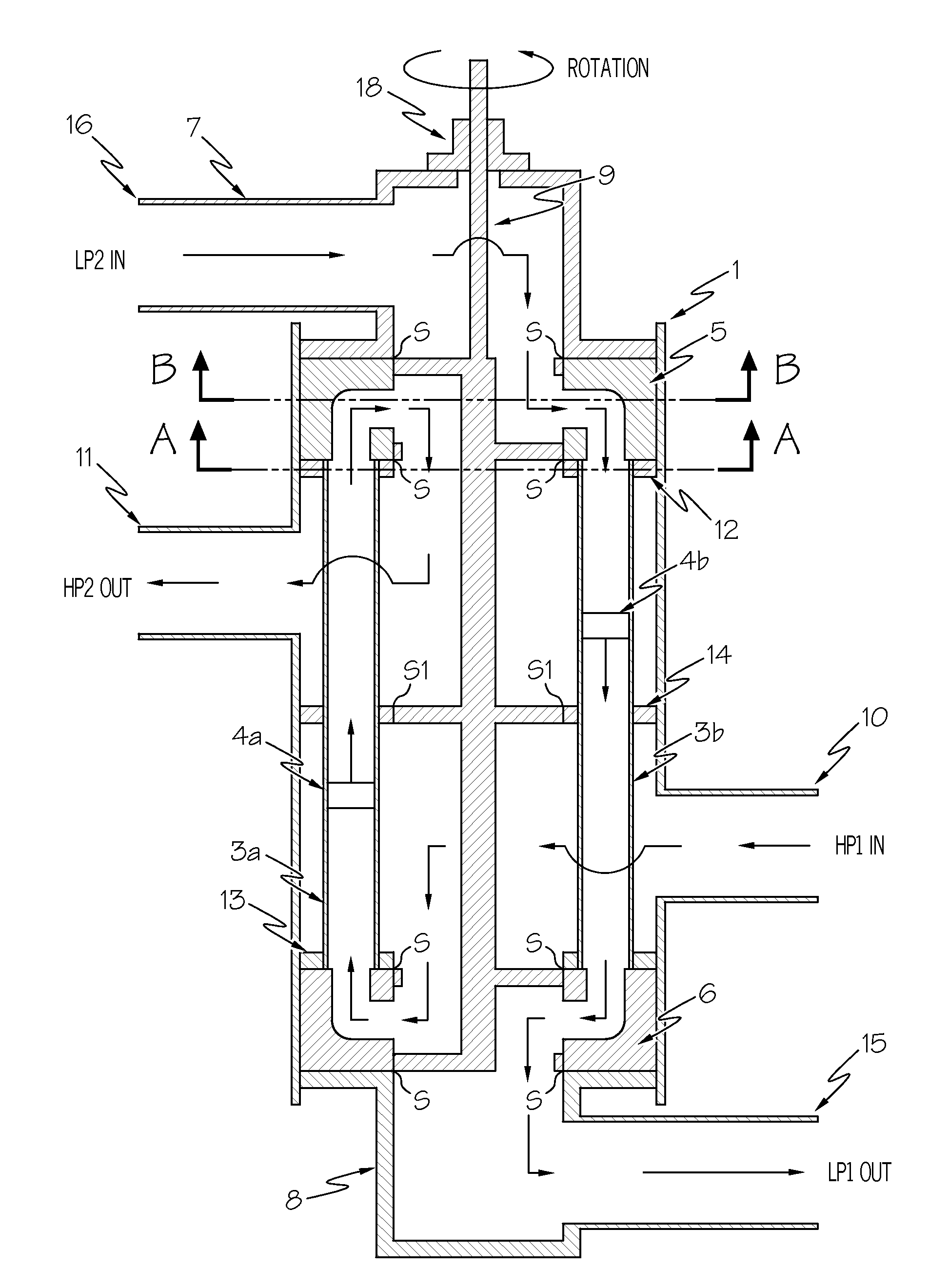

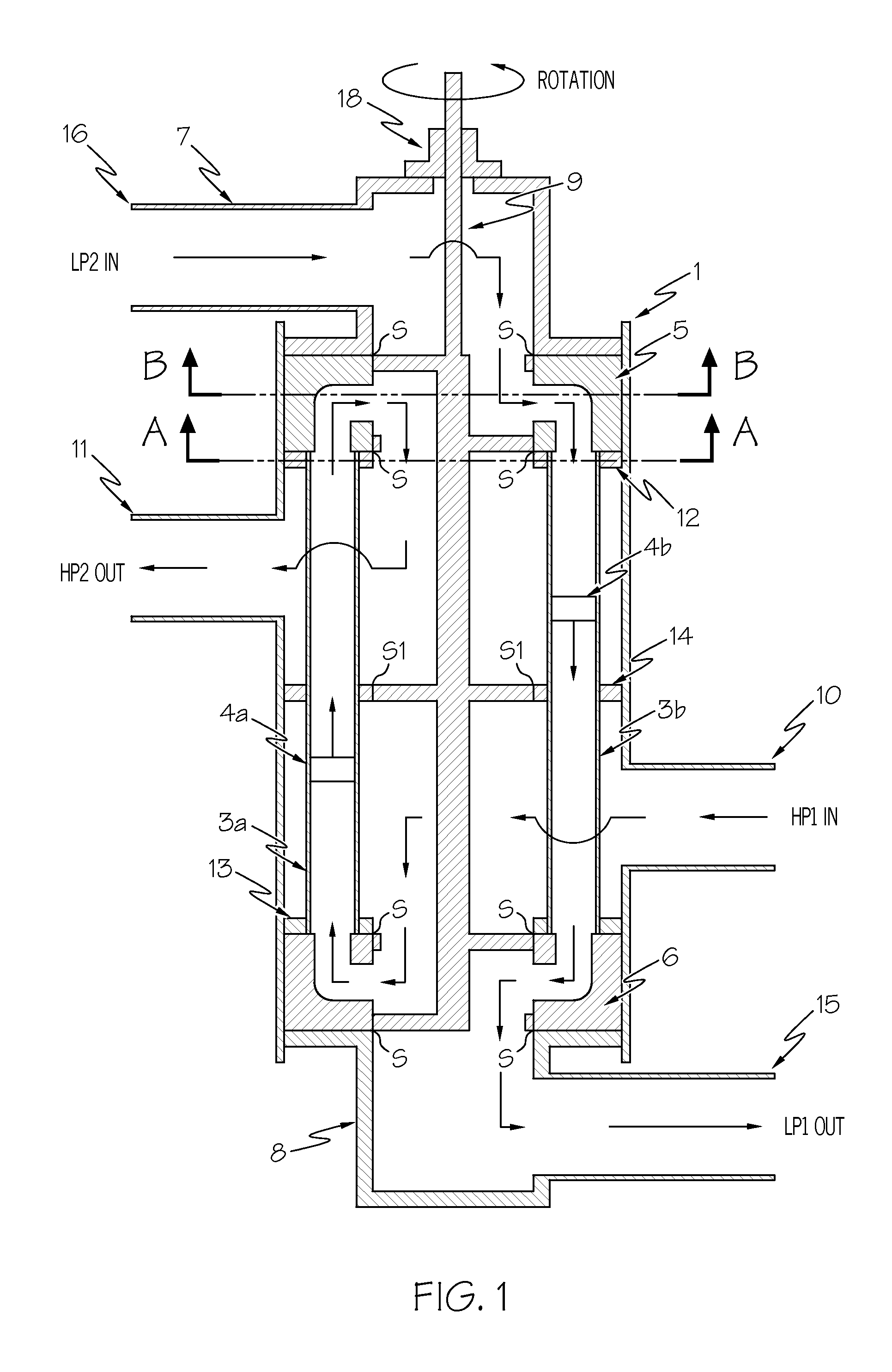

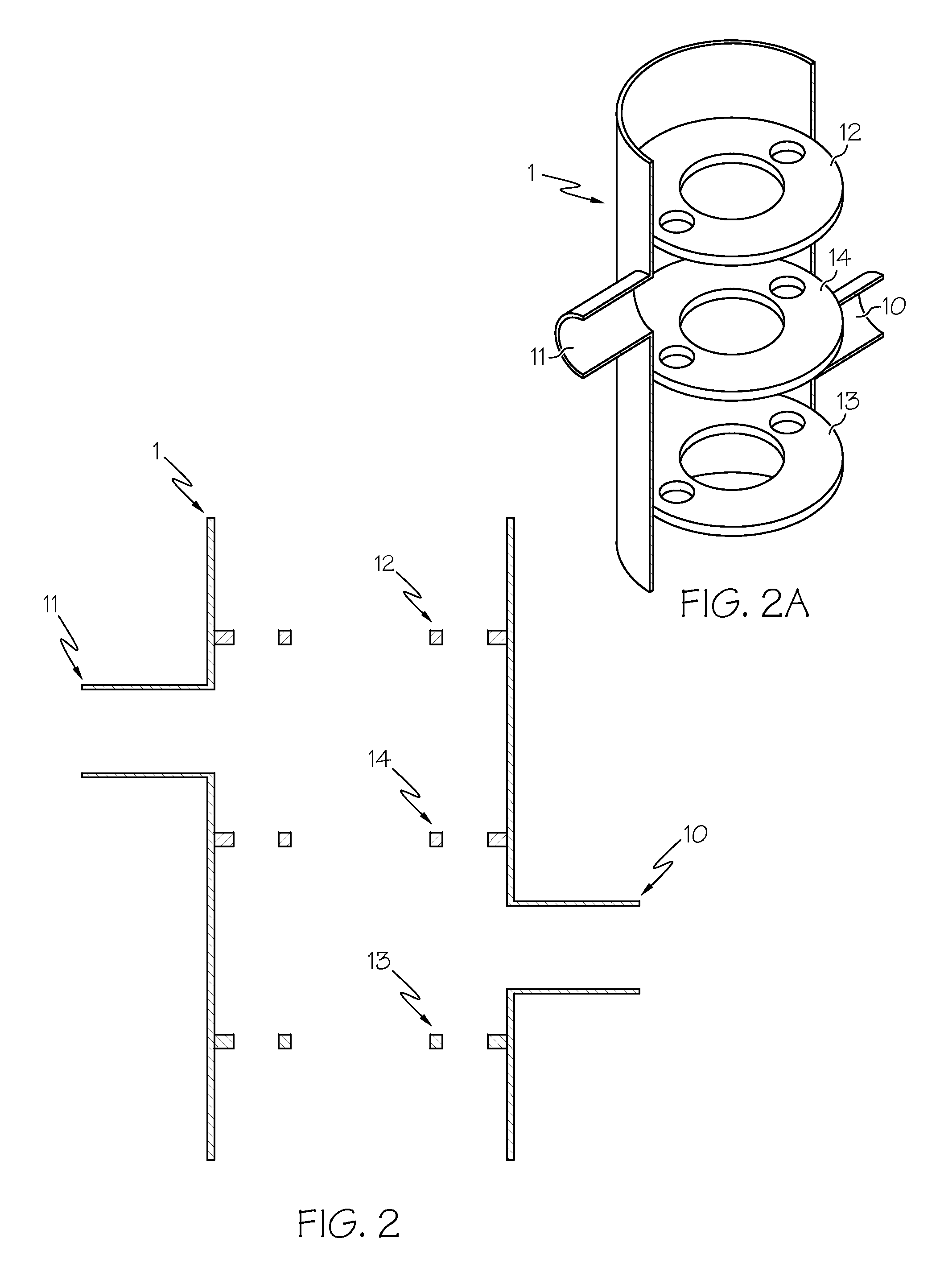

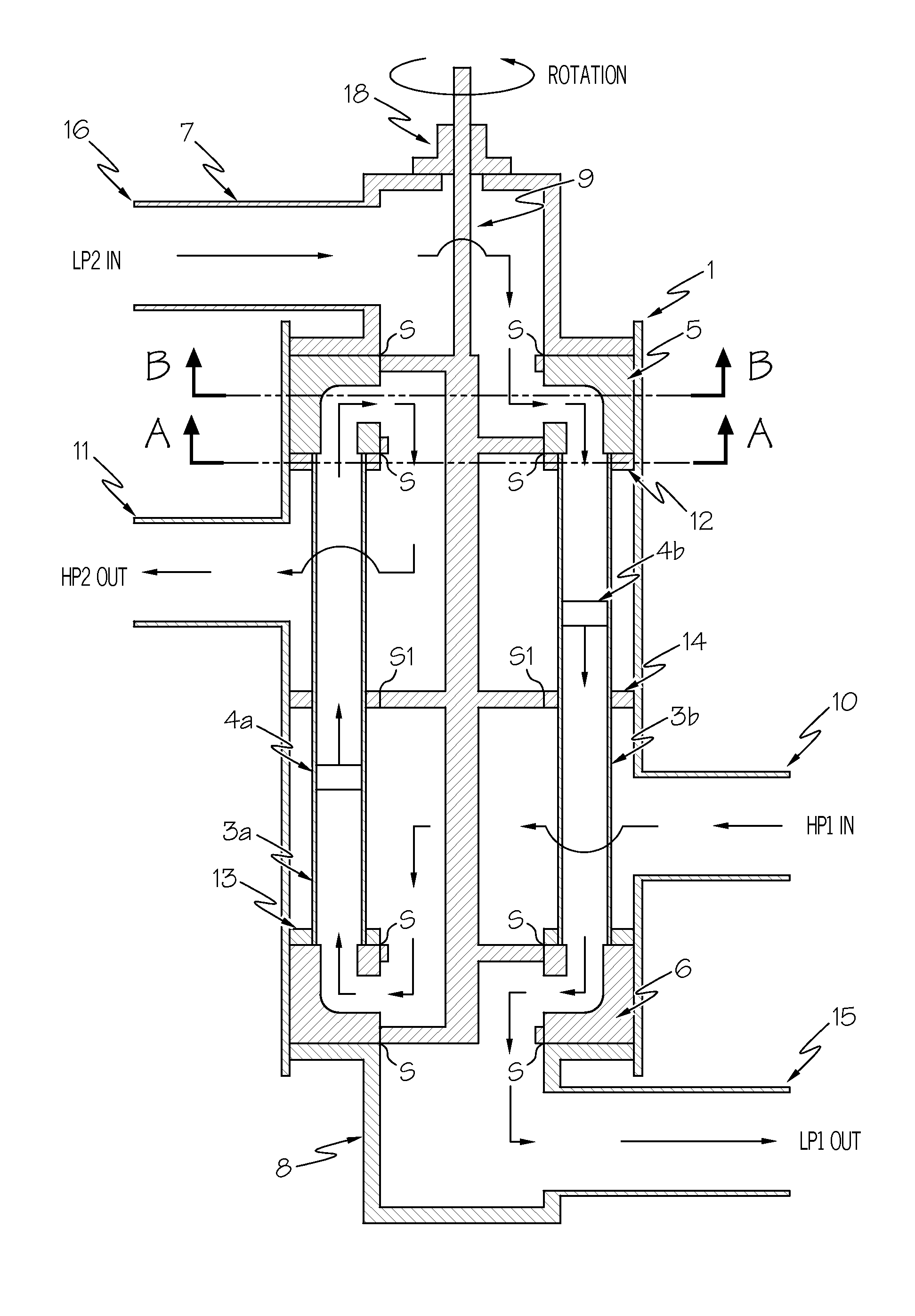

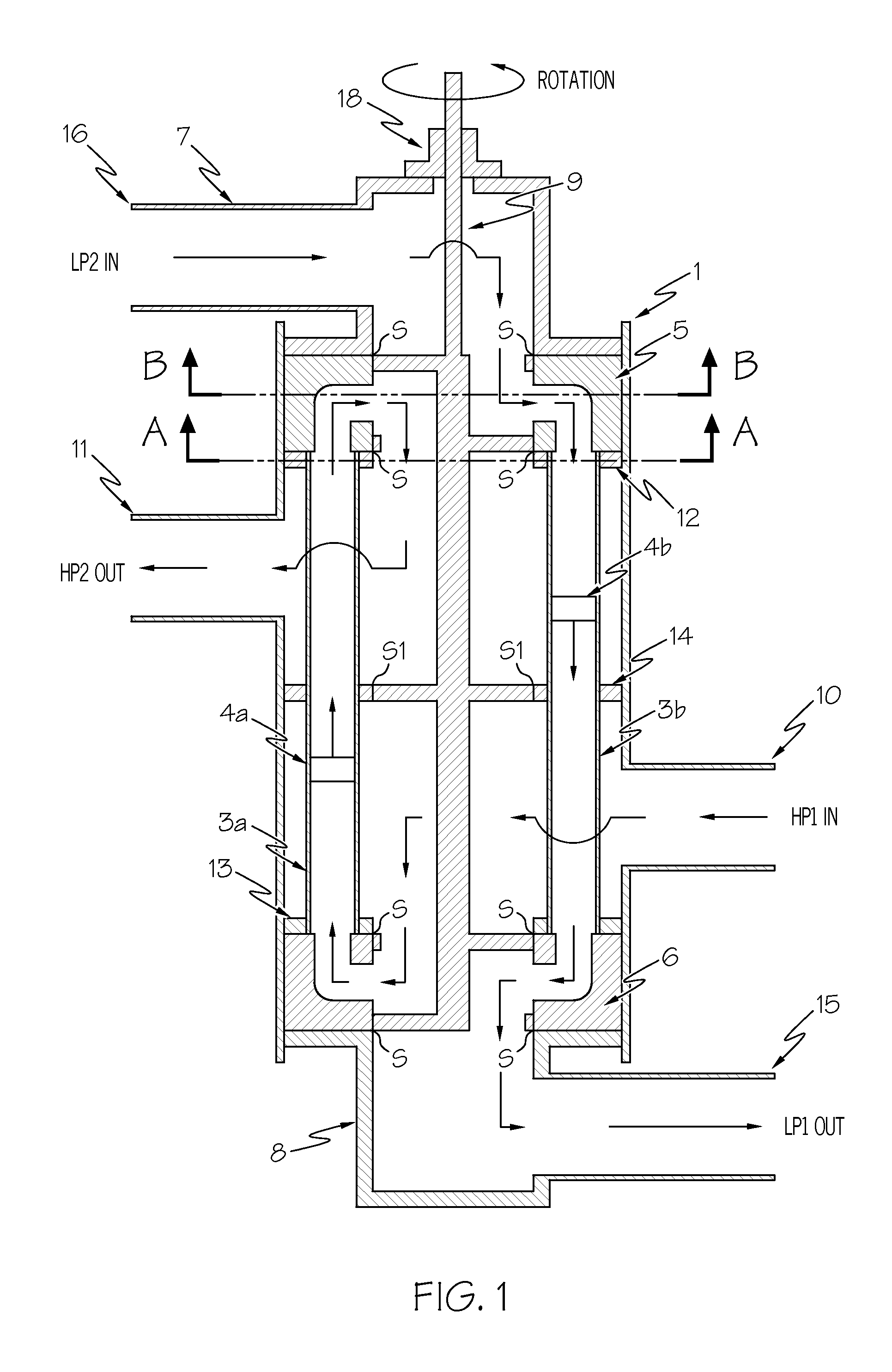

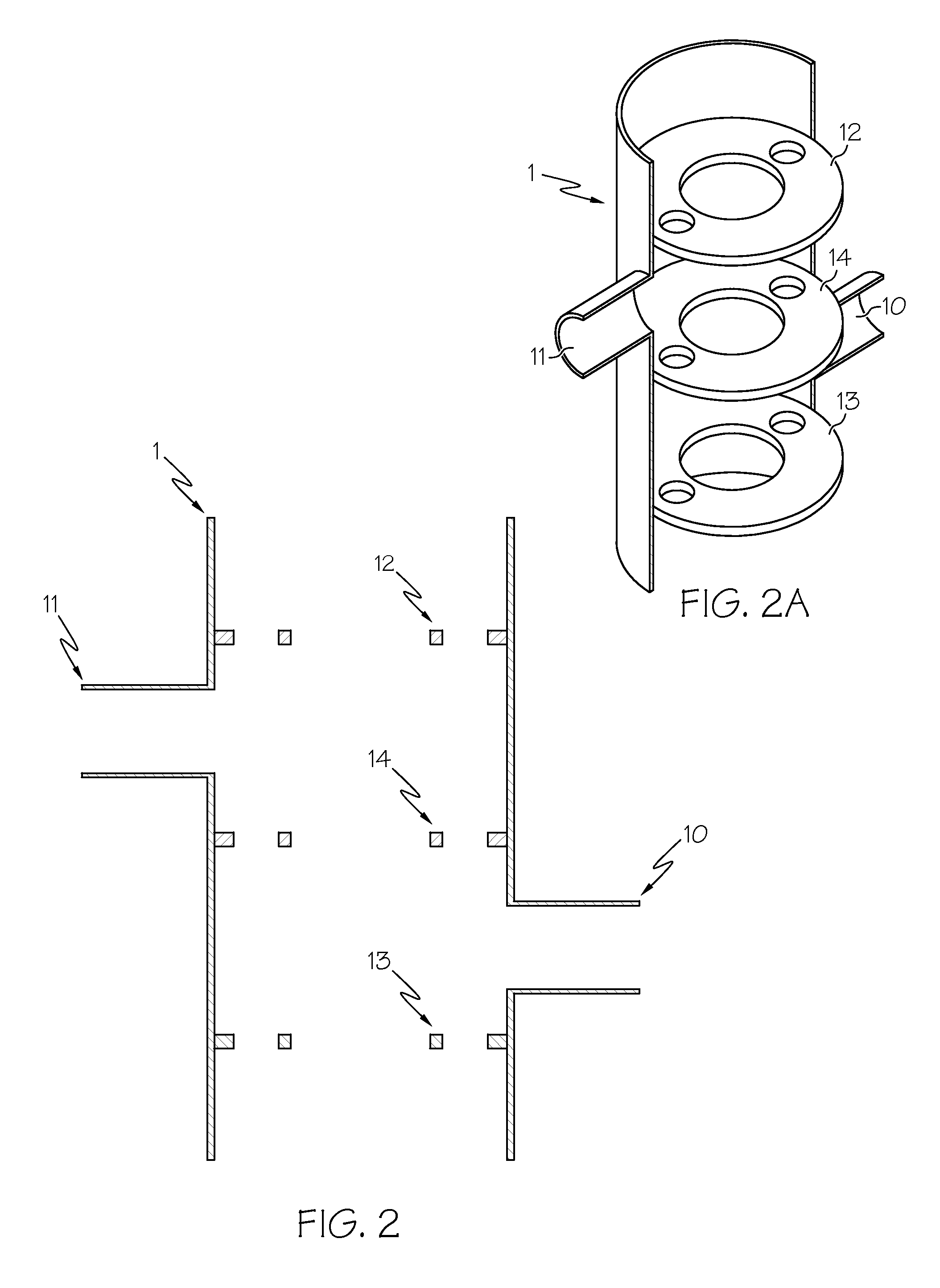

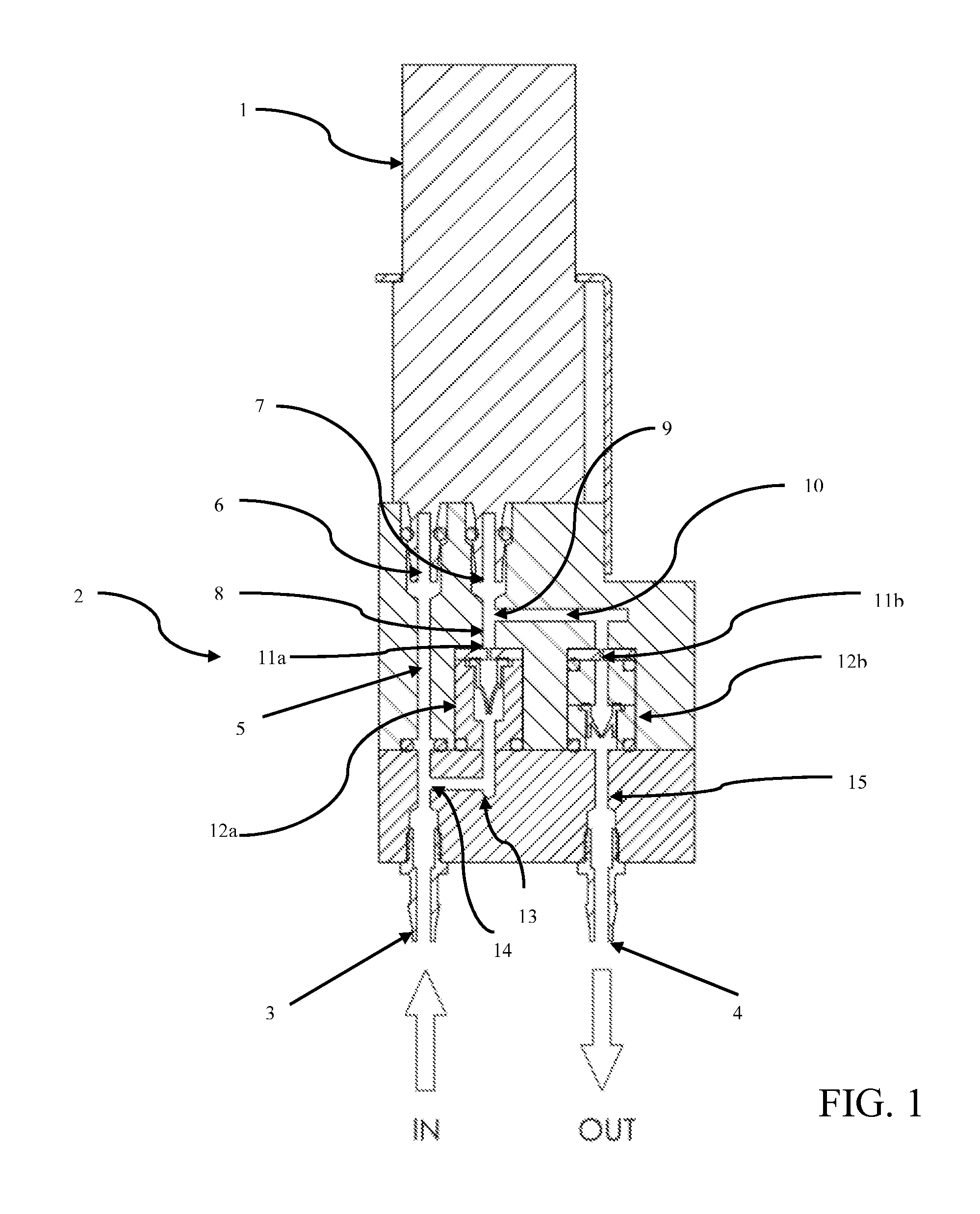

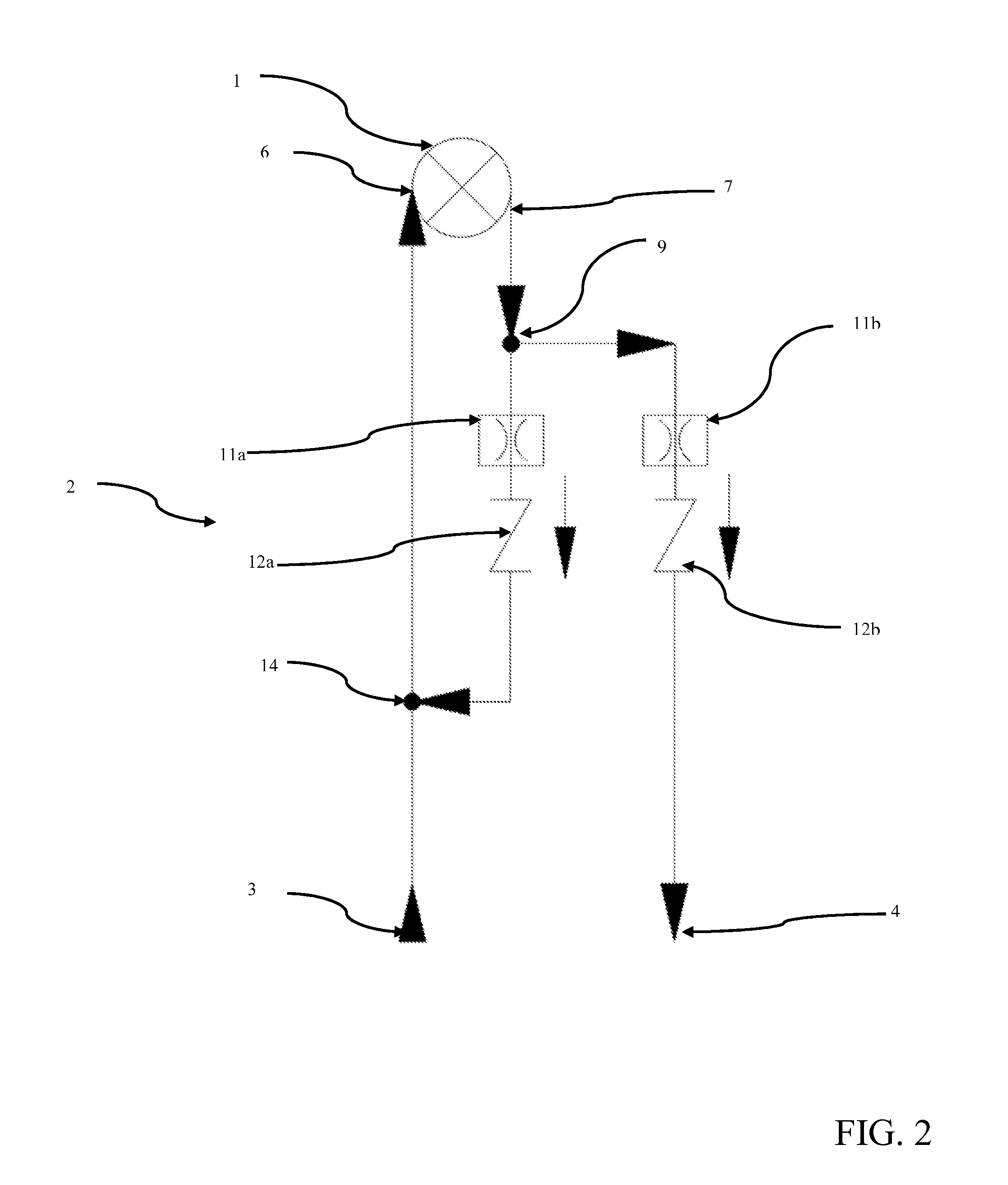

Pressure exchanger

A pressure vessel provided with a first port acting as a high pressure inlet of a first stream and a second port acting as a high pressure outlet. A rotatable valve element is located in the centre of the machine and includes a centre plate, which is utilized to separate high pressure streams. At each end of the valve element are valves. The valves ensure that as the valve element rotates the exchange ducts are either both isolated or that one is exposed to high pressure while the other is exposed to low pressure. In operation, a fluid stream is introduced to the machine at high pressure through port and flows around the outside of the exchange duct towards the centre of the machine. The stream then flows downwardly to the valve element, where it then passes through the open ports of the valve element and into flow distributor. The stream then passes into and upwardly in the exchange duct, causing upward displacement of the duct piston, resulting in the pressurization and flow of the second fluid above the duct piston. The second fluid then flows into the upper flow distributor, into the valve element, and then downwardly and finally between the exchange duct and out through the high pressure port. At the same time a fluid stream is introduced to the machine at low pressure through port. This flows into the valve element and then into the flow distributor. From the flow distributor it flows and downwardly into the pressure exchange duct, causing downward displacement of duct piston and resulting in flow of the first fluid below the duct piston, which then flows into the lower flow distributor, into the valve element, and then out of the lower sealing plate at port. A planar radial sealing surface promotes sealing connection between the rotatable valve element and various pressure exchange ducts within the pressure vessel.

Owner:FLOWSERVE HLDG

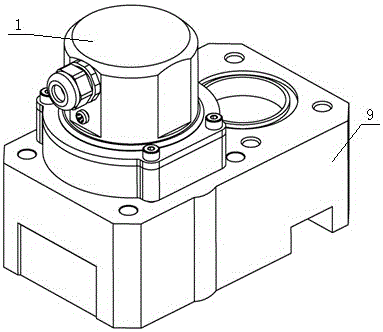

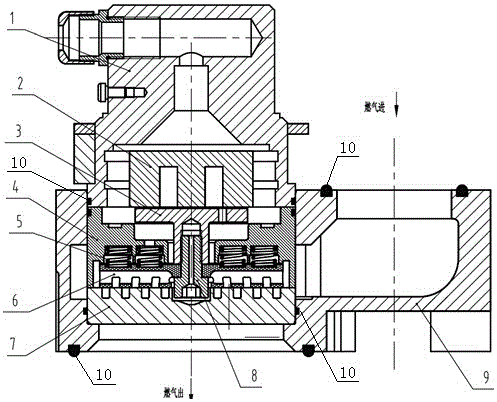

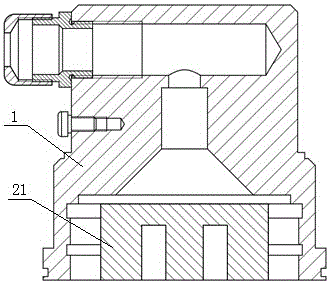

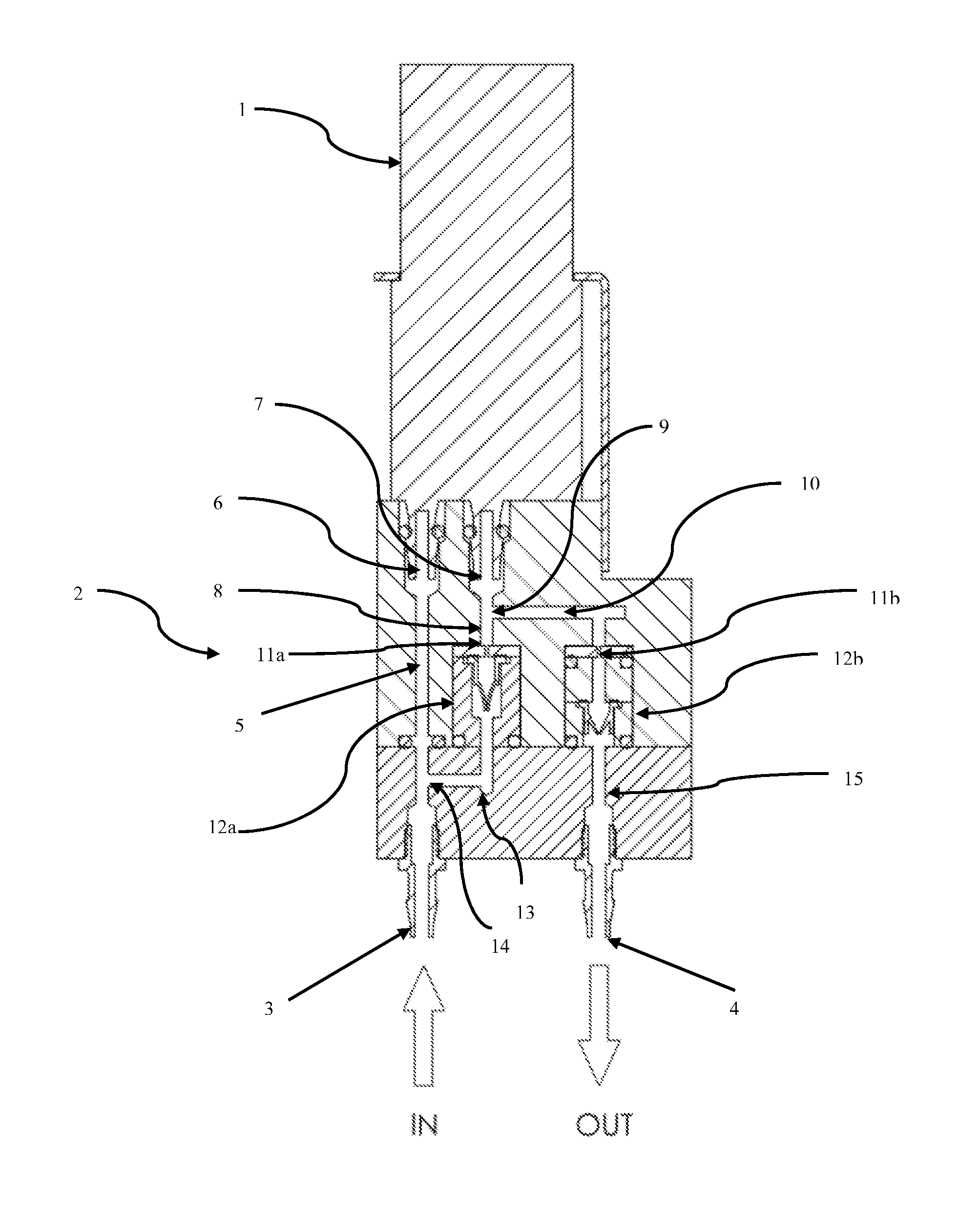

Fuel gas electronic injection valve used for gas fuel engine

ActiveCN106121867AReduce wearGood self-sealing effectInternal combustion piston enginesFuel supply apparatusEngineeringElectromagnetic valve

The invention discloses a fuel gas electronic injection valve used for a gas fuel engine. The fuel gas electronic injection valve comprises a shell, an electromagnetic valve component and a valve element component. The valve element component comprises a valve element, a valve block, a valve seat and an armature, wherein the valve block is installed in the valve element and fixedly connected with the lower end of the armature; when the electromagnetic valve component is powered on, under the effect of electromagnetic force, the armature pulls the valve block to upwards move so as to form a fuel gas channel between the lower surface of the valve block and the upper surface of the valve seat; and when the electromagnetic valve component is powered off, the lower surface of the valve block and the upper surface of the valve seat are attached to form a sealing face, and the fuel gas channel is blocked. The fuel gas electronic injection valve can be suitable for high-speed gas machines and dual-fuel engines, and the requirements of high response speed, accurate fuel gas metering, wide single cylinder power covering scope and the like are met.

Owner:CHONGQING HONGJIANG MACHINERY

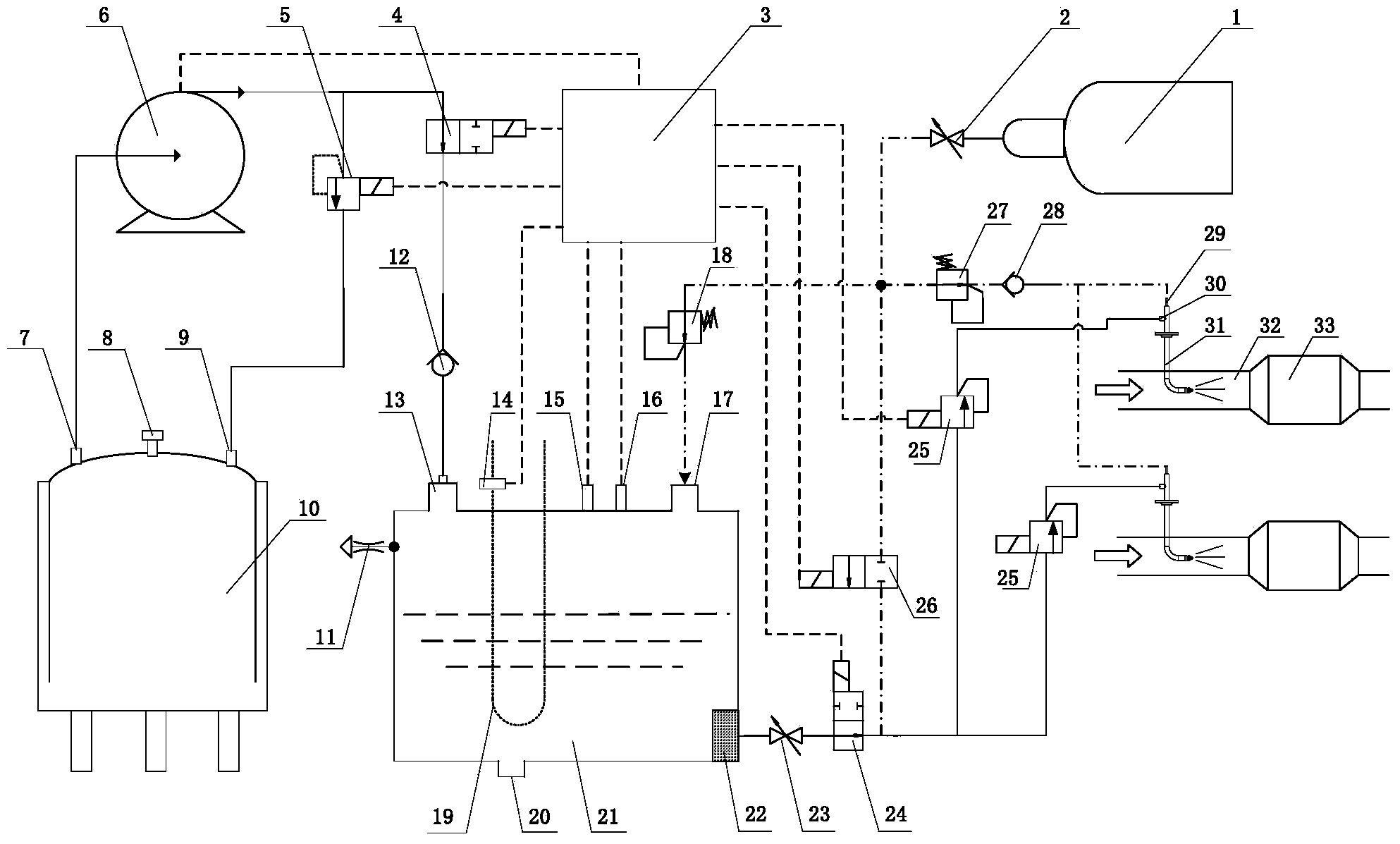

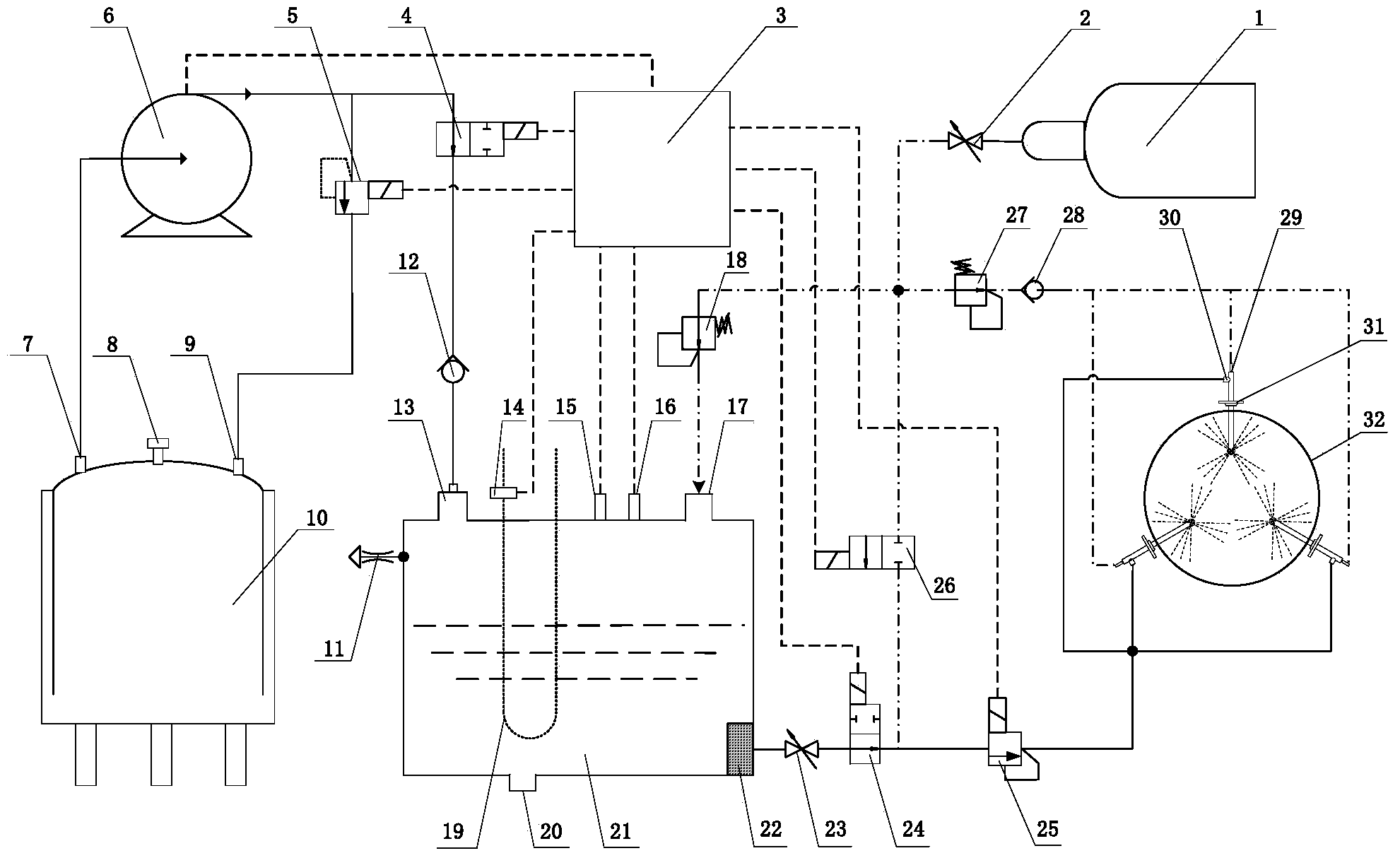

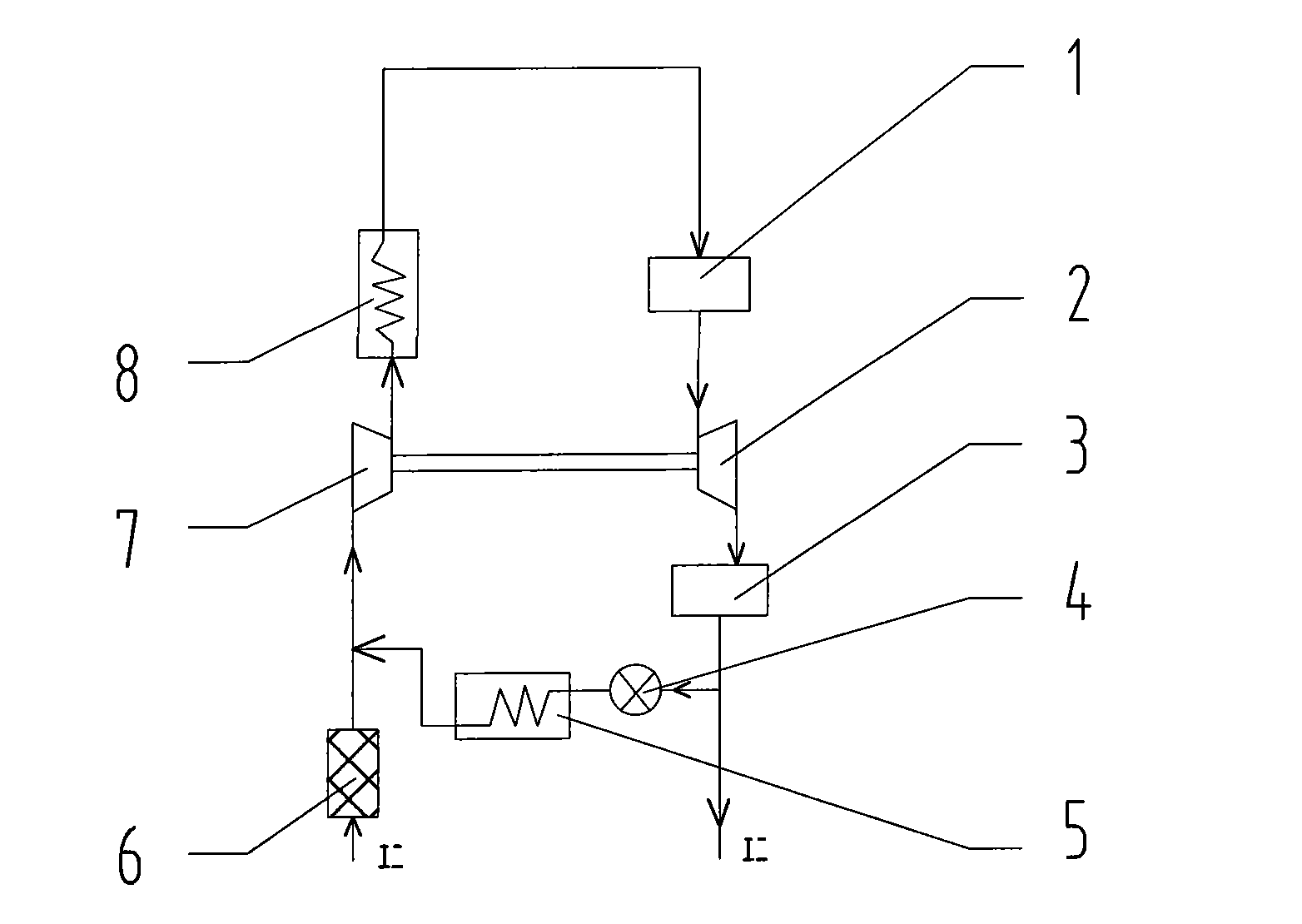

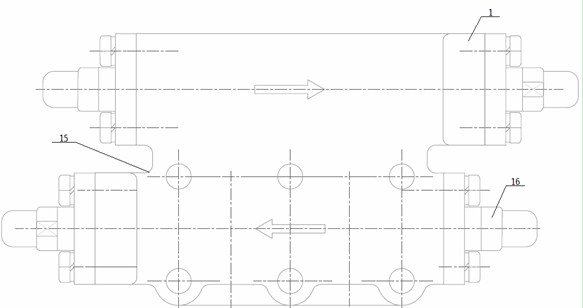

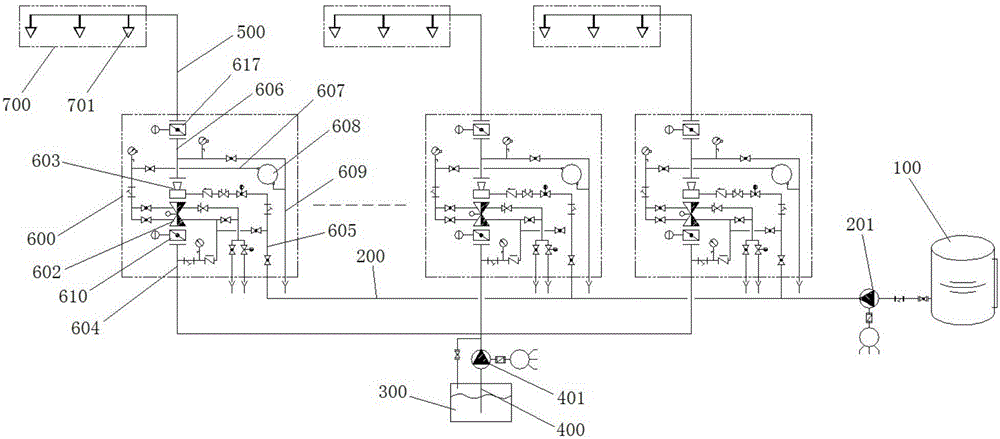

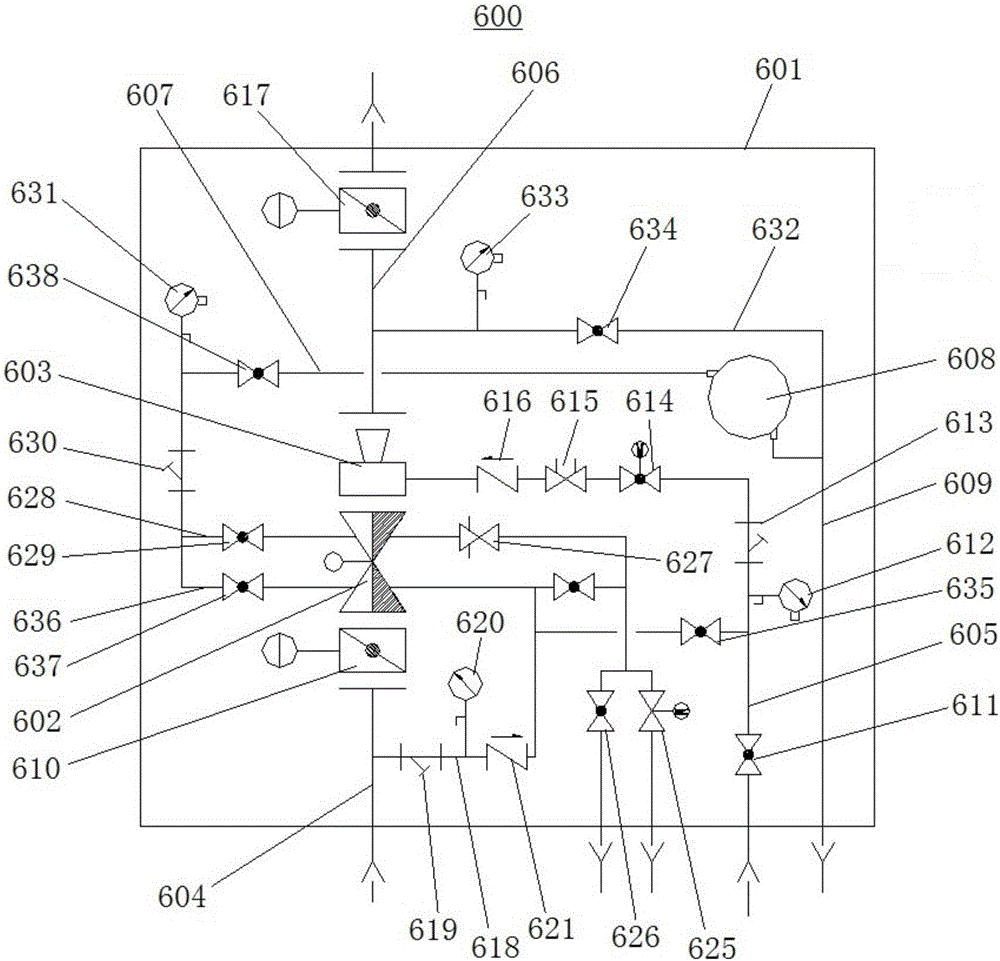

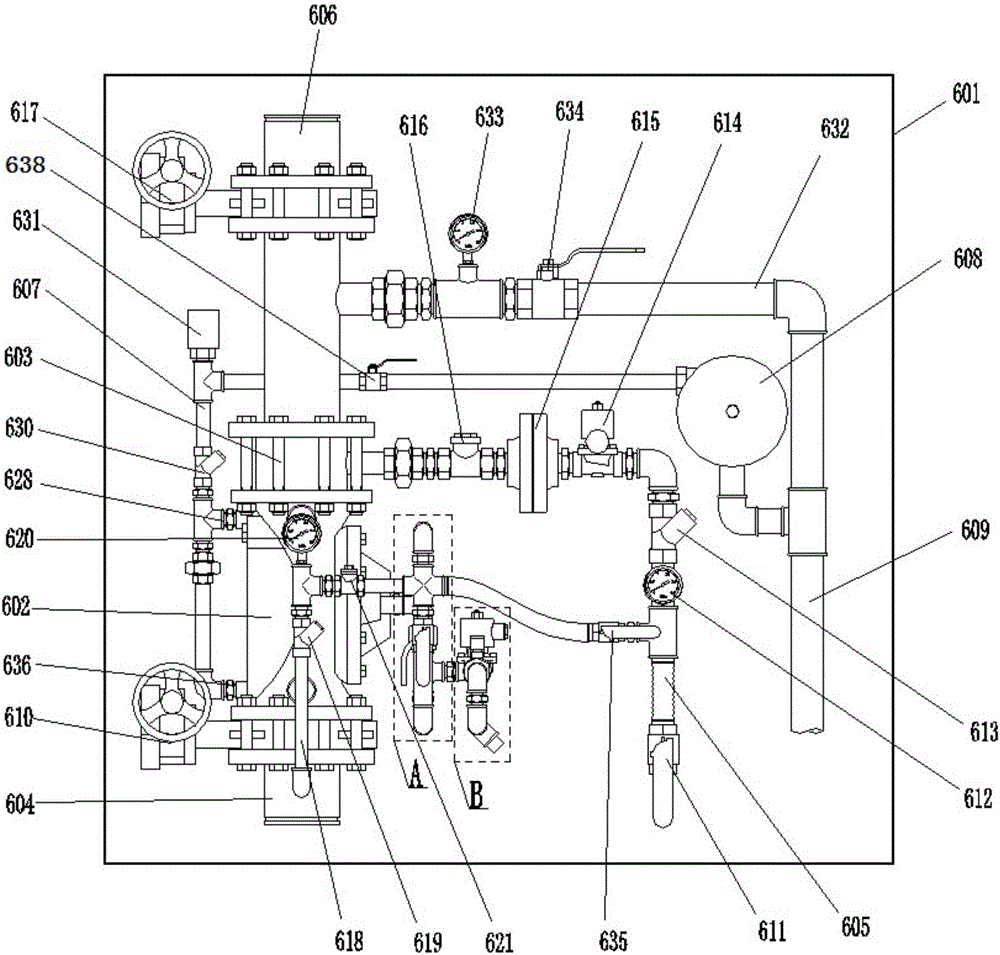

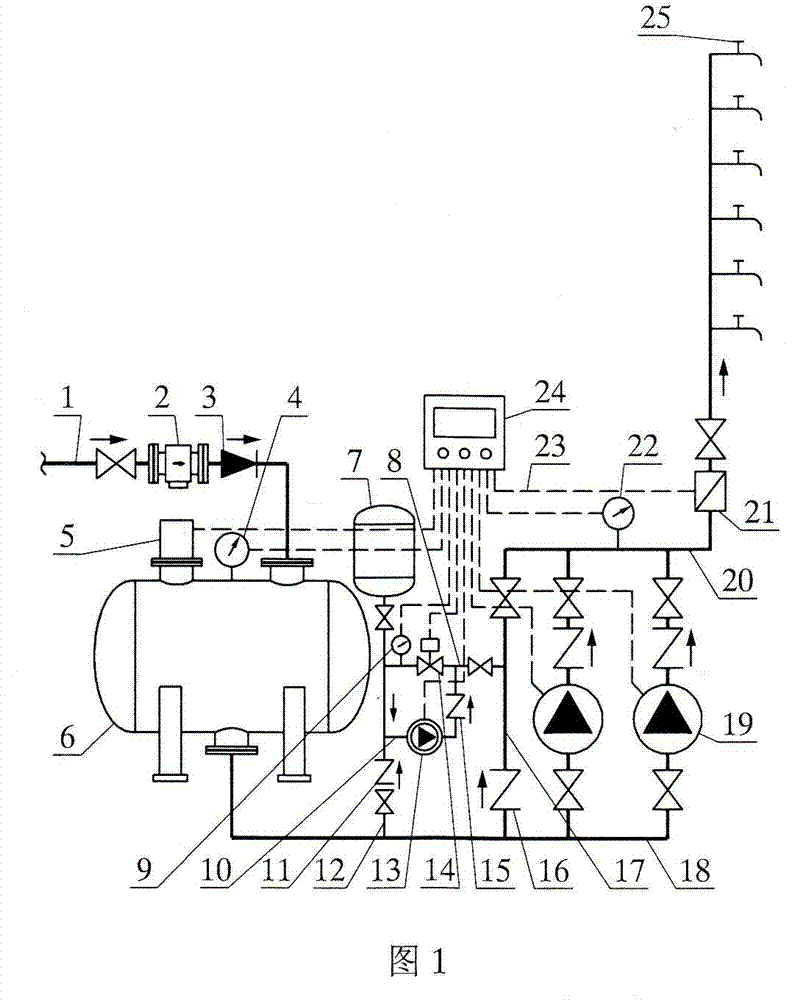

Marine diesel engine SCR common rail type urea solution spraying system

InactiveCN104110293ASmooth sailingWide flow rangeInternal combustion piston enginesExhaust apparatusCommon railAgricultural engineering

The invention discloses a marine diesel engine SCR common rail type urea solution spraying system which comprises a compression air source, a urea solution daily tank, a controller, a metering electromagnetic valve and spraying guns. A pressurizing port of the urea solution daily tank is connected with the compression air source, an output port of the urea solution daily tank is connected with liquid inlets of the spraying guns through the metering electromagnetic valve, gas inlets of the spraying guns are connected with the compression air source, the controller controls the duty ratio of the metering electromagnetic valve to control the volume of the atomized urea solution sprayed by the spraying guns, a liquid level sensor is arranged in the urea solution daily tank, the controller controls a urea solution source to add a urea solution to the urea solution daily tank according to the liquid level information transmitted by the liquid level sensor, and the spraying guns are all located at the front end of an SCR catalyst in an engine exhaust pipe. The marine diesel engine SCR common rail type urea solution spraying system is capable of simultaneously supplying the urea solution to multiple marine diesel engines in real time, high in applicability and obvious in cost saving.

Owner:武汉添蓝发动机排放控制技术有限公司

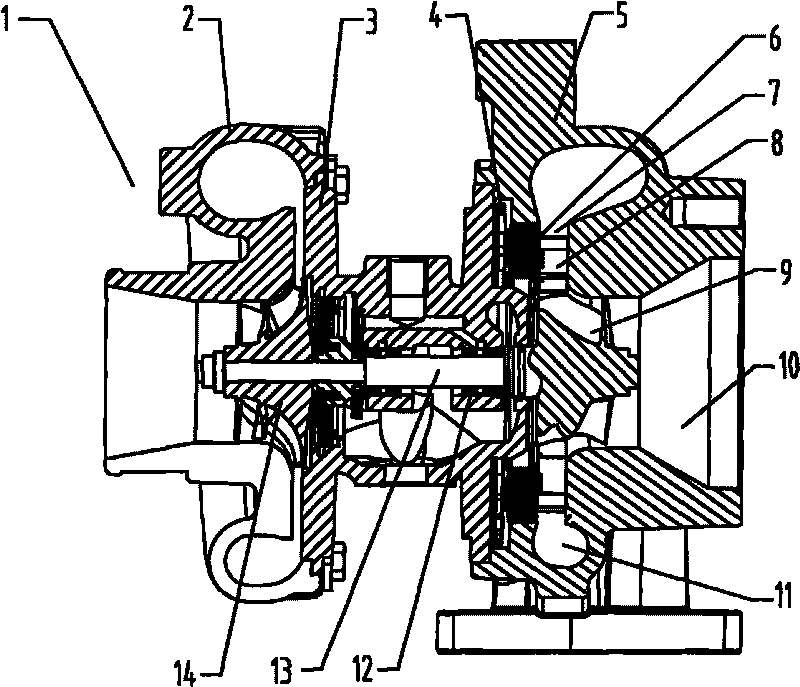

Asymmetric double-channel variable section turbocharger

InactiveCN101694178ALow efficiencyBuilds higher efficiency at low speedsInternal combustion piston enginesImpellerInlet channel

The invention discloses an asymmetric double-channel variable section turbocharger, comprising a turbine volute which is internally provided with a turbine impeller and a volute gas inlet channel; the volute gas inlet channel is provided with a volute nozzle at the position close to the turbine impeller; and the volute gas inlet channel comprises a small volute gas inlet channel and a large volute gas inlet channel which is positioned at one side of the small volute gas inlet channel. The asymmetric double-channel variable section turbocharger carries out modification and designing on the traditional turbine volute, adopts the combination of double gas inlet channels, and forms different through flow sections, and effectively utilizes the energy of waste gas of an engine. By fully utilizing the energy of waste gas exhausted by the engine, the asymmetric double-channel variable section turbocharger realizes the same variable section turbine function, can not change the whole structure greatly, and has low cost and easy realization.

Owner:KANGYUE TECH

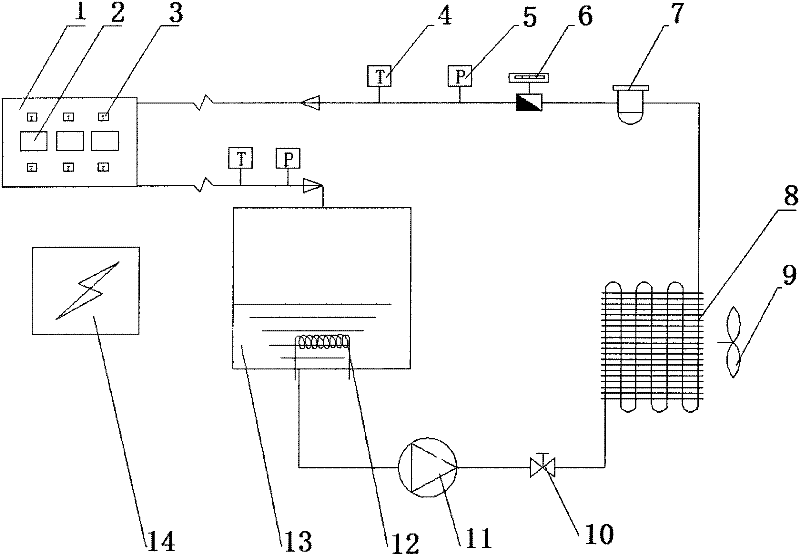

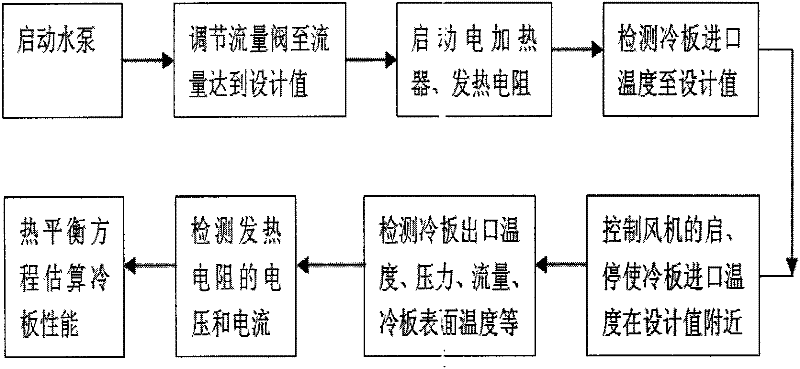

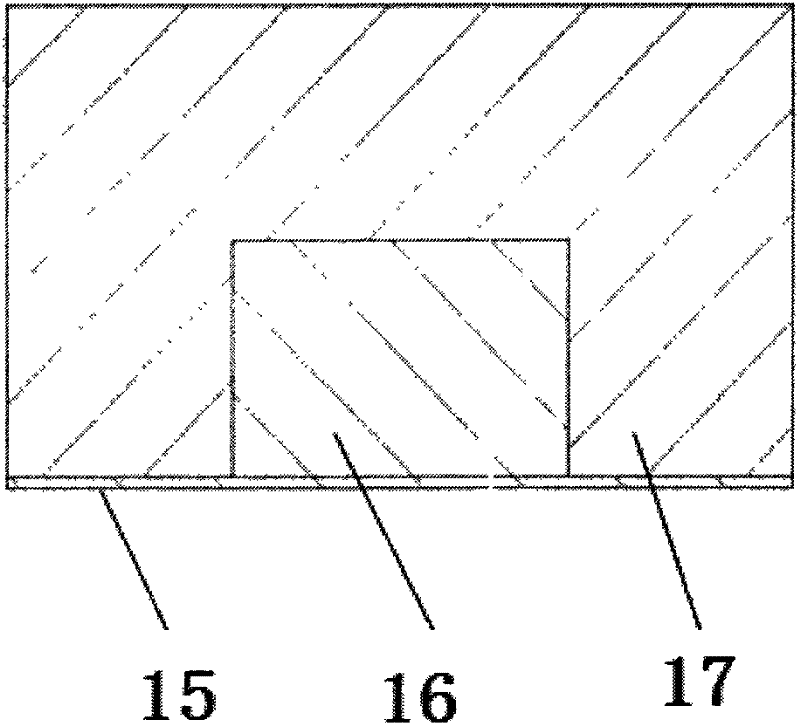

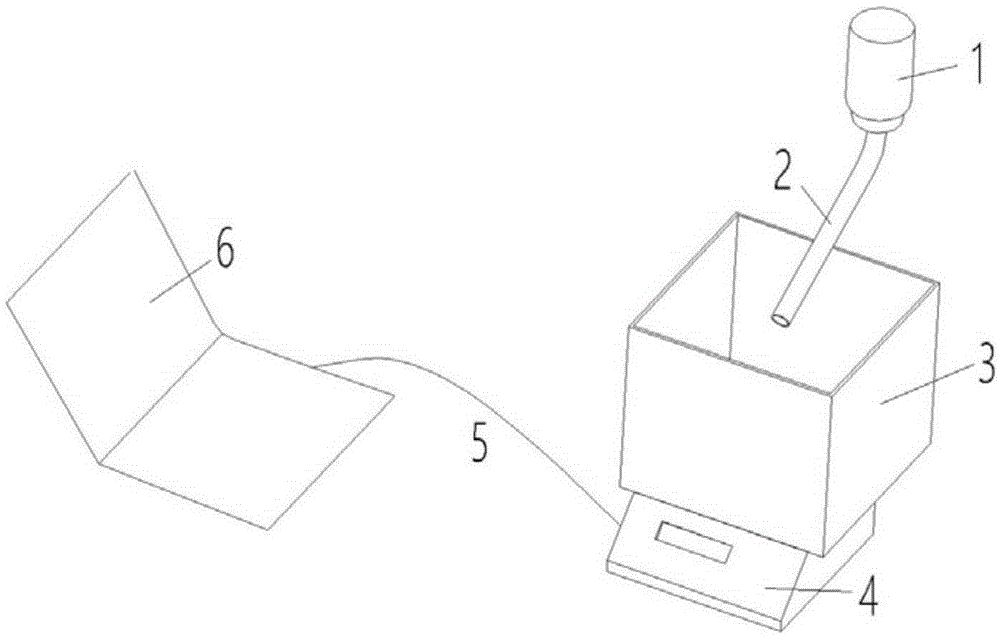

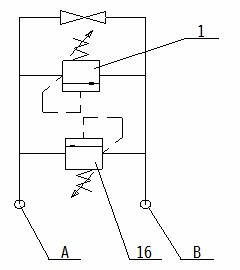

Cold plate performance test device

InactiveCN102374878AWide flow rangeMeet the test requirementsMeasurement devicesElectrical resistance and conductanceHeat resistance

The invention provides a cold plate performance test device which is characterized by comprising a thermometer (4), a pressure meter (5), a flowmeter (6), a filter (7), a heat radiator (8), a flow valve (10), a water pump (11), a water tank (13) and a cold plate (1) which are sequentially connected together in series through a pipeline, wherein a fan (9) is fixed together with the heat radiator (8) through a bracket; an electric heater (12) is arranged on the side wall of the water tank (13) in a threaded connection manner; a heating resistance module (2) and a wall temperature sensor (3) are fixed on the surface of the cold plate (1) through bolts; and a control unit (14) is connected with the heating resistance module (2), the wall temperature sensor (3), the thermometer (4), the pressure meter (5), the flowmeter (6), the fan (9), the water pump (11) and the electric heater (12) through a conductive wire, so that a control part of the device is formed. The cold plate performance test device disclosed by the invention has the advantages of wide measurement range, small measurement error and high measurement precision.

Owner:CHINA NORTH VEHICLE RES INST

Pressure exchanger

ActiveUS8622714B2Reduce complexityEasy to operatePump componentsGas turbine plantsEngineeringDistributor

A pressure vessel provided with a first port acting as a high pressure inlet of a first stream and a second port acting as a high pressure outlet. A rotatable valve element is located in the center of the machine. In operation, a fluid stream is introduced to the machine at high pressure where it then passes through the open ports of the valve element and into flow distributor causing upward displacement of a first duct piston, resulting in pressurization and flow of a second fluid. At the same time the second fluid is introduced to the machine at low pressure and flows into the pressure exchange duct, causing downward displacement of a second duct piston and resulting in flow of the first fluid below the duct piston, which then flows into the lower flow distributor, into the valve element, and then out of the pressure vessel.

Owner:FLOWSERVE HLDG

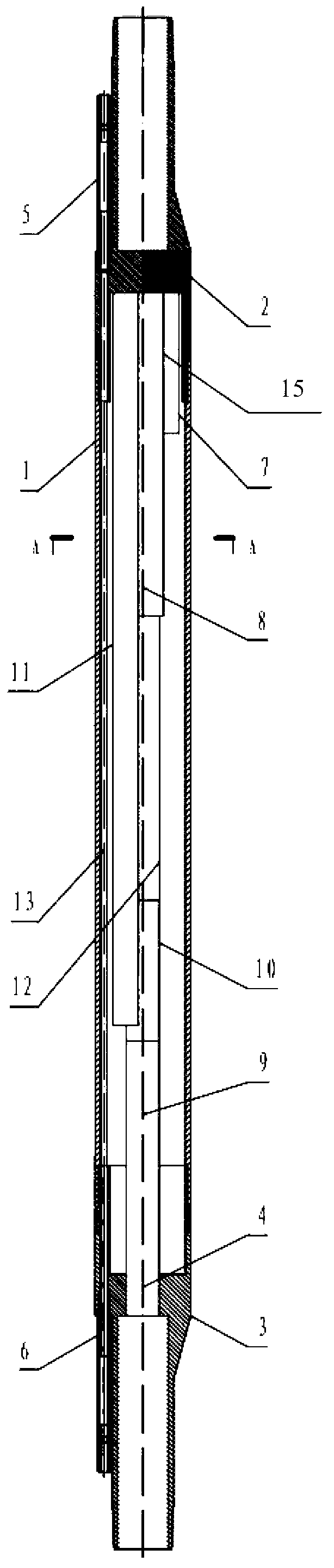

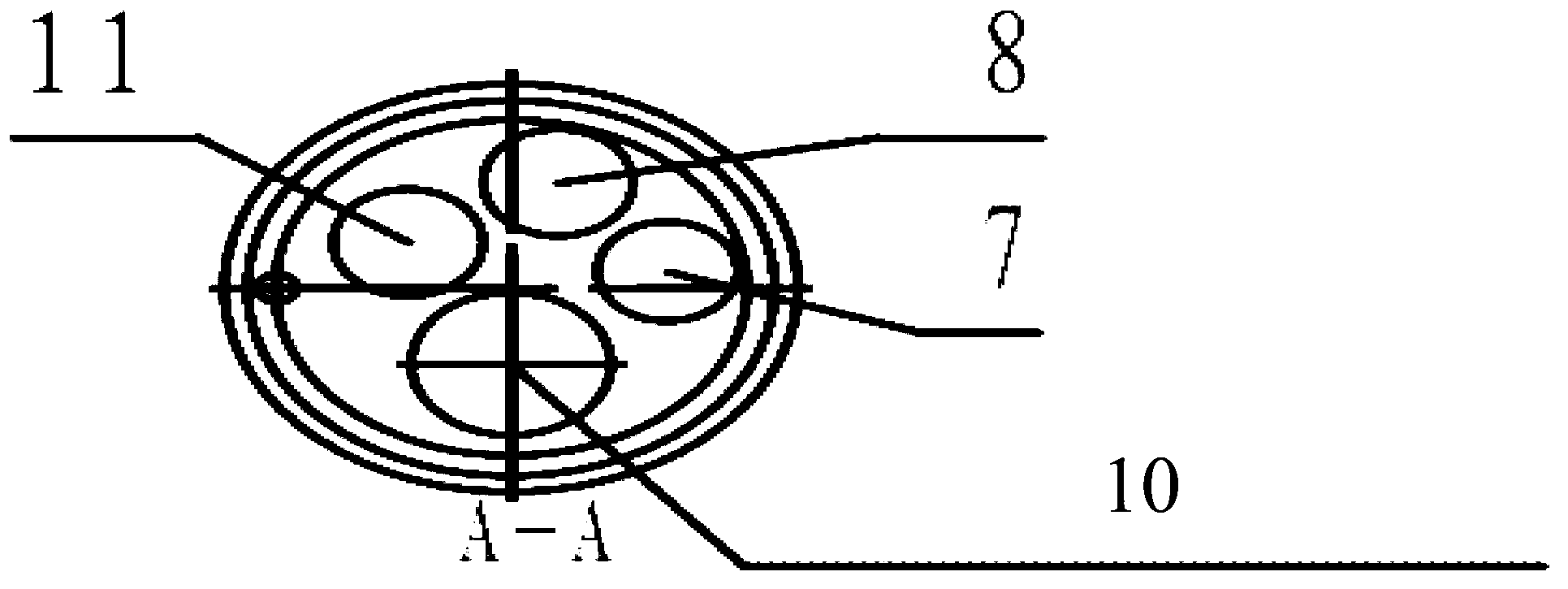

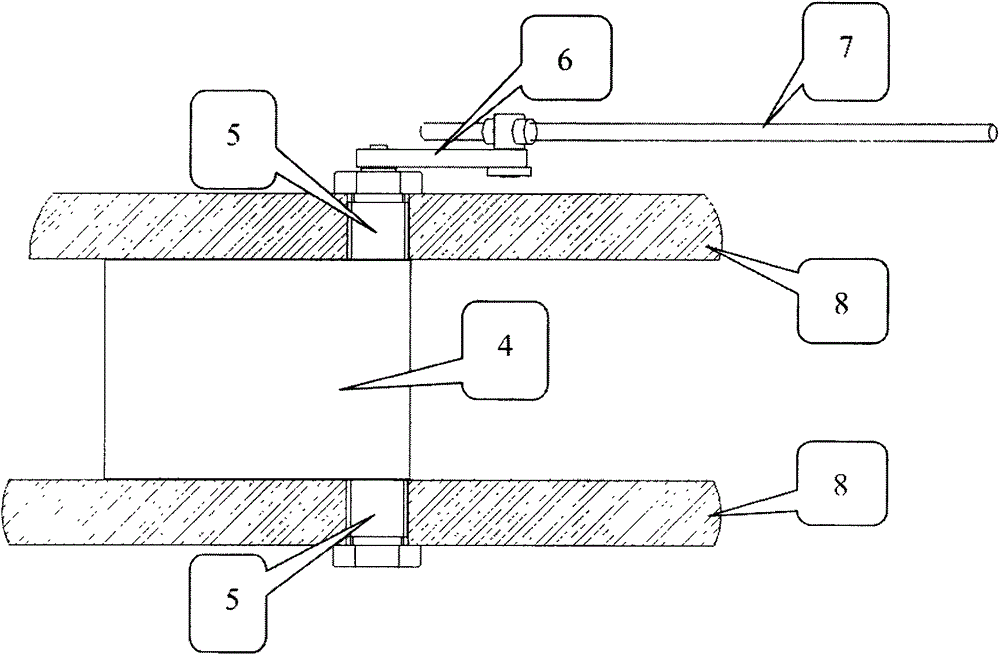

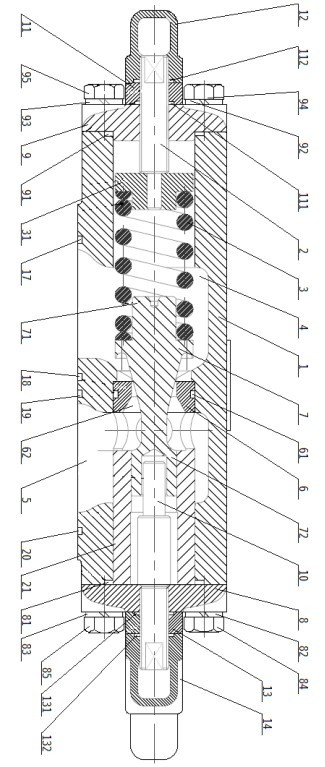

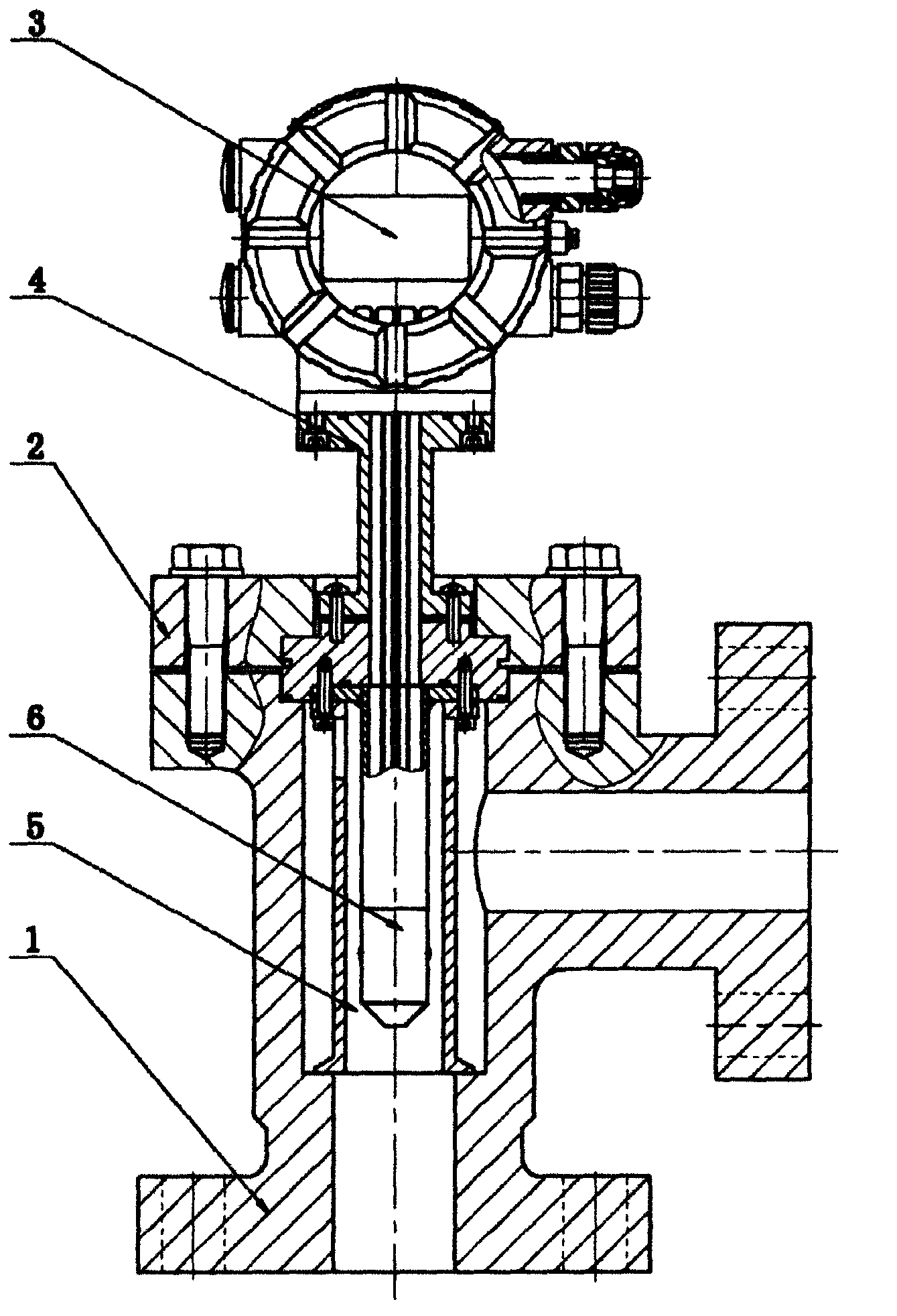

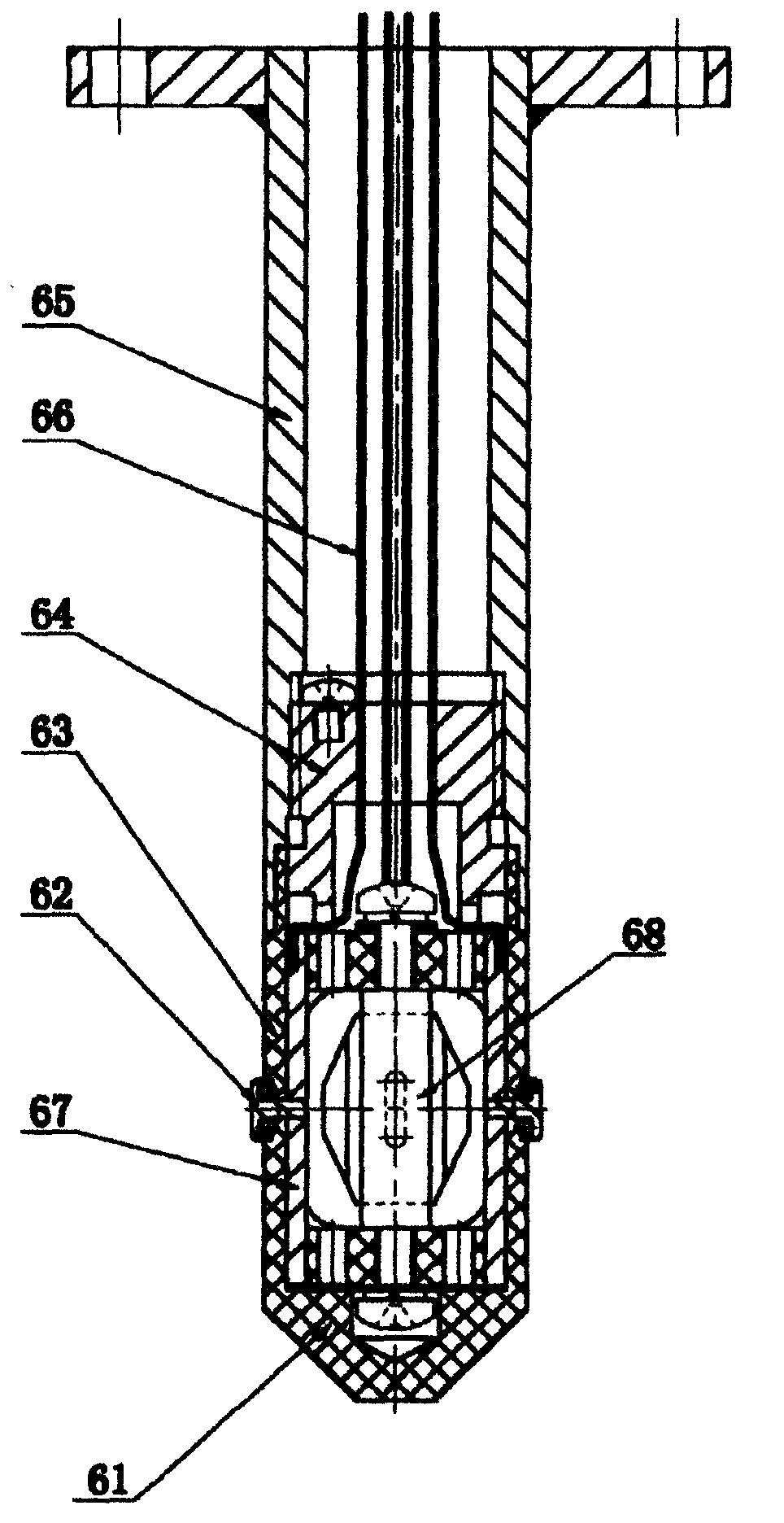

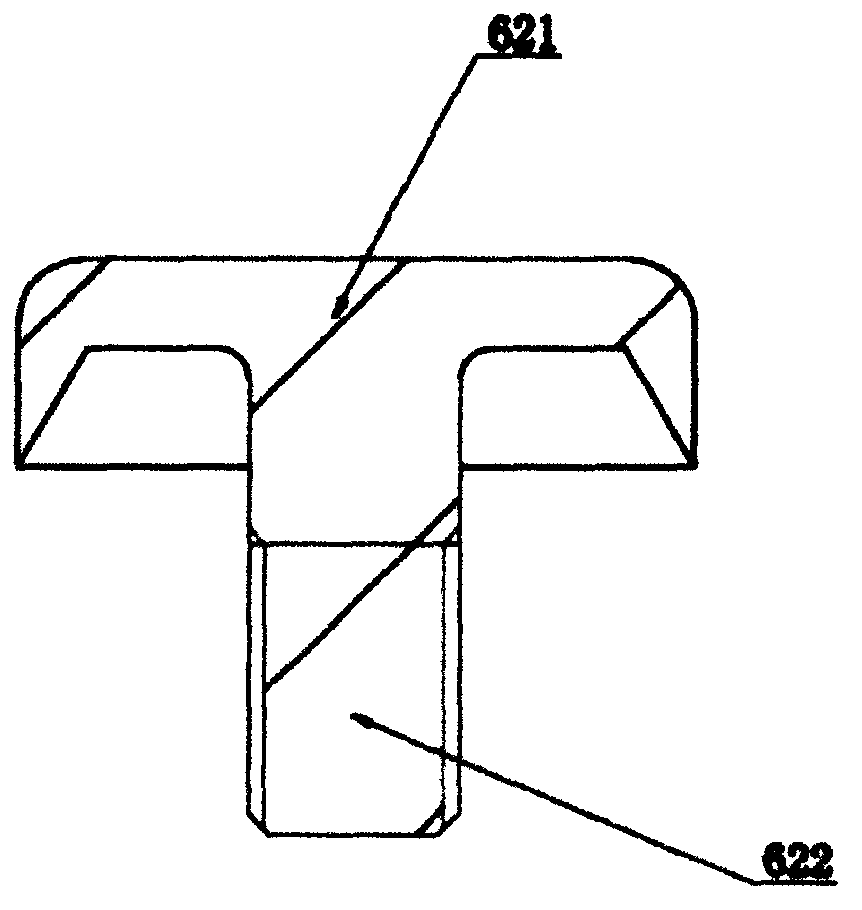

Control device for underground layered flow rate of water injection well

ActiveCN103075136AReal-time monitoring of downhole parameters of water injection wellsWith remote control functionFluid removalElectricityControl signal

The invention discloses a control device for the underground layered flow rate of a water injection well. The lower end of a tubular controller main body is provided with an executing mechanism, a flow passing passage and a cable are penetrated inside the tubular controller main body, the tubular controller main body is connected with a flow rate meter and a test control unit, the executing mechanism is connected with an electric adjustable water nozzle, a liquid inlet connected with the electric adjustable water nozzle is arranged in the flow passing passage, a liquid outlet connected with the electric adjustable water nozzle is arranged on the tubular controller main body, the flow rate meter and the executing mechanism are respectively and electrically connected with the test control unit, the flow rate meter obtains the layered water quantity in real time and transmits the results to the test control unit, when the layered water quantity is not in the preset water quantity range, the test control unit sends control signals to the executing mechanism, and the executing mechanism receives the control signals and regulates the water inlet quantity or the water outlet quantity of the electric adjustable water nozzle. The real-time monitoring on the underground parameters of the water injection well is realized, in addition, the injection quantity is regulated through the executing mechanism, the control device realizes the checking and sealing on a packer through the installation of a checking and sealing pressure meter, and the remote operation and control function is realized.

Owner:CNOOC ENERGY TECH & SERVICES

Fluid control measuring and controlling device

ActiveUS10175669B2Reduce lossesEnable controllabilityProgramme controlMechanical apparatusVena contracta diameterNoise generation

Systems and methods for measuring and controlling fluid flow comprises an orifice plate defining a variable opening, wherein the orifice plate includes an outer assembly comprising a central opening and an inner assembly extending through the central opening. Another embodiment comprises a plurality of blades disposed parallel to each other, wherein the blades are pivotable along its longitudinal axis and include at least one low-flow blade or partial blade and a plurality of high-flow blades The flow device regulates high and very low volumes of fluid with precision, inexpensively, with superior acoustics, reduced energy, a simpler design, and prevents building infiltration. The high turndown device permits use at lower velocities, thereby reducing noise generation and eliminating need for sound-attenuating liners. The high rangeability device combines several part numbers into fewer parts, thereby streamlining product portfolios. Cost benefits associated with the flow device allow equipment to be scaled back 100:1 rather than legacy 4:1, providing energy savings, fewer product variations, simple and more robust applications. The device meets new and old building fresh air, comfort and energy codes. The flow device can be engineered, selected, and sized without sophisticated software programs.

Owner:BEST TECH

Asymmetric split turbine of turbocharger

ActiveCN101634244AAddressing High Discharge Pressure RequirementsReduce control difficultyNon-fuel substance addition to fuelInternal combustion piston enginesTurbochargerEngineering

The invention discloses an asymmetric split turbine of a turbocharger, comprising an engine. The engine is provided with an exhaust tube of the engine, a turbine casing and a turbine rotor, wherein, the turbine casing is provided with a casing high pressure flow channel and a casing low pressure flow channel, the exhaust tube of the engine is provided with a high pressure exhaust manifold and a low pressure exhaust manifold, the high pressure exhaust manifold is connected with the casing high pressure flow channel, the low pressure exhaust manifold is connected with the casing low pressure flow channel, and the A / R value of the casing high pressure flow channel is less than that of the casing low pressure flow channel. By adopting the asymmetric split structure, the two flow channels of the turbine casing have different A / R values and are respectively connected with different exhaust pipelines of the engine, thus effectively lowering the exhaust back pressure of part of engine cylinders and reducing the influence of EGR operation process on the pressurizing unit. The asymmetric split turbine has good succession, simple structure, easy upgrade and switch of products, low cost and easy and fast realization of engineering.

Owner:康跃科技(山东)有限公司

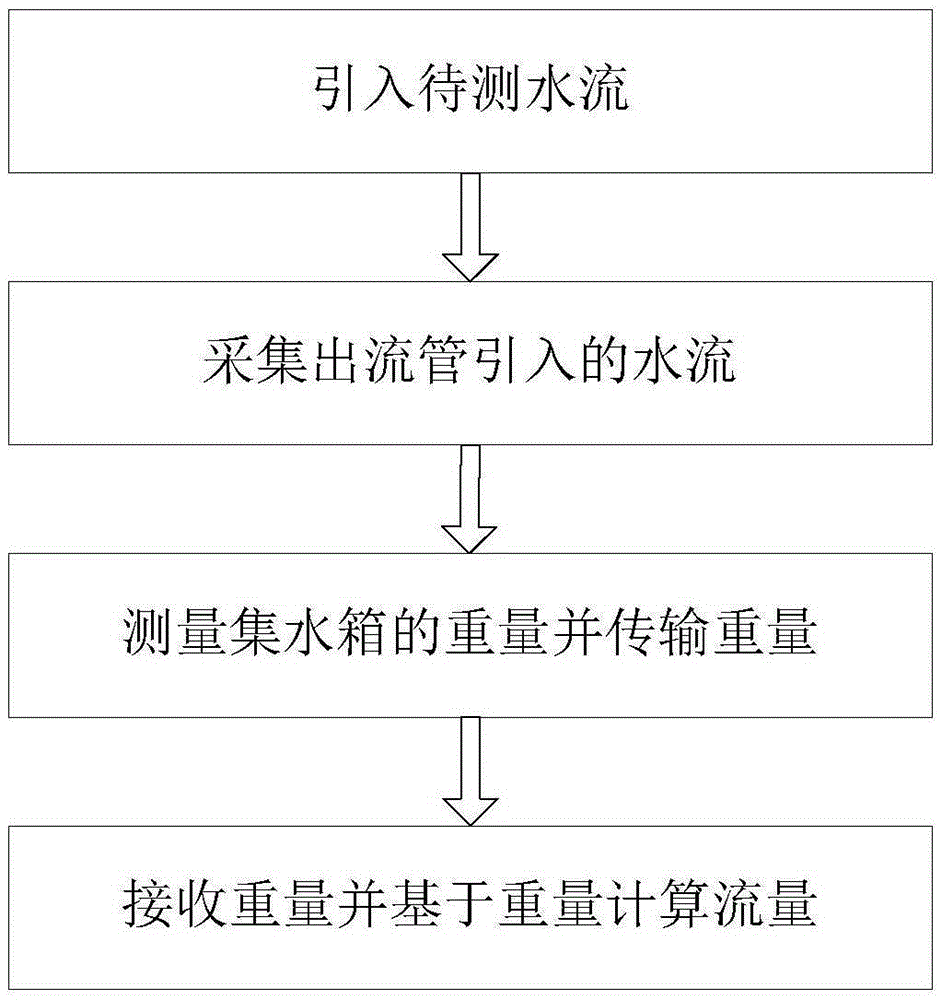

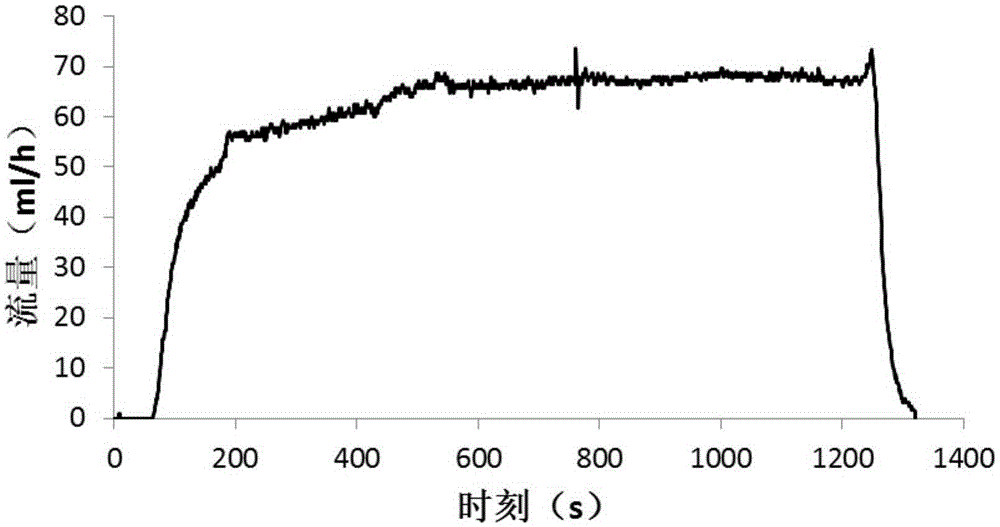

Flow measuring device and method

InactiveCN105403260AHigh data accuracyWide flow rangeIndirect mass flowmetersImage resolutionEngineering

Owner:INST OF GEOGRAPHICAL SCI & NATURAL RESOURCE RES CAS

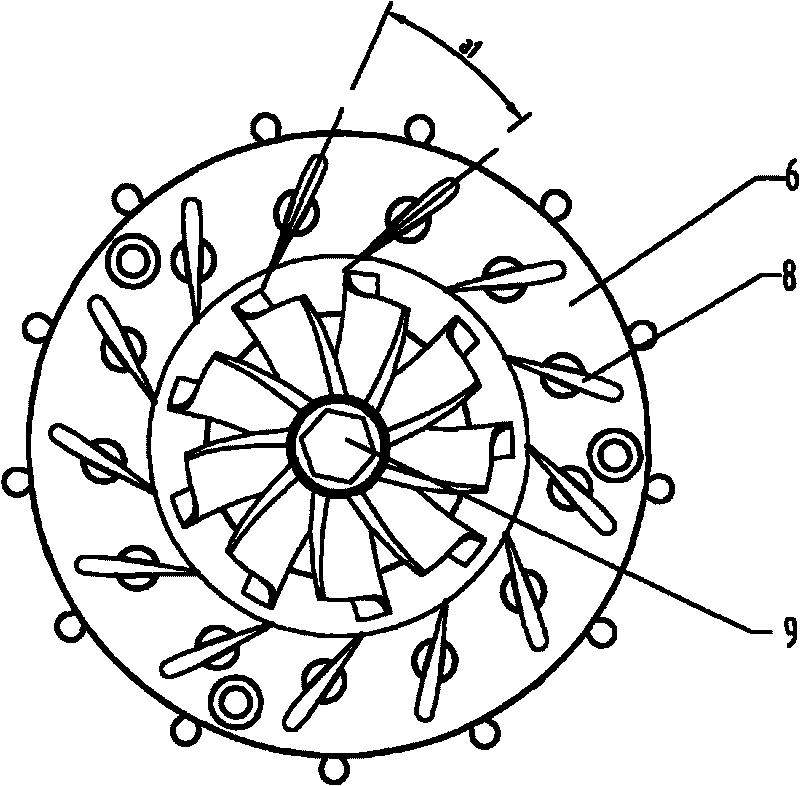

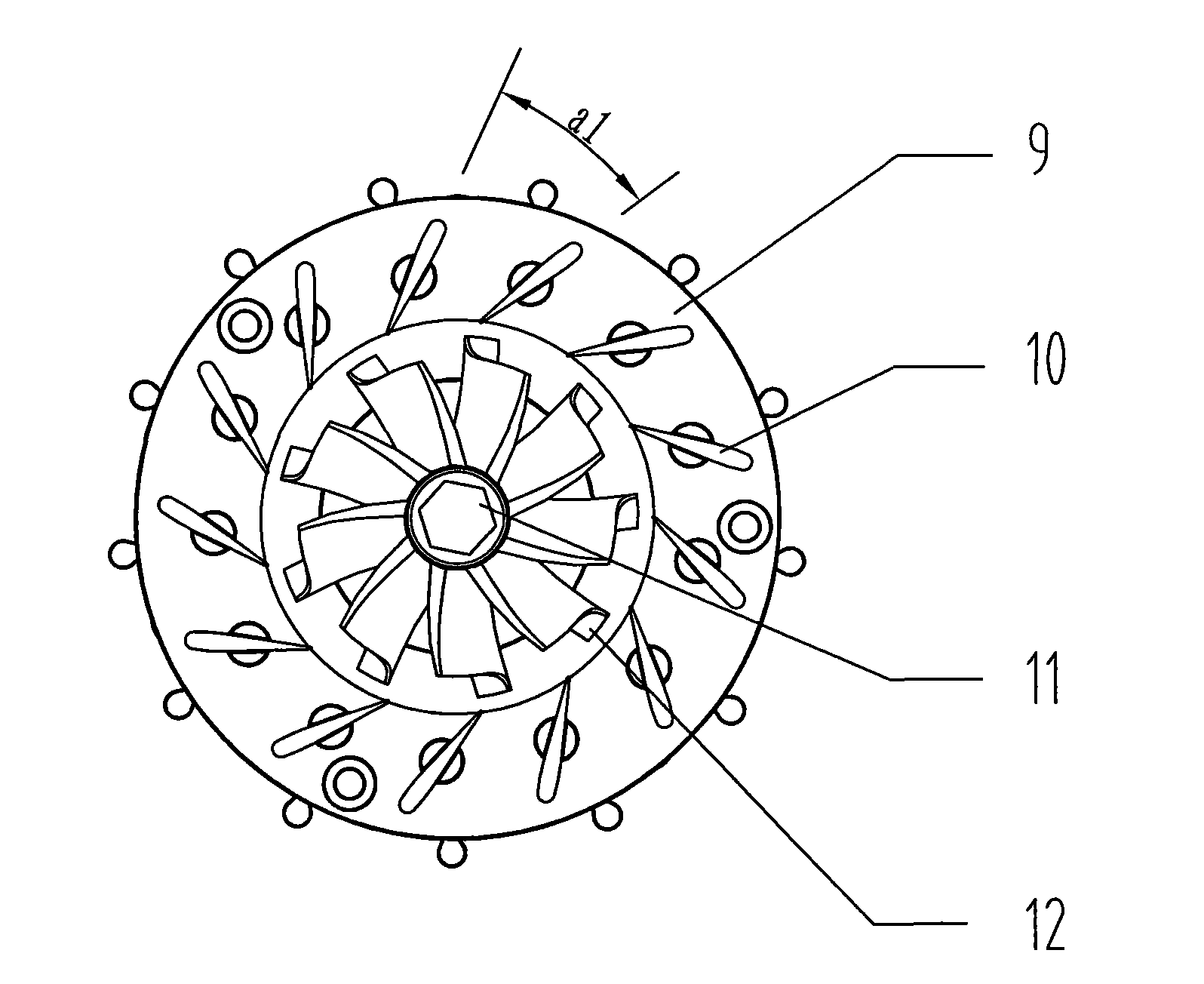

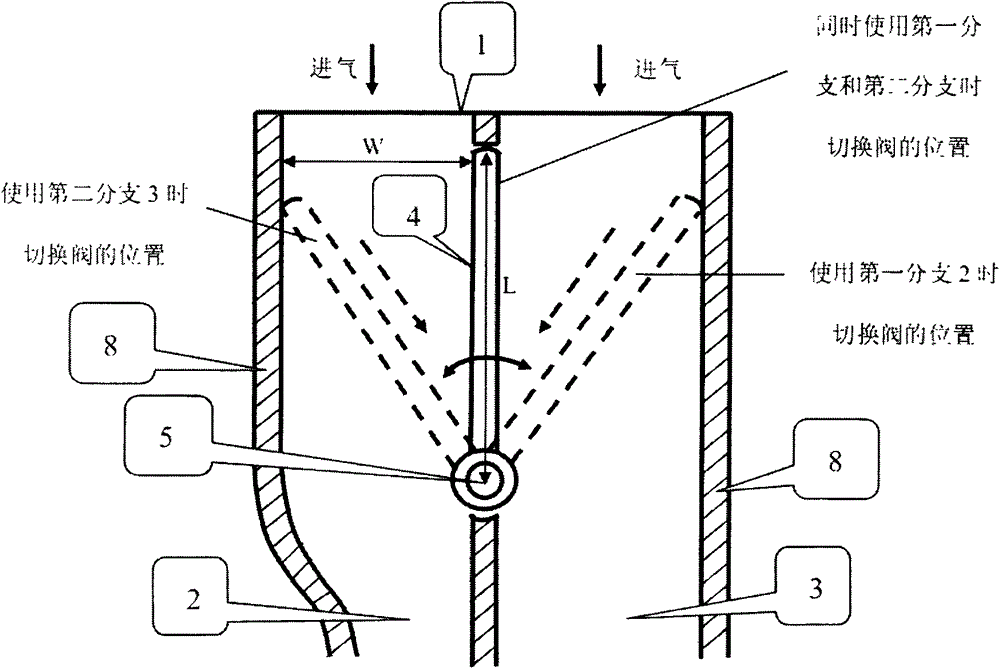

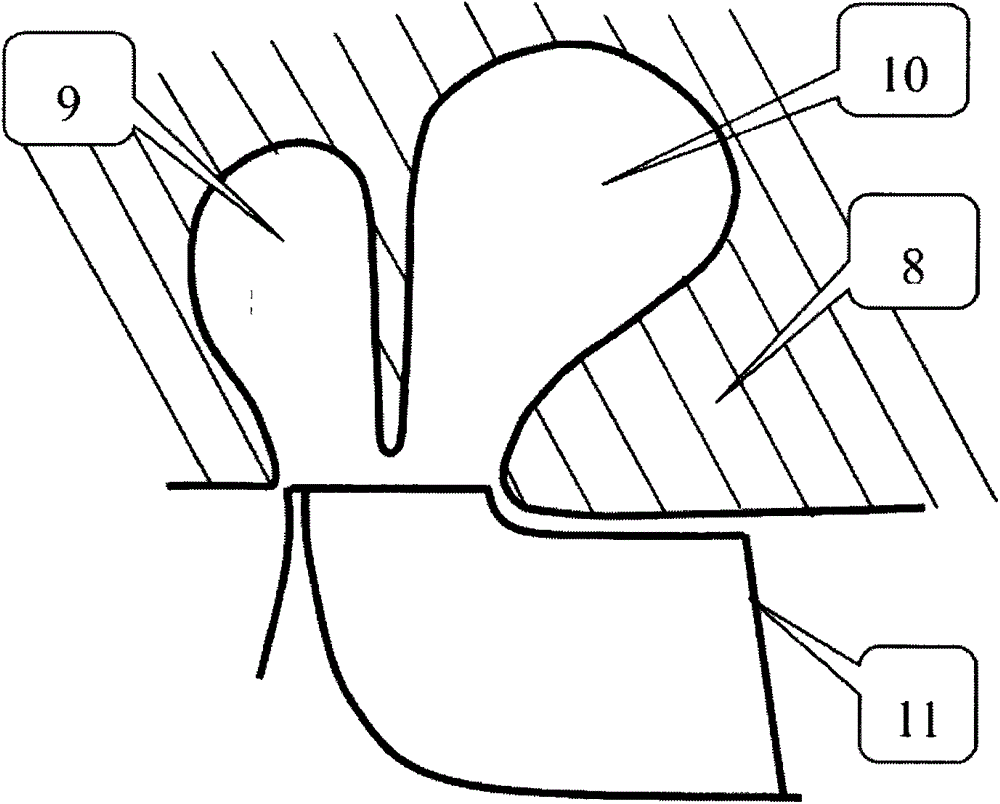

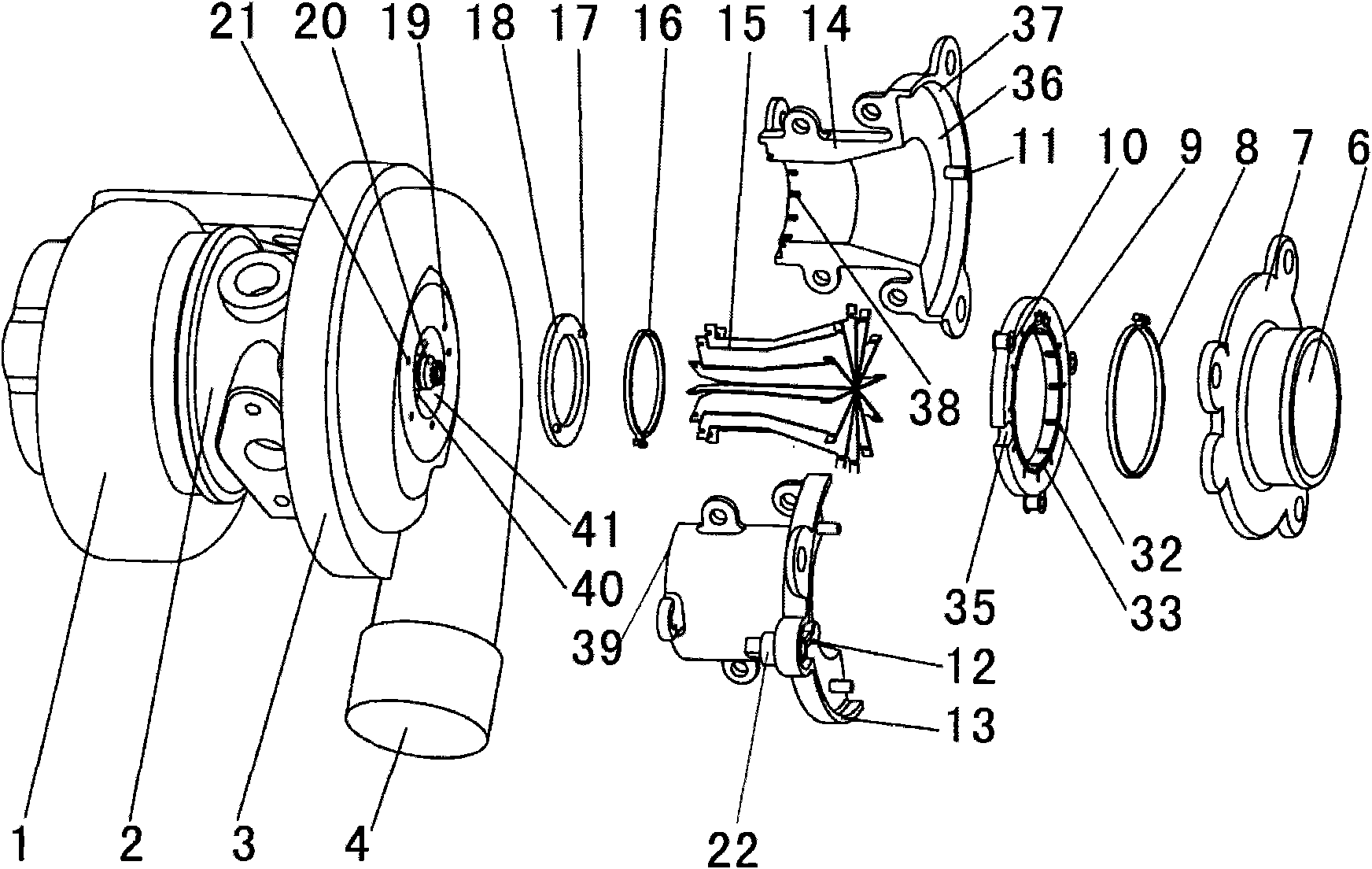

Switchable double-inlet asymmetric turbine volute

The invention relates to a double-inlet asymmetric turbine volute provided with a switching valve. The asymmetric turbine volute comprises a double-channel turbine volute inlet (1) provided with two branches, a first branch (2), a second branch (3) and an asymmetric volute body (8), and is characterized in that the volute body (8) is provided with a first vortex path (9) and a second vortex path (10), wherein an A / R (area / radius) ratio of the first vortex path (9) is smaller than that of the second vortex path (10); the first branch (2) is connected with the first vortex path (9), and the second branch (3) is connected with the second vortex path (10); and the asymmetric turbine volute further comprises the switching valve (4) located on an inlet channel and a control mechanism of the switching valve (4). The swinging switching valve is mounted in the inlet section of the turbine volute for controlling inlet air flow of the double-inlet asymmetric turbine volute, and the turbine flowing range can be effectively enlarged.

Owner:CHINA NORTH ENGINE INST TIANJIN

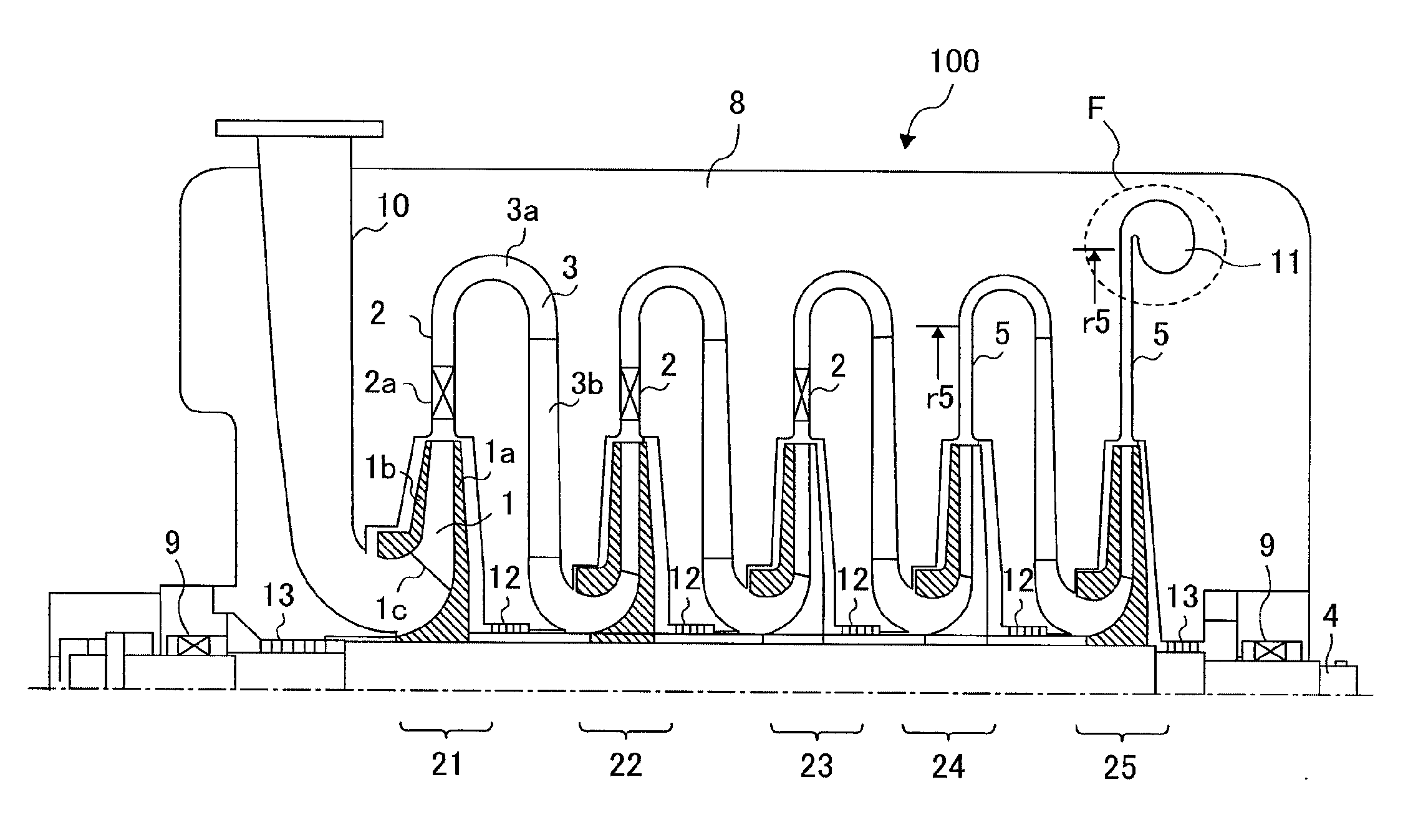

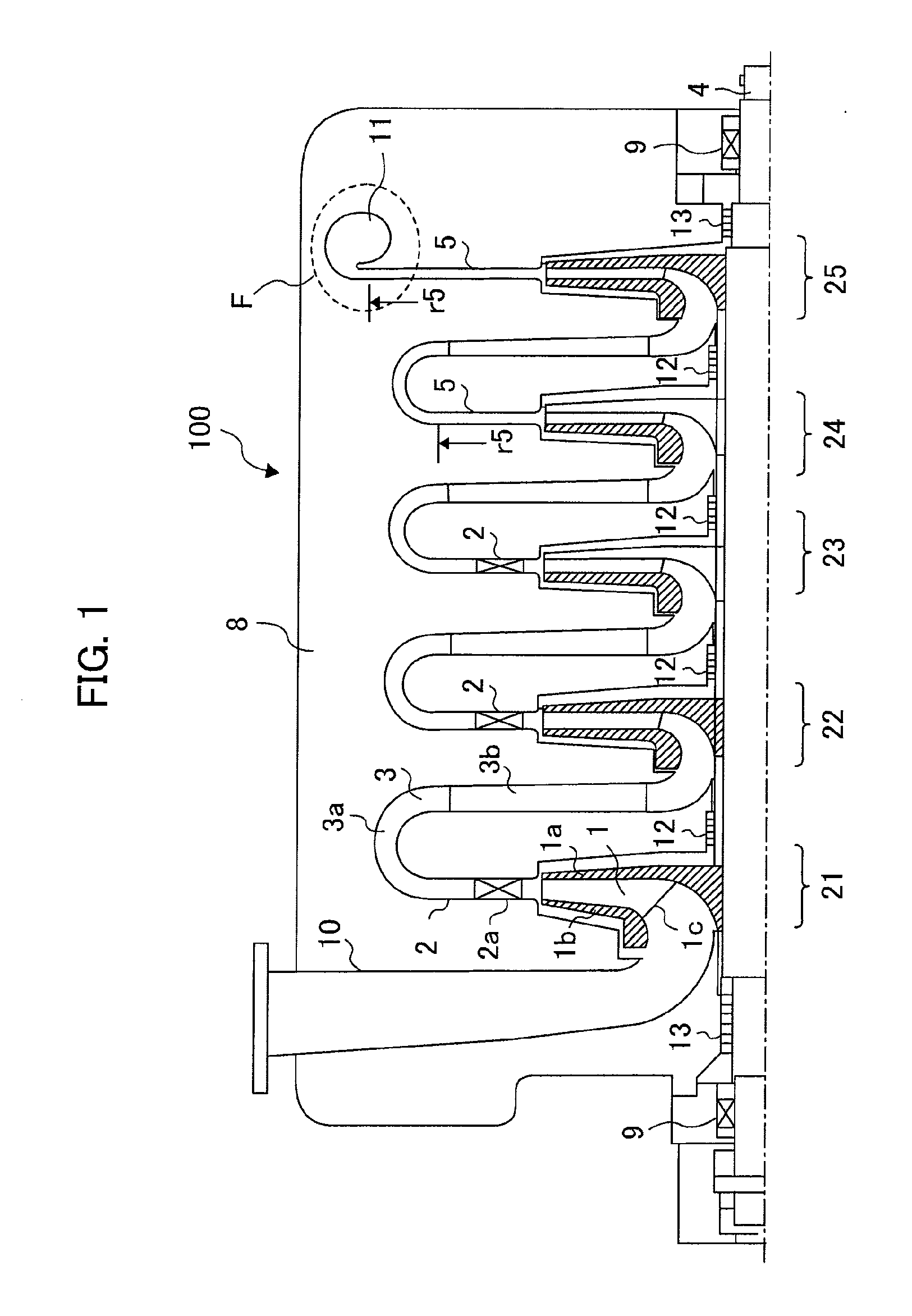

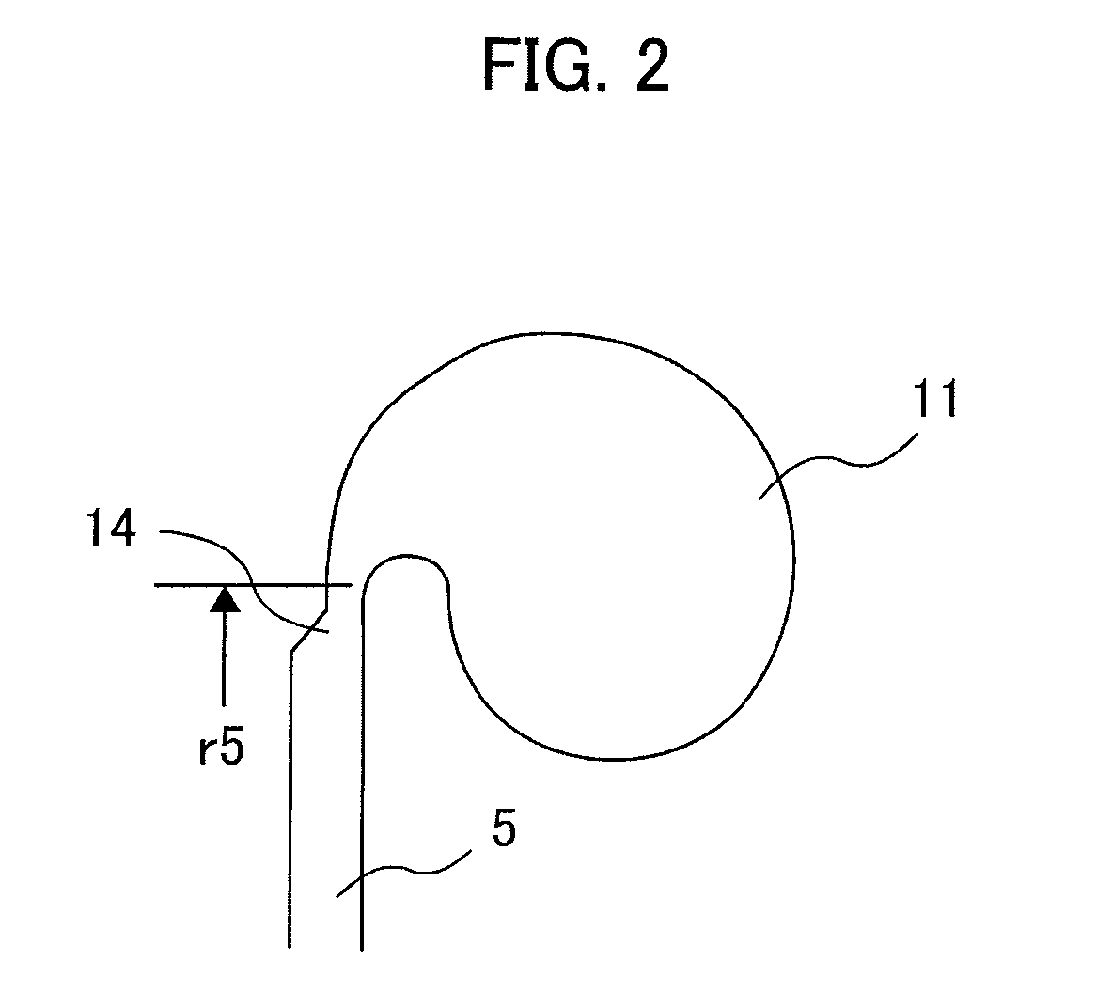

Multistage centrifugal compressor

InactiveUS20100028141A1Raise indexHigh efficiencyPump componentsStatorsCentrifugal compressorEngineering

In a multistage centrifugal compressor, a plurality of impellers is attached to the same rotary shaft. Vaned Diffusers and vaneless diffusers are used, as diffusers, for respective compressor stages configuring the compressor. The vaned diffusers are continuously used from the first compressor stage to the middle compressor stage, and the vaneless diffusers are used for the last compressor stage and the previous stage. While high efficiency is maintained at the compressor stages having the vaned diffusers, an operating flow range is secured at the compressor stages having the vaneless diffusers.

Owner:HITACHI IND PROD LTD

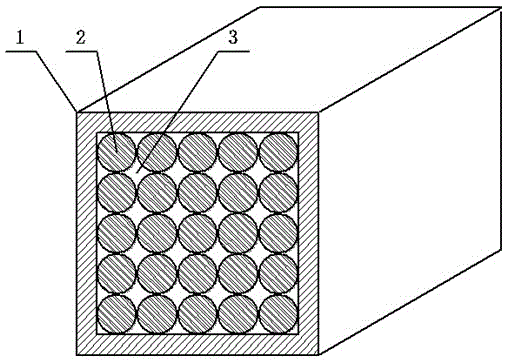

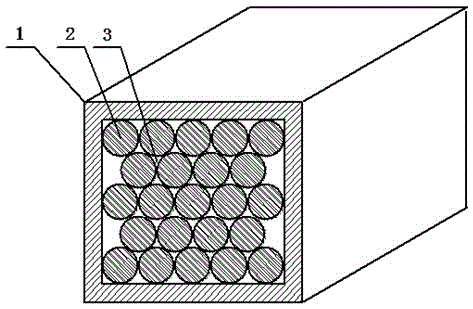

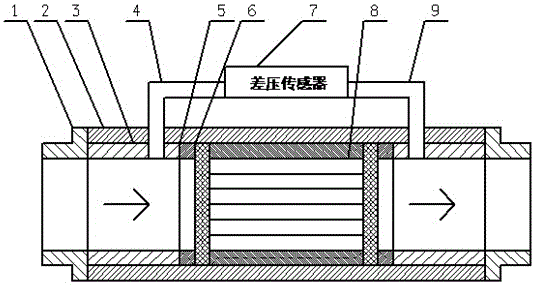

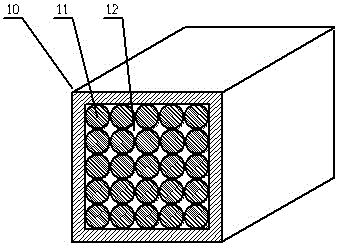

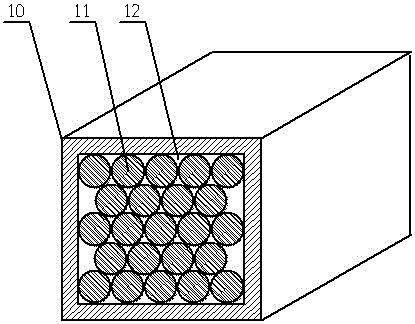

Laminar flow element

ActiveCN105157764AReduce manufacturing costReduce processing difficultyVolume/mass flow by differential pressureInterference fitEngineering

The invention discloses a laminar flow element. The element is composed of a hollow cylinder body and solid round bars, the solid round bars are closely arrayed inside the hollow cylinder body, the solid round bars are fixed to the hollow cylinder body through interference fit, each solid round bar is fixed to the adjacent solid round bars through interference fit, laminar flow channels are constituted by gaps between the solid round bars and the hollow cylinder body and among the solid round bars, and fluid flows through the laminar flow channels, so that laminar flow is formed. The laminar flow element has the advantages of being low in fabrication cost, high in stability of the formed laminar flow and wide in applicable flow scope.

Owner:陕西易度智能科技有限公司

Safety complex function valve and two-way valve composed by same

ActiveCN101907190AAchieve free spinsImprove sealingEqualizing valvesSafety valvesComposite functionEngineering

The invention relates to a safety complex function valve. A valve bush is arranged between the left valve cavity and the right valve cavity in the valve body; a valve core is arranged in the valve bush; the valve core and the valve bush form a conical seal fit; both ends of the valve core are respectively provided with a spring, an adjusting screw and an emergency push rod; both ends of the valve body are respectively fixed with a left valve cap and a right valve cap through bolts; and the left valve cap and the right valve cap are respectively provided with a left cap nut and a right cap nut. The two-way valve comprises a valve body and a reversing valve body, wherein the structure of the reversing valve body is identical to that of the valve body rotated for 180 degrees. A sealing element is respectively arranged between the valve bush and the valve body, between the valve cap and the valve body, between the valve cap and the bolt, on both ends of the sealing nut, and between the valve body and the reversing valve body in the two-way valve. The invention not only can adjust the pressure in two directions, but also can communicate the cavities in forward and backward directions in an emergency; and thus, the invention has the advantages of high safety, favorable sealing effect, wide application range of flow, strong flexibility and simple structure.

Owner:WUHAN MARINE MACHINERY PLANT

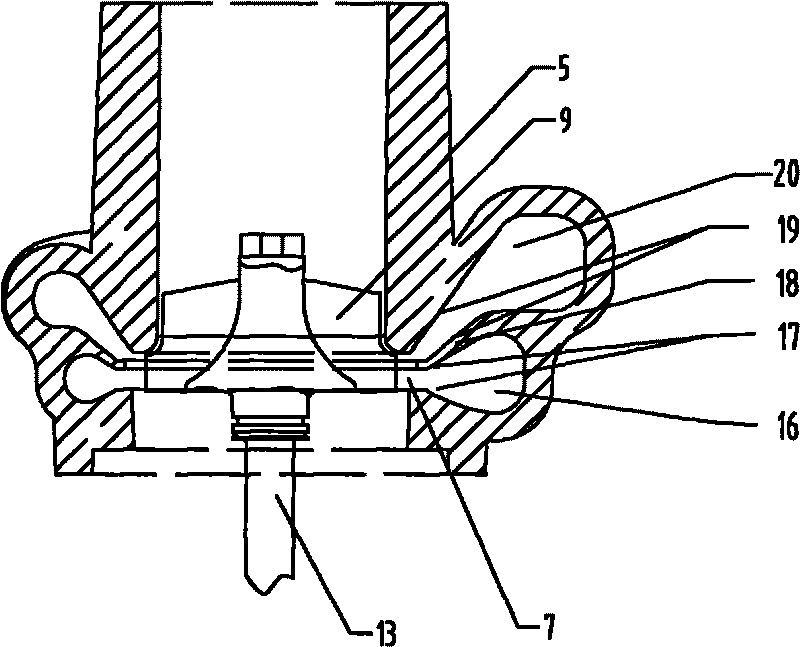

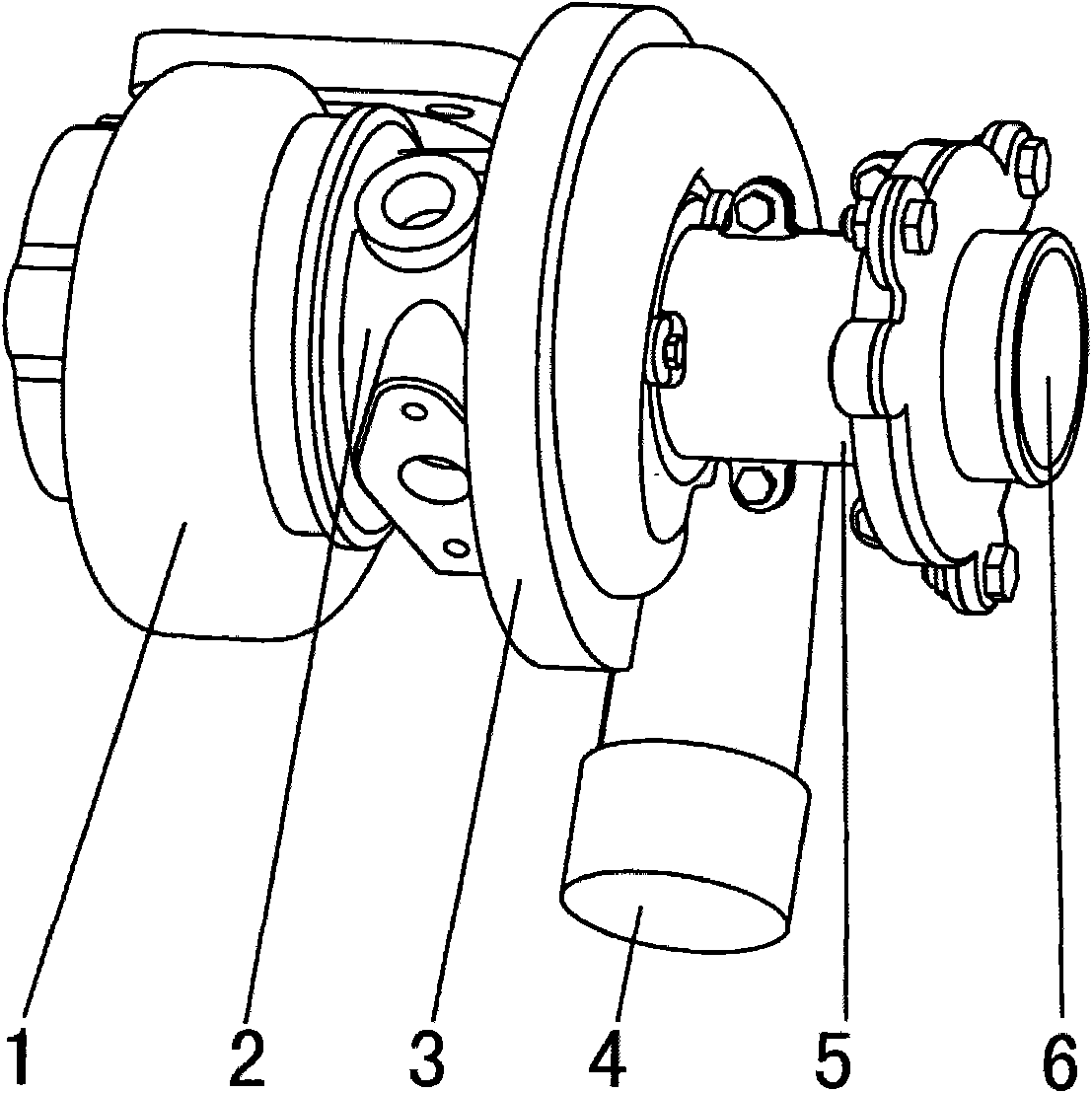

Variable air inlet turbocharger structure

InactiveCN101929381AWide flow rangeImprove efficiencyInternal combustion piston enginesGas turbine plantsTurbochargerStreamflow

The invention provides a turbocharger structure which is applied in the technical field of a turbocharger and can change an air flow direction entering into a press shell. The variable air inlet structure turbocharger comprises a turbine shell (1), a middle shell (2) and the press shell (3); a press shell inlet (41) of the turbocharger structure is provided with an air inlet adjusting device (5) which is capable of changing the air flow direction entering into the press shell (3); the air inlet adjusting device (5) comprises a cavity (34) with a hollow structure; more than one sheet-shaped guide blade (44) is installed in the cavity (34); the air inlet adjusting device (5) further comprises a driving mechanism (49) for driving the guide blade (44) to torque. The technical scheme of the invention can change the air flow direction in the inlet of the gas compressor, efficiently reduce the flow rate while surging, improve the flow rate while blocking, widen the flow rate range of the turbocharger and improve the efficiency and pressure ratio of the turbocharger.

Owner:JAPHL POWERTRAIN SYST

Pilot burner for gas turbine engine

InactiveUS8499564B2Fuel/oxidant ratioSuperiorly controllableBurnersContinuous combustion chamberCombustorGas turbines

A pilot burner (150, 350) for a gas turbine engine delivers an inner non-swirling fuel-oxidant mixture surrounded by an outer swirling fuel-oxidant mixture, thereby providing enhanced mixing with no recirculation zone. At least one fluid-restricting inlet port (166, 366) provides an oxidant to an inner mixing passage (160, 360). The inner mixing passage (160, 360) includes a plurality of fuel outlets (168). An outer annular mixing passage (180) receives oxidant from an upstream port (181) surrounding the inner mixing passage and includes at least one swirler element (186, 386) and fuel outlets (188).

Owner:SIEMENS ENERGY INC

Foam fire extinguishing system

The invention provides a foam fire extinguishing system. A proportional mixer is installed on the outlet end of a deluge valve, the foam liquid input end of the proportional mixer is connected with a foam liquid inlet pipe, fire water is pumped from a fire water source by a fire pump and is controlled to be on or off by the deluge valve, and foam liquid is pumped from a foam liquid tank by a foam liquid pump and is controlled to be on or off by a foam liquid electromagnetic valve. When a fire occurs, the deluge valve and the foam liquid electromagnetic valve can be quickly opened after receiving starting electrical signals which are sent by a fire extinguishing controller, and aqueous film-forming foam mixed liquid is formed by the fire water and the foam liquid through the proportional mixer and is conveyed to a pipe network through a mixed liquid outlet pipe, so that a certain proportion of the aqueous film-forming foam mixed liquid is supplied to the pipe network of the system. The foam fire extinguishing system has the advantages of compact structure and wide applicable pressure and flow range, when the fire occurs, the foam fire extinguishing system can be quickly started, and the aqueous film-forming foam mixed liquid is supplied to the pipe network, so that foam is sprayed to a protected area through a special foam nozzle so as to extinguish the fire.

Owner:广东鹰穗消防设备有限公司

Dosing pump system

ActiveUS20130081718A1Reduce eliminateWide flow rangeFlexible member pumpsRotary piston pumpsControl systemModularity

A compact, modular dosing pump system that is capable of microdose and macrodose volume flow rates, reduces or eliminates the need for additional flow control components such as temperature and pressure sensors, and utilizes a wider operational flow range than existing systems while maintaining the level of accuracy and precision exhibited by conventional dosing pump systems is provided. The dosing pump utilizes a pump and flow circuit, and a control system may be used to deliver a range of fluid volumes. The flow circuit utilizes a networked system of fluid paths and valves to route fluid through the dosing pump system in response to a pressure differential between fluid inlet and fluid outlet ports, while the controller monitors and controls the operation of the system.

Owner:MICRO INFINITY FLOW LLC

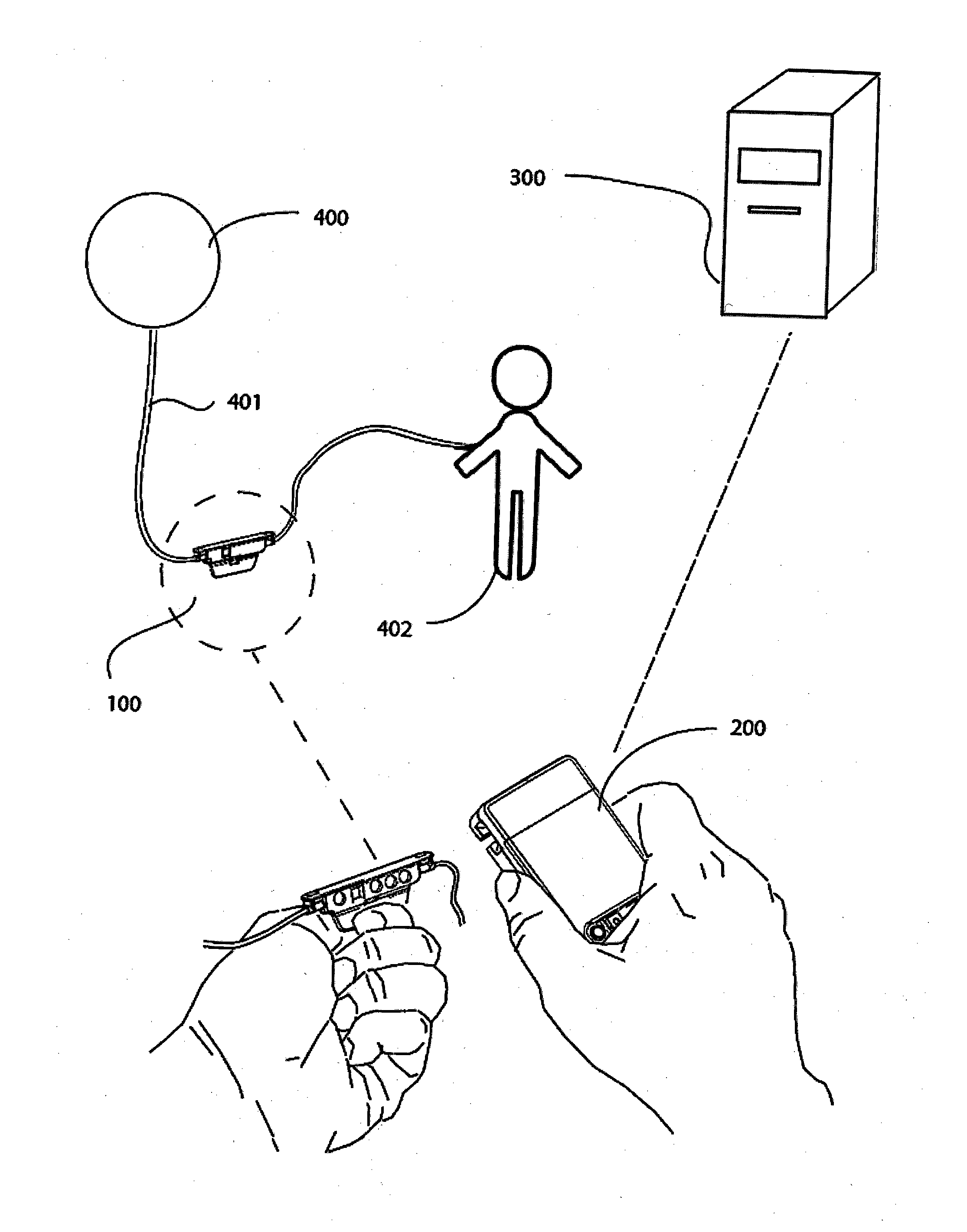

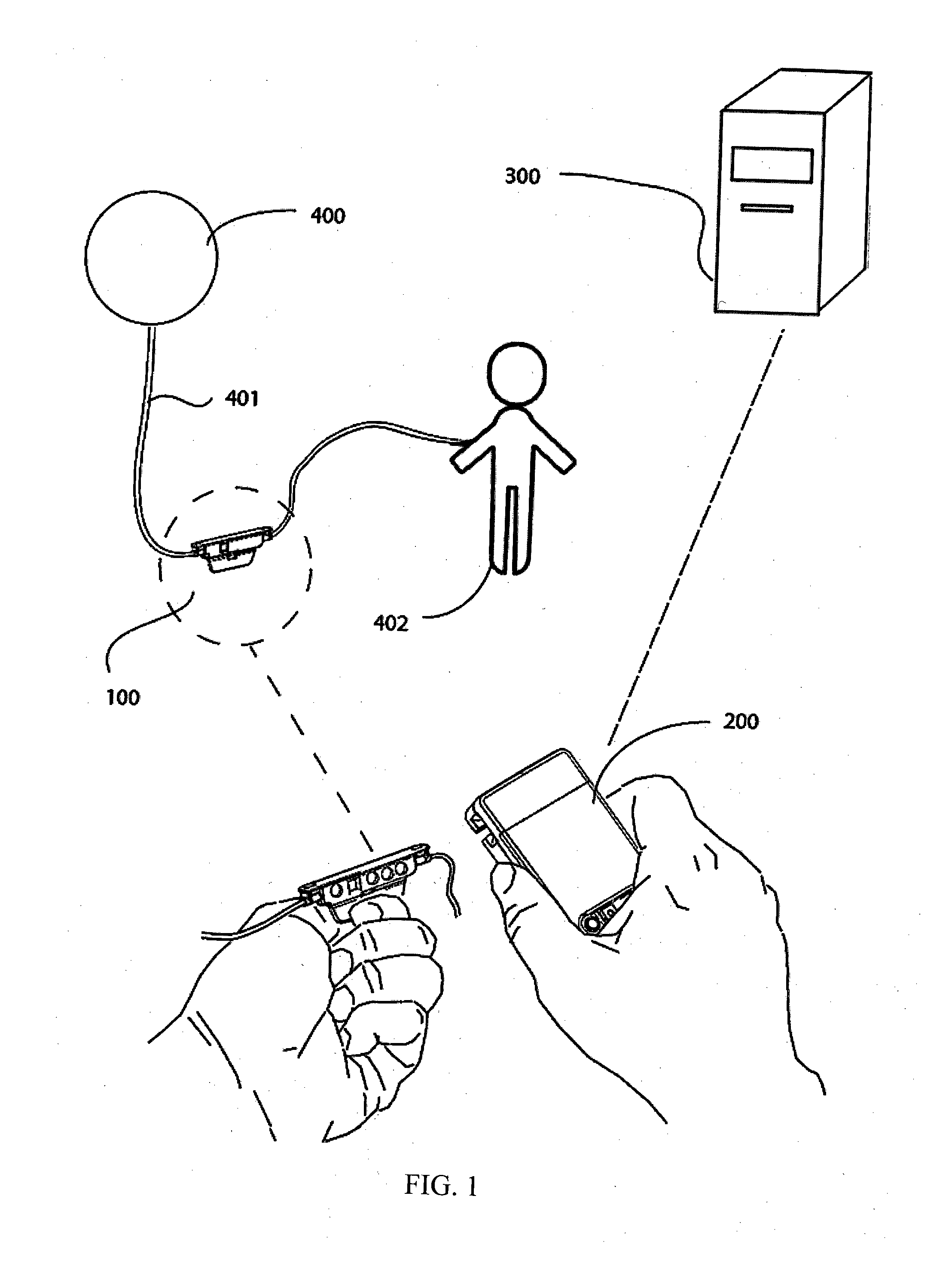

Intravenous (IV) infusion monitoring method and system

ActiveUS20150273144A1Fast thermal responseIncrease fluid velocityVolume/mass flow by thermal effectsMedical devicesEngineeringIntravenous fluid

In a method of determining a flow rate in an intravenous fluid delivery system according to one embodiment of the present invention, the fluid delivery channel forms a segment of the intravenous infusion system. An input thermal signal is emitted into a source location of a fluid delivery channel at an emitting instant. A first output thermal signal is received from a first sensor location of the fluid delivery channel at a first receiving instant. The first sensor location is positioned with a first interval downstream from the source location. The input thermal signal, the first output thermal signal, the emitting instant, the first receiving instant and the first interval define a first measured thermal profile. The first measured thermal profile is matched with a reference thermal profile which corresponds to a reference value, and the flow rate can be determined.

Owner:LEE FREDDIE ENG HWEE

Flowmeter for laminar flow

ActiveCN105091958AReduce manufacturing costWide flow rangeVolume/mass flow by differential pressureRound barHollow cylinder

The invention discloses a flowmeter for laminar flow. The flowmeter comprises end covers, a main body, adjustment cylinder bodies, an upstream pressure guide tube, gaskets, gauze elements, a differential pressure transducer, a laminar flow element and a downstream pressure guide tube, the laminar flow element is composed of a hollow cylinder body and a solid round bar, and the two sides of the laminar flow element are each provided with the corresponding gauze element, the corresponding gasket and the corresponding adjustment cylinder body in sequence. Compared with an existing flowmeter for laminar flow, the flowmeter is lower in production cost, higher in measurement precision and wider in applicable flow range.

Owner:陕西易度智能科技有限公司

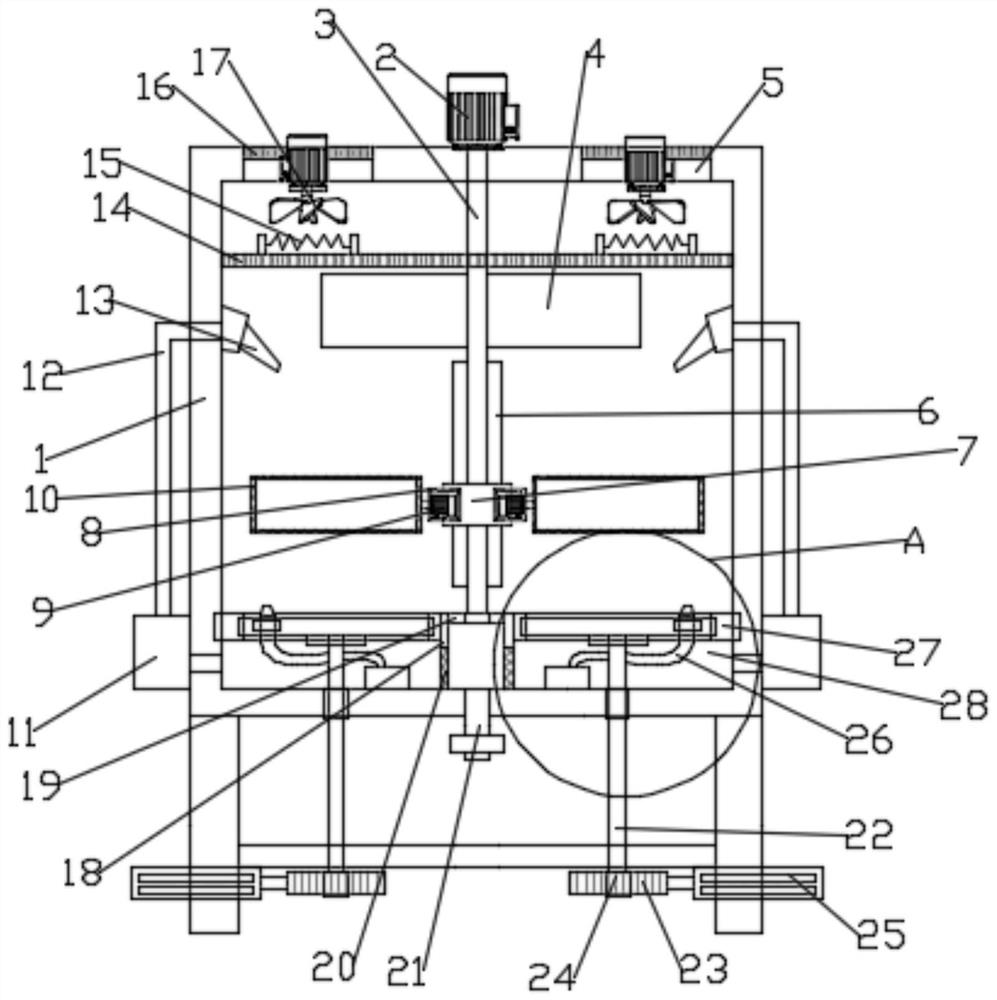

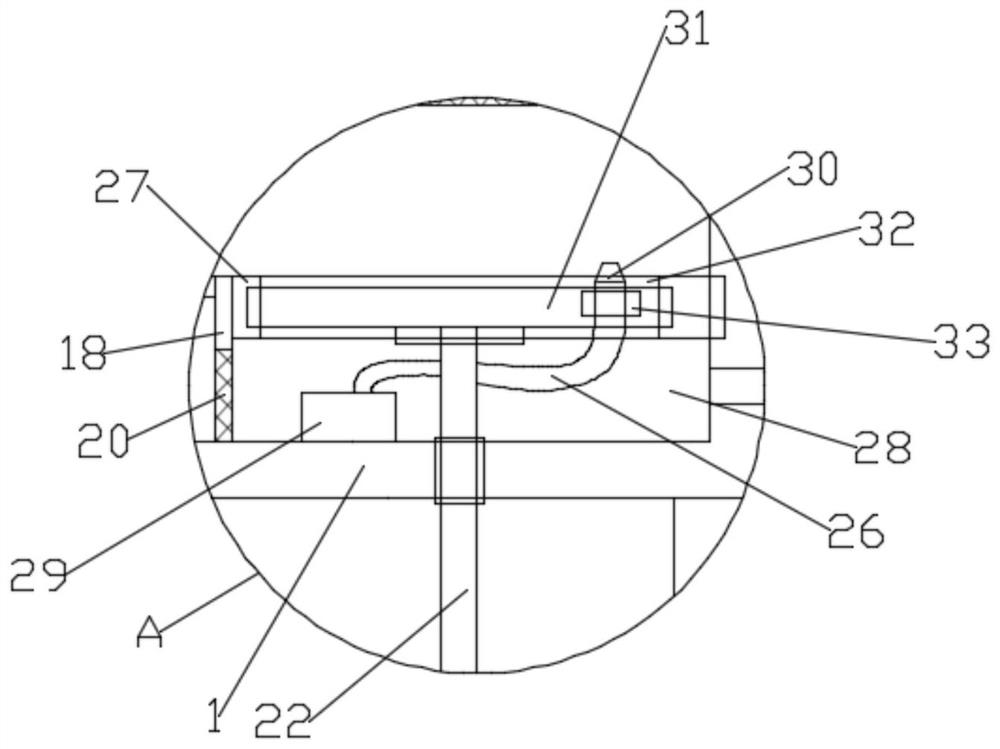

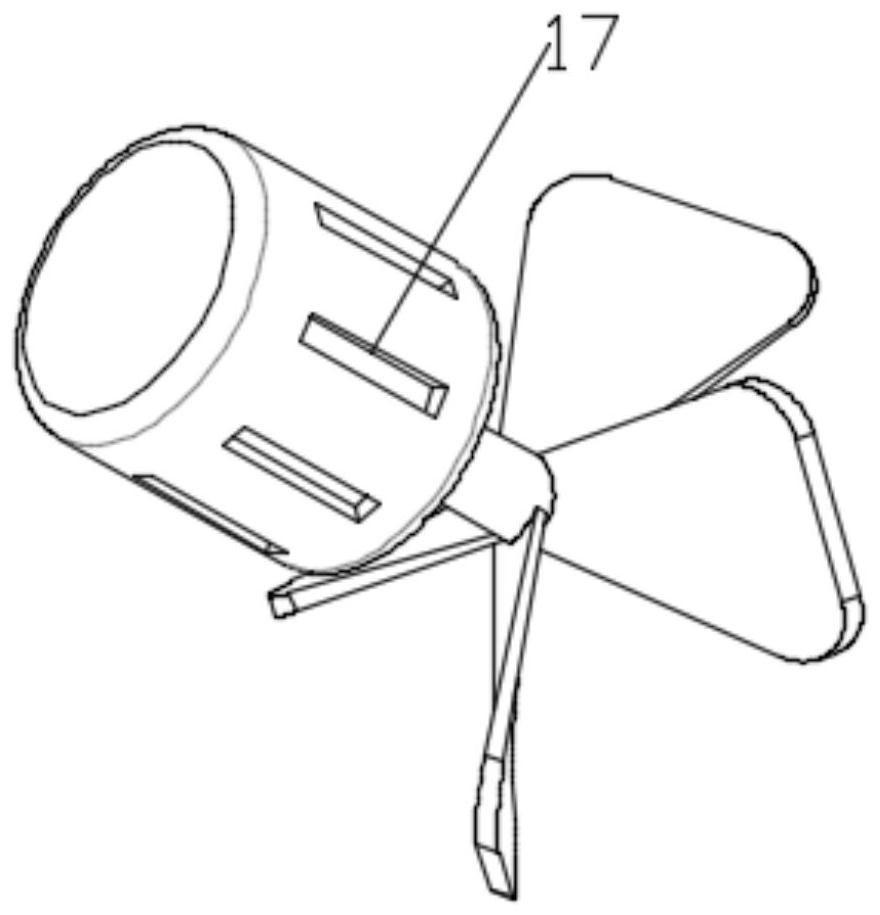

Mechanical engineering part cleaning and machining equipment

PendingCN112317424AImprove tilt effectEasy to cleanDrying gas arrangementsDrying machines with non-progressive movementsRotational axisGear wheel

The embodiment of the invention relates to the technical field of mechanical engineering, and particularly discloses mechanical engineering part cleaning and machining equipment. The equipment comprises a box body. According to the embodiment of the invention, the height position of a lifting screw sleeve can be adjusted according to the rotating direction of an adjusting screw rod driven by a positive and negative rotation servo motor; by starting a liquid pump and a booster pump, cleaning liquid in an inner cavity of the box body can be disturbed through a second nozzle, and the inclinationeffect on mechanical parts in a storage net box is improved; by means of the extension function of an electric extensible rod, a toothed plate is pushed to move, then a rotating shaft is driven to rotate under the linkage effect of the toothed plate and a gear which are meshed with each other, then a rotating disc is driven to rotate, the range of liquid flow sprayed out of the second nozzle is wider, and the cleaning effect on the mechanical parts in the storage net box is improved; and air flow can be introduced into the box body by starting an air blower, and the air flow is heated by a electric heating net and is then blown to the storage net box, so that the mechanical parts in the storage net box are dried.

Owner:WEST ANHUI UNIV

Right-angle high-pressure electromagnetic flow meter

InactiveCN104296812AImprove anti-interference abilitySimple structureVolume/mass flow by electromagnetic flowmetersEngineeringHigh pressure

The invention relates to a right-angle high-pressure electromagnetic flow meter which comprises a flow meter shell, a sealing end cap connected with the flow meter shell, a connection base and an electromagnetic flow converter. A metering cavity is arranged in the flow meter shell, and the connection base is respectively connected with the sealing end cap and the electromagnetic flow converter. The flow meter is characterized in that an electromagnetic flow sensor is further included and is located in the metering cavity, the electromagnetic flow sensor comprises a sensor shell, a measurement electrode, an excitation coil and a magnetic yoke, the measurement electrode is embedded into the outer wall of the sensor shell, the excitation coil and the magnetic yoke are located on the inner wall of the sensor shell, and the excitation coil and the magnetic yoke are connected with the electromagnetic flow converter through cables. The right-angle high-pressure electromagnetic flow meter has the advantages that the Faraday electromagnetic induction principle is adopted, the induction signal amplitude and the fluid flow speed are in direct proportion, the structure is simple, movable components do not exist, the service life is long, maintenance load is little, linear flow measurement is achieved, non-linear revision is not needed, measurement precision is high and the flow range is wide.

Owner:ZHEJIANG AOXIN INSTR

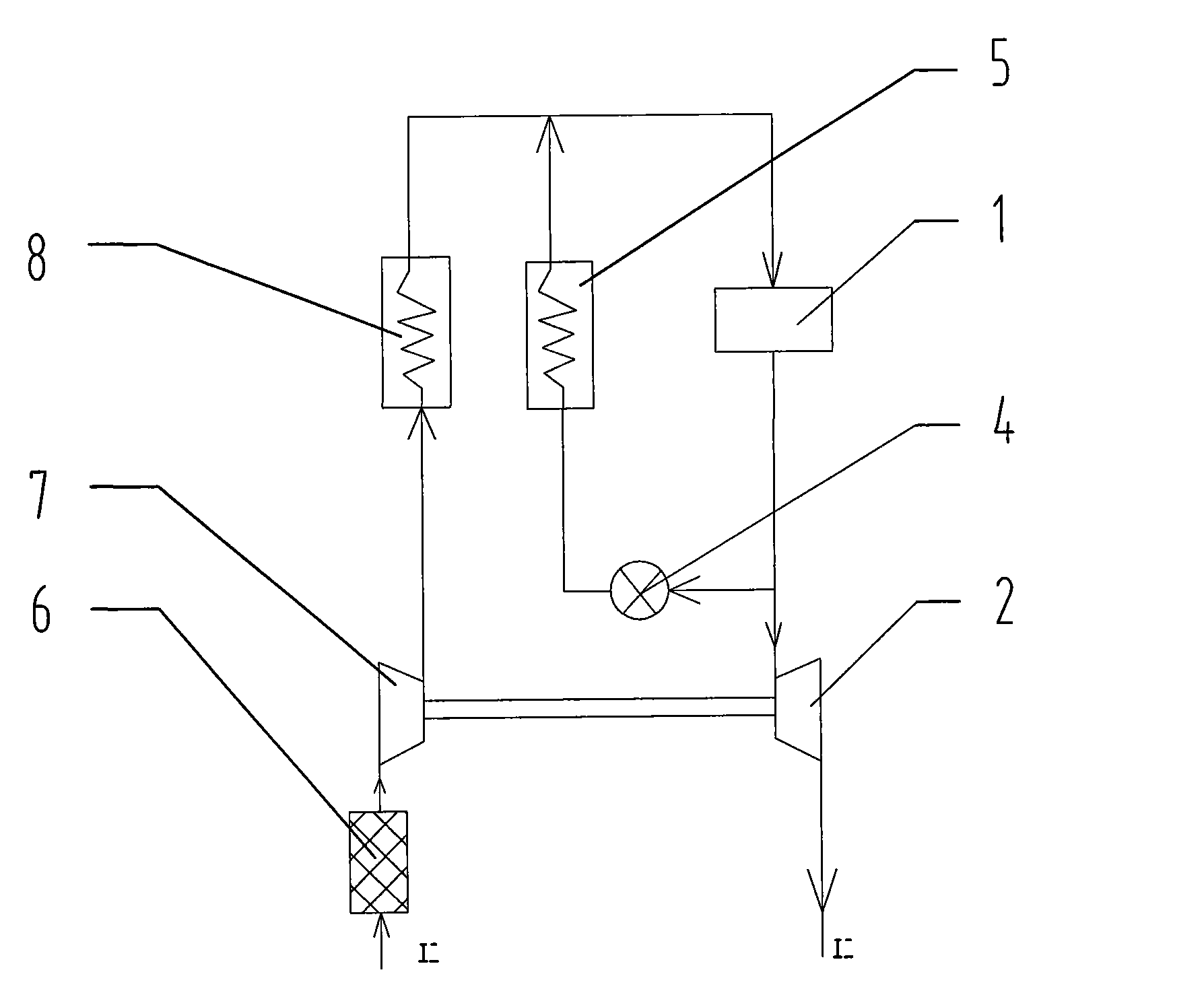

Pot-type pressure-superposed water supply device with small-flow auxiliary pump for energy saving

InactiveCN104846883ATo achieve the effect of energy-saving water supplyWide flow rangeService pipe systemsWater mainsSolenoid valveEngineering

The invention discloses a pot-type pressure-superposed water supply device with a small-flow auxiliary pump for energy saving. The pot-type pressure-superposed water supply device is mainly composed of a flow stabilization compensator, a non-negative-pressure controller, an air pressure water tank, the small-flow auxiliary pump, a solenoid valve, a main pump, a flow detecting device and a control cabinet. A second bypass pipe is arranged between a water distribution header pipe and a water outlet header pipe in the manner of bypassing a main pump, and a small-flow pipe is arranged at the position, behind a third check valve, of the second bypass pipe to be connected with the air pressure water tank; and the solenoid valve and a second pressure detecting meter are installed on the small-flow pipe, and a first bypass pipe is further arranged at the position, by passing the solenoid valve and the second pressure detecting meter, of the small-flow pipe. The pot-type pressure-superposed water supply device has the beneficial effects that the small-flow auxiliary pump and the air pressure water tank are arranged, so that the energy saving water supply effect can be better achieved when the flow is small; the pressure-superposed water supply energy-saving potential is further excavated, and the energy-saving flow range is enlarged; in addition, the using rate of the effective volume of the air pressure water tank can be greatly improved through the small-flow auxiliary pump, and the investment and the occupied land are better saved.

Owner:QINGDAO WANLI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com