Switchable double-inlet asymmetric turbine volute

A turbine box, asymmetric technology, applied in the direction of machines/engines, internal combustion piston engines, mechanical equipment, etc., can solve the problems of high turbine speed and affecting the flow capacity of the turbine, and achieve the effect of widening the turbine flow range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

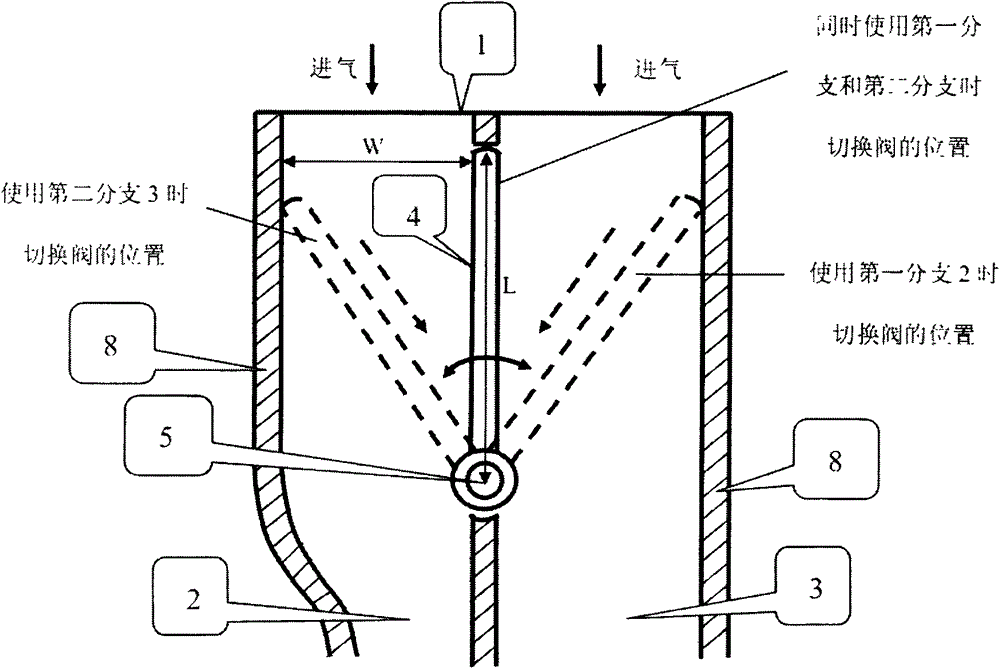

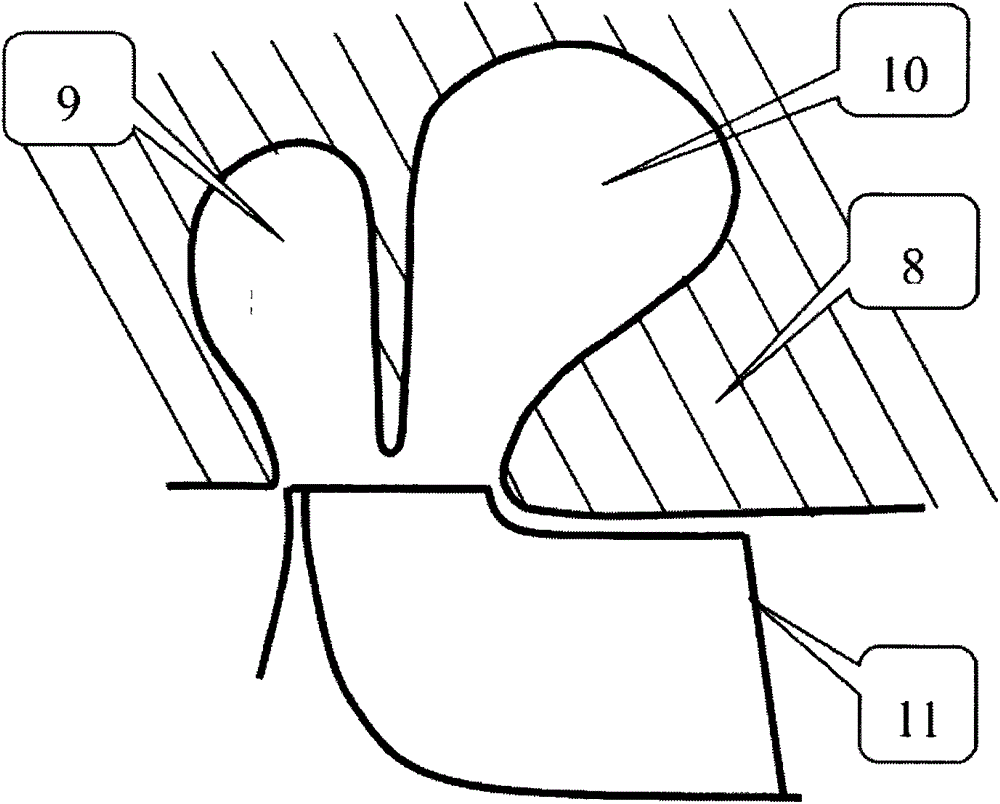

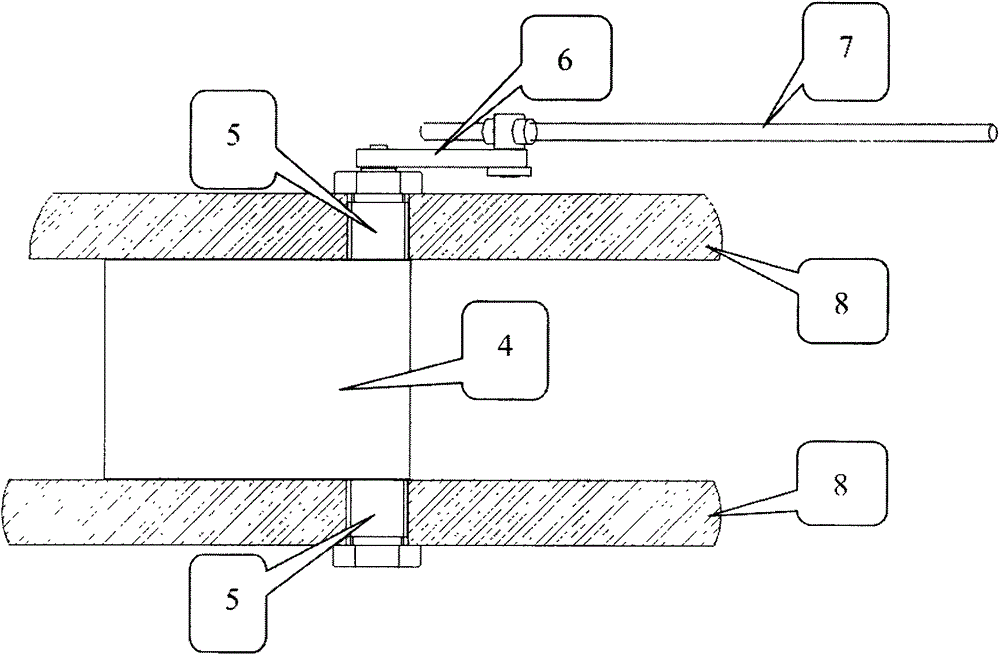

[0027] A double-entry asymmetric turbine box with switching valves, including a double-channel turbine box inlet 1 with two branches, a first branch 2, a second branch 3 and an asymmetrical box 8, the box 8 is equipped with The first scroll 9 and the second scroll 10, wherein the first scroll 9 is smaller than the second scroll 10A / R; the first branch 2 is connected to the first scroll 9, and the second branch 3 is connected to the second scroll Road 10 is connected, and also includes switching valve 4 located in the inlet passage and the control mechanism of switching valve 4, which is characterized in that: the first scroll 9 is aligned with the hub of the turbine, and the second scroll 10 is aligned with the rim of the turbine.

[0028] The A / R ratio will affect the turbine flow and the smoothness of turbine work during the two-branch switching process. Preferably, the A / R ratios of the first scroll 9 and the second scroll 10 are both between 0.4 and 0.8.

no. 3 example

[0030] A double-entry asymmetric turbine box with switching valves, including a double-channel turbine box inlet 1 with two branches, a first branch 2, a second branch 3 and an asymmetrical box 8, the box 8 is equipped with The first scroll 9 and the second scroll 10, wherein the first scroll 9 is smaller than the A / R of the second scroll 10; the first branch 2 is connected to the first scroll 9, and the second branch 3 is connected to the second scroll 10. The two volutes 10 are connected, and also include a switching valve 4 located in the inlet passage and a control mechanism for the switching valve 4, and the feature is that the box body 8 is equipped with an air release valve 12 and an air release valve actuator 13.

[0031] The function of the purge valve 12 is to provide a bypass channel for the air flow when the control mechanism of the switching valve 4 fails, and can further increase the turbine flow.

[0032] When the switching valve is working normally, the bleed v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com