Mechanical engineering part cleaning and machining equipment

A technology of mechanical engineering and processing equipment, applied in lighting and heating equipment, dryers, cleaning methods and utensils, etc., can solve problems such as inability to clean, affect the later use of products, and incomplete cleaning, so as to improve the cleaning effect and improve the The effect of the tilt effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

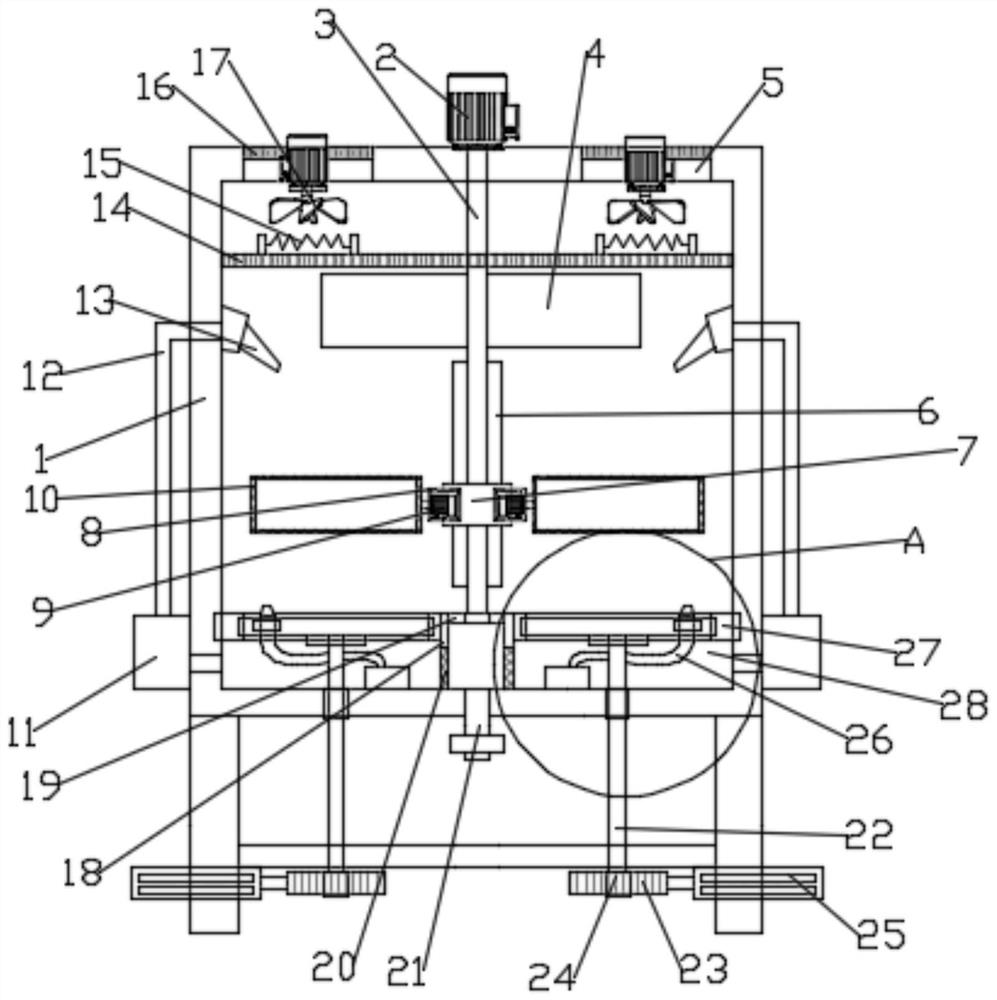

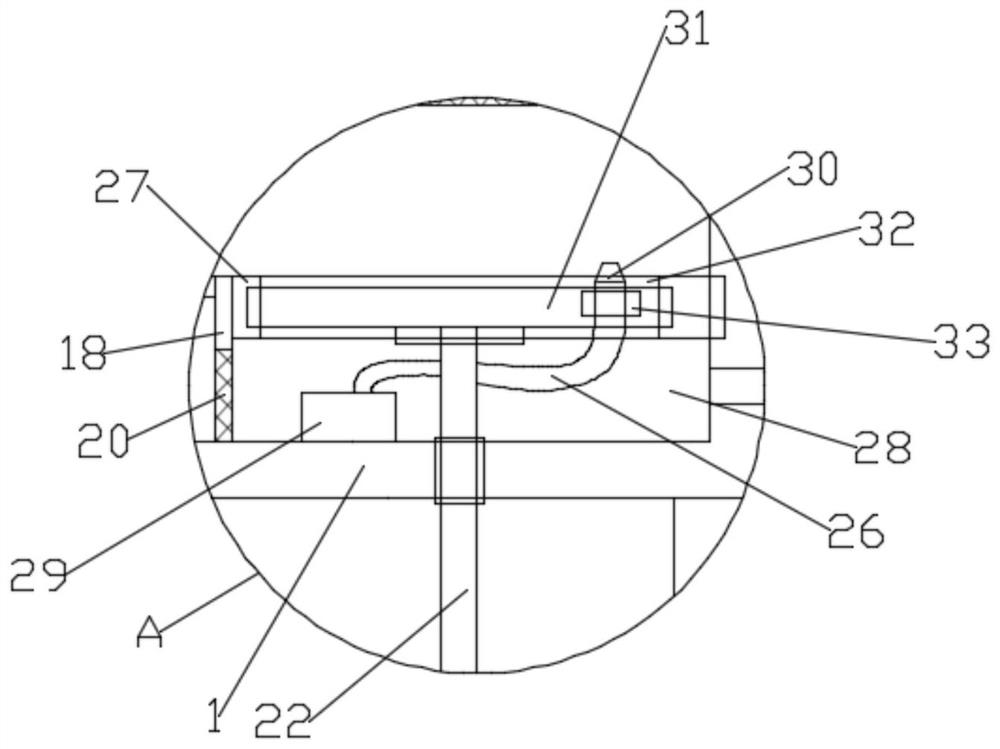

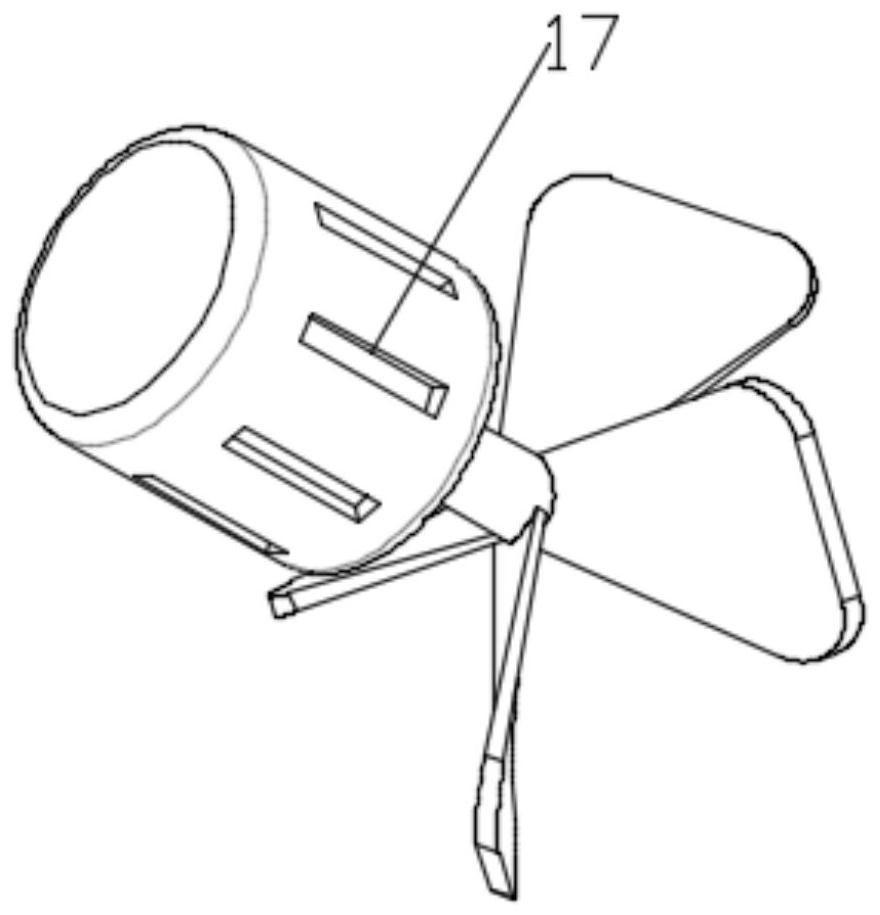

[0024] Such as figure 1 As shown, in the embodiment provided by the present invention, a mechanical engineering parts cleaning and processing equipment includes a box body 1, and an adjusting screw 3 is rotatably arranged in the inner cavity of the box body 1, and the box body 1 A positive and negative servo motor 2 for driving the adjustment screw 3 to rotate is installed on the top plate; the lifting screw sleeve 7 that is slid up and down in the inner cavity of the box body 1 is sleeved on the adjustment screw by threaded connection 3, therefore, according to the rotation direction of the screw rod 3 driven by the forward and reverse servo motor 2, the height position of the lifting nut 7 can be adjusted;

[0025] Further, such as figure 1 and Figure 4 As shown, in the embodiment provided by the present invention, a motor box 8 is fixedly installed on both sides of the lifting screw sleeve 7, and a drive motor 9 is fixedly installed in the motor box 8, and the output sha...

Embodiment 2

[0030] Such as figure 1 As shown, in the embodiment provided by the present invention, a mechanical engineering parts cleaning and processing equipment includes a box body 1, and an adjusting screw 3 is rotatably arranged in the inner cavity of the box body 1, and the box body 1 A positive and negative servo motor 2 for driving the adjustment screw 3 to rotate is installed on the top plate; the lifting screw sleeve 7 that is slid up and down in the inner cavity of the box body 1 is sleeved on the adjustment screw by threaded connection 3, therefore, according to the rotation direction of the screw rod 3 driven by the forward and reverse servo motor 2, the height position of the lifting nut 7 can be adjusted;

[0031] Further, such as figure 1 and Figure 4 As shown, in the embodiment provided by the present invention, a motor box 8 is fixedly installed on both sides of the lifting screw sleeve 7, and a drive motor 9 is fixedly installed in the motor box 8, and the output sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com