Drilling steering tool and drilling system

A drilling and tool technology, applied in the field of drilling steering tools and drilling systems, can solve the problems of unreachable drilling effect, poor bit tilting effect, poor bending effect of rotating shaft, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

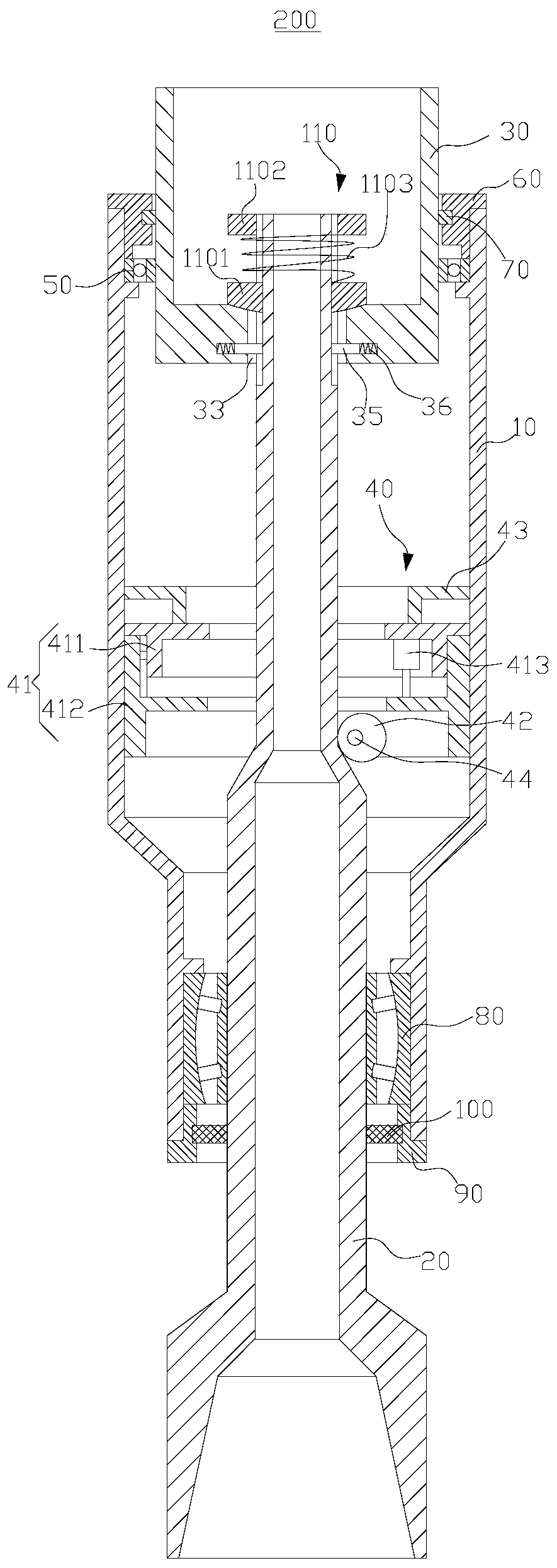

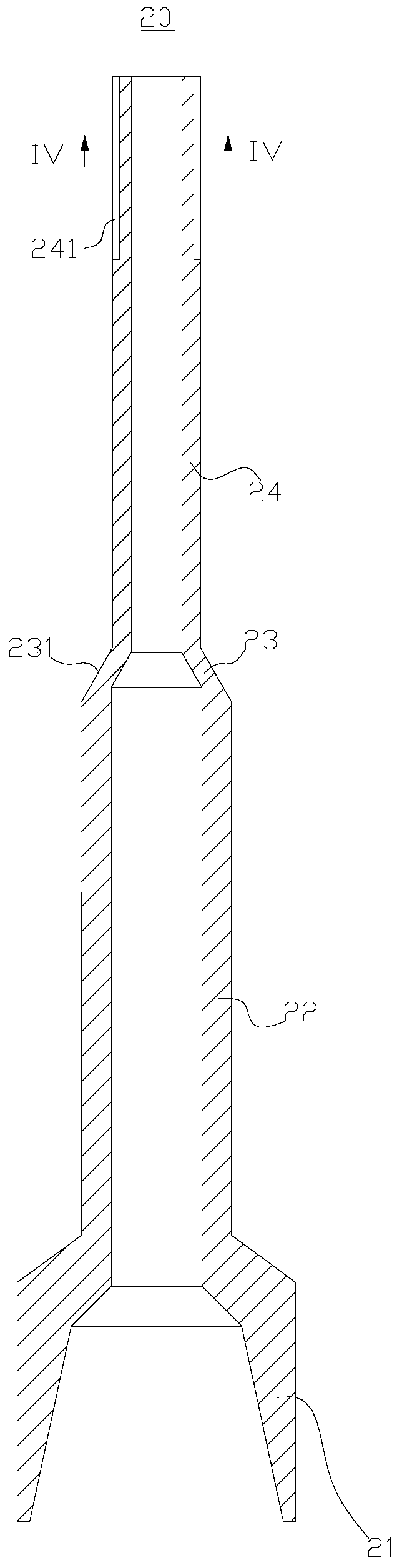

[0047] Such as figure 1 As shown, the present embodiment provides a drilling guide tool 200, comprising a hollow casing 10, a rotating shaft 20, a hollow drill collar 30 and a driving mechanism 40, the rotating shaft 20 is rotatably arranged in the hollow casing 10, and the hollow drill collar 30 and The rotating shaft 20 is connected, and the hollow drill collar 30 can rotate together with the rotating shaft 20 . The driving mechanism 40 is arranged in the hollow jacket 10 , and the driving mechanism 40 is used to bend the rotating shaft 20 .

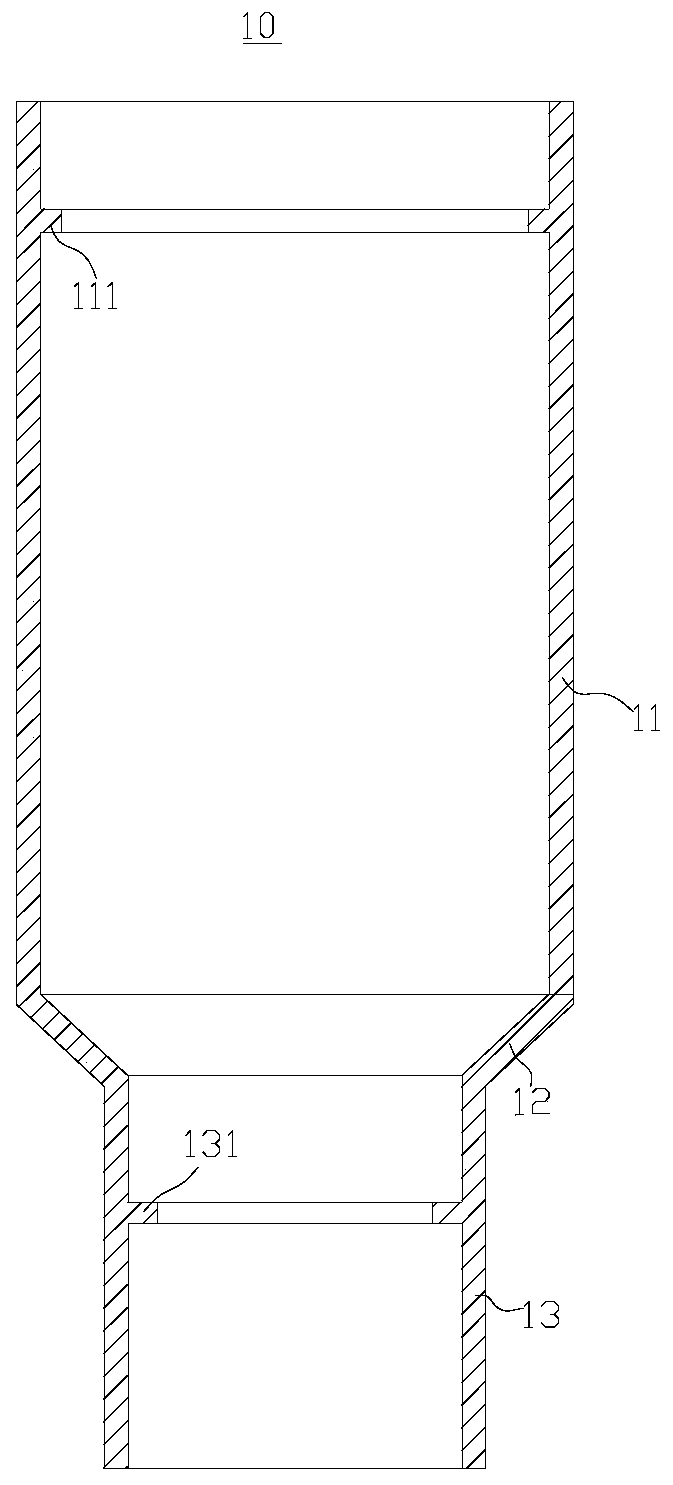

[0048] Such as figure 2 As shown, the hollow jacket 10 is a hollow structure with two ends open, and its cross-section is ring-shaped. The hollow casing 10 includes a coaxially arranged first cylindrical body 11, a transition body 12 and a second cylindrical body 13, the first cylindrical body 11 and the second cylindrical body 13 are connected through the transition body 12, and the inner diameter of the first cylindrical body 11 is...

Embodiment 2

[0061] Such as Figure 8 As shown, this embodiment provides a drilling system 300, including a drilling rig 310, a drill string 320, a drill bit 330 and the drilling steering tool 200 in the above-mentioned embodiments.

[0062] The drilling rig 310 is placed on the ground, one end of the drill string 320 is connected with the drilling machine 310, the drill string 320 extends into the borehole below the ground, the other end of the drill string 320 is connected with the hollow drill collar 30 in the drilling guide tool 200, the drill bit 330 is connected with the The shaft head 21 of the rotating shaft 20 is connected. When the drilling rig 310 is working, the drill string 320 will drive the hollow drill collar 30 and the rotating shaft 20 to rotate, thereby rotating the drill bit 330 to complete the drilling action.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com