Narrow seam wet mopping robot

A technology of robot and robot body, applied in machine parts, cleaning machinery, manual sweeping machinery, etc., can solve the problems of difficult cleaning of narrow gaps, unsatisfactory humidity control effect of rags, etc., and achieve a good cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

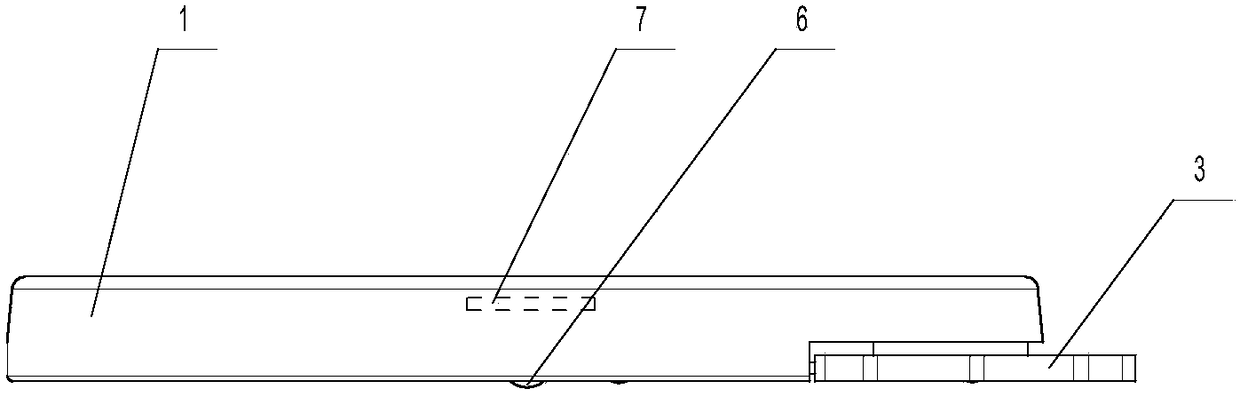

[0083] figure 1 Disclosed in is a narrow-slit wet dragging robot, including a robot body 1, a narrow-slit wet-drag device 3, a robot motion drive device 6, and a control device 7; wherein,

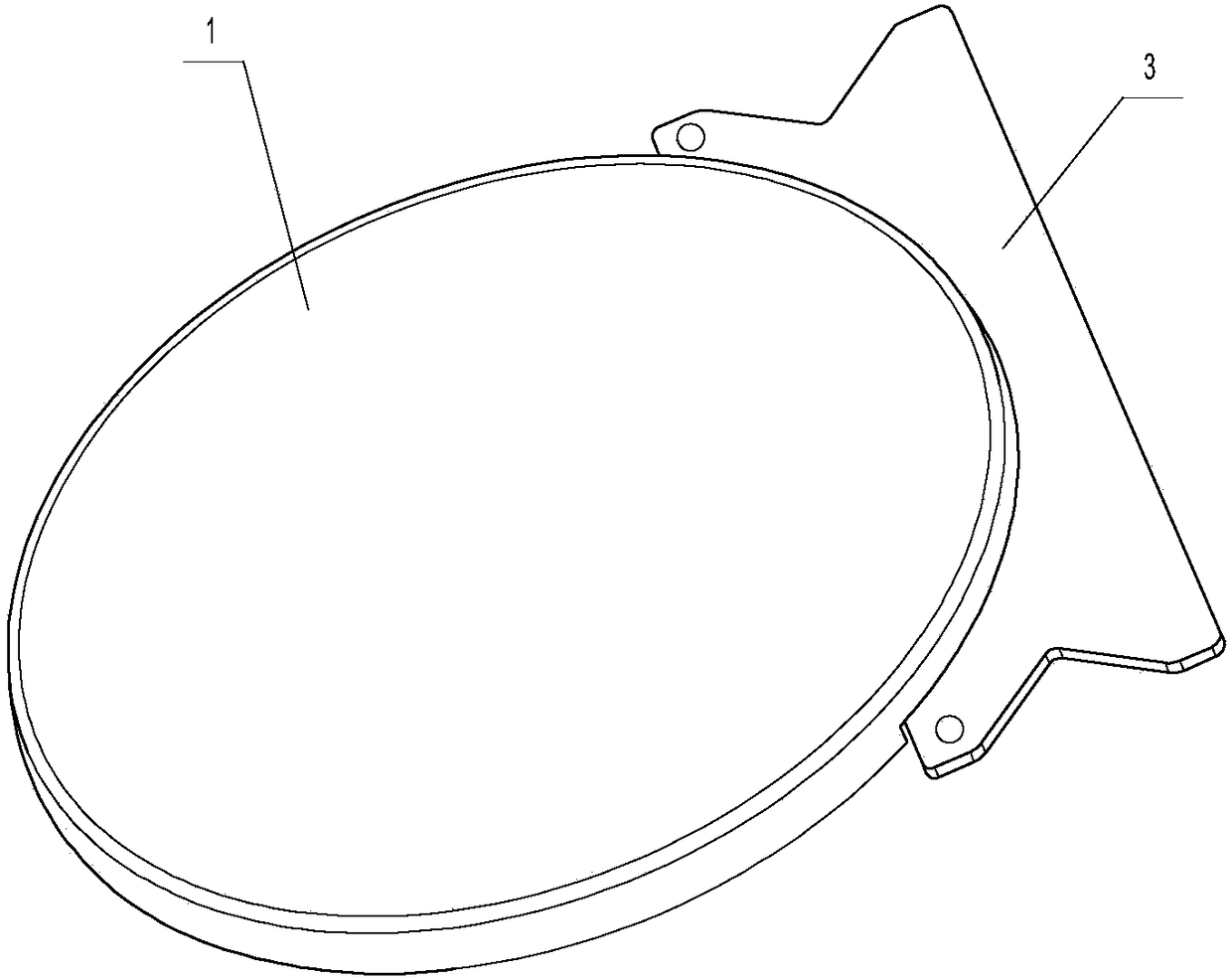

[0084] The robot body 1 has an elliptical shape, so that the robot can pass through narrow spaces more easily;

[0085] The slit wet mopping device 3 includes a housing 31, a wet mopping device 32 located in the housing 31, and a mopping drive device 33. The housing 31 is flat butterfly-shaped, and the height of the housing is less than or equal to 1 cm. The two sides of the housing 31 are respectively provided with L-shaped openings 311 for wet mopping the difficult-to-clean parts; , the slit wet mopping device 3 is connected with the robot body 1 through the telescoping device 8 .

[0086] The wet dragging device 32 includes a rag 321, a cleaning and wetting mechanism 322, a humidity adjustment mechanism 323, and a rag transition support block 324; The adjustment mechanism 323 and the...

Embodiment 2

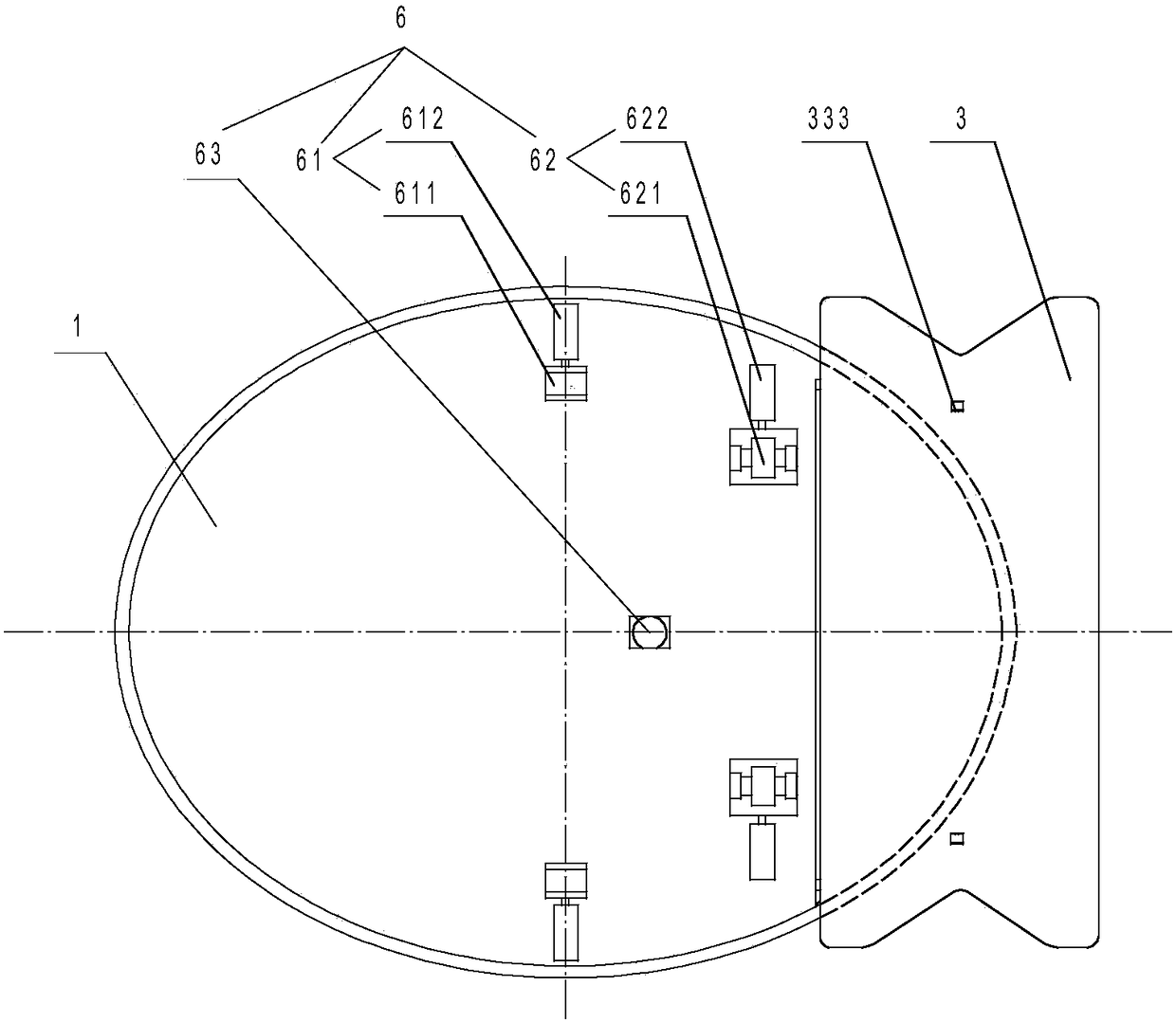

[0094] figure 2 Disclosed in is another narrow-slit wet dragging robot. The basic structure of the robot is the same as in Embodiment 1, and both include a robot body 1, a narrow-slit wet-drag device 3, a robot motion drive device 6 installed at the bottom of the robot body 1, a control The device 7 is different in that: the robot also includes a cleaning mechanism 2 and a fine debris cleaning device 4 .

[0095] The cleaning device 2 includes two cleaning mechanisms 21, a protective sheet 22 and a cleaning motor 23; the protective sheet 22 is coaxially connected with the cleaning mechanism 21, and is used to prevent large-sized garbage from entering the cleaning mechanism; The input end of the cleaning motor 23 is connected with the control device 7, and the output shaft of the cleaning motor 23 is connected with the cleaning mechanism 21.

[0096] The fine debris cleaning device 4 is used for secondary cleaning of the fine debris left by the cleaning device 2 , and the inp...

Embodiment 3

[0098] Embodiment three (best embodiment)

[0099] image 3 Disclosed in is another narrow-slit wet mopping robot. The basic structure of the robot is the same as that of Embodiment 2, including a robot body 1, a cleaning mechanism 2, a narrow-slit wet-mopping device 3, a fine debris cleaning device 4, and a robot body installed on the robot body. 1 The robot motion drive device 6 and control device 7 at the bottom, the difference is that the robot also includes a navigation detection device 5, which is installed on the robot body 1, and the navigation detection device 5 includes a detection sensor. The output of the detection device 5 is connected to the input of the control device 7 .

[0100] The specific structure of the narrow-slit wet dragging robot described in the third embodiment is as follows:

[0101] A narrow gap wet mopping robot, a robot body 1, a cleaning mechanism 2, a narrow gap wet mopping device 3, a fine debris cleaning device 4, a navigation detection de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com