Patents

Literature

76 results about "Drilling action" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

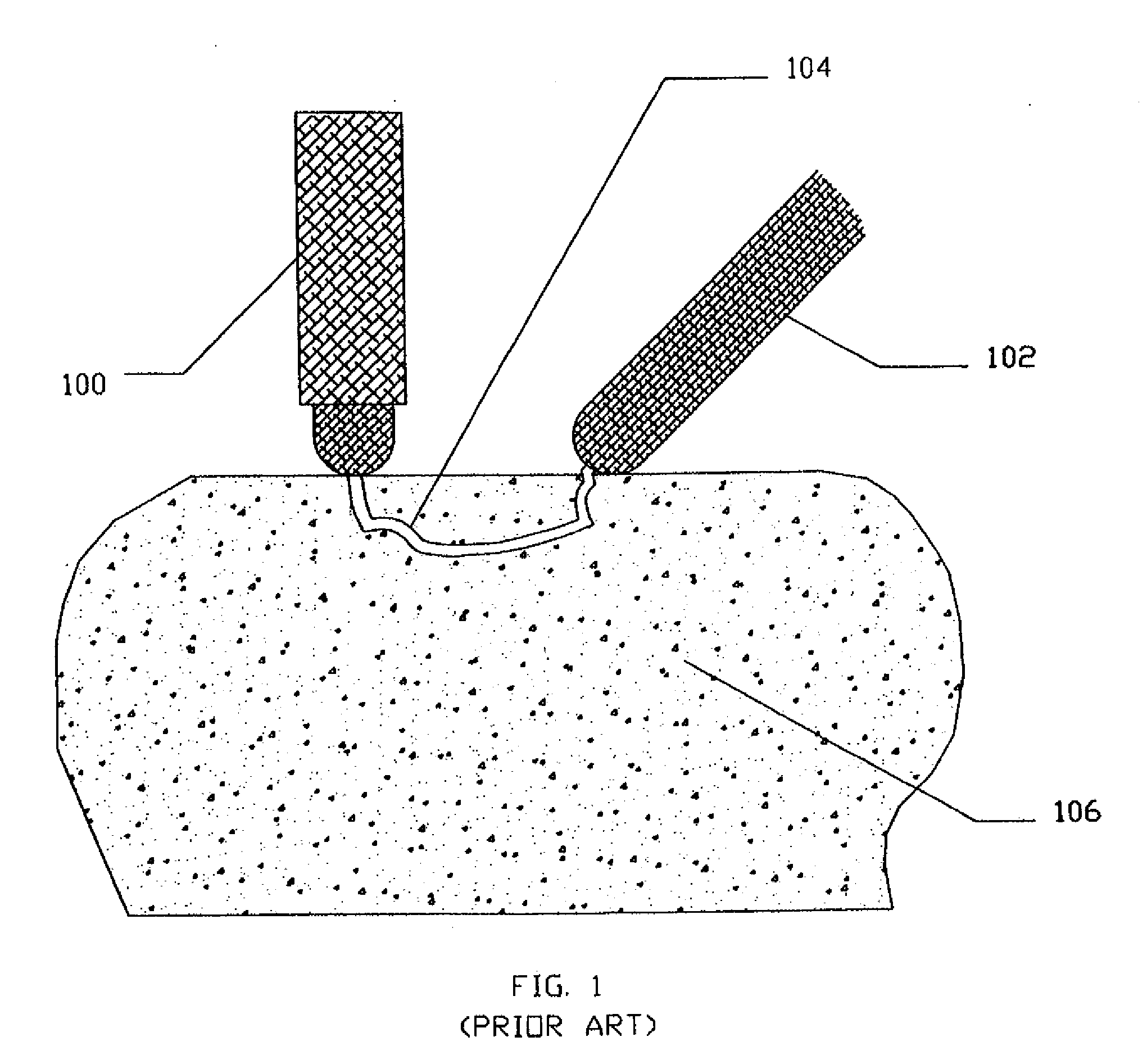

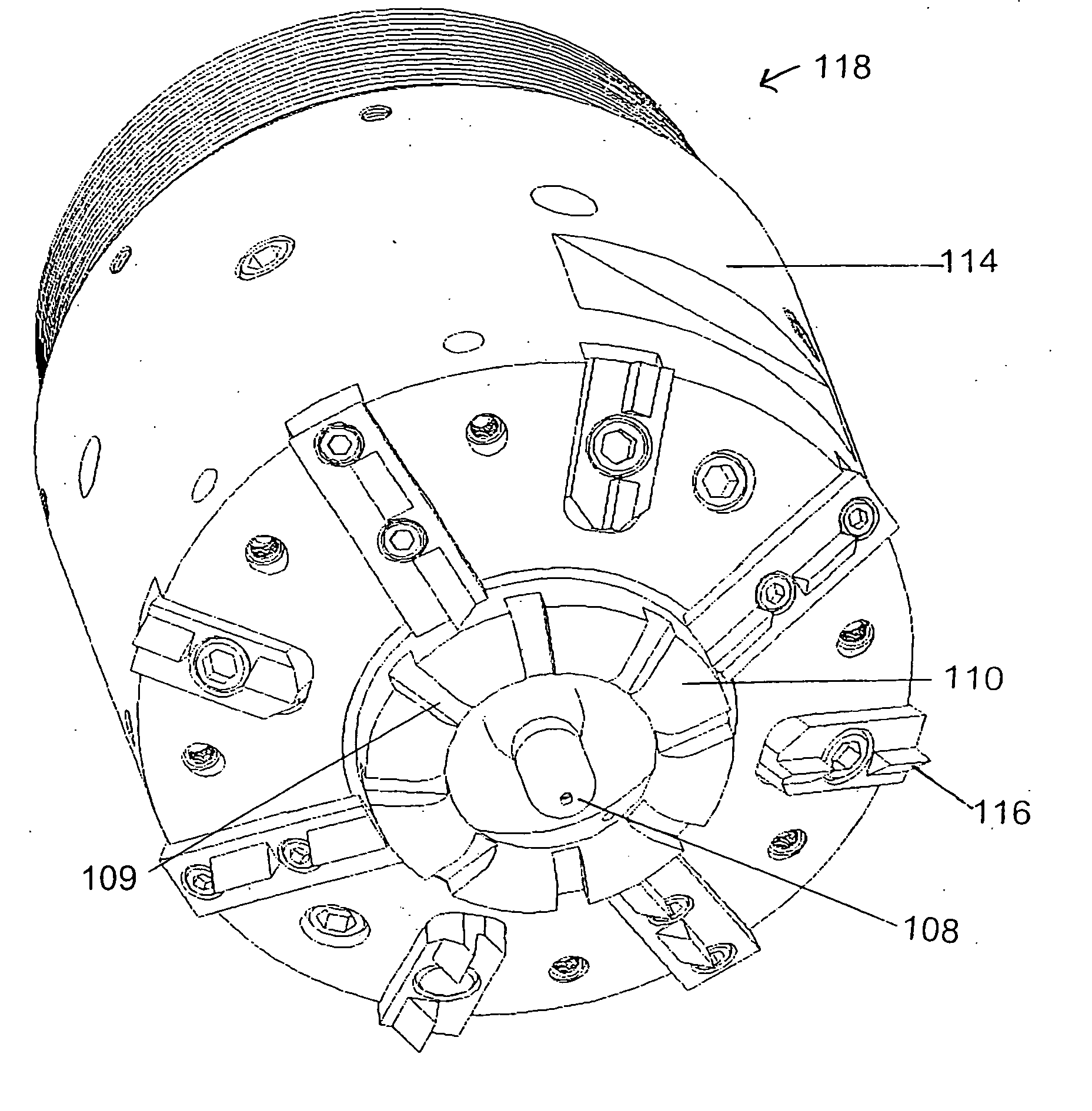

Pulsed Electric Rock Drilling Apparatus with Non-Rotating Bit and Directional Control

The present invention provides for pulsed powered drilling apparatuses and methods. A drilling apparatus is provided comprising a bit having one or more sets of electrodes through which a pulsed voltage is passed through a mineral substrate to create a crushing or drilling action. The electrocrushing drilling process may have, but does not require, rotation of the bit. The electrocrushing drilling process is capable of excavating the hole out beyond the edges of the bit with or without the need of mechanical teeth.

Owner:SDG LLC

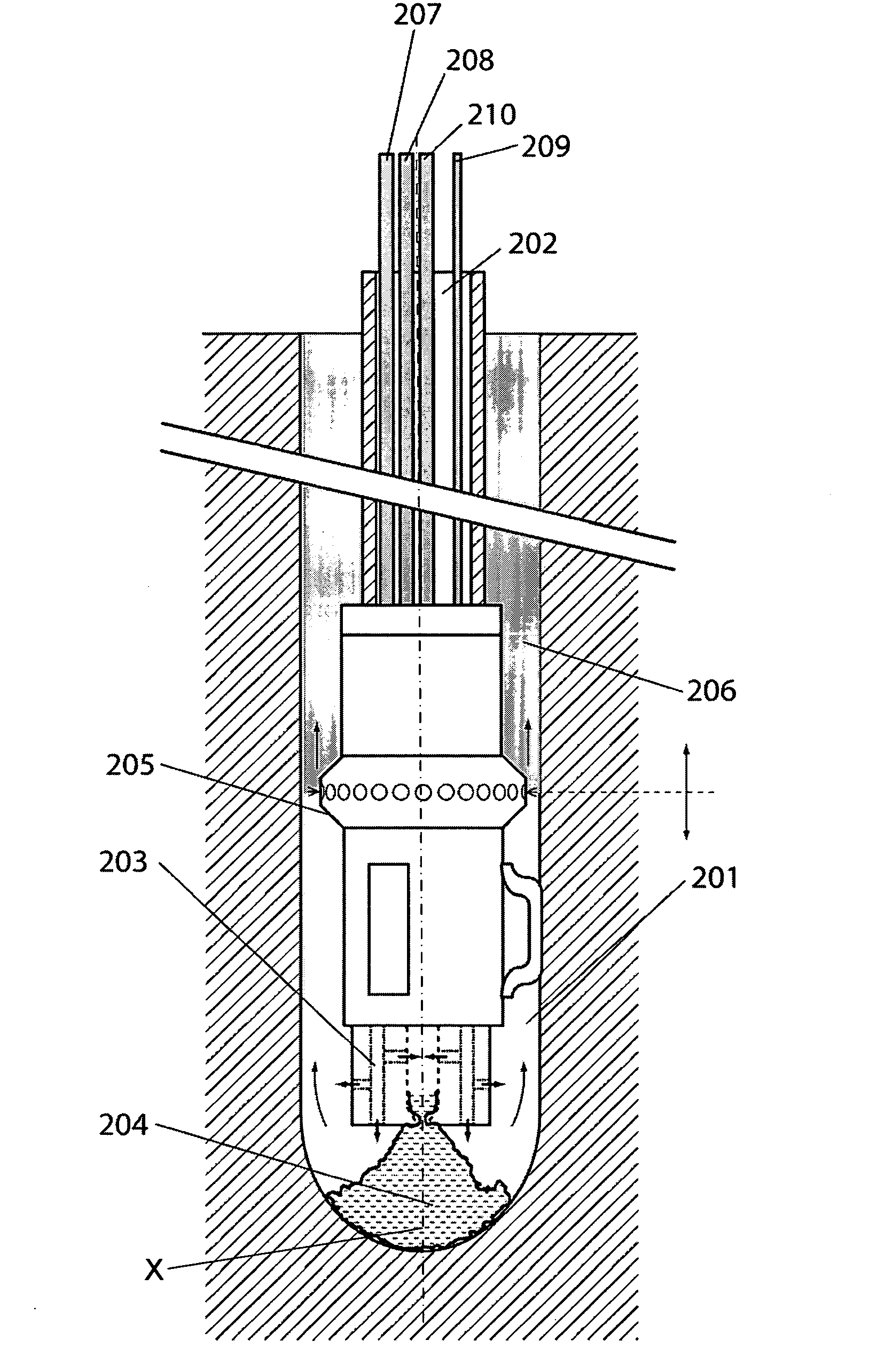

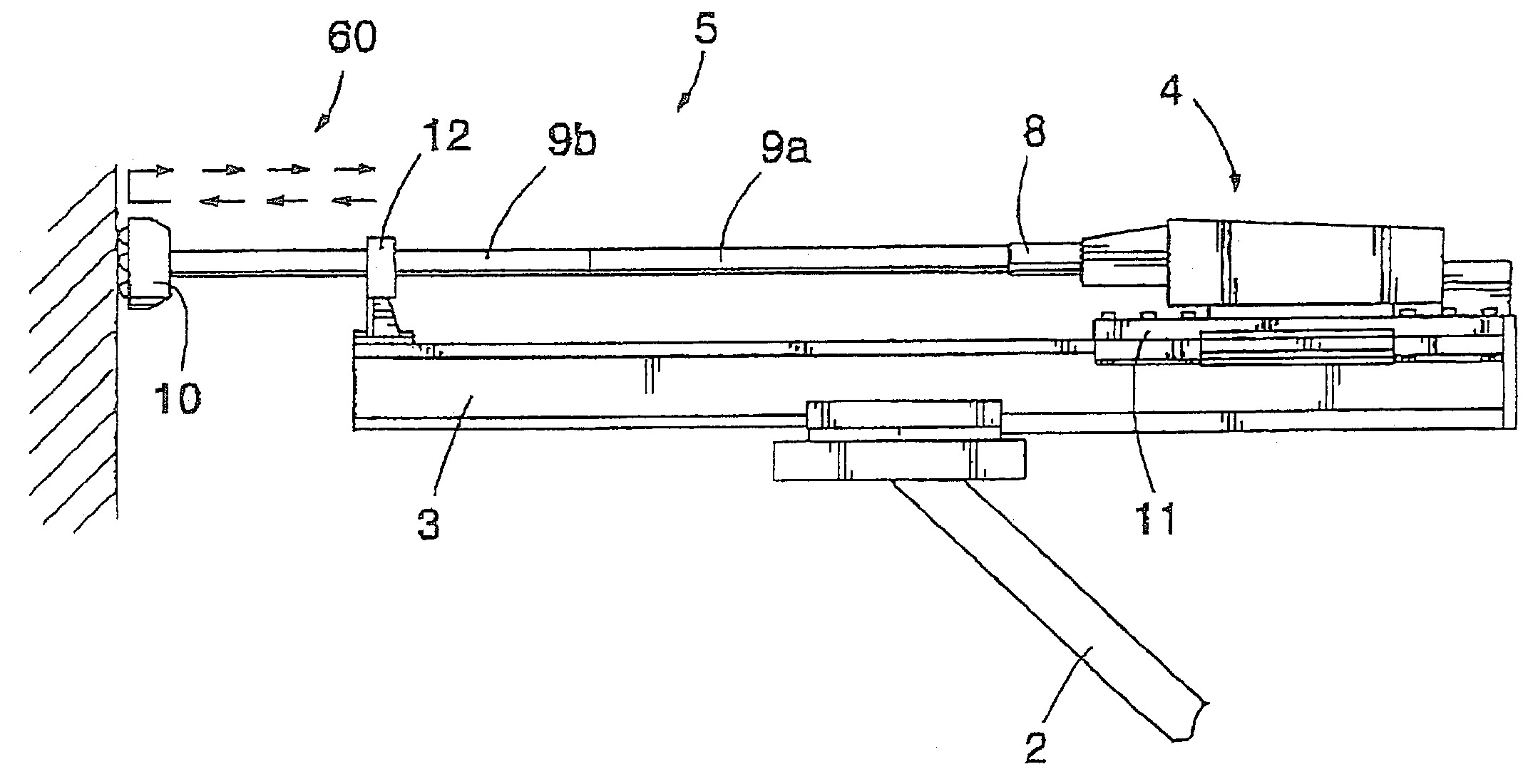

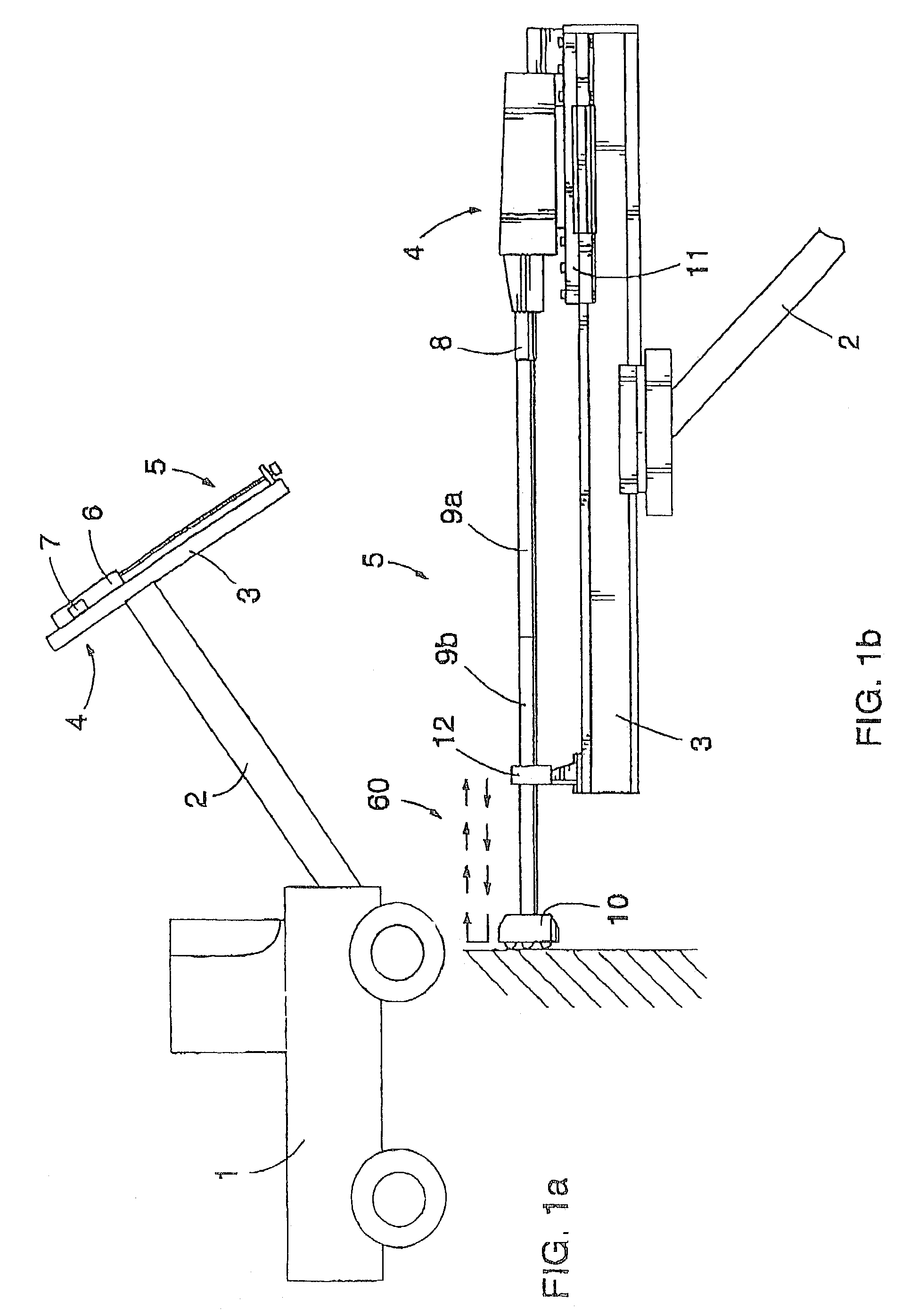

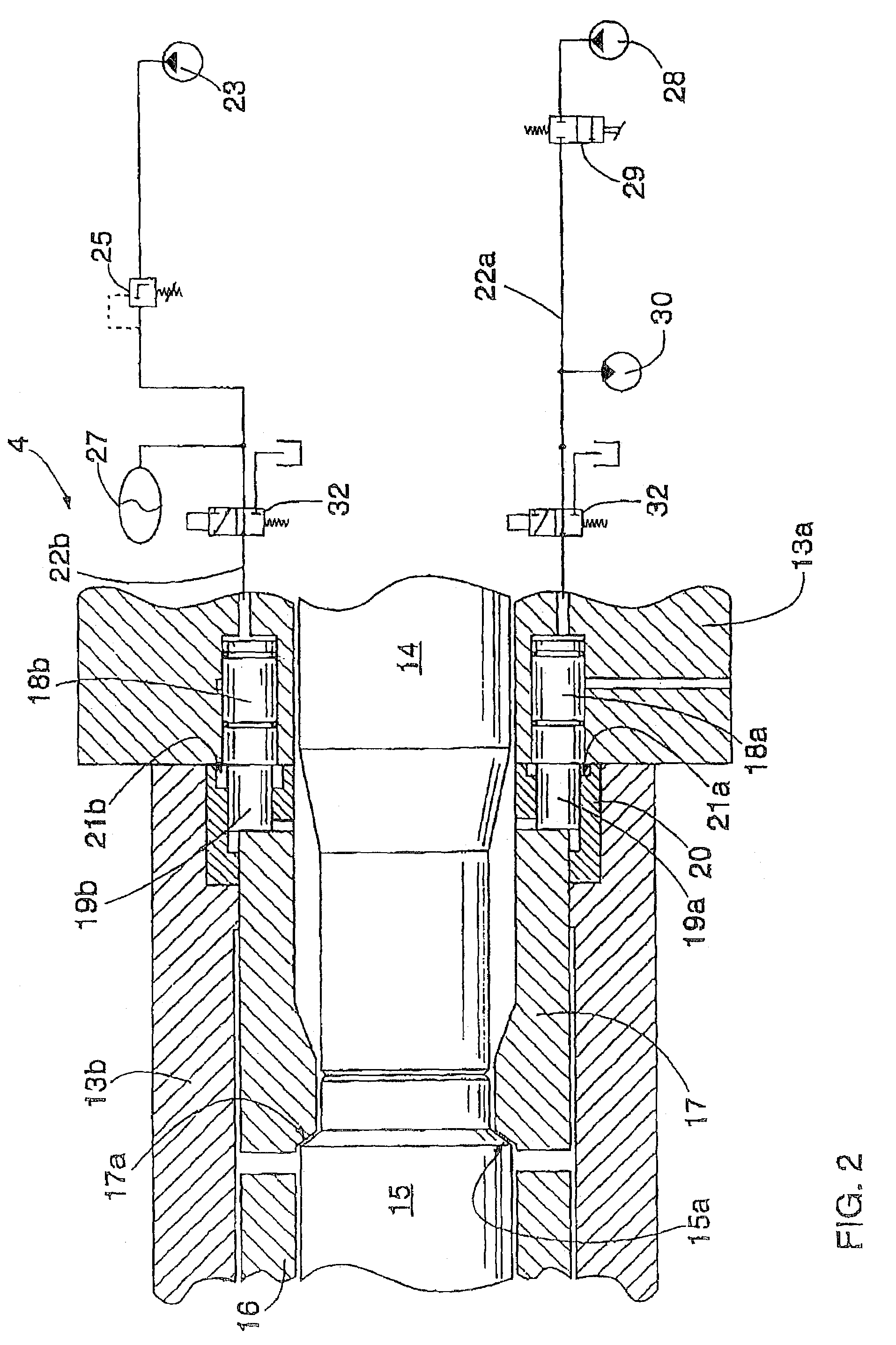

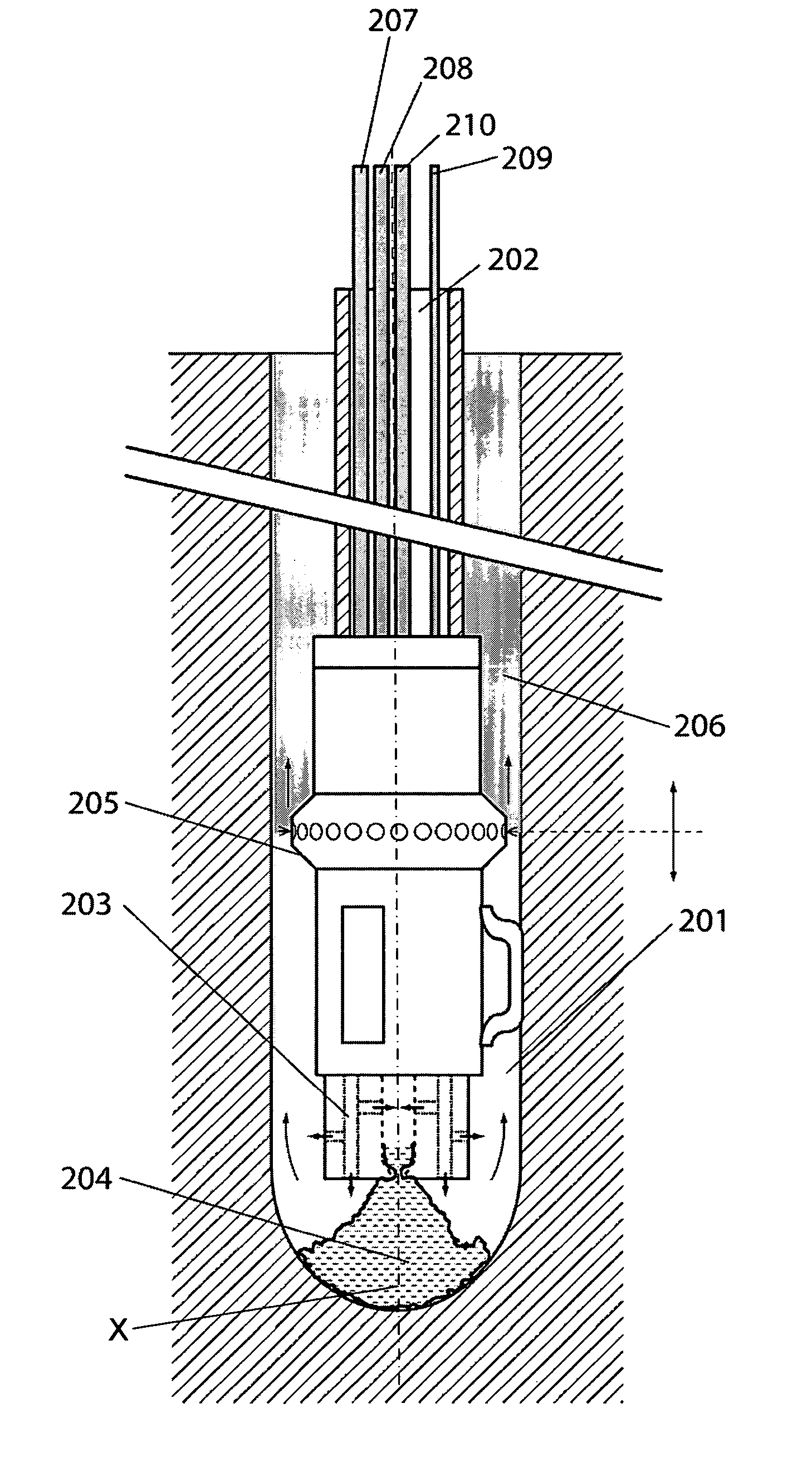

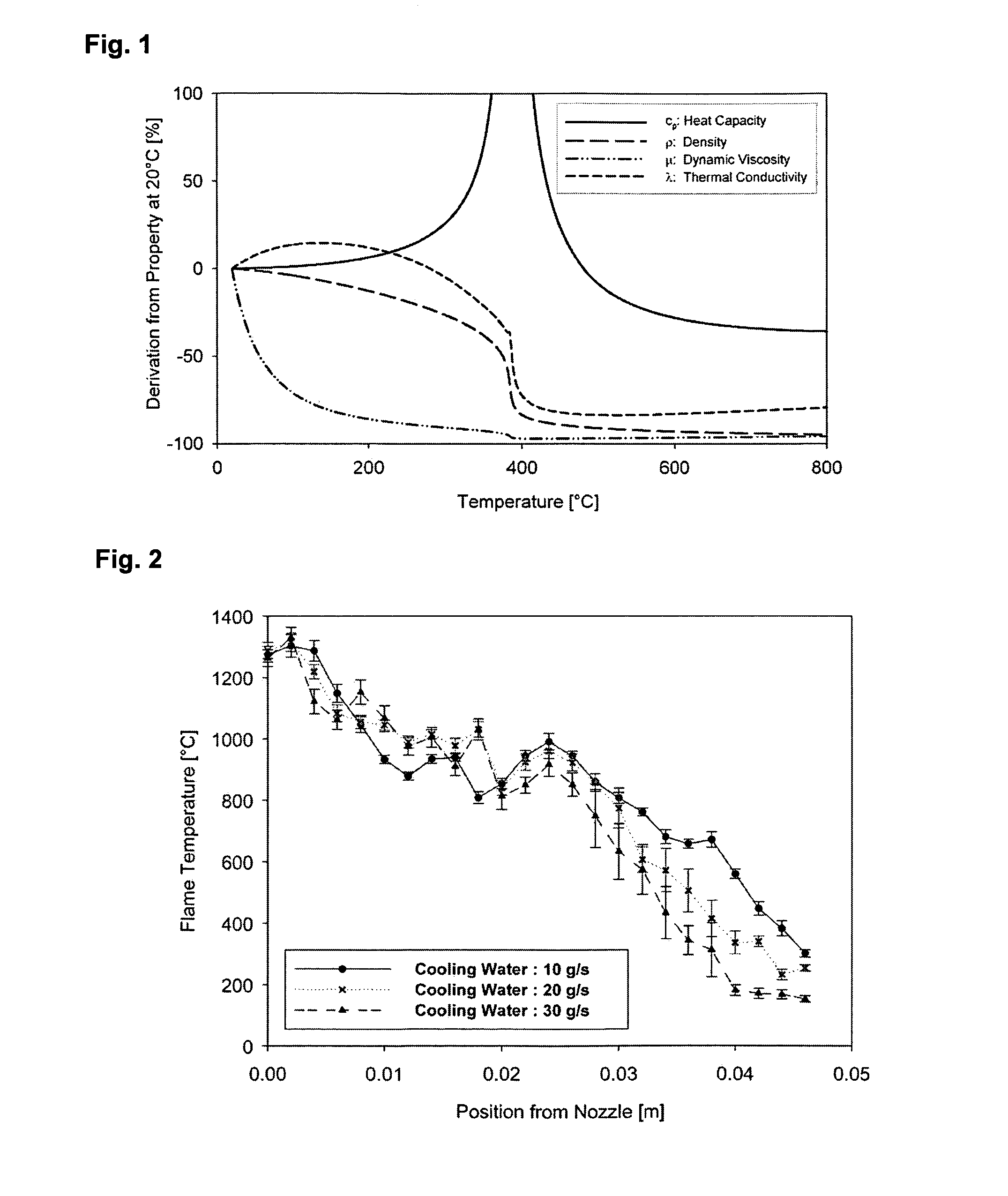

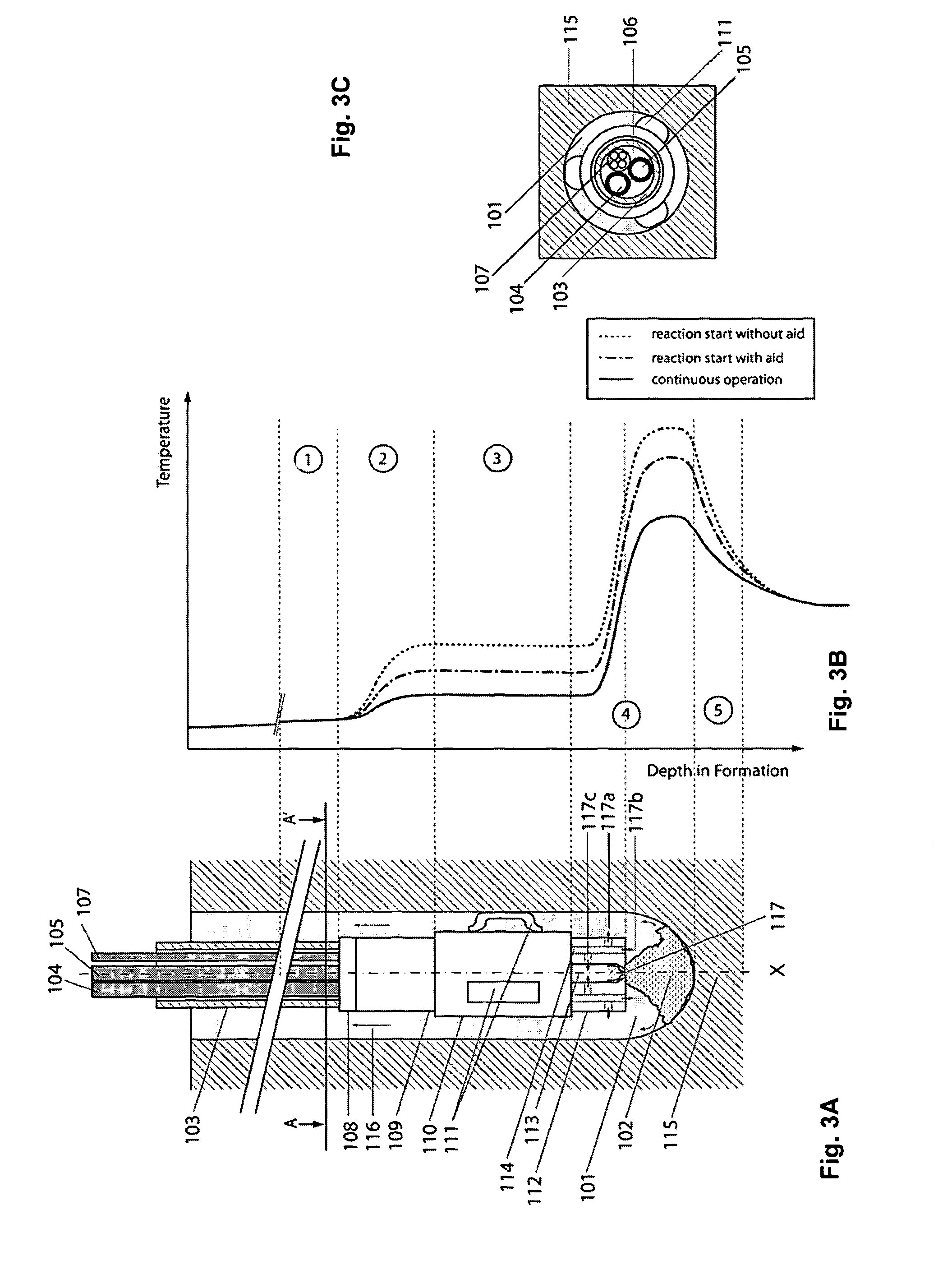

Rock drilling in great depths by thermal fragmentation using highly exothermic reactions evolving in the environment of a water-based drilling fluid

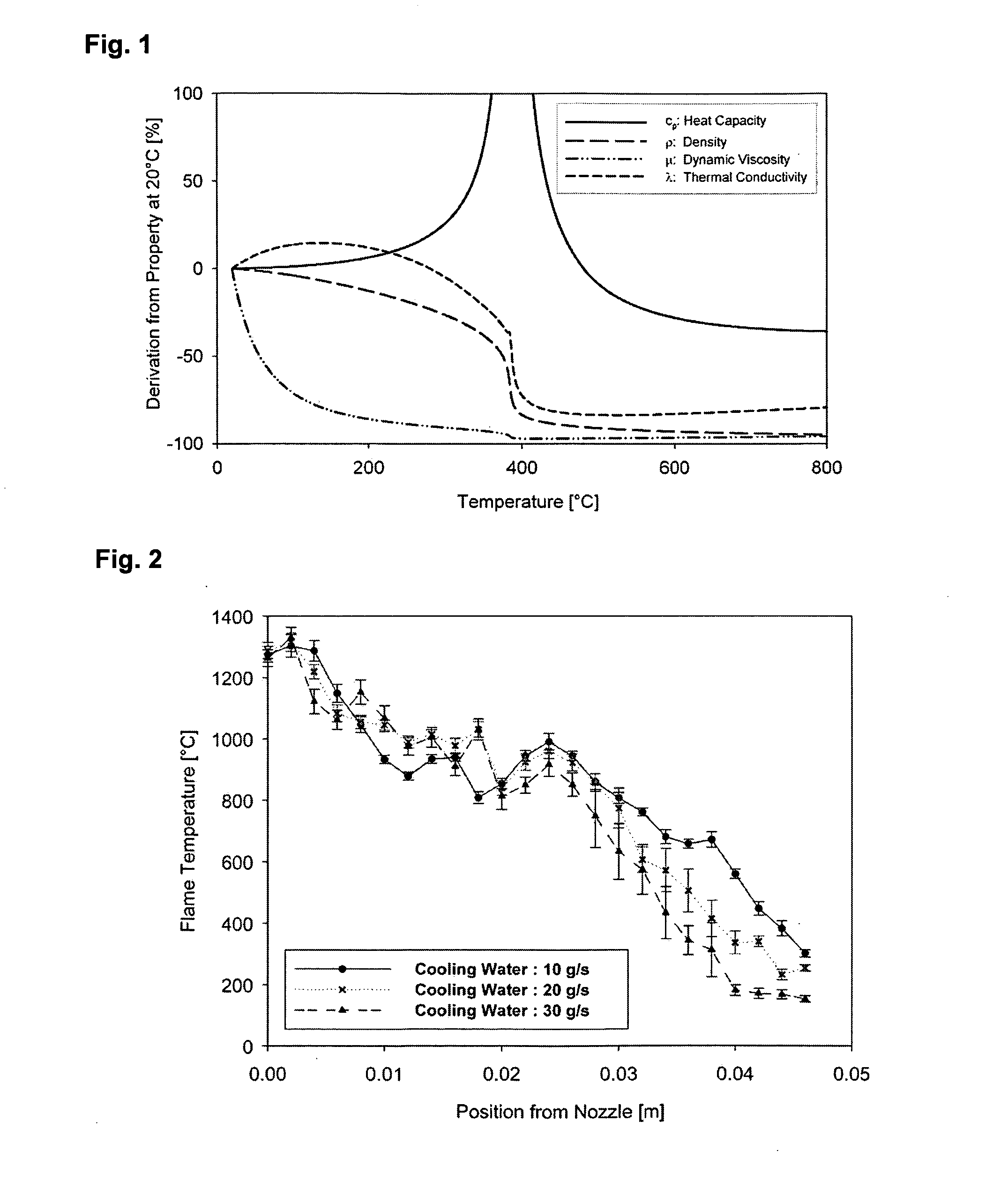

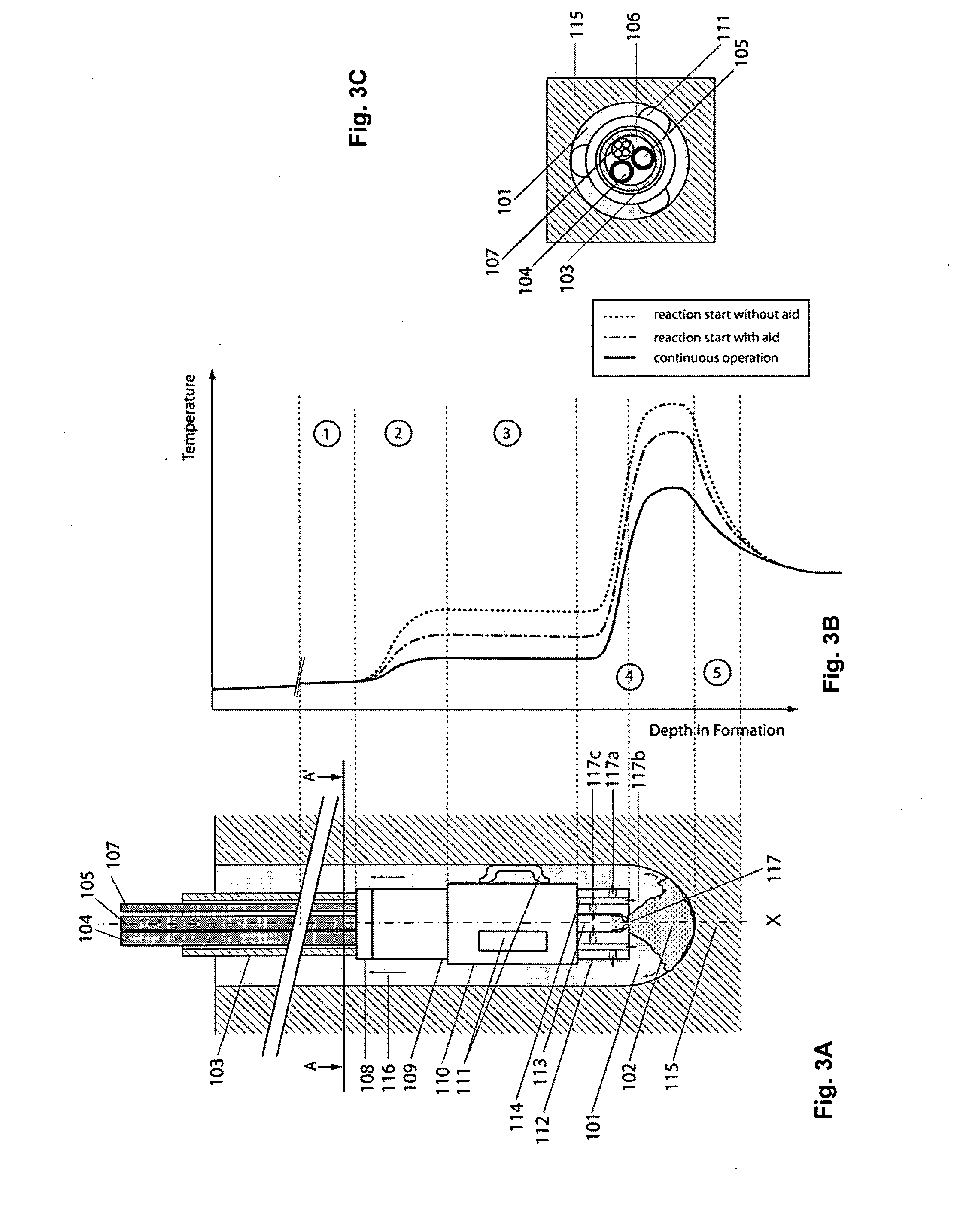

InactiveUS20110303460A1Simple reaction conditionsImprove the environmentDisloding machinesThermal drillingWater basedHigh density

A method and a device to thermally fragment rock for excavation of vertical and directional boreholes in rock formations, preferentially hard rock, using highly exothermic reactions. Exothermic reactions are initiated directly in the pressurized, aqueous environment of a water-based drilling fluid preferably above the critical pressure of water (221 bar). After reaction onset temperatures within the reaction zone exceed the critical temperature for water (374° C.) providing supercritical conditions, which favor the stabilization of the reaction, e.g. a supercritical hydrothermal flame. Since reactions can be run directly in a water-based drilling fluid, the method proposed here allows high density drilling action as in conventional rotary drilling. A part from the hot reaction zone of the proposed reaction can be brought directly to the rock surface in case of hard polycrystalline rock, where high temperatures are required.

Owner:ETH ZZURICH

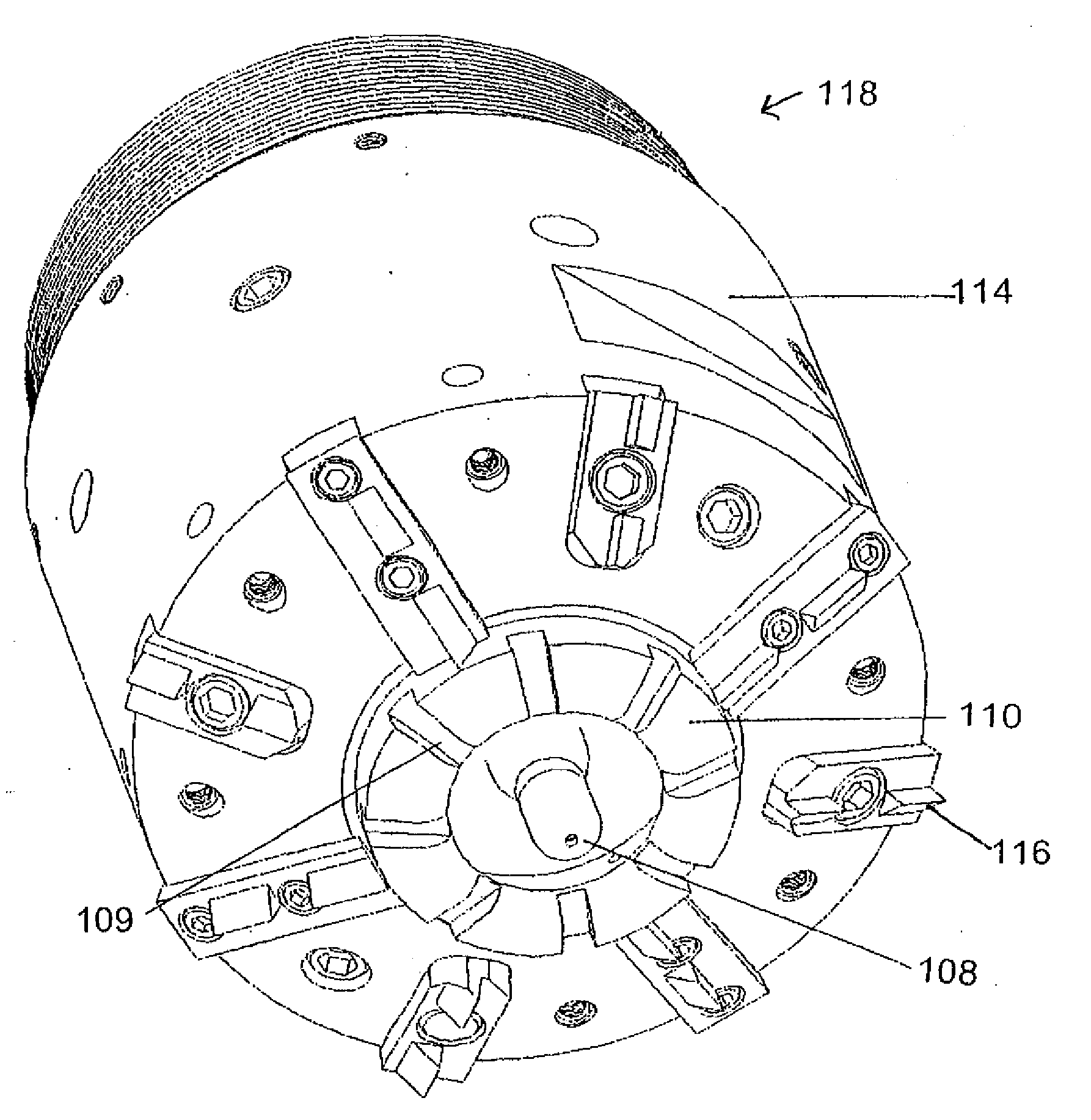

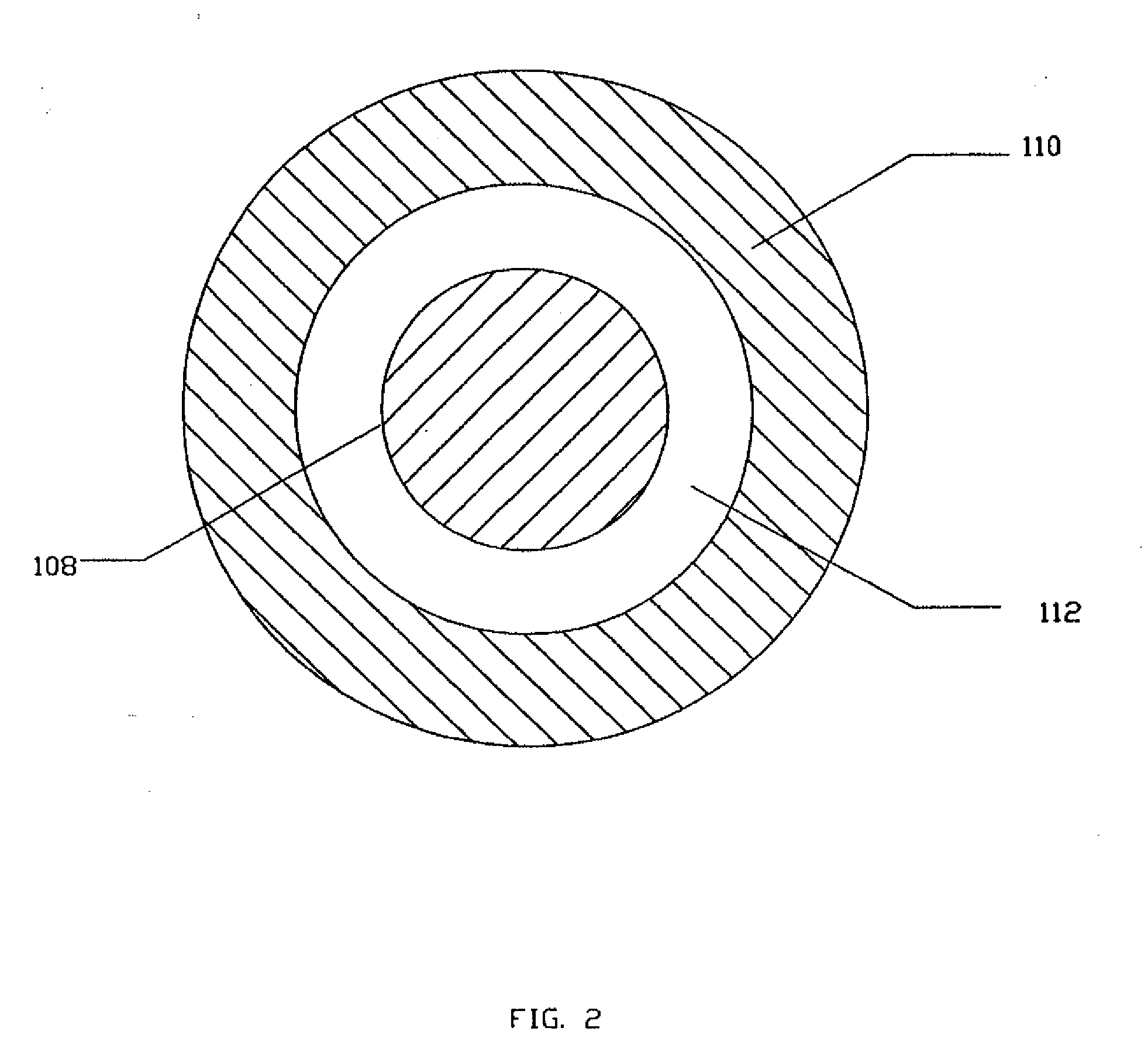

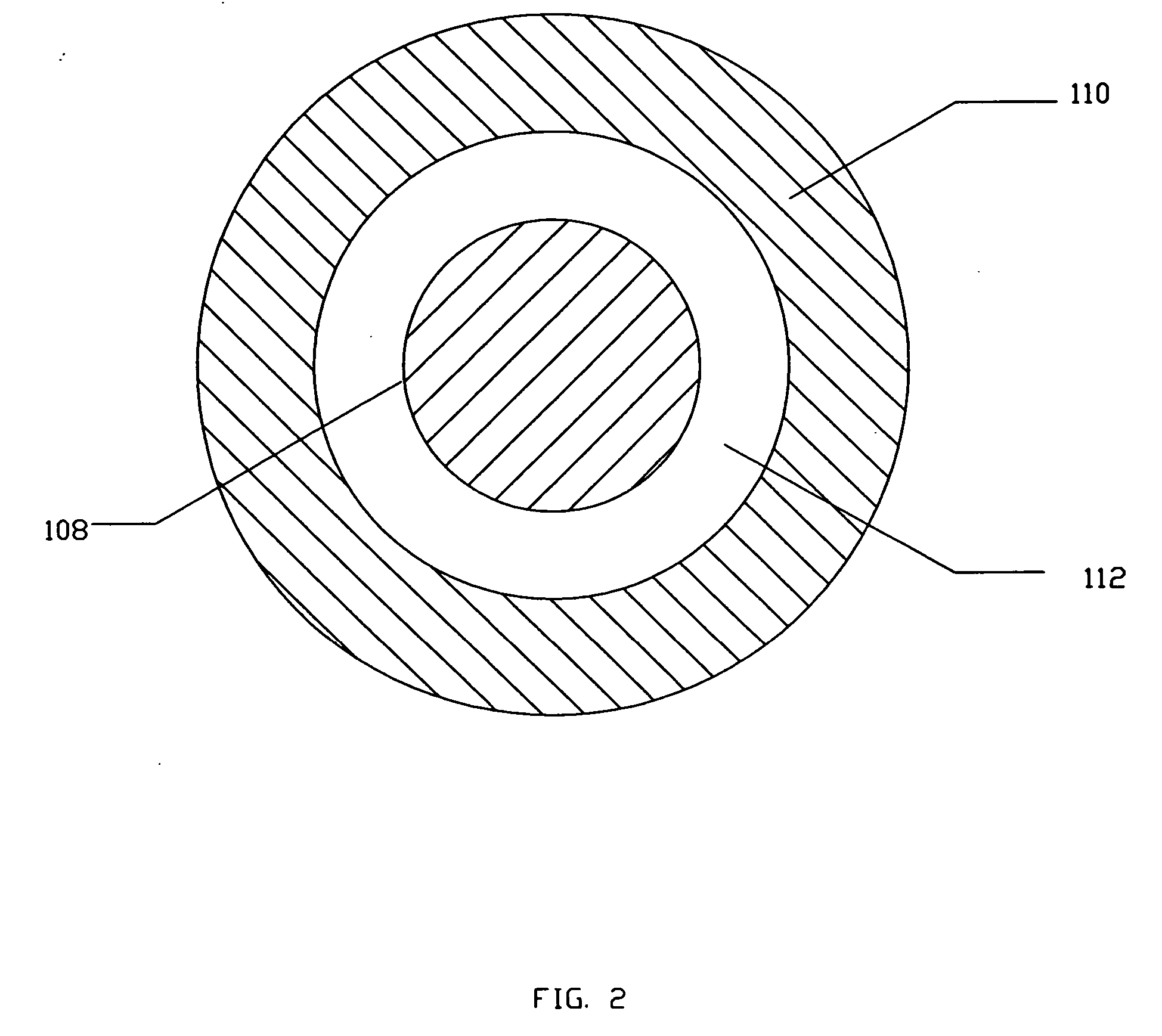

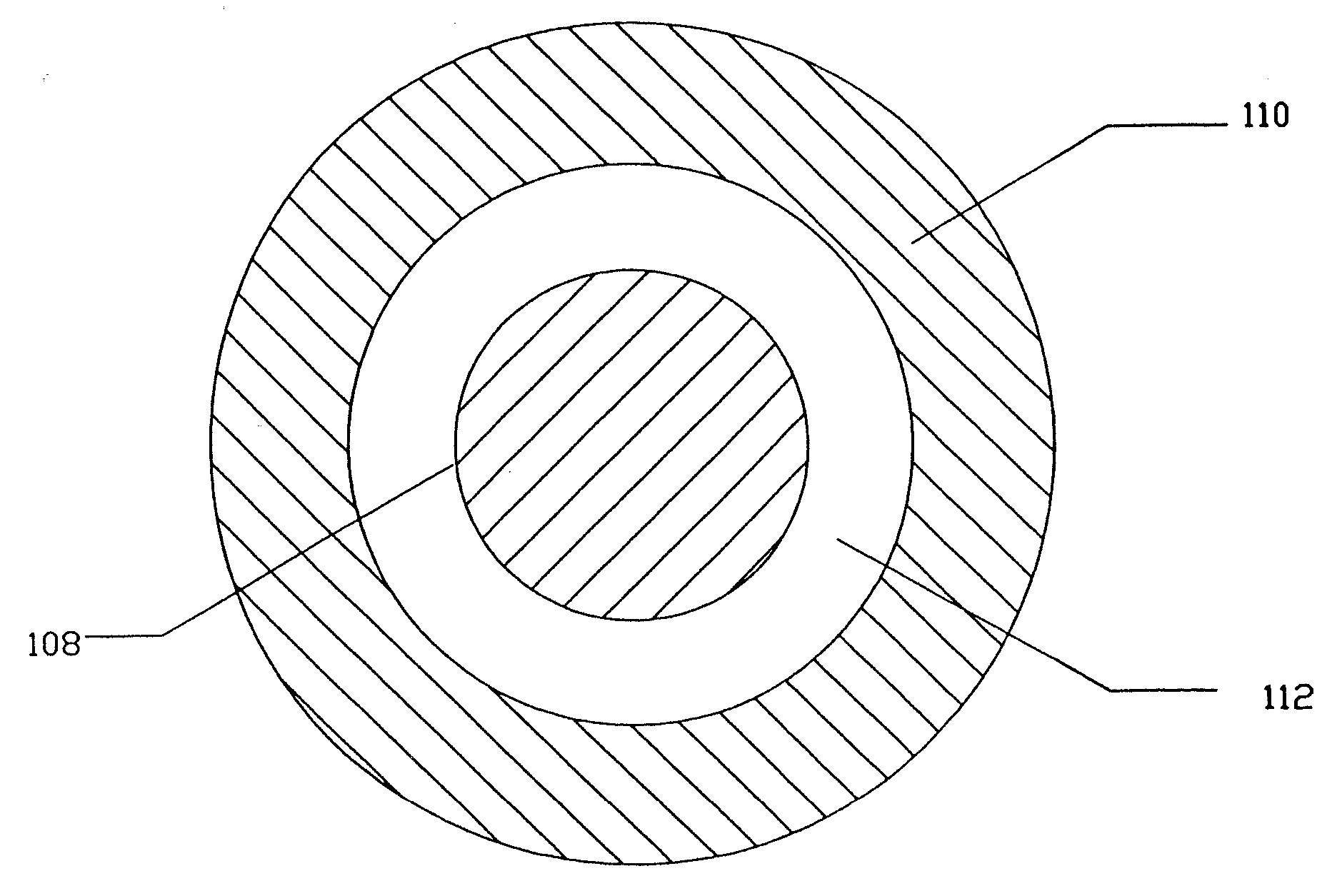

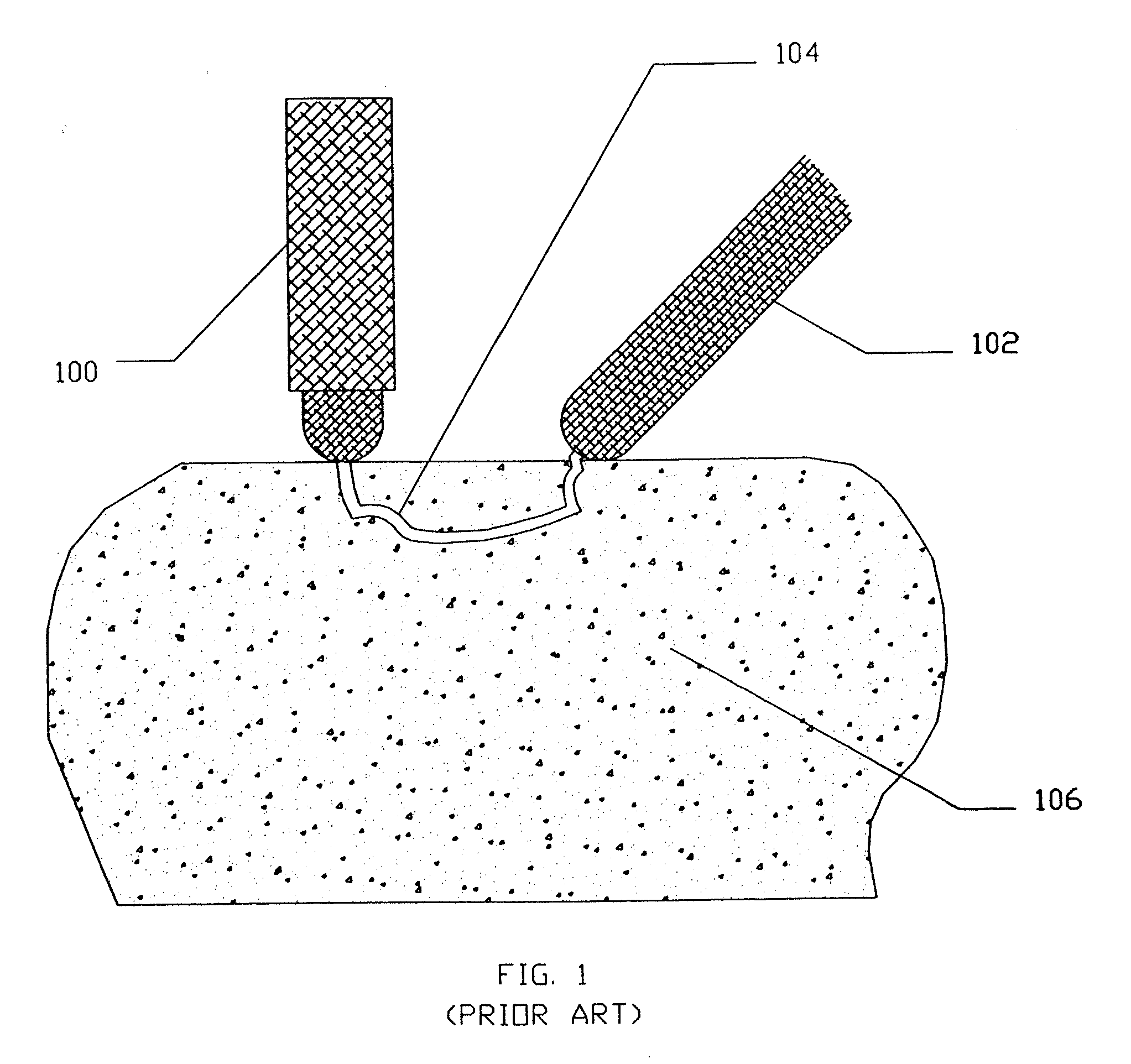

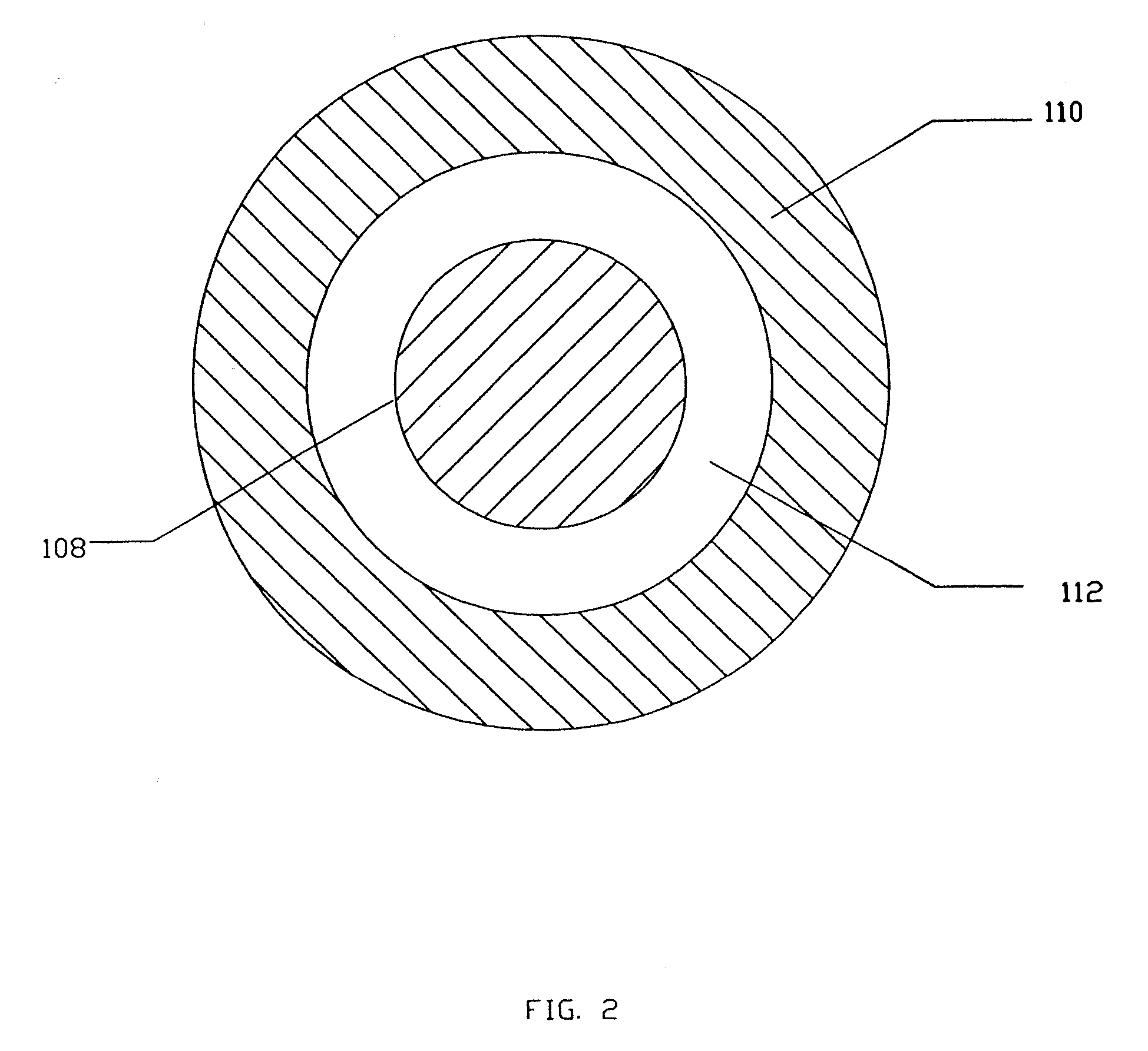

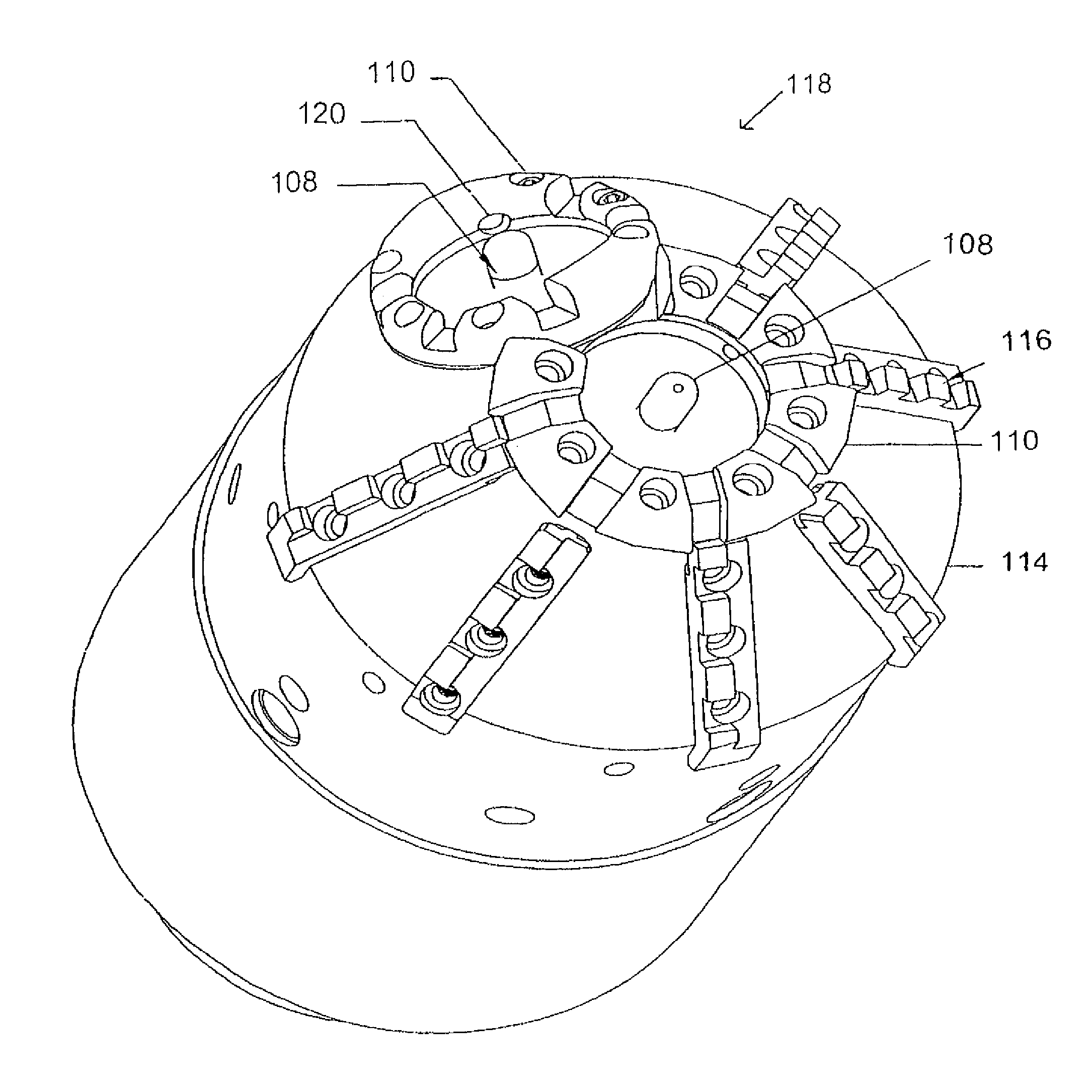

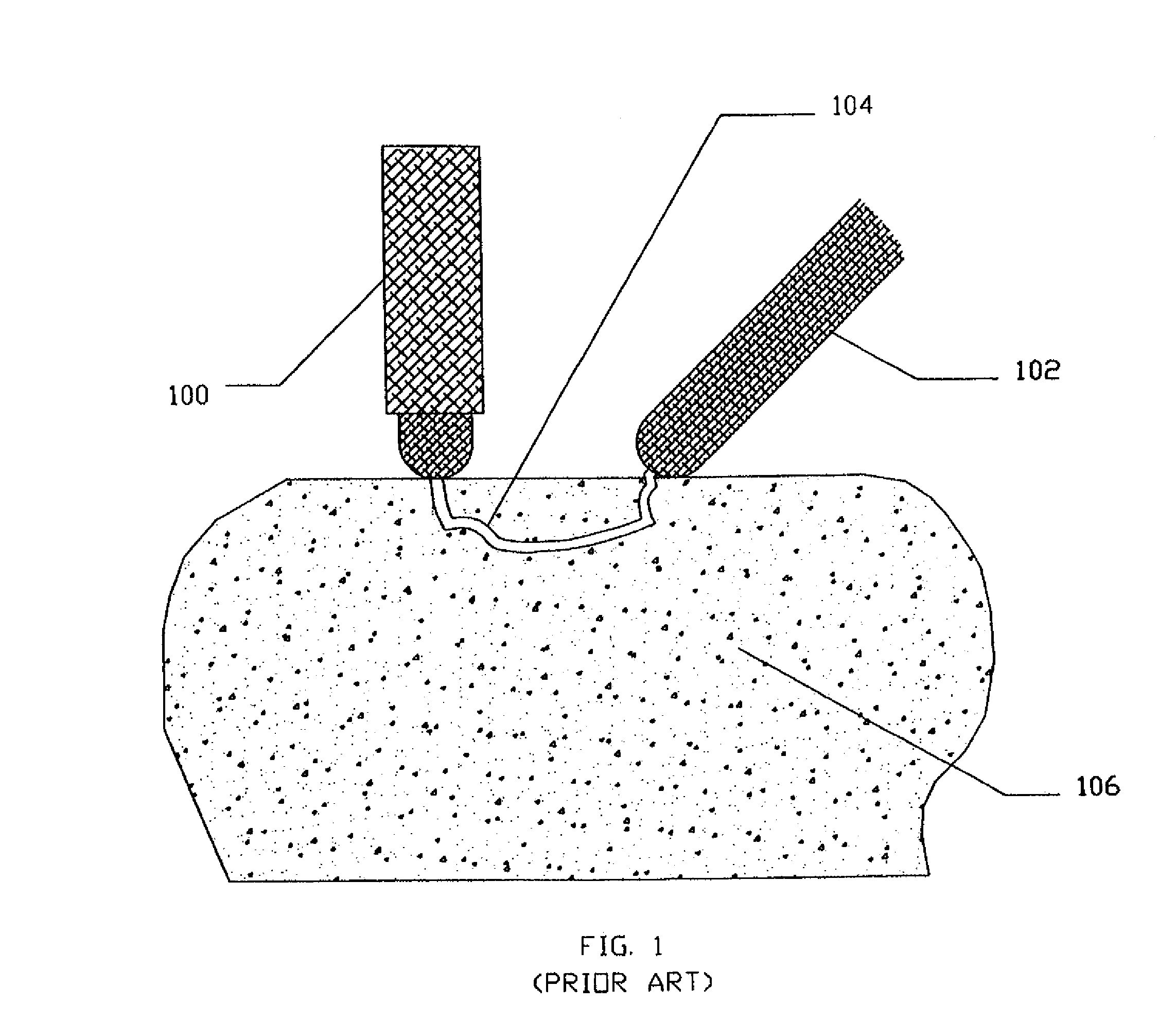

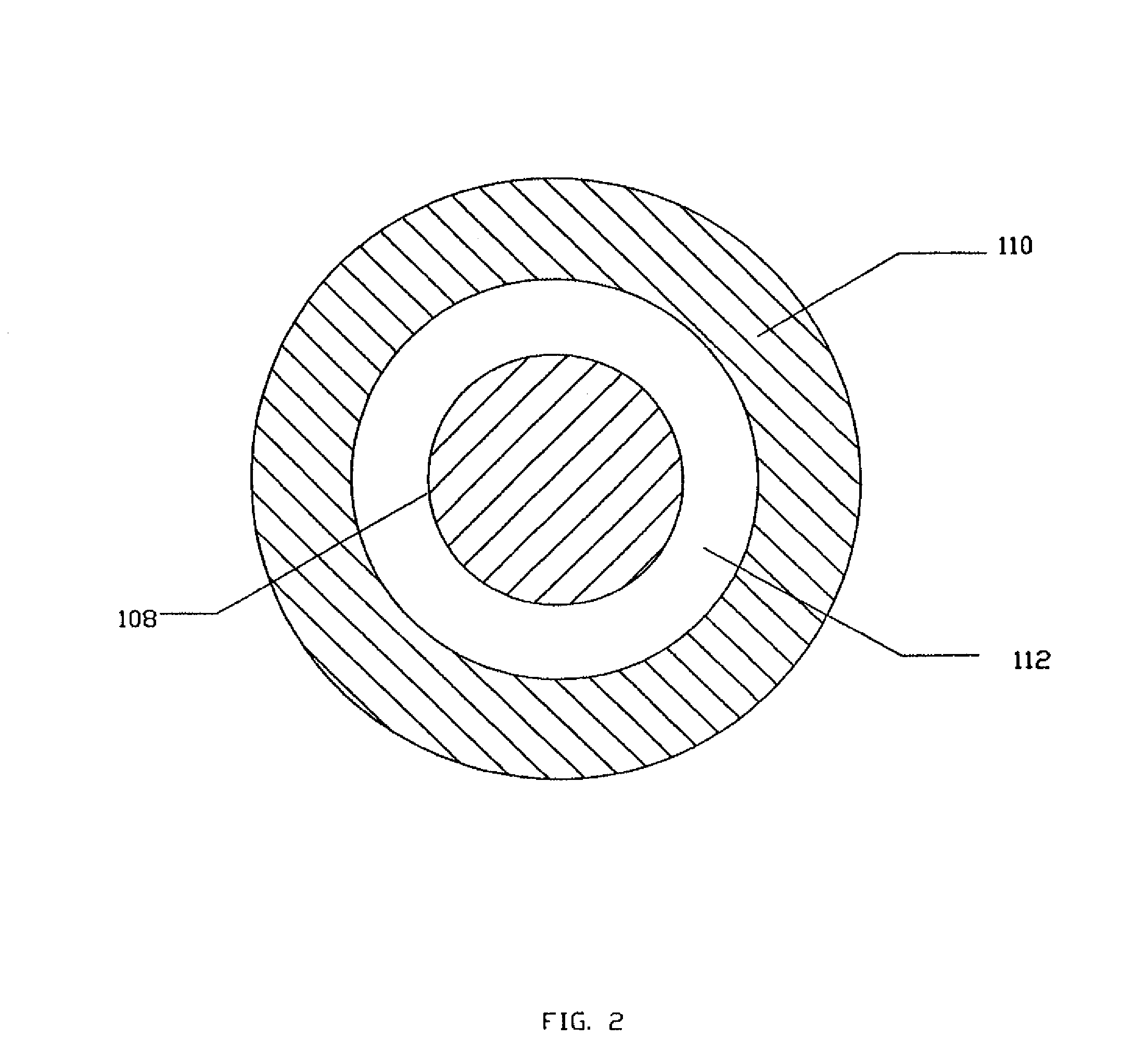

Pulsed electric rock drilling apparatus

The present invention provides for pulsed powered drilling apparatuses and methods. A drilling apparatus is provided comprising a bit having one or more sets of electrodes through which a pulsed voltage is passed through a mineral substrate to create a crushing or drilling action.

Owner:SDG LLC

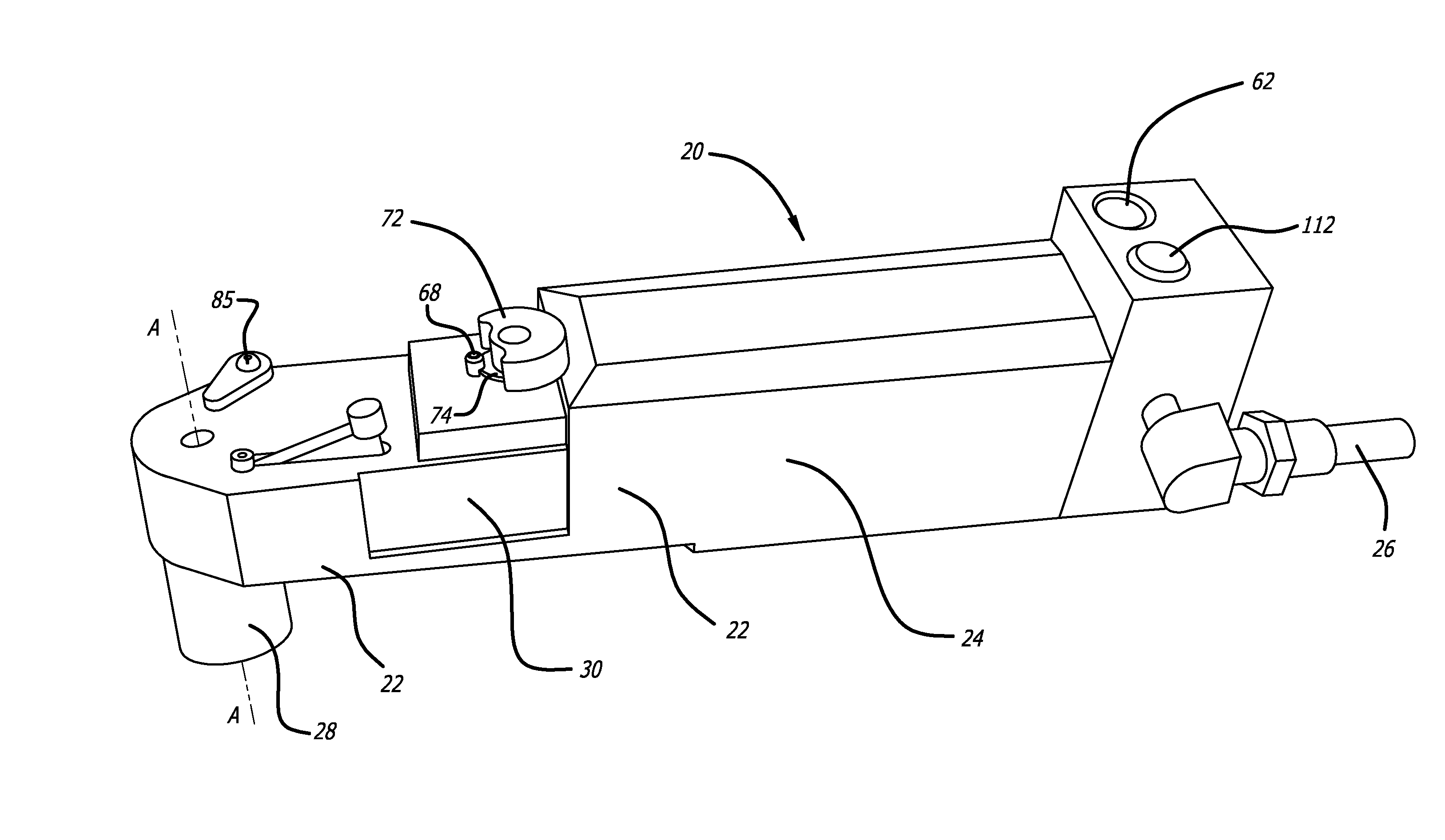

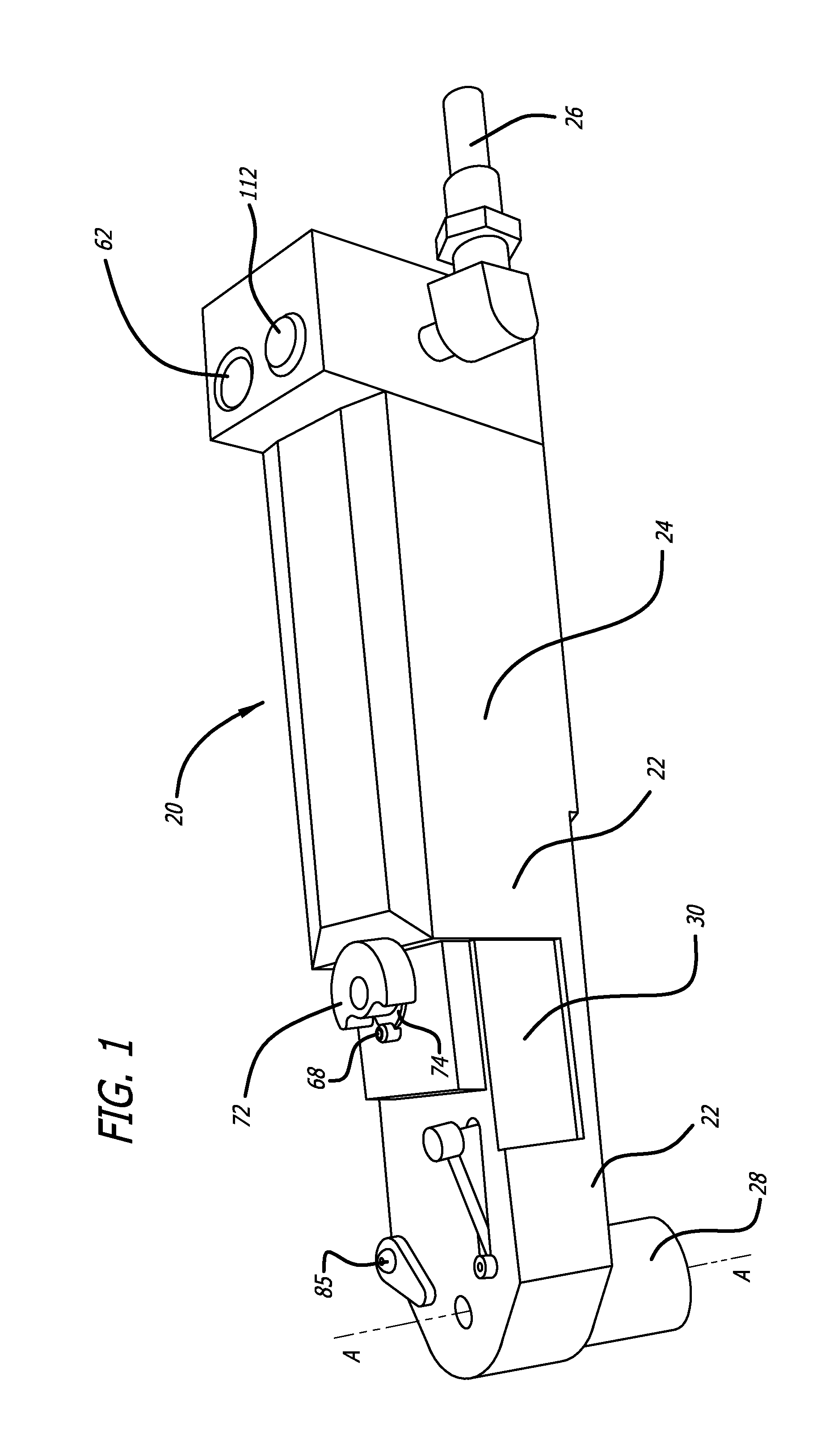

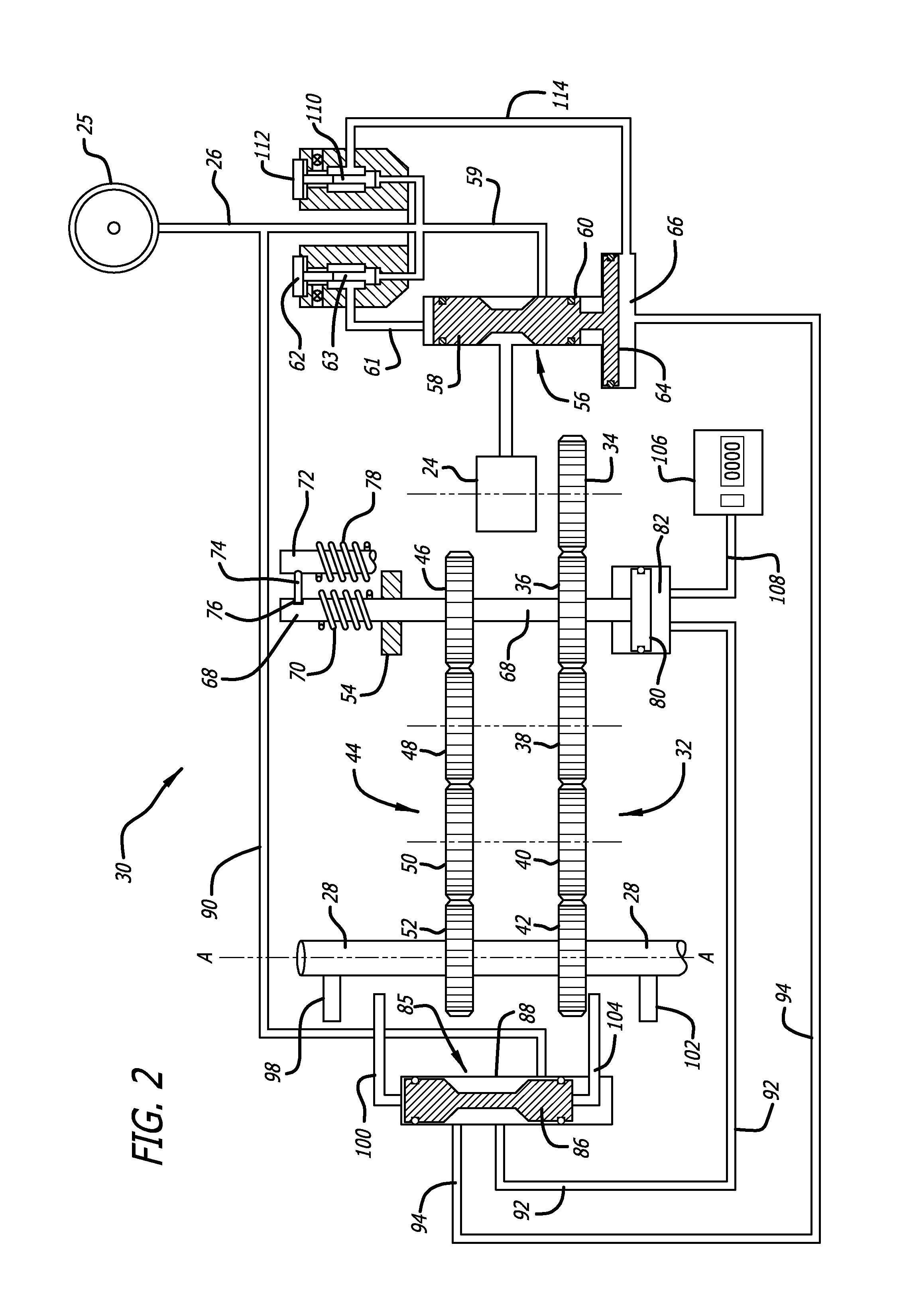

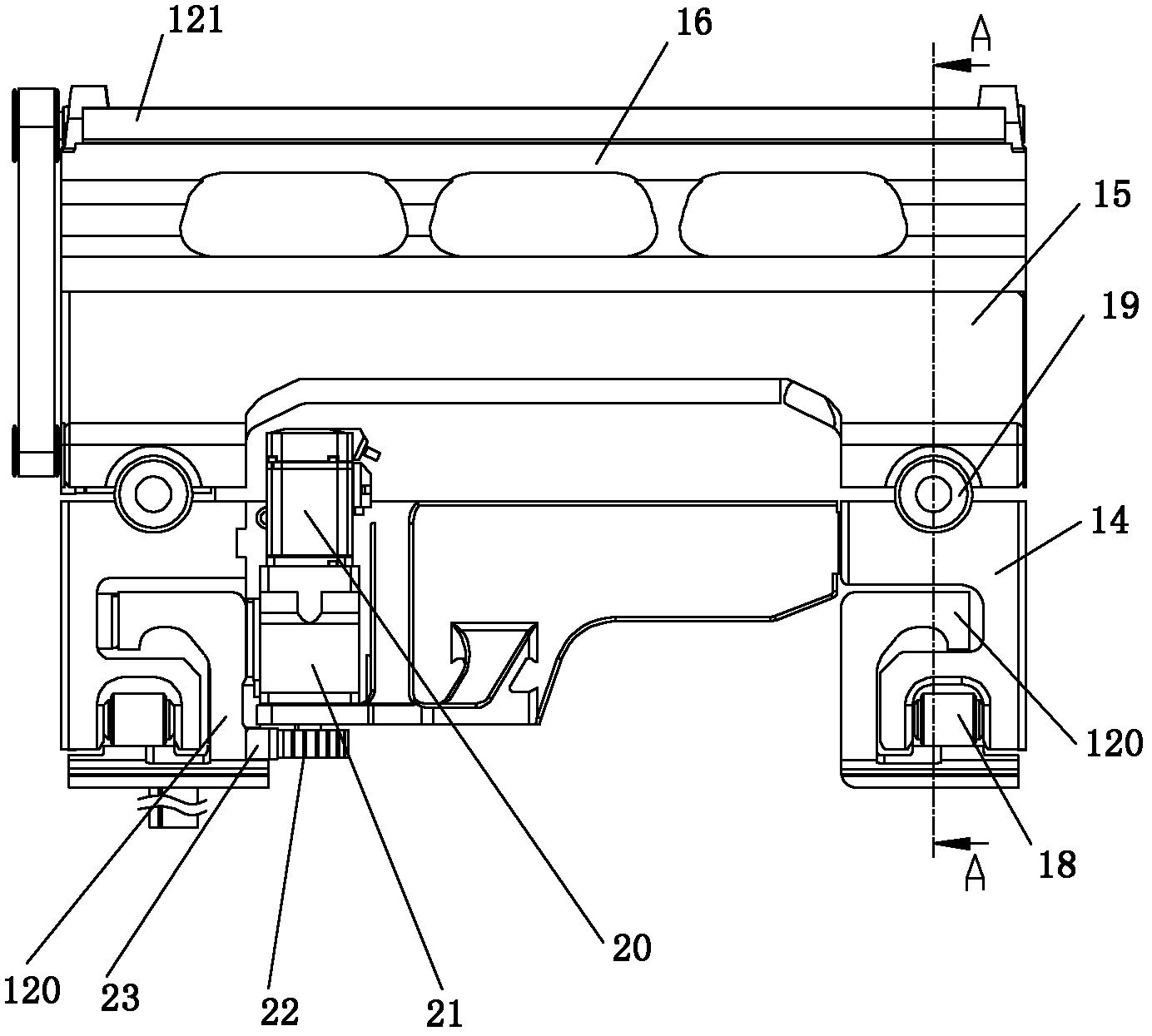

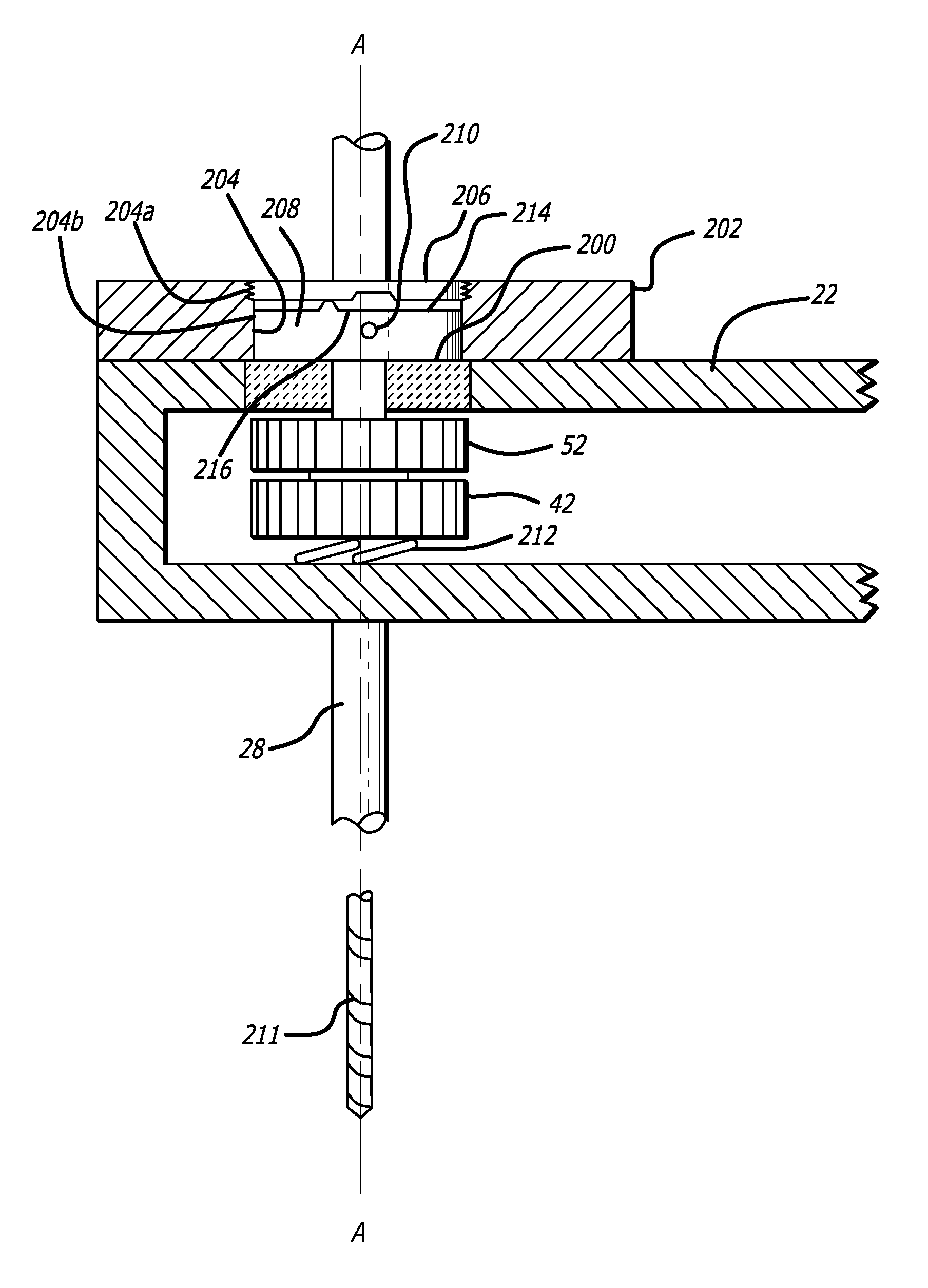

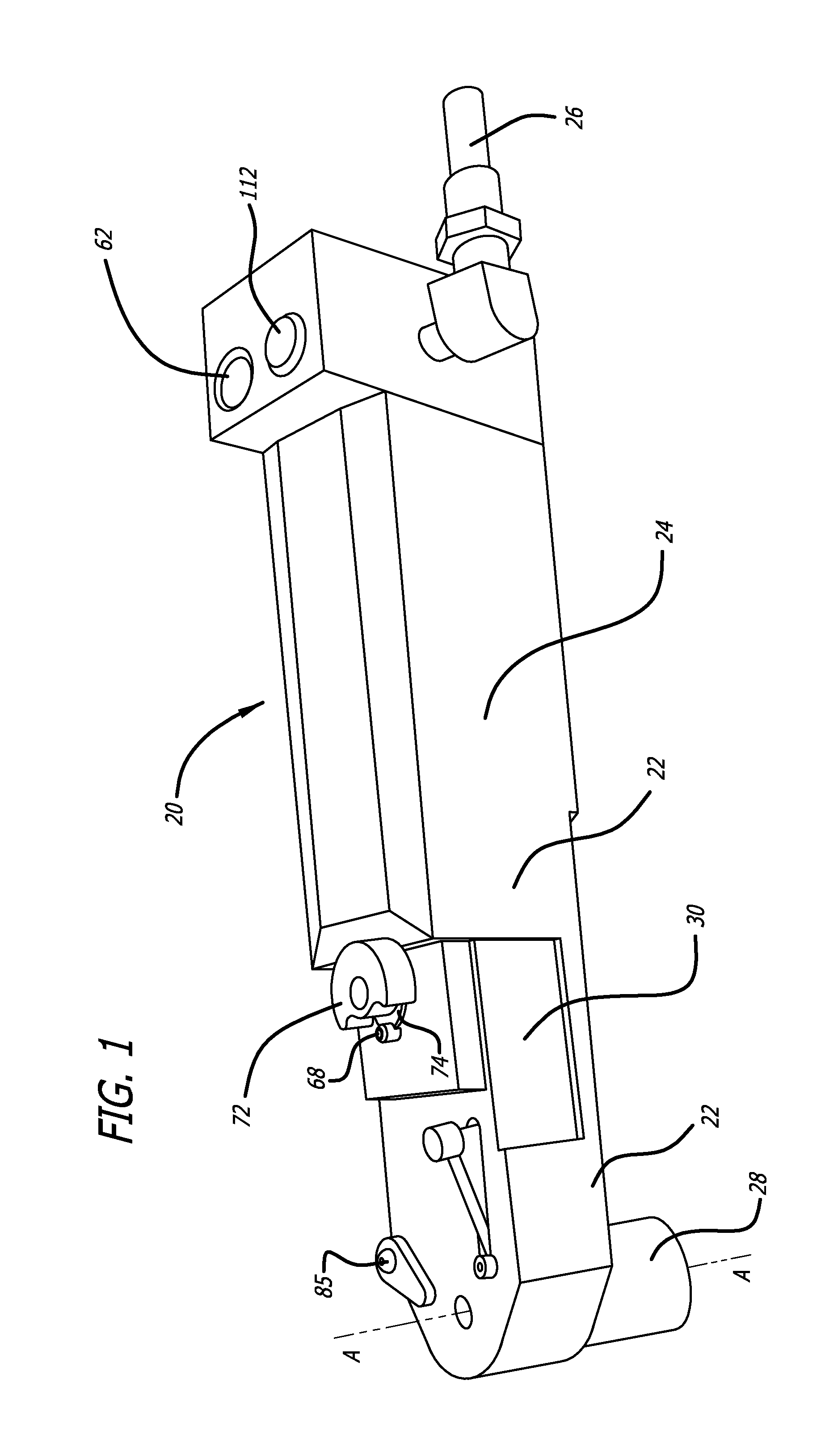

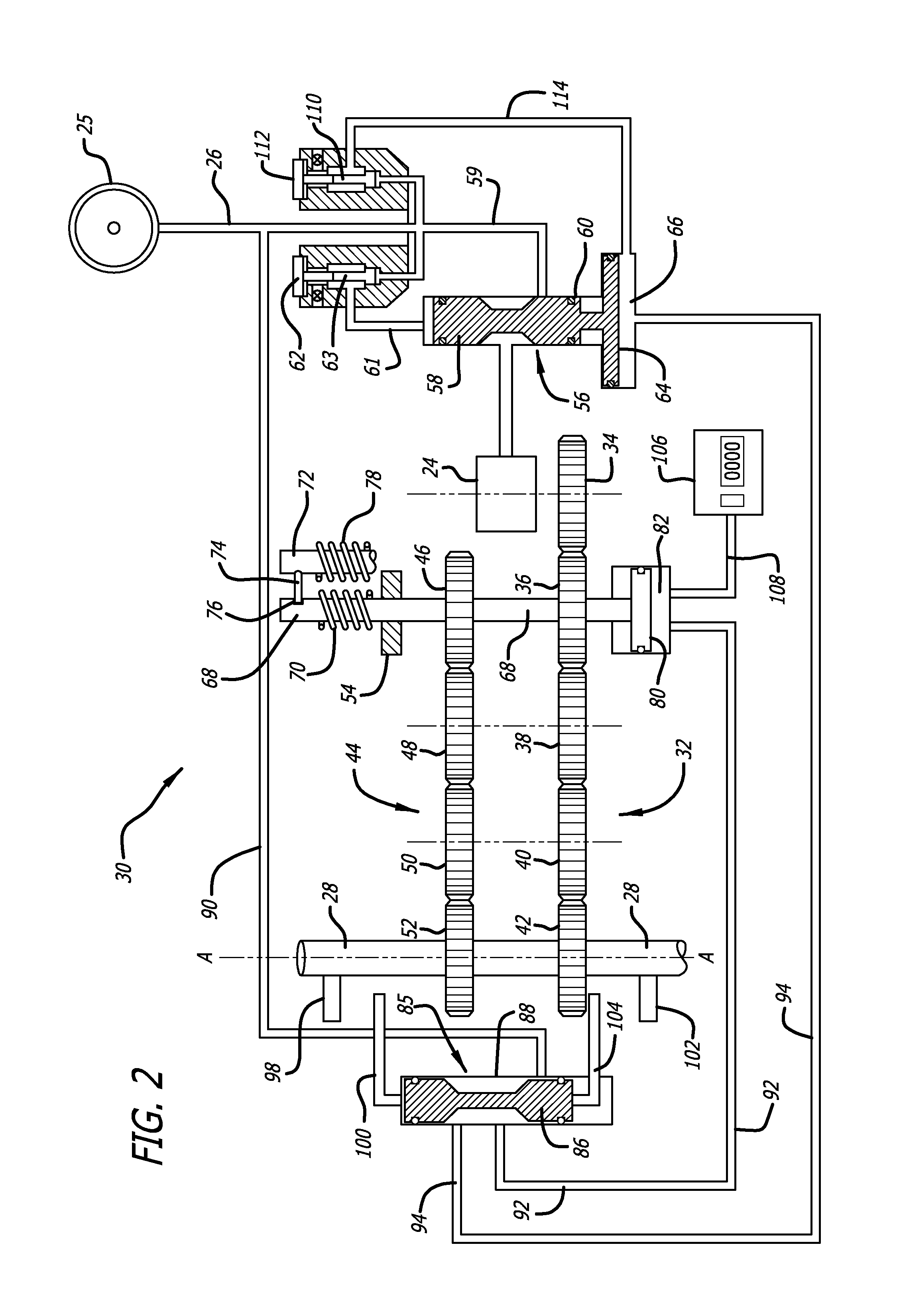

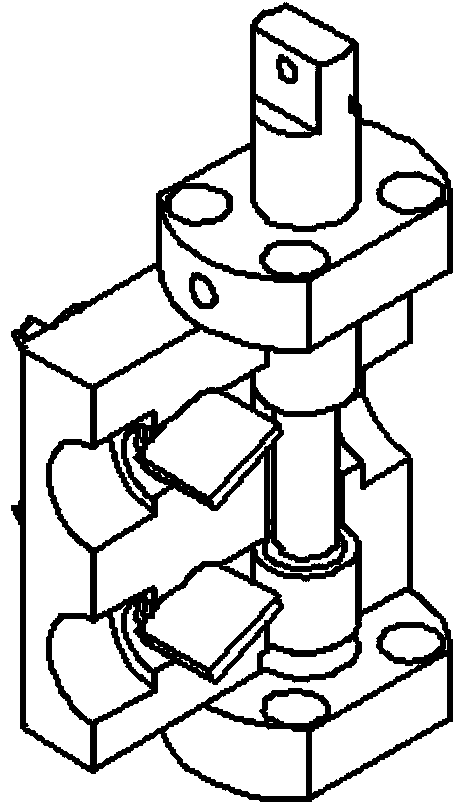

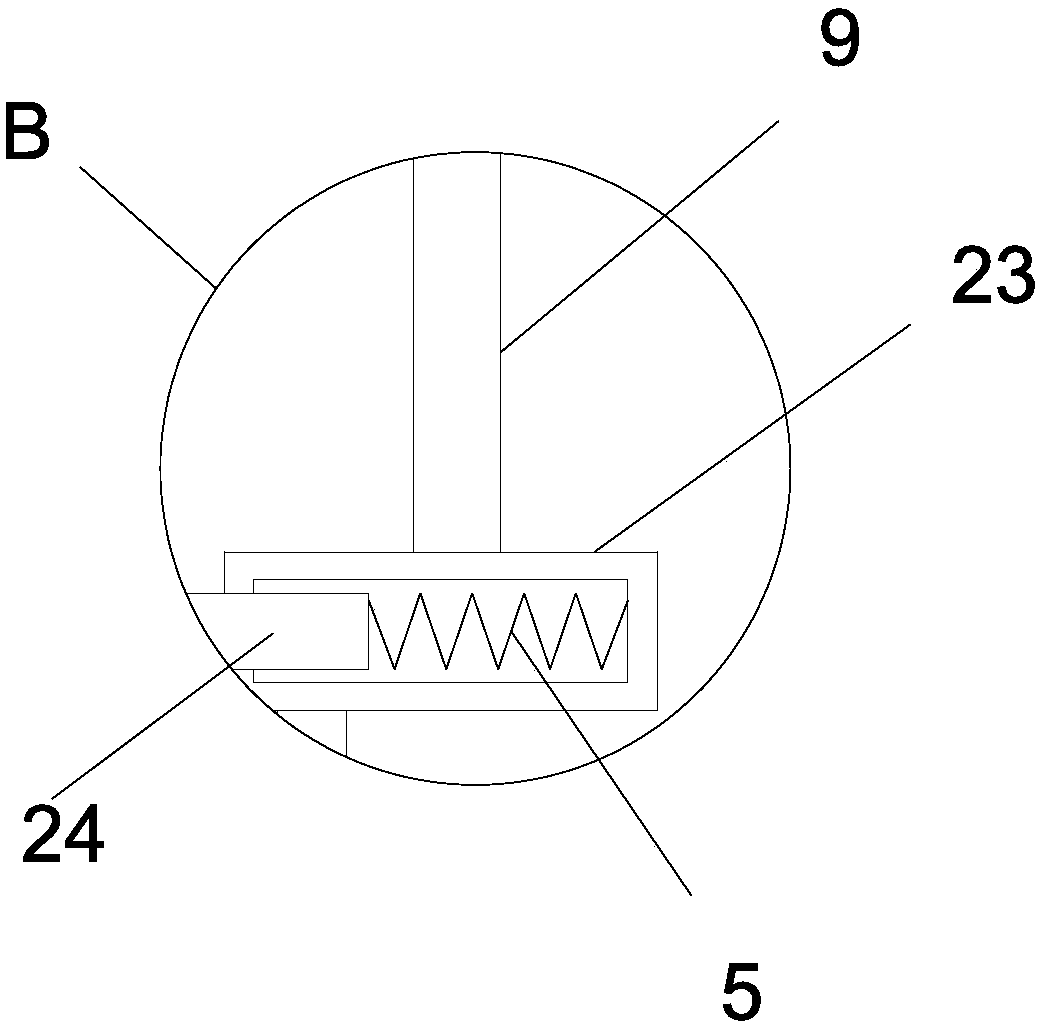

System and method for breaking chips formed by a drilling operation

A drilling machine is provided for breaking chips formed by drilling action into manageable lengths. The drilling machine comprises a first gear having a first axis of rotation, and a cam follower surface. It has a second gear having a second axis of rotation coincident with the first axis of rotation. A housing is provided configured to support the first gear and the second gear, the housing having a cam surface, a spring and a tool holder spindle having a third axis of rotation. The first and second gears are configured to impart both a linear feed and a rotation to the spindle. The first and second axes of rotation are coincident with the third axis of rotation such that the cam surface is urged into contact with the cam follower surface by the spring. The cam surface and the follower surface are shaped such that when the first gear rotates, the first gear is caused repeatedly to retract and then to advance, breaking chips that are formed.

Owner:P V TOOL

Method of Drilling Using Pulsed Electric Drilling

The present invention provides for pulsed powered drilling apparatuses and methods. A drilling apparatus is provided comprising a bit having one or more sets of electrodes through which a pulsed voltage is passed through a mineral substrate to create a crushing or drilling action.

Owner:SDG LLC

Pulsed electric rock drilling apparatus with non-rotating bit

The present invention provides for pulsed powered drilling apparatuses and methods. A drilling apparatus is provided comprising a bit having one or more sets of electrodes through which a pulsed voltage is passed through a mineral substrate to create a crushing or drilling action. The electrocrushing drilling process may have, but does not require, rotation of the bit. The electrocrushing drilling process is capable of excavating the hole out beyond the edges of the bit with or without the need of mechanical teeth.

Owner:SDG LLC

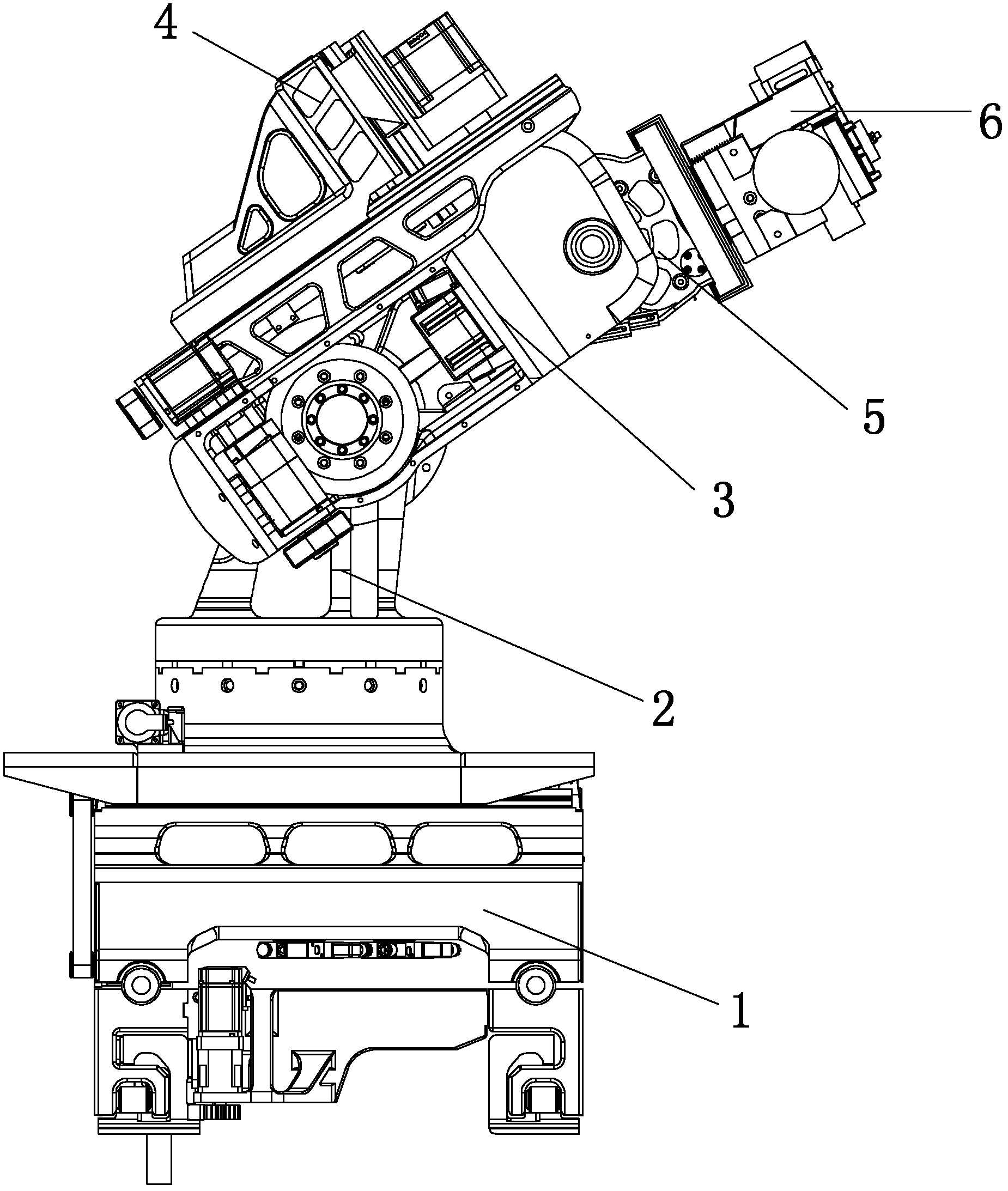

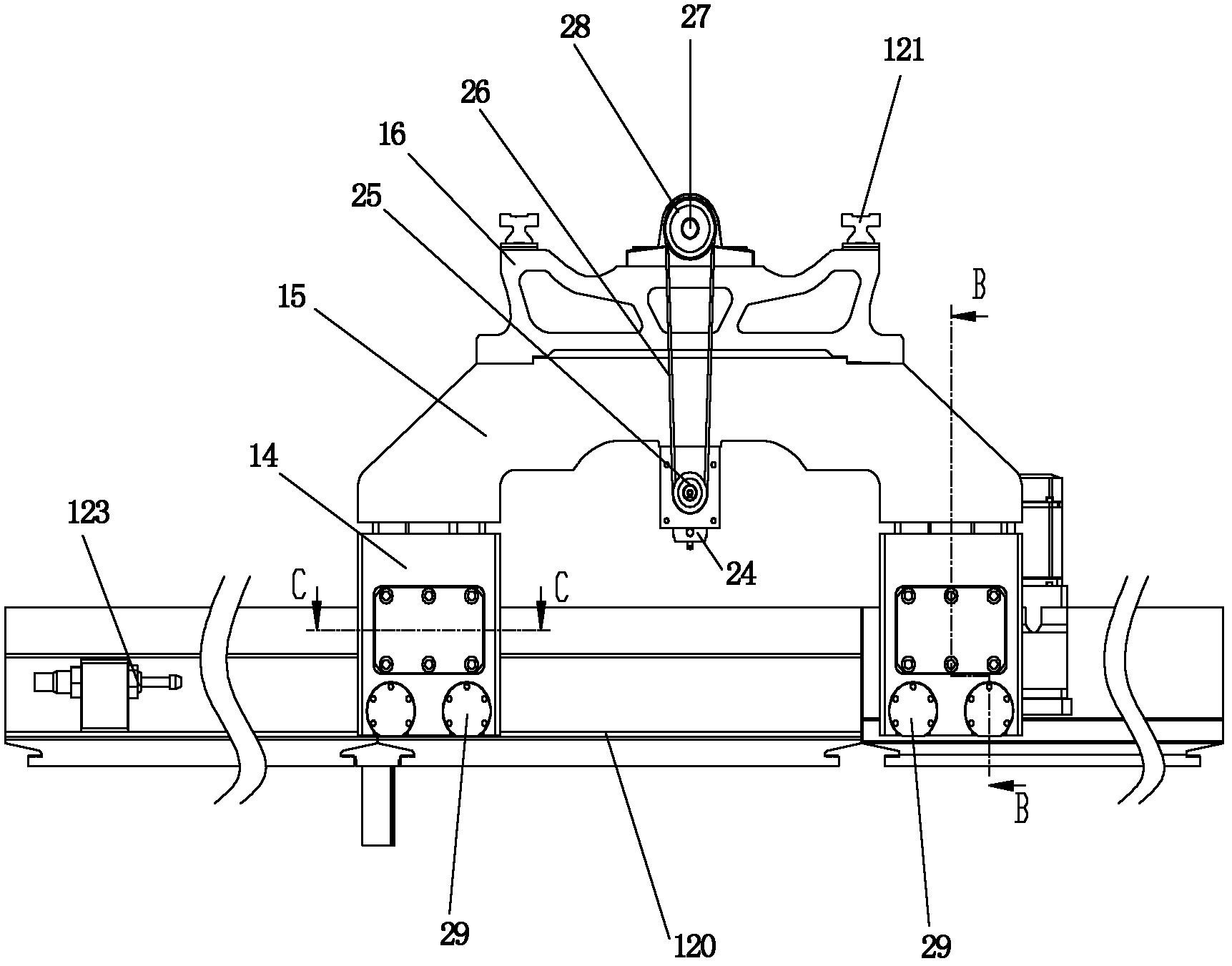

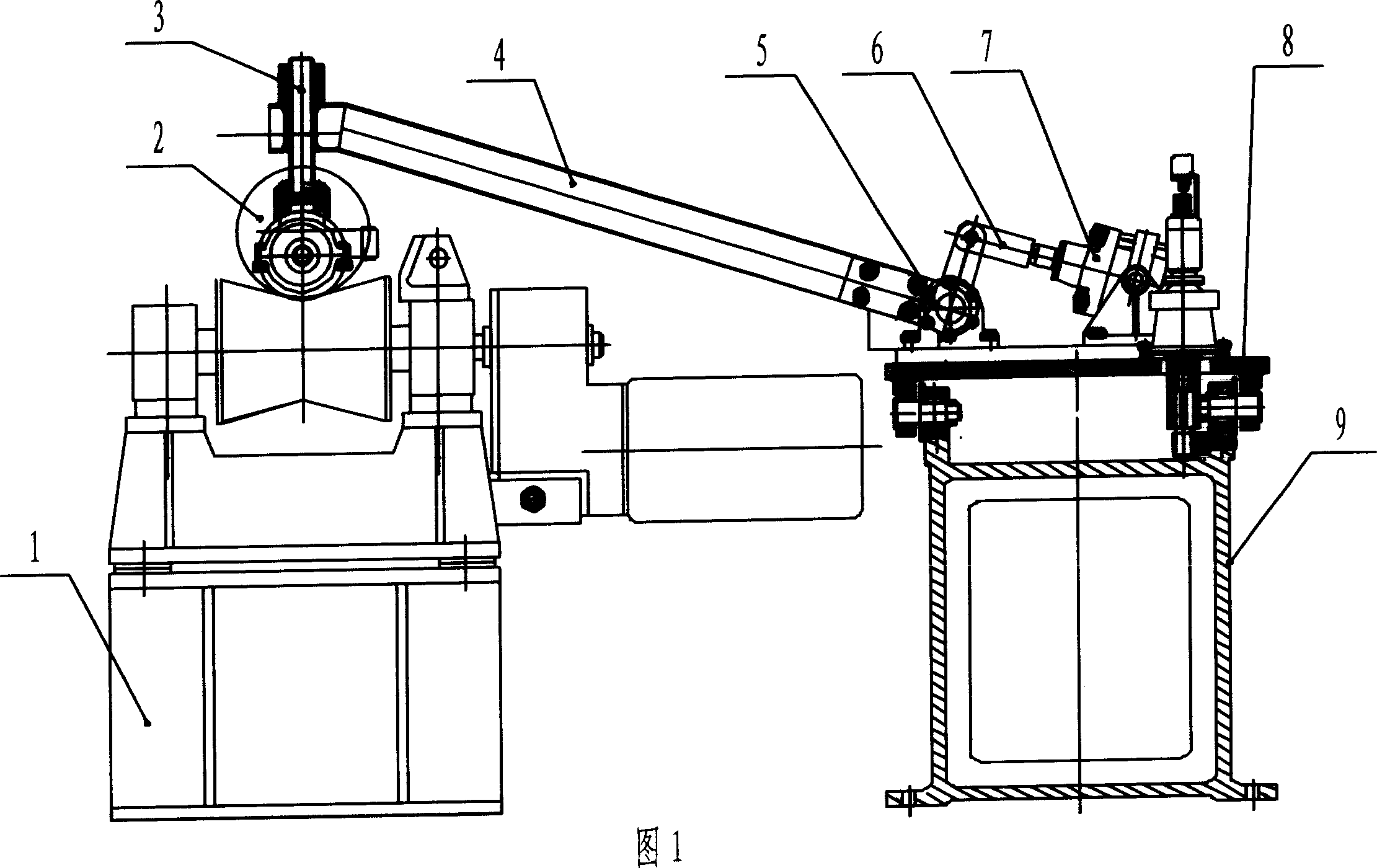

Industrial robot

ActiveCN102658546ACrawl smoothlyRealize unmannedProgramme-controlled manipulatorJointsIndustrial engineeringIndustrial robot

The invention provides an industrial robot, which comprises a base guide rail component, a base component, a large arm component, an engraving and milling component, a wrist component and a claw component, wherein the lower end of the base guide rail component is matched with a guide rail I and can roll along the guide rail I; the lower end of the base component is matched with a guide rail II which is arranged at the upper end of the base guide rail component and can slide along the guide rail II; the base component consists of an upper component and a lower component, wherein the upper component can rotate around the lower component; a shoulder shaft on the large arm component is in floating fit with a shoulder shaft hole formed on the upper part of the upper component, and the large arm component realizes the action of lifting or lowering the arm; the lower part of the engraving and milling component is matched with a guide rail III which is arranged on the side of the large arm component, can slide along the guide rail III and realizes a drilling action; the wrist component is arranged in a mounting hole of the large arm component through a loop bar and finishes the action of lifting and lowering the wrist; and the side of the claw component is matched with a guide rail IV which is arranged on the wrist component, slides along the guide rail IV and realizes the action of opening and closing the claws.

Owner:刘朝龙

Method of opening joints between drilling components, and rock drill

A rock drill includes a string of components interconnected by screw threads and connected to a shank. A percussion piston is reciprocated against the shank during a drilling operation, while a support device applies axial support to the rear of the shank, to enhance the drilling action. When the components are being unscrewed, the percussion piston is actuated to strike the rear end of the drill string, after the support device has at least partially released the axial support of the shank, to enable tensile stress to be generated in the components by the percussive impacts to facilitate unscrewing of the components.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

System and method for breaking chips formed by a drilling operation

A drilling machine is provided for breaking chips formed by drilling action into manageable lengths. The drilling machine comprises a first gear having a first axis of rotation, and a cam follower surface. It has a second gear having a second axis of rotation coincident with the first axis of rotation. A housing is provided configured to support the first gear and the second gear, the housing having a cam surface, a spring and a tool holder spindle having a third axis of rotation. The first and second gears are configured to impart both a linear feed and a rotation to the spindle. The first and second axes of rotation are coincident with the third axis of rotation such that the cam surface is urged into contact with the cam follower surface by the spring. The cam surface and the follower surface are shaped such that when the first gear rotates, the first gear is caused repeatedly to retract and then to advance, breaking chips that are formed.

Owner:P V TOOL

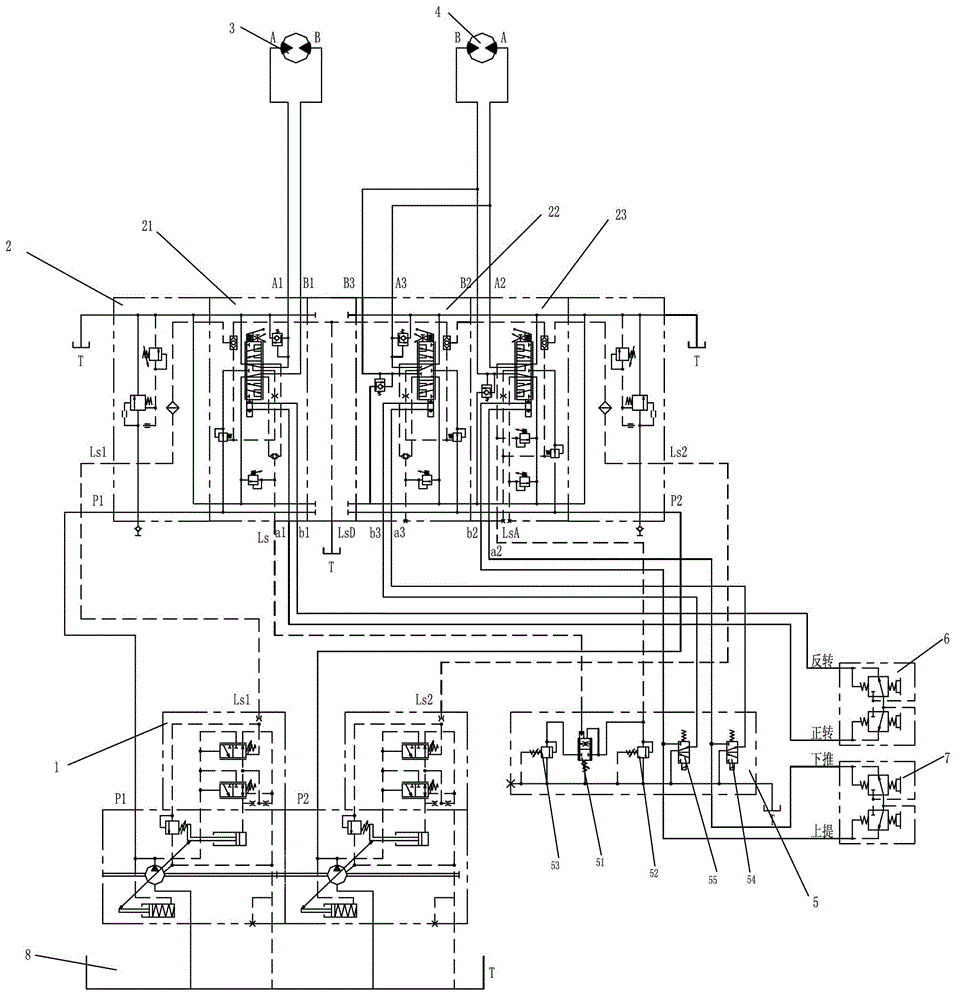

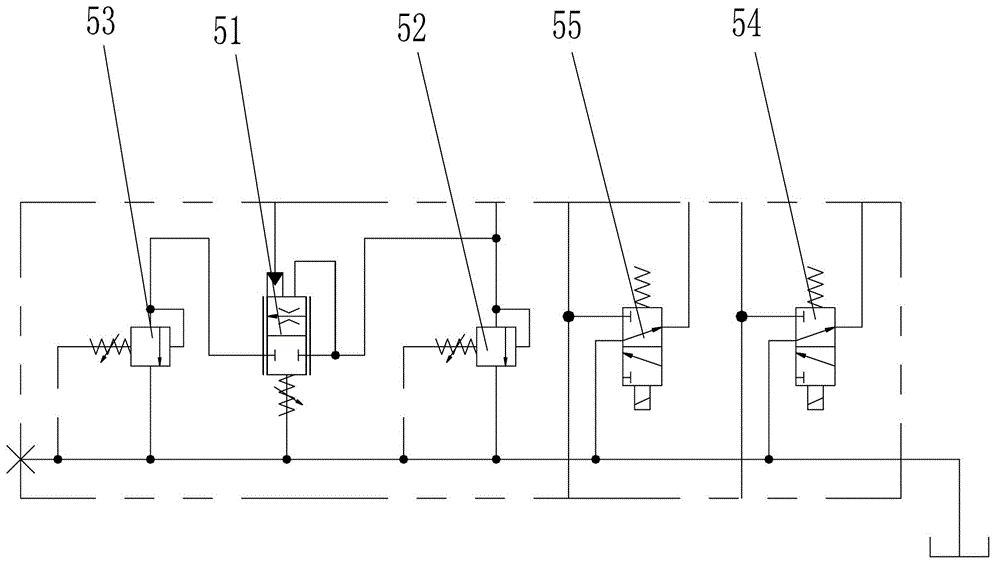

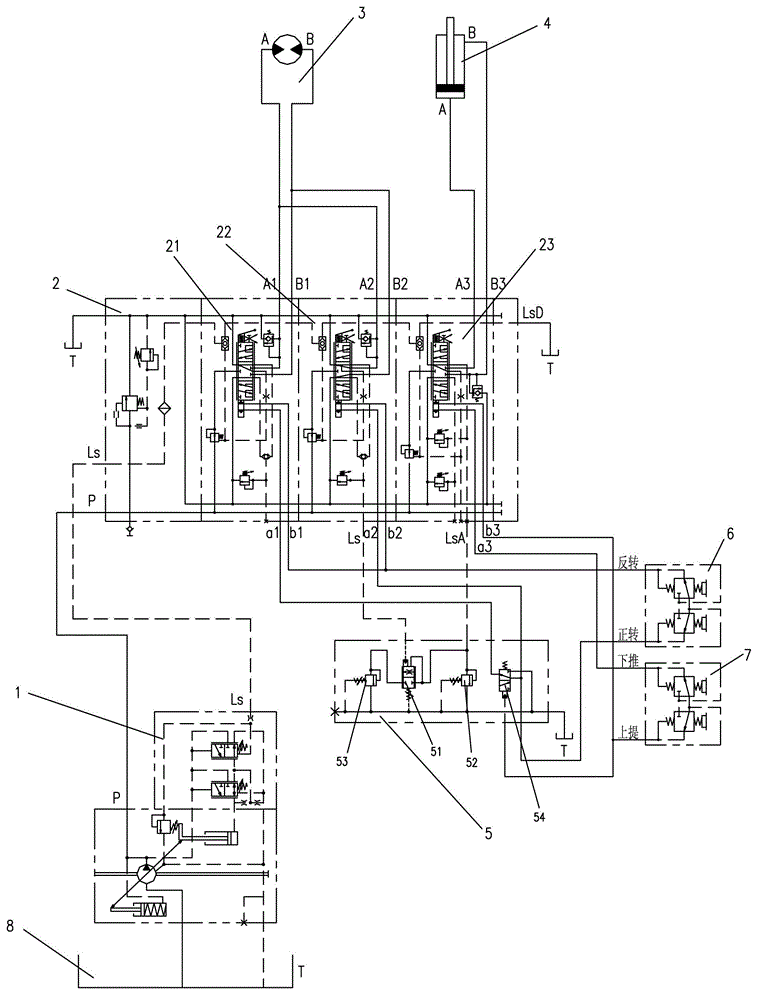

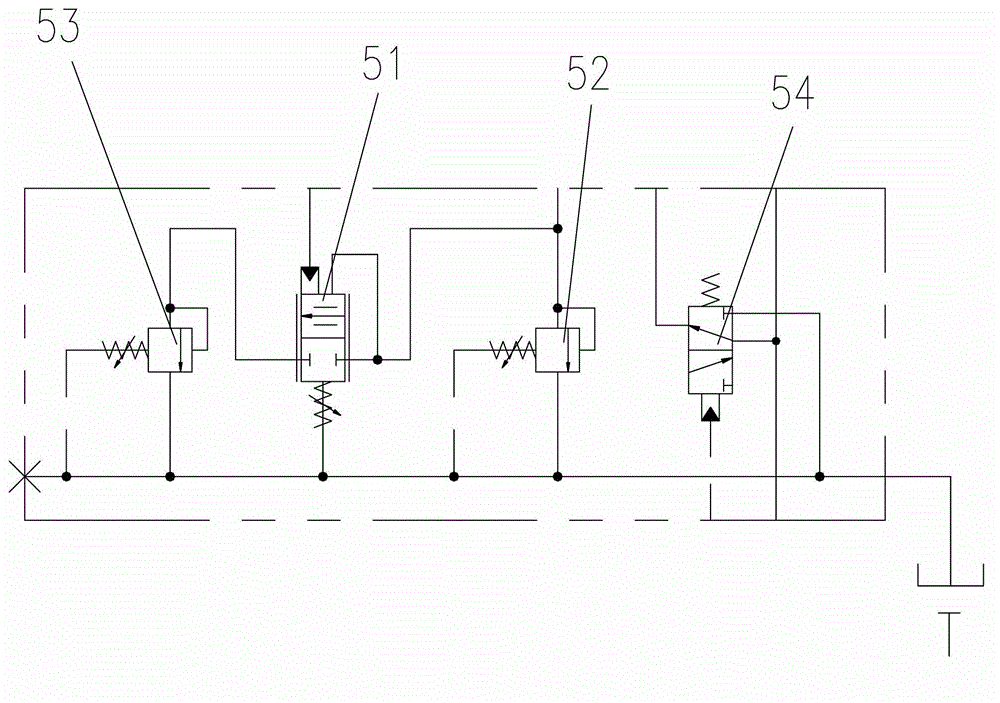

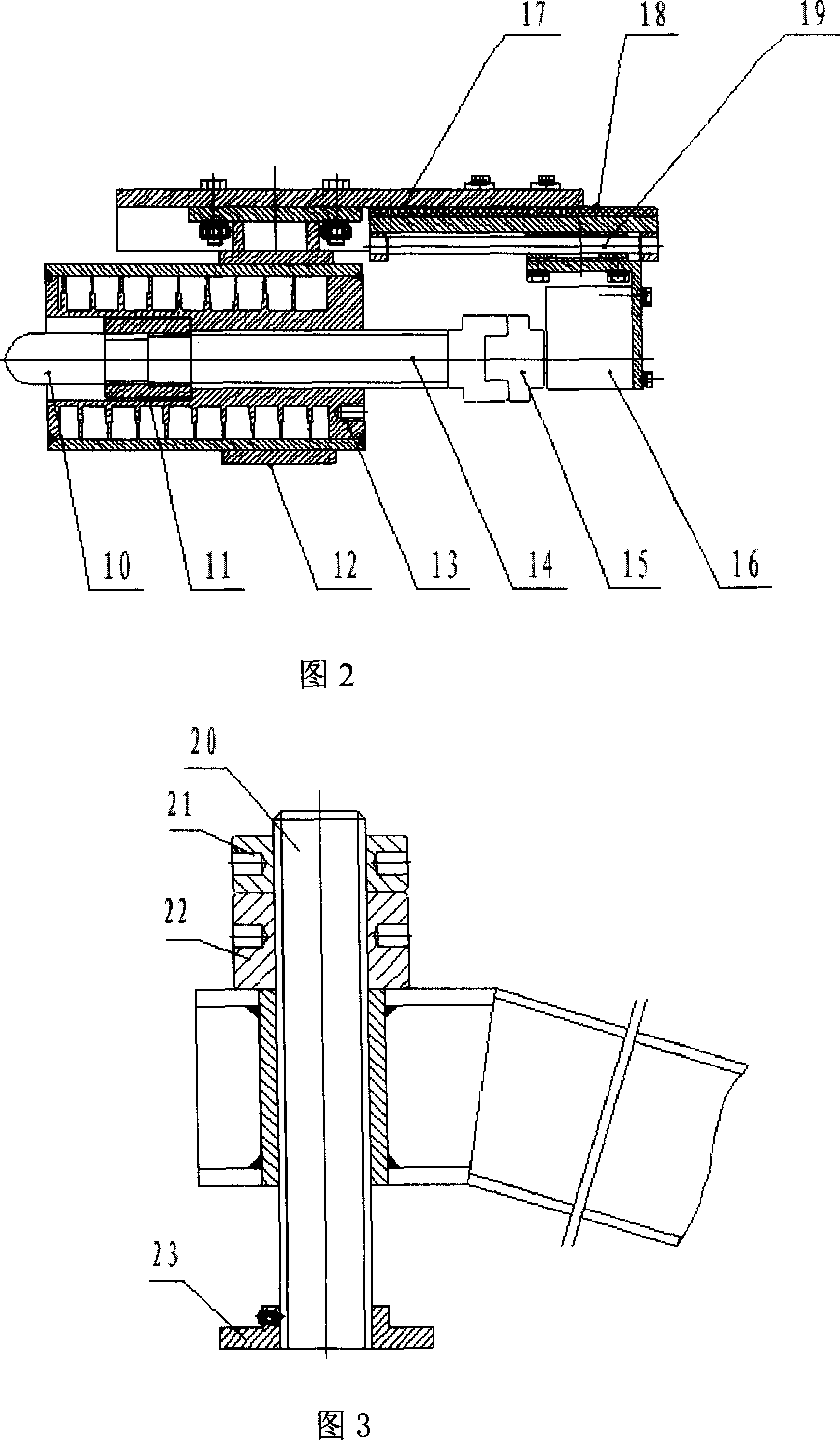

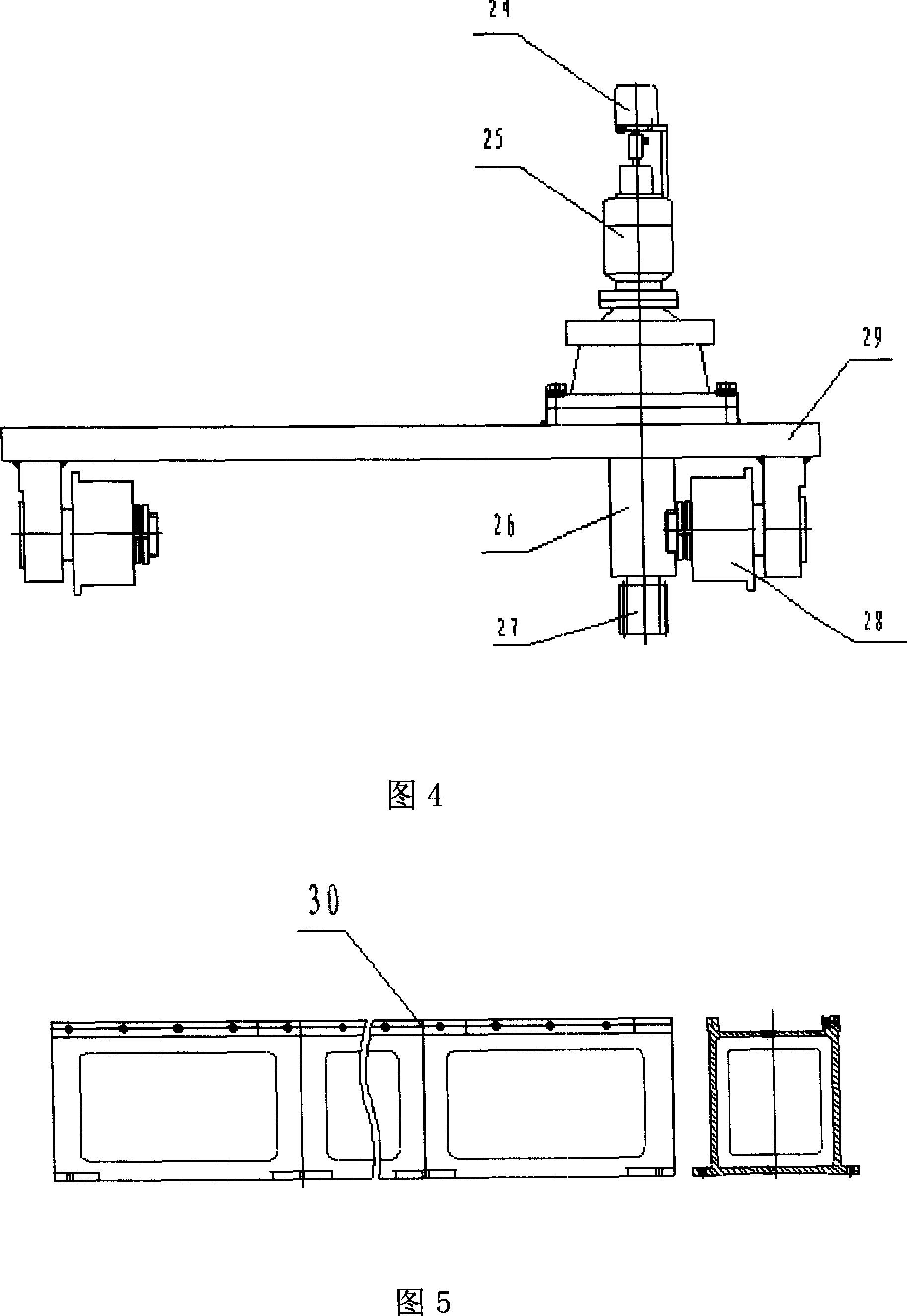

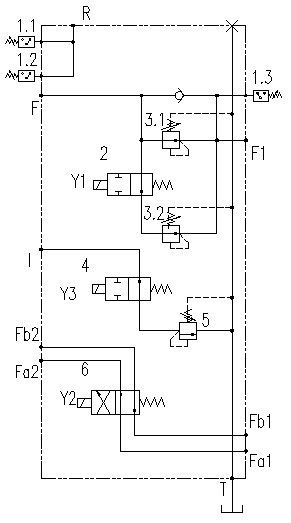

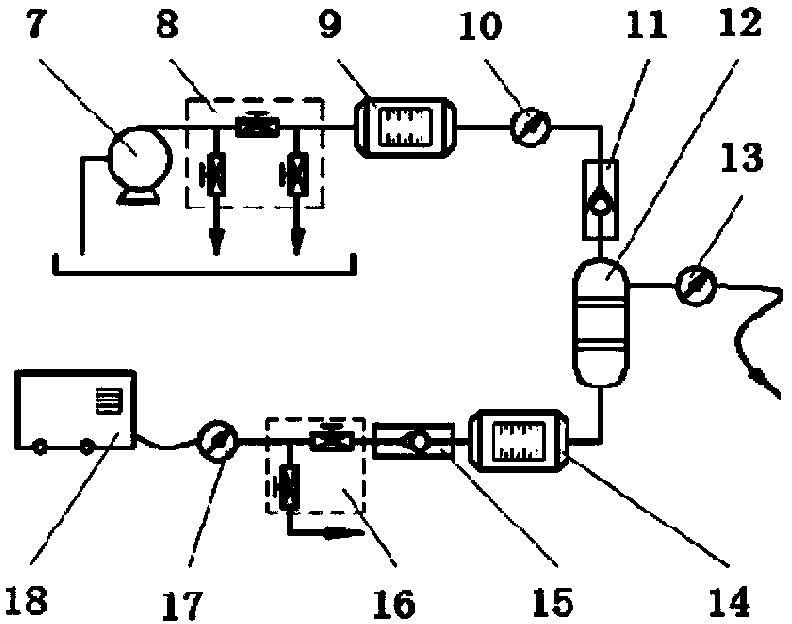

Double-pump hydraulic control loop of key drilling action of cutting drill rig

ActiveCN102747948AAvoid stuck drillPrevent slippingServomotor componentsServomotorsFuel tankEngineering

A double-pump hydraulic control loop of a key drilling action of a cutting drill rig comprises a double linkage load-sensitive variable pump set, a double oil intake linkage load-sensitive multi-way valve, a rotary motor, a propulsion motor, a drilling logic control block, a rotation guide handle, a propulsion guide handle, and a hydraulic oil tank. An oil inlet of the double linkage load-sensitive variable pump set is connected with the hydraulic oil tank. An oil outlet and a load-sensitive opening are connected with an oil inlet and a load-sensitive opening of the double oil intake linkage load-sensitive multi-way valve respectively. Each valve pressure difference compensator of the load-sensitive multi-way valve is provided with an external control opening. The external control openings are connected with the drilling logic control block. The rotation guide handle and the propulsion guide handle are connected with the drilling logic control block or a guide control opening of the load-sensitive multi-way valve. The double-pump hydraulic control loop has the advantages that power head rotation-proportion-controlled propulsion is achieved, independent load-sensitive control of rotation and propulsion is achieved, propulsion speed is increased, and the like.

Owner:SUNWARD INTELLIGENT EQUIP CO LTD

Single-pump hydraulic control loop of key drilling action of cutting drill rig

ActiveCN102747950APrevent slippingImprove auto-adaptabilityServomotor componentsServomotorsFuel tankEngineering

A single-pump hydraulic control loop of a key drilling action of a cutting drill rig comprises a load-sensitive variable pump, a load-sensitive multi-way valve, a rotary motor, a propulsion oil tank, a drilling logic control block, a rotation guide handle, a propulsion guide handle, and a hydraulic oil tank. An oil inlet of the load-sensitive variable pump is connected with the hydraulic oil tank. An oil outlet and a load-sensitive opening of the load-sensitive variable pump are connected with an oil inlet and a load-sensitive opening of the load-sensitive multi-way valve respectively. Each valve pressure difference compensator of the load-sensitive multi-way valve is provided with an external control opening. The external control openings are connected with the drilling logic control block. The rotation guide handle and the propulsion guide handle are connected with the drilling logic control block or a guide control opening of the load-sensitive multi-way valve. The double-pump hydraulic control loop has the advantages that power head rotation-proportion-controlled propulsion is achieved, high-speed rotating with propulsion prior to rotation is achieved, fast rod lifting while retaining certain rotation speed is achieved, and the like.

Owner:SUNWARD INTELLIGENT EQUIP CO LTD

Method for controlling on-line self-centering perforation of seamless tube blank puncher

InactiveCN101011769AImprove product qualityEasy to controlArc welding apparatusControl using feedbackEngineeringManipulator

A way controlling automatic centering perforating for seamless tube blank puncher sets the drilling action parameter, PLC sends out order after computing the data received through communication cable, fine controlling the forward and backward of the cart running on the track, with the robot moving to finish the actions like centering, inducing contacting and arcing till the completion of the centering drilling of holes. It is exact in controlling, accurate in centering, high in quality with quick drilling speed. It improves the quality of seamless tube with reduced rolling cost.

Owner:包头市钢威机电有限公司

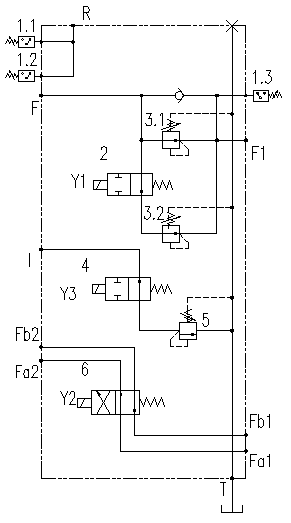

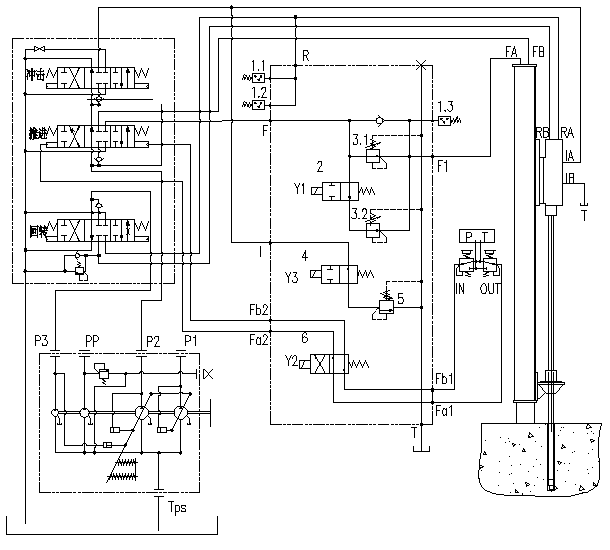

Electro-hydraulic logic control loop of rock drilling actions of hydraulic rock drilling machine

ActiveCN102425401APush stuck drillEffective air defenseFluid-pressure actuator componentsAutomatic control for drillingElectro hydraulicPressure control

The invention relates to an electro-hydraulic logic control loop of rock drilling actions of a hydraulic rock drilling machine. A first pressure relay, a second pressure relay, a third pressure relay, a first pressure reducing valve, a second pressure reducing valve, a first electromagnetic directional valve, a second electromagnetic directional valve and an overflow valve or a speed regulating valve constitute a first logical control loop of controlling two-stage pressure propulsion by revolution pressure and simultaneously controlling low-pressure impact by low-pressure propulsion; the third pressure relay, the second electromagnetic directional valve and the overflow valve or the speed regulating valve constitute a second logic control loop for controlling two-stage impact pressure by propulsion pressure; and the second pressure relay and a third electromagnetic directional valve constitute a logic control loop of controlling propulsion and lifting by revolution pressure.

Owner:SUNWARD INTELLIGENT EQUIP CO LTD

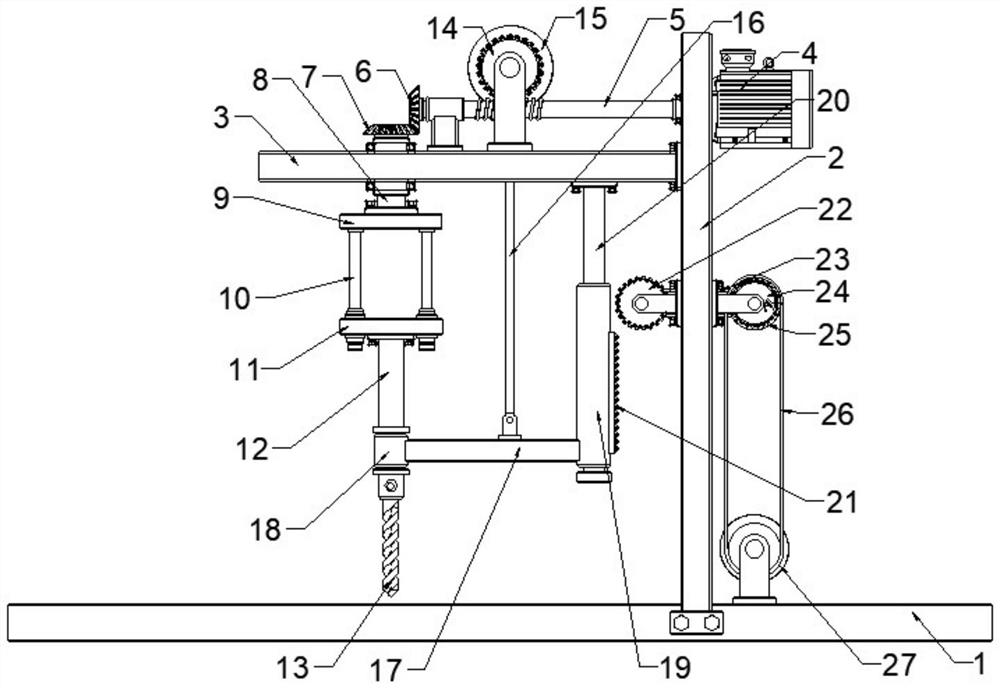

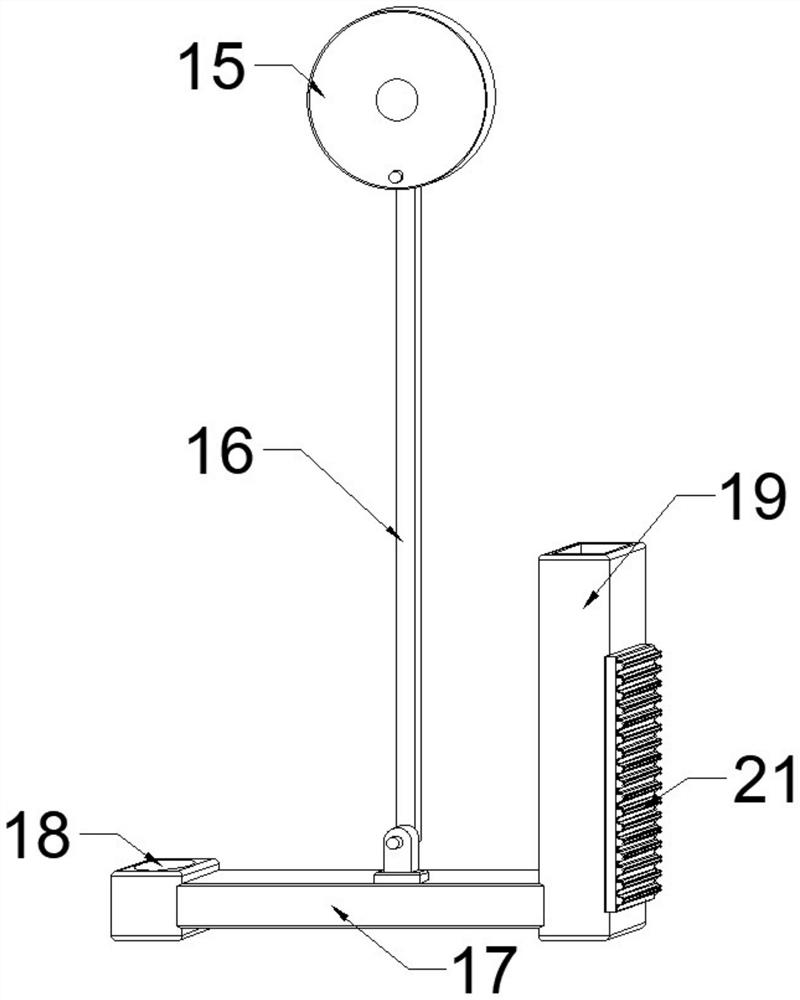

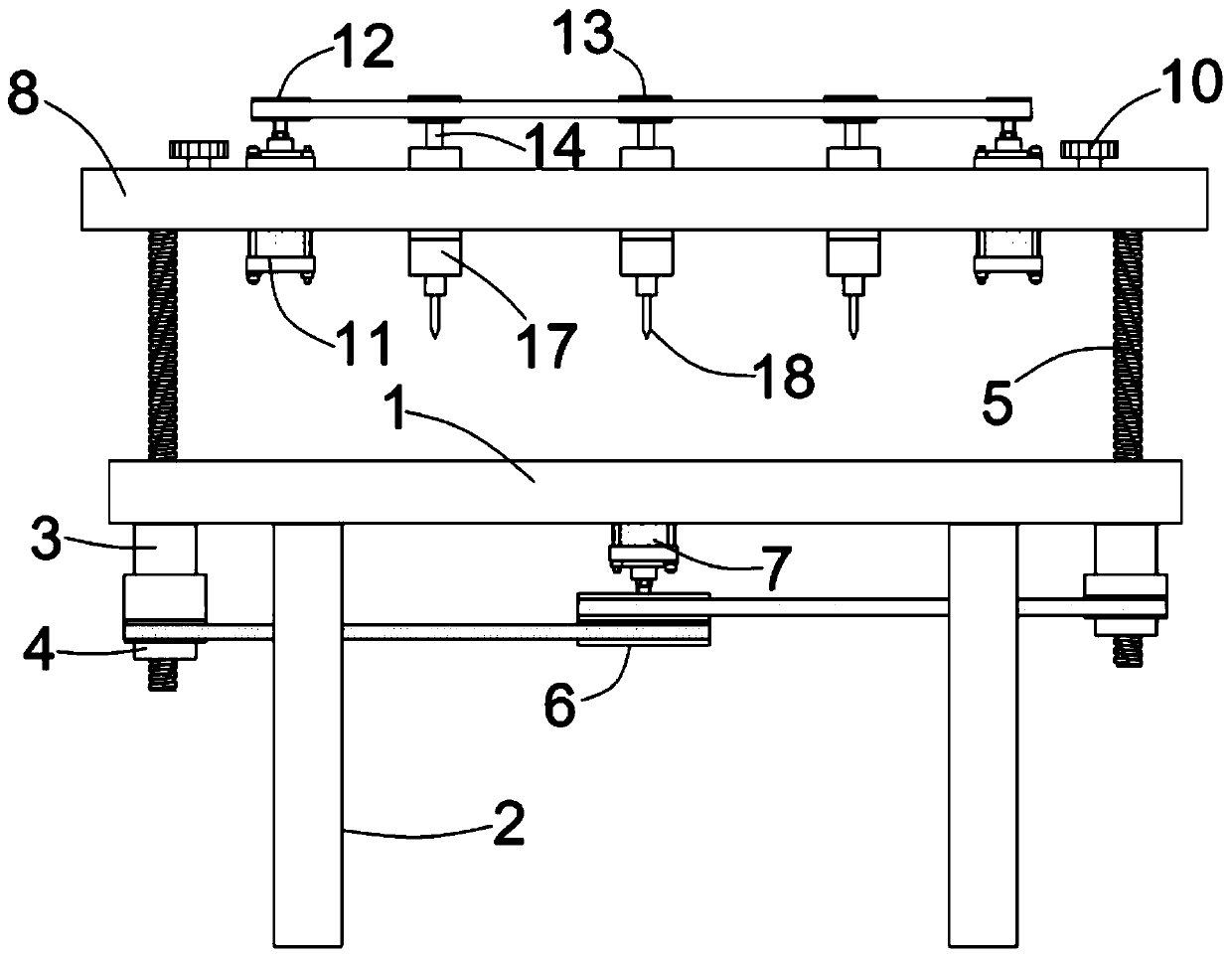

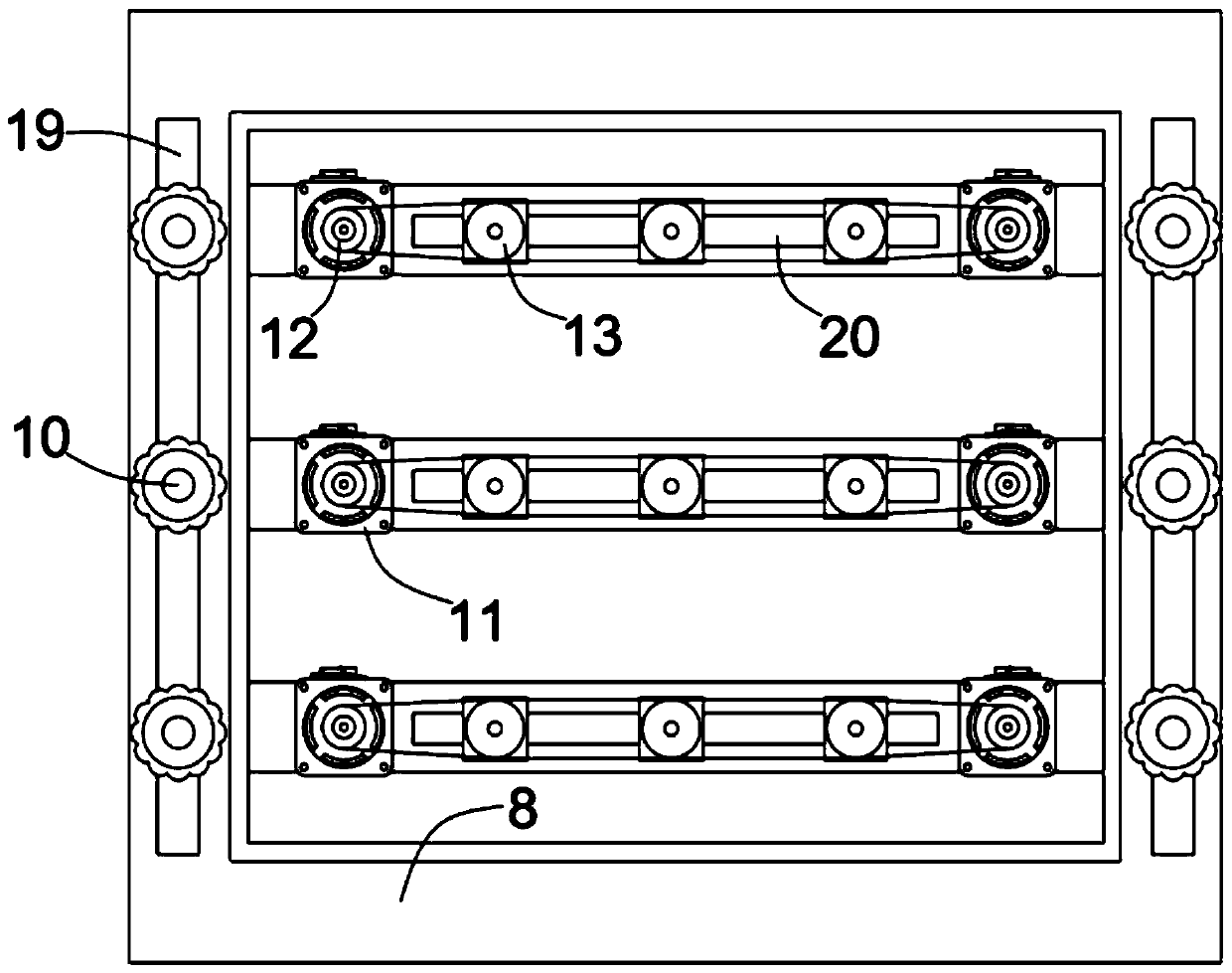

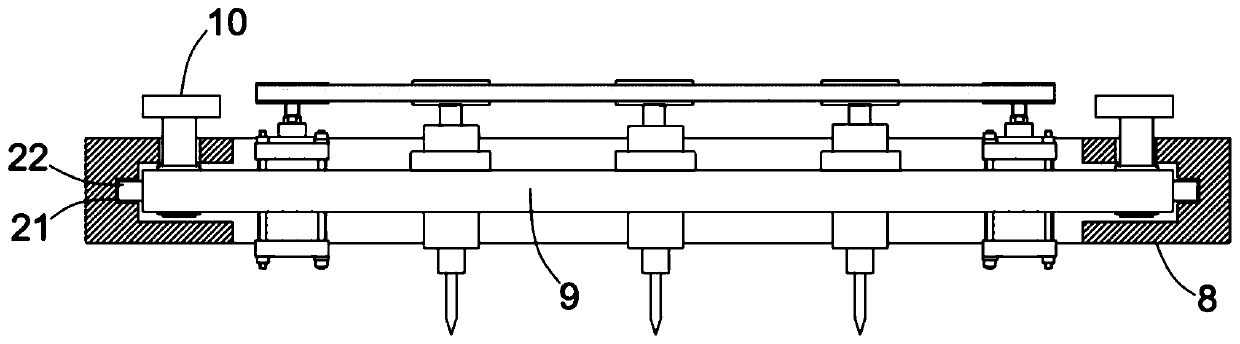

Continuous equidistant drilling equipment for mechanical production

InactiveCN111940777ARealize automatic feed functionBoring/drilling componentsBoring/drilling machinesEngineeringPhysics

The invention discloses continuous equidistant drilling equipment for mechanical production. A driving mechanism is mounted on a fixing frame, a drill rod is connected to the lower portion of the fixing frame through a transmission assembly, the transmission assembly is connected with the driving mechanism, and the transmission assembly is vertically and movably mounted at the lower portion of thefixing frame through a reciprocating structure; and the reciprocating structure is connected with the driving mechanism, and a one-way transmission assembly is installed on a supporting piece. The driving mechanism acts to drive the transmission assembly to act, the transmission assembly drives the drill rod to rapidly rotate to execute the drilling action, meanwhile, the driving mechanism drivesthe reciprocating structure to drive the transmission assembly to continuously move up and down and back and forth, and then the drill rod is driven to vertically move for transposition while drilling at high speed; and the reciprocating structure drives the one-way transmission assembly to act in the process of moving up and down and back and forth, the one-way transmission assembly drives a feeding wheel to rotate intermittently in one direction, then the automatic feeding function of a workpiece is achieved, and equidistant drilling is conducted on the workpiece in cooperation with the drill rod moving up and down and back and forth and rotating.

Owner:湖南省宝满科技开发有限公司

Efficient accurate punching device

InactiveCN109877356ASimple structureEasy maintenanceBoring/drilling componentsBoring/drilling machinesPunchingDrive shaft

The invention discloses an efficient accurate punching device. A punching table is included. Lead screw bases are movably provided with lead screw lifting bases. The lead screw lifting bases are connected with driving belt wheels through a belt. The driving belt wheels are fixedly arranged on a drive shaft of a lifting motor. The ends, away from the lead screw lifting bases, of lifting lead screwsare fixedly connected with a punching device supporting plate. The punching device supporting plate is movably provided with a plurality of moving plates. Punching motors are further fixedly arrangedon the two sides of the moving plates. Connecting shafts are movably inserted in shaft sleeves. The shaft sleeves are movably arranged in moving grooves of the moving plates. The ends, away from thedriving belt wheels, of the connecting shafts are fixedly provided with drill chucks. The drill chucks are fixedly provided with drill bits. The efficient accurate punching device is simple in structure, a plurality of drilling actions can be finished at a time, the stroke and the rotation speed of stepping motors are adjusted according to the drilling depth and drilling material needs, the drilling depth and drill bit safety are effectively guaranteed, and the drilling efficiency is greatly improved.

Owner:安徽省鑫矿液压机械有限责任公司

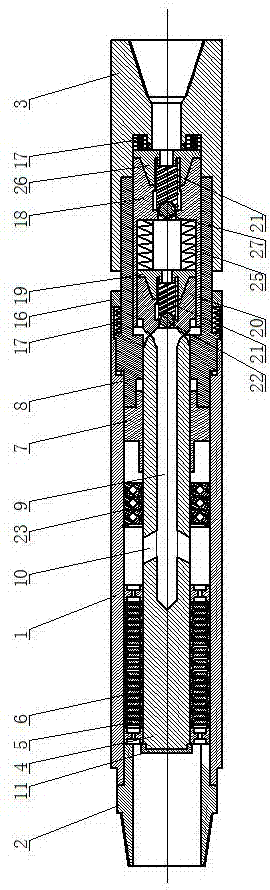

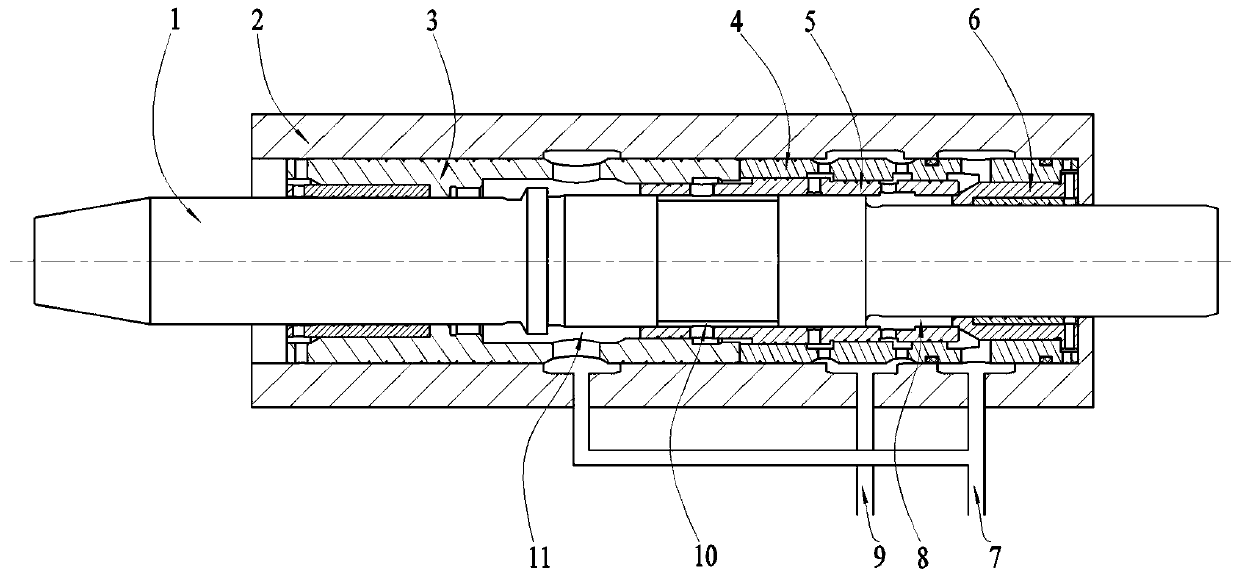

Coupling impactor used for petroleum drilling

PendingCN107542397AImprove rock breaking efficiencyAvoid mud baggingBorehole drivesHydro energy generationCompressed fluidPetroleum

The invention relates to a coupling impactor used for petroleum drilling, and belongs to the technical field of petroleum drilling and production equipment. The impactor comprises a shell, an upper connector, a lower connector, a central shaft, a turbine fixed valve, a turbine moving valve, an upper hammer block and a lower hammer block, the upper connector is in threaded connection with one end of the shell, and the central shaft is installed in the shell at the inner side of the upper connector through the turbine fixed valve and the turbine moving valve; the upper hammer block is fixedly installed on the central shaft, and the lower hammer block is installed on the central shaft at one side of the upper hammer block in a sleeving mode, and the lower hammer block is in key connection with the shell. According to the coupling impactor used for petroleum drilling, under the action of drilling fluid, the upper hammer block is driven by the central shaft to produce periodical axial impact and periodic torsional impact on the lower hammer block, at the same time, the lower end of the central shaft makes an upper piston body periodically compress the fluid in a cavity, so that the drilling fluid periodically produces a certain pressing effect before entering in a drill bit, and pulse fluctuation is formed; under the coupling action, the contact stress between the drill bit and rocks and the rock crushing effect can be effectively improved, rock crushing efficiency, the drilling speed are improved, the drilling cost is reduced, and meanwhile, the phenomena of drill bit nozzle plugging and drill bit balling are avoided.

Owner:YANGTZE UNIVERSITY

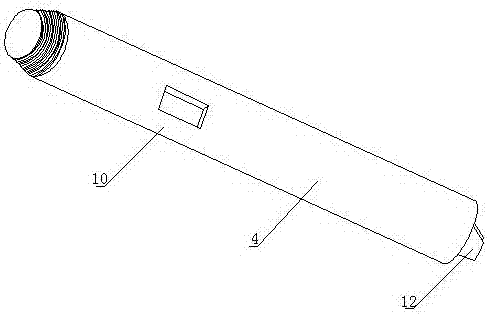

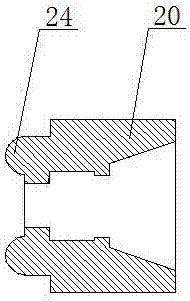

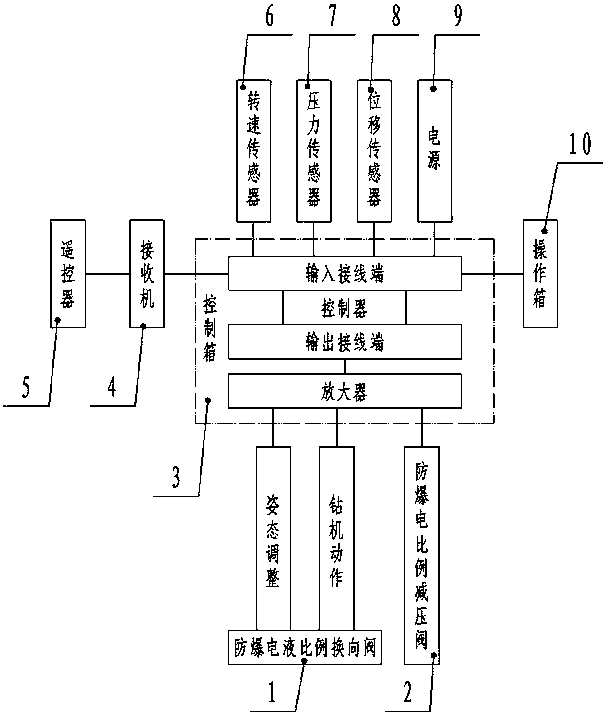

Electrohydraulic control system for coal mine roof bolter

PendingCN109854225AAddress flexibilitySolve labor intensityAnchoring boltsAutomatic control for drillingFailure rateElectric control

The invention belongs to the technical field of anchor bolt support used for underground coal mine, and specifically relates to an electrohydraulic control system for a coal mine roof bolter, which solves the problem that a hydraulic control system of an existing roof bolter is complicated, is high in failure rate, is troublesome in automation and remote control, and is low in work efficiency. Thesystem includes an explosion-proof electro-hydraulic proportional reversing valve, an explosion-proof electric proportional pressure reducing valve, a control box, a receiver, a remote controller, arotational speed sensor, a pressure sensor, a displacement sensor, a power supply, an operation box, and an electric control part. The electrohydraulic control system is used for controlling motion ofthe bolter, the operation box and the remote controller are used for operation, a drilling action is completed with one button, an anchoring action is completed with one button, the labor intensity of workers is reduced, an operation position is relatively flexible, remote control and automation control are achieved, a labor environment is improved, and work efficiency is improved.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

Electric drill facilitating drilling of inclined hole

ActiveCN108176879AOutflow no longerEasy to drill oblique holesMetal working apparatusPortable drilling machinesEngineeringAtmospheric pressure

The invention discloses an electric drill facilitating drilling of an inclined hole. The electric drill comprises a machine body assembly and an angle adjusting assembly. The angle adjusting assemblyis mounted on a machine body of the machine body assembly through a sleeve with rods in a sleeving mode; the sleeve with the rods is arranged on the rear side of the angle adjusting assembly; and themachine body assembly further comprises a rear cover, a motor gland, a middle moving block, sliding covers A, springs B, a cushion block, a drill bit, sliding covers B, springs C, springs A, a front cover, a cutting liquid storing cavity and bent holes. The electric drill is provided with the angle adjusting assembly, so that drilling of the inclined hole is facilitated; cutting liquid storing holes are formed inside the machine body, when the drilling action is conducted, the air pressure between the front cover and the machine body is increased, a gap between the drill bit and the front cover is small relative to holes in grooves of the middle moving block, and therefore, cutting liquid flows out from the front end of the drill bit under the effect of the air pressure and takes the cooling and lubricating effects; when the motor stops rotating, the middle moving block stops moving, the drill bit stops rotating, the sliding covers A and the sliding covers B reset under the effects ofthe springs B and the springs C, and the cutting liquid does not flow out any more; and thus convenience is achieved.

Owner:宁波赛广宏科技有限公司

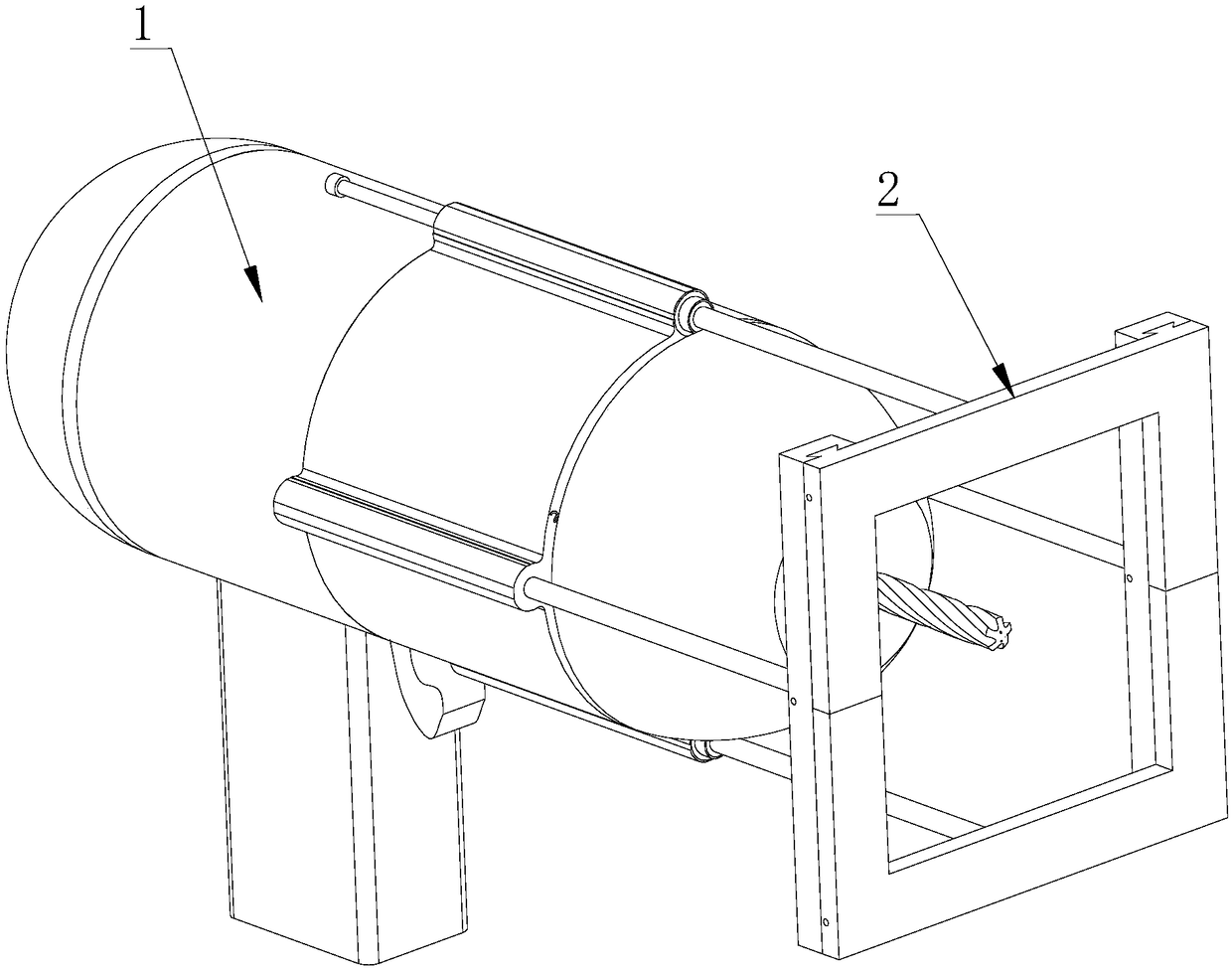

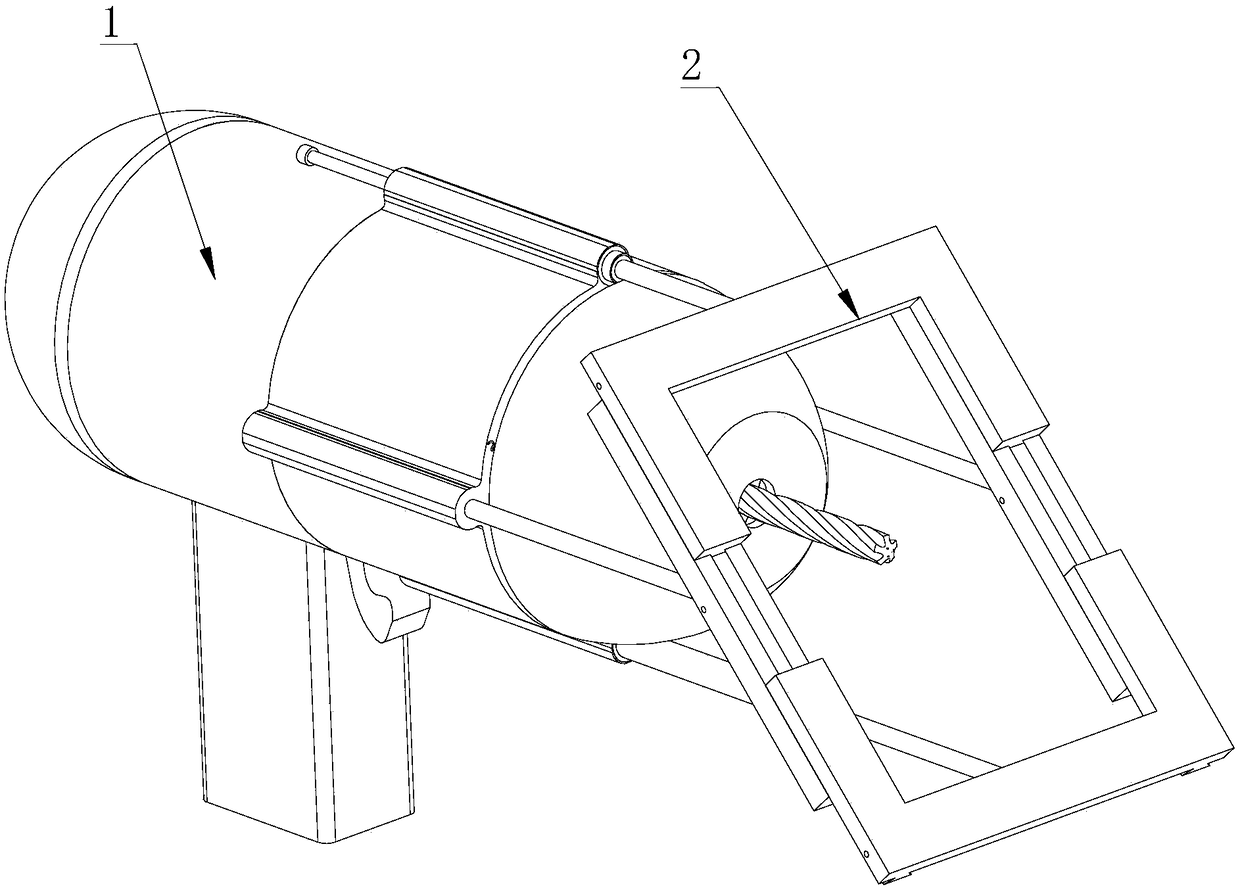

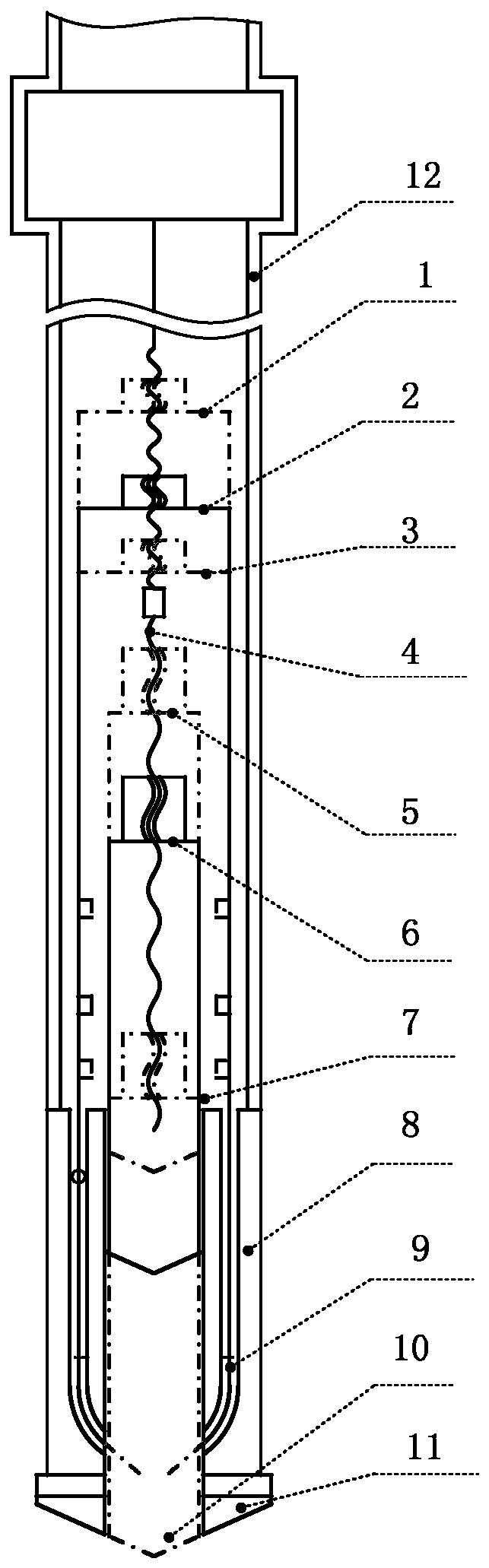

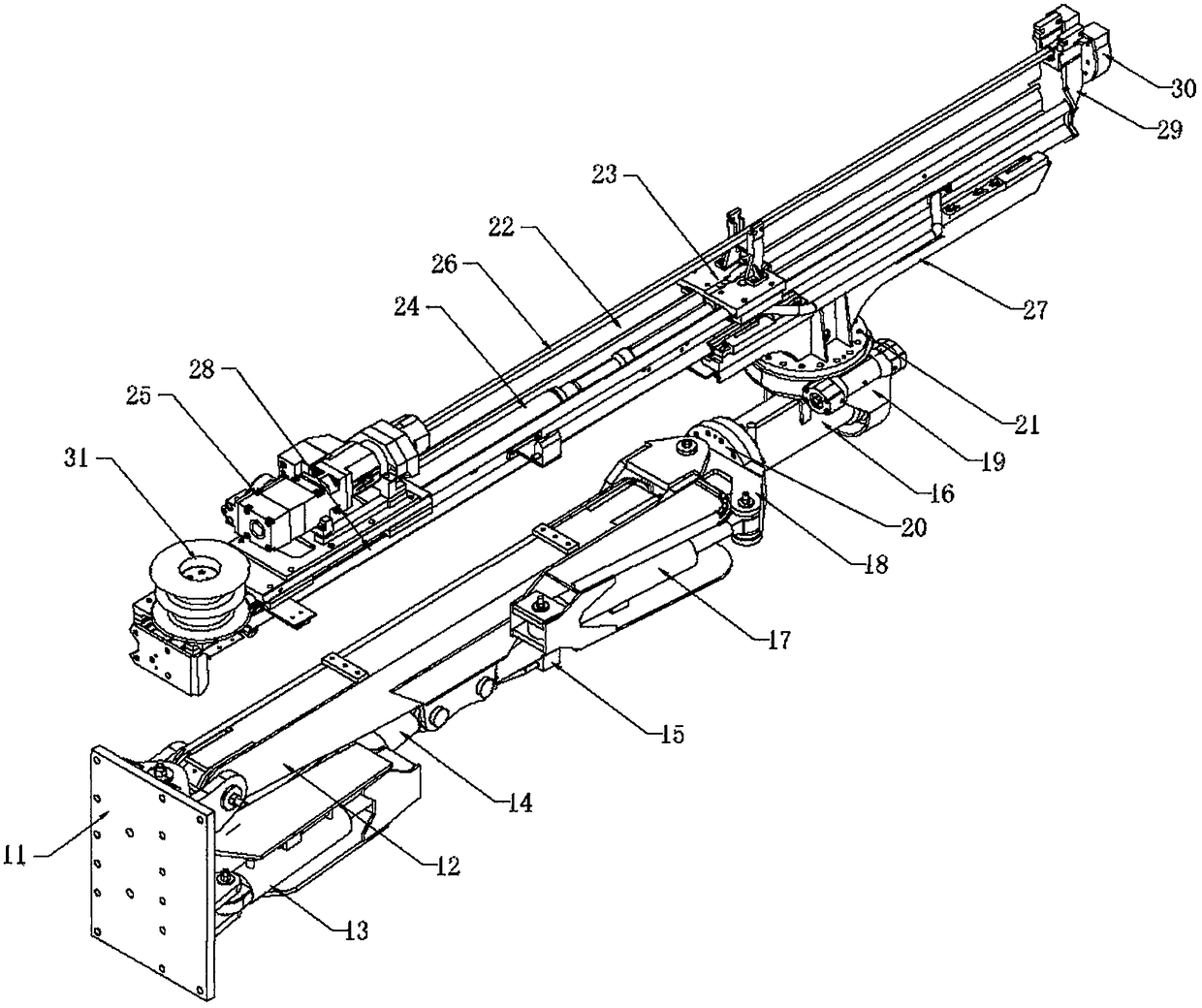

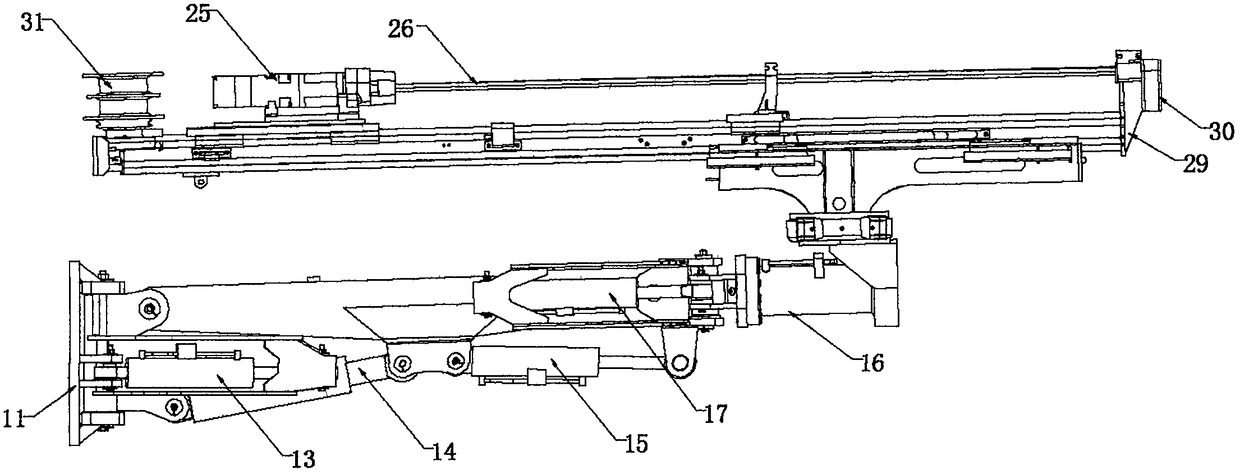

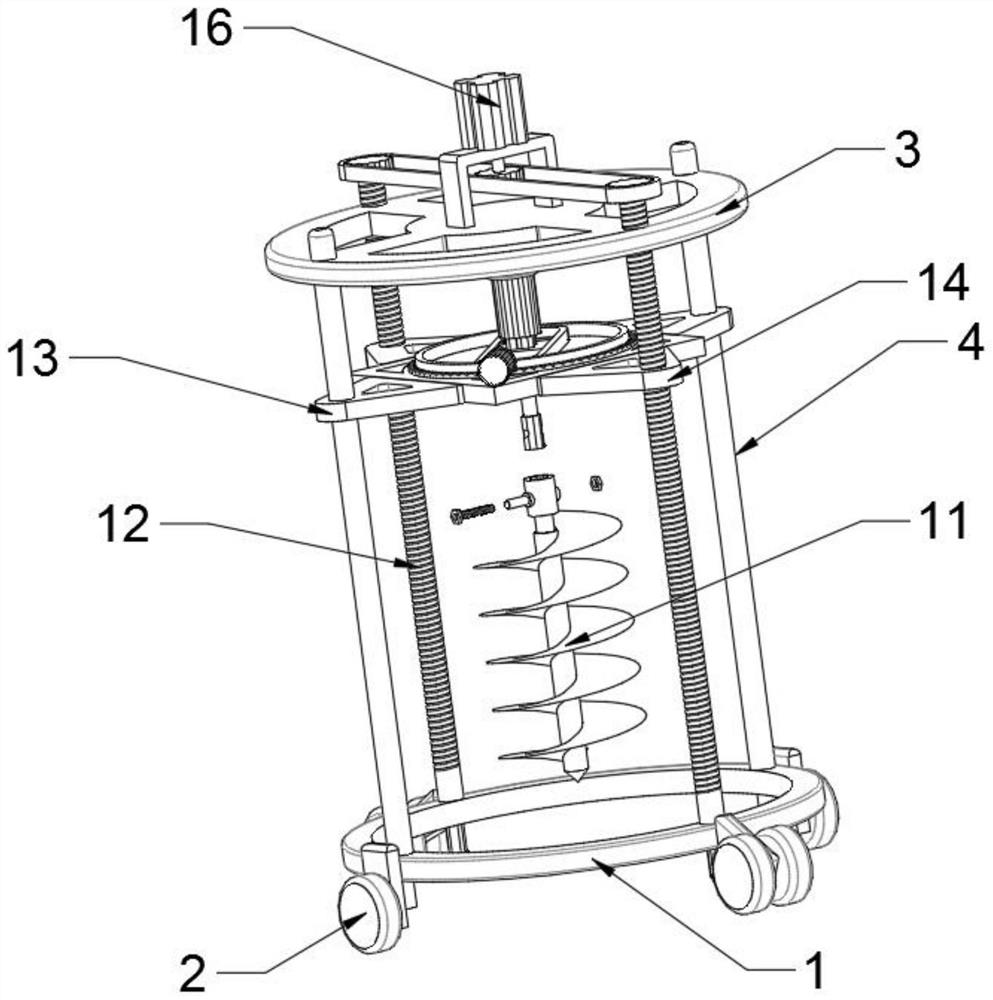

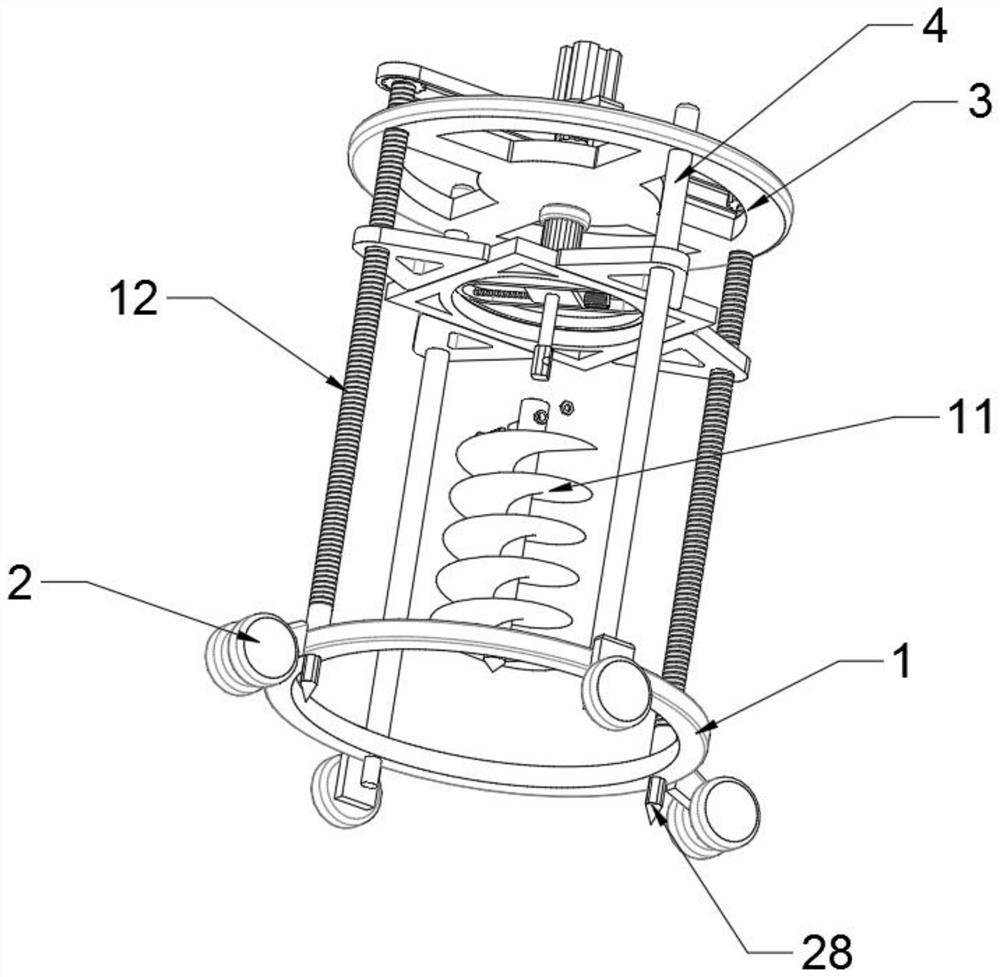

Multi-point multi-time sampling executing mechanism suitable for frozen soil type extraterrestrial star soil

ActiveCN110907216ADo multiple jobsMeet lightweight design requirementsWithdrawing sample devicesSoil typeSoil science

The invention discloses a multi-point multi-time sampling executing mechanism suitable for frozen soil type extraterrestrial star soil, and relates to the field of deep space sampling detection. According to the environmental characteristics of the extraterrestrial stars and the distribution characteristics of the frozen soil type extraterrestrial star soil, in combination with the sampling and detecting requirements of the extraterrestrial star soil, the multi-point multi-time sampling executing mechanism suitable for the frozen soil type extraterrestrial star soil is provided. According to the scheme, the mechanism needs to be carried on a detector body and mainly comprises a core fixing mechanism, a core breaking mechanism, a two-way lead screw, a drill rod, a drill bit, a core breakingmechanism guide sleeve and the like. Under driving of two external motors, drilling action of extraterrestrial star soil is achieved through the drill bit and the drill rod; fixed-point coring, coreshearing and cutting, in-situ transferring and sample core spitting actions on frozen earth extraterrestrial star soil are achieved through design between the core fixing mechanism and the core breaking mechanism and matching of motion parameters. Through the transfer of the detector, the functions of multi-point multi-time sampling of different sampling points and the like are realized. At present, the scheme is verified by a frozen soil type extraterrestrial star soil simulation test, and the sampling effect is good.

Owner:BEIJING SATELLITE MFG FACTORY

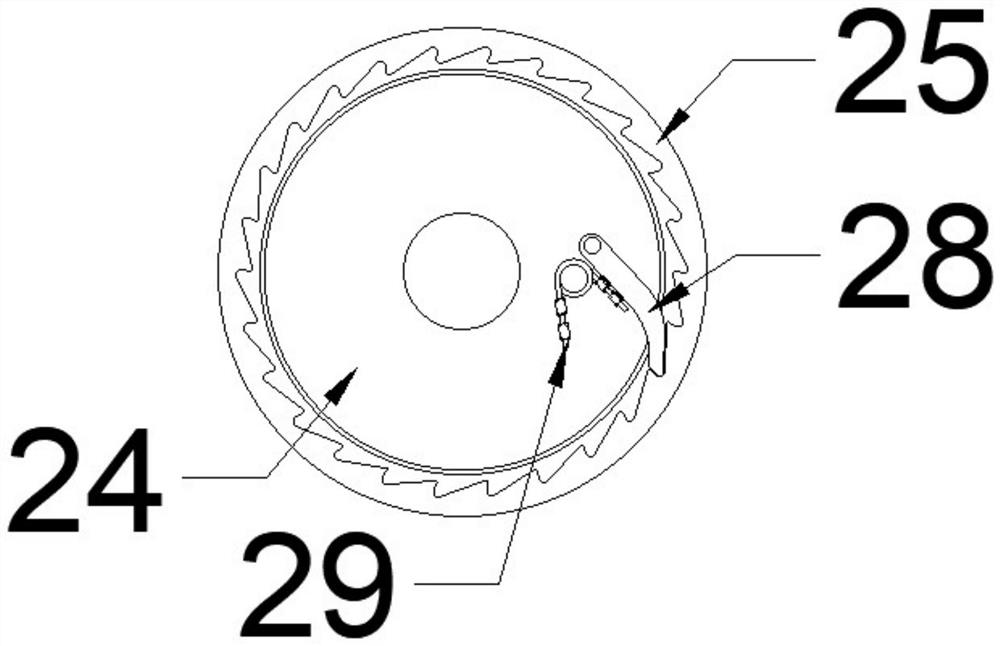

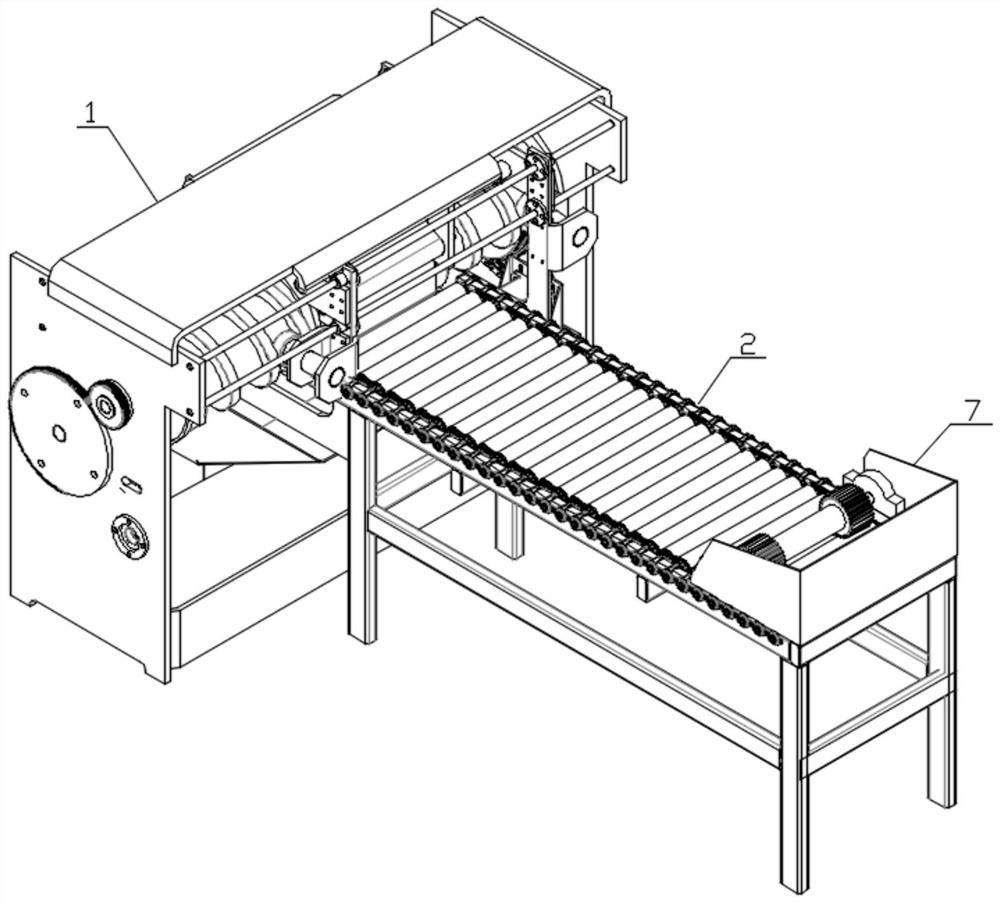

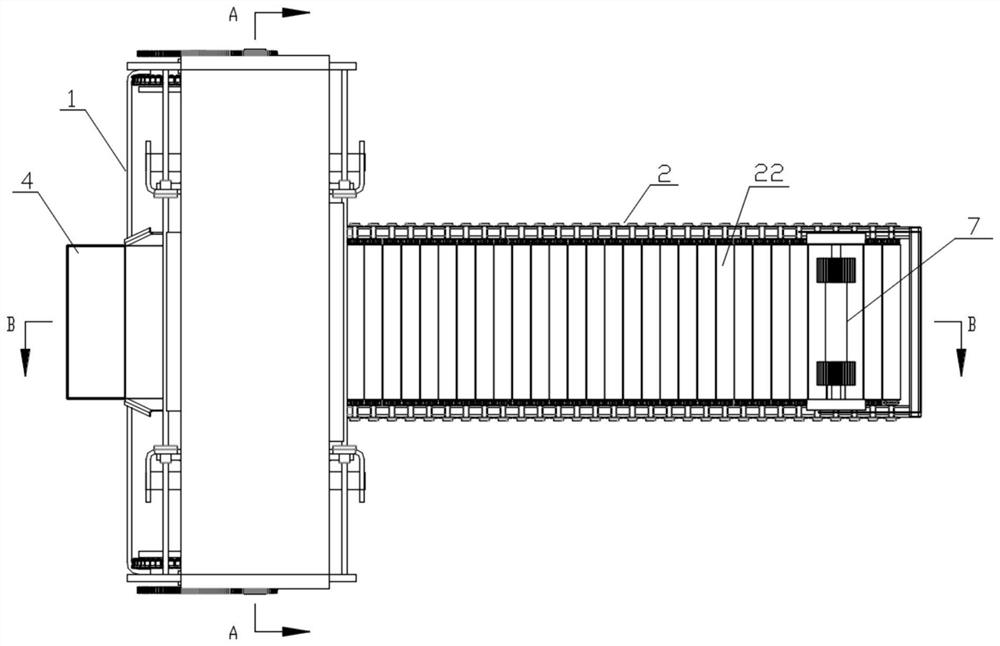

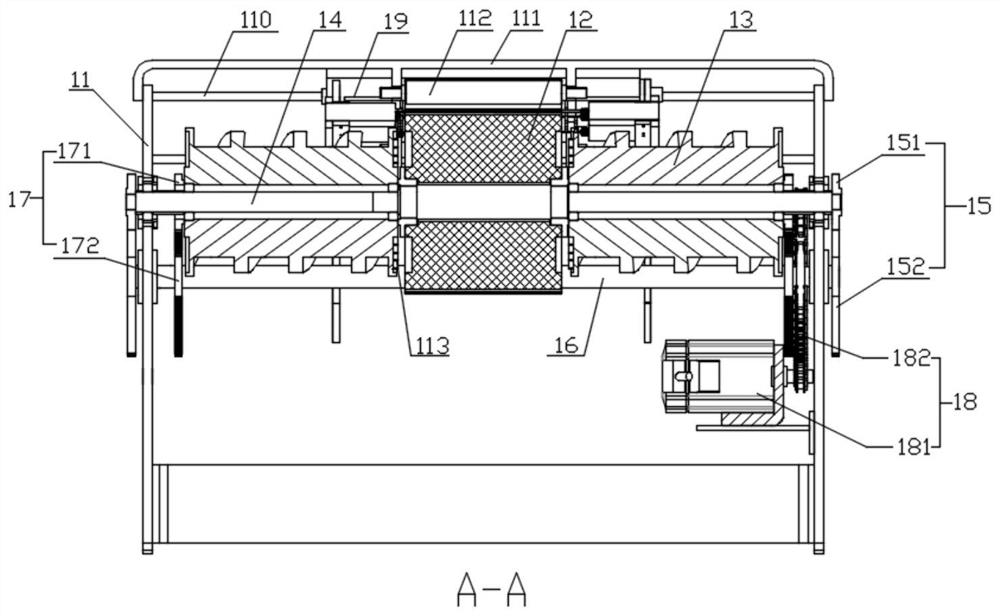

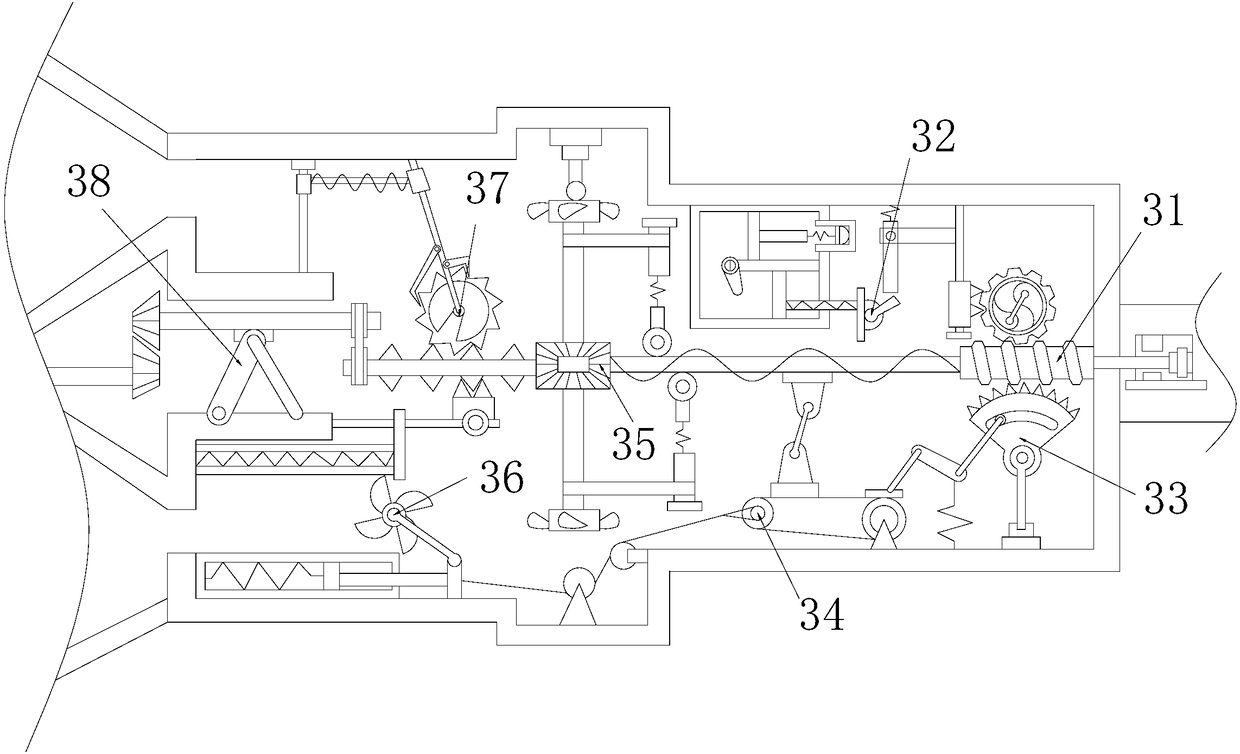

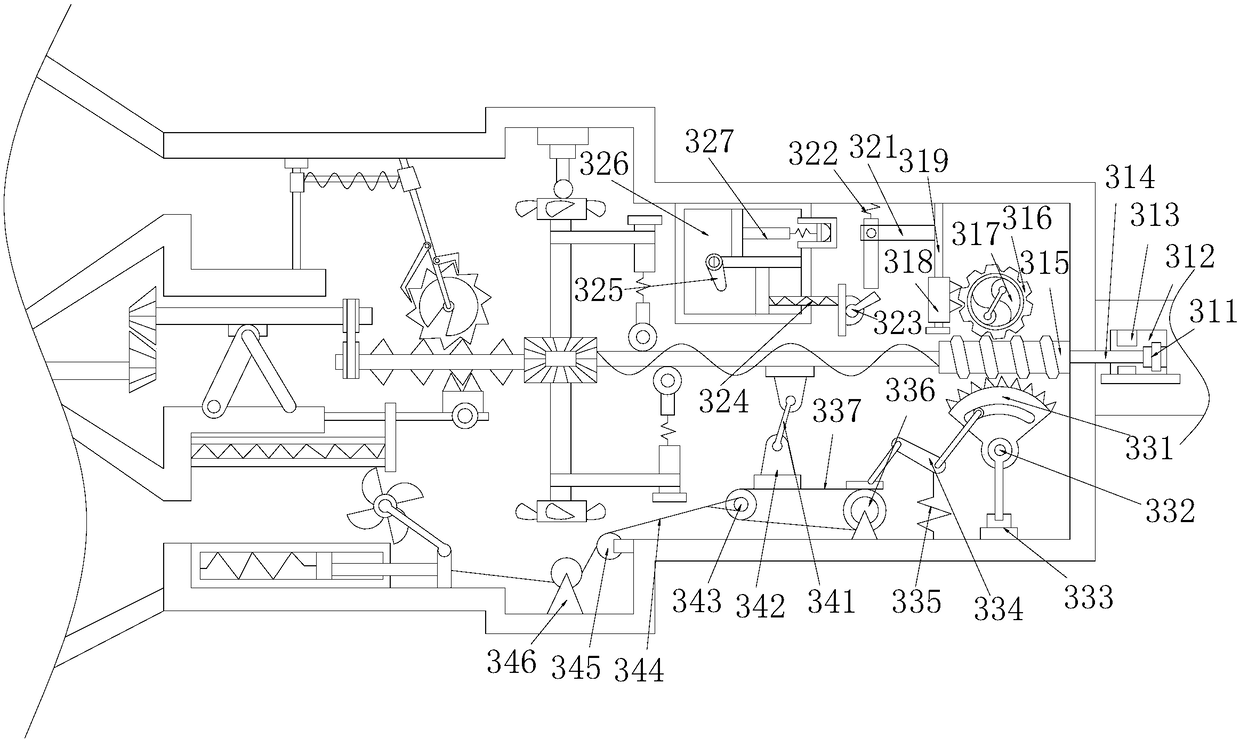

Automatic bamboo straw drilling machine

ActiveCN111958698ARealize automatic drilling operationImprove drilling efficiencyStationary drilling machinesConveyorsDrive shaftControl engineering

The invention relates to the technical field of bamboo straw processing, in particular to an automatic bamboo straw drilling machine. The machine comprises a conveyor used for horizontally conveying materials, and further comprises a drilling device and a bamboo straw feeding mechanism, wherein the drilling device is connected to the conveyor, and the bamboo straw feeding mechanism is arranged atthe feeding end of the conveyor; and the drilling device comprises a rack, a feeding roller, a spiral shaft, a roller transmission shaft, a first intermittent rotating structure, a synchronous shaft,a second intermittent rotating structure, a transmission mechanism, a drilling mechanism, a guide rod, a tensioning support, a tensioning mechanism and a spring, wherein the roller transmission shaftis rotationally arranged between the two side walls of the rack. According to the bamboo straw drilling machine, automatic drilling operation on a bamboo straw can be realized, through reasonable arrangement of the structure of the drilling device, a single motor drives feeding and drilling actions to be carried out, and compared with feeding and drilling driving by a multi-driving mechanism, thedevice can make feeding and drilling beats more adaptive, so that later debugging is avoided, use is more convenient, and the machine is suitable to further popularize and apply.

Owner:武夷学院

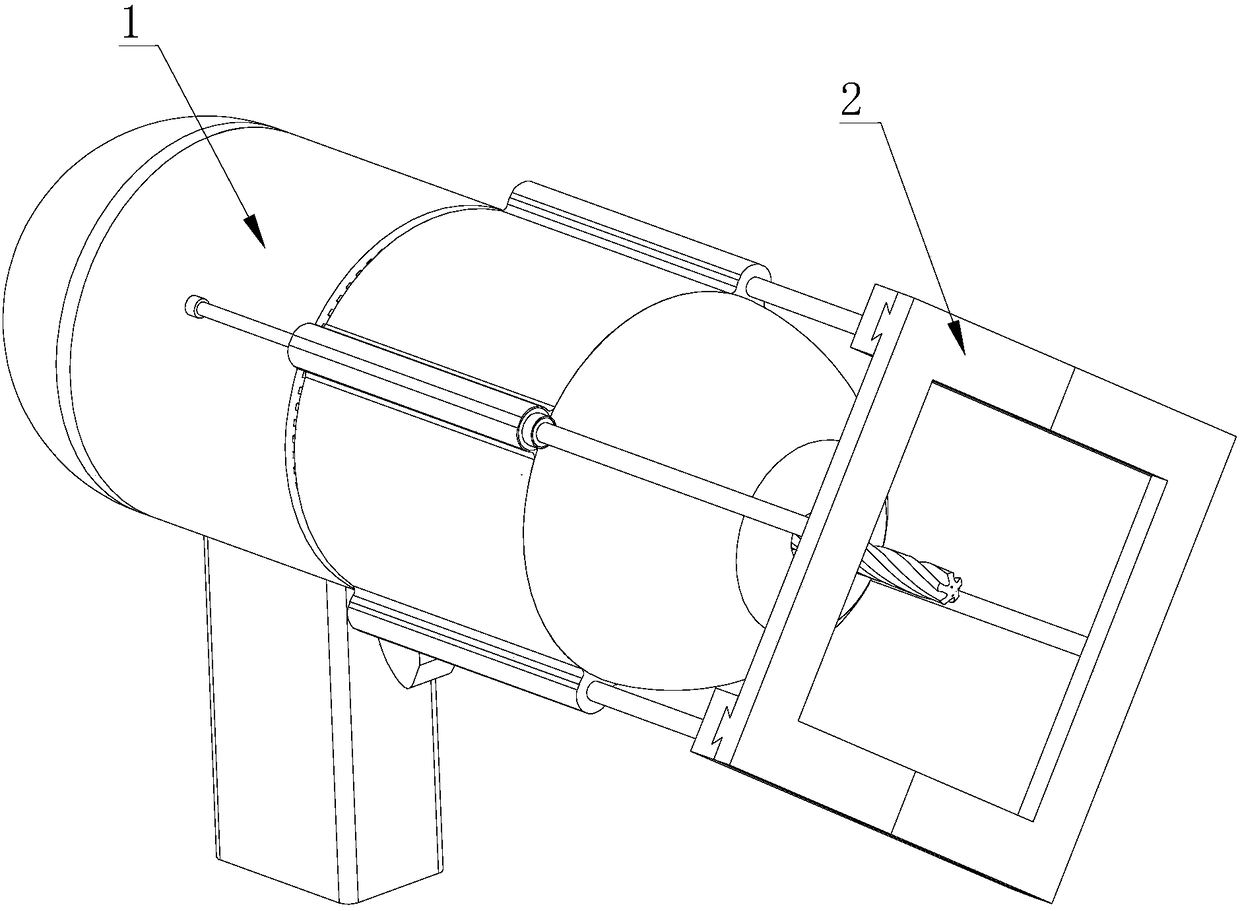

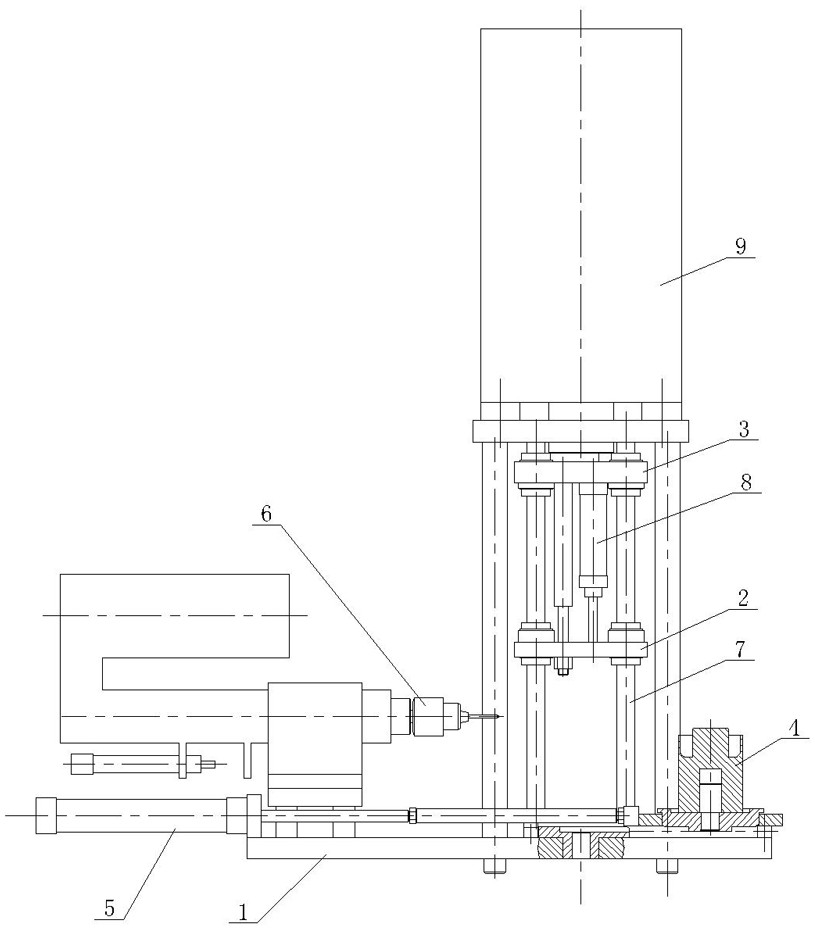

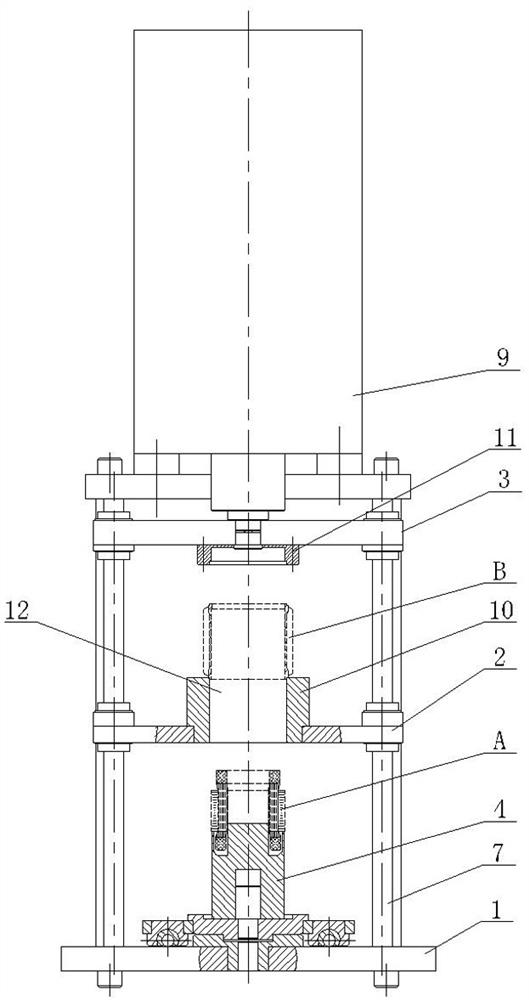

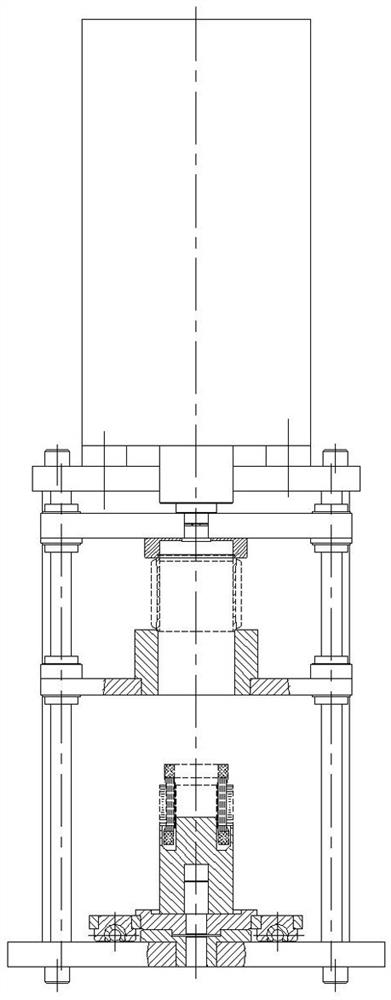

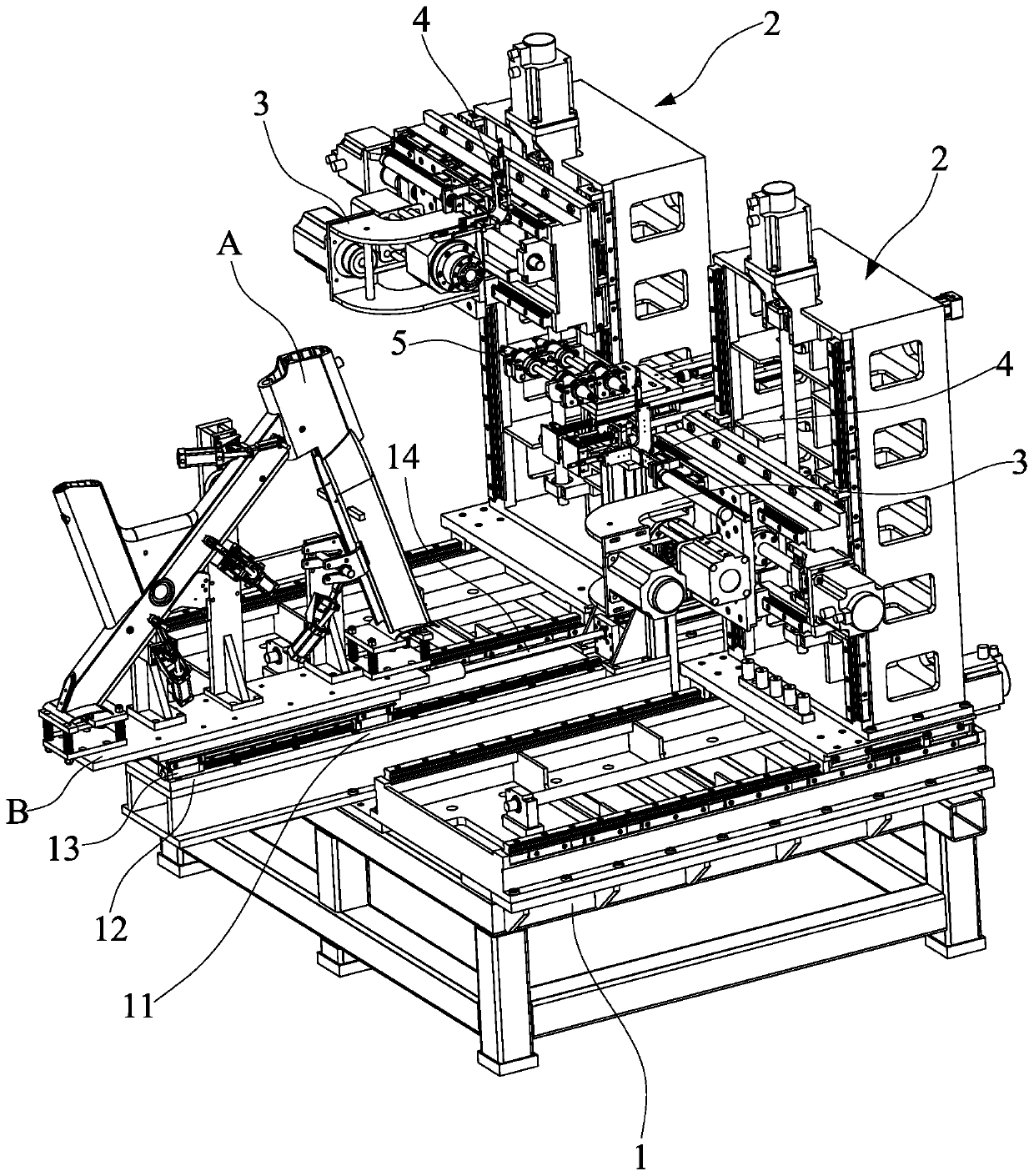

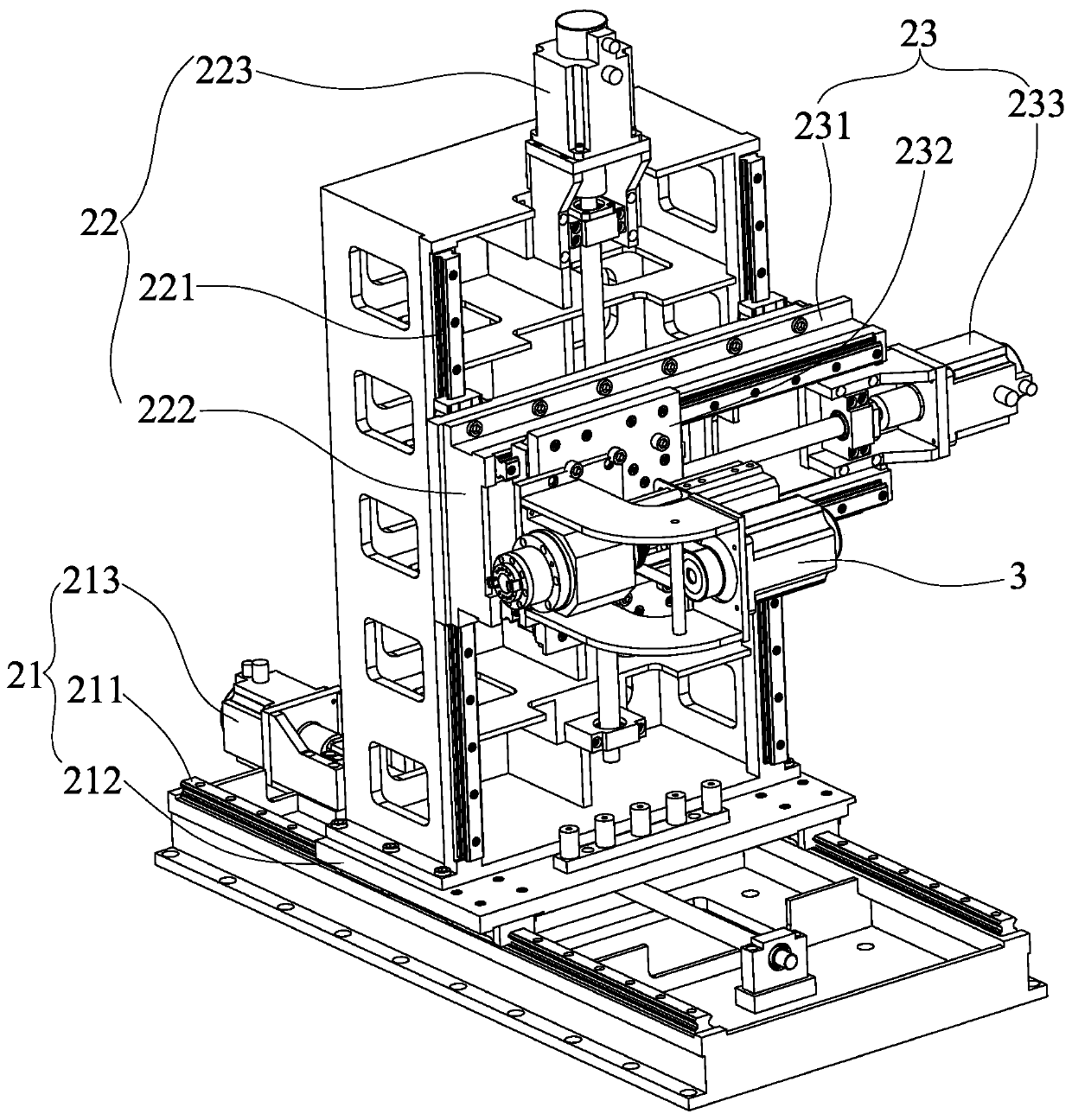

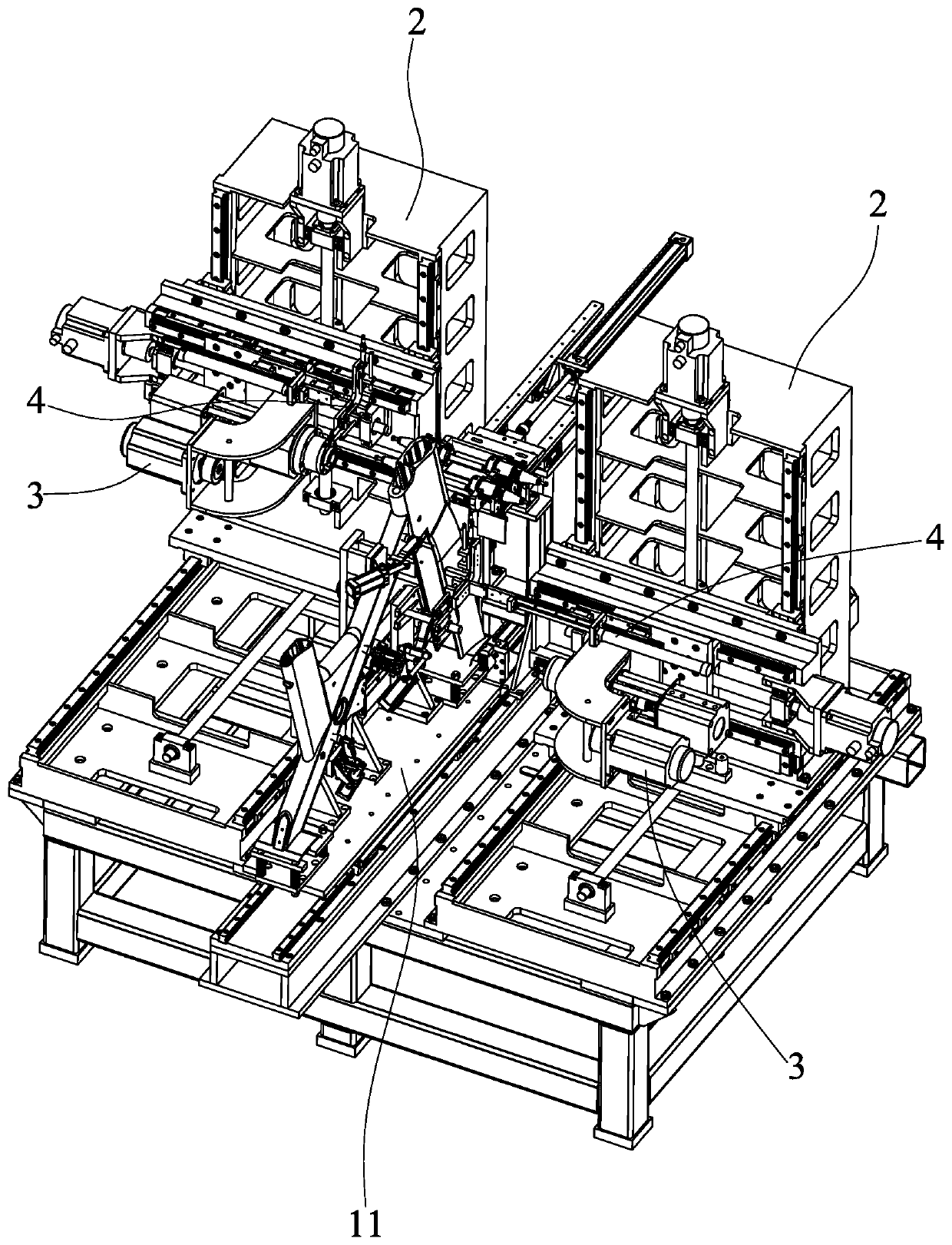

Assembling process and equipment for motor stator and motor shell

InactiveCN111987872AEfficient and high-quality assemblyHigh precisionManufacturing stator/rotor bodiesSet screwElectric machine

The invention discloses an assembling process of a motor stator and a motor shell. The process is characterized by comprising the following steps: firstly, placing a stator on a stator seat for innerhole positioning; placing the casing on the casing seat for excircle positioning; aligning centers of the casing and the stator up and down; then the casing clamping cylinder pushing the casing seat to position and clamp the casing; the stator press-fitting cylinder pushing the positioned and clamped casing to move downwards; pressing the stator into the machine shell to the required size, then the drill bit power head drilling the set screw hole in the machine shell from the side face direction, after the drilling action is completed, the drill bit power head retreating in place, the stator press-fitting air cylinder ascending in place, the machine shell clamping air cylinder loosening in place, and finally taking out the machine shell and the stator assembly which are subjected to press-fitting drilling. According to the invention, the assembly of the motor stator and the casing can be completed with high efficiency and high quality. Meanwhile, the invention provides the assembly equipment of the assembling process.

Owner:BADA MECHANICAL & ELECTRICAL

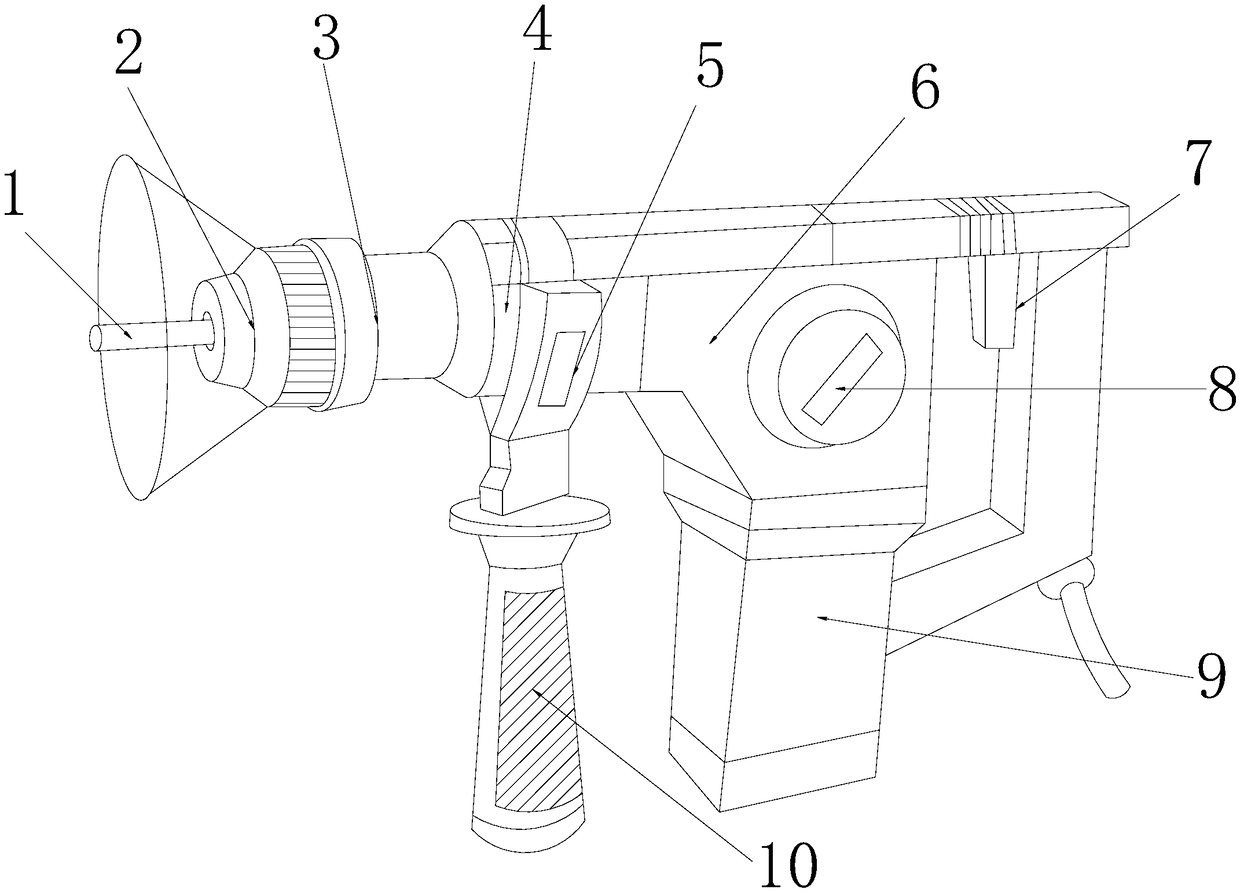

Auxiliary drilling device for installing building monitoring mark

InactiveCN108580973AStrong forward and reverse functionAvoid pollutionPortable percussive toolsPortable power-driven toolsAir pollutionGun barrel

The invention discloses an auxiliary drilling device for installing a building monitoring mark. The auxiliary drilling device structurally comprises an impact drill column head, a shaft rod rotating seat, a axial-rotating dust-proof barrel, a gun barrel groove shell, a Y-shaped clamping buckle frame, a motor transmission box, a trigger holding handle frame, a key lock hole disc, a micro stepping motor and an auxiliary handle rod, wherein the axial-rotating dust-proof barrel is nested at the left end of the gun barrel groove shell, and the impact drill column head is inserted into the left sideof the shaft rod rotating seat. According to the auxiliary drilling device, the axial-rotating dustproof barrel is provided with a motor shaft moving device, a double-push-rod piston cylinder, a fluted disc traction mechanism, a roller transmission mechanism, a shaft rod rotating device and a spring telescopic device, a ratchet wheel rotating mechanism and an impact shaft rod supporting seat, sothat the functional performance of forward and reverse rotating of the drilling device is high, the drilling intensity is increased through forward rotating, the dust and the gravel are sucked in thereverse rotation manner through reverse rotating, the air pollution is avoided, the cost is also saved, the engineering progress is improved, the integrated synchronous multifunctional effect is achieved, meanwhile, forward and reverse rotating isolation does not interfere with the drilling action, so that the building monitoring mark is more convenient to install.

Owner:南安易盾格商贸有限公司

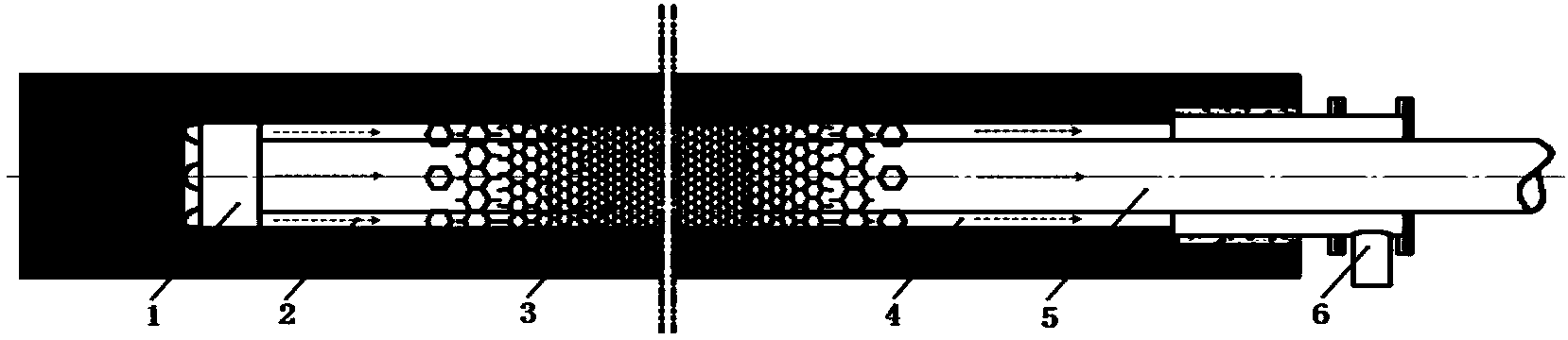

Method and device for constructing bedding gas extraction long drilled holes of soft coal seams

ActiveCN103452508ASafe and fast drillingOvercoming the Insufficiency of the Drilling TechnologyFlushingCooling effectEngineering

The invention discloses a method and a device for constricting bedding gas extraction long drilled holes of soft coal seams. The method and the device are applied to drilling the bedding gas extraction long drilled holes of the soft coal seams, and are characterized in that two types of gas-based fluid including compressed air and stable foams are used as drilled hole washing media, are alternately injected into a drilled hole, reach the bottom of the hole, then flow into annular clearance via flow channels in a drill bit, cool the drill bit and carry coal cinder dust which is generated along with drilling actions of the drill bit at the bottom of the hole, then the drilled hole washing media and the coal cinder dust return the outside of the hole, stable foam flow carries the coal cinder dust, and cools and lubricates drilling tools, and compressed air flow washes the bottom of the hole and pushes stable foam slug to flow. The method and the device have the advantages that the cinder discharge capacity is high, a drilling tool cooling effect is good, orifices are free of dust pollution, the rotation pressure of a drilling machine can be obviously reduced while the drilling capacity of the drilling machine is improved, and the drilling machine can normally drill holes in water-containing coal seams; the flow rates of gas and liquid are regulated under the control of special valve blocks by the aid of the method and the device, the device can be operated easily and conveniently, is small in size and is light, the method and the device are applicable to underground drilling construction operation environments of coal mines, and the like.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

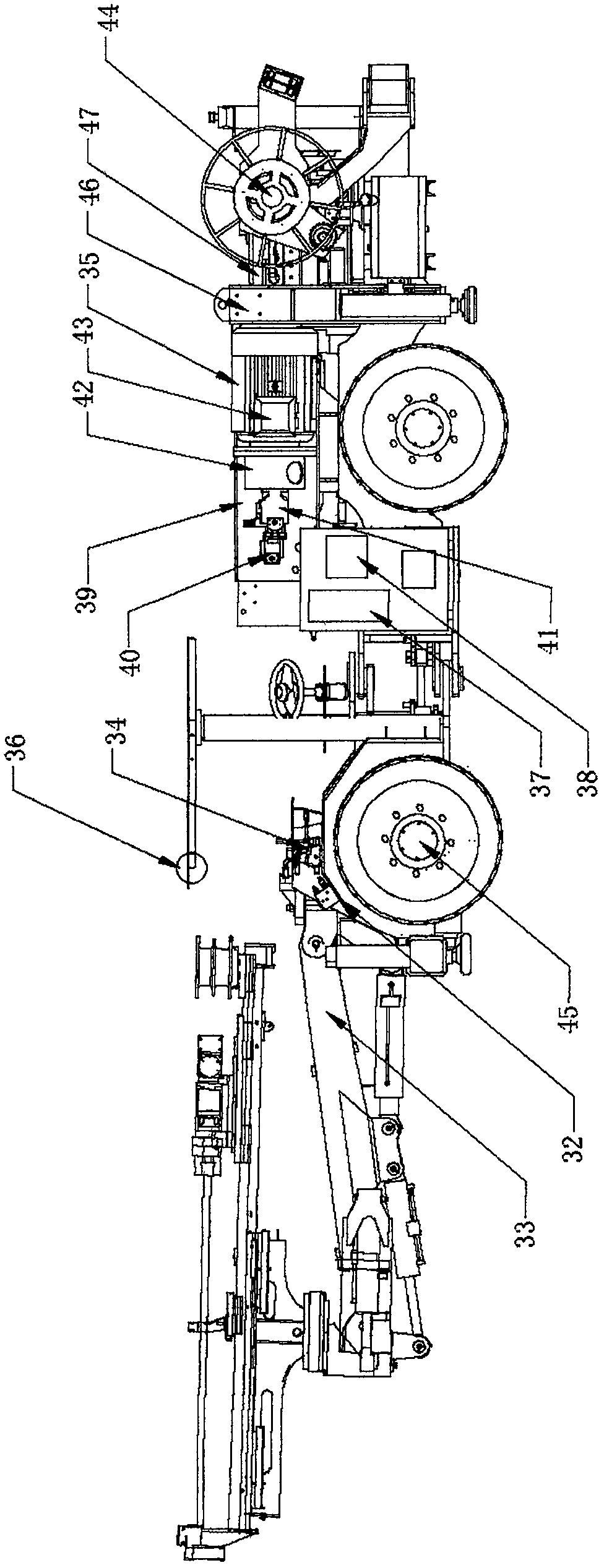

Drill jumbo with remote control function and control method thereof

PendingCN109424318AKeep healthyEnsure safetyDerricks/mastsDrilling machines and methodsSolenoid valveRemote control

The invention provides a drill jumbo with a remote control function and a control method thereof, and relates to the field of engineering machinery. The drill jumbo comprises a jumbo body, a working arm, a solenoid valve hydraulic control system, a power system, a remote control and a camera; the working arm is connected with the jumbo body and used for performing rock drilling action; the workingarm is provided with multiple oil cylinders, and the oil cylinders cooperate with one another to adjust the working angle of the working arm; the solenoid valve hydraulic control system is connectedwith the working arm and used for controlling the action of the oil cylinders; the power system is connected with the solenoid valve hydraulic control system to control the solenoid valve hydraulic control system to work; the remote control is in communication connection with the power system to remotely control the power system to work; and the camera is arranged on the jumbo body and used for collecting image information of an operation place. The drill jumbo with the remote control function and the control method thereof have the advantages that the remote operation can be achieved, an operating worker does not have to breathe noxious gas on site, rock falling during drilling can also be avoided, and the safety of the workers is ensured.

Owner:向勇 +1

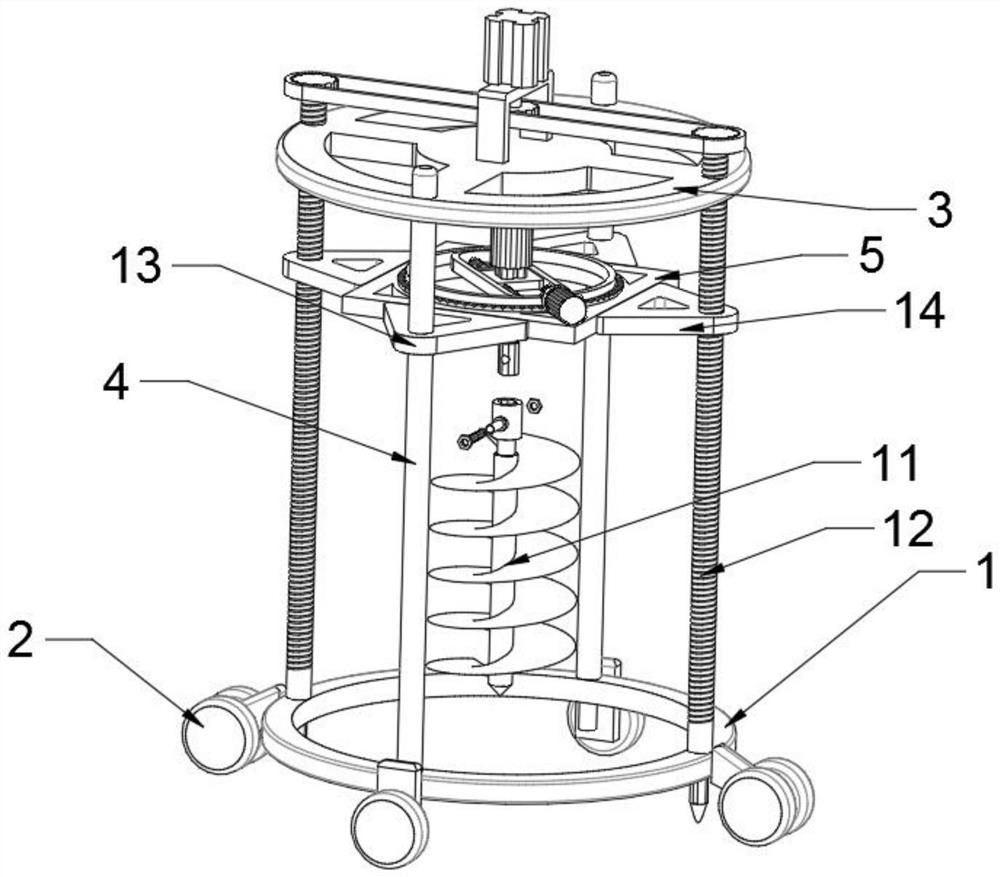

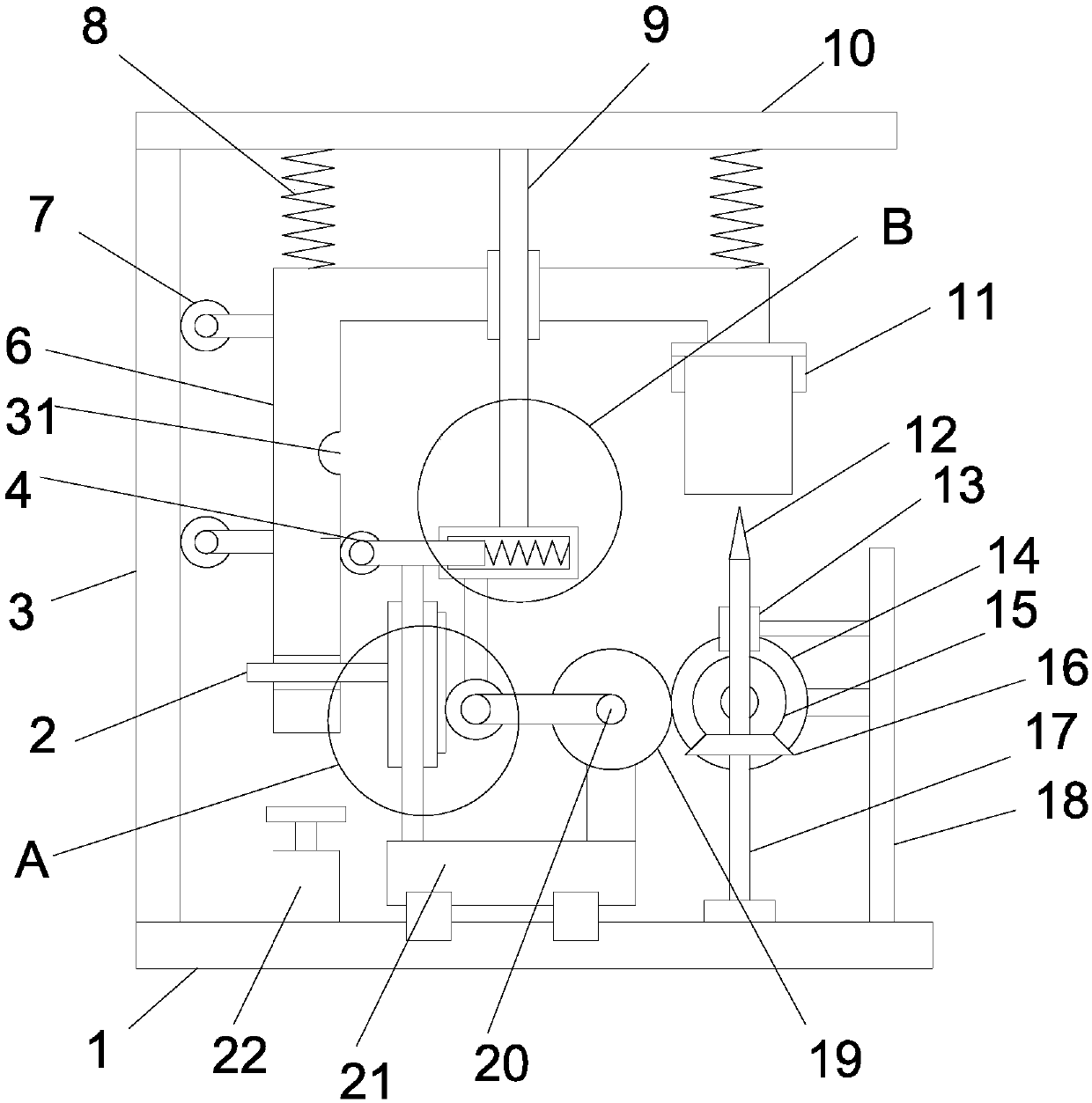

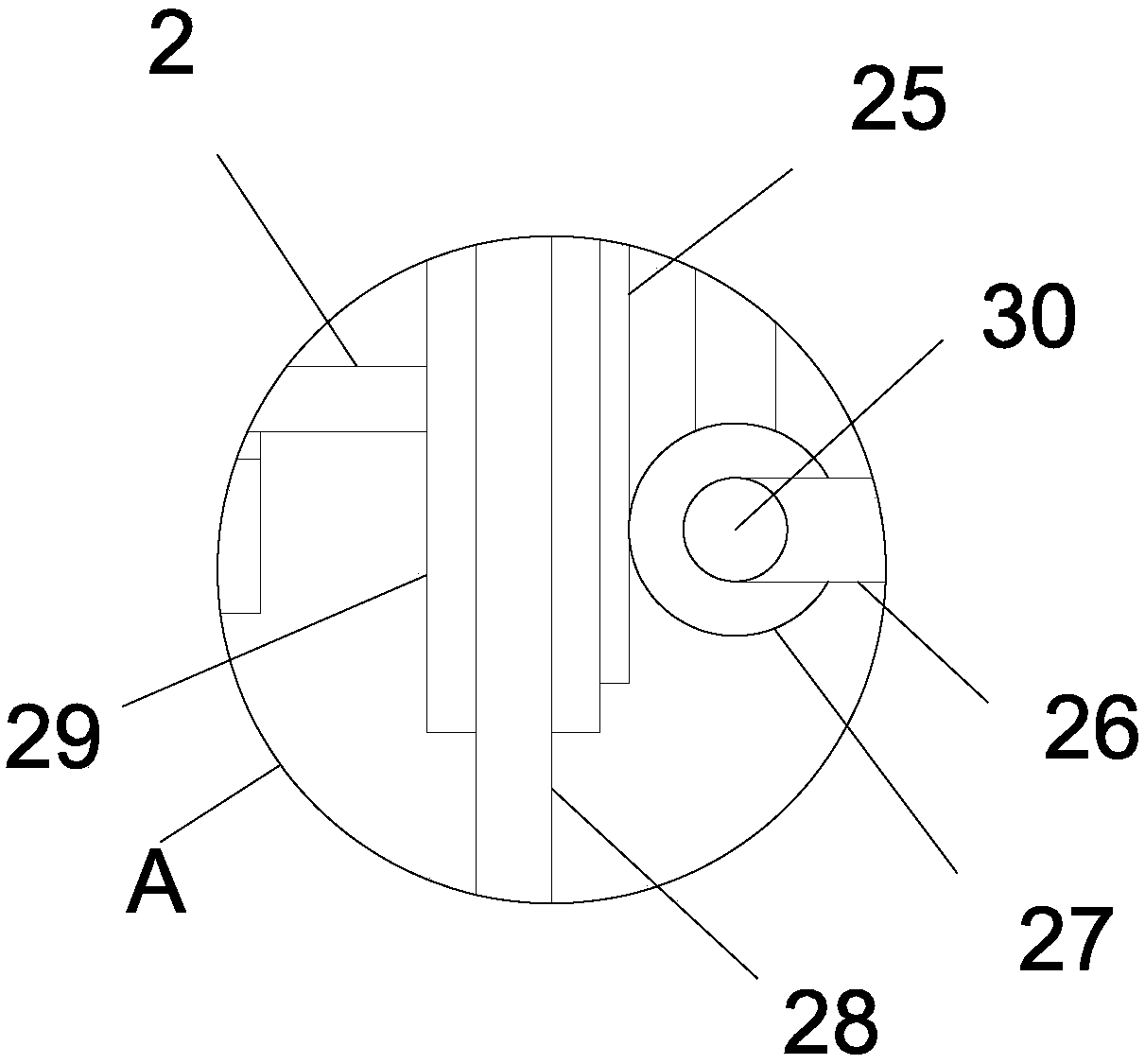

Soil drilling machine for garden engineering

PendingCN111734305AEasy plantingEasy to moveDrill bitsPlantingAgricultural engineeringElectric machinery

The invention relates to the technical field of garden engineering, in particular to a soil drilling machine for garden engineering. The soil drilling machine comprises a round frame base equipped with rollers, wherein the upper side of the round frame base is horizontally provided with a top plate, the round frame base and the top plate are provided with a vertical moving component that controlsthe vertical position of the a moving frame, the moving frame is provided with a circular opening, a circular rotating frame is matched in the circular opening, the moving frame is provided with a driving component for driving the circular rotating frame, a strip frame is horizontally fixed in the circular rotating frame, a horizontal moving component that controls the horizontal position of the moving plate is arranged in the strip frame, a first driving motor is fixedly installed on the moving plate, a drilling head is vertically arranged on the lower side of the rotating rod, and the drilling head is connected to the rotating rod through the fixed component. The soil drilling machine can realize a drilling action, is simple and convenient to operate, and can automatically position and fix the overall device during the downward movement of the drilling head, without additional operations. The device can change the diameter of the drilling at the same time.

Owner:段建锋

Drilling device with protecting function

InactiveCN107838457AQuality assuranceIncreased protectionBoring/drilling machinesEngineeringBevel gear

The invention discloses a drilling device with a protecting function. The drilling device with the protecting function comprises a bottom plate, a left vertical plate is vertically and fixedly installed on the bottom plate, limiting springs are vertically and fixedly installed on the lower bottom face of a top plate, an L-shaped support is fixedly installed at the lower ends of the limiting springs, and a positioning arc groove is formed in the right side wall of the L-shaped support. A sliding rod is vertically arranged on the L-shaped support in a penetrating mode, a driving bevel gear is coaxially and fixedly installed on a first gear, a limiting shaft sleeve is fixedly installed on the left side of a right vertical plate, and a rotating shaft is rotationally arranged in the limiting shaft sleeve in a penetrating mode. According to the drilling device with the protecting function, a drill bit is driven to rotate through the rotating shaft, a clamp clamps a workpiece and moves downwards, and the drilling action to the workpiece is achieved; after the drill bit finishes drilling the workpiece, a position roller is clamped in the positioning arc groove, a sliding seat drives a second gear to move leftwards, the second gear breaks away from a first gear, the drill bit stops rotating, the protecting function is well achieved, safety accidents can be effectively prevented, and meanwhile the drilling quality of the workpiece is guaranteed.

Owner:李奇宏

Rock drilling in great depths by thermal fragmentation using highly exothermic reactions evolving in the environment of a water-based drilling fluid

InactiveUS8967293B2Avoids potential blowoutsPrevent crashDisloding machinesThermal drillingWater basedHigh density

A method and a device to thermally fragment rock for excavation of vertical and directional boreholes in rock formations, preferentially hard rock, using highly exothermic reactions. Exothermic reactions are initiated directly in the pressurized, aqueous environment of a water-based drilling fluid preferably above the critical pressure of water (221 bar). After reaction onset temperatures within the reaction zone exceed the critical temperature for water (374° C.) providing supercritical conditions, which favor the stabilization of the reaction, e.g. a supercritical hydrothermal flame. Since reactions can be run directly in a water-based drilling fluid, the method proposed here allows high density drilling action as in conventional rotary drilling. A part from the hot reaction zone of the proposed reaction can be brought directly to the rock surface in case of hard polycrystalline rock, where high temperatures are required.

Owner:ETH ZZURICH

Method for detecting broken pin of drilling machine

InactiveCN104384570ANeedle breakage did not occurImprove judgment efficiencyDrilling/boring measurement devicesEngineeringPrinted circuit board

The invention discloses a method for detecting a broken pin of a drilling machine. The method comprises the steps of 1, designing the layout of inner holes of a plate to obtain the layout design drawing of the inner holes of the plate; 2, editing the layout design drawing of the inner holes of the plate by a script editor; adding a new hole at the side of the plate for the holes with the same type of aperture size on the original layout design drawing of the inner holes of the plate; enabling the drilling action of the new holes with different aperture sizes to be carried out after other holes with the corresponding aperture sizes are drilled, and taking the modified layout design drawing of the inner holes of the plate as a layout drawing provided with a broken pin detection module; 3, according to the layout drawing provided with the broken pin detection module, using the drilling machine to carry out the drilling work, obtaining a printed circuit board (PCB) subjected to the drilling work, and checking the new holes distributed at the side of the PCB to obtain the result of whether the broken pin exists in the drilling machine or not. The method is capable of reliably and efficiently detecting whether the broken pin exists in the drilling machine or not.

Owner:VICTORY GIANT TECH HUIZHOU CO LTD

Automatic position-finding drilling machine and automatic position-finding drilling method thereof

PendingCN110405249AReduce labor intensityImprove drilling efficiencyAutomatic control devicesFeeding apparatusPunchingProgrammable logic controller

The invention discloses an automatic position-finding drilling machine and an automatic position-finding drilling method thereof. The automatic position-finding drilling machine comprises a base seat,a movable module, a drilling mechanism, a position-finding mechanism and a PLC (programmable logic controller), wherein a fixed machining area is arranged on the base seat, a tool storage knife restused for containing a drill bit is arranged at one end, close to the fixed machining area, of the base seat, the movable module is arranged on one side of the base seat, and the PLC is connected withthe movable module, the drilling mechanism and the position-finding mechanism. According to the automatic position-finding drilling machine, the position-finding mechanism is matched with the PLC to automatically acquire the punching information of the workpiece, automatic drilling is realized through cooperation of the drilling mechanism, the moving module and the PLC, drilling position determination and drilling action execution are achieved through the automatic position-finding drilling machine, the drilling efficiency and precision are improved, and the labor intensity of workers is reduced.

Owner:LAND AMERICA HEALTH & FITNESS

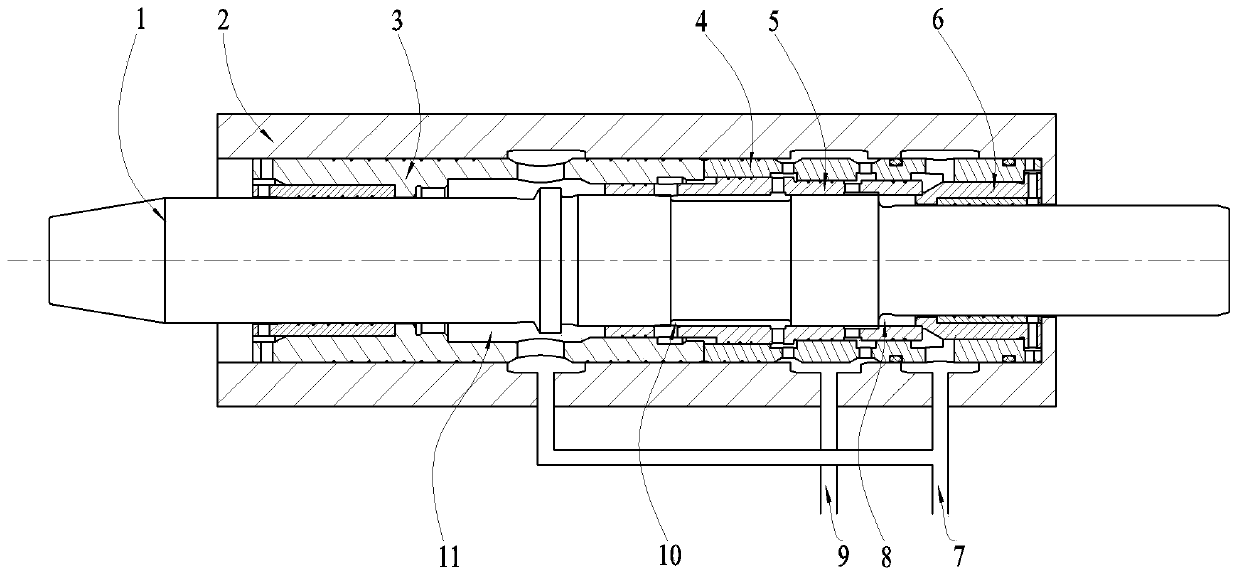

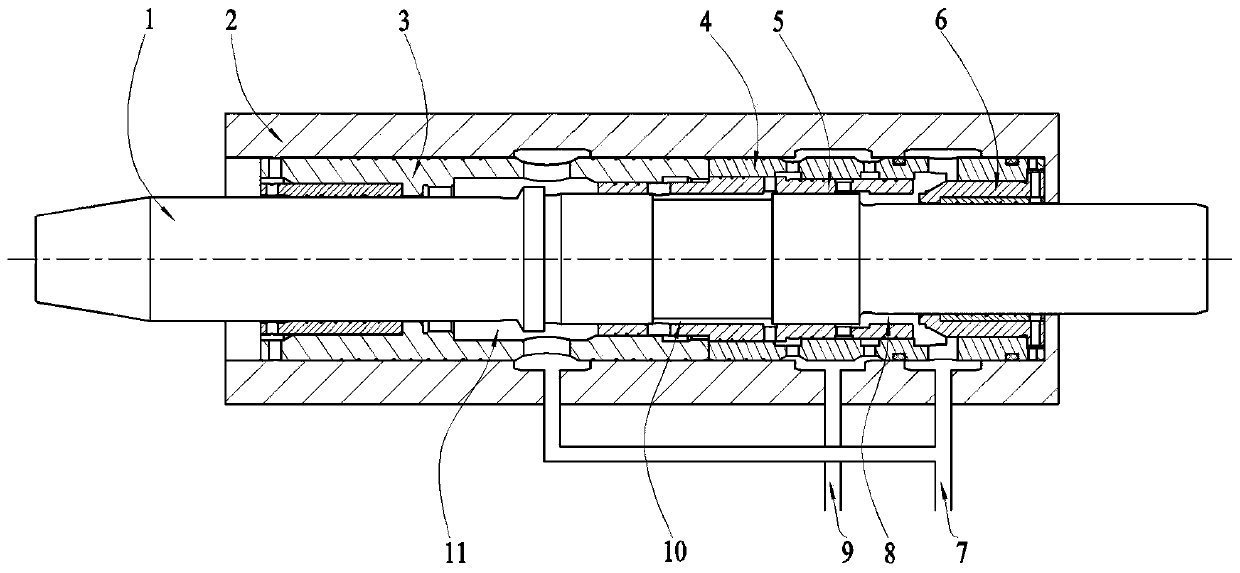

Axial reversing rock drilling device with compact structure

ActiveCN111561260ASave spaceLight in massConstructionsReciprocating drilling machinesReciprocating motionRock cutting

The invention patent discloses an axial reversing rock drilling device with a compact structure. An impact piston and a front guide sleeve are installed with a clearance fit; a reversing valve and a rear guide sleeve are installed with a clearance fit; the reversing valve and the front guide sleeve are installed with a clearance fit; the front guide sleeve and a middle guide sleeve are installed with a transitional fit to a cylinder block; and the middle guide sleeve and the rear guide sleeve are installed with a transition fit. A high-pressure oil inlet pipeline and a piston rear cavity are cut off and communicated under the interaction of the reversing valve and the impact piston; the high-pressure oil inlet pipe and a piston front cavity are always open; and a low-pressure oil return pipeline is cut off and communicated with a piston middle cavity and the piston rear cavity under the interaction of the reversing valve and the impact piston. Through the switch of high-pressure oil and low-pressure oil, a force that causes the impact piston and the reversing valve to continuously reciprocate is generated at the effective action surface of the impact piston and the reversing valve,so as to realize the rock drilling action of the impact piston.

Owner:HUNAN UNIV OF ARTS & SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com