Assembling process and equipment for motor stator and motor shell

A motor stator and assembly process technology, applied in the direction of electromechanical devices, electric components, manufacturing motor generators, etc., can solve the problems of difficult to ensure high-quality assembly, difficult to ensure position accuracy, low production efficiency, etc., to achieve fast production speed, Ensure assembly quality and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in detail below by specific embodiment:

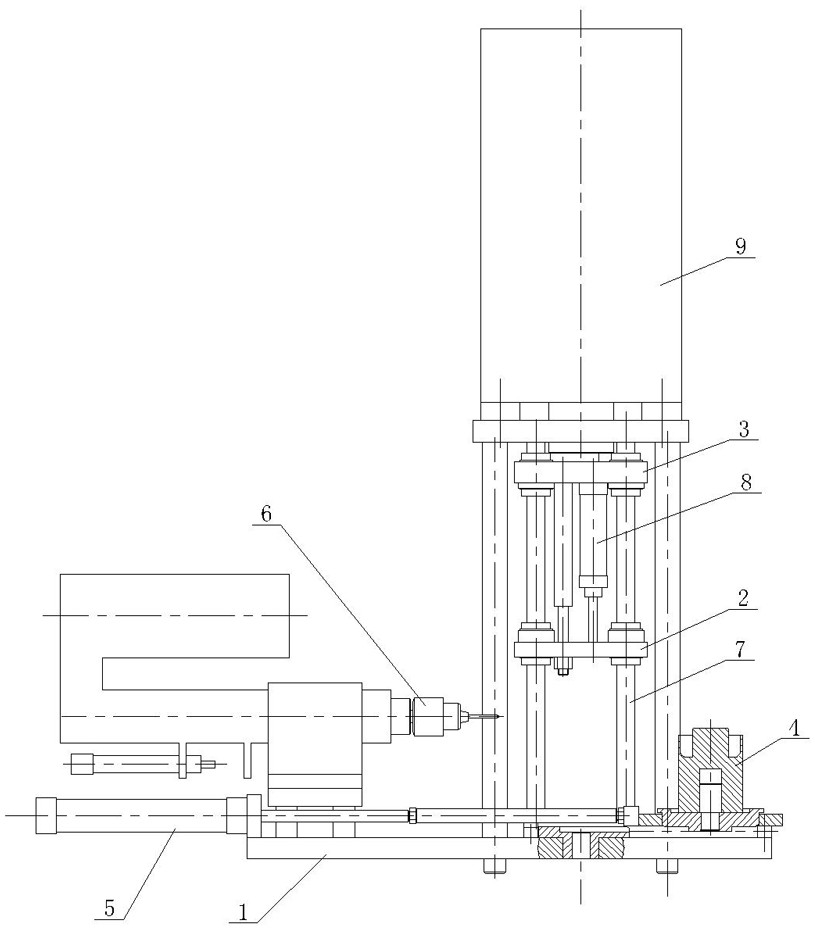

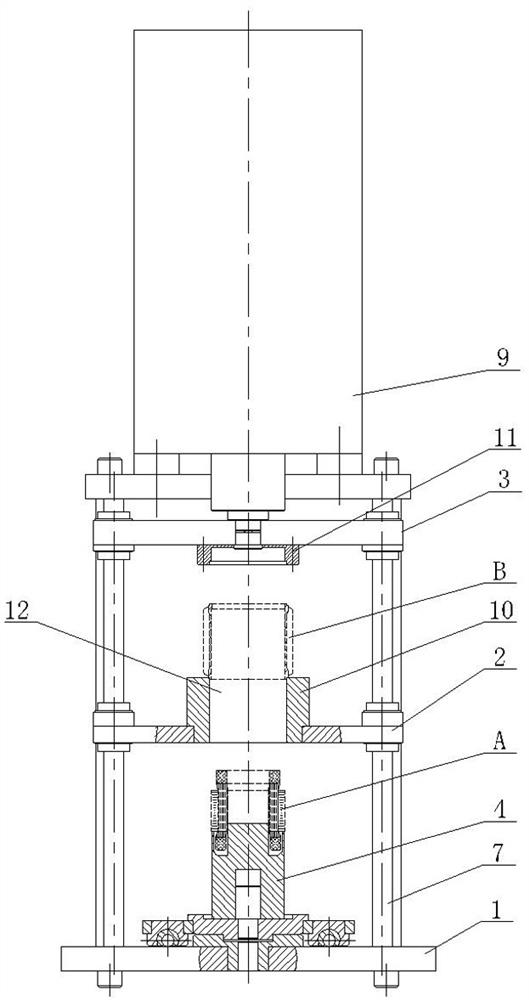

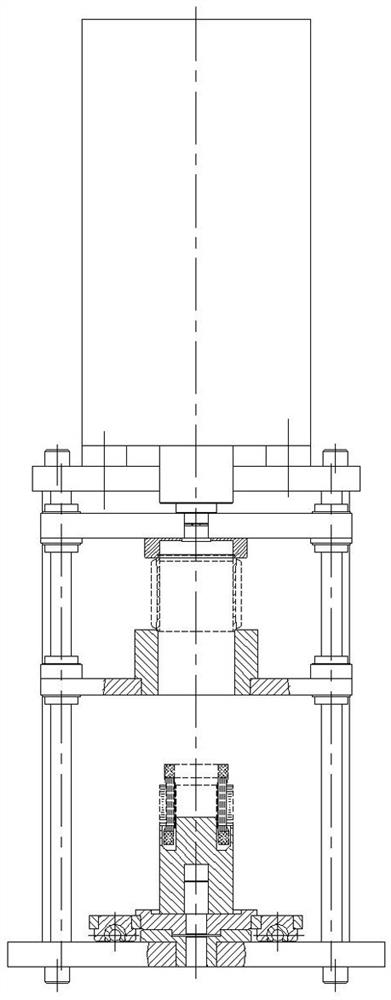

[0019] Such as figure 1 , 2 As shown, the assembly equipment of the motor stator and the casing of the present invention includes a bottom template 1, a middle template 2 and a top template 3, the bottom template 1 is fixedly arranged, and the stator seat 4 is installed on the bottom template 1, and the stator seat 4 is connected to the stator A. The center of the inner hole is positioned, the stator base 4 can be moved forward and backward on the bottom formwork 1, the stator base 4 is connected with the moving cylinder 5 of the stator base, and the bottom formwork 1 is equipped with a drilling power head 6; the middle formwork 2 is placed on the bottom formwork 1 The top of the upper part is set up and down to be guided by the guide column 7, the middle formwork 2 is connected with the casing clamping cylinder 8, the casing clamping cylinder 8 is fixedly installed on the top formwork 3, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com