Patents

Literature

108results about How to "Meet lightweight design requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

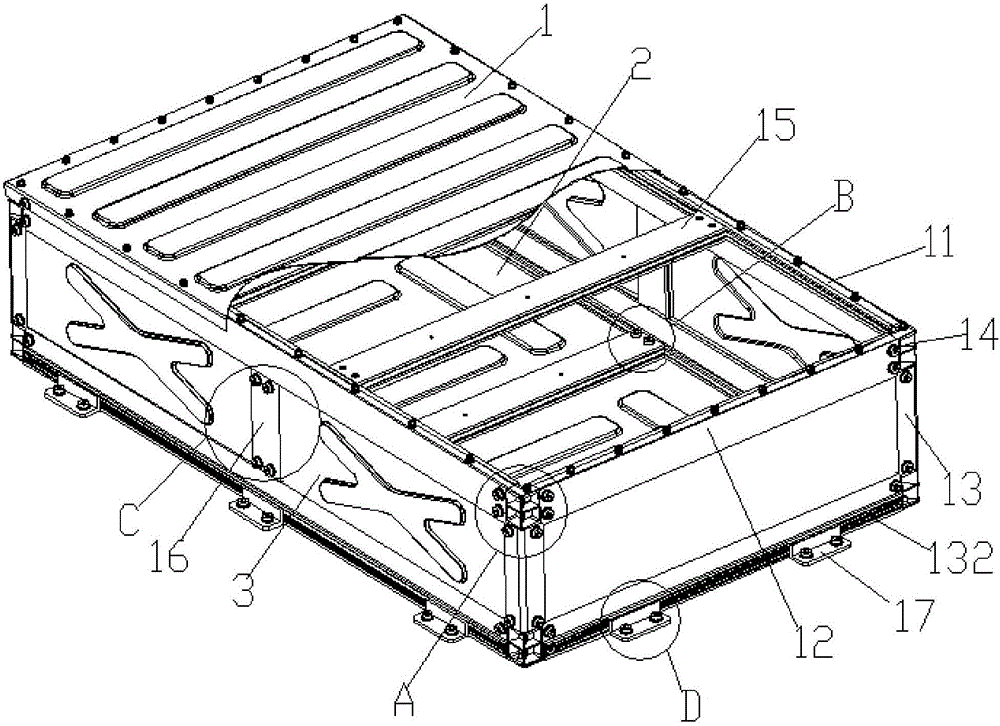

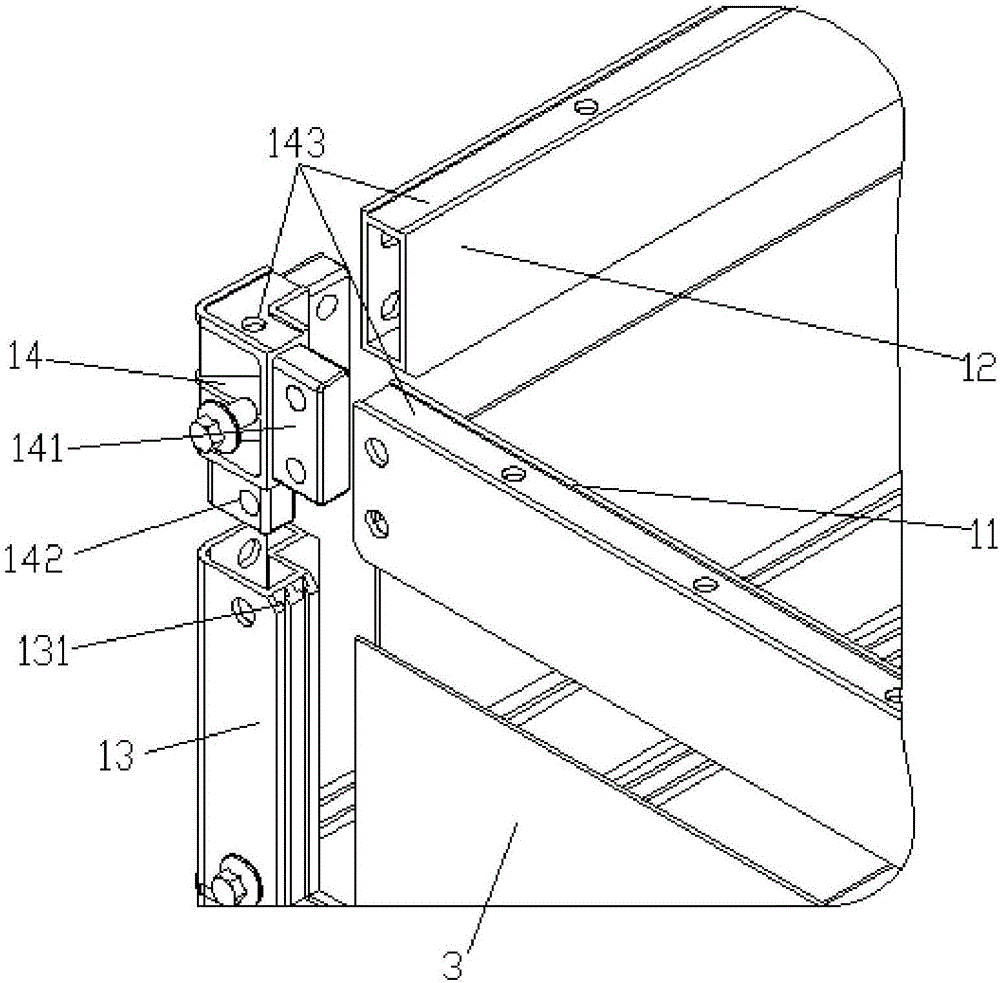

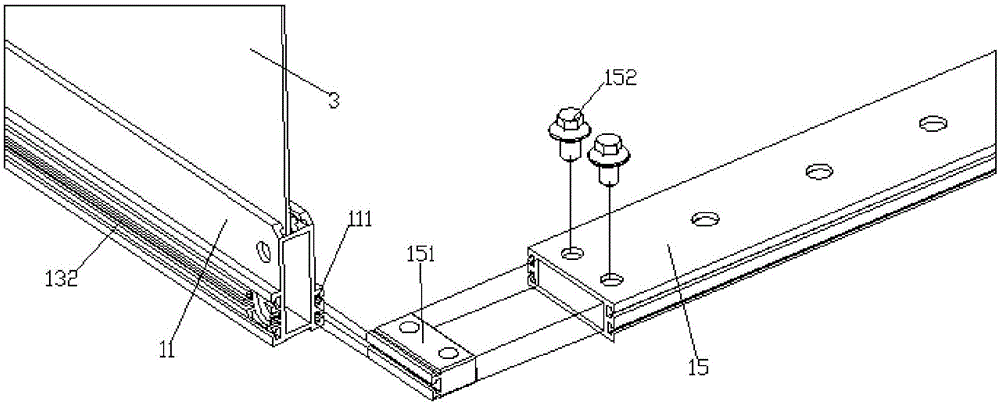

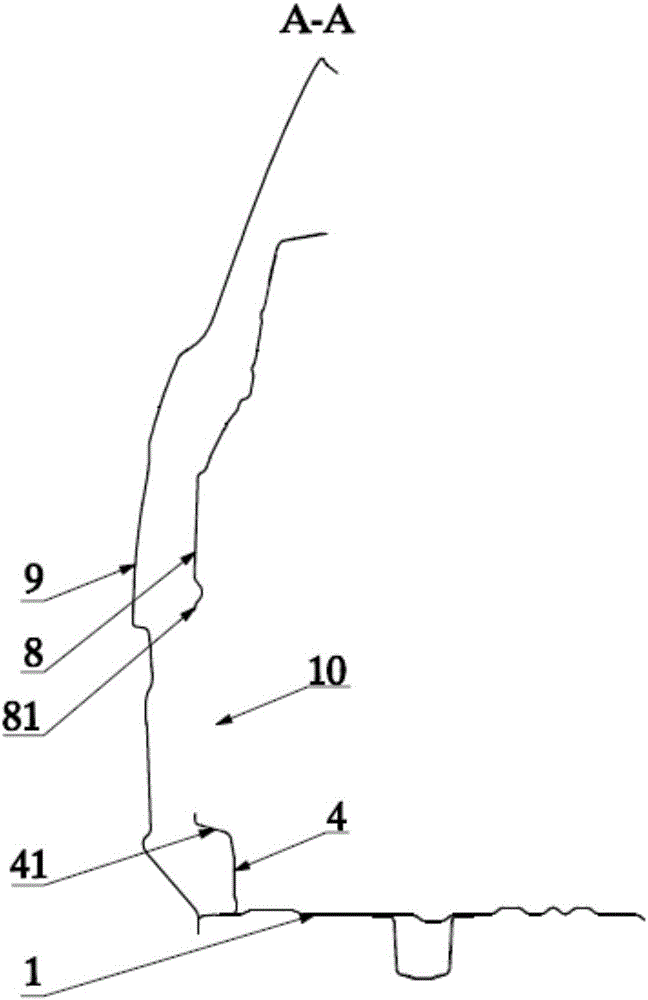

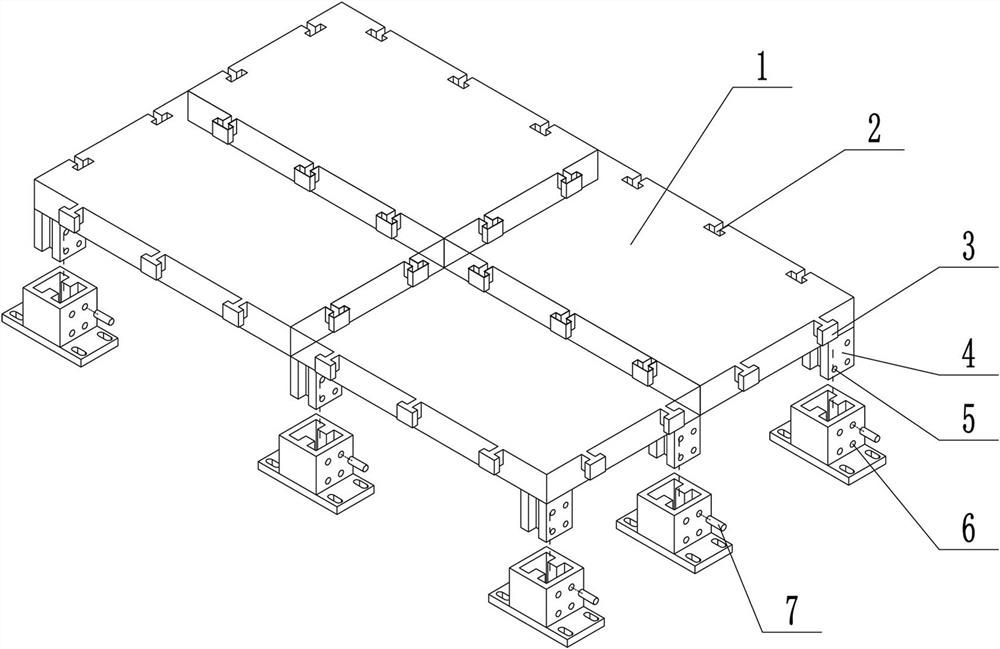

Battery pack frame

PendingCN106711368AExpandableIncrease energy densityCell component detailsEconomic benefitsBattery pack

The invention relates to a battery pack frame, which comprises a movable plug-in type frame body used for the placing of battery modules, wherein the movable plug-in type frame body is mainly formed by splicing a plurality of linear cross beams, linear longitudinal beams and liner vertical beams through corner connecting pieces. According to the scheme provided by the invention, the linear cross beams, the linear longitudinal beams and the liner vertical beams are plugged in and spliced to form the movable plug-in type frame body, and according to the required size dimension of the battery frame, the linear cross beams, the linear longitudinal beams and the liner vertical beams with different length dimensions are selected and are then spliced and fixed through the corner connecting pieces, so that a battery pack has extensibility, the development of a mold is reduced, and the installation dimension requirements of different vehicle models are met; in addition, the battery pack frame is convenient to install and disassemble, and the economic benefit of the battery pack frame is improved.

Owner:苏州奥杰汽车工业有限公司

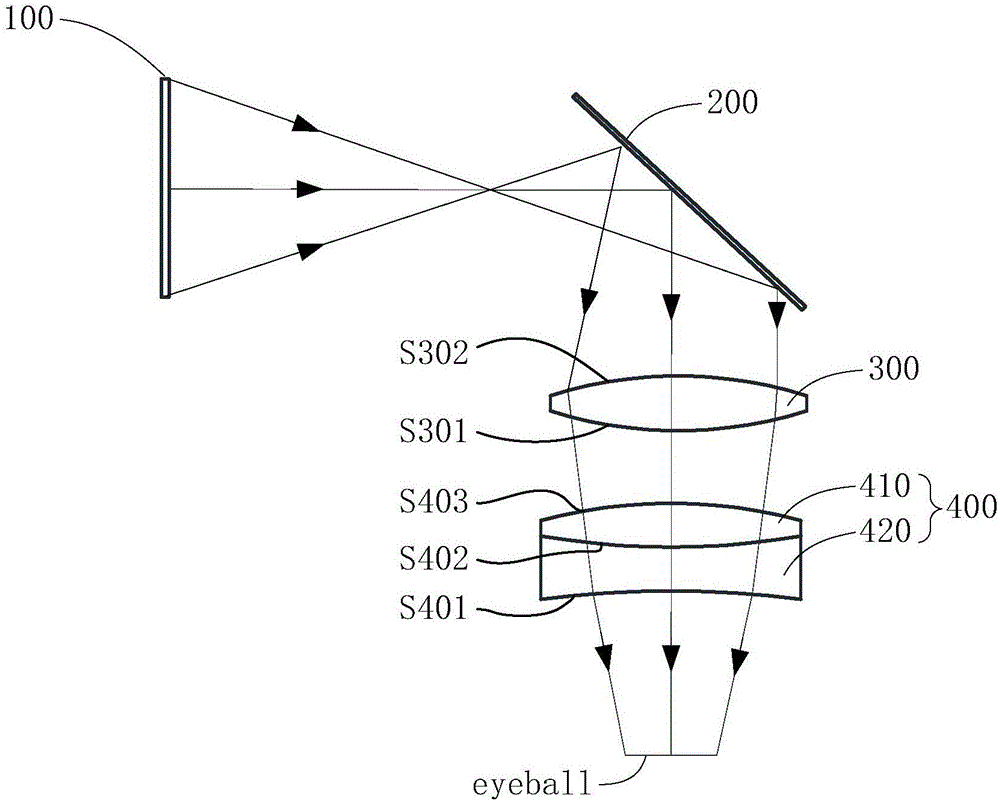

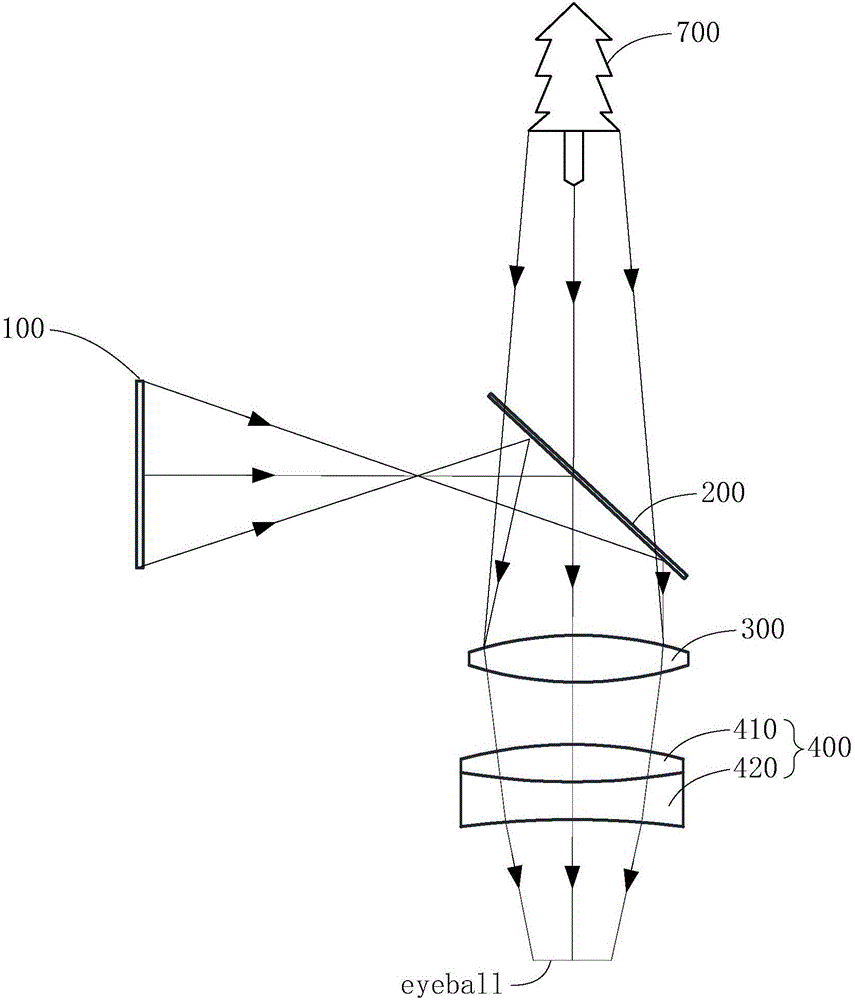

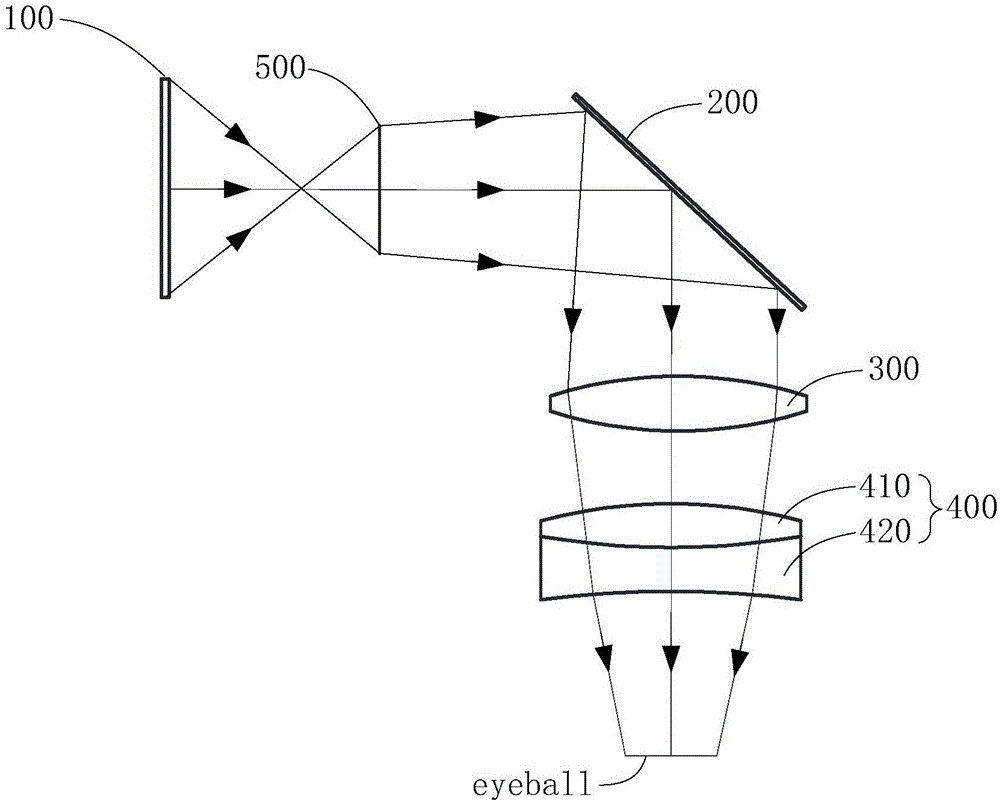

Image display apparatus and head-mounted display device

InactiveCN106338830ACorrection of Field CurvatureControl Distortion SizeOptical elementsImaging qualityDisplay device

The invention discloses an image display apparatus. The image display apparatus comprises a display screen, and an ocular-side double-convex lens, a reflection element and a first achromatic lens which are disposed on an image light transmission optical path of the display screen, wherein the first achromatic lens is coaxially arranged with the ocular-side double-convex lens and is disposed at the light- emitting side of the ocular-side double-convex lens, an optical axis of the display screen and an optical axis of the ocular-side double-convex lens form a preset included angle, the reflection element is disposed between the display screen and the ocular-side double-convex lens, and image light is reflected on the reflection element, sequentially penetrates the ocular-side double-convex lens and the first achromatic lens, and then reaches a watching side so as to form a virtual image. The invention further discloses a head-mounted display device. According to the formed optical system, the system space volume can be reduced, compressed and amplified, a series of image errors such as coma, astigmation, aberration and the like can be improved, the magnitude of distortion is controlled, and under the condition that viewers can see amplified virtual images with excellent image quality, the requirements of a conventional head-mounted display device for miniaturization and light-weight design are satisfied.

Owner:SUPERD CO LTD

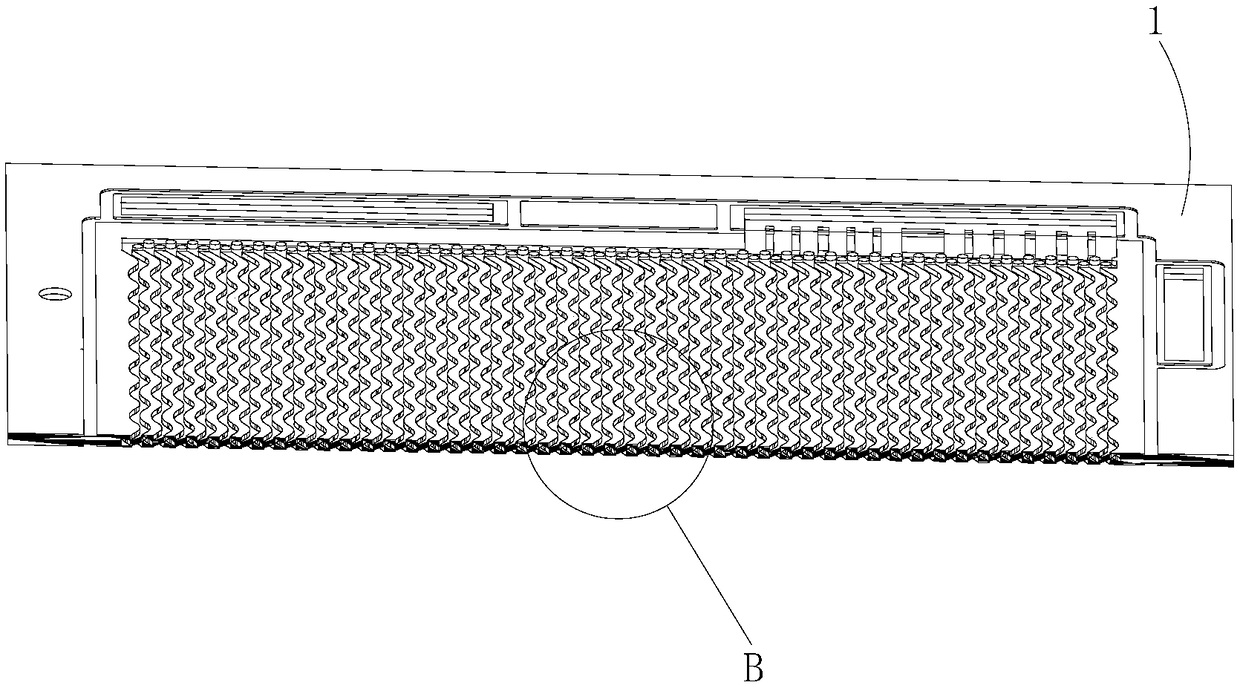

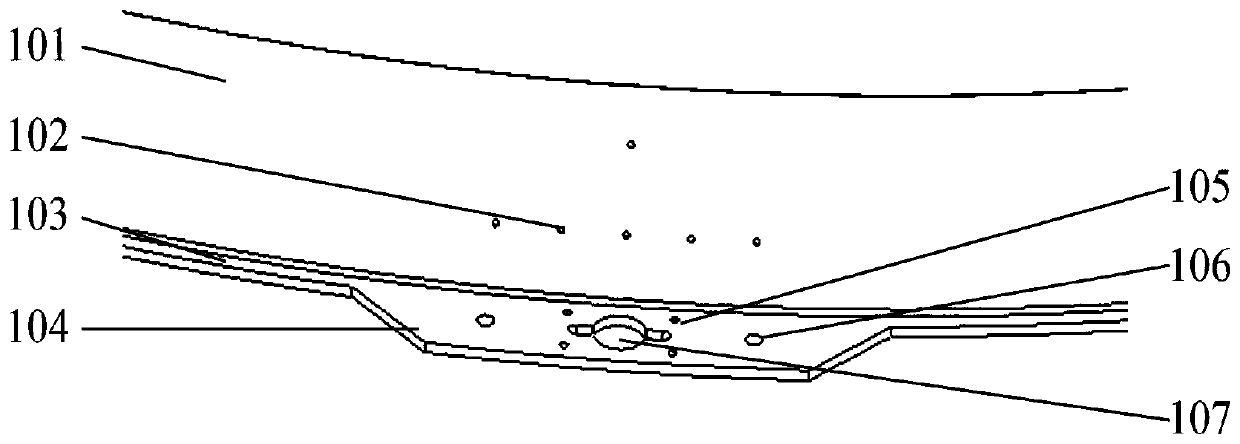

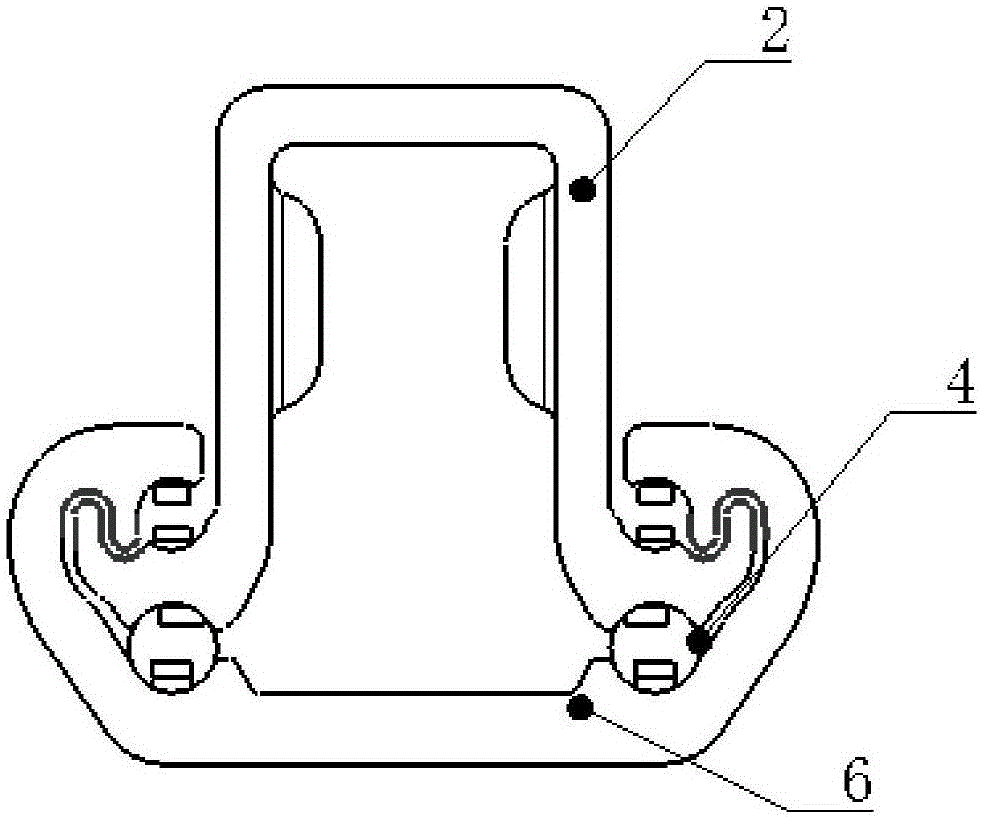

Bipolar plate of proton exchange membrane fuel battery

PendingCN108695524AReduce thicknessReduce volumeSolid electrolyte fuel cellsCollectors/separatorsCoolant flowWave shape

The invention discloses a bipolar plate of a proton exchange membrane fuel battery. The bipolar plate comprises a first metal single plate, wherein the first metal single plate is provided with a plurality of first bosses at intervals, and a first groove is formed between any two adjacent first bosses; a second metal single plate is provided with a plurality of second bosses at intervals, and a second groove is formed between any two adjacent second bosses; the number of the first bosses is the same with the number of the second bosses, the first bosses correspond to the second bosses, the first bosses and the second bosses are respectively in a wave shape and are the same in the extending directions, and the bending direction of each first boss is opposite to the bending direction of eachsecond boss; a coolant flow field is formed between each first boss and the corresponding second groove, and an air flow field is respectively formed on each first groove and each second boss. The bipolar plate has the advantages that the air flow fields and the coolant flow fields are distributed in an embedding way, so that the thickness of the bipolar plate of the proton exchange membrane fuelbattery is greatly reduced, and the light-weight design requirement is met.

Owner:WUHAN POLYTECHNIC UNIVERSITY

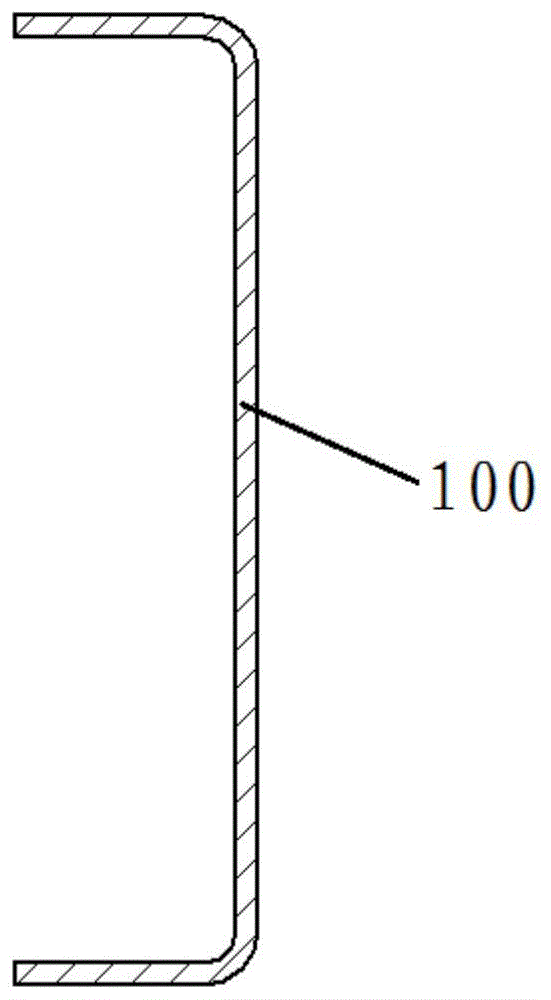

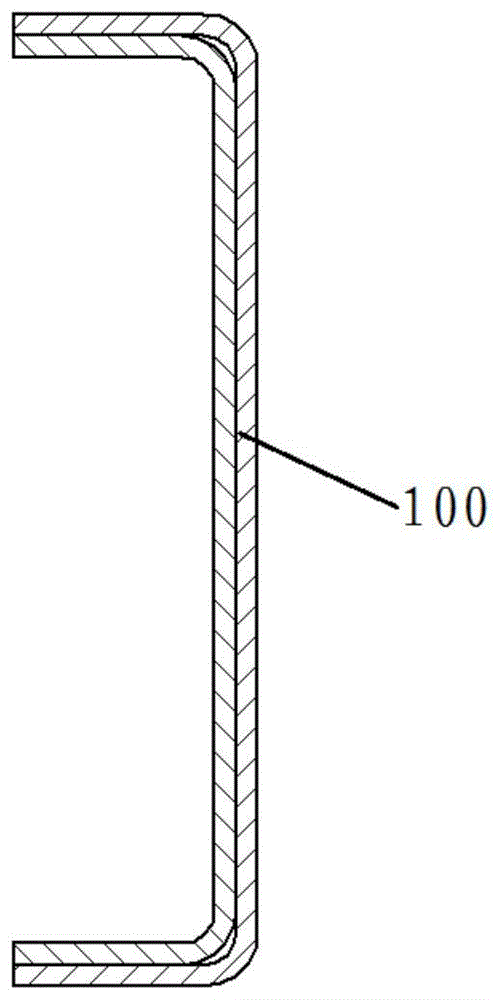

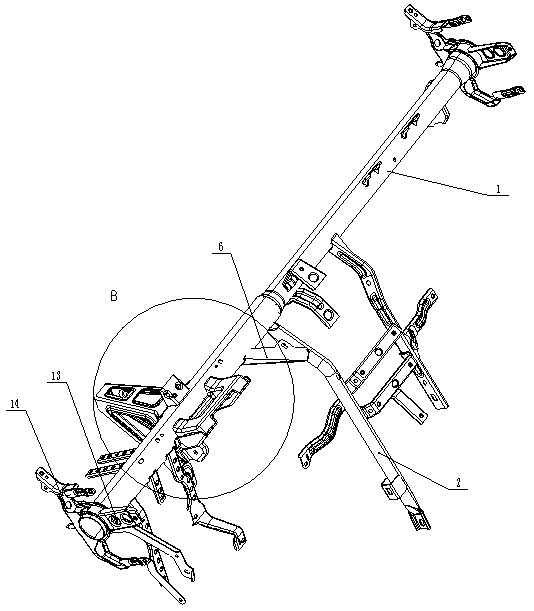

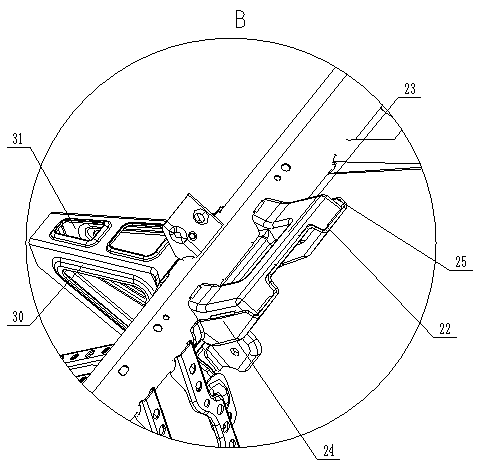

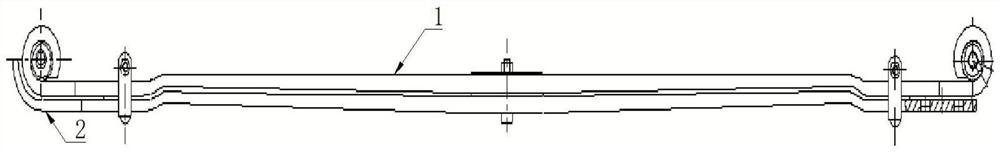

Heavy truck frame assembly

InactiveCN106553696AEasy to install and arrangeImprove fuel economyUnderstructuresVehicle frameEngineering

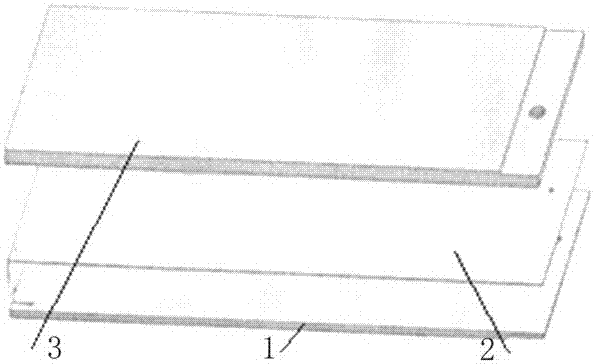

The invention discloses a heavy truck frame assembly. The heavy truck frame assembly comprises a transverse beam (1), a left longitudinal beam (2) and a right longitudinal beam (3). The left longitudinal beam (2) is connected with the right longitudinal beam (3) through the transverse beam (1). C-shaped section beams are adopted as the left longitudinal beam (2) and the right longitudinal beam (3). The left longitudinal beam (2) and the right longitudinal beam (3) are of a symmetric structure. Each of the left longitudinal beam (2) and the right longitudinal beam (3) is composed of a front bearing section (21), a connecting transition section (22) and a rear bearing section (23), wherein an upper plane of the front bearing section (21), an upper plane of the connecting transition section (22) and an upper plane of the rear bearing section (23) are located on the same horizontal plane, and the section height of the front bearing section (21) is smaller than that of the rear bearing section (23). The heavy truck frame assembly has the beneficial effects that the bearing capability is high, the anti-twisting capability is high, the overall mass is low, and the fuel economy is high.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

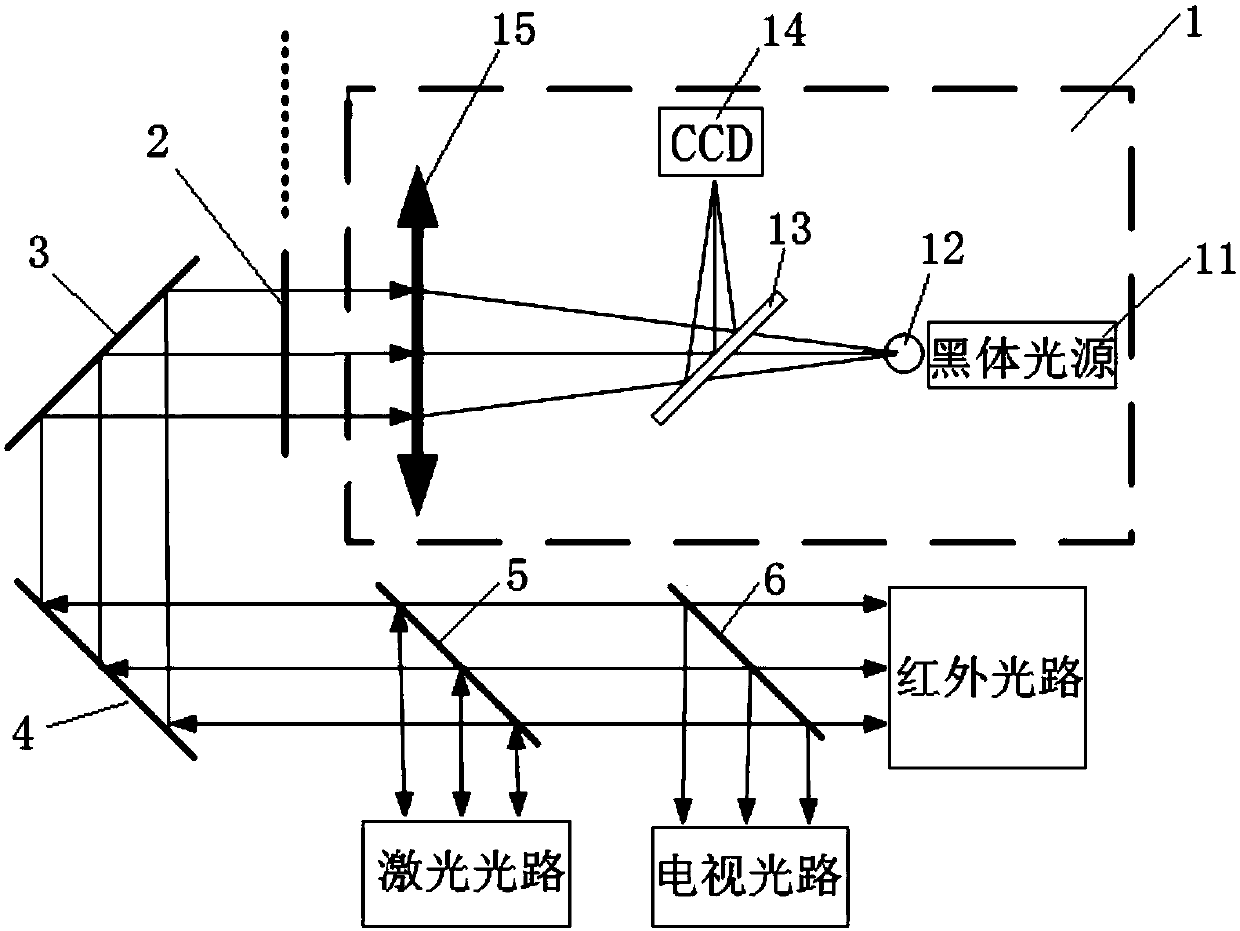

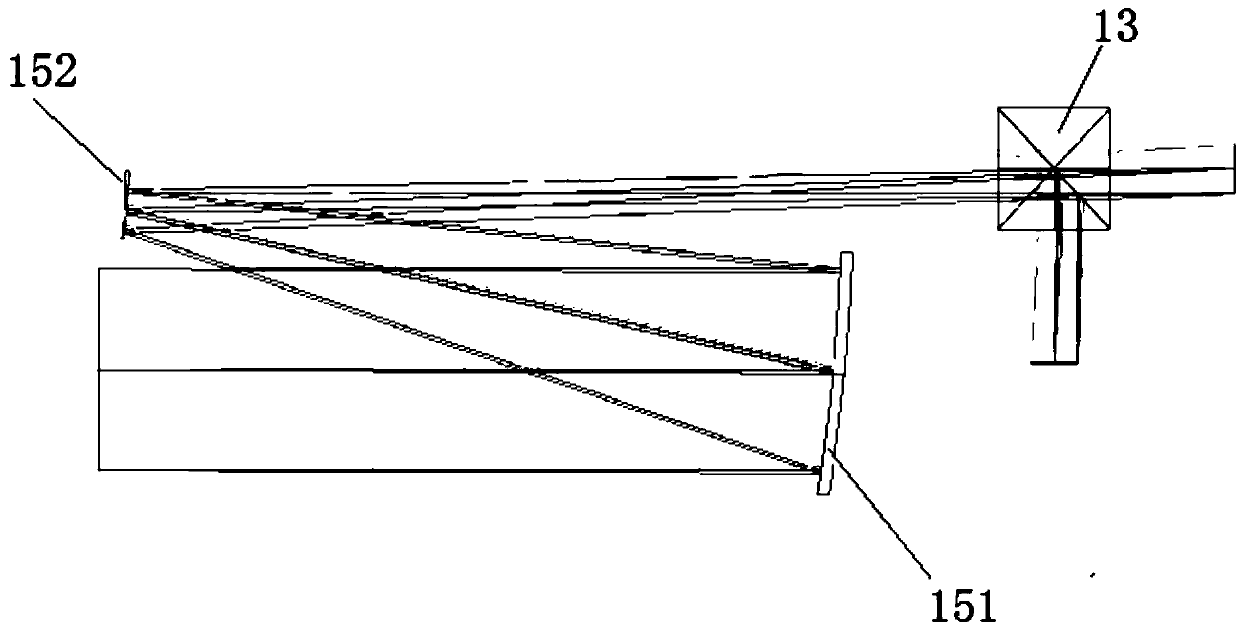

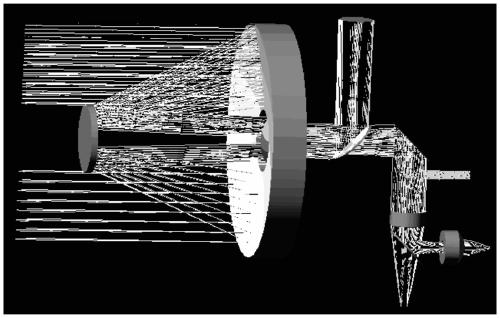

Onboard three-optical-axis consistency test component, system and method

PendingCN109580177AConformance Test ImplementationResolve detectionOptical axis determinationLens position determinationBeam splitterConsistency test

The invention relates to an onboard three-optical-axis consistency test component, system and method. The test component comprises a collimator, a beam splitter, a target plate, a CCD detector and a blackbody light source; the beam splitter, the target plate, the CCD detector and the blackbody light source are positioned at one end of the converging light entrance of the collimator; the target plate is positioned on the focal plane of the collimator; the blackbody light source is used for illuminating the target plate; the emergent light of the target plate reaches the converging light entrance of the collimator via the beam splitter; and the emergent light of the converging light entrance of the collimator reaches the CCD detector via the beam splitter. The test method comprises the stepsof 1, transferring a datum; 2, testing the drift angle of the optical axis of the laser light path via the CCD detector; and 3, testing the respective drift angles of the television light path optical axis and the infrared light path optical axis via the blackbody light source. According to the component, system and method provided by the invention, the problems that the existing test system andmethod are limited in accuracy, large in optical adjustment difficulty and not applicable to being onboard are solved.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

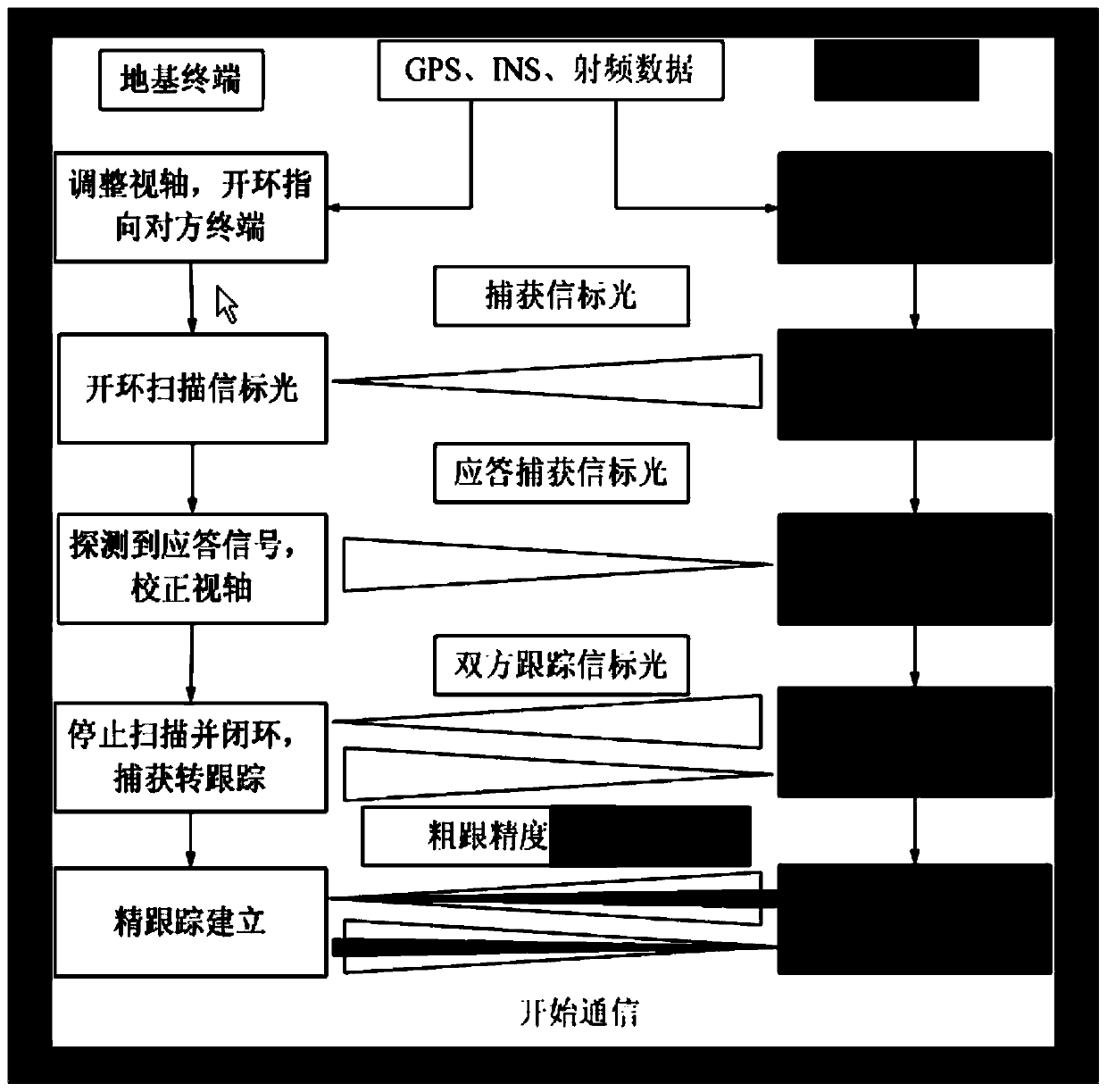

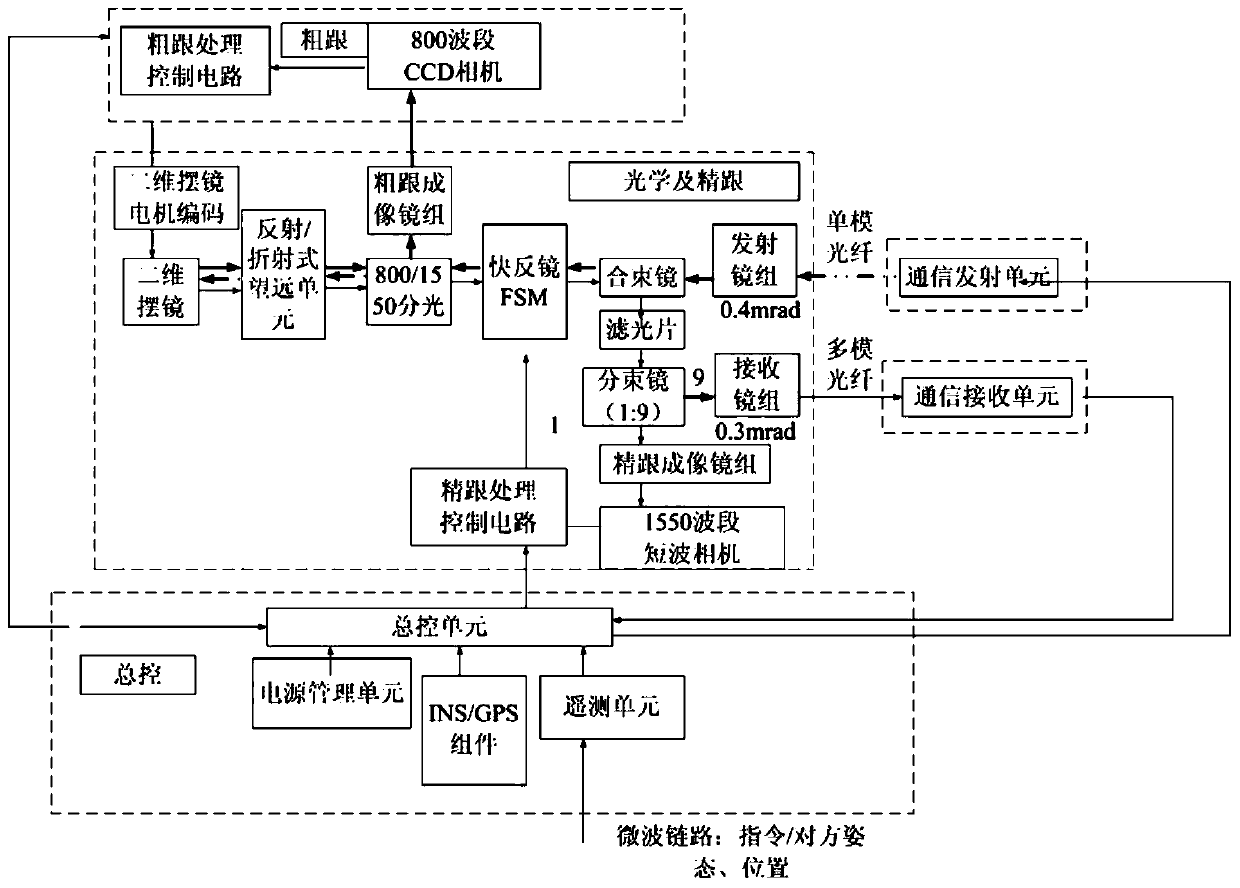

Light and small airborne high-speed laser communication method

PendingCN111147137AIncrease transfer rateImprove anti-interference abilityFree-space transmissionElectromagnetic transmittersTelecommunications linkMiniaturization

The invention belongs to the technical field of laser communication, and particularly relates to a light and small airborne high-speed laser communication method. The method comprises the steps that 1, initial alignment is conducted between an airborne terminal and a foundation terminal; 2, open-loop capture is performed between the airborne terminal and the foundation terminal; 3, coarse trackingis carried out between the airborne terminal and the foundation terminal; 4, fine tracking is carried out between the airborne terminal and the foundation terminal, and a communication link is established; and step 5, two-way communication is realized between the airborne terminal and the foundation terminal. The method innovatively adopts an asymmetric single beacon and a rapid capture, alignment and tracking technology and has the advantages of miniaturization, high transmission rate and high anti-interference capability.

Owner:TIANJIN JINHANG INST OF TECH PHYSICS

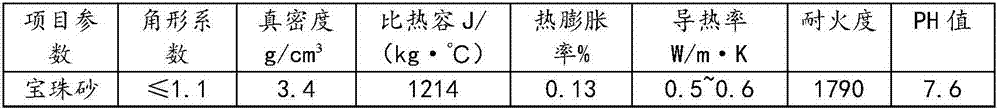

Coated sand and preparation method thereof

InactiveCN107234209AMeet thin wallMeet lightweight design requirementsFoundry mouldsFoundry coresCasting defectPolyresin

The invention provides a coated sand and a preparation method thereof, which relate to the technical field of casting. The coated sand includes pearl sand, resin, curing agent, coupling agent, lubricant, auxiliary materials and silica sand; wherein, the pearl sand accounts for 80% to 90% of the total weight of the coated sand, and the resin accounts for 1% to 3% of the total weight of the coated sand, the curing agent accounts for 0.5% to 1% of the total weight of the coated sand, and the coupling agent accounts for 0.04% to 1% of the total weight of the coated sand 0.08%, the lubricant accounts for 0.1%-0.5% of the total weight of the coated sand, the auxiliary material accounts for 0.3%-0.7% of the total weight of the coated sand, and the balance is the silica sand. The coated sand and its preparation method provided in this embodiment can effectively eliminate and reduce casting defects such as oil channel core deformation, cylinder notch, sand sticking, air holes, and wall thickness tolerance, and improve the quality of castings.

Owner:TONGLIN CASTING IND

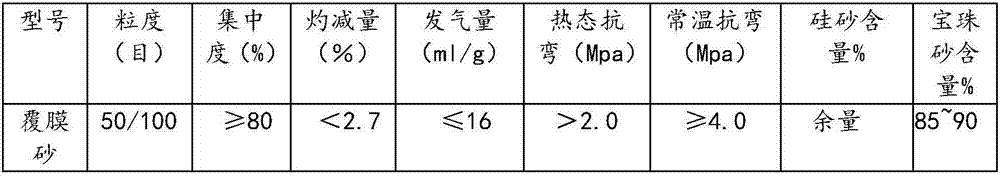

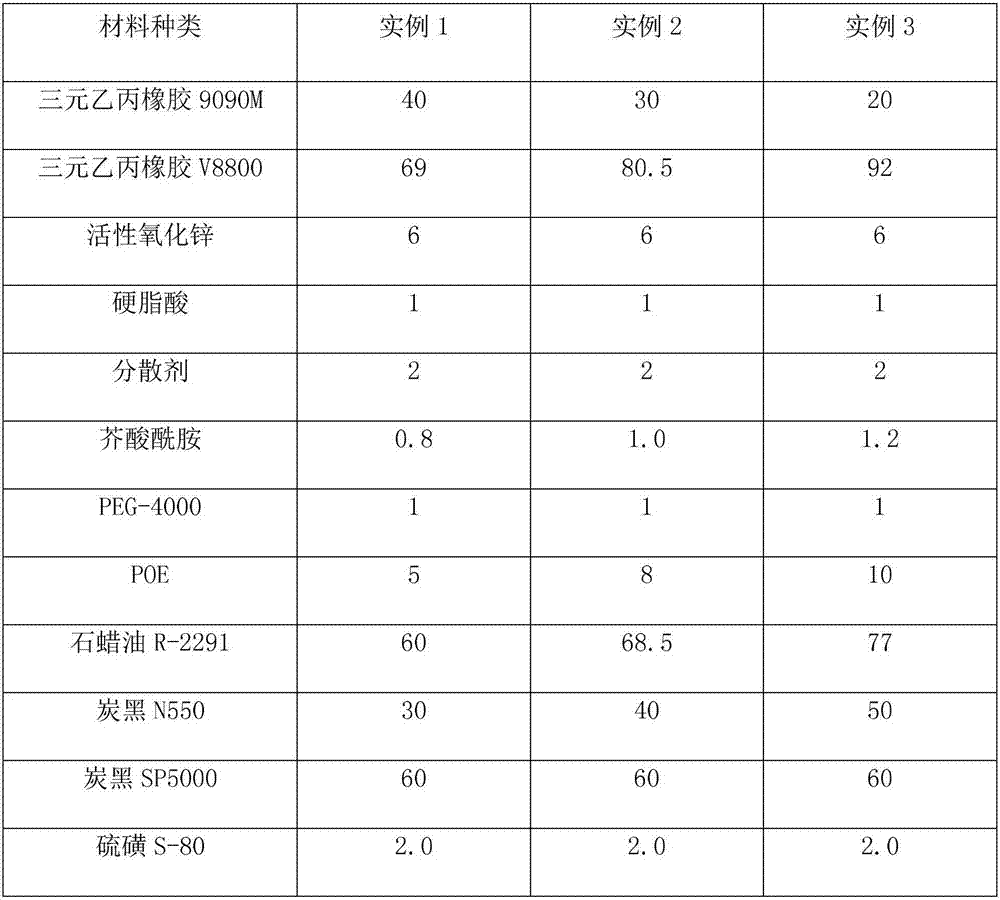

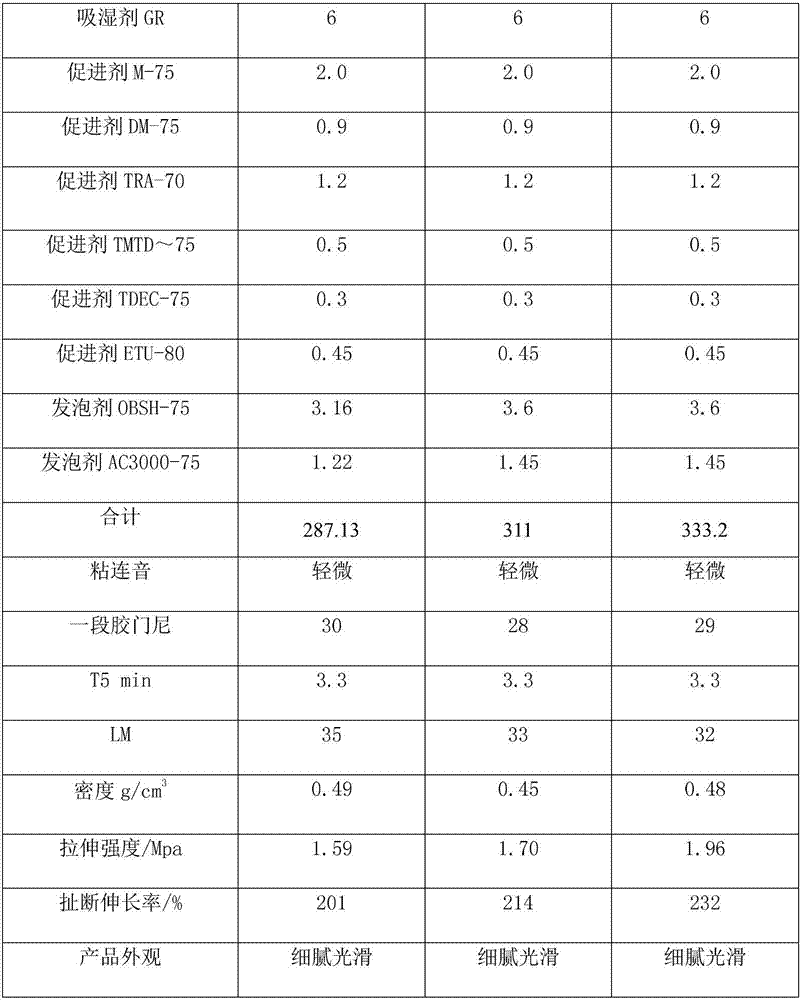

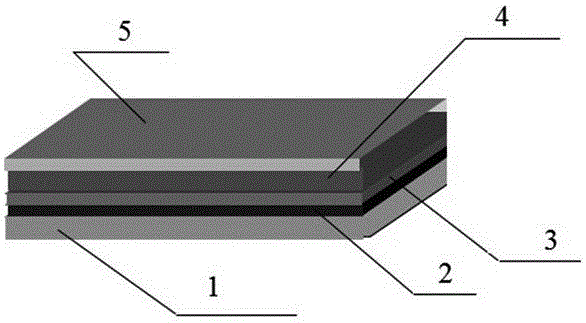

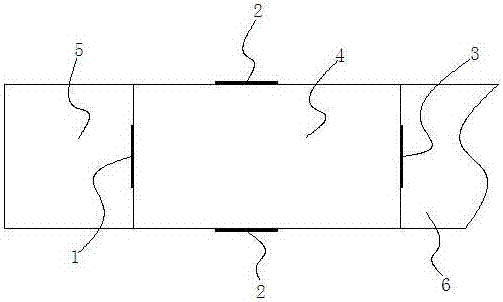

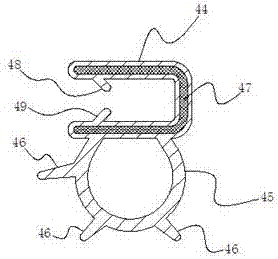

Sponge foaming rubber for car door sealing strip and preparation method thereof, car door sealing strip and preparation method thereof

InactiveCN107418061ALow viscosityConducive to lightweight designEngine sealsVehicle sealing arrangementsElastomerPolyolefin

The invention provides sponge foaming rubber for a car door sealing strip and a preparation method thereof, a car door sealing strip and a preparation method thereof. The sponge foaming rubber for the car door sealing strip, provided by the invention, is prepared from the following components in parts by weight: 20 to 40 parts of ethylene-propylene-diene monomer 9090M, 69 to 92 parts of ethylene-propylene-diene monomer V8800, 5 to 7 parts of active zinc oxide, 1 to 2 parts of stearic acid, 1 to 3 parts of a dispersant, 0.8 to 1.4 parts of erucamide, 1 to 2 parts of PEG-4000 (Polyethylene Glycol-4000), 5 to 10 parts of POE (Polyolefin Elastomer), 60 to 77 parts of paraffin oil R-2291, 30 to 50 parts of carbon black N550, 50 to 70 parts of carbon black SP5000, 1.5 to 2.5 parts of sulfur S-80, 6 to 10 parts of a moisture absorbent GR, 3 to 6.4 parts of an accelerant, 3 to 3.6 parts of a foaming agent OBSH-75 (Oxydibenzenesulfonyl Hydrazide-75) and 1.1 to 1.5 parts of a foaming agent AC3000-75. By adopting a formula of the sponge foaming rubber for the car door sealing strip, provided by the invention, the prepared sponge rubber has relatively low density and can meet a lightweight design; meanwhile, the obtained rubber also can have relatively good physical performance, so that the utilization quality of the car door sealing strip utilizing the sponge foaming rubber can also be improved.

Owner:NUOBO RUBBER PRODION

Emission-rate-controllable heat control material and preparing method thereof

InactiveCN106756851AIncreased requirements for resistance to space radiationImprove stabilityVacuum evaporation coatingSputtering coatingAbsorption rateSilicon dioxide

The invention discloses an emission-rate-controllable heat control material. The emission-rate-controllable heat control material comprises a base, an aluminum oxide transition layer used for improving adhesion force, a silver film used for improving sunlight reflectivity, an aluminum oxide film used for improving the infrared emission rate and a silicon dioxide layer used for antireflection. The surface of the base is sequentially provided with the aluminum oxide transition layer, the silver film, the aluminum oxide film and the silicon dioxide layer from interior to exterior. According to the heat control material, regulation on different absorption rates / emission rates can be achieved, lightweight design can be achieved, the heat control material is suitable for emission-rate-controllable heat control coatings of new-generation spacecraft which have the beneficial effects of being low in weight, small in size and isothermal in whole-spacecraft, the cost is low, the technology is simple, the space environment is good in stability, and different requirements for emission rates of different parts on the surface of a spacecraft and the requirement for improving space irradiation resistance of the heat control material are met.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

Manufacturing method of rapid power concentrated rail motor coach motor car carbon fiber locomotive door

ActiveCN107187066AReduce weightSmall shape and position toleranceDoor arrangementDomestic articlesWork in processEngineering

The invention discloses a manufacturing method of a rapid power concentrated rail motor coach motor car carbon fiber locomotive door. According to the manufacturing method, an outer panel, an inner panel and a door body framework are manufactured through carbon fiber materials in a die pressing integrated molding manner and are then pasted together. Pasting includes the steps that (1) the position between the outer panel and the door body framework is smeared with epoxy resin adhesive; (2) the outer panel and the door body framework are clamped together and are then sent to an oven to be backed, and therefore the outer panel and the door body framework are completely pasted; (3) an acoustic insulating material is taken out from the oven to be placed into the door body framework; (4) the position between the inner panel and the door body framework is smeared with epoxy resin adhesive; (5) the outer panel, the inner panel and the door body framework are clamped together to form a locomotive door semi-finished product, and then the locomotive door semi-finished product is sent to the oven to be baked; and (6) after baking is completed, the locomotive door semi-finished product is taken out from the oven and is subject to follow-up machining treatment, and a finished product is formed. According to the manufacturing method, the light design requirement is met, and the manufacturing accuracy is high.

Owner:TIANYI IND HUNAN RAILWAY PROFESSIONAL TECH COLLEGE

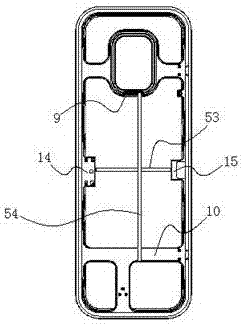

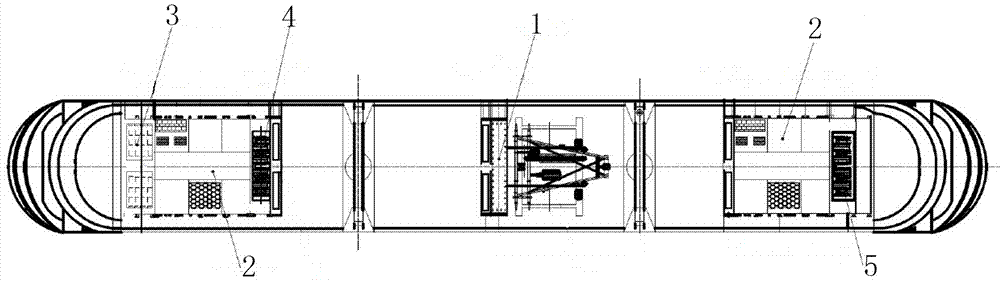

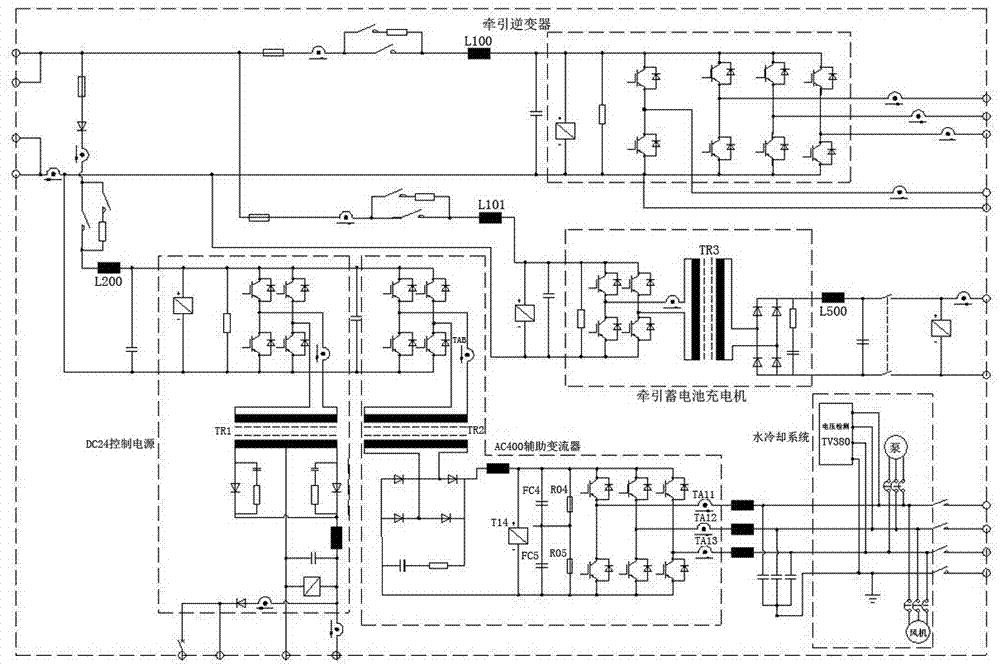

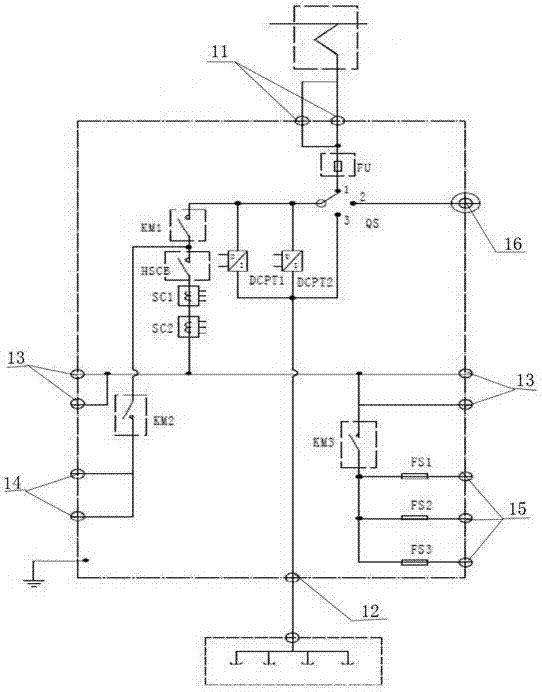

Electric transmission system of low-floor light rail vehicle

PendingCN107487220AFulfilling installation space requirementsMeet lightweight design requirementsElectric locomotivesPropulsion by batteries/cellsElectric power transmissionTransformer

The invention relates to electric transmission systems of vehicles, in particular to an electric transmission system of a low-floor light rail vehicle. The problem that a traditional electric transmission system cannot adapt to a low-floor light rail vehicle is solved. The electric transmission system of the low-floor light rail vehicle electric comprises a high-voltage box, two traction auxiliary converters, a brake resistor box, a 24V storage battery and a traction storage battery. The high-voltage box comprises a main fuse, an isolating switch and a high-speed circuit breaker. Each traction auxiliary converter comprises a traction inverter, a smoothing reactor, a DC24V control power supply, an AC400V auxiliary inverter and a traction storage battery charger, wherein transformers included in the DC24V control power supply, the AC400V auxiliary inverter and the traction storage battery charger are high-frequency transformers. The high-voltage box, the traction auxiliary converters and the brake resistor box are all of box-type design with the height being no more than 530 mm. The electric transmission system has the characteristics of being high in integration degree, small in size, high in reliability, good in seismic resistance, high in protection grade, powerful in function and the like.

Owner:CRRC YONGJI ELECTRIC CO LTD

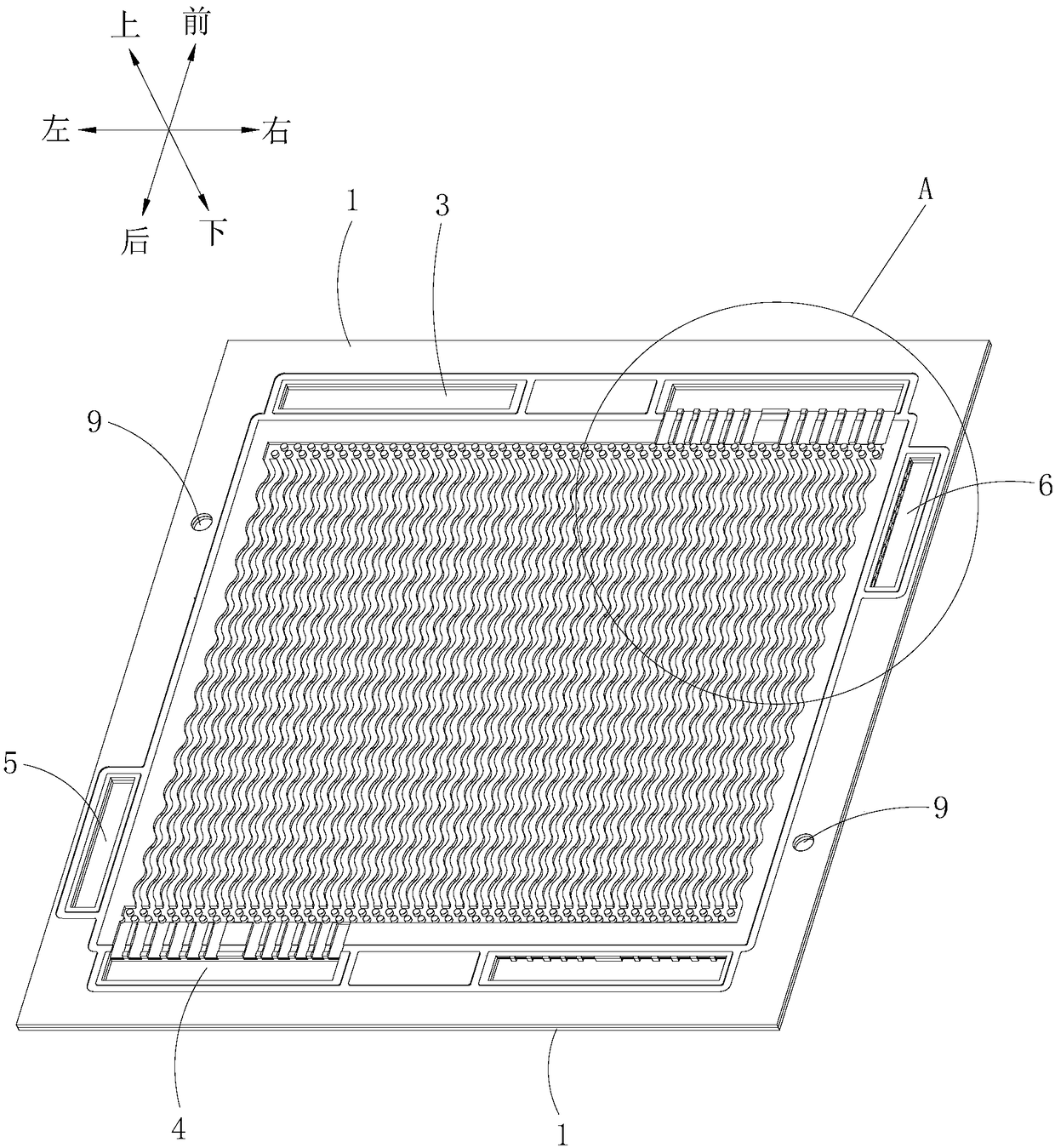

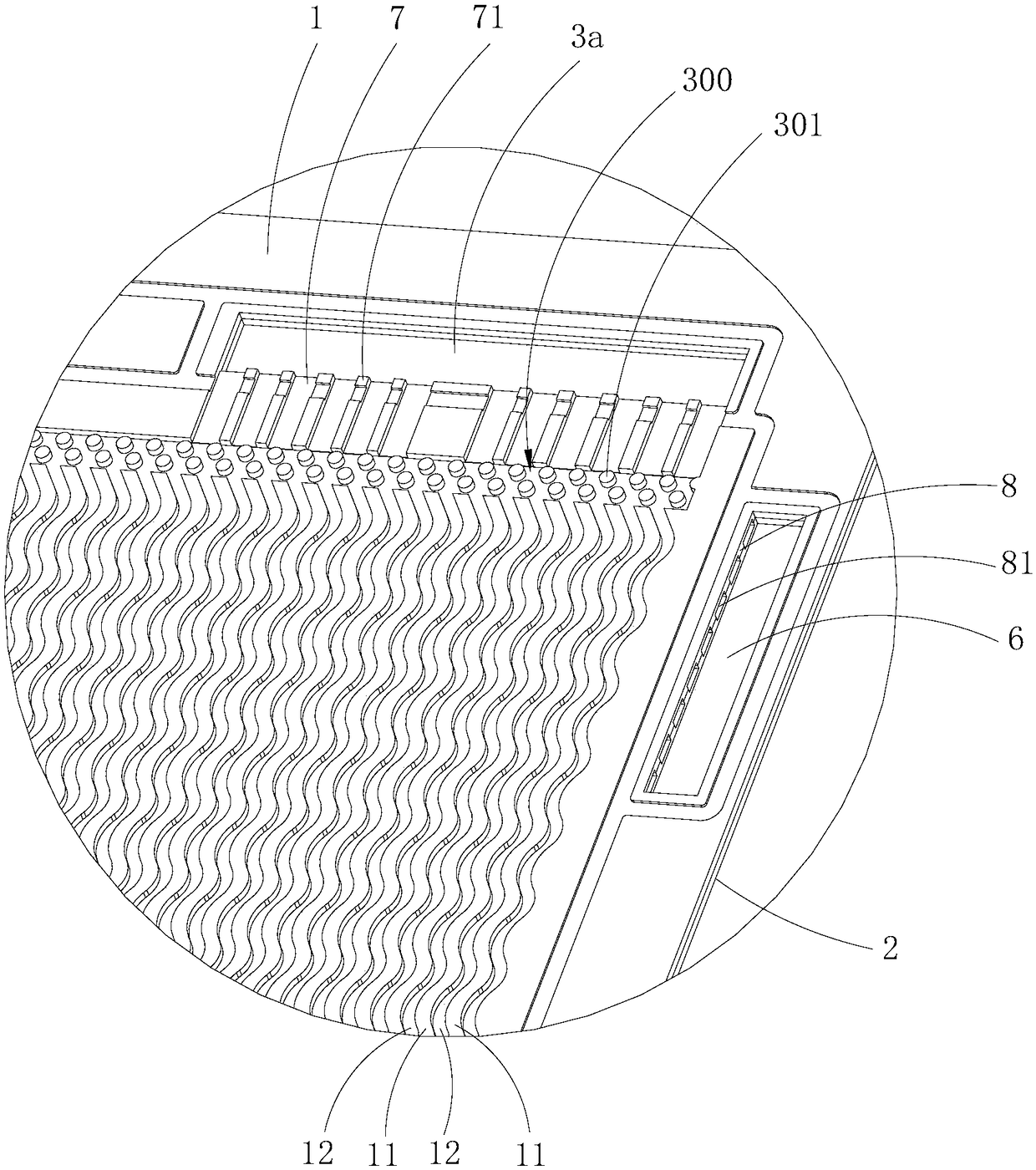

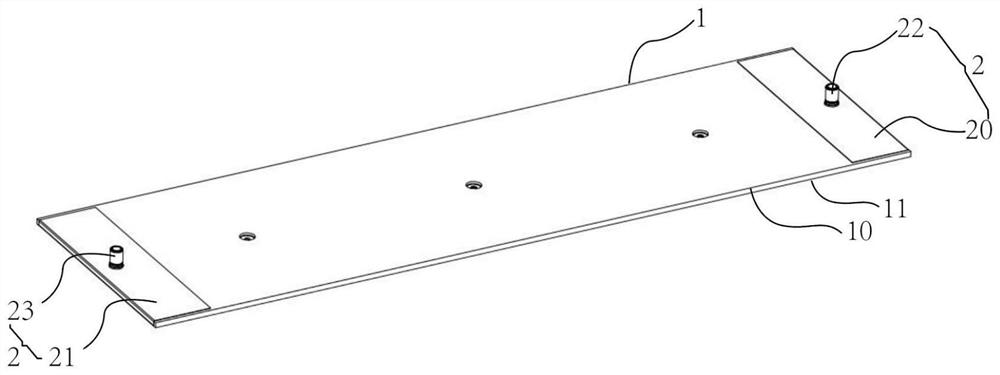

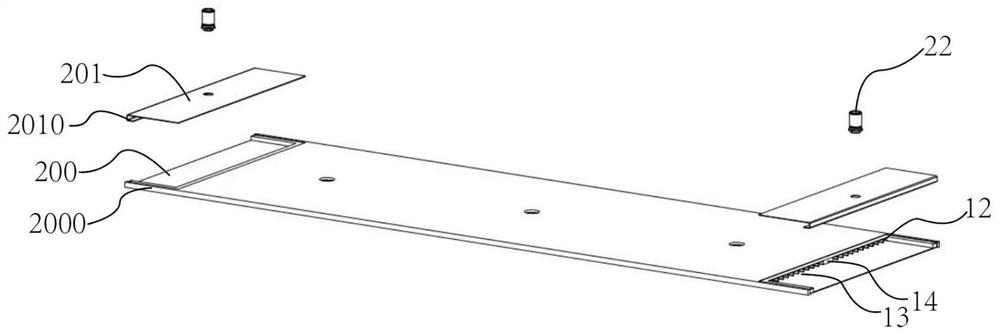

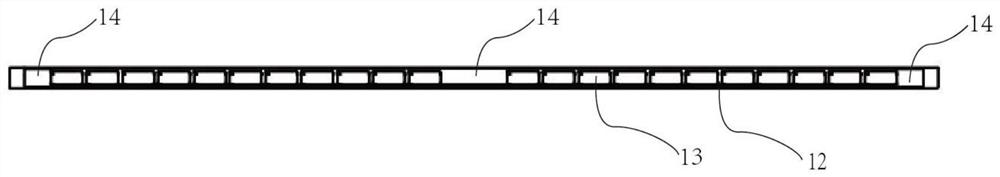

Battery liquid cooling plate structure and automobile battery

InactiveCN111952691AImprove cooling effectSimple processSecondary cellsAutomotive batteryEngineering

The invention relates to a battery liquid cooling plate structure and an automobile battery. The battery liquid cooling plate structure comprises a liquid cooling plate main body and a liquid inlet and outlet structure. The liquid cooling plate main body comprises an upper cooling plate and a lower cooling plate arranged side by side up and down, a plurality of partition plate ribs arranged between the upper cooling plate and the lower cooling plate at intervals, and a cooling cavity between the upper cooling plate and the lower cooling plate is divided into a plurality of cooling flow channels by the plurality of partition plate ribs. The liquid inlet and outlet structure comprises a liquid inlet plate structure and a liquid outlet plate structure which are arranged at the two ends of theliquid cooling plate body respectively, a liquid inlet cavity communicated with one end of the cooling flow channel is formed in the liquid inlet plate structure, and a liquid outlet cavity communicated with the other end of the cooling flow channel is formed in the liquid outlet plate structure; a liquid inlet head communicated with the liquid inlet cavity is arranged on the liquid inlet plate structure, and a liquid outlet head communicated with the liquid outlet cavity is arranged on the liquid outlet plate structure. According to the present invention, the processing technology of the battery liquid cooling plate is simplified, so that the liquid cooling plate meets the design requirement of light weight, and meanwhile, the cooling and heat dissipation performance of the liquid cooling plate is improved.

Owner:东风时代(武汉)电池系统有限公司

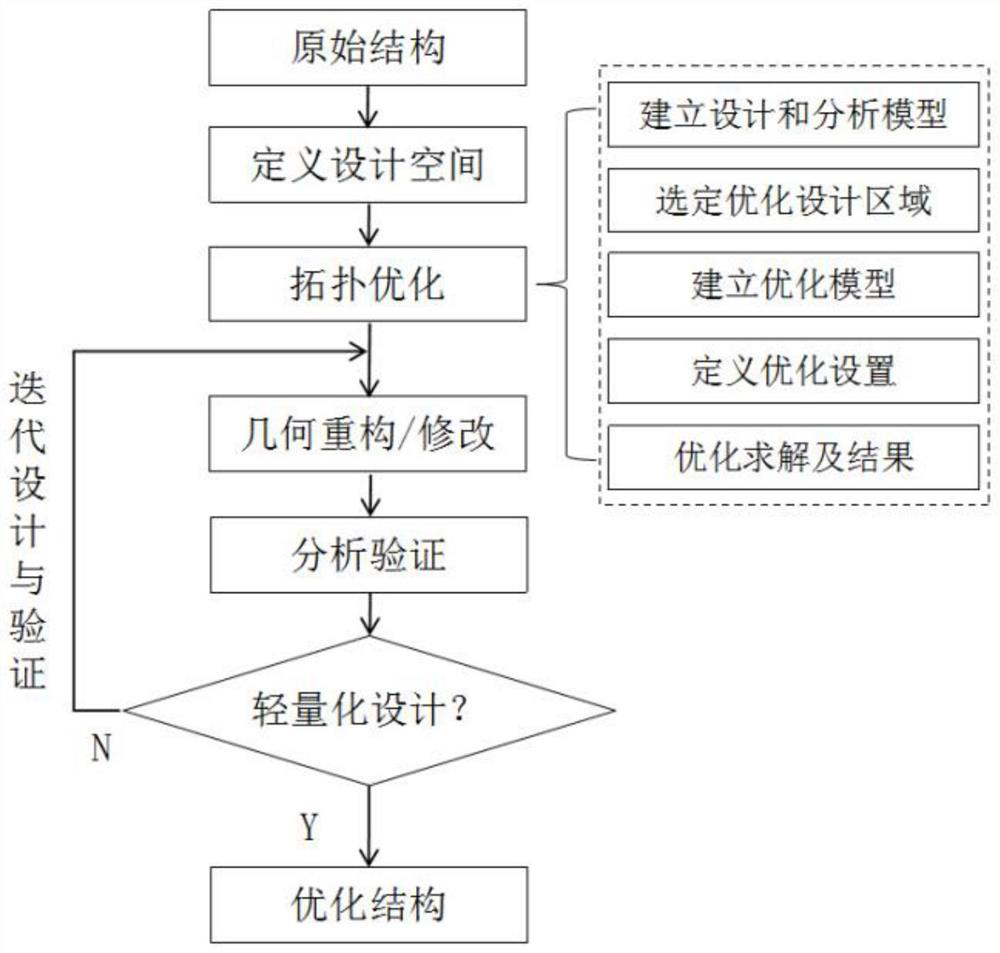

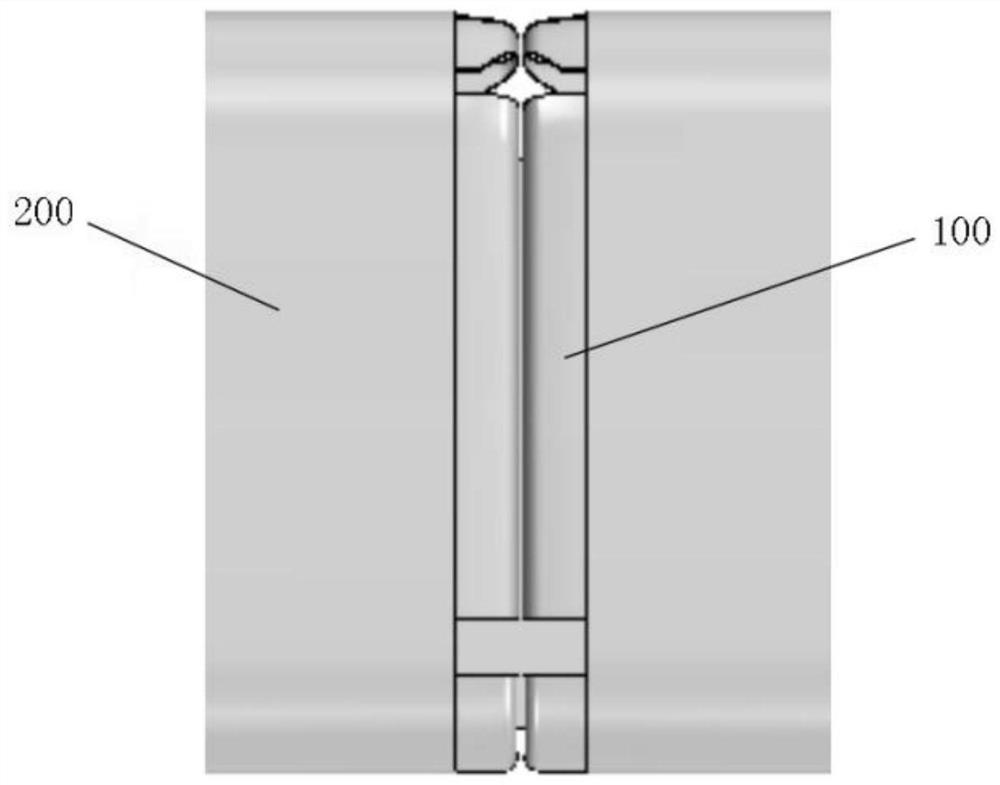

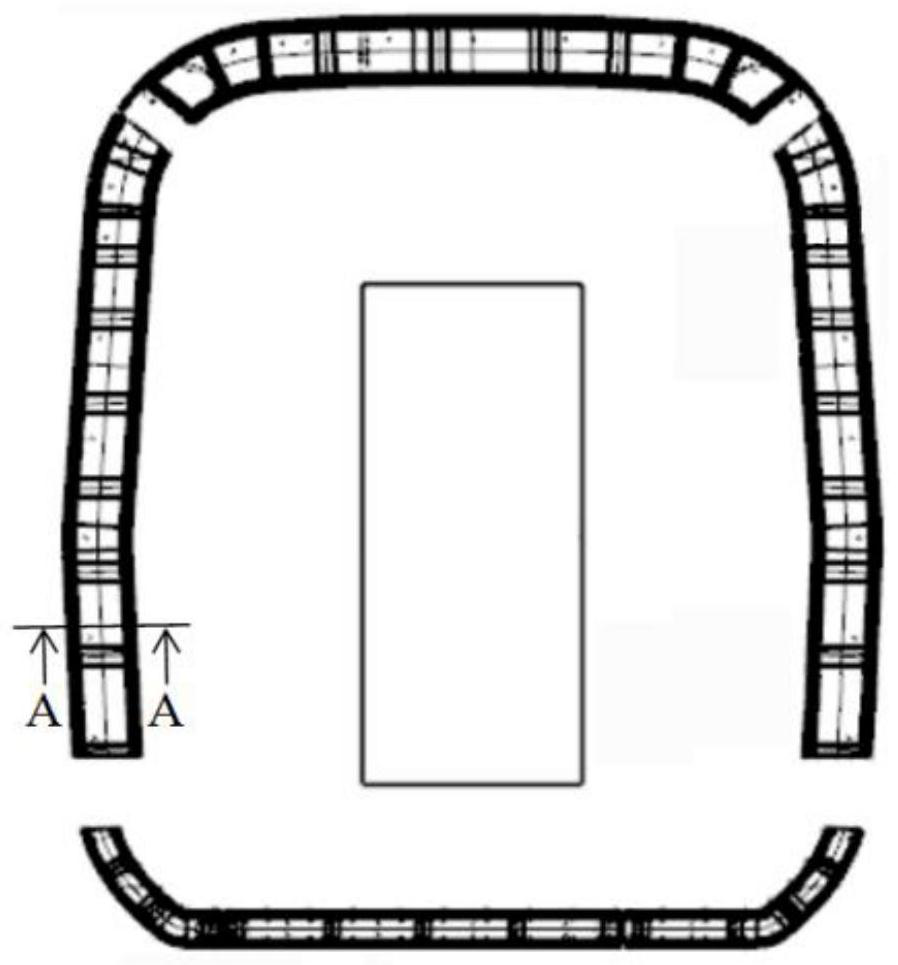

Optimization method for outer windshield structure of high-speed train, and outer windshield structure

PendingCN111985052AIncrease lateral stiffnessRaise the first-order bending natural frequencyGeometric CADSustainable transportationAlgorithmStructural engineering

The invention discloses an optimization method for an outer windshield structure of a high-speed train, and the outer windshield structure. The optimization method comprises the following steps: defining an outer windshield structure design space according to the geometric boundary dimension of the section of an original outer windshield structure, performing topological optimization design on thedesign area to obtain a topological optimization design result, performing geometric reconstruction and modification on the topological optimization design result to obtain a topological optimizationouter windshield structure section, comparing the topologically optimized section of the outer windshield structure with the section of the original outer windshield structure for verification, if the section of the outer windshield structure meets the lightweight design requirement, finishing optimization, and if the lightweight design requirement is not met, returning to the geometric reconstruction and modification step for iterative design and comparative verification. According to the optimization method and the outer windshield structure, under the condition that the mass of an originalstructure is not increased, the transverse rigidity of the outer windshield structure is improved, the drag reduction effect of the installed outer windshield structure is better, the transverse deformation resistance is improved, and the lightweight design requirement of the outer windshield structure is met.

Owner:CENT SOUTH UNIV +1

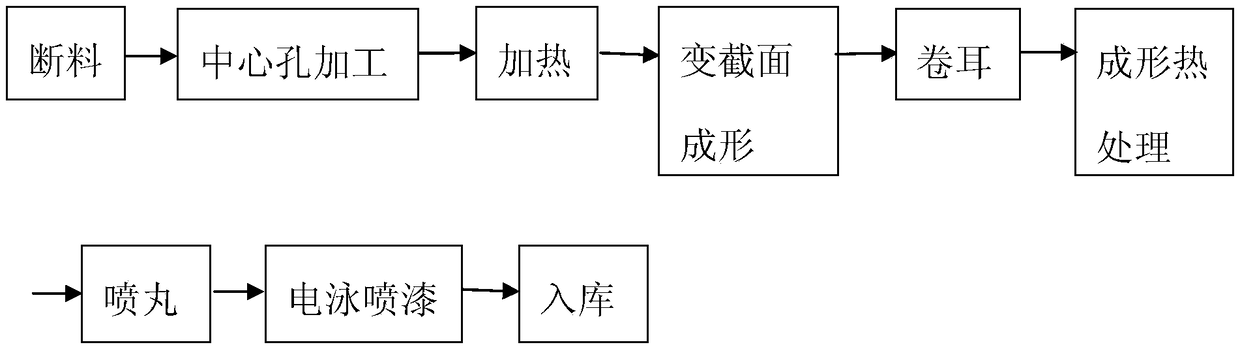

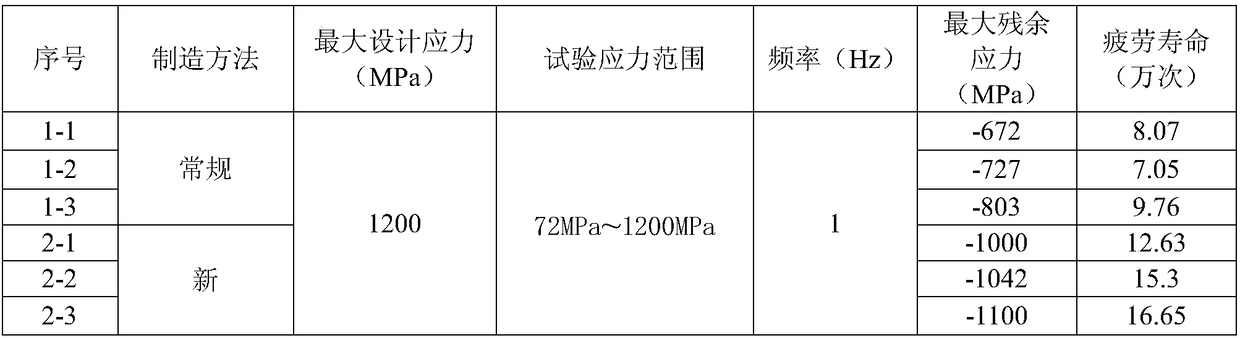

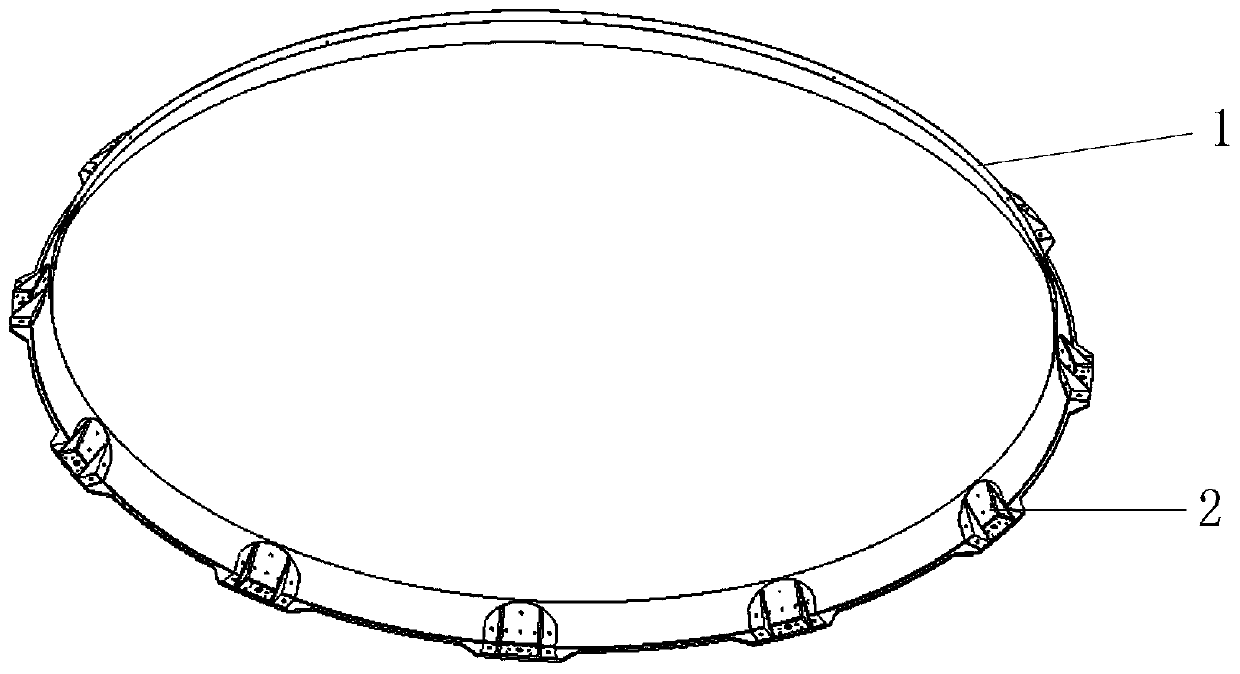

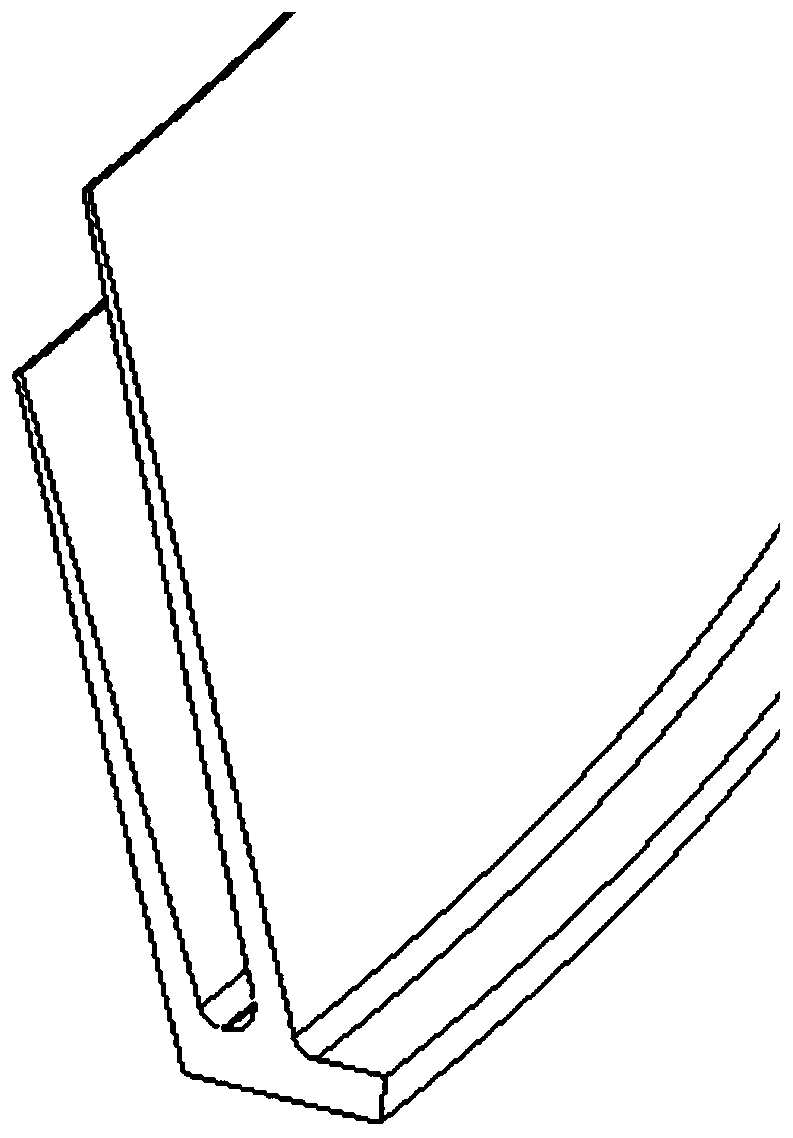

High-stress and long-service-life variable section single steel plate spring and manufacturing method thereof

InactiveCN108869594ASimple structureSimplify the manufacturing processLeaf springsFurnace typesShape changeElectrophoresis

The invention relates to the technical field of steel plate spring machining, in particular to a high-stress and long-service-life variable section single steel plate spring and a manufacturing methodthereof. The high-stress and long-service-life variable section single steel plate spring comprises a single steel plate spring body which is high-strength spring flat steel, wherein the tensile strength of the high-strength spring flat steel is larger than or equal to 1,870 MPa, and the yield strength is larger than or equal to 1,680 MPa; after forming, the section of the variable section singlesteel plate spring is in a parabola shape changing in the length direction of the variable section single steel plate spring, and front-back symmetry and left-right symmetry are achieved with a center bolt hole as the center. The manufacturing method of the high-stress and long-service-life variable section single steel plate spring comprises the procedures of material breakage, center hole machining, heating, variable section forming, lug rolling, forming heat treatment, shot blasting, electrophoresis paint spraying and warehousing. Through two-time shot blasting including free shot blastingand high-stress shot blasting, the residual compressive stress of the surface of the stretching side of the single spring is improved. The high-stress and long-service-life variable section single steel plate spring is simple in structure, and the single steel plate spring manufacturing process is simplified; and meanwhile, the bearing capability is improved, the vehicle lightweight design requirement is met, the tensile fatigue strength of the single steel plate spring is improved, and the fatigue life of the single steel plate spring is prolonged.

Owner:NANJING NAVECO AUTOMOBILE CO LTD

Composite material structure applicable to point-connected spacecraft

ActiveCN109911246ASolve lightweightReduce structural weightCosmonautic partsArtificial satellitesEngineeringUltimate tensile strength

The invention relates to a composite material structure applicable to a point-connected spacecraft in the field of star-arrow connecting structures. The composite material structure comprises a force-bearing barrel lower end frame and reinforcing corner boxes, wherein the section of the force-bearing barrel lower end frame is F-shaped; the force-bearing barrel lower end frame mainly comprises an inclined plane, riveting holes, a flanging flange and connecting flanges; the section of the reinforcing corner boxes is L-shaped; riveting holes are formed in the reinforcing corner boxes; the reinforcing corner boxes are riveted to the inclined plane of the lower end frame; the sections of the reinforcing corner boxes are fitted to the surfaces of the inclined plane and the connecting flanges. The composite material structure meets a lightweight design requirement of a force-bearing barrel of a new-generation Mars probe structural platform in China and also guarantees the connecting strengthand the connecting rigidity during connection with a carrier.

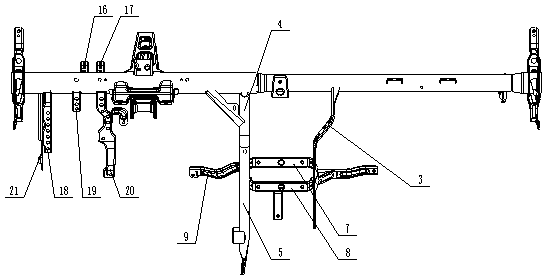

Automobile instrument panel tubular beam assembly

PendingCN108791516ALight in massMeet lightweight design requirementsSuperstructure subunitsAutomotive engineeringWall mount

The invention discloses an automobile instrument panel tubular beam assembly. The automobile instrument panel tubular beam assembly comprises a tubular beam middle pipe arranged in the car body widthdirection and opposite to a car body front wall structure. Lateral mounting brackets are separately arranged at two ends of the tubular beam middle pipe and used for fixedly connecting with the car body front wall structure. An electric appliance mounting bracket, a front wall mounting bracket, a steering column mounting bracket and a center control mounting bracket are further arranged on the tubular beam middle pipe correspondingly. The automobile instrument panel tubular beam assembly is characterized in that the center control mounting bracket comprises a left supporting rod and a right supporting rod which are arranged in the axial direction of the tubular beam middle pipe at intervals, a left supporting rod entirety and a right supporting rod entirety are inclined downwards in the direction of back to the front wall structure of the car body, a connecting end portion used for connecting a car body front floor is formed at the external end of the left supporting rod, and the leftsupporting rod is of a round tube structure. The automobile instrument panel tubular beam assembly has the advantages that the design light weight requirement can be better met, better rigidity can beachieved, and the cost can be reduced.

Owner:力帆科技(集团)股份有限公司

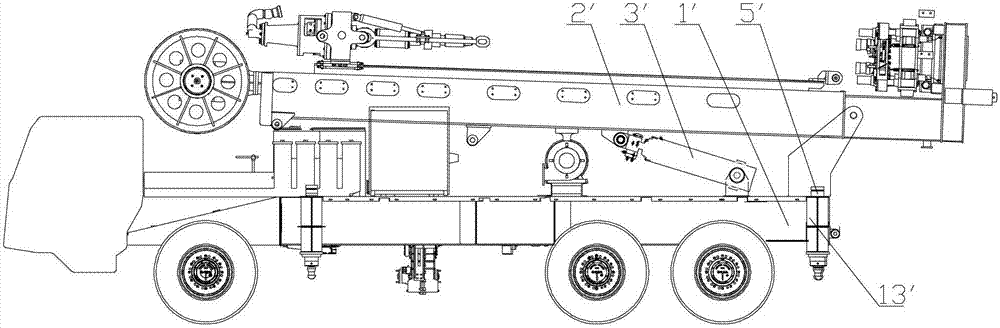

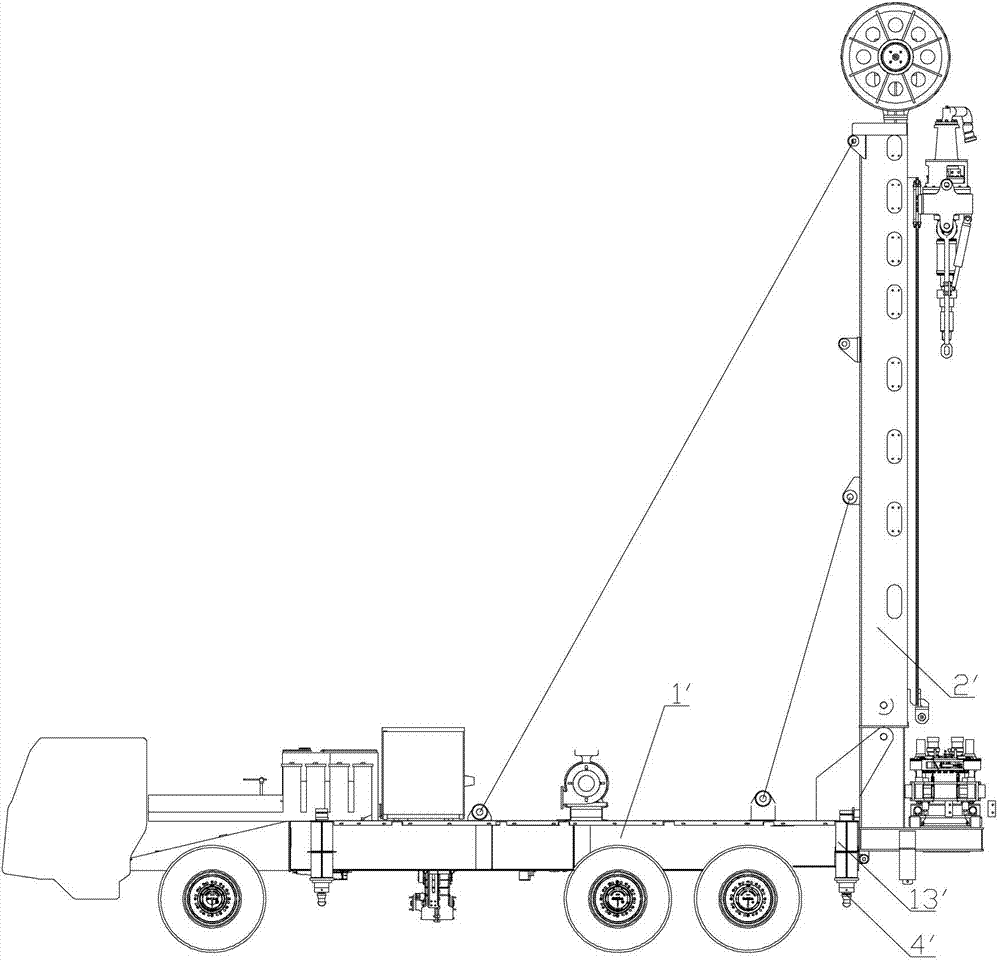

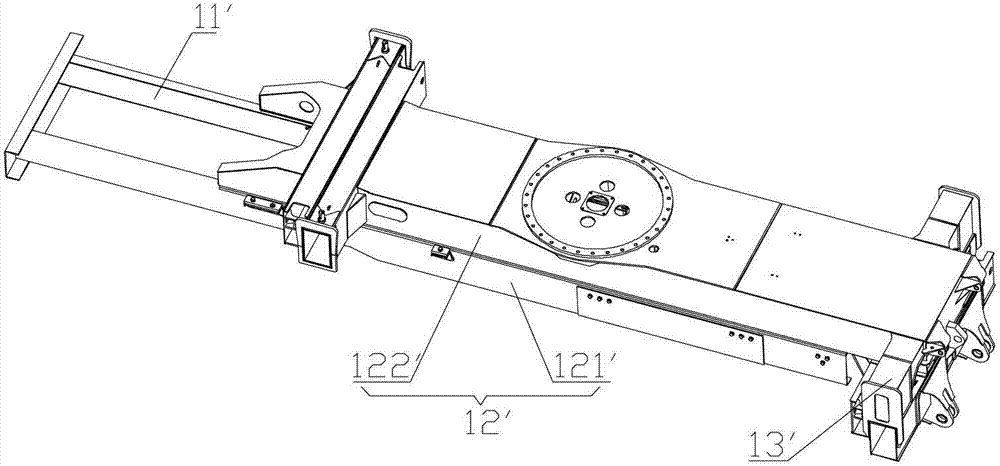

Drilling rig and rig frame thereof

The invention discloses a rig frame of a drilling rig. The rig frame of the drilling rig comprises a rig frame front part and a rig frame rear part which are mutually connected, wherein the rig frame front part is of a channel beam structure, and the rig frame rear part is of an integral box-type structure. The integral box-type structure is free of the problem of rig frame connection, so that the problem of connecting misplacement of a main rig frame and a secondary rig frame in the prior art is resolved. In addition, the bending resistance and the torsion resistance of the integral box-type structure are high, the inertia moment of the cross section is strengthened, the stress of the whole drilling rig is improved, and the working stability of the rig frame is improved. Due to the fact that inertia moment of the cross section is decided by the size of a box and has little relationship with plate thickness, after a double-layer connecting structure combined by a mediate and small box and channel beams in the prior art is changed into the larger integral box-type structure, on the premise that the rigidity and the strength are guaranteed, the wall thickness of the rig frame rear portion can be appropriately reduced, and the weight of the rig frame is lowered. In addition, after the rig frame rear portion is of the integral box-type structure, an operator does not need to buy a universal chassis to modify the rig frame, and production cost is lowered.

Owner:XUZHOU HEAVY MASCH CO LTD

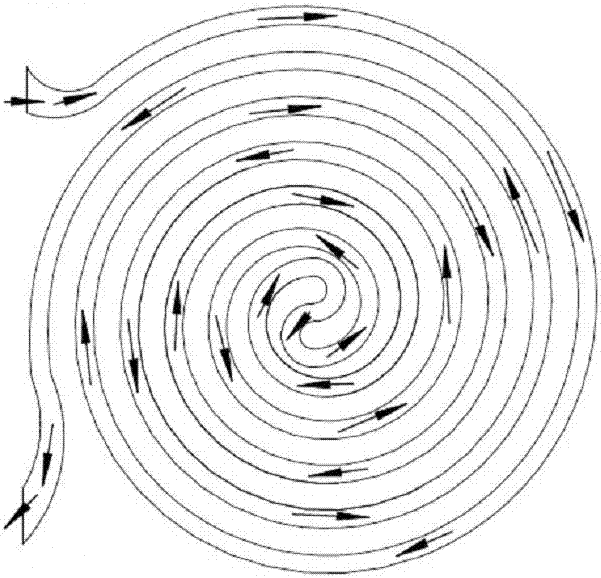

Three-phase inversion power module based on two-way spiral flow channel water cooling heat radiation substrate

ActiveCN107171573AReasonable designSmooth layoutConversion constructional detailsCooling/ventilation/heating modificationsComputer moduleEngineering

The invention relates to the inversion power module and particularly relates to a three-phase inversion power module based on a two-way spiral flow channel water cooling heat radiation substrate. The three-phase inversion power module based on the two-way spiral flow channel water cooling heat radiation substrate solves problems that a present heat radiation flow channel is not reasonable, poor in heat radiation, big in size and weight and not easy to perform fast plug-pull installation. In the scheme of the three-phase inversion power module based on the two-way spiral flow channel water cooling heat radiation substrate, a three-phase inversion power circuit is arranged on the two-way spiral flow channel water cooling heat radiation substrate; a T-shaped composite mother board and a drive board are stacked on the two-way spiral flow channel water cooling heat radiation substrate; a support seat is arranged in the front edge of the two-way spiral flow channel water cooling heat radiation substrate; water connectors and fixed blocks are arranged on two sides of the two-way spiral flow channel water cooling heat radiation substrate; and screw rods and a handle go through the fixed blocks. The advantages of the three-phase inversion power module based on the two-way spiral flow channel water cooling heat radiation substrate has advantages that flow resistance of a cooling liquid is small and heat radiation is uniform; the water connectors are easy to mount and dismount without affecting processing accuracy; and the layout is not affected by the flow channel; circuit electric inductance is small and working reliability of a thermal performance power module is high. Furthermore, the three-phase inversion power module based on the two-way spiral flow channel water cooling heat radiation substrate is compact in layout, small in volume and light in weight, saves cost; the interfaces are preposed in sequence, which is easy to maintain and saves external fast connection device; and a driving signal is high in anti-interference.

Owner:CRRC YONGJI ELECTRIC CO LTD

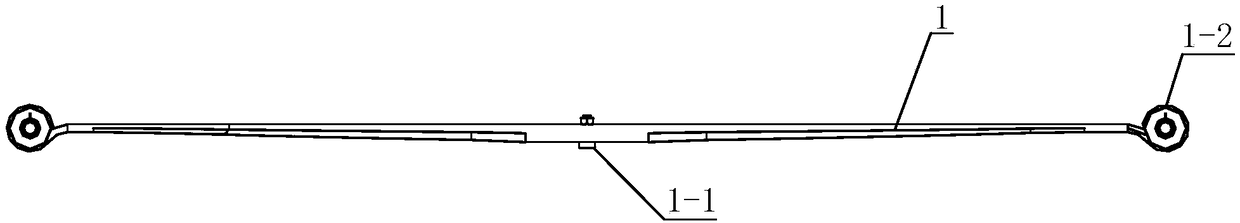

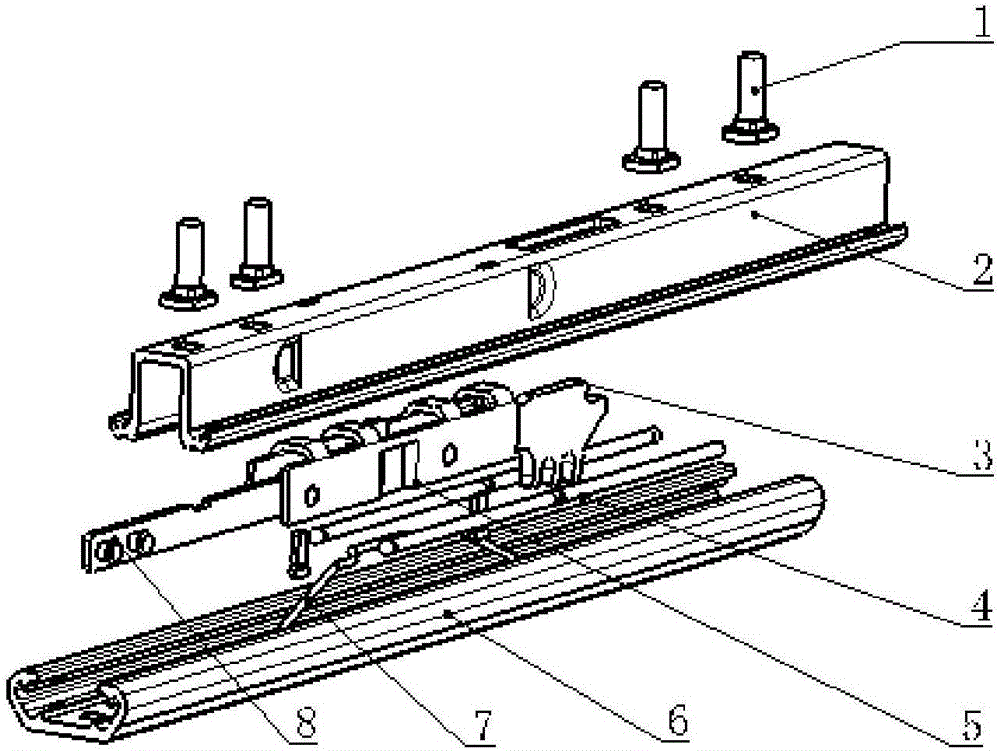

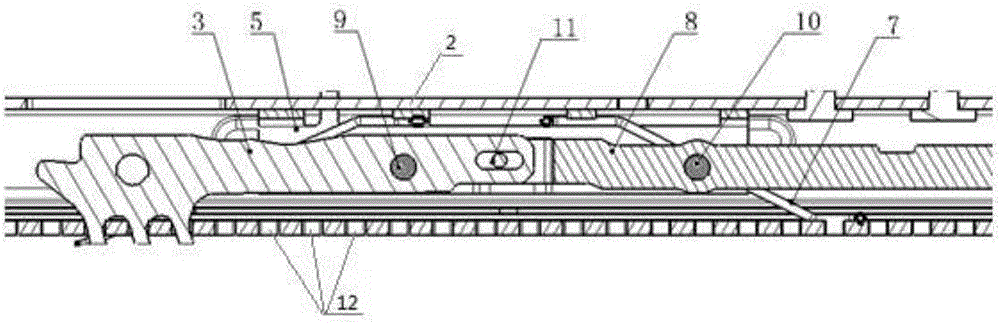

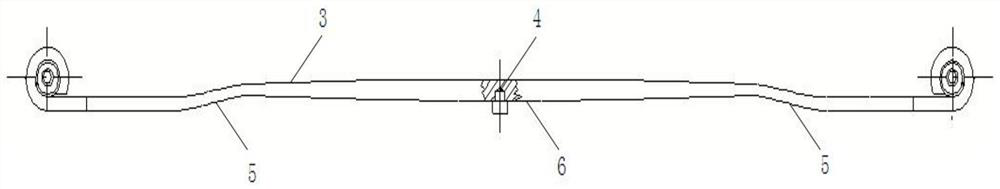

Lightweight automobile seat slide rail

The invention relates to a lightweight automobile seat slide rail which is composed of two symmetrical slide rails connected through a rigid connecting rod, wherein a single slide rail comprises an upper rail body, a lower rail body, a cavity and a locking mechanism assembly; the upper rail body and the lower rail body are combined to form the cavity; the locking mechanism assembly is arranged in the cavity; the locking mechanism assembly comprises a locking mechanism holder, a locking mechanism and an unlocking mechanism; the locking mechanism holder is vertically fixed on the top surface of the upper rail body; the locking mechanism comprises a first pin shaft arranged on the locking mechanism holder and a locking sheet fixed by being parallel to the locking mechanism holder by the first pin shaft; the unlocking mechanism comprises a second pin shaft arranged on the locking mechanism holder and an unlocking sheet fixed by being parallel to the locking mechanism holder by the second pin shaft; the locking sheet and the unlocking sheet are moveably connected through a groove. According to the invention, different materials including aluminum alloy, plastic nylon, high-strength steel, and the like, are reasonably and efficiently applied to the corresponding parts of the slide rail; the strength requirement is met while the weight is light; the lightweight design requirement is met; the structure and the technique are simplified; the production period and cost are reduced.

Owner:合肥延锋云鹤汽车座椅有限公司

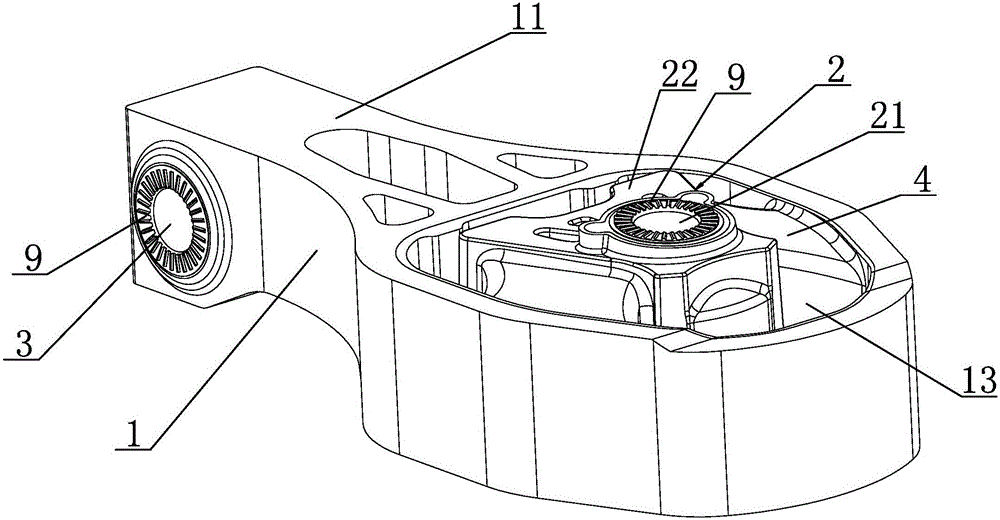

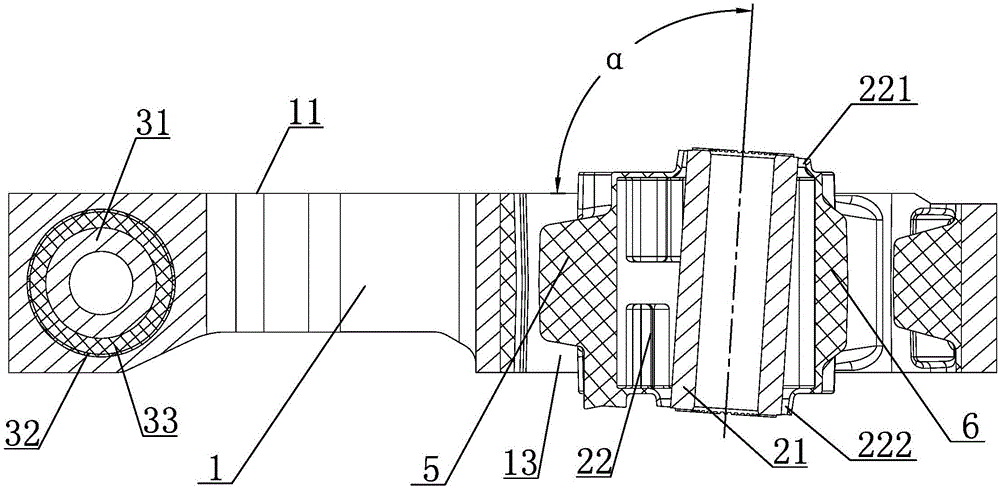

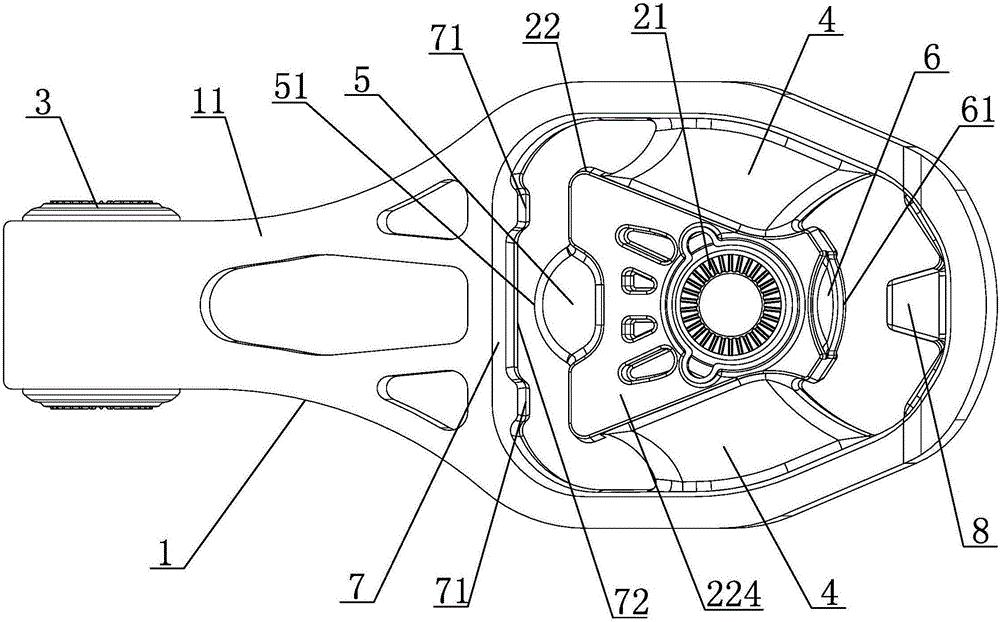

Torsion resistant pull rod of power assembly

ActiveCN106427516AControl installation angleGuaranteed stabilityJet propulsion mountingInternal combustion mountingVehicle frameAcute angle

The invention discloses a torsion resistant pull rod of a power assembly. The torsion resistant pull rod comprises a pull rod bracket, a large liner bushing and a small liner bushing, wherein the large liner bushing and the small liner bushing are respectively arranged at two ends of the pull rod bracket; the large liner bushing comprises a large liner bushing inner pipe; and the small liner bushing comprises a small liner bushing inner pipe. The torsion resistant pull rod is characterized in that the upper surface of the pull rod bracket is a flat end surface; the central axis of the small liner bushing inner pipe is parallel to the upper surface of the pull rod bracket; an oblique obtuse angle is formed between the central axis of the large liner bushing inner pipe and the upper surface of the pull rod bracket; when one end of the pull rod bracket is connected with the power assembly through the small liner bushing, an oblique acute angle is formed between the upper surface of the pull rod bracket and a level surface; and the difference between the oblique obtuse angle and the oblique acute angle is 90 degrees. The torsion resistant pull rod disclosed by the invention has the advantages that after the pull rod bracket of the torsion resistant pull rod is mounted in a preset angle, the upper surface or the lower surface of the large liner bushing inner pipe can be mounted on a vehicle body or a sub vehicle frame in a flat clinging manner, so that the mounting stability and the whole using stability of the torsion resistant pull rod are guaranteed.

Owner:NINGBO TUOPU GROUP CO LTD

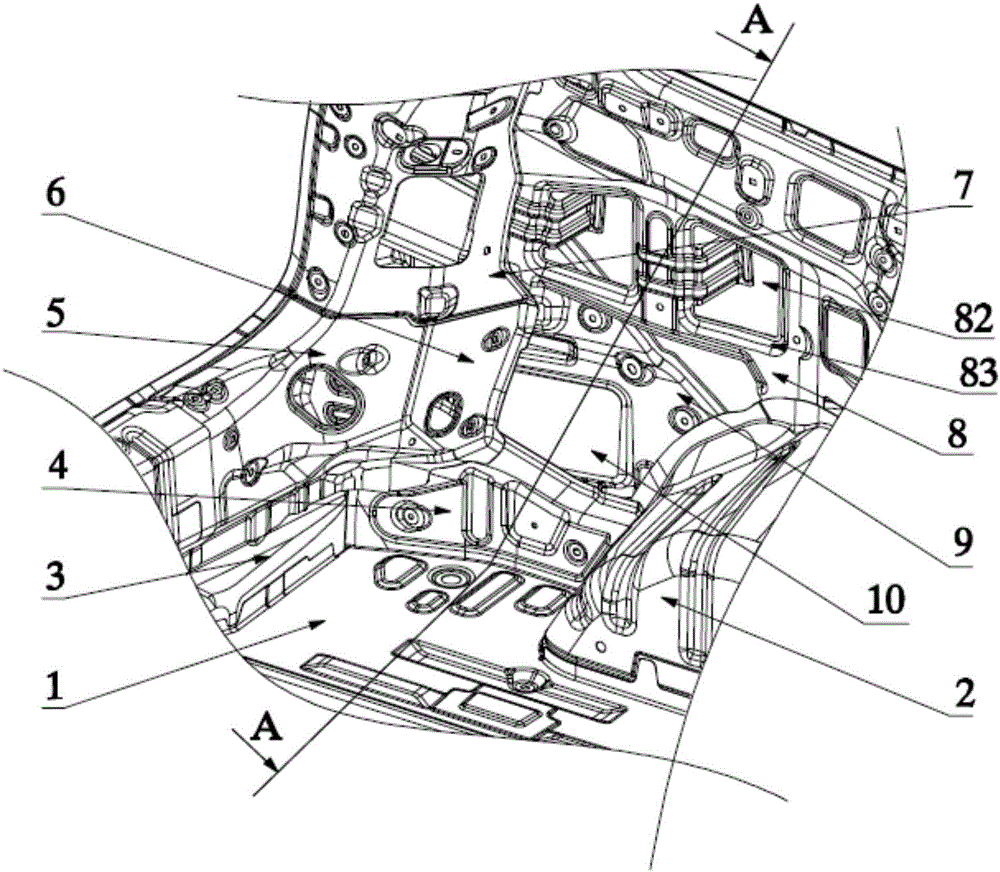

Novel overlapping structure for rear coaming and side coaming

InactiveCN106428220AMeet lightweight design requirementsReduce development costsSuperstructure subunitsTorsional rigidityOverlapping structures

The invention discloses a novel overlapping structure for a rear coaming and a side coaming. The overlapping structure comprises a rear floor, a rear wheel bulge, a rear coaming lower cover plate, a rear coaming side plate, a rear coaming connecting plate, a rear coaming supporting plate, a rear stand column inner plate, a rear side coaming inner plate and a rear side coaming outer plate, wherein the lower end of the rear wheel bulge is overlapped with the rear floor; the rear coaming lower cover plate is overlapped with the rear floor; the rear coaming side plate is overlapped to the rear floor; the lower end of the rear coaming connecting plate is overlapped with the upper end of the rear coaming lower cover plate, and the lower end of the rear coaming supporting plate is overlapped with the upper end of the rear coaming side plate; the lower end of the rear stand column inner plate is overlapped to the upper end of the rear coaming connecting plate and the upper end of the rear coaming supporting plate; a cavity structure is formed by the surrounding of the rear side coaming inner plate, the rear wheel bulge, the rear coaming side plate and the rear coaming supporting plate; and the lower end of the rear side coaming outer plate is overlapped to the rear floor and coated on the rear side coaming inner plate. According to the novel overlapping structure disclosed by the invention, the light weight design requirements of automobiles are achieved; besides, the developing cost of a mould of the rear side coaming inner plate is reduced, the material utilization rate is improved, and the developing cost of the whole automobile is reduced; and the novel overlapping structure disclosed by the invention has high strength and high torsional rigidity.

Owner:北汽瑞翔汽车有限公司

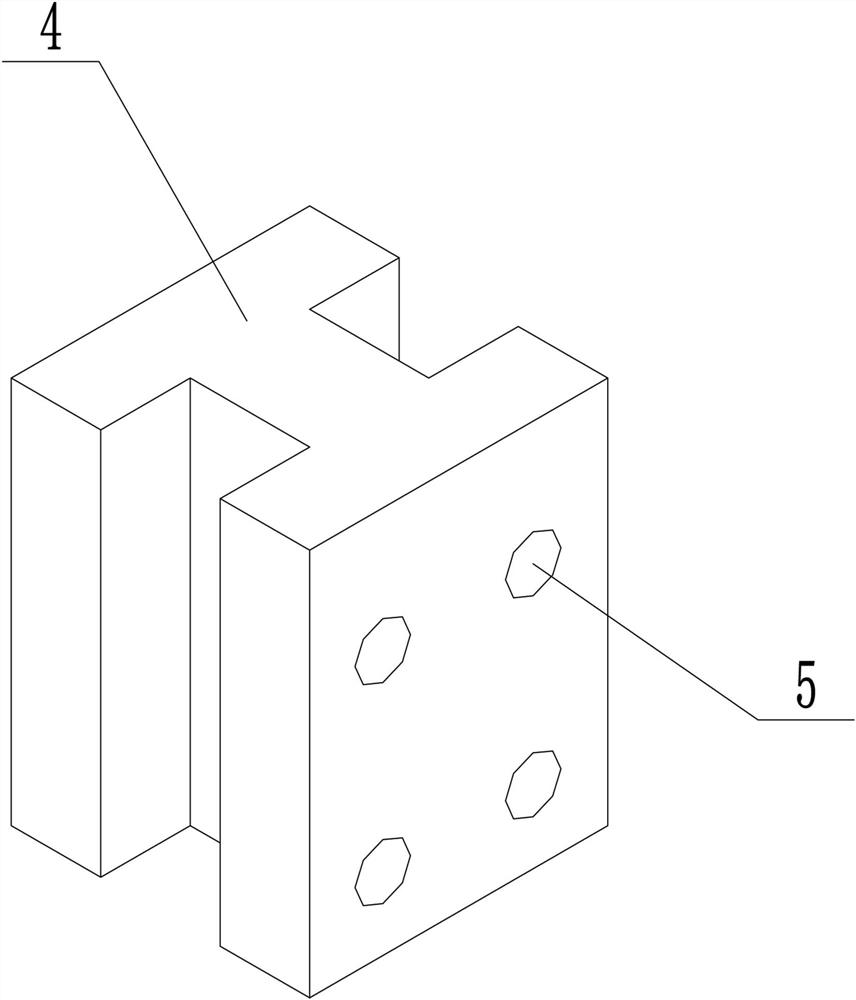

Light steel floor system structure of fabricated building

PendingCN111608316AFit closelyShort construction periodFloorsArchitectural engineeringStructural engineering

The invention relates to a light steel floor system structure of a fabricated building. The light steel floor system structure comprises a light steel floor system, I-shaped inserting blocks arrangedat four corners of the bottom end of the light steel floor system, and prefabricated mounting seats which are mounted on a building base body or supporting columns and correspond to the I-shaped inserting blocks in position, and the I-shaped inserting blocks are matched with the prefabricated mounting seats; and protruding blocks are arranged on the two adjacent side walls of the light steel floorsystem, grooves matched with the protruding blocks in shape are formed in the other two side walls of the light steel floor system, and every two adjacent light steel floor systems are connected through matching between the protruding blocks and the grooves. According to the adopted light steel floor system structure, the construction period is short, the construction efficiency is high, the assembly type structural design is adopted, mounting is convenient, the mounting precision is high, floor systems are in close fit, gaps are small, and the structure is firm.

Owner:INST OF ECONOMIC & TECH STATE GRID HEBEI ELECTRIC POWER +1

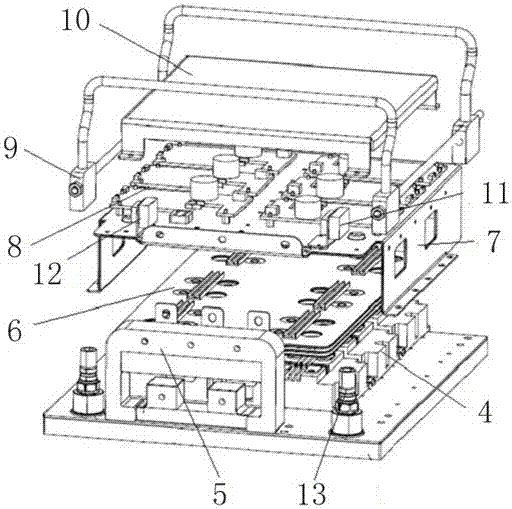

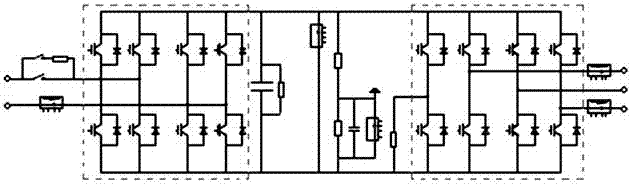

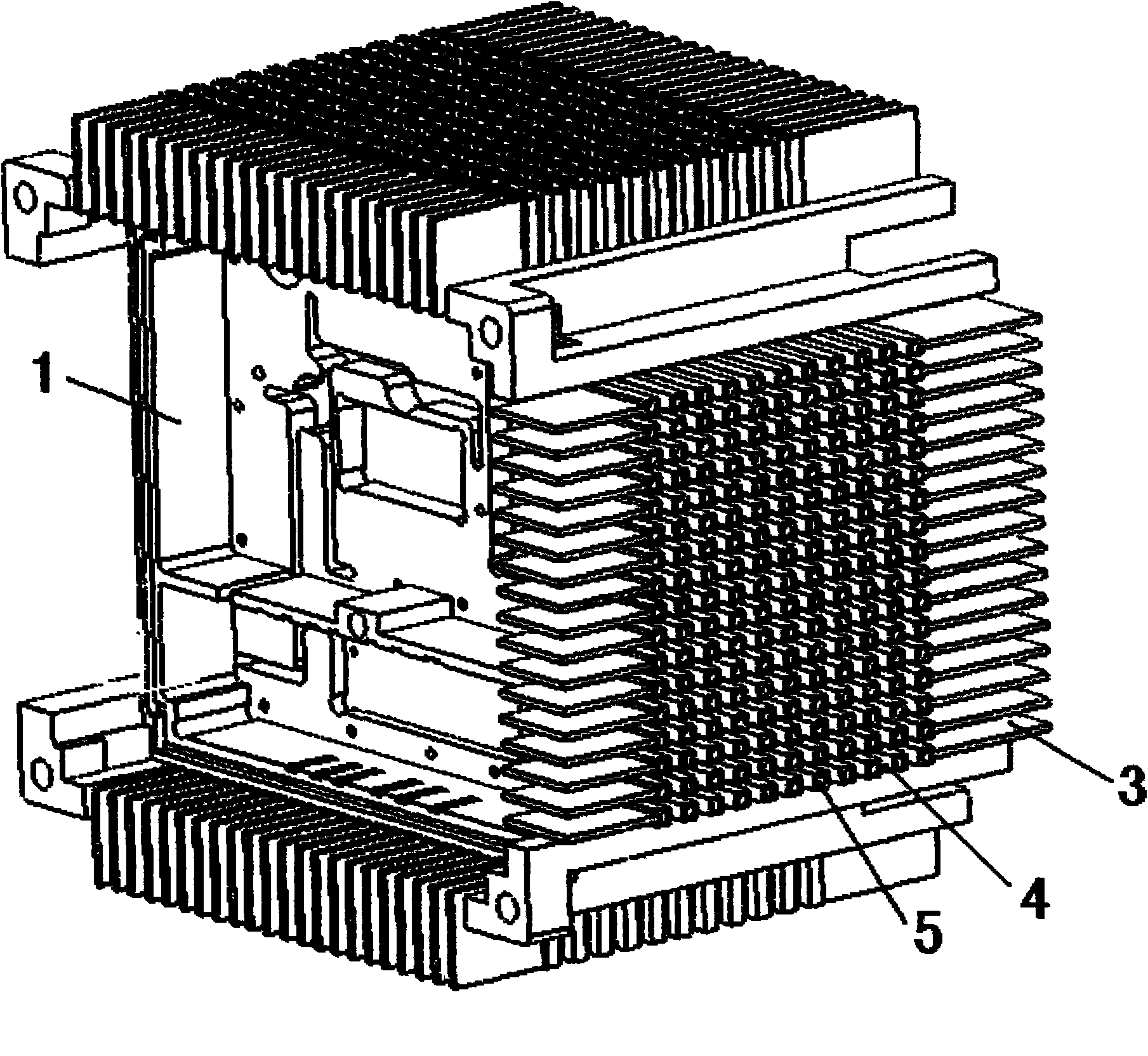

Traction converter device based on high-compatibility power unit

ActiveCN107294400AMeet lightweight design requirementsReduce the amount of research and developmentAc-ac conversionElectrical resistance and conductanceFour quadrants

The invention relates to a traction converter device, in particular to a traction converter device based on a high-compatibility power unit, and solves the problems of single function, incompatibility, long development period and large economic cost of spare parts of the existing power module unit. The scheme is as follows: the device comprises two power units respectively formed by connecting four paths of half-bridge circuits in parallel, an input end peripheral circuit, a middle peripheral circuit, a chopping resistor and an output end peripheral circuit, wherein the power unit at the left side is assembled at the input end and forms a four-quadrant rectifier unit through parallel application of two paths of half-bridges; the power unit at the right side is assembled at the output end and three paths of half-bridges form an inverter unit and the remaining path of half-bridge and the chopping resistor form a chopping unit. The device has the advantages that through the standardized power unit module, the research and development number of the power units can be reduced and the design cycle is greatly reduced; the types of components in the converter device are reduced; and the simplification of the power units and electric interfaces is realized.

Owner:CRRC YONGJI ELECTRIC CO LTD

Single-leaf spring for heavy truck

InactiveCN111810564AMeet lightweight design requirementsReduce weightLeaf springsInterference fitEngineering

The invention discloses a single-leaf spring for a heavy truck. The single-leaf spring comprises a single-leaf spring eye sheet, the single-leaf spring eye sheet is a spring sheet with the unequal width and the thickness changing in the length direction, and the spring sheet with a trapezoidal section or a parabola section. A positioning pin is arranged in a center hole of the single-leaf spring eye sheet, the positioning pin and the center hole are in interference fit, and the single-leaf spring eye sheet is rigidly connected to a chassis axle through the center hole and the positioning pin.Compared with a two-leaf spring, the weight of the single-leaf spring eye sheet can be reduced by 20% or above, a middle clamped areas is small in width and thick in section, and the material utilization rate of the middle clamped area can be effectively increased. In addition, the middle of the single-leaf spring eye sheet is small in cracking risk, and the risk that due to the fact that the middle clamped area cracks, vehicle steering fails is reduced.

Owner:东风汽车底盘系统有限公司

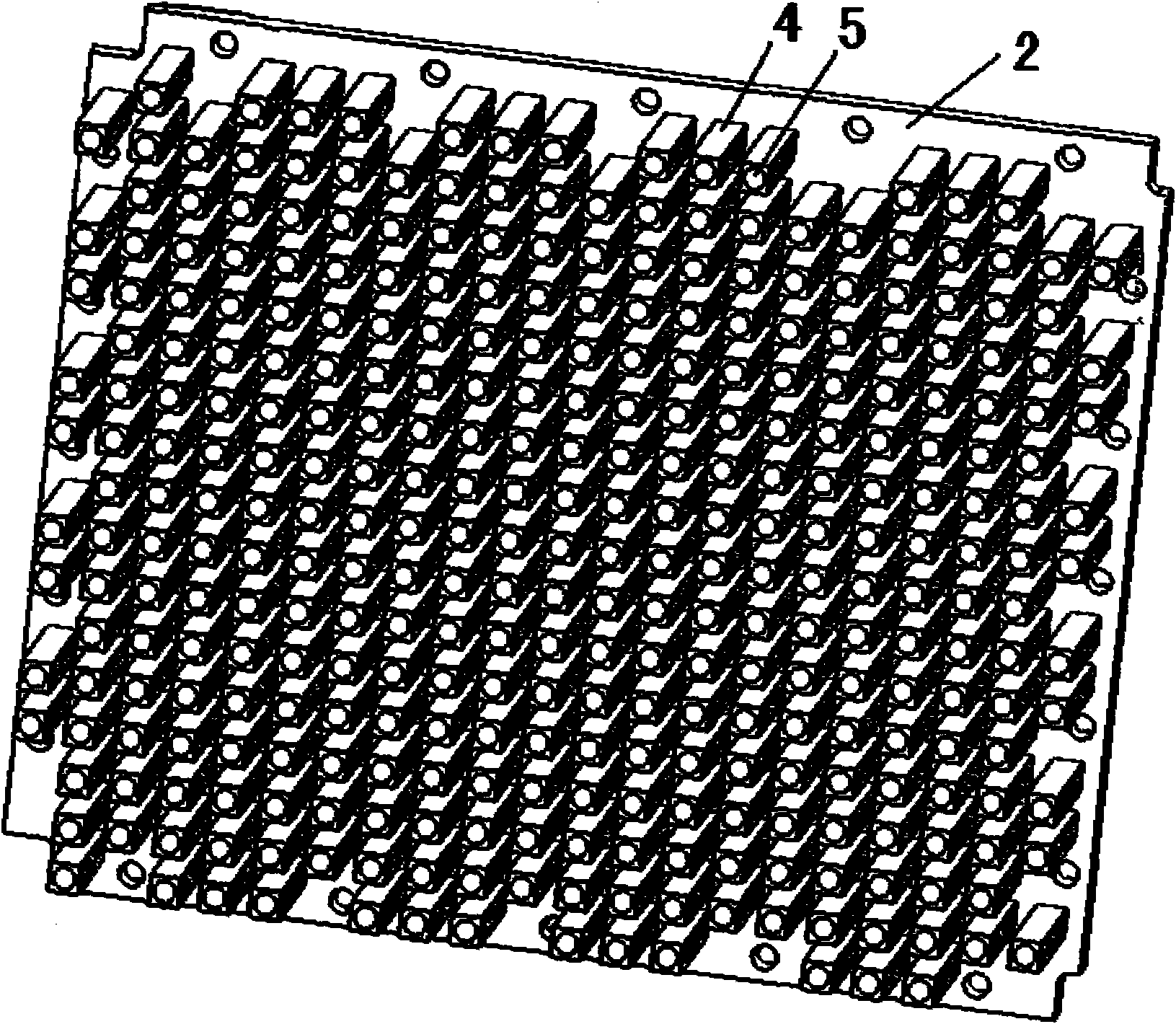

Method for manufacturing radiator and radiator

The invention discloses a method for manufacturing a radiator and the radiator. The method comprises the following steps of: processing polygonal or circular radiating guide posts on a shell of the radiator, simultaneously processing radiating fins on the edge of the shell, connecting the radiating fins and the radiating guide posts on the edge, and drilling deep holes in the centers of the radiating guide posts to enlarge the radiating surface area of the shell and lighten the weight of the shell; and processing polygonal or circular radiating guide posts on a cover plate of the radiator, and drilling deep holes in the centers of the radiating guide posts to enlarge the radiating surface area of the cover plate and lighten the weight of the cover plate. By skillfully combining the radiating fins and the radiating guide post and greatly enlarging the outer surface area of the radiator, the method improves the convection and heat radiation capabilities of the radiator at the same time of lightening the weight so as to greatly promote the radiating capability of the radiator and realize the miniaturization and lightweight design requirements of high-power electronic equipment products.

Owner:LINQUAN AEROSPACE MOTOR CO LTD

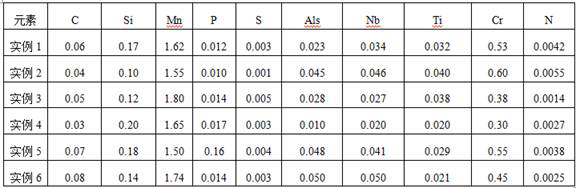

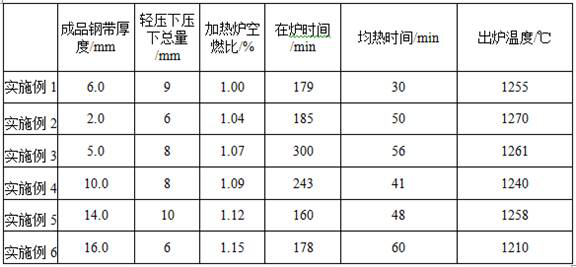

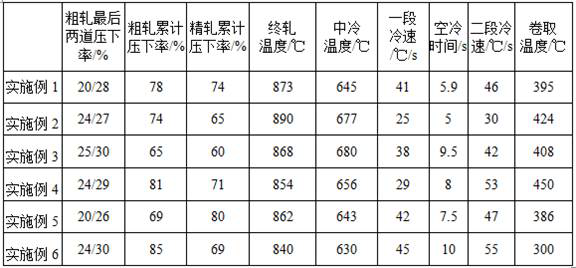

High-impact-toughness automotive frame steel belt and production method thereof

The invention relates to a high-impact-toughness automotive frame steel strip and a production method thereof. The high-impact-toughness automotive frame steel strip comprises the following chemical components in percentage by weight of 0.03%-0.08% of C, 0.10%-0.20% of Si, 1.50%-1.80% of Mn, less than or equal to 0.017% of P, less than or equal to 0.005% of S, 0.010%-0.050% of Als, 0.020%-0.040% of Ti, 0.020%-0.050% of Nb, 0.30%-0.60% of Cr, less than or equal to 0.0055% of N, and the balance Fe and other ineveitable residual elements. A sectional cooling process is selected in cooling after rolling in a rolling process, and a uniform and fine ferrite and bainite double-phase structure is obtained by accurately controlling the temperature, the cooling speed and the air cooling time, so that steel has good low-temperature impact toughness while having high strength.

Owner:HANDAN IRON & STEEL GROUP +1

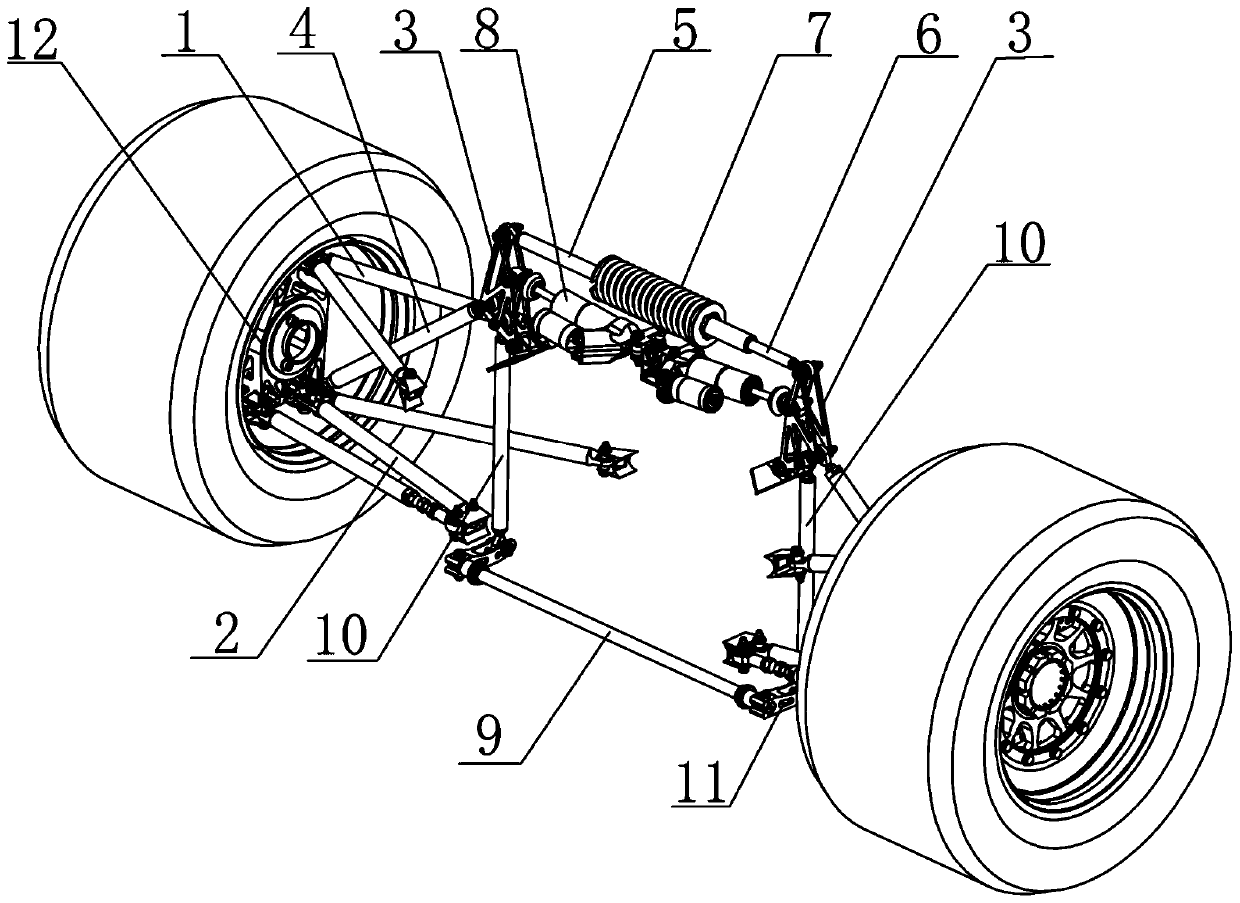

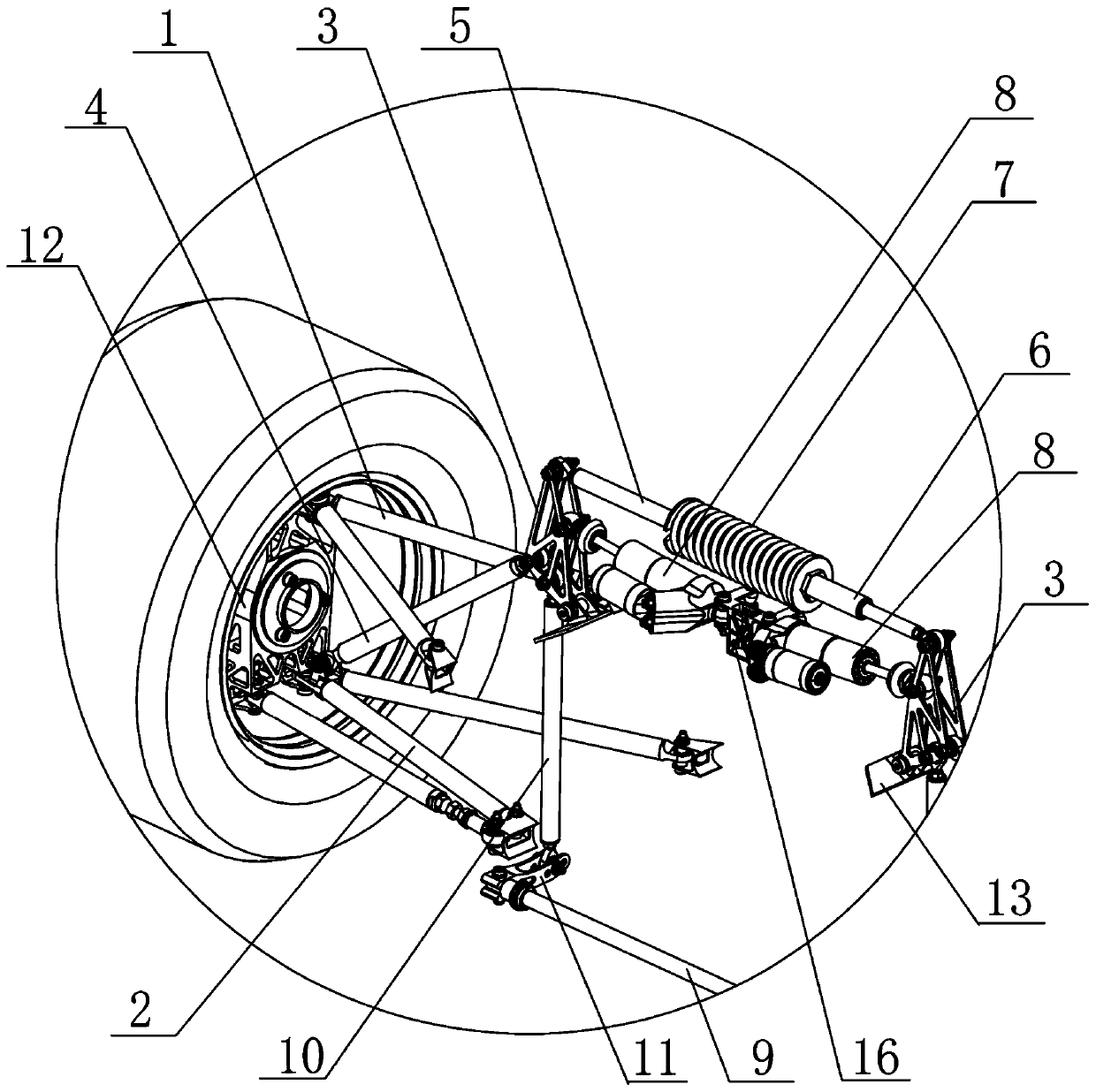

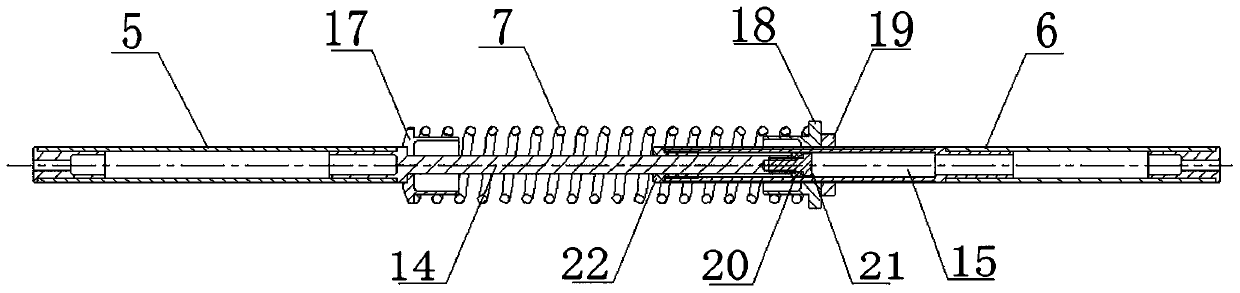

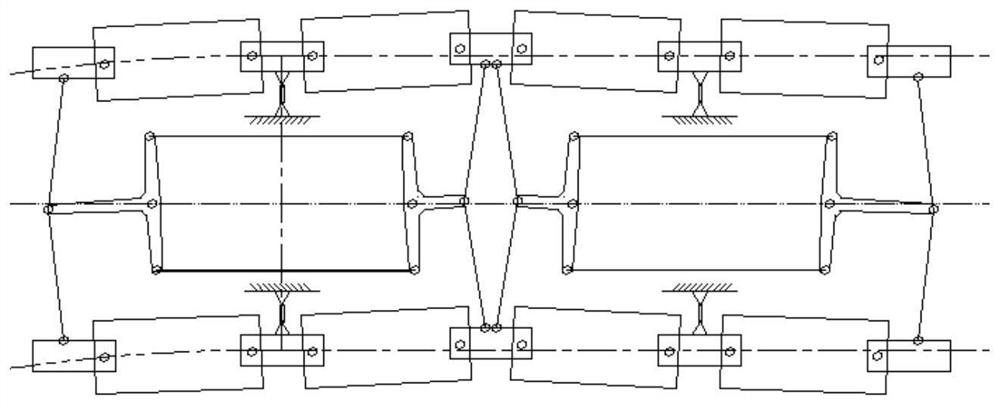

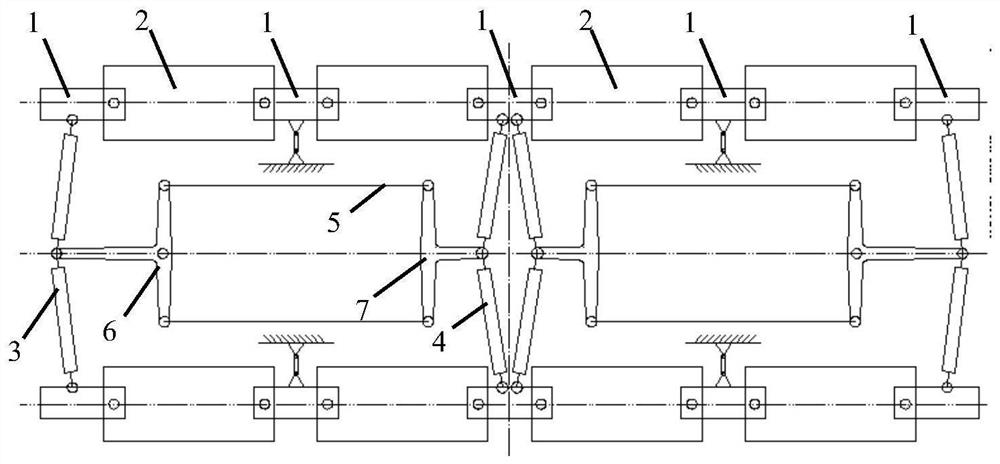

Single-coil spring double-damping suspension system with completely decoupled rigidity

ActiveCN111152613AEasy to adjustReduce weightInterconnection systemsResilient suspensionsCoil springPiston rod

The invention relates to a single-coil spring double-damping suspension system with completely decoupled rigidity. The single-coil spring double-damping suspension system is a vehicle suspension system based on ADAMSCar multi-body dynamics simulation. The single-coil spring double-damping suspension system comprises an upper cross arm, a lower cross arm, triangular arms, a push rod, a left guide rod, a right guide rod, spiral springs, dampers, an anti-roll rod, anti-roll rod connecting rods and anti-roll rod force arms, the upper cross arm and the lower cross arm are connected with a wheel upright and a vehicle body; two ends of a push rod are respectively hinged with the lower cross arm and the triangular arm; the left guide rod and the right guide rod are hinged to the triangular arm respectively, a piston rod of the left guide rod extends into a piston through hole of the right guide rod, the left guide rod and the right guide rod are sleeved with the spiral springs, the two dampersare hinged to the triangular arms on the two sides respectively, and the triangular arms are hinged to the anti-toppling rod force arms fixedly connected to the two sides of the anti-toppling rod through the anti-toppling rod connecting rods. According to the invention, the linear rigidity and the angular rigidity of the suspension are completely decoupled, and meanwhile, the lightweight design requirement is fully realized.

Owner:JILIN UNIV

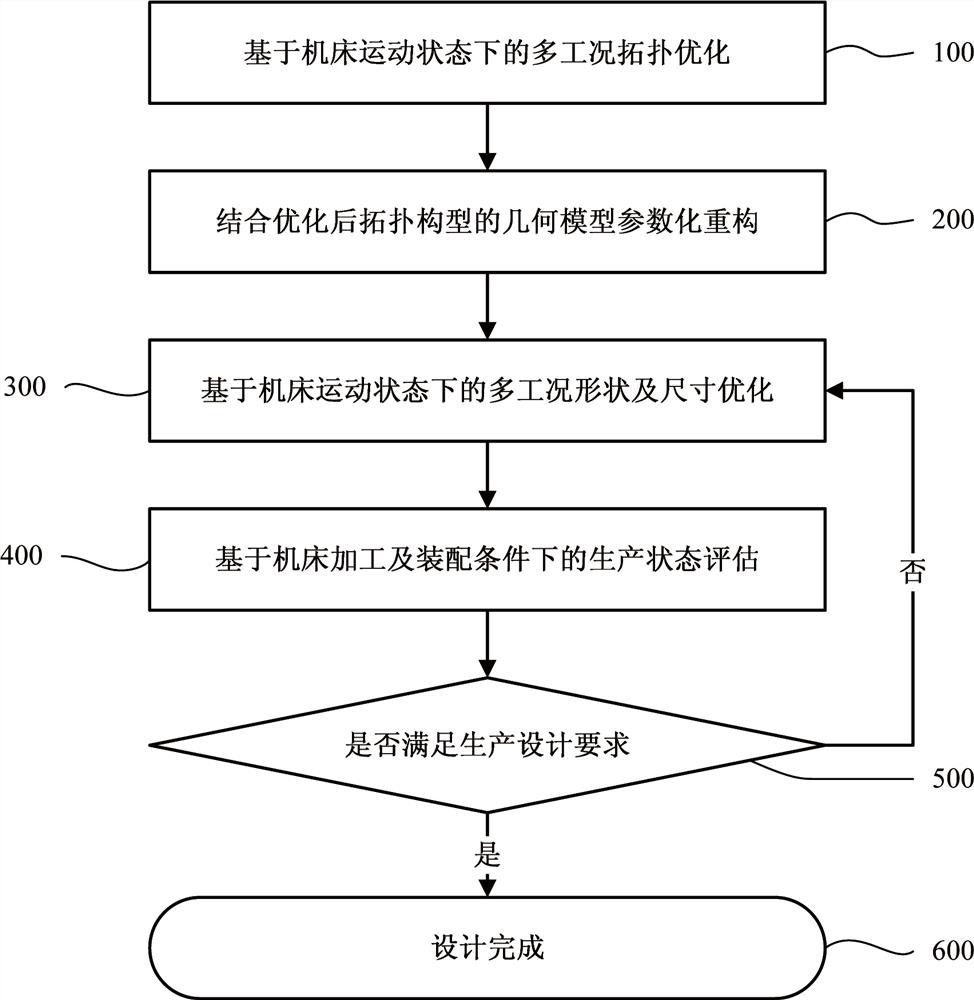

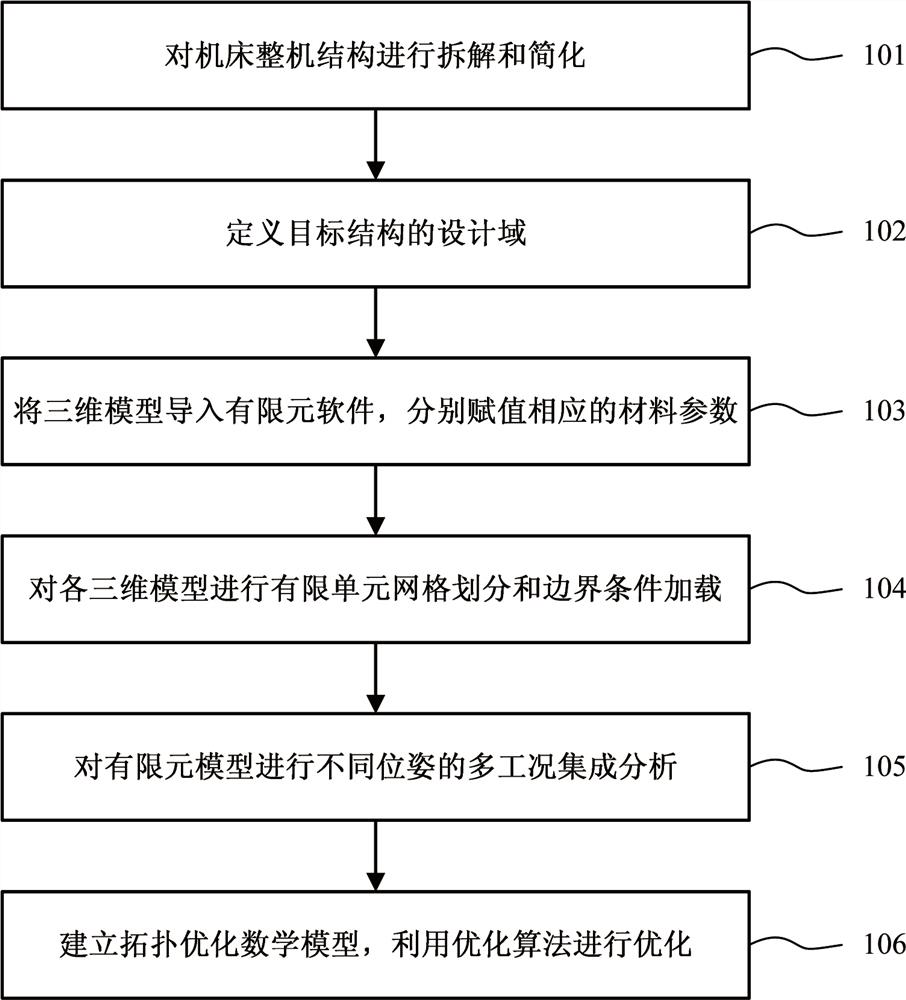

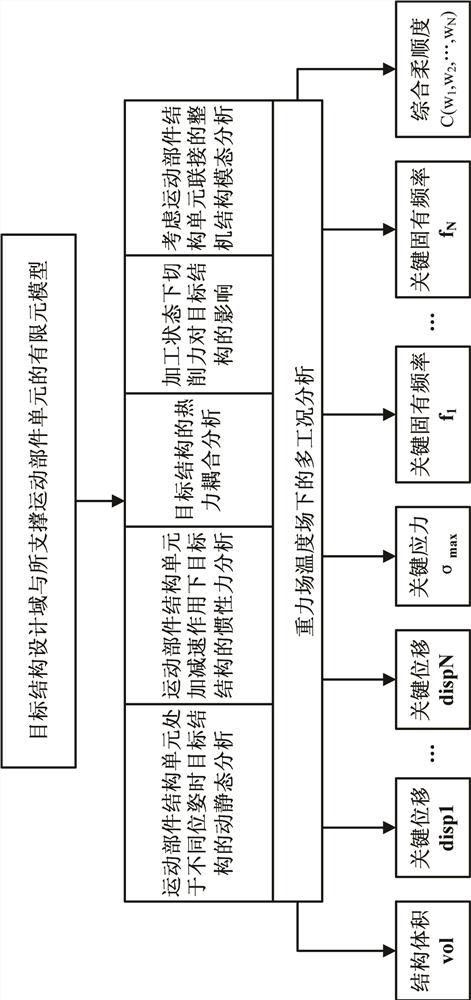

Key host assembly structure optimization design method based on machine tool working state

PendingCN112487673AIn line with the actual working statusMeet rigid requirementsGeometric CADDesign optimisation/simulationGeometric modelingProcess engineering

The invention relates to a structure optimization design method of a machine tool component, in particular to a key host component structure optimization design method based on a machine tool workingstate. The method comprises the following steps: A, performing multi-working-condition topological optimization based on a machine tool motion state; B, parameterization reconstruction is carried outon the geometric model combined with the optimized topological structure; C, optimizing the shape and the size based on multiple working conditions of the machine tool in the motion state; D, performing production state evaluation based on machine tool machining and assembling conditions. The method is not limited to an assembly structure needing to be optimized, but comprehensively considers complete machine mounting structures such as the motion connecting piece and the supported piece, and fully considers various motion states and various working conditions of the machine tool, so that theoptimized design index is closer to the actual working state of the machine tool, and the optimized structure is higher in reliability.

Owner:BEIJING JINGDIAO GRP CO LTD

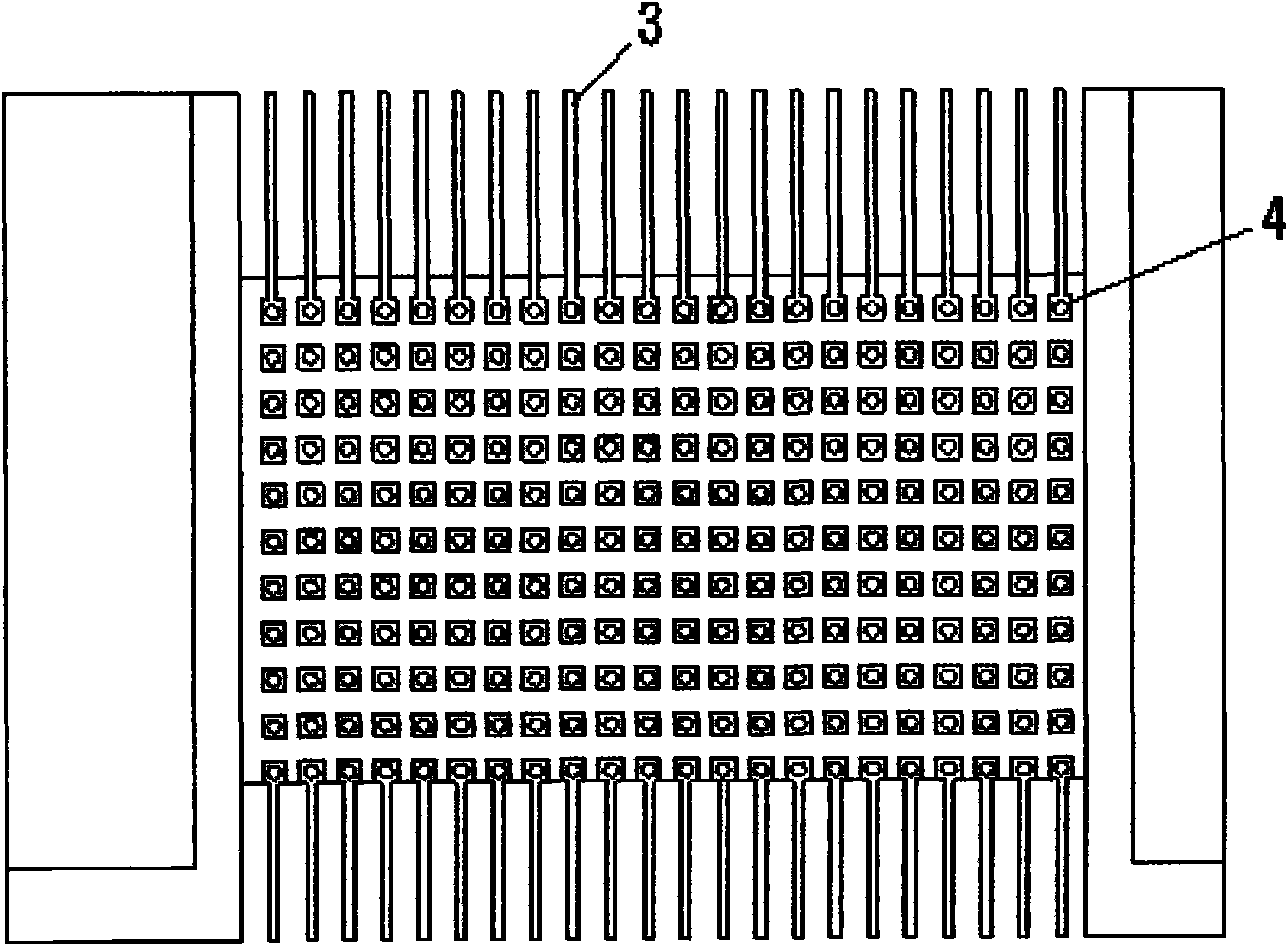

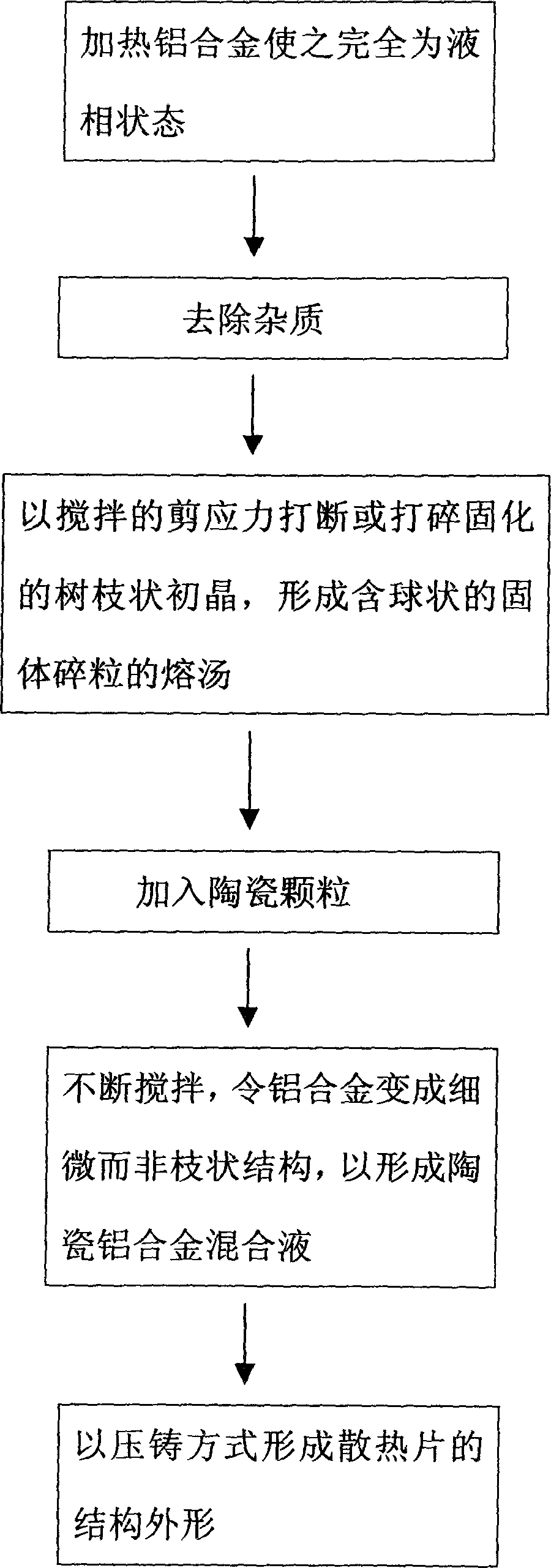

Structure of thermal fin with high heat conductivity and its manufacturing method

InactiveCN1463039AMeet lightweight design requirementsImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesDie castingSolid particle

Shearing strength generated by stirring breaks or destroys dendritical primary crystal in solid / liquid two phases area of aluminum alloy so as to form melted soup containing spherical solid broken pieces. Then, ceramics grains are added into the melted soup and the solid particles in the liquid phase metal are utilized to disperse the ceramics grains. Under the action of continuous stirring, the aluminum alloy is turned to small and non-branched structure, becoming the compact mixed liquor of ceramics / aluminum alloy. Finally, the construction shape of the thermal fins is made by die-casting process. In the invention, plasticity of aluminum alloy and high heat conductivity of ceramics grains give the shape and good heat radiating effect of the thermal fins.

Owner:富骅企业股份有限公司

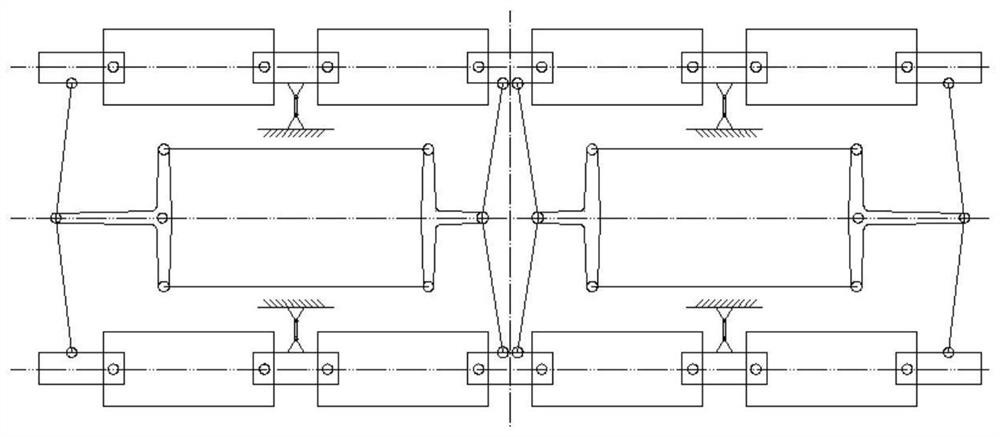

Guide mechanism suitable for four-suspension-module magnetic levitation vehicle

ActiveCN111823877ASolve the problem of rigid connection of transverse tie rodsReduce internal loadElectric propulsionPhysicsSuspension (vehicle)

The invention discloses a guide mechanism suitable for a four-suspension-module magnetic levitation vehicle. The mechanism comprises a first pair of sliding tables, a second pair of sliding tables, athird pair of sliding tables, a fourth pair of sliding tables and a fifth pair of sliding tables which are arranged in a longitudinal direction, and each pair of sliding tables is arranged in a transverse direction. The guide mechanism comprises a first guide structure and a second guide structure which are symmetrically arranged along a longitudinal center line and a transverse center line; two transverse end parts of a long T-shaped rotating arm and two transverse end parts of a short T-shaped rotating arm of the first guide structure are connected through two pull rods, and the third end part of the long T-shaped rotating arm is hinged with one ends of two first elastic connecting pieces; and the third end part of the short T-shaped rotating arm is hinged with one ends of the two secondelastic connecting pieces. A problem of rigid connection of transverse pull rods of an existing guide mechanism is effectively solved, coupling between the 1-position sliding table, the 3-position sliding table and the 5-position sliding table is effectively reduced through elastic deformation of the elastic connecting pieces, all the suspension modules are kept in good postures when going in andout of a curve, and an internal load of the guide mechanism is effectively reduced when going in and out of the curve.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com