Optimization method for outer windshield structure of high-speed train, and outer windshield structure

A technology of high-speed trains and optimization methods, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve the effect of improving the ability of the outer windshield to resist lateral deformation, and the effect of aerodynamic drag reduction and noise reduction of the outer windshield Weakening, complex structure assembly and other issues, to achieve the effect of meeting the requirements of light weight, reduced quality and design requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

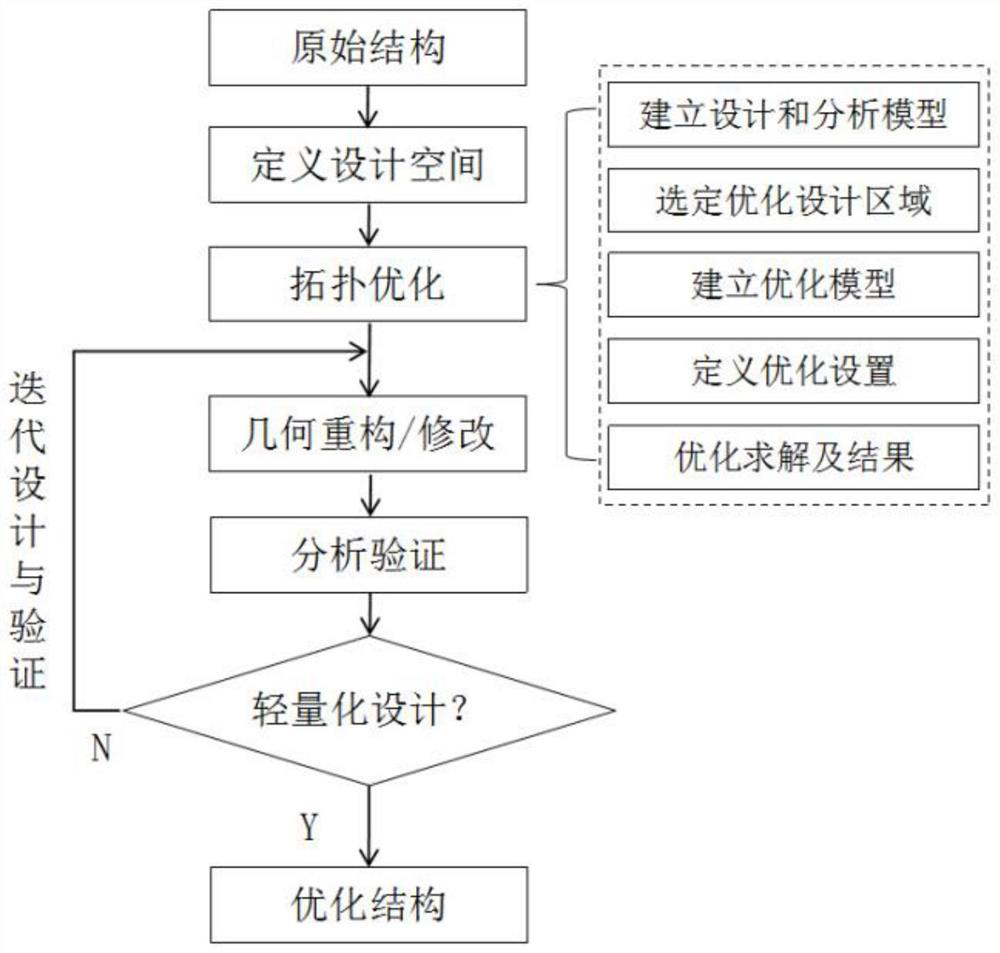

[0042] see figure 1 , a method for optimizing the outer windshield structure of a high-speed train according to an embodiment of the present invention, comprising the following steps:

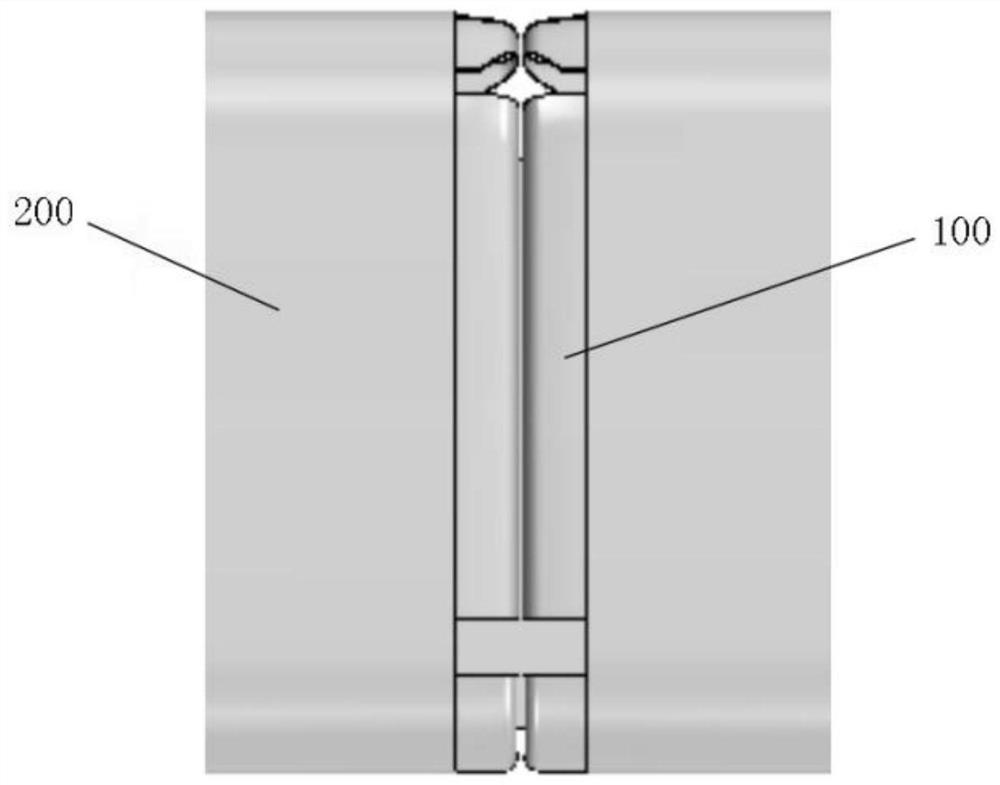

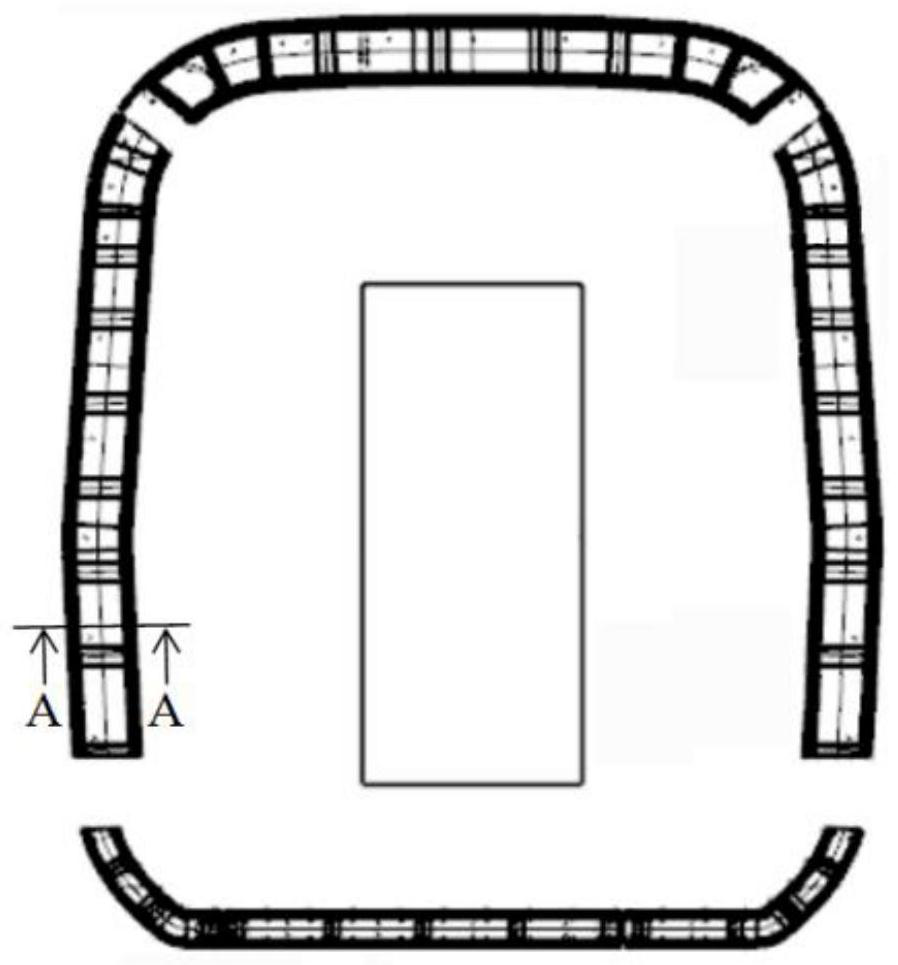

[0043] Step S1: According to the original outer windshield structure (that is, the existing outer windshield structure, see Figure 2 to Figure 4 ) section geometric dimensions, define the design space of the outer windshield structure, the design space includes the non-design area and the design area, the non-design area is the area from the outer contour of the section of the original outer windshield structure to a certain thickness inward, and the design area is the original The area within the non-design area of the section with external windshield structure;

[0044] Step S2: Perform topology optimization design on the design area to obtain topology optimization design results; the goals of topology optimization design include improving the lateral stiffness of the original outer winds...

Embodiment 2

[0080] see Figure 7 , Figure 8 and Figure 9 , an outer windshield structure for a high-speed train according to an embodiment of the present invention. The outer windshield structure 100 for a high-speed train is designed by using the optimization method of the first embodiment of the present invention. The outer windshield structure 100 mainly includes a first outer windshield wall 1 , a second outer windshield wall 2 and an outer windshield arc segment 3 . Wherein, the two ends of the outer windshield arc section 3 are respectively connected with the first outer windshield wall 1 and the second outer windshield wall 2 to form a U-shaped outer windshield profile; The inner wall of the junction of 3 is provided with a first small rib 4; the inner wall of the junction of the second outer windshield wall 2 and the outer windshield arc section 3 is provided with a second small rib 5; at the root of the first outer windshield wall 1 The inner wall is provided with a first la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com