Corrugated steel plate composite shear wall

A combination of shear wall and steel plate technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of rapid decline in bearing capacity of corrugated steel plate walls, troublesome processing and on-site installation, unfavorable rapid construction, etc., to eliminate adverse effects, Facilitate rapid construction and improve the effect of hysteresis curve pinching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

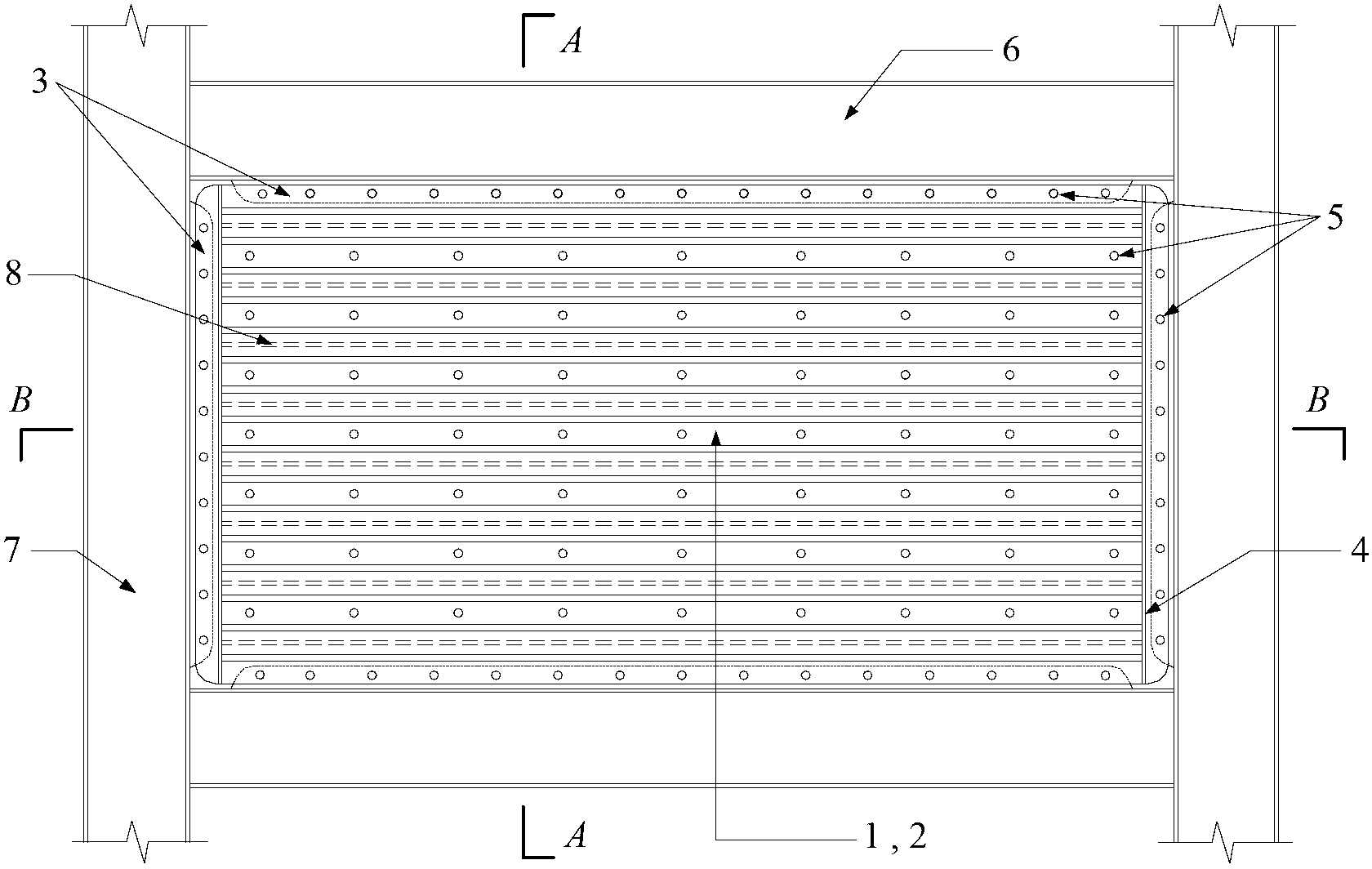

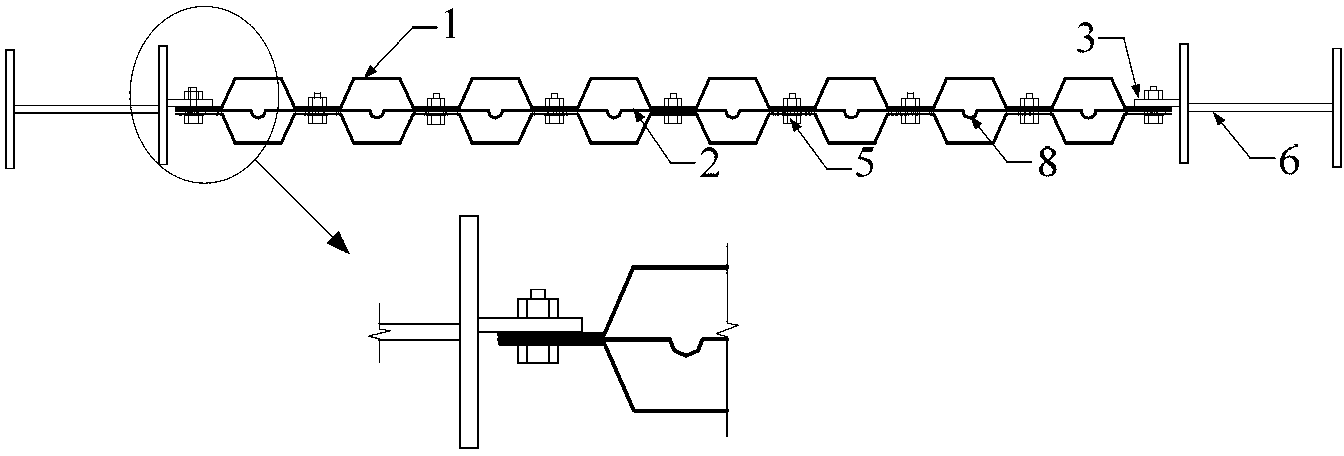

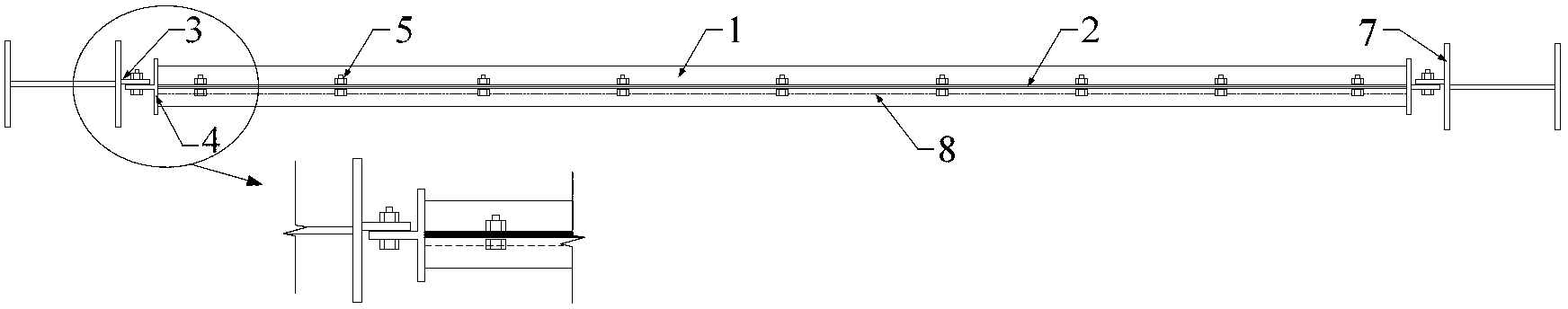

[0015] Attached below Figure 1~3 , The embodiment of the present invention will be described in detail.

[0016] As shown in the figure, an improved composite shear wall with corrugated steel plate includes the following components:

[0017] 1-Trapezoidal corrugated steel plate;

[0018] 2-Flat steel plate with corrugation;

[0019] 3——Fish plate;

[0020] 4——T-shaped steel;

[0021] 5——High-strength bolts;

[0022] 6——Frame beam;

[0023] 7——Frame column;

[0024] 8-ripples.

[0025] An improved composite shear wall with corrugated steel plate proposed by the present invention is composed of trapezoidal corrugated steel plate (1), corrugated flat steel plate (2), fish plate (3), T-shaped steel (4), and high-strength bolts ( 5) Composed of frame beams (6) and frame columns (7).

[0026] The corrugated flat steel plate (2) is obtained by pressing the flat steel plate to form corrugations (8) every one wavelength of the trapezoidal corrugated steel plate. The composite shear wall panel is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com