Inclined double-layer folded plate steel plate shear wall

A steel plate shear wall, double-layer technology, applied in the direction of walls, building materials, building components, etc., can solve the problems such as the inability of the thin steel plate shear wall to give full play to the strength and ductility of steel, the overall instability, and the reduction of steel consumption. , to reduce the repair workload, dissipate seismic energy well, and improve the ability to dissipate seismic energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

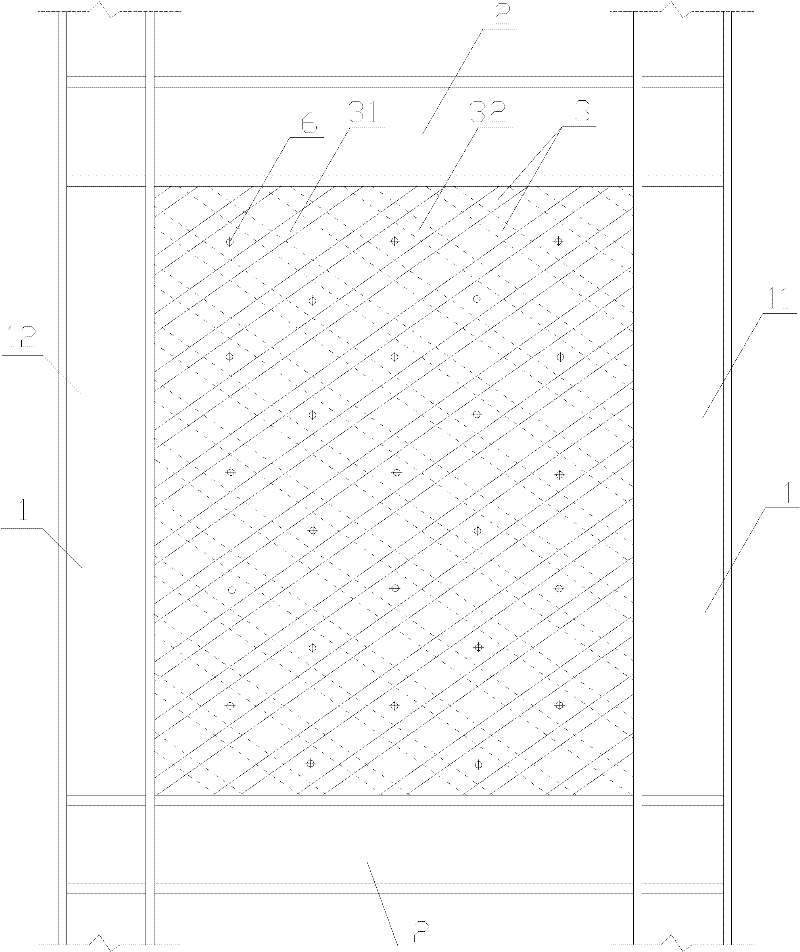

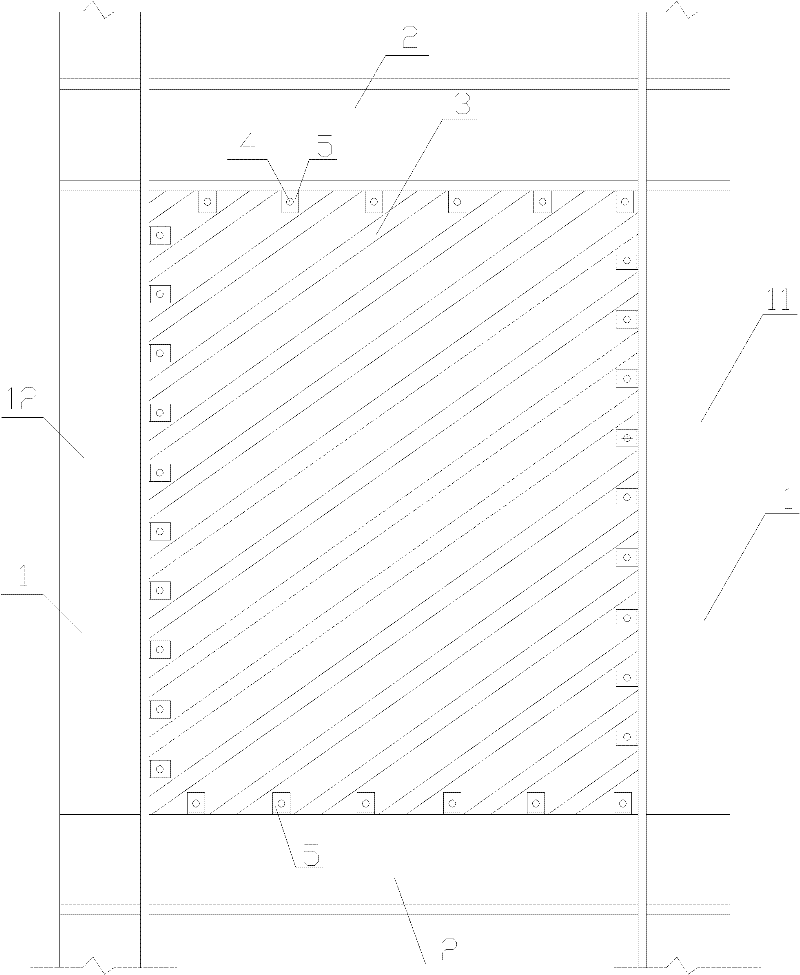

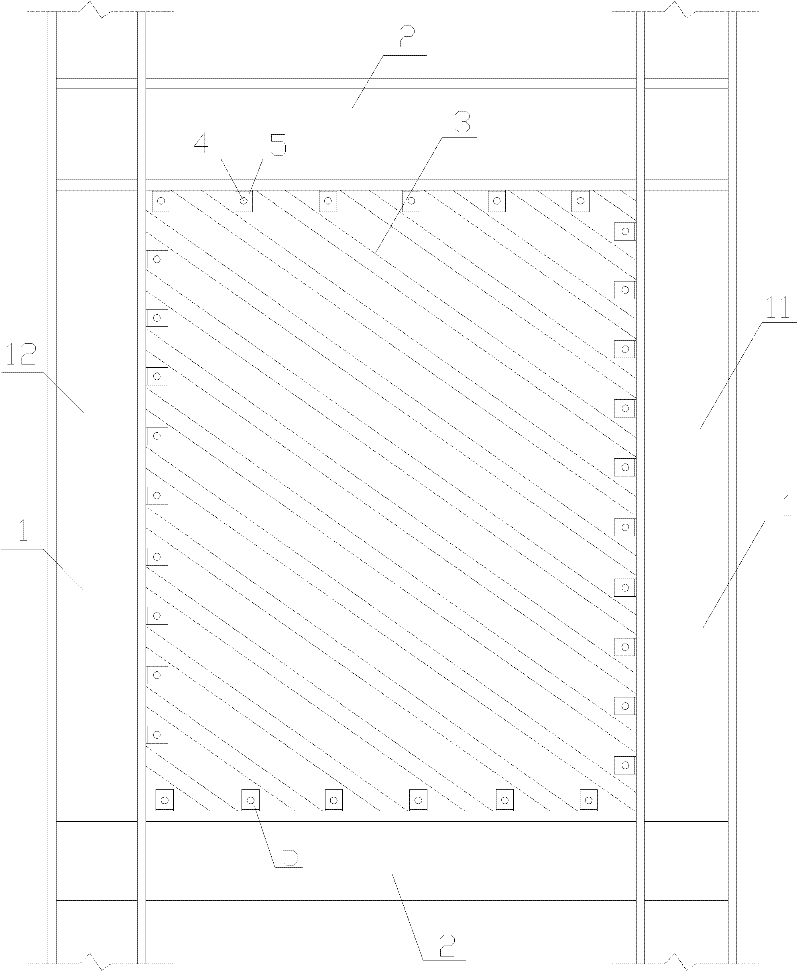

[0026] like figure 1 , figure 2 and image 3 As shown, the present invention is an obliquely placed double-layer folded plate steel plate shear wall. The frame column 1 and the frame beam 2 are connected to form a square frame. In the frame, there is an inner filling plate 3 connected with the frame column 1 and the frame beam 2. The frame Column 1 includes parallel first frame column 11 and second frame column 12, inner filler plate 3 is composed of identical first folded plate 31 and second folded plate 32, and first folded plate 31 is composed of mutually spaced first protrusions. Protrusion 311 and the first groove 312 are connected, and the second flap 32 is composed of the second protrusion 321 and the second groove 322 that are spaced apart from each other. It is characterized in that the first protrusion 311 and the first groove 312...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com