Patents

Literature

440results about How to "Good drag reduction effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

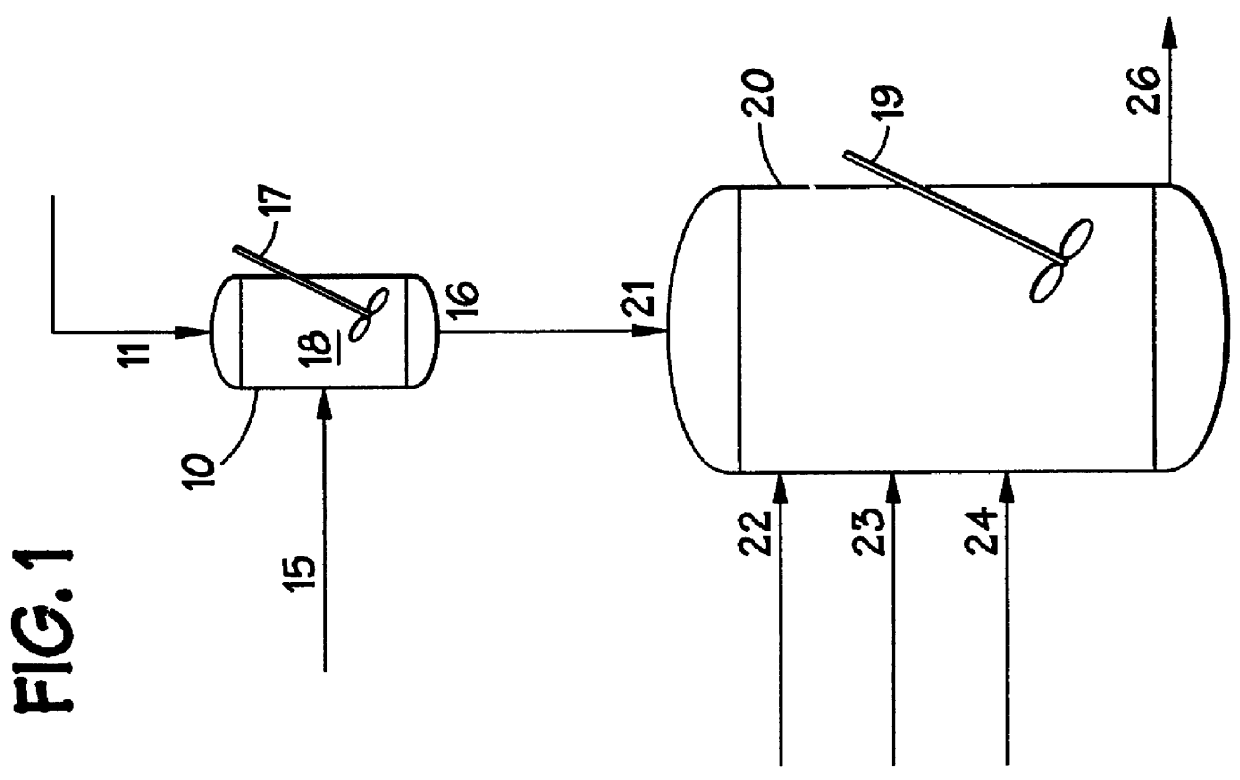

Methods for forming amorphous ultra-high molecular weight polyalphaolefin drag reducing agents

InactiveUS6015779AReduce frictional energy lossHigh molecular weightOther chemical processesLiquid organic insulatorsHalohydrocarbonAlpha-olefin

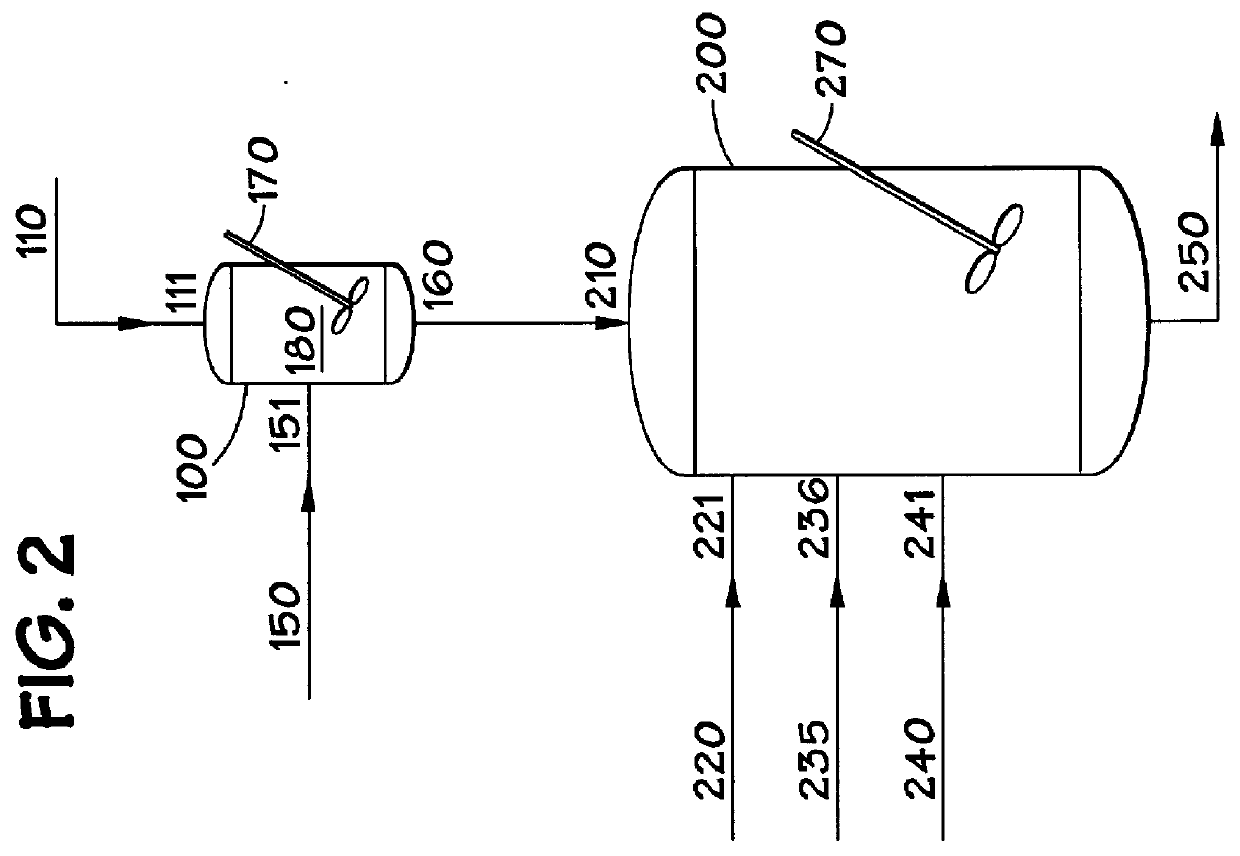

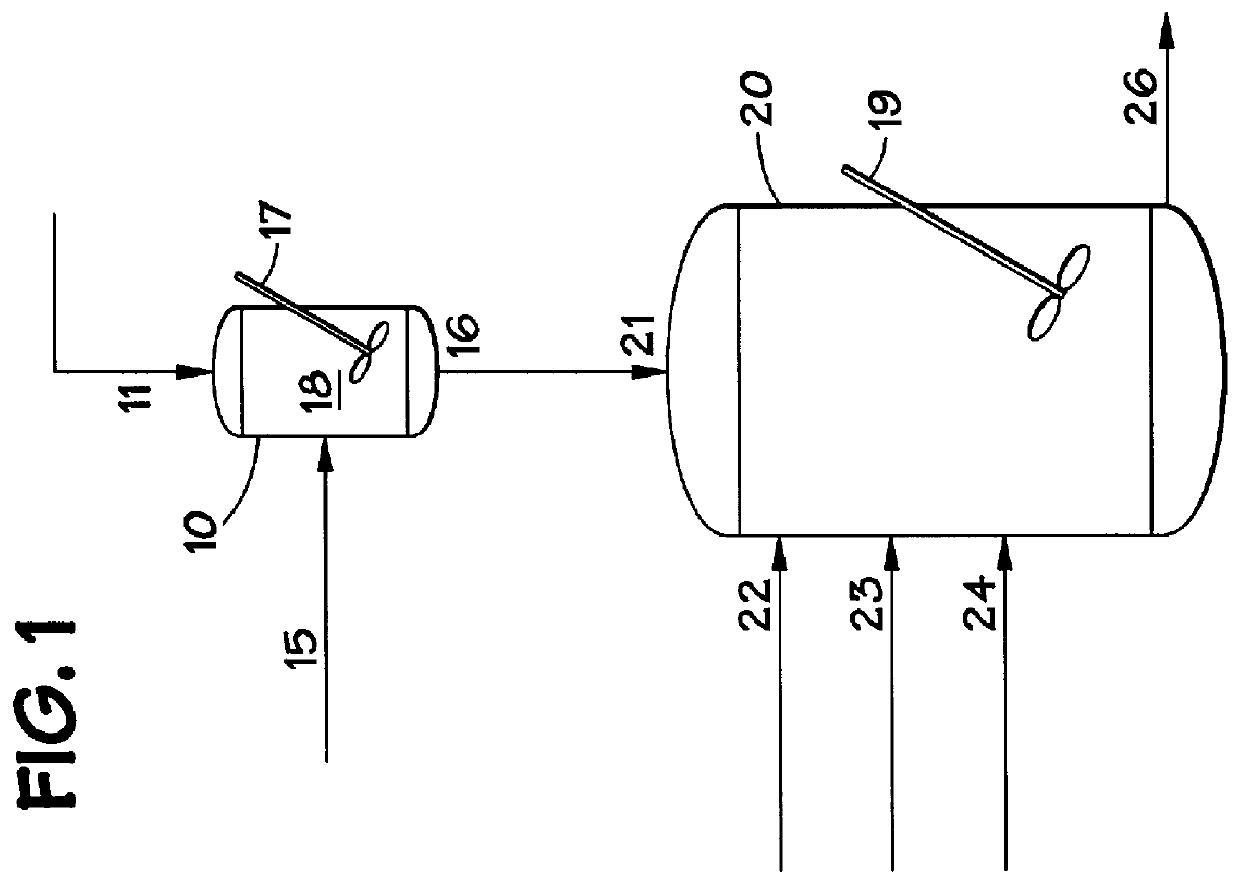

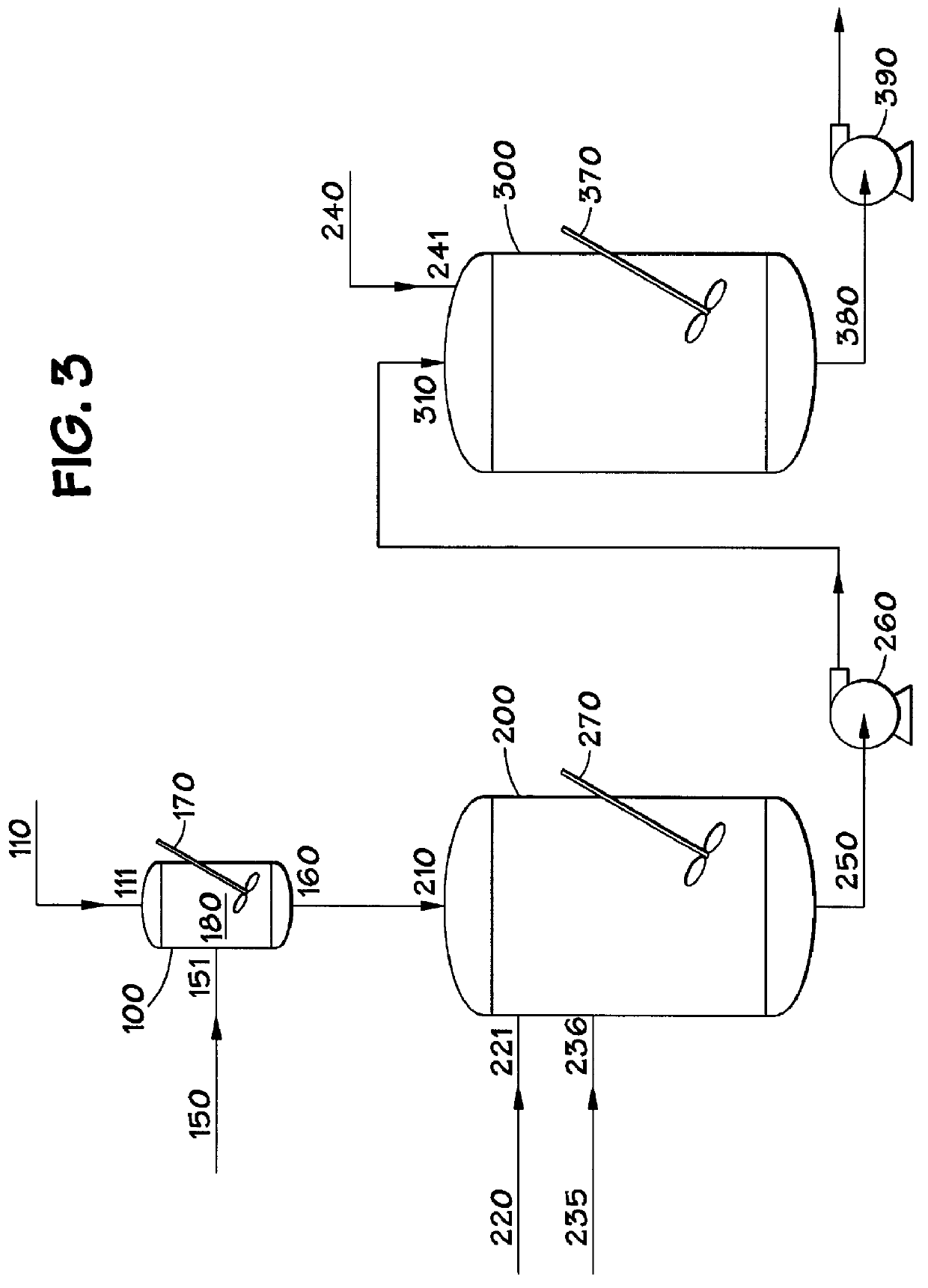

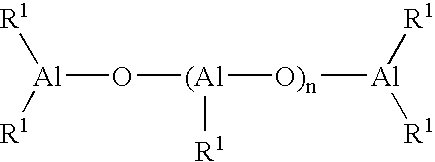

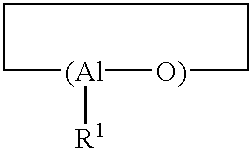

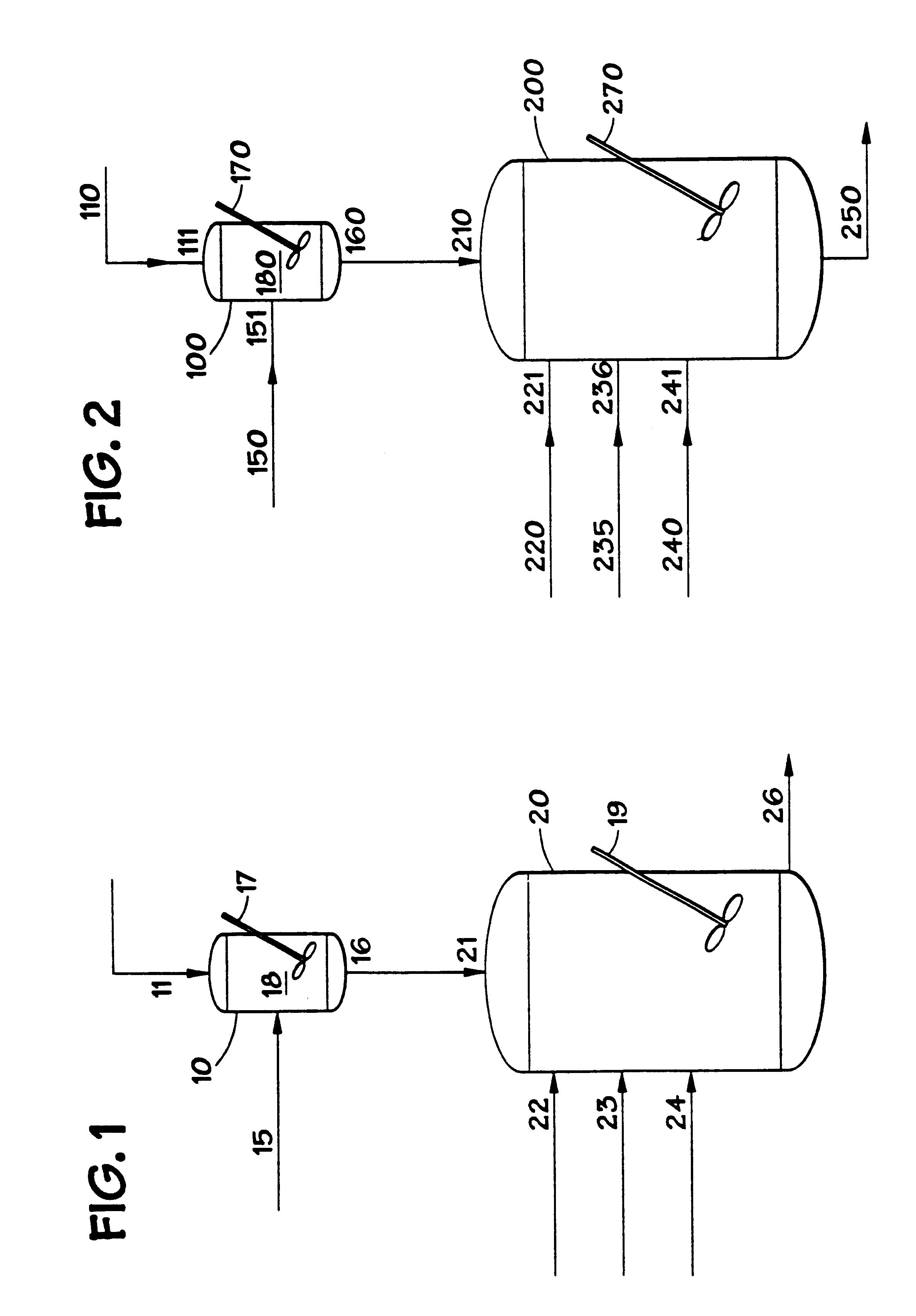

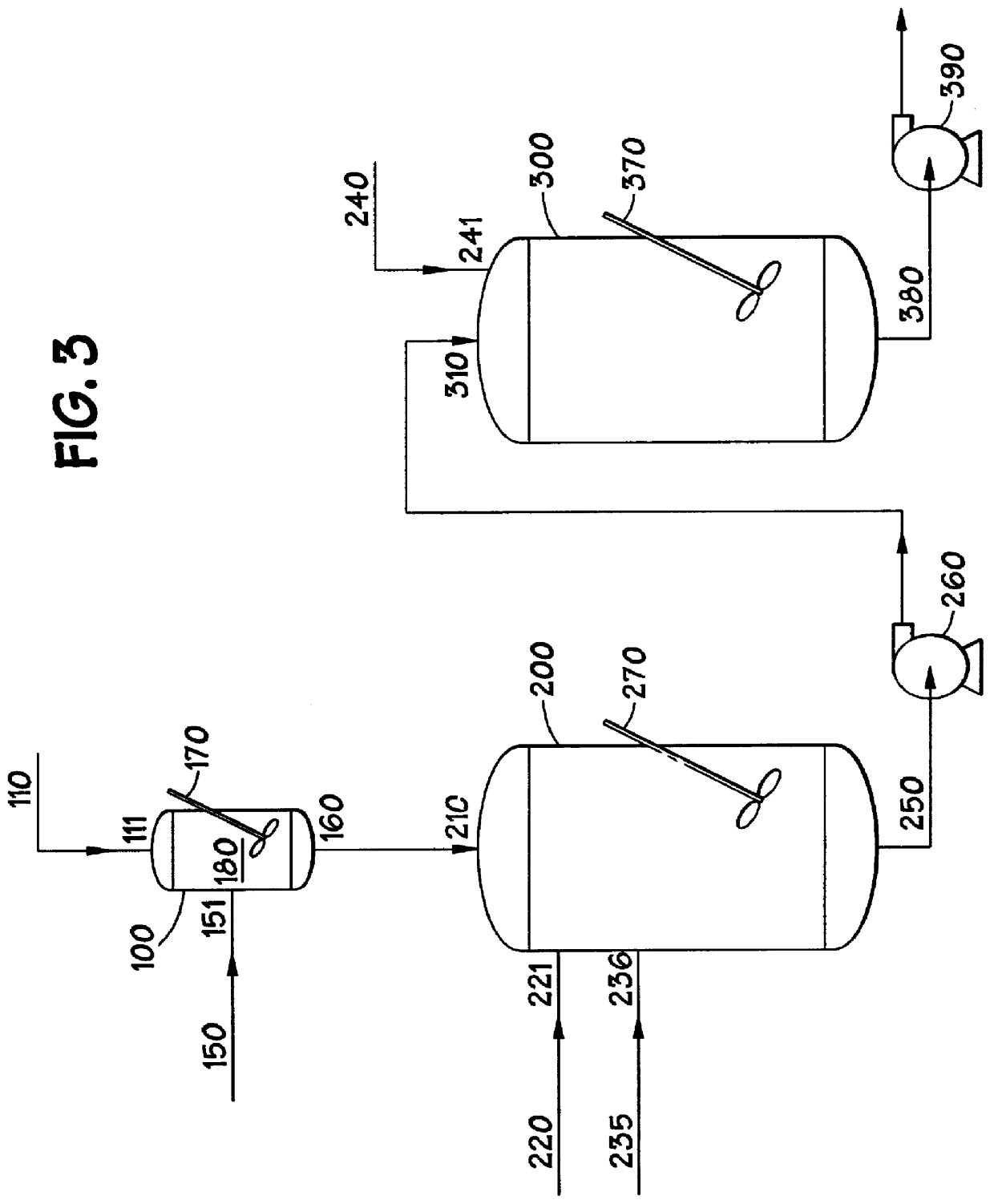

A composition including polyalphaolefins that function as drag reducing agents and a process for the preparation of polyalphaolefins that function as drag reducing agents are disclosed. The process includes contacting alpha olefin monomers with a catalyst system, which includes a catalyst and an activator (co-catalyst) in a reactant mixture. The catalyst is a transition metal catalyst, preferably titanium trichloride, and the co-catalyst may include an alkylaluminoxane, alone or in combination, with a dialkylaluminum halide or a halohydrocarbon. The polymerization of the alpha olefin monomers produces a non-crystalline, ultra-high molecular weight polyalphaolefin having an inherent viscosity of at least 10 dL / g. The addition of the alkylaluminoxane during the polymerization process provides for a non-crystalline, ultra-high molecular weight polyalphaolefin and a more uniform molecular weight distribution of the resulting polyalphaolefin, thereby creating a drag reducing agent superior to known drag reducing agents. A process for forming a drag reducing agent comprising a non-crystalline, ultra-high molecular weight polyalphaolefin having an inherent viscosity of about at least 10 dL / g and a process for reducing drag in a conduit are also disclosed.

Owner:MPOWER SPECIALTY CHEM

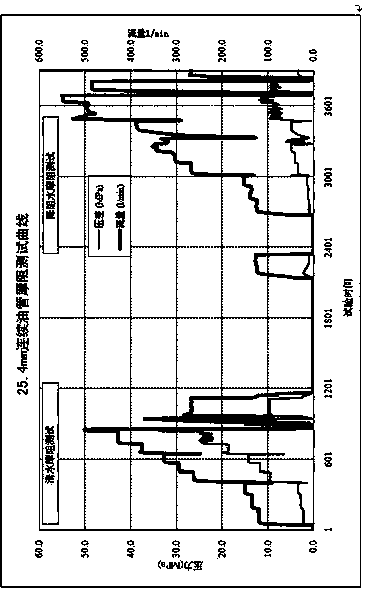

Low-friction recyclable slickwater fracturing fluid suitable for compact oil and gas reservoirs and preparation method thereof

The invention relates to a low-friction recyclable slickwater fracturing fluid system suitable for compact oil and gas reservoirs and a preparation method thereof. Every tonnage of water is added with 0.06-0.25% of a water soluble drag reducer by mass, 0.2-0.5% of a demulsification cleanup additive by mass and 0.5% of a clay stabilizer by mass for evenly mixing to obtain a slickwater fracturing fluid; the prepared slickwater fracturing fluid is a reverse phase micro-emulsion system, and has the characteristics such as low viscosity, thorough gum breaking, easy flowing back, good expansion prevention performance and low friction; the resistance reducing effect is obvious; compared with clear water, the resistance reducing effect can achieve 50-70%; in the scene hydraulic fracturing operation, the resistance reducing rate of the water soluble drag reducer is 42.5% higher than that of the traditional guanidine gum slickwater in the case that the construction displacement is 3.5 m<3> / min.

Owner:PETROCHINA CO LTD

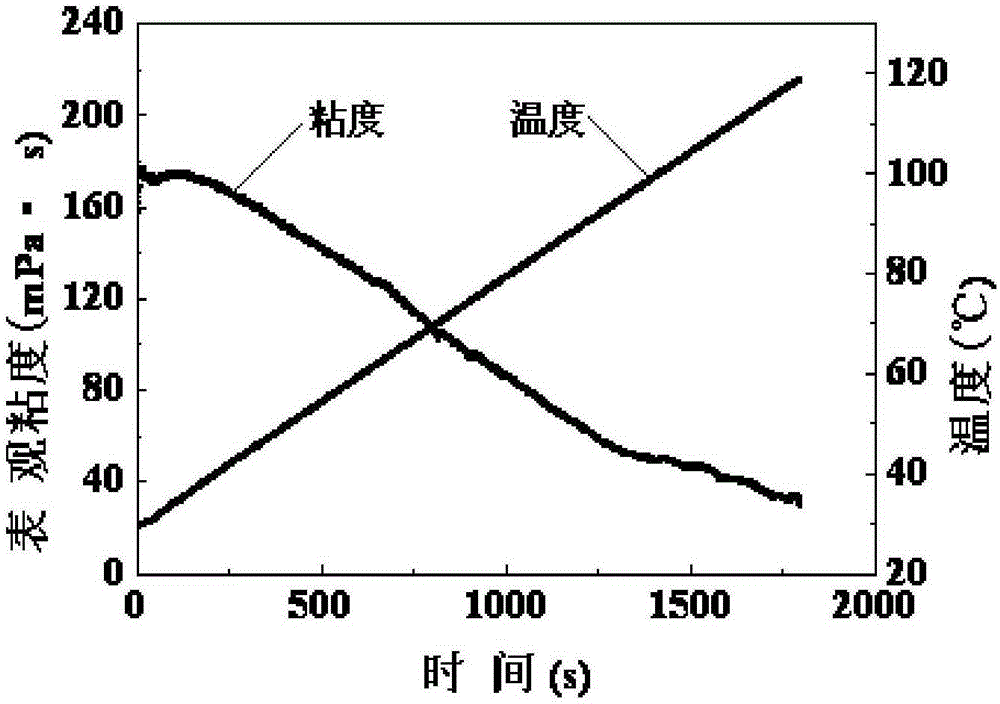

Gas pipeline drag reducer and preparation thereof

The invention relates to a gas pipeline drag reducer used in gas and particularly natural gas conveying pipeline drag reduction and a preparation method thereof, relating to a macromolecular compound composition and the pipeline system technical field. The gas pipeline drag reducer is characterized in that: the drag reducer is synthesized by long-chain acid and enamine according to a molar ratio of between 1:1 and 2.2:1. The preparation method comprises the following steps that: the long chain acid in proportional quantity is added in a reaction container; a heater is started so as to carry out heating while stirring; when temperature reaches to 100 DEG C, the long chain acid is melted, and the enamine in proportional quantity is added at the same time; nitrogen is fed in to carry out protection, and the mixture is preheated to between 120 and 140 DEG C; after preheating is finished, programmed heating is carried out till temperature is increased to between 210 and 220 DEG C; a stirrer is removed and a vacuum pump is connected to carry out evacuation for 2 to 4 hours; when reaction is finished, brown solid crude product can be obtained after cooling down. The gas pipeline drag reducer has obvious drag reduction effect on gas pipelines, direct source of raw materials, simple operation, moderate reaction conditions, relatively simple process and low requirements on equipment, and is easy to realize large-scale industrialized production.

Owner:PETROCHINA CO LTD

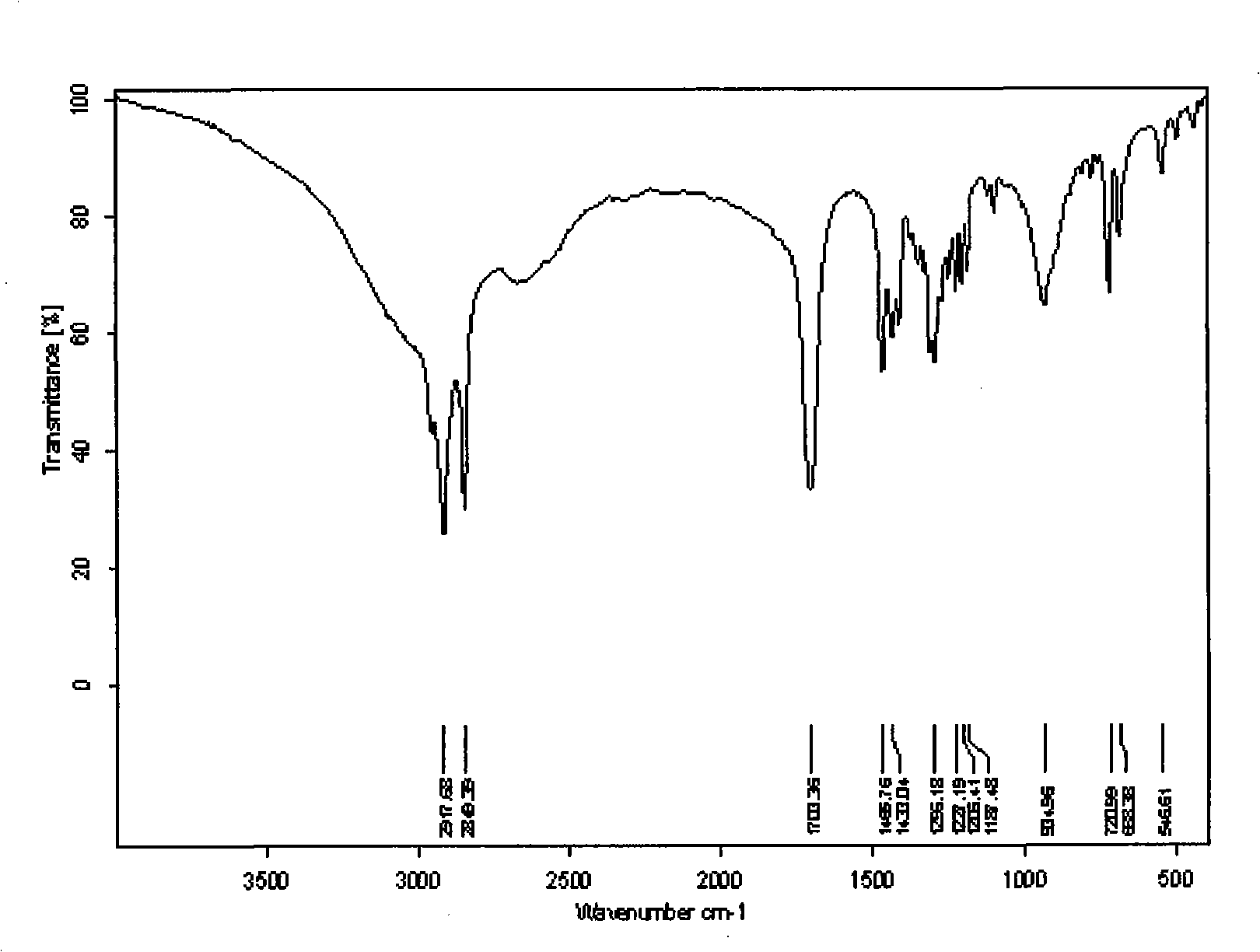

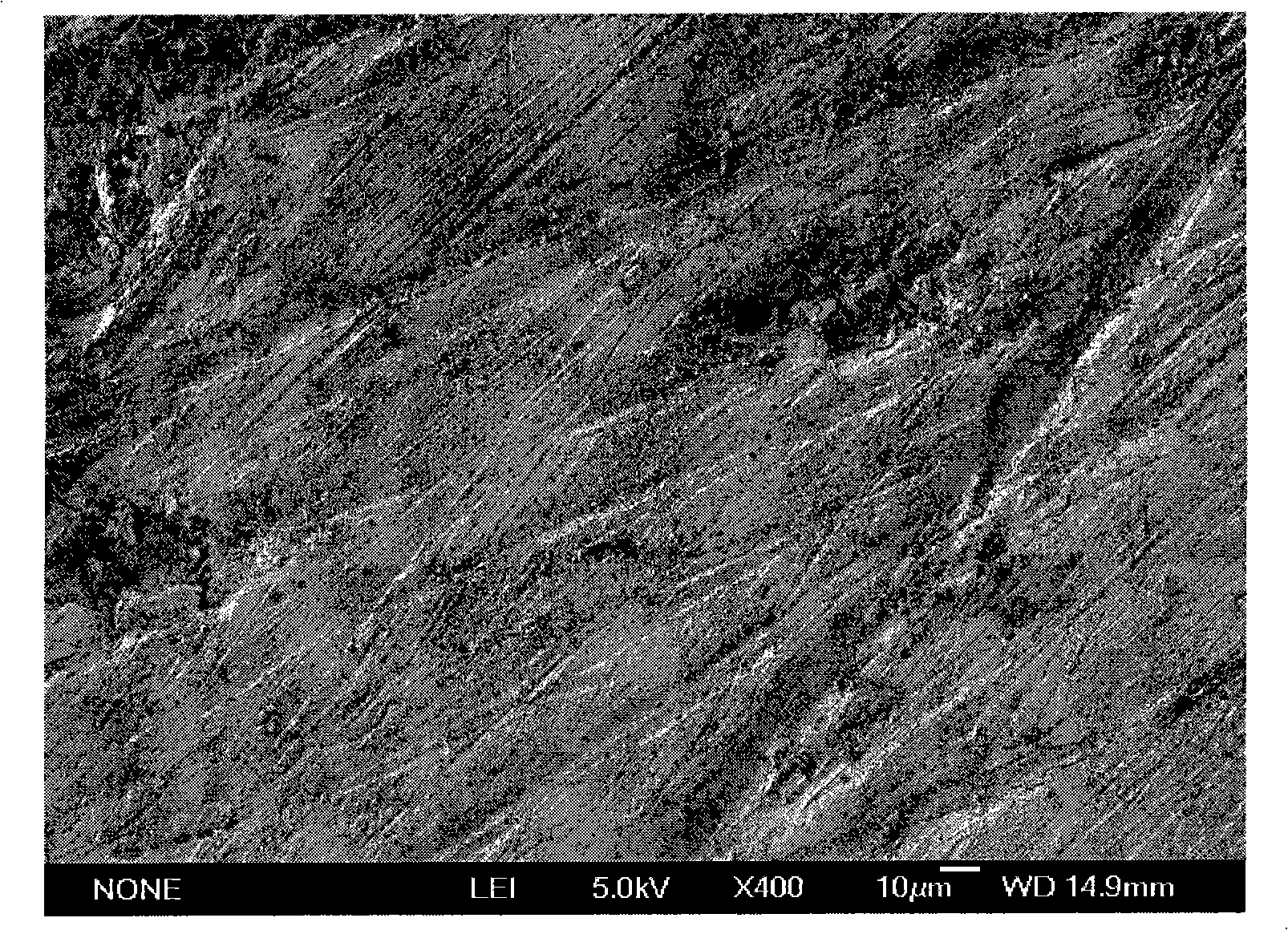

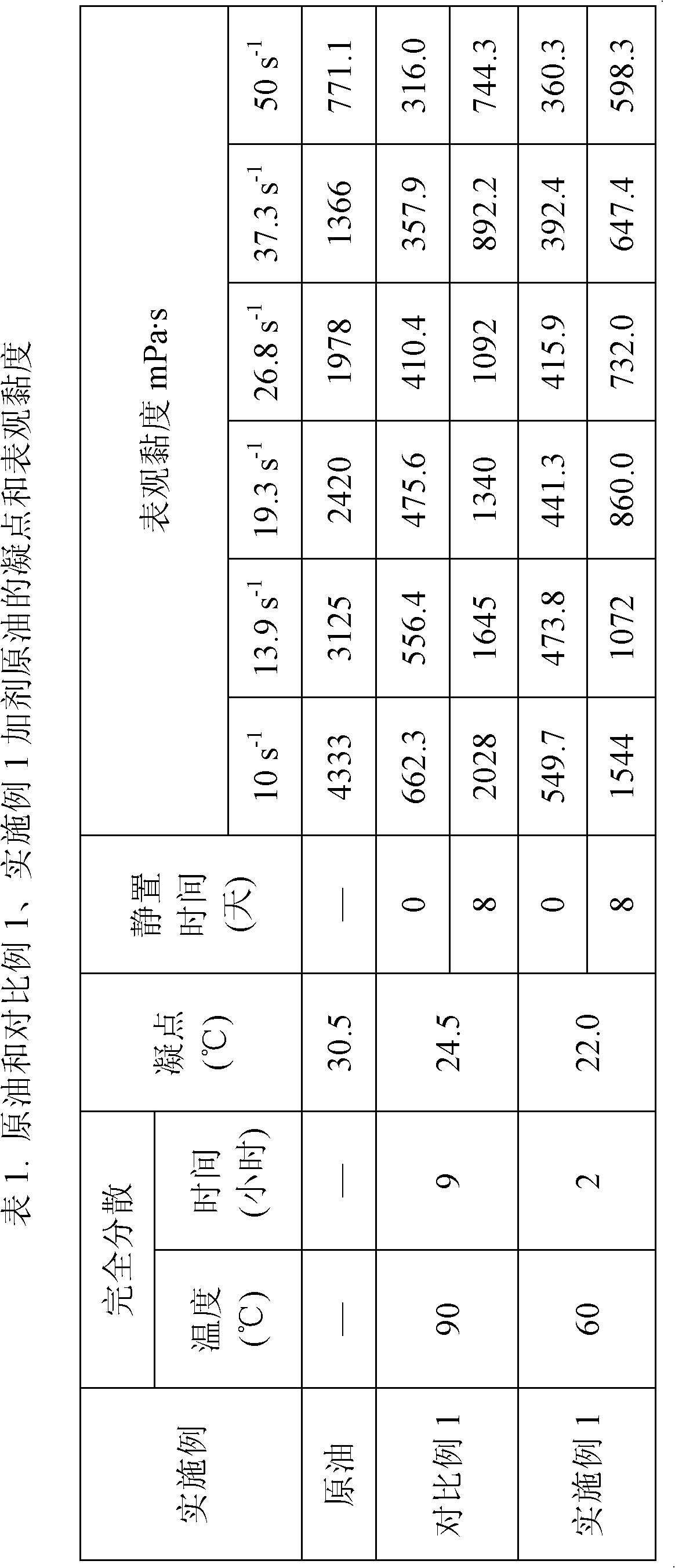

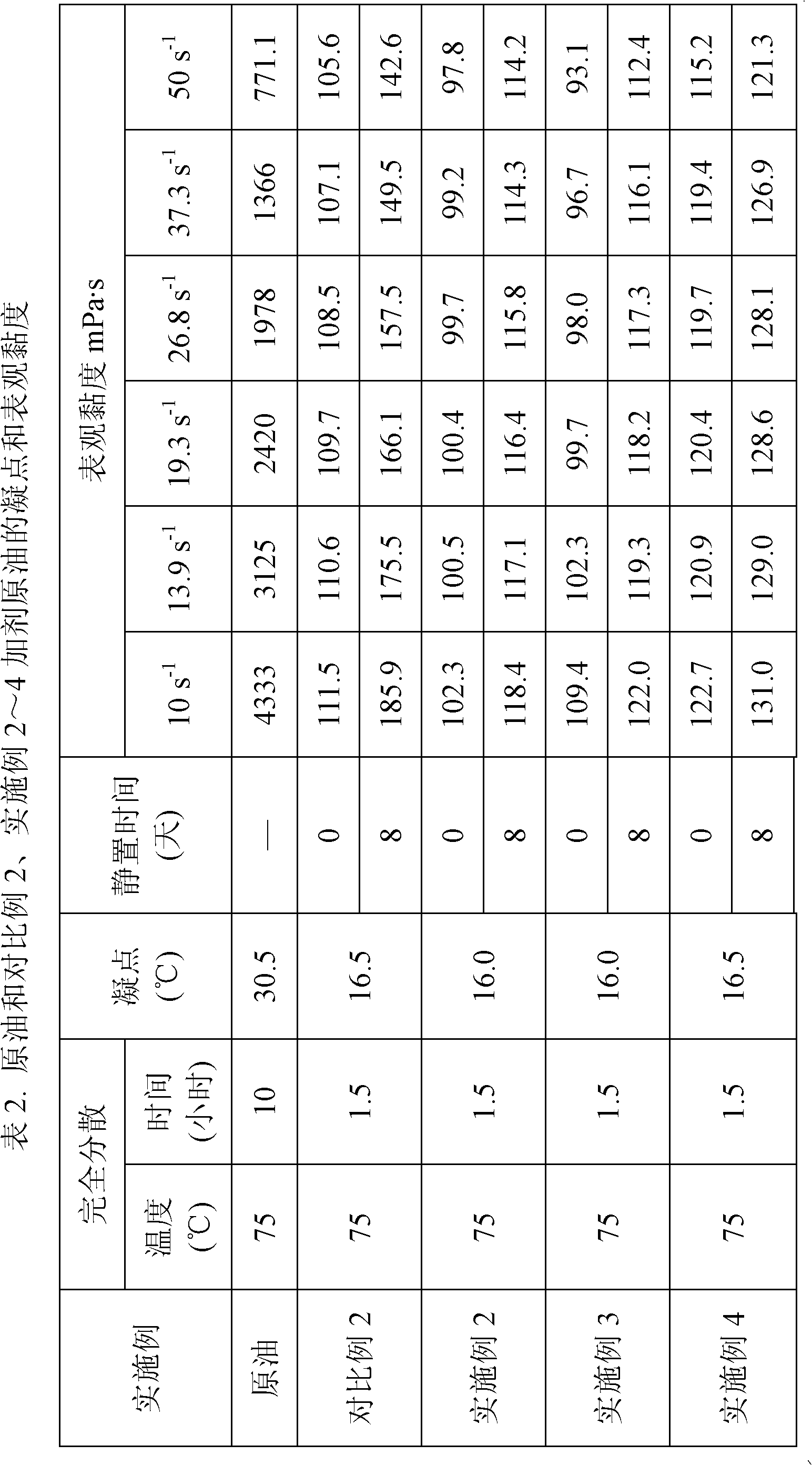

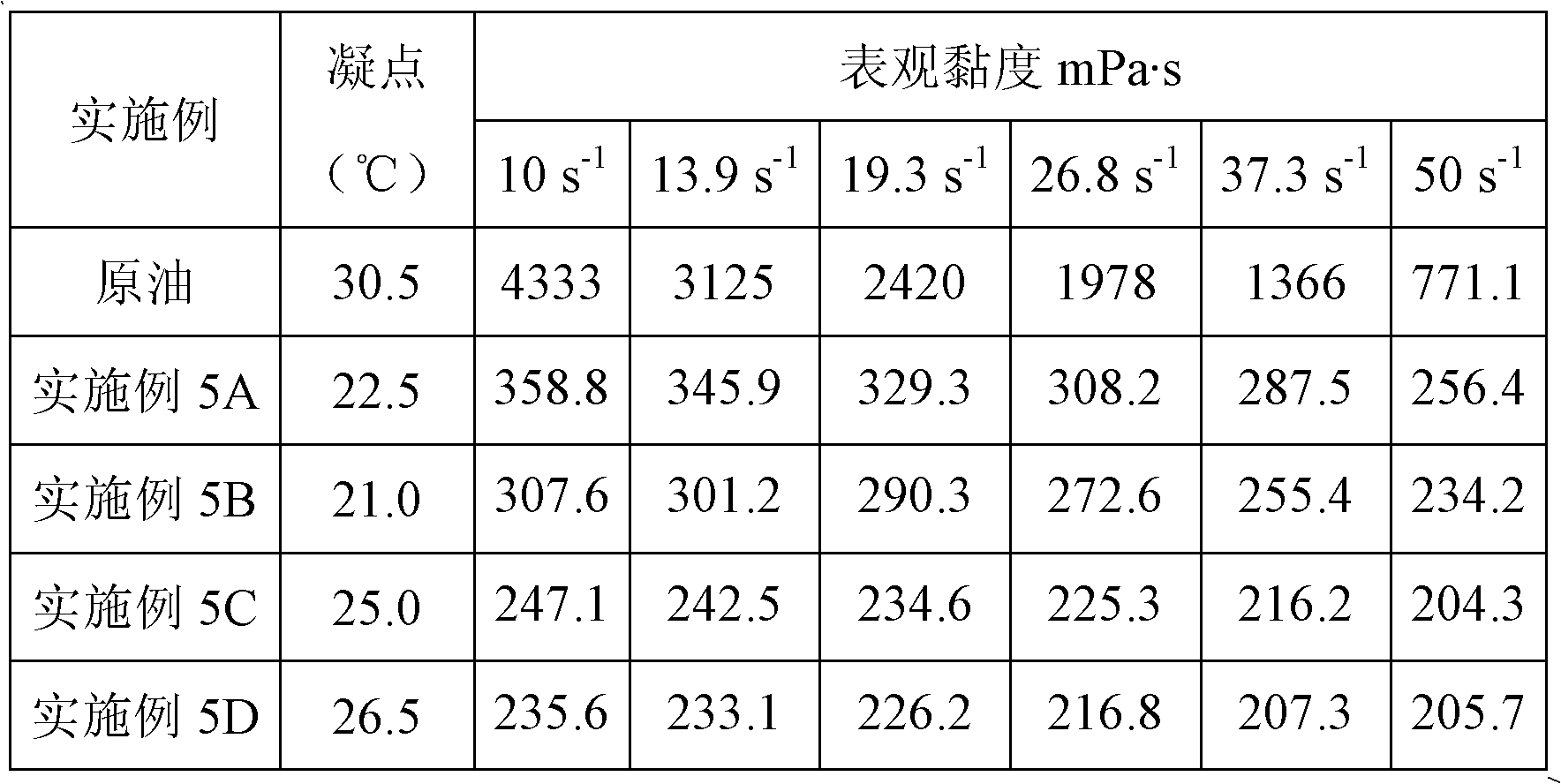

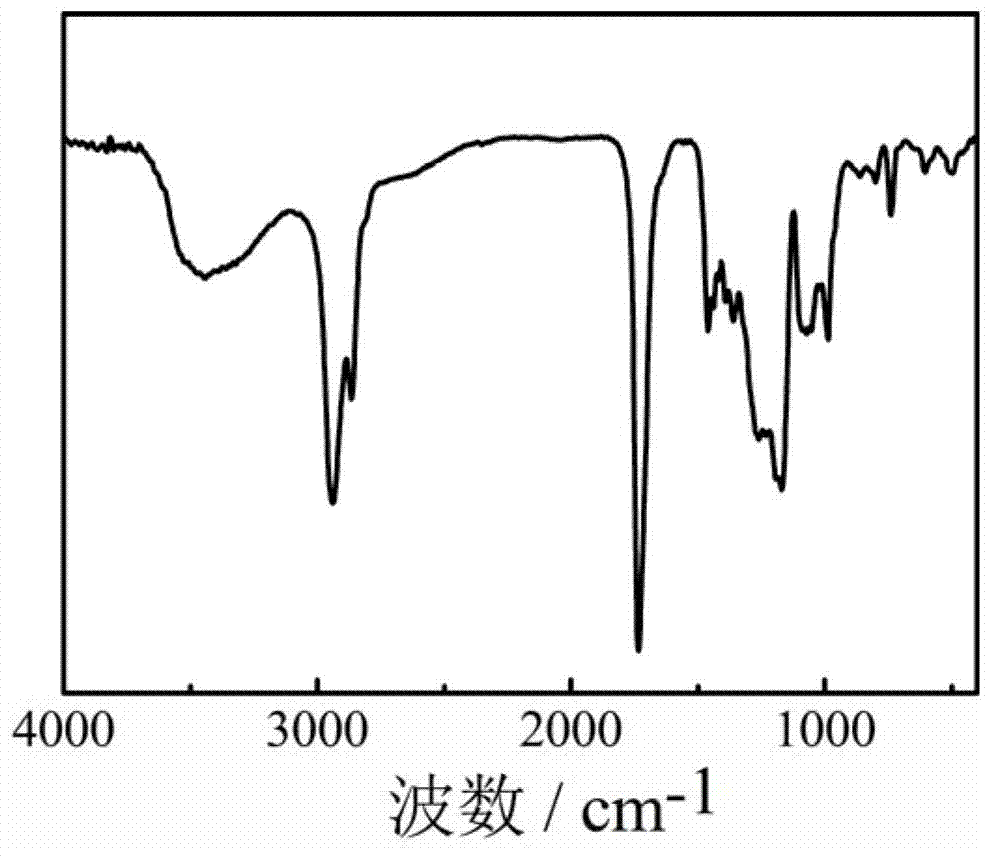

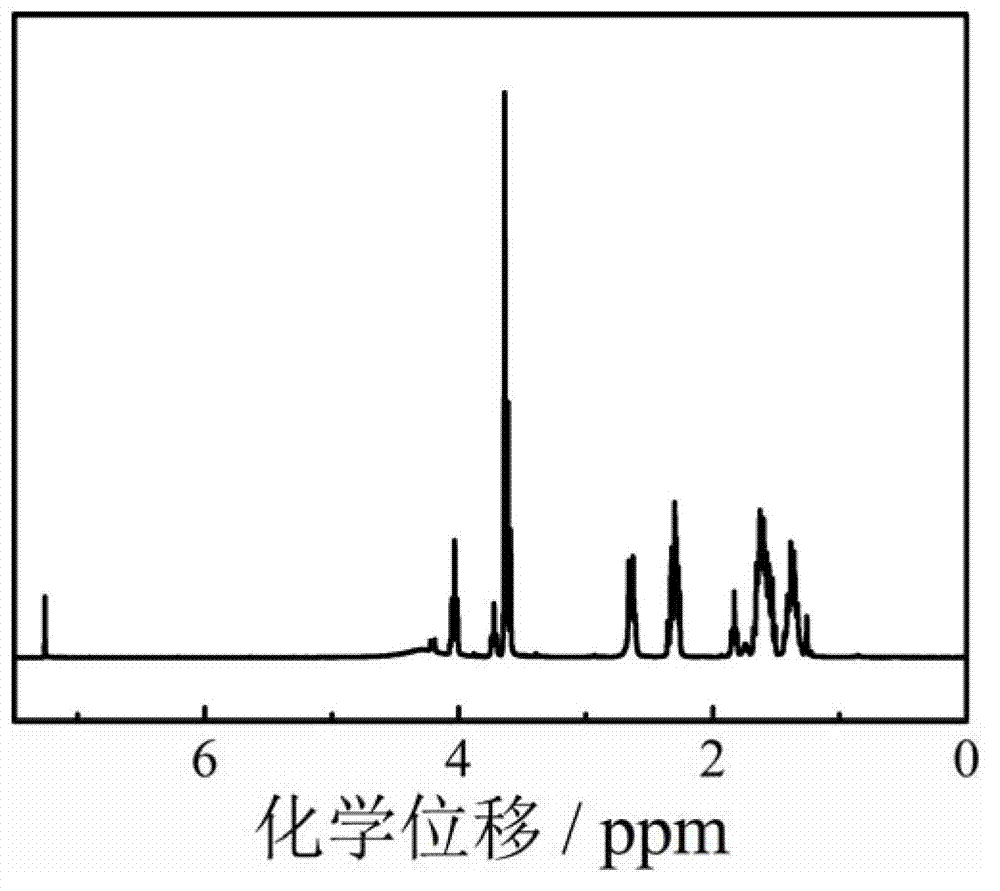

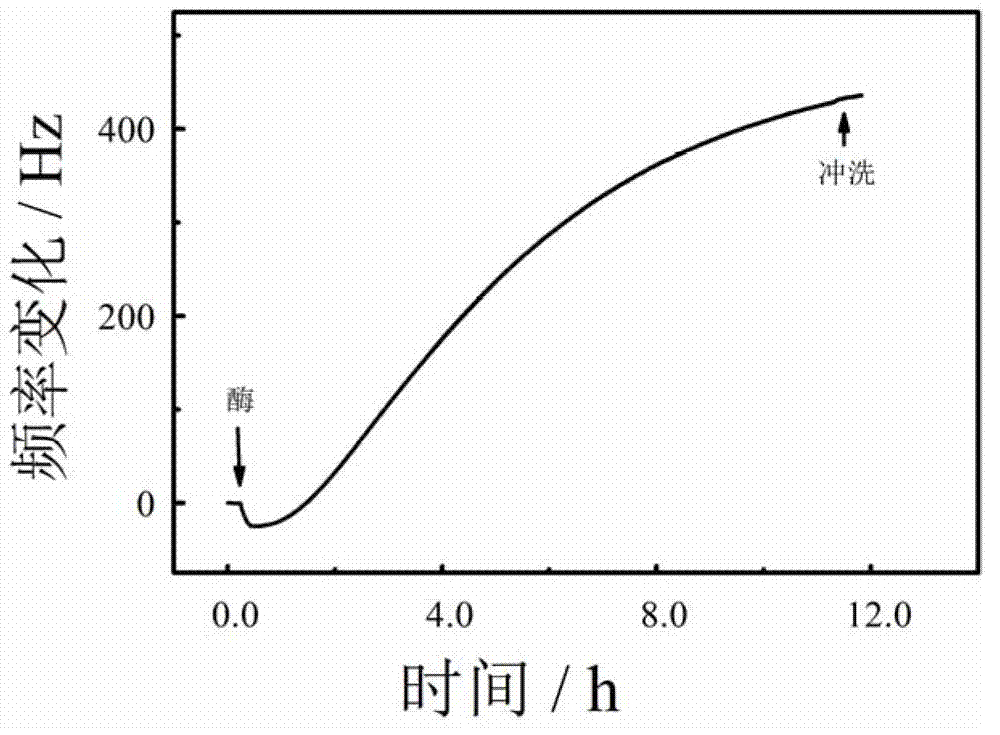

Crude oil viscosity-breaking pour-point depressant composition, and preparation method and application thereof

ActiveCN102127409AUnique synergyGood viscosity and pour point reduction effectDrilling compositionWaxOil transportation

The invention belongs to the field of oil transportation, and particularly relates to a crude oil viscosity-breaking pour-point depressant composition, and a preparation method and application thereof. At the temperature of higher than plasticizing temperature of organic pour-point depressant, 0-3% by mass of coupling agent, 0-10% by mass of high-molecular processing assistant, and the balance ofinorganic pour-point depressant and organic pour-point depressant are melted, uniformly mixed and granulated to obtain the crude oil viscosity-breaking pour-point depressant composition. The crude oil viscosity-breaking pour-point depressant composition is uniformly dispersed in a liquid dispersion medium, and proportionally injected into crude oil, so that the crude oil can be transported. The inorganic pour-point depressant and organic pour-point depressant in the crude oil viscosity-breaking pour-point depressant composition have a synergetic effect, and can effectively lower the solidifying point and viscosity of the waxy crude oil, so that the crude oil has favorable fluidity at low temperature and favorable rheologic timeliness, thereby enhancing the crude oil transportation efficiency and safety level and lowering the transportation cost.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Acrylamide polymer thickener and preparation method thereof, and fracturing fluid

ActiveCN106146730AHigh temperature resistanceImprove high temperature resistanceDrilling compositionPolymer scienceFracturing fluid

The invention provides an acrylamide polymer thickener and a preparation method thereof, and a fracturing fluid, wherein the acrylamide polymer thickener is composed of the components by the mass percentage: 20%-45% of a hydrophilic propenyl monomer, 4%-6% of a hydrophobic propenyl monomer, 1%-2% of an emulsifier, 0.2%-0.5% of an initiator, a latent crosslinking agent and the balance water, wherein the latent crosslinking agent accounts for 0.5%-1.8% of the total mass of the hydrophilic propenyl monomer and the hydrophobic propenyl monomer; the acrylamide polymer thickener provided by the invention solves the technical problems in the prior art that a polymer thickener has poor temperature resistance and salt tolerance and poor shearing stability, and the prepared acrylamide polymer thickener has high-temperature performance, and can effectively meet the requirements of on-site construction of slick water fracturing.

Owner:PETROCHINA CO LTD

Pyridine saline gas transmission pipeline drag reduction agent and preparation method thereof

ActiveCN101575495AGood drag reduction effectRaw material source directlyOther chemical processesPipeline systemsRotary evaporatorPhosphate

The invention discloses a pyridine saline gas transmission pipeline drag reduction agent and a preparation method thereof. The pyridine saline gas transmission pipeline drag reduction agent is prepared from pyridines compounds, fluo phosphate, and halogenated hydrocarbon according to the mol ratio of 1:1:1-1.5:2:1. The preparation method comprises the following steps: adding the pyridines compounds and the halogenated hydrocarbon of the proportional quantities into a reaction vessel, and under the condition of stirring the mixture in the inert atmosphere, controlling the reaction temperature and reflux for reaction; after the reaction is finished, stopping heating, and cooling the reaction mixture, wherein the upper layer of the reaction mixture is yellowish liquid, and the lower layer of the reaction mixture is a white crystal; in the inert atmosphere, pouring out the yellowish liquid on the upper layer, and crashing the white crystal for suction filtration; putting the white crystal into a heat insulating purifier, adding a solvent into the heat insulating purifier, and in the inert atmosphere, re-crystallizing the mixture for 2-3 times to obtain a white crystal; adding an organic solvent, the white crystal and the fluo phosphate in a certain proportion into the reaction vessel, stirring the mixture in the inert atmosphere, and controlling the temperature for reaction; after the reaction is finished, carrying out suction filtration on the liquid rapidly, and removing undissolved substances to obtain a crude product containing the solvent; and steaming a small amount of the organic solvent from the crude product by a rotary evaporator, then putting the crude product in a vacuum oven to make the organic solvent steamed radically, and obtaining a product.

Owner:PIPECHINA SOUTH CHINA CO

Preparation method and application of main chain fracture type polyacrylic acid silane ester resin

ActiveCN103396513AEfficient regulated releaseMake sure to keepAntifouling/underwater paintsPaints with biocidesPolyesterPolymer science

The invention discloses a preparation method and an application of main chain fracture type polyacrylic acid silane ester resin. The method comprises the following steps of: mixing a cyclic monomer, a vinyl monomer and a vinyl silane ester monomer in a solvent according to a proportion, and then, adding a composite initiator accounting for 0.01-5% of the total mass percent of the monomers, and reacting at a temperature of 25-150 DEG C under the protection of argon or nitrogen to prepare the main chain fracture type polyacrylic acid silane ester resin; and the monomers are composed of 5-95wt% of cyclic monomer, 0-90wt% of vinyl monomer and 5-95wt% of vinyl silane ester monomer. According to the resin obtained by the invention, the side chain silane ester can hydrolyze under the action of seawater and the polyester chain segment of a main chain can generate chain scission under the action of seawater, thereby solving the dependence of traditional self-polishing materials on navigational speed, effectively regulating and controlling a stain-proofing agent to release at a constant speed, maintaining active substances on the coating surface of a ship and well meeting the anti-fouling requirements of ships, submarines and offshore production platform facilities with low navigational speeds.

Owner:SOUTH CHINA UNIV OF TECH

Sulfuric acid ester gas pipeline drag reduction agents and preparation method thereof

ActiveCN101575497AGood drag reduction effectRaw material source directlyOther chemical processesPipeline systemsGas pipelineSulfuric Acid Esters

The invention discloses sulfuric acid ester gas pipeline drag reduction agents for drag reduction of long-distance pipelines of gas, particularly natural gas and a preparation method thereof. The drag reduction agents are formed by sulfuric acid esters, aromatic compounds and heterocyclic compounds according to the molar ratio of 1:5:1-1.5:10:1. The preparation method comprises the steps of: 1) adding a heterocyclic compound and an aromatic compound with certain proportion into a reactor, adding nitrogen for protection, and stirring for fixed time period at low temperature, and then adding sulfuric acid ester; 2) reacting for certain time to ensure that a formed liquid is changed into opacity and layering from initial lucidity and transparency; 3) using extraction layering to separate a residual liquid and a generated sulfuric acid ester drag reduction agent; and 4) distilling a residual liquid of an organic solvent under reduced pressure to obtain a product in vacuum. The drag reduction agents have obvious effect on the drag reduction of gas pipelines, have the advantages of direct raw material sources, simple operation, mild reaction conditions, relatively simple process and low requirement on equipment, and are easy to realize mass industrialized production.

Owner:PIPECHINA SOUTH CHINA CO

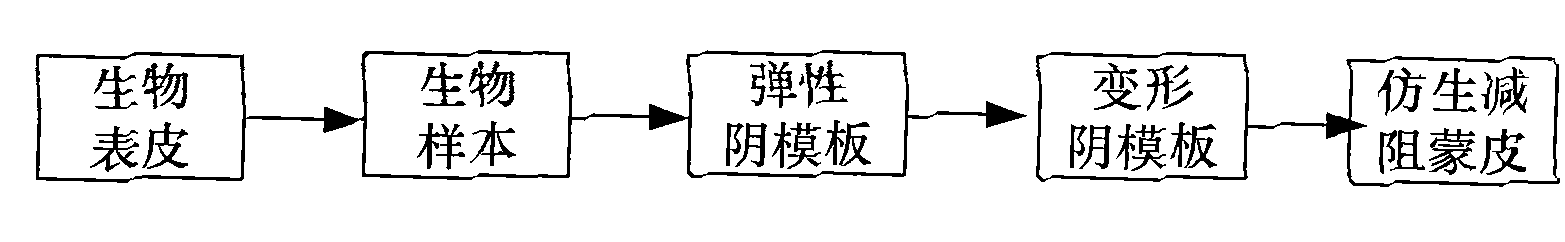

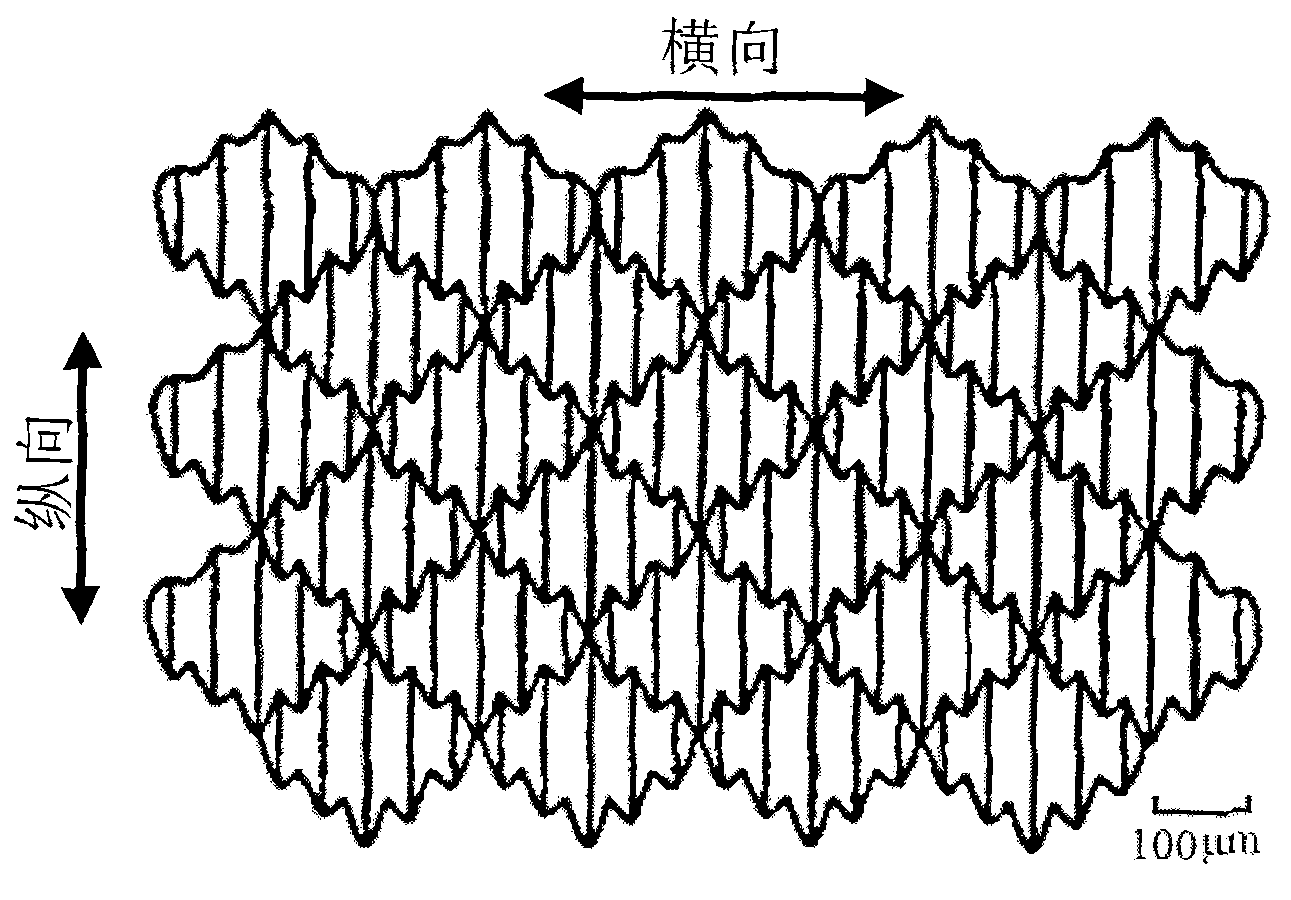

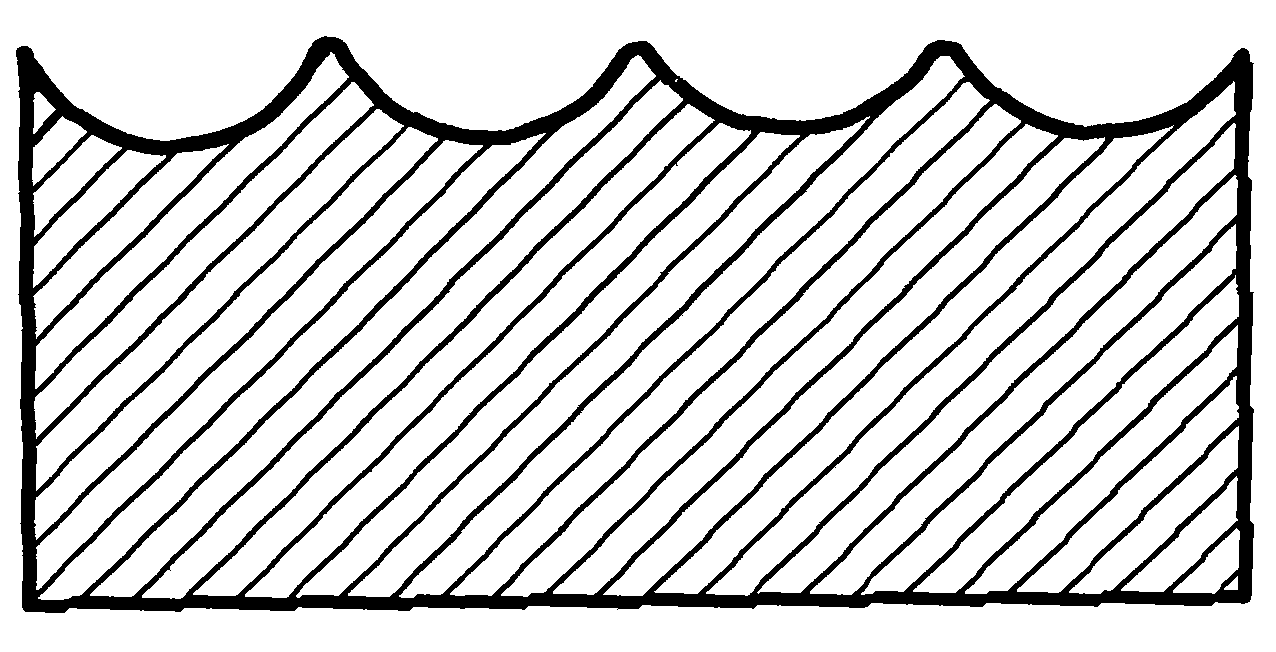

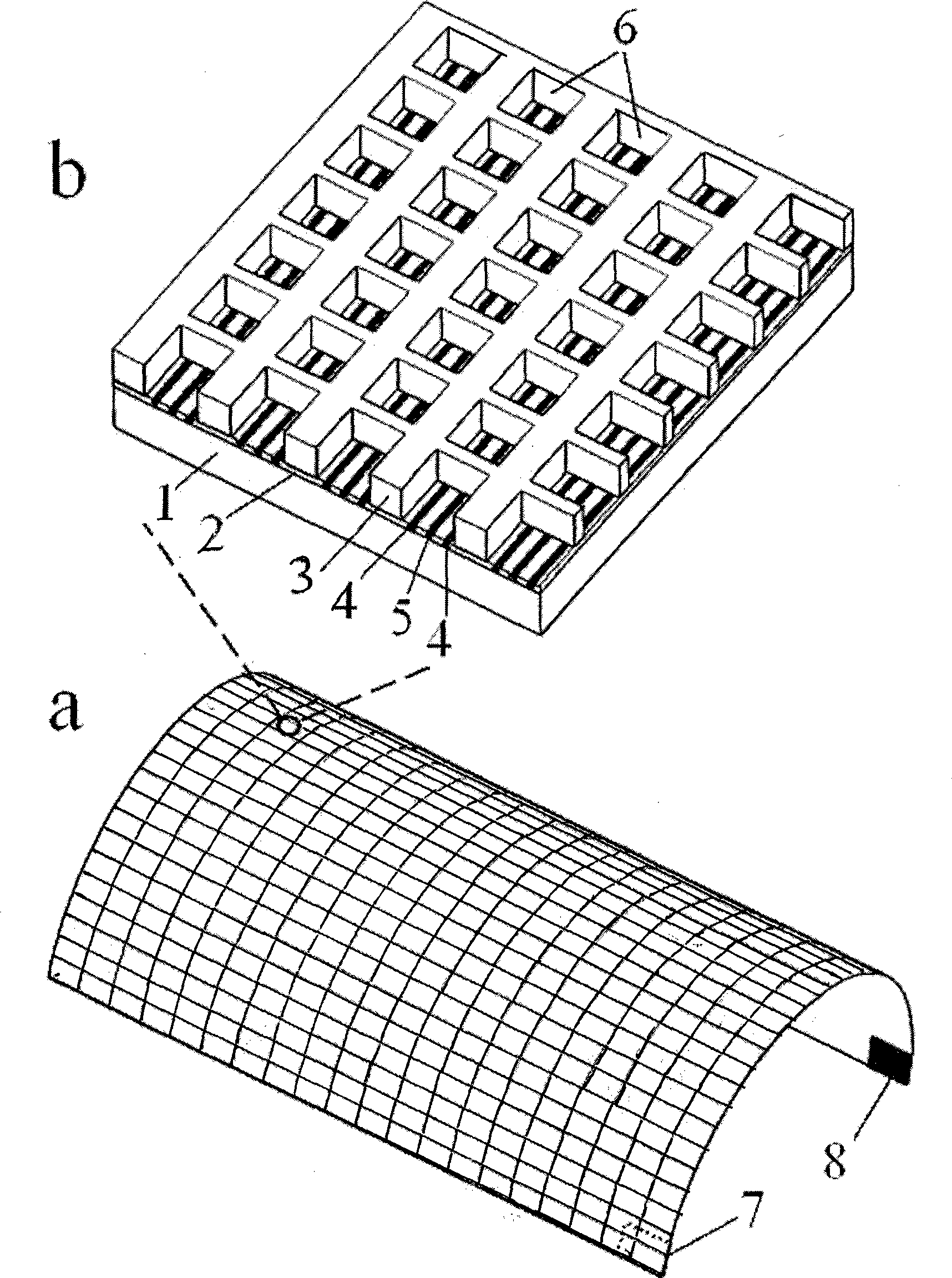

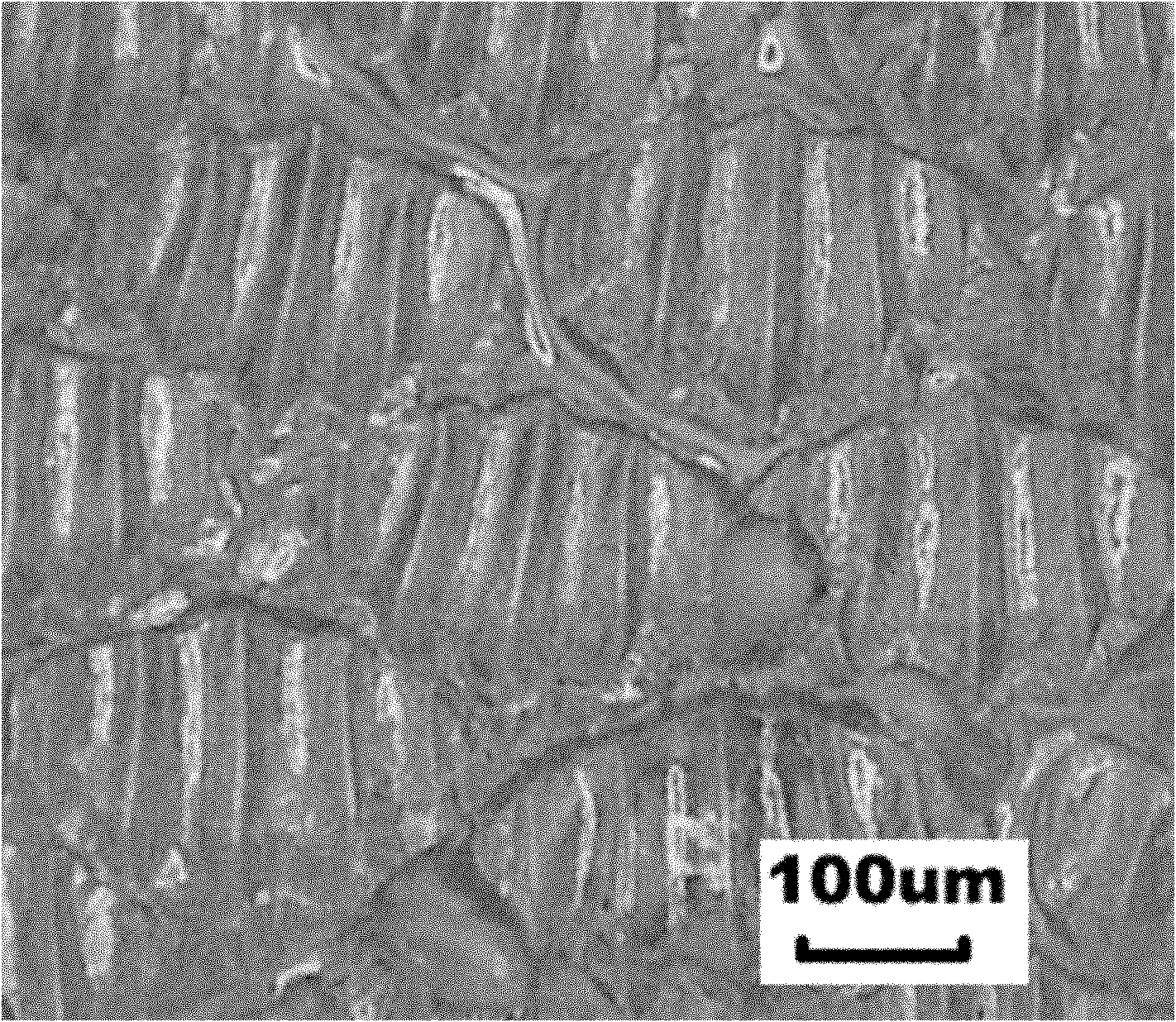

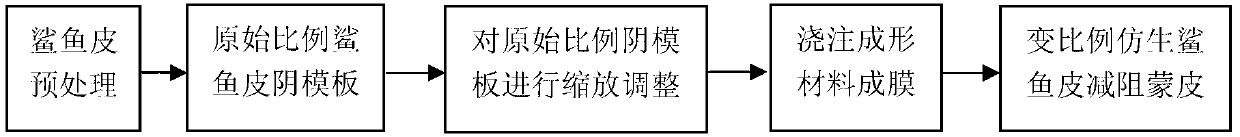

Manufacture method of transformative shark-simulation anti-drag skin based on adjustable surface appearance and size

InactiveCN101913407AReduce external forceIncrease elasticityWatercraft hull designHydrodynamic/hydrostatic featuresSkin appearanceManufacturing technology

The invention relates to a manufacture method of a transformative shark-simulation anti-drag skin based on adjustable surface appearance and size, which comprises the following four steps:(1) manufacturing a shark-skin biometric template; (2) manufacturing a silicon rubber elastic female template; (3) manufacturing a transformative shark-appearance-simulation anti-drag skin and researching a law;and (4) manufacturing the transformative shark-appearance-simulation anti-drag skin according to the requirements of application objects. The elastic female template manufactured by applying the invention has more than 95% of similarity to that of original shark skin appearance, the size of the skin surface appearance of the shark-simulation anti-drag skin manufactured by applying the invention can be adjusted according to the parameters of the common speed, the dielectricviscosity and the like of the application objects, and the anti-drag effect of the shark-simulation anti-drag skin approaches the optimum state. The manufacture method of a transformative shark-simulation anti-drag skin based on adjustable surface appearance and size has good utility value and wide application prospects in the field of simulation manufacture technology.

Owner:BEIHANG UNIV

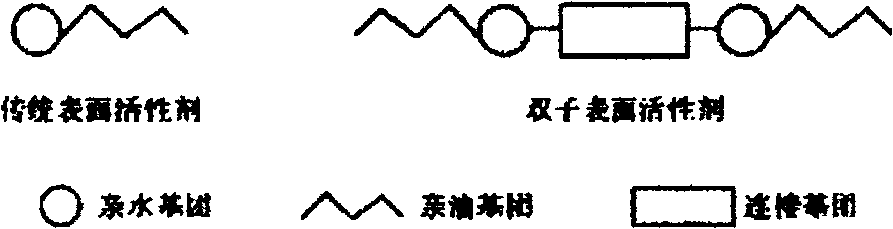

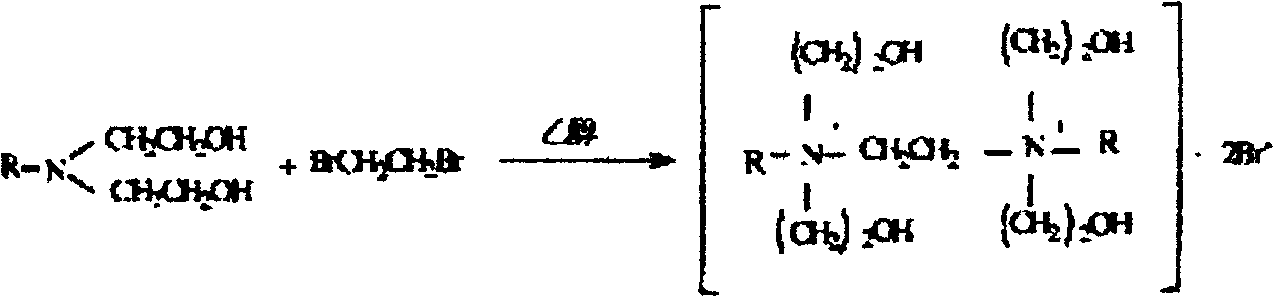

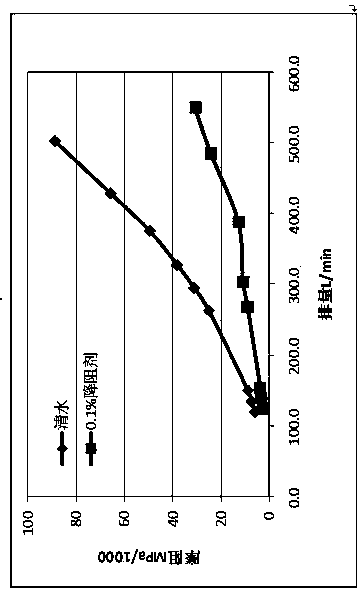

Synthetic method of gemini quaternary ammonium salt surfactant and application as drag reduction agent

InactiveCN102151514AGood drag reduction performanceHigh biosecurityTransportation and packagingScale removal and water softeningIonSolvent

The invention discloses a method for synthesizing gemini long chain alkyl quaternary ammonium salts by enabling long chain alkyl tertiary amine mixture to be reacted with dibromo hydrocarbon or epoxy chloropropane and an application as a drag reduction and energy conservation agent of a circulating water system. The method comprises the following steps: stirring and dissolving the long chain alkyl tertiary amine mixture in an organic solvent, and heating to reflux temperature; slowly adding dibromoethane or epoxy chloropropane for generating mixture of asymmetric and symmetric gemini long chain alkyl quaternary ammonium salts; stopping the reaction when the tertiary amine conversion rate is above 75%, and performing vacuum evaporation for recovering the solvent; and using deionized water to dissolve distillation products, and oxidizing the non-converted raw material to tertiary amine oxide with hydrogen peroxide at the temperature of 60-80 DEG C. A gemini quaternary ammonium salt surfactant is used as main molecules of the drag reduction agent, an organic acid corrosion inhibitor is used as auxiliary ions, the molar ratio of the main molecules to the auxiliary ions is 1: (2.4-6.0), then the drag reduction agent which is applicable to the range of 5-95 DEG C is prepared, and the drag reduction efficiency of the drag reduction agent to the circulating water system achieves 40%-70%, and the corrosion inhibition efficiency achieves 60%-95%. By adopting the gemini long chain alkyl quaternary ammonium salt surfactant, the problems of strong corrosion, great irritation and a narrow range of applicable temperature of the traditional long chain alkyl quaternary ammonium salt surfactant can be overcome.

Owner:TIANJIN VOCATIONAL INST

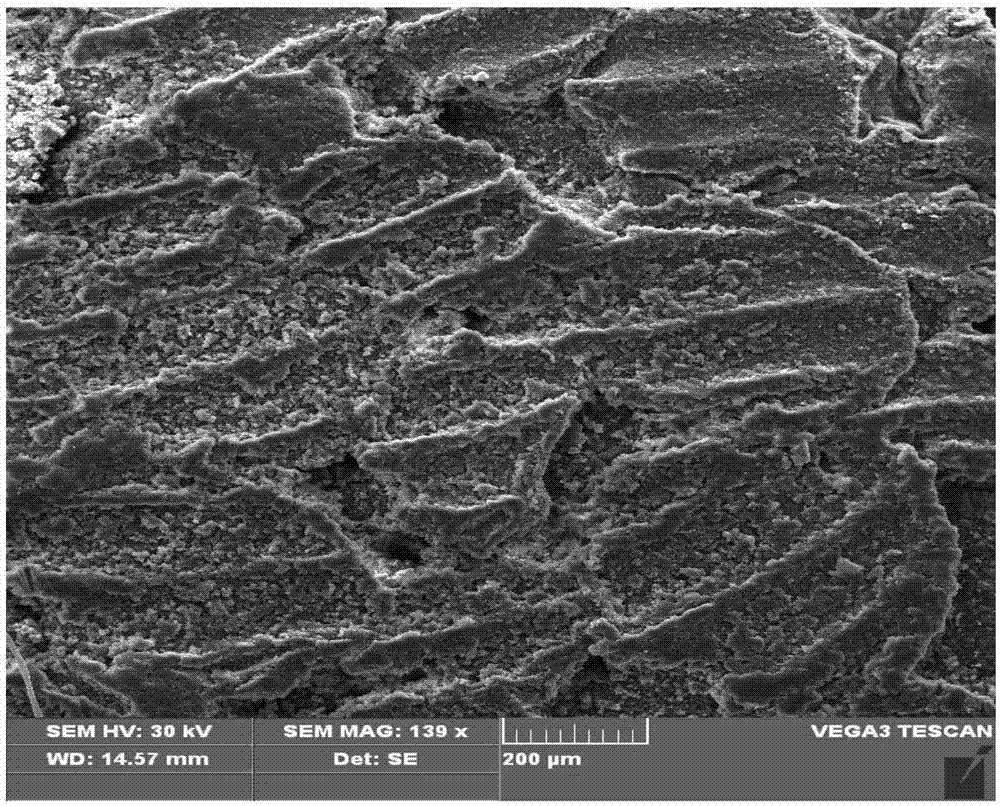

Method for preparing super-hydrophobic bionic metal surface through ultrafast laser technology

ActiveCN108393588AGood drag reduction effectReduce stayLaser beam welding apparatusMicro nanoMicro structure

The invention discloses a method for preparing a super-hydrophobic bionic metal surface through an ultrafast laser technology and relates to the technical field of bionic surface manufacturing. The method comprises the following steps that a metal sample is subjected to mechanical grinding and polishing; the metal sample is subjected to ultrasonic cleaning; ultrafast laser is replaced with a circular polarization glass filter, and then micro-nano structure induction processing is conducted; the metal sample is subjected to anti-dragging micro-structure processing; and the processed metal sample is subjected to ultrasonic cleaning, placed in a fluoroalkyl silane liquid solution for soaking, and taken out to be blown-dried. According to the method, the surface integrating super-hydrophobic and anti-dragging features is successfully prepared by fully utilizing the characteristics of a femtosecond laser micro-nano processing technology, retention of water drops on the metal surface in theflight environment is reduced to the greatest extent, and thus the dampproof and anti-icing effects are maximized.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Physical grounding resistance reducing agent

InactiveCN1472750AWill not pollutePhysical health hazardConductive materialElectrical resistance and conductanceSoil resistivity

The agent mainly consists of electrode graphite and cement, which is an ideal conduction material for earthing and has low resistivity for durative action and stability service. It can satisfy earthing protective requirements for various electric or microelectronic equipment with in quite long period under the various environmental conditions.

Owner:成都圣威电气有限公司

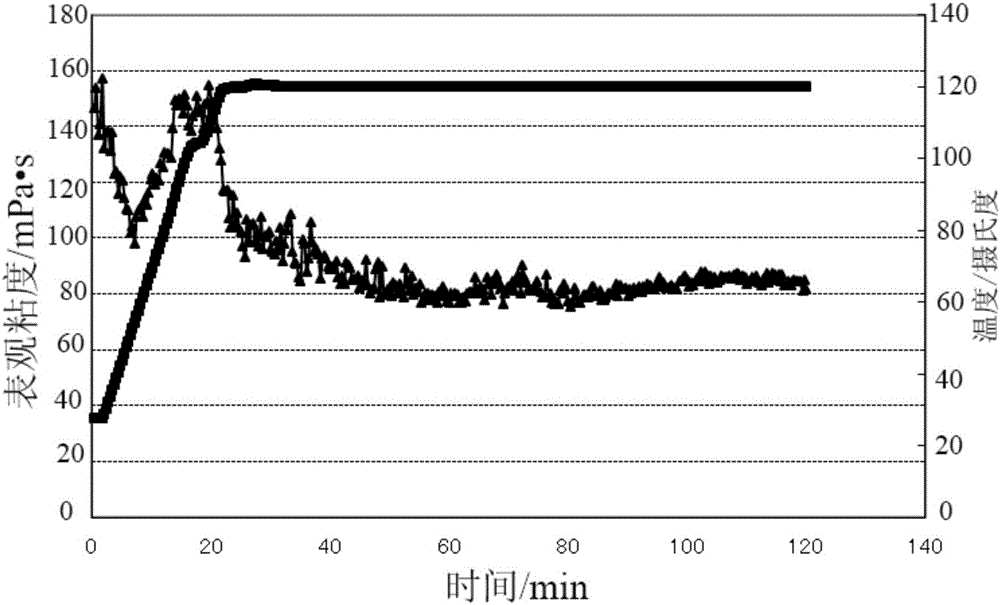

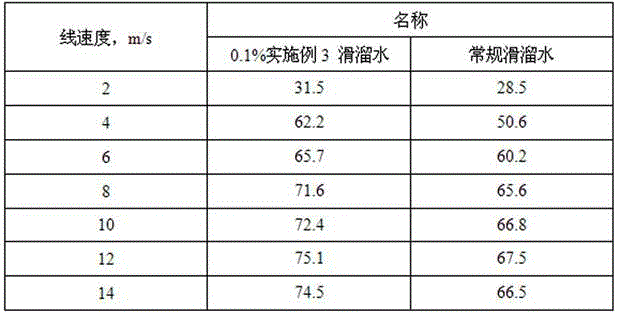

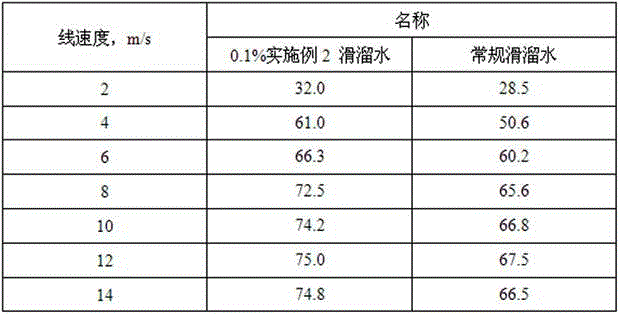

Slippery water fracturing fluid with ultra-low interfacial tension with crude oil after degradation

The invention discloses a slippery water fracturing fluid with ultra-low interfacial tension with crude oil after degradation. The slippery water fracturing fluid is prepared from an ultra-low interfacial tension drag reducer, a demulsify-cleanup additive, a clay stabilizer and a degrading agent. A preparation method of the slippery water fracturing fluid comprises steps as follows: 0.02%-0.10% in percentage by mass of the ultra-low interfacial tension drag reducer, 0.1%-0.2% in percentage by mass of the demulsify-cleanup additive and 0.3% in percentage by mass of the clay stabilizer are added to every ton of water, the agents are mixed to form a homogeneous solution, and 0.08% of the degradation agent is added from a mixing tank of blending equipment during construction. Additives of the slippery water fracturing fluid are all liquid phase, and the slippery water fracturing fluid can be quickly dispersed in water, have good salt tolerance, are not easily affected by the content of bacteria in a fluid preparation solution and have a stable drag reduction effect under the construction displacement of 6-20 m<3> / min; when applied to improvement of low-permeability oil and gas reservoirs, the slippery water fracturing fluid can reduce the interfacial tension between a gel breaking liquid and crude oil and reduce string and construction friction, helps production of the crude oil, increases of the yield of the crude oil and can be prepared repeatedly from backflow fracturing fluids.

Owner:PETROCHINA CO LTD

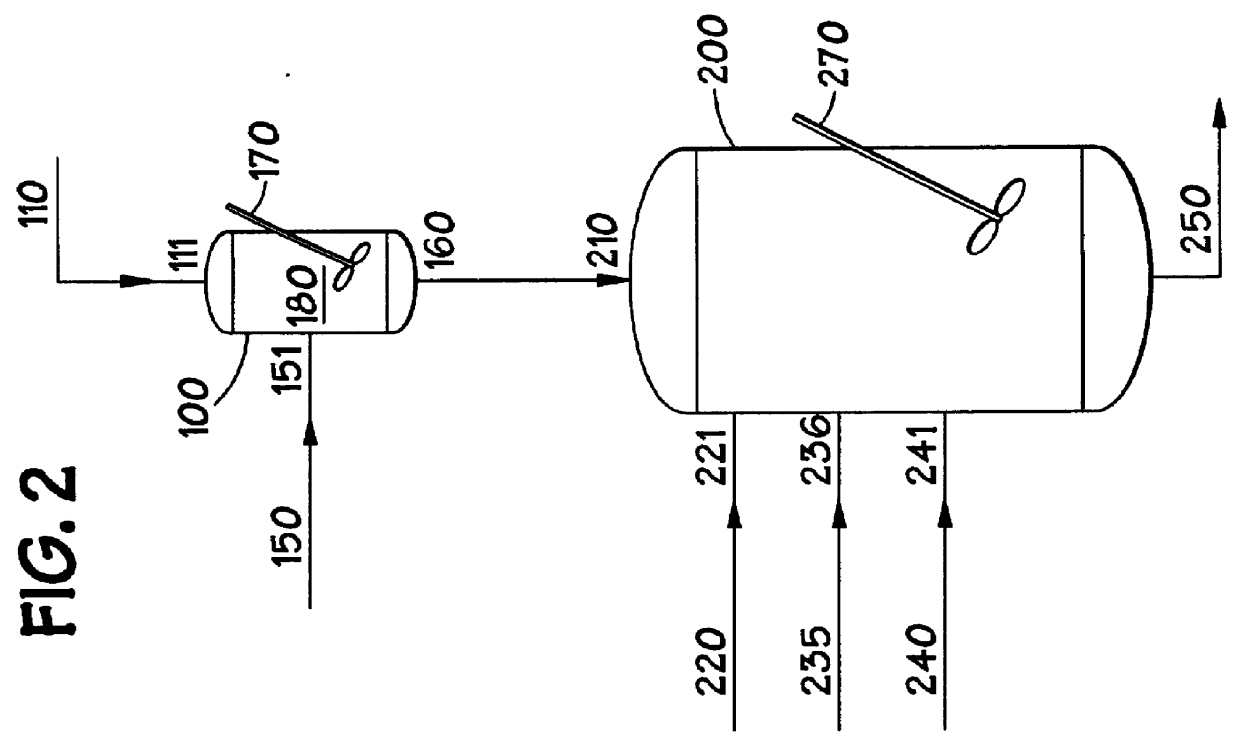

Methods for forming amorphous ultra-high molecular weight polyolefins for use as drag reducing agents

InactiveUS6730750B2Low costReduce polymerizationHydrocarbon by isomerisationCatalystsPolyolefinLiquid hydrocarbons

The present invention is directed to improved drag reducing agents and methods of forming improved drag reducing agents comprising the steps of isomerizing olefin monomers to form isomerized olefin monomers, polymerizing the isomerized olefin monomers in the presence of at least one catalyst to form a polyolefin drag reducing agent having unexpectedly superior drag reduction properties when combined with liquid hydrocarbons, such as viscous crude oil. Therefore, the drag reducing agents of the present invention may be introduced into conduits, such as pipelines, to increase the flow of the hydrocarbons through the conduit.

Owner:CMC MATERIALS INC

Preparation method for poly-2-olefine drag reducer of pipe oil transporting product

A process for preparing the alpha-olefine as the drag reduce used for delivering oil in pipeline includes such steps as loading monomers into reactor, adding catalyst while stirring in the condition of isolating air, adding the oil-soluble polyester, polyether or ester-ether copolymer solution to which the alpha-olefine polymer is not dissolved, and reacting at -50-20 deg.C for 3-10 days. Its advantages are simple process, and high molecular weight, high effect, high stability and low viscosity of product.

Owner:PIPECHINA SOUTH CHINA CO

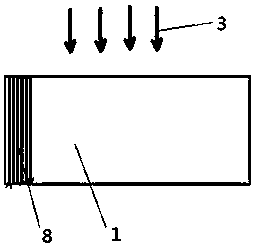

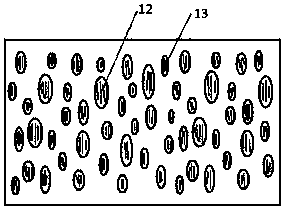

Flexible MEMS resistance reducing covering and method of manufacturing the same

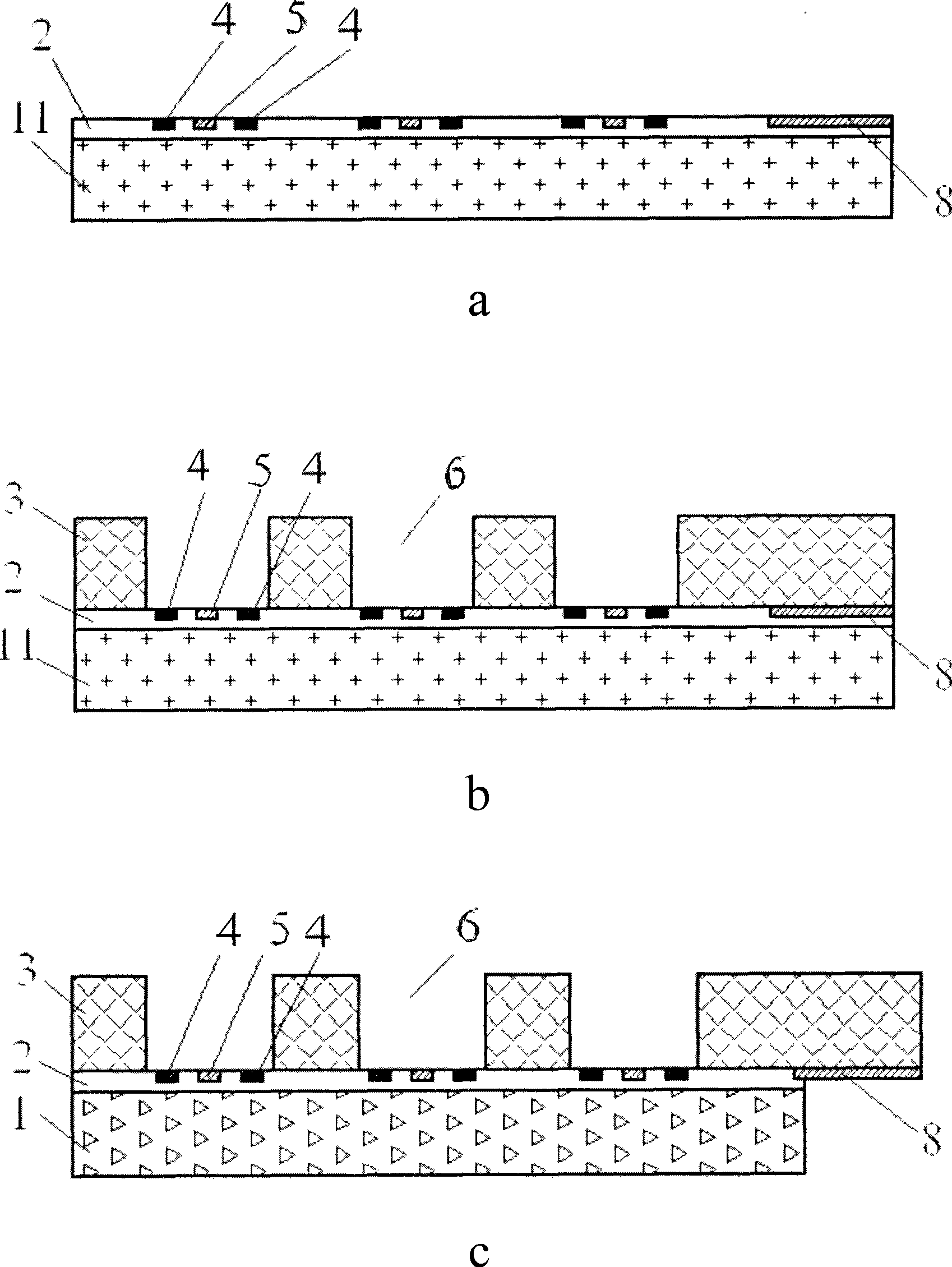

InactiveCN101486438AAchieve residencyImplement auto-replenishmentTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesElectrolysisMicrobubbles

The invention discloses a flexible MEMS resistance-reducing skin and a manufacturing method thereof used for reducing skin friction resistance during the advancing of on-water or underwater vehicles, which employs micro-fine resident bubbles to reduce resistance and belongs to the fields of micro-machinery and fluid dynamics. The upper surface of the skin is a surface layer coated with micro-pit arrays and processed by surface soakage; electrolytic anodes and cathodes of comb-shaped micro-fine planar metal, which are attached on an insulating layer, are arranged at the bottom of the micro-pits; a flexible substrate is positioned below the insulating layer; wire leading terminals for electrodes are arranged on the lower surface of the skin; and both the surface layer and the substrate are made by flexible materials. The overall thickness of the resistance reducing skin is at sub-millimeter level, and the skin is in the status of flexible film. The manufacturing method is an MEMS micro machining technique compatible with the flexible MEMS technology. The flexible MEMS resistance-reducing skin is coated on the outer surfaces of the on-water or underwater vehicles, with power thereof supplied by the on-water or under-water vehicles. Micro-bubbles stably residing in the micro-pits are formed by water electrolysis reaction to coat most parts of the surfaces of the on-water or under-water vehicles, thus realizing the function of reducing skin friction resistance.

Owner:WUXI RES INST OF APPLIED TECH TSINGHUA UNIV +1

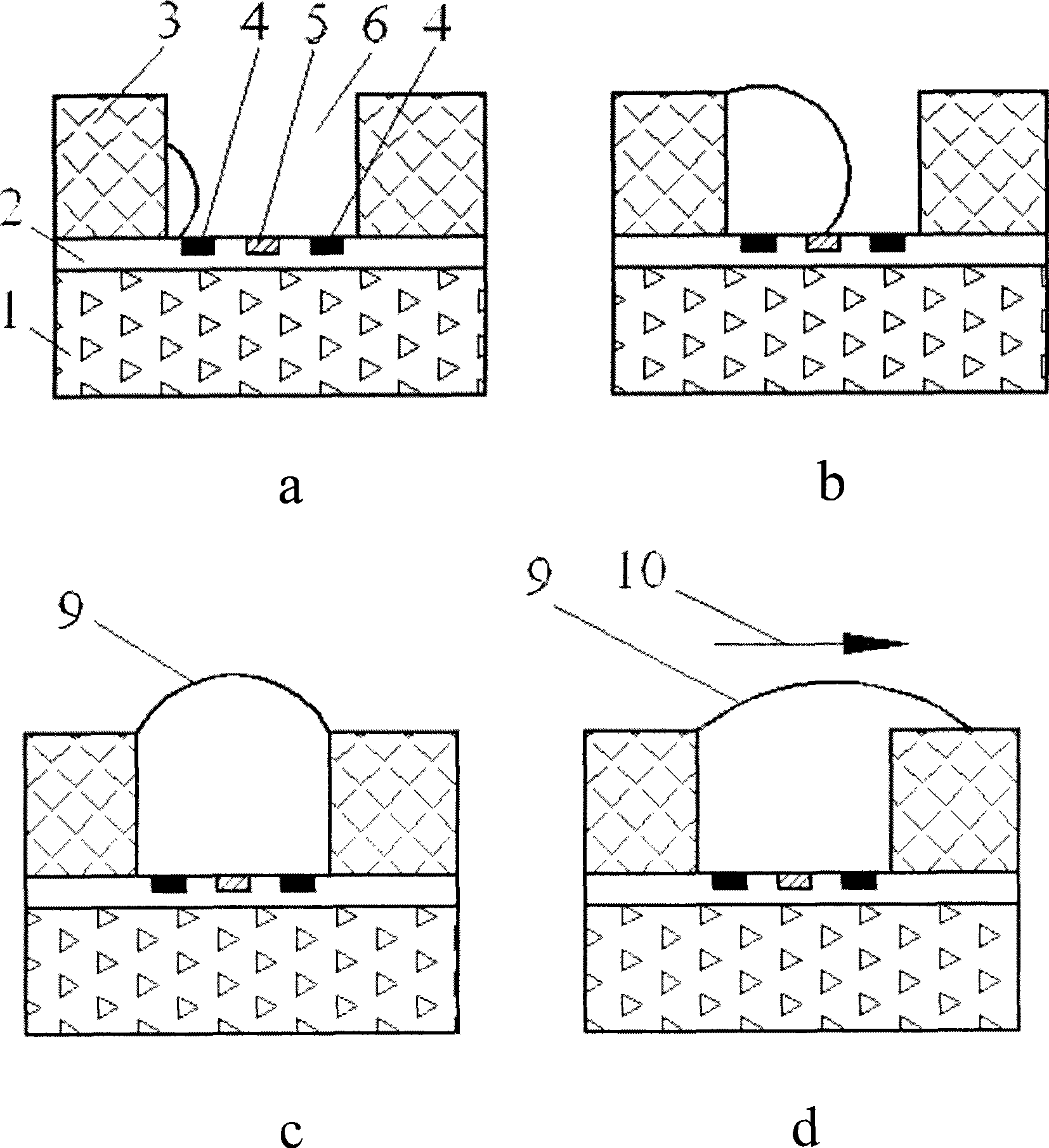

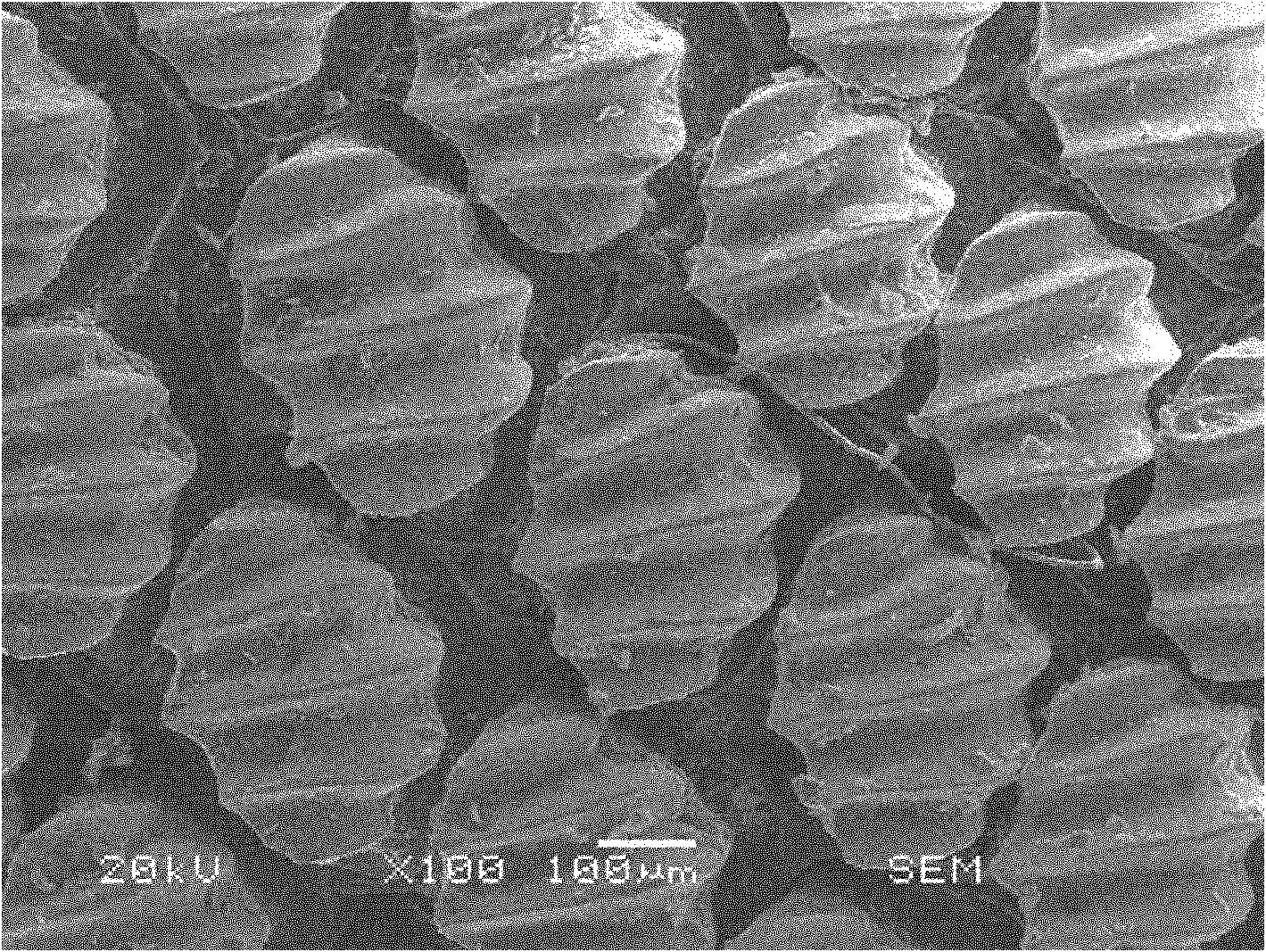

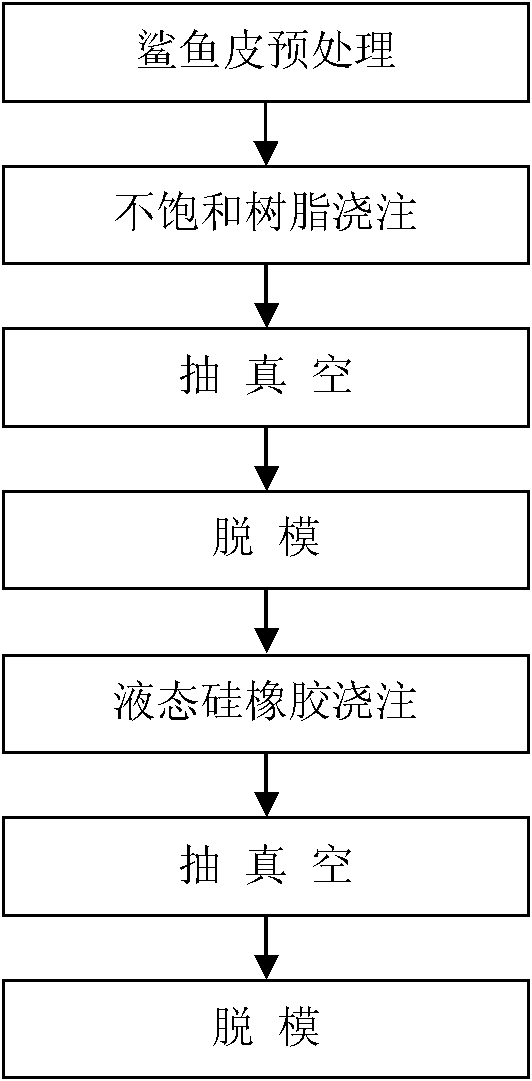

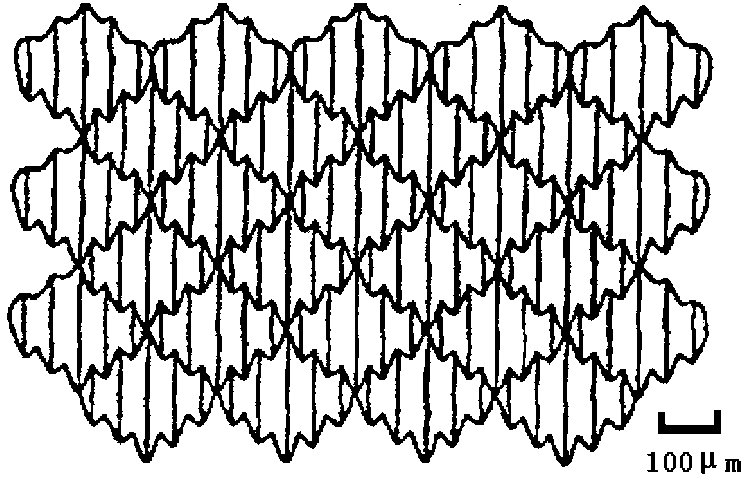

Method for copying sharkskin surface micro groove structure

InactiveCN101966753ASolve the accuracy problemSolve the difficulty of strippingReplication methodSharkskin

The invention discloses a method for copying a sharkskin surface micro groove structure and belongs to the technical field of biological constraint molding. The method is characterized by comprising the following implementation steps: pretreating sharkskin; blowing mold release agent; pouring unsaturated resin; vacuumizing; releasing the unsaturated resin from a mold; blowing mold release agent; pouring liquid silicon rubber; vacuumizing; and releasing the liquid silicon rubber from a mold. The silicon rubber simulation sharkskin thin film obtained by the steps can copy the surface with a riblet micro groove structure of a shark completely and clearly and can be widely used in fields of resistance reduction in aircraft, ship and oil pipe projects and other projects.

Owner:DALIAN UNIV OF TECH

Preparation method and application of multifunctional polyamine amide for oil field

The invention relates to a preparation method of multifunctional polyamine amide for an oil field. The preparation method comprises the steps of: firstly dissolving long-chain fatty acyl polyamine prepared from long-chain fatty acid and polyethylene polyamine in an organic solvent in a container, adding a cross-linking agent to the container under stirring, stirring and heating reactants in the container, and cooling to room temperature to finally obtain a light yellow solution, namely a polyamine amide solution in the container; or evaporating the organic solvent from the light yellow solution obtained in the container to obtain light yellow waxy solid, namely polyamine amide. In application, polyamine amide is dissolved in an organic solvent to prepare a solution, the solution is added to crude oil to obtain a mixture, when the solidifying point of the crude oil is reduced by 5-25 DEG C and the viscosity of the crude oil is reduced by 30-80%, the mixture is prepared into an aqueous solution with mass concentration of 100-10000 ppm, and the corrosion inhibition of the aqueous solution is measured to obtain that the corrosion inhibition rate of the aqueous solution to the steel sheets in different concentrations of hydrochloric acid is 40-90%.

Owner:西安利奇材料科技有限公司

High-temperature resistant CO2 foam cleaning and associated fracturing fluid and preparation method and application thereof

ActiveCN106675546AFast water solubilityEasy to prepareFluid removalDrilling compositionCross-linkPolymer science

The invention provides high-temperature resistant CO2 foam cleaning and associated fracturing fluid and a preparation method and application thereof. The high-temperature resistant CO2 foam cleaning and associated fracturing fluid comprises a fracturing fluid base solution, a cross-linking agent, a gel breaker and liquid CO2, wherein the cross-linking agent and the gel breaker account for 0.3%-0.8% and 0-0.05% of the fracturing fluid base solution in parts by weight separately; and the liquid CO2 accounts for 30%-70% of total volume of the CO2 foam cleaning and associated fracturing fluid. The high-temperature resistant CO2 foam cleaning and associated fracturing fluid provided by the invention has the characteristics of being few in additive types, simple in preparation, controllable in crosslinking, low in residue, low in damage, low in friction, high in foaming efficiency, high in flowback rate and resistant to high temperature.

Owner:PETROCHINA CO LTD

Thickener and preparation method and application thereof

ActiveCN106279523AGood drag reduction effectGood thickening effectDrilling compositionFracturing fluidPropenyl

The invention provides a thickener and a preparation method and application thereof. The preparation method of the thickener includes the following steps that 1, 25-35 parts by weight of hydrophilic propenyl monomers are dissolved in 65-75 parts by weight of water, then the pH value is regulated, and a solution with the pH of 6.5-7.5 is obtained; 2, 1-5 parts by weight of hydrophobic monomers and 0.5-2 parts by weight of emulsifier are added into the solution, stirring is carried out, and 0.05-0.3 part by total weight of initiator is added in batches under a protective atmosphere for a polymerization reaction, wherein the hydrophilic propenyl monomers include acrylamide, acrylic acid and 2-acrylamido-2-methylpropane sulfonic acid in the weight ratio of (15-20):(4-5):(5-15). By adding the thickener in the process of preparing fracturing fluid from highly mineralized water, the fracturing fluid with a high thickening capacity can be formed, and fracturing construction requirements can be effectively met.

Owner:PETROCHINA CO LTD

Preparation method of multifunctional emulsion type drag reducer for shale gas fracturing

InactiveCN105669895AExcellent anti-expansion abilityIncrease connection forceDrilling compositionReaction temperatureOil phase

The invention provides a preparation method of a multifunctional emulsion type drag reducer for shale gas fracturing. The preparation method comprises steps as follows: (1) firstly, an aqueous phase is prepared from water, anionic monomers, nonionic monomers and cationic monomers, the anionic monomers are added to the water, the mixture is neutralized to have the pH of 7 by the aid of a functional base, and then the nonionic monomers, the cationic monomers and an aid are added; (2) an oil phase is prepared from a solvent and an emulsifier which accounts for 5%-20% of the solvent in mass; (3) the aqueous phase and the oil phase are mixed, the water accounts for 10%-60% of the mixture in mass in the aqueous phase and oil phase mixture, high-speed shearing emulsification is performed, and then an initiator is slowly added at the reaction temperature of 20-80 DEG C under protection of nitrogen so as to initiate an emulsion polymerization reaction; (4) after the reaction is ended, a product is cooled to the room temperature, a low-surface-tension reverse phase agent is added, and the multifunctional drag reducer is obtained. The preparation method has the benefits as follows: the anti-swelling ability is outstanding, the discharge aiding effect is good, the drag reducer is multifunctional, and construction is convenient.

Owner:SHENGLI OILFIELD SHENGLI CHEM

Controlled manufacturing method for shark imitated drag reduction surface structure under variable environment

ActiveCN102849205AImprove production efficiencyLow costFuselage bulkheadsEngineeringApplication object

The invention discloses a controlled manufacturing method for a shark imitated drag reduction surface structure under a variable environment. The method comprises the following steps of: 1, preparing an original-ratio sharkskin biological female template; 2, designing shape parameters of a deformed imitated shark required to be manufactured according to the requirement of an application environment; and 3, preparing a variable-proportion bionic drag reduction skin according to the application environment. The variable-proportion bionic sharkskin shaped drag reduction skin prepared by using the method has a functional structure completely in accordance with the original sharkskin shape, but has different shape parameters. By using the method for making the bionic drag reduction skin, the size of the surface shape of the skin can be adjusted according to the parameters such as common speed, different parts of the outer surface and the medium viscosity of an application object, so that the drag reduction effect of the shark imitated drag reduction skin is in an optimal state. The method has high practical value and broad application prospect in the technical field of bionic manufacturing.

Owner:BEIHANG UNIV

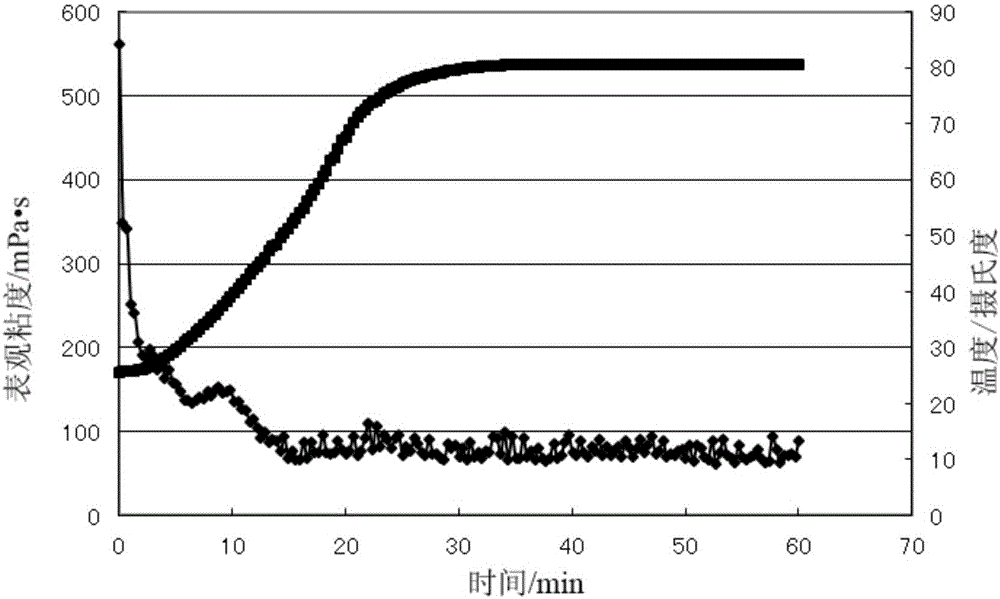

Shale gas well slickwater fracturing fluid system high-efficiency emulsion quick water-soluble drag reducer

ActiveCN103937484AEasy to useGood drag reduction effectDrilling compositionFracturing fluidDouble bond

The invention relates to a shale gas well slickwater fracturing fluid system high-efficiency emulsion quick water-soluble drag reducer, belonging to the technical field of oilfield drag reducers. The drag reducer is prepared by initiating polymerization of a component A, a component B and a component C by a free-radical initiator in water, wherein the component A is composed of a plurality of nonionic water-soluble monomers with carbon-carbon double bond; the component B is a water-soluble polymer stabilizer of univalent cationic monomers; and the component C is a univalent cationic inorganic salt. The drag reducer is simple to use, quick to hydrate and convenient to add, is green and environment-friendly, and has the advantages of high dissolution rate, no bubbling, salt resistance, calcium resistance, pollution resistance, high temperature resistance, favorable compatibility, no need of adding defoaming agent and the like; and the drag reduction efficiency can reach 70% when the drag reducer is used in fracturing. The drag reducer solves the problems of high tendency to granulation and low tendency to hydration in the use process of the existing drag reducer using dry powder, and the problem that the poor compatibility among various different ions and chemical assistants in the fracturing fluid can directly influence the feasibility and effectiveness of the slickwater fracturing.

Owner:荆州市现代菲氏化工科技有限公司

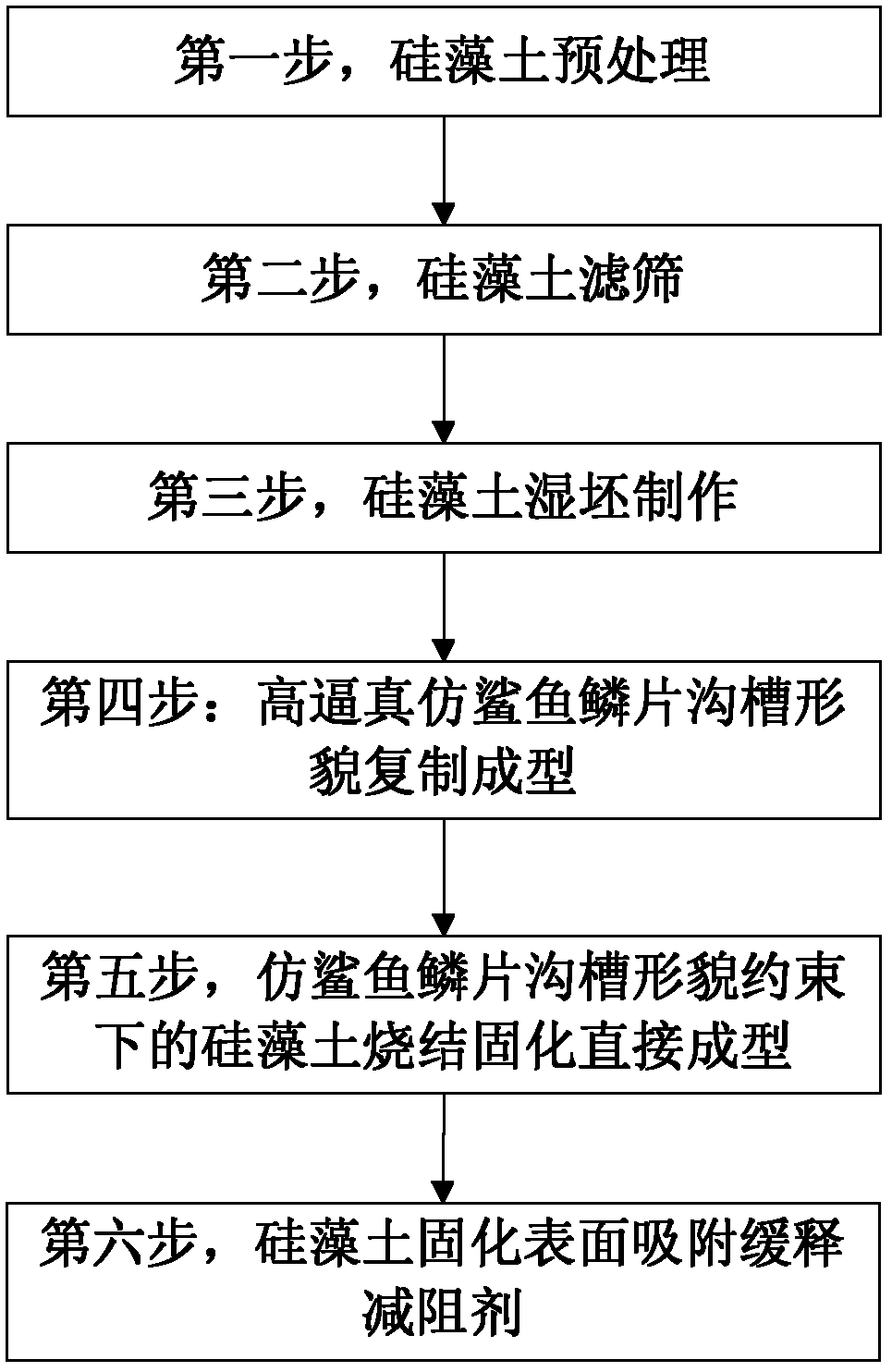

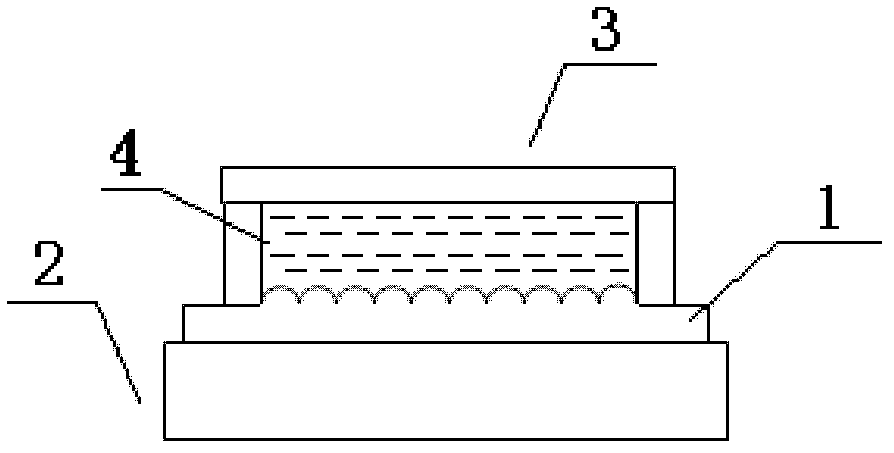

Manufacture method for diatomite composite drag reduction surface absorbed with drag reducer

InactiveCN102424602AGood drag reduction effectImprove adhesionWatercraft hull designCeramicwareReduction functionDrag reducing agent

The present invention relates to the technical field of bionics, specifically to a manufacture method for a drag reduction surface. The manufacture method for the diatomite composite drag reduction surface absorbed with a drag reducer comprises: 1) carrying out a diatomite pretreatment process; 2) carrying out a diatomite filtering and screening process; 3) carrying out a diatomite wet blank manufacture process; 4) duplicating and forming a groove morphology of the high-fidelity artificial shark scales; 5) carrying out sintering, curing and direct forming for the diatomite under the artificial shark scale groove morphology constraint; 6) absorbing a sustained release drag reducer on the cured diatomite surface to prepare the diatomite composite drag reduction surface absorbed with the drag reducer. According to the present invention, the drag reducer is absorbed to the artificial shark diatomite composite drag reduction surface, such that the drag reduction function of the artificial shark scale grooves is provided, and the drag reduction function due to sustained release of the self-lubricating mucus by the artificial shark is further provided.

Owner:SHANDONG UNIV OF TECH

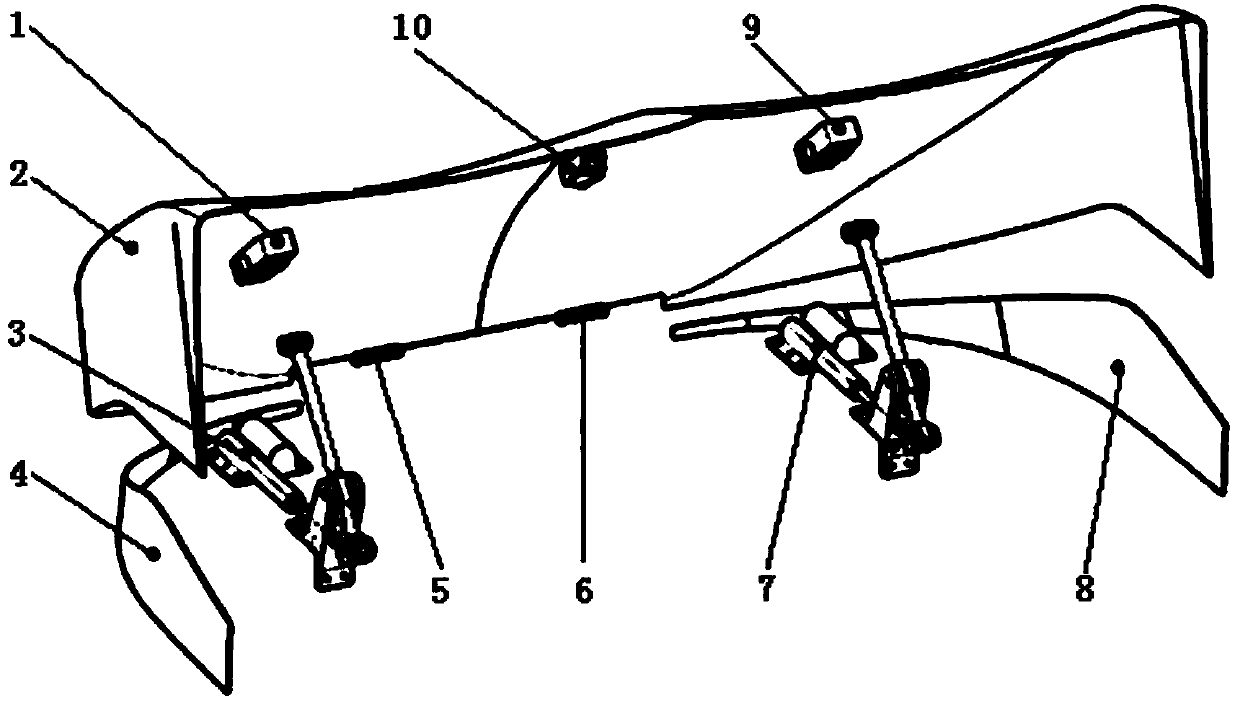

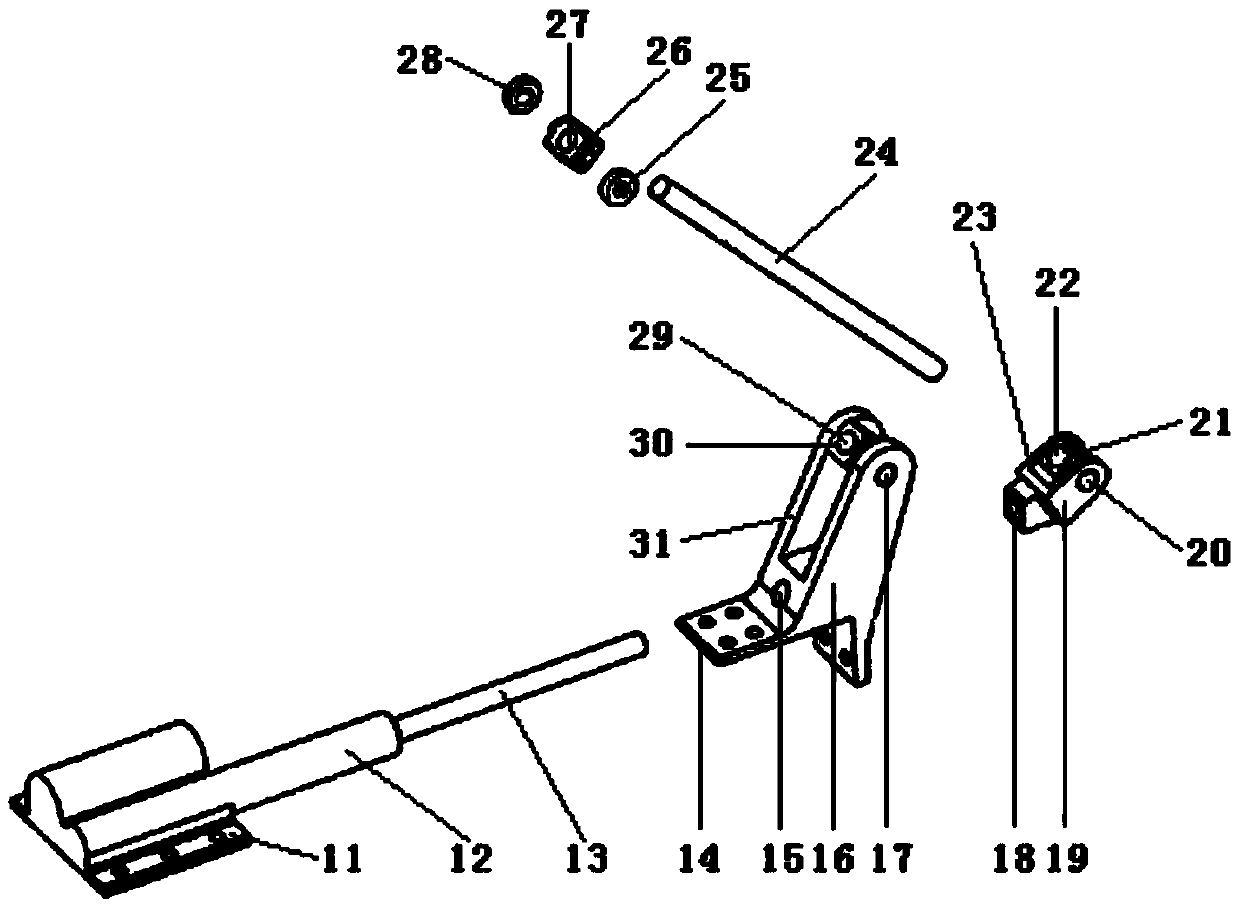

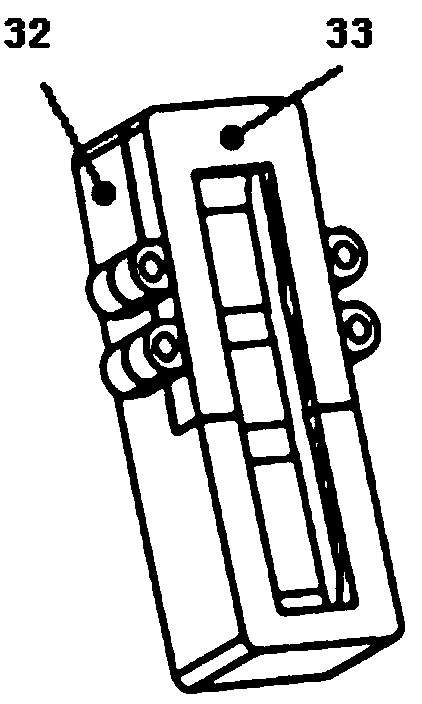

Automatically-adjustable dome for truck

InactiveCN103738421ASimple structureTotal mass is smallAerodynamics improvementVehicle body streamliningAutomatic controlSelf locking

The invention discloses an automatically-adjustable dome for a truck, which belongs to the technical field of automobile parts. According to the automatically-adjustable dome for the truck, two self-locking structures are fixedly connected to the upper portion of the dome, and two push rod support seat structures are fixedly connected to the top of a cab and movably connected with the slide way cavities of the two self-locking structures respectively; the upper portion of the dome is movably connected with the front end of the top of the cab; the lower portions of two domes are fixedly connected with the both ends of the top of the cab respectively; an electric control device comprises a circuit board located in the interior, as well as a gear-type adjustor, an automatic control switch and a power supply switch which are located in the exterior, and a vehicle power supply is used for supplying power; a sensor and two electric push rods are connected with the electric control device. The automatically-adjustable dome for the truck disclosed by the invention is simple in structure, convenient to operate, safe and reliable, and capable of automatically adjusting the height thereof rapidly and conveniently according to the different heights of the containers carried in the truck or different working conditions such as no-load, thus realizing a good drag reduction effect and saving fuel oil; the height of the dome can also be randomly controlled in a part of occasions, thus improving the adaptability of the device; corrective designs can also be performed aiming at different truck types, thus achieving a wide adaptation range of the truck types.

Owner:JILIN UNIV

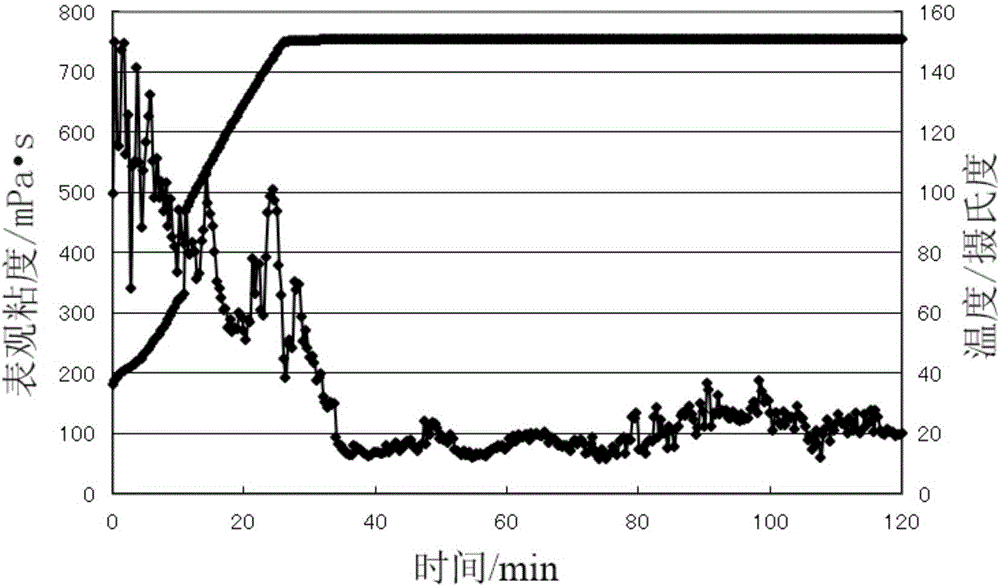

Inverse emulsion drag reduction agent for fracturing shale gas by using quick water and preparation method thereof

ActiveCN103881693AImprove structural stabilityGood drag reduction effectDrilling compositionFracturing fluidSodium hydrogen sulphite

The invention discloses an inverse emulsion drag reduction agent for fracturing a shale gas by using quick water and a preparation method thereof, and relates to the technical field of petroleum engineering. The inverse emulsion drag reduction agent is a macromolecular water soluble polymer which is prepared from acrylamide, sodium acrylate and dodecyl methacrylate copolymerized in an inverse emulsion, and azo diisobutyl hydrochloride and sodium hydrogen sulfite as complex initiation systems. A long-chain hydrophobic monomer is introduced into the drag reduction agent, so that the shear resistance of the drag reduction agent in a high displacement pump injection process is improved, meanwhile, the drag reduction agent is prepared from the inverse emulsion in a polymerization manner, the product is a liquor and instant, the liquor demands of a continuous mixed construction technology for fracturing the shale gas are met, the dosage for field use is 0.06-0.8% of mass of clean water, and the drag reduction rate can be up to 73%.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Methods for forming amorphous ultra-high molecular weight polyalphaolefin drag reducing agents using a halohydrocarbon

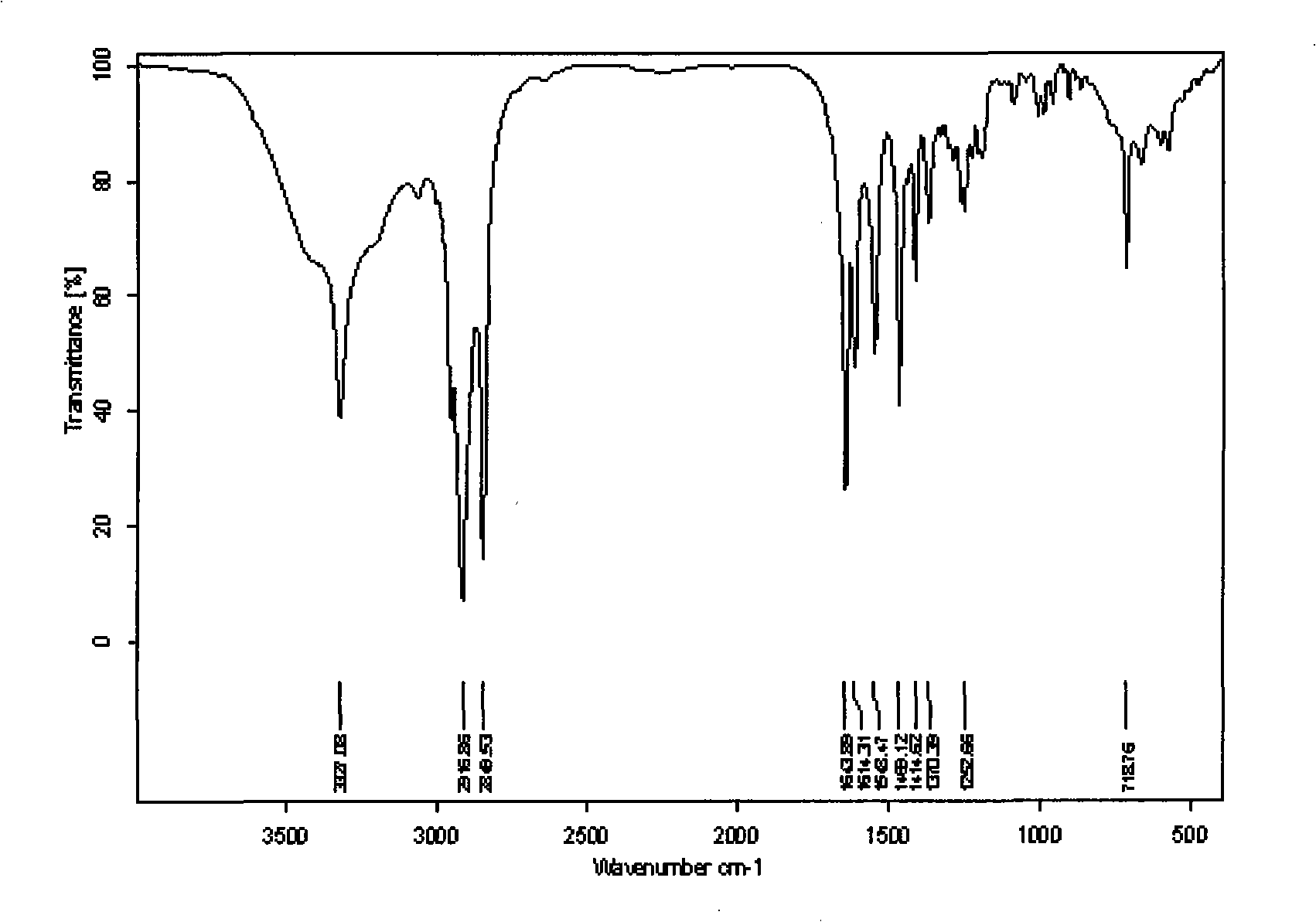

InactiveUS6162773AGood drag reduction effectInherent viscosityOther chemical processesLiquid organic insulatorsHalohydrocarbonAluminoxane

A composition including polyalphaolefins that function as drag reducing agents and a process for the preparation of polyalphaolefins that function as drag reducing agents are disclosed. The process includes contacting alpha olefin monomers with a catalyst system, which includes a catalyst and an activator (co-catalyst) in a reactant mixture. The catalyst is a transition metal catalyst, preferably titanium trichloride, and the co-catalyst may include an alkylaluminoxane, alone or in combination, with a dialkylaluminum halide or a halohydrocarbon. The polymerization of the alpha olefin monomers produces a non-crystalline, ultra-high molecular weight polyalphaolefin having an inherent viscosity of at least 10 dL / g. The addition of the alkylaluminoxane during the polymerization process provides for a non-crystalline, ultra-high molecular weight polyalphaolefin and a more uniform molecular weight distribution of the resulting polyalphaolefin, thereby creating a drag reducing agent superior to known drag reducing agents. A process for forming a drag reducing agent comprising a non-crystalline, ultra-high molecular weight polyalphaolefin having an inherent viscosity of about at least 10 dL / g and a process for reducing drag in a conduit are also disclosed.

Owner:MPOWER SPECIALTY CHEM

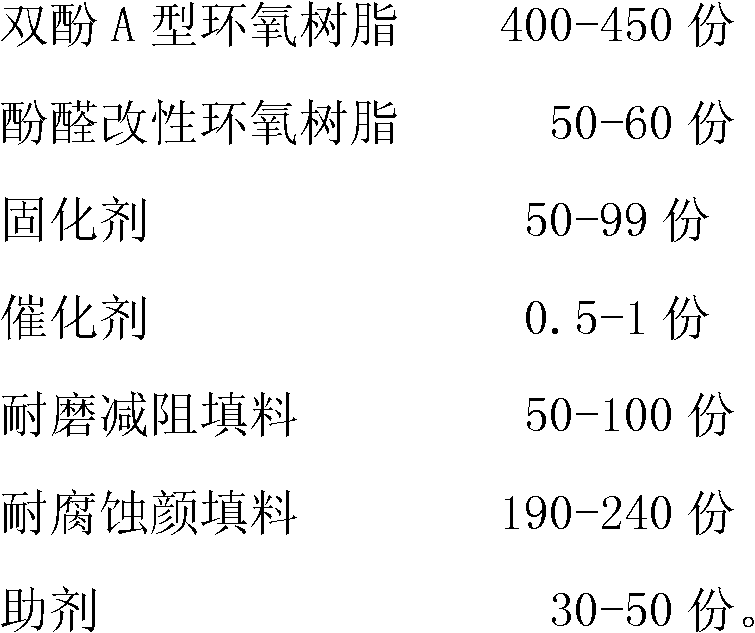

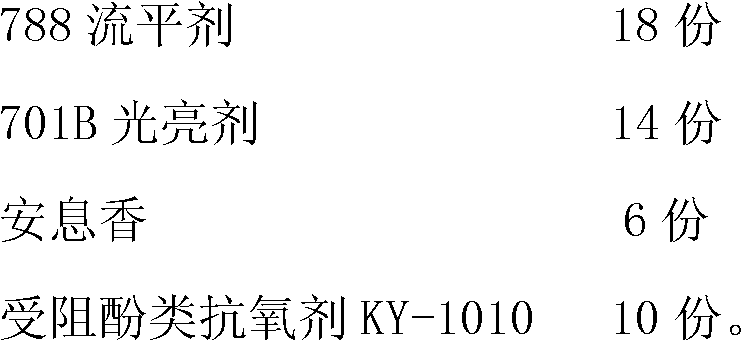

Fired epoxy powder coating special for hot rolling coating of large-caliber steel pipes

InactiveCN102643595AImprove performanceImprove corrosion resistancePowdery paintsEpoxy resin coatingsWear resistantDry mixing

The invention relates to a fired epoxy powder coating special for hot rolling coating of large-caliber steel pipes, which includes formula raw materials, by weight, 400-500 parts of bisphenol A-type epoxy resin, 50-60 parts of phenolic aldehyde modified epoxy resin, 50-99 parts of curing agent, 0.5-1 part of catalyst, 50-100 parts of wear-resistant damping filler, 190-240 parts of corrosion-resistant pigment and filler and 30-50 parts of auxiliaries. The preparation method of the fired epoxy powder coating includes, adding the above raw materials into a high-speed mixer, adding to an extruder after dry mixing, fusing, mixing, cooling and preforming at extrusion temperature ranging from 80 DEG C to 90 DEG C, crushing by a crusher, classifying, screening and packaging to be the powder coating. After being used by users and detected by relative authorized departments, the fired epoxy powder coating special for hot rolling coating of large-caliber steel pipes excellent in corrosion resistance is excellent in coating efficiency and corrosion resistance, indexes thereof can meet those of the-like imported products, some of the indexes even exceed those of foreign products, and price is superior to that of the imported products. In addition, the fired epoxy powder coating special for hot rolling coating of large-caliber steel pipes is deeply appreciated by the users.

Owner:天津翔盛伟业粉末涂料有限公司

Imidazole saline gas transmission pipeline drag reduction agent and preparation method thereof

ActiveCN101575496AGood drag reduction effectSource directlyOther chemical processesPipeline systemsRefluxOrganic solvent

The invention discloses an imidazole saline gas transmission pipeline drag reduction agent and a preparation method thereof. The imidazole saline gas transmission pipeline drag reduction agent is prepared from imidazoles compounds, fluo phosphate and halogenated hydrocarbon according to the mol ratio of 1:1:1-1:2:1.5. The preparation method comprises the following steps: adding the imidazoles compounds and the halogenated hydrocarbon into a reaction vessel, stirring the mixture in the inert atmosphere, and controlling the temperature and reflux for reaction; after the reaction is finished, stopping heating, and cooling the reaction product to ensure that the upper layer is yellowish liquid and the lower layer is a white crystal; in the inert atmosphere, pouring out the yellowish liquid, and crushing the white crystal for suction filtration; putting the white crystal into a heat insulating purifier, adding a solvent into the heat insulating purifier, and in the inert atmosphere, re-crystallizing the mixture for 2-3 times to obtain a white crystal; adding an organic solvent, the white crystal, and the fluo phosphate into the reaction vessel, stirring the mixture in the inert atmosphere, and controlling the temperature for reaction; after the reaction is finished, carrying out suction filtration on the liquid rapidly to obtain a crude product containing the solvent; and steaming a small amount of the organic solvent from the crude product, and then evaporating the organic solvent radically to obtain a product.

Owner:PIPECHINA SOUTH CHINA CO

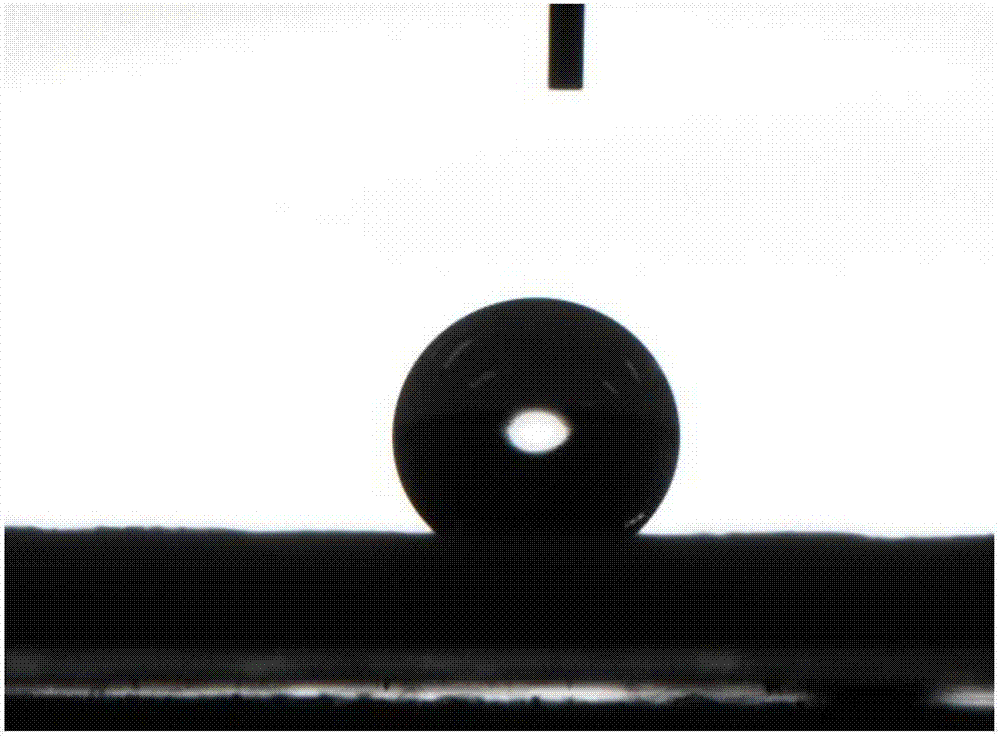

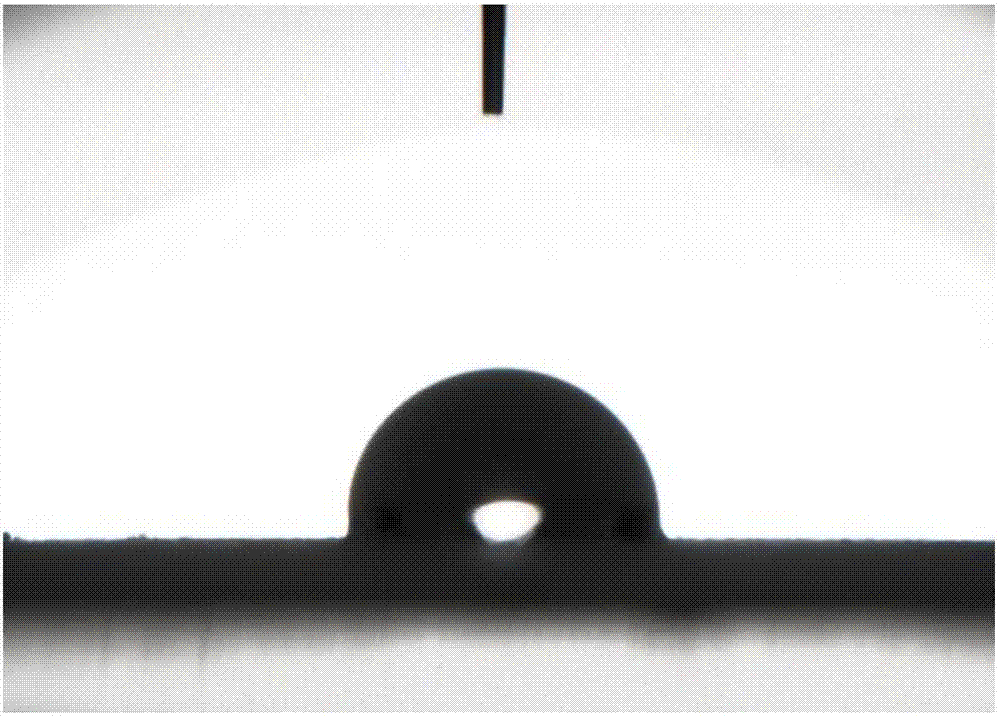

Self-repairing super-hydrophobic anti-drag elastomer thin film and preparation method thereof

ActiveCN107459668AHas super hydrophobic effectSelf-healing superhydrophobic propertiesMicro nanoElastomer

The invention relates to a self-repairing super-hydrophobic anti-drag elastomer thin film and a preparation method thereof. A sharkskin V-shaped groove structure is copied on the surface of an elastomer, and a polyarcylamide-polyfluoroalkyl acrylate segmented copolymer capable of self assembling and forming a micro-nano structure is further grafted on the surface of the elastomer; thus, the thin film has self-repair super-hydrophobic performance, a static water contact angle can reach 150 degrees or more, and a rolling angle is smaller than 10 degrees. When the anti-drag film is attached to a rotational viscometer rotor to perform an anti-drag performance test, drag reducing efficiency can reach 20%. The self-repairing super-hydrophobic anti-drag elastomer thin film disclosed by the invention has the advantages that 1, a super-hydrophobic anti-drag method and a bionic anti-drag method are combined together, so that the anti-drag film can have a better anti-drag effect under a laminar condition and a turbulent condition; 2, after surface chemical components of polyfluoroalkyl acrylate grated to the surface of the super-hydrophobic film are damaged, the polyfluoroalkyl acrylate can be self repaired after being soaked by a solvent or being heated under high temperature, so that the film can have a super-hydrophobic effect again.

Owner:NORTHWESTERN POLYTECHNICAL UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com