Fired epoxy powder coating special for hot rolling coating of large-caliber steel pipes

A fusion-bonded epoxy powder and large-diameter technology, applied in the coating field, can solve the problems of low thermal coating efficiency, low coating efficiency, and poor coating effect of large-diameter steel pipes, achieve good anti-corrosion detection results, improve cleanliness, The effect of improving anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

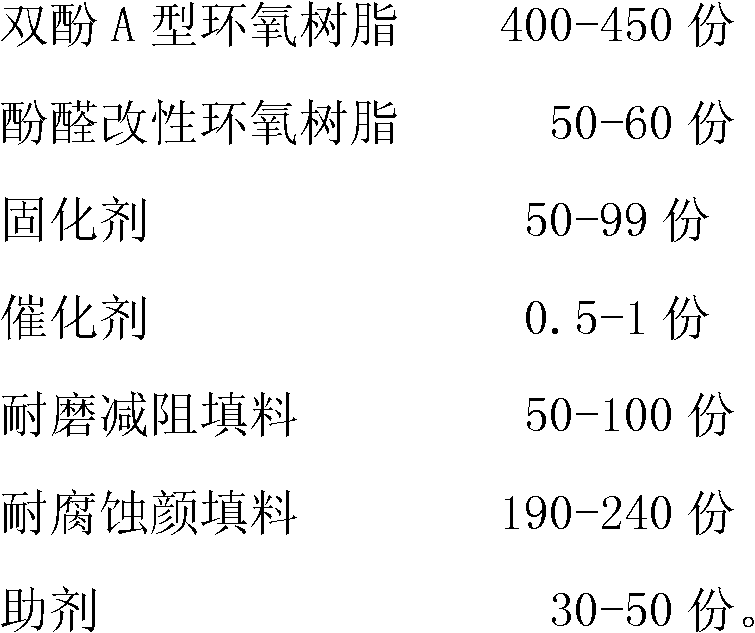

[0032] A kind of fusion-bonded epoxy powder coating special for hot roller coating of large-diameter steel pipes, the composition of its raw materials and the parts by weight are as follows:

[0033] 1. DOW D.E.R.331J bisphenol A epoxy resin 400 parts

[0034] 2. 60 parts of 704 epoxy resin

[0035] 3. 50 parts of phenolic curing agent

[0036] 4. 0.5 parts of imidazole

[0037] 5. Wear-resistant and drag-reducing filler 100 parts.

[0038] The drag-reducing filler is composed of glass micropowder and ceramic microspheres, and its weight ratio is glass micropowder:ceramic microsphere=1:1.

[0039] 6. Corrosion-resistant pigments and fillers 240 parts

[0040] The pigment and filler are composed of precipitated barium sulfate, mica powder and wollastonite, and the parts by weight are respectively:

[0041] Precipitated barium sulfate 160 parts

[0042] Mica powder 32 parts

[0043] 48 parts of wollastonite;

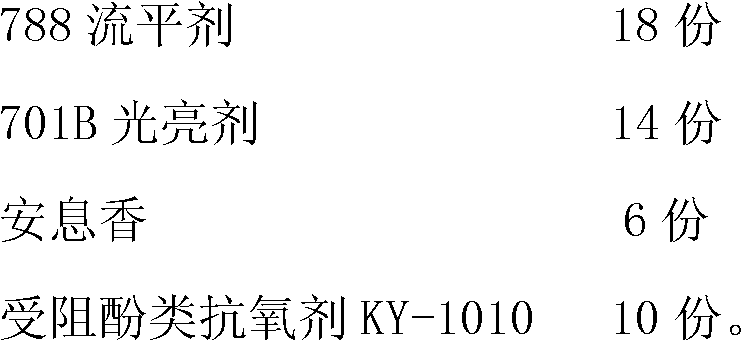

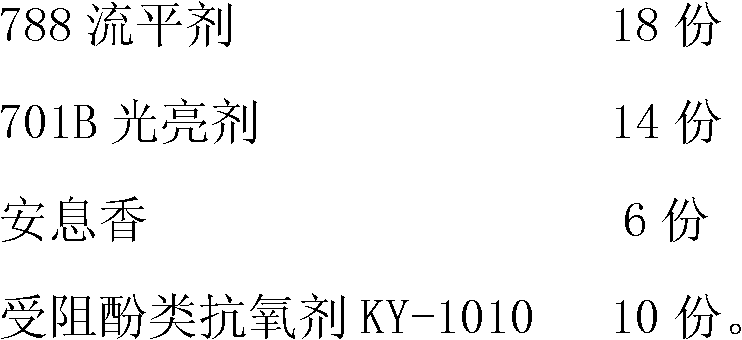

[0044] 7. 48 parts of additives

[0045] The additive is com...

Embodiment 2

[0050] A kind of fusion-bonded epoxy powder coating special for hot roller coating of large-diameter steel pipes, the composition of its raw materials and the parts by weight are as follows:

[0051] 1. DOW D.E.R.331J bisphenol A epoxy resin 450 parts

[0052] 2. 50 parts of 704 epoxy resin;

[0053] 3. 80 parts of phenolic curing agent;

[0054] 4. 1 part of imidazole;

[0055] 5. 60 parts of wear-resistant and drag-reducing filler.

[0056]The drag-reducing filler is composed of glass micropowder and ceramic microspheres, and its weight ratio is glass micropowder:ceramic microsphere=1:1.

[0057] 6. Corrosion-resistant pigments and fillers 210 parts

[0058] The pigment and filler are composed of precipitated barium sulfate, mica powder and wollastonite, and the parts by weight are respectively:

[0059] Precipitated barium sulfate 140 parts

[0060] Mica powder 28 parts

[0061] 42 parts of wollastonite;

[0062] 7. 48 parts of additives

[0063] The additive is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com