Inverse emulsion drag reduction agent for fracturing shale gas by using quick water and preparation method thereof

A technology of inverse emulsion and drag reducer, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of low solid content of drag reducer, unfavorable industrial production, complicated production process, etc., and simplify the production process , Improve structural stability and resistance reduction performance, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

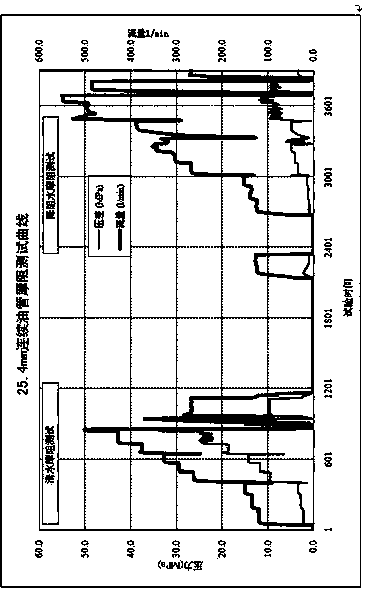

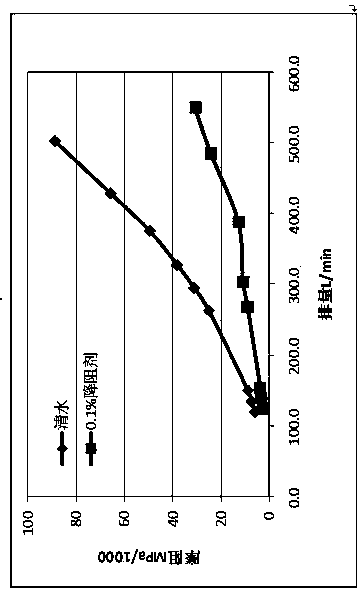

Image

Examples

Embodiment 1

[0037] Embodiment 1 (produced by 400kg)

[0038] Add 121.7kg of clear water to the reactor, add 30kg of anionic monomer acrylic acid, add 16.7kg of sodium hydroxide and a sodium hydroxide solution prepared with 25kg of clear water, adjust the pH value to about 6.5, and add 98.5kg of nonionic monomer microbial method propylene Amide, 0.3kg initiator azobisisobutylamidine hydrochloride and 1kg cosolvent sodium bicarbonate are stirred until fully dissolved to obtain an aqueous phase solution; 9kg sorbitan monooleic acid is added in 15# white oil of 90kg ester and 1kg sorbitan trioleate and 1.5kg of oil-soluble monomer lauryl methacrylate, stir evenly to obtain an oil phase; add the above-mentioned aqueous phase solution dropwise to the oil phase under continuous stirring, and add dropwise After the completion of high-speed emulsification for 30 minutes to obtain a stable inverse emulsion system; dissolve 0.3 kg of sodium bisulfite with 5 kg of clear water, and add the aqueous s...

Embodiment 2

[0039] Embodiment 2 (produced by 400kg)

[0040]Add 121.6kg of clear water to the reaction kettle, add 32kg of anionic monomer acrylic acid, add 17.8kg of sodium hydroxide and 25kg of clear water to prepare the sodium hydroxide solution, adjust the pH value to about 6.5, add 96kg of non-ionic monomer microbial method acrylamide , 0.15kg initiator azobisisobutylamidine hydrochloride and 1kg cosolvent sodium bicarbonate, stir until fully dissolved to obtain an aqueous phase solution; add 9kg sorbitan monooleate in 15# white oil of 90kg and 1kg of sorbitan trioleate and 2kg of oil-soluble monomer lauryl methacrylate, stir to obtain an oil phase; the above-mentioned aqueous phase solution is added dropwise to the oil phase under continuous stirring, and after the addition is completed, High-speed emulsification for 30 minutes to obtain a stable inverse emulsion system; dissolve 0.45 kg of sodium bisulfite in 5 kg of clear water, and add the aqueous solution of sodium bisulfite d...

Embodiment 3

[0041] Embodiment 3 (produced by 400kg)

[0042] Add 116.6kg of clear water to the reaction kettle, add 35kg of anionic monomer acrylic acid, add 19.5kg of sodium hydroxide and 25kg of clear water to prepare the sodium hydroxide solution, adjust the pH value to about 6.5, add 95kg of non-ionic monomer microbial method acrylamide , 0.3kg initiator azobisisobutylamidine hydrochloride and 1kg cosolvent sodium bicarbonate, stir until fully dissolved to obtain an aqueous phase solution; add 8.5kg sorbitan monooleic acid in 15# white oil of 90kg ester and 1.5kg sorbitan trioleate and 2kg of oil-soluble monomer lauryl methacrylate, stir evenly to obtain an oil phase; add the above-mentioned aqueous phase solution dropwise to the oil phase under continuous stirring, and add dropwise After the completion of high-speed emulsification for 30 minutes to obtain a stable inverse emulsion system; dissolve 0.6 kg of sodium bisulfite with 5 kg of clear water, and add the aqueous solution of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com