Patents

Literature

795results about How to "Short production time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nano artificial dura mater with multi functional-layers and preparation method thereof

ActiveCN101507661AReliable strengthGood flexibilityFilament/thread formingProsthesisHydrophobic polymerDura mater

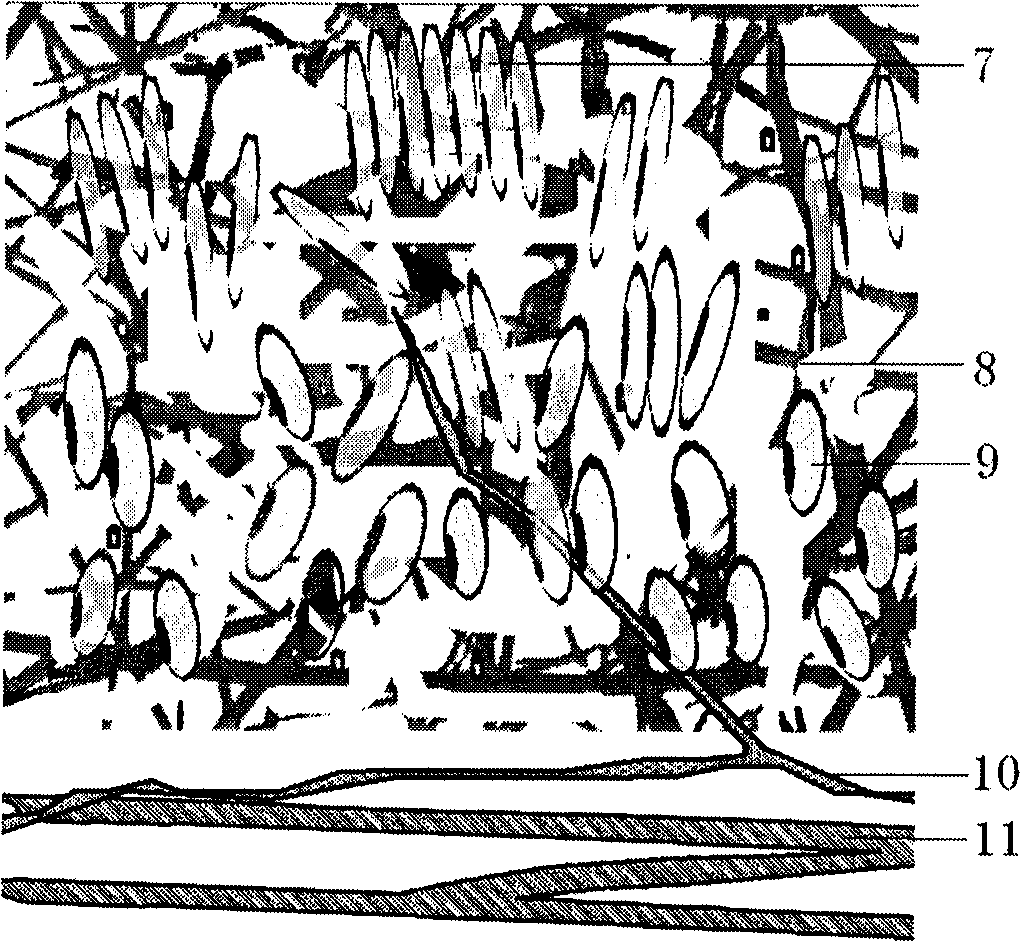

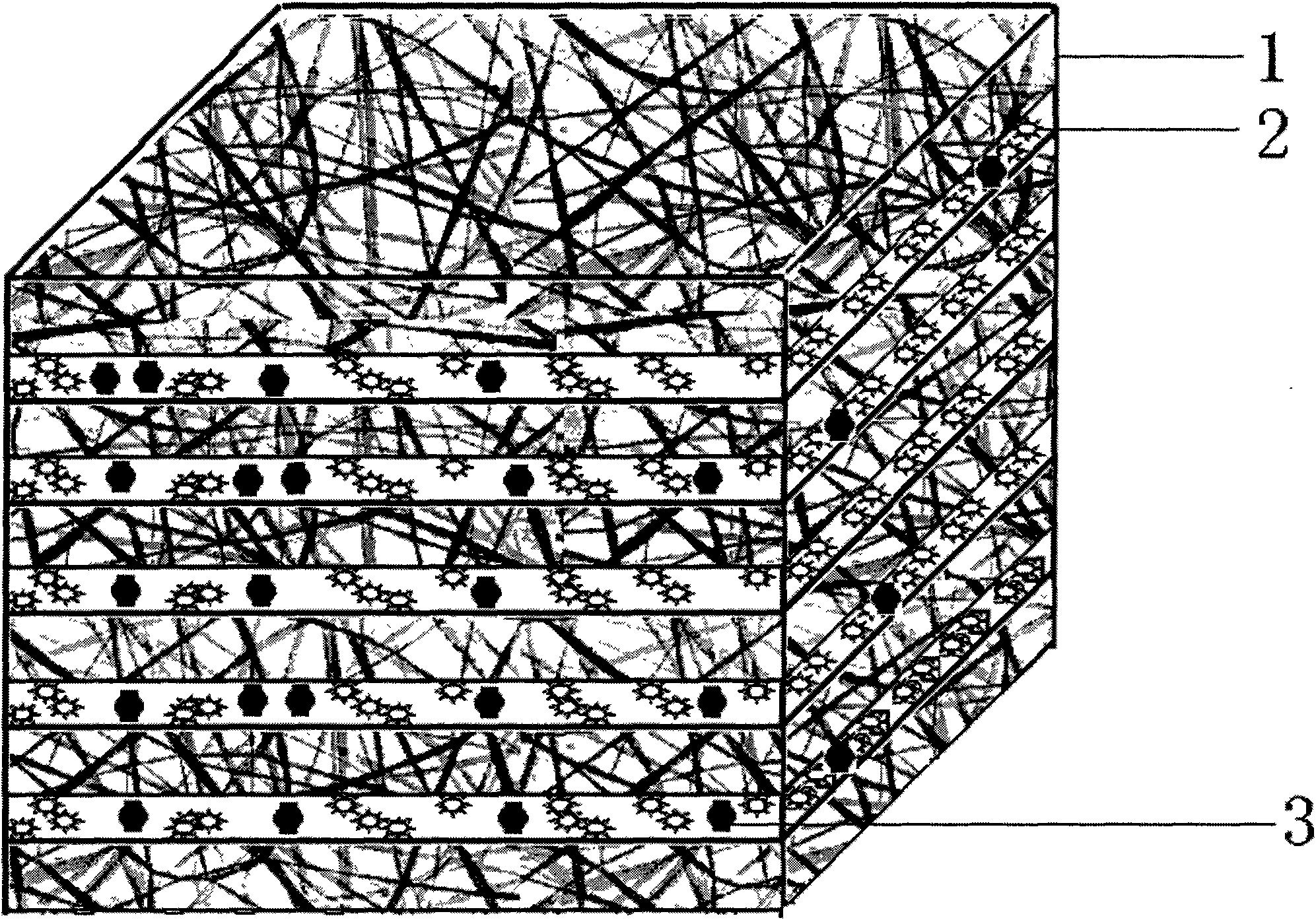

The invention provides a nano artificial dura mater with a plurality of functional layers, which comprises a structure with at least two layers; the layer facing the brain is a hydrophobic anti-adhesion electrospun layer; and the layer back to the brain is a hydrophilic nano cytoskeletal layer. The invention also provides a method for preparing the nano artificial dura mater, which comprises the following steps: preparing an electrospun solution of a hydrophobic polymer; preparing an electrospun solution of a hydrophilic polymer; preparing the prepared electrospun solution of the hydrophobic polymer into the hydrophobic anti-adhesion electrospun layer through static spinning; and preparing the hydrophilic nano cytoskeletal layer on the anti-adhesion electrospun layer from the prepared electrospun solution of the hydrophilic polymer through static spinning, receiving a membrane structure, and obtaining the nano artificial dura mater. The mechanical features of the nano artificial dura mater can meet the requirements on tensile strength and flexibility of adaptation diseases; and the nano artificial dura mater can be freely cut as required, and has wide application prospect.

Owner:MEDPRIN REGENERATIVE MEDICAL TECH

Chromium-free zinc aluminum anticorrosive paint and preparation method

InactiveCN101899254AReduce microcracksImprove adhesionAnti-corrosive paintsEpoxy resin coatingsChromium freeOrganic solvent

The invention relates to a chromium-free zinc aluminum anticorrosive paint and a preparation method. The invention adopts the technical scheme that the preparation method comprises the following steps of: stirring 5 to 25 weight percent of flake zinc powder and 5 to 15 weight percent of flake aluminum powder uniformly, adding 25 to 40 weight percent of organic solvent, 1.1 to 1.8 weight percent of dispersant, 3 to 8 weight percent of corrosion inhibitor and 3 to 10 weight percent of inorganic additive into the powder, and stirring the mixture for 20 to 40 minutes to form a base material; and then stirring 5 to 15 weight percent of modified resin, 1 to 3 weight percent of organic silane coupling agent and 25 to 30 weight percent of organic solvent uniformly, and adding the mixture into the base material; or stirring the mixture for 30 to 50 minutes to obtain the chromium-free zinc aluminum anticorrosive paint; or stirring the mixture for 30 to 50 minutes, adding 0.05 to 0.5 weight percent of hydroxyethyl cellulose into the mixture, and stirring the mixture for 20 to 50 minutes to obtain the chromium-free zinc aluminum anticorrosive paint. The preparation method has the characteristics of environment friendliness, low energy consumption and low cost; and a coating coated by the prepared chromium-free zinc aluminum anticorrosive paint has high impact strength, good corrosion resistance, strong bonding force and high hardness.

Owner:襄阳普士利工程器材有限公司 +1

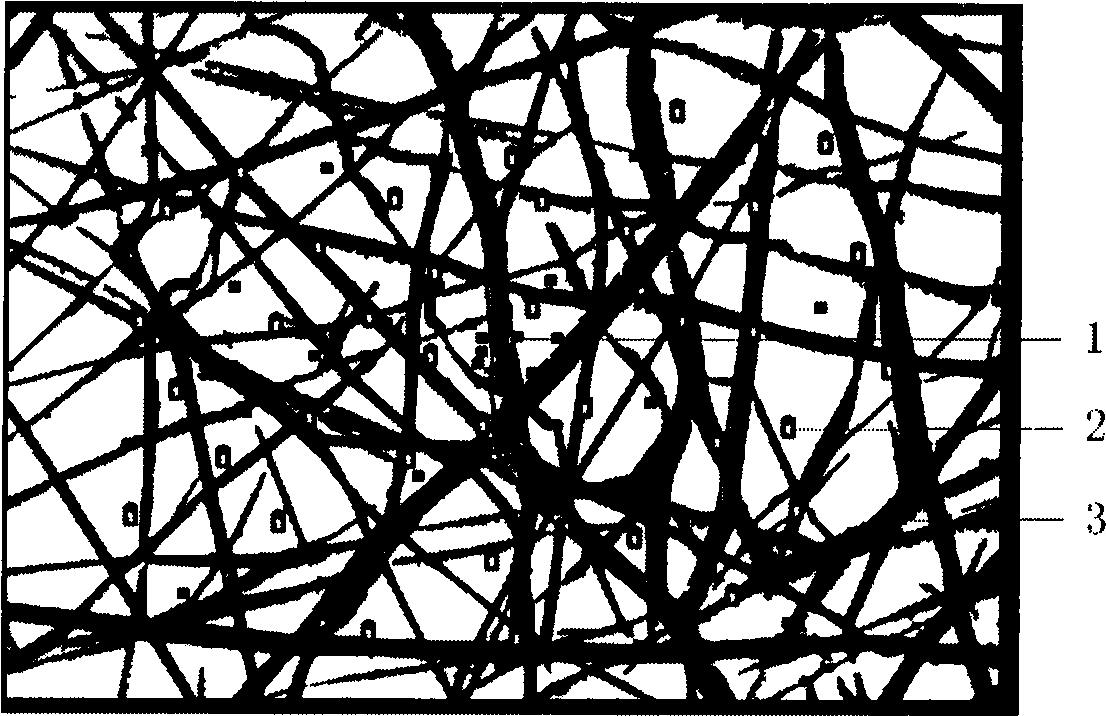

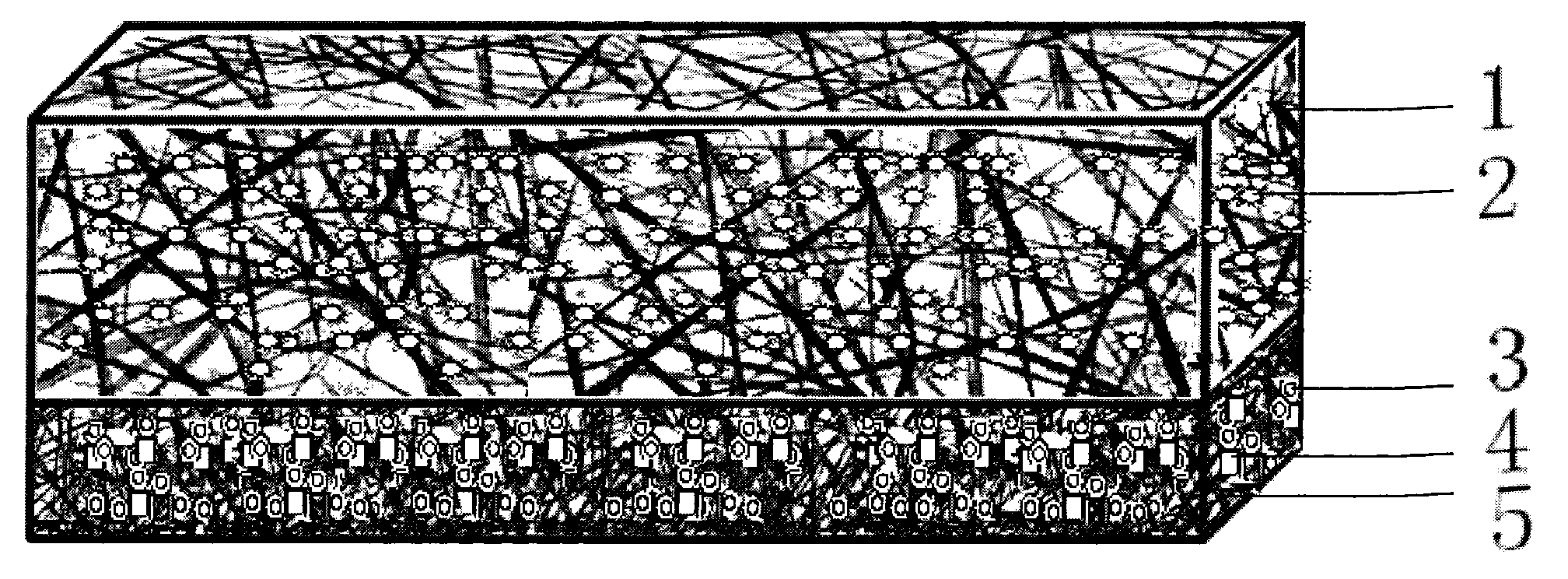

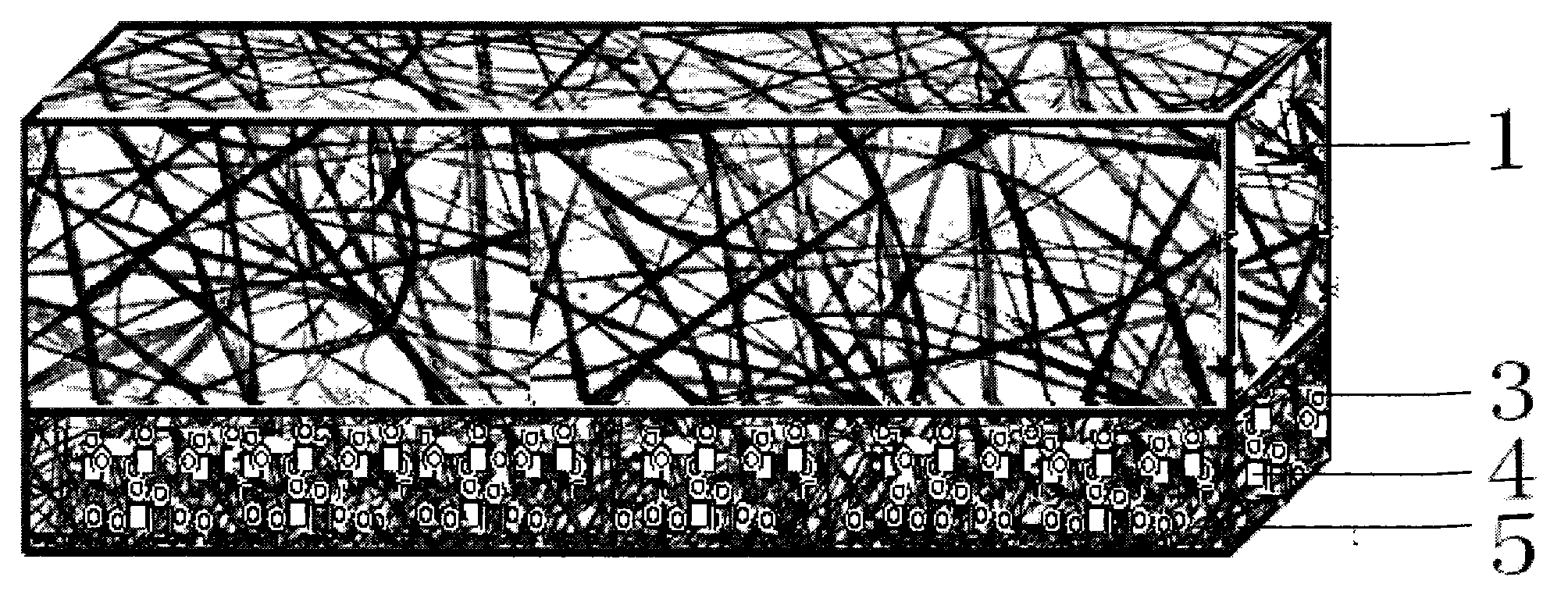

Medical anti-sticking membrane and preparation method thereof

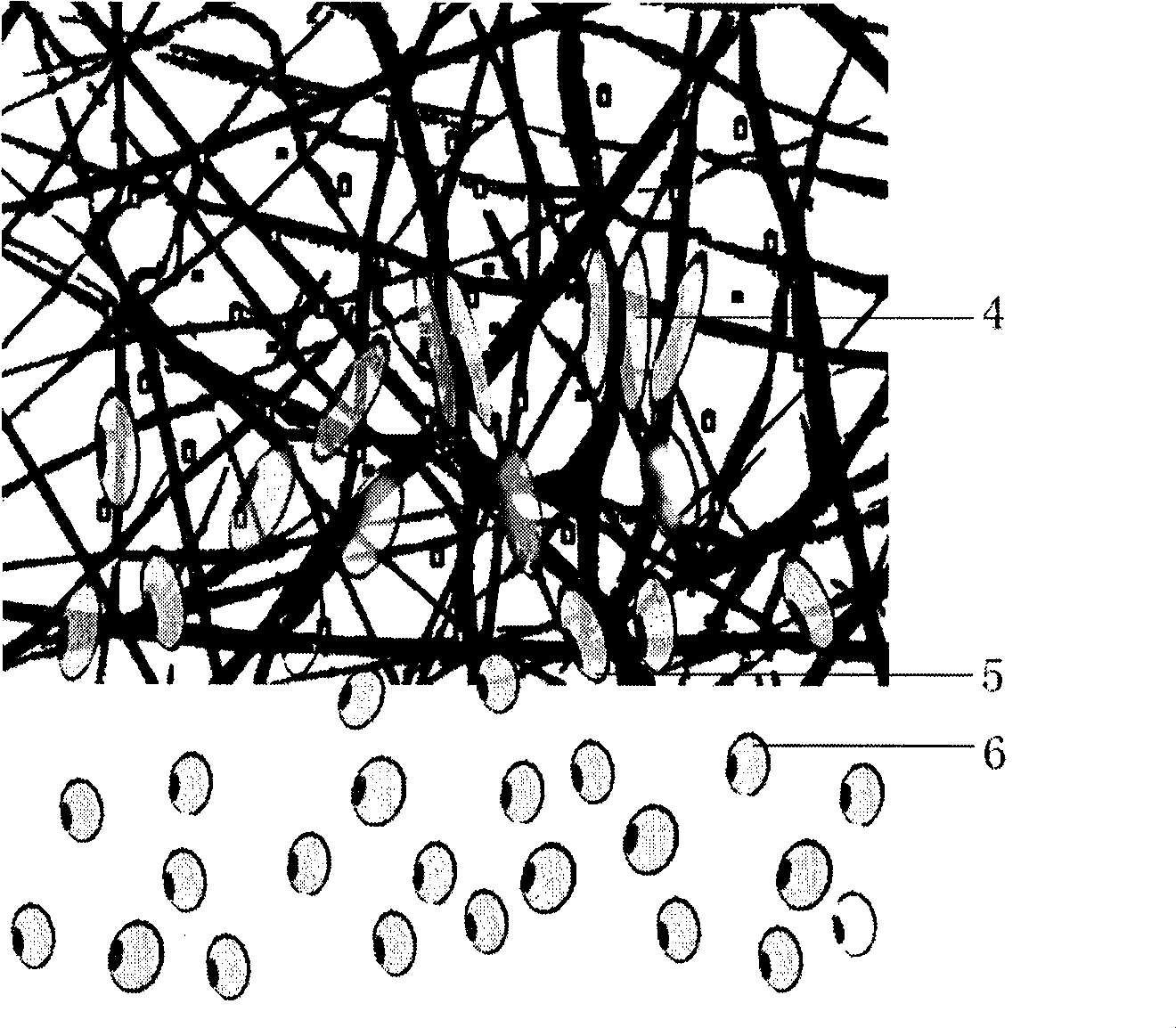

The invention provides a medical anti-sticking membrane and a preparation method thereof. The anti-sticking membrane comprises a nanometer frame and hydrosol attached thereon. The hydrosol is internally packed with one or several kinds of styptic medicament or / and anti-sticking medicament. The invention also provides a preparation method of the anti-sticking membrane, comprising the following steps of: preparing electro-spinning solution, styptic medicament and / or anti-sticking medicament-containing hydrosol solution and crosslinker solution; receiving static spinning with the crosslinker solution to obtain the nanometer frame; printing the styptic medicament and / or anti-sticking medicament-containing hydrosol solution onto the nanometer frame by an ink-jet printer, and solidifying the hydrosol solution to obtain the anti-sticking membrane. The anti-sticking membrane has good capability and biological compatibility, and nontoxicity as well as nonirritant, can be completely degraded and absorbed, is compounded with controllably released styptic medicament or / and anti-sticking medicament, has controllable degrading time and speed, and conquers defects of the prior art.

Owner:MEDPRIN REGENERATIVE MEDICAL TECH

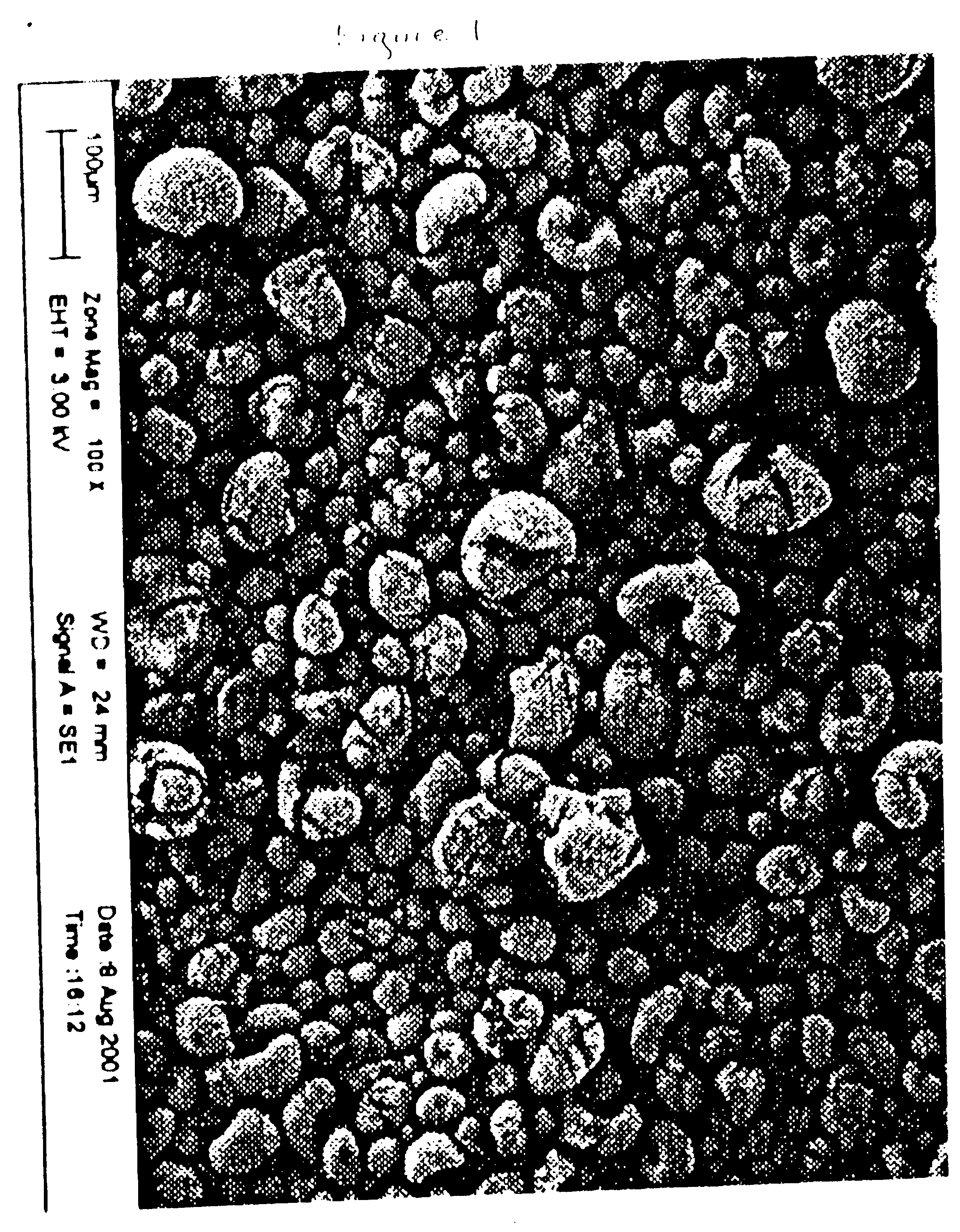

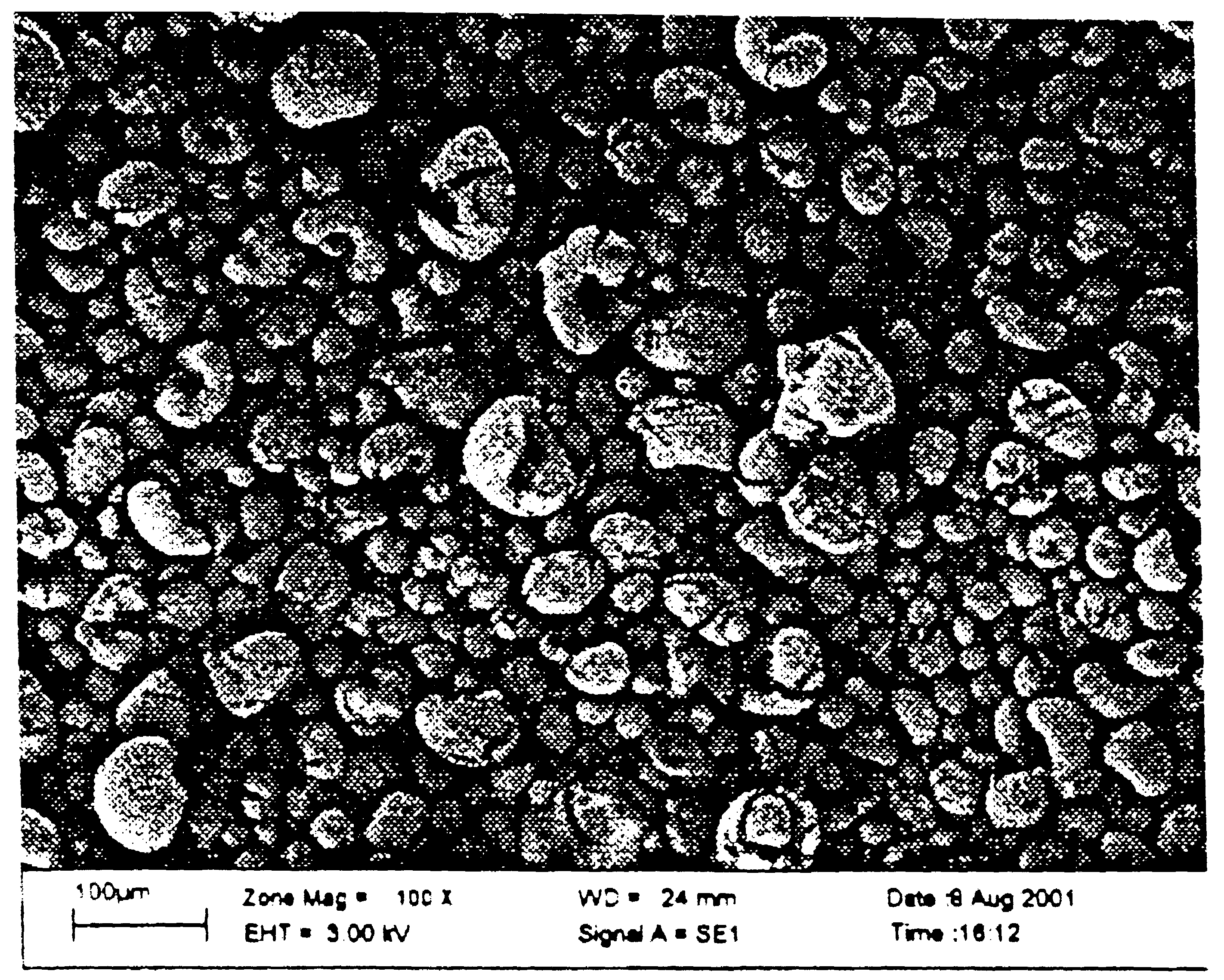

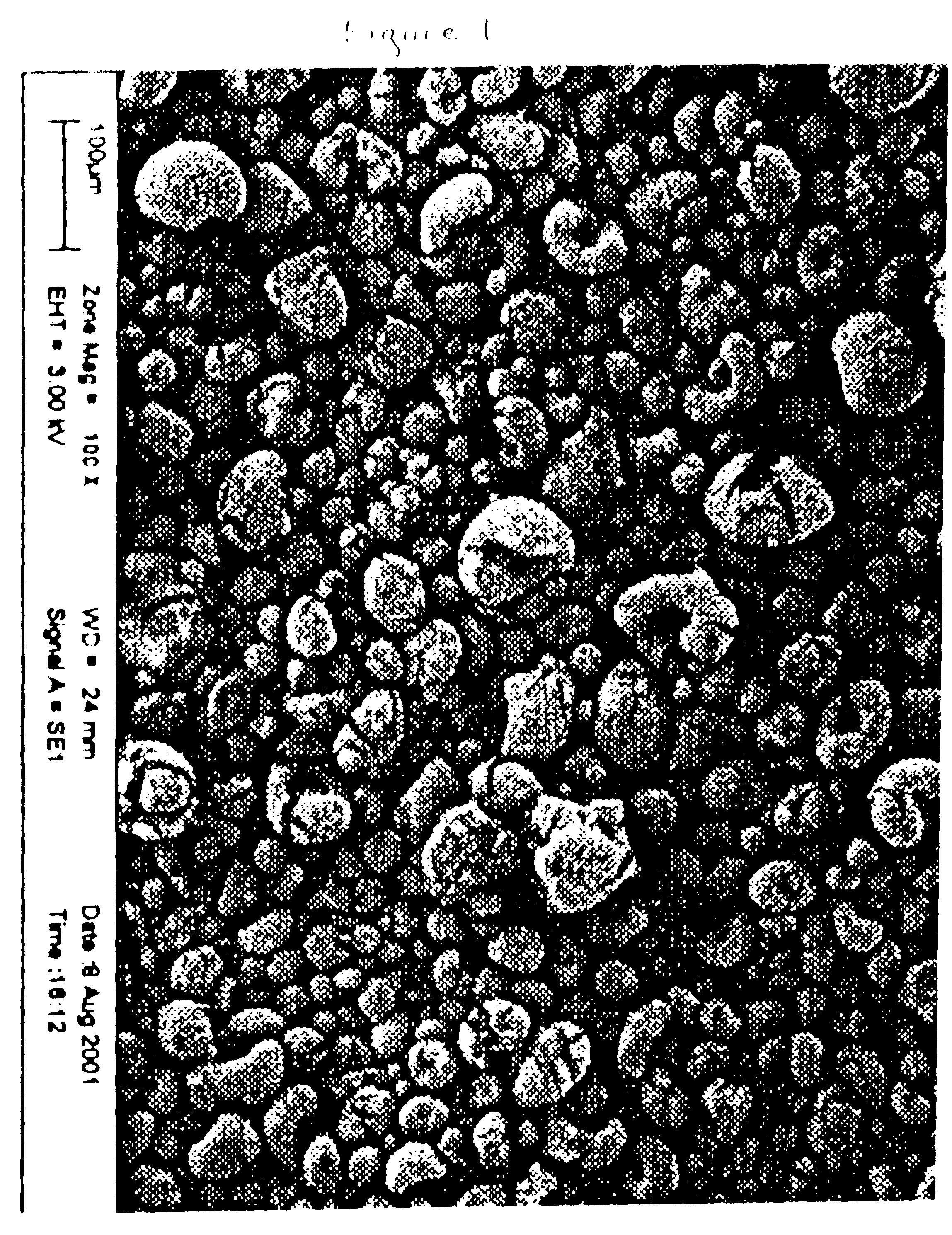

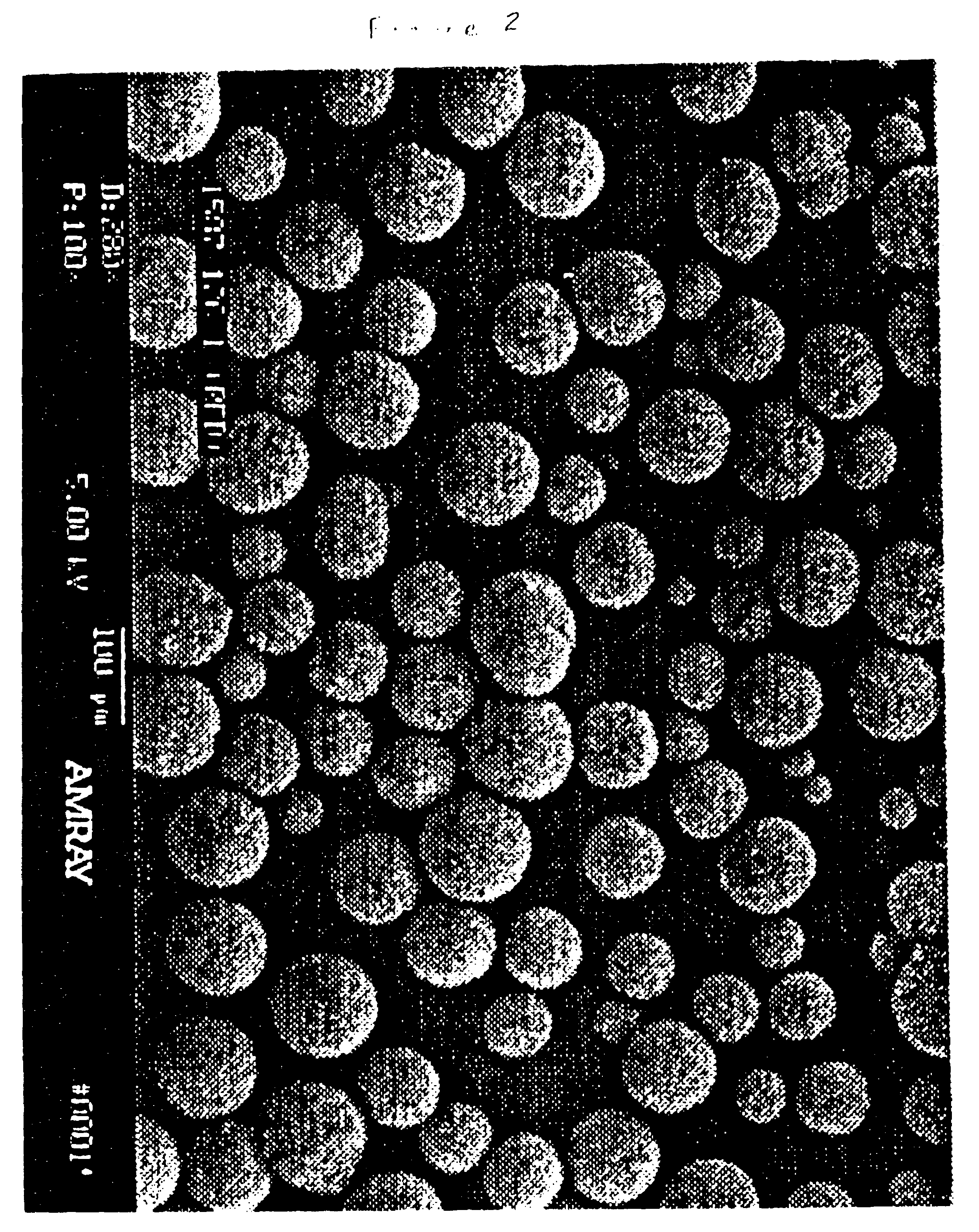

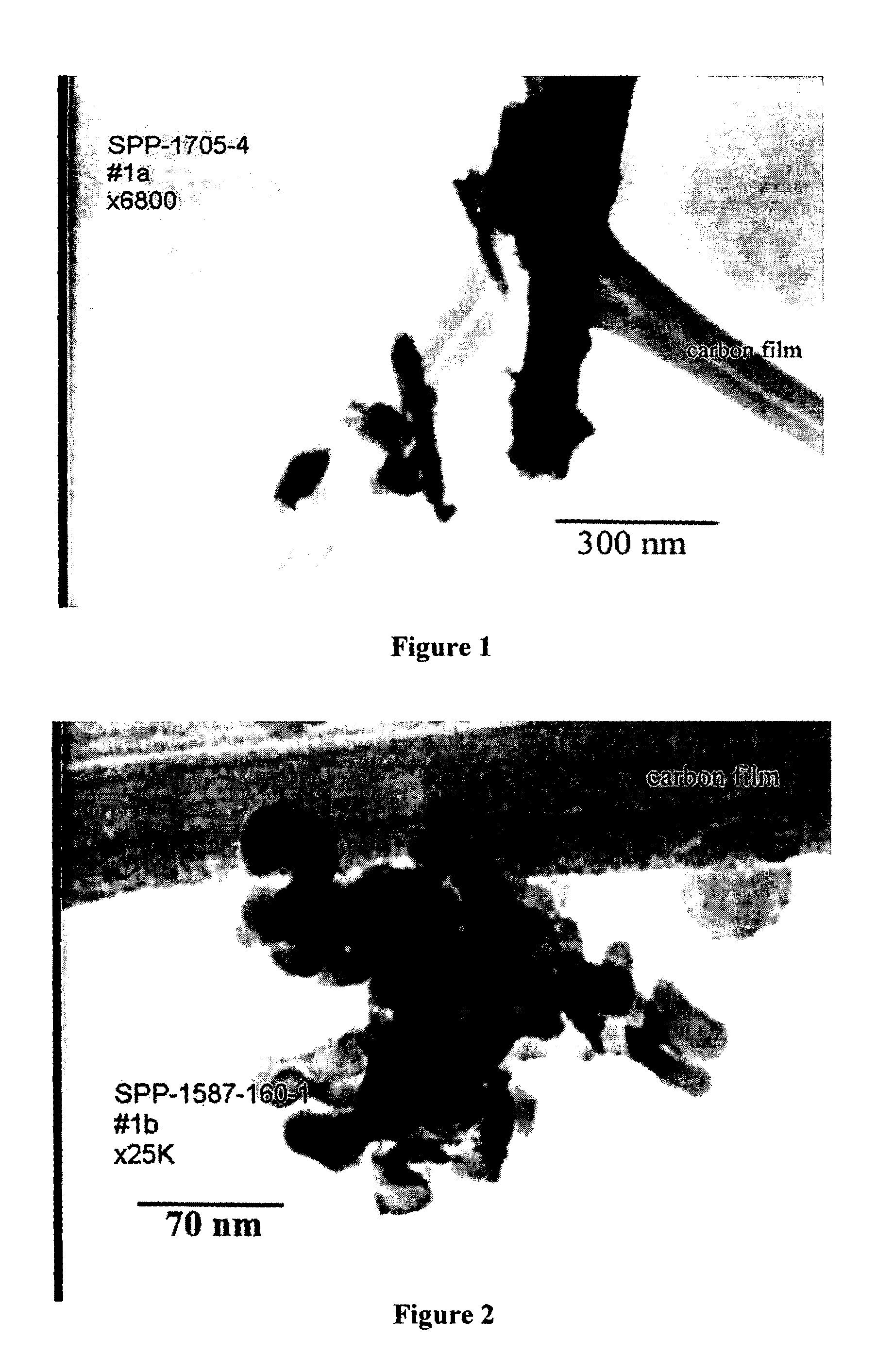

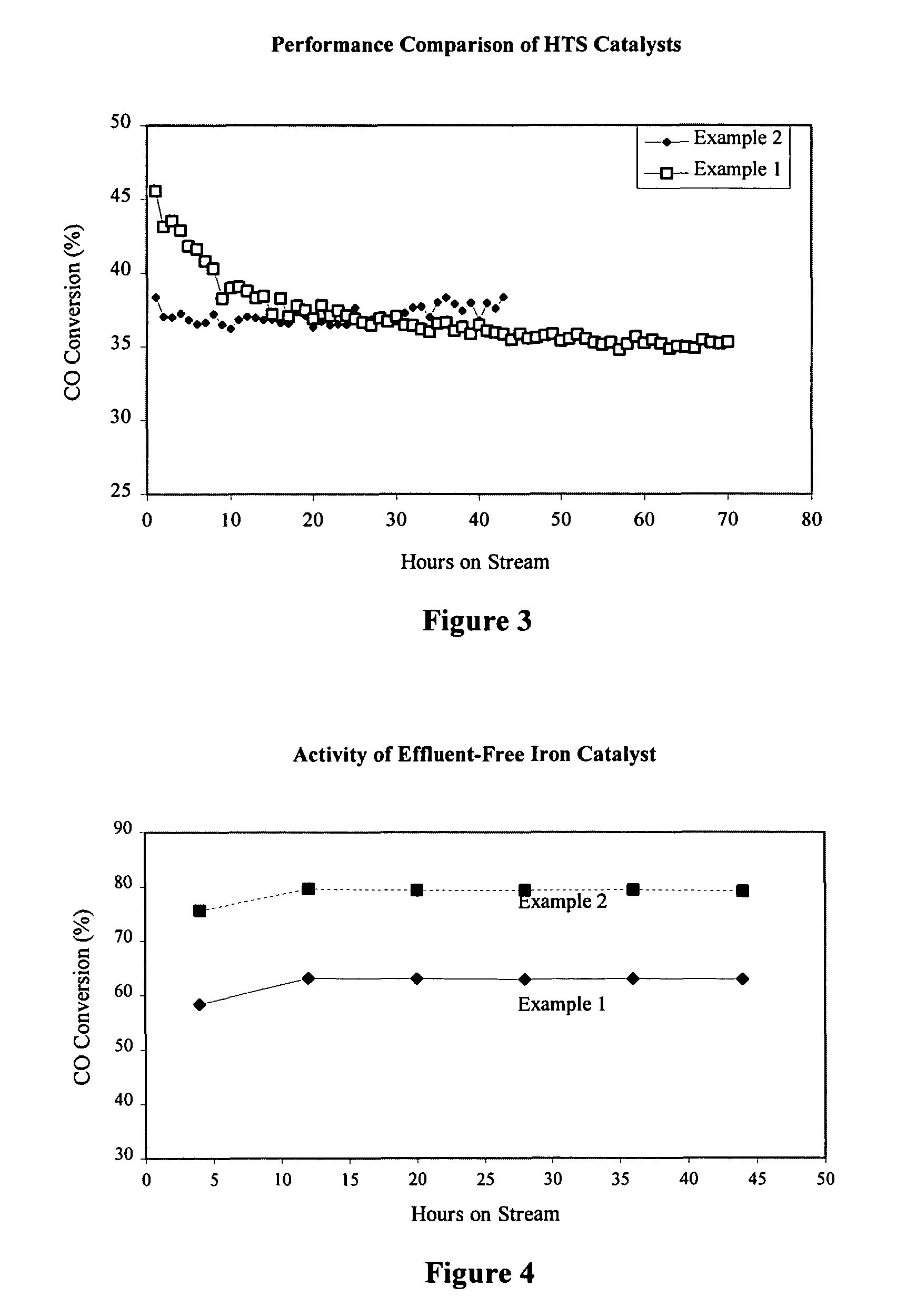

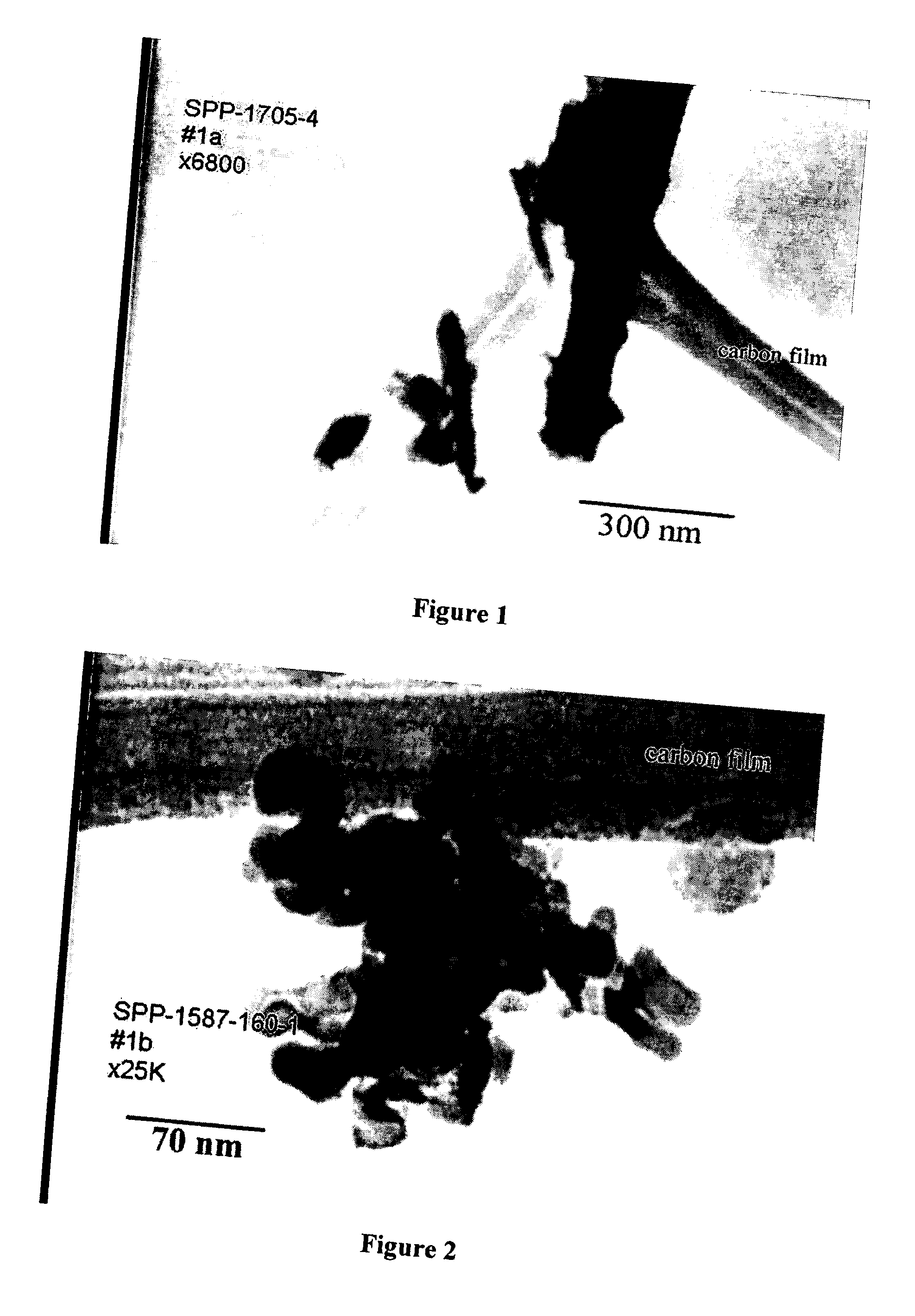

Fischer-tropsch catalyst prepared with a high purity iron precursor

InactiveUS20040009871A1Reduce the amount requiredShort production timeOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPtru catalystMetallurgy

A Fischer-Tropsch catalyst comprising iron and at least one promoter is prepared via a method which comprises the preparation of a high purity iron precursor and which uses a nominal amount of water in the catalyst production. The catalyst particles prepared with the high purity iron precursor have an essentially spherical particle shape, a relatively narrow particle size distribution range, and a high surface area.

Owner:SUED CHEM IP GMBH & CO KG

Nano bionic wound-surface cover and preparation method thereof

ActiveCN101507835AAddress barriers to developmentAvoid inconvenienceProsthesisElectrospinningEngineering

The invention provides a nanometer bionic wound-surface cover and a preparation method thereof. The nanometer bionic wound-surface cover comprises a nanometer bionic bracket and hydrosol attached to the bracket, wherein the hydrosol covers one or a plurality of cytokines. The preparation method for the nanometer bionic wound-surface cover provided by the invention comprises the steps of preparingan electrostatic-spinning solution, a cytokine-containing hydrosol solution and a crosslinker solution, preparing the nanometer bionic bracket by use of electrostatic spinning, using an ink-jet printer to print the cytokine-containing hydrosol solution onto the nanometer bionic bracket, and the like, wherein electrostatic spinning and printing can be repeated so as to form the wound-surface covers different in thickness. The preparation method adopts an in-situ autologous stem-cell engineering technique and adopts stem-cell chemotactic factors to attract autologous stem cells to directionally migrate, enter a wound surface and be differentiated according to designed requirements, thereby avoiding inconvenience caused by using viable cells, achieving rehabilitation effects the same with orbetter than that of using the viable cells and having broad application prospects.

Owner:MEDPRIN REGENERATIVE MEDICAL TECH

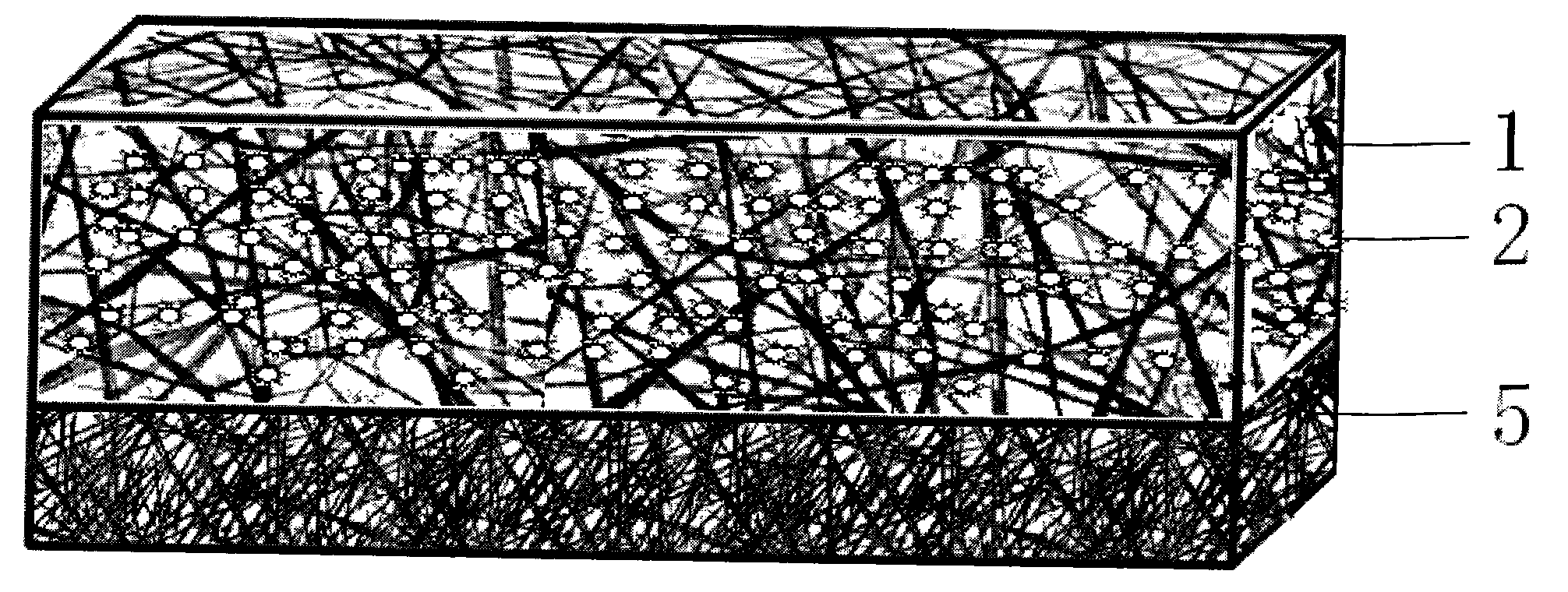

Artificial articular cartilage based on autologous cells and preparation method thereof

ActiveCN101574543AImprove mechanical propertiesAvoid inconvenienceJoint implantsElectrospinningHYDROSOL

The invention provides artificial articular cartilage based on autologous cells and a preparation method thereof. The artificial articular cartilage comprises a nano bionic support and hydrosol adhered to the nano bionic support, wherein one or more cytokines are coated into the hydrosol. The invention also provides the method for preparing the artificial articular cartilage, which comprises the following steps: preparing an electrostatic spinning solution, a cytokine-containing hydrosol solution and a crosslinking agent solution; using the crosslinking agent solution to receive electrostatic spinning so as to prepare the nano bionic support; and using an ink jet printer to print the cytokine-containing hydrosol solution on the nano bionic support, and curing the hydrosol to obtain the artificial articular cartilage. The three-dimensional support adopted by the invention has ideal degradation speed and is degraded after the regeneration of an articular cartilage layer, can meet the requirement of actual clinical application, can be completely degraded, and has good abrasion resistance and lubricity so as to be capable of replacing the cartilage before the regeneration of the articular cartilage layer.

Owner:MEDPRIN REGENERATIVE MEDICAL TECH

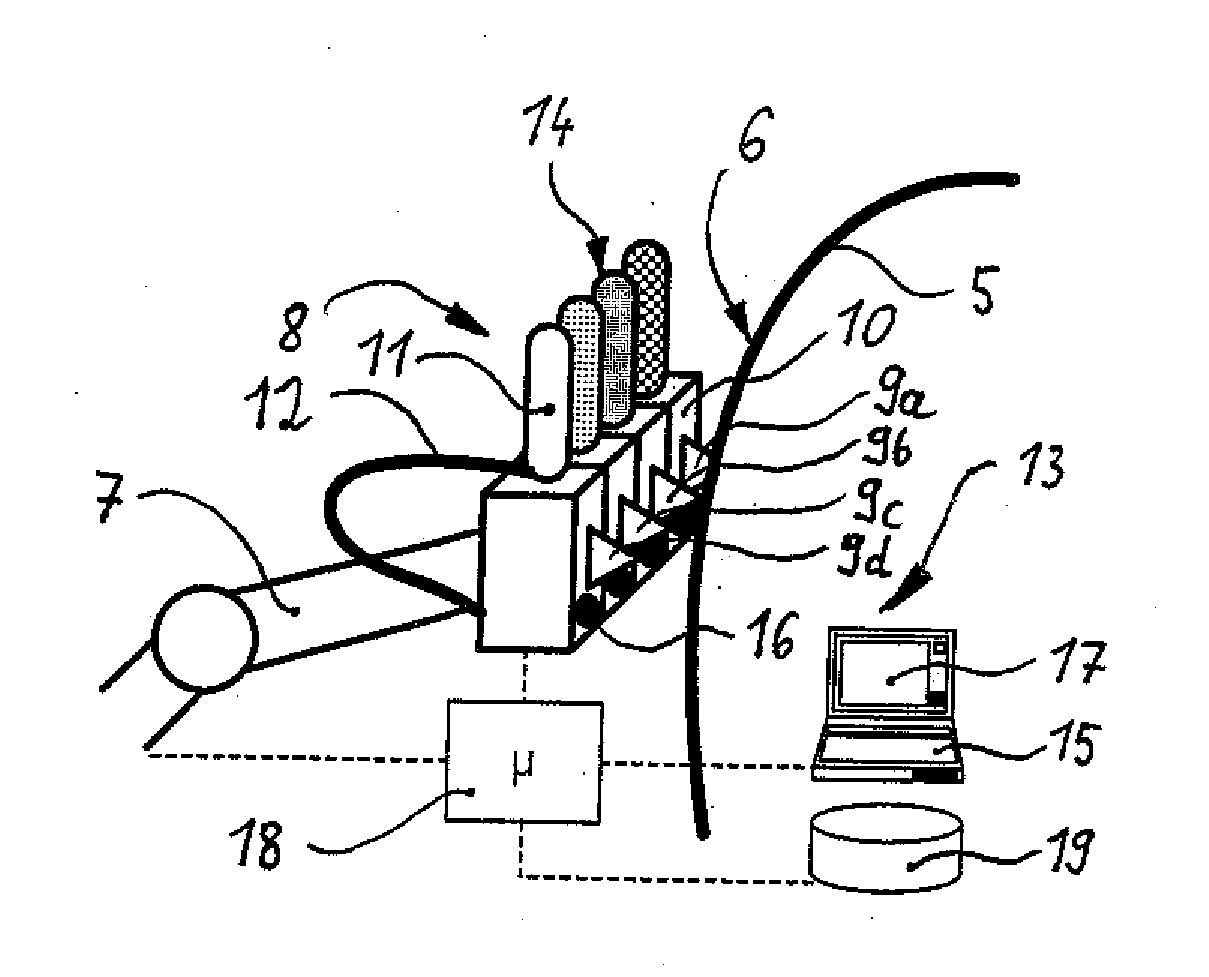

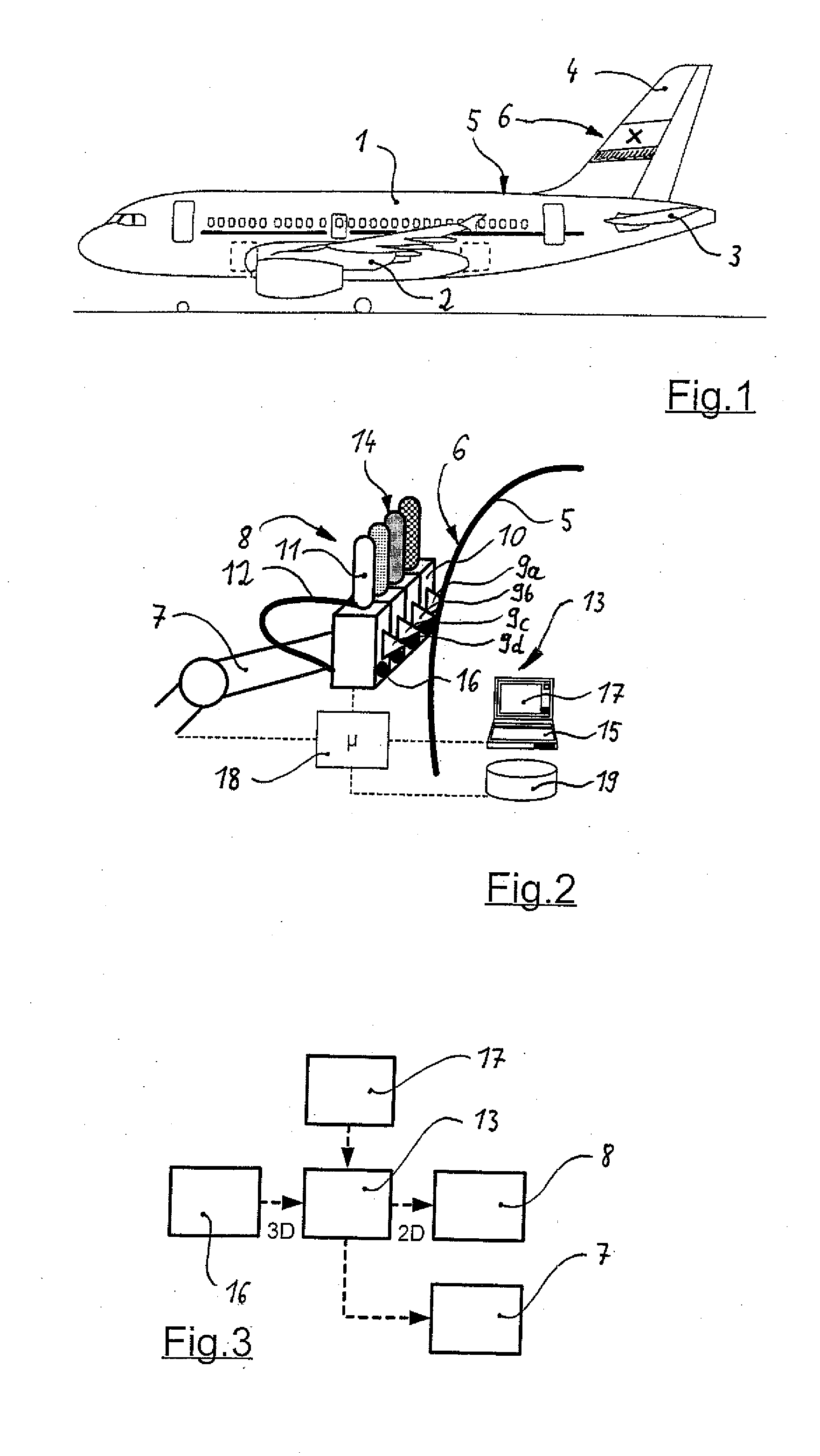

Device and method for painting curved outer surfaces of an aircraft

ActiveUS20100304009A1Durably applyShort production timeProgramme controlLiquid surface applicatorsEngineeringAirplane

A device for painting a curved outer surface of an aircraft includes a paint applicator having a plurality of spray painting heads each assigned to one of a plurality of different base color supply units containing one of polyurethane aircraft paint and ink. The device further includes a spatially adjustable positioning device configured to move the paint applicator relative to the curved outer surface and at least one sensor device configured to determine a three-dimensional geometry of the curved outer surface. The device also includes a control unit configured to coordinate a movement of the positioning device with a paint output of the paint applicator, wherein the control unit is configured to alternately activate each of the plurality of spray painting heads so as to produce a picture motif so as to derive a two-dimensional driving geometry based on the three-dimensional geometry.

Owner:AIRBUS OPERATIONS GMBH

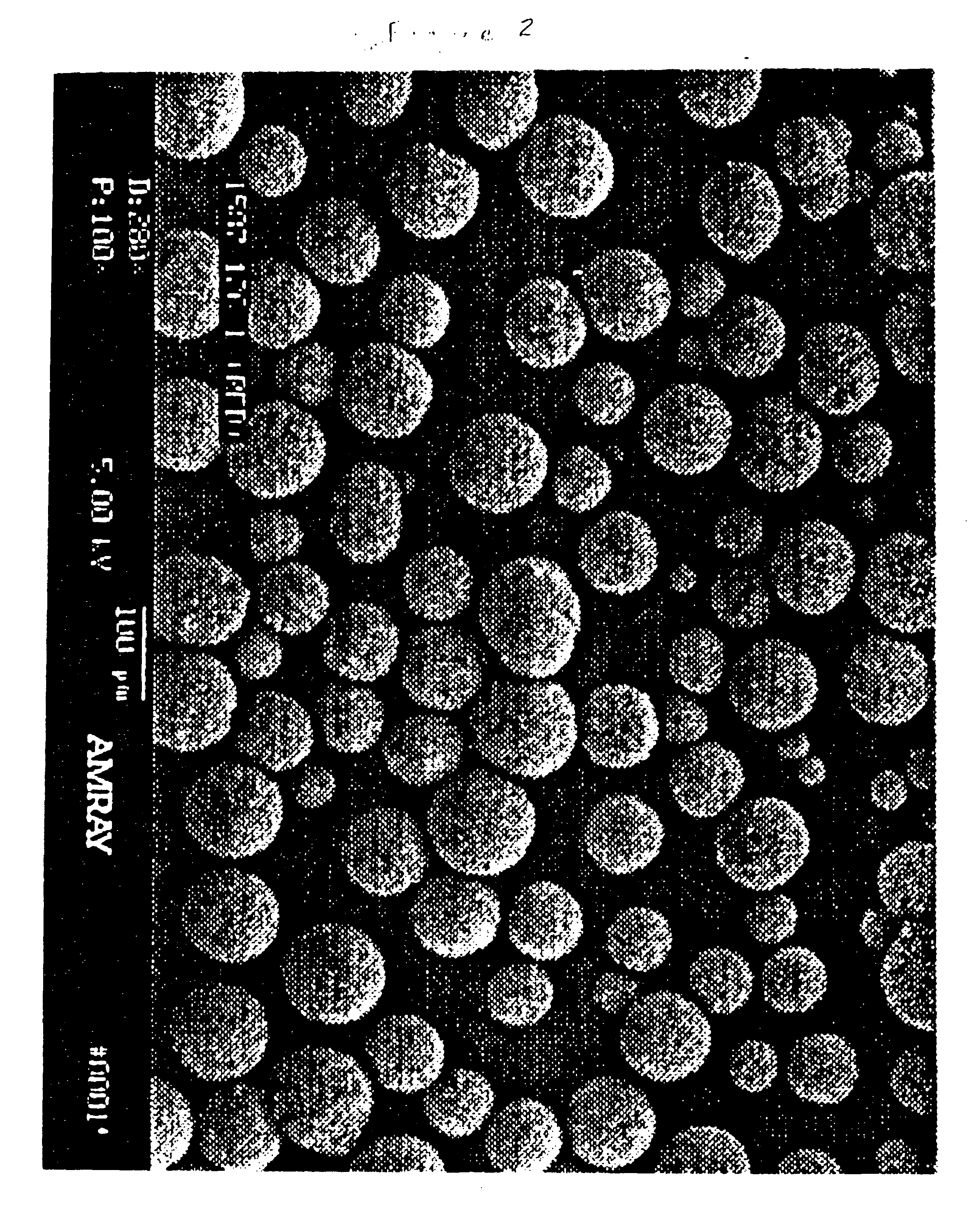

Fischer-tropsch catalyst prepared with a high purity iron precursor

InactiveUS7199077B2Reduce the amount requiredShort production timeOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationHigh surface areaSpherical form

A Fischer-Tropsch catalyst comprising iron and at least one promoter is prepared via a method which comprises the preparation of a high purity iron precursor and which uses a nominal amount of water in the catalyst production. The catalyst particles prepared with the high purity iron precursor have an essentially spherical particle shape, a relatively narrow particle size distribution range, and a high surface area.

Owner:SUED CHEM IP GMBH & CO KG

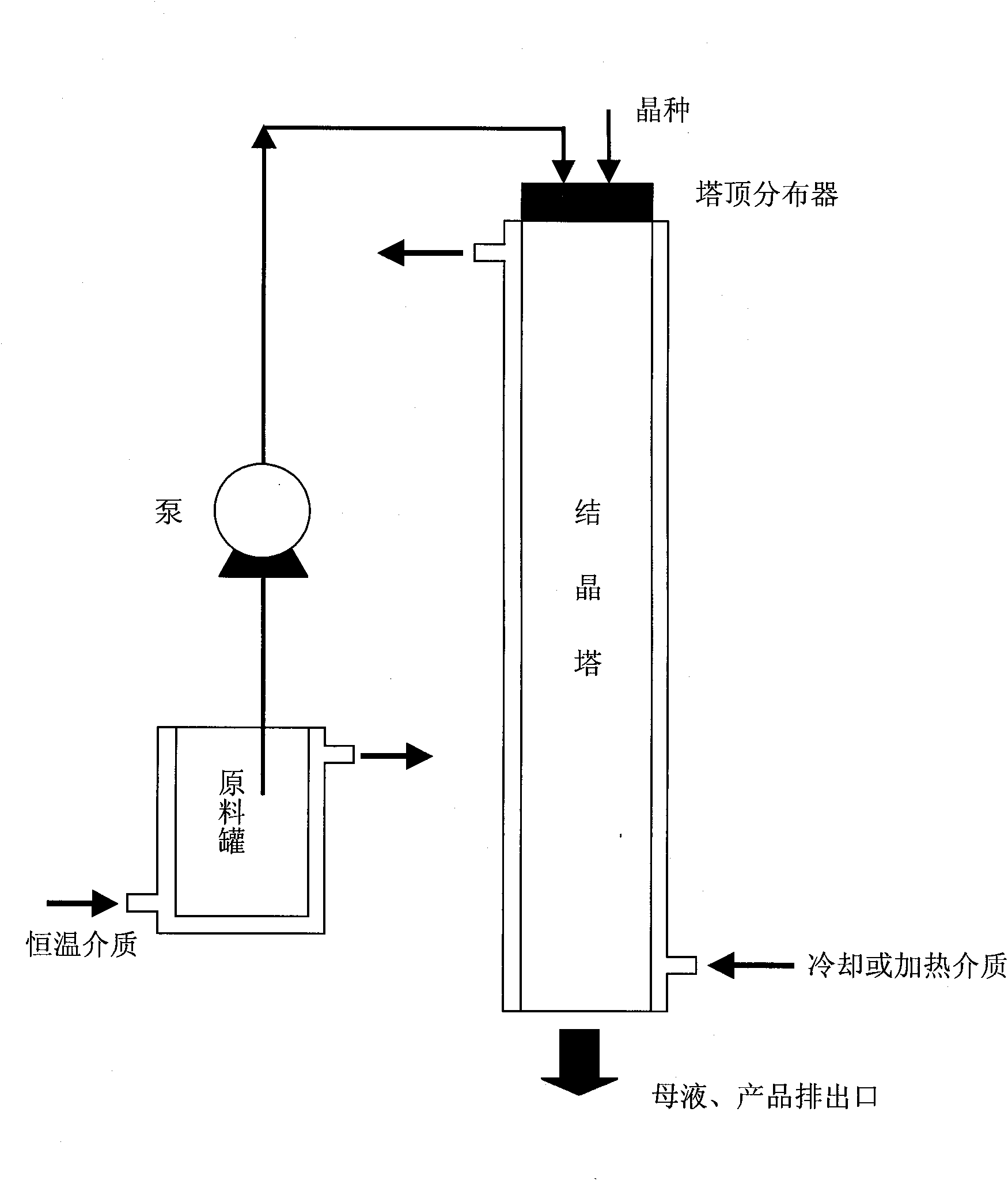

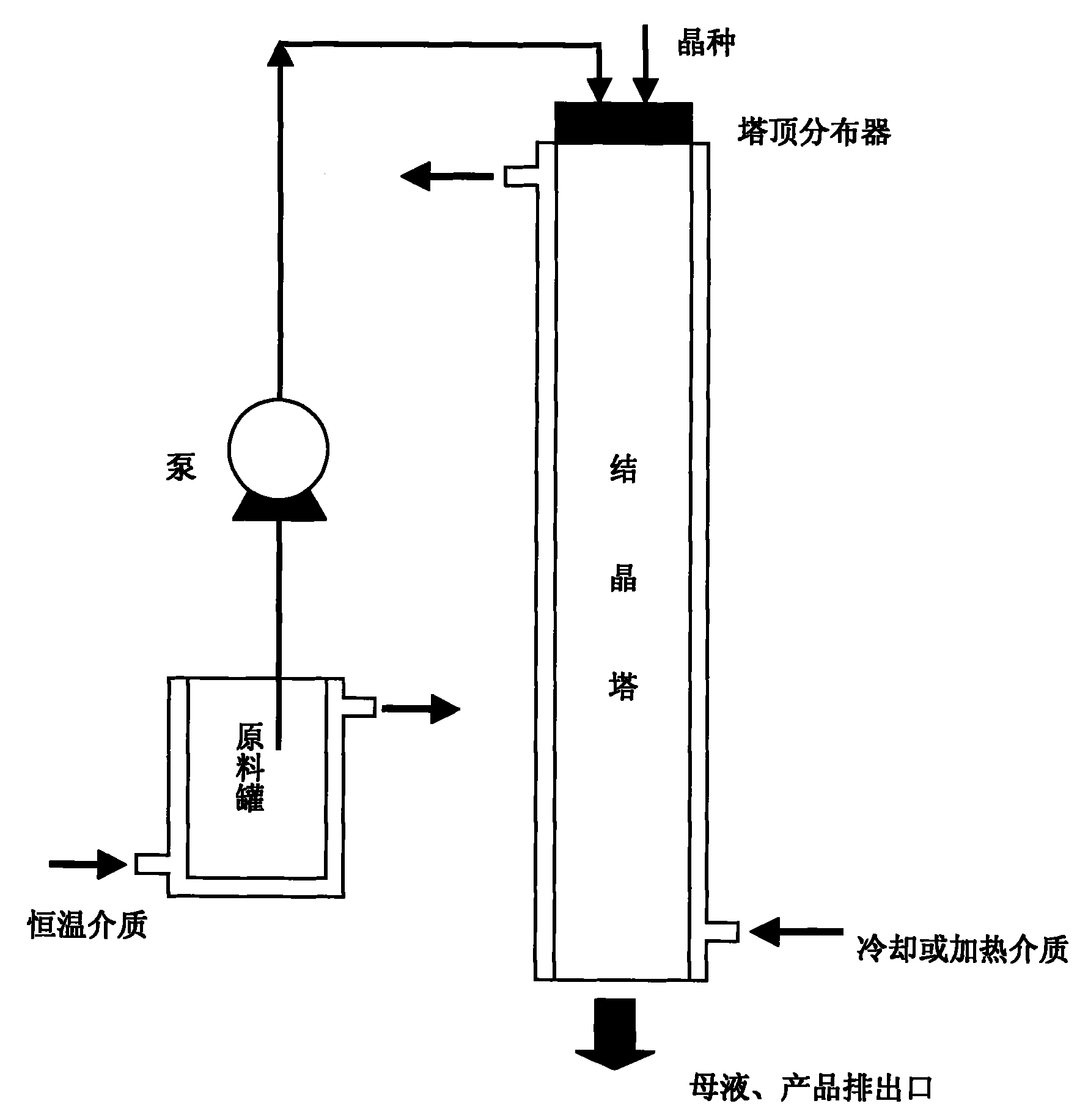

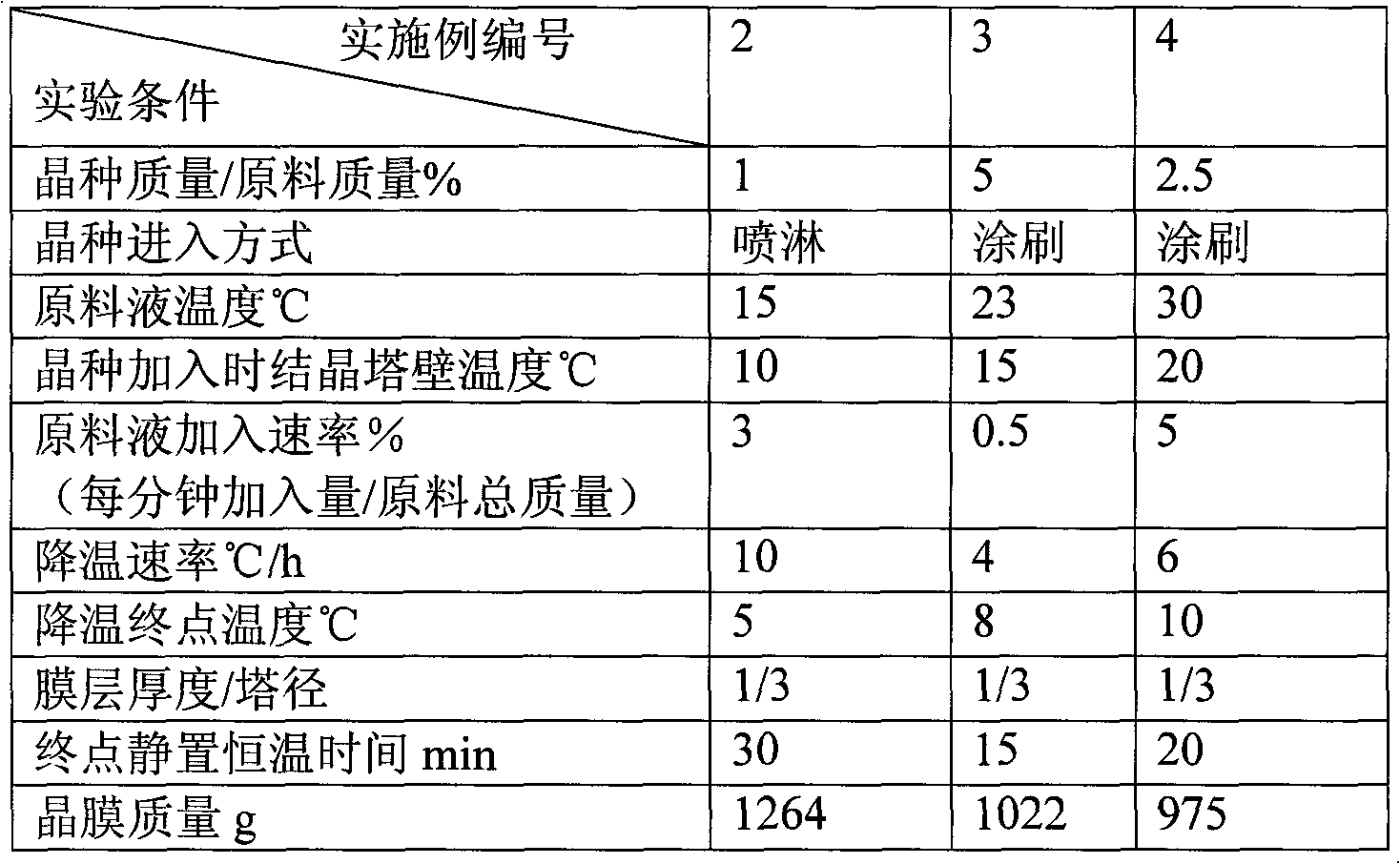

Method for preparing electronic grade phosphoric acid through liquid membrane crystallization

The invention relates to a method for preparing electronic grade phosphoric acid through liquid membrane crystallization. The method comprises the following steps: slowly pouring seed crystals which are prepared in advance, in a column crystallizer, wherein the temperature of the wall of the column crystallizer is controlled to 10-20 DEG C; (2) adding liquid phosphoric acid in the column crystallizer form the top of the crystallizer while using cooling medium in the jacket of the column crystallizer to reduce the temperature of the column crystallizer to 5-10 DEG C, wherein raw material crystallizes and grows on the seed crystals to form a crystal film and uncrystallized liquid flows out from the bottom of the column crystallizer; stopping adding materials when the thickness of the crystal film is 1 / 4-1 / 3 of the diameter of the column crystallizer, keeping temperature for 15-30min to discharge feed liquid which does not form film; heating the column crystallizer to 15-29 DEG C and keeping temperature for 0.5-2h so as to melt the film layer, collecting the discharged liquid as a product; and (4) repeating the step (1), (2) and (3) by using the obtained product as raw material to perform secondary liquid film crystallization and obtaining the electronic grade phosphoric acid product. The method has simple operation, short production time, low energy consumption and high impurity removal rate, and the electronic grade phosphoric acid product with a concentration of 87-90% can be directly obtained.

Owner:TIANJIN UNIV

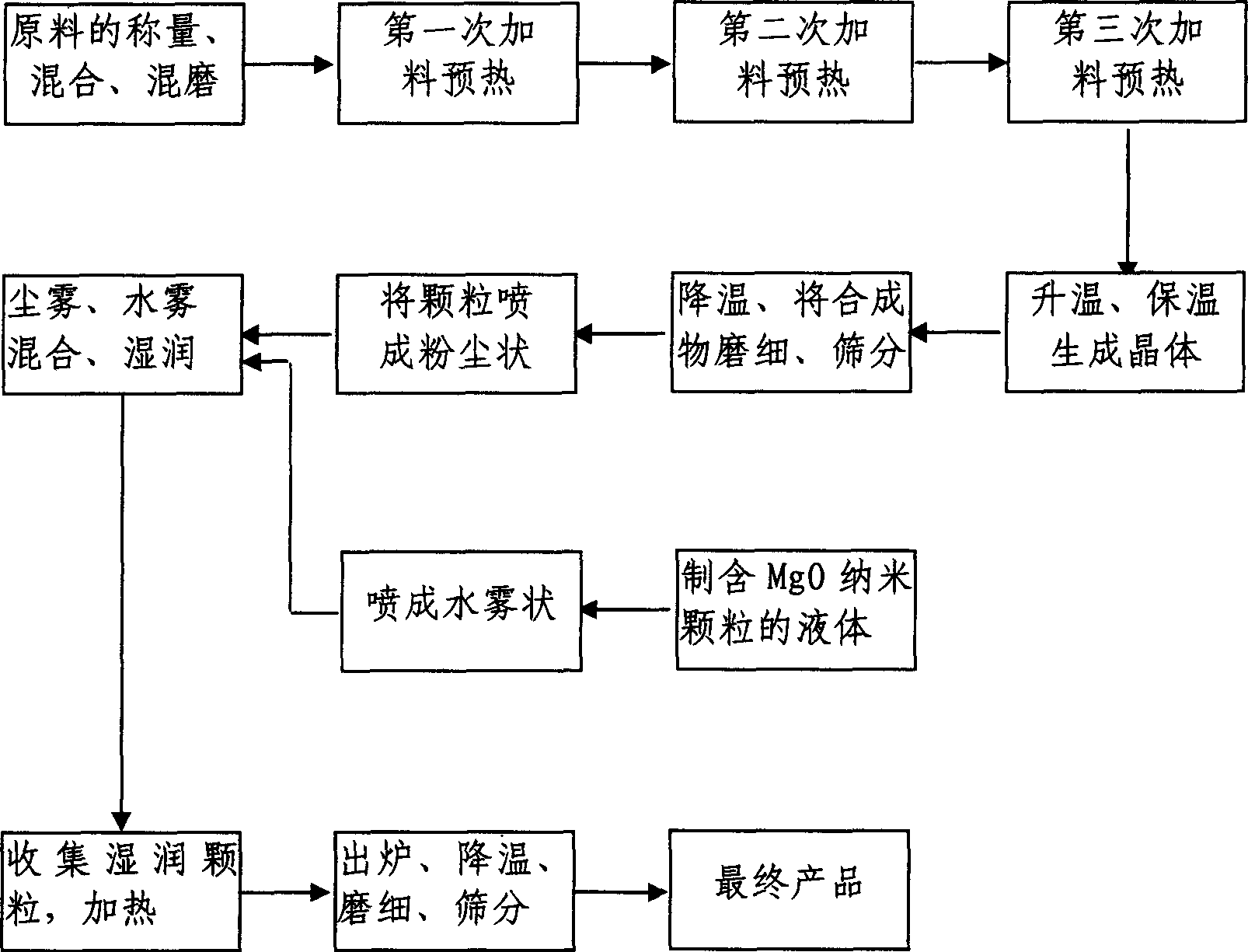

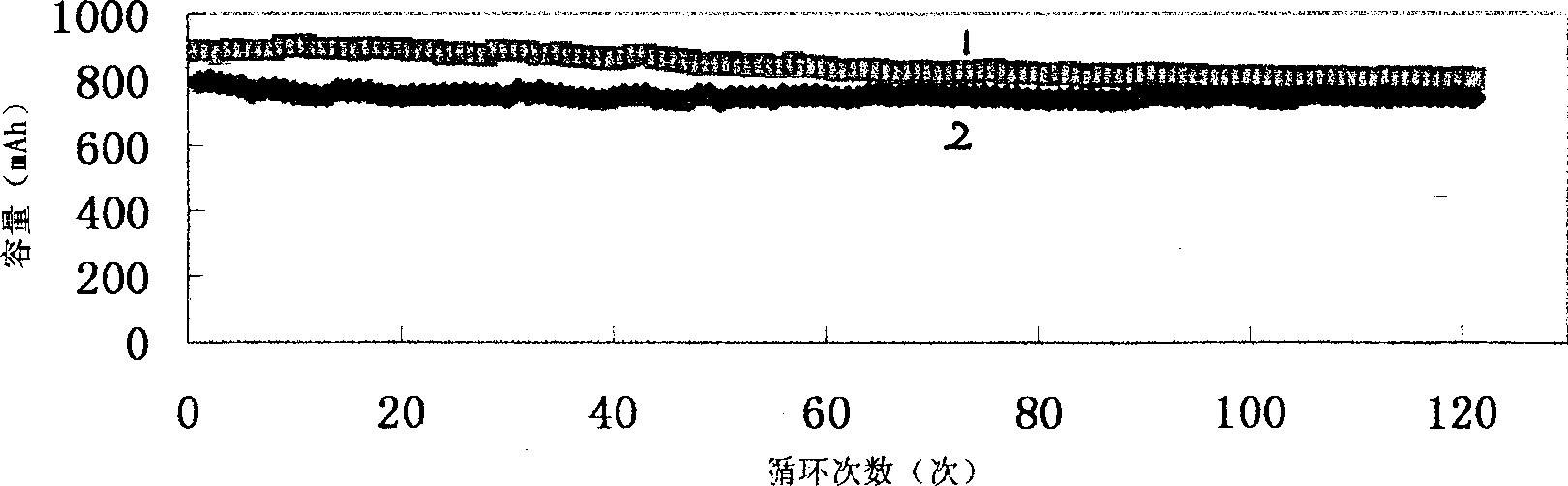

Doping and surface coating lithium nickel cobalt dioxide and its preparing method

This invention relates to lithium ion battery positive electrode mixture and surface nickel-to-cobalt acid lithium and its process method, which is characterized by the following: materials particle inner crystal core is LiNixCoyMgzO2 or LiNixCoyMnzO2; mixing Mg, Mn, or rare earth; outside surface layer is of nanometer MgO. The process method adopts three times adding and heating under 800 degrees temperature. The advantages of this invention embodies in crystal, structure, particle shape, large intensity and good flow and large capacity.

Owner:黎彦希

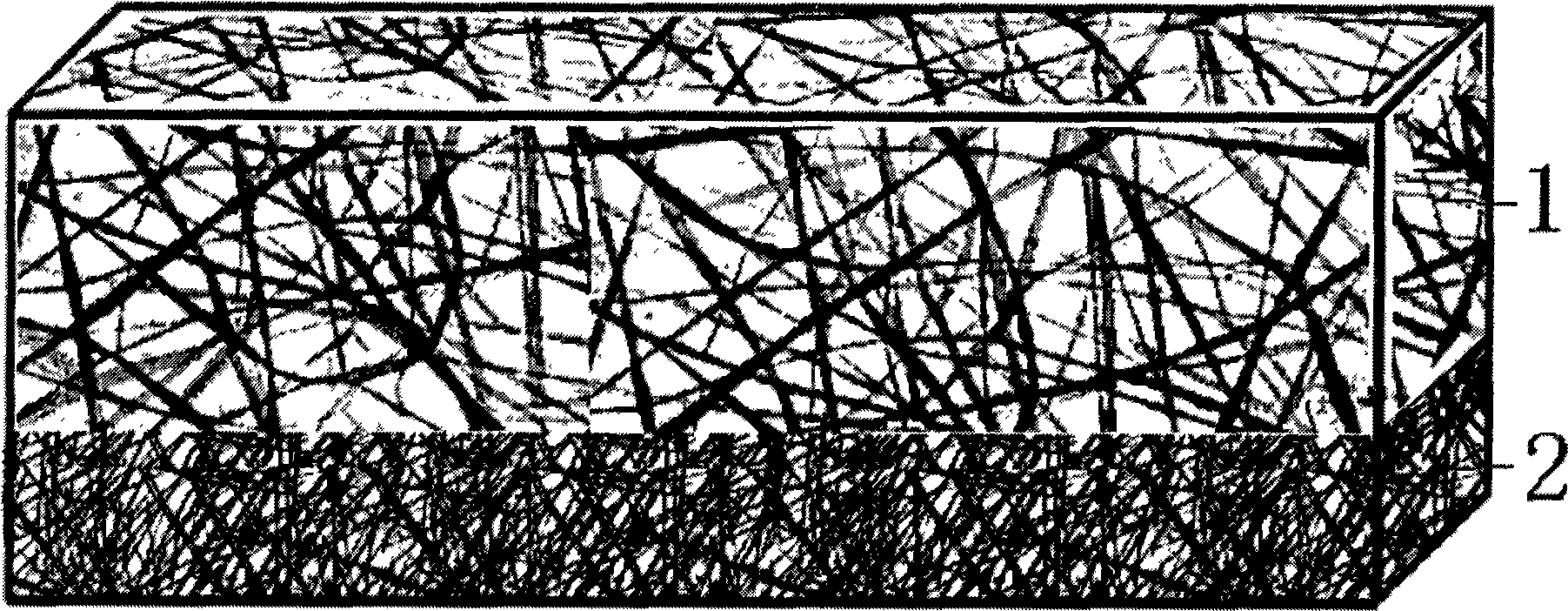

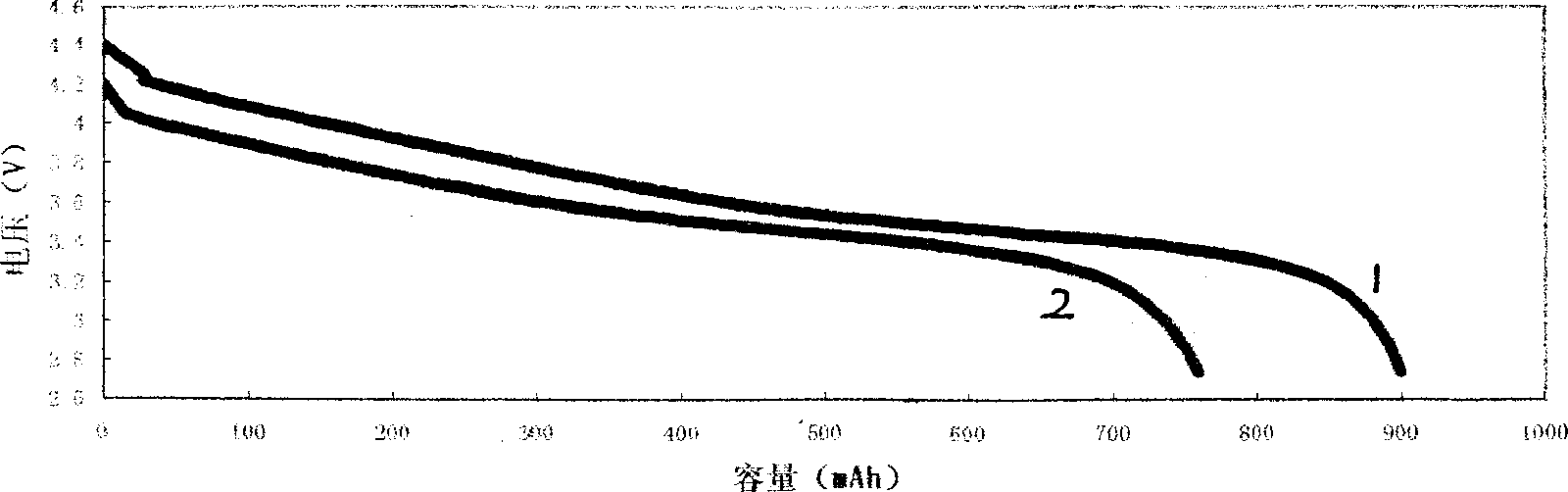

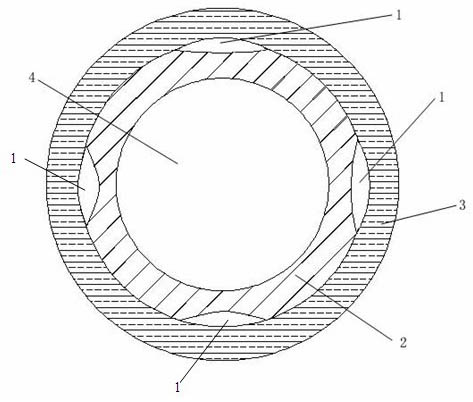

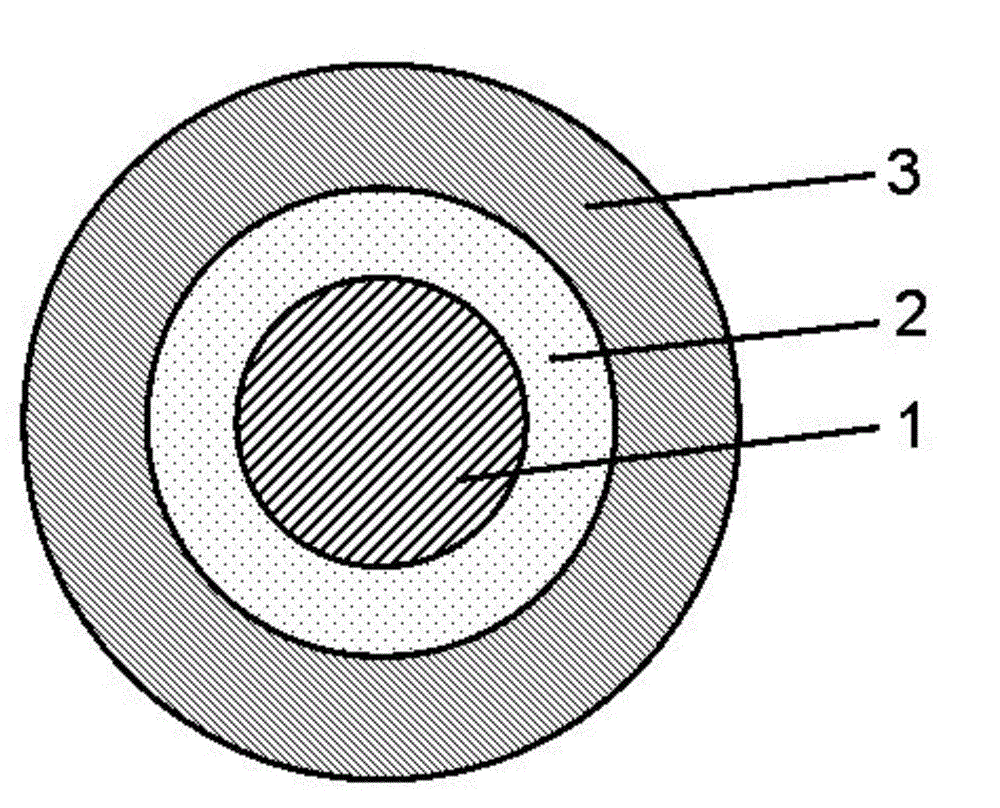

Nerve conduit and preparation method thereof

ActiveCN102688076AAddress barriers to developmentModerate intensitySurgeryCatheterCatheterNerve repair

The invention discloses a nerve conduit and a preparation method thereof. The nerve conduit consists of an inner layer, an outer layer and at least one minitype cavity for storing a bioactive factor solution, wherein the inner layer is of a hydrophilic cell scaffold layer, and the outer layer is of a hydrophobic nerve conduit scaffold layer. The nerve conduit can further comprise a transition layer between the inner layer and the outer layer. The preparation method of the nerve conduit comprises the steps of preparing the inner layer by adopting an electrostatic spinning method, then adding the material for preparing the cavity, then preparing the outer layer, and taking out or dissolving the material for preparing the cavity, thus obtaining the nerve conduit. The nerve conduit has the minitype cavity, so that bioactive factors can be loaded by a manner of injection, soaking and the like as required before operation, thus not only leading the production quality to be easily controlled, but also being capable of greatly improving the survival rate of the bioactive factors, more efficiently promoting the regeneration of nerves, and enhancing the restoration effect of nerves.

Owner:MEDPRIN REGENERATIVE MEDICAL TECH

Nano artificial dura mater capable of being used as medicine sustained-release system and preparation method thereof

The invention provides a nano artificial dura mater capable of being used as a medicine sustained-release system, having the structure which comprises at least two layers, i.e. a hydrophobic anti-blocking electro-spun layer which faces the cerebrum, and a hydrophilic nano cytoskeleton layer which backs on to the cerebrum; and cell factors and / or medicines are arranged in any layer of the artificial dura mater by way of blended spinning. The invention also provides a method for preparing the nano biomimic artificial dura mater. Compared with an artificial mater prepared by the single utilization of the electro-spinning technology, the artificial mater to which the medicines and the cell factors are added by blending technology can effectively prevent infection and faster promote the regeneration process of the artificial mater. The invention also provides a novel medicine loading and releasing mode for treating cerebral diseases, the loaded medicines can be directly and efficiently transferred into the cranial cavity along with the implantation of the dura mate and can be released according to requirements, and therefore the invention realizes favorable treatment effect and has broad application prospect.

Owner:MEDPRIN REGENERATIVE MEDICAL TECH

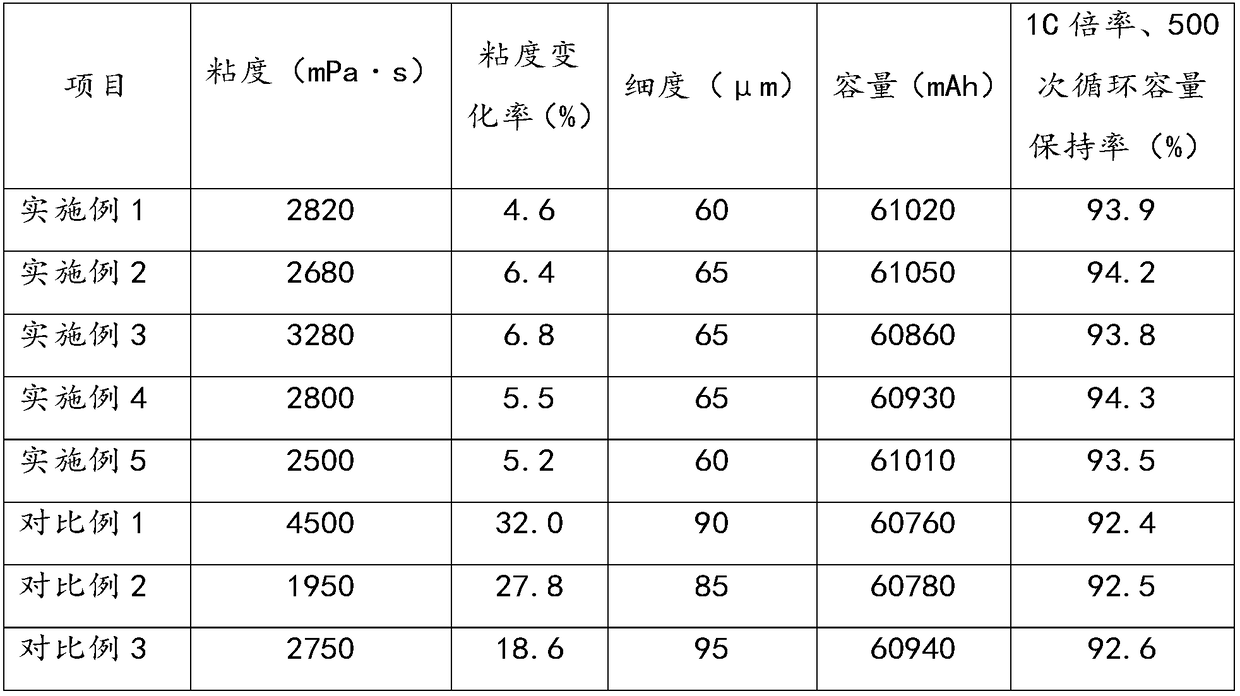

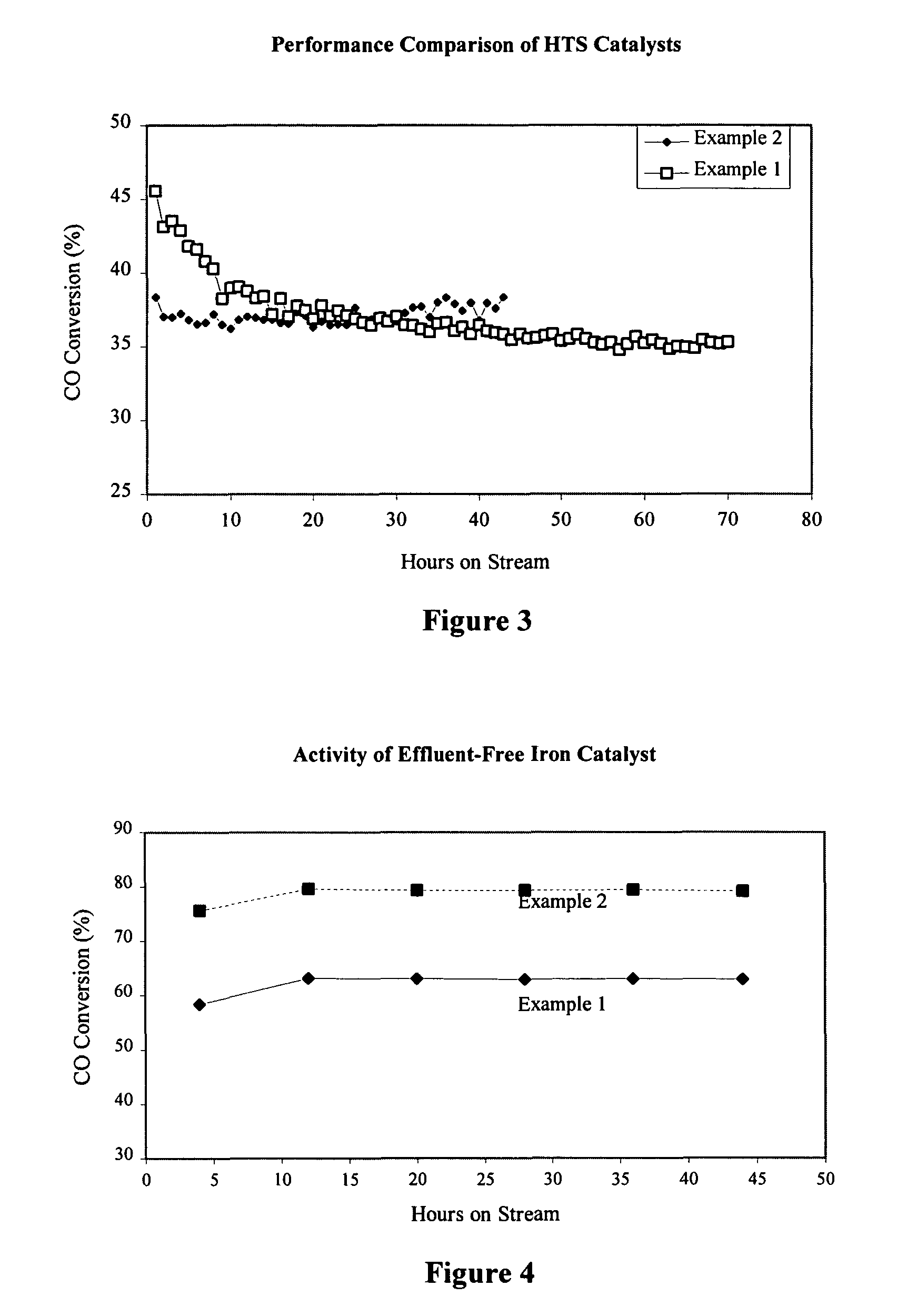

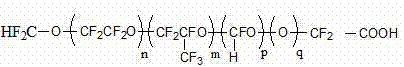

High temperature shift catalyst prepared with a purity iron precursor

InactiveUS7037876B2Reduce the amount requiredShort production timeHydrogenOther chemical processesWater-gas shift reactionFixed bed

A high temperature water gas shift catalyst comprising iron and at least one promoter is prepared via a method which comprises the preparation of a high purity iron precursor and which uses a nominal amount of water in the catalyst production. The catalyst prepared according to the inventive method is more efficient in hydrogen production under the high temperature water gas shift reaction conditions in a fixed bed test than prior art catalysts of similar composition.

Owner:SUD CHEM INC

Preparation process of lithium ion battery negative paste, lithium ion battery negative pole plate and lithium ion battery

ActiveCN108305987AEvenly dispersedQuality improvementElectrode manufacturing processesElectrode carriers/collectorsPhysical chemistrySodium-ion battery

The invention belongs to the technical field of a lithium ion battery, and relates to a preparation process of lithium ion battery negative paste, a lithium ion battery negative pole plate and a lithium ion battery. The preparation process of the lithium ion battery negative paste comprises the following steps of (a) mixing a negative active substance, a conductive additive, a dispersion agent anda thickening agent in a dried way to obtain mixed powder; (b) adding a solvent, performing uniform mixing to obtain primary paste with solid content being 67-69wt%; (c) adding the solvent again, performing uniform mixing to obtain secondary paste with solid content being 58-62wt%; (d) adding the solvent again, performing uniform mixing to obtain third paste with solid content being 54-56wt%; and(e) adding a binding agent into the third paste, and performing uniform mixing to obtain the lithium ion battery negative paste. The process is simple and is easy to operate, the preparation time canbe remarkably prepared, the equipment utilization ratio is improved, meanwhile, the mixing is uniform, and the dispersion performance, the consistency and the fineness of the paste are improved.

Owner:BEIJING NAT BATTERY TECH

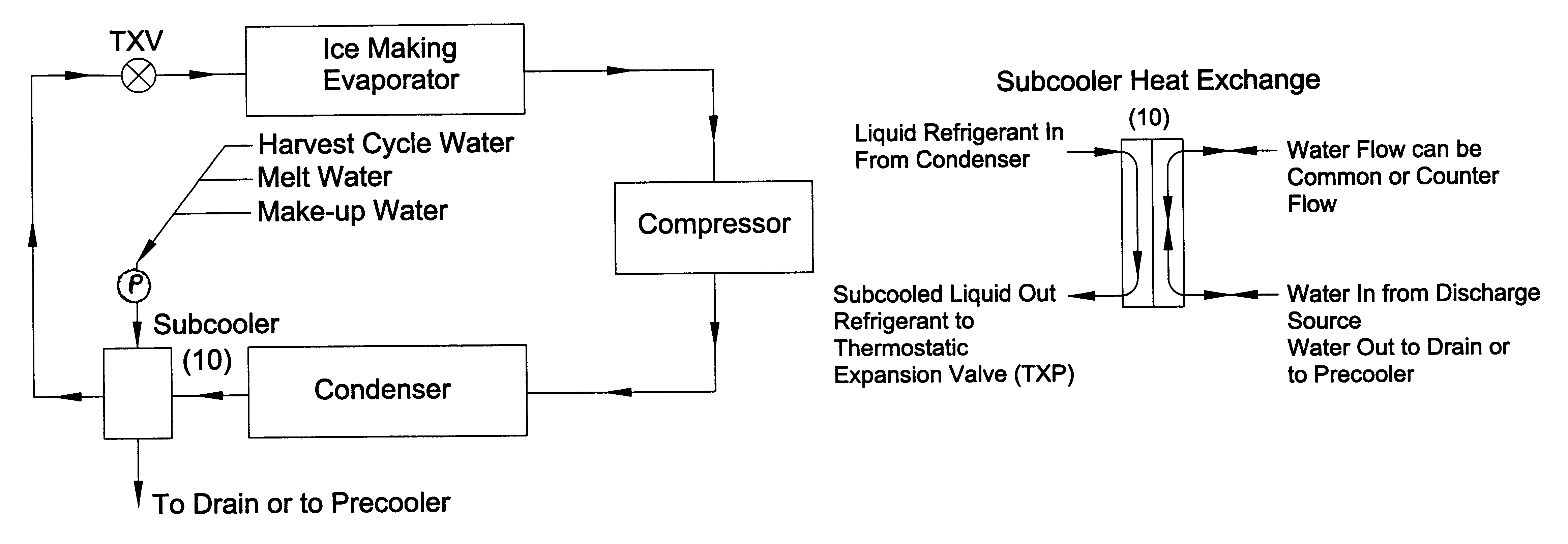

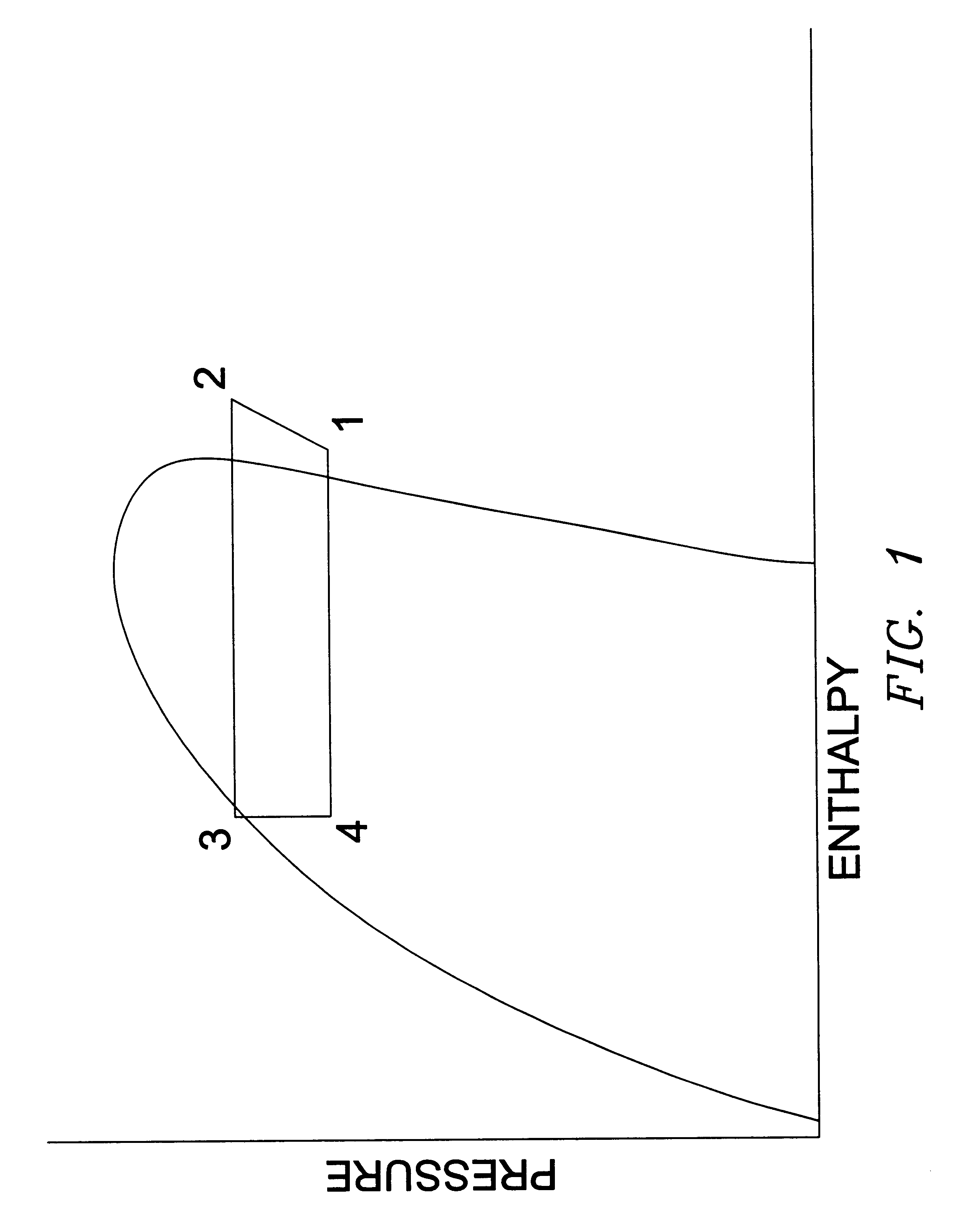

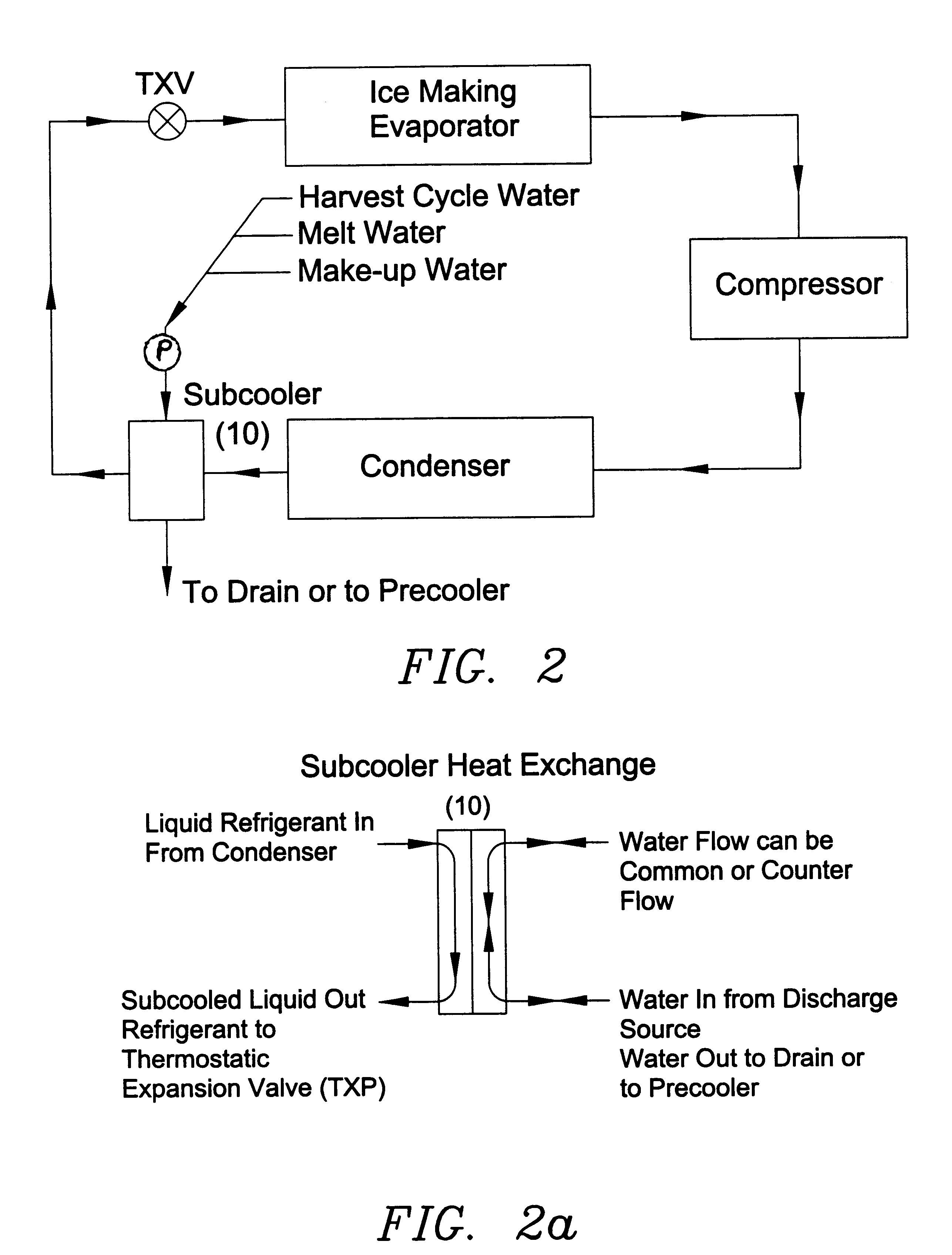

Utilization of harvest and/or melt water from an ice machine for a refrigerant subcool/precool system and method therefor

InactiveUS6237359B1Comprehensive understandingReduce heat dissipationSkin implantsFood processingCounter flowWater discharge

A system for providing liquid refrigerant subcooling, subsequent to that subcooling accomplished by the primary condenser of an ice machine, by means of utilizing cold harvest and / or melt water discharge from said ice machine. The subcooler is connected in fluid communication with the output of a pump that pumps stored ice machine discharge water to directly flow through the subcooler from a bottom portion to a top portion in a counter-flow direction and then to discharge such that the subcooler utilizes the pumped and flowing cold discharge water from the ice machine for providing maximum available subcooling to the liquid refrigerant of said ice machine

Owner:OLIVE TREE PATENTS 1 +1

High-temperature direct-injection disperse ink as well as preparation method and application thereof

The invention discloses high-temperature direct-injection disperse ink as well as a preparation method and an application thereof. The ink is prepared from the following raw materials in parts by weight: 15-60 parts of high-temperature disperse dye, 0.3-20 parts of dispersant, 30-60 parts of organic solvent, 10-50 parts of water, 0.5-10 parts of surfactant, 0.05-0.2 part of preservative and 0.05-0.2 part of defoamer. The preparation method comprises the steps of evenly mixing the high-temperature disperse dye, the dispersant, the organic solvent and water together, adding zirconium beads for grinding and dispersing, and then adding the rest organic solvent, water, the surfactant, the preservative and the defoamer to the mixture, mixing evenly, and filtering to obtain the filtrate. The ink is applied to a novel industrial digital textile printing machine and in particular to a textile printing machine with a precision work 508GS nozzle; the ink can be directly injected for printing by using the printing machine, and therefore, the utilization rate of the ink is increased, the cost is reduced and the environmental pollution is reduced; the ink can be dyed quickly at high temperature without transfer printing, and thus has the advantages of short dyeing time, firm dyeing and the like.

Owner:深圳市墨库图文技术有限公司

Composite refining agent for metallurgy and processing technique thereof

InactiveCN102653809AComponent content is reasonableShort production timeProcess efficiency improvementCelluloseSodium Bentonite

The invention relates to a composite refining agent for metallurgy and a processing technique thereof. The refining agent is characterized in that the refining agent comprises the following raw materials by weight percent: 25-38% of CaSi, 3-10% of SiC, 15-40% of CaF2, 5-15% of CaO, 1-5% of rare earth, 10-30% of metal manganese powder, 5-10% of calcium carbide and 2-8% of binder, wherein the binder is formed by natural calcium bentonite, sodium carbonate and cellulose sodium; and the composite refining agent is prepared through grinding, mixing, sieving and drying according to the formula of the components. The composite refining agent has the advantages of short smelting cycle, few product impurities, good molten steel purifying effect, high product quality and low energy consumption.

Owner:张晖

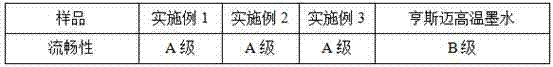

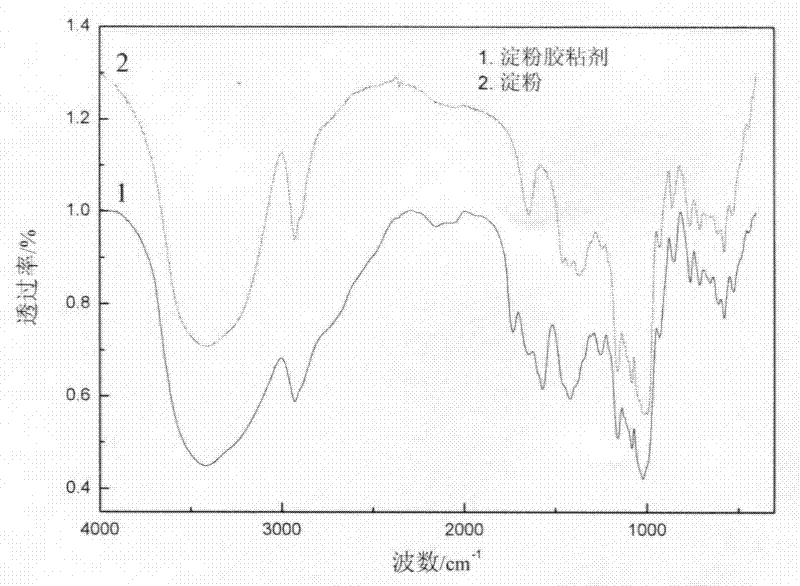

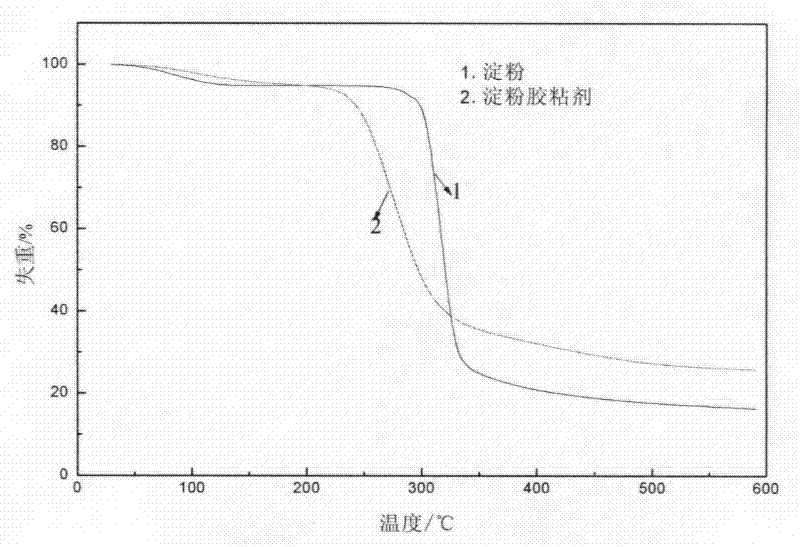

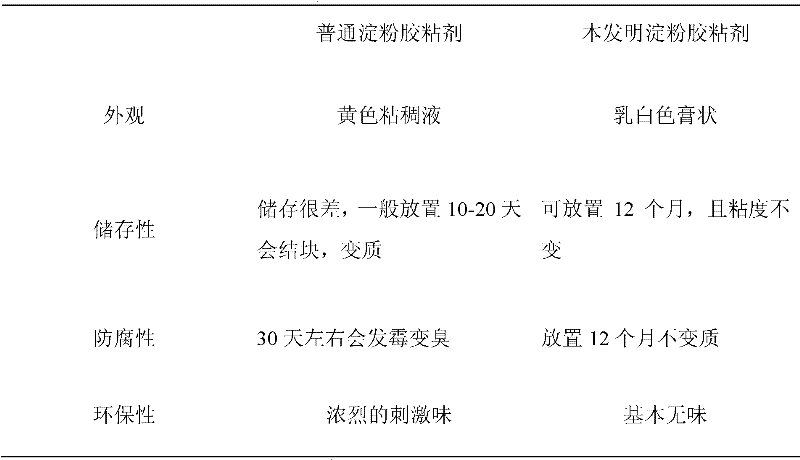

Corn starch adhesive for building and preparation method thereof

InactiveCN102391797AReduce consumptionReduce oxidationStarch derivtive adhesivesAcetic anhydrideAdhesive

The invention provides a corn starch adhesive for a building and a preparation method thereof. The adhesive is prepared from the following components in parts by mass: 10-30 parts of corn starch, 50-150 parts of tap water, 0.1-0.8 part of oxidant, 0.5-2 parts of esterifying agent, 0.4-0.8 part of alkali, 0.4-0.5 part of acid regulating agent, 0.1-0.2 part of preservative, 0.005-0.001 part of tributyl phosphate and 0.01-0.02 part of catalyst, wherein the oxidant is hydrogen peroxide; the esterifying agent is acetic anhydride, maleic anhydride or phthalic anhydride; and the catalyst is ferrous sulfate, copper sulfate or ferric chloride. The corn starch adhesive is a starch adhesive formed by directly gelatinizing oxidized and esterified starch, has good bonding effect and has the advantages of simple process, low cost, no environment pollution and the like.

Owner:SHANXI UNIV

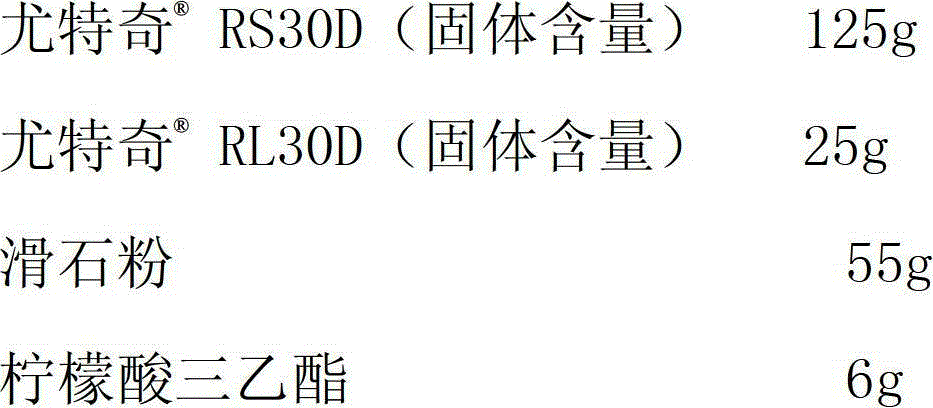

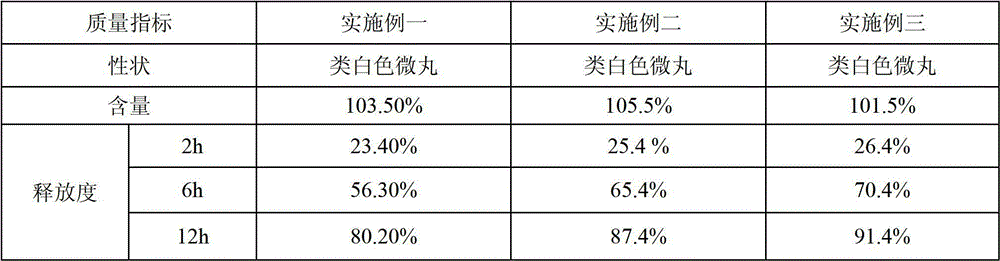

Vitamin C sustained-release pellets and method for preparing same

ActiveCN102908319AHigh drug loadingLarge particle sizeOrganic active ingredientsMetabolism disorderSustained release pelletsVitamin C

A vitamin C sustained-release pellet applied to the vitamin C sustained-release preparation field and a method for preparing the same are disclosed. The vitamin C sustained-release pellet is composed of a vitamin C sustained-release pill and a sustained-release coating, wherein the vitamin C sustained-release pill is composed of a mother nucleus and a lamination layer, or composed of a vitamin C and vitamin C pill accessory, or composed of vitamin C; the sustained-release coating is composed of a sustained-release coating material and a sustained-release coating accessory, or composed of the sustained-release coating material; the vitamin C sustained-release pill accessory is one or two selected from a filler and a binder; the sustained-release coating accessory is one or two selected from a plasticizer and an antisticking agent; the weight percentage content of the vitamin C in the mother nucleus is the same as that in the lamination layer; and the filler is one or several selected from microcrystalline cellulose, powdered sugar, starch, dextrin and lactose. The vitamin C sustained-release pellet disclosed by the invention is simple in prescription, free of metal-chelator or antioxidant, great in unit volume drug loading capacity, good in stability and capable of keeping sustained release for a long time; and the preparation method of the vitamin C sustained-release pellet is short in operation time and low in cost.

Owner:SHENYANG NO 1 PHARMA FACTORY DONGBEI PHARMA GRP

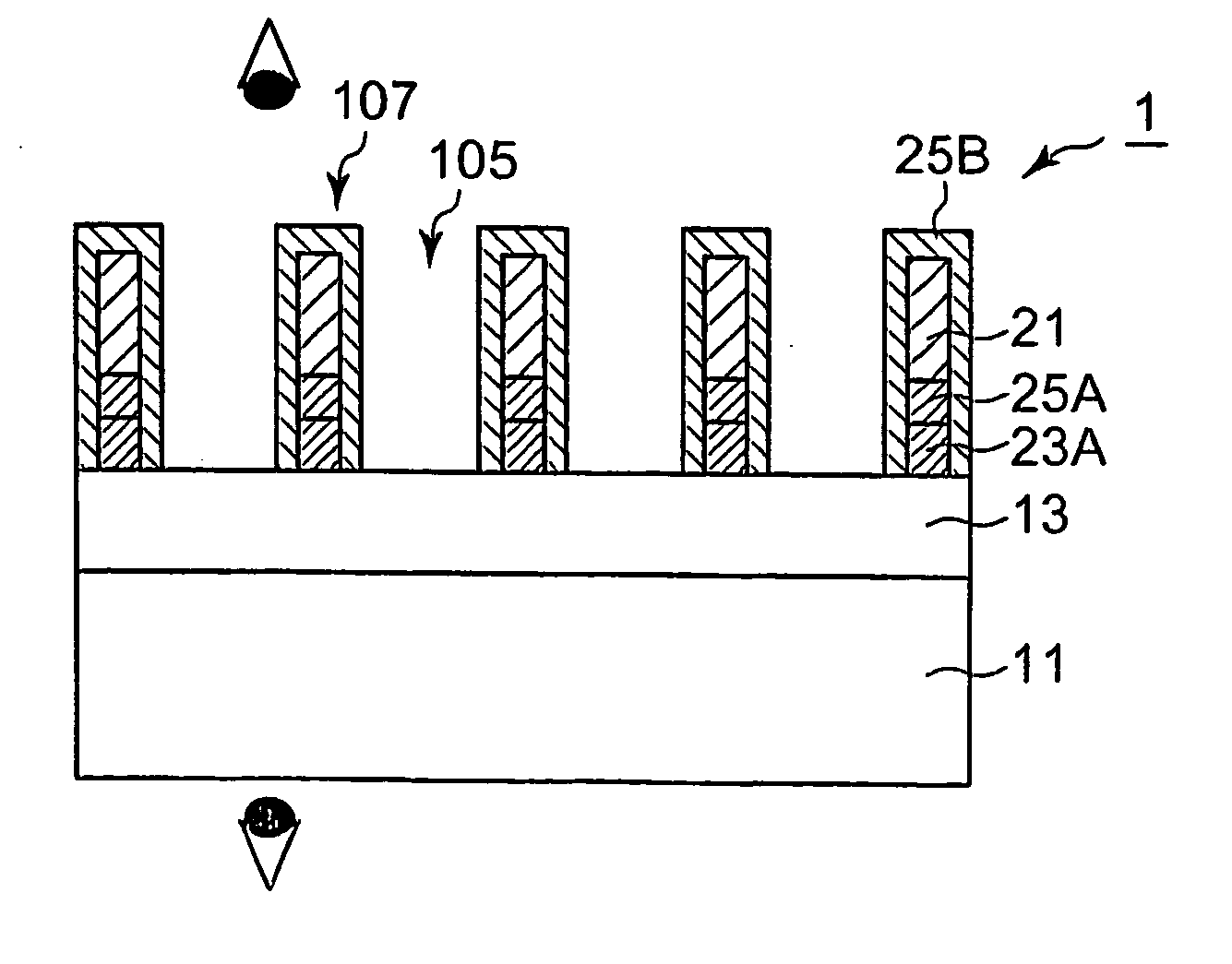

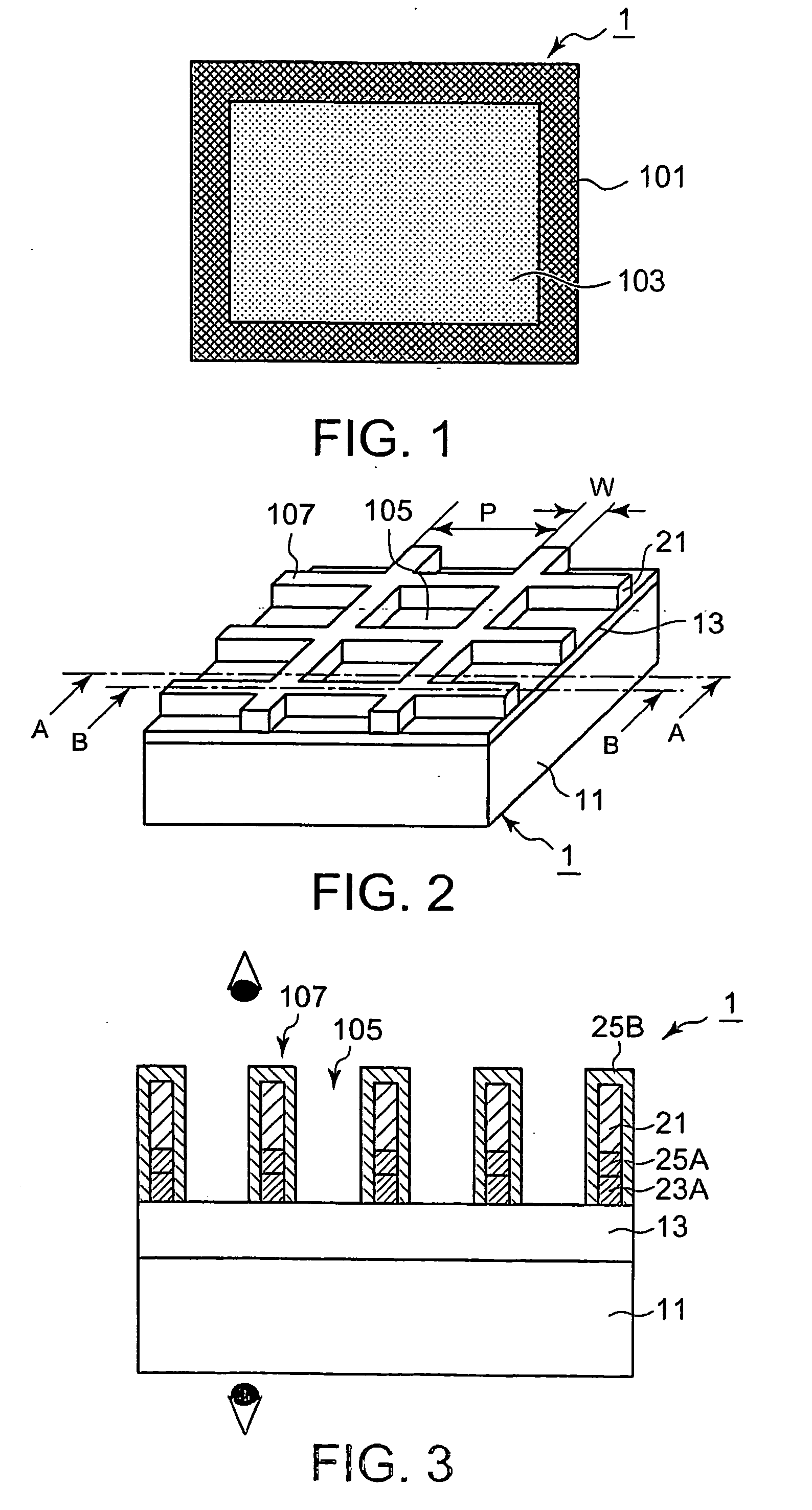

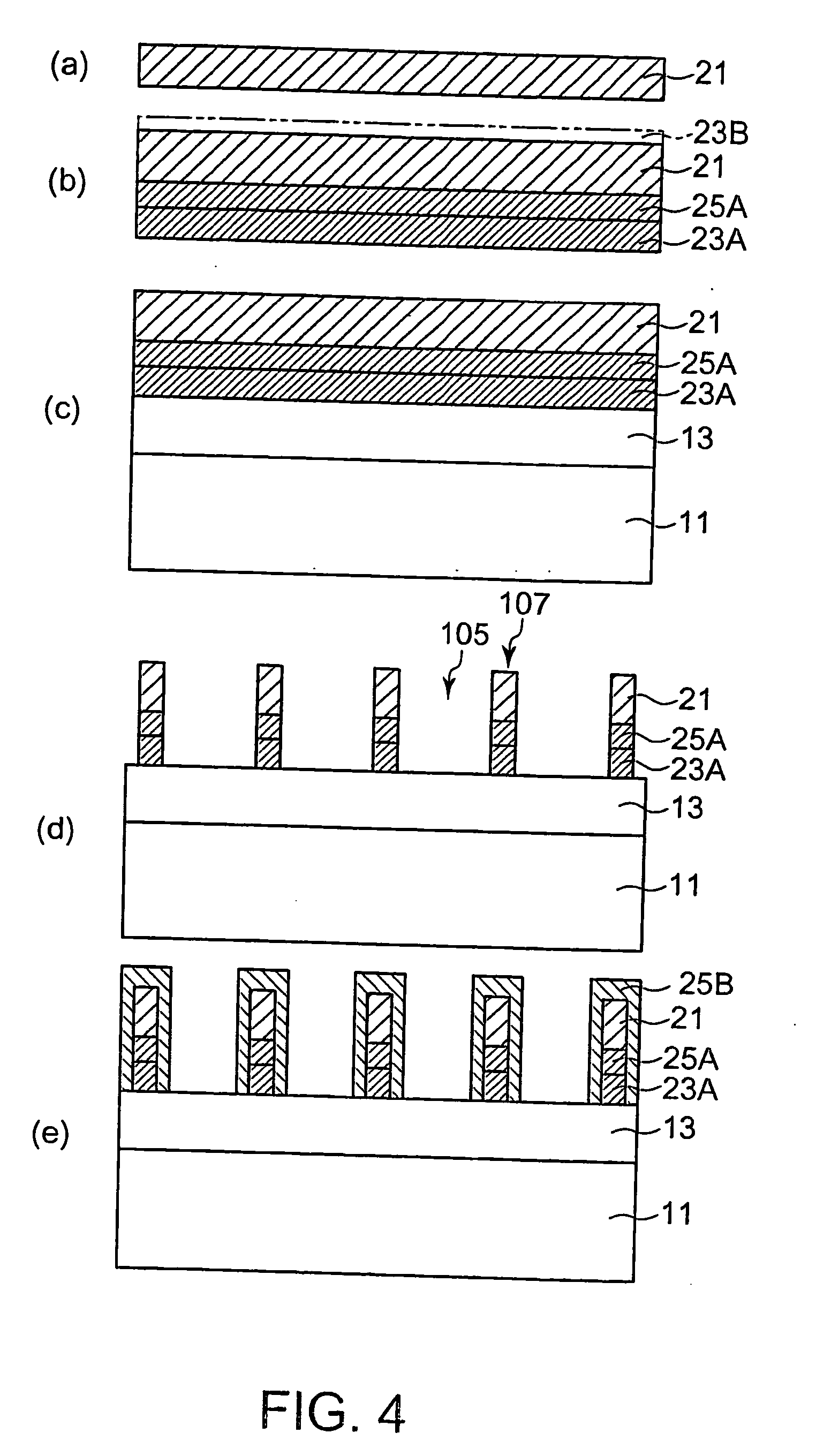

Electromagnetic wave shielding filter and process for producing the same

ActiveUS20070102192A1Improve adhesionShort timeCathode-ray/electron-beam tube vessels/containersMagnetic/electric field screeningAdhesiveElectromagnetic shielding

An electromagnetic wave shielding filter comprises a transparent substrate 11, and a metal mesh layer 21 with line parts 107 that define openings 105 of the mesh, laminated to one surface of the transparent substrate 11 by an adhesive 13. A first blackening layer 25A and an anticorrosive layer 23A are successively formed on the surfaces, on the transparent substrate side, of the line parts 107 of the metal mesh layer 21. A second blackening layer 25B is formed on surfaces, on the side opposite to the transparent substrate 11, of the line parts 107 of the metal mesh layer 21, and also on side faces of the line parts 107.

Owner:DAI NIPPON PRINTING CO LTD

Flexible thermal cure silicone hardcoats

ActiveUS7857905B2Short production timeHigh elongationOther chemical processesCoatingsOrganic solventPliability

The present invention relates to thermal cure silicone hardcoat compositions that are prepared with an aqueous / organic solvent silicone dispersion, partial organoalkoxysilane condensate and silylating agent. The novel heat curable silicone hardcoats are useful on various substrates with improved flexibility.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

Process for producing yeast from waste beer yeast liquid

The technological process of preparing zymogen with waste beer yeast liquid includes the following steps: heating waste beer yeast liquid to 50-55 deg.c and maintaining at the temperature for certain period while controlling pH 5.5-6.5; adding salt, potassium dihydrogen phosphate and magnesium chloride to promote cell wall breaking and autolysis while maintaining the temperature and stirring; adding enzyme preparation before maintaining for 25-30 hr to dissolve cell completely and to make amino acid, nucleotide and other nutrients dissolved into solution; and further centrifugation, concentration and disinfection to obtain zymogen. Owing to the addition of helicase and neutral proteinase as enzyme preparation and the strict control in reaction temperature and pH value, the zymogen prepared is delicious and mellow and may be used as seasoning. In addition, the production process is short and high in yield.

Owner:TANGSHAN LUCHU IND & TRADING

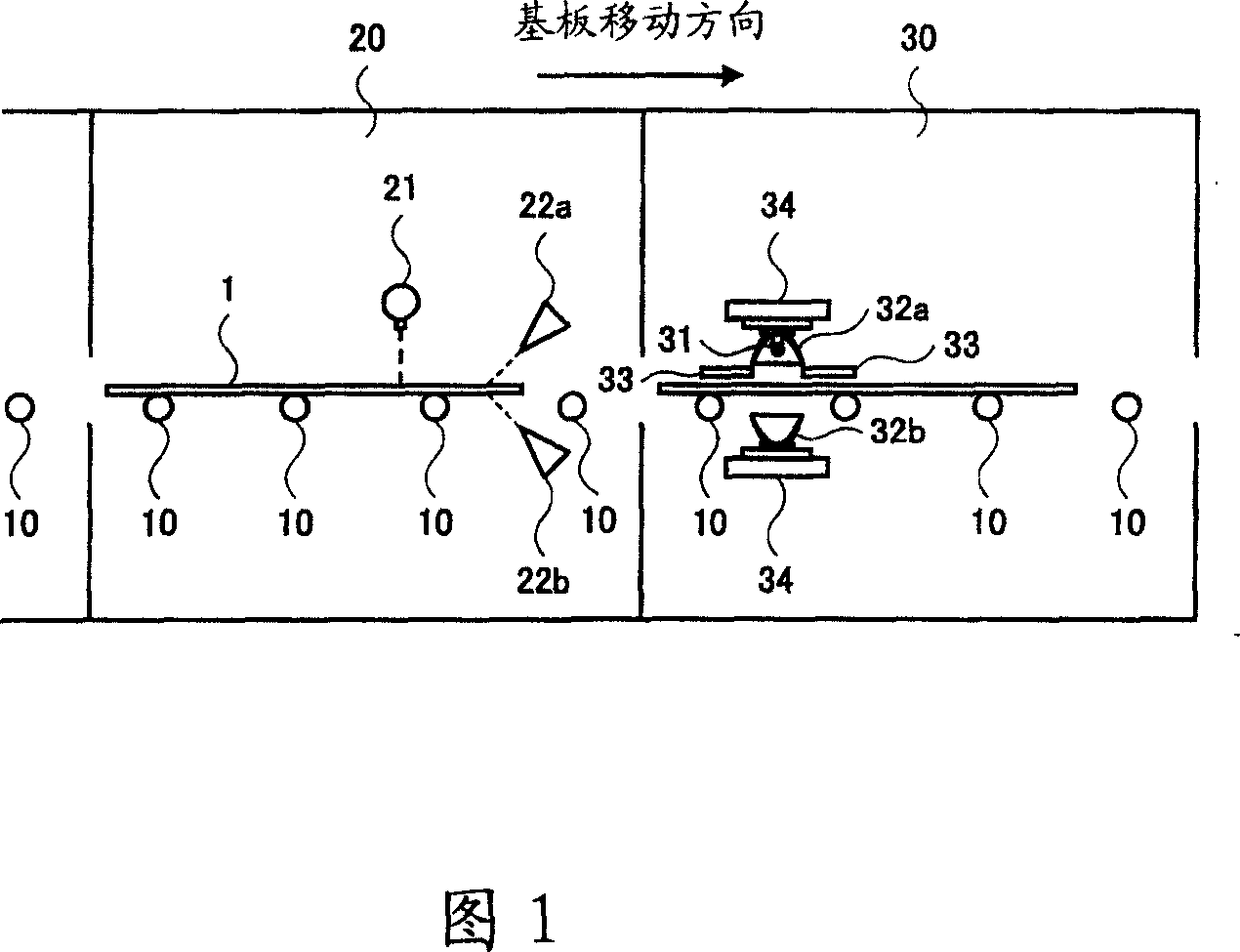

Substrate drying device and method, and substrate producing method

InactiveCN1941282ADry evenlyReduce air usageDrying using combination processesSemiconductor/solid-state device manufacturingAir knifeMoving speed

The present invention can move substrates with high speed, at the same time equably dry substrates. Nozzle (21) supplies cleaning liquid to the surface of the substrate 1, air knives (22a, 22b) eject air to the surface of back of the substrate (1). The air ejected from air knife (22a) makes the cleaning liquid supplied by nozzle (21) move toward the opposite direction of the substrate moving direction on the substrate (1). Adjusting the quantity of the cleaning liquid supplied by nozzle (21) and the quantity and speed of the air ejected from air knife (22a) in order to make the cleaning liquid moving speed slower than the substrate moving speed. Therefore, forming the continuous and thin liquid film of cleaning liquid on the whole surface of the substrate (1) under the air knife (22a). The liquid film forming on the surface of the substrate (1) is vaporized when it through the lower part of the halogen lamp (31), and is wiped off from one end of the substrate (1) continuously.

Owner:HITACHI HIGH-TECH CORP

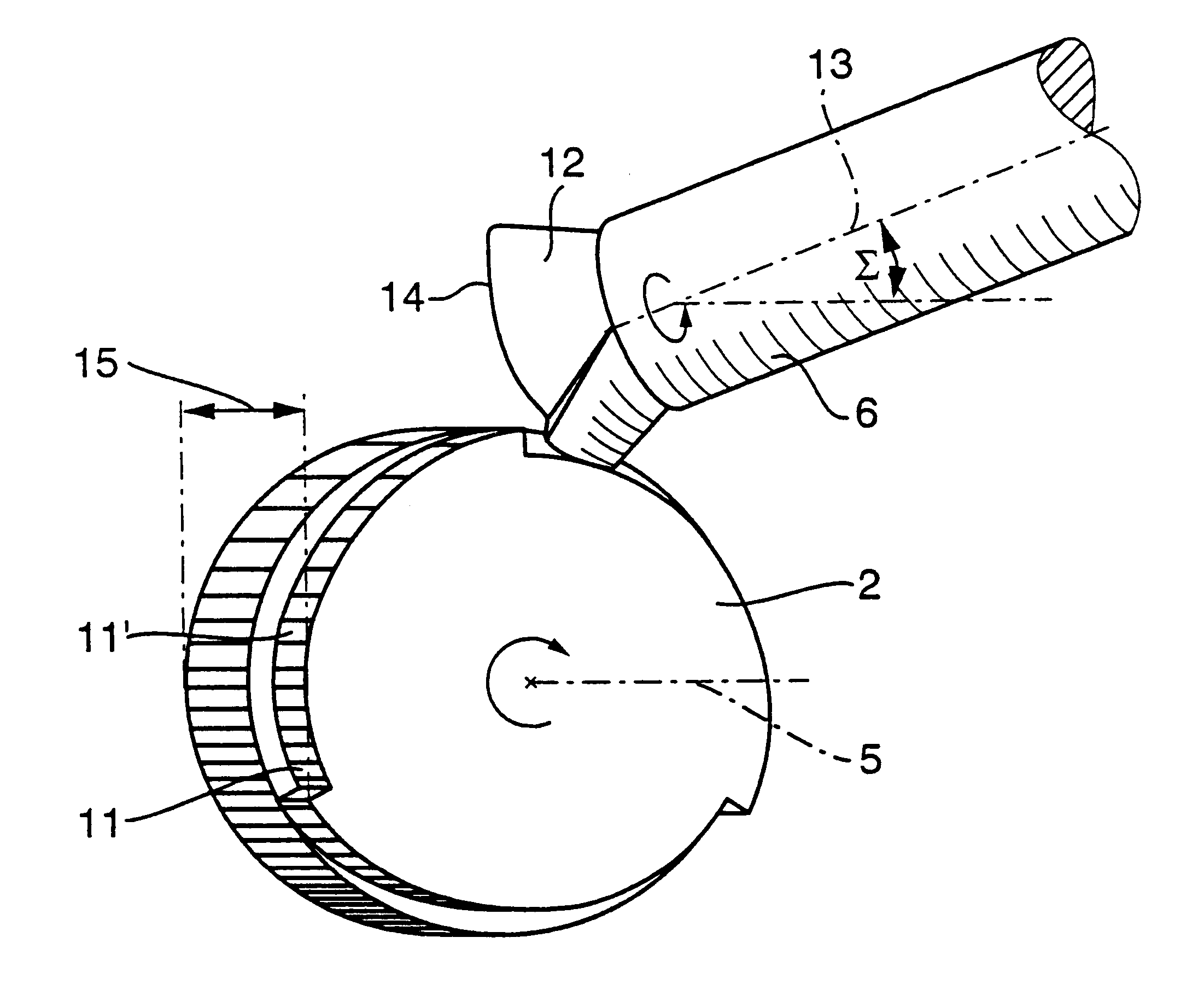

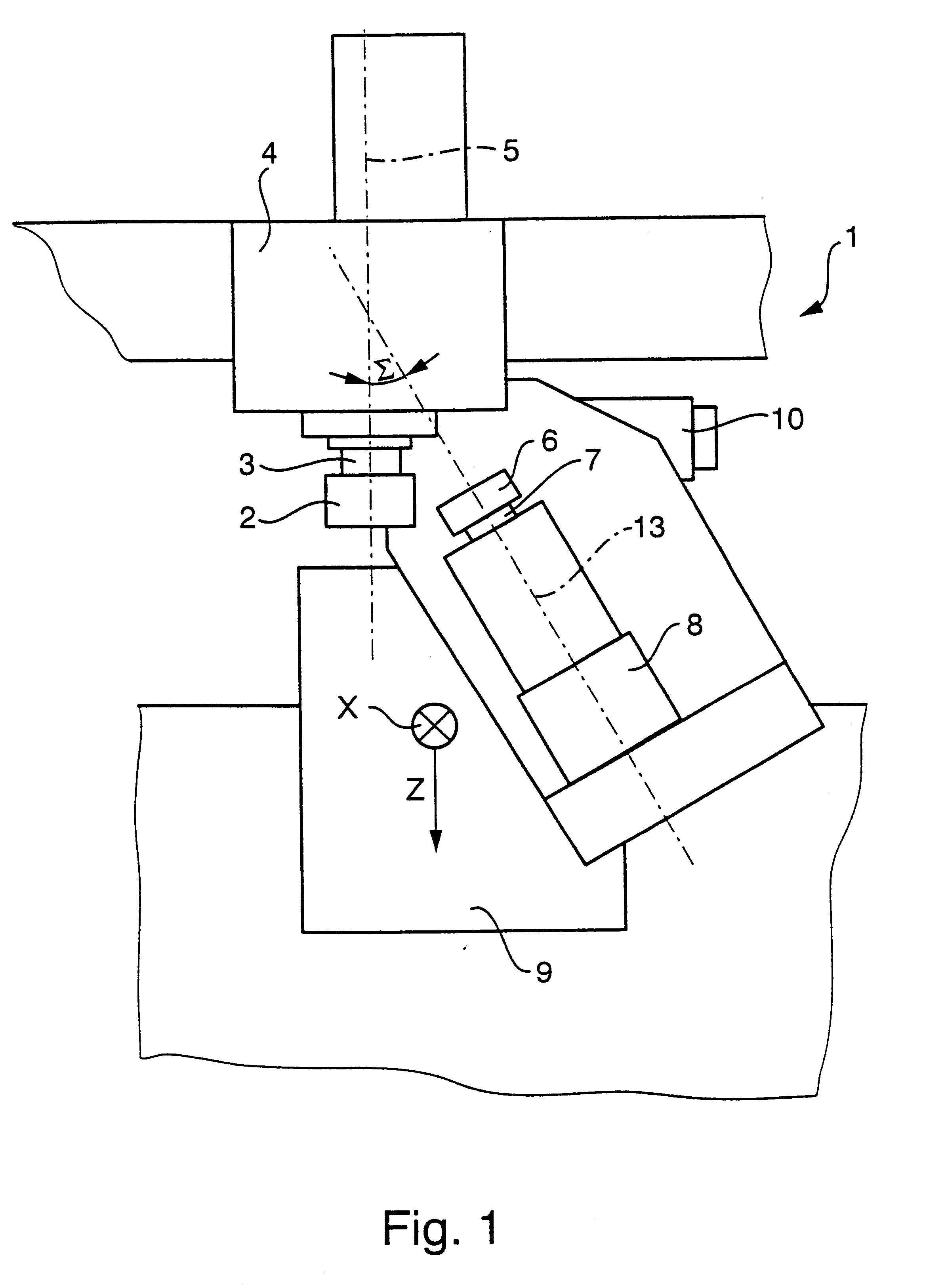

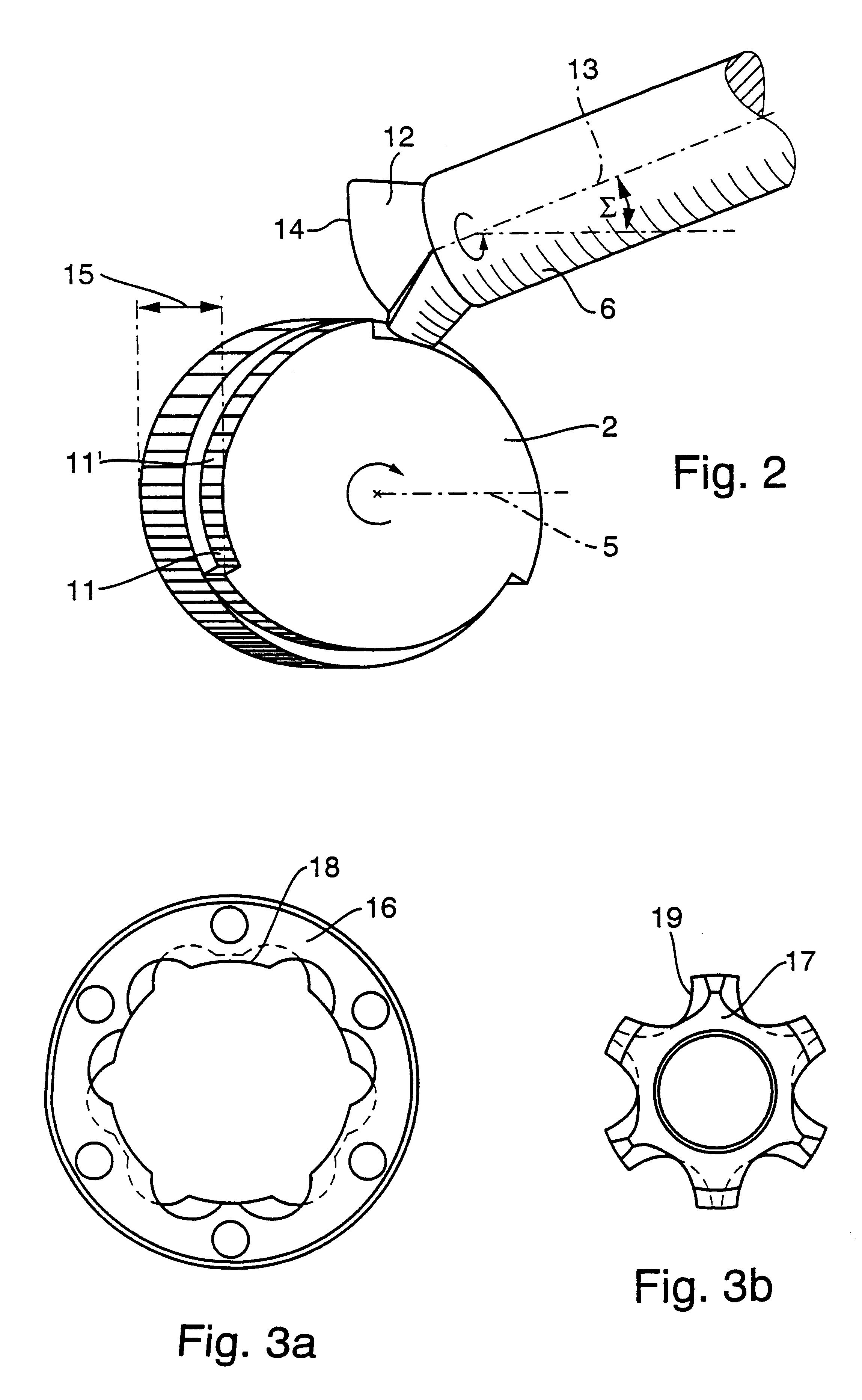

Generation of periodic structures on rotationally symmetrical components

InactiveUS6394718B1Highly precise, quick and cost-effectiveFast processingPlaning/slotting machinesMilling machinesSymmetrical componentsEngineering

The invention relates to the generation of periodic profiles on at least approximately rotationally symmetrical blanks, such as, for example, the generation of shaft-hub connection profiles such as circular wedge profiles, splined shaft profiles, etc., on shaft or hub blanks. To this end, the use of generating skiving is proposed, which permits the production of any desired periodic profiles on rotationally symmetrical blanks and is far superior to rival processes with regard to the productive machining time.

Owner:DAIMLER AG

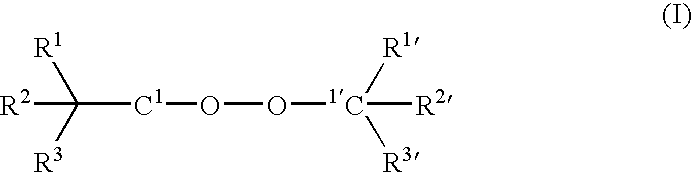

Modified Polymer Compositions, Modification Process and Free Radical Generating Agents

InactiveUS20100181096A1Maintain good propertiesQuality improvementOrganic chemistryInsulated cablesPolymer sciencePolymer composition

The application relates to a method for modifying a polymer composition, to modified polymer compositions, to an article, preferably wire or cable, including said modified polymer composition, to a process for preparing an article, preferably a wire or cable, to the use of said modified polymer in one or more layers of a wire or cable, as well as to a compound for use as a radical generating agent for modifying a polymer composition.

Owner:BOREALIS TECH OY

High temperature shift catalyst prepared with a high purity iron precursor

InactiveUS20040077483A1Efficient productionLess contaminantHydrogenOther chemical processesWater-gas shift reactionFixed bed

A high temperature water gas shift catalyst comprising iron and at least one promoter is prepared via a method which comprises the preparation of a high purity iron precursor and which uses a nominal amount of water in the catalyst production. The catalyst prepared according to the inventive method is more efficient in hydrogen production under the high temperature water gas shift reaction conditions in a fixed bed test than prior art catalysts of similar composition.

Owner:SUD CHEM INC

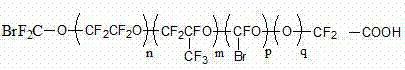

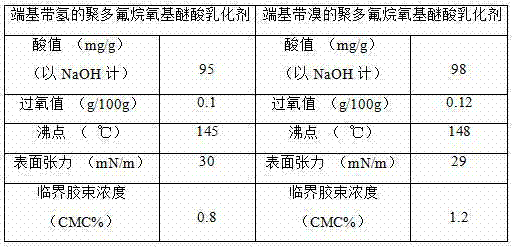

Fluorine-containing polymer and preparation method thereof

The invention discloses a fluorine-containing polymer and a preparation method thereof. One or more fluorinated monomers is / are subjected to liquid polymerization by using polyfluothane oxy ether acid as an emulsifier to obtain the fluorine-containing polymer free of perfluoro-octanoic acid or perfluoro-octylsulfonic acid, wherein the polyfluothane oxy ether acid is a halogen-terminated or hydrogen-terminated polyfluothane oxy ether acid emulsifier. The technical scheme mainly relates to the following three improvements: (1) the polyfluothane oxy ether acid or salt thereof selected instead of PFOA / PFOS as the fluorine-containing emulsifier can be effectively used in aqueous emulsion polymerization reaction of fluorinated monomers; (2) the prepared fluorine-containing polymer is free of perfluoro-octanoic acid or perfluoro-octylsulfonic acid, and thus, satisfies the environmental requirement; and (3) the fluorine-containing polymer conforms to the cost accounting, can greatly enhance the single-kettle yield of the equipment on the premise of not increasing the production equipment and personnel, and meanwhile, can enhance the polymerization time, polymerization yield and other production indexes.

Owner:成都晨光博达新材料股份有限公司

Silicone-acrylate emulsion and production process thereof

The invention relates to a silicone-acrylate emulsion which includes the materials of the following weight portions: 2.7 to 3.3 portions of SDBS, 4.5 to 5.5 portions of OP-10, 1.35 to 1.65 portions of ammonium sulphate, 3.6 to 4.4 portions of KH-570, 54 to 66 portions of methyl methacrylate, 69.3 to 84.7 portions of butyl acrylate, 28.8 to 35.2 portions of methacrylic acid, 9 to 11 portions of TT935 and 280 to 320 portions of deionized water. The invention also relates to the production technique of the silicone-acrylate emulsion which includes the preparation for the nuclear of an organic silicon acrylate polymer and the synthesis of the silicone-acrylate emulsion. The invention has the characteristics of high bonding performance, high resistance to elements, high water resistance, high dirt-resistance, anti-aging, no pollution, unique production technique, short production period, simple operation, low production cost and being suitable for the industrial production in large scale. The dopes manufactured by using the silicone-acrylate emulsion of the invention as basic materials are broadly applied to the indoor and outdoor walls.

Owner:四川伟才高新材料有限公司

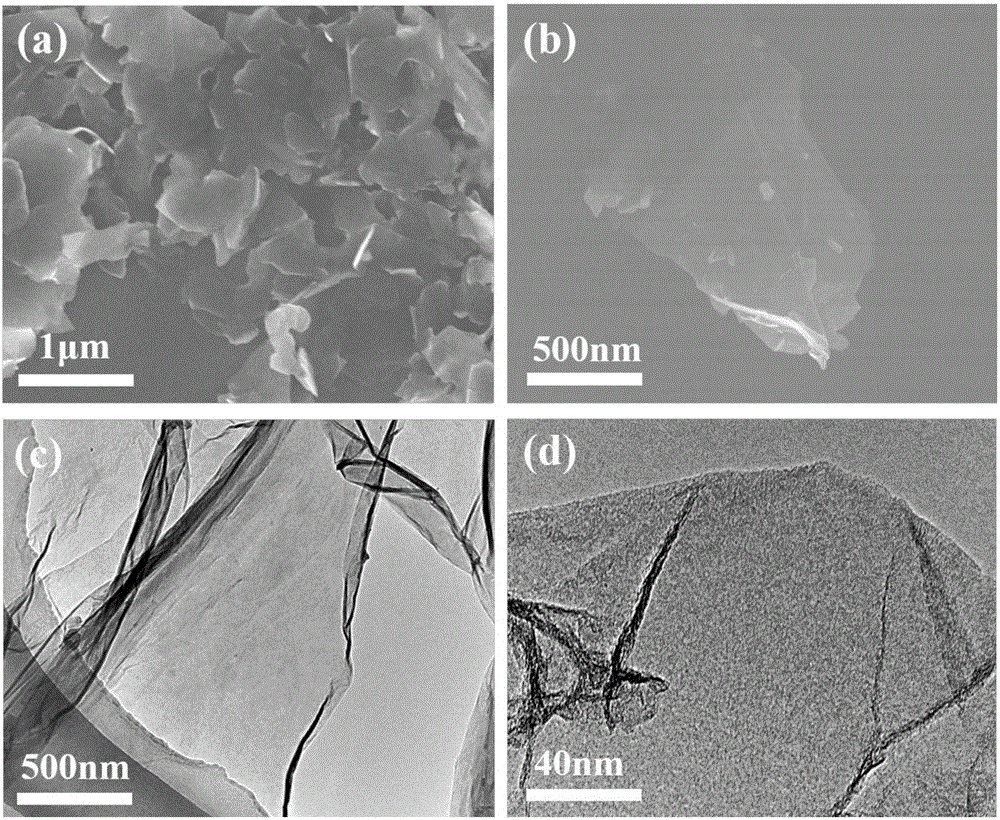

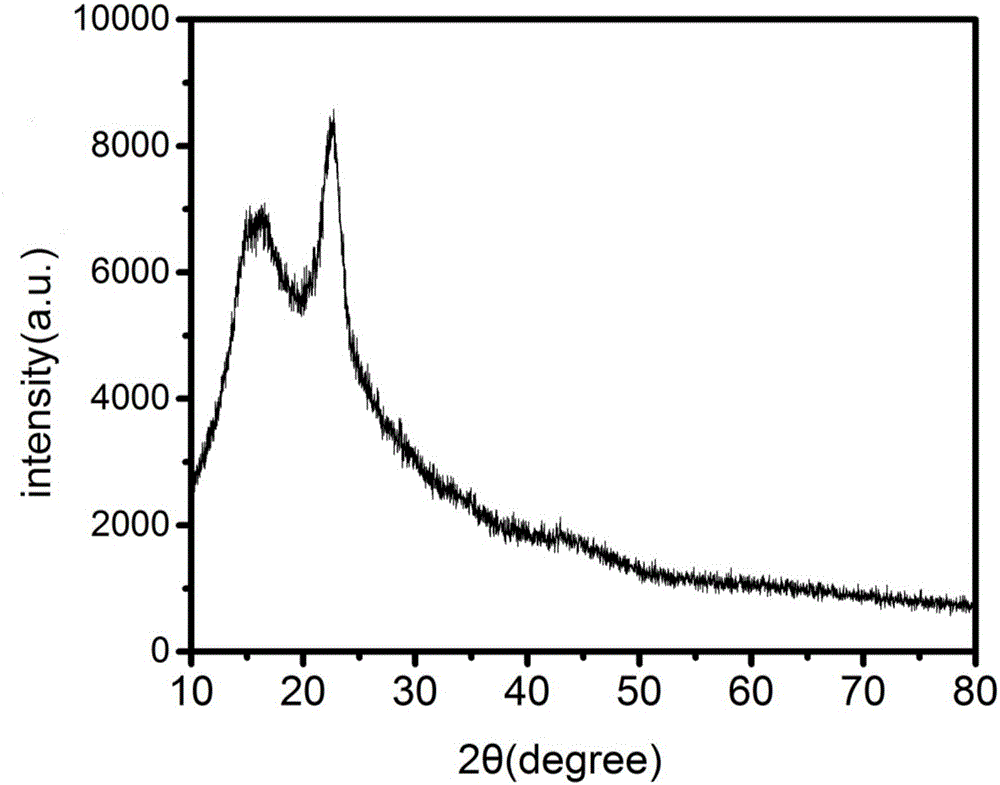

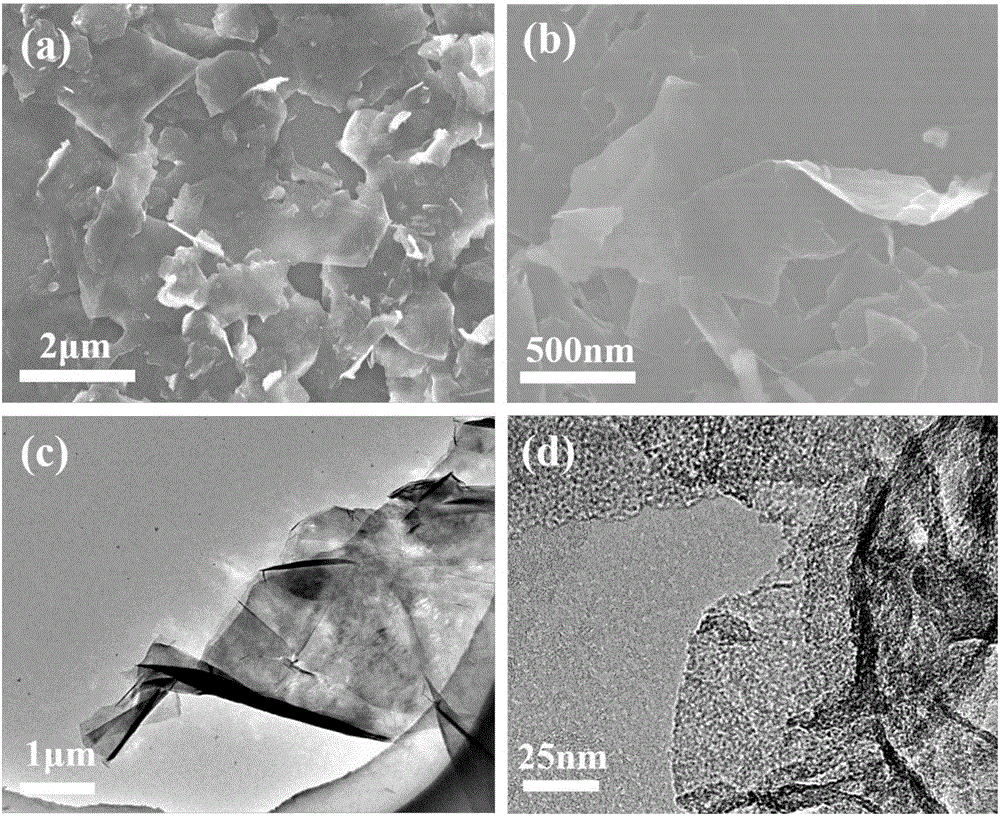

Method for preparing graphene two-dimensional material through liquid-phase stripping

The invention provides a method for preparing a graphene two-dimensional material through liquid-phase stripping. The method comprises the following steps: (1) dispersing graphite into water and / or an organic solvent, maintaining the mixture temperature at 20-80 DEG C, alternatively preforming emulsified cutting and strong ultrasonic, wherein the graphene concentration in the mixture is 0.15-10g / L; (2) separating the product in the step (1) by use of a centrifuging method, taking the separated supernatant as the graphene dispersion liquid, wherein the centrifuging rate is 1000-6000rpm, and the centrifuging time is 5-30min. The commercial graphite with low price is used as the raw material, the organic solvent with good graphene dispersion property is used as the solvent for liquid-phase stripping, the ethanol, the isopropanol and other organic solvents are pollution-free, low in cost and recyclable; by use of the method of combining the emulsified cutting and the strong ultrasonic, the production time is short, the period is 6-20h, the method is simple, and the efficiency is high; the obtained graphene yield is high and can achieve 2%.

Owner:北京华科讯能石墨烯新技术研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com