High-temperature direct-injection disperse ink as well as preparation method and application thereof

A technology of dispersing ink and high temperature, which is applied in application, ink, household utensils, etc. It can solve the problems of environmental pollution, high printing cost, etc., and achieve the effect of reducing production cost, bright color, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

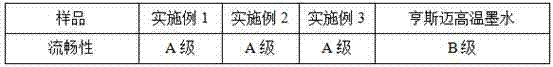

Examples

preparation example Construction

[0039] The preparation method of high-temperature direct jet dispersion ink comprises the following steps:

[0040] 1) Weigh each raw material according to the following parts by mass: 15-60 parts of high-temperature disperse dye, 0.3-20 parts of dispersant, 30-60 parts of organic solvent, 10-50 parts of water, 0.5-10 parts of surfactant, preservative 0.05-0.2 parts, 0.05-0.2 parts of defoamer;

[0041]2) After mixing high-temperature disperse dye, dispersant, 1 / 3~1 / 2 water, 1 / 3~1 / 2 organic solvent and 1 / 3~1 / 2 water evenly, add zirconium with a diameter of 0.25~0.35mm Grind and disperse the beads for 25-30 hours to obtain a dispersion liquid, in which the volume ratio of high-temperature disperse dye and dispersant to zirconium beads is 1: (5-7), and the grinding speed is 2200-2800 rpm;

[0042] 3) Add the remaining organic solvent, water, surfactant, preservative, and defoamer to the above dispersion, stir at 1500-2000 rpm for 50-80 minutes, and then filter with a filter me...

Embodiment 1

[0060] Example 1 Preparation of High Temperature Direct Injection Dispersed Ink

[0061] 1) Weigh each raw material according to the following parts by mass: 30 parts of high-temperature disperse blue dye, 5 parts of dispersant MF (sodium methylenebismethylnaphthalene sulfonate), 42 parts of polypropylene glycol, 5 parts of diethylene glycol, water 16.75 parts, 1 part of surfactant ABS (dodecylbenzenesulfonic acid and its sodium salt), 0.1 part of preservative Proxel GXL, 0.15 part of defoamer BYK-088;

[0062] 2) At room temperature (18-27°C), mix high-temperature disperse blue dye 73, 1 / 2 polypropylene glycol, 1 / 2 diethylene glycol, 1 / 2 water, 1 / 2 surfactant ABS and After the dispersant MF is mixed evenly, use zirconium beads with a diameter of 0.25 to 0.35 mm to grind and disperse the mixture for 28 hours in a sand mill to obtain a dispersion liquid. The ratio is 1:6, and the grinding speed is 2400 rpm;

[0063] 3) Put the above dispersion into the reaction kettle, add ...

Embodiment 2

[0064] Example 2 Preparation of High Temperature Direct Injection Dispersed Ink

[0065] 1) Weigh each raw material according to the following parts by mass: 35 parts of high-temperature disperse red dye, 5 parts of dispersant MF (sodium methylenebismethylnaphthalene sulfonate), 40 parts of polypropylene glycol, 5 parts of diethylene glycol, water 13.95 parts, 0.8 parts of surfactant ABS (dodecylbenzenesulfonic acid and its sodium salt), 0.1 parts of preservative Proxel GXL, 0.15 parts of defoamer BYK-088;

[0066] 2) At room temperature (18-27°C), mix high-temperature disperse red dye 167, 1 / 2 polypropylene glycol, 1 / 2 diethylene glycol, 1 / 2 water, 1 / 2 surfactant ABS and After the dispersant MF is mixed evenly, use zirconium beads with a diameter of 0.25 to 0.35 mm to grind and disperse the mixture for 28 hours in a sand mill to obtain a dispersion liquid. The ratio is 1:6, and the grinding speed is 2400 rpm;

[0067] 3) Put the above dispersion into the reaction kettle, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com