Patents

Literature

30 results about "Digital textile printing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Digital textile printing is described as any ink jet based method of printing colorants onto fabric. Most notably, digital textile printing is referred to when identifying either printing smaller designs onto garments (T-shirts, dresses, promotional wear; abbreviated as DTG, which stands for Direct to Garment) and printing larger designs onto large format rolls of textile. The latter is a growing trend in visual communication, where advertisement and corporate branding is printed onto polyester media. Examples are: flags, banners, signs, retail graphics.

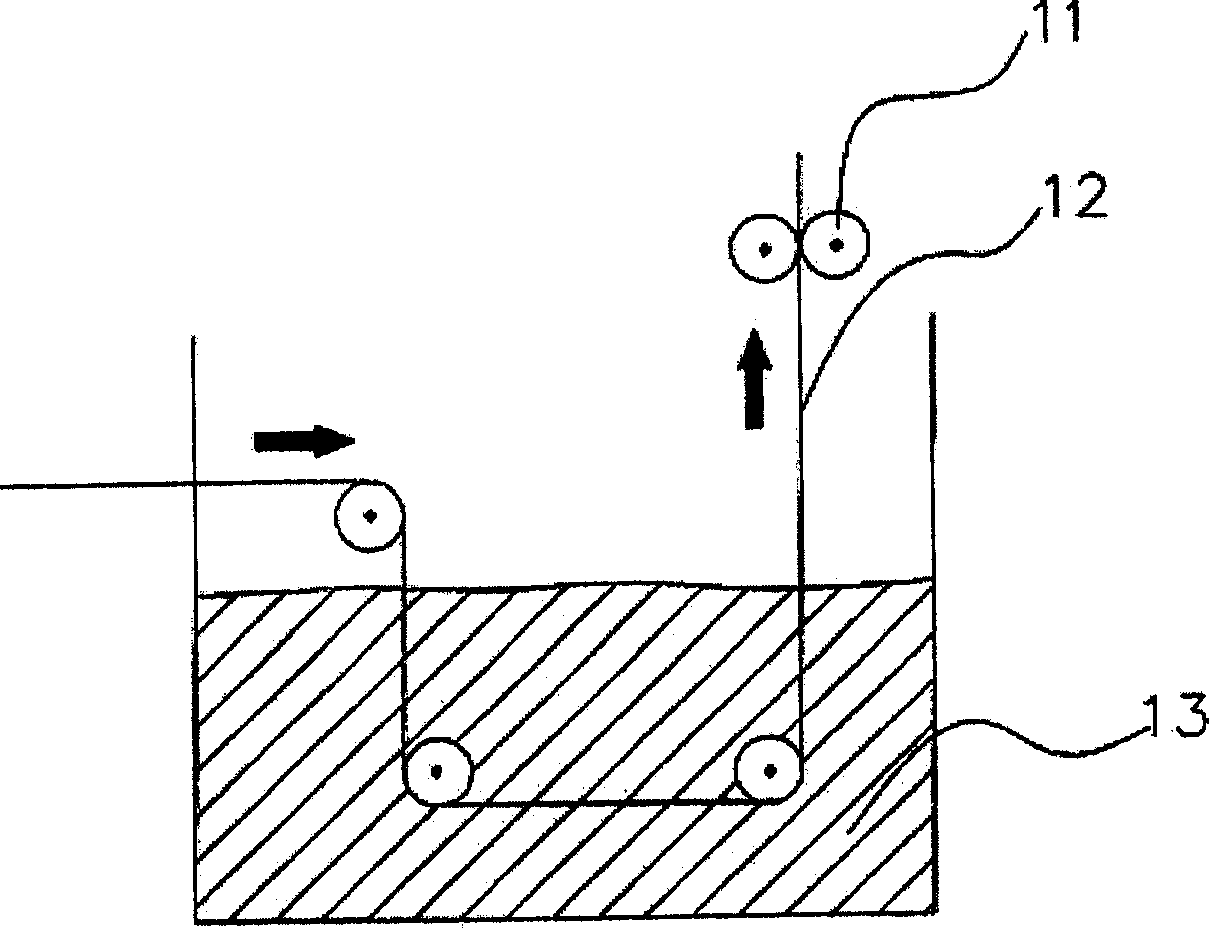

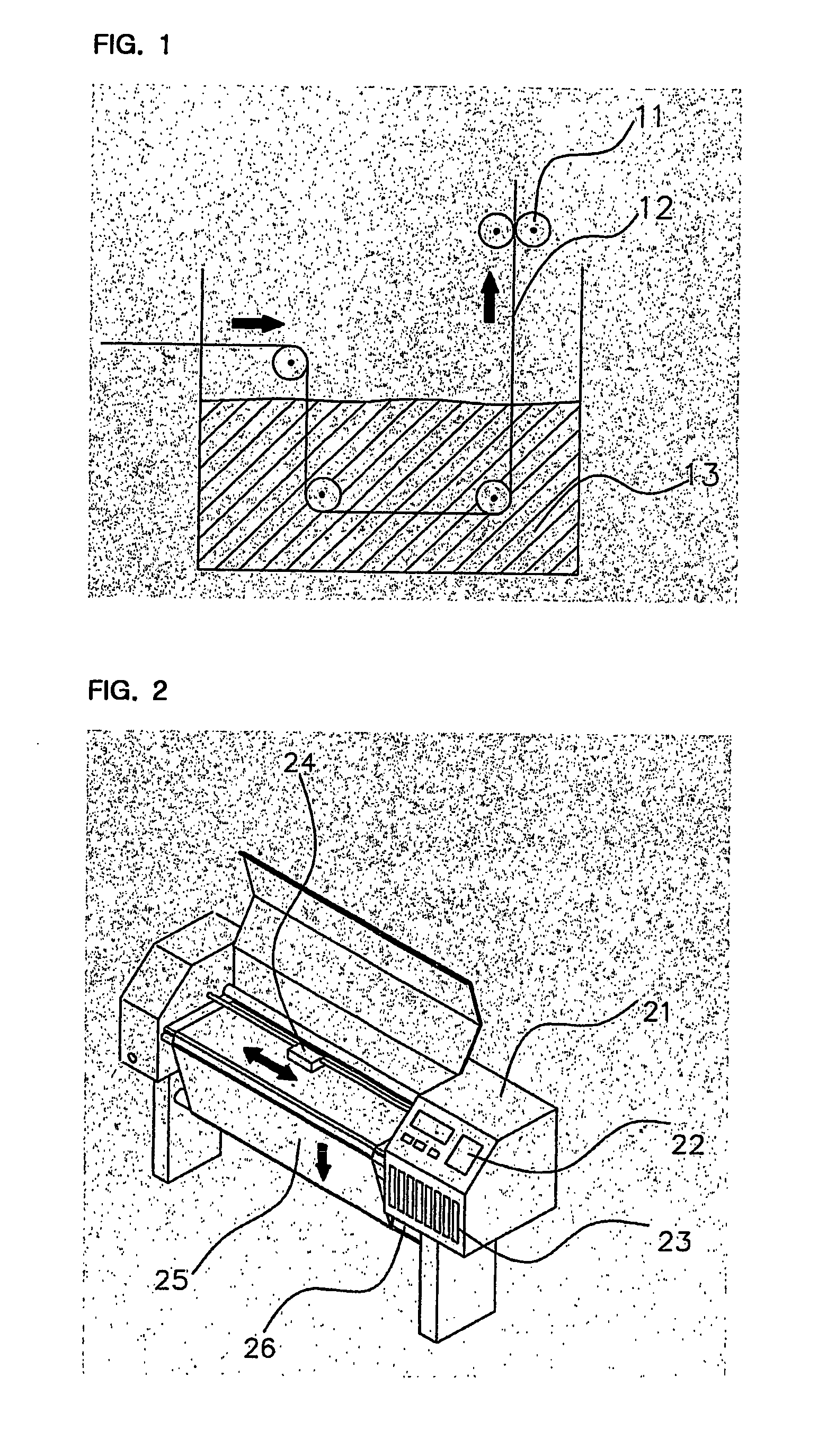

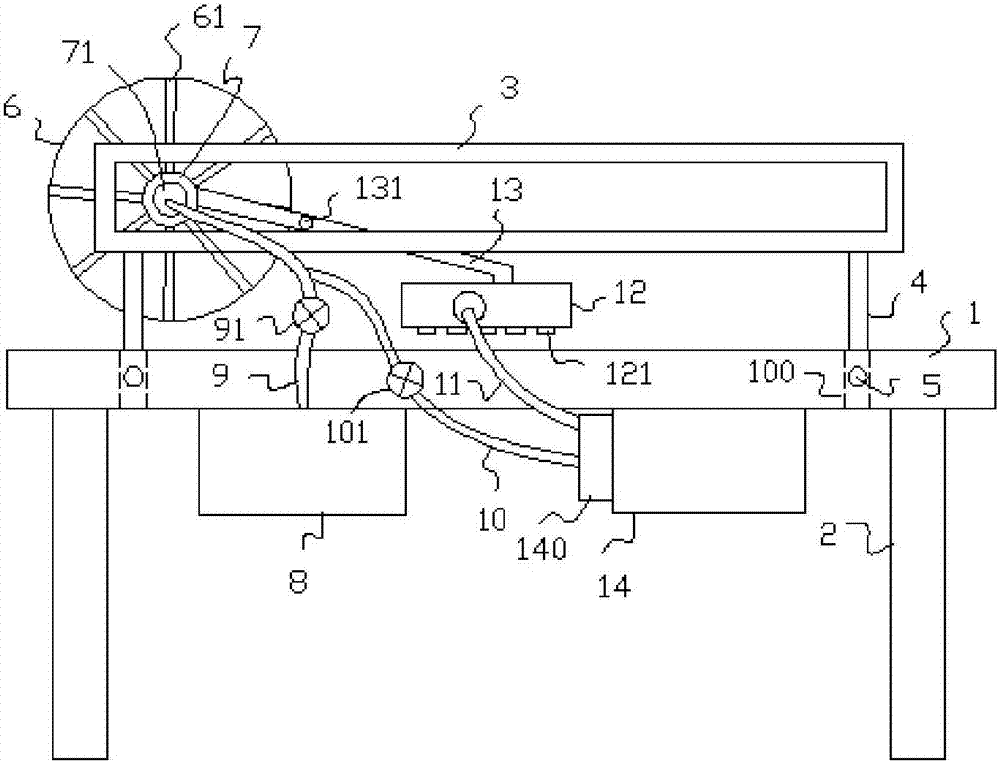

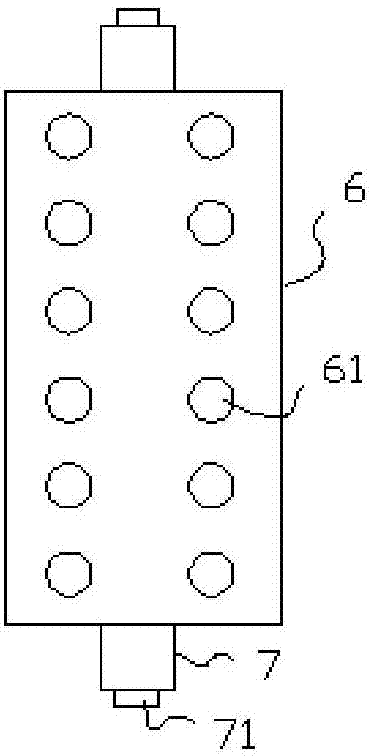

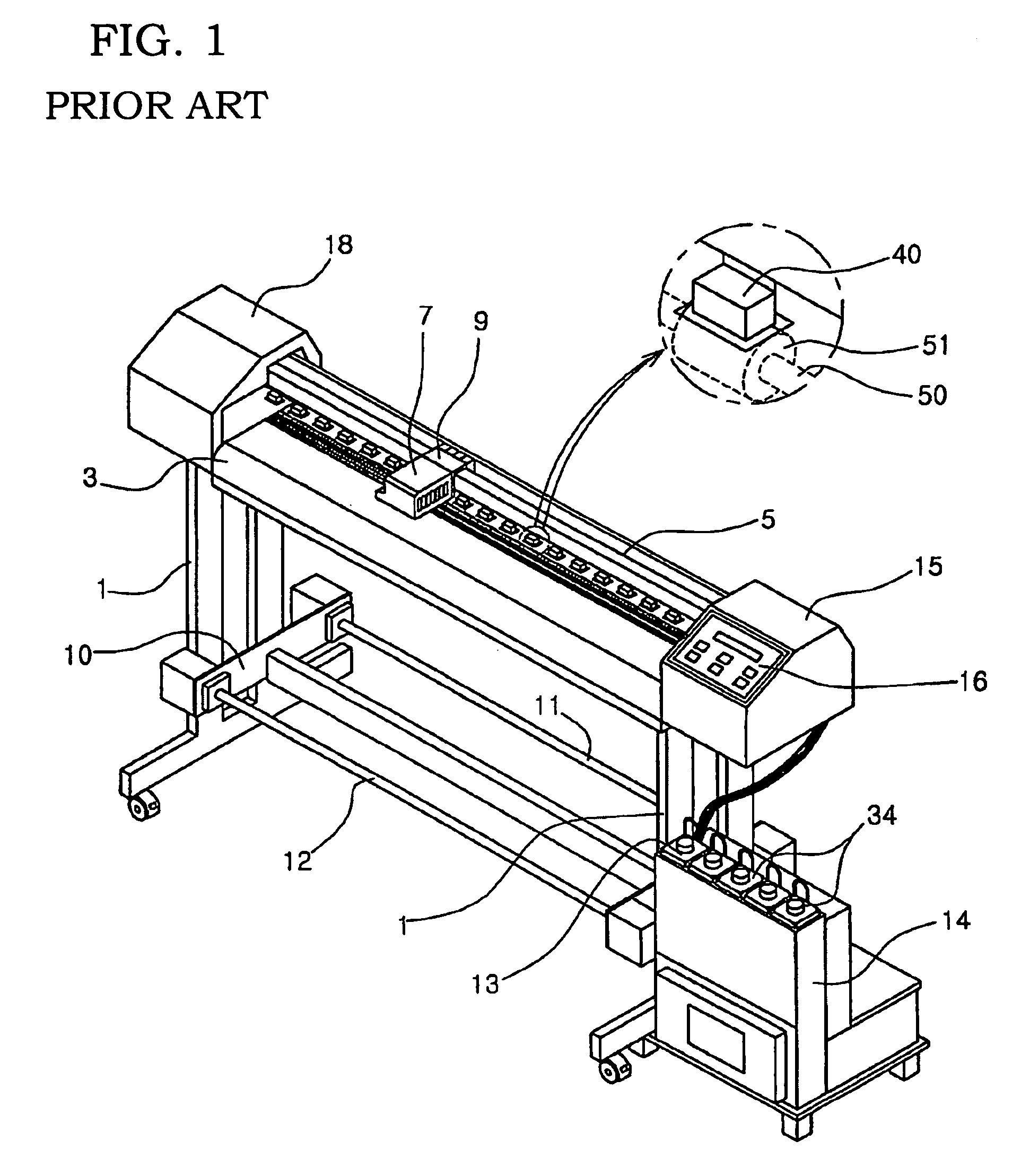

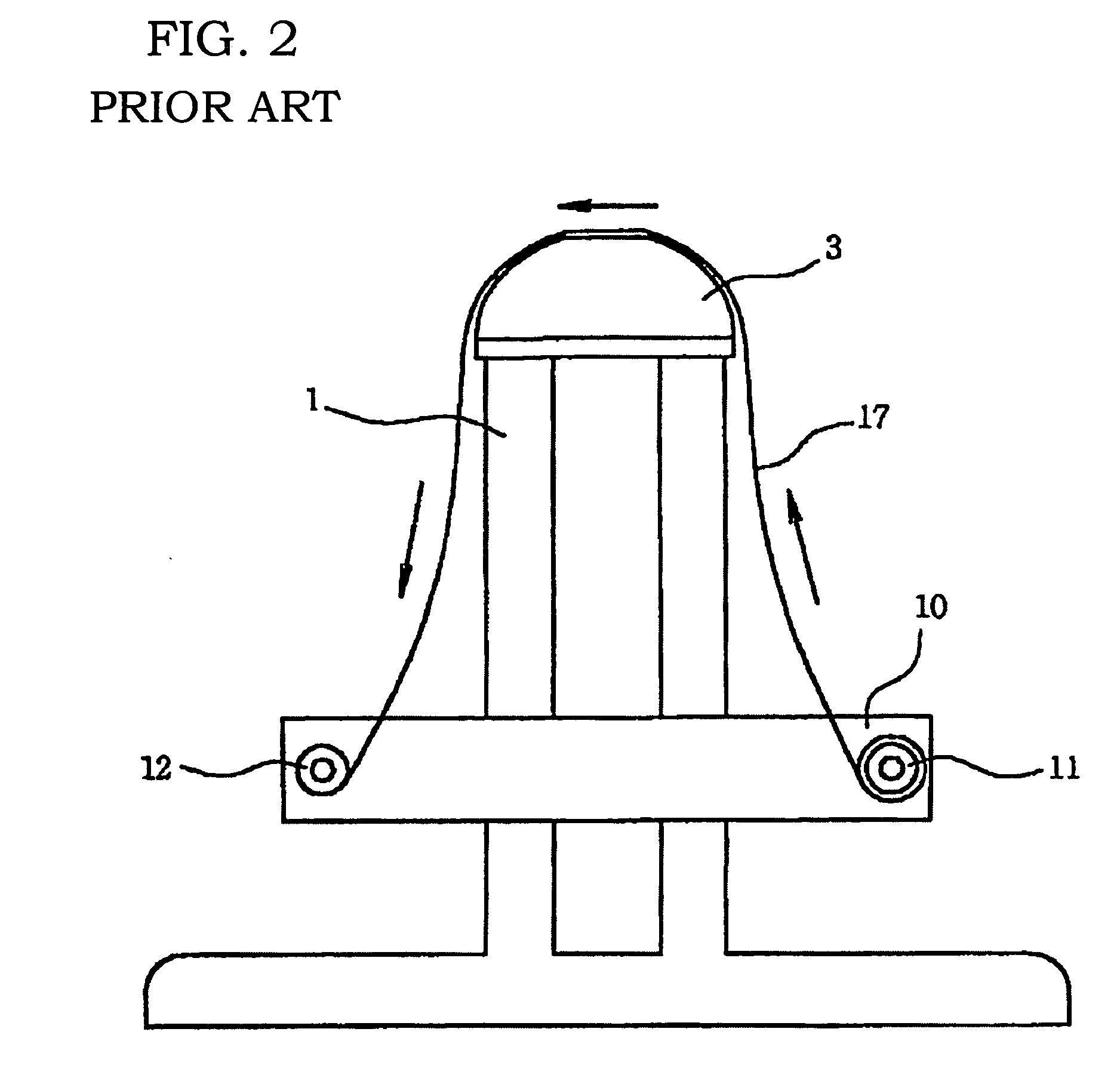

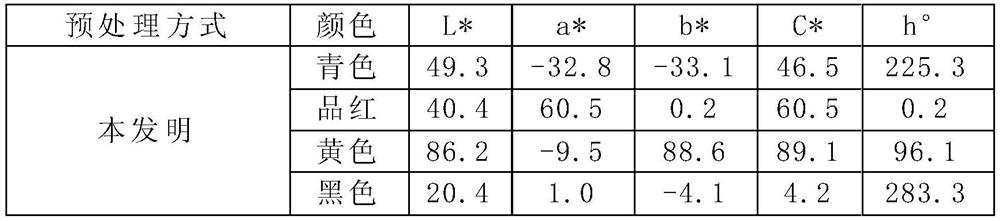

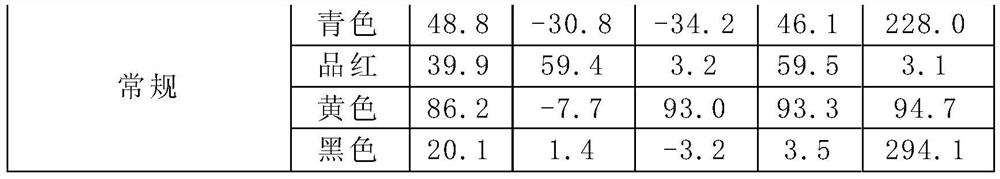

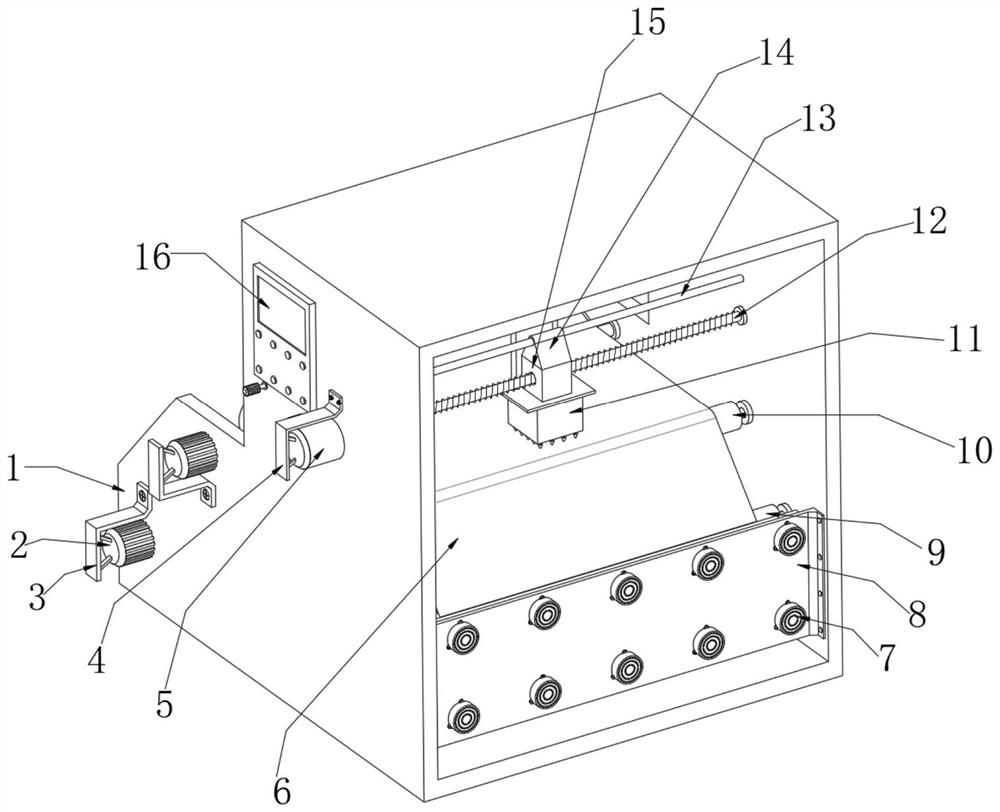

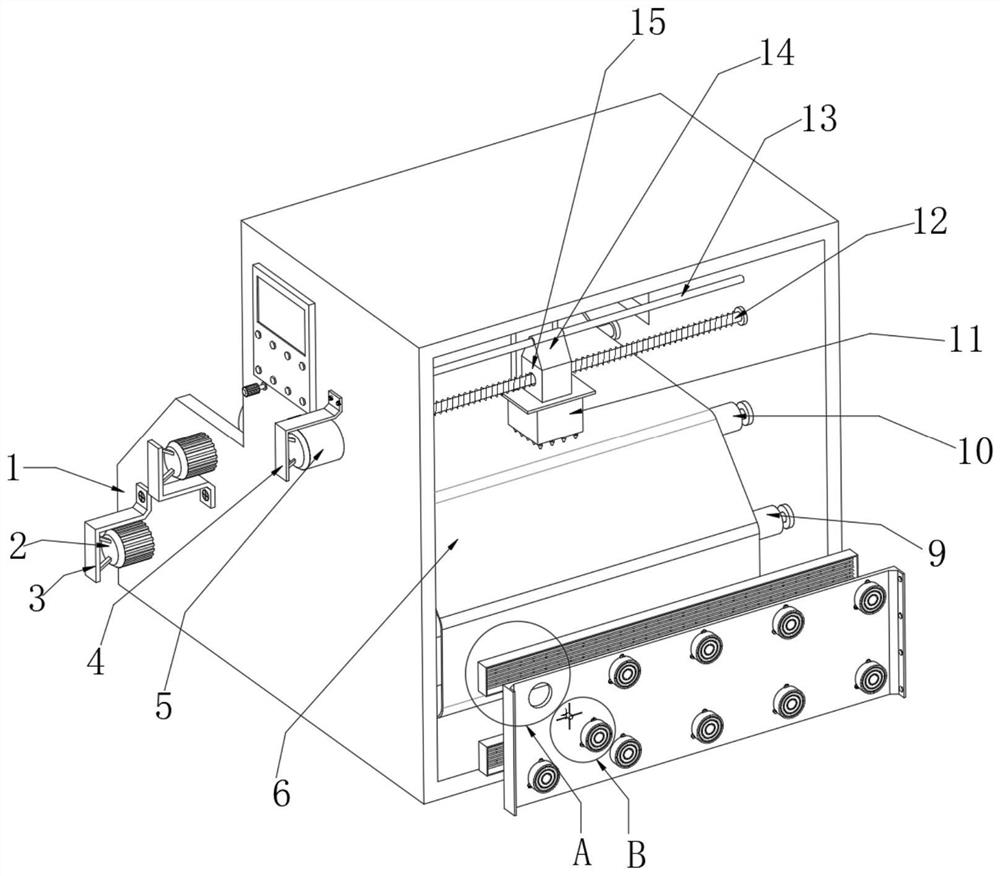

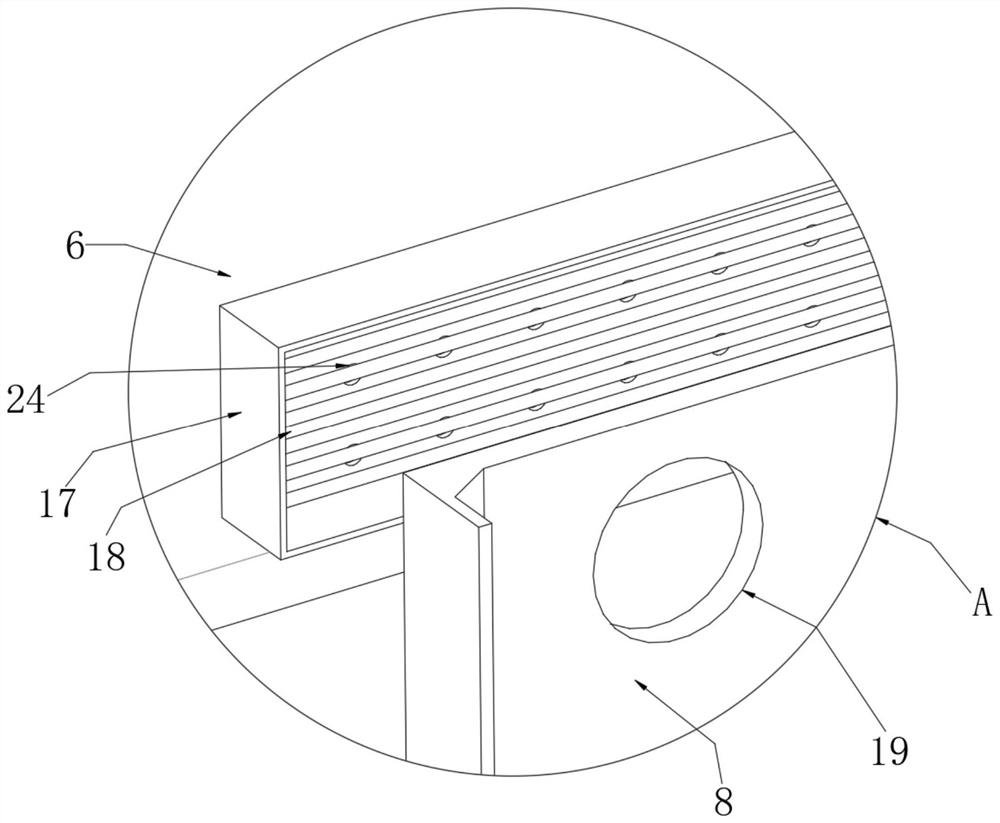

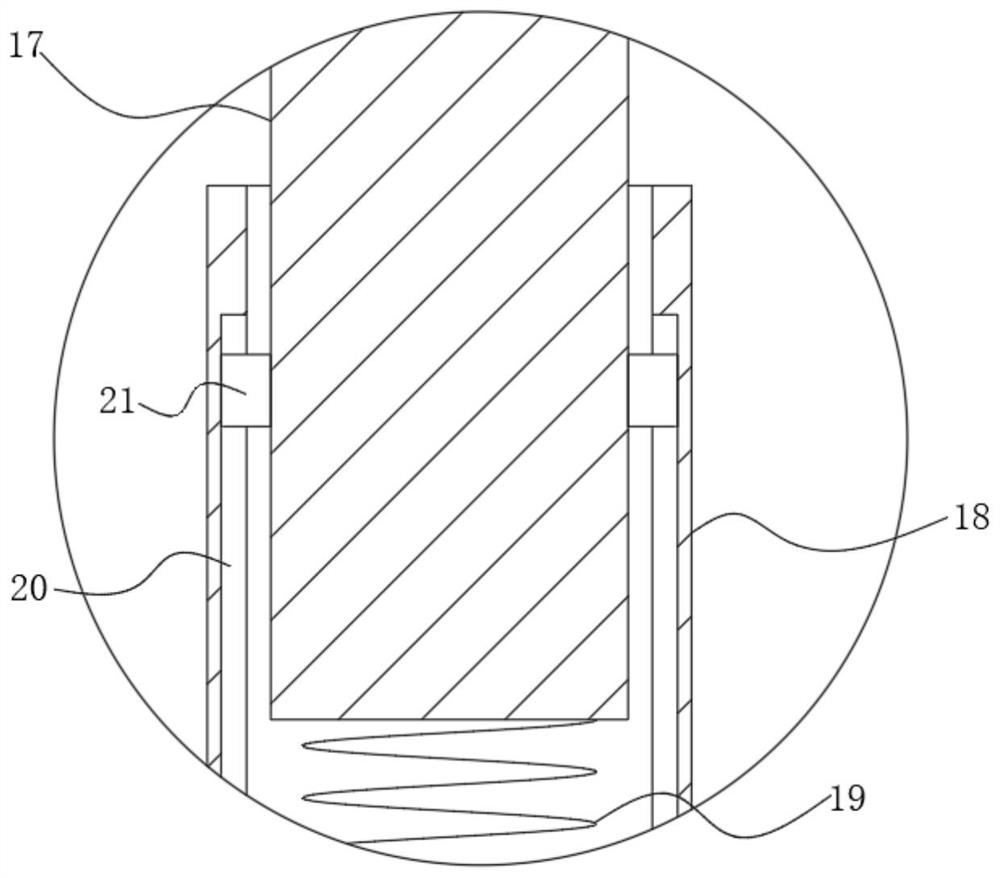

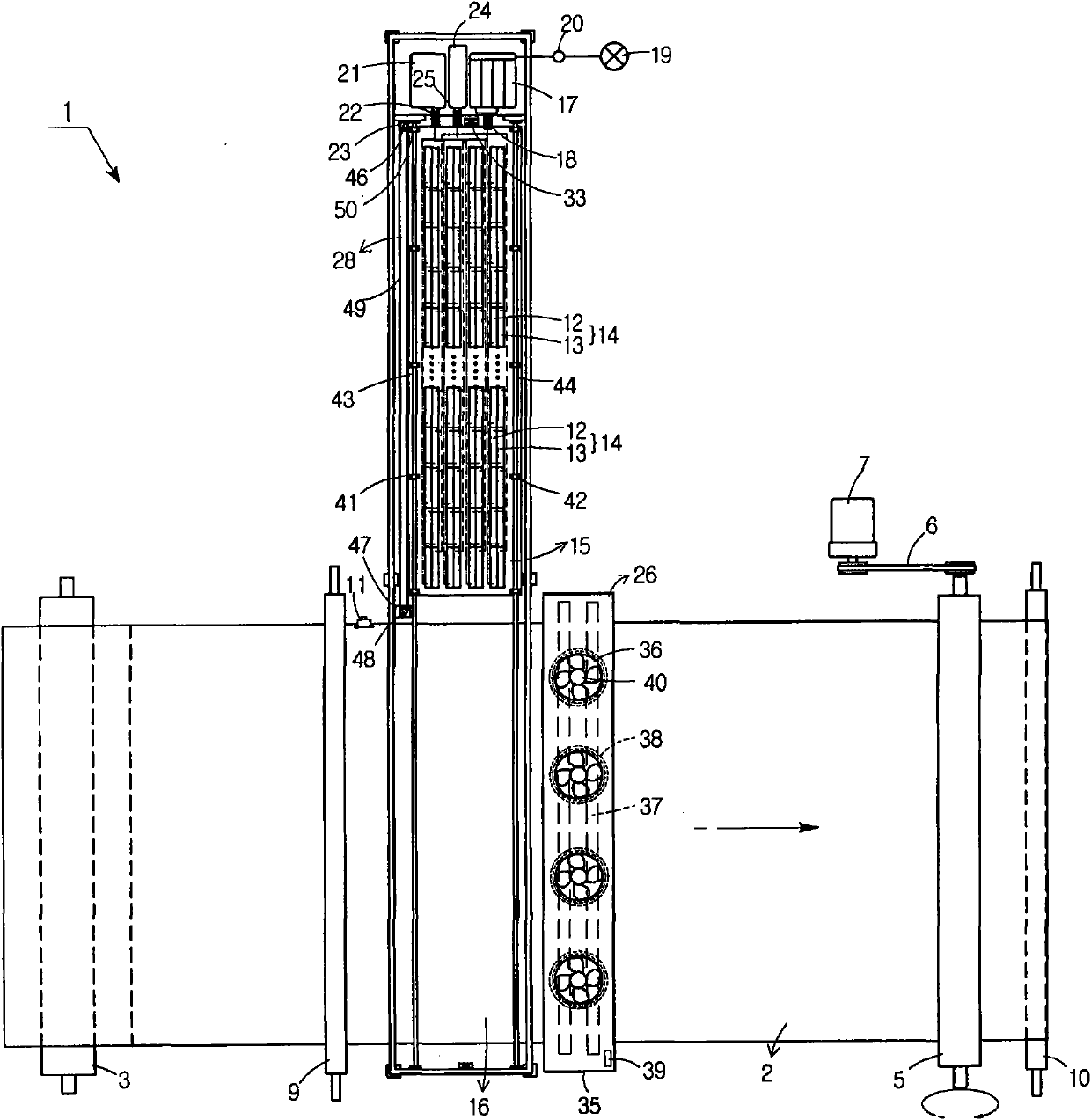

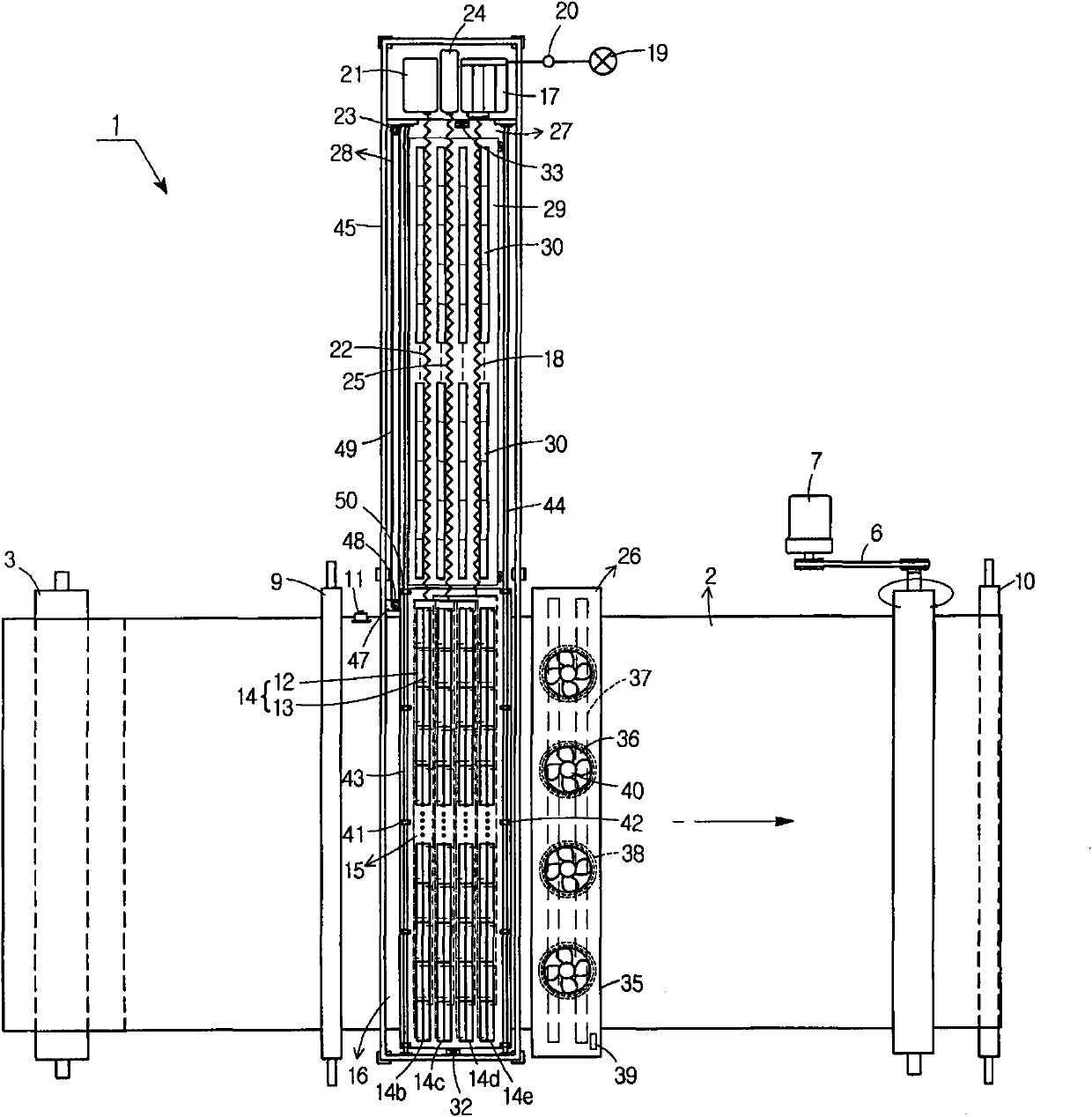

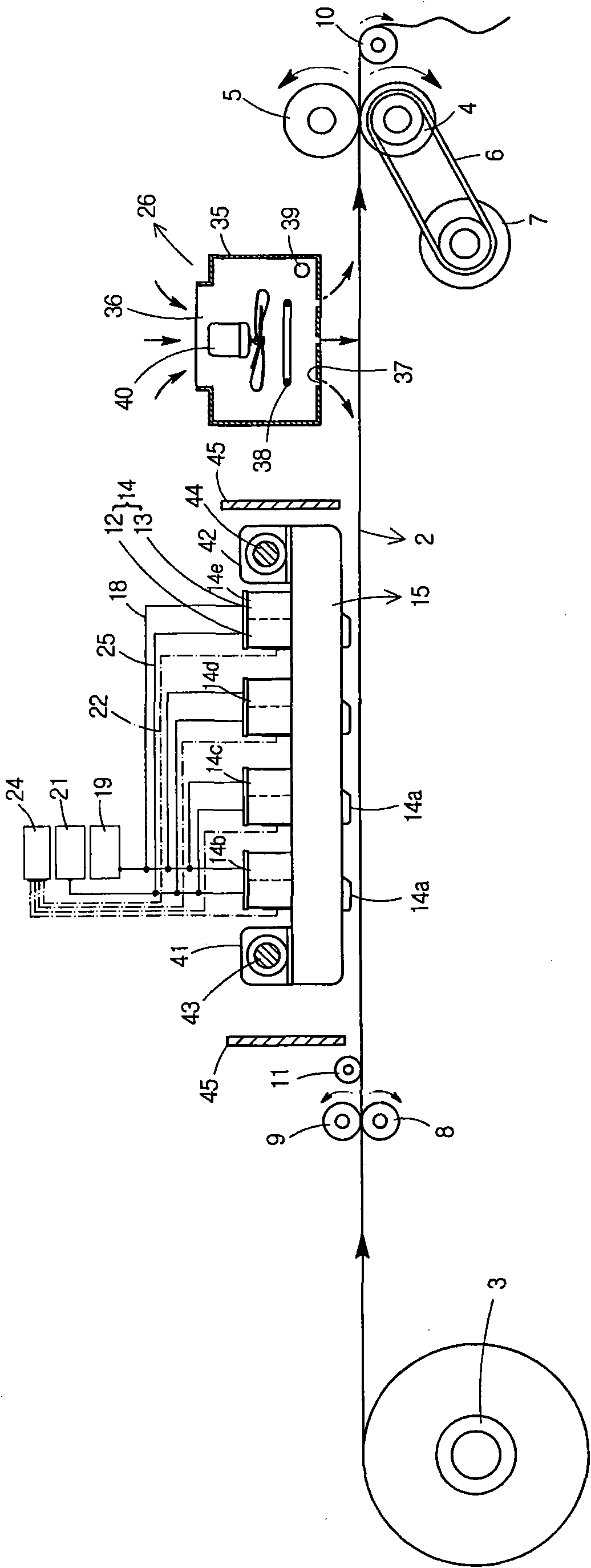

Pretreatment method and apparatus of textile applying inkjet printer, digital textile printing method and apparatus comprising it

Owner:INKTEC CO LTD

Pretreatment method and apparatus of textile applying inkjet printer, digital textile printing method and apparatus comprising it

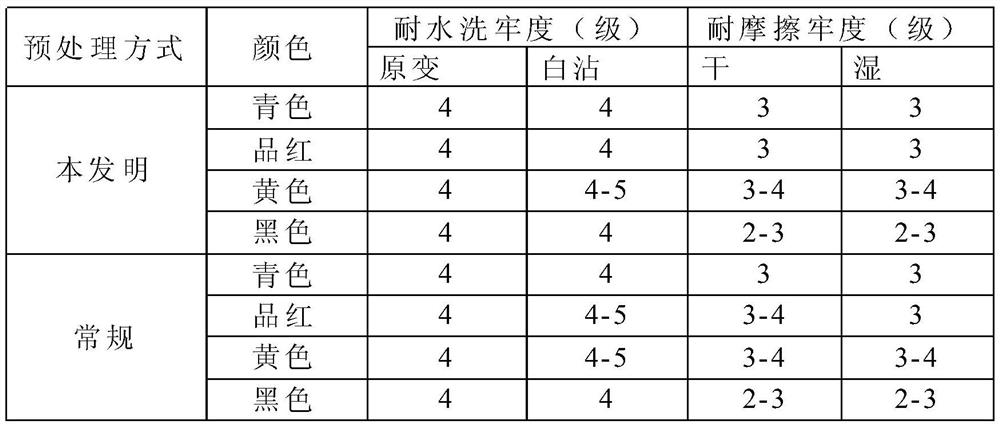

InactiveUS20070040879A1Good colorDeterioration in feelingMeasurement apparatus componentsTypewritersPretreatment methodProcess engineering

The present invention is to provide a method and an apparatus for overcoming complication of the pretreating process due to diversification of materials by digitalizing a method for pretreating a fabric in an inkjet printing process by using an inkjet device, and further, an inkjet printing method and an inkjet printing apparatus for enabling the inkjet printing work to be continuously conducted on the basis of the said pretreatment. The present invention comprises a pretreatment liquid reservoir for enabling the pretreatment mixed liquid to be applied or respective containers to be filled with individual component compositions of a pretreatment liquid, a control unit for controlling application of the pretreatment liquid and a pretreatment head for applying the pretreatment liquid to the fabric, and it may additionally comprise a dryer for drying the pretreated fabric and a printing head for performing the actual printing work. The present invention can solve the problems incidental to the conventional pretreating method and further provide a method and an apparatus for enabling a continuous process to be executed.

Owner:INKTEC CO LTD

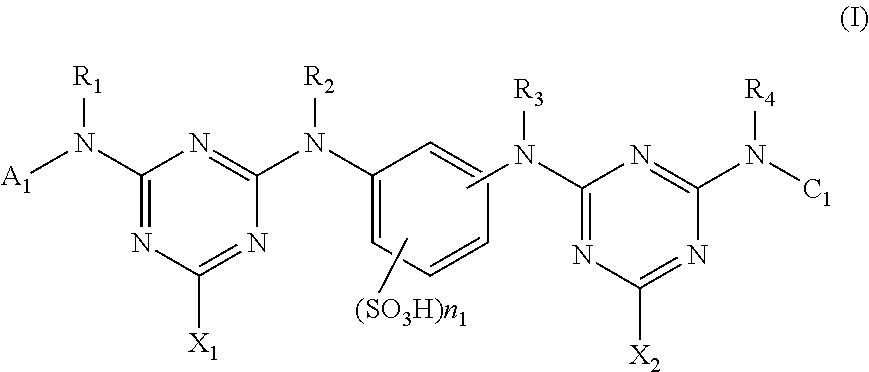

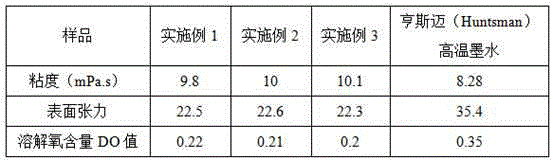

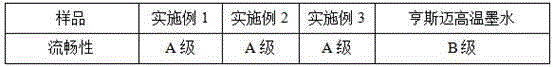

High-temperature direct-injection disperse ink as well as preparation method and application thereof

The invention discloses high-temperature direct-injection disperse ink as well as a preparation method and an application thereof. The ink is prepared from the following raw materials in parts by weight: 15-60 parts of high-temperature disperse dye, 0.3-20 parts of dispersant, 30-60 parts of organic solvent, 10-50 parts of water, 0.5-10 parts of surfactant, 0.05-0.2 part of preservative and 0.05-0.2 part of defoamer. The preparation method comprises the steps of evenly mixing the high-temperature disperse dye, the dispersant, the organic solvent and water together, adding zirconium beads for grinding and dispersing, and then adding the rest organic solvent, water, the surfactant, the preservative and the defoamer to the mixture, mixing evenly, and filtering to obtain the filtrate. The ink is applied to a novel industrial digital textile printing machine and in particular to a textile printing machine with a precision work 508GS nozzle; the ink can be directly injected for printing by using the printing machine, and therefore, the utilization rate of the ink is increased, the cost is reduced and the environmental pollution is reduced; the ink can be dyed quickly at high temperature without transfer printing, and thus has the advantages of short dyeing time, firm dyeing and the like.

Owner:深圳市墨库图文技术有限公司

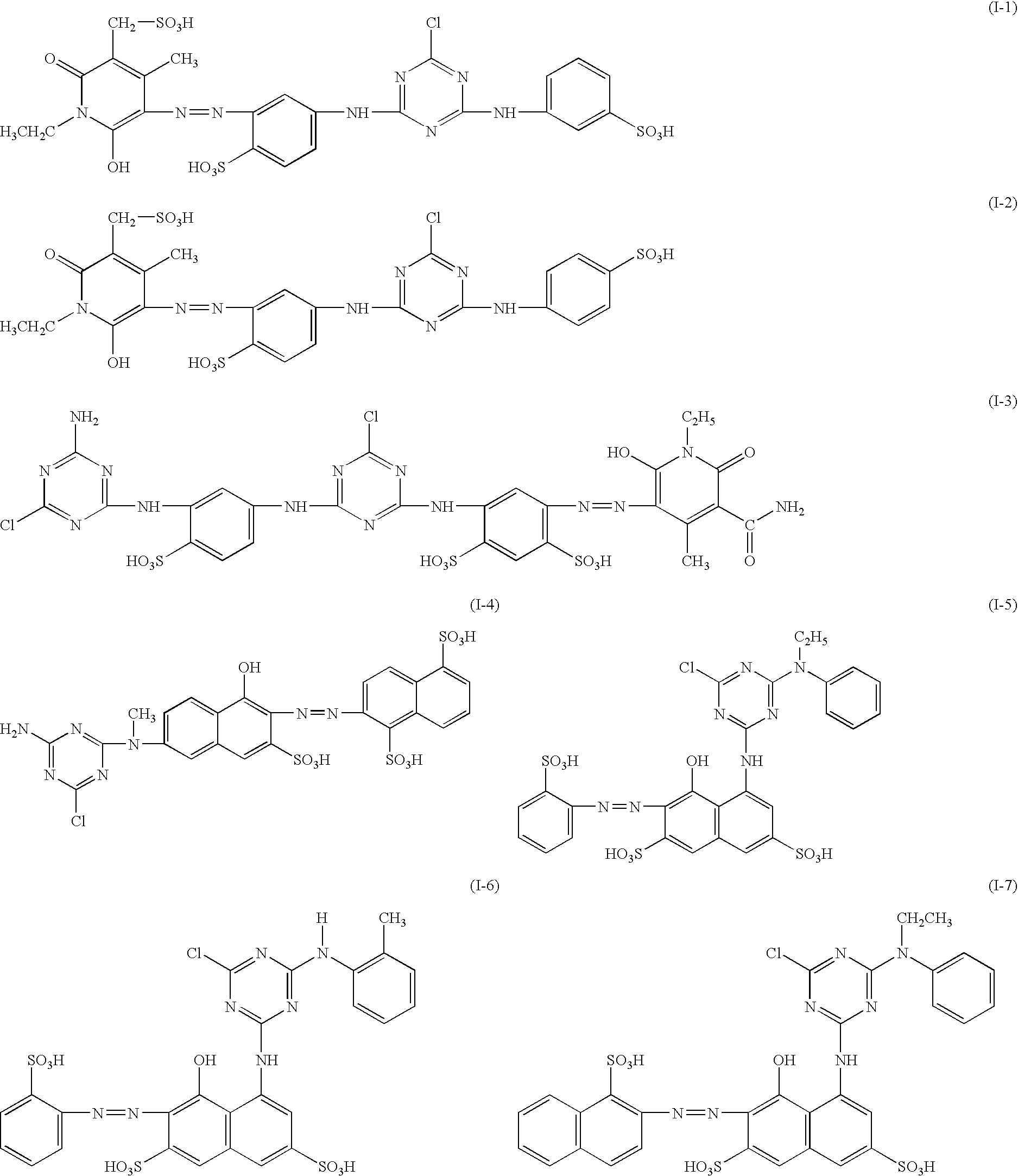

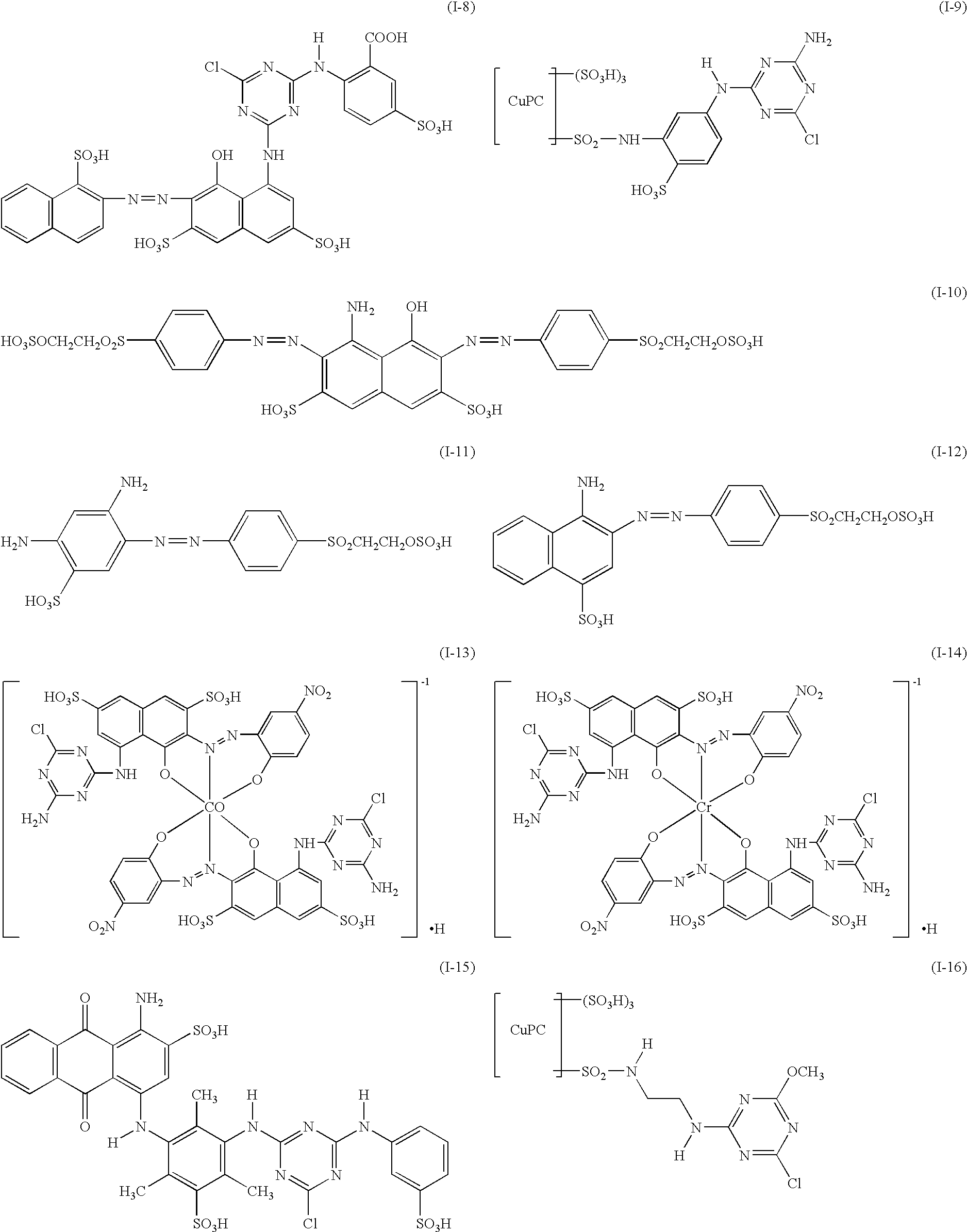

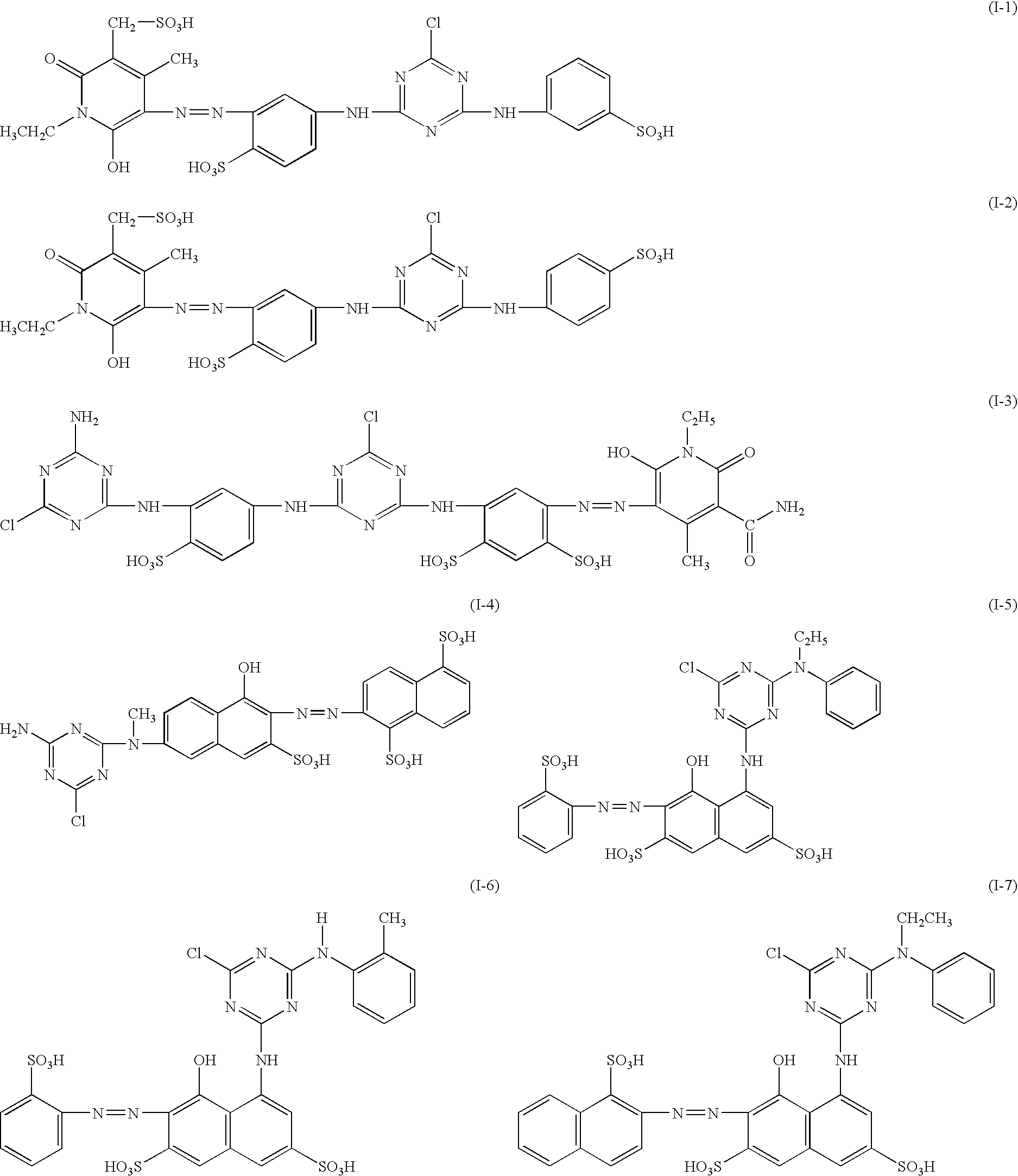

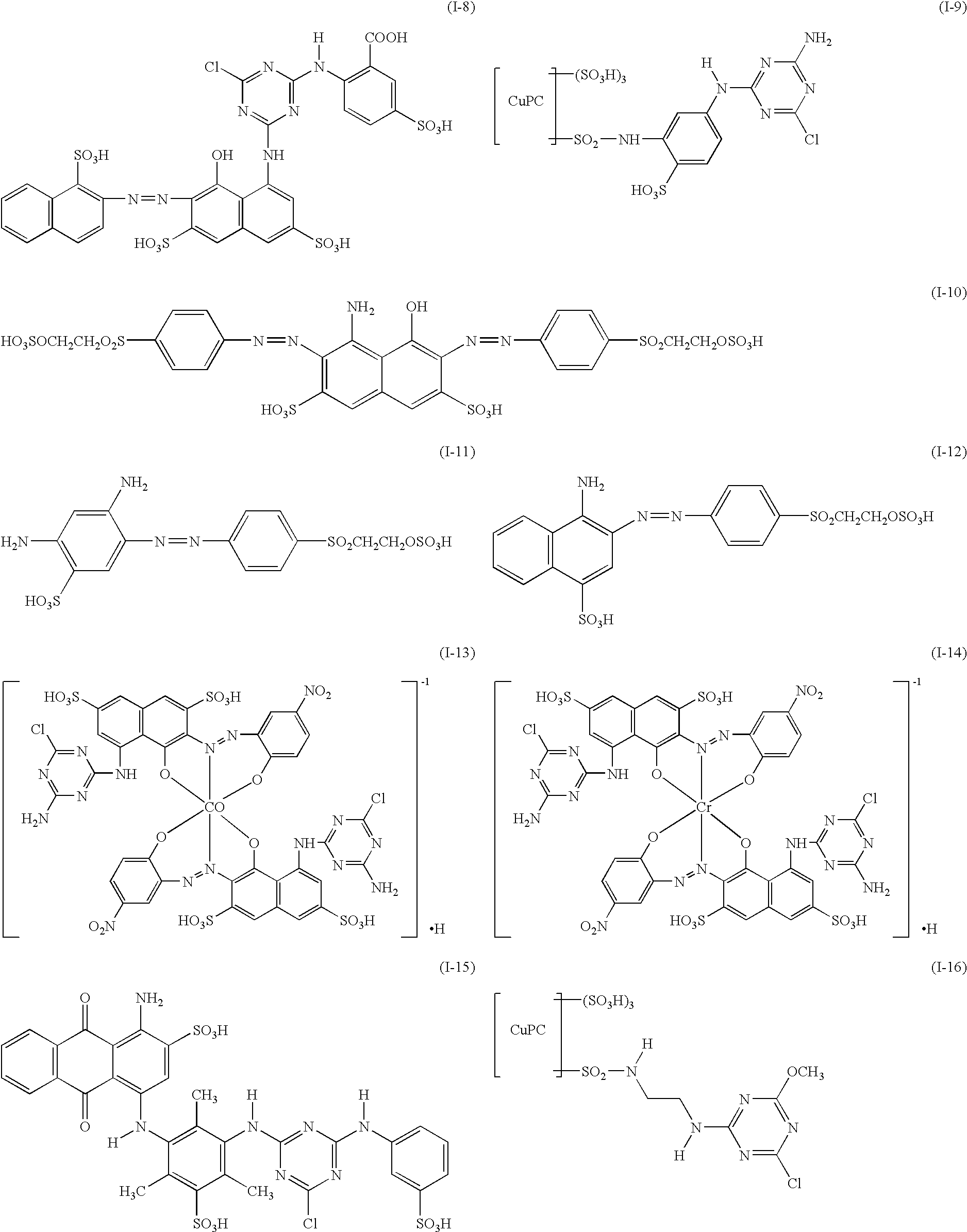

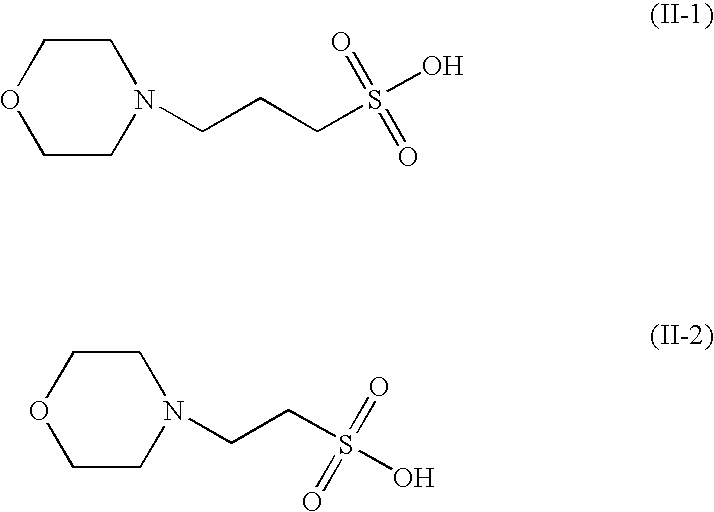

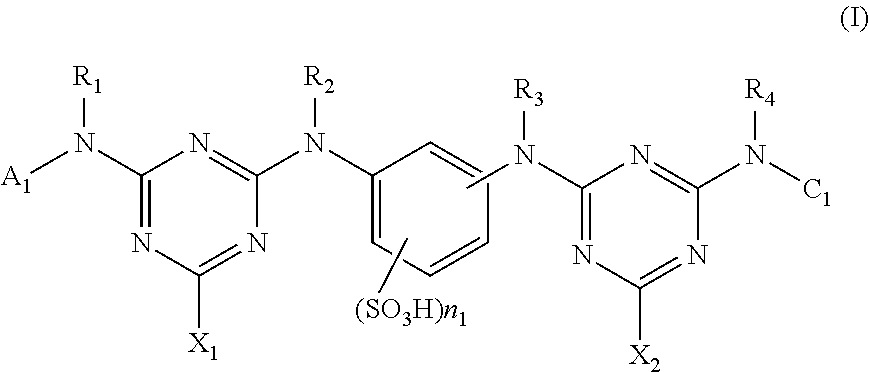

High fixation ink composition for digital textile printing

InactiveUS20160326384A1High ink compositionGood storage stabilityAntifouling/underwater paintsReactive dyesDigital printingSolvent

The present invention is related to a novel high fixation ink composition for digital textile printing, which comprises: (A) at least one reactive dye compound with two reactive groups in an amount of 1% to 50% by weight; (B) an organic buffer in an amount of 0.05% to 10% by weight; (C) a humectant in an amount of 10% to 50% by weight; and (D) a solvent in remaining amount. When the aforesaid ink composition is applied in digital textile printing, fixation rate of dye on fabrics is high.

Owner:EVERLIGHT CHEMICAL INDUSTRIAL CORPORATION

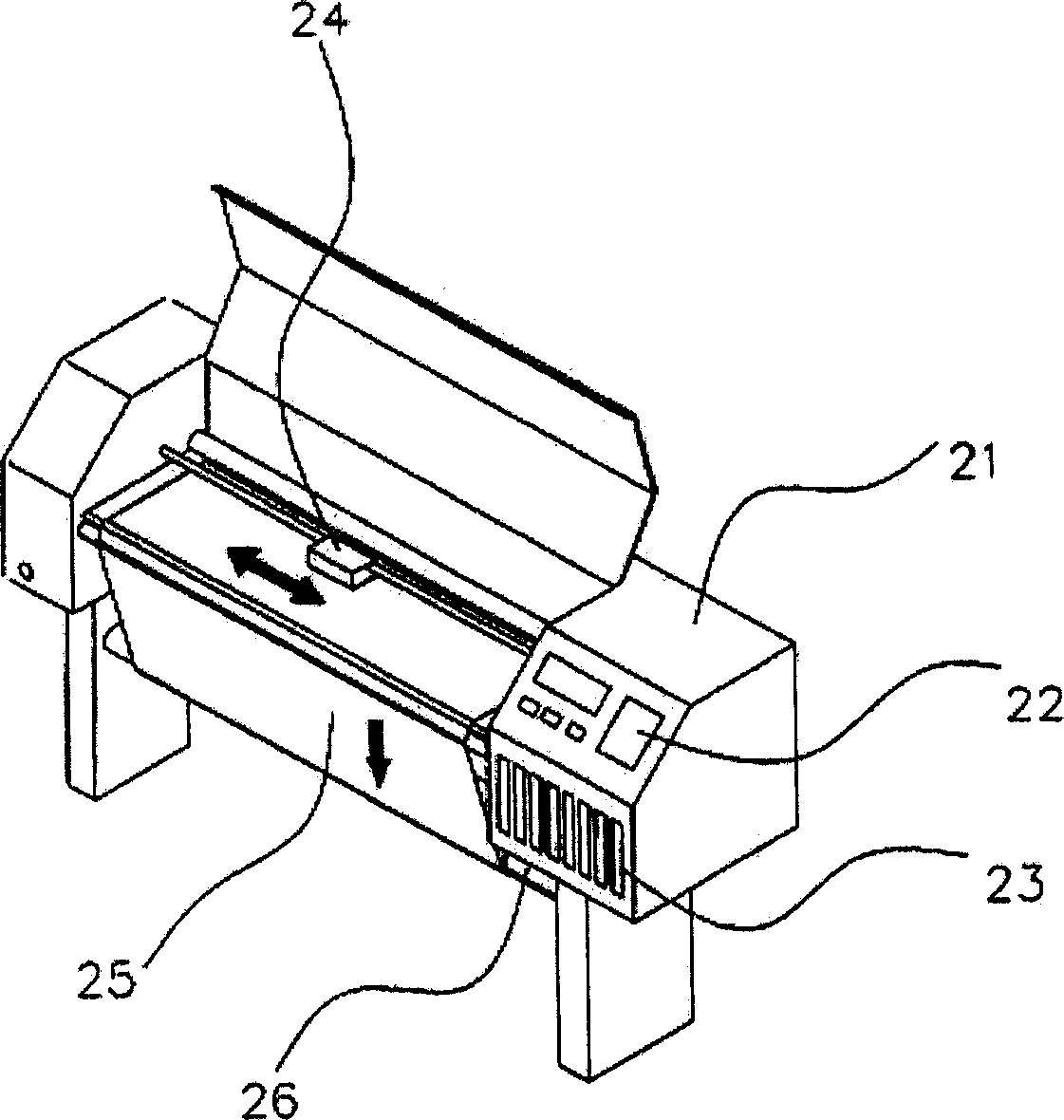

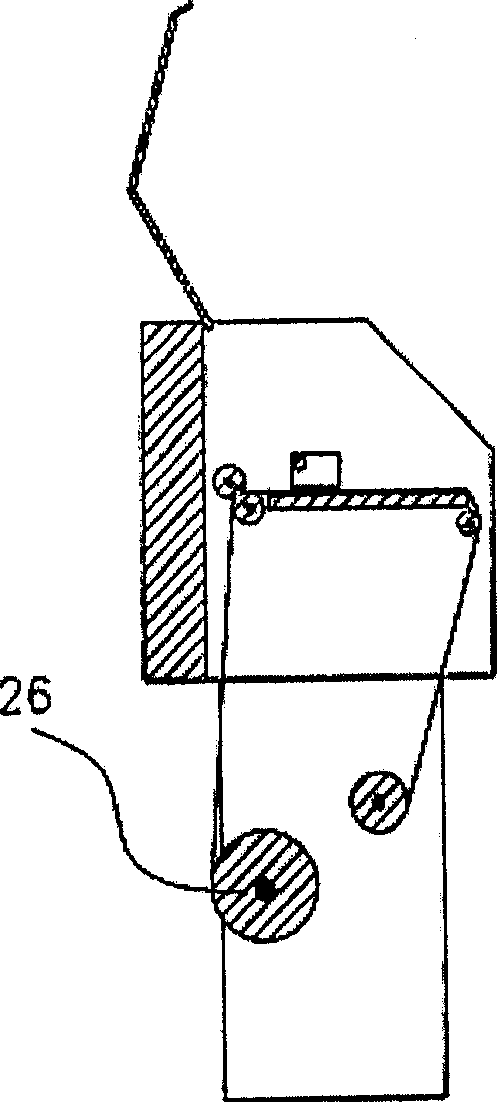

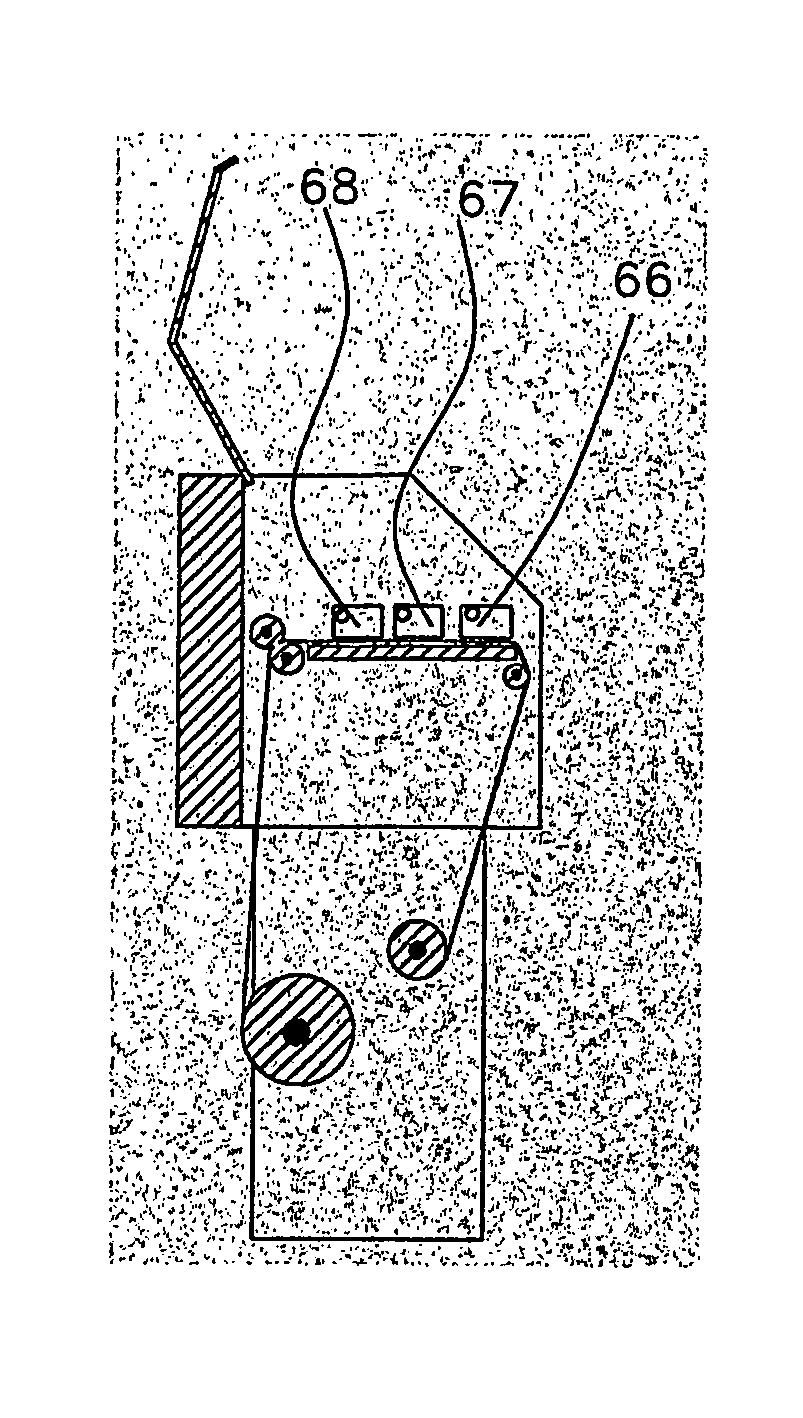

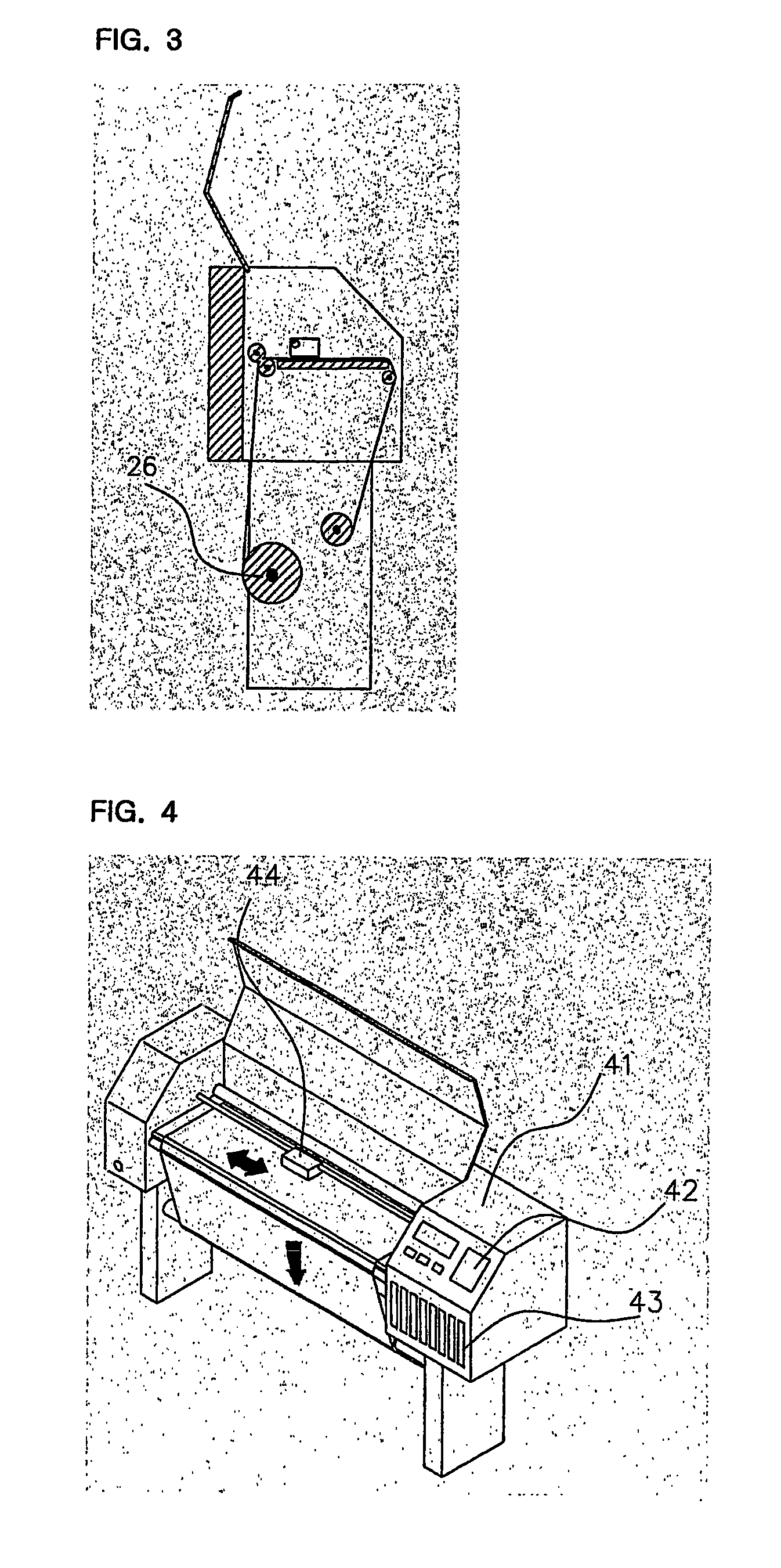

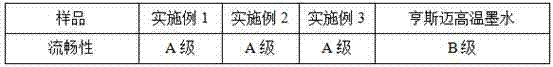

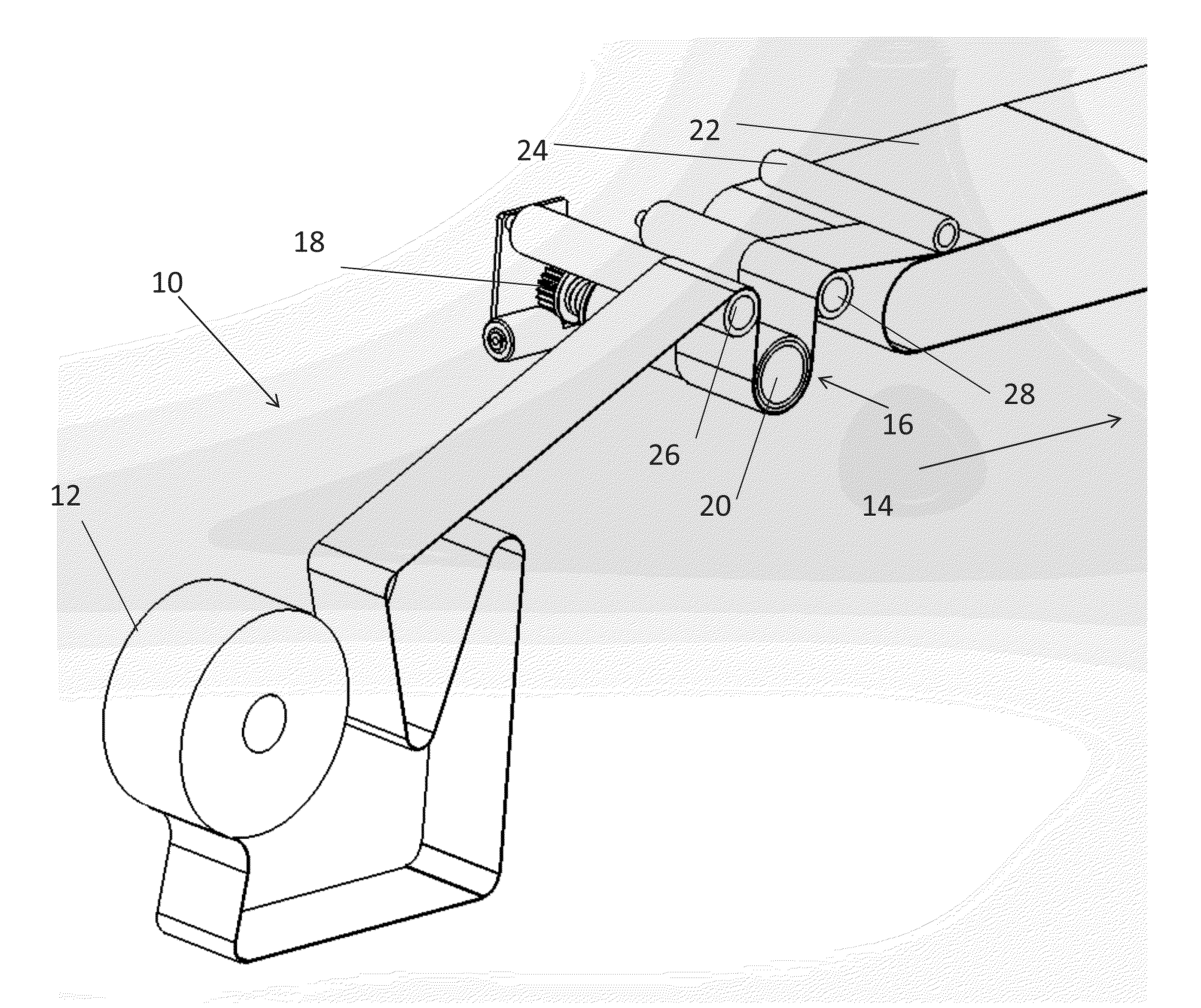

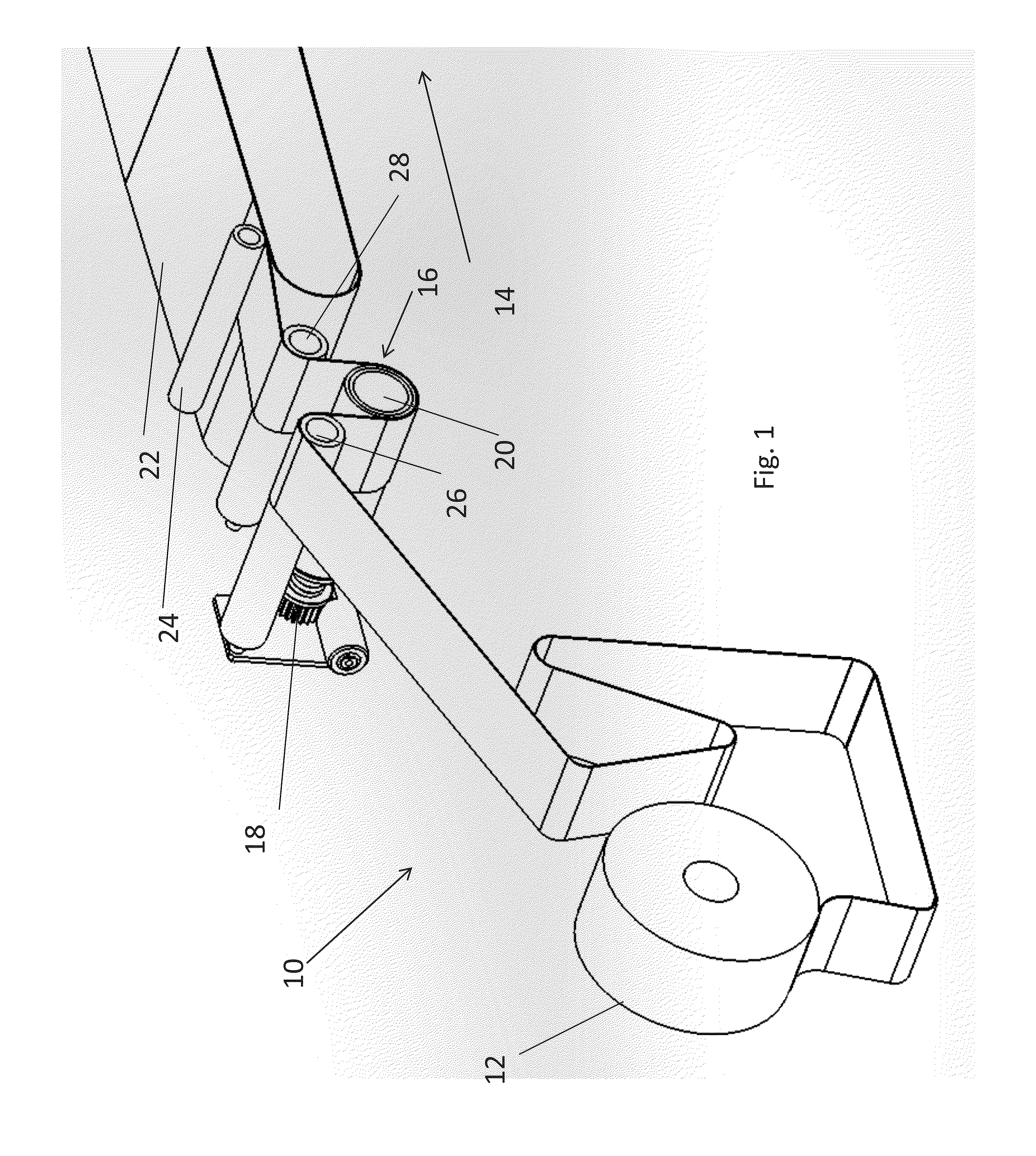

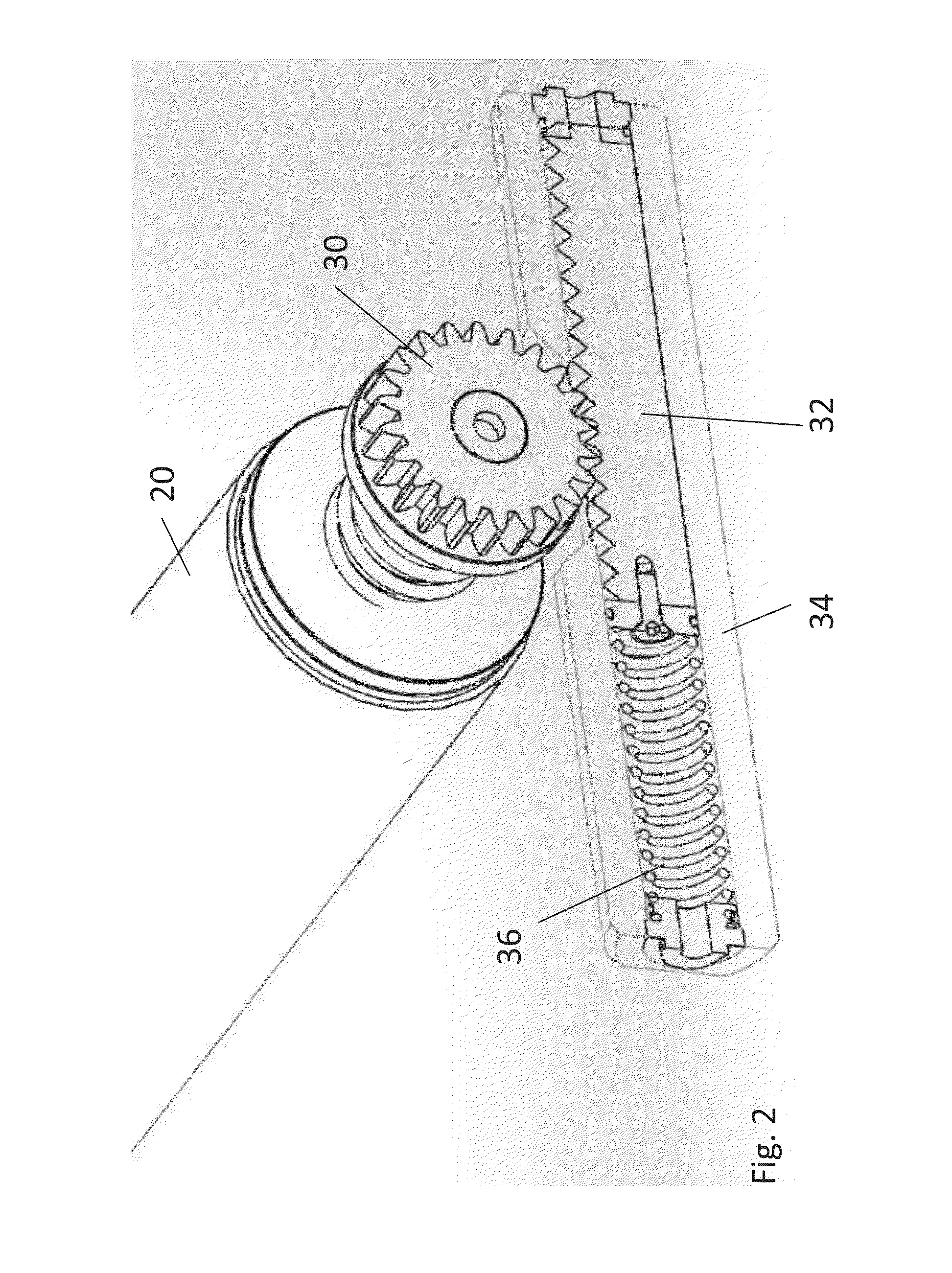

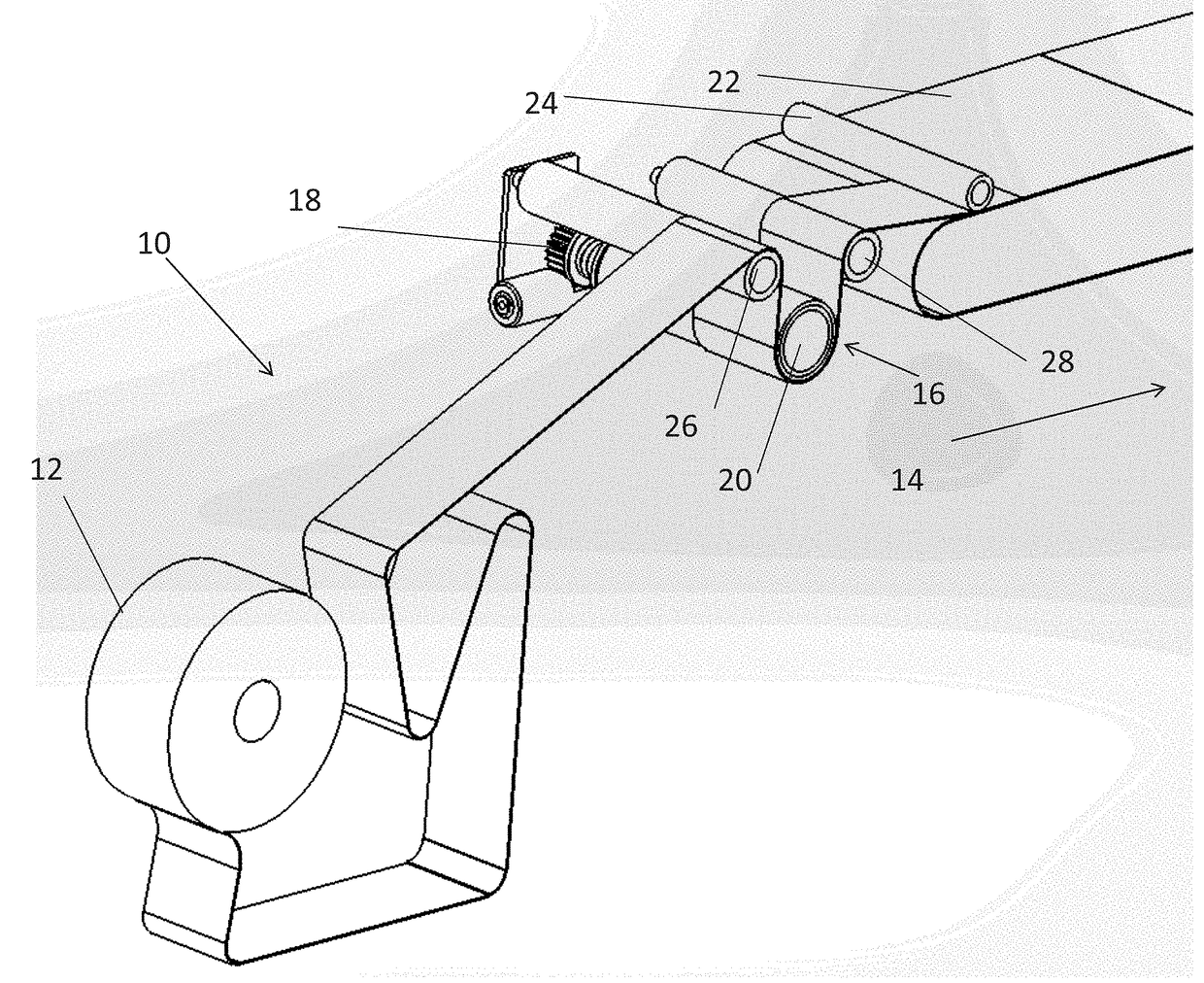

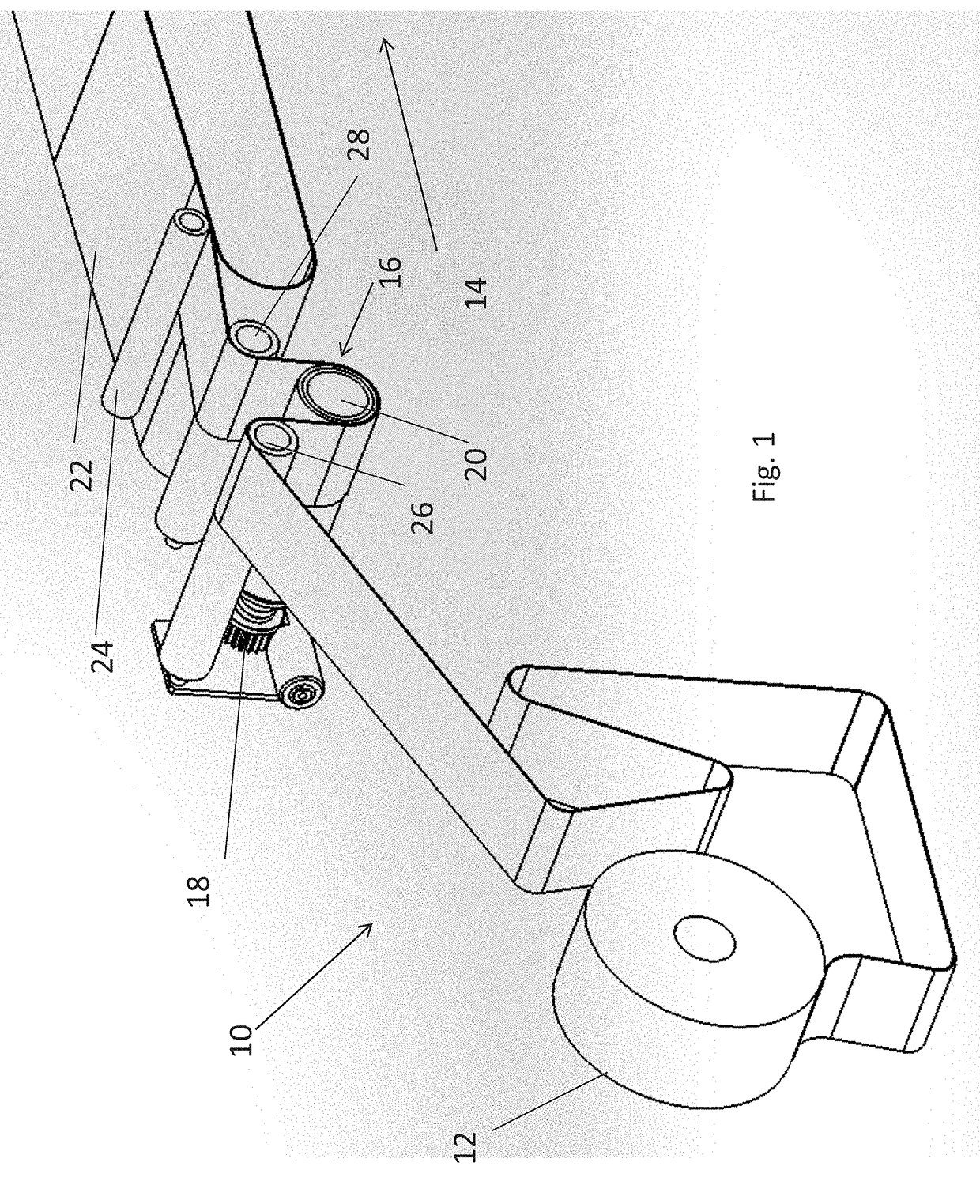

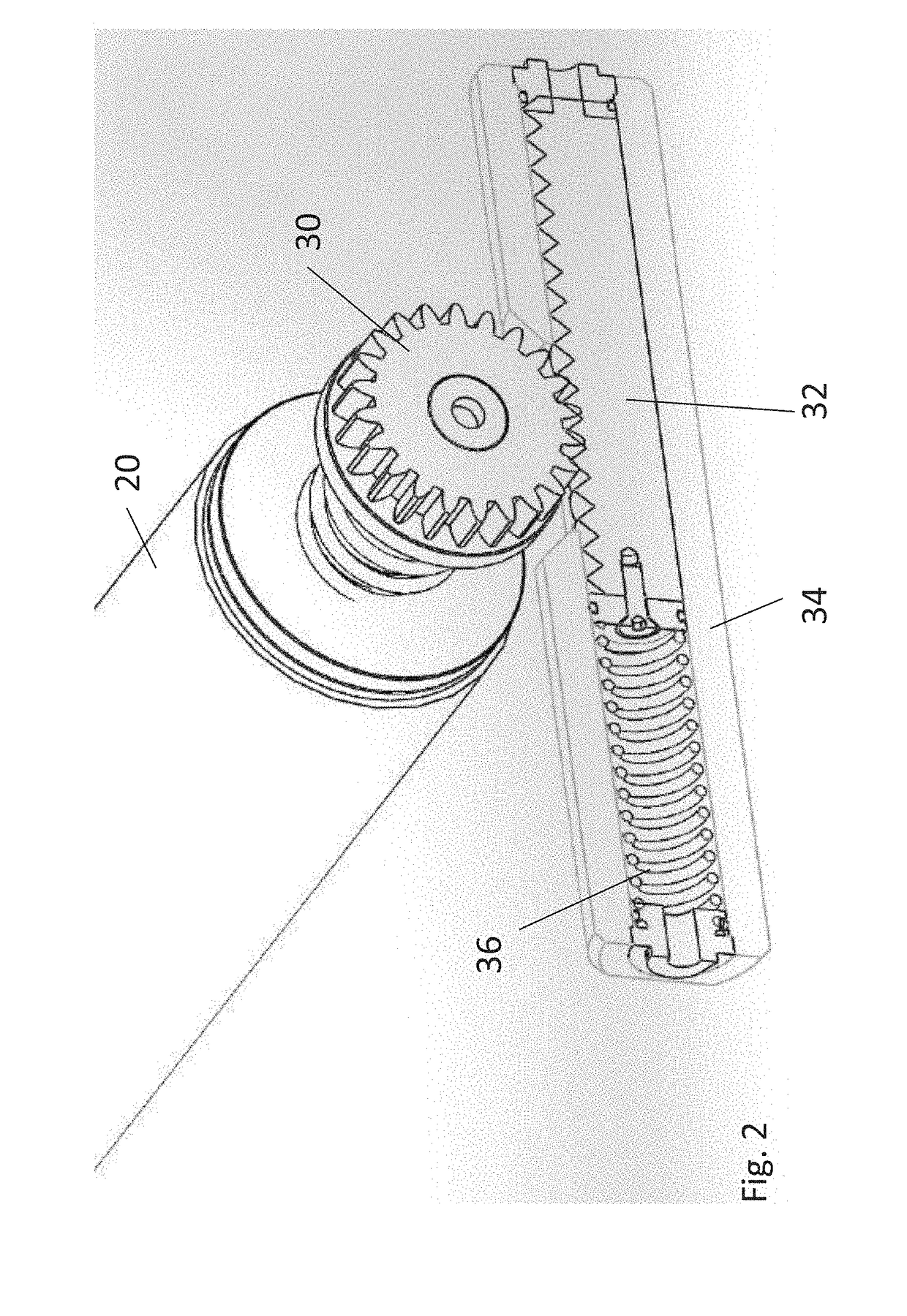

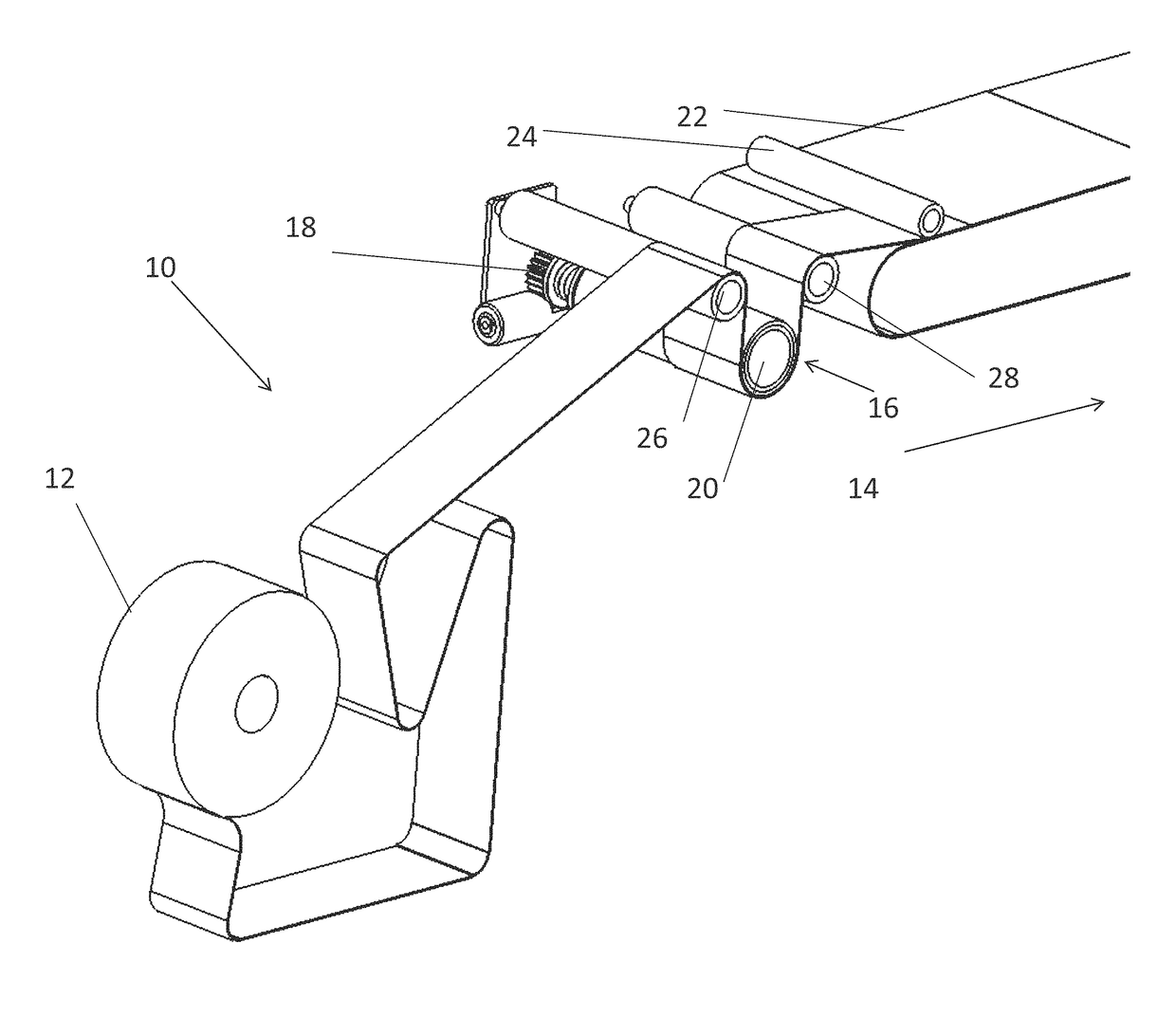

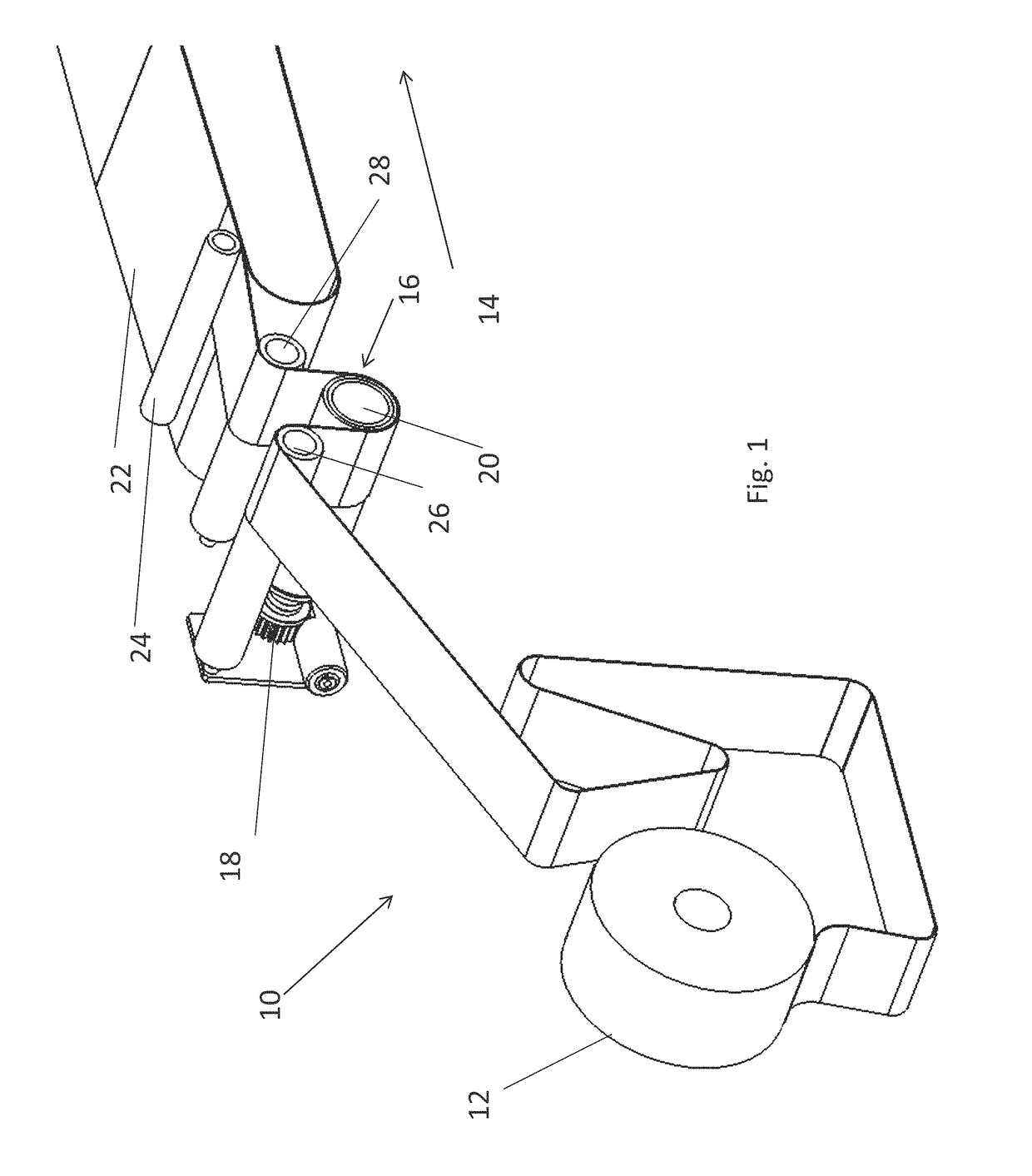

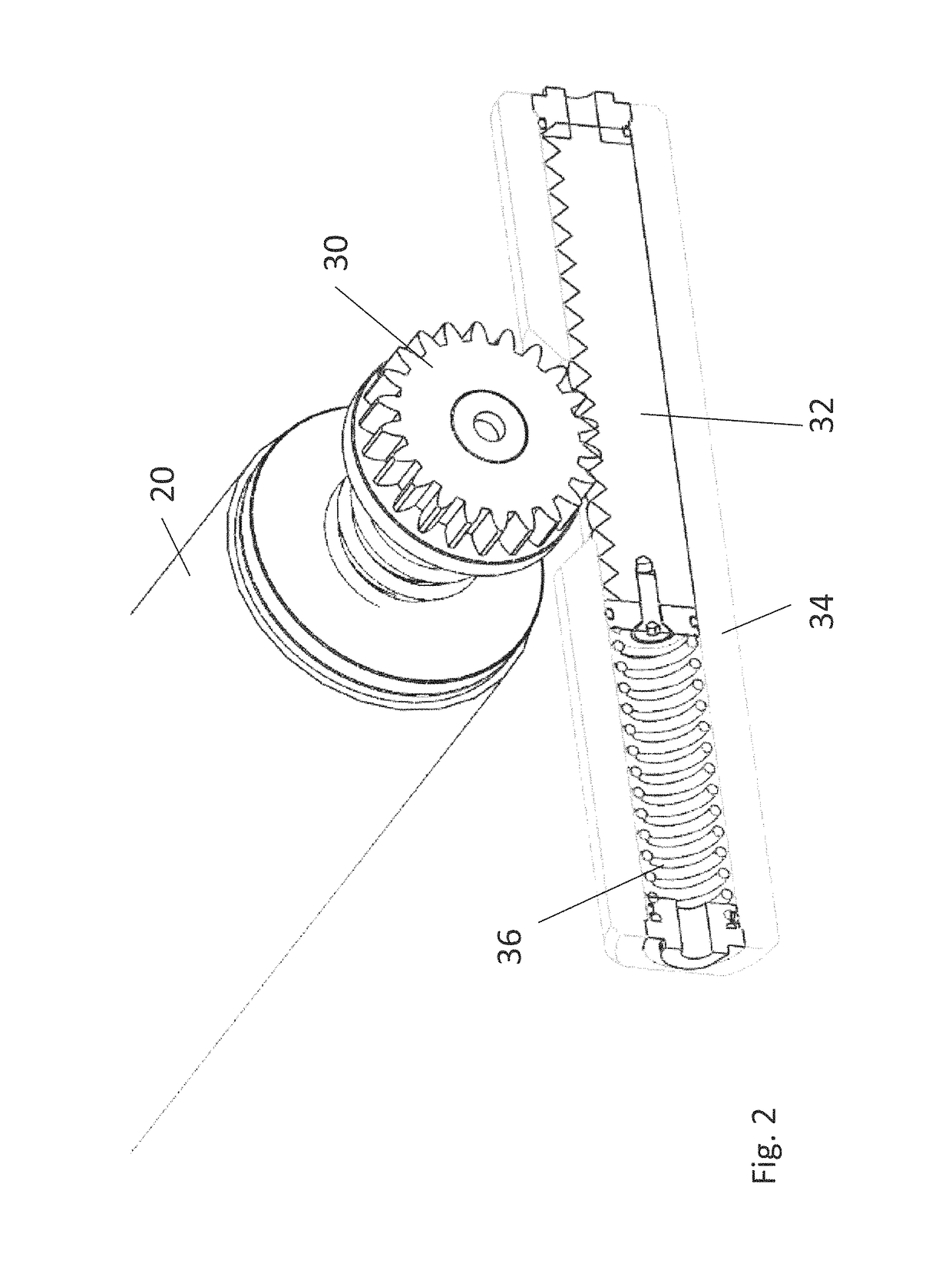

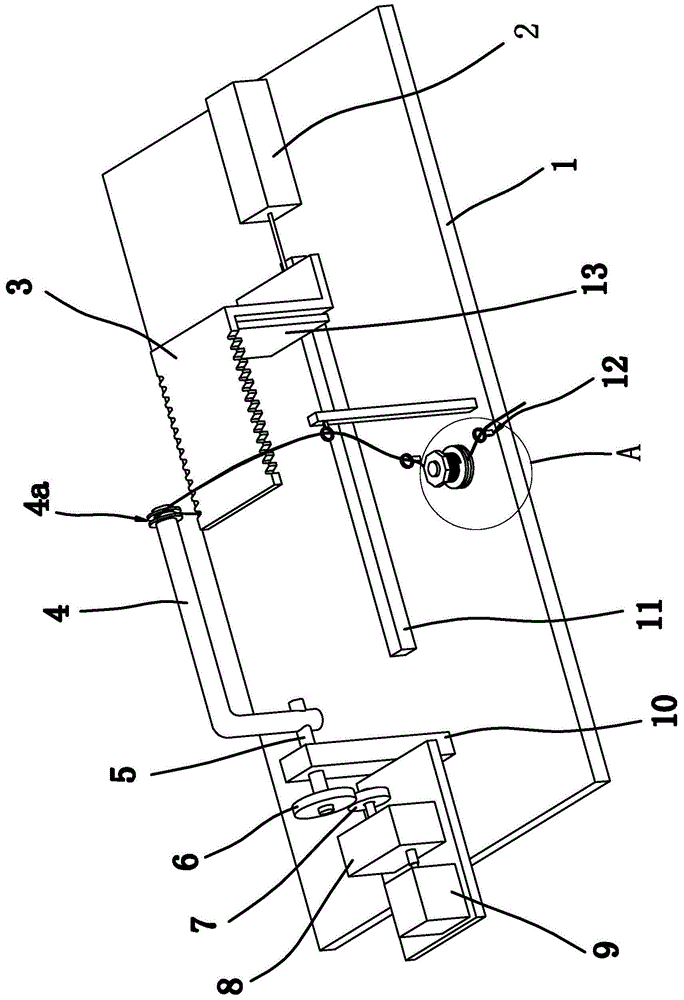

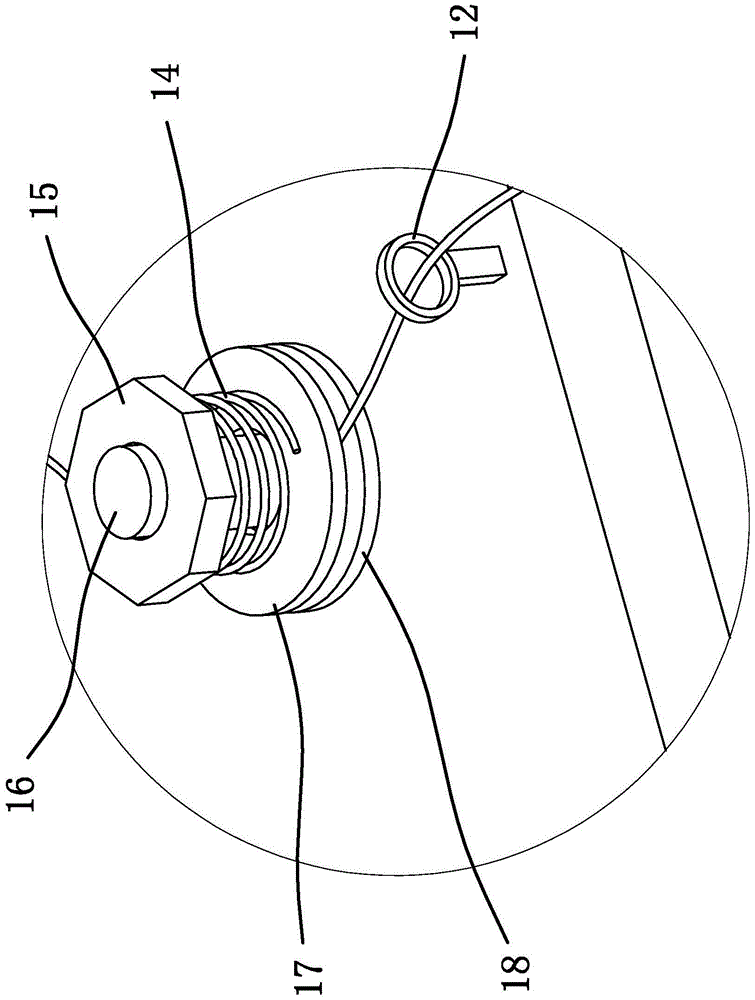

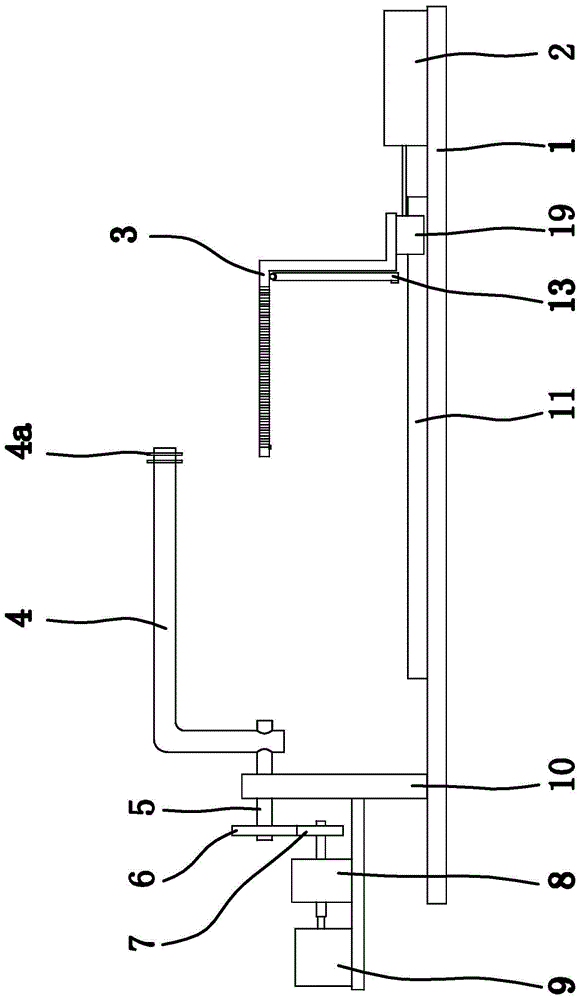

Tensioning mechanism for a textile feed to a stepped operation digital textile printer

A textile feed for a stepped operation digital textile printer, comprises a textile feeding mechanism, and a tension storage mechanism. The textile feeding mechanism feeds the textile in a forward direction onto the printer, but is at the same time mechanically connected to a tension storage mechanism which is tensioned by the forward feeding. At the end of the feed step, the tension storage mechanism releases respectively stored tension to cause the feed mechanism to briefly reverse feed, thereby to pull the textile taut and take up any slack caused by the feeding step. The textile is thus kept taut, to allow effective digital printing by the printer.

Owner:KORNIT DIGITAL TECHNOLOGIES LTD

Eight-color digital textile printing method

InactiveCN102501659AIncrease brightnessLess pattern color errorOther printing apparatusEngineeringPrinting ink

The invention discloses an eight-color digital textile printing method. The method comprises the following steps of: 1, separating needed printing colors by using a computer; 2, arranging two sets of ink of eight primary colors in total in eight ink cartridges of a digital textile printing machine, wherein the eight primary colors are respectively C, M, Y, K, C1, M1, Y1 and K1 respectively representing cyan, red, yellow, black, light cyan (cerulean), pink, orange yellow and gray and can be used separately, the first four colors are deep cyan, deep red with yellow light, light yellow, pure dark, the last four colors are cerulean, deep pink belonging to red with purple light, orange yellow and gray, each of the eight ink cartridges is equipped with a sensitive printing ink heads so that every ink cartridge can be controlled by the computer freely, two or more than two of the eight primary colors can be blended mixed freely as required and mixed colors are printed on a pretreated textile product under control of the computer to form lines or patterns; 3, washing the printed textile product with water to remove surface colors from the textile product and then drying the textile product to obtain a finished product. Through adoption of the method disclosed by the invention, the eight colors can be matched and mixed freely and the mixed colors are improved in both color light and color match error so that required colors can be printed on a textile product.

Owner:SHAOXING YUANSE DIGITAL TECH

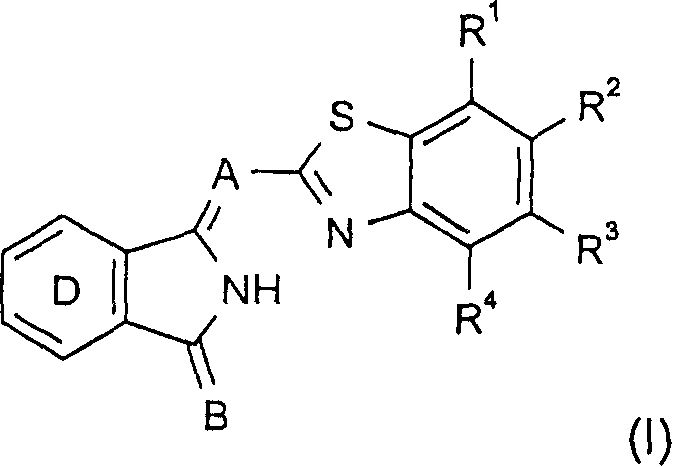

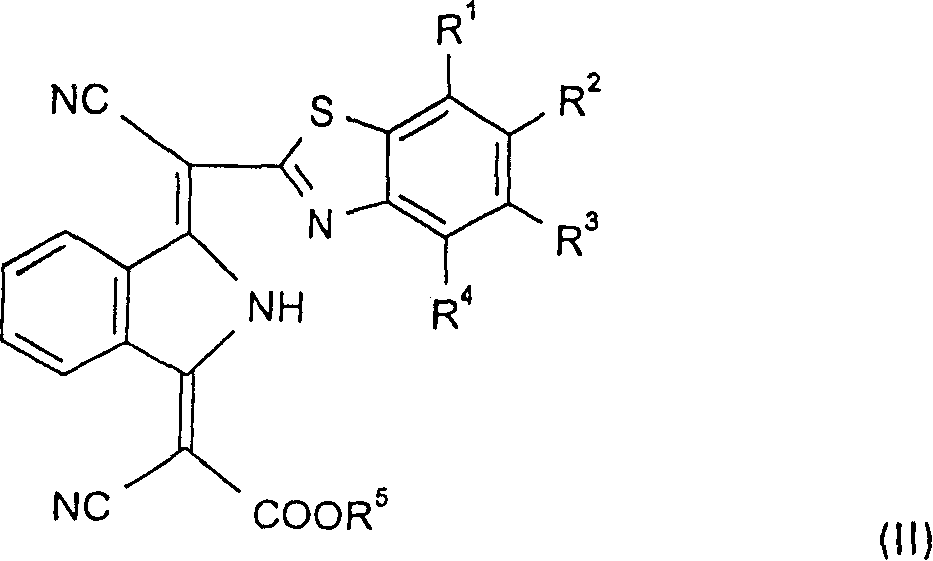

Inc composition

InactiveUS20090211488A1High pH stabilityGood storage stabilityReactive dyesInksEngineeringCellulose fiber

The present invention relates to a novel ink composition and, more particularly, to an ink composition for digital textile printing, which is suitable for ink-jet printing on cellulose fiber materials. The novel ink composition of the present invention has stable pH value, fine storage stability, smoothness and ease in printing, and reduction in color deterioration.

Owner:EVERLIGHT USA INC

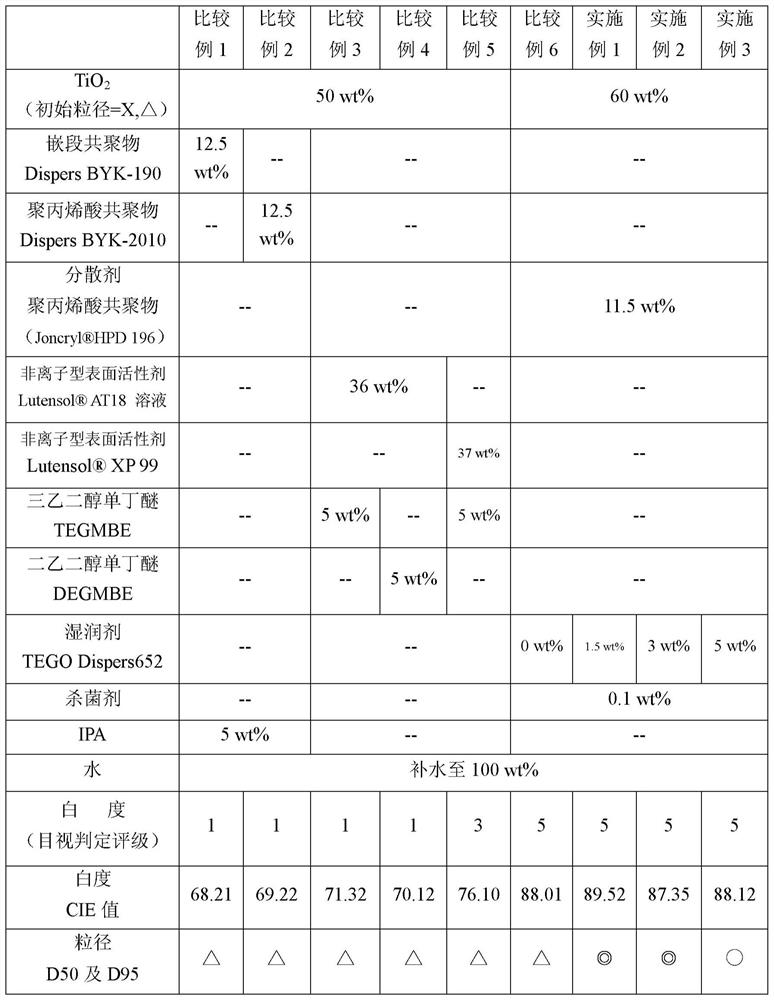

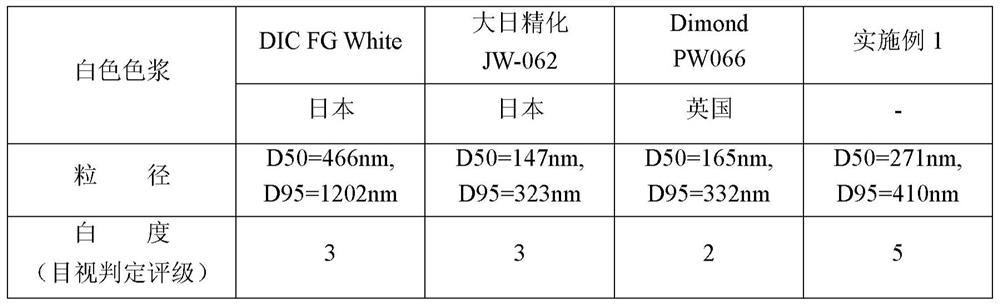

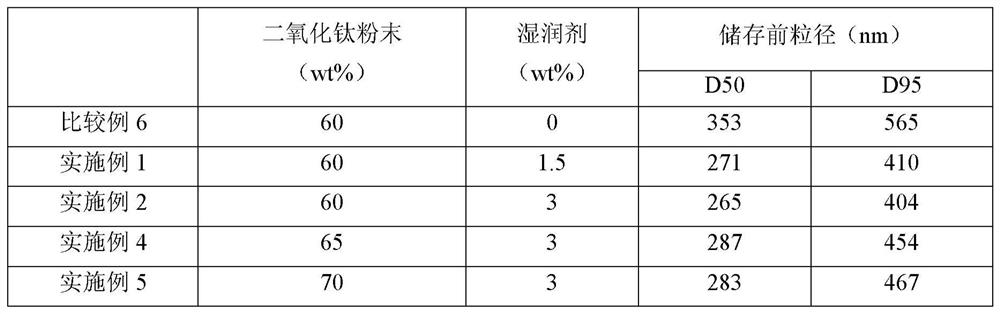

Ultra-high whiteness aqueous white color paste for digital textile printing ink and an ink composition using the same

InactiveUS20190345354A1Improve stabilityUltra-high whitenessInksDyeing processDigital textile printingRutile

An ultra-high whiteness aqueous white color paste for digital textile printing ink is provided, which comprises: 40 wt % to 70 wt % of TiO2 powders; 1 wt % to 5 wt % of a wetting agent; 2 wt % to 12 wt % of a dispersant; and rest of water. Herein, the TiO2 powders are rutile TiO2 powders, the wetting agent is a fatty acid derivative, and the dispersant is an acrylic acid copolymer. In addition, the present disclosure thrther provides an ink composition using the aforesaid ultra-high whiteness aqueous white color paste.

Owner:EVERLIGHT CHEMICAL INDUSTRIAL CORPORATION

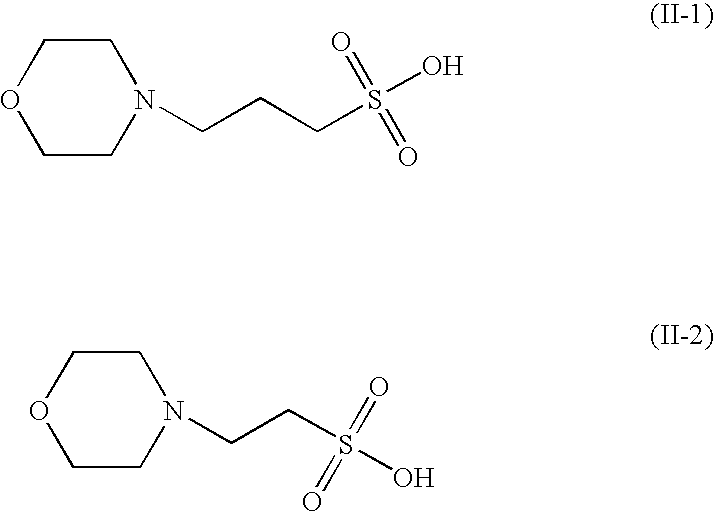

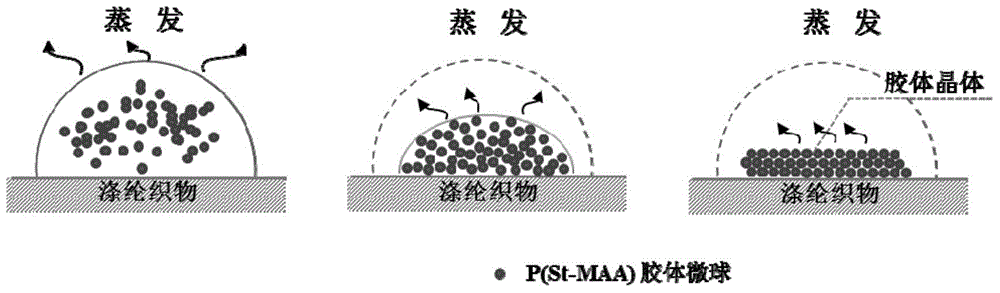

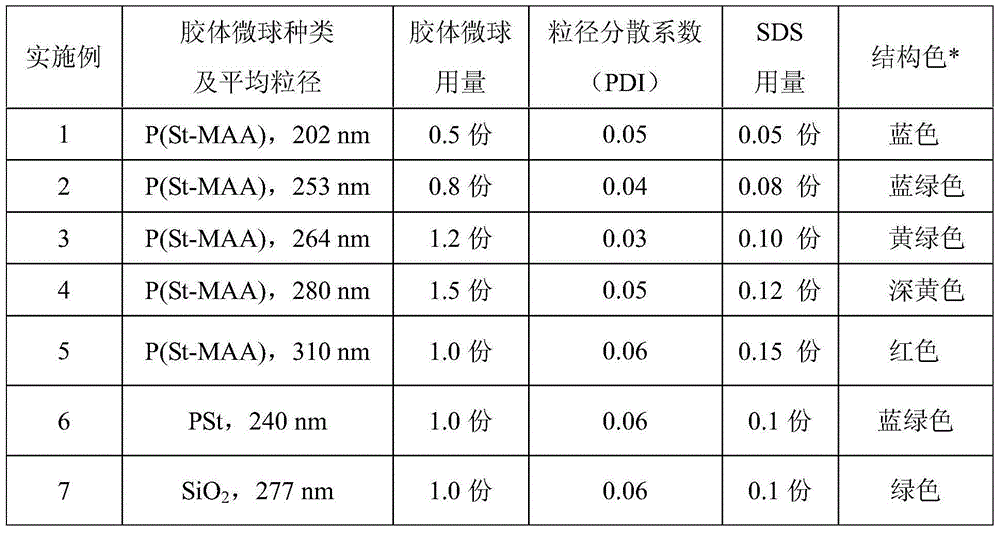

A kind of colloidal microsphere ink and its application for textile digital printing structural color

ActiveCN103788770BMeet the needs of ecological environmental protectionEfficient use ofInksDyeing processEcological safetyMicrosphere

The invention relates to a textile digital printing technology, and in particular discloses colloidal microsphere ink for coloring a textile digital printing structure and application of the colloidal microsphere ink. The colloidal microsphere ink for coloring the textile digital printing structure is characterized in that the colloidal microsphere ink is prepared by uniformly dispersing a mixture mainly consisting of the following components in parts by weight: 0.5-1.5 parts of mono-disperse colloidal microsphere which is 200-400nm in grain size (in terms of solid content), 0.05-0.15 part of an anionic surfactant (dispersant), 0.05-0.5 part of a pH regulator (regulating pH to 7-8) and 100 parts of deionized water. The colloidal microsphere ink formula disclosed by the invention is specifically developed to adapt to performance of coloring the textile digital printing structure; to adapt to a requirement of the textile on ecological safety, various materials of the invention are non-toxic and tasteless; to adapt to a requirement of the textile on flexibility, an ultra-thin photonic crystal structural film is sprayed and constructed as required through digital technology, which rarely affects hand feeling of the textile.

Owner:浙江中蝶坊新材料科技股份有限公司

Pressing device for digital textile printing machine

InactiveCN106945411APlay a role in flatteningPlay the role of ironingTypewritersOther printing apparatusTextile printerEngineering

The invention relates to the technical field of digital textile printing, in particular to a pressing device for a digital textile printing machine. The pressing device for the digital textile printing machine can conduct ironing on fabrics and has the dust collection function and the cooling function. The structure of the pressing device comprises a workbench. Supporting legs are arranged at the bottom of the workbench. A pressing roller is arranged on the workbench. The two sides of the pressing roller are rotationally connected with transversely arranged guide rails through rotating shafts. The inner rotating shaft is connected with the drive device through a chain. A hollow cavity is arranged in the pressing roller. A plurality of through holes are formed between the side face of the cavity and the outer surface of the pressing roller. The outer rotating shaft penetrates through a vent hole. The inner end of the vent hole is connected with the cavity. The outer end of the vent hole is connected with the left end of a first connecting pipe through a rotary connector, and the right end of the first connecting pipe is connected with a steam generating device. The first connecting pipe is provided with a first ball valve. The pressing device for the digital textile printing machine is easy to operate, convenient to use and suitable for treatment of multiple kinds of fabrics.

Owner:苏州艾虎数码科技有限公司

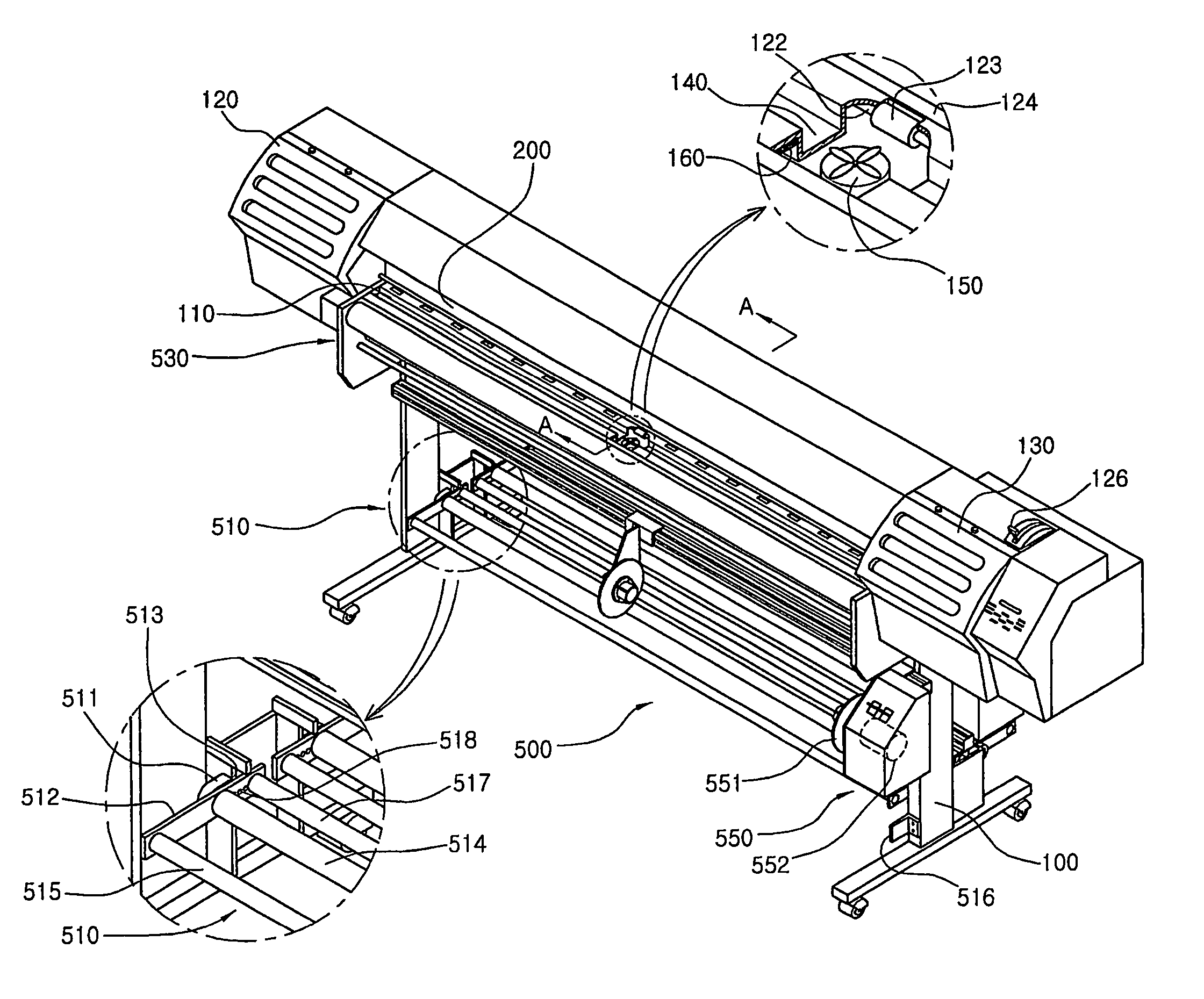

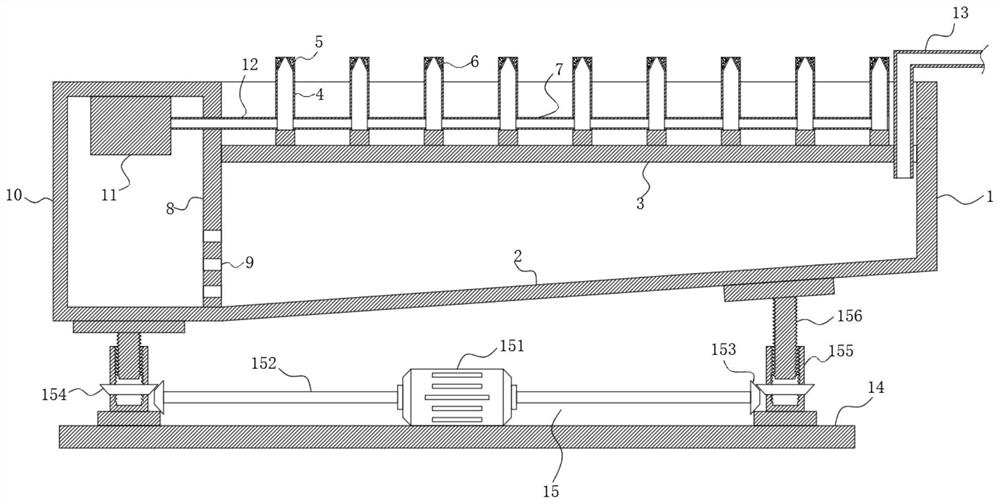

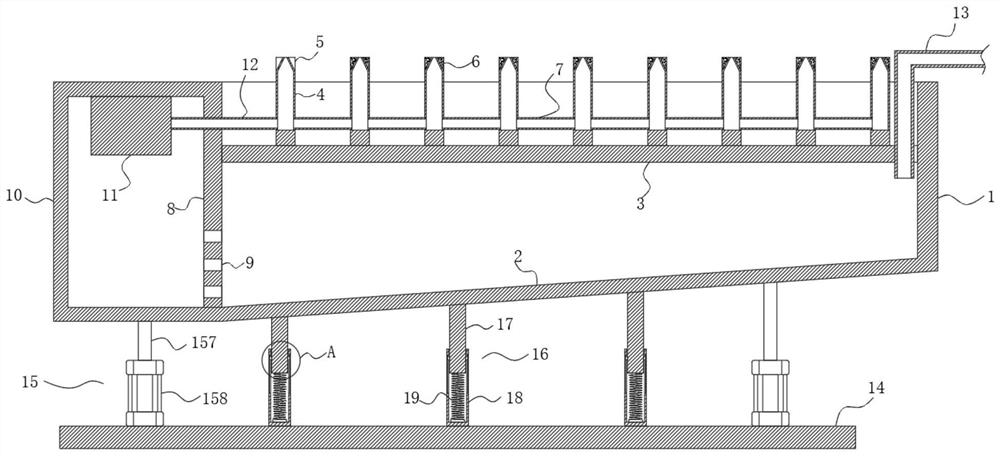

Digital textile printer

InactiveUS7399132B2Preventing defective printing operationEfficient printingPlaten pressesDuplicating/marking methodsRubber materialTextile printer

A digital textile printer includes front and rear feeding devices driven by a transfer axil within a driving panel of the front and the rear of a base to prevent distortion and wrinkle phenomena generating defective printing to perform effectively the textile printing even to very thin textile fabrics, an ink-retrieving hole along to the transfer axil on the top of the base to collect the residues of the injected ink passing through a printing material to prevent ink from spreading at the printing material, at least one suction pan in the inside of the base to collect easily the residues of the injected ink to hasten dries of ink, and a heater of rubber material in the inside of the front of the base to hasten dries of the printing material passing through the ink-retrieving hole.

Owner:TAEIL SYST CO LTD

Tensioning mechanism for a textile feed to a stepped operation digital textile printer

Owner:KORNIT DIGITAL TECHNOLOGIES LTD

Method for digital textile printing in wet state

InactiveCN111607989AAvoid skewAvoid problems such as yellowingDyeing processTextile printerProcess engineering

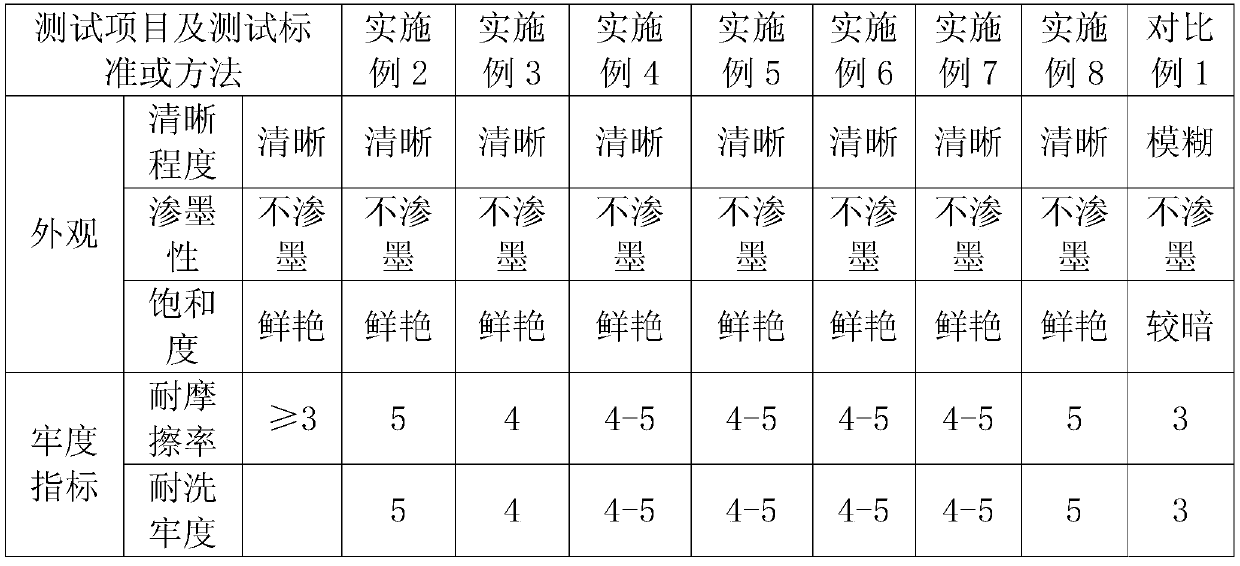

The invention belongs to the technical field of textile digital printing, and in particular relates to a method for digital textile printing in a wet state. The method comprises the following processsteps of preparation of a pretreatment working fluid; squeegee treatment of uniformly squeegeeing the pretreatment working fluid on the dry textile; and a printing treatment of directly digitally printing, drying, steaming and washing the wet textiles after the squeegee treatment without the operation of drying. The method for digital textile printing in the wet state can solve the problems of weft skew, yellowing, pretreatment liquid and energy waste caused by pretreatment using a tentering setting machine in the prior art, and the digital printing products using the method are full and bright in colors.

Owner:SHANDONG HUANGHE DELTA INST OF TEXTILE SCI & TECH RES INST

Tensioning mechanism for a textile feed to a stepped operation digital textile printer

Owner:KORNIT DIGITAL TECHNOLOGIES LTD

A kind of high-temperature direct jet dispersion ink and its preparation method and application

The invention discloses a high-temperature direct spray dispersion ink, its preparation and application. The ink is made of the following raw materials in parts by mass: 15-60 parts of high-temperature disperse dyes, 0.3-20 parts of dispersants, 30-60 parts of organic solvents, 10-50 parts of water, 0.5-10 parts of surfactants, preservatives 0.05-0.2 parts, 0.05-0.2 parts of defoamer. The preparation method is to mix the high-temperature disperse dye, dispersant, organic solvent and water, add zirconium beads to grind and disperse, then add the remaining organic solvent, water, surfactant, preservative, defoamer, and mix well , and get the filtrate by filtration. The ink of the present invention is applied to a new type of industrial digital textile printing machine, especially suitable for a textile printing machine with a Seiko 508GS nozzle, which can be used for direct inkjet printing through the printing machine, improves ink utilization, reduces costs, and reduces environmental pollution; and can be used at high temperatures Rapid dyeing, no need for transfer, has the advantages of short dyeing time and fast dyeing.

Owner:深圳市墨库图文技术有限公司

Ink composition

InactiveUS7967903B2Improve stabilityGood storage stabilityReactive dyesInksTextile printerPolymer science

The present invention relates to a novel ink composition and, more particularly, to an ink composition for digital textile printing, which is suitable for ink-jet printing on cellulose fiber materials. The novel ink composition of the present invention has stable pH value, fine storage stability, smoothness and ease in printing, and reduction in color deterioration.

Owner:EVERLIGHT USA INC

Digital textile printing machine

InactiveCN114633558AQuick spray toEject evenlyRotary stirring mixersTransportation and packagingTextile printerPrinting ink

The invention discloses a textile digital printing machine, and relates to the technical field of digital printing machines, the textile digital printing machine comprises a machine body, the outer wall of one side of the machine body is fixedly connected with two groups of driving assemblies, the two groups of driving assemblies are respectively connected with an unwinding roller and a winding roller, a non-woven fabric body is wound on the outer wall of the circumference of the unwinding roller, and the winding roller is connected with the non-woven fabric body. And a translation assembly is arranged in the machine body, and a spray head body is fixedly connected to one side of the translation assembly. According to the non-woven fabric printing device, printing ink in the storage box can be sprayed out more evenly, the printing quality of a non-woven fabric body is effectively improved, and after printing work of the non-woven fabric body is completed, a control valve on one side of a material guide pipe is closed, and a control valve on one side of a liquid guide pipe is opened; and at the moment, the clean water in the cavity flows out to effectively clean the spray head body, and the situation that the subsequent spraying and printing work of the spray head body is affected due to ink residues in the spray head body is avoided.

Owner:佛山诺为喷印设备有限公司

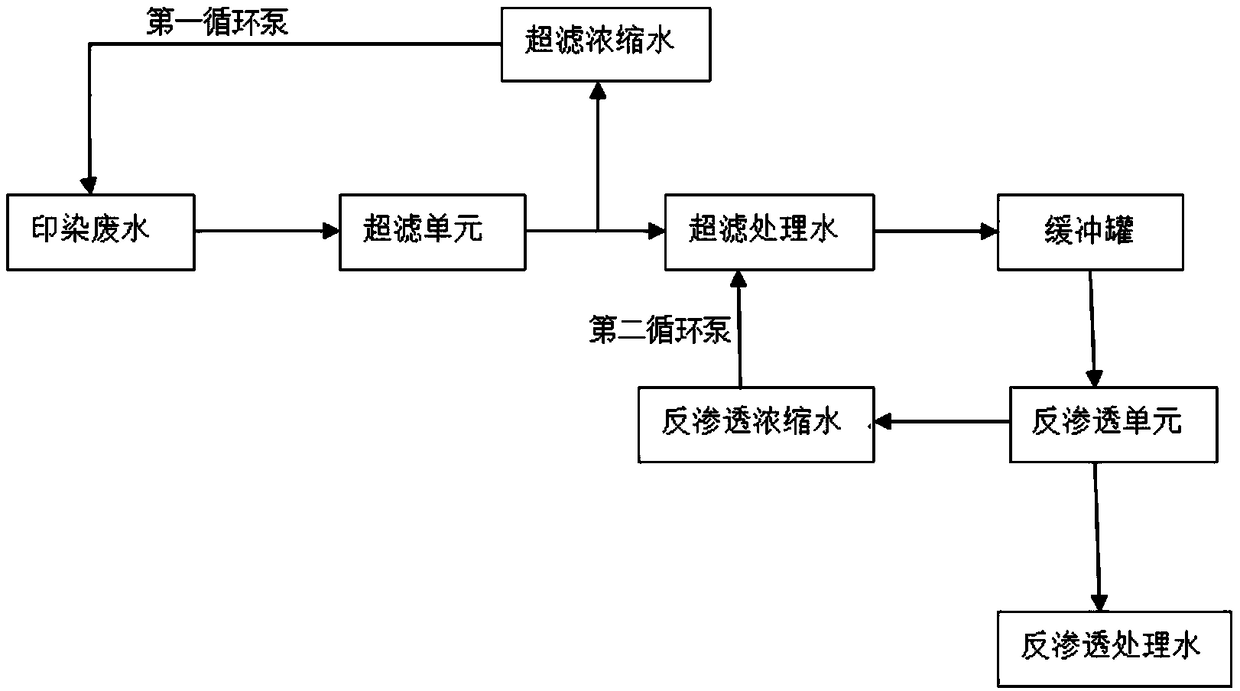

Direct treatment method of digital printing wastewater

InactiveCN109368830AImprove processing efficiencyEfficient removalWater/sewage treatmentMultistage water/sewage treatmentUltrafiltrationReverse osmosis

The invention provides a direct treatment method of digital printing wastewater, comprising the steps of treating digital printing wastewater from a digital textile printing process through an ultrafiltration treatment process so as to separate ultrafiltration concentrate and ultrafiltration treated water from the digital printing wastewater; treating the ultrafiltration treated water by means ofreverse osmosis so as to separate reverse osmosis concentrate and reverse osmosis treated water from the ultrafiltration treated water. The ultrafiltration concentrate is circulated to mix the same with newly supplied printing wastewater; the reverse osmosis concentrate is circulated to mix the same with the ultrafiltration treated water. The direct treatment method is used for directly treating dyeing wastewater from digital textile printing; treating efficiency of the direct treatment method is improved by lowering organic carbon load of a membrane.

Owner:江苏爱特恩高分子材料有限公司

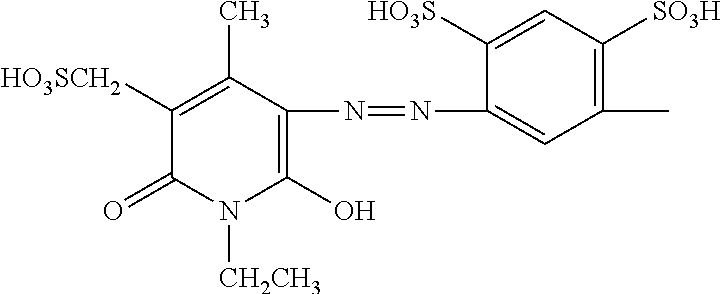

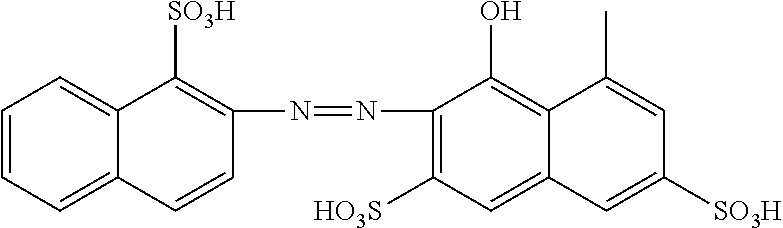

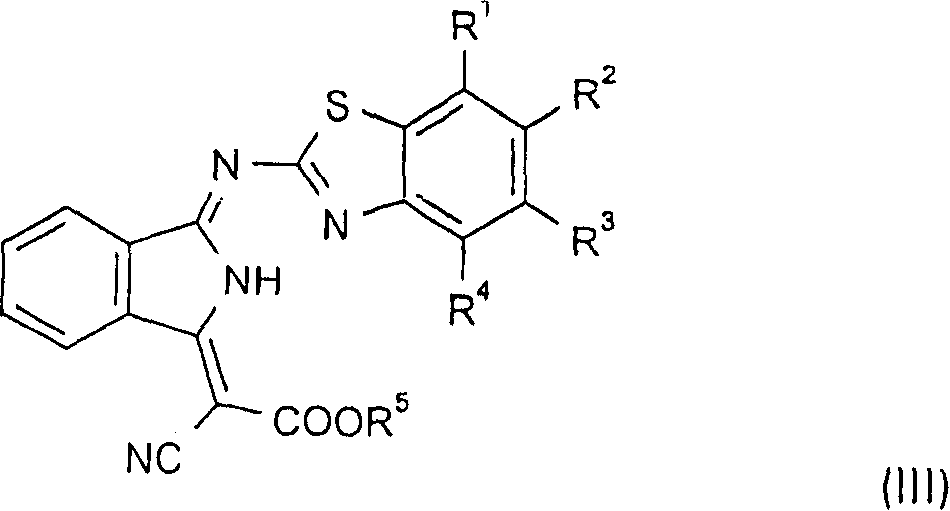

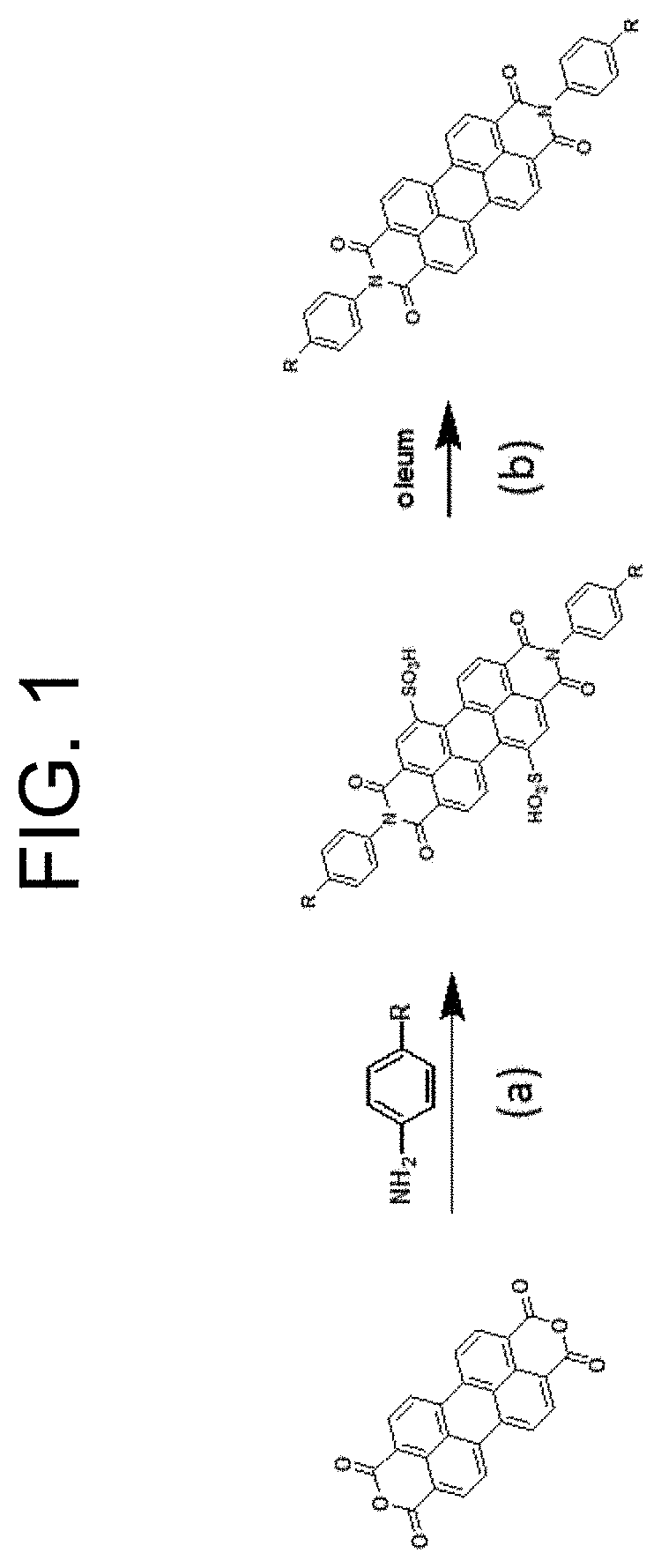

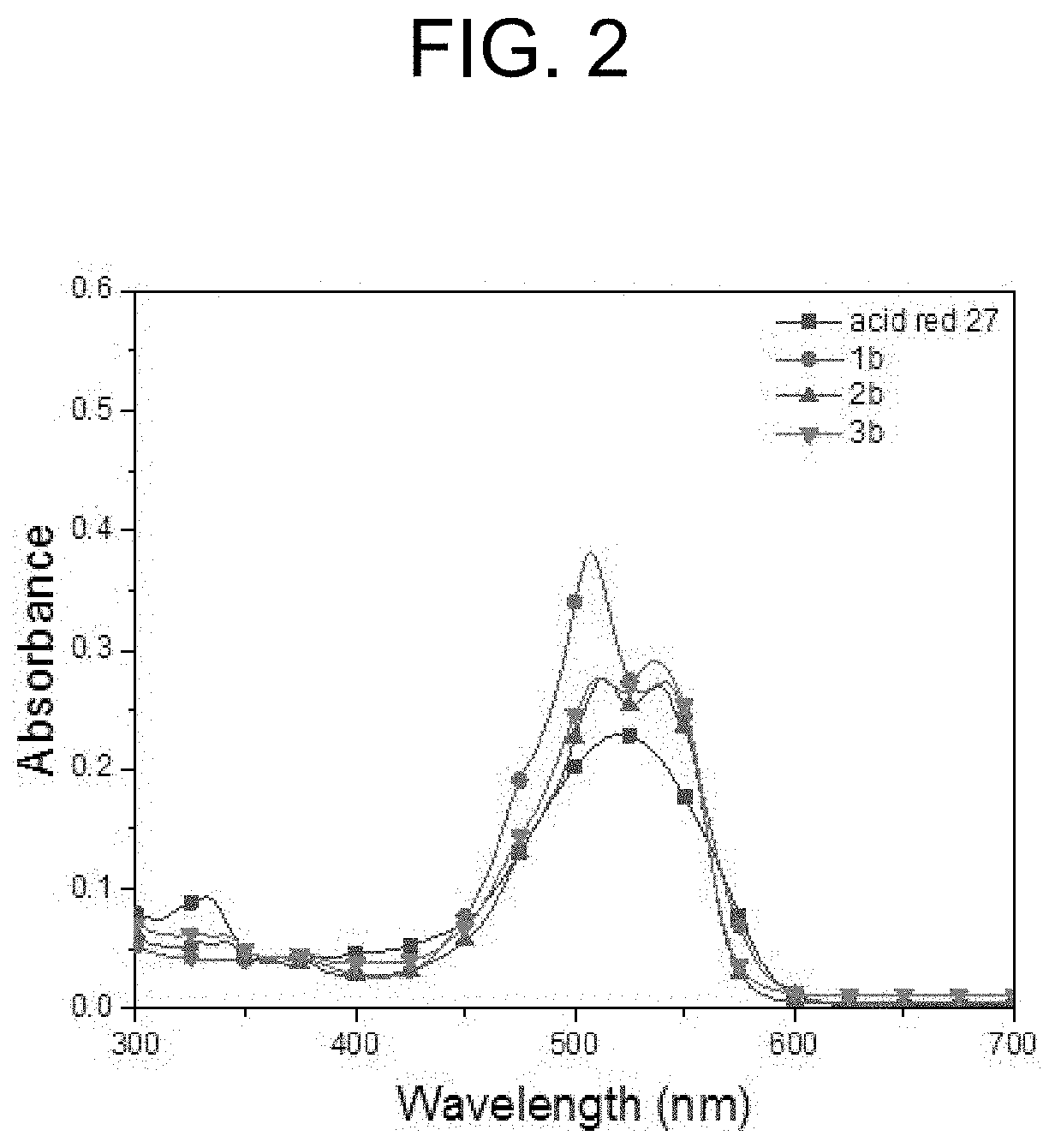

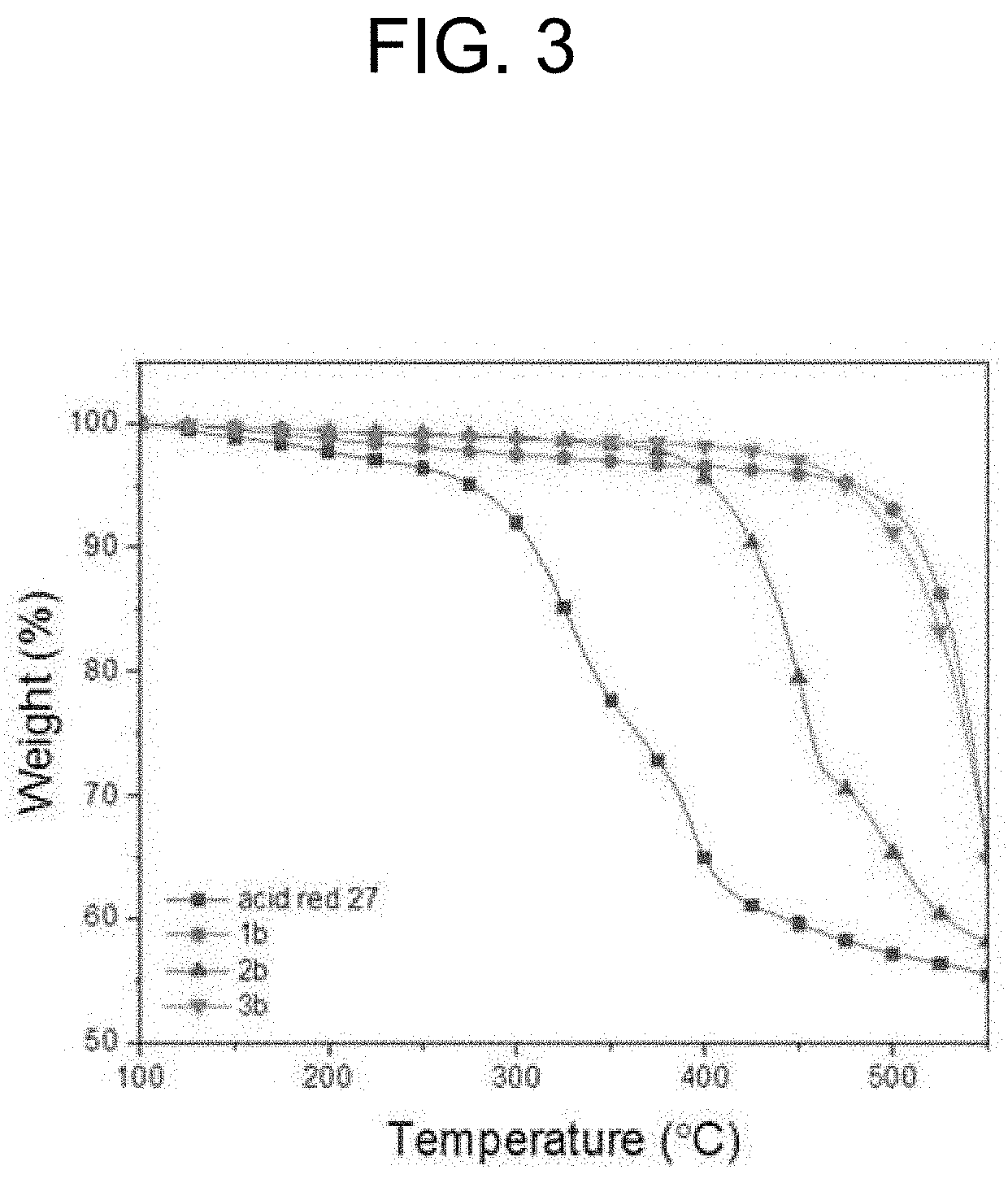

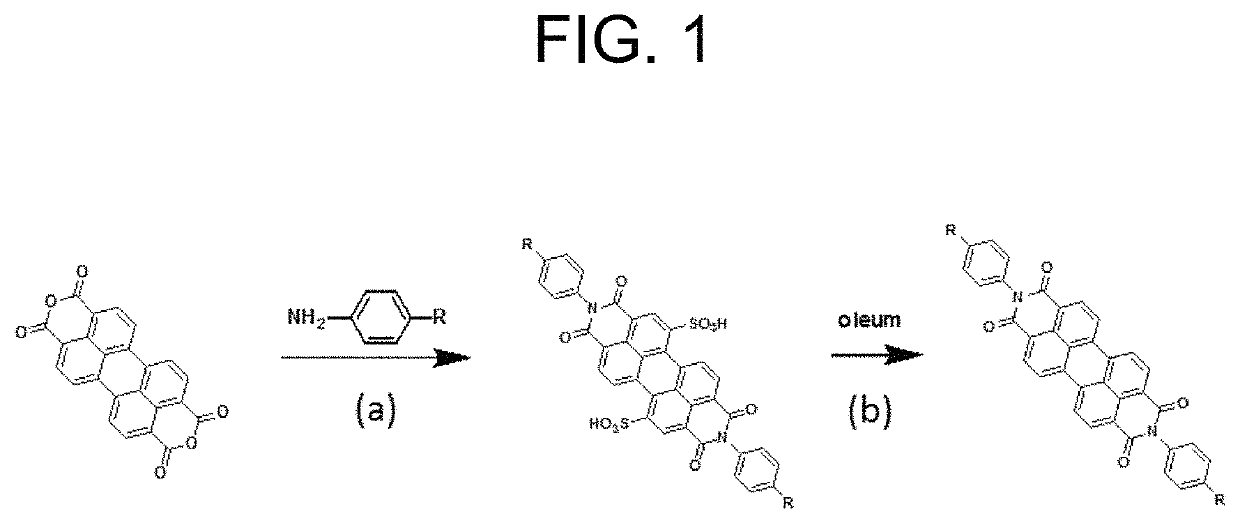

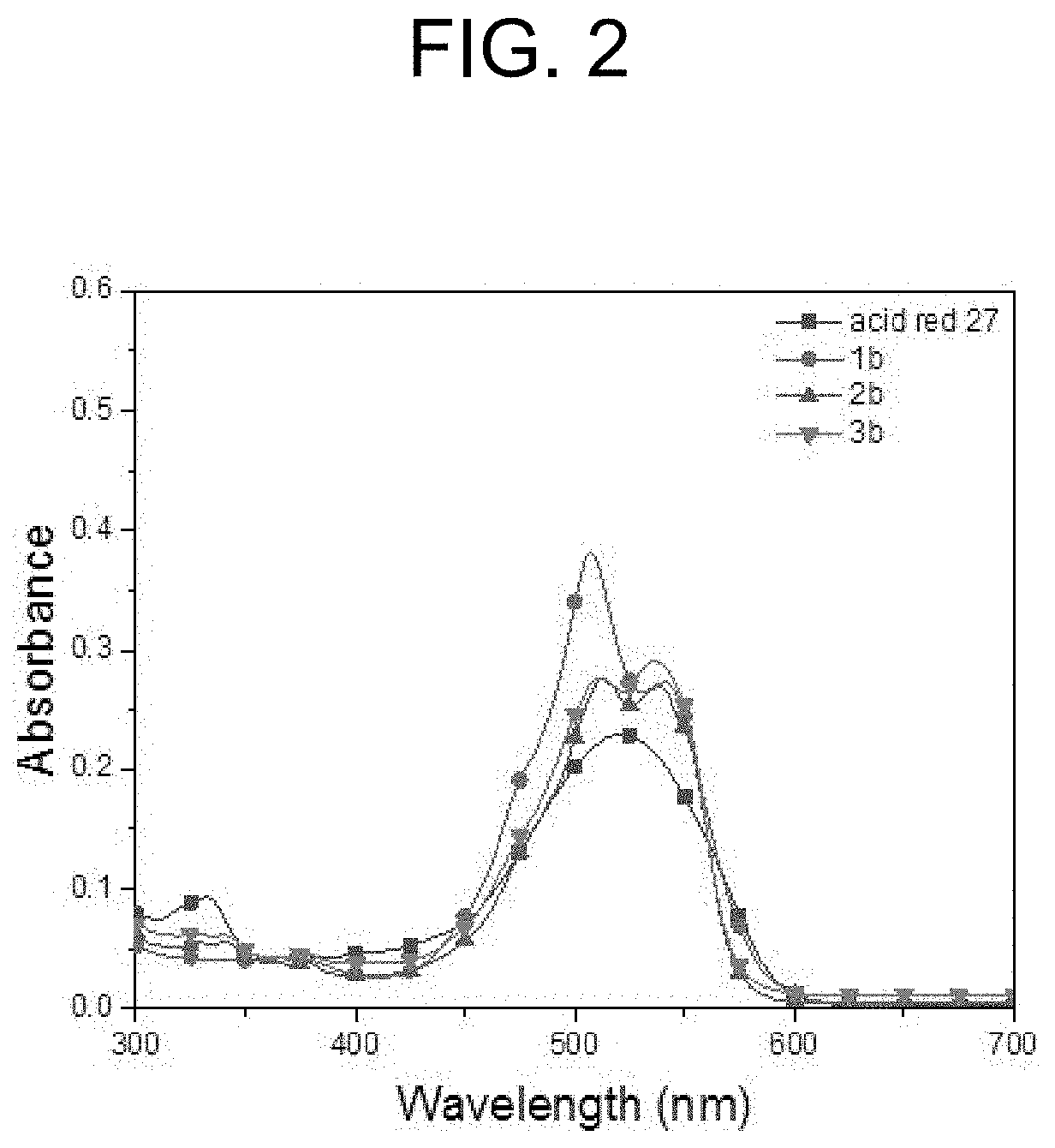

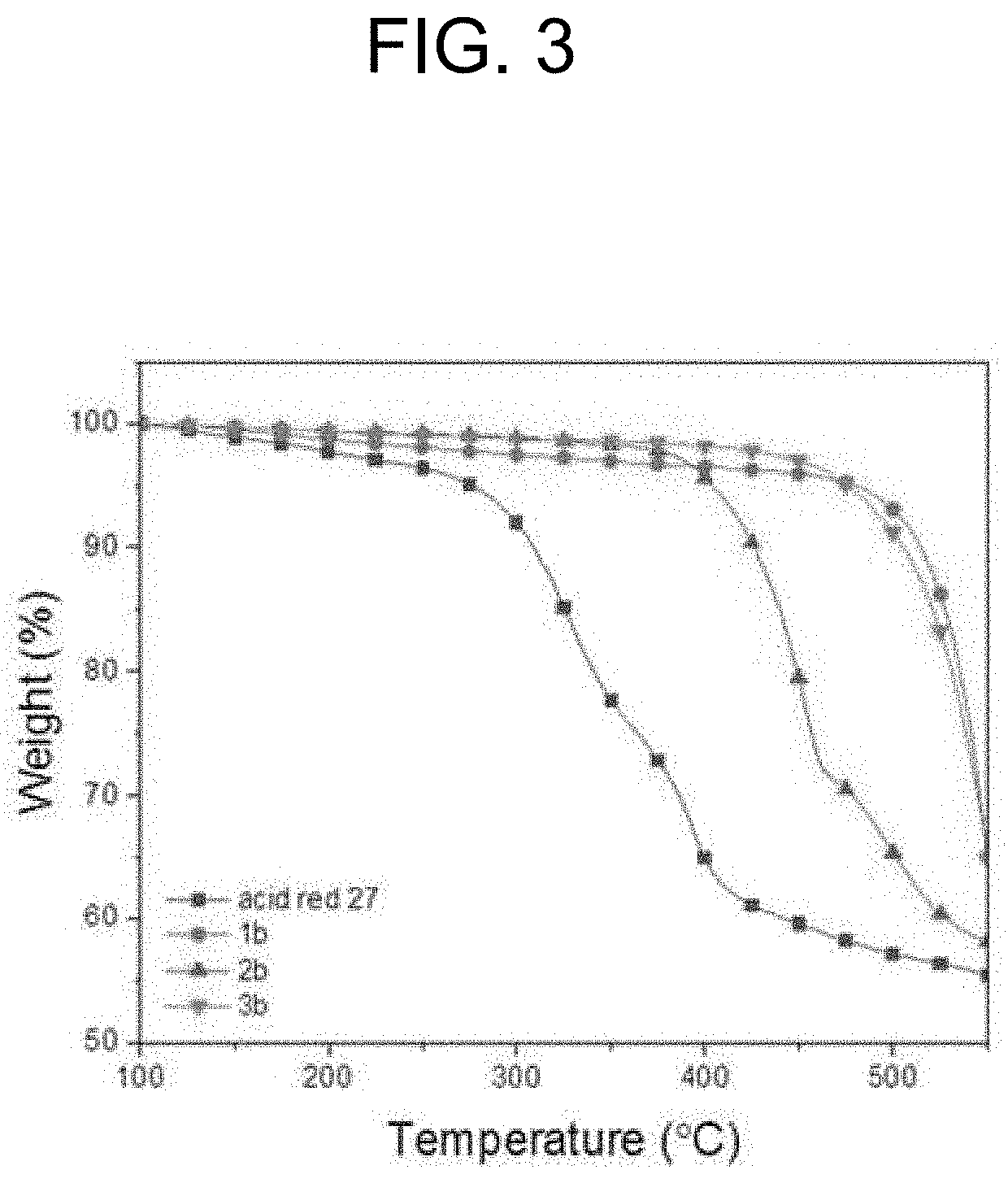

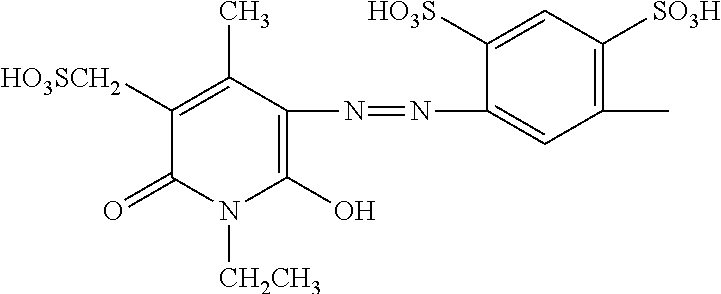

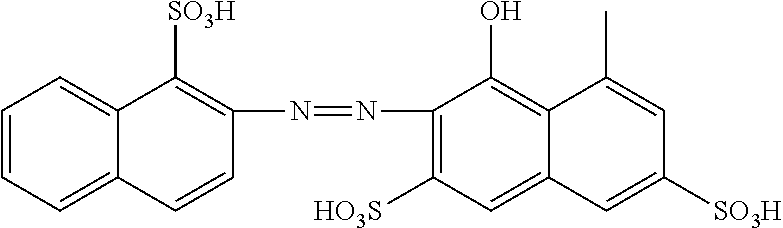

High-saturation scarlet color dye ink for high-speed inkjet process

ActiveUS20200109288A1Increase speedNaphthalimide/phthalimide dyesInksTextile printerDigital textile printing

Highly saturated scarlet dye ink for a high-speed inkjet process and a method of preparing the highly saturated scarlet dye ink are disclosed. In particular, an ink composition according to the present invention includes a dye including a compound represented by Formula 1, and further includes, in addition to the dye, distilled water, a surfactant, and an additive. The ink composition develops a highly saturated scarlet color that is unable to be developed by existing inks for digital textile printing (DTP), and has high water solubility, excellent heat resistance, and light-fastness, and thus may be effectively used as dye and ink for a high-speed inkjet process.

Owner:KOREA INST OF IND TECH

A kind of novel gel anti-swimming agent specially used for digital printing paint ink and preparation method thereof

The invention provides a novel special gel antimigrant superclear for digital printing pigment ink and a preparation method of the gel antimigrant superclear. The novel special gel antimigrant superclear comprises nano-silicon sol, glucose modified gel, an auxiliary and a solvent, and the specified preparation method comprises the following steps: (1), adding a silicon precursor into an ethanol water solution, stirring uniformly, dropwise adding an ethanol water solution containing an acid catalyst, mixing, and rapidly stirring to obtain the nano-silicon sol; (2), adding glucose, methacrylic acid and acrylamide into the solvent, stirring at room temperature, further adding ethylene glycol dimethacrylate and ammonium persulfate, heating and stirring, and cooling to room temperature to obtain the glucose modified gel; (3), adding the glucose modified gel prepared in the step (2) and the nano-silicon sol prepared in the step (1) into a solvent containing a dispersing agent, regulating the PH value of the solution, stirring, diluting, slowly dropwise adding a cross-linking agent and an initiator, heating and stirring, and then leaving to stand to obtain the novel special gel antimigrant superclear for the textile pigment ink.

Owner:杭州万海纳米科技有限公司

High-saturation scarlet color dye ink for high-speed inkjet process

ActiveUS11104805B2Other chemical processesNaphthalimide/phthalimide dyesTextile printerDigital textile printing

Highly saturated scarlet dye ink for a high-speed inkjet process and a method of preparing the highly saturated scarlet dye ink are disclosed. In particular, an ink composition according to the present invention includes a dye including a compound represented by Formula 1, and further includes, in addition to the dye, distilled water, a surfactant, and an additive. The ink composition develops a highly saturated scarlet color that is unable to be developed by existing inks for digital textile printing (DTP), and has high water solubility, excellent heat resistance, and light-fastness, and thus may be effectively used as dye and ink for a high-speed inkjet process.

Owner:KOREA INST OF IND TECH

Orange ink for digital printing of textile

InactiveCN110468609AImprove comfortColorfulDyeing processMicroballoon preparationTextile printerWater based

The invention provides orange ink for digital printing of a textile, which belongs to the field of textile pigments, and can solve the problems of hard hand feeling, dull color, low color fastness, unrepresentable brightness and serious service dyeing of a printed textile obtained from existing pigment ink.The orange ink for digital textile printing provided by the technical scheme is prepared from the following materials in parts by weight: 20- 40 parts of orange microcapsule pigment, 10- 20 parts of water-base resin, 5- 15 parts of quick-drying solvent, 5- 15 parts of moisture preserving solvent, and 0.5- 1 part of a surfactant.A microcapsule technology is applied to preparation of the pigment ink for digital printing of the textile, and the printed textile obtained therefrom has the advantages of high color fastness, high textile comfort, safety, and bright color; when the ink is used as textile printing ink, no surface dyeing occurs, and a reduction cleaning process can be omitted,thus reducing environmental pollution and lowering production cost.

Owner:QINGDAO UNIV

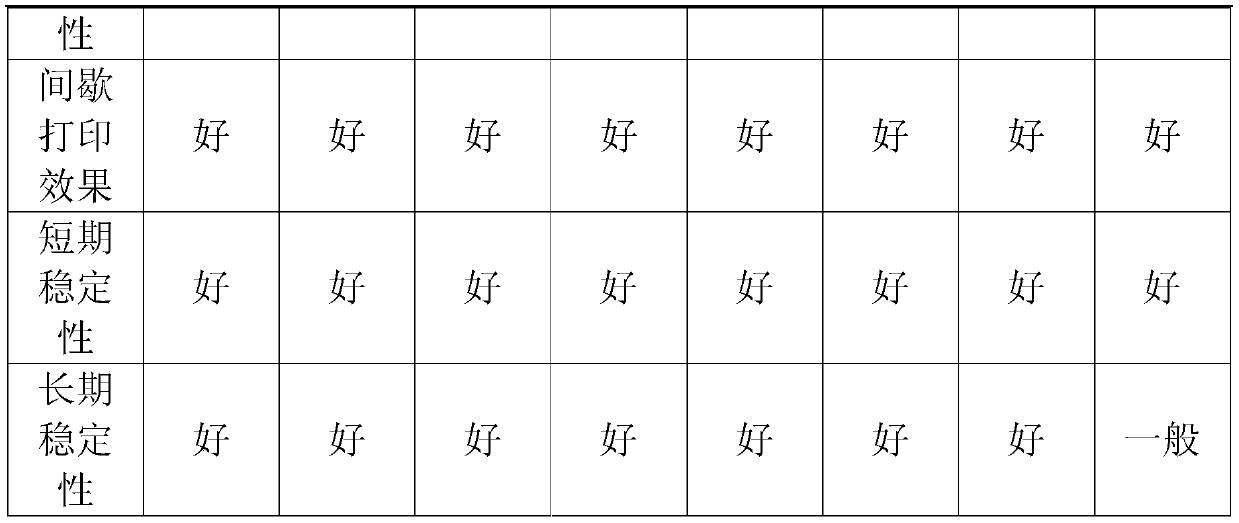

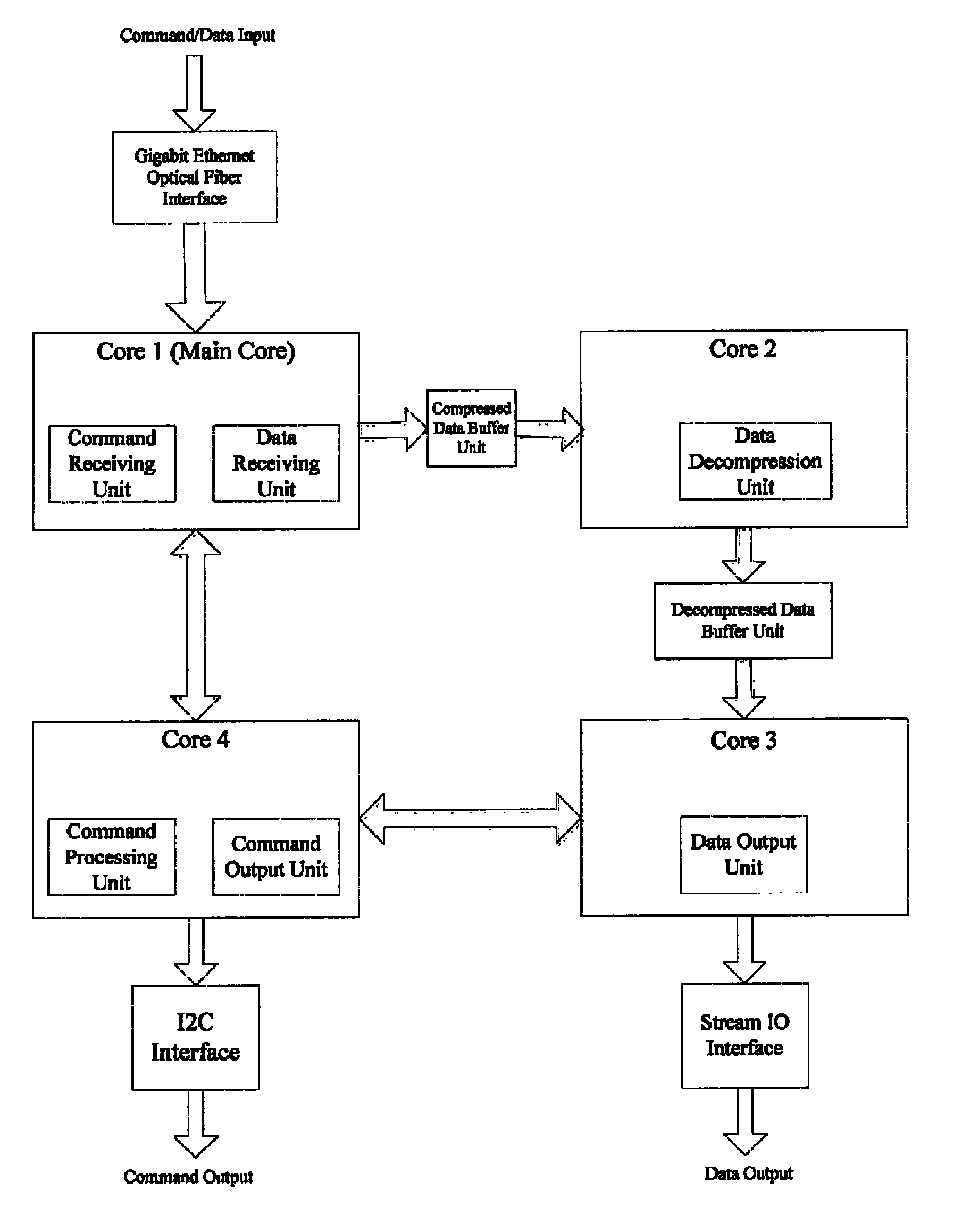

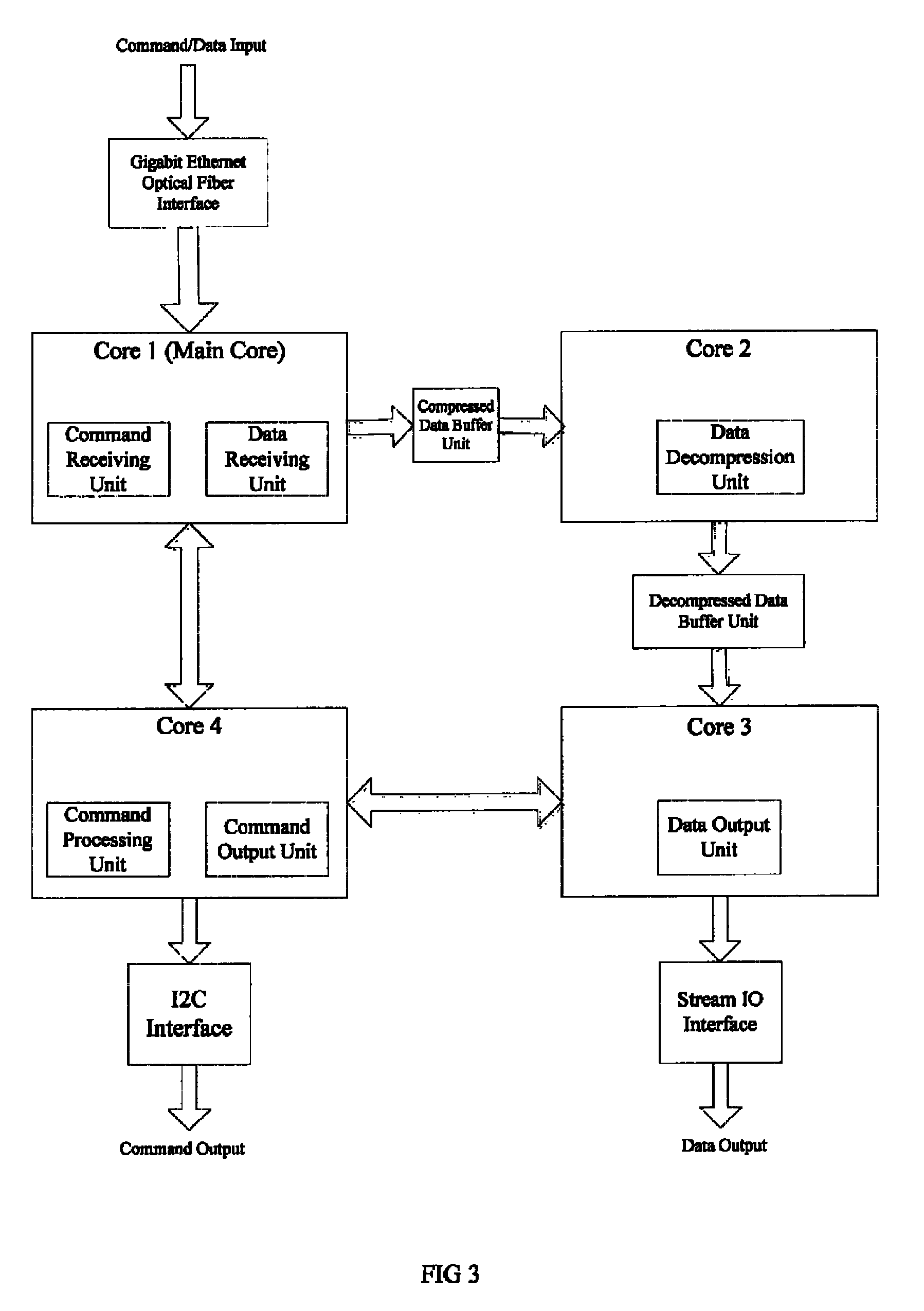

Multi-core processor based high-speed digital textile printing processing system and method

InactiveUS9053408B2Improve efficiencyIncrease transfer speedVisual presentation using printersDigital output to print unitsHandling systemDigital textile printing

The present invention discloses a multi-core processor based high-speed digital textile printing processing system, comprising a gigabit Ethernet interface, a I2C interface, a Stream IO interface and a multi-core processor; the multi-core processor comprises a command receiving unit, a command processing unit, a command output unit, a data receiving unit, a compressed data buffer unit, a data decompression unit, a decompressed data buffer unit and a data output unit; meanwhile, the present invention also disclosed a multi-core processor based high-speed digital textile printing processing method. The present invention is centered on high-performance multi-core processor, which aims to implement high-speed transmission of printing data from PC to printing nozzle via the gigabit Ethernet and Stream IO interface as well as processing and transfer of printing commands via the gigabit Ethernet and I2C interface. Meanwhile, it is also capable of executing such processing as decompression of printing images and image rotation, which has significantly improved the work efficiency of digital textile printing system.

Owner:ZHEJIANG UNIV

High fixation ink composition for digital textile printing

InactiveUS10093816B2High compositionImprove responseAntifouling/underwater paintsReactive dyesDigital printingSolvent

Owner:EVERLIGHT CHEMICAL INDUSTRIAL CORPORATION

Method and apparatus for digital textile printing

PendingCN113840953AReduce needAccurate depositionLiquid/gas/vapor removal by suctionTypewritersProcess engineeringDigital textile printing

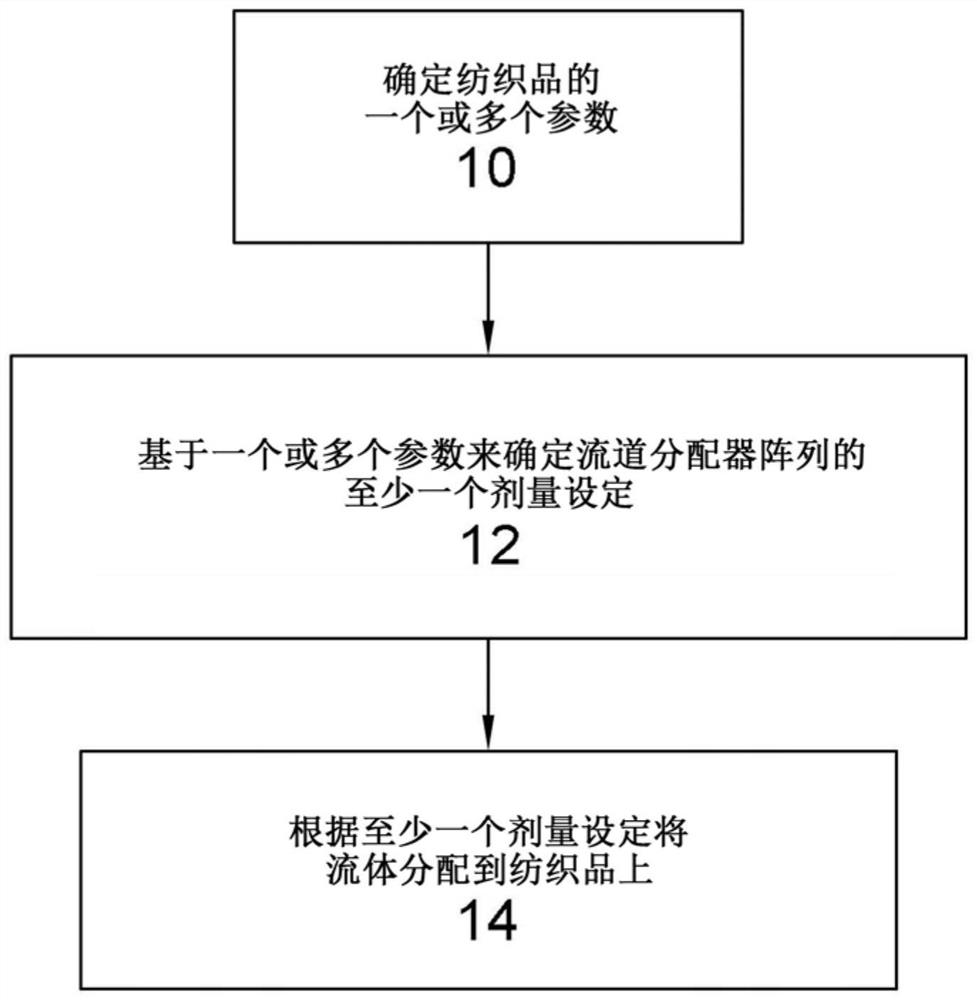

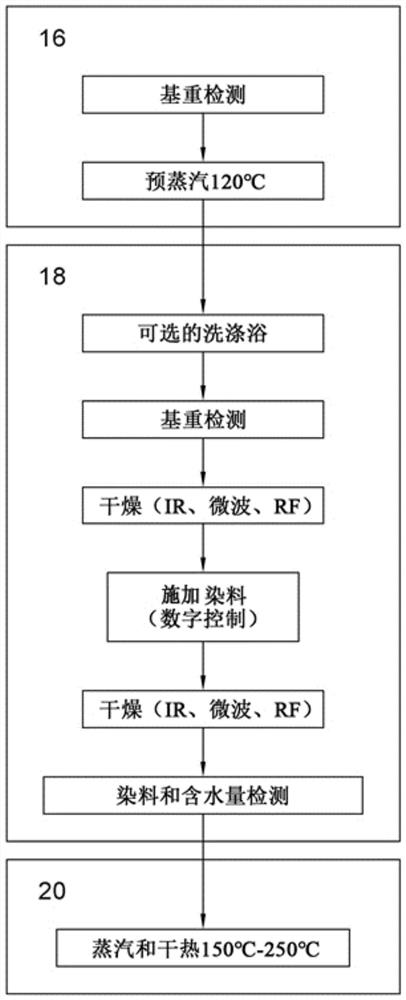

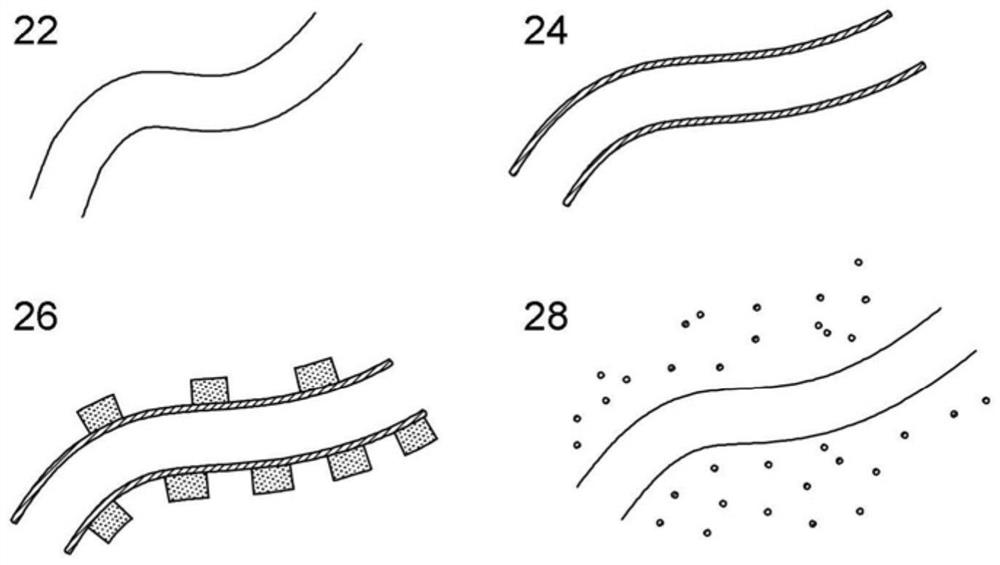

A method for digitally controlled application and fixation of dyestuff to a textile on a processing line is provided. The method comprises the steps of: determining one or more parameters of a textile (10); determining, by a processor, at least one dose setting for an array of flow channel dispensers of the processing line, wherein determining the at least one dose setting is based on the one or more parameters (12); dispensing, by the array of flow channel dispensers, dyestuff onto the textile according to the at least one dose setting (12); and delivering energy to the substrate to fix the dyestuff in the textile.

Owner:ALCHEM TECH LTD

A computer color matching method for textile digital jet printing and its positioning device

ActiveCN105034591BMeet the test requirementsHigh color matching accuracyPrinting press partsColor correctionDigital printing

The invention provides a computer color matching method for digital jet printing of textiles and a positioning device thereof, belonging to the technical field of textiles. It solves the technical problems that the color matching method in the prior art is difficult to guarantee the color matching accuracy because the ribbon cannot be freely sampled when it is used for color matching of ribbons. The computer color matching method for textile digital jet printing comprises the following steps: a. sampling; b. making samples; c. color matching; d. making dye liquor: e. making samples; f. color correction; and its positioning device . The invention has the advantages of high color matching accuracy and free sampling of ribbons.

Owner:JIAXING VOCATIONAL TECHN COLLEGE

Spray head moisturizing system for digital textile printing equipment

ActiveCN114750515AEliminate cloggingGentle yet effective hydrationTypewritersTextile printerWet steam

The invention discloses a digital textile printing equipment nozzle moisturizing system which comprises a water tank, a partition plate is fixedly connected to the side face of the water tank, a steam generator is arranged in a steam generation box, a supporting plate is fixedly connected to the upper side of the water tank, a moisturizing pipe is fixedly connected to the supporting plate, and a steam pipe is arranged on the side face of the steam generator. A mounting plate is arranged at the bottom end of the water tank, and a lifting mechanism is arranged between the upper end of the mounting plate and the bottom end of the water tank. According to the spray head moisturizing system for the digital textile printing equipment, liquid in the water tank is converted into steam through the steam generator, the steam is conveyed into the moisturizing pipe through the steam pipe and the guide pipe to moisturize the spray head, the steam moisturizing means is mild and effective, and the phenomenon that the spray head is blocked is effectively eradicated.

Owner:上海楚球智能科技有限公司

Digital textile printing high-speed output equipment

InactiveCN102059858BHigh speed outputIncrease productivityTypewritersTextile printerDigital textile printing

Owner:朴名焕

Ultra-high whiteness aqueous white colorant for digital textile printing ink and ink composition using the same

An ultra-high whiteness water-based white colorant for digital textile printing ink, comprising: 40wt% to 70wt% titanium dioxide powder; 1wt% to 5wt% wetting agent; 2wt% to 12wt% dispersant; and the balance of water. The titanium dioxide powder is rutile titanium dioxide, the wetting agent is a fatty acid derivative, and the dispersing agent is a polyacrylic acid copolymer. In addition, the present invention also provides an ink composition using the ultra-high whiteness water-based white colorant.

Owner:EVERLIGHT CHEMICAL INDUSTRIAL CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com