A computer color matching method for textile digital jet printing and its positioning device

A computer color matching and digital jet printing technology, which is used in printing machines, general parts of printing machinery, printing and other directions, can solve the problem of difficult to guarantee color matching accuracy, and achieve the effects of fast adjustment, high color matching accuracy and reliable clamping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

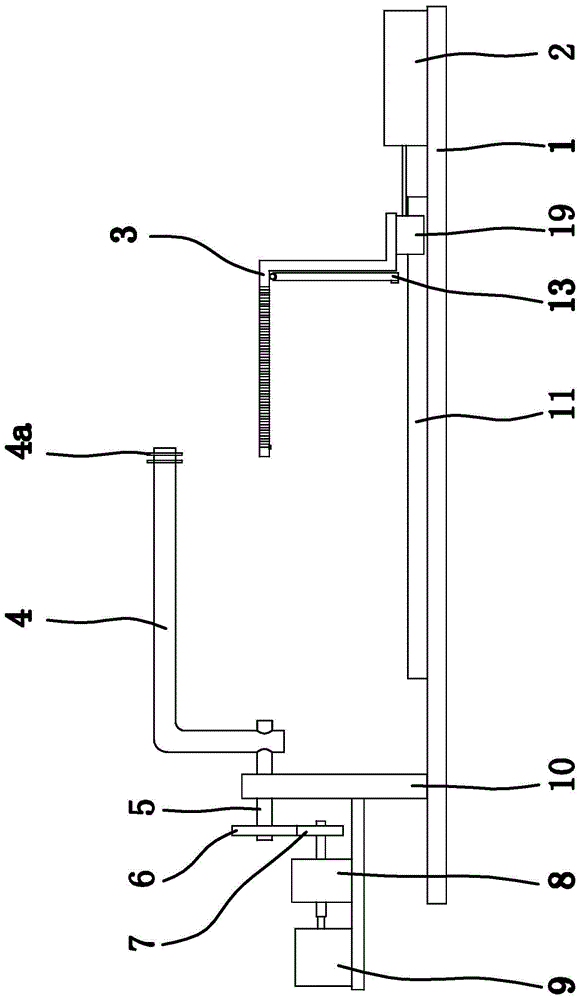

[0051] Such as Figure 5 As shown, the computer color matching method of the textile digital printing, the method comprises the following steps:

[0052] a. Sampling: Cut the webbing purchased from outside or provided by the customer, cut it into a sample with a length of 80cm, and mark it;

[0053] b. Make the sample: Position the sample through the positioning device to make a sample with a length and width of 3cm*3cm to meet the size requirements for large-aperture measuring holes in computer color matching;

[0054] c. Color matching: test and analyze the color of the sample through the computer, and store the obtained color parameters into the computer;

[0055] d. Make dyeing solution: Put the dyes of several colors into the dyeing vat according to the color parameters obtained by the computer, add a certain amount of water, mix them evenly, and make a dyeing solution;

[0056] e. Make a small sample: dye the white embryo webbing with dyeing solution, and use an ordina...

Embodiment 2

[0059] Such as Figure 5 As shown, the computer color matching method of the textile digital printing, the method comprises the following steps:

[0060] a. Sampling: Cut the webbing purchased from outside or provided by the customer, cut it into a sample with a length of 85cm, and mark it;

[0061] b. Make the sample: Position the sample through the positioning device to make a sample with a length and width of 3cm*3cm to meet the size requirements for large-aperture measuring holes in computer color matching;

[0062] c. Color matching: test and analyze the color of the sample through the computer, and store the obtained color parameters into the computer;

[0063] d. Make dyeing solution: Put the dyes of several colors into the dyeing vat according to the color parameters obtained by the computer, add a certain amount of water, mix them evenly, and make a dyeing solution;

[0064] e. Make a small sample: dye the white embryo webbing with dyeing solution, and use an ordina...

Embodiment 3

[0067] Such as Figure 5 As shown, the computer color matching method of the textile digital printing, the method comprises the following steps:

[0068] a. Sampling: Cut the webbing purchased from outside or provided by the customer, cut it into a sample with a length of 90cm, and mark it;

[0069] b. Make the sample: Position the sample through the positioning device to make a sample with a length and width of 3cm*3cm to meet the size requirements for large-aperture measuring holes in computer color matching;

[0070] c. Color matching: test and analyze the color of the sample through the computer, and store the obtained color parameters into the computer;

[0071] d. Make dyeing solution: Put the dyes of several colors into the dyeing vat according to the color parameters obtained by the computer, add a certain amount of water, mix them evenly, and make a dyeing solution;

[0072] e. Make a small sample: dye the white embryo webbing with dyeing solution, and use an ordina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com