Three-D small range force sensor

A force sensor and small-range technology, applied in the field of force sensors, can solve the problems of force measurement range, resolution and dimension not suitable for contact force detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

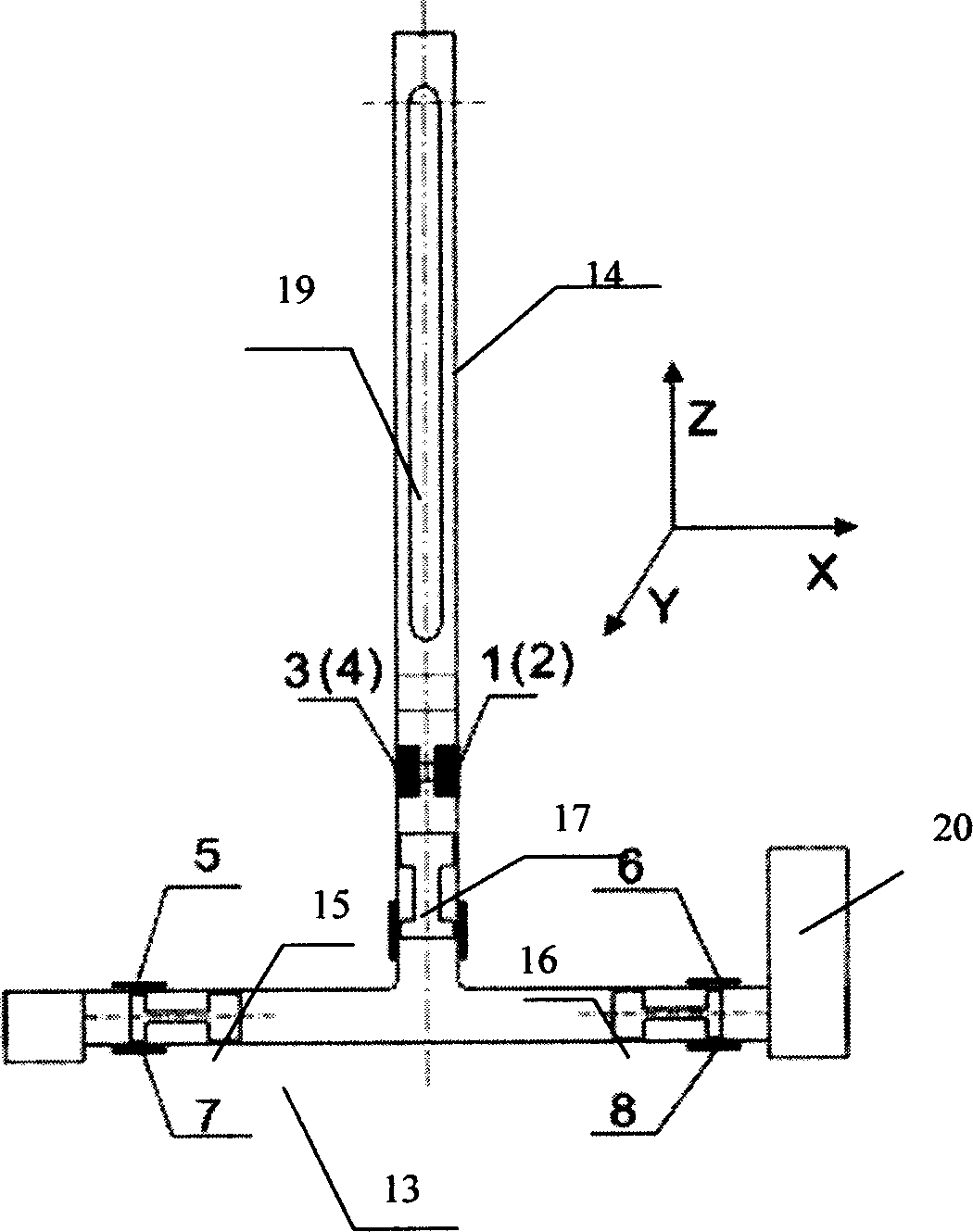

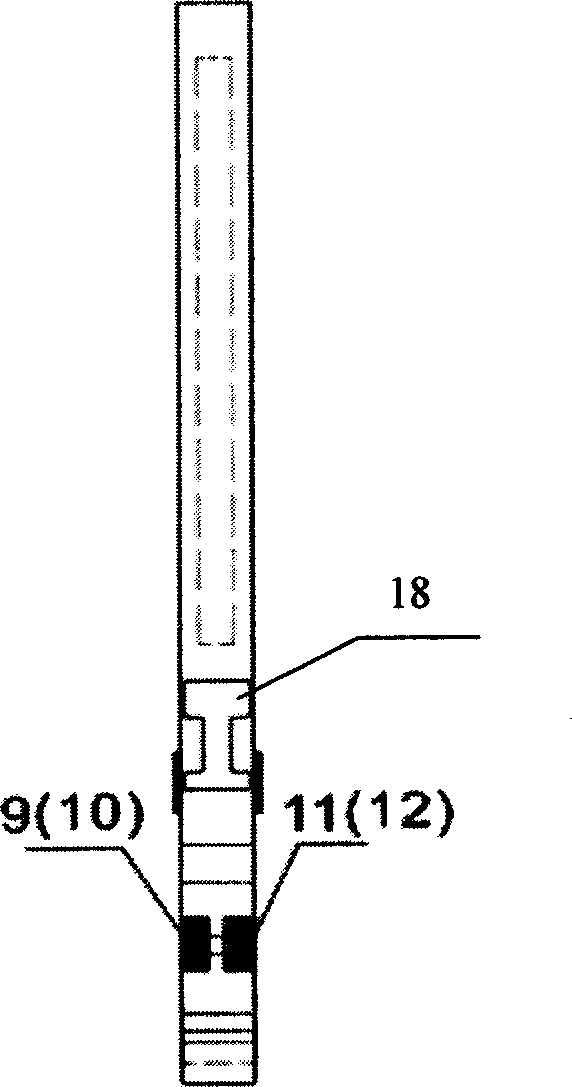

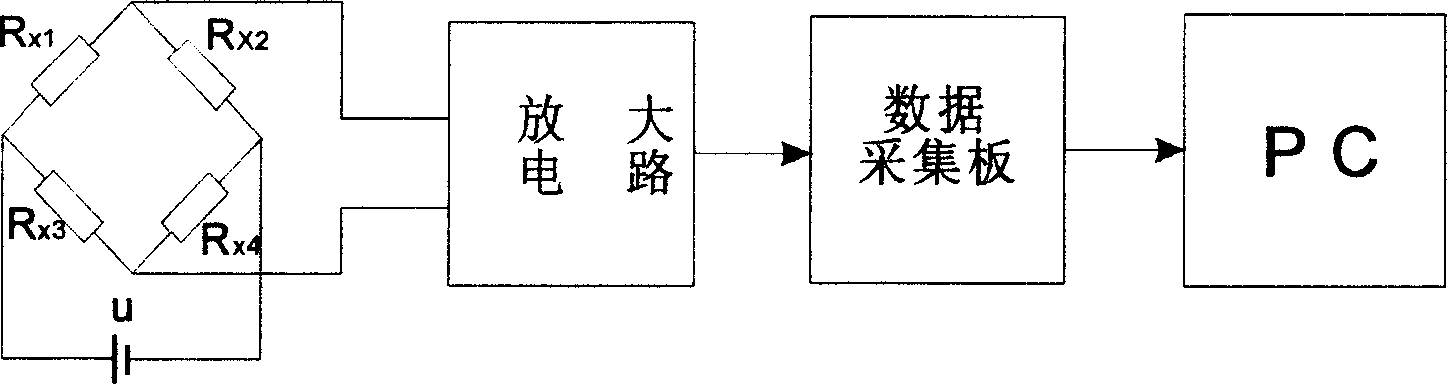

[0019] like figure 1 , figure 2 As shown, the three-dimensional small-range force sensor of this embodiment is an integral inverted "T"-shaped structure, including a horizontal beam 13 and a vertical beam 14 made of elastic body. Wherein, the left end of the horizontal beam 13 is opened with a left end "H" shaped through hole 15 along the Y direction, and the right end is opened with a right end "H" shaped through hole 16 along the Y direction. The "H"-shaped through-hole 15 at the left end and the "H"-shaped through-hole 16 at the right end are arranged symmetrically, and a strain gauge 5, 7 is pasted on the outer surface of the upper and lower walls of the left end of the "H"-shaped hole 15 at the left end, and the "H"-shaped hole 16 at the right end The outer surfaces of the upper and lower walls of the right end of the upper and lower walls are each pasted with a strain gauge 6, 8, and the strain gauges 5, 7, 6, and 8 constitute the first group of Wheatstone bridges; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com