Nondestructive detection device for tunnel linings

A non-destructive testing and lining technology, applied in measuring devices, analyzing solids using sonic/ultrasonic/infrasonic waves, and using sonic/ultrasonic/infrasonic waves for material analysis, etc., can solve the problems of high labor intensity, manual knocking, low detection efficiency, etc. , to achieve the effect of improving objectivity, increasing adaptability and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

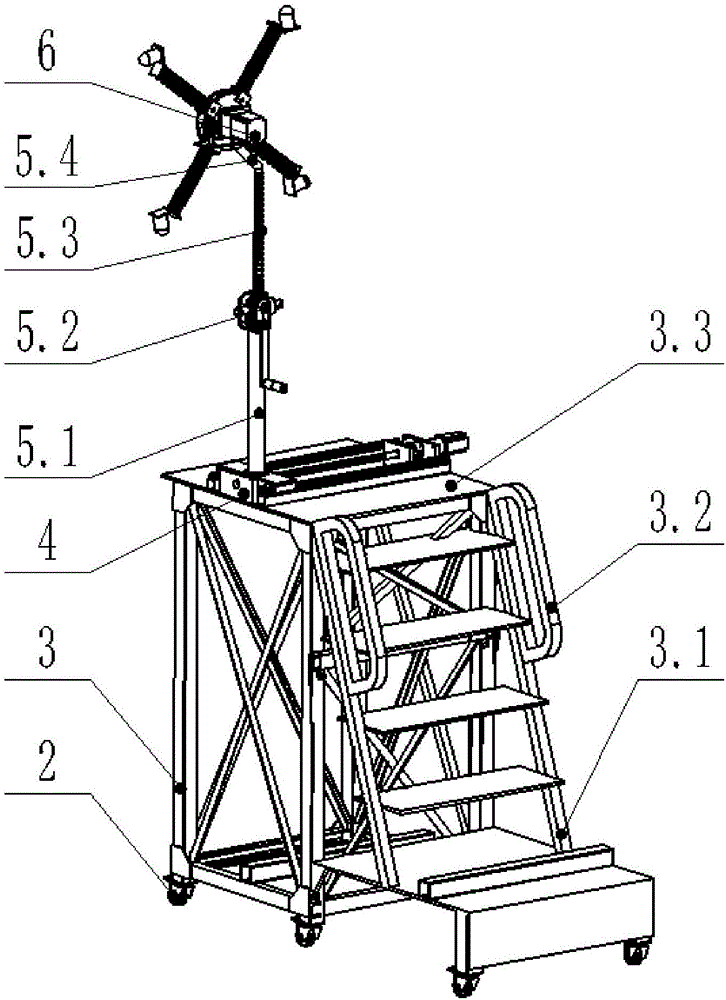

[0030] Embodiment 1: The present invention provides a kind of tunnel lining non-destructive testing device, its structure is as follows figure 1 As shown, it includes a swivel caster with brake 2, a workbench 3, a distance fine-tuning component 4, a height adjustment component 5, an automatic knocking component 6 and a host computer with peripherals.

[0031] The said swivel caster with brake 2 is installed on the lower end of the base 3.1 of the workbench 3, and is used to adjust the position of the device in the working state, and lock the brake of the swivel caster with brake for tunnel lining detection, and It is very convenient to move and transfer the device by using universal casters with brakes when detecting the working state.

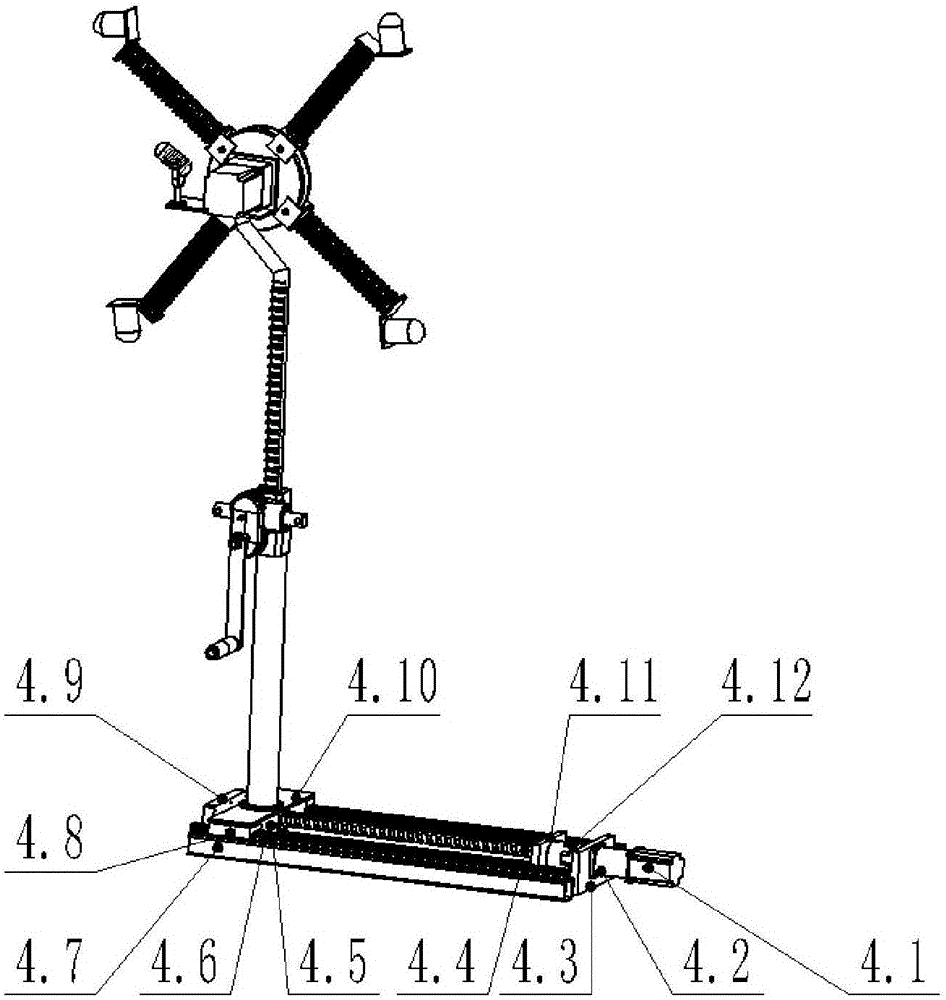

[0032] The workbench 3 is provided with a base 3.1, an escalator 3.2 and a worktable 3.3, the worktable and the base are used to support the distance fine-tuning assembly 4 installed on the worktable, and the height adjustment assembly 5 and t...

Embodiment 2

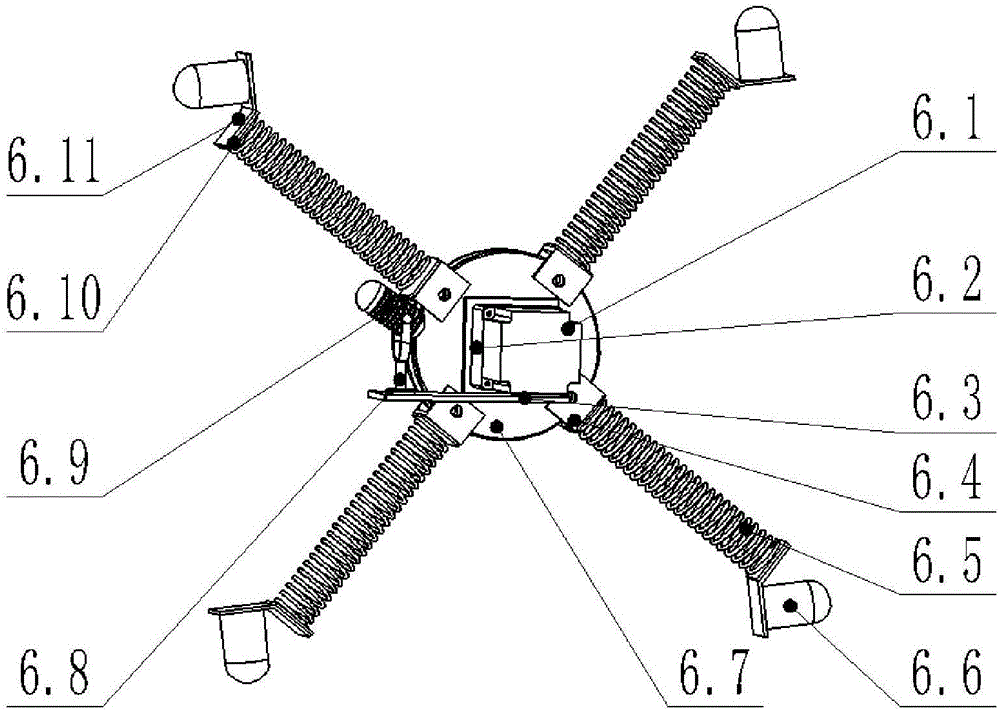

[0047] Embodiment 2: The present invention provides a non-destructive testing device for tunnel lining. Its structure, assembly process and testing operation steps are basically the same as those in Embodiment 1, except that the device is fixed on the cylindrical rack bar of the height adjustment assembly 5. It is connected with 4 inclined support rods 5.4 and an automatic knocking assembly 6, which can realize the simultaneous detection of 4 measuring lines in the same tunnel.

Embodiment 3

[0048] Embodiment 3: The present invention provides a tunnel lining non-destructive testing device, the structure of which is the same as that of Embodiment 2, that is, four inclined support rods 5.4 and automatic knocking rods are fixedly connected to the cylindrical rack rod of the height adjustment assembly 5. Hitting assembly 6, the only difference is that 2 such detection devices of the same structure of the present invention are fixed on the same railway engineering vehicle 1 during use, so as to realize the simultaneous detection of 8 measuring lines of single-track railway tunnels.

[0049] The tunnel lining non-destructive testing device of the present invention adopts a modular design, which is convenient to assemble and disassemble, and simple to operate. The detection of the tunnel lining by the device is a non-destructive detection, which has good detection objectivity, a large detection surface, high detection efficiency and reliable detection results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com