Patents

Literature

767 results about "Computer data processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The computer is also known as electronic data processing machine. This method of processing data is very fast and accurate. For example, in a computerized education environment results of students are prepared through computer; in banks, accounts of customers are maintained (or processed) through computers etc.

Computer system for automatic organization, indexing and viewing of information from multiple sources

ActiveUS20040177319A1Efficient storageMultimedia data indexingFile access structuresComputer data processingData processing

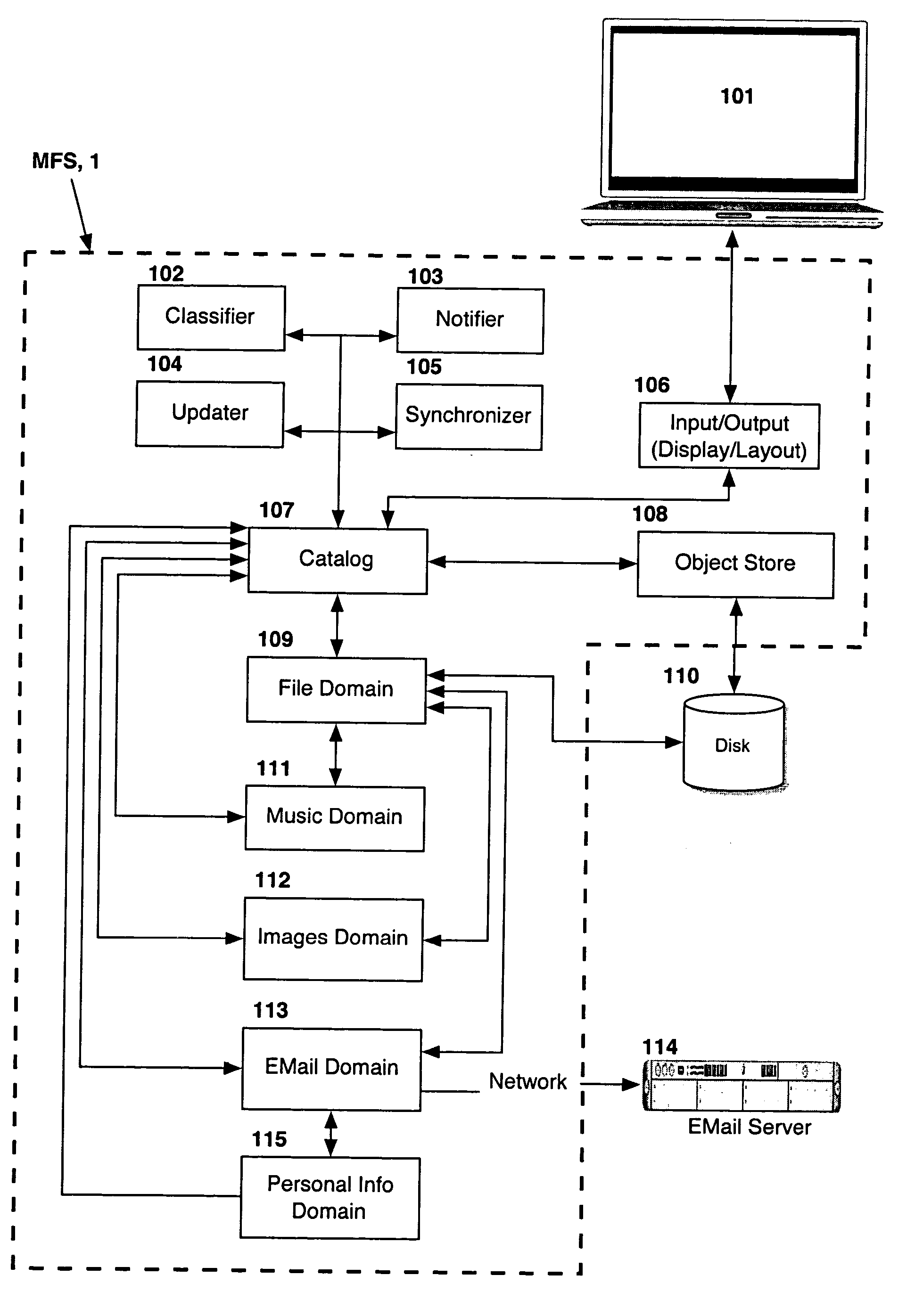

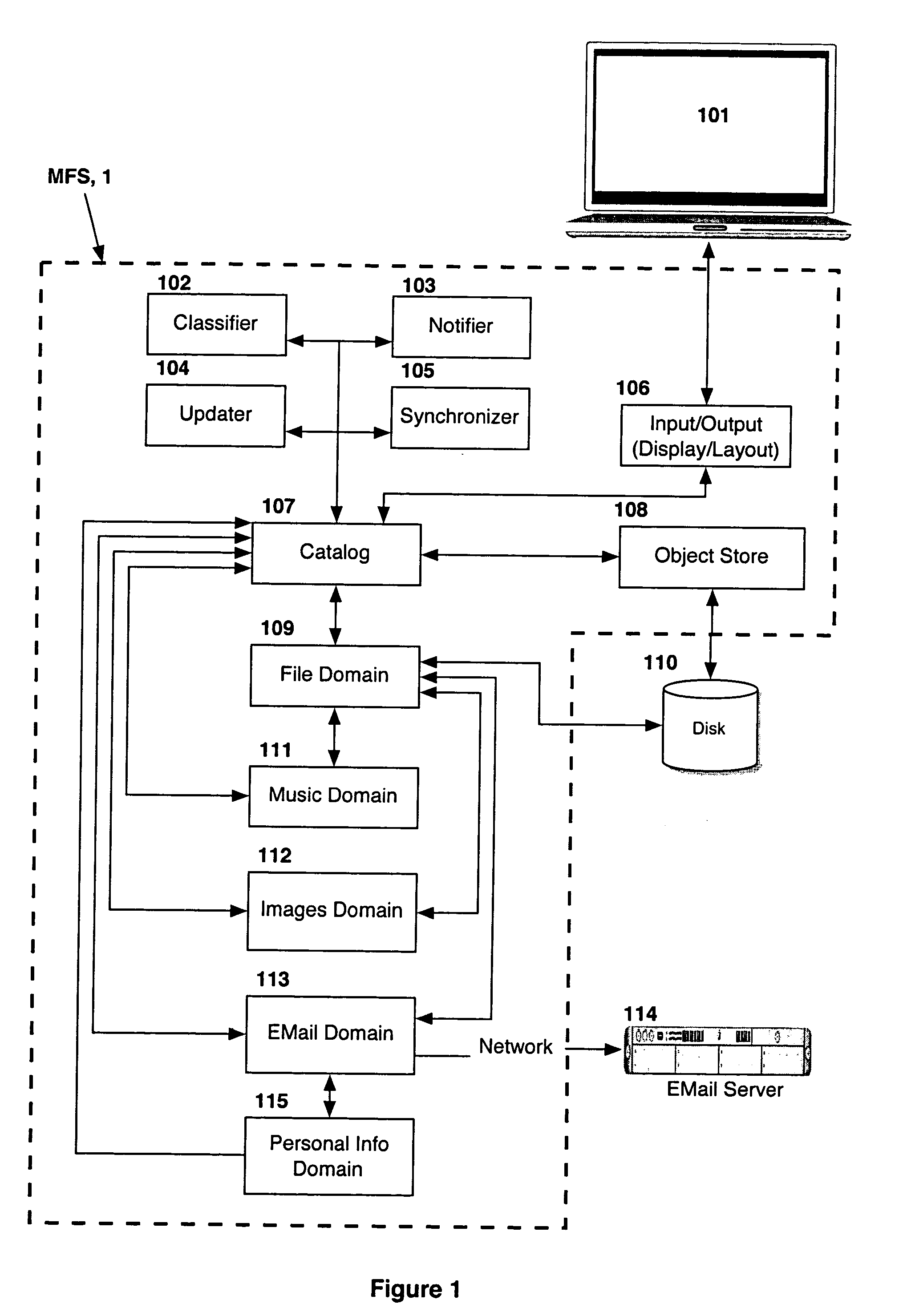

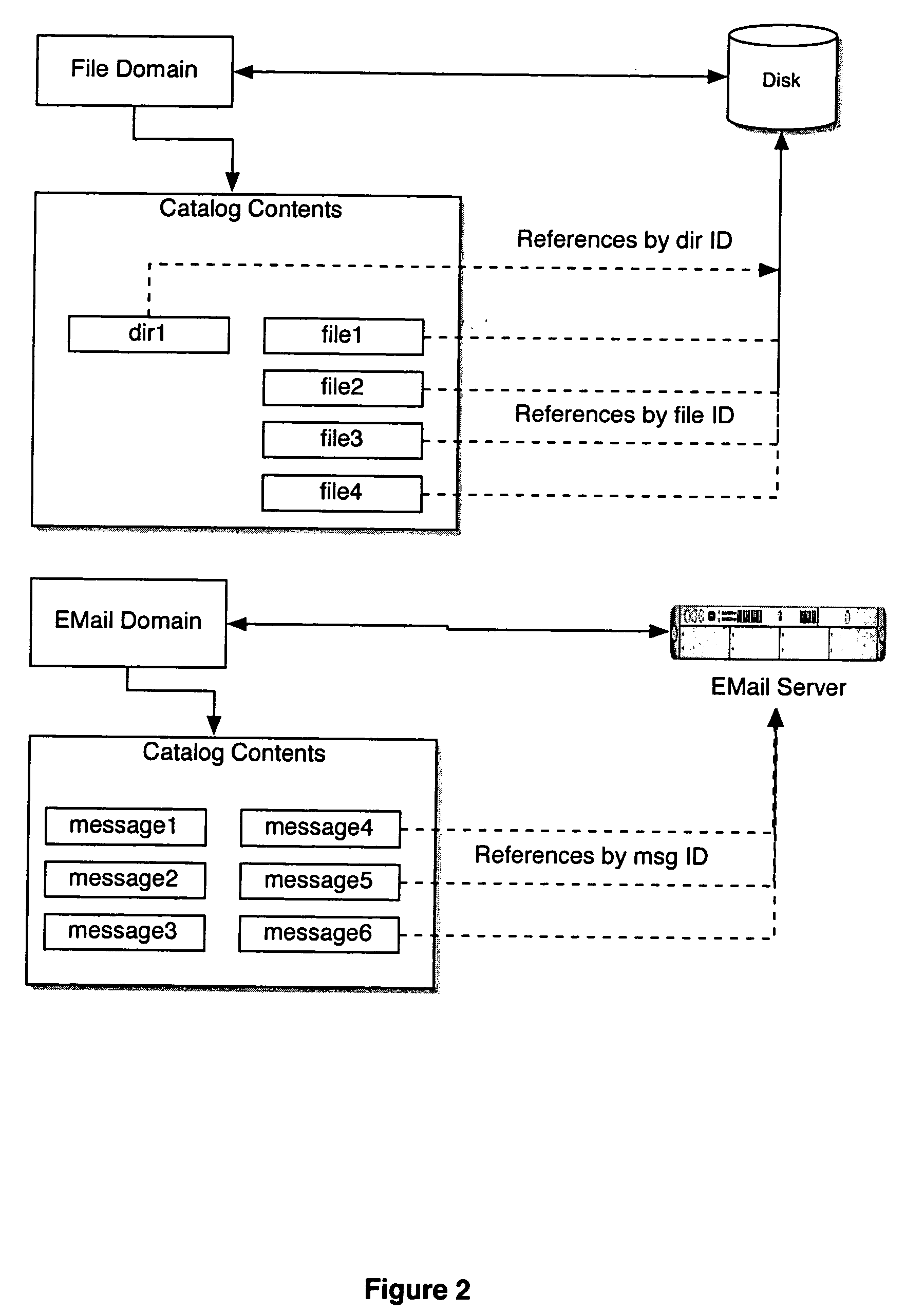

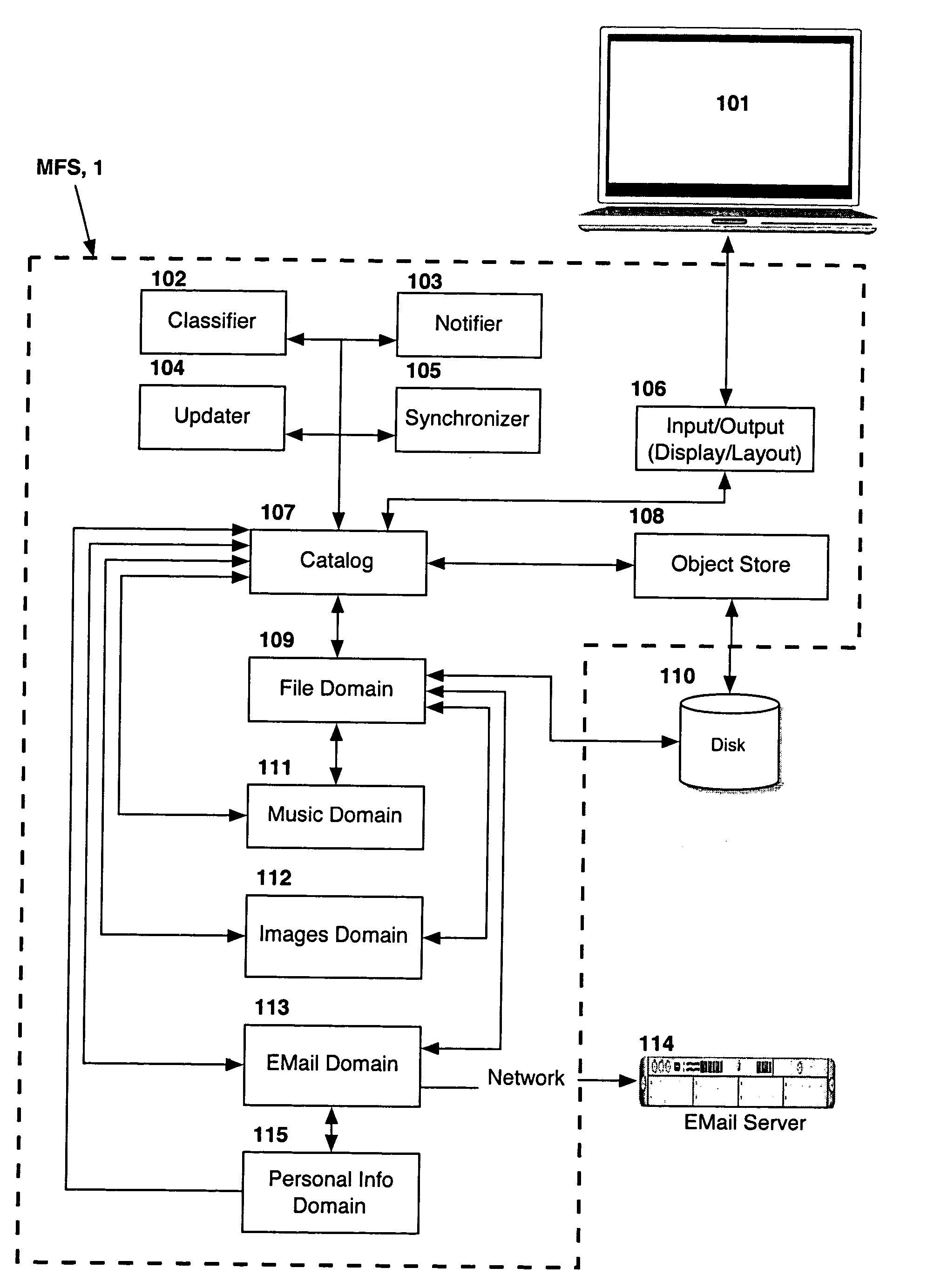

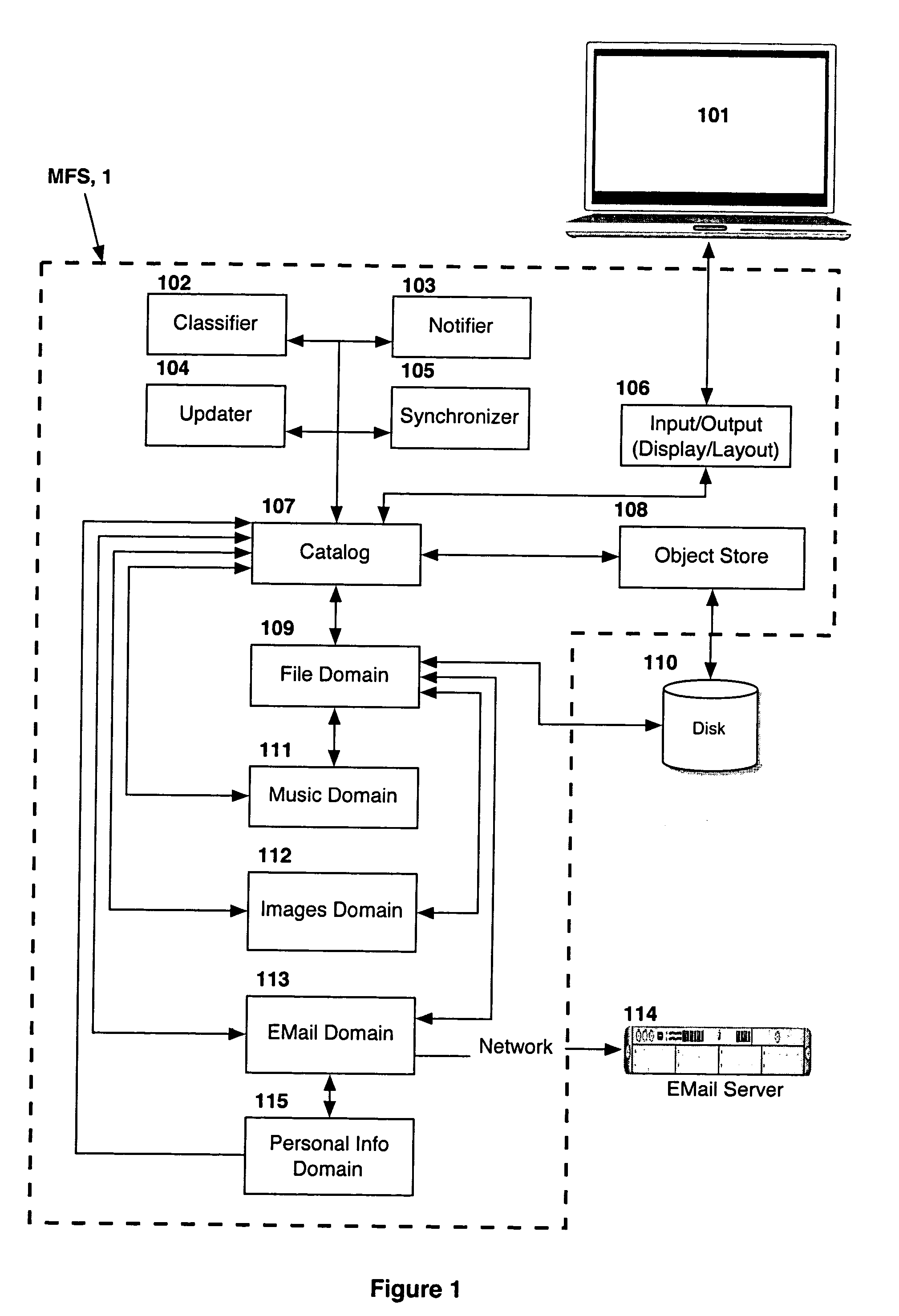

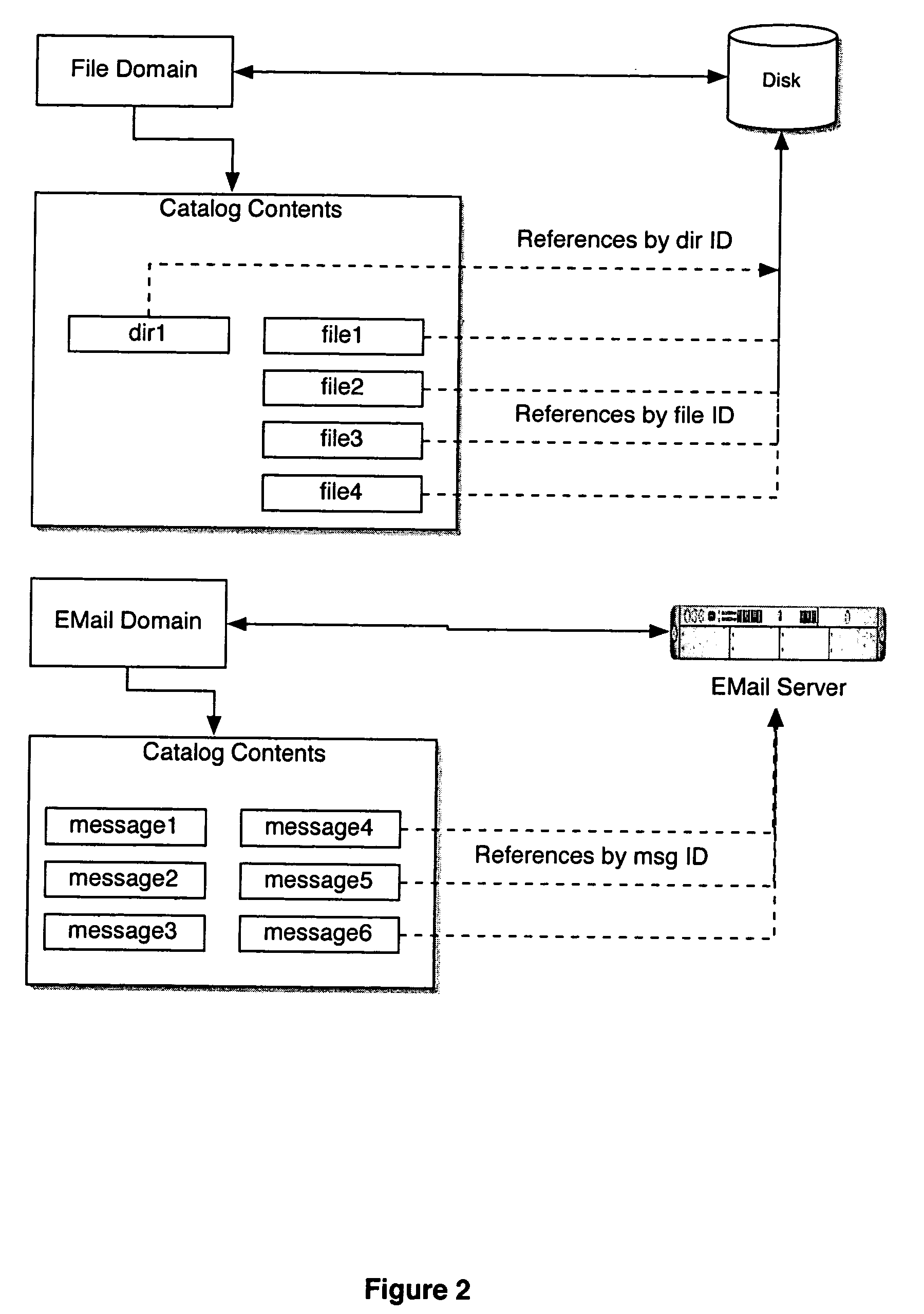

A computer data processing system including a central processing unit configured with a novel integrated computer control software system for the management of data objects including dynamic and automatic organization, linking, finding, cross-referencing, viewing and retrieval of multiple objects regardless of nature or source. The inventive system provides underlying component architecture having an object-oriented database structure and a metadata database structure which is unique in storing only one instance of each object while linking the object to multiple collections and domains by unique metadata links for the grouping into and retrieval from any of the collections. The system employs configurable, extensible attribute / properties of data objects in metadata format, and a truly user-friendly configurable interface that facilitates faster, more unified, comprehensive, useful and meaningful information management. Additional features include a sticky path object hierarchy viewing system, key phrase linking, viewing by reference, and drag-and-drop relationship link creation.

Owner:EHIERARCHY LLC

Computer system for automatic organization, indexing and viewing of information from multiple sources

ActiveUS7275063B2Facilitate communicationMultimedia data indexingFile access structuresPathPingSoftware system

Owner:EHIERARCHY LLC

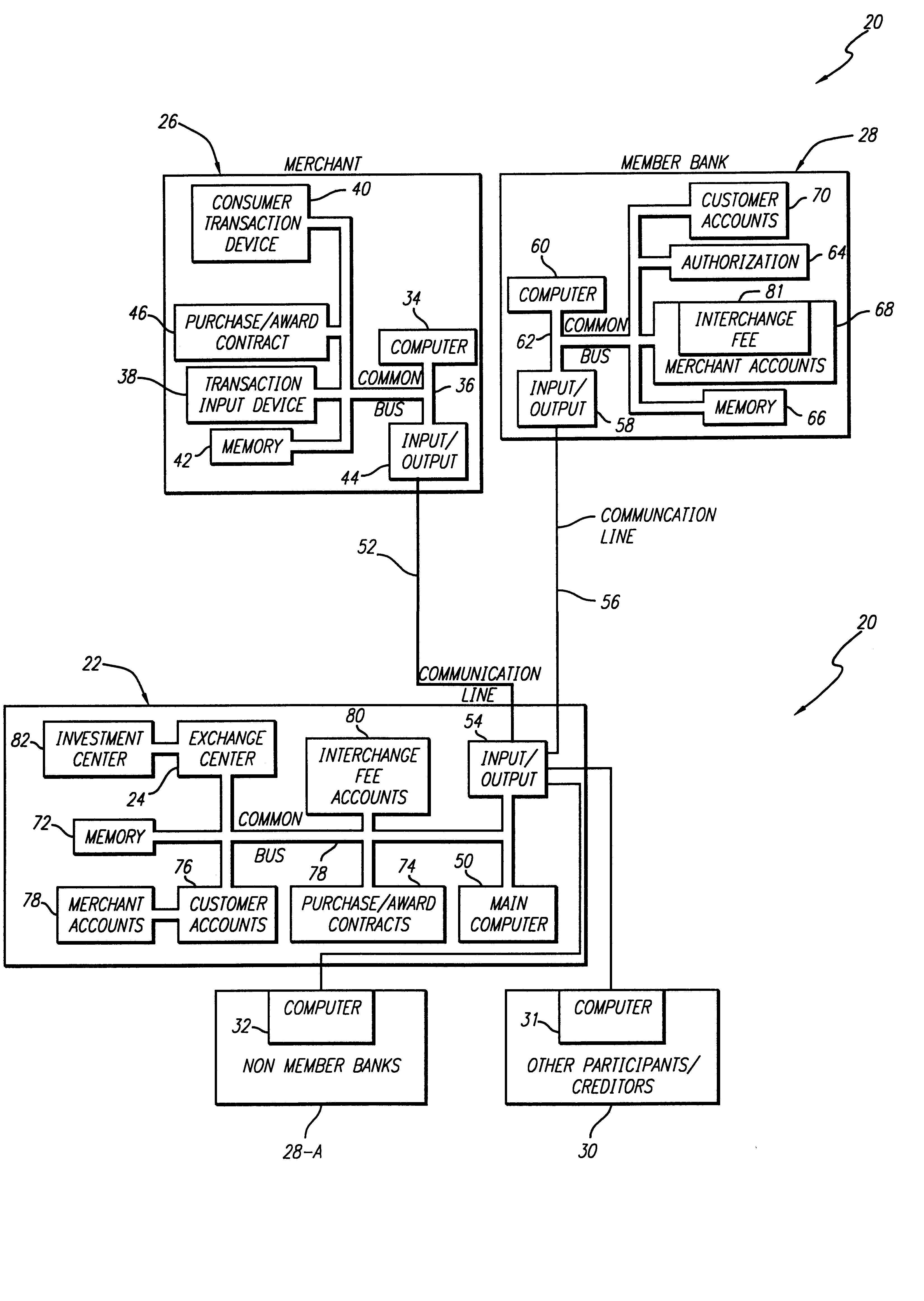

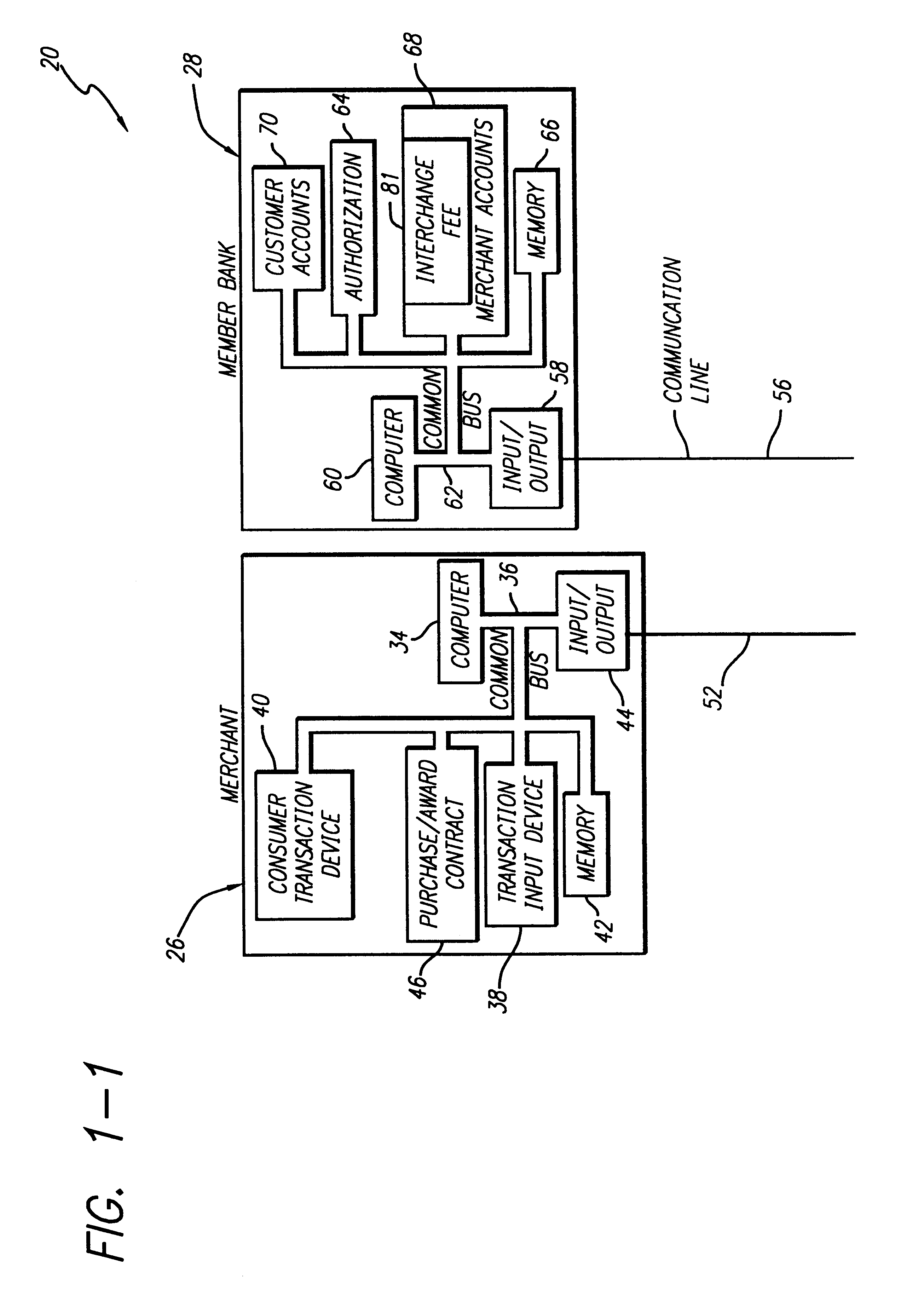

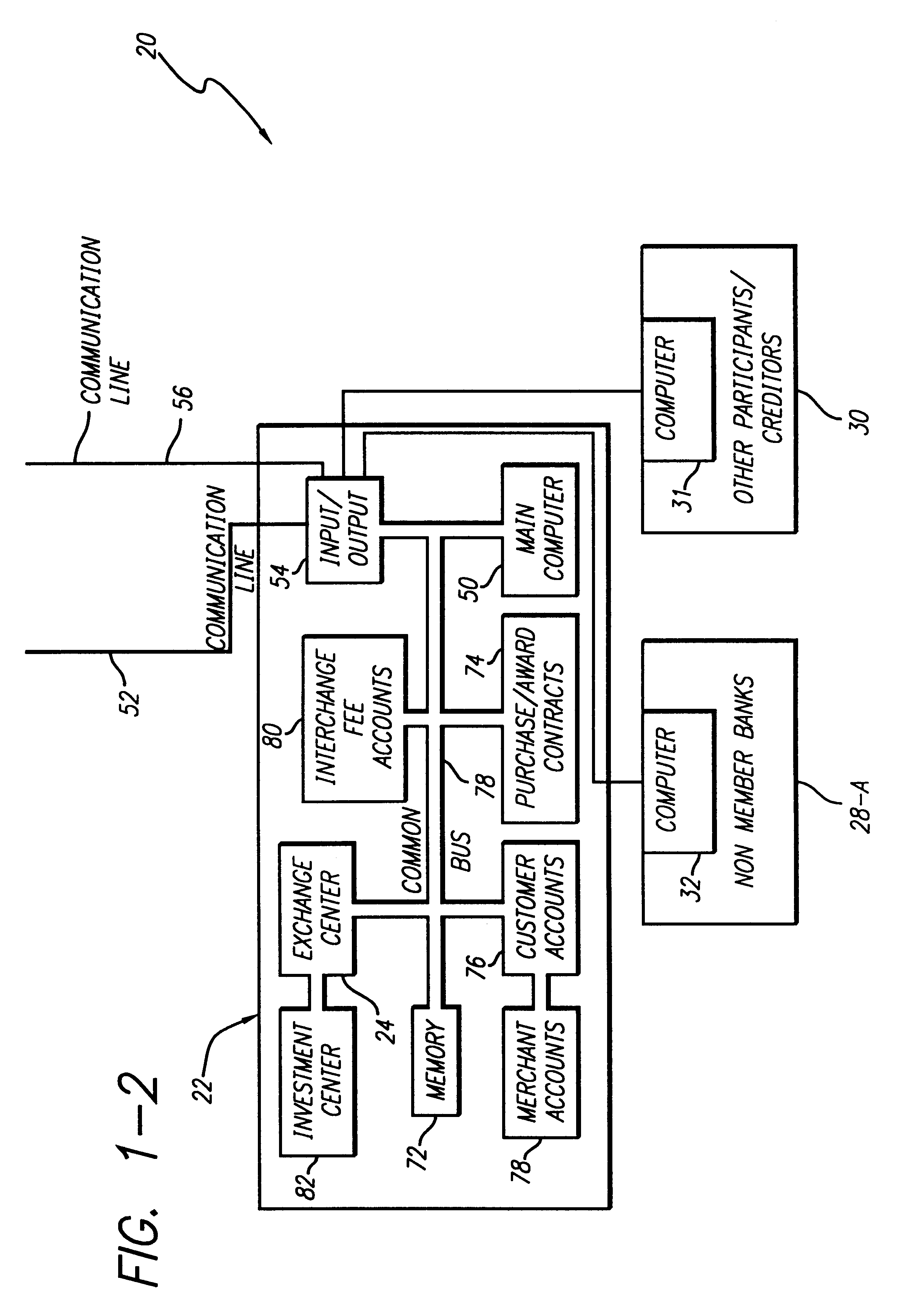

Internet-based credit interchange system of converting purchase credit awards through credit exchange system for purchase of investment vehicle

An Internet-based purchase credit award interchange center is described which interfaces with a credit award exchange center for conversion of any form of merchant or purchase credit award resulting from customer purchase of goods or services to investment in a mutual fund and / or investment vehicle utilizing computer data processing methods. Preassigned purchase credit accumulations earned by a consumer are exchanged from a merchant or creditor through or combination of credit cards, co-branded credit cards, PIN cards, debit and smart cards, coupons, stamps, proof of purchase, rebates, or any form of purchase award of merchant or creditors choice for an investment in a mutual fund or other investment vehicle. A specific implementation is described wherein a credit card account having investment credit awards is issued through the Internet to a customer. While inputting information through the Internet necessary for establishing the credit card account, the customer also provides any information needed to authorize the purchase of investment vehicles on his or her behalf. Any forms that need to be signed by the customer to authorize purchase of the investment vehicles may be printed out by the customer. The customer may also select, via the Internet, particular investment vehicles out of a group of possible investment vehicles. Subsequent use of the credit card by the customer automatically results in accrual of credit award accumulations in the selected investment vehicle.

Owner:KALINA DYAN T

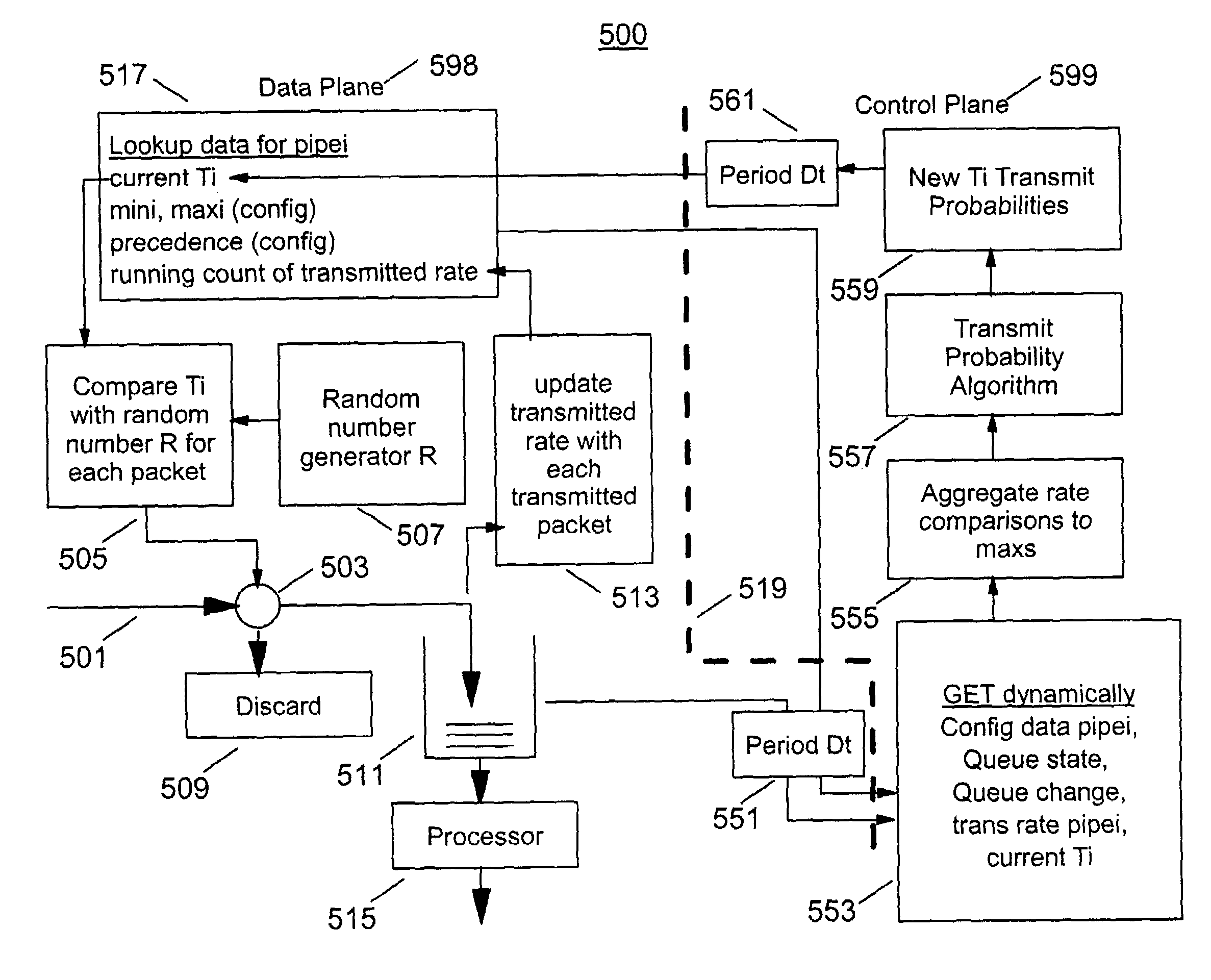

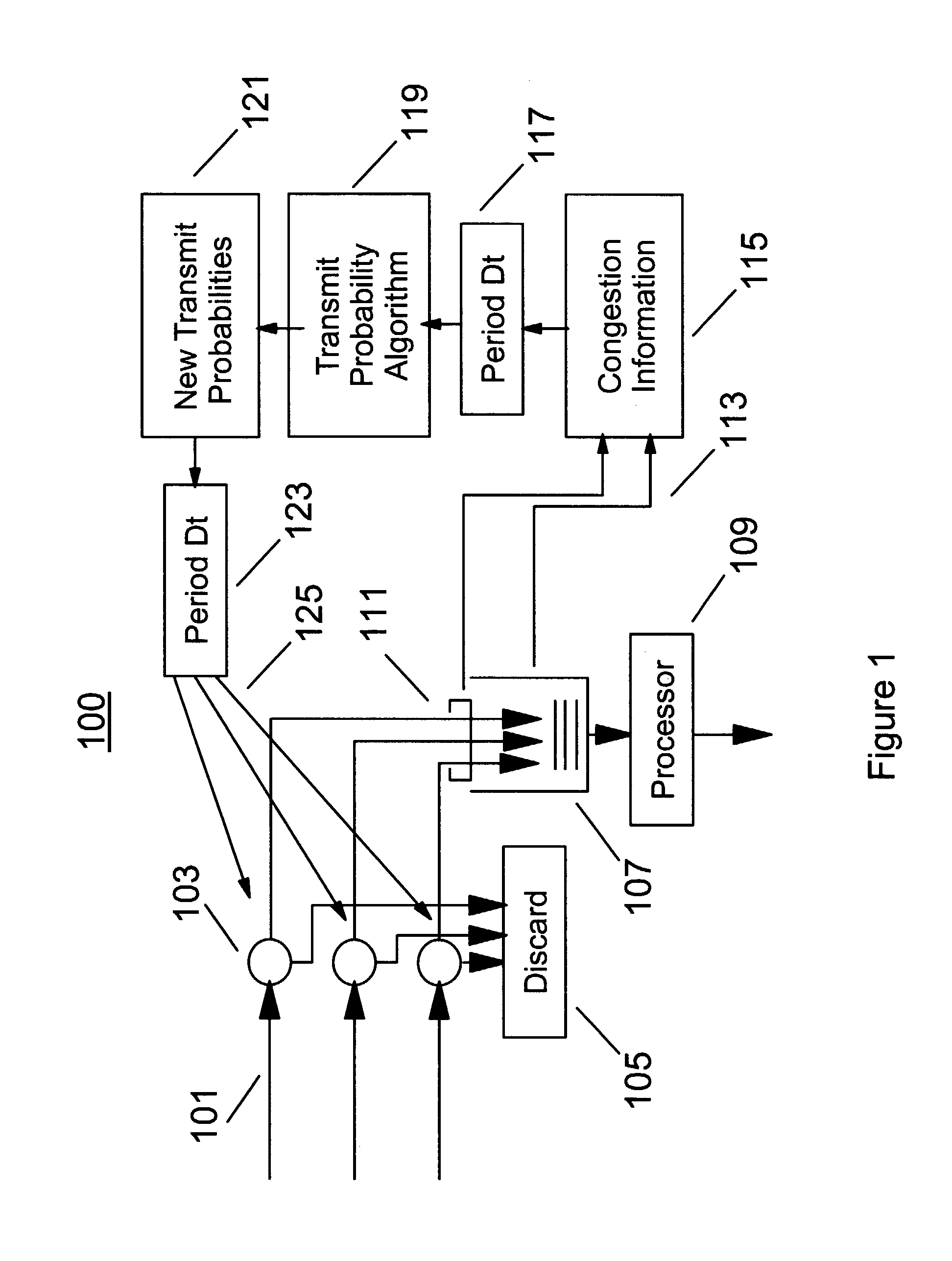

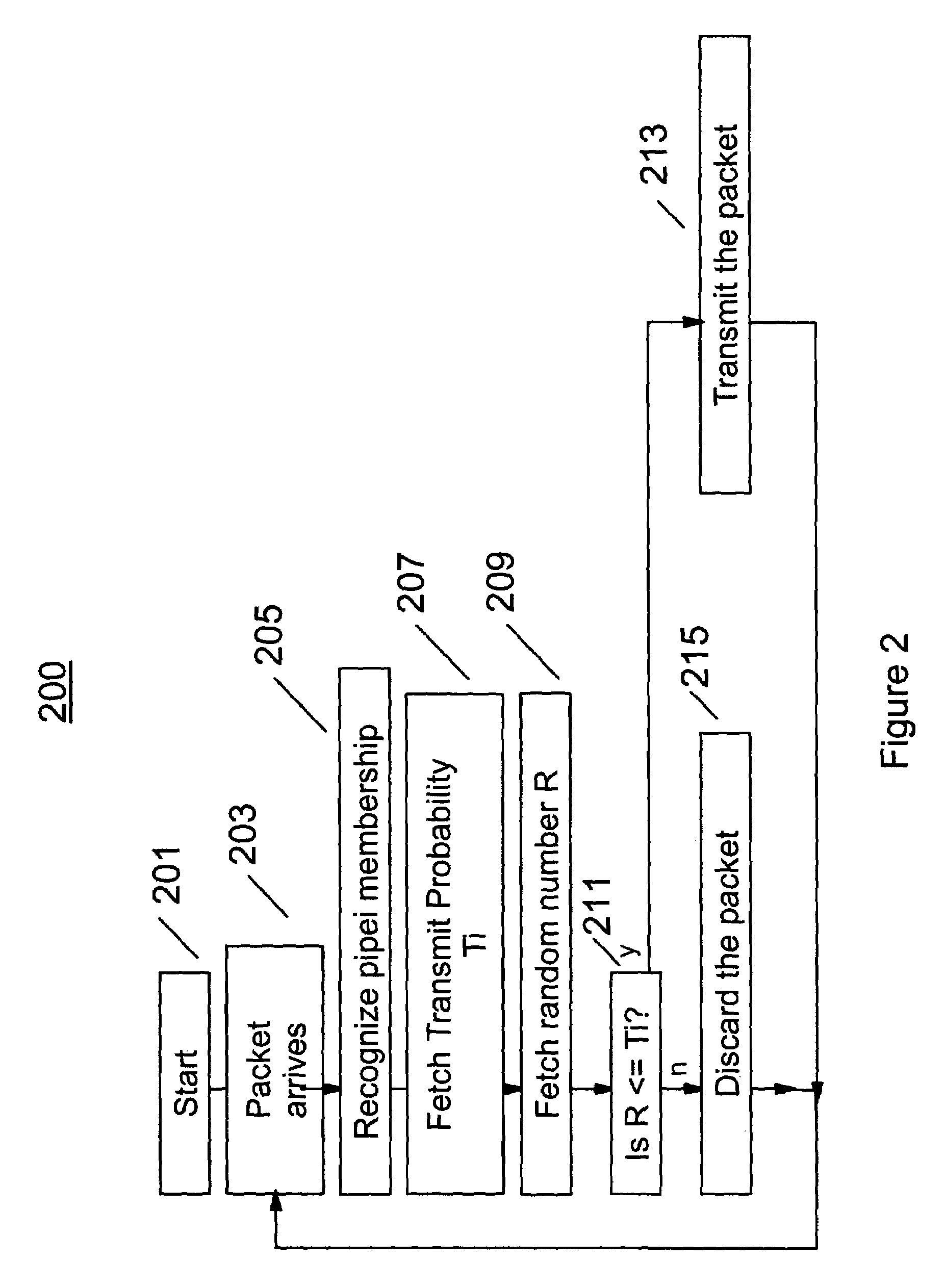

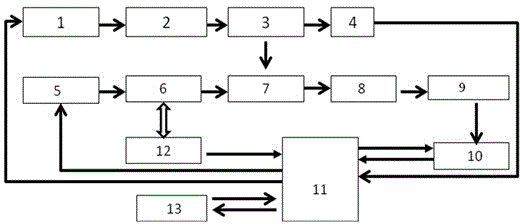

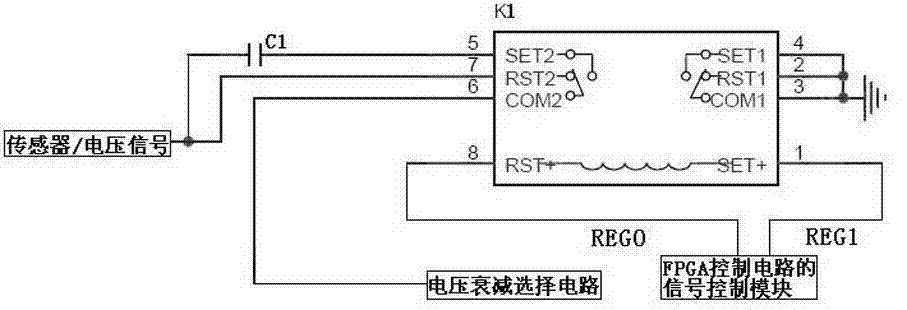

System and method for automatic management of many computer data processing system pipes

ActiveUS7710874B2Attenuation bandwidthReduce information required can be stored in algorithm processorError preventionFrequency-division multiplex detailsComputer data processingComputer science

A process control method and system including partitioning transmit decisions and certain measurements into one logical entity (Data Plane) and partitioning algorithm computation to update transmit probabilities into a second logical entity (Control Plane), the two entities periodically communicating fresh measurements from Data Plane to Control Plane and adjusted transmit probabilities from Control Plane to Data Plane. The transmit probability may be used in transmit / discard decisions of packets or instructions exercised at every arrival of a packet or instruction. In an alternative embodiment, the transmit probability may be used in transmit / delay decisions of awaiting instructions or packets exercised at every service event.

Owner:TWITTER INC

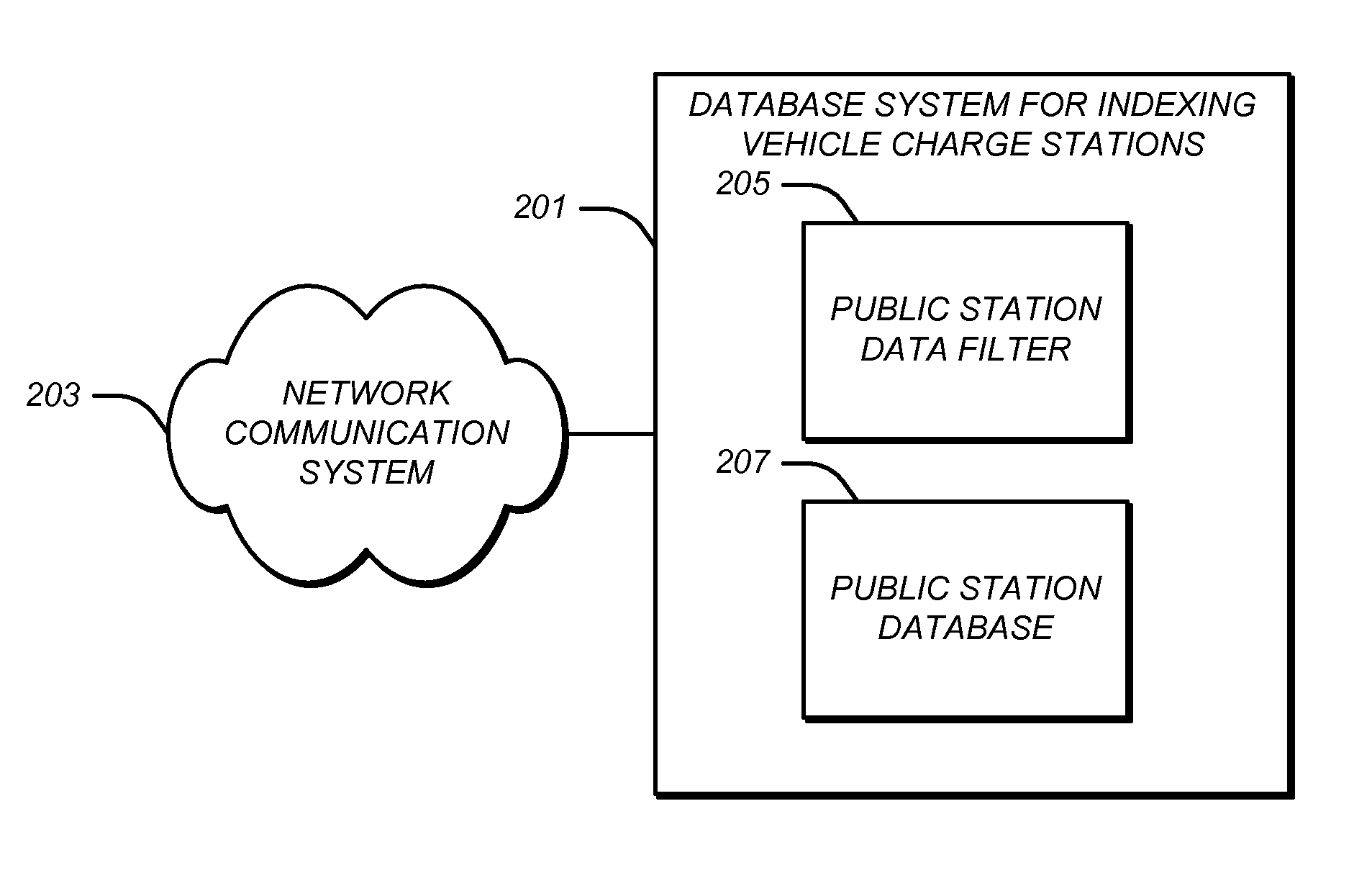

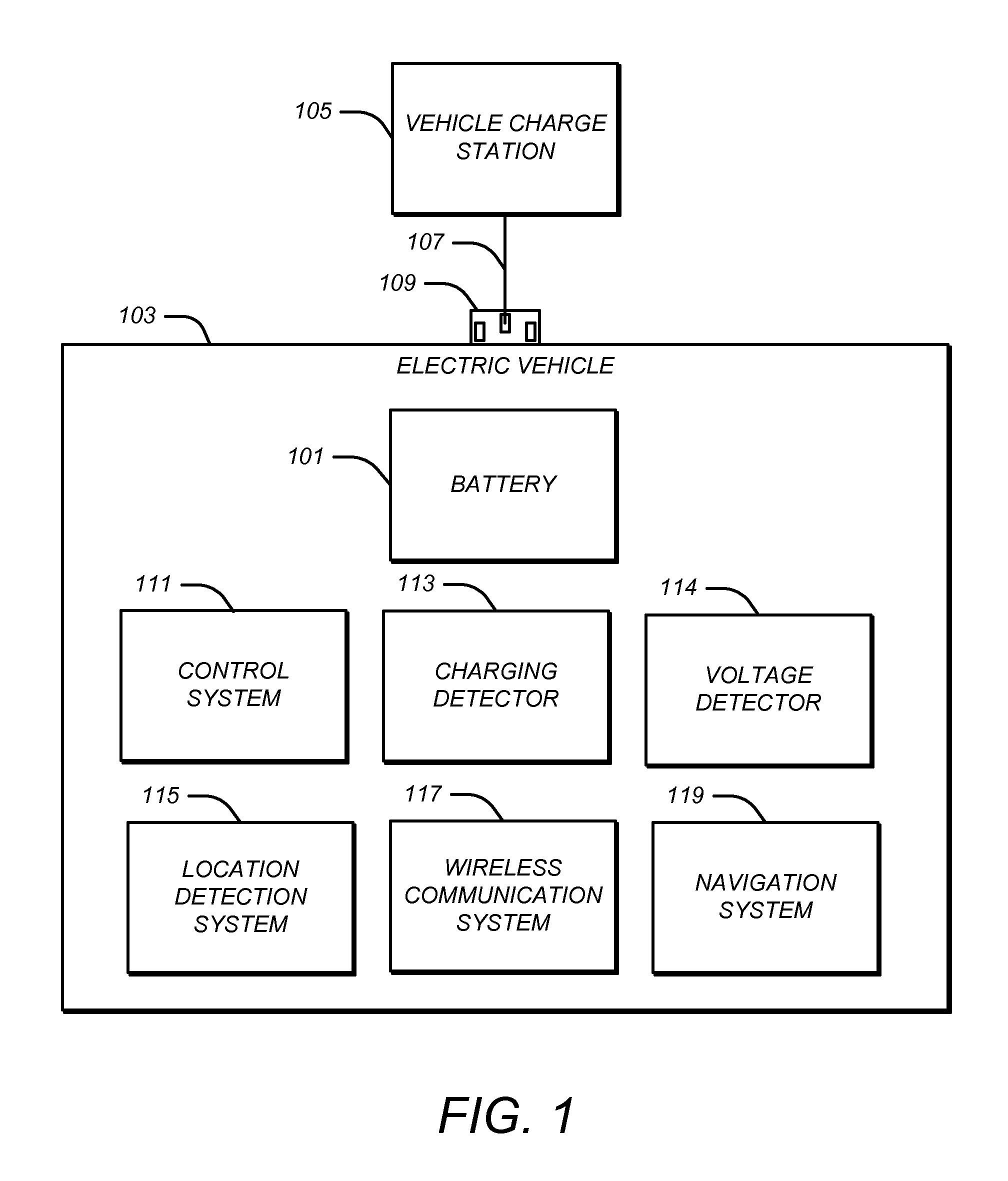

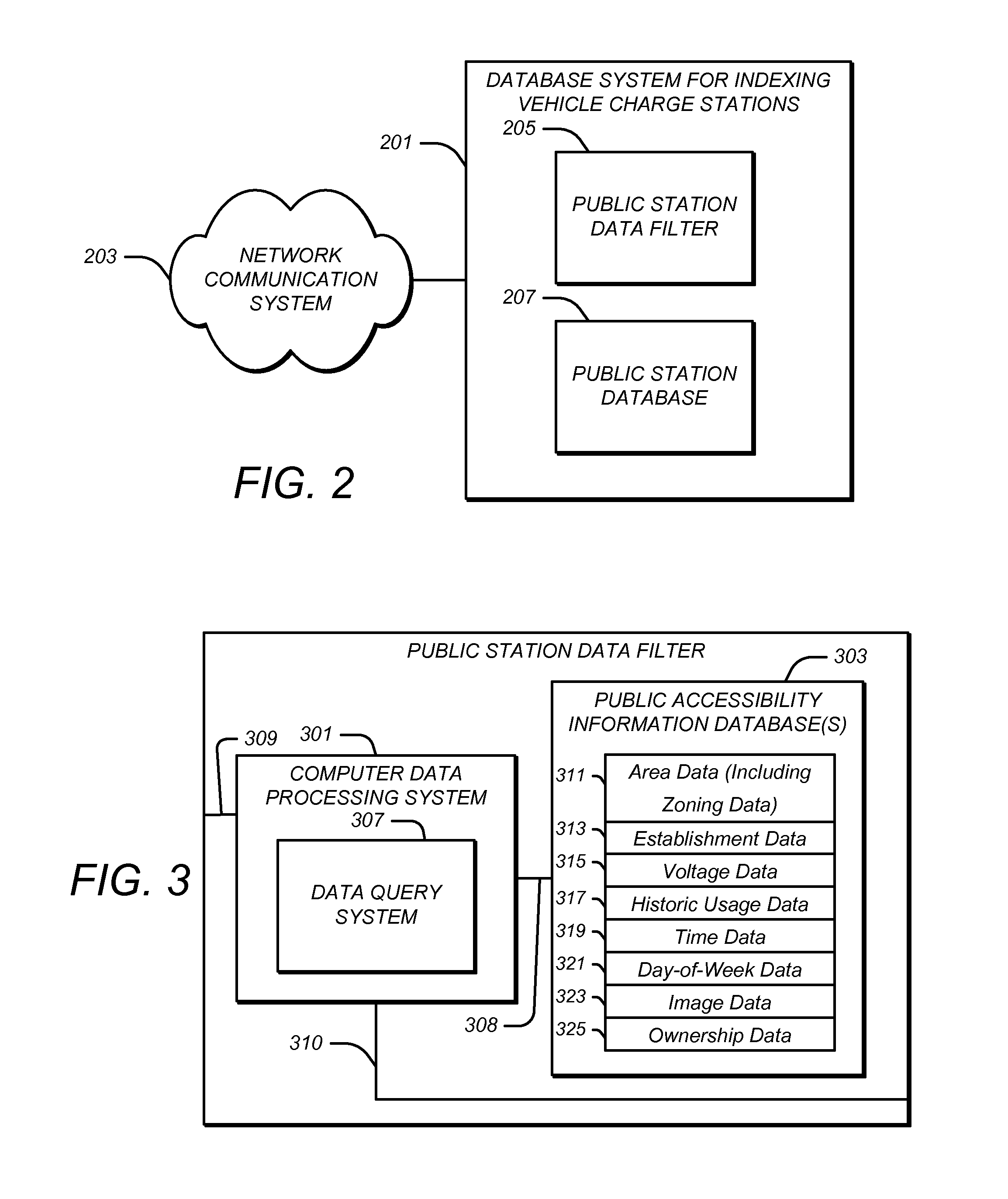

Automated system for determining whether vehicle charge station is publicly accessible

A system may automatically identify whether a vehicle charge station is publicly accessible. A location data input may receive location data which is indicative of the location of the vehicle charge station. A public accessibility data input may receive accessibility data which is relevant to determining whether the vehicle charge station is publicly accessible. A computer data processing system may determine whether the vehicle charge station is publicly accessible based on the accessibility data. A data output may deliver output data indicative of whether the vehicle charge station is publicly accessible based on the determination of such public accessibility by the computer data processing system.

Owner:TOYOTA MOTOR SALES USA

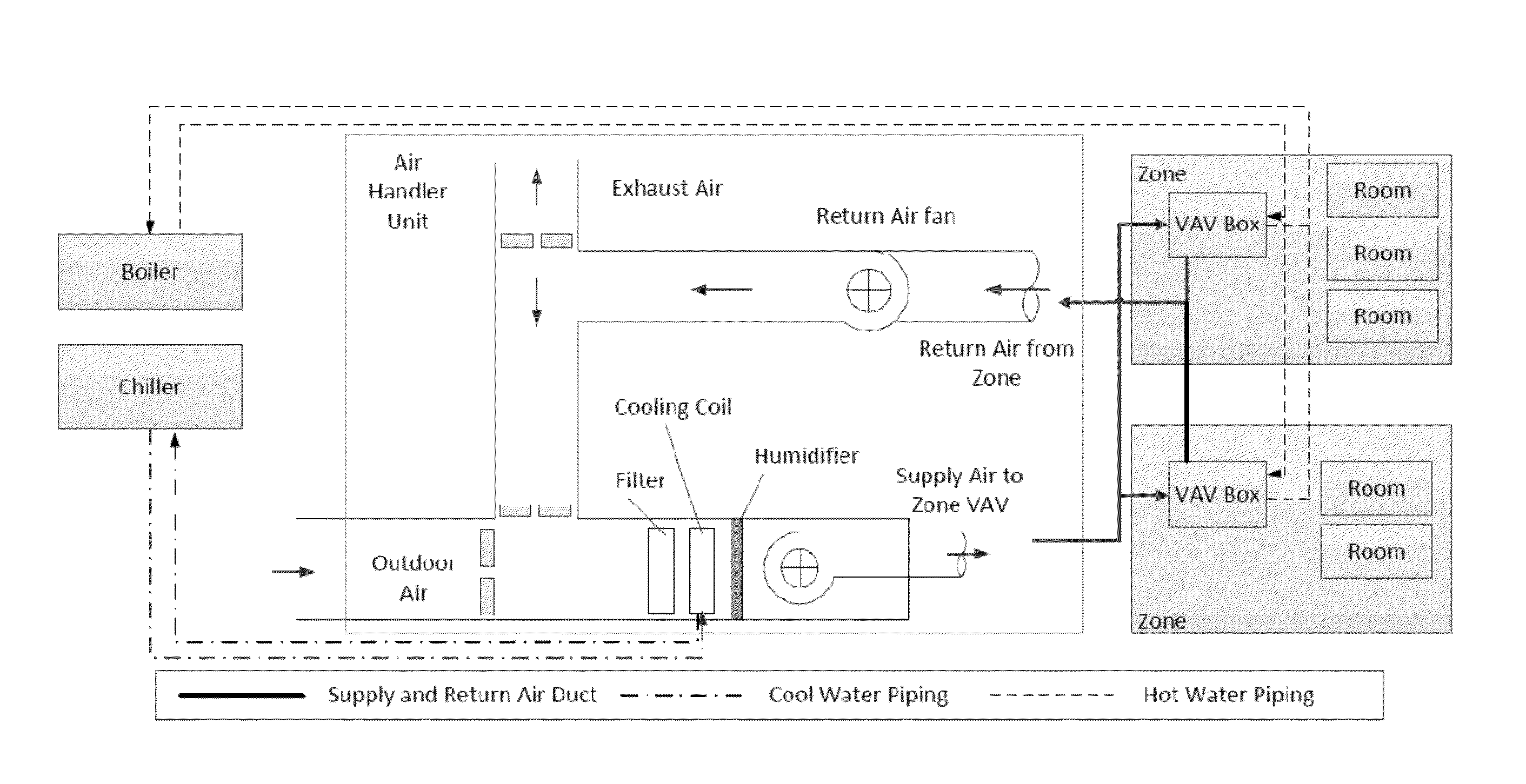

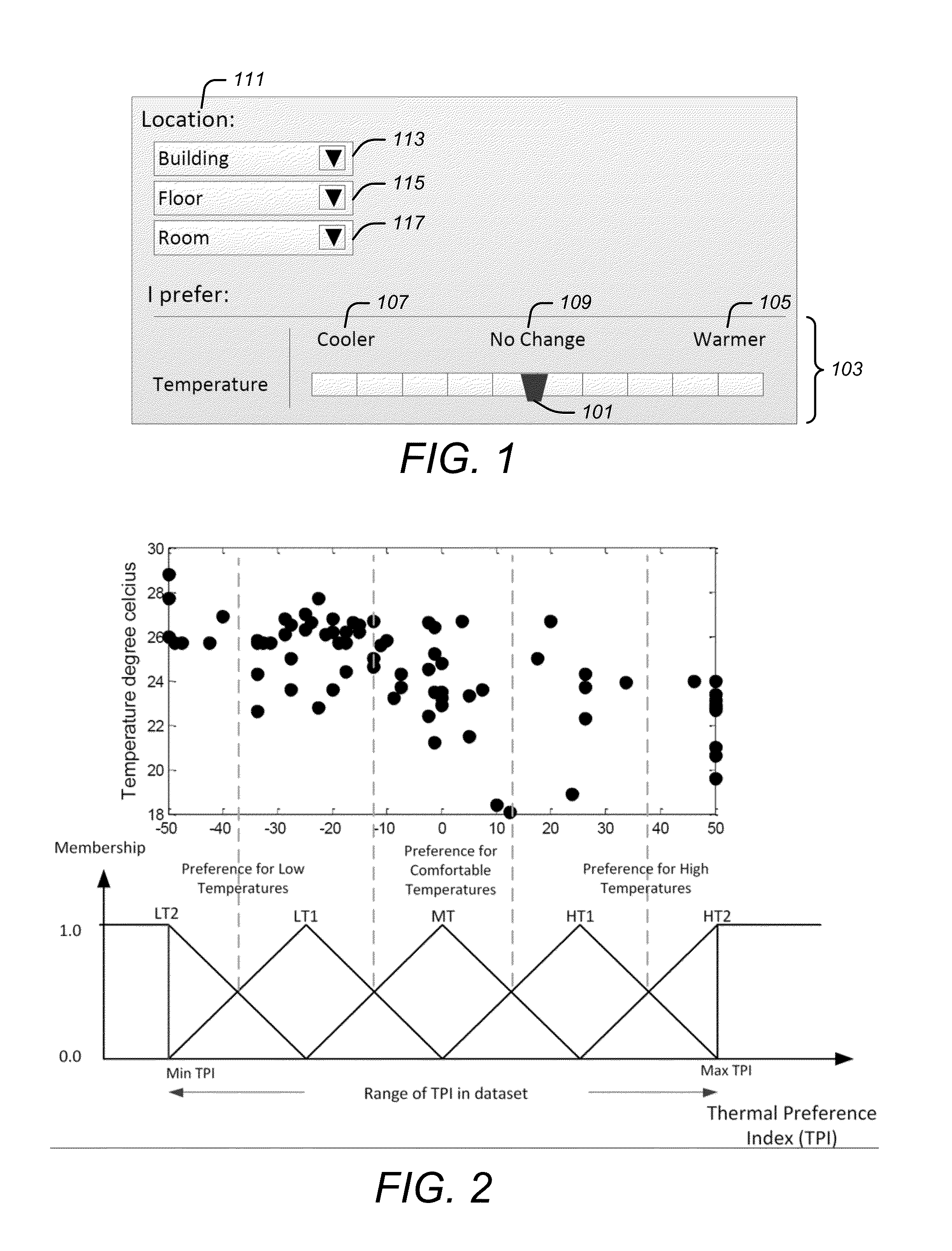

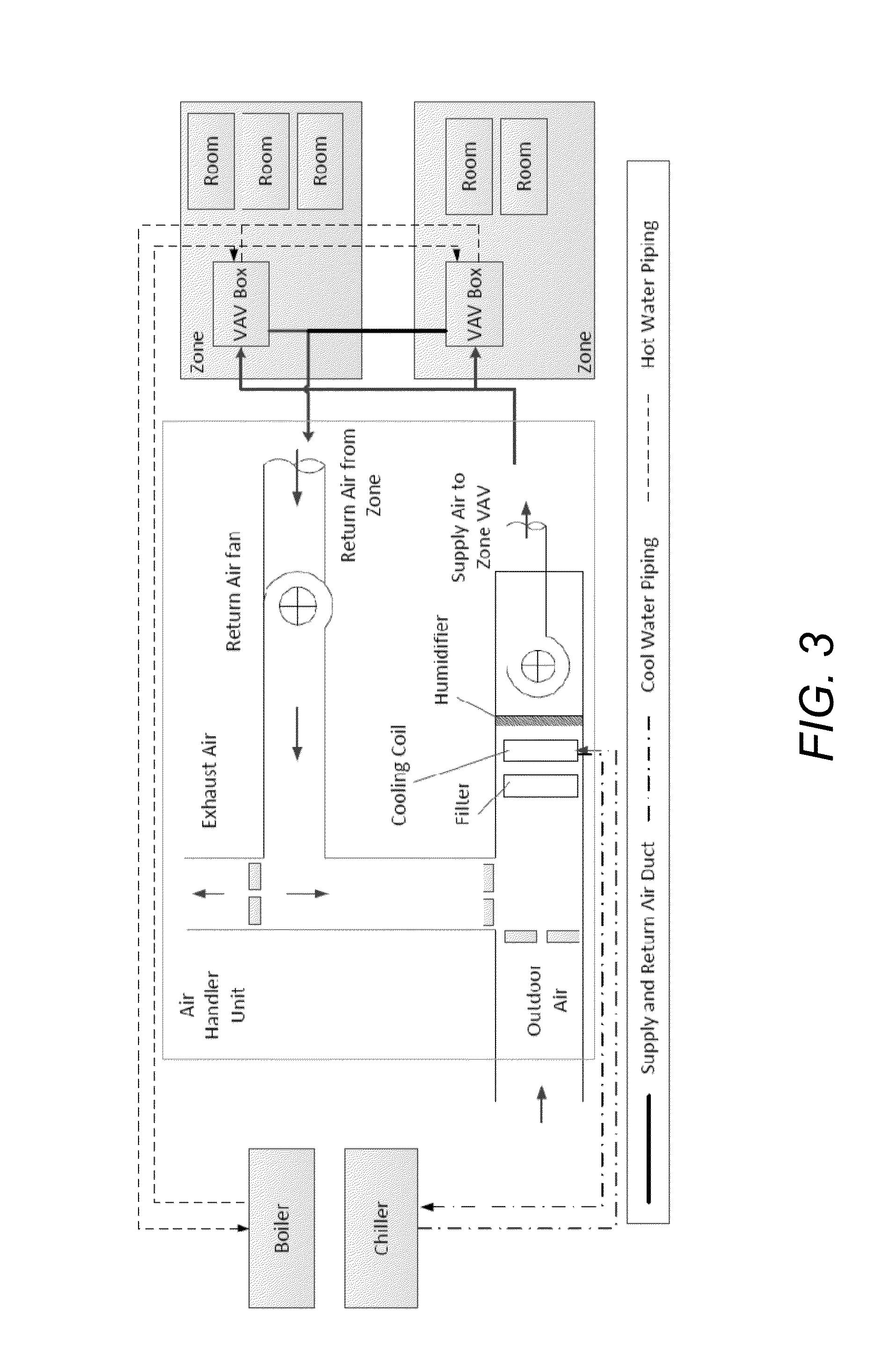

Human-building interaction framework for personalized comfort driven system operations in buildings

InactiveUS20140277765A1Programme controlSampled-variable control systemsPersonalizationOperating energy

A computer data processing system may provide control information for controlling how an environmental control system controls an environment within a building. The computer data processing system may receive and store reports from multiple users and / or may receive and store reports at different times from a user. Each report may provide information concerning how the user perceives the comfort level of the user's environment at the time the user supplies the information. The computer data processing system may determine and generate the control information for controlling how the environmental control system controls the environment based on the information concerning how each user perceives the comfort level of the user's environment at the time each user provides the information. In addition or instead, the computer data processing system may determine and generate such control information based on the information concerning how a user perceives the comfort level of the user's environment at the different times the user supplies the information.

Owner:UNIV OF SOUTHERN CALIFORNIA

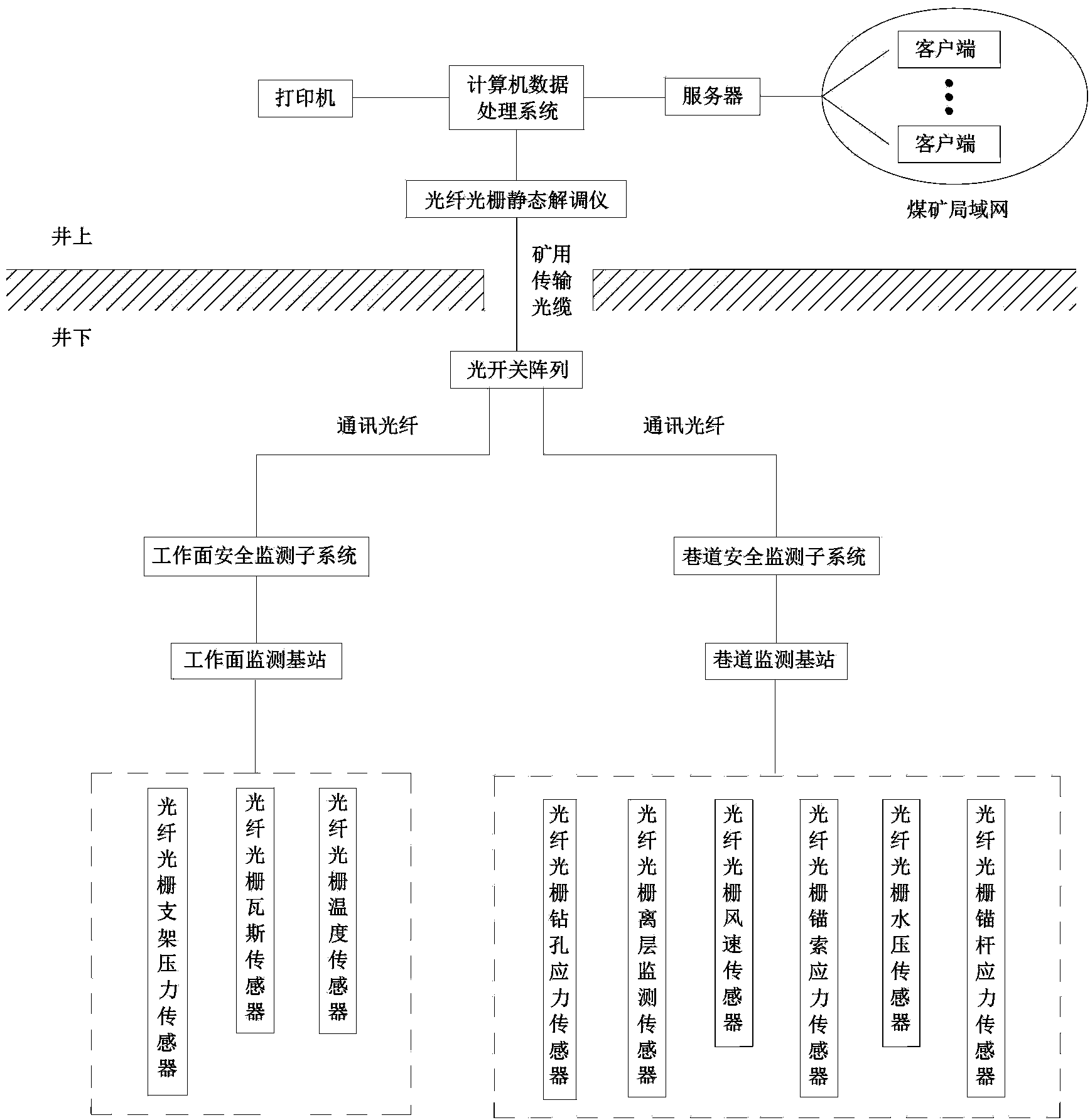

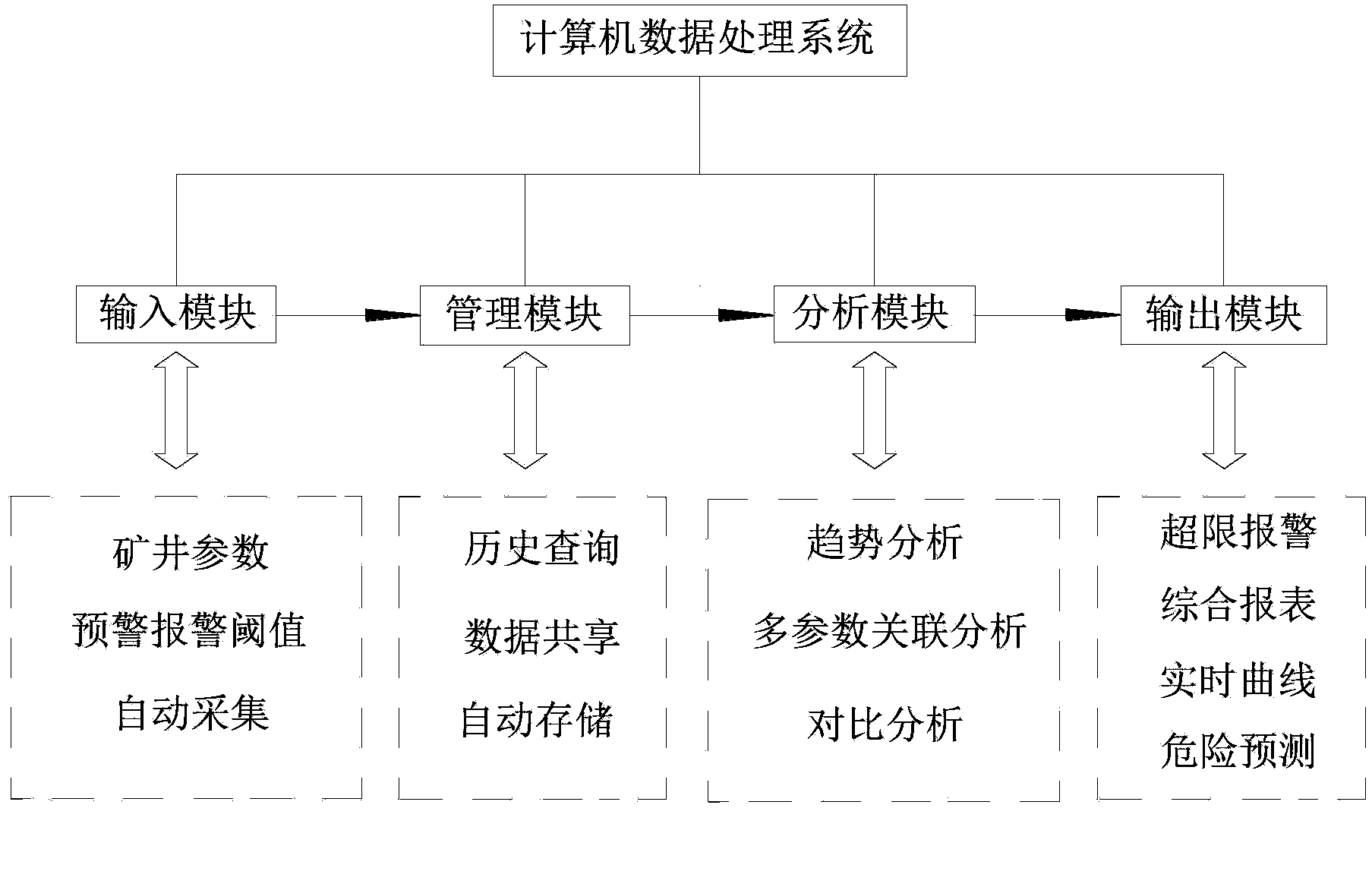

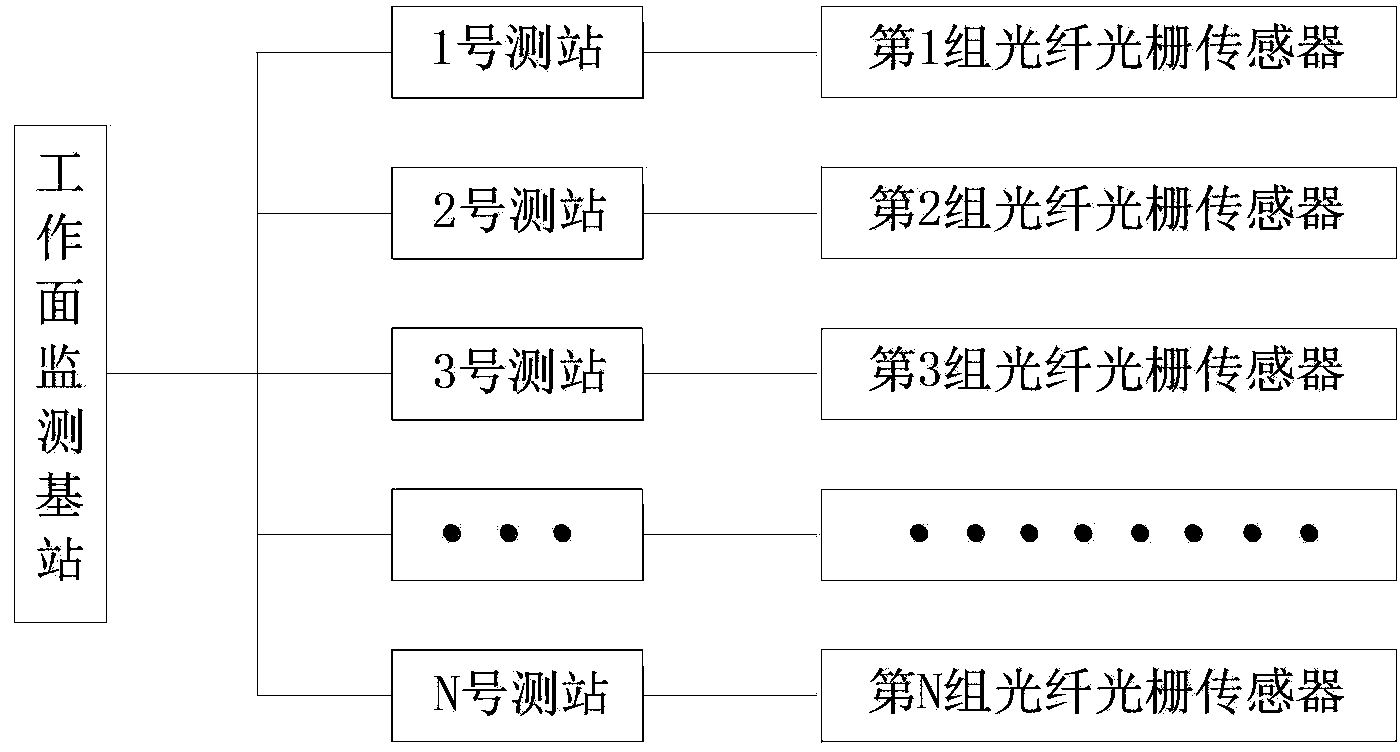

Coal mine underground safety comprehensive monitoring system based on fiber grating sensors

ActiveCN103362553AEnsure stabilityReal-time monitoring of water inflowMining devicesThermometers using physical/chemical changesGratingEngineering

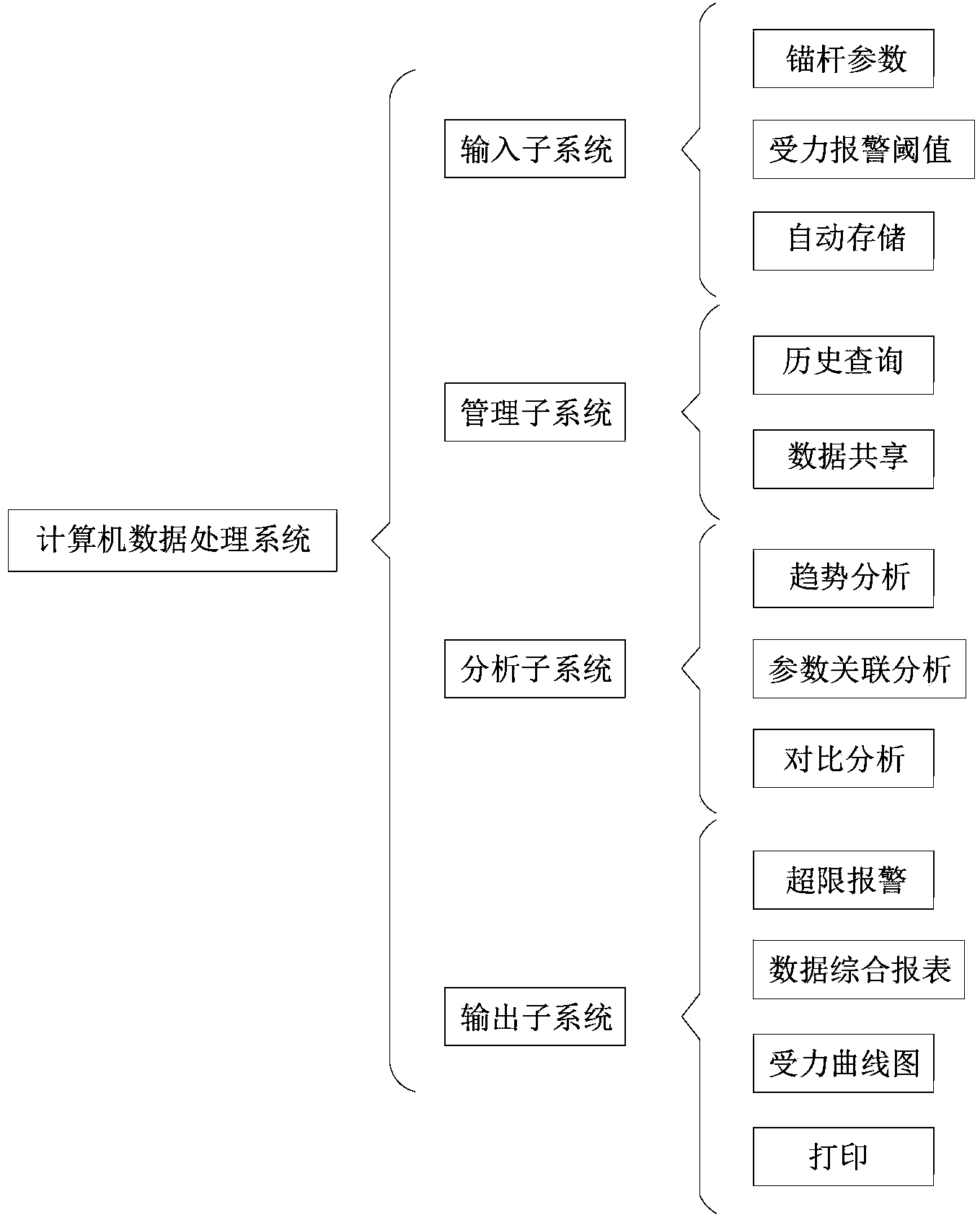

A coal mine underground safety comprehensive monitoring system based on fiber grating sensors and belongs to a coal mine underground safety monitoring system. The system comprises an aboveground part and an underground part; the aboveground part comprises a static fiber grating demodulator, a computer data processing system, a printer, a server and a client; the underground part comprises an optical switch array, a working face safety monitoring subsystem and a laneway safety monitoring subsystem; each of the two monitoring subsystems at least comprises a monitoring base station; each monitoring base station at least comprises a survey station; each survey station is corresponding to one group of fiber grating sensors; the advantage is that the system adopts multiple survey stations to perform underground multi-parameter monitoring, integrates the fiber grating sensors, adopts all-optical survey and optical fibers for signal transmission, is intrinsically safe, has high anti-electromagnetic interference capability and a good monitoring effect, realizes real-time continuous long-term on-line monitoring and the sharing of data in an entire mining area to better guide the safety production of a coal mine, can effectively reduce safety accidents of the coal mine and realizes safe and efficient production of the coal mine.

Owner:CHINA UNIV OF MINING & TECH

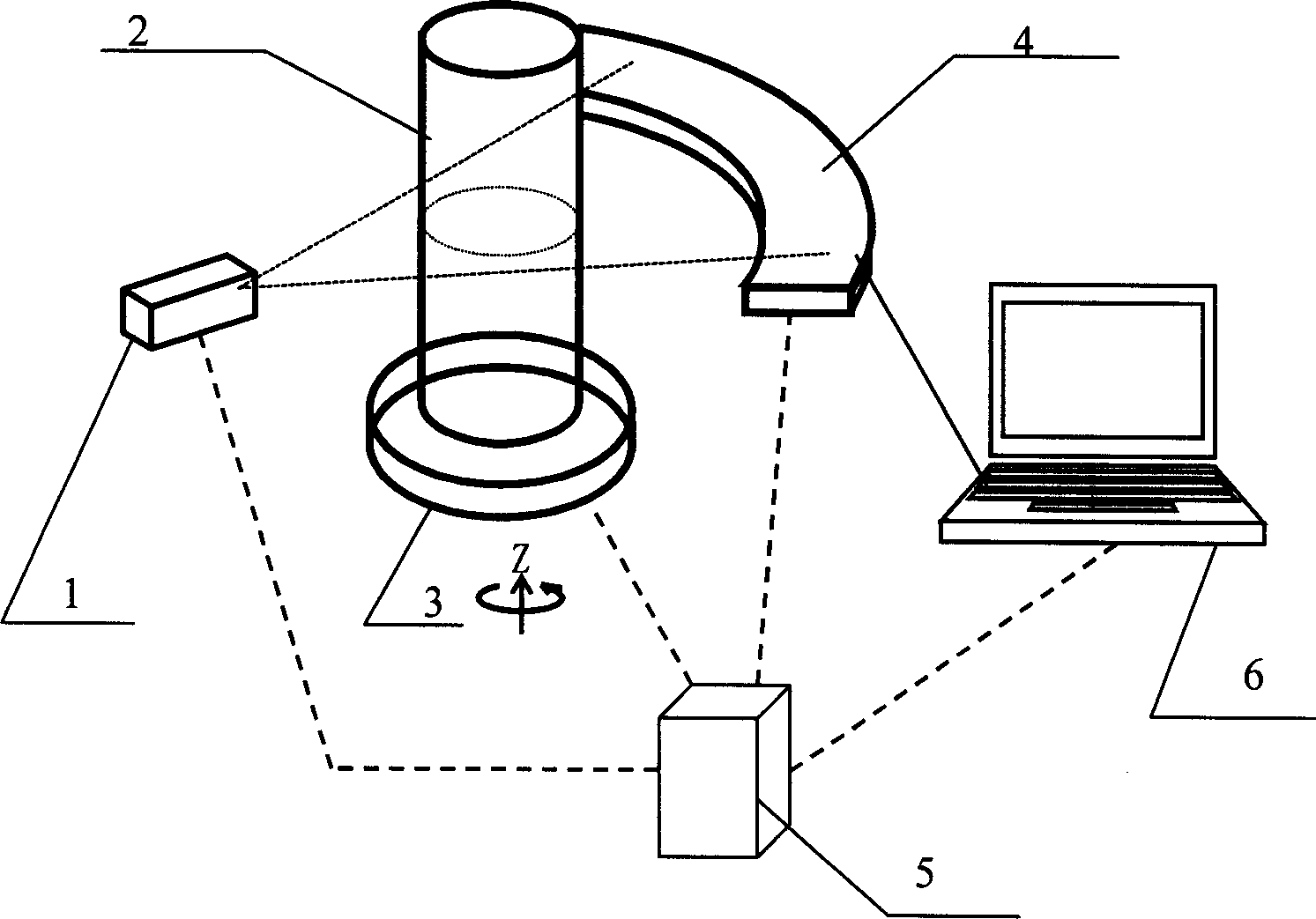

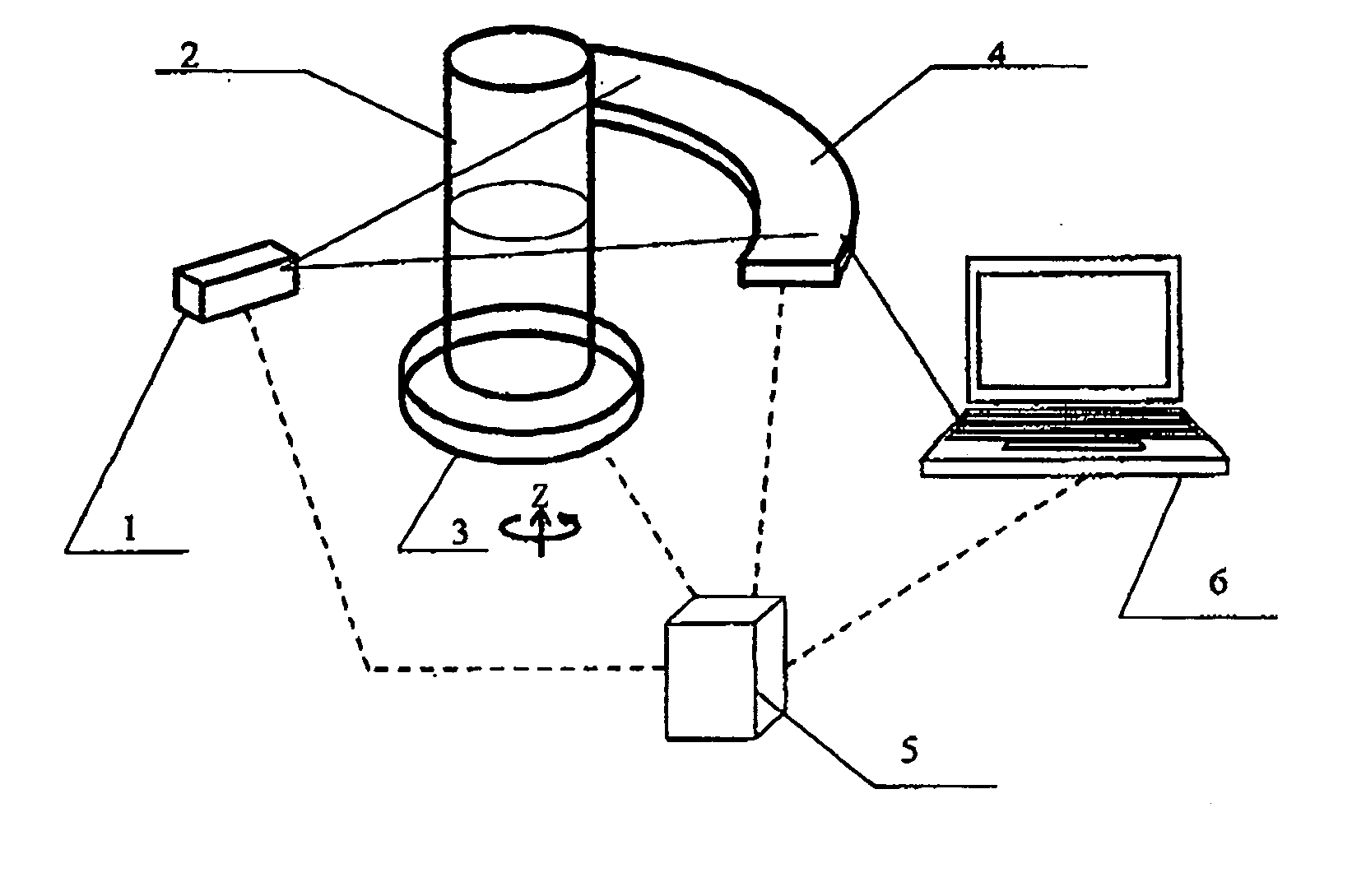

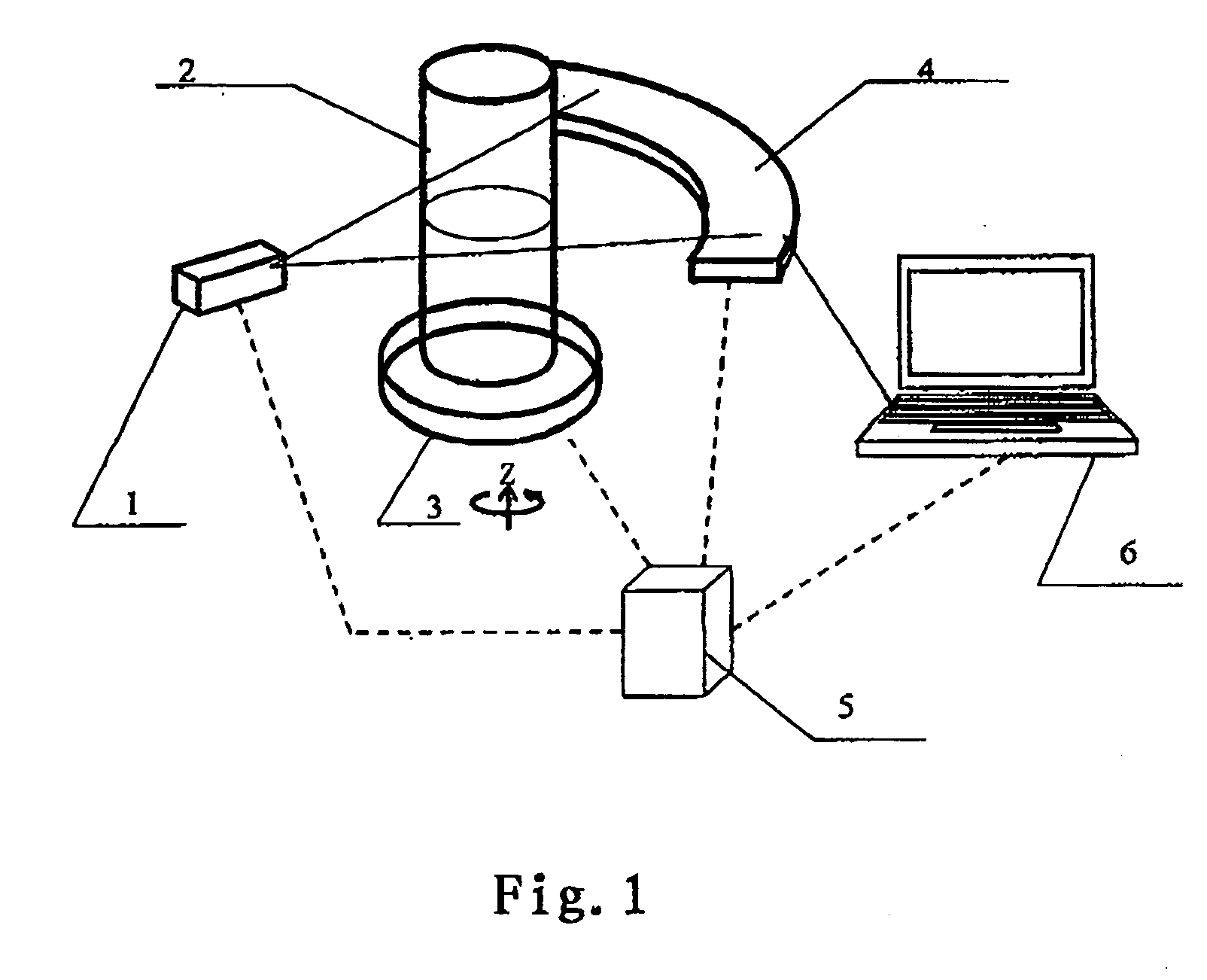

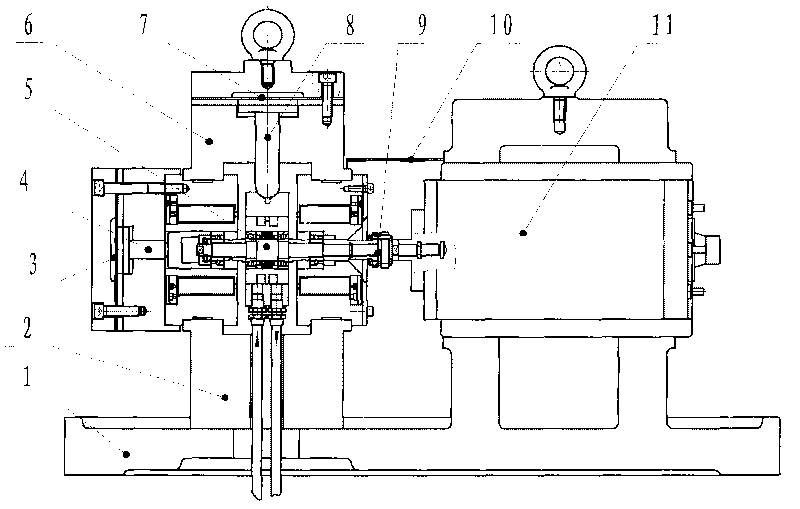

Safety CT inspection and inspector for liquid by ray resource

ActiveCN1779444AReduce volumeImprove anti-interference abilityMaterial analysis by transmitting radiationLiquid densityLight beam

A method for carrying out CT safety detection on liquid by radioactive source includes setting detected liquid article on rotary platform, emitting ray on liquid article by radioactive source and passing ray through said article to be received by detector and data collector just facing ray beam and to be formed as projective data, transmitting projective data to computer data processor for obtaining liquid density of detected liquid article, comparing obtained density to density of dangerous article stored in databank and displaying detection result of detected liquid article in direct ¿C viewing way.

Owner:TSINGHUA UNIV +1

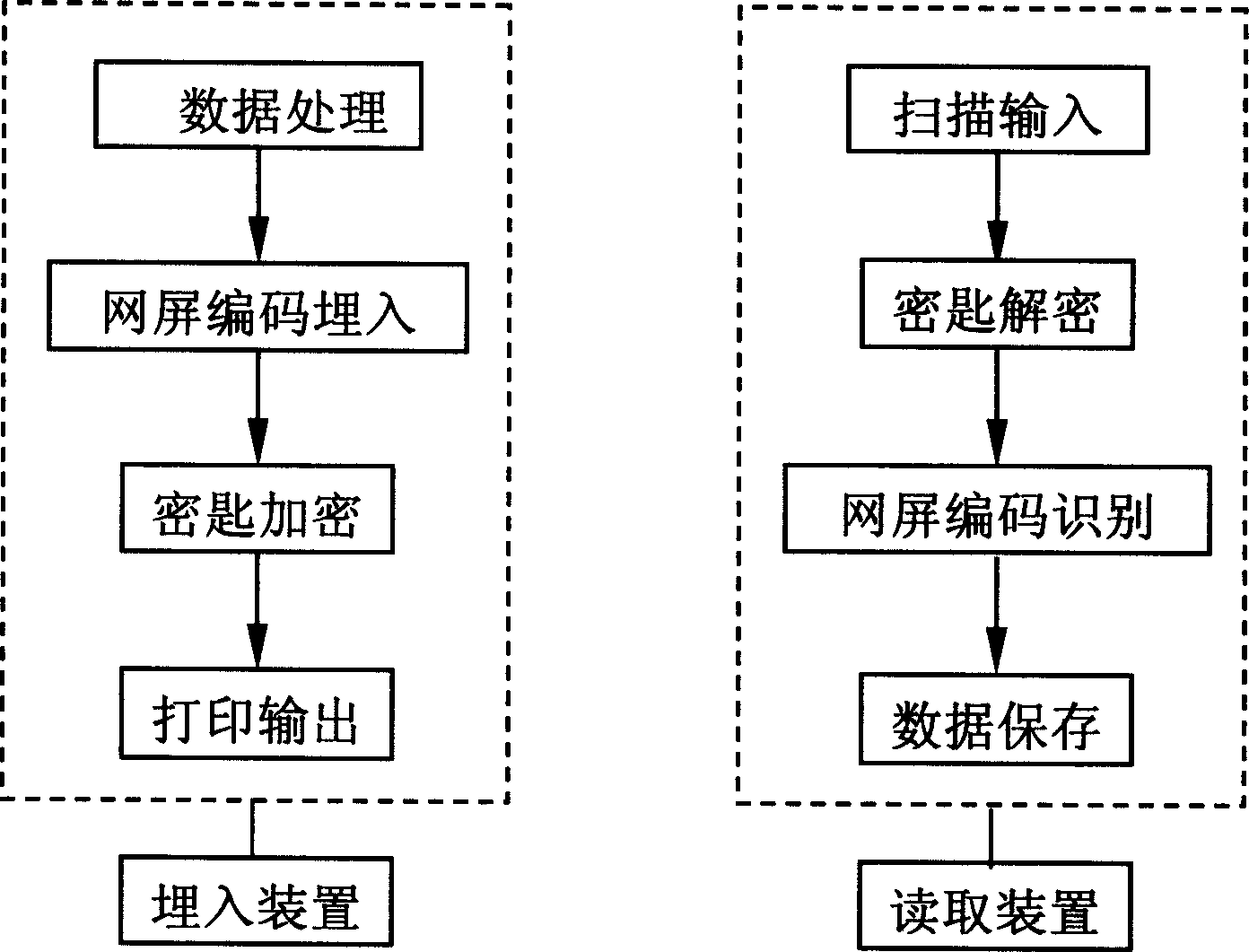

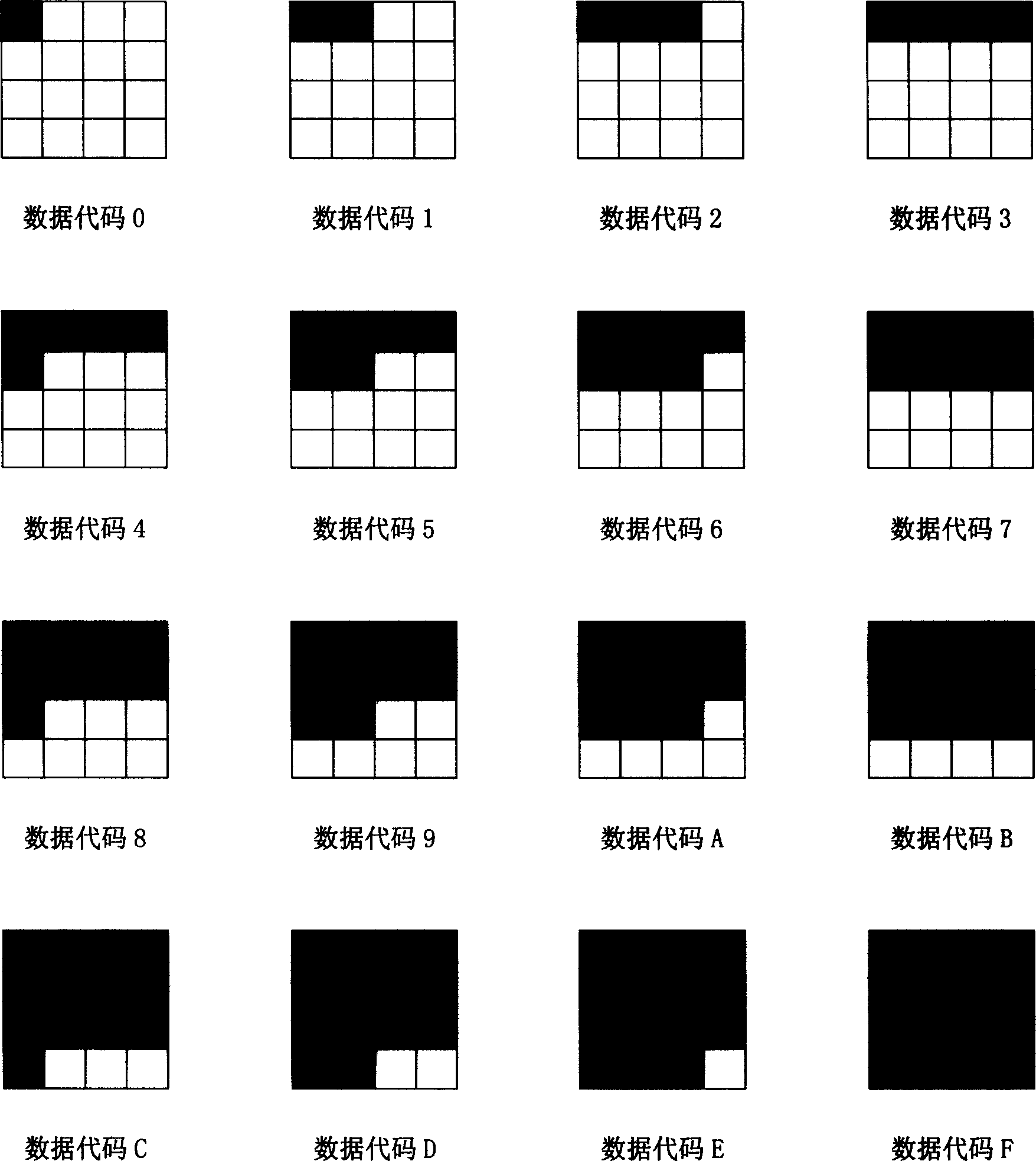

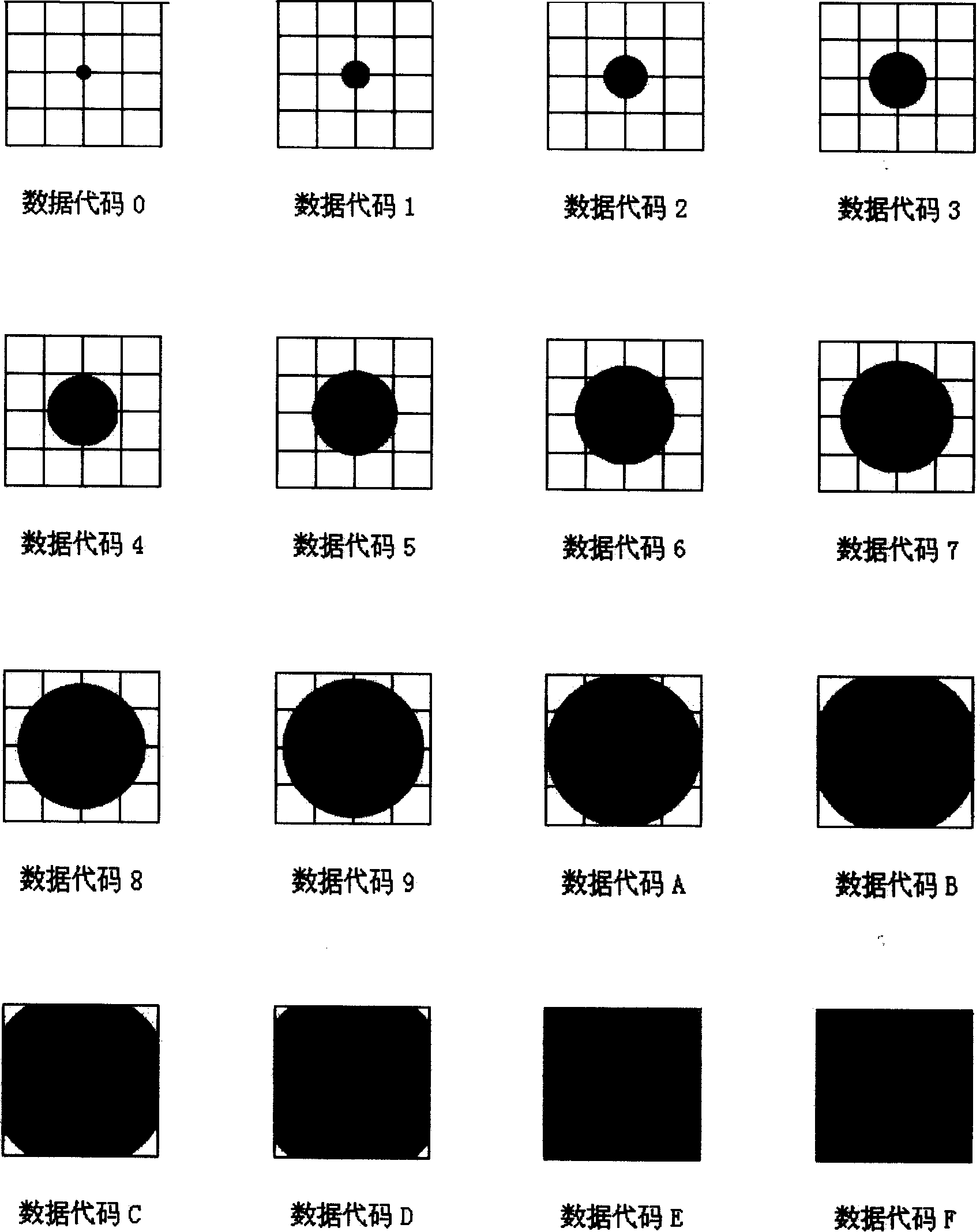

Network screen coding control method capable of recording mass data on paper

The invention relates to a net screen coding control method which can record plenty of data on paper. It includes net screen code embedding device which is composed by computer data process module, net screen code embedding module, key encryption module and printout module; net screen code reading device which is made up with scan input module, key decryption module, net screen code identification module and data storage module. The two devices make a system which can recode plenty of data on paper. Adopting the invention, plenty of data storage and net screen code which can recode plenty of data is realized through printing on paper or press. And confidential files' encryption and decryption is realized by using electronic files' method. Under condition of same area with two dimension bar code, the code method can record nearly ten times of information than two dimension bar and there is no limitation on occupied space and Chinese character record. It also resolves the problem of information loss because of local pollution. Data information can be embedded into image to resolve image quality destruction.

Owner:顾泽苍

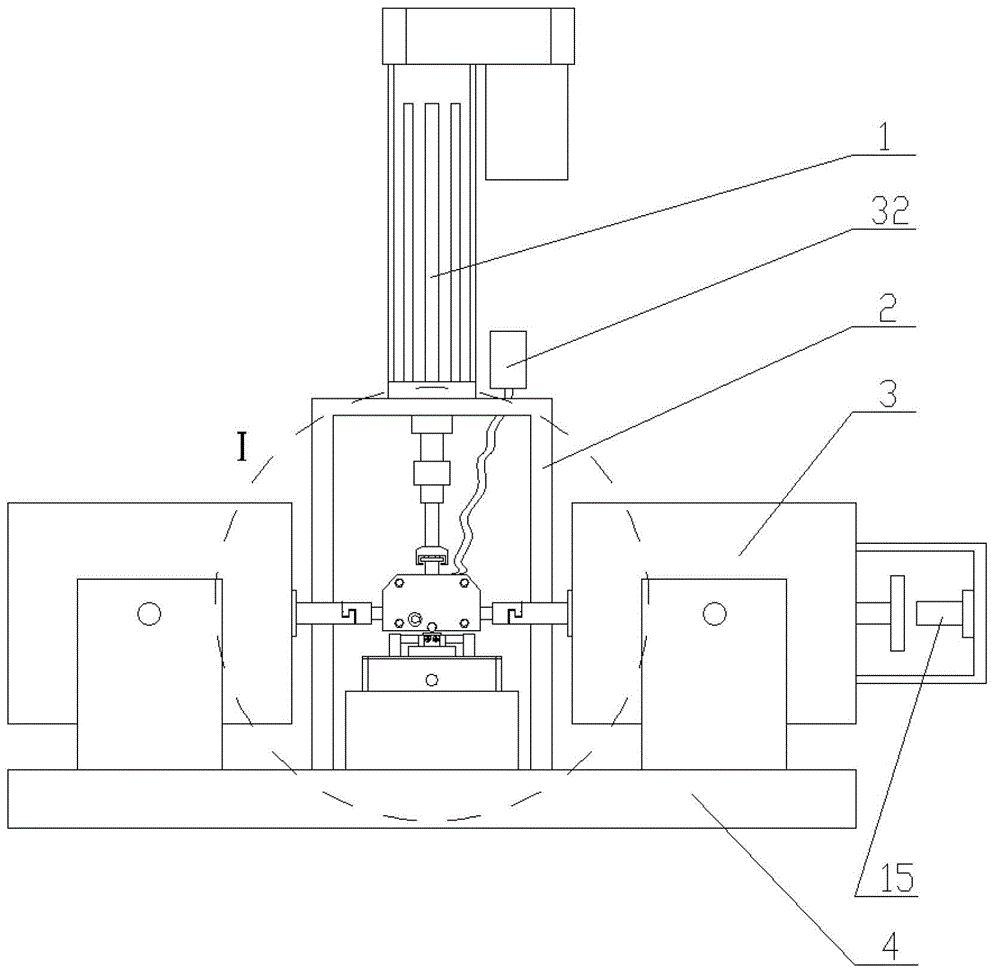

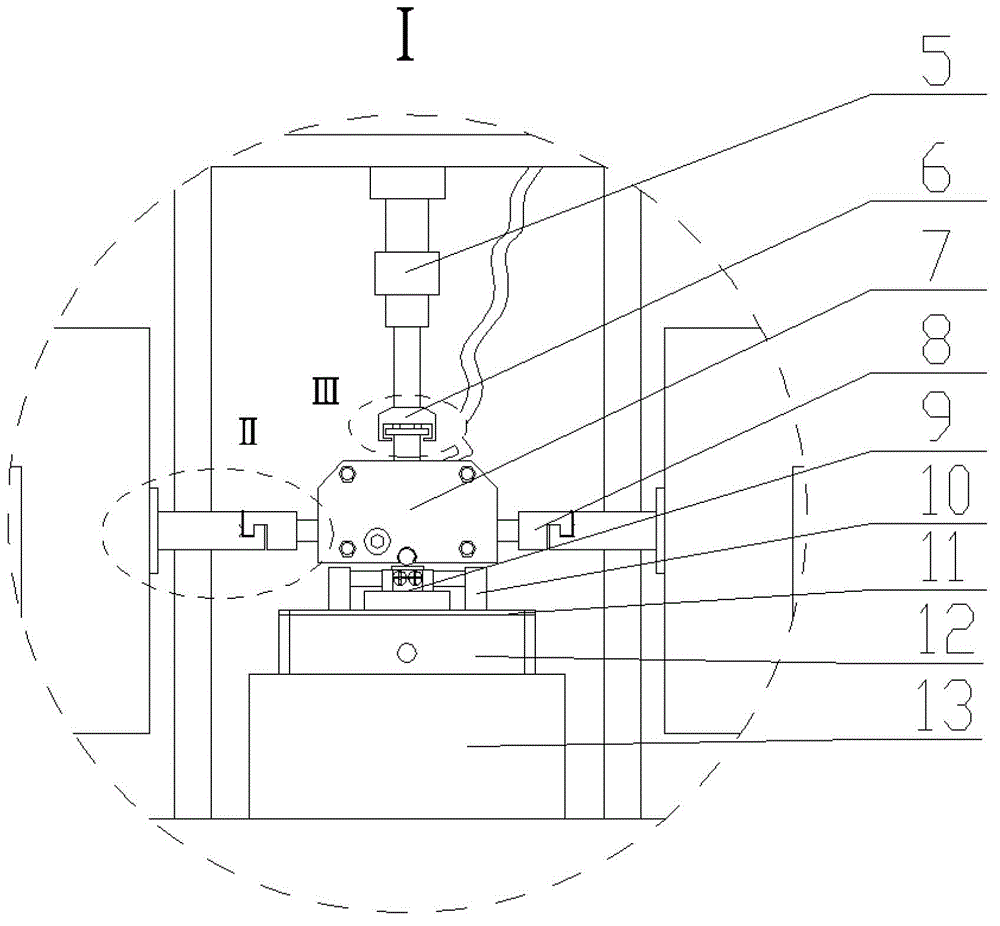

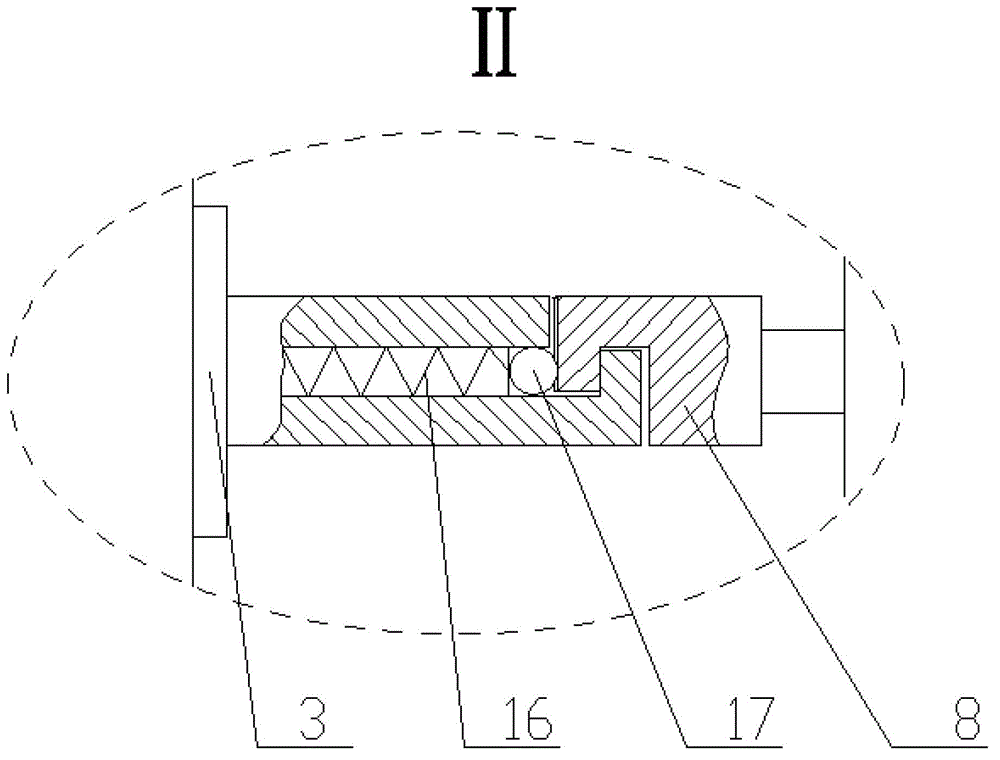

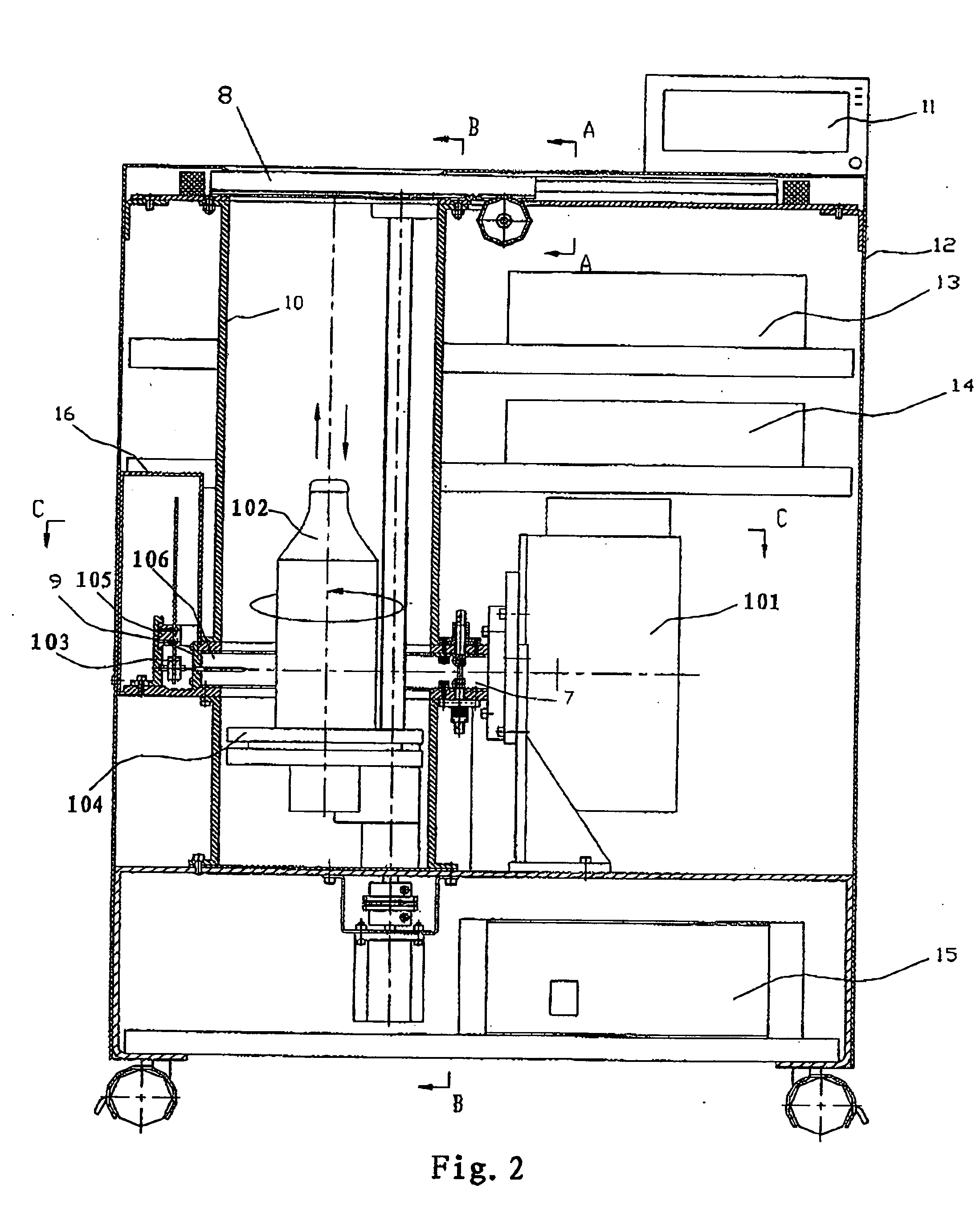

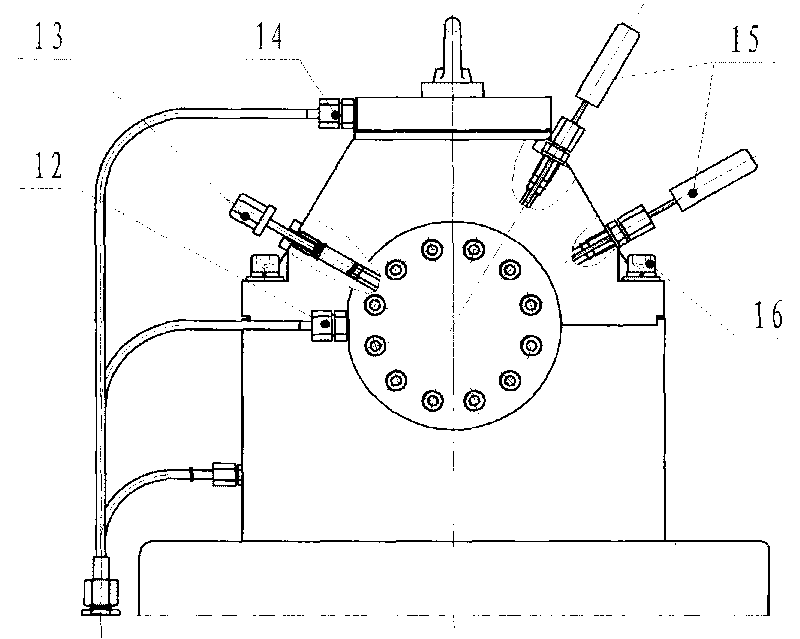

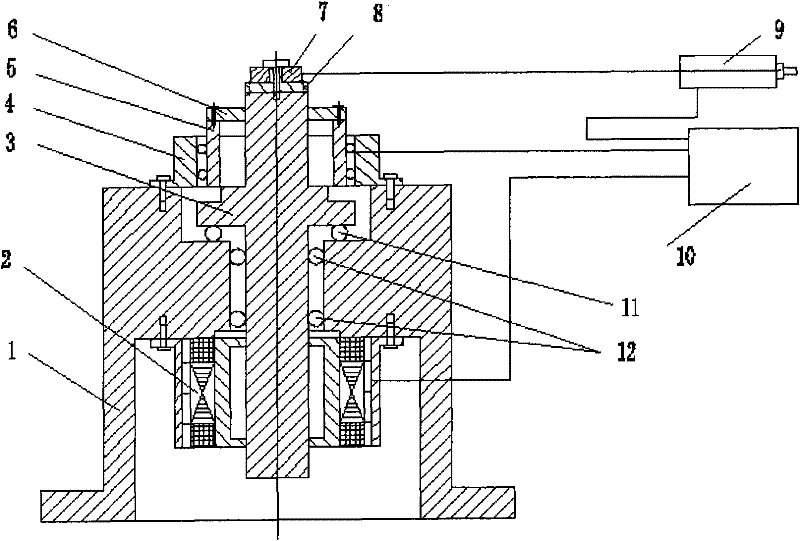

Micro-movement friction and abrasion testing machine

InactiveCN103063530AThe excitation amplitude is adjustableAdjustable vibration modeUsing mechanical meansInvestigating abrasion/wear resistanceClosed loop feedbackEngineering

The invention discloses a micro-movement friction and abrasion testing machine. The micro-movement friction and abrasion testing machine is that two symmetrically arranged electric vibration exciters are adopted and used as excitation sources for generating micro-movement friction between friction pairs; a loading device is adopted and used for applying positive pressure to the friction pairs; a force sensor is adopted and used for collecting a positive pressure signal; a computer data processing device is arranged and produces a closed-loop feedback control together with the acquired positive pressure signal, and the load applied by the loading device is kept constant. In addition, the computer data processing device is used for recording and analyzing the positive pressure signal acquired by the sensor, a micro-movement friction force signal, and a displacement signal, acquired by a displacement sensor, of each electric vibration exciter and then are automatically outputting the signals to generate abrasion performances for a sample A and a sample B of the friction pairs; and therefore, the micro-movement friction and abrasion testing machine has the characteristics of being adjustable in vibration excitation amplitude, variable in vibration mode, convenient to operate and move, high in loading precision, and reproducible in project service condition, the experimental data is high in repeatability and can be used for evaluating the micro-movement friction and abrasion performance of a material.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

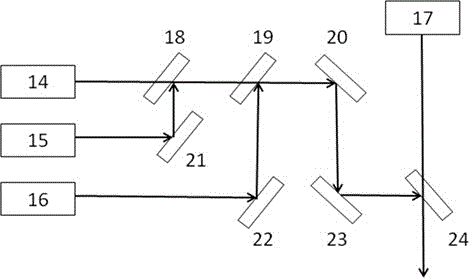

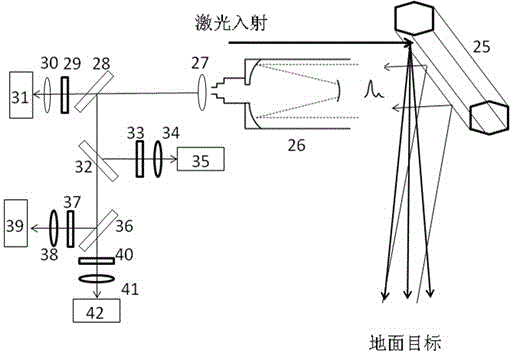

On-board colorful three-dimensional scanning laser radar

ActiveCN103954971AEnhanced color resolutionImprove stabilityElectromagnetic wave reradiationEngineeringLaser source

An on-board colorful three-dimensional scanning laser radar comprises a laser emission unit, a scanning unit, a signal detection signal, a time sequence control circuit and a computer data processing unit, wherein the scanning unit comprises a motor driver, a motor, a polyhedral scanning rotating mirror and an angle encoder, and the motor driver, the motor and the polyhedral scanning rotating mirror are sequentially connected, the angle encoder is connected with the motor, and the laser emission unit comprises a laser driver, a colorful laser source, an optical emission system and a PIN detector which are sequentially connected. The signal detection signal comprises a receiving optical system, a colorful laser signal detector and a multi-channel data acquisition unit which are sequentially connected. The time sequence control circuit is respectively connected with the laser driver, the PIN detector and the multi-channel data acquisition unit. The on-board colorful three-dimensional scanning laser radar can simultaneously obtain colorful laser spectral information and laser point cloud information of a target ground feature, accordingly obtains a colorful laser imaging of a target through three-dimensional reconstruction and strengthens the colorful resolution capability.

Owner:WUHAN UNIV

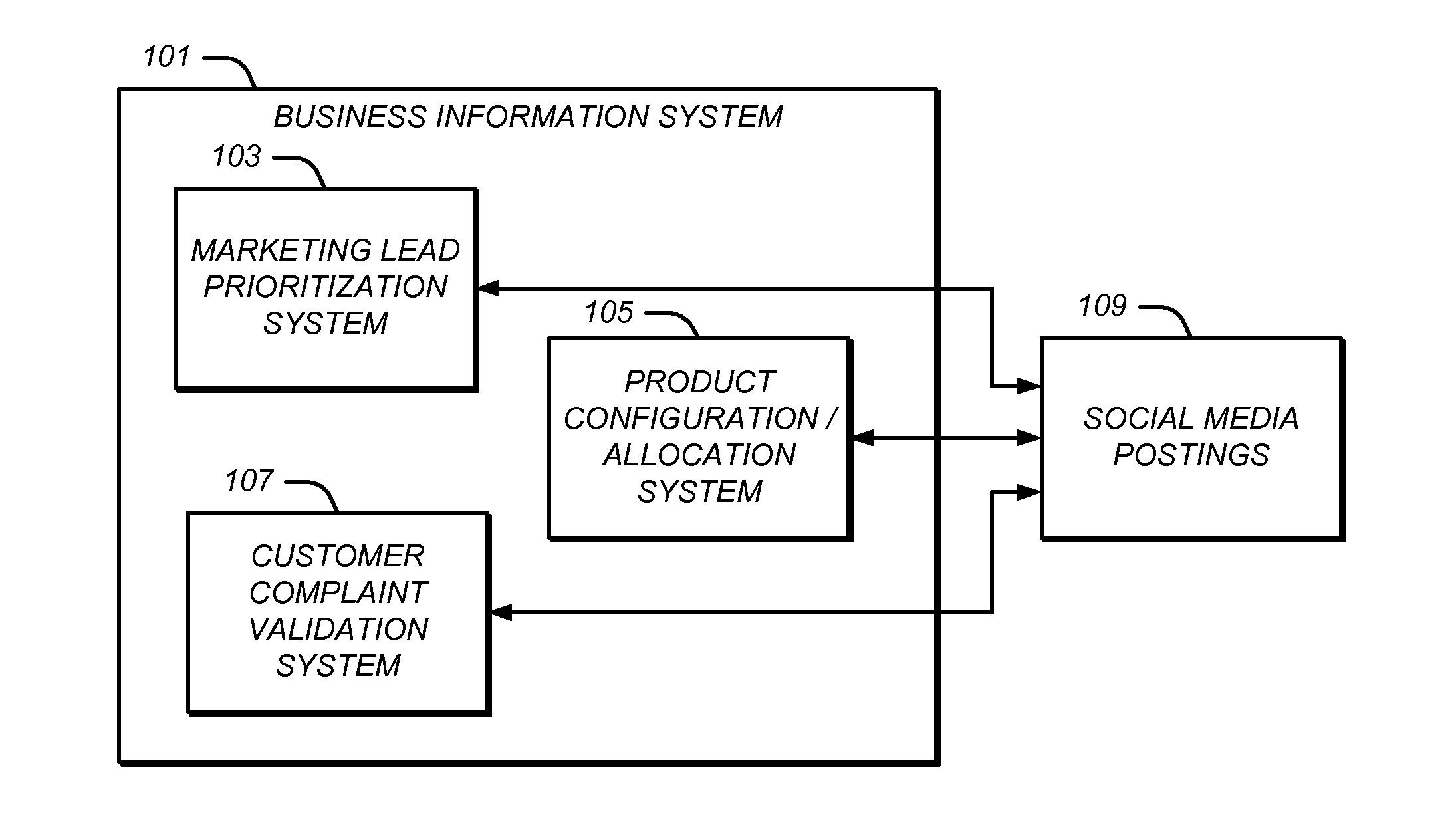

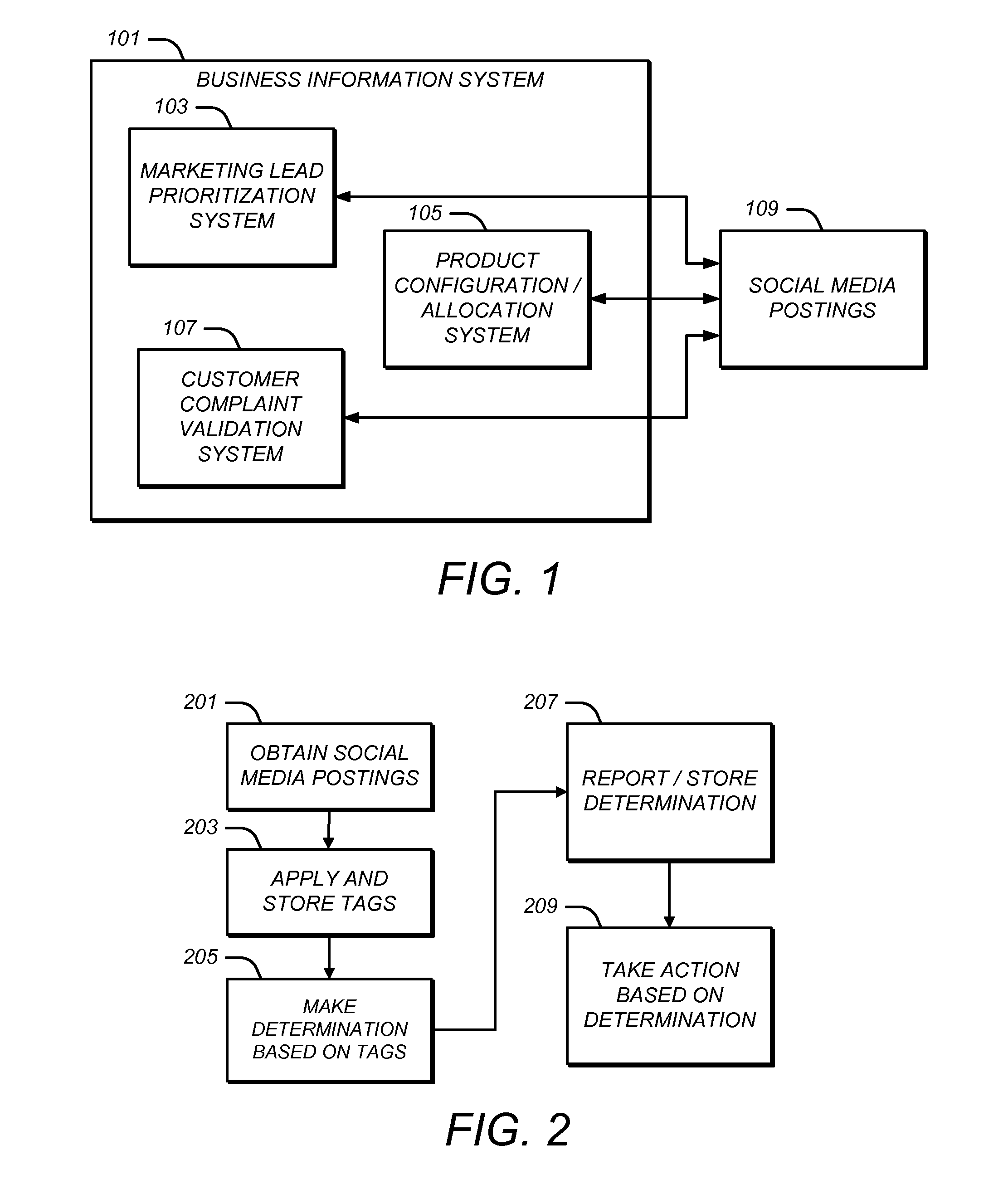

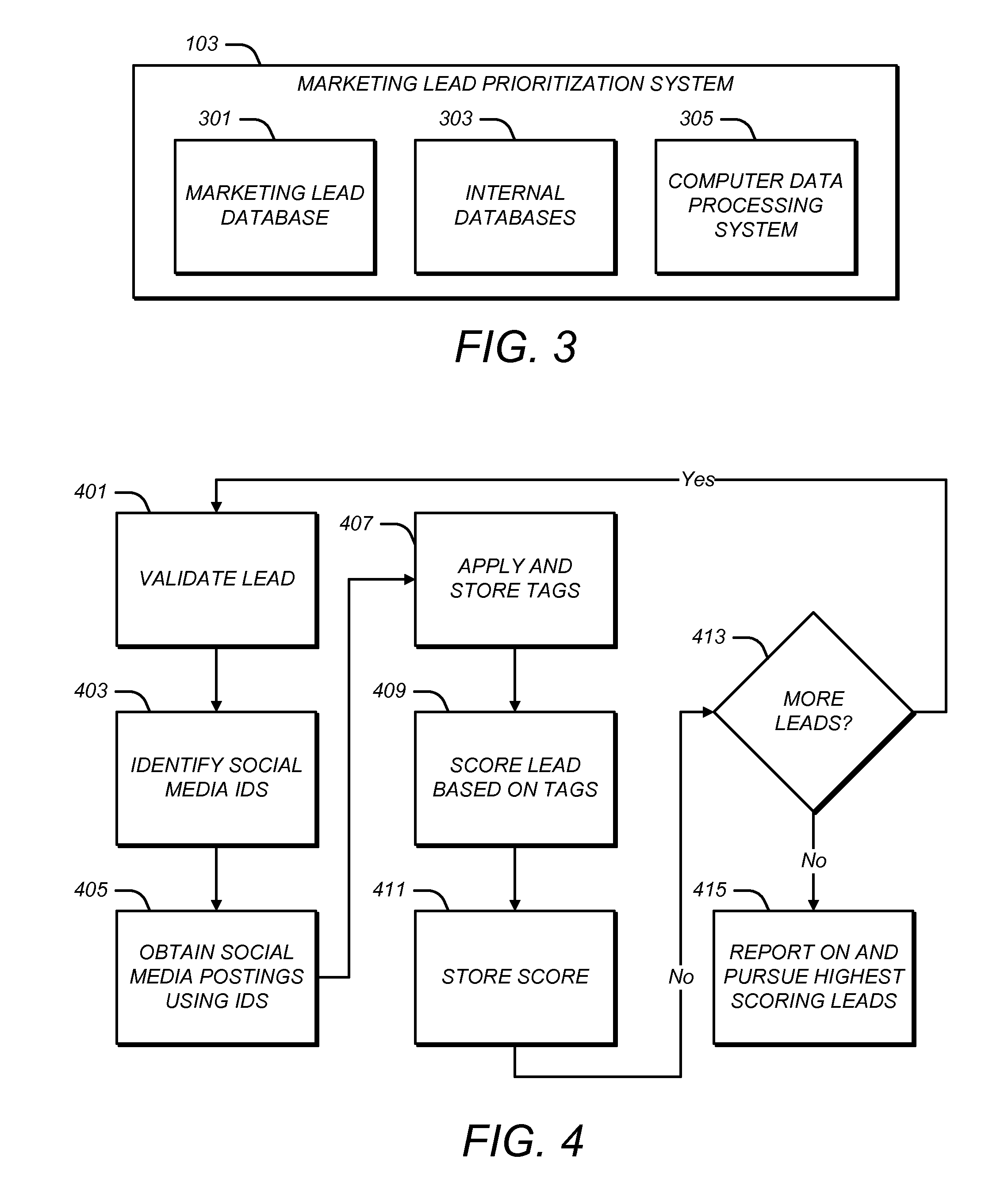

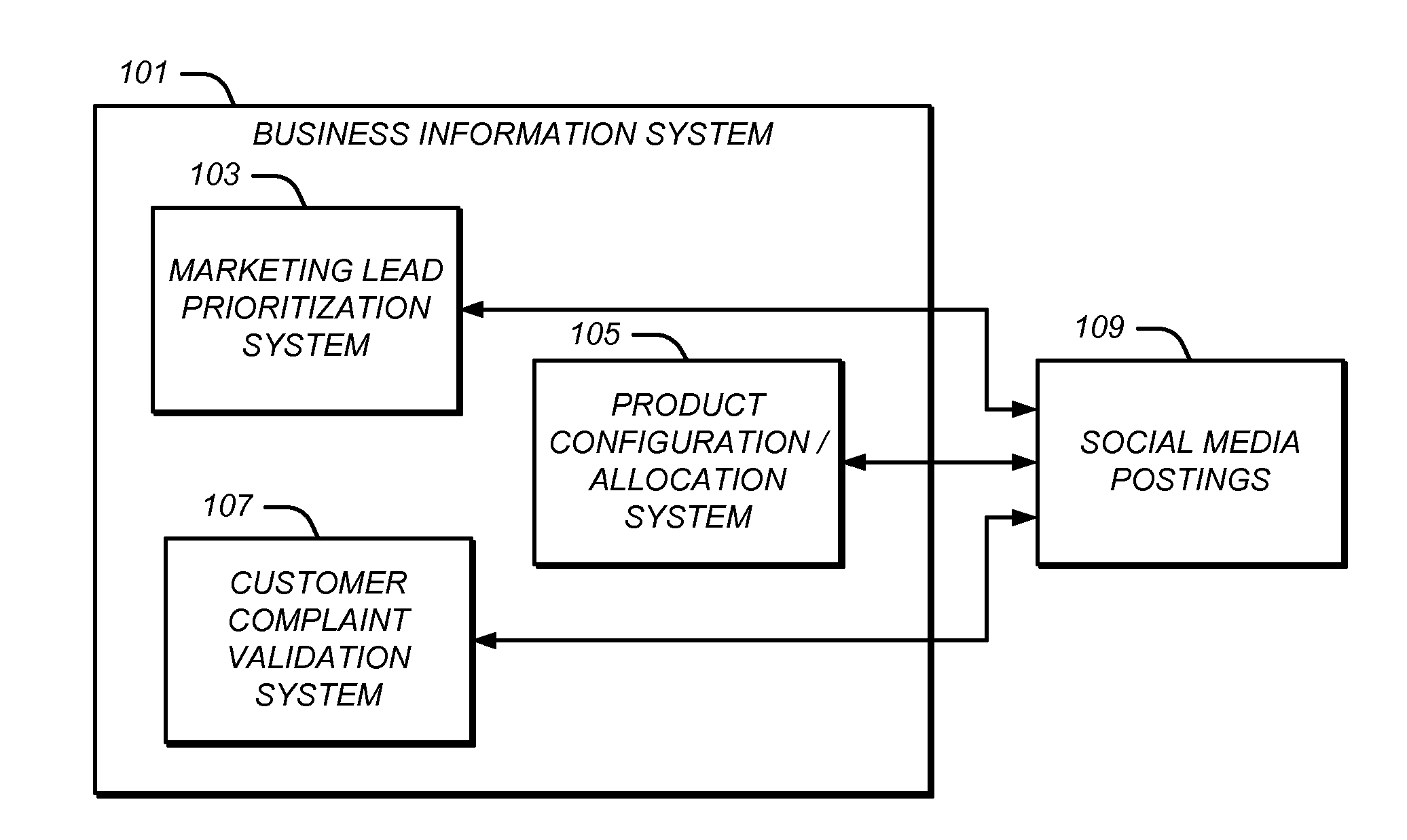

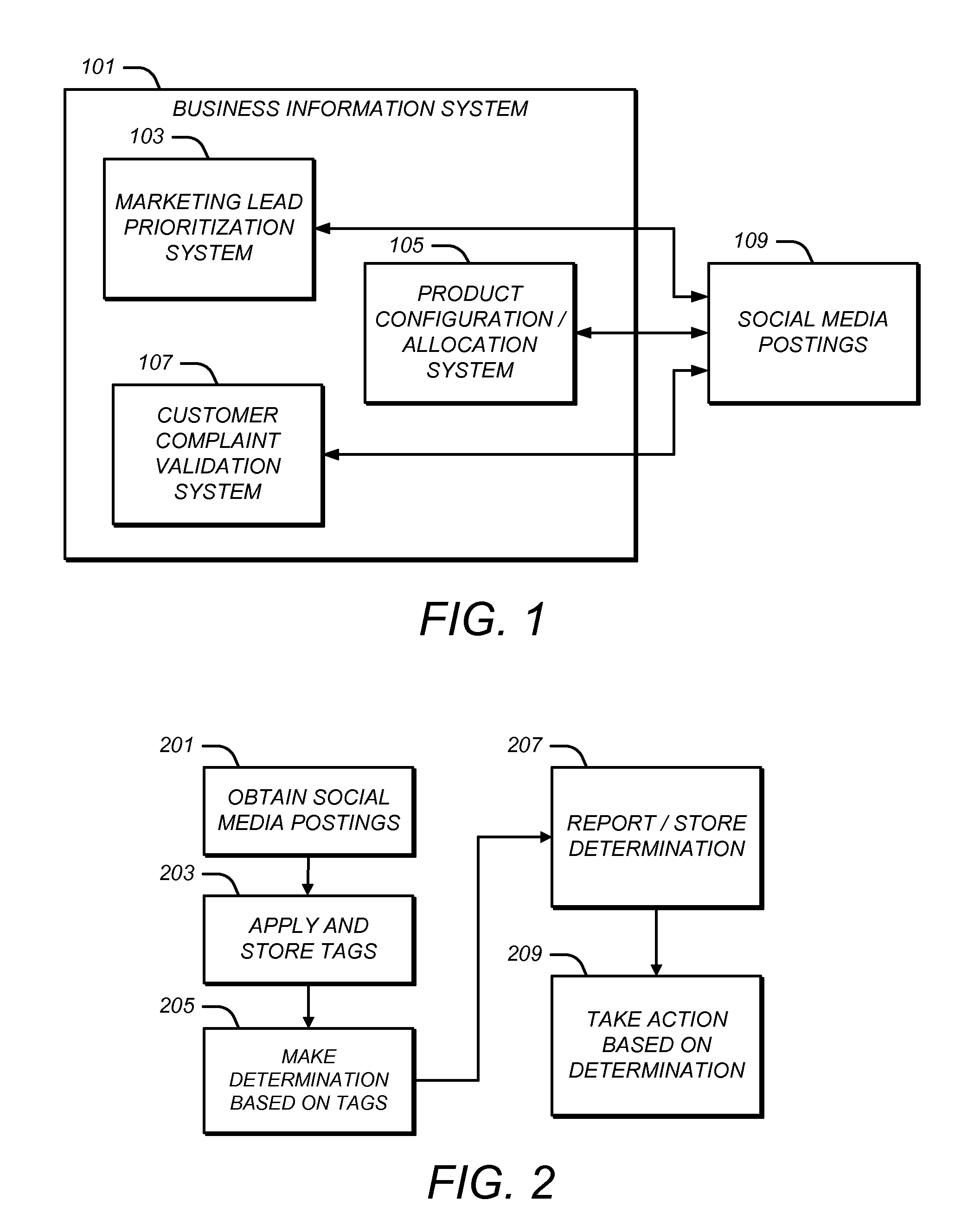

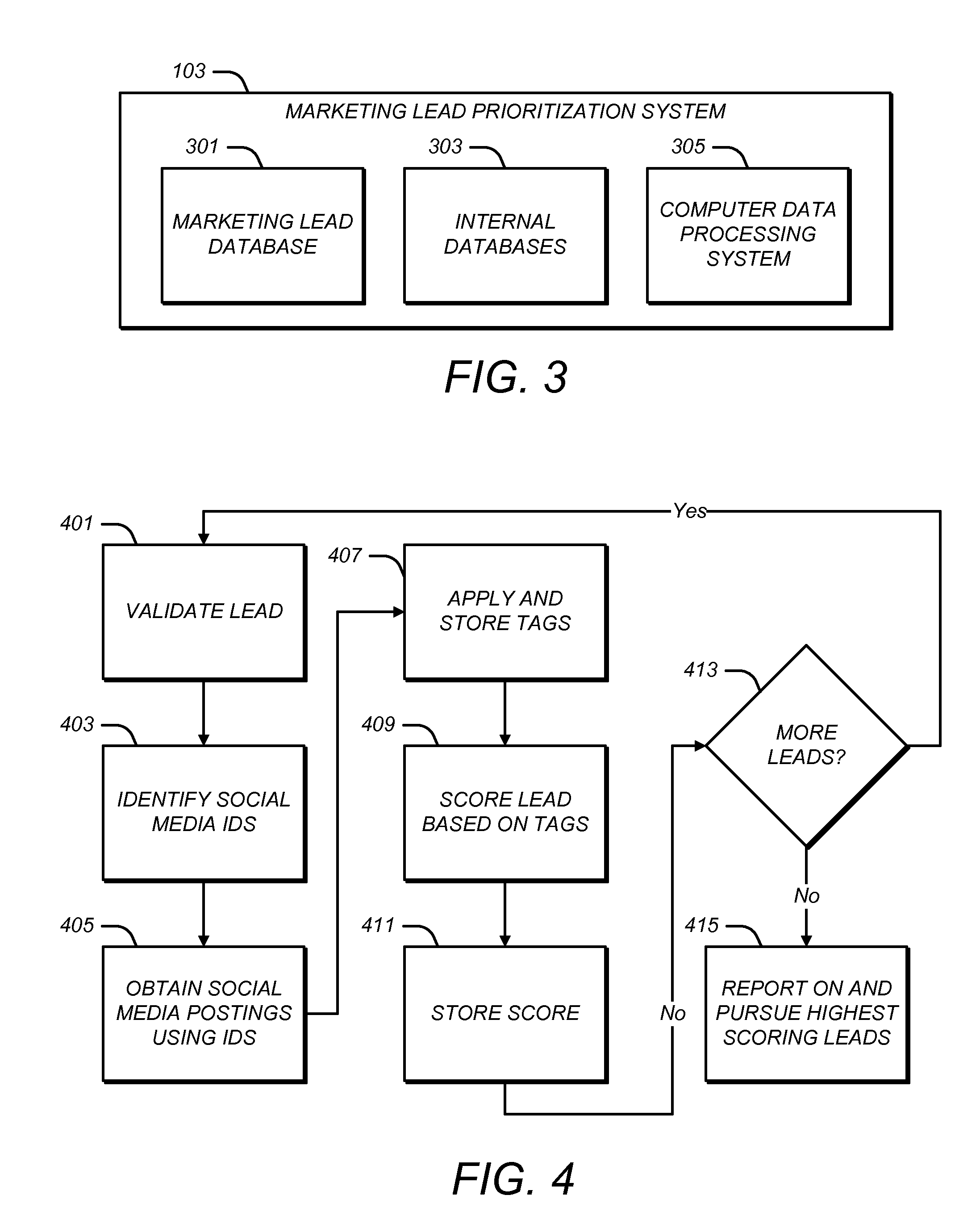

Prioritizing marketing leads based on social media postings

Owner:TOYOTA MOTOR SALES USA

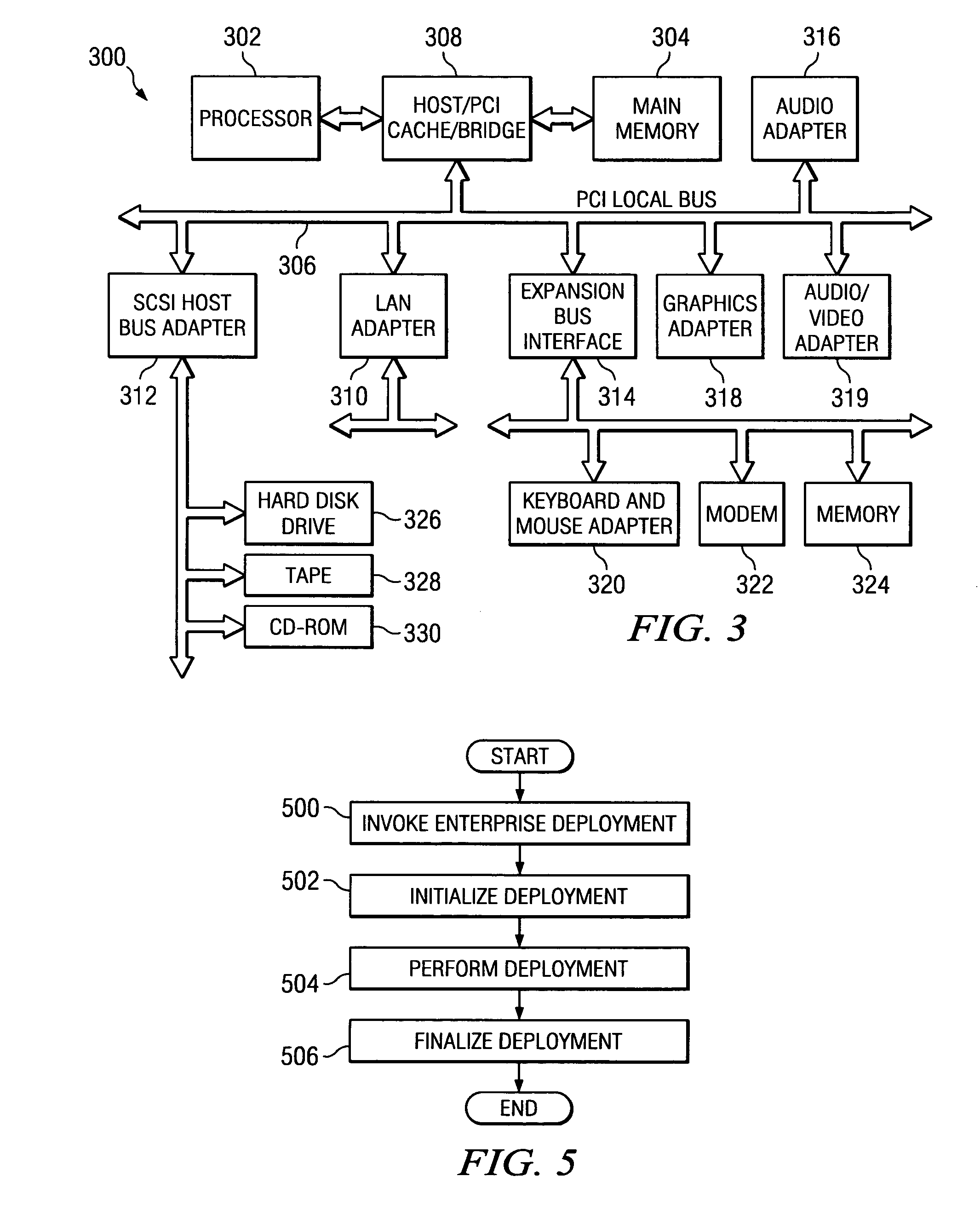

Algorithm for automated enterprise deployments

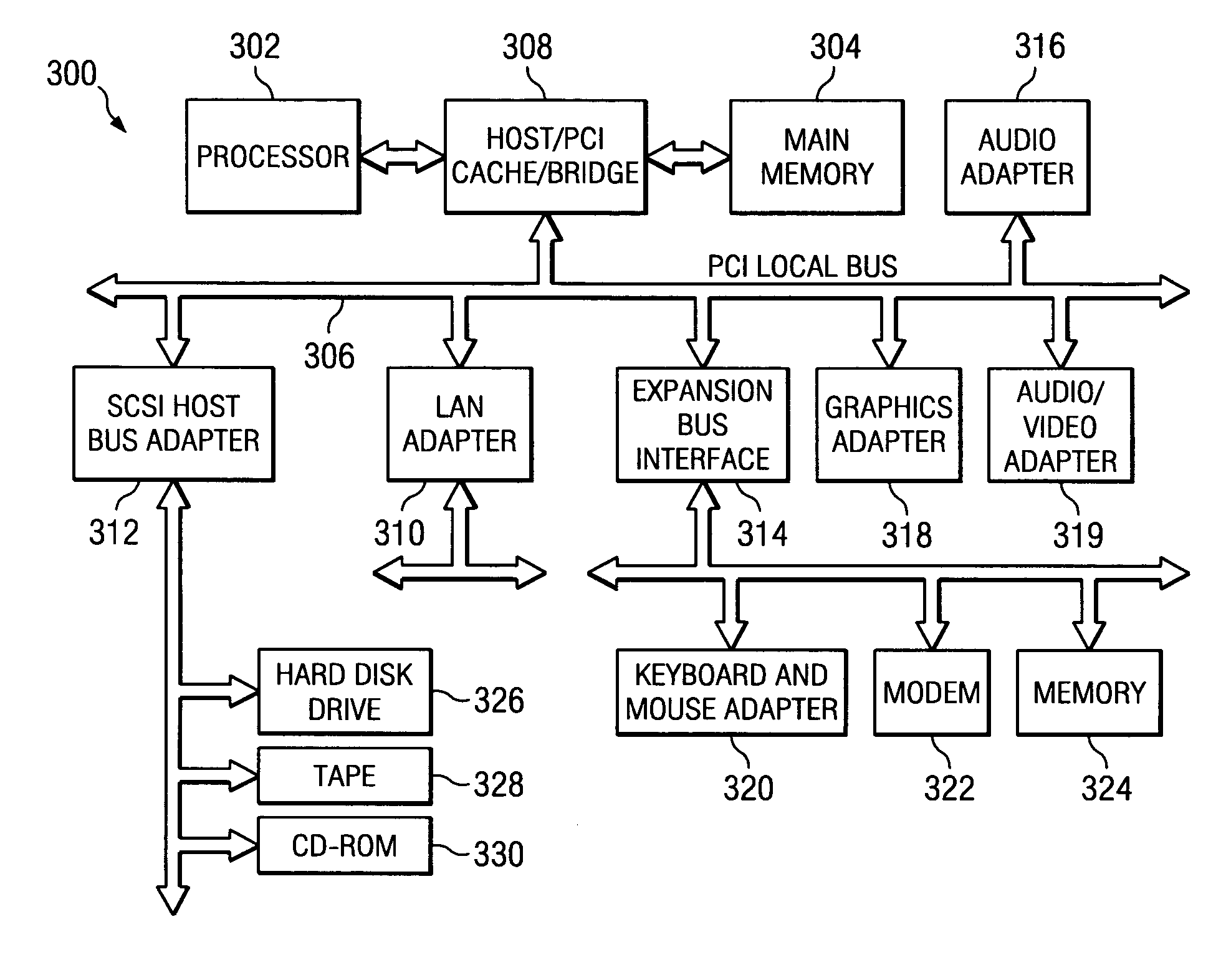

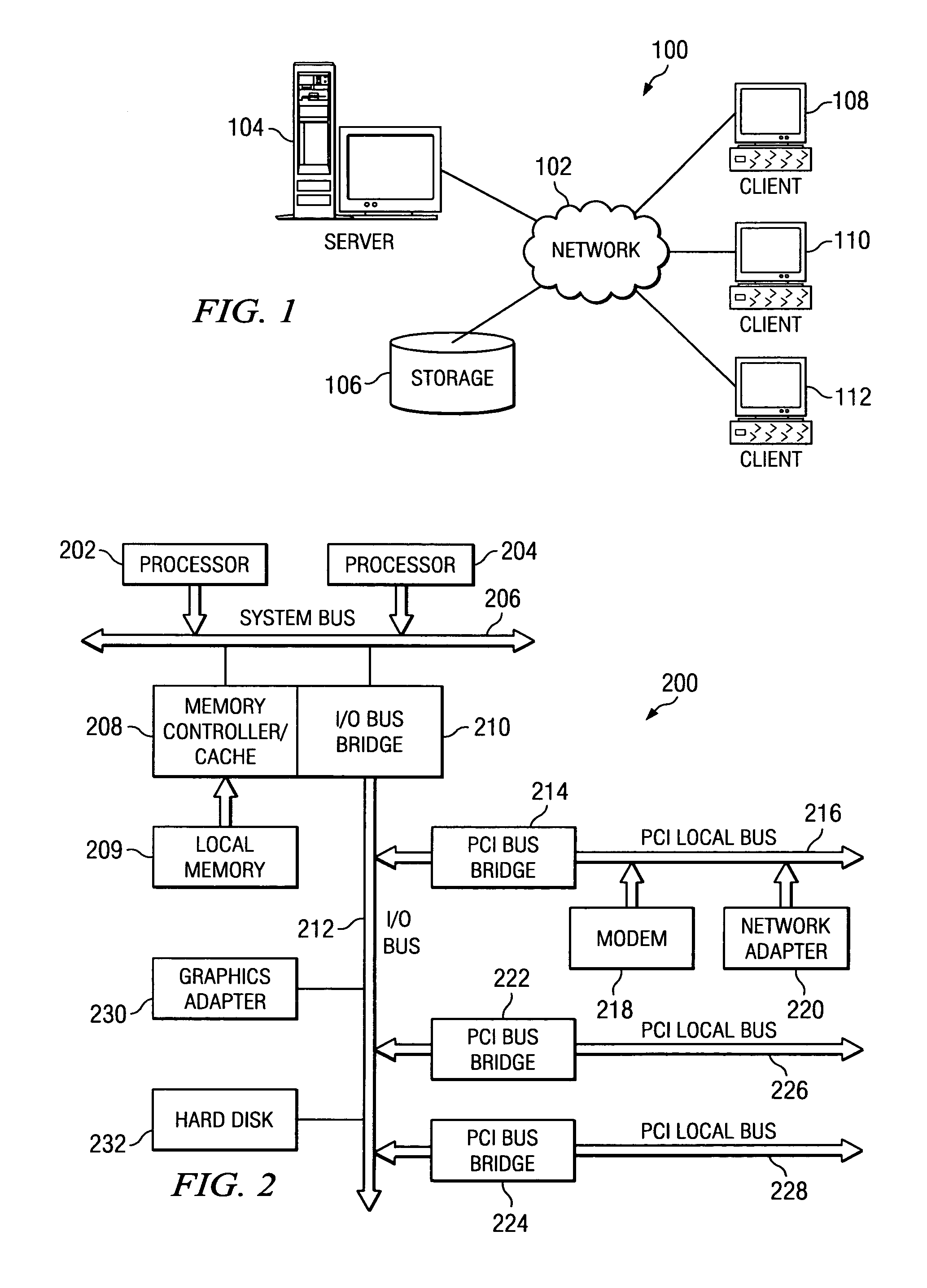

InactiveUS20060123040A1Automate deploymentSpecial data processing applicationsSoftware deploymentInitComputer data processing

A method of automating the deployment of a number of enterprise applications on one or more computer data processing systems. Each enterprise application or update is stored in a dynamic distribution directory and is provided with identifying indicia, such as stage information, target information, and settings information. When automated enterprise deployment is invoked, computer instructions in a computer readable medium provide for initializing deployment, performing deployment, and finalizing deployment of the enterprise applications or updates.

Owner:IBM CORP

CT method and apparatus for liquid safety-detection with a radiation source

ActiveUS20060239402A1Small volumeImprove anti-interference abilityWithdrawing sample devicesUsing wave/particle radiation meansLiquid densityRadiation imaging

A CT method and an apparatus for liquid safety-detection with a radiation source relate to a radiation imaging detecting technology field. The invention comprises using a radiation source, a detector and data collector, a computer data processor; and the main steps are: 1) a liquid article to be detected being placed onto a rotary platform which is rotatable; 2) the ray emitted from the radiation source passing through the liquid article, and being received and formed into projection data by the detector and data collector; and 3) the projection data being transmitted to the computer data processor, which processes it to obtain the liquid density of the detected article, compares the result with the densities of dangerous articles in a current database, and then visually displays the detected information of the detected liquid article. Comparing to the prior art, the invention has a small volume, a strong anti-interference, a high accuracy of detection, an easy shielding, and a high use safety and reliability.

Owner:TSINGHUA UNIV +1

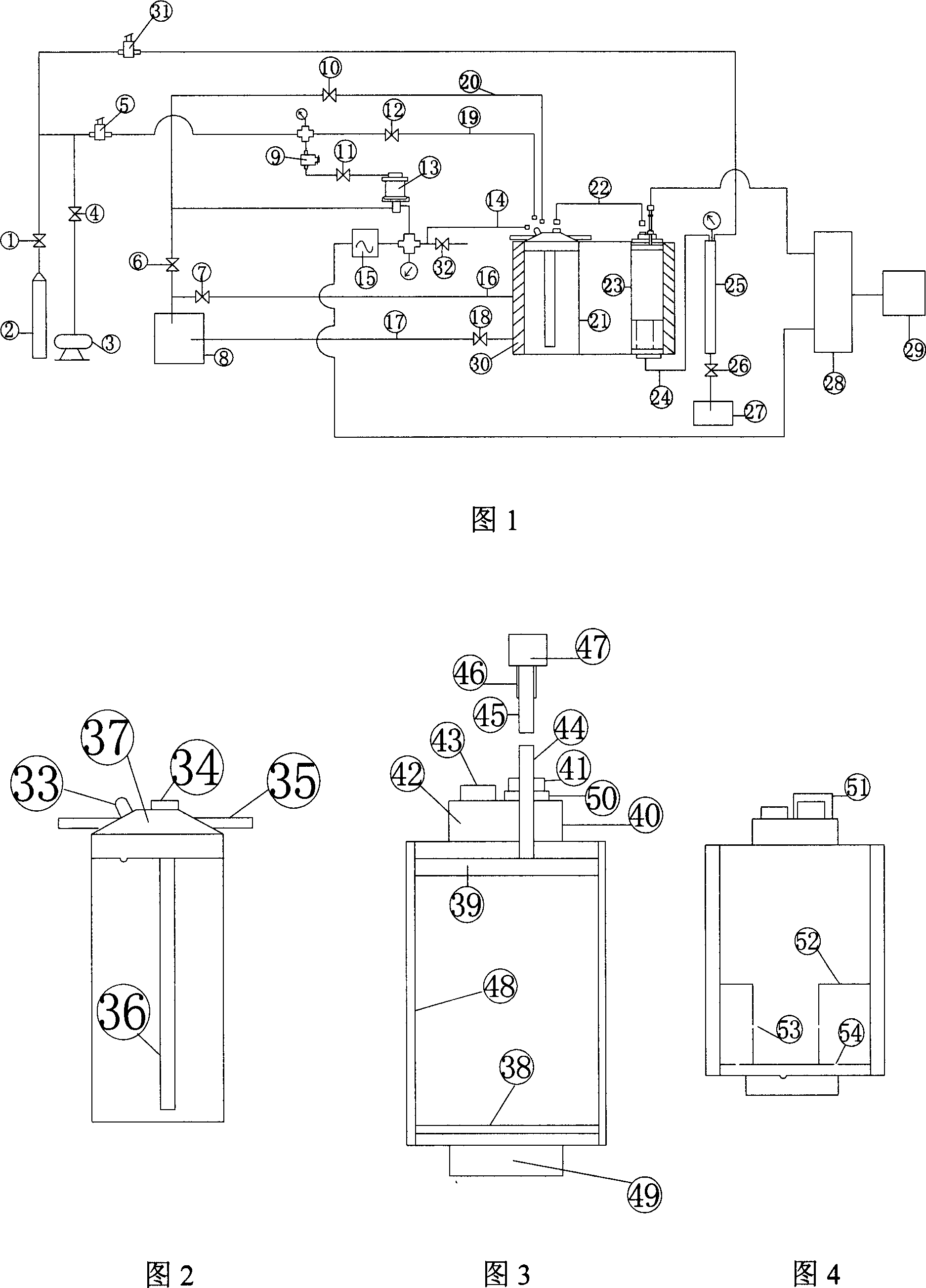

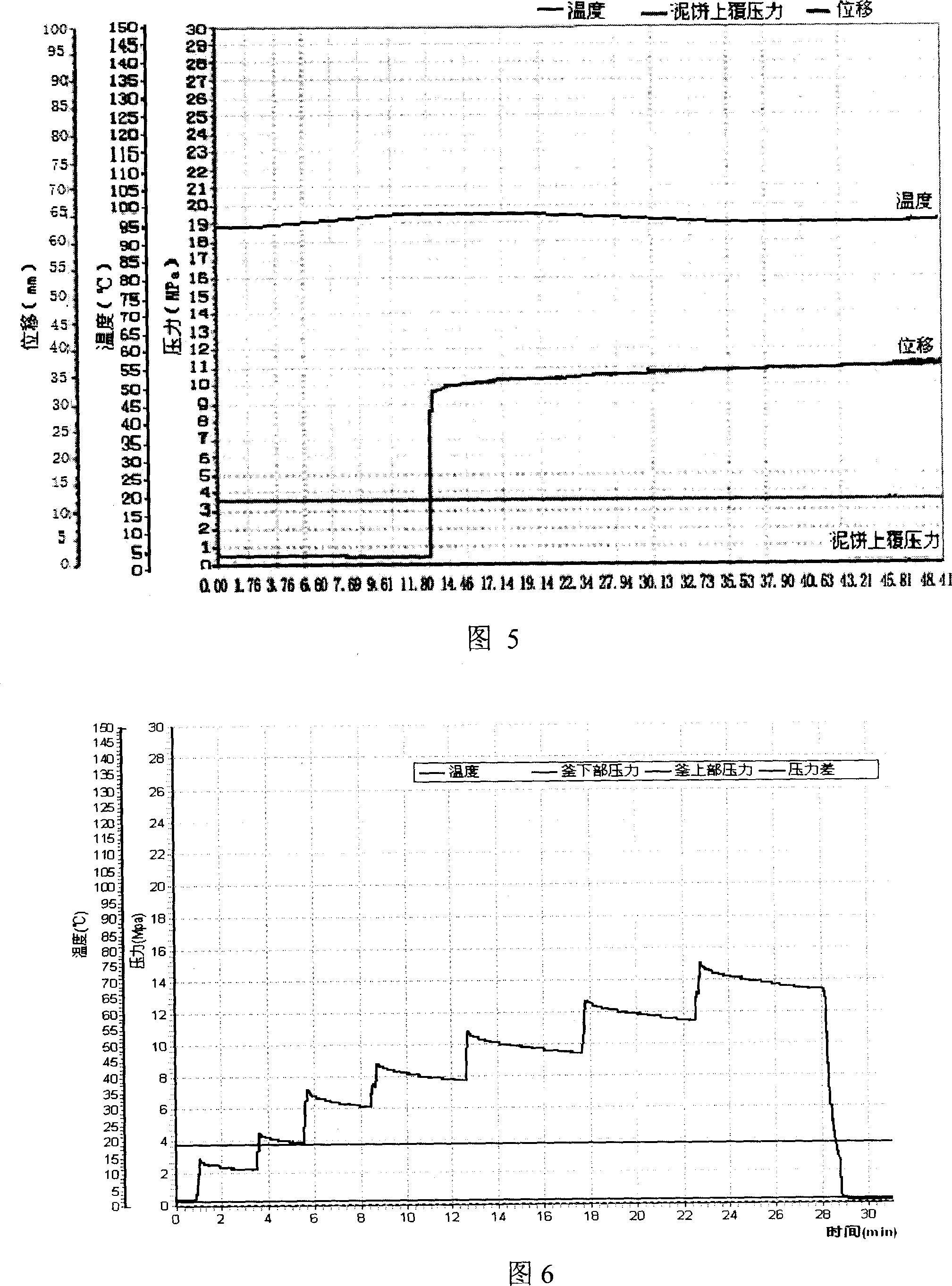

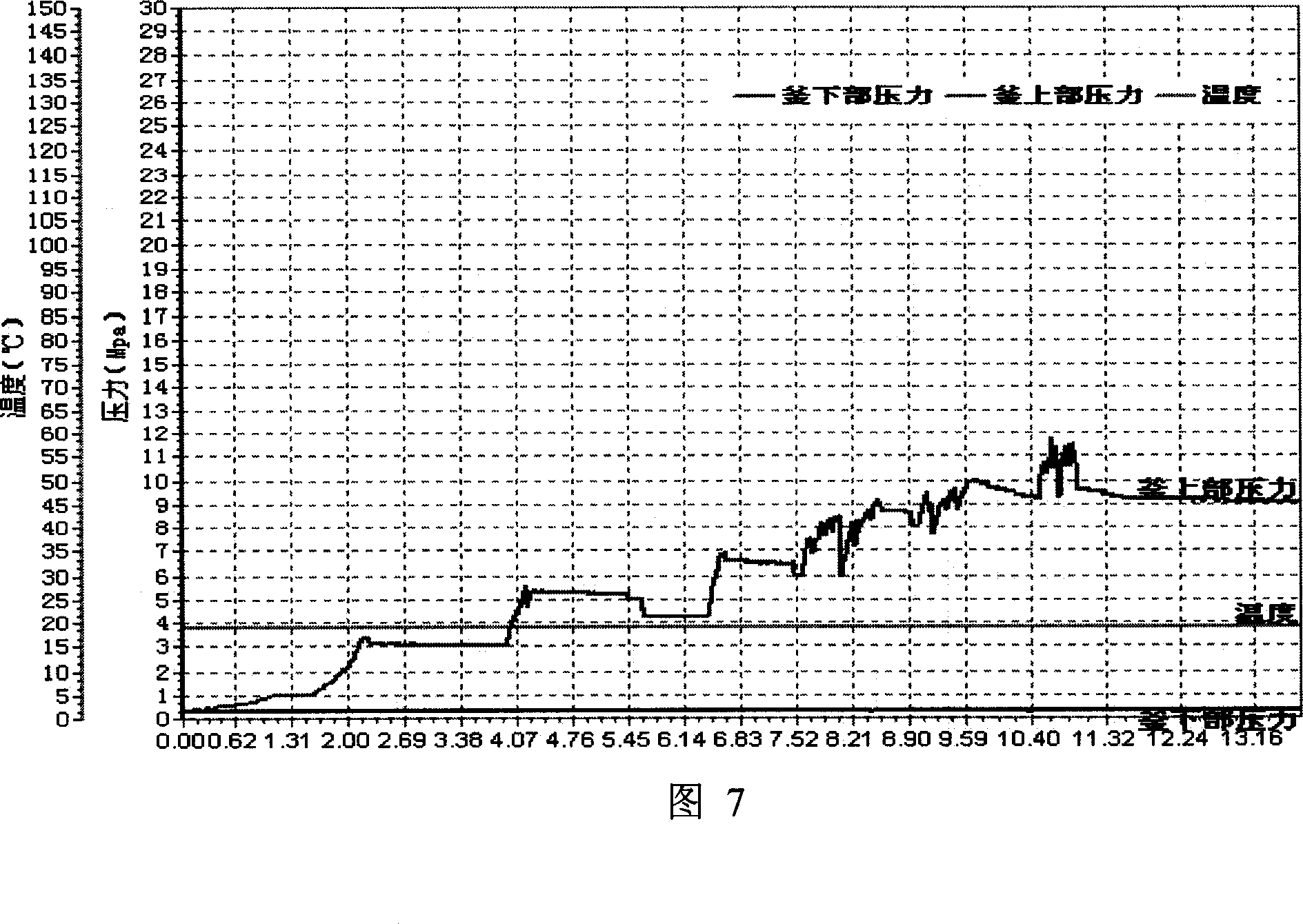

Bearing strength experiment instrument of high-temperature high-pressure mud cake plugging

ActiveCN101109739AEvaluation of closureThe experimental effect is intuitiveBorehole/well accessoriesMaterial analysisSlurryData treatment

The invention provides a tester for the bearing and plugging strength of a mud cake under high temperature and high pressure, which can simulate the static conditions in a well and test the invasion depth of slurry filter liquid, bearing strength of mud cake, plugging and bearing strength against cracks in drilling for oil (gas) wells. The tester essentially comprises a mud-cake performance evaluation and test vessel assembly, a pressure pipe system, a temperature control system, a displacement record system, an automatic cleaning system and a computer data processing system. The tester allows all-sided simulation of the temperature, pressure and stratum features (seepage) under a well, determination the plugging and bearing strength of mud cakes, optimization of drilling fluid, rapid and safe drilling, therefore the tester is of a very wide application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

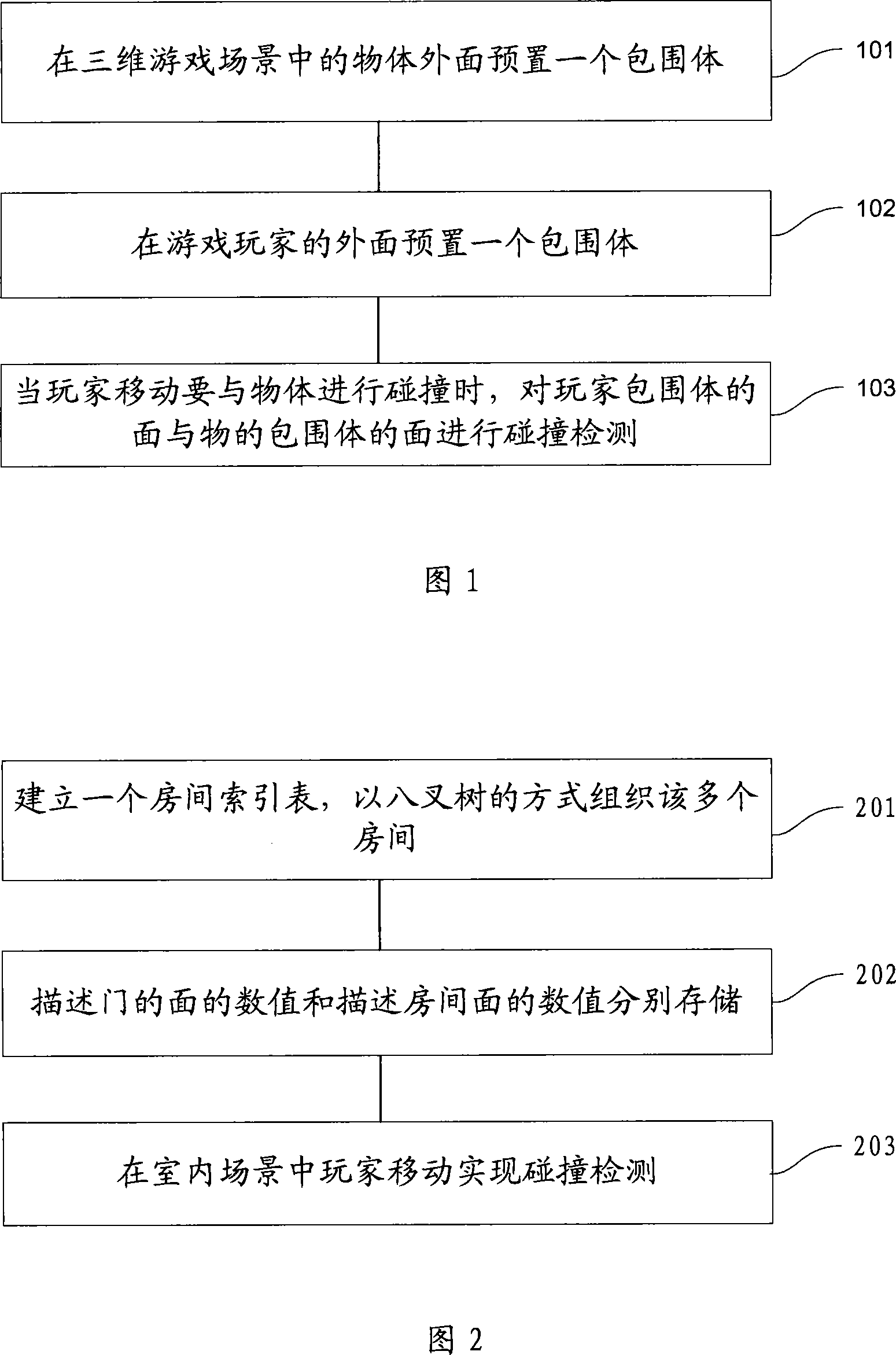

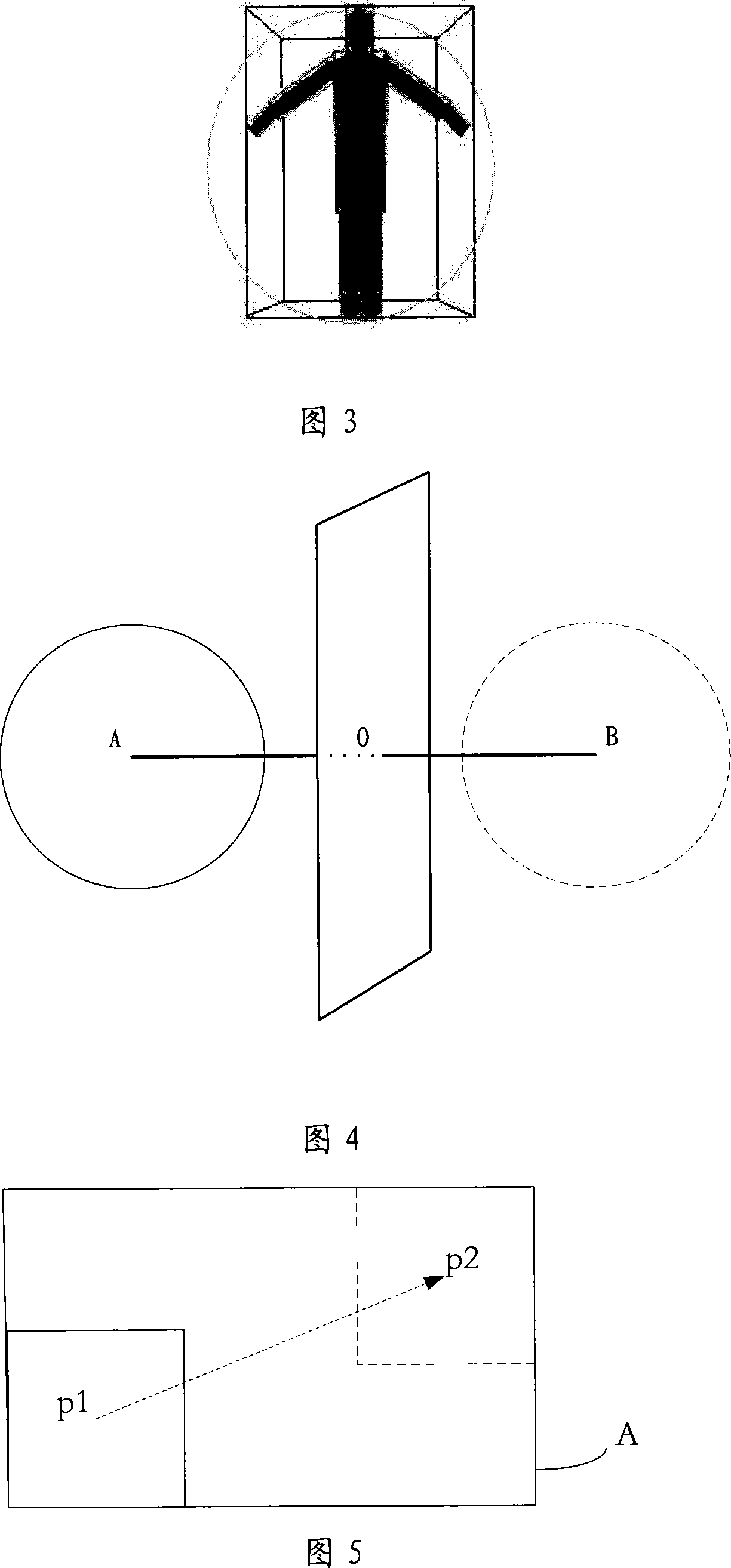

Method for realizing three-dimensional game collision detection at server end

This invention provides a method which can realize games collision detection in server-side in the three-dimensional, including the following steps: 3D gaming scene in the pre-positioning objects outside a bounding box, referred to the bounding box of siege or a major part of that siege the face value of the documents stored on the map in the game; gamers outside preset a bounding box, which covers the bounding box player or players surrounded the main part of the plane that bounding box Numerical documents stored on the game map ; When mobile gamers collisions with objects, the players bounding box of the surface and the surface bounding box for collision detection. By optimizing the game scenes, the game will be the scene of various complex objects and gamers 'description' into a bounding box, thus change collision between complex objects into collision between the limited surface of the siege, then greatly reducing burden of the computer data processing.

Owner:BEIJING KINGSOFT SOFTWARE +3

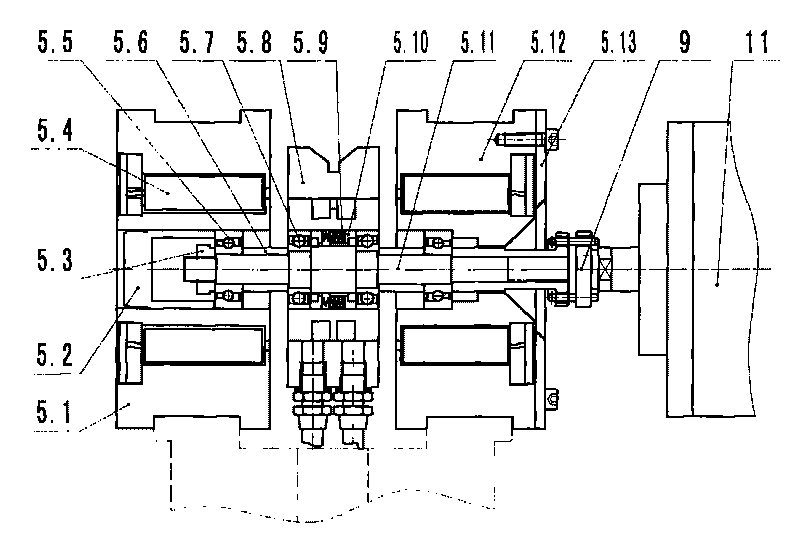

High-temperature high-speed test method for sealed bearing

InactiveCN101718625AImprove the state of stressEasy to achieve high speedMachine bearings testingElectricityComputer control system

The invention relates to a high-temperature high-speed test method for a sealed bearing, which comprises the following steps of: firstly designing a testing device, installing two sets of testing accompanying bearings on a testing main shaft, and pretightening through a set of spring and a pressure ring; installing the two sets of testing bearings at the left end and the right end of the testing main shaft, connecting an electric main shaft through a shaft coupling and additionally covering a shield; starting cooling circulating water, adding cooling water into a loading sleeve, starting a hydraulic station, an electric main shaft variable-frequency driving system and a computer control system, applying 20-30 percent of the maximum axial test load and 20-30 percent of the maximum radial test load to the testing bearings, starting the electric main shaft to reach 15-20 percent of the highest rotational speed and running for 15-25 minutes after the heating temperature reaches a set value, and then sequentially adding axial loads and radial loads and increasing the rotational speed of the electric main shaft so as to reach the highest rotational speed when the power consumption current of the electric main shaft tends to be steady; and carrying out computer data processing for the data and images in different time periods of the whole testing process and working out a test conclusion.

Owner:LUOYANG BEARING SCI & TECH CO LTD

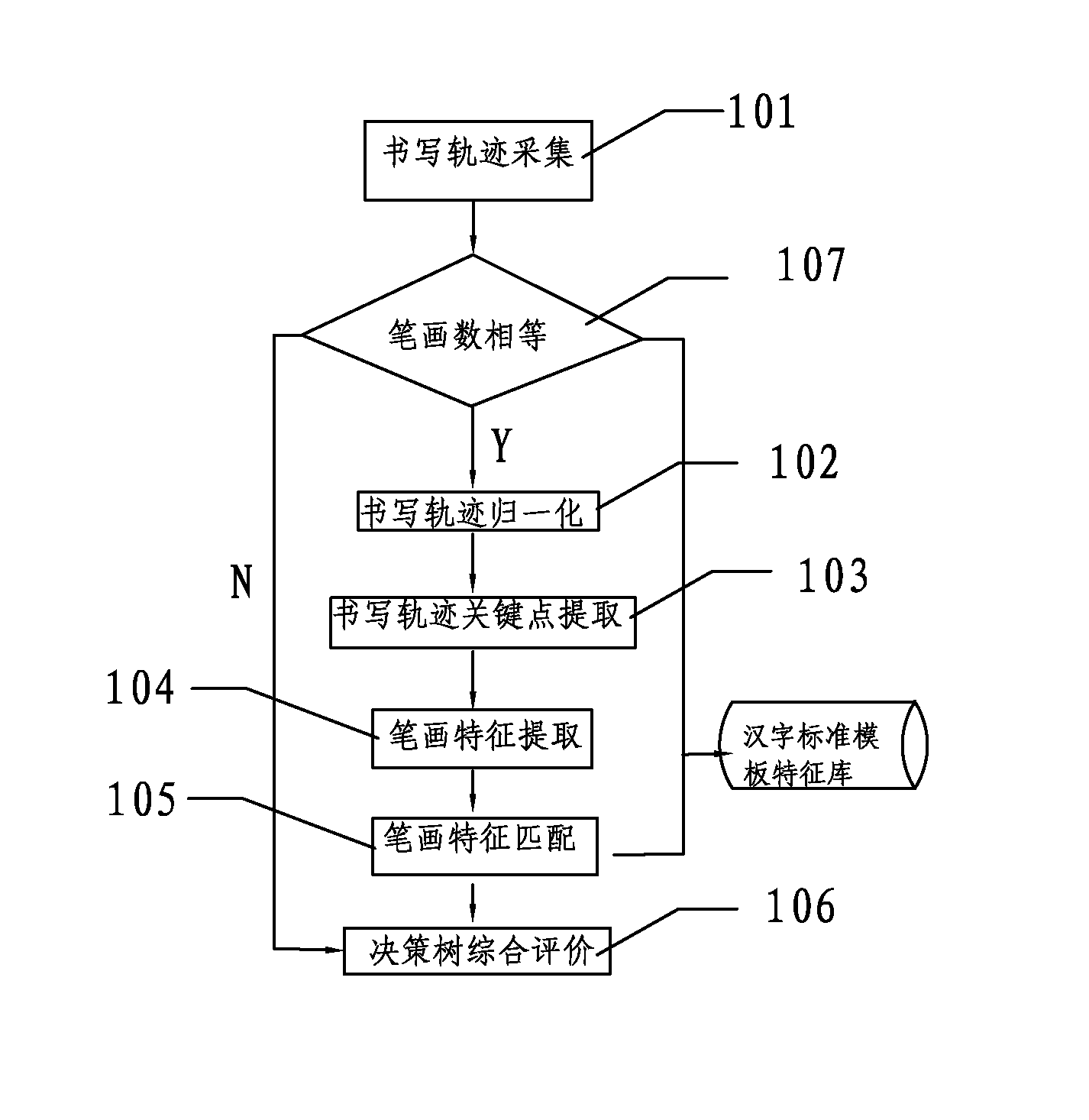

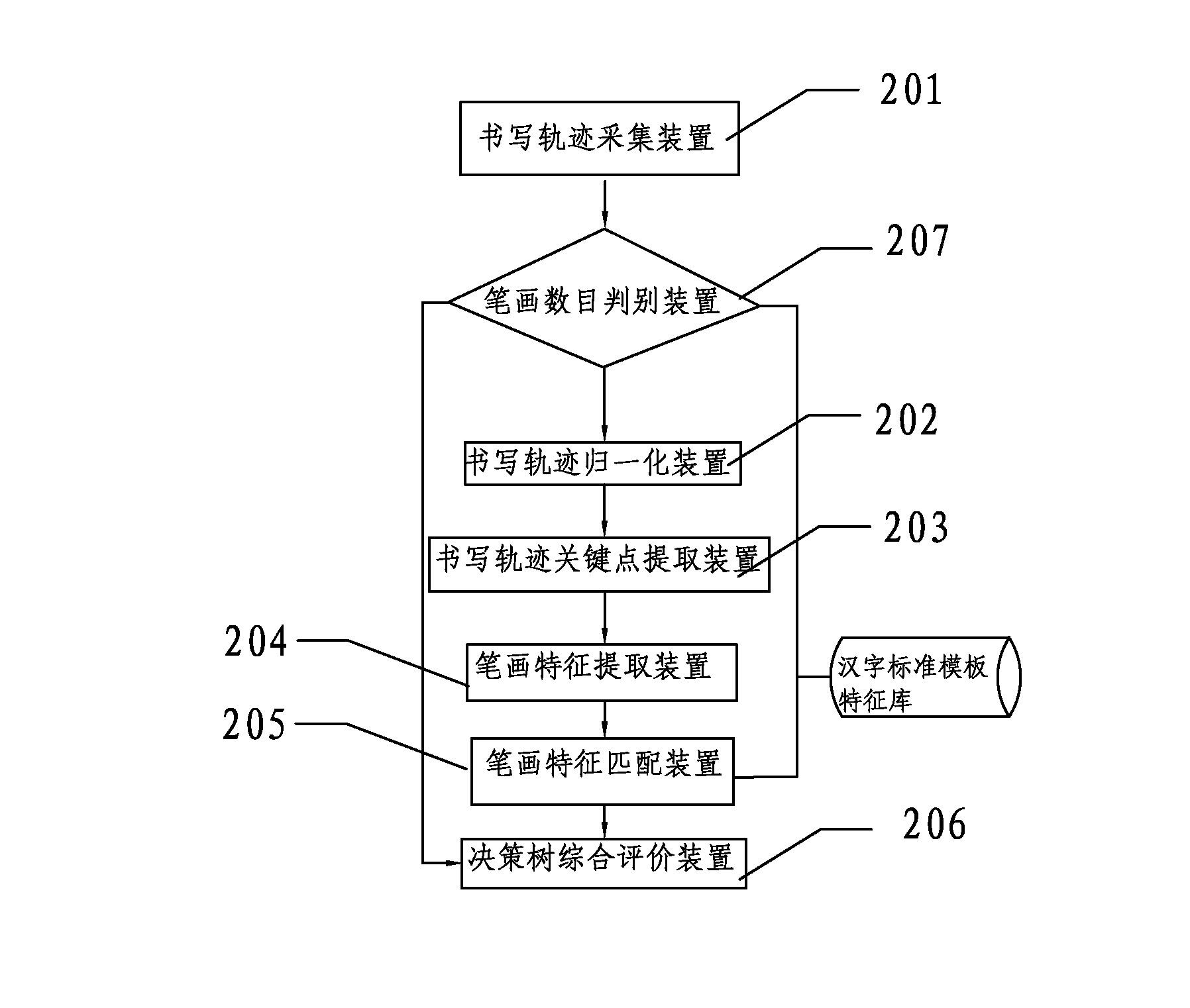

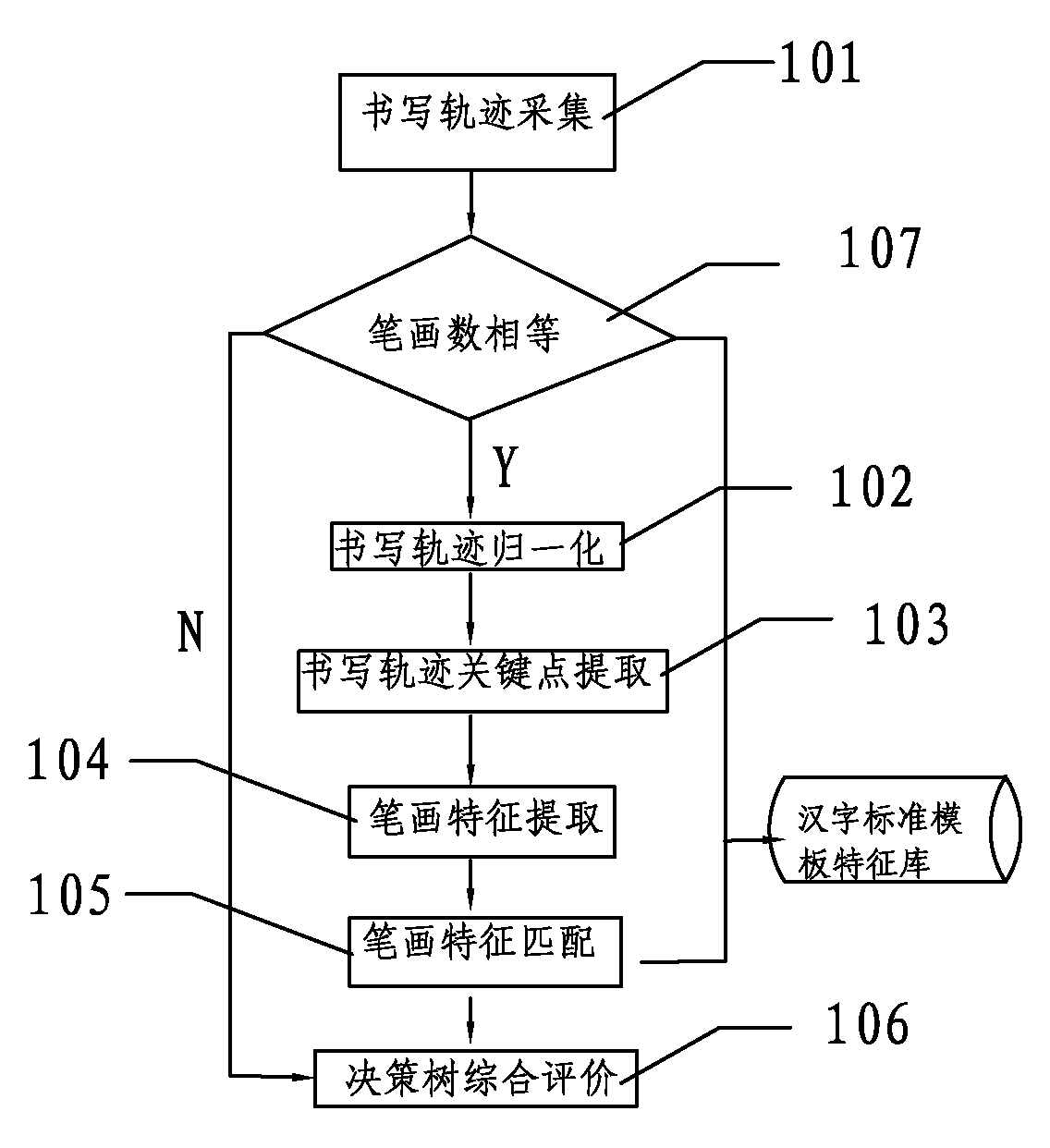

Method and device for judging standardization of writing Chinese characters

The invention relates to the field of computer data processing technology, in particular to a method for judging the standardization of writing Chinese characters. The method comprises six parts of: collecting and recording the stroke tracks of writing Chinese characters; mapping the tracks of writing Chinese characters into a scale coordinate system with a size same as that of a template Chinese character; extracting writing track key points by adopting a Douglas-Peucker algorithm; obtaining the feature vectors of all the strokes according to the obtained key points; matching the stroke features: dynamically planning and matching each stroke of writing the Chinese character with a corresponding stroke of a corresponding Chinese character in a Chinese character standard template feature library; and comprehensively judging the standardization of writing Chinese characters by adopting a decision tree method. The invention can overcome the negative influences caused by subjectivity and the fatigue caused by artificially judging Chinese characters, and can judge the standardization of writing Chinese characters.

Owner:祁亨年

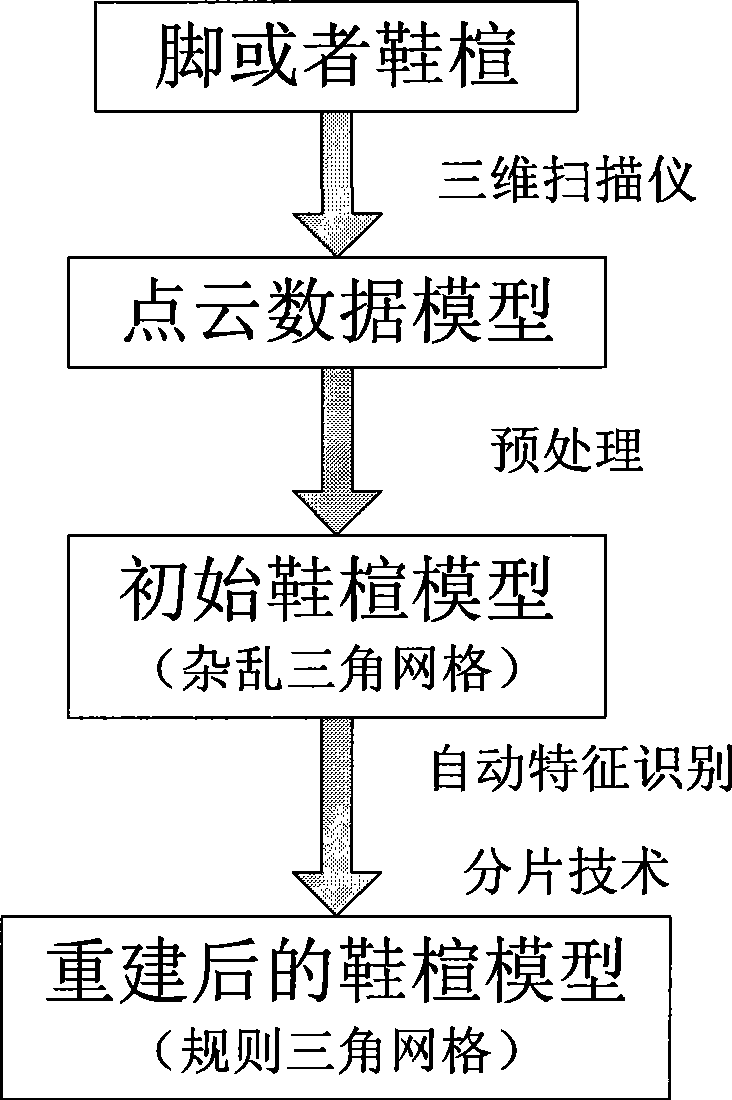

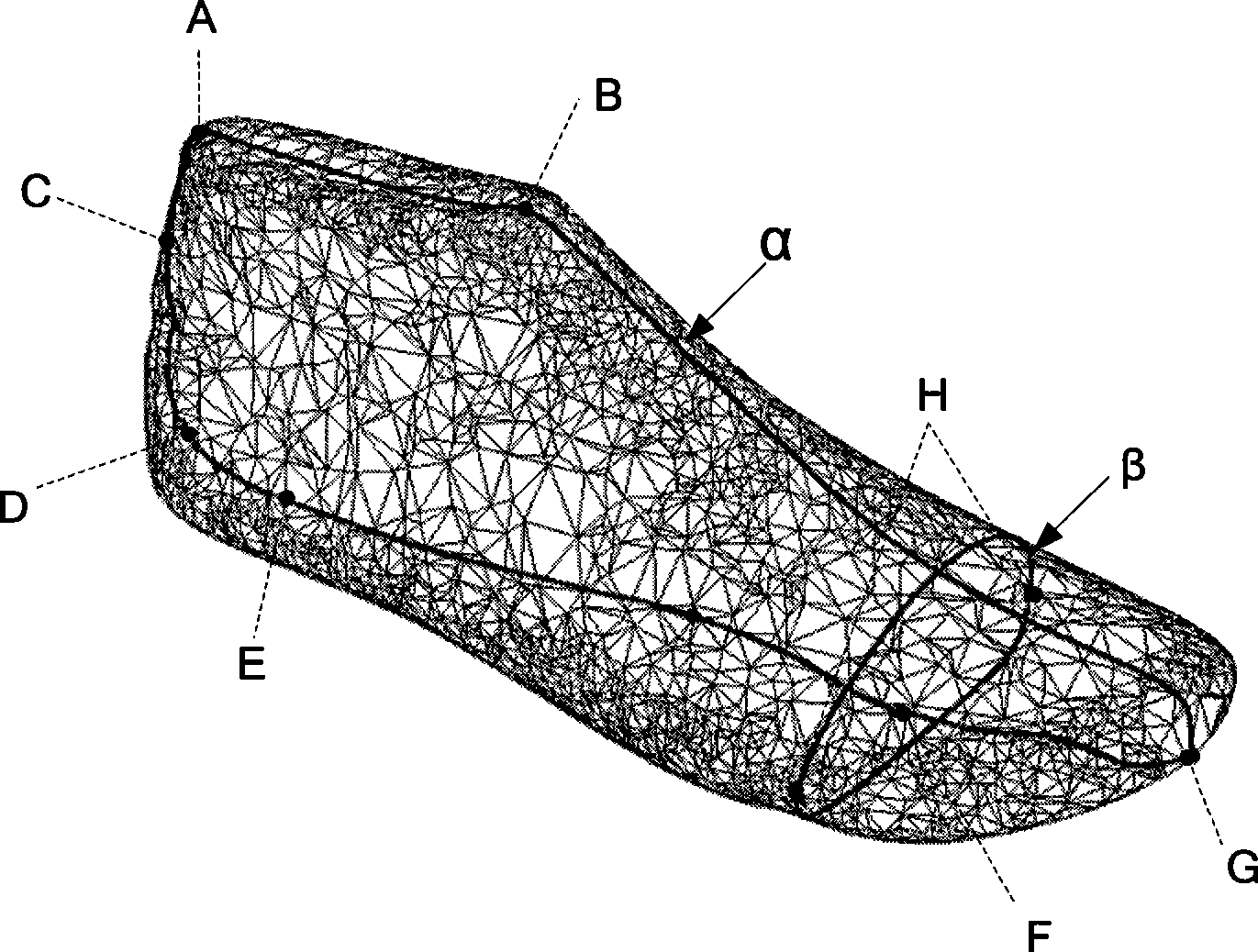

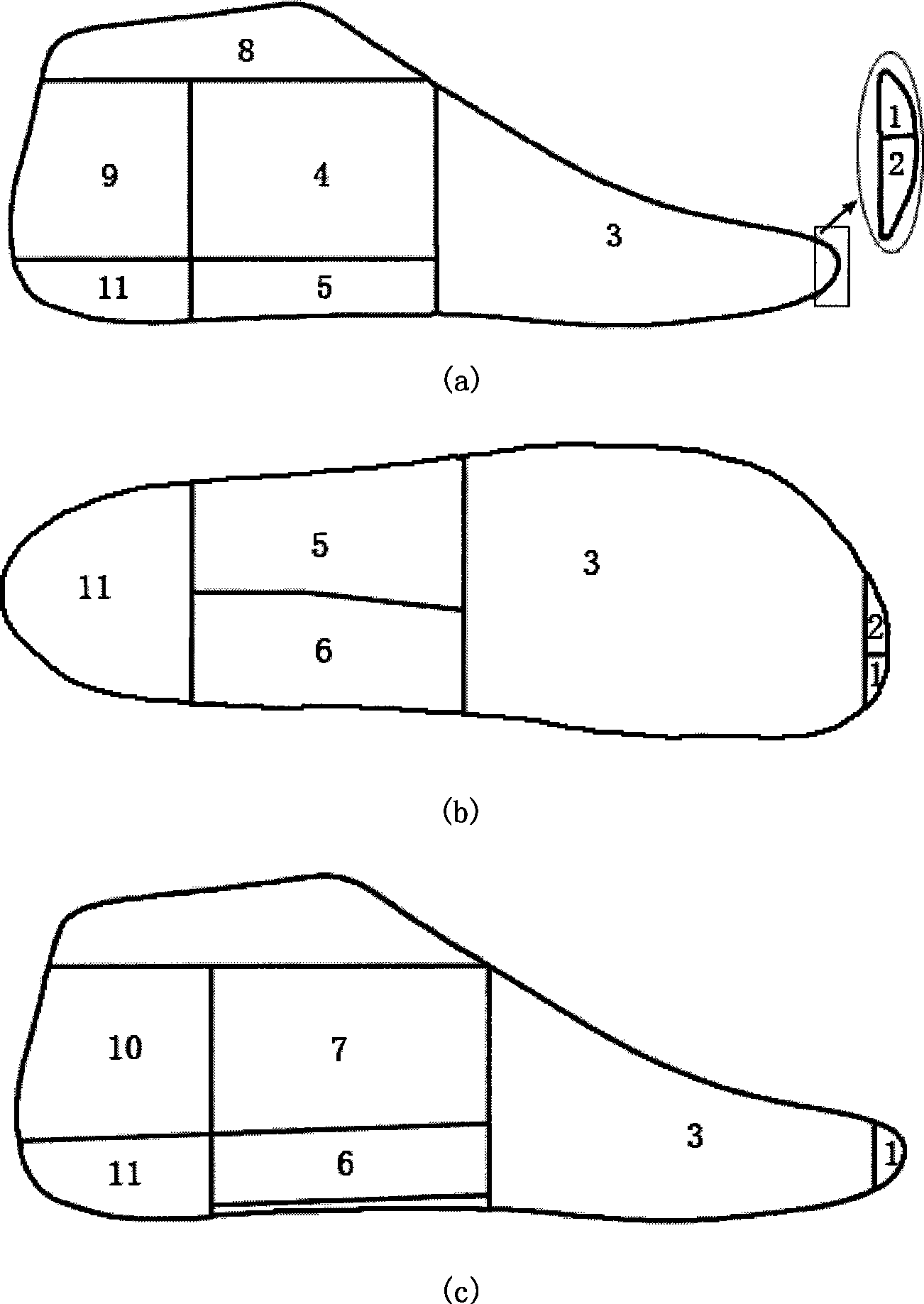

Three-dimensional shoe last rebuilding method based on scanning and inputting

The invention discloses a three-dimensional shoe last reconstruction process based on the scanning input, which comprises scanning a last by a three-dimensional scanner, generating a point cloud data model through the computer data processing, conducting the pre-processing for the point cloud data model to obtain an initial shoe last model, carrying out the automatic character identification, generating all sub face sheets of the shoe last through the surface slicing technology, stitching all the sub face sheets to form the surface of the whole shoe last, thereby gaining the shoe last model after the reconstruction. The invention transforms the shoe last data into a grid model after the point could processing, automatically obtains each character point and each character line of the shoe last through the automatic character identification technology, and eliminates the problems brought by the losses or damages of original character information files. The position with larger surface curvature change is a difficult point to generate a curved surface in the process of generating curved surface of the shoe last, and the surface slicing technology can be adopted to reduce the difficulty of curved components, and sub face sheets in different regions are adopted with appropriate curvature reconstruction methods, thereby guaranteeing the surface accuracy of the shoe last model.

Owner:ZHEJIANG UNIV

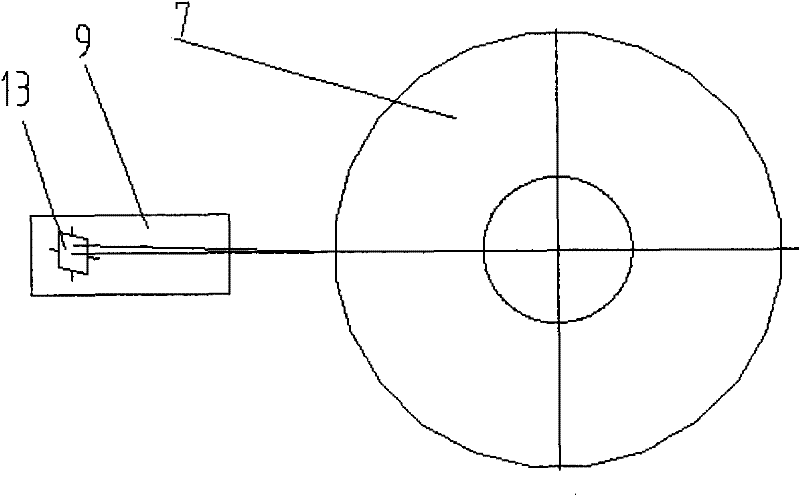

Dynamic angle measurement error detector used in photo-electric axial angle encoder

InactiveCN102128645AOvercome the technical problem of only testing static angle measurement accuracyInstrumentsData processing systemCoupling

The invention relates to a dynamic angle measurement error detector used in a photo-electric axial angle encoder. A fixation part of a to-be-tested encoder is arranged on a base of the detector, a rotary part of the to-be-tested encoder is connected with a revolving shaft by a coupling joint, a polyhedron is fixed on the revolving shaft of the detector, a dynamic signaling autocollimation aims at a reflecting surface of the polyhedron, and a rotator of a torque motor is connected with the revolving shaft. During the detection, the torque motor is controlled by a computer to continuously rotate at a certain speed, and the revolving shaft, the rotary part of the to-be-tested encoder and the polyhedron are driven to rotate by the torque motor. When one operating angle of the polyhedron is turned, and the operating surface of the polyhedron is perpendicular to an optical axis, a trigger circuit sends out trigger impulses. Encoder values can be sampled after a data acquisition system probes trigger impulse signals. After the rotary part of the to-be-tested encoder rotates a circle, a group of sampling values can be obtained, and dynamic angle measurement errors of the to-be-tested encoder can be calculated by a data-processing system of the computer. The dynamic angle measurement error detector can be used for detecting the dynamic errors of the photo-electric axial angle encoder and has higher precision.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

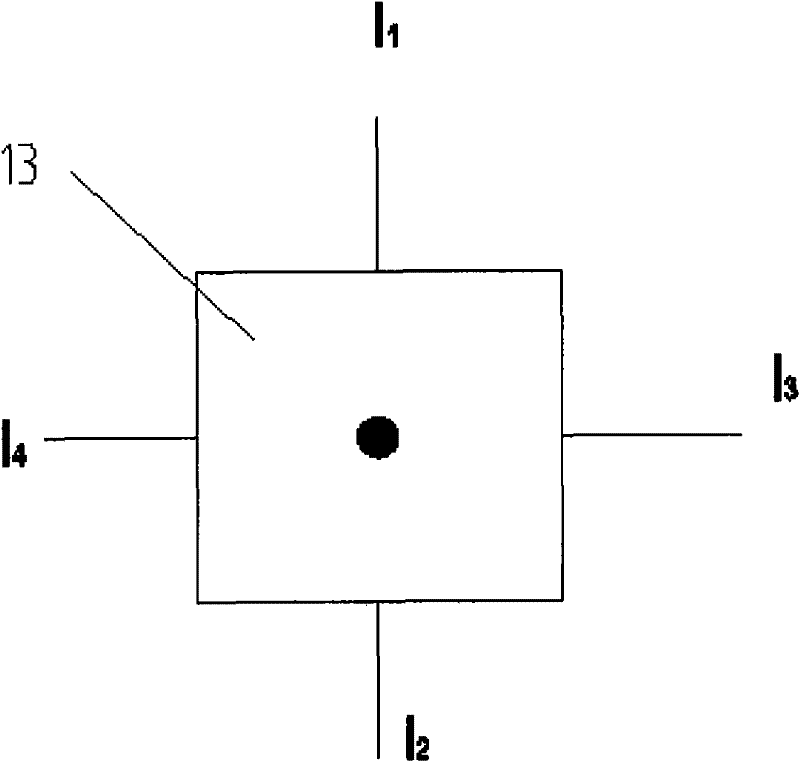

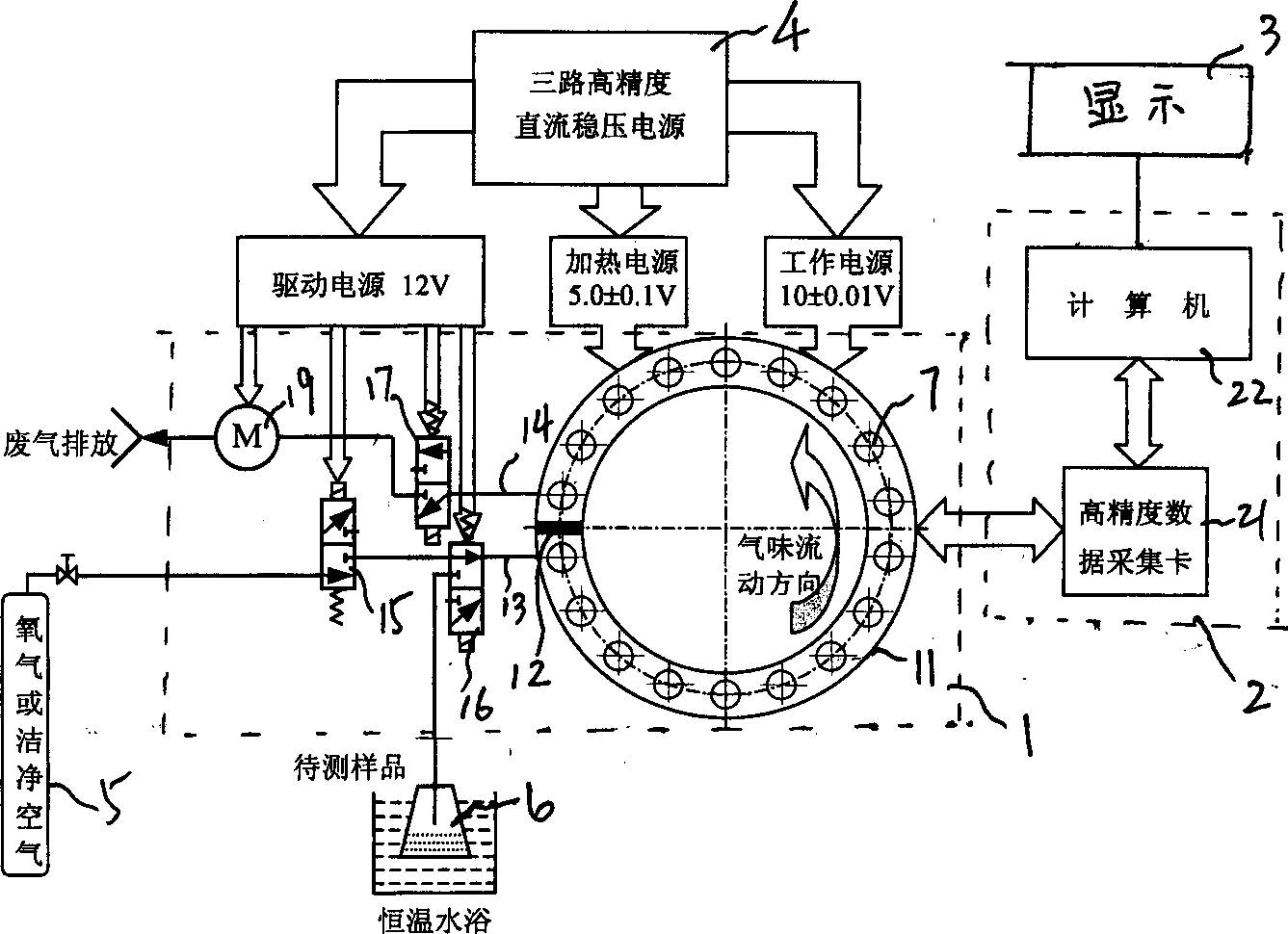

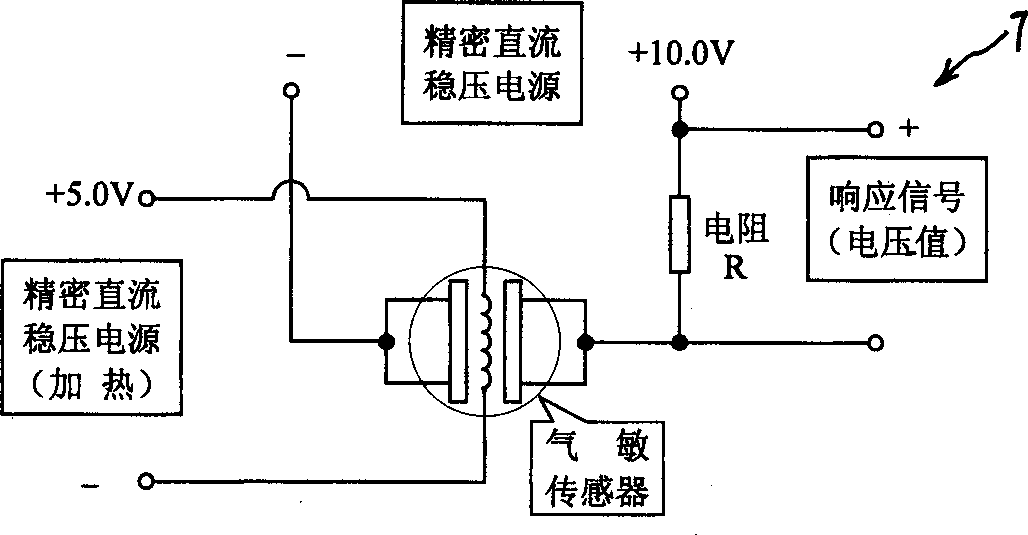

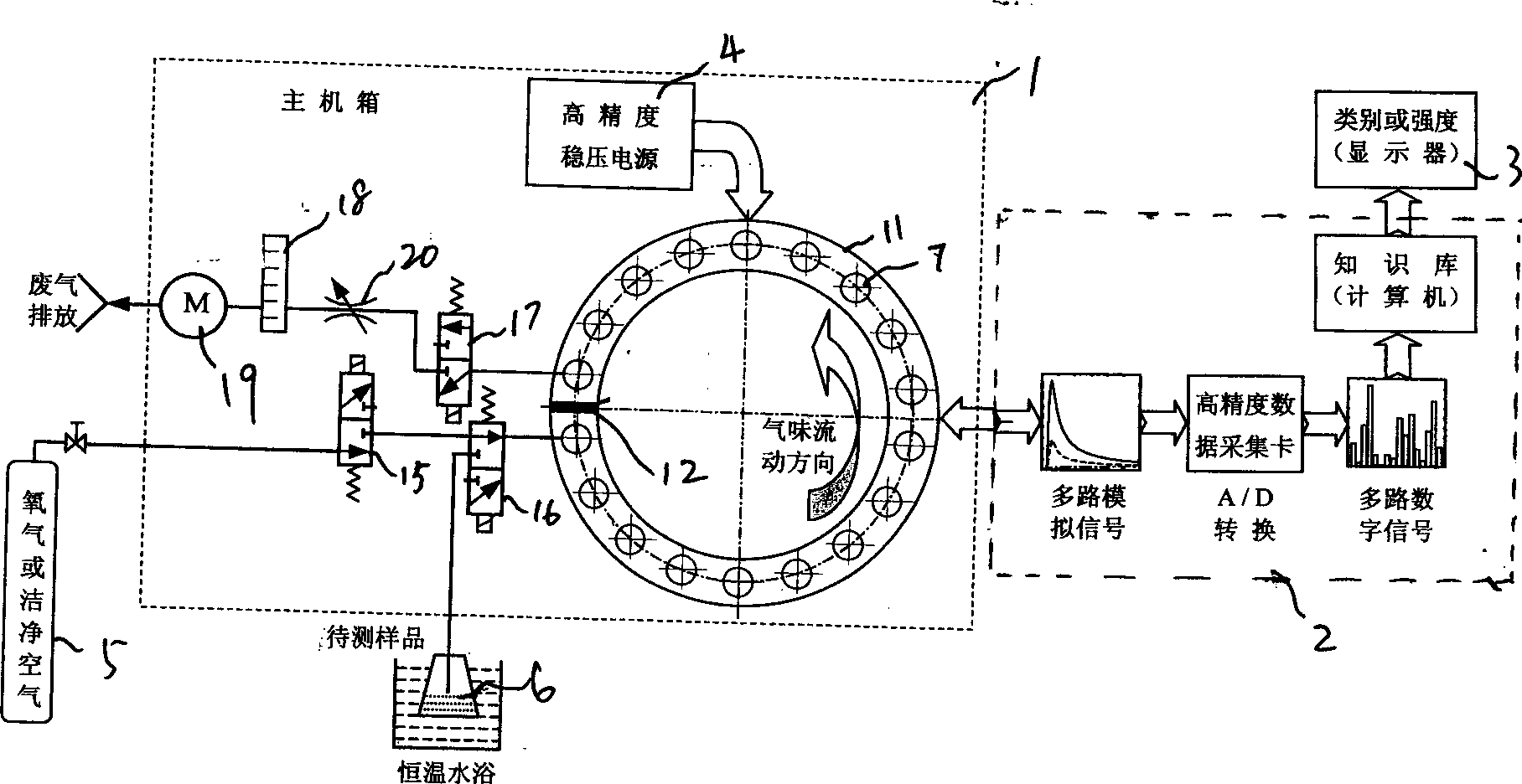

Olfactory simulator and its olfactory simulation testing method

InactiveCN1367381AConcentration did not decreaseSmall volumeMaterial resistanceGas detectorDisplay device

The present invention relates to an olfactory simulation device and its olfactory simulation testing method. Said device is formed from main machine box, computer processing portion, display portion and power supply circuit, and said method includes the following steps: a). the odor to be tested can be sucked into ring testing box by means of miniature diaphragm pump, said gas can be quickly passed through sensing membrane surface of every sensor, then discharged from outlet; b). every response produced by every gas sensor when the gas is passed through every sensor can be collected into datacollecting card, passed through A / D converter to obtain a multidimensional response signal; and c). said signal is processed by computer so as to can obtain the type of odor to be tested, integral intensity and its simple component composition, and can be displayed.

Owner:SHANGHAI HUIBI INTELLIGENCE SCI & TECH

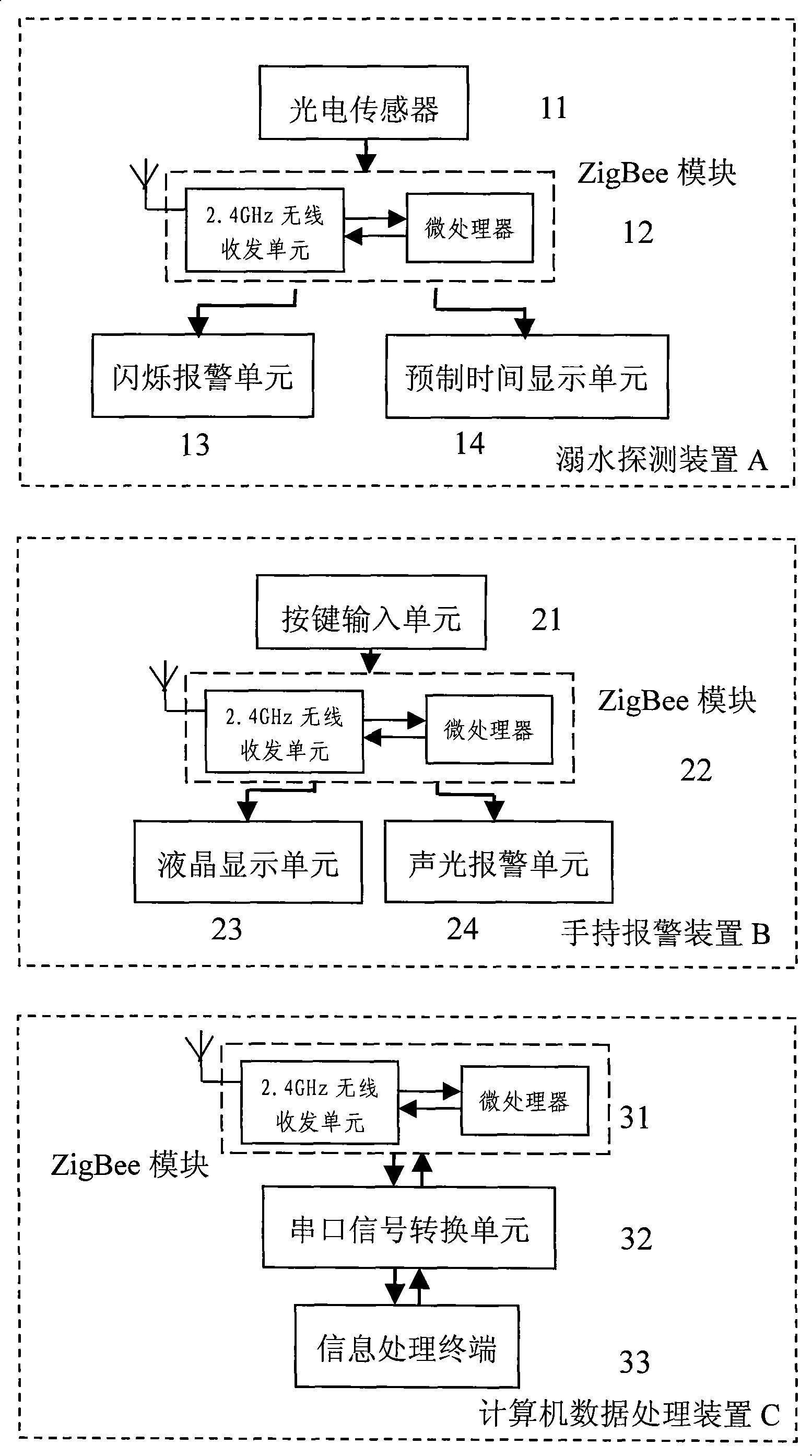

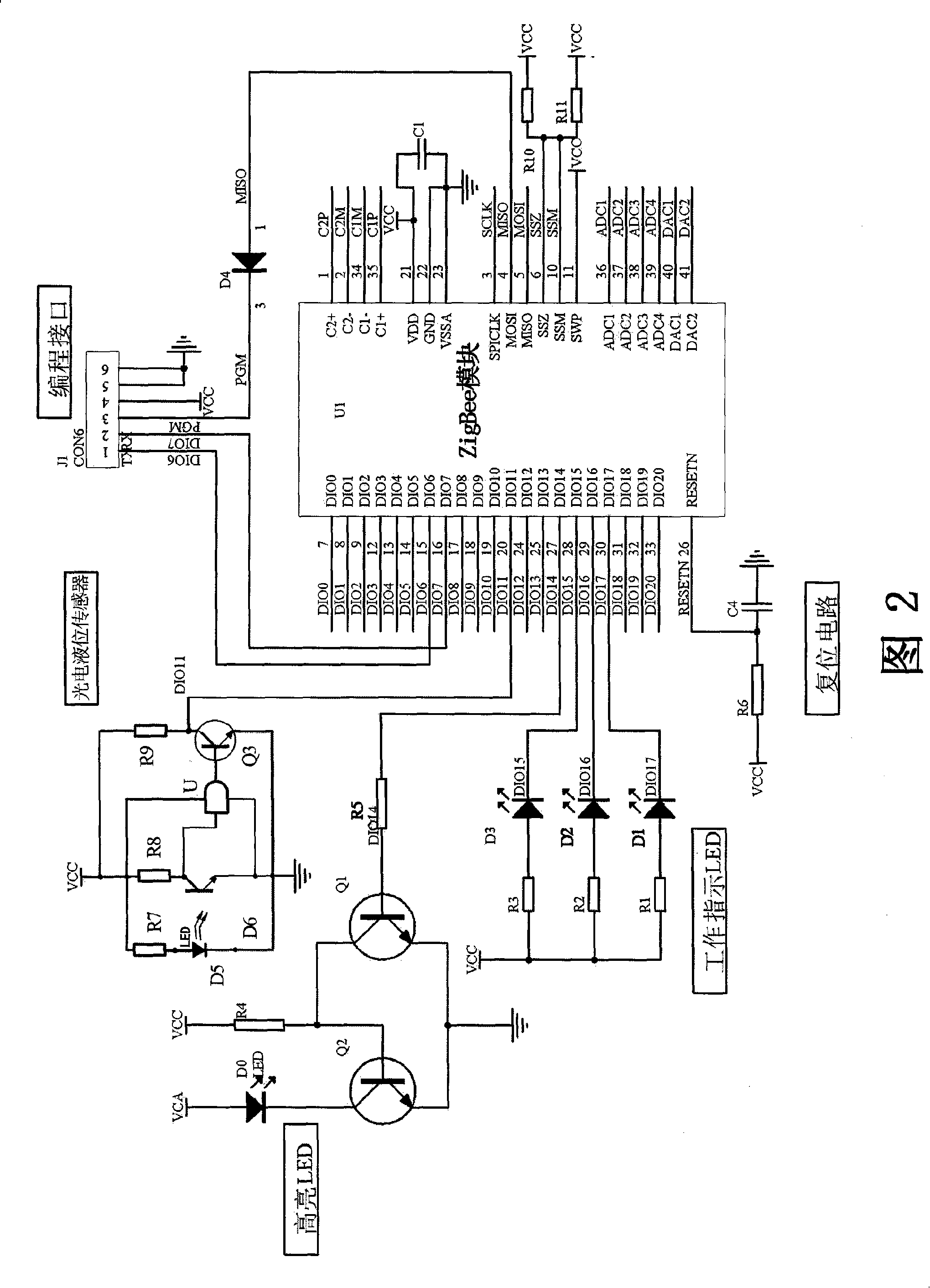

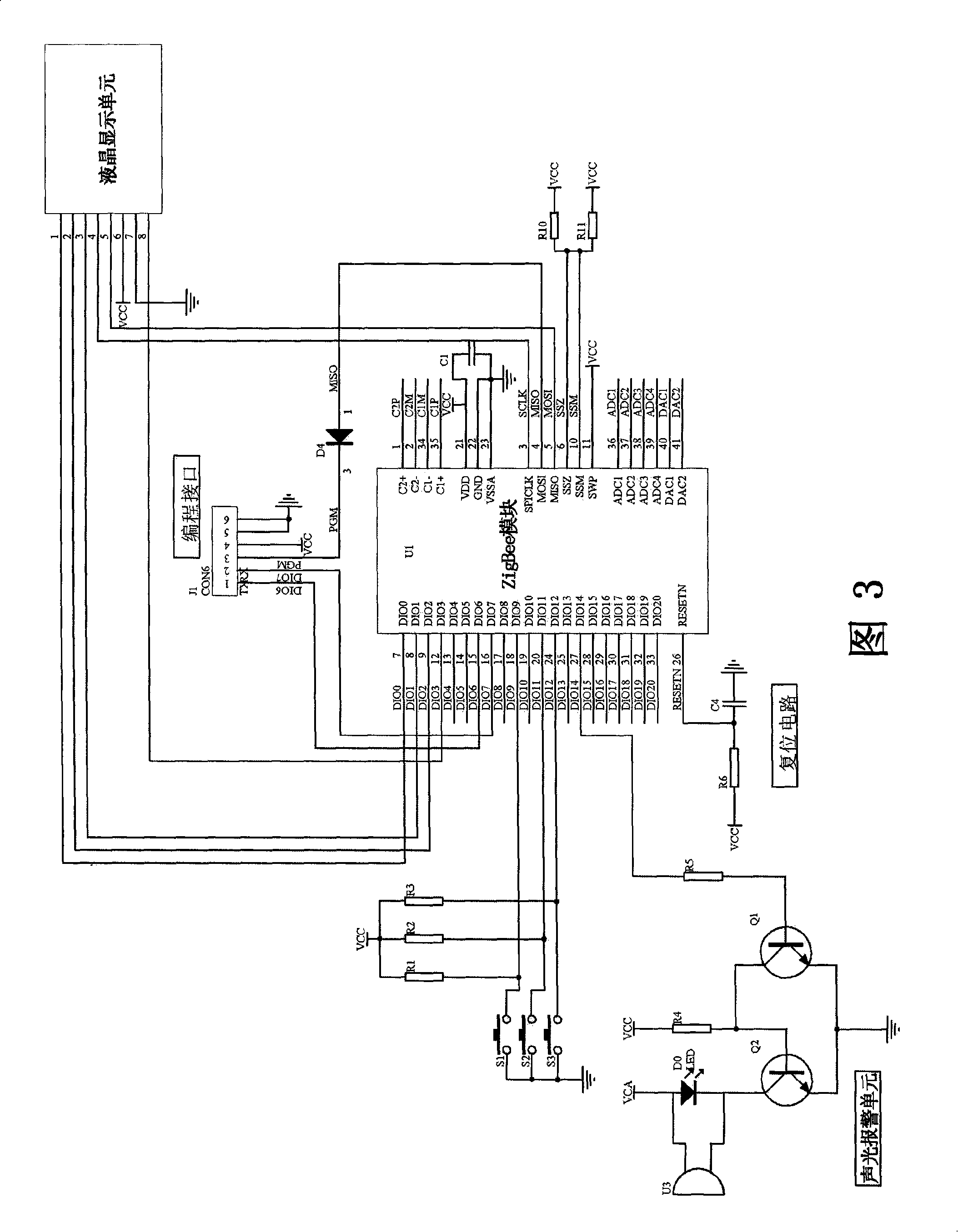

Drowning alarm apparatus in swimming pool

InactiveCN101197060ATimely rescueImprove reliabilityAlarmsElectric transmission signalling systemsCrowdsData treatment

The invention discloses a swimming pool drowning alarm device which consists of a drowning detection device A, a handhold alarm device B and a computer data processing unit. The drowning detection device A is worn on the head of a swimmer, the handhold alarm device B is used by the lifeguard, the computer data processing unit C is used by the management personnel of the swimming pool. Under normal condition, the drowning detection device A sends signals to the handhold alarm device B and the computer data processing unit C at fixed time. When the head of the swimmer is immerged into the water, the drowning detection device A does not send any signal, a timing circuit of the drowning detection device A and the handhold alarm device B as well as the computer data processing unit C is started, the swimmer is judged as the drowning if the given time reaches and the swimmer still does not come out from water. At this time, the drowning detection device A flashes and flickers to display the position of the drowner, the handhold alarm device B and the computer data processing unit C make a sound-light alarm to remind the crowd around, the lifeguard and the management personnel of the swimming pool to implement rescue to the drowner.

Owner:晋捷

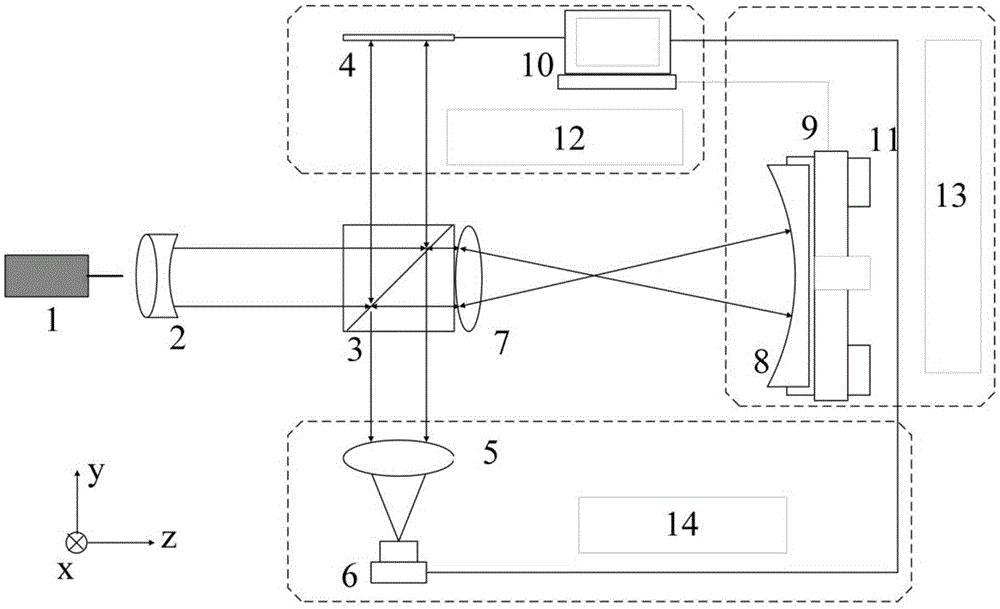

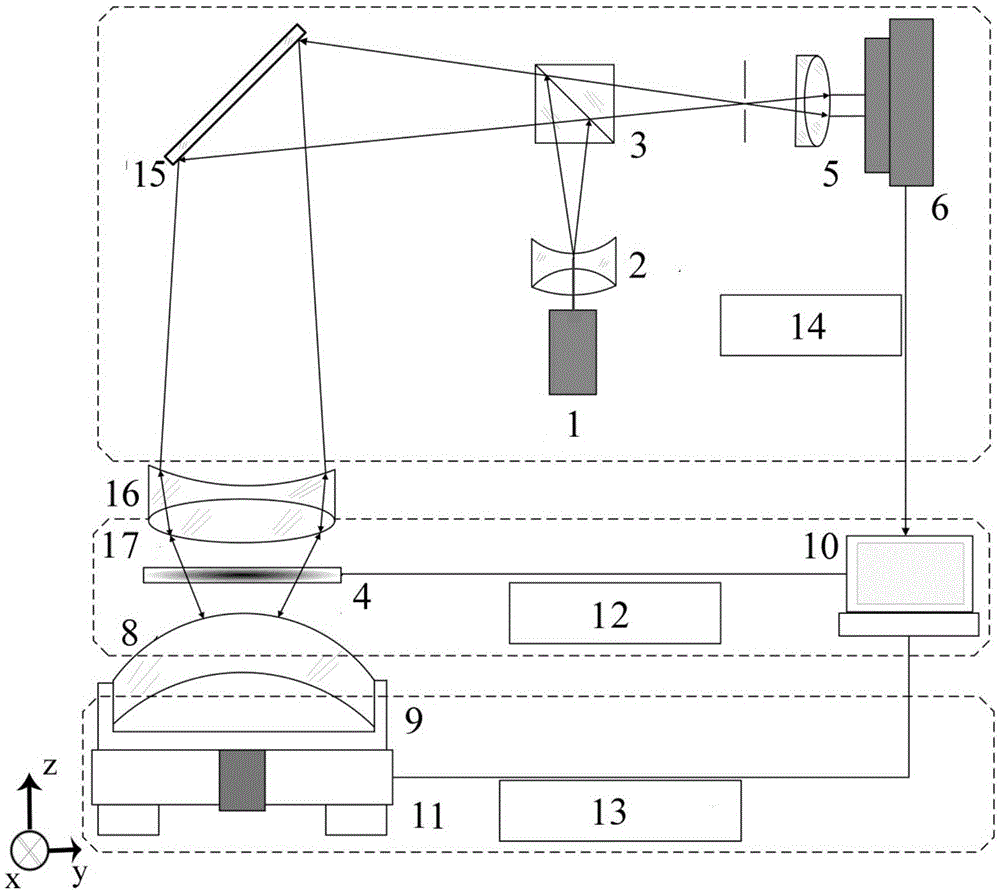

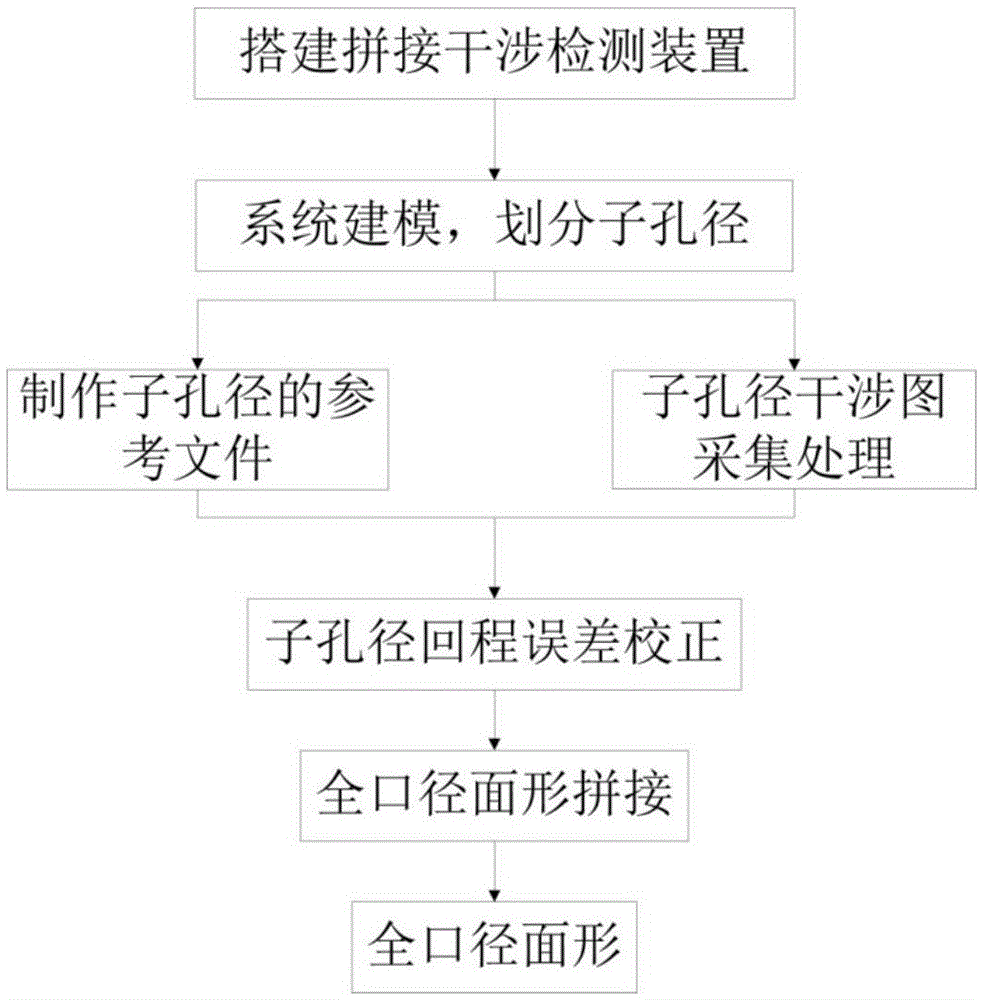

Splicing-interference-detection aspheric surface shape apparatus using distorting lens and method thereof

InactiveCN105423948AIncrease overlapReduce accumulationUsing optical meansRefractive indexEngineering

A splicing-interference-detection aspheric surface shape apparatus using a distorting lens and a method thereof belong to the optical detection technology field. In the invention, an interference detection system, a distorting lens compensation system, a mechanical adjusting mechanism and a computer data processing module are included. The method comprises the following steps of step1, constructing a splicing interference detection apparatus using the distorting lens; step2, dividing a subaperture; step3, removing to a position of the subaperture to be detected and adjusting a distorting lens surface shape or a refractive index according to modeling and interference fringes; step4, carrying out subaperture interferogram acquisition processing; step5, carrying out subaperture backhaul error correction; and step6, carrying out full aperture surface shape splicing. In the invention, the distorting lens and the subaperture splicing interference detection method are combined; the subaperture number needed by full aperture coverage can be effectively reduced and effective areas of each subaperture and an overlapping region are increased; a problem that the overlapping region is small so that splicing precision is influenced is solved.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Validating customer complaints based on social media postings

A system may validate customer complaints about products. The system may include a computer data processing system configured to: query a computer system for social media postings made in a social media network system about the products; determine how widespread each complaint is based on the results of the query; and store information indicative of the determination.

Owner:TOYOTA MOTOR SALES USA

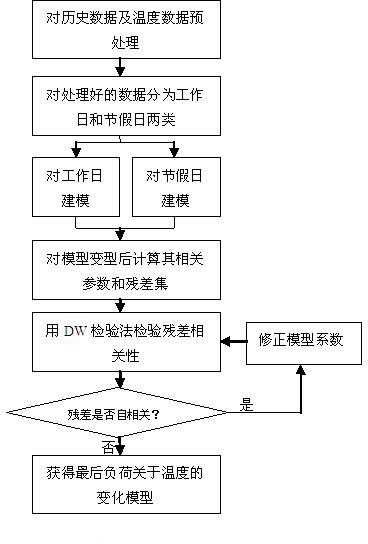

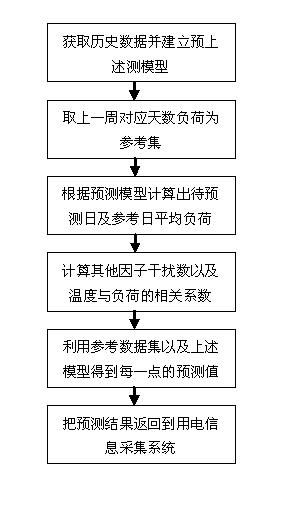

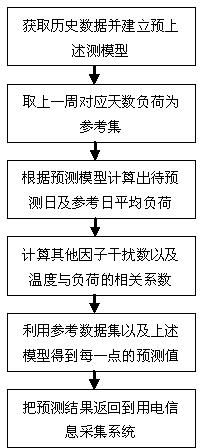

Computer generating method for short-term load forecasting in summer in power consumer electricity-utilization information acquisition system

ActiveCN102521674ARealization of short-term load forecasting in summerImplementation of short-term load forecastingForecastingElectricityLoad forecasting

The invention relates to a computer data processing method, in particular to a method for restoring computer data of a power consumer electricity-utilization information acquisition system. The main points of the method are that: the method comprises the steps of: (1), pre-processing a history electricity-utilization load and a temperature data, (2), building models related to summer temperature and a power load, wherein m and n are parameters and v is a residual set,(3), calculating coefficients rho related to the summer temperature and the load, (4), considering dependence of the data to be predicted corresponding to numerical values in the last week according to the summer temperature data and relevance of the summer temperature data and the load, and obtaining a final load prediction value. The invention provides a short-term prediction method for electricity-utilization load in summer with high accuracy and strong practicability.

Owner:STATE GRID CORP OF CHINA +1

Automatic controlling technical parameter optimization method of metal plate rolling

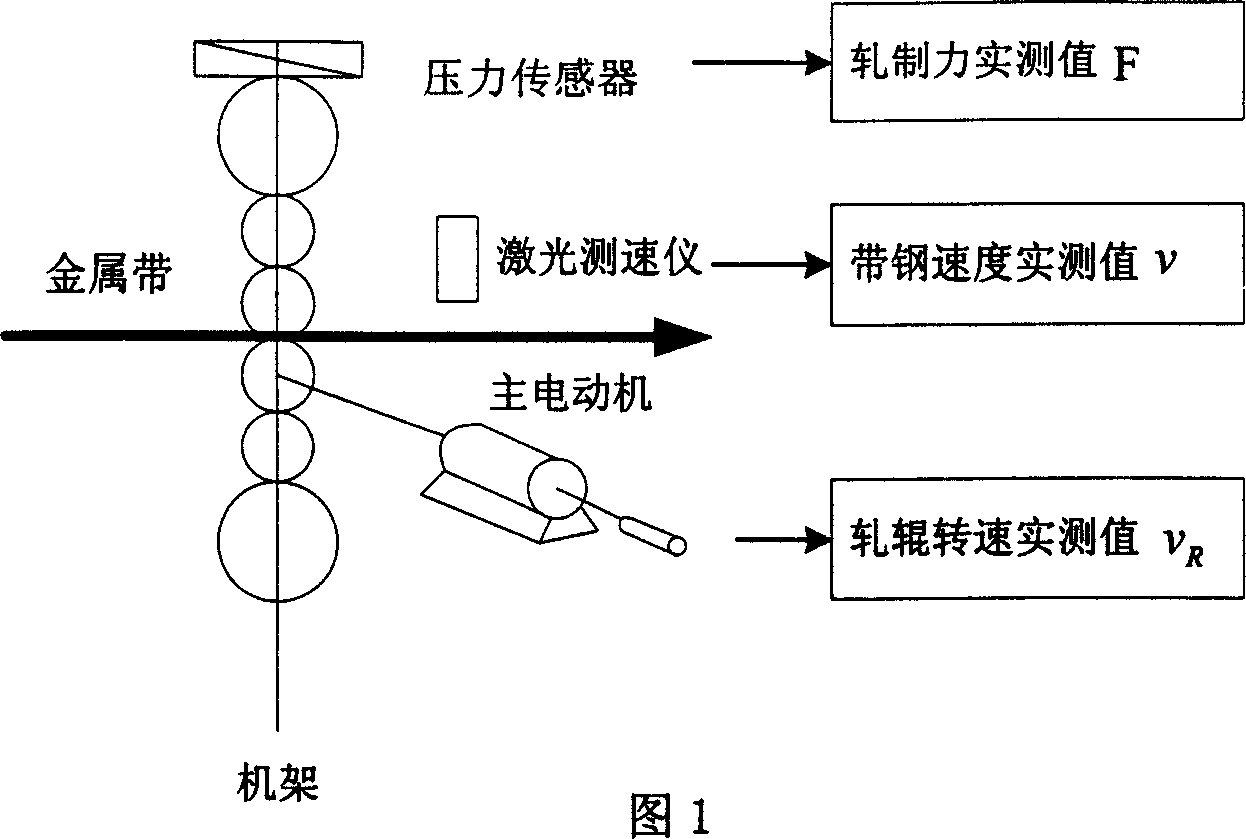

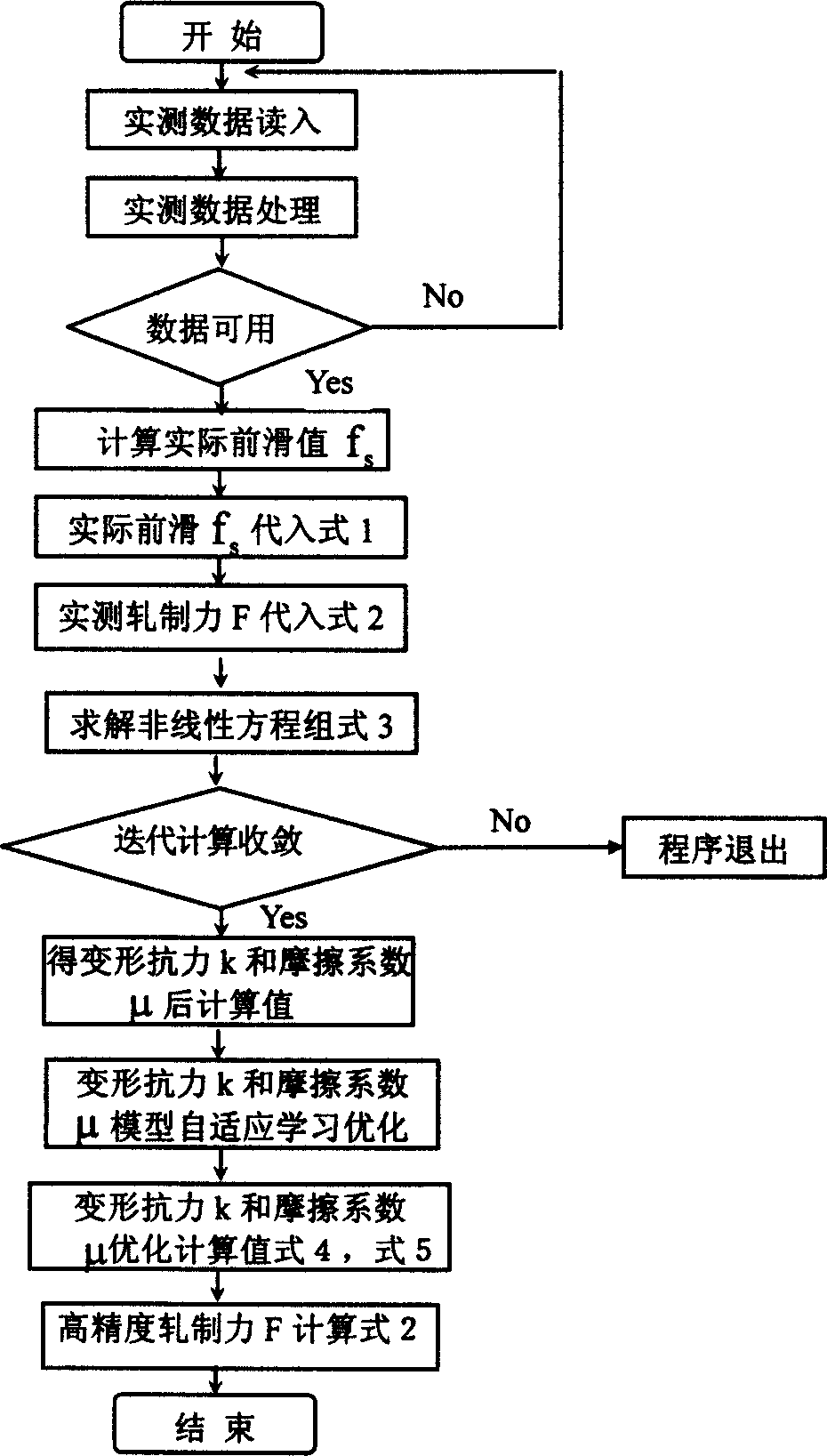

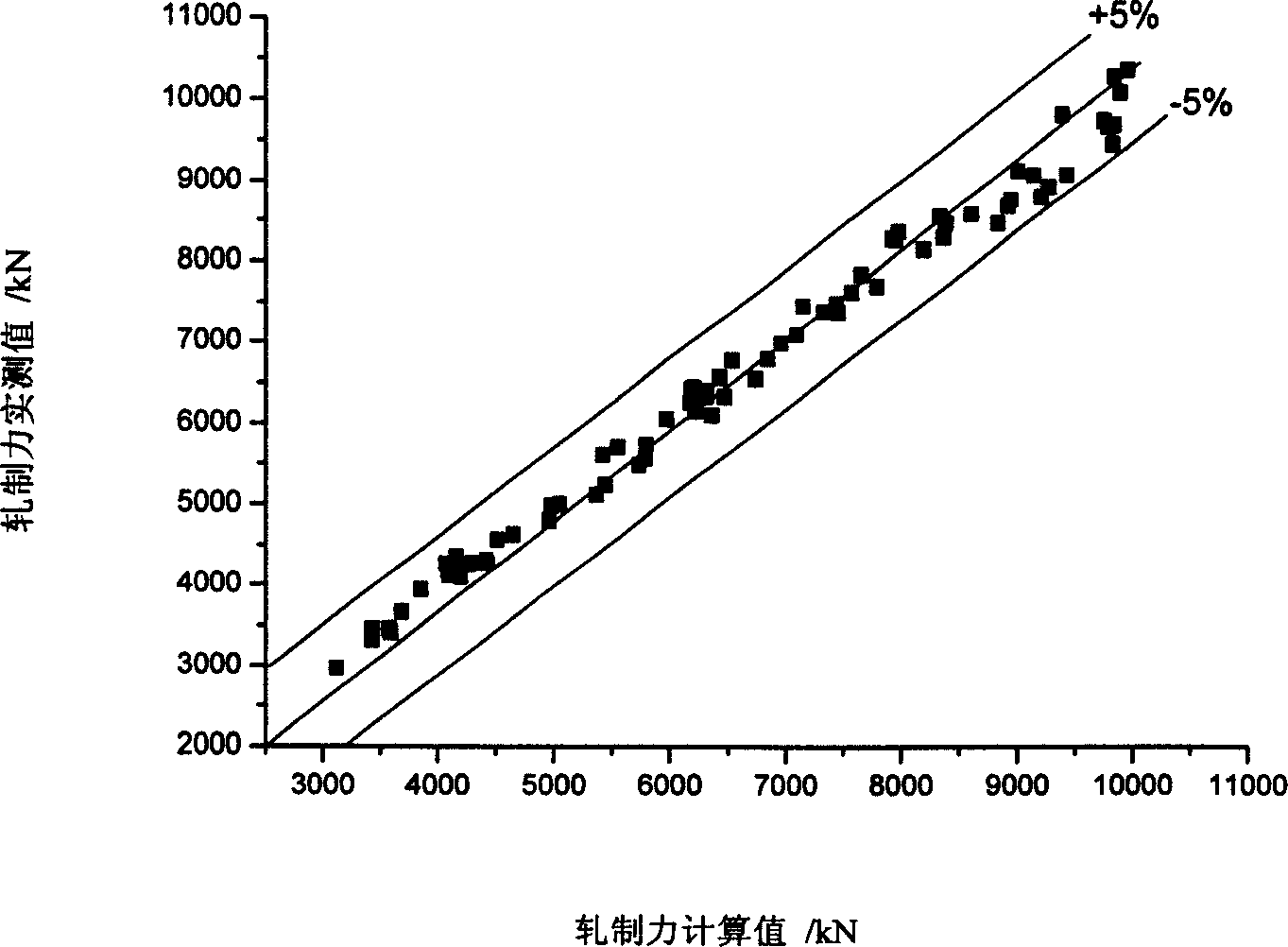

InactiveCN1589986AImproving the effect of adaptive learning optimizationSolve the coupling problemRoll force/gap control deviceAdaptive learningAutomatic control

A method for automatically optimizing the technological parameters in rolling metallic plate or band features use of an automatic control system composed of an in-line automatic measuring unit, a network communication unit and a data processing unit with computer. It includes measuring the rolling force F and advancing value fs, inserting them in a dyadic high-order non-linear equations to find out deforming resistance K and friction coefficient Mu, adaptive learning of the calculation module, and optimizing.

Owner:NORTHEASTERN UNIV

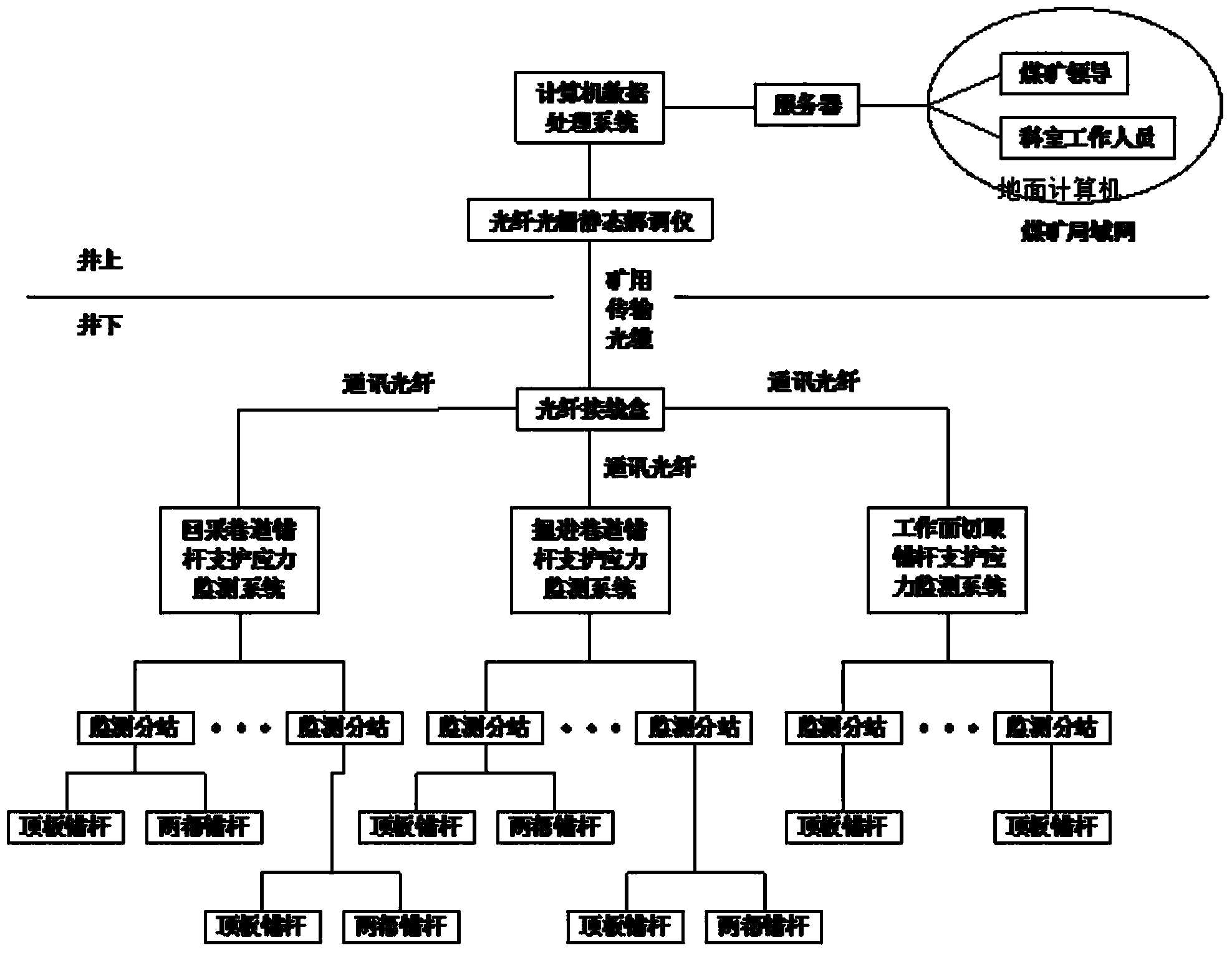

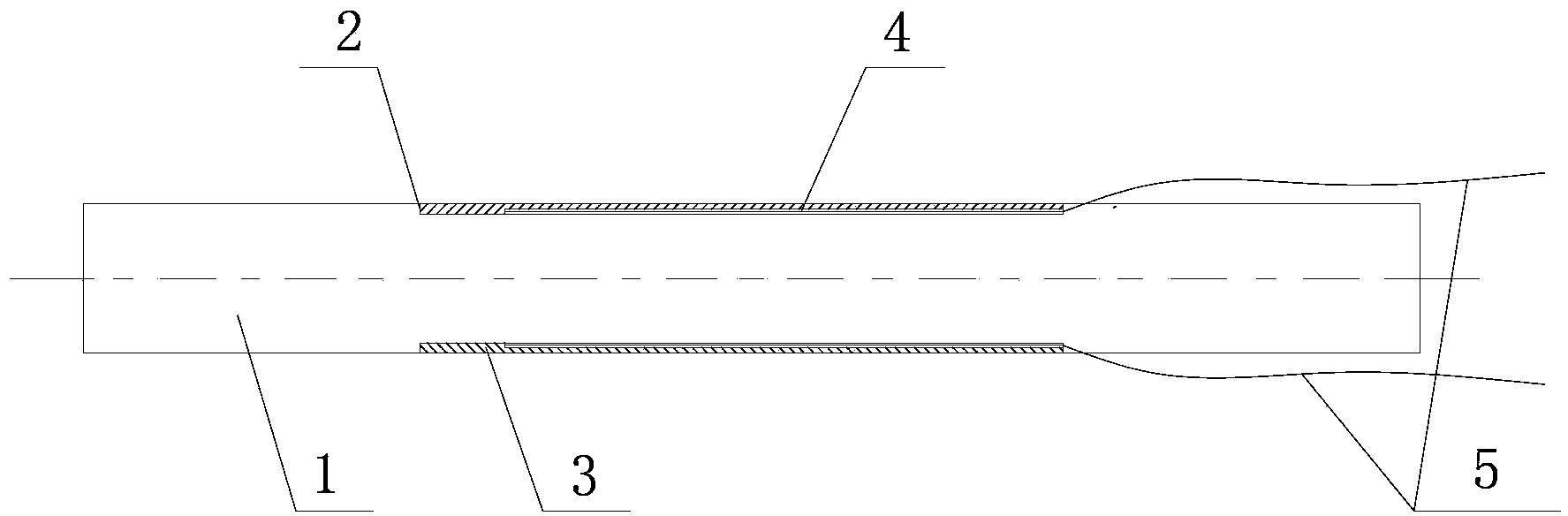

Distributed optical fiber grating anchor rod group stress monitoring system for coal mine roadway

ActiveCN103362552ARealize all-round online real-time monitoringImprove accuracyMining devicesGratingEngineering

The invention discloses a distributed optical fiber grating anchor rod group stress monitoring system for a coal mine roadway, and belongs to anchor rod group stress monitoring systems for coal mine roadways. Each of a mining roadway anchor rod support stress monitoring subsystem, an excavation roadway anchor rod support stress monitoring subsystem and a working face open-off cut anchor rod support stress monitoring subsystem comprises one or more monitoring substations; the communication optical fibers of the three subsystems are connected with a mineral transmission optical cable through an optical fiber connecting box; the mineral transmission optical cable is connected with an input port of an optical fiber grating static demodulator; an output port of the optical fiber grating static demodulator is connected with a computer data processing system; processed monitoring data is shared with a ground computer through a server and a coal mine local area network, so that the online real-time anchor rod group stress monitoring system for the coal mine roadway is formed. An anchor rod group stress monitoring network taking anchor rods as sensing media and optical fibers as transmission carriers adopts a tandem structure; the anchor group stress is measured in a distributed way; the mounting operation is convenient; the labor, the time and the effort are saved; the monitoring expense is reduced.

Owner:CHINA UNIV OF MINING & TECH

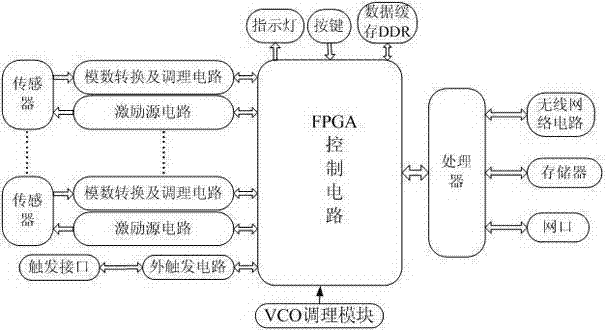

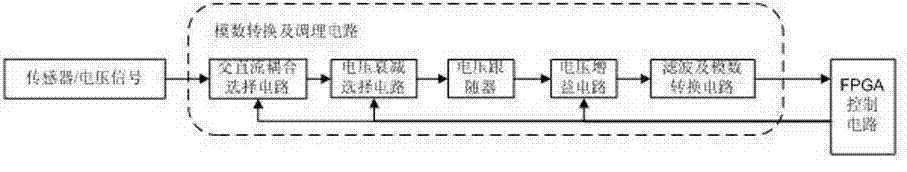

Multichannel data acquisition instrument based on time synchronization

ActiveCN103488112AReduce hardware costsHigh transplantabilityProgramme controlComputer controlComputer hardwareData acquisition

The invention relates to the field of data acquisition and processing, in particular to a multichannel data acquisition instrument based on time synchronization. In order to solve the problems in the prior art, the multichannel data acquisition instrument based on time synchronization is provided. The multichannel data acquisition instrument is used for data acquisition after being subjected to time correction through a VCO adjusting module, an FPGA and a processor are in parallel connection to conduct data transmission, data collected by a sensor are stored in a memory, data of a data storage chip are read to conduct subsequent data processing, or data interaction is conducted through an internet access and an upper computer, and upper computer data processing is conducted. According to the multichannel data acquisition instrument based on time synchronization, the processor, an FPGA control circuit, an analog-digital conversion and conditioning circuit and a sensor circuit are in mutual connection, and the design of the multichannel data acquisition instrument is achieved. The data acquisition instrument based on time synchronization is applied to the field of high-speed data acquisition.

Owner:CHENGDU JOVIAN TECH EXPL

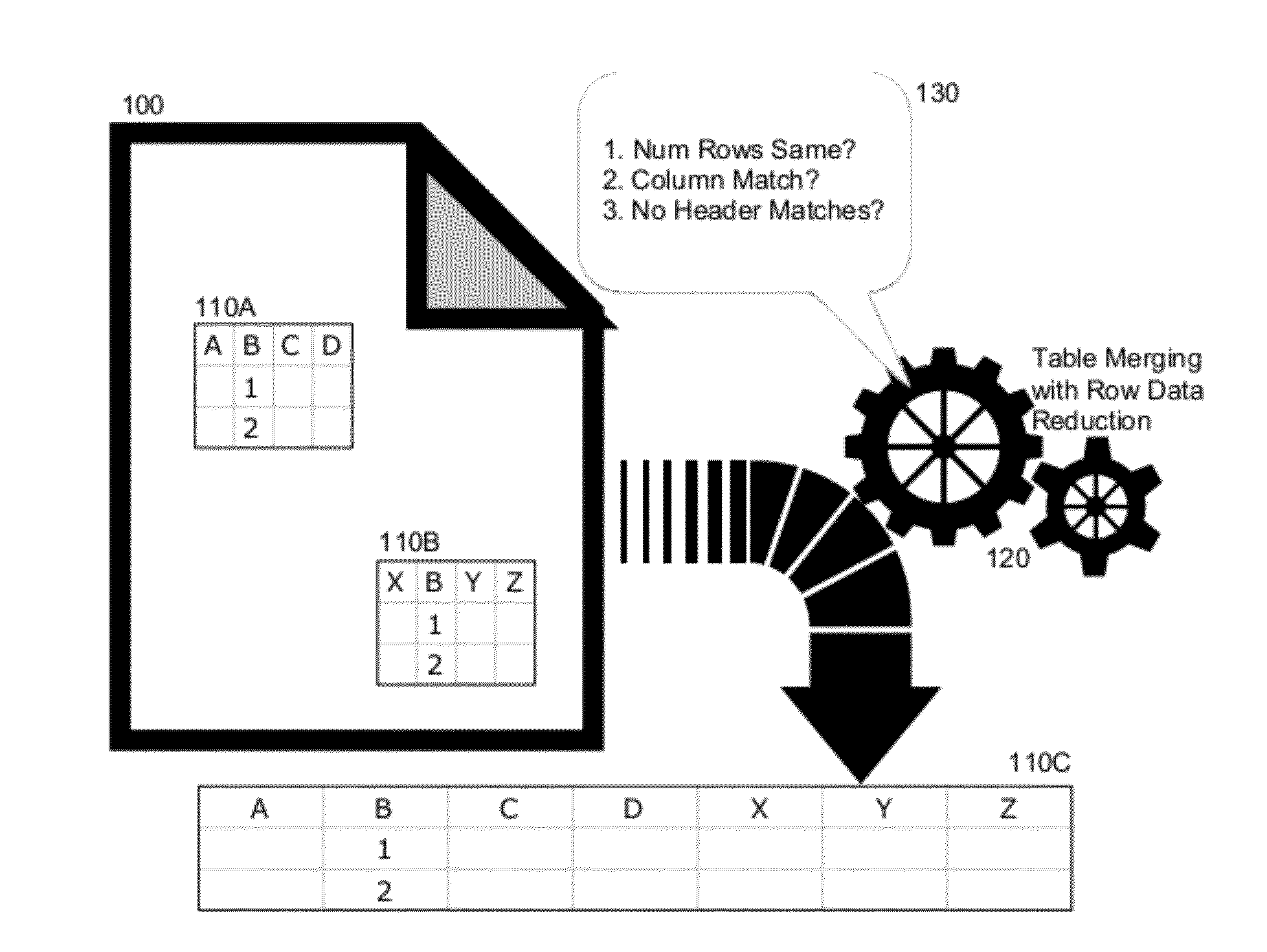

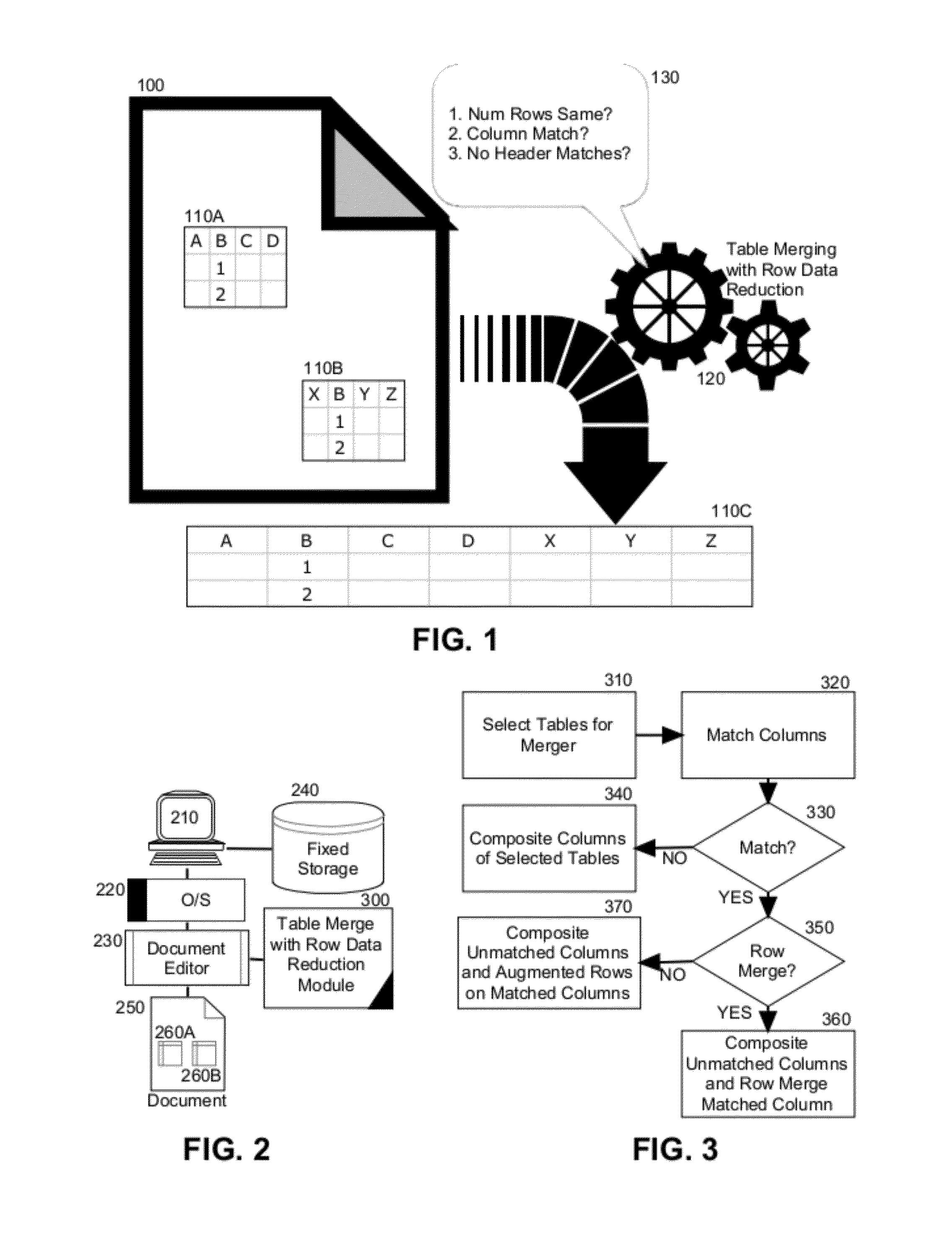

Table merging with row data reduction

InactiveUS20120173226A1Digital data information retrievalDigital data processing detailsData treatmentComputer data processing

Embodiments of the present invention provide a method, system and computer program product for the table merging of correlated columns with row data reduction. In an embodiment of the invention, a method for table merging with row data reduction for merged columns can include selecting a first table of columns and a second table of columns for merger in a computer data processing system. A column of rows in the first table can be matched with a column of rows in the second table. Subsequently, it can be determined that the rows of the first table are the same in number as the rows of the second table and that the matched columns include identical data in the respective ones of the rows. Consequently, a merged table of an aggregation of the columns of the first table and the second table can be generated to exclude from the aggregation one of the matched columns that includes identical data in the respective ones of the rows as the other of the matched columns.

Owner:IBM CORP

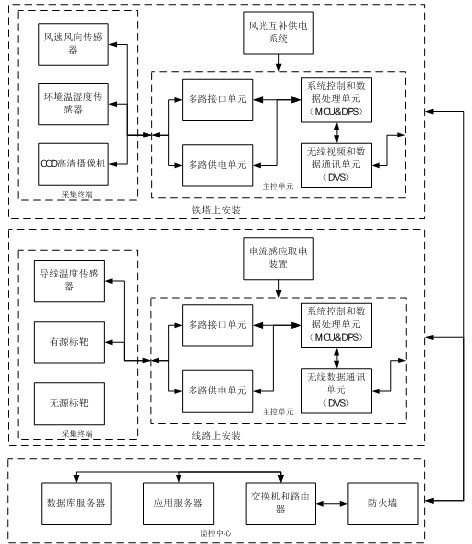

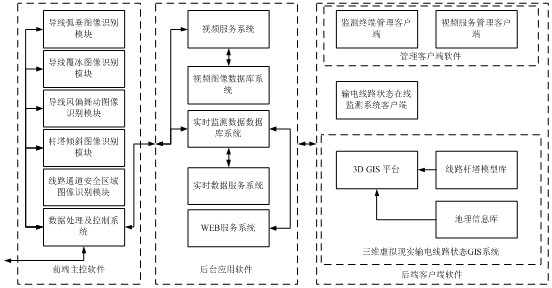

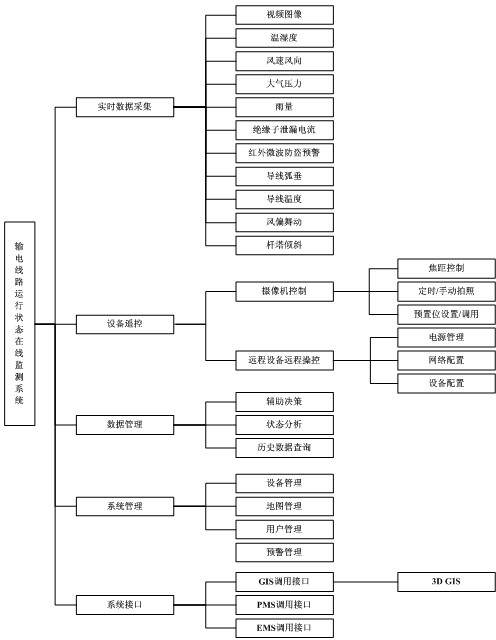

Target image identification transmission line state monitoring system based on visual attention mechanism

InactiveCN102638013AImprove status detection accuracyImprove image recognition efficiencyClosed circuit television systemsApparatus for overhead lines/cablesGeneral Packet Radio ServiceAutomatic control

The invention discloses a target image identification transmission line state monitoring system based on a visual attention mechanism. The target image identification transmission line state monitoring system comprises a monitoring device on a tower pole, another monitoring device on a line and a monitoring center, wherein the monitoring device on the tower pole comprises a data image acquisition terminal, a master control unit and a wind-solar complementary system; the monitoring device on the line comprises an acquisition terminal on the line, a master control unit on the line and a current sensing electricity taking device; and both the monitoring device on the tower pole and the monitoring device on the line send the data to the monitoring center by a wireless video and data communication unit via a GPRS (General Packet Radio Service) / EDGE (Electronic Data Gathering Equipment) / 3G network. The whole system is a comprehensive application system which integrates software and hardware, as well as integrates automatic control, computer data processing and communication, the purpose of all-weather on-line monitoring under any complex weather condition is realized, and the image identification efficiency and the transmission line state detection accuracy are substantially improved.

Owner:CHENGDU SENYUAN SWITCH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com