Coal mine underground safety comprehensive monitoring system based on fiber grating sensors

A fiber grating and comprehensive monitoring technology, which is applied in mining equipment, mining equipment, earthwork drilling, etc., can solve the problems of unsatisfactory long-term monitoring, low degree of automation, and inconvenient data collection, so as to prevent water inrush accidents in coal mines and improve the use environment. The effect of small influence and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

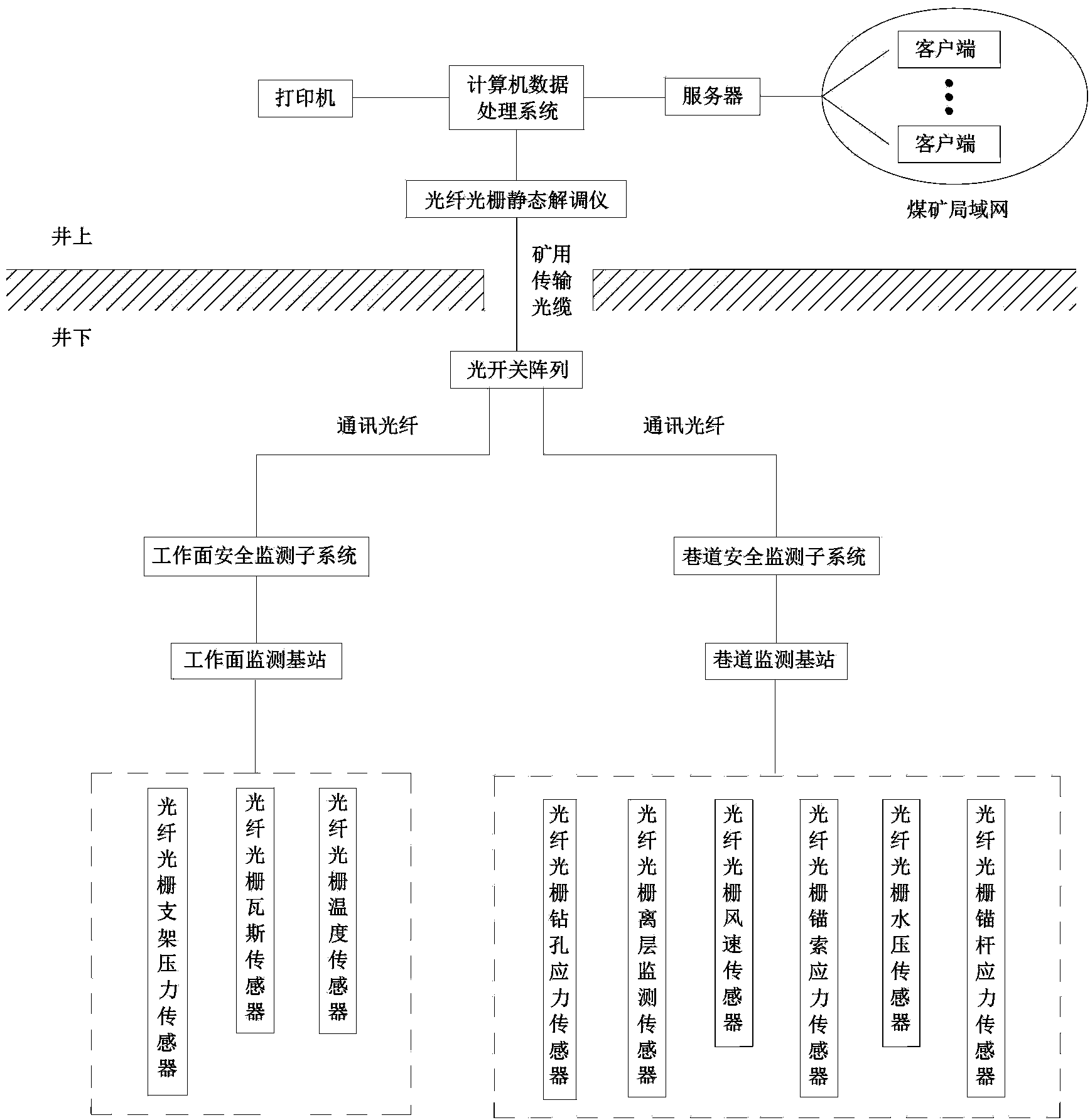

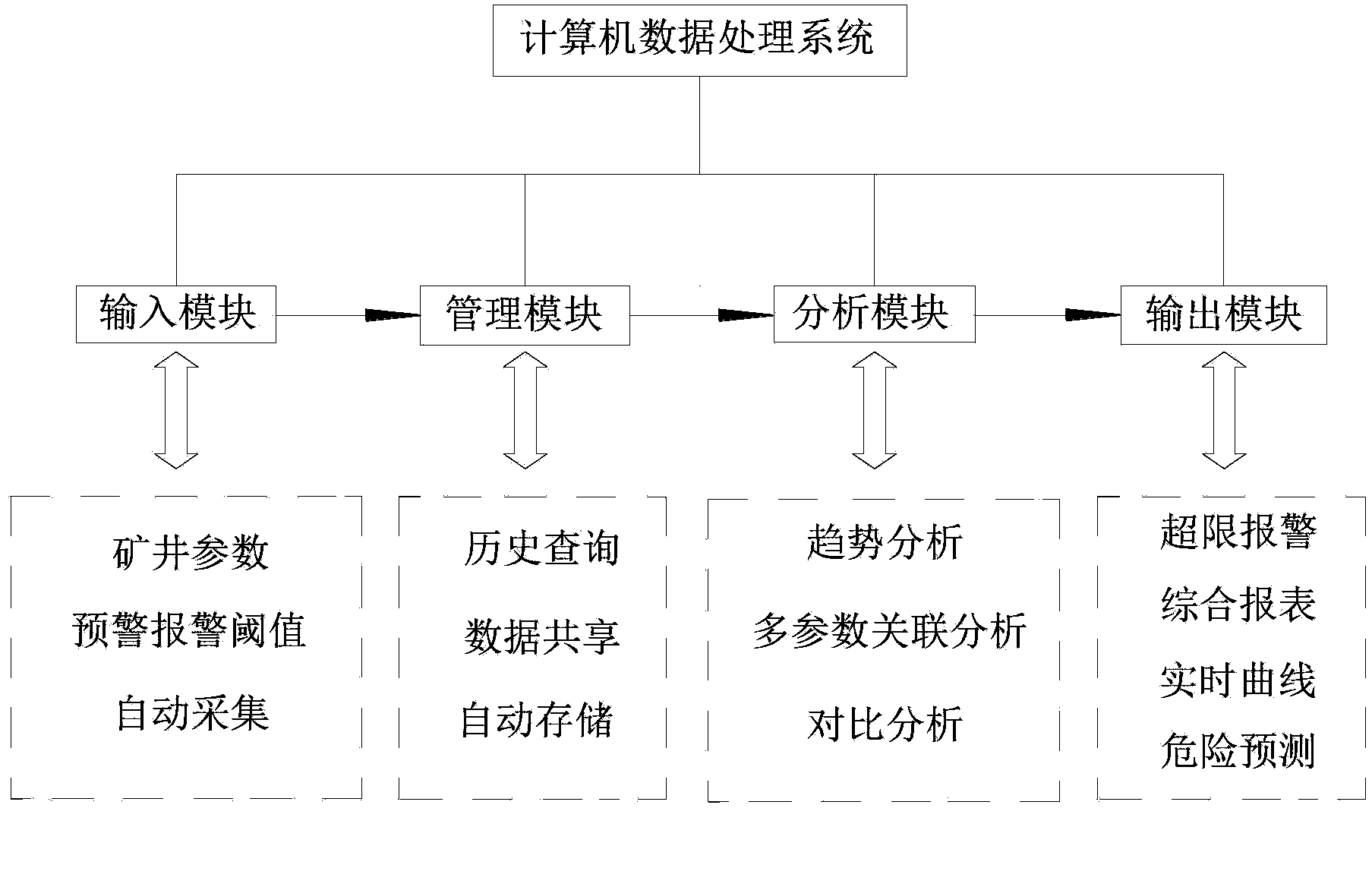

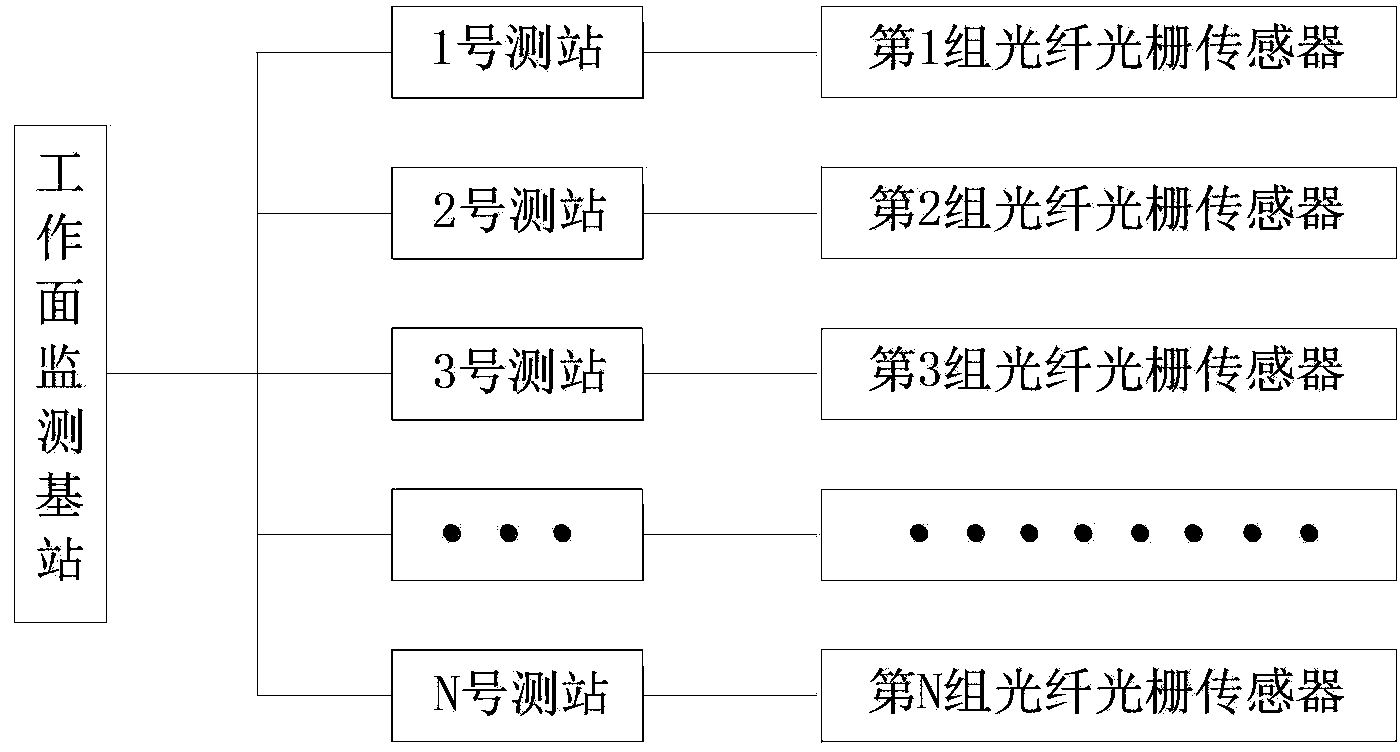

[0034] Example 1: figure 1In the schematic diagram of the overall layout of the system, the coal mine safety comprehensive monitoring system based on fiber grating sensors includes an uphole part and an underground part. The above part includes a fiber grating static demodulator, a computer data processing system, a printer, a server and a client terminal, the client is interconnected with the server through the coal mine LAN, and the fiber grating static demodulator is connected to the underground part through the mine transmission cable; the underground part includes an optical switch array, a working face monitoring subsystem and a roadway monitoring subsystem; A channel of the optical switch array is connected to the working face safety monitoring subsystem, and the working face monitoring subsystem includes at least one working face monitoring base station, wherein each working face monitoring base station includes at least one measuring station, and each measuring station...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com