Automatic controlling technical parameter optimization method of metal plate rolling

A technology of metal strips and process parameters, which is applied in the field of metal rolling, can solve the problems of continuous measurement of deformation resistance and friction coefficient, reduction of parameter calculation accuracy, and simultaneous acquisition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

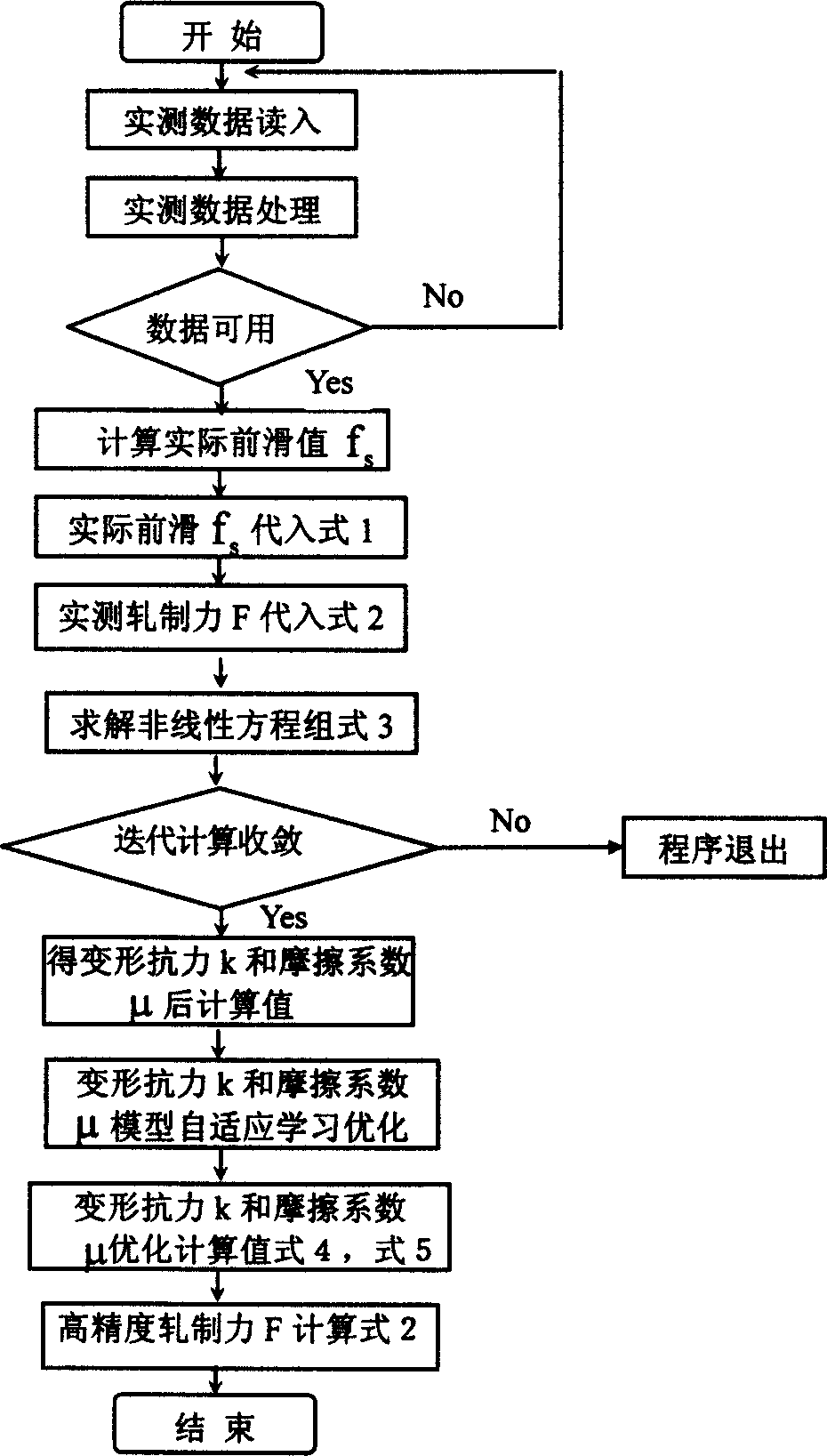

Method used

Image

Examples

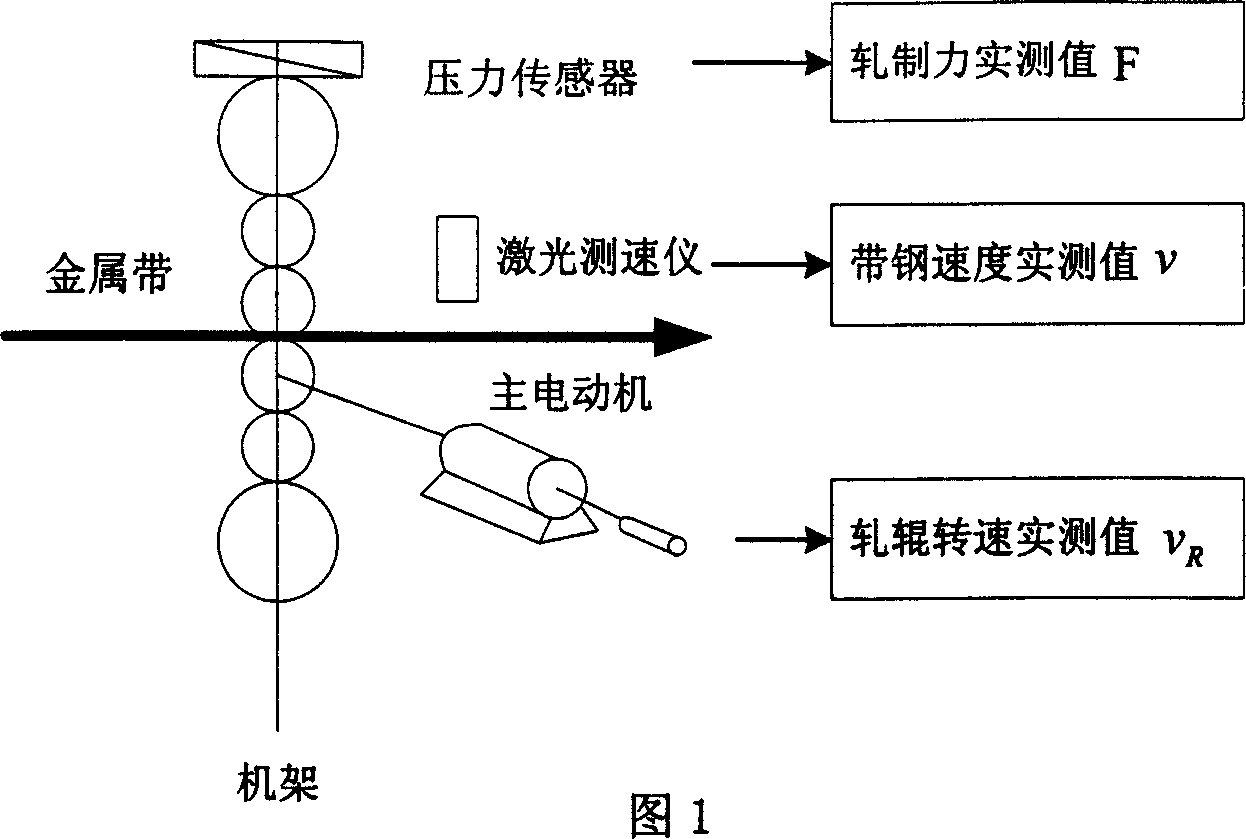

Embodiment Construction

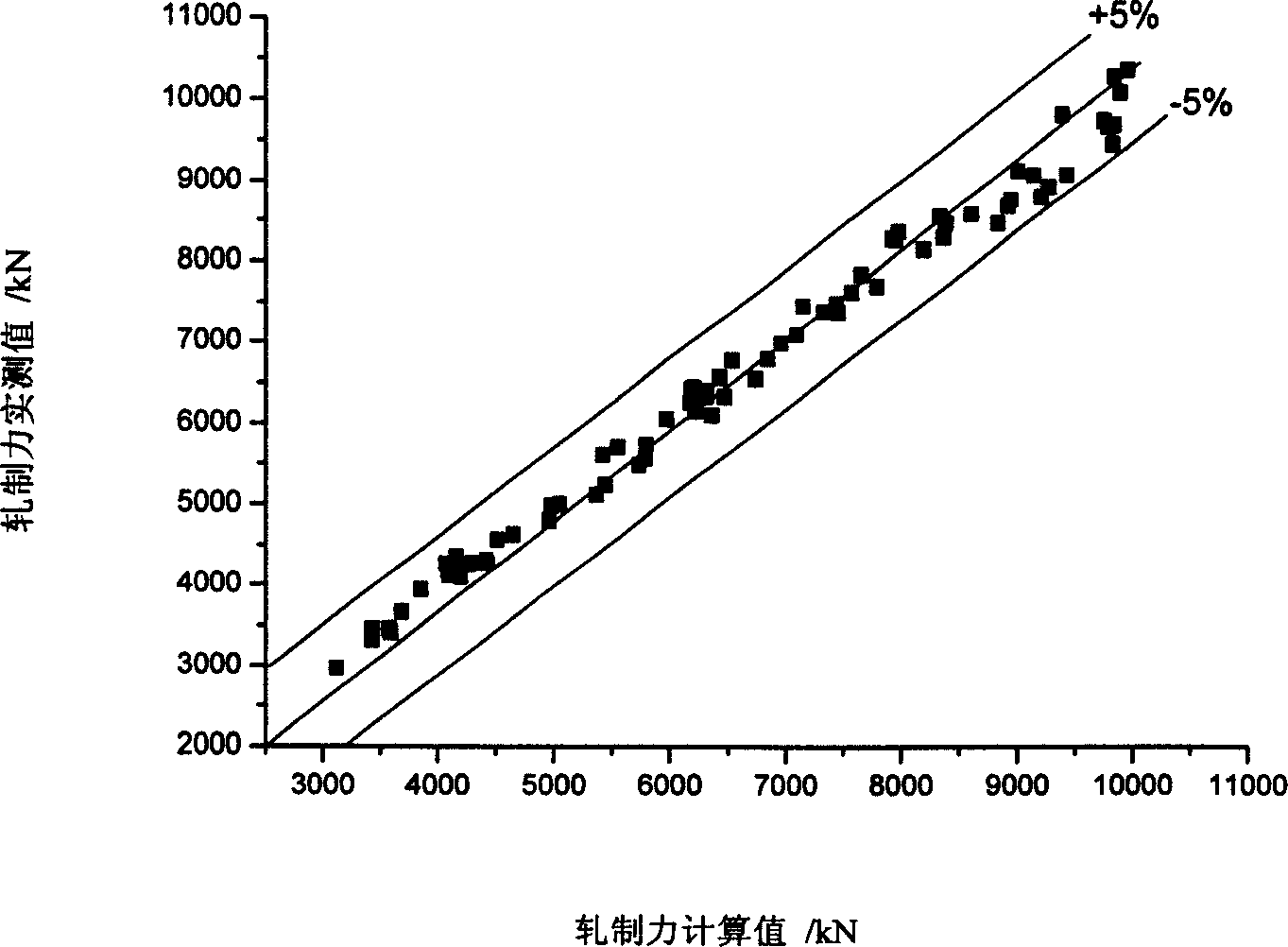

[0061] The invention has been successfully tested on a 1220mm cold rolling mill for cold strip steel. Thickness specification: 1.5-3.5mm; Finished product thickness: 0.2-0.8mm; Width: 550-1020mm; Steel type: SPHC, MRT, Stw22; Work roll diameter: 550mm; Support roll diameter: 1194mm; , Power 3800kW, digital revolution measurement encoder maximum measurement range 1100r / min. The indenter (rolling force sensor) is piezo-magnetic, with a maximum measuring range of 10MN. The speed measurement range of the laser speedometer is 0.6~2520mpm, and the measurement accuracy is ±0.025%. The process optimization computer adopts P4-1.8GHz microcomputer, and the program is written by Visual C++.

[0062] Take the strip rolled steel grade SPHC as an example, the entrance thickness is 2.3mm, the exit thickness is 1.67mm, and the strip width is 1020mm. The motor speed measured by the motor encoder is v R=769m / min, the strip exit velocity v=787m / min measured by the laser velocimeter, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com