Olfactory simulator and its olfactory simulation testing method

A technology of simulating device and olfactory sense, applied in the field of olfactory simulating device, to achieve the effect of shortening recovery time, improving sensitivity and selectivity, and improving test speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

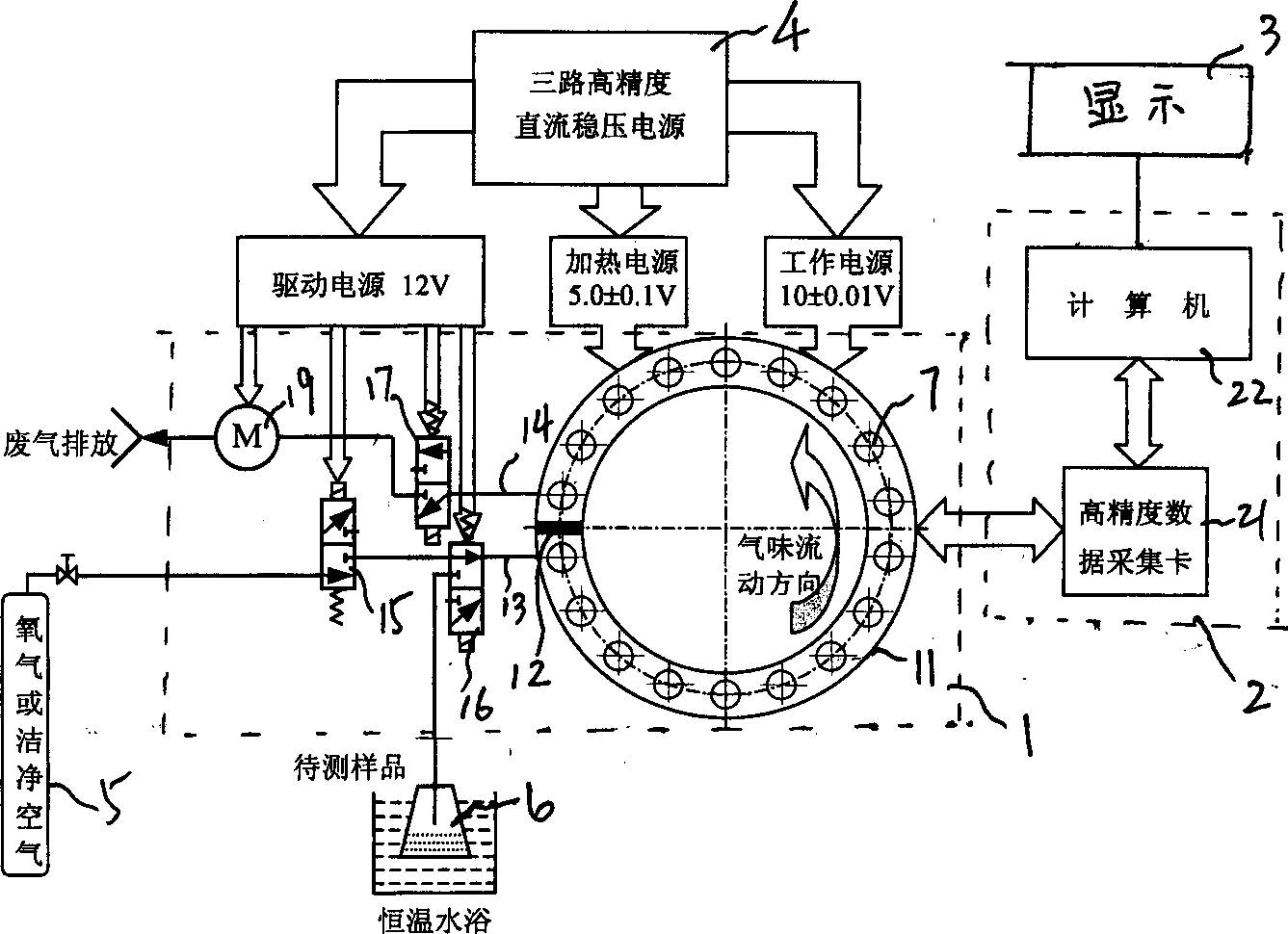

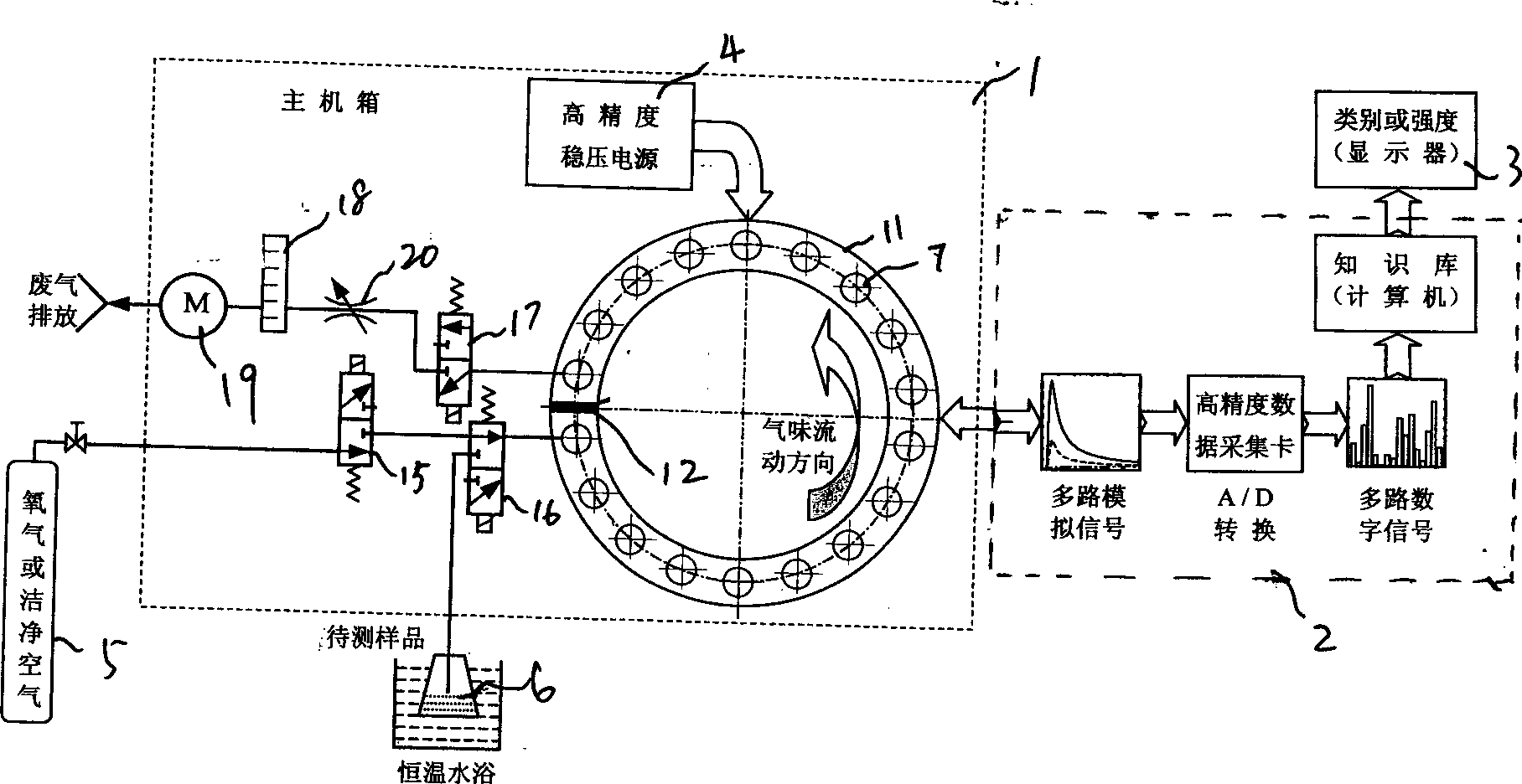

[0042] see figure 1 . The olfactory simulation device of the present invention is an olfactory simulation device, which is characterized in that it is composed of a main box 1 , a computer processing part 2 , a display part 3 and a power supply circuit 4 .

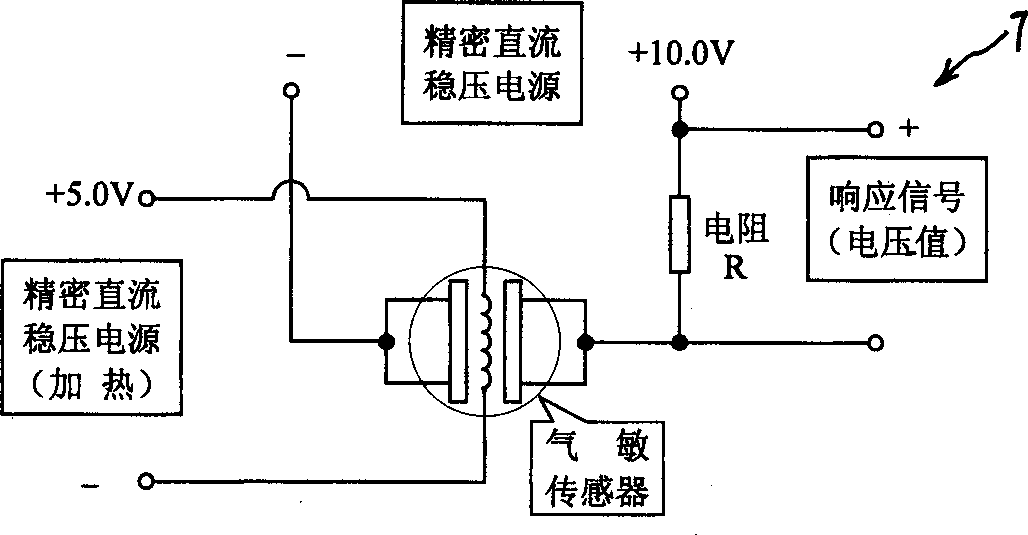

[0043] An annular test box 11 is arranged in the main chassis 1, and a partition 12 is provided on one side of the annular test box. An air inlet and an air outlet are respectively arranged on both sides of the partition, and an air inlet pipe 13 and an air outlet pipe 14 are respectively penetrating through the air inlet and the air outlet. The intake pipe is provided with a second solenoid valve 16 to control the on-off of the test gas and a first solenoid valve 15 to control the on-off of the recovery gas. The first solenoid valve communicates with oxygen or clean air 5 through the pipeline, and the second solenoid valve passes through the pipeline. It is connected to the sample 6 to be tested; the third electromagnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com